baltur TBG 1100 MC Manual User Instructions

UK

SP

TR

РУС

Manual user instructions.

Manual de instrucciones

de uso.

Kullanım talimatları

kılavuzu.

Инструкция по

эксплуатации

中文

使用说明

TBG 1100 MC

- TWO-STAGE MODULATING/PRORESSIVE OUTPUT GAS BURNER

- QUEMADORES DE GAS EL PROGRESO DE LAS FASES / MODULAR

- GAZ BRÜLÖRÜ PROGRESİF /MODÜLER FAZLARI

- ГАЗОВЫЕ ДВУХСТУПЕНЧАТЫЕ ПРОГРЕССИВНЫЕ/

МОДУЛЯЦИОННЫЕ ГОРЕЛКИ

两段火渐进式/比例调节式燃气燃烧器

-

ORIGINAL INSTRUCTIONS (IT)

I

STRUCTIONS ORIGINALES (IT)

ORİJİNAL KULLANIM KILAVUZU (IT)

ОРИГИНАЛЬНЫЕ ИНСТРУКЦИИ

(

ПЕРЕВОД С ИТАЛЬЯНСКОГО ЯЗЫКА

正版说明书。(IT)

0006160025_201305

)

• Before starting to use the burner, read the chapter “WARNING NOTES FOR THE USER: HOW TO USE THE BURNER SAFELY” in

this instruction manual carefully, which is an integral and essential part of the product.

• Carefully read the instructions before starting or maintaining the burner.

• The works on the burner and on the system have to be carried out only by qualified personnel.

• The system electric feeding must be disconnected before starting working on it. If the works are not carried out correctly it is possible

to cause dangerous accidents.

ENGLISH

DANGER

WARNINGS ATTENTION

INFORMATION

1 / 28

0006160025_201305

Declaration of Conformity

We declare that our products

BPM...; BGN…; BT…; BTG…; BTL…; TBML...; Comist…;

GI…; GI…Mist; Minicomist…; PYR…; RiNOx…; Spark...;

Sparkgas...; TBG...;TBL...; TBML ...; TS…; IBR...; IB...

(Variant: … LX, for low NOx emissions)

ENGLISH

Description:

forced air burners of liquid, gaseous and mixed fuels for residential and

industrial use meet the minimum requirements of the European Directives:

2009/142/CE ..............................................(D.A.G.)

2004/108/CE ...............................................(C.E.M.)

2006/95/CE .................................................(D.B.T.)

2006/42/CE ................................................(D.M.)

and conform to European Standards:

UNI EN 676:2008 (gas and combination, gas side)

UNI EN 267:2002 (diesel and combination, diesel side)

These products are therefore marked:

0085

18/11/2010

Dr. Riccardo Fava

Managing Director / CEO

TECHNICAL DATA ........................................................................................................................................................................................................5

BURNER CONNECTION TO THE BOILER .............................................................................................................................................................7

ELECTRICAL CONNECTIONS ..................................................................................................................................................................................9

ASSEMBLING THE GAS TRAIN ................................................................................................................................................................................10

COMMAND AND CONTROL EQUIPMENT FOR GAS BURNERS LFL 1...... ..................................................................................................12

DETAILS OF THE MODULATION CONTROL MOTOR SQM 10 AND SQM 20 FOR REGULATION OF CAMS ........................................16

IGNITION AND ADJUSTMENT ...................................................................................................................................................................................17

HOW TO FIND THE CAUSES OF IMPROPER OPERATION OF TWO-STAGE GAS BURNERS AND HOW TO RECTIFY THEM .......23

WIRING DIAGRAM ...................................................................................................................................................................................

..........................................................................................................................................................................................................................................24

2 / 28

0006160025_201305

WARNING NOTES FOR THE USER HOW TO USE THE BURNER SAFELY

FOREWORD

These warning notes are aimed at ensuring the safe use of the components of heating systems for civil use and the production of hot water.

They indicate how to act to avoid the essential safety of the components

being compromised by incorrect or erroneous installation and by improper

or unreasonable use. The warning notes provided in this guide also seek

to make the consumer more aware of safety problems in general, using

necessarily technical but easily understood language. The manufacturer

is not liable contractually or extra contractually for any damage caused

by errors in installation and in use, or where there has been any failure to

follow the manufacturer’s instructions.

GENERAL WARNING NOTES

• The instruction booklet is an integral and essential part of the product

and must be given to the user. Carefully read the warnings in the booklet as they contain important information regarding safe installation,

use and maintenance. Keep the booklet to hand for consultation when

needed.

• Equipment must be installed in accordance with current regulations,

with the manufacturer’s instructions and by qualifi ed technicians. By

the term ‘qualifi ed technicians’ is meant persons that are competent in

the fi eld of heating components for civil use and for the production of

hot water and, in particular, assistance centres authorised by the manufacturer. Incorrect installation may cause damage or injury to persons,

animals or things. The manufacturer will not in such cases be liable.

• After removing all the packaging make sure the contents are complete

and intact. If in doubt do not use the equipment and return it to the

supplier. The packaging materials (wooden crates, nails, staples, plastic

bags, expanded polystyrene, etc.) must not be left within reach of children as they may be dangerous to them. They should also be collected

and disposed on in suitably prepared places so that they do no pollute

the environment.

• Before carrying out any cleaning or maintenance, switch off the equip-

ment at the mains supply, using the system’s switch or shut-of f systems.

• If there is any fault or if the equipment is not working properly, de-ac-

tivate the equipment and do not attempt to repair it or tamper with it

directly. In such case get in touch with only qualifi ed technicians. Any

product repairs must only be carried out by BALTUR authorised assistance centres using only original spare parts. Failure to act as above

may jeopardise the safety of the equipment. To ensure the effi ciency

and correct working of the equipment, it is essential to have periodic

maintenance carried out by qualifi ed technicians following the manufac-

turer’s instructions.

• If the equipment is sold or transferred to another owner or if the owner

moves and leaves the equipment, make sure that the booklet always

goes with the equipment so it can be consulted by the new owner and/

or installer.

• For all equipment with optionals or kits (including electrical), only origi-

nal accessories must be used.

BURNERS

• This equipment must be used only for its expressly stated use: applied

to boilers, hot air boilers, ovens or other similar equipment and not

exposed to atmospheric agents. Any other use must be regarded as

improper use and hence dangerous.

• The burner must be installed in a suitable room that has ventilation in

accordance with current regulations and in any case suffi cient to ensure

correct combustion

• Do not obstruct or reduce the size of the burner’ air intake grills or the

ventilation openings for the room where a burner or a boiler is installed

or dangerous mixtures of toxic and explosive gases may form.

• Before connecting the burner check that the details on the plate correspond to those of the utility supplies (electricity, gas, light oil or other

fuel).

• Do not touch hot parts of the burner. These, normally in the areas near

to the fl ame and any fuel pre-heating system, become hot when the

equipment is working and stay hot for some time after the burner has

stopped.

• If it is decided not to use the burner any more, the following actions must

be performed by qualifi ed technicians:

a) Switch off the electrical supply by disconnecting the power cable from

the master switch.

b) Cut off the fuel supply using the shut-off valve and remove the control

wheels from their position.

c) Render harmless any potentially dangerous parts.

Special warning notes

• Check that the person who carried out the installation of the burner fi xed

it securely to the heat generator so that the fl ame is generated inside

the combustion chamber of the generator itself.

• Before starting up the burner, and at least once a year, have qualifi ed

technicians perform the following operations:

a) Set the burner fuel capacity to the power required by the heat ge-

nerator.

b) Adjust the combustion air fl ow to obtain combustion yield of at least

the minimum set by current regulations.

c) Carry out a check on combustion to ensure the production of no-

xious or polluting unburnt gases does not exceed limits permitted

by current regulations.

d) Check the adjustment and safety devices are working properly.

e) Check the effi ciency of the combustion products exhaust duct.

f) Check at the end of the adjustments that all the adjustment devices

mechanical securing systems are properly tightened.

g) Make sure that the use and maintenance manual for the burner is

in the boiler room.

• If the burner repeatedly stops in lock-out, do not keep trying to manually

reset but call a qualifi ed technicians to sort out the problem.

• The running and maintenance of the equipment must only be carried

out by qualifi ed technicians, in compliance with current regulations.

ENGLISH

3 / 28

0006160025_201305

WARNING NOTES FOR THE USER HOW TO USE THE BURNER SAFELY

ELECTRICAL SUPPLY

• The equipment is electrically safe only when it is correctly connected to an

effi cient ground connection carried out in accordance with current safety

regulations. It is necessary to check this essential safety requirement.

If in doubt, call for a careful electrical check by a qualifi ed technicians,

ENGLISH

since the manufacturer will not be liable for any damage caused by a

poor ground connection.

• Have qualifi ed technicians check that the wiring is suitable for the

maximum power absorption of the equipment, as indicated in the technical

plate, making sure in particular that the diameter of cables is suffi cient

for the equipment’s power absorption.

• Adapters, multiple plugs and extension cables may not be used for the

equipment’s power supply.

• According to current safety regulations, an omnipolar switch with a contact

opening gap of at least 3 mm is required for the mains supply connection.

• Extract the power cable external insulation as strictly necessary for the

connection, in order to avoid that the cable comes into contact with metal

parts.

• An ominpolar switch in accordance with current safety regulations is

required for the mains supply connection.

• The electrical supply to the burner must have neutral to ground

connection. If the ionisation current has control with neutral not to ground

it is essential to make a connection between terminal 2 (neutral) and the

ground for the RC circuit.

• The use of any components that use electricity means that certain

fundamental rules have to followed, including the following:

- do not touch the equipment with parts of the body that are wet or damp

or with damp feet

- do not pull on electrical cables

- do not leave the equipment exposed to atmospheric agents (such as

rain or sun etc.) unless there is express provision for this.

- do not allow the equipment to be used by children or inexpert persons.

• The power supply cable for the equipment not must be replaced by the

user. If the cable gets damaged, switch off the equipment, and call only

on qualifi ed technicians for its replacement.

• If you decide not to use the equipment for a while it is advisable to switch

off the electrical power supply to all components in the system that use

electricity (pumps, burner, etc.).

a) that the feed line and the train comply with current law and regulations.

b) that all the gas connections are properly sealed.

• Do not use the gas pipes to ground electrical equipment.

• Do not leave the equipment on when it is not in use and always close

the gas tap.

• If the user of is away for some time, close the main gas feed tap to the

burner.

• If you smell gas:

a) do not use any electrical switches, the telephone or any other object

that could produce a spark;

b) immediately open doors and windows to create a current of air that

will purify the room;

c) close the gas taps;

d) ask for the help of qualifi ed technicians.

• Do not block ventilation openings in the room where there is gas

equipment or dangerous situations may arise with the build up of toxic

and explosive mixtures.

FLUES FOR HIGH EFFICIENCY BOILERS AND SIMILAR

It should be pointed out that high effi ciency boilers and similar discharge

combustion products (fumes) at relatively low temperatures into the fl ue.

In the above situation, traditional fl ues (in terms of their diameter and heat

insulation) may be suitable because the signifi cant cooling of the combustion

products in these permits temperatures to fall even below the condensation

point. In a fl ue that works with condensation there is soot at the point the

exhaust reaches the atmosphere when burning light oil or heavy oil or the

presence of condensate water along the fl ue itself when gas is being burnt

(methane, LPG, etc.). Flues connected to high effi ciency boilers and similar

must therefore be of a size (section and heat insulation) for the specifi c use

to avoid such problems as those described above.

GAS, LIGHT OIL, OR OTHER FUEL SUPPLIES

General warning notes

• Installation of the burner must be carried out by qualifi ed technicians

and in compliance with current law and regulations, since incorrect

installation may cause damage to person, animals or things, for which

damage the manufacturer shall not can be held responsible.

• Before installation it is advisable to carry out careful internal cleaning

of all tubing for the fuel feed system to remove any residues that could

jeopardise the proper working of the burner.

• For fi rst start up of the equipment have qualifi ed technicians carry out

the following checks:

• If you decide not to use the burner for a while, close the tap or taps that

supply the fuel.

Special warning notes when using gas

• Have qualifi ed technicians check the following:

0006160025_201305

4 / 28

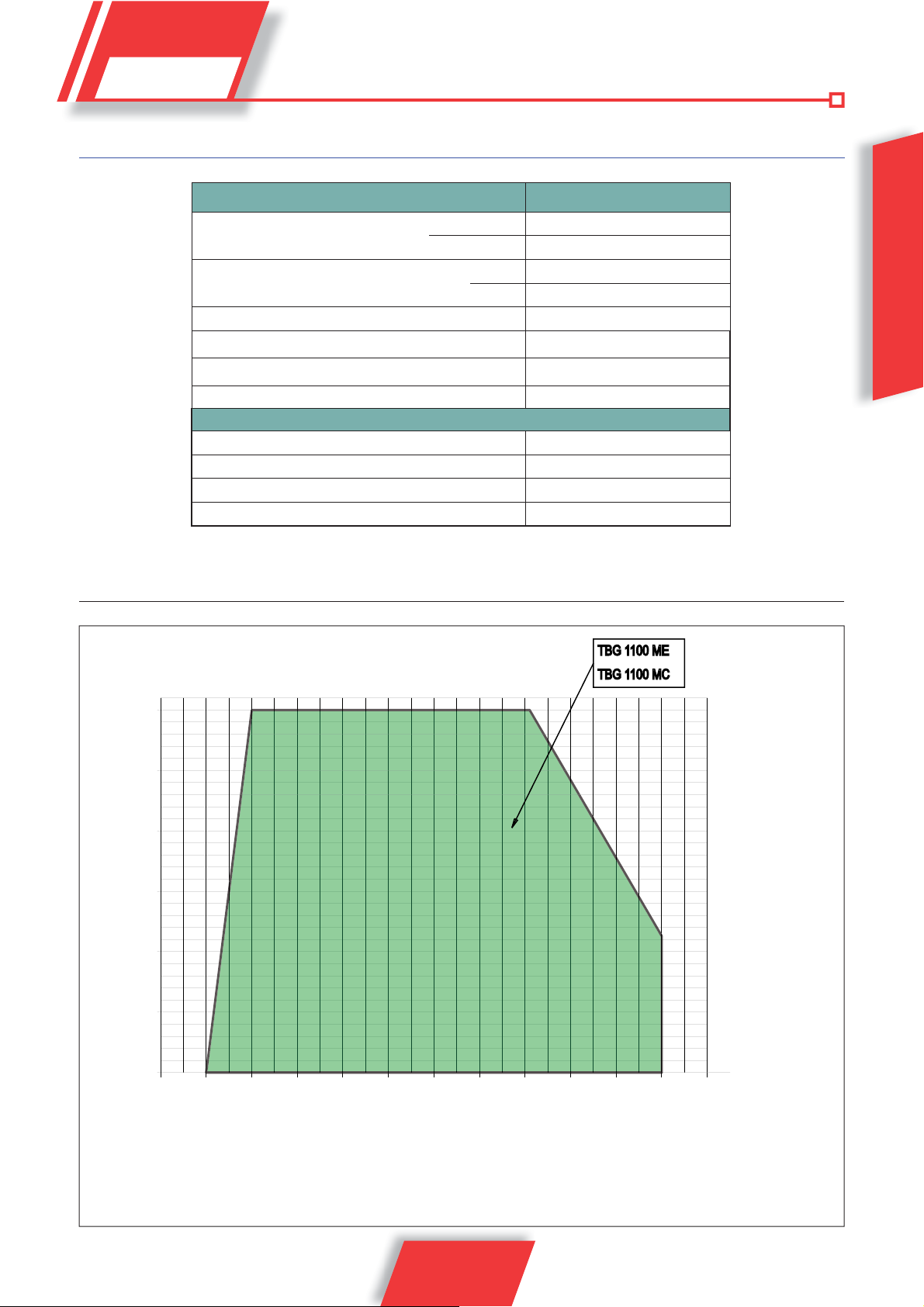

TECHNICAL DATA

THERMAL CAPACITY

FAN MOTOR

ABSORBED ELECTRICAL POWER

IGNITION TRANSFORMER

MAX kW

MIN kW

kW

TBG 1100 MC

11000

1000

22 kW - 50 Hz

.

2940 rev./min

23

ENGLISH

8 kV - 30 mA

POWER SUPPLY VOLTAGE

FLAME DETECTOR IONISATION ELECTRODE

SUPPLIED MATERIAL

INSULATING SEAL

STUD BOLTS

HEXAGON NUTS

FLAT WASHERS

OPERATING RANGE

mbar

26

25

3N ~ 400 V - 50 Hz

2

No. 4 M 20

No. 4 M 20

No. 4 Ø 20

0002922900

20

15

10

5

0

234567

1 8910 11 12

The operating ranges are obtained from test boilers corresponding to Standard EN676 and are

indicative of the burner-boiler combination. For correct working of the burner the size of the combustion

chamber must correspond to current regulations; if not the manufacturers must be consulted.

The operating ranges have been obtained at a room temperature of 20°C and at a barometric pressure of 1013

mbar (around 0 metres above sea level).

5 / 28

0006160025_201305

kWx1000

ENGLISH

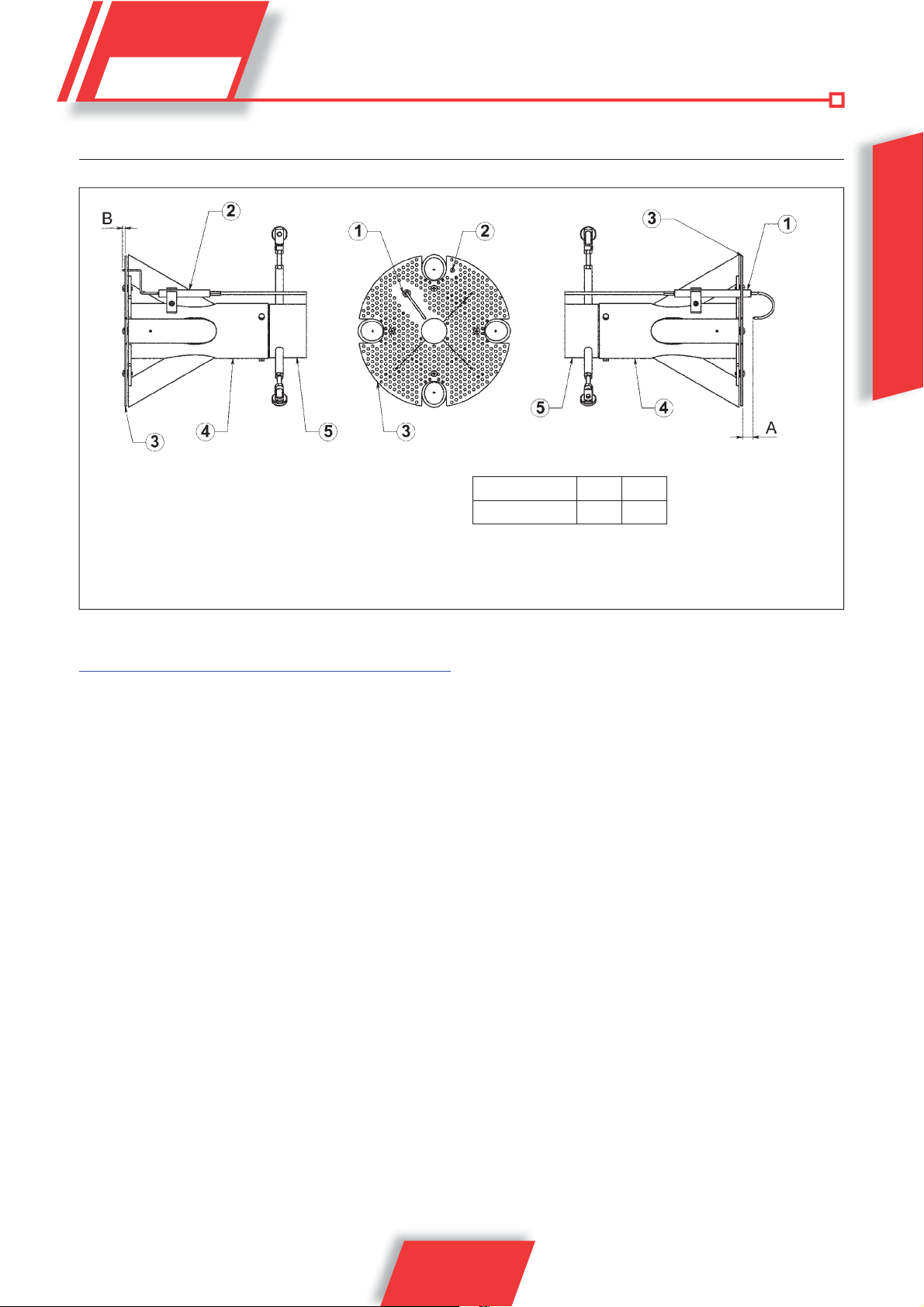

1 Combustion head

2 Seal

3 Burner connection flange

4 Butterfly gas valve

5 Modulator activation servomotor

6 Synoptic control panel

7 Air pressure switch

8 Air gate unit

9 Electrical panel

10 Hinge

11 Fan motor

12 Intake air conveyor

13

Gas pressure plug on the head

14

Adjusting air/gas modulator

N° 0002471390

A A1 A2 B B1 B2 B5 C C1 D E Ø F Ø R I I1 L Ø M N Ø

TBG 1100 MC 1230 570 660 1000 740 260 310 2030 190 720 451 DN 80 1300 520 520 594 M20 460

DESIGN CHARACTERISTICS

The burner consists of:

• Ventilating part in light aluminium alloy.

• Centrifugal fan for high performances.

• Intake air conveyor.

• Combustion head complete with stainless steel nozzle and

steel flame disc.

• Flame inspection glass

• Three-phase electric motor to run fan.

• Air pressure switch to ensure the combustion air presence.

• Gas train complete with control valve, operating and safety

valves, valve seal control, minimum and maximum pressure

switch, pressure control and gas filter.

0006160025_201305

• Automatic command equipment and burner control according

to European regulation EN298.

• Flame detection by ionisation electrode.

• Control panel including on/off - automatic/manual operation

switches and minimum/maximum selector, operation and lockour indicator lights

• Electric system with protection class IP54.

6 / 28

TECHNICAL FUNCTIONAL CHARACTERISTICS

• Gas burner compliant with European standard EN676.

• Operation with two progressive power stages.

• Combustion head with partial recirculation of combusted gases

with reduced NOx emissions (class II in European standard

EN676).

• Hinge opens both ways to permit convenient access to the mixer

without dismantling the burner from the boiler.

• Minimum and maximum air flow adjustment for first and second

stage by means of modulator with mechanical cam activated

by an electric servomotor.

• Gate closing in pause to prevent any heat dispersion to the flue.

• Valve seal control according to European Standard EN 676.

BURNER CONNECTION TO THE BOILER

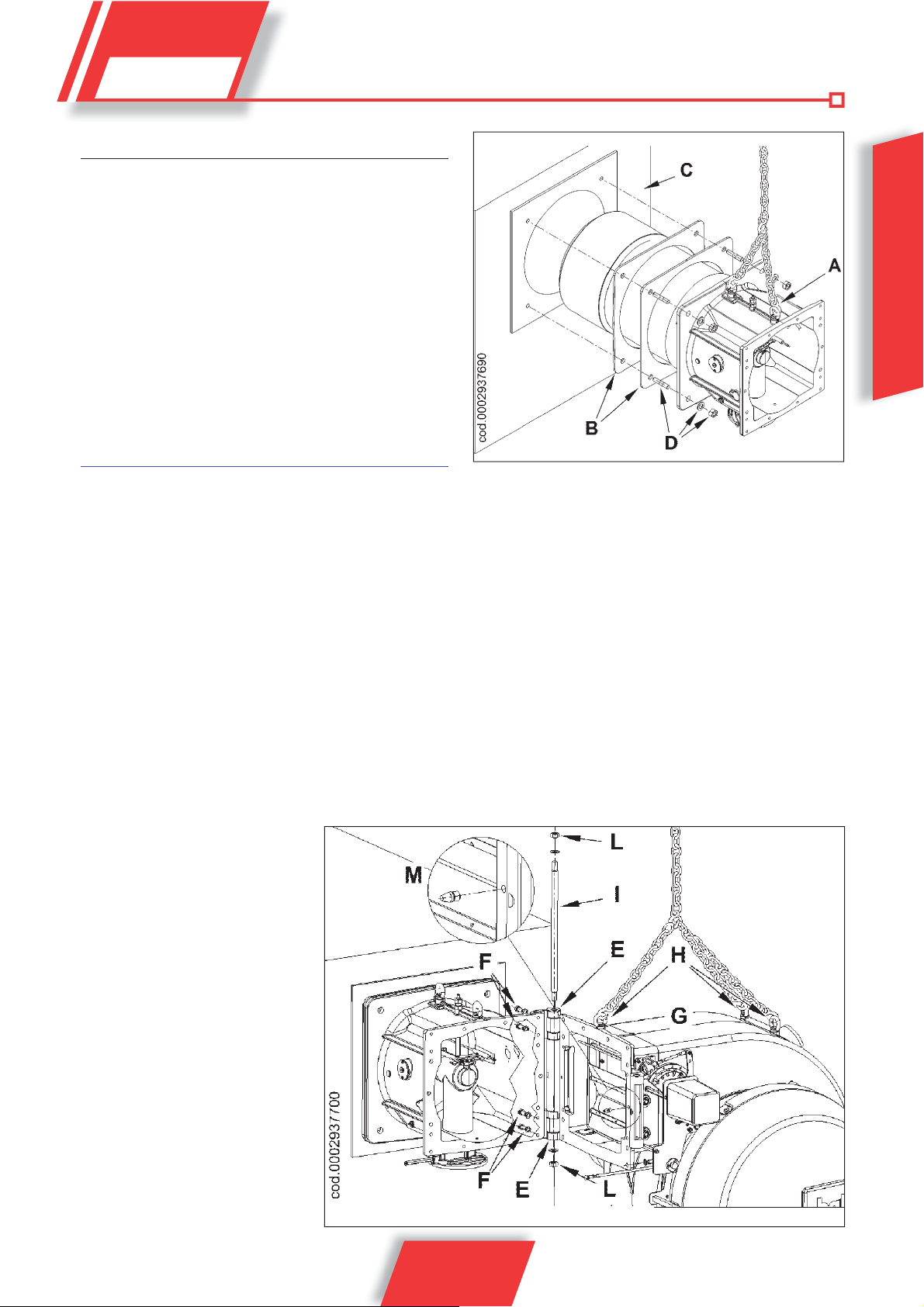

ASSEMBLING THE HEAD UNIT

The combustion head is packaged separately from the body of

the burner.

Anchor the head unit to the boiler door as follows:

• Position the insulating seals on the lung (B).

• Anchor the flange of the lung (A) to the boiler (C) with the stud

bolts, washers and nuts provided (D), moving the lung with

the eye bolts.

Completely seal the gap between the burner sleeve and

the hole in the refractory material inside the boiler door with

suitable material.

FIG.1

ENGLISH

ASSEMBLY THE VENTILATING BODY

The burner hinge can be opened both ways, it is therefore possible

to choose the opening side of the ventilating body

manufactured for hinge installation on the right side. To enable the

maximum opening and so facilitate maintenance operations, it is

recommended to install the hinge on the

side of the burner opposite to the position

where the gas train is installed.

For a correct installation of the ventilating

body, follow the procedure described

below:

• After installing the head unit on the

boiler, assemble the two hinges (E)

on the lung using the 4 screws (F) and

the corresponding washers, without

tightening the screws completely

(hinges are pre-assembled on the

right side, but it is possible to mount

them on the opposite side).

• Place the ventilating body (G)

corresponding to the two hinges

(FIG 2). To handle the ventilating

body, use the specific chains or

ropes anchored to the eyebolts (H).

• Insert pin I, then lock it using the nuts

L and the corresponding washers,

taking care that the abutting surfaces

. The burner is

FIG.2

7 / 28

0006160025_201305

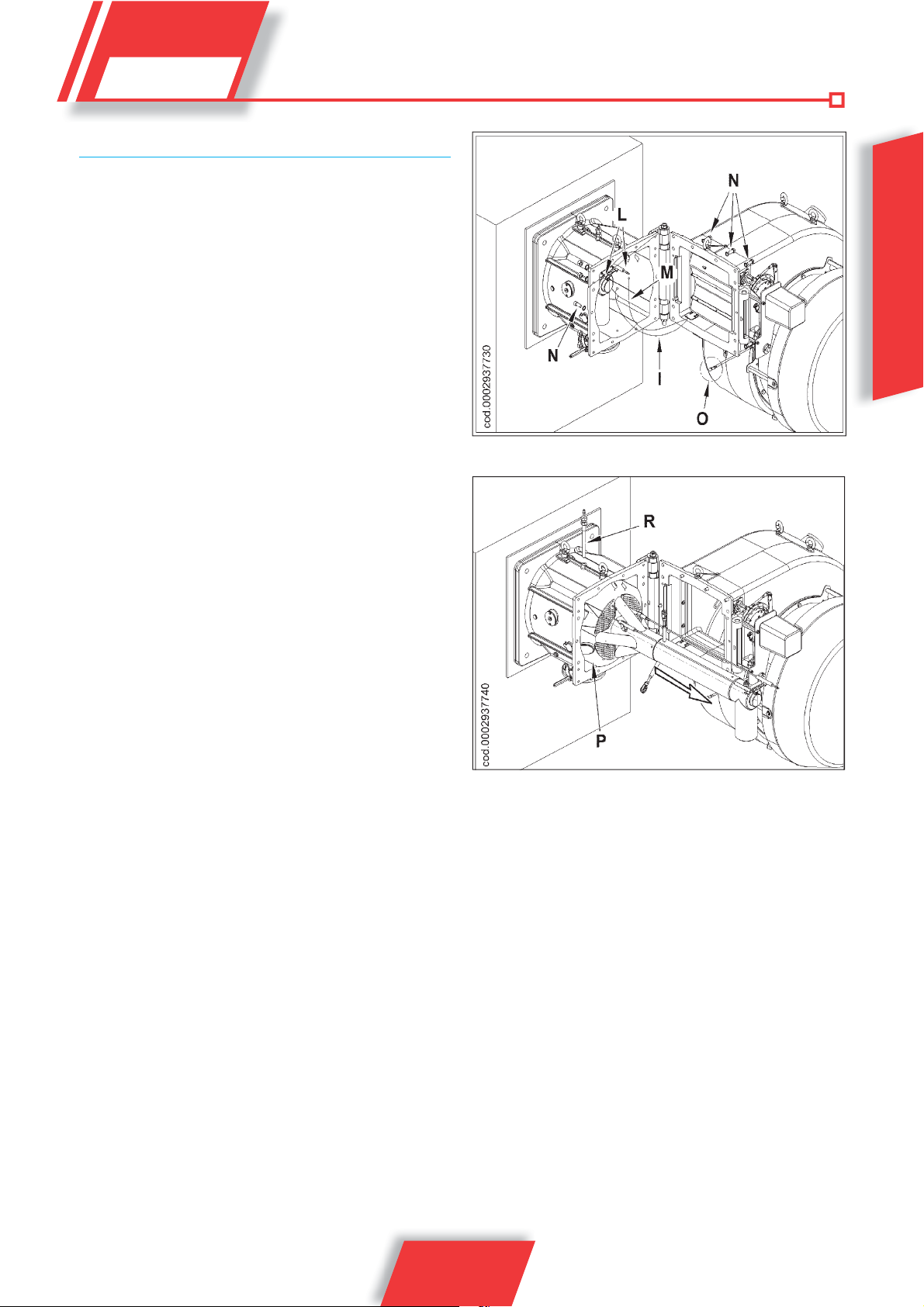

• of the two hinges are perfectly in contact with the corresponding

surfaces of the scroll. Do not tighten the nuts (L) too deeply, as

this may make hinge rotation difficult.

At this stage, avoid tightening the hinge screws (F) completely

and removing lifting chains.

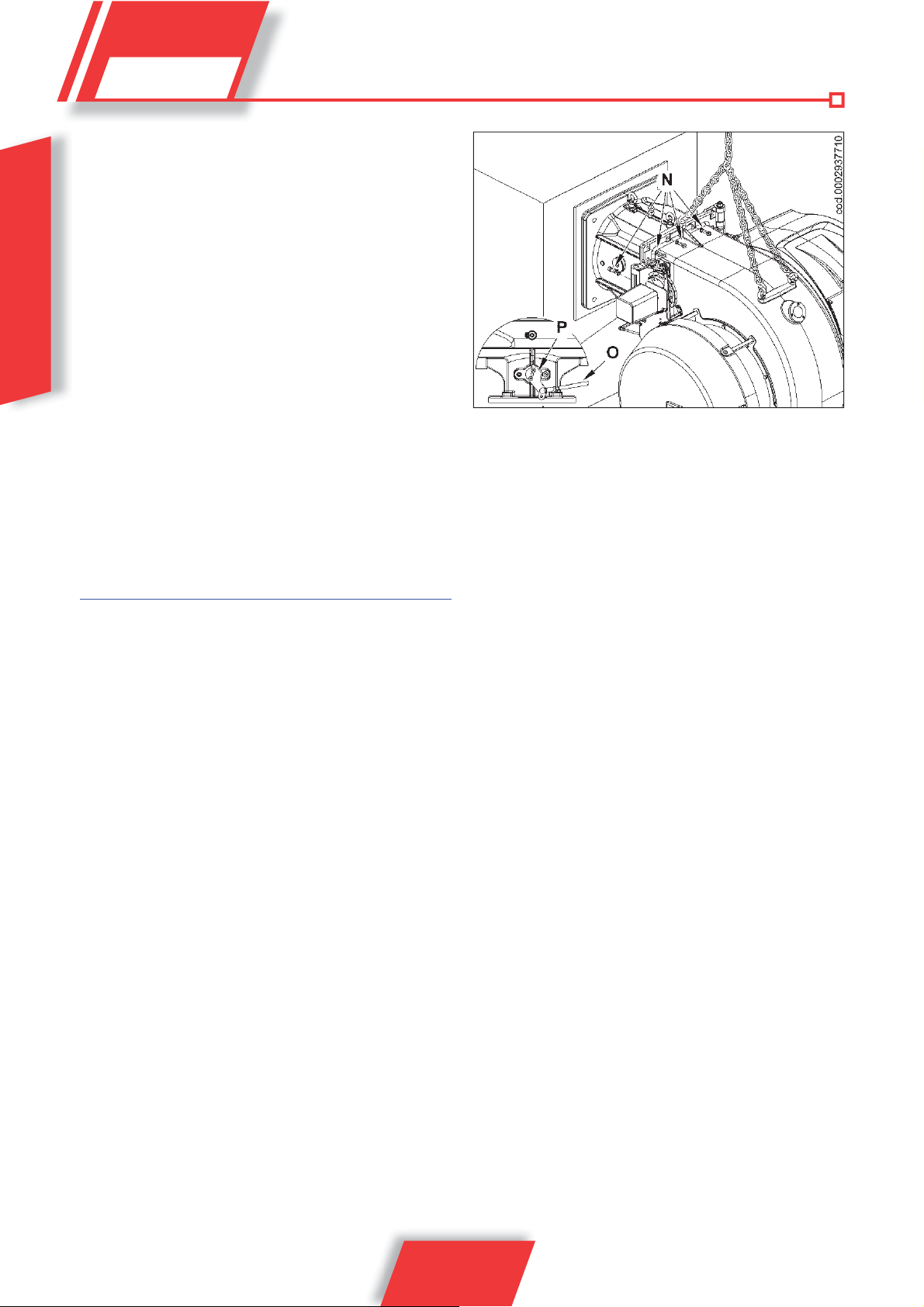

• Tighten the centring pin M (FIG 2) on the fan flange, opposite

to the hinge side.

•

Keeping the chains anchored to the eyebolts, turn the ventilating

ENGLISH

body and place the fan flange in contact with the lung flange,

checking that the pin M is inserted in the corresponding hole

(FIG 3).

• Close the burner using the screws N and the corresponding

washers. After connecting the ventilating body to the head unit,

proceed with the final tightening of the 4 screws (F) that fasten

the hinges (FIG 2), then unhook the lifting chains or ropes.

• Connect the tie rod (O) to the lever (P) of the gas flow adjusting

throttle (FIG 3).

When it is necessary to open the burner, disconnect the tie

rod O and the connectors of gas solenoid valves.

ELECTRICAL CONNECTIONS

FIG.3

It is advisable to make all electrical connections using a flexible

electrical wire. Electrical lines must be kept away from hot parts.

Make sure that the power line to which the unit will be connected,

has frequency and voltage values suitable for the burner. Make sure

that the main power line, the relative fuse-equipped switch (essential)

and any limiter are capable of withstanding the maximum current

absorbed by the burner.

For more details, see the relevant wiring diagrams for each single

burner.

5

8 / 28

0006160025_201305

50

ASSEMBLING THE GAS TRAIN

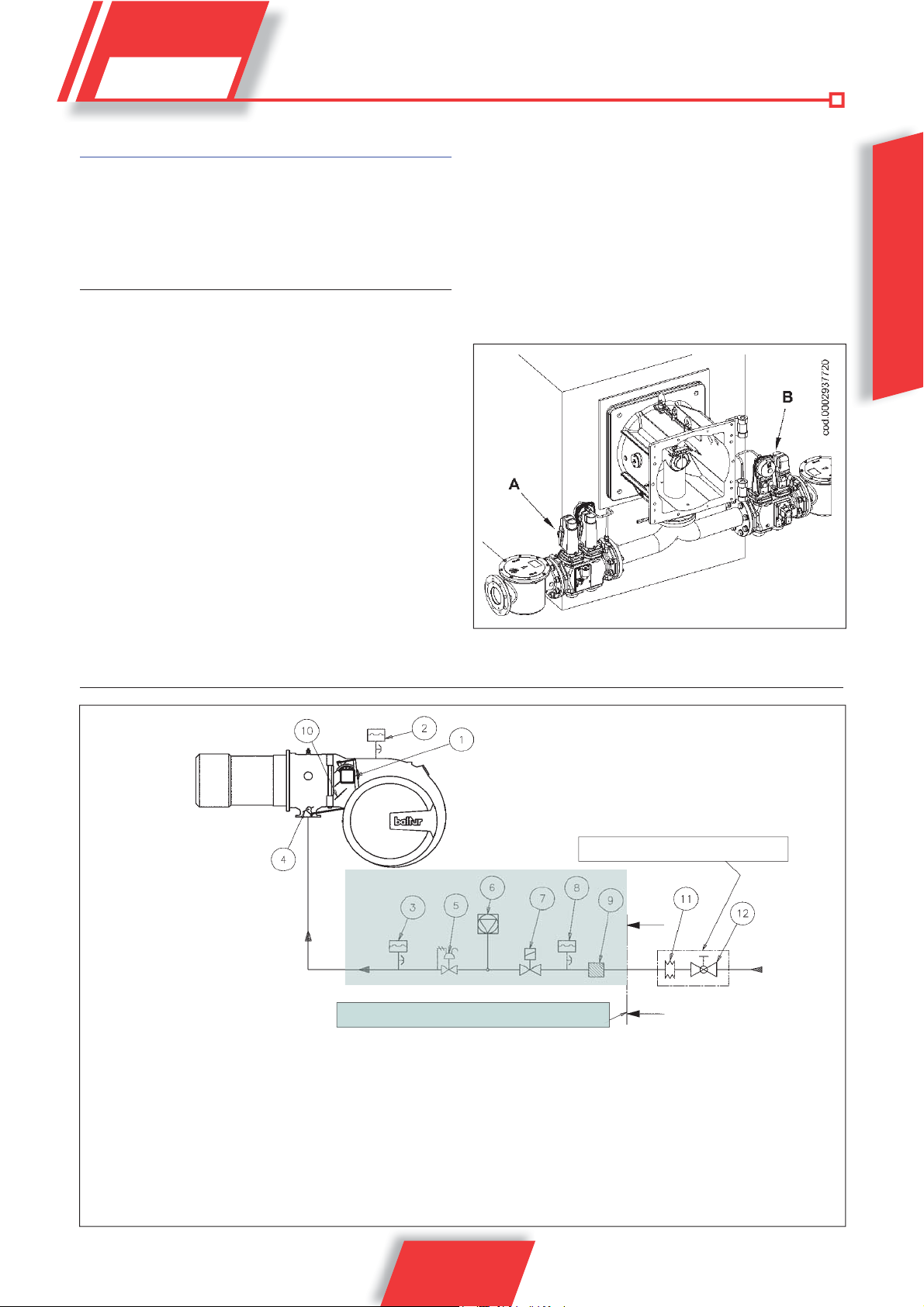

The EN 676 approved gas train is sold separately from the burner.

The gas train can be assembled in different ways: A and B. Choose

the most rational position for the set-up of the boiler room and the

position in which the gas pipe arrives.

DIAGRAM ILLUSTRATING GAS TRAIN PRINCIPLE

Install a manual on/off valve upstream of the gas valve

according to the layout shown in the diagram illustrating the

gas train principle.

To ensure optimal functioning of the pressure control, it should

be applied to the horizontal pipe after the filter

regulator must be adjusted while operating at the maximum flow

effectively used by the burner. The outgoing pressure must be

adjusted to a value slightly below the maximum possible value

(the value obtained by screwing in the adjustment screw almost

completely); in this case, the outgoing regulator pressure increases

as the adjustment screw is tightened, and decreases as it is

slackened.

. The gas pressure

BASIC DIAGRAM OF BURNER SUPPLY LINE

ENGLISH

29111

GAS TRAIN SUPPLIED BY THE MANUFACTURER

1) Air/gas adjustment servomotor

2) Air pressure switch

3) Maximum gas pressure switch

4) Gas supply modulating control butterfly valve

5) Operating gas valve with pressure regulator

6) Valve seal control device (obligatory for burner with

maximum nominal thermal output over 1200 kW)

7) Safety gas valve

0006160025_201305

RESPONSIBILITY OF THE INSTALLER

8) Minimum gas pressure switch

9) Gas filter

10) Air adjustment gate

11) Vibration-proof joint (not included in supply)

12) Manual shut-off valve (not included in supply)

9 / 28

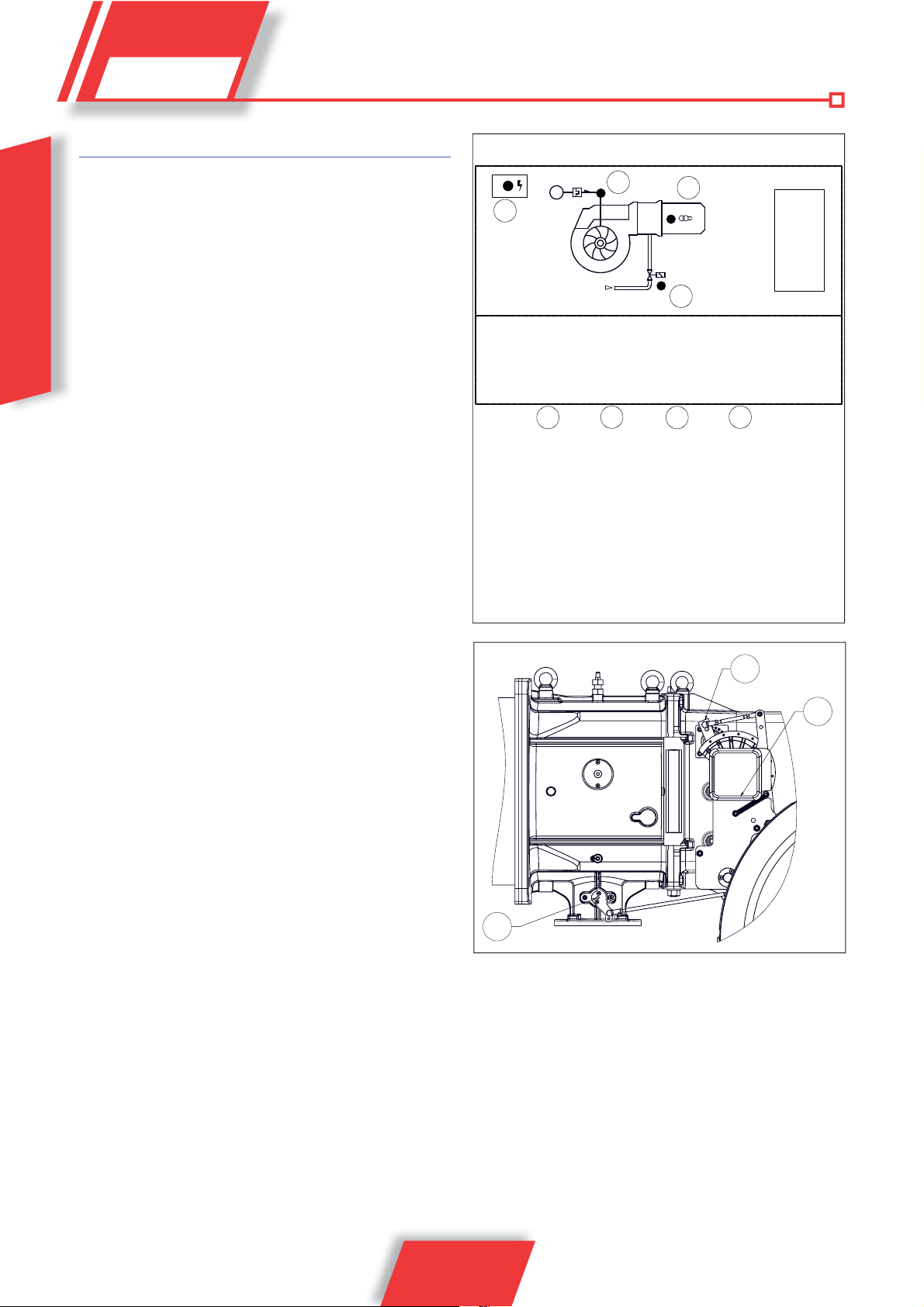

OPERATION DESCRIPTION

The gas train supplied is composed of an ON/OFF safety valve and

a single stage slow opening main valve. The gas flow adjustment in

the first and second stage is carried out by a streamlined butterfly

valve (11) activated by the electric servomotor (9). The movement

of the air shutter (10) is caused by the rotation of the servomotor

(9) through the lever and strap system (3). For the adjustment of

the air damper position according to the power burned in the first

and second stage, consult section: “Starting up and adjustment”. If

ENGLISH

when the main switch (1) is closed, the thermostats are closed, the

voltage reaches the command and control equipment which starts

the burner (2).

This turns on the fan motor for preventilation of the combustion chamber.

At the same time the rotation of the command servomotor (9) which

brings the gas throttle (11) and the air gate (10), through the action of

leverage, in the opening position corresponding to the second flame.

The preventilation phase comes only with the air gate in the second

flame position. At the end of the preventilation phase, the gas throttle

and the air shutter are returned to the ignition position, then the ignition

transformer (4) comes on and the gas valves (5) open.

The presence of the flame, detected by the control device, permits

continuation and completion of ignition, turning off the ignition

transformer. Then passing on to the second stage of power through

the progressive opening of the gas throttle and the air gate at the same

time. At the moment in which the demand for heat from the system

is satisfied, the boiler thermostat will intervene and shut down the

boiler. The air gate through the rotation of the servomotor will reach

the closed position when inactive. In the event that the control device

does not detect the presence of a flame, the control box activates

a “safety shut down” (8) within three seconds of the opening of the

main gas valve. In “safety lock-out” mode the valves are closed again

immediately. To release the equipment from its safety position, press

the release button (8).

MV

3

4

2

GAS

1

1 Main switch on/off

2 Power LED

3 Fan motor thermal relay activation indicator light (if foreseen)

4 Ignition transformer indicator light

5 Gas valves indicator light

6 AUTOMATIC - MANUAL operation selector

7 MIN - MAX power switch

8 Unlocking push-button with lock indicator light

6

5

7

8

sino ttico T BG1100 MC.ai

10 / 28

0006160025_201305

MODULATION OPERATION DESCRIPTION

When the burner is ignited at the minimum flow-rate, if the modulation

probe allows it (adjusted to a temperature or pressure which is

greater than that present in the boiler) the air adjustment servomotor

begins to operate,

- in a clockwise direction the air flow increases,

- in an anti-clockwise direction the air flow decreases,

causing a gradual increase in the combustion air flow and

consequently of the gas, until it reaches the maximum flow setting

of the burner. The burner remains in the maximum flow position until

the temperature or pressure is high enough to trip the modulation

probe, which reverses the rotation of the air adjustment servomotor.

Reverse rotation of the servomotor and consequently a reduction in

gas and air flow take place in short time intervals. By this method,

the modulation system tries to bring the amount of heat supplied

to the boiler in line with the heat that the boiler puts out to service.

The modulation probe installed on the boiler measures any request

variation and automatically adjusts fuel and combustion air supply,

by starting the air/gas adjustment servomotor and increasing or

reducing rotation as necessary. If the limit value (temperature or

pressure) at which the stop device is set (thermostat or pressure

switch) is reached even with gas supply at minimum level, the burner

is shut down by the device.

When temperature or pressure returns below the shut-down device

tripping value, the burner is activated once again according to the

program described in the previous section.

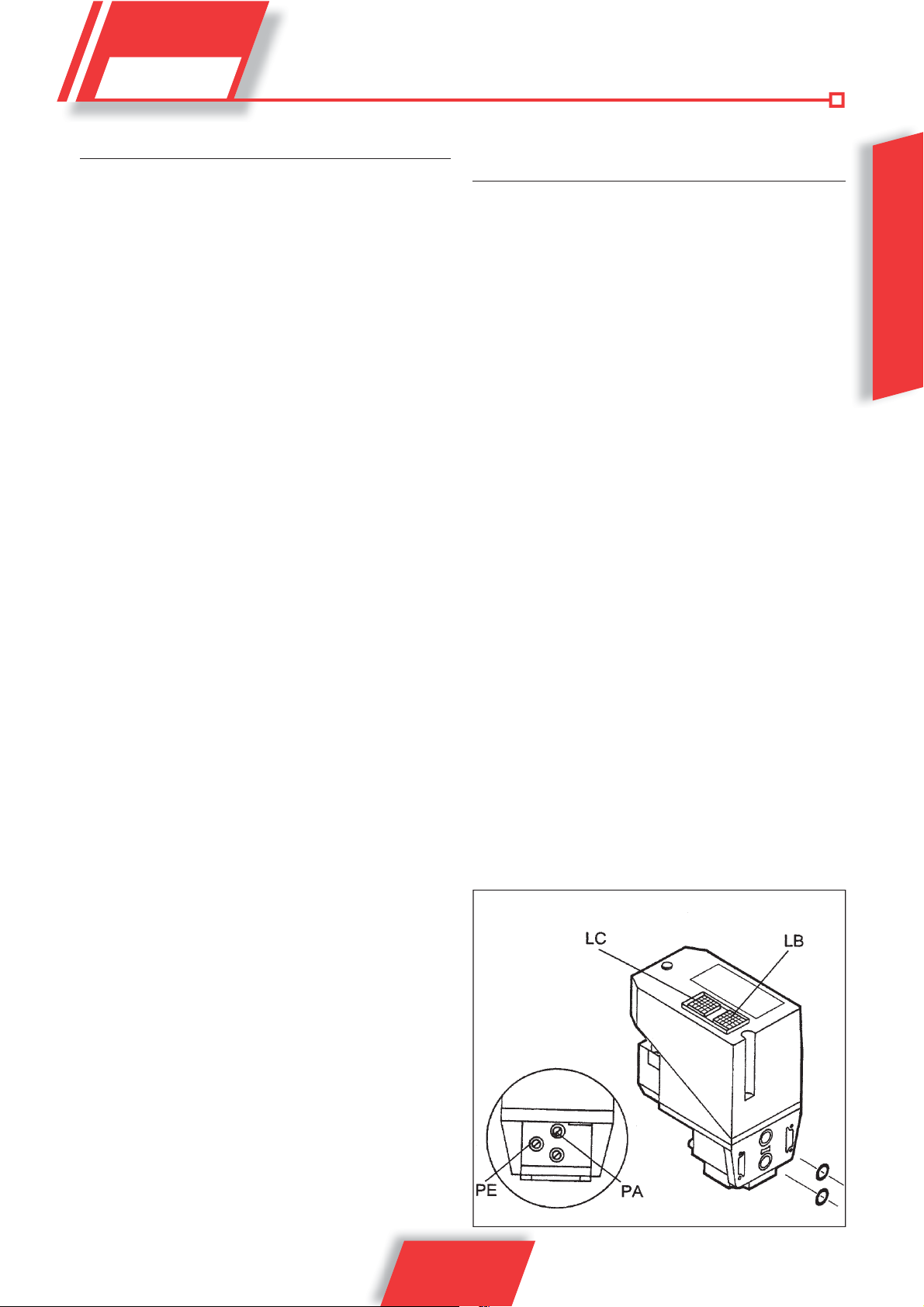

“VPS 504” VALVE TIGHTNESS

CONTROL (IF PRESENT)

It checks the tightness of gas cut-off valves. This check is carried

out as soon as the boiler thermostat authorises burner operation

creating, by means of a membrane pump, an overpressure greater

than the upstream pressure by 20 mbar in the test circuit.

If you wish to carry out a check, place a pressure gauge

corresponding to the PA pressure plug.

If the test circuit has a positive result, the LC authorisation lamp

(yellow) switches on after a few seconds. In order to restart, it is

necessary to unlock the equipment using the LB light button. The

fuse can be accessed using a screwdriver to remove the cover that

is located near the sockets for electrical connection; a spare fuse

is located in the upper part of the tightness control, under the cap.

remark: purchasing the specific kit, it is possible to install the

tightness control on the ramps that are not equipped with it.

ENGLISH

11 / 28

0006160025_201305

VPS504.tif

COMMAND AND CONTROL EQUIPMENT

FOR GAS BURNERS LFL 1...

Command and control equipment for mid and large output blownair burners

(intermittent service *) for 1 or 2 stage burners or for modulating

burners with air pressure monitoring for air shutter control. The

command and control equipment feature the EC mark according

to the Gas and Electromagnetic Compatibility Directive.

ENGLISH

* For safety reasons, it is important to perform a controlled stop

each 24 hours!

As regards the standards

The following LFL1.... features fully comply with the Standards

and ensure an extremely high safety level:

• The flame detector test and false flame test start immediately

after the tolerated post-combustion time. If the valves remain

open, or do not close immediately after the regulation stop, a

shutdown in lock condition is triggered at the end of the allowed

post-combustion time. The tests finish only at the end of the

pre-ventilation time of the next start-up.

• The validity of operation of the flame control circuit is checked

every time the burner starts up.

• The fuel valve control contacts are checked for wear during the

post-ventilation time.

• A built-in fuse in the appliance protects the control contacts from

any overloads that may occur.

of ignition flame on start-up); OPEN at the beginning and MIN

at the end of the pre-ventilation time. If the servomotors fail to

position the air damper in the preset points, the burner does

not start.

• Ionization current minimum value = 6mA

• UV cell current minimum value = 70mA

• Phase and neutral must not be inverted.

• Any assembly position and place (IP40 protection)

As for the burner control

• The equipment allows operation with or without post-ventilation.

• Air shutter controlled command to ensure pre-ventilation at

nominal air flow. Controlled positions: CLOSED or MIN (position

Equipment features

Equipment and

relevant programmer

LFL 1,333 Cyclic relay 3 31.5 6 3 12

Safety time

in seconds

Pre-ventilation time

with open damper (in

seconds)

Pre-ignition (in

seconds)

Post - ignition

in seconds

Time between 1st

fl ame and modulation

in seconds

start

12 / 28

0006160025_201305

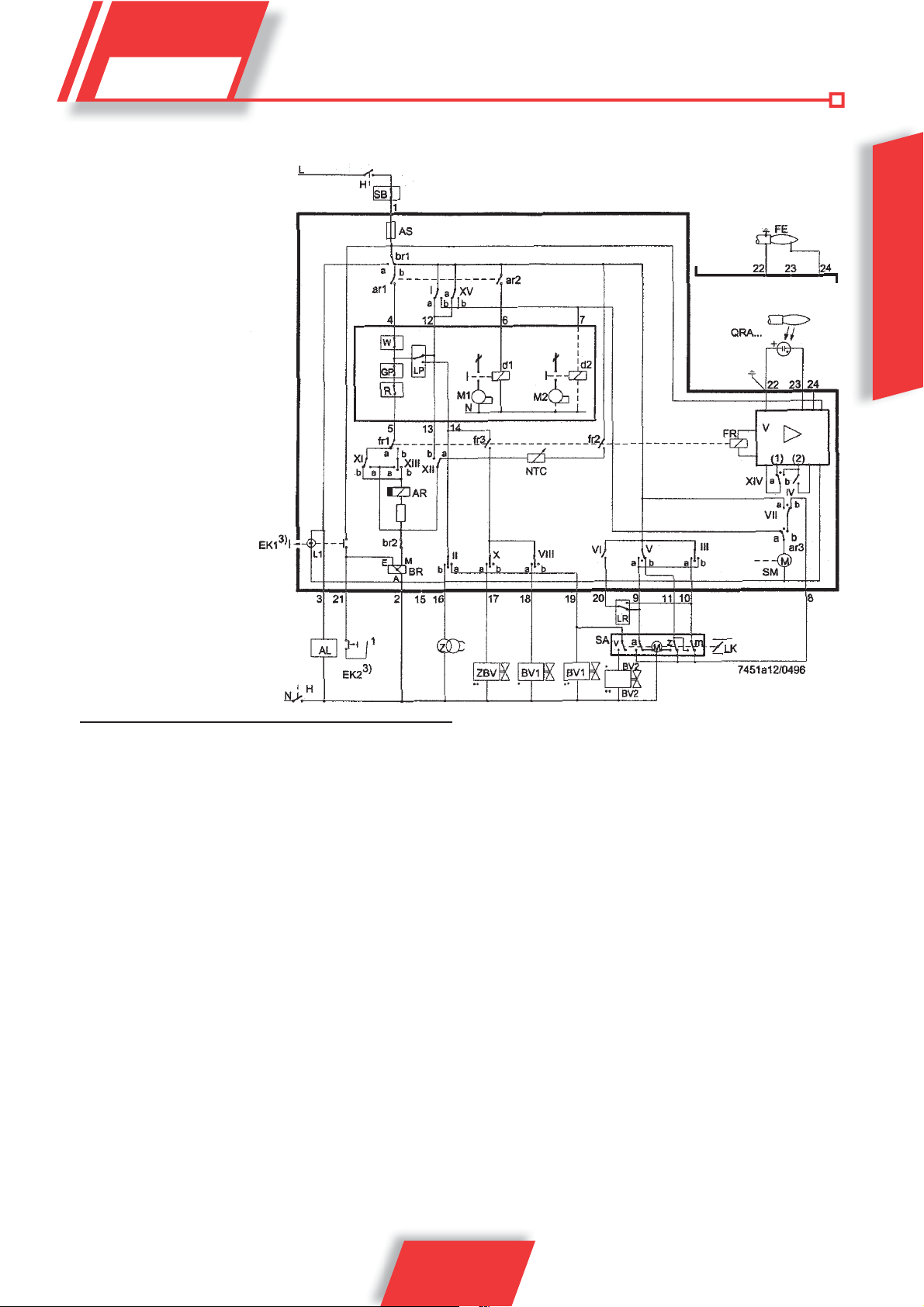

Electric connections

For the safety valve connection

refer to the drawing provided

by the burner manufacturer

ENGLISH

Key

a Limit switch contact for air gate OPEN position

AL Remote lockout warning device (alarm)

AR Main relay (load relay) with «ar» contacts

AS Device fuse

BR Lockout relay with «br» contacts

BV... Fuel valve

bv... Control contact for gas valve CLOSED position

d... Remote switch or relay

EK... Locking button

FE Ionisation current probe electrode

FR Flame relay with «fr» contacts

GP Gas pressure switch

H Main switch

L1 Fault warning light

L3 "Ready for operation" signal

LK Air damper

LP Air pressure switch

LR Load controller

m Auxiliary changeover switch for the air damper’s MIN position

M... Fan or burner motor

NTC NTC resistor

QRA... Probe

UVR Thermostat or pressure switch

RV Fuel valve with continuous regulation

S Fuse

SA Air gate servomotor

SB Safety limiter (temperature, pressure, etc.)

SM Programmer synchronous motor

v In case of servomotor: auxiliary contact for consensus to fuel

valve according to the air damper position

V Flame signal amplifi er

W Limit thermostat or pressure switch

z In case of servomotor: limit switch contact for air damper

CLOSED position

Z Ignition transformer

ZBV Pilot burner fuel valve

• Valid for forced draft burners, with one pipe

•• Valid for pilot burners with intermittent operation

(1) Input for operating voltage increase for UV probe (probe test)

(2) Input for fl ame relay forced excitation during operation test of

the fl ame supervision circuit (contact XIV) and during t2 safety

time (contact IV)

³) Do not press EK for more than 10 s.

13 / 28

0006160025_201305

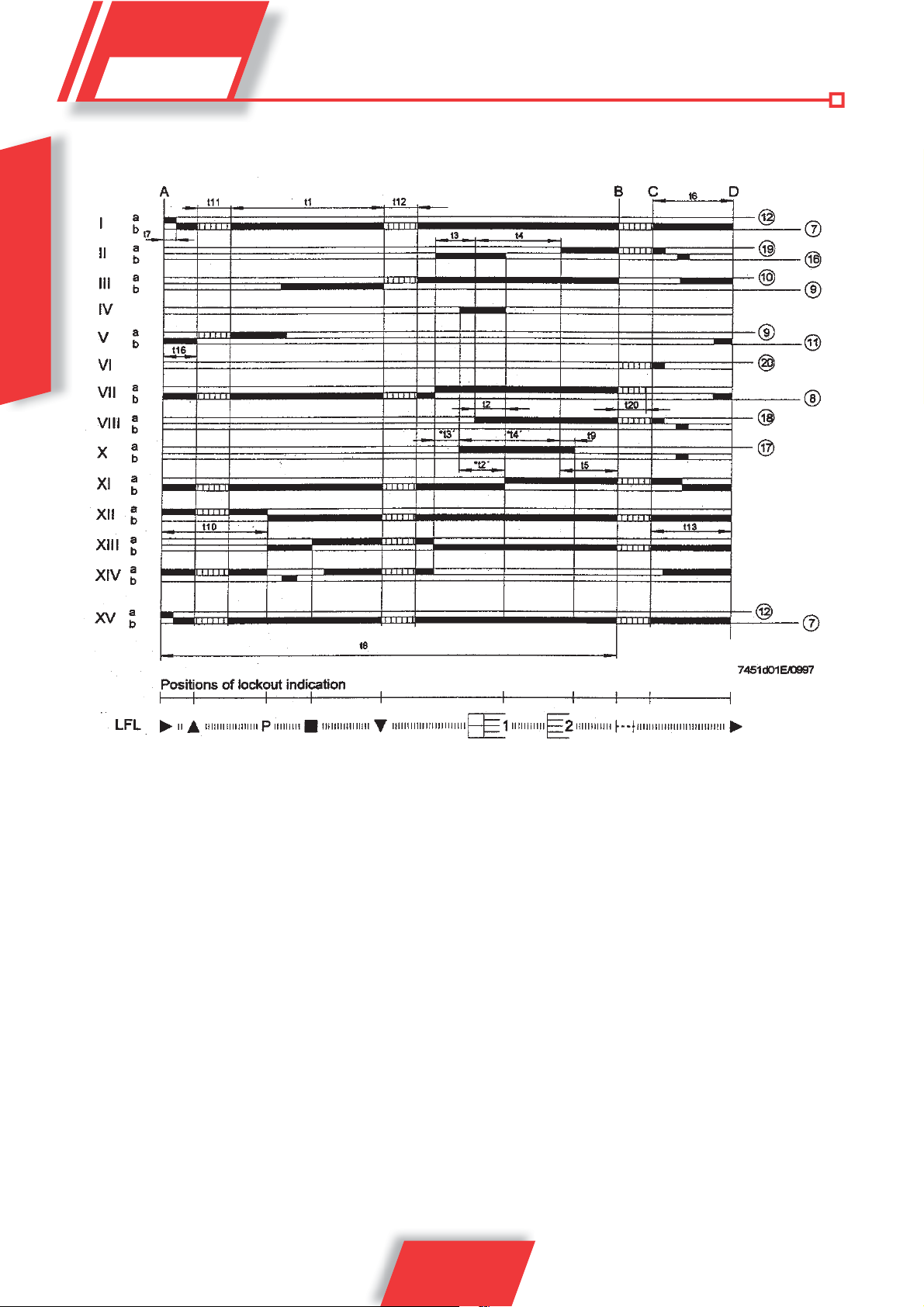

Notes on the programmer

programmer sequence

ENGLISH

Time key

time (50 Hz)

in seconds

31,5 t1 Pre-ventilation time with open air gate

3 t2 Safety time

- t2’ Safety time or fi rst safety time with burners using

pilot burners

6 t3 Short pre-ignition time (ignition transformer on ter-

minal 16)

- t3’ Long pre-ignition time (ignition transformer on terminal 15)

12 t4 Time between the t2' start and the consensus to the

valve on terminal 19 with t2

- t4’ Time between the t2' start and the consensus to the

valve on terminal 19

12 t5 Time between t4 end and the consensus to the

power regulator or the valve on terminal 20

18 t6 Post-ventilation time (with M2)

3 t7 Time between consensus upon start-up and the

voltage to terminal 7 (start delay for fan motor M2)

72 t8 Start-up duration (without t11 and t12)

3 t9 Second safety time for burners using pilot burners

12 t10 Time from start-up to the beginning of the air pres-

sure control without air damper real travel time

t11 Damper opening travel time

t12 Damper travel time in low fl ame position (MIN)

18 t13 Allowed post-combustion time

6 t16 Starting delay of consensus to air damper OPEN-

ING

27 t20 Time up to automatic closure of the programmer

mechanism after burner start-up

NOTE: With voltage at 60 Hz the times are reduced by nearly

20%.

14 / 28

0006160025_201305

t2´, t3´, t4´:

Such time intervals are valid only for burner command and control

equipment of series 01, i.e. LFL1.335, LFL1.635, LFL1.638. They do

not apply to burners of the series 02 since they have a simultaneous

activation of the X and VIII cams.

Operation

The drawings above show both the connection circuit and the

sequencer mechanism control program.

A Start-up confirmation by means of thermostat or the installation

pressure switch “R”.

A-B Start-up program

B-C Normal burner operation (on the basis of “LR” power regulator

control commands)

C Stop controlled by “R”

C-D Programmer return to start-up position A, post-ventilation.

During periods of burner inactivity, only the 11 and 12 control

outputs are powered and the air damper is CLOSED by the "z"

limit switch of the relevant servomotor. During the probe test

and the false flame test, also the flame supervision circuit is

powered (terminals 22/23 and 22/24).

Safety standards

on, any missing air pressure indication triggers a

shutdown!

Lock-out stop due to malfunction of the flame detection circuit.

Start-up sequence stops, because the position signal for

low flame was not sent to terminal 8 by auxiliary switch “m”.

Terminals 6, 7 and 15 remain live until fault removal!

1 Lock-out stop, due to lack of flame signal at the end of the

first safety time.

2 Lock-out stop, because no flame signal was received at the

end of the second safety time (main flame signal with pilot

burners at intermittent operation).

Lock-out stop, due to lack of flame signal during burner

operation.

If a shutdown occurs between start-up and pre-ignition with no

symbol, usually the cause is a premature flame, i.e. faulty, flame

signal caused for example by the self-ignition of an UV pipe.

ENGLISH

• In association with the use of QRA…, grounding of terminal 22

is compulsory.

• The power cables must conform to existing national and local

standards.

• LFL1… is a safety device, and it is therefore forbidden to open

it, tamper with it or modify it!

• The LFL1… device must be completely insulated from the mains

before carrying out any operations on it!

• Check all the safety functions before activating the unit or after

replacing a fuse!

• Provide protection against electric shock on the unit and all

electric connections.

• During use and maintenance, take care to prevent any infiltration

of condensation water on the controls.

• Electromagnetic emissions must be verified during use.

Control program in case of stopping and indication of stop

position

As a rule, in the event of any kind of stop, the fuel flow is immediately

cut off. At the same time both the programmer and the switch position

indicator remain in the same position. The symbol on the indicator

reading disk indicates the fault type.

No start-up, due to failure of a contact or lock-out stop to

close during or at the end of the command sequence because

of external lights (for example: flames not extinguished, leak

of the fuel valve, defects in the flame control circuit, etc.)

Shutdown indications

a-b Start-up program

b-b’ “Trips” (without contact confi rmation)

b(b’)-a Post-ventilation program

Start-up sequence stops, because the OPEN signal was not

sent to terminal 8 by limit switch contact “a”. T erminals 6, 7 and

15 remain live until fault removal!

P Shutdown, due to no air pressure signal. From this moment

0006160025_201305

LFL1..., series 01LFL1..., series 02

15 / 28

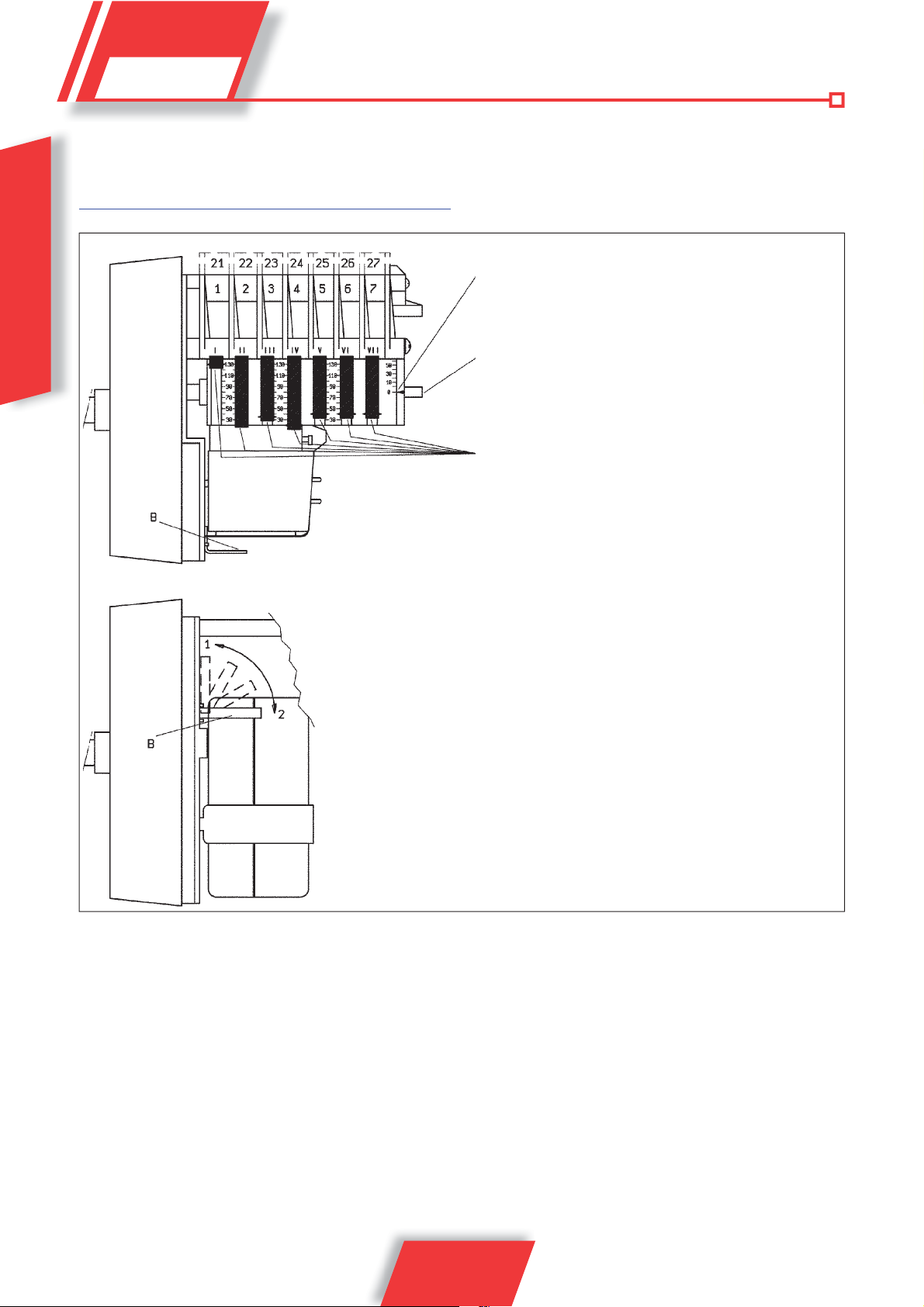

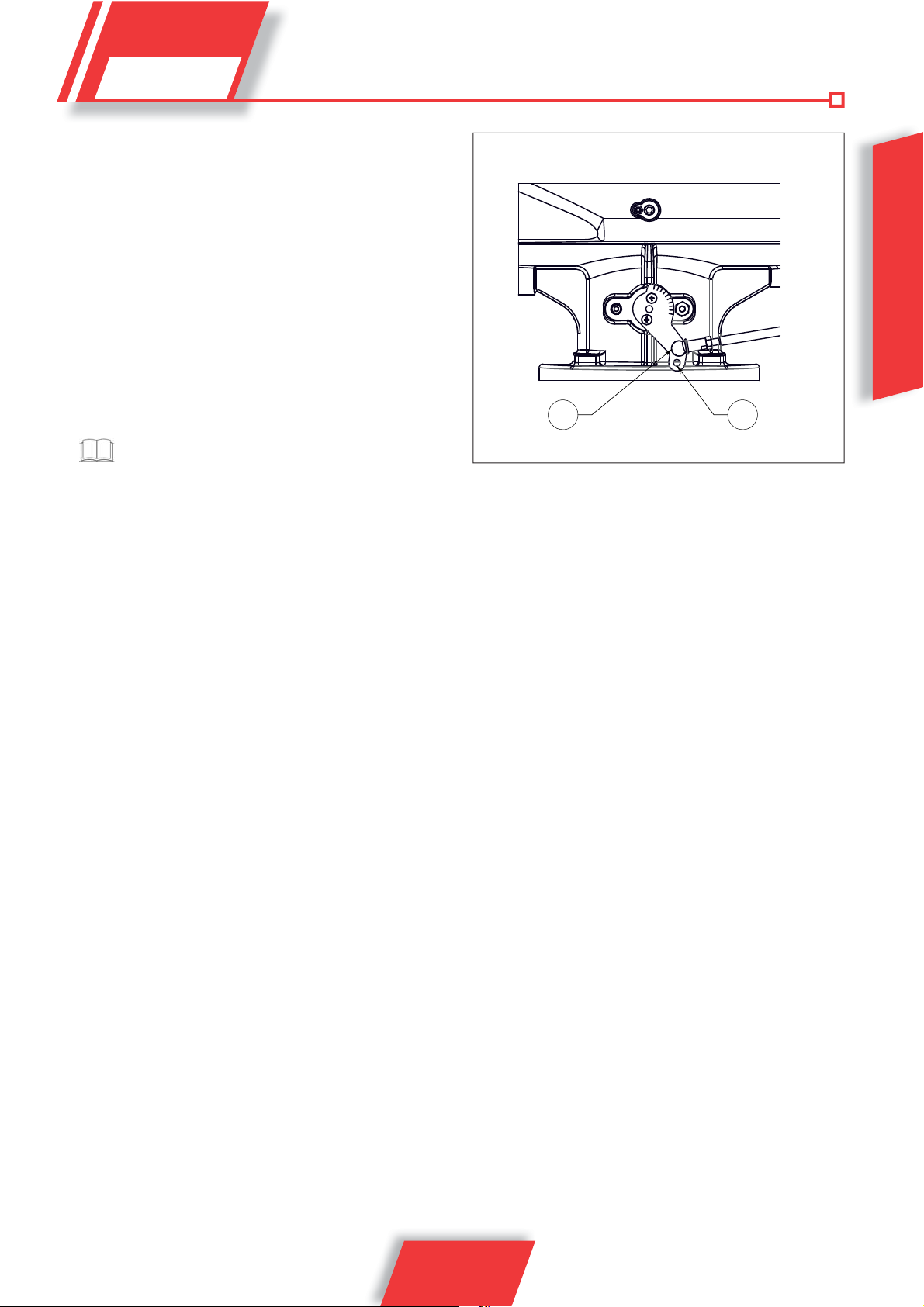

DETAILS OF THE MODULATION

CONTROL MOTOR SQM 10 AND SQM

20 FOR REGULATION OF CAMS

Reference index

ENGLISH

0002937530.tif

Camshaft

Adjustable cams

B = On and off lever for motor - camshaft coupling.

- Position 1 = disabled

- Position 2 = enabled

I MAXIMUM AIR OPENING (130°)

II TOTAL AIR CLOSURE (BURNER OFF) (0°)

III IGNITION AIR OPENING (CAM III MAXIMUM) (35°)

IV MINIMUM AIR OPENING (LOWER THAN CAM IV) (15°)

To modify the adjustment of the 3 cams used, use the respective red rings (I - II - III....).

The index on the red ring indicates on the respective reference scale the rotation angle

set for each cam.

16 / 28

0006160025_201305

DIAGRAM ILLUSTRATING REGULATION OF COMBUSTION HEAD AND DISTANCE OF ELECTRODE DISK

0002937680

ENGLISH

1) Ionising electrode

2) Ignition electrode

3) Flame disk

4) Mixer

5) Gas delivery pipe

IGNITION AND ADJUSTMENT

Instructions for manual burner operation

Combustion may be checked throughout the entire burner operating

range by controlling the equipment manually.

Set the switch (6) to manual position (MAN).

Use the switch (7) to increase or decrease gas and air.

After completing the check, set the switch (6) to automatic position

(AUT).

• Check that there is water in the boiler and that the system’s

gate valves are open.

• Make absolutely sure that the products of combustion can be

released freely (boiler and flue dampers must be open).

• Check that the voltage of the electrical line corresponds to that

required by the burner. Electrical connections (motor and main line)

must be prepared for the voltage available. Check that all electrical

connections made on-site are performed correctly as shown in

our wiring diagram. To prevent operation of the second flame,

open the second stage thermostat circuit.

• Adjusting power upon first start-up

- Position the ignition gas flow adjustment cam on the electric

servomotor to an opening angle of 35° (0002937530). If it

exists, open the safety valve flow regulator completely.

- Now switch on the switch (1). The command equipment

thus receives voltage and the programmer causes the

burner to switch on as described in chapter “OPERATION

DESCRIPTION”. During preventilation, make sure that the air

pressure control switch changes its status (from the closed

position without pressure measurement to the closed position

AB

TBG 1100 MC 20 5

with pressure measurement). If the air pressure switch does

not detect sufficient pressure, the ignition transformer (4) is not

switched on, nor are the gas valves (5) and so the equipment

is stopped in “lock-out” (8) mode.

- On first switching on repeated “lock outs” may occur due to

the following reasons:

- The gas piping has not been vented correctly and so there is

not enough gas to provide a stable flame.

- “Lock out” with flame presence could be caused by flame

instability in the ionisation area, due to an incorrect air/gas

ratio.

- Correct the air flow acting on the screw(s)

(12), corresponding to the bearing (13).

- in a clockwise direction the air flow increases,

- in an anti-clockwise direction the air

flow decreases.

Proceed with the regulation of the air until a position is found

which allows ignition without resulting in blocking.

- It may occur that the ionisation current is disturbed by the

discharge current of the ignition transformer (the two currents

have a common path on the burner’s “mass”) so the burner

locks out due to an insufficient ionisation. Invert the supply

(230V side) of the ignition transformer.

- This problem may also be caused by an insufficient “ground

connection” to the burner’s casing.

• Adjusting second stage power.

After completing first ignition adjustment, turn the switch (7)

towards

17 / 28

0006160025_201305

• the maximum (MAX) so as to get the maximum air and gas delivery.

Ensure that the gas flow adjustment cam in the second

stage of the electric servomotor is positioned at 130°.

- To regulate the gas flow operate the valve pressure regulator .

Consult the instructions related to the installed gas valve

model. Avoid keeping the burner running if the heating

capacity is greater than the maximum amount allowed for

the boiler, to avoid damaging it.

- For adjusting the air flow rate, operate on the screws (12),

ENGLISH

correct the rotation angle of the air gate in the suitable position

to guarantee the right quantity for the power burned.

- Check the combustion parameters with appropriate

instruments (C0

max= 10%, O2 min=3%, CO max=0,1%)

2

• Adjusting first stage power.

After having adjusted the burner in the second stage, put the

burner into the first stage. Turn switch (7) towards the minimum

(MIN) without varying the adjustment of the gas valve already

performed.

- Adjust the gas flow in the 1

st

stage to the desired value using

the adjustment cam IV for servomotor minimum output (see

0002937530).

- If necessary, correct the combustion air supply adjusting the

screw(s) (12).

- Check the combustion parameters in the 1

appropriate instruments (C02 max= 10%, O2 min=3%, CO

max=0,1%)

• Adjusting the flow rate for ignition

- Once adjustment of the first stage has been carried out,

the burner needs to be switched off and check that ignition

occurs properly. If necessary, it is possible to optimise burner

adjustment in the start-up phase proceeding as follows:

- Adjust the gas flow in the start-up phase, using the adjustment

cam III for ignition output adjustment (see 0002937530). It is

often advisable to set cam III at a slightly higher angle than

cam IV for first stage.

- If necessary, correct the combustion air supply adjusting the

screw(s) (12).

• The air pressure switch prevents the opening of the gas valves

if the air pressure is not the foreseen one. The pressure switch

must therefore be adjusted to intervene closing the contact

when the air pressure in the burner reaches a sufficient

value. If the air pressure switch does not detect pressure

greater than that calibrated, the equipment runs through

its cycle but does not switch on the ignition transformer and

does not open the gas valves and so the burner “locks-out”.

To ensure correct operation of the air pressure switch you

must, with burner on and in 1

st

stage, increase its adjustment

until it is triggered and immediately “locks-out” the burner.

Adjust the setting of the pressure switch to a level slightly below

the actual air pressure detected in first stage operation. Release

the burner and check that it starts up correctly.

• The gas control pressure switch (minimum) prevents burner

st

stage with

MV

3

4

2

GAS

1

1 Main switch on/off

2 Power LED

3 Fan motor thermal relay activation indicator light (if foreseen)

4 Ignition transformer indicator light

5 Gas valves indicator light

6 AUTOMATIC - MANUAL operation selector

7 MIN - MAX power switch

8 Unlocking push-button with lock indicator light

6

5

7

8

sino ttico T BG1100 MC.ai

18 / 28

0006160025_201305

• operation when gas pressure is not the foreseen one. The

minimum pressure switch must make use of the contact which

is closed when the pressure switch detects a pressure higher

than its own setting. Therefore the adjustment of the minimum

pressure switch must be carried out when the burner is started

up, in accordance with the pressure that is found from time to

time. The triggering (opening of the circuit) of any of the pressure

switches when the burner is running (flame on) causes the

burner to stop immediately. When first switching on the burner

it is essential to check that it works properly.

• Check the triggering of the ionisation electrode by disconnecting

the cable of terminal 24 of the terminal board and switch on the

burner. The equipment must run through its cycle completely

and, three seconds after the ignition flame has formed, “lock-out”.

• Check the efficiency of the boiler pressure switches or

thermostats (they should shut down the burner when triggered).

Once the adjusting operations are completed, visually check

that the thin plate on which the bearing acts has a progressive

profile. Using the special instruments check also that in the

passage from the 1

do not move too much away from the optimal values.

The butterfly valve for gas adjustment is factory set at lever

position "1". If it is necessary to decrease the adjustment

range (opening angle of the gas butterfly valve), place the

joint to position “2”.

st

to the 2nd stage combustion parameters

ENGLISH

19 / 28

0006160025_201305

AIR PRESSURE SWITCH OPERATION

DESCRIPTION

The air pressure switch is used to lock the equipment if air pressure

is not at the expected value. The pressure switch must be set to

close the normally open contact, when the air pressure in the burner

reaches a suffi cient value.

T o verify that the air pressure switch is operating correctly , con while

the burner is ignited at its minimum setting, while the burner is ignited

ENGLISH

at its minimum setting. Reset the burner by pushing the appropriate

button and readjust the pressure switch to an adequate value to

detect the existent air pressure during the pre-ventilation phase.

GAS PRESSURE SWITCH OPERATION

DESCRIPTION

The pressure switches for checking gas pressure (minimum

and maximum) prevent the burner from operating when gas pressure is not between the expected ranges. The specifi c function of

the pressure switches clearly reveals that the pressure switch for

controlling minimum pressure uses the NO contact (normally open)

which is closed when the pressure switch detects a pressure value

above the value it is set to, while the pressure switch for controlling

maximum pressure uses the NC contact (normally closed) which is

closed when the pressure switch detects a pressure lower than the

value it is set to. The minimum and maximum gas pressure switches

must be set when testing the burner, on the basis of the pressure

measured in each case. The pressure switches are connected in

a way in which tripping (opening the circuit) of one of the pressure

switches when burner is working (fl ame on), will shut down the

burner immediately.

Adjustment before switching on the burner:

set the minimum pressure switch to the lowest setting on the scale,

set the maximum pressure switch to the highest setting on the scale.

Adjustment after burner calibration:

With the burner at the maximum delivery, regulate the pressure

switch for minimum pressure by increasing the regulation value

until the burner shuts down, read the value on the regulation ferrule and set it to a value diminished by 5 mbar. With the burner off,

regulate the pressure switch for maximum pressure, diminishing

the regulation value until the NC (normally closed) contact opens.

Read the value on the regulation ferrule and set it to a value increased by 5 mbar.

in case only one pressure switch is installed on the gas train

it must be a pressure switch for minimum pressure.

press aria001

20 / 28

0006160025_201305

MAINTENANCE

The burner does not require any particular maintenance, it is recommended at least to carry out the following operations at the end of

the heating season:

• Clean the air shutters, the air pressure switch with pressure

intake and the pipe.

• Check the conditions of the ionisation electrode.

• Have the boiler cleaned and, if necessary, also the chimney by

specialized personnel (stove repairer); a clean boiler is more

efficient, lasts longer and is quieter.

• Periodically check that the gas filter is clean for gas burners.

• In order to clean the combustion head, its components must

be disassembled. Be careful during the reassembly operations

to exactly centre the gas diffuser with regard to the electrodes,

making sure that they are not earthed, which would result in the

locking of the burner. It should also be checked that the ignition

electrode spark occurs only between the electrode itself and the

perforated sheet disk.

Periodically test combustion gases and check that the emissions

values are correct.

Check that all components of the combustion head are in good

condition, have not been deformed by high temperatures and are

free from impurities or deposits deriving from the installation environment or from poor combustion. If it is necessary to clean the

combustion head, take out its components according to the procedure described below:

• unscrew the anchoring screws (N), disconnect the tie rod (O)

and open the ventilating body;

• pull out the ignition (I) and ionization cables (M) from their

electrode terminals (L);

• unscrew the screw (R) from the lung (P);

• pull out the entire mixer unit in the direction shown by the

arrow. Having completed the maintenance work, replace the

combustion head, following in reverse order the operations

described above, after having checked the correct position of

the electrodes of ignition and of ionization (see 0002937680).

ENGLISH

21 / 28

0006160025_201305

IONISATION CURRENT MEASUREMENT

The minimum ionisation current needed to run the equipment is 6

μA. The burner flame generates a significantly higher current, which

usually does not require any control by the equipment.

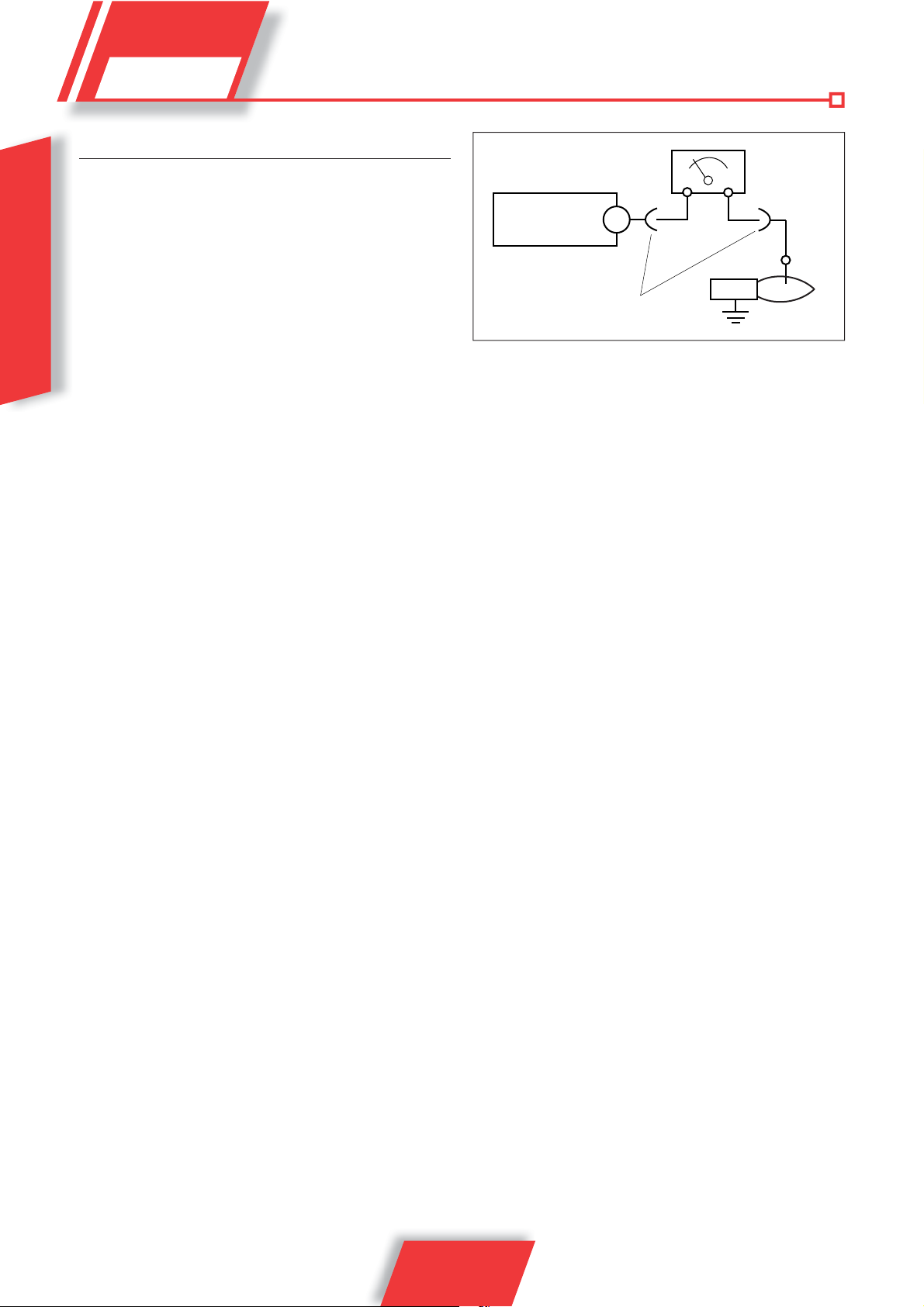

Should the ionisation current need to be measured, a microammeter

must be connected in series to the ionisation electrode lead by

opening the connector “C”, see wiring diagram.

LFL 1.3xx

24

M

-

+

ionizzazione LFL.ai

FE

ENGLISH

C

22 / 28

0006160025_201305

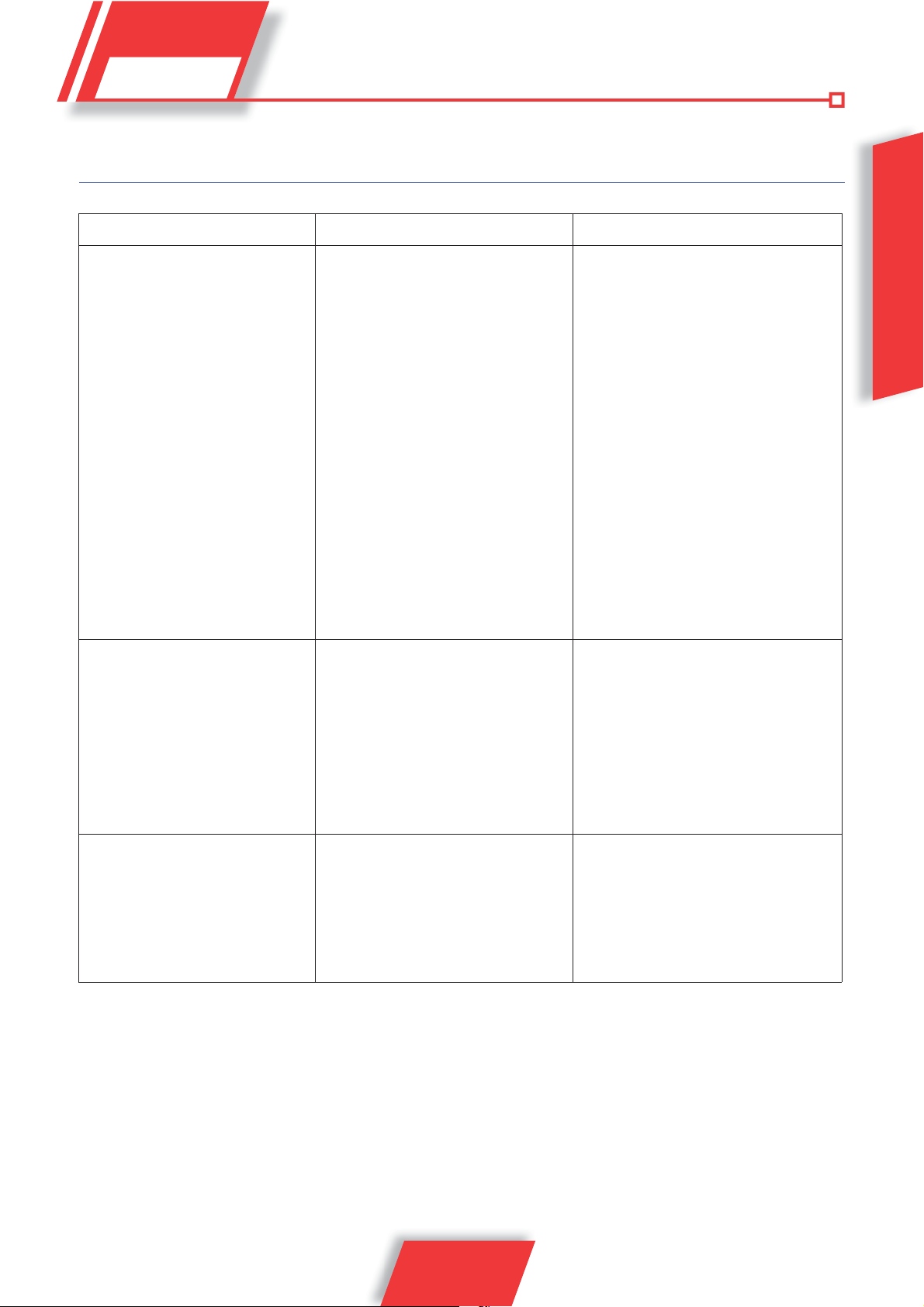

HOW TO FIND THE CAUSES OF IMPROPER OPERATION OF TWOSTAGE GAS BURNERS AND HOW TO RECTIFY THEM

PROBLEM POSSIBLE CAUSE SOLUTION

Appliance locked out due to no flame

(red light lit). The fault is in the flame

control device.

The burner goes into “lock-out”, gas

flows, but there is no flame (red light on).

Fault in ignition circuit.

The burner goes into “lock-out”, gas

flows, but there is no flame (red light on).

• Disturbance to ionization current from the

ignition transformer.

• Flame sensor (ionisation probe)

inefficient.

• Flame sensor (ionisation probe) position

incorrect.

• 4) Ionization probe or relative earth cable.

• Electrical connection cut-off by flame

sensor.

• Inefficient draught or fumes passage

blocked.

• Flame disk or combustion heads dirty

or worn.

• Equipment fault.

• No ionization.

• Fault in ignition circuit

• Ignition transformer cable discharges

to earth.

• Ignition transformer cable disconnected.

• Ignition transformer faulty.

• The distance between electrode and

earth is incorrect.

• Isolator dirty, so electrode

discharges to earth.

• Air/gas ratio incorrect.

• Gas pipe has not been properly bled of

air (in the case of first ignition).

• The gas pressure is insufficient

orexcessive.

• Air flow between disk and head too

narrow.

• Invert the ignition transformer power supply

(230V side) and check using an analogue

micro-ammeter.

• Replace flame sensor

• Correct the position of the flame sensor,

and then check its efficiency by connecting

the analogue micro-ammeter.

• Check visually and using the instrument.

• Restore the connection.

• Ensure that the boiler fumes passage and

chimney connection are free.

• Visually check and replace, if necessary.

• Replace it.

• If the “earth” of the equipment is not

efficient, do not check the ionization

current. Check the efficiency of the “earth”

at the terminal concerned in the equipment

and at the “earth” connection of the electric

system.

• Check the ignition transformer power

supply (230V) and high voltage circuit

(electrode to earth or isolator broken under

locking terminal).

• Replace it.

• Connect it.

• Replace it.

• Position at the correct distance

• Clean or change the isolator or electrode.

• Correct the air/gas ratio (there is probably

too much air or very little gas)

• Bleed the gas pipe again, taking great care.

• Check the maximum gas pressure value at

the time of ignition (use a waterpressure

gauge, if possible).

• Adjust the disk/head opening.

ENGLISH

23 / 28

0006160025_201305

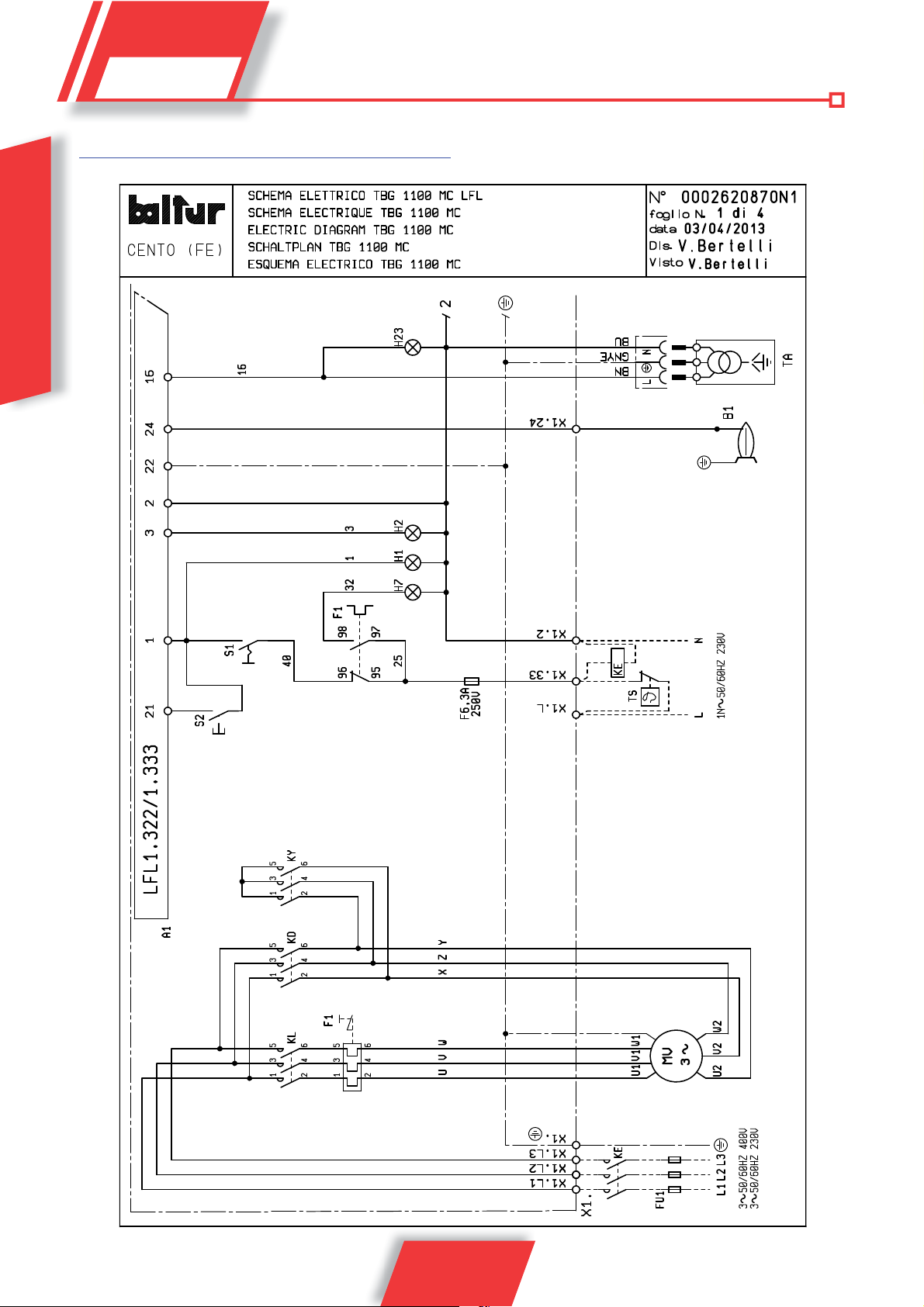

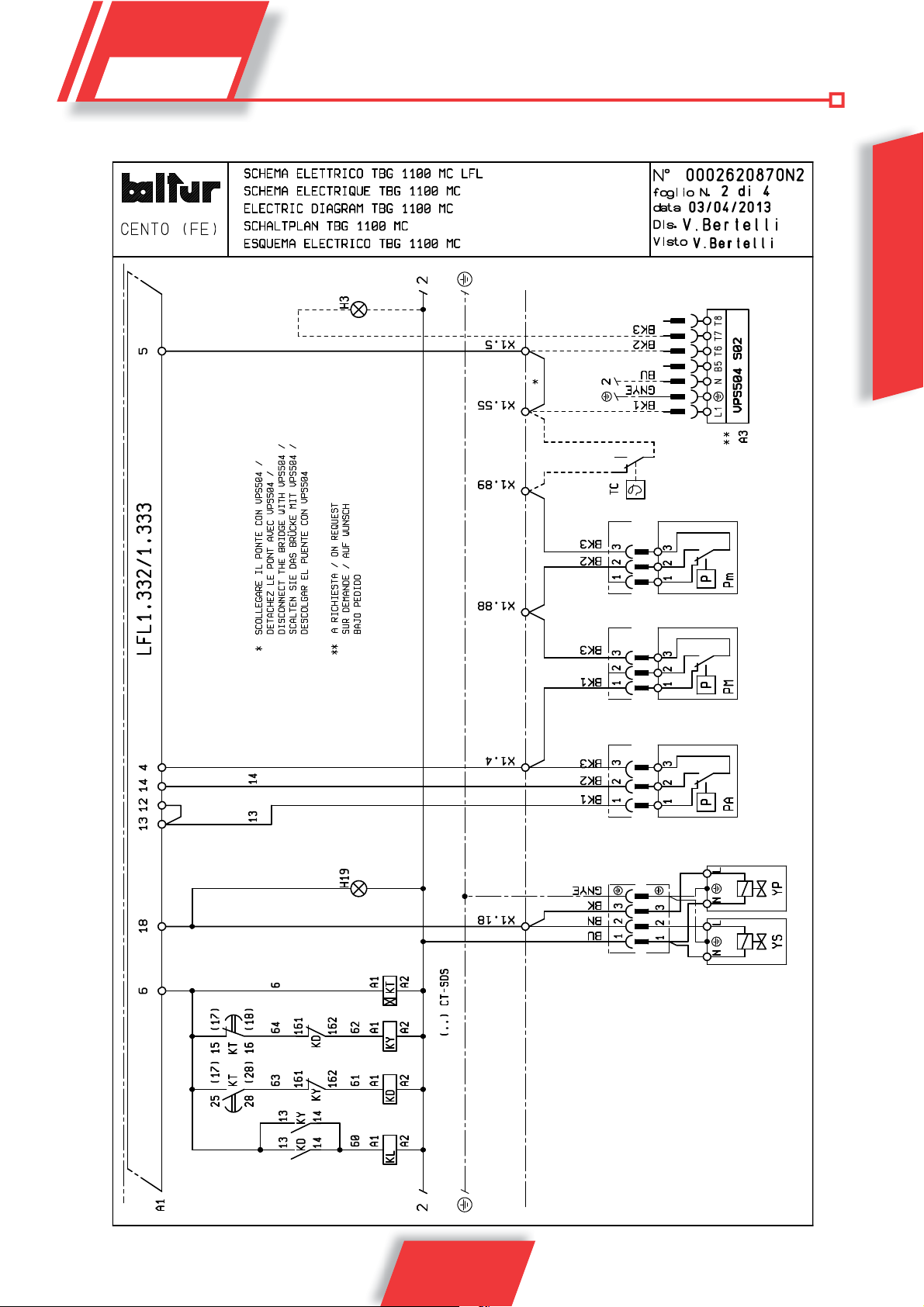

WIRING DIAGRAM

ENGLISH

24 / 28

0006160025_201305

ENGLISH

* DISCONNECT THE JUMPER WITH VPS504

** OPTIONAL

25 / 28

0006160025_201305

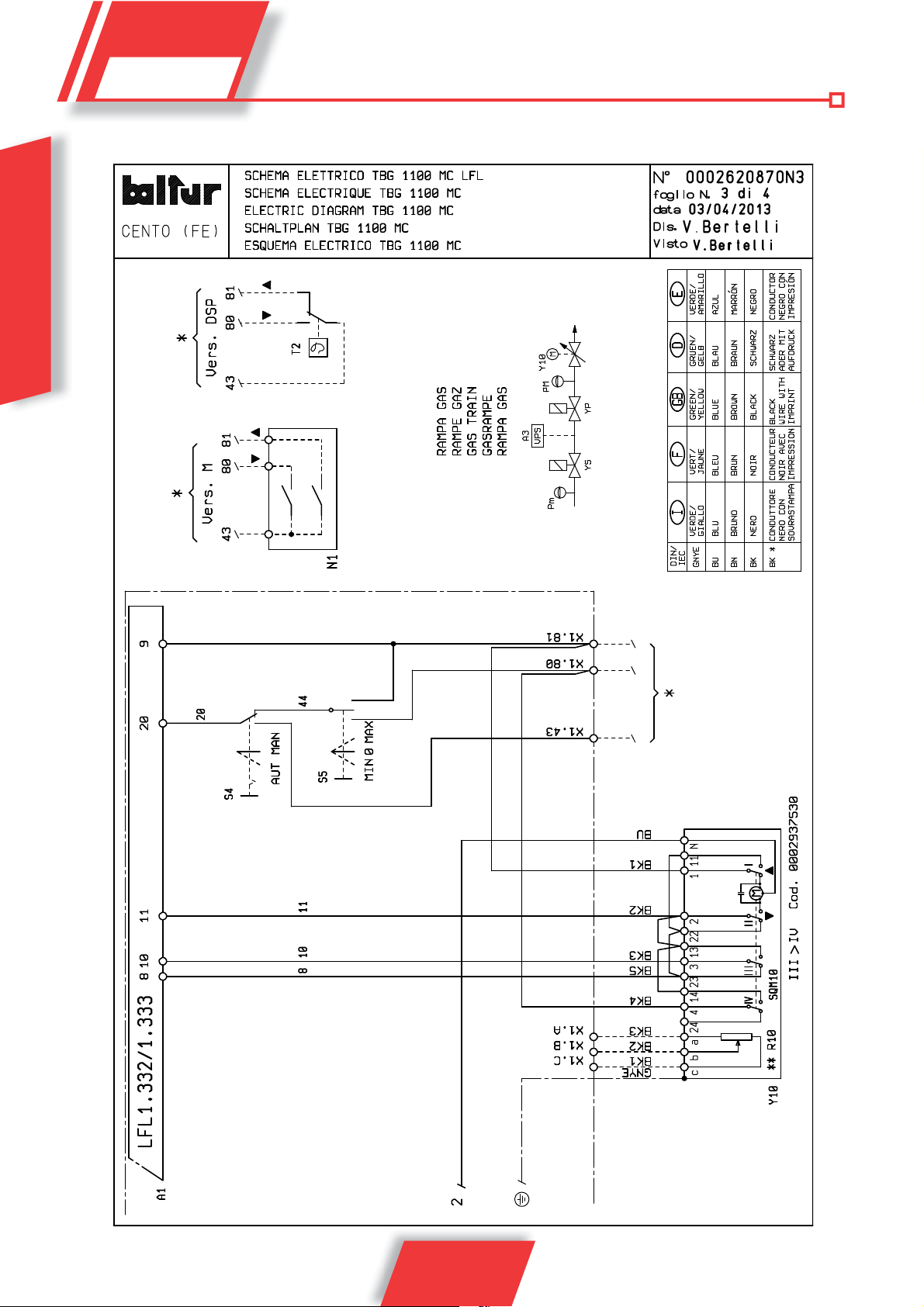

ENGLISH

GAS TRAIN

26 / 28

0006160025_201305

** OPTIONAL ITEM

IT

A1 EQUIPMENT

A3 VALVE SEAL CONTROL

B1 IONISATION ELECTRODE

F1 THERMAL RELAY

FU1 FUSES

H1 OPERATION INDICATOR LIGHT

H19 MAIN VALVES ON LIGHT

H2 LOCK INDICATOR LIGHT

H23 TRANSFORMER LAMP

H3 LDU11 SHUTDOWN WARNING LIGHT

H7 FAN MOTOR THERMAL RELAY BLOCK LAMP

KD TRIANGLE CONTACTOR

KE EXTERNAL CONTACTOR

KL LINE CONTACTOR

KT TIMER

KY STAR CONTACTOR

MV MOTOR

N1 ELECTRONIC REGULATOR

P M MAXIMUM PRESSURE SWITCH

PA AIR PRESSURE SWITCH

Pm MINIMUM PRESSURE SWITCH

R10 POTENTIOMETER

S1 START/STOP SWITCH

S2 RELEASE BUTTON

S4 AUT-MAN SELECTOR

S5 MIN-MAX SWITCH

T2 2

TA IGNITION TRANSFORMER

TC BOILER THERMOSTA T

TS SAFETY THERMOSTAT

X1 BURNER TERMINAL

Y10 AIR SERVOMOTOR

YP MAIN SOLENOID VALVE

YS SAFETY SOLENOID VALVE

nd

STAGE THERMOSTAT

ENGLISH

DIN / IEC EN

GNYE GREEN / YELLOW

BU BLUE

BN BROWN

BK BLACK

BK* BLACK CONNECTOR WITH OVERPRINT EN A1

CONTROL BOX B1

0006160025_201305

27 / 28

ENGLISH

28 / 28

0006160025_201305

Loading...

Loading...