Page 1

Operating

C00269

Instructions

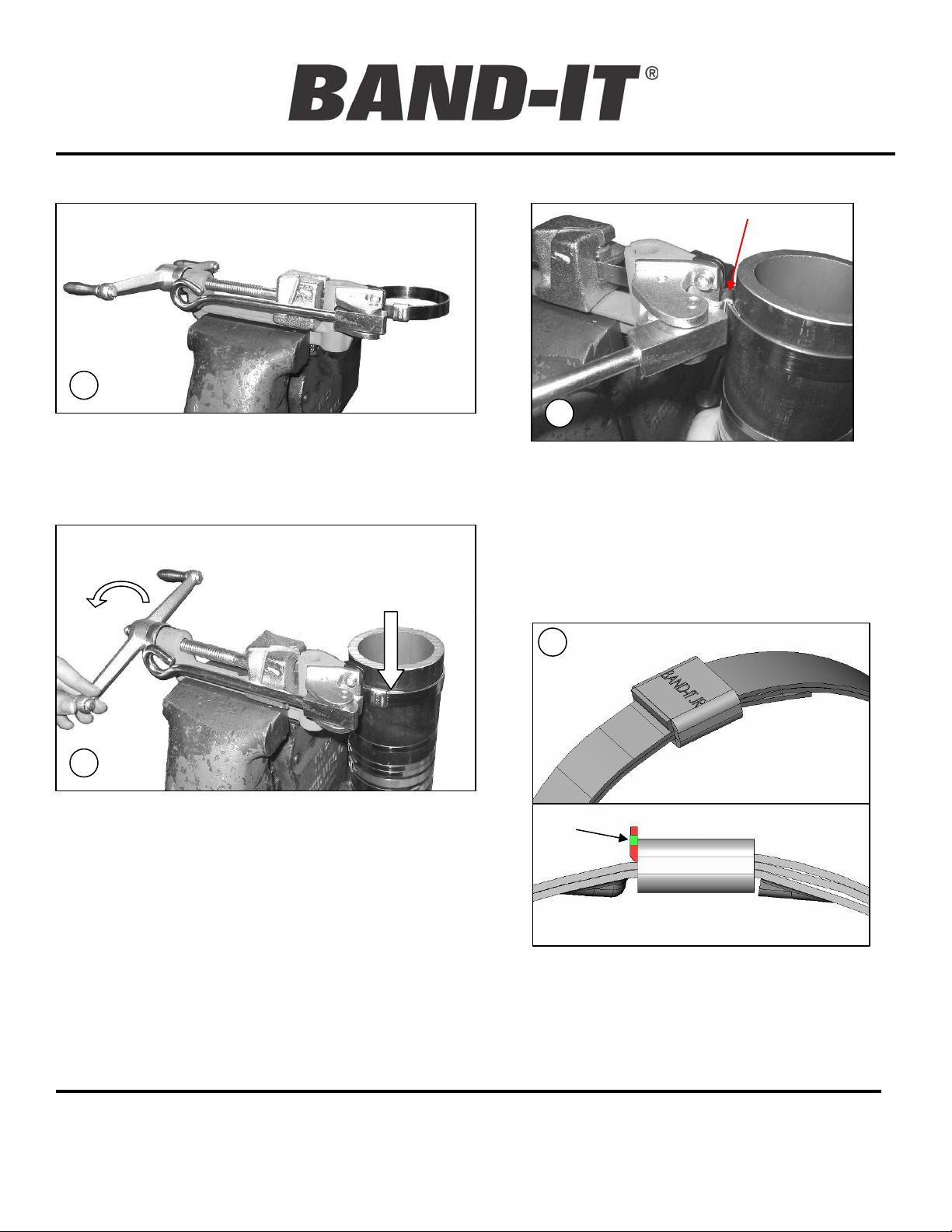

1

Place BAND-IT tool in vise. Insert clamp in tool and

grip end of band by Band Gripper Lever. NOTE:

The spring load of the band gripper is not

intended to secure and prevent the band from

slipping during the tension process.

2

Insert hose in clamp. Take up clamp by turning the

handle of BAND-IT TOOL clockwise while holding

band gripper tight against band. To feel movement of

band, place finger on BAND-IT BAND at buckle edge

(shown by arrow) while tensioning with tool handle.

When you no longer feel band moving through

buckle, MAXIMUM PRESSURE HAS BEEN

EXERTED BY BAND-IT BAND.

NOTE: USE OF VISE IS OPTIONAL

FOR BAND WIDTHS OF ½” OR

LESS. WE STRONGLY SUGGEST

SECURING THE TOOL IN A VISE

FOR CLAMPS WIDER THAN ½”.

To Install a BAND-IT Junior Clamp:

JR. Hand Tool

B

3

A. Roll hose over approximately 30°,

BACKING OFF TENSION HANDLE ½ to 1

turn only through course of rollover,

depending on type and size of hose.

B. Grip buckle with hook in nose by

pushing cutter handle. Push cutter handle

farther to cut the band completing BANDIT JR. Clamp.

4

CORRECT

The finished BAND-IT JR. Smooth I.D. Clamp.

Lip lock will be bent upward 90° and have a

cut-off edge (shown in green) that is flush to

the edge of the buckle. Edges shown in red

are too high or too low and may result in lower

lock strength or sharp edges.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 1 of 3

Document # P45087 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2012

All rights reserved

Page 2

Repair Parts &

C00269

Assembly

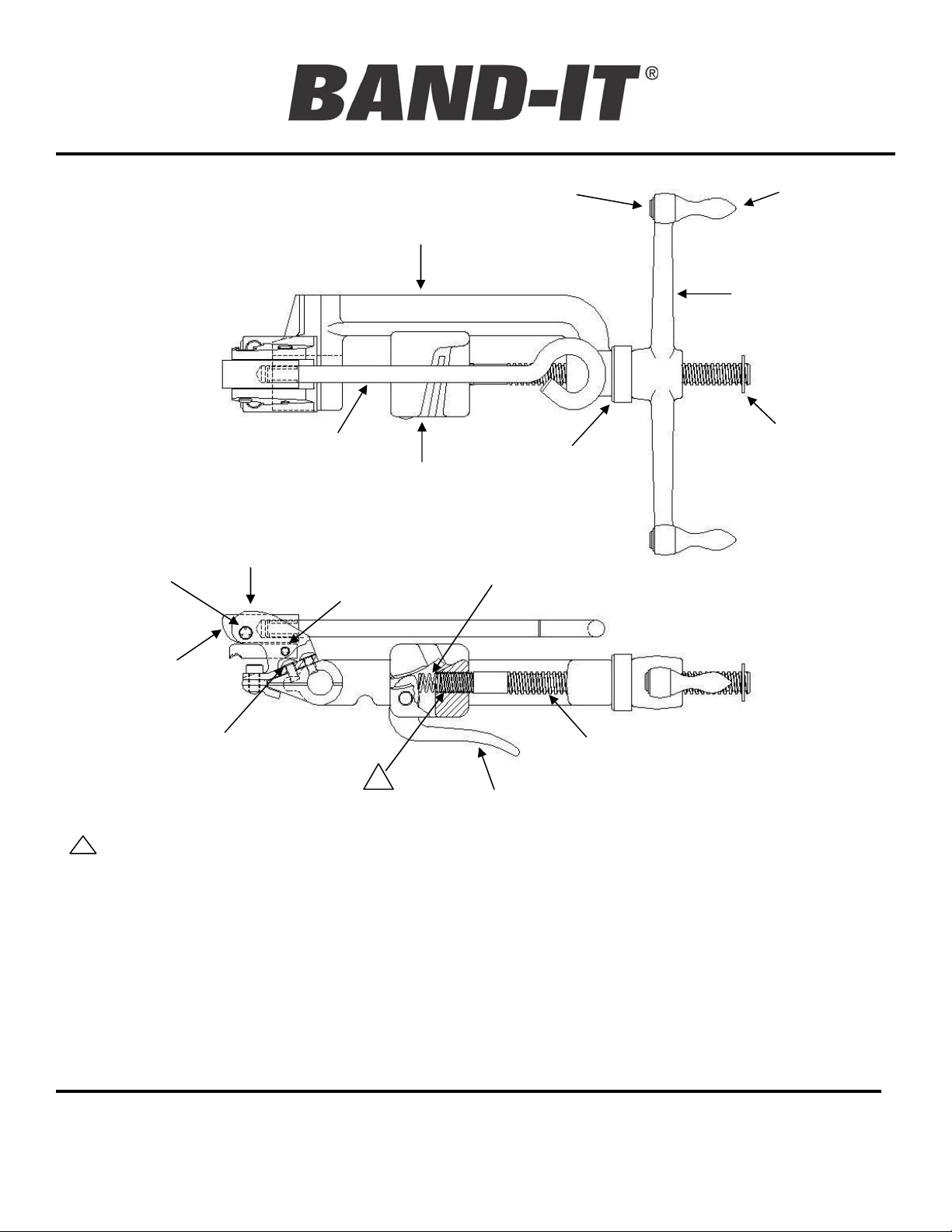

JR. ADAPTER

PIVOT PIN

CUTTER BAR HANDLE

JR. ADAPTER BODY

HOOK PIVOT PIN

EXTERNAL RETAINING RING

TOOL FRAME

SLIDE BLOCK

JR. Hand Tool

SPIN GRIP

TENSION HANDLE

SCREW RETAINING RING

THRUST BEARING

GRIPPER SPRING

JR. ADAPTER CAM

BUTTON

HEAD SCREW

1

NOTES:

1. To assist in removing threaded parts, apply heat (softens locking compound).

2. When connecting the tension screw to the slide block, or button head screws to the JR. adapter body, clean threads

(male and female) of foreign matter, then apply two drops of medium strength locking compound (Loctite 242 or equiv.)

onto male threads and connect parts together.

3. Before using BAND-IT JR. tool check to see that the cutter blade and backing plate are fully tightened. Loose screws

can cause breakage of cutter blade or backing plate. Use hex key provided with tool to tighten screws if needed.

4. Assemble tension handle, then attach retaining ring to tension screw in location shown. Place ring on groove, then

push ring against a hard surface such as a table until it snaps securely in place.

5. Kit # C01899 contains one each of a C01887 band gripper, C03186 gripper spring and C01787 pin. Replace all parts

as a set to maximize tool performance. Periodic cleaning of band gripper teeth will improve tool performance.

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

BAND GRIPPER

Page 2 of 3

TENSION SCREW

Document # P45087 Rev. I

BAND-IT-IDEX, Inc. 2012

All rights reserved

© Copyright

Page 3

Repair Parts &

Assembly

REPAIR PARTS LIST FOR C00269

C00269

JR. Hand Tool

PART # DESCRIPTION

C02240 TOOL FRAME

C01687 THRUST BEARING

C01387 SLIDE BLOCK

TENSION HANDLE AND SCREW KIT

C00689

C01899

J01499

J02299

J93099*

J00587 SHEAR HOOK (DESIGN MAY VARY)

J00987 HOOK PIVOT PIN

S48087 SCREW, BUTTON HD. #10-32 X 3/8 L

J01387 HEX KEY, 3/16” SPECIAL LENGTH

INCLUDES: SPIN GRIP, EXTERNAL

RETAINING RING, SCREW RETAINING RING,

AND TENSION HANDLE

GRIPPER ASSEMBLY KIT

INCLUDES: GRIPPER, PIN, AND GRIPPER

SPRING

HANDLE ASSEMBLY, JR. ADAPTER

INCLUDES: JR. ADAPTER CAM AND HANDLE

BODY KIT, JR. ADAPTER

INCLUDES: JR. ADAPTER BODY AND CAM

PIVOT PIN

CUTTER BLADE KIT

INCLUDES: CUTTER BLADE, BACKING

PLATE, SCREWS AND HEX KEY

J93099 CUTTER BLADE KIT*

SCREWS

CUTTER BLADE

*NOTE: Replacement cutter blade kit

design may vary.

Replace all parts as a kit.

Operating Tip: Keep the bolts tight

(8-14 ft-lbs.). A loose bolt may cause

cracking or premature wear of the

cutter blade and/or backing plate.

This could result in improper clamp

tensioning, locking, and cutting.

Operating Tip: Keep the leading

edges of the cutter blade and

backing plate free of metal shavings.

Metal shavings will result in clamp

tail gouging during tensioning. Clean

and hone the leading edges by

hand. Do not use power tools.

Honing should polish surfaces,

not remove material.

BACKING

PLATE

Refer to website for warranty information: http://www.band-it-idex.com/warranty.html

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street

Denver, CO 80216-3070 USA

P: 1-800-525-0758

F: 1-800-624-3925

www.BAND-IT-IDEX.com

Page 3 of 3

Document # P45087 Rev. I

BAND-IT-IDEX, Inc. 2012

© Copyright

All rights reserved

Loading...

Loading...