baltur BGN 200 LX, BGN 390 LX, BGN 390 LX-V, BGN 200 LX-V, BGN 540 LX Maintenance, Use And Installation Manual

...

EN

SP

FR

0006081062_200904

Manuale

istallazione,

impiego,

manutenzione.

BGN 200 LX / LX-V

BGN 300 LX / LX-V

BGN 390 LX / LX-V

BGN 540 LX / LX-V

Maintenance,

use and

installation

manual

Manual de

mantenimiento,

uso e

instalación

Manuel

d’installation,

utilisation et

entretien

0006081062_200904

- Before using the burner for the first time please carefully read the chapter “WARNINGS NOTES FOR THE USER : HOW

TO USE THE BURNER SAFELY” in this instruction manual, which is an integral and essential part of the product. The

works on the burner and on the esystem have to be carried out only by competent people.

- Read carefully the instructions before starting the burner and service it.

- The system electric feeding must be disconnected before starting working on it.

- If the works are not carried out correctly it is possible to cause dangerous accidents.

- Antes de empezar a usar el quemador lea detenidamente el folleto “ADVERTENCIAS DIRIGIDAS AL USUARIO PARA

USAR CON SEGURIDAD EL QUEMADOR” que va con el manual de instrucciones y que constituye una parte integrante

y esencial del producto.

- Lea atentamente las instrucciones antes de poner en funcionamento los quemadores y efectuar las tareas de mantenimiento.

- Los trabajos que se efectúen al quemador y a la instalación deben ser efectuados sólamente por personal cualificado.

- La alimentación eléctrica de la instalación se debe desconectar antes de iniciar los trabajos.

- Si los trabajos no son efectuados correctamente se corre el riesgo de que se produzcan accidentes peligrosos.

- Avant de commencer à utilise le brûleur,lire attentivement les recommandations de la notice “RECOMMANDATIONS A

L’ATTENTION DE L’UTILISATEUR POUR UN USAGE DU BRULEUR EN TOUTE SECURITE” jointe au manuel d’instructions et qui constitue une partie intégrante et essentielle du produit.

- Lire attentivement les instructions avant de mettre en fonction le bruleur et pour son entretien correct.

- Les travaux sur le bruleur et sur l’installation doivent etre executes seulement par du personnel qualifie.

- L’alimentation electrique de l’installation doit etre debranche avant de commencer les travaux.

- Si les travaux ne sont pas executes correctement il y a la possibilite de causer de dangereux incidents.

E

N

G

L

I

S

H

F

R

A

Ç

A

I

S

E

S

P

A

Ñ

O

L

S

S

S

- Prima di iniziare a usare il bruciatore leggere attentamente quanto esposto nell’opuscolo “AVVERTENZE PER L’UTENTE, PER

L’USO IN SICUREZZA DEL BRUCIATORE” presente a corredo del manuale istruzioni, che costituisce parte integrante ed essenziale

del prodotto.

- Leggere attentamente le istruzioni prima di mettere in funzione il bruciatore o di eseguire la manutenzione.

- I lavori sul bruciatore e sull’impianto devono essere eseguiti solo da personale qualificato.

- L’alimentazione elettrica dell’impianto deve essere disinserita prima di iniziare i lavori.

- Se i lavori non sono eseguiti correttamente si rischiano incidenti pericolosi.

I

T

A

L

I

A

N

O

0006081062_200904

33 / 36

0006081062_200904

I

T

A

L

I

A

N

O

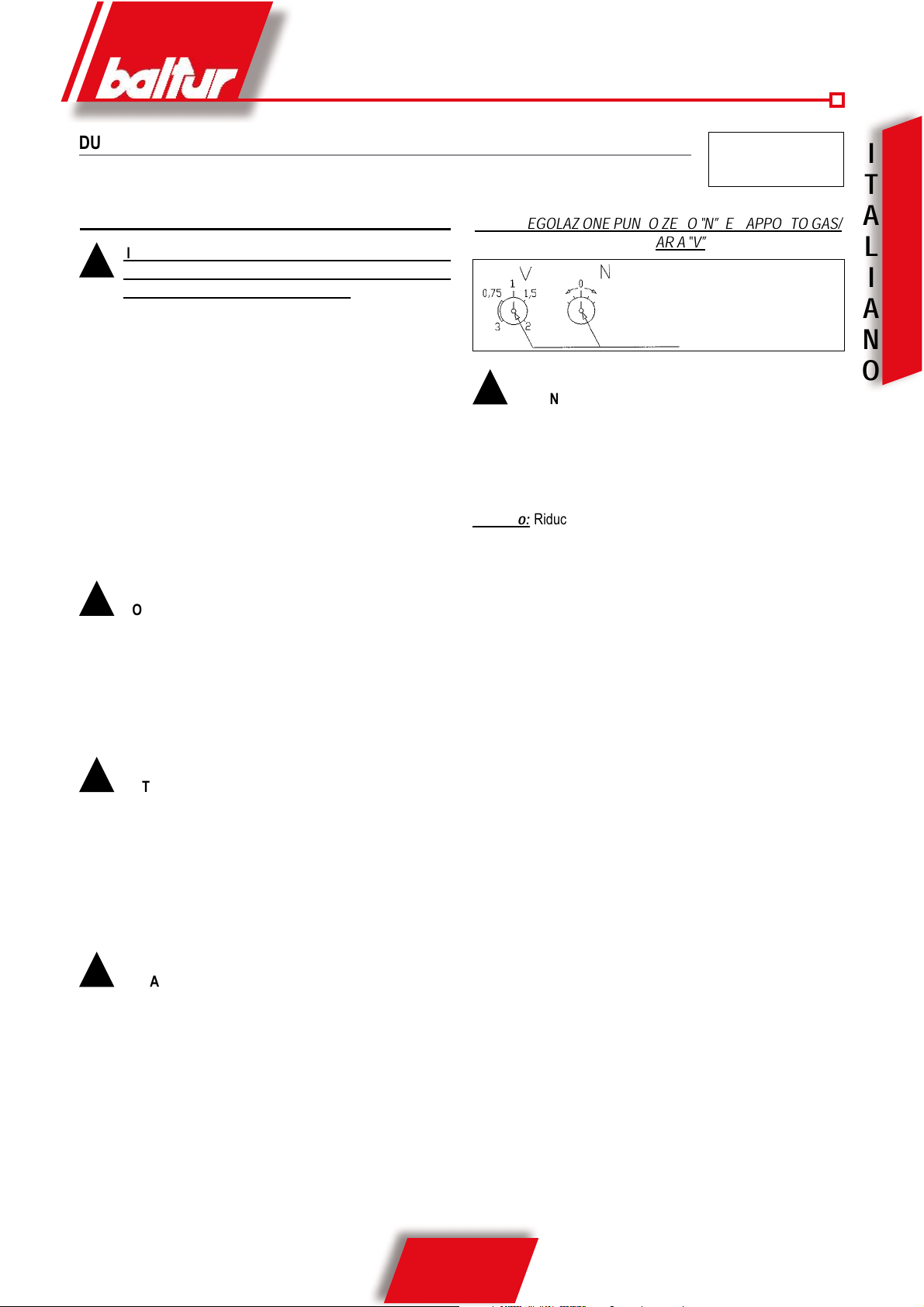

DUNGS mod. MB-VEF BO1 / DMV-VEF

Taratura del gruppo regolazione-pressione

!

Il gruppo regolazione- pressione viene pre-tarato in

fabbrica. I valori di taratura devono essere poi adattati

sul posto alle esigenze dell‘ impianto.

La valvola modulante mod. MB-VEF B01 opera aumentando

automaticamente l’erogazione del gas se aumenta l’erogazione

dell’aria, e riduce automaticamente l’erogazione del gas se viene

ridotta l’erogazione dell’aria. Pertanto l’erogazione della quantità di

gas al “minimo“ ed al “massimo” del bruciatore deve essere regolata esclusivamente regolando il “minimo” e il “massimo”, dell’aria di

combustione. In pratica si opera sulle due “cammes” che regolano

il minimo e il massimo del servomotore di regolazione dell’aria.

Tenendo presente questo principio, consigliamo di agire come esposto di seguito per regolare il bruciatore. Accedere e mantenere il

bruciatore al minimo della modulazione (valvola modulante aperta

al minimo), verificare il contenuto di CO

2

, oppure O2 e CO nei fumi

e correggere, se necessario, con la vite di regolazione per correzione punto zero ”N” il rapporto gas/aria, ottenuto con lo spostamento parallelo delle curve caratteristiche (vedi diagramma).

!

NOTA: Per diminuire la quantità di aria rispetto al gas

e quindi per aumentare la percentuale di CO2 portare la

regolazione ‘N” verso valori positivi (+). Per aumentare

la quantità di aria rispetto al gas e quindi per diminuire la

percentuale di CO2, portare la regolazione “N” verso valori

negativi (-). Portare il bruciatore al massimo della modulazione misurare il contenuto di CO2 oppure O2e CO nei fumi

e correggere, se necessario, il rapporto tarato agendo sulla

vite “V” fino a quando il valore misurato è ottimale.

!

NOTA: Per diminuire la quantità di aria rispetto al gas e

quindi per aumentare la percentuale di CO2 portare la regolazione “V” verso rapporti più grandi. Per aumentare la

quantità di aria rispetto al gas e quindi per diminuire la percentuale di CO2 portare la regolazione “V” verso rapporti

più piccoli (vedi diagramma). Una volta regolato il massimo

della modulazione, ritornare nella posizione di minimo e

verificare le regolazioni precedentemente effettuate. Se

necessario correggere nuovamente il punto “0” con la regolazione “N”

!

NOTA: Quando per ottenere ai bassi carichi (modulazione

al minimo) valori di CO2 oppure O2 buoni, è stato necessario eseguìre una modifica parallela della caratteristica,

occorre verificare nuovamente la regolazione del rapporto

gas-aria e, se necessario, variare il rapporto gas/aria con

la vite “V”.

Sede per chiave esagonale cava da 2,5 mm.

N° 0002910621 /

0006080717

Rev. 22/10/2004

!

ATTENZIONE: Da quanto sopra esposto risulta evidente

che la variazione di pressione dell’aria, che si ottiene nel

bruciatore, agendo sul dispositivo di regolazione dell’aria alla

testa di combustione (variazione della sezione di passaggio

dell’aria) determina automaticamente ed inevitabilmente una

variazione di erogazione di gas.

Esempio:

Riducendo la sezione di passaggio dell’aria tra testa e

disco si ottiene un aumento della pressione aria nel bruciatore e

una riduzione, dell’erogazione di aria nel focolare, di conseguenza

la valvola gas MB-VEF B01 rileva l’aumento di pressione e aumenta

l’erogazione del gas, diventa quindi indispensabile la correzione

(riduzione) dell’erogazione di gas agendo sui relativi dispositivi di

cui la valvola è provvista.

VITI DI REGOLAZIONE PUNTO ZERO “N” E RAPPORTO GAS/

ARIA “V”

34 / 36

0006081062_200904

I

T

A

L

I

A

N

O

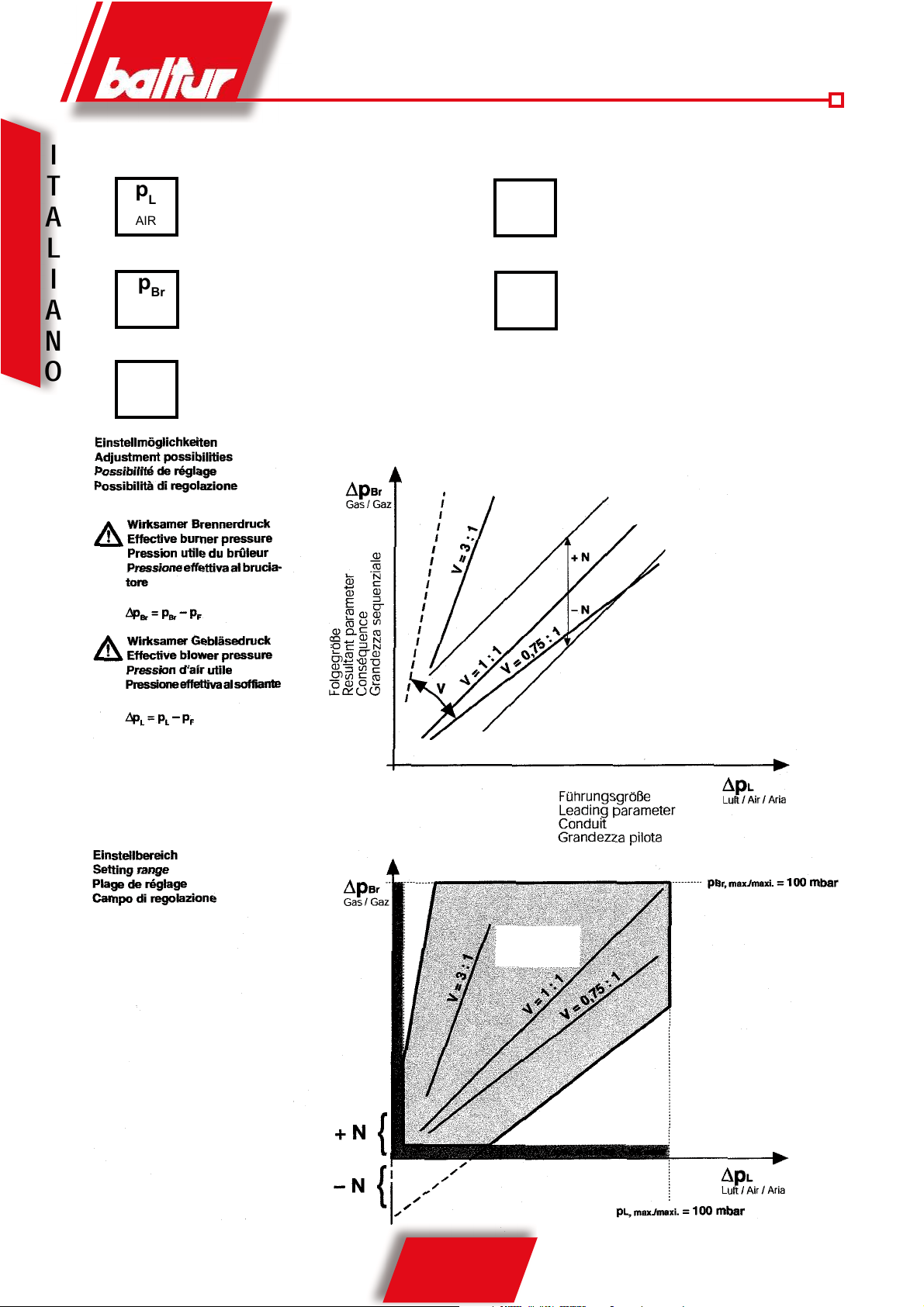

p

L

AIR

p

Br

GAS

p

F

Combustion

atmosfere

V

min./mini

max/maxi

N

± 1 mbar

p

L

max/maxi = 100 mbar

V

max/maxi = 3:1

p

F

max/maxi = +5 mbar

pBrmax/maxi = 100 mbar

p

L

min./mini = 0,4 mbar

pBrmin./mini = 0,5 mbar

pFmin./mini = -2 mbar

V

min./mini = 0,75:1

V

= pBr: p

L

Correzione punto zero ± 1 mbar

MB-VEF

Campo di regolazione

35 / 36

0006081062_200904

I

T

A

L

I

A

N

O

ISTRUZIONI PER L’ACCERTAMENTO DELLE CAUSE DI IRREGOLARITÁ NEL FUNZIONAMENTO DEI

BRUCIATORI DI GAS A DUE STADI E LORO ELIMINAZIONE

IRREGOLARITÁ CAUSA POSSIBILE RIMEDIO

L’apparecchio va in “blocco” con

fiamma (lampada rossa accesa).

Guasto circoscritto al dispositivo di

controllo fiamma.

1) Disturbo della corrente di Ionizzazione

da parte del trasformatore di accensione.

2) Sensore di fiamma (sonda ioniz-zazione

o cellula UV) inefficiente

3) Sensore di fiamma (sonda ioniz-zazione

o cellula UV) in posizione non corretta.

4) Sonda ionizzazione o relativo cavo a

massa

5) Collegamento elettrico interrotto del

sensore di fiamma

6) Tiraggio inefficiente o percorso fumi

ostruito.

7) Disco fiamma o testa di combustione

sporchi o logori.

8) Cellula UV sporca o unta.

9) Apparecchiatura guasta.

10) Manca ionizzazione.

1) Invertire l’alimentazione (lato 230V)

del trasformatore di accensione e

verificare con micro-amperometro

analogico

2) Sostituire il sensore di fiamma

3) Correggere la posizione del sensore di

fiamma e, successivamente, verificarne

l’efficienza inserendo il micro-amperometro analogico.

4) Ve r if i ca r e vi s i va m en t e e co n

strumento.

5) Ripristinare il collegamento.

6) Controllare che i passaggi fumo caldaia/

raccordo camino siano liberi.

7) Verificare visivamente ed eventualmente sostituire.

8) Pulire adeguatamente.

9) Sostituirla.

10) Se la “massa” dell’apparecchiatura non

è efficiente non si verifica la corrente

di ionizzazione. Verificare l’efficienza

della “massa” all’apposito morsetto della

apparecchiatura e al collegamento a

“terra” dell’impianto elettrico.

L’apparecchio va in “blocco”, il

gas esce, ma la fiamma non è present e ( l a mpada rossa ac c e s a ).

Guasto circoscritto al circuito di

accensione.

1) Guasto nel circuito di accensione.

2) Cavetto trasformatore d’accensione

scarica a massa.

3) Cavetto trasformatore di accensione

scollegato.

4) Trasformatore d’accensione guasto

5) La distanza tra elettrodo e massa non

è corretta.

6) Isolatore sporco e quindi l’elettrodo

scarica a massa.

1) Verificare l’alimentazione del trasfor-

matore d’accensione (lato 230V) e

circuito alta tensione (elettrodo a massa

o isolatore rotto sotto il morsetto di

bloccaggio).

2) Sostituirlo.

3) Collegarlo.

4) Sostituirlo.

5) Metterlo alla corretta distanza.

6) Pu l i re o sostitu i r e l’isolatore e

l’elettrodo.

L’apparecchio va in “blocco”, il gas

esce, ma la fiamma non è presente

(lampada rossa accesa.

1) Rapporto aria/gas non corretto.

2) La tubazione del gas non è stata

ade g u atamente s fogata da ll’aria

(caso di prima accensione).

3) La pressione del gas è insufficiente o

eccessiva.

4) Passaggio aria tra disco e testa

troppo chiuso.

1) Correg g ere il rappo r to ari a/gas

(probabilmente c’è troppa aria o poco

gas)

2) Sfogare ulteriormente, con le dovute

cautele, la tubazione del gas.

3) Verificare il valore della pressione gas

al momento dell’accensione (usare

manometro ad acqua, se possibile).

4) Adeguare l’apertura disco/testa.

36 / 36

0006081062_200904

I

T

A

L

I

A

N

O

1 / 36

0006081062_200

904

E

N

G

L

I

S

H

ENGLISH PAGE

- Technical specifications ...................................................................................................................................... “ 4

- Gas supply line - Fixing the burner to the boiler ................................................................................................ “ 13

- Measuring the pressure in the combustion chamber.......................................................................................... “ 14

- Electrical connections - Description of the operation - Description of the modulation operation........................ “ 15

- Ignition and gas regulation (methane) ................................................................................................................ “ 17

- Air regulation on the combustion head - Maintenance ..................................................................................... “ 19

- Air regulation servomotor ..................................................................................................................................“ 22

- LFL... Control box ............................................................................................................................................... “ 24

- MB-VEF B01 Monobloc valve ........................................................................................................................... “ 28

- Irregularity - cause - remedy............................................................................................................................... “ 35

- Electric diagrams ................................................................................................................................................ “ 149

!

Note

i

Information

I

Warning

Statement of Conformity

We hereby declare under our own responsibility, that our “CE” marked products Series:

Sparkgas…; BTG…; BGN…; Minicomist…; Comist…; RiNOx…, BT…; BTL…;

GI…; GI…Mist; PYR…; TS…, TBG...,

Description:

domestic and industrial blown air burners fired by gas, oil and dual fuel respect the

minimal regulation of the European Directives:

• 90/396/EEC (G.A.D)

• 92/42/EEC (B.E.D)

• 89/336/EEC (E.M.C. Directive)

• 73/23/EEC (Low Voltage Directive)

• 98/37 EEC (Machinery Directive)

and have been designed and tested in accordance with the European Standards:

• EN 676 (gas and dual fuel, gas side)

• EN 267 (light oil and dual fuel, oil side)

• EN 60335-1, 2003

• EN 50165: 1997 + A1:2001

• EN 55014 -1 (1994) and –2 (1997)

Surveillance accordingly Gas Appliances Directive 90/396/EEC made by:

CE0085 - DVGW

The Vice President and Managing Director:

Dr. Riccardo Fava

2 / 36

0006081062_200

904

E

N

G

L

I

S

H

FOREWORD

These warning notes are aimed at ensuring the safe use of the components of heating systems for civil use and the production of hot water.

They indicate how to act to avoid the essential safety of the components

being compromised by incorrect or erroneous installation and by improper

or unreasonable use. The warning notes provided in this guide also seek

to make the consumer more aware of safety problems in general, using

necessarily technical but easily understood language. The manufacturer

is not liable contractually or extra contractually for any damage caused

by errors in installation and in use, or where there has been any failure to

follow the manufacturer’s instructions.

GENERAL WARNING NOTES

• The instruction booklet is an integral and essential part of the product

and must be given to the user. Carefully read the warnings in the booklet as they contain important information regarding safe installation,

use and maintenance. Keep the booklet to hand for consultation when

needed.

• Equipment must be installed in accordance with current regulations,

with the manufacturer’s instructions and by qualified technicians. By

the term ‘qualified technicians’ is meant persons that are competent in

the field of heating components for civil use and for the production of

hot water and, in particular, assistance centres authorised by the manu-

facturer. Incorrect installation may cause damage or injury to persons,

animals or things. The manufacturer will not in such cases be liable.

• After removing all the packaging make sure the contents are complete

and intact. If in doubt do not use the equipment and return it to the

supplier. The packaging materials (wooden crates, nails, staples, plastic

bags, expanded polystyrene, etc.) must not be left within reach of children as they may be dangerous to them. They should also be collected

and disposed on in suitably prepared places so that they do no pollute

the environment.

• Before carrying out any cleaning or maintenance, switch off the equipment at the mains supply, using the system’s switch or shut-off systems.

• If there is any fault or if the equipment is not working properly, de-activate the equipment and do not attempt to repair it or tamper with it

directly. In such case get in touch with only qualified technicians. Any

product repairs must only be carried out by BALTUR authorised assistance centres using only original spare parts. Failure to act as above

may jeopardise the safety of the equipment. To ensure the efficiency

and correct working of the equipment, it is essential to have periodic

maintenance carried out by qualified technicians following the manufacturer’s instructions.

• If the equipment is sold or transferred to another owner or if the owner

moves and leaves the equipment, make sure that the booklet always

goes with the equipment so it can be consulted by the new owner and/

or installer.

• For all equipment with optionals or kits (including electrical), only original accessories must be used.

BURNERS

• This equipment must be used only for its expressly stated use: applied

to boilers, hot air boilers, ovens or other similar equipment and not

exposed to atmospheric agents. Any other use must be regarded as

improper use and hence dangerous.

• The burner must be installed in a suitable room that has ventilation in

accordance with current regulations and in any case sufficient to ensure

correct combustion

WARNING NOTES FOR THE USER HOW TO

USE THE BURNER SAFELY

• Do not obstruct or reduce the size of the burner’ air intake grills or the

ventilation openings for the room where a burner or a boiler is installed

or dangerous mixtures of toxic and explosive gases may form.

• Before connecting the burner check that the details on the plate correspond to those of the utility supplies (electricity, gas, light oil or other

fuel).

• Do not touch hot parts of the burner. These, normally in the areas near

to the flame and any fuel pre-heating system, become hot when the

equipment is working and stay hot for some time after the burner has

stopped.

• If it is decided not to use the burner any more, the following actions must

be performed by qualified technicians:

a) Switch off the electrical supply by disconnecting the power cable from

the master switch.

b) Cut off the fuel supply using the shut-off valve and remove the control

wheels from their position.

c) Render harmless any potentially dangerous parts.

Special warning notes

• Check that the person who carried out the installation of the burner fixed

it securely to the heat generator so that the flame is generated inside

the combustion chamber of the generator itself.

• Before starting up the burner, and at least once a year, have qualified

technicians perform the following operations:

a) Set the burner fuel capacity to the power required by the heat ge-

nerator.

b) Adjust the combustion air flow to obtain combustion yield of at least

the minimum set by current regulations.

c) Carry out a check on combustion to ensure the production of no-

xious or polluting unburnt gases does not exceed limits permitted

by current regulations.

d) Check the adjustment and safety devices are working properly.

e) Check the efficiency of the combustion products exhaust duct.

f) Check at the end of the adjustments that all the adjustment devices

mechanical securing systems are properly tightened.

g) Make sure that the use and maintenance manual for the burner is

in the boiler room.

• If the burner repeatedly stops in lock-out, do not keep trying to manually

reset but call a qualified technicians to sort out the problem.

• The running and maintenance of the equipment must only be carried

out by qualified technicians, in compliance with current regulations.

I

3 / 36

0006081062_200

904

E

N

G

L

I

S

H

ELECTRICAL SUPPLY

• The equipment is electrically safe only when it is correctly connected to an

efficient ground connection carried out in accordance with current safety

regulations. It is necessary to check this essential safety requirement.

If in doubt, call for a careful electrical check by a qualified technicians,

since the manufacturer will not be liable for any damage caused by a

poor ground connection.

• Have qualified technicians check that the wiring is suitable for the

maximum power absorption of the equipment, as indicated in the technical

plate, making sure in particular that the diameter of cables is sufficient

for the equipment’s power absorption.

• Adapters, multiple plugs and extension cables may not be used for the

equipment’s power supply.

• An ominpolar switch in accordance with current safety regulations is

required for the mains supply connection.

• The electrical supply to the burner must have neutral to ground

connection. If the ionisation current has control with neutral not to ground

it is essential to make a connection between terminal 2 (neutral) and the

ground for the RC circuit.

• The use of any components that use electricity means that certain

fundamental rules have to followed, including the following:

- do not touch the equipment with parts of the body that are wet or damp

or with damp feet

- do not pull on electrical cables

- do not leave the equipment exposed to atmospheric agents (such as

rain or sun etc.) unless there is express provision for this.

- do not allow the equipment to be used by children or inexpert

persons.

• The power supply cable for the equipment not must be replaced by the

user. If the cable gets damaged, switch off the equipment, and call only

on qualified technicians for its replacement.

• If you decide not to use the equipment for a while it is advisable to switch

off the electrical power supply to all components in the system that use

electricity (pumps, burner, etc.).

GAS, LIGHT OIL, OR OTHER FUEL SUPPLIES

General warning notes

• Installation of the burner must be carried out by qualified technicians

and in compliance with current law and regulations, since incorrect

installation may cause damage to person, animals or things, for which

damage the manufacturer shall not can be held responsible.

• Before installation it is advisable to carry out careful internal cleaning

of all tubing for the fuel feed system to remove any residues that could

jeopardise the proper working of the burner.

• For first start up of the equipment have qualified technicians carry out

the following checks:

• If you decide not to use the burner for a while, close the tap or taps that

supply the fuel.

Special warning notes when using gas

• Have qualified technicians check the following:

a) that the feed line and the train comply with current law and

regulations.

b) that all the gas connections are properly sealed.

• Do not use the gas pipes to ground electrical equipment.

• Do not leave the equipment on when it is not in use and always close

the gas tap.

• If the user of is away for some time, close the main gas feed tap to the

burner.

• If you smell gas:

a) do not use any electrical switches, the telephone or any other object

that could produce a spark;

b) immediately open doors and windows to create a current of air that

will purify the room;

c) close the gas taps;

d) ask for the help of qualified technicians.

• Do not block ventilation openings in the room where there is gas

equipment or dangerous situations may arise with the build up of toxic

and explosive mixtures.

FLUES FOR HIGH EFFICIENCY BOILERS AND SIMILAR

It should be pointed out that high efficiency boilers and similar discharge

combustion products (fumes) at relatively low temperatures into the flue.

In the above situation, traditional flues (in terms of their diameter and heat

insulation) may be suitable because the significant cooling of the combustion

products in these permits temperatures to fall even below the condensation

point. In a flue that works with condensation there is soot at the point the

exhaust reaches the atmosphere when burning light oil or heavy oil or the

presence of condensate water along the flue itself when gas is being burnt

(methane, LPG, etc.). Flues connected to high efficiency boilers and similar

must therefore be of a size (section and heat insulation) for the specific use

to avoid such problems as those described above.

WARNING NOTES FOR THE USER HOW TO

USE THE BURNER SAFELY

I

4 / 36

0006081062_200

904

E

N

G

L

I

S

H

TECHNICAL DATA

BGN

200 LX

BGN

300 LX

BGN

390 LX

BGN

540 LX

THERMIC CAPACITY

MAX kW 2150 3600 3950 5900

MIN kW

250 400 400 600

MOTOR

kW 3 7,5 7,5 15

r.p.m. 2870 2870 2870 2920

ABSORBED ELECTRICAL POWER kW 3,50 8,00 8,00 15,5

FUSE A 400 V 20 25 25 50

IGNITION TRANSFORMER 8 kV - 30 mA

VOLTAGE 3 ~ 400 V - 50 Hz

FLAME DETECTOR IONISATION PROBE Photocell UV

Natural Gas

FLOW RATE MAX m³n/h 216 362 397 593

MIN m³n/h

25 40 40 60

PRESSURE MAX mbar 360

STANDARD ACCESSORIES

BURNER FIXING FLANGE 1 1 1 1

ISOLATING GASKET 1

1 1 2

STUD BOLTS N° 4 - M12 N° 4 - M20 N° 4 - M20 N° 6 - M20

EXAGONAL NUTS N° 4 - M12 N° 4 - M20 N° 4 - M20 N° 6 - M20

FLAT WASHERS N° 4 - M12 N° 4 - M20 N° 4 - M20 N° 6 - Ø20

BGN

200 LX-V

BGN

300 LX-V

BGN

390 LX-V

BGN

540 LX-V

THERMIC CAPACITY

MAX kW 2150 3600 3950 5900

MIN kW 250 400 400 600

MOTOR

kW 3 7,5 7,5 15

r.p.m. 2870 2870 2870 2920

ABSORBED ELECTRICAL POWER kW 3,50 8,00 8,00 15,5

FUSES A 400 V 10 25 25 50

IGNITION TRANSFORMER 8 kV - 30 mA

VOLTAGE 3 ~ 400 V - 50 Hz

FLAME DETECTOR IONISATION PROBE Photocell UV-

Natural Gas

FLOW RATE MAX m³n/h 216 362 397 593

MIN m³n/h 25 40 40 60

PRESSURE MAX mbar 360

STANDARD ACCESSORIES

BURNER FIXING FLANGE 1 1 1 1

ISOLATING GASKET 1

1 1 2

STUD BOLTS N° 4 - M12 N° 4 - M20 N° 4 - M20 N° 6 - M20

EXAGONAL NUTS N° 4 - M12 N° 4 - M20 N° 4 - M20 N° 6 - M20

FLAT WASHERS N° 4 - M12 N° 4 - M20 N° 4 - M20 N° 6 - Ø20

5 / 36

0006081062_200

904

E

N

G

L

I

S

H

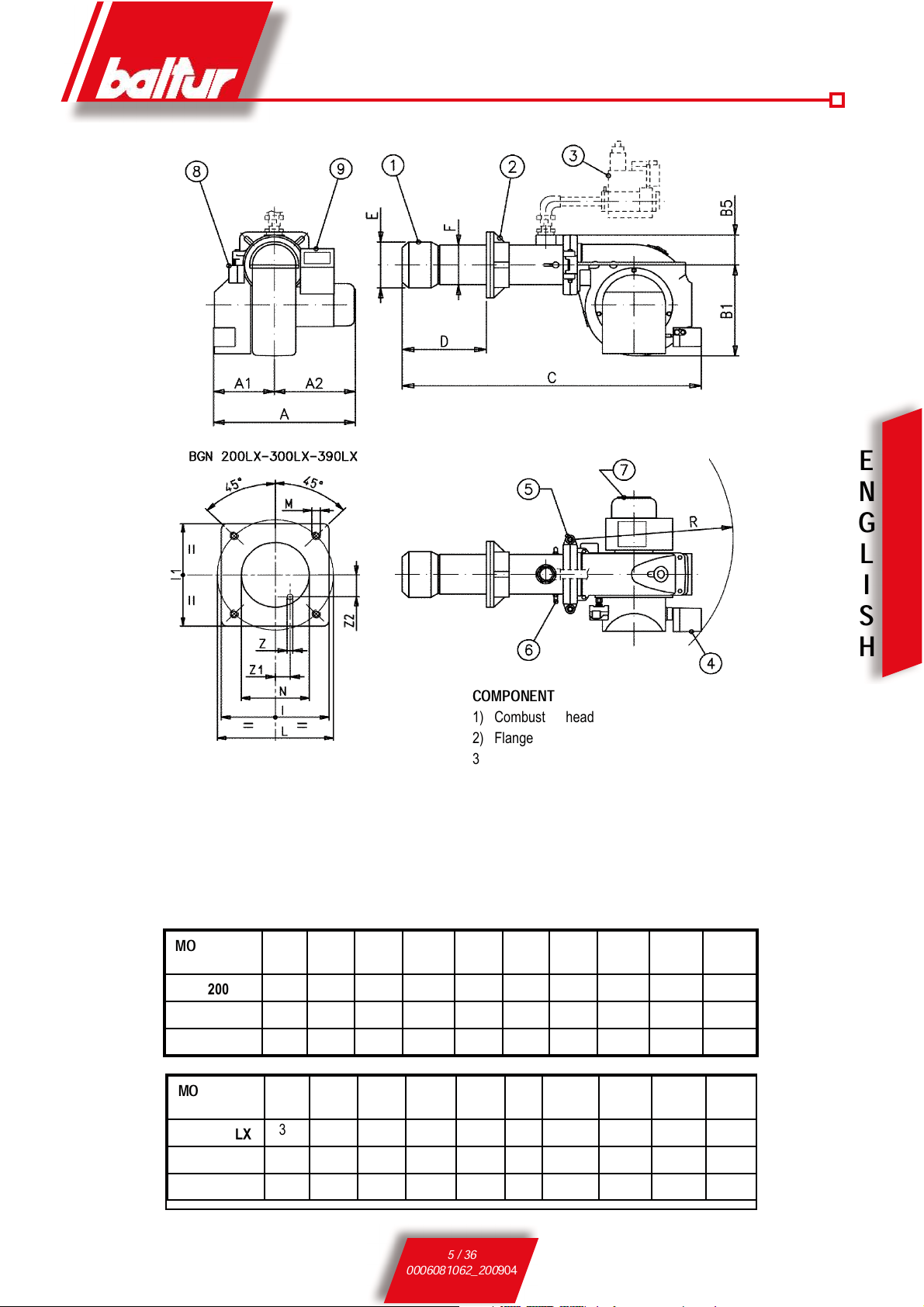

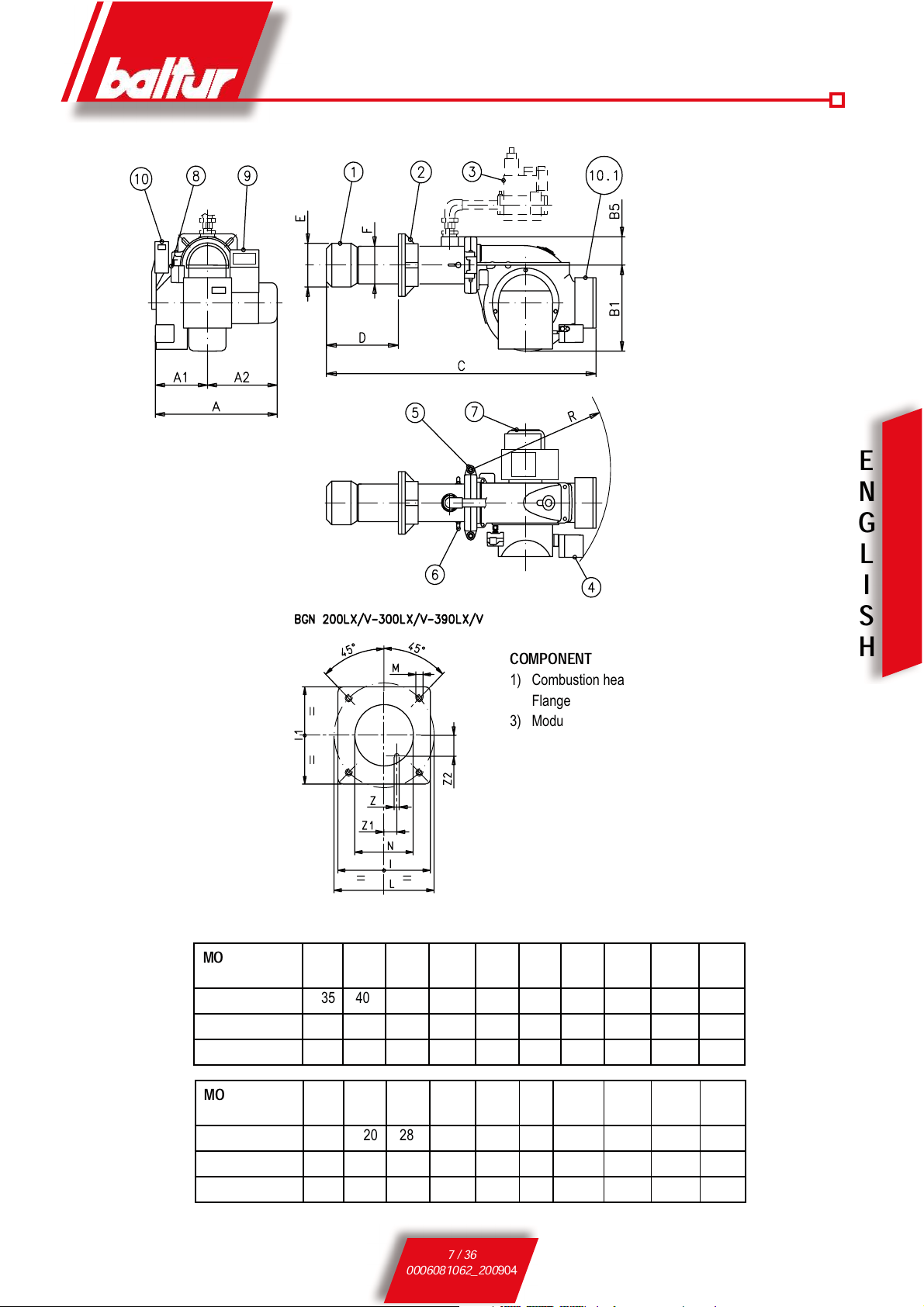

COMPONENT

1) Combustion head

2) Flange

3) Modulation valve

4) Air regulation servomotor

5) Hinge

6) Combustion head air

control knob

7) Fan motor

8) Air pressure switch

9) Control box

MOD.

A A1 A2 B1 B5 C D

MINDMAX

E

Ø

F

Ø

BGN 200 LX

835 400 435 580 150 1630 280 480 300 220

BGN 300 LX

880 400 480 580 177 1630 280 480 316 275

BGN 390 LX

880 400 480 580 177 1630 280 480 316 275

MOD.

I I1 L

MINLMAX

M N

ØRMAX

Z

Z1 Z2

BGN 200 LX

320 320 280 370 M12 260 980 12 113 54

BGN 300 LX

440 440 400 540 M20 360 980 12 150 87

BGN 390 LX

440 440 400 540 M20 360 980 12 150 87

0002471090

6 / 36

0006081062_200

904

E

N

G

L

I

S

H

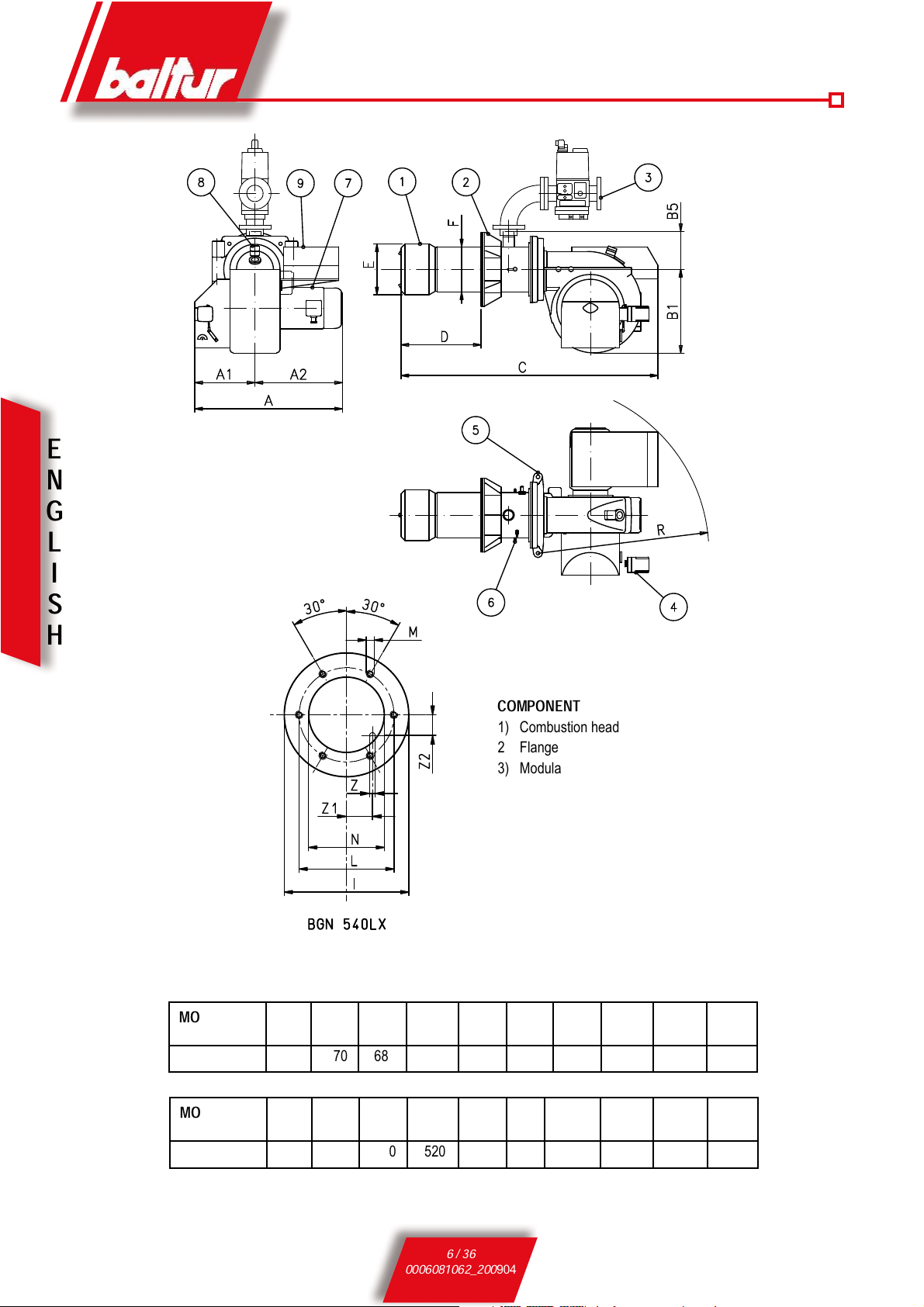

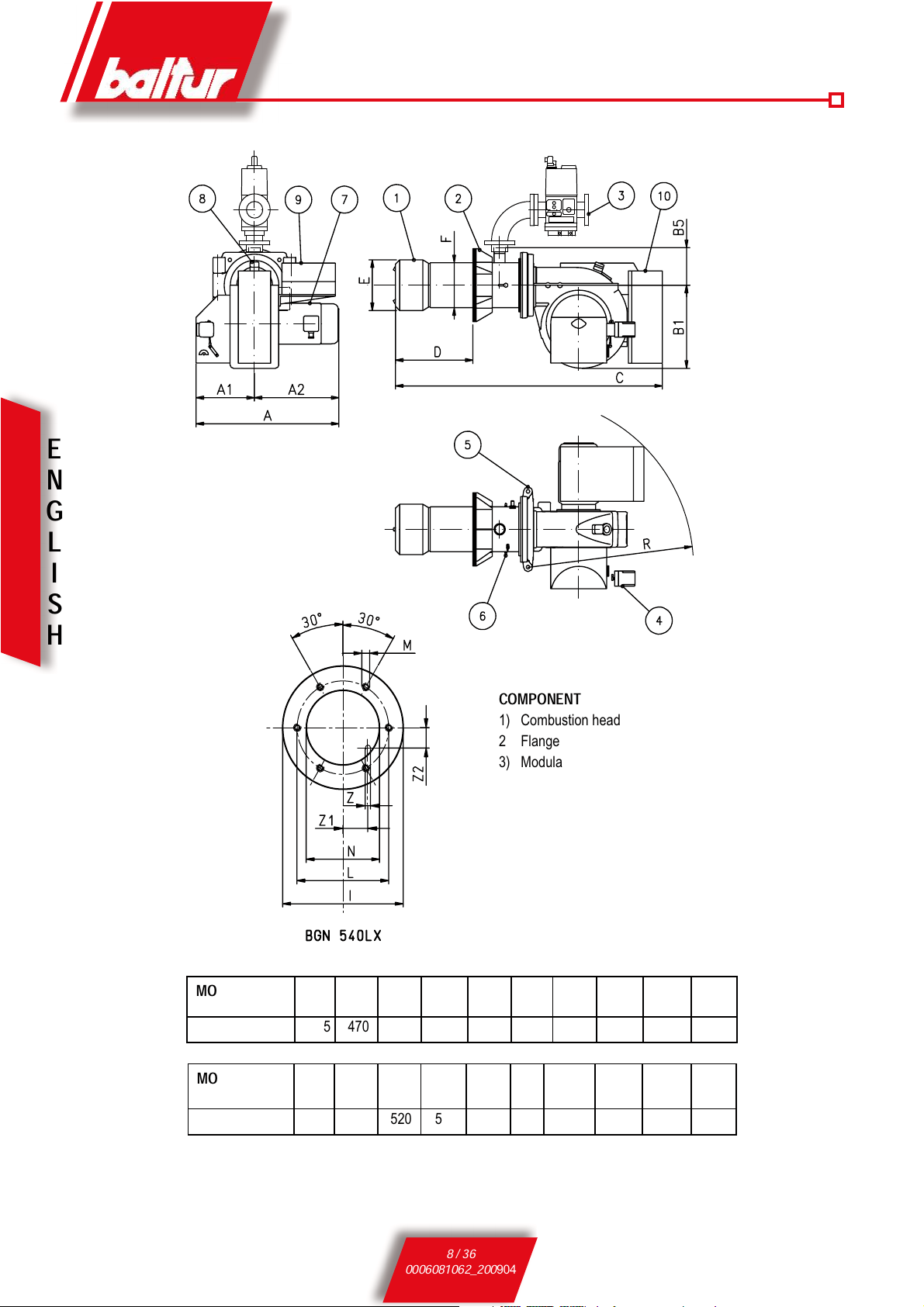

COMPONENT

1) Combustion head

2) Flange

3) Modulation valve

4) Air regulation servomotor

5) Hinge

6) Combustion head air

control knob

7) Fan motor

8) Air pressure switch

9) Control box

MOD.

A A1 A2 B1 B5 C D

MINDMAX

E

Ø

F

Ø

BGN 540 LX

1155 470 685 695 283 2110 330 600 400 355

MOD.

I I1 L

MINLMAX

M N

ØRMAX

Z

Z1 Z2

BGN 540 LX

580 - - 520 520 M20 430 1170 12 131 156

0002470911

7 / 36

0006081062_200

904

E

N

G

L

I

S

H

COMPONENT

1) Combustion head

2) Flange

3) Modulation valve

4) Air regulation servomotor

5) Hinge

6) Combustion head air control knob

7) Fan motor

8) Air pressure switch

9) Control box

10) Frequency converter (BGN 200 LX-V)

10.1) Frequency converter

(BGN 300 / 390 LX-V)

MOD.

A A1 A2 B1 B5 C D

MINDMAXEØ

F

Ø

BGN 200 LX-V

835 400 435 580 150 1630 280 480 300 220

BGN 300 LX-V

880 400 480 580 177 1870 280 480 316 275

BGN 390 LX-V

880 400 480 580 177 1870 280 480 316 275

MOD.

I I1 L

MINLMAX

M N

ØRMAX

Z

Z1 Z2

BGN 200 LX-V

320 320 280 370 M12 260 980 12 113 54

BGN 300 LX-V

440 440 400 540 M20 360 980 12 150 87

BGN 390 LX-V

440 440 400 540 M20 360 980 12 150 87

0002471101

8 / 36

0006081062_200

904

E

N

G

L

I

S

H

COMPONENT

1) Combustion head

2) Flange

3) Modulation valve

4) Air regulation servomotor

5) Hinge

6) Combustion head air control knob

7) Fan motor

8) Air pressure switch

9) Control box

10)Frequency converter

MOD.

A A1 A2 B1 B5 C D

MINDMAXEØ

F

Ø

BGN 540 LX-V

1155 470 685 695 283 2165 330 600 400 355

MOD.

I I1 L

MINLMAX

M N

ØRMAX

Z

Z1 Z2

BGN 540 LX-V

580 - - 520 520 M20 430 1360 12 131 156

0002471111

9 / 36

0006081062_200

904

E

N

G

L

I

S

H

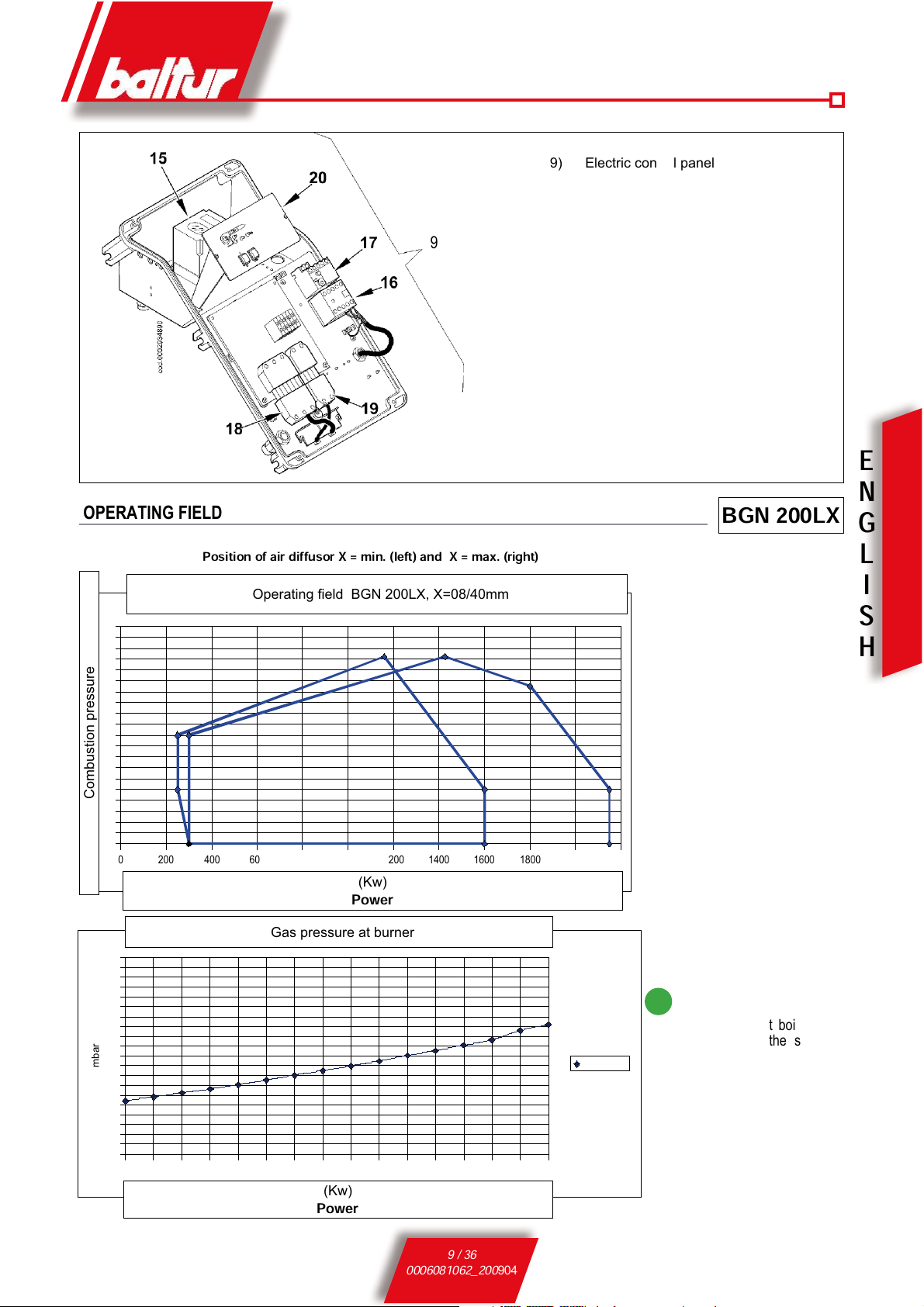

9

9) Electric control panel

15) Control box

16) Motor contactor

17) Thermal relay

18) 7-pole plug

19) 4-pole plug

20) Schematic panel

1400 1450 1500 1550 1600 1650 1700 1750 1800 1850 1900 1950 2000 2050 2100 2150

0

4

8

12

16

20

24

28

32

36

40

Gas pressure at burner

X = 40 mm

Power rate [kW]

mbar

0 200 400 600 800 1000 1200 1400

1600

1800 2000

2200

-5

-3

-1

1

3

5

7

9

11

13

15

Campo di lavoro/Operating field/Arbeitsfeld BGN 200 LX, X = 8/40 mm

Potenzialità / Power / Kapazität [kW]

Position of air diffusor X = min. (left) and X = max. (right)

BGN 200LX

Operating field BGN 200LX, X=08/40mm

(Kw)

Power

Combustion pressure

(Kw)

Power

Gas pressure at burner

OPERATING FIELD

i

The working fields are ob-

tained from test boilers corresponding to the standard

EN676 and are indicatively

for the combination burnerboiler. For correct working

of the burner the size of the

combustion chamber must

correspond to current regulations; if not the manufacturers

must be consulted.

10 / 36

0006081062_200

904

E

N

G

L

I

S

H

1200 1400 1600 1800 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800

0

4

8

12

16

20

24

28

32

36

40

44

48

Pressione gas al bruciatore/Gas pressure at burner/Gasdruck am Brenner

X = 40 mm

Potenzialità / Power rate / Kapazität [kW]

mbar

0 250 500 750 1000 1250

1500

1750 2000 2250 2500 2750 3000 3250 3500 3750

4000

-5

-3

-1

1

3

5

7

9

11

13

15

17

Campo di lavoro/Operating field/Arbeitsfeld BGN 300 LX, X = 10/40 mm

Potenzialità / Power / Kapazität [kW]

Position of air diffusor X = min. (left) and X = max. (right)

BGN 300LX

Operating field BGN 300LX, X=10/40mm

(Kw)

Power

Combustion pressure

(Kw)

Power

Gas pressure at burner

OPERATING FIELD

i

The working fields are obtained from test boilers correspon-

ding to the standard EN676 and are indicatively for the combination burner-boiler. For correct working of the burner the

size of the combustion chamber must correspond to current

regulations; if not the manufacturers must be consulted.

11 / 36

0006081062_200

904

E

N

G

L

I

S

H

1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000

3200

3400 3600 3800 4000

0

4

8

12

16

20

24

28

32

36

40

44

48

Pressione gas al bruciatore/Gas pressure at burner/Gasdruck am Brenner

X = 40 mm

Potenzialità / Power rate / Kapazität [kW]

mbar

0 250 500 750 1000 1250 1500 1750 2000 2250 2500 2750 3000 3250 3500 3750

4000

-5

-3

-1

1

3

5

7

9

11

13

15

17

Operating field BGN 390 LX, X = 10/40 mm

PFeu...power...kW

pFR...combustion pressure...mbar

Position of air diffusor X = min. (left) and X = max. (right)

BGN 390LX

Operating field BGN 300LX, X=10/40mm

(Kw)

Power

Combustion pressure

(Kw)

Power

Gas pressure at burner

OPERATING FIELD

i

The working fields are obtained from test boilers correspon-

ding to the standard EN676 and are indicatively for the combination burner-boiler. For correct working of the burner the

size of the combustion chamber must correspond to current

regulations; if not the manufacturers must be consulted.

12 / 36

0006081062_200

904

E

N

G

L

I

S

H

Position of air diffusor X = min. (left) and X = max. (right)

BGN 540LX

OPERATING FIELD

i

The working fields are obtained from test boilers corresponding

to the standard EN676 and are indicatively for the combination

burner-boiler. For correct working of the burner the size of the combustion chamber must correspond to current regulations; if not the

manufacturers must be consulted.

13 / 36

0006081062_200

904

E

N

G

L

I

S

H

GAS SUPPLY LINE

The general gas supply situation is illustrated here alongside The gas

train is EN 676 certified and is supplied separately from the burner.

A manual stop valve and a damper joint must be installed as indicated in

the diagram.

If the gas train has a pressure regulator not incorporated in a monoblock

valve, we recommend you following this practical advice on the installation of accessories on the gas piping close to the burner:

1) To prevent large pressure drops on ignition it is best if there is a

1.5 to 2 m length of piping between the point of application of the

stabilizer or pressure reducer and the burner. This pipe must have a

diameter equal to or greater than the connector to the burner.

2) For the better working of the pressure regulator it is advisable to attach

it to horizontal piping after the filter. The gas pressure regulator must

be adjusted while working at the maximum capacity actually used

by the burner. The delivery pressure must be adjusted to a figure

slightly lower than the maximum obtainable.

(that which is obtained when the regulation screw is turned almost

to the end); in the specific case, tightening the regulation screw

the regulator delivery pressure increases and when it is loosened it

decreases.

!

If the burner is equipped with gas valves, model SKP 70 .....,

the pressure regulator needs not be installed since in its

normal operation the above valve also functions as pressure

regulator.

GENERAL GAS BURNER SYSTEM

GENERAL DIAGRAM FOR

INSTALLATION OF GATE-FILTER-STABILIZER-

ANTI-VIBRATION JOINT-OPENABLE PITTING

8780GB.tif

Legend

1) Manual shut off valve

2) Anti-vibration joint

3) Gas filter

4) Minimum gas pressure switch

5) Safety valve

Gas train supplied by the manufacturer

The job of the installer

6) Pressure regulator

7) Valves seal control device (obligatory

for burner with maxmum nominal thermal output over 1200 kW)

8) Two-stage working valve

9) Control servomotor

10) Air adjustment gate

11) Air pressure switch

12) Combustion head

14 / 36

0006081062_200

904

E

N

G

L

I

S

H

COMBUSTION HEAD ASSEMBLY

Following the drawing, connect the tube on the attachment on the

flange and fix with the screw

To put in place insulation flange 2, which must be positioned

between the burner and the plate of boiler 1, the end of the combustion head must first be removed.

a) Adjust position of connector flange 4 by loosening screws 6

so that the combustion head penetrates into the combustion

chamber the amount recommended by the generator’s manufacturer.

b) Position seal insulation 3 on the tube unit.

c) Fasten the combustion head assembly to the boiler 1 using the

stud bolts, washers and the nuts provided 5.

d) With suitable material, completely seal the space between the

tube unit of the burner and the hole on the refractory plate inside

the boiler door.

0002934880

Pressure transmission pipe in

combustion chamber

Burner flange

Pressure detection pipe connection

nipple in combustion chamber

Pressure take-off in

combustion chambe

CHAMBER FOR MODEL BGN 540 LX

FOR MODELS BGN 200 LX÷BGN390 LX

N° 0002934900

Pressure detection pipe

connection nipple in combustion

chambe

Rigid pipe

fastening

screws

00029333821

Cut pipe flush with

diffusor

Pressure takeoff in

combustion

chamber

Plate and refractory

wall hole to be

drilled to Ø 12

MEASURING THE PRESSURE IN THE COMBUSTION CHAMBER

If the hole in the door is too small to allow the hose to pass and the

door has no flame inspection window it will be necessary to make

a Ø 12 in order to install the pressure take-up hose (supplied with

the burners), whose position is shown in the flange drilling-plate

drawning

s n° 0002471100 - 0002933821.

1 Boiler plate

2 Flange with insulating materials

3 Seam with insulating materials

4 Burner securing flange

5 Stud bolts, washers and nuts for fastening to the boiler

6 Nuts screws and washers to fasten flange to the sleeve

Rigid pipe that reads

combustion chamber

pressure

15 / 36

0006081062_200

904

E

N

G

L

I

S

H

ELECTRICAL CONNECTIONS

The three-phase power supply line must have a switch with

fuses. The regulations further require a switch on the burner’s

power supply line, outside the boiler room and in an easily

accessed position. For the electrical connections (line and

thermostats), follow the wiring diagram enclosed. To carry out

the connection of the burner to the power supply line proceed

as follows:

1) Remove the lid by unscrewing the 4 screws (1) in figure ,

without removing the transparent door. In this way the burner’s

electrical panel can be accessed. .

2) Slacken le screws (2) and, after removing the cable

float (3), pass the two 7 and 4 pole plugs through the hole (see

figure 2). Connect the power supply cables (4) to the contactor,

connect the cable to ground (5) and close the cable holder.

3) Reposition the cable float as in figure 3. Turn the cam (6) so

that the float exerts sufficient pressure on the two cables, then

tighten the screws that fasten the cable float. Finally, connect

the two 7 and 4-pole plugs.

!

the housings for the cables for the 7 and 4-pole plugs

are provide respectively for cable Ø 9.5÷10 mm and Ø

8.5÷9 mm, this to make sure the protection rating is

IP 54 (standard IEC EN60529) for the electrical panel.

4) To reclose the electrical panel lid, tighten the 4 screws (1)

with a torque of about 5 Nm to ensure the correct seal. At this

point, to be able to access the control panel (8), unfasten the

transparent door (7), using slight touch pressure in the direction

of the arrows in figure 4, move it the short distance to separate

it from the lid.

5) to properly resecure the transparent door on the panel proceed

as indicated in 5:position the hooks at their hooking points and

(9) slide the door in the direction indicated by the arrow until it

clicks. It is now well sealed.

Figure1

Figure 2

Figure 4

Figure 5

!

Important:

only qualified technicians may open the

burner’s electrical panel.

Figure 3

16 / 36

0006081062_200

904

E

N

G

L

I

S

H

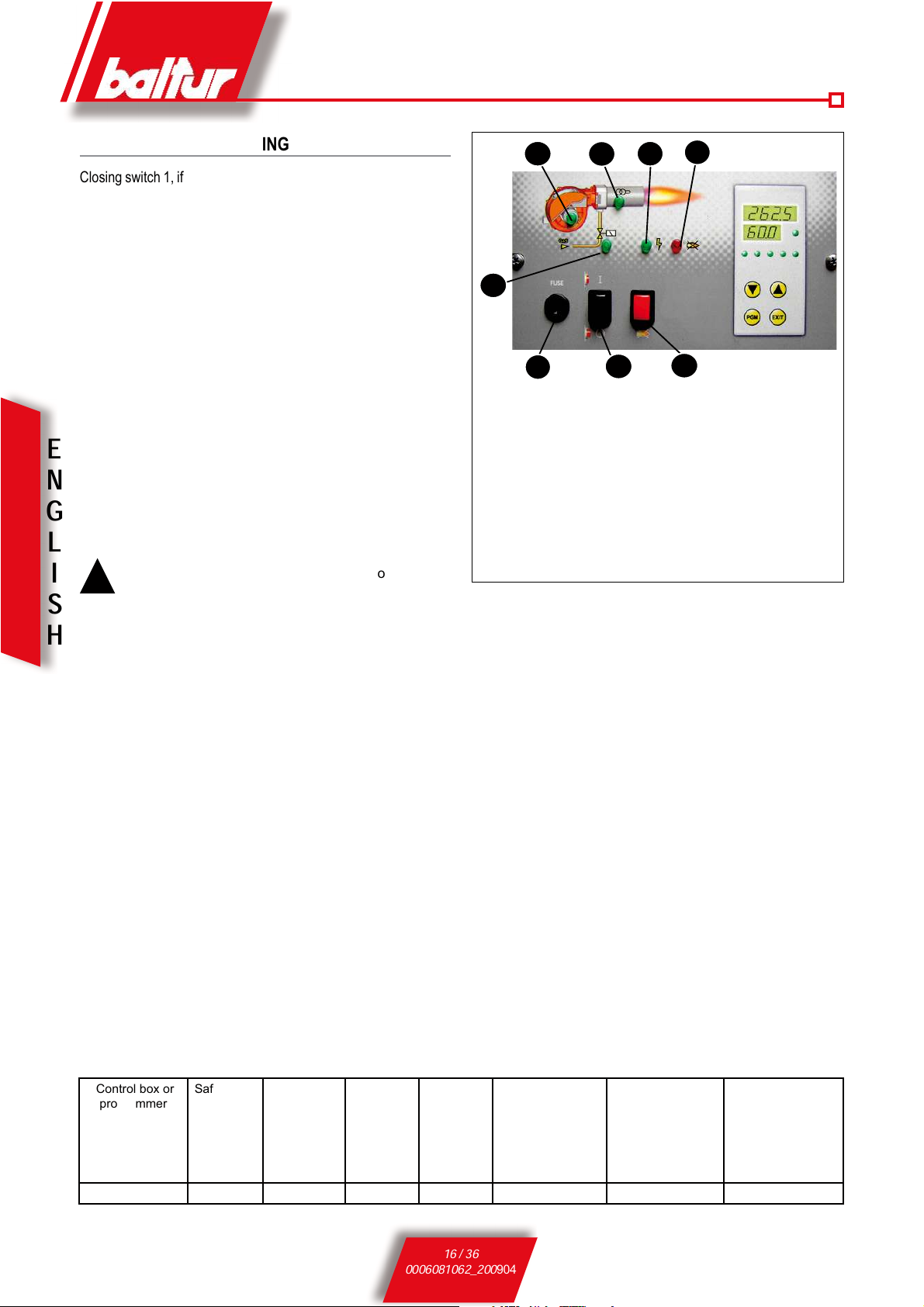

Control box or

programmer

Safety timesPreventila-

tion time

s

Pre-

ignition

s

Post-

ignition

s

Time betwe-

en opening of

pilot valves and

opening of main

valves

s

Cut out of pilot

flame after opening

of main valves

s

Time between opening1st flame valve

and 2nd flame

valve

s

LFL 1.333 3 31,5 6 3 12 3 12

DESCRIPTION OF WORKING

Closing switch 1, if the thermostats are closed, the voltage reaches

the command and control equipment (switching on of LED 2) which

starts it working. The fan motor is thus switched on (LED 3) to carry

out the preventilation of the combustion chamber, at the same time

the air damper control servo motor moves to the opening position

corresponding to the maximum regulated power.

At the end of the preventilation stage the air damper has to be

returned to the ignition flame position. If the pressure control switch

for the ventilation air detects sufficient pressure, the ignition transformer goes on (LED 4) and, after two seconds, the main gas and

safety valves open (LED 5)

Note that:

a) The main valve has a device for the proportional adjustment of

the air to gas ratio.

b) The safety valve is an ON/OFF type.

c) The air damper is activated by an electric servo motor (see

0002933220 to 200Lx at 390Lx and 0002933490 for 540Lx), re-

member that when the burner is stopped by

the thermostat, the gate damper

is brought back by the servo motor to its closed position.

!

The gas supply at the ignition flame position must generally be greater than the minimum modulation capacity. The ignition flame position can be adjusted with

the air damper control servo motor. (see 0002933220

to 200Lx at 390Lx and 0002933490 for 540Lx).

The presence of the flame, detected by the control device

itself, permits the continuance and completion of the ignition stage with the switching off of the ignition transformer.

Subsequently the servo motor progressively opens the air

damper and the pneumatic valve allows the gas supply to

increase to its set maximum.

If there is no flame, the control box stops in its “safety lockout” (LED 7) within 3 seconds from the opening of the main

valve. In the case of safety lock-out the valves immediately

close again. To release the control box from its safety position press button 8 on the display panel.

DESCRIPTION OF MODULATION WORKING

When the burner is running at minimum capacity, if the modulation probe allows, (adjusted to a temperature or pressure value

greater than that in the boiler) the air adjustment servo motor

starts to turn causing gradual increase in combustion air supply and, consequently also of gas, up to the maximum supply

for which the burner has been set. The increase in the fan air

pressure is detected by the proportional gas valve sensor which

gradually adjusts gas supply to the change in air pressure.

The burner stays at maximum delivery until the temperature or

pressure reaches a level high enough to cause the modulation probe to turn the air adjustment servo motor in the opposite direction.

The backward rotation and consequent reduction in gas and air

supply happens at brief time intervals. With this manoeuvre the

modulation system seeks to balance the quantity of heat supplied

to the boiler with that which the boiler itself provides. The modulation probe applied to the boiler detects changes in demand and

automatically adjusts the supply of fuel and of combustion air,

switching on the servo motor with an increased or decreased rotation. If, even with fuel supply at minimum, the limit value is reached

(temperature or pressure) for which the device is set for complete

stop, (through thermostat or pressure switch) the burner is stopped

by the device.

By lowering the temperature or pressure again below the burner

stop device-triggering figure it is switched on again in accordance

with the program described in the previous paragraph.

1

2

3

4

6

8

7

5

1 Main ON-OFF switch

2 Live voltage light

3 Fan working light

4 Transformer on light

5 Gas valves working indicator light

6 Safety fuses

7 Control box lock-out light

8 Control box release button

17 / 36

0006081062_200

904

E

N

G

L

I

S

H

IGNITION AND GAS REGULATION (METHANE)

1) Make sure that the combustion head penetrates into the com-

bustion chamber by the quantity required by the manufacturer.

Check that the device that turning off the air on the combustion

head is in the proper position for the required fuel supply (the

air passage between disk and head must be sensibly reduced

in case of low fuel supply. In the contrary case, if the fuel supply

is quite high, the air passage between disk and head must be

opened). See chapter “Combustion head regulation”.

2) If not already done when connecting the burner to the gas

pipes, taking the necessary measures and opening doors and

windows, it is necessary to bleed the air contained in the pipes.

Open the union on the pipes close to the burner, and slightly

open the gas stop cock(s). Wait until you smell the typical gas

smell, and then close the cock. Wait for the necessary time,

according to the specific conditions, until the gas present in the

room is dispersed outside and then restore the connection of

the burner to the gas piping.

3) Check that there is water in the boiler and that the plant dampers

are open.

4) Make sure that the combustion product discharge can occur

freely (boiler and chimney dampers open).

5) Check that the electrical line voltage corresponds to that required for the burner, and that the electrical connections (motor and main line) are preset for the available voltage value.

Check that all electrical connections implemented on the spot

are properly executed as per our wiring diagram.

6) Apply a pressure gauge with suitable scale to the gas pressure take-off to measure the regulation value (if the expected

pressure rate allows it, it is preferable to use a water column

instrument, do not use hand instruments for low pressures).

7) Regulate the air for the ignition flame, for minimum flame and

high flame, following the instructions for regulating air damper

control electrical motor shown in the following pages. In practice, set the low flame and high flame air regulation cams to

the suitable positions according to the desired thermal power

for low and high flame.

8) By acting on the special screw for adjusti ng the gas

and air pressure ratio, on the gas valve mod. MB-VEF..,

DMV-VEF.., set the desired value (see the specific instructions for the gas valve MB-VEF.., DMV-VEF.. in the following

pages).

9) With the burner panel switch set to “0” and main circuit breaker

on, manually turn the contactor off and check that the motor

runs in the correct direction. If necessary, invert the place of two

cables of the line supplying the three-phase motor to reverse

the direction of rotation.

10) Instructions for manual mode worki ng of the burner

Combustion control can be carried out over the whole modulation range while manually controlling the MPA 22 equipment.

For this use modulation connector (B) in the diagram, which is

provided with the burner as standard. After disconnecting the

4-pole plug (A) which takes the signals from the thermostat or

the RWF 40 adjustor, insert the connector in position (B). Use

the +/- buttons to increase or reduce the gas and air supply.

After this control, put the 4-pole plug (A) back in so as to reset

automatic mode modulation

!

Note: Pre-ventilation is carried out with open air and thus,

during the same, the regulation servomotor is enabled, and

it runs a complete opening stroke up to the “maximum” set.

Only when the regulation servomotor returns to the “ignition”

position, the control box continues its ignition program by

enabling the transformer and the ignition gas valves.

During the pre-ventilation step, make sure that the air pressure

control switch changes position (from off position without pressure

detection it must switch to the off position with air pressure detection). If the air pressure switch does not detect the sufficient pressure (it does not switch position), the ignition transformer and the

flame gas valves are not enabled, and thus the control box “locks”.

To “unlock”, press the “unlock” push button(8). At the first stage there

may occur further “locks” due to:

a) The gas pipes have not been sufficiently air-bled, and thus the

gas quantity is not sufficient to allow a stable flame.

b) The “lock” with presence of flame may be caused by instability

of the same in the ionisation zone for an incorrect air/gas ratio.

Remedy is by varying the quantity of supplied air and/or gas so

as to find the correct ratio. The same problem may be caused

by a wrong air/gas distribution in the combustion head.

Remedy is by operating on the combustion head regulation device,

by adjusting the closing or opening of the air passage between

head and gas diffuser.

11) Set the burner to minimum flame (modulation servomo-

18 / 36

0006081062_200

904

E

N

G

L

I

S

H

tor set to minimum), check the quantity and appearance

of the flame making the necessary adjustments: see

instructions elating to the gas valve model MB-VEF..,

DMV-VEF.. Afterwards, check the supplied gas quantity by

reading the meter. If necessary, adjust the gas output and the

relevant combustion air by operating as described above. Then,

check the combustion with the special instruments (see chapter

“Combustion control”.

12) After adjusting the “minimum”, set the modulation switch to MAX

(maximum). The air regulation servomotor sets to “maximum”

and as a consequence, also the gas supply reaches the “maximum”. The quantity of supplied gas is then checked by reading

the meter. With burner ignited at the maximum existing output,

measure the gas flow rate by calculating the difference between

two reads performed after one minute from one another. By

multiplying the measured value by sixty, a sixty-minute flow

rate – that is, one hour – is obtained. By multiplying the hourly

output (m3/h) by the gas heat value, you obtain the delivered

power in Kcal/h, which must correspond or be very close to that

required by the burner (lower heat value for methane = 8550

Kcal/h). Avoid operating the burner if the flow rate is more than

the admissible for the boiler so as to prevent possible damages to the same. Shut down the burner after the two meter

reads.

13)To change the maximum gas output, operate on the air flow

rate regulator since the gas flow rate automatically adjust to

the air supply. Then, operate on the cam regulating the air

damper maximum aperture position (see dr. n° 0002933220 -

0002933490). Reduce the aperture angle of the air damper to

reduce the gas flow rate, and vice versa. To change the gas/air

ratio, see instruction of gas valve MB-VEF.., DMV-VEF..

14)Afterwards, check the combustion with the special instruments

and if necessary, check the existing regulation (air and optionally

gas). Check with the special instruments that the carbon oxide

(CO) percentage in the flue gas does not exceed the maximum

admissible value of 0.1% and that CO2 does not exceed 10%

for methane. (See chapter “Combustion control”)

15) After adjusting the operation to the high flame (maximum)

you must operate so that the air regulation servomotor sets

to the minimum to perform the control also in this position.

16) To set the air – and thus gas – regulation servomotor to the

minimum, the modulation switch must be pressed to MIN.

17) When the air servomotor is set to minimum, and it is necessary

to change the combustion conditions (gas/air), see the instructions for regulating gas valves model MB-VEF.., DMV-VEF..

18) It is advisable to perform the combustion control using the

instruments and, if necessary, change the previous regulation

also in some intermediate points of the modulation stroke.

19) Now, check the correct automatic modulation operation now

check correct automatic modulation operation, inserting the

boiler’s previously removed 4-pole plug.

20) The air pressure switch has the function of locking the control box

if the air pressure is not correct. The pressure switch must thus be

set to start by closing the contact (a normally open contact) when

air pressure in the burner reach a sufficient value. Note that if the

normally open contact does not close (insufficient air pressure),

the control box performs its cycle but the ignition transformer does

not start, the gas valves do not open and as a consequence, the

burner stops in lock. To check the correct operation of the air

pressure switch, set the burner to the minimum output, increase

the regulation value so as to check when it should start to immediately “lock” the burner. Unlock the burner by pressing the

special push button and restore the pressure switch regulation

to a sufficient value to detect the existing air pressure during

the pre-ventilation step. The pressure switch connection circuit

provides for the automatic control; thus, the contact provided to

be closed when at rest (fan off, and thus, absence of air pressure

in the burner) must implement this condition, or the control box

does not start (the burner remains off).

21) The gas pressure control switches (minimum and maximum),

if installed, have the function of preventing the burner from

operating when gas pressure does not range in the expected

values. From the specific function of the pressure switches, it

is evident that the minimum pressure control switch must used

the contact that is closed when it detects a higher pressure than

that to which it is set, the maximum pressure control switch must

use the contact that is closed when it detects a lower pressure

than that to which it is set. Therefore, the gas maximum and

minimum pressure switch regulation must be performed during

the burner general test and inspection, based on the pressure

measured each time. Pressure switches are electrically connected in series; thus shutting down the burner.

22) Only for BGN 540 Lx

In case of UV photoelectric cell, after at least one minute from ignition extract the photoelectric cell from its housing. When the UV

photoelectric cell is extracted from its housing, it cannot “see” the

ultraviolet radiation emitted by the flame and thus, the relevant

relay de-energises. The burner immediately shuts down in “lock”.

A light greasiness strongly affects the passage of ultraviolet

beams through the UV photoelectric cell bulb, thus preventing the internal photosensitive element from receiving the

necessary radiation for a correct operation. If the bulb is dirty

with light oil, heavy oil, etc., clean it accurately. Note that a

simple finger contact can cause a light greasiness, sufficient

to impair the UV photoelectric cell operation. The UV photoelectric cell does not “see” daylight or the light of a common

candle. A possible sensibility check can be made with a flame

(lighter, candle) or with the electrical discharge occurring

between the electrodes of a common ignition transformer.

To ensure a correct operation, the UV photoelectric cell current

value must be sufficiently stable, and must not decrease below

the minimum value required for the specific control box. Said

value is shown in the wiring diagram. It may be necessary to

experimentally search the best position by making the body

containing the photoelectric cell slide (axial or rotation movement) with respect to the fixing clamp.

23) Check the efficiency of the boiler thermostats or pressure

switches (their start must shut down the burner).

19 / 36

0006081062_200

904

E

N

G

L

I

S

H

AIR REGULATION ON COMBUSTION HEAD

(See dr. n° 0002933310)

I

Warning:

When, as in this case, the burner is provided with gas valves

model MB-VEF.., DMV-VEF.., by moving the air regulation

device on the combustion head there automatically and

unavoidably occurs a gas output variation (see chapter Valve

operation principle, model MB-VEF.., DMV-VEF..).

The combustion head is equipped with a regulation device, so as to

open or close the air passage between disk and head. By closing

the passage, it is thus possible to obtain a high pressure upstream

of the disk also for low flow rates. The high air speed and turbulence

allows a better penetration of the same into the fuel and therefore,

an excellent mixture and flame stability. It may be necessary to have

a high air pressure upstream of the disk, so as to prevent flame

pulses. This condition is indispensable when the burner operates

on pressurised combustion chamber and/or with high heating load.

From what said above it is evident that the device closing the air

on the combustion head must be set to such position as to always

obtain, behind the disk, a very high air pressure value. It is advisable

to regulate so as to have such air closure on the head as to require

the opening of the air damper regulating the flow of the burner

ventilator suction. Of course, this condition must only occur when

the burner is operating at the maximum desired output. In practice,

the regulation must start with the device that closes the air on the

combustion head in an intermediate position, igniting the burner for

an indicative regulation as explained above.

When the maximum desired output is reached, correct the position

of the device closing the air on the combustion head by moving it

forwards or backwards so as to have a suitable air flow for the output,

with suction air regulation damper sensibly open

(see dr. n° 0002933310).

!

To facilitate the combustion head regulation, see table (dr.

n° 0002933200)

When reducing the air passage on the combustion head, avoid

closing it completely, which may cause an excessive heating of

the head with a consequent quick deterioration. Perfectly adjust to

central position with respect to the disk. Note that if not perfectly

centred with respect to the disk may cause a wrong combustion and

an excessive head heating, with a consequent quick deterioration.

The check is carried out by looking through the inspection hole on

the rear side of the burner. Afterwards, tighten the screws locking the

position of the air regulation device on the combustion head.

!

Check that ignition is regular because if the controller

has been moved forward, the output air speed could be

so high as to make ignition difficult. In such a case, it is

necessary to move backwards, degree by degree, the

regulator until reaching the position in which the igni-

tion is regular and accept this new position as definitive.

We still remind you that it is preferable, for the small flame,

to limit the air quantity to the minimum indispensable to have

a safe ignition even in the most demanding case.

The minimum ionisation current for the control box to run is 6

µA. The burner flame generates a markedly higher current that

will not normally require any control box checks.

If you want to measure the ionisation current you have to con

-

nect a milliammeter in series to the ionisation electrode cable,

opening connector “C” (see diagram).

20 / 36

0006081062_200

904

E

N

G

L

I

S

H

AIR ADJUSTMENT PRINCIPLE

N° 0002933310

NOT CORRECT ADJUSTMENT

Big air passage opening

Burner’s adjustable

head

Combustion air inlet

Gate very closed

Burner’s head adjusting and

fixing knob

Burner’s adjustable

head

Air passage relatively closed

CAUTION: avoid complete closure

CORRECT ADJUSTMENT

Burner’s head adjusting and fixing knob

Combustion air inlet Gate sensibly open

MAINTENANCE

The burner does not need special maintenance. However, it is advisable to check that the gas filter is clean. It may also be necessary to

clean the combustion head. In this case, dismantle the components

of the mouth.

Be careful when assembling again, so as to prevent the electrodes

from to earth or in short circuit.

Also check that the ignition electrode spark only occurs between

the same and the drilled plate disk.

21 / 36

0006081062_200

904

E

N

G

L

I

S

H

COMBUSTION HEAD ADJUSTMENT DIAGRAM

N° 0002933200

Gas inlet

Ignition electrode

Burner fixing

flange

Burner’s head adjustment knob

Move forward to open the air passage

between the disk and the head, move

backward to close it.

X = Disk/head distance

(see diagram relative to the specific burner model)

NOTE: if the distance “X” is reduced the NOx emissions value

falls. Always adjust the distance “X” between the

minimum and maximum valuesspecified in the work

field.

ELECTRODES ADJUSTMENT DIAGRAM BGN 200 ÷ 390 LX / LX-V

1 - Ionisation electrode

2 - Ignition electrode

3 - Flame disk

4 - Gas diffuser

5 - Gas delivery pipe

N° 0002934430

MOD. A B

BGN 200 LX/LX-V 5 5

BGN 300 LX/LX-V 5 5

BGN 390 LX/LX-V 5 5

ELECTRODES ADJUSTMENT DIAGRAM BGN 540 LX / LX-V

N° 0002933850

22 / 36

0006081062_200

904

E

N

G

L

I

S

H

23 / 36

0006081062_200

904

E

N

G

L

I

S

H

CAMS REGULATION SERVONMOTOR SQM 10-20 FOR BGN - LX

N° 0002933490

24 / 36

0006081062_200

904

E

N

G

L

I

S

H

CONTROL BOX FOR GAS BURNERS LFL 1.333

serie 02

Control box for burners of average and high power, with forced

draught, intermittent service (*), 1 or 2 stages, or modulating types,

with supervision of the air pressure for controlling the air damper.

This control box bears the EC mark, in accordance with the Gas

and Electromagnetic Compatibility Directive.

* For reasons of safety, it is necessary to make at least one controlled stop every 24 hours!

As regards the standards

The following LFL1… features exceed the standards, offering a high

level of additional safety:

- The flame detector test and false flame test start immediately after

the tolerated post-combustion time. If the valves remain open, or

do not close completely after adjustment stops, a lock-out stop

is triggered at the end of the tolerated post-combustion period.

The tests will end only at the end of the pre-ventilation time of

the next start-up.

- The validity of working of the flame control circuit is checked each

time the burner starts up.

- The fuel valve control contacts are checked for wear during the

post-ventilation time.

- A built-in fuse in the appliance protects the control contacts from

any overloads that may occur.

As regards the burner control

- The equipment allows operation with or without post-ventilation.

- Controlled activation of the air damper to ensure pre-ventilation

with nominal airflows. Positions checked: CLOSED or MIN (position of ignition flame on start-up); OPEN at the beginning and

MIN at the end of the pre-ventilation time. If the servomotor does

not position the air damper at the points described, the burner

does not start-up.

- Ionization current minimum value = 6mA

- UV cell current minimum value = 70mA

- Phase and neutral must not be inverted.

- Any place may be used for installation and assembly (IP40

protection).

25 / 36

0006081062_200

904

E

N

G

L

I

S

H

Electrical connections

The burner manufacturer’s diagram is valid for the relief valve connections.

Legend

For the entire catalogue sheet

a Limit switch commutation contact for air damper OPEN

position

AL Remote signalling of lock-out stop (alarm)

AR Main relay (operating relay) with “ar…” contacts

AS Appliance fuse

BR Lock-out relay with “br…” contacts

BV Fuel valve

bv... Control contact for gas valve CLOSED position

d… Remote control switch or relay

EK… Lock-out push-button

FE Ionization current probe electrode

FR Flame relay with “fr…” contacts

GP Gas pressure switch

H Main switch

L1 Fault indicator light

L3 Ready for operation indicator

LK Air damper

LP Air pressure switch

LR Power regulator

m Auxiliary commutation contact for air damper MIN position

M… Motor fan or burner

NTC NTC resistor

QRA.. UV probe

R Thermostat or pressure probe

RV Fuel valve with continuous regulation

S Fuse

SA Air damper servomotor

SB Safety limiter (temperature, pressure, etc.)

SM Programmer synchronous motor

v In the case of servomotor: auxiliary contact for consensus

for fuel valve depending on air damper position

V Flame signal amplifier

W Thermostat or safety pressure switch

z In the case of servomotor: limit switch commutation con-

tact for air damper CLOSED position

Z Ignition transformer

ZBV Pilot burner fuel valve

• Valid for forced draught burners, with obe tube

•• Valid for pilot burners with intermittent operation

(1) Input for increasing operating voltage for UV probe (probe

test)

(2) Input for forced energizing of flame relay during functional

test of flame supervision circuit (contact XIV) and during

safety time t2 (contact IV)

3

) Do not press EK for more than 10 seconds

26 / 36

0006081062_200

904

E

N

G

L

I

S

H

Notes on the programmer

Programmer sequence

Times Legend

time (50 Hz) in seconds

31.5 t1 Pre-ventilation time with air damper open

3 t2 Safety time

- t2’ Safety time or safety time with burners that use pilot

burners

6 t3 Short pre-ignition time (ignition transformer on terminal

16)

- t3’ Long pre-ignition time (ignition transformer on terminal

15)

12 t4 Time between beginning of t2’ and valve consensus on

terminal 19 with t2

- t4’ Time between beginning of t2’ and valve consensus on

terminal 19

12 t5 Time between end of t4 and consensus at power regu-

lator or at valve on terminal 20

18 t6 Post-ventilation time (with M2)

3 t7 Time between consensus for start-up and voltage at

terminal 7 (start delay for fan motor M2)

72 t8 Start-up duration (without t11 and t12)

3 t9 Second safety time for burners that use pilot burners

12 t10 Time from start-up to beginning of air pressure control

without air damper travel time

t11 Air damper opening travel time

t12 Air damper in flow flame position (MIN) travel time

18 t13 Permitted post-combustion time

6 t16 Initial delay of consensus for air damper OPENING

27 t20 Time up to automatic closure of programmer mechanism

after burner start-up

Output signals on terminal

27 / 36

0006081062_200

904

E

N

G

L

I

S

H

Stop indications

NOTE:

With voltages at 60 Hz, the times are reduced by about 20%.

t2’, t3’, t3’:

These times are valid only for series 01 or LFL1.335, LFL1.635,

LFL1.638 burner control and command equipment.

They are not valid for types of Series 032, since they involve simultaneous activation of cams X and VIII.

Working

The above diagrams illustrate both the connection circuit and the

sequencer mechanism control program.

A Consensus for start-up by means of installation thermostat or

pressure switch “R”.

A-B Start-up program

B-C Normal burner operation (on the basis of “LR” power regulator

control commands)

C Stop controlled by “R”

C-D Return of programmer to start-up position “A”, post-ventilation.

During periods of inactivity of the burner, only the command

outputs 11 and 12 are powered, and the air damper is in the

CLOSED position, determined by limit switch “z” of the air

damper servo motor. During the probe test and false flame

test, the flame supervision test is also powered (terminals

22/23 and 22/24).

Safety standards

• In association with the use of QRA…, earthing of terminal 22

is compulsory.

• The power cables must conform to existing national and lo-

cal standards.

• LFL1… is a safety device, and it is therefore forbidden to

open it, tamper with it or modify it!

• The LFL1… device must be completely insulated from the

mains before carrying out any operations on it!

• Check all the safety functions before activating the unit or

after replacing a fuse!

• Provide protection against electric shock on the unit and all

electric connections. This is ensured by following the assembly instructions correctly!

• During operation and maintenance, prevent infiltration of

condensate into the command and control equipment.

• Electromagnetic discharges must be checked on the applica-

tion plan.

Control program in the event of stopping, indicating position of

stop

As a rule, in the event of any kind of stop, the fuel flow is cut off

immediately. At the same time, the programmer remains immobile,

as does the switch position indicator. The symbol visible on the

indicator reading disk indicates the type of fault.

◄ No start-up, because of failure in closing of a contact or

lock-out stop during or at the end of the command sequence

because of external lights (for example: flames not extinguished, loss at the level of the fuel valve, defects in the

flame control circuit, etc.)

▲ Start-up sequence stops, because the OPEN signal was not

sent to terminal 8 by limit switch contact “a”. Terminals 6, 7

and 15 remain powered until the defect is eliminated.

P Lock-out stop, because of lack of air pressure signal.

Any lack of pressure from this moment onwards will cause

a lock-out stop!

▄ Lock-out stop because of flame detection circuit malfun-

ction.

▼ Start-up sequence stops, because the position signal for

low flame was not sent to terminal 8 by auxiliary switch

“m”. Terminals 6, 7 and 15 remain powered until the fault is

eliminated.

1 Lock-out stop, due to lack of flame signal at the end of the

first safety time.

2 Lock-out stop, because no flame signal was received at the

end of the second safety time (main flame signal with pilot

burners at intermittent operation).

▌ Lock-out stop, due to lack of flame signal during burner

operation.

If a lock-out stop occurs at any moment between the start and preignition without a symbol, the cause is generally to be attributed

to a premature or abnormal flame signal caused, for example, by

self-ignition of a UV tube.

LFL …, Series 01 LFL …, Series 02

a-b Start-up program

b-b’ “Trips” (without contact confirmation)

b(b’)-a Post-ventilation program

28 / 36

0006081062_200

904

E

N

G

L

I

S

H

DUNGS mod. MB-VEF BO1

N° 0002910621

- INSTRUCTIONS FOR MONOBLOC VALVE WITH CONTINUOUS MODULATION OPERATION

1

Electrical connection for pressure switch (DIN 43650))

2

Electrical connection for valves (DIN 43 650)

3

Pressure switch

4

Input flange

5

Test point connection G 1/8 upstream of filter, possible on both sides.

6

Filter (below cover)

7

Type plate

8

G 1/8 pressure connection for pL blower pressure

9

Setting screw, ratio V

10

Test point connection G 1/8 downstream of filter possible of both sides

11

Test point connection M4 down- stream of V2

12

Setting screw, zero point adjustment N

13

G 1/8 pressure connection for p F furnace pressure

14

G 1/8 pressure connection for p Br

burner pressure

15

Output flange

16

Test point connection G 1/8 downstream of V1, possible on both sides

17

Operation display V1, V2 (optional)

18

Pulse line

Pressure taps

1,3,4,6 Screwed sealing plug G 1/8

2 Measuring nozzle

5 Screwed sealing plug M4

7,8,9 Female thread for pulse lines G 1/8 P

L

, P

F

0 Filter cup

29 / 36

0006081062_200

904

E

N

G

L

I

S

H

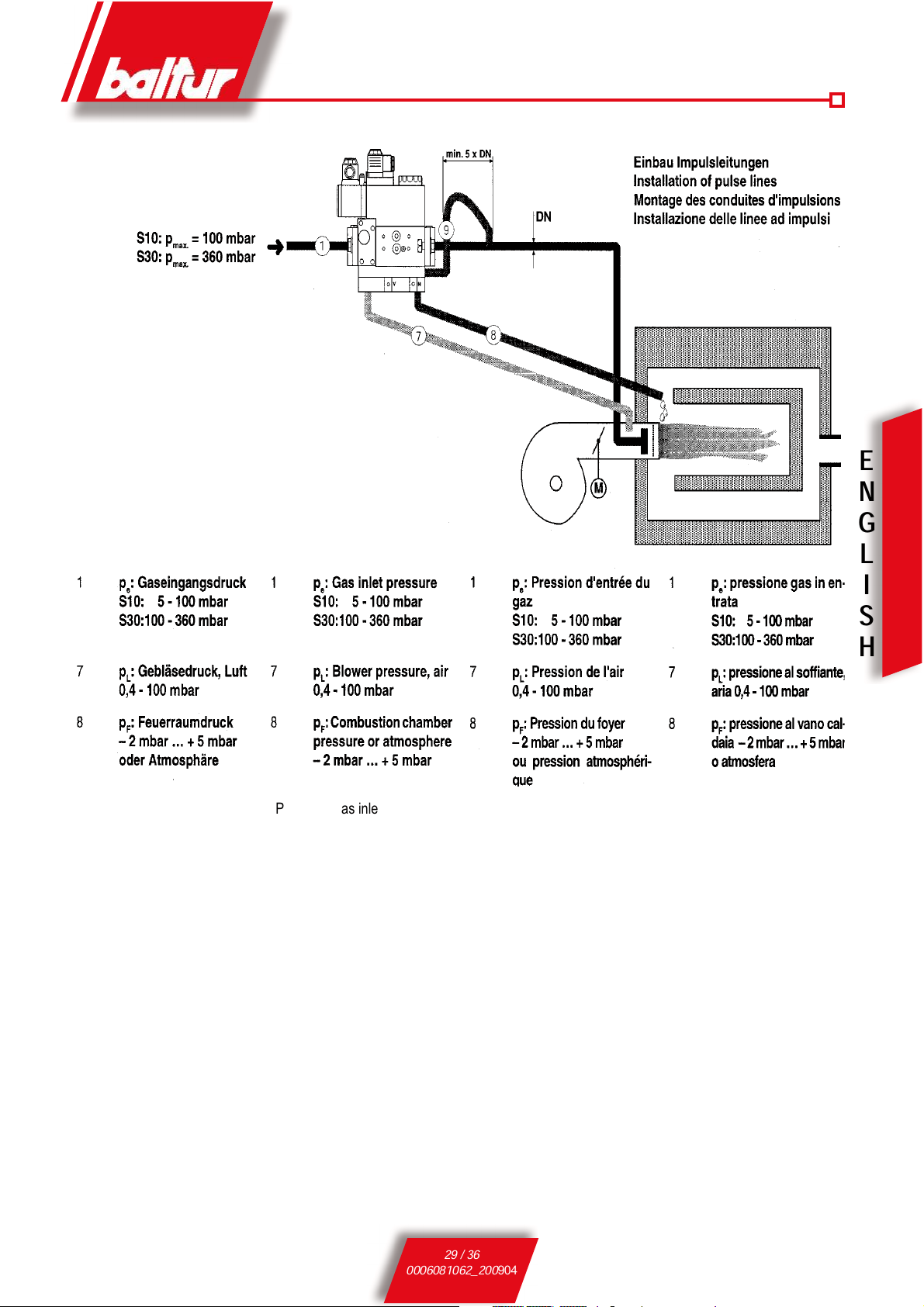

Pe Gas inlet pressure

30 / 36

0006081062_200

904

E

N

G

L

I

S

H

DUNGS mod. DMV-VEF 5065/11 - 5125/11

N° 0006080717

Rev. 2002/06

INSTRUCTIONS FOR DOUBLE SOLENOID VALVE GAS-AIR-RATIO CONTROL

31 / 36

0006081062_200

904

E

N

G

L

I

S

H

33 / 36

0006081062_200

904

E

S

P

A

Ñ

O

L

DUNGS mod. MB-VEF BO1 / DMV-VEF

TARADO DEL GRUPO DE REGULACIÓN - PRESIÓN

!

The pressure – adjustment unit is factory set. Settings should

then be adapted on site to suit the needs of the system.

La válvula modulante mod. MB-VEF B01 opera aumentando

automáticamente la cantidad de salida del gas si aumenta el caudal del

aire, y reduce automáticamente la cantidad de salida del gas si se reduce el