baltur TBG 85 ME, TBG 210 ME, TBG 150 ME, TBG 120 ME User Instruction Manual

SP

user instructions manualUKManual de instrucciones

para el uso.

FR

Manuel d'instructions

pour l'utilisation.

TBG 85 ME

TBG 120 ME

TBG 150 ME

TBG 210 ME

TR

Kullanım talimatları

kılavuzu.

РУС

Руководство инструкции

по эксплуатации.

中文

使用说明

- TWO-STAGE PROGRESSIVE / MODULATING GAS BURNERS WITH

ELECTRONIC CAM BT 3..

- QUEMADORES DE GAS DE DOS ETAPAS PROGRESIVAS / MODULANTES CON LEVA ELECTRÓNICA BT 3..

- BRULEURS DE GAZ A DEUX ALLURES PROGRESSIVES / MODULANTES AVEC CAME ELECTRONIQUE BT 3..

- BT 3.. ELEKTRONİK KAMLI İLERLEMELİ / MODÜLASYON İKİ FAZLI

GAZ BRÜLÖRLERİ

- ДВУХСТУПЕНЧАТЫЕ ГАЗОВЫЕ ПРОГРЕССИВНЫЕ / МОДУЛЯЦИОННЫЕ ГОРЕЛКИ С ЭЛЕКТРОННЫМ КУЛАЧКОМ BT 3..

二段渐进式/电子凸轮”BT 3“调控式燃气燃烧器

ORIGINAL INSTRUCTIONS (IT)

I

NSTRUCCIONES ORIGINALES (IT

I

STRUCTIONS ORIGINALES (IT)

ORİJİNAL KULLANIM KILAVUZU (IT)

ОРИГИНАЛЬНЫЕ ИНСТРУКЦИИ

(

ПЕРЕВОД С ИТАЛЬЯНСКОГО ЯЗЫКА

正版说明书。(IT)

)

)

0006081531_201203

- Before using the burner for the first time please carefully read the chapter “WARNING NOTES FOR THE USER:

BALTUR S.p.A.

Via Ferrarese 10 - 44042 CENTO (Ferrara) ITALIA

Tel. 051.684.37.11 Fax 051.685.75.27/28

(International Tel. ++39.051.684.37.11 - Fax ++39.051.683.06.86)

http://www.baltur.it - http://www.baltur.com - E-MAIL info@baltur.it

HOW TO USE THE BURNER SAFELY” in this instruction manual, which is an integral and essential part of the product.

- Read carefully the instructions before starting the burner and servicing it.

- The works on the burner and on the system should be carried out only by qualified personnel.

- The system power supply must be disconnected before starting working.

- If the works are not carried out correctly it is possible to cause dangerous accidents.

Declaration of Conformity

We declare that our products

BPM...; BGN…; BT…; BTG…; BTL…; TBML...; Comist…;

GI…; GI…Mist; Minicomist…; PYR…; RiNOx…; Spark...;

Sparkgas...; TBG...;TBL...; TBML ...; TS…; IBR...; IB...

(Variant: … LX, for low NOx emissions)

Description:

forced air burners of liquid, gaseous and mixed fuels for residential and

industrial use meet the minimum requirements of the European Directives:

2009/142/CE ..............................................(D.A.G.)

2004/108/CE ...............................................(C.E.M.)

2006/95/CE .................................................(D.B.T.)

2006/42/CE ................................................(D.M.)

and conform to European Standards:

ENGLISH

UNI EN 676:2008 (gas and combination, gas side)

UNI EN 267:2002 (diesel and combination, diesel side)

These products are therefore marked:

0085

Dr. Riccardo Fava

18/11/2010

!

WARNINGS / NOTES

TECHNICAL SPECIFICATIONS ....................................................................................................................................................................................... 4

CONNECTING THE BURNER TO THE BOILER

GAS SUPPLY LINE

ELECTRICAL CONNECTIONS

DESCRIPTION OF TWO-STAGE PROGRESSIVE OPERATION

NATURAL GAS IGNITION AND ADJUSTMENT

IONISATION CURRENT MEASUREMENT

ADJUSTING THE AIR ON THE COMBUSTION HEAD

MAINTENANCE

HOW TO FIND THE CAUSES OF IMPROPER OPERATION HOW TO RECTIFY THEM

ELECTRIC DIAGRAM

.......................................................................................................................................................................................................... 8

........................................................................................................................................................................................ 9

......................................................................................................................................................................12

............................................................................................................................................................................................................... 15

...................................................................................................................................................................................................... 17

i

INFORMATION

............................................................................................................................................................. 7

................................................................................................................................... 10

..............................................................................................................................................................11

................................................................................................................................................... 14

Managing Director / CEO

I

DANGER / CAUTION

.............................................................................................. 16

1 / 20

0006081531_201203

I

accordance with current regulations and in any case suf cient to ensure

ventilation openings for the room where a burner or a boiler is installed

• If it is decided not to use the burner any more, the following actions must

• Check that the person who carried out the installation of the burner xed

b) Adjust the combustion air ow to obtain combustion yield of at least

• If the burner repeatedly stops in lock-out, do not keep trying to manually

WARNING NOTES FOR THE USER HOW TO USE THE BURNER SAFELY

FOREWORD

These warning notes are aimed at ensuring the safe use of the components of heating systems for civil use and the production of hot water.

They indicate how to act to avoid the essential safety of the components

being compromised by incorrect or erroneous installation and by improper

or unreasonable use. The warning notes provided in this guide also seek

to make the consumer more aware of safety problems in general, using

necessarily technical but easily understood language. The manufacturer

is not liable contractually or extra contractually for any damage caused

by errors in installation and in use, or where there has been any failure to

follow the manufacturer’s instructions.

GENERAL WARNING NOTES

• The instruction booklet is an integral and essential part of the product

and must be given to the user. Carefully read the warnings in the booklet as they contain important information regarding safe installation,

use and maintenance. Keep the booklet to hand for consultation when

needed.

• Equipment must be installed in accordance with current regulations,

with the manufacturer’s instructions and by quali ed technicians. By

the term ‘quali ed technicians’ is meant persons that are competent in

the eld of heating components for civil use and for the production of

ENGLISH

hot water and, in particular, assistance centres authorised by the manufacturer. Incorrect installation may cause damage or injury to persons,

animals or things. The manufacturer will not in such cases be liable.

• After removing all the packaging make sure the contents are complete

and intact. If in doubt do not use the equipment and return it to the

supplier. The packaging materials (wooden crates, nails, staples, plastic

bags, expanded polystyrene, etc.) must not be left within reach of children as they may be dangerous to them. They should also be collected

and disposed on in suitably prepared places so that they do no pollute

the environment.

• Before carrying out any cleaning or maintenance, switch off the equipment at the mains supply, using the system’s switch or shut-off systems.

• If there is any fault or if the equipment is not working properly, de-activate the equipment and do not attempt to repair it or tamper with it

directly. In such case get in touch with only quali ed technicians. Any

product repairs must only be carried out by BALTUR authorised assistance centres using only original spare parts. Failure to act as above

may jeopardise the safety of the equipment. To ensure the ef ciency

and correct working of the equipment, it is essential to have periodic

maintenance carried out by quali ed technicians following the manufacturer’s instructions.

• If the equipment is sold or transferred to another owner or if the owner

moves and leaves the equipment, make sure that the booklet always

goes with the equipment so it can be consulted by the new owner and/

or installer.

• For all equipment with optionals or kits (including electrical), only original accessories must be used.

BURNERS

• This equipment must be used only for its expressly stated use: applied

to boilers, hot air boilers, ovens or other similar equipment and not

exposed to atmospheric agents. Any other use must be regarded as

improper use and hence dangerous.

• The burner must be installed in a suitable room that has ventilation in

correct combustion

• Do not obstruct or reduce the size of the burner’ air intake grills or the

or dangerous mixtures of toxic and explosive gases may form.

• Before connecting the burner check that the details on the plate correspond to those of the utility supplies (electricity, gas, light oil or other

fuel).

• Do not touch hot parts of the burner. These, normally in the areas near

to the ame and any fuel pre-heating system, become hot when the

equipment is working and stay hot for some time after the burner has

stopped.

be performed by quali ed technicians:

a) Switch off the electrical supply by disconnecting the power cable from

the master switch.

b) Cut off the fuel supply using the shut-off valve and remove the control

wheels from their position.

c) Render harmless any potentially dangerous parts.

Special warning notes

it securely to the heat generator so that the ame is generated inside

the combustion chamber of the generator itself.

• Before starting up the burner, and at least once a year, have quali ed

technicians perform the following operations:

a) Set the burner fuel capacity to the power required by the heat ge-

nerator.

the minimum set by current regulations.

c) Carry out a check on combustion to ensure the production of no-

xious or polluting unburnt gases does not exceed limits permitted

by current regulations.

d) Check the adjustment and safety devices are working properly.

e) Check the ef ciency of the combustion products exhaust duct.

f) Check at the end of the adjustments that all the adjustment devices

mechanical securing systems are properly tightened.

g) Make sure that the use and maintenance manual for the burner is

in the boiler room.

reset but call a quali ed technicians to sort out the problem.

• The running and maintenance of the equipment must only be carried

out by quali ed technicians, in compliance with current regulations.

2 / 20

0006081531_201203

equipment or dangerous situations may arise with the build up of toxic

It should be pointed out that high ef ciency boilers and similar discharge

In the above situation, traditional ues (in terms of their diameter and heat

insulation) may be suitable because the signi cant cooling of the combustion

products in these permits temperatures to fall even below the condensation

point. In a ue that works with condensation there is soot at the point the

exhaust reaches the atmosphere when burning light oil or heavy oil or the

presence of condensate water along the ue itself when gas is being burnt

(methane, LPG, etc.). Flues connected to high ef ciency boilers and similar

must therefore be of a size (section and heat insulation) for the speci c use

I WARNING NOTES FOR THE USER HOW TO USE THE BURNER SAFELY

ELECTRICAL SUPPLY

• The equipment is electrically safe only when it is correctly connected to an

ef cient ground connection carried out in accordance with current safety

regulations. It is necessary to check this essential safety requirement.

If in doubt, call for a careful electrical check by a quali ed technicians,

since the manufacturer will not be liable for any damage caused by a

poor ground connection.

• Have quali ed technicians check that the wiring is suitable for the

maximum power absorption of the equipment, as indicated in the technical

plate, making sure in particular that the diameter of cables is suf cient

for the equipment’s power absorption.

• Adapters, multiple plugs and extension cables may not be used for the

equipment’s power supply.

• An ominpolar switch in accordance with current safety regulations is

required for the mains supply connection.

• The electrical supply to the burner must have neutral to ground

connection. If the ionisation current has control with neutral not to ground

it is essential to make a connection between terminal 2 (neutral) and the

ground for the RC circuit.

• The use of any components that use electricity means that certain

fundamental rules have to followed, including the following:

- do not touch the equipment with parts of the body that are wet or damp

or with damp feet

- do not pull on electrical cables

- do not leave the equipment exposed to atmospheric agents (such as

rain or sun etc.) unless there is express provision for this.

- do not allow the equipment to be used by children or inexpert

persons.

• The power supply cable for the equipment not must be replaced by the

user. If the cable gets damaged, switch off the equipment, and call only

on quali ed technicians for its replacement.

• If you decide not to use the equipment for a while it is advisable to switch

off the electrical power supply to all components in the system that use

electricity (pumps, burner, etc.).

GAS, LIGHT OIL, OR OTHER FUEL SUPPLIES

General warning notes

• Installation of the burner must be carried out by quali ed technicians

and in compliance with current law and regulations, since incorrect

installation may cause damage to person, animals or things, for which

damage the manufacturer shall not can be held responsible.

• Before installation it is advisable to carry out careful internal cleaning

of all tubing for the fuel feed system to remove any residues that could

jeopardise the proper working of the burner.

• For rst start up of the equipment have quali ed technicians carry out

the following checks:

• If you decide not to use the burner for a while, close the tap or taps that

supply the fuel.

Special warning notes when using gas

• Have quali ed technicians check the following:

a) that the feed line and the train comply with current law and

regulations.

b) that all the gas connections are properly sealed.

• Do not use the gas pipes to ground electrical equipment.

• Do not leave the equipment on when it is not in use and always close

the gas tap.

• If the user of is away for some time, close the main gas feed tap to the

burner.

• If you smell gas:

a) do not use any electrical switches, the telephone or any other object

that could produce a spark;

b) immediately open doors and windows to create a current of air that

will purify the room;

c) close the gas taps;

d) ask for the help of quali ed technicians.

• Do not block ventilation openings in the room where there is gas

and explosive mixtures.

FLUES FOR HIGH EFFICIENCY BOILERS AND SIMILAR

combustion products (fumes) at relatively low temperatures into the ue.

to avoid such problems as those described above.

ENGLISH

3 / 20

0006081531_201203

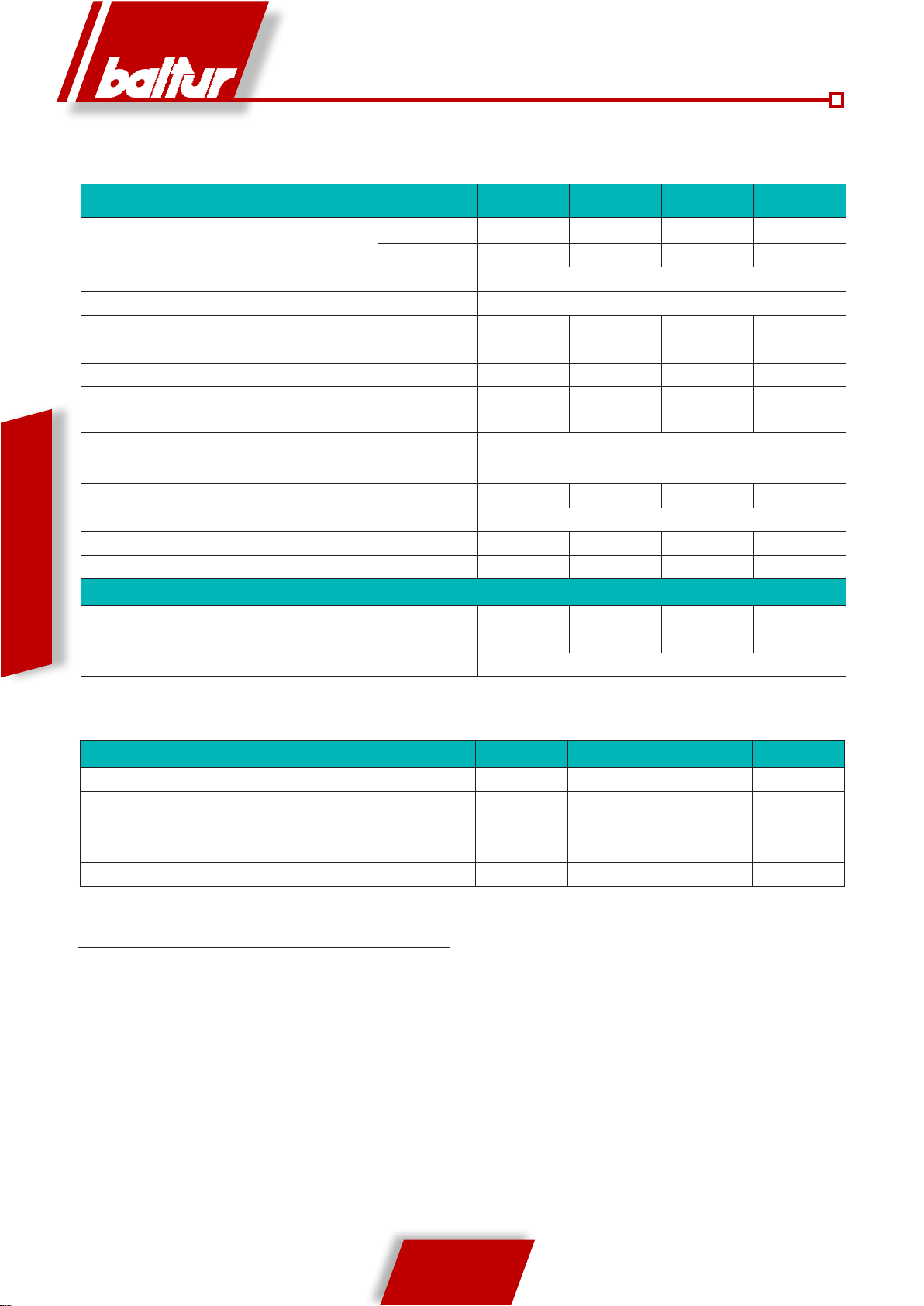

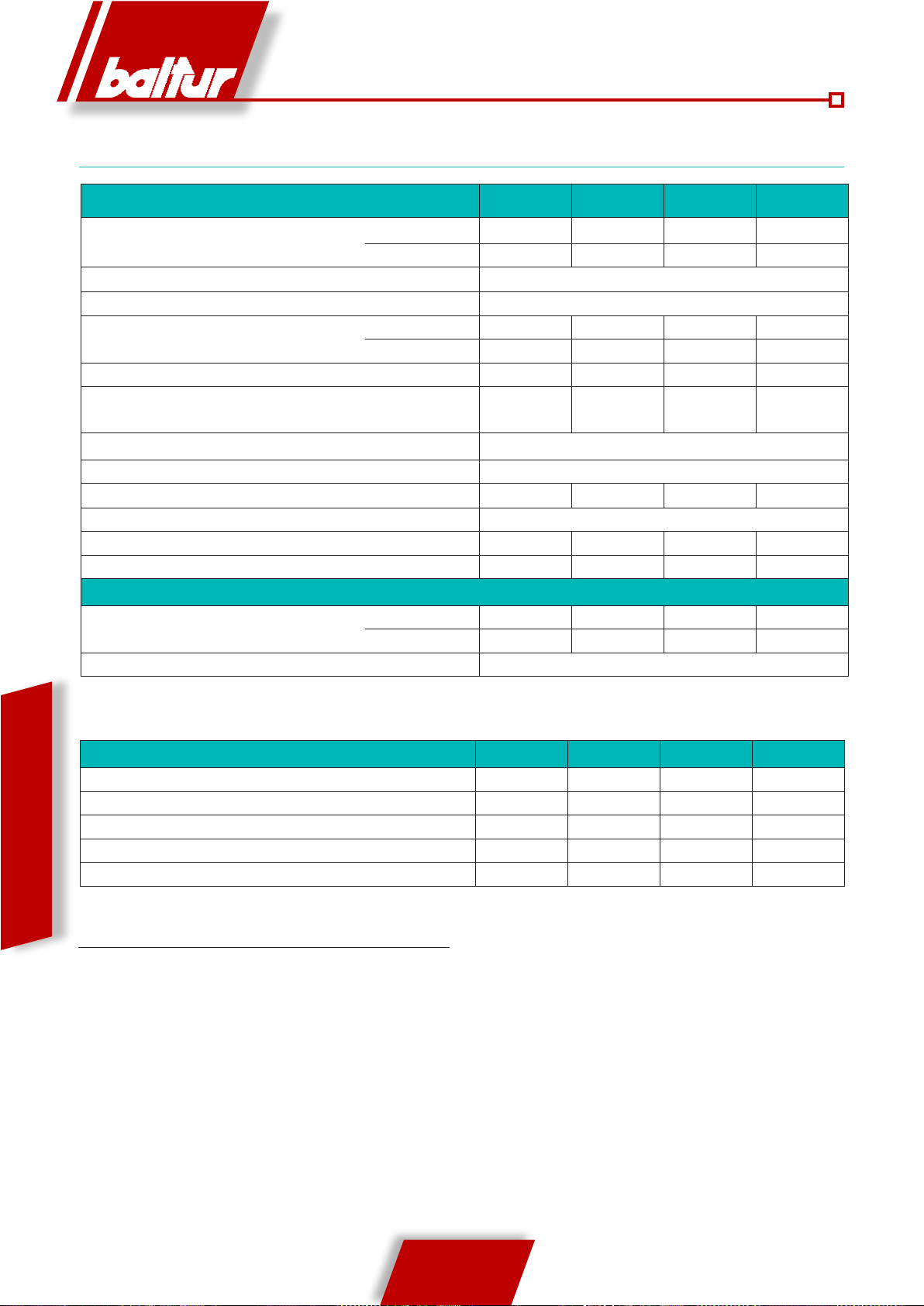

TECHNICAL SPECIFICATIONS

TBG 85ME TBG 120ME TBG 150ME TBG 210ME

HEATING CAPACITY

OPERATION Two-stage progressive / modulating burner

NOx EMISSIONS mg/kWh < 120 (Class II EN 676)

MOTOR

ABSORBED ELECTRICAL POWER* kW 1.20 1.60 2.40 3.2

LINE FUSE A 400 V 6 10 10 16

IGNITION TRANSFORMER 26 kV - 40 mA – 230 V / 50 Hz

VOLTAGE 3N ~ 400 V ±10%- 50 Hz

PROTECTION RATING IP 40

FLAME DETECTOR IONISATION PROBE

NOISE** dBA 73 75.5 79 85

WEIGHT kg 78 87 91 94

ENGLISH

NATURAL GAS (G 20)

FLOW RATE

PRESSURE MAX mbar 500

*) Total absorption at start with ignition transformer on.

**) Noise levels measured in the laboratory of the manufacturer with burner running on test boiler, at maximum rated heating capacity.

MAX kW 850 1200 1500 2100

MIN kW 170 240 300 400

kW 1.1 1.5 2.2 3

r.p.m. 2800 2800 2800 2800

MAX m³n/h 85.5 120.7 150.9 211.2

MIN m³n/h 17 24.1 30.2 40.3

STANDARD ACCESSORIES TBG 85ME TBG 120ME TBG 150ME TBG 210ME

BURNER COUPLING FLANGE 2 2 2 2

INSULATING GASKET 1 1 1 1

STUD BOLTS No. 4 M 12 No. 4 M 12 No. 4 M 12 No. 4 M 12

HEXAGONAL NUTS No. 4 M 12 No. 4 M 12 No. 4 M 12 No. 4 M 12

FLAT WASHERS/ No. 4 Ø 12 No. 4 Ø 12 No. 4 Ø 12 No. 4 Ø 12

TECHNICAL AND FUNCTIONAL SPECIFICATIONS

• Two-stage progressive / modulating output operation.

• Gas adjustment using the butterfly valve controlled by the step

servomotor electronically controlled.

• Combustion head with partial recycling of exhaust gases at low

NOx emissions (class II).

• High fan output, low electrical absorption, low noise.

• Ambidextrous hinge opening for easy access to the combustion

head when burner is installed.

• Airflow adjustment with linear opening shutter driven by a step

servomotor electronically controlled.

• Closing of air shutter in pause.

• Control panel prepared for connection by plugs/sockets

(supplied) with 4 and 7 poles.

• Control panel with protection rating IP55.

• Sliding coupling flange to the generator, to adapt the

protuberance of the head to various types of heating generators.

• High modulation ratio 1:5.

• Gas train exit possibility at the top or at the bottom.

4 / 20

0006081531_201203

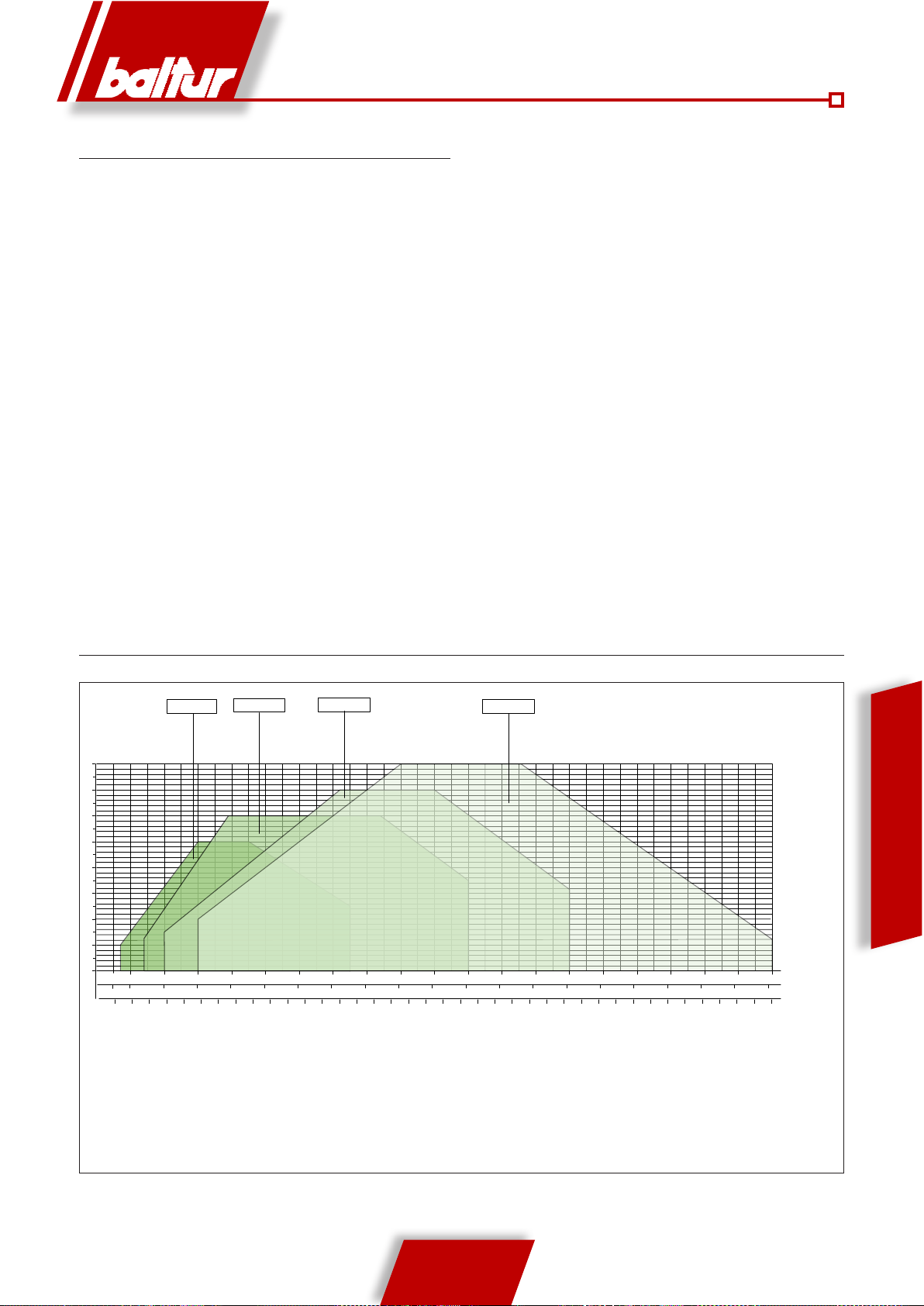

2

4

6

8

0

10

12

14

mbar

15015200 300 400 500 600 700 800 900 1000 1100

20 30 40 50 60 70 80 90

100 110

6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44

m

n³/h(Metano)

m

n³/h(G.P.L.)

kW

1200 1300

120 130

46 48 50

1400 1500 1600

16

140 150 160

52 54 56 58 60 62

1700 1800 1900

2000

170 180 190

200

64 66 68 70 72 74 76 78

2100

210

80 82

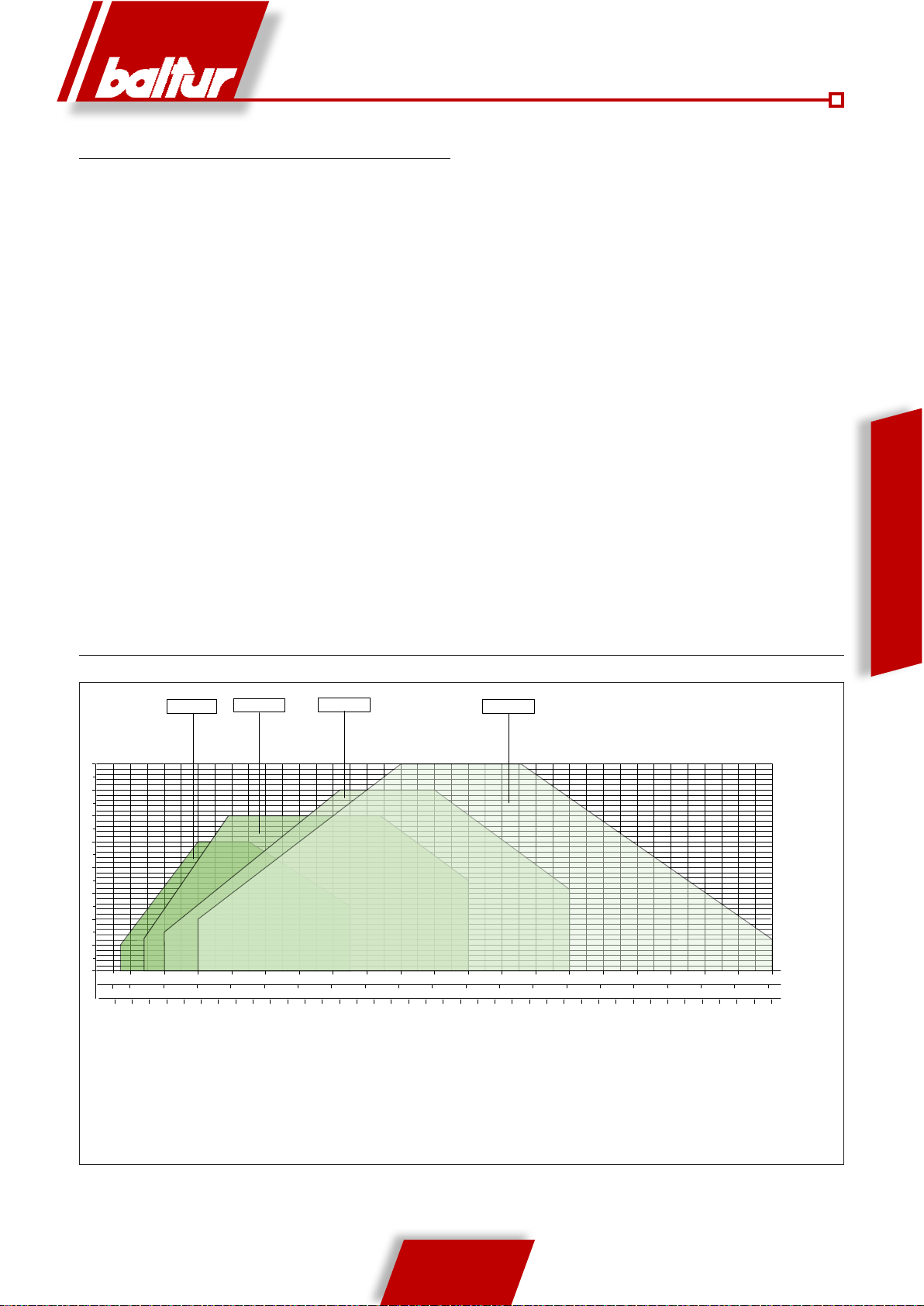

TBG 85ME

TBG 120ME TBG 150ME

TBG 210ME

MANUFACTURING CHARACTERISTICS

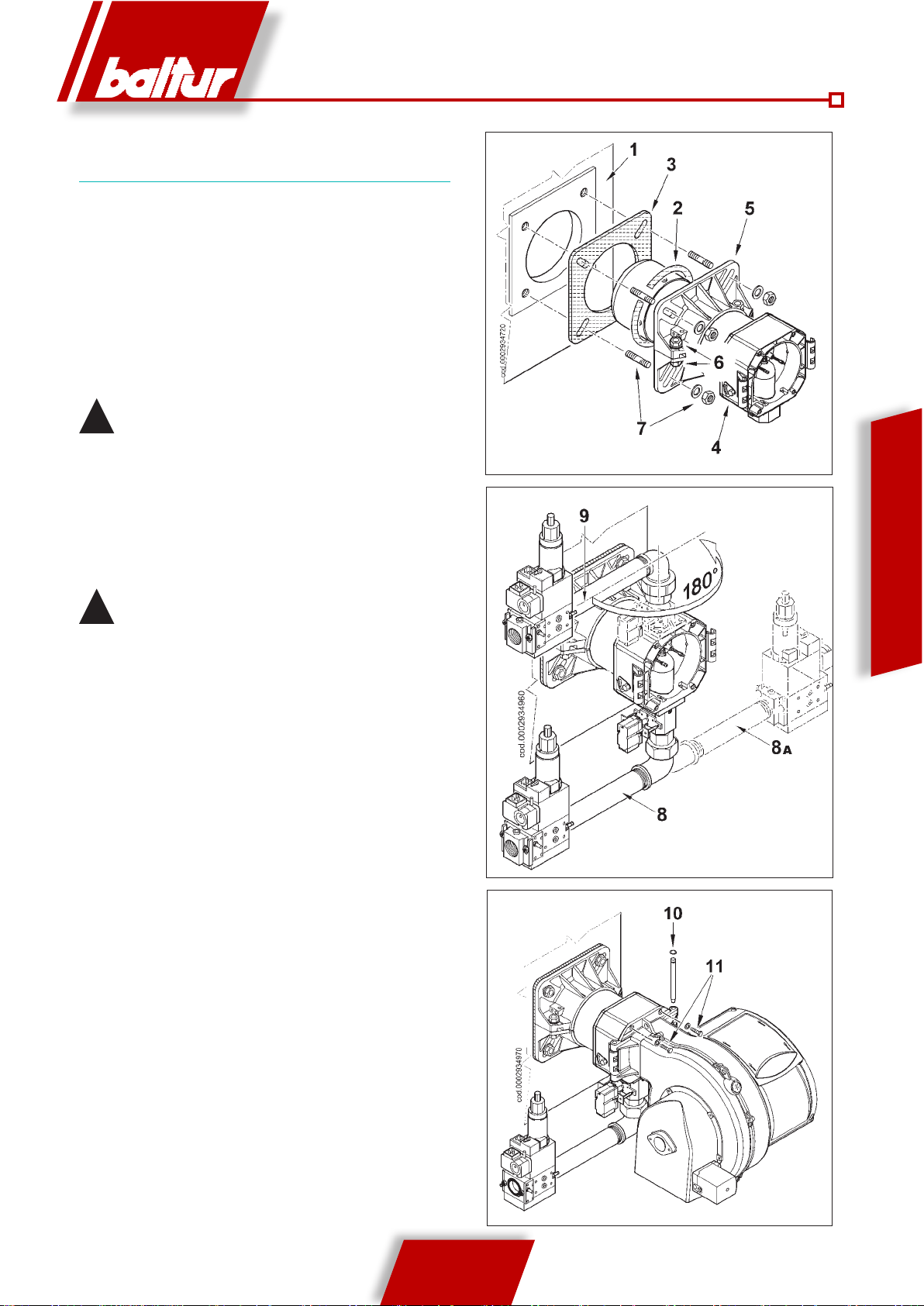

The burner consists of the following parts:

• Combustion air intake with insert in soundproofing material

designed to obtain optimum linear air shutter opening.

• Control panel complete with operation mimic panel and indicator

lights.

• Electronic command and control systems according to EN298,

with microprocessor with integrated valve tightness control and

eBus connection ability.

• Display showing the operating sequence and error code.

• Flame detection by ionisation electrode.

• Gas train complete with security valve and electromagnetic

actuator, minimum pressure switch, pressure regulator and

gas filter.

• Burner/train intelligent connectors (error proof).

ENGLISH

OPERATING RANGE

The operating ranges are obtained from test boilers corresponding

to the standard EN676 and are indicative of the burner-boiler

combination. For correct burner operation the size of the

combustion chamber must correspond to current regulations; if

not the manufacturers must be consulted.

0006081531_201203

5 / 20

0002922800

N° 0002471120

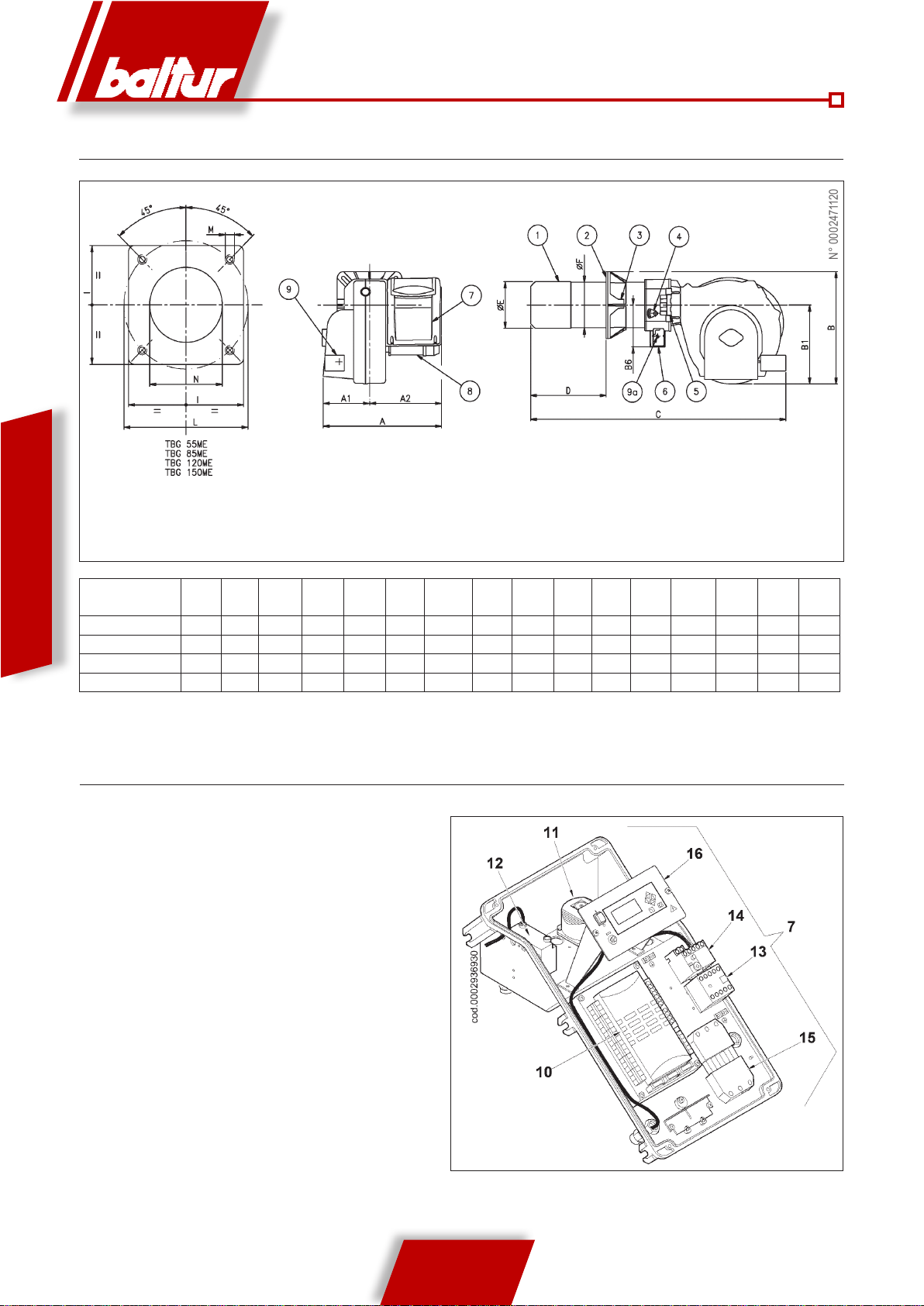

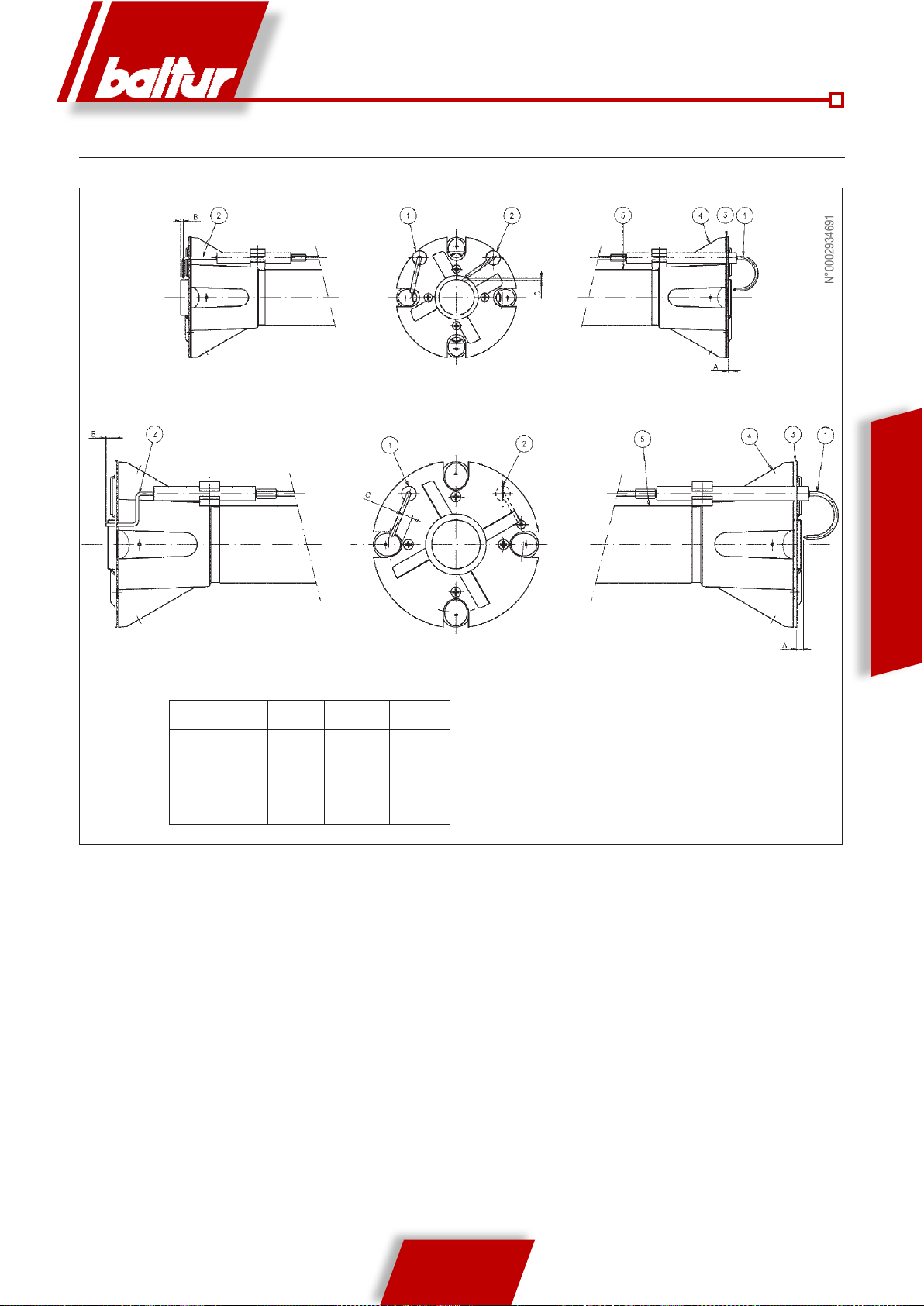

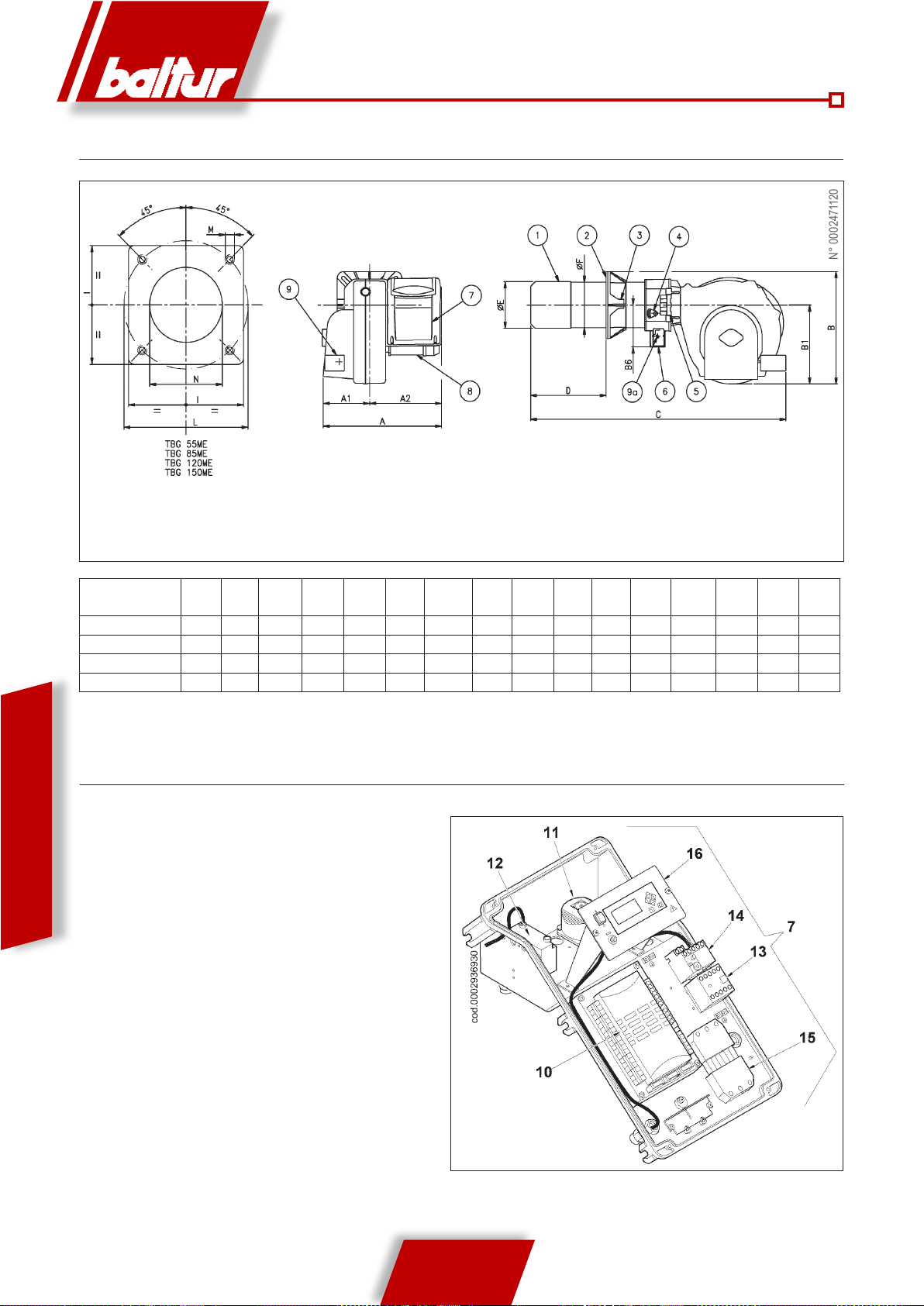

OVERALL DIMENSIONS

ENGLISH

MOD. G A1 A2 B B1 B6 C

TBG 85ME 610 240 370 520 380 200 1265 175 400 180 178 280 250 325 M12 190

TBG 120ME 610 240 370 540 380 200 1265 200 450 224 219 320 280 370 M12 235

TBG 150ME 610 240 370 540 380 200 1265 200 450 240 219 320 280 370 M12 250

TBG 210ME 610 240 370 540 380 200 1315 200 450 250 219 320 280 370 M12 255

ELECTRICAL PANEL COMPONENTS

10) Equipment

11) Air pressure switch

12) Ignition transformer

13) Motor contactor

1) Combustion head

2) Gasket

3) Burner coupling ange

4) Combustion head adjustment device

5) Hinge

6) Gas train coupling ange

7) Electrical panel

8) Motor

9) Air adjustment servomotor

9a) Gas adjustment servomotor

D

MINDMAX

E F E

L

MINLMAX

M H

14) Thermal Relay

15) 7 pole plug

16) Mimic panel

6 / 20

0006081531_201203

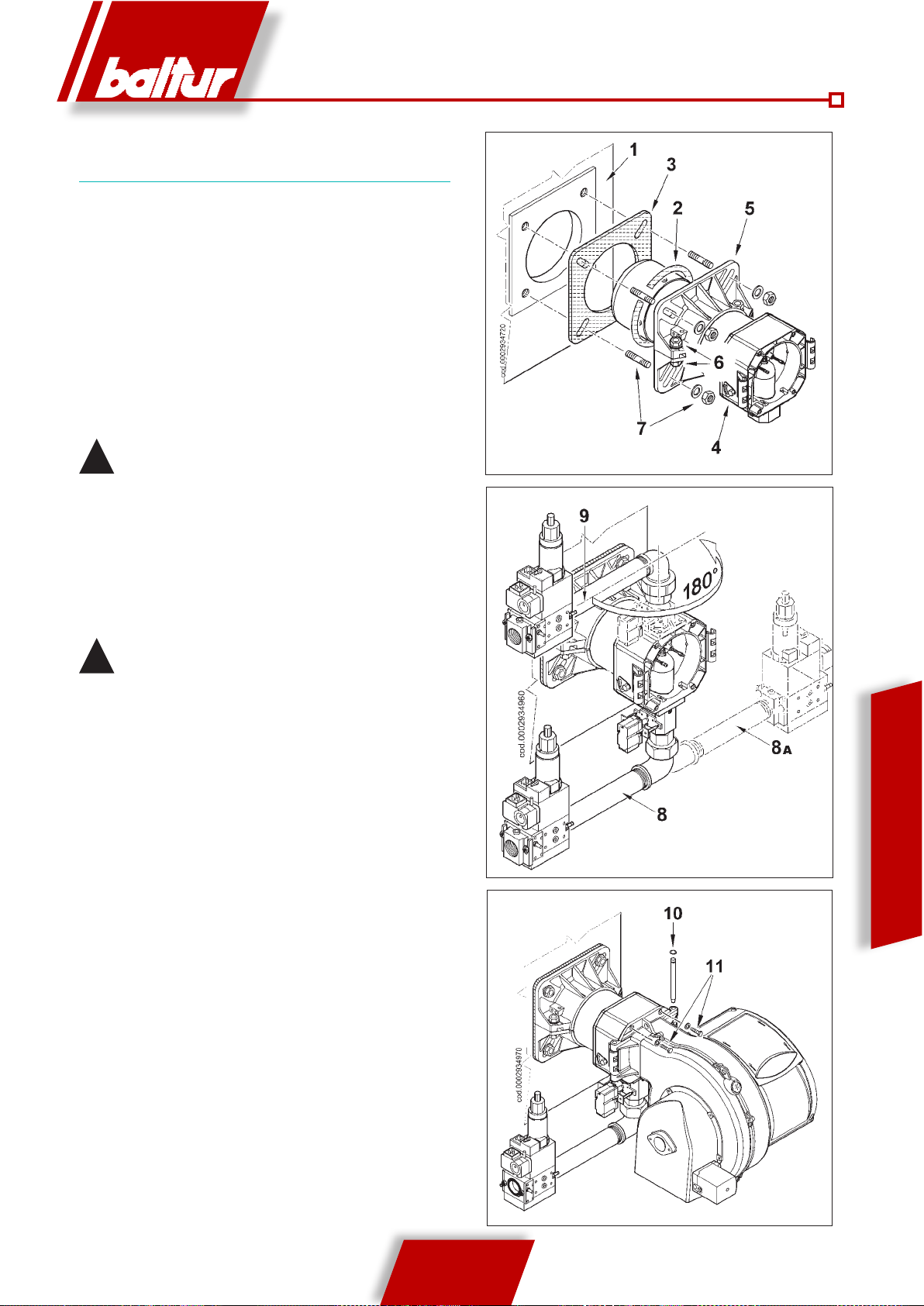

CONNECTING THE BURNER TO THE

BOILER

ASSEMBLING THE HEAD UNIT

A) Adjust the position of the coupling flange 5 by

loosening the screws 6 so that the combustion

head penetrates into the furnace to the extent

recommended by the generator manufacturer.

B) Position the insulating gasket 3 on the sleeve

inserting cord 2 between flange and gasket.

C) Fasten the Head unit 4 to the boiler 1 by means of

the stud bolts, washers and the nuts provided 7.

Completely seal the gap between the burner sleeve and

!

the hole in the refractory material inside the boiler door

with suitable material.

ASSEMBLING THE GAS TRAIN

There are different ways of assembling the valve train,

8, 8a and 9 as shown in the drawing. Choose the most

rational position for the set-up of the boiler room and

the position in which the gas pipeline arrives.

In case of very large valves, e.g. DN65 or DN80, make

!

sure there is a suitable support to prevent excessive

stress on the gas train fitting.

ENGLISH

ASSEMBLING THE VENTILATING UNIT

A) Position the half-hinge on the burner scroll in line

with those on the head unit.

B) Insert the hinge pin 10 in the position considered

most suitable.

C) Connect the cables (ignition and ionisation) to the

corresponding electrodes, close the hinge, locking

the burner by means of screws 11.

0006081531_201203

7 / 20

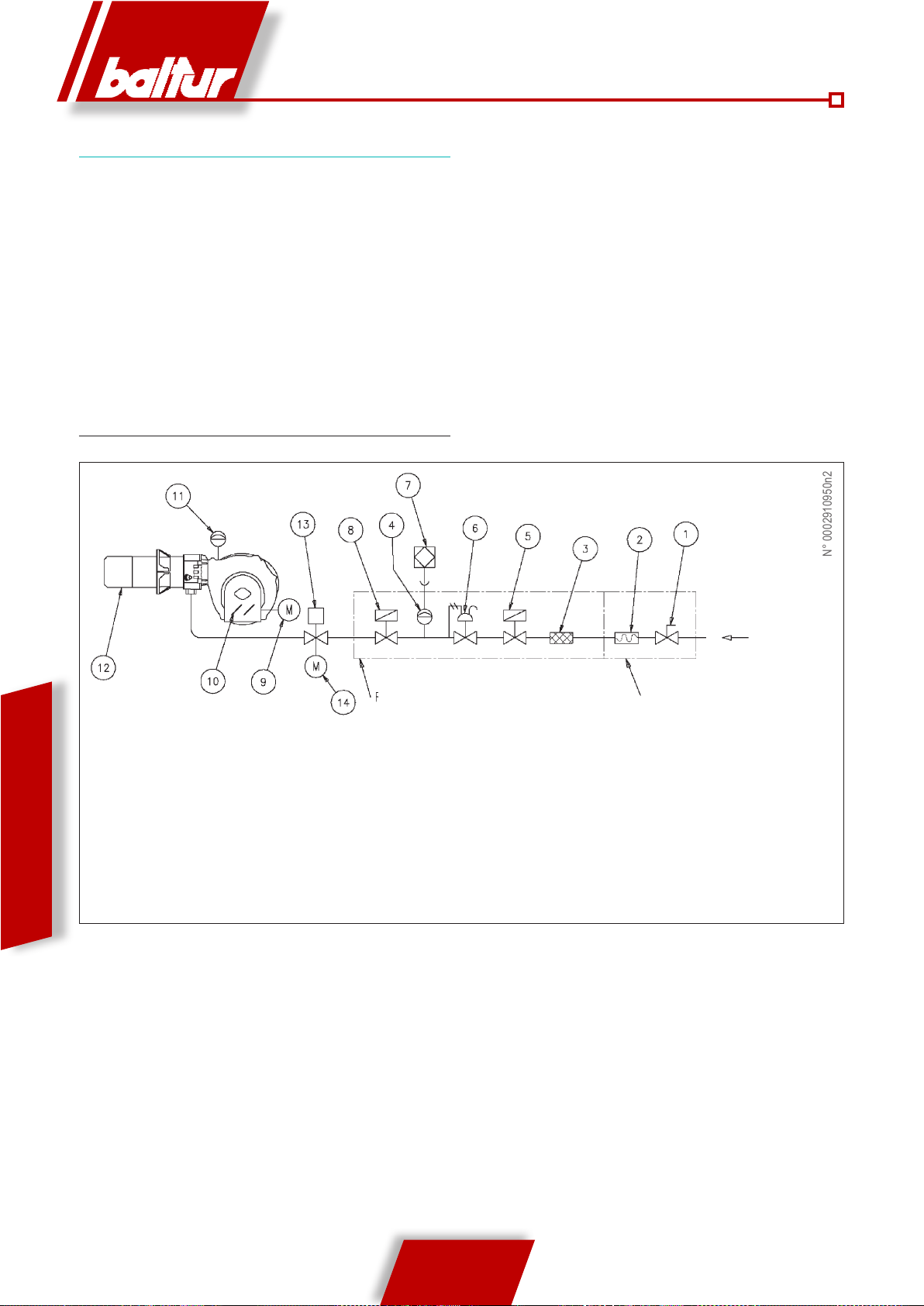

N° 0002910950n2

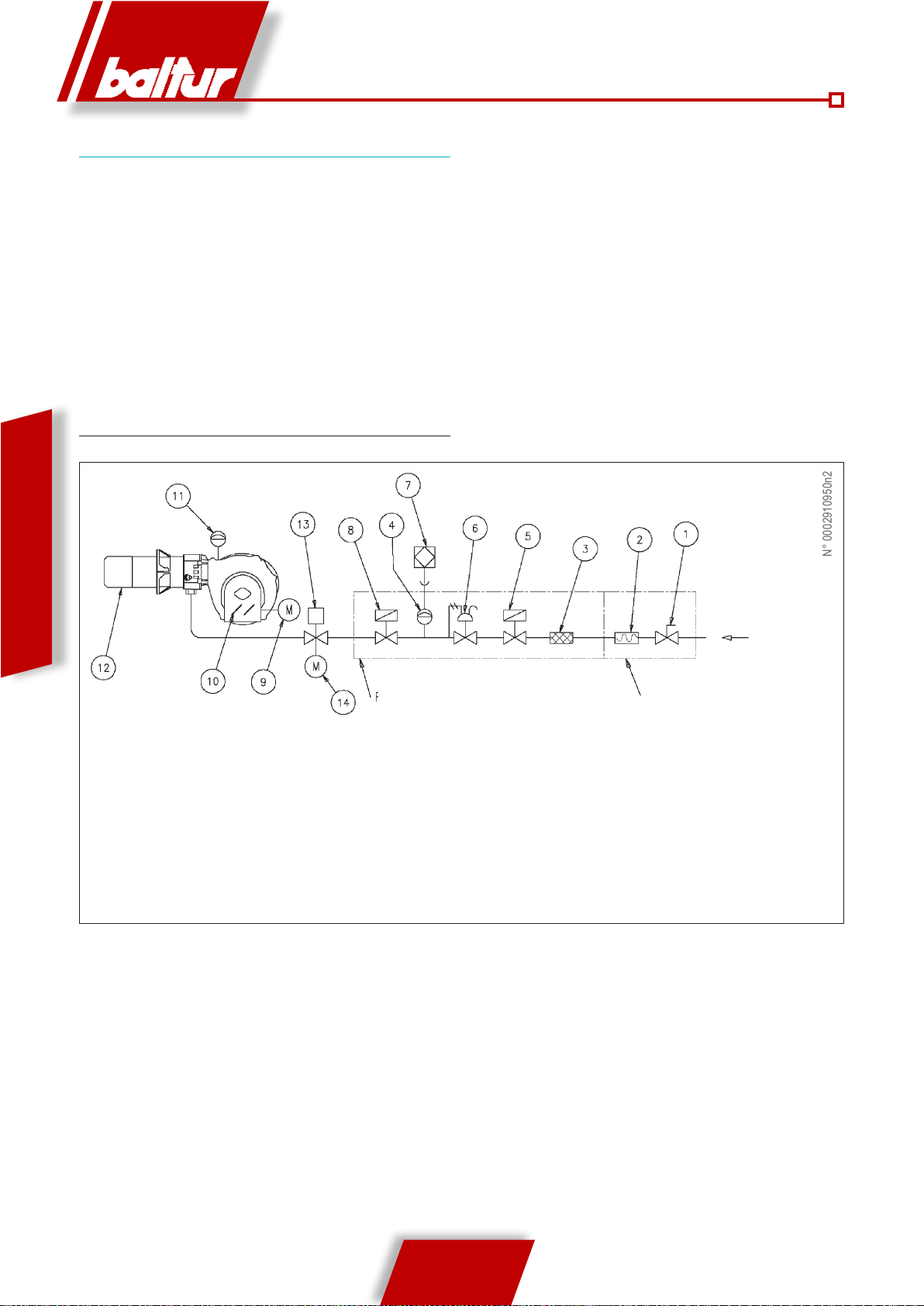

GAS SUPPLY LINE

The gas supply diagram is shown in the figure below.

The gas train is certified in accordance with Standard

EN 676 and is supplied separately from the burner. A

manual shut off valve and an anti-vibration joint must

be installed upstream of the gas valve, as shown in the

diagram.

GENERAL GAS BURNER DIAGRAM

ENGLISH

1) Manual shut off valve

2) Anti-vibration joint

3) Gas filter

4) Minimum gas pressure switch

5) Safety valve

6) Pressure regulator

7) Valve tightness control device

Gas train supplied by the manufacturer

8) Main valve

9) Air adjustment servomotor

10) Air adjustment shutter

11) Air pressure switch

12) Combustion head

13) Gas adjustment butterfly valve

14) Air/gas adjustment servomotor

Responsibility of the installer

8 / 20

0006081531_201203

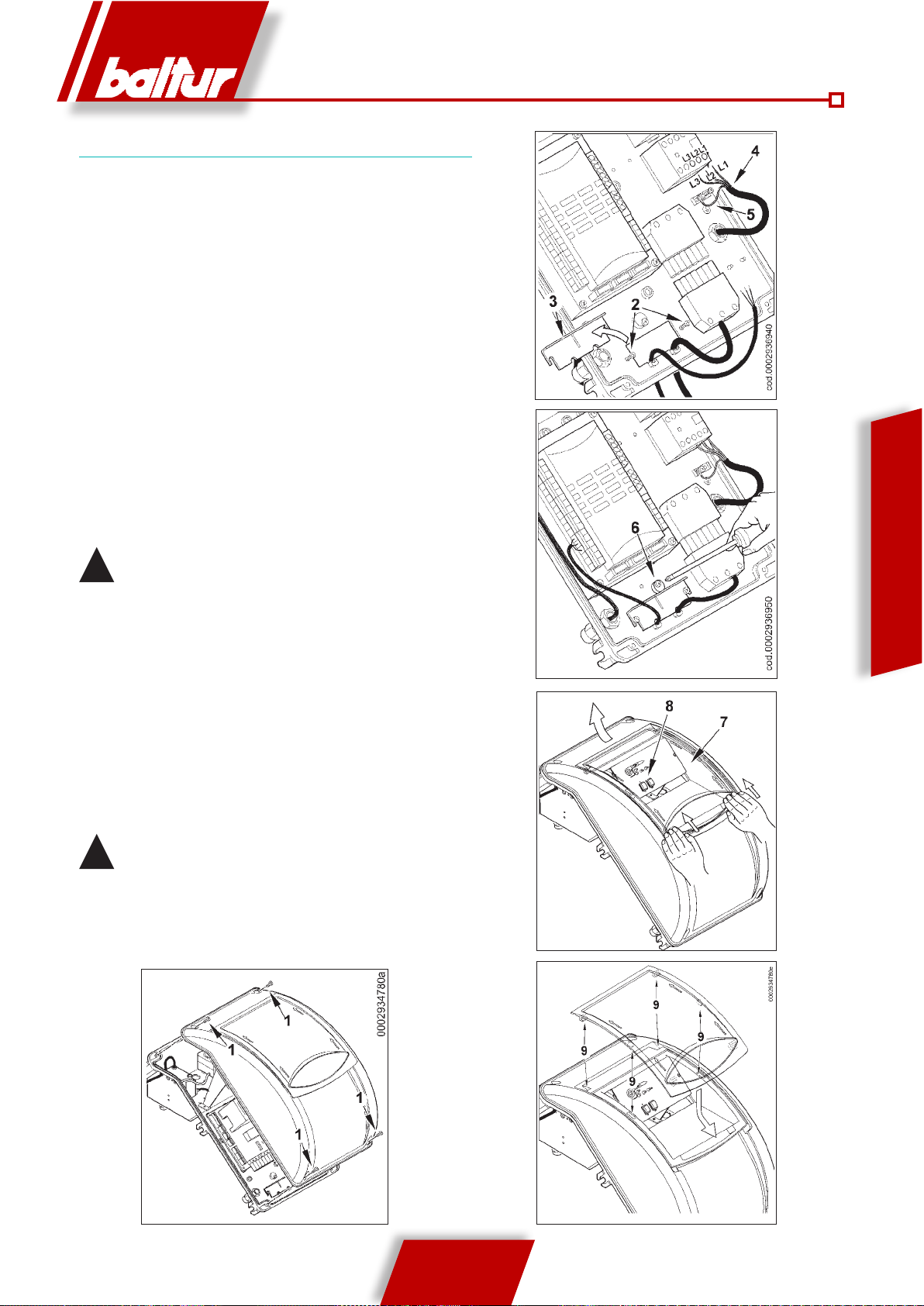

ELECTRICAL CONNECTIONS

The three-phase power supply line must have a switch with fuses.

Moreover, the Standards require a switch on the burner power supply

line, placed outside the boiler room and in an easily accessible position.

For the electrical connections (line and thermostats), follow the attached

wiring diagram. To carry out the connection of the burner to the power

supply line proceed as follows:

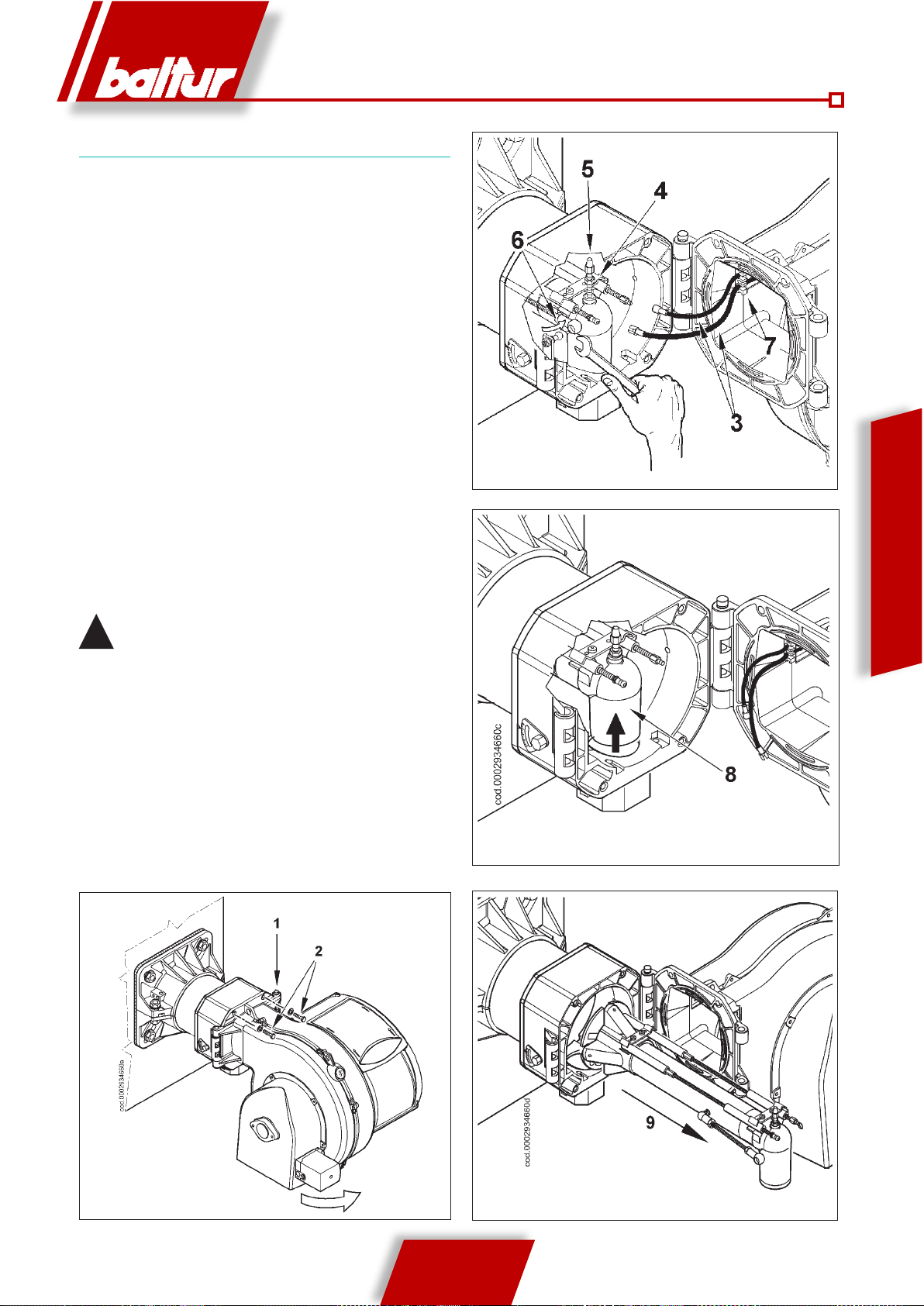

1) Remove the lid by unscrewing the 4 screws (1) in figure

1, without removing the transparent door. In this way

the burner’s electrical panel can be accessed.

2) Loosen the screws (2) and after removing the cable

clamp plate (3), make the 7 pole plug and modulation

control cable come through the hole (fig. 2). Connect

the power supply cables (4) to the radio control switch,

fix the earth cable (5) and tighten the cable gland.

3) Reposition the cable clamp plate (fig. 3). Turn the cam

(4) so that the plate exerts sufficient pressure on the

two cables, then tighten the screws that fasten the plate.

Finally connect the 7 pole plug and the modulation

control cables.

The housings for the cables are provided respectively

!

for cable Ø 9.5÷10 mm and Ø 8.5÷9 mm, this ensures the

protection rating is IP 54 (Standard IEC EN60529) for the

electrical panel.

4) To reclose the electrical panel lid, tighten the 4 screws (1) with a

tightening torque of about 5 Nm to ensure correct tightness. At this

point, to access the control panel (8), unhook the transparent door

(7), pressing gently with your hands in the direction of the arrows

shown in figure 4, slide it a short distance to separate it from the

lid.

Fig. 2

ENGLISH

Fig. 3

5) To secure the transparent door on the panel properly, proceed as

indicated in figure 5: position the hooks at their hooking points (9),

slide the door in the direction indicated by the arrow until you hear

a click that ensures its seal.

important: only professionally qualified personnel may open

!

the burner electrical panel.

Fig. 4

9 / 20

0006081531_201203

Fig. 5Fig. 1

DESCRIPTION OF TWO-STAGE

PROGRESSIVE OPERATION

Blown air burners with electronic modulation may be used on

hearths under strong pressure or in a vacuum, according to the

corresponding operating curves. They combine a very stable flame

with total safety and high performance.

The burner is equipped with a LAMTEC electronic cam model “BT

3xx” controlled by a microprocessor with intermittent operation, to

control and monitor blower gas burners with electronic modulation

by means of two regulating motors (air/gas). During operation as

automatic burner, a valve tightness control is also incorporated. To

better understand the operation of the “BT 3xx” electronic cam, read

carefully the instructions in the attached manual.

The term two-stage progressive operation means that transition

from the first to the second stage flame (from minimum to maximum

operation) is progressive in terms of both amount of combustive air

supply and the amount of fuel, offering significant benefits for the

stability of pressure in the gas supply network. Ignition is preceded

by the combustion chamber pre-ventilation (as set forth by the

Standards), with air open and with a duration of approx. 30 seconds.

If the air pressure switch has detected a sufficient pressure, the

ignition transformer activates at the end of the ventilation phase

and after 3 seconds the safety and main valves open in sequence.

ENGLISH

The gas reaches the combustion head, mixes with air supplied by

the fan and ignites. The gas supply is regulated by the butterfly gas

valve. Three seconds after the valves (main and safety) activate,

the ignition transformer switches off. Thus the burner is ignited at

2

the ignition point (

by the control device (ionisation probe immersed in the flame).

The programmer relay moves past the locking position and sends

voltage to the air/gas supply adjustment servomotors, which go

to the minimum point (200). If the second stage boiler thermostat

(or pressure switch) allows it (set to a temperature or pressure

value higher than the existing value in the boiler), the air/gas

supply servomotors will start to turn, gradually increasing gas and

combustion air supplies up to the maximum supply to which the

burner has been set (999).

The “BT 3xx” electronic cam commands the

!

burner, activating the combustive air and gas

servomotor on the basis of a pre-set curve.

The burner remains in the maximum supply position until the

temperature or pressure has reached a sufficient value to cause

the second stage boiler thermostat (or pressure switch) to trip,

which makes the air/gas supply adjustment servomotors turn in the

opposite direction to the previous one, gradually reducing gas and

combustive air supply until the minimum value.

If the limit value (temperature or pressure) at which the stop device

is set (thermostat or pressure switch) is reached even with gas

supply at minimum level, the burner is shut down by the device. As

the temperature or pressure drops below the shut-down device's

set point, the burner will be turned on again as described above.

During normal operation the second stage boiler thermostat (or

pressure switch) applied to the boiler detects variations in demand

and automatically adapts fuel and combustion air supplies, activating

the air/gas supply adjustment servomotors with increasing or

decreasing rotation. This causes the air/gas supply control system

). The presence of the flame is detected

to balance the amount of heat supplied to the boiler with the amount

it gives off during use.

If a flame does not appear within three seconds from the opening

of the gas valves, the control equipment will lockout (shutting down

the boiler completely and showing the corresponding error message

on the display (3)).

To "unlock" the equipment, press the RESET button (4) for about

half a second.

DETAIL OF BUTTERFLY VALVE FOR GAS FLOW

REGULATION BY MEANS OF SERVOMOTOR

farfallaTBG ME

A

B

A Butterfly gas valve position reference index.

B Gas modulation servo motor.

10 / 20

0006081531_201203

NATURAL GAS IGNITION AND ADJUSTMENT

1) The air contained in the piping must be bled out,

with due precautions and with doors and windows

open. Open the fitting on the piping situated near

the burner and then open a little the gas shut-off

valve (or valves). When the characteristic odour of

gas can be smelled, close the shut-off valve. Wait

long enough for the gas in the room to disperse, and

then connect the burner to the gas pipe again and

open the valve again.

2) Check that there is water in the boiler and that the

system gates are open.

3) Make absolutely sure that the products of combustion

can be released freely (boiler shutter valve and flue

open).

4) Make sure that the voltage of the power line to

which the burner is to be connected corresponds

to that required by the burner and that the electrical

connections (motor or main line) are designed for

the voltage rating available. Also check that all the

electrical connections carried out on site are in

accordance with our wiring diagram.

5) Make sure that the combustion head is long enough

to enter the furnace to the extent specified by the

boiler manufacturer. Check that the air adjustment

device on the combustion head is in the correct

position for the fuel supply required (the air passage

between the disk and the head must be reduced

for low supply and relatively wide when supply is

higher). See chapter “Combustion head airflow

adjustment”.

6) Fit a pressure gauge with suitable full scale (where

1

5

1 - Main switch On/Off

2 - Programming keys

3 - Display

4 - Confirm or RESET key

5 - Fuse

3

4

2

the pressure level envisaged allows it, a liquid

column manometer is preferable; do not use pointer

gauges for low pressures) to the pressure outlet port

on the gas pressure switch.

7) With the switch (1) on the mimic panel switched to

“O” and the main switch turned on, manually close

the remote control switch and check that the motor

revolves in the correct direction. If necessary,

exchange the position of the two cables in the line

that feeds the motor in order to reverse the direction

of revolution.

8) Now switch on the main switch. With the control

equipment receivin g elect r i c a l p o w e r, th e

programmer will cause the burner to start up as

described in chapter “Operation description”. For

burner adjustment, refer to the supplied instructions

for the "BT 3xx" electronic cam.

9) After having adjusted the "minimum", (200) bring the

burner towards the maximum, using the controls on

the “BT 3xx” keyboard.

10) We recommend that you check combustion

using the appropriate instrument at all intermediate

points on the modulation route (from 200 to 999),

checking the gas flow rate by reading the meter.

It is essential to check, with a suitable instrument,

that the percentage of carbon monoxide (CO)

present in the fumes does not exceed the limit set

by regulations in force at the time of installation.

11) Now check the proper automatic operation of

modulation. This ensures that the equipment

receives the signal from the electronic modulation

regulator, if the burner is the modulating model,

or from the second stage thermostat or pressure

switch, if it is a two stage progressive burner.

12) The air pressure switch has the purpose of switching the

equipment into the safety (lock-out) status if the air pressure is

not what it should be. The pressure switch must therefore be set

to close the contact (closed during operation) when air pressure

in the burner is sufficient. The pressure switch connection circuit

is self controlling. Therefore, the contact which is meant to be

closed in a non operating status (fan stopped and thus no air

pressure in burner), should in fact be in this status, otherwise

the command/control equipment will not be switched on (burner

remains inoperative). Please note that if the contact meant to

be closed during operation does not close (insufficient air pressure), the equipment carries out its cycle but the ignition transformer is not switched on and the fuel valves do not open. As

a result, the burner stops. To verify that the air pressure switch

is operating correctly, while the burner is ignited at its minimum

setting, increase the adjustment value until the switch triggers

instant “lock” stop of the burner. Release the burner by pushing

the appropriate button and readjust the pressure switch to an

adequate value to detect the existent air pressure during the

pre-ventilation phase.

13) The pressure switches for checking gas pressure (minimum

display lamtec BT3xx

ENGLISH

11 / 20

0006081531_201203

and maximum) prevent the burner from operating when gas pressure

is between the expected values. The specific function of the

pressure switches clearly reveals that the pressure switch for

controlling minimum pressure must use the contact which is

closed when the pressure switch detects a pressure value

above the value it is set to, while the pressure switch for

controlling maximum pressure must use the contact that is

closed when the pressure switch detects a pressure lower

than the value it is set to. Minimum and maximum gas pressure

switches must be set when the burner is tested. Setting depends

on pressure detected from time to time. Tripping of any of the

gas pressure switches (in the sense of opening the circuit) will

therefore prevent the equipment and therefore the burner from

working. When the burner is working (flame on), tripping the

gas pressure switches (opening the circuit) will shut down the

burner immediately. When testing the burner, it is very important

to check that the pressure switches are working properly. By

using the adjustment devices, it can be verified whether the

pressure switch that stops the burner actually operates (i.e.

opens the circuit).

14) Verify the flame detector operation as follows:

- disconnect the wire coming from the ionisation electrode,

- Start up the burner;

ENGLISH

- The equipment will complete the control cycle and after

two seconds will lock the burner due to the lack of ignition

ame;

- switch off the burner;

- Re-connect the wire to the ionisation electrode.

This test should also be conducted with the burner already on;

the equipment should "lock" immediately when the wire from

the ionisation electrode is disconnected.

IONISATION CURRENT MEASUREMENT

The minimum current needed to run the equipment is 1.4 µA. The

burner provides a significantly higher current and therefore does not

normally require any checks at all. Should however, the ionisation

current need to be measured, a microammeter must be connected

in series to the ionisation electrode lead by opening the connector

“C” as illustrated in the figure.

ioniz_BT3xx

15) Check the efficiency of the boiler thermostats or pressure

switches (when tripping they must stop the burner).

Check that ignition occurs normally since if

!

the mixer is not positioned correctly, it may

happen that the speed of the delivery air is so

high that ignition is difficult. If this happens,

the mixer must be shifted back by degrees

until it is in a position in which ignition

occurs normally, and this new position can

be regarded as the final position.

Remember that for the ignition flame, it is better to limit the

amount of air to the amount strictly indispensable to ensure

safe ignition even in the most difficult cases.

12 / 20

0006081531_201203

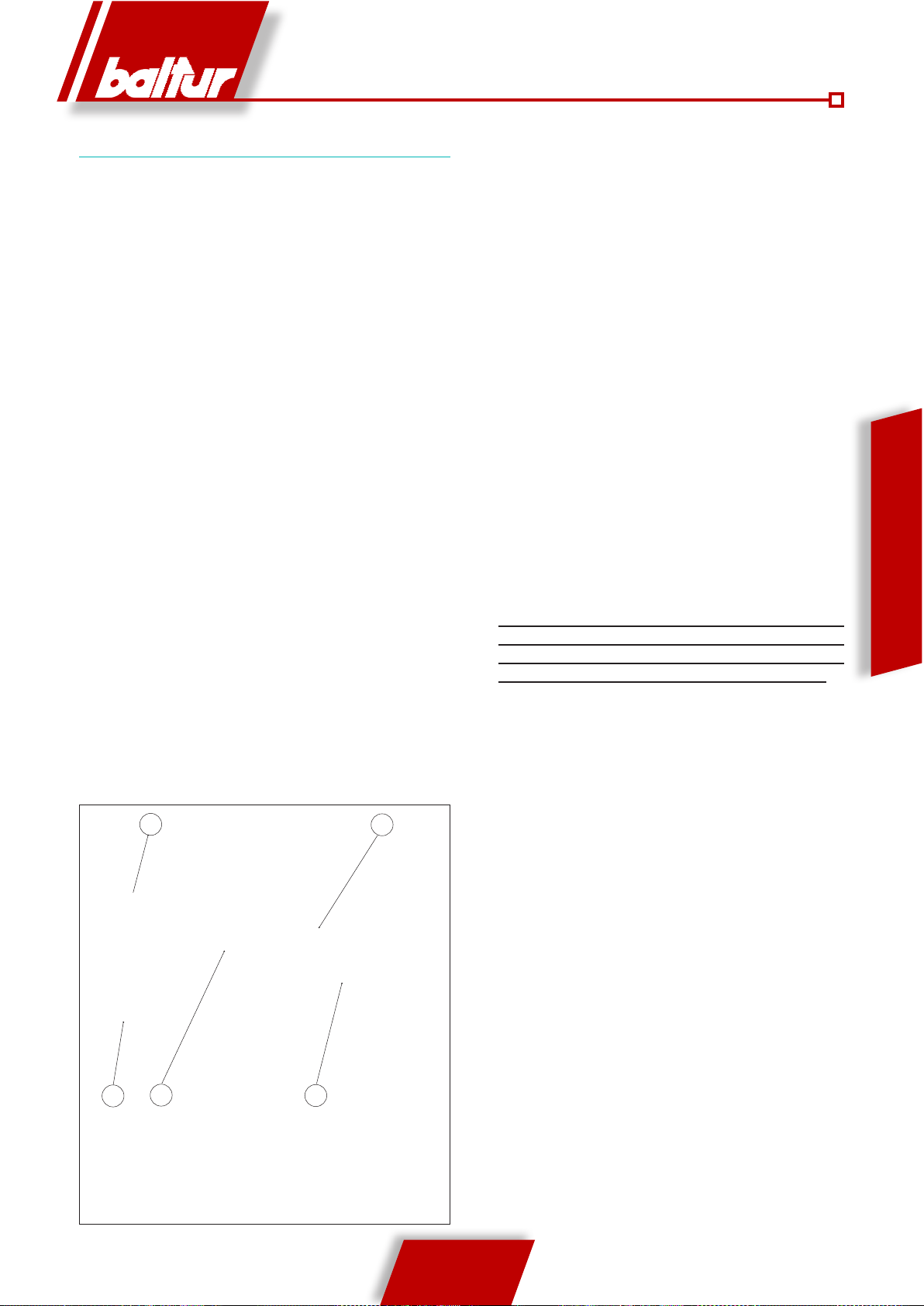

N°0002934691

ELECTRODES/IONISATION PROBE ADJUSTMENT DIAGRAM

TBG 85P / 85PN / 85ME,

ENGLISH

TBG 120P / 120PN / 120ME, TBG 150P / 150PN / 150ME,

TBG 210P / 210PN / 210ME

Mod. A B C

TBG 85ME 5 3 3

TBG 120ME 5 5 TBG 150ME 15 5 6

TBG 210ME 5 5 -

1 Ionisation electrode

2 Ignition electrode

3 Flame disk

4 Mixer

5 Gas delivery pipe

13 / 20

0006081531_201203

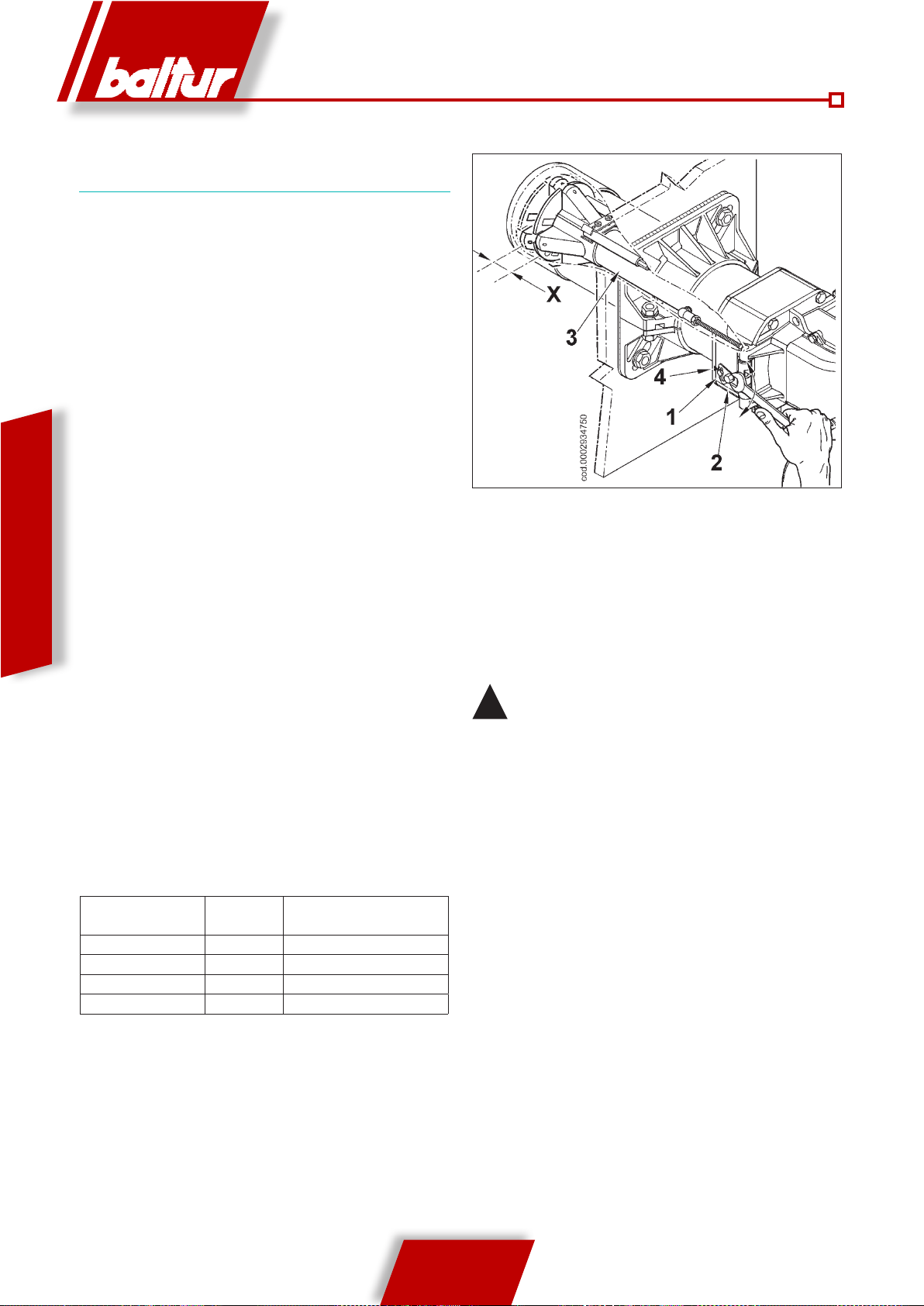

ADJUSTI NG THE AI R ON THE

COMBUSTION HEAD

The combustion head has an adjustment device so that

the air passage between the disk and the combustion

head can be opened or closed. You are thus able to

obtain, by closing the passage, high pressure upstream

of the disk even at low capacity. The high speed and

turbulence of the air provides for its greater penetration

into the fuel and therefore an excellent mixture and

flame stability. High air pressure upstream of the disk

may be necessary to prevent flame fluctuations, this

is particularly essential when the burner works on the

furnace that is pressurised and/or at a high thermal load.

It is clear from the above that the device that closes the

air to the combustion head must be set at a position

such as to always obtain very high air pressure behind

the disk. It is advisable to adjust it in such a way as to

obtain a closure of the air at the combustion head that

will require a significant opening of the air shutter that

regulates the suction flow from the burner fan. This must

of course be the case when the burner is working at the

required maximum supply.

In practice you have to start the adjustment with the

ENGLISH

device that closes the air at the combustion head in

an intermediate position, switching on the burner for

approximate adjustment as explained previously.

When the required maximum supply has been

reached, the position of the device that closes the

air at the combustion head has to be corrected,

moving it forward and backwards, in order to obtain

an air flow suitable for the supply with the air shutter

considerably open.

COMBUSTION HEAD ADJUSTMENT DIAGRAM

X= Combustion head-disk distance; adjust the distance X following

the indications below:

a) loosen screw 1

b) turn screw 2 to position the combustion head 3, referring to

index 4.

c) adjust the distance X between minimum and maximum

according the indications in the table.

The above adjustments are indicative only; position the

!

combustion head according to the characteristics of the

combustion chamber

BURNER X Value indicated by index 4

TBG 85ME 5÷ 36 1 ÷ 4.5

TBG 120ME 17÷ 54 1 ÷ 5

TBG 150ME 17÷ 36 1 ÷ 3.2

TBG 210ME 14 ÷ 51 1 ÷ 5

0006081531_201203

14 / 20

MAINTENANCE

Analyse combustion gases and check that the emission values are

correct at least once a year, in compliance with current law.

Check the fuel filter: if it is dirty, replace it.

Check that all components of the combustion head are in good

condition, have not been deformed by high temperatures and contain

no impurities or deposits from the installation environment or from

poor combustion; check the efficiency of electrodes.

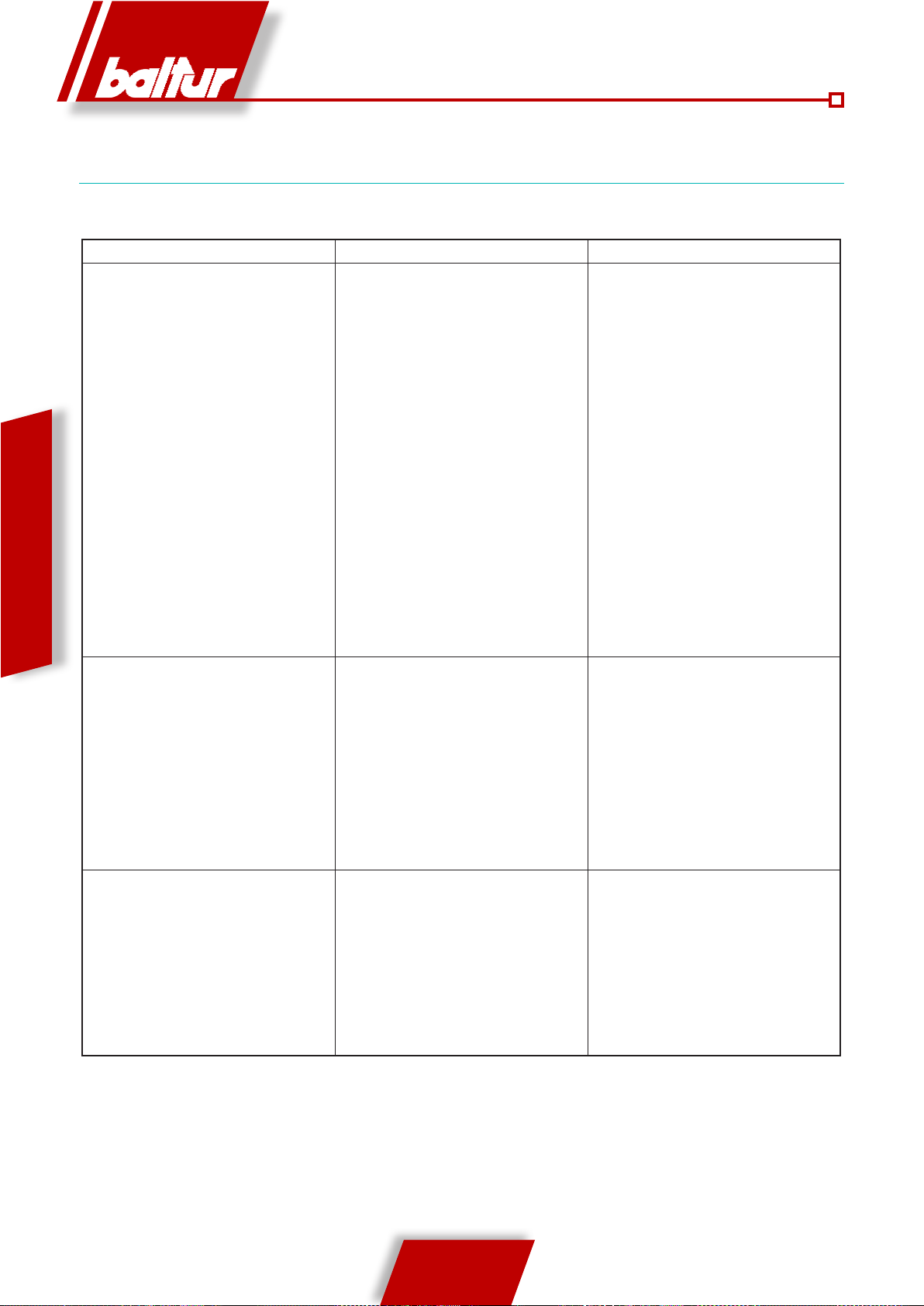

If it is necessary to clean the combustion head, take out its

components according to the procedure described below:

Unscrew the two screws (2) and turn the burner around the pin (1)

in the hinge.

After pulling out the ignition and ionisation cables (3) from the

terminals of the respective electrodes, unscrew completely the

nut (4) and tighten the screw (5), moving it forward inside the gas

delivery fitting (8) far enough to permit subsequent dismantling of

the mixing unit. With the same wrench turn the ball joint (6) in the

direction indicated by the arrow, unhooking the lever that moves the

combustion head forward.

Slightly raise the gas delivery fitting (8) and remove the entire mixing

unit in the direction indicated by the arrow (9). Having completed

the maintenance works, refit the combustion head, following in

reverse order the operations described above, after having checked

the correct position of the ignition and ionisation electrodes (see

0002934691).

When closing the burner, gently pull towards the

!

electrical panel, putting the two ignition and ionisation

cables slightly in tension, then arrange them into their

housings (7) as in figure 2. This will ensure that the two

cables do not get damaged by the fan during burner

operation.

figura-2

ENGLISH

gura 1

15 / 20

0006081531_201203

figura-3

figura-4

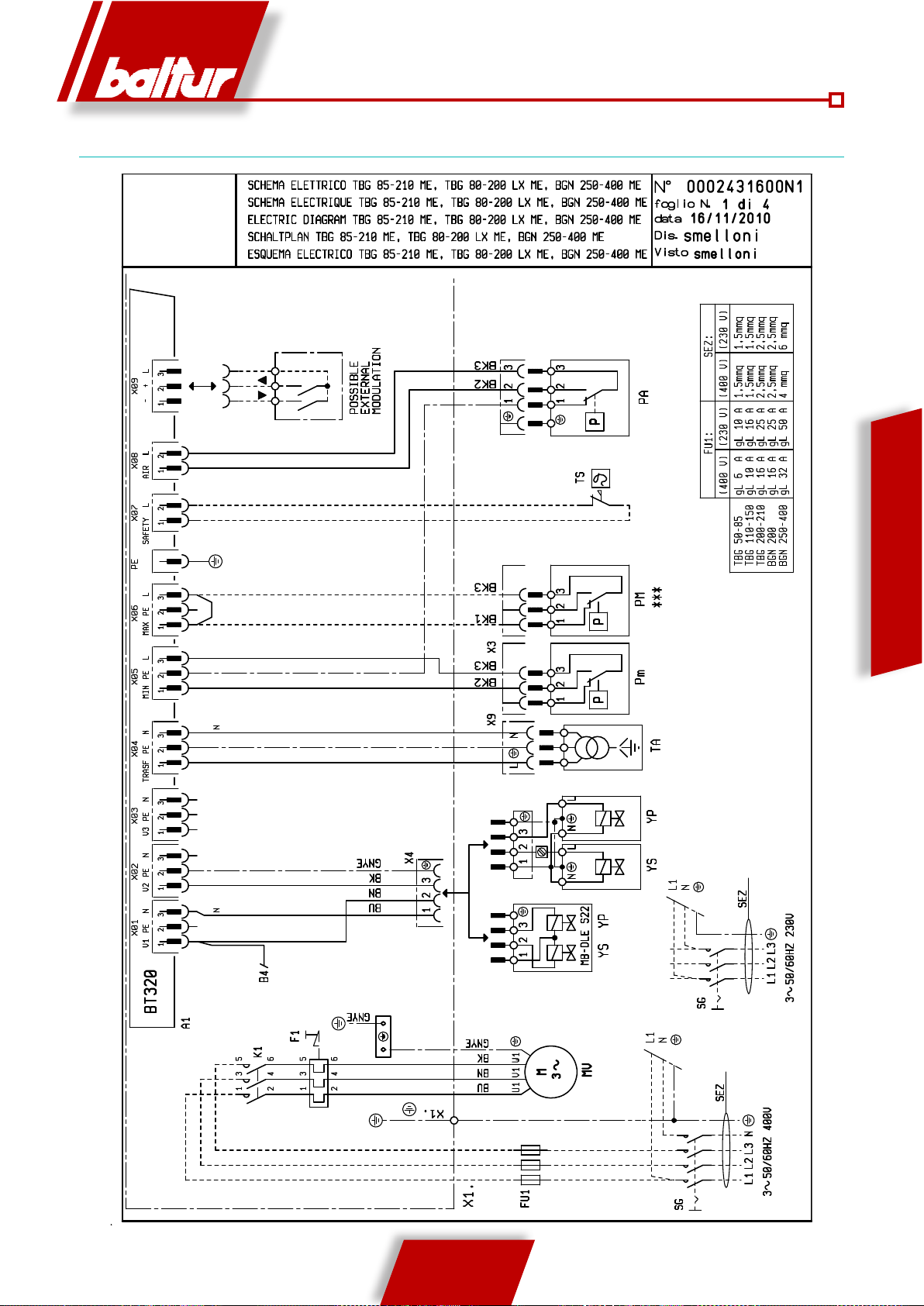

HOW TO FIND THE CAUSES OF IMPROPER OPERATION OF TWO-STAGE GAS BURNERS

AND HOW TO RECTIFY THEM

The equipment goes into “lock-out” with

the f lame ( red ligh t on) . Mal functioning is due to the flame

control device.

ENGLISH

The equipment goes into “lock-out”,

gas ows out, but there is no ame

(red light on).

F a u l t i n i g n i t i o n

circuit.

The equipment goes into “lock-out”,

gas ows out, but there is no ame

(red light on)

PROBLEM POSSIBLE CAUSE SOLUTION

1) Disturbance to ionisation current from

ignition transformer.

2) Inefficient flame sensor (ionisation

probe).

3) Flame sensor (ionisation probe) position

incorrect.

4) Ionisation probe or relative earth cable.

5) Flame sensor electrical connection

cut-off.

6) Inefcient draught or fumes passage

blocked.

7) Flame disk or combustion head dirty

or worn.

8) Faulty equipment.

9) No ionisation.

1) Fault in ignition circuit.

2) Ignition transformer cable discharges

to earth.

3) Ignition transformer cable disconnected.

4) Faulty ignition transformer.

5) The distance between electrode and

earth is incorrect.

6) Isolator dirty, therefore the electrode

discharges to earth

1) Air/gas ratio incorrect.

2) Gas piping has not been properly bled

of air (in the case of rst ignition).

3) The gas pressure is insufcient or

excessive.

4) Air passage between disk and head

too narrow.

1) Invert the ignition transformer power

supply (230V side) and check using an

analogue micro-ammeter.

2) Replace the ame sensor

3) Correct the position of the ame sensor,

and then check its efciency by connecting the analogue micro-ammeter.

4) Check visually and using the instrument.

5) Restore the connection.

6) Ensure that the boiler fumes passage

and chimney connection are free.

7) Visually check and replace, if necessary.

8) Replace.

9) If the “earth” of the equipment is not

efcient, the ionisation current cannot

be checked. Check the efciency of the

“earth” at the terminal concerned in the

equipment and at the “earth” connection

of the electric system.

1) Check the ignition transformer power

supply (230V) and high voltage circuit

(electrode to earth or isolator broken

under locking terminal).

2) Replace.

3) Connect.

4) Replace.

5) Position at the correct distance

6) Clean or change the isolator or electrode.

1) Correct the air/gas ratio (there

is probably too much air or very

little gas)

2) Bleed the gas pipe again, taking

great care.

3) Check the gas pressure value at

the time of ignition (use a water

pressure gauge, if possible).

4) Adjust the disk/head opening.

16 / 20

0006081531_201203

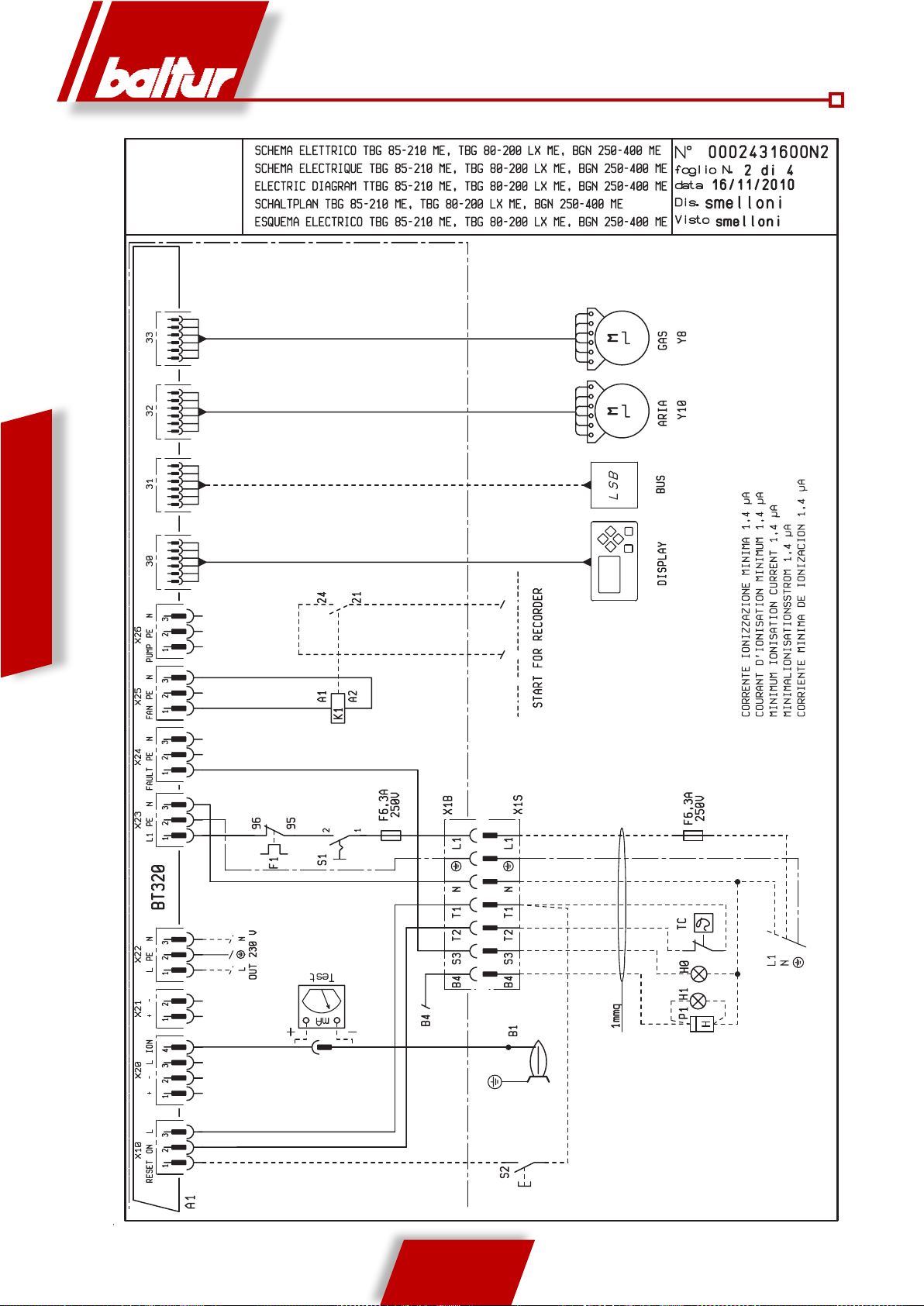

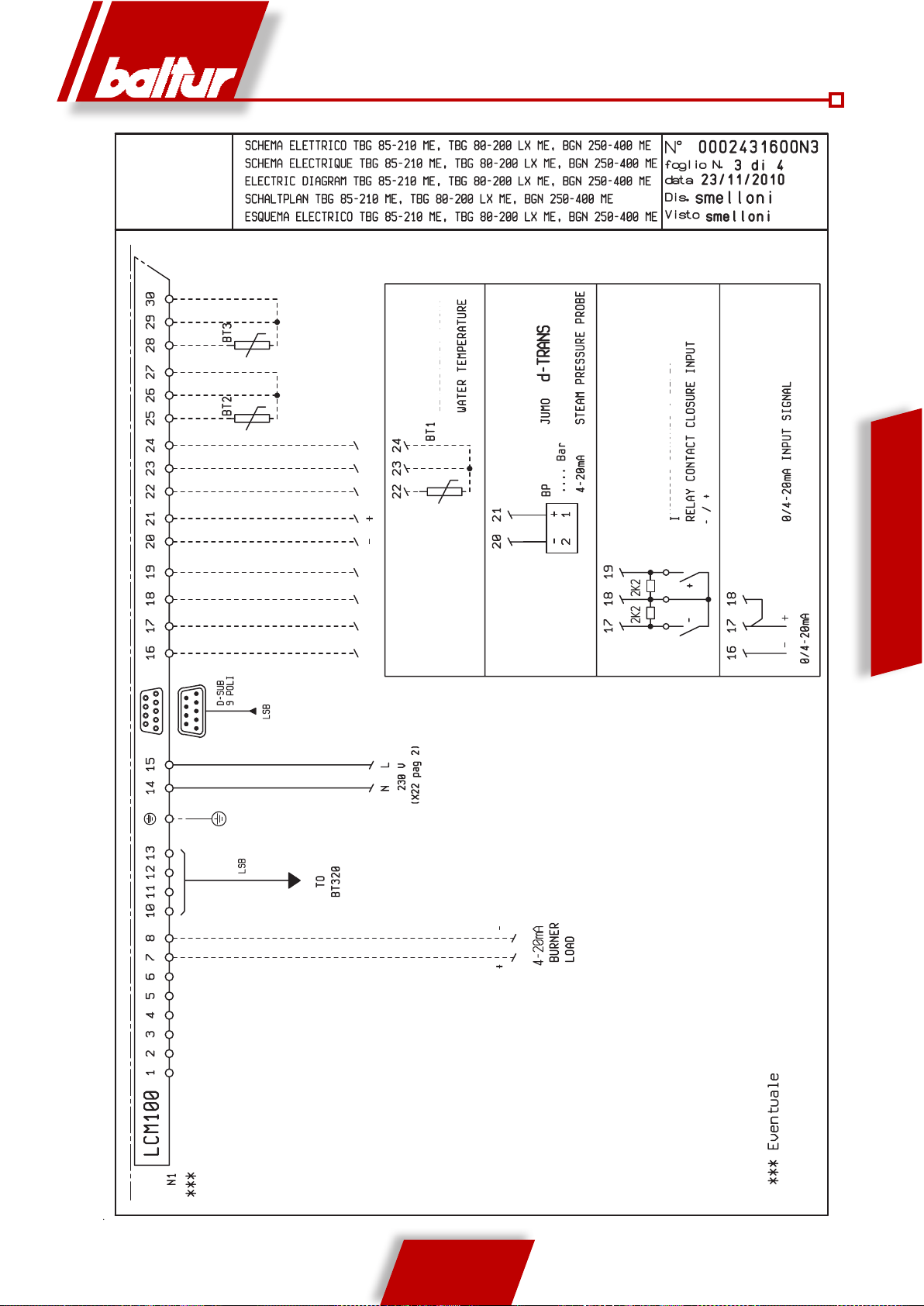

WIRING DIAGRAM

ENGLISH

17 / 20

0006081531_201203

ENGLISH

MINIMUM IONISATION CURRENT 1,5 µA

START FOR RECORDER

18 / 20

0006081531_201203

GAS TEMPERA-

TURE

PROBE

OUTER TEM-

PERATURE

PROBE

WATER TEMPERATURE

PRESSURE PROBE

RELAY COMMAND INPUT

COMMAND INPUT 0/4 - 20 mA

ENGLISH

19 / 20

0006081531_201203

*** POSSIBLE

ENGLISH

ABBREVIATION EN

A1 EQUIPMENT

B1 IONISATION ELECTRODE

BP PRESSURE PROBE

BT 1-3 TEMPERATURE PROBE

DW VALVE TIGHTNESS CONTROL PRESSURE SWITCH

F1 THERMAL RELAY

FU1 FUSES

HO EXTERNAL SHUTDOWN INDICATOR LIGHT

H1 OPERATION LIGHT

K1 MOTOR RELAY

MV MOTOR

N1 ELECTRONIC REGULATOR

P M GAS MAX. PRESSURE SWITCH

P1 HOUR METER

PA AIR PRESSURE SWITCH

Pm GAS MIN. PRESSURE SWITCH

S1 ON-OFF SWITCH

S2 RESET PUSH BUTTON

SG MAIN SWITCH

TA IGNITION TRANSFORMER

TC BOILER THERMOSTAT

TS SAFETY THERMOSTAT

X1 BURNER TERMINAL

X1B/S POWER SUPPLY CONNECTOR

X3 Pm CONNECTOR

X4 YP CONNECTOR

X9 TRANSFORMER CONNECTOR

Y8 GAS SERVOMOTOR

Y10 AIR SERVOMOTOR

YP MAIN ELECTROVALVE

YS SAFETY ELECTROVALVE

DIN / IEC EN

GNYE GREEN / YELLOW

BU BLUE

BN BROWN

BK BLACK

BK* BLACK CONNECTOR WITH OVERPRINT

20 / 20

0006081531_201203

- Antes de empezar a usar el quemador léase atentamente lo expuesto en el folleto “ADVERTENCIAS PARA EL USUARIO, PARA EL

BALTUR S.p.A.

Via Ferrarese 10 - 44042 CENTO (Ferrara) ITALIA

Tel. 051.684.37.11 Fax 051.685.75.27/28

(International Tel. ++39.051.684.37.11 - Fax ++39.051.683.06.86)

http://www.baltur.it - http://www.baltur.com - E-MAIL info@baltur.it

USO CON SEGURIDAD DEL QUEMADOR” presente junto con el manual de instrucciones, que constituye parte integrante y esencial

del producto.

- Leer atentamente las instrucciones antes de poner en funcionamiento los quemadores o efectuar las tareas de mantenimiento.

- Los trabajos que se efectúen al quemador y a la instalación deben ser efectuados solamente por personal cualificado.

- La alimentación eléctrica de la instalación se debe desconectar antes de iniciar los trabajos.

- Si los trabajos ne se llevan a cabo correctamente, se pueden ocasionar accidentes peligrosos.

Declaración de conformidad

Declaramos que nuestros productos

BPM...; BGN…; BT…; BTG…; BTL…; TBML...; Comist…;

GI…; GI…Mist; Minicomist…; PYR…; RiNOx…; Spark...;

Sparkgas...; TBG...;TBL...; TBML ...; TS…; IBR...; IB...

(Variante: … LX, para emisiones reducidas de NOx)

Descripción:

los quemadores por aire a presión de combustibles líquidos, gaseosos y mixtos

para uso residencial e industrial cumplen los requisitos mínimos de las directivas comunitarias:

2009/142/CE ..............................................(D.A.G.)

2004/108/CE ...............................................(C.E.M.)

2006/95/CE .................................................(D.B.T.)

2006/42/CE ................................................(D.M.)

y cumplen las normas europeas:

UNI EN 676:2008 (gas y combinación, lado gas)

UNI EN 267:2002 (diésel y combinación, lado diésel)

Estos productos están marcados con:

0085

Dr. Riccardo Fava

18/11/2010

!

ADVERTENCIAS / NOTAS

CARACTERÍSTICAS TÉCNICAS ..................................................................................................................................................................................... 4

APLICACIÓN DEL QUEMADOR A LA CALDERA

LÍNEA DE ALIMENTACIÓN

CONEXIONES ELÉCTRICAS

DESCRIPCIÓN DEL FUNCIONAMIENTO DE DOS ETAPAS PROGRESIVAS

ENCENDIDO Y REGULACIÓN CON METANO

MEDICIÓN DE LA CORRIENTE DE IONIZACIÓN

REGULACIÓN DEL AIRE EN EL CABEZAL DE COMBUSTIÓN

MANTENIMIENTO

INSTRUCCIONES PARA VERIFICAR LAS CAUSAS DE IRREGULARIDADES EN EL FUNCIONAMIENTO Y SU ELIMINACIÓN

ESQUEMA ELECTRICO

.............................................................................................................................................................................................. 8

.......................................................................................................................................................................................... 9

........................................................................................................................................................................................................... 15

.................................................................................................................................................................................................. 17

i

INFORMACIÓN

............................................................................................................................................................ 7

............................................................................................................................................................... 11

..........................................................................................................................................................12

..................................................................................................................................... 14

Director Gerente/Director General

I

PELIGRO / ATENCIÓN

............................................................................................................... 10

.............................. 16

ESPAÑOL

1 / 20

0006081531_201203

• No hay que obstruir ni reducir las sección de las rejillas de aspiración del

colocado el quemador o una caldera, para evitar que se creen situaciones

de las placa correspondan con los de la red de alimentación (eléctrica,

están cerca de la llama y del eventual sistema de precalentamiento del

combustible y se calientan durante el funcionamiento, permaneciendo ca-

• Cuando se decida no utilizar de nitivamente el quemador, hay que encargar al personal cuali cado profesionalmente que realice las operaciones

a) Desconectar la alimentación eléctrica quitando el cable de alimentación

c) Hacer que sean inocuas las partes que podrían ser potenciales fuentes

• Asegurarse de que quien se ha encargado de la instalación del quemador

lo haya jado rmemente al generador de calor de manera que la llama se

el personal cuali cado profesionalmente tiene que realizar las siguientes

c) Controlar la combustión para evitar que se formen gases no quemados

nocivos o contaminantes, superiores a los límites consentidos por las

e) Comprobar que funcione correctamente el conducto de expulsión de

g) Asegurarse de que en el local donde está la caldera estén las instruc-

rearmándolo manualmente; diríjase al personal cuali cado profesional-

I

ADVERTENCIAS DIRIGIDAS AL USUARIO PARA USAR EL QUEMADOR EN

CONDICIONES DE SEGURIDAD PRELIMINARES

Estas advertencias tienen la nalidad de contribuir a la seguridad cuando

se utilizan las partes que se usan en instalaciones de calefacción de uso

civil y producción de agua caliente para uso sanitario, indicando qué hay

que hacer y las medidas que hay que adoptar para evitar que sus características originarias de seguridad dejen de serlo por una eventual instalación

incorrecta, un uso erróneo, impropio o inadecuado. La difusión de las

advertencias suministradas en esta guía tiene la nalidad de sensibilizar

al público de «consumidores» sobre los problemas de seguridad con un

lenguaje necesariamente técnico pero fácilmente comprensible. Queda

excluida toda responsabilidad contractual y extracontractual del fabricante

por daños causados debidos a errores en la instalación, en el uso y por no

haber respetado las instrucciones dadas por el fabricante en cuestión.

ADVERTENCIAS GENERALES

• El libro de instrucciones constituye una parte integrante y esencial del

producto y tiene que entregarse al usuario. Hay que leer detenidamente

las advertencias contenidas en el libro de instrucciones pues suministran

indicaciones importantes sobre la seguridad de la instalación, el uso y

el mantenimiento. Conserve con cuidado el libro para poder consultarlo

en cualquier momento.

• La instalación del aparato debe realizarse respetando las normas vigentes,

según las instrucciones del fabricante, y tiene que realizarla el personal

cuali cado profesionalmente. Por personal cuali cado profesionalmente

se entiende el que cuenta con una competencia técnica en el sector de la

calefacción de uso civil y producción de agua caliente para uso sanitario

y, en concreto, los centros de asistencia autorizados por el fabricante.

Una instalación errónea pueda causar daños a personas, animales y

cosas, de los que el fabricante no se hace responsable.

• Después de haber quitado todo el embalaje hay que asegurarse de que

el contenido esté íntegro. En caso de dudas no utilice el aparato y diríjase

al proveedor. Las partes del embalaje (jaula de madera, clavos, grapas,

bolsas de plástico, poliestireno expandido, etc.) no tienen que dejarse al

alcance de los niños pues son potenciales fuentes de peligro. Además,

para evitar que contaminen, tienen que recogerse y depositarse en sitios

destinados a dicha nalidad.

• Antes de realizar cualquier operación de limpieza o de mantenimiento hay

que desconectar el aparato de la red de alimentación eléctrica mediante

ESPAÑOL

el interruptor de la instalación con los órganos de corte a tal efecto.

• En caso de avería y/o mal funcionamiento del aparato hay que desactivarlo,

absteniéndose de realizar cualquier intento de reparación o intervención

directa. Diríjase exclusivamente a personal cuali cado profesionalmente.

La eventual reparación de los aparatos tiene que hacerla solamente un

centro de asistencia autorizado por BALTUR utilizando exclusivamente

repuestos originales. Si no se respeta lo anteriormente se puede comprometer la seguridad del aparato. Para garantizar la e cacia del aparato

y para que funcione correctamente es indispensable que el personal

cuali cado profesionalmente realice el mantenimiento periódicamente

ateniéndose a las indicaciones suministradas por el fabricante.

• Si el aparato se vende o pasa a otro propietario, o si usted se muda de

casa y deja el aparato, hay que asegurarse siempre de que el libro de

instrucciones esté siempre con el aparato para que pueda ser consultado

por el nuevo propietario y/o instalador.

• Para todos los aparatos con elementos opcionales o kits ( incluidos los

eléctricos) hay que utilizar solo accesorios originales.

QUEMADORES

• Este aparato está destinado solo al uso para el que ha sido expresamente

previsto: aplicación a calderas, generadores de aire caliente, hornos u

otras cámaras de combustión similares, situados en un lugar resguardado

de agentes atmosféricos. Cualquier otro uso se considera impropio y

por lo tanto peligroso.

• El quemador tiene que instalarse en un local adecuado con aberturas

mínimas de ventilación, según lo que prescriben las normas vigentes,

que sean su cientes para obtener una combustión perfecta.

aire del quemador ni las aberturas de ventilación del local donde está

peligrosas como la formación de mezclas tóxicas y explosivas.

• Antes de conectar el quemador hay que asegurarse de que los datos

gas, gasóleo u otro combustible).

• No hay que tocar las partes calientes del quemador pues normalmente

lientes incluso después de una parada no prolongada del quemador.

siguientes:

del interruptor general.

b) Cerrar la alimentación del combustible por medio de la válvula de

corte y quitar los volantes de mando de su alojamiento.

de peligro.

Advertencias particulares

forme dentro de la cámara de combustión del generador en cuestión.

• Antes de poner en marcha el quemador y por lo menos una vez al año,

operaciones:

a) Regular el caudal del combustible del quemador según la potencia

que requiere el generador de calor.

b) Regular el caudal de aire comburente para obtener un valor de

rendimiento de la combustión que sea por lo menos igual que el

mínimo impuesto por las normas vigentes.

normas vigentes.

d) Comprobar que funcionen bien los dispositivos de regulación y

seguridad.

los productos de la combustión.

f) Al nal de todas las regulaciones controlar que todos los sistemas

de bloqueo mecánico de los dispositivos de regulación estén bien

apretados.

ciones de uso y mantenimiento del quemador.

• Si el quemador se para bloqueándose varias veces no hay que insistir

mente para remediar el problema anómalo.

• El manejo y el mantenimiento tienen que hacerlos solo el personal

cuali cado profesionalmente, respetando las disposiciones vigentes.

2 / 20

0006081531_201203

• En caso de ausencia prolongada del usuario del aparato hay que cerrar

b) abrir inmediatamente puertas y ventanas para crear una corriente de

un aparato de gas para evitar situaciones peligrosas como la formación

descargan en la chimenea los productos de la combustión (humos) a una

mismas hace probablemente que la temperatura disminuya por debajo del

punto de condensación. En una chimenea que trabaja con un régimen de

condensación se forma hollín en la zona de salida a la atmósfera cuando se

quema gasóleo o fuel-oil, o se forma agua de condensación a lo largo de la

chimenea en cuestión, cuando se quema gas (metano, G.L.P., etc.). Según

lo anteriormente mencionado se deduce que las chimeneas conectadas a

I

ADVERTENCIAS DIRIGIDAS AL USUARIO PARA USAR EL QUEMADOR EN

CONDICIONES DE SEGURIDAD PRELIMINARES

ALIMENTACIÓN ELÉCTRICA

• La seguridad eléctrica del aparato se consigue solo cuando el mismo

está conectado correctamente a una buena instalación de puesta a

tierra, realizado tal y como establecen las normas de seguridad vigentes. Es necesario comprobar este requisito de seguridad fundamental.

En caso de dudas, pida al personal cuali cado profesionalmente que

haga un control detenido de la instalación eléctrica pues el fabricante

no se hace responsable de los posibles daños causados por la falta

de puesta a tierra de la instalación.

• Haga que el personal cuali cado profesionalmente controle que la

instalación eléctrica sea adecuada a la potencia máxima absorbida

por el aparato, indicada en la placa, comprobando concretamente que

la sección de los cables de la instalación sea idónea a la potencia

absorbida por el aparato.

• Para la alimentación general del aparato de la red eléctrica no está

permitido el uso de adaptadores, enchufes múltiples y/o alargaderas.

• Para la conexión a la red hay que poner un interruptor omnipolar

como prevé la normativa de seguridad vigente.

• La alimentación eléctrica del quemador tiene que tener el neutro a

tierra. En caso de supervisión de la corriente de ionización con el

neutro no conectado a tierra es indispensable conectar entre el borne

2 (neutro) y la tierra el circuito RC.

• El uso de cualquier componente que utilice energía eléctrica comporta

el respeto de algunas reglas fundamentales como:

- no tocar el aparato con partes del cuerpo mojadas o húmedas y/o

con los pies descalzos.

- no tirar de los cables eléctricos

- no dejar el aparato expuesto a agentes atmosféricos (lluvia, sol, etc.)

de no ser que no esté expresamente previsto.

- no permitir que el aparato lo usen niños o personas inexpertas.

• El cable de alimentación del aparato no tiene que cambiarlo el

usuario. En caso de que el cable esté roto, apague el aparato y para

cambiarlo, diríjase exclusivamente a personal profesionalmente

cuali cado.

• Si decide no utilizar el aparato durante un cierto periodo es oportuno

apagar el interruptor eléctrico de alimentación de todos los componentes de la instalación que utilizan energía eléctrica (bombas, quemador,

etc.).

ALIMENTACIÓN CON GAS, GASÓLEO U OTROS COMBUSTIBLES

Advertencias generales

• La instalación del quemador tiene que realizarla el personal profesionalmente cuali cado y debe ajustarse a las normas y disposiciones

vigentes, ya que una instalación errónea puede causar daños a

personas, animales o cosas, de los que el fabricante no puede ser

considerado responsable.

• Antes de la instalación se aconseja hacer una buena limpieza de todos los tubos de la instalación de abastecimiento del combustible para

evitar posibles residuos que podrían comprometer el buen funcionamiento del quemador.

• La primera vez que se pone en funcionamiento el aparato, el personal

cuali cado profesionalmente tiene que controlar:

a) la estanqueidad en el tramo interior y exterior de los tubos de

abastecimiento del combustible;

b) la regulación del caudal del combustible según la potencia

requerida por el quemador;

c) que el quemador esté alimentado por el tipo de combustible para

el que ha sido diseñado;

d) que la presión de alimentación del combustible esté comprendida dentro de los valores indicados en la placa del quemador;

e) que la instalación de alimentación del combustible esté dimensionada para el caudal necesario del quemador y que tenga todos los

dispositivos de seguridad y control prescritos por las normas

vigentes.

• Si se decide no utilizar el quemador durante un cierto periodo hay que

cerrar la llave o llaves de alimentación del combustible.

Advertencias particulares para el uso del gas

• El personal cuali cado profesionalmente tiene que controlar:

a) que la línea de abastecimiento de combustible y la rampa se

ajusten a las normativas vigentes.

b) que todas las conexiones del gas sean estancas.

• No utilizar los tubos del gas como puesta a tierra de aparatos eléctricos.

• No dejar el aparato inútilmente conectado cuando no se utilice y cerrar

siempre la llave del gas.

la llave principal que abastece gas al quemador.

• Si se advierte olor de gas:

a) no accionar los interruptores eléctricos, el teléfono ni cualquier otro

objeto que pueda provocar chispas;

aire que puri que el local;

c) cerrar las llaves del gas;

d) pedir que intervenga el personal cuali cado profesionalmente.

• No obstruir las aberturas de ventilación del local donde está instalado

de mezclas tóxicas y explosivas.

CHIMENEAS PARA CALDERAS DE ALTO RENDIMIENTO Y SIMILARES

Es oportuno precisar que las calderas de alto rendimiento y similares

temperatura relativamente baja. En el caso arriba mencionado las chimeneas tradicionales, dimensionadas comúnmente (sección y aislamiento

térmico) pueden no ser adecuadas para funcionar correctamente pues

el enfriamiento que los productos de la combustión sufren al recorrer las

calderas de alto rendimiento y similares tienen que estar dimensionadas

(sección y aislamiento térmico) para su uso especí co para evitar el inconveniente arriba descrito.

ESPAÑOL

3 / 20

0006081531_201203

CARACTERÍSTICAS TÉCNICAS

TBG 85ME TBG 120ME TBG 150ME TBG 210ME

POTENCIA TÉRMICA

FUNCIONAMIENTO Biestadio progresivo / modulante

EMISIONES NOx mg/kWh < 120 (Clase II según EN 676)

MOTOR

POTENCIA ELÉCTRICA ABSORBIDA* kW 1,20 1,60 2,40 3,2

FUSIBLE DE LÍNEA A 400 V 6 10 10 16

TRANSFORMADOR DE ENCENDIDO 26 kV - 40 mA – 230 V / 50 Hz

TENSIÓN 3N ~ 400 V ±10%- 50 Hz

GRADO DE PROTECCIÓN IP 40

DETECCIÓN DE LLAMA SONDA DE IONIZACIÓN

RUIDO dBA 73 75,5 79 85

PESO kg 78 87 91 94

GAS NATURAL (G 20)

CAUDAL

PRESIÓN MÁX. mbar 500

*) Absorción total, en fase de departida, con transformador de encendido activado.

**) Presión sonora medida en el taller del fabricante, con quemador activo en la caldera de prueba, con caudal térmico nominal máximo

MÁX kW 850 1200 1500 2100

MÍN kW 170 240 300 400

kW 1,1 1,5 2,2 3

r.p.m. 2800 2800 2800 2800

MÁX. m³n/h 85,5 120,7 150,9 211,2

MÍN m³n/h 17 24,1 30,2 40,3

MATERIAL PROPORCIONADO TBG 85ME TBG 120ME TBG 150ME TBG 210ME

BRIDA DE CONEXIÓN DEL QUEMADOR 2 2 2 2

JUNTA AISLANTE 1 1 1 1

PRISIONEROS N° 4 M 12 N° 4 M 12 N° 4 M 12 N° 4 M 12

ESPAÑOL

TUERCAS / EXAGONAL NUTS N° 4 M 12 N°4 M 12 N° 4 M 12 N° 4 M 12

ARANDELAS PLANAS N° 4 Ø 12 N° 4 Ø 12 N° 4 Ø 12 N° 4 Ø 12

CARACTERÍSTICAS TÉCNICO FUNCIONALES

• Funcionamiento en dos etapas progresivas / modulantes de

potencia.

• Regulación del gas mediante válvula de mariposa, accionada

por un servomotor paso a paso, controlado electrónicamente.

• Cabezal de combustión de recirculación parcial de los gases

quemados de emisiones reducidas de NOx (clase II).

• Elevado rendimiento de ventilación, bajas absorciones

eléctricas, bajo ruido.

• Bisagra con apertura en los dos sentidos para acceder cómodamente

a la cabeza de combustión con el quemador montado.

• Regulación del caudal del aire con válvula de apertura

lineal movida por un servomotor paso a paso, accionado

electrónicamente.

• Cierre de la válvula de aire en pausa.

• Cuadro eléctrico predispuesto con conexión mediante clavijas/

tomas (suministradas) de 4 y 7 polos.

• Cuadro eléctrico con grado de protección IP55.

• Brida de conexión al generador deslizante para adaptar el

saliente del cabezal a los distintos tipos de generadores de

calor.

• Elevada relación de modulación1:5.

• Posibilidad de salida de la rampa del gas desde arriba o desde

abajo.

4 / 20

0006081531_201203

2

4

6

8

0

10

12

14

mbar

15015200 300 400 500 600 700 800 900 1000 1100

20 30 40 50 60 70 80 90

100 110

6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44

m

n³/h(Metano)

m

n³/h(G.P.L.)

kW

1200 1300

120 130

46 48 50

1400 1500 1600

16

140 150 160

52 54 56 58 60 62

1700 1800 1900

2000

170 180 190

200

64 66 68 70 72 74 76 78

2100

210

80 82

TBG 85ME

TBG 120ME TBG 150ME

TBG 210ME

CARACTERÍSTICAS CONSTRUCTIVAS

El quemador está compuesto por:

• Entrada del aire comburente dotado de inserto de material

fonoabsorbente, y diseñado para obtener una óptima linealidad

de la apertura de la válvula del aire.

• Panel de mandos con sinóptico de funcionamiento con testigos

luminosos.

• Equipo electrónico de mando y control según la norma EN298,

con microprocesador, con control de estanqueidad de las

válvulas integrado, con capacidad de conexión eBus.

• Pantalla de visualización de la secuencia de funcionamiento y

del código de las anomalías.

• Detección de la llama mediante electrodo ionizador.

• Rampa de gas con válvula de seguridad y de funcionamiento

por accionamiento electromagnético, presóstato de mínima,

regulador de presión y filtro del gas.

• Conectores inteligentes quemador/rampa (a prueba de error).

CAMPO DE TRABAJO

Los campos de trabajo se obtienen en calderas de prueba conformes

a la norma EN676 y son indicativos para los acoplamientos del

quemador-caldera. Para el funcionamiento correcto del quemador

las dimensiones de la cámara de combustión deben conformarse

con la normativa vigente; de lo contrario, hay que consultarse con

los fabricantes.

0006081531_201203

5 / 20

0002922800

ESPAÑOL

N° 0002471120

DIMENSIONES TOTALES

TBG 85ME 610 240 370 520 380 200 1265 175 400 180 178 280 250 325 M12 190

TBG 120ME 610 240 370 540 380 200 1265 200 450 224 219 320 280 370 M12 235

TBG 150ME 610 240 370 540 380 200 1265 200 450 240 219 320 280 370 M12 250

TBG 210ME 610 240 370 540 380 200 1315 200 450 250 219 320 280 370 M12 255

COMPONENTES EL CUADRO ELÉCTRICO

ESPAÑOL

1) Cabezal de combustión

2) Junta

3) Brida de unión al quemador

4) Dispositivo de regulación del cabezal

5) Bisagra

MOD. A A1 A2 B B1 B6 C

10) Equipo

11) Presóstato del aire

12) Transformador de encendido

13) Contactor motor

6) Brida de conexión a la rampa del gas

7) Cuadro eléctrico

8) Motor

9) Servomotor de regulación del aire

9a) Servomotor de regulación del gas

D

MÍN.DMÁX.

E F I

L

MÍN.LMÁX.

M N

14) Relé térmico

15) Clavija 7 polos

16) Panel sinóptico

6 / 20

0006081531_201203

APLICACIÓN DEL QUEMADOR A LA

CALDERA

MONTAJE DEL GRUPO CABEZAL

A) Adecuar la posición de la brida de conexión 5

aflojando los tornillos 6 de modo que el cabezal de

combustión penetre en la cámara de combustión

en la cantidad aconsejada por el fabricante del

generador.

B) Colocar en el tubo la junta aislante 3 interponiendo

la cuerda 2 entre la brida y la junta.

C) Fijar los Grupos Cabezal 4 a la caldera 1 mediante

lo s prisioneros, las arandel as y las tue rcas

correspondientes que se suministran 7.

Sellar completamente con material adecuado el espacio

!

situado entre el tubo del quemador y el orificio en el

refractario dentro de la tapa de la caldera.

MONTAJE DE LA RAMPA DE GAS

Son posibles diversas soluciones de montaje 8, 8a, 9 de

la rampa de las válvulas como se muestra en el dibujo

de al lado. Seleccionar la posición más lógica en base

a la conformación del local de la caldera y a la posición

de llegada de las tuberías del gas.

Con válvulas de dimensiones notables, por ej. DN65 o

!

DN80 prever un soporte adecuado para evitar esfuerzos

excesivos en el empalme de conexión de la rampa del

gas.

MONTAJE DEL CUERPO VENTILANTE

A) Colocar las semibisagras presentes en el caracol

del quemador en correspondencia con las presentes

en el grupo del cabezal.

B) Introducir el perno de la bisagra 10 en la posición

que se considere más idónea.

C) Conectar los cables (encendido e ionización) a

los electrodos correspondientes, cerrar la bisagra

fijando el quemador mediante los tornillos 11.

0006081531_201203

ESPAÑOL

7 / 20

N° 0002910950n2

LÍNEA DE ALIMENTACIÓN

La pantalla del principio de la línea de alimentación

del gas se muestra en la figura de debajo. La rampa

del gas está homologada según la normativa EN 676

y se proporciona de forma separada del quemador. Es

preciso instalar, antes de la válvula del gas, una válvula

de detección manual y una junta antivibrante, colocados

según lo que se indica en el esquema.

ESQUEMA DE PRINCIPIO DEL QUEMADOR DEL

GAS

ESPAÑOL

Rampa de gas suministrada por el fabricante

1) Válvula de detección manual

2) Junta antivibrante

3) Filtro del gas

4) Presóstato de presión mínima del gas

5) Válvula de seguridad

6) Regulador de presión

7) Dispositivo de control de la estanqueidad de las válvulas

A cargo del instalador

8) Válvula de trabajo

9) Servomotor de regulación del aire

10) Clapeta de regulación del aire

11) Presóstato del aire

12) Cabezal de combustión

13) Válvula de mariposa de regulación del gas

14 Servomotor de regulación del gas

8 / 20

0006081531_201203

Loading...

Loading...