Page 1

MOTION CONTROL

NextMove ES

Motion Controller

Installation Manual

8/03 MN1928

Page 2

Page 3

Contents

1 General Information 1-1.................................

2 Introduction 2-1........................................

2.1 NextMove ES features 2-1..................................

2.2 Receiving and inspection 2-3................................

2.2.1 Identifying the catalog number 2-3....................................

2.3 Units and abbreviations 2-4..................................

3 Basic Installation 3-1....................................

3.1 Introduction 3-1............................................

3.1.1 Location requirements 3-1..........................................

3.1.2 Installing the NextMove ES card 3-2..................................

3.1.3 Other requirements for installation 3-2................................

4 Input / Output 4-1......................................

4.1 Introduction 4-1............................................

4.2 96-pin edge connector 4-1...................................

4.2.1 96-pin connector pin assignment 4-2..................................

4.3 Analog I/O 4-3.............................................

4.3.1 Analog inputs 4-3..................................................

4.3.2 Analog outputs 4-5.................................................

4.4 Digital I/O 4-6..............................................

4.4.1 Digital inputs 4-6..................................................

4.4.2 Digital outputs 4-8.................................................

4.4.3 Error output - Error Out 4-10..........................................

4.5 Other I/O 4-11..............................................

4.5.1 Stepper control outputs 4-11..........................................

4.5.2 Encoder inputs 4-12................................................

4.5.3 RS232 serial connection 4-13........................................

4.5.4 USB connection 4-14...............................................

4.5.5 CAN connection 4-15...............................................

4.6 Connection summary - minimum system wiring 4-17.............

MN1928

Contents i

Page 4

5 Backplanes 5-1........................................

5.1 Introduction 5-1............................................

5.2 BPL010-501 non-isolated backplane 5-2.......................

5.2.1 Analog inputs 5-2..................................................

5.2.2 Analog outputs (demands) 5-3.......................................

5.2.3 Digital inputs 0-7 5-4...............................................

5.2.4 Digital inputs 8-15 5-4..............................................

5.2.5 Digital inputs 16-19 5-5.............................................

5.2.6 Digital outputs 0-7 5-5..............................................

5.2.7 Digital outputs 8-11 5-6.............................................

5.2.8 Stepper axes outputs 0-1 5-7........................................

5.2.9 Stepper axes outputs 2-3 5-8........................................

5.2.10 Power inputs 5-9..................................................

5.2.11 Encoder input 0 5-9................................................

5.2.12 Encoder input 1 5-10................................................

5.2.13 RS232 serial communication 5-10.....................................

5.3 BPL010-502/503 backplane with opto-isolator card 5-11..........

5.3.1 Analog inputs 5-12..................................................

5.3.2 Analog outputs (demands) 5-14.......................................

5.3.3 Digital inputs 0-7 5-15...............................................

5.3.4 Digital inputs 8-15 5-16..............................................

5.3.5 Digital inputs 16-19 5-17.............................................

5.3.6 Digital outputs 0-7 5-19..............................................

5.3.7 Digital outputs 8-11 5-21.............................................

5.3.8 Stepper axes outputs 0-1 5-22........................................

5.3.9 Stepper axes outputs 2-3 5-23........................................

5.3.10 Power inputs 5-24..................................................

5.3.11 Encoder input 0 5-24................................................

5.3.12 Encoder input 1 5-25................................................

5.3.13 RS232 serial communication 5-25.....................................

6 Operation 6-1..........................................

6.1 Introduction 6-1............................................

6.1.1 Connecting the NextMove ES to the PC 6-1............................

6.1.2 Installing WorkBench v5 6-1.........................................

6.1.3 Starting the NextMove ES 6-1.......................................

6.1.4 Preliminary checks 6-2.............................................

6.1.5 Power on checks 6-2...............................................

6.2 WorkBench v5 6-3..........................................

6.2.1 Help file 6-3......................................................

6.2.2 Starting WorkBench v5 6-4..........................................

6.3 Configuring an axis 6-6.....................................

6.3.1 Selecting a scale 6-6...............................................

6.3.2 Setting the drive enable output 6-7...................................

6.3.3 Testing the drive enable output 6-9...................................

6.4 Stepper axis - testing 6-10....................................

6.4.1 Testing the output 6-10..............................................

ii Contents

MN1928

Page 5

6.5 Servo axis - testing and tuning 6-11............................

6.5.1 Testing the demand output 6-11.......................................

6.5.2 An introduction to closed loop control 6-13..............................

6.6 Servo axis - tuning for current control 6-16......................

6.6.1 Selecting servo loop gains 6-16.......................................

6.6.2 Underdamped response 6-18.........................................

6.6.3 Overdamped response 6-19..........................................

6.6.4 Critically damped response 6-20......................................

6.7 Servo axis - eliminating steady-state errors 6-21.................

6.8 Servo axis - tuning for velocity control 6-22.....................

6.8.1 Calculating KVELFF 6-22............................................

6.8.2 Adjusting KPROP 6-25..............................................

6.9 Digital input/output configuration 6-27..........................

6.9.1 Digital input configuration 6-27........................................

6.9.2 Digital output configuration 6-28.......................................

6.10 Saving setup information 6-29.................................

6.10.1 Loading saved information 6-30.......................................

7 Troubleshooting 7-1....................................

7.1 Introduction 7-1............................................

7.1.1 Problem diagnosis 7-1..............................................

7.1.2 SupportMe feature 7-1.............................................

7.2 NextMove ES indicators 7-2.................................

7.2.1 Status display 7-2.................................................

7.2.2 Surface mount LEDs D3, D4, D16 and D20 7-3.........................

7.2.3 Communication 7-4................................................

7.2.4 Motor control 7-4..................................................

7.2.5 WorkBench v5 7-5.................................................

8 Specifications 8-1......................................

8.1 Introduction 8-1............................................

8.1.1 Input power 8-1...................................................

8.1.2 Analog inputs 8-1..................................................

8.1.3 Analog outputs 8-1.................................................

8.1.4 Digital inputs (non-isolated) 8-2......................................

8.1.5 Digital inputs (opto-isolated) 8-2......................................

8.1.6 Digital outputs - general purpose (non-isolated) 8-3.....................

8.1.7 Digital outputs - general purpose (opto-isolated) 8-3.....................

8.1.8 Digital output - error output (non-isolated) 8-3..........................

8.1.9 Error relay (opto-isolated backplanes) 8-4.............................

8.1.10 Encoder inputs 8-4................................................

8.1.11 Stepper control outputs 8-4..........................................

8.1.12 CAN interface 8-4.................................................

8.1.13 Environmental 8-5.................................................

8.1.14 Weights and dimensions 8-5........................................

MN1928

Contents iii

Page 6

Appendices

A Appendix A-1..........................................

A.1 Axis renumbering A-1.......................................

iv Contents

MN1928

Page 7

AustralianBaldorPtyLt

d

1 General Information

Copyright Baldor (c) 2003. All rights reserved.LT0202A00

This manual is copyrighted and all rights are reserved. This document or attached software may not,

in whole or in part, be copied or reproduced in any form without the prior written consent of BALDOR.

BALDOR makes no representations or warranties with respect to the contents hereof and specifically

disclaims any implied warranties of fitness for any particular purpose. The information in this

document is subject to change without notice.

BALDOR assumes no responsibility for any errors that may appear in this document.

Mintt is a registered trademark of Baldor.

Windows 95, Windows 98, Windows ME, Windows NT, Windows 2000 and Windows XP are

registered trademarks of the Microsoft Corporation.

Limited Warranty:

For a period of two (2) years from the date of original purchase, BALDOR will repair or replace without

charge controls and accessories which our examination proves to be defective in material or

workmanship. This warranty is valid if the unit has not been tampered with by unauthorized persons,

misused, abused, or improperly installed and has been used in accordance with the instructions and/or

ratings supplied. This warranty is in lieu of any other warranty or guarantee expressed or implied.

BALDOR shall not be held responsible for any expense (including installation and removal),

inconvenience, or consequential damage, including injury to any person or property caused by items of

our manufacture or sale. (Some countries and U.S. states do not allow exclusion or limitation of

incidental or consequential damages, so the above exclusion may not apply.) In any event,

BALDOR’s total liability, under all circumstances, shall not exceed the full purchase price of the

control. Claims for purchase price refunds, repairs, or replacements must be referred to BALDOR with

all pertinent data as to the defect, the date purchased, the task performed by the control, and the

problem encountered. No liability is assumed for expendable items such as fuses. Goods may be

returned only with written notification including a BALDOR Return Authorization Number and any

return shipments must be prepaid.

1

Baldor UK Ltd

Mint Motion Centre

6 Bristol Distribution Park

Hawkley Drive

Bristol, BS32 0BF

Telephone: +44 (0) 1454 850000

Fax: +44 (0) 1454 850001

Email: technical.support@baldor.co.uk

Web site: www.baldor.co.uk

Baldor Electric Company

Telephone: +1 479 646 4711

Fax: +1 479 648 5792

Email: sales@baldor.com

Web site: www.baldor.com

Baldor ASR GmbH

Telephone: +49 (0) 89 90508-0

Fax: +49 (0) 89 90508-492

Baldor ASR AG

Telephone: +41 (0) 52 647 4700

Fax: +41 (0) 52 659 2394

Email: technical.support@baldor.ch

Australian Baldor Pty Ltd

Telephone: +61 2 9674 5455

Fax: +61 2 9674 2495

Baldor Electric (F.E.) Pte Ltd

Telephone: +65 744 2572

Fax: +65 747 1708

Baldor Italia S.R.L

Telephone: +39 (0) 11 56 24 440

Fax: +39 (0) 11 56 25 660

General Information 1-1MN1928

Page 8

Safety Notice

Only qualified personnel should attempt to start-up, program or troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts or parts that are

controlled by this equipment. Improper use can cause serious or fatal injury.

Precautions

WARNING: Do not touch any circuit board, power device or electrical connection before you

WARNING: Be sure that you are completely familiar with the safe operation and programming

WARNING: The stop input to this equipment should not be used as the single means of

WARNING: Improper operation or programming may cause violent motion of the motor shaft

CAUTION: The safe integration of this equipment into a machine system is the responsibility

CAUTION: Electrical components can be damaged by static electricity. Use ESD

first ensure that no high voltage is present at this equipment or other equipment to

which it is connected. Electrical shock can cause serious or fatal injury.

of this equipment. This equipment may be connected to other machines that have

rotating parts or parts that are controlled by this equipment. Improper use can

cause serious or fatal injury.

achieving a safety critical stop. Drive disable, motor disconnect, motor brake and

other means should be used as appropriate.

and driven equipment. Be certain that unexpected motor shaft movement will not

cause injury to personnel or damage to equipment. Peak torque of several times

the rated motor torque can occur during control failure.

of the machine designer. Be sure to comply with the local safety requirements at

the place where the machine is to be used. In Europe these are the Machinery

Directive, the ElectroMagnetic Compatibility Directive and the Low Voltage

Directive. In the United States this is the National Electrical code and local codes.

(electrostatic discharge) procedures when handling this drive.

1-2 General Information MN1928

Page 9

2 Introduction

2.1 NextMove ES features

NextMove ES is a high performance multi-axis intelligent controller for servo and stepper

motors.

NextMove ES features the MintMT motion control language. MintMT is a structured form of

Basic, custom designed for stepper or servo motion control applications. It allows you to get

started very quickly with simple motion control programs. In addition, MintMT includes a wide

range of powerful commands for complex applications.

2

Standard features include:

H Control of 4 stepper and 2 servo axes.

H Point to point moves, software cams and gearing.

H 20 general purpose digital inputs, software configurable as level or edge triggered.

H 12 general purpose digital outputs and 1 error output.

H 2 differential analog inputs with 12-bit resolution.

H 2 single-ended analog outputs with 12-bit resolution.

H RS232 and USB serial connections.

H CANopen or proprietary Baldor CAN protocol for communication with MintMT controllers

and other third party devices.

H Programmable in MintMT.

Introduction 2-1MN1928

Page 10

Included with NextMove ES is the Baldor Motion Toolkit CD. This contains a number of utilities

and useful resources to get the most from you MintMT controller. These include:

H Mint WorkBench v5

This is the user interface for communicating with the NextMove ES. Installing Mint

WorkBench v5 will also install firmware for NextMove ES.

H PC Developer Libraries

Installing Mint WorkBench v5 will install ActiveX interfaces that allow PC applications to be

written that communicate with the NextMove ES.

This manual is intended to guide you through the installation of NextMove ES.

The chapters should be read in sequence.

The Basic Installation section describes the mechanical installation of the NextMove ES.

The following sections require knowledge of the low level input/output requirements of the

installation and an understanding of computer software installation. If you are not qualified in

these areas you should seek assistance before proceeding.

Note: You can check that you have the latest firmware and WorkBench v5 releases by

visiting the website www.supportme.net.

2-2 Introduction MN1928

Page 11

2.2 Receiving and inspection

When you receive your NextMove ES, there are several things you should do immediately:

1. Check the condition of the packaging and report any damage immediately to the carrier

that delivered your NextMove ES.

2. Remove the NextMove ES from the shipping container but do not remove it from its anti-static

bag until you are ready to install it. The packing materials may be retained for future shipment.

3. Verify that the catalog number of the NextMove ES you received is the same as the

catalog number listed on your purchase order. The catalog/part number is described in

the next section.

4. Inspect the NextMove ES for external damage during shipment and report any damage to

the carrier that delivered it.

5. If the NextMove ES is to be stored for several weeks before use, be sure that it is stored

in a location that conforms to the storage humidity and temperature specifications shown

in section 3.1.1.

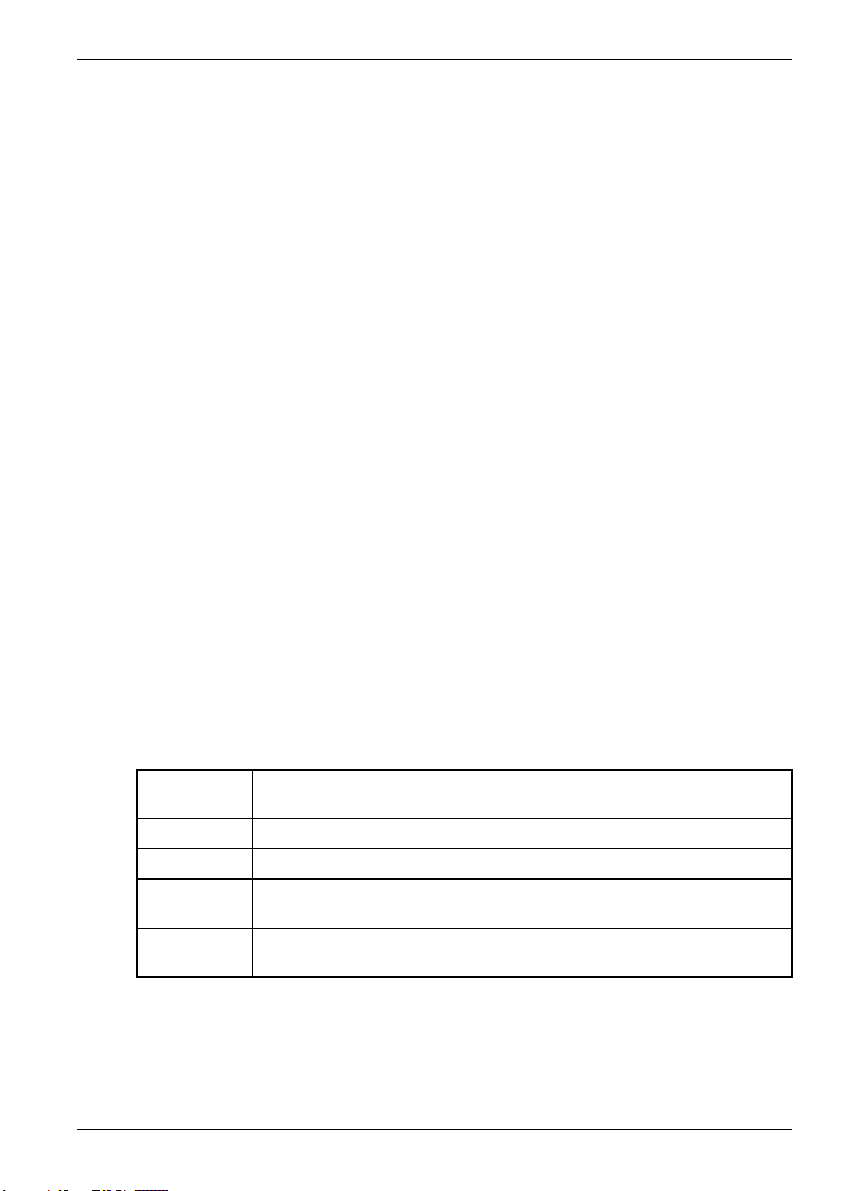

2.2.1 Identifying the catalog number

NextMove ES cards are available with a number of optional backplane connector cards. As a

reminder of which products have been installed, it is a good idea to write the catalog numbers

in the space provided below.

NextMove ES catalog number:

Backplane catalog number: BPL010-50_______

Installed in: ________________________

A description of the catalog numbers are shown in the following table:

Catalog

number

NES002-501 NextMove ES controller card with USB connection

BPL010-501 Backplane card: Non-isolated

BPL010-502 Backplane card: Opto-isolated with ‘PNP’ (current sourcing) outputs and

BPL010-503 Backplane card: Opto-isolated with ‘NPN’ (current sinking) outputs and

Description

‘active high’ inputs.

‘active low’ inputs.

NES002-501

Date: ______

Introduction 2-3MN1928

Page 12

2.3 Units and abbreviations

The following units and abbreviations may appear in this manual:

V Volt (also VAC and VDC)...............

WWatt..............

A Ampere...............

Ω Ohm...............

µF microfarad..............

pF picofarad..............

mH millihenry.............

Φ phase...............

ms millisecond..............

µs microsecond..............

ns nanosecond..............

Kbaud kilobaud (the same as Kbit/s in most applications)...........

MB megabytes.............

CDROM Compact Disc Read Only Memory.........

CTRL+E on the PC keyboard, press Ctrl then E at the same time..........

mm millimeter.............

m meter...............

in inch...............

ft feet...............

lb-in pound-inch (torque).............

Nm Newton-meter (torque).............

DAC Digital to Analog Converter............

ADC Analog to Digital Converter............

AWG American Wire Gauge............

(NC) Not Connected............

2-4 Introduction MN1928

Page 13

3 Basic Installation

3.1 Introduction

You should read all the sections in Basic Installation.

It is important that the correct steps are followed when installing the NextMove ES.

This section describes the mechanical installation of the NextMove ES.

3.1.1 Location requirements

You must read and understand this section before beginning the installation.

3

CAUTION: To prevent equipment damage, be certain that input and output signals

CAUTION: To ensure reliable performance of this equipment be certain that all

CAUTION: Avoid locating the NextMove ES immediately above or beside heat

CAUTION: Avoid locating the NextMove ES in the vicinity of corrosive substances or

The safe operation of this equipment depends upon its use in the appropriate environment.

The following points must be considered:

H The NextMove ES is designed to be mounted in a IEC297 / DIN41494 rack with card

frames and guides to support the card.

H The NextMove ES must be installed in an ambient temperature of 0°C to 40°C (32°F to

104°F).

H The NextMove ES must be installed in relative humidity levels of less than 80% for

temperatures up to 31°C (87°F) decreasing linearly to 50% relative humidity at 40°C

(104°F), non-condensing.

H The NextMove ES must be installed where the pollution degree according to IEC664 shall

not exceed 2.

H There shall not be abnormal levels of nuclear radiation or X-rays.

are powered and referenced correctly.

signals to/from the NextMove ES are shielded correctly.

generating equipment, or directly below water steam pipes.

vapors, metal particles and dust.

Basic Installation 3-1MN1928

Page 14

3.1.2 Installing the NextMove ES card

CAUTION: Before touching the card, be sure to discharge static electricity from your

The NextMove ES is designed to be mounted in a IEC297 / DIN41494 rack with card frames

and guides to support the card. An additional backplane card is recommended (see section 5).

1. Mount the backplane connector card (optional) at the rear of the rack system.

2. Slide the NextMove ES card into the guide rails, ensuring that it plugs securely into the

backplane connector.

3. Confirm that any neighboring cards or equipment are not touching the NextMove ES card.

body and clothing by touching a grounded metal surface. Alternatively,

wear an earth strap while handling the card.

3.1.3 Other requirements for installation

H The NextMove ES requires +5V and ±12V power supplies. The total power requirement

(excluding any option cards) is +5V at 1A, +12V at 50mA and -12V at 50mA. If digital

outputs are to be used, a supply will be required to drive them - see section 4.4.2.

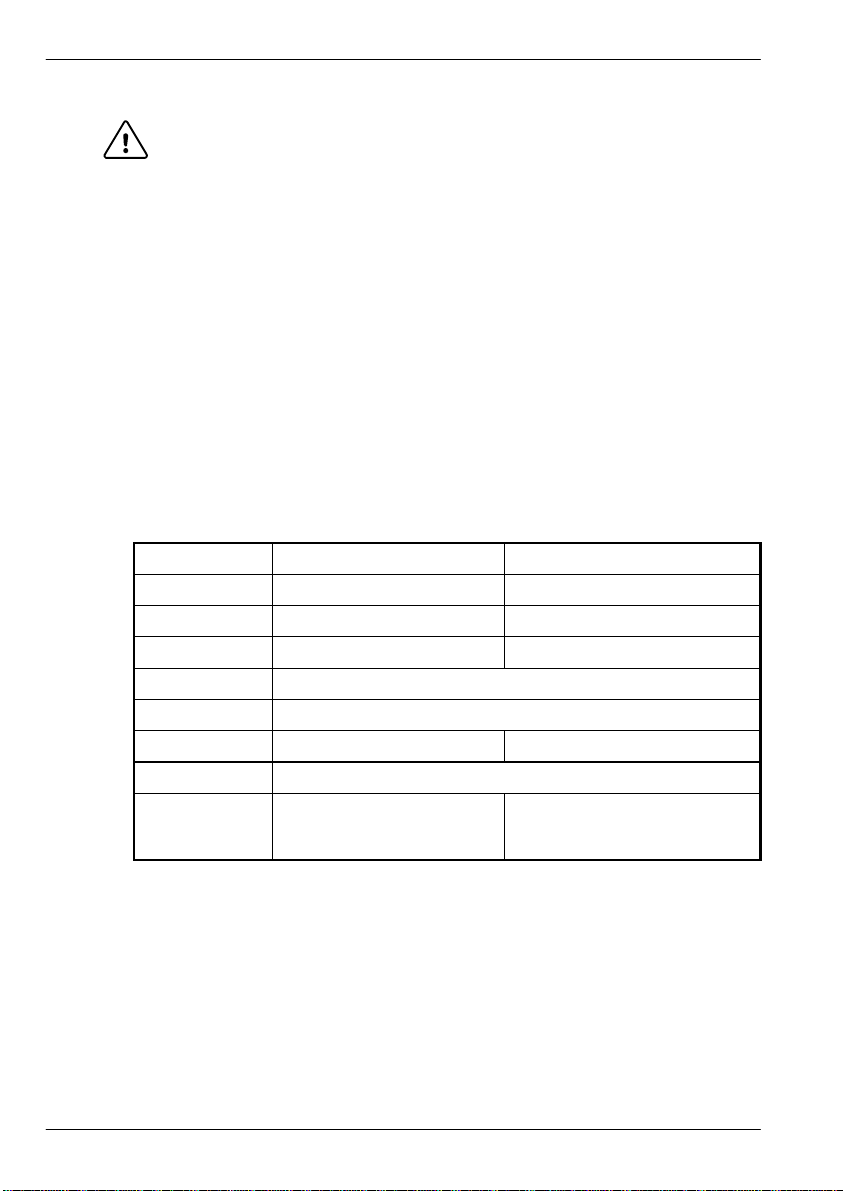

H A PC that fulfills the following specification:

Minimum specification Recommended specification

Processor Intel Pentium 133MHz Intel PentiumII 400MHz or faster

RAM 32MB 128MB

Hard disk space 40MB 60MB

CD-ROM ACD-ROMdrive

Serial port One free serial (COM) port, or USB port

Screen 800 x 600, 256 colors 1024 x 768, 16-bit color

Mouse A mouse or similar pointing device

Operating

system

Windows 95, Windows NT Windows 98*, Windows ME*,

Windows NT*, Windows 2000 or

Windows XP

* For USB support, Windows 2000 or Windows XP is required. Software installation will be

described later, in section 6.

H A serial cable (connected as shown in section 4.5.3) or a USB cable.

H Your PC operating system user manual might be useful if you are not familiar with Windows.

3-2 Basic Installation MN1928

Page 15

4 Input / Output

4.1 Introduction

This section describes the input and output capabilities of the NextMove ES.

The following conventions will be used to refer to the inputs and outputs:

I/O Input / Output..............

DIN Digital Input.............

DOUT Digital Output...........

AIN Analog Input.............

AOUT Analog Output...........

Most external connections to the NextMove ES card are made using an optional backplane

card, described in section 5.

4.2 96-pin edge connector

cba

4

Key

1

The pin assignment for the 96-pin DIN41612 connector is shown in

Table 1.

Component side

32

Input / Output 4-1MN1928

Page 16

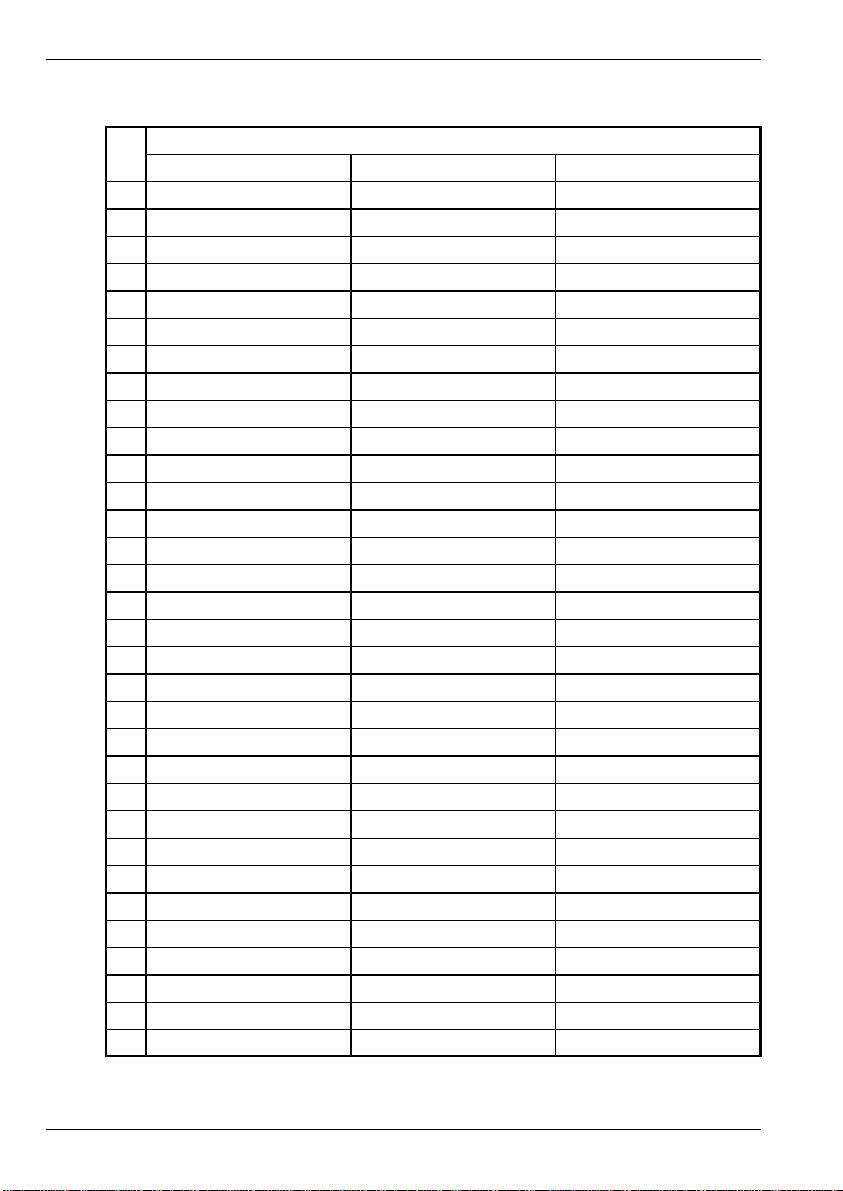

4.2.1 96-pin connector pin assignment

Pin c b a

1 +5VDC +5VDC +5VDC

2 +5VDC +5VDC +5VDC

3 DGND DGND DGND

4 DOUT6 DOUT7 OUT COM

5 DOUT3 DOUT4 DOUT5

6 DOUT0 DOUT1 DOUT2

7 Encoder 1 CHB+ Encoder 0 CHA+ Encoder 0 CHB+

8 Encoder 1 CHZ+ Encoder 0 CHZ+ Encoder 1 CHA+

9 Encoder 1 CHA- Encoder 0 CHZ- Encoder 1 CHZ-

10 Encoder 0 CHB- Encoder 0 CHA- Encoder 1 CHB-

11 DIN16 Error Out DGND

12 !RST IN DGND DGND

13 DGND DOUT9 DOUT8

14 STEP2 STEP1 STEP0

15 DIR2 DIR1 DIR0

16 DOUT10 DGND (NC)

17 DGND AOUT2 (NC)

18 DIN4 DIN15 DIN2

19 DIN3 DIN5 DIN7

20 DIN6 DIN1 RXD

21 DIN0 RTS TXD

22 DOUT11 AOUT3 CTS

23 DIN14 STEP3 DIR3

24 DIN17 DIN13 DIN10

25 DIN18 DIN9 DIN11

26 DIN12 DIN19 DIN8

27 Demand0 (AOUT0) Demand1 (AOUT1) AIN1-

28 AIN1+ AIN0+ AIN0-

29 +12VDC +12VDC +12VDC

30 AGND AGND AGND

31 -12VDC -12VDC -12VDC

32 Shield Shield Shield

Table 1 - 96-pin connector pin assignment

Row

4-2 Input / Output MN1928

Page 17

4.3 Analog I/O

The NextMove ES provides:

H Two 12-bit resolution analog inputs.

H Four 12-bit resolution analog outputs.

4.3.1 Analog inputs

The analog inputs are available on pins a28 & b28 (AIN0) and a27 & c28 (AIN1).

H Differential inputs.

H Voltage range: ±10V.

H Resolution: 12-bit with sign (accuracy ±4.9mV @ ±10V input).

H Input impedance: 120kΩ.

H Sampling frequency: 4kHz maximum, 2kHz if both inputs are enabled.

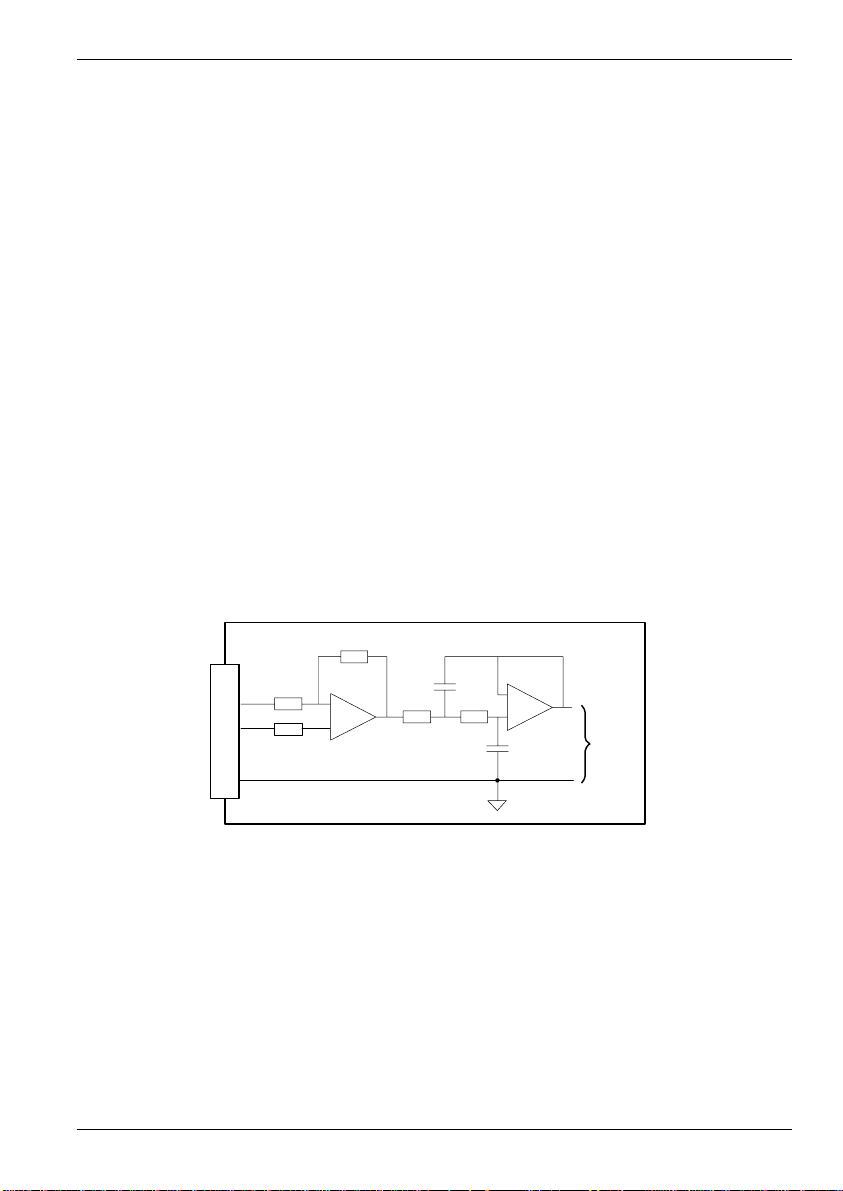

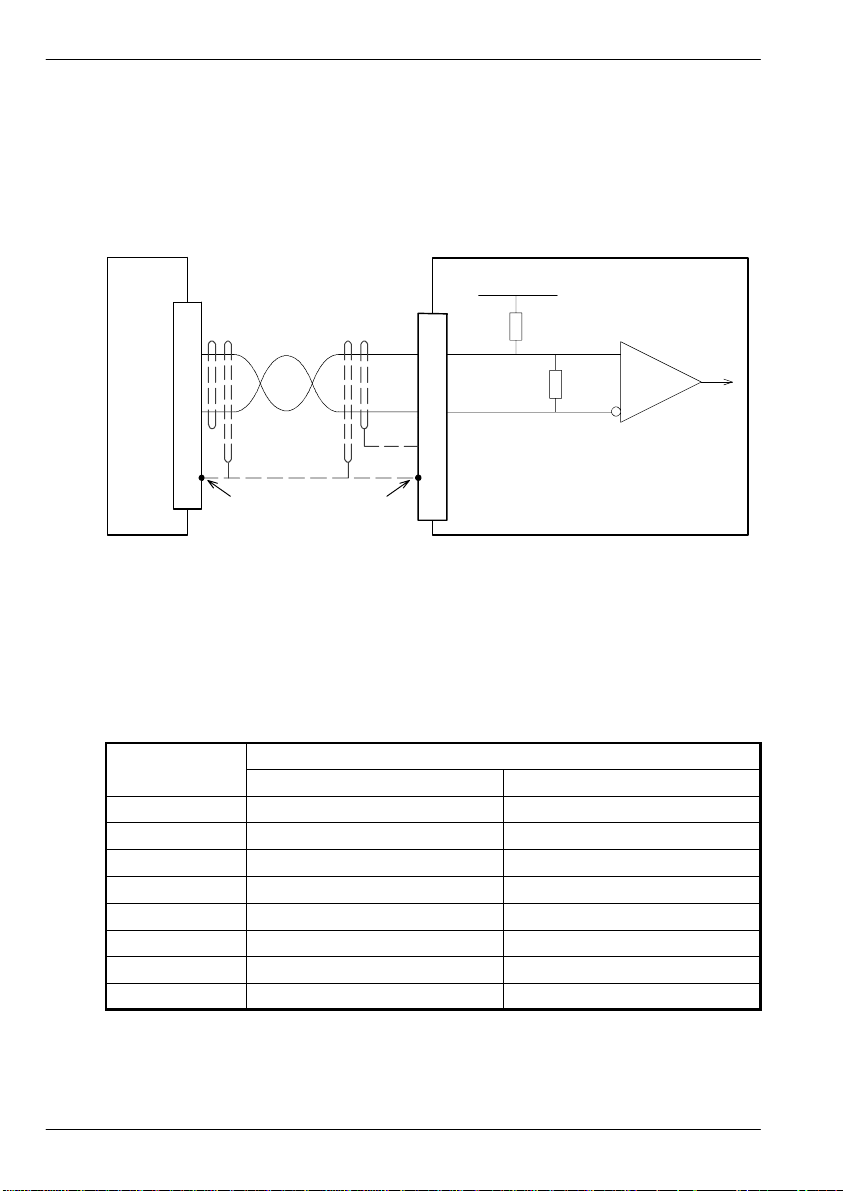

The analog inputs pass through a differential buffer and second order low-pass filter with a

cut-off frequency of approximately 1kHz.

Both inputs are normally sampled at 2kHz. However, an input can be disabled by setting

ADCMODE to4(_acOFF). With one input disabled, the remaining input will be sampled at 4kHz.

In MintMT, analog inputs can be read using the ADC keyword. See the MintMT help file for full

details of ADC and ADCMODE.

AIN0-

AIN0+

AGND

NextMove ES

a28

b28

a30

120k

120k

15k

22nF

-

+

10k 10k

-

+

10nF

MintMT

ADC.0

Figure 1 - Analog input, AIN0 shown

For differential inputs connect input lines to AIN+ and AIN-. Leave AGND unconnected.

Input / Output 4-3MN1928

Page 18

AIN0+

AIN0-

b28

AIN0

a28

(ADC.0)

a30

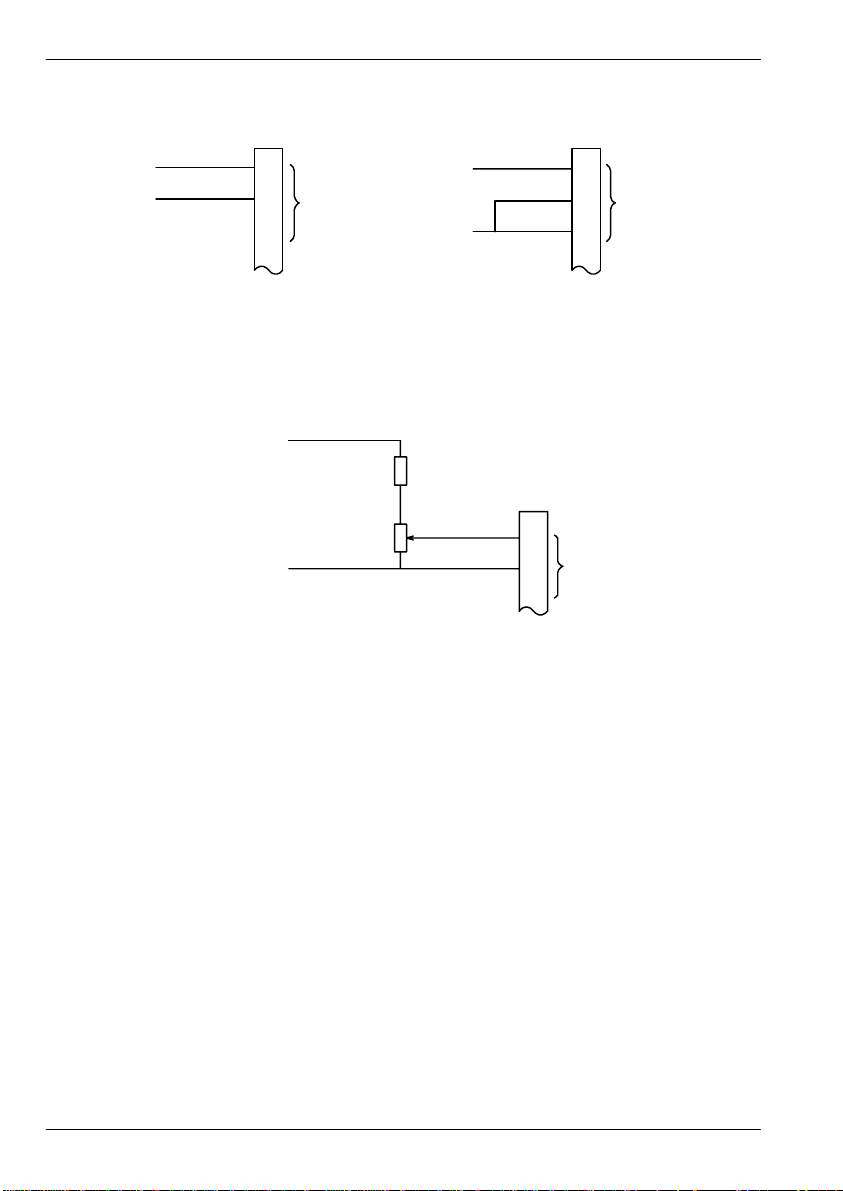

Differential connection Single ended connection

AIN0+

GND

b28

a28

a30

AIN0

(ADC.0)

Figure 2 - AIN0 analog input wiring

+24VDC

1.5kΩ, 0.25W

0V

1kΩ,0.25W

potentiometer

b28

a28

a30

AIN0

(ADC.0)

Figure 3 - Typical input circuit to provide 0-10V (approx.) input from a 24V source

4-4 Input / Output MN1928

Page 19

4.3.2 Analog outputs

The four analog outputs are available on a range of pins, as shown in section 4.2.1.

H Four independent analog outputs.

H Output range: ±10VDC (±0.1%).

H Resolution: 12-bit (accuracy ±4.9mV).

H Output current: 10mA maximum.

H Update frequency: 10kHz maximum (factory default 1kHz).

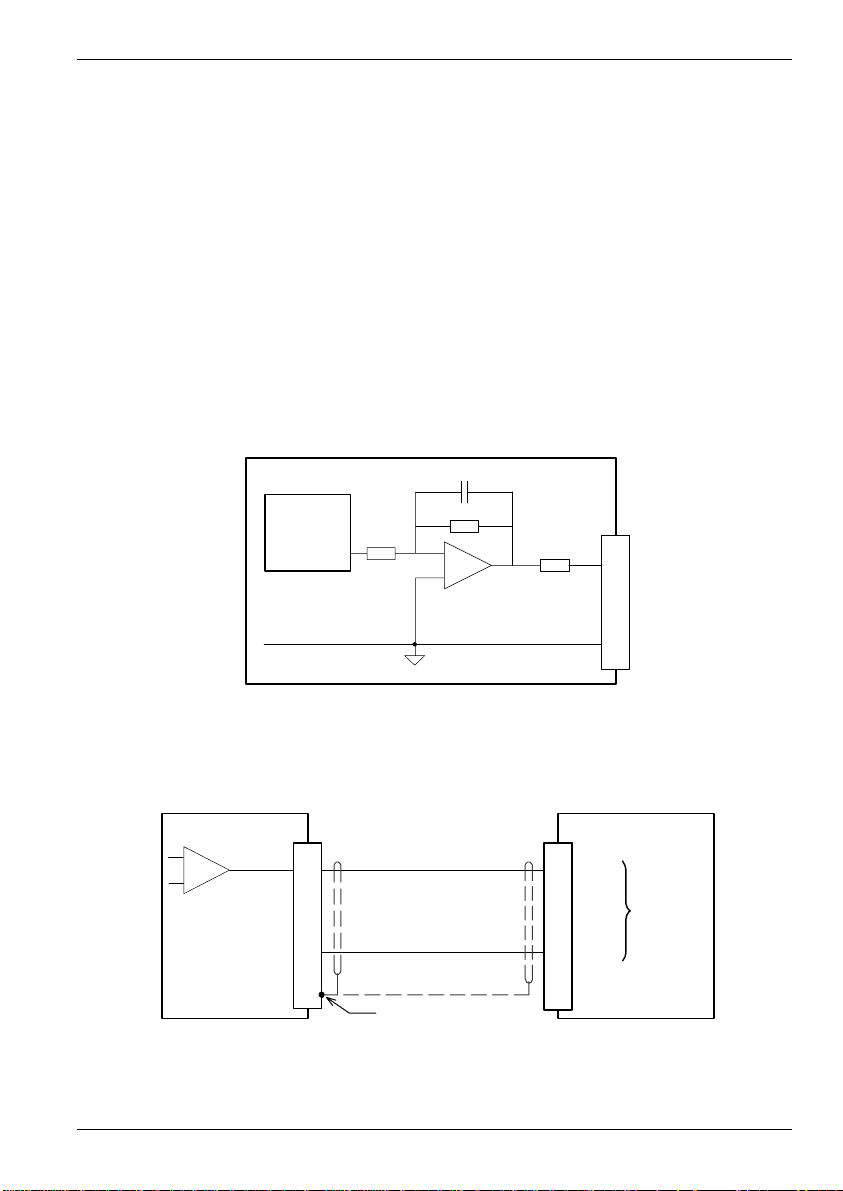

MintMT and the Mint Motion Library use analog outputs Demand0 and Demand1 to control

servo drives. Demand outputs 0 and 1 correspond to servo axes 4 and 5 respectively. The

Demand2 and Demand3 outputs may be used as general purpose analog outputs. See the

DAC keyword in the MintMT help file.

The analog outputs may be used to drive loads of 1kΩ or greater. Shielded twisted pair cable

should be used. The shield connection should be made at one end only.

NextMove ES

-

+

NextMove ES

Demand

±100%

30k

100pF

120k

-

TL084

+

Figure 4 - Analog output - Demand0 shown

Demand0

AGND

c27

a30

a32Shield

Connect overall shield at

one end only

47R

MicroFlex/ servo amplifier

13

12

AIN0+

AIN0-

c27

a30

Demand0

AGND

Servo

amplifier

±10VDC

demand

input

Figure 5 - Analog output - typical connection to a servo amplifier (Baldor MicroFlex shown)

Input / Output 4-5MN1928

Page 20

4.4 Digital I/O

The NextMove ES provides:

H 20 general purpose digital inputs.

H 12 general purpose digital outputs.

4.4.1 Digital inputs

The digital inputs are available across a range of pins, as shown in section 4.2.1. All digital

inputs have a common specification:

H 5V digital inputs with internal pull-up resistors. Can also be assigned to special purpose

functions such as Home, Limit, Stop and Error inputs.

H Sampling frequency: 1kHz.

NextMoveES

+5V

10k

DIN0

DGND

c21

a3

74AHCT14

1nF

MintMT

INX.0

GND

Figure 6 - General purpose digital input - DIN0 shown

CAUTION: Do not connect 24V signals to the digital inputs.

These unprotected inputs are connected directly to TTL compatible 74AHCT14 devices. If an

input is configured as edge triggered, the triggering pulse must have a duration of at least 1ms

(one software scan) to guarantee acceptance by MintMT. The use of shielded cable for inputs

is recommended.

4.4.1.1 General purpose inputs

The general purpose digital inputs DIN0 - DIN19 can be shared between axes, and are

programmable in Mint (using a range of keywords beginning with the letters INPUT... ) to

determine their active level and if they should be edge triggered. The state of individual inputs

can be read directly using the INX keyword. See the MintMT help file.

A general purpose digital input can be assigned to a special purpose function such as a home,

limit, stop or error input. See the keywords HOMEINPUT, LIMITFORWARDINPUT,

LIMITREVERSEINPUT, STOPINPUT, and ERRORINPUT in the MintMT help file.

4-6 Input / Output MN1928

Page 21

4.4.1.2 Auxiliary encoder inputs - DIN17 (STEP), DIN18 (DIR), DIN19 (Z)

DIN17-DIN19 may also be used as an auxiliary encoder input. DIN17 accepts step (pulse)

signals and DIN18 accepts direction signals, allowing an external source to provide the

reference for the speed and direction of an axis. The step frequency (20MHz maximum)

determines the speed, and the direction input determines the direction of motion. Both the

rising and falling edges of the signal on DIN17 cause an internal counter to be changed. If 5V

is applied to DIN18 (or it is left unconnected) the counter will increment. If DIN18 is grounded

the counter will be decremented.

Typically, one channel of an encoder signal (either A or B) would be used to provide the step

signal on DIN17, allowing the input to be used as an auxiliary (master) encoder input. The

input can be used as a master position reference for cam, fly and follow move types. For this,

the MASTERSOURCE keyword must be used to configure the step input as a master (auxiliary)

encoder input. The master position reference can then be read using the AUXENCODER

keyword.

Since a secondary encoder channel is not used, DIN18 allows the direction of motion to be

determined. The Z signal on DIN19 can be supplied from the encoder’s index signal, and may

be read using the AUXENCODERZLATCH keyword.

See the MintMT help file for details of each keyword.

4.4.1.3 Reset input - !RSTIN

When grounded, the reset input will cause a hardware reset of the NextMove ES. This is

equivalent to power-cycling the NextMove ES. Due to the internal pull-up resistor, the reset

input may be left floating.

4.4.1.4 Typical digital input wiring

MicroFlex / equipment output

+5V

10k

NEC PS2562L-1

Status+

Status-

3

2

DIN0

DGND

c21

1nF

a3

Figure 7 - Digital input - typical connections from Baldor MicroFlex

74AHCT14

Input / Output 4-7MN1928

NextMoveES

MintMT

INX.0

GND

Page 22

4.4.2 Digital outputs

The digital outputs are available across a range of pins, as shown in section 4.2.1.

H 12 general purpose digital outputs.

H One error output, configurable as a general purpose digital output.

H Update frequency: Immediate.

There are 12 general purpose digital outputs. An output can be configured in MintMT as a

general purpose output, a drive enable output or a global error output. Outputs can be shared

between axes and can be configured using WorkBench v5 (or the OUTPUTACTIVELEVEL

keyword) to determine their active level.

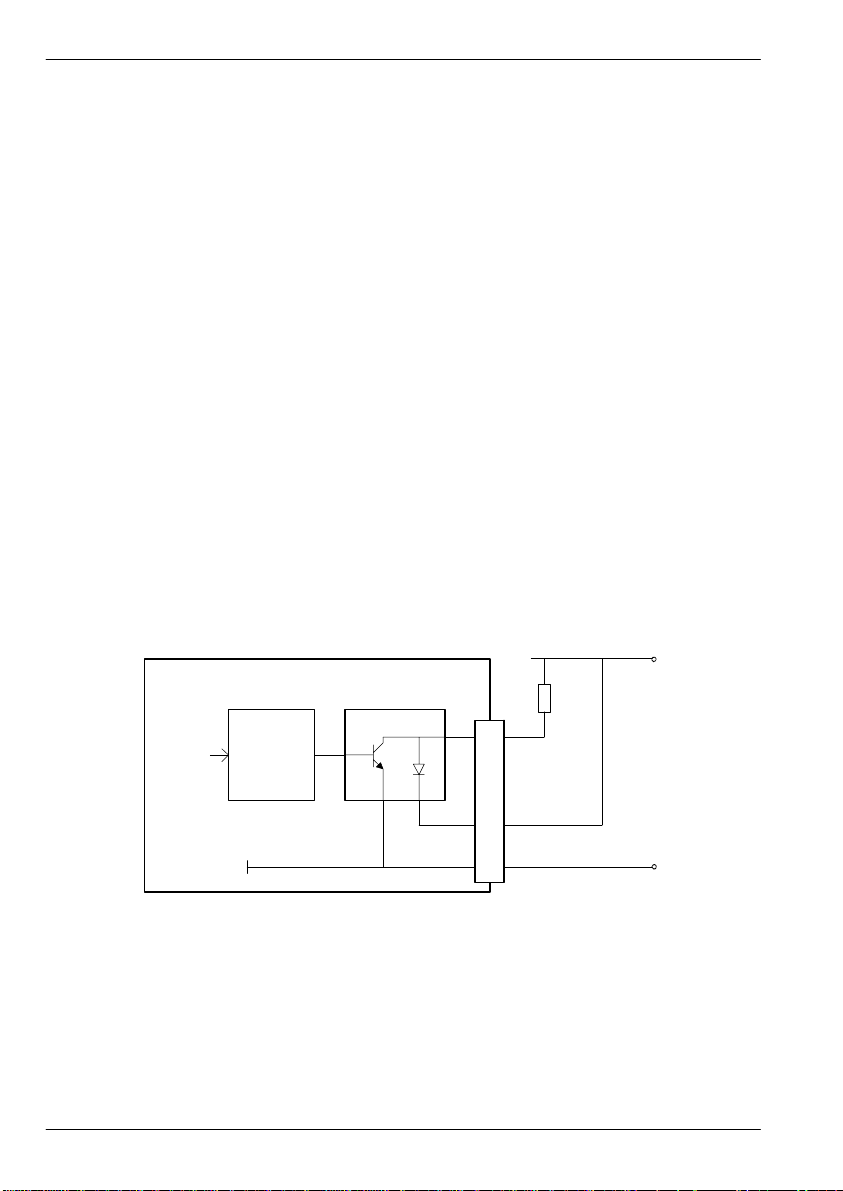

4.4.2.1 DOUT0 - DOUT7

Outputs DOUT0 - DOUT7 are driven by a ULN2803 device. The outputs are designed to sink

current from an external supply (typically 24VDC), but have no overcurrent or short circuit

protection. When an output is activated, it is grounded through the ULN2803.

The ULN2803 has a maximum power dissipation of 2W at 25°C. The total output requirements

of DOUT0 - DOUT7 must not exceed this limit. The maximum current limit for an individual

output is 500mA if only one output is in use, reducing to 150mA if all outputs are in use. These

limits are for a 100% duty cycle.

If the outputs are driving inductive loads such as relays, connect the OUT COM connection to

the output’s power supply, as shown in Figure 8. This will connect internal clamp diodes on all

outputs.

NextMove ES

MintMT

OUTX.0

ULN2803

c6

74AHCT244

DOUT0

Output

Load

Load

supply

24V

Connect to supply if

using inductive loads

a4

GND

a3

OUT COM

DGND

Load

supply

GND

Figure 8 - Digital outputs (DOUT0-7) - DOUT0 shown

4-8 Input / Output MN1928

Page 23

4.4.2.2 DOUT8 - DOUT11

Outputs DOUT8 - DOUT11 are driven by a ULN2003 device. The outputs are designed to sink

current from an external supply (typically 24VDC), but have no overcurrent or short circuit

protection. When an output is activated, it is grounded through the ULN2003.

The ULN2003 has a maximum power dissipation of 900mW at 25°C. The total output

requirements of DOUT8 - DOUT11 must not exceed this limit. The maximum current limit for

an individual output is 400mA if only one output is in use, reducing to 50mA if all outputs are in

use. These limits are for a 100% duty cycle.

DOUT8 - DOUT11 are sourced from the same ULN2003 device as the DIR2 and STEP2

outputs (see section 4.5.1), so the current demands of these signals must also be considered.

If an output is driving an inductive load such as a relay, a suitably rated diode must be fitted

across the relay coil, observing the correct polarity. This is to protect the output from the

back-EMF generated by the relay coil when it is de-energized.

NextMove ES

MintMT

OUTX.8

ULN2003

74AHCT244

GND

a13

a3

DOUT8

DGND

Load

supply

24V

Output Load

(Relay w ith

diode shown)

Load

supply

GND

Figure 9 - Digital outputs (DOUT8-11) - DOUT8 shown

Input / Output 4-9MN1928

Page 24

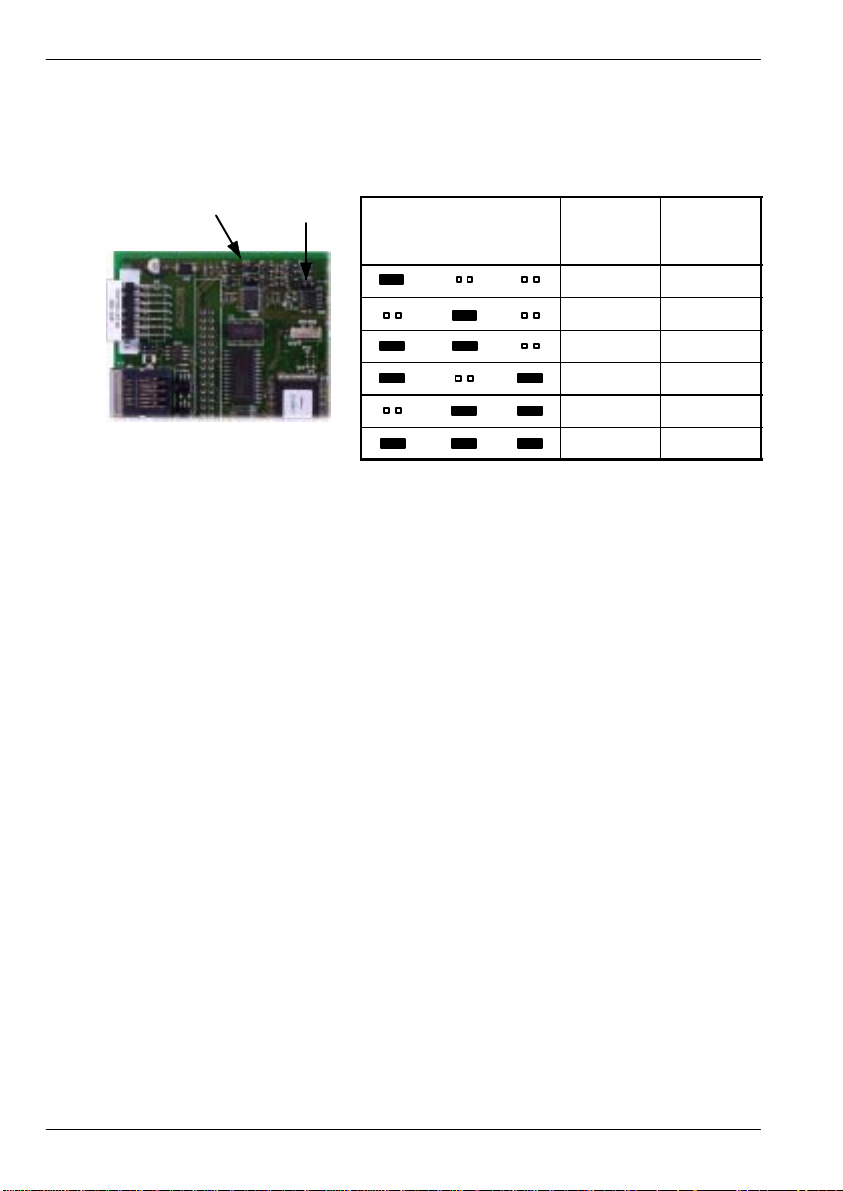

4.4.3 Error output - Error Out

The error output is available on pin b11. This 5V 100mA output can be used to stop external

equipment in the event of an error. The output level can be controlled using jumpers JP3, JP4

and JP5 as shown in Table 2. The jumpers are situated at the top edge of the card.

JP3

JP4

JP5

Jumpers

JP3 JP4 JP5

Inactive

state

(no error)

Floating 5V

0V Floating

0V 5V

5V Floating

Floating 0V

5V 0V

Table 2 - Error Out level configuration

There are a number of methods for controlling the error output.

4.4.3.1 RELAY keyword

If the NextMove ES is connected to an opto-isolated backplane (optional) the output directly

controls the relay (see section 5.3.1.1). For this reason, the error output can be controlled by

the RELAY keyword. The command RELAY=1 will enable the error output; the command

RELAY=0 will disable it. This is true regardless of whether an opto-isolating backplane is

connected.

4.4.3.2 DRIVEENABLEOUTPUT keyword

The DRIVEENABLEOUTPUT keyword can be used to configure the error output as the drive

enable output. For example, the command DRIVEENABLEOUTPUT.1=_RELAY0 will mean

that the error output will be the drive enable output for axis 1. When axis 1 is enabled, the

error output will be activated and the axis enabled. If multiple axes are configured to use the

error output as their drive enable output, enabling one axis will enable all of them. Similarly, if

one axis is disabled, all will be disabled.

Active

state

(error)

The RELAY keyword cannot control the error output if is configured as a drive enable output.

4.4.3.3 GLOBALERROROUTPUT keyword

By default, the error output is used as the global error output. In the event of an error on any

axis, the global error output will be deactivated. This action overrides the state of the error

output defined by other methods, such as the drive enable status or RELAY keyword.

Alternatively, the GLOBALERROROUTPUT keyword can be used to configure a general purpose

digital output to be the global error output.

See the MintMT help file for details of each keyword.

4-10 Input / Output MN1928

Page 25

4.5 Other I/O

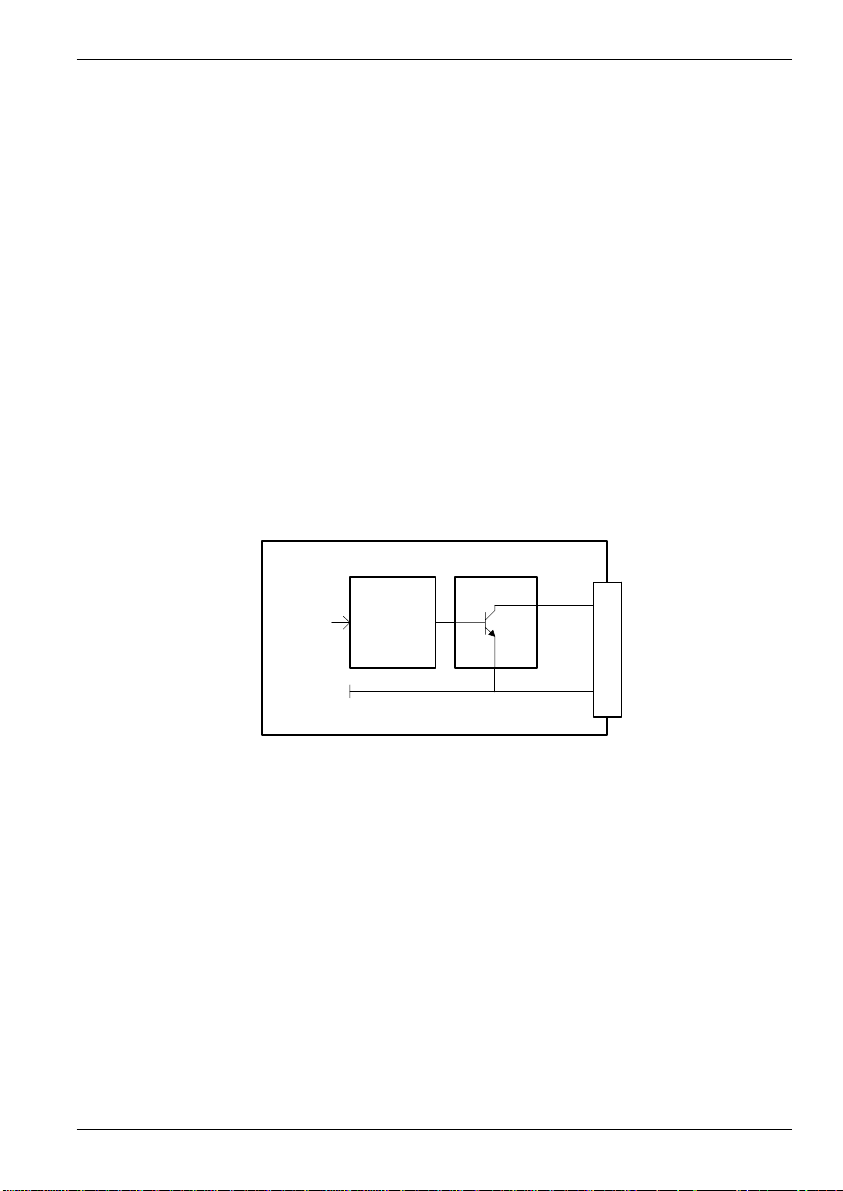

4.5.1 Stepper control outputs

The stepper control outputs are available across a range of pins, as shown in section 4.2.1.

There are four sets of stepper motor control outputs, operating in the range 10Hz to 1MHz.

Each of the step (pulse) and direction signals from the NextMove ES is driven by a ULN2003

open collector Darlington output device.

The ULN2003 has a maximum power dissipation of 900mW at 25°C. The total combined

output requirements of DIR0 - DIR2 and STEP0 - STEP2 must not exceed this limit. The

maximum current limit for an individual output is 400mA if only one output is in use, reducing to

50mA if all outputs are in use. These limits are for a 100% duty cycle.

DIR3 and STEP3 are sourced from the same ULN2003 device as the DOUT8 - DOUT11

outputs (see section 4.4.2.2), so the current demands of these signals must also be

considered.

It is recommended to use separate shielded cables for the step outputs. The shield should be

connected at one end only.

NextMove ES

Step

Output

ULN2003

74AHCT244

a14

STEP0

GND

Figure 10 - Stepper output - STEP0 output shown

DGNDa3

Input / Output 4-11MN1928

Page 26

4.5.2 Encoder inputs

AandBsignal

The encoder inputs are available on pins a7-a10, b7-b10 and c7-c10. See section 4.2.1.

Two incremental encoders may be connected to NextMove ES, each with complementary A, B

and Z channel inputs. Each input channel uses a MAX3095 differential line receiver with pull

up resistors and terminators. Encoders must provide RS422 differential signals. The use of

individually shielded twisted pair cable is recommended. See section 8.1.10 for details of the

encoder power supply.

MicroFlex

X7 encoder

output

CHA+

1

6CHA-

Connect overall shield to

connector backshells /

shield connections.

CHA+

CHA-

Twisted pair

DGND

Shield

NextMove ES

10k

b7

b10

Connect internal shield to DGND.

a11

Do not connect other end.

a32

Vcc

120R

MAX3095

to CPU

Figure 11 - Encoder channel input - typical connection from a servo amplifier

(Baldor MicroFlex shown)

4.5.2.1 Encoder input frequency

The maximum encoder input frequency is affected by the length of the encoder cables.

The theoretical maximum frequency is 20 million quadrature counts per second. This is

equivalent to a maximum frequency for the A and B signals of 5MHz. However, the effect of

cable length is shown in Table 3:

A and B signal

frequency

meters feet

Maximum cable length

1.3MHz 2 6.56

500kHz 10 32.8

250kHz 20 65.6

100kHz 50 164.0

50kHz 100 328.1

20kHz 300 984.2

10kHz 700 2296.6

7kHz 1000 3280.8

Table 3 - Effect of cable length on maximum encoder frequency

4-12 Input / Output MN1928

Page 27

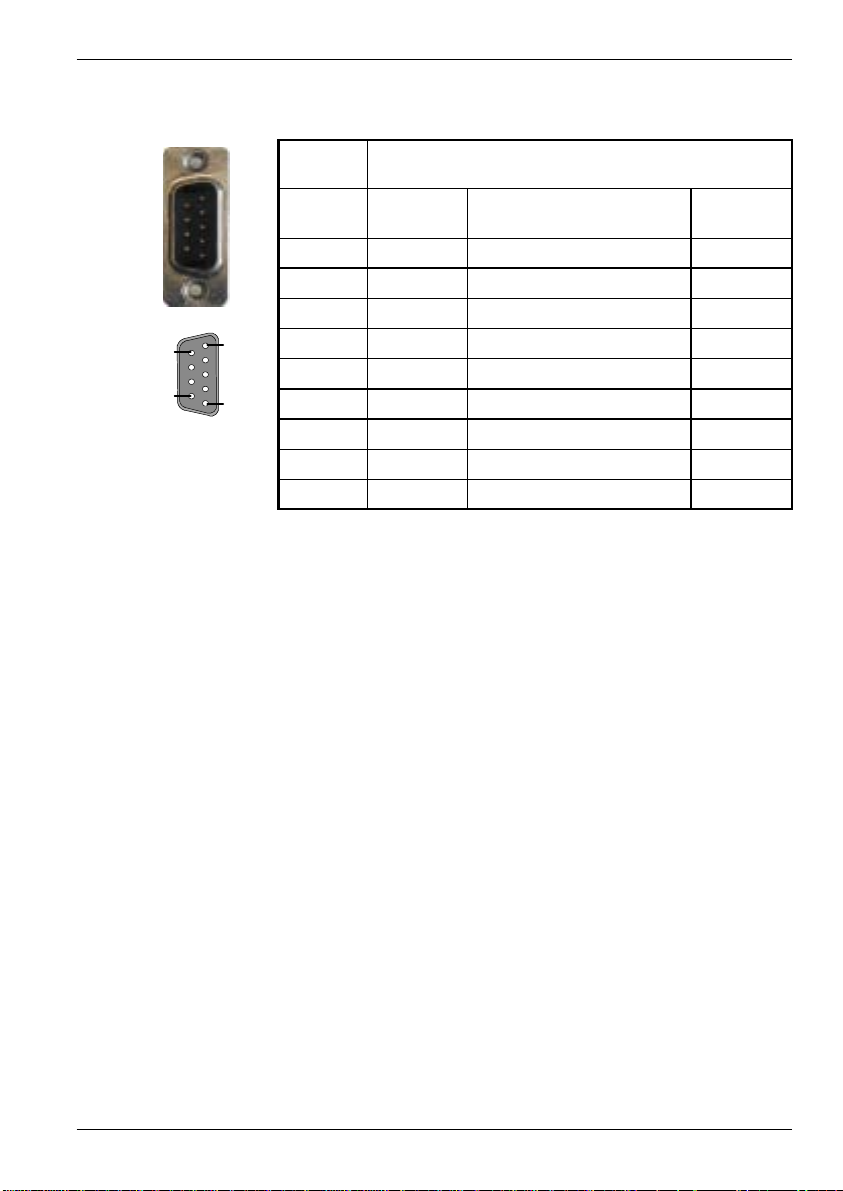

4.5.3 RS232 serial connection

Location Serial

Mating connector: 9-pin female D-type

Pin Name Description 96-pin

connector

1 Shield Shield connection a32

2 RXD Receive Data a20

3 TXD Transmitted Data a21

6

1

4 (NC) (Not connected) a16*

5 DGND Digital ground a3

9

5

6 (NC) (Not connected) a17*

7 RTS Request To Send b21

8 CTS Clear To Send a22

9 DGND Digital ground a3

* Pins a16 and a17 are linked on the NextMove ES.

The serial connector duplicates the signals present on the 96-pin connector. It is used to

connect the NextMove ES to the PC running WorkBench v5, or other controller. If an optional

Baldor backplane is being used, its serial connector (section 5.2.13 or 5.3.13) will carry the

same signals. Do not attempt to use more than one set of serial connections at the same time.

The port provides a full-duplex RS232 serial port with the following preset configuration:

H 57,600 baud

H 1startbit

H 8 data bits

H 1stopbit

H No parity

H Hardware handshaking lines (RS232) RTS and CTS must be connected.

The configuration can be changed using the SERIALBAUD keyword. It is stored in EEPROM

and restored at power up. The port is capable of operation at up to 115,200 baud.

The port is configured as a DCE (Data Communications Equipment) unit so it is possible to

operate the controller with any DCE or DTE (Data Terminal Equipment). Full duplex

transmission with hardware handshaking is supported.

Only the TXD, RXD and 0V GND connections are required for communication. Pins 4 and 6

are linked on the NextMove ES.

Input / Output 4-13MN1928

Page 28

NextMove ES

(DCE)

RS232

RXD 2

TXD 3

GND 5

RTS 7

CTS 8

Connect overall

shield to connector

backshell.

COM

2RXD

3TXD

5GND

7RTS

8CTS

9--pin

Computer

COM Port

(DCE / DTE)

Figure 12 - RS232 serial port connections

The maximum recommended cable length is 3m (10ft) at 57.6Kbaud. When using lower baud

rates, longer cable lengths may be used up to maximum of 15m (49ft) at 9600 baud. A suitable

cable is available from Baldor, catalog number CBL001-501.

4.5.4 USB connection

Location USB

Mating connector: USB Type B (downstream) plug

Pin Name Description

142

1 VBUS USB +5V

2 D- Data-

3 D+ Data+

4 GND Ground

3

The USB connector can be used as an alternative method for connecting the NextMove ES to

a PC running WorkBench v5, or other controller. The NextMove ES is a self-powered, USB 1.1

compatible device. The maximum recommended cable length is 5m.

4-14 Input / Output MN1928

Page 29

4.5.5 CAN connection

The CAN connection is made using the RJ45 connector on the NextMove ES card.

Location

NextMove ES card

Pin Name Description

1 CAN+ CAN channel positive

2 CAN - CAN channel negative

3 - (NC)

1

8

4 CAN 0V Ground/earth reference for CAN signals

5 CAN V+ CAN power V+ (12-24V)

6 - (NC)

7 - (NC)

8 - (NC)

Description

Opto-isolated CAN interface using a RJ45 connector.

CAN offers serial communications over a two wire twisted pair cable up to maximum length of

500m (1640ft). It offers very high communication reliability in an industrial environment; the

probability of an undetected error is 4.7x10

-11

. CAN is optimized for the transmission of small

data packets and therefore offers fast update of I/O devices (peripheral devices) connected to

the bus. The maximum (default) transmission rate on NextMove ES is 500Kbit/s.

Correct operation of CAN can only be achieved with screened/shielded twisted-pair cabling.

For improved noise immunity, CAN+ and CAN- must form a twisted pair with the shield

connected to the connector backshell, as shown in Figure 13. A range of suitable CAN cables

are available from Baldor, with catalog numbers beginning CBL004-5...

Baldor HMI

Operator Panel

7

2

NextMove ES

RJ45 connector

Twisted pair Twisted pairs

T

R

0V

1

2

4

5

Figure 13 - Typical CAN network connections

NextMove ES

RJ45 connector

1

2

4

524V

End node

1

2

T

R

4

5

Input / Output 4-15MN1928

Page 30

The CAN channel is opto-isolated. A voltage in the range 12-24V must be applied to pin 5 of

the CAN connector. An internal voltage regulator provides the 5V required for the isolated CAN

circuit. Practical operation of the CAN channel is limited to 500Kbit/s owing to the propagation

delay of the opto-isolators.

The CAN channel must be terminated by a 120Ω resistor connected

between CAN+ and CAN- at both ends of the network and nowhere

else. If the NextMove ES is at the end of the network then ensure

that jumper JP1, located just below the status display, is in position.

This will connect an internal terminating resistor.

JP1

A very low error rate over CAN can only be achieved with a suitable

wiring scheme, so the following points should be observed:

H The connection arrangement is normally a multi-point drop. The CAN cables should have

a characteristic impedance of 120Ω and a delay of 5ns/m. Other characteristics depend

upon the length of the cabling:

Cable length

Maximum

Resistance Conductor

theoretical

bit rate

0m ~ 300m (0ft ~ 984ft) 500Kbit/s <60mΩ/m 0.34 ~ 0.60mm

300m ~ 600m (984ft ~ 1968ft) 100Kbit/s <40mΩ/m 0.50 ~ 0.60mm

600m ~ 1000m (1968ft ~ 3280ft) 50Kbit/s <26mΩ/m 0.75 ~ 0.80mm

H The 0V connection of all of the nodes on the network must be tied together through the

CAN cabling. This ensures that the CAN signal levels transmitted by NextMove ES or

CAN peripheral devices are within the common mode range of the receiver circuitry of

other nodes on the network.

4.5.5.1 CANopen and Baldor CAN

The NextMove ES can communicate with other MintMT controllers over a CANopen network.

Baldor CAN is a proprietary CAN protocol, allowing the NextMove ES to communicate with a

range of Baldor ioNode CAN peripherals.

area

2

2

2

CANopen is a networking system based on the serial bus CAN. It uses the international CAN

standard ISO 11898 as the basis for communication. The Mint firmware implements a

CANopen protocol, based on the ‘Communication Profile’ CiA DS-301, which supports both

direct access to device parameters and time-critical process data communication. This

provides support for a range of Baldor and third-party devices. The NextMove ES has the

ability to act as the network manager node or as a slave on the CANopen network.

Baldor CAN is also a networking system based on the serial bus CAN. It uses the

international CAN standard ISO 11898 as the basis for communication. Optional MintMT

firmware can be downloaded to implement a proprietary Baldor protocol on CAN bus 2, based

on CAL (the CAN Application Layer). This supports both direct access to device parameters

and time-critical process data communication. Baldor CAN provides support for the full range

of Baldor ioNode CAN peripherals.

The baud rate and node number of the NextMove ES can be set using the BUSBAUD and

NODE keywords.

4-16 Input / Output MN1928

Page 31

4.6 Connection su mmary - minimum system wiring

As a guide, Figure 14 shows an example of the typical minimum wiring required to allow the

NextMove ES and a single axis stepper amplifier to work together. The optional opto-isolating

backplane card BPL010-502 is shown. Details of the connector pins are shown in Table 4.

+24V user supply

X4

Serial

X2 X3

Encoder0 Encoder1

X1

Host PC

Backplane

X6

X5

X13

X12

X11

NextMove ES

Drive amplifier (axis 0)

Pulse+

PulseDirection+

DirectionFault relay

Gnd

Enable

Gnd

X10

X9

X8

X7

+5V supply

±12V supply

Common

earth/ground

Notes:

In this example, the backpl ane’ s relay contacts are being

used to apply the 24V user supply to the drive amplifier’s

Enable input.

The backplane’s relay is driv en by the NextMove ES Error

Out signal. This signal may be c ontrolled by the keywords

DRIVEENABLEOUTPUT, GLOBALERROROUTPUT or RELAY.

The drive amplifier’s Fault relay connecti ons are shown

connected to digital input 0. If an error occurs, it can be

detected by using the MintMT Event IN0 ev ent.

The INPUTACTIVELEVEL keyword can be used to alter the

active state of the digital input.

Figure 14 - Example minimum system wiring

Input / Output 4-17MN1928

Page 32

Backplane

S

t

l

f

0Step(pulse)

i

t

D

i

t

i

l

f

0Di

t

ioni

t

connector

Pin Name of

card

X6 9 USR GND User power supply GND Enable signal ground

X8 9 REL NO Switched relay contact Enable signal input

signal

10 REL COM Common relay connection

Function Connection on drive

(Note: drive may be

labelled differently)

(linkedtoUSRV+)

X9 2 STEP0-

3 STEP0+

4 DIR0-

5 DIR0+

X12 1 DIN0 Digital input 0 Fault relay output

11 USR GND User power supply GND Fault relay GND

Table 4 - Connector details for minimum system wiring shown in Figure 14

ep signa

rec

on signa

or axis

or axis

rec

npu

npu

4-18 Input / Output MN1928

Page 33

5 Backplanes

5.1 Introduction

This section describes the optional backplane cards available for use with the NextMove ES.

These cards all provide standard wiring connections to the NextMove ES, but there are a

number of variants available:

H Baldor part number BPL010-501: Non-isolated backplane.

H Baldor part number BPL010-502: Isolated PNP backplane.

H Baldor part number BPL010-503: Isolated NPN backplane.

It is recommended to use one of these dedicated backplanes with your NextMove ES.

Each table shows the required mating connector and the associated pin on the NextMove ES

96-pin connector. Where multiple pins exist with the same function, for example AGND, one

example pin number is shown, but any identically named pin represents the same electrical

connection.

See section 4.2 for details of the 96-pin connector.

5

Input / Output 5-1MN1928

Page 34

5.2 BPL010-501 non-isolated backplane

This backplane provides direct connection to the NextMove ES signals without isolation. The

electrical specifications of all signals are therefore the same as described in section 4.

In the following sections, the signals AGND, DGND and Shield are listed with nominal

corresponding pins on the 96-pin connector, although they are all electrically connected on the

backplane. The OUT COM pin on connector X11 is not connected to ground.

Some signals are duplicated on multiple identically named pins on the 96-pin connector.

In these cases, only the lowest numbered pin is listed.

CAUTION: Some components are static sensitive devices. T ake appropriate ESD

precautions when handling the backplane.

5.2.1 Analog inputs

Location X8

10

1

See section 4.3.1 for electrical specifications of the analog inputs.

Mating connector: Weidmüller Omnimate BL 3.5/10

Pin Name Description 96-pin

10 Shield Shield connection a32

9 DGND Digital ground a3

8 !RSTIN Reset input c12

7 ERROR Error output b11

6 AGND Analog ground a30

5 AIN1- Analog input AIN1- a27

4 AIN1+ Analog input AIN1+ c28

3 AGND Analog ground a30

2 AIN0- Analog input AIN0- a28

1 AIN0+ Analog input AIN0+ b28

connector

5-2 Input / Output MN1928

Page 35

5.2.2 Analog outputs (demands)

Location X7

12

1

See section 4.3.2 for electrical specifications of the analog outputs.

Mating connector: Weidmüller Omnimate BL 3.5/12

Pin Name Description 96-pin

12 Shield Shield connection a32

11 AGND Analog ground a30

10 DEMAND3 Analog output AOUT3 b22

9 Shield Shield connection a32

8 AGND Analog ground a30

7 DEMAND2 Analog output AOUT2 b17

6 Shield Shield connection a32

5 AGND Analog ground a30

4 DEMAND1 Demand 1 output (AOUT1) b27

3 Shield Shield connection a32

2 AGND Analog ground a30

1 DEMAND0 Demand 0 output (AOUT0) c27

connector

Input / Output 5-3MN1928

Page 36

5.2.3 Digital inputs 0-7

Location X12

10

1

See section 4.4.1 for electrical specifications of the digital inputs.

Mating connector: Weidmüller Omnimate BL 3.5/10

Pin Name Description 96-pin

10 Shield Shield connection a32

9 DGND Digital ground a3

8 DIN7 Digital input DIN7 a19

7 DIN6 Digital input DIN6 c20

6 DIN5 Digital input DIN5 b19

5 DIN4 Digital input DIN4 c18

4 DIN3 Digital input DIN3 c19

3 DIN2 Digital input DIN2 a18

2 DIN1 Digital input DIN1 b20

1 DIN0 Digital input DIN0 c21

5.2.4 Digital inputs 8-15

Location X13

10

1

Mating connector: Weidmüller Omnimate BL 3.5/10

Pin Name Description 96-pin

10 Shield Shield connection a32

9 DGND Digital ground a3

8 DIN15 Digital input DIN15 b18

7 DIN14 Digital input DIN14 c23

6 DIN13 Digital input DIN13 b24

5 DIN12 Digital input DIN12 c26

4 DIN11 Digital input DIN11 a25

3 DIN10 Digital input DIN10 a24

2 DIN9 Digital input DIN9 b25

1 DIN8 Digital input DIN8 a26

connector

connector

See section 4.4.1 for electrical specifications of the digital inputs.

5-4 Input / Output MN1928

Page 37

5.2.5 Digital inputs 16-19

Location X6

5

1

See section 4.4.1 for electrical specifications of the digital inputs.

Mating connector: Weidmüller Omnimate BL 3.5/5

Pin Name Description 96-pin

5 DGND Digital ground a3

4 DIN19 Digital input DIN19 b26

3 DIN18 Digital input DIN18 c25

2 DIN17 Digital input DIN17 c24

1 DIN16 Digital input DIN16 c11

5.2.6 Digital outputs 0-7

Location X11

10

1

Mating connector: Weidmüller Omnimate BL 3.5/10

Pin Name Description 96-pin

10 DGND Digital ground a3

9 OUT COM Common a4

8 DOUT7 Digital output DOUT7 b4

7 DOUT6 Digital output DOUT6 c4

6 DOUT5 Digital output DOUT5 a5

5 DOUT4 Digital output DOUT4 b5

4 DOUT3 Digital output DOUT3 c5

3 DOUT2 Digital output DOUT2 a6

2 DOUT1 Digital output DOUT1 b6

1 DOUT0 Digital output DOUT0 c6

connector

connector

See section 4.4.2 for electrical specifications of the digital outputs.

Input / Output 5-5MN1928

Page 38

5.2.7 Digital outputs 8-11

Location X5

5

1

See section 4.4.2 for electrical specifications of the digital outputs.

Mating connector: Weidmüller Omnimate BL 3.5/5

Pin Name Description 96-pin

5 DGND Digital ground a3

4 DOUT11 Digital output DOUT11 c22

3 DOUT10 Digital output DOUT10 c16

2 DOUT9 Digital output DOUT9 b13

1 DOUT8 Digital output DOUT8 a13

connector

5-6 Input / Output MN1928

Page 39

5.2.8 Stepper axes outputs 0-1

Location X9

12

Mating connector: Weidmüller Omnimate BL 3.5/12

Pin Name Description 96-pin

connector

12 Shield Shield connection a32

11 DIR1+ Direction output 1+ b15

10 DIR1- Direction output 1-

9 STEP1+ Step (pulse) output 1+ b14

8 STEP1- Step (pulse) output 1-

1

7 DGND Digital ground a3

6 Shield Shield connection a32

5 DIR0+ Direction output 0+ a15

4 DIR0- Direction output 0-

3 STEP0+ Step (pulse) output 0+ a14

2 STEP0- Step (pulse) output 0-

1 DGND Digital ground a3

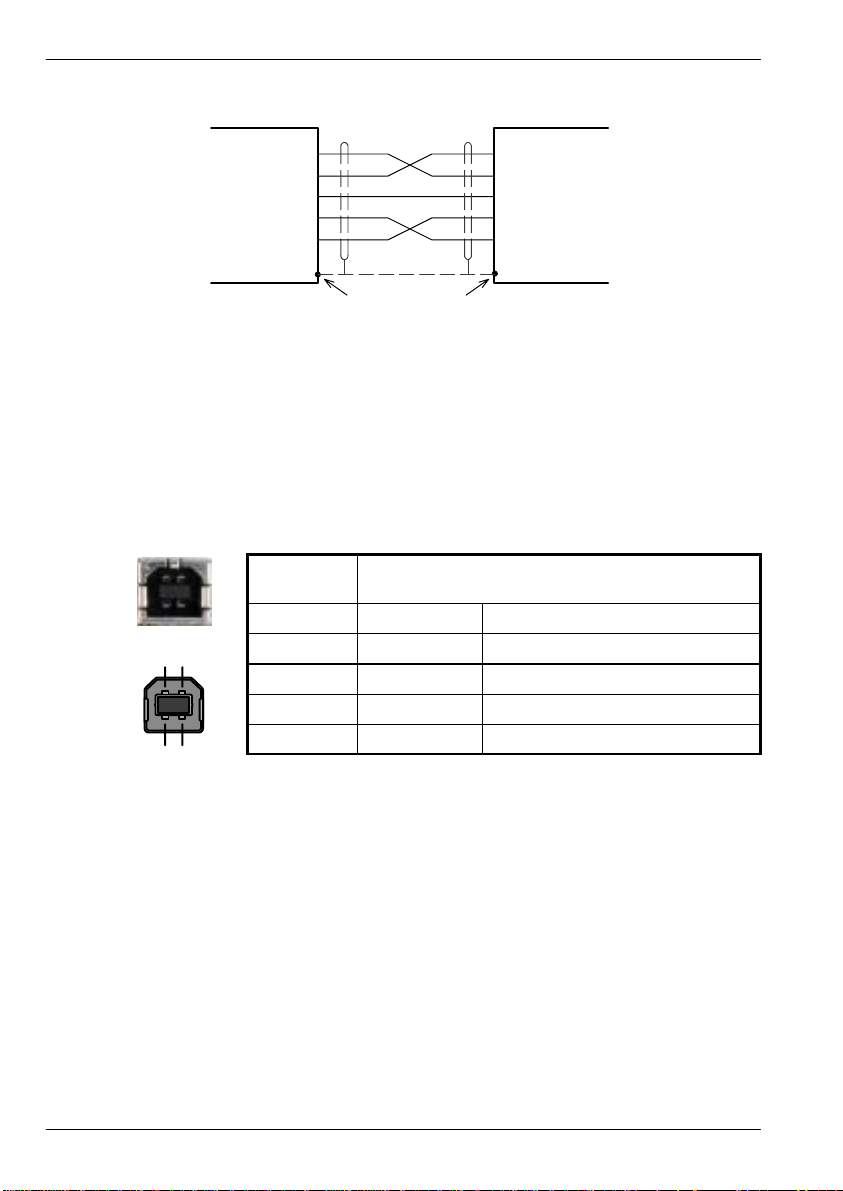

The stepper outputs on the backplane are driven by DS26LS31 line drivers, providing RS422

differential outputs.

CAUTION: The DS26LS31 drivers are static sensitive devices. T ake appropriate ESD

precautions when handling the backplane.

NextMove ES

Step

Output

GND

Backplane

DS26LS31

74AHCT244

ULN2003

96

pin

connector

Figure 15 - Stepper output - STEP0 output shown

‘X9’

STEP0-

2

STEP0+3

DGND

1

Input / Output 5-7MN1928

Page 40

5.2.9 Stepper axes outputs 2-3

Location X10

12

Mating connector: Weidmüller Omnimate BL 3.5/12

Pin Name Description 96-pin

connector

12 Shield Shield connection a32

11 DIR3+ Direction output 3+ a23

10 DIR3- Direction output 3-

9 STEP3+ Step (pulse) output 3+ b23

8 STEP3- Step (pulse) output 3-

1

7 DGND Digital ground a3

6 Shield Shield connection a32

5 DIR2+ Direction output 2+ c15

4 DIR2- Direction output 2-

3 STEP2+ Step (pulse) output 2+ c14

2 STEP2- Step (pulse) output 2-

1 DGND Digital ground a3

The stepper outputs on the backplane are driven by DS26LS31 line drivers, providing RS422

differential outputs.

CAUTION: The DS26LS31 drivers are static sensitive devices. T ake appropriate ESD

precautions when handling the backplane.

NextMove ES

Step

Output

GND

74AHCT244

ULN2003

connector

pin

Backplane

96

DS26LS31

1

2

‘X10’

STEP2-

STEP2+3

DGND

Figure 16 - Stepper output - STEP2 output shown

5-8 Input / Output MN1928

Page 41

5.2.10 Power inputs

Location X1

5

1

See section 3.1.3 for power requirements.

5.2.11 Encoder input 0

Location X3 Encoder0

9

6

5

1

Mating connector: Weidmüller Omnimate BL 3.5/5

Pin Name Description 96-pin

connector

5 DGND Digital ground a3

4 DGND Digital ground a3

3 +5 +5V input a1

2 -12 -12V input a31

1 +12 +12V input a29

Mating connector: 9-pin male D-type

Pin Name Description 96-pin

connector

1 CHA+ Channel A signal b7

2 CHB+ Channel B signal a7

3 CHZ+ Index channel signal b8

4 Shield Shield connection a32

5 DGND Digital ground a3

6 CHA- Channel A signal complement b10

7 CHB- Channel B signal complement c10

8 CHZ- Index channel signal complement b9

9 +5V out Power supply to encoder a1

Input / Output 5-9MN1928

Page 42

5.2.12 Encoder input 1

Location X2 Encoder1

Mating connector: 9-pin male D-type

Pin Name Description 96-pin

1 CHA+ Channel A signal a8

2 CHB+ Channel B signal c7

3 CHZ+ Index channel signal c8

4 Shield Shield connection a32

9

6

5

5 DGND Digital ground a1

6 CHA- Channel A signal complement c9

1

7 CHB- Channel B signal complement a10

8 CHZ- Index channel signal complement a9

9 +5V out Power supply to encoder a1

See section 4.5.2 for specifications of the encoder inputs.

5.2.13 RS232 serial communication

Location X4 Serial

6

9

1

5

Mating connector: 9-pin female D-type

Pin Name Description 96-pin

1 Shield Shield connection a32

2 RXD Receive Data a20

3 TXD Transmitted Data a21

4 (NC) (Not connected) a16*

5 DGND Digital ground a3

6 (NC) (Not connected) a17*

7 RTS Request To Send b21

8 CTS Clear To Send a22

9 DGND Digital ground a3

connector

connector

This serial connector carries the same signals as the serial connector on the NextMove ES

control card. Do not use both serial connectors at the same time.

*Pins4and6arelinkedontheNextMoveES.

5-10 Input / Output MN1928

Page 43

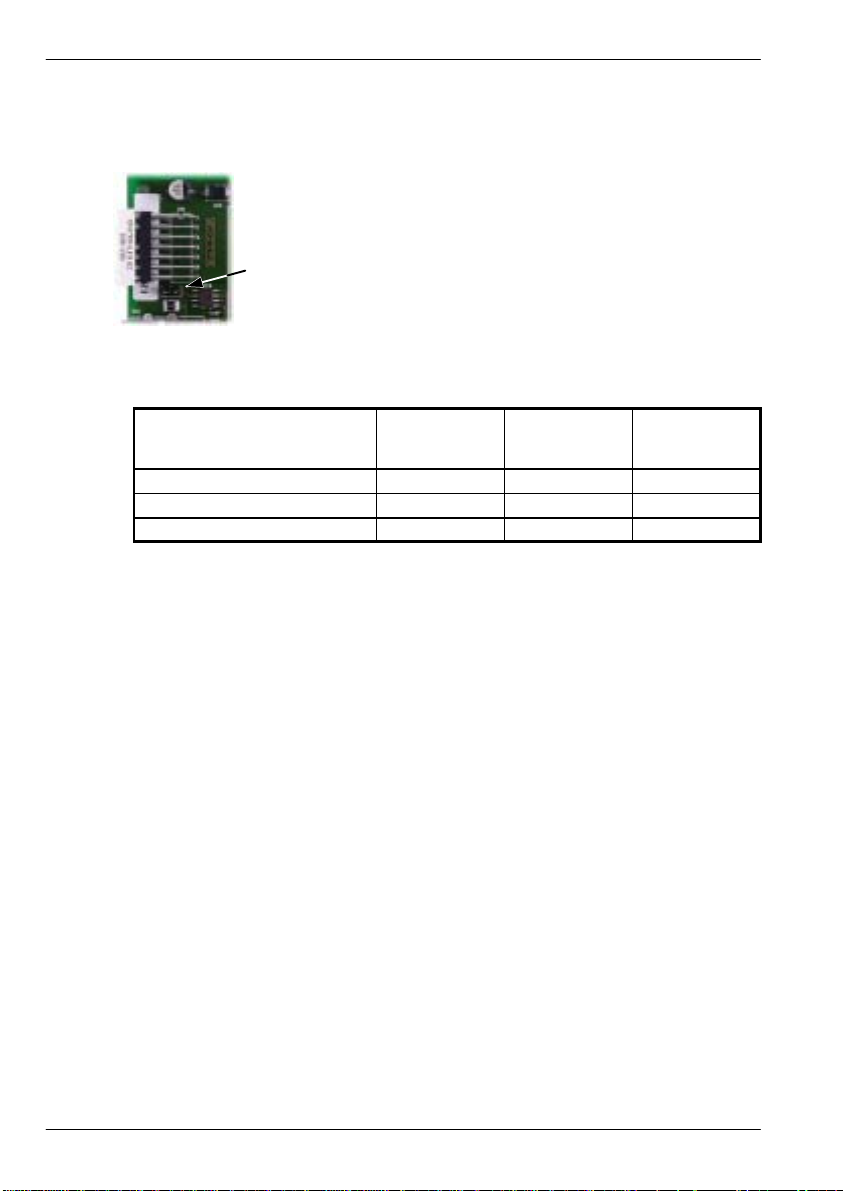

5.3 BPL010-502/503 backplane with opto-isolato r card

These backplanes are provided with an additional plug in card which provides opto-isolation

for many of the NextMove ES signals.

On BPL010-502, the general purpose digital outputs are PNP (current sourcing) outputs.

The general purpose digital inputs are activated when a positive voltage is applied.

On BPL010-503, the general purpose digital outputs are NPN (current sinking) outputs.

The general purpose digital inputs are activated when grounded.

There are two 96-pin connectors present on the opto-isolating backplane. The male connector

accepts the opto-isolator card. The female 96-pin connector nearest the edge of the backplane

accepts the NextMove ES card. The backplane will not operate without the opto-isolating card.

In the following sections, the signals AGND, DGND and Shield are listed with nominal

corresponding pins on the 96-pin connector, although they are all electrically connected on the

backplane. The OUT COM pin on connector X11 is not connected to ground.

All terminals labeled USR GND are electrically connected on the backplane, but are not

connected to the AGND, DGND or Shield terminals. USR GND forms an independent

common connection for the 0V side of the external power supply used for the digital inputs and

outputs. It will be necessary to link the OUT COM or USR COM terminal to USR GND to allow

the digital outputs to operate. However, the OUT COM and USR COM connectors have

different purposes depending on model - see sections 5.3.6.1 and 5.3.6.2.

Some signals are duplicated on multiple identically named pins on the 96-pin connector.

In these cases, only the lowest numbered pin is listed.

CAUTION: Some components are static sensitive devices. T ake appropriate ESD

precautions when handling the backplane.

Input / Output 5-11MN1928

Page 44

5.3.1 Analog inputs

Location X8

10

Mating connector: Weidmüller Omnimate BL 3.5/10

Pin Name Description NextMove ES

96-pin

connector

10 REL COM Common relay contact

9 REL NO Normally open relay contact

8 REL NC Normally closed relay contact

7 REL COM Common relay contact

1

6 Shield Shield connection a32

5 AIN1- Analog input AIN1- a27

4 AIN1+ Analog input AIN1+ c28

3 AGND Analog ground a30

2 AIN0- Analog input AIN0- a28

1 AIN0+ Analog input AIN0+ b28

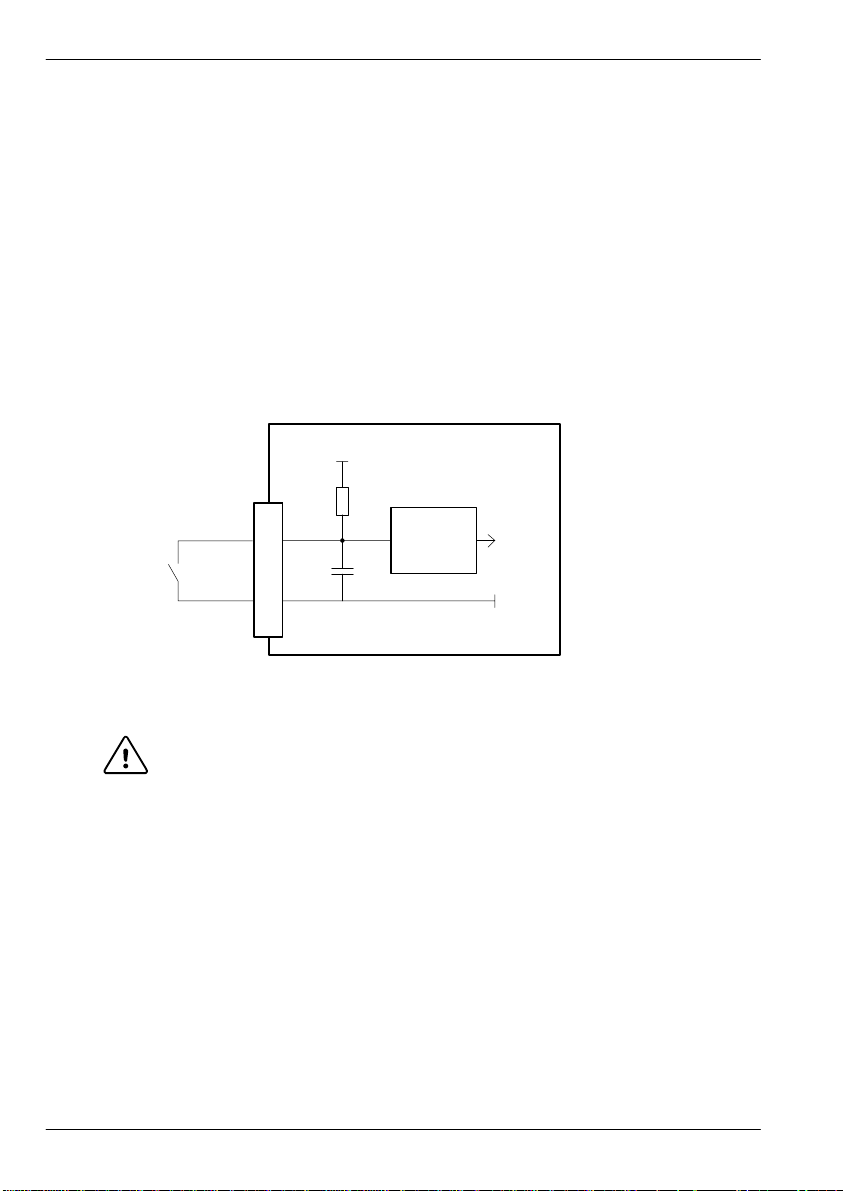

The analog inputs on the backplane are connected directly to the NextMove ES and do not

pass through any circuitry on the opto-isolator card. See section 4.3.1 for electrical

specifications of the analog inputs.

AIN0-

Backplane

2

1

3

96

pin

connector

NextMove ES

120k

120k

15k

22nF

-

+AIN0+

10k 10k

-

+

10nF

MintMT

ADC.0

‘X8’

AGND

Figure 17 - Analog input, AIN0 shown

5-12 Input / Output MN1928

Page 45

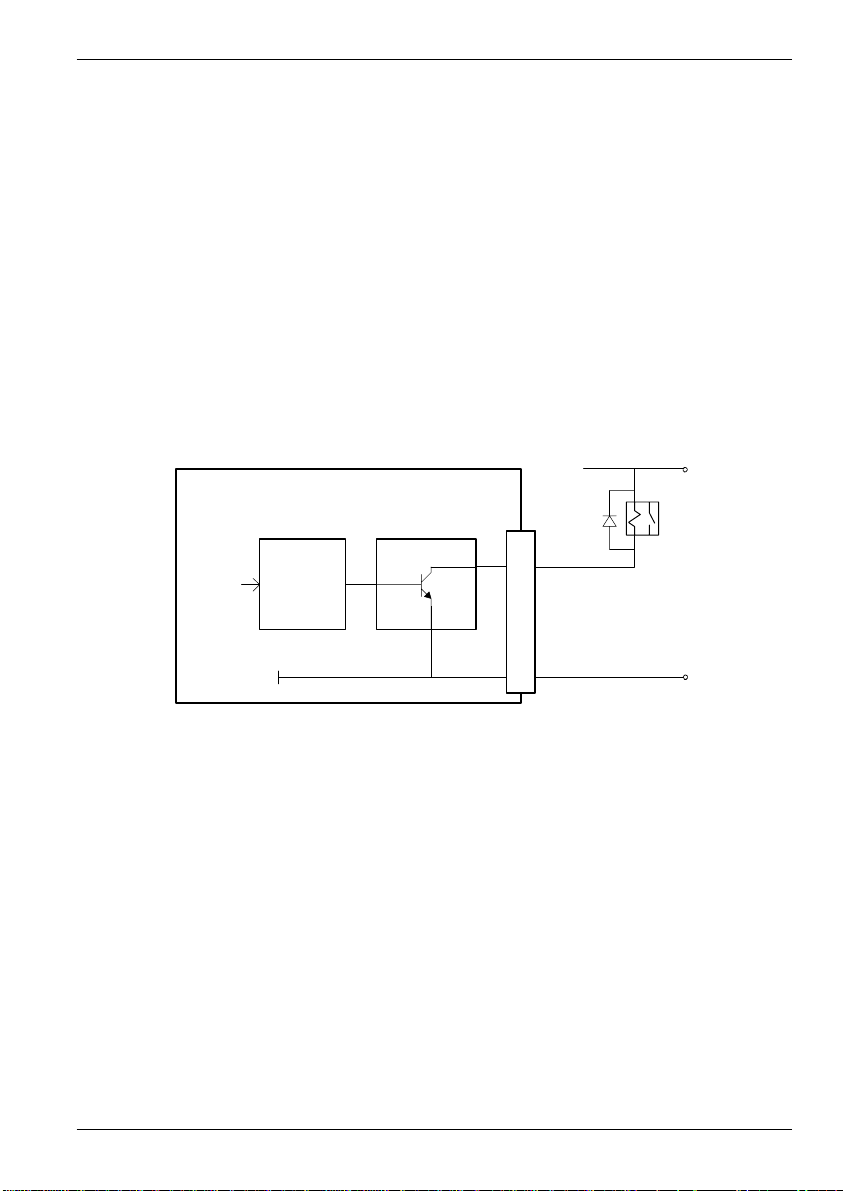

5.3.1.1 Error relay connections

The double-pole relay on the opto-isolator card is controlled directly by the Error Out signal

(section 4.4.3), as shown in Figure 18.

NextMove ES

MintMT

GLOBALERROROUTPUT

or

DRIVEENABLEOUTPUT

Control

circuitry

Error Out

96

pin

connector

+5V

Relay

Backplane

7

9

8

‘X8’

REL COM

REL NO

REL NC

Figure 18 - Relay connections

The error output can be controlled by the RELAY keyword, and can be configured as the global

error output by setting GLOBALERROROUTPUT to 1000 (_RELAY0). See the Mint MT help file.

While there is no error, the relay is energized, and REL COM is connected to REL NO.

When an error occurs, the relay is de-energized, and REL COM is connected to REL NC.

CAUTION: It is important that the NextMove ES jumper settings are correct to allow it

to control the backplane relay. JP4 must be fitted. Jumpers JP3 and JP5

must be removed. See section 4.4.3 for jumper locations.

Input / Output 5-13MN1928

Page 46

5.3.2 Analog outputs (demands)

Location X7

12

Mating connector: Weidmüller Omnimate BL 3.5/12

Pin Name Description NextMove ES

96-pin

connector

12 Shield Shield connection a32

11 AGND Analog ground a30

10 DEMAND3 Analog output AOUT3 b22

9 Shield Shield connection a32

1

8 AGND Analog ground a30

7 DEMAND2 Analog output AOUT2 b17

6 Shield Shield connection a32

5 AGND Analog ground a30

4 DEMAND1 Demand 1 output (AOUT1) b27

3 Shield Shield connection a32

2 AGND Analog ground a30

1 DEMAND0 Demand 0 output (AOUT0) c27

The outputs on the backplane are connected directly to the NextMove ES and do not pass

through any circuitry on the opto-isolator card. See section 4.3.2 for electrical specifications of

the analog outputs.

NextMove ES

100pF

Backplane

’X7’

Demand

±100%

30k

120k

-

TL084

+

47R

96

pin

connector

1

2

DEMAND0

AGND

Figure 19 - Analog output, DEMAND0 shown

5-14 Input / Output MN1928

Page 47

5.3.3 Digital inputs 0-7

Location X12

10

1

The BPL010-502 and BPL010-503 opto-isolating cards use different input configurations.

Sections 5.3.5.1 and 5.3.5.2 describe the two input types.

Mating connector: Weidmüller Omnimate BL 3.5/10

Pin Name Description NextMove ES

96-pin

connector

10 Shield Shield connection a32

9 USR GND Customer power supply ground

8 DIN7 Digital input DIN7 a19

7 DIN6 Digital input DIN6 c20

6 DIN5 Digital input DIN5 b19

5 DIN4 Digital input DIN4 c18

4 DIN3 Digital input DIN3 c19

3 DIN2 Digital input DIN2 a18

2 DIN1 Digital input DIN1 b20

1 DIN0 Digital input DIN0 c21

Input / Output 5-15MN1928

Page 48

5.3.4 Digital inputs 8-15

Location X13

10

1

The BPL010-502 and BPL010-503 opto-isolating cards use different input configurations.

Sections 5.3.5.1 and 5.3.5.2 describe the two input types.

Mating connector: Weidmüller Omnimate BL 3.5/10

Pin Name Description NextMove ES

96-pin

connector

10 Shield Shield connection a32

9 USR GND Customer power supply ground

8 DIN15 Digital input DIN15 b18

7 DIN14 Digital input DIN14 c23

6 DIN13 Digital input DIN13 b24

5 DIN12 Digital input DIN12 c26

4 DIN11 Digital input DIN11 a25

3 DIN10 Digital input DIN10 a24

2 DIN9 Digital input DIN9 b25

1 DIN8 Digital input DIN8 a26

5-16 Input / Output MN1928

Page 49

5.3.5 Digital inputs 16-19

Location X6

10

1

The BPL010-502 and BPL010-503 opto-isolating cards use different input configurations.

Sections 5.3.5.1 and 5.3.5.2 describe the two input types.

Mating connector: Weidmüller Omnimate BL 3.5/10

Pin Name Description NextMove ES

10 Shield Shield connection a32

9 USR GND Customer power supply ground

8 USR GND Customer power supply ground

7 USR V+ Customer power supply

6 USR V+ Customer power supply

5 !RST IN Reset input c12

4 DIN19 Digital input DIN19 b26

3 DIN18 Digital input DIN18 c25

2 DIN17 Digital input DIN17 c24

1 DIN16 Digital input DIN16 c11

96-pin

connector

Input / Output 5-17MN1928

Page 50

5.3.5.1 BPL010-502 - Active high inputs

The user power supply connection USR GND is common to all inputs. To activate an input, a

voltage must be applied that is sufficient to cause at least 5mA in the input circuit. To ensure

that an input becomes inactive, the current must be less than 1mA.

Backplane & opto-isolator card

‘X6’

NextMove ES

User

supply

24V

User

supply

GND

DIN16

‘X6’

USR GND

1

2k2

8

TLP521-4

96

pin

connector

+5V

10k

74AHCT14

Figure 20 - Digital input circuit (DIN16) with ‘active high’ inputs

5.3.5.2 BPL010-503 - Active low inputs

The user power supply connection USR V+ is common to all inputs. To activate an input it

must be grounded to the 0V side of the user power supply (USR GND). The internal pull-up

resistor on the NextMove ES allows the input to be left floating when inactive or not being

used.

Backplane & opto-isolator card

‘X6’

User

supply

24V

User

supply

GND

USR V+

‘X6’

DIN16

6

2k2

1

TLP521-4

96

pin

connector

+5V

10k

74AHCT14

MintMT

INX.16

GND

NextMove ES

MintMT

INX.16

GND

Figure 21 - Digital input circuit (DIN16) with ‘active low’ inputs

5-18 Input / Output MN1928

Page 51

5.3.6 Digital outputs 0-7

Location X11

10

1

The digital outputs DOUT0 - DOUT7 are buffered by the opto-isolator card.

* The BPL010-502 and BPL010-503 opto-isolating cards use different output driver ICs, as

shown in Figures 22 and 23. Due to the pin configuration of these ICs, the functions of the X11

connector’s USR COM and OUT COM pins are different on the PNP and NPN cards.

Sections 5.3.6.1 and 5.3.6.2 describe the two output types.

Mating connector: Weidmüller Omnimate BL 3.5/10

Pin Name Description NextMove ES

96-pin

connector

10 USR COM Common supply connection* a3

9 OUT COM Common* a4

8 DOUT7 Digital output DOUT7 b4

7 DOUT6 Digital output DOUT6 c4

6 DOUT5 Digital output DOUT5 a5

5 DOUT4 Digital output DOUT4 b5

4 DOUT3 Digital output DOUT3 c5

3 DOUT2 Digital output DOUT2 a6

2 DOUT1 Digital output DOUT1 b6

1 DOUT0 Digital output DOUT0 c6

CAUTION: Digital outputs DOUT8 - DOUT11 on connector X5 are not buffered by the

opto-isolator card - see section 5.3.7.

Input / Output 5-19MN1928

Page 52

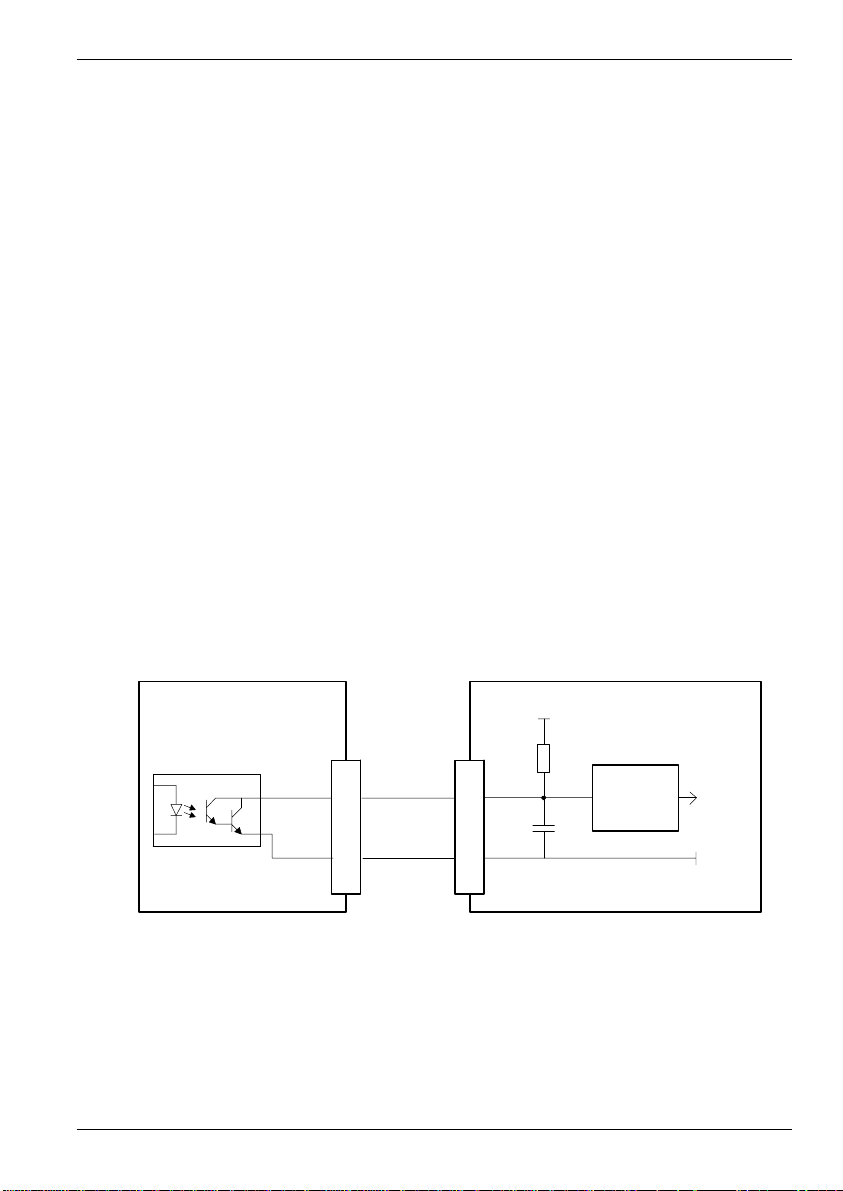

5.3.6.1 BPL010-502 - PNP outputs

An external supply (typically 24VDC) is used to power the UDN2982 output devices, as shown

in Figure 22. When an output is activated, current is sourced from the user supply through the

UDN2982, which can source up to 75mA per output (all outputs on, 100% duty cycle).

Connect OUT COM to the user supply GND. This will connect internal transient suppression

diodes on all outputs. If an output is used to drive a relay, a suitably rated diode must be fitted

across the relay coil, observing the correct polarity (see Figure 24). The use of shielded cable

is recommended.

6

10

1

9

‘X6’

USR V+

‘X11’

USR COM

DOUT0

OUT COM

Output

Load

User

supply

24V

User

supply

GND

NextMove ES

OUTX.0

Control

circuitry

96

pin

connector

Backplane & opto-isolator card

+5V

2k2

UDN2982

TLP521-4

Figure 22 - Digital output circuit (DOUT0-7) with ‘PNP’ current sourcing module - DOUT0 shown

5.3.6.2 BPL010-503 - NPN outputs

An external supply (typically 24VDC) is used to power the UDN2803 output devices and drive

the load, as shown in Figure 23. When an output is activated it is connected to USR COM

through the ULN2803, which can sink up to 150mA per output (all outputs on, 100% duty

cycle). Connect OUT COM to the user supply 24V. This will connect internal transient

suppression diodes on all outputs. If an output is used to drive a relay, a suitably rated diode

must be fitted across the relay coil, observing the correct polarity (see Figure 24). The use of

shielded cable is recommended.

6

1

9

10

‘X6’

USR V+

‘X11’

DOUT0

OUT COM

USR COM

Output

Load

User

supply

24V

User

supply

GND

NextMove ES

OUTX.0

Control

circuitry

96

pin

connector

Backplane & opto-isolator card

+5V

2k2

ULN2803

TLP521-4

Figure 23 - Digital output circuit (DOUT0-7) with ‘NPN’ current sinking module - DOUT0 shown

5-20 Input / Output MN1928

Page 53

5.3.7 Digital outputs 8-11

Location X5

Mating connector: Weidmüller Omnimate BL 3.5/5

5

Pin Name Description NextMove ES

96-pin

connector

1

5 DGND Digital ground a3

4 DOUT11 Digital output DOUT11 c22

3 DOUT10 Digital output DOUT10 c16

2 DOUT9 Digital output DOUT9 b13

1 DOUT8 Digital output DOUT8 a13

CAUTION: Digital outputs DOUT8 - DOUT11 on the backplane are not buffered by

the opto-isolator card; they are connected directly to the NextMove ES

outputs.

When an output is activated, it is grounded through the ULN2003, which can sink up to 50mA

per output (all outputs on, 100% duty cycle). If an output is used to drive a relay, a suitably

rated diode must be fitted across the relay coil, observing the correct polarity. This is to protect

the output from the back-EMF generated by the relay coil when it is de-energized.

User

supply

NextMove ES

MintMT

OUTX.8

74AHCT244

ULN2003

96

pin

connector

Backplane

1

’X5’

DOUT8

24V

Output Load

(Relay with

flyback diode

shown)

GND

5

Figure 24 - Digital output circuit (DOUT8-11) - DOUT8 shown

DGND

User

supply

GND

Input / Output 5-21MN1928

Page 54

5.3.8 Stepper axes outputs 0-1

Location X9

12

Mating connector: Weidmüller Omnimate BL 3.5/12

Pin Name Description NextMove ES

96-pin

connector

12 Shield Shield connection a32

11 DIR1+ Direction output 1+ b15

10 DIR1- Direction output 1-

9 STEP1+ Step (pulse) output 1+ b14

1

8 STEP1- Step (pulse) output 1-

7 DGND Digital ground a3

6 Shield Shield connection a32

5 DIR0+ Direction output 0+ a15

4 DIR0- Direction output 0-

3 STEP0+ Step (pulse) output 0+ a14

2 STEP0- Step (pulse) output 0-

1 DGND Digital ground a3

The stepper outputs on the backplane are driven by DS26LS31 line drivers, providing RS422

differential outputs.

CAUTION: The DS26LS31 drivers are static sensitive devices. T ake appropriate ESD

precautions when handling the backplane.

NextMove ES

Step

Output

GND

74AHCT244

ULN2003

connector

pin

Backplane

96

DS26LS31

1

2

‘X9’

STEP0-

STEP0+3

DGND

Figure 25 - Stepper output - STEP0 output shown

5-22 Input / Output MN1928

Page 55

5.3.9 Stepper axes outputs 2-3

Location X10

12

Mating connector: Weidmüller Omnimate BL 3.5/12

Pin Name Description 96-pin

connector

12 Shield Shield connection a32

11 DIR3+ Direction output 3+ a23

10 DIR3- Direction output 3-

9 STEP3+ Step (pulse) output 3+ b23

8 STEP3- Step (pulse) output 3-

1

7 DGND Digital ground a3

6 Shield Shield connection a32

5 DIR2+ Direction output 2+ c15