Safety is our

greatest concern.

We work at it.

BALL VALVES

Raising the Threshold of Quality

Lowering the Cost of Ownership

Contents

1

®

Balon Mission 2

Manufacturing 3

The Company 4

The Valve 5

Sealing Principle 6

Valve Construction and Design 7

Stem Design 8

Fire Safety 10

Balon Installations 11

Series F, Screwed End 12

Series F, Flanged End, Lever Operated 18

Balon Installations 23

Series F, Flanged End, Gear Operated 24

Series F, Ductile Iron, Flanged End, Lever Operated 26

Series US, Weld X Weld 28

Series US, Weld X Flange 30

Series S, Screwed End 32

Series LM, Screwed End 36

Series LS, Screwed End 38

Balon Installations 40

Technical and Engineering Data 41

Product Identification Key 46

Terms and Conditions 47

Balon Installations 48

Click on title to jump to that page.

The Balon Mission

2

®

■ Produce valves with the safety of those who use

them as our uppermost and defining goal.

■ Provide our customers with valves

which perform as promised, at a price

which reflects their true value to the user.

■ Meet the service needs of our customers by

maintaining a trained full-time staff of field

technicians located in all geographical areas.

■ Respond promptly and courteously to all customer

and distributor inquiries, questions, and problems.

■ Make certain that all Balon employees

understand and implement our commitment

to customer attention and customer satisfaction.

■ Treat our vendors, customers, distributors, and

employees with equanimity and honesty.

To assure growth for

the Company and

opportunity for all

employees, it shall be

our dedicated aim to:

Manufacturing

®

3

Balon: The Company

®

4

Situated on ten acres in Oklahoma City,

this facility typifies the Balon concept

and approach to producing a superior

valve.

Because growth has been rapid, it has

been a policy to gear ahead of the

actual demand so that good deliveries

can be sustained and so that surges in

demand do not restrict our capability to

pursue an ongoing program of product

improvement and expansion.

Moreover, it has been our policy over

the years to control the manufacture of

our valves in every possible way, and

this has meant basic manufacture of all

components, including molding of

seats, and close-tolerance machining of

balls.

The people who manufacture the Balon

ball valve take pride in their work. And

it is this pride of craftsmanship that sets

Balon apart from its competition.

By utilizing the most modern

equipment and facility available today,

Balon is able to do many things more

quickly than those manufacturers

whose equipment and facilities have

become outdated and costly. We will

continue to recognize that the Balon

name must be synonymous with raising

the threshold of quality and lowering the

cost of ownership.

©

2001 Balon Corporation

Balon: The Ball V alve

®

5

Unblemished Safety Record:

After almost four decades of producing

valves and having no injuries nor property damage result from the failure of a

Balon valve, we are proud to claim that

we make the safest ball valves available

on the market today.

This safety record did not come from

shying away from the tough high

pressure applications in the field. It did

not arise from cutting corners to lower

the cost of making valves to the

ultimate peril of those who operate

them. It was not borne of cosmetic

contrivance nor gimmickry and

gadgetry.

It has been the calculated result of a

rational, intentional and concerted effort

to address every possible hazard and

to design and manufacture valves with

an inherent margin of safety far

surpassing that of others on the market.

Total Commitment: More than

innovative design goes into producing a

superior valve. More than controlled

and precision manufacturing methods.

More than overall engineering expertise.

More than effective marketing and

distribution. To produce a valve noted

for its superiority in performance, safety,

dependability and for its consistent

quality implies a total commitment in all

of these phases.

Combined Effort: Balon Corporation,

since its beginning in 1965, has

coupled improved design features,

advanced manufacturing methods and

practical common sense engineering

approaches with a well planned, highly

supportive and field channeled

marketing and distribution program.

The natural result of this effort has been

that the Balon ball valve has attained a

reputation for excellence unequaled by

any other ball valve on the market.

Individual Pride: Many manufacturers

have adopted the philosophy that

valves are best made by turning them

out on sophisticated machines

incapable of exercising judgment as to

the quality of the final product. At

Balon, we believe that people — not

machines — produce valves. Our valves

are produced by perfection-minded

craftsmen who use specialized

machines as tools to help them make a

better valve.

Continued Support: It is with this

philosophy in mind that we will continue

to provide a better valve, an advanced

valve. And we will support this product

with a concerted program of design,

manufacturing, engineering and

marketing.

Balon Corporation’s 260,000 square feet of modern office and manufacturing capability is shown in this aerial view.

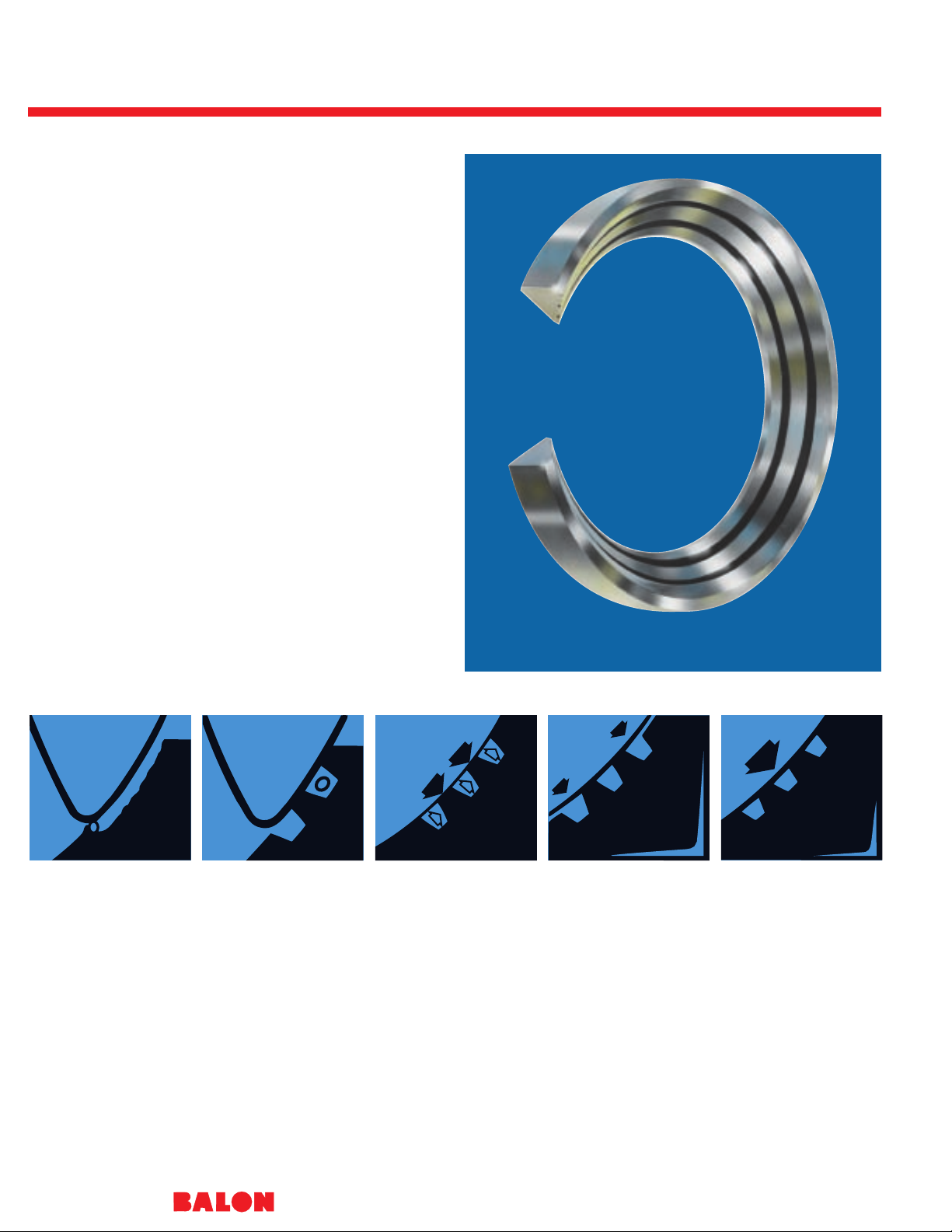

Multi-Seal: The Heart of the V alve

®

6

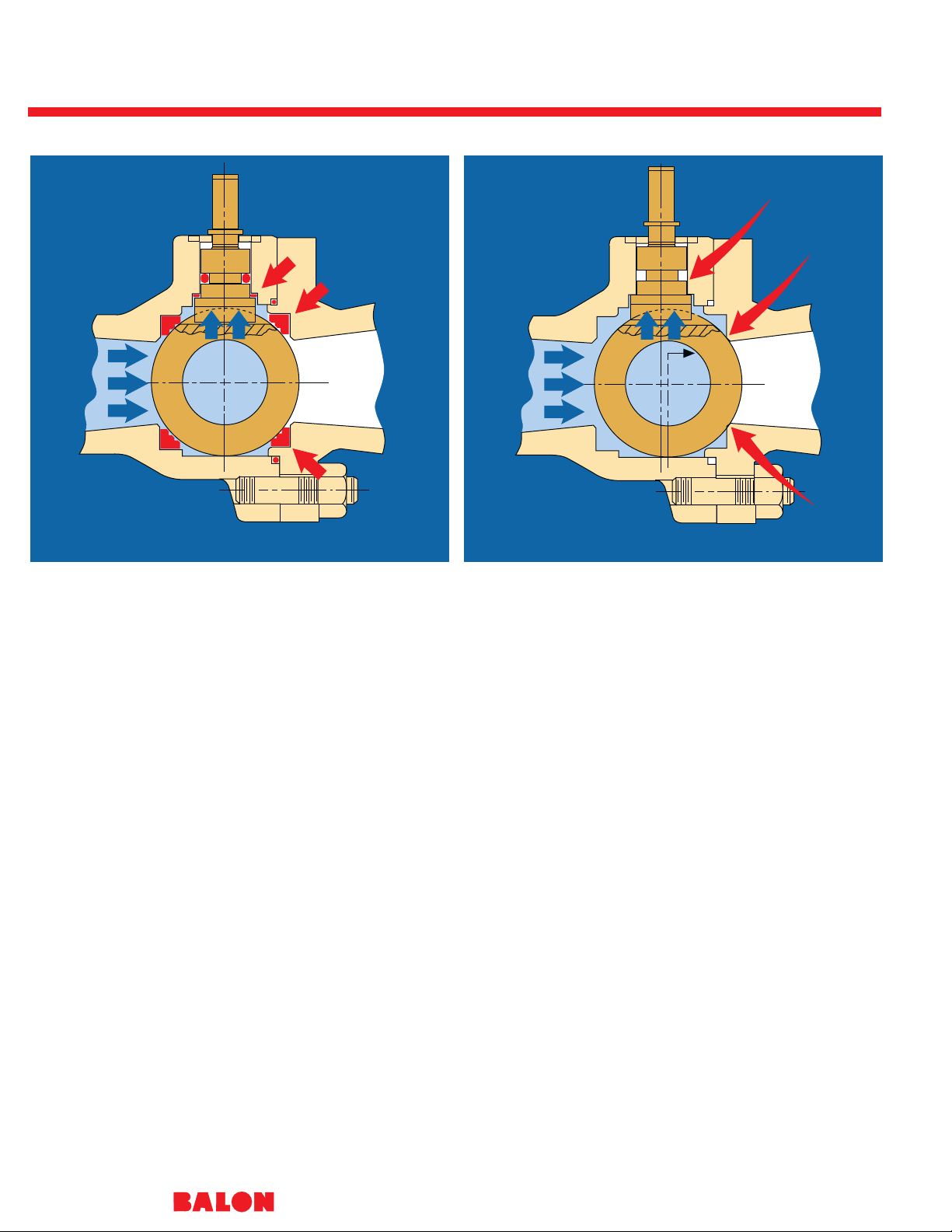

Notice the grooves. These grooves loosely receive any grit

that might be present when the valve is closed. When the

valve is opened, the foreign matter washes harmlessly away,

where an ordinary valve seal could have been scored across

its entire surface. Balon’s seal is good as new.

Notice the seal rings. Not just one ring… a series. That’s

where Multi-Seal gets another big sealing edge over plain

seals. The rings assure a concentrated seal, providing a bubble tight seal at high and low pressures, the tighter the seal…

the better the shut-off.

Notice the tapered outer walls. These tapered walls on the

Multi-Seal provide automatic seal-to-ball tensioning and selfadjustment to wear. Much longer life and complete troublefree performance is what you get. That’s why you don’t need

a repair kit.

How long will the Balon Multi-Seal last? Our sales records

of replacement seats indicate that most Balon valves sold

have provided many years of trouble-free performance.

It has been tested on water pumped at 1,000 psi operating

pressure with shock loading on shutoff up to 1,800 psi. After

a million shutoffs, it still sealed bubble tight.

Patented

ORDINARY SEALS

are damaged during

shutoff. As flow is

squeezed through fineline opening, foreign

particles are trapped.

Complete shutoff

grinds them into seal.

Results: premature

damage, leakage,

valve failure.

MULTI-SEAL

receives particles

loosely in grooves, to

be washed harmlessly

away during next

opening. Valve seals

bubble tight again,

through repeated

shutoffs.

MULTI-SEAL’S

series groove design

features blunt-edge

seal members for

superior sealing

efficiency. And the

grooves form supertight “fluid seal rings.”

Each seal member,

working with the next

one, creates exclusive

“staged differential

pressure sealing,” for

tightest shutoff

possible at all

pressures.

MULTI-SEAL

adjusts itself to wear!

Outer walls are tapered

to permit selfcompensation to valve

load and seal

engagement demand.

The design permits

thrust loading to

realign seat toward

optimum sealing

engagement.

THE MULTI-SEAL

DESIGN permits

selection of seal

material best suited to

abrasive, high and low

pressure applications

in toughest services.

And the relief pockets

formed by the tapered

walls, with the series

grooving, provide selfcompensation for swell

to permit easy-turning,

long-life operation. it

takes a better seal to

make a better valve…

and the best ball valve

is a Balon.

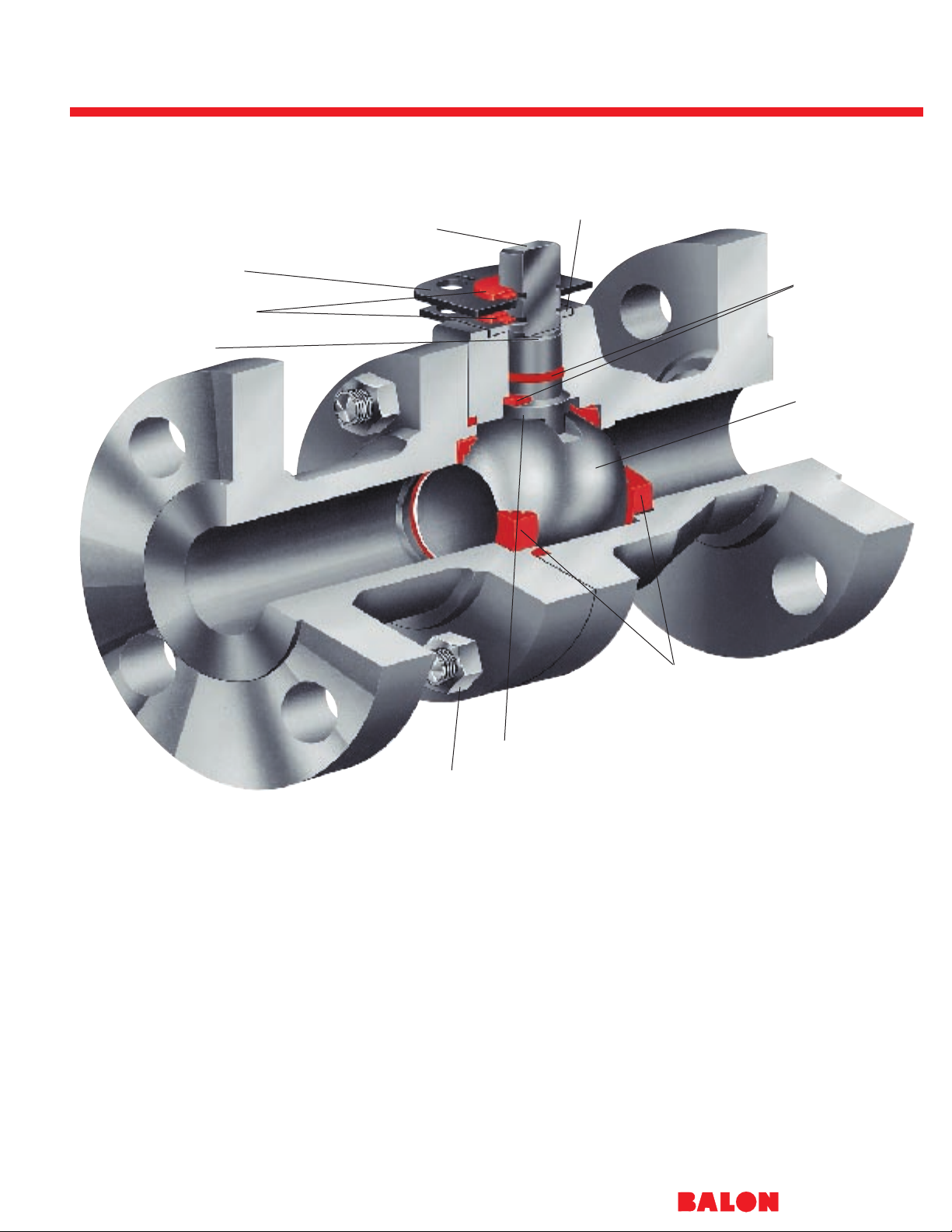

The Balon V alve: T otally Advanced

®

7

Unique Sealing Approach

The Balon ball valve is the culmination

of many years of arduous design and

development effort which has been

focused on providing a clearly better

choice in ball valves. It is a refinement

of features proven superior during

usage of Balon ball valves in thousands

of installations since 1965.

As described on the facing page,

the multi-seal seat design has given

impetus to the development of an

overall valve which embodies several

design improvements.

Backseated Stem

Stems are backseated and therefore

blowout proof. And they provide metalto-metal backup sealing in the event of

a fire. This secondary metal-to-metal

sealing is also provided internally behind

the seat area.

Simplified Top Works

Bolts and glands and complicated stem

assemblies are totally absent in the

Balon valve to assure a simpler, more

trouble-free valve. Hazards associated

with bolted stem retainers and packing

adjustment screws or bolts have been

eliminated. Even the stops are internal

and give dual precise topping support

during opening or closing. The stem

area is grease-packed and protected

by dual plastic weather guards to shield

this vital area from external elements.

Precise Manufacturing Control

Balon uses only the highest quality

materials to assure the strength and

uniformity necessary for applications

where they are used. To further

enhance the overall operational

superiority of the valve, all balls are

machined in-house by Balon’s spherical

machining process which assures a

consistently accurate spherical contour.

They are superbly finished and polished.

This high integrity finish, along with

multi-seal’s advanced sealing capability,

provides highest sealing efficiency and

substantially reduced operating torque.

Valve safety is no accident. We do it by design.

SAFETY SHEAR GROOVE

PROTECTIVE WEATHER GUARDS

LOCKING PLATE

RECTANGULAR STEM WRENCH AREA

PATENTED

INTERNAL TWIN STOPS

SELECTIVE DUAL

STEM SEALING

ULTRA SMOOTH

HIGH SPHERICITY

BALL

PATENTED

MULTI-SEAL SUPER

EFFICIENCY SEALING

BACKSEATED BLOWOUT-PROOF STEM

STRONG BOLTED CONSTRUCTION

Balon has eliminated the need for grease fittings, lube channels, and regular lubrication, versus other designs.

•

•

•

•

•

•

•

•

•

•

•

•

•

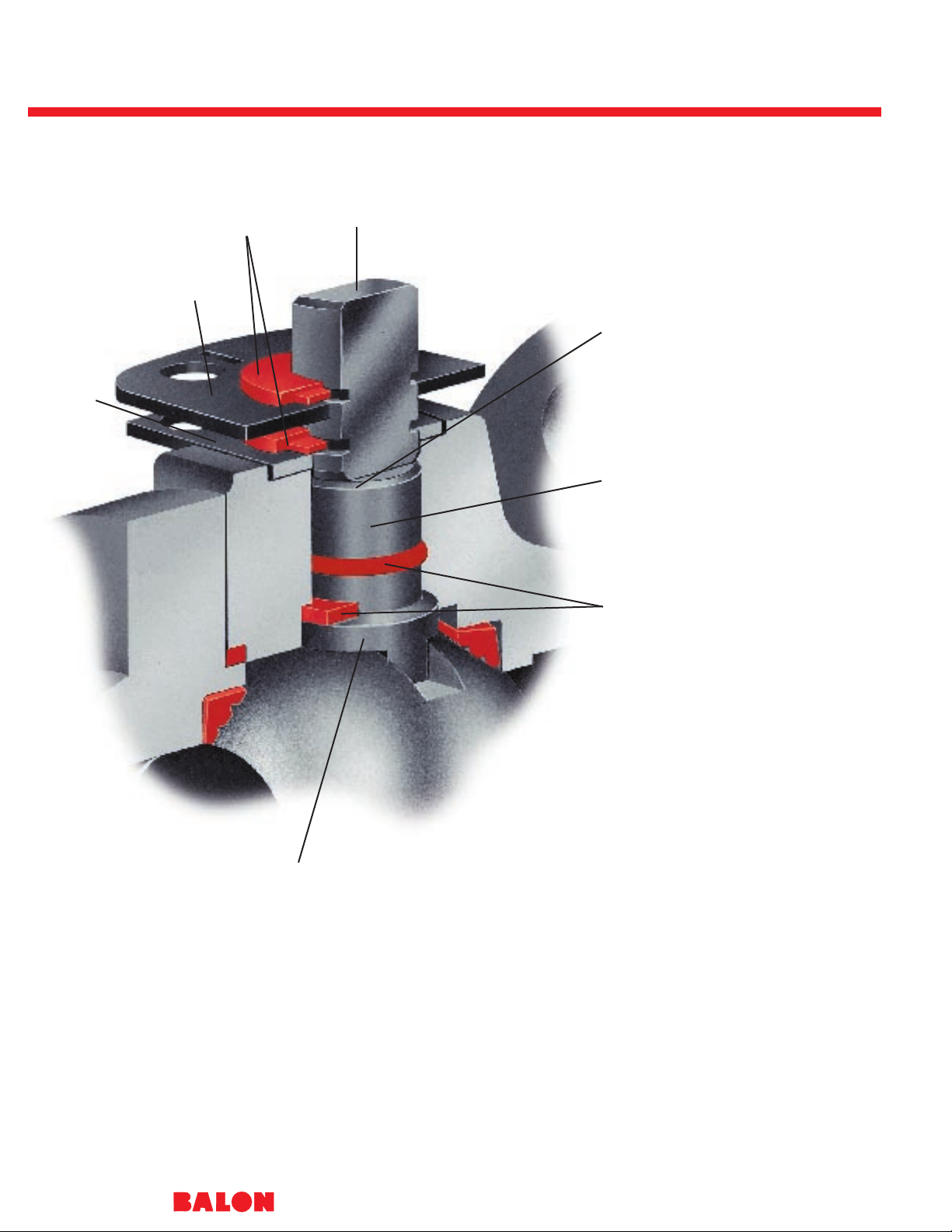

A T otally New Concept in Stem Design

®

8

Simple Design

In keeping with Balon’s philosophy of

design which envisions simplification

and improvement instead of improvement by complication, the Balon stem

design solves many problems associated with the common stem design. The

overall utility of the ball valve is related in

no small way to the basic stem design.

Certain standard designs originated

early and were followed through by ball

valve manufacturers in the years following the advent of the ball valve itself

during World War II.

The Balon Stem: New

Solutions For Old Problems

The Balon design represents the result

of a total attack on specific problems

associated with the outdated design. In

the past, it has been a frequent practice

to retain stems by use of external

retainers secured by use of external

bolts or screws. Often these bolted

arrangements also provided stem packing adjustment. The problem of leaking

stems was amplified because of the

complexity of the assembly itself.

The absence of backseating in early

designs opened the way for stem

blowout in the event of failure of the

retaining assembly or as a result of

forcible operation of the valve.

In many former designs, double O-rings

were incorporated on the theory that

should one O-ring fail to seal, then the

second O-ring would perform the sealing job. However, higher pressures

trapped between the O-rings often

caused high operating torque and other

operating problems.

A Combination of Improvements

As shown here, the Balon design is

simple, yet solves these problems. The

clean, functional design of the stem

assembly represents dramatic improvement in many ways over conventional

designs. As is true of the overall Balon

approach, the Balon stem does not

present just one special modification or

design innovation. Rather, it represents

the bringing together of interrelated

improvements, resulting in total

improvement and total superiority.

PROTECTIVE WEATHER GUARD

KEEPS MOISTURE FROM STEM AREA

LOCKING PLATE STANDARD

BODY KEYED

STOP PLATE

CONTAINS

PATENTED

INTERNAL

TWIN STOPS

RECTANGULAR WRENCH STEM AREA

FACILITATES USE OF STANDARD WRENCH

SAFETY SHEAR GROOVE - PREVENTS

STEM BLOWOUT RESULTING FROM

EXCESSIVE TORQUE

EXTRA LARGE STEM FOR

STRENGTH AND SAFETY

SELECTIVE DUAL SEALING WITH THRUST

WASHER FOR HIGHER PRESSURE AND O-RING

FOR LOWER PRESSURE

METAL-TO-METAL BACKSEATING FOR FIRE

SAFETY AND BLOWOUT PREVENTION

•

•

•

•

•

•

•

•

•

•

Balon has eliminated the need for grease fittings, lube channels, and regular lubrication, versus other designs.

Safer ...Simpler ...Better Sealing

®

9

NO SPECIAL HANDLE NEEDED

While handles can be provided for

operation of the Series F and Series S,

the heavy-duty rectangular stem design

allows for usage of standard wrenches

where it is necessary to conserve

space, and to prevent accidental operation of the valve, or simply where standard wrenches are more convenient.

To further enhance the service life and

ease of operation, the stem area is fully

grease-packed and then sheltered by

dual nylon weather guards. External

elements such as dirt, sand, and salt air

atmosphere are kept out.

NO BOLTS, SCREWS, PACKING

GLANDS

The Balon design eliminates

troublesome bolting, adjustment

screws, and packing glands. Problems

of adjustment, blowout resulting from

failure of retaining assembly, and

external attack by corrosion and foreign

abrasives are all solved. By simplifying

the stem assembly, fewer parts are

involved and therefore the possibilities

for trouble are significantly reduced.

Because there are no grease channels

or lubricating ports there are no leak

paths which can result in stem leakage.

PATENTED INTERNAL DUAL STOPS

Instead of external stops and exposed

bolting, the stem is supported laterally

by a stop plate keyed into the body

head. This plate has integral broached

stops contralaterally positioned so that

the stem is stopped simultaneously on

both sides whether being opened or

closed. This dual stopping action eliminates deflection and stress on the

stem. Perfect alignment is assured in

SELECTIVE DOUBLE SEALING

Balon utilizes a TFE thrust washer for

primary sealing at higher pressures.

For lower pressures and vacuum, the

O-ring provides the sealing. The stem

region between the two seals cannot

remain pressurized - as can happen in

conventional double O-ring arrangements - since at lower line pressures,

the TFE seal will permit bleed back into

body region. Two seals, but only one

acting at any given time.

Safety is our greatest concern. We work at it.

the stem bore, and therefore more trouble free and longer life stem and stem

seal service. Dual stops keep ball in

precise position against the seat, and in

the open position this prevents exposure of the seat to damage and wear

from the flow. Sealing effectiveness is

sustained and extended.

BLOWOUT PROOF

Notice that the stem is backseated

against an inner shoulder, and not

retained by external bolts or screws or

retaining plates. Blowout is inherently

denied by this positive method of stem

retention. Balon has machined a safety

shear groove on each side of the stem

at the base of the wrench flats, but

safety above the stem seals, and above

the inner shoulder. Should excessive

torque be applied to the stem, it would

shear above the shoulder and above

the sealing area. No blowout. No

release of hazardous material.

A More Complete Solution to Fire Safety

®

10

Figure A: Valve closed and seals intact. Figure B: Valve is closed, seals completely dissipated.

In 1965, after many years of

development and testing, Balon

patented and introduced a ball valve

which represented a dramatic turning

point in valve safety. It was the first ball

valve with a backseated stem to prevent

stem blowout; first with packless stem

gland housing, eliminating stem

adjustment mechanisms; first with a

stem shear groove to assure controlled

stem breakage above the backseat in

the event of twist-off; first with full

spectrum fire safety for metal-to-metal

secondary sealing at all potential leak

points. Balon then encased these

safety improvements in a rugged bolted

body assembly capable of better

withstanding violent thrust loading and

line stresses so common in highpressure line applications.

Fire safety in ball valves has become a

major consideration as more and more

ball valves have been used in hazardous

environments.

The Balon ball valve has been designed

to provide maximum backup sealing in

the event resilient seals are destroyed

by heat or fire.

Controlled Spacing

The valve internals, with seals intact,

can be seen in Figure “A.” In the closed

position the ball is held off of secondary

metal seat provision.

The seat and seat pocket are made

oversize in radial dimension, allowing

close spacing of the ball and metal seat

provision. In operation, with prime seals

in place, this controlled spacing prevents

damage to the surface finish of the ball.

It can also be seen that the stem is

backseated, and with seals in place the

primary stem seal holds the stem off

of metal shoulder machined in the

valve body.

Secondary Stem Seal

In Figure “B,” the seals have been fully

dissipated, ball has moved downstream

onto the secondary metal seat, and the

stem has been checked, metal-tometal, against the inner shoulder.

As can be seen, the stem is free to

move upward when subjected to a

slight amount of pressure, onto the

machined metal inner shoulder, thus

substantially restricting any flow past

the stem into the atmosphere.

Straight Ahead Ball Movement

The stem tongue is keyed into a linear

milled slot, straight and perpendicular

to the bore of the valve. In the closed

position, the ball is free to move downstream onto the secondary metal seating, functioning at that moment as a

simple ball check valve.

The ball itself is confined in the body

with just enough vertical and horizontal

clearance to assure free and easy

operation. This keeps the ball in uniform

alignment so that ball movement onto

backseating - should it become

necessary - is consistently on a straight

course, without deflection up, down,

or sideways.

The valve may be positioned in either

vertical or horizontal installations, and

retain its secondary metal-to-metal

sealing capability.

These very simple provisions are

intended to provide full operational

safety, but of course positive assurance

of total fire safety cannot be given due

to the many variable conditions which

can arise. Every attempt has been

made in the design of the Balon valve to

provide as safe a valve as is practicable

within the scope of economic feasibility

for the user.

Balon ball valves have been

successfully tested by an independent

laboratory in accordance with API

Standard 6FA “Fire Test For Soft

Seated Ball Valves.” Results of this

testing are available on request from

Balon’s headquarters office.

Balon Installations

®

11

Designed...

to give superior performance where

superior performance is critical — in the

field. Simple, yet effective. Safe, yet

practical. Versatile, yet economical.

Built...

for the rugged and demanding oil and

gas applications. Stronger. Tougher.

Crafted for hard use and extra

staying power.

Proven...

with millions of valves in the field —

exceptionally dependable, more troublefree, and capable of indefinite maintenance-free service life.

Series F Screwed End

®

12

The Balon Series F carbon

steel screwed end ball valve is

of bolted two-piece construction

to assure positive protection

against end adapter blow-out

which can occur in most

screwed construction valves.

The Series F is available to

meet a wide range of pressure

and applications, and when

ordered with 316 stainless

steel ball and stem it meets

NACE requirements.

Firesafe design and built-in

locking device are standard on

the Series F.

Carbon Steel

®

13

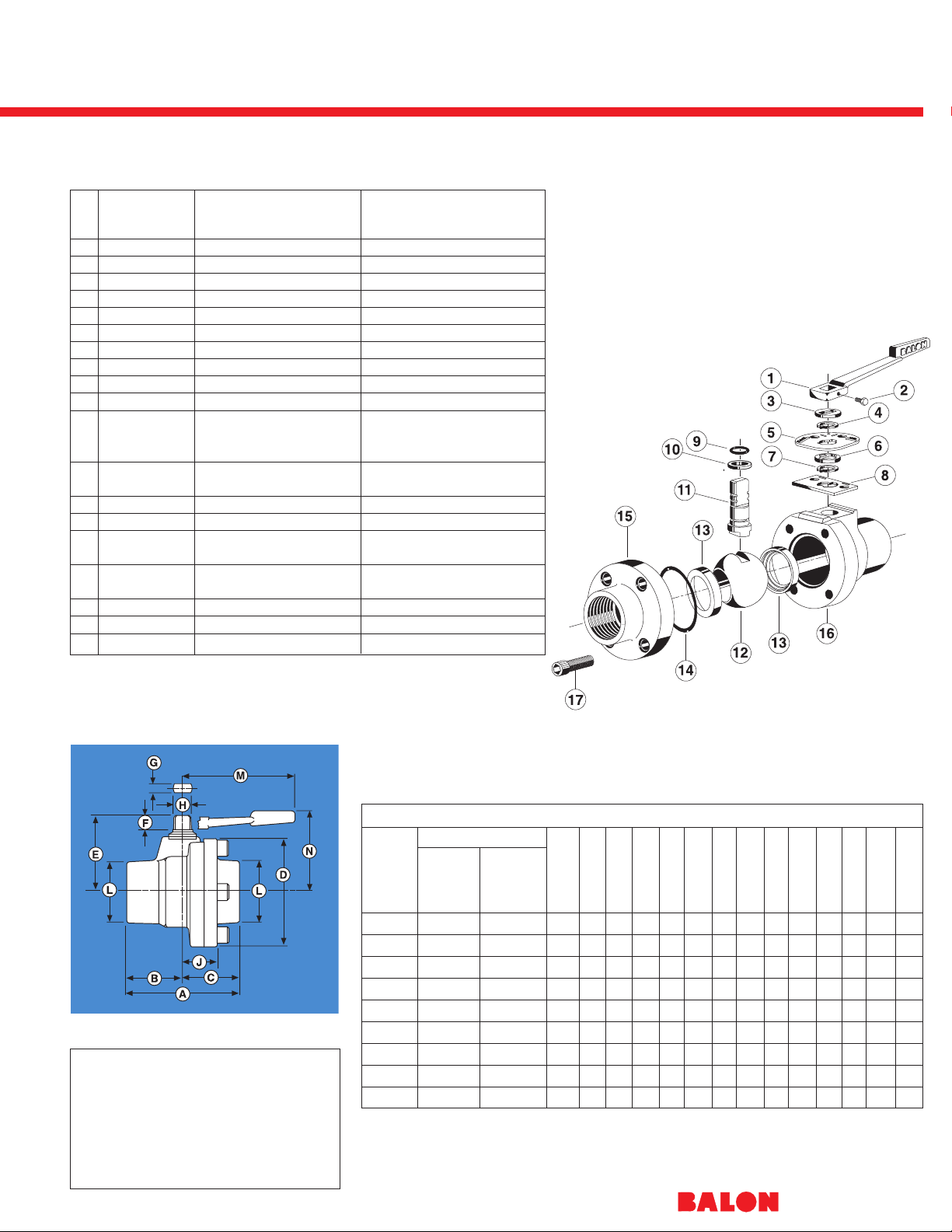

BALON SERIES “F” - CARBON STEEL - SCREWED END - DIM. DATA

CAT. NO.

STANDARD TRIM NACE TRIM

SIZE

CARBON STEEL 316 STAINLESS

PORT WP A B C D E F G H J L M N

BALL & STEM STEEL BALL & STEM

1 x 1 x 1 1F-F93-SE 1F-F93N-SE 1 2500 37⁄8115⁄16115⁄1633⁄823⁄

8

1

⁄2.340 .685 11⁄817⁄843⁄82

1 x 1 x 1 1F-F03-SE 1F-F03N-SE 1 3000 37⁄8115⁄16115⁄1633⁄823⁄

8

1

⁄2.340 .685 11⁄817⁄843⁄82

11⁄2x 11⁄2x 11⁄211⁄2F-F93-SE 11⁄2F-F93N-SE 11⁄22500 51⁄425⁄825⁄851⁄835⁄

8

3

⁄4.434 .873 15⁄821⁄271⁄45

2 x 11⁄

2

x 2 2R-F93-SE 2R-F93N-SE 11⁄22500 5

1⁄

2

23⁄423⁄451⁄835⁄

8

3

⁄4.434 .873 15⁄837

1

⁄45

2 x 11⁄2 x 2 2R-F03-SE 2R-F03N-SE 11/23000 51⁄223⁄423⁄451⁄835⁄

8

3

⁄4.434 .873 15⁄837

1

⁄45

2 x 2 x 2 2F-F93-SE 2F-F93N-SE 2 2000 53⁄427⁄827⁄861⁄843⁄

8

7

⁄8.497 .998 2 31⁄8101⁄453⁄

8

3 x 2 x 3 3R-F93-SE 3R-F93N-SE 2 2000 75⁄8313⁄16313⁄1667⁄843⁄

8

7

⁄8.497 .998 21⁄1641⁄4101⁄453⁄

8

3 x 3 x 3 3F-F63-SE 3F-F63N-SE 3 1500 83⁄843⁄1643⁄1685

3

⁄411⁄16.747 1.373 21⁄241⁄420 63⁄

4

4 x 3 x 4 4R-F63-SE 4R-F63N-SE 3 1500 87⁄847⁄1647⁄1685

3

⁄411⁄16.747 1.375 27⁄1651⁄420 63⁄

4

Dimensions

NACE CAPABILITY

Most Series F Carbon Steel and Ductile

Iron Valves can be provided to meet

NACE Standard MR-01-75, current revision, for Sulfide Stress Resistant Metallic

Material for Oil Field Equipment.

WP is for valve equipped with standard nylon seats.

See Chart on Page 43 for TFE ratings.

ITEM PART NAME

MATERIAL MATERIAL

(STANDARD) STAINLESS STEEL (NACE)

1 Handle* Ductile iron Ductile iron

2 Handle bolt Standard hex bolt Standard hex bolt

3 Weather guard Polyethylene Polyethylene

4 Lock plate retainer Carbon spring steel Carbon spring steel

5 Lock plate Carbon steel - zinc plated Carbon steel - zinc plated

6 Dust cover Polyethylene Polyethylene

7 Stop plate retainer Carbon spring steel Carbon spring steel

8 Stop plate Carbon steel zinc plated Carbon steel zinc plated

9 Stem O-ring Buna Fluorocarbon

10 Stem seal TFE TFE

11 Stem Carbon steel zinc plated AISI A-316

ASTM A311-79 Class B stainless steel annealed

ASTM A-276-316

12 Ball AISI 1018 nickel chrome plated ASTM A-743-CF8M/316

annealed stainless steel

13 Ball seat Nylon (TFE optional) Nylon (TFE optional)

14 Body O-ring Buna Fluorocarbon

15 End adapter ASTM 216 grade WCB annealed ASTM 216 grade WCB annealed

carbon steel carbon steel

16 Body ASTM 216 grade WCB annealed ASTM 216 WCB annealed

carbon steel carbon steel

17 Body bolts ANSI B18.3 ANSI/ASTM A574 ASTM A-193/B7M

18 Body stud nuts ASTM A-194 ASME SA 194 2H ASTM A-194 2HM

19 Body stud bolts ASTM A-193 ASME SA-193 B-7 ASTM A-193 B-7M

Material Description Lever Operated

Bolted Construction

1" thru 4"

to 3000 PSI WP

* Balon valves are designed to be operated

with a standard open-end wrench.

Handle and Handle Bolt are optional.

Series F Screwed End

®

14

The Balon Series F ductile

iron is an excellent lower cost

alternative to carbon steel

screwed end valves with no

sacrifice in safety or

performance life.

The ductile iron used to make

the Series F is a higher grade

of ductile whose physical

properties are enhanced by

special heat treating that

provides a yield strength

greater than that of carbon

steel, and better overall

corrosion resistance.

Built-in locking devices are

standard, and all Balon ductile

iron valves can be provided

with 316 stainless steel balls

and stems for corrosive media

and to meet NACE

requirements.

Ductile Iron

®

15

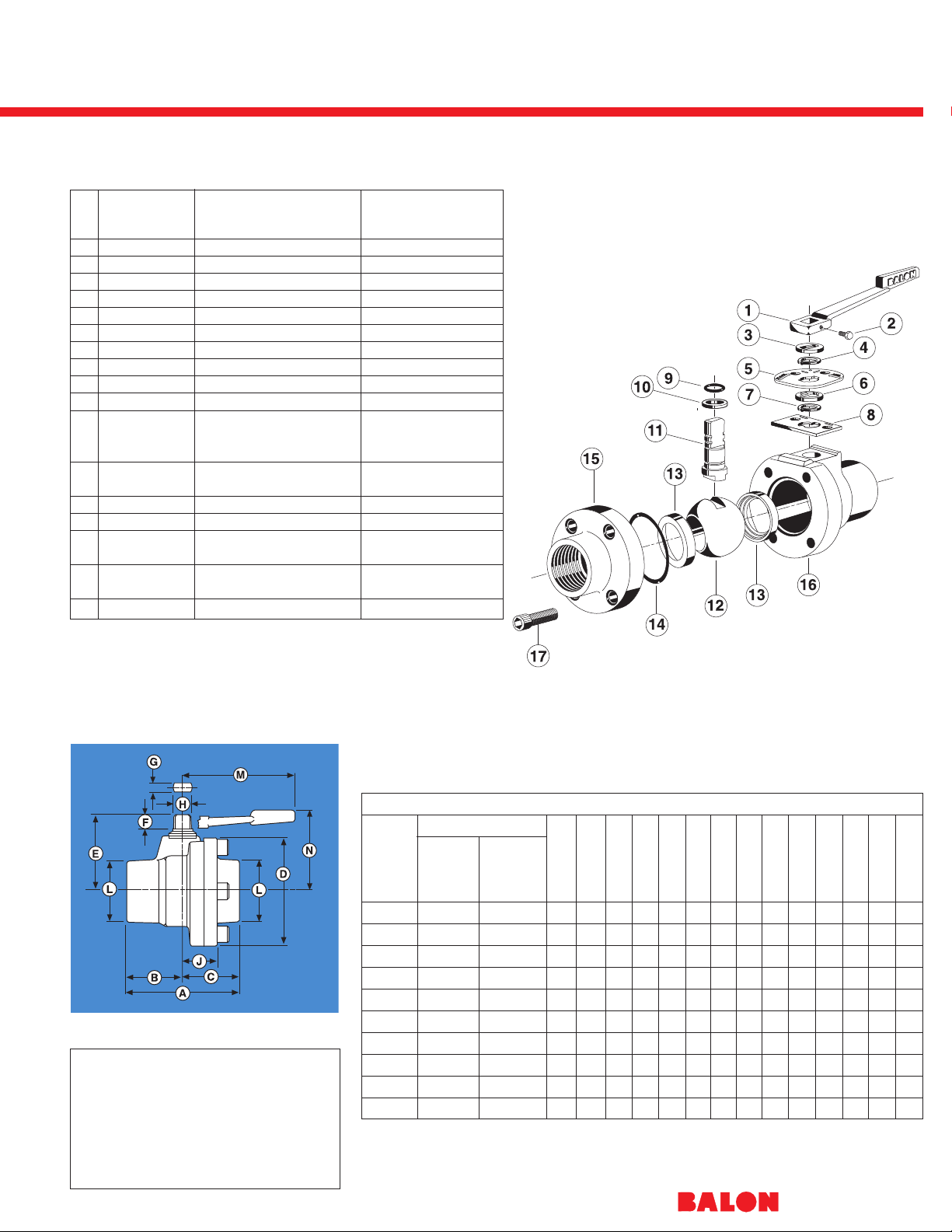

ITEM PART NAME

MATERIAL MATERIAL

(STANDARD) STAINLESS STEEL (NACE)

1 Handle* Ductile iron Ductile iron

2 Handle bolt Standard hex bolt Standard hex bolt

3 Weather guard Polyethylene Polyethylene

4 Lock plate retainer Carbon spring steel Carbon spring steel

5 Lock plate Carbon steel - zinc plated Carbon steel - zinc plated

6 Dust cover Polyethylene Polyethylene

7 Stop plate retainer Carbon spring steel Carbon spring steel

8 Stop plate Carbon steel zinc plated Carbon steel zinc plated

9 Stem O-ring Buna Fluorocarbon

10 Stem seal TFE TFE

11 Stem Carbon steel zinc plated AISI A-316

ASTM A311-79 Class B stainless steel annealed

ASTM A-276-316

12 Ball AISI 1018 nickel chrome plated ASTM A-743-CF8M/316

annealed stainless steel

13 Ball seat Nylon (TFE optional) Nylon (TFE optional)

14 Body O-ring Buna Fluorocarbon

15 End adapter ASTM-A395 class ASTM-A395 class

60-40-18 fully annealed 60-40-18 fully annealed

16 Body ASTM-A395 class ASTM-A395 class

60-40-18 fully annealed 60-40-18 fully annealed

17 Body bolts ANSI B18.3 ANSI/ASTM A574 ASTM A-193/B7M

Material Description

BALON SERIES “F” - DUCTILE IRON - SCREWED END - DIM. DATA

CAT. NO.

STANDARD TRIM NACE TRIM

SIZE

CARBON STEEL 316 STAINLESS

PORT WP A B C D E F G H J L M N

BALL & STEM STEEL BALL & STEM

1 x 1 x 1 1F-F92-SE 1F-F92N-SE 1 2000 37⁄8115⁄16115⁄1633⁄823⁄

8

1

⁄2.340 .685 11⁄817⁄843⁄82

2 x 11⁄

2

x 2 2R-F92-SE 2R-F92N-SE 11⁄22000 51⁄223⁄423⁄447⁄835⁄

8

3

⁄4.434 .873 15⁄83 71⁄45

2 x 2 x 2 2F-F62-SE 2F-F62N-SE 2 1500 53⁄427⁄827⁄861⁄843⁄

8

7

⁄8.497 .998 2 31⁄8101⁄453⁄

8

2 x 2 x 2 2F-F92-SE 2F-F92N-SE 2 2000 53⁄427⁄827⁄861⁄843⁄

8

7

⁄8.497 .998 2 31⁄8101⁄453⁄

8

21⁄2x 21⁄2 x 21⁄221⁄2F-F62-SE 21⁄2F-F62N-SE 21/21500 7 31⁄231⁄267⁄851⁄411⁄16.622 1.248 21⁄435⁄816 53⁄

4

3 x 2 x 3 3R-F62-SE 3R-F62N-SE 2 1500 71⁄435⁄835⁄863⁄443⁄

8

7

⁄8.497 .998 21⁄841⁄4101⁄453⁄

8

3 x 2 x 3 3R-F92-SE 3R-F92N-SE 2 2000 71⁄435⁄835⁄863⁄443⁄

8

7

⁄8.497 .998 21⁄841⁄4101⁄453⁄

8

3 x 3 x 3 3F-F42-SE 3F-F42N-SE 3 1000 81⁄841⁄1641⁄1673⁄453⁄411⁄16.747 1.373 21⁄241⁄420 63⁄

4

4 x 3 x 4 4R-F42-SE 4R-F42N-SE 3 1000 85⁄845⁄1645⁄1673⁄453⁄411⁄16.747 1.375 21⁄251⁄420 63⁄

4

4 x 4 x 4 4F-F32-SE 4F-F32N-SE 4 750 93⁄8411⁄16411⁄1691⁄463⁄811⁄16.747 1.375 31⁄855⁄820 73⁄

8

Dimensions

NACE CAPABILITY

Most Series F Carbon Steel and Ductile

Iron Valves can be provided to meet

NACE Standard MR-01-75, current revision, for Sulfide Stress Resistant Metallic

Material for Oil Field Equipment.

WP is for valve equipped with standard nylon seats. See Chart on Page 43 for TFE ratings.

Lever Operated

Bolted Construction

1" thru 4" to 2000 PSI WP

* Balon valves are designed to be operated

with a standard open-end wrench.

Handle and Handle Bolt are optional.

Series F Screwed End / Grooved End

®

16

The Balon Aluminum Bronze

Series F ball valve provides a

good alternative to higher

priced stainless steel valves,

particularly in CO2secondary

recovery applications.

Balon utilizes a 9D aluminum

bronze which has a higher

nickel content than other

aluminum bronze alloys such

as 9A, 9B, and 9C, thus pro-

viding much better corrosion

resistance.

A firesafe design, the Balon

aluminum bronze includes a

built-in locking device, bolted

construction, and 316 stainless

steel ball and stem, all as

standard features, and meets

NACE requirements.

Aluminum Bronze

®

17

ITEM PART NAME MATERIAL NACE (STANDARD)

1 Handle* Ductile iron

2 Handle bolt Standard hex bolt

3 Weather guard Polyethylene

4 Lock plate retainer Carbon spring steel

5 Lock plate Carbon steel - zinc plated

6 Dust cover Polyethylene

7 Stop plate retainer Carbon spring steel

8 Stop plate Carbon steel zinc plated

9 Stem O-ring Fluorocarbon

10 Stem seal TFE

11 Stem AISI A-316 stainless steel annealed ASTM A-276-316

12 Ball ASTM A-743 CF8M annealed stainless steel

13 Ball seat Nylon (TFE optional)

14 Body O-ring Fluorocarbon

15 End adapter ASTM B148-9D

16 Body ASTM B148-9D

17 Body bolts ASTM A-193/B7M

Material Description

BALON SERIES “F” - ALUMINUM BRONZE - SCREWED END - DIM. DATA

CATALOG

SIZE

NO.

PORT WP A B C D E F G H J L M N

NACE TRIM

316 SS STEEL

BALL & STEM

1 x 1 x 1 1F-F04N-SE 1 3000 37⁄8115⁄16115⁄1633⁄823⁄

8

1

⁄2.340 .685 11⁄817⁄843⁄82

2 x 11⁄

2

x 2 2R-F04N-SE 11⁄23000 51⁄223⁄423⁄447⁄835⁄

8

3

⁄4.434 .873 15⁄83 71⁄45

2 x 2 x 2 2F-F94N-SE 2 2000 53⁄427⁄827⁄861⁄843⁄

8

7

⁄8.497 .998 2 31⁄8101⁄453⁄

8

Dimensions

BALON SERIES “F” - ALUMINUM BRONZE - GROOVED END - DIM. DATA

CATALOG

SIZE

NO.

PORT WP A B C D E F G H J L M N

NACE TRIM

316 SS STEEL

BALL & STEM

2 x 11⁄2x 2 2R-F94N-GE 11⁄22000 51⁄223⁄423⁄447⁄835⁄

8

3

⁄4.497 .873 15⁄823⁄871⁄45

WP is for valve standard equipped with nylon seats. See Chart, page 43. TFE ratings.

Lever Operated

Bolted Construction

1" thru 2"

to 3000 PSI WP

* Balon valves are designed to be operated

with a standard open-end wrench.

Handle and Handle Bolt are optional.

Series F Flanged End

®

18

Balon Series F carbon steel

flanged end ball valves are

manufactured to meet the

most rigid industry standards

such as ANSI, API, MSS, etc.

All Balon flanged end

valves are two-piece bolted

construction, requiring no

lubrication, and are easily

field repairable. All have

built-in locking devices as

standard.

The Series F has been

successfully fire tested by an

independent laboratory to

meet API-6FA and BS-5655

firesafe standards.

Carbon Steel

®

BALON SERIES “F” - CARBON STEEL - FLANGED END - DIM. DATA

CAT. NO.

STANDARD TRIM NACE TRIM

SIZE

CARBON STEEL 316 STAINLESS

PORT A B C D E F G H J M N

BALL & STEM STEEL BALL & STEM

1 x 1 x 1 1F-F13 1F-F13N 1 5 2 3 33⁄823⁄

8

1

⁄20.340 0.685 11⁄1643⁄83

11⁄2x 11⁄2x 11⁄211⁄2F-F13 11⁄2F-F13N 11⁄261⁄223⁄433⁄45 35⁄

8

3

⁄40.434 0.873 11⁄271⁄45

2 x 11⁄2x 2 2R-F13 2R-F13N 11⁄27 23⁄441⁄45 35⁄

8

3

⁄40.434 0.873 11⁄271⁄45

2 x 2 x 2 2F-F13 2F-F13N 2 7 23⁄441⁄46 43⁄

8

7

⁄80.497 0.998 113⁄16101⁄453⁄

8

21⁄2x 21⁄2 x 21⁄221⁄2F-F13 21⁄2F-F13N 21/271⁄23 41⁄263⁄451⁄411⁄160.622 1.248 2 16 53⁄

4

3 x 2 x 3 3R-F13 3R-F13N 2 8 3 5 6 43⁄

8

7

⁄80.497 0.998 2 101⁄453⁄

8

3 x 3 x 3* 3F-F13 3F-F13N 3 8 25⁄853⁄871⁄253⁄411⁄160.747 1.373 23⁄820 63⁄

4

4 x 3 x 4 4R-F13 4R-F13N 3 9 31⁄251⁄277⁄853⁄411⁄160.747 1.373 27⁄1620 63⁄

4

4 x 4 x 4** 4F-F13 4F-F13N 4 9 31⁄453⁄49 63⁄811⁄160.747 1.373 27⁄820 73⁄

8

6 x 4 x 6 6R-F13 6R-F13N 4 101⁄243⁄453⁄493⁄863⁄811⁄160.747 1.373 3 20 73⁄

8

(For larger sizes, see page 25.)

19

ITEM PART NAME

MATERIAL MATERIAL STAINLESS

(STANDARD) STEEL (NACE)

1 Handle* Ductile iron Ductile iron

2 Handle bolt Standard hex bolt Standard hex bolt

3 Weather guard Polyethylene Polyethylene

4 Lock plate retainer Carbon spring steel Carbon spring steel

5 Lock plate Carbon steel - zinc plated Carbon steel - zinc plated

6 Dust cover Polyethylene Polyethylene

7 Stop plate retainer Carbon spring steel Carbon spring steel

8 Stop plate Carbon steel zinc plated Carbon steel zinc plated

9 Stem O-ring Buna Fluorocarbon

10 Stem seal TFE TFE

11 Stem Carbon steel zinc plated ASTM A-316

ASTM A311-79 Class B stainless steel annealed

ASTM A-276-316

12 Ball AISI 1018 nickel chrome plated ASTM A-743-CF8M/316

annealed stainless steel

13 Ball seat Nylon (TFE optional) Nylon (TFE optional)

14 Body O-ring Buna Fluorocarbon

15 End adapter ASTM 216 grade WCB annealed ASTM 216 grade WCB annealed

carbon steel carbon steel

16 Body ASTM 216 grade WCB annealed ASTM 216 grade WCB annealed

carbon steel carbon steel

17 Body stud nuts ASTM A-194 ASME SA 194 2H ASTM A-194 2HM

18 Body stud bolts ASTM A-193 ASME SA-193 B-7 ASTM A-193 B-7M

19 Body bolts ANSI B18.3 ANSI/ASTM A574 ASTM A-193/B7M

Material Description

WP is for valve equipped with standard nylon seats. See Chart on page 43 for TFE ratings.

* Balon valves are designed to be operated

with a standard open-end wrench.

Handle and Handle Bolt are optional.

Dimensions

Lever Operated

ANSI Class 150

285 PSI W.P.

* Flange tapped one end for four -

5

⁄8 - 11 x 2 cap screws or four -

5

⁄8 - 11 x 2 3⁄4 studs.

** Flange tapped one end for eight -

5

⁄8 - 11 x 2 cap screws or eight -

5

⁄8 - 11 x 2 3⁄4 studs.

Most Series F Flanged end valves are available for low temperature service. Consult

factory for price and availability.

All Series F available with 316 SS and NACE.

Series F Flanged End Carbon Steel

®

BALON SERIES “F” - CARBON STEEL - FLANGED END - DIM. DATA

CAT. NO.

STANDARD TRIM NACE TRIM

SIZE

CARBON STEEL 316 STAINLESS

PORT A B C D E F G H J M N

BALL & STEM STEEL BALL & STEM

2 x 11⁄2x 2 2R-F33 2R-F33N 11⁄281⁄233⁄443⁄45 35⁄

8

3

⁄4.434 .873 15⁄871⁄45

2 x 2 x 2 2F-F33 2F-F33N 2 81⁄233⁄443⁄461⁄243⁄

8

7

⁄8.497 .998 17⁄8101⁄453⁄

8

3 x 2 x 3 3R-F33 3R-F33N 2 111⁄843⁄463⁄861⁄243⁄

8

7

⁄8.497 .998 21⁄8101⁄453⁄

8

3 x 3 x 3 3F-F33 3F-F33N 3 111⁄845⁄861⁄28 53⁄411⁄16.747 1.373 21⁄220 63⁄

4

4 x 3 x 4 4R-F33 4R-F33N 3 12 5 7 8 53⁄411⁄16.747 1.373 25⁄820 63⁄

4

4 x 4 x 4 4F-F33 4F-F33N 4 12 51⁄867⁄893⁄863⁄811⁄16.747 1.373 31⁄820 73⁄

8

6 x 4 x 6 6R-F33 6R-F33N 4 157⁄86 97⁄810 63⁄811⁄16.747 1.373 33⁄820 73⁄

8

(For larger sizes, see page 25.)

20

WP is for valve equipped with standard nylon seats. See Chart on page 43 for TFE ratings.

Dimensions

Lever Operated

ANSI Class 300

740 PSI W.P.

Most Series F Flanged end valves are available for low temperature service. Consult

factory for price and availability.

All Series F available with 316 SS and NACE.

* Balon valves are designed to be operated

with a standard open-end wrench.

Handle and Handle Bolt are optional.

ITEM PART NAME MATERIAL (STANDARD) MATERIAL (NACE)

1 Handle* Ductile iron Ductile iron

2 Handle bolt Standard hex bolt Standard hex bolt

3 Weather guard Polyethylene Polyethylene

4 Lock plate retainer Carbon spring steel Carbon spring steel

5 Lock plate Carbon steel - zinc plated Carbon steel - zinc plated

6 Dust cover Polyethylene Polyethylene

7 Stop plate retainer Carbon spring steel Carbon spring steel

8 Stop plate Carbon steel zinc plated Carbon steel zinc plated

9 Stem O-ring Buna Fluorocarbon

10 Stem seal TFE TFE

11 Stem Carbon steel zinc plated AISI A-316

ASTM A311-79 Class B stainless steel annealed

ASTM A-276-316

12 Ball AISI 1018 nickel chrome plated ASTM A-743-CF8M/316

annealed stainless steel

13 Ball seat Nylon (TFE optional) Nylon (TFE optional)

14 Body O-ring Buna Fluorocarbon

15 End adapter ASTM 216 grade WCB annealed ASTM 216 grade WCB annealed

carbon steel carbon steel

16 Body ASTM 216 grade WCB annealed ASTM 216 WCB annealed

carbon steel carbon steel

17 Body stud nuts ASTM A-194 ASME SA 194 2H ASTM A-194 2HM

18 Body stud bolts ASTM A-193 ASME SA-193 B-7 ASTM A-193 B-7M

19 Body bolts ANSI B18.3 ANSI/ASTM A574 ASTM A-193/B7M

Material Description

Series F Flanged End Carbon Steel

®

21

ITEM PART NAME MATERIAL (STANDARD) MATERIAL (NACE)

1 Handle* Ductile iron Ductile iron

2 Handle bolt Standard hex bolt Standard hex bolt

3 Weather guard Polyethylene Polyethylene

4 Lock plate retainer Carbon spring steel Carbon spring steel

5 Lock plate Carbon steel - zinc plated Carbon steel - zinc plated

6 Dust cover Polyethylene Polyethylene

7 Stop plate retainer Carbon spring steel Carbon spring steel

8 Stop plate Carbon steel zinc plated Carbon steel zinc plated

9 Stem O-ring Buna Fluorocarbon

10 Stem seal TFE TFE

11 Stem Carbon steel zinc plated AISI A-316

ASTM A311-79 Class B stainless steel annealed

ASTM A-276-316

12 Ball AISI 1018 nickel chrome plated ASTM A-743-CF8M/316

annealed stainless steel

13 Ball seat Nylon (TFE optional) Nylon (TFE optional)

14 Body O-ring Buna Fluorocarbon

15 End adapter ASTM 216 grade WCB annealed ASTM 216 grade WCB annealed

carbon steel carbon steel

16 Body ASTM 216 grade WCB annealed ASTM 216 WCB annealed

carbon steel carbon steel

17 Body stud nuts ASTM A-194 ASME SA 194 2H ASTM A-194 2HM

18 Body stud bolts ASTM A-193 ASME SA-193 B-7 ASTM A-193 B-7M

19 Body bolts ANSI B18.3 ANSI/ASTM A574 ASTM A-193/B7M

Material Description

BALON SERIES “F” - CARBON STEEL - FLANGED END - DIM. DATA

CAT. NO.

STANDARD NACE TRIM

SIZE TRIM 316 STAINLESS PORT A B C D E F G H J M N

CARBON STEEL STEEL

RF RTJ RF RTJ RF RTJ

BALL & STEM BALL & STEM

1x1x1 1F-F63 1F-F63N 1 81⁄281⁄2311⁄16311⁄1647⁄847⁄833⁄823⁄

8

1

⁄20.340 0.685 11⁄1643⁄83

11⁄2x11⁄2x11⁄211⁄2F-F63 11⁄2F-F63N 11⁄291⁄291⁄241⁄1641⁄1657⁄1657⁄1653⁄835⁄

8

3

⁄40.434 0.873 13⁄471⁄45

2x11⁄2x2 2R-F63 2R-F63N 11⁄2111⁄2115⁄851⁄1651⁄867⁄1661⁄253⁄835⁄

8

3

⁄40.434 0.873 13⁄471⁄45

2x2x2 2F-F63 2F-F63N 2 111⁄2115⁄843⁄4413⁄1663⁄4613⁄1661⁄243⁄

8

7

⁄80.497 0.998 21⁄8101⁄453⁄

8

21⁄2x21⁄2x21⁄221⁄2F-F63 21⁄2F-F63N 21⁄213 131⁄8513⁄1657⁄873⁄1671⁄471⁄251⁄411⁄160.622 1.248 23⁄816 53⁄

4

3x2x3 3R-F63 3R-F63N 2 14 141⁄853⁄4513⁄1681⁄485⁄1665⁄843⁄

8

7

⁄80.497 0.998 21⁄4101⁄463⁄

4

3x3x3 3F-F63 3F-F63N 3 14 141⁄851⁄259⁄1681⁄289⁄168 53⁄411⁄160.747 1.373 23⁄420 63⁄

4

4x3x4 4R-F63 4R-F63N 3 17 171⁄867⁄8615⁄16101⁄8103⁄1685⁄853⁄411⁄160.747 1.373 27⁄820 63⁄

4

*(For larger sizes, see page 25.)

Dimensions

WP is for valve equipped with standard nylon seats. See Chart on page 43 TFE ratings.

Lever Operated

ANSI Class 600

1480 PSI W.P.

Note: Specify RF for raised face; RTJ for ring type joint when ordering. All ANSI 600 class valves available for low temp

service. Consult factory for price and availability.

Most Series F Flanged end valves are available for low temperature service. Consult

factory for price and availability.

All Series F available with 316 SS and NACE.

* Balon valves are designed to be operated

with a standard open-end wrench.

Handle and Handle Bolt are optional.

Series F Flanged End Carbon Steel

®

22

* Balon valves are designed to be operated with a standard

open-end wrench.

Handle and Handle Bolt are optional.

** Nylon Seats standard 900 Class, Acetal Seats

standard 1500 Class.

ITEM PART NAME MATERIAL (STANDARD) MATERIAL (NACE)

1 Handle* Ductile iron Ductile iron

2 Handle bolt Standard hex bolt Standard hex bolt

3 Weather guard Polyethylene Polyethylene

4 Lock plate retainer Carbon spring steel Carbon spring steel

5 Lock plate Carbon steel - zinc plated Carbon steel - zinc plated

6 Dust cover Polyethylene Polyethylene

7 Stop plate retainer Carbon spring steel Carbon spring steel

8 Stop plate Carbon steel zinc plated Carbon steel zinc plated

9 Stem O-ring Buna Fluorocarbon

10 Stem seal TFE TFE

11 Stem Carbon steel zinc plated AISI A-316

ASTM A311-79 Class B stainless steel annealed

ASTM A-276-316

12 Ball AISI 1018 nickel chrome plated ASTM A-743-CF8M/316

annealed stainless steel

13 Ball seat ** Acetal — Nylon Acetal — Nylon

14 Body O-ring Buna Fluorocarbon

15 End adapter ASTM 216 grade WCB annealed ASTM 216 grade WCB annealed

carbon steel carbon steel

16 Body ASTM 216 grade WCB annealed ASTM 216 WCB annealed

carbon steel carbon steel

17 Body stud nuts ASTM A-194 ASME SA 194 2H ASTM A-194 2HM

18 Body stud bolts ASTM A-193 ASME SA-193 B-7 ASTM A-193 B-7M

19 Body bolts ANSI B18.3 ANSI/ASTM A574 ASTM A-193/B7M

Material Description

1500 ANSI - SERIES “F” BALON BALL VALVE - DIM. DATA ANSI 3705 W.P.

CAT. NO.

STANDARD NACE TRIM

SIZE TRIM 316 STAINLESS PORT A B C D E F G H J M N

CARBON STEEL STEEL

RF RTJ RF RTJ RF RTJ

1x1x1 1F-F03 1F-F03N 1 10 10 43⁄843⁄855⁄855⁄841⁄423⁄

8

1

⁄20.340 0.685 11⁄443⁄83

2x11⁄2x2 2R-F03 2R-F03N 11⁄2141⁄2145⁄865⁄1663⁄883⁄1681⁄461⁄435⁄

8

3

⁄40.434 0.873 115⁄1671⁄45

900 ANSI - SERIES “F” BALON BALL VALVE - DIM. DATA ANSI 2220 W.P.

CAT. NO.

STANDARD NACE TRIM

SIZE TRIM 316 STAINLESS PORT A B C D E F G H J M N

CARBON STEEL STEEL

RF RTJ RF RTJ RF RTJ

1x1x1 1F-F93 1F-F93N 1 10 10 43⁄843⁄855⁄855⁄841⁄423⁄

8

1

⁄20.340 0.685 11⁄443⁄83

2x11⁄2x2 2R-F93 2R-F93N 11⁄2141⁄2145⁄865⁄1663⁄883⁄1681⁄461⁄435⁄

8

3

⁄40.434 0.873 115⁄1671⁄45

2x2x2 2F-F93 2F-F93N 2 141⁄2145⁄86 61⁄1681⁄289⁄167 43⁄

8

7

⁄80.497 0.998 21⁄4101⁄453⁄

8

3x2x3 3R-F93 3R-F93N 2 15 151⁄861⁄465⁄1683⁄4813⁄167 43⁄

8

7

⁄80.497 0.998 21⁄4101⁄463⁄

4

Dimensions

Lever Operated

ANSI Class 900

2220 PSI W.P.

ANSI Class 1500

3705 PSI W.P.

Note: Specify RF for raised face; RTJ for ring type joint when ordering.

Most Series F Flanged end valves are available for low temperature service. Consult

factory for price and availability.

All Series F available with 316 SS and NACE.

Balon Installations

®

23

Series F Flanged End

®

24

The Balon design and advanced

manufacturing methods have

allowed us to provide an easy

operating, low maintenance,

and lower cost alternative to

the more expensive and

trouble-prone trunnion type

ball valves.

In keeping with our emphasis

on personnel safety, our 4” full

bore and larger ANSI 600 class

and our 6” full bore and larger

ANSI 150 and 300 class

valves are equipped with

gear operators as standard.

This eliminates the need for

extremely long operating

handles which can be a

significant hazard to operating

personnel both offshore

and onshore.

These gear operated valves are

firesafe, require no lubrication,

and are standard with 316

stainless steel ball and stem.

All meet NACE requirements.

Dimensions

Carbon Steel

®

25

ITEM PART NAME MATERIAL (NACE)

1 Gear Operator

2 Hand Wheel

3 Drive Pin

4 Gear Box Adapt. Plate ASTM A536-72 ductile iron A395-74 class 60-40-18

5 Stem Key Steel key stock

6 Stem Retainer Ring Carbon spring steel

7 Mounting Plate ASTM A536-72 ductile iron A395-74 class 60-40-18

8 Gear Box Mtg. Screws ANSI B18.3 82 button head cap screw

9 Mtg. Plate Screws ANSI B18.3 82 SHCS modified

10 Lock Washers ANSI B27.1 zinc plated internal tooth

11 Mounting Screws ANSI B18.3 SHCS

12 Stem O-ring Fluorocarbon

13 Stem seal TFE

14 Stem AISI A-316 stainless steel annealed ASTM A276-316

15 End Adapter ASTM 216 grade WCB annealed carbon steel

16 Body ASTM 216 grade WCB annealed carbon steel

17 Body O-ring Fluorocarbon

18 Ball Seats * Nylon (Acetal optional)

19 Ball ASTM A-743-CF8M/316 annealed stainless steel

20 Body Stud Bolts ASTM A193 B-7M

21 Body Stud Nuts ASTM A194 2HM

Material Description

Above valves sold standard with 316 SS trim (NACE) and gear operated with hand wheel.

* Ball Seats Acetal standard 6" full 600 (6F-F63N).

BALON SERIES “F” GEAR OPERATED BALL VALVE DIM. DATA

ANSI CAT. NO. A B

CLASS SIZE PORT NACE TRIM WP RF RJ RF RJ C D E F G

316 SS STEEL

BALL & STEM

150 6x6x6 6 6F-F13N* 285 101⁄2NA 41⁄

2

NA 33⁄

8

93⁄414 91⁄21111⁄

16

150 8x6x8 6 8R-F13N 285 111⁄2NA 51⁄

8

NA 33⁄

8

93⁄414 91⁄21111⁄

16

150 8x8x8 8 8F-F13N 285 18 NA 8 NA 5 12 18 13 14

150 10x8x10 8 10R-F13N 285 21 NA 9 NA 5 12 18 13 14

300 6x6x6 6 6F-F33N 740 15

7

⁄8NA 65⁄

8

NA 43⁄

8

97⁄814 91⁄

4

12

300 8x6x8 6 8R-F33N 740 161⁄2NA 71⁄

2

NA 43⁄

8

97⁄814 91⁄

4

12

600 4x4x4 4 4F-F63N** 1480 17 171⁄873⁄

8

77⁄

16

3 81⁄1612 101⁄4101⁄

8

600 6x4x6 4 6R-F63N** 1480 22 221⁄893⁄

16

91⁄

4

3 81⁄1612 101⁄4101⁄

8

600 6x6x6 6 6F-F63N** 1480 22 221⁄885⁄8811⁄1641⁄

2

10 18 11 12

600 8x6x8 6 8R-F63N** 1480 26 261⁄8105⁄81011⁄1641⁄

2

10 18 11 12

Gear Operated

Bolted Construction

ANSI Class 150

285 PSI W.P.

ANSI Class 300

740 PSI W.P.

ANSI Class 600

1480 PSI W.P.

Note: Gear operator available with locking flange.

Consult factory.

*Flange tapped one end for eight 3⁄4”- 10 x 21⁄2cap

screws or eight 3⁄4”- 10 x 3 studs.

**Specify RF for raised face; RTJ for ring type joint when

ordering.

Most Series F Flanged end valves are available for low temperature service. Consult

factory for price and availability.

Note: Above valves sold standard with 316 SS trim (NACE) and gear operated.

Series F Flanged End

®

26

Designed to eliminate the high

maintenance lubricated plug

and ball valves. Made of high

grade ductile iron, the Series

“F” needs no lubrication and is

maintenance free.

While priced competitively to

the lubricated valves, the

Series “F” comes standard

with Multi-Seal seats, non

adjustable stem sealing,

internal twin stops, safety

shear groove, built-in lock-

ing device and more.

The Series “F” Ductile Iron

Flanged end valves are avail-

able to meet NACE MR-0175,

current revision, and can be

provided with either flat-faced

or raised-face configurations.

Ductile Iron

®

27

Material Description

ITEM PART NAME MATERIAL DESCRIPTION MATERIAL DESCRIPTION (NACE)

1 Handle* Ductile iron Ductile iron

2 Handle bolt Standard hex bolt Standard hex bolt

3 Weather Guard Polyethylene Polyethylene

4 Lock plate retainer Carbon spring steel Carbon spring steel

5 Lock plate Carbon steel - zinc plated Carbon steel - zinc plated

6 Dust cover Polyethylene Polyethylene

7 Stop plate retainer Carbon spring steel Carbon spring steel

8 Stop plate Carbon steel zinc plated Carbon steel zinc plated

9 Stem O-ring Buna Fluorocarbon

10 Stem seal TFE TFE

11 Stem Carbon steel zinc plated AISI A-316 stainless steel

ASTM A311-79 Class B annealed ASTM A-276-316

12 Ball AISI 1018 nickel ASTM A-743-CF8M/316 annealed

chrome plated stainless steel

13 Ball seat Nylon (TFE optional) Nylon (TFE optional)

14 Body O-ring Buna Fluorocarbon

15 End adapter ASTM A395 class ASTM A395 class 60-40-18

60-40-18 fully annealed fully annealed

16 Body ASTM A395 class ASTM A395 class

60-40-18 fully annealed 60-40-18 fully annealed

* Balon valves are designed to be operated

with a standard open-end wrench.

Handle and Handle Bolt are optional.

Lever Operated

2" - 6"

ANSI Class 125

Flat Face 200 PSI W.P.

ANSI Class 150

Raised Face 250 PSI W.P.

ANSI Class 300

Raised Face 640 PSI W.P.

Dimensions

BALON SERIES “F” LEVER OPERATED BALL VALVE DIM. DATA

STANDARD NACE TRIM

WP

SIZE

TRIM 316 STAINLESS

PORT CLASS 125 FLAT FACE (FF) A B C E F G H M NCV

CARBON STEEL STEEL

CLASS 150 RAISED FACE (RF)

BALL & STEM BALL & STEM

2x11⁄2x2 2R-F12 2R-F12N 11⁄

2

FF 200 7 23⁄441⁄435⁄

8

3

⁄4.434 .873 7 1/4 5 159

RF 250

3x2x3 3R-F12 3R-F12N 2 FF 200 8 3 5 4

3

⁄

8

3

⁄4.497 .998 101⁄453⁄8263

RF 250

4x3x4 4R-F12 4R-F12N 3 FF 200 9 3

3

⁄855⁄853⁄

4

7

⁄8.747 1.373 20 63⁄4744

RF 250

6x4x6 6R-F12 6R-F12N 4 FF 200 10

1

⁄2313⁄16611⁄1663⁄

8

7

⁄8.747 1.373 20 73⁄8868

RF 250

WP

CLASS 300 RAISED FACE (RF)

2x11⁄2x2 2R-F32 2R-F32N 11⁄

2

RF 640 81⁄223⁄453⁄435⁄

8

3

⁄4.434 .873 7 1/4 5 171

3x2x3 3R-F32 3R-F32N 2 RF 640 11

1

⁄

8

3 8

1

⁄843⁄

8

3

⁄4.497 .998 101⁄453⁄8290

4X3X4 4R-F32 4R-F32N 3 RF 640 12

3

3

⁄

8

8

5

⁄853⁄

4

7

⁄8.747 1.373 20 63⁄4814

All Series F available with 316 SS and NACE.

WP is for valve equipped with standard nylon seats. See Chart on page 43 for TFE ratings.

Series US Weld X Weld

®

28

The Series US weld end ball

valve provides a stronger,

more durable, easier operating

and a better sealing valve that

is dramatically superior to oth-

ers on the market.

General Features

■ Heat dissipating fins

provide an extra margin of

protection for the resilient

seats and seals by

dissipating the heat

imposed during the final

welding process.

■ MULTI-SEAL grooved and

tapered seats provide

tighter sealing and easier

operation at high and low

operating pressures.

■ Heavy duty stainless steel

3/8" diameter stops.

■ Heavy Duty forged steel

components.

■ Solid balls which have a

straight through flow path

instead of being concave

or hollow, thus reducing

turbulence and pressure

drop.

Carbon Steel

®

29

ITEM PART NAME MATERIAL DESCRIPTION

1 Body ASTM A105

2 Adapter ASTM A105

3 Ball Carbon steel – nickel chrome plated

4 Seats Nylon

5 Stem 316 stainless steel

6 Body O-ring Buna-N

7 Stem O-ring Buna-N

8 Stem seal TFE

9 Lock plate Stainless steel

10 Weather seal Rubber

11 Roll pin Stainless steel

12 Stop pin Stainless steel

13 Drive nut, 2" square Ductile iron

Material Description

E

F

A

PORT

E

D

C

B

* Equal to equivalent length of pipe.

1

2

3

4

2

6

6

4

5

8

7

13

11

10

9

12

Patented

BALON SERIES “US” WELD X WELD END BALON BALL VALVE - DIM. DATA CLASS 150 - WP 285 PSI

SIZE A B C D E F Cv CAT. NO.

PORT

2 x 11⁄2x 2 11⁄

2

11.8 5 35⁄

8

2 41⁄

2

148 2R-US13-BW

2 x 2 x 2 2 11.8 51⁄

2

41⁄

2

2 41⁄

2

* 2F-US13-BW

3 x 21⁄2x 3 21⁄

2

11.8 61⁄

8

51⁄

4

2 41⁄

2

550 3R-US13-BW

3 x 3 x 3 3 11.8 63⁄

4

61⁄

4

2 41⁄

2

* 3F-US13-BW

4 X 3 X 4 3 12.8 63⁄

4

61⁄

4

2 41⁄

2

662 4R-US13-BW

4 X 4 X 4 4 12.8 71⁄

2

67⁄

8

2 41⁄

2

* 4F-US13-BW

6 X 4 X 6 4 13.8 71⁄

2

67⁄

8

2 41⁄

2

800 6R-US13-BW

BALON SERIES “US” WELD X WELD END BALON BALL VALVE - DIM. DATA CLASS 300 - WP 740 PSI

SIZE A B C D E F Cv CAT. NO.

PORT

2 x 11⁄2x 2 11⁄

2

11.8 5 35⁄

8

2 41⁄

2

148 2R-US33-BW

2 x 2 x 2 2 11.8 51⁄

2

41⁄

2

2 41⁄

2

* 2F-US33-BW

3 x 21⁄2x 3 21⁄

2

11.8 61⁄

8

51⁄

4

2 41⁄

2

550 3R-US33-BW

3 x 3 x 3 3 11.8 63⁄

4

61⁄

4

2 41⁄

2

* 3F-US33-BW

4 X 3 X 4 3 12.8 63⁄

4

61⁄

4

2 41⁄

2

662 4R-US33-BW

4 X 4 X 4 4 12.8 71⁄

2

67⁄

8

2 41⁄

2

* 4F-US33-BW

6 X 4 X 6 4 13.8 71⁄

2

67⁄

8

2 41⁄

2

800 6R-US33-BW

NOTE: Valve is seal welded and is not repairable.

Series US Weld X Flange

®

30

To broaden the user benefits

of the Series US, Balon has

added the weld-by-flange

configuration to the weld-by-

weld line of the series. The

weld-by-flange valve adds sig-

nificant versatility to the Series

US, and mirrors the same

worthwhile and meaningful

features of the weld-by-weld

line such as:

■ Heat dissipating fins

on the weld end side of the

valve for convenient and

safe field welding.

■ Balon's thirty-six year

performance record with its

special grooved and

tapered MULTI-SEAL seat

design.

■ Rugged stainless steel

3/8" diameter stops.

■ Balls which, because they

are solid instead of hollow,

provide a straight-through

flow path, thus assuring

reduced turbulence and

pressure drop across the

valve.

Carbon Steel

®

31

ITEM PART NAME MATERIAL DESCRIPTION

1 Body ASTM A105

2 Adapter ASTM A105

3 Ball Carbon Steel – nickel chrome plated

4 Seats Nylon

5 Stem 316 Stainless steel

6 Body O-ring Buna-N

7 Stem O-ring Buna-N

8 Stem seal TFE

9 Lock plate Stainless steel

10 Weather seal Rubber

11 Roll pin Stainless steel

12 Stop pin Stainless steel

13 Drive nut, 2" square Ductile iron

Material Description

A

PORT

F

C

B

E

D

F

G

* Equal to equivalent length of pipe.

1

2

3

4

2

6

6

4

5

8

7

13

11

10

9

12

Patented

BALON SERIES “US” WELD X FLANGE END BALON BALL VALVE - DIM. DATA CLASS 150 - WP 285 PSI

SIZE A B C D E F G Cv CAT. NO.

PORT

2 x 11⁄2x 2 11⁄

2

9.4 5.9 5 6 2 41⁄

2

148 2R-US13-WF

2 x 2 x 2 2 10.0 5.9 51⁄

2

624

1

⁄

2

* 2F-US13-WF

3 x 21⁄2x 3 21⁄

2

9.9 5.9 61⁄

8

71⁄

2

24

1

⁄

2

550 3R-US13-WF

3 x 3 x 3 3 11.3 5.9 63⁄

4

71⁄

2

24

1

⁄

2

* 3F-US13-WF

4 X 3 X 4 3 10.9 6.4 63⁄

4

924

1

⁄

2

662 4R-US13-WF

4 X 4 X 4 4 12.1 6.4 71⁄

2

924

1

⁄

2

* 4F-US13-WF

BALON SERIES “US” WELD X FLANGE END BALON BALL VALVE - DIM. DATA CLASS 300 - WP 740 PSI

SIZE A B C D E F G Cv CAT. NO.

PORT

2 x 11⁄2x 2 11⁄

2

10.15 5.9 5 61⁄

2

24

1

⁄

2

148 2R-US33-WF

2 x 2 x 2 2 10.2 5.9 51⁄

2

61⁄

2

24

1

⁄

2

* 2F-US33-WF

3 x 21⁄2x 3 21⁄

2

11.46 5.9 61⁄

8

81⁄

4

24

1

⁄

2

550 3R-US33-WF

3 x 3 x 3 3 11.5 5.9 63⁄

4

81⁄

4

24

1

⁄

2

* 3F-US33-WF

4 X 3 X 4 3 12.4 6.4 63⁄

4

10 2 41⁄

2

662 4R-US33-WF

4 X 4 X 4 4 12.4 6.4 71⁄

2

10 2 41⁄

2

* 4F-US33-WF

NOTE: Valve is seal welded and is not repairable.

Series S Screwed End / Grooved End / UNI-directional Screwed End

®

32

Designed originally to

accommodate the intermediate

pressures in the oil and gas

industry, the popularity of the

Series S has resulted in a

continued extension of sizes,

pressures, and materials.

The Series S is available in

Balon ductile iron in pressures

from 500 psi to 2000 psi, and

in carbon steel and stainless

steel in pressures to 3000 psi.

All have built-in locking

devices and, unlike others on

the market, require no lubrica-

tion for the life of the valve.

UNI-directional modification

for tank draw-down service.

While no design can prevent a

valve from freezing, Balon has

introduced a new UNI-directional

modification which reduces

the likelihood that a temporary

freeze will result in permanent

damage to the valve. This

design modification incorpo-

rates a relief hole in the

upstream side of the closed

ball. When water trapped

inside the ball cavity freezes

and expands, the relief hole

allows dissipation of the

increased internal pressure.

As shown in the diagram

on the following

page, the addition of the relief

hole renders the valve

unidirectional with the body

side of the valve positioned

upstream for proper sealing

and operation. Balon’s new

UNI-directional modification is

available as an option

within the Series S

valve line.

Ductile Iron

®

33

ITEM PART NAME MATERIAL MATERIAL STAINLESS STEEL

(STANDARD) (NACE)

1 *Handle Ductile iron Ductile iron

2 Handle bolt Standard hex bolt Standard hex bolt

3 Weather guard Polyethylene Polyethylene

4 Lock plate retainer Carbon spring steel Carbon spring steel

5 Lock plate Carbon steel - zinc plated Carbon steel - zinc plated

6 Dust cover Polyethylene Polyethylene

7 Stop plate retainer Carbon spring steel Carbon spring steel

8 Stop plate Carbon steel zinc plated Carbon steel zinc plated

9 Stem O-ring Buna Fluorocarbon

10 Stem seal TFE TFE

11 Stem Carbon steel zinc plated AISI A-316 stainless steel

ASTM A311-79 Class B annealed ASTM A-276-316

12 Ball AISI 1018 nickel chrome plated ASTM A-743-CF8M/316

annealed stainless steel

13 Ball seat Nylon (TFE optional) Nylon (TFE optional)

14 Body O-ring Buna Fluorocarbon

15 End adapter ASTM A395 class 60-40-18 ASTM A395 class 60-40-18

fully annealed fully annealed

16 Body ASTM A395 class 60-40-18 ASTM A395 class 60-40-18

fully annealed fully annealed

Material Description

RELIEF HOLE, UPSTREAM

WHEN VALVE IS CLOSED

FLOW INDICATOR FOR

UNI-DIRECTIONAL VALVES ONLY

UNI-DIRECTIONAL VALVE

Lever Operated

Threaded Construction

1" thru 4"

To 2000 PSI WP

All Series S available with 316 SS and NACE.

* This reduced port valve has a 21⁄2" bore for increased flow.

BALON SERIES “S” SCREWED END - DIM. DATA

CAT. NO.

STANDARD TRIM NACE TRIM

SIZE CARBON STEEL 316 STAINLESS PORT WP A B C D E F G H L LL M N

BALL & STEM STEEL BALL & STEM

1x1x1 1F-S62-SE 1F-S62N-SE 1 1500 3

7

⁄

8

1

15

⁄

16

1

15

⁄

16

2

1

⁄

4

2

3

⁄

8

1

⁄

2

0.340 0.685 1

7

⁄

8

2 4

3

⁄

8

2

1x1x1 1F-S92-SE 1F-S92N-SE 1 2000 4 2 2 2

1

⁄

2

2

3

⁄

8

1

⁄

2

.0.340 0.685 2

1

⁄

16

2 4

3

⁄

8

2

1x1x1 1F-S42-SE 1F-S42N-SE 1 1000 3

7

⁄

8

1

15

⁄

16

1

15

⁄

16

2

1

⁄

4

2

3

⁄

8

1

⁄

2

0.340 0.685 1

7

⁄

8

2 4

3

⁄

8

2

2x1

1

⁄

2

x2 2R-S62-SE 2R-S62N-SE 1

1

⁄

2

1500 5

1

⁄

4

2

5

⁄

8

2

5

⁄

8

3

3

⁄

8

3

5

⁄

8

3

⁄

4

0.434 0.873 3 3 7

1

⁄

4

5

2x1

1

⁄

2

x2 2R-S92-SE 2R-S92N-SE 1

1

⁄

2

2000 5

1

⁄

2

2

3

⁄

4

2

3

⁄

4

3

3

⁄

4

3

5

⁄

8

3

⁄

4

0.434 0.873 3

1

⁄

4

3

1

⁄

4

7

1

⁄

4

5

2x1

1

⁄

2

x2 2R-S42-SE 2R-S42N-SE 1

1

⁄

2

1000 5

1

⁄

4

2

5

⁄

8

2

5

⁄

8

3

3

⁄

8

3

5

⁄

8

3

⁄

4

0.434 0.873 3 3 7

1

⁄

4

5

2x1

1

⁄

2

x2 2R-S32-SE 2R-S32N-SE 1

1

⁄

2

750 5

1

⁄

4

2

5

⁄

8

2

5

⁄

8

3

3

⁄

8

3

5

⁄

8

5

⁄

8

0.434 0.873 3

1

⁄

8

3

1

⁄

8

7

1

⁄

4

5

2x2x2 2F-S32-SE 2F-S32N-SE 2 750 5

3

⁄

4

2

7

⁄

8

2

7

⁄

8

4

1

⁄

4

4

3

⁄

8

3

⁄

4

0.497 0.998 3 3 10

1

⁄

4

5

3

⁄

8

2x2x2 2F-S62-SE 2F-S62N-SE 2 1500 6 3 3 4

3

⁄

4

4

3

⁄

8

3

⁄

4

0.497 0.998 3

3

⁄

4

3

3

⁄

4

10

1

⁄

4

5

3

⁄

8

2x2x2 2F-S42-SE 2F-S42N-SE 2 1000 5

3

⁄

4

2

7

⁄

8

2

7

⁄

8

4

1

⁄

4

4

3

⁄

8

3

⁄

4

0.497 0.998 3 3 10

1

⁄

4

5

3

⁄

8

2x2x2 2F-S92-SE 2F-S92N-SE 2 2000 6 3 3 4

3

⁄

4

4

3

⁄

8

3

⁄

4

0.497 0.998 3

1

⁄

4

3

1

⁄

4

10

1

⁄

4

5

3

⁄

8

*3x2

1

⁄

2

x3 3R-S42-SE 3R-S42N-SE 2

1

⁄

2

1000 7

5

⁄

8

3

13

⁄

16

3

13

⁄

16

5

1

⁄

4

5

1

⁄

4

1

1

⁄

16

0.622 1.248 4

1

⁄

8

4 16 5

3

⁄

4

3x2x3 3R-S62-SE 3R-S62N-SE 2 1500 7

1

⁄

4

3

5

⁄

8

3

5

⁄

8

5 4

3

⁄

8

3

⁄

4

0.497 0.998 4

1

⁄

2

4

1

⁄

2

10

1

⁄

4

5

3

⁄

8

3x3x3 3F-S32-SE 3F-S32N-SE 3 750 8 4 4 6 5

3

⁄

4

7

⁄

8

0.747 1.373 4

1

⁄

8

4 20 6

3

⁄

4

3x2x3 3R-S32-SE 3R-S32N-SE 2 750 7

1

⁄

4

3

1

⁄

2

3

3

⁄

4

4

1

⁄

2

4

3

⁄

8

3

⁄

4

0.497 0.998 4

1

⁄

8

4 10

1

⁄

4

5

3

⁄

8

3x3x3 3F-S42-SE 3F-S42N-SE 3 1000 8

3

⁄

4

4

3

⁄

8

4

3

⁄

8

6 5

3

⁄

4

7

⁄

8

0.747 1.373 4

1

⁄

2

4

1

⁄

2

20 6

3

⁄

4

4x3x4 4R-S32-SE 4R-S32N-SE 3 750 8

3

⁄

4

4

3

⁄

8

4

3

⁄

8

6 5

3

⁄

4

7

⁄

8

0.747 1.373 5

9

⁄

16

5

1

⁄

4

20 6

3

⁄

4

4x3x4 4R-S42-SE 4R-S42N-SE 3 1000 8

3

⁄

4

4

3

⁄

8

4

3

⁄

8

6 5

3

⁄

4

7

⁄

8

0.747 1.373 5

9

⁄

16

5

1

⁄

4

20 6

3

⁄

4

4x4x4 4F-S22-SE 4F-S22N-SE 4 500 9

3

⁄

8

4

11

⁄

16

4

11

⁄

16

7

1

⁄

2

6

3

⁄

8

1

1

⁄

16

0.747 1.373 5

9

⁄

16

5

1

⁄

4

20 7

3

⁄

8

Dimensions

BALON SERIES “S” GROOVED END - DIM. DATA

CAT. NO.

STANDARD TRIM NACE TRIM

SIZE

CARBON STEEL 316 STAINLESS

PORT WP A B C D E F G H L LL M N

BALL & STEM STEEL BALL & STEM

2x11⁄2x2 2R-S32-GE 2R-S32N-GE 11⁄2750 51⁄8211⁄1627⁄1633⁄835⁄

8

5

⁄80.434 0.873 23⁄823⁄871⁄45

3x2x3 3R-S32-GE 3R-S32N-GE 2 750 7

1

⁄431⁄233⁄441⁄243⁄

8

3

⁄40.497 0.998 31⁄231⁄2101⁄453⁄

8

4x3x4 4R-S32-GE 4R-S32N-GE 3 750 87⁄841⁄243⁄86 53⁄

4

7

⁄80.747 1.373 41⁄241⁄220 63⁄

4

* Balon valves are designed to be operated

with a standard open-end wrench.

Handle and Handle Bolt are optional.

WP is for valve equipped with standard nylon

seats. See Chart on page 43 TFE ratings.

Series S Screwed End Carbon Steel

®

34

ITEM PART NAME MATERIAL MATERIAL STAINLESS STEEL

(STANDARD) (NACE)

1 Handle* Ductile iron Ductile iron

2 Handle bolt Standard hex bolt Standard hex bolt

3 Weather guard Polyethylene Polyethylene

4 Lock plate retainer Carbon spring steel Carbon spring steel

5 Lock plate Carbon steel - zinc plated Carbon steel - zinc plated

6 Dust cover Polyethylene Polyethylene

7 Stop plate retainer Carbon spring steel Carbon spring steel

8 Stop plate Carbon steel zinc plated Carbon steel zinc plated

9 Stem O-ring Buna Fluorocarbon

10 Stem seal TFE TFE

11 Stem Stress proof zinc plated AISI A-316 stainless steel

ASTM A311-79 Class B annealed ASTM A-276-316

12 Ball AISI 1018 nickel chrome plated ASTM A-743-CF8M

annealed stainless steel

13 Ball seat Nylon-Acetal Nylon-Acetal

14 Body O-ring Buna Fluorocarbon

15 End adapter ASTM 216 grade WCB annealed ASTM 216 grade WCB annealed

carbon steel carbon steel

16 Body ASTM 216 grade WCB annealed ASTM 216 grade WCB annealed

carbon steel carbon steel

Material Description Lever Operated

Threaded Construction

To 3000 PSI WP

BALON SERIES “S” SCREWED END - DIM. DATA

CAT. NO.

STANDARD TRIM NACE TRIM

SIZE CARBON STEEL 316 STAINLESS PORT WP A B C D E F G H L LL M N

BALL & STEM STEEL BALL & STEM

1x1x1 1F-S93-SE 1F-S93N-SE 1 2500 4 2 2 23⁄423⁄

8

1

⁄20.340 .685 21⁄162 43⁄82

1x1x1 1F-S03-SE 1F-S03N-SE 1 3000 4 2 2 23⁄423⁄

8

1

⁄20.340 .685 21⁄162 43⁄82

2x11⁄2x2 2R-S93-SE 2R-S93N-SE 11⁄22500 51⁄223⁄423⁄441⁄435⁄

8

3

⁄40.434 .873 31⁄231⁄271⁄45

2x11⁄2x2 2R-S03-SE 2R-S03N-SE 11⁄23000 51⁄223⁄423⁄441⁄435⁄

8

3

⁄40.434 .873 31⁄231⁄271⁄45

2x2x2 2F-S03-SE 2F-S03N-SE 2 3000 6 31⁄827⁄847⁄843⁄

8

3

⁄40.497 .998 31⁄231⁄2101⁄453⁄

8

2x2x2 2F-S93-SE 2F-S93N-SE 2 2500 6 31⁄827⁄847⁄843⁄

8

3

⁄40.497 .998 31⁄231⁄2101⁄453⁄

8

Dimensions

All Series S available with 316 SS and NACE.

* Balon valves are designed to be operated

with a standard open-end wrench.

Handle and Handle Bolt are optional.

Series S Screwed End Stainless Steel

®

35

ITEM PART NAME MATERIAL STAINLESS STEEL

(STANDARD NACE)

1 Handle* Ductile iron

2 Handle bolt Standard hex bolt

3 Weather guard Polyethylene

4 Lock plate retainer Stainless steel

5 Lock plate Stainless steel

6 Dust cover Polyethylene

7 Stop plate retainer Stainless steel

8 Stop plate Stainless steel

9 Stem O-ring Fluorocarbon

10 Stem seal TFE

11 Stem AISI A-316 stainless steel annealed ASTM A-276-316

12 Ball ASTM A-743-CF8M/316 annealed stainless steel

13 Ball seat Acetal-nylon

14 Body O-ring Fluorocarbon

15 End adapter ASTM A351-CF8M annealed stainless steel

16 Body ASTM A351-CF8M annealed stainless steel

Material Description Lever Operated

Threaded Construction

To 3000 PSI WP

BALON SERIES “S” SCREWED END - DIM. DATA

CAT. NO.

NACE TRIM

SIZE 316 STAINLESS PORT WP A B C D E F G H L LL M N

STEEL BALL & STEM

1x1x1 1F-S95N-SE 1 2000 4 2 2 23⁄423⁄

8

1

⁄20.340 .685 21⁄162 43⁄82

1x1x1 1F-S05N-SE 1 3000 4 2 2 23⁄423⁄

8

1

⁄20.340 .685 21⁄162 43⁄82

2x11⁄2x2 2R-S95N-SE 11⁄22000 51⁄223⁄423⁄443⁄435⁄

8

3

⁄40.434 .873 31⁄231⁄271⁄45

2x11⁄2x2 2R-S05N-SE 11⁄23000 51⁄223⁄423⁄441⁄435⁄

8

3

⁄40.434 .873 31⁄231⁄271⁄45

2x2x2 2F-S95N-SE 2 2000 6 31⁄827⁄847⁄843⁄

8

3

⁄40.497 .998 31⁄231⁄2101⁄453⁄

8

2x2x2 2F-S05N-SE 2 3000 6 31⁄827⁄847⁄843⁄

8

3

⁄40.497 .998 31⁄231⁄2101⁄453⁄

8

Dimensions

* Balon valves are designed to be operated

with a standard open-end wrench.

Handle and Handle Bolt are optional.

Series LM Screwed End

®

36

A Simple Superior Valve

The Series LM valve is a low

cost route to quality. Since

introduced, it has become a

favorite valve for drip service,

meter hookups, blow down,

emergency shutdown, and

anywhere a dependable

quarter turn block valve is

needed.

Machined from barstock, this

valve is priced low enough for

low pressure service, but the

rugged bolted construction

assures strength and rigidity

for high pressure service in the

plant and in the field.

The wide ranging capability of

this valve is enhanced by the

316 stainless steel ball and

stem which are standard in all

Series LM valves.

General Features

■ Locking device and handle

■ Socket head bolting for

strength.

■ Multi-seal seats standard.

■ Smooth uninterrupted

external surfaces - no

corrosion traps.

■ Symmetry of design allows

versatile in-line position

or placement.

■ Low torque operation at

full rated pressure.

■ Nylon seats standard with

TFE optional (see chart

page 42).

■ NACE available.

Carbon Steel

®

14

15

BALON 3000 PSI WP - SERIES “LM” BALON BALL VALVE - DIM. DATA

CAT. NO.

STANDARD TRIM NACE TRIM

SIZE

316 STAINLESS 316 STAINLESS

PORT WP A B C D E F G

STEEL BALL & STEM STEEL BALL & STEM

1

⁄4x 3⁄8x 1⁄4LM-02362 LM-02362-N

3

⁄83000 11⁄411⁄831⁄215⁄

8

5

⁄

8

21⁄

4

1

⁄

4

1

⁄2x 3⁄8x 1⁄2LM-05361 LM-05361-N

3

⁄4x 3⁄4x 3⁄4LM-07362 LM-07362-N

3

⁄43000 2 113⁄1647⁄821⁄

4

1 35⁄

8

3

⁄

8

1 x 3⁄4x 1 LM-10361 LM-10361-N

All Series LM available with NACE trim.

All Series LM available with NACE trim.

Dimensions

ITEM PART NAME MATERIAL DESCRIPTION MATERIAL DESCRIPTION

(STANDARD) (NACE)

1 Weather guard Polyethylene Polyethylene

2 Stem nut ANSI B18.8.2-179 zinc plated ANSI B18.8.2-179 zinc plated

3 Lock plate AISI: 1008 HR steel zinc plated AISI: 1008 HR steel zinc plated

4 Handle AISI: 1008 HR steel zinc plated AISI: 1008 HR steel zinc plated

5 Stem washer Acetal Acetal

6 Stop Pin ANSI B18.8.2-179 zinc plated ANSI B18.8.2-179 zinc plated

7 Stem O-ring Buna Fluorocarbon

8 Stem seal TFE TFE

9 Stem AISI: Type 316 stainless steel AISI: Type 316 stainless steel

10 Body AISI: 1215 zinc plated AISI: 1018 zinc plated

11 Ball seat Nylon (TFE optional) Nylon (TFE optional)

12 Ball AISI: 316 stainless steel AISI: 316 stainless steel

13 Body seal Buna Fluorocarbon

14 End adapter AISI: 1215 zinc plated AISI: 1018 zinc plated

15 Body bolts ANSI B18.3-1982 ANSI ASTM

ASTM A/574-1980 A-193-B7M

Material Description

Lever Operated

Bolted Body Construction

3000 PSI W.P.

37

* Handle and locking device standard on all Series LM ball valves.

WP is for valve equipped with standard nylon seats. See Chart on page 43 for TFE ratings.

Series LS Screwed End

®

38

The Series LS solid stainless

steel ball valve has been

designed to stand up consis-

tently against the very tough-

est of applications. It is intend-

ed for services such as CO2,

H2S, saltwater, and other

severely corrosive