Page 1

OPERATOR'S MANUAL FOR YOUR

MODEL PC13R

SERIAL NUMBER _______________

BALDOR GENERATORS

3815 OREGON STREET ◊ P.O. BOX 200 ◊ OSHKOSH WI 54902-0200

TELEPHONE: (920) 236-4200 ◊ FAX: (920) 236-4219

FORM#: S-PSG-002-25 D:\ISO9001\FORMS\S-PSG-002-37\msw

EFFECTIVE/REVISED: 6/29/01

Page 2

FORWARD

This manual contains the information you need to safely and efficiently operate your generator

set. During the preparation of this manual every effort was made to ensure the accuracy of its

contents.

DO NOT OPERATE THIS GENERATOR SET UNTIL YOU CAREFULLY READ THIS

MANUAL AND UNDERSTAND THE SAFETY WARNINGS AND INSTRUCTIONS

CONTAINED IN IT. While safety is built into every Baldor Pow'R Gard generator set, careless or

improper operation could possibly result in mechanical failure, property damage, severe injury

or even death.

Note that this manual covers only very basic information in regards to the engine. A separate

owner's manual for the engine is supplied with this unit for your use. Please refer to this manual

for information relative to engine operation, maintenance, recommendations and additional

safety warnings.

As soon as you receive your generator set, inspect it closely for shipping damage. If you find

some damage, notify the transportation company immediately and file a freight damage claim.

Think of this manual as a tool to help you get the most out of your generator set. WE

STRONGLY SUGGEST THAT YOU KEEP THIS MANUAL WITH YOUR GENERATOR SET

AND MAKE IT AVAILABLE TO ANYONE USING THE GENERATOR SET. You should refer

to the manual when questions arise in regards to the operation of the generator set and

carefully observe all safety warnings and instructions contained in it.

Baldor Generators, formerly Pow'R Gard Generator Corporation has been in business since

1965. The generator sets we manufacture have earned the reputation of being of high quality

and a dependable product. We take pride in this fact and continue to keep our quality standards

high on our list of priorities. We are also constantly researching new technological ideas to

determine if they could be used to make our generator sets even better.

Thank you for purchasing your Baldor Pow'R Gard Generator Set.

- i -

Page 3

SAFETY WARNINGS

♦

Place protective covers and guards over the rotating parts, if rotating parts such as the drive shaft, pulley,

belt, etc. are left exposed, they are potentially hazardous.

♦ When cleaning, repairing or inspecting, make sure all moving parts have stopped.

♦ Prior to working on the generator set, disconnect the spark plug and battery to prevent accidental starting.

♦ Use only original equipment or authorized replacement parts. Use of correct parts will assure the operator of

the safety integrity that was designed into the unit.

♦ Unauthorized modifications to the generator set may impair the function and/or safety of the unit.

♦ Do not operate the generator set without a muffler. Inspect periodically and replace if necessary.

♦ Do not touch the hot exhaust components or the high voltage spark plug and coil terminals. While Spark Plug

Voltages are not normally lethal, an involuntary jerk of the hand caused by a hot surface or by an electrical

shock can result in injury.

♦ Repair of electrical generating equipment requires specialized skills. Repair personnel must have a

thorough understanding of generator and small engine repair procedures.

♦ Never inhale exhaust gases. They contain carbon monoxide; a colorless, odorless and extremely

dangerous gas that can cause unconsciousness or death. Symptoms of carbon monoxide poisoning

can include: dizziness, nausea, headaches, sleepiness, vomiting or incoherency. If you or anyone else

experiences any of these symptoms, get out into the fresh air immediately. Shut the unit down and

do not operate it until it has been inspected and, if necessary, repaired.

♦ Never Operate the generator set indoors or in a poorly ventilated area such as a tunnel or cave.

♦ CALIFORNIA PROPOSITION 65 WARNING: engine exhaust from this product contains chemicals known to

the state of California to cause cancer, birth defects or other reproductive harm.

♦ Know how to stop the engine quickly and understand the operation of all controls.

- ii -

Page 4

SAFETY WARNINGS

♦ Never permit anyone to operate the generator set without proper instructions.

♦ Never allow children to operate the generator set.

♦ Children and pets must be kept away from the area of operation due to the possibility of burns from hot

engine components or injury from any equipment the generator set is powering.

♦ Always wear eye protection and Hearing protection when working near the generator set.

♦ Operate the generator set only with the guards, shields and other safety items in place and working

properly.

♦ Do not put hands, feet, tools or other objects near rotating parts.

♦ Use reasonable care when moving or lifting the unit. The generator set may move around inside the wrap

frame creating "Pinch Points".

♦ Do not run the generator set while it is being moved.

♦ Do not support the generator set from the top of the wrap frame.

♦ Do not operate the generator set while under the influence of alcohol, drugs or medication.

♦ When transporting or using a generator set with the wheel option, secure the unit to prevent it from moving

around.

♦ Do not tamper with or change the engine speed as it has been preset at the factory for proper operation.

♦ Keep hands and face away from the carburetor when the air cleaner is being moved. A sudden backfire can

cause serious burns.

♦ Be careful of hot parts. The muffler and other generator parts become very hot while the engine is running.

♦ Do not "jump start" the generator set.

♦ Sulfuric acid can cause severe injury and can give off gases, which are corrosive and potentially explosive.

Avoid contact with skin, eyes, and clothing. In case of contact, flush area immediately with water.

♦ When transporting a generator set, secure it to prevent it from moving or shifting.

♦ Know how to stop the engine quickly and understand the operation of all controls.

♦ Do not operate electrical equipment while standing in water, on wet ground or with wet hands or shoes.

♦ Use extreme caution when working on electrical components. Potentially dangerous voltage is present

when the engine is running.

- iii -

Page 5

SAFETY WARNINGS

♦ Always treat the electrical circuits as if they were energized.

♦ Disconnect all leads plugged into the unit Prior to working on it.

♦ Have the electrical circuits serviced only by qualified technicians.

♦ Inspect wiring frequently and replace frayed, broken or poor leads.

♦ Do not connect this unit to any building's electrical system unless you utilize an approved transfer switch or

the main service entrance switch has been disconnected and locked open.

♦ Circuit overload protection must be provided in accordance with national electrical codes and local

regulations.

♦ Check GFCI Receptacles monthly by using the "Test" and "Reset" buttons designed into them.

♦ Depending on your application it may be mandatory to ground or not ground this unit to earth ground.

Comply with local electrical codes.

○ ○ ○ ○ FOR GASOLINE OR DIESEL POWERED GENERATOR SETS ○ ○ ○ ○

♦ Operate the generator set on a level surface. If the generator set is tilted, fuel spillage may result.

♦ Handle fuel with care. It is highly flammable. Use only clean, properly marked and approved safety

containers for refueling and storing fuel.

♦ Stop the engine and allow it to cool before refueling.

♦ Do not overfill the fuel tank. Only fill the tank to within 1/2" of the top of the tank to allow space for fuel

expansion.

♦ If fuel is spilled, wipe it up carefully and wait until the fuel has dried before starting the engine.

♦ Make sure the fuel cap is properly closed after refueling.

♦ Never operate the generator set while smoking.

♦ Never operate the generator set near an open flame.

♦ Never store the generator set with fuel in the tank indoors or in an enclosed, poorly ventilated enclosure

where fuel fumes may reach an open flame, electrical spark or pilot light as on a furnace, water heater,

clothes dryer, etc.

♦ When transporting over long distances or rough roads, drain the fuel tank to prevent leakage and spillage.

- iv -

Page 6

SAFETY WARNINGS

○ ○ ○ ○ FOR GASOLINE OR DIESEL POWERED GENERATOR SETS ○ ○ ○ ○

♦ Check all fuel supply piping and their connections on a monthly basis for fuel leaks.

♦ Use only approved piping and componentry in your fuel supply system.

♦ A professional, experienced technician should only install the fuel supply system.

♦ Do not run the fuel line up against any sharp objects.

♦ Comply with NFPA regulations and your local codes in regard to shut-off valves, regulators, etc. and any

other recommendations or requirements they may have.

♦ Keep the generator set at least three feet away from buildings or other structures.

♦ Keep the generator set away from flammable and other hazardous materials (trash, rags, lubricants,

explosives, paints, etc.)

♦ Keep the generator set free of grass, leaves and excessive grease and oils.

♦ Allow the generator set to cool before transporting it or storing it indoors.

♦ Have fire extinguisher accessible and nearby while operating the generator set.

♦ This generator set must not be used on or near any forest covered brush covered or grass covered land

unless the engine's exhaust system is equipped with a spark arrester and it must be maintained

in effective working order by the operator.

♦ Operation inside an enclosed compartment or building is a potential fire hazard and should not be done

unless approval is obtained from Baldor Generators. Engine/Generator overheating can cause severe

damage due to restricted, obstructed or improper airflow that is necessary for the proper cooling of the unit.

♦ Hot exhaust gases being discharged by the engine must never be directed toward anything that could catch

fire or explode.

- v -

Page 7

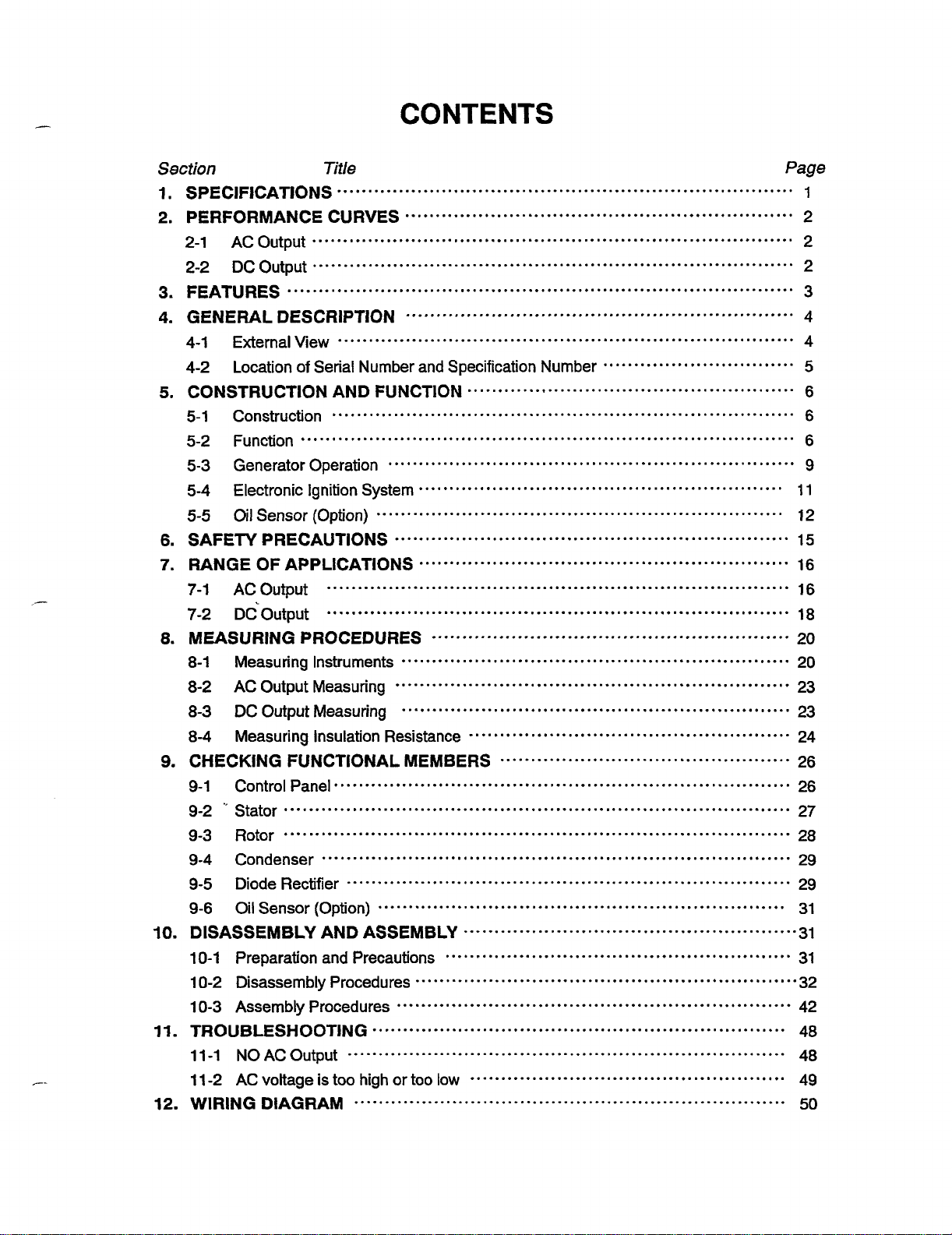

Section

Warranty Information............................................................................................... 51

1

.

2

.

3

.

4

.

5

.

6

.

7

.

.

Title

Page

8

.

9

.

10

.

11

.

12

.

Page 8

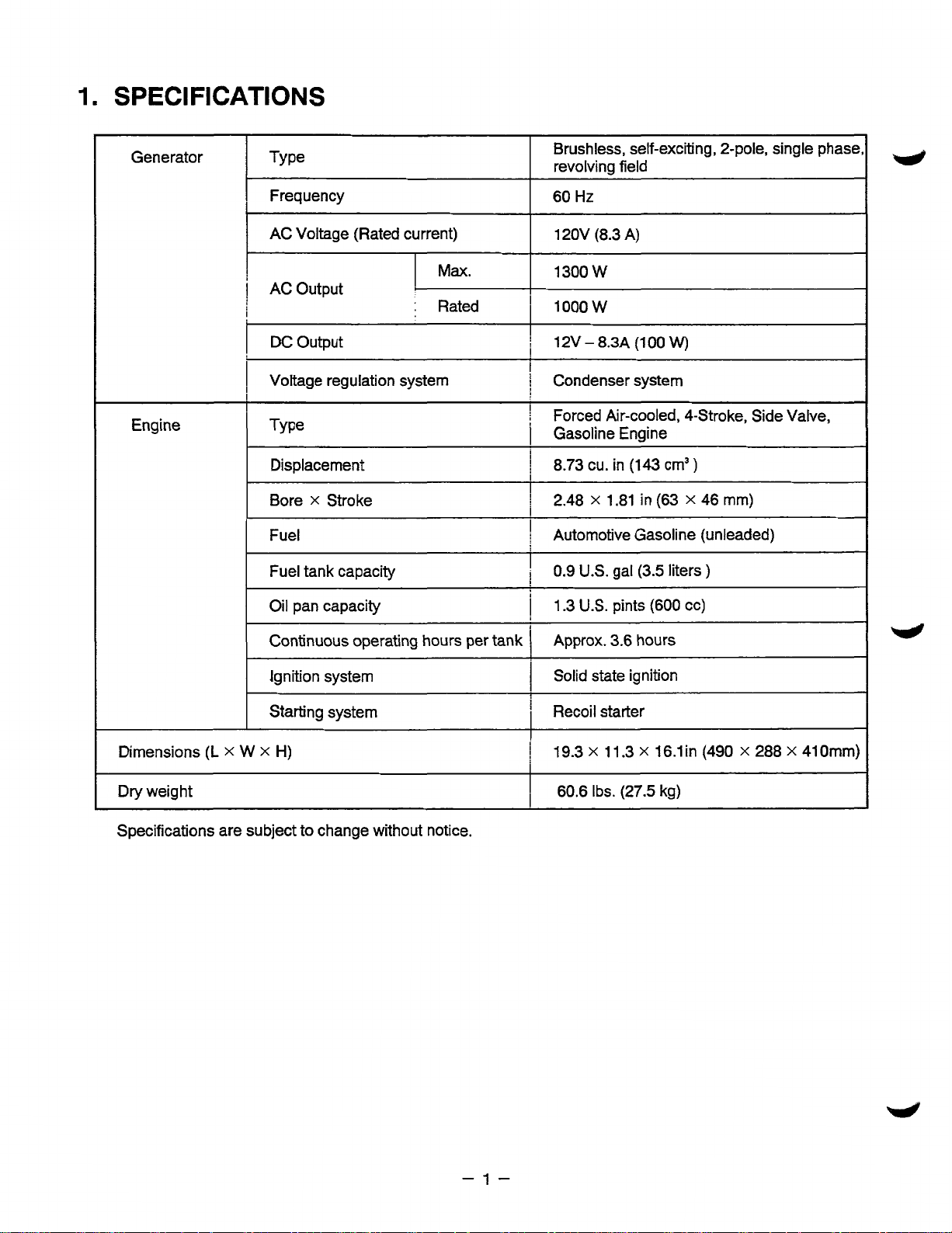

1

SPECIFICATIONS

Generator

Engine

TY Pe

T-

Frequency

AC Voltage (Rated current)

Max.

AC Output

:

Rated

DC

Output

Voltage regulation system

Type

I

Displacement

Bore

x

Stroke

Fuel

Fuel tank capacity

Oil pan capacity

Continuous operating hours per tank

Brushless, self-exciting, 2-pole, single phase,

revolving field

60

Hz

120V

(8.3

A)

1300

W

I

1ooow

’

12V-

8.3A

cu. in

gal

pints

3.6

(100 W)

(143

cm’)

in

(63

(3.5

(600

hours

x

liters

cc)

46 mm)

j

I

I

Condenser system

I

:

Forced Air-cooled, 4-Stroke, Side Valve,

I

Gasoline Engine

I

I

8.73

i

I

2.48 x 1.81

i

1

Automotive Gasoline (unleaded)

I

0.9

i

I

I

8

I

U.S.

1.3

U.S.

Approx.

Ignition system

Starting system

I

Dimensions

Dry

weight

Specifications are subject to change without notice.

(L

X

W X H)

1

I

1

I

I

I

I

I

Solid state ignition

Recoil starter

19.3

60.6

x

1

1.3 x 16.1

Ibs.

(27.5 kg)

in

(490 x 288 X 41

Omm)

-1-

Page 9

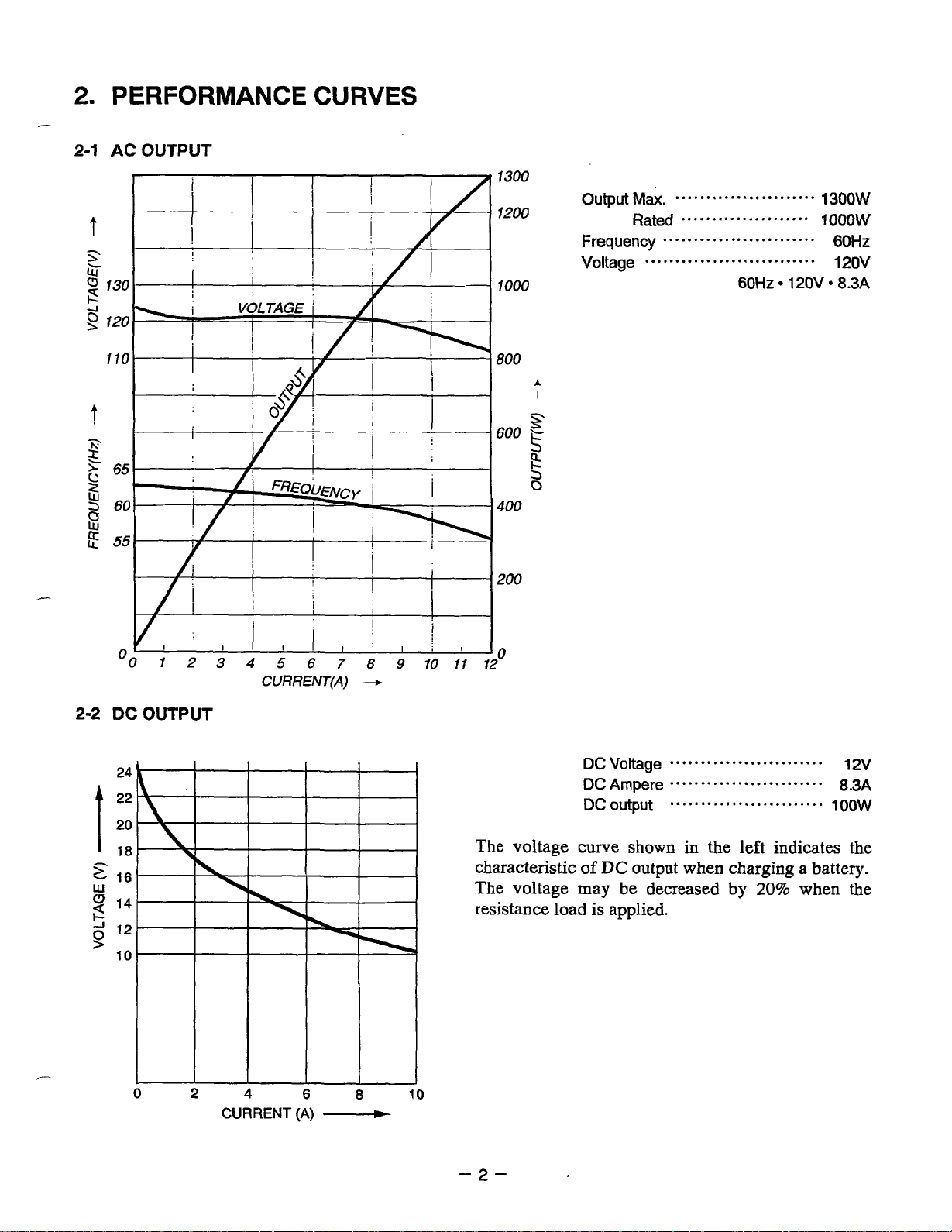

2.

PERFORMANCE

2-1

AC

OUTPUT

CURVES

7300

1200

1000

800

A

I

s

600 e

3

E

3

0

400

2-2

DC

OUTPUT

200

1

2

3

4567

CURRENT(A)

9

10

11

The voltage curve shown in the

of

DC

characteristic

output when charging a battery.

The voltage may be decreased

resistance load

is

applied.

by

left

20%

indicates the

when the

”

0

2

4

CURRENT

6

(A)

8

-

10

-2-

Page 10

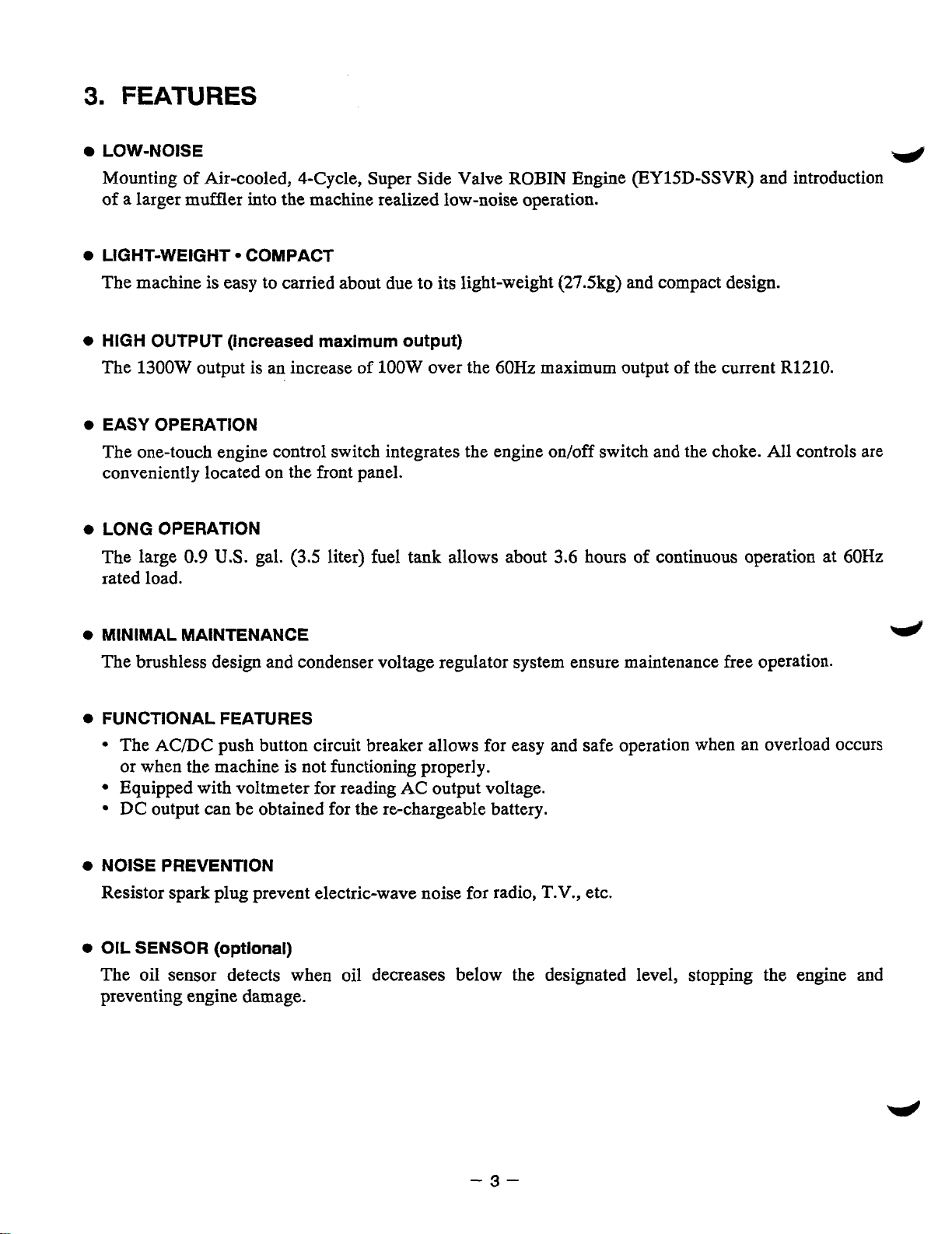

3.

FEATURES

LOW-NOISE

Mounting of Air-cooled, 4-Cycle, Super Side Valve ROBIN Engine (EYlSD-SSVR) and introduction

of a larger muffler into the machine realized low-noise operation.

0

LIGHT-WEIGHT COMPACT

The machine is easy to carried about due to its light-weight (27.5kg) and compact design.

0

HIGH

The 1300W output is an increase of lOOW over the

0

EASY OPERATION

OUTPUT (increased maximum

output)

6OHz

maximum output of the current R1210.

The one-touch engine control switch integrates the engine on/off switch and the choke. All controls are

conveniently located on the front panel.

0

LONG OPERATION

The large

0.9

U.S.

gal. (3.5 liter) fuel tank allows about

3.6

hours of continuous operation at

rated load.

4

60Hz

0

MINIMAL MAINTENANCE

The brushless design and condenser voltage regulator system ensure maintenance

0

FUNCTIONAL FEATURES

The AC/DC push button circuit breaker allows for easy

is

or when the machine

not functioning properly.

and

safe operation when an overload occurs

free

operation.

Equipped with voltmeter for reading AC output voltage.

DC

output can be obtained for the re-chargeable battery.

0

NOISE PREVENTION

Resistor spark plug prevent electric-wave noise for radio,

0

OIL

SENSOR (optional)

T.V.,

etc.

The oil sensor detects when oil decreases below the designated level, stopping the engine and

preventing engine damage.

-d

-3-

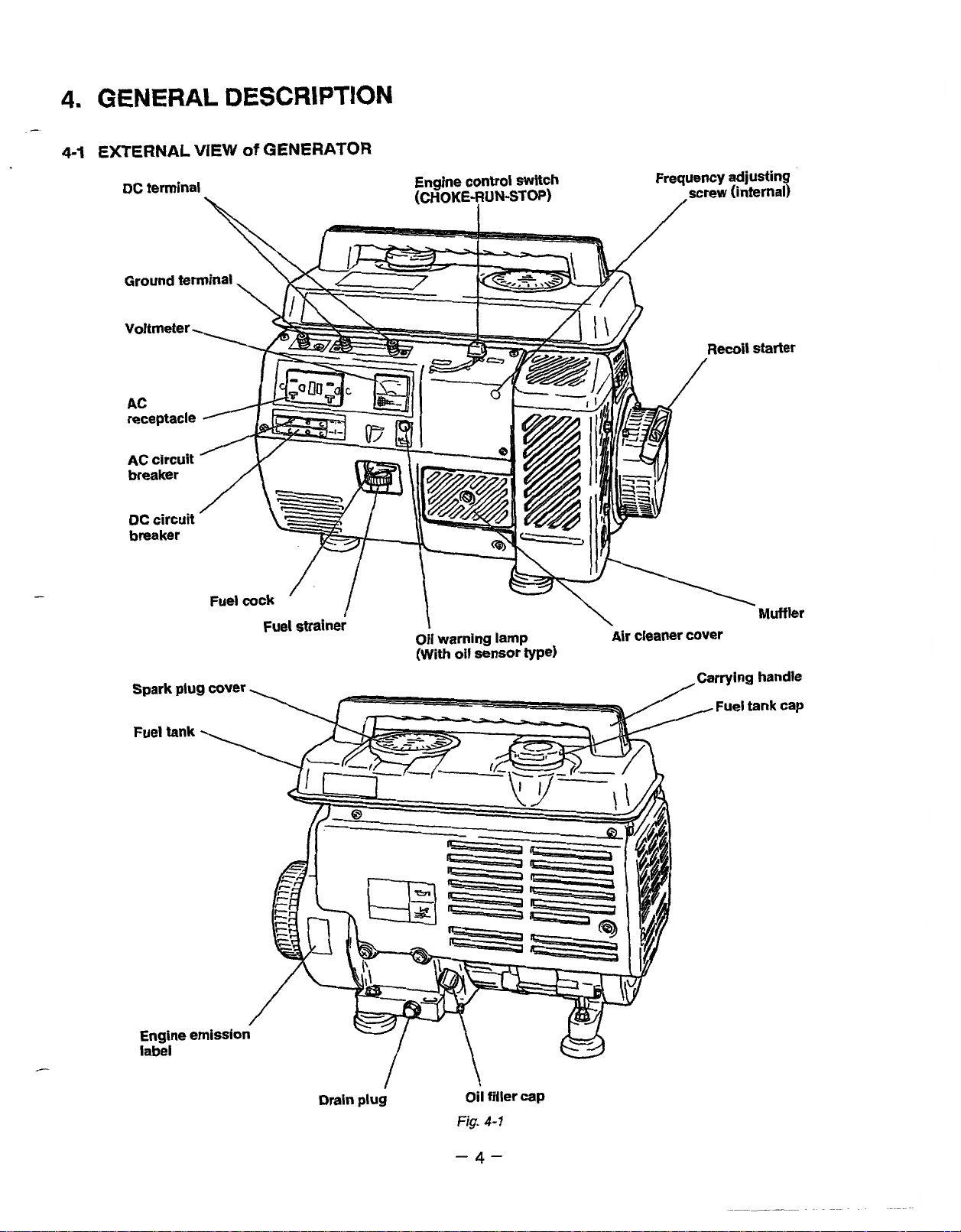

Page 11

4.

GENERAL

DESCRIPTION

4-1

TERNAL

EX

DC

VIEW

terminal Engine control

of

GENERATOR

(CHOKE-RUN-STOP)

1

switch

Frequency adjusting

,screw (internal)

starter

Fuel cock

'

Fuel strainer

I

\

I

Oil warning lamp

(With

oil

sensor type)

\

Air

cleaner cover

\

Muffler

Carrying handle

.

Fuel tank cap

Drain plug Oil

filler

Fig.

4-1

-4-

cap

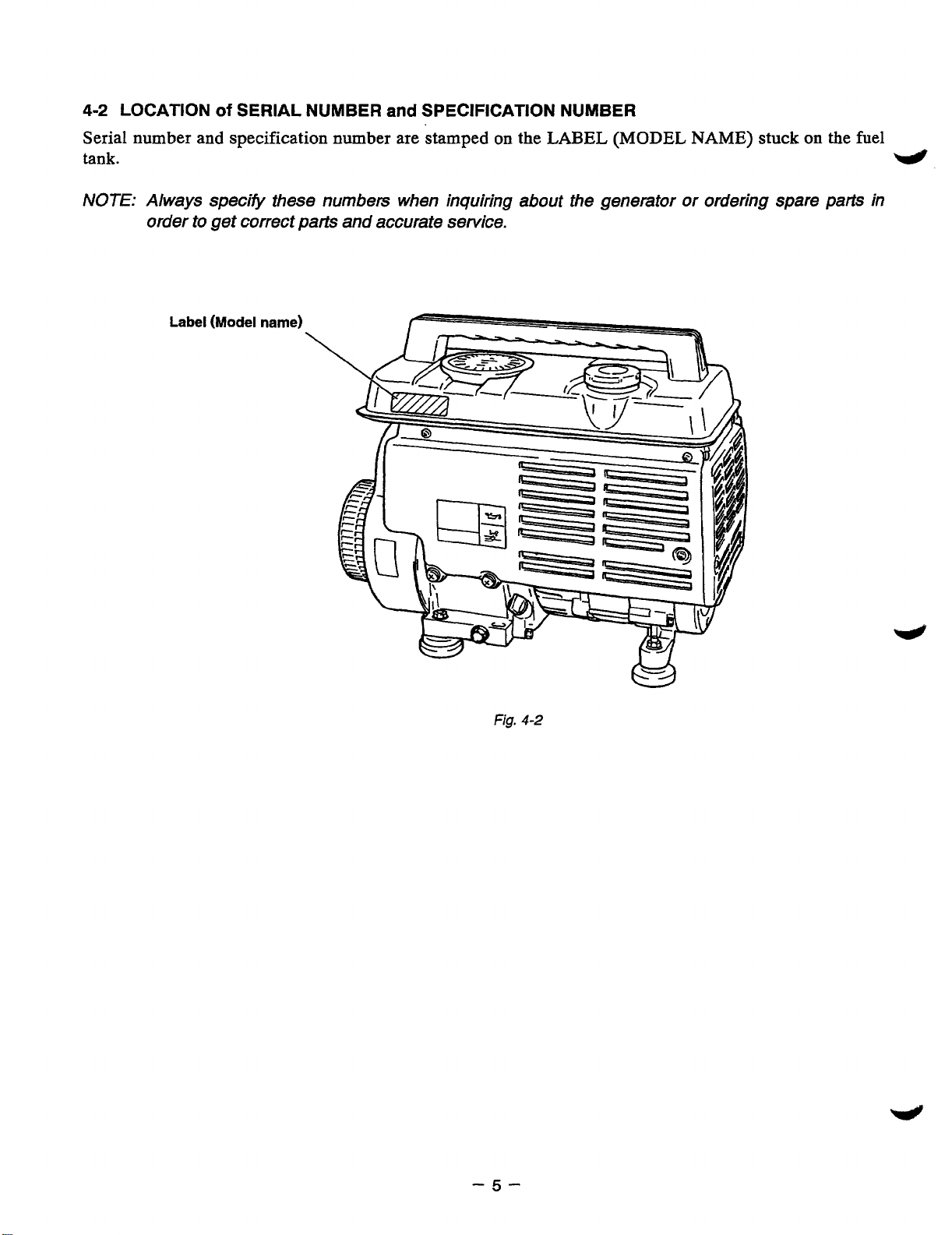

Page 12

4-2

LOCATION

of

SERIAL NUMBER

and

SPECIFICATION NUMBER

Serial number and specification number are stamped

tank.

NOTE:

Always speciiy these numbers when inquiring about the generator or ordering spare parts in

parts

and

order to get correct

Label

(Model

name)

accurate service.

\

on

the

LABEL

(MODEL

NAME)

stuck

on

the fuel

-1

Fig.

4-2

-5-

Page 13

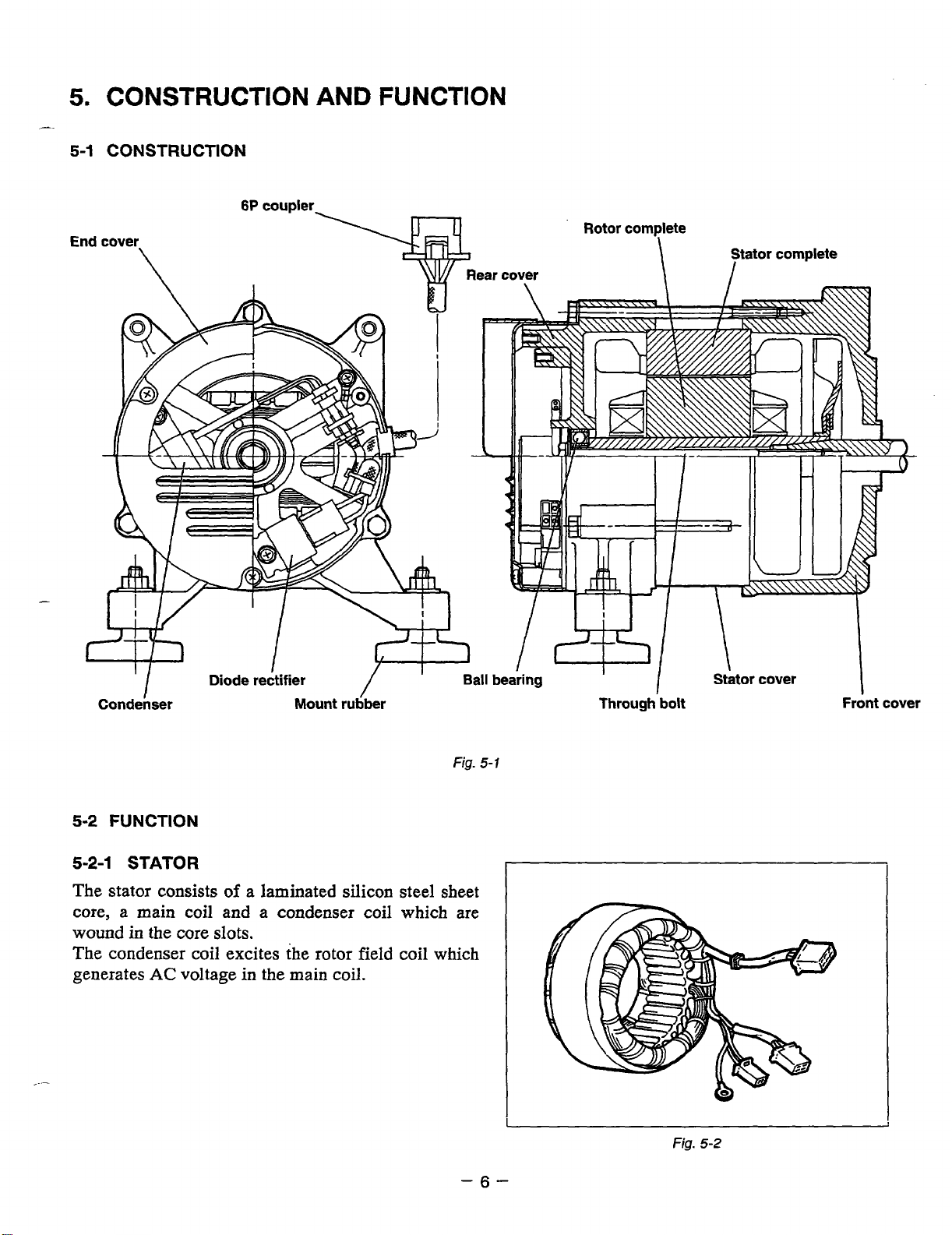

5.

CONSTRUCTION

5-1

CONSTRUCTION

6P

coupler

AND

\rll

FUNCTION

Rear

cover

Rotor complete

\

\

Stator complete

I

'I

Condenser Mount rubber

5-2

FUNCTION

5-2-1

The stator consists

core, a main coil and a condenser coil which are

wound

The condenser

generates

STAT0

in

the core slots.

AC

Diode rectifier

R

of

a laminated silicon steel sheet

coil

excites the rotor field coil which

voltage

in

the main coil.

'

Ball

Fig.

bearing

5-1

I

Through bolt

\

Stator cover

Front cover

-6-

Fig.

5-2

Page 14

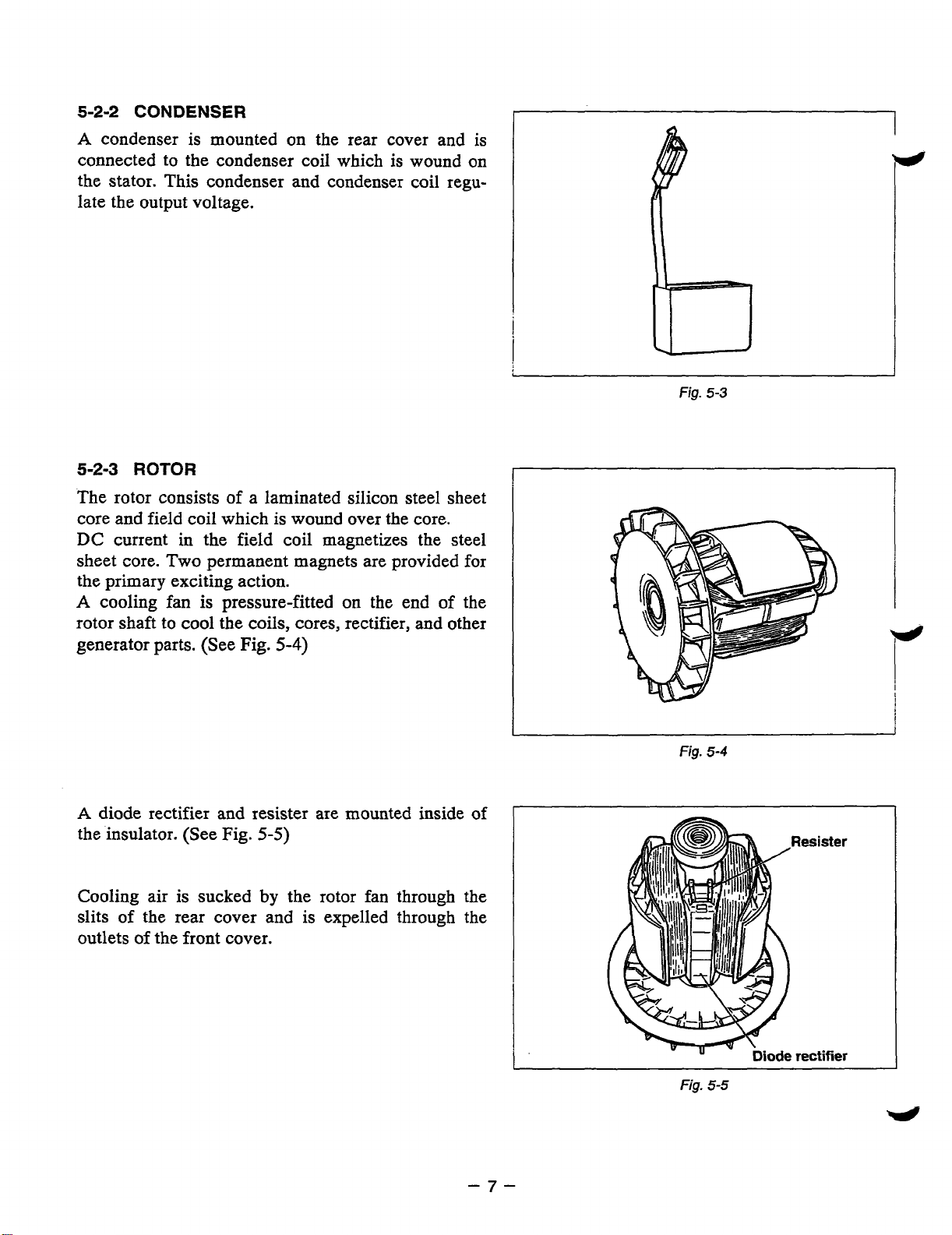

5-2-2

A

CONDENSER

condenser

is

mounted on the rear cover and is

connected to the condenser coil which is wound on

the stator. This condenser and condenser coil regulate the output voltage.

Fig.

5-3

5-2-3

ROTOR

The rotor consists of a laminated silicon steel sheet

core and field coil which is wound over the core.

DC current in the field coil magnetizes the steel

sheet core. Two permanent magnets are provided for

the

primary exciting action.

A

cooling fan

rotor shaft to cool the

generator parts.

A

diode rectifier

the .insulator. (See Fig.

is

pressure-fitted on the end of the

coils,

cores, rectifier, and other

(See

Fig.

5-4)

and

resister are mounted inside of

5-5)

Cooling air is sucked by the rotor fan through the

slits of the rear cover and is expelled through the

of

outlets

the front cover.

Fig.

5-4

-7-

Fig.

5-5

Page 15

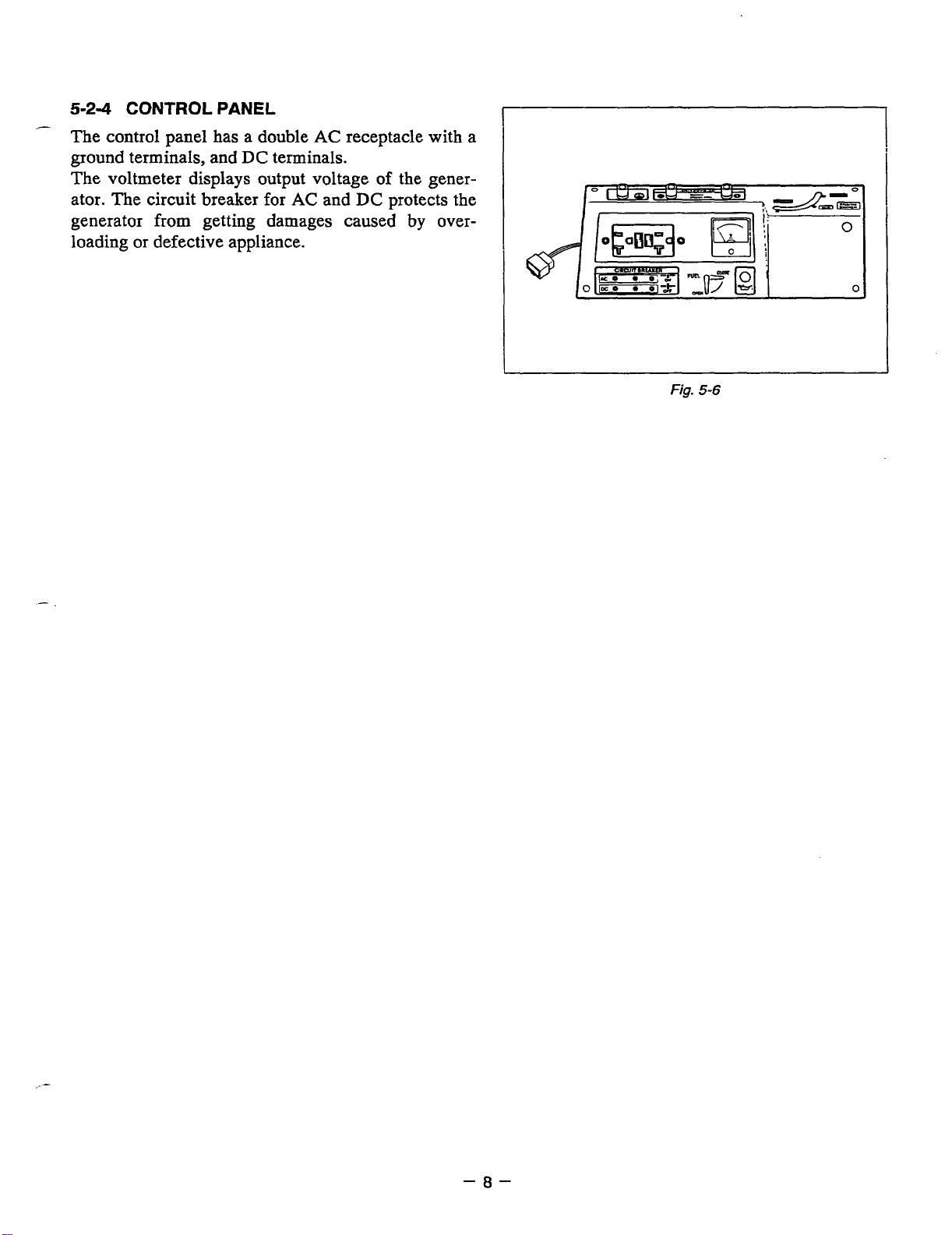

5-2-4

CONTROL

PANEL

The control panel has a double

ground terminals, and

DC

AC

terminals.

receptacle with a

The voltmeter displays output voltage of the generator. The circuit breaker for

generator

from getting damages caused

AC and

DC

protects the

by

over-

loading or defective appliance.

Fig.

5-6

-8-

Page 16

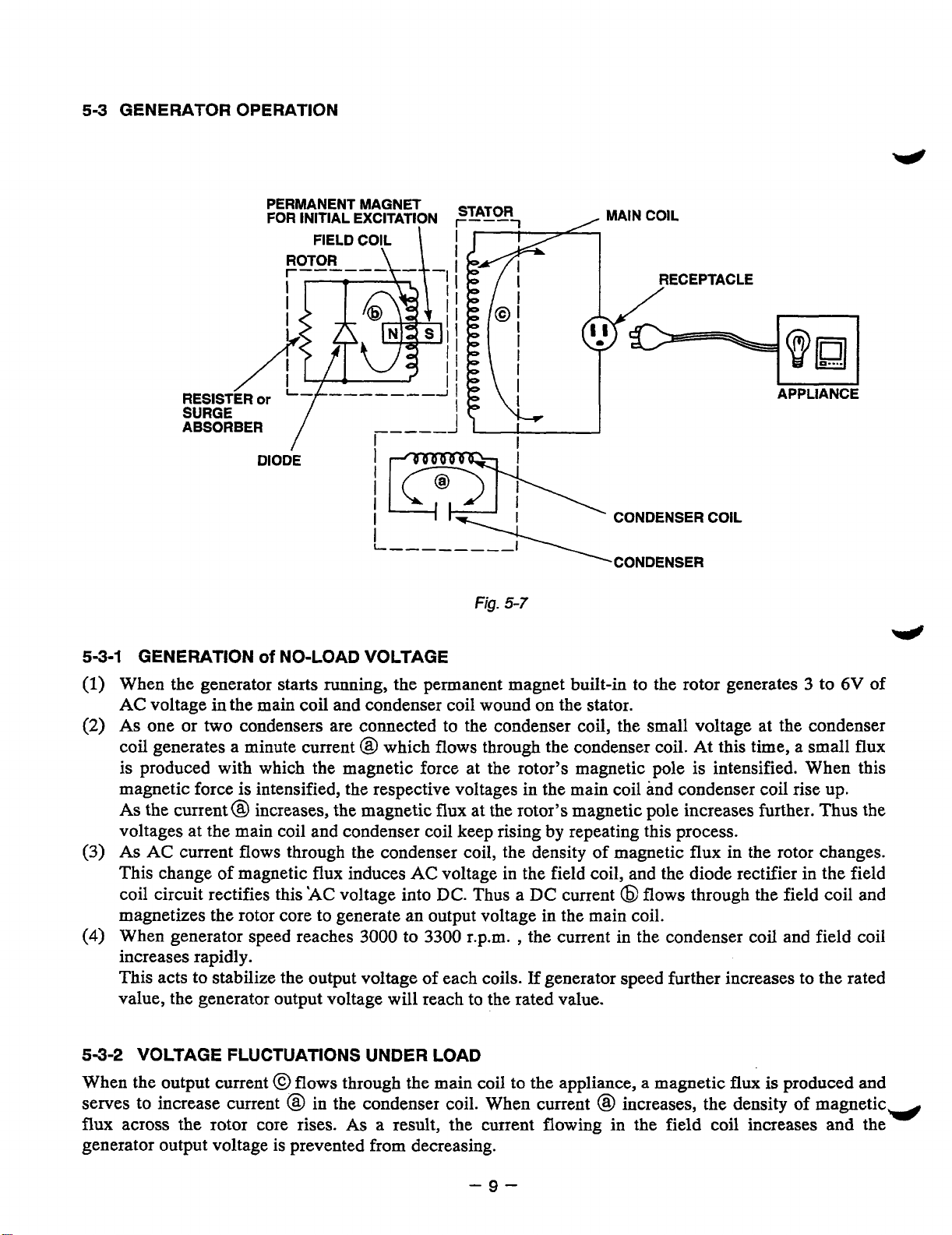

5-3

GENERATOR OPERATION

PERMANENT MAGNET

FOR

INITIAL EXCITATION

I

I

Fig.

I

‘CONDENSER

5-7

5-3-1

SURGE

ABSORBER

GENERATION

Of

NO-LOAD VOLTAGE

When the generator starts running, the permanent magnet built-in to the rotor generates 3 to

AC voltage in the main coil and condenser coil wound on the stator.

As one or two condensers are connected to the condenser coil, the small voltage at the condenser

@

coil generates a minute current

is

produced with which the magnetic force at the rotor’s magnetic pole

which flows through the condenser coil. At this time, a small flux

is

intensified. When this

magnetic force is intensified, the respective voltages in the main coil and condenser coil rise up.

As

the current @ increases, the magnetic flux at the rotor’s magnetic pole increases further. Thus the

voltages at the main coil and condenser coil keep rising by repeating this process.

of

As AC current flows through the condenser coil, the density

AC

This change of magnetic flux induces

‘AC

coil circuit rectifies this

voltage into

magnetizes the rotor core to generate an output voltage in

When generator speed reaches

3000

voltage in the field coil, and the diode rectifier in the field

DC.

Thus a DC current @ flows through the field coil and

the

to

3300

r.p.m. , the current in

magnetic flux in the rotor changes.

main coil.

the

condenser coil and field coil

increases rapidly.

This acts to stabilize the output voltage of each coils.

If

generator speed further increases

value, the generator output voltage will reach to the rated value.

to

the rated

6V

of

5-3-2

VOLTAGE FLUCTUATIONS UNDER LOAD

When the output current @ flows through the main coil to the appliance, a magnetic flux

@

serves to increase current

flux across the rotor core rises.

in the condenser coil. When current @ increases, the density of magnetic

As

a result, the current flowing in the field coil increases and the

generator output voltage is prevented from decreasing.

-9-

is

produced and

w

Page 17

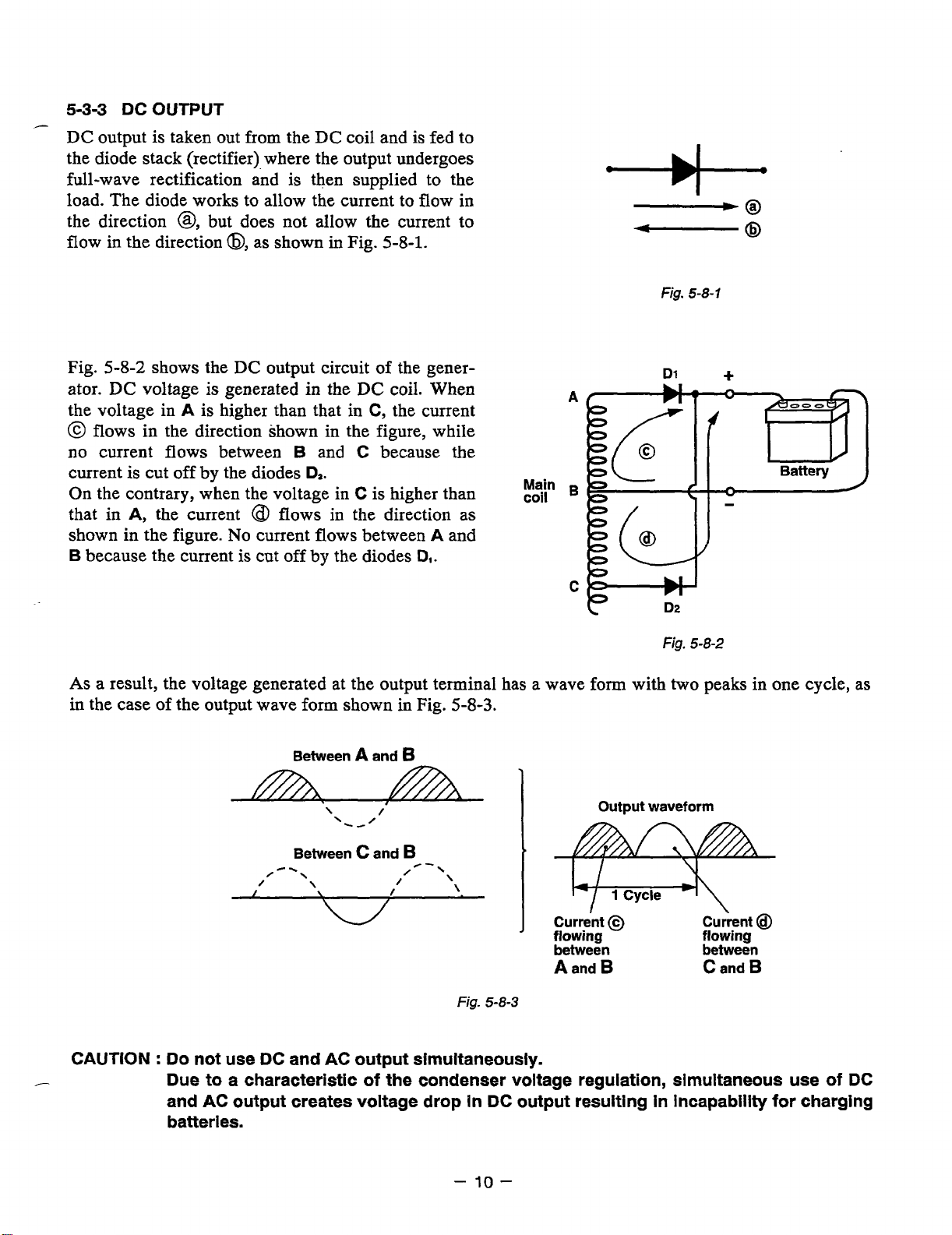

5-3-3

DC

OUTPUT

-

DC output

the diode stack (rectifier) where the output undergoes

full-wave rectification and is then supplied to the

load. The diode works to allow the current to

the direction

flow in the direction

Fig.

5-8-2

ator.

the voltage in

@

flows in the direction shown in the figure, while

no current flows between

current

On

the

that in

shown in the figure.

B

because the current is cut off by the diodes

is

taken out

@,

shows the DC output circuit

DC

voltage

A

is

cut off by the diodes

contrary, when the voltage in C is higher than

A,

the current

from

the DC coil and is fed to

flow

but does not allow the current to

8,

as shown

is

generated in the

is higher than that

@

flows in the direction as

No

current flows between A and

in

Fig.

5-8-1.

of

DC

coil. When

in

Cy

the current

B

and C because the

D,.

the gener-

D,.

in

Main

coil

4

-a

-0

Fig.

5-8-1

Dl

+

As

a result, the voltage generated at the output terminal has a wave form with two peaks in one cycle, as

in the case of the output wave form shown in Fig.

Between A and

\

'"0

Between c and

-.

0\

CAUTION : Do not use DC and

-

Due to a characteristic

and

AC

output creates voltage drop In

batterles.

/

I

\

\

AC

output simultaneously.

of

Fig.

5-8-2

5-8-3.

6

/

B

/-

'\

/

I

\

1

j

Fig.

5-8-3

the condenser voltage regulation, simultaneous use of DC

DC

output resulting in incapability for charging

Output

Curre'nt

flowing flowing

between between

A

and

B

0

waveform

C

and

B

-

10

-

Page 18

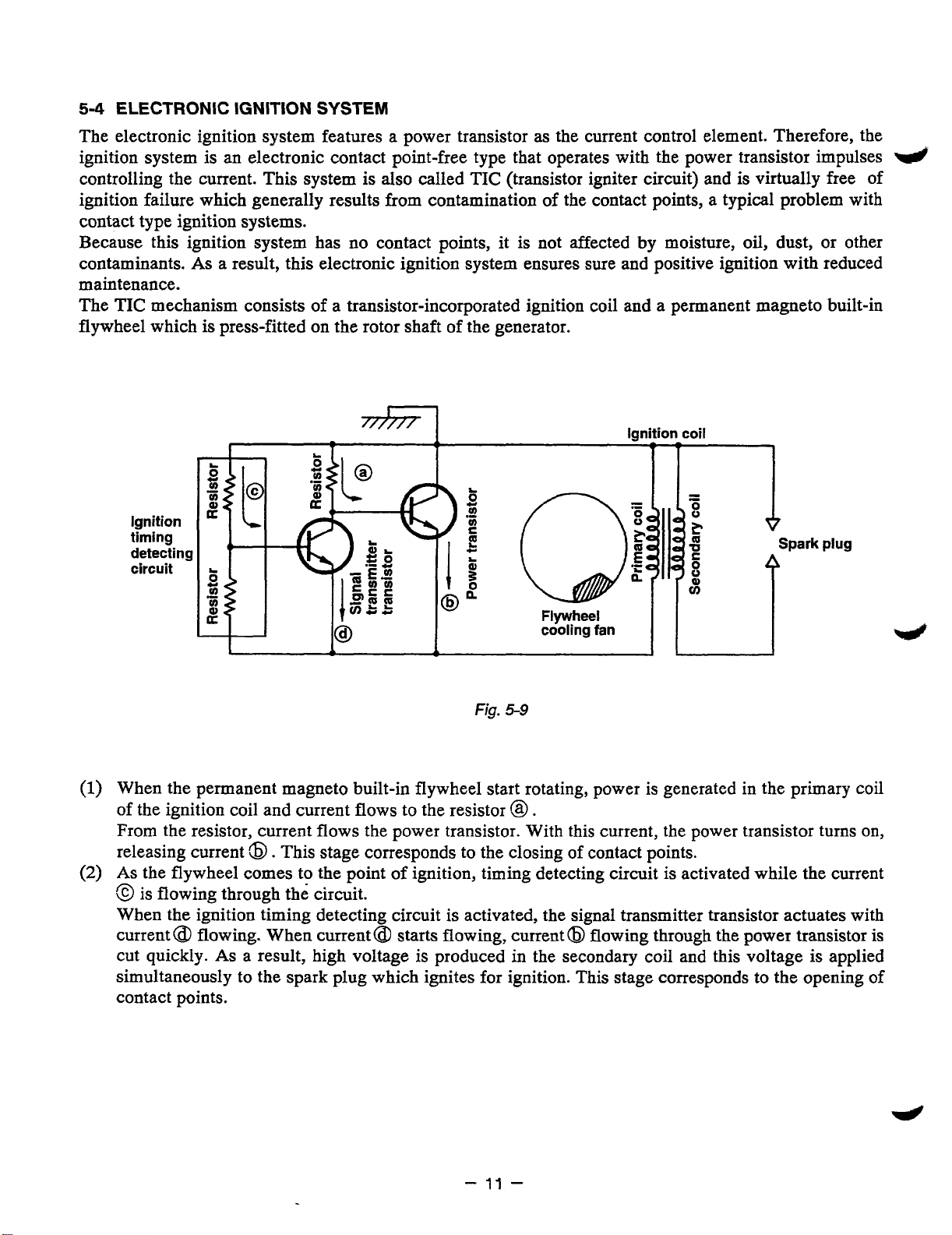

5-4

ELECTRONIC

The electronic ignition system features a power transistor as the current control element. Therefore, the

ignition system

controlling the current. This system

ignition failure which generally results from contamination

contact type ignition systems.

Because this ignition system has

contaminants.

maintenance.

TIC

The

flywheel which

mechanism consists of a transistor-incorporated ignition coil and a permanent magneto built-in

IGNITION

is

an electronic contact point-free type that operates with the power transistor impulses

As

a result, this electronic ignition system ensures sure and positive ignition with reduced

is

press-fitted

SYSTEM

is

also

called TIC (transistor igniter circuit) and

no

contact points, it

on

the rotor shaft of the generator.

is

virtually free of

of

the contact points, a typical problem with

is

not affected by moisture,

oil,

dust, or other

4

Fig.

5-9

(1)

When the permanent magneto built-in flywheel start rotating, power

@

of the ignition coil and current flows to the resistor

From the resistor, current flows the power transistor. With this current, the power transistor turns

releasing current

(2)

As

the flywheel comes to the point of ignition, timing detecting circuit

@

is flowing through the circuit.

When the ignition timing detecting circuit

current @ flowing. When current @ starts flowing, current @ flowing through the power transistor

cut

quickly.

simultaneously to the spark plug which ignites for ignition. This stage corresponds to the opening of

contact points.

a.

This stage corresponds to the closing of contact points.

As

a result, high voltage is produced

is

activated, the signal transmitter transistor actuates with

.

in

the secondary coil and this voltage

is

generated in the primary coil

is

activated while the current

is

applied

on,

is

-

11

-

Page 19

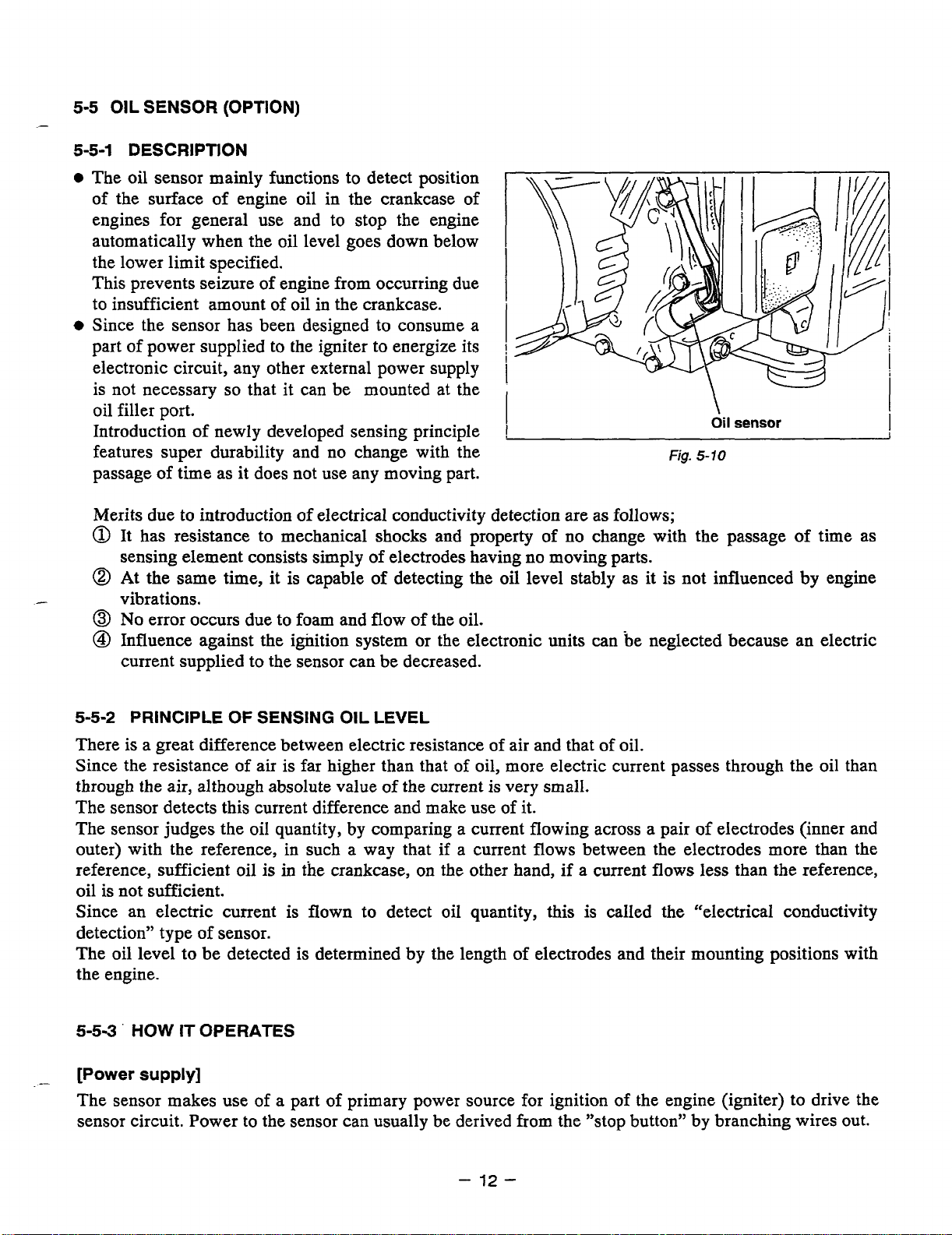

5-5

-

OIL SENSOR

(OPTION)

-

5-5-1

0

0

DESCRIPTION

The oil sensor mainly functions to detect position

of the surface of engine oil in the crankcase

engines for general use and to stop the engine

automatically when the oil level goes down below

the lower limit specified.

This prevents seizure of engine from occurring due

in

to insufficient amount of oil

Since the sensor has been designed to consume a

part

of

power supplied to the igniter to energize its

electronic circuit, any other external power supply

is not necessary

oil filler port.

Introduction of newly developed sensing principle

features super durability and

passage

Merits due to introduction

0

@

@

@

of

It has resistance to mechanical shocks and property of no change with the passage of time as

sensing element consists simply of electrodes having no moving parts.

At the same time, it

vibrations.

No

error occurs due to foam and flow of the oil.

Influence against the ignition system or the electronic units

current supplied to the sensor can be decreased.

so

that it can be mounted at the

time as it does not use any moving part.

is

the crankcase.

no

change with the

of

electrical conductivity detection are as follows;

capable of detecting the oil level stably as it

of

I

I

I

!

i

\

oil

sensor

Fig.

5-10

is

not influenced

can

be neglected because an electric

by

engine

I

I

i

i

1

i

5-5-2

There is a great difference between electric resistance of air and that of oil.

Since the resistance

through the

The sensor detects this current difference and make use of it.

The sensor judges the oil quantity, by comparing a current flowing across a pair

outer) with the reference, in such a way that if a current flows between the electrodes more than the

reference, sufficient oil

oil is

Since an electric current is flown to detect oil quantity, this

detection” type

The oil level to be detected is determined by the length of electrodes and their mounting positions with

the engine.

5-5-3

”

[Power

The sensor makes use of a part of primary power source for ignition of the engine (igniter) to drive

sensor circuit. Power to the sensor can usually be derived from the ”stop button” by branching wires out.

PRINCIPLE

air,

not

sufficient.

’

HOW

IT

supply]

OF

SENSING

of

air is far higher than that of oil, more electric current passes through the oil than

although absolute value of the current

is

in the crankcase, on the other hand,

of sensor.

OPERATES

OIL

LEVEL

is

very smalI.

of

electrodes (inner and

if

a current flows less than the reference,

is

called the “electrical conductivity

the

-

12

-

Page 20

[Judgement

When sufficient oil is in the crankcase, both of inner and outer electrodes are immersed in the oil through

which current flows across the electrodes. The sensor judges that oil in the crankcase is sufficient.

When oil level goes down and the inner electrode is exposed to the air due to consumption of oil, no

current flow between the electrodes as air

The sensor in this case judges that oil

of

oil

level]

is

considered to be electrically non-conductive.

is

insufficient.

4

[Decision

Oil level at the electrodes may go

by vibration even if a sufficient oil is in the crankcase.

For that reason, the sensor has an electronic timer circuit to prevent it from interpreting as short of oil

when amount of oil is sufficient. The sensor has been designed

when oil-shortage

The timer employs an integration circuit and it is to be reset when the inner electrode is soaked in the oil

again before the sensor decides it as oil-shortage.

The

“threshold level”.

[Automatic stop

When

of engine.

Once the stopping circuit is activated, it keeps functioning until it confirms that the engine has made a

complete stop, then the circuit stops functioning automatically.

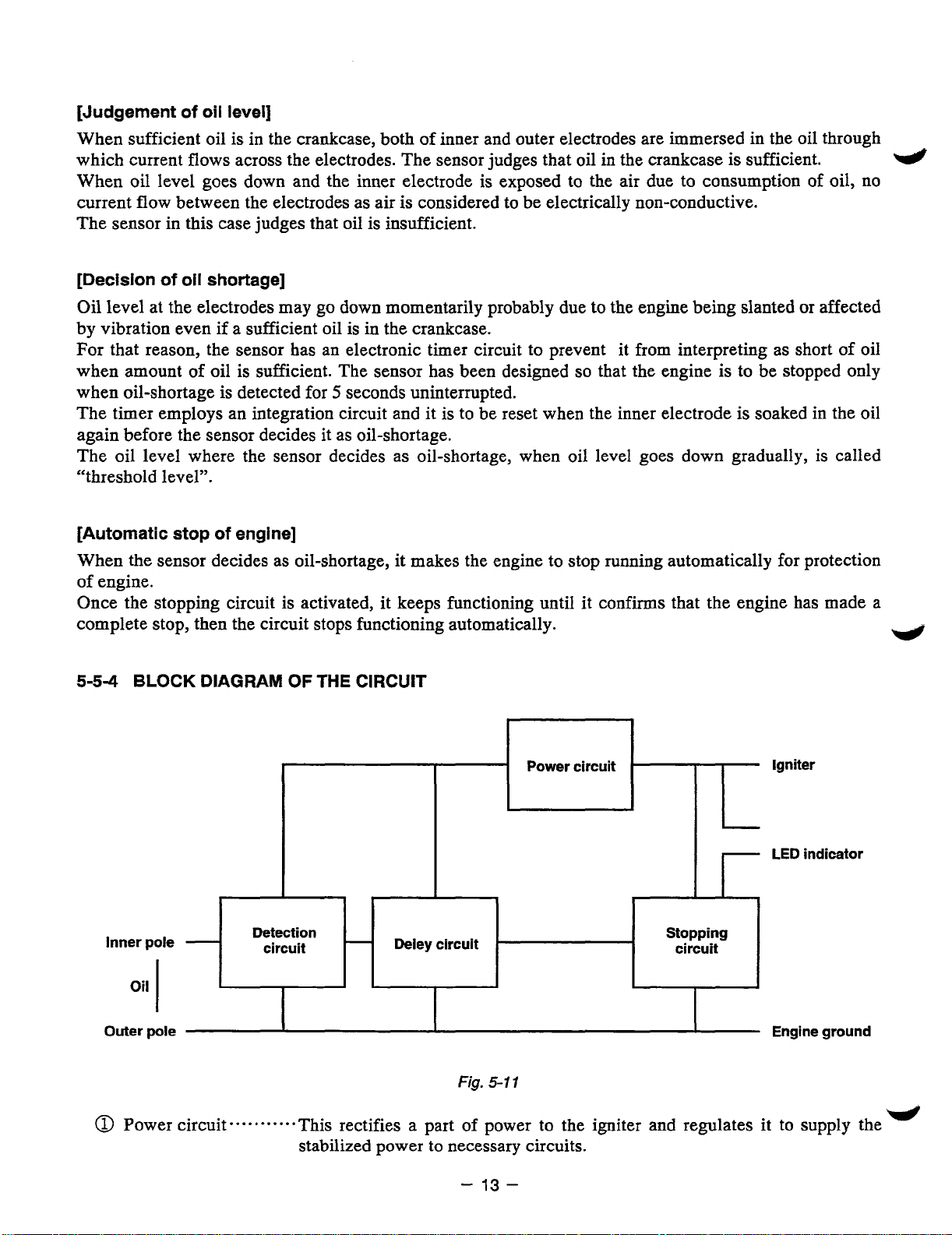

5-5-4

of

oil

shortage]

down

momentarily probably due to the engine being slanted or affected

so

that the engine is to be stopped only

is

detected

oil level where the sensor decides

of

engine]

the

sensor decides as oil-shortage, it makes the engine to stop running automatically for protection

BLOCK

DIAGRAM

for

5

OF THE

seconds uninterrupted.

as

oil-shortage, when oil level goes down gradually,

CIRCUIT

is

called

e

Power circuit

Inner pole

oil

Outer

0

Power circuit----*-*---- This rectifies a part of power to the igniter and regulates it to supply the

-

I

pole

Detection

circuit

stabilized power

-

Deley circuit

Fig.

to

necessary circuits.

-

5-1

1

13-

Stopping

circuit

Igniter

LED

indicator

Engine ground

-1

Page 21

@

Detection circuit*****-* This detects quantity of oil, sufficient or not, according to difference of

electric resistance across inner and outer electrodes.

Delay circuit

@

stopping circuit

5-5-5

(1)

(2)

”

CAUTIONS TO

Oil sensor unit

0

Be sure not to damage each wire.

Broken or short-circuited power supply wires and/or a grounding wire in particular may lead to

malfunction or breakdown.

Mounting and wiring of oil sensor unit

0

Although this has been designed to have enough anti-noise properties in practical use, do not route

the sensor wirings in the vicinity of noise-generating sources such

cords. This may cause malfunction or breakdown.

@

Since capacity of power source

kept as low as possible.

Be sure to use terminals with a high contact reliability

**.*.-**.-*

-

-

* * *

BE

This prevents the sensor from making an unnecessary stop of the engine by

oil

momentary lowering of the

affected by vibration in spite of sufficient oil in the crankcase.

-

This automatically stops the engine running.

Also, the LED indicator for warning can be’

stopped. We have the wires

TAKEN ON HANDLING

is

limited, current flown in the electronic circuit of the sensor is

THE

level due

to

be connected to LED available.

SENSOR

of

more than that

to

the engine being slanted or

lit

while the engine

as

ignition plugs or high voltage

of

tinned terminals.

is

being

(3)

Operation of oil sensor

0

If operating with the engine kept tilted, oil surface inside of the engine varies and the correct oil

level can not to be detected which in turn obstructs the preventing function of engine seizure.

the

Operate

@

When starting the engine with an insufficient oil in the crankcase, engine starts once then

automatically after it runs for about 5 seconds.

@

When the engine has been stopped by the oil sensor, voltage remained in the electronic circuit

prevents the sensor from being re-started for

Try

to re-start the engine after 3 seconds or more.

engine by keeping it level.

3

seconds after the engine stop.

it

stops

-

14-

Page 22

6.

Use extreme caution near fuel. A constant danger of explosion or fire exists.

Do

not fill the fuel tank while the engine

tank. Be careful not to spill fuel when refueling. If spilt, wipe

Do

not place inflammable materials near the generator.

Be careful not to put fuel, matches, gunpowder, oily cloth, straw, and any other inflammables near the

generator.

Do

not operate

Always operate

Otherwise the engine may overheat and also, the poisonous carbon monoxide contained

gases will endanger human lives. Keep the generator at least

facilities during use.

Operate

If the generator

generator may tip over.

the

the

generator in a room,cave or

in

a well-ventilated area.

generator

is

on

a level surface.

tilted or moved during use, there

is

running.

Do

not smoke or use open flame near the fuel

it

and let dry before starting the engine.

tunnel.

in

the exhaust

1

m

(4

feet) away from structures or

is

a danger of fuel spillage and a chance that the

4

Do

not operate with wet hands or in the rain.

Severe electric shock may occur. If the generator

before starting.

Don’t pour water over the generator directly nor wash

If

the generator is wet with water, the insulations will be adversely affected and may cause current

leakage and electric shock.

Do

not connect

This may cause a short-circuit or damage to the generator.

Never connect the generator to the existing house wiring.

when the commercial power source is recovered.

Don’t operate the generator with its cover removed.

The operator may be injured or suffer electric shock.

CAUTION; If the circuit breaker tripped

can be an overload or a short-circuit.

In

appliance and plugs for faulty wiring.

the

generator to the commercial power lines.

off

such a case, stop operation immediately and carefully check the electrical

is

as a result

wet by rain

it

with water.

If

of

using an electrical appliance, the cause

or

snow, wipe

connected, the generator will burn out

it

and thoroughly dry it

4

-

15-

Page 23

7.

-

7-1

AC

OUTPUT

Generally, the power rating of an electrical appliance indicates the amount of work that can be done by it.

The electric power required for operating an electrical appliance is not always equal to the output

wattage of the appliance. The electrical appliances generally have a label showing their rated voltage,

frequency, and power consumption (input wattage). The power consumption of an electrical appliance is

it.

the power necessary for using

factor and starting wattage must be taken into consideration.

In

order to determine the right size generator, it

be connected to the unit.

Refer to the followings to calculate the power consumption of each appliance or equipment by its type.

When using a generator for operating an electrical appliance,the power

is

necessary to add the total wattage of all appliances to

Incandescent lamp, heater, etc. with a power factor of

Total power consumption must be equal to or less than the rated output

Example:

Fluorescent lamps, Motor driven tools, light electrical appliances, etc. with a smaller power

factor

A

rated 1OOOW generator can turn ten lOOW incandescent lamps

1

.O

of

the generator.

on.

Select a generator with a rated output equivalent to 1.2 to 2 times of the power consumption of the

of

load. Generally the starting wattage

motor driven tools and light electrical appliances are 1.2 to

times lager than their running wattage.

Example:

NOTE

NOTE

Mercury lamps with a smaller power factor

A

rated 250W electric drill requires a 400W generator to

7:

If a power factor correction capacitor

power shall be required to drive the lamp.

2:

Nominal wattage of the fluorescent lamp generally indicates the output wattage of the

lamp.

Therefore, if the fluorescent lamp has no special indication as to the power consumption,

efficiency should be taken into account as explained in item

is

not applied to the fluorescent lamp, the more

start

it.

(5)

on the following page.

Loads for mercury lamps require 2 to 3 times the indicated wattage during start-up.

Example:

A

400W mercury lamp requires

A

rated 1OOOW generator can power one 400W mercury lamp

800W

to 1200W power source to be turned

on.

3

Initially loaded motor driven appliances such as water pumps,compressors,etc.

These appliances require large starting wattage which

Example:

NOTE

NOTE

A

rated

9OOW

1:

Motor-driven appliances require the aforementioned generator output only at the starting.

Once their motors are started, the appliances consume about

power consumption

for other electrical appliances.

2:

Motor-driven appliances mentioned in items

starting power depending on the kind of motor and start-up load. If it is difficult to

determine the optimum generator capacity, select a generator with a larger capacity.

compressor requires a 4500W generator to drive it.

so

that the excess power generated

-

16-

is

3

to 5 times of running wattage.

1.2

to 2 times their rated

by

the generator can be used

(3)

and

(4)

vary in their required motor

Page 24

Appliances without any indication as to power consumption

Some appliances have no indication as to power consumption; but instead the work load (output)

indicated.

formula mentioned below.

Efficiencies of some electrical appliances are as follows:

Example

Example

In

such a case, power consumption

(Output of electrical appliance)

(Efficiency)

Single-phase motor

Three-phase motor

Fluorescent lamp

1

:

A

40W fluorescent lamp means that

efficiency

explained in

you will get the figure of the necessary capacity

generator with a rated output

fluorescent lamps.

2:

Generally speaking, a 400W motor means that its work load

this motor

is

used for a motor-driven tool, the capacity of the generator should be multiplied by

1.2

- - - -

- - - -

to 3 and

- - - - - -

*

- - -

*

*

- -

- -

- - - - -

is

0.7

and accordingly, power consumption will be

Item(2),

is

0.7

and power consumption will be

570W

is

to

be worked out according to the numerical

-

-

(Power consumption)

*

-

-

0.6

-

- -

-

*

0.65

- -

0.7

multiply this power consumption value of 57W by

as

explained in the

0.75

-

0.9

-

0.8

of

1OOOWcapacity can light nine to fourteen 40W

The smaller the motor, the

>lower the efficiency.

its

luminous output

of

a generator. In other words, a

is

400

+

0.7=

570W. When this motor

item(3).

is

40

400W. Efficiency of

40W.

+

Its

0.7=

1.2 - 2

57W.

is

*

As

and

Applicable wattage

Appliance

60Hz

lncandesent lamp,

Fluorescent lamp, mercury lamp , Electric

Pump, compressor up to about

I

NOTES: Wiring between generator and electrical appliances

1.

Allowable current

Use a cable with an allowable current that is larger than the rated input current of the load

(electricalappliance).

the cable will become excessively heated and deteriorate the insulation, possibly burning it

out.

Table

2.

Cable length

If

conductors decreasing the input voltage to the load (electrical appliance). As a result, the load

can be damaged.

Table

7-2

a long cable is

7-2

hot

plate

Table

of

cable

If

the input current is larger than the allowable current

shows cables and their allowable currents for your reference.

used,

shows voltage drops per

a voltage drop occurs due to the increased resistance in the

tool

100

I

I

I

I

7-1

meters

of

up

up to about

cable.

to

lOOOW

800W

250W

of

I

I

I

I

the

cable used,

w

-

17-

Page 25

Sectional

mm'

Allowable

A

Gauge

wlre element current area

No./

No./mm

I

Voltage

0.75

1.25

2.0

5.5

7

12

17

23 3.5

35

Voltage drop indicates as V

R

means resistance

I

means electric current through

4!

means the length of the wire

The length

7-2 DC OUTPUT

of

wire indicates round length, it means twice the length from generator to electrical tools.

(

52

3010.18

5010.18

37

10.26

45

10.32

7010.32

=

100

/lo0

m)

Table

XRXIXl

on

the above table.

the

wire

(A).

(m).

7-2

NOTE

When the generator

:

Do not use DC and AC output simultaneously.

to

a

Due

AC output creates voltage drop in DG output resulting in incapability

characteristic

is

employed

electrolyte in the battery.

7-2-1 SPECIFIC

The specific gravity

S20 = St

GRAVITY

of

electrolyte varies by temperature

+

0.0007

where

S20 : The specific gravity at

St : Measured value

t

:

Temperature at the time

of

the condenser voltage regulation, simultaneous

to

charge batteries, attentions should be paid to the specific gravity

OF

BATTERY ELECTROLYTE

(t-20)

20°C

of

measurement (Electrolyte)

use

of

DC and

for

charging batteries.

of

;

so

it

must be converted to the one at

20°C.

-

18

-

Page 26

7-2-2

SPECIFIC GRAVITY

OF

BATTERY

ELECTROLYTE AND

CHARGING

CONDITION

Specific gravity (20.c)

1.260

1.240

1.220

1.200

1.180

1.160

I

7-2-3

BATTERY

1.140

CAPACITY

1

The battery capacity is expressed

of

capable

one ampere current for one hour.

in

100

the unit

87

75

62

50

37

25

Charging

Charging

Immediate Charging is necessary.

I

of

AH (ampere-hour). One

Remarks Charglng condintion

is

not necessary.

is

necessary.

AH

stands for the capacity

w

-

19-

Page 27

8.

MEASURING PROCEDURES

-

8-1

MEASURING INSTRUMENTS

8-1

-1

“Dr.

ROBIN” GENERATOR TESTER

The “Dr. Robin”generator tester is exclusively designed for fast, easy diagnosis and repair

generators.

The “Dr. Robin” has the following features:

(1)

Functions

of

voltmeter, frequency meter, megger tester, capacitance meter and circuit tester

are combined in one unit.

(2)

Fast and easy readout by digital indicator.

(3)

Built-in automatic battery checker indicates the

time to change batteries.

(4)

Tester and accessories are installed in a handy, sturdy case for easy carrying.

0

SPECIFICATIO

US

of

Robin

I

Fig.

8-7

Model

a

m-

d

CI)

.-

K

Voltage

Frequency

Resistance

Dr.

Robin

0-5OOV

25-70HZ

0.1 -1,999

AC

R

5’

8

Condenser Capacity

s

insulation Resistance

I

Circuit Protector

I

Power Source

Accessories

Dimensions

Weight

(L X W

X

H)

I

Test leads with needle probes

Test leads with jack plugs

285 mmx200 rnmxl10 mm

I

Table

8-1

10-100

3MR

Fuse

1.6kg

,uF

.

.

.

. . .

.

.

I

1 set

1 set

The “Dr. Robid’generator tester can be ordered from Robin generator distributors by the following part

number.

I

Dr.

Robin

-

If you do not have a “Dr. Robid’generator tester,use the instruments described

Part

Number

:

388-47565-08

1

for checking generator parts.

-

20

-

in

the following section

Page 28

8-1-2

INSTRUMENTS

VOLTMETER

AC

voltmeter is necessary. The approximate

voltage ranges

various types

0

to

15OV:

of

the voltmeters to be used

of

generators are as follows:

Type with

an

output voltage

or 120V

0

to

300V:

Type with an output voltage

230 or 240V

0

to 150V, 0 to 330V: Dual voltage type

(2)

AMMETERS

is

AC ammeter

necessary.

An

AC

ammeter with

a range that can be changed according to the

of

current rating

desirable. (About

a given generator

10A,

20A,

1OOA)

is

of

of

AC

for

110

220,

most

I

For

AC

fig.

8-2

(3)

FREQUENCY METER

Frequency range : About 45 to

NOTE:

Be

careful

input

voltage range.

65Hz

of

the frequency meter’s

I

For

Fig.

Fig.

AC

8-3

8-4

-1

-

21

-

Page 29

-

(4)

CIRCUIT TESTER

is

This circuit tester

used for measuring re-

sistance, etc.

(5)

MEGGER TESTER

Used for measuring generator insulation resistance.

Select one with testing voltage range of

500V.

I

Fig.

8-5

(6)

ENGINE TACHOMETER

of

There are various types

tachometers,

contactless type, contact type, and strobe type.

The contact type can be used only when the

generator and engine have been disassembled.

The contactless type is recommended.

The PET-2100E engine tachometer is available

from your Robin distributors.

Please inquire by the part number PET-2100E.

such

as

-

22

-

Fig.

Fig.

8-6

8-7

Page 30

8-2

AC

OUTPUT MEASURING

4

To

AC

receptacle

Fig.

8-8

Measurement is executed with the circuit as shown in Fig.

1.0

lamp with a power factor of

the rated load and rated speed

is

the AC output

8-3

DC

OUTPUT MEASURING

normal.

I

Rated voltage

Voltage range

I

To

DC

Terminal

-l

is suitable

is

confirmed to be within the voltage range specified in the table below,

Table

I

8-2

as

a load for the generator. When the AC output measured at

120v

1

17-1

30V

I

P

8-8.

An electric heater or an incandescent

I

Measurement of DC output

by adjusting the load to the generator.

output is normal.

Note : If a battery is connected

approximately

the battery.

is

executed with the switch turned

as

I

to

2V.

Therefore, carefully observe the electrolyte level and do not overcharge

Fig.

8-9

ON

while the current is regulated at 8.3A

If

the voltage is within the range from

a

load to the generator, the

-

23

-

DC

6V

to

14V,

the voltage

output voltage will increase by

Page 31

8-4

MEASURING INSULATION

RESISTANCE

Use a “Dr. Robin”generator tester in megger tester

mode or use a megger tester to check

resistance. Connect a megger tester

to

the

insulation

one

of

receptacle output terminals and the ground terminal, then

measure the insulation resistance. An insulation resistance

original insulation resistance at the time

from the factory

If

it

ator and measure the insulation resistance

of

1

megohm or more

is

10

megohm or more.)

is

less than 1 megohm, disassemble the gener-

is

normal. (The

of

shipment

of

the

stator, rotor and control panel individually.

fig.

8-70

0

STATOR

(1)

Measure the insulation resistance between

BROWN lead and the core.

(2)

Measure the insulation resistance between

LOW lead and the core.

(3)

-

Measure

BLACK lead and the core.

0

ROTOR

the

insulation resistance between

Measure the insulation across one

of

terminals

the rotor and the core.

of

the soldered

YEL-

I

I

Fig.

8-1

1

J

Fig.

8-12

-

24

-

Page 32

0

CONTROL

PANEL

Measure the insulation resistances between the live

parts and the grounded parts.

Any part where the insulation resistance

leakage and electric shock.

Replace the faulty part.

is

less than

I

1M8

Fig.

has faulty insulation,

8-13

and

may cause electric

I

-

25

-1

-

Page 33

9.

CHECKING FUNCTIONAL MEMBERS

9-1

CONTROL PANEL

Fig.

9-1

9-1

-1

AC RECEPTACLES

Using a “Dr. Robin”or a circuit tester, check continuity between the two terminals at the rear

on

receptacles while the receptacle is mounted

the control panel. When continuity is found between the

of

the AC

output terminals of the receptacle with a wire connected across these terminals, the AC receptacle

normal. When the wire

is

removed and

no

continuity is found between these terminals, the receptacles

are also normal.

is

-

Fig.

9-2A

-

26

-

Fig.

9-26

Page 34

9-1-2

DC

TERMINAL

Check continuity between the DC terminals at the rear of the control panel using a circuit tester, under

the condition that the DC terminals is mounted

on the control panel. (See Fig.

9-1.)

When continuity between the DC terminals is confirmed with a wire connected across the terminals, and

if

is not confirmed

the wire

is

removed, the DC terminals are normal. (See Fig.

9-1.)

w

9-1-3

Check continuity between the two terminals

while it is mounted

If

OFF,

9-14

Check the voltmeter

CIRCUIT

continuity

BREAKER

is

confirmed when the breaker

the circuit breaker

VOLTMETER

on

the control panel.

is

is

normal.

if

it operates correctly by apply-

at

the rear side of the circuit breaker using a circuit tester

ON,

ing specified voltage. Voltmeters caunot be checked

with a circuit tester because its internal resistance

too large.

and no continuity is confirmed when the breaker is

AC

is

Voltmeter

Fig.

9-3

9-2 STATOR

Disengage connectors

on

the wires from stator and

check the resistance between wires with a

“Dr. Robin” or a circuit tester referring to the following table.

-

27

-

I

I

Fig.

9-4

Page 35

-

Hz

Specification

Voltage

AC

Windlng

Brown

I

White

DC

Windlng

Green

I

Green

(Rxl

R

+lo%)

Condenser Winging

Black / Black

60

1

20v

Table

1.4

9-1

Q

0.62

Q

4.8

NOTE: If the circuit tester is not sufficiently accurate$ may not show the values given and may give

erroneous readings.

Erroneous reading will also occur when there is a wide variation of resistance among coil

windings or when measurement is performed at ambient temperatures different from

ZO"C(68"F).

9-3

ROTOR

1)

Using the "Dr. Robin"or a circuit tester, measure the resistance

Fig.

(See

-

9-5.)

(RxlR+10%)

Resistance

ef

the field coil.

R

_-

NOTE

I:

Because a diode is soldered to

ends at the terminals, resistance may

measured only when tester probes touch

the terminals in one combination of polarity. Therefore, if no resistance reading

appears, try checking in reverse polarity.

NOTE

2:

If

the circuit tester is not sufficiently accu-

rate,

it

and may give erroneous readings.

Erroneous reading will also occur when

there is a wide variation of resistance

among coil windings or when meas-

urement is performed

peratures different from

2)

Measure the resistance

may

not show the values given

at

ambient tem-

20°C

of

the resister.

the

(68°F).

coil

be

Fig.

9-5

-

28

-

Page 36

9-4

CONDENSER

w

Use a "Dr. Robin" in capacitance meter mode to check the capacity

of

condensers. (See Fig.

9-6.)

NOTE:

If

If

condenser.

9-5

DIODE

Be sure to discharge condensers by shorting condenser leads each other before

checking their capacitance,or the accurate

reading cannot be obtained.

10

,uF

such

an

instrument

is

unavailable, the condenser can be checked by replacing with a new one.

the generator performs good with new condenser, the cause

RECTIFIER

of

Fig.

trouble

9-6

is

defect in original

Geen>

Green

Fig.

9-7

h

Diode rectifier

'4

Circuit tester\

Fig.

9-8

The internal circuit

Check continuity between each terminal using a circuit tester

of

the diode rectifier is as shown

in

Fig.

9-7.

as

shown in Fig.

Green Green

9-8.

-

29

-

Page 37

Checking table for analogue circuit tester.

~~~ ~ ~ ~~~ ~

Analogue clrcult tester

Green

@

Apply red

of

the clrcult tester

needle

Green

Red

Checking table for digital circuit tester.

~~ ~ ~~ ~ ~~ ~

Apply black Oneedle

Green

of

Green

the clrcult tester

Red

No

continuity

_-

NOTE

NOTE

NOTE

Digital

Apply black

of

the clrcult tester

1:

Because

digital circuit tester, polarity

2:

“Continuity” means forward direction characteristics

circuit condition (in which

clrcult tester

0

needle

of

the difference

Green

Green

Red

Table

of

measuring method between the analogue circuit tester and the

of

tester needles should be reversed,

a

pointer

of

resistance to some extent. When result

Apply red @needle

Green Green Red

9-2-2

of

the diode, and different from short

the tester goes out

of

the checking indicates failure even in one

of

the clrcult tester

of

its

normal scale), shows

No

continuity

section,replace with a new one.

3:

“Simpson“ brand analogue testers have the characteristic as same as the digital circuit tester.

L

-

30

-

Page 38

9-6

OIL

SENSOR (OPTION)

1.

Disconnect two

(2)

wires comming from the sen-

sor at the connection.

2.

Loosen the sensor to remove it from the engine.

3.

Plug the opening of oil filler hole (created after

sensor

is

removed) with suitable means such as oil

gauge.

4. Connect the removed wires again with the oil

sensor.

5.

Start the engine with the oil sensor removed and

~~ ~

Fig.

9-9

confirm if;

5

a. Engine stops after

b.

Engine does not stop after more than

NOTE : The sensor will not operate properly when wire is broken or poorly connected.

Check the wires for correct connection.

If

it fails to stop within 5 seconds after the wirings have checked, the sensor

Replace the sensor with new one.

seconds which

is

normal, or

10

seconds which

is

unusual.

is

wrong.

10.

10-1

DISASSEMBLY

PREPARATION

1)

Be

sure to memorize the location of individual parts when disassembling the generator so that the

AND

and

PRECAUTIONS

ASSEMBLY

generator can be reassembled correctly.. Tag the disassembled part with the necessary information to

facilitate easier and smoother reassembling.

2)

For more convenience, divide the parts into several groups and store them in boxes.

3)

To

prevent bolts and nuts from being misplaced or installed incorrectly, place them temporarily back

at their original position.

4)

Handle disassembled parts with care; clean them before reassembly using a neutral cleaning fluid.

5)

Use all disassembly /assembly tools properly, and use the proper tool for each specific job.

-

31

-

Page 39

10-2

DISASSEMBLY

c

itep

-

1.

Side

cover

2.

PROCEDURES

(1)

Remove the side cover

four

M5

X

8

screws. (See Fig.

(1)

Remove the rear cover

three

M5

X

8

screws and

screws. (See Fig.

10-2.)

by

unscrewing

10-1

by

unscrewing Rear cover

two

M8

(+)

Plus screw

driver

(+)

Plus driver

Tool

~~~ ~~

.)

X

10

3.

Control panel

Fig.

(1)

10-

1

Pull the

remove

four

M5

I

knob

off

the

control panel

X

8

screws.

the

control lever and

by

unscrewing

(See

Fig.

Fig.

10-3.)

10-3

Fig.

10-2

I

(+)

Plus driver

-

-

32

-

Page 40

'art

to remove

'I

Description

I

Remarks

Tool

Couplers

and plugs

(D'

Iscon-

nection)

(1)

Disengage the couplers

from

the

wires

of

control panel. pushing the

6P

couplers (Yellow, Red,

Yellow,

Brown,

(See Fig.

(2)

Disengage the connectors

White)

10-4.)

lamp (option)

(See Fig.

10-5.)

of

stator wires Pull the couplers while

\

Green/

of

oil warning

hook.

locking

Fig.

Press

the hook

pull

out

to disconnect.

Press the hook

pull out to disconnect.

CONTROL PANEL SIDE

of

the coupler and

of

the coupler and

10-4

STATOR SIDE

-

33

-

Fig.

10-5

Page 41

5.

'art

to

remove

Front cover

(1)

Remove the element cover

unscrewing

(See Fig.

(2)

Remove the

three

M5

M6

X

12

10-6.)

front

cover by unscrewing

X

8

screws. (See Fig.

1

by

screw.

10-6.)

(-)

(+)

Tool

~

Driver

Driver

6.

Fuel pipe

and plug

(Disconnection)

(1)

Discharge fuel from the

1.

Shut the fuel striner.

2.

Remove

3.

Put a vessel

the

strainer cup.

to

Element

tank.

receive fuel under the

Fig.

cover

10-6

strainer and open the fuel cock

discharge fuel.

4.

Attach the strainer

(See

Fig.

cup

10-7.)

to the strainer

body

(2)

Disconnect fuel hose from the strainer.

Loosen the hose clamp

on

top of the

strainer and pull out the fuel hose from

the

strainer. (See Fig.

10-8.)

Use utmost care about

fire hazard.

Wipe off spilt fuel

to

throughly.

Do

not lose the filler

screen.

Pliers

Fig.

70-7

II

-

34

-

Fig.

10-8

Page 42

Step

-

'art to remove

7.

Fuel tank

handle

Description

(1) Remove the handle cover

the

two

M3

X

10

screws.

(2)

Pull

off

the breather

(3)

Remove the handle

the

two

M8

M3

x

nuts.

pipe.

body

Handle cover

by

unscrewing

by

taking

I

The

removed without

disassembling the

handle.

off

Remarks

fuel tank

can

be

I

(+)

12mm

Tool

Driver

box

wrench

M8

Nut

(2

I

pcsj

Fig.

-1

10-9

-

35

-

Page 43

Part

to

remove

Description

Remarks

I

Tool

Fuel tank

Bracket

(Cover)

(1)

Remove the

two

M6X

12

flange bolts

from the blower housing.

(See Fig.

10-10.)

(2) Remove the fuel tank by taking off the

two

M8

nuts from

tank.

(See

Fig.

Fig.

10-1

0

(1)

Remove the bracket cover from the

generator by loosening the

bolts. (See Fig.

10-1

10-12.)

1.)

the

bottom

two

M8

of

X

the

30

Fig.

10-1

lOmm box wrench

12mm

box wrench

7

12mm box wrench

End cover

(1)

Remove the end cover from the generator

by unscrewing the four

(See Fig.

10-12.)

M5

X

Fig.

10

screws.

10-12

I

I

(+)

Driver

-

36

-

Page 44

I

step

I

Part

to

remove

I

Description

I

Remarks

I

Tool

11.

Rear bracket

(1) Loosen and take out the three

bolt.

(See

Fig. 10-13.)

(2)

Remove condenser from

(3)

Remove the connector

rectifier and then remove the

terminal from the rear bracket.

(See Fig. 10-14.)

rear

of

M6

cover

bracket.

the diode

earth

cable

lOmm box wrench

Box spanner

Box spanner and

screw driver

(+)

Fig.

10-13

(4) Remove

evenly with a plastic mallet.

(See Fig. 10-15.)

(5)

Remove mount rubbers from rear cover.

(See Fig. 10-16.)

the

rear

bracket, tapping it

Fig.

10-14

Plastic mallet

Wrench

I

Fig.

10-15

-

37

-

Fig.

10-16

Page 45

Itep

-

12.

Part

Stator

to remove

(1)

Remove the stator

(See

Fig.

10-17.)

Descrlptlon

cover.

I

Remarks

Tool

(2)

Pull off the stator from the front cover Never

tapping the core. with

(See

Fig.

10-18.)

Fig.

10-17

a

plastic mallet. winding and the lead.

tap

n

on

the

Fig.

Plastic mallet

10-18

-

38

-

\

Fig.

10-19

Fig.

cover

10-20

Page 46

Step

-

13.

'art

to

Rotor

remove

Descrlptlon

(1) Take off the through bolt.

Apply a box wrench on the head of

through bolt. Hit the wrench handle with

a hammer counter-clockwise to loosen.

Fig.

10-21

(2) Put the engine on the working table

recoil starter side down.

Remarks

Tool

Box wrench

Plastic hammer

(3)

Use a bolt and oil as a tool for pulling

out rotor in the following procedures

1.

Pour engine oil

into

the center hole of

rotor shaft.

Fill with oil to the shaft end.

(See

Fig. 10-22.)

2. Prepare a bolt with the following

thread size

3.

Apply a few turns

:

M8

X

P

1.25

of

seal tape around

the tip of the bolt.

(See Fig.

10-23.)

:

Fig.

10-22

I

Fig.

10-23

-

39

-

Page 47

Dart

to

remove

Descrlptlon

I

Remarks

Tool

13.

Rotor

4.

Screw the bolt into the thread of the

rotor shaft.

5.

Torque the bolt using a socket wrench

until the rotor comes off loose.

*

The hydraulic pressure inside the rotor

takes

shaft

engine shaft.

(4) Wipe off oil throughly from rotor shaft

and engine

apart the

PTO

shaft.

rotor

from the

12mm box spanner

or

Socket wrench

14.

Front bracket

(1)

Remove the front bracket, which

mounted on the main bearing cover

the engine,

bolts.

(See

by

taking out four

Fig.

10-25.)

Fig.

Fig.

10-24

M8

10-25

is

12mm box spanner

of

X

18

-

-

40

-

Page 48

Part to remove

Mount

rubbers

Description

(1)

Remove mount bracket

Remove mount rubbers

bracket.

8

q.5

Nut

~

:

Spa.

or

2pcs.

from

engine.

from

mount

Remarks

Tool

I

12

mm

wrench

Mount bracket

Fig.

10-26

\

Mount rubber

-

41

-

Page 49

10-3

”

ASSEMBLY PROCEDURES

10-3-1

FRONT

BRACKET

Install the front bracket on the main bearing cover of

the engine, engaging the faucet joint.

(See

Fig.

10-27.)

M8

X

18mm bolt and washer assy

TIGHTENING TORQUE

10.1

ft

9

Ibs.

1175

-

1370N-crn

140

kg

=

cm

10-3-2

1)

ROTOR

Wipe off oil from the tapered portion of engine shaft and matching tapered hole of rotor shaft.

(See Figs. 10-28 and

10-29.)

-.***..-..-*

4pcs.

Fig.

10-27

Fig.

Fig.

10-28

70-29

Install rotor on the engine shaft and tighten the

through-bolt.

of

Apply a wrench on the head

hit

wrench handle clockwise with a hammer

tighten.

If

I

I

(See

Fig.

10-30.)

an impact wrench

TIGHTENING TORQUE

8.7

-

10.1

ft

1175

-

1370N-cm

120

-

140

kg

is

available, use it.

Ibs.

cm

through bolt and

I

-

to

42

-

I

Fig.

10-30

Page 50

10-3-3

STATOR

Holding the rear bracket and stator, fit them to

the front bracket. Match the mounting hole

the rear bracket and that of the rotor bearing,

and softly strike the outside periphery

bracket with a plastic hammer.

4.0

55

10-31.)

-

5.4

-

735 N cm

-

M6

boll

ft

Ibs.

75kg-cm

i

to fix the rear brack-

(See Fig.

Attach the stator cover around the stator.

Tighten the three

et to the front bracket .

TIGHTENING TORQUE

535

of

the rear

of

Fig.

10-31

(4)

Put the grommet in the groove of the rear bracket and secure the wire.

Note

:

Fix

the

wire

from

the stator and diode stack with the

10-3-4

Put condenser to rear cover.

CONDENSER

5

0

X

10

mm tapping Screw ----..----*.----..

TIGHTENING TORQUE

2.4

-

325

-

4.0

ft

-

Ibs.

535 N cm

55

kg

cm

2

pcs.

clamp

Condenser

at

the

bottom

of

the groove.

-43-

Fjg.

10-32

Page 51

10-3-5

"

Set the end cover

M5

10-3-6 BRACKET (COVER)

END COVER

X

10

screws.

on

the rear bracket with four

Mount the bracket (cover)

M8

secure them with

10-3-7

(1)

FUEL TANK AND FUEL

Connect the rubber pipe to the engine carburetor and fasten

X30

Attach the banjo to the opposite end

on

the rear bracket and

bolts.

PIPE

(CONNECTION)

of

the rubber pipe, tighten it with a hose clamp, and fasten the

pipe to the fuel strainer with the banjo bolt.

Note : Mount the fuel strainer with the banjo outlet upward.

_-

(2)

Fasten the strainer to the front bracket with the joint nuts.

(3)

Secure the mounting tab on the bottom of the fuel tank and the blower housing with

Insert the attaching bolts

M8

nuts.

on

the other end of tank into the mount bracket hole and

Fig.

it

with a hose clamp.

10-33

M6

secure

X12

bolts.

it with two

(4)

Connect the rubber pipe

First, fit the hose clamp

on

the rubber pipe, connect the strainer and fuel tank, then fasten the rubber

pipe with the hose clamps.

Note :Apply a drop of oil to the rubber pipe

fuel tank.

10-3-8 FUEL TANK HANDLE

(1)

Match

(2)

Completely insert the breather pipe over the bolt.

Note : There is a hole at the center of the breather pipe for air bleeding. Set the breather pipe

(3)

Fix both ends of the handle cover with

hole

the

handle hole with the bolt

is

directed upward.

so

that it may easily be connected to the strainer and the

on

the top of the fuel tank and secure it with M8 nuts.

M3

X

10

screws.

-

44

-

so

that the

Page 52

M3

Handle cover

x

10

Screw

(2

pcs.)

-1

To

Carburetor

To

Carburetor

Is

Hose clamp

M8

/

Nut

(2

pcs.)

10-3-9

(I)

(2)

FRONT COVER

Secure the front cover, on which fuel strainer

have been mounted, with three

(See Fig.

10-35.)

Secure the element cover with

(See Fig.

10-35.)

Hose clamp

AND

ELEMENT COVER

M5

M6

X

X

12

8

screws.

screws.

Rubber hose

Rubber hose

Fig.

10-34

"..,-

Fuel strainer

-

45

-

Element cover

F@.

10-35

Page 53

10-3-10 CONNECTION

-

.

(1)

Connect the wires drawn out from the stator to

the wires from the control

OF

WIRES

box.

(See Fig. 10-36.)

(2)

Press the couplers until the locking hook engages

securely.

(3)

Connect the

oil

warning lamp (option) wire. (See

Fig. 10-36.)

[WIRE CONNECTIONS BETWEEN CONTROL PANEL AND STATOR]

\

fig.

10-36

6P coupler Wire color

Green / Yellow

CONTROL

10-3-1 1 CONTROL PANEL

(1)

Put the control panel over the control lever and

secure it with four

(2)

Attach the

knob

to

:

Yellow, Red, GreenrYellow, Brown, White

M5

PANEL

screws.

SIDE

the control lever.

Green / Yellow

STATOR

SIDE

Note

:After

c

the couplers and connectors have been

connected and secured to the control panel,

secure

control panel.

the wires with a wire band to the

-

46

-

Fig.

10-37

Page 54

10-3-1

2

REAR

COVER

Secure the rear cover with three

M8

X

two

10-3-13

Secure the side cover

10 screws.

SIDE

COVER

with

four

M5X8

M5X8

screws.

screws and

Fig.

70-38

-

47

-

Page 55

-

11

=

TROUBLESHOOTING

11-1

NO

AC

OUTPUT

11-1 -1

CHECKING STATOR

1) Remove control panel and disconnect couplers on

wiring.

2)

Measure the resistance between terminals on

stator leads.

Refer to Table

9-1

(page

28)

for normal re-

sistance.

[Remedy]

If

stator

11

w

is

defective, replace with new one.

-1

-2

CHECKING

CONDENSER

If an instrument (Q.C.-meter or C-meter) for measuring capacity of condenser

of

capacity

NORMAL CAPACITY

condenser.

OF

CONDENSER

Fig.

11-1

is

available, check the

1

OpF

w

If