Page 1

AS-09(12)UR4SVNVG

SERVICE MANUAL

编号:XM00009562

编制:项目组长 李本卫

校对:电控 于心艳 张永良

结构 卢瑞艳

系统 李本卫

审核 1:

杜建伟

审核 2:

赵可可

审核 3: 殷显鑫

审核 4: 陆汉宁

批准:

王剑锋

海信科龙空调有限公司

2010 年 03 月

Page 2

Table of contents

Page

1.OPERATING RANGE 1

2.SPECIFICATION 2

2-1 Unit specifications 2

2-2 Major component specifications 3

2-3 Other component specifications 4

3.OUTLINES AND DIMENSIONS 6

3-1 INDOOR 6

3-2 OUTDOOR 7

4.REFRIGERANT FLOW DIAGRAM 8

4-1 Refrigerant flow diagram 8

4-2 Evacuation procedures 9

4-3 Evacuation direction 9

5.ELECTRICAL DATA 11

5-1 Electric wiring diagrams 11

5-2 Electric control 12

5-3 Sensor parameter 16

6.CONTROL MODE 18

6-1 control mode 18

7.TROUBLESHOOTING 26

7-1 Error codes 26

7-2 Service flow chart 28

8.CHECKING COMPONENTS 32

8-1 Check refrigerant system 32

8-2 Check parts unit 34

9.DISASSEMBLY INSTRUCTIONS 38

9-1 Indoor 38

Page 3

9-2 Outdoor 41

10.PARTS LIST 45

10-1 Indoor 45

10-2 Outdoor 47

Page 4

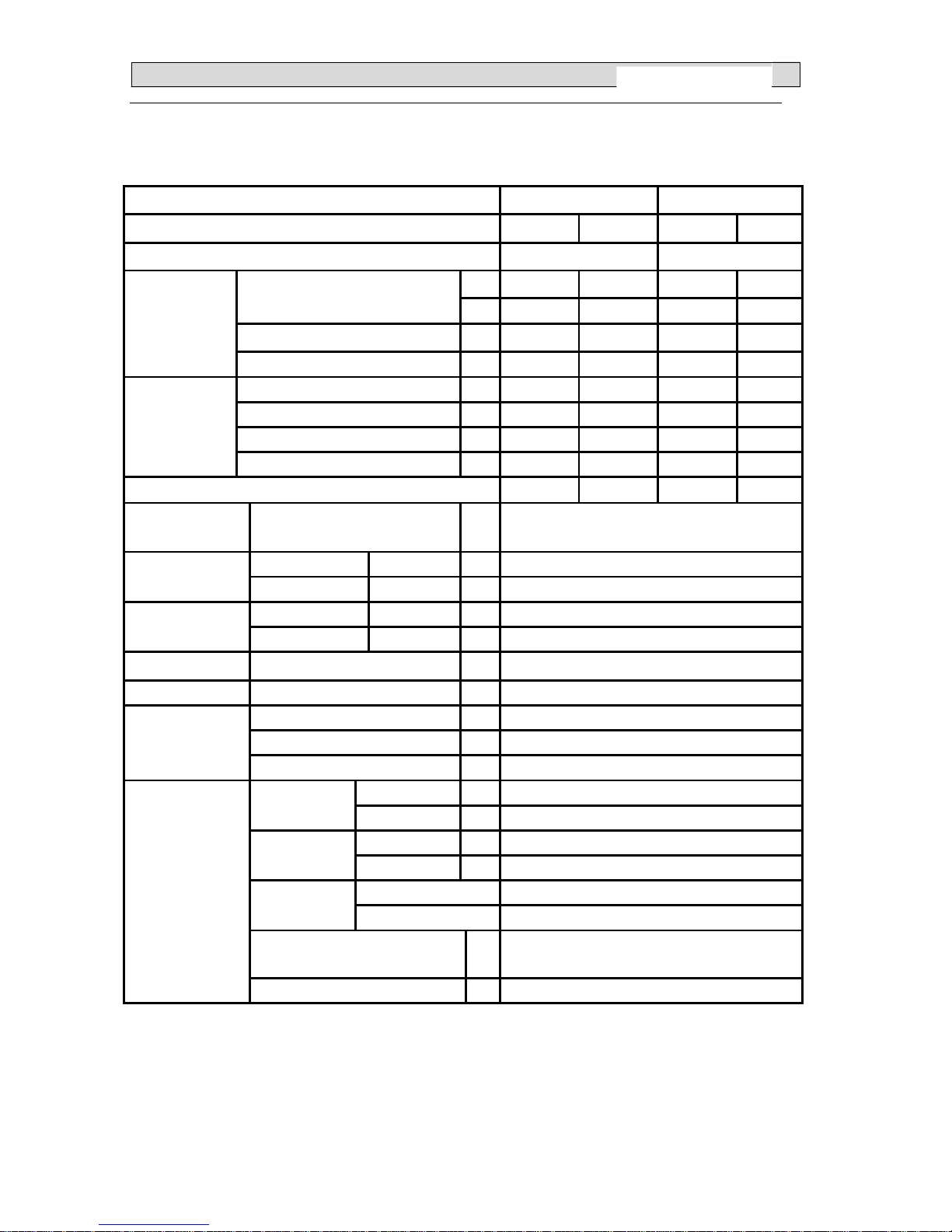

11.. OOPPEERRAATTIINNGG RRAANNGGE

E

AASS--0099((1122))UURR44SSVVNNVVGG

T emperature Indoor Air Intake T emp. Outdoor Air Intake T emp

Maximum

32℃ D.B./23℃ W.B. 43 ℃ D.B./26℃ W.B.

COOLING

Minimum

21℃ D.B./15℃ W.B. 21 ℃ D.B./15℃ W.B.

Maximum

27℃ D.B./18℃ W.B. 24℃ D.B./18℃ W.B.

HEATING

Minimum

20℃ D.B/≤15℃ W.B -7℃ D.B./-8℃ W.B.

1

Page 5

22.. SSPPEECCIIFFIICCAATTIIOONNSS

2-1. Unit specifications

NOTE :Test conditions:

Model

Function Cooling Heating Cooling Heating

Power supply a.c 220V/50Hz

BTU 9000 11000 11000 11500Capacity

kW 2.65 3.25 3.2 3.37

Dehumidification l /h 1.0

—-

1.0

—-

Capacity

Air flow m

3

/h

520 550 520 550

Rated current A 3.7 4.1 4.5 4.1

MAX. current A 8.0 10.0 8.0 10.0

Rated input kW 0.82 0.89 0.99 0.92

Electrical data

MAX. input kW 1.70 2.0 1.70 2.0

EER/COP 3.22 3.62 3.22 3.66

MAX.operating

pressure

High MP 4.15

Indoor unit

L×W×H

cm

75×19

×25

Net size

Outdoor unit

L×W×H

cm

72×24

×48

Indoor unit

L×W×H

cm

84×31

×27

Package size

Outdoor unit

L×W×H

cm

85×36

×53

Net weight Indoor unit / Outdoor unit kg 9.0/28.0

Gross weight Indoor unit / Outdoor unit kg 10.5/30.5

Liquid pipe mm 6.00

Gas pipe mm 9.52

Refrigerant

piping

Connection method Flared

Indoor unit dB 40 Sound level

(Hi)

Outdoor unit dB 52

Indoor unit rpm 1250 Fan speed

(Hi)

Outdoor unit rpm 880

Indoor unit 1 Fan speed

regulator

Outdoor unit 1

Refrigerant filling

capacity(R410A)

kg 0.72

Special

remarks

Throttle mode CAPILLARY( Shot T

ube Throttle Valve)

Cooling : Indoor: DB27℃/ WB19℃ Outdoor: DB35℃/ WB24℃

Heating: Indoor: DB20

℃/ WB15℃ Outdoor: DB7℃/ WB 6℃

2

BSGI 09 (12)

BSGI 09

BSGI 12

Page 6

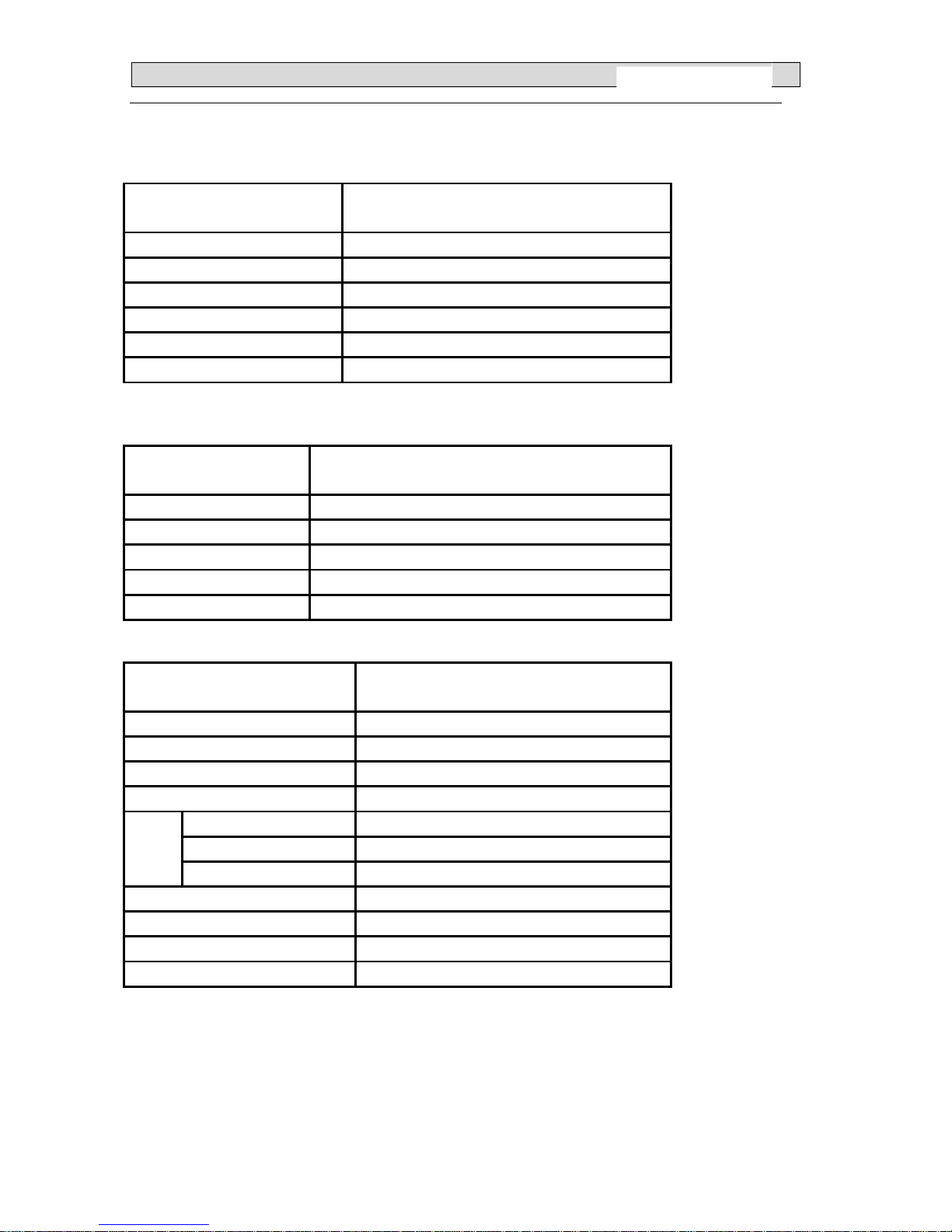

22.. SSPPEECCIIFFIICCAATTIIOONNSS

2-2. Major component specifications

2-2-1.INDOOR FAN MOTOR

ELECTRIC PERFORMANCE PARAMETER

Motor model RGP18

Rated power source 220V 50Hz

Phases/Poles 1/4

Rated load output(W) 16

Rated speed(r/min) 1330

Ambient temperature( )℃

-5℃~+43℃.

2-2-2 OUTDOOR FAN MOTOR

ELECTRIC

PERFORMANCE

PARAMETER

Motor model YDK29-6I-19

Rated power source 220V 50Hz

Phases /Poles 1/6

Rated load output(W) 28

Ambient temperature( )℃

-5℃~+43℃.

2-2-3. COMPRESSOR

ELECTRIC PERFORMANCE PARAMETER

Compressor model C-1RZ 089H 1E

Compressor type Rotary

Rated power 675W

Current (A) 4.20

Motor type DC brushless motor

Starting type DC Inverter

Motor

Winding resistance

0.744Ω

(at 25 )℃

Number of cylinder 1

Oil type FV50 B X

Oil charge (cc) 350

Ambient temperature( )℃

-7℃~

+43 .℃

3

BSGI 09(12)

Page 7

22.. SSPPEECCIIFFIICCAATTIIOONNSS

2-3. Other component specifications

2-3-1. INDUCTANCE

ELECTRIC PERFORMANCE PARAMETER

Inductance model Rated power source -

Loop winding rated current - Rated

current(A)

Filter winding rated current Loop winding rated inductance - Rated

inductance

(mH)

Filter winding rated inductance -

Ambient temperature( )℃ -

2-3-2. INDUCTANCE (1343046,A)

ELECTRIC PERFORMANCE PARAMETER

Inductance model R1250HSB

Rated power source 220V 50Hz

Rated current(A) 12

Rated inductance(mH) 5

Ambient temperature( )℃

-20℃~

+70 .℃

2-3-3. FILTER

ELECTRIC PERFORMANCE PARAMETER

Filter model RTLB-12T047-02JF

Rated current(A) 12

Rated power source 220V 50Hz

Filter frequency range 150K—30MHHz

Temperature range( )℃

-25℃~+85℃

.

2-3-4. STEPPER MOTOR

ELECTRIC PERFORMANCE PARAMETER

Stepper Motor model 24BYJ48

Voltage(DC) 12V

Number of phase 4

Drive mode 1-2phase excitation unipolar drive

Resistance per phase

200Ω

±7%

Temperature range( )℃

-10℃~

+40 .℃

4

BSGI 09(12)

Page 8

22.. SSPPEECCIIFFIICCAATTIIOONNSS

2-3-5. OVERLOAD PROTECTION

ELECTRIC

PERFORMANCE

PARAMETER

Model INT11L-3979

Reset temperature( )℃ 95±5℃

Trip temperature( )℃ 115±3℃

5

BSGI 09(12)

Page 9

33.. OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOO

3-1. INDOOR

23mm631mm

94mm

750mm

65mm

250mm

190mm

50mm

50mm

50mm

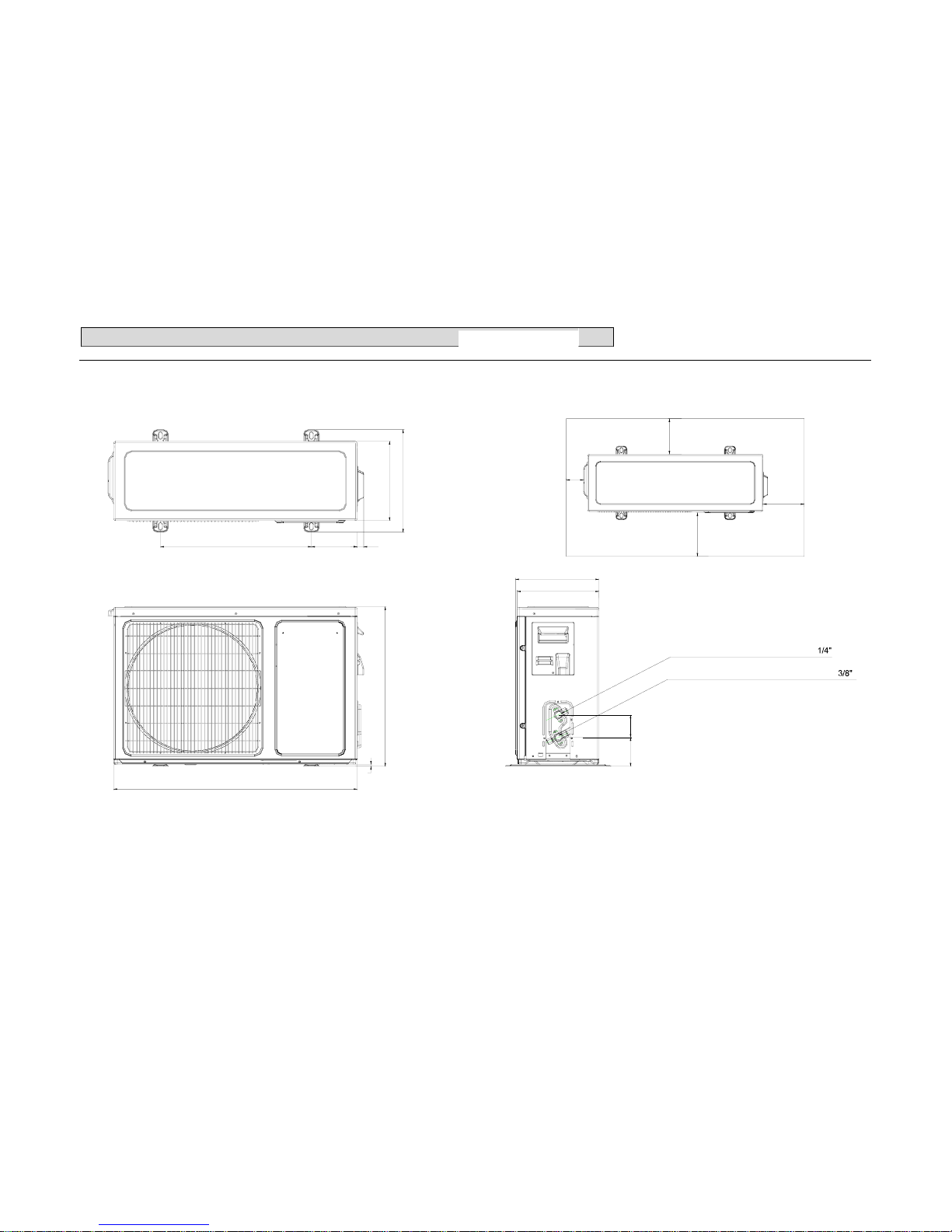

3-2.OUTDOOR

6

BSGI 09(12)

Page 10

33.. OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOO

443

240

245

240

6

715

482

310

134.5 19

NARROW TUBE SERVICE VALVE Φ9.52 ( )

WIDE TUBE SERVICE VALVE

Φ6.0( )

6887

>40cm

>25cm

>10cm

>5cm

7

BSGI 09(12)

Page 11

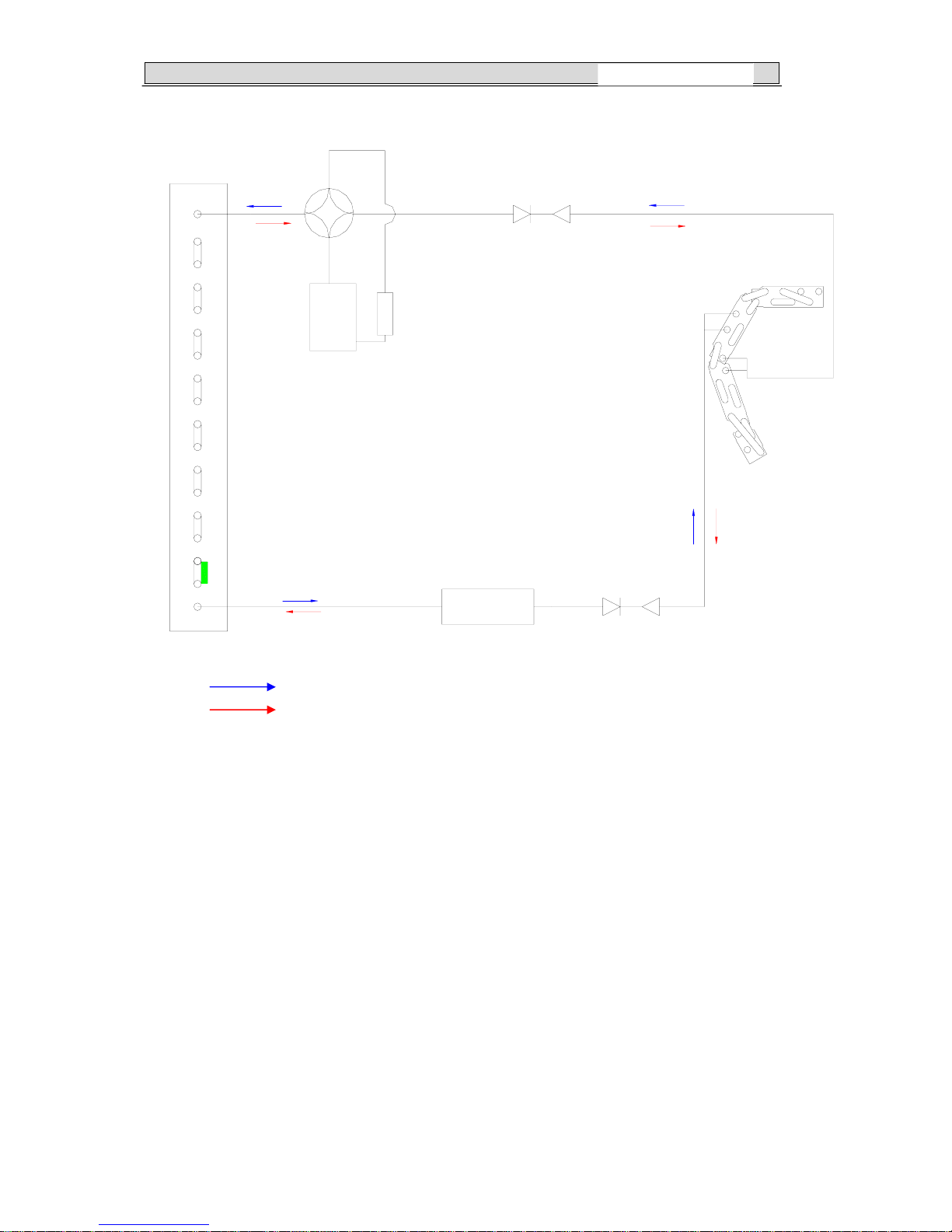

44.. RREEFFRRIIGGEERRAANNTT FFLLOOWW DDIIAAGGRRAAM

M

4-1. Refrigerant flow diagram :

INDOOROUTDOOR

EVAPORATOR

CONDENSER

CHECK VALVE ASS'Y

COMPRESSOR

CAPILLARY(Shot Tube

Throttle Valve )

Remark: COOLING CYCLE

Remark: HEATING CYCLE

4-2. Evacuation procedures:

8

BSGI 09(12)

Page 12

44.. RREEFFRRIIGGEERRAANNTT FFLLOOWW DDIIAAGGRRAAM

M

EVACUATION PROCEDURES

Connect the r efriger ant pi pes (both the l iquid and gas

pipes) between the indoor and the outdoor units.

Remove the service port cap of the stop valve on the side of the

outdoor unit gas pipe. ( The stop valve will not work in its initial

state fresh out of the factory (totally closed with cap on).

Connect the gage manifold valve and the vacuum pump to the service port of the stop valve on

the gas pipe side of the outdoor unit.

Run the vacuum pump for more than 15 minutes and at this time confirm that the pressure gage

indicates -0.1 Mpa (-76 cmHg).

Check the vacuum with the gage manifold valve, then close the gage manifold valve, and stop the

vacuum pump.

Leave it as is for one or two minutes .Make sure the pointer of the gage manifold valve remains

in the same position.

Close

Open

Hexagonal

wrench

Stop valve

pipe

Connection

Gage manifold valve

Stop valve

Liquid pipe

Stop valve

Hexagonal wrench

Gas pipe

Caps

Service port

Vacuum pump

Remove the gage man ifold valve qu ickly from th e service po rt of the stop valve.

After refrigerant pipes are connected and evacuated, fully open all stop valves

on gas and liquid pipe sides.

Operating without fully opening lowers the performance and causes trouble.

Pipe length

7m maximum

No gas charge is

needed.

Pipe length

exceeding 7m

Charge the prescribed

amount of gas.

Tighten the cap to the service port to obtain the initial status.

Retighten the cap.

Leak test

4-3. Evacuation direction:

9

BSGI 09(12)

Page 13

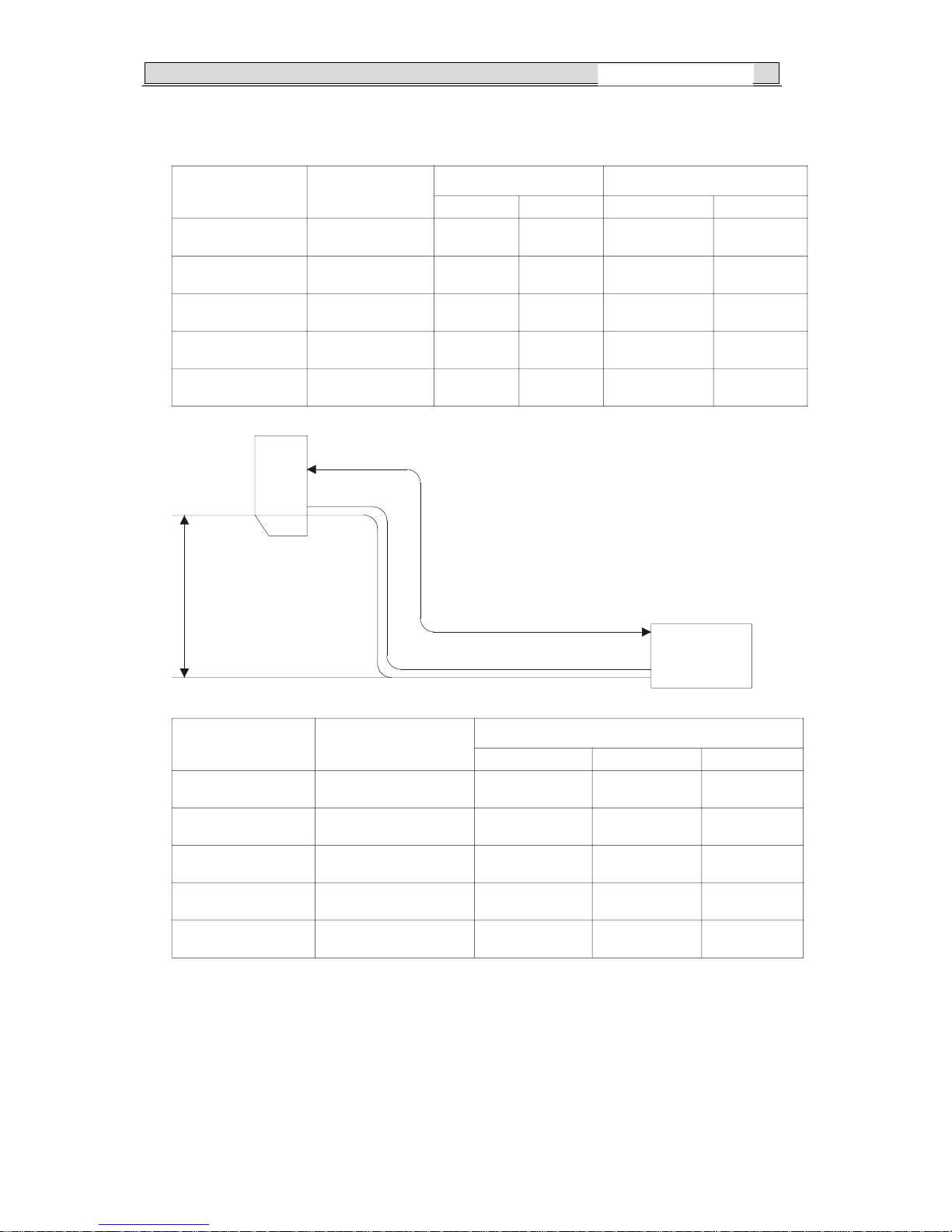

44.. RREEFFRRIIGGEERRAANNTT FFLLOOWW DDIIAAGGRRAAM

M

MAX. REFRIGER ANT PIPING LENGTH

Models

Refrigerant Piping

Max. Length: m

A

Piping size (OD) : mm Length of connecting pipe : m

Gas

Liquid Indoor unit

Outdoor unit

Models

Indoor

unit

Outdoor unit

MAX. HEIGHT DIFFERENCE

Outdoor unit precharged

(up to 7m)

Refrigerant piping length

15m7m

Max. Height

difference 7m

Refrigerant piping

Max. Length

A

ADDITIONAL: R EFRIGERANT CHARGE(R-410A: g)

AS 09(12)UR4SVNZC

-

15 9 52

.

6.00

720

75

0

Canculation :Xg=25g/m*(A-7)m

10m

200

AS 09(12)UR4SVNZC

-

10

BSGI 09(12)

Page 14

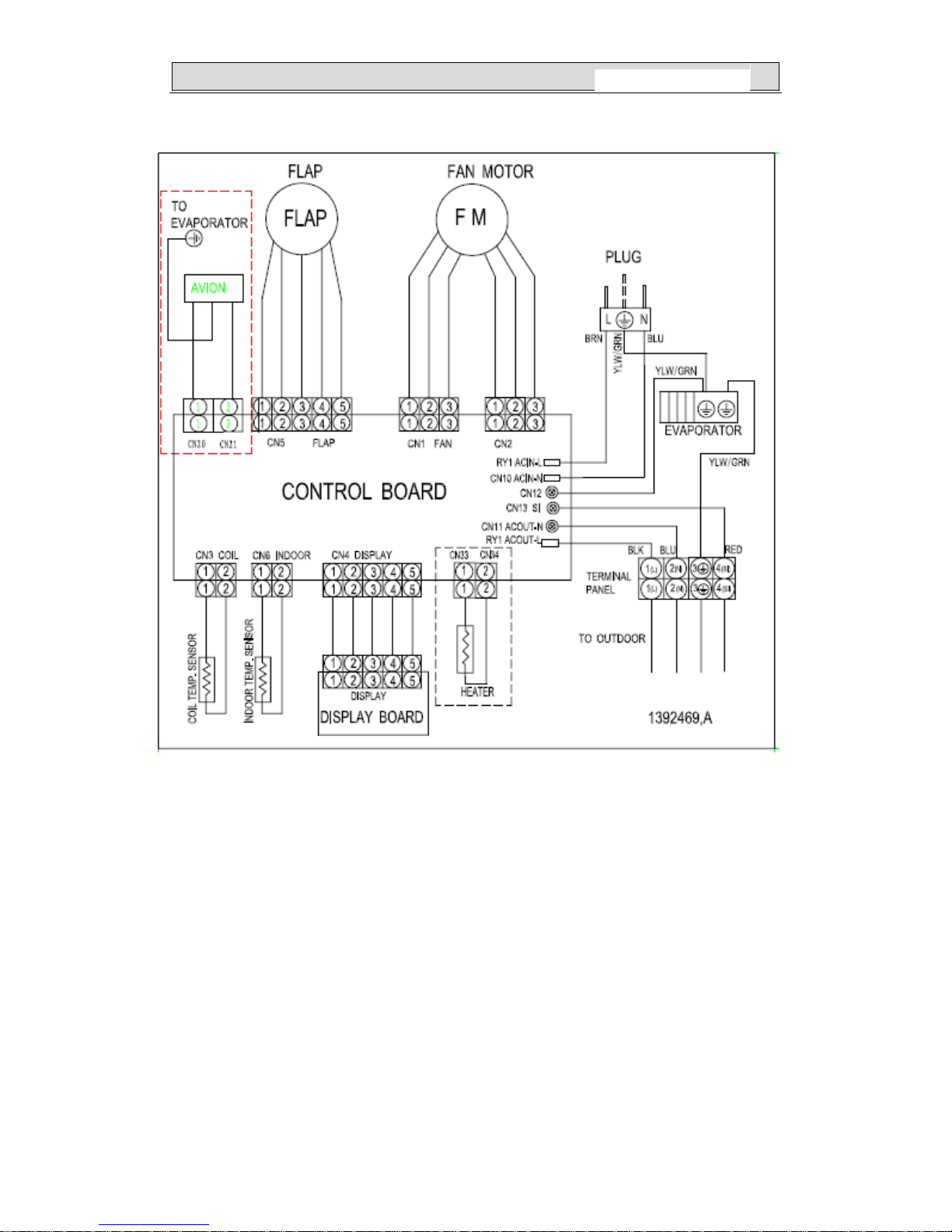

55.. EELLEECCTTRRIICCAALL DDAATTAA

5-1.Electrical wiring diagrams

1.INDOOR

11

BSGI 09(12)

Page 15

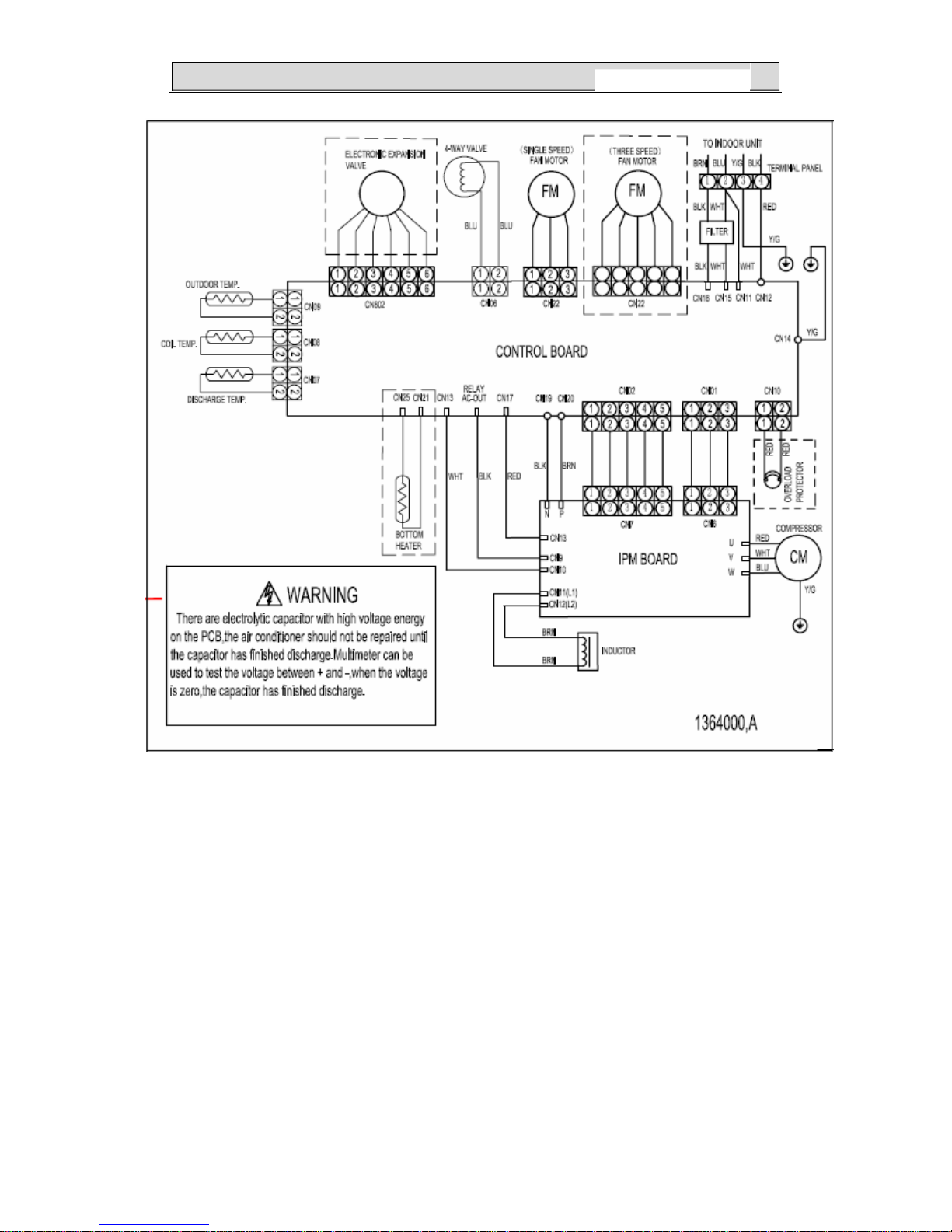

55.. EELLEECCTTRRIICCAALL DDAATTAA

12

2.OUTDOOR

5-2. Electric control

1.Indoor control

BSGI 09(12)

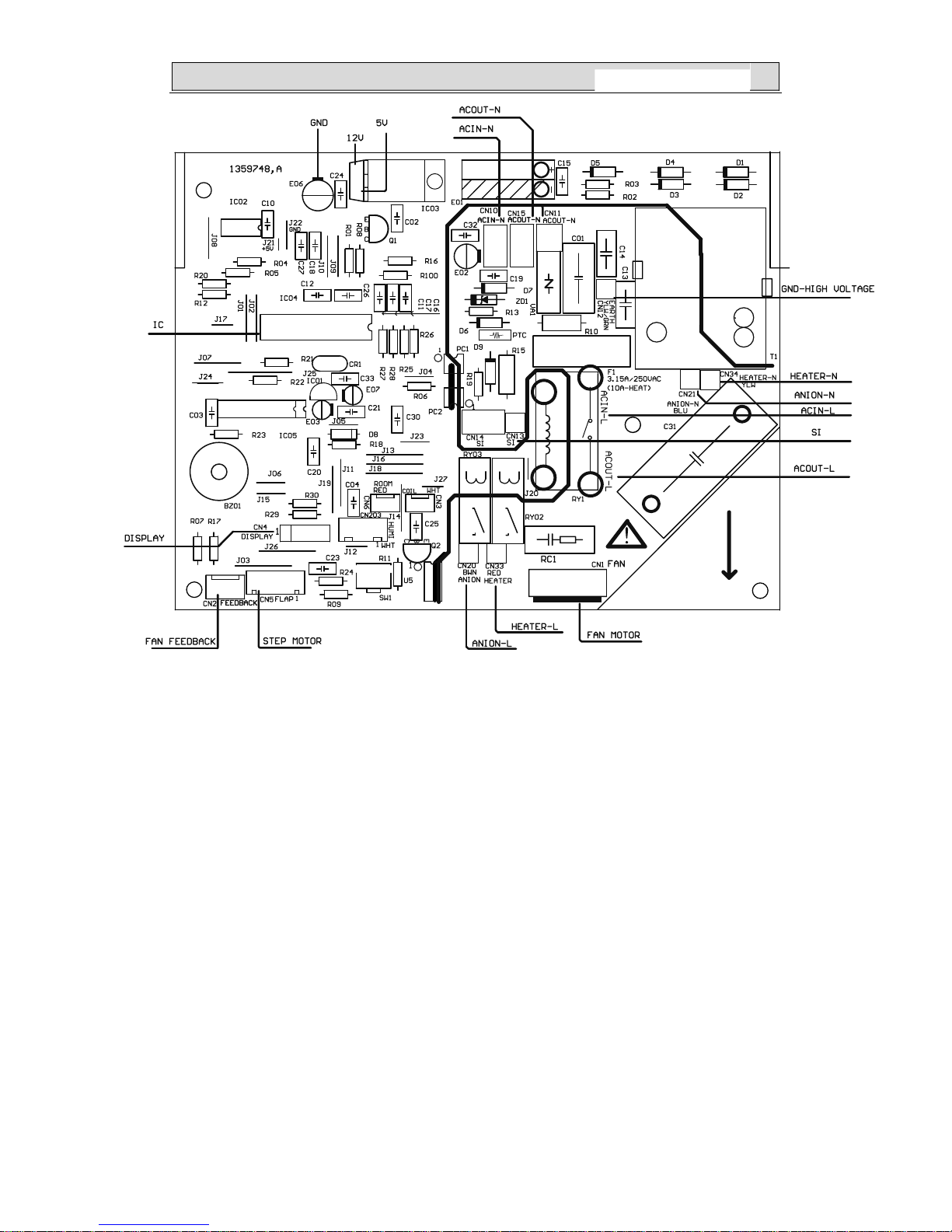

Page 16

55.. EELLEECCTTRRIICCAALL DDAATTAA

13

2.Outdoor control

BSGI 09(12)

Page 17

55.. EELLEECCTTRRIICCAALL DDAATTAA

14

OUT IPM:

BSGI 09(12)

Page 18

55.. EELLEECCTTRRIICCAALL DDAATTAA

15

BSGI 09(12)

Page 19

55.. EELLEECCTTRRIICCAALL DDAATTAA

1. THE PARAMETER OF OUTDOOR COMPRESSOR TEMPERATURE SENSOR:

(R0=187.25K±6.3%;R

100

=3.77K±2.5K;B=3979±1%)

T(℃) R(KΩ) V(v) DEC HEX T(℃) R(KΩ) V(v) DEC HEX T(℃) R(KΩ) V(v) DEC HEX

-30 966.1 0.1014 5 5 26 55.46 1.3252 68 44 82 6.662 3.7507 191

BF

-29 910.3 0.1075 5 5 27 53.11 1.3678 70 46 83 6.446 3.7813 193

C1

-28 858 0.1139 6 6 28 50.86 1.4112 72 48 84 6.239 3.8111 194

C2

-27 809 0.1206 6 6 29 48.72 1.4552 74

4A

85 6.039 3.8404 196

C4

-26 763.1 0.1277 7 7 30 46.68 1.4997 76

4C

86 5.846 3.8691 197

C5

-25 720 0.1351 7 7 31 44.74 1.5446 79

4F

87 5.661 3.8970 199

C7

-24 679.6 0.1429 7 7 32 42.89 1.5901 81 51 88 5.482 3.9243 200

C8

-23 641.7 0.1511 8 8 33 41.13 1.6359 83 53 89 5.309 3.9512 202

CA

-22 606.1 0.1597 8 8 34 39.44 1.6824 86 56 90 5.143 3.9773 203

CB

-21 572.7 0.1687 9 9 35 37.84 1.7289 88 58 91 4.982 4.0029 204

CC

-20 541.3 0.1782 9 9 36 36.3 1.7762 91

5B

92 4.827 4.0279 205

CD

-19 511.7 0.1881 10

A

37 34.84 1.8235 93

5E

93 4.678 4.0522 207

CF

-18 484 0.1984 10

A

38 33.44 1.8713 95

5F

94 4.534 4.0760 208

D0

-17 457.9 0.2092 11

B

39 32.11 1.9190 98 62 95 4.395 4.0992 209

D1

-16 433.3 0.2206 11

B

40 30.83 1.9673 100 64 96 4.261 4.1218 210

D2

-15 410.2 0.2325 12

C

41 29.61 2.0157 103 67 97 4.132 4.1439 211

D3

-14 388.5 0.2448 12

C

42 28.45 2.0640 105 69 98 4.007 4.1655 212

D4

-13 368 0.2577 13

D

43 27.34 2.1124 108

6C

99 3.886 4.1866 214

D6

-12 348.7 0.2712 14

E

44 26.27 2.1612 110

6E

100 3.77 4.2070 215

D7

-11 330.5 0.2853 15

F

45 25.25 2.2099 113 71 101 3.658 4.2269 216

D8

-10 313.4 0.2999 15

F

46 24.28 2.2584 115 73 102 3.549 4.2465 217

D9

-9 297.2 0.3153 16 10 47 23.35 2.3068 118 76 103 3.444 4.2655 218

DA

-8 281.9 0.3312 17 11 48 22.46 2.3552 120 78 104 3.343 4.2839 218

DA

-7 267.5 0.3478 18 12 49 21.6 2.4038 123

7B

105 3.15 4.3197 220

DC

-6 253.9 0.3651 19 13 50 20.79 2.4516 125

7D

106 3.059 4.3367 221

DD

-5 241.1 0.3830 20 14 51 20.01 2.4994 127

7F

107 2.97 4.3535 222

DE

-4 229 0.4016 20 14 52 19.26 2.5471 130 82 108 2.884 4.3699 223

DF

-3 217.6 0.4209 21 15 53 18.54 2.5947 132 84 109 2.802 4.3856 224

E0

-2 206.8 0.4409 22 16 54 17.85 2.6420 135 87 110 2.721 4.4012 224

E0

-1 196.6 0.4617 24 17 55 17.19 2.6889 137 89 111 2.721 4.4012 224

E0

0 186.9 0.4833 25 18 56 16.56 2.7352 139

8B

112 2.644 4.4162 225

E1

1 177.8 0.5056 26 19 57 15.96 2.7809 142

8E

113 2.569 4.4309 226

E2

2 169.2 0.5285 27

1A

58 15.38 2.8265 144 90 114 2.496 4.4452 227

E3

3 161 0.5525 28

1B

59 14.82 2.8719 146 92 115 2.426 4.4591 227

E3

4 153.3 0.5770 29

1C

60 14.29 2.9163 149 95 116 2.358 4.4727 228

E4

5 146 0.6024 31

1E

61 13.78 2.9603 151 97 117 2.292 4.4859 229

E5

6 139 0.6289 32

1F

62 13.28 3.0048 153 99 118 2.228 4.4988 229

E5

7 132.5 0.6557 33 21 63 12.81 3.0479 155

9B

119 2.167 4.5112 230

E6

8 126.3 0.6835 35 23 64 12.36 3.0902 158

9E

120 2.107 4.5235 231

E7

9 120.4 0.7123 36 24 65 11.93 3.1319 160

A0

121 2.049 4.5354 231

E7

10 114.8 0.7418 38 26 66 11.51 3.1736 162

A2

122 2.049 4.5354 231

E7

11 109.5 0.7722 39 27 67 11.11 3.2144 164

A4

123 1.994 4.5467 232

E8

12 104.4 0.8039 41 29 68 10.73 3.2541 166

A6

124 1.887 4.5689 233

E9

13 99.66 0.8357 43

2B

69 10.36 3.2938 168

A8

125 1.836 4.5796 234

EA

14 95.13 0.8686 44

2D

70 10 3.3333 170

AA

126 1.787 4.5899 234

EA

15 90.82 0.9024 46

2C

71 9.659 3.3717 172

AC

127 1.739 4.6000 235

EB

16 86.74 0.9369 48

2E

72 9.331 3.4094 174

AE

128 1.693 4.6098 235

EB

17 82.85 0.9723 50 32 73 9.016 3.4464 176

B0

129 1.649 4.6192 236

EC

18 79.16 1.0085 51 33 74 8.712 3.4829 178

B2

130 1.605 4.6286 236

EC

19 75.65 1.0455 53 35 75 8.421 3.5185 179

B3

20 72.32 1.0832 55 37 76 8.14 3.5537 181

B5

21 69.15 1.1217 57 39 77 7.869 3.5882 183

B7

22 66.13 1.1610 59

3B

78 7.609 3.6220 185

B9

23 63.27 1.2009 61

3D

79 7.359 3.6551 186

BA

24 60.54 1.2416 63

3F 80

7.118 3.6876 188

BC

25 57.94 1.2830 65 41 81 6.885 3.7195 190

BE

16

BSGI 09(12)

Page 20

55.. EELLEECCTTRRIICCAALL DDAATTAA

2. THE PARAMETER OF THE COIL AND INDOOR AND OUTDOOR SENSOR:

(R

0

=15K±2%;B=3450±2%)

T(℃) R(KΩ) V(v) DEC HEX T(℃) R(KΩ) V(v) DEC HEX T(℃) R(KΩ) V(v) DEC HEX

-30 67.94 0.3235 16 10 18 6.962 2.0151 103 67 66 1.297 3.9186 200 C8

-29 64.25 0.3408 17 11 19 6.688 2.0636 105 69 67 1.258 3.9443 201 C9

-28 60.79 0.3588 18 12 20 6.427 2.1120 108 6C 68 1.22 3.9696 202 CA

-27 57.53 0.3776 19 13 21 6.178 2.1603 110 6E 69 1.184 3.9939 204 CC

-26 54.48 0.3971 20 14 22 5.939 2.2089 113 71 70 1.149 4.0178 205 CD

-25 51.6 0.4174 21 15 23 5.712 2.2570 115 73 71 1.116 4.0406 206 CE

-24 48.9 0.4384 22 16 24 5.494 2.3053 118 76 72 1.083 4.0636 207 CF

-23 46.35 0.4603 23 17 25 5.286 2.3533 120 78 73 1.051 4.0862 208 D0

-22 43.96 0.4829 25 19 26 5.086 2.4014 122 7A 74 1.021 4.1077 209 D1

-21 41.7 0.5065 26 1A 27 4.896 2.4489 125 7D 75 0.9914 4.1290 211 D3

-20 39.58 0.5307 27 1B 28 4.714 2.4963 127 7F 76 0.963 4.1497 212 D4

-19 37.58 0.5558 28 1C 29 4.539 2.5436 130 82 77 0.9354 4.1701 213 D5

-18 35.69 0.5818 30 1E 30 4.372 2.5904 132 84 78 0.9088 4.1898 214 D6

-17 33.91 0.6087 31 1F 31 4.212 2.6369 134 86 79 0.8831 4.2091 215 D7

-16 32.23 0.6363 32 20 32 4.059 2.6830 137 89 80 0.8582 4.2280 216 D8

-15 30.65 0.6648 34 22 33 3.912 2.7288 139 8B 81 0.8342 4.2463 217 D9

-14 29.15 0.6942 35 23 34 3.772 2.7738 141 8D 82 0.8109 4.2643 217 D9

-13 27.74 0.7244 37 25 35 3.637 2.8188 144 90 83 0.7884 4.2818 218 DA

-12 26.4 0.7556 39 27 36 3.508 2.8631 146 92 84 0.7666 4.2988 219 DB

-11 25.14 0.7875 40 28 37 3.384 2.9070 148 94 85 0.7455 4.3155 220 DC

-10 23.95 0.8202 42 2A 38 3.265 2.9504 150 96 86 0.725 4.3318 221 DD

-9 22.82 0.8539 44 2C 39 3.151 2.9932 153 99 87 0.7053 4.3476 222 DE

-8 21.75 0.8885 45 2D 40 3.041 3.0358 155 9B 88 0.6861 4.3631 223 DF

-7 20.74 0.9237 47 2F 41 2.936 3.0775 157 9D 89 0.6676 4.3781 223 DF

-6 19.79 0.9596 49 31 42 2.835 3.1188 159 9F 90 0.6496 4.3929 224 E0

-5 18.88 0.9966 51 33 43 2.739 3.1590 161 A1 91 0.6323 4.4071 225 E1

-4 18.02 1.0343 53 35 44 2.646 3.1990 163 A3 92 0.6156 4.4209 225 E1

-3 17.2 1.0731 55 37 45 2.556 3.2387 165 A5 93 0.5993 4.4345 226 E2

-2 16.43 1.1122 57 39 46 2.471 3.2771 167 A7 94 0.5836 4.4477 227 E3

-1 15.7 1.1520 59 3B 47 2.388 3.3155 169 A9 95 0.5683 4.4606 227 E3

0 15 1.1929 61 3D 48 2.309 3.3528 171 AB 96 0.5535 4.4732 228 E4

1 14.34 1.2342 63 3F 49 2.233 3.3896 173 AD 97 0.5391 4.4855 229 E5

2 13.71 1.2765 65 41 50 2.159 3.4262 175 AF 98 0.5251 4.4975 229 E5

3 13.11 1.3195 67 43 51 2.089 3.4615 177 B1 99 0.5115 4.5093 230 E6

4 12.55 1.3623 69 45 52 2.021 3.4965 178 B2 100 0.4983 4.5207 231 E7

5 12.01 1.4063 72 48 53 1.956 3.5306 180 B4 101 0.4855 4.5319 231 E7

6 11.5 1.4506 74 4A 54 1.893 3.5644 182 B6 102 0.4731 4.5427 232 E8

7 11.01 1.4959 76 4C 55 1.832 3.5977 183 B7 103 0.461 4.5534 232 E8

8 10.55 1.5410 79 4F 56 1.774 3.6299 185 B9 104 0.4492 4.5638 233 E9

9 10.1 1.5878 81 51 57 1.718 3.6616 187 BB 105 0.4378 4.5739 233 E9

10 9.684 1.6338 83 53 58 1.664 3.6926 188 BC 106 0.4268 4.5838 234 EA

11 9.284 1.6805 86 56 59 1.612 3.7231 190 BE 107 0.416 4.5934 234 EA

12 8.903 1.7276 88 58 60 1.562 3.7528 191 BF 108 0.4055 4.6029 235 EB

13 8.54 1.7749 91 5B 61 1.513 3.7824 193 C1 109 0.3953 4.6121 235 EB

14 8.194 1.8226 93 5D 62 1.467 3.8106 194 C2 110 0.3854 4.6211 236 EC

15 7.864 1.8704 95 5F 63 1.422 3.8386 196 C4

16 7.549 1.9185 98 62 64 1.379 3.8658 197 C5

17 7.249 1.9667 100 64 65 1.337 3.8927 199 C7

17

BSGI 09(12)

Page 21

66.. CCOONNTTRROOLL MMOODDEEL

L

6-1. Major general technical parameters

6-1-1 Conditionings for operation: Ambient temperatures: (-15 - +45

℃), relative humidity (45 -

85%).

6-1-2 Remote receiver distance: 8 m.

6-1-3 Remote receiver angle: Less than 80 degrees.

6-1-4 Temperature control accuracy: ±1℃.

6-1-5 Time error: Less than 1%.

6-1-6 The power supply for the air conditioner is a.c 220V

, 50Hz, with its fluctuation in the

range of (198~264V).

6-2. Functions of the controller

6-2-1 Display panel

I. Control functions of the remote controller (See op

erating and installation manual)

II. Display of the indoor unit

Information on the screen:

The picture of the display i

s as follows:

Displaying Scheme:

T emperature display:Display set temperatu

re or indoor temperature , and display fault code

in trouble indicating. An error code is displayed according to the signal from the indoor CPU.

The error code will flash for 5 seconds while displayed.

Running indicator:It is on during oper

ation. It flashes in 10s after the sleep modehas been

setted.

TIMER indicator:When

the timer mode works, the indicator will be lighted.

Sleep indicator:When the sleep mode works, th

e indicator will be lighted.

Compressor indicator:It

lights up when compressor is running.

Remote control receiver: This

section receives signals from the remote controller.

6-3. Control function

6-3-1 Emergency switch

6-3-1-1 Press the emergency switch once to turn o

n the machine and press it again to turn off

the machine; in the automatic mode, the indoor control temperature is set at 24℃ with the

indoor fan speed setting is automatic and the flaps sweep.

6-3-1-2 When the machine is turned on (in the OFF condition),

press and hold the emergency

18

BSGI 09(12)

Page 22

66.. CCOONNTTRROOLL MMOODDEEL

L

switch for 5 seconds, the buzzer rings for 3 times and the controller starts in the trial operation.

The trial operation is the forced cooling with the indoor fan speed being set at high speeds,

the flaps sweeping and the air conditioner’s operation is irrelevant with room temperatures.

6-3-1-3 If a remote signal has been received during the emergency run, the ma

chine will

operate upon the command of such a remote signal.

6-3-2 Operator-machine communication

6-3-2-1 The air conditioner has a thermal sensor to detect room temperatures. Some remote

controller is

equipped with a thermal sensor (Such remote controller has the function of

man-machine communication. For details, refer to the section for the remote controller). In

addition, there is a thermal sensor at the indoor air inlet. In the case where the remote

controller is equipped with a thermal sensor, the default setting for room temperatures is

subject to the detection by the remote controller. The remote controller detects the room

temperature once every 20 seconds, and automatically transmits a signal at an interval of 3

minutes or when a change in the room temperature is detected. If the indoor control unit has

not received a remote signal for more than 10 minutes, the control function will be

automatically switched over to the thermal sensor on the indoor unit.

6-3-2-2 Neither the turning on nor turning of

f operation will cancel the operator-machine

communication function.

6-3-2-3 In default, the air conditioner is set to st

art the operator-machine communication

function.

6-3-3 Timer function

6-3-3-1 Timer on: When set to start in a time by the remote controller

, the air conditioner starts

in the timer on condition. When the set time is up, the air conditioner will turn on and operates

in the preset conditions after receiving a signal from the remote controller. If the air conditioner

has not received a signal from the remote controller when the set time is up, it will

automatically start and operate in the preset conditions.

6-3-3-2 Timer off: When set to stop in a set time by the remote controller, the air conditioner

will start in the timer off condition. When the set time is up, the air conditioner will turn off after

19

BSGI 09(12)

Page 23

66.. CCOONNTTRROOLL MMOODDEEL

L

receiving a signal from the remote controller. If the air conditioner has not received a signal

from the remote controller when the set time is up, it will turn off automatically.

6-3-3-3 Neither the turning on nor turning off operation will cancel the tim

er function (Some

remote controller has a simple one-hour timer off function and excludes this operation).

6-3-4 Sleep

6-3-4-1 In the heating, cooling or dehumidifying mo

de, press the “Sleep” button on the remote

controller to start or cancel the sleep function in turn, and at the same time the sleep icon on

the display screen will be on or off accordingly.

6-3-4-2 According to the different needs, there are four dif

ferent sleep modes to choose.

During the time of sleep mode, the set temperature will change automatically.

6-3-4-3 In default, the setting is to cancel the sleep function. Turning off the unit will also

cancel the sleep function.

6-3-4-4 The sleep function is valid for 8 hours. The air condition

er will turns off and cancel the

sleep function after the sleep function works for 8 hours.

6-3-5 High efficient run function (This function is invalid)

In the heating (except for the single cooling unit), cooling o

r dehumidifying mode, it may be set

for high efficient run with the indoor fan speed changed to the high efficient fan speed and the

compressor operating at the highest frequency as available. If the display screen can display

the frequency, the frequency displayed on the screen is up to the maximum. It will restore to

the previous run state after 15 minutes operation automatically.

6-3-6 Automatic run (SMART) mode

If there is no man-machine communication function af

ter the unit is started, the indoor fan

operates at the ultra-low flowrate for 20 seconds before selecting a run mode; the room

temperatures are detected during this period for the selection of a run mode.

In the first operation:

a. When

T

room

– T

set

>3℃, it starts in the cooling mode;

b.

When -3℃≤T

room

– T

set

≤3℃, it starts in the ventilation run mode;

c. When

T

room

– T

set

<-3℃, it starts in the heating mode.

After the first run in the cooling or heating mode, the mode will be changed as the following:

20

BSGI 09(12)

Page 24

66.. CCOONNTTRROOLL MMOODDEEL

L

a. When T

room

– T

set

>3℃, it will be changed to the cooling mode;

b. When

T

room

– T

set

<-3℃, it will be changed to the heating mode;

c.

When these conditions are not met, it will remain in the previous run mode.

When the temperature setting is changed, re-judgment will be made

for the run mode

according to the descriptions mentioned above; when the compressor is halted for 10 minutes,

the re-judgment will be made for the run mode.

6-3-6-1 Switch between the cooling a

nd heating mode:

T

ambient

t

set

+3

t

set

t

set

-3

Cooling Heating mode Cooling

6-3-6-2 Cooling→heating turnover

operation

Cooling→h

eating: the compressor stops; 50 s later the 4-way valve is activated and 3 minutes

more the compressor turns on.

Heating→co

oling: the compressor stops, 50 s later the 4-way valve is interrupted and 3

minutes more the compressor turns on.

6-3-6-3 There is temperature compensation during the auto-run, which is same as cooling and

heating.

6-3-7 Cooling-run mode

6-3-7-1 Temperature compensation

Principle for compensation: The compensation is available o

nly if the proper sensor is used

and it is not available when it is subject to the sensor on the remote controller.

6-3-7-2 Outdoor Fan

The outdoor fan’s speeds are divided into two levels which can be changed over according to

out

door ambient temperatures.

When operating at a fixed frequency, the outdoor fan is forced to operate at the high speed.

6-3-7-3 Indoor fan

When the fan speed is set at the high, medium a

nd low fan speeds, the fan runs at a preset

speed. When the fan speed setting is automatic, the fan speed is set based on the difference

in room temperatures.

21

BSGI 09(12)

Page 25

66.. CCOONNTTRROOLL MMOODDEEL

L

T

room-Tset

Indoor fan speed

T

room-Tset

≤20C

Low

20C <T

room-Tset

<40C

Medium

T

room-Tset

≥40C

High

6-3-7-4 Prevention against condensation and insuf

ficient heat exchange at the low indoor fan

speed.

When the indoor fan speed is set at the low fan spe

ed, the compressor’s power is restricted as

in the low temperature cooling.

6-3-7-5 4-way valve

State: It is interru

pted in cooling.

Switchover: When initially powered on for cooling, the 4-way valve is interrupted immediately.

When the heating is changed to the cooling, it nee

ds an interval of 50 seconds for the 4-way

valve to change over from being activated to being interrupted.

6-3-8 Heating-run mode

6-3-8-1 Temperature compensation

Principle for compensation: The compensation is available only if the prope

r sensor is used

and it is not available when it is subject to the sensor on the remote controller or line controller.

6-3-8-2 Indoor fan

The fan speed is set at the high, medium or low fan speed, it operates at

a preset speed (in

the cold air prevention, it is forced to run at the ultra-low flowrate or stop).

When the fan speed is set in the auto-r

un, the fan speed setting is made according to the room

temperature differences (except for the cold air prevention).

T

set-Troom

Indoor Fan Speed

T

set-Troom

≤20C

Low

20C <T

set-Troom

<40C

Medium

T

set-Troom

≥40C

High

6-3-8-3 Cold air prevention

In the heating-run, to prevent the indoor fan from blowing cold

air, the indoor fan speed is

different from the set speed after turning on air-conditioner.

6-3-8-4 Residual heat blowing off

22

BSGI 09(12)

Page 26

66.. CCOONNTTRROOLL MMOODDEEL

L

When the compressor is turned off in the heating run, the indoor fan does not stop at once, but

until the indoor evaporator temperature is below 23

0

C, but for 30 seconds at the latest.

When the compressor is turned off in the heating run, the indoor fan does not stop at once, but

until the indoor evaporator temperature is below 230C, but for 30 seconds at the latest.

6-3-8-5 Outdoor fan 6-3-8-5 Outdoor fan

The outdoor fan speeds are divided into three level

s which can be changed over according to

outdoor ambient temperatures.

The outdoor fan speeds are divided into three levels which can be changed over according to

outdoor ambient temperatures.

6-3-8-6 4-way valve 6-3-8-6 4-way valve

State: It is electrified in h

eating. State: It is electrified in heating.

Switchover: When initially powered on for heating, the 4-way valve is activated immediately

. Switchover: When initially powered on for heating, the 4-way valve is activated immediately.

In the change from cooling to heating, it needs an interval of 50 seconds for the 4-way valve to

change o

ver from being interrupted to being activated.

In the change from cooling to heating, it needs an interval of 50 seconds for the 4-way valve to

change over from being interrupted to being activated.

6-3-9 Dehumidifying mode 6-3-9 Dehumidifying mode

The dehumidifying mode is illustrated as follows: The dehumidifying mode is illustrated as follows:

Indoor Ambient Temperature

IIIIII

Tset

16

0

C

Time

Dehumidifying area I: Operation at the frequency

in the range (30–80 Hz) according to Δt

(T

indoor ambient-Tset

).

Dehumidifying area I: Operation at the frequency in the range (30–80 Hz) according to Δt

(T

indoor ambient-Tset

).

Δt(℃) Δ

t(℃)

f(Hz) f(Hz)

0 30

0.5 30

1 40

1.5 50

≥2 60

Efficient 80

23

BSGI 09(12)

Page 27

66.. CCOONNTTRROOLL MMOODDEEL

L

Dehumidifying area II: The compressor stops for 5 minutes and operators for 5 minutes at the

lowest frequency.

Dehumidifying area III: The compressor stops.

6-3-10 Air Blowing mode

The outdoor unit does not work while the indoor fan runs with the fan speed

selectable at the

auto, low, medium and high speeds.

When being auto, the fan speed is determined i

n the cooling mode (with the temperature

setting of 24

0

C in default).

The high, medium and low fan speeds are same with that in the cooling mode.

6-3-11 Compressor operating state indication

When the compressor is in operation, The 3 LED indicator light

s on the control panel of

the outdoor unit indicates the causes of the restriction on the compressor’s current

operating frequency.

Symbols for indicator light:: ★

: ON Ο: flashing ×: OFF

LED1 LED2 LED3

The cause of the restriction on the compressor

’s current

operating frequency

1

Ο Ο Ο

Normal frequency ascent and descent with no restriction

on the frequency

2

× ×

★

Frequency descent or restriction on frequency ascent

caused by over current

3

×

★ ★

Frequency descent or restriction on frequency ascent

caused by anti-freeze in cooling or overload control in

heating

4

★

×

★

Frequency descent or restriction on frequency ascent

caused by too high compressor discharge temperature

5

×

★

×

Restriction on maximum operation operating frequency

caused by too low voltage on the supply circuit

6

★ ★ ★

Operating at a fixed frequency (when in a capacity

measurement or forced operation at a fixed frequency.)

8

★

× ×

Communication frequency drops.

6-3-12 Special notes

6-3-12-1 The outdoor unit of this model is electrified

by the indoor unit control. After the system

24

BSGI 09(12)

Page 28

66.. CCOONNTTRROOLL MMOODDEEL

L

starts to operate, the indoor unit supplies the outdoor unit (except for the ventilation mode). If

the EEPROM data is read correctly after turning on the power, the indoor unit’s beeper rings

one time, or if it is not the case the beeper will ring two times and the system cannot be started.

Normally, when the indoor unit receives a control signal from the remote controller and

emergency button, the system will be started and the beeper will ring two times, and in other

cases, the beeper will ring one time.

6-3-12-2 This model can achieve the power interruption restoration function

by the selection of

the EEPROM data. The power interruption restoration is applied only for the basic functions

(turning ON and OFF, setting temperatures, modes, fan speeds and flap’s position) and not for

other special functions such as sleep, timing and power-saving run.

25

BSGI 09(12)

Page 29

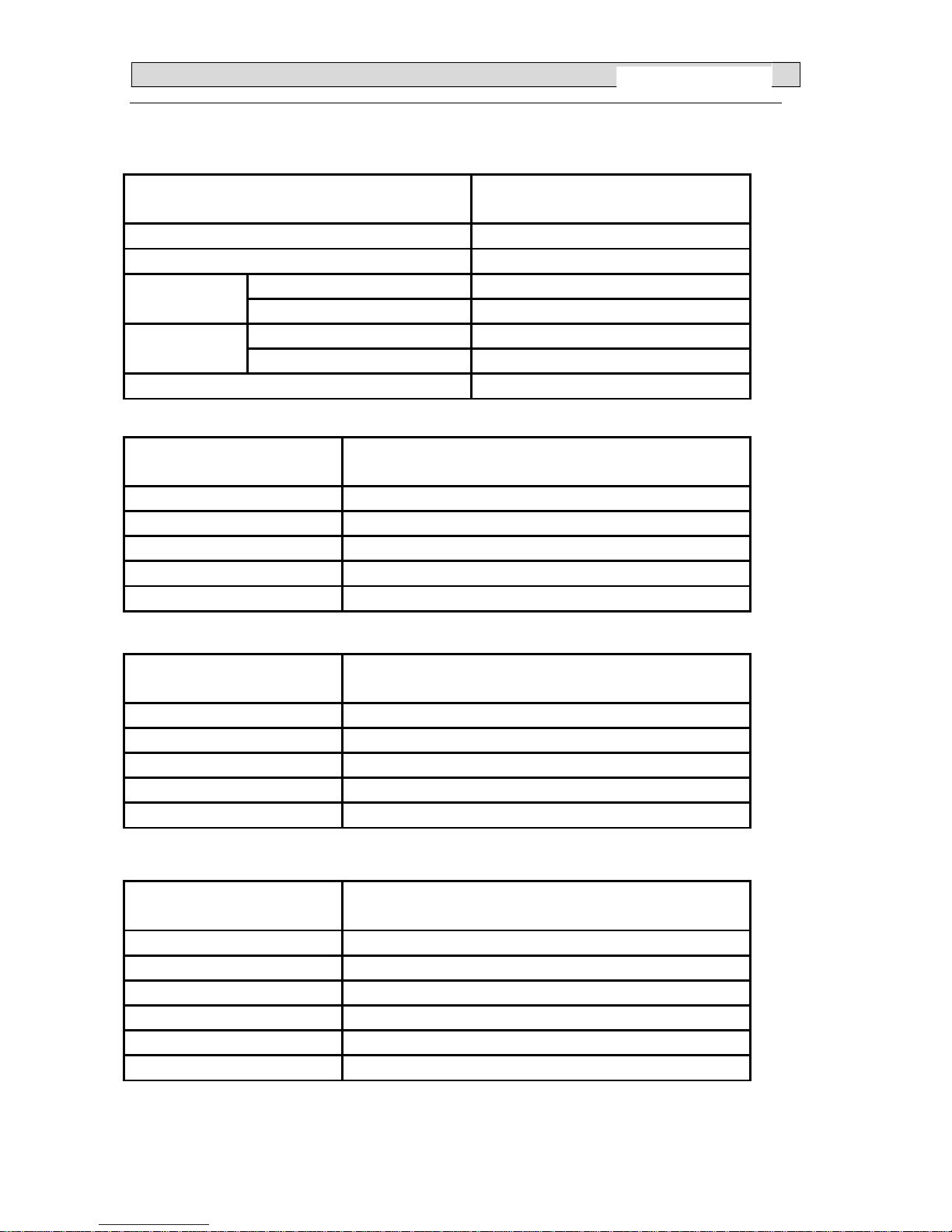

77.. TTRROOUUBBLLEE SSHHOOOOTTIINNGG

7-1. Trouble alarm

Trouble List

Indication on the outdoor unit

When the compressor is interrupted, the outdoor LEDs are used to

indicate the troubles listed below:

Symbols for indicator lights: ★: ON Ο: flashing ×: OFF

LED1 LED2 LED3 Troubles

1

× × ×

Normal

2

× ×

★ Unused

3

×

★

×

Outdoor heat exchanger temperature sensor be

protected

4 ★

× ×

Compressor temperature sensor short-circuited,

open circuited or the corresponding test circuit in

trouble

5 ★

×

★ Outdoor heat exchanger temperature sensor

short-circuited, open circuited or the corresponding

test circuit in trouble

6 ★ ★

×

Outdoor atmosphere temperature sensor

short-circuited, open circuited or the corresponding

test circuit in trouble

9

× × Ο

Signal communication abnormal (indoor – outdoor)

10

× Ο ×

Power module (IPM)protection

11 ★

Ο

★ Maximum current control

12 ★

Ο ×

Current overload control

13

× Ο

★ Compressor discharge temperature too high

14 ★ ★

Ο

Over and under-voltage control

18

×

★

Ο

Compressor housing temperature too high

19 ★ ★ ★ Outdoor memory in trouble

20

× Ο Ο

Indoor heat exchanger temperature sensor be

protected

22

Ο Ο ×

DC compressor fails to start

23

Ο × Ο

DC compressor out of step

Indication by the indoor unit

Press the high power for 4 times in a row and the trouble codes

listed below will be displayed.

0 No trouble 16 Anti-freeze or overload control

1 Outdoor coil temperature sensor

in trouble

18 DC compressor fails to start

2 Compressor temperature sensor

in trouble

19 DC compressor out of step

3 Voltage transformer in trouble

4 Current transformer in trouble

5 IPM module protection

26

BSGI 09(12)

Page 30

77.. TTRROOUUBBLLEE SSHHOOOOTTIINNGG

6 Over and under-voltage control 33 Room temperature sensor in

trouble

7 Communication trouble 34 Indoor coil temperature sensor in

trouble

8 Current overload control 36 Communication between the

indoor and outdoor in trouble

9 Maximum current control 39 Indoor fan motor operation

abnormal

10

Communication trouble(between

outdoor unit and driver unit)

40 Grid protection alarm (cabinet

type)

11 Outdoor EEPROM in trouble 41 Detecting failures by

zero-crossing

13 Compressor exhaust

temperature too high control

14 Outdoor ambient temperature

sensor in trouble

15 Compressor housing

temperature control

27

BSGI 09(12)

Page 31

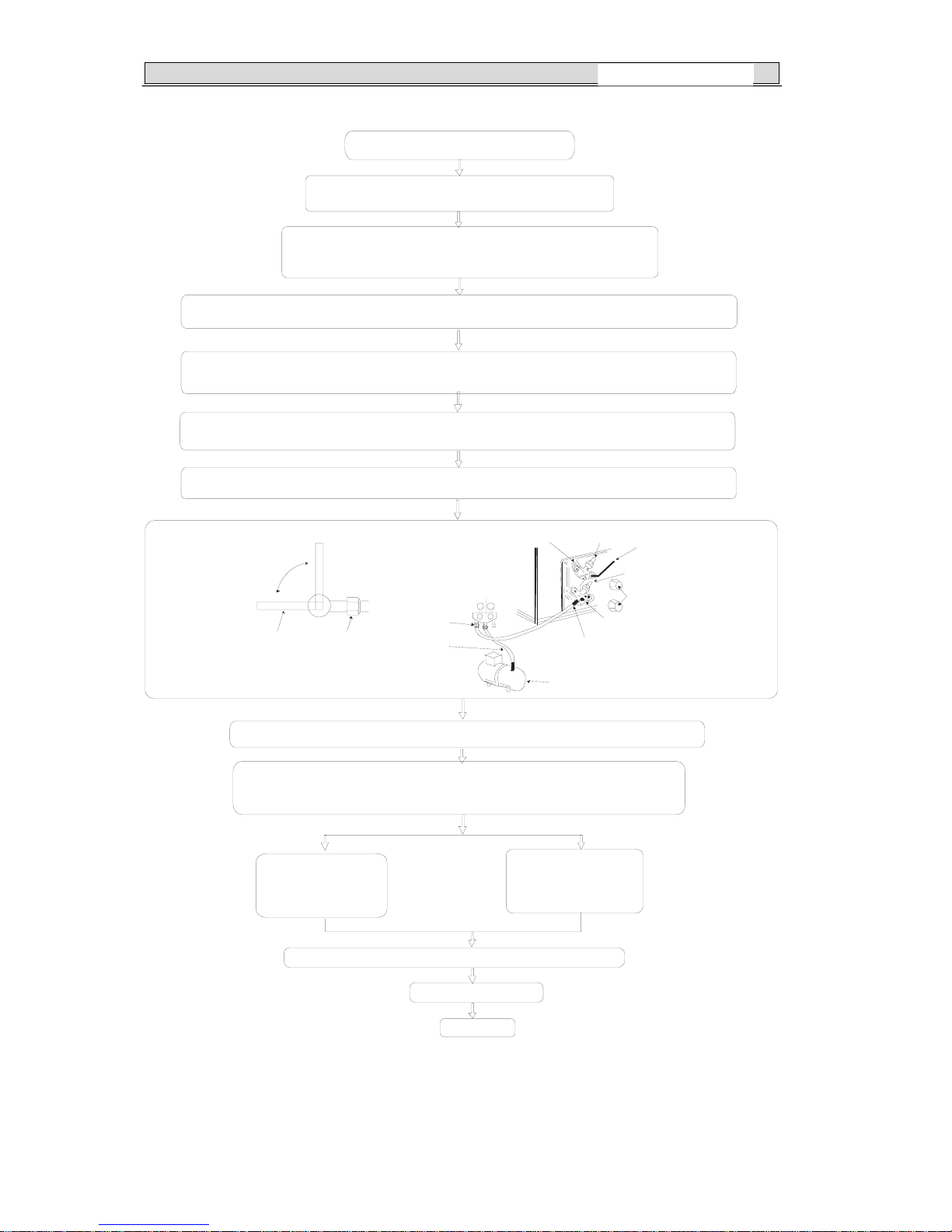

77.. TTRROOUUBBLLEE SSHHOOOOTTIINNGG

7-2. Service flow chart

Switch on the power

supply

No

No

Yes

No

No

Yes

No

Yes

Yes

Yes

No

Yes

No

Check the first and secondary

voltage.

The first voltage:220V

The secondary voltage:

*C15:12V

CN4(1,2terminal):5V

Are the wires poorly

connected?

Check all wires are

connected correctly

No

Replace it.

Indoor control board is faulty.

Display board

trouble

No

Replace

the

control

board

Does it receive the

remote controller

signal?

Yes

Start up self-test

function

Is the remote

controller in good

condition

Check the result

Replace the battery press

ACL button.

Retry remote operation.

After replacing

the display

board.

Display board

problem

Replace the

indoor board.

Is there still

trouble?

Yes

Check operation

Is indoor control

board short

circuit?

Check and find

short circuit or open

circuit among other

components such

as

transformer or

fan motor

Replace the indoor

Yes

Is the fuse(F01,

3.15A/250V) blown?

Does DLED screen

display normally?

Yes

No

After replacing the

display board, Is there

still trouble?

28

BSGI 09(12)

Page 32

77.. TTRROOUUBBLLEE SSHHOOOOTTIINNGG

Yes

Error code 34

Indoor Coil sensor

trouble

Error code 33

Indoor temperature

sensor

Replace the

indoor pcb board

Does the resistance

of thermistor h

ave

the characteristics

on part 6-3

Take out from

CN6 ,Measure the

resistance of thermistor

Does the unit exit hot

protector

Replace the

thermistor

Take out from

CN3 ,Meaure the

resistance of thermistor

No

Error code 14

Outdoor temperature

sensor trouble

Measure resistance

of the sensor of

CN15(Yellow)

Measure resistance

of the sensor of

CN14(Black)

Does the resistance

of thermistor have

the characteristic on

part 6-3 (SENSOR

PARAMETER)

Yes

No

Replace the thermistor

Outdoor coil sensor

trouble

Error code 1

Replace the

outdoor board

Voltage of power supply is abnormal

Error code 6 Error code 2, 13

Compressor over heat

protection

Is the surface of

compressor very hot?

No

Normal protecton

Yes

Is the resistance of

compressor discharge

sensor correct?

Replace it

No

Yes

Outdoor control board

No

Normal

protection

Is the voltage of power

supply

normal of AC

198~253V?

Yes

faulty, replace it

Outdoor IPM board fault,

replace it.

29

BSGI 09(12)

Page 33

77.. TTRROOUUBBLLEE SSHHOOOOTTIINNGG

30

Error code 39

Indoor fan motor trouble

Is indoor fan motor running?

Set the air conditioner operate

in fan mode

Does fan motor stop with the

remote controller

Check the connector of

indoor motor

Does the socket CN1(1-3) of

indoor control board

have power input

Indoor control board faulty

and replace it

Is resistance of main winding

0?(short circuit) or

~

?(open

circuit)?

Replace the indoor fan

motor

Insert screwdriver into to rotate

indoor fan motor slowly for 1

revolution or over, and measure

voltage CN2(1-3)

Does voltage repeat DC 0V and

DC 5V?

no

yes

yes

no

yes

yes

no

no

no

yes

BSGI 09(12)

Page 34

77.. TTRROOUUBBLLEE SSHHOOOOTTIINNGG

31

Error code 36

Communication trouble

Are all the lead wires connected

between indoor and outdoor unit?

Connect the indoor and

outdoor unit again according

to the wiring diagram

Is there power output between

indoor T/B 1 and 2 AC220V?

And "S" of indoor terminal block

DC24V?

Indoor control

board in trouble

Does the power

indicator(LED) of outdoor

control board(PCB) light

up?

Replace the

outdoor IPM board

and start up again

Is the 15A fuse(F03) of outdoor PCB

blown?

Is the 3.15A fuse(F02) of outdoor

PCB blown?

Is the 3.15A fuse(F01) of outdoor

PCB blown?

Is there power input b etween 1 and 2

on terminal block of outdoor unit?

Is there power output between 1 and

2 on terminal block of indoor unit?

Is there power output(AC220V) of

indoor unit between "N out" and "L

out"?

Indoor control board and

replace it

Is the system in

good condition?

Outdoor IPM

board trouble

Indoor control board

fault, replace it.

Is the system in

good condition?

Display board fault,

replace it

Check operation

Replace fuse

Is unsafety voltage part of outdoor

control board short circuit?(such as fan

motor, 4-way valve windi ng)

Outdoor control board

trouble and replac e it.

Normal protection

and replace fuse

The control system of

outdoor unit has short circuit

trouble, chec k the connection

wire,outdoor contr ol board,

IPM, rectifier and electrolyse

capacitor

Connection wire trouble

and check

Connection wire trouble

and check

Connection wire troub le

and check

Replace the trouble unit

yes

no

no

yes

yes

yes

no

yes

no

no

yes

no

yes no

no

yes

yes

yes

yes

yes

no

no

no

no

BSGI 09(12)

Page 35

88.. CCHHEECCKKIINNGG CCOOMMPPOONNEENNTTS

S

8-1. Check refrigerant system

TEST SYSTEM FLOW

Conditions: Compressor is running.

② The air condi

tion should be installed in good ventilation.

Tool: Pressure Gauge

Technique: see feel test

SEE---Tube defrost.

FEEL---The difference tube temperature.

TEST--- Test pressure.

cooling run heating run

Lo

Hi

Outdoor unit

Pressure

gauge

Lo

Hi

Outdoor unit

Pressure

gauge

Test system flow

32

BSGI 09(12)

Page 36

88.. CCHHEECCKKIINNGG CCOOMMPPOONNEENNTTS

S

33

Cooling mode

Test system

pressure.Does the low

pressure normal at

service part ?

The pressure on the

high side.

The pressure on the

low side.

Recharge refrigerant

after air purging with

the vacuum

pump.Does the low

pressure nomal over

again?

Air remaining at the

refrigerant system.

yes

The system wants

refrigerant.The service

people must be ration

refrigerant

(about 100g/

per)in the cooling

mode fixed

frequency.Is the low

pr

essure rise ?

NO

Recharge refrigerant .

yes

The refrigerant system

blocked.Please check

the Capillary Tube( or

electronic expansion

valve)Is it blocked?

Unsolder the capillary tube

ASS'Y(or electronic expansion

valve).The capillary tube1 is blown

by N

2

.

Check check valve and 4way valve.

If the pressure is

close t

o static

pressure?

NO

NO

4-way valve collude or

compressor exhaust very

ebb.

NO

yes

yes

Heating mode

Test system

pressure.Does the

high pressure normal

at service part ?

The pressure on the

high side.

The pressure on the

low side.

Recharge refrigerant

after air purging with

the vacuum

pump.Does the high

pressure normal over

again?

Air remaining at the

refrigerant system.

yes

The system wants

refrigerant.The service

people must be ration

refrigerant(about 100g/

per

)in cooling mode fixed

frequency state .Is the

high pressure rise in

heating m

ode?

NO

Recharge refrigerant

yes

NO

Remove the back

panel."see"the

capillary tube1 and

capillary tube2.Is it

defrosting?

If the pressure is close

to s

tatic pressure?

4-way valve collude or

compressor exhaust every

ebb.

yes

Check heat exchanger and

4-way valve.

yes

NO

The capillary tube

blocked.Unsolder the

capillary tube ASS'Y.The

capillary tube1 and capillary

tube2 is blown by N

2

.

NO

BSGI 09(12)

Page 37

88.. CCHHEECCKKIINNGG CCOOMMPPOONNEENNTTS

S

8-2.Check parts unit

1. INDOOR FAN MOTOR

.MOTOR EXAMINE AND REPAIR

Circuit diagram

34

Test in resistance.

TOOL: Multimeter.

Test the resistance of the main winding.

The indoor fan motor is fault if the

resistance of main winding 0(short circuit)or∞(open circuit).

Test in voltage

TOOL: Multimeter.

Insert screwdriver into to rotate indoor fan

motor slowly for 1 revolution or

over,and measure voltage “BLACK” and “GND” on motor. The voltage repeat 0V

DC and 5V DC.

Notes:

1) Please don’t hold motor by lead wires.

2) Please don’t plug IN/OUT the motor connector while power ON.

3) Please don’t drop .Hurl or dump motor against hard

material.Malfunction may not

be observed at early stage after such shock.But it may be found later,This type of

mishandling void our warranty.

2. OUTDOOR FAN MOTOR

MOTOR EXAMINE AND REPAIR

BROWN

WHITE

A

M

PINK

WINDING

""

""

M The main winding

A

The auxiliary winding

Capacitor

Hot protector 140

℃

Winding resistance ( at 20 )

M: 295.5Ω

A:175.5Ω

Test in resistance.

TOOL: Multimeter.

Test the resistance of the main winding. The outdoor fan motor is fault if the

resist

ance of main winding 0(short circuit)or∞(open circuit).

Notes:

1) Please don’t hold motor by lead wires.

2) Please don’t plug IN/OUT the motor connector while power ON.

3) Please don’t drop .Hurl or dump motor against hard

material.Malfunction may not

be observed at early stage after such shock.But it may be found later,This type of

mishandling void our warranty.

BLACK

WHITE

M

A

W

INDING

""

""

M The main winding

A The a u xil i ar y windin g

Capacitor

Hot protector 100

℃

BROWN

BLACK

YELLOW

V

cc

V

out

GND

BSGI 09(12)

Page 38

88.. CCHHEECCKKIINNGG CCOOMMPPOONNEENNTTS

S

3. COMPRESSOR

1. Coil Resistance::0.744Ω (at 20

)

2. COMPRESSOR EXAMINE AND REPAIR.

DC

INVERT ER

CONTROLLER

&

RU

()

SV

()

TW

()

OVERLOAD PROTECTION

POWER

Test in resistance.

TOOL: Multimeter.

Test the resistance of the winding. The compressor is fault if the

resistance of

winding 0(short circuit)or∞(open circuit)

Familiar trouble: 1) Compressor motor lock. 2)Discharg

e pressure value approaches

static pressure value .3) Compressor motor winding abnormality.

Notes:

1)Don’t put a compressor on its side or turn over.

2) Please assembly the compressor in yo

ur air conditioner rapidly after removing

the plugs. Don’t place the comp. In air for a long time.

3) Avoiding compressor running in r

everse caused by connecting electrical wire

incorrectly.

4) Warning! In case AC voltage is impr

essed to compressor, the compressor

performance will be lowered because of its rotor magnetic force decreasing.

4. OVERLOAD PROTECTION

OVERLOAD PROTECTION SPECIFICATIONS

1) Reset Temperature: 90±5

2) Trip Temperature: 120±4

5. INDUCTANCE

Familiar error: 1) Sound abnormality 2) Insulation resist

ance disqualification.

6. FILTER

35

BSGI 09(12)

Page 39

88.. CCHHEECCKKIINNGG CCOOMMPPOONNEENNTTS

S

Test in resistance.

TOOL: Multimeter.

Test the resistance of “LOAD” port. The filter is fault if the resistance of winding

0(short circuit)or∞(

open circuit)

7. STEPPER MOTOR

Test in resistance.

TOOL: Multimeter.

Test the resistance of winding. The stepper motor is fault if the resistance of

winding 0

(short circuit)or∞(open circuit).

8-2-3. Check others

1. FUSE

Checking continuity of fuse on PCB

ASS’Y.

1) Remove the PCB ASS’Y from the electrical component box. Then pull out the

fuse from the

PCB ASS’Y (Fig.1)

Fuse

PCB Ass抷

Fig.1

2) Check for continuity using a multimeter

as shown in Fig.2.

36

BSGI 09(12)

Page 40

88.. CCHHEECCKKIINNGG CCOOMMPPOONNEENNTTS

S

Fuse

Fig.2

2. CAPACITOR

Remove the lead wires from the capacitor

terminals, and then place a probe on the

capacitor terminals as shown in Fig.3.Observe the deflection of the pointer, setting the

resistance measuring range of the multimeter to the maximum value.

The capacitor is “good” if the pointer bounces to

a great extent and then gradually

returns to its original position.

The range of deflection and deflection time dif

fer according to the capacity of the

capacitor.

Compressor motor

capacitor

Fan motor

capacitor

Multimeter

Fig.3

37

BSGI 09(12)

Page 41

99.. DDIISSAASSSSEEMMBBLLYY IINNSSTTRRUUCCTTIIOONNSS

38

9-1.INDOOR

1..

. '

Rem ov e the ins t allat ion plat e

Take out the s c rew of t he ins t allat ion plat e and rem ov e the ins t allat ion plat e.

2 R em ov e t h e m ount ing plat e

Take out t he m ount ing plat e .

3 R em ov e t he f ron t panel ASS Y

1 H old t he bot h s ides of t he f ront panel and drag it t ow ards oneself and rem ov e it .

2 Take away t he air filters in t he grille.

3 Take out t he dis play panel an d rem ov e t he display panel.

..

)

)

)

OPERATION PROCEDURE AND PHOTOS

Screw

Iinstalla tion plat e

Mounting plate

Front plate

Air filters

Grille

Display panel

BSGI 09(12)

Page 42

99.. DDIISSAASSSSEEMMBBLLYY IINNSSTTRRUUCCTTIIOONNSS

39

4 Take out t he 4 sc rew s o f t he grille and rem ov e t he gril le.

grille and remove t he grille.

)

Screws

4

1

3 and evaporator ASS Y

Tak e out th e room temp eratu re sen sor a nd coil sen sor on the eva pa rator

.

)

)

) '

.

Remove th e el ectri cal con trol b ox

1 Ta k e out th e s crew of th e el ectri ca l cover a nd remov e it.

2 Remove the i n door coi l sens or from the s ens or br acket.

3 Ta ke ou t the s crews of the el ectri cal contr ol b ox an d d i s connect a l l th e connectors on the printed ci rcui t b oard ,

Screws

the el ectri ca l cover

Room temperature sensor

Di spla y con nector p lug

then remove th e electri cal b ox .

5. Remov e the eva p ora tor .

2) Ta k e out th e 6 s crews of the eva p ora tor s u pportor and remove th e eva p ora tor s up p ortor.

Screws

Screws

Coil sensor

Electrical box

Fan motor p lug

Step per motor p lug

Screw

BSGI 09(12)

Page 43

99.. DDIISSAASSSSEEMMBBLLYY IINNSSTTRRUUCCTTIIOONNSS

40

then remove the evaporator.

Evaporator.

6 remove the indoor cross flow fan and fan motor

1 Take out the 2 screws of the cover and remove the cov er of th e bearing housing.

. -

)

2 Take out the 3 screws of the motor cover and remove the m otor cover. Take out the 1 special scr ew connecting the cross-flow fan.

)

Screws

Bearing housing

Cover

Screws

Cover

3)

Remove tthe fan motor and the cross-flow fan.

Special screw

Fan motor

Cross flow f an

-

7. '

Remove the base ASS Y.

Drain hose ASS Y

'

Base ASS Y

'

9-2. Outdoor

BSGI 09(12)

Page 44

99.. DDIISSAASSSSEEMMBBLLYY IINNSSTTRRUUCCTTIIOONNSS

41

1.Remove the top panel the front panel

1)Take out the 8 screws of the top panel and remove the top panel.

8 screws Top panel

2. Remove the front panel

1)Take out the 9 screws of the top panel and remove the panel.

Front panel

9 Screws

3. Remove the side panel

1)Take out the 1 screws of the side cover and remove the cover.

1 screws side cover

BSGI 09(12)

Page 45

99.. DDIISSAASSSSEEMMBBLLYY IINNSSTTRRUUCCTTIIOONNSS

42

2) Take out the 11 screws of the side panel and remove the side panel.

11 screws side panel

4. Take out the 2 screws and remove the electrical control box .

2 screws electrical box filter

5. Remove the fan,fan motor,fan support。

1)Take out the special nut of the fan and remove the fan.

2)Take out the 4 screws of the fan motor and remove the fan motor.

3)Take out the 3 screws of the fan support and remove the fan support.

Special Nut 4 screws fan support 3 screws

BSGI 09(12)

Page 46

99.. DDIISSAASSSSEEMMBBLLYY IINNSSTTRRUUCCTTIIOONNSS

43

6.Remove the partition plate

1) Take out the 3 screws and remove the partition palte。

2)Take out the 4 screws and remove the inductance。

3 screws 4 screws on the partiton

partiton plate

BSGI 09(12)

Page 47

99.. DDIISSAASSSSEEMMBBLLYY IINNSSTTRRUUCCTTIIOONNSS

44

7.Check up the other parts of the outdoor units.

1)Check-up the condenser ass’y .

2)Check-up the compressor ass’y.

3)Check-up the base ass’y.

4)Check-up the 4 way valve,capillary tube and check valve.

Condenser ass’y Base ass’y Compressor check valve 4 way valve

BSGI 09(12)

Page 48

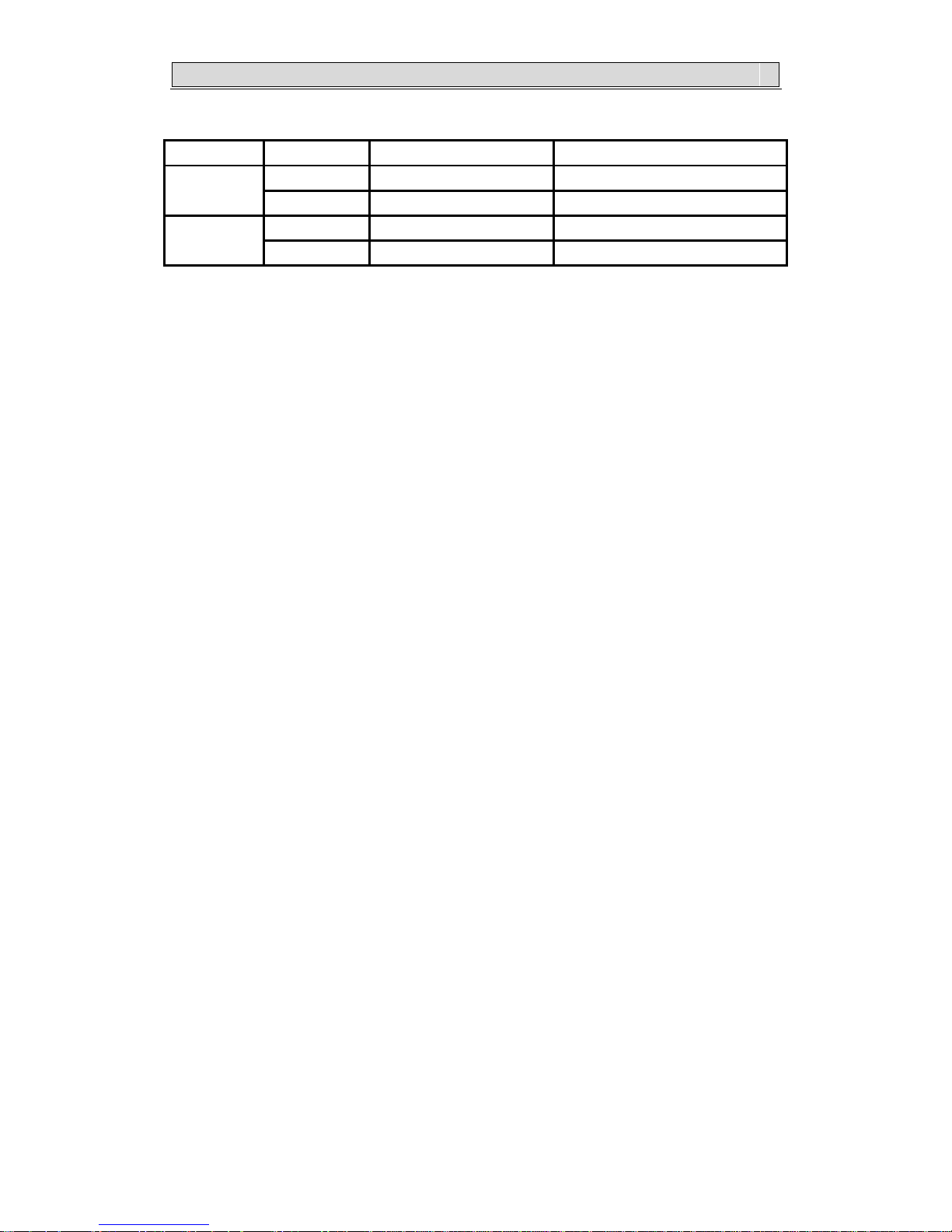

1100.. PPAARRTTSS LLIISST

T

10-1.Indoor

1. Parts

45

BSGI 09(12)

Page 49

1100.. PPAARRTTSS LLIISST

T

46

2. LIST

Key No. No. Part No. Description Q’ty

1 1359354 G1K30/R00.02-01

Front Panel

1

2

1320776 K33B10003

Air Filter Ass’y

2

3

1359347 G1K30/R00.02-02 grill Ass'y 1

4

1203331 RZA-2-2219-043-XX-0 Evaporator bracket 1

5

1336907 K37320147

Evaporator Ass’y

1

6

1203072

RZA-0-2510-106-XX-1

Bearing Ass’y

1

7

1304065 RZA-2-2509-123-03-0

Cross-Flow Fan Ass’y

1

8

1334532

K33930002

Drainage Hose Ass’y

1

9

1204031

RZA-2-2514-112-XX-0

Rubber Ring

1

10

1203273

RZA-2-2231-019-XX-0

Base

1

11

1203356

RZA-2-2230-114-XX-0

Installation Ass’y

1

12

1203639

RZA-2-2362-032-XX-0 fixed board 1

13

1225096

DG13B1-01

Stepper Motor

1

14

1203627 RZA-2-2360-004-XX-0

Inner Flap

1

15

1203661

RZA-2-2478-112-XX-0 flap fixed plate 2

16

1203280 RZA-2-1519-037-XX-0

Blade

2

17

1359263

G1K30/R00.01-01 flap 1

18

1334123

K1B310114

Fan motor Ass’y

1

19

1385308

G1K30/R00.02-03

Wire cover

1

20

1376464

K36E10050

Terminal Board

1

21

1370941

K33830008

Electrical Control Box

Cover

1

22

1359305

G1K30/R00.05-01

Electrical Control Box

1

23

1359783

K36412006

Control Board Ass’y

1

24

1339928 K34350015 power cord clip 1

25

1203961

RZA-2-5304-016-01-2 fixed clip 1

26

1344017

K18410037

Power cord

1

27

1369203

+DG11E4-24(HSN)

Remote Controller

1

28

1203664 RZA-2-2514-113-XX-0

Motor Cover

1

29

1326150

K11330003

Sensor Ass’y

1

30

1201218

RZA-0-5259-105-XX-0

Sensor Ass’y

1

31

1359396

G1G30/R00.05.01-00 display panel 1

32

1356581 G2C30/R00.02-03 Displey Film 1

BSGI 09(12)

Page 50

1100.. PPAARRTTSS LLIISST

T

10-2. Outdoor

1. Part

s

27

32

31

30

29

28

26

25

24

23

21

20

19

16

7

6

5

4

3

22

18

17

15

14

12

13

11

1

2

8

9

10

33

34

47

BSGI 09(12)

Page 51

1100.. PPAARRTTSS LLIISST

T

48

2. LIST

Key No. No.

PART NO. PART NAME Q'TY

1 12768461 W1B0D/R00.02.01-02 FAN GUARD 1

2 1247907 W1E0L/R00.02.01-00 FRONT PANEL 1

3 1313821 DG22Z1-20 PROPELLOR FAN 1

4 1335251 K1B310136 FAN MOTOR ASSY 1

5 1308210 W1E0L/R00.02-05 FAN SUPPORTER 1

6 1370585 K37340290 CONDENSER ASSY 1

7 1248091 W1E0L/R00.02-03 SUPPORT POLE 1

8 1247912 W1E0L/R00.02.02-01 TOP COVER 1

9 1246331 W1E0L/R00.04-02 SIDE PANEL 1

10 1276574 W1A1L/00.02-01 SIDE COVER 1

11 1380347 K1C510072 AMBIENT TEMPERATURE SENSOR 1

12 1380309 K1C510070 COIL TEMPERATURE SENSOR 1

13 1380315 K1C510071 DISCHARGE TENPERATURE SENSOR 1

14 1333773 K36470066

IPM ASSY

1

1370655 K36412115(AS-12UR4SVNVG) CONTROL BOARD ASSY 1

15

1378922 K36412195(AS-09UR4SVNVG) CONTROL BOARD ASSY 1

16 1369822 K33AE0023

RADIATOR

1

17 1366827 K33530061 ELECTRICAL BOX 1

18 1370575 K33170071 CONNECTION PLATE 1

19 1201078 RZA-0-5306-026-XX-0 TERMINAL BOARD 1

20 1304089 RZA-2-5304-092-XX-0 CLIP ASSY 1

21 1336846 K13410009

FILTER

1

22 1343046 K13270010

INDUCTANCE

23 1370996 K37550187 4-WAY VALVE 1

24 1371707 K37410431 PIPE ASSY 1

25 1379652 RZA-0-4515-01B-43-0 STOP VAVLE 1

26 1379680 RZA-0-4518-01B-43-0 STOP VAVLE 1

27 1370576 K33660044 PARTITION SUPPORT PLATE 1

28 1350173 K37210155

COMPRESSOR ASSY

1

29 1205548 RZA-2-2476-137-XX-0 NOISE DEFENING COVER 1

30 1205547 RZA-2-2476-135-XX-0 NOISE DEFENING COVER 1

31 1376475 K33AB0070 NOISE DEFENING COVER 1

32 1322905 K33AB0031 NOISE DEFENING COVER 1

33 1248461 W1A1L/00.01.01-03 VALVE SUPPORT 1

34 1370947 K31120136 BASE ASSY 1

BSGI 09(12)

Loading...

Loading...