ESCORT MEMORY SYSTEMS

COBALT HF

RFID CONTROLLERS

High Frequency Passive Radio Frequency Identification Controllers

For the Cobalt HF Series of RFID Controllers:

x HF-CNTL-232-01

x HF-CNTL-422-01

x HF-CNTL-485-01

x HF-CNTL-USB-01

x HF-CNTL-IND-01

OPERATOR’S MANUAL

How to Install, Configure and Operate

Escort Memory Systems’

Cobalt HF RFID Controllers

scort Memory Systems reserves the right to make modifications and improvements

to its products and/or documentation without prior notification. Escort Memory

Systems shall not be liable for technical or editorial errors or omissions contained

E

herein, nor for incidental or consequential damages resulting from the use of this

material.

The text and graphic content contained herein may be used, printed and distributed only

when all of the following conditions are met:

x Permission is first obtained from Escort Memory Systems.

x The content is used for non-commercial purposes only.

x Copyright information is clearly displayed (Copyright © 2006, Escort Memory

Systems, All Rights Reserved).

x The content is not modified.

The following are trademarks and/or registered trademarks of Escort Memory Systems, a

Datalogic Group Company: Escort Memory Systems®, and the Escort Memory Systems

logo, Subnet16™, Cobalt HF™, RFID AT WORK™, C-Macro™, C-MacroBuilder™,

CBx™ and RFID Dashboard™.

Third party product names mentioned herein are used for identification purposes only and

may be trademarks and/or registered trademarks of their respective companies: Philips,

Rockwell Automation (ControlLogix, RSLogix 500) Texas Instruments, Infineon, Modicon,

Belden, Microsoft and the Open DeviceNet Vendor Association (ODVA).

Cobalt HF RFID Controllers - Operator’s Manual

P/N: 17-1320 REV 01 (03-06)

Copyright © 2006 Escort Memory Systems, all rights reserved, published in USA.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 3 OF 116

FCC & CE COMPLIANCE NOTICE

FCC & CE COMPLIANCE NOTICE

FCC PART 15.105

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment uses, generates, and can radiate radio frequency energy and, if not installed

and used in accordance with these instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

x Reorient or relocate the receiving antenna.

x Increase the separation between the equipment and receiver.

x Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

x Consult the dealer or an experienced radio/TV technician for help.

ART 15.21

FCC

Users are cautioned that changes or modifications to the unit not expressly approved by

Escort Memory Systems may void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference that may cause undesired operation.

This product complies with CFR Title 21 Part 15.225.

CE

This product is compliant to CE requirements and has been tested and complies with EN300-330, EN-300-683, EN 60950, IEC 68-2-1, IEC 68-2-6, IEC 68-2-27 and IEC 68-2-28.

TELEC

This product has been certified under:

Regulations for Enforcement of the Radio Law Article 6, section 1, No. 1

Certification #: PENDING

P

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 4 OF 116

TABLE OF CONTENTS

TABLE OF CONTENTS

FCC & CE COMPLIANCE NOTICE................................................... 4

TABLE OF CONTENTS................................................................... 5

LIST OF TABLES........................................................................... 9

LIST OF FIGURES ....................................................................... 10

CHAPTER 1: GETTING STARTED ............................................... 11

1.1 INTRODUCTION............................................................... 11

1.1.1 Company Background ............................................................... 11

1.1.2 About this Manual .................................................................... 11

1.2 FEATURES OF THE C OBALT C ONTROLLER ............................. 12

1.3 C

OBALT C ONTROLLER M ODELS.......................................... 13

1.3.1 Connections & Communication Interface Options .........................13

1.3.2 Cobalt Controllers - Interface Connectors ................................... 14

1.4 CONTROLLER D IMENSIONS................................................ 15

1.4.1 Dimensions for HF-CNTL-232/422-01 Models ..............................15

1.4.2 Dimensions for HF-CNTL-485-01 Model ...................................... 16

1.4.3 Dimensions for HF-CNTL-USB/IND-01 Models ............................. 17

1.5 COBALT HF ANTENNAS .................................................... 18

1.5.1 Cobalt HF Antennas – Models and Sizes..................................... 18

1.5.2 Antenna to Tag Ranges.............................................................19

1.5.3 Connecting the Antenna to the Controller....................................21

1.6 COBALT HF ANTENNA D IMENSIONS..................................... 22

1.6.1 HF-ANT-1010-01 Antenna Dimensions ........................................ 22

1.6.2 HF-ANT-2020-01 Antenna Dimensions ........................................ 23

1.6.3 HF-ANT-3030-01 Antenna Dimensions ........................................ 24

1.6.4 HF-ANT-0750-01 Antenna Dimensions ........................................ 25

1.7 RFID OVERVIEW ............................................................ 26

1.8 S

UBNET16™ MULTIDROP P ROTOCOL................................... 28

CHAPTER 2: COBALT INSTALLATION ........................................ 29

2.1 UNPACK &INSPECT THE C ONTROLLER ................................ 29

2.1.1 Package Contents ....................................................................29

2.1.2 Providing the Power .................................................................30

2.2 INSTALLATION P RECAUTIONS ............................................ 31

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 5 OF 116

TABLE OF CONTENTS

2.2.1 Installation Guidelines .............................................................. 31

2.2.2 Minimum Distance between Antennas ......................................... 31

2.3 INSTALLING THE HF-CNTL-232-01..................................... 32

2.3.1 HF-CNTL-232-01 Installation .....................................................32

2.3.2 HF-CNTL-232-01 Cabling Information ......................................... 32

2.4 INSTALLING THE HF-CNTL-422-01..................................... 35

2.4.1 HF-CNTL-422-01 Installation .....................................................35

2.4.2 HF-CNTL-422-01 Cabling Information ......................................... 35

2.5 INSTALLING THE HF-CNTL-485-01..................................... 38

2.5.1 HF-CNTL-485-01 Installation .....................................................38

2.5.2 HF-CNTL-485-01 Cabling Information ......................................... 39

2.6 INSTALLING THE HF-CNTL-USB-01.................................... 40

2.6.1 HF-CNTL-USB-01 Installation ....................................................40

2.6.2 HF-CNTL-USB-01 Cabling Information ........................................ 40

2.7 INSTALLING THE HF-CNTL-IND-01..................................... 42

2.7.1 HF-CNTL-IND-01 Installation ..................................................... 42

2.7.2 HF-CNTL-IND-01 Cabling Information.........................................43

CHAPTER 3: CONTROLLER CONFIGURATION ............................ 44

3.1 CONFIGURING THE C OBALT VIA RFID DASHBOARD ................. 44

3.2 C

ONFIGURING T HE C OBALT VIA CONFIGURATION T AG ............. 45

3.2.1 Restoring Factory Default Settings.............................................46

3.2.2 Manually Assigning Node ID (-485 Only)..................................... 47

3.2.3 Automatic Node Assignment - Subnet16™ Gateway (-485 Only) ... 48

3.2.4 Automatic Node Assignment - Subnet16™ Hub (-485 Only)..........48

CHAPTER 4: LED STATUS ......................................................... 49

4.1 LED DESCRIPTIONS ........................................................ 49

4.2 E

RROR C ONDITIONS ........................................................ 50

CHAPTER 5: RFID TAGS........................................................... 51

5.1 RFID STANDARDS .......................................................... 51

5.1.1 ISO 14443A/B ..........................................................................51

5.1.2 ISO 15693 ...............................................................................52

5.1.3 ISO 18000-3.1 .........................................................................52

5.2 RFID TAG C OMPATIBILITY ................................................ 53

5.2.1 HMS Series RFID Tags ............................................................. 53

5.2.2 LRP Series RFID Tags..............................................................54

5.3 RFID TAG P ERFORMANCE ................................................ 55

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 6 OF 116

TABLE OF CONTENTS

5.4 RFID TAG E MBODIMENTS ................................................. 55

5.4.1 RFID Labels ............................................................................55

5.4.2 Printed Circuit Board RFID Tags ................................................ 56

5.4.3 Molded RFID Tags....................................................................56

5.5 TAG M EMORY ................................................................ 57

5.5.1 Mapping Tag Memory................................................................57

5.5.2 Tag Memory Optimization.......................................................... 58

CHAPTER 6: COMMAND PROTOCOLS........................................ 60

6.1 COMMAND P ROTOCOL O VERVIEW ....................................... 60

6.2 AB

6.2.1 ABx Fast - Command / Response Procedure ...............................60

6.2.2 ABx Fast - Command Packet Structure .......................................61

6.2.3 ABx Fast - Response Packet Structure .......................................62

6.2.4 ABx Fast - Command Packet Parameters ....................................63

X F AST C OMMAND P ROTOCOL........................................ 60

6.3 CBX C OMMAND P ROTOCOL ............................................... 66

6.3.1 CBx – Command Procedure .......................................................66

6.3.2 CBx – Response Procedure ....................................................... 66

6.3.3 CBx - Command Packet Structure ..............................................67

6.3.4 CBx - Response Packet Structure ..............................................68

6.3.5 CBx - Command Example .......................................................... 69

6.3.6 CBx - Response Example .......................................................... 69

CHAPTER 7: RFID COMMANDS .................................................. 70

7.1 RFID COMMANDS T ABLE .................................................. 70

COMMAND 04: FILL TAG ....................................................................71

COMMAND 05: READ DATA ................................................................ 74

COMMAND 06: WRITE DATA ............................................................... 77

COMMAND 07: READ TAG ID ..............................................................80

COMMAND 08: TAG SEARCH ..............................................................84

COMMAND 0D: START/STOP CONTINUOUS READ ............................... 88

COMMAND 35: RESET CONTROLLER ..................................................95

COMMAND 38: GET CONTROLLER INFO..............................................97

CHAPTER 8: ERROR CODES.................................................... 101

8.1 ERROR C ODE T ABLE ......................................................101

8.2 AB

8.3 CB

X F AST:ERROR R ESPONSE P ACKET S TRUCTURE .............103

X P ROTOCOL:ERROR R ESPONSE P ACKET S TRUCTURE ....... 104

APPENDIX A: COBALT HF SPECIFICATIONS............................. 106

APPENDIX B: MODELS & ACCESSORIES .................................. 107

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 7 OF 116

TABLE OF CONTENTS

C OBALT HF RFID CONTROLLER MODELS .................................... 107

OBALT HF ANTENNA M ODELS ................................................. 107

C

S

UBNET16 GATEWAYS ............................................................107

UBNET16 HUBS ...................................................................107

S

P

OWER S UPPLIES .................................................................. 108

OBALT HF SOFTWARE A PPLICATIONS....................................... 108

C

C

OBALT C ABLES &CONNECTORS..............................................109

RFID T

AGS ..........................................................................110

APPENDIX C: NETWORK DIAGRAMS ........................................ 111

APPENDIX D: ASCII CHART...................................................... 114

WARRANTY .............................................................................. 116

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 8 OF 116

LIST OF TABLES

LIST OF TABLES

Table 1-1: Connections & Communication Interface Options ______________________________________13

Table 1-2: Cobalt Controllers - Interface Connectors ____________________________________________14

Table 1-3: Cobalt HF Antennas – Models and Sizes______________________________________________18

Table 1-4: Antenna to Tag Ranges ___________________________________________________________19

Table 1-5: EMS Tag IC and Memory Capacity__________________________________________________20

Table 2-1: Cobalt Controller - Package Contents________________________________________________29

Table 2-2: Minimum Distance between Antennas ________________________________________________31

Table 2-3: HF-CNTL-232-01 Connector Pin Descriptions_________________________________________33

Table 2-4: HF-CNTL-232-01 Default COM Port Settings _________________________________________34

Table 2-5: HF-CNTL-422-01 Connector Pin Descriptions_________________________________________36

Table 2-6: HF-CNTL-422-01 COM Port Default Settings _________________________________________37

Table 2-7: HF-CNTL-485-01 Connector Pin Descriptions_________________________________________39

Table 2-8: HF-CNTL-USB-01 – 5-Pin Female RK Connector: Pin Descriptions _______________________41

Table 2-9: HF-CNTL-USB-01 – 5-Pin Male Connector: Pin Descriptions ____________________________41

Table 2-10: HF-CNTL-IND-01 - 4-Pin Connector: Pin Descriptions ________________________________43

Table 2-11: HF-CNTL-IND-01 - 5-Pin Connector: Pin Descriptions ________________________________43

Table 4-1: Node ID LED Indicator Definitions__________________________________________________49

Table 5-1: Tag Memory Map Example ________________________________________________________58

Table 6-1: ABx Fast - Command Packet Structure _______________________________________________61

Table 6-2: ABx Fast - Response Packet Structure________________________________________________62

Table 6-3: CBx - Command Packet Structure ___________________________________________________67

Table 6-4: CBx - Response Packet Structure ___________________________________________________68

Table 7-1: RFID Commands Table ___________________________________________________________70

Table 7-2: Continuous Read Mode - LED Behavior ______________________________________________89

Table 8-1: Error Code Table_______________________________________________________________102

Table 8-2: ABx Fast - Error Response Structure _______________________________________________103

Table 8-3: CBx Error Response Structure_____________________________________________________104

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 9 OF 116

LIST OF FIGURES

LIST OF FIGURES

Figure 1-1: HF-CNTL-232/422-01 Dimensions _________________________________________________15

Figure 1-2: HF-CNTL-485-01 Dimensions_____________________________________________________16

Figure 1-3: HF-CNTL-USB/IND-01Dimensions_________________________________________________17

Figure 1-4: Controllers with HF-ANT-1010-01, HF-ANT-2020-01 and HF-ANT-3030-01 Antennas _______18

Figure 1-5: HF-ANT-1010-01 Antenna Dimensions______________________________________________22

Figure 1-6: HF-ANT-2020-01 Antenna Dimensions______________________________________________23

Figure 1-7: HF-ANT-3030-01 Antenna Dimensions______________________________________________24

Figure 1-8: HF-ANT-0750-01 Antenna Dimensions______________________________________________25

Figure 1-9: Industrial Ethernet Subnet16™ Gateway and Hub _____________________________________28

Figure 2-1: HF-CNTL-232-01 – 8-Pin Male M12 Connector_______________________________________32

Figure 2-2: RS232 Interface Cable Schematic __________________________________________________33

Figure 2-3: HF-CNTL-422-01 - 8-Pin Male M12 Connector _______________________________________35

Figure 2-4: RS422 Interface Cable Schematic __________________________________________________36

Figure 2-5: HF-CNTL-485-01 – 5-Pin Male M12 Connector_______________________________________39

Figure 2-6: HF-CNTL-USB-01 - 5-Pin Female M12 Reverse Keyed & 5-Pin Male M12 Connectors________40

Figure 2-7: HF-CNTL-IND-01 - 4-Pin Female M12 D-Code & 5-Pin Male M12 Connectors _____________43

Figure 3-1: RFID Dashboard Utility _________________________________________________________44

Figure 3-2: Cobalt Controller Set to Node ID 01 ________________________________________________47

Figure 5-1: HMS125HT and HMS150HT RFID Tags ____________________________________________53

Figure 5-2: LRP125 and LRP250 RFID Tags___________________________________________________54

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 10 OF 116

CHAPTER 1: GETTING STARTED

CHAPTER 1:

GETTING STARTED

1.1 INTRODUCTION

Welcome to the Cobalt HF RFID Controllers - Operator’s Manual. This manual will

assist you in the installation, configuration and operation of the Cobalt HF RFID

Controllers.

The Cobalt HF family is a complete line of feature-rich, passive high frequency read/write

Radio-Frequency Identification devices that provide RFID data collection and control

solutions to shop floor, item-level tracking and material handling applications. They are

designed to be compact, rugged and reliable, in order to meet and exceed the

requirements of the industrial automation industry.

1.1.1 Company Background

Escort Memory Systems has long been an industry leader in providing Radio Frequency

Identification devices and has built a solid reputation by consistently delivering an

extended selection of quality, durable industrial grade RFID products.

1.1.2 About this Manual

This manual provides guidelines and instructions for installing and operating the Cobalt

HF RFID Controller. Included are descriptions of the RFID command set and examples

demonstrating how to issue commands to the Cobalt HF RFID Controller.

Numbers expressed in Hexadecimal notation, are prefaced with “0x”. For example, the

number

containing Hex values up to 0x7F, their corresponding ASCII characters and decimal

integer equivalents.

in decimal is expressed as

ten

in hexadecimal. See

0x0A

Appendix D

for a chart

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 11 OF 116

CHAPTER 1: GETTING STARTED

1.2 FEATURES OF THE C OBALT C ONTROLLER

x High performance, industrial, multi-protocol RFID controller

x Supports communication interface protocols: Subnet16™, Commercial TCP/IP,

Ethernet/IP™ and Modbus® TCP

x Interface Options: RS232, RS422, RS485, USB and Ethernet

x Reads/Writes ISO 14443A, ISO 15693 and Philips® I•CODE® 1 tag ICs and

compliant RFID tags

x Compatible with HMS-Series and LRP-Series RFID tags from Escort Memory

Systems

x Supports Escort Memory Systems’ ABx Fast & CBx™ command protocols

x Internationally recognized ISM frequency of 13.56 MHz.

x Rugged IP66 rated housing

x 8 LED status indicators for power, COM Activity, RF Activity, Subnet16 Node ID,

system diagnostics and error codes

x Flash memory for software upgrades

x Auto configurable and software programmable

x Unique serial ID number on every controller

x FCC/CE/TELEC agency compliance certification

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 12 OF 116

CHAPTER 1: GETTING STARTED

1.3 COBALT C ONTROLLER M ODELS

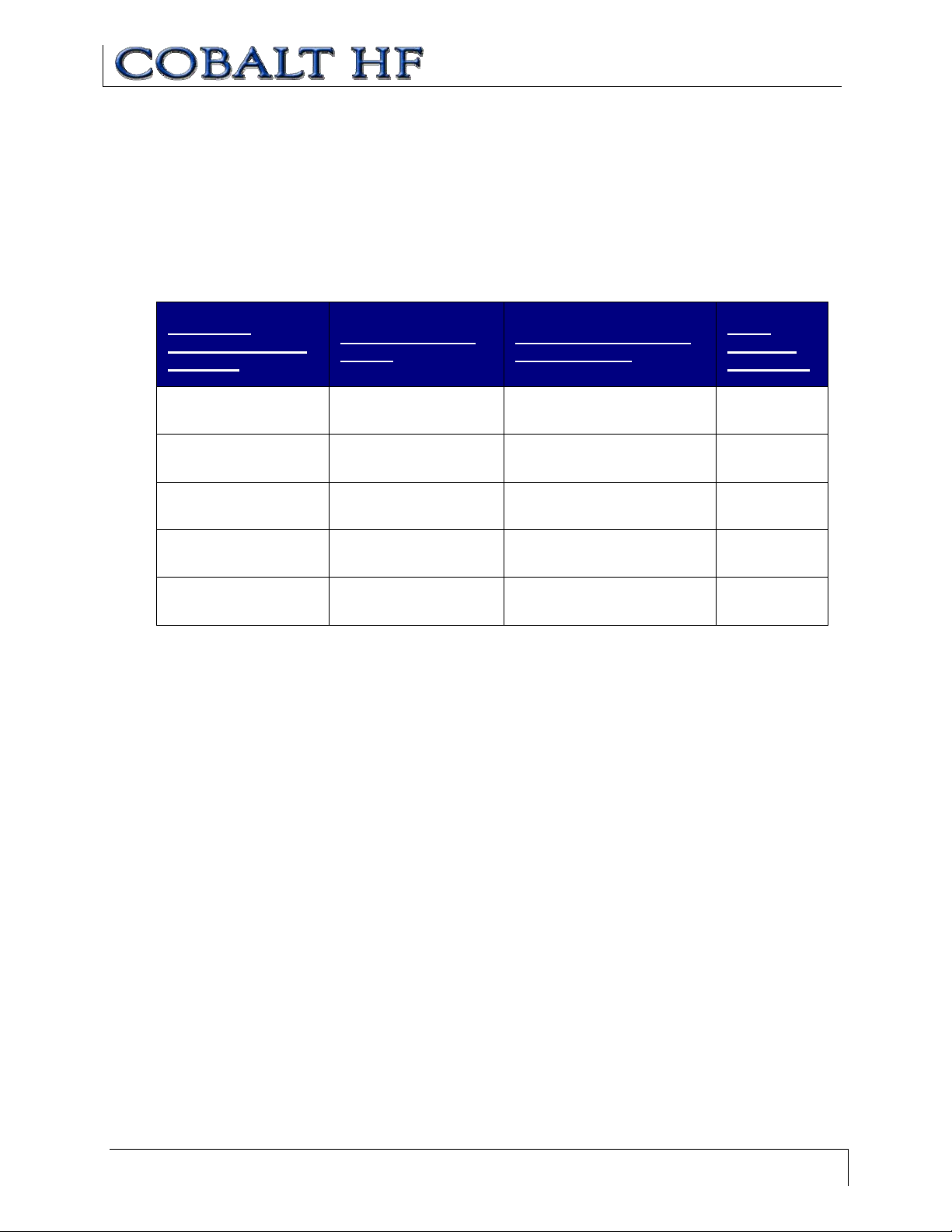

There are five models of the Cobalt HF RFID Controller. Each model is designed to

support a specific communication interface option. The table below lists the five controller

models, their respective connection types and communication interfaces.

1.3.1 Connections & Communication Interface Options

COBALT

CONTROLLER

MODEL

HF-CNTL-232-01

HF-CNTL-422-01

HF-CNTL-485-01

HF-CNTL-USB-01

HF-CNTL-IND-01

Table 1-1: Connections & Communication Interface Options

CONNECTION

TYPE

RS232

RS422

RS485

USB

Ethernet

COMMUNICATION

INTERFACE

Point-to-Point,

Host/Controller

Point-to-Point,

Host/Controller

Multidrop (Subnet16) Bus

Architecture

Point-to-Point,

Host/Controller

TCP/IP, Ethernet/IP,

Modbus TCP

MAX

CABLE

LENGTH

15m

300m

300m

3m

100m

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 13 OF 116

CHAPTER 1: GETTING STARTED

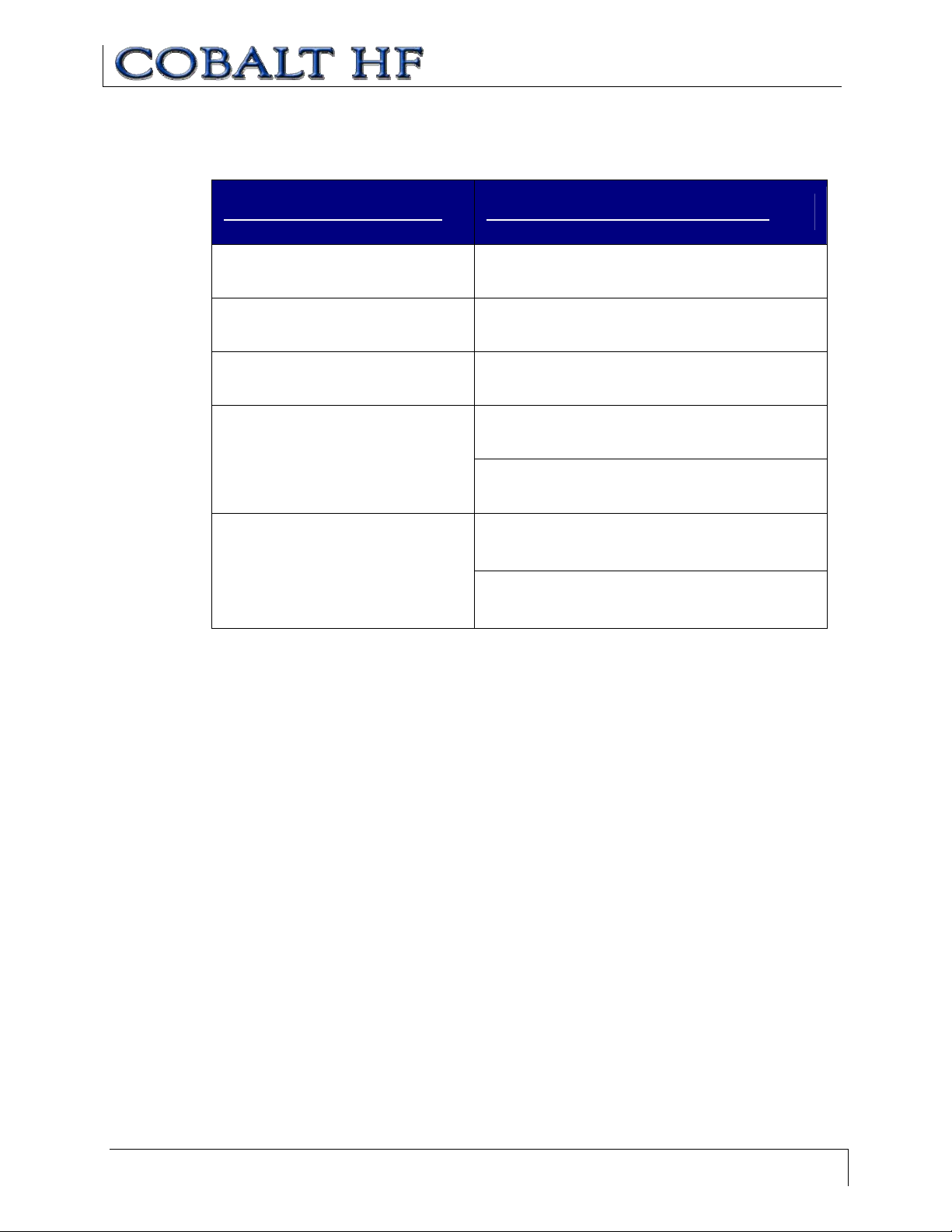

1.3.2 Cobalt Controllers - Interface Connectors

CONTROLLER MODEL INTERFACE CONNECTOR(S)

HF-CNTL-232-01

HF-CNTL-422-01

HF-CNTL-485-01

HF-CNTL-USB-01

(2 connectors)

HF-CNTL-IND-01

(2 connectors)

Table 1-2: Cobalt Controllers - Interface Connectors

8-pin Male M12 connector for power and data

8-pin Male M12 connector for power and data

5-pin Male M12 connector for power and data

5-pin Male M12 connector for power

5-pin Female M12 reverse keyed connector for

data

5-pin Male M12 connector for power

4-pin Female M12 D-Code connector for data

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 14 OF 116

CHAPTER 1: GETTING STARTED

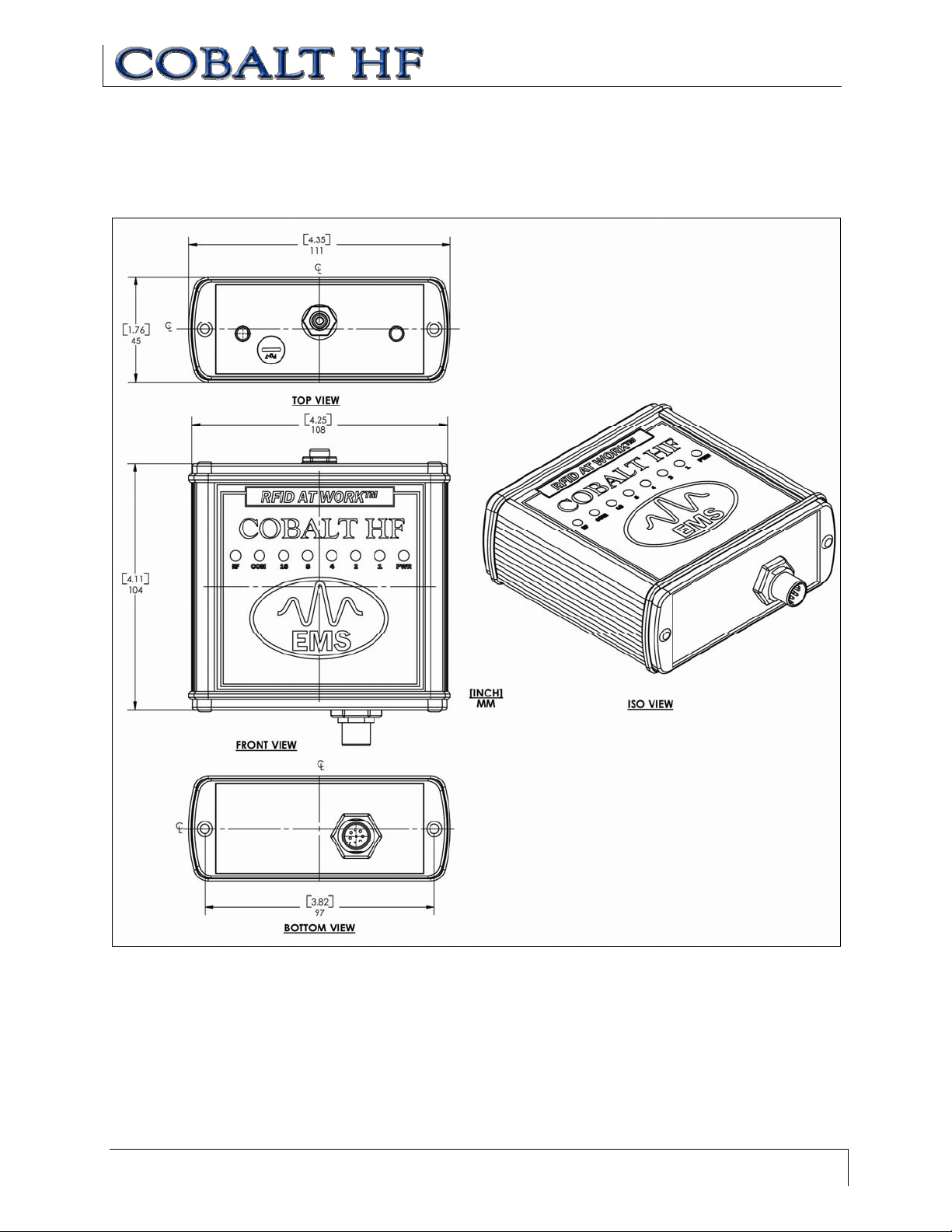

1.4 CONTROLLER D IMENSIONS

1.4.1 Dimensions for HF-CNTL-232/422-01 Models

Figure 1-1: HF-CNTL-232/422-01 Dimensions

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 15 OF 116

CHAPTER 1: GETTING STARTED

1.4.2 Dimensions for HF-CNTL-485-01 Model

Figure 1-2: HF-CNTL-485-01 Dimensions

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 16 OF 116

CHAPTER 1: GETTING STARTED

1.4.3 Dimensions for HF-CNTL-USB/IND-01 Models

Figure 1-3: HF-CNTL-USB/IND-01Dimensions

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 17 OF 116

CHAPTER 1: GETTING STARTED

1.5 COBALT HF ANTENNAS

The Cobalt HF family currently includes four different RFID antennas (three of which are

pictured below). Because the Cobalt Antennas are designed with different dimensions,

they each generate a different size RF field and read/write range.

Figure 1-4: Controllers with HF-ANT-1010-01, HF-ANT-2020-01 and HF-ANT-3030-01 Antennas

1.5.1 Cobalt HF Antennas – Models and Sizes

ANTENNA MODEL ANTENNA SIZE

HF-ANT-1010-01

HF-ANT-2020-01

HF-ANT-3030-01

HF-ANT-0750-01

Table 1-3: Cobalt HF Antennas – Models and Sizes

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 18 OF 116

10cm x 10cm

20cm x 20cm

30cm x 30cm

7cm x 50cm

CHAPTER 1: GETTING STARTED

1.5.2 Antenna to Tag Ranges

C OBALT A NTENNA TO TAG R ANGE TABLE

Tag range values are listed in millimeters and inches (mm / in.).

EMS TAG

LRP125(HT)

LRP125(HT)S

LRP250(HT)

LRP250(HT)S

LRP-P3858

LRP-P3858S

HMS125(HT)

HMS-P138

HMS150(HT)

LRP525HTS

LRP525S

ATTENTION

ANT1010

ANT-2020 ANT-3030

152 / 6.0 203 / 8.0 228 / 9.0

152 / 6.0 216 / 8.5 228 / 9.0

178 / 7.0 267 / 10.5 305 / 12.0

267 / 10.5 381 / 15.0 406 / 16.0

216 / 8.5 292 / 11.5 343 / 13.5

216 / 8.5 292 / 11.5 343 / 13.5

64 / 2.5 64 / 2.5 Not Advised

127 / 5.0 178 / 7.0 178 / 7.0

127 / 5.0 183 / 7.2 165 / 6.5

254 / 10.0 381 / 15.0 432 / 17.0

216 / 8.5 318 / 12.5 356 / 14.0

Table 1-4: Antenna to Tag Ranges

ANT0750

Pending

Pending

Pending

Pending

Pending

Pending

Pending

Pending

Pending

Pending

Pending

TESTING

ENVIRONMENT

Free Air

Free Air

Free Air

Free Air

Free Air

Free Air

Free Air

Free Air

Free Air

Attached to Metal

Attached to Metal

The tag range values listed above are provided for design purposes. Range can be adversely

affected by many environmental factors including metal, moisture and liquids. Testing should

be performed in the actual environment for more precise range results.

See table below for tag ICs and memory capacities.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 19 OF 116

CHAPTER 1: GETTING STARTED

EMS TAG IC AND M EMORY C APACITY

The following table lists the integrated circuit (IC) and memory size of each Escort

Memory Systems’ LRP and HMS-Series RFID tag included in the Antenna to Tag Range

table above.

EMS TAG TAG IC MEMORY SIZE

LRP125(HT)

LRP125(HT)S

LRP250(HT)

LRP250(HT)S

LRP525(HT)S

LRP525S

LRP-P3858

LRP-P3858S

HMS125(HT)

HMS-P138

HMS150(HT)

I•CODE 1 48-bytes + 8-byte ID

I•CODE 2 (SLi) 112-bytes + 8-byte ID

I•CODE 1 48-bytes + 8-byte ID

I•CODE 2 (SLi) 112-bytes + 8-byte ID

I•CODE 2 (SLi) 112-bytes + 8-byte ID

I•CODE 2 (SLi) 112-bytes + 8-byte ID

I•CODE 1 48-bytes + 8-byte ID

I•CODE 2 (SLi) 112-bytes + 8-byte ID

Mifare Classic 736-bytes + 4-byte ID

Mifare Classic 736-bytes + 4-byte ID

Mifare Classic 736-bytes + 4-byte ID

Table 1-5: EMS Tag IC and Memory Capacity

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 20 OF 116

CHAPTER 1: GETTING STARTED

1.5.3 Connecting the Antenna to the Controller

Cobalt HF Antennas mount directly to the top of the Cobalt HF RFID Controller’s housing.

The antenna is first attached to the RF port on the controller and is then fastened to the

controller’s housing with the two M5 screws and matching lock washers included with

each Cobalt HF RFID Controller. Carefully use the provided 4mm hex key wrench to

tighten both M5 screws per the torque specification below:

NTENNA M OUNTING T ORQUE S PECIFICATION

A

Torque Specification for the two M5

screws that hold the antenna to the

controller:

1.7 Nm or 15 lbs per inch ± 10%

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 21 OF 116

CHAPTER 1: GETTING STARTED

1.6 COBALT HF ANTENNA DIMENSIONS

1.6.1 HF-ANT-1010-01 Antenna Dimensions

Figure 1-5: HF-ANT-1010-01 Antenna Dimensions

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 22 OF 116

CHAPTER 1: GETTING STARTED

1.6.2 HF-ANT-2020-01 Antenna Dimensions

Figure 1-6: HF-ANT-2020-01 Antenna Dimensions

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 23 OF 116

CHAPTER 1: GETTING STARTED

1.6.3 HF-ANT-3030-01 Antenna Dimensions

Figure 1-7: HF-ANT-3030-01 Antenna Dimensions

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 24 OF 116

CHAPTER 1: GETTING STARTED

1.6.4 HF-ANT-0750-01 Antenna Dimensions

Figure 1-8: HF-ANT-0750-01 Antenna Dimensions

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 25 OF 116

CHAPTER 1: GETTING STARTED

1.7 RFID OVERVIEW

The Cobalt HF-series products are designed for use with passive RFID tags. Passive

tags require no batteries and are energized by the magnetic field of the Cobalt HF

controller’s antenna. Through inductive coupling, power is induced from the controller’s

antenna into the antenna of the RFID tag. Similar to a transformer, the efficiency of the

energy transferred is a result of the size and number of turns on the transmit antenna

(primary winding) and size and number of turns on the tag’s antenna (secondary

winding). The resonant frequency of each antenna coil and its Q-factor (quality factor)

are primary design concerns for efficient antenna coil and tag coil designs.

Optimum tuned coils for both the antenna and tag will achieve the best energy transfer.

The Q-factor defines how wide of bandwidth the energy is spread over. The RF output

power is fixed within the legal limits, the higher the peak energy at the resonant

frequency the higher the Q value and the narrower the bandwidth. Inversely, the lower

the peak energy at the resonant frequency the lower the Q value and the wider the

bandwidth. Higher the Q values of the two antenna coils will produce the greatest range.

However the with too high a Q value the less tolerant the system will be of shifts of the

resonant frequency. The lower the Q value, the wider the bandwidth and the greater

tolerance the system will have to shifting of the resonant frequency.

Tuned antenna circuits are affected by virtually all materials, whether they are metal,

water, plastic, cement or even the human touch. Some materials will shift the resonant

frequency up, and other materials will shift the frequency down and some have more

affect than others. Metal and water will have the most serious affect on antenna tuning,

metal more so than water. The lower the frequency the less affect metal and water have

on the performance. The 13.56MHz HF frequency provides the best compromise

between range, speed, and immunity to environmental affects. The HF-series products

are designed with optimum antenna designs with Q values required for most applications.

The Cobalt HF-series operates at the ISM (Industrial, Scientific, Medical) internationally

accepted frequency of 13.56MHz. 13.56MHz is considered to be in the High Frequency

spectrum as opposed to 864MHz or 915MHz which fall under the Ultra-High Frequency

or UHF spectrum, or 2.4GHz in the microwave range spectrum. For reference,

13.56MHz falls between the AM and FM radio bands.

Understanding these principals is important when considering the mounting of the HF

Controller’s antenna and the RFID tag. Unless the tag or antenna is designed specifically

for mounting close to metal, non-metallic mounting brackets and non-metallic tag spacers

are required to achieve optimum read and write ranges.

Electrical noise generated by motors, conveyors and other automation equipment can

produce excessive electrical noise which can negatively affect the RF communications.

The Cobalt HF series products should only be used on well grounded systems.

Conveyors systems should be tied directly to earth ground by an electrician. All cables

used on and around the RFID system must be shielded cables. Cable shields should

typically be grounded at both ends, however, differences in ground potentials can

produce “ground loops” and in those cases the ground connection may need to be lifted

at one end of the cable.

The range performance specified in this and other Escort Memory Systems publications

refer to the free air measurement, meaning there is no metal in the field. Because the

proximity to metal and other environmental conditions affect read and write range, it is

impossible for Escort Memory Systems to state the absolute range that will be achieved

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 26 OF 116

CHAPTER 1: GETTING STARTED

in for all conditions. The system integrator must validate the performance as the

products are to be used and can not rely solely on the published range specifications.

The Cobalt HF RFID Controller is compatible with Escort Memory Systems LRP and

HMS series RFID tags. HMS series tags are referred to as proximity whereas the LRP

series are referred to as vicinity tags and have longer range. HMS tags utilize ISO

14443A integrated circuits while the LRP series utilize Philips ICODE1 and ISO15693

integrated circuits manufactured by Phillips, Fujitsu, and Infineon. The Cobalt HF-series

is also capable of reading other ISO15693 compliant tags.

For more information on RFID tags, see

Chapter 5: RFID Tags.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 27 OF 116

CHAPTER 1: GETTING STARTED

1.8 SUBNET16™ MULTIDROP PROTOCOL

The HF-CNTL-485-01 model includes support for Escort Memory Systems’ Subnet16™

Multidrop RFID networking protocol. Under the Subnet16 protocol, up to 16 HF-CNTL485-01 RFID Controllers can be connected via a trunk and tap network to an Industrial

Ethernet Subnet16™ Gateway (GWY-01-IND-01) or TCP/IP Subnet16™ Gateway

(GWY-01-TCP-01) interface module.

HF-CNTL-485-01 models can also be connected directly to an Industrial Ethernet

Subnet16™ Hub (HUB-04-IND-01) or TCP/IP Subnet16™ Hub (HUB-04-TCP-01)

interface module. The Subnet16™ Hubs have four independent controller ports, four

digital inputs and four digital outputs.

Figure 1-9: Industrial Ethernet Subnet16™ Gateway and Hub

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 28 OF 116

CHAPTER 2: COBALT INSTALLATION

CHAPTER 2:

COBALT INSTALLATION

2.1 UNPACK &INSPECT THE C ONTROLLER

Unpack the Cobalt Controller hardware and accessories. Retain the original shipping

carton and packing material in case an item needs to be returned. Inspect each piece

carefully, if an item appears to be damaged, notify your Escort Memory Systems product

distributor.

2.1.1 Package Contents

The Cobalt HF RFID Controller product package contains the following components:

PART

NUMBER

HF-CNTL-

17-312

20-1950

20-3915

69-1289

00-3000

CBL-1487

XXX

X

QUANTITY DESCRIPTION

-01

1 Cobalt HF Series RFID Controller

1 HF-CNTL-XXX-01 - Installation Guide

2

2

1 Tool - Hex #4 (4mm L-Key)

1 Cobalt HF Series - Configuration Tag

1

Table 2-1: Cobalt Controller - Package Contents

Antenna Mounting Screws (M5 x 20mm,

Hex #4, Stainless Steel)

Spring Washers for Antenna Mounting

Screws (M5, Stainless Steel)

Field Mountable 5-Pin Female M12

Connector for Power Connection (USB and

IND Models).

XXX = Model Designation (232, 422, 485, USB or IND)

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 29 OF 116

CHAPTER 2: COBALT INSTALLATION

2.1.2 Providing the Power

Cobalt Controllers require an electrical supply voltage of 10~30VDC and have a power

consumption of 12W (450mA @ 24VDC).

Employ a regulated power supply that is capable of delivering these requirements. Below

is a list of power supplies available from Escort Memory Systems.

OBALT HF RFID CONTROLLERS -POWER S UPPLY PART N UMBERS

C

x 00-1166: (24VDC, 1.88A max, 45W)

x 00-1167: (24VDC, 4.17A max, 100W)

x 00-1168: (24VDC, 5.0A max, 120W)

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 30 OF 116

CHAPTER 2: COBALT INSTALLATION

2.2 INSTALLATION P RECAUTIONS

RF performance and read/write range can be negatively impacted by the proximity of

metallic objects. Avoid mounting the antenna within 15cm (6 inches) of any metallic

object or surface.

2.2.1 Installation Guidelines

x Do not route cables near unshielded cables or near wiring carrying high voltage

or high current. Cross cables at perpendicular intersections and avoid routing

cables near motors and solenoids.

x Avoid mounting the Cobalt Controller near sources of EMI (electro-magnetic

interference) or near devices that generate high ESD (electro-static discharge)

levels.

x In the event that electrical interference is encountered (as indicated by a

reduction in read/write performance) try relocating the controller to an area away

from the potential source of interference.

x Plan to perform a test phase where you will construct a small scale, independent

network that includes only the essential devices required to test your RFID

application. To avoid possible interference with other devices, avoid connecting

your RFID testing environment to an existing local area network.

x The Cobalt HF Controller is designed to withstand 8kV of direct electro-static

discharge (ESD) and 15kV of air gap discharge. However, it is not uncommon for

some conveyor applications to generate considerably higher ESD levels. Use

adequate ESD prevention measures to dissipate potentially high voltages.

2.2.2 Minimum Distance between Antennas

When using multiple Cobalt HF Controllers/Antennas, maintain the recommended

minimum distance between adjacent Cobalt Antennas (see table below).

COBALT

ANTENNA

1010

2020

3030

0750

1010 2020 3030 0750

60cm 75cm 90cm 50cm

75cm 90cm 1.2m 65cm

90cm 1.2m 2m 90cm

50cm 65cm 90cm 50cm

Table 2-2: Minimum Distance between Antennas

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 31 OF 116

CHAPTER 2: COBALT INSTALLATION

2.3 INSTALLING THE HF-CNTL-232-01

2.3.1 HF-CNTL-232-01 Installation

1. Attach the Cobalt HF Antenna to the Cobalt HF Controller (refer to Section 1.5.3).

2. Following the guidelines in Section 2.2.1, select a suitable location for the Cobalt

HF Controller/Antenna. If necessary, fabricate mounting brackets from durable

plastic.

3. Fasten the combined controller and antenna to the mounting fixture using two M5

(#10) diameter screws, each passing through the antenna’s mounting holes and

secured with locking washers and nuts. Tighten screws to 1.7 Nm or 15 lbs per

inch ± 10%.

4. Connect the 8-pin female M12 end of a serial communications cable to the 8-pin

male M12 connector on the Cobalt HF-CNTL-232-01.

5. Connect the opposite end of this cable to an available COM port on the host

computer (see Section 2.3.2, below, for cabling information).

6. Provide a power supply for the controller that is capable of delivering 10~30VDC,

12W.

7. Turn the power supply ON. The green power LED and the yellow Node ID 1 LED

will remain lit. The Node ID 1 LED indicates that the controller is in RS232 mode.

2.3.2 HF-CNTL-232-01 Cabling Information

Figure 2-1: HF-CNTL-232-01 – 8-Pin Male M12 Connector

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 32 OF 116

CHAPTER 2: COBALT INSTALLATION

HF-CNTL-232-01 CONNECTOR P IN D ESCRIPTIONS

PIN # DESCRIPTION

1

2

3

4

5

6

7

8

RS232 I

10~30VDC PWR

0VDC (POWER GND)

NOT CONNECTED

NOT CONNECTED

NOT CONNECTED

RX

TX

SGND (SIGNAL GROUND)

Table 2-3: HF-CNTL-232-01 Connector Pin Descriptions

NTERFACE C ABLE S CHEMATIC

Figure 2-2: RS232 Interface Cable Schematic

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 33 OF 116

CHAPTER 2: COBALT INSTALLATION

HF-CNTL-232-01 DEFAULT COM PORT SETTINGS

COM PORT PARAMETER DEFAULT SETTING

Baud

Data Bits

Stop Bits

Parity

Handshaking

9600

8

1

None

None

*

Table 2-4: HF-CNTL-232-01 Default COM Port Settings

* The Cobalt HF-CNTL-232-01 supports baud rates of 9600, 19.2k, 38.4k, 57.6k and

115.2k.

HF-CNTL-232-01 C

ABLING PART N UMBERS

x CBL-1478: (RS232 Cable, Female, DB9, 2.5mm DC Jack).

x CBL-1488-XX: (8-pin, Female M12 w/ Bare Wires).

x CBL-1491: (8-pin, Female M12 Right Angle Field Mountable Connector).

x CBL-1492-XX: (8-pin, Female M12 Right Angle, Bare Wires).

x CBL-1493: (8-pin, Female M12 Straight Field Mountable Connector).

x Recommended Bulk RS232 cable - Belden P/N: 9941.

(XX = Cable Length in Meters)

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 34 OF 116

CHAPTER 2: COBALT INSTALLATION

2.4 INSTALLING THE HF-CNTL-422-01

2.4.1 HF-CNTL-422-01 Installation

1. Attach the Cobalt HF Antenna to the Cobalt HF Controller (refer to Section 1.5.3).

2. Following the guidelines in Section 2.2.1, select a suitable location for the Cobalt

HF Controller/Antenna. Fabricate mounting brackets from durable plastic, if

necessary.

3. Fasten the combined controller and antenna to the mounting fixture using two M5

(#10) diameter screws, each passing through the antenna’s mounting holes and

secured with locking washers and nuts. Tighten screws to 1.7 Nm or 15 lbs per

inch ± 10%.

4. Connect the 8-pin female M12 connector from a serial communications cable to

the 8-pin male M12 connector on the Cobalt HF RFID Controller (refer to Section

2.4.2 below for cabling information).

5. Attach the other end of the serial cable to the RS422 port on the host PC. Follow

wiring instructions included with the host RS422 interface.

6. Provide a regulated power supply of 10~30VDC, 12W for the controller.

7. Turn the power supply ON. The green power LED and the yellow Node ID 2 LED

will remain ON while power is applied to the unit. The Node ID 2 LED indicates

that the controller is in RS422 mode.

2.4.2 HF-CNTL-422-01 Cabling Information

Figure 2-3: HF-CNTL-422-01 - 8-Pin Male M12 Connector

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 35 OF 116

CHAPTER 2: COBALT INSTALLATION

HF-CNTL-422-01 CONNECTOR P IN D ESCRIPTIONS

PIN # DESCRIPTION

1

2

3

4

5

6

7

8

RS422 I

10~30VDC PWR

0VDC (POWER GND)

+TX (A)

-TX (B)

+RX (A)

-RX (B)

NOT CONNECTED

SGND (SIGNAL GND)

Table 2-5: HF-CNTL-422-01 Connector Pin Descriptions

NTERFACE C ABLE S CHEMATIC

Figure 2-4: RS422 Interface Cable Schematic

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 36 OF 116

CHAPTER 2: COBALT INSTALLATION

HF-CNTL-422-01 COM PORT D EFAULT S ETTINGS

COM PORT PARAMETER DEFAULT SETTING

Baud

Data Bits

Stop Bits

Parity

Handshaking

9600

8

1

None

None

*

Table 2-6: HF-CNTL-422-01 COM Port Default Settings

* The Cobalt HF-CNTL-422-01 supports baud rates of 9600, 19.2k, 38.4k, 57.6k and

115.2k.

HF-CNTL-422-01 C

ABLING PART N UMBERS

x CBL-1491: (8-pin, Female, M12 Right Angle Field Mountable Connector)

x CBL-1493: (8-pin, Female, M12 Straight Field Mountable Connector)

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 37 OF 116

CHAPTER 2: COBALT INSTALLATION

2.5 INSTALLING THE HF-CNTL-485-01

2.5.1 HF-CNTL-485-01 Installation

1. Attach the Cobalt HF Antenna to the Cobalt HF Controller (refer to Section 1.5.3).

2. Following the guidelines in Section 2.2.1, select a suitable location for the Cobalt

HF Controller/Antenna. Fabricate mounting brackets from a durable plastic if

necessary.

3. Fasten the combined controller and antenna to the mounting fixture using two M5

(#10) diameter screws, each passing through the antenna’s mounting holes and

secured with locking washers and nuts. Tighten screws to 1.7 Nm or 15 lbs per

inch ± 10%.

4. Follow the installation instructions from the Subnet16 Gateway or Subnet16 Hub

Operator’s Manual. Connect the 5-pin female end of a Subnet cable to the

controller’s 5-pin male M12 connector. Use only Escort Memory Systems

Subnet16 approved cables. (See

accessories).

5. Provide a regulated power supply of 10~30VDC, 12W for the controller.

Appendix B

for a complete list of cabling

6. Turn the power supply ON. The green power LED on the unit will illuminate when

power is applied to the unit. The yellow Node ID LEDs, when lit, display the

Subnet16 Node ID (in binary) that is currently assigned to the controller. Note:

the default Node ID is Node 00; in which case none of the yellow Node ID LEDs

will be lit.

Note: the Gateway and Hub Operator’s Manuals are available online at www.ems-

rfid.com.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 38 OF 116

CHAPTER 2: COBALT INSTALLATION

2.5.2 HF-CNTL-485-01 Cabling Information

Figure 2-5: HF-CNTL-485-01 – 5-Pin Male M12 Connector

HF-CNTL-485-01 C

ONNECTOR P IN D ESCRIPTIONS

PIN # DESCRIPTION

1

2

3

4

5

SIGNAL GND

10~30VDC PWR

0V (POWER GND)

TX/RX+

TX/RX-

Table 2-7: HF-CNTL-485-01 Connector Pin Descriptions

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 39 OF 116

CHAPTER 2: COBALT INSTALLATION

2.6 INSTALLING THE HF-CNTL-USB-01

2.6.1 HF-CNTL-USB-01 Installation

1. Attach the Cobalt HF Antenna to the Cobalt HF Controller (refer to Section 1.5.3).

2. Following the guidelines in Section 2.2.1, select a suitable location for the Cobalt

HF Controller/Antenna. Fabricate mounting brackets from a durable plastic if

necessary.

3. Fasten the combined controller and antenna to the mounting fixture using two M5

(#10) diameter screws, each passing through the antenna’s mounting holes and

secured with locking washers and nuts. Tighten screws to 1.7 Nm or 15 lbs per

inch ± 10%.

4. Download the Cobalt HF USB driver from the Escort Memory Systems Web site

www.ems-rfid.com

(

USB driver. Do not connect the USB cable at this time.

5. Provide a power supply: 10~30VDC, 12W.

6. Attach the 5-pin female M12 connector from a power supply cable to the 5-pin

male M12 connector on the Cobalt Controller.

). Follow instructions provided with the download to install the

7. Connect the 5-pin male M12 reverse keyed connector end of the Cobalt HF USB

Cable (CBL-1513) to the 5-pin female M12 connector on the Cobalt Controller.

Do not plug the USB cable into the PC yet.

8. Turn the power supply ON. The green power LED and the yellow LED 4 will

remain ON while power is applied to the unit. The LED 4 light indicates that the

controller is in USB mode.

9. After the USB drivers are installed and the Cobalt HF Controller completes its

boot cycle, plug the remaining end of the USB cable into a USB port on the host

PC.

2.6.2 HF-CNTL-USB-01 Cabling Information

Figure 2-6: HF-CNTL-USB-01 - 5-Pin Female M12 Reverse Keyed & 5-Pin Male M12 Connectors

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 40 OF 116

CHAPTER 2: COBALT INSTALLATION

HF-CNTL-USB-01 – 5-PIN F EMALE RK CONNECTOR:PIN D ESCRIPTIONS

PIN # DESCRIPTION

1

2

3

4

5

+5V

D-

D+

GND

SHIELD

Table 2-8: HF-CNTL-USB-01 – 5-Pin Female RK Connector: Pin Descriptions

HF-CNTL-USB-01 – 5-P

IN M ALE C ONNECTOR:PIN D ESCRIPTIONS

PIN # DESCRIPTION

1

2

3

4

5

SHIELD GND

10~30VDC PWR

0V (POWER GND)

NOT CONNECTED

NOT CONNECTED

Table 2-9: HF-CNTL-USB-01 – 5-Pin Male Connector: Pin Descriptions

HF-CNTL-USB-01 C

ABLING PART N UMBERS

x CBL-1513: (Cable, 5-Pin Male M12, USB, 3M)

x CBL-1514: (USB Connector for HF-CNTL-USB-01)

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 41 OF 116

CHAPTER 2: COBALT INSTALLATION

2.7 INSTALLING THE HF-CNTL-IND-01

2.7.1 HF-CNTL-IND-01 Installation

1. Attach the Cobalt HF Antenna to the Cobalt HF Controller (refer to Section 1.5.3).

2. Following the guidelines in Section 2.2.1, select a suitable location for the Cobalt

HF Controller/Antenna. Fabricate mounting brackets from a durable plastic if

necessary.

3. Fasten the combined controller and antenna to the mounting fixture using two M5

(#10) diameter screws, each passing through the antenna’s mounting holes and

secured with lock washers and nuts. Tighten screws to 1.7 Nm or 15 lbs per inch

± 10%.

4. Attach the 5-pin female M12 connector end from a power supply cable to the 5pin male M12 connector on the Cobalt Controller. The other end of this cable

should connect to a regulated power supply capable of delivering 10~30VDC,

12W.

5. Attach the 4-pin male M12 D-Code connector from a CAT 5E (or better) industrial

Ethernet cable (CBL-1515-XX) to the 4-pin female D-Code connector on the

Cobalt Controller.

6. Connect the other end of the Subnet16 compatible communications cable to an

RJ45 interface adapter. Attach the other end from the RJ45 interface adapter to

an available Ethernet port on the host PC.

7. Turn the power supply ON. The green power LED on the unit will illuminate. The

yellow Node ID 8 LED will be lit when the controller is using its default IP

address. The yellow Node ID 16 LED will be lit when the controller is operating

with a user defined IP address.

HF-CNTL-IND-01 D

EFAULT IP ADDRESS

192.168.253.110

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 42 OF 116

CHAPTER 2: COBALT INSTALLATION

2.7.2 HF-CNTL-IND-01 Cabling Information

Figure 2-7: HF-CNTL-IND-01 - 4-Pin Female M12 D-Code & 5-Pin Male M12 Connectors

HF-CNTL-IND-01 – 4-P

IN C ONNECTOR:PIN D ESCRIPTIONS

PIN # DESCRIPTION

1

2

3

4

+ TX

+ RX

- TX

- RX

Table 2-10: HF-CNTL-IND-01 - 4-Pin Connector: Pin Descriptions

HF-CNTL-IND-01 – 5-P

IN C ONNECTOR:PIN D ESCRIPTIONS

PIN # DESCRIPTION

1

2

3

4

SHIELD GND

10~30VDC PWR

0V (POWER GND)

NOT CONNECTED

5

NOT CONNECTED

Table 2-11: HF-CNTL-IND-01 - 5-Pin Connector: Pin Descriptions

HF-CNTL-IND-01

CBL-1487

x

CBL-1515-05

x

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 43 OF 116

-C

ABLING PART N UMBERS

: (Connector, Straight Female, M12, 5-Pin, Field Mountable)

: (Cable, 5M, Ethernet/M12, 5-Pin, Male, D-Code)

CHAPTER 3:

CONTROLLER CONFIGURATION

CHAPTER 3:

CONTROLLER CONFIGURATION

Stored in the Cobalt’s flash memory is a group of settings and parameters known as the

“Controller Configuration.” These parameters indicate, for example, the Command

Protocol in use, the Tag IC to recognize and the software version currently installed.

The Controller Configuration can be modified by using Escort Memory Systems’ RFID

Dashboard™ utility or through the use of an HF-Series Configuration Tag (included

with the Cobalt Controller).

3.1 CONFIGURING THE COBALT VIA RFID

D

ASHBOARD

The RFID Dashboard utility is a software application that allows users to view, modify,

save and update the configuration settings of their Cobalt Controllers.

Note: there are two versions of the RFID Dashboard: one for serial connections

(-232, -422, -USB) and one for TCP/IP connections (-485, -IND).

x Download the appropriate version of the RFID Dashboard from

www.ems-rfid.com

x Follow the instructions included with the software to install the RFID Dashboard

and set the Cobalt Controller’s configuration.

.

Figure 3-1: RFID Dashboard Utility

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 44 OF 116

CHAPTER 3:

CONTROLLER CONFIGURATION

3.2 CONFIGURING T HE C OBALT VIA

C ONFIGURATION TAG

As noted, Cobalt Controllers are software configurable via the RFID Dashboard utility.

However, they can also be configured and initialized through the use the HF-Series

Configuration Tag supplied with each unit.

The Configuration Tag can be used to restore factory default values for all versions of the

Cobalt HF RFID Controller. For the Cobalt HF-CNTL-485-01 model, the Configuration

Tag can also be used manually to set the controller’s Node ID number.

ONFIGURATION T AG M EMORY M AP

C

The Configuration Tag is a 112-byte ISO 15693 compliant tag. Of the 112 bytes of

memory, the first 80 bytes (addresses 0x0000 – 0x0079) are allocated to storing factory

data. The first 16 bytes (addresses 0x0000 through 0x0015) are locked because they

contain specific data that the controller reads to identify the tag as a Configuration Tag.

The remaining 32 bytes (addresses 0x0080 – 0x0111) are not locked and can be written

to. All addresses on the Configuration Tag are readable.

NOTE: It is recommended to write your Cobalt product model and serial number on the

tag and store it in a safe place.

CONFIGURATION TAG INSTRUCTIONS

COBALT 232 or COBALT 422 Models:

x Cycle power or issue reset command (0x35) with this tag in

the RF field to reset factory defaults (9600, N, 8, 1, N).

COBALT 485 Models:

x Cycle power or issue reset command (0x35) with this tag in

the RF field to reset factory defaults & Node ID to 00.

x Move the tag out of the field and then back into the field to

increment the Node ID.

x A Gateway or Hub interface module will auto-assign the next

available Node ID to the controller when it is set to Node ID

0, connected to the Subnet16 network, and this tag is brought

into the field after power-up.

P/N: 00-3000

Configuration Tag – Front Configuration Tag – Back

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 45 OF 116

CHAPTER 3:

CONTROLLER CONFIGURATION

3.2.1 Restoring Factory Default Settings

Note: read all instructions carefully prior to performing any of the operations below.

To restore factory defaults:

1. Place the Configuration Tag in the antenna’s RF field.

2. Reset power to the Cobalt Controller or issue the reset command (Command

0x35).

3. Two seconds after power returns to the Cobalt HF, remove the Configuration Tag

from the antenna’s RF field.

Default settings will be restored and the controller’s configuration will be reset. After

successfully resetting the controller to factory defaults, the unit will be configured to the

following values:

x Command Protocol: ABx Fast – without Checksum (-232, -422 and -USB models)

x Tag Type Recognized: ISO 15693 (IǜCode SLi)

x Serial Communications: 9600, N, 8, 1, N (-232 and -422 models)

x Subnet Node ID: 00 (-485 model only)

x IP Address: 192.168.253.110 (-IND model only)

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 46 OF 116

CHAPTER 3:

CONTROLLER CONFIGURATION

3.2.2 Manually Assigning Node ID (-485 Only)

Place the Configuration Tag in the antenna’s RF field and cycle power to the HF-

1.

CNTL-485-01controller or issue the reset command (Command 0x35). The

controller’s Node ID number will be reset to the default value of 00(all yellow

Node ID LEDs should be off).

After power returns to the unit, remove the Configuration Tag from the RF field

2.

and then immediately place it back into the RF field once again to increment the

Node ID number from 00 to 01. The Node ID 1 LED should now be lit.

Note that the Node ID number is incremented by one each time the Configuration

Tag is withdrawn from and re-introduced to the controller’s RF field. This procedure

can be used to cycle through all 16 available Node ID numbers. After reaching Node

ID 16, incrementing the Node ID value once more returns the controller to Node ID

00.

Repeat step 2 until the desired Node ID number is set.

3.

Reset power to the unit with the Configuration Tag OUT of RF range. Allow the

4.

unit to reset and resume operation under its new Node ID number.

For the -485 model, the lit Node ID LEDs display (in binary) the controller’s currently

assigned Node ID number. For example, if the Node ID 1, 2 and 4 LEDs are lit, the

controller has been assigned Node ID 07. See

information regarding the Cobalt’s LEDs.

Chapter 4: LED Status

for more

Figure 3-2: Cobalt Controller Set to Node ID 01

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 47 OF 116

CHAPTER 3:

CONTROLLER CONFIGURATION

3.2.3 Automatic Node Assignment - Subnet16™ Gateway

(-485 Only)

Through the use of the Configuration Tag, a Subnet16 Gateway can automatically

assign the Node ID number to a controller connected via Subnet16 network. Follow the

steps below to allow a Subnet16 Gateway to automatically assign the Node ID number to

a Cobalt HF-CNTL-485-01.

With the HF-CNTL-485-01 disconnected from the Subnet16 network, place the

1.

Configuration Tag in the antenna’s RF field and cycle power to the HF-CNTL485-01controller.

After power returns to the unit remove the Configuration Tag from RF range.

2.

Verify that all Node ID LEDs are off - indicating that the controller’s Node ID

number has been reset to

Connect the controller to the Subnet16 network and cycle power to the Gateway

3.

and Subnet16 network bus.

While the Gateway is restarting, place the Configuration Tag in the antenna’s RF

4.

field. Allow several seconds for the Gateway to recognize the controller and

assign it an available Node ID number. Remove the Configuration Tag from RF

range.

00.

3.2.4 Automatic Node Assignment - Subnet16™ Hub

(-485 Only)

Subnet16 Hubs, which have four independent controller ports, automatically assign each

attached RFID controller the corresponding Node ID number of the port to which it is

connected. For example, if a controller is attached to port 1 on the Hub, it will be

assigned Node ID 01. If a controller with a previously configured Node ID number of 03 is

connected to port 2, the Hub will override the controller’s current Node ID number and will

automatically change it from 03 to 02.

To have the Hub automatically assign the Node ID number to the RFID controller, follow

the steps below:

Connect the HF-CNTL-485-01 to the Subnet16 Hub

1.

Place the Configuration Tag in the antenna’s RF field and cycle power to the HF-

2.

CNTL-485-01controller.

After power returns to the unit, remove the Configuration Tag from RF range.

3.

Verify that all Node ID LEDs are off - indicating that the controller’s Node ID

number has been reset to

Cycle power to the Hub and Subnet16 network bus.

4.

While the Hub is restarting, place the Configuration Tag in the antenna’s RF field.

5.

Allow several seconds for the Hub to recognize the controller and assign it the

corresponding Node ID number of the controller port for which it is attached.

Remove the Configuration Tag from RF range.

00.

For more information regarding the Subnet16 Gateway or Hub,please refer to the

Operator’s Manuals of each product - available online at

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 48 OF 116

www.ems-rfid.com

.

CHAPTER 4: LED STATUS

CHAPTER 4:

LED STATUS

Cobalt HF RFID Controllers have eight LEDs located on the front panel. These LEDs

display RF and communications activity, diagnostic information and power and Node ID

status.

4.1 LED DESCRIPTIONS

RF LED, color is red. The RF LED will

light when RF power is being

transmitted.

COM LED, color is green. The COM

(communications) LED indicates that

data is being transmitted. Upon receiving

a command, the COM LED will begin flashing

ON and OFF. After the controller completes

the operation and generates a command

response, the COM LED flashing will halt.

NODE ID LEDs (x5), colors are yellow

(see table below).

PWR LED, color is green. The PWR

(power) LED will remain ON while power

is applied to the Cobalt HF Controller.

ODE ID LED INDICATOR D EFINITIONS

N

NODE ID LED DESCRIPTION

Node ID 1 RS232 enabled

Node ID 2 RS422 enabled

Node ID 4 USB enabled

Node ID 8 Default IP Address enabled:

196.169.253.110 (-IND model only)

Node ID 16 Custom IP Address enabled (-IND model only)

All 5 Node ID LEDs LEDs Display Node ID in binary format (-485 model only)

Table 4-1: Node ID LED Indicator Definitions

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 49 OF 116

CHAPTER 4: LED STATUS

4.2 ERROR C ONDITIONS

When an error occurs, the red RF LED and one or more yellow LEDs will flash in unison.

The yellow LEDs represent the error code in binary notation. These LEDs will continue to

flash the error code until a valid command is received by the controller. If an

unrecoverable error occurs, the LEDs will continuously flash the error code until the

Cobalt Controller has been reset.

See

Chapter 8

for a list of error codes and their descriptions.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 50 OF 116

Loading...

Loading...