CHAPTER 5: RFID TAGS

CHAPTER 5:

RFID TAGS

RFID tags, which are also referred to as transponders, smart labels, or

inlays, come in a variety of sizes, memory capacities, read ranges,

frequencies, temperature survivability ranges and physical

embodiments.

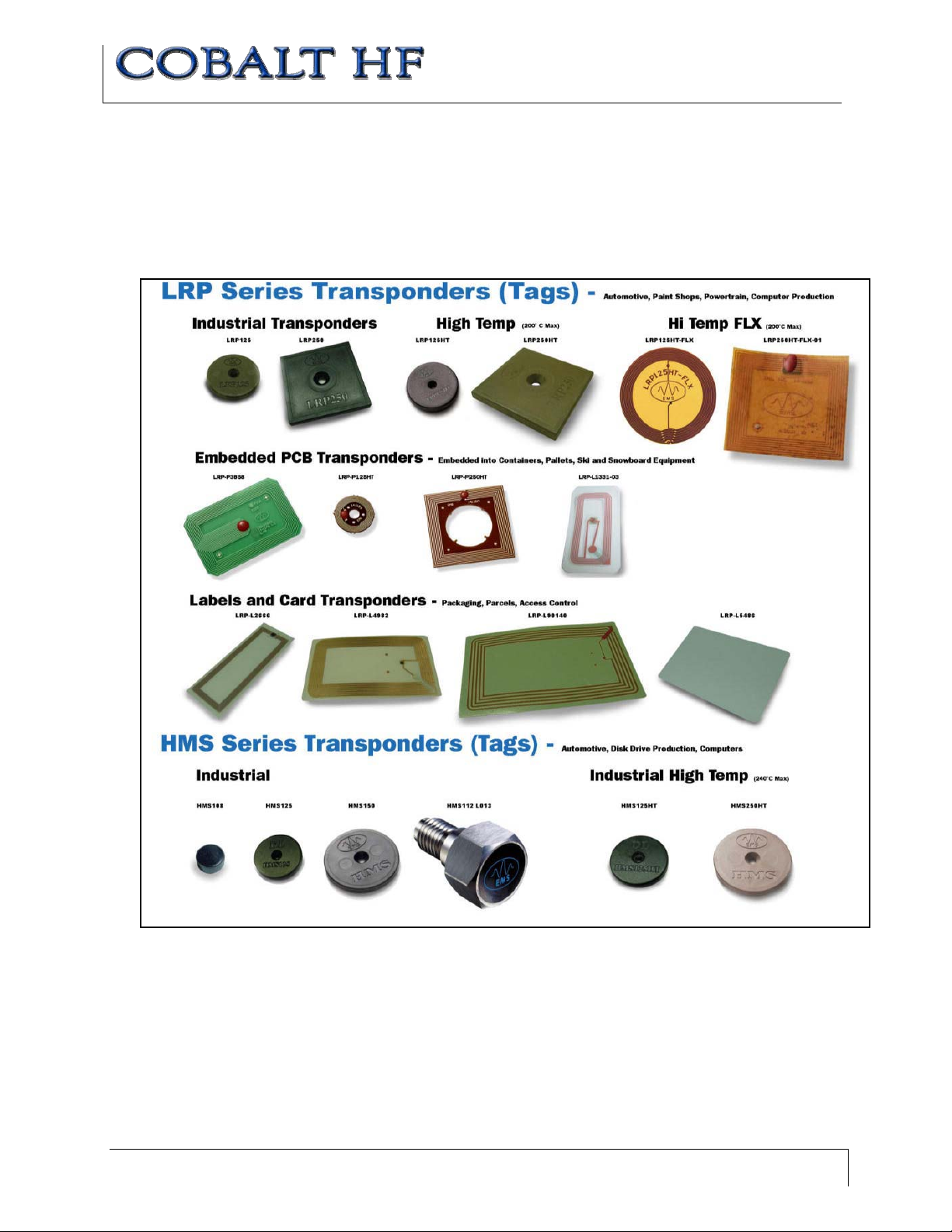

Escort Memory Systems offers many different RFID tag models. Cobalt

Controllers are capable of reading all Escort Memory Systems’ HMS

and LRP series RFID tags as well most of those produced by other

manufacturers. Our patented tags can be read through obstructions

such as water, wood, plastic and more. Our specialty high-temperature

(HT) models are capable of surviving temperatures of 415° F.

5.1 RFID STANDARDS

It is important to note that not all 13.56MHz RFID tags are compatible with Cobalt

Controllers and even tags that are said to be compliant with ISO15693 or ISO14443

standards may not actually be compatible with RFID controllers adhering to the same

standards. This is partially due to the fact that these ISO standards are so new that they

leave many features open to the discretion and interpretation of the RFID equipment

manufacturer to implement or define. When using another manufacturer’s tags, ensure

compatibility of those tags with your RFID system provider.

5.1.1 ISO 14443A/B

RFID integrated circuits (ICs) designed to meet ISO 14443A and/or ISO 14443B

standards were originally intended to be embedded in secure smart cards such as credit

cards, passports, bus passes, ski lift tickets, etc. For this reason, there are many security

authentication measures implemented within the air protocol between the RFID controller

and the tag.

ISO 14443A/B compliant tags and controllers incorporate security authentication through

the exchanging of software “keys.” The RFID controller and the tag must use the same

security keys to authenticate communication before the transfer of data will begin. The

Cobalt Controller’s operating system manages these security features, making their

existence transparent to the user. However, it is important to understand the implications

associated with ISO 14443 when using another manufacturer’s RFID tags. Because of

these security “features,” an ISO 14443 tag made by one manufacturer may not

necessarily be readable by a Cobalt Controller and, likewise, an Escort Memory Systems

ISO 14443 compliant tag might not be readable by another manufacturer’s RFID

controller. The Cobalt Controllers support Escort Memory Systems’ security keys for use

on Philips mifare ISO 14443A tags.

Escort Memory Systems was one of the first companies to adopt ISO 14443 standards

and has incorporated much of the technology into our products designed for industrial

automation applications. But because most industrial environments do not require the

same level of security that monetary or passport applications necessitate, some features

have not been implemented in the Cobalt HF product line.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 51 OF 116

5.1.2 ISO 15693

ISO 15693 was established at a time when the RFID industry identified that the lack of

standards was preventing the market from growing. Philips Semiconductor and Texas

Instruments were, at that time, the major manufacturers producing RFID ICs for the

Industrial, Scientific, and Medical (ISM)

own unique protocol and modulation algorithm. Philips Semiconductor’s I-CODE® and

Texas Instruments Tag-it® product lines were eventually standardized on the mutually

compatible ISO 15693 standards. After the decision was made to standardize, the door

was opened for other silicon manufacturers to enter the RFID business, many of which

have since contributed to other RFID ISO definitions. This healthy competition has led to

rapid growth in the RFID industry and has pushed the development of new standards,

such as ISO 18000 for Electronic Product Code (EPC) applications.

5.1.3 ISO 18000-3.1

The ISO 18000 standard has not been implemented in the Cobalt HF product line at the

time of publication of this manual. It is a planned product enhancement for future

releases. The emerging ISO 18000 Standard will provide enhanced support for EPC and

Unique Identification (UID) tag applications.

CHAPTER 5: RFID TAGS

frequency of 13.56MHz. However, each had their

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 52 OF 116

CHAPTER 5: RFID TAGS

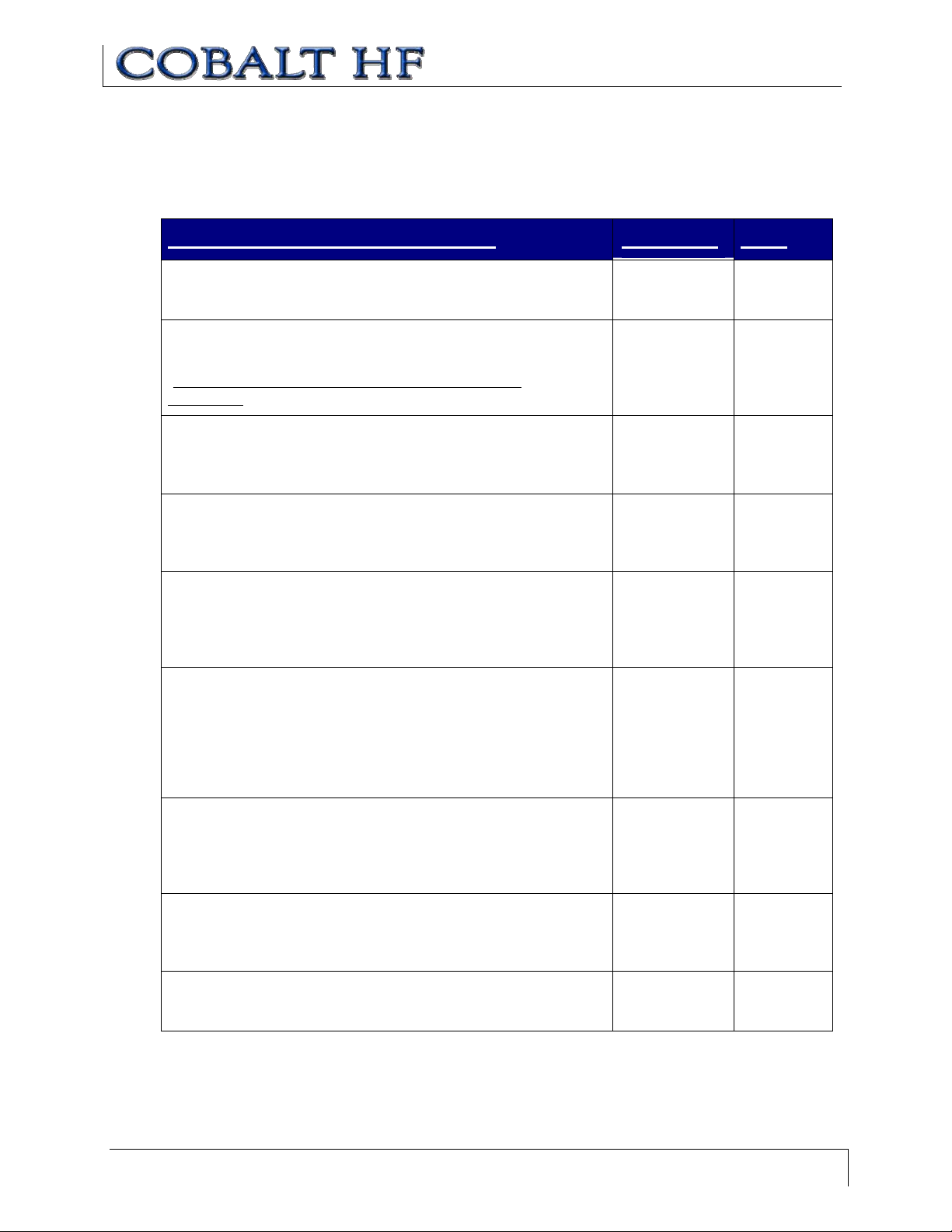

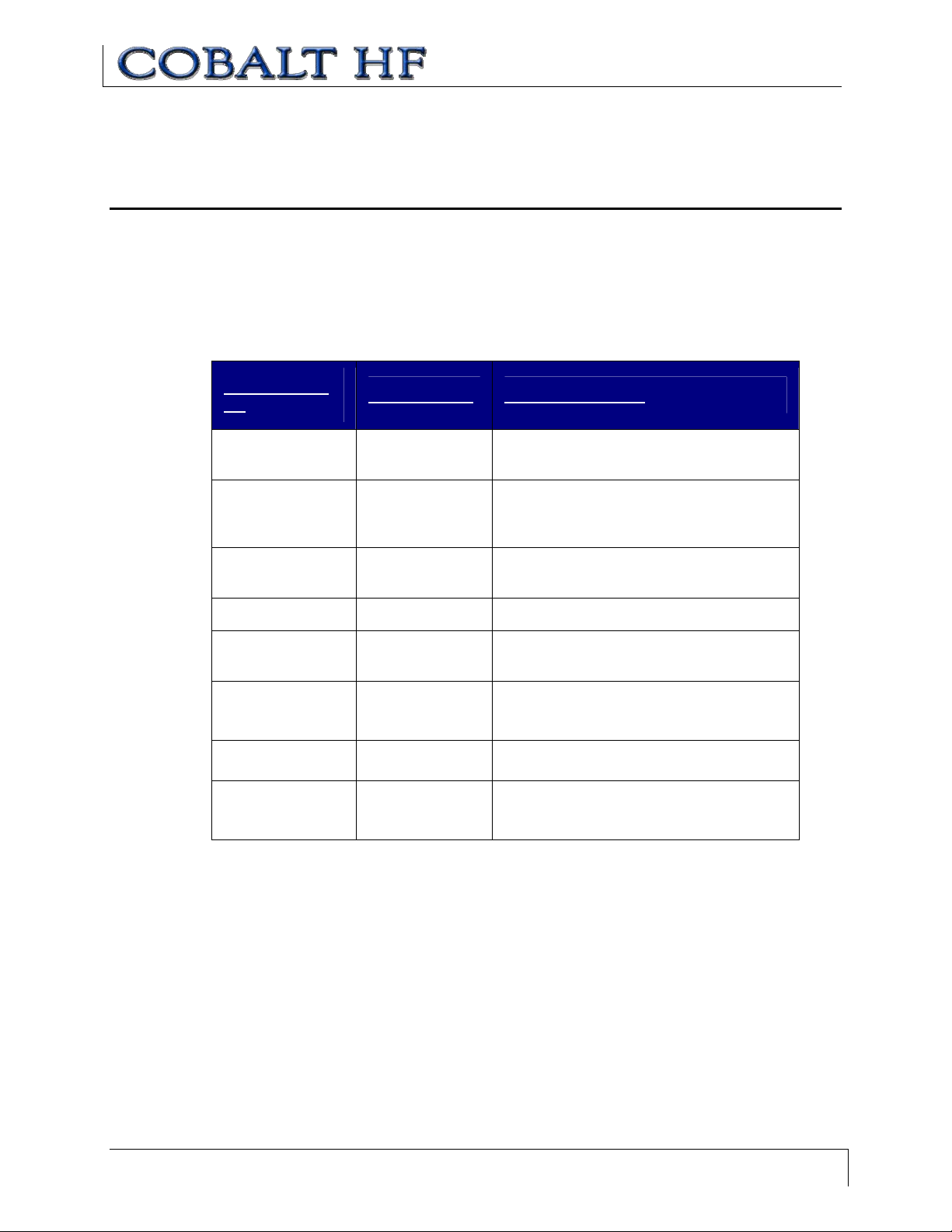

5.2 RFID TAG COMPATIBILITY

The following RFID tags are compatible with the Cobalt HF Controller:

5.2.1 HMS Series RFID Tags

Integrated Circuits (ICs) used in Escort Memory Systems’ HMS-Series RFID tags include:

x Philips mifare Classic, 1 kilobyte (KB) + 32-bit Tag ID (ISO 14443A). One KB is

the total memory in the IC. Of this memory, 736 bytes are available for user data.

x Philips mifare Classic, 4 KB + 32-bit Tag ID (ISO 14443A). Four KB is the total

memory in the IC. Of this memory, 3,440 bytes are available for user data.

Figure 5-1: HMS125HT and HMS150HT RFID Tags

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 53 OF 116

CHAPTER 5: RFID TAGS

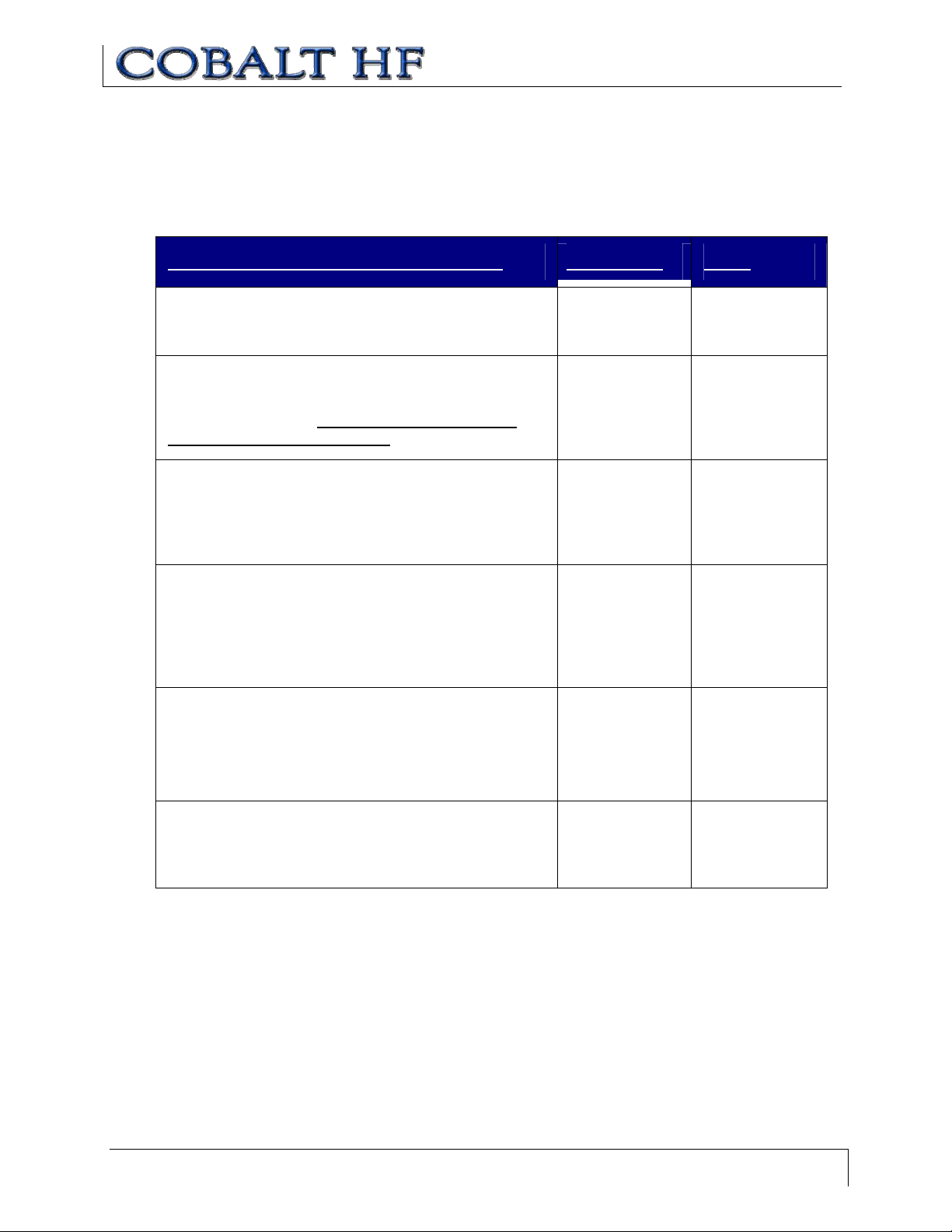

5.2.2 LRP Series RFID Tags

ICs used in Escort Memory Systems’ LRP-Series RFID tags include:

x Philips I•CODE 1, 48-byte + 64-bit Tag ID

x Philips I•CODE SLi, 112-byte + 64-bit Tag ID (ISO 15693)

x Texas Instruments Tag-it, 32-byte + 64-bit Tag ID (ISO 15693)

x Infineon My-D Vicinity, 1kb + 64-bit Tag ID (ISO 15693)

Figure 5-2: LRP125 and LRP250 RFID Tags

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 54 OF 116

CHAPTER 5: RFID TAGS

5.3 RFID TAG PERFORMANCE

Many factors can affect the performance between the controller’s antenna and the tag’s

antenna. These include, but are not limited to: the tag integrated circuit (IC), the antenna

coil design, the antenna conductor material, the antenna coil substrate, the bonding

method between tag IC antenna coil, and the embodiment material.

Additionally, the mounting environment of the tag and controller can hinder performance

due to other materials affecting the tuning of either antenna. Escort Memory Systems has

undergone extensive testing to produce tags that obtain optimum performance with our

RFID controllers. In most cases, optimal range will be obtained when mounting the tag

and controller antenna in locations free from the influence of metals, ESD and EMI

emitting devices.

5.4 RFID TAG EMBODIMENTS

RFID tags come in a variety of sizes and packages. The most common and cost effective

tag embodiment is the RFID label.

5.4.1 RFID Labels

RFID Labels (inlays or inlets) are the lowest cost RFID tag solution and are typically used

in an open system in which the tag leaves the facility attached to a product or is

destroyed at the end of the process.

An inlay is a substrate (made of polyester or Mylar) with a

printed, screened or etched antenna coil. Sometimes the

coil consists of a wire that is laid down onto the substrate

and is bonded to it with heat. Typically, the RFID IC is

attached by means of flip-chip technology and the

electrical connections are made by means of conductive

epoxies.

RFID inlays are usually applied to sticker backed paper to

create label tags which are manufactured in high volumes

on roll-to-roll production equipment. Inlays can be

laminated an used in smart credit cards, providing a low

cost RFID tag with some protection from impact damage.

The materials and procedures used to manufacture an RFID label’s antenna coil are

critically important. Low cost processes (such as printing or screening) produce low

quality antenna coils which can exhibit poor conductivity and cracking when flexed.

Labels with copper wire wound coils are generally considered efficient conductors of RF

energy and can usually survive considerable flexing, but are often more expensive due to

more involved production processes.

RFID labels with etched copper antenna coils have been found to be the most reliable,

semi-low cost tag solution. Etched inlay antenna coils are usually of consistent quality

and can survive a great deal of flexing and bending. However, because etching is

inherently a subtractive process, the cost per tag increases in part due to copper and

other metals discarded during the fabrication process.

As RFID label manufacturing technology advances, there have been several new

developments made in the areas of high volume, low cost, antenna coil manufacturing.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 55 OF 116

CHAPTER 5: RFID TAGS

One area, in particular, that has shown recent promise is the process of electroplating

printed or screened antenna coils with an additional layer of copper to improve durability

and conductivity.

5.4.2 Printed Circuit Board RFID Tags

RFID tags that incorporate Printed Circuit Board (PCB) technology are designed for

encasement inside totes, pallets, or products that can provide the protection normally

associated with injection-molded

enclosures.

These tags are made primarily from

etched copper PCB materials (FR-4,

for example) and are die bonded by

means of high quality wire bonding.

This procedure ensures reliable

electrical connections that are

superior to flip-chip assembly

methods. The RFID tag’s integrated

circuit is then encapsulated in epoxy

to protect it and the electrical

connections.

5.4.3 Molded RFID Tags

Molded tags, which are PCB tags

that have been protected with a durable resin overmolding, are the most rugged and

reliable type of tag offered by Escort Memory Systems. These tags are designed for

closed loop applications where the tag is reused;

thereby the cost of the tag can be amortized over

the life of the production line.

Typically, molded tags will be mounted to a pallet

or carrier which transports the product throughout

the production process. Some of the applications

for these tags include, but are not limited to:

embedding the tag into concrete floors for location

identification by forklifts and automatically guided

vehicles (AGVs), shelf identification for storage

and retrieval systems, and tool identification.

High temperature (HT) tags, using patented

processes and specialized materials, allow tags to

survive elevated temperatures, such as those

found in automotive paint and plating applications.

Escort Memory Systems offers a wide variety of

molded tags that have been developed over the

years for real world applications.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 56 OF 116

5.5 TAG M EMORY

Tag memory addressing begins at address 00 (0x0000), with the highest addressable

memory location equal to one less than the total number of bytes in the tag. Each

address is equal to one byte (8-bits), where the byte is the smallest addressable unit of

data. So for example, writing 8-bytes to a tag beginning at address 00 will actually fill

addresses 00 through 07 with 64-bits of data in all.

Depending on the manufacturer, RFID labels, molded tags and embedded PCBs can

have differing memory storage capacities

blocks of bytes that can vary in structure from manufacturer to manufacturer. Even when

compliant to ISO standards, byte memory addressing can differ from one manufacturer to

another. For example, tag memory can be organized in blocks of 4 or 8 bytes, depending

on the RFID IC. Additionally, all bytes may not be available for data storage as some

bytes may be used for security and access conditions. For more information regarding a

specific RFID tag’s memory allocation, please refer to IC manufacturer’s published

datasheet or Website.

Escort Memory Systems has taken great care to simplify tag memory addressing. The

mapping from logical address to physical address is handled by the Cobalt Controller’s

operating system. Users only need to indicate the starting address location on the tag

and the number of bytes to be read or written.

CHAPTER 5: RFID TAGS

and organization. Tag memory is grouped into

Is it a Bit or a Byte?

Customers need to understand that there are some RFID tag manufacturers that

measure and specify their tag memory size by the total number of bits, as this method

generates a much larger (8X) overall number. Escort Memory Systems, on the other

hand, prefers to specify total tag memory size in terms of bytes (rather than in bits), as

this method more closely reflects how data is stored and retrieved from a tag and is

typically what users really want to know.

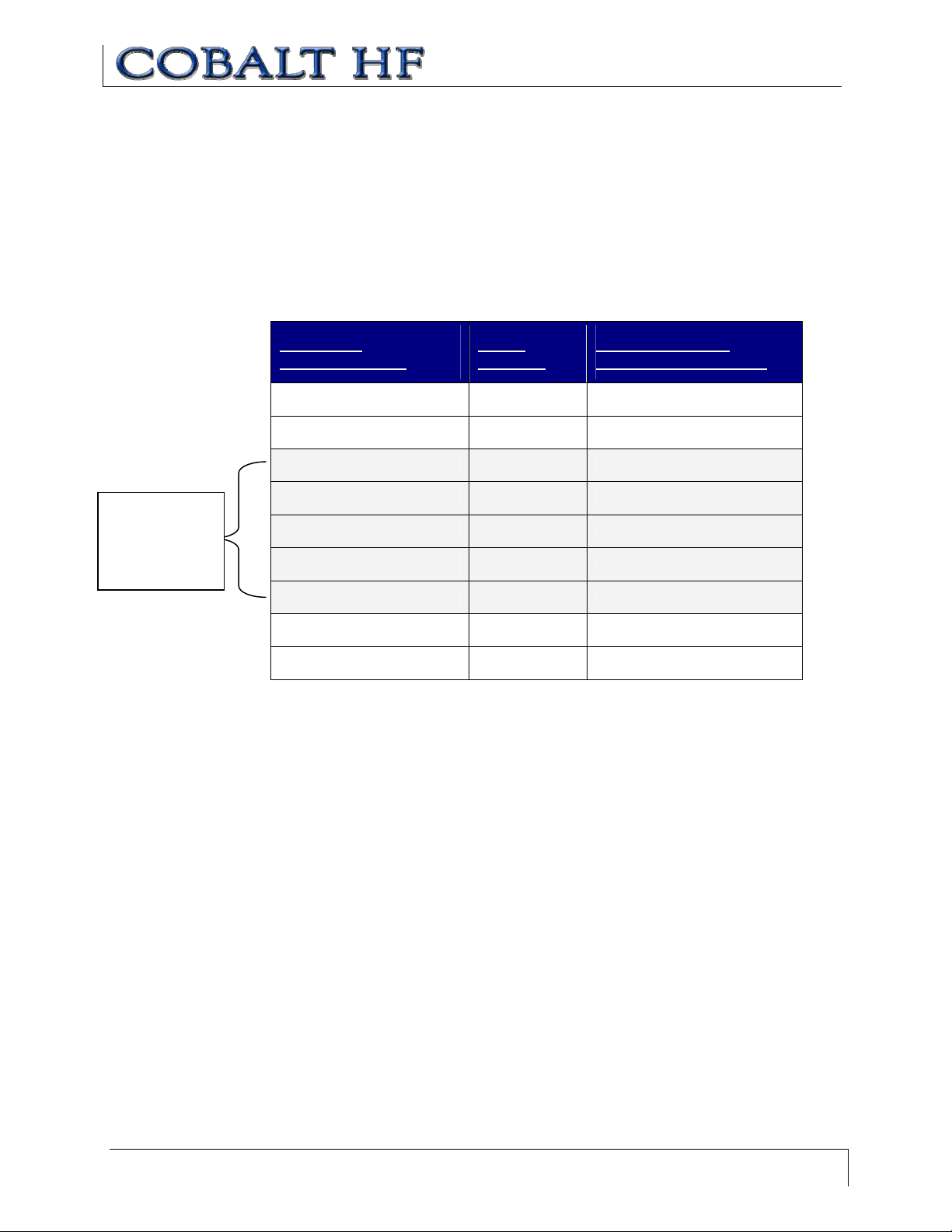

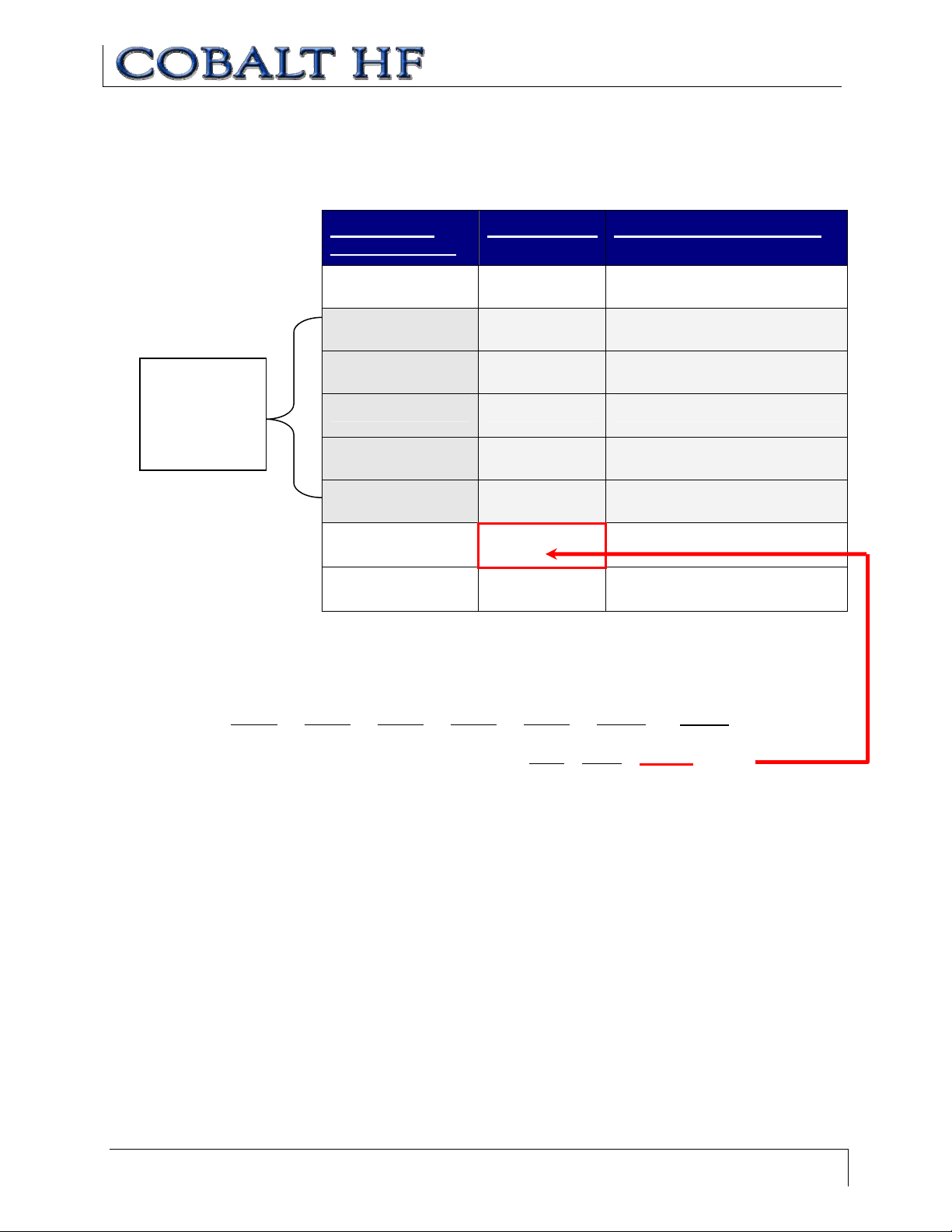

5.5.1 Mapping Tag Memory

Creating an RFID Tag Memory Map

Creating a Tag Memory Map is much like creating a spreadsheet that outlines the actual

data you plan to capture as well as the specific tag memory locations in which you wish

to store said data. Tag Memory maps should be carefully planned, simple and

straightforward. It is advisable to allow additional memory space than is initially required

as inevitably a need will arise to store more data.

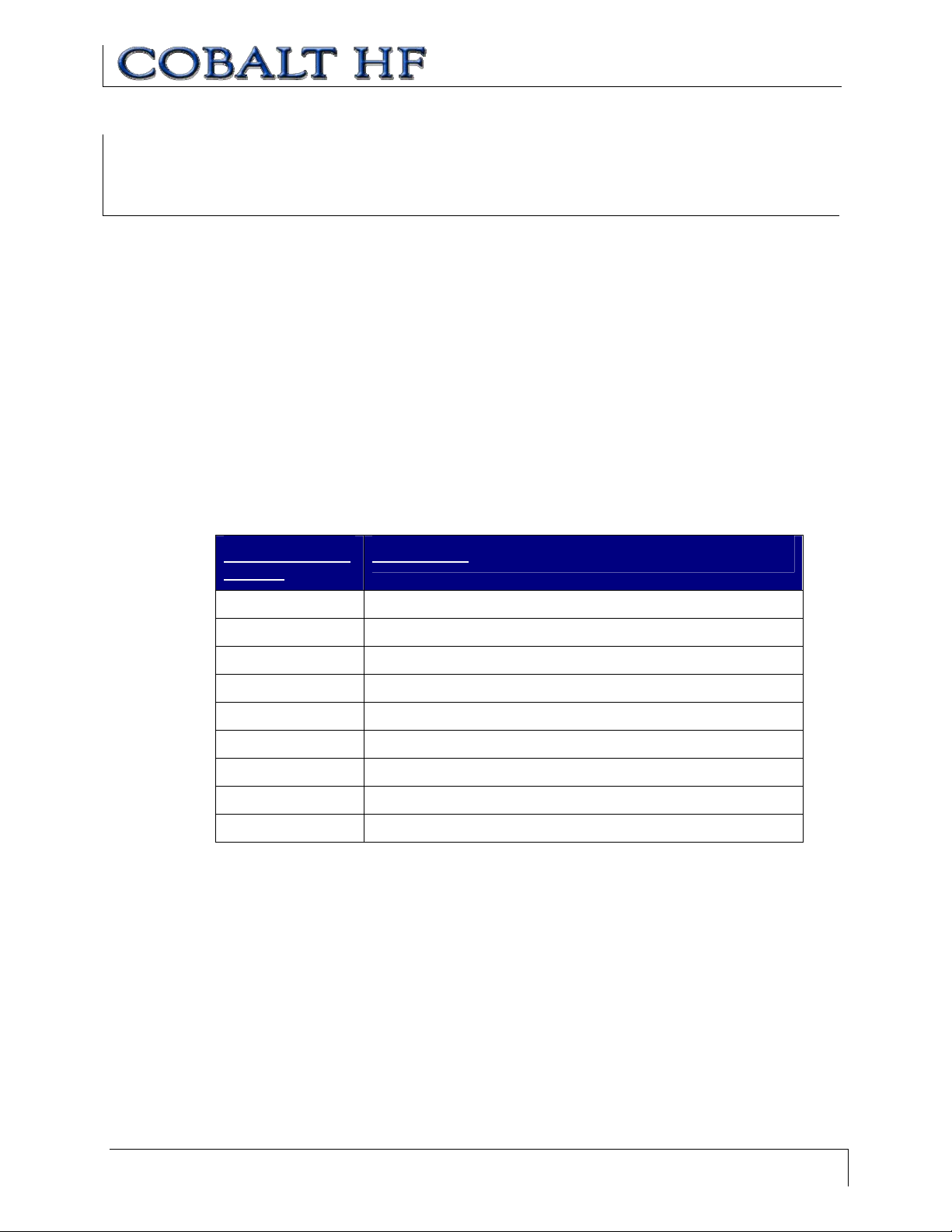

In the example below, 90-bytes of a 112-byte tag have been allocated to areas of the

Memory Map (leaving roughly 20% free for future uses). Because a short paragraph of

alphanumeric characters could quickly use all 90 bytes, creating an efficient mapping

scheme which utilizes all 720-bits (out of the 90-bytes allocated) will provide a better use

of tag space.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 57 OF 116

CHAPTER 5: RFID TAGS

TAG M EMORY M AP E XAMPLE

TAG ADDRESS USAGE

00 – 15

16 - 47

48 - 63

64 - 71

72 - 89

90 - 111

Serial #

Model #

Production Date

Lot #

Factory ID

Reserved for Future Use

Table 5-1: Tag Memory Map Example

5.5.2 Tag Memory Optimization

Data stored in tag memory is always written in binary (1’s and 0’s). Binary values are

notated using the hexadecimal numbering system (otherwise it might be confusing

viewing a page full of 1’s and 0’s).

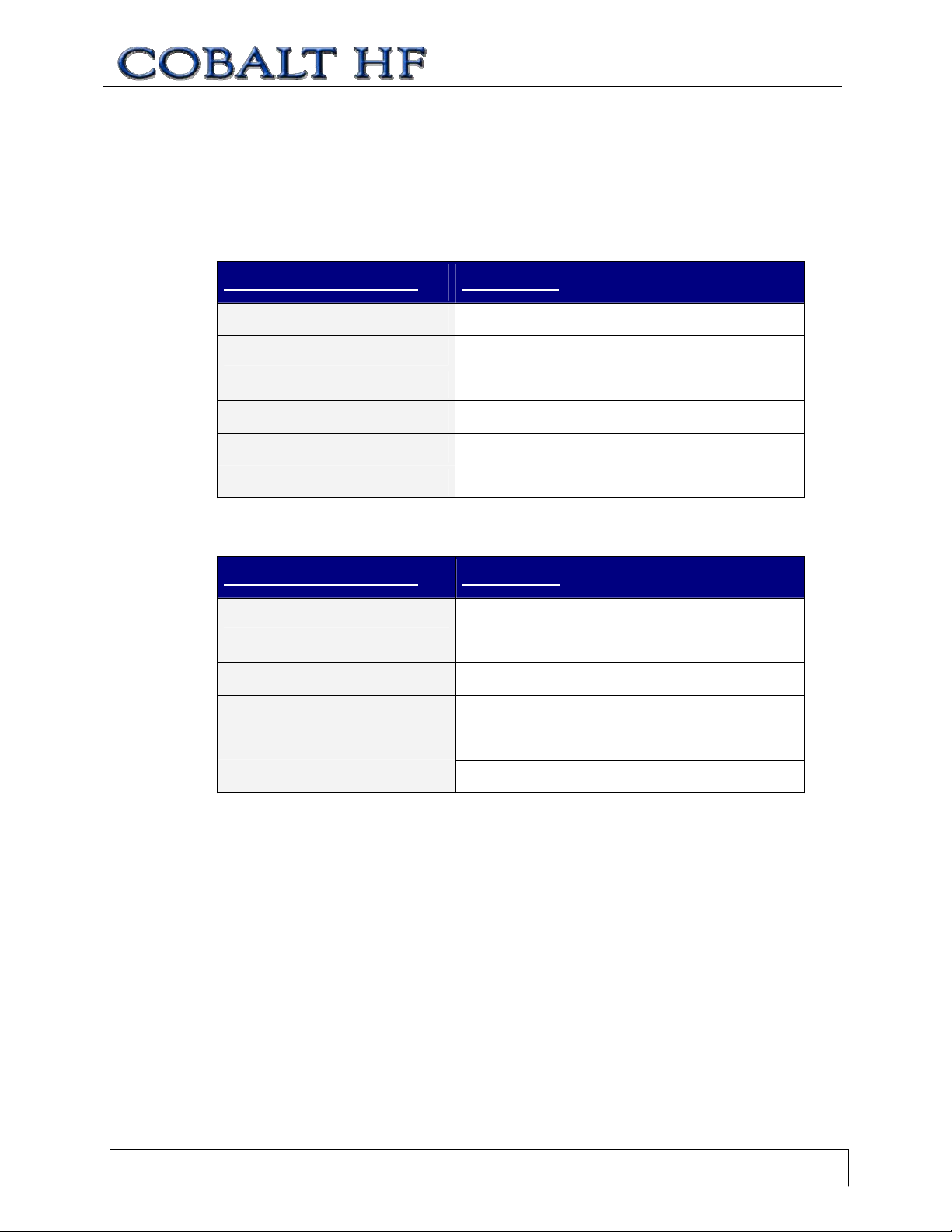

Below is an example of how hexadecimal notation is used to simplify the process of

expressing the decimal number 52,882.

Decimal Binary Hexadecimal

52,882 1100 1110 1001 0010 CE92

Rather than using five bytes to store the five individual ASCII characters representing the

numerical values 5, 2, 8, 8, and 2 (ASCII bytes: 0x35, 0x32, 0x38, 0x38 and 0x32), by

simply writing two Hex bytes (0xCE and 0x92), 60% less tag memory is required to store

the same amount of information.

When an alphabetical character is to be written to a tag, the Hex equivalent of the ASCII

value is written to the tag. So for example, to write a capital “D” (ASCII value 0x44), the

Hex value 0x44 is written to the tag.

Additionally, if a database with look up values is used in the RFID application, the logic

level of the individual bits within the tag can be used to further maximize tag memory.

(Note: refer to

Appendix D

in this document for a chart of ASCII characters, their

corresponding Hex values and their decimal value equivalents).

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 58 OF 116

CHAPTER 5: RFID TAGS

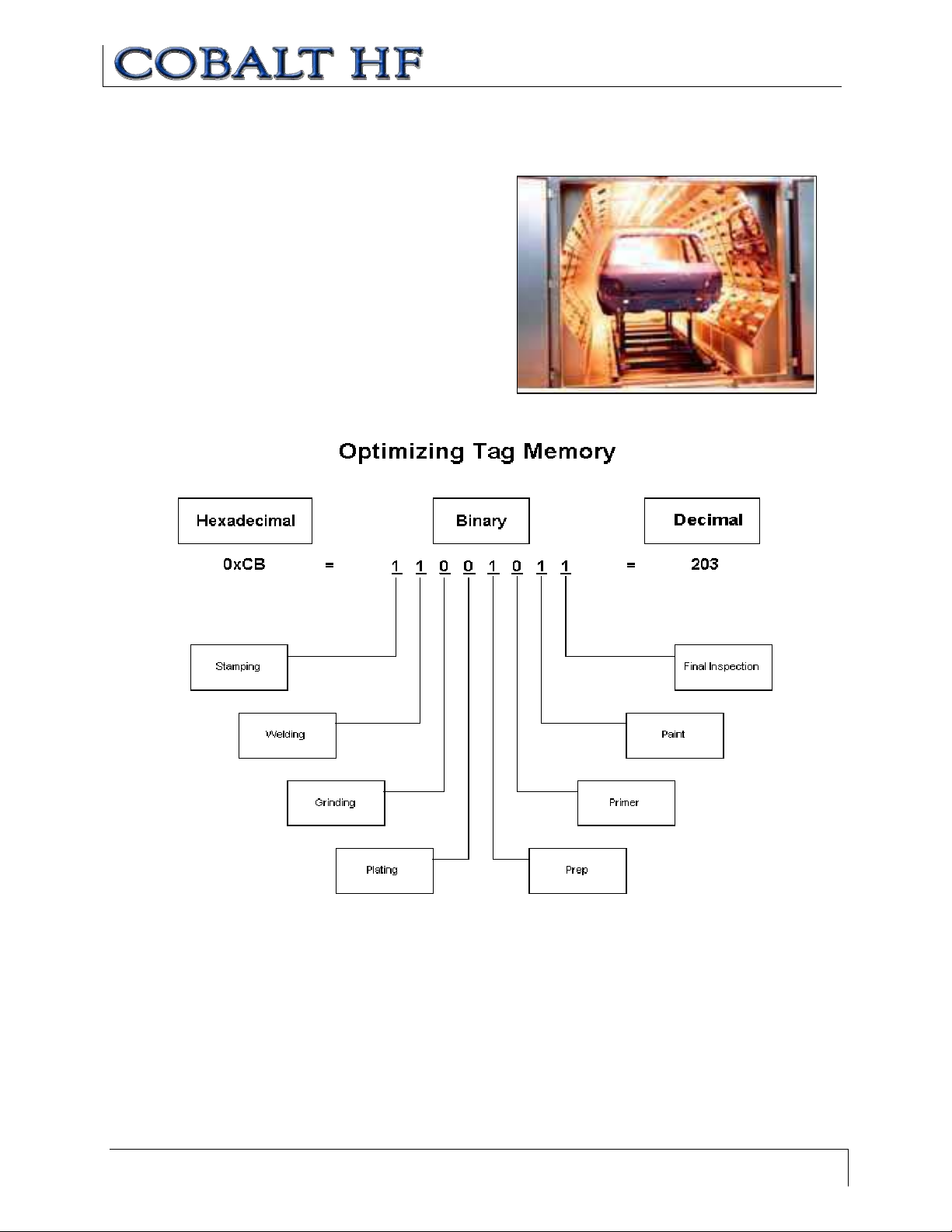

O PTIMIZING THE T AG

The following example illustrates how a

single byte (8 bits) can be used to track

an automobile’s inspection history at

eight inspection stations. The number

one (1) represents a required operation

and the number zero (0) represents an

operation that is not required for a

particular vehicle.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 59 OF 116

CHAPTER 6: COMMAND PROTOCOLS

CHAPTER 6:

COMMAND PROTOCOLS

6.1 COMMAND P ROTOCOL O VERVIEW

In order to correctly recognize and execute commands, the Cobalt HF and the host must

be able to communicate using the same language. The language that is used to

communicate is referred to as the Command Protocol.

There are two Command Protocols used by Cobalt HF RFID Controllers.

x ABx Fast Command Protocol

(-232, -422 and –USB models).

x CBx Command Protocol

drop (Subnet16) networks and Industrial Ethernet applications (-485 and –IND

models).

These two Command Protocols have different packet structures and parameter settings,

which are explained later in this chapter.

– for Point-to-Point, Host/Controller applications

– for multiple RFID controller configurations, Multi-

6.2 ABX F AST C OMMAND P ROTOCOL

The command protocol used by the Cobalt HF -232, -422 and -USB Controllers for Pointto-Point data transmission is known as the ABx Fast Command Protocol. ABx Fast has

a single-byte oriented packet structure that permits the rapid execution of RFID

commands while requiring the transfer of a minimal number of bytes.

ABx Fast supports the inclusion of an optional checksum byte. By default, the HF-CNTL232, -422 and -USB controllers are configured to use ABx Fast without the checksum

option. However, when increased data integrity is required, the checksum should be

utilized. See Section 6.2.4 for more on using the checksum parameter.

6.2.1 ABx Fast - Command / Response Procedure

After an RFID command is issued by the host, a packet of data, called the “Command

Packet” is sent to the Cobalt Controller. The command packet contains information that

instructs the controller to perform a certain task.

The Cobalt Controller automatically parses the incoming data packet, searching for a

specific pair of start characters, known as the “Command Header.” (Note: in ABx Fast,

the Command Header / Start Characters are 0x02, 0x02). When a Command Header is

recognized, the controller then checks for proper formatting and the presence of a

Terminator byte. (Note: in ABx Fast, the Terminator byte is 0x03).

Having identified a valid command, the controller will attempt to execute the instructions,

after which it will generate a host-bound response message containing EITHER the

results of the attempted command or an error code if the operation failed.

All commands will generate a response from the controller. Before sending another

command, the host must first process (remove from memory) any pending response

data.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 60 OF 116

CHAPTER 6: COMMAND PROTOCOLS

6.2.2 ABx Fast - Command Packet Structure

The packet structure of every ABx Fast command contains certain basic elements,

including a Command Header, a number of command parameters and a Terminator.

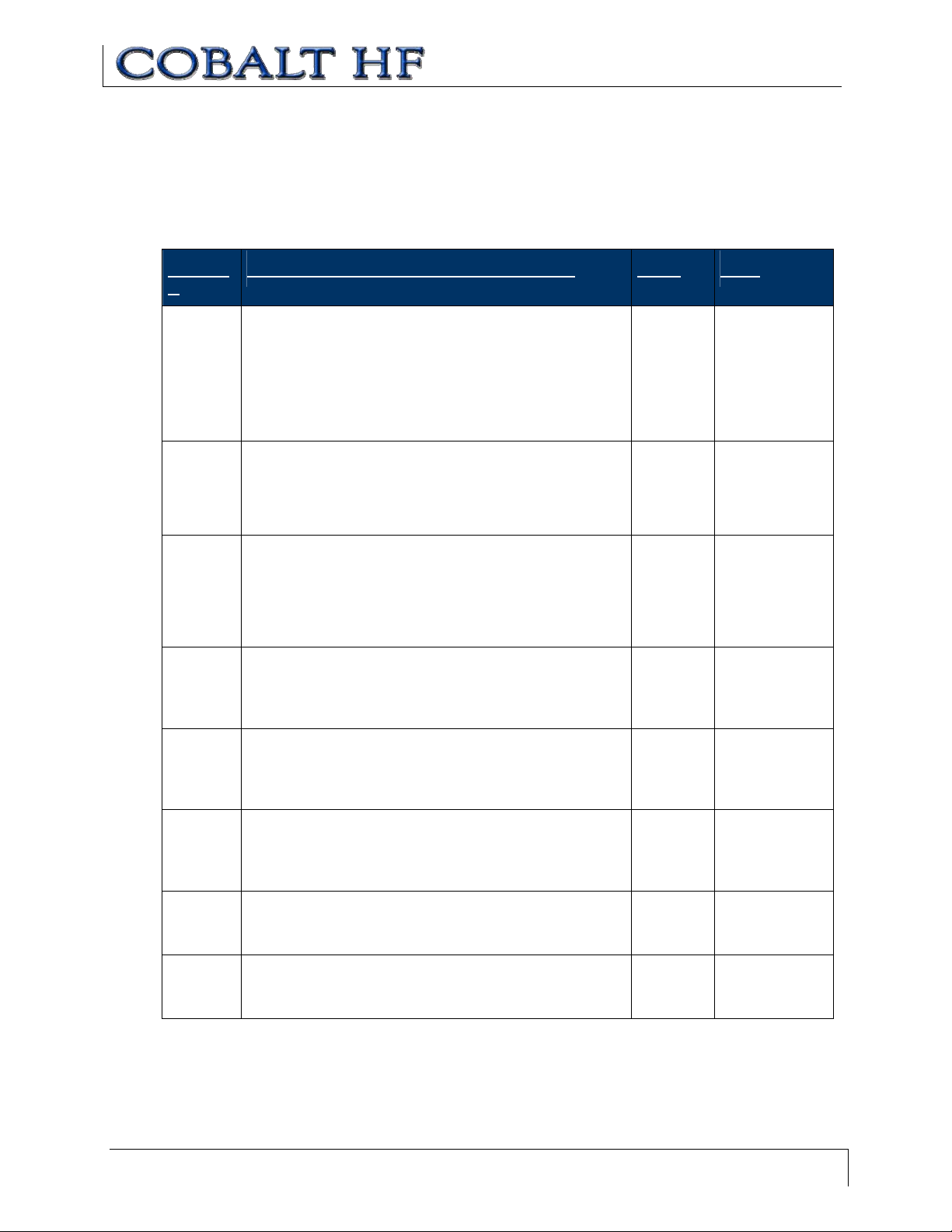

COMMAND PACKET PARAMETER CONTENT SIZE

COMMAND HEADER:

The first two bytes of an ABx Fast Command Packet:

COMMAND SIZE:

This 2-byte value defines the number of bytes in the packet

(excluding Header, Command Size, Checksum and

Terminator).

COMMAND ID:

This single-byte value indicates the RFID command to execute.

START ADDRESS:

The 2-byte Start Address parameter indicates the location of

tag memory where a read or write operation shall begin.

READ/WRITE LENGTH:

The 2-byte Read/Write Length parameter represents the

number of bytes that are to be retrieved from or written to the

RFID tag.

TIMEOUT VALUE:

This 2-byte integer indicates the maximum length of time for

which the controller will attempt to complete the command.

Measured in milliseconds, this value can have a range of

0x0001 to 0xFFFE or between 1 and 65,534 msecs (0x07D0 =

2000 x .001 = 2 seconds).

0x02, 0x02 2 bytes

0x0008

2-byte

integer

0x06

1 byte

(Write Data)

0x0000

2-byte

integer

0x0001

2-byte

integer

0x07D0

2-byte

integer

ADDITIONAL DATA:

This parameter uses one byte to hold a single character for fill

operations and supports the use of multiple bytes when several

characters are needed for write commands (when applicable).

CHECKSUM:

This optional parameter holds a single-byte checksum (only

applicable when using ABx Fast with Checksum).

TERMINATOR:

0x00

One or

more bytes

(when

applicable)

optional

1 byte

(when

applicable)

0x03 1 byte

Single-byte command packet terminator:

Table 6-1: ABx Fast - Command Packet Structure

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 61 OF 116

CHAPTER 6: COMMAND PROTOCOLS

6.2.3 ABx Fast - Response Packet Structure

After performing a command, the Cobalt HF will generate a host-bound response

message. ABx Fast responses contain a Response Header, a number of response

values (or retrieved data bytes), and a Terminator.

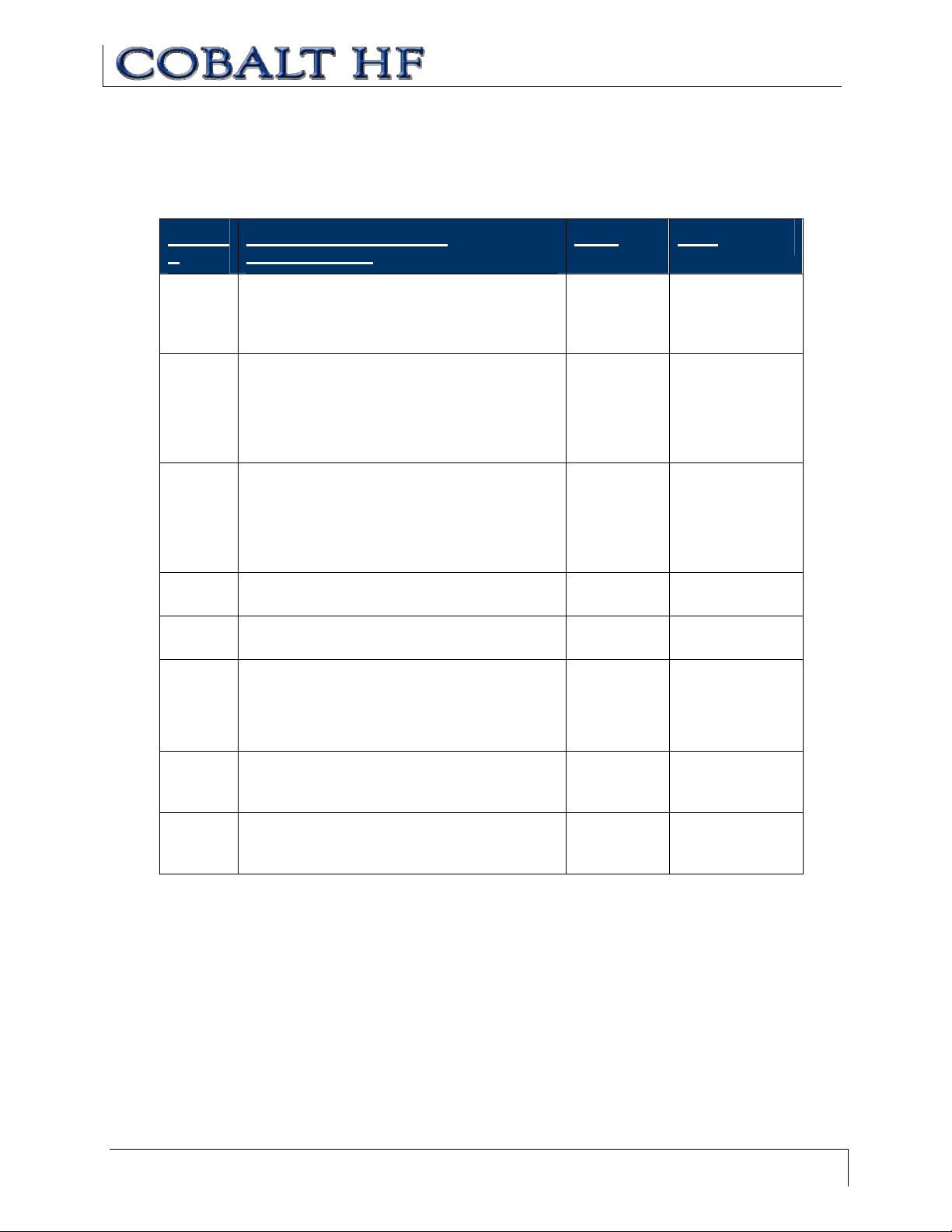

RESPONSE PACKET PARAMETER CONTENT SIZE

RESPONSE HEADER:

The first two bytes of an ABx Fast response packet.

RESPONSE SIZE:

This 2-byte integer defines the total number of bytes in

the response packet (excluding Header, Response

Size, Checksum and Terminator).

COMMAND ECHO:

The single-byte Command Echo parameter reiterates

the Hex value of the command for which the response

packet was generated.

RETRIEVED DATA:

This parameter is used to hold one or more bytes of

data that was requested by the command (when

applicable).

CHECKSUM:

This optional parameter holds a single-byte checksum

(only applicable when using ABx Fast with

Checksum).

0x02, 0x02 2 bytes

0x0001 2-byte integer

0x06 1 byte

Data

1 or more bytes

(when

applicable)

Optional

1 byte

(when

applicable)

TERMINATOR:

0x03 1 byte

Single-byte response packet terminator:

Table 6-2: ABx Fast - Response Packet Structure

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 62 OF 116

CHAPTER 6: COMMAND PROTOCOLS

6.2.4 ABx Fast - Command Packet Parameters

C OMMAND S IZE

Command

Size = number

of bytes in

these fields

The ABx Fast protocol requires that the byte count, known as the

Command Size

, be

specified as a 2-byte integer. To calculate Command Size, add the total number of bytes

within the command packet while excluding the two bytes for the Header, the two bytes

for the Command Size, the one byte for the Checksum (if present) and the one byte for

the Terminator (see example below).

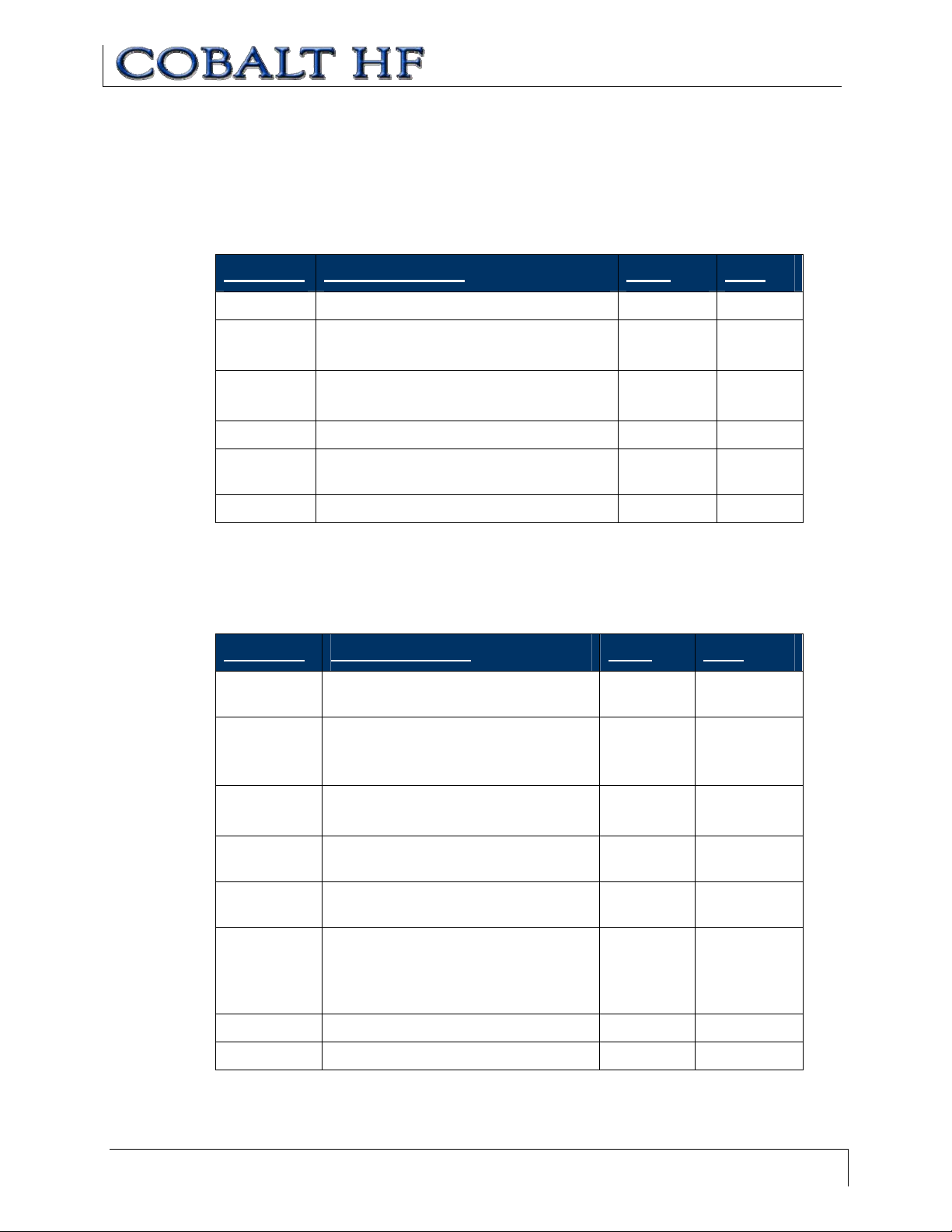

PACKET

PARAMETER

Header

Command Size

Command ID

Start Address

Read/Write Length

Timeout Value

Additional Data Bytes

Checksum

Terminator

# OF

BYTES

INCLUDED IN

COMMAND SIZE?

2 No

2 No

1 Yes

2 Yes

2 Yes

2 Yes

1 Yes

1 No

1 No

In the above command packet example, 8 bytes of data are located between the

Command Size parameter and the Checksum parameter. Therefore, the Command Size

for this example is 0x0008.

TART A DDRESS

S

The Start Address parameter is holds a two-byte integer representing the tag memory

address location where a read or write operation will begin.

EAD/WRITE LENGTH

R

The two-byte Read/Write Length parameter indicates the number of bytes that are to be

read from or written to the RFID tag.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 63 OF 116

CHAPTER 6: COMMAND PROTOCOLS

T IMEOUT V ALUE PARAMETER

ABx Fast commands include a two-byte Timeout Value parameter (measured in

increments of one millisecond) that is used to limit the length of time that the Cobalt HF

will attempt to complete a specified operation.

The maximum Timeout Value is 0xFFFE or 65,534 milliseconds (slightly longer than one

minute). Setting a long Timeout Value does not necessarily mean that a command will

take any longer to execute. This value only represents the period of time for which the

Cobalt HF will attempt execution of the command.

IMPORTANT

During write commands, the tag must remain within the antenna’s RF field until the write

operation completes successfully, or until the Timeout Value has expired.

If a write operation is not completed before the tag leaves the controller’s RF field, data

may be incompletely written.

C HECKSUM P ARAMETER

The ABx Fast Command Protocol supports the inclusion of an additional checksum byte

that is used to verify the integrity of data being transmitted between host and controller.

The checksum is calculated by adding together (summing) the byte values in the

command packet (less the Header, Checksum and Terminator parameters), and then

subtracting the total byte sum from 0xFF. Therefore, when the byte values of each

parameter (from Command Size to Checksum) are added together, the byte value sum

will equal 0xFF.

To enable the use of the checksum parameter, download the RFID Dashboard Utility

www.ems-rfid.com

from

, and use it to set the ABx Protocol parameter to ABx Fast with

Checksum.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 64 OF 116

CHAPTER 6: COMMAND PROTOCOLS

C HECKSUM E XAMPLE

The following example depicts Command 0x05 (Read Data) using a checksum.

Checksum =

[0xFF – (sum

of these

fields)]

Add the byte values from the Command Size, Command ID, Start Address, Read Length

and Timeout Value parameters together and subtract from 0xFF. Resulting value will be

the checksum.

COMMAND

CONTENTS USED IN CHECKSUM

PARAMETER

Header 0x02, 0x02 n/a

Command Size 0x0007 0x00, 0x07

Command ID 0x05 0x05

Start Address 0x0001 0x00, 0x01

Read Length 0x0004 0x00, 0x04

Timeout Value 0x07D0 0x07, 0xD0

Checksum

0x17

n/a

Terminator 0x03 n/a

[0x07

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 65 OF 116

+ 0x05 + 0x01 + 0x04 + 0x07 + 0xD0] = 0xE8

The checksum equation is: [0xFF

– 0xE8] = 0x17

CHAPTER 6: COMMAND PROTOCOLS

6.3 CBX C OMMAND P ROTOCOL

The CBx Command Protocol, utilized by the Cobalt -485 and -IND models, includes

Multi-drop Subnet16 networking support for use with Industrial Ethernet applications.

CBx is based on a double-byte oriented packet structure where commands always

contain a minimum of six data “words,” even when one (or more) parameters are not

applicable to the command. CBx does not support the inclusion of a checksum byte.

The CBx packet structures described herein are protocol independent and can be

implemented the same for all Industrial Ethernet protocols (Ethernet/IP, Modbus TCP,

etc.).

6.3.1 CBx – Command Procedure

C OBALT HF-CNTL-485-01 – COMMAND P ROCEDURE

Commands are initiated by a host PC or Programmable Logic Controller (PLC) and are

distributed to the controller via a Subnet16 Gateway or Subnet16 Hub Interface Device

that is connected to the host or PLC by standard Ethernet cabling.

After a command is sent, it is executed either directly by the interface device (Gateway or

Hub) or is otherwise routed to the RFID controller specified in the command. Note that

when issuing controller-bound commands, instructions are directed to the appropriate

RFID controller by specifying the “Node ID Number” of the particular controller. Each

Cobalt -485 Controller on a Multi-drop Subnet16 network is assigned an individual Node

ID number.

OBALT HF-CNTL-IND-01 – COMMAND P ROCEDURE

C

Commands are initiated by a host PC or Programmable Logic Controller (PLC) and are

distributed directly to the controller via an M12 D-Code to Ethernet cable.

After a command is sent, it is immediately executed by the Cobalt Controller. Note that

instructions are directed to the controller by specifying in the command the “Node ID

Number” of the Cobalt Controller. For the Cobalt HF-CNTL-IND-01, the Node ID will

always be 01 (0x01).

6.3.2 CBx – Response Procedure

Following the execution of an RFID command, the controller will automatically generate a

host-bound response message that contains EITHER the results of the attempted

command or an error code if the operation could no be completed successfully.

Similar to ABx Fast, all CBx commands will generate a response from the controller.

Before the host can send another command to the controller, it must first process

(remove from memory) the controller’s pending response data.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 66 OF 116

CHAPTER 6: COMMAND PROTOCOLS

6.3.3 CBx - Command Packet Structure

As noted, CBx commands contain a minimum of six words. Below is the structure of a

standard CBx command packet. For the Cobalt HF-CNTL-485-01 model, refer to the

Subnet16 Gateway or Subnet16 Hub - Operator’s Manuals.

WORD#COMMAND PACKET PARAMETER MSB LSB

01

02

03

04

05

Overall Length: 2-byte integer indicating the number

of 16-bit “words” in the entire command packet. This

value will always be at least 6, as each command has

a minimum of 12-bytes (or 6 words). Overall Length

will increase when additional data words are used in

the command (for fills, writes, etc.).

AA in MSB

Command ID: single-byte value indicating command

to perform in LSB.

00 in MSB

Node ID: single-byte Node ID number of the controller

to which the command is intended. (Must be 0x01 for

Cobalt -IND).

Timeout Value: 2-byte integer representing the length

of time allowed for the completion of the command,

measured in 1 millisecond units (when applicable).

Start Address: 2-byte integer indicating the location of

tag memory where the Read/Write operation will begin

(when applicable).

0x00

0x06 +

(number of

additional data

words, if any)

0xAA Command ID

0x00 0x01

Timeout

Timeout LSB

MSB

Start MSB Start LSB

06

Read/Write Length: 2-byte integer indicating the

number of bytes that are to be Read/Written beginning

Length

MSB

Length LSB

at the Start Address (when applicable).

07

Additional Data – (bytes 1 & 2) used to hold 2-bytes

D1 D2

of data used for writes and fills (when applicable).

08

Additional Data – (bytes 3 & 4): used to hold 2-bytes

D3 D4

of data for writes and fills (when applicable).

Table 6-3: CBx - Command Packet Structure

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 67 OF 116

CHAPTER 6: COMMAND PROTOCOLS

6.3.4 CBx - Response Packet Structure

After performing a command, the Cobalt HF RFID Controller will issue a host-bound

response message. Below is the packet structure of a standard CBx response message.

WORD#RESPONSE PACKET

PARAMETER

01

Overall Length: 2-byte value indicating the

number of “words” in the response packet.

This value will always be at least 6 words.

02

AA in MSB

Command Echo: single-byte value

indicating the command that was performed

in LSB.

03

Instance Counter in MSB

(see description below)

Node ID Echo in LSB (will be 0x01 for the

Cobalt -IND)

04

05

06

Month and Day timestamp Month DOM

Hour and Minute timestamp Hour Minutes

Second timestamp in MSB

MSB LSB

0x00

06 + (number of

additional data

words retrieved)

0xAA Command Echo

Instance

Node ID Echo

Counter

Seconds N-bytes

Number of Additional Data Bytes

Retrieved in LSB

07

Retrieved Data – (bytes 1 & 2) used to hold

D1 D2

2-bytes of retrieved data (when applicable).

08

Retrieved Data – (bytes 3 & 4) used to hold

D3 D4

2-bytes of retrieved data (when applicable).

Table 6-4: CBx - Response Packet Structure

I

NSTANCE COUNTER

The Instance Counter is a one-byte value used by a Subnet16 Gateway or Subnet16

Hub to track the number of responses generated by a given Node ID number. The

Gateway/Hub tallies in its internal RAM separate Instance Counter values for each Node

ID. The Instance Counter value is incremented by one following each response. If, for

example, 10 responses were generated by the controller assigned Node ID 01, its

Instance Counter value will read 10. When the Gateway/Hub is power cycled or

rebooted, all Instance Counter values will be reset to zero (0x00).

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 68 OF 116

CHAPTER 6: COMMAND PROTOCOLS

6.3.5 CBx - Command Example

In the example below, Command 0x05 (Read Data) is issued to the Cobalt Controller

assigned to Node ID 01. The controller will be instructed to read 4 bytes of data from a

tag beginning at tag address 0x20. The Timeout Value has been set to two seconds for

the completion of this command (0x07D0 = 2000 x .001 = 2 seconds).

WORD # DESCRIPTION MSB LSB

01 Overall Length of Command

02 AA

03 00

04

05

in MSB

Command ID

in MSB

Node ID

2-byte

2-byte

in LSB: (0x01 for the Cobalt)

Timeout Value

Start Address

in LSB: (0x05: Read Data)

measured in ms

for the Read

Operation: (0x0020)

06

2-byte

Read Length

: (0x0004)

6.3.6 CBx - Response Example

Below is an example of a typical controller response after successfully executing the

Read Data command (as issued in the previous example).

WORD # DESCRIPTION MSB LSB

01 Overall Length of Response

(in words)

02 AA

in MSB

Command Echo

(0x05 Read Data)

in LSB:

(in words)

0x00 0x06

0xAA 0x05

0x00 0x01

0x07 0xD0

0x00 0x20

0x00 0x04

0x00 0x08

0xAA 0x05

03 00

in MSB

Node ID Echo

04 Month

(March 19

05 Hour

and

and

in LSB

Day

th

)

Minute

timestamp:

timestamp

0x00 0x01

0x03 0x13

0x0A 0x0B

(10:11: AM)

06 Seconds

timestamp in MSB

0x24 0x04

(:36 seconds)

# of Additional Data Bytes

Retrieved

07 Retrieved Data

08 Retrieved Data

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 69 OF 116

in LSB: (0x04)

(bytes 1 & 2)

(bytes 3 & 4)

0x01 0x02

0x03 0x04

CHAPTER 7: RFID COMMANDS

CHAPTER 7:

RFID COMMANDS

Most RFID commands can be divided into two primary categories: READ and WRITE.

Read commands retrieve data from a tag or obtain information from the controller. Write

commands transfer information to a tag or update settings on the controller.

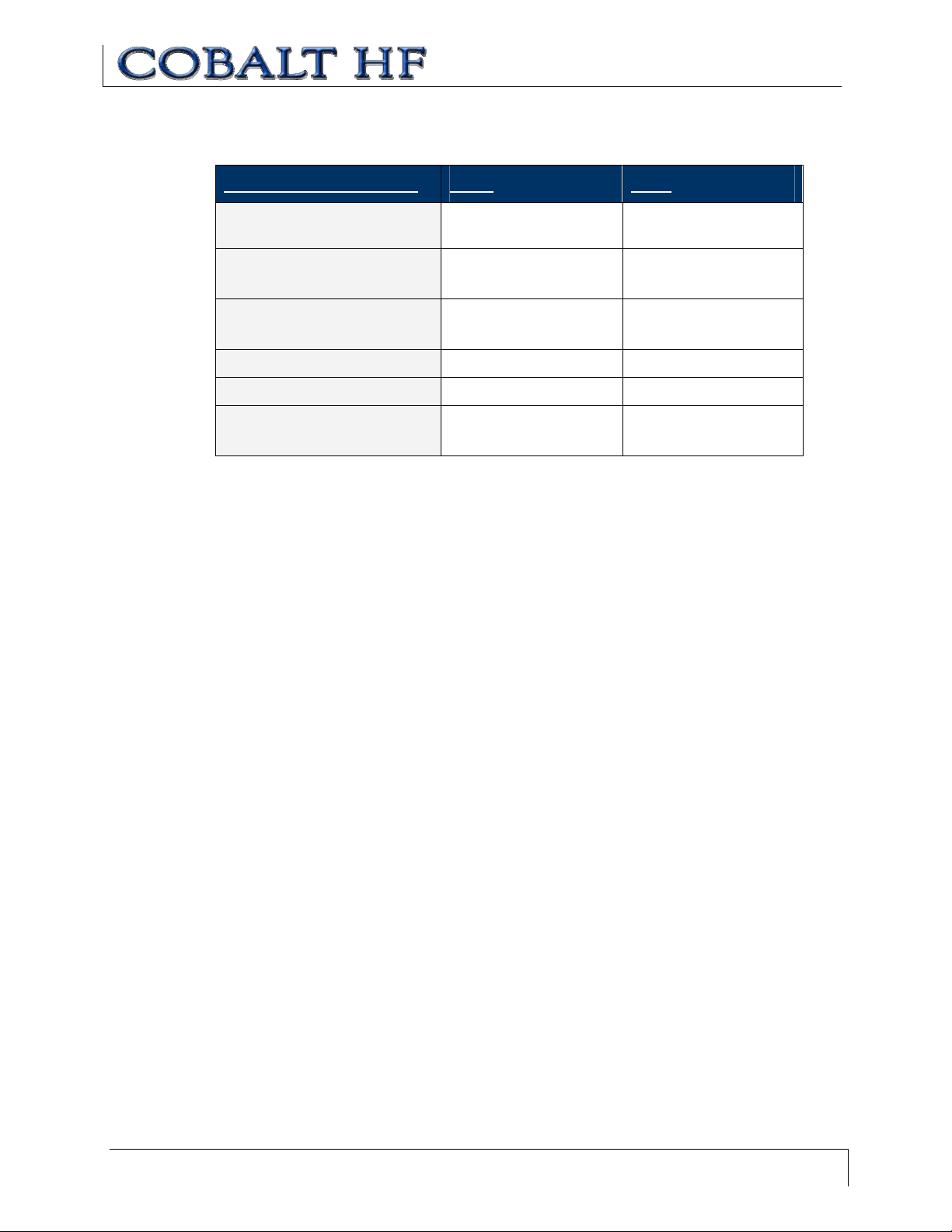

7.1 RFID COMMANDS TABLE

COMMAND

ID

0x04

0x05

0x06

0x07

0x08

0x0D

0x35

0x38

COMMAND DESCRIPTION

Fill Tag

Read Data

Write Data

Read Tag ID

Tag Search

Start/Stop

Continuous

Read

Reset

Controller

Get

Controller

Info

Writes a specified data byte to all defined

tag addresses.

Reads a specified length of data from

contiguous (sequential) areas of tag

memory.

Writes a specified number of bytes to a

contiguous area of tag memory.

Reads a tag’s unique tag ID number.

Instructs the controller to search for a tag

in its RF field.

Instructs the controller to start or stop

Continuous Read mode.

Resets power to the controller.

Reads hardware, firmware and serial

number information from the controller.

Table 7-1: RFID Commands Table

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 70 OF 116

COMMAND 04:

FILL TAG

Command 04 instructs the RFID controller to fill multiple contiguous addresses of an

RFID tag with a single data byte value. This command is commonly used to clear

sequential segments of tag memory by writing a one-byte value repeatedly across a

specified range of tag addresses.

This command requires one Data Byte Value, a Start Address and a Fill Length. It will

then proceed to fill the tag with the Data Byte Value, for the specified number of

consecutive bytes, beginning at the Start Address.

When the Start Address is set to zero (0x0000), the fill will begin at the first available byte

of tag memory. When the Fill Length is set to zero (0x0000), the controller will write fill

data from the Start Address to the end of the tag’s memory. The Timeout Value is

measured in 1-millisecond increments and can have a value of 0x0001 to 0xFFFE (1 65,534 milliseconds). If the Fill Length extends beyond the last byte in the tag, the

controller will return an error.

OMMAND 04 (FILL TAG)-ABX F AST C OMMAND S TRUCTURE

C

CHAPTER 7: RFID COMMANDS

PARAMETER

FIELD

Header

Command Size

Command ID

Start Address

Fill Length

Timeout Value

Data Byte Value

Checksum

Terminator

CONTENT

0x02, 0x02 (the header for all ABx Fast commands).

0x0008

1-byte Command ID Number (0x04).

2-byte value indicating tag address where fill will start.

2-byte value indicating the total number of bytes to be filled.

2-byte value (0x0001 – 0xFFFE).

1-byte value for the data byte to be used as fill.

Optional

0x03 (the terminator for all ABx Fast commands).

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 71 OF 116

CHAPTER 7: RFID COMMANDS

C OMMAND 04 (FILL TAG)-ABX FAST C OMMAND E XAMPLE

This example instructs the Cobalt HF to fill an entire tag with the ASCII character 'A'

(Data Byte Value 0x41) starting at the beginning of the tag (address 0x0000). A Timeout

Value of 2 seconds (0x07D0) is set for the completion of the command.

Command from Host

PARAMETER FIELD CONTENT

Header

Command Size

Command ID

Start Address

Fill Length

Timeout Value

Data Byte Value

Checksum

Terminator

0x02, 0x02

0x0008

0x04

0x0000

0x0000

0x07D0

0x41

Optional

0x03

Response from Controller

PARAMETER FIELD CONTENT

Header

Response Size

Command Echo

Checksum

0x02, 0x02

0x0001

0x04

Optional

Terminator

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 72 OF 116

0x03

CHAPTER 7: RFID COMMANDS

C OMMAND 04 (FILL TAG)-CBX C OMMAND E XAMPLE

This example instructs the Cobalt Controller to fill an entire tag with the ASCII character

'A' (Data Byte Value 0x41) starting at the beginning of the tag (address 0x0000). A

Timeout Value of 2 seconds (0x07D0) is set for the completion of the command.

Command from Host

PARAMETER FIELD MSB LSB

Overall Length of Command

0x00 0x07

(in words)

in MSB

AA

Command ID

in MSB

00

Node ID

2-byte

in LSB (Cobalt –IND = 01)

Timeout Value

in LSB: (0x04)

measured in

0xAA

0x04

0x00 0x01

0x07 0xD0

ms (0x07D0 = 2 seconds)

Start Address

Fill Length

Fill Byte

00

in MSB (A = 0x41)

in LSB

0x00 0x00

0x00 0x00

0x41 0x00

Note: The “Fill Length” in the Tag Fill Command represents the number of bytes to fill on

the tag, not the length of the ‘fill byte data’ provided in the command, which is always just

a single byte.

Response from Controller

DESCRIPTION MSB LSB

Overall Length of Response

0x00 0x06

(in words)

in MSB

AA

Command Echo

in MSB

00

Node ID Echo

in LSB

in LSB (0x04)

0xAA

0x04

0x00 0x01

(Cobalt –IND = 0x01)

Month

Hour

and

and

Minute

Seconds

in LSB

00

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 73 OF 116

timestamp

Day

timestamp

timestamp in MSB

Month DOM

Hour Minutes

Seconds 0x00

COMMAND 05:

READ DATA

Command 05 instructs the controller to retrieve a specific number of bytes of data from a

contiguous (sequential) area of an RFID tag’s memory.

When the Start Address is set to zero (0x0000), the controller will start reading at the

beginning (or first accessible byte) of the tag. The minimum Read Length is one byte, the

maximum is the entire read/write address space of the tag. Timeout Value is measured in

1-millisecond increments and can have a value of 0x0001 to 0xFFFE (1 to 65,534

milliseconds). If the Read Length exceeds beyond the last available tag address, the

controller will return an error code.

OMMAND 05 (READ DATA )-ABX F AST C OMMAND S TRUCTURE

C

PARAMETER FIELD CONTENT

CHAPTER 7: RFID COMMANDS

Header

Command Size

Command ID

Start Address

Read Length

Timeout Value

Checksum

Terminator

0x02, 0x02

0x0007

1-byte Command ID (0x05).

2-byte value for the starting read

address.

2-byte value for the number of bytes to

read.

2-byte value measured in 1-ms units

(0x0001 – 0xFFFE).

Optional

0x03

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 74 OF 116

CHAPTER 7: RFID COMMANDS

C OMMAND 05 (READ D ATA)-ABX FAST C OMMAND E XAMPLE

This example instructs the controller to read four bytes of data from a tag starting at

address 0x0001. A Timeout Value of 2 seconds (0x07D0 = 2000 x 1 millisecond

increments) is set for the completion of the command.

Command from Host

PARAMETER FIELD CONTENT

Header

Command Size

Command ID

Start Address

Read Length

Timeout Value

Checksum

Terminator

0x02, 0x02

0x0007

0x05

0x0001

0x0004

0x07D0

Optional

0x03

Response from Controller

PARAMETER FIELD CONTENT

Header

Response Size

Command Echo

Data from Address 0x0001

Data from Address 0x0002

0x02, 0x02

0x0005

0x05

0x05

0xAA

Data from Address 0x0003

Data from Address 0x0004

Checksum

Terminator

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 75 OF 116

0xE7

0x0A

Optional

0x03

CHAPTER 7: RFID COMMANDS

C OMMAND 05 (READ D ATA)-CBX C OMMAND E XAMPLE

This example instructs the controller to read four bytes of data from a tag starting at

address 0x0001. A Timeout Value of 2 seconds (0x07D0 = 2000 x 1 millisecond

increments) is set for the completion of the command.

Command from Host

PARAMETER FIELD MSB LSB

Overall Length of Command

in MSB

AA

Command ID

in MSB

0x00

Node ID

2-byte

Timeout Value

in LSB (0x05)

in LSB (Cobalt -IND = 0x01)

measured in ms

(in words)

0x00 0x06

0xAA

0x05

0x00 0x01

0x07 0xD0

(0x07D0 = 2 seconds)

Start Address

Read Length

0x00 0x01

0x00 0x04

Response from Controller

PARAMETER FIELD MSB LSB

Overall Length of Response

in MSB

AA

Command Echo

in MSB

00

Node ID Echo

in LSB

in LSB

(in words)

0x00 0x08

0xAA

0x05

0x00 0x01

Month

Hour

and

and

Seconds

# of Bytes Read Data

Read Data

Read Data

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 76 OF 116

timestamp

Day

Minute

timestamp

timestamp in MSB

in LSB

(bytes 1 and 2)

(bytes 3 and 4)

Month DOM

Hour Minutes

Seconds 0x04

0x01 0x02

0x03 0x04

COMMAND 06:

WRITE DATA

Command 06 instructs the controller to write information to an RFID tag. This command

is used to store segments of data in contiguous tag memory locations. It is capable of

transferring up to 100 bytes of data from the host to the tag with one command.

The shortest possible Write Length is one (0x0001). When the Start Address is set to

zero (0x0000), the controller will begin writing to the first available byte of tag memory.

The Timeout Value is measured in 1-millisecond increments and can have a value of

0x0001 to 0xFFFE (1 to 65,534 milliseconds). If the Write Length exceeds beyond the

last available tag address, the controller will return an error code.

OMMAND 06 (WRITE D ATA )-ABX FAST C OMMAND S TRUCTURE

C

PARAMETER FIELD CONTENT

CHAPTER 7: RFID COMMANDS

Header

Command Size

Command ID

Start Address

Write Length

Timeout Value

Data Byte Value

Checksum

Terminator

0x02, 0x02

0x0007 + N (where N = the number of Data Bytes

to be written).

0x06

2-byte value for the tag address where the write

will begin.

2-byte value for the number of bytes to write.

2-byte value measured in 1 millisecond units

(0x0001 – 0xFFFE).

1-byte for each data value to be written to tag.

Optional

0x03

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 77 OF 116

CHAPTER 7: RFID COMMANDS

C OMMAND 06 (WRITE D ATA )–ABX F AST C OMMAND E XAMPLE

This example writes the five ASCII characters H, E, L, L, O (Data Byte Values: 0x48,

0x45, 0x4C, 0x4C and 0x4F) to the tag starting at address 0x0000. A Timeout Value of 2

seconds (0x07D0 = 2000 x 1 millisecond increments) is set for the completion of this

command.

Command from Host

PARAMETER FIELD CONTENT

Header

Command Size

Command ID

Start Address

Write Length

Timeout Value

Data Byte Value = H

Data Byte Value = E

Data Byte Value = L

Data Byte Value = L

Data Byte Value = O

Terminator

0x02, 0x02

0x000C

0x06

0x0000

0x0005

0x07D0

0x48

0x45

0x4C

0x4C

0x4F

0x03

Response from Controller

PARAMETER FIELD CONTENT

Header

0x02, 0x02

Response Size

Command Echo

Terminator

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 78 OF 116

0x0001

0x06

0x03

CHAPTER 7: RFID COMMANDS

C OMMAND 06 (WRITE D ATA )–CBX C OMMAND EXAMPLE

This example writes the five ASCII characters H, E, L, L, O (Data Byte Values: 0x48,

0x45, 0x4C, 0x4C and 0x4F) to the tag starting at address 0x0000. A Timeout Value of 2

seconds (0x07D0 = 2000 x 1 millisecond increments) is set for the completion of this

command.

Command from Host

PARAMETER FIELD MSB LSB

Overall Length of Command

in MSB

AA

Command ID

in MSB

00

Node ID

2-byte

Timeout Value

in LSB (0x06)

in LSB (Cobalt -IND = 01)

measured in ms

Start Address

Length of Write

Write Data

Write Data

Write Data

in LSB

00

(in bytes)

(bytes 1 and 2)

(bytes 3 and 4)

(byte 5) in MSB

(in words)

0x00 0x09

0xAA

0x06

0x00 0x01

0x07 0xD0

0x00 0x00

0x00 0x05

0x48 0x45

0x4C 0x4C

0x4F 0x00

Response from Controller

PARAMETER FIELD MSB LSB

Overall Length of Response

(in words)

0x00 0x06

in MSB

AA

Command Echo

in MSB

00

Node ID Echo

Month

Hour

Seconds

00

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 79 OF 116

and

and

in LSB

Minute

timestamp in MSB

in LSB

in LSB (Cobalt = 01)

timestamp

Day

timestamp

0xAA

0x06

0x00 0x01

Month DOM

Hour Minutes

Seconds 0x00

COMMAND 07:

READ TAG ID

This command instructs the RFID controller to locate a tag in RF range and retrieve its

unique tag identification number.

RFID tags are assigned a unique tag ID number during the manufacturing process. After

a tag ID number has been assigned to a tag, the value cannot be altered and is not

considered part of the available read/write memory space of the tag.

x ISO 14443 compliant tags receive a 4-byte tag ID number. By using just four

x ISO 15693 compliant tags are given an 8-byte tag ID number. When using eight

OMMAND 07 (READ TAG ID) – ABX F AST C OMMAND S TRUCTURE

C

PARAMETER FIELD CONTENT

CHAPTER 7: RFID COMMANDS

bytes, tag manufacturers can generate over 4.2 billion possible ISO 14443

compliant tag ID numbers.

bytes, manufacturers can generate over 280 trillion possible tag ID numbers.

Header

Command Size

Command ID

Timeout Value

Checksum

Terminator

0x02, 0x02

0x0003

0x07

2-byte value, measured in 1 millisecond units.

(0x0001 – 0xFFFE).

Optional

0x03

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 80 OF 116

CHAPTER 7: RFID COMMANDS

C OMMAND 07 (READ TAG ID) – ABX FAST C OMMAND E XAMPLE

This example instructs the controller to retrieve a tag’s ID. In this example, the 8-byte tag

ID number is E0040100002E16AD. A Timeout Value of two seconds is set for the

completion of this command.

Command from Host

PARAMETER FIELD CONTENT

Header

Command Size

Command ID

Timeout Value

Checksum

Terminator

0x02, 0x02

0x0003

0x07

0x07D0

Optional

0x03

Response from Controller

PARAMETER FIELD CONTENT

Header

Response Size

Command Echo

Tag ID

(bytes 1-8)

Checksum

0x02, 0x02

0x0009

0x07

0xE0 0x04 0x01 0x00 0x00 0x2E 0x16 0xAD

Optional

Terminator

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 81 OF 116

0x03

CHAPTER 7: RFID COMMANDS

C OMMAND 07 (READ TAG ID) – CBX C OMMAND E XAMPLE

This example instructs the controller to retrieve a tag’s ID. In this example the 8-byte tag

ID number is E0040100002E16AD. A Timeout Value of 2 seconds is set for the

completion of this command.

Command from Host

PARAMETER FIELD MSB LSB

Overall Length of Command

in MSB

AA

Command ID

in MSB

00

Node ID

2-byte

Timeout Value

in LSB (0x07)

in LSB (Cobalt –IND = 01)

measured in ms

(in words)

0x00 0x06

0xAA

0x07

0x00 0x01

0x07 0xD0

(0x07D0 = 2 seconds)

Not Used:

Not Used:

(0x00, 0x00)

(0x00, 0x00)

0x00 0x00

0x00 0x00

Response from Controller

PARAMETER FIELD MSB LSB

Overall Length of Response

in MSB

AA

Command Echo

in MSB

00

Node ID Echo

in LSB

in LSB

(in words)

0x00 0x0A

0xAA

0x

07

0x00 0x01

Month

Hour

Seconds

and

and

Minute

timestamp in MSB

Number of Tag ID Bytes Retrieved

Day

timestamp

timestamp

Month DOM

Hour Minutes

Seconds 0x08

in LSB

(0x08)

Tag ID

Tag ID

Tag ID

Tag ID

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 82 OF 116

(bytes 1 & 2)

(bytes 3 & 4)

(bytes 5 & 6)

(bytes 7 & 8)

0xE0 0x04

0x01 0x00

0x00 0x2E

0x16 0xAD

CHAPTER 7: RFID COMMANDS

Response if tag not found

PARAMETER FIELD MSB LSB

Overall Length of Response

Error Flag

Command Echo

in MSB

00

Node ID Echo

Month

Hour

Seconds

in MSB

in LSB

in LSB

and

and

timestamp

Day

Minute

timestamp

timestamp in MSB

(in words)

# of Additional Data Bytes Retrieved

LSB

Error Code

in MSB (0x07 = “Tag Not

Found Error”)

in LSB

00

0x00 0x07

0xFF

0x07

0x00 0x01

Month DOM

Hour Minutes

Seconds 0x01

in

0x07 0x00

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 83 OF 116

COMMAND 08:

TAG SEARCH

Command 08 instructs the controller to search for the presence of a tag within RF range

of the antenna. If the controller finds a tag it will return a Command Response to the host.

The Timeout Value is measured in 1-millisecond increments and can have a value of

0x0001 to 0xFFFE (1 to 65,534 milliseconds).

OMMAND 08 (TAG S EARCH)–ABX F AST C OMMAND S TRUCTURE

C

PARAMETER FIELD CONTENT

CHAPTER 7: RFID COMMANDS

Header

Command Size

Command ID

Timeout Value

Checksum

Terminator

0x02, 0x02

0x0003 for this command

0x08

2-byte value measured in 1 millisecond units

(0x0001 – 0xFFFE).

Optional

0x03

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 84 OF 116

CHAPTER 7: RFID COMMANDS

C OMMAND 08 (TAG S EARCH)–ABX F AST C OMMAND E XAMPLE

This example checks for an RFID tag within range of the antenna. The checksum is

enabled and the Timeout Value is set for 2 seconds (0x07D0 = 2000 milliseconds) for the

completion of this command.

Command from Host

PARAMETER FIELD CONTENT

Header

Command Size

Command ID

Timeout Value

Checksum

Terminator

0x02, 0x02

0x0003

0x08

0x07D0

0x1D

0x03

Response from Controller

PARAMETER FIELD CONTENT

Header

Response Size

Command Echo

Checksum

Terminator

0x02, 0x02

0x0001

0x08

0xF6

0x03

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 85 OF 116

CHAPTER 7: RFID COMMANDS

C OMMAND 08 (TAG S EARCH)–CBX C OMMAND E XAMPLE

This command will instruct the controller to search for the presence of a tag within RF

range of the antenna.

Command from Host

PARAMETER FIELD MSB LSB

Overall Length of Command

0x00 0x06

(in words)

in MSB

AA

Command ID

in MSB

00

Node ID

2-byte

in LSB (Cobalt = 1)

Timeout Value

in LSB (0x08)

0xAA

0x08

0x00 0x01

0x07 0xD0

measured in ms (0x07D0 = 2

seconds)

Not Used:

Not Used:

(0x00, 0x00)

(0x00, 0x00)

0x00 0x00

0x00 0x00

Response from Controller

PARAMETER FIELD MSB LSB

Overall Length of Response

0x00 0x06

(in words)

in MSB

AA

Command Echo

in LSB

0xAA

0x08

in MSB

00

Node ID Echo

Month

Hour

and

and

Seconds

in LSB

00

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 86 OF 116

in LSB

timestamp

Day

Minute

timestamp

timestamp in MSB

0x00 0x01

Month DOM

Hour Minutes

Seconds 0x00

CHAPTER 7: RFID COMMANDS

Response if tag not found

PARAMETER FIELD MSB LSB

Overall Length of Response

(in words)

Error Flag

Command Echo

in MSB

00

Node ID Echo

Month

Hour

Seconds

in MSB

in LSB

in LSB

and

and

timestamp

Day

Minute

timestamp

timestamp in MSB

Number of Additional Data

: 0x01

Bytes

Error Code

in MSB (0x07 =

“Tag Not Found Error”)

in LSB

00

0x00 0x07

0xFF

0x08

0x00 0x01

Month DOM

Hour Min

Seconds 0x01

0x07 0x00

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 87 OF 116

CHAPTER 7: RFID COMMANDS

COMMAND 0D:

START/STOP CONTINUOUS READ

Command 0D instructs the controller to start (or stop) Continuous Read Mode.

When the Cobalt Controller is in Continuous Read Mode, it will constantly emit RF energy

in an attempt to read any tag that comes into range of the antenna. As a tag enters the

antenna field, it is immediately read and the data is passed to the host. The controller will

continue to read the tag but will not re-send the same data to the host until the tag has

moved outside the RF field for a specified time period. This parameter is known as the

Delay Between Duplicate Reads

controller is in Continuous Read Mode.

If another RFID command is executed while the controller is in Continuous Read Mode,

the Cobalt HF will temporarily stop Continuous Reading to execute the command, after

which the controller will return to Continuous Read Mode.

The Start/Stop Continuous Read command contains three primary components: a Start

Address, a Read Length and a Delay Between Duplicate Reads value.

, which prevents redundant data transmissions when the

x Start Address: The Start Address is a 2-byte integer indicating the tag address

location where the read will begin.

x Read Length: The Read Length is a 2-byte integer that represents the number

of tag data bytes of retrieve. By setting this parameter to one (0x01) or higher,

Continuous Read Mode will be switched ON at the completion of the command.

Setting the Read Length to zero (0x00) will turn Continuous Read Mode off.

x Delay Between Duplicate Reads: During Continuous Read Mode, any tag that

comes within range of the antenna will be constantly read and the requested data

from the tag will be passed to the host. This single-byte delay parameter

indicates the number of seconds that a tag must remain out of RF range before it

can be re-read and have its data sent to the host for a second time. It is

implemented to enable the operator to limit the volume of information sent by the

controller. The Delay Between Duplicate Reads parameter can have a value of 0

to 60 seconds. When the Delay Between Duplicate Reads value is set to 0, the

controller will continuously read AND transmit duplicate tag data to the host.

Continuous Read at Power-up

By default, Continuous Read Mode is not restarted if the controller is reset. However,

through the use of the RFID Dashboard Utility, the Cobalt Controller can be configured

to enter Continuous Read Mode automatically after a reset or power-up. See Section 3.1

for more information regarding the RFID Dashboard Utility or visit:

www.ems-rfid.com

.

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 88 OF 116

CHAPTER 7: RFID COMMANDS

C ONTINUOUS R EAD M ODE LED BEHAVIOR

LED BEHAVIOR DESCRIPTION

PWR

COM

ON The controller is powered and functioning.

BLINKS ONCE Delay Between Duplicate Reads is set to 1 or

greater and a tag has entered the RF field.

COM

BLINKING Delay Between Duplicate Reads is set to 0 and a

tag is in the RF field.

RF

BLINKING Delay Between Duplicate Reads is set to 0 and a

tag is in the RF field.

RF

BLINKS ONCE Delay Between Duplicate Reads is set to 1 or

greater and a tag has entered the RF field.

RF

ON The controller is in Continuous Read Mode and no

tag is present.

Table 7-2: Continuous Read Mode - LED Behavior

OMMAND 0D (START/STOP C ONTINUOUS R EAD)–

C

X F AST C OMMAND S TRUCTURE

AB

PARAMETER FIELD CONTENT

Header

Command Size

0x02, 0x02

0x0006

Command ID 0x0D

Start Address

2-byte value for the tag address where the read

will start.

Read Length

Delay Between Duplicate

Reads

2-byte value for number of bytes to be read.

1-byte value for number of seconds a tag must

be out of RF range before the controller will retransmit data from same tag.

Checksum

Terminator

Optional

0x03

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 89 OF 116

CHAPTER 7: RFID COMMANDS

C OMMAND 0D (START/STOP C ONTINUOUS R EAD)–

X F AST C OMMAND E XAMPLE

AB

This example places the controller in Continuous Read mode and reads four bytes of

data from the tag starting at address 0x0001. The Delay Between Duplicate Reads is set

to two seconds (0x02 = 2 x 1 second increments).

Starting Continuous Read - Command from Host

PARAMETER FIELD CONTENT

Header

Command Size

0x02, 0x02

0x0006

Command ID 0x0D

Start Address

Read Length

Delay Between Duplicate Reads

Checksum

Terminator

0x0001

0x0004

0x02

Optional

0x03

Starting Continuous Read - Initial Response from Controller

PARAMETER FIELD CONTENT

Header

Response Size

0x02, 0x02

0x0001

Command Echo 0x0D

Checksum

Terminator

Optional

0x03

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 90 OF 116

CHAPTER 7: RFID COMMANDS

Continuous Read Mode Evoked - Response from Controller (after Tag Read)

PARAMETER FIELD CONTENT

Header

Response Size

0x02, 0x02

0x0005

Command Echo 0x0D

Data from address 0x0001

Data from address 0x0002

Data from address 0x0003

Data from address 0x0004

Checksum

Terminator

0x05

0xAA

0xE7

0x0A

Optional

0x03

To exit out of Continuous Read mode, issue Command 0D with zero (0x0000) in the

Read Length parameter field.

Stopping Continuous Read - Command from Host

PARAMETER FIELD CONTENT

Header

Command Size

0x02, 0x02

0x0006

Command ID 0x0D

Start Address

Read Length

Delay Between Duplicate Reads

Checksum

Terminator

0x0001

0x0000

0x02

Optional

0x03

Stopping Continuous Read - Response from Controller

PARAMETER FIELD CONTENT

Header

Response Size

0x02, 0x02

0x0001

Command Echo 0x0D

Checksum

Terminator

Optional

0x03

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 91 OF 116

CHAPTER 7: RFID COMMANDS

C OMMAND 0D (START/STOP C ONTINUOUS R EAD)–

X C OMMAND E XAMPLE

CB

This example places the controller in Continuous Read Mode and reads 4 bytes of data

from the tag starting at address 0x0001. The Delay Between Duplicate Reads is set to 2

seconds (0x02 = 2 x 1 second increments).

Starting Continuous Read - Command from Host

PARAMETER FIELD MSB LSB

Overall Length of Command

in MSB

AA

Command ID

in MSB

00

Node ID

in MSB

00

1-byte

Delay Between Duplicate Reads

in LSB (0x0D)

in LSB (Cobalt -IND = 01)

(in words)

0x00 0x06

0xAA

0x0D

0x00 0x01

0x00 0x02

in LSB

Start Address

Read Length

(in bytes)

0x00 0x01

0x00 0x04

Starting Continuous Read - Initial Response from Controller

PARAMETER FIELD MSB LSB

Overall Length of Response

in MSB

AA

Command Echo

in MSB

00

Node ID Echo

in LSB

in LSB

(in words)

0x00 0x06

0xAA

0x0D

0x00 0x01

Month

Hour

and

and

Seconds

in LSB

00

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 92 OF 116

timestamp

Day

Minute

timestamp

timestamp in MSB

Month DOM

Hour Min

Seconds 0x00

CHAPTER 7: RFID COMMANDS

Continuous Read Mode Evoked - Response from Controller (after Tag Read)

PARAMETER FIELD MSB LSB

Overall Length of Response

in MSB

AA

in LSB

Day

in LSB

timestamp

timestamp

Command Echo

in MSB

00

Node ID Echo

Month

Hour

Seconds

and

and

Minute

timestamp in MSB

(in words)

0x00 0x08

0xAA

0x05

0x00 0x01

Month DOM

Hour Minutes

Seconds 0x04

# of Bytes Read Data

Read Data

Read Data

(bytes 1 & 2)

(bytes 3 & 4)

0x05 0xAA

0xE7 0x0A

To exit out of Continuous Read Mode, re-issue the command with zero (0x0000) for the

Read Length.

Stopping Continuous Read - Command from Host

PARAMETER FIELD MSB LSB

Overall Length of Command

in MSB

AA

Command ID

in LSB (0x0D)

(in words)

0x00 0x06

0xAA 0x0D

in MSB

00

Node ID

in MSB

00

1-byte

in LSB (Cobalt = 01)

Delay Between Duplicate Reads

0x00 0x01

0x00 0x02

in LSB

Start Address

Read Length

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 93 OF 116

(in bytes)

0x00 0x00

0x00 0x00

CHAPTER 7: RFID COMMANDS

Stopping Continuous Read - Response from Controller

PARAMETER FIELD MSB LSB

Overall Length of Response

(in words)

in MSB

AA

in LSB

timestamp

Day

in LSB

timestamp

Command Echo

in MSB

00

Node ID Echo

Month

Hour

Seconds

00

and

and

in LSB

Minute

timestamp in MSB

0x00 0x06

0xAA

0x0D

0x00 0x01

Month DOM

Hour Minutes

Seconds 0x00

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 94 OF 116

COMMAND 35:

RESET CONTROLLER

Command 35 will cause the controller to cycle power - effectively rebooting the device without clearing any stored configuration information. Command 35 will reset the

controller’s configuration to default settings when a Configuration Tag is placed in the

antenna’s RF field prior to execution.

OMMAND 35 (RESET CONTROLLER)–ABX F AST C OMMAND S TRUCTURE

C

PARAMETER FIELD CONTENT

CHAPTER 7: RFID COMMANDS

Header

Command Size

Command ID

Checksum

Terminator

C OMMAND 35 (RESET C ONTROLLER)–ABX F AST C OMMAND E XAMPLE

This example resets power to the controller.

Command from Host

PARAMETER FIELD CONTENT

Header

Command Size

Command ID

Checksum

Terminator

0x02, 0x02

0x0001

0x35

optional

0x03

0x02, 0x02

0x0001

0x35

Optional

0x03

Response from Controller

PARAMETER FIELD CONTENT

Header

Response Size

Command Echo

Checksum

Terminator

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 95 OF 116

0x02, 0x02

0x0001

0x35

Optional

0x03

CHAPTER 7: RFID COMMANDS

C OMMAND 35 (RESET C ONTROLLER)–CBX C OMMAND E XAMPLE

Command from Host

DESCRIPTION MSB LSB

Overall Length of Command

0x00 0x06

(in words)

in MSB

AA

Command ID

in MSB

00

Node ID

Not Used:

Not Used:

Not Used:

in LSB

(default: 0x00, 0x00)

(default: 0x00, 0x00)

(default: 0x00, 0x00)

in LSB

0xAA

0x35

0x00 0x01

0x00 0x00

0x00 0x00

0x00 0x00

Response from Controller

DESCRIPTION MSB LSB

Overall Length of Response

0x00 0x06

(in words)

in MSB

AA

Command Echo

Instance Counter

Node Echo

in LSB

in LSB

in MSB

0xAA

0x35

Instance Counter 0x01

Month

Hour

Seconds

00

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 96 OF 116

and

and

timestamp in MSB

in LSB

Day

Minute

timestamp

timestamp

Month Day

Hour Min

Seconds 0x00

COMMAND 38:

GET CONTROLLER INFO

Command 38 is used to retrieve hardware version, serial number and installed firmware

identification information from the controller.

OMMAND 38 (GET CONTROLLER I NFO)–

C

X F AST C OMMAND S TRUCTURE

AB

PARAMETER FIELD CONTENT

CHAPTER 7: RFID COMMANDS

Header

Command Size

Command ID

Checksum

Terminator

0x02, 0x02

0x0001

0x38

Optional

0x03

C OMMAND 38 (GET C ONTROLLER I NFO)–

X F AST C OMMAND E XAMPLE

AB

This example will query the Cobalt HF and retrieve specific internal hardware information.

Command from Host

PARAMETER FIELD CONTENT

Header

Command Size

Command ID

Checksum

Terminator

0x02, 0x02

0x0001

0x38

Optional

0x03

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 97 OF 116

Response from Controller

CHAPTER 7: RFID COMMANDS

PARAMETER

FIELD

Header

Response Size

Command Echo

RF Controller

Type

Major Release

Digit

Minor Release

Digit

Correction

Release Digit

CONTENT DESCRIPTION CONTENT

SAMPLE

2-byte Response Header (0x02, 0x02) 0x02, 0x02

2-byte value for the total number of bytes in the

0x001B

response packet, less Header, Command Size,

Checksum and Terminator bytes.

0x38 0x38

Controller Type default = 1 (0x01) 0x01

The MAJOR release ASCII digit in the product

0x30

version number. Example product version

number:

0.0t.14

.

Major Release Digit in this example = 0

The MINOR release ASCII digit in the product

0x30

version number. Example product version

number:

0.0t.14

.

Minor Release Digit in this example = 0

The CORRECTION ASCII digit in the product

0x74

version number. Example product version

number:

0.0t.14.

Correction Release Digit in this example = t

Point Release

Digit

Hardware

Version

Block 0, 1, and 2

CRC

Block 3, and 4

CRC

RC632 ID

RC632 RFU

RC632 Serial

Number

RC632 Internal

Information

The POINT RELEASE digit in the product

version number. Example product version

number:

0.0t.14.

Point Release Digit in this example = 14

Cobalt HF-xxx-01Hardware Version, default =

01 (0x01)

2-byte value for block 0, 1, and 2 CRC:

(example: 986E)

2-byte value for block 3, and 4 CRC: (example:

986E)

5-byte value for the RC632 ID:

(example: 30FFFF0F04)

3-byte value for the RC632 RFU.

(example: 000000)

4-byte value for the RC632 Serial Number.

(example: 05E19644)

2-byte value for the RC632 internal.

(example: B669)

0x0E

0x01

0x986E

0x986E

0x30, 0xFF,

0xFF, 0x0F,

0x04

0x00, 0x00,

0x00

0x05, 0xE1,

0x96, 0x44

0xB669

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 98 OF 116

CHAPTER 7: RFID COMMANDS

RC632 RsMaxP

Single-byte value for the RC632 RsMaxP:

0x65

(example: 65)

RC632

Information CRC

Terminator

Single-byte value for the RC632 Information

CRC. (example: A6)

0x03 0x03

0xA6

Controller Information (retrieved in the above example response)

RF Controller Type: 1

Product Version Number: 0.0T.5

Hardware Version: 01

Block 0, 1, and 2 CRC: 986E

Block 3, and 4 CRC: 986E

RC632 ID: 30FFFF0F04

RC632 RFU: 000000

RC632 Serial Number: 05E19644

RC632 internal: B669

RC632 RsMaxP: 65

RC632 Information CRC: A6

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 99 OF 116

CHAPTER 7: RFID COMMANDS

C OMMAND 38 (GET C ONTROLLER I NFO)–CBX C OMMAND E XAMPLE

Command from Host

DESCRIPTION MSB LSB

Overall Length of Command

in MSB

AA

Command ID

in LSB (0x38:Get Controller

0x00 0x06

0xAA

0x38

Info)

in MSB

0x00

Node ID in LSB

Not Used:

Not Used:

Not Used:

(default: 0x00, 0x00)

(default: 0x00, 0x00)

(default: 0x00, 0x00)

(Cobalt –IND = 01)

0x00 0x01

0x00 0x00

0x00 0x00

0x00 0x00

Response from Controller

DESCRIPTION MSB LSB

Overall Length of Response

(in words)

0x00 0x06 + number of

additional data

words retrieved

Command Echo

Instance Counter

Node ID Echo

in LSB

in MSB

0xAA

Instance

Counter

0x38

0x01

Month

Hour

and

and

Seconds

timestamp

Day

Minute

timestamp

timestamp in MSB

Month Day

Hour Min

Seconds N-bytes

Number of Additional Data Bytes

Retrieved

Node Info:

in LSB

(bytes 1 & 2)

Node Info -

Node Info - byte 2

byte 1

Node Info:

(bytes 3 & 4) (…etc.)

Node Info -

Node Info - byte 4

byte 3

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 100 OF 116

CHAPTER 8: ERROR CODES

CHAPTER 8:

ERROR CODES

If the Cobalt Controller encounters a fault during operation, the response that is

generated will include a 1-byte error code. Entering an invalid Start Address for a Read

Data command, for example, will generate Error Code 0x32 (Invalid Programming

Address).

8.1 ERROR C ODE T ABLE

ERROR

CODE

0x04

0x05

0x06

0x07

0x08

0x21

0x23

0x30

0x31

0x32

0x34

ERROR NAME DESCRIPTION

FILL TAG FAILED Fill Operation Failed

READ DATA FAILED Read Data Command Failed

WRITE DATA FAILED Write Data Command Failed

READ TAG ID FAILED Read Tag ID Command Failed

TAG SEARCH FAILED Tag Search Command Failed / No

Tag Found

INVALID SYNTAX Command Contained a Syntax

Error

INVALID TAG TYPE Invalid or Unsupported Tag Type

INTERNAL CONTROLLER

ERROR

INVALID CONTROLLER TYPE Invalid Controller Type (when

INVALID PROGRAMMING

ADDRESS

INVALID VERSION Invalid Software Version (when

Generic Internal Controller Error

Setting Configuration)

Invalid Tag Address Specified in

the Command

Setting Configuration)

0x35

0x36

0x37

0x83

0x84

COBALT HF RFID CONTROLLERS OPERATOR’S MANUAL

P/N: 17-1320 REV 01 (03-06) PAGE 101 OF 116

INVALID RESET Invalid Hardware Reset

SET CONFIGURATION

FAILED