Page 1

DSM S--Series

Integrated Stepper Motor / Driver

Installation Manual

04/07 MN1940

Page 2

Page 3

Contents

1 General Information 1-1.................................

2 Introduction 2-1........................................

2.1 DSM S-Series integrated motor and driver 2-1.................

2.1.1 Option availability 2-2..............................................

2.2 Receiving and inspection 2-3................................

2.2.1 Identifying the catalog number 2-3....................................

2.3 Units and abbreviations 2-4..................................

3 Basic Installation 3-1....................................

3.1 Introduction 3-1............................................

3.1.1 Location requirements 3-1..........................................

3.1.2 Mounting the DSM 3-2.............................................

3.1.3 Other requirements for installation 3-6................................

4 Input / Output 4-1......................................

4.1 Introduction 4-1............................................

4.1.1 Basic connections 4-1..............................................

4.2 Motor power input 4-2.......................................

4.2.1 Wire sizes 4-3....................................................

4.3 Logic inputs 4-4............................................

4.3.1 Logic input descriptions 4-4.........................................

4.3.2 Input timing 4-5...................................................

4.3.3 Sinking / sourcing input configuration 4-6..............................

4.4 SPI interface 4-8...........................................

4.4.1 SPI connector 4-8.................................................

4.4.2 SPI signal descriptions 4-9..........................................

4.5 Connection summary - minimum system wiring 4-10.............

5 Operation 5-1..........................................

5.1 Introduction 5-1............................................

5.1.1 Connecting the DSM to the PC 5-1...................................

5.1.2 Installing the USB driver 5-1.........................................

5.1.3 Installing the virtual COM port driver 5-1...............................

5.1.4 Determining the virtual COM port number 5-2..........................

5.1.5 Installing Baldor SPI Interface 5-2....................................

5.1.6 Starting the controller and DSM 5-3...................................

MN1940

Contents i

Page 4

5.2 Baldor SPI Interface 5-4.....................................

5.2.1 Starting Baldor SPI Interface 5-4.....................................

5.2.2 Configuration parameters 5-4........................................

6 Troubleshooting 6-1....................................

6.1 Introduction 6-1............................................

6.1.1 Problem diagnosis 6-1..............................................

6.1.2 Further support 6-1................................................

6.1.3 Communication problems 6-1........................................

6.1.4 Motor control problems 6-2..........................................

7 Specifications 7-1......................................

7.1 Introduction 7-1............................................

7.1.1 Input power 7-1...................................................

7.1.2 Motor speed & torque - DSMS17 7-2.................................

7.1.3 Motor speed & torque - DSMS23 7-4.................................

7.1.4 Motor speed & torque - DSMS34 7-6.................................

7.1.5 Digital inputs 7-9..................................................

ii Contents

MN1940

Page 5

AustralianBaldorPtyLt

d

1 General Information

LT0227A02 Copyright Baldor (c) 2007. All rights reserved.

This manual is copyrighted and all rights are reserved. This document or attached software may not,

in whole or in part, be copied or reproduced in any form without the prior written consent of BALDOR.

BALDOR makes no representations or warranties with respect to the contents hereof and specifically

disclaims any implied warranties of fitness for any particular purpose. The information in this

document is subject to change without notice.

BALDOR assumes no responsibility for any errors that may appear in this document.

Mintt is a registered trademark of Baldor.

Windows 95, Windows 98, Windows ME, Windows NT , Windows 2000 and Windows XP are

registered trademarks of the Microsoft Corporation.

Limited Warranty:

For a period of two (2) years from the date of original purchase, BALDOR will repair or replace without

charge controls and accessories which our examination proves to be defective in material or

workmanship. This warranty is valid if the unit has not been tampered with by unauthorized persons,

misused, abused, or improperly installed and has been used in accordance with the instructions and/or

ratings supplied. This warranty is in lieu of any other warranty or guarantee expressed or implied.

BALDOR shall not be held responsible for any expense (including installation and removal),

inconvenience, or consequential damage, including injury to any person or property caused by items of

our manufacture or sale. (Some countries and U.S. states do not allow exclusion or limitation of

incidental or consequential damages, so the above exclusion may not apply.) In any event,

BALDOR’s total liability, under all circumstances, shall not exceed the full purchase price of the

control. Claims for purchase price refunds, repairs, or replacements must be referred to BALDOR with

all pertinent data as to the defect, the date purchased, the task performed by the control, and the

problem encountered. No liability is assumed for expendable items such as fuses. Goods may be

returned only with written notification including a BALDOR Return Authorization Number and any

return shipments must be prepaid.

Baldor UK Ltd

Mint Motion Centre

6 Bristol Distribution Park

Hawkley Drive

Bristol, BS32 0BF

Telephone: +44 (0) 1454 850000

Fax: +44 (0) 1454 850001

Email: technical.support@baldor.co.uk

Web site: www.baldor.co.uk

Baldor Electric Company

Telephone: +1 479 646 4711

Fax: +1 479 648 5792

Email: sales@baldor.com

Web site: www.baldor.com

Baldor ASR GmbH

Telephone: +49 (0) 89 90508-0

Fax: +49 (0) 89 90508-491

Baldor ASR AG

Telephone: +41 (0) 52 647 4700

Fax: +41 (0) 52 659 2394

Email: technical.support@baldor.ch

Australian Baldor Pty Ltd

Telephone: +61 2 9674 5455

Fax: +61 2 9674 2495

Baldor Electric (F.E.) Pte Ltd

Telephone: +65 744 2572

Fax: +65 747 1708

www.baldormotion.com

1

Baldor Italia S.R.L

Telephone: +39 (0) 11 56 24 440

Fax: +39 (0) 11 56 25 660

General Information 1-1MN1940

Page 6

www.baldormotion.com

Safety Notice

Only qualified personnel should attempt the start-up procedure or troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts or parts that are

controlled by this equipment. Improper use can cause serious or fatal injury.

Precautions

Do not touch any circuit board, power device or electrical connection before you first

ensure that no high voltage is present at this equipment or other equipment to which it is

WARNING

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

NOTICE

NOTICE

NOTICE

NOTICE

connected. Electrical shock can cause serious or fatal injury. Only qualified personnel

should attempt to start-up, program or troubleshoot this equipment.

Be sure that you are completely familiar with the safe operation and programming of this

equipment. This equipment may be connected to other machines that have rotating parts

or parts that are controlled by this equipment. Improper use can cause serious or fatal

injury.

The stop input to this equipment should not be used as the single means of achieving a

safety critical stop. Drive disable, motor disconnect, motor brake and other means should

be used as appropriate.

Improper operation or programming may cause violent motion of the motor shaft and

driven equipment. Be certain that unexpected motor shaft movement will not cause injury

to personnel or damage to equipment.

Be sure all wiring complies with the National Electrical Code and all regional and local

codes. Improper wiring may result in unsafe conditions.

The DSM has components which are sensitive to Electrostatic Discharge (ESD). All

handling should be done at an ESD protected workstation.

To prevent equipment damage, be certain that input and output signals are powered and

referenced correctly.

To ensure reliable performance of this equipment be certain that all signals to/from the DSM

are shielded correctly.

Avoid locating the DSM immediately above or beside heat generating equipment, or directly

below water steam pipes.

Avoid locating the DSM in the vicinity of corrosive substances or vapors, metal particles and

dust.

1-2 General Information MN1940

Page 7

www.baldormotion.com

2 Introduction

2.1 DSM S-Series integrated motor and driver

The DSM S-Series high-torque integrated motor and driver is ideal for designers who want the

simplicity of a motor with on-board electronics. The DSM allows the system designer to decide

the best method of control. The drive’s integrated electronics eliminates the need to run the

motor cabling through the machine, reducing the potential for problems due to electrical noise.

The DSM is a small, powerful and inexpensive solution that will reduce system cost, design

and assembly time for a large range of stepping motor applications.

The DSM family use a NEMA17, NEMA23 or NEMA34 1.8° high torque motor combined with a

microstepping drive, and accept up to 14 resolution settings from 1/2 to 256 microsteps per

step. Setup parameters can be changed ‘on-the-fly’ or downloaded and stored in non-volatile

memory with the use of a simple user interface program which is provided, eliminating the

need for external switches or resistors. The versatile, compact DSM is available in multiple

configurations to fit various system needs.

2

Features include:

H Integrated microstepping drive/NEMA high torque motor.

H Available in various stack lengths from 13 to 47 (model dependent).

H +12 to +75 VDC input voltage (+12 to +48 VDC on DSMS17).

H Optically isolated +5 to +24 VDC inputs, sourcing or sinking.

H Automatic current reduction.

H Automatic communication configuration.

H Rear knob for manual positioning (option M).

H Interfacing by 30 cm (12 in) flying leads (optional 7-pin terminal block on DSMS17/23).

H Graphical User Interface (GUI) for easy parameter setup.

H Extremely compact.

Introduction 2-1MN1940

Page 8

www.baldormotion.com

fly

inglead

r

t

rol

knob

A “Baldor Motion Toolkit CD” is available. This contains the Baldor SPI Interface software,

used for communicating and configuring the DSM.

This manual is intended to guide you through the installation of the DSM. The chapters should

be read in sequence.

The Basic Installation section describes the mechanical installation of the DSM.

The following sections require knowledge of the low level input/output requirements of the

device that will control the DSM, and an understanding of computer software installation. If you

are not qualified in these areas you should seek assistance before proceeding.

Note: You can check that you have the latest releases by visiting the website

www.baldormotion.com/supportme.

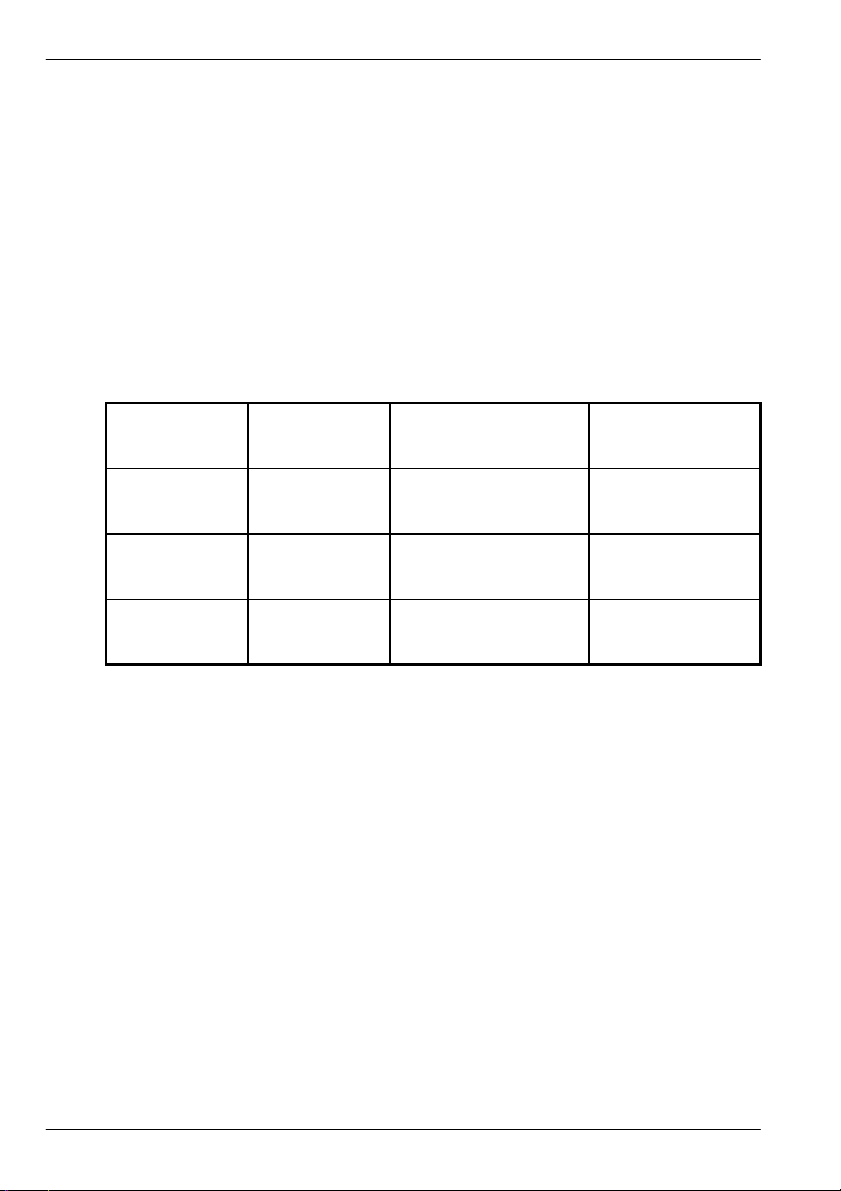

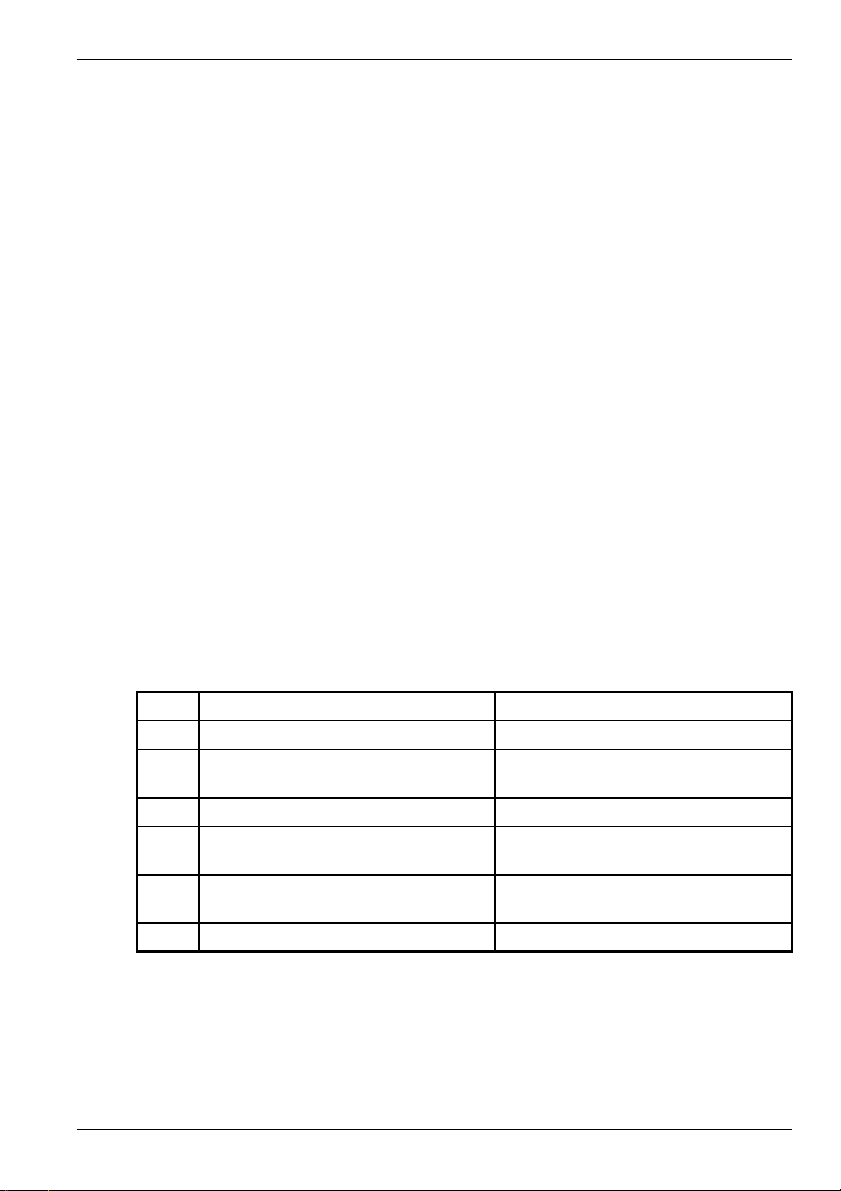

2.1.1 Option availability

Model

DSMS

17

DSMS

23

DSMS

34

‘F’

option

Yes

All models

Yes

All models

Yes

All models

s

‘P’

connecto

option

Yes

All

models

Yes

All

models

No Yes

‘M’

con

option

Yes

All

models

Yes

All

models

All

models

2-2 Introduction MN1940

Page 9

www.baldormotion.com

2.2 Receiving and inspection

When you receive your DSM, there are several things you should do immediately:

1. Check the condition of the packaging and report any damage immediately to the carrier

that delivered your DSM.

2. Remove the DSM from the shipping container and remove all packing material. The container

and packing materials may be retained for future shipment.

3. Verify that the catalog number of the DSM you received is the same as the catalog

number listed on your purchase order. The catalog/part number is described in the next

section.

4. Inspect the DSM for external damage during shipment and report any damage to the

carrier that delivered it.

5. If the DSM is to be stored for several weeks before use, be sure that it is stored in a

location that conforms to the storage humidity and temperature specifications shown in

section 3.1.1.

2.2.1 Identifying the catalog number

Different models of DSM are available. As a reminder of which product has been installed, it is

a good idea to write the catalog number in the space provided below.

DSM catalog number:

Installed in: ________________________

A description of a catalog number is shown here, using the example DSMS34F-3B-M:

Meaning Alternatives

DSMS DSM S-series family -

34 NEMA 34 frame size

F Flying lead connections P=7-pin terminal block

3 Large stack size

Supply voltage 12 - 75 VDC

B

(DSMS23 / DSMS34 only)

M (Optional) Manual control knob -

DSMS______-______-__

Date: ______

17=NEMA 17;

23=NEMA 23

1=Small stack size;

2=Medium stack size

A=Supply voltage 12 - 48 VDC

Introduction 2-3MN1940

Page 10

2.3 Units and abbreviations

The following units and abbreviations may appear in this manual:

V Volt (also VAC and VDC)...............

WWatt..............

A Ampere...............

Ω Ohm...............

mΩ milliohm.............

μF microfarad..............

pF picofarad..............

mH millihenry.............

Φ phase...............

ms millisecond..............

μs microsecond..............

ns nanosecond..............

mm millimeter.............

m meter...............

in inch...............

ft feet...............

lb·in pound inch (torque).............

N·m Newton meter (torque).............

ADC Analog to Digital Converter............

ASCII American Standard Code for Information Interchange...........

AWG American Wire Gauge............

CDROM Compact Disc Read Only Memory.........

CTRL+E on the PC keyboard, press Ctrl then E at the same time..........

DAC Digital to Analog Converter............

EMC Electromagnetic Compatibility............

HMI Human Machine Interface.............

ISO International Standards Organization.............

Kbaud kilobaud (the same as Kbit/s in most applications)...........

MB megabytes.............

Mbps megabits/s...........

(NC) Not Connected............

NEMA National Electrical Manufacturers Association...........

RF Radio Frequency..............

SPI Serial Peripheral Interface.............

www.baldormotion.com

2-4 Introduction MN1940

Page 11

3 Basic Installation

3.1 Introduction

You should read all the sections in Basic Installation.

It is important that the correct steps are followed when installing the DSM.

This section describes the mechanical installation of the DSM.

3.1.1 Location requirements

Ensure you have read and understood the warnings and cautions in section 1.

The safe operation of this equipment depends upon its use in the appropriate environment.

The following points must be considered:

H The DSM is designed to be mounted indoors, permanently fixed and located.

H The DSM must be secured by the holes in the faceplate.

Because the DSM consists of two core components, a drive and a motor, attention must be

paid to the thermal specifications of both the motor and the electronics. The following

maximum temperatures apply to the DSM:

H The DSM heat sink temperature must not exceed 85 °C (185 °F).

H The DSM motor temperature must not exceed 100 °C (212 °F).

www.baldormotion.com

3

Basic Installation 3-1MN1940

Page 12

3.1.2 Mounting the DSM

Ensure you have read and understood the location requirements in section 3.1.1. Mount the

DSM by the four holes in the faceplate. M5 bolts or screws are recommended.

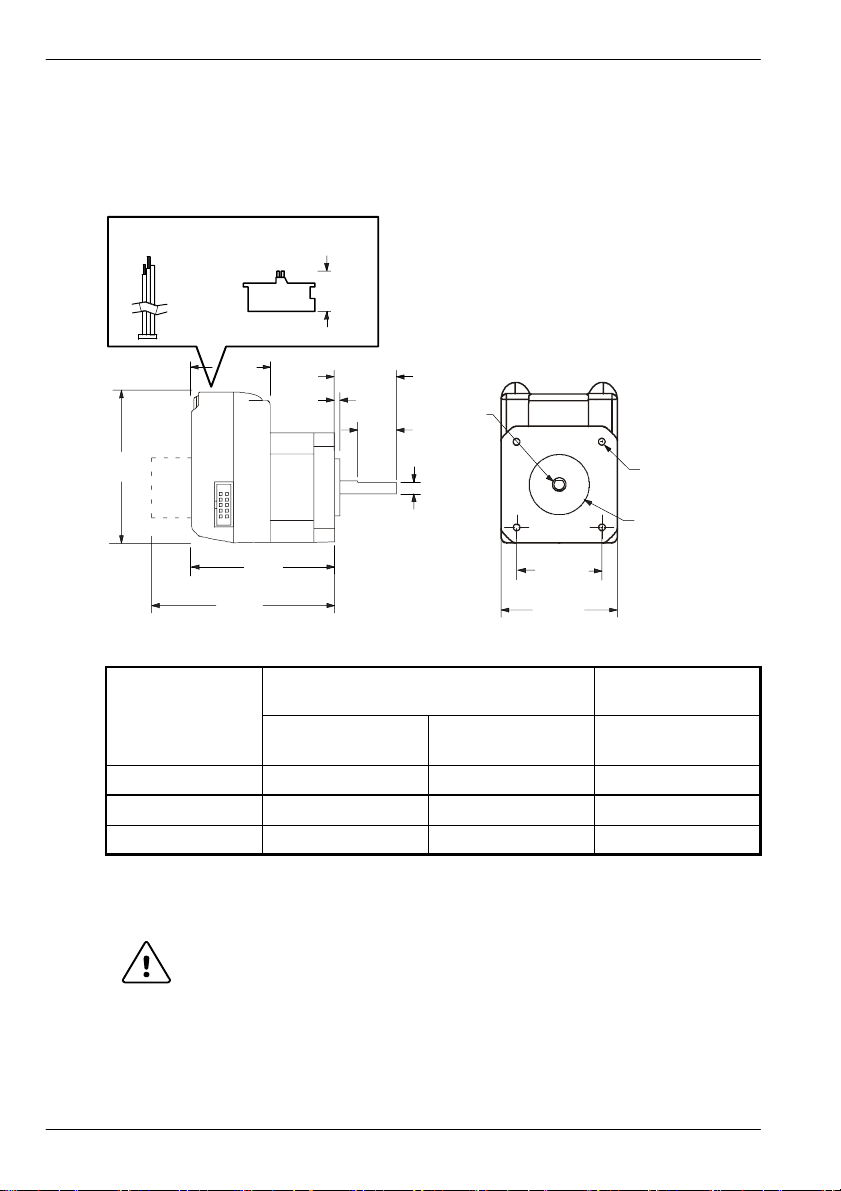

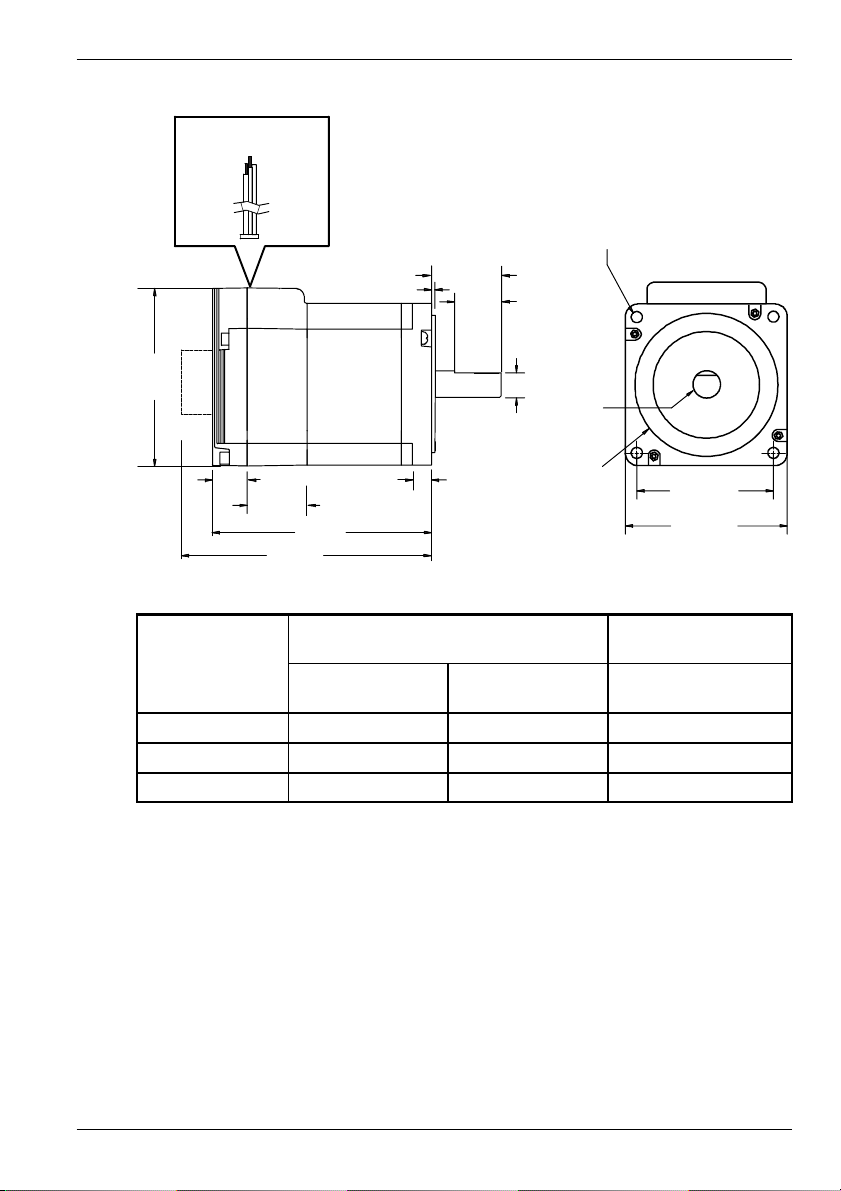

3.1.2.1 Dimensions - DSMS17

www.baldormotion.com

Flying leads

305 (12)

58.3

(2.3)

DSM

Model

‘P’ connector option

30.2

(1.19)

P1

P2

L

MAX

L

MAX2

11. 2 (0.44)

2

(0.08)

L

MAX

24

(0.94)

15

(0.59)

4.5

(0.18)

Dimensions

(mm / inches)

(with control knob)

Ø5

(0.2)

L

MAX2

All dimensions shown as

mm (inches)

31 (1.22)

Square

42.7 (1.68)

Square

4xØM3x0.5 thread

x 3.8 (0.15) deep

Ø22 (0.87)

Weight

DSMS17x-1A 55.9 (2.20) 70.9 (2.79) 277.8 (9.8)

DSMS17x-2A 61.7 (2.43) 76.7 (3.02) 297.7 (10.5)

DSMS17x-3A 70.4 (2.77) 85.6 (3.37) 428.1 (15.1)

g/oz

Figure 1 - Package dimensions - DSMS17

Use care when installing the mounting screws on all DSMS17 models. The

mounting holes on the flange are not drilled through, so the maximum length for

CAUTION

screw threads into the motor flange is 3.5 mm (0.14 in). See Figure 2. The

maximum torque for the M3x0.5 screw is 9 kg·cm (7.8 lb-in).

3-2 Basic Installation MN1940

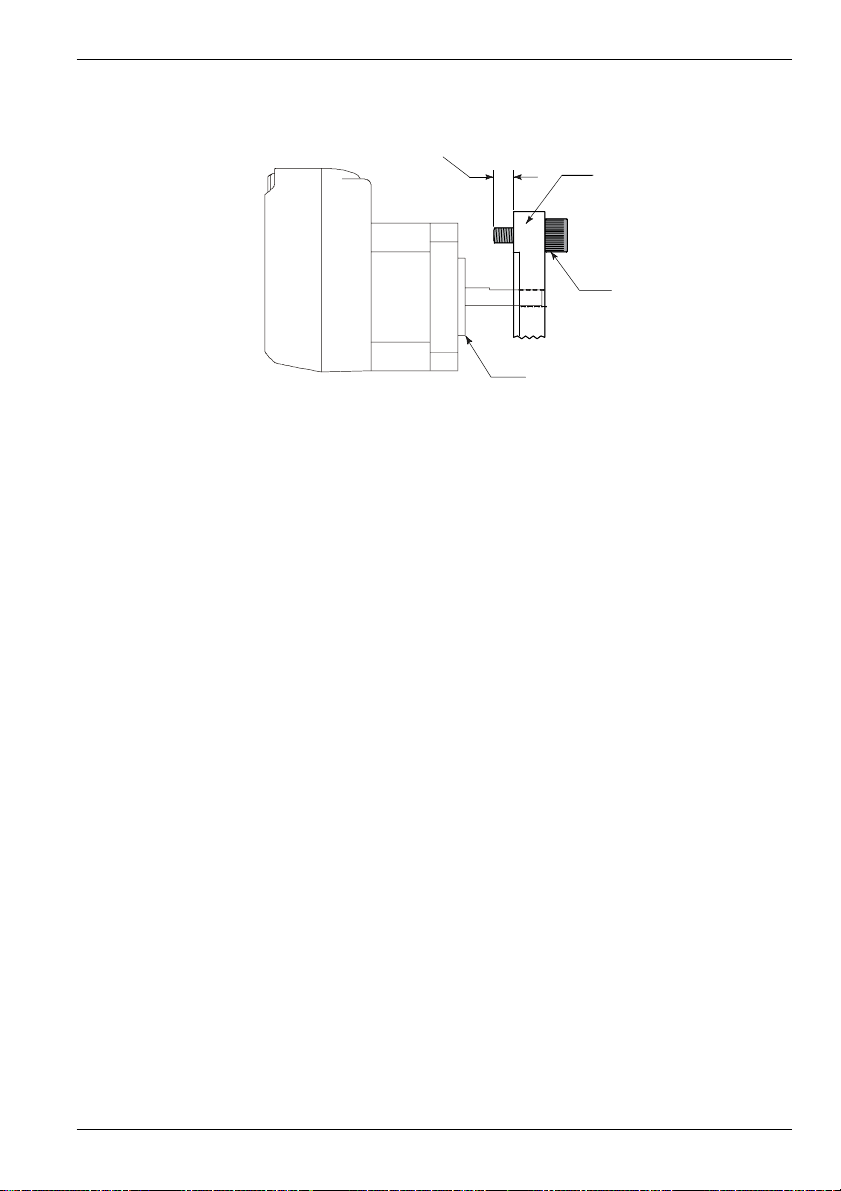

Page 13

Maximum length of

screw threads into

the motor housing is

3.5 mm (0.14 in)

DSMS17

Figure 2 - Screw thread limitation - DSMS17

www.baldormotion.com

Customer’s

mounting flange

M3 x 0.5 screw

Basic Installation 3-3MN1940

Page 14

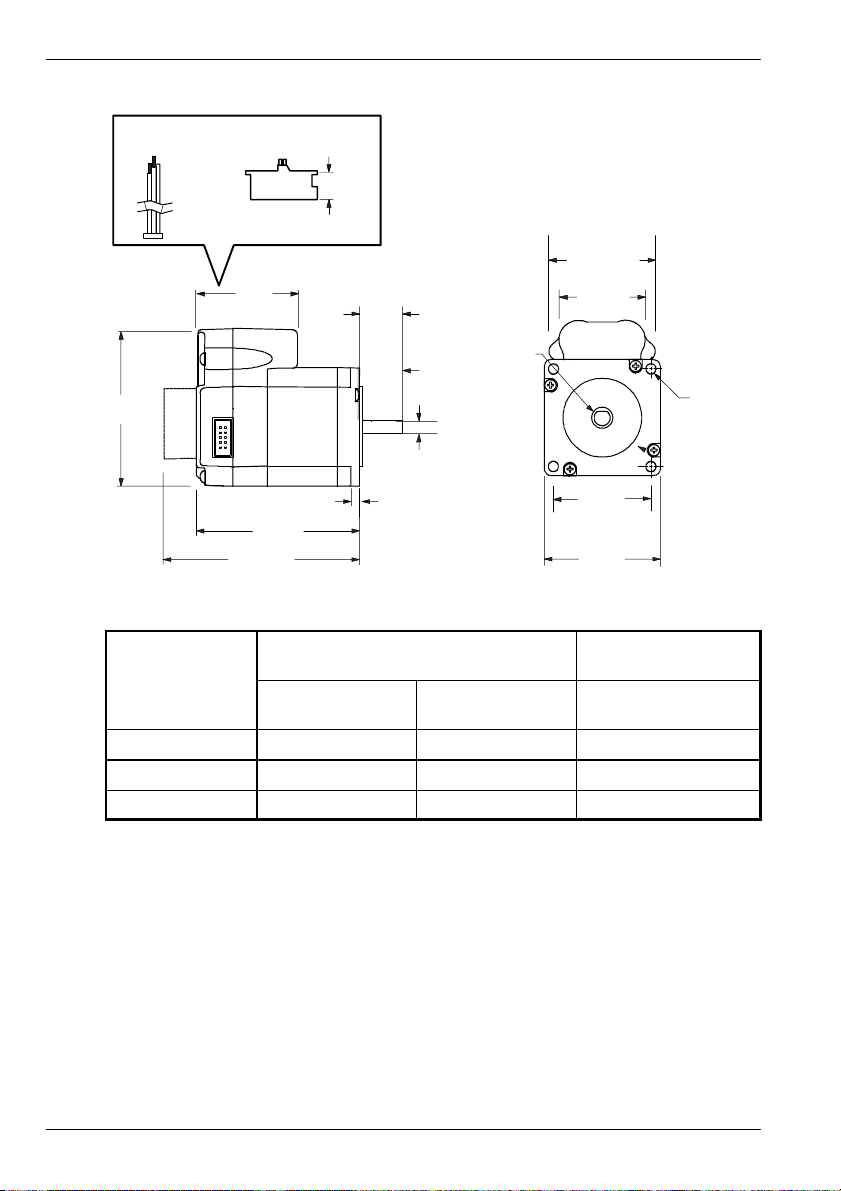

3.1.2.2 Dimensions - DSMS23

Flying leads

305 (12)

75.2

(2.96)

‘P’ connector option

48.3

(1.9)

P1

P2

L

MAX2

L

MAX

11. 2 (0.44)

4.9

(0.19)

(0.81)

(0.59)

5.8

(0.23)

20.6

15

All dimensions shown as

mm (inches)

51.2

(2.02)

41.4

(1.63)

Ø6.35

(0.25)

47.14

(1.86)

Square

56.4

(2.22)

Square

www.baldormotion.com

4xØ5 (0.2)

DSMS

Model

L

MAX

Dimensions

(mm / inches)

(with control knob)

L

MAX2

Weight

kg / lb

DSMS23x-1B 67.31 (2.65) 85.34 (3.36) 0.61 (1.35)

DSMS23x-2B 76.71 (3.02) 94.74 (3.73) 0.75 (1.65)

DSMS23x-3B 98.55 (3.88) 116.6 (4.59) 1.11 (2.45)

Figure 3 - Package dimensions - DSMS23

3-4 Basic Installation MN1940

Page 15

3.1.2.3 Dimensions - DSMS34

Flying leads

305 (12)

www.baldormotion.com

4xØ5.5 (0.22)

37 (1.46)

25 (0.98)

13 (0.51)

Ø14

(0.55)

Ø73

(2.87)

L

MAX2

(with control knob)

94.7

(3.73)

Motor

Stack

18.6 (0.73)

L

MAX

L

MAX2

2 (0.08)

31.8 (1.25)

All dimensions shown as

Dimensions

(mm / inches)

L

MAX

10 (0.39)

mm (inches)

DSMS34F-1B 94.2 (3.71) 112.3 (4.42) 1.9 (4.19)

DSMS34F-2B 114.3 (4.50) 132.3 (5.21) 2.5 (5.5)

DSMS34F-3B 154.2 (6.07) 172.2 (6.78) 4.0 (8.8)

Figure 4 - Package dimensions - DSMS34

69.6 (2.74)

86.1 (3.39)

Weight

kg / lb

3.1.2.4 Securing DSM cables

Some applications may require that the DSM moves with the axis motion. If this is a

requirement of your application, the motor leads must be properly anchored. Secure the flying

leads to the motor body using adhesive cable clamps. This will prevent flexing and tugging

which can cause damage at critical connection points in the DSM electronics.

Do not bundle the logic leads together with the DSM power leads.

Basic Installation 3-5MN1940

Page 16

www.baldormotion.com

3.1.3 Other requirements for installation

H The DSM requires a power supply as described in section 4.2.

H A PC that fulfills the following specification:

Minimum specification Recommended specification

Processor Intel Pentium 133 MHz Intel PentiumII 400 MHz or faster

RAM 32MB 128 MB

Hard disk space 40 MB 60 MB

CD-ROM ACD-ROMdrive

USB port USB port

Screen 800 x 600, 256 colors 1024 x 768, 16-bit color

Mouse A mouse or similar pointing device

Operating

system

H A USB-SPI cable (connected as shown in section 4.4.1). Part CBL055-501 is recommended.

H Your PC operating system user manual might be useful if you are not familiar with Windows.

Windows 95, Windows NT Windows 98, Windows ME,

Windows NT, Windows 2000 SP1

or Windows XP

3-6 Basic Installation MN1940

Page 17

4 Input / Output

www.baldormotion.com

4.1 Introduction

This section describes the input and output connections of the DSM.

Logic level cables must not run parallel to power cables. Power cables will introduce noise into

the logic level cables and make the system unreliable. Logic level cables must be shielded to

reduce the chance of induced noise. The shield needs to be grounded at the signal source to

AC ground; the other end of the shield must not be connected. This allows the shield to act as

adrain.

Do not connect or disconnect any wiring when power is applied! Disconnect the

AC power side to power down the DC power supply. For battery operated

CAUTION

4.1.1 Basic connections

Flying

leads

systems, connect a transient suppressor across the power switch to prevent arcs

and high voltage spikes.

Color Description Pin

White +5 VDC Optocoupler reference 1..

(NC)

Orange Step Cloc k input 3..... ........

Blue CW/CCW Direction input 4... ....

Brown Enable/Disable input 5.... ......

Black Motor power GND 6..... .......

Red Motor power 7......... ..........

(12-48 VDC or 12-75 VDC)

4

‘P’ connector

Models with ‘P’

connector option

(DSMS17P... /

DSMS23P... only)

SPI interface

(NC)

1

3

(NC)

5

GND +5 V Out

Master Out /

Slave In

(NC)

7

9

2

(NC)

Chip Select

4

6

8

Clock

Master In /

10

Slave Out

Figure 5 - Basic connection summary

Input / Output 4-1MN1940

Page 18

4.2 Motor power input

The DSM requires an unregulated DC power supply. The power supply current will depend

upon voltage and load, but will not exceed 2 A (DSMS17 / DSMS23) or 4 A (DSMS34).

www.baldormotion.com

Location

Input voltage

Flying leads (red and black), ‘P’ connector

+12 to +48 VDC (DSMS17)

range

+12 to +75 VDC (DSMS23, DSMS34)

Volta ge ripple ±10%

Input current 2 A maximum (DSMS17 / DSMS23)

4 A maximum (DSMS34)

The maximum input voltage of the DSM includes motor back EMF, power supply

ripple and high line.

CAUTION

A characteristic of all motors is back EMF. Back EMF is a source of current that can push the

output of a power supply beyond the maximum operating voltage of the driver. As a result,

damage to the stepper driver could occur over a period of time. Care should be taken so that

the back EMF does not exceed the maximum input voltage rating of the DSM.

Cable length, wire gauge and power conditioning devices play a major role in the performance

of the DSM. The length of the DC power supply cable to a DSM should not exceed 15 m

(50 ft). If cabling of 15 m (50 ft) or longer is required, the additional length may be gained by

adding an AC power supply cable (see Figures 6 and 7). Power supply leads to the DSM need

to be twisted. If more than one DSM is to be connected to the same power supply, run

separate power and ground leads from the supply to each driver.

From

DC S uppl y

+24 V

0V

500 μF

per

Amp

Cable length up to 15 m

Shielded

twisted

pair

Connect shield to

earth ground at

supply end onl y

Ferrite

sleeve

Pi type

RFI filter

flying lead

+

-

flying lead

To

DSM

Red

Black

Figure 6 - Power supply connections, cable length less than 15 m

From

AC

Supply

Transformer:

0-28VACRMSfor

48 VDC systems.

20 - 48 VAC RMS for

75 VDC systems

Full wave

bridge

rectifier

Pi type

RFI filter

500 μF

per

Amp

Cable length up to 15 m

Shielded

twisted

pair

Connect shield to

earth ground at

supply end onl y

Ferrite

sleeve

Pi type

RFI filter

flying lead

+

-

flying lead

To

DSM

Red

Black

Figure 7 - Power supply connections, cable length more than 15 m

4-2 Input / Output MN1940

Page 19

www.baldormotion.com

()(

)

p

p

p

p

4.2.1 Wire sizes

Table 1 describes the wire sizes to provide optimal protection against EMI and RFI. Correct

wire size is determined by the current requirement and the cable length. The actual cable type,

wire gauge, shield type and filtering devices used are dependent on the customer’s application

and system. Always use shielded twisted pairs for AC and DC supply cables. For logic wiring

(see section 4.3) AWG22 wire is recommended.

Supply current

1 A peak

2 A peak

3 A peak

4 A peak

Cable length

(meters)

3 10 20 0.5

8 25 20 0.5

15 50 18 1.0

23 75 18 1.0

30 100 16 1.3

3 10 20 0.5

8 25 18 1.0

15 50 16 1.3

23 75 14 2.0

30 100 14 2.0

3 10 18 1.0

8 25 16 1.3

15 50 14 2.0

23 75 12 3.3

30 100 12 3.3

3 10 18 1.0

8 25 16 1.3

15 50 14 2.0

23 75 12 3.3

30 100 12 3.3

Cable length

(feet)

Minimum

Wire Gauge

AWG mm

2

Table1-Powerwireratings

Input / Output 4-3MN1940

Page 20

www.baldormotion.com

4.3 Logic inputs

The DSM has three optically isolated logic inputs. These inputs are isolated to minimize or

eliminate electrical noise coupled onto the drive control signals, and are over-voltage

protected. The inputs may be configured as either sinking inputs or sourcing inputs (model

dependent, see section 4.3.3), with the Optocoupler Reference (white) lead as the reference.

This allows the DSM to be interfaced to a variety of controllers.

DSM

Optocoupler

reference

Step clock

input

Direction

input

Enable input

470R

470R

750R

HCPL0630

HCPL0630

PS2701-1

Figure 8 - Opto-isolated digital input circuit (sinking only)

4.3.1 Logic input descriptions

4.3.1.1 Step clock (orange flying lead)

The step clock input is where the motion clock from the control circuitry will be connected. The

motor will advance one microstep in the plus or minus direction (based upon the state of the

direction input) on the step clock edge that causes the opto-isolator to be active. The size of

this increment or decrement will depend on the microstep resolution setting. The maximum

frequency on the step clock input is 2.0 MHz, with a minimum pulse width of 400 ns.

4.3.1.2 Direction (blue flying lead)

The direction input controls the CW/CCW direction of the motor. A logic high (default,

unconnected) will cause the motor to rotate in the CW direction (seen while looking at the face

of the motor). A logic low on the input will cause the motor to rotate in the CCW direction. This

input is synchronized to the positive going edge of the step clock input. The direction input

may be connected by means of a switch.

4.3.1.3 Enable (brown flying lead)

This input can be used to enable or disable the driver output circuitry. A logic high (when the

enable switch is open, see Figures 9 and 10), causes the driver outputs to be enabled and

step clock pulses will cause the motor to advance. A logic low (when the input switch is

4-4 Input / Output MN1940

Page 21

www.baldormotion.com

closed) will cause the driver output circuitry to be disabled. Note that the internal sine/cosine

position generator will continue to increment or decrement as long as step clock pulses are

being received by the DSM. The enable input is not synchronized to any other input and may

be changed at any time.

4.3.2 Input timing

The direction input and the microstep resolution inputs are internally synchronized to the

positive going edge of the step clock input. When a step clock transitions from low to high on

the positive going edge, the state of the direction input and microstep resolution settings are

latched. Any changes made to the direction and/or microstep resolution will occur on the rising

edge of the step clock pulse following this change. Run Current and Hold Current changes

are updated immediately (see section 5.2.2).

Input / Output 4-5MN1940

Page 22

www.baldormotion.com

4.3.3 Sinking / sourcing input configuration

All DSMS17, 23 and 34 models can be wired to create sinking inputs, where a reference

voltage between +5 and +24 VDC is connected to the Optocoupler Reference (white) lead.

The isolated inputs are then interfaced to a sinking output (which utilizes the same supply as

the opto coupler reference input) such as a switch, open collector, or PLC output. T o maintain

isolation, the input power source should not be connected to the motor power source.

+5 to +24 VDC

(see warning)

Optocoupler reference

(white)

R

LIMIT

INPUT

+5 to +24 VDC

(see warning)

Optocoupler reference

Controller

output

(white)

R

LIMIT

INPUT

Figure 9 - Sinking input configurations

Alternatively, sourcing inputs may be used where the Optocoupler Reference (White) lead is

connected to ground. The isolated inputs are then sourced to between +5 to +24 VDC from a

switch, open collector, or PLC output.

+5 to +24 VDC+5 to +24 VDC

R

Optocoupler reference

(white)

LIMIT

INPUT

Controller

output

Optocoupler reference

(white)

R

LIMIT

INPUT

Figure 10 - Sourcing input configurations

4-6 Input / Output MN1940

Page 23

www.baldormotion.com

NextMove ESB

(models NSB003-501 / NSB003-502 only)

+5 V

Step

Output

GND

Direction

Output

GND

Enable

74AHCT244

74AHCT244

ULN2003

ULN2003

+5 V

+5 V

STEP0

DIR0

DGND

REL COM

REL NC

‘X2’

4

1k*

3

1k*

5

1

‘X12’

7

8

DSM

Optocoupler

reference

Step clock

input

Direction

input

Enable input

Figure 11 - Sourcing input connections from a typical controller

(e.g. NextMove ESB models NSB003-501/502)

Note: * The 1kΩ pull up resistors are optional, but can help prevent noise affecting the

DSM’s inputs.

Input / Output 4-7MN1940

Page 24

www.baldormotion.com

4.4 SPI interface

DSM setup parameters are changed via an SPI (Serial Peripheral Interface) port. This port

uses a 10-pin IDC header, and connects to a USB port on your PC. The recommended

method of connecting the SPI port to the PC is by using parameter setup cable CBL055-501.

The PC requires a standard USB port.

4.4.1 SPI connector

1

3

5

7

9

CAUTION

Location 10-pin IDC header (DSMS17... / DSMS23...)

2

4

6

8

10

Additional flying leads (DSMS34...)

Typical mating connector: AMPMODU MT (Amp 102398-3)

Pin Name Description

1 (NC)

2 (NC)

3 (NC)

4 CS Chip select

5 GND Communication ground

6 +5V out +5 VDC output

7 MOSI Master Out / Slave In

8 CLK Clock

9 (NC)

10 MISO Master In / Slave Out

The +5 VDC output on the SPI connector is used for the setup cable only. This

output is not designed to power external devices.

5-GND

7-MOSI

CS

46 - +5 V out

8-Clock

10 - MISO

CBL055-501

USB/SPI interface electronics

USB cable

to PC

Figure 12 - SPI interface wiring

4-8 Input / Output MN1940

Page 25

www.baldormotion.com

4.4.2 SPI signal descriptions

4.4.2.1 +5 V out

This output is a voltage supply for the setup cable only. It is not designed to power any

external devices

4.4.2.2 CLK

The clock is driven by the master and regulates the flow of the data bits. The master may

transmit data at a variety of baud rates. The clock cycles once for each bit that is transferred.

4.4.2.3 MISO

Carries output data from the DSM back to the SPI master. Only one DSM can transmit data

during any particular transfer.

4.4.2.4 CS

This signal is used to turn multiple DSMs on or off.

4.4.2.5 MOSI

Carries output data from the SPI Master to the DSM.

Input / Output 4-9MN1940

Page 26

www.baldormotion.com

4.5 Connection summary - minimum system wiring

As a guide, Figure 13 shows an example of the typical minimum wiring required to operate the

DSM in conjunction with a NextMove ESB controller.

Motor

power

X12

REL COM

REL NC

X2

supply

Red - 12-48 VDC / 12-75 VDC

Black - 0 V

Ferrite & filter

not shown.

DSM

NextMove ESB

DIR0+

+5V

STEP0

(NC)

DGND

Note: For simplicity, the NextMove ESB’s 24 V

power suppl y on connector X1 is not shown.

Figure 13 - Example minimum system wiring (flying leads)

Blue - Direction

White - Optocoupler reference

Orange - Step cl ock

Brown - Enable

CBL055-501

PC USB port > SPI connec tion

(required only during setup)

PC

4-10 Input / Output MN1940

Page 27

www.baldormotion.com

5 Operation

5.1 Introduction

The motor interface is accessed through the Baldor SPI Interface software, which is an easy

to install and easy to use program used to set the DSM’s parameters. The Baldor SPI

Interface is included on the Baldor Motion Toolkit CD.

5.1.1 Connecting the DSM to the PC

The DSM is connected to the PC using a standard USB port. It is recommended to use the

optional CBL055-501 parameter setup cable (see section 4.4).

5.1.2 Installing the USB driver

When the parameter setup cable (CBL055-501) is connected to the PC, Windows XP will

automatically detect it and display the Found New Hardware Wizard. It is now necessary to

install the drivers, which are provided on the CD supplied with the cable. Alternatively, the driver

files can be downloaded from www.baldormotion.com/supportme

folder on the PC.

1. Choose the No, not this time option and click Next >.

2. Choose the Install from a list or specific location (Advanced) option and click Next >.

3. Check the Include this location in the search option. Click Browse and locate the drivers

folder on the CD. For downloaded files, locate the temporary folder containing the extracted

files. Click Next >.

4. When Windows finds the required driver files, a dialog will warn that they have not passed

‘Windows Logo testing’. This is normal for the parameter setup cable’s USB driver, so click

Continue Anyway to continue with the installation.

5. When the Completing the Found New Hardware Wizard message appears, click Finish.

After a few moments, the Found New Hardware Wizard will appear a second time, ready to

install the virtual COM port driver.

and placed in a temporary

5

5.1.3 Installing the virtual COM port driver

As soon as the USB driver has been installed, the PC starts to communicate with the parameter

setup cable’s interface. This immediately reveals the other part of the interface’s hardware, the

virtual communications port (VCP), which provides communication with the DSM motor. The

VCP also requires drivers to be installed, which is why the Found New Hardware Wizard appears

a second time.

1. Choose the No, not this time option and click Next >.

2. Choose the Install from a list or specific location (Advanced) option and click Next >.

3. Check the Include this location in the search option. The previously used location should

already be selected, but if not click Browse and locate the required folder. Click Next >.

Operation 5-1MN1940

Page 28

www.baldormotion.com

4. When Windows finds the required VCP driver files, a dialog will warn that they have not

passed ‘Windows Logo testing’. This is normal for the parameter setup cable’s VCP driver,

so click Continue Anyway to continue with the installation.

5. When the Completing the Found New Hardware Wizard message appears, click Finish.

A final Found New Hardware message will appear on the task bar to inform you that the

hardware is now ready to use.

Note: If the MotiFlex e100 is later connected to a different USB port on the host computer,

Windows may report that it has found new hardware. Either install the driver files

again for the new USB port, or connect the MotiFlex e100 to the original USB port

where it will be recognized in the usual way.

5.1.4 Determining the virtual COM port number

The parameter setup cable’s virtual COM port appears as a normal COM (serial) port in

Windows, and is automatically allocated a COM port number. The Baldor SPI Interface software

normally auto-detects the motor regardless of the allocated COM port. If for any reason the

Baldor SPI Interface software fails to auto-detect the motor (section 5.2.1), it may be necessary

to manually select this COM port.

1. In Windows, right-click the My Computer icon and choose Properties.

2. Choose the Hardware tab and click Device Manager.

3. Expand the Ports (COM & LPT) item.

4. Look for the entry named Baldor USB to SPI ParameterSetup Cable (COM...). The value that

appears after COM is the port number. Make a note of this number.

5.1.5 Installing Baldor SPI Interface

You will need to install the Baldor SPI Interface software to configure the DSM.

1. Insert the CD into the drive.

2. After a few seconds the setup wizard should start automatically. If the setup wizard does not

appear, select Run... from the Windows Start menu and type

d:\Baldor_SPI_Interface.exe

where d represents the drive letter of the CD device.

Follow the on-screen instructions to install the software. The setup Wizard will copy the files

to appropriate folders on the hard drive.

5-2 Operation MN1940

Page 29

www.baldormotion.com

5.1.6 Starting the controller and DSM

If you have followed the instructions in the previous sections, you should have now connected

power sources, inputs and outputs, and the USB cable linking the PC with the DSM. Before

you apply power for the first time, it is very important to verify the following:

H Inspect all power connections for accuracy, workmanship and tightness.

H Verify that all wiring conforms to applicable codes.

H Check all signal wiring for accuracy.

1. Turn on the controller (e.g. NextMove ESB, if connected).

2. Turn on the motor power supply.

Operation 5-3MN1940

Page 30

www.baldormotion.com

5.2 Baldor SPI Interface

The Baldor SPI Interface is a simple application for configuring all aspects of the DSM.

5.2.1 Starting Baldor SPI Interface

On the Windows Start menu, select Programs, BALDOR SPI Interface, BALDOR SPI Interface.

The software will immediately try to establish communication with the DSM. If this step fails, the

word “Disconnected” will appear in red. Check that the DSM is powered and that the cable is

connected, then choose the Port menu item. Select the appropriate USB port from the list of

USB/Serial port options (this is the COM port number found in Windows Device Manager - see

sectio n 5.1.4).

5.2.2 Configuration parameters

These parameters may all be changed ‘on-the-fly’. To select different views, choose the View

menu item.

5.2.2.1 Motion settings view

The motion settings view shows the main configuration parameters for the DSM:

Click in the boxes or use

the arrow buttons to

adjust values.

To revert to default settings,

click Factory, followed by Set.

Parameter Name Range Units Default

MSEL Microstep resolution 1 - 256 microsteps

MRC Motor run current 1 - 100 % 25

HCDT Motor hold current delay time 0 - 65000 ms 500

MHC Motor hold current 0 - 100 % 5

DIR Motor direction override CW or CCW CW

To send the changes to

the DSM, click Set.

256

per step

5-4 Operation MN1940

Page 31

www.baldormotion.com

Microstep Resolution Select (MSEL)

The MSEL parameter specifies the microstep resolution of the DSM. The following table lists

valid MSEL parameter settings:

MSEL value:

Steps per revolution MSEL value: Steps per revolution

1 200

64 12800

2 400 100 20000

4 800 108 21600

(1 microstep = 1 arc minute)

5 1000 125 25000

8 1600 127 25400

(1 microstep = 0.001 mm)

10 2000 128 25600

16 3200 180 36000 (1 microstep = 0.01°)

25 5000 200 40000

32 6400 250 50000

50 10000 256 51200

Motor Run Current (MRC)

The Motor Run Current (MRC) parameter sets the motor run current to a percentage of the full

output current of the DSM driver section.

Hold Current Delay Time (HCDT)

The HCDT parameter sets the delay time between the last c lock pulse and the application of

the holding current.

Motor Hold Current (MHC)

The MHC parameter sets the motor hold current as a percentage of the full output current of

the driver. If the hold current is set to 0, the output circuitry of the driver section will disable

when the hold current setting becomes active. Following the last step clock pulse, the hold

current setting becomes active after the period specified by HCDT.

Direction Override (DIR)

The DIR parameter changes the motor direction relative to the direction input signal, adapting

the direction of the DSM to operate as your system requires.

Factory button

The Factory button resets each parameter in the software to factory default values. Click Set

to apply these values.

Recall! and Upgrade! menu options

The Recall! option uploads the existing parameter settings from the DSM.

The Upgrade! option (if present) must not be used! It currently has no purpose and will

erase the firmware on the DSM, leaving it inoperable. If you have accidentally selected the

Upgrade! option, please contact Baldor customer support.

Operation 5-5MN1940

Page 32

www.baldormotion.com

5.2.2.2 I/O settings view

The I/O settings view shows two additional parameters for the DSM:

Clock Type

The Clock Type parameter configures the step and direction inputs for the type of input signals

being supplied to the motor.

H Step/Dir is the default setting. A waveform supplied to the step

input causes the motor to advance one step for each rising

edge. The direction input is held either high or low to determine

the direction of motion.

H Quadrature requires a pair of waveforms, such as those

typically produced by an incremental encoder. The two

waveforms are at the same frequency but approximately 90° out

of phase (i.e. ‘in quadrature’). One is supplied to the step input,

the other to the direction input. Each edge causes the motor to

Step

Dir

Step

(CHA)

Dir

(CHB)

advance one step, with the direction being determined by the

relative timing of the waveforms. For example, if the rising edge on the step input waveform

is received before the rising edge on the direction input waveform, the motor will turn in one

direction. If the rising edge on the direction input is received first, the motor will turn in the

opposite direction.

H Up / Down requires a waveform to be supplied to either the step

input or the direction input. If the waveform is supplied to the

Step

step input, the motor will turn in one direction. If the waveform

is supplied to the direction input, the motor will turn in the

Dir

opposite direction.

Clock IOF

The Clock IOF parameter sets the frequency of the clock input filter. Values in the range 50 ns

to 12.9 μs (10 MHz to 38.8 kHz) are available.

5-6 Operation MN1940

Page 33

6 Troubleshooting

6.1 Introduction

This section explains common problems and their solutions.

6.1.1 Problem diagnosis

If you have followed all the instructions in this manual in sequence, you should have few

problems installing the DSM. If you do have a problem, read this section first.

6.1.2 Further support

If you need to contact Baldor technical support by telephone or fax, contact details are

provided at the front of this manual. Please have the following information ready:

H The model number or serial number of your DSM (if known).

H A clear description of what you are trying to do.

H A clear description of the symptoms that you can observe.

H The type of motion generated in the motor shaft.

H Give a list of any parameters that you have setup.

www.baldormotion.com

6

6.1.3 Communication problems

If the problem is not listed below please contact Baldor technical support.

Symptom

Baldor SPI interface

cannot detect the

DSM

Check

Check that the DSM is powered.

Check that the SPI interface cable is properly connected. If you

have made your own SPI cable, check that it is wired correctly and

properly connected.

Troubleshooting 6-1MN1940

Page 34

6.1.4 Motor control problems

Symptom Check

Controller outputs

appears to be

working, but will not

cause DSM to turn.

Controller reports

that the DSM is not

moving and drops

the enable line.

Check that the DSM is powered.

Check that the logic connections between motor and controller are

correct.

Confirm that the sense of the enable input is correct to enable the

motor (section 4.3.1.3).

If the controller is expecting a feedback signal but does not receive

one, it may assume the DSM is not turning. This could cause the

controller to report a following error, to disable the DSM, or both.

www.baldormotion.com

6-2 Troubleshooting MN1940

Page 35

7.1 Introduction

This section provides technical specifications of all DSM models.

7.1.1 Input power

Description DSMS17... DSMS23... DSMS34...

Required supply type Unregulated DC

Ripple voltage ±10%

Minimum supply voltage +12VDC +12VDC +12VDC

Maximum supply voltage +48VDC +75VDC +75VDC

Input current (maximum) 2A 1.5A 4A

The maximum input voltage of the DSM includes motor back EMF, power supply

ripple and high line.

CAUTION

7 Specifications

www.baldormotion.com

7

Specifications 7-1MN1940

Page 36

7.1.2 Motor speed & torque - DSMS17

7.1.2.1 DSMS17x-1A...

60

50

40

30

20

Torque (oz·in)

10

0

Description Val ue

Holding torque 22.6 N·cm (32 oz·in)

Detent torque 1.17 N·cm (1.66 oz·in)

Rotor inertia 0.038 kg·cm2(0.00053 oz·in·s2)

7.1.2.2 DSMS17x-2A...

60

50

40

30

20

Torque (oz·in)

10

0

0 1000 2000 3000 4000 5000 6000 7000

0 1000 2000 3000 4000 5000 6000 7000

24 VDC

48 VDC

(300) (600) (900) (1200) (1500) (1800) (2100)

Speed in full steps per second (RPM)

24 VDC

48 VDC

(300)

(600) (900) (1200) (1500) (1800) (2100)

www.baldormotion.com

42

35

Torque·(N cm)

28

21

14

7

42

35

Torque (N·cm)

28

21

14

7

Speed in full steps per second (RPM)

Description Val ue

Holding torque 42.4 N·cm (60 oz·in)

Detent torque 1.47 N·cm (2.08 oz·in)

Rotor inertia 0.057 kg·cm2(0.00080 oz·in·s2)

7-2 Specifications MN1940

Page 37

7.1.2.3 DSMS17x-3A...

60

50

40

30

20

Torque (oz·in)

10

0

0

Description Val ue

Holding torque 52.9 N·cm (74.9 oz·in)

Detent torque 2.45 N·cm (3.47 oz·in)

Rotor inertia 0.082 kg·cm2(0.00116 oz·in·s2)

24 VDC

48 VDC

1000

(300)

2000 3000 4000

(600) (900) (1200) (1500) (1800) (2100)

Speed in full steps per second (RPM)

www.baldormotion.com

5000 6000 7000

42

35

Torque (N·cm)

28

21

14

7

Specifications 7-3MN1940

Page 38

7.1.3 Motor speed & torque - DSMS23

)

2

2

7.1.3.1 DSMS23x-1B...

225

200

175

150

125

100

75

Torque (oz·in)

50

25

0

0

1000

2000

(600)

3000

(900)

(300)

Speed in full steps per second (RPM)

Description Val ue

Holding torque 64 N·cm (90 oz·in)

Detent torque 2.7 N·cm (3.9 oz·in)

Rotor inertia 0.18 kg·cm2(0.0025 oz·in·s2)

4000

(1200)

5000

(1500)

24 VDC

45 VDC

75 VDC

(1800)

6000

www.baldormotion.com

159

141

124

106

Torque (N·cm)

88

71

53

35

18

7000

(2100)

7.1.3.2 DSMS23x-2B...

Torque (oz·in)

200

175

150

125

100

5

75

50

25

0

0

1000

2000

3000

(300)

(600)

(900)

4000

(1200)

5000

(1500)

24 VDC

45 VDC

75 VDC

(1800)

6000

7000

(2100)

Speed in full stepsper second(RPM

Description Val ue

Holding torque 102 N·cm (144 oz·in)

Detent torque 3.92 N·cm (5.6 oz·in)

Rotor inertia 0.26 kg·cm2(0.0037 oz·in·s2)

7-4 Specifications MN1940

159

141

124

106

88

71

53

35

18

Torque (N·cm)

Page 39

7.1.3.3 DSMS23x-3B...

225

200

175

150

125

100

75

Torque (oz·in)

50

25

0

Description Val ue

Holding torque 169 N·cm (239 oz·in)

Detent torque 6.86 N·cm (9.7 oz·in)

Rotor inertia 0.46 kg·cm2(0.0065 oz·in·s2)

www.baldormotion.com

7000

(2100)

159

141

124

106

88

71

53

35

18

Torque (N·cm)

24 VDC

45 VDC

75 VDC

0

1000

(300)

2000

(600)

3000

(900)

4000

(1200)

5000

(1500)

6000

(1800)

Speed in full steps per second (RPM)

Specifications 7-5MN1940

Page 40

7.1.4 Motor speed & torque - DSMS34

7.1.4.1 DSMS34x-1B...

1000

900

800

700

600

500

400

Torque (oz·in)

300

200

100

0

0

1000

2000

(600)

3000

(900)

(300)

Speed in full steps per second (RPM)

Description Val ue

Holding torque 269 N·cm (381 oz·in)

Detent torque 7.7 N·cm (10.9 oz·in)

Rotor inertia 1.0 kg·cm2(0.01416 oz·in·s2)

4000

(1200)

5000

(1500)

24 VDC

45 VDC

75 VDC

6000

(1800)

www.baldormotion.com

706

635

465

Torque (N·cm)

494

423

353

282

211

140

71

7000

(2100)

7-6 Specifications MN1940

Page 41

7.1.4.2 DSMS34x-2B...

1000

900

800

700

600

500

400

Torque (oz·in)

300

200

100

0

0 1000

Description Val ue

Holding torque 406 N·cm (575 oz·in)

Detent torque 10.0 N·cm (14.16 oz·in)

Rotor inertia 1.6 kg·cm2(0.02266 oz·in·s2)

(300)

2000

(600)

3000

(900)

Speed in full steps per second (RPM)

4000

(1200)

5000

(1500)

www.baldormotion.com

24 VDC

45 VDC

75 VDC

6000

(1800)

7000

(2100)

706

635

465

494

423

353

282

211

140

71

Torque (N·cm)

Specifications 7-7MN1940

Page 42

7.1.4.3 DSMS34x-3B...

1000

900

800

700

600

500

400

Torque (oz·in)

300

200

100

0

Description Val ue

Holding torque 749 N·cm (1061 oz·in)

Detent torque 14.0 N·cm (19.83 oz·in)

Rotor inertia 3.4 kg·cm2(0.04815 oz·in·s2)

0 1000

(300)

2000

(600)

3000

(900)

4000

(1200)

5000

(1500)

Speed in full steps per second (RPM)

www.baldormotion.com

24 VDC

45 VDC

75 VDC

6000

(1800)

7000

(2100)

706

635

465

494

423

353

282

211

140

71

Torque (N·cm)

7-8 Specifications MN1940

Page 43

7.1.5 Digital inputs

Description Unit Value

Type Opto-isolated

Supply voltage

Input forward voltage (max)

Input current (typical, 5V)

Input current (maximum allowable)

Maximum input frequency MHz 2.0

Maximum

Minimum

Step clock / Direction

Enable

Step clock / Direction

Enable

Step clock / Direction

Enable

www.baldormotion.com

VDC

24

5

VDC

1.7

1.4

mA

10.6

6.7

mA

15

9.4

Specifications 7-9MN1940

Page 44

www.baldormotion.com

7-10 Specifications MN1940

Page 45

Index

A

Abbreviations, 2-4

B

Baldor SPI Interface, 5-4

clock IOF, 5-6

clock type, 5-6

configuration parameters, 5-4

DIR (direction override), 5-5

direction override (DIR), 5-5

HCDT (hold current delay time), 5-5

hold current delay time (HCDT), 5-5

MHC (motor holding current), 5-5

microstep resolution select (MSEL), 5-5

motor holding current (MHC), 5-5

motor run current (MRC), 5-5

MRC (motor run current), 5-5

starting, 5-4

Basic Installation, 3-1

location requirements, 3-1

mounting, 3-2

securing DSM cables, 3-5

C

Catalog number, identifying, 2-3

Clock IOF, 5-6

Clock Type, 5-6

Connections

basic, 4-1

connector P2, 4-8

direction, 4-4

enable, 4-4

logic inputs, 4-4

motor power, 4-2

step clock, 4-4

D

Dimensions

DSMS17, 3-2

DSMS23, 3-4

DSMS34, 3-5

DIR (direction override), 5-5

Direction input, 4-4

E

Enable input, 4-4

Environmental, 1-2, 3-1

F

Features, 2-1

H

Hardware requirements, 3-6

HCDT (hold current delay time), 5-5

I

Input / Output, 4-1

basic connections, 4-1

connection summary, 4-10

Input timing, 4-5

Installation, 3-1

Baldor SPI Interface, 5-2

USB driver, 5-1

virtual COM port driver, 5-1

virtual COM port number, determining, 5-2

L

Logic inputs, 4-4

direction input, 4-4

enable input, 4-4

sinking / sourcing, 4-6

step clock input, 4-4

timing, 4-5

MN1940

Index

Page 46

M

MHC (motor holding current), 5-5

Mounting, 3-2

DSMS17, 3-2

DSMS23, 3-4

DSMS34, 3-5

securing DSM cables, 3-5

MRC (motor run current), 5-5

O

Operation, 5-1

connecting to the PC, 5-1

installing Baldor SPI interface, 5-2

installing the USB driver, 5-1

installing the virtual COM port driver, 5-1

starting, 5-3

Options, availability, 2-2

input power, 7-1

motor output - DSMS17x-1A, 7-2

motor output - DSMS17x-2A, 7-2

motor output - DSMS17x-3A, 7-3

motor output - DSMS23x-1B, 7-4

motor output - DSMS23x-2B, 7-4

motor output - DSMS23x-3B, 7-5

motor output - DSMS34x-1B, 7-6

motor output - DSMS34x-2B, 7-7

motor output - DSMS34x-3B, 7-8

SPI interface, 4-8

CLK signal, 4-9

CS signal, 4-9

MISO signal, 4-9

MOSI signal, 4-9

signal descriptions, 4-9

SPI connector, 4-8

Step clock input, 4-4

P

Power

connections, 4-2

sources, 7-1

Precautions, 1-2

R

Receiving and Inspection, 2-3

S

Safety Notice, 1-2

Setup, 5-1

Sinking / sourcing configuration, 4-6

Specifications, 7-1

digital inputs, 7-9

T

Troubleshooting, 6-1

U

Units and abbreviations, 2-4

USB, installing the driver, 5-1

V

Virtual COM port (VCP)

installing the driver, 5-1

number, determining, 5-2

W

Wire sizes, 4-3

Index

MN1940

Page 47

Comments

If you have any suggestions for improvements to this manual, please let us know. Write your

comments in the space provided below, remove this page from the manual and mail it to:

Manuals

Baldor UK Ltd

Mint Motion Centre

6 Bristol Distribution Park

Hawkley Drive

Bristol

BS32 0BF

United Kingdom.

Alternatively, you can e-mail your comments to:

manuals@baldor.co.uk

Comment:

continued...

CommentsMN1940

Page 48

Thank you for taking the time to help us.

Comments MN1940

Page 49

Page 50

Baldor UK Ltd

Mint Motion Centre

6 Bristol Distribution Park

Hawkley Drive, Bristol

BS32 0BF

United Kingdom

Visit www.baldormotion.com/supportme for the latest documentation and software releases.

Australia

Australian Baldor PTY Ltd

Tel: +61 2 9674 5455

Fax: +61 2 9674 2495

Europe

Baldor ASR GmbH, Germany

Tel: +49 (0) 89 905 080

Fax: +49 (0) 89 905 08491

Europe (Southern)

Baldor ASR AG, Switzerland

Tel: +41 52 647 4700

Fax: +41 52 659 2394

Japan

Baldor Japan Corporation

Tel: +81 45 412 4506

Fax: +81 45 412 4507

L T0227A02

Mexico

Baldor de Mexico

Tel: +52 477 761 2030

Fax: +52 477 761 2010

Singapore

Baldor Electric PTE Ltd

Tel: +65 744 2572

Fax: +65 747 1708

United Kingdom

Baldor UK Ltd

Tel: +44 1454 850000

Fax: +44 1454 859001

U.S.A. (Headquarters)

Baldor Electric Company

Tel: +1 479 646 4711

Fax: +1 479 648 5792

For additional office locations visit www.baldor.com

PrintedinUK

E Baldor UK Ltd

Loading...

Loading...