Page 1

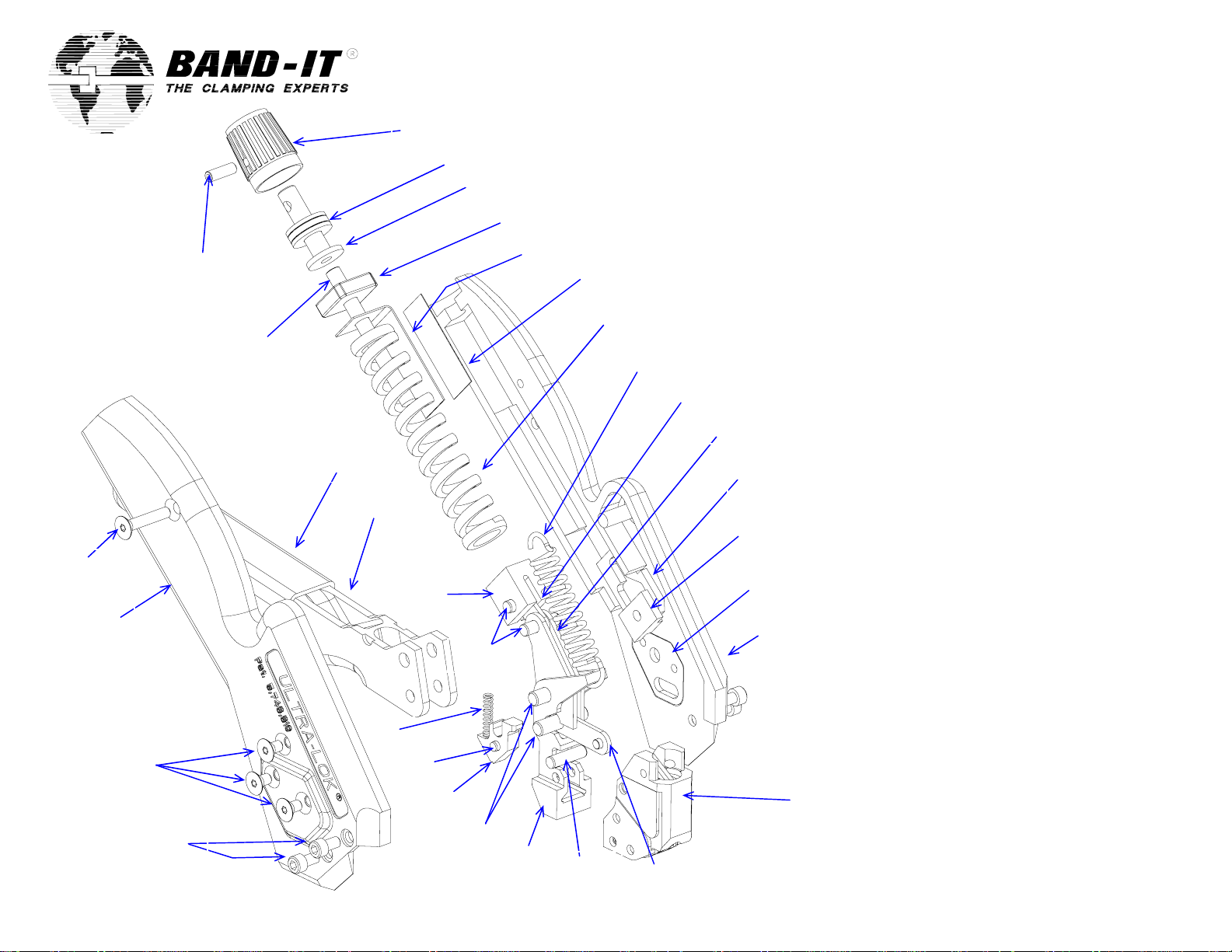

Repair Parts List

A94079 Ultra-Lok Tool

1

25, 34

26

27 x 2, 34

28 x 2, 34

A94051.doc Rev “G“

24, 34

23, 32, 33

22, 31

21

19

18, 32

20

2

17

16, 32

3

14, 32

Item Band-It # Qty Description

1 M53387 1 Knob, adjustment

2 M53287 1 Bearing, thrust (3 pieces)

4

5

6

7, 32

8

9

10 x 2

11 x 2

29 x 2

13 x 2

12

15

14, 32

Cut-off link and pin shown as

a reference from reverse side

3 A92577 1 Cap, tension

4 A93487 1 Block, tension

5 A93587 1 Indicator, tension

6 A92387 1 Decal, tension indicator

7 K02187 1 Spring, die

8 A91787 1 Spring, extension

9 A95487 1 Link, tension

10 A92267 2 Arm, tension

11 A95387 2 Plate, tension

12 K93487 1 Body, left, black

13 A91477 2 Plate, body

14 A73587 3 Pin, dowel, 5/32 x 9/16 lg

15 A91387 1 Lever, pull-up, front load

16 A94887 2 Pin, straight, 3/16 x .780 lg

17 A91187 1 Gripper, pull

18 K97487 1 Pin, .125 x .313 lg

19 A93887 1 Spring,1/8 x 5/8, 25#

20 A92487 1 Plunger, tension

21 K97587 1 Handle

22 M50487 1 Grip, textured, green

23 A94487 1 Screw, set, #10-24 x 2.00 lg

24 A85687 1 Screw, set, #6-32 x 7/16 lg

25 A96087 1 Screw, flt-hd, #6-32 x 3/4 lg

26 K93587 1 Body, right, black

27 A91987 6 Screw, flt-hd, #6-32 x 1/4 lg

28 M54587 4 Screw, cap, #6-32 x 1/4 lg

29 K57887 2 Pad, centering

30

31 - - Adhesive, cyanoacrylate

32 - - Grease, extreme pressure

33 - - Red Loctite (high strength)

34 - - Blue Loctite (med. Strength)

See list of tool head

parts on reverse side

Page 1 of 4

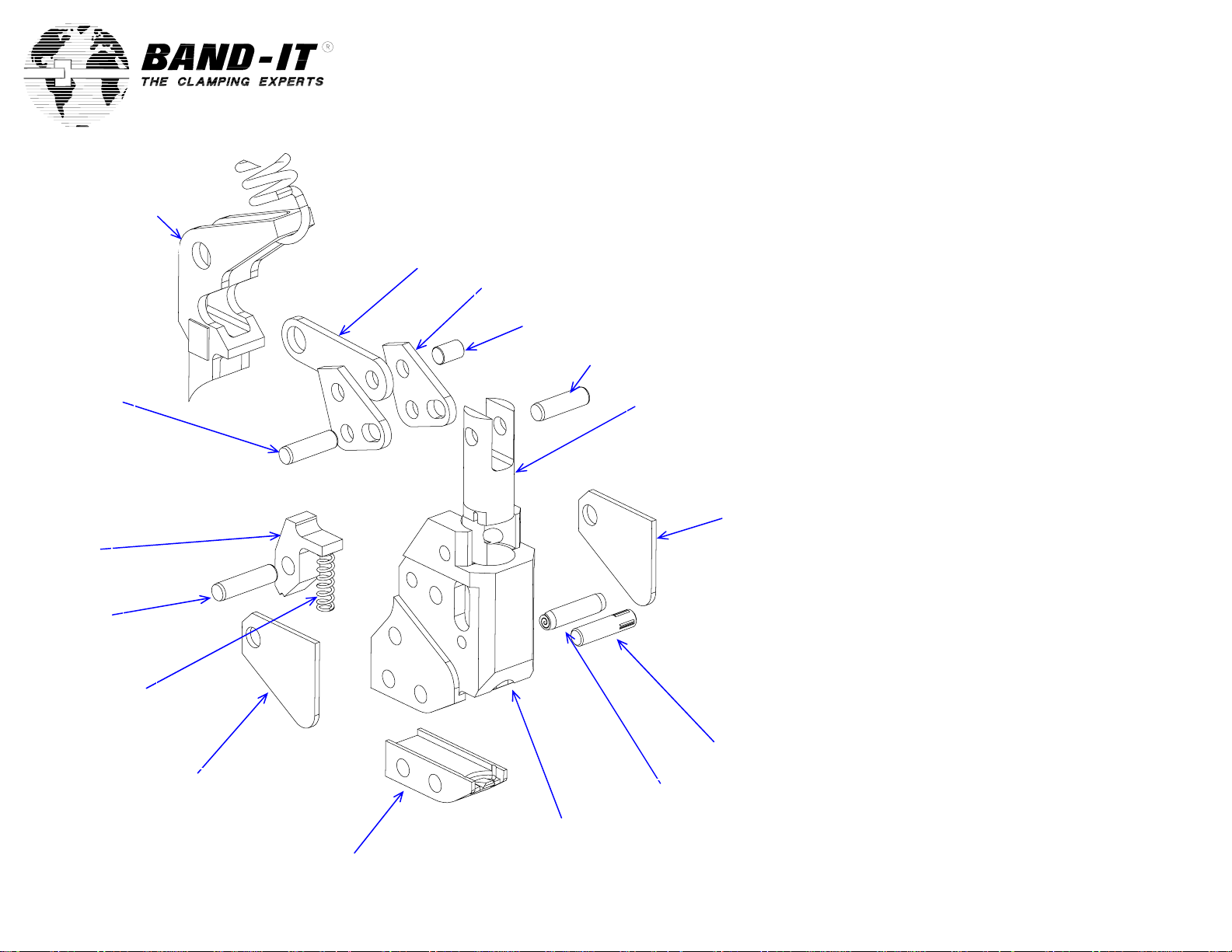

Page 2

Partial view of pull-up

lever and spring shown

as a reference from

previous page

38, 48 39, 48

46

45, 48

44

40

Repair Parts List

A94079 Ultra-Lok Tool

35

36 x 2

37, 48

38, 48

41

47

42

43

Item Band-It # Qty Description

35 A92177 1 Link, cut-off

36 A94987 2 Lever, cut-off

37 A94687 1 Pin, straight, 1/8 x 3/16 lg

38 M01887 2 Pin, dowel, 1/8 x 7/16 lg

39 A92987 1 Knife, Ultra-Lok

40 A94187 2 Cover, head

41 A93977 1 Pin, Groove, 1/8 x 9/16 lg

42 A92677 1 Tool head

43 A92787 1 Blade, Ultra-Lok

44 C09587 1 Spring, 1/8 x 1/2, 13#

45 A84487 1 Pin, dowel, 1/8 x 1/2 lg

46 A91287 1 Gripper, hold

47 A90987 1 Pin, spiral, 1/8 x 1/2 lg

48 - - Grease, extreme pressure

40

A94051.doc Rev “G“

Page 2 of 4

Page 3

Warning:

Always wear safety glasses when operating hand tool.

Instructions:

1. Turn tension adjustment knob until desired

tension setting is displayed in tension indicator

window. Space between numbers counts as

one-half setting. See step 6.

2. Extend handle open to release gripping

mechanism and insert clamp tail into tool

through front load entry.

3. Squeeze handle repeatedly to tighten band

around object. Be sure to release handle

completely to use full pull-up stroke of tool.

Buckle must be secure against the tool head.

Once the preset tension has been reached, the

handle will no longer release completely.

4. To cut-off excess clamp tail, squeeze handle

one last time. Once the band is cut, the handle

must be released to separate the tool from the

clamp.

5. The tool must be reset by extending the handle

out until it snaps into place. The tool will be

ready to apply the next clamp.

6. Tension Setting Range:

.250 Smooth I.D. Ultra-Lok 0 – 8

.250 Smooth I.D. Tie-Lok 0 – 8

.250 Smooth I.D. Jr. single-wrap 0 – 8

.250 BAND-IT Band and A201 Buckle 0 – 8

Operating Instructions

A94079 Ultra-Lok Tool

Tension

Adjustment

Knob

Tension Indicator

Window

Handle

A94051.doc Rev “G“

Page 3 of 4

Page 4

Operating Instructions

A94079 Ultra-Lok Tool

Roll Band Application

A. Turn adjustment knob until tension indicator is set to –0-.

B. While holding handle all the way out from tool body, insert desired length of roll band into rear of tool head.

C. Pull handle towards tool body until band is cut. Hold handle away from tool body. Pull band out from front

of tool head.

D. If making more than one clamp, repeat the above steps.

.015 x .250 wide

roll band

E. Remove band from rear of tool head.

F. Slide buckle onto band until it is up against the buckle stop formed by the tool. “BAND-IT” logo should be

opposite the protrusion on the buckle stop.

G. Slide other end of band through buckle to form a clamp.

A201 buckle

H. Repeat steps 1 through 7 on the previous pages of this instruction sheet.

I. To make another clamp after already clamping an object, do not force handle open, instead, position roll

band behind the tool head and slowly move handle away from tool body until band passes through to

desired length. Pull handle towards tool body until band is cut. Repeat E, F, G, H.

Note: if handle “snaps” out during step I, you must start over with step A.

A94051.doc Rev “G“

Page 4 of 4

Loading...

Loading...