OPERATOR'S MANUAL

LRP830-Series

Long-Range Passive

Reader/Writers

Manual Revision 3, July, ‘00

Publication #17-1271

Escort Memory Systems Warranty

Escort Memory Systems warrants that all products of its own manufacture conform to Es

cort Memory Systems specifications and arefreefromdefects in material and workmanship

when used under normal operating conditions and within the service conditions for which

they were furnished. The obligation of Escort Memory Systems hereunder shall expire one

(1) yearafter delivery, unlessotherwisespecified,andis limited to repairing, or at its option,

replacing without charge, any such product which in Escort Memory System's sole opinion

proves to be defective within the scope of this Warranty. In the event Escort Memory Sys

tems is not able to repair or replace defective products or components within a reasonable

time after receipt thereof, Buyers shall be credited for their value at the original purchase

price. Escort Memory Systems must be notified in writing of the defect or nonconformity

within the warranty period and the affected product returned to Escort Memory Systems

factory or to an authorized service center within thirty (30) days after discovery of such de

fect or nonconformity. Shipment shall not be made without prior authorization by Escort

Memory Systems.

This is Escort Memory Systems' sole warranty with respect to the products delivered here

under. No statement, representation, agreement orunderstandingoral or written, made by

an agent, distributor, representative, or employee of Escort Memory Systems which is not

contained in this warranty, will be binding upon Escort Memory Systems, unless made in

writing andexecutedby an authorized Escort Memory Systems employee. Escort Memory

Systems makes no other warranty of any kindwhatsoever,expressedorimplied, and all im

plied warranties of merchantability and fitness for a particular use which exceed the

aforestated obligation are hereby disclaimed by Escort Memory Systems and excluded

from this agreement. Under no circumstances shall Escort Memory Systems be liable to

Buyer, in contract or in tort, for any special, indirect, incidental, or consequential damages,

expenses, losses or delay however caused.

Equipment or parts which have been subject to abuse, misuse, accident, alteration, neglect, unauthorized repair or installation are not covered by warranty. Escort Memory Systems shall make the final determination as to the existence andcauseofanyalleged defect.

No liability is assumed for expendable items such as lamps andfuses. No warranty is made

with respecttocustom equipment or products produced to Buyer's specifications except as

specifically stated in writing by Escort Memory Systems in the contract for such custom

equipment.

This warranty is the only warranty made by Escort Memory Systems with respect to the

goods delivered hereunder, and may be modified or amended only by a written instrument

signed by a duly authorizedofficerofEscort Memory Systems andacceptedbythe Buyer.

Extended warranties of up to four years are available for purchase for most EMS products.

Contact EMS or your distributor for more information.

-

-

-

-

-

This document contains proprietary informationwhich is protected by copyright. All rights are re

served. The information in this manual has been carefully checked and is believed to be accu

rate; however, no responsibility is assumed for possible inaccuracies or omissions.

Specifications are subject to change without notice.

EMS®, Escort Memory Systems® and the EMS® logo are registered trademarks of Escort

Memory Systems, aDatalogic Group Company. Other brand and product names mentionedare

trademarks or registered trademarks of their respective holders.

Escort Memory Systems

A Datalogic Group Company

170 Technology Circle

Scotts Valley, CA 95066

Telephone (831) 438-7000

FAX (831) 438-5768

www.ems-rfid.com

email: info@ems-rfid.com

Copyright © 2000 Escort Memory Systems

ii LRP830-Series Long-Range Passive Reader/Writer

-

-

TABLE OF CONTENTS

1GETTING STARTED 1

1.1 Introduction.........................1

1.2 Unpacking and Inspection .................3

2MECHANICAL SPECIFICATIONS 4

2.1 Dimensions .........................4

2.2 RF Range and Orientation .................7

2.3 Mounting Guidelines ...................12

Guidelines .........................13

3POWER AND ELECTRICAL INTERFACE 14

3.1 Connector Panel ......................14

3.2 Power Connector .....................15

3.3 COM1/COM2 Connector .................15

Serial Communications Cabling .............16

3.4 DeviceNet Connector ...................16

3.5 Input Connector ......................17

3.6 Output Connector .....................17

3.7 Digital I/O Wiring.....................18

Inputs ...........................18

Outputs ..........................18

3.8 Power Requirement ....................23

Power Options.......................23

Power from the DeviceNet Bus ..............24

Power via the external supply connector .........24

Power from the DeviceNet bus and from an external power

supply ...........................26

3.9 LED Indicators ......................27

4SERIAL AND BUS COMMUNICATIONS 29

4.1 Serial Interfaces ......................29

Digital Board DIP Switch .................30

4.2 Bus Interfaces .......................32

DeviceNet Interface Board DIP Switch .........33

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

iii

5MENU CONFIGURATION 35

5.1 How to Enter Menu Configuration ............35

5.2 Set-up Operating Parameters ...............36

Set COM1 Parameters...................37

Set COM2 Parameters...................37

Set Operating Mode ....................37

Set RF Communication ..................39

Restore Factory Defaults .................39

Return to Main Menu ...................40

5.3 Download New Program .................40

5.4 Downloading DSP Firmware ...............40

5.5 Exit to Operating Mode ..................41

6 RFID INTERFACE 42

6.1 Introduction ........................42

Command Timeout ....................42

DeviceNet and Anticollision ABx Limitations ......44

6.2 ABx Error Codes .....................45

Non-Anticollision Error Codes ..............45

ABx Standard .......................45

ABx Fast .........................46

Anticollision Status Byte .................47

6.3 Anticollision Commands .................48

Family Interrogation ...................48

Family ID .........................48

Anticollision Index ....................49

6.4 ABx Standard Protocol ..................51

ABxS Command 4 (04H): Fill Tag ............51

ABxS Command 5 (05H): Block Read ..........53

ABxS Command 6 (06H): Block Write..........55

ABxS Command 7 (07H): Read Tag Serial Number . . . 57

ABxS Command 8 (08H): Tag Search ..........58

ABxS Command D (0DH): Continuous Block Read . . . 59

ABxS Command 10 (10H): Set Output ..........62

ABxS Command 11 (11H): Input Status .........64

ABxS Command 84 (84H): Fill Tag All .........66

ABxS Command 85 (85H): Block Read All .......68

ABxS Command 86 (86H): Block Write All .......70

ABxS Command 87 (87H): Read Tag SN All ......72

Copyright © 2000 Escort Memory Systems

iv LRP830-Series Long-Range Passive Reader/Writer

ABxS Command 88 (88H): Tag Search All .......74

ABxS Command 89 (89H): EAS Set/Reset All......75

ABxS Command 8A (8AH): EAS Start/Stop .......76

ABxS Command 8D (8DH): Continuous Read All ....78

ABxS Command 8E (8EH): Memory Lock All......80

ABxS Command 94 (94H): SN Fill............82

ABxS Command 95 (95H): SN Block Read ......84

ABxS Command 96 (96H): SN Block Write .......86

ABxS Command 97 (97H): SN Block Read All .....88

6.5 ABx Fast Protocol.....................90

ABx Command Packet Structure: .............90

Command/Response Size .................91

Checksum .........................92

ABxF Command 4 (04H): Fill Tag ............93

ABxF Command 5 (05H): Block Read ..........95

ABxF Command 6 (06H): Block Write..........97

ABxF Command 7 (07H): Read Tag Serial Number . . . 99

ABxF Command 8 (08H): Tag Search .........101

ABxF Command D (0DH): Continuous Block Read . . 102

ABxF Command 10 (10H): Set Output .........105

ABxF Command 11 (11H): Input Status ........107

ABxF Command 84 (84H): Fill All ...........109

ABxF Command 85 (85H): Block Read All.......111

ABxF Command 86 (86H): Block Write All ......113

ABxF Command 87 (87H): Read Tag SN All......115

ABxF Command 88 (88H): Tag Search All .......117

ABxF Command 89 (89H): EAS Set/Reset All .....119

ABxF Command 8A (8AH): EAS Start/Stop ......121

ABxF Command 8D (8DH): Continuous Read All . . . 124

ABxF Command 8E (8EH): Memory Lock All .....127

ABxF Command 94 (94H): SN Fill ...........130

ABxF Command 95 (95H): SN Block Read ......132

ABxF Command 96 (96H): SN Block Write ......134

ABxF Command 97 (97H): SN Block Read All.....136

6.6 ABx ASCII Protocol ...................140

Command Packet Structure: ...............140

Command/Response Size ................141

Checksum ........................142

Example ASCII Command ...............142

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

v

7 LRP830 DEVICENET INTERFACE 144

7.1 Introduction .......................144

Scan Rates ........................144

COM1 LED Indicator ..................145

DeviceNet Interface ...................145

7.2 Interface Board Monitor Mode .............145

Enter Interface Board Monitor..............145

7.2.1 Downloading Firmware to the Interface Board .....147

7.2.2 Downloading with the EC Emulation Program .....148

7.2.3 Display Interface Board Configuration Parameters . . . 148

7.2.4 Interface Board Configuration Editor ..........150

7.2.5 Edit Configuration Command. ..............151

7.2.6 Configuration Parameter Validation ...........153

7.2.7 Standard DeviceNet Parameters .............154

Produce and Consume Sizes ...............154

Produce size — ABx Standard, 8 Byte Read ......154

Produce size — ABx Fast, 8 Byte Read ........155

Consume size — ABx Standard, 8 Byte Read .....155

Consume size — ABx Fast, 8 Byte Read ........156

LRP830 Transmit Message Size .............156

LRP830 Receive Message Size .............157

Protocol: Poll or Strobe .................157

DeviceNet Serial Number ................157

7.2.8 LRP830 Specific Parameters ..............158

Device Type .......................158

ABx separation......................158

ABx Non-separation ...................158

Polled Commands in ABx Non-separation Mode ....159

Error Management ....................159

Trigger Feature .....................160

Buf Flush Enable.....................161

Buf Flush Delay .....................161

7.2.9 Device Type Protocols. .................162

Generic Device Type Protocol..............162

Header Device Type Protocol ..............163

Copyright © 2000 Escort Memory Systems

vi LRP830-Series Long-Range Passive Reader/Writer

ASPECIFICATIONS 165

BMODELS AND ACCESSORIES 166

C ASCII CHART 168

D LRP830 DEMONSTRATION 170

Before You Begin ....................170

Using DNSW32 or DNSW16 ..............171

EDEVICENET PROTOCOL EXAMPLES 178

Header Device Type Protocol ..............179

Header Format ......................179

Header Device Type Command Protocol ........182

Calculating Message Size ................183

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

vii

NOTICE

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate ra

dio frequency energy and, if not installed and used in accordance with the in

structions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try and correct the interference by one or

more of the following measures:

Reorient or relocate the receiving antenna.

n

-

Increase the separation between the equipment and the re

n

-

ceiver.

Connect the equipment into an outlet on a circuit different

n

from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for

n

help.

CAUTION

Changes or modifications not expressly approved by Escort Memory Systems could void the user’s authority to operate the equipment.

Copyright © 2000 Escort Memory Systems

viii LRP830-Series Long-Range Passive Reader/Writer

1 GETTING STARTED

1.1 Introduction

Escort Memory Systems' passive read/write system is a complete family of

field-proven read/write Radio-Frequency Identification products. The sys

tem consists of RFID tags, reader/writers, antennas, controllers, bus inter

faces, and ancillary equipment. Tags can be attached to a product or its

carrier and act as an electronic identifier, job sheet, portable database, or

manifest. Tags are read and updated via an Escort Memory Systems

Reader/Writer, through any nonconductive material, while moving or stand

ing still.

Escort Memory Systems' LRP-Series long-range passive RFID system is the

latest in our line of high performance, industrial RFID equipment. The passive design of the LRP read/write system uses the RF field from the antenna

to power the tag, eliminating the need for tag batteries. The LRP passive

read/write system is designed to provide cost effective RFID data collection

and control solutions to automation and material handling applications.

The LRP system uses the internationally recognized ISM frequency of 13.56

MHZ to both power the tag, and to establish a radio link to transfer the information.

-

-

-

The LRP830 is specifically designed to work with LRP-Series passive tags,

which provide 48 bytes of reprogrammable memory.

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

1

The LRP830 supports the industrial bus protocol DeviceNet. The LRP830

is encased in a NEMA4 enclosure and features two serial ports, 4 optoisolated inputs, 4 opto-isolated outputs. The LRP830-04 is equipped with

an antenna designed for conveyor mounting and the LRP830-08 features a

rectangular plate antenna.

The COM1 serial port is used to receive commands from the host and to

send the data back. The LRP830 COM1 can be configured either as a

DeviceNet, RS232, or RS422 interface.

COM2 is an RS232 serial port used to download new software releases and

to setup the configuration parameters.

Copyright © 2000 Escort Memory Systems

2 LRP830-Series Long-Range Passive Reader/Writer

1.2 Unpacking and Inspection

Unpack the LRP830 and documentation and retain the original shipping

carton and packing material in case any items need to be returned. Inspect

each item carefully for evidence of damage. If any item appears to be dam

aged, notify your distributor immediately. The LRP830 is delivered with the

following components:

LRP830 (-04, -08) Reader/Writer

n

LRP830 to Antenna Cable

n

LRP830 Operator's Manual

n

The following components are required for configuring a complete system:

LRP-Series Passive Read/Write Tags

n

User supplied LRP830-to-host cable

n

DeviceNet host

n

18 - 30 Vdc, 36 W (1.5 A @ 24 Vdc) power supply

n

n

Mating connectors. Please see Appendix B for more

information.

-

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

3

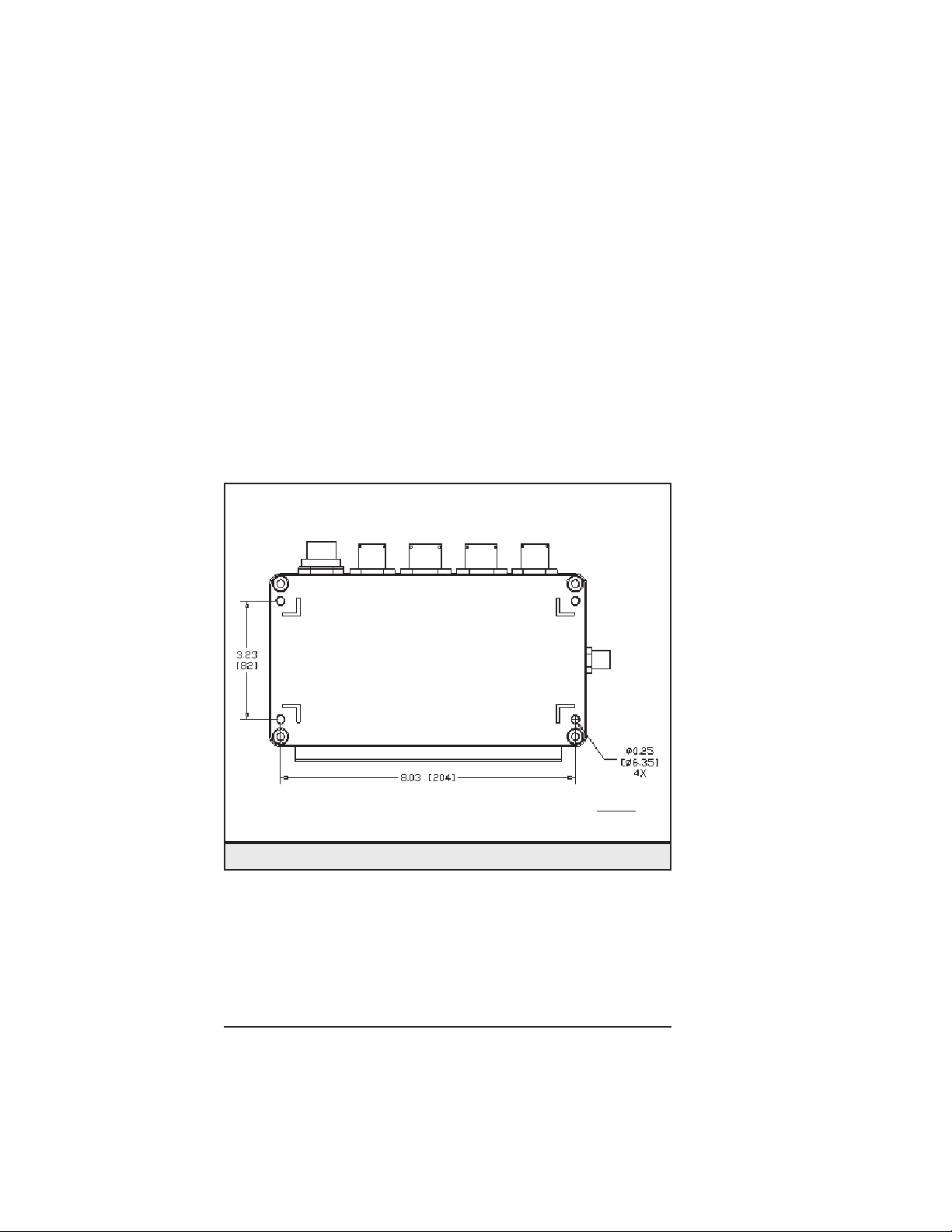

2 MECHANICAL SPECIFICATIONS

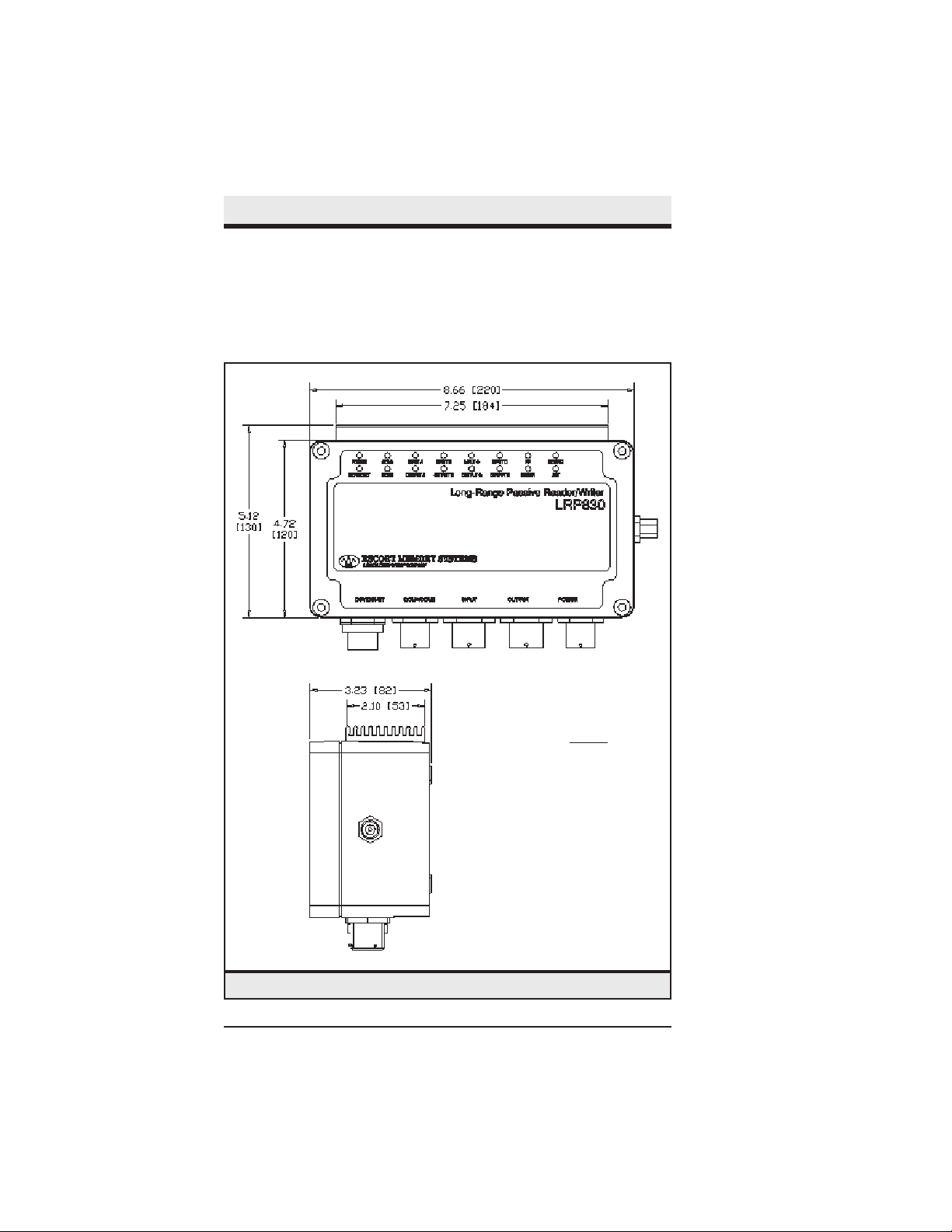

2.1 Dimensions

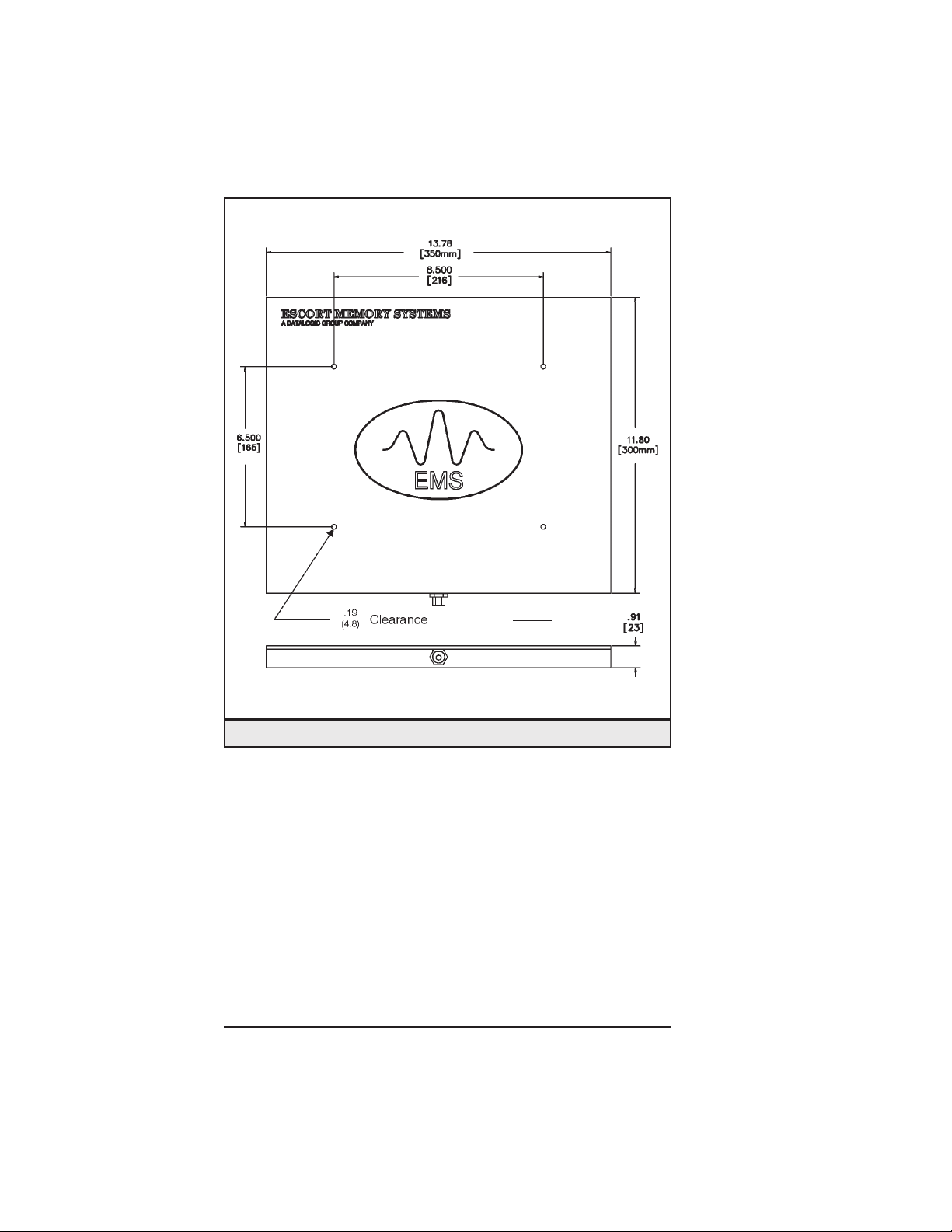

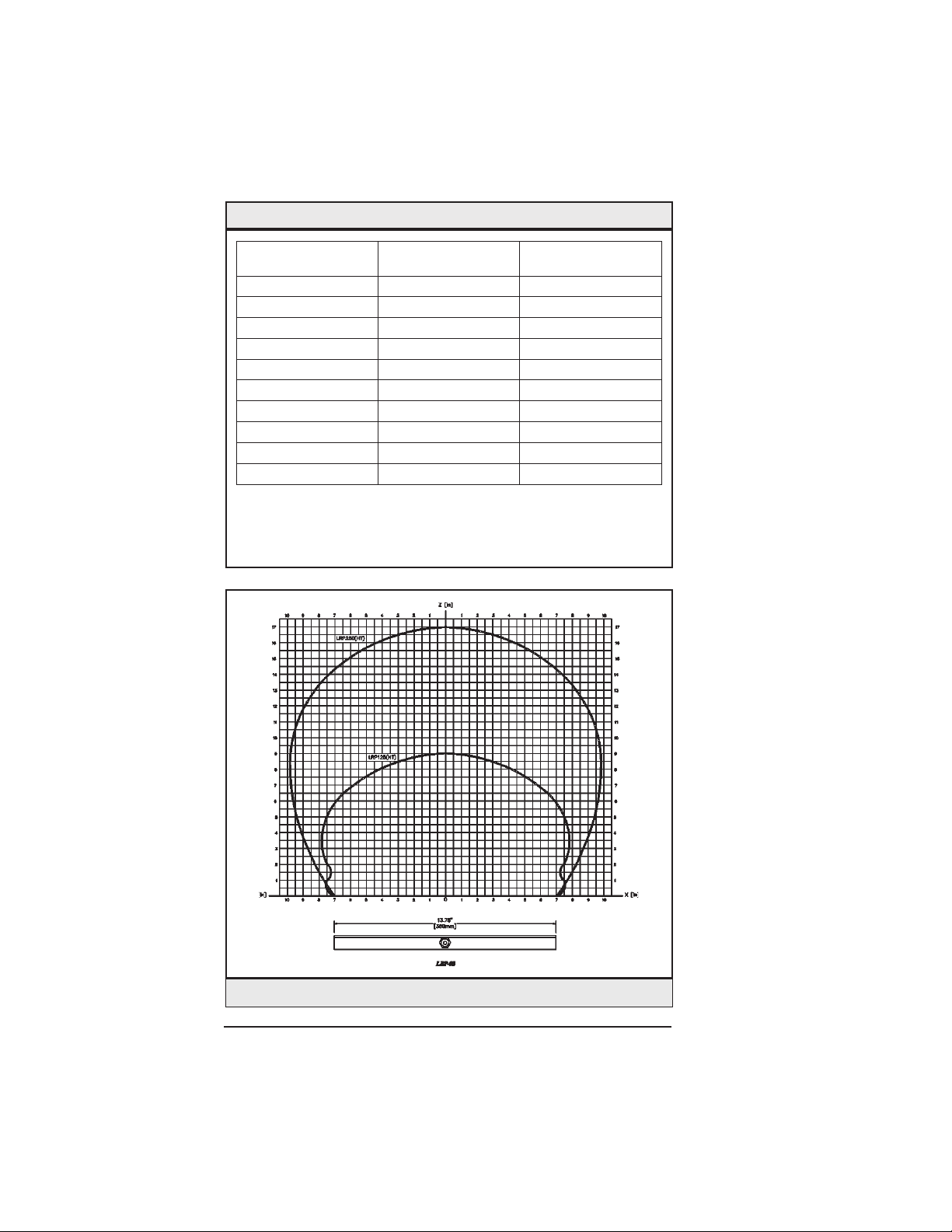

Figure 1 gives the dimensions for the LRP830. Figures 2-3 show the dimen

sions of the 04 and 08 remote antennas.

inches

mm

-

Figure 1 — LRP830 Dimensions

Copyright © 2000 Escort Memory Systems

4 LRP830-Series Long-Range Passive Reader/Writer

Figure 2 — LRP-04 Conveyor-Mount Antenna

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

inches

mm

5

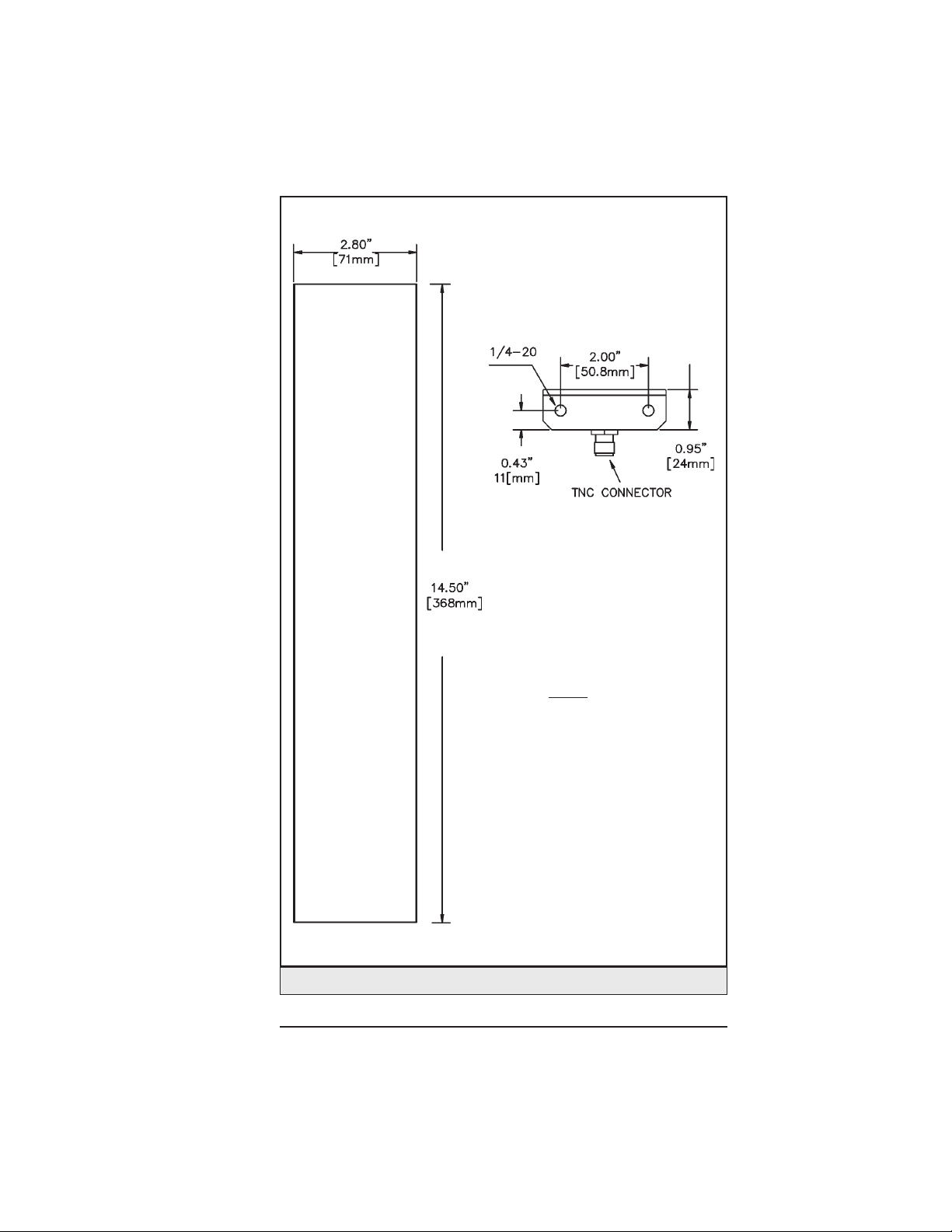

inches

mm

Figure 3 — LRP-08 Antenna Dimensions

Copyright © 2000 Escort Memory Systems

6 LRP830-Series Long-Range Passive Reader/Writer

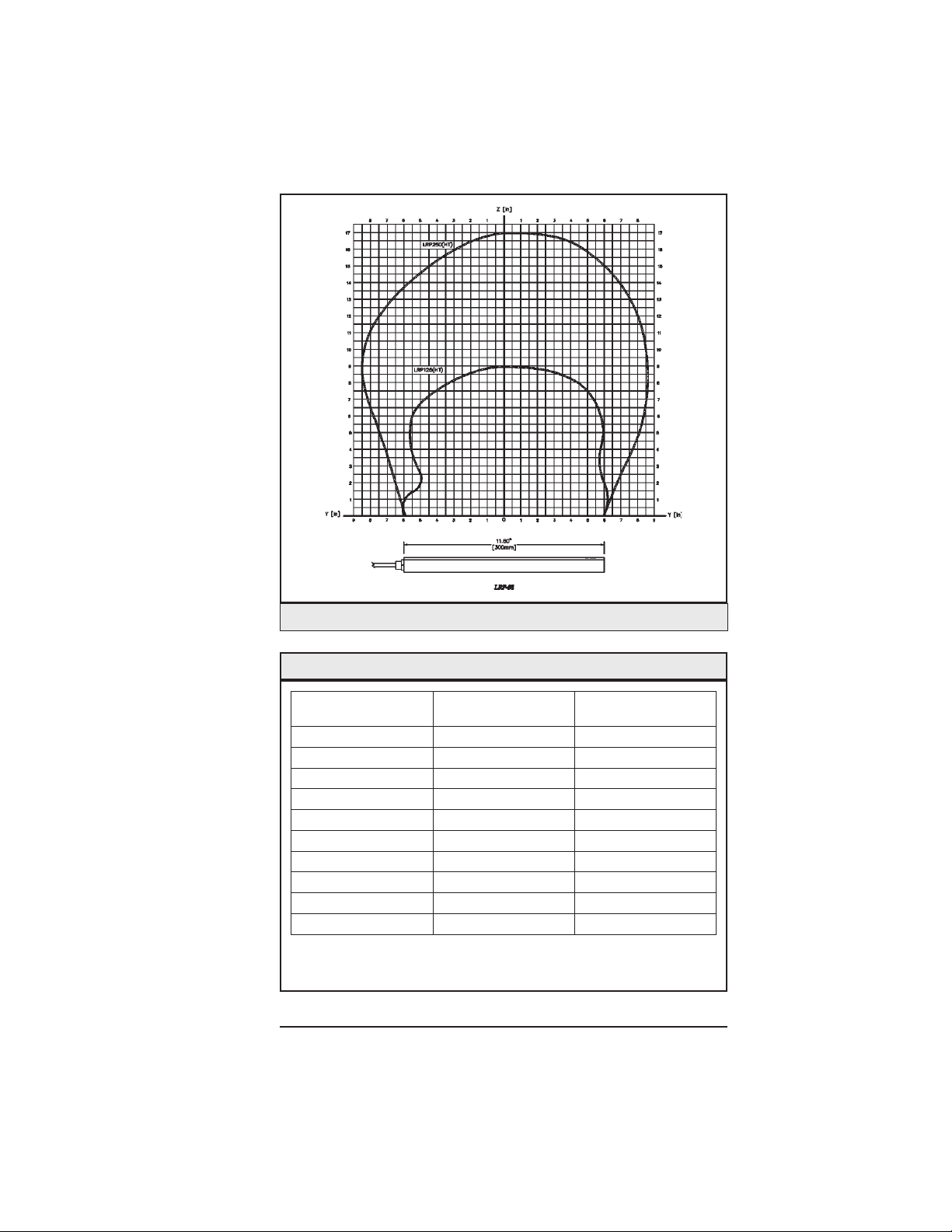

2.2 RF Range and Orientation

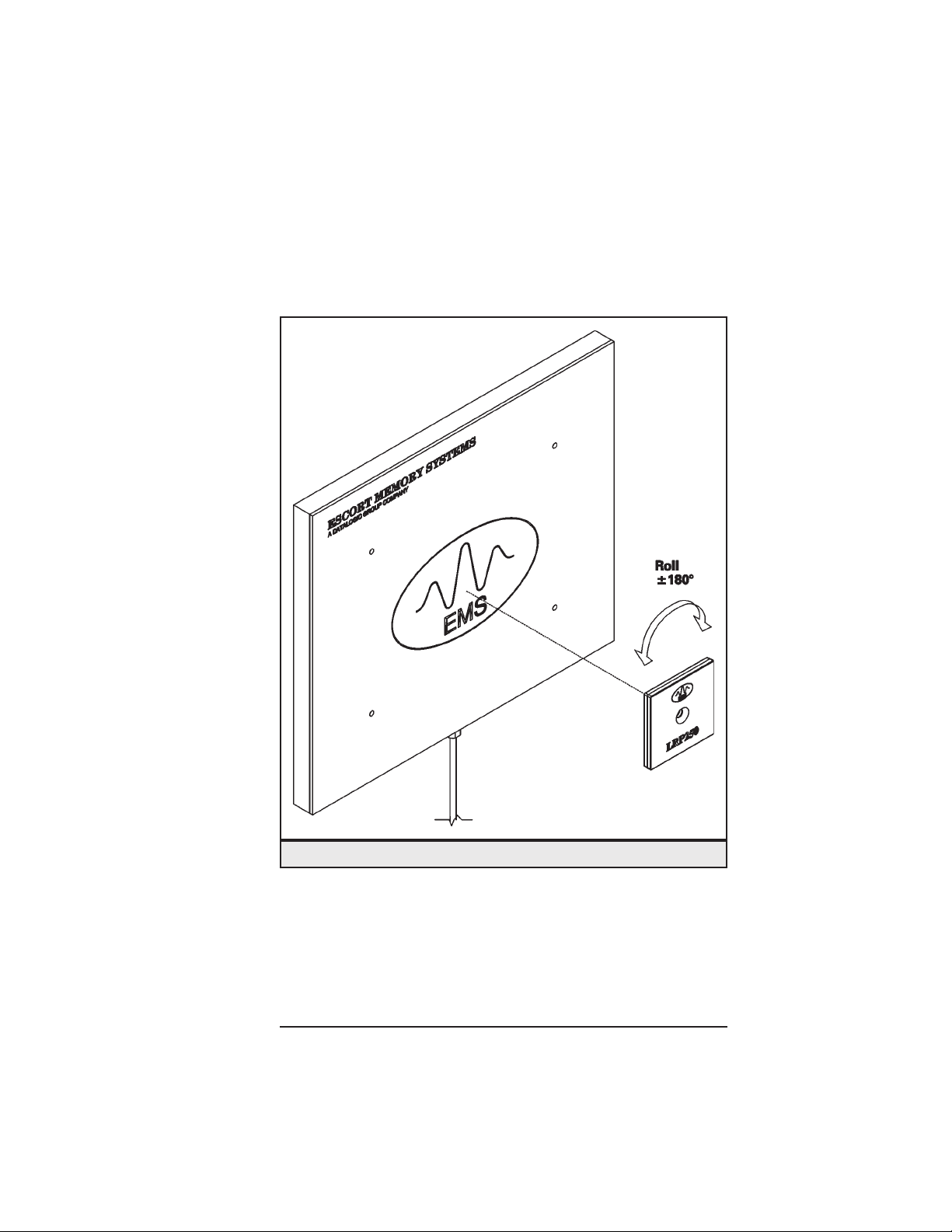

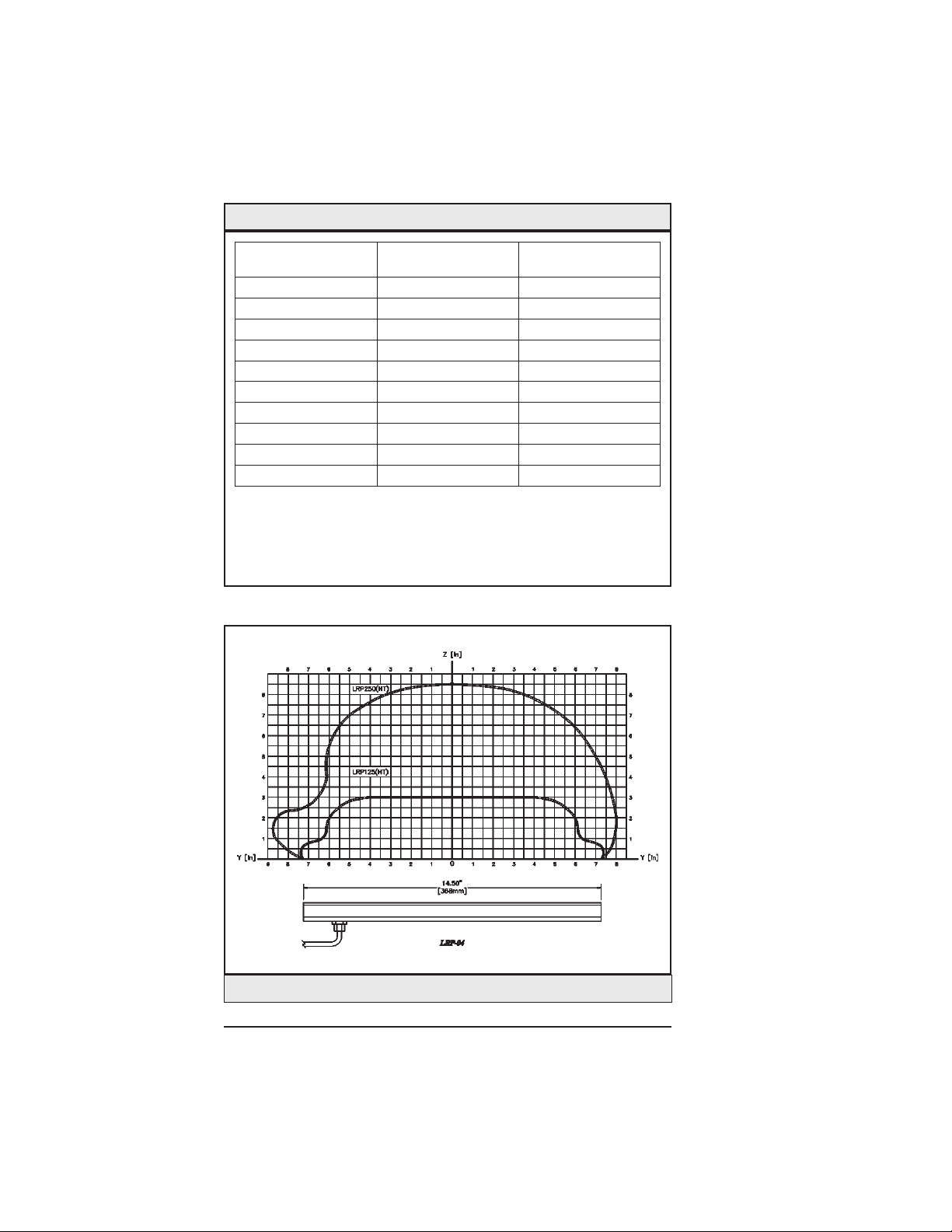

Figure 4 shows the correct tag orientation as it passes the antenna. Figures

5-7 show the RF fields of the LRP830-04 and LRP830-08 antennas. Tables

1- 3 give the typical and guaranteed ranges of the LRP series tags.

Figure 4 — LRP-08 to Tag Orientation

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

7

Table 1 — Antenna to Tag Ranges, LRP-04 Antenna with Metal*

Tag Typical Range (Z)

inches/mm

LRP125(HT) 2.50/64 2.00/51

LRP250(HT) 6.75/171 6.00/152

LRP250HT-FLX 6.75/171 6.00/152

LRP-L5555 6.75/171 6.00/152

LRP-L2666 5.75/146 5.00/127

LRP-L4982 8.00/203 7.00/178

LRP-L90140 9.00/229 8.00/203

LRP-P125 2.50/64 2.00/51

LRP-P3858 6.00/152 5.00/127

LRP-P5050 7.00/178 6.00/152

*These ranges are determined with metal near the -04 antenna as it would be in most conveyor

mountings. The actual tuning and testing of the -04 antenna is done with the antenna mounted be

tween two metal rollers on metal rails. The metal rollers are mounted 1/4” from the antenna.

NOTE: Proximity to metal, CRT devices, and other sources of electromagnetic radiation may affect

the range of the antenna.

Guaranteed Range

inches/mm

-

Figure 5 — Side View of RF Field, LRP-04 Antenna, Metal

Copyright © 2000 Escort Memory Systems

8 LRP830-Series Long-Range Passive Reader/Writer

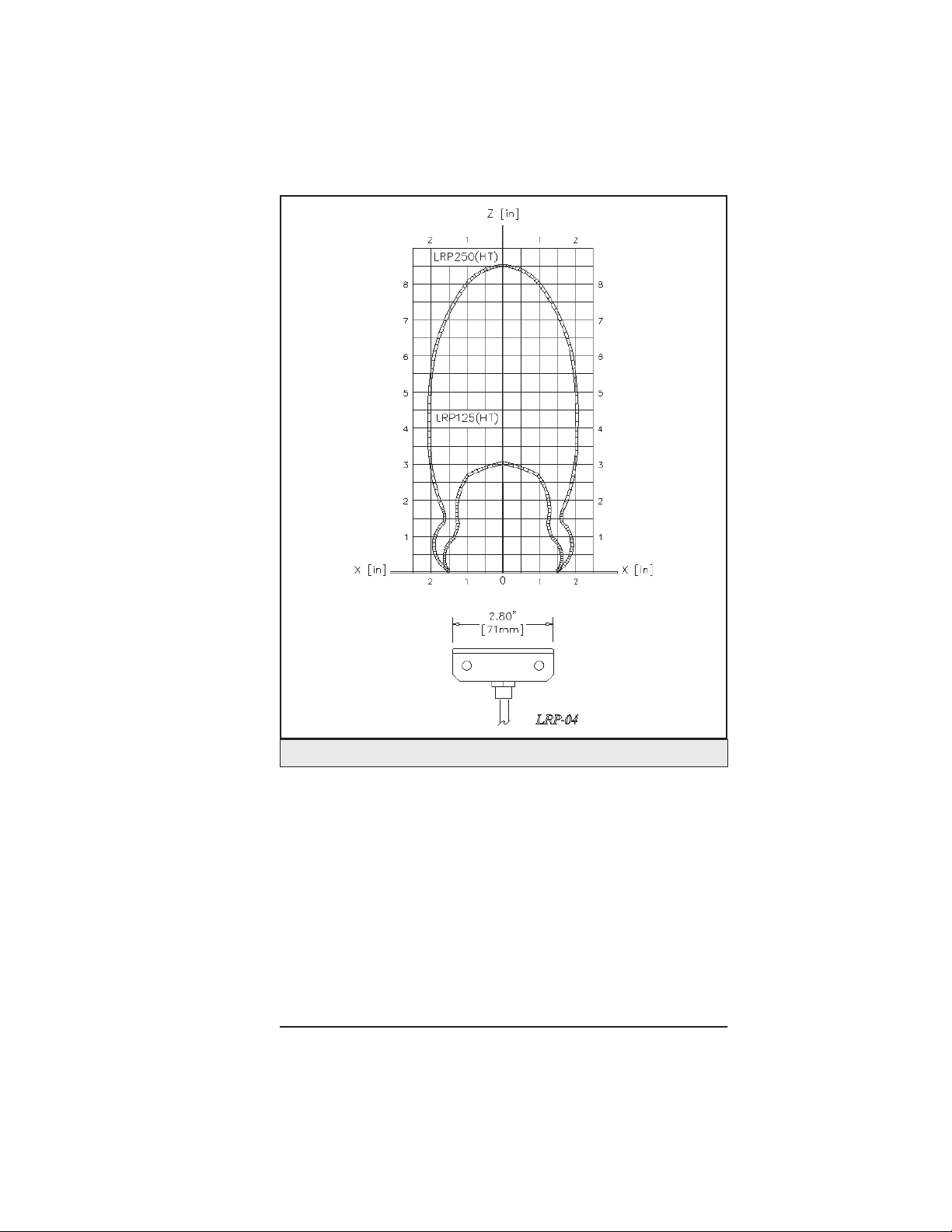

Figure 6 — End View of RF Field, LRP-04 Antenna, Metal

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

9

Table 2 — Antenna to Tag Ranges, LRP-40 Antenna, No Metal*

Tag Typical Range (Z)

inches/mm

LRP125(HT) 3.00/76 2.25/57

LRP250(HT) 8.50/216 7.50/191

LRP250HT-FLX 8.50/216 7.50/191

LRP-L5555 8.50/216 7.50/191

LRP-L2666 7.00/178 6.00/152

LRP-L4982 10.00/254 9.00/229

LRP-L90140 12.00/305 11.00/279

LRP-P125 3.00/76 2.25/57

LRP-P33858 7.50/190 6.50/165

LRP-P5050 8.50/216 7.50/191

*These ranges calculated with no metal near the antenna.

NOTE: Proximity to metal, CRT devices, and other sources of electromagnetic radiation may affect

the range of the antenna.

Guaranteed Range

inches/mm

Figure 7 — End View of RF Field, LRP-08 Antenna, No Metal

Copyright © 2000 Escort Memory Systems

10 LRP830-Series Long-Range Passive Reader/Writer

Figure 8 — Side View of RF Field, LRP-08 Antenna, No Metal

Table 3 — Antenna to Tag Ranges, LRP-08 Antenna, No Metal

Tag Typical Range (Z)

inches/mm

LRP125(HT) 8.00/203 7.00/178

LRP250(HT) 17.00/432 15.00/381

LRP250HT-FLX 17.00/432 15.00/381

LRP-L5555 17.00/432 15.00/381

LRP-L2666 16.00/406 13.00/330

LRP-L4982 20.00/508 18.00/457

LRP-L90140 25.00/635 22.00/559

LRP-P125 8.00/203 7.00/178

LRP-P3858 16.00/406 14.00/355

LRP-5050 17.00/432 15.00/381

*These ranges calculated with no metal near the antenna.

NOTE: Proximity to metal, CRT devices, and other sources of electromagnetic radiation may affect

the range of the antenna.

Guaranteed Range

inches/mm

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

11

2.3 Mounting Guidelines

Electromagnetic radiation and metal affect the range of the LRP830. Mount

the LRP830 and antenna to minimize the impact of these factors. The RF

field of the antenna can also cause errors when antennas are spaced too

closely together. Do not position adjacent antennas closer than 2 meters from

each other.

The remote antennas for the LRP830 have a cable length 2 meters. Sur

rounding the antenna with metal will greatly reduce the reading range of the

antenna. As rule of thumb, keep any metal structure away from the antenna

at least more than the reading range along the axis, and a third of such dis

tance on the side. The mounting holes are accessed through the inside of the

LRP830 Reader/Writer. Refer to Figure 9 for locations and dimensions.

-

-

inches

mm

Figure 9 — LRP830 Mounting Holes

Copyright © 2000 Escort Memory Systems

12 LRP830-Series Long-Range Passive Reader/Writer

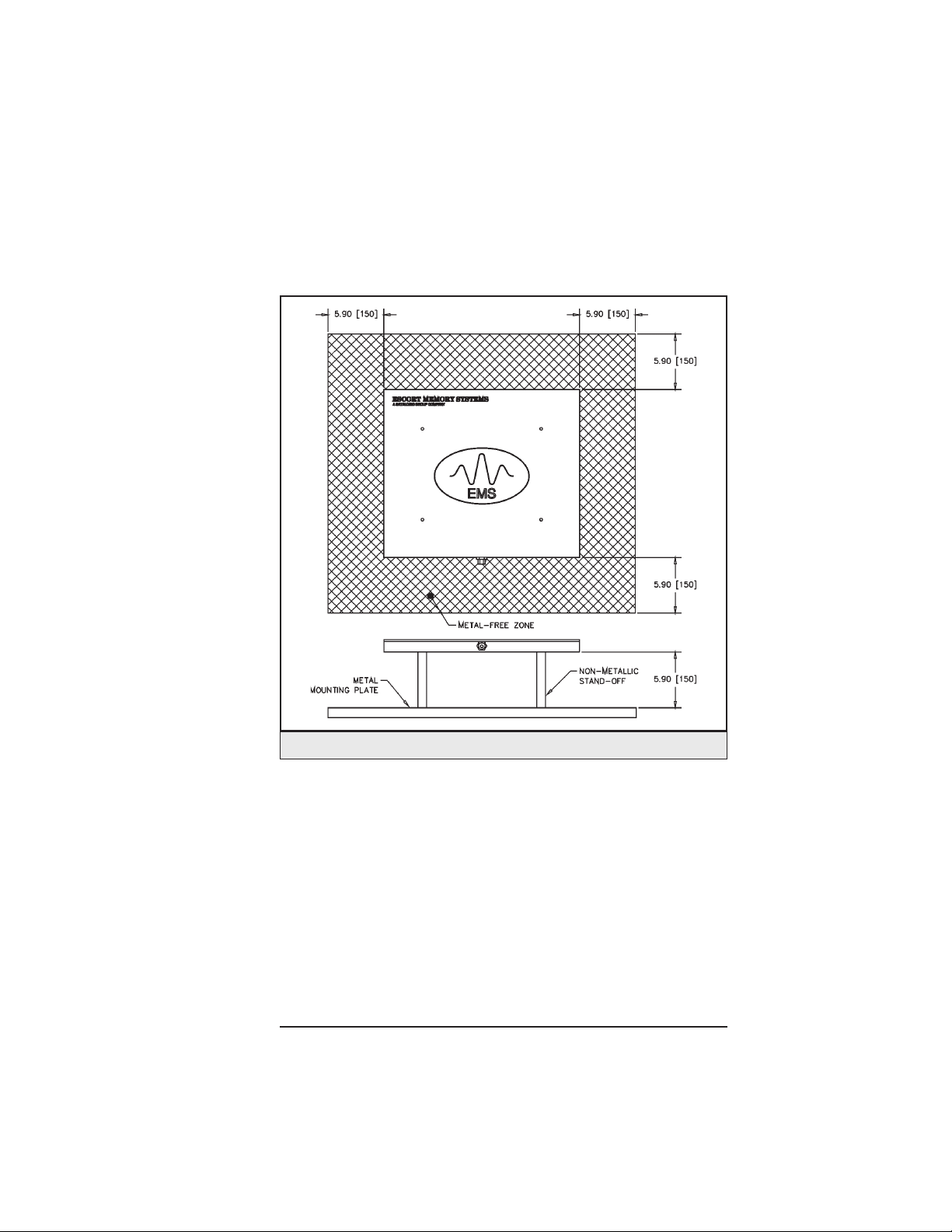

Special mounting instructions must be followed to get optimal read/write

performance from the LRP830-08 antenna. Mount the antenna with a mini

mum 5.90" (150mm) spacing from any metal to the back or sides of the an

tenna, as shown in Figure 10.

-

-

Figure 10 — LRP830-08 Antenna Mounting

Guidelines

n

Isolate the LRP830 and antenna from electromagnetic

radiation.

n

Avoid surrounding LRP830 and remote antenna with metal.

n

Maintain at least 2 meters minimum spacing between adjacent

LRP830s or antennas.

n

Stay within the guaranteed range for the tag to be used.

n

Conform with EIA RS232, RS422 and RS485 standards.

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

13

3 POWER AND ELECTRICAL INTERFACE

3.1 Connector Panel

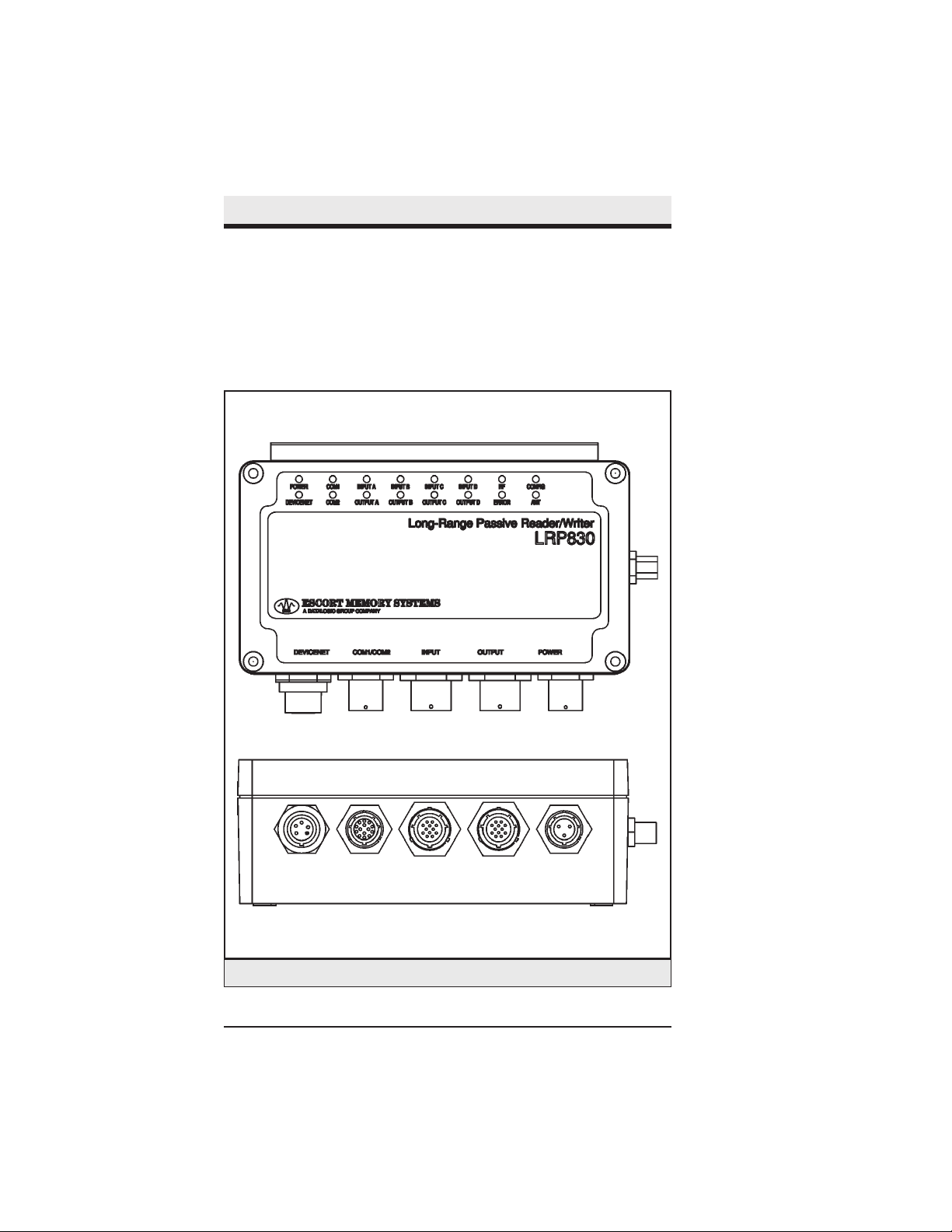

Figure 11 shows the LRP connectors, LEDs and connector panel. Unused

connectors can be sealed with optional connector caps. Please see Appendix

B for ordering information.

Figure 11 — Connector Panel

Copyright © 2000 Escort Memory Systems

14 LRP830-Series Long-Range Passive Reader/Writer

3.2 Power Connector

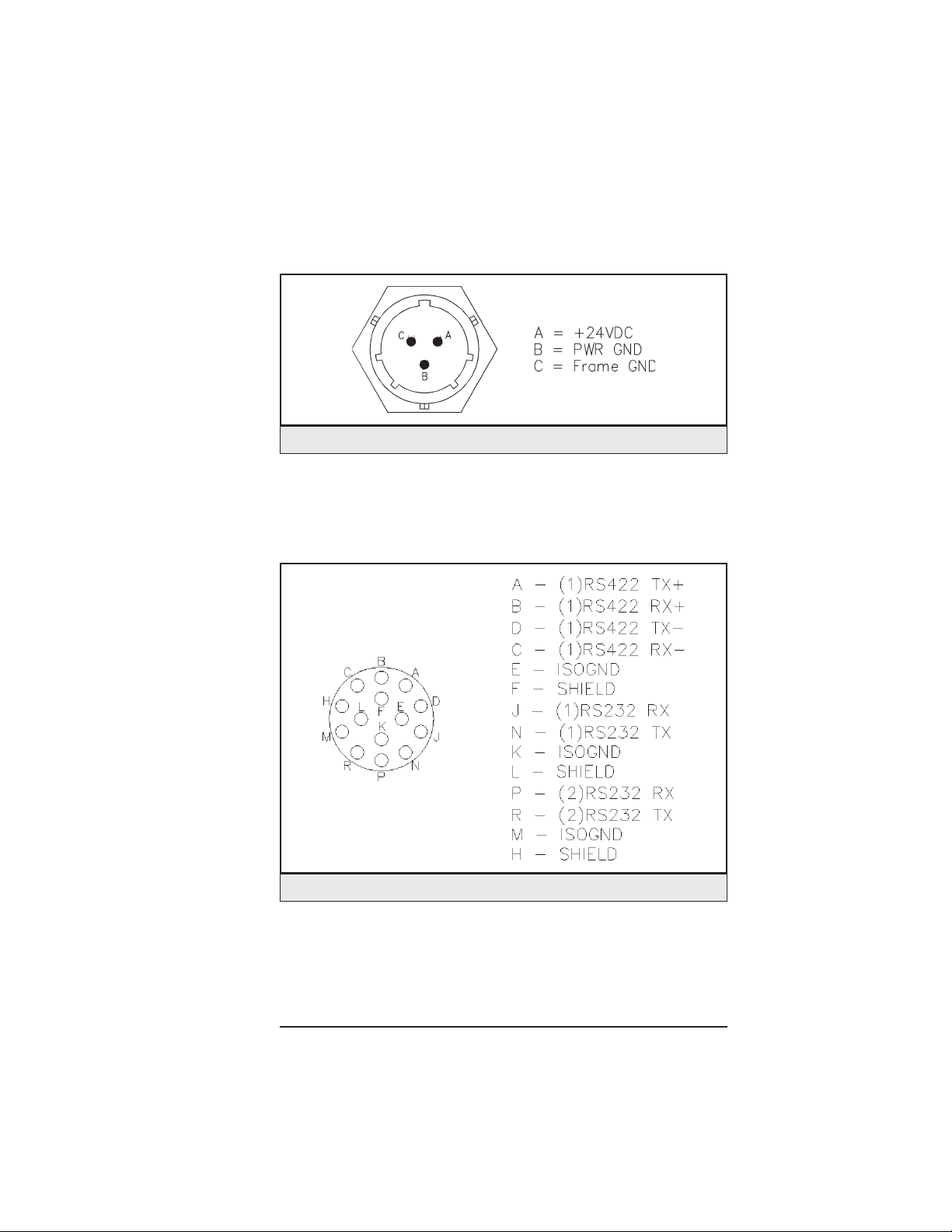

Figure 12 shows the power connector pin designations.

Figure 12 — Power Connector

3.3 COM1/COM2 Connector

Figure 13 shows the connector pin designations for the COM port connections.

Figure 13 — COM1/COM2 Connector

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

15

Serial Communications Cabling

Escort Memory Systems recommends that you use Belden cables 3082A

(trunkline) or 3084A (dropline) for RS485/RS422 communications. Use

Belden cable 9941 for RS232 communications. More information on Belden

cables can be found on their web site at www.belden.com.

3.4 DeviceNet Connector

Figure 14 shows the connections for the DeviceNet connector.

Figure 14 — DeviceNet Connector Pinouts

Copyright © 2000 Escort Memory Systems

16 LRP830-Series Long-Range Passive Reader/Writer

3.5 Input Connector

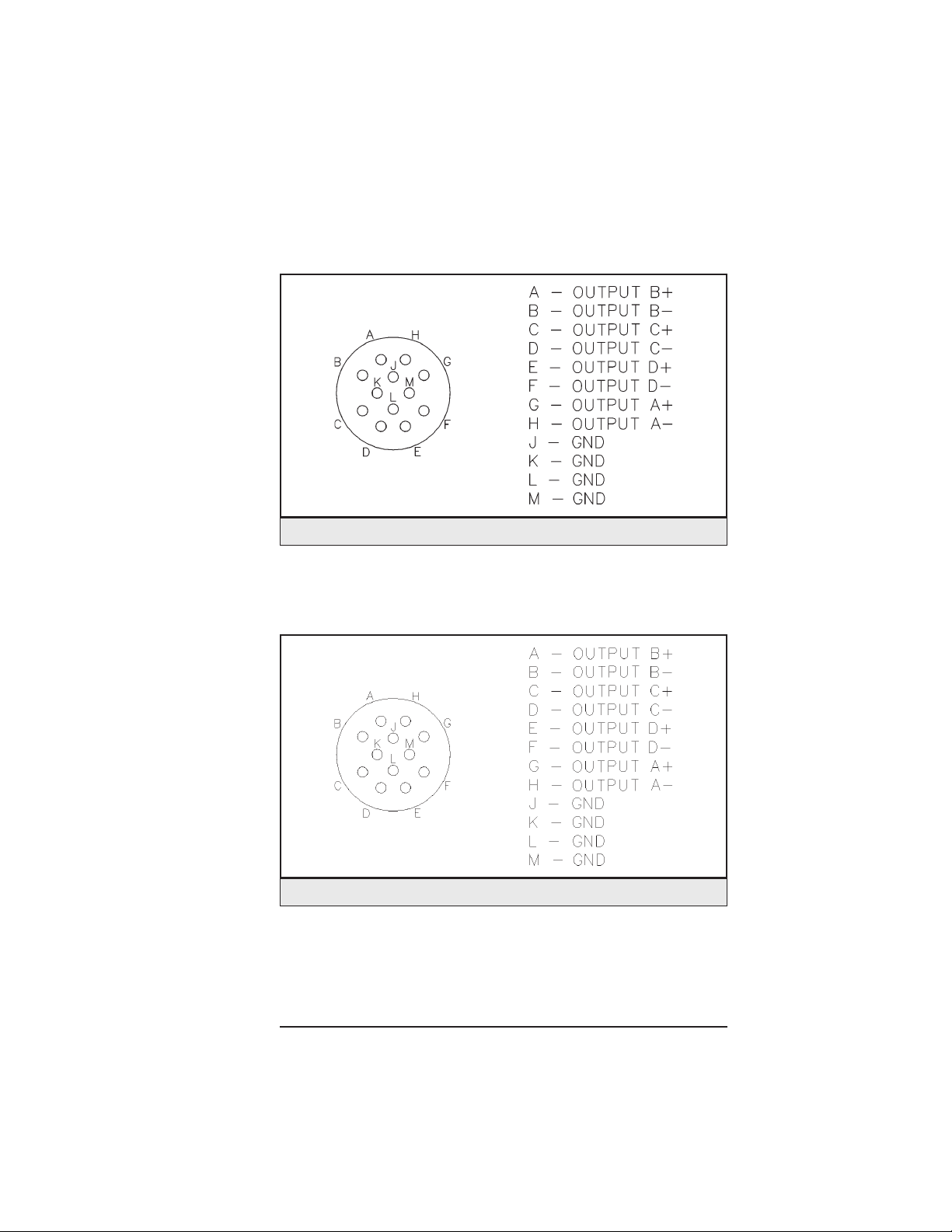

Figure 15 shows the Input Connector pin designations.

Figure 15 — Input Connector Pinouts

3.6 Output Connector

Figure 16 shows the Output Connector pin designations.

Figure 16 — Output Connector Pinouts

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

17

3.7 Digital I/O Wiring

Both the Digital Inputs and Digital Outputs are optically isolated circuits

with no common path between any channel terminal and another channel, or

between any channel and the LRP830 power. Because they are independent

and floating, the external wiring controls their use. The inputs can be config

ured for sensors with a PNP or NPN output. The outputs can be configured

in a Sourcing or Sinking configuration. The examples in Figures 17 through

24 show different connections for common input and output devices.

Inputs

The +IN terminal must be at a higher positive potential than the -IN terminal

for current to be sensed correctly. The voltage range is 4.5 to 30V between

the +IN and the -IN inputs and the maximum current is 25 mA.

Outputs

The output is limited to 30Vdc when off and 500 mA. These are maximum

ratings. A device that operates at 200 mA may destroy the output due to inrush current if that current exceeds 500 mA (e.g. an incandescent light). The

inductive "kick" (back EMF from a collapsing magnetic field) when a relay

is released can impose a voltage higher than 30V and destroy the output

transistor (use a backwards diode to clamp the back EMF).

-

Copyright © 2000 Escort Memory Systems

18 LRP830-Series Long-Range Passive Reader/Writer

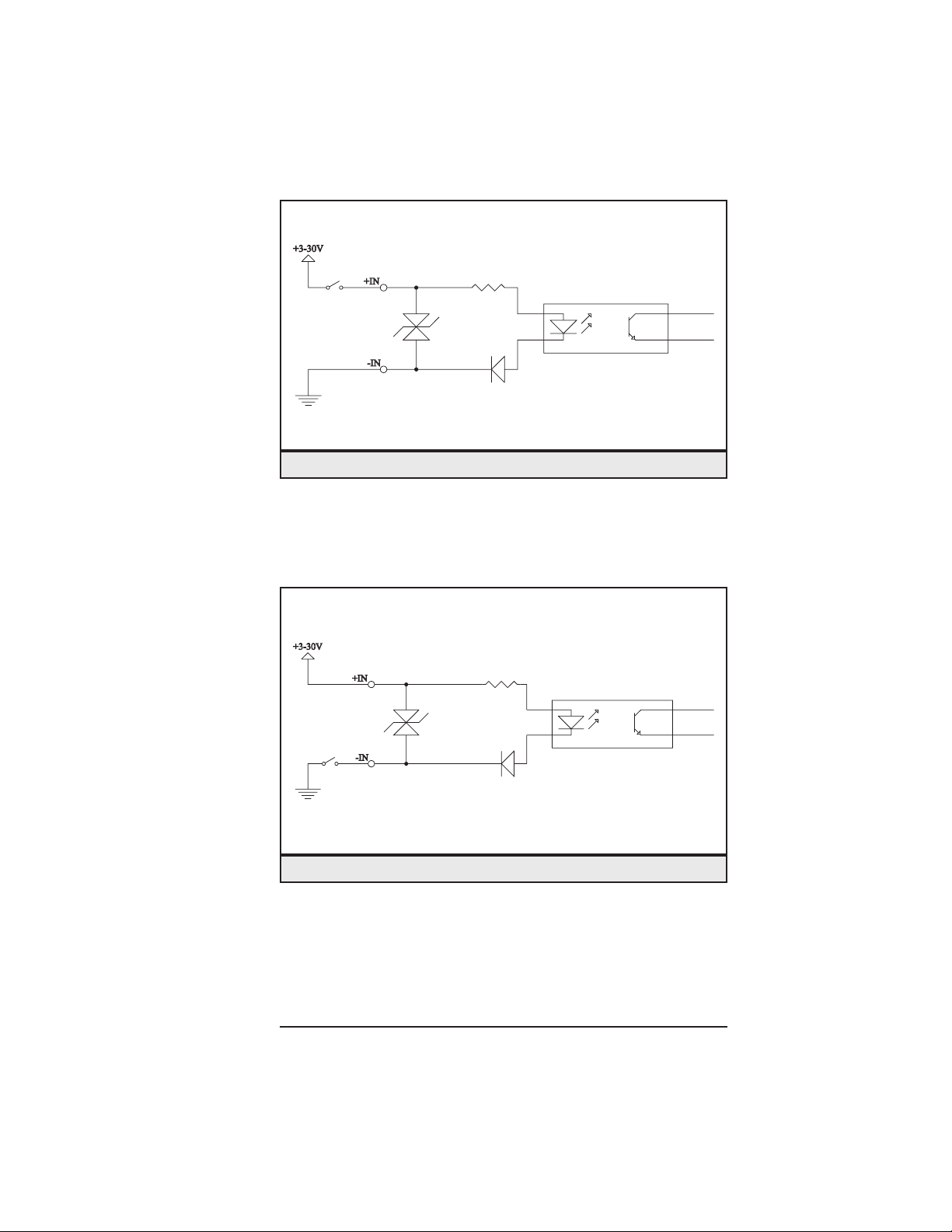

Figure 17 — Input from Sourcing Contact

Figure 17 shows the switch on the high side with the low side grounded. As

this is a "Dry" contact (the current is limited to 15 mA) a high quality sealed

switch should be used.

Figure 18 — Input from Sinking Contact

Figure 18 shows a switch connected on the low side with the high side con

nected to the positive supply. This also requires a high quality sealed contact.

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

-

19

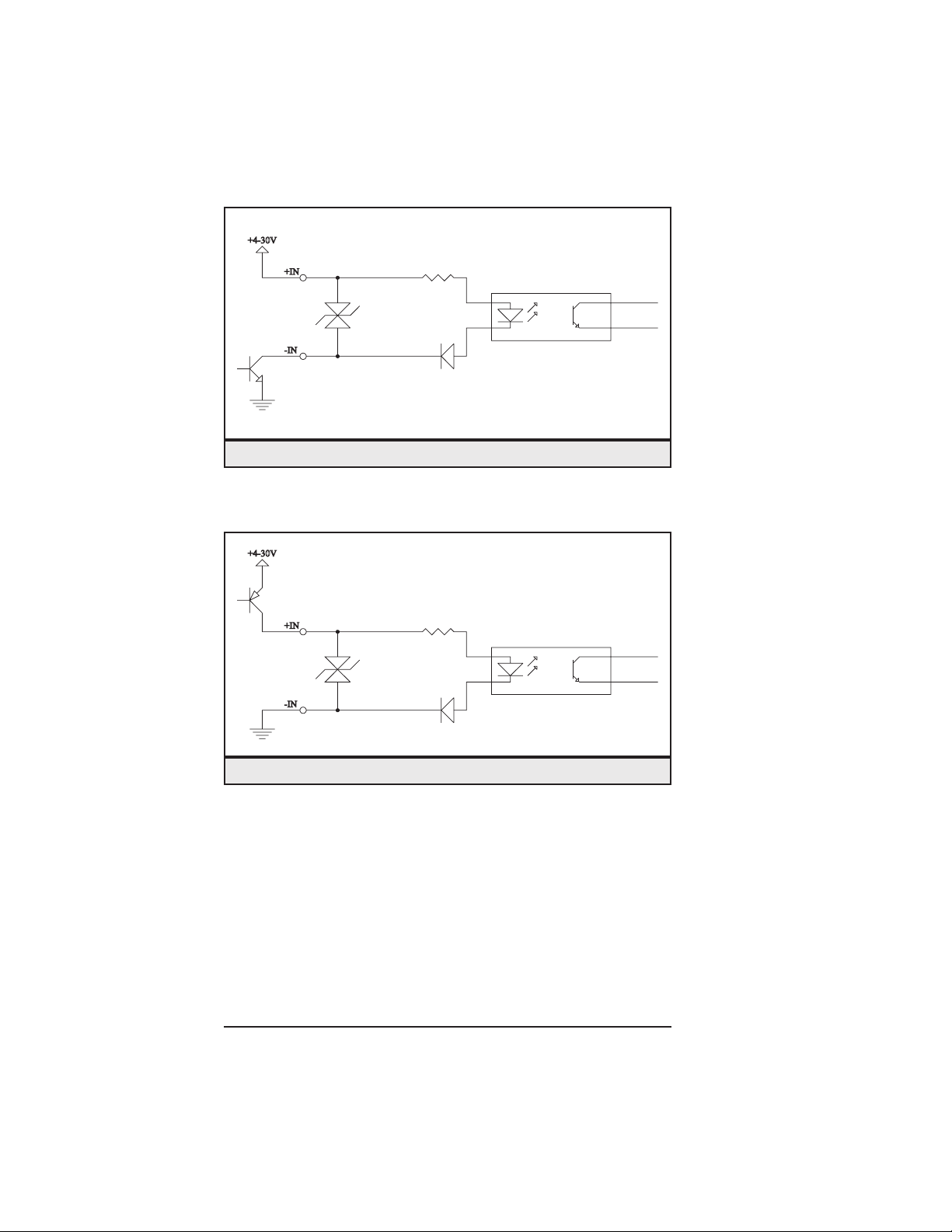

Figure 19 — Input from NPN Sensor

Figure 19 shows an Open Collector NPN output from a photosensor switch

ing to ground. It can be wired as a sinking or low-side contact.

Figure 20 — Input from PNP Sensor

Figure 20 shows an Open Collector PNP output from a photosensor

switches to the positive supply. It can be wired as a sourcing or high-side

contact.

-

Copyright © 2000 Escort Memory Systems

20 LRP830-Series Long-Range Passive Reader/Writer

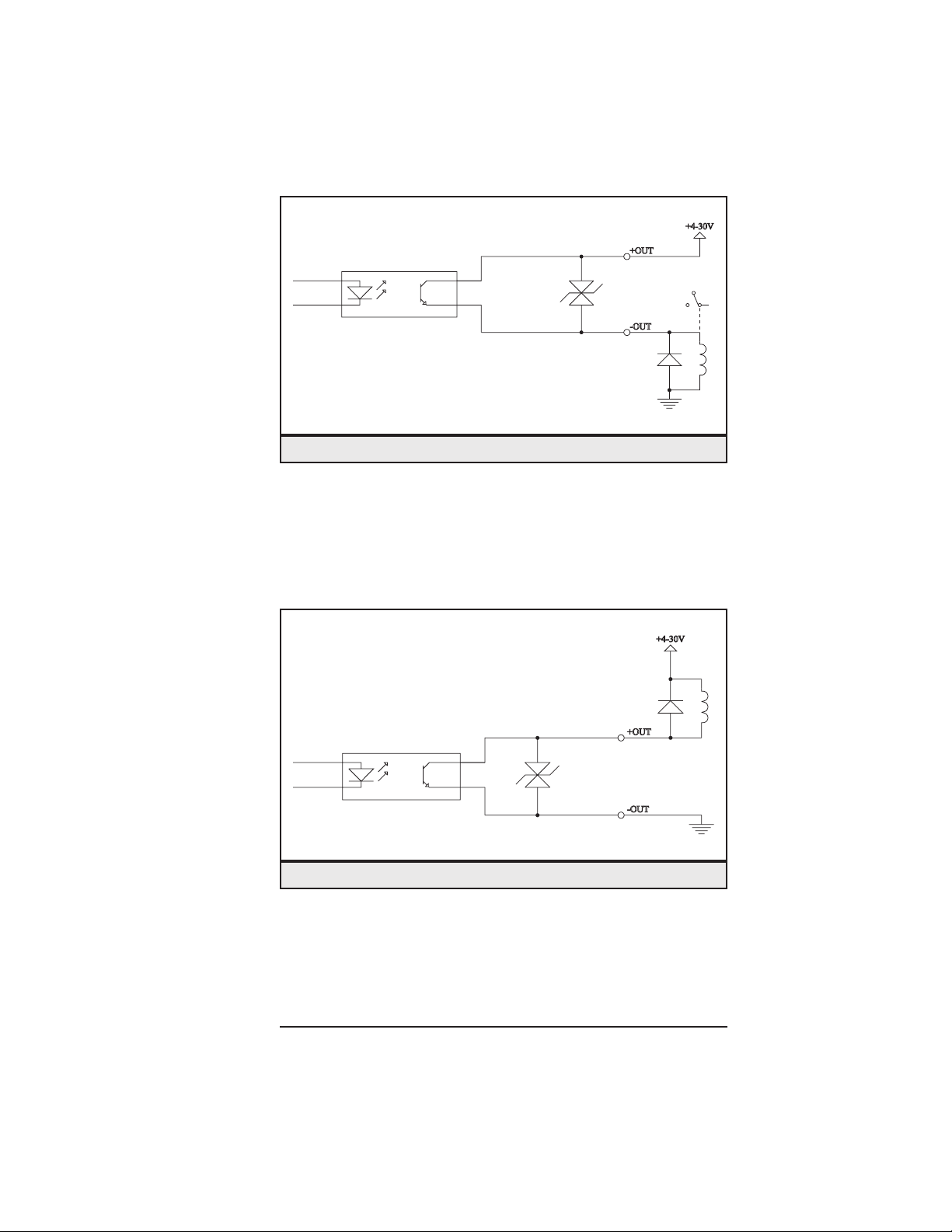

Figure 21 — Sourcing Output "Contact"

Figure 21 shows a relay connected as a current sourcing "Contact." The re

lay is grounded and the +OUT terminal goes to the positive supply. The di

ode across the relay coil is essential to protect the output circuit and reduce

noise along the wiring. It should be connected at the relay to minimize the

length of wiring that could radiate noise. A 1N4001 or similar diode may be

used.

Figure 22 — Sinking Output "Contact"

Figure 22 shows a "Contact" sinking current from a relay, the -OUT terminal

is grounded and the relay goes to the positive supply. This configuration

must also have a diode across the relay coil to protect the circuit and reduce

noise.

-

-

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

21

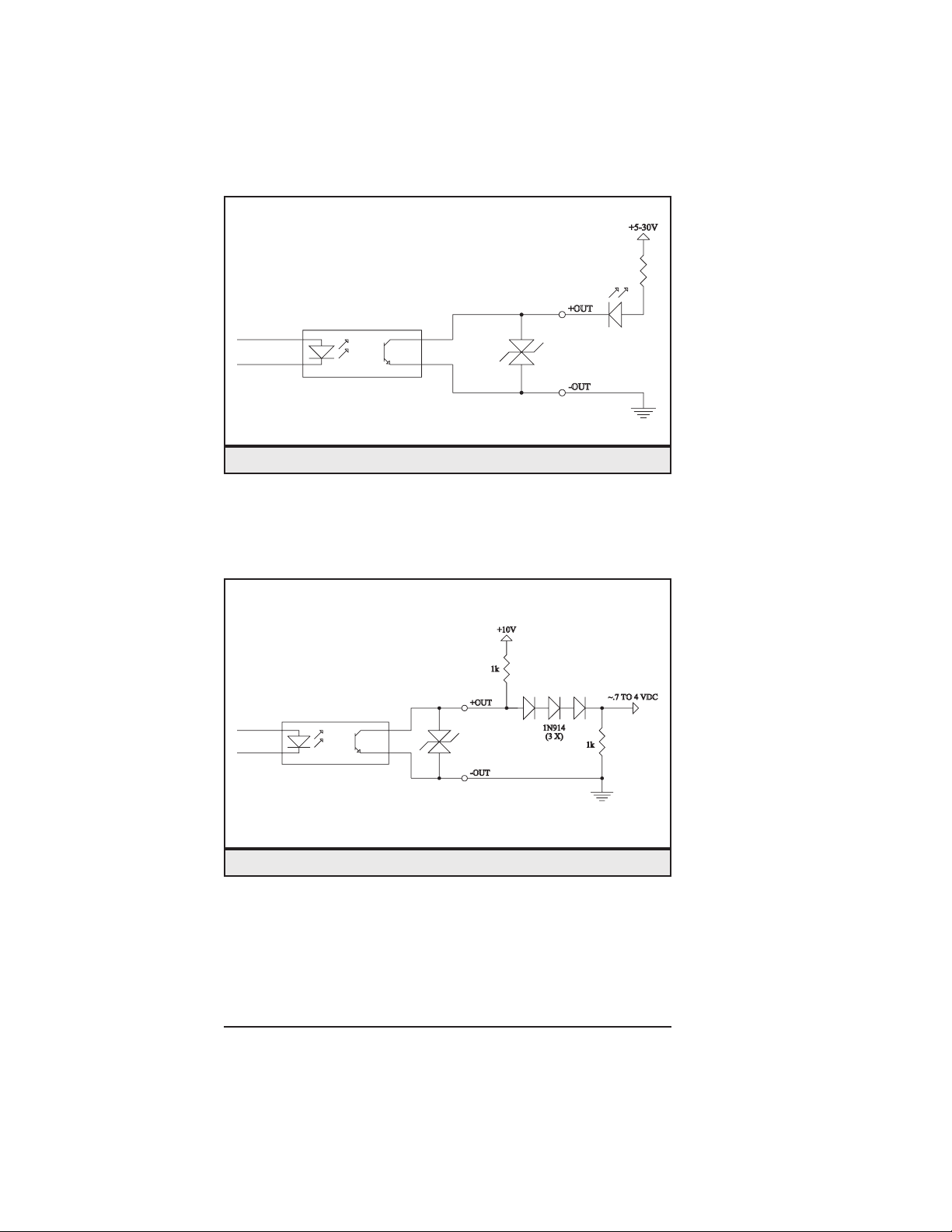

Figure 23 — Sinking Output LED Driver

In Figure 23, the LED and current limiting resistor are in series between the

positive supply and the +OUT terminal. The -OUT terminal is grounded.

The resistor in series with the LED sets the forward current. 1.2K will provide 20 mA LED current when run from 24 Vdc.

Figure 24 — Output to TTL or CMOS

In Figure 24 the output acts as an Open Collector. This will provide a TTL

or CMOS compatible signal when a 1K to 10K pull-up to +5 Vdc (the logic

supply) is used.

Copyright © 2000 Escort Memory Systems

22 LRP830-Series Long-Range Passive Reader/Writer

3.8 Power Requirement

The LRP830 power supply requirement are:

18 to 30Vdc

n

31W maximum power consumption.

n

The maximum current consumption at 24Vdc is 1.3 A.

Power Options

There are three options for powering the LRP830:

Powered from the DeviceNet Bus (default)

n

This is the default configuration for powering the LRP830. If the

power available over your DeviceNet network is not sufficient to

power the LRP830, use one of the following methods.

Powered via the external power connector

n

This is how you must power the LRP830 if you are not connecting

the LRP830 to a DeviceNet network.

n

Powered from an external supply and isolated DeviceNet bus

power (isolated mode)

When the LRP is powered from both sources, the LRP830 will be

opto-isolated from the DeviceNet bus.

The DeviceNet interface board draws 20 mA at 24 Vdc from the

DeviceNet bus when the LRP830 is powered with this method.

Power to the external power connector should conform to the spec

ifications given above.

If you choose to power the LRP830 with an external supply via the power

connector, you must open the LRP830 and changed jumper and cable loca

tions. The following sections describe how to make these changes.

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

23

-

-

Power from the DeviceNet Bus

By default, the LRP830 is configured to run with power supplied by the net

work. In this mode, there is no galvanic isolation between the DeviceNet

wires and the LRP830, and there is no need for a separate power supply.

If you choose to power the LRP830 form the DeviceNet bus, you do not

need to make any internal changes to cables and jumpers. Wire power ac

cording to the pinouts given for the DeviceNet connector in Figure 14, page

16.

Power via the external supply connector

The LRP830 contains components sensitive to electro-static discharge. Take

proper grounding precautions before opening the LRP830.

To change the LRP830 to run in isolated mode:

1. Open the LPR820 by loosening the four captive screws that secure the cover.

2. Refer to Figure 25 and then move the power cable, labeled assembly 10-3110, from connector J7 to J9.

-

-

Figure 25 — Power Cable Connectors J7 andJ9

Copyright © 2000 Escort Memory Systems

24 LRP830-Series Long-Range Passive Reader/Writer

3. The DeviceNet cable, labeled assembly 10-3116, must then ex

change places with the power cable, moving from J9 to J7.

4. Referring to Figure 26, locate jumper J1 and move the shunt from

pins 4 and 3 to pins 2 and 1.

5. Close the LRP830 and connect a separate +24V power supply to

the external power connector shown in Figure 12, page 15.

-

Figure 26 — DeviceNet Board Power Jumper

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

25

Power from the DeviceNet bus and from an external power supply

When the LRP is powered from both sources, the LRP830 will be

opto-isolated from the DeviceNet bus.

The LRP830 contains components sensitive to electro-static discharge. Take

proper grounding precautions before opening the LRP830.

To power the LRP830 from an external supply and the DeviceNet bus:

1. Open the LPR820 by loosening the four captive screws that

secure the cover.

2. Refer to Figure 25 and then move the power cable, labeled assem

bly 10-3110, from connector J7 to J9.

3. The DeviceNet cable, labeled assembly 10-3111, must then

exchange places with the power cable, moving from J9 to J7.

4. Make sure that the jumper on J1of the DeviceNet Interface Board

connects pins 3 and 4, and then close the LRP830.

5. Connect a separate +24V power supply to the external power

connector shown in Figure 12, page 15.

6. Wire the DeviceNet interface and power according to the pinouts

given for the DeviceNet connector in Figure 14, page 16.

-

Copyright © 2000 Escort Memory Systems

26 LRP830-Series Long-Range Passive Reader/Writer

3.9 LED Indicators

The LRP830 has 16 LEDs indicating status of the LRP830 Reader/Writer,

interface communications, and I/O status.

Figure 27 — LRP830 Front with LEDs

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

27

Table 4 shows these LEDs and their meaning.

Table 4 — LED Indicators

LED Color Indicates

PWR red The LRP830 is receiving power

RF green RF Data Transfer

ANT red Antenna on and tag in field

ERROR Red Unsuccessful RF command (.5 sec. flash)

CONFIG green Successful RF command-1.5sec. flash

ERROR +

CONFIG

IN-A yellow Input active

IN-B yellow Input active

IN-C yellow Input active

IN-D yellow Input active

COM1 green/red Incoming data (RX): red

COM2 green/red Incoming data (RX): red

DeviceNet red Data transfer (RX/TX): red

OUT-A green Output active

OUT-B green Output active

OUT-C green Output active

OUT-D green Output active

green/red Entering Operating Mode - 4 alternate flashes

Entering Download Mode via DIP switch 5 (4 flashes)

Configuration Mode initiated (CTRL-D) - Both LEDS flash 4 times

Configuration Mode initiated (CTRL-E) - Both LEDS flash 2 times

Outgoing data (TX): green

Outgoing data (TX): green

Additional LED behavior may be observed during certain commands and

conditions. This behavior will be indicated as appropriate elsewhere in this

manual.

Copyright © 2000 Escort Memory Systems

28 LRP830-Series Long-Range Passive Reader/Writer

4 SERIAL AND BUS COMMUNICATIONS

4.1 Serial Interfaces

The LRP830 has RS232 and RS422 available on the COM1 serial port.

COM2 is configured for RS232 communications and is reserved for down

loading programs to the LRP830 and for setting up the configuration

parameters.

Both RS232 and RS422 interfaces are opto-isolated. The RS422 interface

is specially suitable for long cable, noisy environment links.

The specification for the COM1 interface follows:

Baud rate: 1200, 2400, 4800, 9600, 19200, 38400 bps

n

Data: 7, 8

n

Parity: Even, Odd, None

n

n Handshake: None, Xon/Xoff

The specification for the COM2 interface follows:

-

n

Baud rate: 1200, 2400, 4800, 9600, 19200 bps

n

Data: 7, 8

n

Parity: Even, Odd, None

n

Handshake: None, Xon/Xoff

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

29

Digital Board DIP Switch

The digital board is mounted inside the top of the LRP830 enclosure. The

first 5 switches of the main board sets the COM1 baud rate, electrical inter

face, and the download options for COM2. Switches 6, 7 and 8 are not used

and should remain OFF. When switch 1 and 2 are both set ON, the baud

rate is set via the Configuration Menu.

-

Figure 28 — Digital Board with DIP Switch

NOTE:

When you set switch 5 ON to enable download, the default parameters will

first be restored and saved to the non-volatile memory.

The baud rate configuration on the main board only applies to the RS232

and RS422 serial interfaces. When a Bus Interface (DeviceNet) is selected,

the baud rate is set by the Interface Board DIP switches.

Copyright © 2000 Escort Memory Systems

30 LRP830-Series Long-Range Passive Reader/Writer

NOTE:

DIP switch 4 must be in the default ON position for the DeviceNet interface

to function.

Table 5 Main Board DIP Switch Settings

Download/

Restore

Baud rate Interface

SW 1 SW 2 SW 3 SW 4 SW 5 Settings

ON 19200

ON 38400

ON ON Set from Configuration Menu

ON RS422

ON DeviceNet

ON ON Reserved

Switches 6 through 8 are reserved and must be in the OFF position.

Defaults

9600

RS232

Disabled

ON Enabled Download/ Restore defaults

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

31

4.2 Bus Interfaces

The COM1 serial port, beside the RS232 or RS422 options, can be config

ured as a DeviceNet interface.

The following bus parameters are set by the DIP switches found on the

Interface Board.

DeviceNet interface

Bus Rate: 125K, 250K, 500Kbps

n

DeviceNet Node Address (MAC ID)

n

-

Figure 29 — DeviceNet Interface Board DIP Switch

Copyright © 2000 Escort Memory Systems

32 LRP830-Series Long-Range Passive Reader/Writer

DeviceNet Interface Board DIP Switch

S1 is an eight position DIP switch. Switches 1 to 6 set the DeviceNet Node

address, switches 6 and 7 are reserved and switch 8 sets the bus rate. Table 6

shows these settings.

Table 6 — DeviceNet DIP Switch Settings

DeviceNet Node Switches Bus Rate

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

ON DeviceNet Node 1

ON DeviceNet Node 2

ON ON DeviceNet Node 3

ON DeviceNet Node 4

ON ON DeviceNet Node 5

ON ON DeviceNet Node 6

ON ON ON DeviceNet Node 7

ON DeviceNet Node 8

ON ON DeviceNet Node 9

ON ON DeviceNet Node 10

ON ON ON DeviceNet Node 11

ON ON DeviceNet Node 12

ON ON ON DeviceNet Node 13

ON ON ON DeviceNet Node 14

ON ON ON ON DeviceNet Node 15

ON DeviceNet Node 16

ON ON DeviceNet Node 17

ON ON DeviceNet Node 18

ON ON ON DeviceNet Node 19

ON ON DeviceNet Node 20

ON ON ON DeviceNet Node 21

ON ON ON DeviceNet Node 22

ON ON ON ON DeviceNet Node 23

ON ON DeviceNet Node 24

ON ON ON DeviceNet Node 25

ON ON ON DeviceNet Node 26

ON ON ON ON DeviceNet Node 27

ON ON ON DeviceNet Node 28

ON ON ON ON DeviceNet Node 29

ON ON ON ON DeviceNet Node 30

ON ON ON ON ON DeviceNet Node 31

Settings

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

33

Table 5 — DeviceNet DIP Switch Settings (cont.)

DeviceNet Node Switches Bus Rate

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

ON DeviceNet Node 32

ON ON DeviceNet Node 33

ON ON DeviceNet Node 34

ON ON ON DeviceNet Node 35

ON ON DeviceNet Node 36

ON ON ON DeviceNet Node 37

ON ON ON DeviceNet Node 38

ON ON ON ON DeviceNet Node 39

ON ON DeviceNet Node 40

ON ON ON DeviceNet Node 41

ON ON ON DeviceNet Node 42

ON ON ON ON DeviceNet Node 43

ON ON ON DeviceNet Node 44

ON ON ON ON DeviceNet Node 45

ON ON ON ON DeviceNet Node 46

ON ON ON ON ON DeviceNet Node 47

ON ON DeviceNet Node 48

ON ON ON DeviceNet Node 49

ON ON ON DeviceNet Node 50

ON ON ON ON DeviceNet Node 51

ON ON ON DeviceNet Node 52

ON ON ON ON DeviceNet Node 53

ON ON ON ON DeviceNet Node 54

ON ON ON ON ON DeviceNet Node 55

ON ON ON DeviceNet Node 56

ON ON ON ON DeviceNet Node 57

ON ON ON ON DeviceNet Node 58

ON ON ON ON ON DeviceNet Node 59

ON ON ON ON DeviceNet Node 60

ON ON ON ON ON DeviceNet Node 61

ON ON ON ON ON DeviceNet Node 62

ON ON ON ON ON ON DeviceNet Node 63

ON 500k

ON ON Reserved

Settings

125k

ON 259k

Copyright © 2000 Escort Memory Systems

34 LRP830-Series Long-Range Passive Reader/Writer

5 MENU CONFIGURATION

The LRP830 feature a menu-driven program designed to give convenient

access to the serial parameters, restore defaults or change operating modes.

5.1 How to Enter Menu Configuration

Begin by connecting the COM2 port to your PC host (see table below) and

running EC that is available on the diskette or from Escort Memory Sys

tems’ Web site at www.ems-rfid.com.

LRP830 Standard PC Serial Port

COM2 Pin Number Signal Name DB9 Pin Number Signal Name

RTX2 RX

PRX3 TX

M GND 5 GND

Set the serial parameters to the LRP830 default settings or the last known

state of COM2.

The default settings for COM2 are as follows:

Baud 9600

Parity None

Data bits 8

Stop bits 1

Flow control None

-

If you can not establish communications with COM2, do the following to

restore the default values.

1. Place DIP switch five in the ON position and cycle power to

the LRP830 or press the reset switch. This will load the default

values.

2. Place DIP switch 5 in the OFF position and cycle power once

more.

Please refer to Chapter 4, Serial and Bus Communications for more infor

mation on the serial interface.

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

35

-

To enter the Main Board configuration menu, cycle power or press the reset

switch, and then press CTRL-D within the first seven seconds of the initial

ization. The LRP830 will enter the Configuration Menu. As the LRP830

starts the Configuration program, both the RF and CONFIG LEDs will

flash. The Main Board Configuration menu will display with the current

software version number together with the DSP firmware version.

******************************************************

LRP830 Standard Program

Software V1.7C, June 2000

DSP Firmware V1.7B, August 2000

*******************************************************

[1] Set-up Operating Parameters

[2] Download New Program

[3] Download DSP Firmware

[4] Exit to Operating Mode

Enter Selection:

5.2 Set-up Operating Parameters

To change the operating parameters of the LRP830, enter 1 at the initial

menu. The following menu will be displayed, listing the current settings:

The exact appearance of the menu display will depend on the settings you

have made, and will be updated when you save your changes.

Serial Port COM1: RS232, 9600, N, 8, 1, No handshake (DIP switches)

Serial Port COM2: RS232, 9600, N, 8, 1, No handshake

Operating Mode: ABx Standard

RF Communication: Fast Mode

-

[1] Set COM1 Parameters

[2] Set COM2 Parameters

[3] Set Operating Mode

[4] Set RF Communications

[5] Restore Factory Defaults

[6] Return to Main Menu

Enter Selection:

Enter the number of the sub-menu you wish to enter. When you have made

your selection you will be prompted to save your changes to the non-volatile

EEPROM. For the new settings to take effect, you must save your changes

to the EEPROM and reset the LRP830. If you do not save changes to the

EEPROM, the new settings will be effective only until the LRP830 is reset.

Copyright © 2000 Escort Memory Systems

36 LRP830-Series Long-Range Passive Reader/Writer

The following sub-menus are presented here in their entirety. Actually the

menus will presented one option at time, advancing as you enter selections.

Some options shown are dependent on earlier selections.

Set COM1 Parameters

Selecting 1 from the above menu will present the following display for the

COM1 parameters. These settings are valid only if you are not using the

DeviceNet Interfaces (e.g. DIP switch 4 is in the OFF position). Enter the

appropriate number at each prompt. The default values are indicated by an

asterisk (*).

*** Set COM1 Parameters ***

Baud Rate? [0] 1200 [1] 2400 [2] 4800 [3] 9600* [4] 19200 [5] 38400

Data size? [0] 7 bit [1] 8 bit*

Parity? [0] None* [1] Even [2] Odd

Handshake? [0] None* [1] Xon/Xoff

Save Changes to EEPROM? [0] No [1] Yes

Set COM2 Parameters

Selecting 2 from the above menu will bring to the following display for the

COM2 parameters. Enter the appropriate number at each prompt. The

default values are indicated by an asterisk.

*** Set COM2 Parameters ***

Baud Rate? [0] 1200 [1] 2400 [2] 4800 [3] 9600* [4] 19200

Data size? [0] 7 bit [1] 8 bit*

Parity? [0] None* [1] Even [2] Odd

Handshake? [0] None* [1] Xon/Xoff

Save Changes to EEPROM? [0] No [1] Yes

Set Operating Mode

The Set Operating Mode menu allows you to choose the command protocol

the LRP830 will use or configure it to automatically enter Continuous Read

Mode upon start-up.

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

37

*** Set Operating Mode ***

Command Protocol? [0] ABx Standard* [1] ABx Fast [2] ABx ASCII

Checksum? [0] Disabled* [1] Enabled

Power up in Continuous Read Mode? [0] NO [1] Single Tag [2] Multiple Tag

Start Address (0 to 47)

Length (1 to 48)

Delay Between Duplicate Decodes (0 to 60)

Raw Read Response? [0] NO [1] CR terminate [2] CR/LF terminate

Save Changes to EEPROM? [0] No [1] Yes

Command Protocol?

The LRP830 offers three modes for the transfer of data and commands. ABx

Standard (ABxS) uses only the LSB for tag data while ABx Fast (ABxF)

will use both the MSB and the LSB for the passing of data. ABx ASCII

(ABxA) mode permits RFID operations using seven bit data packets in the

form of printable ASCII characters.

Checksum?

ABx Fast and ABx ASCII also permits you to include a checksum in the

command. To use a checksum value with the ABx commands, you must

enable the checksum option. It is recommended that you enable the

checksum option.

Power up in Continuous Read Mode?

You also have the option of setting the LRP830 to start-up in Continuous

Read Mode. When you have configured the LRP830 to function in this

manner, you do not issue commands to the LRP830. It will, upon start-up,

enter directly into a Continuous Read Mode. Since this bypasses the normal

command parameters, you must specify the Continuous Read Mode

parameters.

The LRP830 will respond to other commands and resume Continuous Read

Mode when completed.

This option will not function over a DeviceNet bus.

If you are using your LRP830 in this mode, you must choose if you want the

LRP830 to read a single tag or read multiple tags within the field.

To exit Continuous Read Mode you must either re-enter the configuration

menu and select NO from the Power up in Continuous Read Mode option,

or issue a Continuous Read command from the host with a read length of 0

as described in Chapter 6, RFID Interface.

Copyright © 2000 Escort Memory Systems

38 LRP830-Series Long-Range Passive Reader/Writer

Start Address (0-47)

Enter the tag address where you want the read to begin.

Length (1-48)

Enter the length of the read you wish the LRP830 to perform. Make certain

that the length value does not exceed the number of possible addresses fol

lowing the starting tag address. Entering a read length of 0 will disable Con

tinuous Read Mode.

Delay Between Identical Decodes (0-60)

The Delay Between Identical Decodes parameters can have a value of 0 to

60 seconds. When the Delay Between Identical Decodes is set to 0, the

LRP830 will continuously read AND transmit tag data to the host. This can

flood the buffers and cause communication errors and data loss.

Raw Read Response?

If you have selected ABx Fast or ABx ASCII, you have the option of stripping the command protocol from the data and adding a terminator to separate the data packets. You can choose a CR (0DH) or CR/LF (0DH, 0AH) to

terminate the data.

Set RF Communication

-

The LRP830 should be configured with the default (0) Fast Mode.

*** Set RF Communication ***

RF Communication? [0] Fast Mode* [1] Standard Mode 0

Save Changes to EEPROM? [0] No [1] Yes

Restore Factory Defaults

It is often helpful during troubleshooting to restore the LRP830 to known

default values. To do so, select 1from this menu.

*** Restore Factory Defaults ***

Restore Factory Default? [0] No [1] Yes

The restored defaults will be saved to the EEPROM. The communication

defaults can also be restored by placing the main board DIP switch number 5

in the ON position and then restarting the LRP830. After you have saved

any changes, you must re-initialize the LRP830 with switch 5 in the OFF

position.

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

39

Return to Main Menu

When you have completed your configuration, entering 5 will return you to

the initial menu. Unsaved changes will be effective until the LRP830 is re

set. Saved changes will be loaded automatically the next time the LRP830 is

reset.

-

5.3 Download New Program

Before attempting to download new firmware to the LRP830 main board,

read the instructions provided in a readme.txt file on the update diskette.

When you select 2 from the Main Menu, the LRP830 will display informa

tion on the current program and prompt you to begin the download.

*** Download New Program***

Program Size :21824 Bytes

Program Checksum :5AE0H (OK)

Free Program Memory :39600 Bytes

Flash Write Counter :2 times

Press a key to start Downloading

After you have pressed a key, the LRP830 will display:

Send the Intel Hex file. Downloading now.

Send the new program file via your terminal emulation program in ASCII

text or Hexadecimal format. Wait 10 seconds after the download is complete

before resetting the LRP830.

IMPORTANT:

It is not necessary to download firmware into the unit unless instructed to do

so by Escort Memory Systems technical support personnel.

-

5.4 Downloading DSP Firmware

Before attempting to download new firmware to the LRP830 main board,

read the instructions provided in a readme.txt file on the update diskette.

When upgrading software in the controller the number and meaning of the

configuration parameters may not match between the old and new software.

The old settings may not be interpreted properly with the new software. Be

Copyright © 2000 Escort Memory Systems

40 LRP830-Series Long-Range Passive Reader/Writer

-

fore downloading another version of software, display and record the current

configuration settings. Then download the new software version. Set switch

5 (on the main board) on and apply power to initialize the configuration pa

rameters to their default states. When the LEDs stop flashing, turn Switch 5

to Off and press the reset switch. Enter the Configuration Menu and re-enter

any non-default configuration parameters.

When you select 3 from the Main Menu, the LRP830 will prompt you to

begin the download.

*** Download DSP Firmware***

Press a key to start Downloading

After you have pressed a key, the LRP830 will display:

Send the Intel Hex file. Downloading now.

Send the new firmware via your terminal emulation program in ASCII text

or Hexadecimal format. The firmware will be automatically transferred to

the DSP Flash Memory. Wait 10 seconds after the download is complete

before resetting the LRP830.

Record: 750

Download OK

File Transfer to DSP

Blocco 24/24

DSP Flash Programming...

New Firmware Transferred to DSP

WARNING:

Do not download INTERFACE BOARD firmware to the main board.

IMPORTANT:

It is not necessary to download firmware into the unit unless instructed to do

so by Escort Memory Systems technical support personnel.

5.5 Exit to Operating Mode

This option is available if you wish to use temporary, unsaved, configuration

parameters. The unsaved options you have selected will be used until the

LRP830 is reset and the saved parameters are restored.

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

41

6 RFID INTERFACE

6.1 Introduction

The LRP830 offer three possible command protocols: ABx Standard, ABx

Fast and ABx ASCII. The ABx Standard format is word-based and is com

patible with most existing RFID systems by Escort Memory Systems. The

ABx Fast protocol is a byte-based packet structure that permits command

execution with fewer total bytes transferred. The ABx ASCII protocol is also

a byte-based format that permits the execution of RFID commands using a

seven-bit ASCII character set.

The ABx Fast protocol is the most efficient and therefore recommended by

Escort Memory Systems. Table 7 lists the ABx commands available for the

LRP830.

The LRP830 command set is made of two subsets: the ‘Non-Anticollision’

commands and the ‘Anticollision’ commands. The Anticollision commands

allow you to manage the multiple-tags-in-field capability of the LRP system.

Command Timeout

-

Most commands have a timeout value that is used to limit the time the

LRP830 will attempt to complete the specified operation. This value is given

in 1 ms increments with a maximum value of 65,534 ms. A timeout value of

0 will generate a syntax error.

Between 500ms and 1000ms is recommended for a timeout value for single

tag commands. Shorter timeouts may result in diminished range. A 30ms

timeout value is the shortest allowable timeout and should only be used for

short range, single tag command applications. Multiple tag commands will

require longer timeout values. For time critical applications the timeout

value should be tested to obtain the maximum performance value. A longer

timeout value does not mean that the command will take any longer to exe

cute if the tag being addressed is in the field, it only represents the period of

time (in milliseconds) the unit will attempt to execute the command. If the

tag is present, the response time to execute the command will be the same

whether the timeout is 100ms or 10,000ms.

Copyright © 2000 Escort Memory Systems

-

42 LRP830-Series Long-Range Passive Reader/Writer

NOTE:

The delay between the characters of the command packet the LRP830 can

not be longer than 200 ms.

Table 7 - ABx Command Set Listing

Non-Anticollision Commands

04 Hex Fill Tag

05 Hex Block Read

06 Hex Block Write

07 Hex Read Tag Serial Number

08 Hex Tag Search

0D Hex Continuous Block Read*

10 Hex Set Output

11 Hex Input Status

Anticollision Commands

84 Hex Fill Tag All*

85 Hex Block Read All*

86 Hex Block Write All*

87 Hex Read Tag Serial All*

88 Hex Tag Search All*

89 Hex EAS Set/Reset

8A Hex EAS Start/Stop

8D Hex Continuous Read All*

8E Hex Memory Lock

94 Hex SN Fill

95 Hex SN Block Read

96 Hex SN Block Write

97 Hex SN Block Read All*

-

*These commands can not be used with DeviceNet.

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

43

DeviceNet and Anticollision ABx Limitations

The LRP830 does not support the following “All” commands in multiple

tag-in-field mode (i.e. Anticollision Index is not 0) over a DeviceNet

interface:

Command Number Command

84H Fill Tag All

85H Block Read All

86H Block Write All

87H Read Tag SN All

88H Tag Search All

8DH Continuous Read All

97H SN Block Read All

The entire command set is available for point-to-point serial communica

tions.

-

Copyright © 2000 Escort Memory Systems

44 LRP830-Series Long-Range Passive Reader/Writer

6.2 ABx Error Codes

Non-Anticollision Error Codes

The LRP830 will return an error if it encounters a fault during operation.

Table 7 lists the possible error codes in Hexadecimal format.

Table 7 — Non-Anticollision Error Codes

Error Code Description

04H Fill Operation has failed

05H Block Read has failed

06H Block Write has failed

08H Search Tag Operation failed

21H Input Command does not match pre-defined format (syntax error)

Additionally there are internal DSP errors, F1H through F5H, for use by

Escort Memory Systems technical support.

ABx Standard

ABxS error codes are returned in the LSB of the second register passed to

the PLC. The format of the error response is shown below.

MSB LSB Remarks

AAH FFH Command Error

00H XXH Error Code

FFH FFH Message Terminator

A Block Write fail error message would appear as: AAFF 0006 FFFFH.

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

45

ABx Fast

The format of the error response is shown below.

Field Bytes Contents

Header

<STX><STX>

Response Size 00H

Error Flag FFH

Error Code XXH

Checksum XXH

Terminators <ETX> 03H

02H

02H

02H

A Block Write fail error message would appear as: 0202 0002 FF06 F803H.

ABx ASCII

The format of the error response is shown below.

Field # of ASCII

characters

Header

<STX><STX> 2

Response Size 4 Packet length in bytes excluding the header, response size,

Error Flag 2 FFH

Error Code 2 XXH - see Table 7 for details

Checksum 2 XXH - optional checksum

Terminators <ETX> 1 <ETX> 03H

Contents

<STX> 02H

<STX> 02H

checksum and terminator bytes

In ABx ASCII format the response size is the number of hex values and not

the number of ASCII characters used to represent the hex value.

A Block Write fail error message would appear as an ASCII character

string: <STX><STX>0002FF06F8<ETX>.

In hexadecimal the commands appears as:

02H 02H 30H 30H 30H 32H 46H 46H 30H 36H 46H 38H 03H

Copyright © 2000 Escort Memory Systems

46 LRP830-Series Long-Range Passive Reader/Writer

Anticollision Status Byte

When the anticollision commands encounter a fault condition they indicate

the set a bit in a STATUS byte returned in the response. The format of the

response is otherwise the same as a successful response.

The STATUS byte is defined as follows:

76543210

Antenna

Failure

R/W Error Collisions Internal

Error

Timeout Verify

Error

Reserved Reserved

Some of the conditions are the same as found in the non-anticollision com

-

mands, other are new and relate only to the anticollision.

If any of the flag bits of the returned Status are set, then that condition

occurred during the command execution. Multiple conditions can occur in

the same command.

Antenna There is an error at the antenna

Failure

R/W error Error during the tag memory access

Collision Collisions detected: more than one tag in the field answered to

the LRP830 at the same time, meaning a higher Anticollision

Index probably needs to be set

Internal Error Internal error in low-level firmware

(contact Escort Memory Systems technical assistance)

Timeout Timeout expired

Verify Error Set when re-read verification fails

Syntax Errors

Syntax errors (error code 21H) will be returned in the same format as

described for the non-anticollision commands.

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

47

6.3 Anticollision Commands

Family Interrogation

The anticollision commands always have a Family ID and an Anticollision

Index as parameters. These parameters manage the read/writes when multi

ple tags are in the same reading field. The Family ID and Anticollision Index

can be used separately or together. If the Family ID is zero, that feature is

disabled, if the Anticollision Index is zero, this feature (and multiple

tag-in-field) is disabled as well.

If both the features are disabled, the commands operate exactly the same as

the Non-Anticollision commands.

Family ID

The Family ID is a 1 byte field in the LRP tag memory at address 0. When

the Family ID parameter is set to zero, the command is broadcast to all the

tags in the field. On the other hand, if it is not equal to zero, only the tags

with the specified Family ID in byte 1will respond to the LRP830.

This feature can help in implementing a multi-level organization of the tags,

by permitting the selective reading of tags by Family ID. This gives faster

access to the tags than by using Anticollision Index alone. As previously

noted, Family ID and the Anticollision Index can be used together for

increased efficiency.

-

When using the Family ID feature, the first byte of tag memory is reserved,

and thus only 47 bytes are allowed to be used. When the feature is disabled,

48 bytes are available for user data.

For this reason, in the read and write commands, once the parameter Family

ID is not equal to zero, the addresses can go from 1 to 47, and the size from

0 to 47. However, when the Family Code is zero, the addresses can start

from 0, and the size can be up to 48.

In order to initialize a tag with a chosen Family ID, byte 0 in the tag must be

set to that value by means of a Block Write or a Block Write All command.

Copyright © 2000 Escort Memory Systems

48 LRP830-Series Long-Range Passive Reader/Writer

Anticollision Index

The Anticollision Index controls the tag reading algorithm to achieve the

fastest reading speed for the number of tags expected in the reading field at

any given moment. It also can disable the multiple tag-in-field feature when

set to 0.

The Anticollision Index should be set in relation to the maximum number of

tags possibly present in the reading field at one time. Setting the

Anticollision Index higher increases the number of tags that will be expected

to be read in the field. Lowering the Index speeds up the tag read operation.

Selecting the Anticollision Index is therefore a tradeoff choice between the

number of tags in the reading field, and the time required to read/write to

them. Regardless of the index setting, ALL tags present will be read. The in

dex simply makes the process more efficient.

None of the Anticollision Index values will absolutely limit the number

of tags that can be read by the LRP830. The following table can assist you

in setting the Index value, but tests should be done to find the best value.

The allowed values are from 0 to 7.

Anticollision Index Max number of tags

0 1 (*)

1 2-4

2 4-8

3 8-16

4 16-32

5 32-64

6 64-128

7 >128

(*) anticollision disabled

-

Some commands return or have as a parameter, the Serial Number (SN).

The tag serial number is a unique read-only, 64 bit (8 bytes) code in the tag

memory. SN commands can be used to selectively write to a specific tag,

identified by the SN. A target tag can be identified with a previous SN read

command.

Note that the anticollision commands, except SN Block Write, SN Fill and

Tag Search All, will return a response packet only after the timeout is ex

pired. If the command has the Anticollision Index set to 0, then a response

will be returned after the first successful operation.

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

49

The Anticollision Commands return a successful response whenever the op

eration has successfully been completed on at least 1 tag. They will return an

Error Response when no tag, as permitted by the Family ID and

Anticollision Index, can be found in the antenna field.

-

Note also that all the start addresses, byte lengths and packet sizes are ex

pressed in 2 byte words, in order to be compatible with the HMS commands

and to allow future developments.

-

Copyright © 2000 Escort Memory Systems

50 LRP830-Series Long-Range Passive Reader/Writer

6.4 ABx Standard Protocol

6.3 ABx Standard Protocol

The ABx standard is a binary protocol, word (2-byte) oriented, so the syntax

table reports the Most Significant Byte (MSB) and the Least Significant

Byte (LSB). In the serial transmission, the MSB is transmitted first.

ABxS Command 4 (04H): Fill Tag

DESCRIPTION

Fill an RFID tag with a one byte value over multiple contiguous addresses.

DISCUSSION

This command is commonly used to clear an RFID tag's memory. It writes a

one byte value repetitively across a specified range of tag addresses.

The fill function requires one data value byte, a starting address, and a fill

length. It will then proceed to fill the tag with the data value byte, starting at

the specified start address for the specified number of consecutive bytes.

When Fill Length is set to 0, the LRP830 will write fill data from the start

address to the end of the tag's memory. The timeout value is given in 1 msec

increments and can have a value of 1EH to FFFEH (65,534 ms). When the

timeout is set to 0, the LRP830 will return a syntax error.

Field Remarks

Command Command number in hex preceded by AAH

Start Address The tag address where the fill will start

Fill Length The number of tag addresses to be filled in bytes

Timeout Timeout value given in 1 ms units (1EH - FFFEH)

Data Value Byte The byte to be used as fill

Message Terminator FFFFH

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

51

EXAMPLE

Writes 'A' (41H) to the tag starting at address 0005H for the following next

consecutive 10 bytes. A timeout of 2 seconds (07D0H = 2000 x 1 msec

increments) is set for the completion of the configuration.

Command from Host

MSB LSB Remarks

AAH 04H Perform Command 4

00H 05H Start Address = 0005H

00H 0AH Fill Length= 10 bytes

(0064H)

07H D0H Timeout value

00H 41H Data Value Byte = 41H

FFH FFH Message Terminator

Response from LRP830

MSB LSB Remarks

AAH 04H Command echo

FFH FFH Message Terminator

Copyright © 2000 Escort Memory Systems

52 LRP830-Series Long-Range Passive Reader/Writer

ABxS Command 5 (05H): Block Read

DESCRIPTION

Read a block of data from an RFID tag.

DISCUSSION

This command is used to read segments of data from contiguous areas of tag

memory. It is capable of handling up to 48 bytes of data transferred to the

host with one command. The timeout value is given in 1 msec increments

and can have a value of 1EH to FFFEH (65,534 ms). When the timeout is

set to 0, the LRP830 will return a syntax error.

The Block Read command consists of a start address and length, followed

by the message terminator, FFFFH, as shown below. If the read range ex

ceeds the last tag address, the LRP830 will return error message 21H, in

-

-

valid format.

The data read from the tag is returned in the LSB of the register, and the

MSB is always 00H.

Field Remarks

Command Command number in hex preceded by AAH

Start Address The tag address where the read will start

Read Length The number of tag addresses to be read

Timeout Timeout value given in 1 ms units (1EH - FFFEH)

Message Terminator FFFFH

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

53

EXAMPLE:

Reads 8 bytes of data from the tag starting at address 0001H. A timeout of 2

seconds (07D0H = 2000 x 1 msec increments) is set for the completion of

the Block Read.

Command from Host

MSB LSB Remarks

AAH 05H Perform command 5

00H 01H Start Address = 0001H

00H 08H Read Block Length = 8 bytes

(0008H)

07H D0H Timeout Value

FFH FFH Message Terminator

Response from LRP830

MSB LSB Remarks

AAH 05H Command echo

00H 52H Read Data1=52H

00H 46H Read Data2=46H

00H 49H Read Data3=49H

00H 44H Read Data4=44H

00H 20H Read Data5=20H

00H 54H Read Data6=54H

00H 61H Read Data7=61H

00H 67H Read Data8=67H

FFH FFH Message Terminator

Copyright © 2000 Escort Memory Systems

54 LRP830-Series Long-Range Passive Reader/Writer

ABxS Command 6 (06H): Block Write

DESCRIPTION

Write a block of data to an RFID tag.

DISCUSSION

This command is used to write segments of data to contiguous areas of tag

memory. It is capable of transferring up to 48 bytes of data transferred from

the Host with one command. The timeout value is given in 1 msec incre

ments and can have a value of 1EH to FFFEH (65,534 ms). When the time

out is set to 0, the LRP830 will return a syntax error.

The Block Write command consists of a start address followed by the data

stream to be written to the RFID tag. If the write range exceeds the last tag

address, the LRP830 will return error message 21H, invalid format. The

LRP830 will also return an error if the write length is 0.

The data to be written to the tag is contained in the LSB of the register, and

the MSB is always 00H.

Field Remarks

Command Command number in hex preceded by AAH

Start Address The tag address where the write will start

Write Length The number of tag addresses to be written to in bytes

Timeout Timeout value given in 1 ms units (1EH - FFFEH)

Write Data The data to be written

Message Terminator FFFFH

-

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

55

EXAMPLE:

Writes 4 bytes of data to the tag starting at address 0020H. A timeout of 2

seconds (07D0H = 2000 x 1 msec increments) is set for the completion of

the Block Write.

Command from Host

MSB LSB Remarks

AAH 06H Perform Command 6

00H 20H Start Address = 0020H

00H 04H Write Length = 4 bytes

07H D0H Timeout Value

00H 52H Write Data1=52H

00H 46H Write Data2=46H

00H 49H Write Data3=49H

00H 44H Write Data4=44H

FFH FFH Message Terminator

Response from LRP830

MSB LSB Remarks

AAH 06H Command echo

FFH FFH Message Terminator

Copyright © 2000 Escort Memory Systems

56 LRP830-Series Long-Range Passive Reader/Writer

ABxS Command 7 (07H): Read Tag Serial Number

DESCRIPTION

Retrieve the eight-byte tag serial number.

DISCUSSION

Each LRP tag has an unique (2

64

possible numbers) serial number. This

number can not be changed and is not part of the 48 available data bytes. Tag

ID will be return in the LSB only, with the MSB as 00H.

Field Remarks

Command Command number in hex preceded by AAH

Timeout 2-byte timeout value in 1 ms increments (1EH - FFFEH)

Message Terminator FFFFH

EXAMPLE:

This example will wait until a tag is in range and then reads the 8-byte serial

number. In this example the SN is 1E6E3DC200000000H in hexadecimal.

Command from Host

MSB LSB Remarks

AAH 07H Perform Command 7

07H D0H Timeout

FFH FFH Message Terminator

Response from LRP830

MSB LSB Remarks

AAH 07H Command Echo

00H 1EH First SN byte

00H 6EH Second SN byte

00H 3DH Third SN byte

00H C2H Fourth SN byte

00H 00H Fifth SN byte

00H 00H Sixth SN byte

00H 00H Seventh SN byte

00H 00H Eighth SN byte

FFH FFH Message Terminator

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

57

ABxS Command 8 (08H): Tag Search

DESCRIPTION

Check to see if there is an RFID tag in the LRP830 field.

DISCUSSION

This command will activate LRP830 to "look" for a tag in the RF field. If the

LRP830 finds a tag it will return a command echo to the host. The timeout

value is given in 1 msec increments and can have a value of 1EH to FFFEH

(65,534 ms). When the timeout is set to 0, the LRP830 will return a syntax

error. If no tag is present, it will return an error message. See Section 6.2 for

more information on error codes.

Field Remarks

Command Command number in hex preceded by AAH

Timeout 2-byte timeout value in 1 ms increments (1EH - FFFEH)

Message Terminator FFFFH

EXAMPLE

Checks for an RFID tag in the RF field. A timeout of 2 seconds (07D0H =

2000 x 1 msec increments) is set for the completion of the Tag Search.

Command from Host

MSB LSB Remarks

AAH 08H Perform Command 8

07H D0H Timeout Value

FFH FFH Message Terminator

Response from LRP830

MSB LSB Remarks

AAH 08H Command echo

FFH FFH Message Terminator

Copyright © 2000 Escort Memory Systems

58 LRP830-Series Long-Range Passive Reader/Writer

ABxS Command D (0DH): Continuous Block Read

DESCRIPTION

When in Continuous Block Read mode, the LRP830 sends block reads con

tinuously to any tag in range of the antenna. When a tag enters the RF field,

it is read and the data passed to the host computer. The LRP830 continues to

read the tag but will not send the same data to the host until the tag has been

outside the RF field for a specified time period. This Delay Between Identi

cal Decodes feature prevents redundant data transmissions when the

LRP830 is in Continuous Block Read mode.

DISCUSSION

The initiate/cancel Continuous Block Read command contains three param

eters: read length, start address, and delay between identical decodes. The

read length parameter switches the mode. Any valid, non-zero length (1-48)

will set the LRP830 into Continuous Block Read mode. A read length value

of 00H will turn Continuous Block Mode off.

The Delay Between Identical Decodes value can have a value of 0 to 60

seconds. When the Delay Between Identical Decodes is set to 0, the LRP830

will continuously read AND transmit tag data to the host. This can flood the

buffers and cause communication errors and data loss.

-

-

If the LRP830 receives other commands from the host, it will execute them

and then resume Continuous Block Read mode. To exit Continuous Block

Read mode, issue the command with a read length of 0.

In Continuous Block Read mode, the LEDs will display as follows:

LED Behavior Description

ANT LED ON Assumes the Antenna is powered and functioning

CONFIG LED BLINK Tag entered the RF field

RF LED ON A tag has been read and is still in the field

RF LED OFF A read tag has been out of range for the specified time

NOTE:

This command can not be used over a DeviceNet interface.

Copyright © 2000 Escort Memory Systems

LRP830-Series Long-Range Passive Reader/Writer

59

The command is formatted as follows.

Field Remarks

Command Command number in hex preceded by AAH

Start Address 2 byte value for the start address in the tag

Read Length 2 byte value for the block read length

Delay Between

Identical Decodes

Message Terminator FFFFH

Time the tag must be out of the antenna range before the LRP830 will

transmit data again from that tag. Value is expressed in 1 second units.

EXAMPLE

This example places the LRP830 in Continuous Block Read mode and reads

8 bytes of data from the tag starting at address 0001H. A delay between

identical reads of 2 seconds (0002H = 2 x 1 second increments) is set.

Command from Host

MSB LSB Remarks

AAH 0DH Perform Command D

00H 01H Start address

00H 08H Read 8 bytes

00H 02H 2 second delay

FFH FFH Message Terminator

Response from LRP830

MSB LSB Remarks

AAH 0DH Command echo

FFH FFH Message Terminator

The LRP830 will first return an acknowledgment of the command followed

by a response containing read data when a tag enters the antenna field.

Response from LRP830

MSB LSB Remarks

AAH 0DH Command echo

00H 52H Read data byte 1

00H 46H Read data byte 2

00H 49H Read data byte 3

00H 44H Read data byte 4

00H 41H Read data byte 5

00H 20H Read data byte 6

00H 54H Read data byte 7

00H 61H Read data byte 8

FFH FFH Message Terminator

Copyright © 2000 Escort Memory Systems