Page 1

Series 29

Digital DC Control

Installation & Operating Manual

9/03 MN792

Page 2

Page 3

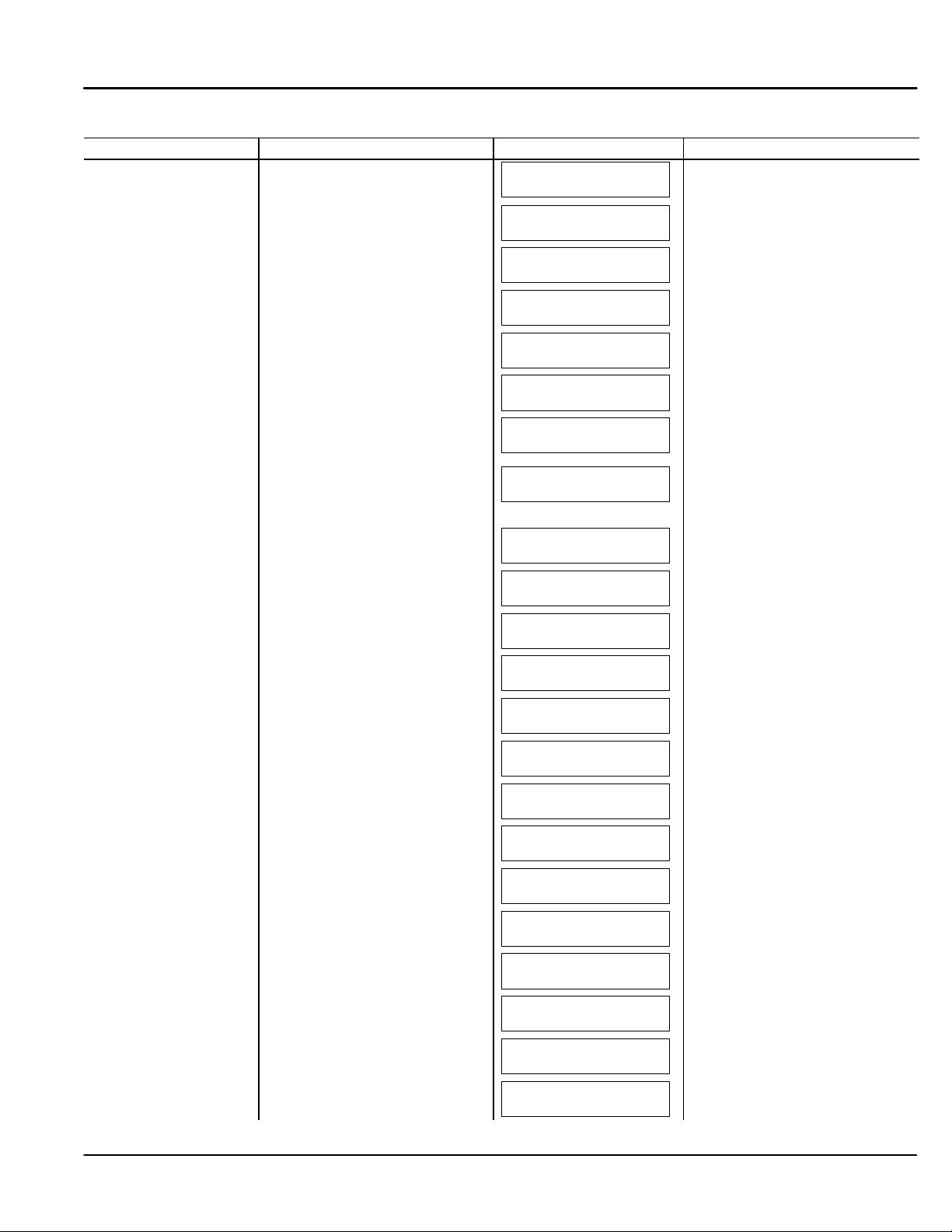

Table of Contents

Section 1

Quick Start 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Minimum Connection Requirements 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power and Motor Connections 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference and Jumpers for Keypad Operation 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Settings (for Keypad Operation) 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference and Jumpers for Remote Operation 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Feedback 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Link 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2

General Information 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Compliance 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enclosure Sizes 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited W arranty 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Notice 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3

Getting Started 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Overview 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Loops 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control and Communications 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local and Remote Modes 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Source / Destination Tags 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Block 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 4

Receiving and Installation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving & Inspection 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location Considerations 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cover Removal 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Installation 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Vent Kit 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Remote Keypad Installation 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Installation 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Grounding 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Impedance 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Disconnect 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protection Devices 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Isolation Transformer Sizing 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single Phase Power 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Connections 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Power 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Connections 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

M-Contactor 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents iMN792

Page 4

Blower Motor Starter 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermal Protection 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Encoder Installation 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tachometer Installation 4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control I/O Signal Connections 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Inputs 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Outputs 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Inputs 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Outputs 4-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS232 Connections 4-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Port (P3) Configuration 4-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 5

Switch Setting and Start-Up 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre–Operation Checks 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power up in Local Mode with Armature Feedback 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power up in Remote Mode with Feedback 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Autotune 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Loop Adjustment 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Stopping Methods 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upload/Download Procedure 5-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DUMP Procedure 5-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 6

Programming 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu System 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Descriptions 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Inputs 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Outputs 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AUX I/O 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration 6-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure Drive 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Loop 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Profile 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Inputs 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Outputs 6-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Control 6-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarms 6-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jog/Slack 6-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menus 6-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OP Station 6-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii Table of Contents MN792

Page 5

Password 6-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PID 6-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Raise/Lower 6-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ramps 6-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setpoint Sum 1 6-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Loop 6-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advanced 6-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standstill 6-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stop Rates 6-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Port P3 6-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5703 Support 6-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEC Option 6-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 7

Keypad Operation 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad LED Status 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Messages 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Menu 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

L/R Key 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROG Key 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu System 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Shortcuts and Special Key Combinations 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick Tag Information 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restore Factory Settings 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 button reset 7-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation Examples 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select a Menu View Level 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Language Selection 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Password Protection 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deactivate a Password 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Save Settings 7-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 8

Troubleshooting 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset a Trip Condition 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Conditions 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial (P3) Errors 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Messages 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Last Alarm 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Health Word 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Health Store 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Board LED Trip Information (Frame 4 and 5) 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents iiiMN792

Page 6

Manage Trips from the Keypad 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trip Messages 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbolic Alarm Messages 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self Test Alarms 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Trip Conditions 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Trip Conditions 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inhibiting Alarms 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Points 8-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 8-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair 8-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 9

Specifications & Product Data 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Display 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Specifications 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Encoder 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tachometer 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Tightening Torque 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ratings 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EMC Filters 9-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

CE Guidelines A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Declaration of Conformity A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EMC – Conformity and CE – Marking A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EMC Installation Instructions A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B

Parameter Table B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Values B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameters Listed by Tag Number B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameters Listed by Name B-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameters Listed by Keypad Menu B-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameters Listed by WB Block B-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C

Block Diagram C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv Table of Contents MN792

Page 7

Section 1

Quick Start

The basic steps for connection and setup are provided in this section. Detailed descriptions of each step and

parameter settings are provided later in this manual. Be sure to comply with all applicable codes when installing

this control. The Series 29 DC control is a one way control. That is, it is non–regen and cannot reverse

direction. It operates in the forward direction only. All references to reverse operation or regen operation apply

to the Series 30 DC Control only.

Minimum Connection Requirements Refer to Section 4 for cover removal procedure.

Power and Motor Connections

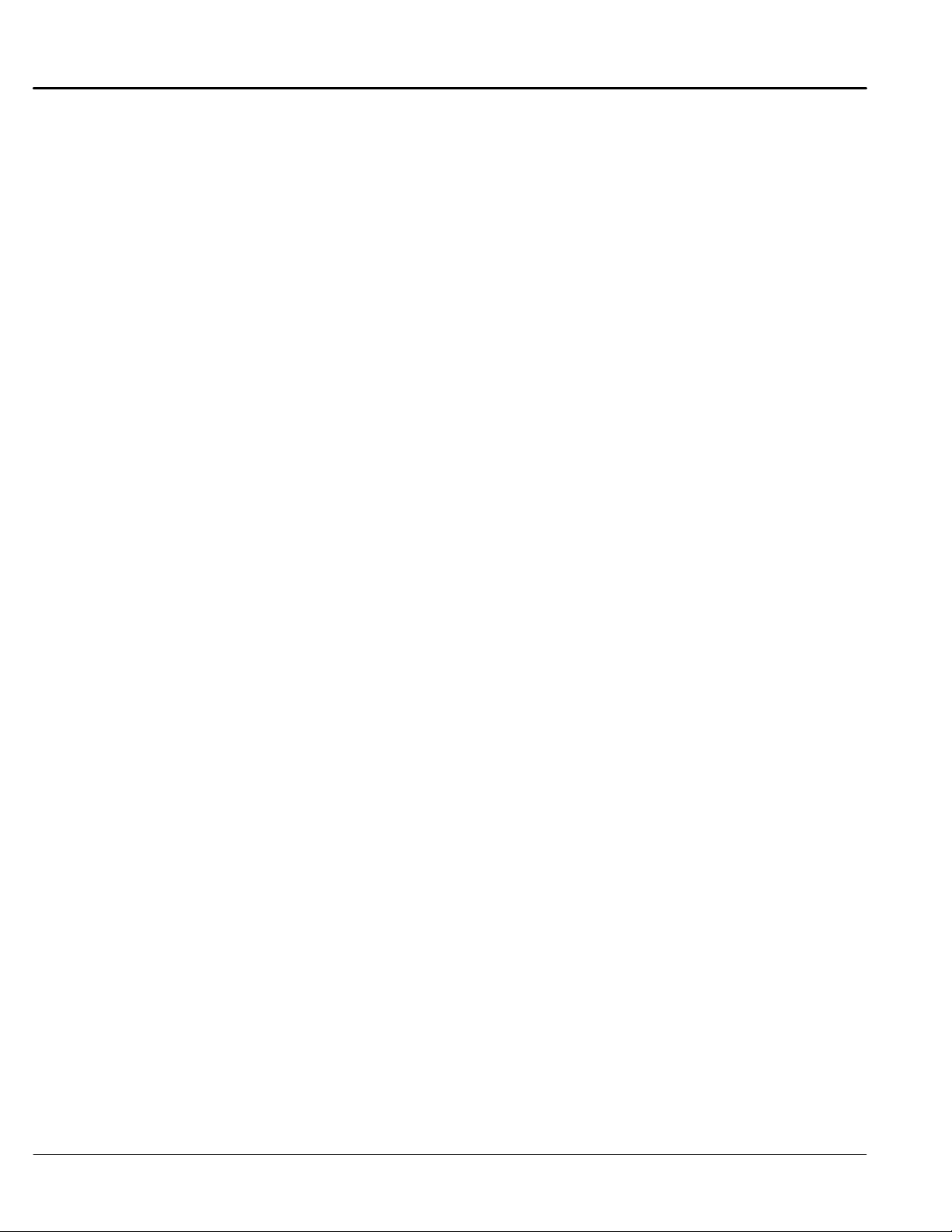

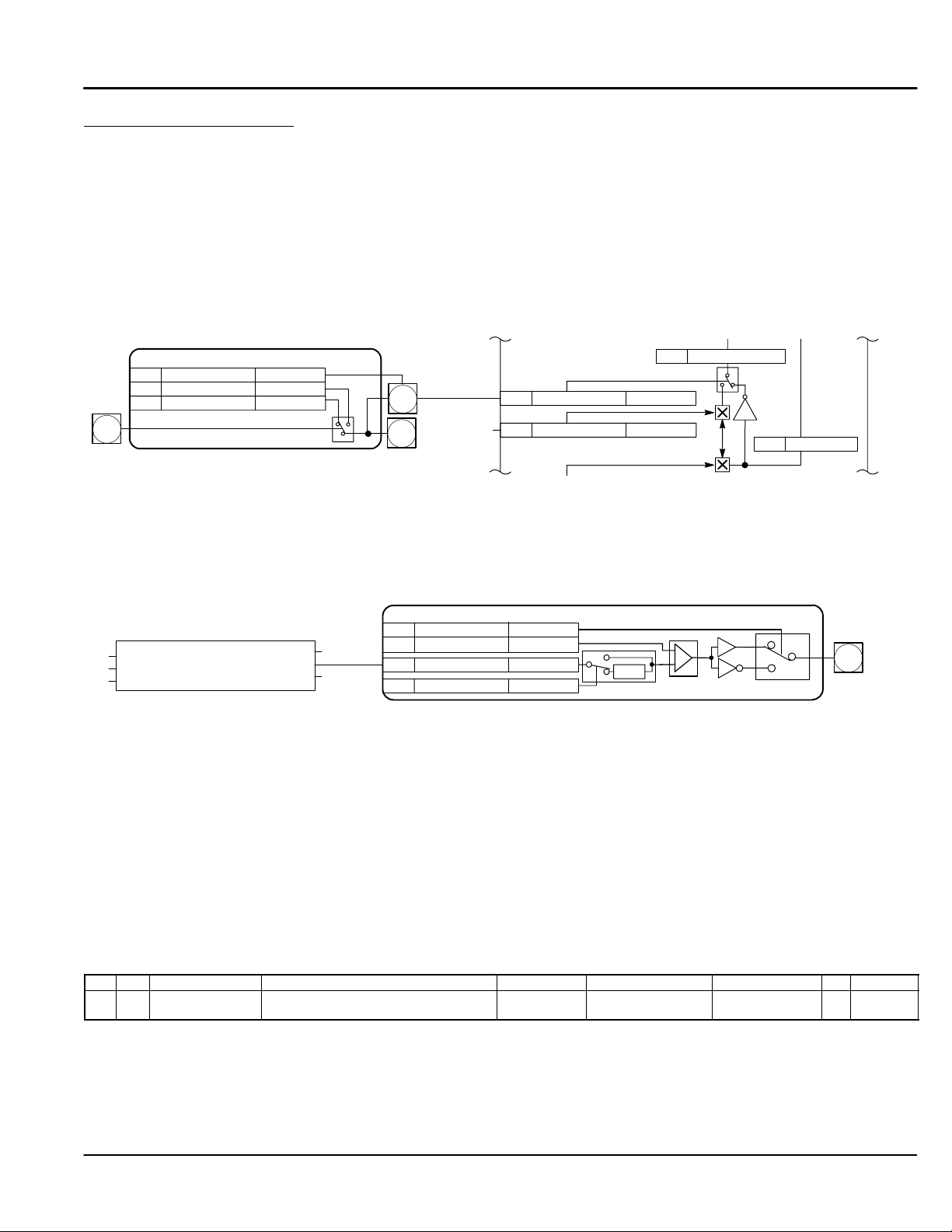

Figure 1-1 shows the minimum connections required at the power connector.

Figure 1-1 Power Connections

3 Phase

Power

L1

L2

L3

GND

Thermistor

For Size 1 & 2 controls, be sure the

logic power jumper is in the correct

position. Refer to Figure 4-9.

To 1 Phase 115VAC Control Power

(except units with internal

control transformer,

100hp and less)

or jumper TH1 to TH2 if

motor thermistor is not connected.

Armature

Reference and Jumpers for Keypad Operation

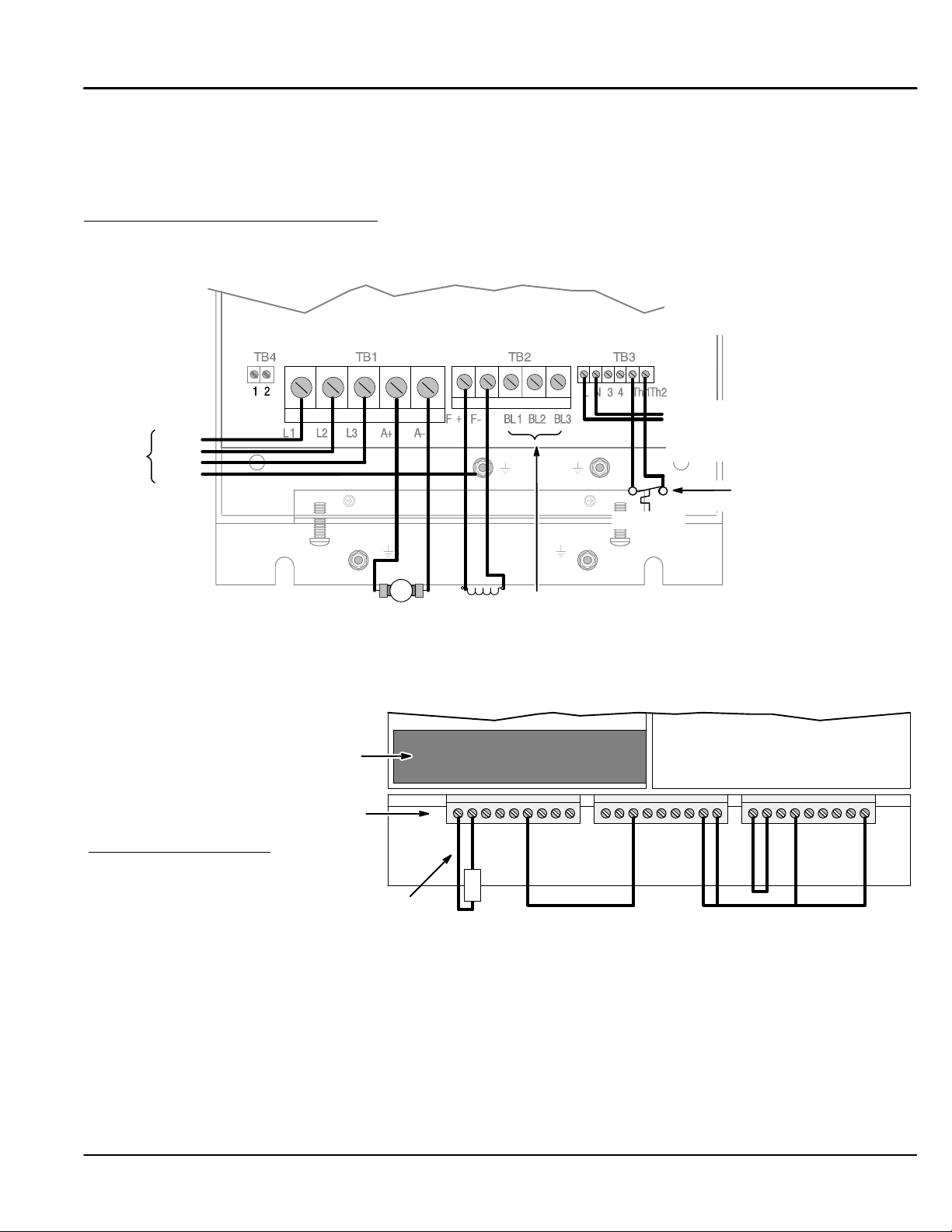

For keypad operation, the speed reference connections are not required. Speed is set at the keypad. Figure

1-2 shows the minimum connections required A, B and C signal connectors for Keypad operation.

Figure 1-2 Reference and Jumper Connections

If Optional Speed Feedback Board is used, refer

to Speed Feedback at the end of this section.

Signal Connections

Minimum jumper connections:

A1 to A2 – 500 ohm jumper for 20mA input

A6 to B3 – Analog Input 5 = +10VDC

B8 to C9 – PROG Stop = +24VDC

B9 to C9 – Coast Stop = +24VDC

C4 to C9 – Enable = +24VDC

C1 to C2 – No External Trip

Parameter Settings (for Keypad Operation)

The factory settings should be sufficient to operate the control using the “Local” mode with the keypad. Only a

few changes to the motor data parameters must be made. Before any parameters can be changed, set

System::Configure I/O::Configure Enable to enable. All LEDs will blink during configuration.

Note: To separate the various menu level designation, a double colon is used (System::Configure I/O).

500 ohm

Jumper for

0-20mA

Field

AB

0V 1

AnIn 1 2

500

Motor Starter on Size 1 & 2 controls.

AnIn 2 3

AnIn 3 4

AnIn 4 5

AnIn 5 6

AnOut 1 7

AnOut 2 8

0V 1

Not Used 2

Arm I Fbk 9

+10V Ref 3

DigOut 1 5

DigOut 2 6

DigOut 3 7

-10V Ref 4

Prog Stop 8

Coast Stop 9

Motor Blower connections when using optional

C

0V 1

Start 3

DigIn E 4

DigIn R 5

Ext Trip 2

+24V 9

DigIn 1 6

DigIn 2 7

DigIn 3 8

Quick Start 1-1MN792

Page 8

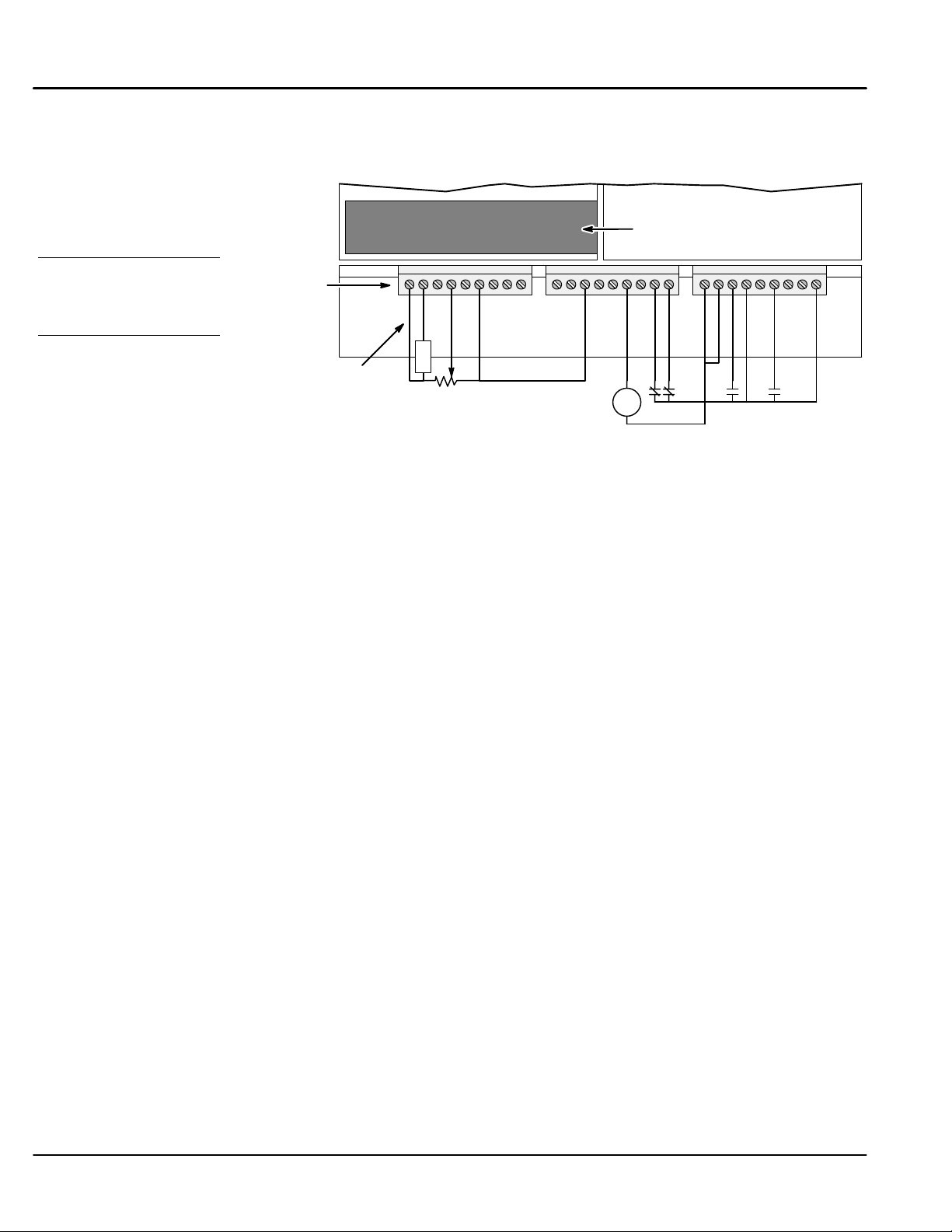

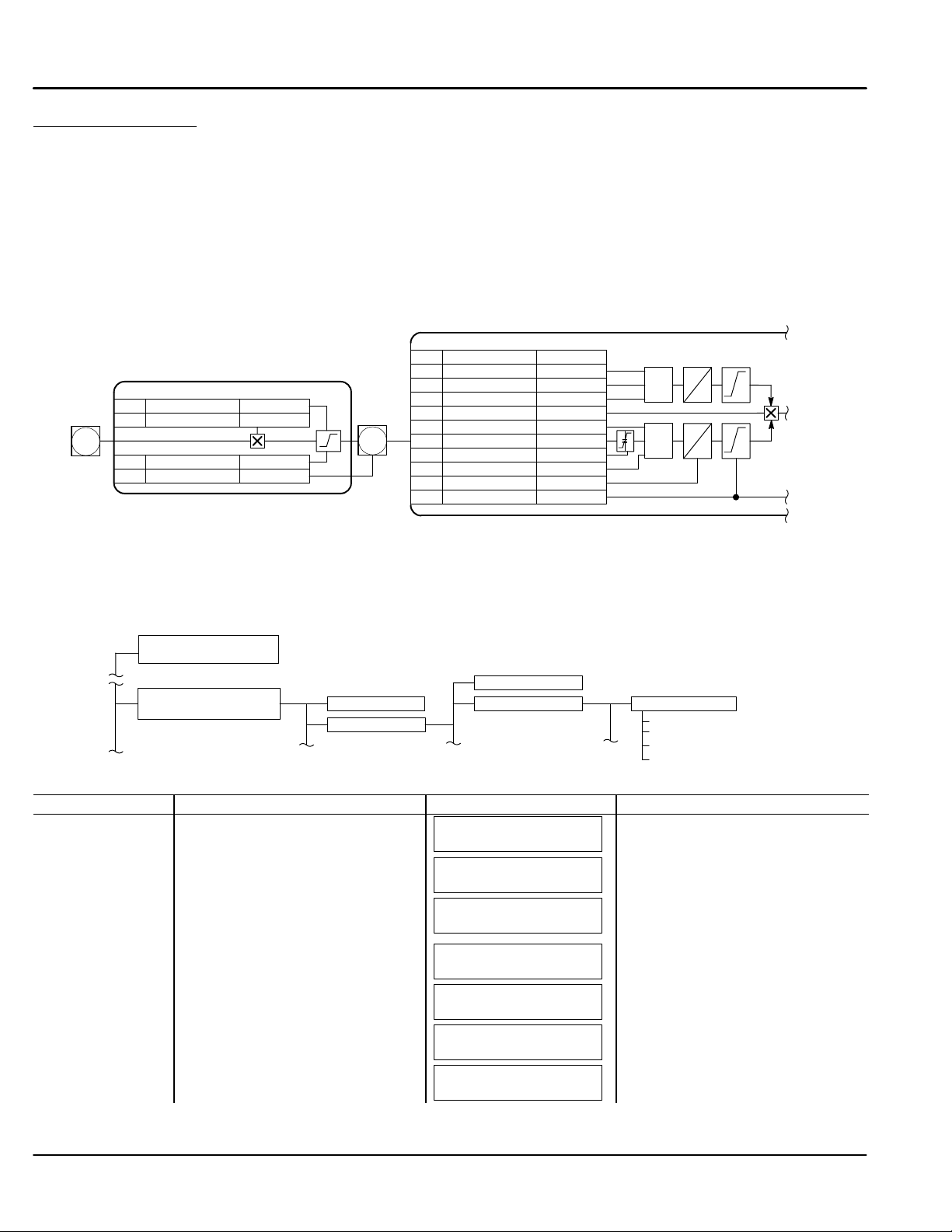

Reference and Jumpers for Remote Operation

For remote operation, the speed reference and other connections are made at the terminal strip connector. Not

all of these connections are shown in Figure 1-3.

Figure 1-3 Reference and Jumper Connections

Speed Reference connections:

A1 – one end of Pot

B3 – one end of Pot

A4 – wiper of Pot

C1 to C2 – No External Trip

Minimum jumper connections:

A1 to A2 – 500 ohm jumper for 20mA input

A6 to B3 – Analog Input 5 = +10VDC

C4 to C9 – Enable = +24VDC

C1 to C2 – No External Trip

Jumper if contacts are not used:

B8 to C9 – PROG Stop = +24VDC

B9 to C9 – Coast Stop = +24VDC

The Health relay (24VDC coil) may be installed between B6 and C1

to provide fault indication to an external device or circuit.

Signal

Connections

AB

500 ohm

Jumper for

0-20mA

Optional Speed

Feedback Board

0V 1

AnIn 1 2

AnIn 2 3

AnIn 3 4

AnIn 4 5

AnIn 5 6

AnOut 1 7

AnOut 2 8

500

0V 1

DigOut 1 5

Arm I Fbk 9

Not Used 2

DigOut 2 6

-10V Ref 4

+10V Ref 3

C

0V 1

Start 3

DigIn E 4

DigIn R 5

DigOut 3 7

Prog Stop 8

Coast Stop 9

Ext Trip 2

+24V 9

DigIn 1 6

DigIn 3 8

DigIn 2 7

DH

Jog

Start

Health Relay

PROG Stop

Coast Stop

Speed Feedback The factory setting for speed feedback is Armature Voltage which does not require an optional feedback

board. If an optional board must be used, refer to its manual to install and set the board configuration.

Serial Link A PC COM port may be connected to the control at the System Port (P3). At Menu Level : Serial Links, all of

the parameters can be set for your application.

1-2 Quick Start MN792

Page 9

and scroll the menu choices, and “M” goes to next level menu and “E” comes back up one menu level.

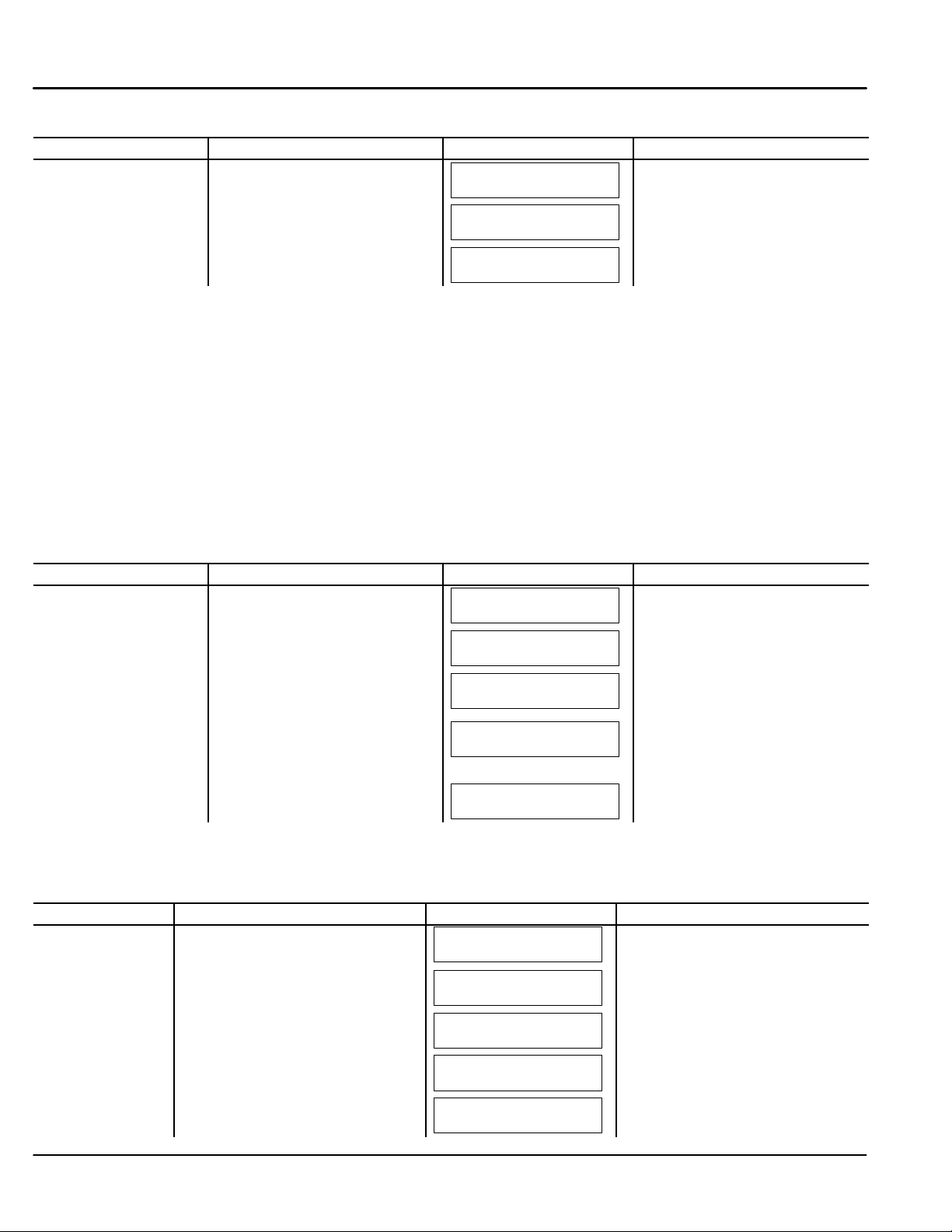

Action Description Display Comments

Apply Power Keypad Display shows this opening

Press “PROG” key

Press “M” key

Press “M” key Access the menus.

Press

Press “M” key Access the Configure Drive Menu

Press “M” key Access Configure Enable.

Press key

Press “E” key Return to the Configure Drive Menu

Press

message.

Scroll to “Configure Drive” menu.

Change Disabled to Enabled.

Set the motor volts.

FORWARD

REF: 0.00%

BALDOR DC DRIVE

DC 4Q 15A

DC 4Q 15A

MENU LEVEL

MENU LEVEL

DIAGNOSTICS

MENU LEVEL

CONFIGURE DRIVE

CONFIGURE DRIVE

CONFIGURE ENABLE

CONFIGURE ENABLE

DISABLED

CONFIGURE ENABLE

ENABLED

CONFIGURE DRIVE

CONFIGURE ENABLE

NOM MOTOR VOLTS

Local control display.

This message may be different for

each control size.

Press M twice to go down 2 menu

levels

Configure enable is disabled and

no parameter value can be

changed.

Configure enable must be enabled

to allow a change to any parameter

value. All LED’s on keypad are

blinking to show it is enabled.

Use up and down arrows to set the

motor voltage.

Press

Press

Press

Press

Press

Press

Press

Press

Press

Press

Press

Set the armature current.

Set the field current (skip if field is

in voltage mode.

Set the field control mode (voltage

or current).

Field Volts Ratio=

(field volts/AC supply)*100

Set the current limit

(normally 100%).

Leave autotune off.

Select Armature Volts, Analog

TACH or Encoder.

Set the pulses per REV of the

encoder.

Set the encoder max speed (100%

speed).

Change the polarity of the encoder

signal if needed.

The Speed Loop Integral Gain.

ARMATURE CURRENT

FIELD CURRENT

FLD. CTRL MODE

FLD. VOLTS RATIO

MAIN CURR. LIMIT

AUTOTUNE

SPEED FBK SELECT

ENCODER LINES

ENCODER RPM

ENCODER SIGN

SPD INT TIME

Use up and down arrows to set.

Press “E” when done.

Use up and down arrows to set.

Press “E” when done.

Use up and down arrows to set.

Press “E” when done.

Use up and down arrows to set.

Press “E” when done.

Use up and down arrows to set.

Press “E” when done.

Autotune after calibration is

complete.

Use up and down arrows to set.

Press “E” when done.

Use up and down arrows to set.

Press “E” when done.

Use up and down arrows to set.

Press “E” when done.

Use up and down arrows to set.

Press “E” when done.

Use up and down arrows to set.

Press “E” when done.

Press

The Speed Loop Proportional Gain.

SPEED PROP GAIN

Use up and down arrows to set.

Press “E” when done.

Quick Start 1-3MN792

Page 10

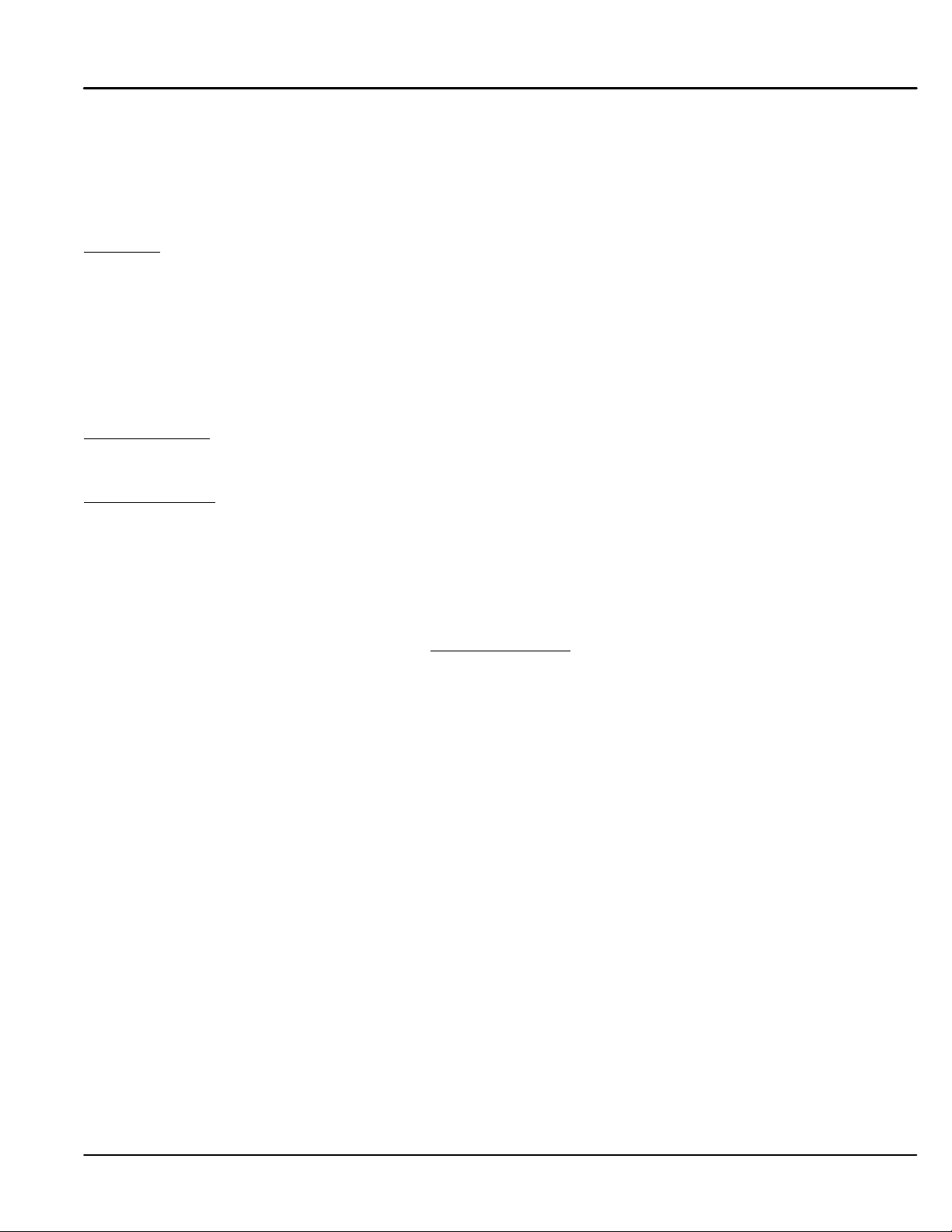

Configure the drive parameters and block diagram connections.

Action Description Display Comments

Press “M” key

Press “M” key Access the menus.

Press or

Scroll to “Configure Drive” menu.

Setup Parameters

At Menu Level : Setup Parameters, several sub menus set values for your application:

Ramps, AUX I/O, Op Station, Jog/Slack, Raise/Lower, Special Blocks, Field Control, Current Profile, Inverse

Time, Stop Rates, Calibration, Inhibit Alarms, Current Loop, Speed Loop, Standstill and Setpoint Sum 1.

Password

At Menu Level : Password, a password can be set to prevent unauthorized access to the setup and other

parameters.

Configure I/O

At Menu Level : System : Configure I/O, make the connections using the Tags to configure the block diagram to

your application.

Autotune

At Menu Level : Configure Drive, set Autotune to On, press “E” to exit configure menu. At the keypad, press L/R

for local mode. Press Run, the drive will autotune. When the drive stops and no error messages are displayed,

autotune was successful. Repeat the Save Parameters procedure to ensure the new values are saved.

When completed, change the Configure Enable parameter from Enabled to Disabled.

DC 4Q 15A

MENU LEVEL

MENU LEVEL

DIAGNOSTICS

MENU LEVEL

SETUP PARAMETERS

Press “E” when done.

Action Description Display Comments

Press or

Press “M” key Access the Configure Drive Menu

Press “M” key Access Configure Enable.

Press key

Press “E” key 2 times Return to the Menu Level.

Scroll to “Configure Drive” menu.

Change Disabled to Enabled.

MENU LEVEL

CONFIGURE DRIVE

CONFIGURE DRIVE

CONFIGURE ENABLE

CONFIGURE ENABLE

ENABLED

CONFIGURE ENABLE

DISABLED

Press M twice to go down 2 menu

levels

Configure enable is disabled and

no parameter value can be

changed.

Configure enable must be enabled

to allow a change to any parameter

value. All LED’s on keypad are

blinking to show it is enabled.

MENU LEVEL

CONFIGURE DRIVE

Save Parameters

At Menu Level : Save Parameters, save the settings you have programmed into the control. This will be the

parameters that are restored for use after power up. If you do not save the parameters, the factory settings (or

the last saved) will be used after a power up.

Action Description Display Comments

Start at Menu

Level 1

Press

Scroll to “PARAMETER SAVE” menu.

Press “M” key

Press Press to save parameters.

Press “E” key Exit one level

MENU LEVEL

DIAGNOSTICS

MENU LEVEL

PARAMETER SAVE

PARAMETER SAVE

UP TO ACTION

PARAMETER SAVE

REQUESTED

MENU LEVEL

PARAMETER SAVE

Parameters are saved. Except the

“Local Setpoint”.

Press “E” several times to return to

the top level.

1-4 Quick Start MN792

Page 11

Section 2

General Information

Copyright Baldor 2002. All rights reserved.

This manual is copyrighted and all rights are reserved. This document may not, in whole or in part, be copied or

reproduced in any form without the prior written consent of Baldor.

Baldor makes no representations or warranties with respect to the contents hereof and specifically disclaims any

implied warranties of fitness for any particular purpose. The information in this document is subject to change

without notice. Baldor assumes no responsibility for any errors that may appear in this document.

Microsoft and MS–DOS are registered trademarks, and Windows is a trademark of Microsoft Corporation. UL

and cUL are registered trademarks of Underwriters Laboratories.

Overview The Series 29 DC control is a one way control. That is, it is non–regen and cannot reverse direction. It

CE Compliance A custom unit may be required, contact Baldor. Compliance to Directive 89/336/EEC is the responsibility of the

Enclosure Sizes Five enclosure sizes are available:

operates in the forward direction only. All references to reverse operation or regen operation apply to the Series

30 DC Control only. The Baldor Digital DC control is a three phase, full wave, DC motor armature and field

control. The SCR bridge converts three phase AC power to controlled DC to operate the DC motor armature.

The AC input is also used for the reference transformer input to operate power supplies and synchronize to the

AC input line. This control is of the NEMA Type C designation.

The control may also be used with permanent magnet field motors and DC spindle drive motors. In addition,

standard feedback from armature may be used. An optional Encoder, Tachometer or resolver feedback is

available with optional expansion boards. The control can be configured to operate in a number of modes

depending upon the application requirements and user preference.

It is the responsibility of the user to determine the correct operating mode to use for the application. These

choices are made using the keypad as explained in this manual.

system integrator. A control, motor and all system components must have proper shielding, grounding, and

filtering as described in MN1383. Please refer to MN1383 for installation techniques for CE compliance. For

additional information, refer to Section 4 and Appendix A of this manual.

Size 1 15A to 35A

Size 2 40A to 165A

Size 3 180A to 270A

Size 4 380A to 830A

Size 5 850A and larger

Limited Warranty

For a period of one (1) year from the date of original purchase, BALDOR will repair or replace

without charge controls and accessories which our examination proves to be defective in

material or workmanship. This warranty is valid if the unit has not been tampered with by

unauthorized persons, misused, abused, or improperly installed and has been used in

accordance with the instructions and/or ratings supplied. This warranty is in lieu of any other

warranty or guarantee expressed or implied. BALDOR shall not be held responsible for any

expense (including installation and removal), inconvenience, or consequential damage,

including injury to any person or property caused by items of our manufacture or sale. (Some

states do not allow exclusion or limitation of incidental or consequential damages, so the above

exclusion may not apply.) In any event, BALDOR’s total liability, under all circumstances, shall

not exceed the full purchase price of the control. Claims for purchase price refunds, repairs, or

replacements must be referred to BALDOR with all pertinent data as to the defect, the date

purchased, the task performed by the control, and the problem encountered. No liability is

assumed for expendable items such as fuses.

Goods may be returned only with written notification including a BALDOR Return Authorization

Number and any return shipments must be prepaid.

General Information 2-1MN792

Page 12

Product Notice Intended use:

These drives are intended for use in stationary ground based applications in industrial power installations

according to the standards EN60204 and VDE0160. They are designed for machine applications that require

variable speed controlled three phase brushless AC motors.

These drives are not intended for use in applications such as:

– Home appliances

– Mobile vehicles

– Ships

– Airplanes

Unless otherwise specified, this drive is intended for installation in a suitable enclosure. The enclosure must

protect the control from exposure to excessive or corrosive moisture, dust and dirt or abnormal ambient

temperatures.

In the event that a control fails to operate correctly, contact Baldor for return instructions.

Safety Notice: This equipment contains high voltages. Electrical shock can cause serious or fatal injury. Only qualified

personnel should attempt the start–up procedure or troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts or parts that are driven by this

equipment. Improper use can cause serious or fatal injury. Only qualified personnel should attempt the start–up

procedure or troubleshoot this equipment.

– System documentation must be available at all times.

– Keep non-qualified personnel at a safe distance from this equipment.

– Only qualified personnel familiar with the safe installation, operation and maintenance of this device

should attempt start-up or operating procedures.

– Always remove power before making or removing any connections to this control.

PRECAUTIONS: Classifications of cautionary statements.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in

injury or death.

Caution: Indicates a potentially hazardous situation which, if not avoided, could result in

damage to property.

Continued on next page.

2-2 General Information MN792

Page 13

PRECAUTIONS:

WARNING: Do not touch any circuit board, power device or electrical connection before you

WARNING: Be sure that you are completely familiar with the safe operation of this equipment.

WARNING: Be sure all wiring complies with the National Electrical Code and all regional and

WARNING: Be sure the system is properly grounded before applying power. Do not apply AC

WARNING: Do not remove cover for at least five (5) minutes after AC power is disconnected

WARNING: Improper operation may cause violent motion of the motor and driven equipment.

WARNING: Motor circuit may have high voltage present whenever AC power is applied, even

WARNING: If a motor is driven mechanically, it may generate hazardous voltages that are

WARNING: The user must provide an external hard-wired emergency stop circuit to disable

first ensure that power has been disconnected and there is no high voltage

present from this equipment or other equipment to which it is connected.

Electrical shock can cause serious or fatal injury.

This equipment may be connected to other machines that have rotating parts or

parts that are controlled by this equipment. Improper use can cause serious or

fatal injury.

local codes or CE Compliance. Improper wiring may cause a hazardous

condition.

power before you ensure that grounds are connected. Electrical shock can cause

serious or fatal injury.

to allow capacitors to discharge. Electrical shock can cause serious or fatal

injury.

Be certain that unexpected movement will not cause injury to personnel or

damage to equipment.

when motor is not moving. Electrical shock can cause serious or fatal injury.

conducted to its power input terminals. The enclosure must be grounded to

prevent a possible shock hazard.

the control in the event of an emergency.

Continued on next page.

General Information 2-3MN792

Page 14

Caution: To prevent equipment damage, be certain that the input power has correctly sized protective

devices installed as well as a power disconnect.

Caution: Avoid locating the control immediately above or beside heat generating equipment, or

directly below water or steam pipes.

Caution: Avoid locating the control in the vicinity of corrosive substances or vapors, metal particles

and dust.

Caution: Suitable for use on a circuit capable of delivering not more than the RMS symmetrical short

circuit amperes listed here at rated voltage.

Horsepower RMS Symmetrical Amperes

1.5–50 5,000

51–200 10,000

201–400 18,000

401–600 30,000

601–900 42,000

Caution: Baldor recommends not using “Grounded Leg Delta” transformer power leads that may

create ground loops and degrade system performance. Instead, we recommend using a

four wire Wye.

Caution: Logic signals are interruptible signals; these signals are removed when power is removed

from the drive.

Caution: The safe integration of the drive into a machine system is the responsibility of the machine

designer. Be sure to comply with the local safety requirements at the place where the

machine is to be used. In Europe this is the Machinery Directive, the ElectroMagnetic

Compatibility Directive and the Low Voltage Directive. In the United States this is the

National Electrical code and local codes.

Caution: Controls must be installed inside an electrical cabinet that provides environmental control

and protection. Installation information for the drive is provided in this manual. Motors and

controlling devices that connect to the driver should have specifications compatible to the

drive.

Caution: Do not tin (solder) exposed wires. Solder contracts over time and may cause loose

connections.

Caution: Electrical components can be damaged by static electricity. Use ESD (electro-static

discharge) procedures when handling this control.

Caution: This control is not designed for regenerative use with stabilized shunt or compound wound

motors. If stabilized shunt or compound wound are to be used, the series field must be

isolated and not connected. Contact the motor manufacturer for motor derating

specifications under these conditions.

2-4 General Information MN792

Page 15

Section 3

Getting Started

Control Overview

Control Loops

In very simple terms, control of the DC motor is maintained by Control Loops. An inner Current Loop and an

outer Speed Loop are used. These control loops are shown in the Block Diagram of Appendix C. From the

keypad, you can select the control loops to be used by the Control to provide either:

Normally a current or speed feedback signal is applied to the appropriate loop to control the process. While

current feedback sensors are built–in, speed feedback is normally provided directly from the armature sensing

circuit (default), or by “Tachogenerator” or encoder connection to an option board.

• Current Control

• Speed Control (factory setting)

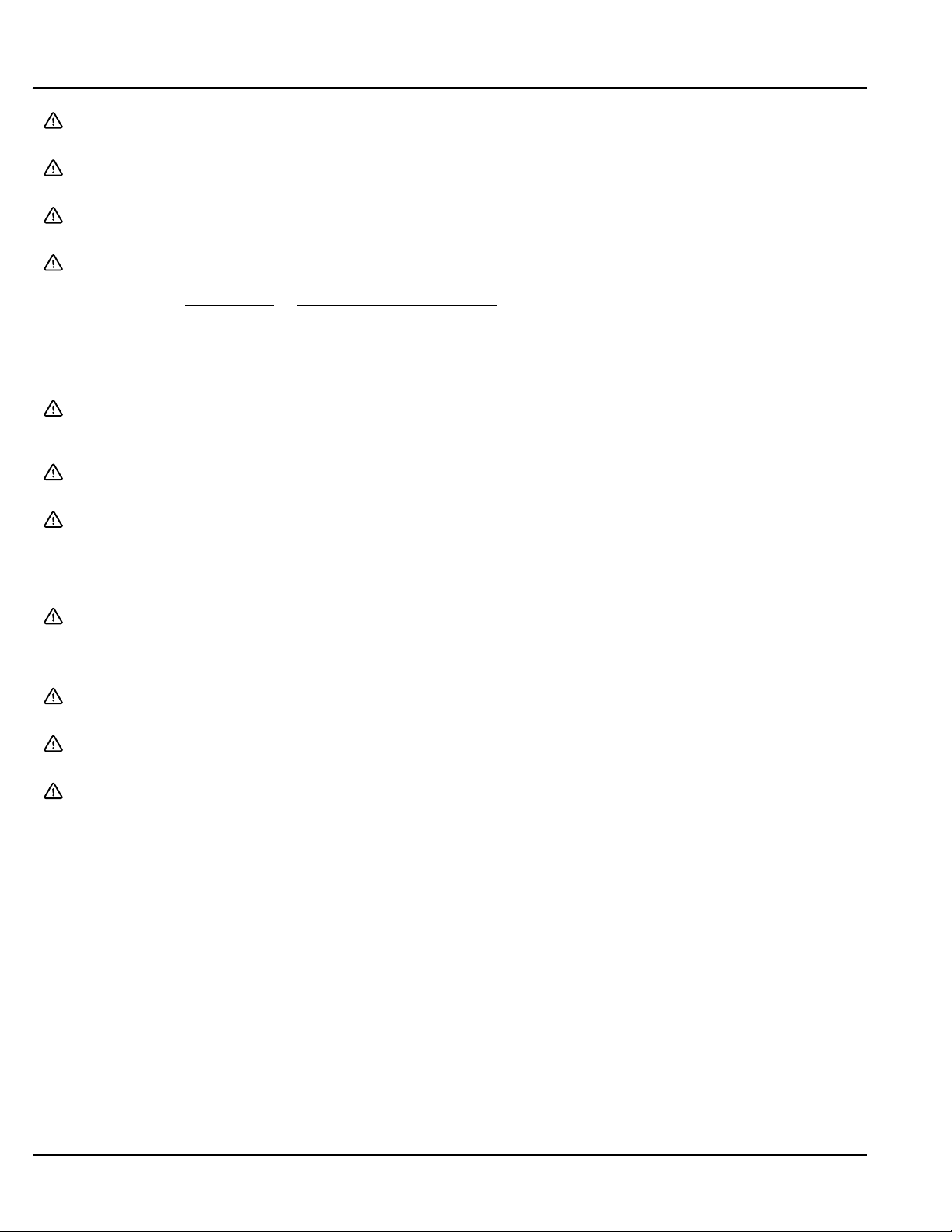

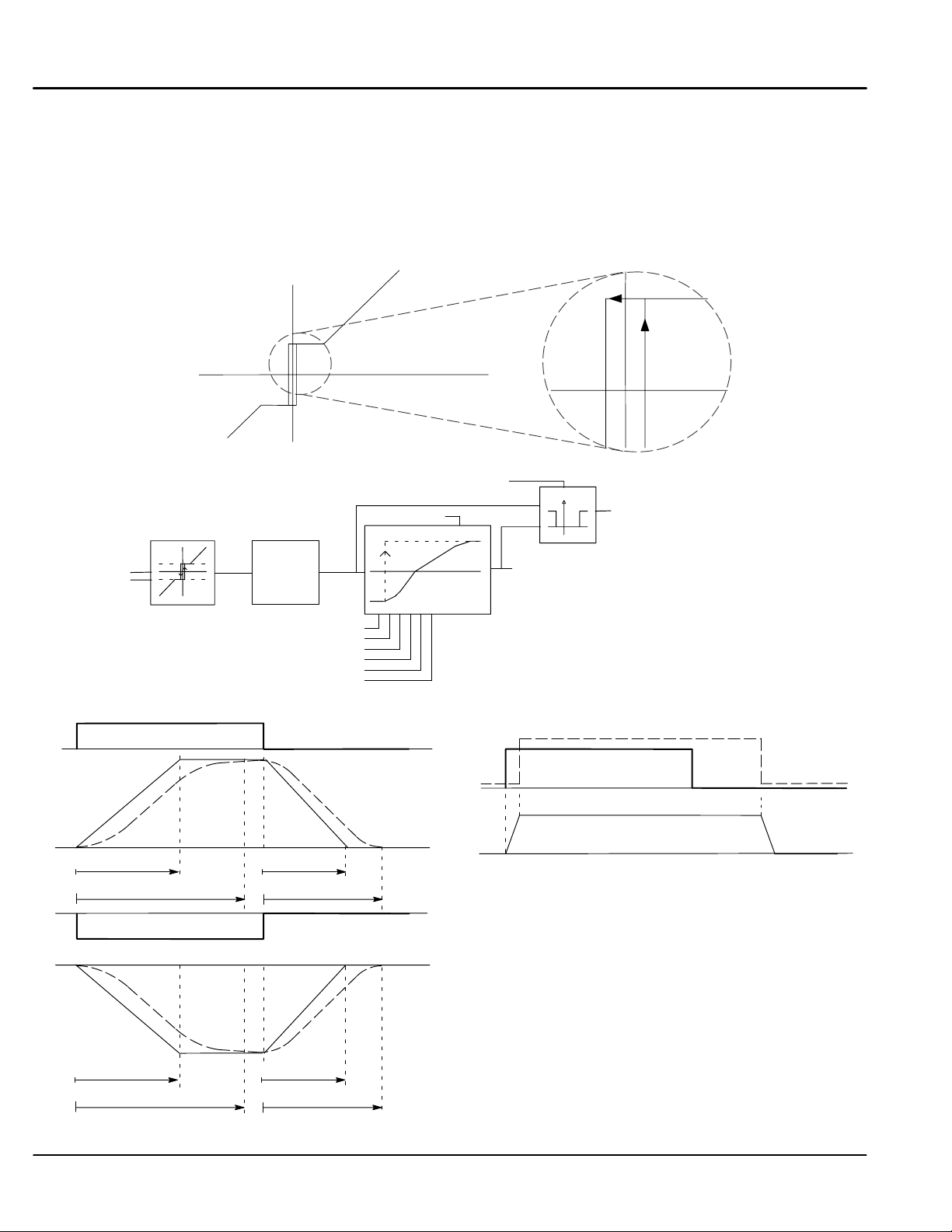

Figure 3-1 Speed Control

speed increase due to fieldweakening

Armature remains constant

Voltage 200V

Field Current 5.7A

field current reduced

base

speed

During speed control the speed of the motor can be increased by adjusting the motor field. Weakening the field

current allows an increase in motor speed beyond that normally achieved for the motor rated armature voltage.

Control and Communications

Some of the internal blocks of this control must be connected for your application. This means that you must

understand the application and how the software blocks should be connected to implement your design. The

block diagram in Appendix C shows the factory set connections. These diagrams assist in understanding this

concept and will be described next.

The Keypad (Operator Station) provides access to parameters, diagnostic messages, trip settings and full

application programming. The heart of the control is a microprocessor that provides advanced features such as:

• Complex control algorithms not achievable by simple analog techniques.

• Software configured control circuitry that uses standard software blocks.

• Serial link communications with other drives or a PC for advanced process systems.

armature voltage

Speed

To customize drive performance for optimum use, you may need to configure, or reroute software connections to

and from the drive’s inputs and outputs and to and from the drive’s software blocks. You can configure the drive

and change software block parameter values either using the keypad or with a personal computer (PC) running

the software package Workbench D (see MN794).

Getting Started 3-1MN792

Page 16

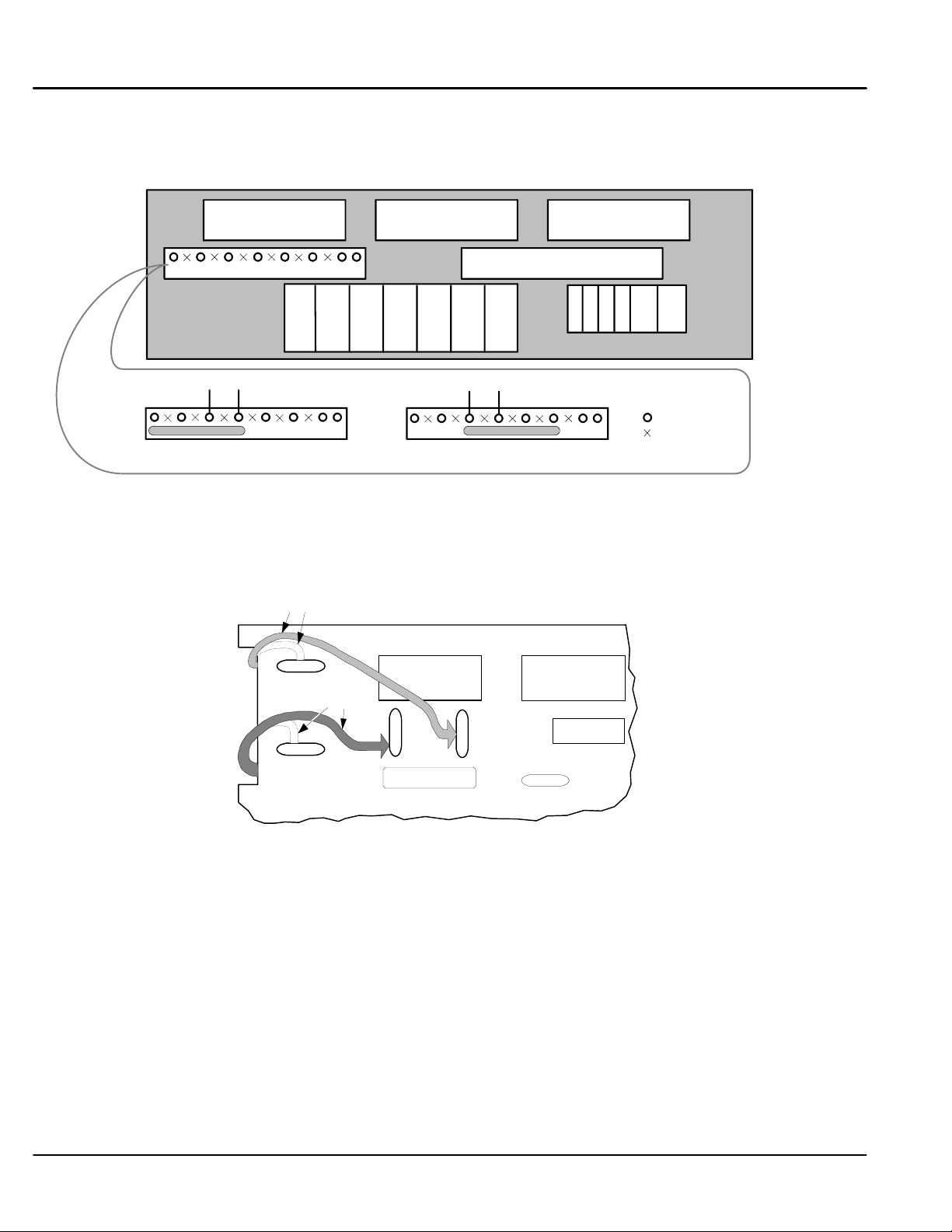

Local and Remote Modes

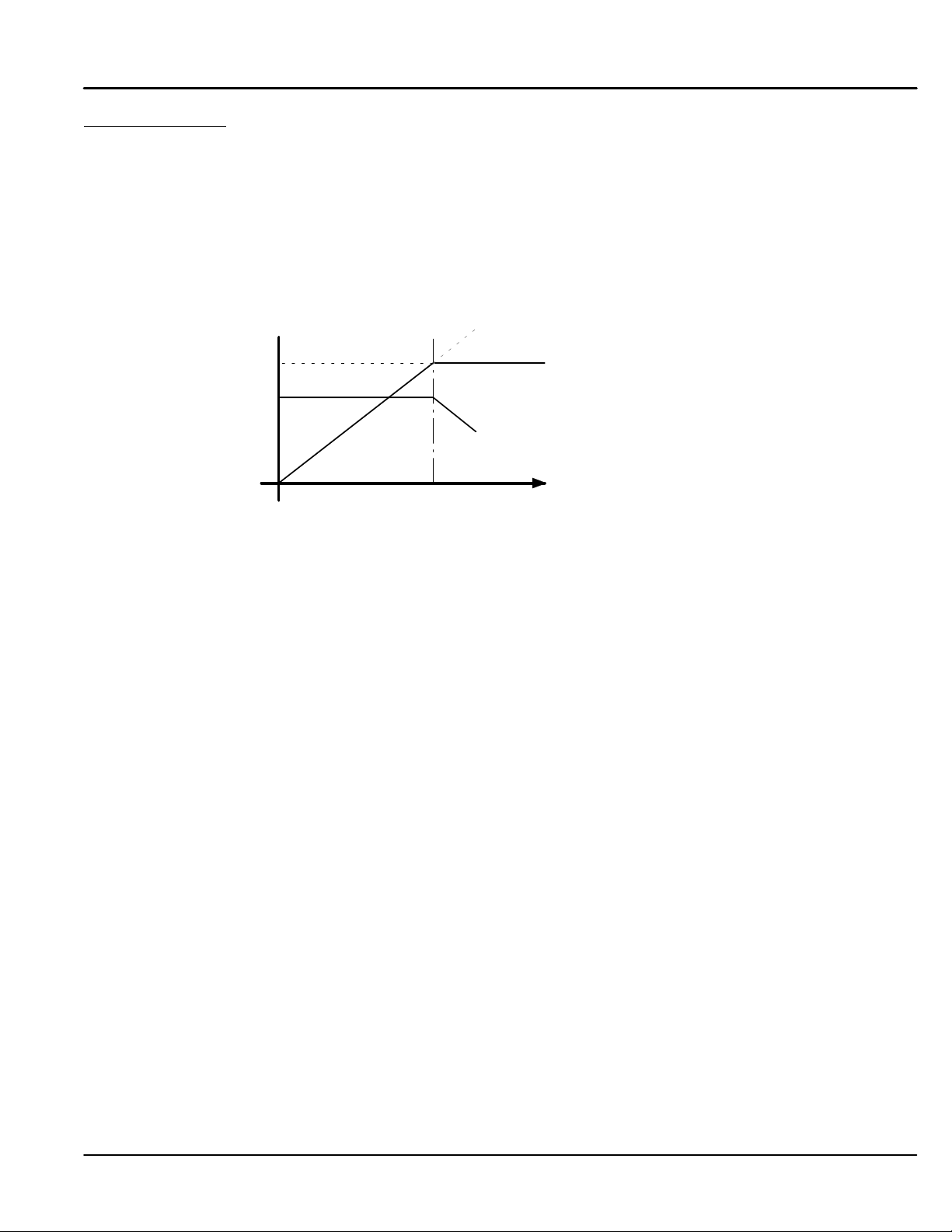

Determine what operating mode is best for your application. Four modes are possible, see Figure 3-2.

Figure 3-2 Local and Remote Modes

Local:

Keypad Setting

(Factory Setting)

Remote:

Terminal Strip Setting

Preset

Analog & Digital

Inputs and Outputs

Remote:

Serial Setting

Remote:

COMMS Setting

For local operation, use the keypad to change parameters or control operation.

Process control and other applications may require the control to be used in remote mode with

analog and digital input/output signals performing all control operations. The control is

configured in this mode from the factory.

Remote Serial mode is used to initially setup and configure the parameters of the control.

For applications that are controlled by a PC that is running suitable software. Workbench D is

recommended.

For Baldor RS485/Modbus, Profibus DP and DeviceNet.

Two forms of control are in operation at all times: Start/Stop Control and Speed Control. These are operate by

local or remote control.

Local

The keypad is used to set motor speed and other parameters. The Start, Stop and Jog keys then control motor

rotation.

Remote

A speed reference signal (pot) and the various analog and digital inputs and outputs are used for speed control

and rotation of the motor shaft.

3-2 Getting Started MN792

Page 17

Source / Destination Tags

The control is very flexible because of the programming capability. The software block diagram of the control is

shown in Appendix C. Each logic block has inputs and outputs. These I/O points are called “Tags” because

they have a tag number associated with it and shown in brackets “[tag]” . Some tags are read only values and

some are read/write. Besides setting the value of each parameter, its source or destination connections can be

programmed. This means you can connect inputs and outputs of logic blocks as you desire to implement your

application.

Destination Tag example

Consider Digital Input 1. The external connection (input) is made at the C connector pin 6. The block diagram of

this input is shown in Figure 3-3. Tag [102] is the destination tag for the output signal. The destination is

presently set to 90. This connects the output of Digital Input 1 to the Bipolar Clamps [90] input of the Current

Loop Logic Block. The value of [102] Digital output is determined by the switch position, either the value of [103]

or [104] will be applied to the output as the input changes from false to true.

Digital Input 1 – DIGIN 1 (C6)

Tag Parameter Setting

[102] Destination Tag 90

[104] Value for False 0.00%

Digital

[103] Value for True 0.01%

Input 1

C6

Source Tag example

Consider Digital Output 1. The external connection (output) is made at the B connector pin 5. The block

diagram of this input is shown in Figure 3-4. Tag [97] is the source tag for the input signal. The source is

presently set to 77. This means that Digital output 1 receives its input signal from [77] At Zero Speed parameter

from the Standstill Logic Block. To connect Digital Output 1 to the At Zero Setpoint parameter, simply change

[97] Source Tag value from 77 to 78.

Standstill

[11] Standstill Logic

[12] Zero Threshold

At Zero Setpoint [78][306] Source Tag

At Zero Speed [77]

At Standstill [79]

Figure 3-3 Digital Inputs

Current Loop

[102]

[71]

Diagnostic

connection

[90] Bipolar Clamps Digital IN 1

[48] NEG I Clamp Analog IN 4

Figure 3-4 Digital Outputs

Digital Output 1 – DIOUT 1 (B5)

Tag Parameter

[359] Inverted False

[195] Threshold (>)

[97] Source Tag 77

[43] Modulus True

Setting

0.00%

ABS

[88] NEG I Clamp

-1

[87] POS I Clamp

B5

Digital

Output 1

From these examples, it is easy to see that several things are required to program the control.

1. First, you must understand the application and know how to implement it in the control parameters.

2. Second, layout all of the connections for your application using the block diagrams in Appendix C.

3. Third, program the connections and parameter preset values. To do this you will need to refer to the

Parameter Values in Appendix B. This will tell you where in the keypad menu system you can locate

each parameter value or [tag].

For example, find [97] in Appendix B, (see Figure 3-5). To locate [97] using the keypad, begin at the System

menu, select Configure I/O menu, then select Digital Outputs menu, finally select Digital Output 1 (B5)

parameter. Change the value of that parameter to the desired value.

Note: Tag number “[97]” is not shown at the keypad for the Digital Output 1 (B5) parameter value. To display

the [TAG] number of the parameter, display the parameter value then press the “M” key to show the

parameters tag number. Appendix B and C are the key to programming your application.

Figure 3-5

Table B-1 Parameters Listed by Tag Number

Tag R/W Name Keypad Menu WB Block Range Factory Setting MN Notes

97 RW Source Tag SYSTEM::CONFIGURE I/O::DIGITAL

OUTPUTS::DIGOUT 1 (B5)

4. Select the next parameter and repeat step 3.

Digout 1 (B5) 0 to 549 77 cp 2, 3

Continued

Getting Started 3-3MN792

Page 18

Programming Block A very important step to installing this control is to determine the configuration that will best implement your

application. Each input and output of each block has an assigned tag number. Tags are connected in software

much like jumper wires are used in hardware. The control is shipped with a factory set software connection.

This may be changed at any time. The method of changing these connections (source or destination tags) is

described later in the programming Section 6 of this manual.

Note: It is important to correctly set the software to implement your application in the most efficient way. Some

parameters are Tags (connections) and others are programmed values. Be careful when programming

to be sure the correct input or output is being set.

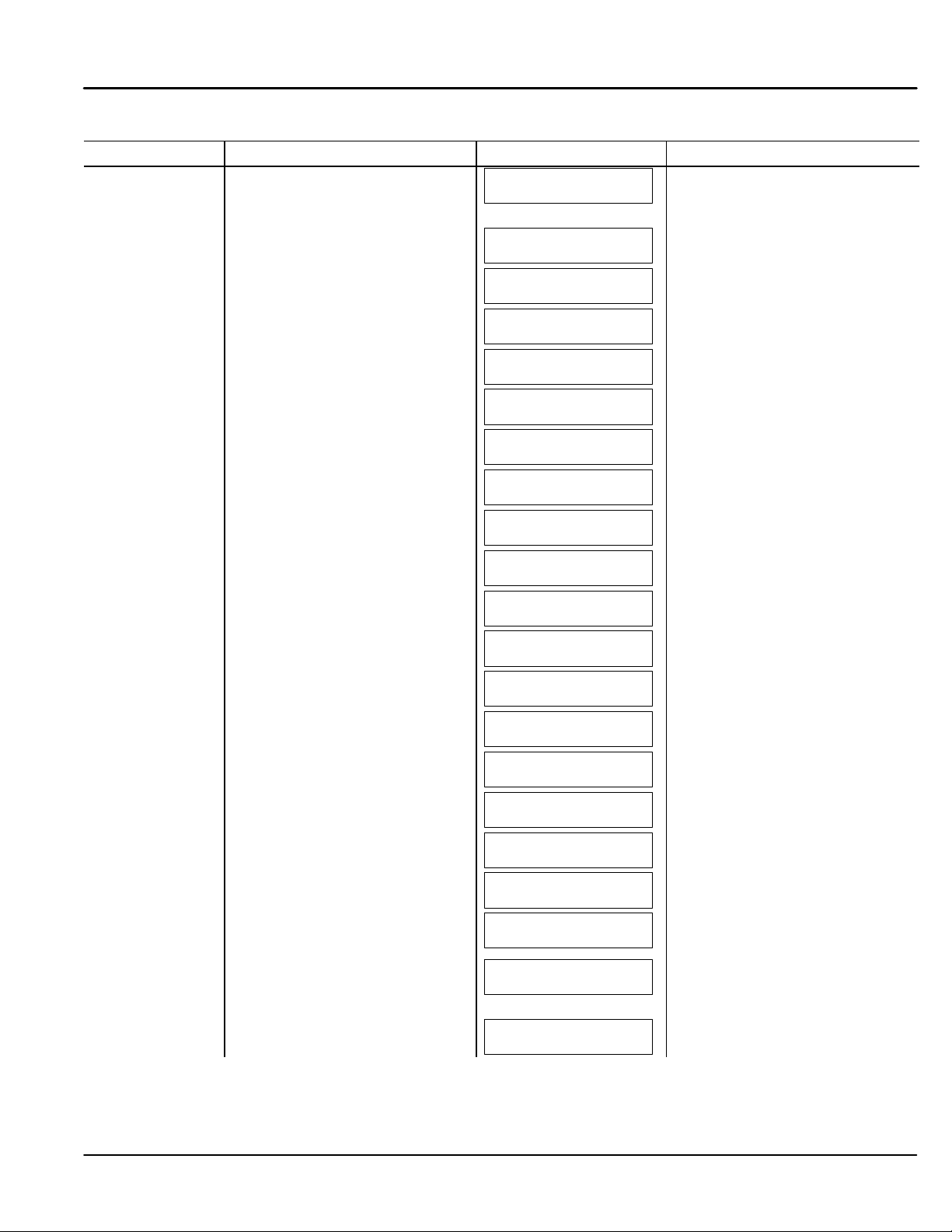

Example (View Analog Input 1 parameter settings)

As an example, a portion of the block diagram is shown in Figure 3-6. The output of Analog Input 1 [246] is

connected to [100] “Input 1” of Setpoint Sum 1 block. Each input and output shown on these diagrams is

programmable.

Figure 3-6 Analog Input Example

Setpoint Sum 1

Analog

Input 1

A2

Analog Input 1 – ANIN 1 (A2)

Tag Parameter

[231] Max Value +100.00%

[230] Calibration 1.0000

[232] Min Value -100.00%

[246] Destination Tag 100

Factory Setting

[246]

Tag Parameter

[292] Sign 0 Positive

[208] Ratio 0 1.0000

[309] Input 0 0.00%

[420] Divider 0 1.0000

[423] Input 2 0.00%

[6] Ratio 1 1.0000

[100] Input 1 0.00%

[131] Deadband Width 0.00%

[419] Divider 1 1.0000

[8] Sign 1 Positive

[375] Limit 105.00%

Factory Setting

A/B

A/B

+

-

+

+

+

+

-

The parameter values for Analog Input 1 can be changed at the keypad. Figure 3-7 shows a partial map of the

menu levels. The Analog Input 1 parameters are at Level 4 under the Level 3 Analog Inputs. The keypad

operation is shown in Table 3-1. Figure 3-7 can be used to visualize the menu structure that is being navigated

in Table 3-1.

Figure 3-7

1234

Diagnostics

Menu Levels

Configure Enable

System

Software

Configure I/O

Analog Inputs ANIN1 (A2)

Calibration

MAX Value

MIN Value

Destination Tag

Table 3-1 Set Analog Input 1 for 4–20mA

Action Description Display Comments

Apply Power Keypad Display shows this opening

message.

Press “PROG” key

Press M Access the menus.

Press Scroll to System menu. Press

several times.

Press M Access the System menus.

Press

Scroll to Configure I/O menu.

Press M Access Configure I/O menu.

FORWARD

REF: 0.00%

BALDOR DC DRIVE

DC 4Q 35A

MENU LEVEL

DIAGNOSTICS

MENU LEVEL

SYSTEM

SYSTEM

SOFTWARE

SYSTEM

CONFIGURE I/O

CONFIGURE I/O

CONFIGURE ENABLE

This message may be different for

each control.

This is menu level 1. Refer to Figure

3-7 for a description of the menu

levels.

This is menu level 1, System

parameters.

This is menu level 2.

3-4 Getting Started MN792

Page 19

Table 3-1 Set Analog Input 1 for 4–20mA Continued

Action

Description Display Comments

Press M Access Configure I/O menu.

Press

Change Configure Enable to Enabled.

Press E Access Configure I/O menu.

Press

Scroll to analog inputs menu.

Press M Access analog inputs 1 menu.

Press M Access Calibration menu.

Press M View or change the Calibration value.

Press E

Press

Scroll to next menu.

Press M View or change the MAX Value menu.

Press E

Press

Scroll to next menu.

Press M View or change the MIN Value menu.

Press E

Press

Scroll to next menu.

Press M View or change the Destination tag

Value menu.

Press E Press “E” several times to return to

the Configure Enable menu.

Press M Access Configure I/O menu.

Press M Access Configure I/O menu.

Press

Change Configure Enable to Disabled.

Press E

CONFIGURE ENABLE

DISABLE

CONFIGURE ENABLE

ENABLED

CONFIGURE I/O

CONFIGURE ENABLE

CONFIGURE I/O

ANALOG INPUTS

ANALOG INPUTS

ANIN1 (A2)

ANIN1 (A2)

CALIBRATION

CALIBRATION

1.0000

ANIN1 (A2)

CALIBRATION

ANIN1 (A2)

MAX VALUE

MAX VALUE

100.00%

ANIN1 (A2)

MAX VALUE

ANIN1 (A2)

MIN VALUE

MIN VALUE

–100.00%

ANIN1 (A2)

MIN VALUE

ANIN1 (A2)

DESTINATION TAG

DESTINATION TAG

100

ANIN1 (A2)

DESTINATION TAG

CONFIGURE I/O

CONFIGURE ENABLE

CONFIGURE ENABLE

ENABLED

CONFIGURE ENABLE

DISABLED

CONFIGURE I/O

CONFIGURE ENABLE

This is menu level 3. Before any

parameter values can be changed,

Configure Enable must be “Enabled”

(it is normally disabled”).

Note that the LED’s on Keypad are

flashing until changed back to Disable.

Move back one menu level using the

E key.

This is menu level 4.

Use the and keys to change the

value. Press E when finished.

Use the and keys to change the

value. Press E when finished.

Use the and keys to change the

value. Press E when finished.

Use the and keys to change the

value. Press E when finished.

This is menu level 2.

This is menu level 3. Before the

control can be used again, Configure

Enable must be “Disabled”.

Note when is pressed, the keypad

will briefly display “calibrating”

followed by Disabled and all Keypad

LED’s stop blinking.

Press the “E” key several times to move back through the menu items or press “PROG” to return to control operation.

Note: When changing a numeric value, pressing the “M” key will change the cursor position one digit to the left.

Getting Started 3-5MN792

Page 20

3-6 Getting Started MN792

Page 21

Section 4

Receiving and Installation

Receiving & Inspection

Baldor Controls are thoroughly tested at the factory and carefully packaged for shipment. When you receive

your control, there are several things you should do immediately.

1. Observe the condition of the shipping container and report any damage immediately to the

commercial carrier that delivered your control.

2. Remove the control from the shipping container and remove all packing materials. The container and

packing materials may be retained for future shipment.

3. Verify that the part number of the control you received is the same as the part number listed on your

purchase order.

4. Inspect the control for external physical damage that may have been sustained during shipment and

report any damage immediately to the commercial carrier that delivered your control.

5. If the control is to be stored before use, be sure that it is stored in a location that conforms to

published storage humidity and temperature specifications stated in this manual.

Location Considerations The location of the control is important. Installation should be in an area that is protected from direct

sunlight, corrosives, harmful gases or liquids, dust, metallic particles, and vibration. Exposure to these can

reduce the operating life and degrade performance of the control.

Several other factors should be carefully evaluated when selecting a location for installation:

1. For effective cooling and maintenance, the control should be mounted vertically on a smooth

non-flammable surface.

2. At least 1.0 inches (25mm) top and bottom clearance must be provided for air flow. At least 0.4

inches (10mm) clearance is required between controls (each side).

3. Operating Altitude derating. Up to 1640 feet (500 meters) no derating required. Derate the

continuous and peak output current by 1% for each 660 feet (200 meters) above 1640 feet.

Maximum operating altitude 16,500 feet (5,000 meters).

4. Operating Temperature derating. 0°C to 45°C (Sizes 1, 2); 0°C to 40°C (Sizes 3,4,5) ambient.

Above rated temperature, derate the continuous and peak output current by 2% per °C above rating.

Maximum ambient is 55°C.

Table 4-1 Watts Loss Ratings

Catalog No. Output

Current (A)

BC29D7A35–CO7 35 117 BC29D7A380–CO1/CO2 380 1230

BC29D7A70–CO7 70 234 BC29D7A500–CO1/CO2 500 1590

BC29D7A110–CO7 110 354 BC29D7A725–CO1/CO2 725 2265

BC29D7A165–CO7 165 519 BC29D7A830–CO1/CO2 830 2580

BC29D7A243–CO1/CO2 243 840 BC29D7A1580–CO1/CO2 1580 4890

Watts Loss

(W)

Catalog No. Output

Current (A)

Watts Loss

(W)

Receiving & Installation 4-1MN792

Page 22

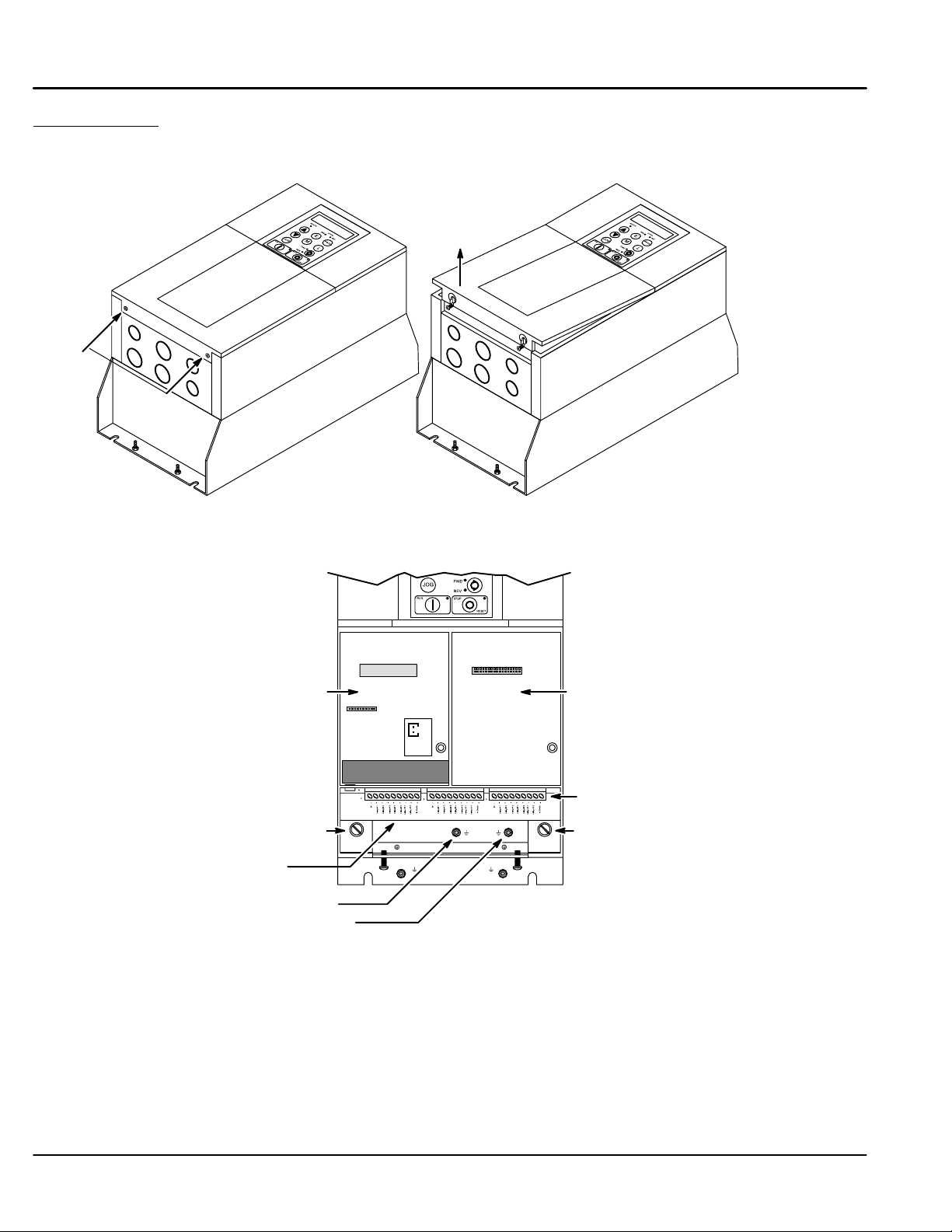

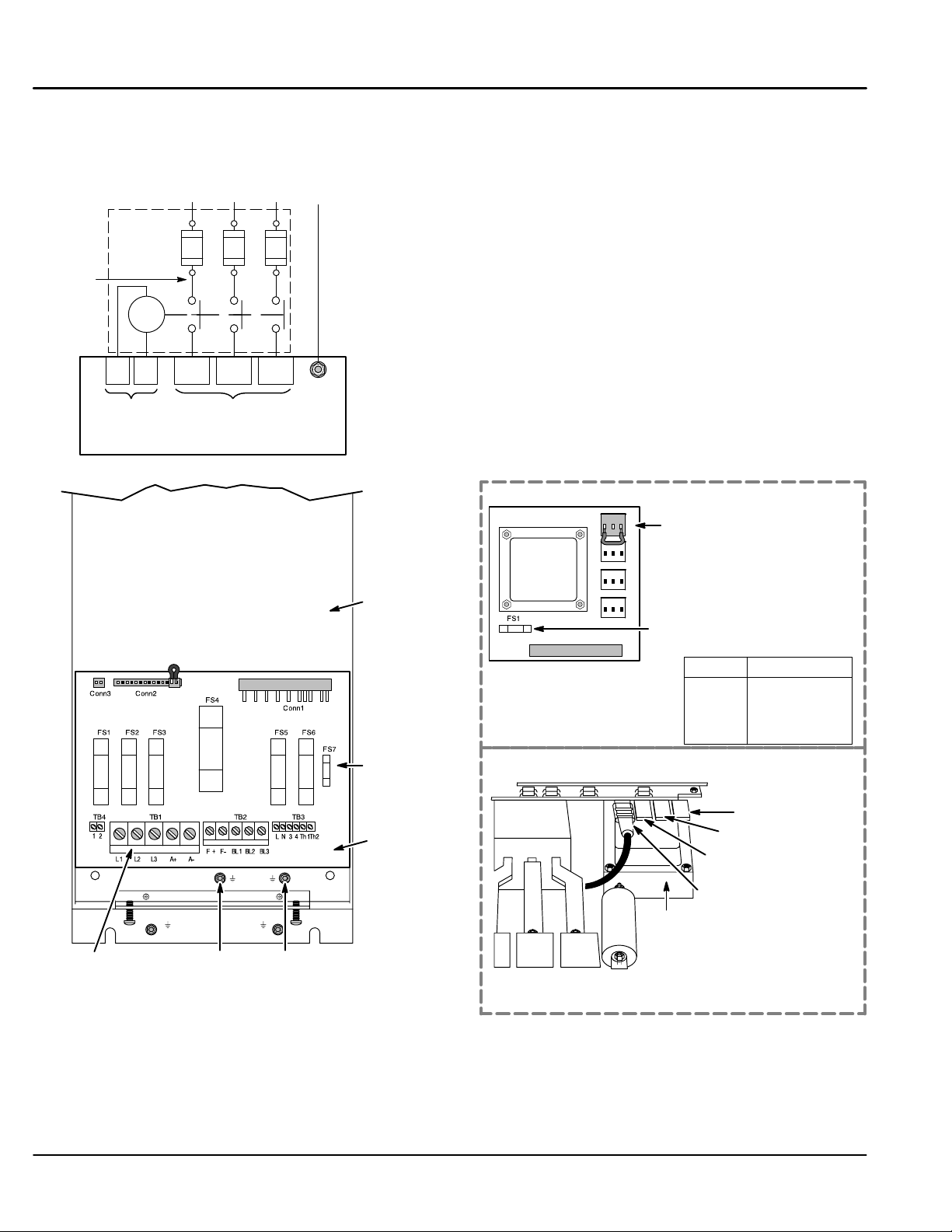

Cover Removal To connect power and signal wires, the cover must be removed. This procedure describes how to access all

terminal connections inside the control.

1. Loosen the two cover screws shown in Figure 4-8, then lift and remove the cover as shown.

Figure 4-1 Top Cover Removal

Lift and

remove cover

Cover

Screws

(2)

2. Locate the two 1/4 turn screws shown in Figure 4-2. Rotate each screw 1/4 turn CCW. This releases

the control from the base.

Figure 4-2 Signal Connections

Feedback Expansion

Board location

1/4 Turn Screw 1/4 Turn Screw (1/4 turn to release,

Power Connections (Control and base must

be opened to view, see Figure 4-9)

Power Ground

Motor Ground

Communications Expansion

Board location

Signal Connections

press screw into hole to close).

See Recommended Tightening Torques in Section 9.

4-2 Receiving & Installation MN792

Page 23

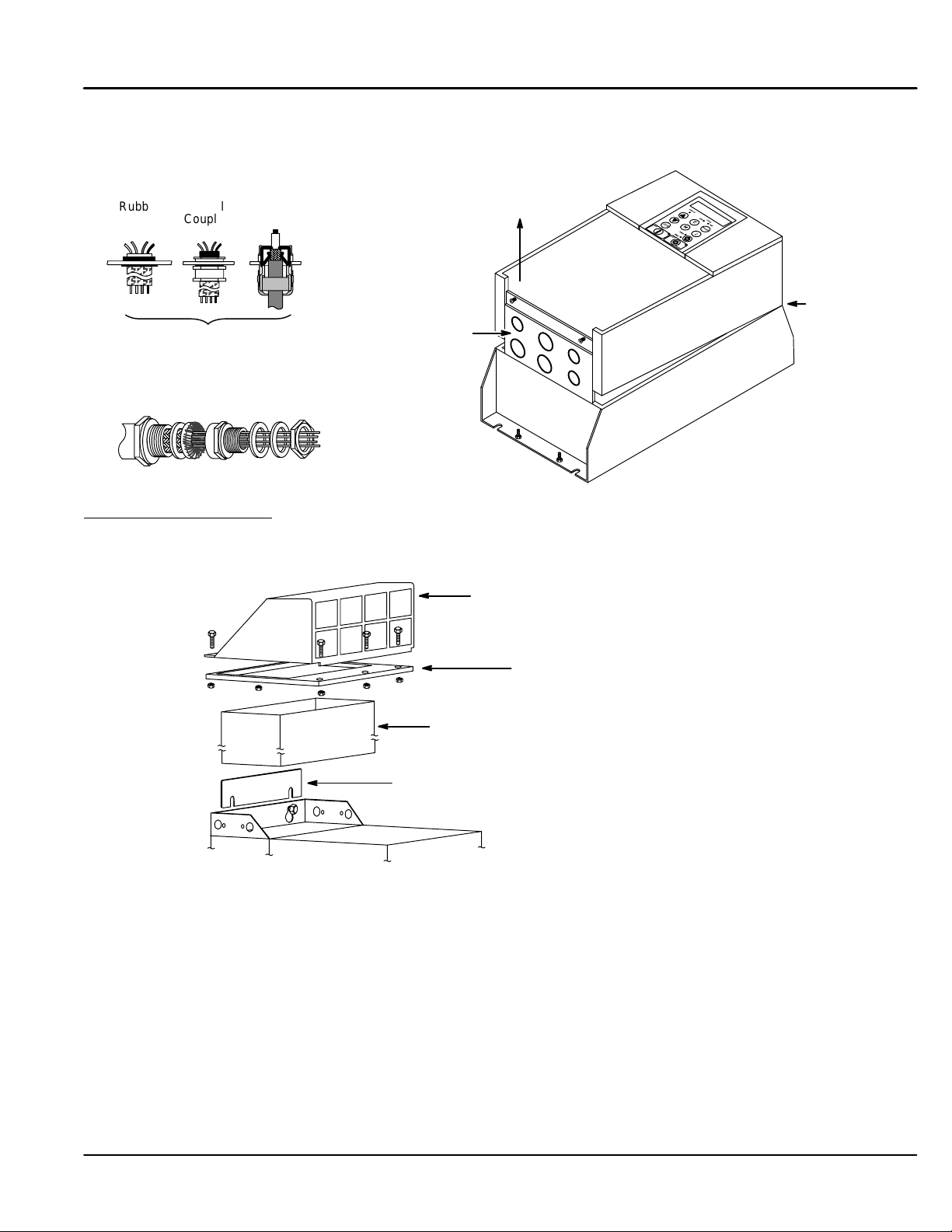

Cover Removal Continued

3. The control and base are hinged and are opened as shown in Figure 4-3.

Figure 4-3 Hinged Assembly

Rubber

Grommet

The knock–out panel is part of the base

assembly to allow connections to be made.

Use the correct size rubber grommet,

conduit coupling or 360 degree coupling.

Metal

Coupling

360 Degree Coupling

360 Degree

Coupling

Mechanical Installation

Mount the control to the mounting surface. The control must be securely fastened to the mounting surface by

the control mounting holes. The location of the mounting holes is shown in Section 9 of this manual.

External Vent Kit (Size 4 & 5 controls only)

Raise the control to

expose the base

Knock–out

panel

Hinge

Control

Base

Upper Housing

Foam gasket stretches over duct prior to

attaching upper housing.

Duct slides down between duct clip and mounting

panel and fits within the sides of the control housing.

Fit duct clip under fasteners at top of drive.

Be sure it is tight against the mounting panel.

Receiving & Installation 4-3MN792

Page 24

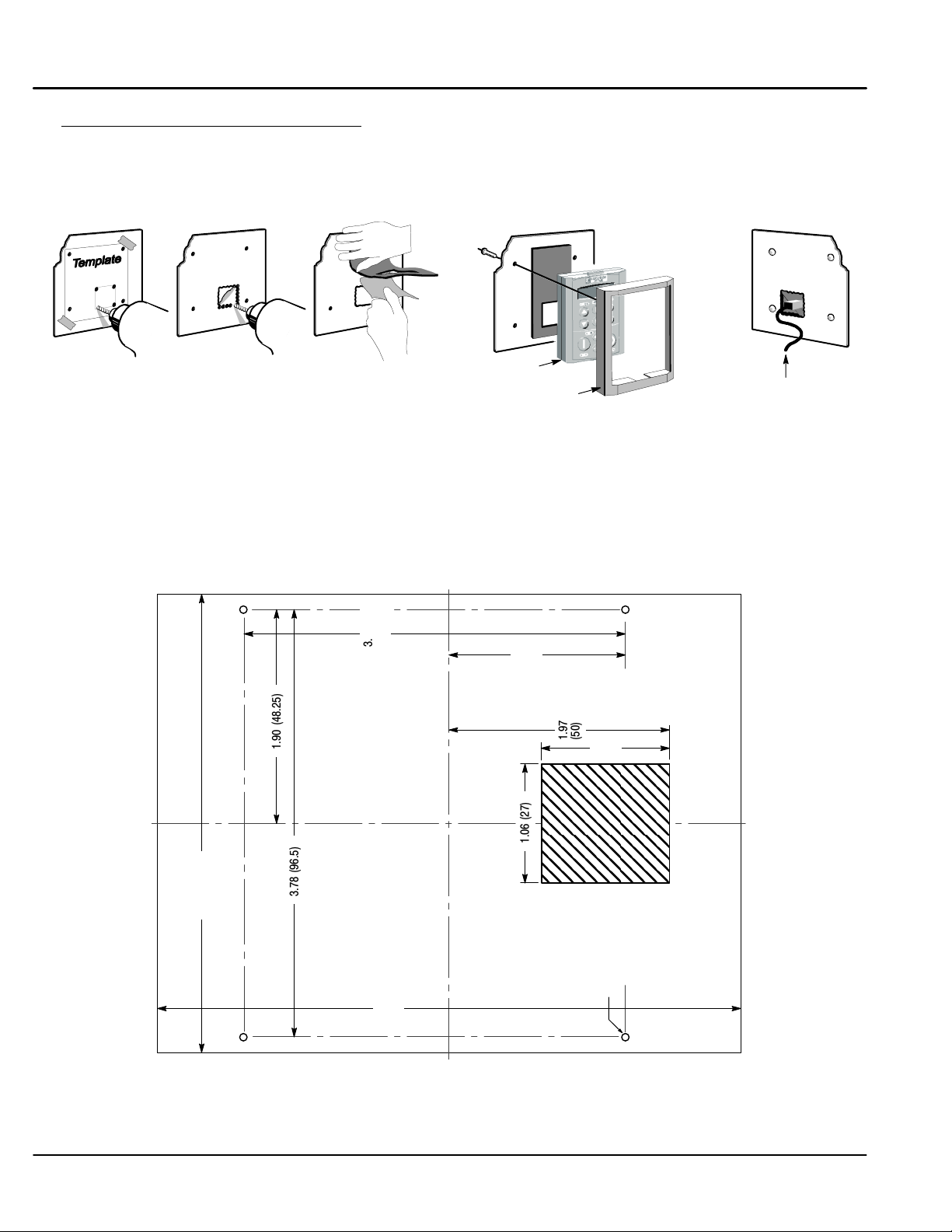

Optional Remote Keypad Installation (Enclosure rating of IP54 when correctly mounted). The keypad may be

remotely mounted using optional Baldor keypad extension cable.

Tools Required:

• Center punch, file and screwdrivers (Phillips and straight) and crescent wrench.

• #19 drill and drill motor .

Figure 4-4 Remote Keypad Installation

5

1

Mounting Instruction:

2

3

4

Keypad ACBD01A01

Bezel ACBD02A01

1. Locate a flat mounting surface. Place the template on the mounting surface (step 1).

2. Accurately center punch the mounting holes.

3. Drill holes for the two mounting screws.

4. Use the drill to remove metal for the 27 x 29 mm rectangular hole (step 2).

5. Debur the rectangular hole making sure the panel stays clean and flat.

6. Remove the protective film from the keypad gasket (step 3).

7. Assemble the keypad to the panel. Use two screws provided (step 4).

8. Connect the 10 ft. cable at the keypad and P3 of the control (step 5).

Figure 4-5 Template

CBLD030KP

4.09 (104)

1.90 (48.25)

3.78 (96.5)

3.40

(86.5)

5.22

(132.5)

1.57

1.06 (27)

(40)

1.97

(50)

1.14

0.16 (4.0) Dia.

(29)

Bottom

4 Places

4-4 Receiving & Installation MN792

Page 25

Electrical InstallationAll interconnection wires between the control, AC power source, motor, host control and any operator

interface stations should be in metal conduits. Use listed closed loop connectors that are of appropriate size for

wire gauge being used. Connectors are to be installed using crimp tool specified by the manufacturer of the

connector. Only class 1 wiring should be used.

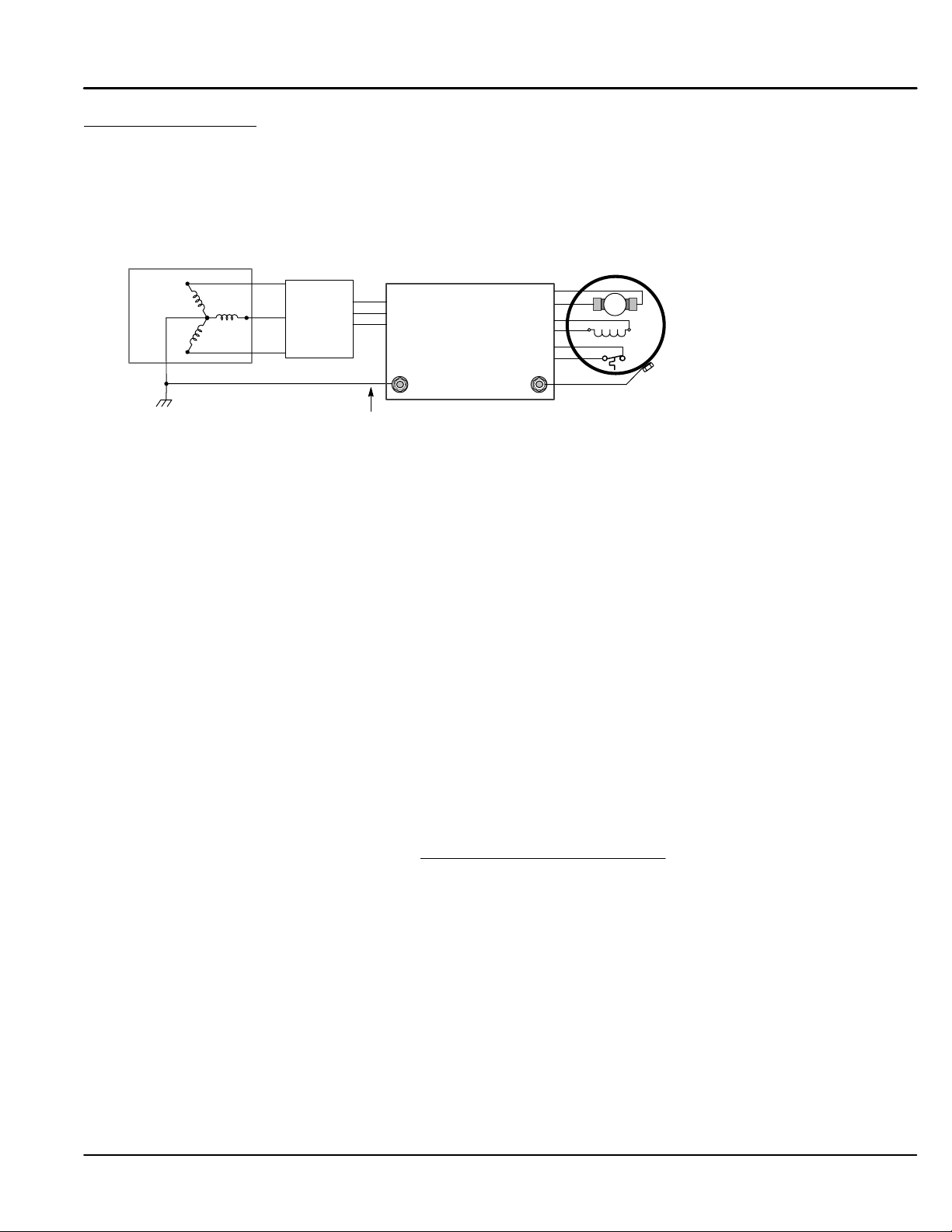

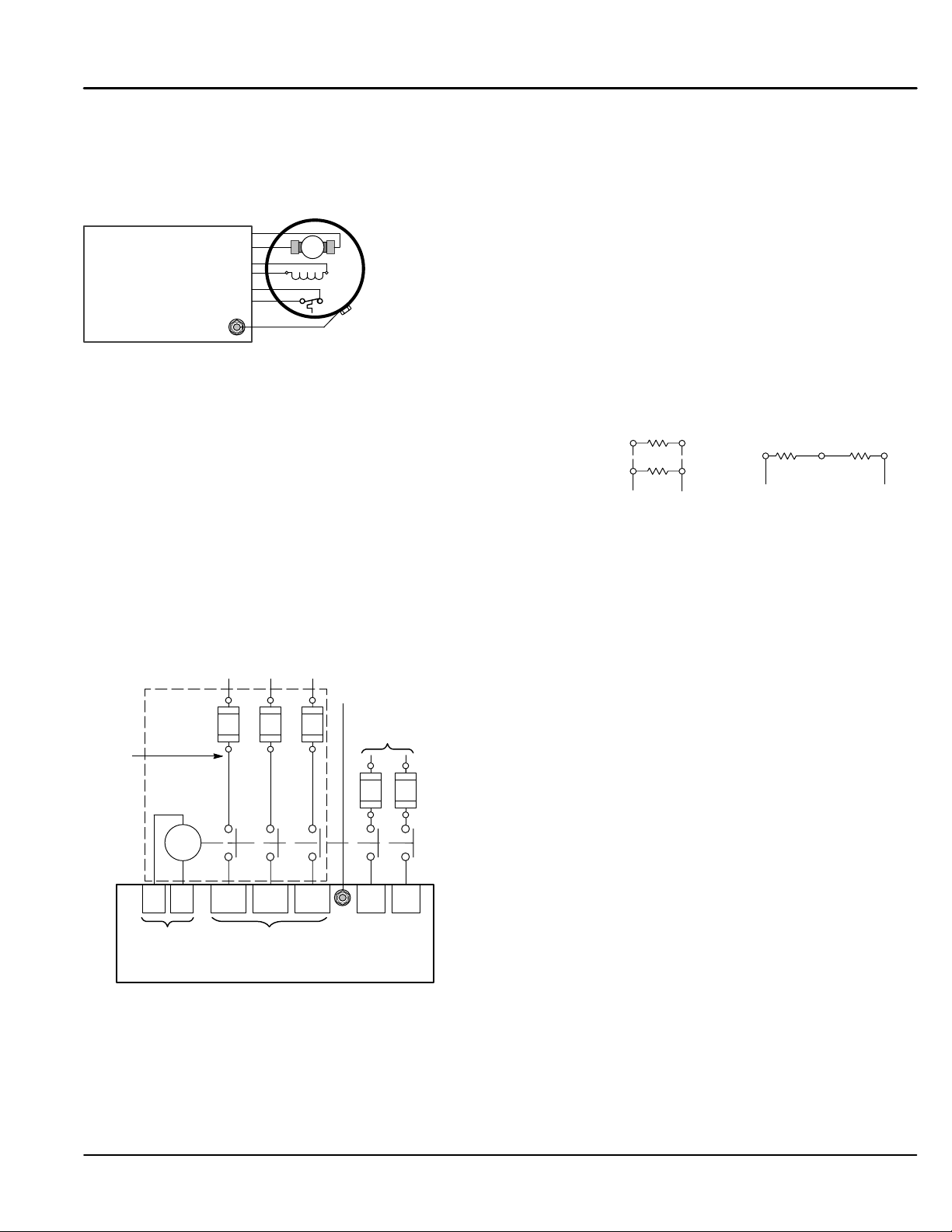

System Grounding Baldor controls are designed to be powered from standard single and three phase lines that are electrically

symmetrical with respect to ground. System grounding is an important step in the overall installation. The

recommended grounding method is shown in Figure 4-6.

Figure 4-6 Recommended System Grounding (3 phase) for UL

Note: Wiring shown for clarity of grounding method only. Not representative of actual terminal block location.

AC

Supply

(Mains)

Earth

Driven Earth Ground

(Facility Ground)

L1

Disconnect

L2

and Fuses

L3

Four Wire “Wye”

Route all power wires L1, L2, L3 and Earth

(Ground) together in conduit or cable.

L1

L2

L3

Control

TH1

TH2

A+

A–

F+

F–

Motor

See Recommended Tightening Torques in Section 9.

+

+

Armature

Field

Thermistor

GND

Ungrounded Distribution System

With an ungrounded power distribution system it is possible to have a continuous current path to ground through

the MOV devices. To avoid equipment damage, an isolation transformer with a grounded secondary is

recommended. This provides three phase AC power that is symmetrical with respect to ground.

Input Power Conditioning

Baldor controls are designed for direct connection to standard single and three phase lines that are electrically

symmetrical with respect to ground. Certain power line conditions must be avoided. An AC line reactor or an

isolation transformer may be required for some power conditions.

• If the feeder or branch circuit that provides power to the control has permanently connected power

factor correction capacitors, an input AC line reactor or an isolation transformer must be connected

between the power factor correction capacitors and the control.

• If the feeder or branch circuit that provides power to the control has power factor correction

capacitors that are switched on line and off line, the capacitors must not be switched while the control

is connected to the AC power line. If the capacitors are switched on line while the control is still

connected to the AC power line, additional protection is required. TVSS (Transient Voltage Surge

Suppressor) of the proper rating must be installed between the AC line reactor or an isolation

transformer and the AC input to the control.

Line Impedance The control requires a 5% maximum line impedance (voltage drop across the reactor is 5% when the control

draws rated input current). If the impedance of the incoming power does not meet the requirement for the

control, a 3 phase line reactor can be used to provide the needed impedance in most cases. Line reactors are

optional and are available from Baldor.

The input impedance of the power lines can be determined as follows:

Measure the line to line voltage at no load and at full rated load.

Use these measured values to calculate impedance as follows:

%Impedance +

(Volts

No Load Speed

(Volts

* Volts

No Load Speed

Full Load Speed

)

)

100

Power Disconnect A power disconnect should be installed between each input power source and the control for a fail–safe

method to disconnect power. The control will remain in a powered-up condition until all input power is removed

from the control and the internal voltage is depleted.

Protection Devices The control must have a suitable input power protection device installed. Input and output wire size is

based on the use of copper conductor wire rated at 75 °C. Table 4-3 describes the wire size to be used for

power connections and Table 4-4 describes the ratings of the protection devices.

Recommended fuse sizes are based on the following:

UL 508C suggests a fuse size of four times the continuous output current of the control.

Dual element, time delay fuses should be used to avoid nuisance trips due to inrush current when

power is first applied.

Receiving & Installation 4-5MN792

Page 26

Electrical Installation Continued

Isolation Transformer Sizing

Use the information in Table 4-2 to select the KVA rating of the transformer based on the HP rating of the

control. The secondary voltage will be the input voltage to the control and the impedance should be 2% or less.

One exception to Table 4-2 is when the DC armature voltage is less than the AC input voltage. If this is the

case, use the following formula:

KVA + 0.00163 VAC

Secondary

IDC

Secondary

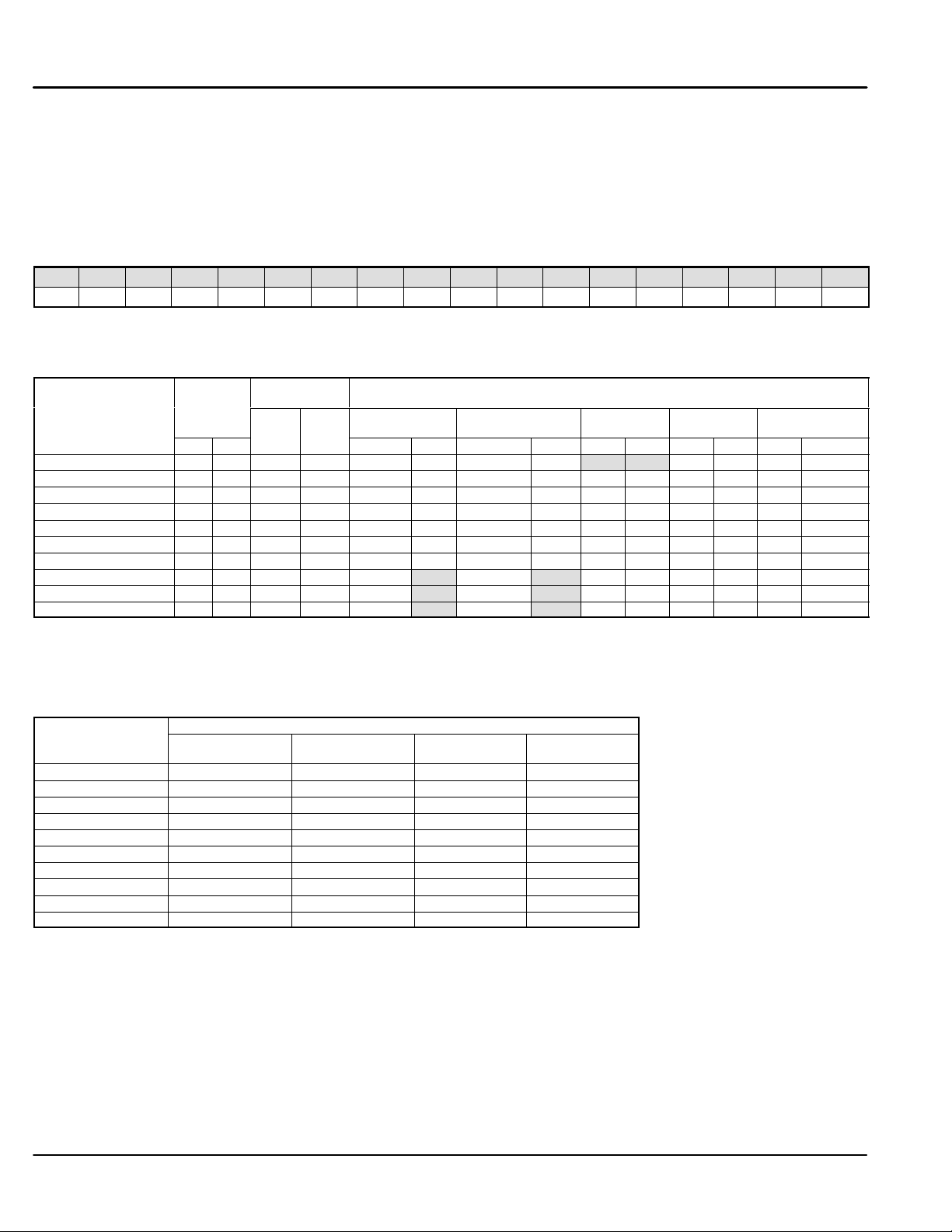

Table 4-2 Isolation Transformer KVA Selection

HP 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150 200 250 300

KVA 7.5 11 14 20 27 34 40 51 63 75 93 118 145 175 220 275 330

Single Phase Power Since the control rectifies all three input power phases, operation from a single phase power source is

not possible.

Table 4-3 Wire Size

Armature

Maximum

Catalog

Number

BC29D7A35-CO7 20 15 35 53 8 8.37 8 8.37 14 2.08 12-22 3.31-0.326

BC29D7A70-CO7 40 30 70 105 4 21.2 3 26.7 14 2.08 14 2.08 6-18 13.3-0.823

BC29D7A110-CO7 60 50 11 0 165 1 42.4 1/0 53.5 14 2.08 14 2.08 6-18 13.3-0.823

BC29D7A165-CO7 100 75 165 248 3/0 85.0 4/0 107.0 14 2.08 14 2.08 6-18 13.3-0.823

BC29D7A243-CO1/CO2 150 120 243 365 300kcmil 152 350kcmil 177 14 2.08 14 2.08 6-18 13.3-0.823

BC29D7A380-CO1/CO2 200 150 380 570 700kcmil 355 750kcmil 380 8 8.37 14 2.08 6-18 13.3-0.823

BC29D7A500-CO1/CO2 300 225 500 750 1250kcmil 634 1500kcmil 760 8 8.37 14 2.08 6-18 13.3-0.823

BC29D7A725-CO1/CO2 400 327 725 1088 1″x3″ BB* 1″x3″ BB* 8 8.37 14 2.08 6-18 13.3-0.823

BC29D7A830-CO1/CO2 500 335 830 1245 1″x3″ BB* 1″x4″ BB* 8 8.37 14 2.08 6-18 13.3-0.823

BC29D7A1580-CO1/CO2 900 650 1580 2370 2″x4″ BB* 2″x4″ BB* 8 8.37 14 2.08 6-18 13.3-0.823

Maximum

Output **

HP kW

Current

Cont. Peak

(Amps) (Amps)

3 AC Input Armature

AWG MM

2

AWG MM2AWG MM2AWG MM2AWG MM

* BB is copper Bus Bar.

** Hp and kW are approximate at 500VDC Armature voltage.

Note: All wire sizes based on 75°C copper wire, 40°C ambient temperature, 4-6 conductors per conduit or raceway.

Wire Size

Field Power

Supply

Logic Power

Supply

BL1,BL2,BL3

Table 4-4 Protection Devices

Catalog

Number

BC29D7A35-CO7 A60Q40 A70QS50-14F 4 3

BC29D7A70-CO7 A50QS80-4R A70QS80 10 3

BC29D7A110-CO7 A50QS125-4R A70QS150 10 3

BC29D7A165-CO7 A50QS175-4R A70QS200 10 3

BC29D7A243-CO1/CO2 A50QS300-4R A70P350 10 3

BC29D7A380-CO1/CO2 A070URD32KI0400 A130URD73LI0450 30 3

BC29D7A500-CO1/CO2 A070URD32KI0630 A130URD73LI0700 30 3

BC29D7A725-CO1/CO2 A070URD32KI0800 A130URD73LI0900 30 3

BC29D7A830-CO1/CO2 A070URD32KI0900 14URD93TTF1250 30 3

BC29D7A1580-CO1/CO2 A070URD32KI0900 * 12.5URD94TDF2300M 30 3

3 AC Line

(Ferraz–Shawmut)

(Ferraz–Shawmut)

* 6 fuses per drive.

Fuse Rating

Armature

Field Supply (A) Logic Supply (A)

2

4-6 Receiving & Installation MN792

Page 27

Electrical Installation Continued

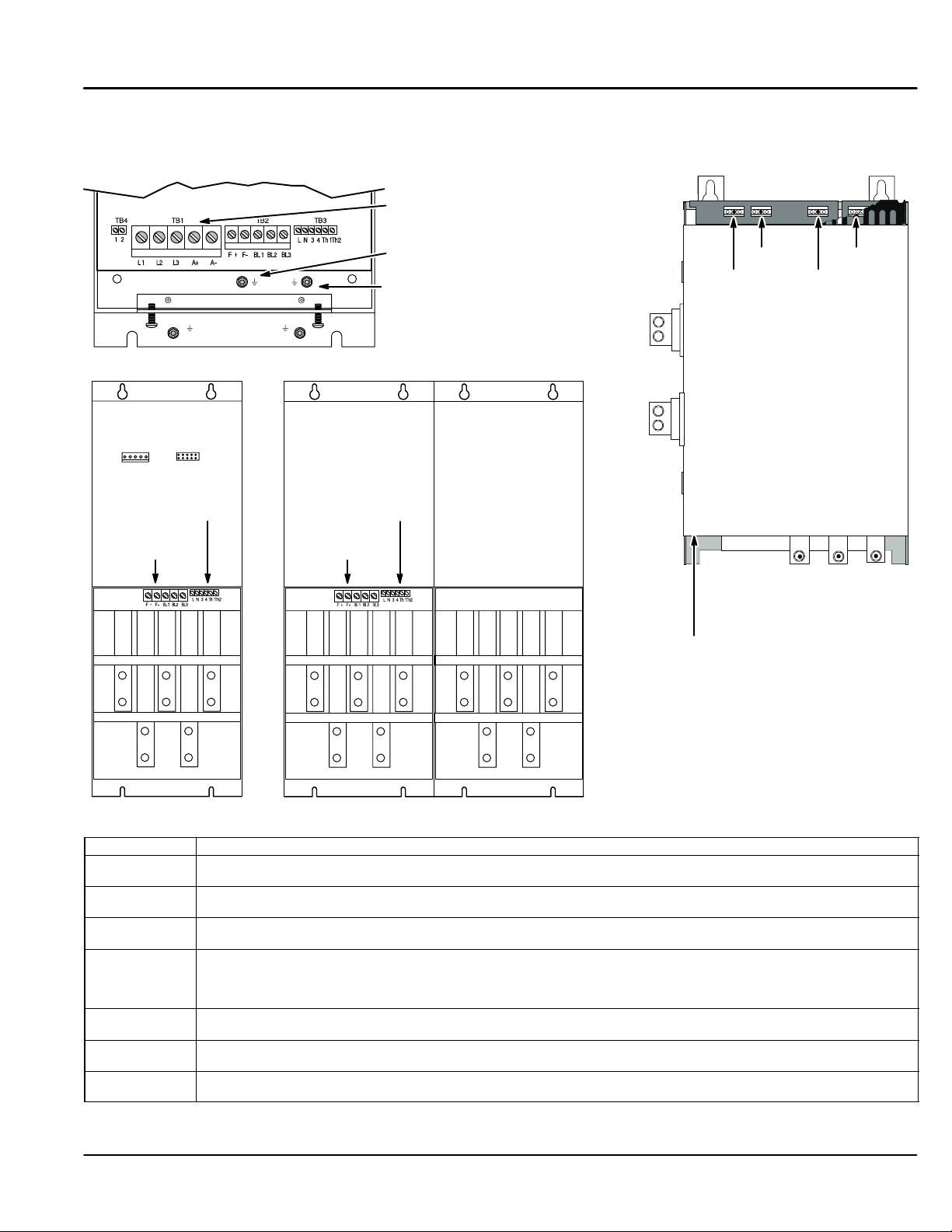

Figure 4-7 Size 1–5 Power Terminal Locations

Size 1 and 2 Size 3

Power Connections

Size 4

Logic Supply,

Contactor &

Thermistor

Connections

Field

Connections

L1 L2 L3

AC Main Supply

Motor Ground

Logic Supply,

Contactor &

Thermistor

Connections

Field

Connections

L1 L2 L3

Earth from

Size 5

L1 L2 L3

D1, D2

A+

A–

THERM+ and

THERM– are

on separate bd.

in door assembly

D3, D4

D1 = FL1

D2 = FL2

D3 = F–

D4 = F+

D5 = 3

D6 = 4

D7 = N

D8 = L

D7, D8

D5, D6

L1 L2 L3

A+

A-

A+

A+

A-

A-

See Recommended Tightening Torques in Section 9.

Table 4-5 Power Connector Signals

Terminal Description

L1, L2, L3 Main AC input power. A 3–phase AC contactor should be connected in the main AC power supply connections.

A+, A– The motor armature is connected to busbar terminals A+ and A–. If a DC contactor is used the contactor poles

F+, F– Connect the motor field (–) to terminal F– and field (+) to terminal F+. If the motor has no field connections, is a

FL1, FL2 An external field supply may be used for Size 2–5 controls. Connect this supply to terminals FL1 and FL2. The

3, 4 Size 3–5, the AC Contactor coil can be connected between TB3–3 (line) and TB3–4 (neutral) and its purpose is to

L, N Single phase AC power for logic circuits. The auxiliary supply must be connected directly to the incoming supply,