Page 1

LinStep+ Single–Axis

Microstepping Indexer/Driver

Installation & Operating Manual

7/01 MN1853

Page 2

Table of Contents

Section 1

General Information 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Compliance 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Notice 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2

Product Overview 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3

Receiving and Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving & Inspection 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location Considerations 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Dissipation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Installation 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Grounding 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Disconnect 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protection Devices 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Connections 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS232/Keypad Installation 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–232 PC Connections 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS485 PC Connections 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discrete I/O Connections 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limits Connections 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Encoder Connections 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Connections 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LXOpto 44 and 88 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DB25 Pin to Screw Terminal Converter 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PNP Converter 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-Up Procedure 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Off Checks 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power On Checks 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents iMN1853

Page 3

Section 4

Keypad Operation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Run Menu 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

JOG Menu 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edit Menu 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROG 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POS 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HELP Menu 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COPY Menu 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROG 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TO PAD 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FROM 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DEL Menu 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 5

Setup 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure Motor 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure Encoder 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure Your Application 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the I/O 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Optional LXOPTO 44/88 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure the Output States 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure End of Travel Switch Polarity 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure JOG Parameters 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure HOME Parameters 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure Power–up Program 5-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure Serial Communications 5-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure Miscellaneous Setup Parameters 5-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 6

Keypad Programming 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commands 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 6-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Variables 6-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Arithmetic Operands and Equations 6-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boolean Operators 6-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logical Operators 6-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Increment/Decrement Variables 6-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expressions 6-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Programming Samples 6-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii Table of Contents MN1853

Page 4

Section 7

Troubleshooting 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 8

Specifications & Product Data 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Identification 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 9

CE Guidelines 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Declaration of Conformity 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EMC – Conformity and CE – Marking 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EMC Installation Instructions 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Template A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Keypad Mounting Template A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents iiiMN1853

Page 5

iv Table of Contents MN1853

Page 6

Section 1

General Information

Copyright Baldor 2001. All rights reserved.

This manual is copyrighted and all rights are reserved. This document may not, in

whole or in part, be copied or reproduced in any form without the prior written

consent of Baldor.

Baldor makes no representations or warranties with respect to the contents hereof

and specifically disclaims any implied warranties of fitness for any particular

purpose. The information in this document is subject to change without notice.

Baldor assumes no responsibility for any errors that may appear in this document.

Microsoft and MS–DOS are registered trademarks, and Windows is a trademark of

Microsoft Corporation.

UL and cUL are registered trademarks of Underwriters Laboratories.

CE Compliance

A custom unit may be required, contact Baldor. Compliance to Directive

89/336/EEC is the responsibility of the system integrator. A control, motor and all

system components must have proper shielding, grounding, and filtering as

described in MN1383. Please refer to MN1383 for installation techniques for CE

compliance. For additional information, refer to Sections 3 and 9 of this manual.

Limited Warranty

For a period of two (2) years from the date of original purchase, BALDOR will repair or

replace without charge controls and accessories which our examination proves to be

defective in material or workmanship. This warranty is valid if the unit has not been

tampered with by unauthorized persons, misused, abused, or improperly installed and

has been used in accordance with the instructions and/or ratings supplied. This warranty

is in lieu of any other warranty or guarantee expressed or implied. BALDOR shall not be

held responsible for any expense (including installation and removal), inconvenience, or

consequential damage, including injury to any person or property caused by items of our

manufacture or sale. (Some states do not allow exclusion or limitation of incidental or

consequential damages, so the above exclusion may not apply.) In any event, BALDOR’s

total liability, under all circumstances, shall not exceed the full purchase price of the

control. Claims for purchase price refunds, repairs, or replacements must be referred to

BALDOR with all pertinent data as to the defect, the date purchased, the task performed

by the control, and the problem encountered. No liability is assumed for expendable items

such as fuses.

Goods may be returned only with written notification including a BALDOR Return

Authorization Number and any return shipments must be prepaid.

General Information 1-1MN1853

Page 7

Product Notice Intended use:

These drives are intended for use in stationary ground based applications in

industrial power installations according to the standards EN60204 and VDE0160.

They are designed for machine applications that require 2 phase stepper motors.

These drives are not intended for use in applications such as:

– Home appliances

– Mobile vehicles

– Ships

– Airplanes

Unless otherwise specified, this drive is intended for installation in a suitable

enclosure. The enclosure must protect the control from exposure to excessive or

corrosive moisture, dust and dirt or abnormal ambient temperatures. The exact

operating specifications are found in Section 8 of this manual.

The installation, connection and control of drives is a skilled operation,

disassembly or repair must not be attempted.

In the event that a control fails to operate correctly, contact the place of purchase

for return instructions.

Safety Notice: This equipment contains high voltages. Electrical shock can cause serious or fatal

injury. Only qualified personnel should attempt the start–up procedure or

troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts or

parts that are driven by this equipment. Improper use can cause serious or fatal

injury. Only qualified personnel should attempt the start–up procedure or

troubleshoot this equipment.

– System documentation must be available at all times.

– Keep non-qualified personnel at a safe distance from this equipment.

– Only qualified personnel familiar with the safe installation, operation and

maintenance of this device should attempt start-up or operating

procedures.

– Always remove power before making or removing any connections to

this control.

PRECAUTIONS: Classifications of cautionary statements.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in injury or death.

Caution: Indicates a potentially hazardous situation which, if not avoided,

could result in damage to property.

Continued on next page.

1-2 General Information MN1853

Page 8

PRECAUTIONS:

WARNING: Do not touch any circuit board, power device or electrical

connection before you first ensure that power has been

disconnected and there is no high voltage present from this

equipment or other equipment to which it is connected.

Electrical shock can cause serious or fatal injury.

WARNING: Be sure that you are completely familiar with the safe operation

of this equipment. This equipment may be connected to other

machines that have rotating parts or parts that are controlled by

this equipment. Improper use can cause serious or fatal injury.

WARNING: Be sure all wiring complies with the National Electrical Code and

all regional and local codes or CE Compliance. Improper wiring

may cause a hazardous condition.

WARNING: Be sure the system is properly grounded before applying power.

Do not apply AC power before you ensure that grounds are

connected. Electrical shock can cause serious or fatal injury.

WARNING: Do not remove cover for at least five (5) minutes after AC power

is disconnected to allow capacitors to discharge. Electrical

shock can cause serious or fatal injury.

WARNING: Improper operation may cause violent motion of the motor and

driven equipment. Be certain that unexpected movement will not

cause injury to personnel or damage to equipment.

WARNING: Motor circuit may have high voltage present whenever AC power

is applied, even when motor is not moving. Electrical shock can

cause serious or fatal injury.

WARNING: If a motor is driven mechanically, it may generate hazardous

voltages that are conducted to its power input terminals. The

enclosure must be grounded to prevent a possible shock hazard.

WARNING: A DB Resistor may generate enough heat to ignite combustible

materials. To avoid fire hazard, keep all combustible materials

and flammable vapors away from brake resistors.

WARNING: The user must provide an external hard-wired emergency stop

circuit to disable the control in the event of an emergency.

Caution: To prevent equipment damage, be certain that the input power has

correctly sized protective devices installed as well as a power disconnect.

Caution: Avoid locating the control immediately above or beside heat generating

equipment, or directly below water or steam pipes.

Caution: Suitable for use on a circuit capable of delivering not more than the RMS

symmetrical short circuit amperes listed here at rated voltage.

Horsepower RMS Symmetrical Amperes

1–50 5,000

Continued on next page.

General Information 1-3MN1853

Page 9

Caution: To prevent keypad damage, be sure keypad mounting screws do not

extend more than 0.2 (5) into keypad assembly.

Caution: Avoid locating the control in the vicinity of corrosive substances or

vapors, metal particles and dust.

Caution: Baldor recommends not using “Grounded Leg Delta” transformer power

leads that may create ground loops and degrade system performance.

Instead, we recommend using a four wire Wye.

Caution: Logic signals are interruptible signals; these signals are removed when

power is removed from the drive.

Caution: The safe integration of the driver into a machine system is the

responsibility of the machine designer. Be sure to comply with the local

safety requirements at the place where the machine is to be used. In

Europe this is the Machinery Directive, the ElectroMagnetic Compatibility

Directive and the Low Voltage Directive. In the United States this is the

National Electrical code and local codes.

Caution: Drivers must be installed inside an electrical cabinet that provides

environmental control and protection. Installation information for the drive

is provided in this manual. Motors and controlling devices that connect to

the driver should have specifications compatible to the drive.

Caution: Do not tin (solder) exposed wires. Solder contracts over time and may

cause loose connections.

Caution: Electrical components can be damaged by static electricity. Use ESD

(electro-static discharge) procedures when handling this control.

Caution: Do not connect or disconnect motor wires from the control while power is

on. If motor leads are disconnected while the control is powered up,

damage to the control may result.

1-4 General Information MN1853

Page 10

Section 2

Product Overview

Overview The design of LinStep and LinStep+ microstepping motor drivers (also called a

driver or control) and the internal cooling tunnel are revolutionary. These drivers

consume less panel space than other controls and keep internal electronics cool

and clean for years of reliable performance and operation. LinStep+ single and

dual–axis drivers are used with Baldor motion controls and other popular stepper

controllers that provide step and direction (or CW/CCW step pulses) . They are

ideally suited to control Baldor single and dual–axis linear stepping motors. Figure

2-1 shows how the LinStep+ driver is placed in a linear stepper motor system.

The open loop linear stepper motor provides the most economical linear motor

positioning solution. There are two types of linear stepper motors: a single–axis

linear stepper motor and the compact dual–axis linear stepper motor. Linear

stepper motors include the motor, positioning system and bearings in two

components: a moving forcer and a stationary platen.

Figure 2-1 Motion Control with LinStep+

LinStep+

Single Axis

Indexer/

Driver

Linear stepper motors move in discrete incremental moves called steps. The size

of each step is determined by the spacing of the teeth in the platen and how the

coils are energized. Baldor 2–phase motors travel 0.010 inches (0.254mm) in a

single full step yielding 100 steps per inch. Baldor 4–phase motors travel 0.005

inches (0.127mm) in a step. When the coils are energized in a predetermined

pattern, the forcer will move down the platen. Reversing the pattern will reverse

the direction of travel. The microstep frequency determines the velocity of the

forcer. Linear stepper motors produce their maximum force at zero speed. As

speed increases the ability to switch winding current decreases due to motor

inductance. This results in lower forces at higher speeds.

Contact your local Baldor distributor or sales representative for assistance with

sizing and compatibility. Custom motors or motors not manufactured by Baldor

may be used. Please contact your local Baldor distributor or sales representative

for assistance.

Motors Baldor LinStep+ Drivers are compatible with many Linear Stepper motors from

Baldor and other manufacturers. Compatible Baldor motors include: (refer to

BR1800 for additional motor information).

Linear

Step Motor

Single Axis

Stepping Motor

Axis 1

S LMSS Series Single Axis

S LMDS Series Dual Axis

Product Overview 2-1MN1853

Page 11

2-2 Product Overview MN1853

Page 12

Section 3

Receiving and Installation

Receiving & Inspection

Baldor Drivers are thoroughly tested at the factory and carefully packaged for

shipment. When you receive your driver, there are several things you should do

immediately.

1. Observe the condition of the shipping container and report any damage

immediately to the commercial carrier that delivered your driver.

2. Remove the driver from the shipping container and remove all packing

materials. The container and packing materials may be retained for

future shipment.

3. Verify that the part number you received is the same as the part number

listed on your purchase order.

4. Inspect for external physical damage that may have been sustained

during shipment and report any damage immediately to the commercial

carrier that delivered your driver.

5. If the driver is to be stored for several weeks before use, be sure that it is

stored in a location that conforms to published storage humidity and

temperature specifications stated in this manual.

Location Considerations The location of the driver is important. Installation should be in an area

that is protected from direct sunlight, corrosives, harmful gases or liquids, dust,

metallic particles, and vibration. Exposure to these can reduce the operating life

and degrade performance of the driver.

Several other factors should be carefully evaluated when selecting a location for

installation:

1. For effective cooling and maintenance, the driver should be mounted on

a smooth, non-flammable vertical surface.

2. At least 3 inches (75mm) top and bottom clearance must be provided for

air flow. Between drivers (each side), allow at least 0.1 inch (2.5mm).

3. Altitude derating. Up to 3300 feet (1000 meters) no derating required.

Derate the continuous and peak output current by 1.1% for each 330

(100) above 3300 feet. Maximum altitude is 8300 (2540m).

4. Temperature derating. From 0°C to 40°C ambient no derating

required. Above 40°C, derate the continuous and peak output current by

2.5% per °C above 40°C. Maximum ambient is 50°C.

Power Dissipation

Cooling requirements can be determined if you know the maximum (or

continuous) current output from the microstepping driver, I

dissipation, W

= 5 + 3.4ID +0.15I

W

Diss

Mechanical Installation

Mount the driver to the mounting surface. The driver must be securely fastened to

the mounting surface by the driver mounting holes. The location of the mounting

holes is shown in Section 8 of this manual. Use #8 (M4) cap screws.

as follows:

Diss

2

D

. Calculate heat

D

Receiving & Installation 3-1MN1853

Page 13

Electrical InstallationAll interconnection wires between the driver, AC power source, motor, host

driver and any operator interface stations should be in metal conduits. Use listed

closed loop connectors that are of appropriate size for wire gauge being used.

Connectors are to be installed using crimp tool specified by the manufacturer of

the connector. Only class 1 wiring should be used.

System Grounding Baldor drivers are designed to be powered from standard single phase lines

that are electrically symmetrical with respect to ground. System grounding is an

important step in the overall installation to prevent problems. The recommended

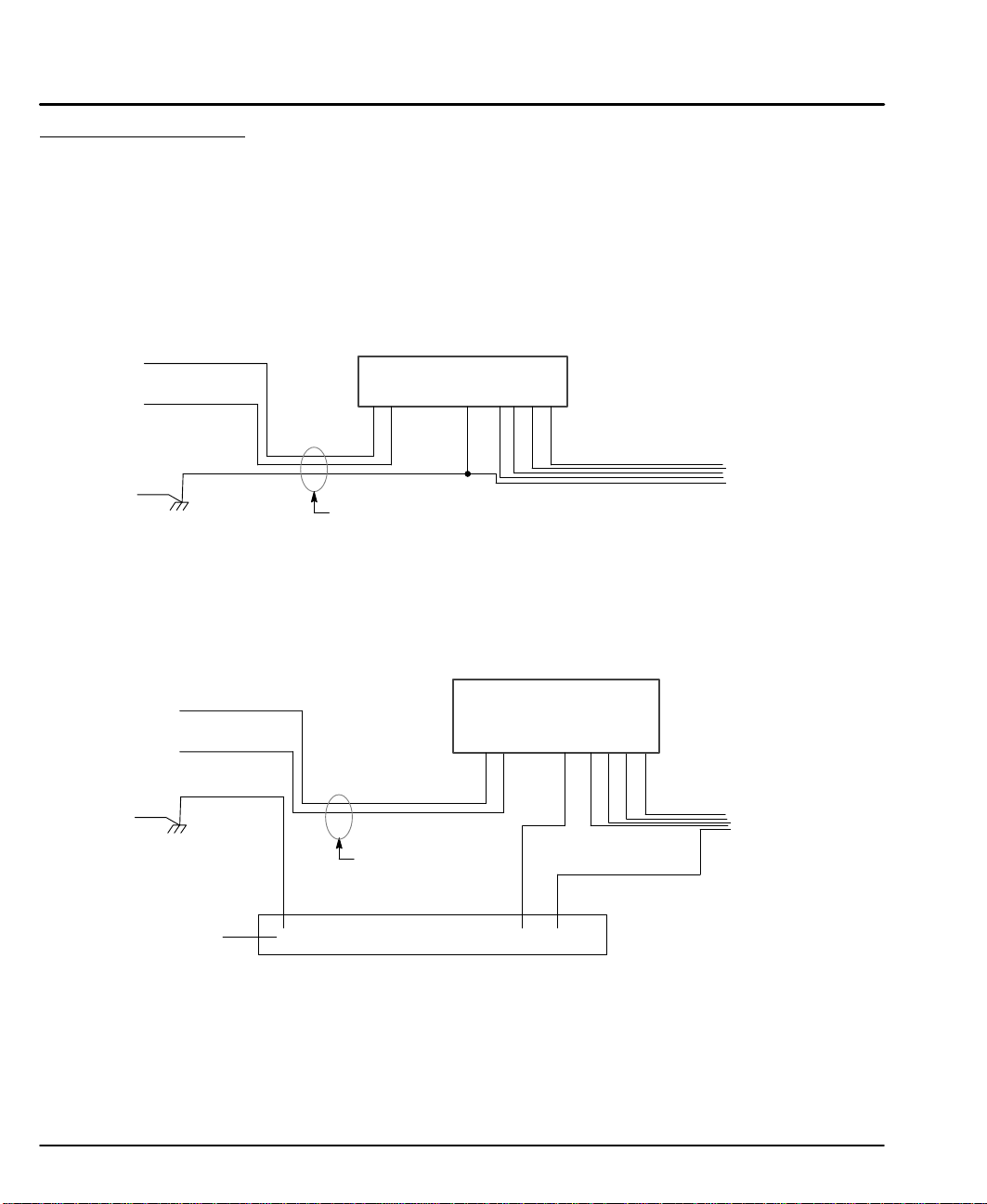

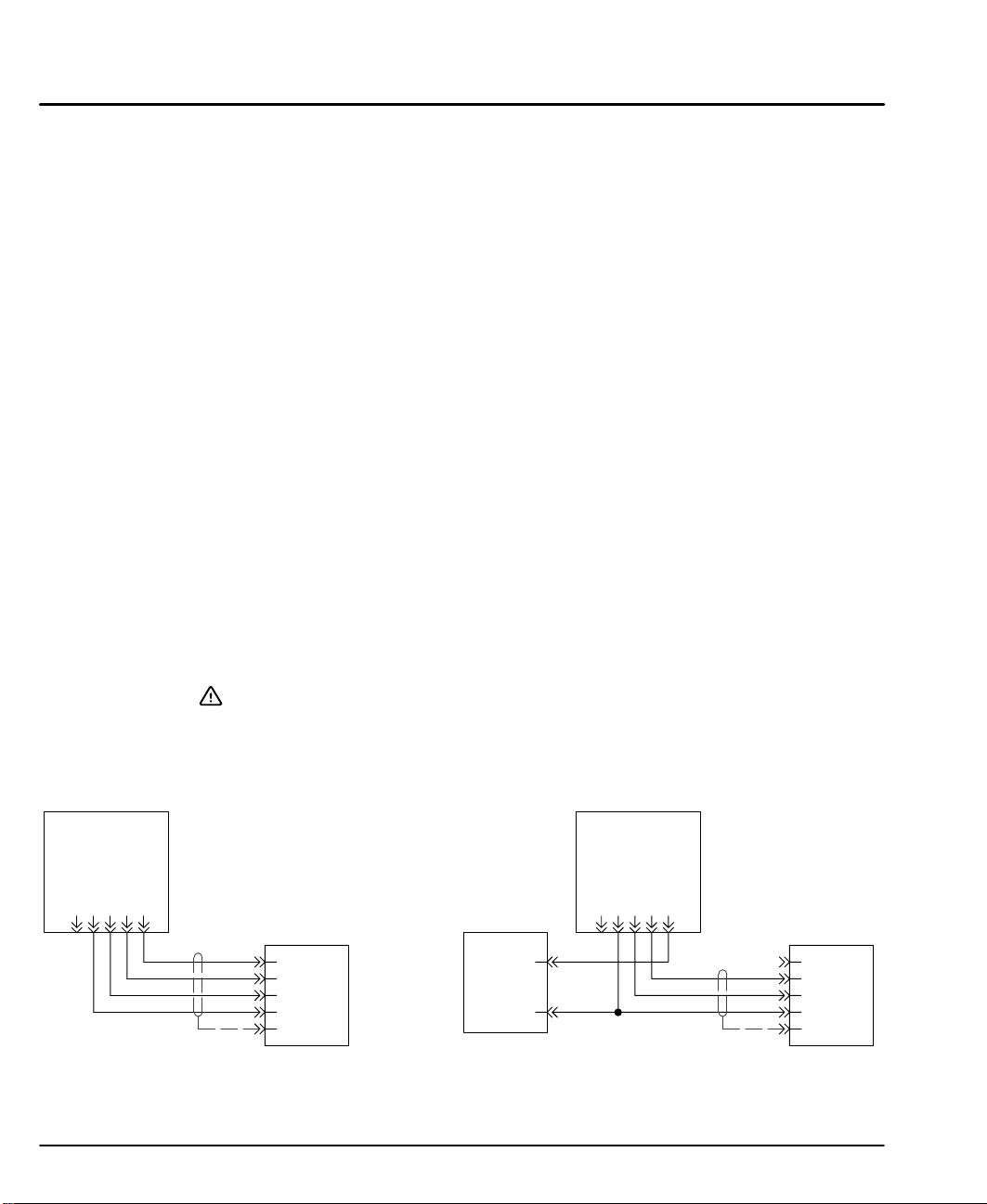

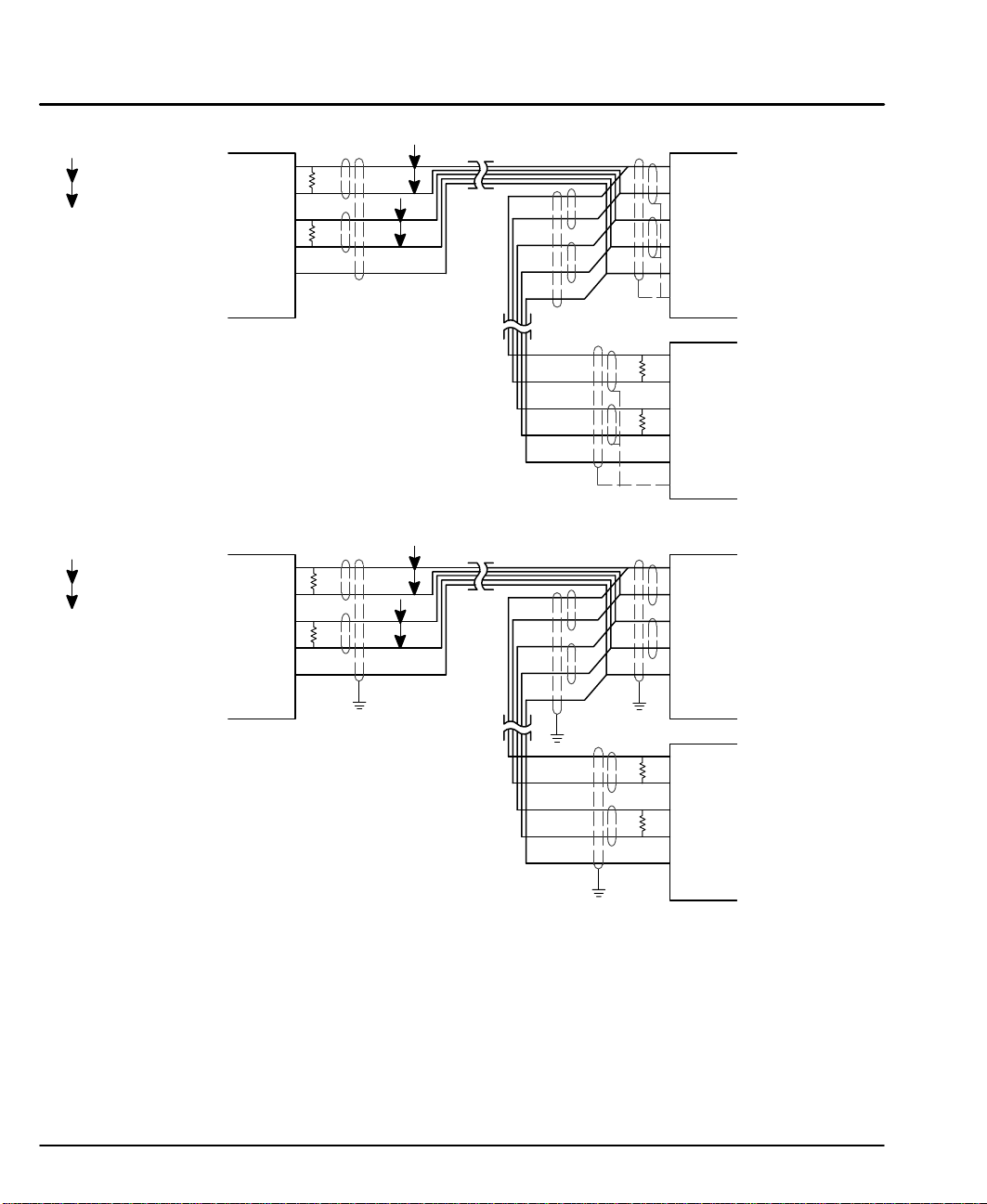

grounding method is shown in Figure 3-1 for UL compliant systems (Figure 3-2 for

CE compliant systems).

Figure 3-1 Recommended System Grounding for UL

AC Main

Supply

L

N

Microstepper Driver

L

N

GND

B+A– B–A+

Note:

Wiring shown for clarity of grounding

method only. Not representative of

actual terminal block location.

Safety

Ground

Driven Earth

Ground Rod

(Plant Ground)

Note: Use shielded cable for driver signal wires. Route driver signal wires in

conduit. These wires must be kept separate from power and motor wires.

Earth

Route all 3 wires L, N, and Earth

(Ground) together in conduit or

cable.

Figure 3-2 Recommended System Grounding (1 phase) for CE

AC Main

Supply

Safety

Ground

Note: Use shielded cable for driver signal wires. Route driver signal wires in

L

N

Earth

Driven Earth

Ground Rod

(Plant Ground)

All shields

conduit. These wires must be kept separate from power and motor wires.

Route all power

wires together in

conduit or cable.

Enclosure Backplane (see Section 8)

Microstepper Driver

LN

GND

A+

Linear

Motor

Ground per NEC and Local codes.

Note:

Wiring shown for clarity of

grounding method only. Not

B+A– B–

representative of actual

terminal block location.

Linear

Motor

Motor

GND

3-2 Receiving & Installation MN1853

Page 14

System Grounding

Continued

Ungrounded Distribution System

With an ungrounded power distribution system it is possible to have a continuous

current path to ground through the MOV devices. To avoid equipment damage, an

isolation transformer with a grounded secondary is recommended.

Input Power Conditioning

Certain power line conditions must be avoided. An AC line reactor or an isolation

transformer may be required for some power conditions.

• If the feeder or branch circuit that provides power to the driver has

permanently connected power factor correction capacitors, an input AC

line reactor or an isolation transformer must be connected between the

power factor correction capacitors and the driver.

• If the feeder or branch circuit that provides power to the driver has power

factor correction capacitors that are switched on line and off line, the

capacitors must not be switched while the driver is connected to the AC

power line. If the capacitors are switched on line while the driver is still

connected to the AC power line, additional protection is required. TVSS

(Transient Voltage Surge Suppressor) of the proper rating must be

installed between the AC line reactor or an isolation transformer and the

AC input to the driver.

Power Disconnect A power disconnect should be installed between the input power service

and the driver for a fail–safe method to disconnect power. The driver will remain in

a powered-up condition until all input power is removed from the driver and the

internal bus voltage is depleted.

Protection Devices The driver must have a suitable input power protection device installed.

Input and output wire size is based on the use of copper conductor wire rated at

75 °C. Table 3-1 describes the wire size to be used for power connections and the

ratings of the protection devices. Use the recommended circuit breaker or fuse

types as follows:

Circuit Breaker: 1 phase, thermal magnetic.

Equal to GE type THQ or TEB for 115 or 230 VAC

Time Delay Fuses: Buss LPN on 115 VAC or

Buss FRN on 230 VAC or equivalent.

Recommended fuse sizes are based on the following:

UL 508C suggests a fuse size of four times the continuous output

current of the driver.

Dual element, time delay fuses should be used to avoid nuisance trips

due to inrush current when power is first applied.

Receiving & Installation 3-3MN1853

Page 15

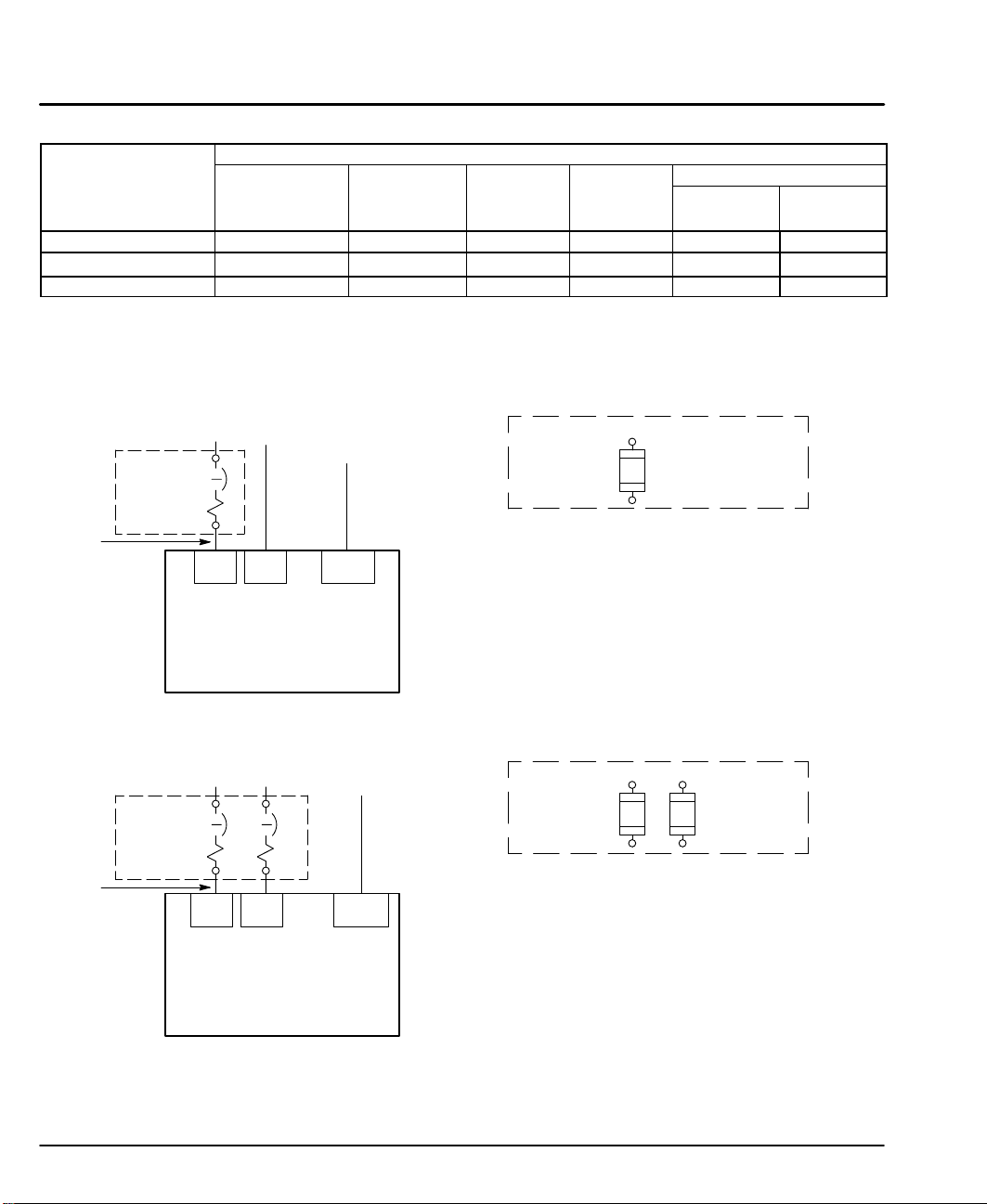

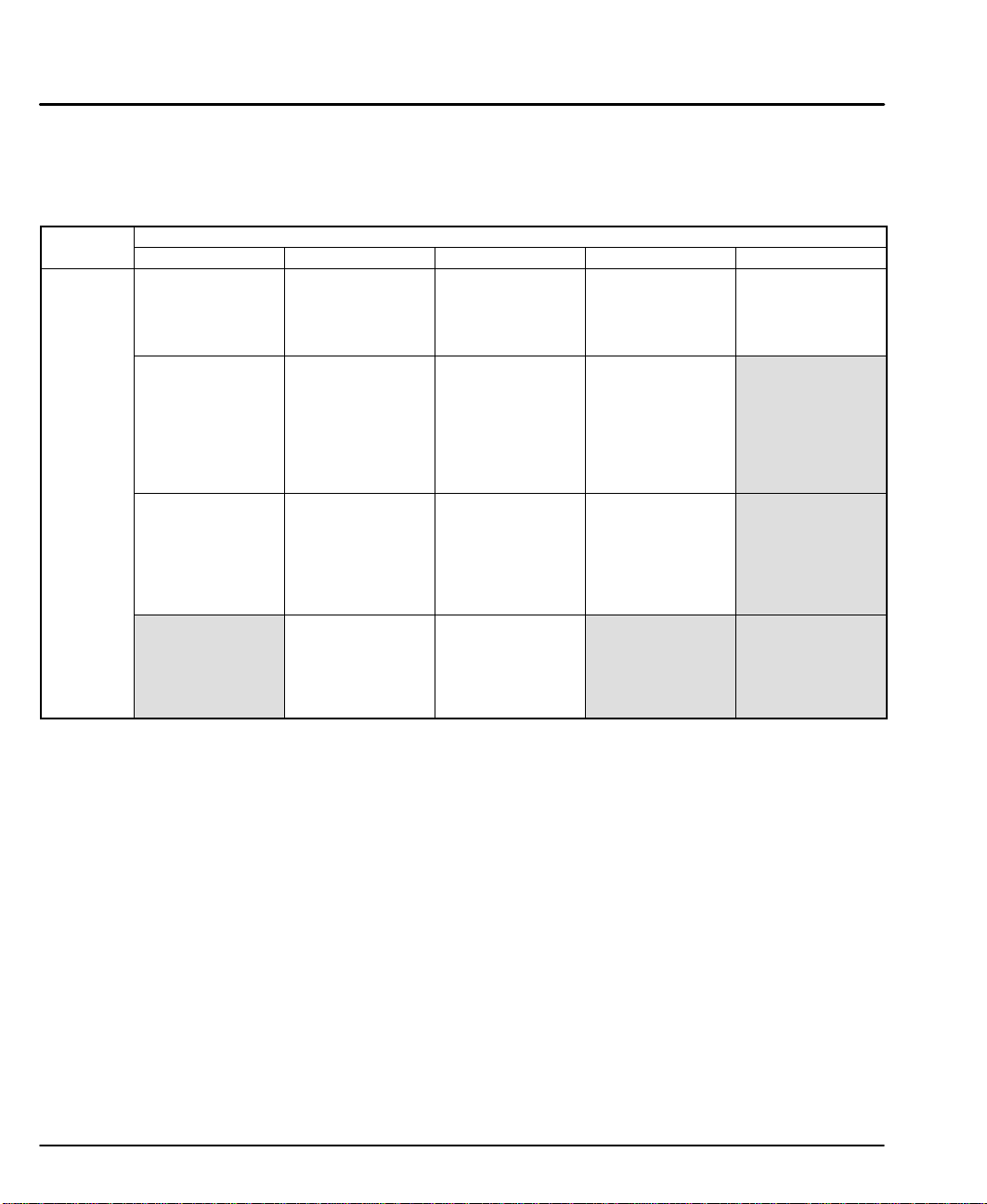

Table 3-1 Wire Size and Protection Devices

Incoming Power

Catalog Number

LX1P1A07F9

LX1P2A06

LX1P1A03

Nominal Input

Voltage

115V (1f)

115V (1f)

230V (1f)

Continuous Input

Continuous

Output

(RMS)

Amps

Input

Breaker

(A)

7.9A 30 30 14 2.5

6.0A 20 20 14 2.5

3.9A 20 20 14 2.5

Input Fuse Wire Gauge

Time

Delay (A)

AWG

(USA)

Note: All wire sizes are based on 75°C copper wire. Higher temperature smaller gauge wire may

be used per NEC and local codes. Recommended fuses/breakers are based on 25°C

ambient, maximum continuous driver output current and no harmonic current.

Power Connections Power connections are shown in Figures 3-3 and 3-4.

Figure 3-3 115VAC Single Phase AC Power Connections

L1

Note 1

2

minimum, 6AWG). For CE

Note 1

Note 2

* Circuit

Breaker

L1 Neutral

LN

Baldor

LinStep+

Earth

GND

Note 3 & 4

Note 5

Alternate *

Fuse

Connection

Notes:

1. See “Protection Devices” described in this section.

2. Metal conduit or shielded cable should be used. Connect

conduits so the use of a Reactor or RC Device does not

interrupt EMI/RFI shielding.

3. Use same gauge wire for Earth ground as is used for L and N.

(VDE (Germany) requires 10mm

Compliance, connect Earth to the backplane of the enclosure.

4. Reference EMC wiring in Section 8.

5. GND is located on the motor terminal strip.

* Components not provided with driver.

2

mm

(Europe)

Figure 3-4 230VAC Single Phase AC Power Connections

L1 L2

Note 1

Note 1

L1 L2

* Circuit

Earth

Note 3 & 4

Alternate *

Fuse

Connection

Breaker

GND

Note 5

Notes:

1. See “Protection Devices” described in this section.

2. Metal conduit or shielded cable should be used. Connect

3. Use same gauge wire for Earth ground as is used for L and N.

4. Reference EMC wiring in Section 8.

5. GND is located on the motor terminal strip.

* Components not provided with driver.

conduits so the use of a Reactor or RC Device does not

interrupt EMI/RFI shielding.

(VDE (Germany) requires 10mm2 minimum, 6AWG). For CE

Compliance, connect Earth to the backplane of the enclosure.

Note 2

L1 L2

Baldor

LinStep+

3-4 Receiving & Installation MN1853

Page 16

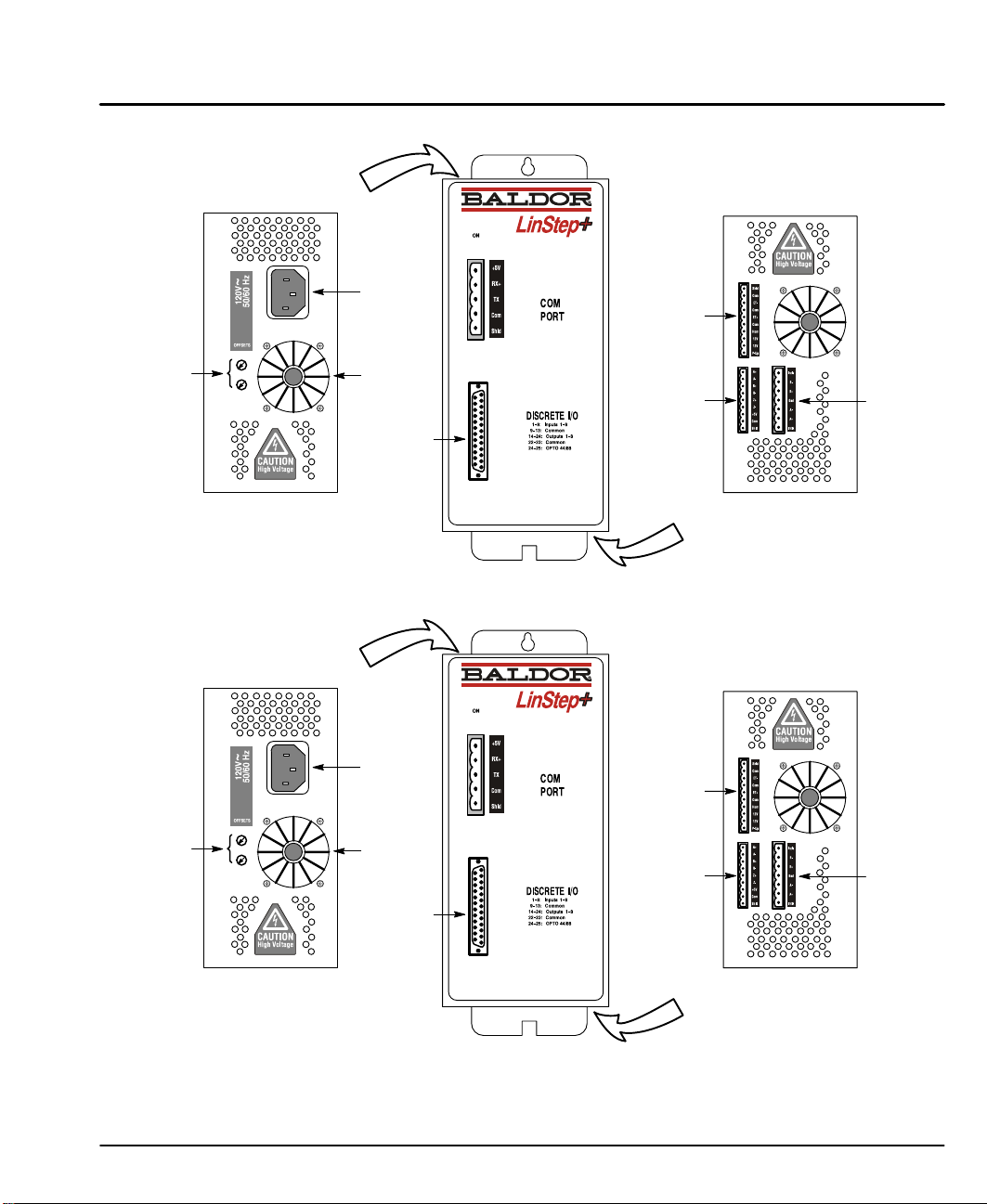

Offset

Adjustments

Figure 3-5 Connection Locations (115VAC, 1 Axis)

Top Connections

Figure 3-6 Connection Locations (230VAC, 1 Axis)

AC

Power

Input

Fan

Discrete I/O

Connector

Limits

Connector

Encoder

Connector

Motor

Connector

Bottom Connections

Offset

Adjustments

Top Connections

AC

Power

Input

Fan

Discrete I/O

Connector

Limits

Connector

Encoder

Connector

Motor

Connector

Bottom Connections

Receiving & Installation 3-5MN1853

Page 17

RS232/Keypad Installation Procedure: (optional keypad – LXKP)

Optional Remote Keypad Installation

The keypad may be remotely mounted and sealed to NEMA 4 specification by

using the gasket and 6 ft (1.8m) cable included. The keypad assembly is

complete with the screws and gasket required to mount it to an enclosure. The

gasket has adhesive on one side that must be placed toward the enclosure.

Tools Required:

• Center punch.

3

/16" drill bit (for clearance mounting holes).

•

1

•

/2" (12.7) and 1-1/2" (38.1) standard knockout punch.

• (4) 6-32 nuts and washers (or M3.5 hardware).

• Remote keypad mounting template. A tear out copy is

provided at the end of this manual for your convenience.

Mounting Instructions: (see remote keypad mounting template)

1. Locate a flat mounting surface. Material should be sufficient thickness (14

gauge minimum).

2. Place the template on the mounting surface or mark the holes as shown.

3. Accurately center punch the 4 mounting holes (labeled E for SAE or M for

metric) and the three large Cut–Out holes.

4. Drill four

3

/16" holes (at E or M).

5. Make the three large Cut–Out holes using the punch manufacturers instructions.

6. Debur knockout and mounting holes making sure the panel stays clean and flat.

7. Apply the adhesive backed gasket to the enclosure.

8. Assemble the keypad to the panel. Non–conductive screws and washers

should be used to electrically isolate the keypad from the enclosure.

Caution: To prevent keypad damage, be sure keypad mounting screws

do not extend more than 0.2 (5) into keypad assembly.

9. Connect the keypad cable to the keypad connector of the main circuit board,

Figure 3-7.

Figure 3-7 Keypad (Nullmodem) Connections

Keypad

GND

N/C

+5VDC

R

T

x

x

Standard Connections External +5VDC

LinStep+

RS232 / Keypad

Connector

+5VDC

R

x

T

x

GND

Shld

Note: A 6ft (1.8m) cable is provided with the keypad. If a longer cable is

to be used, an external +5VDC @ 500mA power supply is required.

External

P.S.

+5VDC

GND

Keypad

N/C

GND

R

x

T

x

+5VDC

Connections

LinStep+

RS232 / Keypad

Connector

+5VDC

R

x

T

x

GND

Shld

3-6 Receiving & Installation MN1853

Page 18

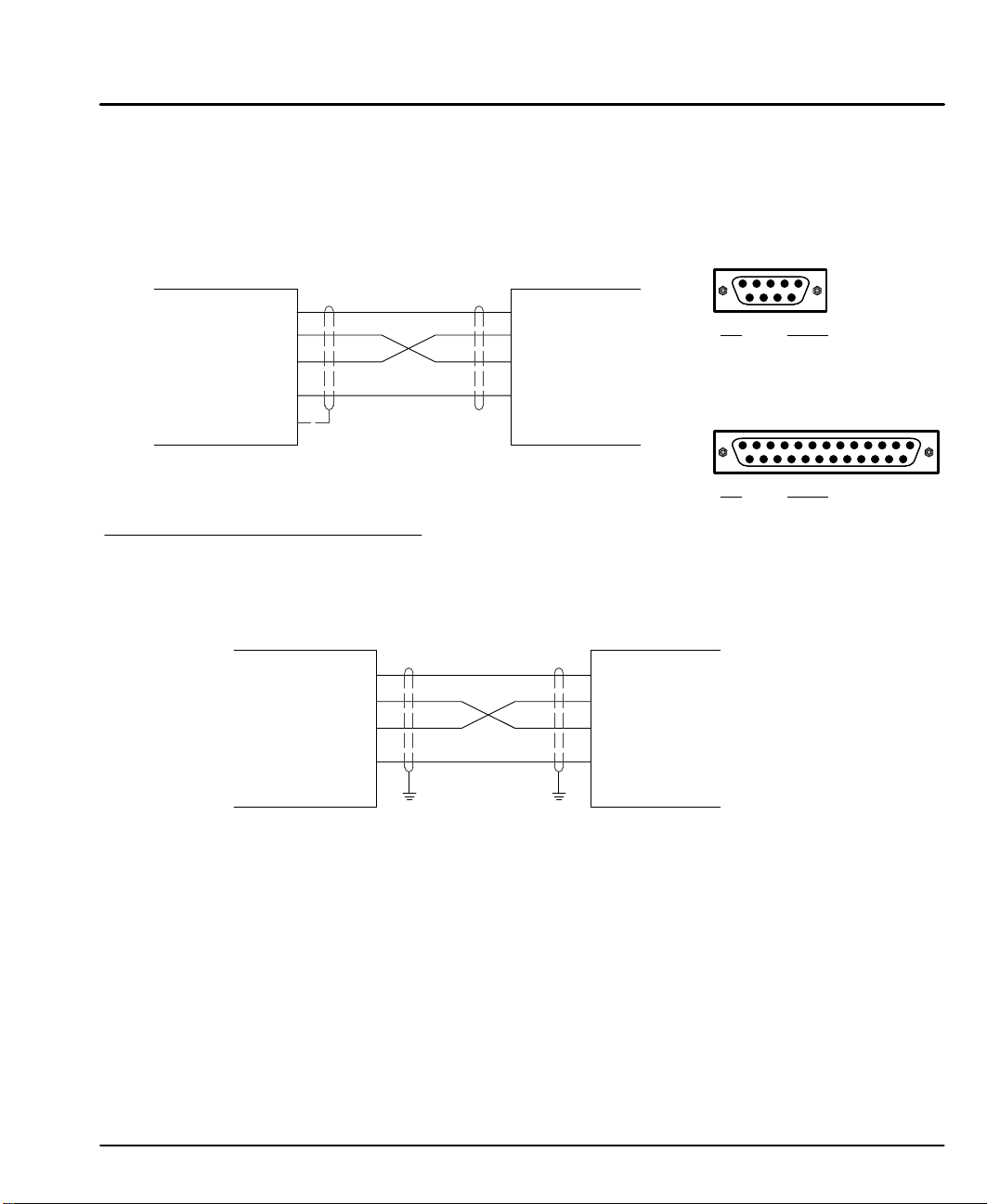

RS–232 PC Connections

A null modem connection must be made between the LinStep+ and the computer

COM port. This will ensure that the transmit and receive lines are properly

connected. Either a 9 pin or a 25 pin connector can be used at the computer,

Figure 3-8. Maximum recommended length for RS232 cable is 6 ft. (1.8 meter).

Figure 3-8 9 & 25 Pin RS-232 Cable Connections for UL Installations

RS232/Keypad Connector

9 Pin Connector

+5V +5V

LinStep+

(DCE)

If required, RTS, CTS, DSR and DTR may also be

connected for a full null modem connection.

Jumper

RTS to CTS

DSR to DTR

RXD

TXD

GND

Chassis

9 Pin 25 Pin

7 to 8

4 to 6

4 to 5

6 to 20

Figure 3-9 9 & 25 Pin RS-232 Cable Connections for CE Installations

RS232/Keypad Connector

+5V +5V

Control

(DCE)

Note: For CE installations, connect the overall shield at each end of the cable to

RXD

TXD

GND

PE PE

PE. The voltage potential between the PE points at each end of the cable

must be Zero Volts.

Computer

RXD

COM

TXD

Port

GND

(DTE)

Computer

RXD

COM

Port

TXD

(DTE)

GND

Pin

2 RXD

3 TXD

5 GND

25 Pin Connector

Pin

2 RXD

3 TXD

7 GND

Signal

Signal

Receiving & Installation 3-7MN1853

Page 19

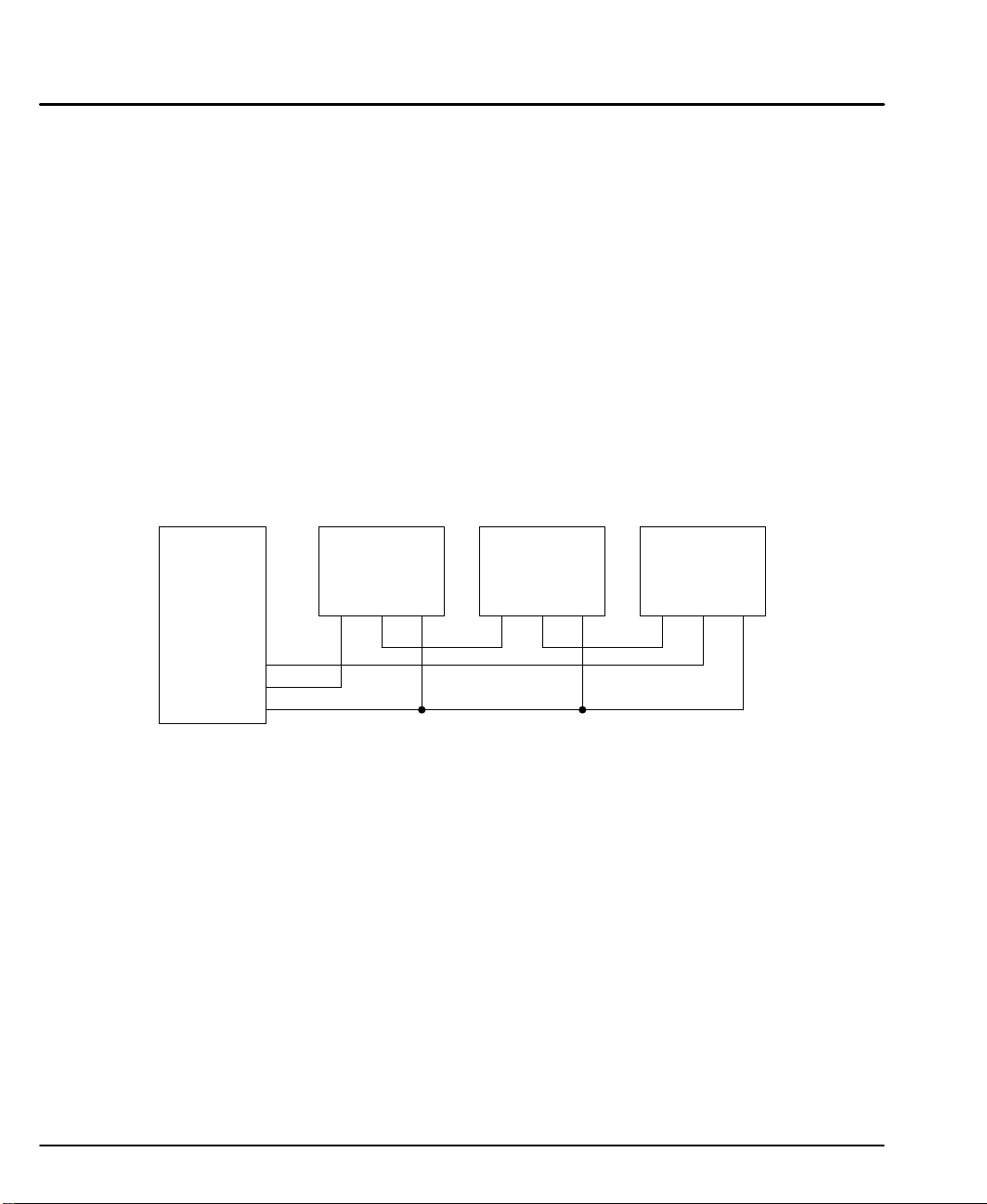

Daisy Chain Connections

LinStep+ can support daisy chaining. The unit address (range 1–99) can be set

with the keypad, through Application Developer, or with a terminal program using

the Unit Number (UN) command, or the entire chain may be addressed at once

using the Auto–Address (AA) command. Connect as shown in Figure 3-10.

Rules for Daisy Chain Operation

1. All LinStep’s in a daisy chain must have their device address assigned in

ascending order away from the host device. This allows the Load All (LA

– EX) commands to work properly. Addresses do not have to be

sequential, but must be in ascending order.

Example: 1, 2, 4, 6, 8 is valid addressing. 6, 3, 10, 8, 2 is not valid.

2. Do not duplicate unit addresses.

3. RS–232C “Echo” should be turned on for each unit in the daisy chain.

Disabling RS–232C Echo will prevent daisy chain operation.

4. All RS–232C connections must be correctly made.

5. “Device Addressing” RS–232C commands (for a specific LinStep+

device) must have the correct address specified in the command.

6. Status commands require the correct address.

Figure 3-10 Daisy Chain Connection

PC / Host

Device

RXD

TXD

GND

LinStep+

Unit 1

RXD

TXD GND

LinStep+

Unit 2

RXD

TXD GND

LinStep+

Unit 3

RXD

TXD GND

3-8 Receiving & Installation MN1853

Page 20

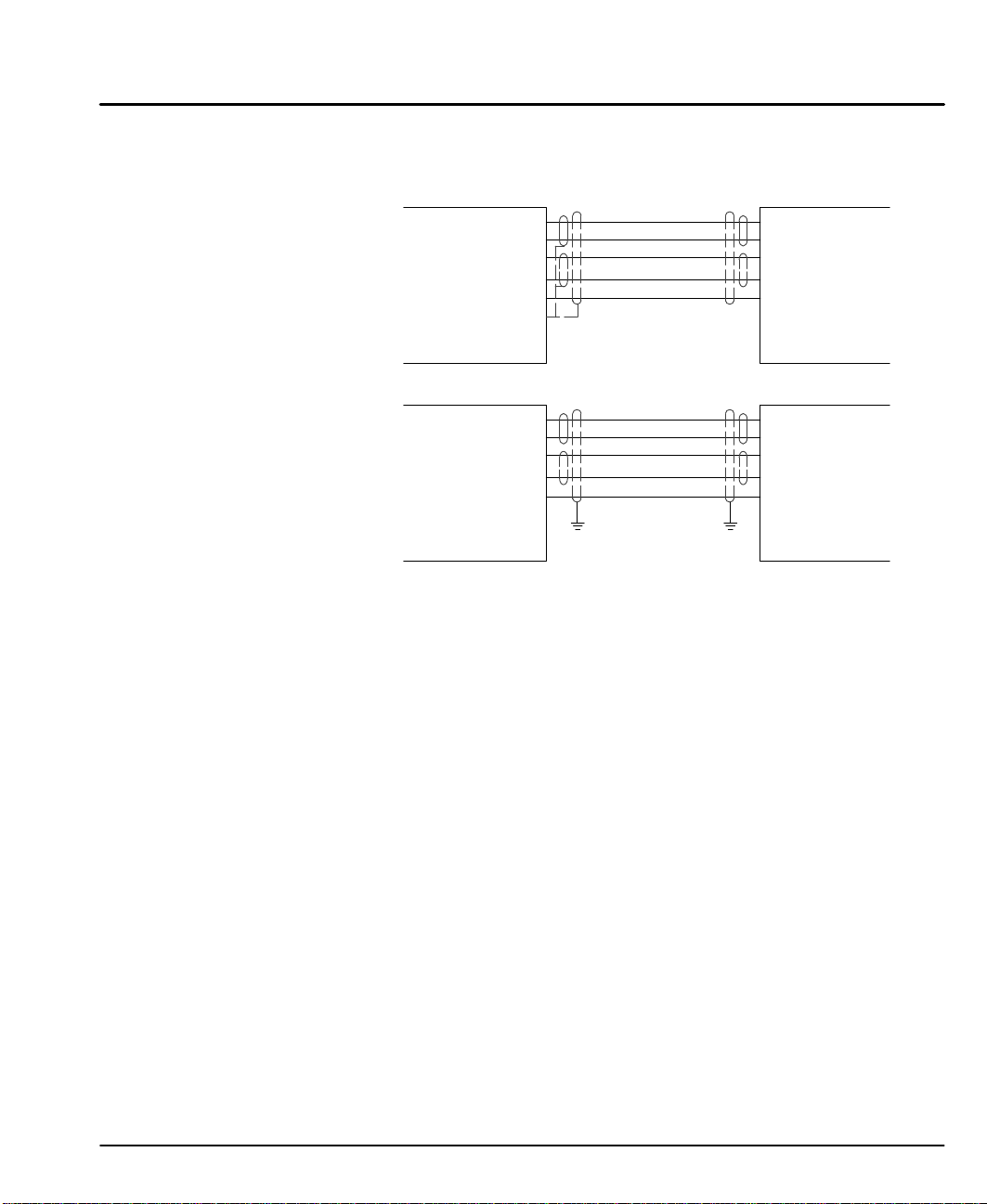

RS485 PC Connections

Standard RS485 connections are shown in Figure 3-11 and 3-12. Maximum cable

length is 3280 ft (1000M).

Figure 3-11 9 Pin RS-485 Cable Connections For UL Installations

Figure 3-12 9 Pin RS-485 Cable Connections For CE Installations

Note: For CE installations, connect the overall shield at each end of the cable to PE. The

voltage potential between the PE points at each end of the cable must be Zero Volts.

RS485 Multi-Drop Connections

What does termination or a termination resistor do?

Termination resistance is used to match the impedance of the load to the

impedance of the transmission line (cable) being used. Unmatched impedance

causes the transmitted signal to not be fully absorbed by the load. This causes a

portion of the signal to be reflected back into the transmission line (noise). If the

Source impedance, Transmission Line impedance, and Load impedance are all

equal, these reflections (noise) are eliminated.

Termination does increase load current and sometimes changes the bias

requirements and increases the complexity of the system.

What is a termination resistor?

A resistor is added in parallel with the receiver input to match the impedance of the

cable being used. Typically, the resistor value that is used is 100 ohm or 120 ohm.

Resistors with 90 ohms or less should never be used.

Where are these resistors placed?

Terminators or Termination resistors are placed in parallel with the receiver at both

ends of a transmission line. This means that you should never have more than

two terminators in the system (unless repeaters are being used).

How many resistors should my system have?

Terminators or Termination resistors are placed in parallel with the receiver at both

ends of a transmission line. This means that you should never have more than

two terminators in the system (unless repeaters are being used).

LinStep+

LinStep+

RX+

RX–

TX+

TX-

DGND

Chassis

RX+

RX–

TX+

TX-

DGND

Chassis

PE PE

TX+

TX–

RX+

RX-

DGND

TX+

TX–

RX+

RX-

DGND

PC / Host

Device

PC / Host

Device

Receiving & Installation 3-9MN1853

Page 21

P

= Twisted Pair

Figure 3-13 RS485 4 Wire Multi-Drop for UL Installations

P

P

Shields

PC / Host

Device

RX+

RX–

TX+

TX-

DGND

GND

*

T

R

*

T

R

TX+

TX–

RX+

RX-

DGND

GND

First

Unit

Use twisted pair shielded cable

with an overall shield.

* Terminating resistor TR is 120 W typical value. Only

the PC and last control are terminated.

Figure 3-14 RS485 4 Wire Multi-Drop for CE Installations

*

T

P

= Twisted Pair

PC / Host

Device

RX+

RX–

TX+

TX-

DGND

GND

R

*

T

R

Use twisted pair shielded cable

with an overall shield.

* Terminating resistor TR is 120 W typical value. Only

the PC and last control are terminated.

P

P

PE

Shields

PE

PE

PE

T

R

*

TX+

TX–

T

R

*

RX+

RX-

DGND

GND

TX+

TX–

RX+

RX-

DGND

GND

T

R

*

TX+

TX–

T

R

*

RX+

RX-

DGND

GND

Last

Unit

First

Unit

Last

Unit

Note: For CE installations, connect the overall shield at each end of the cable to PE. The

voltage potential between the PE points at each end of the cable must be Zero Volts.

3-10 Receiving & Installation MN1853

Page 22

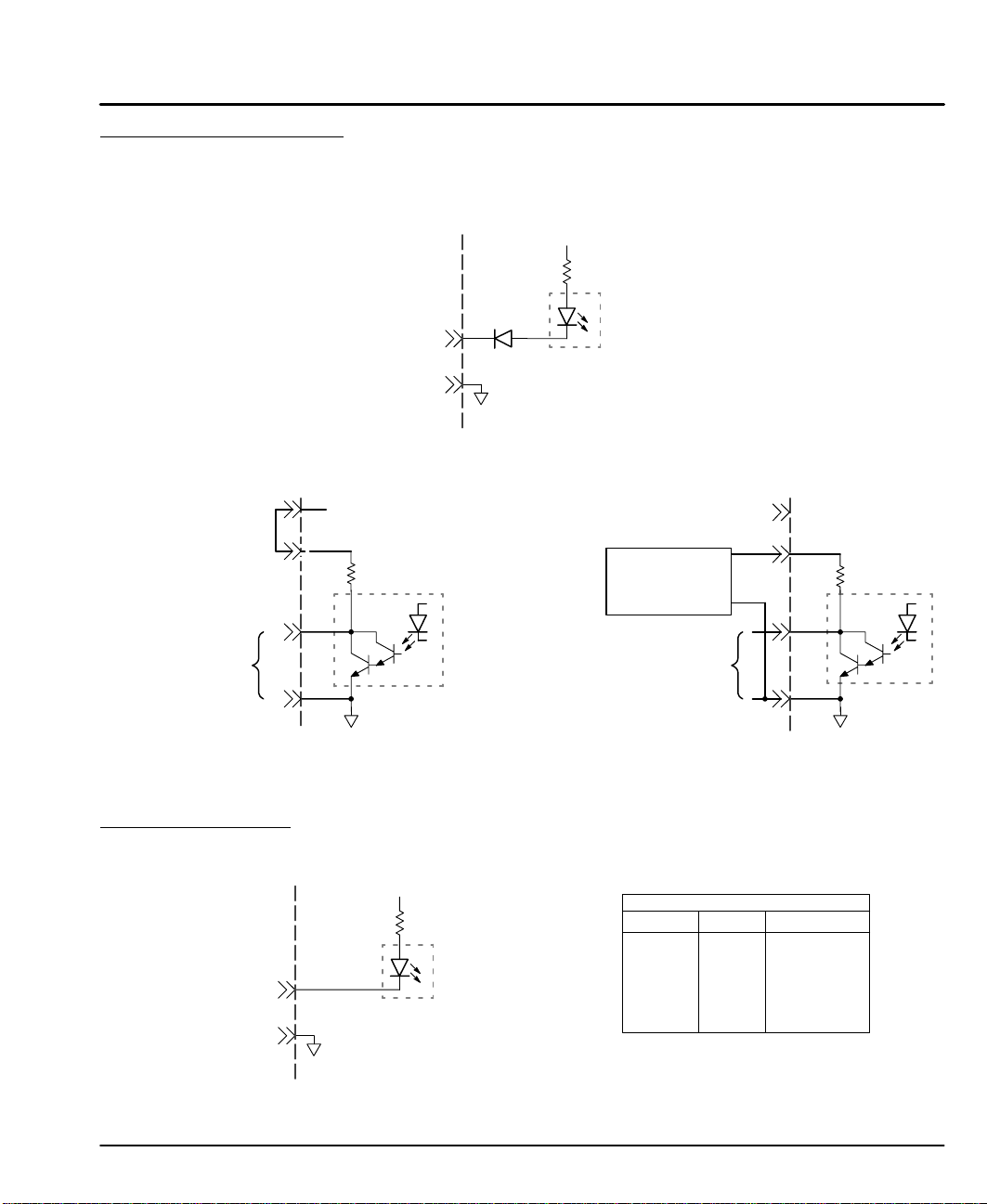

Discrete I/O Connections

The 25 pin “Discrete I/O” connector (Figure 3-5) contains the Input 1–8, Output

1–8 and OPTO 44/88 connections. (See Figures 3-15, 3-16 and the Section

“OPTO 44/88” description.

Figure 3-15 Opto Isolated Input Connections (Inputs 1–8)

Figure 3-16 Programmable Output Connections

Standard 12V Output Connections Optional 24V Output Connections

Jumper

12V

P–Up

Inputs 1–8

(Isolated)

Com

10kÙ

470 Ù

Common

(Isolated)

+5VDC (Isolated)

Opto

Isolator

(Remove Jumper)

External

+24VDC

Supply

+24V

Com

12V

P–Up

10kÙ

Outputs 1–8

(Programmable)

Com

Opto

Isolator

Factory installed jumper for 12VDC pull–up operation.

Maximum current sink capability is 100mA per output

and 350mA maximum from internal 12VDC supply.

Limits Connections

Figure 3-17 Opto Isolated Input Connections (Inputs 1–8)

+5VDC (Isolated)

715 Ù

Isolated Inputs

(Home, ET+, ET–)

Com

Opto

Isolator

Common

(Isolated)

Outputs 1–8

(Programmable)

Com

Opto

Isolator

Remove factory installed jumper from terminal P–Up.

Connect an external 24VDC supply to terminals P–Up

and Com. (Terminal P–Up must be positive).

Limits

Limit

+V

0V

Output

Drive Color

12V

Com

ET±

Brown

Green

White/Red

Receiving & Installation 3-1 1MN1853

Page 23

Encoder Connections (Refer to MN1800 for wire color and lead information.)

Twisted pair shielded wire with an overall shield should be used. Figures 3-18 and

3-19 show the connections between the encoder and the encoder connector.

Figure 3-18 Differential Encoder Connections for UL Installations

Encoder

Figure 3-19 Differential Encoder Connections for CE Installations

Encoder

Connection of shields to digital ground is optional.

PE

Table 3-2 Encoder Color Code

Encoder

Signal PVS100 Danaher (9–Pin D)

A+ White Green 6

A– Gray Yellow 1

B+ Orange Blue 8

B– Red Violet 3

Z+ (Index) N/A Red 9

Z– (Index) N/A Orange 5

+5VDC Black Brown 7

GND Brown Black 2

Inner shield Blue – 4

Outer shield Violet – Shell

A+

A–

B+

B–

Z+

Z–

+5V

DGND

A+

A–

B+

B–

Z+

Z–

+5V

DGND

A+

A–

B+

B–

C+ (Index)

C– (Index)

+5V

DGND

Shell (Chassis)

A+

A–

B+

B–

C+ (Index)

C– (Index)

+5V

DGND

Shell (Chassis)

3-12 Receiving & Installation MN1853

Page 24

Motor Connections The A+, A–, B+ and B– phase outputs provide power to the motor windings.

These connections are shown in Figures 3-5 and 3-6. The motor windings can be

connected in series or parallel as shown in Figure 3-20. For Baldor motors, refer

to MN1800 for lead information.

Interlock (INTLK)

The two INTLK pins must be jumpered together at the motor connector for the

drive to apply power to the motor. If the interlock wire breaks, or the connector is

removed, the current to the motor is immediately stopped, the drive faults (latched)

and flashes the dual function LED labeled Over Volt./INTLK. Interlock wires longer

than 5 inches can create noise generated shutdowns.

Ground (GND)

GND is internally connected to the Earth pin on the Power connector. This provides

a convenient terminal for grounding the motor frame and a motor cable shield.

Figure 3-20 Stepper Motor Connections

Series Motor Connections

Parallel Motor Connections

B–

Motor

Connector

Interlock

B–

B+

Ground

B+

A–

A+

INTLK

A–

A+

Interlock

Motor

Color Phase

White

Red

Green

Orange

Black

(Refer to MN1800 for

A+

A–

B+

B–

GND

wire color and lead information.)

INTLK

AY0165A00 Leadwire Connection (9 pin to flying leads)

Color Pin# Description

White 1 A1+ Winding

2 N.C.

Green 3 B1+ Winding

4 N.C.

Black 5 Ground

6 N.C.

Red 7 A1– Winding

8 N.C.

Orange 9 B1– Winding

6

7

8

9

Male (D Sub)

1

When a Male D Sub connector is used, use the pin

2

3

4

5

When flying leads are used, use the color codes

B–

B+

A–

A+

INTLK

INTLK

numbers to connect the forcer.

to connect the forcer.

Receiving & Installation 3-13MN1853

Page 25

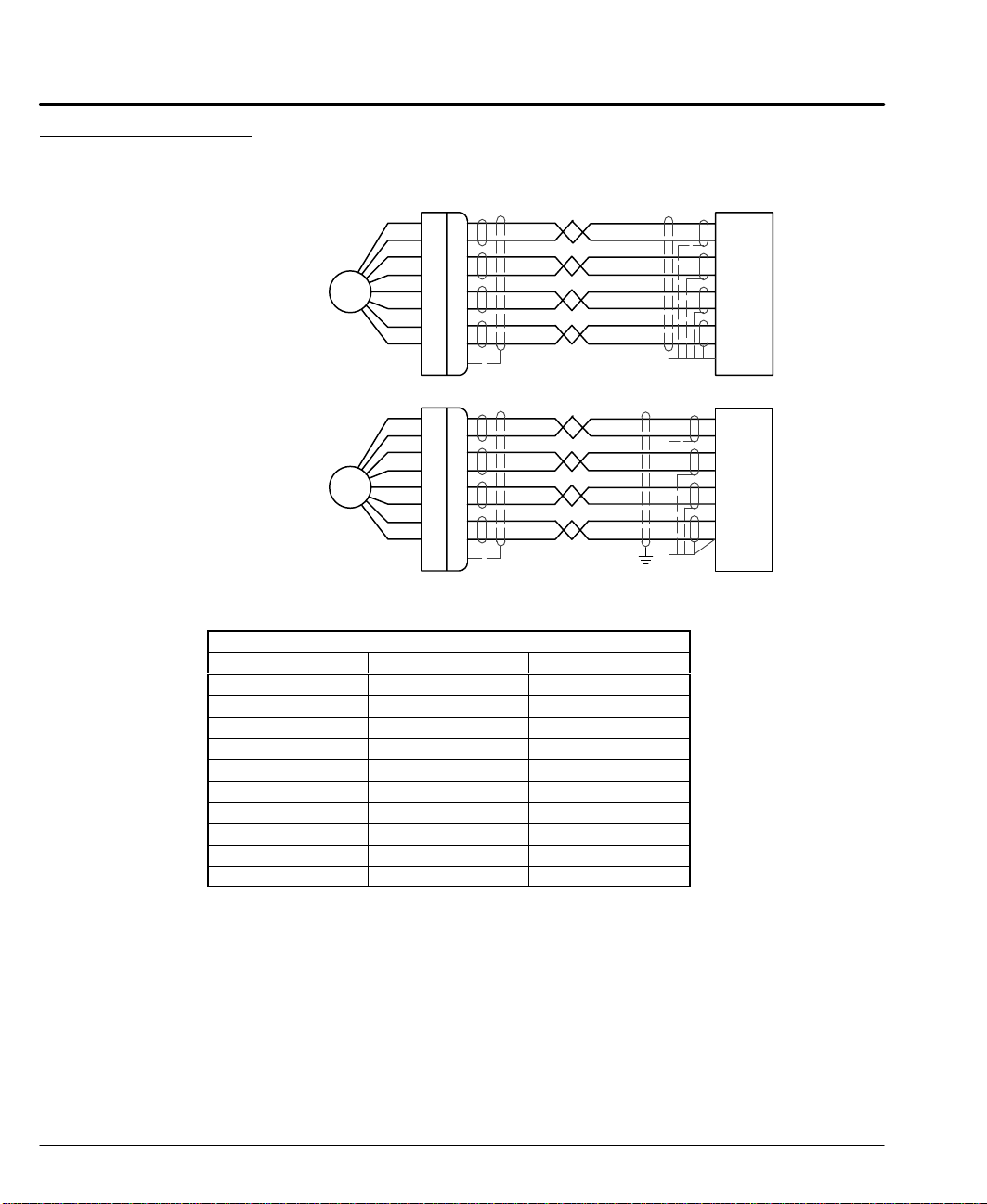

Section 1

General Information

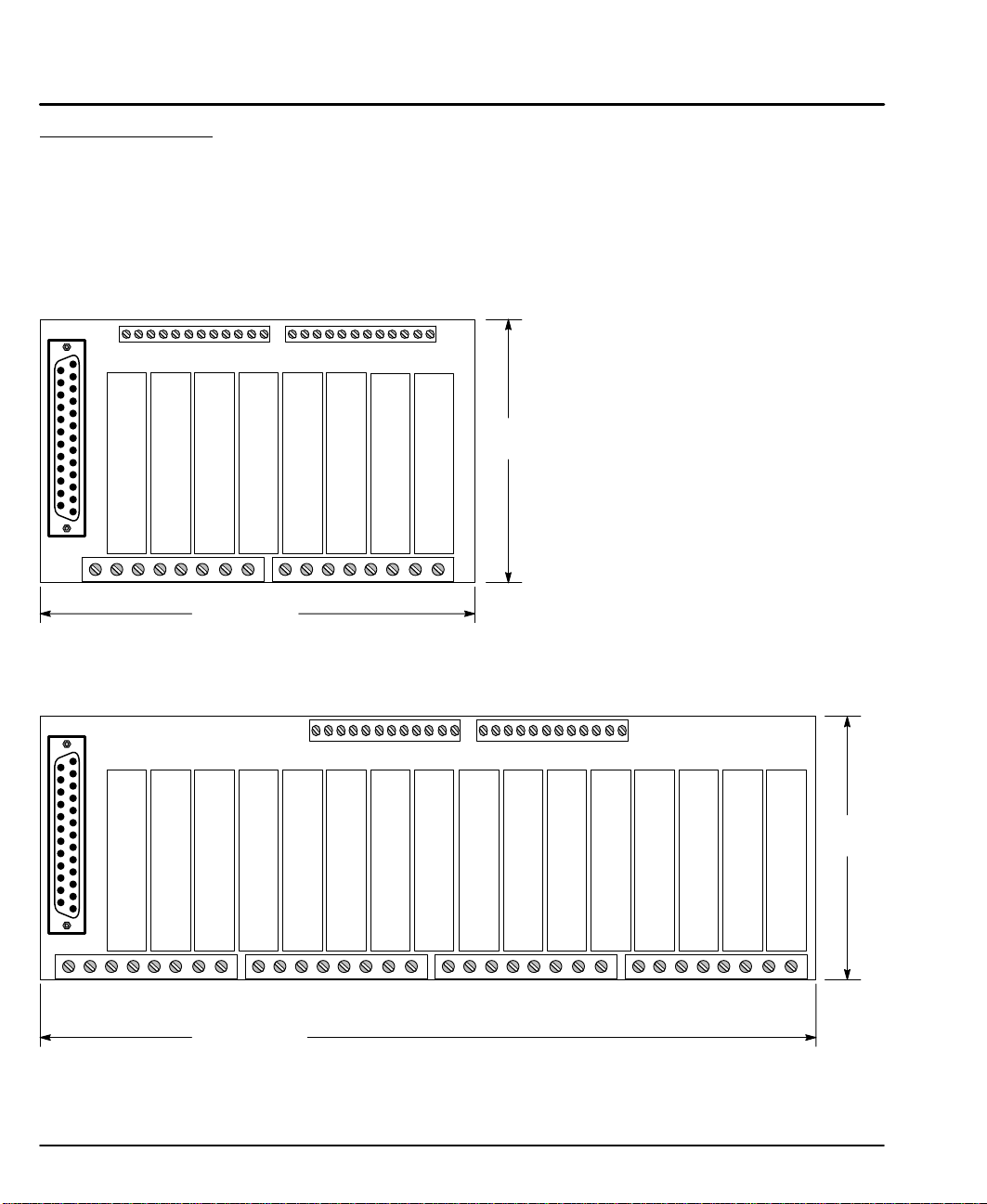

LXOpto 44 and 88 Break out box and accessories.

Two break out boxes are available; LXOpto44 accepts up to 8 conditioning

modules and LXOpto88 accepts up to 16 conditioning modules. Figure 3-21

shows the layout and dimensions of each. Each allows the use of discrete inputs

and outputs and provide the ability to perform signal conditioning.

Figure 3-21 OPTO Racks

LXOpto 44

Note 1

Note 1

Note 2

Note 2

Note 2

Note 2

Note 2

Note 1

Note 1

J1

IN OUT

J2

IN1

IN2

Input 1 Module

Note 2

Note 2

Note 2

COM

IN3

IN4

COM

IN5

IN6

COM

Input 2 Module

Input 3 Module

Note 2

Note 2

Note 2

IN7

IN8

COMO1O2

Input 4 Module

Output 1 Module

COMO3O4

COMO5O6

Output 2 Module

J4

I1+

I1–

I2+

I2–

I3+

I3–

I4+

I4–

O1+

O1–

O2+

O2–

O3+

5.525

(133.40)

Note 2

J3

COMO7O8

COM

3.60

(91.44)

Output 3 Module

Output 4 Module

J5

O3–

O4+

O4–

Notes

1. Do Not Use.

2. Always usable (no corresponding

module).

3. Do not use IN1–4 or O1–4 if a

corresponding LXOPTO module is being

used. Using the same J2 or J3 signal

with a module in place may result in

equipment damage.

4. J1 connector connects to the DB25

“Discrete I/O” connector on LinStep+.

LXOpto 88

Note 1

J1

Note 1

IN OUT

J2

IN1

IN2

COM

IN3

IN4

COM

Note 2

Note 2

IN5

IN6

Note 2

Note 2

COM

IN7

Note 2

Note 2

IN8

COMO1O2

Note 1

COMO3O4

Note 1

COMO5O6

Note 2

Note 2

Note 2

Note 2

COMO7O8

Note 2

Note 2

COM

J3

3.60

(91.44)

Input 1 Module

Input 2 Module

Input 3 Module

Input 4 Module

Input 5 Module

Input 6 Module

Input 7 Module

Input 8 Module

Output 1 Module

Output 2 Module

Output 3 Module

Output 4 Module

Output 5 Module

Output 6 Module

Output 7 Module

Output 8 Module

I1+

I1–

I2+

I2–

I3+

I3–

I4+

I4–

I5+

I5–

I6+

I6–

I7+

I7–

I8+

J4 J5

I8–

O1+

O1–

O2+

O2–

O3+

O3–

O4+

J6 J7

O5+

O5–

O6+

O6–

O7+

O7–

O8+

O4–

O8–

10.10

(256.54)

3-14 Receiving & Installation MN1853

Page 26

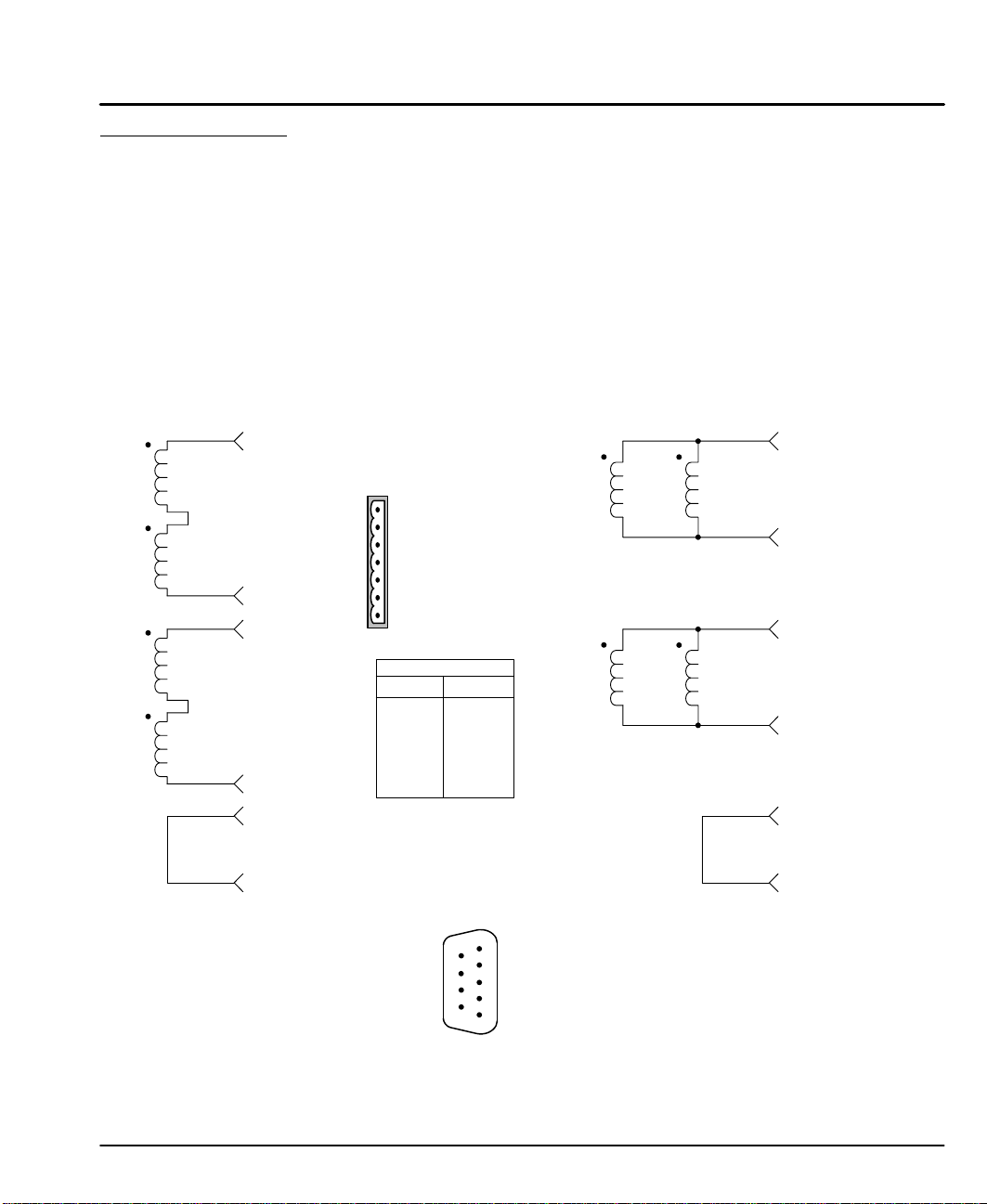

Section 1

General Information

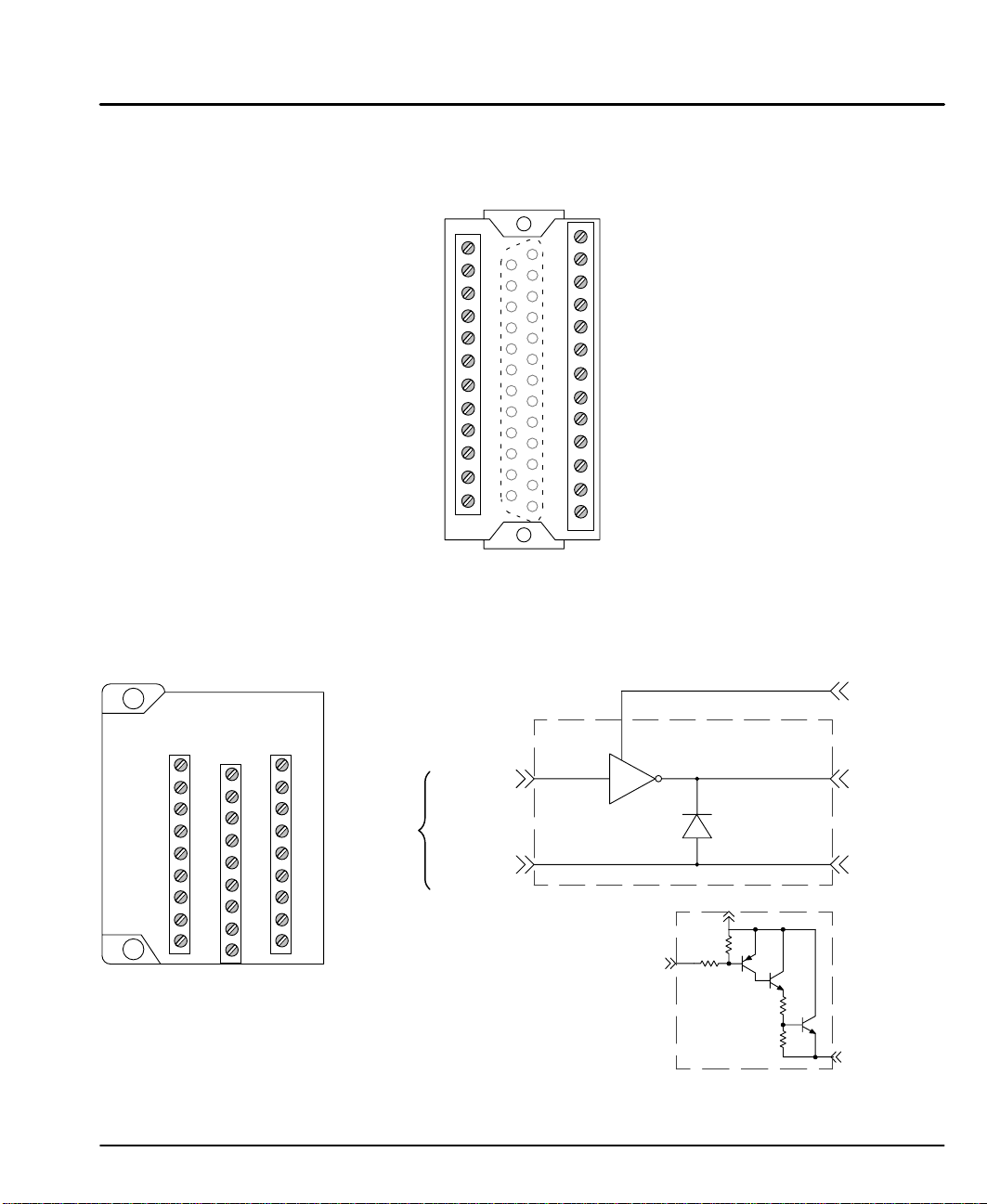

DB25 Pin to Screw Terminal Converter

The LXDB25 converter allows connection of individual wires to the DB25 pin

connector. The terminal configuration is shown in Figure 3-22.

Figure 3-22 LXDB25 Converter

Pin25: +5VDC for LXOPTO Box

Pin24: +5VDC for LXOPTO Box

Pin23: Common

Pin22: Common

Pin21: Output 8

Pin20: Output 7

Pin19: Output 6

Pin18: Output 5

Pin17: Output 4

Pin16: Output 3

Pin15: Output 2

Pin14: Output 1

PNP Converter

The LXPNPBO converts NPN outputs from the LinStep+ to PNP compatible

outputs, shown in Figure 3-23. Inputs IN1–8 connect directly to the LinStep+

NPN inputs. Outputs 1–8 are PNP outputs. PUp and COM are the 12VDC or

24VDC pull up and common power supply connections.

PUp

PUp

Com

Com

Com

Com

Com

PUp

PUp

IN8

IN7

IN6

IN5

Com

IN4

IN3

IN2

IN1

O8

O7

O6

O5

Com

O4

O3

O2

O1

From

LinStep+

Figure 3-23

Typical LXPNPBO

Output Connection

NPN Input

Terminal

Co

m

Pin13: Common

Pin12: Common

Pin11: Common

Pin10: Common

Pin9: Common

Pin8: Input 8

Pin7: Input 7

Pin6: Input 6

Pin5: Input 5

Pin4: Input 4

Pin3: Input 3

Pin2: Input 2

Pin1: Input 1

V

s

In Out

U1

In

V

7.2k

10k

U1

Detail

Typical

PUp

PNP

Output

Terminal

Com

s

7.2k

3k

Out

Receiving & Installation 3-15MN1853

Page 27

Start-Up Procedure

Power Off Checks

Before you apply power, it is very important to verify the following:

1. Verify the AC line voltage at the source matches the control rated

voltage.

2. Inspect all power connections for accuracy, workmanship and tightness.

3. Verify that all wiring conforms to applicable codes.

4. Verify that the control and motor are properly grounded to earth ground.

5. Check all signal wiring for accuracy.

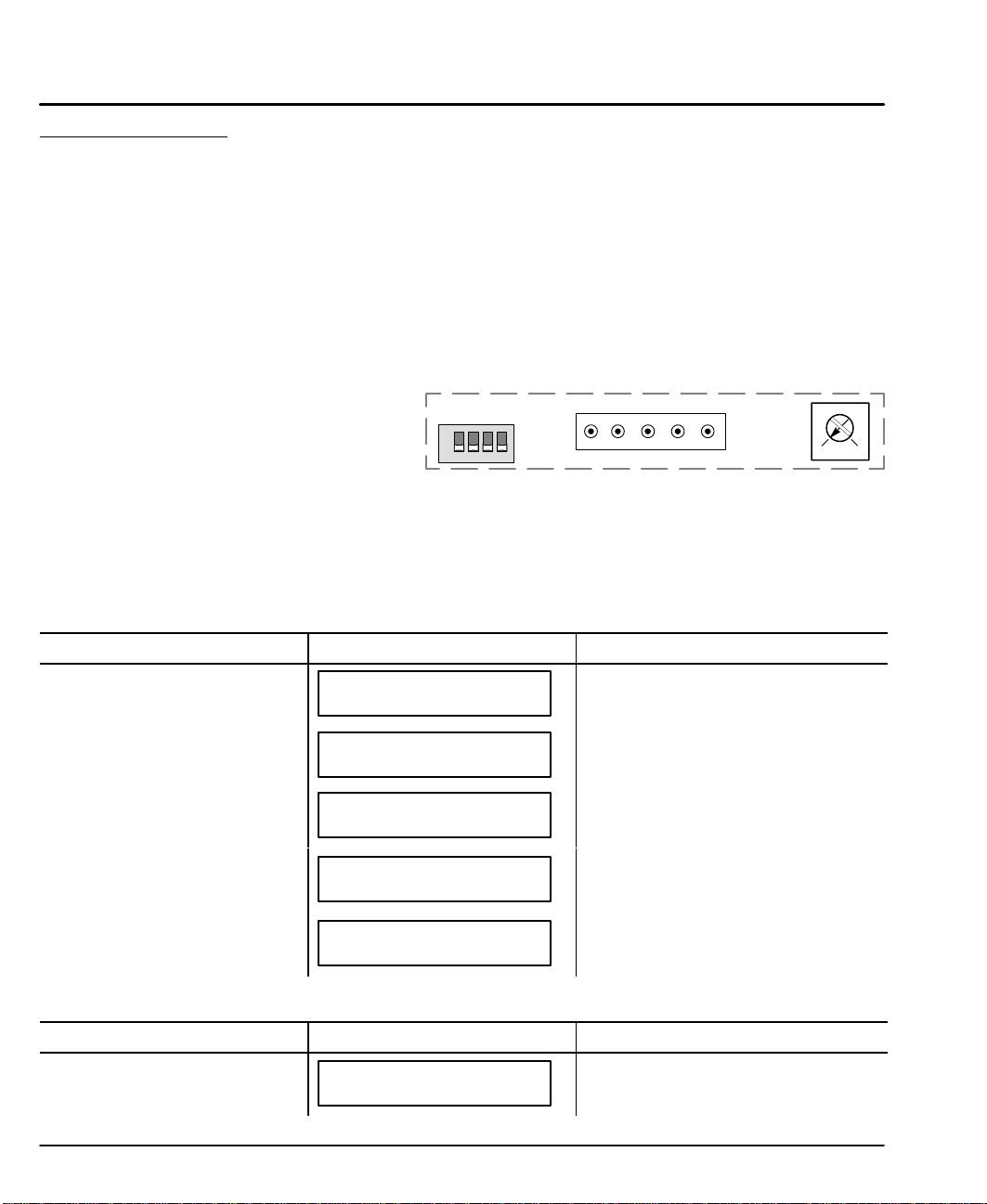

6. Set Keypad DIP switches as desired, Figure 3-24. (Power must be

cycled after a DIP switch position change).

Figure 3-24 Keypad Adjustments

DIP Switch Keypad Operation

12

Off Off Full Keypad Operation

Off On No access to Run, ESC, Edit, Copy , Del

On Off No access to Run, Edit, Copy, Del

On On No access to Edit, Copy, Del

Power On Checks

When power is first applied, the “ON” LED will be green. With the keypad

connected, the LCD display will briefly display the initialization screens.

Note: The LCD display may require contrast adjustment for better viewing. If the

display cannot be seen, adjust the potentiometer in Figure 3-24 for best

viewing.

N/C

ON

1234

Switches 3 and 4 are reserved.

5

GND Rx Tx +5VDC

4213

Action

Apply Power.

Select “Edit, Setup (F2), Motor

(F1), Type (F1), Stepper (F1)”

Select “Current (F1)”.

enter the motor current value.

(Factory setting =0”)

Select “A–RES (F2)”.

Select “INDUCT (F3)”.

+0.0000

00000000 00000000

–↑STEPPER SETUP↓–

00000000 00000000

Axis One Motor Curnt

–Axis One Anti–Res–

–Axis One Inductance–

–↑ HIGH ↓–

Display Comments

Power–up diagnostic display. No errors.

Stepper Set–up display.

Enter the correct setting for your motor.

___Amps

0

Press “ESC” when done.

Enter the unloaded Anti–Res value for

your motor.

Press “ESC” when done.

Select the HIGH or LOW setting for

your motor. Press “ESC” when done

until you return to the main display.

The motor should now be producing torque.

Action

Select “RUN, JOG (F2)”.

3-16 Receiving & Installation MN1853

JOG AXIS +0.0000

<LO> HIGH

Display Comments

Select either Low or High to Jog the

motor position. Confirm proper motor

operation.

Page 28

Section 4

Keypad Operation

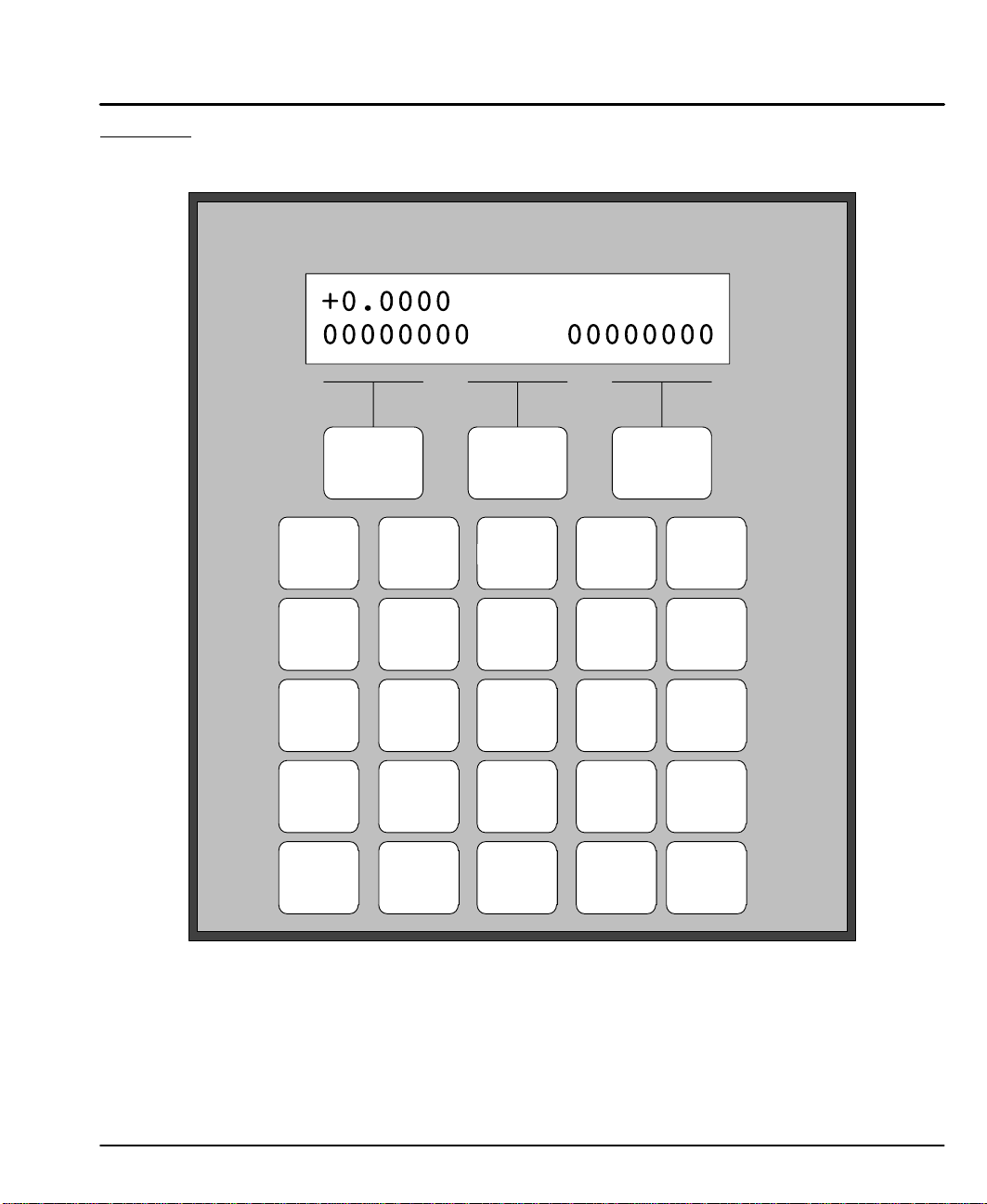

Overview (Firmware versions LinStep+ Sngl SB3.0; Keypad V2.90; FPGA ssr3)

The Keypad layout with the LCD display is shown in Figure 4-1.

Figure 4-1 Keypad and LCD Display

F1 F2 F3

RUN EDIT HELP COPY DEL

ABC

AC

1

DE

JKL

LP

EB

4

STU

MC

ON

7

SP

ESC

F1, F2, F3

Selector keys. Used with numeric keys to select commands in the editor.

Programmable as operator menu selections. (See the FK command for

information on using the function keys within a program.)

Most operations are menu–driven. A menu consists of a title bar (top display line)

and as many as three options or sub–menus (bottom display line). Each option is

displayed above one of the function keys, F1, F2, or F3. Press a function key to

select the corresponding option. Table explains which menus are available.

VE

IF

DEF

2

MNO

5

VWX

8

÷ * =

0

VE

AC

DE

TD

OT

WT

MS

FK

IV

RG

( )

GHI

GO

GH

3

GI

PQR

GT

GS

6

EN

YZ

CL

CT

9

ST

±

[ ]

←

↑

.

ALPHA ENTER

→

↓

,

Keypad Operation 4-1MN1853

Page 29

Menu

Menu

Options

Note: If a menu has more than three options, arrows on both sides of the display

indicate that more options are available. Press the appropriate arrow key to

display one option at a time. To exit a menu without making a selection, or

to back up one menu level, press ESC.

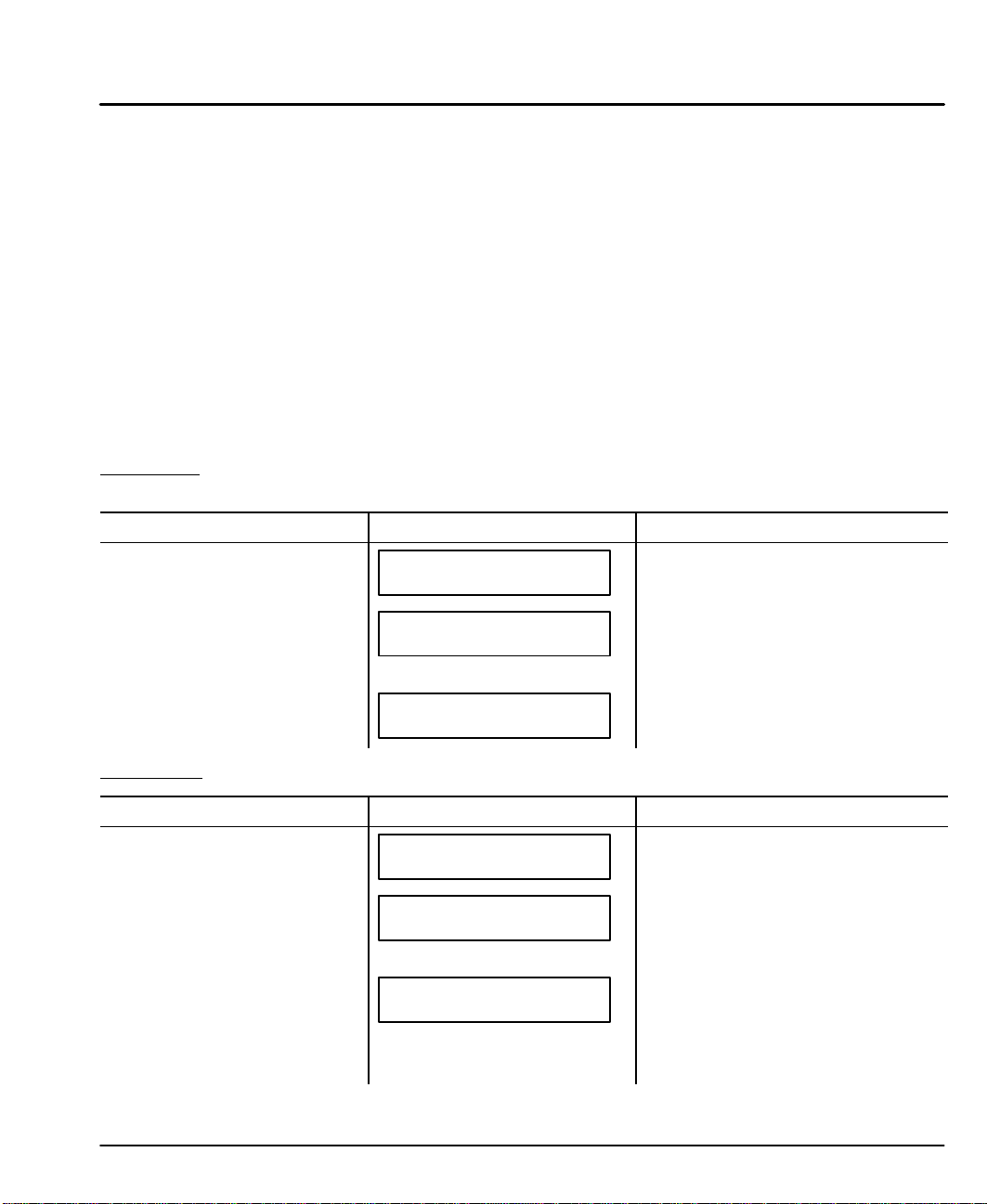

Table 4-1

Menu Key

RUN EDIT HELP COPY DEL

PROG (F1)

Run programs by

name or number.

JOG (F2)

Jog either axis at

low or high

speeds.

Press F1 or F2,

and

any arrow key

(←↑↓→).

TEST (F3)

Run programs in

trace mode, do

amplifier

shutdown and

reset, and test

outputs or moves.

PROG (F1)

Edit or write

programs.

SETUP (F2)

Configure system

components and

operating limits.

POS (F3)

Reset axis

position to zero?

YES NO

(F1) (F3)

LIST (↓) (F1)

Directory of

stored programs,

memory usage

and available

space

In Main Menu:

Provides help on

the function of

RUN, EDIT, or

COPY.

In Menus:

Provides help on

menus.

In Sub–Menus:

Explains setup

choices.

In Editor:

Provides

command

descriptions.

PROGRAM (F1)

To copy programs

within a control

(source file>

destination file)

TO PAD (F2)

To upload data

from control’s

memory to the

keypad.

FROM (F3)

To download data

from keypad

memory to a

control.

Deletes an entire

program or in

editor deletes

characters

RUN

Press RUN to start a program, Jog an axis, or access Test/Debug functions.

EDIT

Press Edit to change setup parameters and programs, list programs, & reset

position counter.

HELP

Provides help information for keys, menus, and command syntax.

COPY

Copies one program to another within the LinStep+.

DEL

Deletes characters in the editor, or deletes entire programs from memory.

0–9

Enters numbers. Used with ALPHA key to enter characters. Used with F1, F2, F3

keys to select commands in the program editor.

ESC

Press ESC to stop a program or to move back one menu level. In program editor,

it saves the program and exits the editor.

4-2 Keypad Operation MN1853

Page 30

+

Selects the motion direction in program editor. May also be used in math

programs or equations.

u=O"

Cursor control keys that are used to scroll through menu choices in the editor.

Moves an axis in JOG mode.

Decimal Point

Used when entering fixed–point numbers.

Comma

Used in multi–axis programs to separate axis command parameters. Part of the

syntax in message and variable “prompt” commands.

Alpha

In the editor, allows entering alpha characters for the keypad.

ENTER

In the program editor, press ENTER to save parameters that have been typed.

Enters a space in the program editor mode.

Run Menu Pressing the RUN key displays a set of sub–menus. Access the sub–menus by

pressing F1 (PROG), F2 (JOG), or F3 (TEST).

Action

Press RUN key

Press F1 (PROG) to run (or

execute) an existing program

number.

OR

Press F1 (PROG) select an

existing program to run.

PROG JOG TEST

>5

>12 GRIND

Display Comments

RUN

↑RUN PROGRAM↓

↑RUN PROGRAM↓

Select a sub–menu, press F1 (PROG),

F2 (JOG), or F3 (TEST).

Use the numeric keys to enter a

program number to run (example, 5 and

press ENTER).

Use the keys to scroll through the list

of programs. Press ENTER to select

the program.

JOG Menu Pressing the RUN key displays a set of sub–menus. Press F2 (JOG).

Action

Press RUN key

Press F2 (JOG) to JOG the

motor.

OR

Use the 0–9 keys to enter the

desired JOG distance.

PROG JOG TEST

JOG AXIS 1 +0.0000

<LO> HIGH

JOG AXIS 1 +0.0000

Dist: .012

Display Comments

RUN

Use the ←↑↓→ keys to JOG the motor.

Press F1 <LO> or F2 HIGH speed.

Press and release an arrow key to

make the motor move this distance.

The arrow pressed determines the

direction of the move. Press and

release an arrow key to move the motor

again. Press ESC to terminate JOG.

Note: Jog speed and acceleration are changed in the “EDIT, SETUP, JOG” menu.

Keypad Operation 4-3MN1853

Page 31

Edit Menu Pressing the EDIT key displays a set of sub–menus.

Action

Press EDIT key

Press ↑ or ↓ key for more sub

menu selections.

PROG SETUP POS

LIST

–↑EDIT↓–

–↑EDIT↓–

Edit, PROG Submenu Create A New Program

1. Press “EDIT, F1 (PROG)” and you will see a display with a blinking

cursor as shown in Figure 4-2.

Figure 4-2 New Program

–↑EDIT PROGRAM↓–

>_

2. Enter an unused identifying number for the program (between 1–400).

(If several programs are stored, you may need to scroll the list to

determine a number that has not been used. )

Note: You may assign a name, rather than a number, to your program if you wish.

See “Naming Your Programs” later in this section.

3. Press ENTER. You will see a blank screen with a blinking cursor in the

upper left corner. The program editor is now ready to accept a program.

4. Once inside the program editor, enter commands by pressing a function

key and then a numeric key. Examples of creating, saving, naming, and

editing programs follow.

Example of entering programming commands found on the #2 key, Figure 4-3.

S To enter the VE command (the upper command on the number 2 key),

press F1 (blue) then press the number 2 key.

S To enter the AC command (the middle command on the number 2 key),

press F2 (yellow) then press the number 2 key.

S To enter the DE command (the lower command on the number 2 key),

press F3 (green) then press the number 2 key.

Display Comments

Select a sub–menu, press F1 (PROG),

F2 (SETUP), or F3 (POS).

Select a sub–menu, press F1 (LIST).

Figure 4-3

DEF

VE

AC

2

DE

4-4 Keypad Operation MN1853

Page 32

Example of entering a program using the 0–9 keys. To create a program with the

commands “AC.3 VE2 DI1 GO”, do the following steps: (you must be in the

program editor, this example is writing to program #2).

1. Press EDIT→F1→2→ENTER to get to the first line of program 2.

2. Press F2, then press the #2 key. This will enter the AC command.

3. Press the decimal key.

4. Press the #3 key.

5. Press ENTER. This will insert a space after the 3 to separate the

commands.

6. Press F1, then press the #2 key. This will enter the VE command.

7. Press the #2 key.

8. Press ENTER. This will insert a space after the 2 to separate the

commands.

9. Press F2, then press the #1 key. This will enter the DI command.

10. Press the #1 key.

11. Press ENTER. This will insert a space after the 1 to separate the

commands.

12. Press F1.

13. Press the #3 key. This will enter the GO command.

14. Press ENTER.

15. The display should now show the program “AC.3 VE2 DI1 GO”.

Save the program

When you have completed the program, and the display shows the program

“AC.3 VE2 DI1 GO”, do the following:

1. Press ESC, the menu of Figure 4-4 is then displayed.

2. Press F1 (YES) or F3 (NO).

Figure 4-4

Save Program?

Yes No

Edit an existing program

1. Press “EDIT, F1 (PROG)” and you will see a display with a blinking

cursor as shown in Figure 4-5. Enter the name of the program you wish

to edit or scroll the list to locate the program.

Remember, ENTER inserts a space (delimiter). DEL deletes a character.

Use the cursor keys to scroll through the program one line at a time.

Figure 4-5

–↑EDIT PROGRAM↓–

>_

Keypad Operation 4-5MN1853

Page 33

Naming a program

A program can be given a descriptive name in addition to the program number that

the LinStep+ assigns it. Program names must be put inside of square brackets,

[program name], at the start of a program. The name can be up to 14 characters,

but the first 10 must be unique. Like variables, the name can be any combination

of characters.

Programs or subroutines are often named to help “self document” a program. It is

usually easier to remember and understand a name than a number. You may call

or branch to a program by name.

Suppose your program has 20 different parts and each part has a different

program name. Simply name each program so an operator will easily recognize

them. When the keypad RUN key is pressed, instead of entering a number, simply

scroll through the list of program names until the desired program is displayed.

Then press ENTER to run the program.

Example of Naming a Program

Add a name [MINE] to the program.

To insert [MINE]:

1. Press F3.

2. Press 0 (zero) key. Insert brackets.

3. Press ALPHA. Move to next character.

4. Press #5 key. Insert M.

5. Press ALPHA. Move to next character.

6. Press #3 key three times. Insert I.

7. Press ALPHA. Move to next character.

8. Press # 5 key two times. Insert N.

9. Press ALPHA. Move to next character.

10. Press #2 key two times. Insert E.

11. Press the

→ key to move cursor to the right of the bracket. The program

name will be as shown in Figure 4-6.

Figure 4-6

[MINE] AC.3 VE2 DI1 GO

12. Press ESC. You will be prompted as shown in Figure 4-7.

Figure 4-7

Save Program_?

YES NO

4-6 Keypad Operation MN1853

Page 34

Entering Characters with the Alpha Key (In edit mode)

The ALPHA key allows you to enter almost any character into a program from the

keypad. This is useful to name your programs or subroutines, call subroutines by

name, make variable names descriptive, use operator messages or prompts, send

messages over RS–232 port or use commands not on the keypad, such as EA

or “ ”.

The letters are found on the 0–9 keys. To insert A, B or C on the #1 key:

1. Press ALPHA.

2. Press the numeric key with the character you want. (In this example,

press the #1 key once to select A, press it twice to select B, and press it

three times if you want the C).

General Rules for Using The Alpha Key

S Any number, letter or character on the 0–9 keys can be placed in a program.

S Press a numeric key 4, 5 , and 6 times to access the lower case letters.

S Press ALPHA prior to each character you wish to enter.

S Press the

S Press ALPHA to move the cursor more than one space.

Use the =O keys for additional alpha characters.

The 19 special characters shown to the right are available by pressing ALPHA and

scrolling through the list using the arrow keys.

1. Press ALPHA.

2. Press ↑ or ↓ to scroll through the list of characters.

3. When the desired character is displayed, press ALPHA or ENTER to

4. Press ESC to leave the editor. The list of characters is shown in Figure

← or → key to move the cursor to the next space.

enter the character. The character will be displayed and the cursor will

move one space to the right.

4-8.

Figure 4-8 Alpha Characters

< > ? ! @ # % & _ :

; \ ′ ″ | ↑ ↓ ← →

Keypad Operation 4-7MN1853

Page 35

Edit, Setup Submenu Table shows the structure within the “EDIT, SETUP” submenu.

Table 4-2 Edit, Setup Submenu

Submenu Setup Parameter Description of Setup Parameter

TYPE Motor parameters

MOTOR

MOTOR

ENC

MECH

I/O

I/O

JOG

JOG

HOME

HOME

PROG

PROG

RS–232C

RS–232C

MISC

MISC

D–RES Drive resolution

DIR Direction of travel

MODE Select open/closed loop mode

E–RES Encoder resolution

FOL–ERR Following error

IN–RANGE Position maintenance window

PMGAIN Position maintenance gain

PMMAX Position maintenance maximum velocity

DIST Distance Units

PITCH The spacing between the photo etched teeth of the motor platen.

VEL Speed units

VMAX Critical speed limit

ACCEL Acceleration units

AMAX Maximum rate of acceleration

INPUTS Input functions

OUTPTS Output functions

OPTOS OPTO module configuration

OUTSTS Configure output states during Powerup, Fault, and Stop/Kill command.

LIMITS Configure EOT polarity (N.O. or N.C.)

ACCEL Jog acceleration

LO–VEL Low jog velocity

HI–VEL High jog velocity

ENABLE Enable/disable jog in RUN menu

MODE Homing method

EDGE Edge of home switch

SWITCH Type of home switch

OFFSET Position counter offset

DIR Final homing direction (positive or negative)

PWR–UP Program to run on power up, if any

SCAN How to scan program select inputs

DELAY Program Select de–bounce time

ECHO Echo characters

UNIT# Serial address

DISP Display mode (not currently implemented)

STOP–RATE Decel rate when stop input activated

TEST Enable Test Menu (not currently implemented)

PASWRD Password setup for operator/administrator access

4-8 Keypad Operation MN1853

Page 36

Edit, POS Submenu Select “Edit, POS” to Reset the Current Position to Zero.

POS is a quick way to reset the motor’s present position to (absolute) zero – a

very useful setup and debugging tool.

Action Display Comments

Press “EDIT, POS” (F3)

Reset Position?

YES NO

Press YES (F1) or NO (F3)

Edit, List Submenu Select “EDIT, ↓, LIST” to view memory usage.

LIST provides a way to view your program memory usage. Standard program

storage is 60K bytes, and the maximum size of a single program is 1,024 bytes.

LinStep+ will store up to 400 programs, with a maximum single program size of

1,024 bytes.

Action

Press “EDIT, ↓, LIST” to

display the number of

programs stored.

Press ↓ to display the total

memory used for program

storage.

Press ↓ to display the total

free memory available.

Press ↓ continuously to scroll

through the list of programs,

displaying the number of bytes

used by each program.

Display Comments

DIRECTORY ↑MORE↓

PROGRAMS: 18

DIRECTORY ↑MORE↓

BYTES USED: 1186

DIRECTORY ↑MORE↓

BYTES FREE: 4958

DIRECTORY ↑MORE↓

5<untitled>: 56 bytes

Keypad Operation 4-9MN1853

Page 37

HELP Menu Press HELP to display a help message related to the menu. Help messages are

often several lines, which you can scroll through using the ↓ and ↑ keys. When

you are finished reading a help message, press ESC to return to the menu.

Pressing HELP in the Main Menu

HELP explains the functions available when you press any of the non–numeric

keys.

Pressing HELP in Menus and Sub–Menus

HELP explains the selections available from your current menu location.

Pressing HELP In the Program Edit function

HELP provides a brief, alphabetical list of commands.

Note: A program must be selected to view the COMMAND SUMMARY.

COPY Menu Pressing the “COPY” key displays three submenu choices.

Action

Press the “COPY” key

– – – COPY – – –

PROG TO PAD FROM

Display Comments

Select a sub–menu, press F1 (PROG),

F2 (TO PAD), or F3 (FROM).

COPY, PROG Submenu Copy one program to another program.

Action Display Comments

Press F1 (PROG) to copy from

a program.

↑SOURCE PROGRAM↓

>5

Enter the source program number.

Or, if you wish, you can scroll

through your list of program names.

Press ENTER when finished.

Enter the new program

number.

↑TARGET PROGRAM↓

>6

If the target program exists, you

must first delete it (see DEL).

Press ENTER when finished.

Note: Remember to change the name of the copied programs to avoid subroutine

call conflicts.

COPY, TO PAD Submenu Copy a program to the keypad from LinStep+ or a PC.

Action

Press F2 (TO PAD). Two

messages are displayed

sequentially.

sequentially.

Receiving From Drive

Saving To EEPROM

may take 40 seconds

Display Comments

Copies a program from LinStep+ to

the keypad. When the “Saving To

EEPROM” message disappears,

EEPROM” message disappears,

the program has been stored in

keypad memory.

4-10 Keypad Operation MN1853

Page 38

COPY, TO PAD Submenu Continued

To copy a program from a PC to the keypad, connect the keypad to the RS232

port of the PC (COM1 or COM2). Start the Application Developer software and

from the Communications menu, click on “Send All”. The keypad will display the

message “Receiving From PC” and a few more messages will quickly appear, then

disappear from the screen. When the keypad display is blank, the transfer is

complete.

COPY, FROM Submenu Copy a program from the keypad to the LinStep+ or to a PC.

Action

Press F3 (FROM). Four

messages are displayed

sequentially.

Receiving From EEPROM

Sending To Drive

Waiting For Processing

Saving To Memory

Display Comments

Copies a program from the keypad to

LinStep+. When the “Saving To

Memory” message disappears, the

transfer is complete.

To copy a program from the keypad to a PC, connect the keypad to the RS232

port of the PC (COM1 or COM2). Start the Application Developer software and

from the Communications menu, click on “Retrieve All” and choose “From

Keypad”. The keypad will display the message “Sending to PC” and a few more

messages will quickly appear, then disappear from the screen. When the keypad

display is blank, the transfer is complete.

DEL Menu The DEL (Delete) key allows you to delete any motion program.

Action

Press the DEL key.

↑DELETE PROGRAM↓

>6

DELETE PROGRAM #6

YES NO

Display Comments

Enter the program number. Or, if

you wish, you can scroll the list of

program names.

Press ENTER when finished.

Press F1 to delete program or F3 to not

delete the program.

DEL is also used to delete text or numeric characters in the editor. Use the cursor

control keys to move over the character you wish to delete, then press DEL.

Keypad Operation 4-11MN1853

Page 39

4-12 Keypad Operation MN1853

Page 40

Section 5

Setup

Overview There are two ways to setup the parameters: use the keypad or use Intelliware

serial communications software. The procedures presented in this section allow

LinStep+ to be configured using the keypad (LXKP). If you are not familiar with

the operation of the keypad, please refer to Section 4 of this manual. To ensure

that LinStep+ is correctly configured, follow all the procedures so that important

parameters are not overlooked.