Page 1

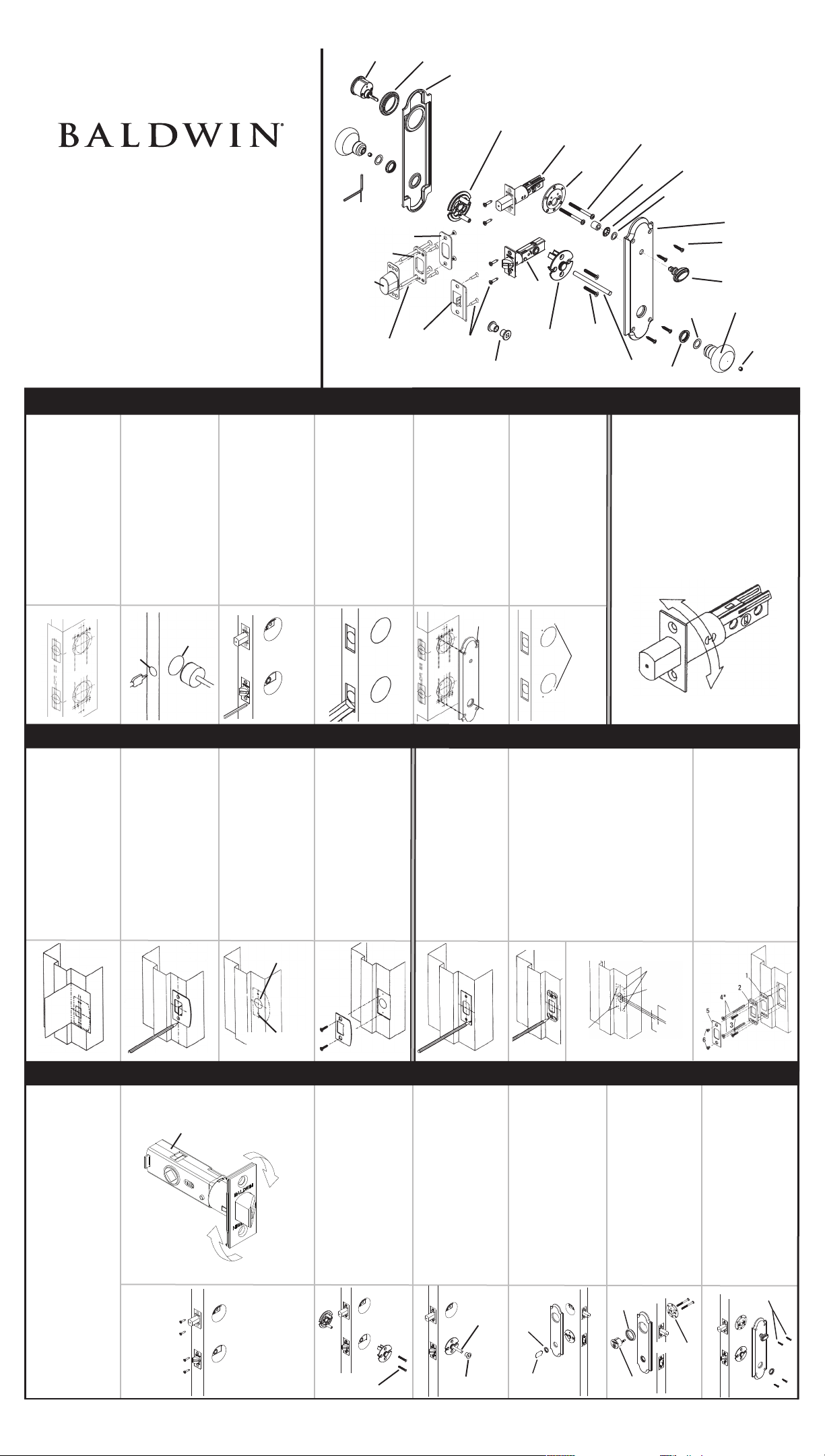

PK.2718

CYLINDER

RING

OUTSIDE PLATE

OUTSIDE

ADAPTOR

DEADBOLT

BACKPLATE

CYLINDER

SCREWS

RETAINING CLIP

INSERT

WAVE WASHER

ALLEN

#10 X 1-7/8”

Single & Double Cylinder

with Escutcheon Plate

Installation Instructions

WRENCH

STRIKE

REINFORCING

STRIKE

DUSTBOX

#10 X 3”

WOOD SCREWS

STRIKE

#8 X 3/4”

SCREWS

ALIGNMENT

BUSHINGS

LATCH

INSIDE

ADAPTOR

1-1/4”

FLAT HEAD

SCREWS

SPINDLE

NYLON

WASHER

RETAINER

INSIDE PLATE

#8 x 3/4” OVAL

HEAD SCREWS

TURN KNOB

KNOB

SET SCREW

DOOR PREPARATION: LATCH, DEADBOLT & MOUNTING HOLES ADJUSTING DEADBOLT BACKSET

1. Fold template

on scored line and

locate, using the

bottom 2-1/8” bore,

at desired height

(about 40” from

floor). Place folded

edge on low side of

door bevel. Mark

hole locations on

the door for

appropriate backset

& plate style.

2. Caution: Re-

check bore hole

locations before

drilling. Drill the

2-1/8” Face Bores

through the door

first. Drill the 1”

diameter Edge Bores

through to the inside

of the 2-1/8” Face

Bore.

3. Insert the latch

& deadbolt into the

edge of the door.

Trace an outline of

the faceplate onto

the door edge.

Mark screw hole

center locations

and drill 1/8” pilot

holes.

4. Remove latch

& deadbolt and

chisel out both areas

marked in Step 3 to

a depth of 5/32” or

until the faceplates

are flush with door

edge.

5. Prior to drilling

the 3/32” holes,

align knob/lever

hole on inside

plate with lower

2-1/8” face bore and

temporarily place

over the template.

Ensure the correct

hole locations were

marked in Step 1.

6. Using a 3/32”

drill bit, drill the

mounting holes 3/4”

deep at the locations

previously marked in

Step 1.

The deadbolt supplied with this

unit has an adjustable

backset feature. It will be set at

2-3/8” backset. To adjust

to 2-3/4” backset, grasp body

and twist faceplate/bolthead

assembly 180° until it stops.

Unit is now ready for

installation in a 2-3/4” backset

configuration.

1” DIA.

EDGE

BORE

2-1/8”

FACE

BORE

THRU-HOLES

KNOB/

LEVER

HOLE

3/32”

MOUNTING

HOLES

STRIKE PREPARATION – LATCH STRIKE PREPARATION – DEADBOLT

1. Using the strike

portion of the marking template, locate

and mark strike

mounting screws

and centering points

for your door thickness.

2. Align the strike

and trace outline

onto the door frame

using mounting

screw marks for

location.

3. At the screw

marks, drill (2) 1/8”

dia. pilot holes for

the screws. Bore

7/8” dia. X 3/4”

deep hole.

7/8”

EDGE BORE

4. Chisel out the

area marked in

step 2 to a depth of

1/16” or until strike

is flush with door

frame.

Install strike using

(2) #8 Flat Head

combination screws.

1. Close door and

extend deadbolt

several times.

Deadbolt center will

leave mark on door

frame. If mark is not

present, rub chalk

on deadbolt center

and repeat.

Position strike on

center mark. Trace

outside of strike and

mounting holes.

2. Position the reinforcing strike and

mark locations for reinforcing screws.

Drill (2) 5/32” pilot holes for 3” long

screws and (2) 1/8” pilot holes for #8

x 3/4” long screws. Mark drill points

5/16” above and below centering

point. Bore (2) 1” dia. holes x 1-1/4”

deep. Chisel out holes for dust box.

DRILL 1/8” DIA.

PILOT HOLES FOR

#8 SCREWS.

BORE 1” DIA. HOLE

ABOVE AND BELOW

CENTERING POINT.

5/16” ABOVE

CENTER POINT

3. Chisel out area

7/32” deep or until all

strikes are flush with

the door frame.

Install strike as

illustrated.

NOTE: LUBRICANT

RECOMMENDED

WHEN INSTALLING

3” REINFORCING

SCREWS.

SINGLE CYLINDER INSTALLATION

1. a. With backset

marking facing

up, grasp the latch

faceplate and rotate

to assure bevel side

of latchbolt faces

jamb.

b. Deadbolt should

be thrown prior to

installation. Slide

the latch & deadbolt into the door

as shown. Secure

with (2) #8 x ¾”

screws per each

component.

A.

BACKSET MARKING MUST BE

FACING UP

B.

1/8” PILOT HOLES

FOR #8 SCREWS

2. Install both adaptors onto door and

insert (2) 1-1/4” Flat

Head Screws into

inside adaptor. The

inside adaptor will

have thru-holes and

countersinks for the

screws. Do not fully

tighten at this time.

1-1/4”

SCREWS

3.Insert the spindle

into the latch with

the ends protruding

from both adaptors.

Slide the alignment

bushings onto the

spindle ends and

into the adaptors.

Tighten the screws

and remove the

alignment bushings.

SPINDLE

ALIGNMENT

BUSHINGS

DRILL 5/32” DIA.

PILOT HOLES

FOR 3” SCREWS.

4. Place the outside rose onto the

adaptor and thread

on retainer using

the spanner tool.

Do not fully tighten.

RETAINER

SPANNER

TOOL

CENTER LINE

5/16” BELOW

CENTER POINT

5. Insert the cylinder

into outside ring.

Slide the cylinder

tailpiece into

deadbolt and place

cylinder & ring into

outside plate. Place

backplate against

door & secure with

(2) #10 screws.

RING

BACKPLATE

CYLINDER

6. Place interior

plate subassembly

onto door, inserting

the cylinder tailpiece

into back of the

turnpiece. Thread

retainer onto adaptor. Do not fully

tighten. Install #8

oval head screws

into door. Do not

fully tighten.

WOOD SCREWS

Page 2

SINGLE CYLINDER INSTALLATION – CONTINUED

7. Rotate turnpiece

to check operation

of deadbolt.

Tighten all screws

and retainers.

Rotate turnpiece

again to check operation of deadbolt.

8. Insert the

spindle into a

knob or lever.

Align scribed mark

with correct door

thickness and

secure with set

screw.

1-3/4”

1-3/8”

9. Slide a nylon

washer onto the

base of both knobs

or levers. Slide the

spindle with the

previously attached

knob or lever into

the latch with the set

screw pointed down

and toward the

hinges of the door.

Secure the other

knob or lever to the

exposed spindle

end.

TURNPIECE

or

SET SCREW

SPINDLE

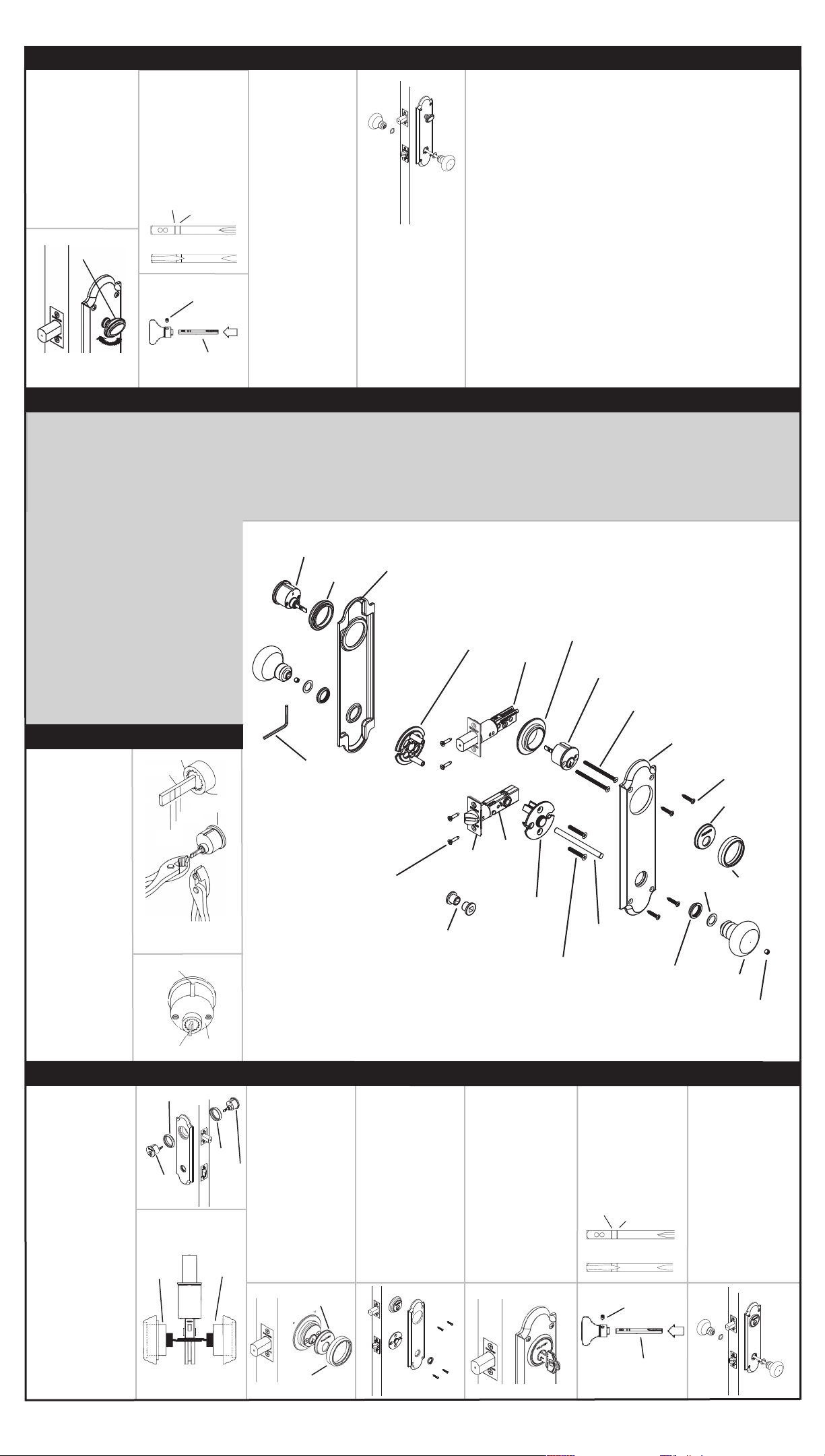

DOUBLE CYLINDER INSTALLATION

Follow Steps #1 through #4 in the Single Cylinder Installation

section before proceeding to Step # 1.

DOUBLE CYLINDER INSTALLATION

1. a. Carefully break

off cylinder tailpiece at

required mark for your

door thickness.

Caution: Use (2)

pairs of pliers as

shown or tailpiece

will be damaged.

b. Align tailpiece with

slot. Keep tailpiece

vertical and curved

toward right side of hole

as illustrated.

A.

B.

TAILPIECE

2-1/4”

SLOT

2”

CYLINDER

1-3/4”

CYLINDER

ALLEN

WRENCH

OUTSIDE

RING

#8 X 3/4” SCREWS

OUTSIDE PLATE

ALIGNMENT

BUSHINGS

OUTSIDE

ADAPTOR

FACE

PLATE

DEADBOLT

LATCH

INSIDE

ADAPTOR

FLAT HEAD SCREWS

COLLAR

1-1/4”

CYLINDER

SPINDLE

#10 X 1-7/8”

CYLINDER SCREWS

INSIDE PLATE

#8 x 3/4” OVAL

HEAD SCREWS

NYLON WASHER

RETAINER

CYLINDER

CAP

INSIDE RING

(THREADED)

KNOB

CYLINDER

CYLINDER

TAILPIECE

DOUBLE CYLINDER INSTALLATION – CONTINUED

2. Insert the cylinder

into ring. Slide the

cylinder tailpiece into

the deadbolt and place

cylinder & ring into

outside plate.

Keeping tailpiece

OUTSIDE

CYLINDER

vertical and curved

toward right side

of the hole, insert

inside cylinder with

threaded collar into

the deadbolt.

Consumer Help Line 1-800-566-1986

OUTSIDE

CYLINDER

RING

TOP VIEW

COLLAR

CYLINDER

INSIDE

CYLINDER

3. Insert (2) #10

screws through inside

cylinder and thread

into outside cylinder.

Place cylinder cap

over inside cylinder

INSIDE

and secure with inside

cylinder ring.

CYLINDER CAP

INSIDE CYLINDER

RING

4. Place interior plate

onto door. Thread

retainer onto adaptor.

Do not fully tighten.

Install #8 oval head

screws into door. Do

not fully tighten.

5. Insert key to check

operation of deadbolt.

Tighten all screws and

retainers.

Rotate key again to

check operation of

deadbolt

©2011 Baldwin Hardware Corporation, Lake Forest, CA PK.2718

6. Insert the spindle

into a knob or

lever. Align scribed

mark with correct

door thickness and

secure with set

screw.

1-3/4”

1-3/8”

or

SET SCREW

SPINDLE

SET SCREW

7. Slide a nylon washer

onto the base of both

knobs or levers. Slide

the spindle with the previously attached knob or

lever into the latch with

the set screw pointed

down and toward the

hinges of the door.

Secure the other knob

or lever to the exposed

spindle end.

Loading...

Loading...