INSTALLATION AND OPERATOR’S MANUAL

Balmar’s Smartgauge™ battery monitoring system

provides accurate dependable information about

battery condition, without the need for shunts and

complicated programming. Simply select the battery

program that most closely matches your battery

technology.

The Smartgauge™ features Voltage and State of

Charge (SoC%) displays, and can be used to

provide alarms for low battery voltage and capacity.

As with all electrical components, take time to read

and follow the instructions provided in this manual.

Failure to do so could result in damage to the

Smartgauge™ and/or your electrical system.

VOLTS

Set

Emergency

Connect

Smartgauge™

BATTERY MONITOR

Smartgauge

SmartBank

SmartBank

PGM/Battery 2

Alarm

STATUS

Select

BATT 2

Exit

Advanced Battery

Monitor System

™

SECTION TOPIC PAGE

CONTENTS

1.0 Introduction ....................................................................................................... ....... Page 2

2.0 Quick Start Guide ............................................................................................. ........ Page 3

2.1 Smartgauge Installation Basics ...................................................................... ........ Page 5

2.2 Important Installation Notes......................................................................... ............ Page 5

3.0 Initial Smartgauge Start Up ................................................................................ ..... Page 6

3.1 Determining Battery Charge Status......................................................................... Page 6

3.2 Calibrating Battery Charge Status................................................................... ........ Page 7

3.3 Power Up After Power Loss ......................................................................... ........... Page 7

4.0 Basic Monitor Use .............................................................................................. ...... Page 8

4.1 Set Up Menu............................................................................................................... Page 9

4.2 Set Up Mode – Battery Type ................................................................ .................... Page 9

4.3 Set Up Mode – Charge Status ............................................................ .................. Page 10

4.4 Alarm Functions .......................................................................... ........................... Page 10

4.5 Defeating Error Codes ................................................................. ......................... Page 13

4.6 Set Up Display Behavior......................................................... ................................ Page 14

4.7 Set Up Display Brightness ............................................................... ..................... Page 14

4.8 Set Up Menu Lock ........................................................................... ....................... Page 15

5.0 Error Codes.............................................................................................................. Page 15

6.0 Reset to Factory Defaults ............................................................. ......................... Page 16

7.0 Alarm Outputs .............................................................................. .......................... Page 17

8.0 Alarm Notes ........................................................................ .................................... Page 17

9.0 Addendum................................................................................................................ Page 17

10.0 Specications .................................................................................... ..................... Page 18

11.0 Warranty ........................................................................................ .......................... Page 19

12.0 Smartgauge Display Flowcharts................................................ ............................ Page 19

BALMAR LLC. MARYSVILLE, WA 98271 USA – WWW.BALMAR.NET – +1-360-435-6100

©2016 Balmar LLC. Reproduction is forbidden without permission

QF-137 Rev B

SECTION 1.0 – INTRODUCTION PAGE 2

The Smartgauge™ battery monitor employs advanced battery monitoring techniques to provide

battery voltage and State of Charge (SoC%) information in a manner that’s both highly accurate

and self correcting. Smartgauge™ is unconventional – please read this manual fully to understand

how and why it works.

Further technical support can be obtained from Balmar Customer Service at +1-360-435-6100.

Features:

• House (Primary) Battery Voltage

• House (Primary) Battery State of Charge

• Engine (Secondary) Battery Voltage

• High/Low Battery Voltage alarms for each battery

• High/Low State of Charge alarm for House (Primary) battery

• Bright LED daylight readable display

• Volt free alarm contact for ring external alarms, relays etc

How the Smartgauge™ Works

Conventional battery monitors count amp hours in/out of the battery to determine the battery’s State

of Charge (SoC). This method is inherently inaccurate due to the State of Charge of the battery not

necessarily being linked to the amount of energy a battery can deliver (due to temperature, how quickly

the battery was charged/discharged, battery age, and other outside factors). Unless the battery monitor

is regularly reset (either automatically by fully charging the battery or manually reset by the user), the

reading error will compound (known as synchronization error).

In most battery monitors, a shunt is used to monitor amperage in or out of the battery. Unfortunately, in

many cases shunts can be incorrectly installed, and inaccurate amperage readings occur.

Smartgauge™ uses just two wires to monitor the battery. Through these wires, we use proprietary

test methods to generate data. This data is then compared to detailed computerized battery models.

Smartgauge™ compares real world data with those models to generate information on the battery’s

State of Charge. In independent testing Smartgauge™ was found to be within 5% accuracy at all times.

Highly accurate SoC information not only allows you to condently make decisions about how you use

your electrical system, it also allows you to automate certain functions – like load shedding or generator

start/stop.

Smartgauge™ uses a self correcting algorithm to determine battery State of Charge, so over time

it actually becomes more and more accurate. This self correction also means that Smartgauge™

automatically adjusts for battery degradation as the batteries are repeatedly cycled. Smartgauge™

needs to see 2-3 charge/discharge cycles to synchronize with the batteries.

CAUTIONS AND WARNINGS

CAUTION: Statements Identied with the word CAUTION relate to practices that may

damage Smartgauge

WARNING: Statements identied with the word WARNING relate to practices that may

cause injury or death.

PAGE 3

SECTION 1.0 – INTRODUCTION

CAUTION & WARNING: This manual is written with the intention for use by a qualied electrical

technician. It does not identify normal practices or procedures that would be expected of a qualied

electrician. Please review and comply with any installation and/or safety standards, such as those

provided by ABYC or other agencies regulating electrical system safety. Please review the instruction

manuals for any equipment or tools that you may be using to complete this installation.

CAUTION: Please fully review this manual before commencing installation.

Certicate of Conformity:

Declaration of Conformity

Smartgauge™ is in compliance with the requirements of EU Electromagnetic Compatibility (EMC)

Directive 89/336/EEC. Smartgauge™ complies with RoHS (Reduction of Hazardous Substances)

Directive 2002/95/EC. Smartgauge™ contains no Lead. At the end of life, Smartgauge™ should be

disposed of as normal electrical waste.

SECTION 2.0 – QUICK START GUIDE

CAUTION & WARNING:

Batteries are hazardous

items. Please follow battery manufacturer’s recommendations for health

and safety. Use only the

appropriate tools in conjunction with manufacturer’s instructions. Isolate

both battery and AC power

supplies before attempting

installation.

CAUTION & WARNING:

The Quick Start Guide

does not refer to each and

every Caution & Warning

Statement in this manual. Be sure to observe

safe working practices

at all times. Refer to the

full manual if you are unsure of any practices that

may damage the Smartgauge™ unit, your system

wiring or health.

The Quick Start section of this guide assumes Smartgauge™ is being installed

for the rst time. If this is not the case, please refer to the main section of this

manual as the power up sequence will be different.

The Smartgauge™ display panel is typically mounted at the dash or navigation

area, or in other locations where it can be easily accessed for viewing. The rectangular display panel requires a rough opening measuring 3.75” wide by 2.55” tall,

as illustrated in Diagram 1. The overall dimensions are 4.40” wide by 3.00” tall. The

panel depth is 1”. Access to the rear of the monitor is necessary for the installation

of ground and positive sense wires from the monitor directly to the battery banks. In

addition, there are terminals for wiring connections to install separate wires for an

audible or visual low-voltage/low-battery capacity alarm. Four cutout dimples can be

found on the back of the mounting ange of the monitor’s display if mounting screws

are desired.

Diagram 1

Once a location has been determined for the monitor panel, sensing and ground

wires can be run to the batteries, as described in Diagram 2 on the following page.

SECTION 2.0 – QUICK START GUIDE

The Smartgauge™ does not require a separate

shunt for installation. Battery voltage and State

of Charge are both determined via sense wires

connected directly to the positive terminals of

one or both battery banks. To install:

1. Run a 16 gauge (AWG) ground wire

from the GND terminal on back of the

Smartgauge™ to the battery negative post

of the house battery bank.

2. Run a 16 gauge (AWG) positive sense wire

from the B1 terminal on Smartgauge™ to

the battery positive post of the house battery bank. This wire must be fused at 3

amps with the fuse holder installed as

close to the battery as possible – note that

the fuse should be outside any battery

compartment where battery gases may

accumulate. It should not be run to bus-bars,

isolation switches, fuse panels etc.

3. If a second battery is to be monitored

for voltage, run an additional 16 gauge

(AWG) wire, fused at 3 amps, from the B2

terminal on Smartgauge™ to the positive

battery post of the second battery bank.

Again, this fuse should be located as close

to the battery as possible (but not inside the

battery compartment if combustible gases

can build up).

HOUSE

BATTERY BANK

TO SYSTEM GROUND

Rear of Smartgauge

PAGE 4

ENGINE

BATTERY BANK

Diagram 2

Once the ground and positive sense wires are connected, the monitor display will indicate the software and

battery model revisions. The Smartgauge™ will then show “bt 1” in the display and the PGM/Batt 2 LED will be

ashing. Use the STATUS button to scroll through the program choices, as listed below:

Number Battery type

1 Deep-cycle ooded lead acid

(Examples: Trojan, US Battery, Rolls, Interstate, Exide, Deka/East Penn, Dyno, Crown, Superior)

2 Gel Cell

(Examples: Deka/East Penn GEL, Sonnenschein Prevalier GEL)

3 AGM – Absorbed Glass Mat

(Examples: Lifeline AGM, Firey AGM, Deka/East Penn AGM, US Battery AGM, Rolls AGM, Optima AGM)

4 Dual-purpose lead acid

5 Carbon ber lead acid

6 Sealed, maintainance-free lead acid

**NOTE: There are two distinct types of AGM battery. The rst are similar to standard lead/acid with the addition

of a glass matt separator. The second have this glass mat separator but also additional chemicals added. The rst

type have similar charging voltages to Deep Cycle Lead/Acid (14.6V/29.2V max) – in this instance Smartgauge™

should be set to Battery Type 1. Examples include AGM TPPL batteries such as Odyssey TPPL and Northstar

TPPL batteries. The second type have lower charging voltages (similar to Gel) at around (14.0-14.2V/28.0-

28.4V) max – in this instance Smartgauge™ should be set to Battery Type 3.

When the desired battery type number is shown, press VOLTS (set) or BATT 2 (exit). The display will show house

battery voltage. Pressing BATT 2 will display the voltage on the engine battery and the PGM/Batt 2 LED will be lit.

PAGE 5

Pressing the STATUS button will display the charge status as a percentage.

Initially, battery charge status will be shown at 75%. During the rst run cycle,

the Smartgauge™ will begin to synchronize itself. It will typically take two or

three discharge and recharge cycles for the Smartgauge™ to “learn” to accurately read your house battery’s State of Charge. Synchronization is not an

instant effect. The Smartgauge™ will continue to track battery condition with

increasing accuracy over time.

This completes installation and initial setup of Smartgauge™. For operation

and details of further functions such as alarms, error codes, etc., refer to the

main section of the owner’s manual.

SECTION 2.0 – QUICK START GUIDE

SECTION 2.1 – Smartgauge INSTALLATION BASICS

The purpose of this manual is to enable the installer to install Smartgauge™ in a manner that permits it to

operate as designed. This manual’s purpose is not to educate the installer on the legal requirements of any

particular type of installation. The manufacturer, supplier, dealer and/or their agents cannot know what the nal

installation will be and therefore cannot know what the legal requirements of such installation may be.

Installation of Smartgauge™ is simple and should be completed in a short time. Only two wires are required to

operate Smartgauge™ for normal single-bank system, with only three wires required for a dual-bank installation.

SECTION 2.2 – IMPORTANT INSTALLATION NOTES

1. The sense wire connected to the B1 terminal on the back of the Smartgauge™ must be connected to the

house (primary) battery bank. The B2 terminal should be connected to the engine starting battery via the

secondary sense wire.

2. Both battery banks must be either 12 volts or 24 volts. The Smartgauge™ cannot be used in a mixed installation with 12-volt and 24-volt battery banks.

3. Battery banks connected to the Smartgauge™ MUST share a common ground. It is not possible to install the

Smartgauge on 2 isolated battery systems or on 2 battery systems with a common positive.

4. Keep wire runs the between the Smartgauge™ and the batteries as short as possible. Use at least 16-gauge

(AWG) wire for B1 sense, B2 sense and Negative (Ground) connections.

5. B1 and B2 sense wires must be fused as near to the batteries as possible. A 3-amp ATC fuse is recommended for each sense wire installed.

6. Positive voltage sense and negative (ground) wires must be connected directly to the battery posts of the

batteries being monitored. Connecting them to busses or other non-battery terminal connections could result

in poor or inaccurate monitor performance.

7. Do not use positive sense wires or ground wires as power sources for other loads (like warning lights or audible alarms. Doing so will affect Smartgauge™ accuracy.

8. If Smartgauge™ is replacing a shunt-based monitor or ammeter, do not connect the sense wires to the exist-

ing shunt. The sense wires MUST be connected directly to the batteries being monitored.

SECTION 3.0 – INITIAL START-UP

OFF = No SmartBank Connected

Fast Flash = SmartBank Standby

Slow Flash = SmartBank High Voltage Disconnect

VOLTS

Set

Emergency

Connect

Smartgauge™

SmartBank

SmartBank

PGM/Battery 2

Alarm

STATUS

Select

BATT 2

Exit

Advanced Battery

Monitor System

PAGE 6

ON = Battery 2 Voltage Displayed

Flashing = Programming Mode

ON = Alarm Triggered

Display Battery 2 Volts

(Engine Battery)

Display Battery 1

(House Battery Bank)

Volts

Display Battery 1

(House Battery Bank)

Status (State of Charge)

On powering up Smartgauge™ for the rst time, the display will show the software revision information. The following are just examples. They are required for troubleshooting.

r1.03 = Software revision 1.03

b1.05 = Battery model revision 1.05

Smartgauge™ will then display “SC” indicating that it’s determining system battery voltage. Depending on the

system voltage detected during the system check, the Smartgauge™ will display “SC12” or “SC24”. Refer to the

chart at the end of this manual headed “12.1 – First time power up or following factory reset” for specics.

The next display will indicate “bt 1”. This is your opportunity to select the battery type. Refer to Section 4.2,

headed “Battery types”, for further details. Pressing the STATUS button will scroll through the available battery

types. Pressing the VOLTS button will store the battery program you select based on your battery type. The

display will ash four times to signify the data has been written to computer memory. The display will then show

the current battery voltage.

That completes the installation and initial set-up.

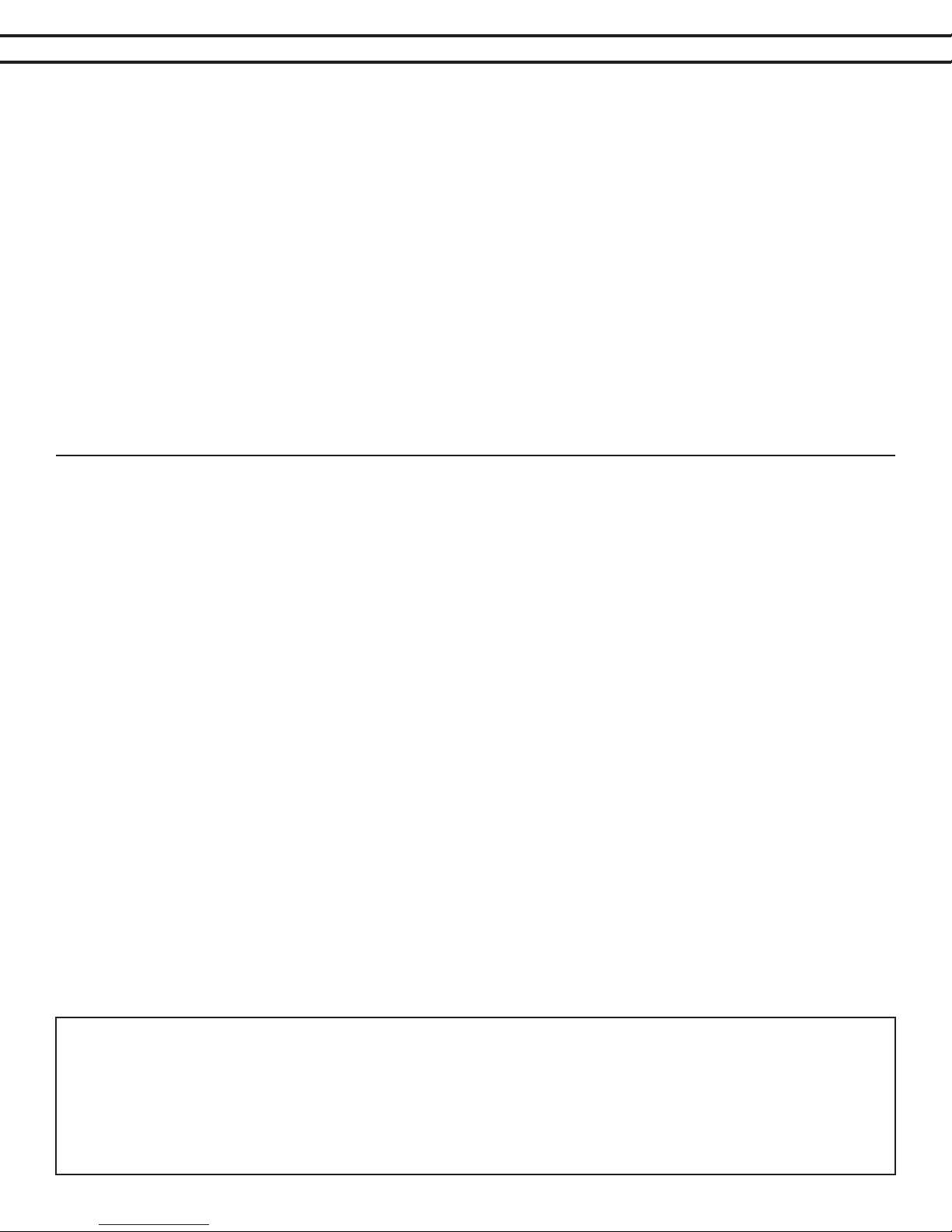

SECTION 3.1 – DETERMINING BATTERY CHARGE STATUS

Once the Smartgauge™ has completed its initial start-up routine, you can determine the

charge status of the primary (house) battery bank by pressing the STATUS button. The

charge status will be displayed as a percentage. During the rst operation, the monitor

will display “C 75”, indicating 75 percent charge. As the Smartgauge™ goes through

its rst charge cycle, it will begin to “learn” the actual condition of the batteries, and it

will more accurate during subsequent periods of operation. If you know the actual level

of charge, you also have the option to manually set the charge status. See page 7 for

multiple methods for calibrating the monitor to ensure accuracy.

To revert to the Battery Voltage, press the VOLTS button. Pressing the BATT 2 button

will show the voltage on Battery 2 if the Smartgauge has been wired to both house and

starting batteries. The PGM/Batt 2 LED will be lit whenever voltage at the starting battery is being displayed.

To revert to the voltage or charge status of the house battery bank, press the VOLTS button or the STATUS

button.

PAGE 7

SECTION 3.2 – CALIBRATING BATTERY CHARGE STATUS

Initially Smartgauge™ defaults to an SoC of 75%. There are 4 very simple ways

this can be corrected:

1. If you know what the State of Charge is (for instance you may know the batteries

to be fully charged) you can enter the set-up menu and manually set the charge

status to what you know it to be. SoC can be manually set to any value between

0 and 100%. Enter the set-up menu as usual, then press the SET key until “Cxxx”

is displayed. Press and hold the SELECT button. The display will scroll from zero

to 100. When the desired value is displayed, press the VOLTS button. The display

will ash to show the value has been stored. The display will then move onto the

next menu item.

2. Charge or discharge the batteries to approach 75%. When the actual State of

Charge of the batteries and the displayed charge status meet, Smartgauge™ will

be in perfect synchronization with the batteries and will track the charge status

from that time onward.

3. Leave Smartgauge™ working for 48 hours. Use the battery system as usual,

Smartgauge will automatically catch up over the next 2-3 charge and discharge

cycles of the battery bank. Unlike all other battery state of charge meters currently

available, Smartgauge™ becomes more accurate the longer it is used. All other

battery state of charge meters become less accurate the longer they are used

and require multiple recalibrations.

4. The last method is to switch on a charging device and wait until you know the bat-

teries are fully charged (by the charger switching into oat charge mode). Then

manually set the SoC to 100%.

Important Note

On initial power-up, the Smartgauge™ performs a system check to determine

whether the system voltage is 12 volt or 24 volt. Smartgauge™ does this by taking eight voltage readings and averaging them. The Smartgauge™ decides whether this measured battery voltage indicates a 12- or 24-volt system. If,

at the time of this check, the battery voltage is outside the normal range, the Smartgauge™ may detect the wrong

system voltage. This is possible when Smartgauge™ is installed on a 24-volt system with extremely low battery voltage. The low voltage could result in the Smartgauge™ determining that the system is a 12-volt system. Alternately,

the Smartgauge™ could be connected to a 12-volt system with a faulty charger that’s applying high voltage to the

batteries. This would cause Smartgauge™ to incorrectly detect a 24-volt system.

If either of these happen, then Smartgauge™ simply will not operate. Once normal battery voltage is restored, the

Smartgauge™ will show a permanent HI or LO reading and an “E04” error. If this happens the solution is to reset the

monitor to factory default value, ensure the battery voltage is correct, and re-apply power.

SECTION 3.3 – POWER UP FOLLOWING POWER LOSS

The Smartgauge™ must always be connected to the batteries being monitored in order to operate. It cannot operate

and accurately track the State of Charge of the batteries if the sense wire is disconnected from the house battery bank.

Should sensing voltage be disrupted, it may be necessary to revert to one of the four methods described in Section

3.2.

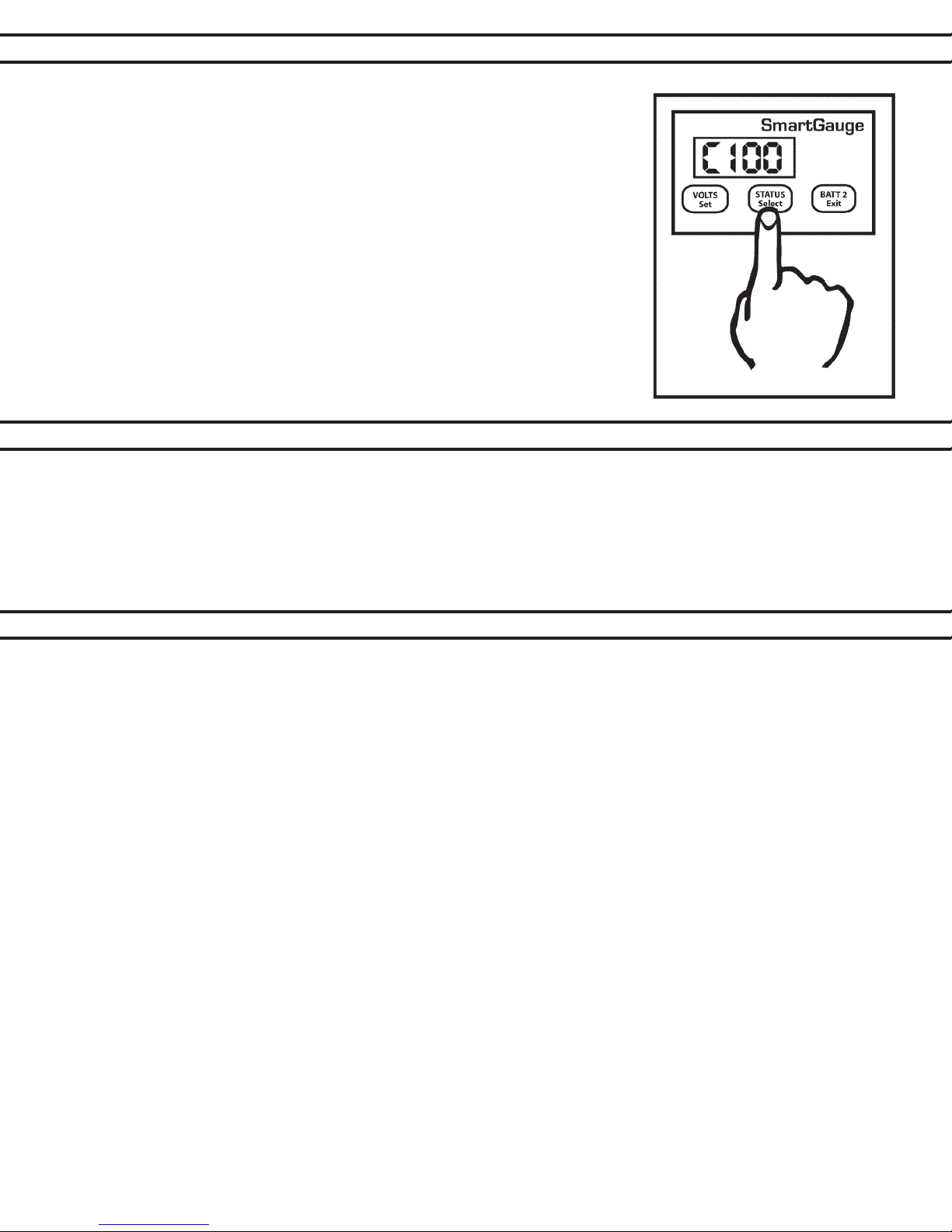

When a power failure occurs, the display will alternate between volts and “E01” (error 01 – lost power) until a key

is pressed. This is to alert the user to the fact that power has been lost. “E01” will continue to ash until a button is

pressed, if another error occurs the new error will not take over, “E01” will remain as the priority error. If the display

goes into sleep mode the error will always continue to ash. Again this is to alert the user to a problem.

The “E01” error alerts the user to the fact that power has been lost and therefore the charge status may no longer be

accurate. This is the sole reason for this error code. Once a button is pressed the display will move on to show a gure

– for example, 2.36 or 17.49 – This is the approximate time in hours and minutes since power was reapplied. It will

count up to a maximum of 99 hours and 59 minutes and will then remain at that display. This may help A) identify the

problem and B) make a better decision on whether the charge status will need to be reset or whether Smartgauge™

will have already re-synchronized itself.

SECTION 3.3 – POWER UP FOLLOWING POWER LOSS

PAGE 8

There is no need to reset any other functions. Smartgauge™ will remember all settings (with the exception that

status alarms will have been disabled). Refer to the ow chart headed “Re power up following power failure” for

details of the expected display at the back of the manual.

Note that re powering up Smartgauge™ results in a completely different

display from when it is rst powered up following rst installation (or following a

reset to factory defaults). In particular it does not carry out the System Check

(“SC”) and does not ask for the battery type. Both these parameters are stored

in non-volatile memory and will be retained from the previous use. Also note

that following re-application of power Smartgauge™ will continue to operate

as previously so, given time, it will successfully re-calibrate the charge status

of the batteries.

Note that previously set Status alarm will now be switched off. If for some reason it is required to revert the unit

to “as new” status, prior to rst installation (perhaps the unit is being moved to a new installation) then refer to

Section 6.0.

SECTION 4.0 – BASIC MONITOR USE

Pressing the VOLTS button will display house battery voltage. Pressing the

STATUS button will display charge status of the house battery bank. Pressing the

BATT 2 button will show the voltage on the engine starting battery and the PGM/

Batt 2 LED will light up to indicate that engine battery voltage is currently being

displayed. To return to house battery bank display, press VOLTS or STATUS.

If no buttons are activated for two minutes, the display will go into sleep mode.

This is a power saving feature. Smartgauge™ will continue to operate, calculating

the charge status and monitoring for error conditions, alarms etc. Pressing

any button will bring Smartgauge™ out of sleep mode and the display will

operate for an additional two minutes. Sleep mode may be defeated if required

(refer to “Display Modes” at the back of the manual).

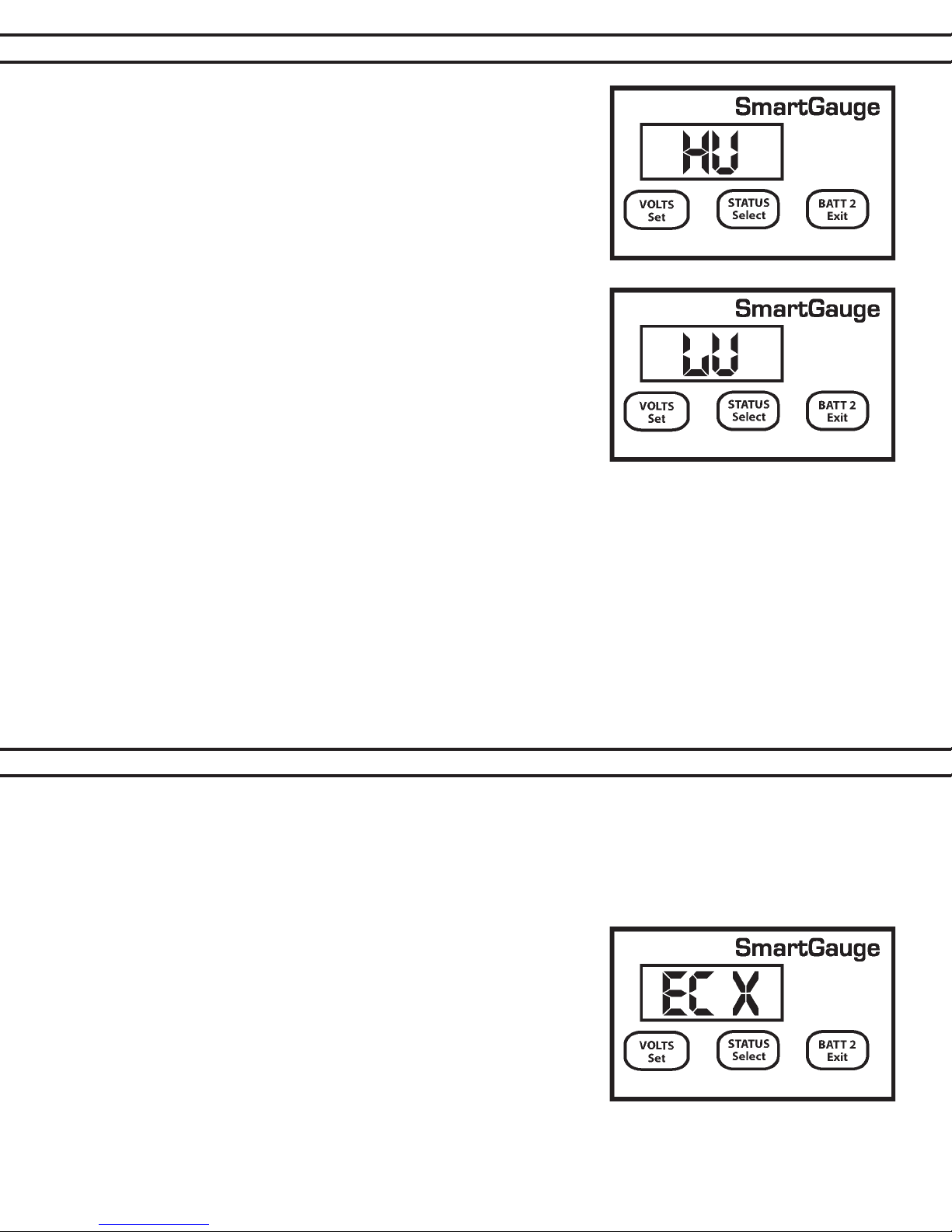

If the battery voltage goes outside the measurement range (>17 volts or <9 volts

for 12-volt systems) or (>34 volts or <18 for 24-volt systems), the volts display

will show “HI” or “LO” while the voltage remains outside of range. An “E04” error

will also be displayed and will remain displayed to alert the user to a problem – until a button is pressed. If the

battery voltage remains below the low-voltage warning for the set battery type an “E02” error will be displayed.

If the battery voltage remains above the high-voltage warning for the set battery type, an “E03” error will be

displayed.

The high and low voltage warnings described above are outside the preset limits which vary for each battery

type. “HI” or “LO” voltage displays should be responded to promptly, as battery damage or other dangerous

con- ditions may be responsible for the alerts. If power is lost an “E01” error will be displayed.

“HI” and “LO” error displays are only shown if the display is currently set to “Volts”. They are not displayed

if the display is set to “Status”. They are also not shown if the display has gone into sleep mode. But the

resulting error message will remain displayed. All error codes are displayed regardless of monitor mode.

They are shown even if the display has gone into sleep mode.

PAGE 9

The Smartgauge™ set-up menu allows the user to set and adjust a variety of the

monitor’s features:

To enter the set-up menu press both the VOLTS and STATUS buttons simultaneously and

keep them pressed. After 2 seconds the display will change to “bt x” (battery type x).

When in the set-up menu, the PGM/Batt 2 LED will ash.

During set-up mode, all internal calculations stop. For this reason there is a time limit on

the set-up menu. Each item to be set will allow approximately two minutes for the user to

set the function. After two minutes elapse, the currently displayed selection will be written to

Smartgauge™ memory and the set-up menu will be exited. Smartgauge™ will then revert

to normal operation. When in the set-up menu, the main legends on the buttons are no longer active. Instead

the secondary legends are the appropriate functions. The secondary legends are in blue

smaller letters underneath the main legends.

Pressing the SELECT button will scroll the current displayed value or option to the

next available one. At the last value, Smartgauge™ will cycle to the rst value and

continue. Pressing the SELECT button will simply scroll round and round all available values

indenitely. Pressing the SET button will set the displayed value. When the value has been

selected, the display will ash 4 times to indicate the value has been written to memory. The

display will then move on to the next menu item.

Pressing the EXIT button does the same as pressing the SET button except that after

writing the value to memory, it exits the set-up menu instead of moving on to the next item.

SECTION 4.1 – SET UP MODE

At any time, when moving onto a new menu item, the existing value (be it alarm voltage set points, battery types,

display modes etc) will be displayed rst. Pressing the SET button will show each selected item without ever

changing any of them. This allows you to look through the menu to check all the settings without changing any

of them or having to remember what they should be set to.

SECTION 4.2 – SET UP MODE –

When entering the set-up menu, the programming mode is the battery type, shown as “bt x” where “bt” signies battery type and “x” shows the current selected type. If this is a rst power up, “x” will be 1. Otherwise it will

show whatever setting is the currently selected battery type. If you are unable to identify your battery technology,

please contact your battery supplier for advice.

The battery types are numbered 1 to 7 and are as follows:

• Type 1 Standard wet cell deep cycle Lead Acid - Use this setting for:-

1. Standard vented Lead Acid deep cycle

2. Lead acid recombinant (have a catalyzer in the cap to recombine the oxygen and hydrogen back into

water that is normally lost during charging in a standard Lead Acid battery). Do not confuse with VRLA

(AGM or Gel).

• Type 2 Gel Cell – Use this setting only for Gel Cells

• Type 3 AGM - Absorbed Glass Matt (VRLA)

1. Use only for genuine AGM batteries. NOTE: There are two very distinct types of AGM batteries with very

different operational characteristics. In one type the only real difference is that the electrolyte is held in a

glass matt. This type usually have charge voltages very similar to ooded wet cell batteries. The off load

terminal voltages will also be very similar to ooded wet cell batteries. If your AGM batteries are of this

type then Smartgauge™ should be set to battery type 1.

BATTERY TYPE

2. The other type of AGM have additional chemicals in the battery and require lower charge voltages and

the off load terminal voltages will be similar to gel cells. This type require Smartgauge to be set to battery

type 3.

SECTION 4.2 – SET UP MODE –

BATTERY TYPE

PAGE 10

• Type 4 – HYBRID (Also known as Antimony/Calcium or Hi-Calcium.)

1. Usually identied by being sealed but the acid inside the battery is still liquid. Many are tted with a ‘magic

eye’ to give an approximate indication of battery condition. Usually marked maintenance free and its normally not possible to open the top of the battery.

• Type 5 – Carbon Fiber

1. Lead/Acid batteries with Carbon Fiber additives to the plates.

• Type 6 – Maintenance free, Calcium/Calcium.

1. Marketed as a semi-traction battery.

• Type 7 – Custom Program

2. Do not select type 7 unless your Smartgauge™ has been supplied with a specic battery program. Type

7 only appears on the set-up menu after the initial power up sequence.

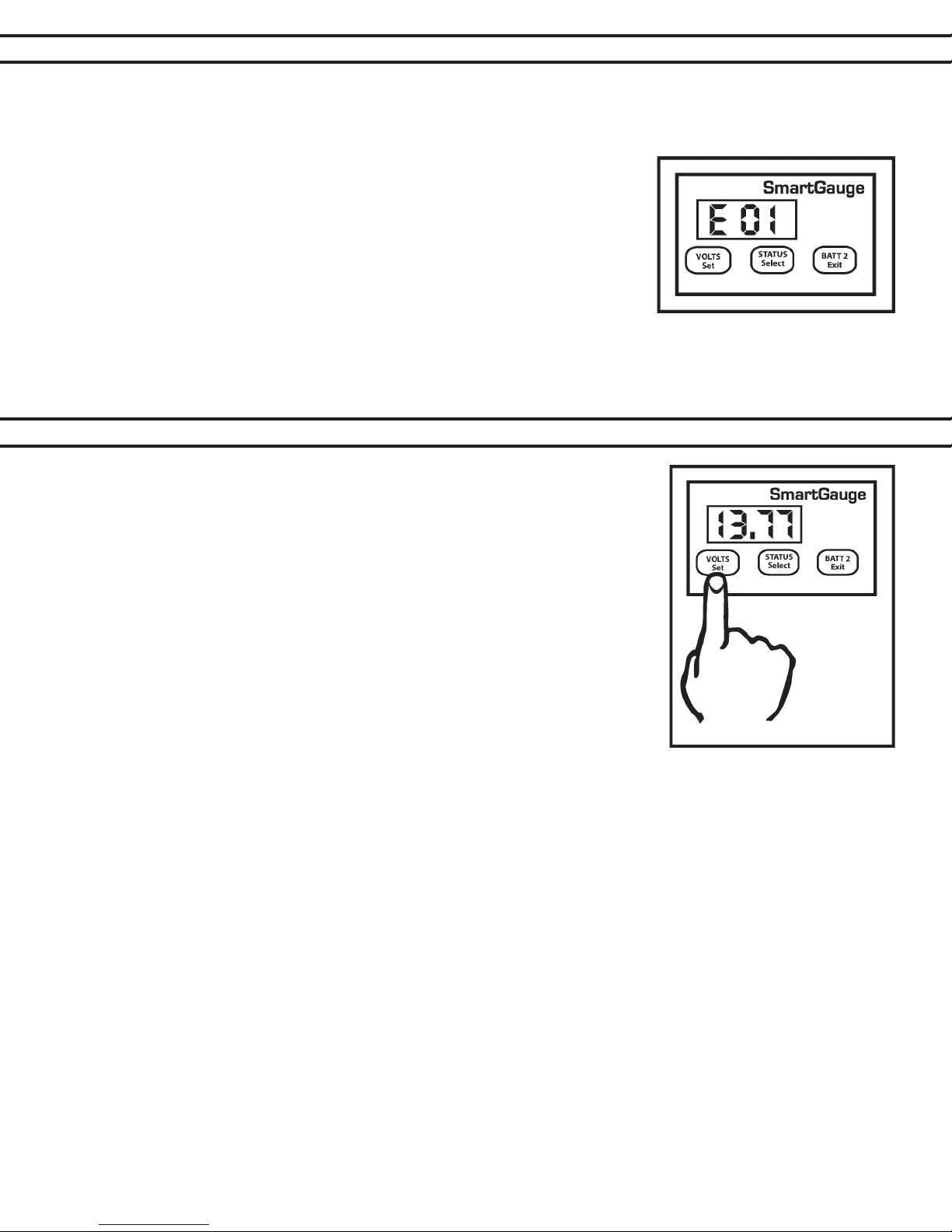

SECTION 4.3 – SET UP MODE –

CHARGE STATUS

Charge status can be manually set to any value between 0 and 100%. Enter the set-up

menu as usual, then press the SET key until “Cxxx” is displayed. “C” signies charge

status. The xxx displayed will be the current calculated charge status. Pressing the

SELECT button will scroll up to and including 100 then cycle to zero and start again.

When the desired value is displayed, press the VOLTS key. The display will ash to

show the value has been stored. The display will then move onto the next menu item.

Alternatively, pressing the EXIT button will write the value to memory then exit the

set-up menu.

SECTION 4.4 – SET UP MODE –

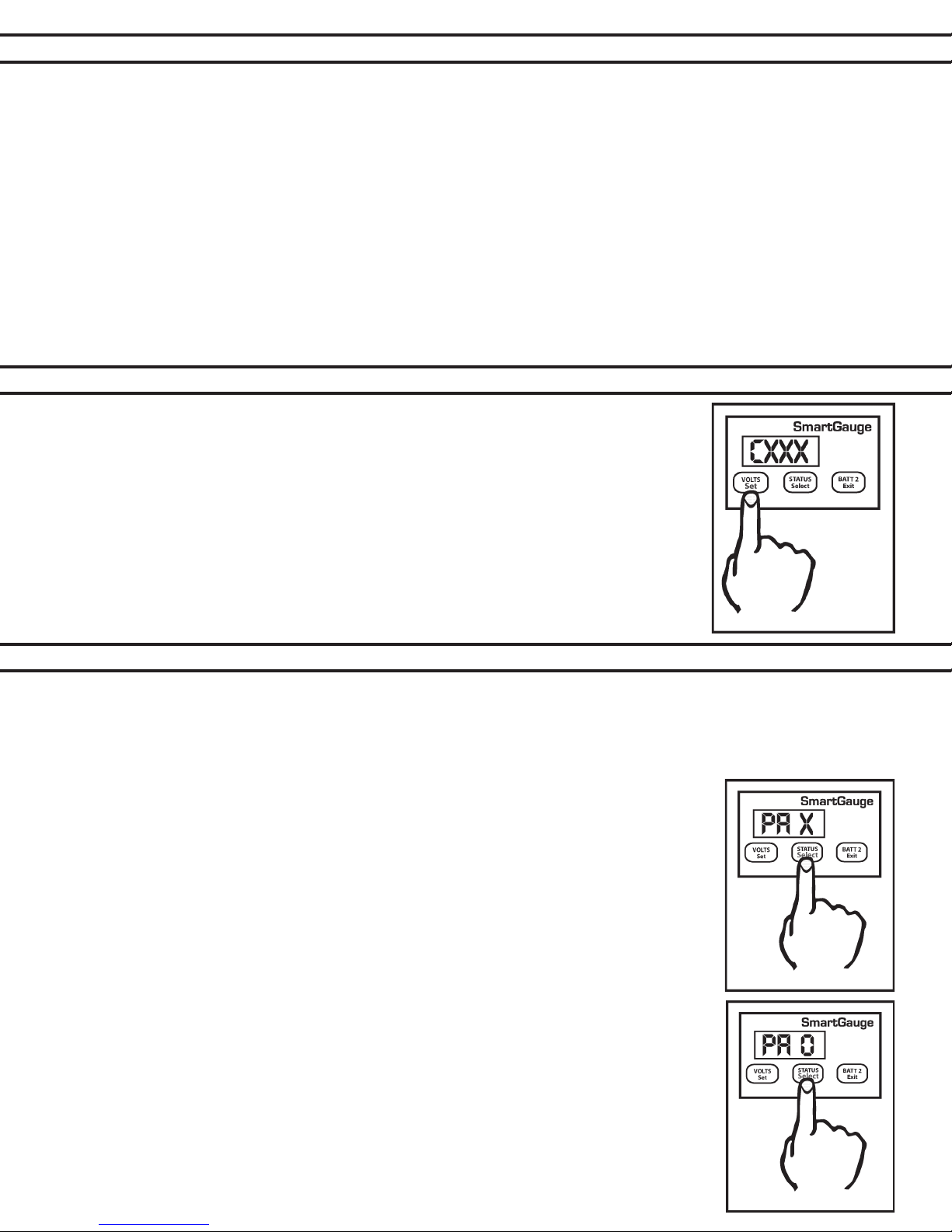

There are two levels of alarm settings in Smartgauge™. The rst is the Primary Alarm which can be set OFF or can

be used to access low/high voltage or low SoC function. See Section 7.0 for information regarding alarm outputs.

Primary Alarm:

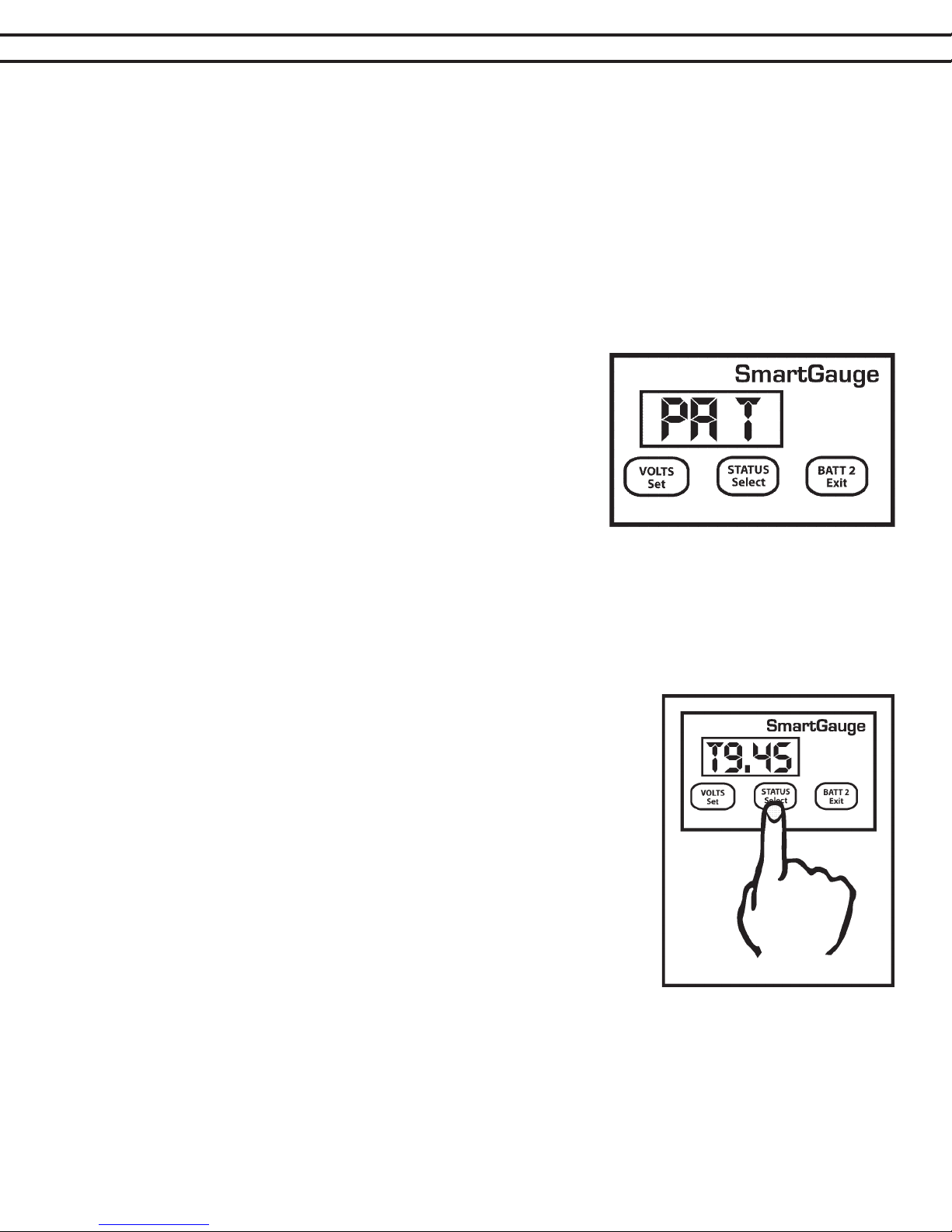

On entering this section of the set-up menu the display will show “PA x”. PA signifying Primary Alarm. “x” displaying

either “O” “ U” “ S”. or “t”. “O” means alarms are switched Off.

“U” means Uoltage (Voltage) alarm is enabled, “S” means low Status alarm is enabled. “t”

means a timed low status alarm is enabled. “S” and “t” type alarms are more fully described

under their respective headings. The SELECT button will scroll round them. The SET button

will set the desired alarm. The display will ash showing the value was written to memory.

Changing the alarm type will cancel any currently active alarms and reset the timed alarm

timers to the user’s programmed default value.

ALARM FUNCTIONS

On selecting “PA O” the display will ash and then move onto the next item in the set-up

menu, Secondary Alarm.

Individual Alarm Selection:

Set-up mode – Voltage Alarm:

1. On selecting “PA U” the display will ash to show the value was written to memory. The dis-

play will then show either “Hi” or “Lo”. The SELECT button will alternate between these two

options. “Hi” sets a high-voltage alarm. “Lo” sets a low-voltage alarm. Pressing SET will store

the value.

2. The display will then show “xx.xx” which is the lower voltage trip point. Once this is set (using

the SELECT and SET buttons) the display will again show “xx.xx” which is the upper voltage

trip point.

PAGE 11

If a low voltage alarm was set, the lower voltage trip point is the

voltage below which the actual battery voltage will have to fall in

order to trigger (activate) the alarm output. This is the activation

voltage. The factory default for this value is 11.80 volts. Pressing the SELECT button will scroll this value up to and including

16.50 volts. It will then cycle to 10.50 volts then continue to scroll

upwards. When the desired value is displayed, press the SET

button to write the value to memory, the display will ash. The

upper voltage trip point is the voltage which the actual battery

voltage will have to rise to in order to deactivate the alarm. This

is the deactivation voltage. The factory default for this is 13.20

volts. Pressing the Select button will scroll this value up to 16.50

volts, it will then wrap round to whatever value was previously entered for the alarm activation voltage. This

means that no matter what you do, Smartgauge™ will not allow this value to be set lower than the activation

voltage.

Pressing the SET button will write the value to memory. If a high voltage alarm

was set then the procedure remains identical except the upper voltage trip

point is the voltage which the battery voltage will have to rise to in order to acti-

vate the alarm. Once the alarm is triggered, the battery voltage will have to fall

back down below the lower voltage trip point in order to deactivate the alarm.

SECTION 4.4 – SET UP MODE –

ALARM FUNCTIONS

The display will then move on to the next item in the set-up menu, secondary

alarms. Remember, at any time in the set-up menu, pressing the EXIT button

will write the current value to memory then exit the set-up menu.

Clarication – For a low voltage alarm:

1. The battery voltage has to fall below the activation voltage to trigger the

alarm.

2. The battery voltage has to rise to the deactivation voltage to kill the alarm.

So if the activation voltage is set to 12.00 volts then the battery voltage will

have to fall to 11.99 volts to trigger the alarm. If the deactivation voltage is set

to 12.80 volts then the battery voltage will have to rise to 12.80 to cancel the alarm. Although the battery voltage

is displayed to a resolution of 0.05 volts (0.1 volts in 24 volt systems), internally it is measured and dealt with to

a ner resolution.

While 16.50 volts may seem very high for a maximum low voltage setting,

this does allow the low voltage alarm to be used for two extra functions. One

is as a “charger failure” alarm, the other is to enable the feature to be used to

auto-start a generator set feeding a constant current type battery charger and

shutting the generator down at the correct time.

For a high voltage alarm:-

1. The battery voltage has to rise to the deactivation voltage to trigger the

alarm.

2. The battery voltage has to fall below the activation voltage to kill the alarm.

Status Alarm

There are two types of Low-Status alarms. The rst is exactly the same as

the low-voltage alarm but operates on charge status instead of on battery

voltage. So the alarm will activate once the charge status falls below the chosen

activation status, and will deactivate after the charge status rises back up to the chosen deactivation status. This

type is designated in the display as “PA S”

The “PA S” type alarm is set in exactly the same way as the “PA U” alarm except “PA S” is selected instead of “PA

U”. i.e. the activation status will be set, followed by the deactivation status.

SECTION 4.4 – SET UP MODE –

Clarication:

1. The SoC% has to fall below the activation status to trigger the alarm.

2. The SoC% has to rise to the deactivation status to kill the alarm. The range limits are:

1. Activation status = 1 to 75%

2. Deactivation status = activation status to 100%

Factory defaults are activation status = 50%, deactivation status = 95%. These would be typical gures used for

an auto start gen-set (See Note 2 in addendum for additional information).

The “PA t” alarm is slightly different. If this alarm is set, the alarm will trigger (be activated) once the charge status falls below the activation status. The alarm will remain triggered until the status rises back up to the same

activation level but then, once this happens, a timer is started which counts down from the set time period, and

when it reaches zero, the alarm is deactivated. The main reason for this

type of alarm is to enable an auto start generator set to be started once

the charge status falls to a certain level and then run for a certain xed

period (see Note 2 in addendum).

On selecting “PA t” the display will ash to show the value was written

to memory. The display will then show “xx” which is the charge status

below which the actual battery charge status will have to fall in order to

trigger (activate) the alarm output. This is the activation status. The factory default for this value is 50%. Pressing the SELECT button will scroll

this value up to and including 75%. It will then cycle to 1 and continue to

scroll upwards. When the desired value is displayed, press the SET button to write the value to memory, the display will ash as usual. The activation status is now set. Note that this activation status shares the same memory

as that used for the normal low status alarm. So changing one, will change the other.

ALARM FUNCTIONS

PAGE 12

The display will now show “tx.xx”, indicating the time, in hours and minutes, that the alarm will remain activated.

The default is 4 hours. However, if an alarm of this type is actually active when you enter the set-up menu (i.e.

the alarm LED is on), then this gure will be the current time remaining, on the current countdown timer, rounded

to the nearest 15 minutes. This enables the user to increase or decrease the

remaining time for an existing alarm timer run.

Pressing the SELECT button will increase this time in steps of 15 minutes up

to a maximum of 9 hours and 45 minutes and cycle back to 15 minutes. Once

the desired time is reached, pressing the SET button will, as usual, cause the

display to ash, the value will be written to memory and the display will move

on to the next item in the set-up menu.

If an alarm is not active at the time you enter the set-up menu then this time

period will become the default time period for all future status timed alarms.

Remember, changing alarm type will cancel any currently active alarms. If this

menu item is entered while a timed alarm run is active and it shows the time remaining on the current run (as opposed to your default run time), only the time

remaining on the current run will be affected.

The normal full time for a timed alarm run will not be changed and will remain

as you last set it (or at the factory default if no changes have been made). It

is not possible to change the default run time whilst a timed alarm run is active. Note that this timed period is

approximate. The timed period and the display will be accurate to within about 10% Also note that internally

Smartgauge™ counts in seconds whereas the display only shows the minutes. It is rounded to the nearest minute so when the display counts down and reaches zero, there could in fact be 30 seconds remaining.

Set-up mode - Alarms – General

Once an alarm is triggered, the alarm output will activate. The Alarm LED on the front panel will illuminate and

the display will alternate between its current display (for 3 seconds) and the alarm display (for 1 second). The

PAGE 13

alarm display will either show “A LU” for Alarm Low Voltage, “A HU” for

Alarm High Voltage or “A LS” for Alarm Low Status. If “PA t” has been

set, then when the alarm triggers, the display will alternate in 2 ways. It

will show the current display (3 seconds), then it will show “A Lt” (Alarm

Low status timed),(1 second), it will then revert to the normal display (3

seconds), it will then show the time in hours and minutes until the alarm

is due to deactivate (for 1 second). For 9 hours 45 minutes, the display

would show “t9.45”. Note that when the display reaches 0.00 there could

actually be up to 30 seconds remaining. This is because the timer does

not display the seconds.

Changing the alarm type will cancel any currently active alarms. Alarm

set points and timers can be changed, and the existing alarm will remain

active. But actually changing the alarm type (such as from low voltage

to low status) will cancel the currently active alarm. This is a simple way

of cancelling an active alarm. If the display is in sleep mode then the

alarm output will still activate but the alarm status display will not show,

however the Alarm LED on the front panel will still light up. Pressing

either button will show what type of alarm has activated in case you

forget which type you set. And in the case of “PA t” will show the time

remaining before deactivation.

SECTION 4.4 – SET UP MODE –

ALARM FUNCTIONS

Indicates Alarm – High Voltage

Indicates Alarm – Low Voltage

Set-up mode - Secondary Alarm

The secondary alarm activates the alarm output, which can drive an external audible warning device or warning

light in an error code event. The display will show “SA x”, “SA” signifying Secondary Alarm, “x” showing the current setting. The default is “O”, Off. “x” can be set to any of the following:- O Off Default. Error codes will never

activate the alarm output.

U Voltage Error codes E 02 and E 03 (low- or high-voltage warnings for selected battery type) will activate the

alarm output. Note that if error codes are disabled (the next function in the set-up menu) this secondary alarm will

not operate. Range Error code “E04” (measurement range error) will activate the alarm output. Power lost Error

code “E01” (Power lost) will activate the alarm output. Note that if any error codes are disabled (the next function

in the set-up menu) then the disabled error codes will not activate this alarm.

SECTION 4.5 – SET UP MODE –

In some circumstances, it may be necessary to defeat the error code functions in Smartgauge™. Most

installations, particularly those where loads are used at the same time as charging, use what are known as 2 or

3 stage chargers. These chargers use a combination of an initial (the rst stage) “constant current” charge cycle

(usually referred to as the bulk stage) then switch to a second stage of constant voltage (usually referred to as

the acceptance or absorption cycle). Three stage chargers then switch to a third cycle known as “oat”. These

types of chargers usually keep to within very well accepted voltage limits during the charge cycle.

Certain constant voltage chargers may provide a very high charge

voltage of around 16 volts or more for a short period of time which can

trigger repetitive or continual E 03 error codes in Smartgauge™. For this

reason the next setting on the set-up menu allows error codes E 02 and

E 03 to be defeated. The display will show “EC x” signifying Error Codes

and “x” being either “1” for error codes enabled (the default) or “O” for

error codes disabled. Note that this setting only affects error codes E 02

and E 03. The other error codes will continue to operate. Note that error

code E 02 is a low voltage warning code. The reason this code is also

disabled is that users of the types of chargers that may trigger the E 03 error code are usually experienced users

who are aware of how far they can push batteries in order to get the maximum usage from them.

DEFEATING ERROR CODES

SECTION 4.5 – SET UP MODE –

If the “Secondary Alarm” function has been set to activate the alarm on E 02 or E 03, or set to activate the alarm

on all error codes, and E 02 and E 03 have been disabled then they will no longer trigger the alarm. The remaining error codes will still activate the alarm as programmed.

DEFEATING ERROR CODES

PAGE 14

SECTION 4.6 – SET UP MODE –

There are three display modes available in the Smartgauge™. The modes

apply whether the display is showing volts or charge status.

The default factory setting displays for 2 minutes before going into sleep

mode. This mode is signied in the set-up menu as “dt t” meaning display

type = timed. This display will remain active for 2 minutes following a button

press. It will then go back to sleep. Pressing a button will switch the display

back on for another 2 minutes.

The second display mode is “dt A” meaning “display type = Always” where the

display will always be on and will never go into sleep mode.

The third display mode is “dt U” meaning “display type = Voltage” where the

display will go into sleep mode, after 2 minutes, as usual, below a certain voltage but will always remain on above a certain voltage. This voltage is actually

the upper voltage trip point for the high/low voltage alarm. The factory default

setting for this is 13.20 volts (26.40 volts on 24 volt systems). So if this display mode (“dt U”) is selected and the alarm factory defaults have not been

adjusted, the display will blank as normal after 2 minutes if the battery voltage

is below this level but will always be on above this voltage. This makes sense

in so far as if the battery voltage is above this level then clearly the batteries

are either being charged or they are well charged and in either case the extra

few milliamps of power consumed is not an issue. It also allows a keen eye to

keep watch on the battery charge voltage without having to continually press

buttons. But when the charger is switched off Smartgauge™ will revert to the

minimum required current draw by blanking the display 2 minutes later.

DISPLAY BEHAVIOR

Note that whilst this setting uses the upper deactivation voltage level of the

low voltage alarm, the low voltage alarm does not have to be enabled or

ac- tive for this function to operate. The two functions merely share the same

value.

To select the display mode, enter the set-up menu as usual, then press the VOLTS button until “dt x” is displayed.

“dt” signifying display type, the x showing either t, A or U. Now press the STATUS button to scroll through the

three or four values. Press VOLTS to conrm the choice. The display will ash to show the value has been written

to memory. The display will then move onto the next menu item.

SECTION 4.7 – SET UP MODE –

The display brightness is fully adjustable to enable the Smartgauge™ to be used in any light conditions. One

of the advantages of this type of display (LED – Light Emitting Diode) as opposed to the other common display

(LCD – Liquid Crystal Display) is that they can be read in zero light conditions as well as daylight. To adjust the

display brightness enter the set-up menu, then press the VOLTS key until

“db x” is displayed. “db” signies display brightness, x indicates the current

brightness which will be from 1 to 8. The factory default value is 4.

Pressing the STATUS button will scroll through the values, cycling to 1 when

8 is reached. You will see the brightness change as you scroll through the

values. When you nd the brightness level that best suits your environment,

press the VOLTS button. The display will ash to show the value has been

stored then Smartgauge™ will move on to the nal item in the set-up menu.

DISPLAY BRIGHTNESS

PAGE 15

SECTION 4.8 – SET UP MODE –

MENU LOCK

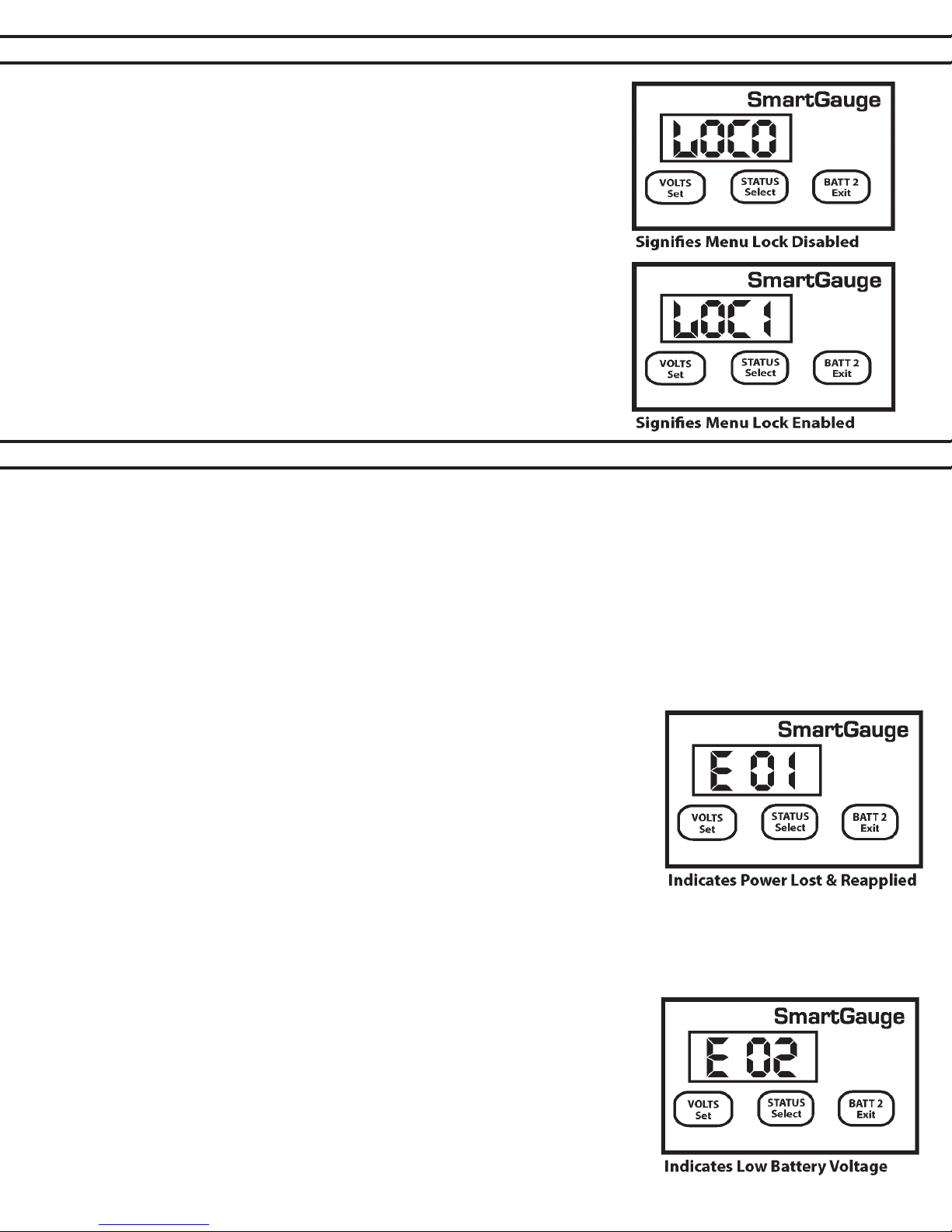

The last item in the set-up menu will display Loc0. This allows access to

the set-up menu to be denied.

Pressing STATUS will alternate between Loc0 (meaning lock is disabled)

and Loc1 (meaning lock is enabled). Setting Loc0 will allow Smartgauge to

continue to operate exactly as before. Setting Loc1 will prevent future access to the set-up menu. All other functions of Smartgauge remain iden- tical. If Loc1 is set, then any future attempts to enter the set-up menu will be

completely ignored. In order to unlock Smartgauge™ it will be necessary

to attempt to perform a “reset to factory defaults”.

If the lock is disabled (Loc0), then “reset to factory defaults” will operate as

usual. If the lock is enabled (Loc1) then attempting to perform a “reset to

factory defaults” will not do so. It will simply unlock the unit to, once again,

allow access to the set-up menu.

SECTION 5.0 – ERROR CODES

Error codes do not indicate a problem with Smartgauge™. They indicate a problem with the installation or other

equipment such as chargers. For instance, a continual “E03” error signies a charger fault, not a Smartgauge™ fault.

With all “Exx” type error codes, the code is displayed alternately with the current display. If the display has gone into

sleep mode, the error code will still be displayed. This is to ensure that an error does not go unnoticed

The error code will continue to be displayed after the fault condition that caused the error has cleared. This means

that if, for instance, the charger is intermittently faulty, and occasionally charging at a much higher voltage than it

should be, this would force an error “E03” which would remain in the display even after the charger had gone back to

functioning correctly. In order to clear the error code simply press any button.

If another error occurs while an earlier error is displayed, the new error code will take precedence. The exception to

this is the unique case of an “E01” (lost power) error. This error takes precedence over all other errors.

“E01” – Power was lost and reapplied.

If power to the Smartgauge is lost, the Smartgauge™ has no way to to

determine the duration of power loss. Therefore, the “E01” may indicate that the

charge status may be incorrect and that any primary status alarms will have been

disabled. Alarm set points will still be as they were last set but the actual alarm will

be switched off and will remain so until re enabled by the user. Any low voltage

alarms or secondary alarms will remain set as they were prior to the power loss.

Pressing any button will clear the “E01” error code. The display will then show

the time in hours and minutes since power was reapplied (up to a maximum of

99 hours, 59 minutes). Pressing any button will clear this display. If no button is

pressed, the display will time out after 2 minutes then revert to normal

operation. While showing the time since re-power, the PGM LED will ash.

As with all errors, using the Secondary Alarm function described in the section regarding the set-up menu it is

possible to set the “E01” error to trigger the alarm output, perhaps to sound an audible alarm or light up a warning

light.

“E02” – Battery voltage has been below acceptable level for battery type.

Each battery type has certain voltage and time limits, which, if exceeded, may

damage the batteries.

For instance if a deep-cycle lead acid battery experiences a terminal voltage

lower than 10.2 volts for any appreciable length of time it may cause serious,

immediate, permanent damage to the battery. Smartgauge™ has different voltage

and time limits for each battery type. If this limit is exceeded then Smartgauge™

will generate an “E02” error. This error will alert the user to the problem. Be

SECTION 5.0 – ERROR CODES

aware that if this error code occurs it is an indication of a sever problem in the installation that, if allowed to persist,

will eventually destroy the batteries. Note that this error means the voltage and time limits have been outside of

range since a button was last pressed. It does not mean they are currently being exceeded. The error is stored

after the fault has cleared until the error is cleared by pressing a button.

PAGE 16

“E03” – Battery voltage has been above acceptable level for battery type.

This is similar to “E02” but for high voltage. The voltage level and time limits vary

dependent upon battery type. For example a wet cell antimony/antimony battery is far

more tolerant of high voltage levels than Gel cells and AGM types. Wet cell

calcium batteries are even more tolerant than antimony/antimony. Wet cell batteries

can tolerate 15 volts or more for long periods of time (always assuming the production

of explosive gasses is dealt with) whereas even 14.6 volts could severely damage Gel

cell or AGM batteries in a very short time.

This error means the voltage and time limits have been exceeded since the last error

was cleared. It does not mean they are currently being exceeded. The error is stored

after the fault has cleared until the error is cleared by pressing a button. Error codes

E 02 and E 03 can be disabled by the user. Refer to Section 4.5 for instructions.

“E04” – Battery voltage has been above acceptable level for battery type.

SmartGauge™ can accurately measure voltages between 9.00 and 17.00 volts in 12 volt mode and between 18.00

and 34.00 volts in 24 volt mode. If these limits are exceeded SmartGauge™ has no way of measuring the actual

voltage. Also, if these limits are exceeded there is something seriously wrong with the

installation. Such extreme voltages simply should not arise and indicates a serious

problem with the charging system.

HI Battery voltage is above upper measurement limit of 17.00 volts (34.00 volts in 24

volt installations).

LO Battery voltage is below lower measurement limit of 9.00 volts (18.00 volts in 24

volt installations). Note that Hi and LO errors will clear as soon as the voltage returns

to within the measurement range. They will, however, leave an “E04” error code on

the display. Repeated displays of the “E04” error code may indicate a system ground

error or a potential battery cell fault. The “E04” error indicates a condition which should

be addressed by a qualied electrician.

SECTION 6.0 – RESET TO FACTORY DEFAULT

Circumstances such as change of battery technology, or the need to override a

menu lock, require that you return the Smartgauge™ to its Factory Default state.

To return the monitor to its default settings:

1. Disconnect the power feed to Smartgauge™ (pull the fuses in each feed wire out).

2. Press both the VOLTS and STATUS buttons and keep them pressed.

3. Reapply power, still keeping the buttons pressed.

4. Smartgauge™ will display the software revision as usual. Keep the buttons pressed.

5. Smartgauge™ will display the battery model revision as usual. Keep the buttons

pressed.

6. The display will go blank.

7. Remove your ngers from the buttons.

8. Smartgauge™ will ash “Fr” (Factory reset).

9. Smartgauge™ will completely reset its internals to the factory defaults.

Smartgauge™ will now operate exactly like a new unit on rst power up

beginning by displaying the software revision. NOTE – If the set-up menu

lock had been set prior to this, then attempting to perform a “reset to factory

defaults” will not do so on the rst attempt. It will simply disable the menu

lock. A second attempt will perform the reset to factory defaults.

PAGE 17

1. The alarm output consists of 3 terminals labelled COM

(Common), NC (Normally Closed) and NO (Normally Open).

COM is connected internally via a relay to the NC terminal and

disconnected from the NO terminal. When an alarm is

activated the COM terminal is internally connected to the NO

terminal and disconnected from the NC terminal. At no time

are NC and NO terminals connected together (break before

make).

These three terminals are totally isolated from the rest of

Smartgauge ™ which means you can use them for more or less

anything within the following constraints:

1. The maximum voltage between any of the three terminals and/or the DC system to which Smartgauge™ is

connected is 48 volts. Exceeding this voltage may damage Smartgauge™, and will invalidate warranty.

2. The maximum permissible current to be carried by the alarm terminals is 500mA (0.5 amps). Exceeding this

current may damage Smartgauge and invalidates the warranty.

If either of these need to be exceeded then use the alarm output to operate an external relay with the required

specications.

SECTION 7.0 – ALARM OUTPUTS

SECTION 8.0 – ALARM NOTES

Assuming the low voltage alarm has been enabled it operates as follows:

1. Assume the low voltage activation setting is set to 12.00 volts and the deactivation setting is set to 13.20

volts. The battery voltage is at 12.6 volts. The alarm output is not active. COM is connected to NC. NO is not

connected to anything. The alarm LED is unlit.

2. As the battery voltage falls eventually it will reach 12.00 volts. The alarm output remains as above. When the

battery voltage falls to 11.99 volts (i.e. below the activation level) the alarm output will activate. COM is now

connected to NO. NC is not connected to anything. The alarm LED will light up. An audible alert connected

to the batteries via COM and NO will now beep.

3. As the voltage rises to say 12.80 volts the alarm output remains in this state. The battery voltage rises to

13.20 volts, the alarm output deactivates, COM is once again connected to NC and NO is connected to

nothing. The alarm LED will go off again. The sounder will go silent. Operation of the standard low status

alarm is identical to that of the low voltage alarm except, of course, that it operates on the charge status as

opposed to the battery voltage. Timed low status operates slightly differently. (See Section 9.0 Addendum.)

SECTION 9.0 – ADDENDUM

Charge Status during charging and discharging

During discharge, the Smartgauge™ accurately tracks the State of Charge of the batteries. When the opportunity

arises, the Smartgauge™ polls the battery voltage and uses the results of this measurement to compare with

its calculated gures for charge status. Smartgauge™ uses this information to adjust its battery model and the

Smartgauge™ algorithm so that future discharge cycles become more and more accurate. This is one of the

ways in which Smartgauge™ automatically adjusts itself to compensate for battery aging and the consequent

reduced battery capacity as they get older. This is also one of the ways in which Smartgauge™ is superior to a

meter based on the amp hours counting principle. This is a continual process that continues throughout the life

of the batteries so that Smartgauge™ always shows the percentage power remaining as a fraction of the actual

currently available battery capacity, as opposed to a percentage of what used to be available when the batteries

were new.

Discharging is the important phase, as this is when one really needs to know the State of Charge. During charging this is not possible due to the presence of the charger preventing Smartgauge™ ever getting an opportunity

to actually measure the charge status. In effect, if it tried, it would be attempting to measure the charge status

of the charger. During charging, Smartgauge™ only shows the calculated charge status as does an amp hours

counter. However Smartgauge™, because it operates on a different principle, calculates a charge status that is

PAGE 18

much more accurate. For this reason, it is possible that, during the charge cycle, the charge status displayed may

not be totally accurate. It will be within 10% of the actual battery charge status.

(Note that once discharging commences, Smartgauge™ will automatically re-synchronize itself within the rst

few minutes of discharge or within the rst 10 minutes of resting if no load is present. Smartgauge™ uses this

information to modify its battery models and algorithm to increase the accuracy of future calculations)

Smartgauge™ will provide a dependable indication (certainly better than an amp hours counter – and certainly

better than a volt meter but it could be that Smartgauge™ shows the charge status to have reached (as a worst

case example) 100% when in actual fact the batteries have only reached 90%.

Not charging to 100% charge state is one of the most common reasons for premature battery failure. Not charging to 100% (or occasionally well in excess of 100%) causes sulfation of the plates which is the main cause of

early battery failure. Therefore, as when using any form of charge status meter, and if using an intelligent charger, do not shut the charger down when Smartgauge™ indicates 100% SoC. Instead, rely upon the charger,

which can reach a much more accurate measurement of when the batteries are actually fully charged.

Also consider the possible results of using the Primary Alarm set to operate on charge status. If this is being

used to operate an auto start generator and charger, and the generator is regularly shut down before reaching

100% charge status this, again, will cause the plates to sulfate.

This is the reason for the option to set the low status alarm to operate for a xed period of time instead of

until reaching a certain charge status. In some installations it may be better to use this option to ensure that the

generator is run for a sufcient period of time. Either way, once discharging commences, Smartgauge™ will resynchronize itself (whatever the nal true charge status that was reached – i.e. it will not simply assume 100%

charge status, as many amp-hours counters do) and then give a true indication of the charge status throughout

the discharge cycle.

SECTION 9.0 – ADDENDUM

Conversely, it may be the case that the Smartgauge only reaches 90% charge status during the charge cycle

when in actual fact the batteries have reached 100% charge status and the intelligent charger has gone into

oat charge. If this happens, again Smartgauge™ will re-synchronize itself during the rst stage of the discharge

cycle.

Whatever happens, whenever Smartgauge™ “gets it wrong”, Smartgauge™ realizes, corrects itself, and uses

the information to modify its battery models and algorithm. An amp-hours counter simply “gets it wrong”, and

does nothing about it, and runs further and further adrift from the true State of Charge.

Smartgauge™ will NOT run out of synchronization with the batteries.

SECTION 10.0 - SPECIFICATIONS

PAGE 19

SECTION 11.0 – WARRANTY

Smartgauge™ is warranted to be free of workmanship defects for a period of 2 years. In the event of a warranty claim,

please contact Balmar Customer Service at +1-360-435-6100 for a return authorization.

Exclusions to this warranty include:

1. Opening the case.

2. Any form of external damage to the case such as drilled holes (excluding the 4 pre-drilled mounting holes) etc.

3. Use of the equipment in any manner not described in this owner’s manual.

4. Attempted modications.

5. Excess voltage or current as a result of incorrect installation.

6. Exceeding the rating of the alarm outputs.

7. Attempting to plug any non-approved equipment into the Smart interface state of chargeket or using the incorrect

type of communications lead.

8. Incorrect installation.

Visit www.balmar.net for more information regarding Balmar warranty policies and procedures.

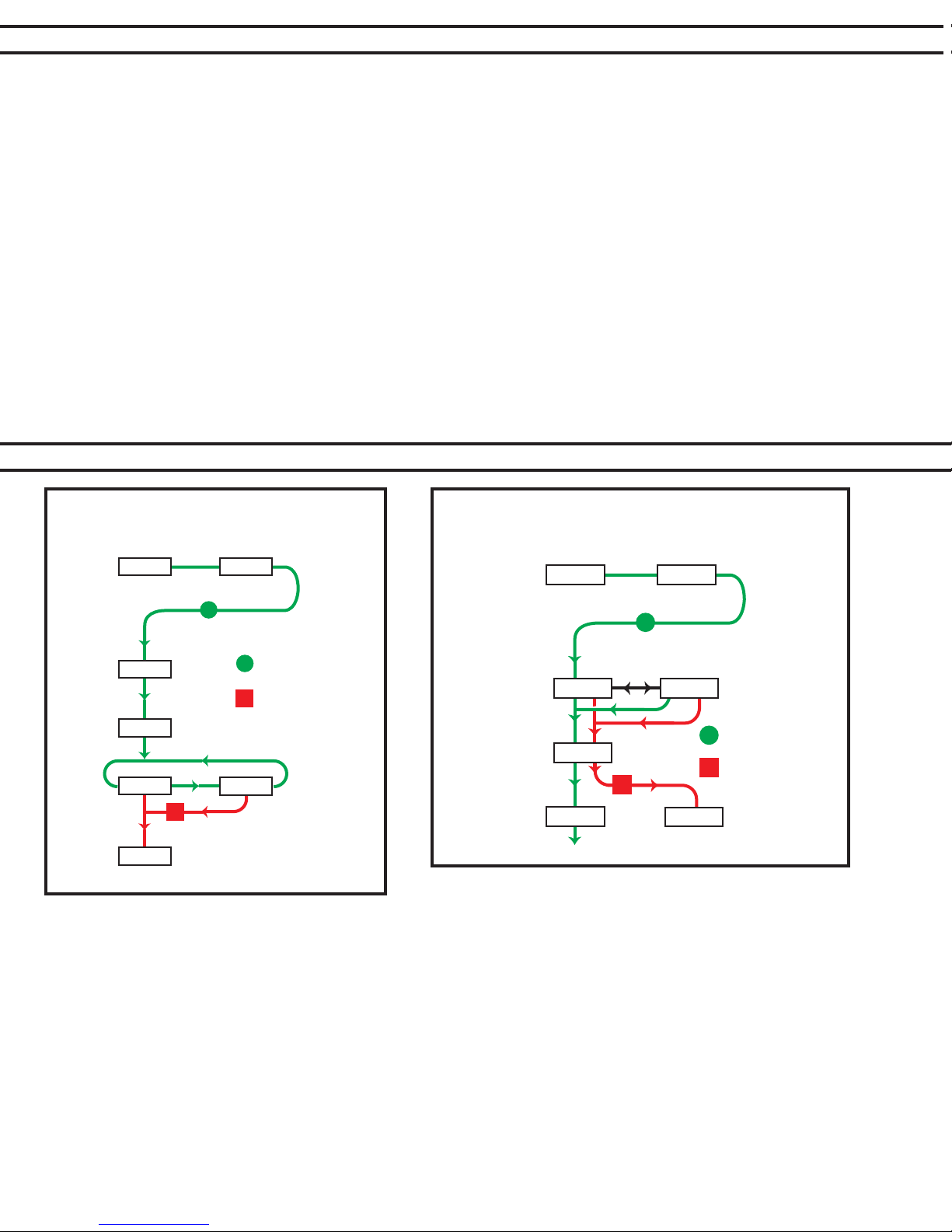

SECTION 12.0 – SMARTGAUGE FLOW CHARTS

12.1 – Display Mode

First Time Power Up/Following Factory Reset

Software

Revision

Checking

System

Voltage

System

Voltage

Selected

r 1.03

b 1.05

SC

SC 12

bt 1 bt 6

12.65

Normal

Display

Selections

STATUS BUTTO N

VOLTS BUTTO N

Battery Model

Revision

Battery

Type

Selections

Software

Revision

Alternatin g

Error/Voltage

Time Since

Re-Power

Hours/Minutes

Normal Display

Voltage

12.2 – Display Mode

Power Up Following Power Failure

r 1.03

12.65

XX.XX

12.65 C 75

b 1.05

E 01

STATUS BUTTO N

VOLTS BUTTO N

Battery Model

Revision

Normal Display

Charge Status

© Copyright 2016 Balmar LLC, Marysville, WA 98271 USA - Reproduction of this manual or any of its parts is

strictly forbidden without express written permission. For more information about this and other Balmar DC charging products,

bisit, www.balmar.net

SECTION 12.0 – SMARTGAUGE FLOW CHARTS

12.3 – Set Up Menu

PAGE 20

12.65

bt x

C X X

PA 0

LO

C 76

PA U

11.8

13.3

HI

PA S

C 50

C 95

NORMAL

OPERATIO N

VOLTS BUTTO N

STATUS BUTTO N

BATT 2 BUTTO N

PA T

C 50

T1.45

SA 0

EC 0 EC 1

dt t dt A dt U

db x

Loc 0

SA U SA r SA P SA A

Loc 1

12.65

NORMAL

OPERATIO N

Loading...

Loading...