Page 1

Multipurpose

Soft Starter

Sizes 8 to 840 AMP

Installation & Operating Manual

9/06 MN894

Page 2

Page 3

Table of Contents

Section 1

General Information 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Major Components 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protection Devices 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configurations 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2

Installation 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving, Inspection and Storage 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Location 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Main Circuit 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protection Devices 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Disconnect 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Non-Motor and Special Motor Applications 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3

Operation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of Starting 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start Adjustments 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ramp Up 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Up 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Time 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Limit 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stop Adjustments 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ramp Down 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Down 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Run Adjustments 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Monitor 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Factor 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Calibration Switch 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Parameters Switch 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Connections 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLOSE TO RUN 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

START/RUN 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHUNT TRIP 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RAMP END 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TACH 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MTR PWR 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CUR MON 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents iMN894

Page 4

Indicators 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power On 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Over Current 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Current 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary of Start and Stop Sequences 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 4

Start-up 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-up Checklist 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Equipment 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick Set-Up 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting Instructions 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Variable Load with Voltage Ramp 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High Friction Load with Voltage Ramp 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inertial Load 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tachometer Mode 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-up Troubleshooting 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 5

Troubleshooting 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preliminary Checks 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Off Checks 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blocking Voltage Check 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCR Tests 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Full Voltage Test 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resistance Test 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCR Replacement 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Control Module Resistance Test 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Chart 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

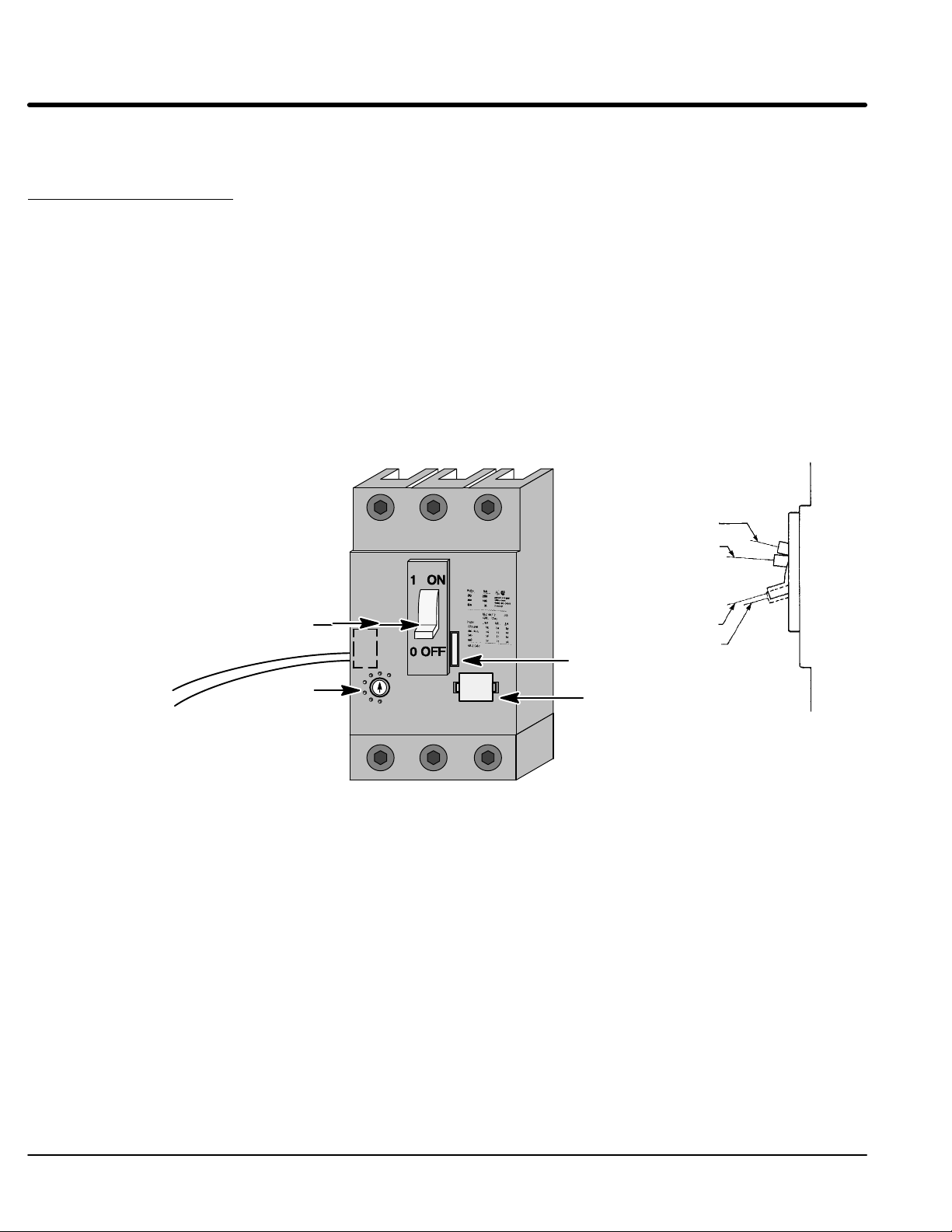

Reset the Circuit Breaker 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset an Overload Relay 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuse Replacement 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii Table of Contents MN894

Page 5

Section 6

Specifications and Product Data 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Identification 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Three Phase Starters 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Three Phase Starters 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wire Size & Tightening Torque Specifications 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting Dimensions 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open Panel 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NEMA 1, 3R and 12 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection Diagrams 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MA Style 8, 16 and 30 AMP 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MB Style 8, 16 and 30 AMP 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MA Style 55 and 80 AMP NEMA 1 and Panels 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MB Style 55 and 80 AMP NEMA 1 and Panels 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NEMA 1 & Panel Mounted Size 160−840 AMP Control Only 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NEMA 1 & Panel Mounted Size 160−840 AMP Combination & Noncombination 6-12. . . . . . . . . . . . . . . . . . . .

NEMA 12 Size 160−840 AMP Combination & Noncombination Bypass 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Reference Information A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Calibration Chart A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick Reference Chart A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overload Relay Adjustment A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B

Circuit Breaker Adjustments B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents iiiMN894

Page 6

iv Table of Contents MN894

Page 7

Section 1

General Information

Introduction Three phase multipurpose soft starter control provides reduced voltage, three phase

motor starting. Ramp up and extended ramp down features provide an effective means

to start and stop material handling equipment and pumping equipment to minimize

spillage and water hammer problems. Adjustable current limit allows constant current

starting of high inertia loads such as chippers, centrifuges and compressors. It also

reduces the peak demand of power required from utility companies or generating

equipment.

Tachometer feedback may be used to provide consistent starting and stopping times with

linear acceleration and deceleration. This is especially important under varying load

conditions like: textile, material handling and pumping equipment.

Six SCR (silicon controlled rectifier) devices are connected in three sets of inverse

parallel configuration to provide full wave voltage and current control of the three phase

AC motor. MOV (metal oxide varistors) provide surge voltage protection at the AC input

to the starter.

Several product features make this soft start control easy to use:

S Two selectable starting methods.

S Individual ramp up and ramp down adjustments.

S Flexible yet simple setup with switch selections and potentiometer adjustments.

S Simple onboard current calibration.

S Indicator lights and status contacts providing information about the starting,

running and stopping conditions.

S Bar graph display provides a visual representation of motor current to assist in

set-up and troubleshooting. (0 to 400% FLA).

S Tachometer input.

S Five output relay contacts.

S Built-in protection features to reduce down time.

General Information 1-1MN894

Page 8

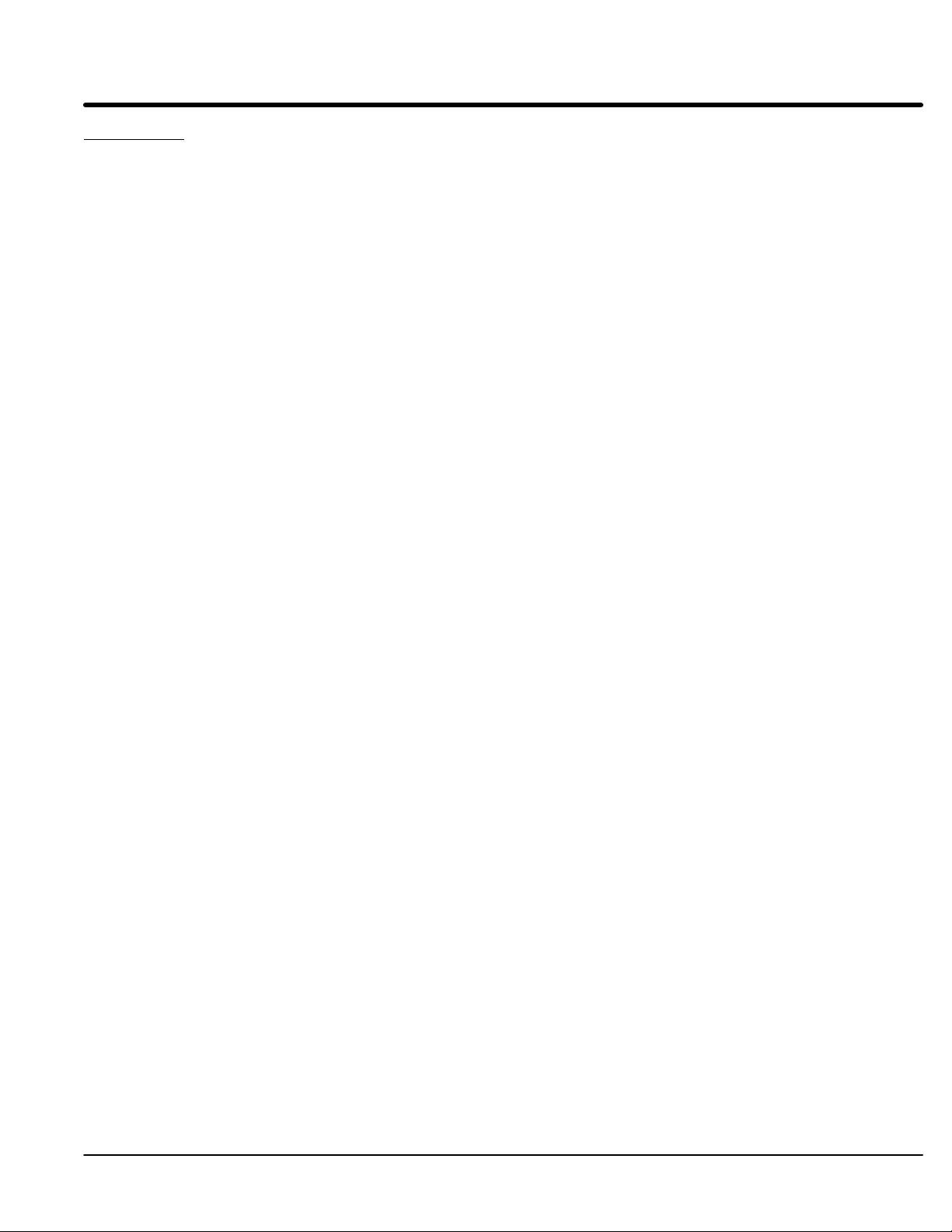

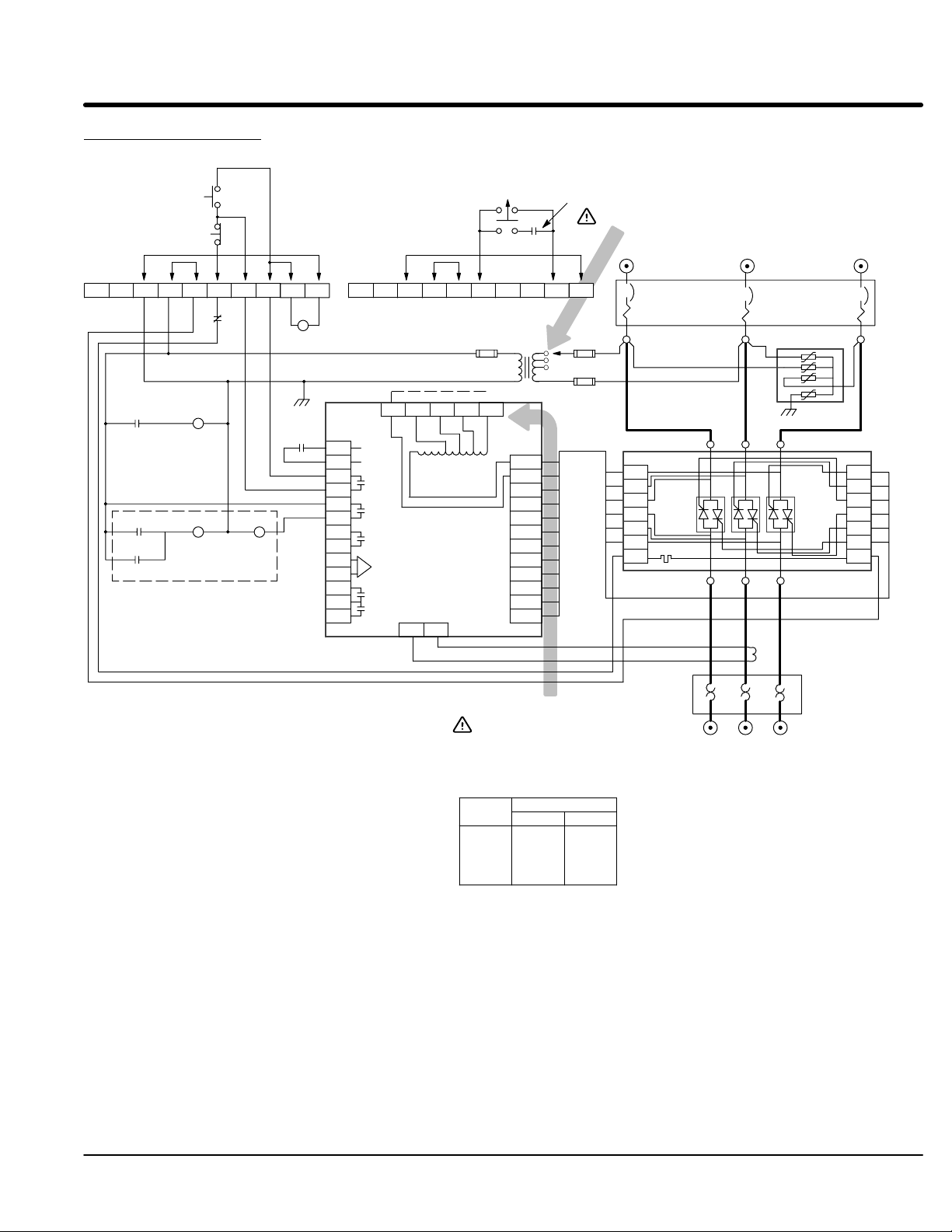

CPT

Figure 1-1 Layout and Identification

T1 T2 T3

GND

L1 L2 L3

F1

F2

F3

OL

R1

R2

TB1

CT1

CT2

CT3

CB

Shunt

Trip

CT4

MOV

LCM

Legend:

CB - Motor Circuit Protector or fusible disconnect

CPT - Control transformer (control voltage)

CT1, 2, 3, 4 - Current Transformer

F1, F2, F3 - Control transformer fuses

GND - Ground connection

LCM - Logic control module

MOV - Metal oxide varistors

OL - Overload relay (electronic)

PC1, 2, 3 - Power Cell

R1, R2 Control Relays

TB1, 2 - Terminal block

PC1 PC2 PC3

Fan Fan

Fan

Overtemperature

Switch

Snubber

Capacitor

Snubber

Resistor

1-2 General Information MN894

Page 9

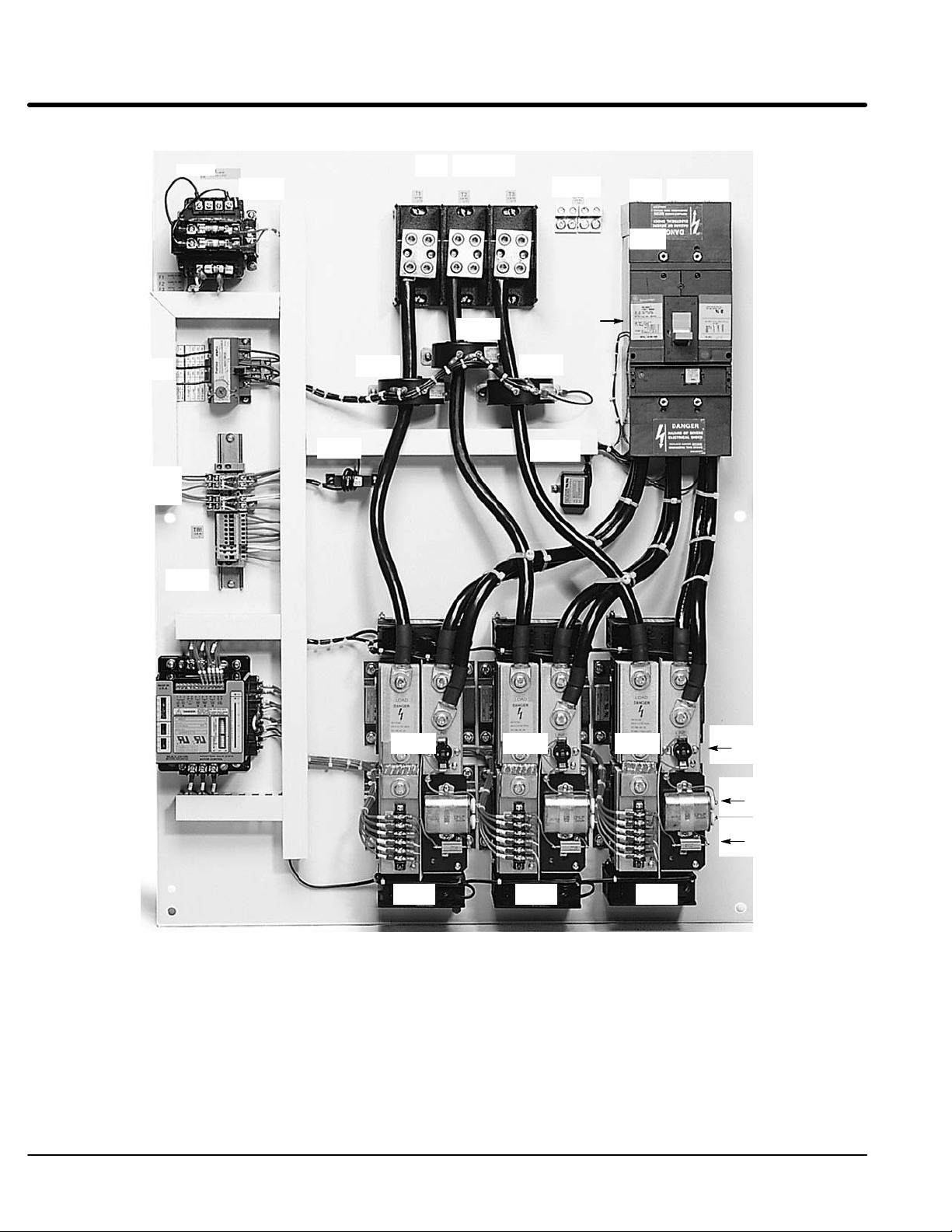

Ramp

Mode

Select

User

Adjustment

Current

Transformer

x

x

Tachometer

Input

Close To

Run

12

13

C

U

R

R

E

N

T

4

5

RDD

CM

OC

TACH

CL

BP

RU

TU

CL

PT

RD

TD

CM

PF

MIN MAX

OFF ONS1

C

A

L

I

B

R

A

T

I

O

N

+

-

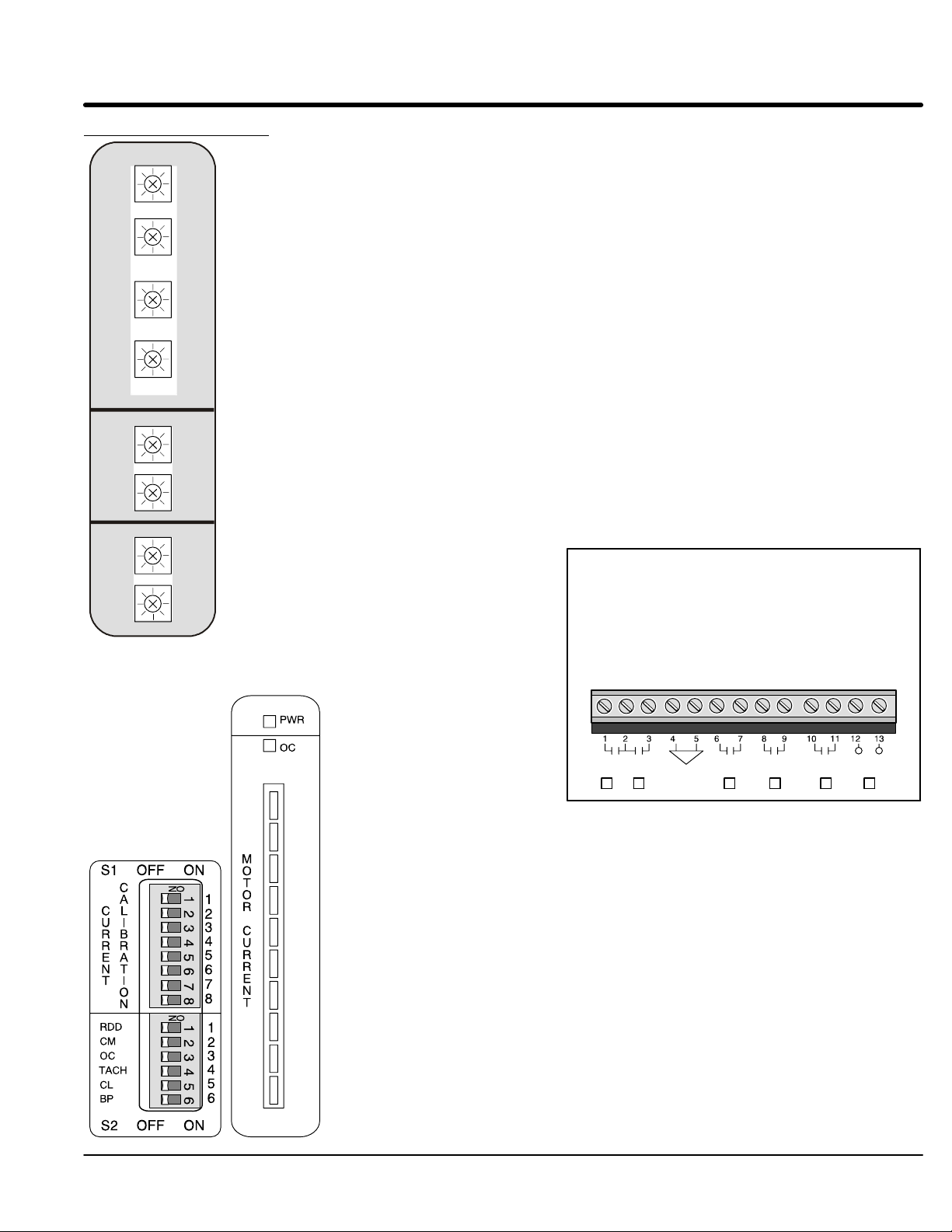

Figure 1-2 Logic Control Module Block Diagram

O

N

123456

1

2

3

4

5

6

OFF ONS2

S

T

A

R

T

S

T

O

P

R

U

N

O

N

12345678

1

2

3

4

5

6

7

8

Reset

Logic

Gates & Sync.

Logic &

Firing

Control

Power

Supply

+

-

Control Power

Overcurrent Trip

Current Monitor

Motor Power

Ramp End

Shunt Trip

Start/Run

Close To Run

115 /230 VAC

Power Input

Power Cell

Gates and

Cathodes

PWR

OC

M

400

O

T

300

O

R

200

C

U

R

100

R

E

N

T

0

%FLA

1

2

3

6

7

8

9

10

11

Status

Lights

Relay

Outputs &

Status

Legend:

BP - Bypass

CL - Current Limit

CM - Current Monitor

OC - Overcurrent

PF - Power Factor

PT - Pulse Time

RD - Ramp Down

RDD - Ramp Down Disable

RU - Ramp Up

S1 − Calibration Switch

TACH - Tachometer

TD - Torque Down

TU - Torque Up

General Information 1-3MN894

Page 10

Major Components (Refer to Figures 1-1 and 1-2).

Logic Control Module (LCM)

The LCM (Logic Control Module) operates in the voltage ramp mode or current limit

mode during ramp up and ramp down (if ramp down is selected). The LCM controls the

amount of current that the power cells deliver to the motor during ramp up and ramp

down. It uses gates and synchronous timing circuits to control the firing times of the

SCR’s in the power cells. The current transformer provides the LCM with motor current

information. The on board current calibration switches (S1-1 thru S1-8), place burden

resistors in parallel with the current transformer to calibrate the LCM to the correct FLA

(full load amperes) of the motor being used.

Current Transformer (CT1) provides starting, stopping and running current information to the LCM. This

information is used to control starting and stopping current, current limit, current monitor

and over current shutdown, power factor effect and motor current bar graph indicator.

(CT2) is required only for sizes 160 through 840 amps. It steps down current to match

primary rating of CT1 transformer.

8, 16 and 30 amp models - CT1 is mounted inside the LCM housing.

55 and 80 amp models - CT1 is mounted externally on the panel.

160 to 840 amp models - CT1 and CT2 are mounted externally on the panel.

CT1 ratio is 6000:1

CT2 ratio is 500:5 for 160, 250 and 420 Amp models.

CT2 ratio is 1000:5 for 600 and 840 Amp models.

Power Cells (PC) Power cells control the voltage delivered to the motor during ramp up and ramp down (if

ramp down is enabled). The LCM controls the duty cycle of the SCR’s in the power cells

(“on” time versus “off” time of each SCR). A power cell contains two silicon controlled

rectifiers (SCR’s). The SCR’s are solid state switches that are able to control large

amounts of current with a small amount of gate current supplied by the LCM.

8, 16 and 30 amp models - six SCR’s are mounted inside the LCM housing.

55 and 80 amp models - SCR’s are mounted in an isolated package containing two

SCR’s for each power cell. With this type of package, three power cells are mounted to a

single heat sink at ground potential. A temperature switch is provided in each cell to

protect the power cell from overheating.

160 to 840 amp models - Each SCR is a disk type package containing one SCR. Two

SCR’s are clamped between two heat sinks. A temperature switch is provided to protect

the SCR assembly from overheating. Heat sinks are mounted on an insulated base with

a terminal block and snubber network. The snubber network is a capacitor resistor series

circuit wired in parallel with the disk type SCR’s. The snubber network enhances the

electrical characteristics of the SCR’s and provides transient voltage protection. This

arrangement makes up one power cell. The power cell is at line potential for both line

and load terminals when line voltage is applied.

Protection Devices

Metal Oxide Varistors (MOV)

An MOV provides voltage surge protection. Voltage surges also called high voltage

spikes are caused by a number of sources. Short duration high voltage spikes caused by

starting and stopping other motor loads or switching On and Off capacitor banks may

appear on the incoming lines. Transients can occur from lightning storms or from other

lightly loaded devices on the same line, such as motors, transformers, or solenoids.

Electrical noise can be caused by lightning, arc welders and heat exchange equipment on

the same transformer bus line.

An MOVs provide protection by absorbing or clamping these transient energy levels.

High energy transients that exceed the MOV rating may damage the MOV and the

multipurpose starter.

1-4 General Information MN894

Page 11

Snubber Network 160 through 840 amp models only. A resistor and capacitor series circuit (snubber) is

wired in parallel with each disk type SCR. The RC network enhances the electrical

characteristics of the SCR and provides high voltage transient protection.

Shorted SCR Detection: If a shorted SCR condition is detected while starting, running or stopping, the SHUNT

TRIP contact will close and the SHUNT TRIP light will indicate the condition.

The SHUNT TRIP contact is used to open the circuit breaker via a shunt trip device.

Also, the shunt trip contact from the LCM module can be used to activate other circuit

interrupting device to remove the motor and control from the AC power line.

When a bypass contactor is used, the shunt trip circuit is disabled when the bypass

contactor is closed. This is accomplished by switching switch BP S2-6 On.

Over Current Shut Down: The control module has an over current detection circuit to trip and shut down the control

if motor current exceeds 450% FLA. To restart, open the Close To Run circuit, then close

it.

Current Monitor: When the motor is at speed (End of Ramp light is “ON”), the current monitor can detect

over current or overload motor conditions. This warning can alert an operator or be used

to stop a motor. It can also be used for indications of jams or blockages.

Motor Overload Protection: Class 30 motor overload protection is required to protect the control and the motor from

repetitive or extended starting conditions, as well as running during an overload condition.

Class 10 or 20 overloads may trip when starting high inertia loads or when operating in

current limit starting mode.

Over Temperature Switch: Power cells have over temperature switches to detect an overheating condition. The

switch is an isolated bimetallic, normally closed contact. If loss of cooling causes a power

cell to overheat, the temperature switch contact will open and shut down the control

circuit.

Note: When a temperature switch opens, the control shuts down. It must be reset

manually to restart the control.

L1

L2

L3

Circuit

Breaker or

Fusible

Disconnect

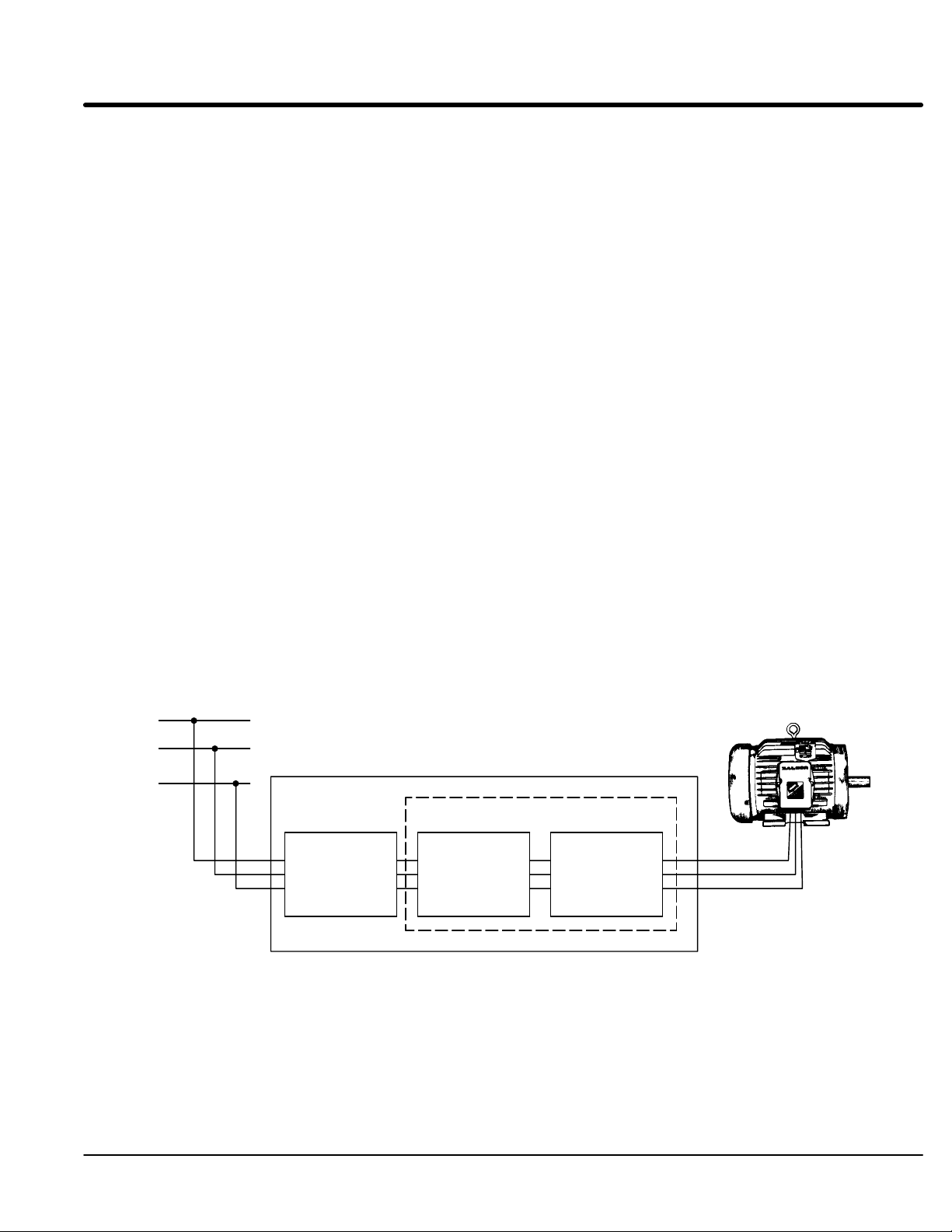

Figure 1-3 Starter Diagram

Combination Starter

Non-Combination Starter

Soft

Start

Control

(Control only)

Overload

Relay

General Information 1-5MN894

Page 12

Configurations

Control Only: Soft start control, without motor overload protection or branch circuit

protection circuit breaker or fusible disconnect switch. Suitable for installation with a

series contactor or as a retrofit for an existing motor starter.

Non-combination Starter: Soft start control with motor overload protection, less branch

circuit protection circuit breaker or fusible disconnect switch. Installation with existing

branch circuit protection would use this configuration.

Combination Starter: Soft start control with motor overload protection and branch circuit

protection and branch circuit protection circuit breaker or fusible disconnect switch. Only

push buttons are required to complete the system. New installations with no existing

control equipment would use this configuration.

Bypass System, Control Only: Soft start control without overload protection and branch

protection. Includes a bypass contactor to shunt the power cells after the control is in the

full run mode to eliminate heat generation across the power cells. Allows installation in a

NEMA 4 or NEMA 12 enclosure.

Bypass System, Non-combination: Soft start control noncombination system with

motor overload protection, less branch circuit protection. Includes a bypass contactor to

shunt the power cells after the starter is in the full run mode to eliminate heat generation

across the power cells. Allows installation in a NEMA 4 or NEMA 12 enclosure.

Bypass System, Combination: Soft start control combination system with motor

overload protection and branch circuit protection circuit breaker or fusible disconnect

switch. Includes a bypass contactor to shunt the power cells after the starter is in the full

run mode to eliminate heat generation across the power cells. Allows installation in a

NEMA 4 or NEMA 12 enclosure.

Enclosures and Ventilation: Soft start controls are available in panel mount or in NEMA

type 1, 12, 3R enclosures. The control will generate approximately 3.3 watts of heat per

running ampere during operation. All factory supplied enclosures are designed to

dissipate this heat under maximum specified operating conditions. If the multipurpose

control is mounted in an enclosure not supplied by the factory, this heat dissipation must

be considered. Adequate ventilation or convection cooling should be provided unless a

bypass contactor is used.

Panel Mount: Soft start control mounted on a panel with provisions for wall or enclosure

installation.

NEMA Type 1 (IP23): Soft start control mounted in a ventilated NEMA type 1 panel

enclosure. Intended for indoor use primarily to provide a degree of protection against

contact with enclosed electrical components. Available for all sizes and configurations.

NEMA 12/3R (IP65/IP32): NEMA 12 enclosure provides protection from dust, dirt, oil

and water. NEMA 3R outdoor installation protects from rain, sleet and snow. A NEMA

12/3R is shipped as a NEMA 12 and to convert to NEMA 3R, remove the drain screw at

the bottom of the enclosure.

1-6 General Information MN894

Page 13

Limited Warranty

For a period of two (2) years from the date of original purchase, BALDOR will

repair or replace without charge controls and accessories which our

examination proves to be defective in material or workmanship. This

warranty is valid if the unit has not been tampered with by unauthorized

persons, misused, abused, or improperly installed and has been used in

accordance with the instructions and/or ratings supplied. This warranty is in

lieu of any other warranty or guarantee expressed or implied. BALDOR

shall not be held responsible for any expense (including installation and

removal), inconvenience, or consequential damage, including injury to any

person or property caused by items of our manufacture or sale. (Some

states do not allow exclusion or limitation of incidental or consequential

damages, so the above exclusion may not apply.) In any event, BALDOR’s

total liability, under all circumstances, shall not exceed the full purchase

price of the control. Claims for purchase price refunds, repairs, or

replacements must be referred to BALDOR with all pertinent data as to the

defect, the date purchased, the task performed by the control, and the

problem encountered. No liability is assumed for expendable items such as

fuses.

Goods may be returned only with written notification including a BALDOR

Return Authorization Number and any return shipments must be prepaid.

General Information 1-7MN894

Page 14

Safety Notice This equipment contains voltages that may be as high as 600 volts! Electrical shock can

cause serious or fatal injury. Only qualified personnel should attempt the start-up

procedure or troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts or parts

that are driven by this equipment. Improper use can cause serious or fatal injury. Only

qualified personnel should attempt the start-up procedure or troubleshoot this equipment.

PRECAUTIONS

WARNING: Do not touch any circuit board, power device or electrical connection before you

first ensure that power has been disconnected and there is no high voltage present

from this equipment or other equipment to which it is connected.

Electrical shock can cause serious or fatal injury.

WARNING: Be sure that you are completely familiar with the safe operation of this equipment.

This equipment may be connected to other machines that have rotating parts or

parts that are controlled by this equipment. Improper use can cause serious or

fatal injury. Only qualified personnel should attempt the start-up procedure or

troubleshoot this equipment.

WARNING: Be sure the system is properly grounded before applying power. Do not apply AC

power before you ensure that all grounding instructions have been followed.

Electrical shock can cause serious or fatal injury.

Caution: To prevent equipment damage, be certain that the electrical service is not capable

of delivering more than the maximum line short circuit current amperes listed for

the control rating.

Caution: Do not “Megger” test the motor while it is connected to the control. Failure to

disconnect motor will result in extensive damage to the control. The control is

tested at the factory for high voltage / leakage resistance as part of Underwriter

Laboratory requirements. Do not megger any part of the control.

Caution: Do not connect power factor correction capacitors to motor terminals. If power

factor correction capacitors are necessary, contact Baldor.

Caution: If a brake motor is used, the initial starting voltage may not be sufficient to release

the brake. It may be necessary to provide separate power for the brake and soft

start control.

Caution: Do not connect AC incoming line power to the Motor terminals T1, T2 and T3.

Connecting AC power to these terminals may result in damage to the control.

Caution: Do not supply any power to the “Close To Run” terminals. Power on these leads

can damage the control. Use a dry contact type that requires no external power to

operate.

Caution: Do not change the position of any switch while power is applied. Changing the

position of a switch during operation can damage the control and cause erratic

behavior of the load.

Caution: To prevent equipment damage, be certain that the electrical service is not capable

of delivering more than the maximum line short circuit current amperes rating.

Caution: This equipment is shipped as a multipurpose apparatus. Before power is applied,

the line voltage selection and the full load current calibration must be correctly set.

Failure to select the proper line voltage or to calibrate the full load current may

cause damage.

1-8 General Information MN894

Page 15

Section 2

Installation

Receiving, Inspection and Storage

When you receive your control, there are several things you should do immediately.

1. Observe the condition of the shipping container and report any damage

immediately to the commercial carrier that delivered your control.

2. Remove the control from the carton. Inspect for shipping damage and report

any damage immediately to your commercial carrier.

3. Verify that the part number of the control you received is the same as the part

number listed on your purchase order.

4. If the control is to be stored for several weeks before use, be sure that it is

stored in a location that is clean, dry and free from corrosives and

contaminants. Storage temperatures must not exceed 140°F (60°C).

Be sure to read an become familiar with the safety notices in Section 1 of this manual.

Failure to observe the product safety notices can result in injury or equipment damage.

If you have questions, please contact your Baldor distributor. Do not proceed unless you

understand the installation and operation requirements and safety notices.

Physical Location The location of the soft start control is important. It should be installed in an area that is

protected from direct sunlight, corrosives, harmful gases or liquids, dust, metallic

particles, and vibration. Exposure to these elements can reduce the operating life and

degrade performance of the control.

Several other factors should be carefully evaluated when selecting a location for

installation:

1. For effective cooling and maintenance, the control should be mounted vertically

on a flat, smooth, non-flammable vertical surface. Heat dissipation of 3.3 watts

per running FLA of the motor must be provided. All factory supplied enclosures

provided adequate heat dissipation.

2. If the control is mounted in an enclosure, sufficient air flow must be provided.

The fan or blower must be rated for at least 0.8 cubic feet per minute for each

ampere of motor FLA rating.

3. Keep high voltage and low voltage wiring separated. If the conduits must

cross, be sure that they cross at 90° angles only.

1. Motor overload protection is required for starters that do not have an overload

protection device.

2. The multipurpose soft starter is suitable for use on a circuit capable of

delivering no more than the short circuit A

3. A short circuit current and overcurrent devices are required for soft start

controls that do not have a circuit breaker or fusible disconnect switch.

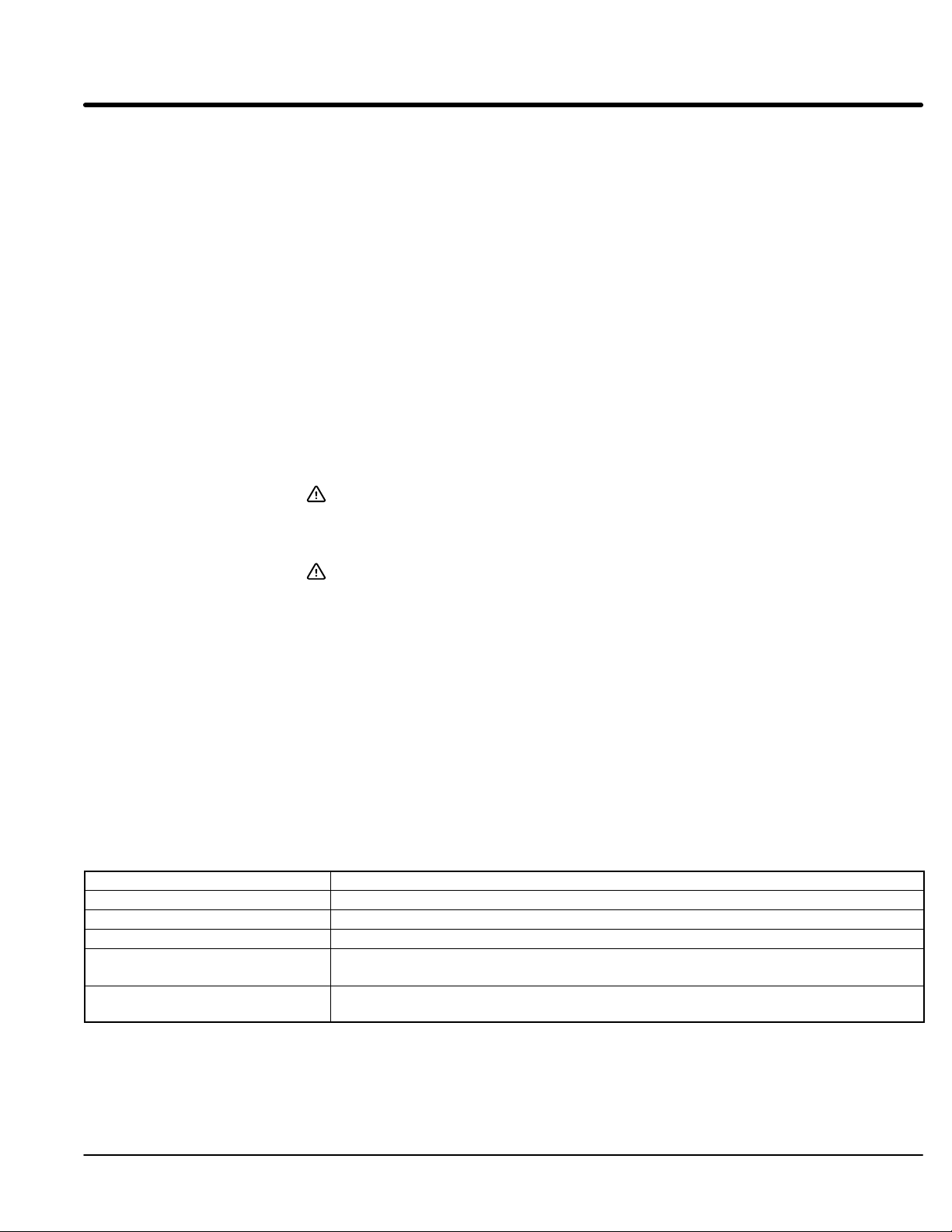

AC Main Circuit

Protection Devices Be sure a suitable input power protection device is installed. Use the recommended circuit

breaker or fuses listed in Table 2-1. Wire sizes and protective device specifications are based

on the maximum output power rating of the control.

Power Disconnect A power disconnect should be installed between the input power service and the control for

a fail safe method to disconnect power. The control will remain in a powered-up condition until

all input power is removed from the control and internal voltages are depleted.

listed in Table 2-1.

RMS

Installation 2-1MN894

Page 16

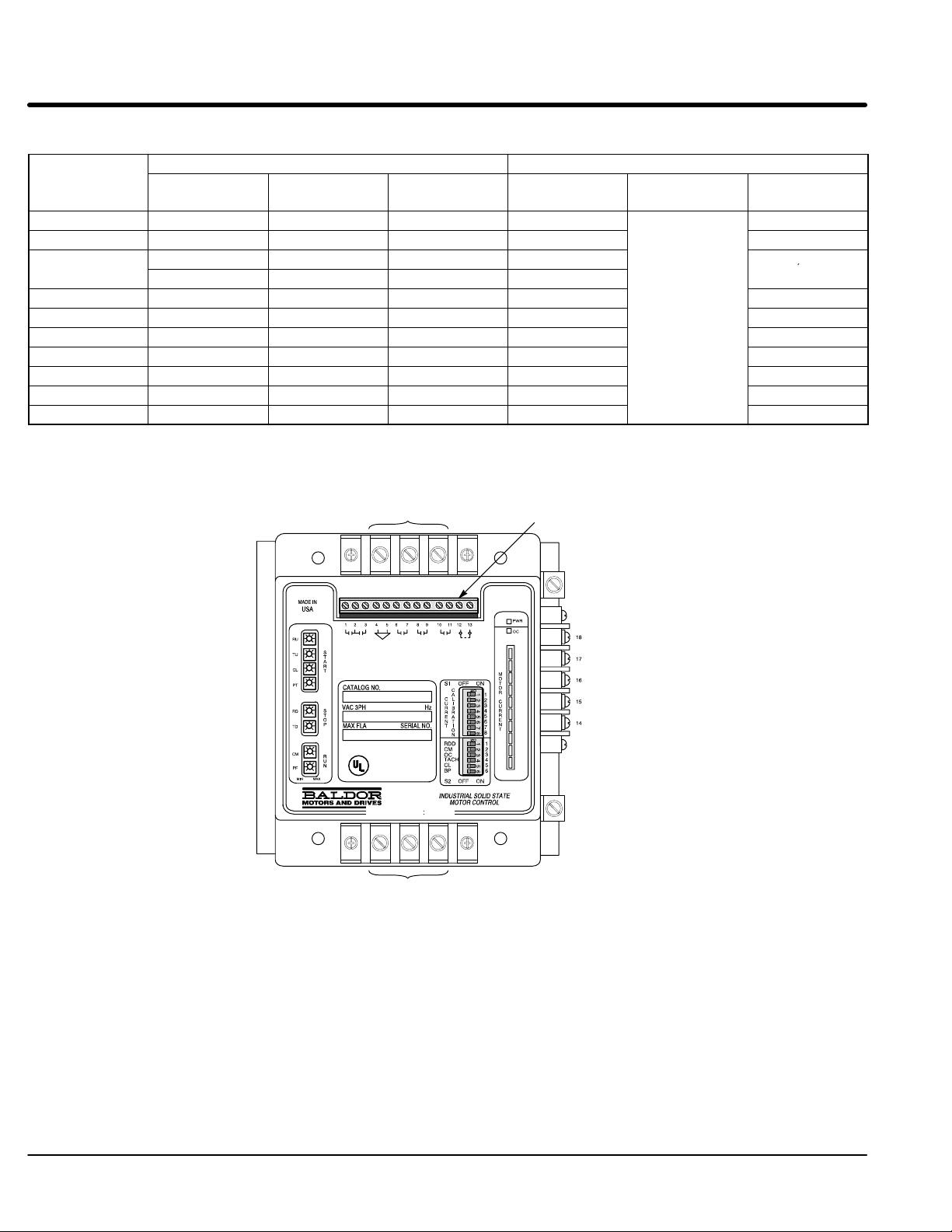

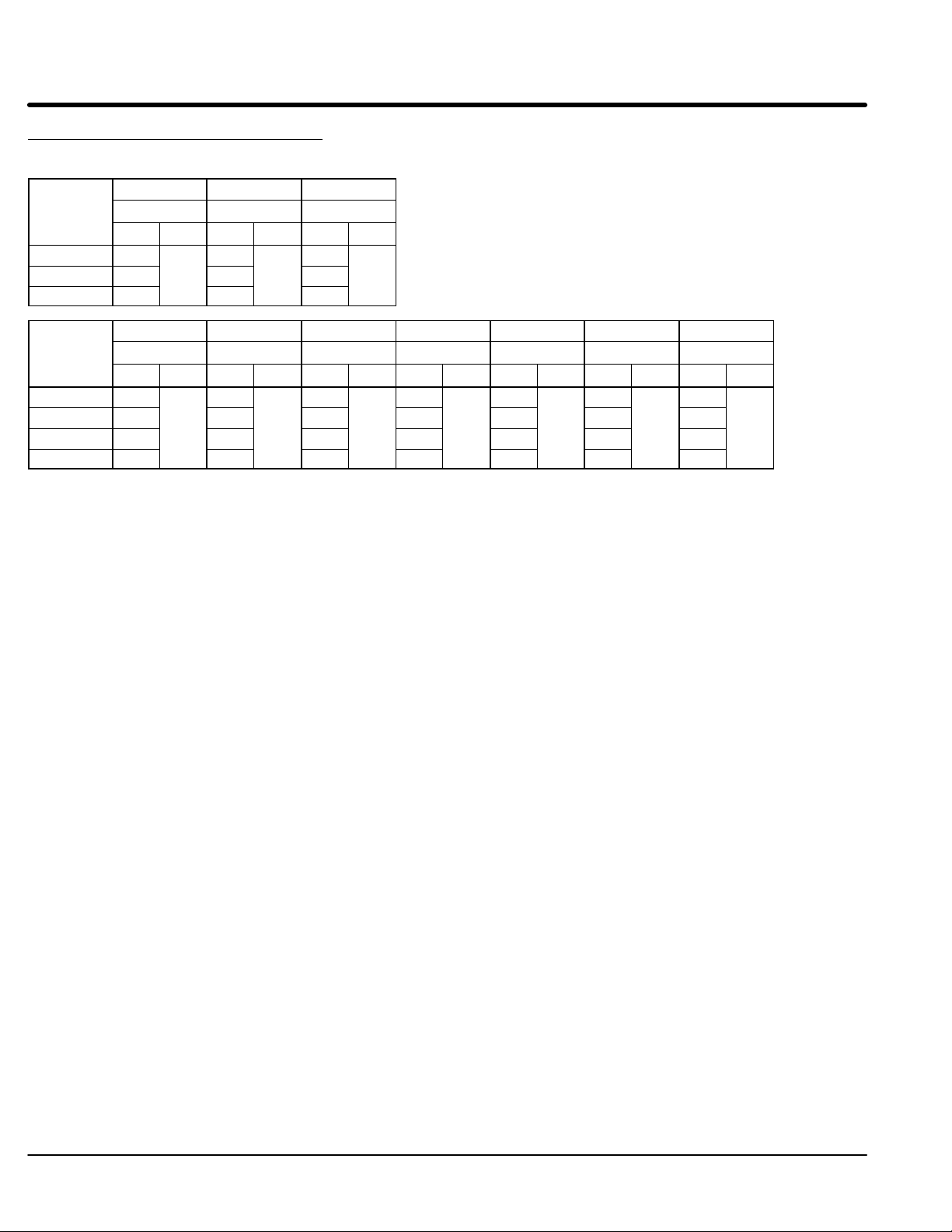

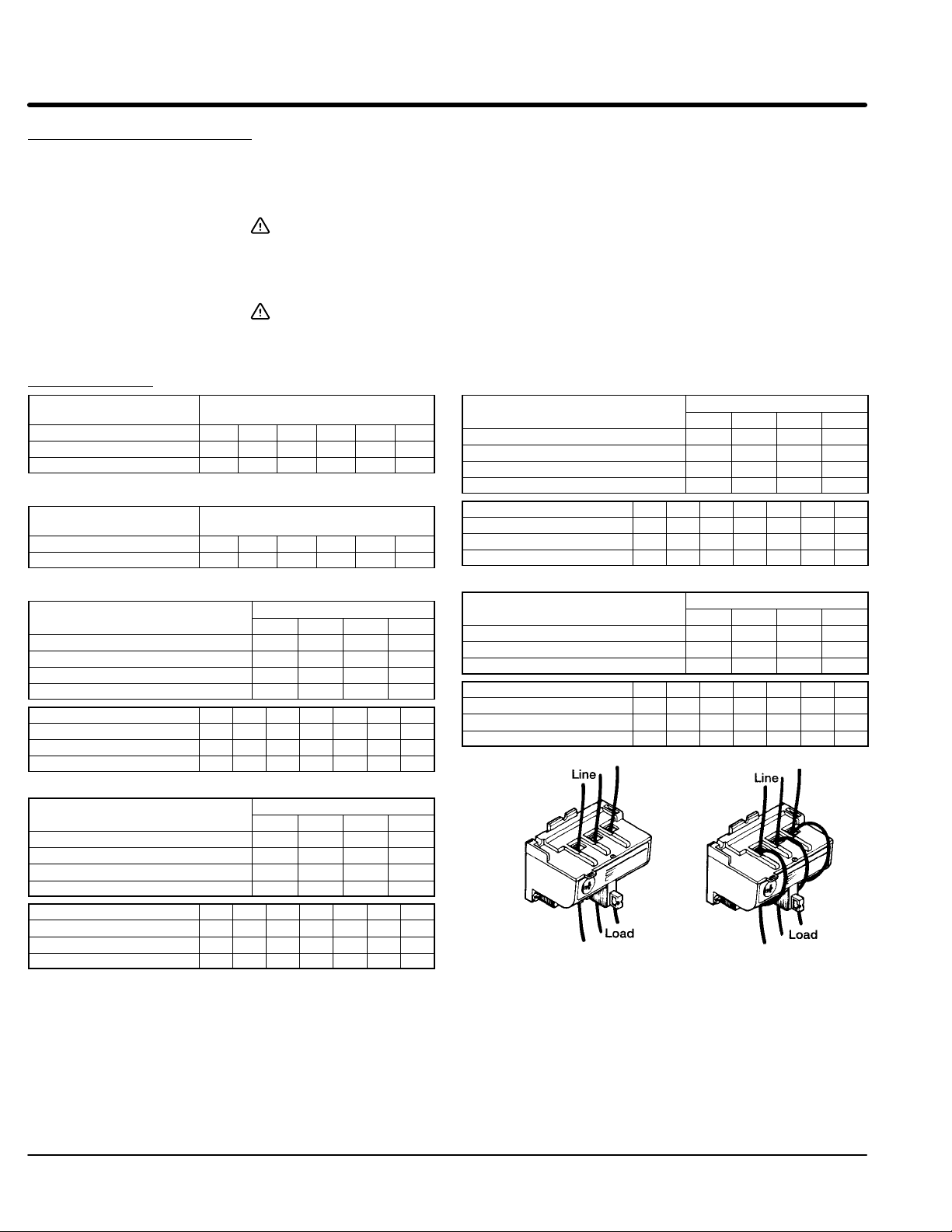

Table 2-1 Three Phase

Rati

,

SFLA

SGLA

SKLA

ng

(AMPS)

Amps Class

Fuse MCP (GE)

Short Circuit

A

RMS

Amps Type

8 100 J 5,000 20 5,000

16 100 J 5,000 20 5,000

30 200 J 5,000 50 5,000

100 RK1 5,000 50

55 175 J 42,000 100

SELA

80 175 J 42,000 100

160 400 RK5 100,000 300

250 400 RK5 100,000 300

420 800 L 100,000 600 42,000

600 800 L 100,000 600 42,000

840 1200 L 100,000 600 42,000

Note: Maximum recommended fuses/breakers are based on 25°C ambient, maximum continuous current.

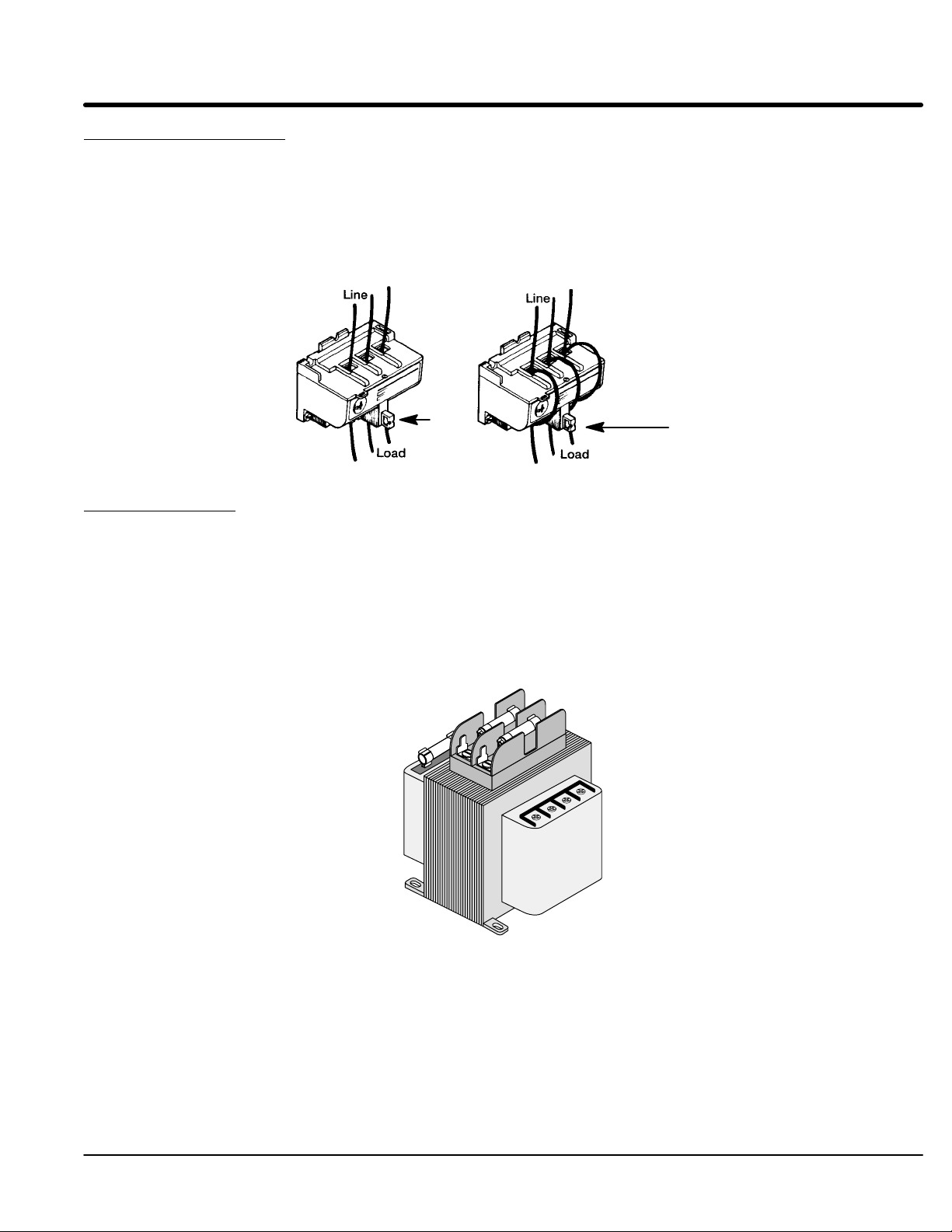

Figure 2-4 Multipurpose Control Terminal Locations

(A) Line Input

L1 L2 L3

(C) Control Connections

(D) GND

Short Circuit

A

RMS

10,000

10,000

42,000

42,000

T1 T2 T3

(A) Motor Output Load

2-2 Installation MN894

(D) GND

Page 17

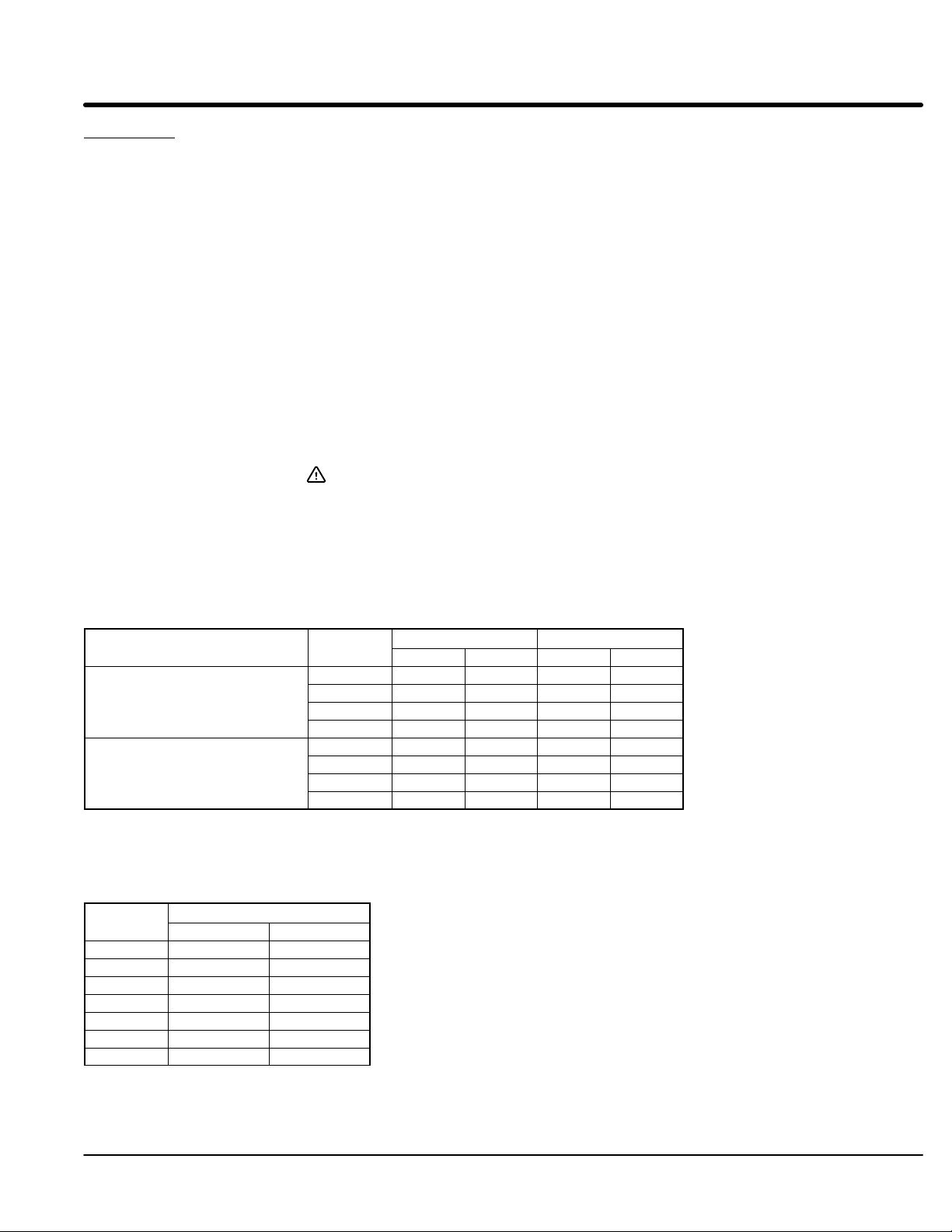

Installation

Starter Rati

Terminal

8, 16 and 30 AMPS

h 840 AMPS

AMPS

1. Mount the panel or enclosure to the mounting surface. The panel or enclosure must be

securely fastened to the mounting surface. Refer to the mounting dimensions in Section 6 of

this manual.

2. Ground the panel and control per NEC article 250 as well as state and local codes.

3. Use copper wire rated for at least 75°C. Refer to Figure 2-4 and Table 2-2 for wire size

recommendations.

4. Connect the incoming AC power wires from the power disconnect and/or protection devices to

L1, L2 and L3 terminals. Tighten each terminal as specified in Figure 2-4 and Table 2-2.

5. * Connect earth ground to the “GND” of the control. Be sure to comply with local codes.

6. Verify the input line voltage is correct.

7. For MA#−XX models, verify the line voltage selection jumpers on the LCM module are properly

set. For MB#−XX models, verify the control transformer primary taps are connected for the line

voltage applied.

8. Connect the three phase power leads of the AC motor to terminals T1, T2, and T3 of the Main

Circuit Terminals.

9. * Connect motor ground wire to the “GND” of the control. Be sure to comply with all applicable

codes.

Caution: Do not supply any power to the “Close To Run” terminals. Power

on these leads can damage the control. Use a dry contact type that

requires no external power to operate.

10. Connect the remaining control terminals as required for your installation. Refer to Figure 2-4 and

Table 2-2 for wire size and terminal torque specifications.

* Grounding by using conduit or panel connection is not adequate. A separate conductor of the

proper size must be used as a ground conductor.

Table 2-2 Recommended Wire Size and Tightening Torque

Torque Wire Size

lb-in Nm AWG mm

2

55 throug

ng

A 20 2.5 10-16 6-1.5

B 35 4 8 10

C 12 1.4 12-22 4-0.34

D 45 5.1 6-14 16-2.5

A Note 1 Note 1 Note 2 Note 2

B Note 1 Note 1 Note 2 Note 2

C 12 1.4 12-22 4-0.34

D 45 5.1 6-14 16-2.5

All wire sizes based on 75°C copper wire, 3% line impedance.

Higher temperature smaller gauge wire may be used per NEC and local codes.

Note1: Refer to the label on the equipment panel for line and load tightening torque values.

Note2: Line and Load wires sizes for 55 through 840 AMP models are as follows:

Wire Size

AWG mm

55 4 25

80 3 30

160 3/0 95

250 350 mcm 185

420 2x 300 mcm 2x 150

600 2x 500 mcm 2x 240

840 3x 500 mcm 2x 240

2

Installation 2-3MN894

Page 18

Non-Motor and Special Motor Applications

Non-motor load: The multipurpose control is designed to provide reduced starting voltage for standard

three phase induction motors. The control may also start non-motor loads for controlled

inrush current applications with resistive or inductive loads. Consult Baldor if the control

is to be used with a non-motor load.

Wye-Delta or The multipurpose control can replace an existing wye-delta or part winding starter.

Part Winding Starter: Begin by removing the existing contactors. Wire the motor in its “RUN” delta

configuration and connect the motor to the control. The control can be used as if it were

controlling a standard design B motor.

Wound Rotor Motors: Consult Baldor if the control is to be used with a wound rotor or slip ring type motor. This

type of load produces high starting torque with reduced starting current and speed. The

multipurpose control provides low starting current and low starting torque. The

multipurpose control can be used for applications that do not require high starting torque

and a continuous speed reduction.

High Slip Motors: The multipurpose control can be used with high slip motors, such as design D. These

motors are used with large inertial loads that require extended starting times. Reduced

starting voltage will reduce the starting current and extend the starting time. Long starting

times may require using slow trip overloads. However, the thermal capabilities of the

motor and control must be evaluated before extending the overload trip times.

Reversing Applications: For reversing applications, two multipurpose controls can be used or a reversing

contactor can be used. Consult Baldor for more information.

Multispeed Motors: Consult Baldor if the control is to be used with a multispeed motor. The control can

be used with a multispeed motor if a multispeed starter is connected between the control

and the motor. In this case, an additional MOV must be connected to the terminal side of

the control. Switching is normally done be auxiliary contacts from the multispeed starter

that are connected to the control circuit of the multipurpose control.

Motors on Grounded and A multipurpose starter should not be used with “Delta” or “Open” ground systems.

open delta systems: Without a proper ground, the circuit to detect a shorted SCR condition may malfunction or

may not be able to detect a shorted SCR condition.

2-4 Installation MN894

Page 19

Section 3

Operation

Types of Starting

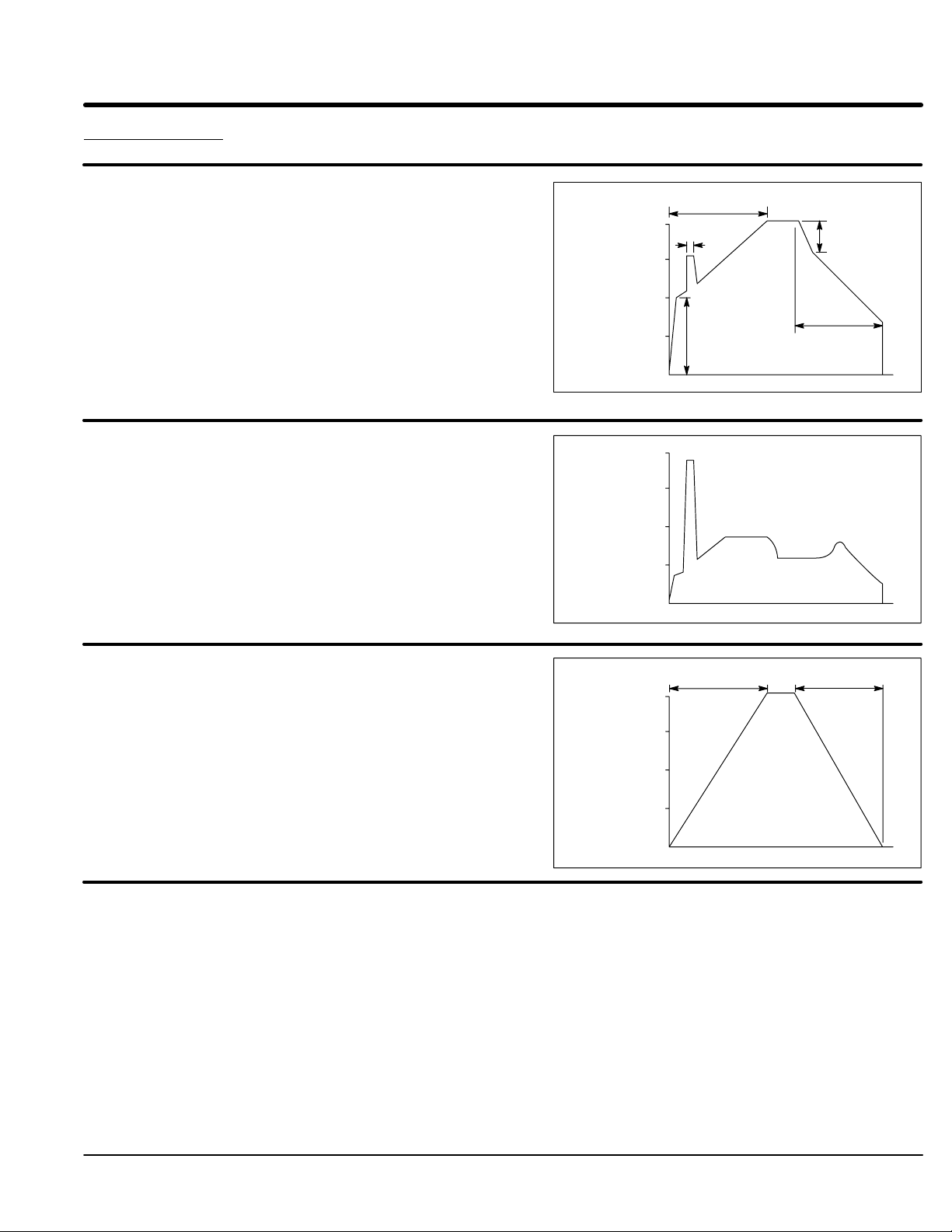

Voltage Starting (S2-4 = OFF)

During start the initial voltage (TU) is set to a level where the

motor will begin to turn when power is applied. The ramp time

(RU) is adjustable to provide a smooth start. The pulse time

(PT) is used for high friction loads to break loose “frozen” loads

with up to 400% FLA.

If a ramp down function is needed, the initial voltage TD setting

is used to lower voltage to a level where the motor will begin to

slow down when the stop button is pushed. Ramp down (RD)

can only extend motor stopping time preventing sudden stopping

problems such as water hammer.

Current Limit Starting (S2-5 = ON)

If current limit starting is selected the starter will operate similar

to voltage starting. On high inertia loads such as chippers and

grinders the Current Limit (CL) setting is what determines the

starting time. The starter will provide that current regardless of

the ramp time setting. The CL setting must be high enough to

provide enough starting current in all starting conditions. Ramp

down (RD) can only extend motor stopping time preventing

sudden stopping problems such as water hammer.

Voltage

Ramp

% Line

Voltage

Current

Limit

% FLA

100

75

50

25

400

300

200

100

RU

PT

CL

TU

0

PT

0

Time

CL

Time

TD

RD

RD

Tach Feedback Starting (S2-4 = ON)

Tach feedback starting/stopping uses a 0-10 VDC Tach signal.

The control will provide voltage to the motor to generate a

smooth linear starting even under cycling load conditions. Ramp

down (RD) can only extend motor stopping time preventing

sudden stopping problems such as water hammer.

Tach

% Full

Speed

100

75

50

25

RUN

RU

0

Time

RD

Operation 3-1MN894

Page 20

Start Adjustments (Refer to Figure 3-1).

Ramp Up Ramp up time (RU) is adjustable from 3 to 50 seconds. RU adjusts the voltage ramp or

the tachometer starting ramp time. For voltage starting, RU adjusts the time it takes the

motor to reach full voltage. Actual acceleration time to full speed depends upon the

motor load and the setting of the additional start adjustments.

For Tach feedback starting, RU adjusts the motor starting time independent of the load

when used with a 0 to 10 VDC tachometer feedback signal. Smooth linear speed ramp

up with constant acceleration is achieved.

Torque Up The initial starting torque (TU) for ramp up is enabled only in the voltage ramp mode.

Usually set high enough to start the motor slowly turning the instant the start button is

pressed.

Pulse Time Starting pulse time (PT) is adjustable from 0 to 1.5 seconds in the voltage ramp mode.

When the start button is pressed, the initial motor voltage depends on the setting of TU.

One second after the start button is pressed, a pulse of approximately 400% FLA will

occur; the duration will depend upon the setting of PT.

Current Limit Current limit (CL) is adjustable from 75 to 400% of FLA. It can be used in both the

voltage and tachometer ramp modes of operation. When CL is enabled (S2-5=ON),

motor starting and stopping current will not exceed the set point of CL, except during PT.

Note: CL must be set high enough to allow the motor to start under maximum load

conditions. In the Tach feedback mode, CL will affect linearity and start and

stop times. The current is held at the CL limit until the motor current

decreases to less than the CL setting, regardless of the RU setting.

Figure 3-1

RU

TU

CL

PT

S

T

A

R

T

Stop Adjustments (Refer to Figure 3-2).

Ramp Down Ramp downtime (RD) extends the stopping time from 5 to 50 seconds. RD can be used

in both the voltage and tachometer modes.

In the tachometer mode, when used with a 0 to 10 VDC tachometer feedback signal, RD

will adjust the actual stopping time independent of motor load condition. Smooth linear

speed ramp down with constant deceleration is achieved.

In the voltage mode, RD adjusts the time it takes to reach minimum motor voltage and

turn off. The actual stopping time will depend on the motor load condition.

Note: Ramp down mode is not suitable for coasting or inertial loads that require

braking. Ramp down will only extend the stopping time.

Torque Down Torque down advance (TD) is adjustable from 0 to 100% advance. TD sets the initial

torque or voltage which ramp down starts and can be used in both voltage and

tachometer modes.

In ramp down mode, when the stop button is pressed, voltage will immediately decrease

to the set point of TD. Control will continue to ramp down to zero speed or voltage,

depending upon RD setting, then the control will turn off.

Figure 3-2

RD

TD

S

T

O

P

3-2 Operation MN894

Page 21

Run Adjustments (Refer to Figure 3-3).

Current Monitor Current monitor set point (CM) is adjustable from 50 to 400% FLA to monitor the running

current after the motor reaches the full run condition.

With CM enabled (S2-2=ON), if the running current exceeds the CM set point, the control

will shut down, the CUR MON contact will close, and the light will illuminate.

With CM disabled (S2-2=OFF), if motor current exceeds CM set point, the control will not

shut down, the CUR MON contact will close and the light will illuminate.

Power Factor Power factor effect (PF) is adjustable from 0 to 100%. PF is used to adjust the maximum

voltage applied to the motor under lightly loaded conditions to minimize motor current

with minimum motor load.

PF is enabled after the motor reaches full on condition.

PF should be turned off (CCW) if more than one motor is used with one control or if a

by-pass contactor is used.

Note: PF adjustment has no effect in bypass mode.

Figure 3-3

MIN MAX

R

U

N

CM

PF

Current Calibration Switch Refer to the multipurpose control Current Calibration Chart in Appendix A. Set switches

S1 to the motor FLA rating. Calibration is based on the motor nameplate full load

amperes (FLA), not necessarily actual running current. Motors with more than 6 times

locked rotor current may require a higher setting to start properly.

Operating Parameters Switch (Refer to Figure 3-4).

Switches S2-1 thru S2-6 select the operating modes that best fit the application.

S2-1 Ramp Down Disable (RDD).

In the “On” position: When the stop button is pressed, the control will immediately turn off.

User stop adjustments RD (ramp down time) and TD (ramp down initial starting torque)

are disabled.

In the “Off” position: When the stop button is pressed, the control will ramp down. In the

voltage mode of operation, ramp down time depends on RD and TD settings and the load

condition.

S2-2 Current Monitor (CM) “On” position: If the motor running current exceeds the Current Monitor (CM) setting, the

control will shut down. The shut down condition is indicated by the current monitor light

and the closure of the current monitor contact. The current monitor is typically used to

shut the control down when a jam occurs. To restart the control, press stop, then start; or

open the close to run circuit, then close it.

“Off” position: If motor running current exceeds the current monitor setting, the current

monitor light and contact will indicate this condition but the control will not shut down.

The current monitor can be used as an over and under current monitor.

S2-3 Over Current Indicator (OC).

“On” position: If an over current trip occurs (current exceeds 450% FLA), the control will

shut down and the condition will be indicated by the OC light and CM light and the

closure of the current monitor contact. To restart the control, press stop then start; or

open the close to run circuit, then close it.

“Off” position: An over current trip is indicated by the over current light and will not affect

the current monitor. The control will shut down.

Operation 3-3MN894

Page 22

S2-4 Tachometer and Voltage Ramp Select (TACH)

“On” position: The control is in the tachometer ramp mode during start and stop. Starting

and stopping times are independent of the load conditions. Ramp up (RU) is dependent

on the ramp up and current limit (CL) settings. RD is dependent on the RD and CL

settings.

Note: Current limit is disabled if S2-5 is “Off”. Operation in the tachometer mode

requires an isolated input tach signal of 0 to 10 volts DC with a 10 msec

response time or better. Tachometers with other voltage ranges may be used

with this control. Consult the factory for instructions.

If the tachometer full speed voltage is less than 10 volts DC, the starting and stopping

times will be proportionally shorter. For example, if the starting and stopping times are

adjusted to 20 seconds with a 0 to 10 volt DC tachometer signal; for a 0 to 5 Volt DC

tachometer signal with the same setting, the time will be 10 seconds.

“Off” position: The control is operating in the voltage ramp mode during start and stop (if

ramp down is selected using S2-1). All user settings for start, stop and run can be used

to set up the control to meet the application requirements. Starting and stopping times

are dependent on the actual load condition and control settings.

S2-5 Current Limit Enable (CL)

“On” position: Starting and stopping current will not exceed the setting of the current limit

setting, except during PT, if pulse start is being used. Current limit must be set high

enough to allow the motor to start under maximum load conditions.

“Off” position: Current limit is disabled. Maximum motor current is then limited by the

over current shutdown circuit to 450% FLA, preset at the factory.

S2-6 By-Pass Select (BP) “On” position: When the end of ramp contact closes, the circuit breaker shunt trip circuit

(the Shunt Trip contact on the Multipurpose control module) is disabled after the starter is

in the full run condition. This allows the use of a by-pass contactor without tripping the

circuit breaker when the power cells are bypassed.

“Off” position: the Shunt Trip circuit is enabled at all times.

Figure 3-4

O

N

RDD

CM

OC

TACH

CL

BP

123456

OFF ONS2

1

2

3

4

5

6

3-4 Operation MN894

Page 23

Control Connections (Refer to Figure 3-5).

CLOSE TO RUN Close to Run terminals 12 and 13. Close to run contact must be closed to initiate ramp

up and run. Close to Run contact must be opened to initiate ramp down to stop. Close to

run contact must be dry and electrically isolated contact. If a voltage is applied to these

terminals, the control may be damaged.

When the Close to Run circuit is closed, the Start/Run light will be on and the contact will

close. This normally open contact is typically used to seal in the start button circuit.

START/RUN Start/Run light and contact terminals 10 and 11. As long as the Closed to Run circuit

remains closed, the Start/Run light and contact will remain activated. This condition also

applies to an over current or a current monitor shutdown.

SHUNT TRIP Shunt Trip light and contact terminals 8 and 9. If the control detects a shorted SCR condition,

the shunt trip light will be on and the contact will close. The shunt trip contact is used to

operate a Shunt Trip device in the circuit breaker or similar disconnection means to remove

the motor and controller from the line should a shorted SCR condition occur.

The shunt trip circuit may also detect loss of phase or low voltage on a phase. The circuit

may not work properly on grounded delta systems or open delta systems. The Shunt Trip

circuit will trip when energized on single phase or an unbalanced line voltage.

RAMP END Ramp End light and contact terminals 6 and 7. In the voltage or the tachometer modes,

when the starting ramp is completed and the control is in the full run mode, the ramp end

light will be on and the contact will close. The starting current limit is then disabled and

CUR MON (running current monitor) is enabled.

Note: Since most loads do not require full voltage and torque to reach full speed,

when control is in the voltage ramp mode, the motor will reach full speed

before the ramp end contact and light are activated. Ramp end will only be

activated after the motor and control reach full voltage.

The ramp end contact can be used to turn on other equipment. The ramp end contact

can be used to close the bypass contactor to reduce heat dissipation of the SCRs.

TACH Tachometer input terminals 4 and 5. The TACH input is used in the tachometer mode

(S2-4=ON). The input required for TACH feedback is a 0 to 10 volt DC signal with a

maximum 10 ms response time.

MTR PWR Motor Power light and contact at terminals 2 and 3. Indicates that voltage and current are

supplied to the motor. If a current monitor or an over current shut down condition occurs,

the contact is deactivated and the light is turned off.

CUR MON Current Monitor light and contact terminals 1 and 2. A user adjusted monitor. Maximum

running current is adjustable from 50% to 400% FLA. Switch S2-2 controls the CM

monitor.

S2-2 “On” position: If motor current exceeds the CUR MON setting, the light will be on

and the contact will close. In addition, the motor power and ramp end LEDs will be off

and their contacts will open. The control will shut down. The Start/Run light will stay on

and the contact will remain closed. Typically used to shut down the control in case of a

mechanical jam. To restart a CUR MON shutdown, press stop then start; or open the

close to run circuit, then close it.

S2-2 “Off” position: If current exceeds the CUR MON setting, the light will be on and the

contact will close for the duration of the over current. The control will not shut down. In

this mode, the CUR MON monitor can be used as an over and under current monitor.

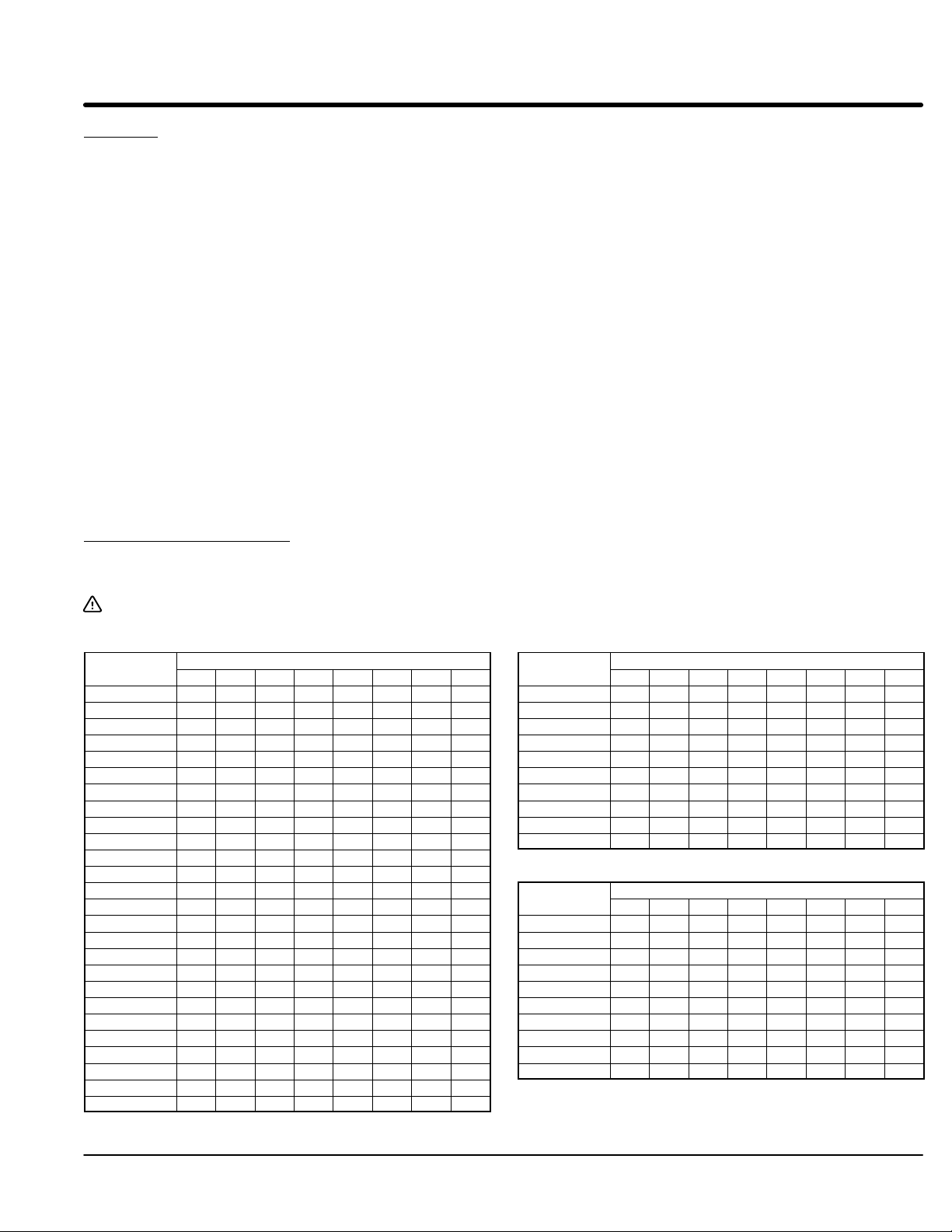

Figure 3-5

CUR

MON

PWR

+

−

CLOSE

TachMTR

End

TRIP

SHUNT

Ramp

START

/ RUN

TO RUN

Operation 3-5MN894

Page 24

Indicators

Power On The PWR light indicates that power is supplied to the internal power supply of the control.

WARNING: If the power light is not illuminated, it does not necessarily mean

that the line voltage is off. Electrical shock hazard may exist.

Measure the voltage at the line terminals before service.

Over Current OC over current shutdown LED. If the control shuts down due to an over current

condition (motor current is greater than 450% FLA), the OC light will be on. To restart the

control, press stop, then start; or open the close to run circuit, then close it.

Motor Current The Motor Current display is a 10 segment bar graph representation of motor current

from 0 to 400% FLA. Used to check ramp up, run and ramp down current conditions

while the control is in operation.

Summary of Start and Stop Sequences

To Start the Motor: Close 12 - 13 (Close to Run) and the following occurs:

1. 10 - 11 close to confirm start command.

2. 2 - 3 close when power is applied to motor. Ramp up cycle begins.

3. 6-7 close at the end of ramp up cycle.

To Stop the Motor: Open 12 - 13 (Close to Run) and the following occurs:

1. 10 - 11 open to confirm stop command.

2. 6-7 opens immediately.

3. 2 - 3 operation depend on ramp down mode selection:

With Ramp Down: 2 - 3 opens when ramp down is complete.

Without Ramp Down: 2 - 3 opens immediately.

Shunt Trip: During normal operation, detection of a shorted SCR, misfiring SCR will

cause the following:

1. 8 - 9 close immediately.

2. Shunt Trip light turns ON.

3. The shunt trip breaker is immediately tripped and all power is removed from the

control and motor.

Note: The shunt trip breaker will only trip if it is connected to the shunt trip contact at

terminals 8 & 9.

3-6 Operation MN894

Page 25

Section 4

Start-up

Safety Notice Be sure to read and understand all notices, warning and caution statements in Section 1

of this manual. If you have any questions about the safe operation of this equipment,

please contact your Baldor representative before you proceed.

Start-up Checklist

Recommended Equipment Volt meter (20kW per volt or better, true RMS meter).

Clamp on ammeter (5 times FLA full scale).

Adjustment wand (provided with multipurpose soft start control).

Overview The following adjustment procedures are examples and are intended to be used as a

guideline to match motor starting characteristics to the load. Actual loads may be

characterized by one or more of the examples. These procedures are intended to help

you design your own procedure for your specific application.

Keep in mind that reducing the starting current by one half will reduce the starting torque

by one fourth. This will cause the motor to take four times longer to reach full speed. In

situations where overloads tend to trip because of long starting times, increase the

starting current and decrease the ramp up time (RU) to help eliminate nuisance trips.

The potentiometer adjustments have a maximum span of 270°. Use the adjustment

wand (provided) to adjust these devices and do not force the adjustments beyond their

mechanical stops.

Caution: This equipment is shipped as a multipurpose apparatus. Before power is applied,

the line voltage selection and the full load current calibration must be correctly set.

Failure to select the proper line voltage or to calibrate the full load current may

cause damage.

Switches S1 and S2 as well as all potentiometer adjustments are not factory preset.

These will be set during the example procedures given in this section.

Before you apply Power

- Verify the installation procedure has been performed correctly.

- Know if your application is one of the “Non-motor and Special Motor

Applications” described in Section 2.

- Verify the wiring to the motor does not have any short circuits.

- Verify the motor is properly connected. Verify the voltage and full load amp

rating on the motor nameplate.

Note: A load must be connected to the control for testing. If the actual load cannot

be connected, connect any small motor temporarily for testing.

- Verify that the control transformer is properly jumpered for the line voltage at

your location. (MB#−XXX models).

- Verify that the control module jumper is correctly set for the line voltage.

(MA#−XXX models).

- Set S1 to the motor nameplate FLA value.

- Set S2 for the type of application.

- Set potentiometers as suggested.

- Verify the overload setting corresponds to the full load current range on the

calibration label.

After you apply Power

- Verify the input voltage to the starter and the 115VAC from the control

transformer (if a control transformer is installed).

- Verify the PWR light is on. (If not, refer to troubleshooting).

- Verify the shunt trip light is OFF. If it is ON, verify the motor is connected and

all three motor phases are present. If the motor is connected and the shunt trip

light is on, do not attempt to start the control. A short in the motor or wiring may

exist.

- Perform the starting procedure for your application.

Start-up 4-1MN894

Page 26

Quick Set-Up 1. Check continuity of the motor wiring and check for phase to phase and

phase to ground short circuits.

2. Connect the control wiring for your application.

(Refer to section 2 for wire size and torque specifications).

3. For MB#−XXX models, verify the control transformer is set for the line voltage.

For MA#−XXX models, verify proper voltage jumper selection on LCM models.

4. Calibrate S1. Refer to Appendix A for switch settings.

Voltage Ramp Starting - (Fans or lightly loaded motors)

5. Set for ramp up with ramp down as follows:

S2-1 = OFF Ramp down disable

S2-2 = OFF Current monitor

S2-3 = OFF Over current shut down

S2-4 = OFF Tachometer enable

S2-5 = OFF Current limit enable

S2-6 = OFF Bypass contactor

Set RU, TU, PT and PF fully CCW.

Set RD and RT at mid point.

6. Set for ramp up with no ramp down as follows:

S2-1 = ON Ramp down disable

S2-2 = OFF Current monitor

S2-3 = OFF Over current shut down

S2-4 = OFF Tachometer enable

S2-5 = OFF Current limit enable

S2-6 = OFF Bypass contactor

Set RU, TU, PT and PF fully CCW.

Note: If the control OC trips, use Current Ramp Starting.

7. Continue with step 14.

Current Ramp Starting - (High inertial loads)

8. Set for ramp up with ramp down as follows:

S2-1 = OFF Ramp down disable

S2-2 = OFF Current monitor

S2-3 = OFF Over current shut down

S2-4 = OFF Tachometer enable

S2-5 = ON Current limit enable

S2-6 = OFF Bypass contactor

Set RU, TU, PT and PF fully CCW.

Set RD and RT at mid point.

9. Set for ramp up with no ramp down as follows:

S2-1 = ON Ramp down disable

S2-2 = OFF Current monitor

S2-3 = OFF Over current shut down

S2-4 = OFF Tachometer enable

S2-5 = ON Current limit enable

S2-6 = OFF Bypass contactor

Set TU, PT, RD, TD and PF fully CCW.

Set RU fully CW.

Set CL to midpoint.

10. Continue with step 14.

4-2 Start-up MN894

Page 27

Tach Feedback Starting

11. Set for ramp up with ramp down as follows:

S2-1 = OFF Ramp down disable

S2-2 = OFF Current monitor

S2-3 = OFF Over current shut down

S2-4 = ON Tachometer enable

S2-5 = OFF Current limit enable

S2-6 = OFF Bypass contactor

Set RU, TU, PT and PF fully CCW.

Set RD and RT at mid point.

12. Set for ramp up with no ramp down as follows:

S2-1 = ON Ramp down disable

S2-2 = OFF Current monitor

S2-3 = OFF Over current shut down

S2-4 = ON Tachometer enable

S2-5 = OFF Current limit enable

S2-6 = OFF Bypass contactor

Set RU, TU, PT and PF fully CCW.

13. Continue with step 14.

WARNING: Be sure the system is properly grounded before applying power.

Do not apply AC power before you ensure that all grounding

instructions have been followed. Electrical shock can cause

serious or fatal injury.

WARNING: Improper operation of control may cause violent motion of the

motor shaft and driven equipment. Be certain that unexpected

motor shaft movement will not cause injury to personnel or damage

to equipment. Certain failure modes of the control can produce

peak torque of several times the rated motor torque.

14. Confirm the Close to Run contact is open.

15. Turn Power ON.

16. Close the Run contact.

17. The motor should just begin to rotate when power is applied and reach Ramp

End in a minimum starting time. The control is properly set if the motor starts

smoothly when power is applied and comes to speed as quickly as possible.

Be sure CL is set high enough so the motor can start with a full load. The

control is finished starting when the Ramp End light is ON.

18. If motor operation is not correct, perform one or more of the following

adjustments:

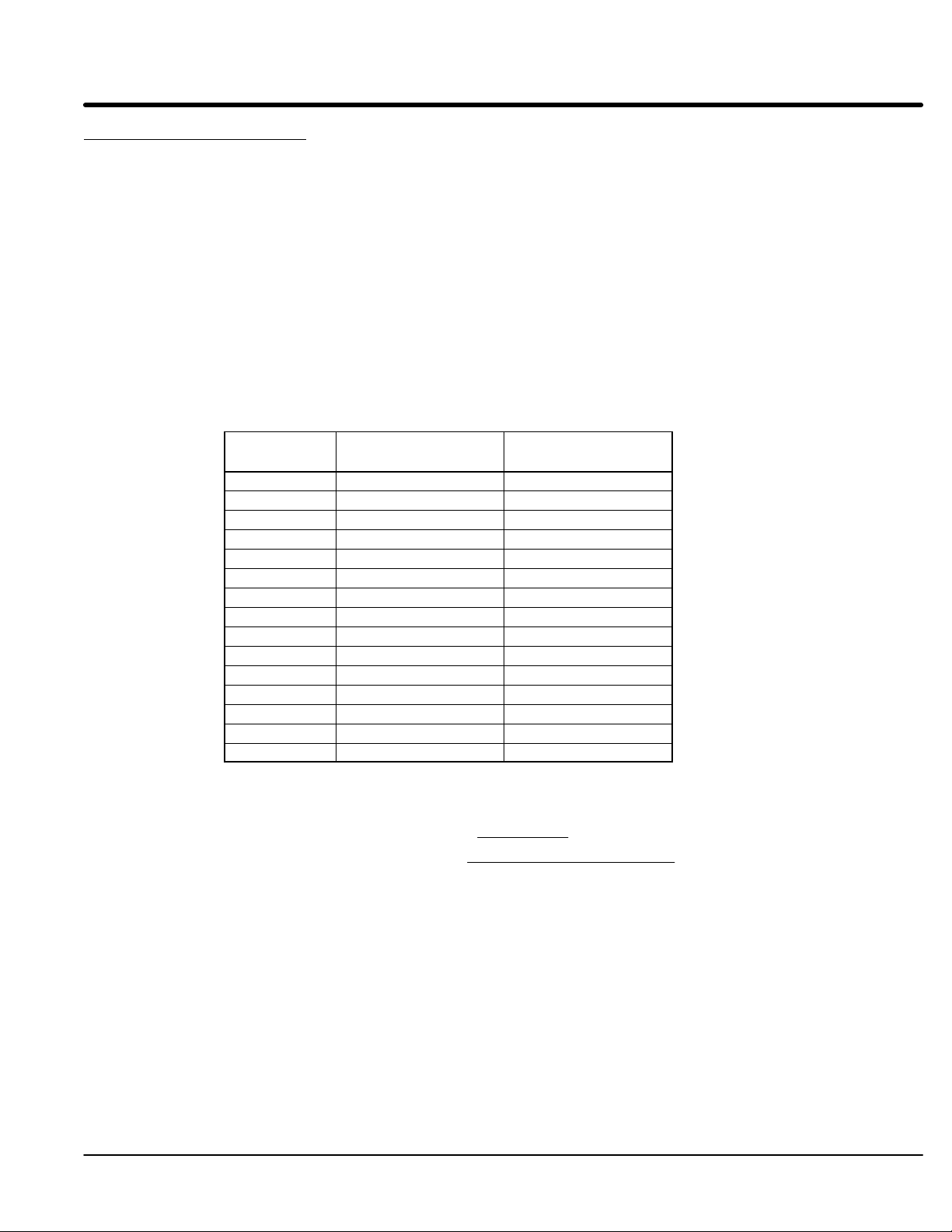

If the motor Remedy

Starts abruptly (jerks) Decrease TU by turning it CCW.

Starts too slowly Increase CL by turning it CW. Then decrease ramp time RU by turning it CW.

Starts too quickly Decrease CL by turning it CCW. Then increase ramp time RU by turning it CCW.

Is connected to a high inertial

load or a high slip motor is used

Is not starting properly Refer to detailed starting instructions for your application for more information on

It may be necessary to increase S1 setting to allow more motor current for faster

starting.

starting adjustments. Also, refer to start-up troubleshooting.

Start-up 4-3MN894

Page 28

Starting Instructions Choose one of the following examples that best matches your application. Read the

procedure and set the control according to the procedure or use the steps to develop

your own procedure.

Variable Load with Voltage Ramp (S2-2=OFF, S2−4=OFF)

Typically used for non-inertial loads, loads that increase with speed and changing loads,

such as axial fans and pumps.

1. Set RU, TU, PT, RD, TD and PF fully counterclockwise CCW).

2. Set CL and CM fully clockwise (CW).

3. Adjust TU clockwise sufficiently to start load slowly moving at moment of

switching.

4. Adjust RU clockwise to achieve desired starting time with normal load

conditions.

Note: Proceed to “Running Adjustment Procedure” if ramp down is not used.

5. Adjust TD clockwise sufficiently to cause the load to slow down soon after the

stop button is pressed, with normal load conditions.

6. Adjust RD clockwise to achieve desired stopping time with normal load

conditions.

Running Adjustment Procedure:

After adjusting the starting and stopping characteristics, current monitor/trip (CM)

and power factor adjustments can be made. If the power factor circuit is not used,

turn the PF adjustment fully counterclockwise.

Power Factor Correction Adjustment (PF):

1. Use an ammeter to measure motor running current.

2. With the motor at full speed, minimum load and the “Ramp End” light ON,

adjust PF clockwise to minimize running current without oscillation. If there is

no noticeable drop in current, repeat this step while measuring motor voltage.

Current Monitor/Trip (CM):

1. Set S2-2=OFF.

2. Press start and allow the motor to reach full speed and the “Ramp End” light to

turn ON.

3. Adjust CM to desired threshold by observing the “CUR MON” light.

4. The “CUR MON” contact can be used to indicates this threshold, or by setting

the S2-2=ON, the starter will shut down. Press stop to reset the shutdown and

trip condition.

Post Adjustment Check List:

1. Check fans for proper operation.

2. If bypass contactor is used, check that the contactor is closing at Ramp End.

3. Using a current probe, measure current on all three motor phases. Be sure the

current is balanced during ramp on, run and ramp down.

4. With the motor in run mode (Ramp End light “ON”), check phase current of all

three phases. Currents should be balanced and within nameplate FLA.

5. Measure the line voltage at the control during ramp up to ensure voltage does

not drop below minimum operating voltage.

4-4 Start-up MN894

Page 29

High Friction Load with Voltage Ramp (S2-2=OFF, S2-4=OFF)

Typically used for loads that require high breakaway torque and low acceleration torque;

i.e., conveyors in icy environment, equipment that resists starting due to lack of use,

traction loads, etc.

1. Set RU, TU, PT, RD, TD and PF fully counterclockwise (CCW).

2. Adjust PT clockwise sufficiently to start load slowly moving at moment of

switching.

3. Adjust TU clockwise sufficiently to keep load moving after starting pulse.

4. Adjust RU clockwise to achieve desired starting time with normal load

conditions.

Note: Proceed to “Running Adjustment Procedure” if ramp down is not used.

5. Adjust TD clockwise sufficiently to cause the load to slow down soon after stop

button is pressed, with normal load conditions.

6. Adjust RD clockwise to achieve desired stopping time with normal load

conditions.

Running Adjustment Procedure:

After adjusting the starting and stopping characteristics, current monitor/trip (CM)

and power factor adjustment can be made. If the power factor circuit is not used,

turn the PF adjustment fully counterclockwise.

1. Use an ammeter to measure motor running current.

2. With the motor at full speed, minimum load and “Ramp End” light on, adjust PF

clockwise to minimize running current without oscillation. If there is no

noticeable drop in current, repeat this step while measuring motor voltage.

Current Monitor/Trip (CM):

1. Press start and allow the motor to reach full speed and the “Ramp End” light to

turn on.

2. Adjust CM to desired threshold by observing the “CUR MON” light.

3. The “CUR MON” contact can be used to signal this threshold, or by setting the

S2-2=ON, the starter will shut down. Press stop to reset the shutdown and trip

condition.

Post Adjustment Check List

1. Check fans for proper operation.

2. If bypass contactor is used, check to ensure that the contactor is closing at

Ramp End.

3. Using a current probe, measure current on all three motor phases. Be sure the

current is balanced during ramp up, run and ramp down.

4. With the motor in run mode (Ramp End light “ON”), check phase current of all

three phases. Currents should be balanced and within nameplate FLA.

5. Measure the line voltage at the control during ramp up to ensure voltage does

not drop below minimum operating voltage.

Start-up 4-5MN894

Page 30

Inertial Load (S2-1=ON, S2-4=OFF, S2-5=ON)

Typically used on coasting and/or flywheel loads; i.e., chippers, centrifuges, compressors,

crushers, chillers, band saws, centrifugal fans and blowers.

Note: Ramp down and pulse start are not normally used with inertial loads.

1. Set TU, PT, RD, TD and PF fully counterclockwise (CCW).

2. Set RU approximately 90% clockwise.

3. Set CL to midpoint.

4. Set CM fully clockwise (CW).

5. Adjust CL sufficiently to allow motor to reach full speed in desired time with

maximum normal load.

Running Adjustment Procedure:

After adjusting the starting and stopping characteristics, current monitor/trip (CM)

and power factor adjustment can be made. If the power factor circuit is not used,

turn the PF adjustment fully counterclockwise.

Power Factor Correction Adjustment (PF):

1. Use an ammeter to measure motor running current.

2. With the motor at full speed, minimum load and the “Ramp End” light ON,

adjust PF clockwise to minimize running current without oscillation. If there is

no noticeable drop in current, repeat this step while measuring motor voltage.

Current Monitor/Trip (CM):

1. Set S2-2=OFF.

2. Press start and allow the motor to reach full speed and the “Ramp End” light to

turn ON.

3. Adjust CM to the desired threshold by observing the “CUR MON” light.

4. The “CUR MON” contact can be used to signal this threshold, or by setting

S2-2=ON, the starter will shut down. Press stop to reset the shutdown and trip

condition.

Post Adjustment Check List:

1. Check fans for proper operation.

2. If a bypass contactor is used, check that the contactor closes at ramp end.

3. Using a current probe, measure current on all three motor phases. Be sure the

current is balanced during ramp up, run and ramp down.

4. With the motor in run mode (ramp end light “ON”), check phase current of all

three phases. Currents should be balanced and within nameplate FLA.

5. Measure the line voltage at the control during ramp up to ensure voltage does

not drop below minimum operating voltage.

4-6 Start-up MN894

Page 31

Tachometer Mode (S2-4=ON, S2-5=OFF)

Typically used for changing loads that require consistent starting and stopping times,

independent of load condition, and pumping applications with severe head pressure to

reduce water hammer; i.e., pumps, conveyors, stackers and other material handling

equipment.

1. Set RU, TU, PT, RD, TD and PF fully counterclockwise (CCW).

2. Set CL and CM fully clockwise (CW).

3. Adjust RU and RD for desired ramp up and ramp down time. RD is only

effective with S2-1=OFF.