Page 1

LINEAR DRIVE

Servo Control

Installation & Operating Manual

Lin+Drive

10/00 MN1851

Page 2

Table of Contents

Section 1

General Information 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Compliance 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Notice 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2

Product Overview 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3

Receiving and Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving & Inspection 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location Considerations 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Installation 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Grounding 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Disconnect 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protection Devices 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X1 Power Connections 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X1 Motor Connections 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

M-Contactor 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Thermostat 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X1 Dynamic Brake Resistor 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X1 +24VDC Logic Supply 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X3 Control Inputs & Digital I/O Connections 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X6 RS232 / 485 Connections 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X7 Encoder Output 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X9 Encoder and Hall Feedback 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 4

Switch Setting and Start-Up 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch AS1 Settings 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-Up Procedure 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Off Checks 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power On Checks 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents iMN1851

Page 3

Section 5

Operation 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Software on your PC 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Minimum system requirements 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Host Communications Setup 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using The Setup Wizard 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set up Software 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Mode 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Parameter 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Velocity Parameter 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Triggered 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Triggered 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initialize Buffers 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Home 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limit Switches 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drift 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Autotune 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Menu Choice Descriptions 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edit 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Watch 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functions 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motion 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windows 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Help 5-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Program 5-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Velocity Parameters 5-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 6

Troubleshooting 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii Table of Contents MN1851

Page 4

Section 7

Specifications & Product Data 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Identification 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24VDC Logic Power Input 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Velocity Control 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Simulated Encoder Output 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Encoder Input 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Interface 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Interface 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regeneration 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 8

CE Guidelines 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Declaration of Conformity 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EMC – Conformity and CE – Marking 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EMC Installation Instructions 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 9

Accessories and Options 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cables 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connectors 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EMC AC Mains Filter 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regeneration Resistor 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Manual Tuning A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Mode A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Parameter A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Velocity Parameter A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drift A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Tuning A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plotting of Move A-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B

Command Set B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents iiiMN1851

Page 5

iv Table of Contents MN1851

Page 6

Section 1

General Information

Copyright Baldor 1999, 2000. All rights reserved.

This manual is copyrighted and all rights are reserved. This document may not, in

whole or in part, be copied or reproduced in any form without the prior written

consent of Baldor.

Baldor makes no representations or warranties with respect to the contents hereof

and specifically disclaims any implied warranties of fitness for any particular

purpose. The information in this document is subject to change without notice.

Baldor assumes no responsibility for any errors that may appear in this document.

Microsoft and MS–DOS are registered trademarks, and Windows is a trademark of

Microsoft Corporation.

UL and cUL are registered trademarks of Underwriters Laboratories.

CE Compliance

A custom unit may be required, contact Baldor. Compliance to Directive

89/336/EEC is the responsibility of the system integrator. A control, motor and all

system components must have proper shielding, grounding, and filtering as

described in MN1383. Please refer to MN1383 for installation techniques for CE

compliance. For additional information, refer to Sections 3 and 8 of this manual.

Limited Warranty

For a period of two (2) years from the date of original purchase, BALDOR will repair or

replace without charge controls and accessories which our examination proves to be

defective in material or workmanship. This warranty is valid if the unit has not been

tampered with by unauthorized persons, misused, abused, or improperly installed and

has been used in accordance with the instructions and/or ratings supplied. This warranty

is in lieu of any other warranty or guarantee expressed or implied. BALDOR shall not be

held responsible for any expense (including installation and removal), inconvenience, or

consequential damage, including injury to any person or property caused by items of our

manufacture or sale. (Some states do not allow exclusion or limitation of incidental or

consequential damages, so the above exclusion may not apply.) In any event, BALDOR’s

total liability, under all circumstances, shall not exceed the full purchase price of the

control. Claims for purchase price refunds, repairs, or replacements must be referred to

BALDOR with all pertinent data as to the defect, the date purchased, the task performed

by the control, and the problem encountered. No liability is assumed for expendable items

such as fuses.

Goods may be returned only with written notification including a BALDOR Return

Authorization Number and any return shipments must be prepaid.

General Information 1-1MN1851

Page 7

Product Notice Intended use:

These drives are intended for use in stationary ground based applications in

industrial power installations according to the standards EN60204 and VDE0160.

They are designed for machine applications that require variable speed controlled

three phase brushless AC motors.

These drives are not intended for use in applications such as:

– Home appliances

– Mobile vehicles

– Ships

– Airplanes

Unless otherwise specified, this drive is intended for installation in a suitable

enclosure. The enclosure must protect the control from exposure to excessive or

corrosive moisture, dust and dirt or abnormal ambient temperatures. The exact

operating specifications are found in Section 7 of this manual.

The installation, connection and control of drives is a skilled operation,

disassembly or repair must not be attempted.

In the event that a control fails to operate correctly, contact the place of purchase

for return instructions.

Safety Notice: This equipment contains high voltages. Electrical shock can cause serious or fatal

injury. Only qualified personnel should attempt the start–up procedure or

troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts or

parts that are driven by this equipment. Improper use can cause serious or fatal

injury. Only qualified personnel should attempt the start–up procedure or

troubleshoot this equipment.

– System documentation must be available at all times.

– Keep non-qualified personnel at a safe distance from this equipment.

– Only qualified personnel familiar with the safe installation, operation and

maintenance of this device should attempt start-up or operating

procedures.

– Always remove power before making or removing any connections to

this control.

PRECAUTIONS: Classifications of cautionary statements.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in injury or death.

Caution: Indicates a potentially hazardous situation which, if not avoided,

could result in damage to property.

1-2 General Information MN1851

Page 8

PRECAUTIONS:

WARNING: Do not touch any circuit board, power device or electrical

WARNING: Be sure that you are completely familiar with the safe operation

WARNING: Be sure all wiring complies with the National Electrical Code and

WARNING: Be sure the system is properly grounded before applying power.

WARNING: Do not remove cover for at least five (5) minutes after AC power

WARNING: Improper operation of control may cause violent motion of the

WARNING: Motor circuit may have high voltage present whenever AC power

WARNING: If a motor is driven mechanically, it may generate hazardous

WARNING: A DB Resistor may generate enough heat to ignite combustible

WARNING: The user must provide an external hard-wired emergency stop

connection before you first ensure that power has been

disconnected and there is no high voltage present from this

equipment or other equipment to which it is connected.

Electrical shock can cause serious or fatal injury.

of this equipment. This equipment may be connected to other

machines that have rotating parts or parts that are controlled by

this equipment. Improper use can cause serious or fatal injury.

all regional and local codes or CE Compliance. Improper wiring

may cause a hazardous condition.

Do not apply AC power before you ensure that grounds are

connected. Electrical shock can cause serious or fatal injury.

is disconnected to allow capacitors to discharge. Electrical

shock can cause serious or fatal injury.

motor and driven equipment. Be certain that unexpected

movement will not cause injury to personnel or damage to

equipment. Peak torque of several times the rated motor torque

can occur during control failure.

is applied, even when motor is not moving. Electrical shock can

cause serious or fatal injury.

voltages that are conducted to its power input terminals. The

enclosure must be grounded to prevent a possible shock hazard.

materials. To avoid fire hazard, keep all combustible materials

and flammable vapors away from brake resistors.

circuit to disable the control in the event of an emergency.

Continued on next page.

General Information 1-3MN1851

Page 9

Section 1

General Information

Caution: Suitable for use on a circuit capable of delivering not more than the RMS

Caution: To prevent equipment damage, be certain that the input power has

Caution: Avoid locating the control immediately above or beside heat generating

Caution: Avoid locating the control in the vicinity of corrosive substances or

Caution: Do not connect AC power to the control terminals U, V and W. Connecting

Caution: Baldor recommends not using “Grounded Leg Delta” transformer power

Caution: Logic signals are interruptible signals; these signals are removed when

Caution: Controls are intended to be connected to a permanent main power source,

Caution: The safe integration of the drive into a machine system is the

Caution: Controls must be installed inside an electrical cabinet that provides

Caution: Do not tin (solder) exposed wires. Solder contracts over time and may

Caution: Electrical components can be damaged by static electricity. Use ESD

Caution: Ensure that encoder wires are properly connected. Incorrect installation

Caution: The holes in the top and bottom of the enclosure are for cable clamps. Be

symmetrical short circuit amperes listed here at rated voltage.

Horsepower

1–50 5,000

correctly sized protective devices installed as well as a power disconnect.

equipment, or directly below water or steam pipes.

vapors, metal particles and dust.

AC power to these terminals may result in damage to the control.

leads that may create ground loops and degrade system performance.

Instead, we recommend using a four wire Wye.

power is removed from the drive.

not a portable power source. Suitable fusing and circuit protection devices

are required.

responsibility of the machine designer. Be sure to comply with the local

safety requirements at the place where the machine is to be used. In

Europe this is the Machinery Directive, the ElectroMagnetic Compatibility

Directive and the Low Voltage Directive. In the United States this is the

National Electrical code and local codes.

environmental control and protection. Installation information for the drive

is provided in this manual. Motors and controlling devices that connect to

the drive should have specifications compatible to the drive.

cause loose connections.

(electro-static discharge) procedures when handling this control.

may result in improper rotation or incorrect commutation.

sure to use an M4 bolt 12mm in length. Longer bolts may short circuit the

electrical components inside the control.

rms Symmetrical Amperes

1-4 General Information MN1851

Page 10

Section 2

Product Overview

Overview The Lin+Drive product is designed to serve the needs of machine designers and

manufacturers. Baldor products have both UL and CE approvals. The Lin+Drive

is a “flexible” versatile compact control for linear brushless motors. This digital

servo control can be tailored to suit many applications. It can accept 0–10VDC

input, standard ±10VDC input, current loop input or 15 preset point to point moves.

Some options are CAN bus interface, internal or external regen, or with customer

provided 24VDC to maintain logic power.

The Lin+Drive can be integrated with Baldors’ motion controllers or to any industry

standard motion controller.

Motors Baldor servo controls are compatible with many motors from Baldor and other

manufacturers. Motor parameters are provided with the PC software making the

setup easy. Baldor compatible motors include:

LMBL Series

LMCF Series

Contact your local Baldor distributor or sales representative for assistance with

motor sizing and compatibility. Custom motors or motors not manufactured by

Baldor may be used. Please contact your local Baldor distributor or sales

representative for assistance.

Command Source

In the analog mode (current or velocity), the control requires a variable 0-10VDC

or ±10VDC external analog signal. Suitable sources can be a PLC or motion

controller.

Positioning Mode

In the positioning mode, up to 15 preset repeatable positions (moves) may be

defined in software. These moves may either be incremental, absolute or mixed.

A specific “preset” position is selected using the switch inputs (machine inputs

1–4) and a “trigger” input activates the move. A home position could also be set if

desired.

Serial Communications Interface

A serial port allows external communication. This means that the Lin+Drive can

interface to a PC (for configuration and control) or to other user–supplied

equipment such as:

Host computers

PLC’s

PC’s

Motion controllers

The serial communication interface supports:

RS232 and the four wire RS–485 communication standards

Baud rate: 9600

Product Overview 2-1MN1851

Page 11

Control Inputs Opto isolated inputs are single ended, user selectable and active high or low:

Enable Machine Input 1

Quit Machine Input 2

Fault Reset Machine Input 3

Home Flag Machine Input 4

Trigger

Note: Machine Inputs 1–4 allow up to 16 digital preset point to point positions.

Control Outputs

One normally closed relay contact provides a dedicated “Drive Ready” output.

Two opto isolated outputs are single ended, active low and are current sinking.

Either output can be assigned to one of the following:

In Position Machine Input 1

CW Warning Machine Input 2

CCW Warning Machine Input 3

Following Error Flag Machine Input 4

Following Error Warning I

2

t Warning

Drive Over Temperature

Encoder Output

The motor encoder signals are available at this output connector (1 to 1).

2-2 Product Overview MN1851

Page 12

Section 3

Receiving and Installation

Receiving & Inspection Baldor Controls are thoroughly tested at the factory and carefully

packaged for shipment. When you receive your control, there are several things

you should do immediately.

1. Observe the condition of the shipping container and report any damage

immediately to the commercial carrier that delivered your control.

2. Remove the control from the shipping container and remove all packing

materials. The container and packing materials may be retained for

future shipment.

3. Verify that the part number of the control you received is the same as the

part number listed on your purchase order.

4. Inspect the control for external physical damage that may have been

sustained during shipment and report any damage immediately to the

commercial carrier that delivered your control.

5. If the control is to be stored for several weeks before use, be sure that it

is stored in a location that conforms to published storage humidity and

temperature specifications stated in this manual.

Location Considerations The location of the control is important. Installation should be in an area

that is protected from direct sunlight, corrosives, harmful gases or liquids, dust,

metallic particles, and vibration. Exposure to these can reduce the operating life

and degrade performance of the control.

Several other factors should be carefully evaluated when selecting a location for

installation:

1. For effective cooling and maintenance, the control should be mounted

on a smooth, non-flammable vertical surface.

2. At least 0.6 inches (15mm) top and bottom clearance must be provided

for air flow. At least 0.4 inches (10mm) clearance is required between

controls (each side).

3. Altitude derating. Up to 3300 feet (1000 meters) no derating required.

Derate the continuous and peak output current by 1.1% for each 330

feet (100 meters) above 3300 feet.

4. Temperature derating. From 0°C to 40°C ambient no derating

required. Above 40°C, derate the continuous and peak output current by

2.5% per °C above 40°C. Maximum ambient is 50°C.

Mechanical Installation

Mount the control to the mounting surface. The control must be securely fastened

to the mounting surface by the control mounting holes. The location of the

mounting holes is shown in Section 7 of this manual.

Receiving & Installation 3-1MN1851

Page 13

Electrical InstallationAll interconnection wires between the control, AC power source, motor, host

control and any operator interface stations should be in metal conduits. Use listed

closed loop connectors that are of appropriate size for wire gauge being used.

Connectors are to be installed using crimp tool specified by the manufacturer of

the connector. Only class 1 wiring should be used.

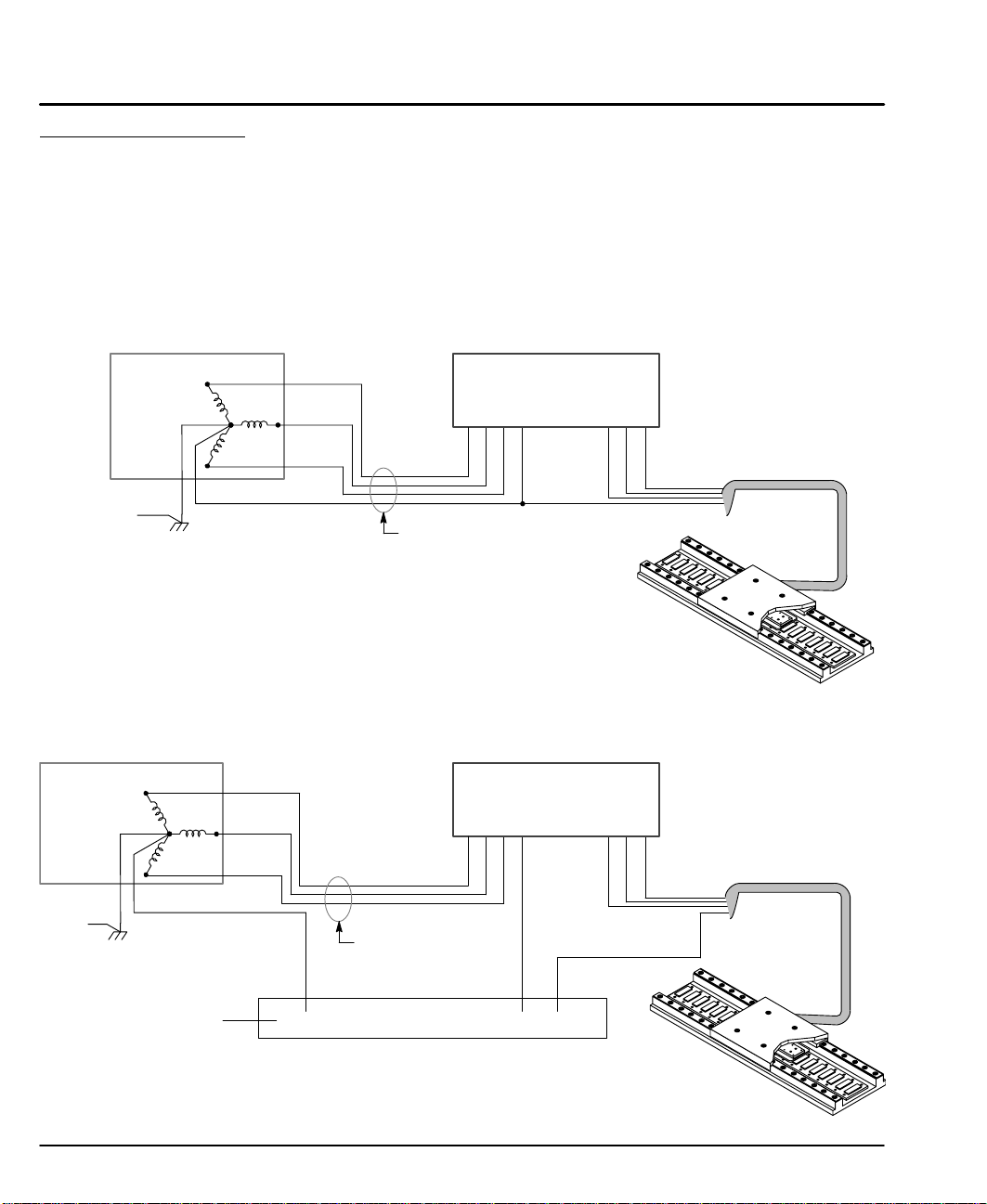

System Grounding Baldor controls are designed to be powered from standard single and three

phase lines that are electrically symmetrical with respect to ground. System

grounding is an important step in the overall installation to prevent problems. The

recommended grounding method is shown in Figure 3-1 and 3-3 for UL compliant

systems (Figure 3-2 and 3-4 for CE compliant systems).

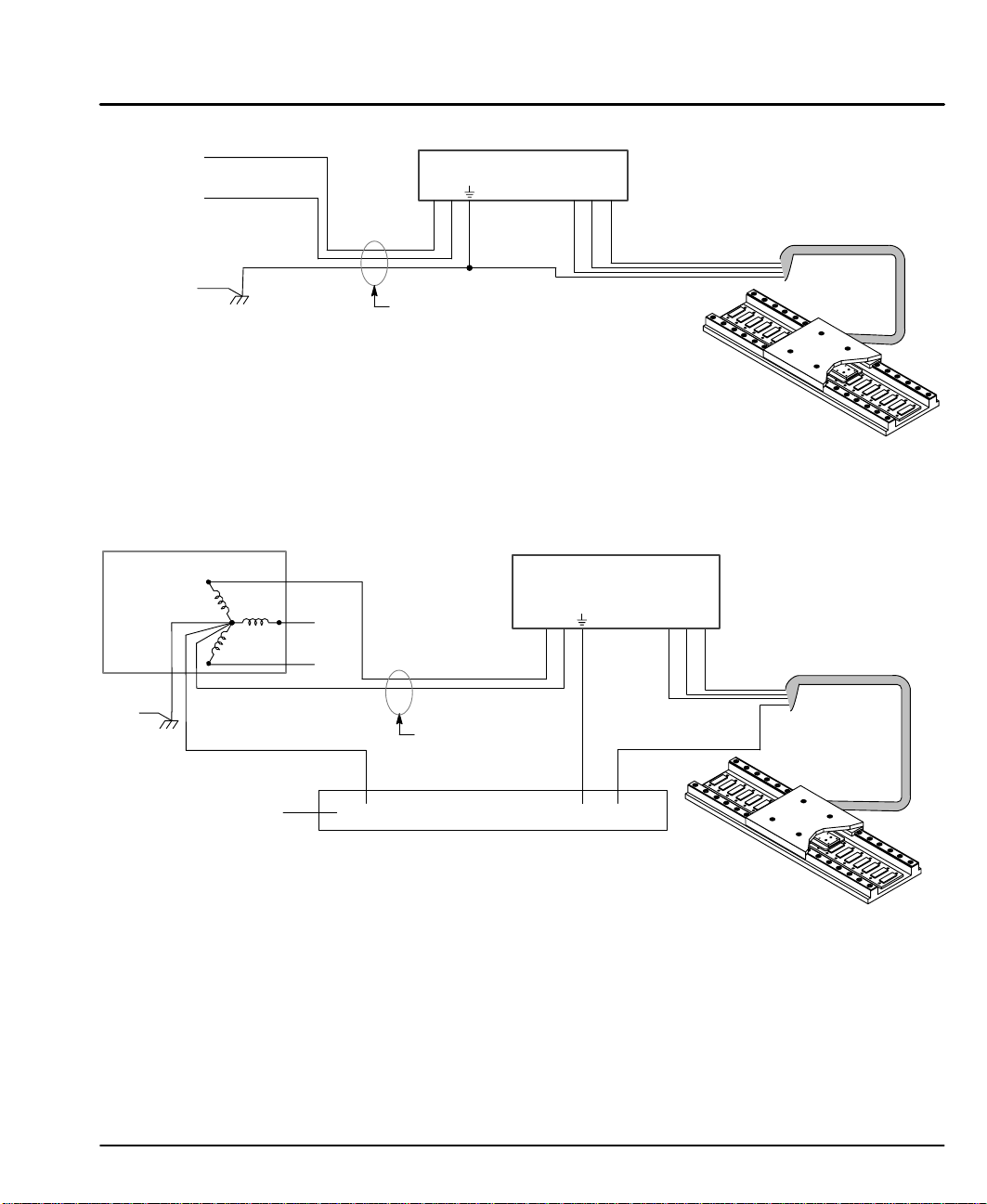

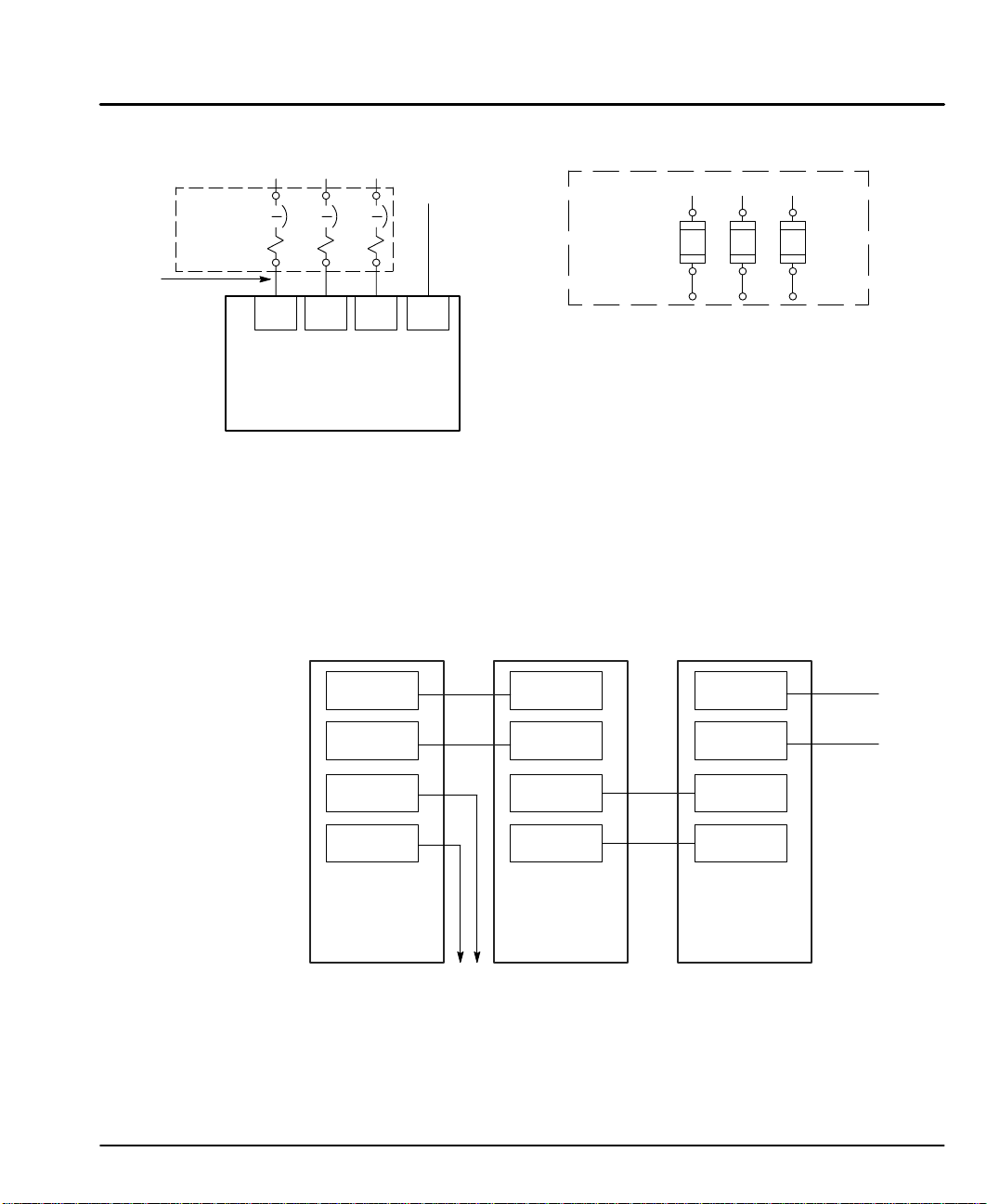

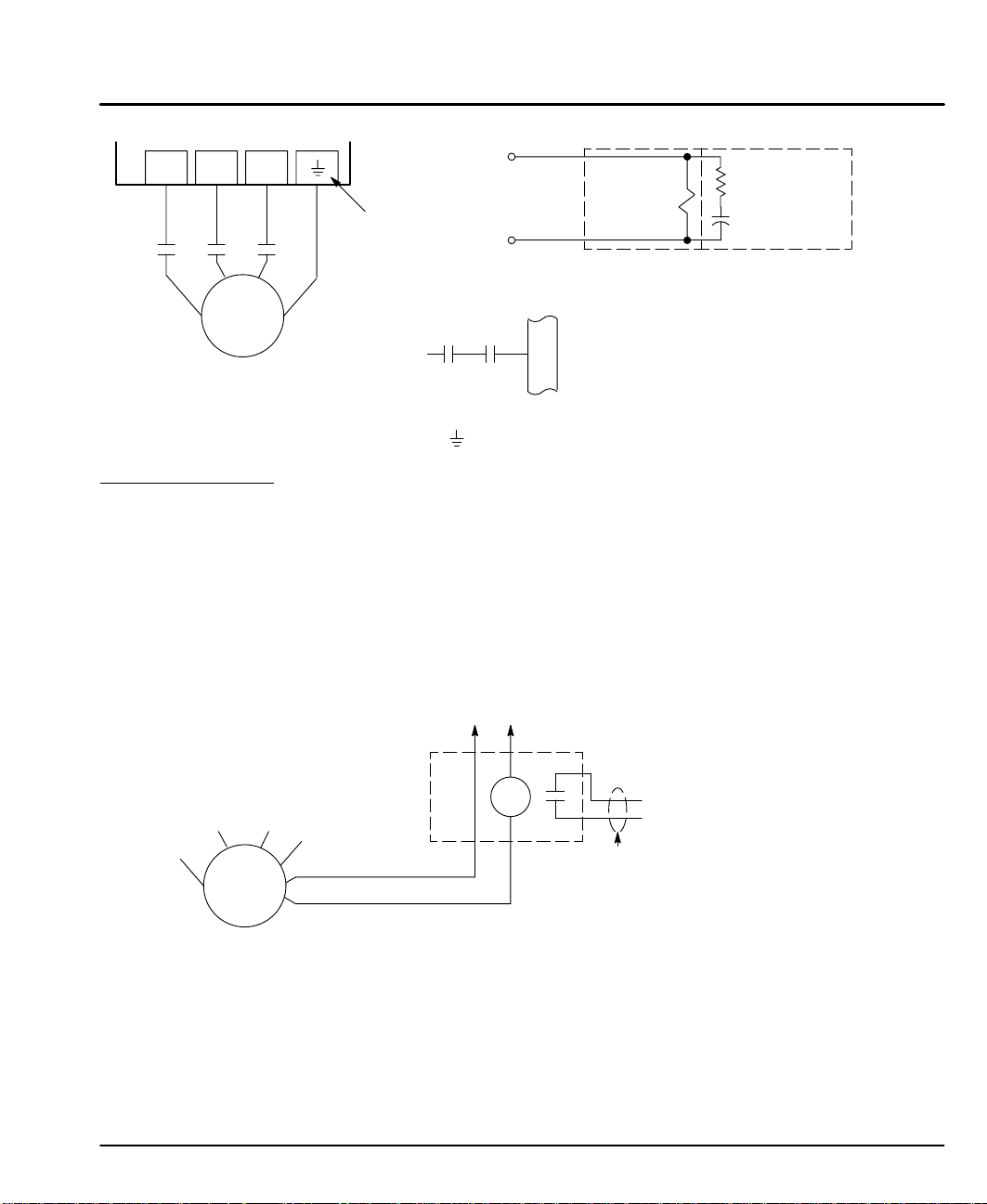

Figure 3-1 Recommended System Grounding (3 phase) for UL

AC Main

Supply

L1

L2

L3

Control

L2 L3 UW

PE

VL1

Note:

Wiring shown for clarity of

grounding method only.

Not representative of actual

terminal block location.

Safety

Ground

Driven Earth

Ground Rod

(Plant Ground)

Note: Use shielded cable for control signal wires. Route

control signal wires in conduit. These wires must be

kept separate from power and motor wires.

Earth

Four Wire

“Wye”

Route all power wires L1, L2, L3 and Earth

(Ground) together in conduit or cable.

Figure 3-2 Recommended System Grounding (3 phase) for CE

AC Main

Supply

Four Wire

“Wye”

Safety

Ground

PE

All shields

L1

L2

L3

Route all power wires

L1, L2, L3 and Earth

(Ground) together in

conduit or cable.

Enclosure Backplane (see Section 8)

Ground per NEC and Local codes.

Control

L2 L3 UW

PE

VL1

Note:

Wiring shown for clarity of

grounding method only.

Not representative of actual

terminal block location.

Motor

GND

Note: Use shielded cable for control signal wires. Route

control signal wires in conduit. These wires must be

kept separate from power and motor wires.

3-2 Receiving & Installation MN1851

Page 14

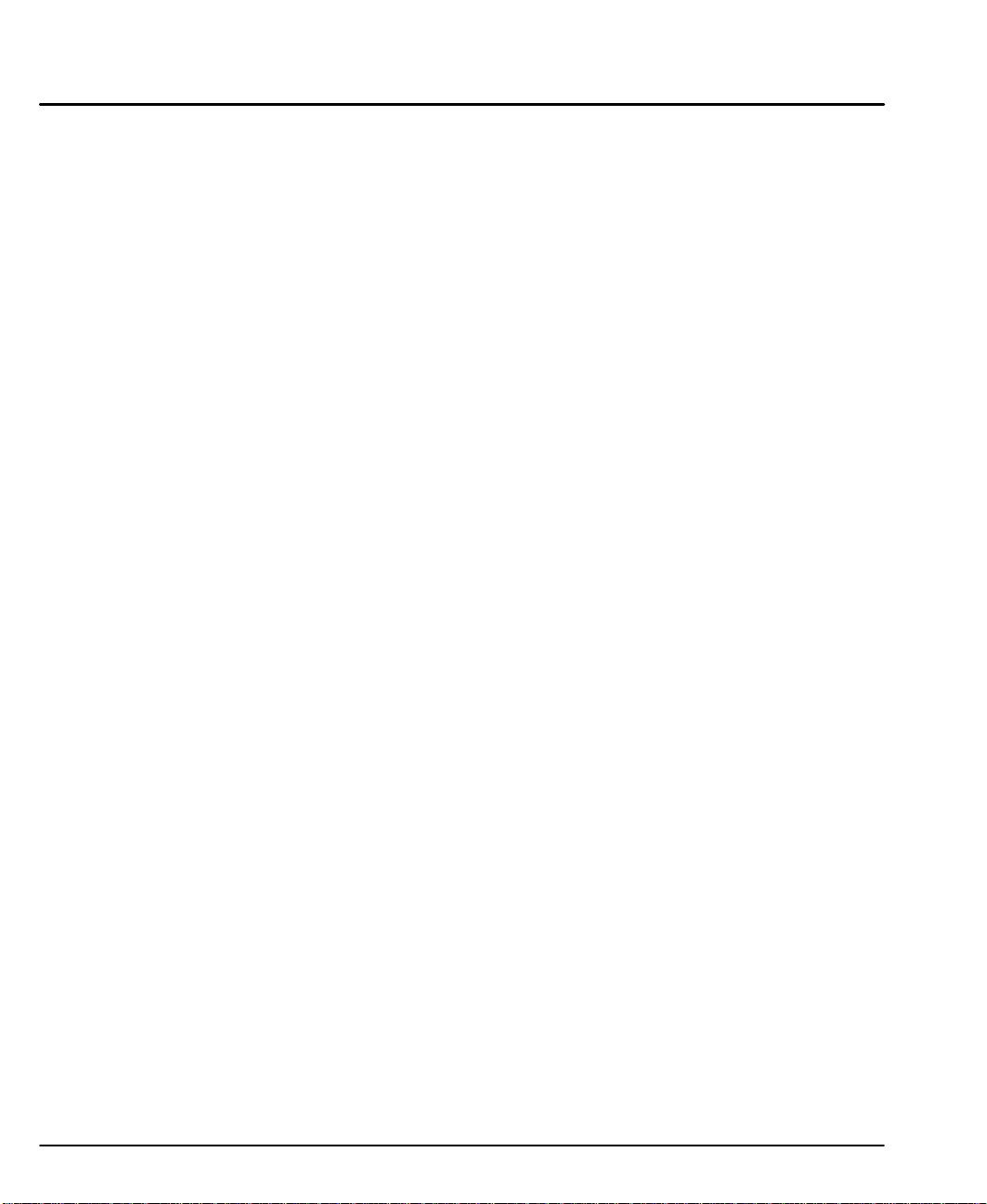

AC Main

Supply

Figure 3-3 Recommended System Grounding (1 phase) for UL

L

Control

N

N UW

VL

Note:

Wiring shown for clarity of grounding

method only. Not representative of

actual terminal block location.

Safety

Ground

Driven Earth

Ground Rod

(Plant Ground)

Note: Use shielded cable for control signal wires. Route

control signal wires in conduit. These wires must be

kept separate from power and motor wires.

Earth

Route all 3 wires L, N, and Earth

(Ground) together in conduit or cable.

Figure 3-4 Recommended System Grounding (1 phase) for CE

AC Main

Supply

Four Wire

“Wye”

Safety

Ground

PE

All shields

L1

L2

L3

Neutral

Enclosure Backplane (see Section 8)

Route all power wires

together in conduit or

cable.

Ground per NEC and Local codes.

Control

LN

VUW

Note:

Wiring shown for clarity of

grounding method only.

Not representative of actual

terminal block location.

Motor

GND

Note: Use shielded cable for control signal wires. Route

control signal wires in conduit. These wires must be

kept separate from power and motor wires.

Receiving & Installation 3-3MN1851

Page 15

System Grounding

Continued

Ungrounded Distribution System

With an ungrounded power distribution system it is possible to have a continuous

current path to ground through the MOV devices. To avoid equipment damage, an

isolation transformer with a grounded secondary is recommended. This provides

three phase AC power that is symmetrical with respect to ground.

Input Power Conditioning

Baldor controls are designed for direct connection to standard single and three

phase lines that are electrically symmetrical with respect to ground. Certain power

line conditions must be avoided. An AC line reactor or an isolation transformer

may be required for some power conditions.

• If the feeder or branch circuit that provides power to the control has

permanently connected power factor correction capacitors, an input AC

line reactor or an isolation transformer must be connected between the

power factor correction capacitors and the control.

• If the feeder or branch circuit that provides power to the control has

power factor correction capacitors that are switched on line and off line,

the capacitors must not be switched while the control is connected to the

AC power line. If the capacitors are switched on line while the control is

still connected to the AC power line, additional protection is required.

TVSS (Transient Voltage Surge Suppressor) of the proper rating must be

installed between the AC line reactor or an isolation transformer and the

AC input to the control.

Power Disconnect A power disconnect should be installed between the input power service

and the control for a fail–safe method to disconnect power. The control will remain

in a powered-up condition until all input power is removed from the control and the

internal bus voltage is depleted.

Protection Devices The control must have a suitable input power protection device installed.

Input and output wire size is based on the use of copper conductor wire rated at

75 °C. Table 3-1 and 3-2 describes the wire size to be used for power connections

and the ratings of the protection devices. Use the recommended circuit breaker or

fuse types as follows:

Circuit Breaker: 1 phase, thermal magnetic.

Equal to GE type THQ or TEB for 115 or 230 VAC

3 phase, thermal magnetic.

Equal to GE type THQ or TEB for 230 VAC or

GE type TED for 460 VAC.

Time Delay Fuses: Buss FRN on 230 VAC or

Buss FRS on 460 VAC or equivalent.

Recommended fuse sizes are based on the following:

UL 508C suggests a fuse size of four times the continuous output

current of the control.

Dual element, time delay fuses should be used to avoid nuisance trips

due to inrush current when power is first applied.

For European installations, you may want to consider the following fast acting

fuse: Gould Shawmut Cat. No. ATMR15 for up to 15 amperes.

3-4 Receiving & Installation MN1851

Page 16

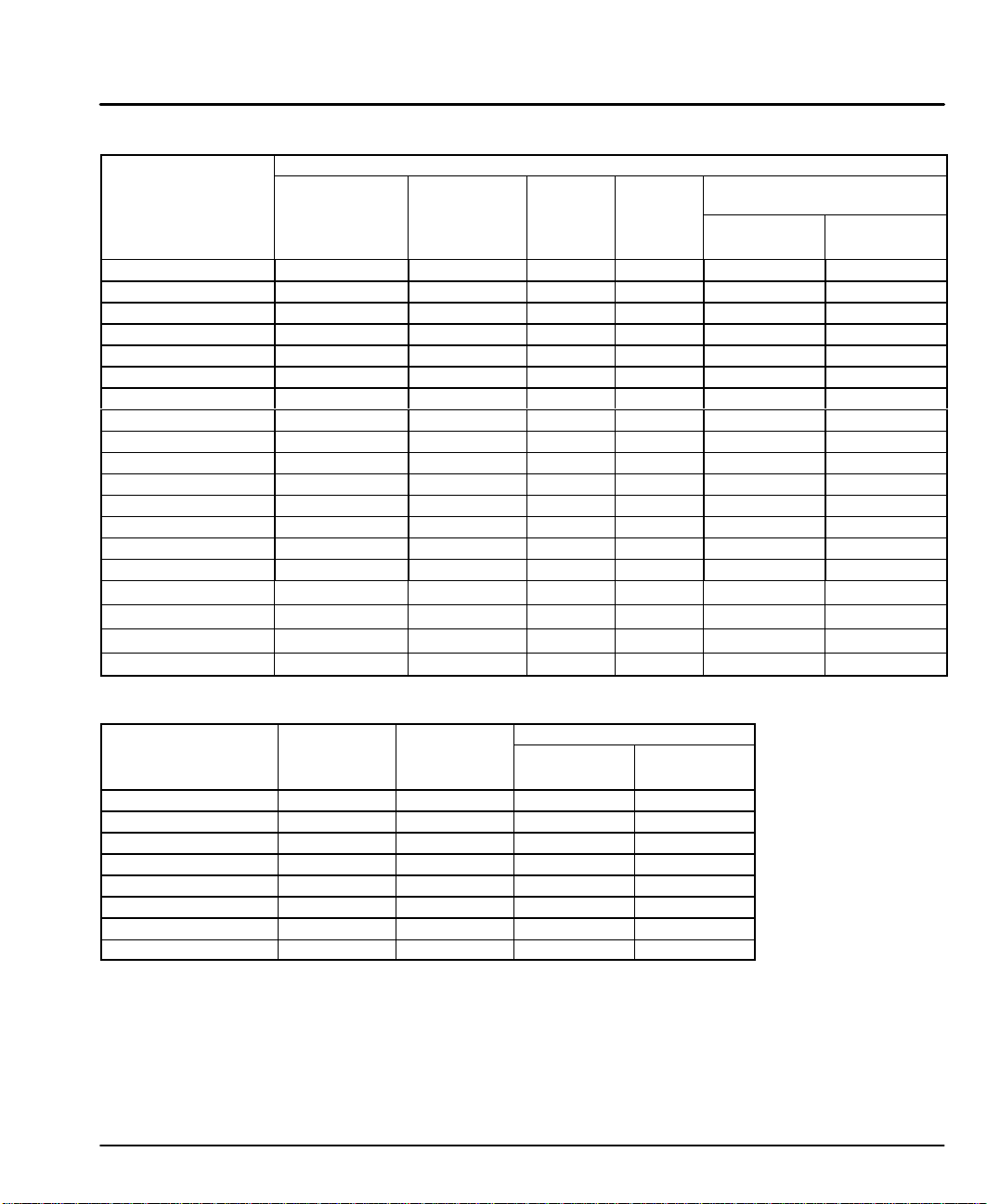

Table 3-1 Wire Size and Protection Devices (for units with Power Supply)

Catalog Number Incoming Power

Input

Input

Fuse

Time

Delay (A)

AWG

(USA)

LP1A02SR-EXXX

LP2A02SR-EXXX

LP1A02TR-EXXX

LP2A02TR-EXXX

LP4A02TB-EXXX

LP1A05SR-EXXX

LP1A05SR-EXXX

LP1A05TR-EXXX

LP2A05TR-EXXX

LP4A05TB-EXXX

LP1A07TR-EXXX

LP2A07TR-EXXX

LP4A07TR-EXXX

LP1A10SR-EXXX

LP2A10SR-EXXX

LP1A15SR-EXXX

LP2A15SR-EXXX

LP4A15TR-EXXX

LP4A20TR-EXXX

Nominal Input

Nominal Input

Voltage

115V (1f)

230V (3f)

115V (1f)

230V (1f)

400/460V (3f)

115V (1f)

230V (3f)

115V (1f)

230V (1f)

400/460V (3f)

115V (1f)

230V (1f)

400/460V (3f)

115V (1f)

230V (3f)

115V (1f)

230V (3f)

400/460V (3f)

400/460V (3f)

Continuous Input

Output

(RMS)

Amps

2.0A 8 8 14 2.5

2.5A 10 10 14 2.5

2.0A 8 8 14 2.5

2.5A 10 10 14 2.5

2.5A 10 10 14 2.5

5A 20 20 14 2.5

5A 20 20 14 2.5

5A 20 20 14 2.5

5A 20 20 14 2.5

5A 20 20 14 2.5

7.5A 30 30 14 2.5

7.5A 30 30 14 2.5

7.5A 30 30 14 2.5

10A 40 40 14 2.5

10A 40 40 14 2.5

15A 60 60 12 2.5

15A 60 60 12 2.5

15A 60 60 12 2.5

20A 60 60 12 2.5

Breaker

(A)

Wire Gauge

(Europe)

mm

2

Table 3-2 Wire Size (for units without Power Supply)

Catalog Number

LP1A02PO-EXXX 160VDC 2.0A 14 2.5

LP2A02PO-EXXX 300VDC 2.5A 14 2.5

LP1A05PO-EXXX 160VDC 5.0A 14 2.5

LP2A05PO-EXXX 300VDC 5.0A 14 2.5

LP1A10PO-EXXX 160VDC 10.0A 12 2.5

LP2A10PO-EXXX 300VDC 10.0A 12 2.5

LP1A15PO-EXXX 160VDC 15.0A 10 2.5

LP2A15PO-EXXX 300VDC 15.0A 10 2.5

Bus

Voltage

Continuous

Continuous

Output

Amps

Note: All wire sizes are based on 75°C copper wire. Higher temperature smaller gauge wire may

be used per NEC and local codes. Recommended fuses/breakers are based on 25°C

ambient, maximum continuous control output current and no harmonic current.

X1 Power Connections

Power connections are shown in Figures 3-5 through 3-8.

Wire Gauge

AWG

(USA)

2

mm

(Europe)

Receiving & Installation 3-5MN1851

Page 17

Figure 3-5 Single Phase AC Power Connections (LP1AxxT & LP2AxxT only)

Note 1

Note 2

* Circuit

Breaker

L1 L2

Earth

Note 3 & 4

Alternate *

Fuse

Connection

L1 L2

Note 1

LN

Baldor

Control

For CE Compliance, refer to Section 8 of this manual.

Figure 3-6 Single Phase AC Power Connections (LP1AxxS only)

L1 L2

Earth

Note 1

Note 2

For CE Compliance, refer to Section 8 of this manual.

* Circuit

Breaker

L1 L2 L3

Baldor

Control

Note 3 & 4

PE

* Components not provided with Control.

Notes:

1. See “Protection Devices” described in this section.

2. Metal conduit or shielded cable should be used. Connect

conduits so the use of a Reactor or RC Device does not

interrupt EMI/RFI shielding.

3. Use same gauge wire for Earth ground as is used for L and N.

(VDE (Germany) requires 10mm

Compliance, connect to the backplane of the enclosure.

4. Reference EMC wiring in Section 8.

2

minimum, 6AWG). For CE

L1 L2

Alternate *

Fuse

Note 1

Connection

* Components not provided with Control.

Notes:

1. See “Protection Devices” described in this section.

2. Metal conduit or shielded cable should be used. Connect

conduits so the use of a Reactor or RC Device does not

interrupt EMI/RFI shielding.

3. Use same gauge wire for Earth ground as is used for L and N.

(VDE (Germany) requires 10mm

Compliance, connect to the backplane of the enclosure.

4. Reference EMC wiring in Section 8.

2

minimum, 6AWG). For CE

Note: These Lin+Drive versions are not designed for use with 400/460VAC

connections.

3-6 Receiving & Installation MN1851

Page 18

Figure 3-7 3 Phase Power Connections (LP2AxxS & LP4AxxT only)

L1 L2 L3

Earth

Note 1

* Circuit

Breaker

Note 2

L1 L2 L3

PE

Baldor

Control

For CE Compliance, refer to Section 8 of this manual.

A shared supply configuration is shown in Figure 3-8. The first drive must have an

internal power supply such as an Option “S” control.

Figure 3-8 Shared Supply Power Connections

L1 L2 L3

Note 3 & 4

Notes:

1. See Protection Device description in this section.

2. Metal conduit or shielded cable should be used. Connect

conduits so the use of a Reactor or RC Device does not interrupt

EMI/RFI shielding.

3. Use the same gauge wire for Earth as used for L1, L2, L3

connections.

3. Use same gauge wire for Earth ground as is used for L and N.

(VDE (Germany) requires 10mm

compliance, connect “PE” to the backplane of the enclosure.

4. Reference EMC wiring in Section 8.

Alternate *

Fuse

Connection

A1 B1 C1

Note 1

* Components not provided with Control.

2

minimum, 6AWG). For CE

VCC+

VCC-

R1

R2

Baldor

Option S

Control

To

Regen

Resistor

VCC+

VCC-

VCC+

VCC-

Baldor

Option P

Control

VCC+

VCC-

VCC+

VCC-

Baldor

Option P

Control

Receiving & Installation 3-7MN1851

Page 19

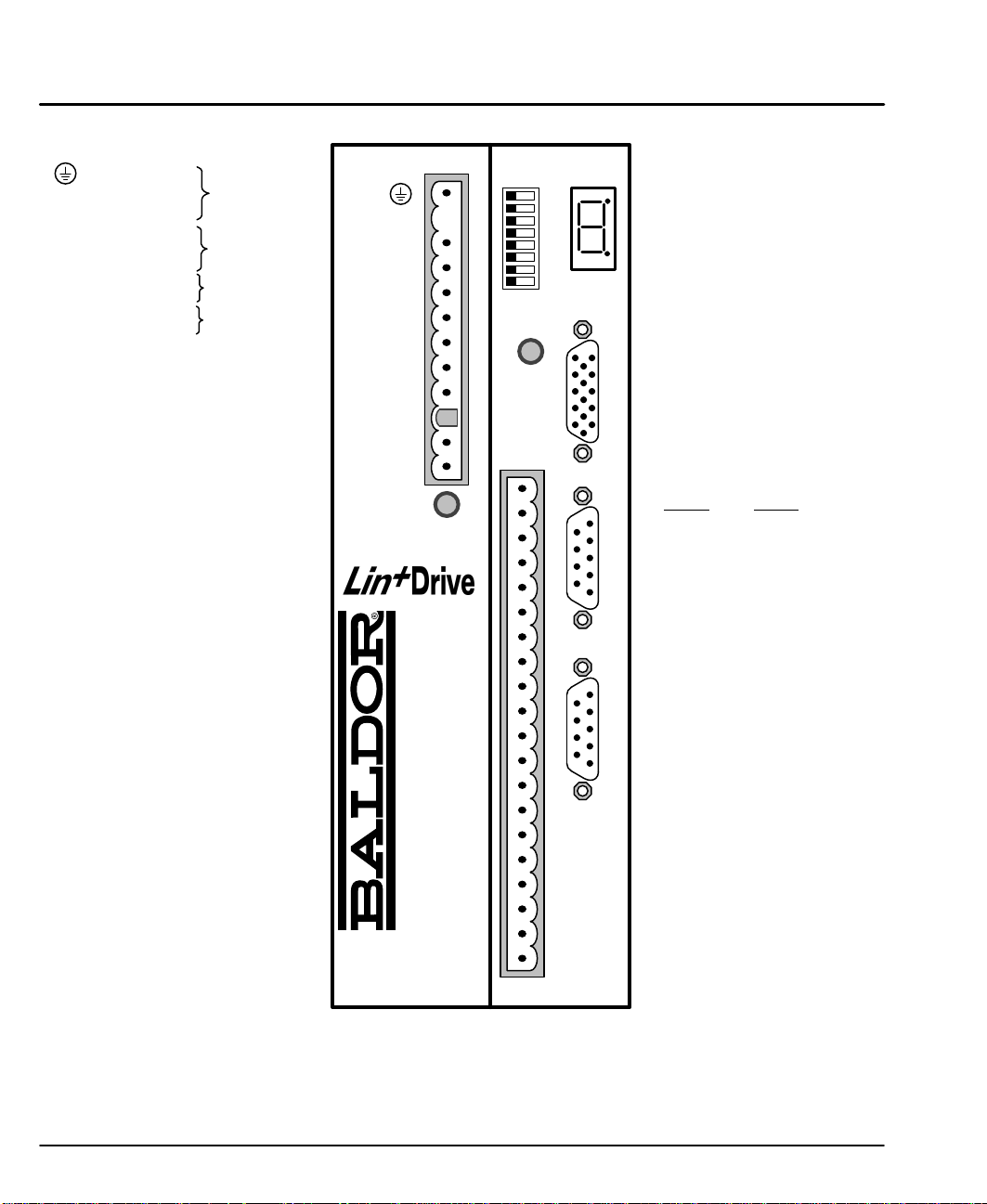

X1 - Power Connector

Figure 3-9 Connector Locations (Single Phase Controls)

Earth

L AC Line

N Neutral

U Motor lead “U”

V Motor lead “V”

W Motor lead “W”

R1 Dynamic Brake

R2 Dynamic Brake

+24V Customer

0V Provided

Terminal tightening torque is

0.5 lb-in (0.6Nm)

X3 - Control Signals & Digital I/O

1 CMD+

2 CMD3 AGND

4 Fault Relay+

5 Fault Relay6CIV

7 CREF

8 CGND

9 Enable

10 MaI3

11 MaI4

12 Quit

13 Fault Reset

14 Home Flag

15 Trigger

16 MaI1

17 MaI2

18 MaO1

19 MaO2

20 DrOK

Input Power

Motor

Dynamic Brake

(Regen Resistor)

LPxAxxxx-xxx3

only

NC

L

N

U

V

W

R1

R2

+24V

0V

DB On

X1

AS1

Off/On

Ready

Monitor

1

2

3

4

5

6

7

8

The holes in the top and

bottom of the enclosure

are for cable clamps. Be

sure to use an M4 bolt

12mm in length. Longer

bolts may short circuit the

electrical components

inside the control.

X9 - Encoder Input

1 CHA+ 9 Hall 3+

2 CHB+ 10 Hall 2+

3 CHC+ 11 +5VDC

4 Hall 1+ 12 Reserved

5 Hall 1– 13 DGND

6 CHA- 14 Hall 3–

7 CHB- 15 Hall 2–

Encoder In X9RS232 / 485 X6Encoder Out X7

8 CHC-

X6 - RS232 / 485

RS232

1 Reserved 1 TX-

2R

x

3T

Data 3 RX+

x

4 DTR 4 RX5 DGND 5 DGND

6 DSR 6 RTS7 RTS 7 RTS+

8 CTS 8 CTS+

9 +5V 9 CTS-

1 CHA+ 6 CHA–

2 CHB+ 7 CHB–

3 CHC+ 8 CHC–

4 Reserved 9 Reserved

5 DGND

RS485

Data 2 TX+

X7 - Encoder Output

Note: Reserved means no

Important:

X3

LPxAxxxx-xxx3 only.

A separate 24VDC supply to the “Logic Power” input is required for

connection is required and

no connection should be

made to this terminal. It is

reserved for future use.

operation. An LPxAxxxx-xxx3 control will not operate without 24VDC

on this input.

3-8 Receiving & Installation MN1851

Page 20

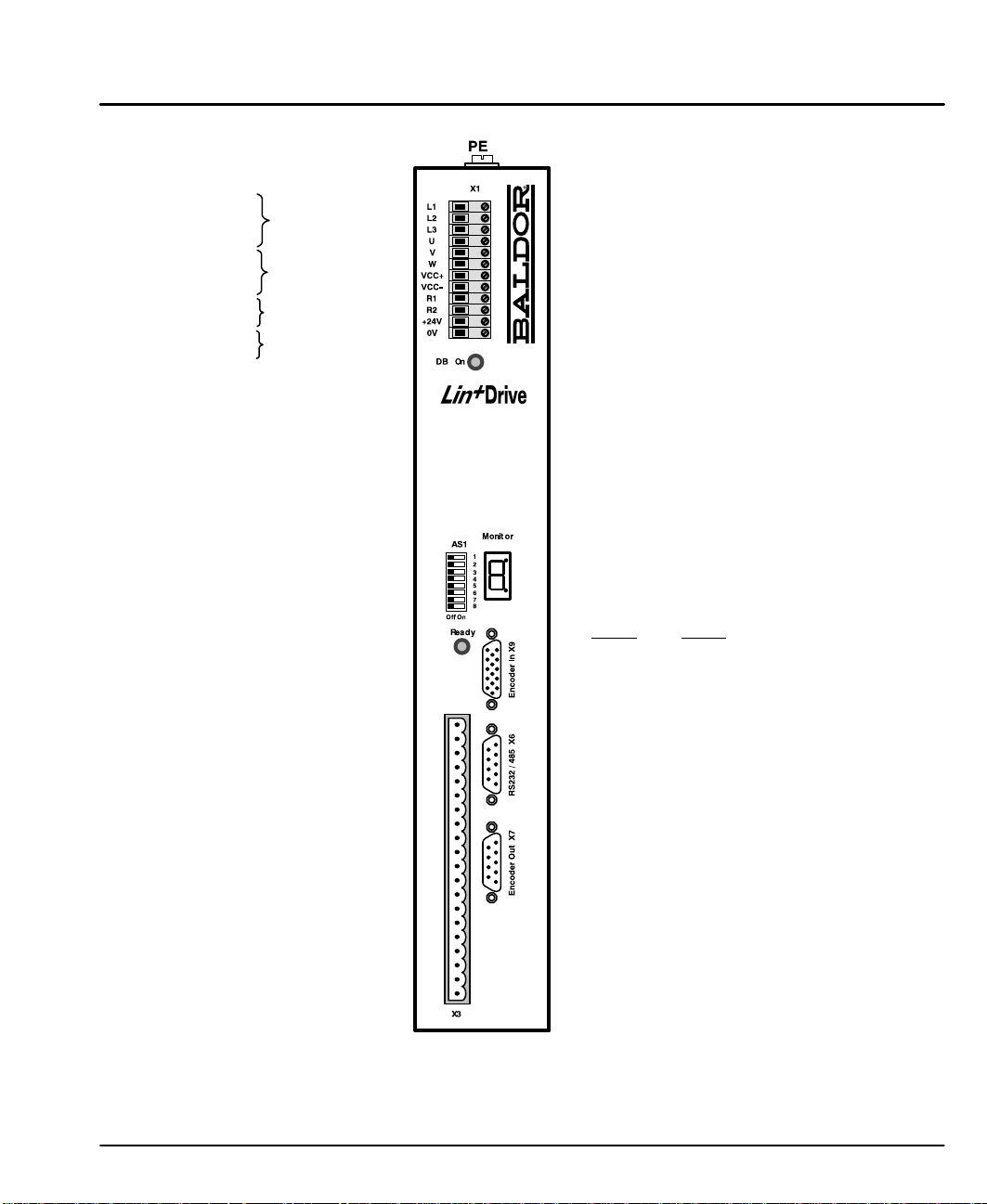

X1 - Power Connector

PE Earth

L1 Phase 1 Input

L2 Phase 2 Input

L3 Phase 3 Input

U Motor lead “U”

V Motor lead “V”

W Motor lead “W”

R1 Dynamic Brake

R2 Dynamic Brake

+24V Customer

0V Provided

Figure 3-10 Connector Locations (Three Phase Controls)

The holes in the top and bottom of the

enclosure are for cable clamps. Be sure

to use an M4 bolt 12mm in length.

Input Power

Motor

Dynamic Brake

(Regen Resistor)

LPxAxxxx-xxx3

only

Longer bolts may short circuit the

electrical components inside the control.

Terminal tightening torque is

0.5 lb-in (0.6Nm)

X3 - Control Signals & Digital I/O

1 CMD+

2 CMD3 AGND

4 Fault Relay+

5 Fault Relay6CIV

7 CREF

8 CGND

9 Enable

10 MaI3

11 MaI4

12 Hold

13 Fault Reset

14 Home Flag

15 Trigger

16 MaI1

17 MaI2

18 MaO1

19 MaO2

20 DrOK

X9 - Encoder Input

1 CHA+ 9 Hall 3+

2 CHB+ 10 Hall 2+

3 CHC+ 11 +5VDC

4 Hall 1+ 12 Reserved

5 Hall 1– 13 DGND

6 CHA- 14 Hall 3–

7 CHB- 15 Hall 2–

8 CHC-

X6 - RS232 / 485

RS232 RS485

1 Reserved 1 TX2R

Data 2 TX+

x

3T

Data 3 RX+

x

4 DTR 4 RX5 DGND 5 DGND

6 DSR 6 RTS7 RTS 7 RTS+

8 CTS 8 CTS+

9 +5V 9 CTS-

X7 - Encoder Output

1 CHA+ 6 CHA–

2 CHB+ 7 CHB–

3 CHC+ 8 CHC–

4 Reserved 9 Reserved

5 DGND

Note: Reserved means no connection is required

and no connection should be made to this

Important:

terminal. It is reserved for future use.

LPxAxxxx-xxx3 only.

A separate 24VDC supply to the “Logic Power” input is required for

operation. An LPxAxxxx-xxx3 control will not operate without 24VDC on this input.

Receiving & Installation 3-9MN1851

Page 21

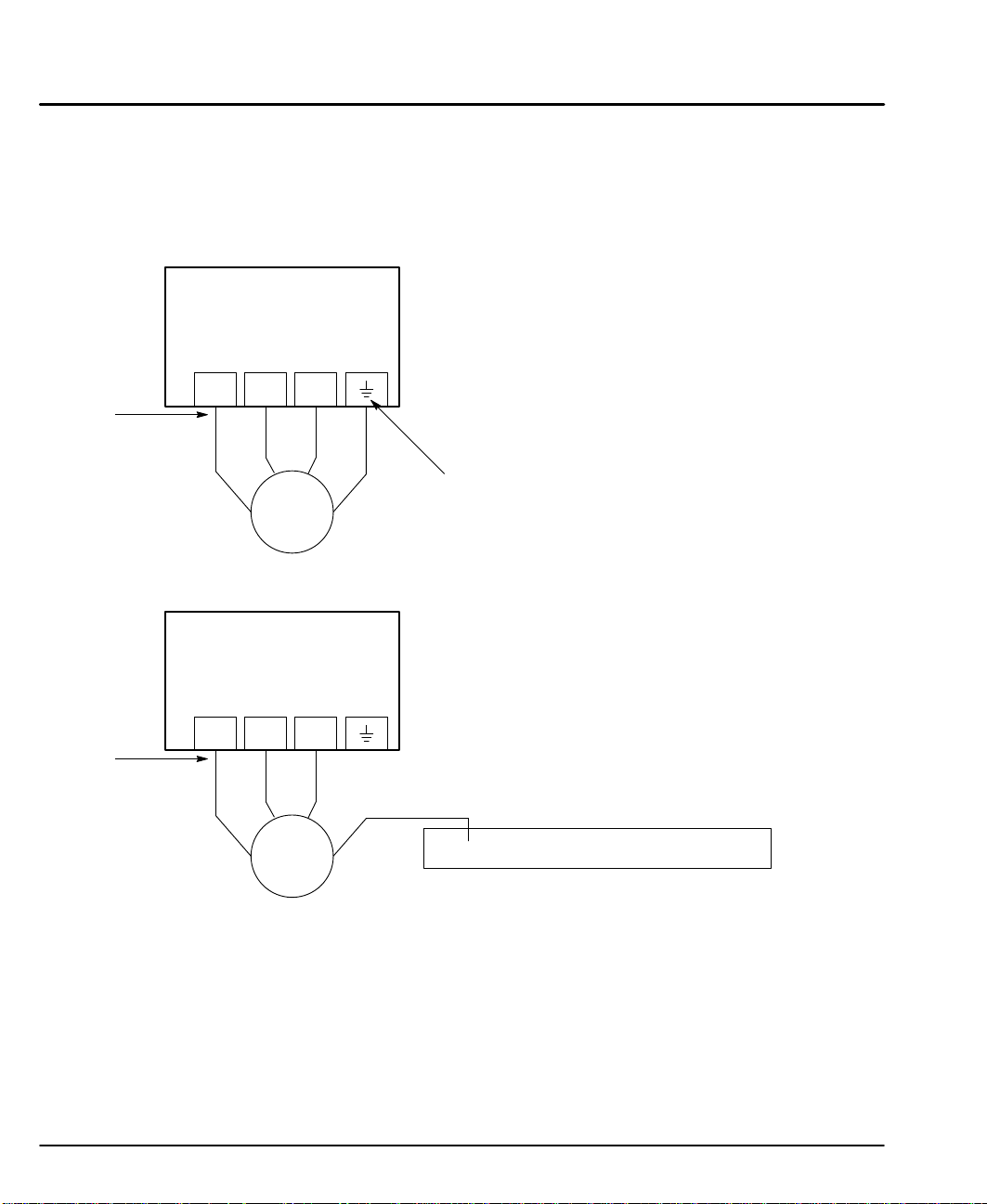

X1 Motor Connections Motor connections are shown in Figures 3-11 and 3-12.

It is important to connect the motor leads U, V and W correctly at the X1 connector

of the control. Incorrect wiring can cause erratic operation including moves at

peak force until the overcurrent limit trips. This will result in a display of “7” and a

“6” on the monitor. If erratic movement of the motor occurs, turn off power

immediately and check the connections of the motor, hall sensors and encoder.

Figure 3-11 Motor Connections for UL

Notes:

Baldor

Control

UVW

Note 1

1. Metal conduit or shielded cable should be used. Connect

conduits so the use of Load Reactor* or RC Device* does not

interrupt EMI/RFI shielding.

2. Use same gauge wire for Earth ground as is used for L and N.

(VDE (Germany) requires 10mm2 minimum, 6AWG).

3. Reference EMC wiring in Section 8.

4. Motor and encoder are phase sensitive. Connect only as

instructed.

* Linear Motor

VW

U

Note 2

G

For three phase controls, this is labeled “PE”.

* Optional components not provided with control.

Figure 3-12 Motor Connections for CE

Notes:

Baldor

Control

UVW

Note 1

VW

U

* Linear Motor

Note 2

G

Note: For CE compliant installations, connect unused leads within the motor cable

to “PE” on both ends of the cable.

M-Contactor If required by local codes or for safety reasons, an M-Contactor (motor circuit

contactor) may be installed. However, incorrect installation or failure of the

M-contactor or wiring may damage the control. If an M-Contactor is installed, the

control must be disabled for at least 20msec before the M-Contactor is opened or

the control may be damaged. M-Contactor connections are shown in Figure 3-13.

1. Metal conduit or shielded cable should be used. Connect

conduits so the use of Load Reactor* or RC Device* does not

interrupt EMI/RFI shielding.

2. Use same gauge wire for Earth ground as is used for L and N.

(VDE (Germany) requires 10mm2 minimum, 6AWG). For CE

compliance, connect motor ground to the backplane of the

enclosure.

3. Reference EMC wiring in Section 8.

4. Motor and encoder are phase sensitive. Connect only as

instructed.

Enclosure Backplane (see Section 8)

* Optional components not provided with control.

3-10 Receiving & Installation MN1851

Page 22

Figure 3-13 Optional M-Contactor Connections

UVW

To Power Source

(Rated Coil Voltage)

Note 1

Note 2

For three phase

controls, this is

labeled “PE”.

M Enable

* Optional components not provided with control.

*

*

MMM

VW

U

G

* Motor

M=Contacts of optional M-Contactor

Notes:

1. Use same gauge wire for Earth ground as is used for L and N. (VDE (Germany) requires10mm2 minimum, 6AWG).

2. For UL installations, connect motor ground to of the control as shown.

For CE installations, connect motor ground to the enclosure backplane (see Figure 3-12).

* M-Contactor

X3

Note: Close “Enable”

9

after “M” contact closure.

* RC Device

Electrocube

RG1781-3

Motor Thermostat A relay contact can be used to isolate the motor thermostat leads for use with

other devices, shown in Figure 3-14. The thermostat or overload relay should be a

dry contact type with no power available from the contact. The optional relay

(CR1) shown provides the isolation required and the N.O. contact is open when

power is applied to the relay and the motor is cold. If the motor thermostat is

tripped, CR1 is de-energized and the N.O. contact closes.

Connect the External Trip Input wires (N.O. relay contact) to a PLC or other

device. Note that a machine input may be used and the PLC software of the

Lin+Drive can define the thermal protection. Do not place these wires in the same

conduit as the motor power leads.

Figure 3-14 Motor Temperature Relay

Customer Provided

Source Voltage

Note: Add appropriately rated protective

device for AC relay (snubber)

or DC relay (diode).

*

CR1

W

V

G

U

Motor Thermostat Leads

* Linear Motor

Do not run these wires in same conduit

as motor leads or AC power wiring.

*

External Trip

Optional, customer provided hardware.

X1 Dynamic Brake Resistor An external DB (dynamic brake or regen resistor) resistor may be

required to dissipate excess power from the DC bus during motor deceleration

operations. Some controls have an internal resistor. For selection of the DB

resistor, refer to the specifications located in Section 7 and the regeneration

resistor specifications in Section 9 of this manual. DB hardware is connected at

R1 and R2 terminals of the X1 connector, Figure 3-9 and 3-10.

Receiving & Installation 3-11MN1851

Page 23

X1 +24VDC Logic Supply For LPxAxxxx-xxx3 only. A separate 24VDC supply to the “Logic

Power” input is required for operation. An external 24 VDC power source must be

used. If bus power is lost, the logic circuits are still active if the 24VDC is present.

This is important to maintain position reference, for example.

If the control was not ordered with this option, do not connect any voltage to these

pins.

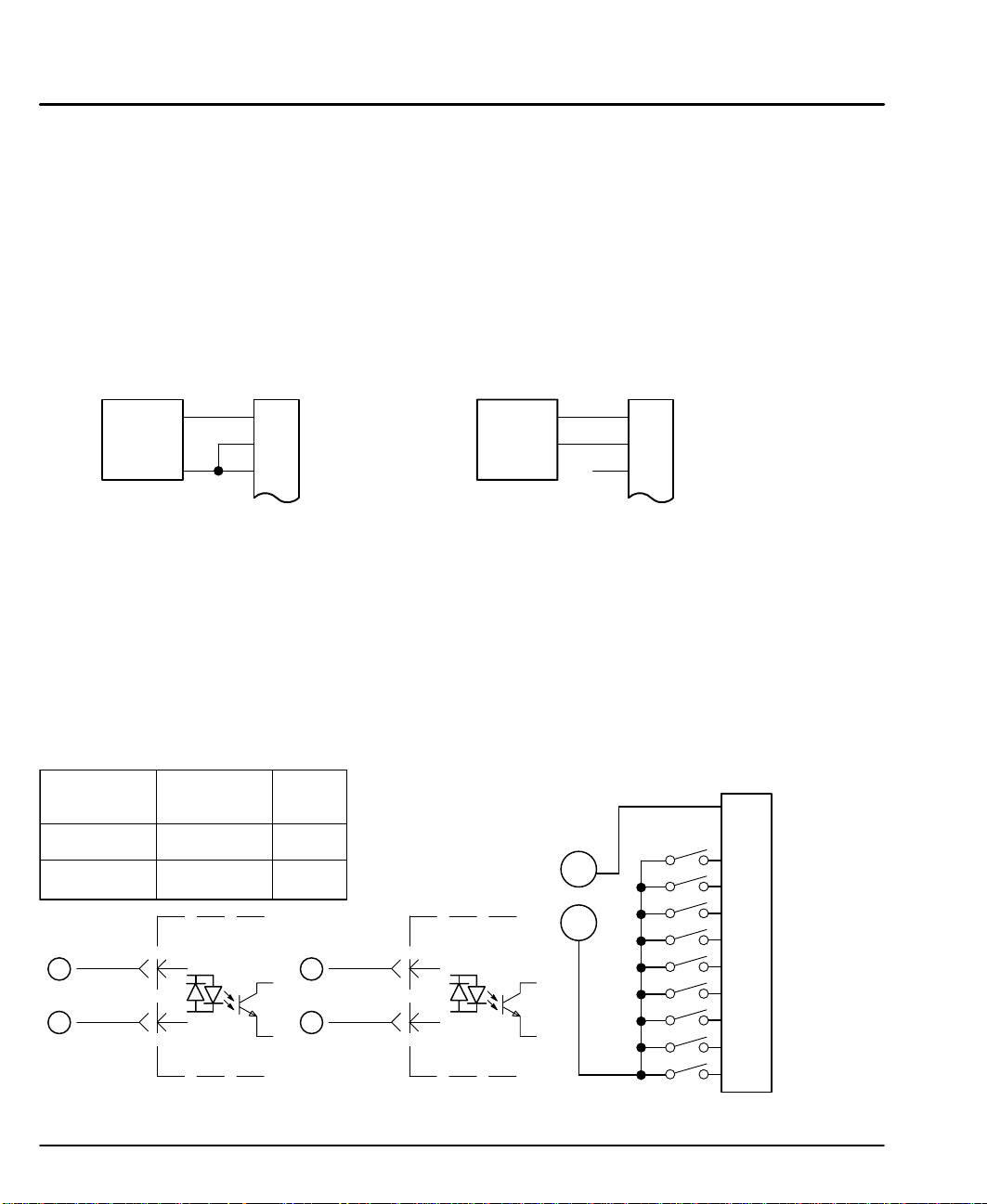

X3 Control Inputs & Digital I/O Connections

Control Inputs X3 pins 1 and 2 allows connection of an external analog command input. This

input can accept a 0-10VDC or ±10VDC signal and can be wired as a single

ended or differential input, shown in Figure 3-15.

Figure 3-15 Control Input Wiring

Single Ended Connection Differential Connection

Signal

Source

X3

1

2

3

CMD+

CMDAGND

Signal

Source

X3

1

2

3

CMD+

CMDAGND

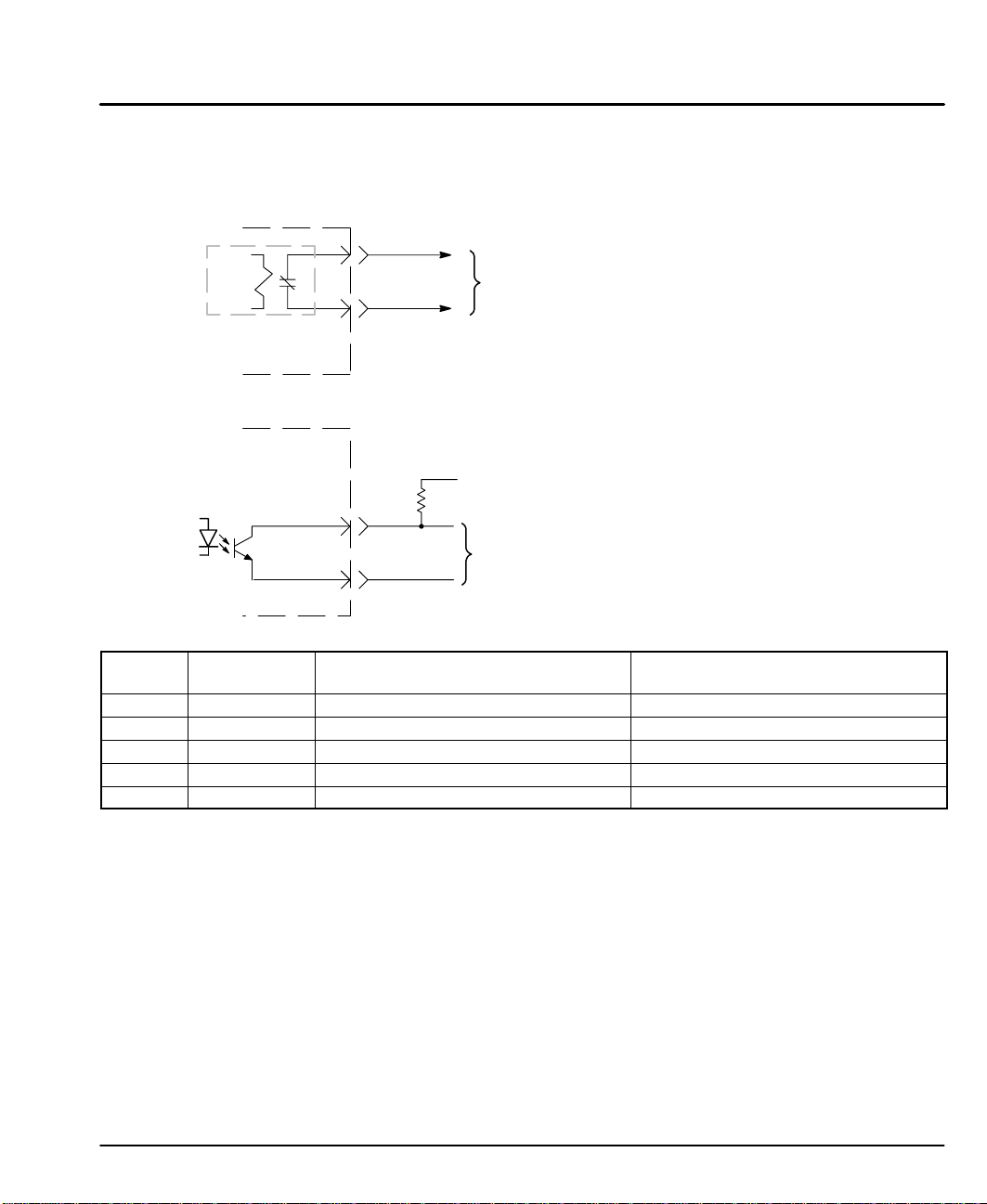

X3 Digital Inputs - Opto Isolated Inputs (uses CREF, X3-7)

Active High (Sourcing) - If pin X3-7 is grounded, an input is active when it is

at +24VDC (+12VDC to +30VDC).

Active Low (Sinking) - If pin X3-7 is at +24VDC (+12VDC to +30VDC), an

input is active when it is grounded.

Logic input connections are made at terminal strip X3. Input connections can be

wired as active High or active Low as shown in Figure 3-16. X3 pin 7 is the

Control Reference point (CREF) for the Opto Isolated Input signals.

Note: An internal 24VDC power supply connection is not available from the control

to power the Opto Input circuits. A customer provided external power

source must be used as indicated in Figure 3-16.

Figure 3-16 Active HIGH /LOW Relationship

Active Low

(Sink)

+24VDC

GND

+24VDC

B

GND

A

Source

Active High

Input

Note: All Opto inputs are referenced to

(Source)

GND

+24VDC

20mA 20mA

9 - 17

7

Typical

Control

A

B

B

A

GND

+24VDC

Sink

CREF, X3-7.

Input

A

B

9 - 17

7

Typical

Control

X3

7

8

9

10

11

12

13

14

15

16

17

CREF

CGND

ENABLE

CW-ENABLE

CCW-ENABLE

QUIT

FAULT RESET

HOME FLAG

TRIGGER

MAI1

MAI2

3-12 Receiving & Installation MN1851

Page 24

X3 Digital Inputs Continued

Table 3-3 Opto Input Signal Conditions

Pin

Number

X3-9 Enable Drive enabled. Drive disabled.

X3-10 MaI3 Machine Input 3 = Logical 1 Machine Input 3 = Logical 0

X3-11 MaI4 Machine Input 4 = Logical 1 Machine Input 4 = Logical 0

X3-12 Quit Stop positioning mode operation Positioning mode is operating

X3-13 Fault Reset Fault Reset is active (reset control). Fault Reset is not active.

X3-14 Home Flag Home flag = closing (rising) edge Home flag = opening (falling) edge

X3-15 Trigger Trigger = closing (rising) edge Trigger = opening (trailing) edge

X3-16 MaI1 Machine Input 1 = Logical 1 Machine Input 1 = Logical 0

X3-17 MaI2 Machine Input 2 = Logical 1 Machine Input 2 = Logical 0

Signal

Name

Switch = Closed (active) Switch = Open (not active)

Signal Name Opto Input Signal Definition

Enable CLOSED allows normal operation.

OPEN disables the control and motor coasts to a stop.

Quit CLOSED cancels any move in progress and the motor will decelerate (at

parameter MOT.ACC) to rest. This input is edge triggered.

OPEN allows position mode operation.

Fault Reset CLOSED allows the control to be cleared or “Reset” for any of the following four

fault conditions (provided that the cause of the fault has been removed):

• Overvoltage • Electronic Fusing

• Undervoltage • Resolver Fault

OPEN allows normal operation.

Home Flag Edge triggered input that is used to sense the “Home Position”.

Trigger Rising edge triggered input that initiates a “point-to-point move”. The move is

defined by the machine inputs MaI1 - 4.

MaI1,2,3,& 4 Four machine inputs are provided. These may be used with the internal PLC

software program. The internal PLC software can cause an event to occur based

on the presence of these inputs.

However, more often these inputs are used to define up to 15 preset positions or

point to point moves. The 16th move is always home. With this method, it is not

possible to use hardware limits (CW and CCW). Therefore, software limits must

be used. Software limits are only active after a homing routine has completed.

Note: Hardware limit switches may be wired in series with the “Enable” input

X3–9. Then if a limit is reached, the control will be disabled.

Receiving & Installation 3-13MN1851

Page 25

X3 Digital Inputs Continued

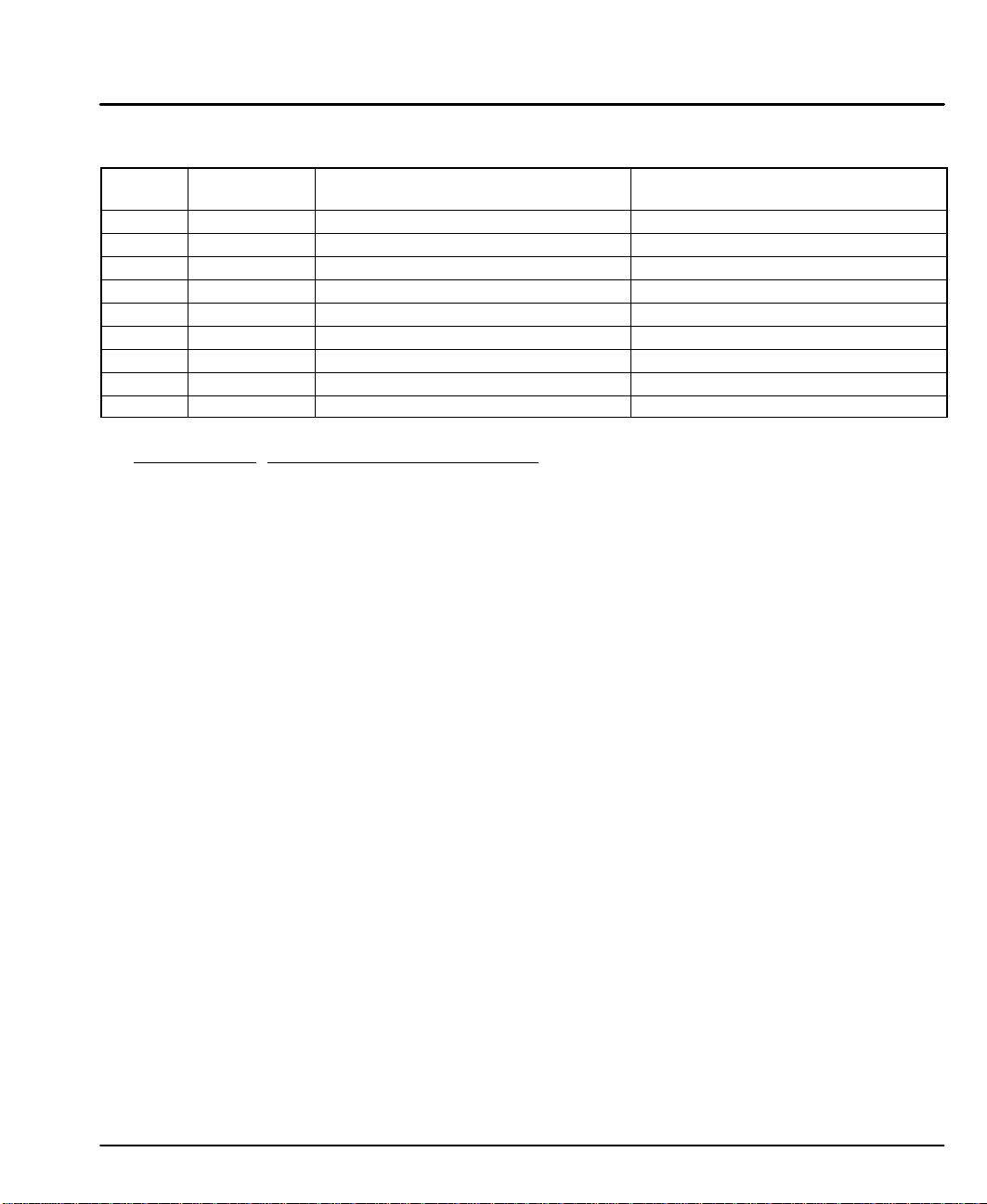

Figure 3-17 Positioning Mode Timing Diagram

See Table 3-4.

Motion in Process

MaI1 - 4

Trigger

Trajectory

Motion Ready =

T3

T2

T1

T4

T5 T6

Table 3-4 Process Duration

Time Required Duration

T1 ≥2ms

T2 ≥1ms

T3 ≥14ms

T4 ≥14ms

T5 ≤14ms

T6 ≤14ms

T7 ≤14ms

T8 ≥100ms

T9 ≥2ms

T10 ≥2ms

Time

Time

T7

Time

Time

Figure 3-18 Homing Process Timing Diagram

T2

Trigger

T4

T8 T9

Trajectory

See Table 3-4.

T10

Recognition Time (T10)

3-14 Receiving & Installation MN1851

Time

Time

Page 26

X3 Digital Outputs

The control outputs are located on the X3 connector. A customer provided,

external power supply must be used if digital outputs are to be used. The opto

outputs provide status information and are not required for operation, Table 3-5.

Relay

Contact is closed when power is on

and no faults are present.

Control

Figure 3-19 Fault Relay Connections

4

5

Customer Provided Interface Circuit

Customer provided external power source: and Non-Inductive Load

110VAC @ 0.3A maximum or

24VDC @ 0.8A maximum

Figure 3-20 Opto Output Connections

35mA Maximum

Typical

18, 19, 20

8

Control Customer Provided Interface Circuit

CGND

Customer Interface Voltage (+12VDC to +30VDC)

(2.2K typical @ 24VDC)

R

L

Output Signal + Common

Output Signal is only available if

Customer Interface Voltage is present.

Table 3-5 Opto Output Signal Conditions

Pin

Number

X3-4 Fault + Drive OK - no faults detected Fault is detected

X3-5 Fault - Drive OK - no faults detected Fault is detected

X3-18 MAO1 Machine Output 1 = Logical 1 Machine Output 1 = Logical 0

X3-19 MAO2 Machine Output 2 = Logical 1 Machine Output 2 = Logical 0

X3-20 DrOK Drive OK - no faults detected Fault is detected

Fault Relay A normally closed relay contact that opens if a fault occurs. The contact is rated:

MaO1 & 2 Two machine outputs are provided. Either output can be set to one of the

DrOK This output is active when the control is ready for operation.

Signal

Name

Switch = Closed (active) Switch = Open (not active)

24VDC @ 0.8A maximum or 110VAC @ 0.3A maximum.

following conditions: CW Warning, CCW Warning, In Position, Error Flag,

Following Error Warning, MAI1-2, Drive Overtemperature or I

Each output is rated 30VDC @ 35mA maximum.

This output is rated 30VDC @ 35mA maximum.

2

T Warning.

Receiving & Installation 3-15MN1851

Page 27

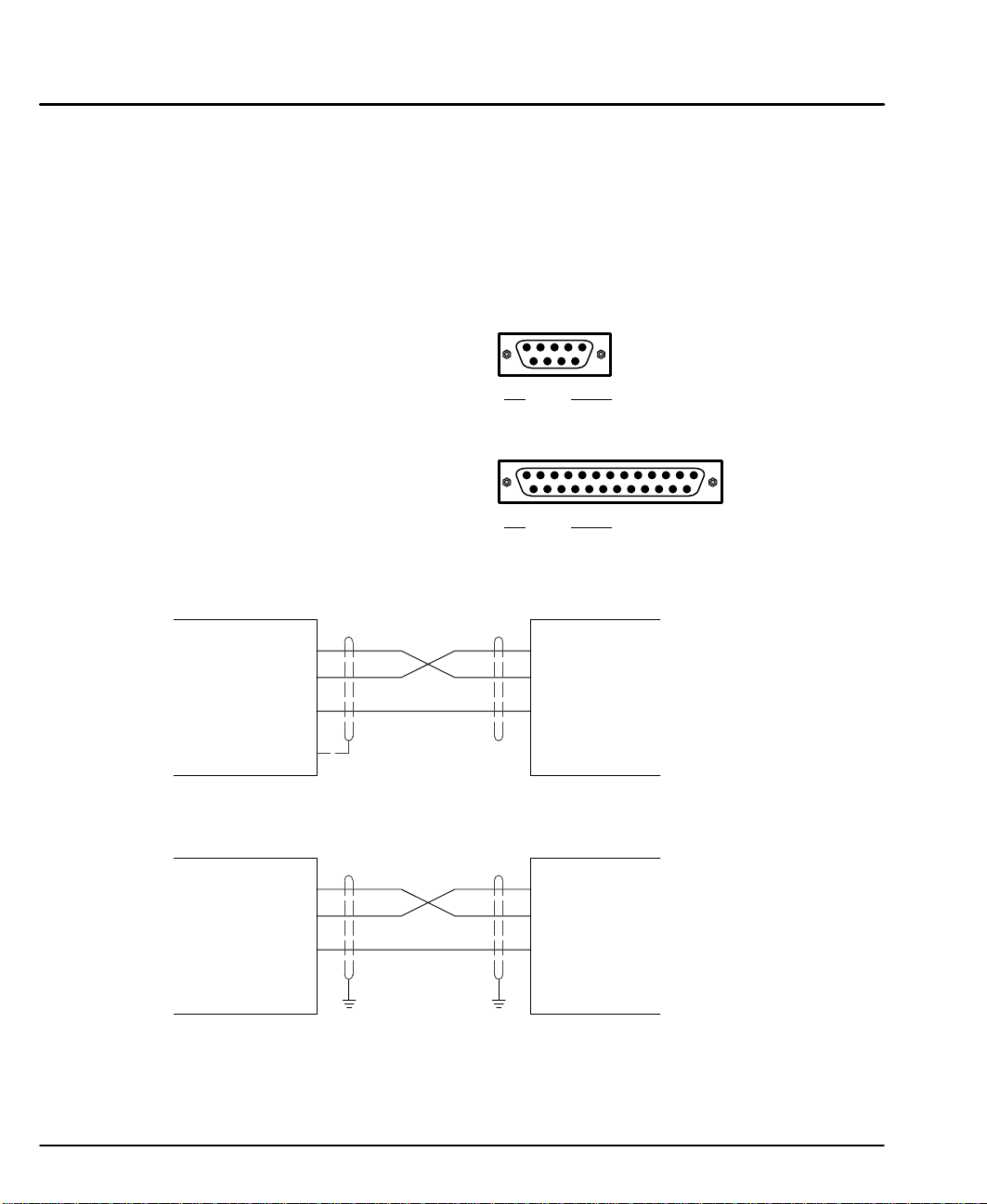

X6 RS232 / 485 Connections

RS232

A null modem cable (also called a modem eliminator cable) must be used to

connect the control and the computer COM port. This will ensure that the transmit

and receive lines are properly connected. Either a 9 pin or a 25 pin connector

can be used at the computer, Figure 3-21. Maximum recommended length for

RS232 cable is 3 ft. (1 meter).

Figure 3-21 9 & 25 Pin RS-232 Cable Connections for UL Installations

9 Pin Connector

RXD

TXD

GND

Signal

25 Pin Connector

Signal

Computer

COM

Port

(DTE)

Control

(DCE)

X6

RXD

TXD

GND

Chassis

Pin

2 RXD

3 TXD

5 GND

Pin

2 RXD

3 TXD

7 GND

Null Modem Cable Connections

Figure 3-22 9 & 25 Pin RS-232 Cable Connections for CE Installations

Null Modem Cable Connections

X6

Control

(DCE)

RXD

TXD

GND

PE PE

RXD

TXD

GND

Computer

COM

Port

(DTE)

Note: For CE installations, connect the overall shield at each end of the cable to PE. The

voltage potential between the PE points at each end of the cable must be Zero Volts.

3-16 Receiving & Installation MN1851

Page 28

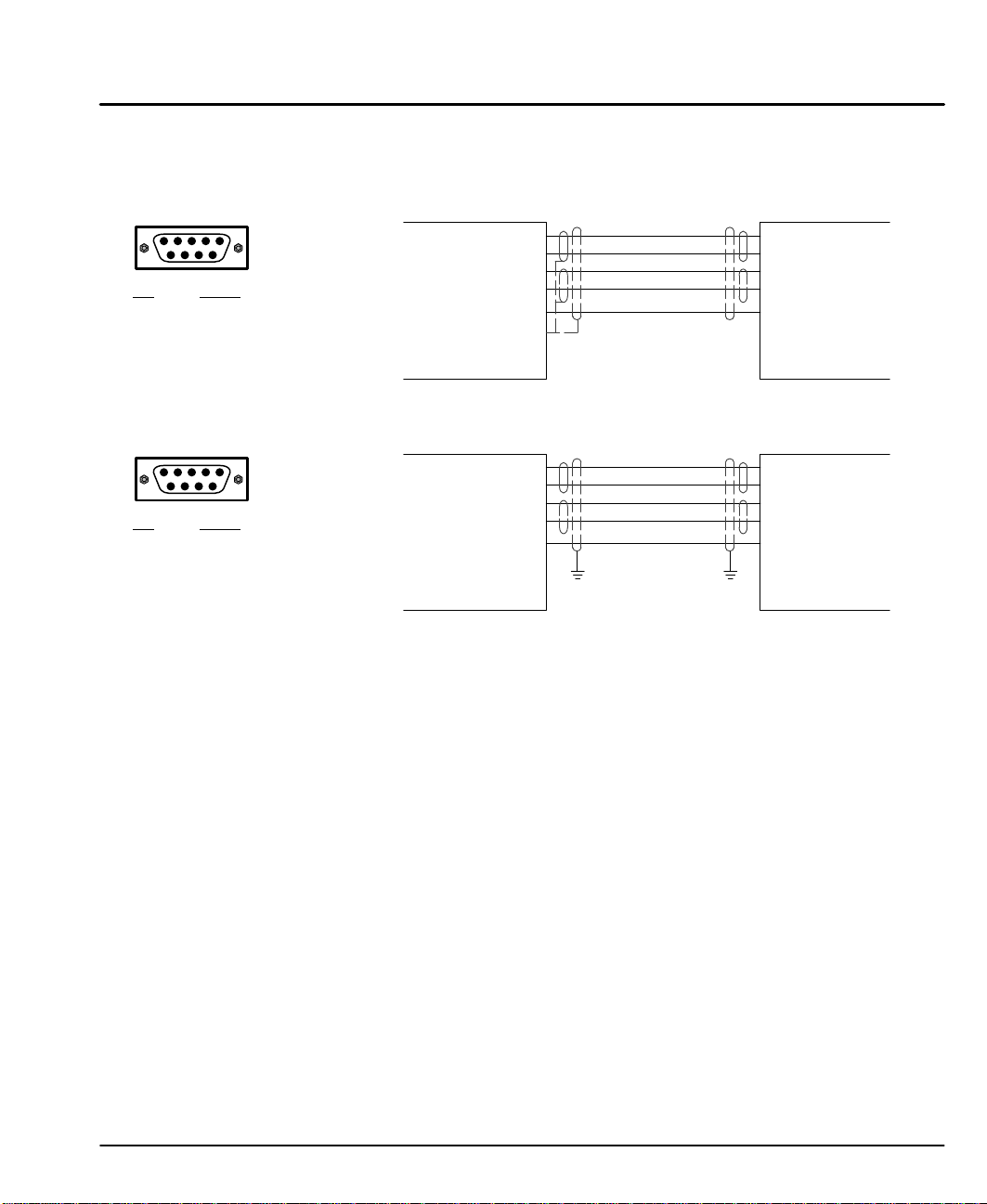

Figure 3-23 9 Pin RS-485 Cable Connections For UL Installations

Pin

1 TX2 TX+

3 RX+

4 RX5 DGND

Signal

RS485

Standard RS485 connections are shown in Figures 3-23 and 3-24. Maximum

cable length is 3280 ft (1000M).

X6

9 Pin Connector

Control

(DCE)

RX+

RX–

TX+

TX-

DGND

Chassis

TX+

TX–

RX+

RX-

DGND

Computer

COM

Port

(DTE)

Figure 3-24 9 Pin RS-485 Cable Connections For CE Installations

Pin

1 TX2 TX+

3 RX+

4 RX5 DGND

Signal

Note: For CE installations, connect the overall shield at each end of the cable to PE. The

voltage potential between the PE points at each end of the cable must be Zero Volts.

X6

9 Pin Connector

Control

(DCE)

RX+

RX–

TX+

TX-

DGND

Chassis

PE PE

TX+

TX–

RX+

RX-

DGND

Computer

COM

Port

(DTE)

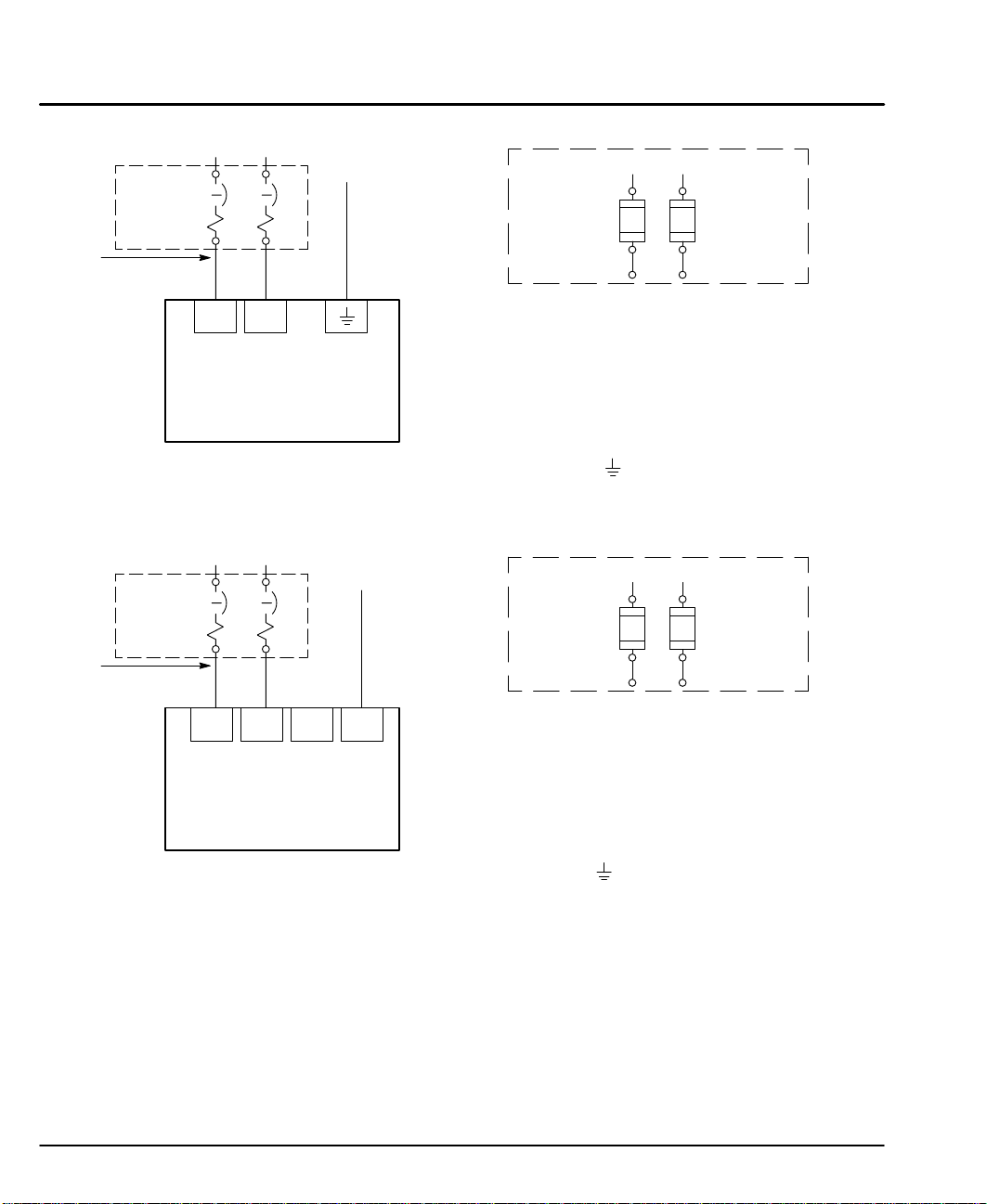

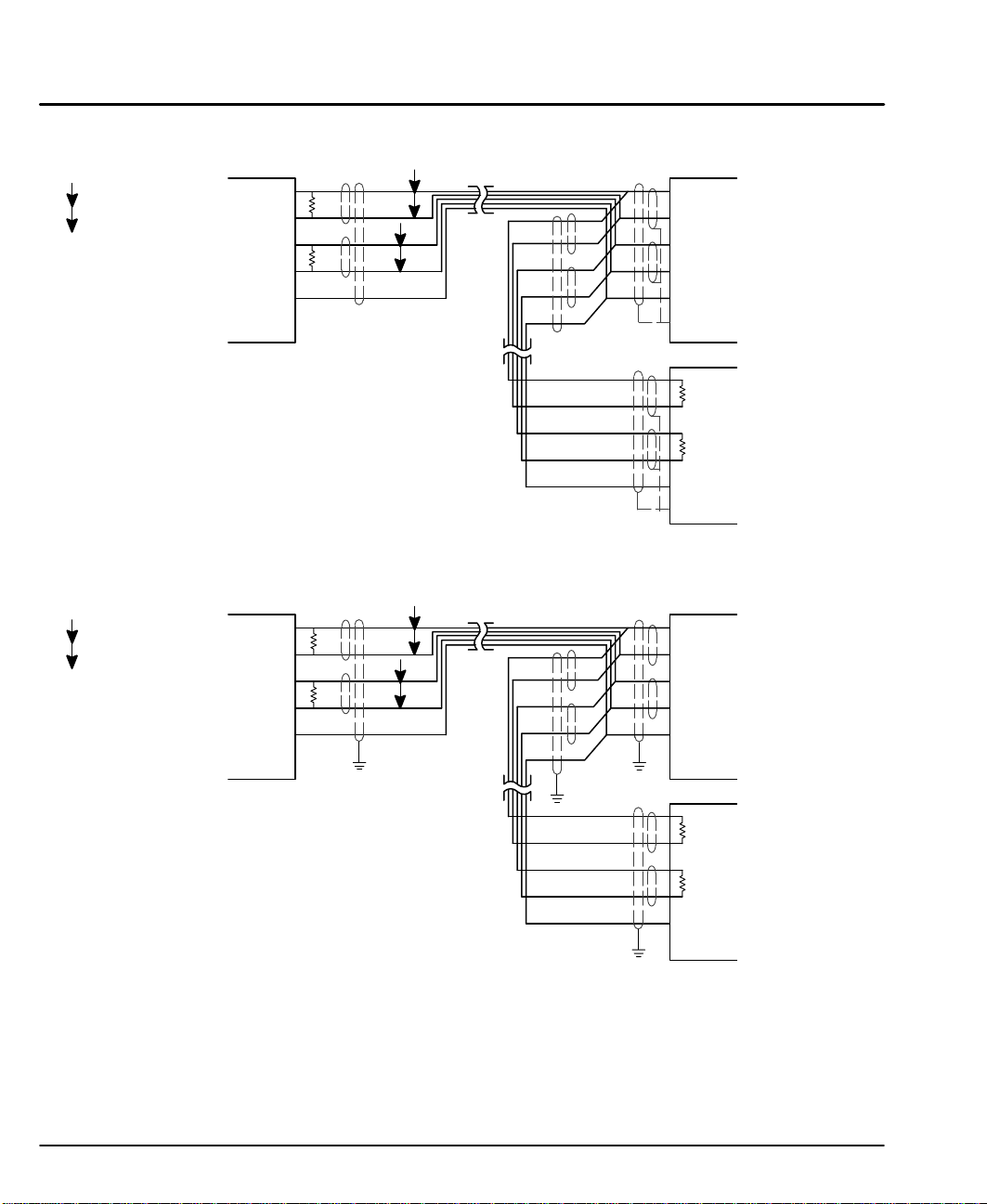

RS485 Multi-Drop Connections

What does termination or a termination resistor do?

Termination resistance is used to match the impedance of the load to the

impedance of the transmission line (cable) being used. Unmatched impedance

causes the transmitted signal to not be fully absorbed by the load. This causes a

portion of the signal to be reflected back into the transmission line (noise). If the

Source impedance, Transmission Line impedance, and Load impedance are all

equal, these reflections (noise) are eliminated.

Termination does increase load current and sometimes changes the bias

requirements and increases the complexity of the system.

What is a termination resistor?

A resistor that is added in parallel with the receiver input to match the impedance

of the cable being used. Typically, the resistor value that is used is 100 ohm or

120 ohm. Resistors with 90 ohms or less should never be used.

Where are these resistors placed?

Terminators or Termination resistors are placed in parallel with the receiver at both

ends of a transmission line. This means that you should never have more than

two terminators in the system (unless repeaters are being used).

How many resistors should my system have?

Terminators or Termination resistors are placed in parallel with the receiver at both

ends of a transmission line. This means that you should never have more than

two terminators in the system (unless repeaters are being used).

Receiving & Installation 3-17MN1851

Page 29

Figure 3-25 RS485 4 Wire Multi-Drop for UL Installations

Host

P

= Twisted Pair

Computer

RX+

RX–

TX+

TX-

DGND

GND

*

T

R

*

T

R

Use twisted pair shielded cable

with an overall shield.

* Terminating resistor TR is 120 W typical value.

Only the PC and last control are terminated.

P

P

Shields

Shields

*

*

T

R

T

R

X6

TX+

TX–

RX+

RX-

DGND

GND

X6

TX+

TX–

RX+

RX-

DGND

GND

Figure 3-26 RS485 4 Wire Multi-Drop for CE Installations

Host

Computer

P

= Twisted Pair

RX+

RX–

TX+

TX-

DGND

GND

Use twisted pair shielded cable

with an overall shield.

* Terminating resistor TR is 120 W typical value.

Only the PC and last control are terminated.

Note: For CE installations, connect the overall shield at each end of the cable to PE. The

voltage potential between the PE points at each end of the cable must be Zero Volts.

See Section 4 of this manual for the description of switch “AS1-1 to AS1-4” for

address settings for multi-drop applications.

*

T

R

*

T

R

P

P

PE

PE

PE

PE

*

*

T

R

T

R

X6

TX+

TX–

RX+

RX-

DGND

GND

X6

TX+

TX–

RX+

RX-

DGND

GND

3-18 Receiving & Installation MN1851

Page 30

X7 Encoder Output

The control provides a buffered encoder output at connector X7. This output may

be used by external hardware to monitor the encoder signals. It is recommended

that this output only drive one circuit load (RS422 interface – 28LS31 device).

Refer to Table 3-6.

Table 3-6 Buffered Encoder Output at X7 Connector

* For UL Installations ONLY. For CE Installations, connect the outer shield on

each end of the cable to the enclosure backplane “PE”.

X7 Pin Signal Name

1 A+

2 B+

3 C+

4 Reserved

5 DGND

6 A–

7 B–

8 C–

9 Reserved

Shell * Chassis (Cable Shield)

Receiving & Installation 3-19MN1851

Page 31

X9 Encoder and Hall Feedback (LPxAxxxx-Exxx)

Twisted pair shielded wire with an overall shield should be used. Figure 3-27

shows the electrical connections between the encoder and the encoder connector.

Figure 3-27 Encoder and Hall Feedback Connections for UL Installations

X9

1

A+

6

Encoder

Hall

Feedback

A–

2

B+

7

B–

C+

3

C–

8

11

+5V

DGND

13

4

Hall 1+

5

Hall 1–

9

Hall 3+

14

Hall 3–

Hall 2+

10

Hall 2–

15

12 Not Used

Shell (Chassis)

Figure 3-28 Encoder and Hall Feedback Connections for CE Installations

X9

1

A+

6

11

13

A–

2

B+

7

B–

3

C+

8

C–

+5V

DGND

Encoder

4

Hall 1+

5

Hall 1–

9

Hall

Feedback

Hall 3+

14

Hall 3–

10

Hall 2+

15

Hall 2–

12

Not Used

Shell (Chassis)

3-20 Receiving & Installation MN1851

Page 32

Section 4

Switch Setting and Start-Up

Switch AS1 Settings

AS1

Off / On

Monitor

1

2

3

4

5

6

7

8

AS1 switches are located on the front panel

between X1 and the “Monitor” LED.

Note: AS1–8 is shown in the “ON” position (Drive

Enabled). All other switches are shown in

the “OFF” position.

Address Setting, AS1-1 to AS1-4 (for Multi-Drop Applications)

Each control address can be set using switches AS1-1 to AS1-4 of each control.

Each control must have a unique address. Refer to Table 4-1.

Table 4-1 Control Address Setting

AS1-1 AS1-2 AS1-3 AS1-4 Control Address (Hexadecimal)

OFF OFF OFF OFF 0 (Factory Setting)

ON OFF OFF OFF 1

OFF ON OFF OFF 2

ON ON OFF OFF 3

OFF OFF ON OFF 4

ON OFF ON OFF 5

OFF ON ON OFF 6

ON ON ON OFF 7

OFF OFF OFF ON 8

ON OFF OFF ON 9

OFF ON OFF ON A

ON ON OFF ON B

OFF OFF ON ON C

ON OFF ON ON D

OFF ON ON ON E

ON ON ON ON F

Switch Setting & Start-Up 4-1MN1851

Page 33

Setting of switches AS1-5 to AS1-8

The function of switches AS1-5 to AS1-8 are described in Table 4-2.

Table 4-2 AS1-5 to AS1-8 Description

Switch Function ON OFF

AS1-5 Not Used

AS1-6 Hold-Position Hold-Position is active. Hold-Position is not active

AS1-7 Offset Tuning Automatic Offset Tuning is

active.

AS1-8 Enable Control is enabled

(Enable is active)

Hold-Position OFF allows normal operation.

ON causes the motor to quickly decelerate to stop and maintain a constant

position (in current or velocity modes). (Time to max velocity = 0 with the Hold

function.)

Offset Tuning OFF allows normal operation.

ON causes Offset Tuning to automatically start the next time Enable is changed

from ON to OFF. The purpose of Offset Tuning is to remove DC offset voltages (on

the command input X3-1 and X3-2) and achieve a stationary motor shaft with

0VDC at the command input. Leave this switch OFF when not in use. See Figure

4-1 for additional information.

Enable OFF disables the control and the motor coasts to a stop.

ON allows normal operation.

Note: AS1-8 and X3-9 must both be enabled to allow control operation.

Automatic Offset Tuning is not

active.

Control is disabled

(Enable is not active)

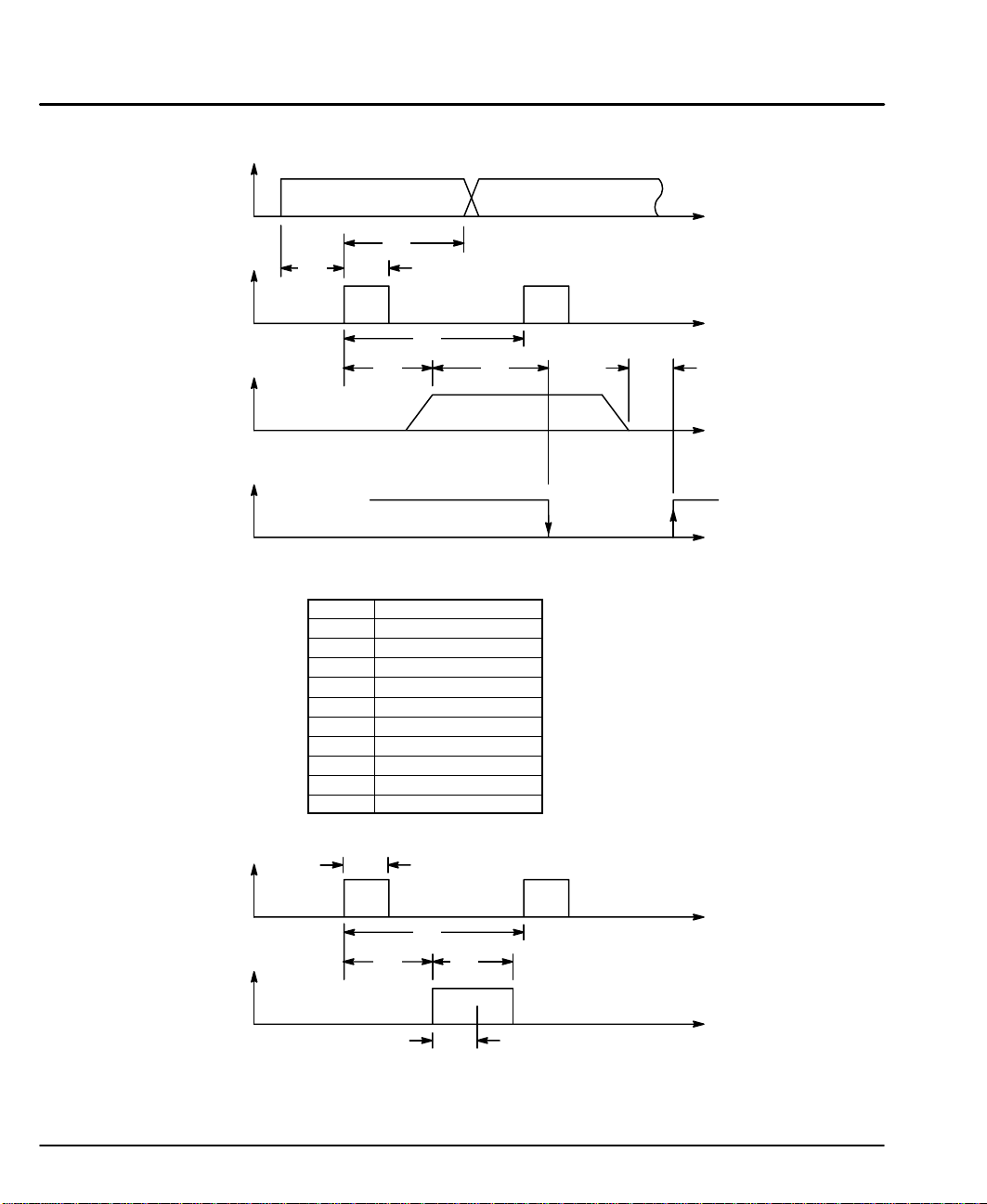

Figure 4-1 Automatic Offset Tuning Timing Diagram

Main

Power

Enable

Switch AS1-8

Offset Tuning

Switch AS1-7

Automatic

Offset Tuning

4-2 Switch Setting & Start-Up MN1851

On

Off

On

On or Off On

Off

On

Off

On

Off

On or Off On

Start

Offset

Tuning

Offset

Tuning

Done

Note: It is important that you set the analog command to 0VDC before the

Automatic Offset Tuning is started.

Time

Time

Time

Time

Page 34

Start-Up Procedure

Power Off Checks

Before you apply power, it is very important to verify the following:

Power On Checks

When power is first applied, the “Monitor” LED display will show four indications if

there is no failure found.

Procedure:

1. Disconnect the load from the motor shaft until instructed to apply a load.

If this cannot be done, disconnect the motor wires at X1-U, V and W.

2. Verify that switches AS1-5 to AS1-8 are set to OFF.

3. Verify the AC line voltage at the source matches the control rated

voltage.

4. Inspect all power connections for accuracy, workmanship and tightness.

5. Verify that all wiring conforms to applicable codes.

6. Verify that the control and motor are properly grounded to earth ground.

7. Check all signal wiring for accuracy.

8. All segments and decimal point are on.

0 Display test.

1 Option number of test (1, 2 etc.).

d Final display with no decimal point (control disabled because

AS1-8 = OFF).

1. Apply AC power.

2. Apply logic power (only if your control is equipped with this option).

3. Verify the Monitor LED power on sequence. If “d” is displayed, continue

otherwise disconnect AC power and refer to the Troubleshooting

procedure.

4. Disconnect AC power.

5. Connect the load to the motor shaft (or connect the motor wires at X1).

6. Apply Logic Power (24VDC) if option is present.

7. Apply AC power.

8. Set switches AS1-7 and AS1-8 to ON.

9. Set switch AS1-8 to OFF (initiate offset tuning).

10. Set switch AS1-7 to OFF.

11. Configure the control using the Setup Software provided.

Refer to Section 5 of this manual.

12. Set switch AS1-8 to ON (drive enabled).

13. Perform System Tuning.

The drive is now ready for use.

Note: To protect the internal fuse, allow at least 1 minute after power down before

turning power on (power Off/On cycle).

Switch Setting & Start-Up 4-3MN1851

Page 35

4-4 Switch Setting & Start-Up MN1851

Page 36

Section 5

Operation

Installing Software on your PC

The setup software is Windows–based. The servo control connects to a serial port

on your PC. The setup wizard will guide you through the necessary steps to

set–up your servo control. Online–help to each topic is available.

Minimum system requirements

Hardware requirements (minimum):

Processor: Intel 80486 / 33 MHz

RAM: 8 MB

Hard Disk Space: 50 MB

Screen: 600 x 480 (minimum)

Recommended: Intel Pentium, 16 MB RAM, 133 MHz, 100 MB Free Space

Software requirements:

Operating system: Windows 3.1x (minimum)

Recommended: Win95 or Windows NT

Installation The following procedure will install the setup software on your computer’s hard

disk:

1. Start Windows. Make sure that no other programs are running during

this installation.

2. Place installation Disk #1 in your computer’s floppy drive.

3. Run A:\Setup.exe (if A:\ is your floppy drive) or double click the file

Setup.exe from My computer, 3.5 inch Floppy (A:).

4. Follow the instructions and insert the other installation disks as required.

After the installation process is finished, a program manager group for Lin+ with a

Lin+ progman icon is created. Double clicking this icon will start the setup

program.

A file “Readme.txt” is included in the master directory of the software. This file

contains installation instructions, change notices from previous revisions and

information that became available after this manual was printed.

Host Communications Setup

Be sure the communications port of the PC is correctly set for communications

with the Drive software. The following examples assume COM1 of the PC is used.

If you are using COM2 – 4, substitute the correct COM port number in the

example.

Windows 3.1 Terminal Emulation

1. Power up the Host and start Windows software.

2. In the “Windows Accessories Group” select “Terminal” ICON.

3. Select “Communications” from the Settings pull down menu within

Terminal program.

4. Set the communications settings for:

9600 Baud rate

8 Data Bits

1 Stop Bit

No Parity

Xon/Xoff Flow Control

COM1

Operation 5-1MN1851

Page 37

5. Select “Binary Transfers” from the Settings pull down menu within

Terminal program.

6. Set the Binary Transfer protocol to XModem/CRC.

7. Close menu and save the settings.

8. Terminal Communications settings are now complete.

Windows 95

1. Power up the Host and start Windows software.

2. In “Control Panel” select and open “System”.

3. Open “Ports”, select the COM port you are using then click “properties”.

Figure 5-2

4. Be sure the port settings are as: Bits per second=9600, Data bits=8,

Parity=none, Stop bits=1 and Flow control=Xon/Xoff.

Windows NT

1. Power up the Host and start Windows software.

2. In “Control Panel”, select and open “Ports” then click “Settings”.

Figure 5-3

3. Be sure the port settings are as: Bits per second=9600, Data bits=8,

Parity=none, Stop bits=1 and Flow control=Xon/Xoff.

5-2 Operation MN1851

Page 38

Using The Setup Wizard

The setup software wizard guides you through each step to set the basic

parameters. This wizard is activated automatically after each start-up of the

software. This automatic start of the Wizard can be turned off. It can be activated

(and reset to automatic start) by Help " Wizard.

Figure 5-1 shows the flowchart of the Setup Wizard.

All parameters can be stored in a file. These saved values can be restored at any

time. To save the configuration, select Setup " Save Configuration. To restore

these parameter values or to configure several controls with the same parameter

sets, select the Setup " Restore Configuration.

Operation 5-3MN1851

Page 39

Figure 5-1 Flowchart of the Setup Wizard

Setup Wizard

Skip

Skip

Sequence 1:

Motor and Control

– App. Bus Voltage

–Enc. Output

– Select the motor

– Control is selected

automatically

Sequence 2:

Operating Mode

– Current

– Velocity

– Positioning

General:

Motor:

Control:

Download

General:

Download

Skip

Skip

Sequence 4:

Velocity Parameters

– Max. Velocity

– Time to

Max. Velocity

– Min. Velocity

– Scaling Factor

Sequence 5:

Auto

Tune

Sequence 6:

Auto tuning

General:

Download

Drift Offset

Offset

Value

(mV)

Download

Close

Skip

Sequence 3:

Current Parameters

General:

– App. Peak Amps

–App. Nom. Amps

–BEMF Compensation

–Scaling Factor

Sequence 4:

Auto Tuning

Procedure

Done

5-4 Operation MN1851

Page 40

Set up Software Opening menu. If you have previously set up the motor and control parameters

and saved them to a file, click FINISH then load the parameter file using the File

" Open selection. If you are setting up parameters for the first time, click NEXT

to go to the Set up Software.

The General menu appears first. If you are using a stock Baldor linear motor, click the Motor tab to

select the motor from the list and these parameters will be entered automatically for you. For a custom