Page 1

Series 35D

Inverter Control

Installation & Operating Manual

8/02

MN735

Page 2

Table of Contents

Section 1

Quick Start 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2

General Information 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Compliance 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Notice 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3

Receiving & Installation 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving & Inspection 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location and Mounting 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cover Removal 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Conditioning 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Grounding 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Impedance 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Reactors 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Reactors 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Disconnect 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protective Devices 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reduced Input Voltage Derating 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Installation 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clamp Terminals 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Connections 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermistor Connections 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Connections 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Brake Resistor 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Relay 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applications/Modes 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Load an Application 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 – Keypad Mode 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 – Standard Run 3 Wire Mode 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 – 3 Speed 2 Wire Mode 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 – EPOT 3 Wire Mode 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 – EPOT 2 Wire Mode 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 – PID 2 Wire Mode 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents iMN735

Page 3

Section 4

Start–Up and Operation 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Description 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics Menu 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu System 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Up 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Change a Parameter Value 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Menu Features 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Definitions 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PI Terms 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Related Parameter Values 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Routine Maintenance 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving Your Application Data 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disposal 4–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 5

Troubleshooting 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trips 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Failures 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 6

Specifications & Product Data 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Specifications 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Display 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Inputs 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Outputs 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Inputs 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Outputs 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relay Output 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ratings 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Dynamic Brake A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

230VAC 1 & 3 Phase Controls A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

460VAC 3 Phase Controls A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Calculations A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RGA and RGJ Assemblies A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B

CE Guidelines B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii Table of Contents MN735

Page 4

Section 1

Quick Start

The basic steps for connection and setup are provided in this section.

Detailed descriptions of each step and parameter settings are provided

later in this manual. Be sure to comply with all applicable codes when

installing this control.

Minimum Connection Requirement

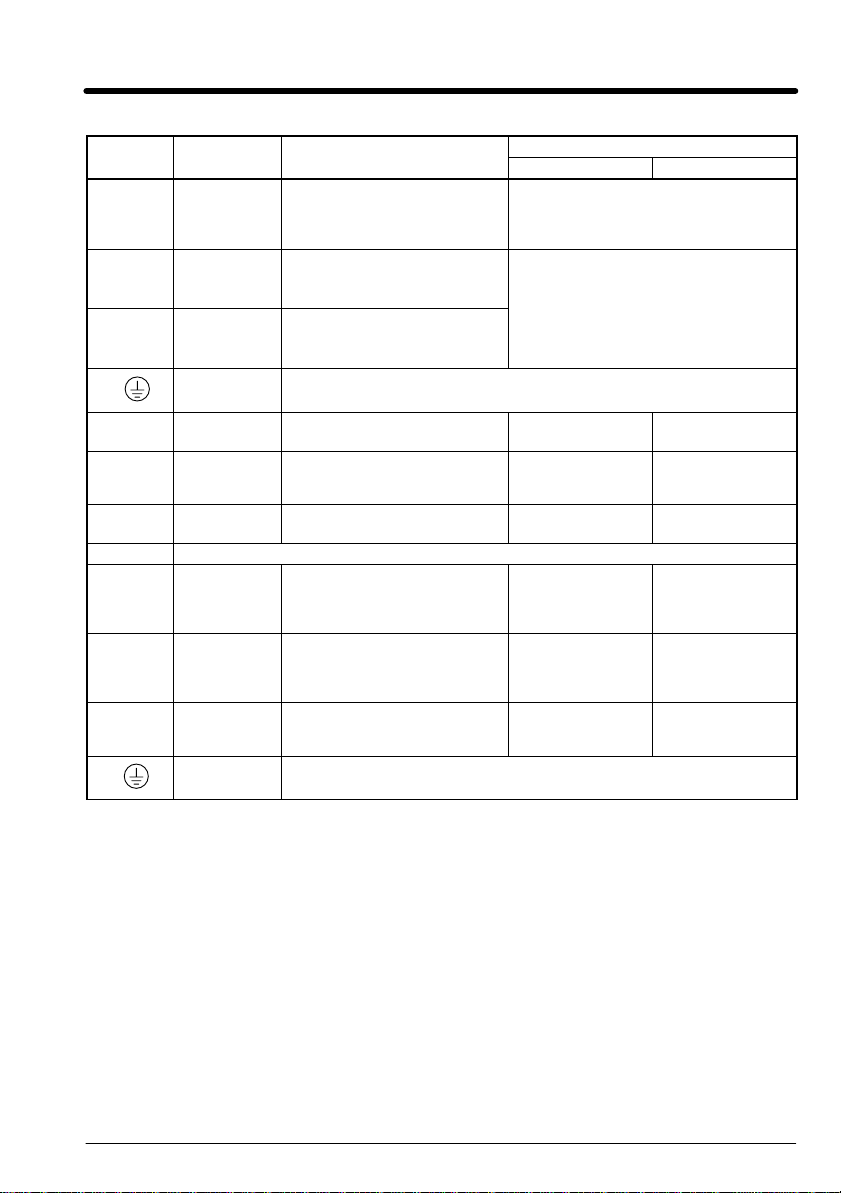

Power and Motor Connections

Figures 1-1and 1-2 show the minimum connections required at the power

connector.

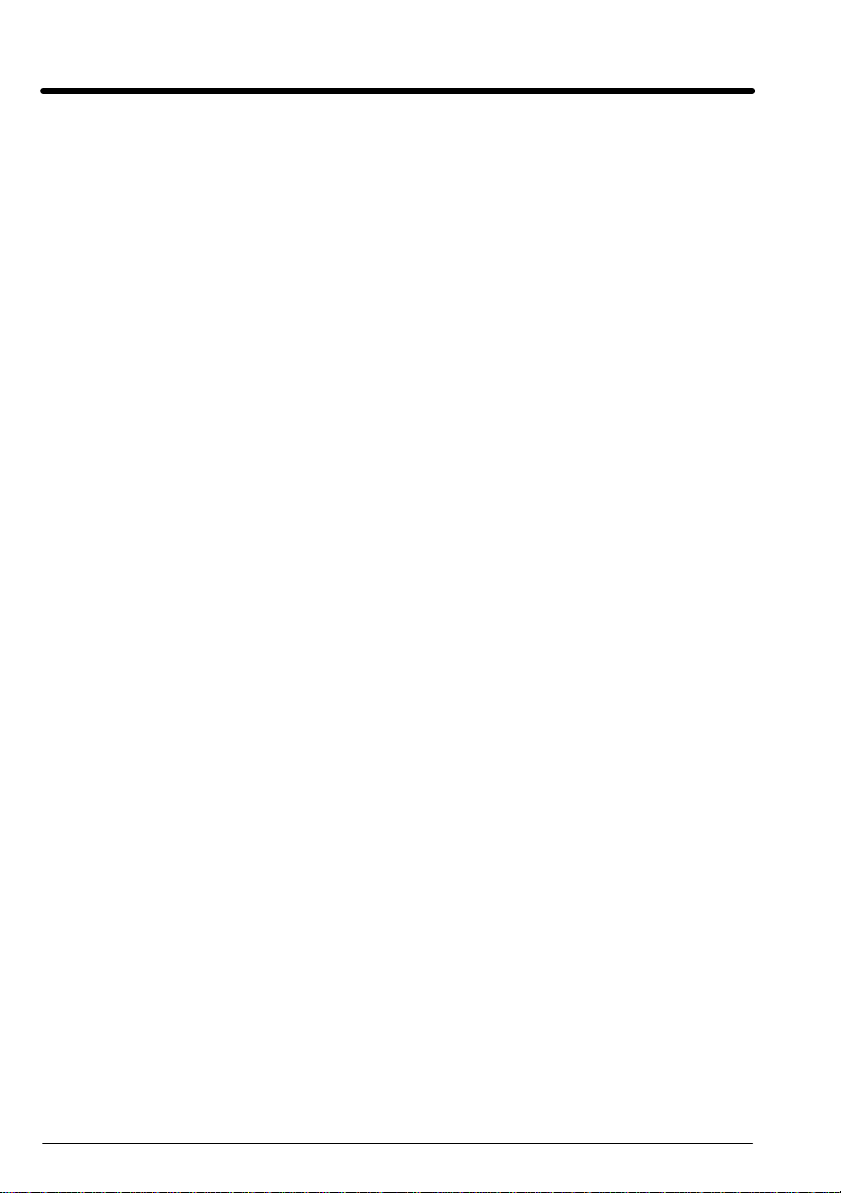

Figure 1-1 Power Connections

Size 2 Shown

s Refer to Section 3 for cover removal procedure.

TH1A and TH1B must

be jumpered if

thermistor is not used

AC Line

Connections

Dynamic Brake

Connections

Motor

Connections

L1, L2, L3, GND

RL1A

RL1B

TH1A

TH1B

L1

L2/N

L3

DC+

DBR

M1/U

M2/V

M3/W

Use 2 Ground

Wires

Motor Cable

Mains Supply

Cable

Use a cable tie

in this area for

control wires.

10

9

8

7

6

5

4

3

2

1

Wire Retainer

(Channel)

Grounded

Cable Clamp

Dynamic Brake Cable

Thermistor Cable

Control Signal Cable

Quick Start 1–1MN735

Page 5

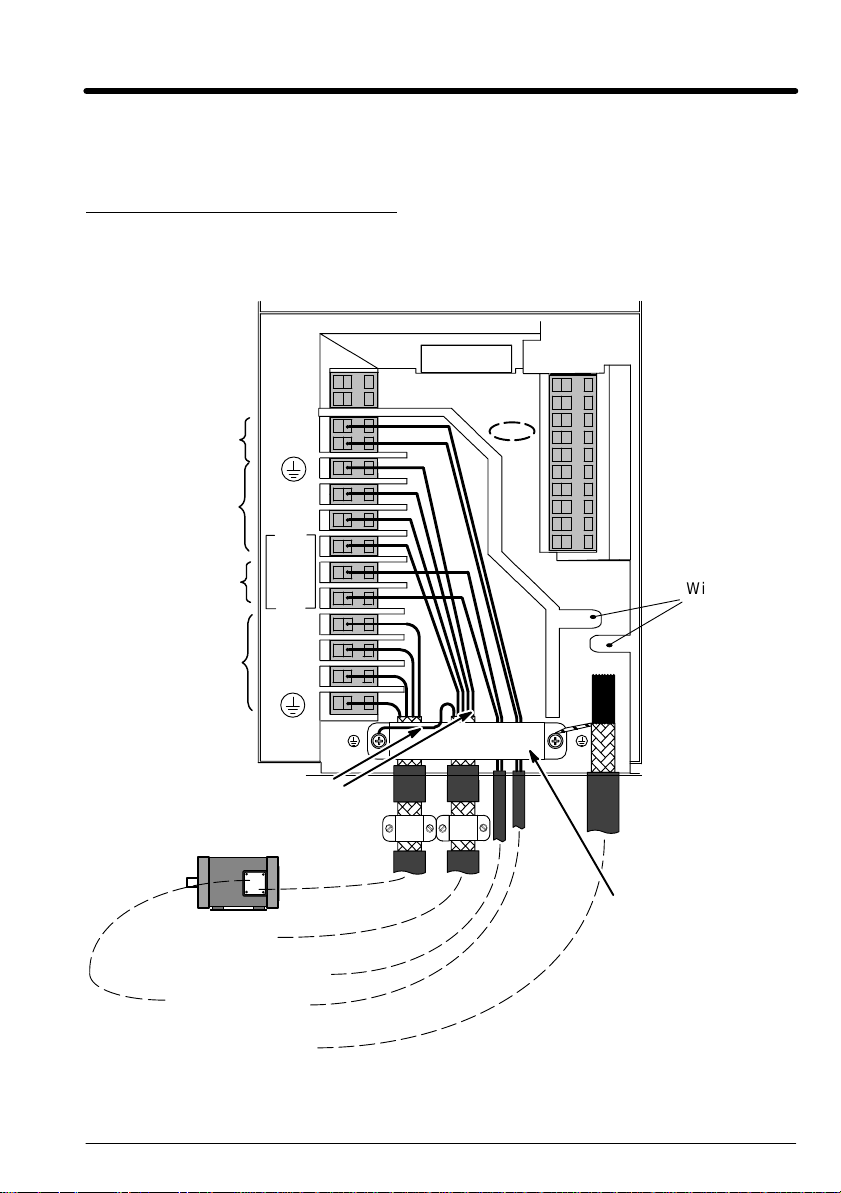

Figure 1-2 Power Connections Continued

10

DIN4/DOUT2

9

8

7

6

5

4

3

2

1

DIN3

DIN2

DIN1

+24V

AOUT1

+10V Ref

AIN2

AIN1

0V

Feedback

Setpoint

See Applications/Modes

10k Speed

Setpoint

Connect 0V to PE (protective earth ground)

for single control installations only. If multiple

controls are used, connect 0V terminals

together and ground to PE at one point only.

Size 1 and 3 Terminal Strips

Size 1

TH1A

TH1B

AC

Line

Motor

L1

L2/N

M1/U

M2/V

M3/W

1φ 230VAC

AC Line

Dynamic

Brake

Motor

Volts or

0–20mA Input

Size 3

TH1A

TH1B

L1

L2

L3

DC+

DBR

DC–

M1/U

M2/V

M3/W

3φ 460VAC

Jumpers and Switches None

Control Terminal Connections See Table 1–2.

Local Mode

No connections are required.

Remote Mode

Control terminals 1 to 10 can be connected as shown in the application

modes described in Section 3 of this manual.

1–2 Quick Start MN735

Page 6

Table 1–1 Power Connection Descriptions

idly t

2000Ω

this t

o

Range

above

380/460VAC±10%

with respect to L2, L3.

380/460VAC±10%

with respect to L1, L3.

emperature.

Terminal Description Function

RLY1 Relay Output Normally open, programmable

TH1A Thermistor Connection to motor thermistor It is good practice to protect motors by using

TH1B Thermistor Connection to motor thermistor

Reference

Terminal

L1 Power Input Single and three phase line

L2/NL2Power Input Single phase neutral (or L2 three

contact for a relay output.

Supply protective earth (PE). This terminal must be connected to a protective (earth)

ground for permanent ground.

connection

phase line connection)

230V 1–Phase 460V 3–Phase

Contact closes when the programmed

condition (see Section 4) is true.

No voltage is present on this contact. 6

conditions are available.

thermistors. A typical resistance (up to a

reference temperature of 125_C) is 200Ω,

rising rap

Connect devices in series between TH1A and

TH1B. Jumper TH1A and TH1B if temperature

sensors are not used.

220/240VAC±10%

with respect to L2/N.

220/240VAC±10%

with respect to L1.

L3 Power Input Three phase line connection Not applicable 380/460VAC±10%

DC- No user connection

DC+ Dynamic Brake Connection to external brake

DBR Dynamic Brake Connection to external brake

M1/U

M2/V

M3/W

Power Outputs 3-phase supply connection for

Reference

Terminal

resistor

resistor

motor

Supply protective earth (PE). This terminal must be connected to a protective (earth)

ground for permanent ground.

Not applicable Frame 2 (high volt

Not applicable Frame 2 (high volt

0 to 220/240VAC

0 to 240Hz

with respect to L1, L2.

only) & 3.

See Internal Dynamic

Brake Switch" table

only) & 3.

See Internal Dynamic

Brake Switch" table

0 to 380/460VAC

0 to 240Hz

Parameter Settings (for Keypad Operation)

The factory settings should be sufficient to operate the control using the

“Local” mode with the keypad. Only a few changes to the motor data

parameters must be made. Before any parameters can be changed, set

System::Configure I/O::Configure Enable to enable. All LEDs will blink

during configuration. After parameter values are changed to meet the

needs of your application, be sure to set System::Configure I/O::Configure

Enable to Disable and do the Parameter Save procedure.

Quick Start 1–3MN735

Page 7

Table 1–2 Analog/Digital Signal Descriptions

U

Volt-f

0-250VAC/24VDC

Terminal

(SELV)

RL1A

RL1B

10 DIN4/

9 DIN3 Digital Input 3. 0-24V source

8 DIN2 Digital Input 2. 0-24V source

7 DIN1 Digital Input 1. 0-24V source

6 +24V 24V ć 24V supply for digital I/O 50mA max

5 AOUT1 Analog Output ć 10mA maximum 0-10V

4 10VREF 10V reference (10mA maximum loading) 10V

3 AIN2 Analog Input 2 0-10V, 4-20mA

2 AIN1 Analog Input 1 - Setpoint. If unused, connect to 0VDC. 0-10V

1 0V 0V - Reference for Analog/Digital I/O

Signal Name Description Range

ser Relay

DOUT2

ree contact - 4A maximum, non-inductive

Configurable I/O, Digital Input 4 or Digital Output 2. 0-24V source

For single control installations, connect pin 1 (0V) to

PE.

For multiple control installations, connect the 0V

terminals of each control together. Then connect only

one control to PE.

open collector

open collector

open collector

open collector

0V

1–4 Quick Start MN735

Page 8

Section 2

General Information

Copyright Baldor 2002. All rights reserved.

This manual is copyrighted and all rights are reserved. This document may

not, in whole or in part, be copied or reproduced in any form without the

prior written consent of Baldor.

Baldor makes no representations or warranties with respect to the contents

hereof and specifically disclaims any implied warranties of fitness for any

particular purpose. The information in this document is subject to change

without notice. Baldor assumes no responsibility for any errors that may

appear in this document.

UL and cUL are registered trademarks of Underwriters Laboratories.

CE Compliance A custom unit may be required, contact Baldor. Compliance to

Directive 89/336/EEC is the responsibility of the system integrator. A

control, motor and all system components must have proper shielding,

grounding, and filtering as described in MN1383. Please refer to MN1383

for installation techniques for CE compliance. For additional information,

refer to Section 3 and Appendix B of this manual.

Limited Warranty

For a period of one (1) year from the date of original purchase, BALDOR

will repair or replace without charge controls and accessories which our

examination proves to be defective in material or workmanship. This

warranty is valid if the unit has not been tampered with by unauthorized

persons, misused, abused, or improperly installed and has been used in

accordance with the instructions and/or ratings supplied. This warranty is

in lieu of any other warranty or guarantee expressed or implied. BALDOR

shall not be held responsible for any expense (including installation and

removal), inconvenience, or consequential damage, including injury to

any person or property caused by items of our manufacture or sale.

(Some states do not allow exclusion or limitation of incidental or

consequential damages, so the above exclusion may not apply.) In any

event, BALDOR’s total liability, under all circumstances, shall not exceed

the full purchase price of the control. Claims for purchase price refunds,

repairs, or replacements must be referred to BALDOR with all pertinent

data as to the defect, the date purchased, the task performed by the

control, and the problem encountered. No liability is assumed for

expendable items such as fuses.

Goods may be returned only with written notification including a BALDOR

Return Authorization Number and any return shipments must be prepaid.

General Information 2–1MN735

Page 9

Product Notice Intended use:

These drives are intended for use in stationary ground based applications

in industrial power installations according to the standards EN60204 and

VDE0160. They are designed for machine applications that require variable

speed controlled three phase brushless AC motors.

These drives are not intended for use in applications such as:

– Home appliances

– Mobile vehicles

– Ships

– Airplanes

Unless otherwise specified, this drive is intended for installation in a

suitable enclosure. The enclosure must protect the control from exposure

to excessive or corrosive moisture, dust and dirt or abnormal ambient

temperatures.

In the event that a control fails to operate correctly, contact Baldor for return

instructions.

Safety Notice

: This equipment contains high voltages. Electrical shock can cause

serious or fatal injury. Only qualified personnel should attempt the start–up

procedure or troubleshoot this equipment.

This equipment may be connected to other machines that have rotating

parts or parts that are driven by this equipment. Improper use can cause

serious or fatal injury. Only qualified personnel should attempt the start–up

procedure or troubleshoot this equipment.

– System documentation must be available at all times.

– Keep non-qualified personnel at a safe distance from this equipment.

– Only qualified personnel familiar with the safe installation, operation

and maintenance of this device should attempt start-up or operating

procedures.

– Always remove power before making or removing any connections to

this control.

PRECAUTIONS: Classifications of cautionary statements.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in injury or death.

Caution: Indicates a potentially hazardous situation which, if not avoided,

could result in damage to property.

Continued on next page.

2–2 General Information MN735

Page 10

PRECAUTIONS:

WARNING: Do not touch any circuit board, power device or electrical

connection before you first ensure that power has been

disconnected and there is no high voltage present from this

equipment or other equipment to which it is connected. Electrical

shock can cause serious or fatal injury.

WARNING: Be sure that you are completely familiar with the safe operation of

this equipment. This equipment may be connected to other

machines that have rotating parts or parts that are controlled by

this equipment. Improper use can cause serious or fatal injury.

WARNING: Be sure all wiring complies with the National Electrical Code and

all regional and local codes or CE Compliance. Improper wiring

may cause a hazardous condition.

WARNING: Be sure the system is properly grounded before applying power.

Do not apply AC power before you ensure that grounds are

connected. Electrical shock can cause serious or fatal injury.

WARNING: Do not remove cover for at least five (5) minutes after AC power is

disconnected to allow capacitors to discharge. Electrical shock

can cause serious or fatal injury.

WARNING: Improper operation may cause violent motion of the motor and

driven equipment. Be certain that unexpected movement will not

cause injury to personnel or damage to equipment.

WARNING: Motor circuit may have high voltage present whenever AC power

is applied, even when motor is not moving. Electrical shock can

cause serious or fatal injury.

WARNING: If a motor is driven mechanically, it may generate hazardous

voltages that are conducted to its power input terminals. The

enclosure must be grounded to prevent a possible shock hazard.

WARNING: The user must provide an external hard-wired emergency stop

circuit to disable the control in the event of an emergency.

Continued on next page.

General Information 2–3MN735

Page 11

Caution: To prevent equipment damage, be certain that the input power

has correctly sized protective devices installed as well as a power

disconnect.

Caution: Avoid locating the control immediately above or beside heat

generating equipment, or directly below water or steam pipes.

Caution: Avoid locating the control in the vicinity of corrosive substances

or vapors, metal particles and dust.

Caution: Suitable for use on a circuit capable of delivering not more than

the RMS symmetrical short circuit amperes listed here at rated

voltage.

Horsepower

RMS Symmetrical Amperes

1.5–50 5,000

51–200 10,000

201–400 18,000

401–600 30,000

601–900 42,000

Caution: Baldor recommends not using “Grounded Leg Delta” transformer

power leads that may create ground loops and degrade system

performance. Instead, we recommend using a four wire Wye.

Caution: Logic signals are interruptible signals; these signals are removed

when power is removed from the drive.

Caution: The safe integration of the driver into a machine system is the

responsibility of the machine designer. Be sure to comply with

the local safety requirements at the place where the machine is to

be used. In Europe this is the Machinery Directive, the

ElectroMagnetic Compatibility Directive and the Low Voltage

Directive. In the United States this is the National Electrical code

and local codes.

Caution: Controls must be installed inside an electrical cabinet that

provides environmental control and protection. Installation

information for the drive is provided in this manual. Motors and

controlling devices that connect to the driver should have

specifications compatible to the drive.

Caution: Do not tin (solder) exposed wires. Solder contracts over time and

may cause loose connections.

Caution: Electrical components can be damaged by static electricity. Use

ESD (electro-static discharge) procedures when handling this

control.

2–4 General Information MN735

Page 12

Section 3

Receiving & Installation

Receiving & Inspection

Baldor Controls are thoroughly tested at the factory and carefully packaged

for shipment. When you receive your control, there are several things you

should do immediately.

1. Observe the condition of the shipping container and report any

damage immediately to the commercial carrier that delivered your

control.

2. Remove the control from the shipping container and remove all

packing materials. The container and packing materials may be

retained for future shipment.

3. Verify that the part number of the control you received is the same as

the part number listed on your purchase order.

4. Inspect the control for external physical damage that may have been

sustained during shipment and report any damage immediately to the

commercial carrier that delivered your control.

5. If the control is to be stored for several weeks before use, be sure that

it is stored in a location that conforms to published storage humidity

and temperature specifications stated in this manual.

Location and Mounting

The location of the control is important. Installation should be in an area

that is protected from direct sunlight, corrosives, harmful gases or liquids,

dust, metallic particles, and vibration. Exposure to these can reduce the

operating life and degrade performance of the control.

Several other factors should be carefully evaluated when selecting a

location for installation:

To maintain compliance with European Electrical Safety Standard

VDE0160(1994)/EN50178 (1998) the control must be mounted inside an

enclosure that requires a tool for opening. The enclosure should provide

15dB attenuation to radiated emissions between 30–100MHz.

Mount the drive vertically on a solid, flat, non–flammable, vertical surface.

It can be panel–mounted, or rail–mounted on a rail complying with

EN50022 (35mm DIN). For DIN mount, hang the unit on the top DIN rail

and push the unit onto the bottom DIN rail until it snaps in to position.

Secure with a screw in the lower hole. See mounting drawing in Section 6

of this manual.

1. For effective cooling and maintenance, the control should be mounted

vertically on a smooth non-flammable surface.

2. At least 4.0 inches (100mm) top and bottom clearance must be

provided for air flow. At least 0.4 inches (10mm) clearance is required

between controls (each side).

3. Operating Altitude derating. Up to 3300 feet (1000 meters) no

derating required. Derate the continuous and peak output current by

1% for each 330 feet (100 meters) above 3300 feet. Maximum

operating altitude 16,500 feet (5,000 meters).

4. Operating Temperature derating. 0°C to 40°C ambient. Linear

derating to 50°C maximum ambient.

Receiving & Installation 3–1MN735

Page 13

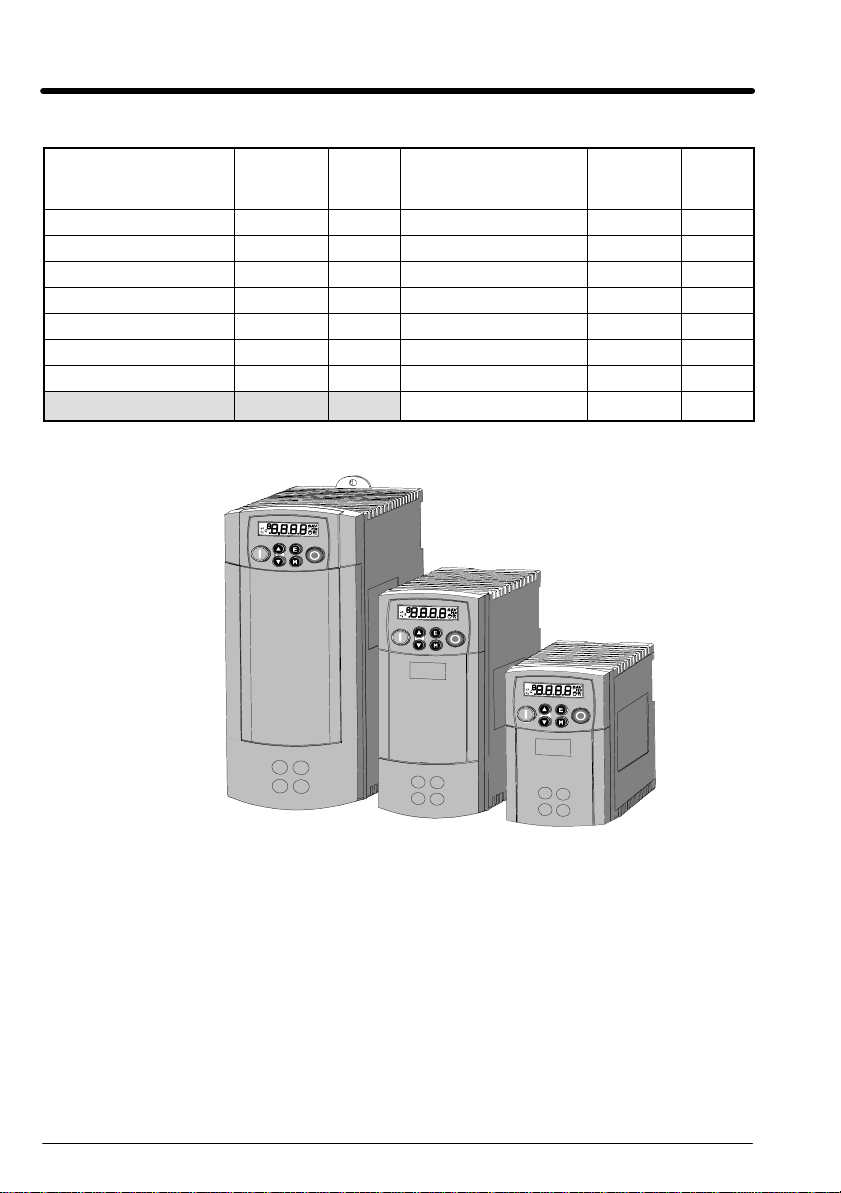

Table 3-1 Watts Loss Ratings

Catalog No.

Output

Current

(A)

Watts

Loss

(W)

Catalog No. Output

Current

(A)

Watts

Loss

ID35D8A1F5–CRH 1.5 26 ID35D4A1F5–CRH 1.5 26

ID35D8A2F2–CRH 2.2 32 ID35D4A02–CRH 2.0 32

ID35D8A03–CRH 3.0 41 ID35D4A2F5–CRH 2.5 40

ID35D8A04–CRH 4.0 52 ID35D4A4F5–CRH 4.5 61

ID35D8A07–CRH 7.0 82 ID35D4A5F5–CRH 5.5 70

ID35D8A10–CRH 10.5 116 ID35D4A09–CRH 9.0 100

ID35D8A16–CRH 16.5 181 ID35D4A12–CRH 12.0 140

ID35D4A16–CRH 16.0 180

Figure 3-1 Inverter Sizes

Size 3

Size 2

Size 1

3–2 Receiving & Installation MN735

Page 14

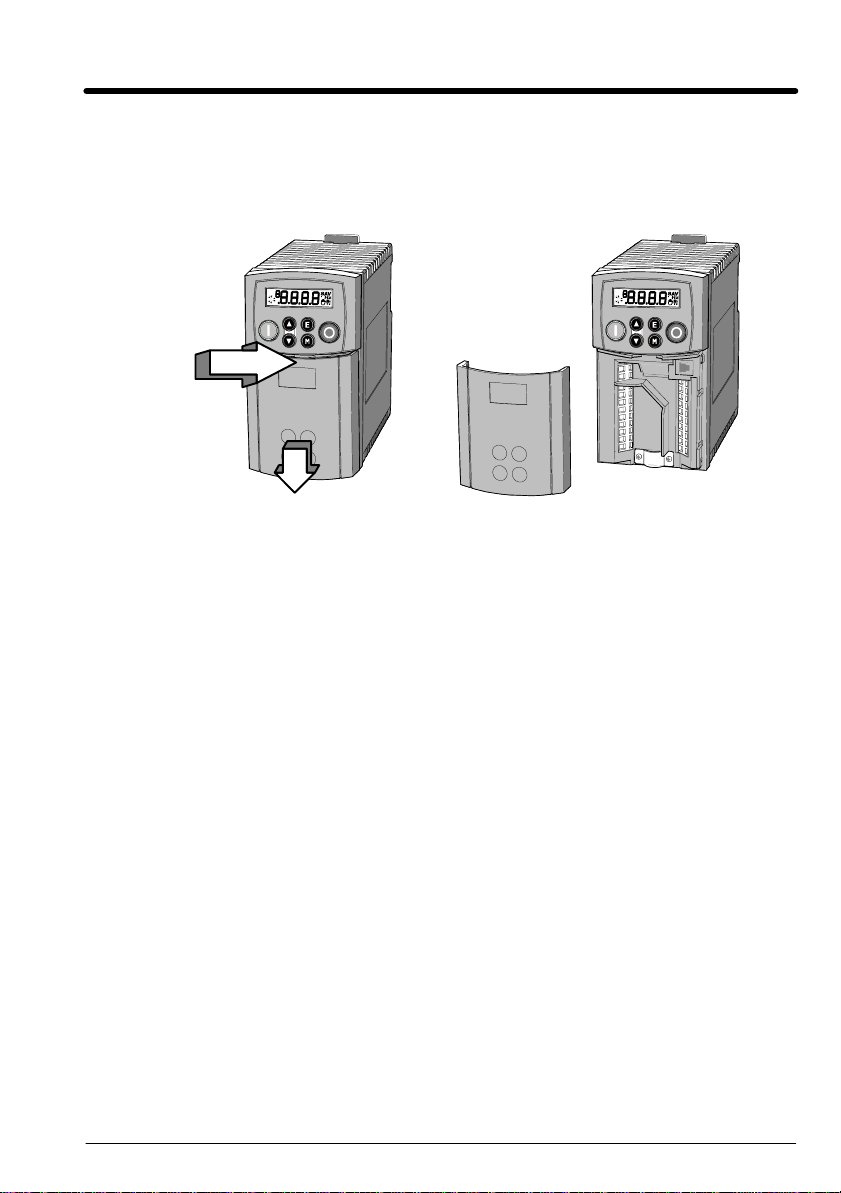

Cover Removal To connect power and signal wires, the cover must be removed. This

1. Press in to

release cover

Power Conditioning

procedure describes how to access all terminal connections inside the

control.

Using your thumbs, press in and slide the cover down as shown in Figure

3-2.

Figure 3-2 Top Cover Removal

2. Slide cover down and remove.

System Grounding Baldor Controls are designed to be powered from standard

three phase power lines that are electrically symmetrical with respect to

ground. System grounding is an important step in the overall installation to

prevent problems.

Ungrounded Distribution System

With an ungrounded power distribution system it is possible to have a

continuous current path to ground through the MOV devices. To avoid

equipment damage, an isolation transformer with a grounded secondary is

recommended. This provides three phase AC power that is symmetrical

with respect to ground.

Input Power Conditioning

Baldor controls are designed for direct connection to standard three phase

lines that are electrically symmetrical with respect to ground. Certain

power line conditions must be avoided. An AC line reactor or an isolation

transformer may be required for some power conditions.

S If the feeder or branch circuit that provides power to the control has

permanently connected power factor correction capacitors, an input

AC line reactor or an isolation transformer must be connected

between the power factor correction capacitors and the control.

S If the feeder or branch circuit that provides power to the control has

power factor correction capacitors that are switched on line and off

line, the capacitors must not be switched while the control is

connected to the AC power line. If the capacitors are switched on line

while the control is still connected to the AC power line, additional

protection is required. TVSS (Transient Voltage Surge Suppressor) of

the proper rating must be installed between the AC line reactor or an

isolation transformer and the AC input to the control.

Receiving & Installation 3–3MN735

Page 15

Line Impedance The Baldor control requires a 1% line impedance minimum . If

the impedance of the incoming power does not meet the requirement for

the control, a 3 phase line reactor can be used to provide the needed

impedance in most cases. Line reactors are optional and are available from

Baldor.

The input impedance of the power lines can be determined as follows:

Measure the line to line voltage at no load and at full rated load.

Use these measured values to calculate impedance as follows:

%Impedance +

(Volts

No Load Speed

(Volts

* Volts

No Load Speed

Full Load Speed

)

)

100

Line Reactors Three phase line reactors are available from Baldor. The line

reactor to order is based on the full load current of the motor (FLA). If

providing your own line reactor, use the following formula to calculate the

minimum inductance required.

0.03)

(V

L +

L* L

Ǹ

(I 3

377)

Where: L Minimum inductance in Henries.

V

L-L

0.03 Desired percentage of input impedance.

Input volts measured line to line.

I Input current rating of control.

377 Constant used with 60Hz power.

Use 314 if input power is 50Hz.

Load Reactors Line reactors may be used at the control output to the motor.

When used this way, they are called Load Reactors. Load reactors serve

several functions that include:

S Protect the control from a short circuit at the motor.

S Limit the rate of rise of motor surge currents.

S Slowing the rate of change of power the control delivers to the motor.

Load reactors should be installed as close to the control as possible.

Selection should be based on the motor nameplate FLA value.

Power Disconnect A power disconnect should be installed between the input

power service and the control for a fail safe method to disconnect power.

The control will remain in a powered-up condition until all input power is

removed from the control and the internal bus voltage is depleted.

Protective Devices Recommended fuse sizes are based on the following:

115% of maximum continuous current for time delay.

150% of maximum continuous current for Fast or Very Fast action.

Note: These general size recommendations do not consider harmonic currents or

ambient temperatures greater than 40°C.

Be sure a suitable input power protection device is installed. Use the

recommended fuses and wire sizes shown in Table 3-2 is based on the use

of copper conductor wire rated at 75 °C. The table is specified for NEMA B

motors.

Reduced Input Voltage Derating All power ratings stated in Section 6 are for

the stated nominal AC input voltages (230 or 460VAC). The power rating of

the control must be reduced when operating at a reduced input voltage.

The amount of reduction is the ratio of the voltage change.

3–4 Receiving & Installation MN735

Page 16

Examples:

A 5hp, 230VAC control operating at 208VAC has a reduced power rating of

4.5hp.

5HP

Likewise, a 3hp, 460VAC control operating at 380VAC has a reduced

power rating of 2.47hp.

3HP

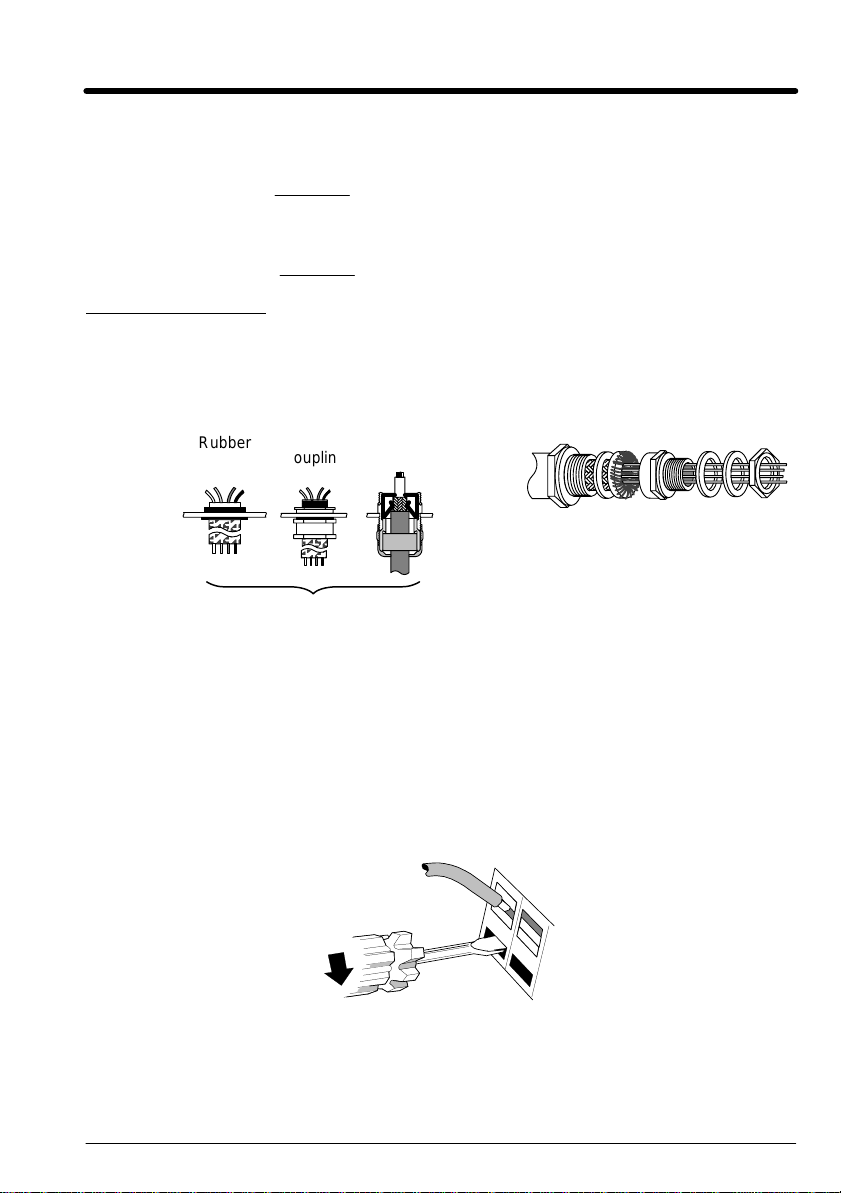

Electrical Installation All interconnection wires between the control, AC power source,

motor, host control and any operator interface stations should be in metal

conduits or shielded cable must be used. Use listed closed loop

connectors that are of appropriate size for wire gauge being used.

Connectors are to be installed using crimp tool specified by the

manufacturer of the connector. Only class 1 wiring should be used.

Rubber

Grommet

Holes are required in the enclosure assembly to allow connections to be

made. Use the correct size rubber grommet, conduit coupling or 360

degree coupling.

Clamp Terminals To install a wire into a clamp terminal, first strip wire insulation

to 0.20–0.24 in. (5–6mm). Insert a flat–blade screwdriver, maximum blade

size 0.138 in. (3.5mm) into the adjacent hole. Do not twist or rotate the

screwdriver as this action may damage the terminal. A very slight

downward pressure on the screwdriver should open the terminals and allow

the wire to be inserted. Insert the wire into the clamp opening (Figure 3-4).

Remove the screwdriver. The terminal provides the correct force for a

secure connection.

208VAC

230VAC

380VAC

460VAC

Figure 3-3 Unshielded and Shielded Couplings

Metal

Coupling

+ 4.5hp

+ 2.47hp

360 Degree

Coupling

Figure 3-4 Clamp Terminal

360 Degree Coupling

Receiving & Installation 3–5MN735

Page 17

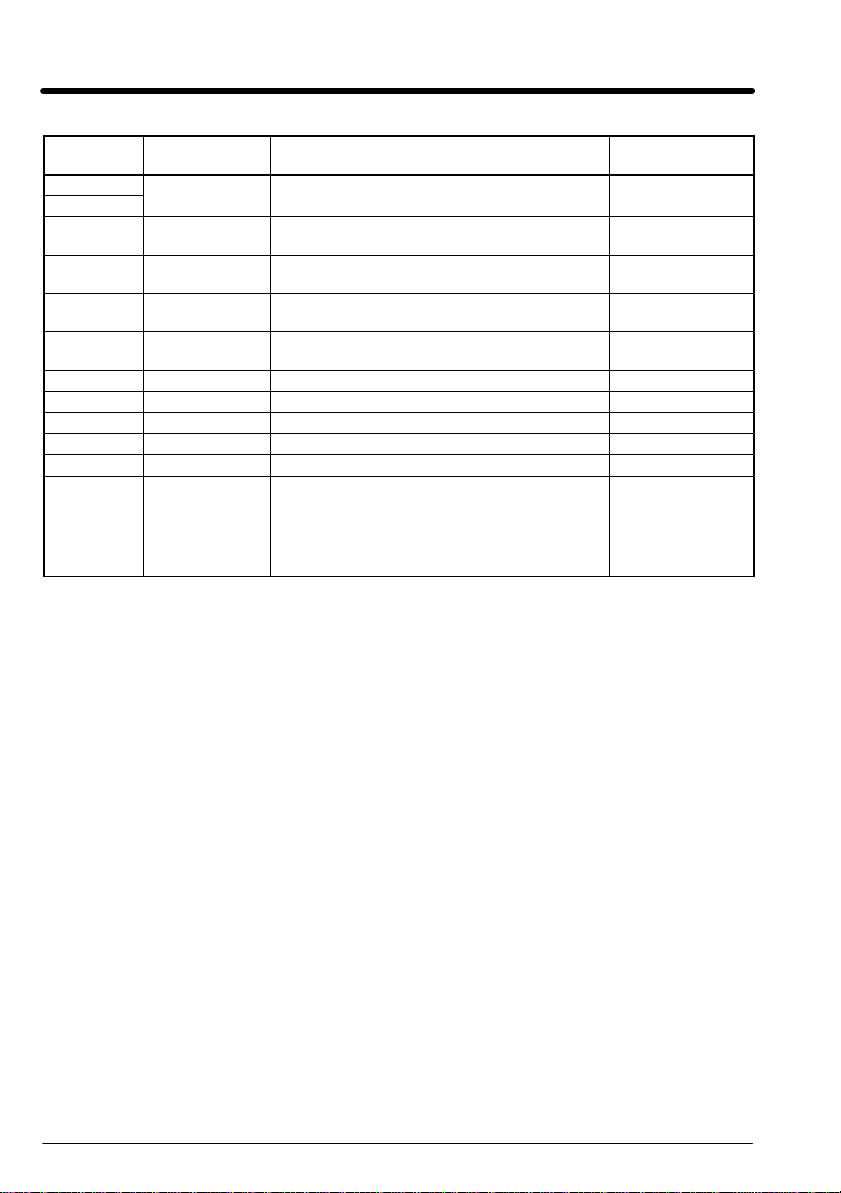

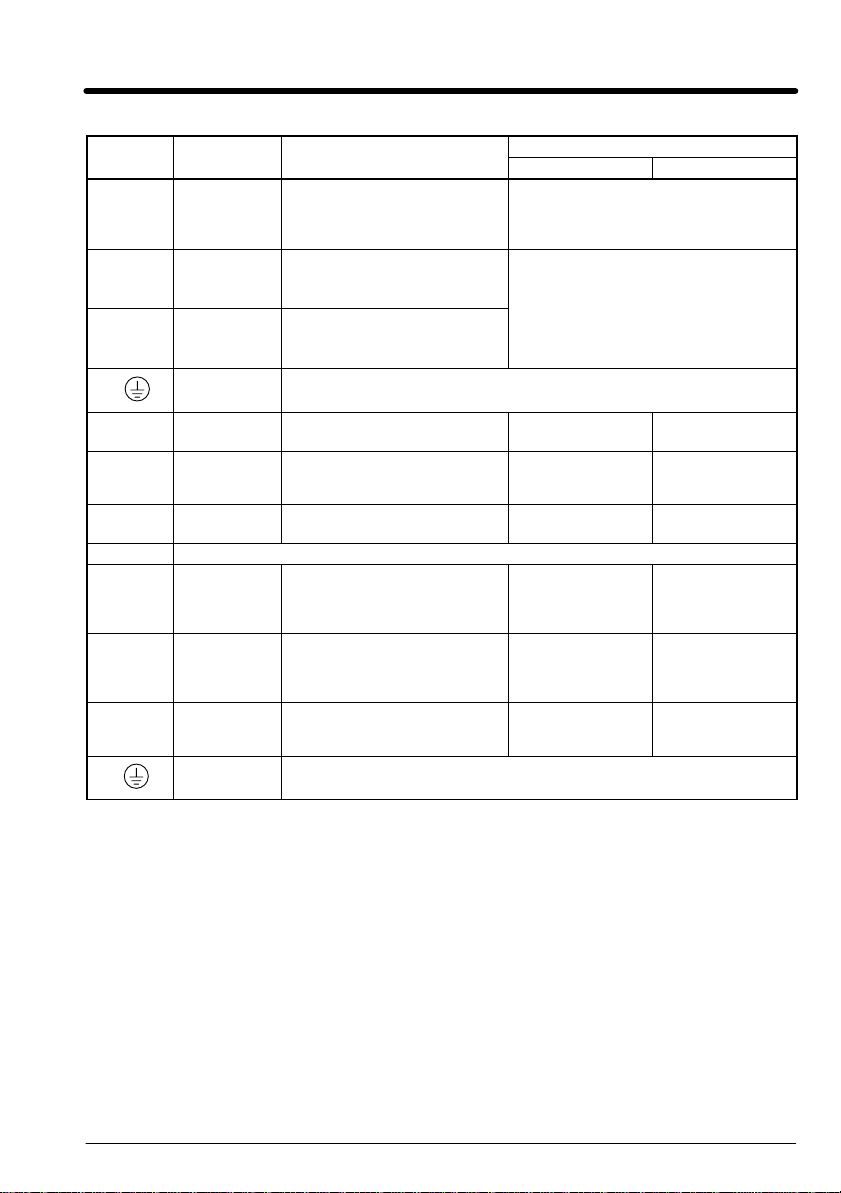

Table 3-2 Wire Size

Output

Catalog

Number

ID35D8A1F5-CRH 1 1.5 2.3 12 2.5 12 2.5

ID35D8A2F2-CRH 1 2.2 3.3 12 2.5 12 2.5

ID35D8A03-CRH 1 3.0 4.5 12 2.5 12 2.5

ID35D8A04-CRH 1 4.0 6.0 12 2.5 12 2.5

ID35D8A07-CRH 2 7.0 10.5 12 2.5 12 2.5

ID35D2A10-CRH 3 10.5 15.8 10 2.5 10 2.5 12 2.5

ID35D2A16-CRH 3 16.5 24.8 10 2.5 10 2.5 12 2.5

ID35D4A1F5-CRH 2 1.5 2.3 12 2.5 12 2.5 12 2.5

ID35D4A02-CRH 2 2.0 3.0 12 2.5 12 2.5 12 2.5

ID35D4A2F5-CRH 2 2.5 3.8 12 2.5 12 2.5 12 2.5

ID35D4A4F5-CRH 2 4.5 6.8 12 2.5 12 2.5 12 2.5

ID35D4A5F5-CRH 2 5.5 8.3 12 2.5 12 2.5 12 2.5

ID35D4A09-CRH 3 9.0 13.5 10 2.5 10 2.5 12 2.5

ID35D4A12-CRH 3 12.0 18.0 10 2.5 10 2.5 12 2.5

ID35D4A16-CRH 3 16.0 24.0 10 2.5 10 2.5 12 2.5

Size

Current

Cont. Peak

(Amps) (Amps)

L1, L2, L3, N,

GND and Motor

AWG MM2AWG MM2AWG MM

Wire Size

DC+, DBR TH1A, TH1B

Note: All wire sizes based on 75°C copper wire, 40°C ambient temperature, 4-6

conductors per conduit or raceway.

Power Connections The signals are shown in Figure 3-5 and described in

Table 3-3.

1. Remove the cover, shown in Figure 3-2.

2. Loosen the grounded cable clamp, Figure 3-5.

3. Connect the Mains Cable, Motor Cable, Dynamic Brake Cable and

Thermistor Cable wires, if used to their proper clamp terminal, Figure

3-5. Be sure the shields of all shielded cables are in contact with the

grounded cable clamp.

Note: This control must have two separate mains earth grounds connected as

shown in Figures 3-5 and 3-6.

4. Tighten the grounded cable clamp screws to securely hold the cables.

2

3–6 Receiving & Installation MN735

Page 18

Table 3-3 Power Connection Descriptions

idly t

2000Ω

this t

o

Range

above

380/460VAC±10%

with respect to L2, L3.

380/460VAC±10%

with respect to L1, L3.

emperature.

Terminal Description Function

RLY1 Relay Output Normally open, programmable

TH1A Thermistor Connection to motor thermistor It is good practice to protect motors by using

TH1B Thermistor Connection to motor thermistor

Reference

Terminal

L1 Power Input Single and three phase line

L2/NL2Power Input Single phase neutral (or L2 three

contact for a relay output.

Supply protective earth (PE). This terminal must be connected to a protective (earth)

ground for permanent ground.

connection

phase line connection)

230V 1–Phase 460V 3–Phase

Contact closes when the programmed

condition (see Section 4) is true.

No voltage is present on this contact. 6

conditions are available.

thermistors. A typical resistance (up to a

reference temperature of 125_C) is 200Ω,

rising rap

Connect devices in series between TH1A and

TH1B. Jumper TH1A and TH1B if temperature

sensors are not used.

220/240VAC±10%

with respect to L2/N.

220/240VAC±10%

with respect to L1.

L3 Power Input Three phase line connection Not applicable 380/460VAC±10%

DC- No user connection

DC+ Dynamic Brake Connection to external brake

DBR Dynamic Brake Connection to external brake

M1/U

M2/V

M3/W

Power Outputs 3-phase supply connection for

Reference

Terminal

resistor

resistor

motor

Supply protective earth (PE). This terminal must be connected to a protective (earth)

ground for permanent ground.

Not applicable Frame 2 (high volt

Not applicable Frame 2 (high volt

0 to 220/240VAC

0 to 240Hz

with respect to L1, L2.

only) & 3.

See Internal Dynamic

Brake Switch" table

only) & 3.

See Internal Dynamic

Brake Switch" table

0 to 380/460VAC

0 to 240Hz

Receiving & Installation 3–7MN735

Page 19

Size 2 Shown

Figure 3-5 Power and Ground Connections

TH1A and TH1B must

be jumpered if

thermistor is not used

AC Line

Connections

Dynamic Brake

Connections

Motor

Connections

L1, L2, L3, GND

RL1A

RL1B

TH1A

TH1B

L1

L2/N

L3

DC+

DBR

M1/U

M2/V

M3/W

Use 2 Ground

Wires

Motor Cable

Mains Supply

Cable

Use a cable tie

in this area for

control wires.

10

9

8

7

6

5

4

3

2

1

Wire Retainer

(Channel)

Grounded

Cable Clamp

Dynamic Brake Cable

Thermistor Cable

Control Signal Cable

3–8 Receiving & Installation MN735

Page 20

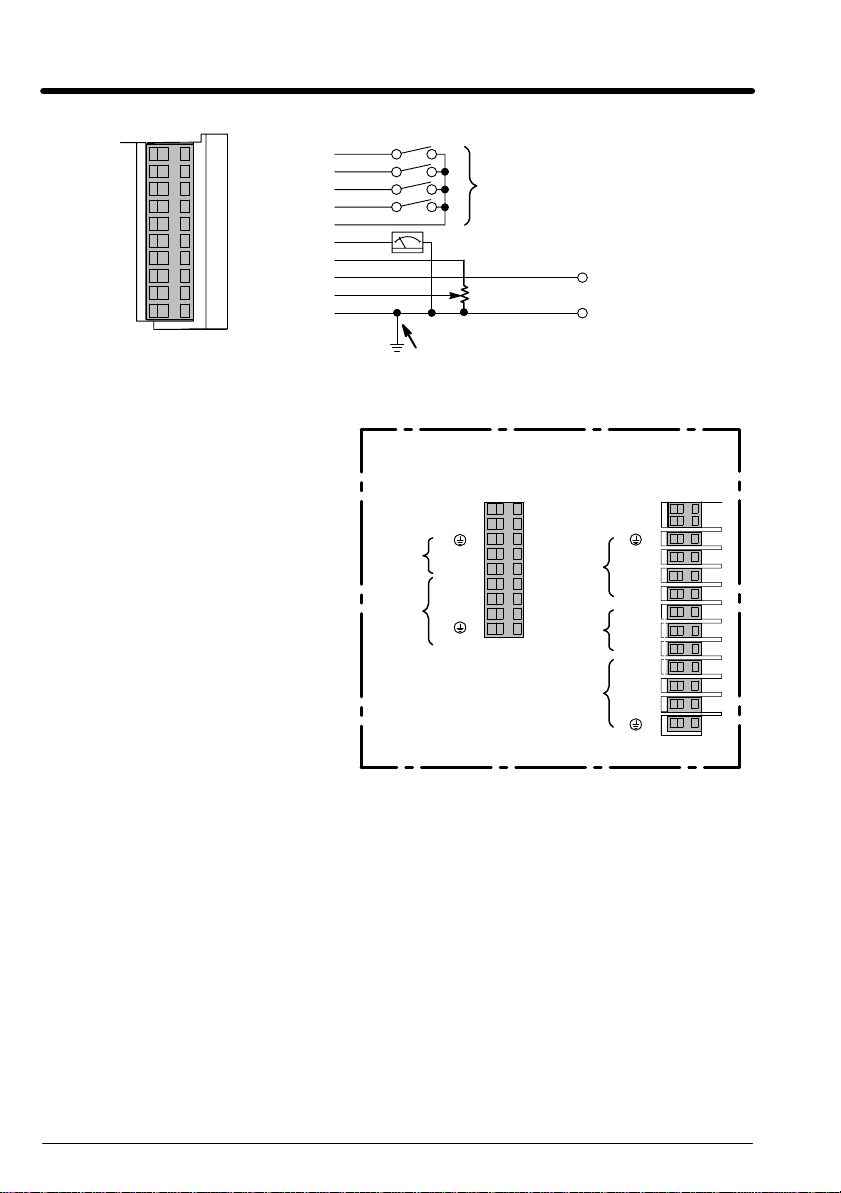

Figure 3-6 Power Connections Continued

10

DIN4/DOUT2

9

8

7

6

5

4

3

2

1

DIN3

DIN2

DIN1

+24V

AOUT1

+10V Ref

AIN2

AIN1

0V

Feedback

Setpoint

See Applications/Modes

10k Speed

Setpoint

Connect 0V to PE (protective earth ground)

for single control installations only. If multiple

controls are used, connect 0V terminals

together and ground to PE at one point only.

Size 1 and 3 Terminal Strips

Size 1

TH1A

TH1B

AC

Line

Motor

L1

L2/N

M1/U

M2/V

M3/W

1φ 230VAC

AC Line

Dynamic

Brake

Motor

Volts or

0–20mA Input

Size 3

TH1A

TH1B

L1

L2

L3

DC+

DBR

DC–

M1/U

M2/V

M3/W

Thermistor Connections (connections are shown in Figure 3-5).

This input is provided for over–temperature detection for motors that have

an internal thermistor. There is no polarity to the thermistor connections.

This provides “Basic” insulation only to the SELV control circuits and

assumes the motor has “Basic” insulation to the windings/mains circuits.

The thermistor type supported is PTC ‘Type A’ as defined in IEC 34–11 Part

2. The resistance thresholds are:

Rising temperature trip resistance: 1650 to 4000 ohms

Falling temperature trip reset resistance 750 to 1650 ohms

If the motor does not have an internal thermistor, you should disable the

thermistor trip function by:

Receiving & Installation 3–9MN735

3φ 460VAC

Page 21

1. Connecting a jumper wire between the thermistor terminals TH1A and

U

Volt-f

0-250VAC/24VDC

TH1B. or

2. Set the parameter Invert Thermistor Input

TRIPS MENU

to 1.

Signal Connections Wire sizes between 12AWG and 28AWG (2.5mm2 to

0.08mm

2

) can be used.

1. With the cover removed, connect the analog and digital inputs and

outputs as shown in Figure 3-5.

The signals are described in Table 3-4.

2. Install the front cover.

Table 3-4 Analog/Digital Signal Descriptions

Terminal

(SELV)

RL1A

RL1B

10 DIN4/

9 DIN3 Digital Input 3. 0-24V source

8 DIN2 Digital Input 2. 0-24V source

7 DIN1 Digital Input 1. 0-24V source

6 +24V 24V ć 24V supply for digital I/O 50mA max

5 AOUT1 Analog Output ć 10mA maximum 0-10V

4 10VREF 10V reference (10mA maximum loading) 10V

3 AIN2 Analog Input 2 0-10V, 4-20mA

2 AIN1 Analog Input 1 - Setpoint. If unused, connect to 0VDC. 0-10V

1 0V 0V - Reference for Analog/Digital I/O

Signal Name Description Range

ser Relay

DOUT2

ree contact - 4A maximum, non-inductive

Configurable I/O, Digital Input 4 or Digital Output 2. 0-24V source

For single control installations, connect pin 1 (0V) to

PE.

For multiple control installations, connect the 0V

terminals of each control together. Then connect only

one control to PE.

open collector

open collector

open collector

open collector

0V

3–10 Receiving & Installation MN735

Page 22

External Brake Resistor

Connect the dynamic brake resistor between terminals DC+ and DBR as

shown in Figure 3-5 and 3-6.

User Relay A customer provided, external DC or AC power supply must be used

if relay output is to be used.

Note: Contact is rated to 250V @ 4A

Volts

Load

Customer Provided Load

resistive (non–inductive).

Contact is open

when power is on

and no faults are

present.

Control

RL1A

RL1B

Applications/Modes There are 6 operating modes. Each mode configures the

terminal strip wiring for a specific application. The following diagrams

document the terminal strip wiring for each (Application 0 to Application 5).

Note: Parameter values are not changed by loading a new Application.

How to Load an Application

In the

The Applications are stored in this menu.

Use the

Press the

menu, go to and press the key.

keys to select the appropriate Application by number.

key to load the Application.

Receiving & Installation 3–11MN735

Page 23

1 – Keypad Mode

In Keypad mode, the control is operated by the keypad and opto isolated

inputs and the analog command inputs are ignored. The analog output

remain active.

Figure 3-7 Keypad Connection Diagram

Speed Output

Pot Reference

Analog Input 2

Analog Input 1

Analog GND

+24VDC

10

9

8

7

6

5

4

3

2

1

Fault

1 Analog GND. Reference for analog inputs.

2 Not used.

3 Not used.

4 +10VDC reference voltage for potentiometer.

5 Analog output that represents the commanded speed output.

6 +24VDC for Optical Inputs power.

7 Not used.

8 Not used.

9 Not used.

10 Not used.

RLY1Digital output that represents the fault status.

RLY1A

RLY1B

3–12 Receiving & Installation MN735

Page 24

2 – Standard Run 3 Wire Mode

In Standard Run mode, the control is operated by the opto isolated inputs

and the analog command input. The opto inputs can be switches as shown

in Figure 3-8 or logic signals from another device.

Figure 3-8 Standard Run Connection Diagram

Analog IN

Select

Open

Closed

Analog Input 1 = 0–10VDC Setpoint

Analog Input 2 = 4–20mA Setpoint

Command

Analog Input 1

Analog Input 2

10K Pot or

0-10VDC

Analog IN SEL

Stop

Run REV

Run FWD

+24VDC

Speed Output

Pot Reference

Analog Input 2

Analog Input 1

Analog GND

10

9

8

7

6

5

4

3

2

1

Fault

1 Analog GND. Reference for analog inputs.

2 Setpoint 0–10VDC. Single ended analog voltage input, referenced to 1.

3 Setpoint 4–20mA. Single ended analog current input, referenced to 1.

4 +10VDC reference voltage for potentiometer.

5 Analog output that represents the commanded speed output.

6 +24VDC for Optical Inputs power.

7 Momentary CLOSED starts motor operation in the Forward direction.

8 Momentary CLOSED starts motor operation in the Reverse direction.

9 Momentary OPEN motor decels to stop.

10 Analog IN Select. OPEN selects Analog Input 1 (2).

CLOSED selects Analog Input 2 (3).

RLY1Digital output that represents the fault status.

RLY1A

RLY1B

Receiving & Installation 3–13MN735

Page 25

3 – 3 Speed 2 Wire Mode

In 3 speed 2 wire mode, the control is operated by the opto isolated inputs

and the analog command input. The opto inputs can be switches as shown

in Figure 3-9 or logic signals from another device.

Figure 3-9 3 Speed Connection Diagram

Speed Select

1 2 Command

Open

Open

Closed

Closed

Open

Closed

Open

Closed

Analog Input 1 & 2 (Add)

Preset Speed 1

Preset Speed 2

Preset Speed 3

Speed Select 2

Speed Select 1

Speed Output

Related Parameters

p302 Preset Speed 1

p303 Preset Speed 2

p304 Preset Speed 3

10K Pot or

Pot Reference

Analog Input 2

Analog Input 1

0-10VDC

Analog Input 1 = 0–10VDC Setpoint

Analog Input 2 = 4–20mA Setpoint

Fault

1 Analog GND. Reference for analog inputs.

2 Setpoint 0–10VDC. Single ended analog voltage input, referenced to 1.

3 Setpoint 4–20mA. Single ended analog current input, referenced to 1.

4 +10VDC reference voltage for potentiometer.

5 Analog output that represents the commanded speed output.

6 +24VDC for Optical Inputs power.

7 CLOSED starts motor operation in the Forward direction.

8 CLOSED starts motor operation in the Reverse direction.

9 Speed Select input 1. Inputs 9 & 10 select preset speeds 1 to 3.

10 Speed Select input 2. Inputs 9 & 10 select preset speeds 1 to 3.

RLY1Digital output that represents the fault status.

Run REV

Run FWD

+24VDC

Analog GND

10

9

8

7

6

5

4

3

2

1

RLY1A

RLY1B

3–14 Receiving & Installation MN735

Page 26

4 – EPOT 3 Wire Mode (Electronic Potentiometer)

In EPOT 3 wire mode, the control is operated by the opto isolated inputs

and the analog command input. The opto inputs can be switches as shown

in Figure 3-10 or logic signals from another device.

Figure 3-10 EPOT Connection Diagram

Note:

Speed Command = Analog1 + Analog2 + EPOT

Analog Input 1 = 0–10VDC Setpoint

Analog Input 2 = 4–20mA Setpoint

10K Pot or

0-10VDC

Decrease

Increase

Stop

Run FWD

+24VDC

Speed Output

Pot Reference

Analog Input 2

Analog Input 1

Analog GND

10

9

8

7

6

5

4

3

2

1

Fault

1 Analog GND. Reference for analog inputs.

2 Setpoint 0–10VDC. Single ended analog voltage input, referenced to 1.

3 Setpoint 4–20mA. Single ended analog current input, referenced to 1.

4 +10VDC reference voltage for potentiometer.

5 Analog output that represents the commanded speed output.

6 +24VDC for Optical Inputs power.

7 Momentary CLOSED starts motor operation in the Forward direction.

8 Momentary OPEN motor decels to stop.

9 Momentary CLOSED increases motor speed while contact is closed.

10 Momentary CLOSED decreases motor speed while contact is closed.

RLY1Digital output that represents the fault status.

RLY1A

RLY1B

Receiving & Installation 3–15MN735

Page 27

5 – EPOT 2 Wire Mode (Electronic Potentiometer)

In EPOT 2 wire mode, the control is operated by the opto isolated inputs

and the analog command input. The opto inputs can be switches as shown

in Figure 3-11 or logic signals from another device.

Figure 3-11 EPOT Connection Diagram

Note:

Speed Command = Analog1 + Analog2 + EPOT

Analog Input 1 = 0–10VDC Setpoint

Analog Input 2 = 4–20mA Setpoint

10K Pot or

0-10VDC

Decrease

Increase

Run REV

Run FWD

+24VDC

Speed Output

Pot Reference

Analog Input 2

Analog Input 1

Analog GND

10

9

8

7

6

5

4

3

2

1

Fault

1 Analog GND. Reference for analog inputs.

2 Setpoint 0–10VDC. Single ended analog voltage input, referenced to 1.

3 Setpoint 4–20mA. Single ended analog current input, referenced to 1.

4 +10VDC reference voltage for potentiometer.

5 Analog output that represents the commanded speed output.

6 +24VDC for Optical Inputs power.

7 CLOSED starts motor operation in the Forward direction.

8 CLOSED starts motor operation in the Reverse direction.

9 Momentary CLOSED increases motor speed while contact is closed.

10 Momentary CLOSED decreases motor speed while contact is closed.

RLY1Digital output that represents the fault status.

RLY1A

RLY1B

3–16 Receiving & Installation MN735

Page 28

6 – PID 2 Wire Mode

In PID 2 wire mode, the control is operated by the opto isolated inputs and

the analog command input. The opto inputs can be switches as shown in

Figure 3-12 or logic signals from another device.

Figure 3-12 PID Connection Diagram

Process

Enable

Open

Closed

Analog Input 1 = 0–10VDC Setpoint

Analog Input 2 = 4–20mA Feedback

Command

Analog Input 1 (Speed Ref)

PID

Process Enable

Speed Output

Pot Reference

Analog Input 2

Related Parameters

p8 Jog Speed

Jog Accel

Jog Decel

10K Pot or

0-10VDC

Analog Input 1

Analog GND

Fault

1 Analog GND. Reference for analog inputs.

2 PID Setpoint 0–10VDC. Single ended analog voltage input, referenced to 1.

3 PID Feedback 4–20mA. Single ended analog current input, referenced to 1.

4 +10VDC reference voltage for potentiometer.

5 Analog output that represents the commanded speed output.

6 +24VDC for Optical Inputs power.

7 Momentary CLOSED starts motor operation in the Forward direction. In Jog mode

(10 Closed), jogs motor in forward direction as long as switch is closed.

8 Momentary CLOSED starts motor operation in the Reverse direction. In Jog mode

(10 Closed), jogs motor in reverse direction as long as switch is closed.

9 CLOSED enables process mode. OPEN selects Analog Input 1 setpoint.

10 CLOSED places control in Jog mode. Forward and Reverse run are used to Jog the motor at

Jog speed.

RLY1Digital output that represents the fault status.

Jog

Run REV

Run FWD

+24VDC

10

9

8

7

6

5

4

3

2

1

RLY1A

RLY1B

Receiving & Installation 3–17MN735

Page 29

3–18 Receiving & Installation MN735

Page 30

Section 4

Start–Up and Operation

Keypad Description

Figure 4-1 Keypad Description

Display

Local

Run

Programming Keys

Key Operation Description

Escape Navigation – Displays the previous level’s menu

Menu Navigation – Displays the next menu level, or the first parameter

Increment Navigation – Move upwards through the menu system

Decrement Navigation – Move down through the menu system

Run Local Mode – Run the drive

Stop Local Mode – Stops the drive. Trip Reset in all modes

Parameter – Returns to the parameter list

Trip Acknowledge – Acknowledges displayed Trip or Error

message

of the current Menu

Parameter – Moves cursor to the left when the parameter is

adjustable

Parameter – Increase value of the displayed parameter

Local Mode – Increase value of the local setpoint

Parameter – Decrease value of the displayed parameter

Local Mode – Decrease value of the local setpoint

Navigation – Press and hold to toggle between Local and

Remote Control modes (refer to Special Menu Features)

Local

Stop

The keypad provides local control and monitoring of the Inverter. Remove

it by simply pulling it from the drive. To install it, push it back into place.

Start–Up and Operation 4–1MN735

Page 31

Display

when in the Parameter menu

when in the Setup menu

when displaying an Alarm code

a negative parameter value

Displays the units for the value:

S for time in seconds, A for current in Amps

V for voltage in Volts, % for percentage

Hz for frequency in Hertz

Represents a rotating motor shaft:

CW = forward rotation

CCW = reverse rotation.

Parameter numbers or values, trip information,

error codes etc. See Drive Status Indications.

Local mode.

(Remote mode when

hand is not visible.

Drive Status Indications (shown on keypad)

Display Status Indication and Meaning Possible Cause

READY/HEALTHY No alarms present.

Remote mode selected

PASSWORD Current password must

be entered before this parameter may

be altered.

LOCAL Local mode selected Added or removed from the display

Enter password to change the parameter.

(See password protection).

letter–by–letter to indicate entering or

leaving Local mode

Diagnostics Menu

Display Name Description

FREQUENCY The current output frequency in Hertz

SPEED SPT The set point as a percentage of MAX SPEED

DC LINK VOLTS VAC √2 = dc link Volts

Not Used

MTR CURRENT The current load value in Amps

4–2 Start–Up and Operation MN735

Page 32

Menu System There are three menu levels as shown in this diagram:

Menu Level 1 Menu Level 2 Parameter Level

Parameter Menu

Remote

Operation

Hold for

2 sec

Local Setpoint

SETUP MENU

Hold for

1 sec

Diagnostic Menu

Menu Level 3

Inputs Menu

Outputs Menu

Trips Menu

Miscellaneous Setup Menu

Start–Up and Operation 4–3MN735

Page 33

Power Up On initial power–up, the drive is in Local control mode and the keypad will

display the Local Setpoint.

.

All parameters are at factory settings. Any changes to these conditions are

automatically saved. The drive will initialize on subsequent power–ups with

the previously saved settings and control mode.

How to Change a Parameter Value

You can change the values of parameters stored in the and

menus. Refer to “Parameter Definitions” for further information.

• View the parameter to be edited and press

to display the

parameter’s value.

• Select the digit to be changed (pressing the

key moves the

cursor from right to left).

• Use the

keys to adjust the value. Hold the key momentarily

to adjust the value marginally, or hold the key to make rapid changes;

the rate of change varies with the time held.

• Press

to return to the parameter display. The new value is

stored.

Special Menu Features

Reset to Factory Settings (2 button Reset)

Turn power on while pressing the Y

and B keys. This loads or restores

the factory settings and application 1.

Select Local or Remote

Remote Control Mode: Allows control using digital and analog inputs and

outputs. Local control keys are inactive when Remote control mode is

selected. In remote mode, the control uses a remote setpoint (analog

Input 1).

Local Control Mode: Provides local control and monitoring of the drive

using the keypad. In local mode, the control uses the local setpoint

parameter (value is adjusted using the keypad).

Note: You can only change between Local and Remote control when the Inverter

is “stopped”, and either

or the Local Setpoint is displayed.

Remote to Local

Note: For safety reasons, the control will not return to Remote mode if this will

cause the drive to start. Verify that the RUN and JOG inputs are low.

HOLD

Then press

4–4 Start–Up and Operation MN735

Page 34

Hold this key down until

the display shows

REMOTE

Hold this key down until

the display spells

LOCAL

Password Protection

When activated, the password prevents unauthorized parameter

modification by making all parameters “read–only”. Password protection is

set–up using the

Steps ACTIVATE TEMPORARY DE-ACTIVATION REMOVE PASSWORD

Actions Display Actions Display Actions Display

1 Try to edit any

2

3 Original

4 A drive will power-up with the last

Default = 0000, de-activated

Any other value is a password

parameter.

parameter with

password activated

parameter

displayed,

password

de-activated

password status. Temporary

de-activation is lost on

power-down.

Quick Application Selection

Press and hold theStop key.

Power up the control.

Continue to hold the key for at least 1 second.

You can navigate immediately to the APPLICATION

parameter,

P

1, from this power–up condition.

Then, press the

Use the

keys to select the appropriate Application by number.

Press the

key to display the current Application.

key to load the Application.

Start–Up and Operation 4–5MN735

Page 35

Parameter Definitions You can program the Inverter for specific applications. The

Inverter is supplied with pre–programmed applications that can be used as

starting points for application–specific programming. Programming is simply

selecting an application, changing some of the parameter values and finally

saving the changes. Each application configures the terminal wiring for a

differently. The Inverter retains the new settings during power–down. The

next time the inverter is powered up, the new settings will be used.

Note: Motor parameters are not changed when a new application is loaded.

Table 4-1 Parameter Definitions

Display

Parameter Description Range Factory

Setting

APPLICATION Selects the applicaton to be used

MAX SPEED The frequency at which the control will run

MIN SPEED The minimum frequency at which the control will

ACCEL TIME The time taken for the control output frequency

DECEL TIME The time taken for the control output frequency

MOTOR

CURRENT

BASE

FREQUENCY

JOG

SETPOINT

RUN STOP

MODE

V/F SHAPE

Application 1: Keypad mode

Application 2: Standard Run 3-Wire

Application 3: 3 Speed 2-Wire

Application 4: EPOT 3-Wire

Application 5: EPOT 2-Wire

Application 6: PID 2-Wire

when maximum setpoint is applied

run.

to ramp up from zero to MAX SPEED

to ramp down from MAX SPEED to zero

This parameter contains the motor nameplate

full-load line current

The output frequency at which maximum

voltage is reached. The default is Product Code

dependent.

Speed the control will run at if the Jog input is

high

RAMP : The motor speed is reduced to zero at

a rate set by DECEL TIME (

pulse is applied at end of ramp

COAST : The motor is allowed to freewheel to a

standstill

INJECTION : On a stop command, the motor

volts are rapidly reduced at constant frequency

to deflux the motor. A low frequency braking

current is then applied until the motor speed is

almost zero. This is followed by a timed DC

pulse to hold the motor shaft.

OUTPUT VOLTS

00%

LINEAR

f

= BASE FREQUENCY

B

P

5). A 2 second

QUADRATIC LAW

f

B

CONSTANT

POWER RANGE

FREQUENCY

0= Application 0

1= Application 1

2= Application 2

3= Application 3

4= Application 4

5= Application 5

6= Application 6

1

7.5 to 240.0Hz 60.0Hz

-100.0 to 100.0% 0.0%

0.0 to 3000.0s 5.0s

0.0 to 3000.0s 5.0s

Product

code

dependent

Product

code

dependent

25.0 to 240.0Hz 60.0Hz

-100.0 to 100.0% 12.0%

0=RAMP

1=COAST

2=INJECTION

0=LINEAR

1=FAN

0

0

4–6 Start–Up and Operation MN735

Page 36

Table 4-1 Parameter Definitions Continued

Display Parameter Description Range Factory

Setting

NORMAL

DUTY

FIXED BOOST

PASSWORD A password may be set to prohibit

Parameters P301 to P308 are visible in the PAR menu when Application 3 is selected in parameter P1

PRESET 0 Preset 0 is normally connected to Setpoint. -100.00 to 100.00% -

PRESET 1 A user-adjustable speed preset -100.00 to 100.00% 20.00%

PRESET 2 A user-adjustable speed preset -100.00 to 100.00% 50.00%

PRESET 3 A user-adjustable speed preset -100.00 to 100.00% 100.00%

PRESET 4 A user-adjustable speed preset -100.00 to 100.00% -10.00%

PRESET 5 A user-adjustable speed preset -100.00 to 100.00% -20.00%

PRESET 6 A user-adjustable speed preset -100.00 to 100.00% -50.00%

PRESET 7 A user-adjustable speed preset -100.00 to 100.00% -100.00%

Parameters P401 to P404 are visible in the PAR menu when Application 4 is selected in parameter P1

R/L RAMP

TIME

R/L MAX

VALUE

R/L MIN VALUE The minimum value for the ramp output -100.0 to 100.0% 0.0%

R/L RESET

VALUE

HEAVY DUTY: the current limit is set to 150%

motor current, inverse time delay is set to 30s

NORMAL DUTY: the current limit is set to

110% motor current, inverse time delay is set

to 10s

P

When

11 is changed from FAN to LINEAR,

P

12 is set to 0 (Heavy Duty)

P

When

11 is changed from LINEAR to FAN,

P

12 is set to 1 (Normal Duty)

P

12 can be changed independently

OUTPUT VOLTS

100%

INCREASED

TORQUE

FLUXING

25%

0%

f

B

= BASE FREQUENCY

unauthorised adjustment of parameters. When

P

99 is set to non-zero you will be required to

match this value before parameters can be

adjusted

The time taken to ramp the Raise/Lower output

from 0.00% to 100.00% of its value

NORMAL FLUXING

INCREASING

BOOST

CONSTANT

POWER RANGE

f

B

FREQUENCY

0=False

1=True

0

0.00 to 25.00% 5.00%

0000 ć FFFF 0000

0.0 to 600.0s 10.0s

The maximum value for the ramp output -100.0 to 100.0% 100.0%

The value the output is set to when Reset is

TRUE, when DIN4 (terminal 10) is 24V in

Application 4

-100.00 to 100.00% 0.00%

Start–Up and Operation 4–7MN735

Page 37

Table 4-1 Parameter Definitions Continued

Display Parameter Description Range Factory

Setting

Parameters P501 and P502 are visible in the PAR menu when Application 5 is selected in parameter P1

PI P GAIN The PID P"roportional gain 0.00 to 100.00 1.00

PI I GAIN The PID I"ntegral gain 0.00 to 100.00 0.00

PID D GAIN ~

PID D FILTER

TC ~

PID FEEDBACK

GAIN ~

PID LIMIT ~

PID SCALING~An overall scale factor which is applied after the

PID ERROR~Error=(Setpoint-Feedback) x (Feedback Gain) x.xx % x.xx %

PID OUTPUT~The output of the PID function block x.xx % x.xx %

DIN 1 INVERT True =Inverts the input signal. 0= False

DIN 2 INVERT True =Inverts the input signal. 0= False

DIN 3 INVERT True =Inverts the input signal. 0= False

DIN 4 INVERT True =Inverts the input signal. 0= False

AIN 1 SCALE

The PID D"erivative gain 0.00 to 100.00 0.00

A first order lag filter to help attenuate high

frequency noise on the derivative term. This

parameter determines the filter time constant.

A multiplier applied to the PID feedback signal -10.00 to 10.00 1.00

Determines the maximum positive and negative

excursion (Limit) of the PID output

PID positive and negative limit clamps

SET::IN Menu

TYPE

SCALE

OFFSET

0.05 to 10.00s 0.05s

0.00 to 300.00% 0.00

-3.0000 to 3.0000 0.00

1= True

1= True

1= True

1= True

-150.0 to 150.0% 100.0%

0

0

0

0

UNPROCESSED

INPUT

0 to 100% of selected TYPE

AIN 1 OFFSET -100.0 to 100.0% 0.00%

AIN 1 TYPE 0= 0-10V

AIN 2 SCALE

AIN 2 OFFSET -100.0 to 100.0% 0.0%

AIN 2 TYPE 0= 0-10V

4–8 Start–Up and Operation MN735

TYPE

UNPROCESSED

INPUT

0 to 100% of selected TYPE

X

SCALE

X

OFFSET

+

+

VALUE

1= 0-5V

-150.0 to 150.0% 100.0%

VALUE

1= 0-5V

2= 0-20mA

3= 4-20mA

0

3

Page 38

Table 4-1 Parameter Definitions Continued

Display Parameter Description Range Factory

Setting

SET::IN Menu Continued

DIN 1 VALUE~The input signal after inversion (if any). 0= False

DIN 2 VALUE~The input signal after inversion (if any). 0= False

DIN 3 VALUE~The input signal after inversion (if any). 0= False

DIN 4 VALUE~The input signal after inversion (if any). 0= False

1= True

1= True

1= True

1= True

AIN 1 VALUE~The analog input signal with scaling and offset. x.x% x.x%

AIN 2 VALUE~The analog input signal with scaling and offset. x.x% x.x%

SET::OUT Menu

AOUT 1

SOURCE

AOUT 1 SCALE

ANALOG OUTPUT

0 NONE

1 DEMAND %

2 CURRENT %

3 PI ERROR %

4 RAISE/LOWER

OUTPUT%

SCALE

OFFSET

Scale

Offset

Absolute

ABS

0= NONE

1= DEMAND

2= CURRENT

3= PI ERROR

0–10V

4= RAISE/LOWER

OUTPUT

-300.0 to 300.0 100.0%

0

0

0

0

1

AOUT 1

OFFSET

AOUT 1

ABSOLUTE

AOUT 1 VALUE

~

DOUT 2

SOURCE

DOUT 2

INVERT

DOUT 2

VALUE ~

RELAY

SOURCE

Value

X

DIN4 / DOUT2

0 NONE

1 HEALTH

2 TRIPPED

3 RUNNING

4 AT ZERO

5 AT SPEED

6 AT LOAD

+

Invert

Output

X

(OUTPUT) As SIP01. Set to 0 for applications

1 & 5.

The output signal that represents the OP21

choice.

RELAY

0 NONE

1 HEALTH

2 TRIPPED

3 RUNNING

4 AT ZERO

5 AT SPEED

6 AT LOAD

Invert

Output

Output

-300.0 to 300.0% 0.00%

0= False

1= True

-300.0 to 300.0% 0.0%

0= NONE (DIN4)

1= HEALTH

2= TRIPPED

3= RUNNING

4= AT ZERO

5= AT SPEED

6= AT LOAD

As SIP01 0

0= False

1= True

0= NONE

1= HEALTH

2= TRIPPED

3= RUNNING

4= AT ZERO

5= AT SPEED

6= AT LOAD

Start–Up and Operation 4–9MN735

0

0

0

2

Page 39

Table 4-1 Parameter Definitions Continued

Display Parameter Description Range Factory

Setting

RELAY INVERT True =Inverts the input signal. 0= False

RELAY VALUE~The output signal that represents the OP31

choice.

1= True

0= False

1= True

SET::TRIP Menu

DISABLE LOOP Disables LOST I LOOP trip (4-20mA) 0= Trip Enabled

AIN2

OVERLOAD

DISABLE

STALL

DISABLE

MOTOR

OVERTEMP

Disables the overload trip (Terminal 3) 0= Trip Enabled

Disables STALL trip 0= Trip Enabled

Disables the motor thermistor trip 0= Trip Enabled

1= Trip Disabled

1= Trip Disabled

1= Trip Disabled

1= Trip Disabled

SET::SETP Menu

Inverse Time Disables the inverse time trip 0= Trip Enabled

Display

(Keypad)

Disables the display (keypad) trip 0= Trip Enabled

1= Trip Disabled

1= Trip Disabled

Jog Accel Time As P4, for Jog 0.0 to 3000.0s 1.0

Jog Decel Time As P5, for Jog 0.0 to 3000.0s 1.0

Ramp Type Selects the ramp type 0=LINEAR

S Ramp Jerk Rate of change of acceleration of the curve in

S Ramp

Continuous

Skip

Frequency 1

Skip Frequency

Band 1

Skip

Frequency 2

Skip Frequency

Band 2

Auto Restart

Attempts

Auto Restart

Delay

Auto Restart

Triggers

units per second

When True and the S Ramp is selected, forces

a smooth transition if the speed setpoint is

changed when ramping. The curve is controlled

by the S Ramp Jerk parameter.

When False, there is an immediate transition

from the old curve to the new curve

The center frequency of skip band 1 in Hz 0.0 to 240.0 Hz 0.0

The width of skip band 1 in Hz 0.0 to 60.0 Hz 0.0

The center frequency of skip band 2 in Hz 0.0 to 240.0 Hz 0.0

The width of skip band 2 in Hz 0.0 to 60.0 Hz 0.0

Determines the number of restarts that will be

permitted before requiring an external fault

reset

The delay between restart attempts for a trip

included in Auto Restart Triggers and Auto

Restart Triggers+. The delay is measured from

all error conditions clearing

Allows Auto Restart to be enabled for a

selection of trip conditions. Refer to Section 5

3

1=S

0.01 to 100.00s

0=FALSE

1=TRUE

0 to 10 0

0.0 to 600.0 s 10.0s

0x0000 to 0xFFFF 0x0000

0

0

1

0

0

0

1

0

0

3

10.00s

1

3

4–10 Start–Up and Operation MN735

Page 40

Table 4-1 Parameter Definitions Continued

Display Parameter Description Range Factory

Setting

Auto Restart

Triggers+

Local MIN

Speed ~

Enabled Keys

~

Application Lock~True prevents editing of parameter P1. 0=FALSE

Detailed Menus True allows Full menu display.

Allows Auto Restart to be enabled for a

selection of trip conditions. Refer to Section 5

The magnitude of the minimum setpoint that will 0.0 to 100.0 % 0.0%

False hides parameters indicated with ~

0x0000 to 0xFFFF 0x0000

0

1=TRUE

0=FALSE

1=TRUE

0

0

Start–Up and Operation 4–11MN735

Page 41

PI Terms PI is used to control the response of any closed loop system. It is

used specifically in system applications involving the control of drives to

provide zero steady state error between Setpoint and Feedback, together

with good transient performance.

P

Proportional Gain (

501)

This is used to adjust the basic response of the closed loop control system.

The PI error is multiplied by the Proportional Gain to produce an output.

Integral (

P

502)

The Integral term is used to reduce steady state error between the setpoint

and feedback values of the PI. If the integral is set to zero, then there will

always be a steady state error.

P Gain

Error

Setpoint

(AIN1)

Feedback

(AIN2)

+

–

I Gain dt

+

+

Output

S Functions as P, PI controller

S Single symmetric limit on output

A Method for Setting–up the PI Gains

Underdamped (oscillatory)

Critically Damped

OUTPUT

SETPOINT

4–12 Start–Up and Operation MN735

Overdamped

Page 42

The gains should be set–up so that a critically damped response is

achieved for a step change in setpoint. An underdamped or oscillatory

system can be thought of as having too much gain, and an overdamped

system has too little.

To set up the P gain, set the I gain to zero. Apply a step change in setpoint

that is typical for the System, and observe the response. Increase the gain

and repeat the test until the system becomes oscillatory. At this point,

reduce the P gain until the oscillations disappear. This is the maximum

value of P gain achievable.

If a steady state error is present, i.e. the feedback never reaches the

setpoint value, the I gain needs to be increased. As before, increase the I

gain and apply the step change. Monitor the output. If the output becomes

oscillatory, reduce the P gain slightly. This should reduce the steady state

error. Increasing the I gain further may reduce the time to achieve zero

steady state error.

These values of P and I can now be adjusted to provide the exact response

required for this step change.

Product Related Parameter Values

Frequency Dependent Parameters

50Hz default 60Hz default

MAX SPEED 50 60

BASE FREQUENCY 50 60

Power Dependent Parameters

Inverter Size Factory

MOTOR

CURRENT

Size 1 : 0.25kw 230V

Size 1 : 0.37kw 230V

Size 1 : 0.55kw 230V

Size 1 : 0.75kw 230V

Size 2 : 1.1kw 230V

Size 2 : 1.5kw 230V

Size 2 : 1.5kw 460V

Size 2 : 2.0kw 460V

Size 2 : 2.5kw 460V

Size 2 : 3.5kw 460V

Size 2 : 4.5kw 460V

Size 2 : 5.5kw 460V

Size 3 : 6.8kw 460V

Size 3 : 9.0kw 460V

Size 3 : 12.0kw 460V

Size 3 : 16.0kw 460V

Setting

1.5A

2.2A

3.0A

4.0A

5.5A

7.0A

1.5A

2.0A

2.5A

3.5A

4.5A

5.5A

6.8A

9.0A

12.0A

16.0A

Start–Up and Operation 4–13MN735

Page 43

Routine Maintenance

Periodically inspect the Inverter for build–up of dust or obstructions that

may affect cooling. Remove any build–up using dry air .

Saving Your Application Data

In the event of a repair, application data will be saved whenever possible.

However, you should record your application settings before returning the

unit. You should actually record the settings after programming. When a

failure occurs, you may not be able to access the parameter values.

Contact Baldor to arrange for the repair.

Disposal This product contains materials which are consignable waste under the

Special Waste Regulations 1996 which complies with the EC Hazardous

Waste Directive – Directive 91/689/EEC. We recommend you dispose of

the appropriate materials in accordance with the valid environmental control

laws. The following table shows which materials can be recycled and which

have to be disposed of in a special way.

Material

Recycle Disposal

metal yes no

plastic materials yes no

printed circuit board no yes

The printed circuit board should be disposed of in one of two ways:

1. High temperature incineration (minimum temperature 1200_C) by an

incinerator authorized under parts A or B of the Environmental

Protection Act.

2. Disposal in an engineered land fill site that is licensed to take

aluminium electrolytic capacitors. Do not dispose of in a land fill site

set aside for domestic waste.

Packaging

During transport our products are protected by suitable packaging. This is

entirely environmentally compatible and should be taken for central

disposal as secondary raw material.

4–14 Start–Up and Operation MN735

Page 44

Section 5

Troubleshooting

Trips The trip display message is briefly displayed repeatedly (flashing) on the

screen to warn of an imminent trip. Some trip conditions need time to take

effect. The warning can allow you time to resolve the situation. The

message will clear when you use the keypad, but after a short time will

reappear until the problem is resolved, or the drive trips.