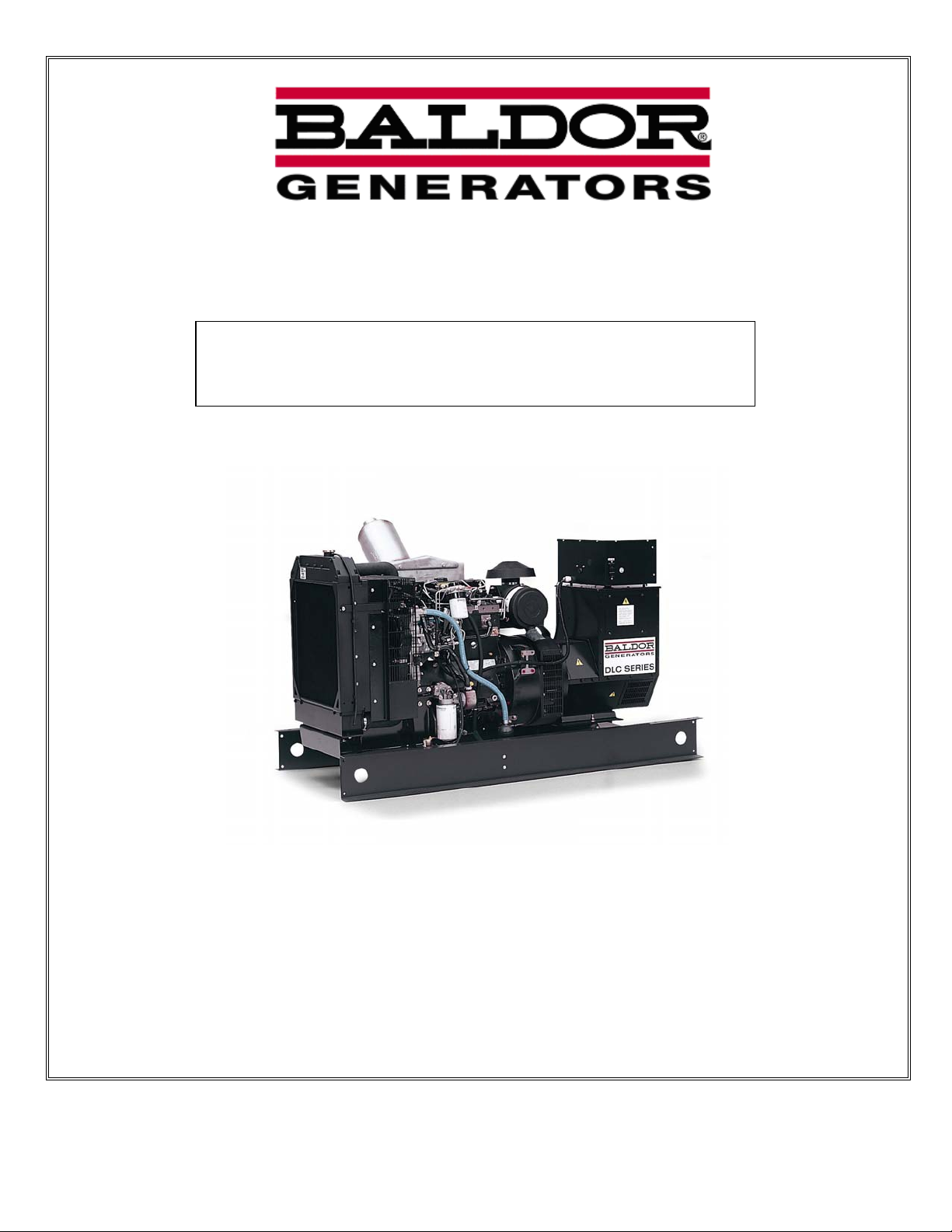

Page 1

PRESENTS YOUR

STANDBY PERMANENT MOUNT SERIES

GENERATOR

OPERATORS MANUAL

BALDOR GENERATORS

3815 OREGON STREET OSHKOSH, WI 54902

PHONE: 920-236-4200 FAX: 920-236-4219

FORM#: S-PSG-002-91 REVISED: 2/25/02

C:\ISO9001\FORMS\S-PSG-00291.MSW EFFECTIVE: 5/3/01

Page 2

FORWARD

This manual contains the information you need to safely and efficiently operate your generator set. During

the preparation of this manual every effort was made to ensure the accuracy of its contents.

Never operate this generator set without first carefully reading this manual and observing all the safety

warnings it presents. While safety is built into every Baldor Pow'R Gard generator set, careless or

improper operation could possibly result in mechanical failure, property damage, severe injury or death.

Note that this manual covers only very basic information in regards to the engine. A separate owner's

manual for the engine is supplied with this unit for your use. Please refer to this manual for information

relative to engine operation, maintenance, recommendations and additional safety warnings.

As soon as you receive your generator set, inspect it closely for shipping damage. If you find some

damage, notify the transportation company immediately and file a freight damage claim.

Think of this manual as a tool to help you get the most out of your generator set. We strongly suggest that

you keep this manual with your generator set and refer to it when questions arise in regards to its

operation.

Baldor Generators, formerly Pow'R Gard Generator Corporation has been in business since 1965. The

generator sets we manufacture have earned the reputation of being of high quality and a dependable

product. We take pride in this fact and continue to keep our quality standards high on our list of priorities.

We are also constantly researching new technological ideas to determine if they could be used to make

our generator sets even better.

Thank you for purchasing your Baldor Pow'R Gard Generator Set.

- i -

Page 3

Ƈ

Place protective covers and guards over the rotating parts, if rotating parts such as the drive shaft, pulley,

belt, etc. are left exposed, they are potentially hazardous.

Ƈ When cleaning, repairing or inspecting, make sure all moving parts have stopped.

Ƈ Prior to working on the generator set, disconnect the spark plug and battery to prevent accidental starting.

Ƈ Use only original equipment or authorized replacement parts. Use of correct parts will assure the operator of

the safety integrity that was designed into the unit.

Ƈ Unauthorized modifications to the generator set may impair the function and/or safety of the unit.

Ƈ Do not operate the generator set without a muffler. Inspect periodically and replace if necessary.

Ƈ Do not touch the hot exhaust components or the high voltage spark plug and coil terminals. While Spark Plug

Voltages are not normally lethal, an involuntary jerk of the hand caused by a hot surface or by an electrical

shock can result in injury.

Ƈ Repair of electrical generating equipment requires specialized skills. Repair personnel must have a

thorough understanding of generator and small engine repair procedures.

Ƈ Never inhale exhaust gases. They contain carbon monoxide; a colorless, odorless and extremely

dangerous gas that can cause unconsciousness or death. Symptoms of carbon monoxide poisoning

can include: dizziness, nausea, headaches, sleepiness, vomiting or incoherency. If you or anyone else

experiences any of these symptoms, get out into the fresh air immediately. Shut the unit down and

do not operate it until it has been inspected and, if necessary, repaired.

Ƈ Never Operate the generator set indoors or in a poorly ventilated area such as a tunnel or cave.

Ƈ CALIFORNIA PROPOSITION 65 WARNING: engine exhaust from this product contains chemicals known to

the state of California to cause cancer, birth defects or other reproductive harm.

Ƈ Know how to stop the engine quickly and understand the operation of all controls.

- ii -

Page 4

Ƈ Never permit anyone to operate the generator set without proper instructions.

Ƈ Never allow children to operate the generator set.

Ƈ Children and pets must be kept away from the area of operation due to the possibility of burns from hot

engine components or injury from any equipment the generator set is powering.

Ƈ Always wear eye protection and Hearing protection when working near the generator set.

Ƈ Operate the generator set only with the guards, shields and other safety items in place and working

properly.

Ƈ Do not put hands, feet, tools or other objects near rotating parts.

Ƈ Use reasonable care when moving or lifting the unit. The generator set may move around inside the wrap

frame creating "Pinch Points".

Ƈ Do not run the generator set while it is being moved.

Ƈ Do not support the generator set from the top of the wrap frame.

Ƈ Do not operate the generator set while under the influence of alcohol, drugs or medication.

Ƈ When transporting or using a generator set with the wheel option, secure the unit to prevent it from moving

around.

Ƈ Do not tamper with or change the engine speed as it has been preset at the factory for proper operation.

Ƈ Keep hands and face away from the carburetor when the air cleaner is being moved. A sudden backfire can

cause serious burns.

Ƈ Be careful of hot parts. The muffler and other generator parts become very hot while the engine is running.

Ƈ Do not "jump start" the generator set.

Ƈ Sulfuric acid can cause severe injury and can give off gases, which are corrosive and potentially explosive.

Avoid contact with skin, eyes, and clothing. In case of contact, flush area immediately with water.

Ƈ When transporting a generator set, secure it to prevent it from moving or shifting.

Ƈ Know how to stop the engine quickly and understand the operation of all controls.

Ƈ Do not operate electrical equipment while standing in water, on wet ground or with wet hands or shoes.

Ƈ Use extreme caution when working on electrical components. Potentially dangerous voltage is present

when the engine is running.

- iii -

Page 5

Ƈ Always treat the electrical circuits as if they were energized.

Ƈ Disconnect all leads plugged into the unit Prior to working on it.

Ƈ Have the electrical circuits serviced only by qualified technicians.

Ƈ Inspect wiring frequently and replace frayed, broken or poor leads.

Ƈ Do not connect this unit to any building's electrical system unless you utilize an approved transfer switch or

the main service entrance switch has been disconnected and locked open.

Ƈ Circuit overload protection must be provided in accordance with national electrical codes and local

regulations.

Ƈ Check GFCI Receptacles monthly by using the "Test" and "Reset" buttons designed into them.

Ƈ Depending on your application it may be mandatory to ground or not ground this unit to earth ground.

Comply with local electrical codes.

ż ż ż ż FOR GASOLINE OR DIESEL POWERED GENERATOR SETS ż ż ż ż

Ƈ Operate the generator set on a level surface. If the generator set is tilted, fuel spillage may result.

Ƈ Handle fuel with care. It is highly flammable. Use only clean, properly marked and approved safety

containers for refueling and storing fuel.

Ƈ Stop the engine and allow it to cool before refueling.

Ƈ Do not overfill the fuel tank. Only fill the tank to within 1/2" of the top of the tank to allow space for fuel

expansion.

Ƈ If fuel is spilled, wipe it up carefully and wait until the fuel has dried before starting the engine.

Ƈ Make sure the fuel cap is properly closed after refueling.

Ƈ Never operate the generator set while smoking.

Ƈ Never operate the generator set near an open flame.

Ƈ Never store the generator set with fuel in the tank indoors or in an enclosed, poorly ventilated enclosure

where fuel fumes may reach an open flame, electrical spark or pilot light as on a furnace, water heater,

clothes dryer, etc.

Ƈ When transporting over long distances or rough roads, drain the fuel tank to prevent leakage and spillage.

- iv -

Page 6

ż ż ż ż FOR GASOLINE OR DIESEL POWERED GENERATOR SETS ż ż ż ż

Ƈ Check all fuel supply piping and their connections on a monthly basis for fuel leaks.

Ƈ Use only approved piping and componentry in your fuel supply system.

Ƈ A professional, experienced technician should only install the fuel supply system.

Ƈ Do not run the fuel line up against any sharp objects.

Ƈ Comply with NFPA regulations and your local codes in regard to shut-off valves, regulators, etc. and any

other recommendations or requirements they may have.

Ƈ Keep the generator set at least three feet away from buildings or other structures.

Ƈ Keep the generator set away from flammable and other hazardous materials (trash, rags, lubricants,

explosives, paints, etc.)

Ƈ Keep the generator set free of grass, leaves and excessive grease and oils.

Ƈ Allow the generator set to cool before transporting it or storing it indoors.

Ƈ Have fire extinguisher accessible and nearby while operating the generator set.

Ƈ This generator set must not be used on or near any forest covered brush covered or grass covered land

unless the engine's exhaust system is equipped with a spark arrester and it must be maintained

in effective working order by the operator.

Ƈ Operation inside an enclosed compartment or building is a potential fire hazard and should not be done

unless approval is obtained from Baldor Generators. Engine/Generator overheating can cause severe

damage due to restricted, obstructed or improper airflow that is necessary for the proper cooling of the unit.

Ƈ Hot exhaust gases being discharged by the engine must never be directed toward anything that could catch

fire or explode.

- v -

Page 7

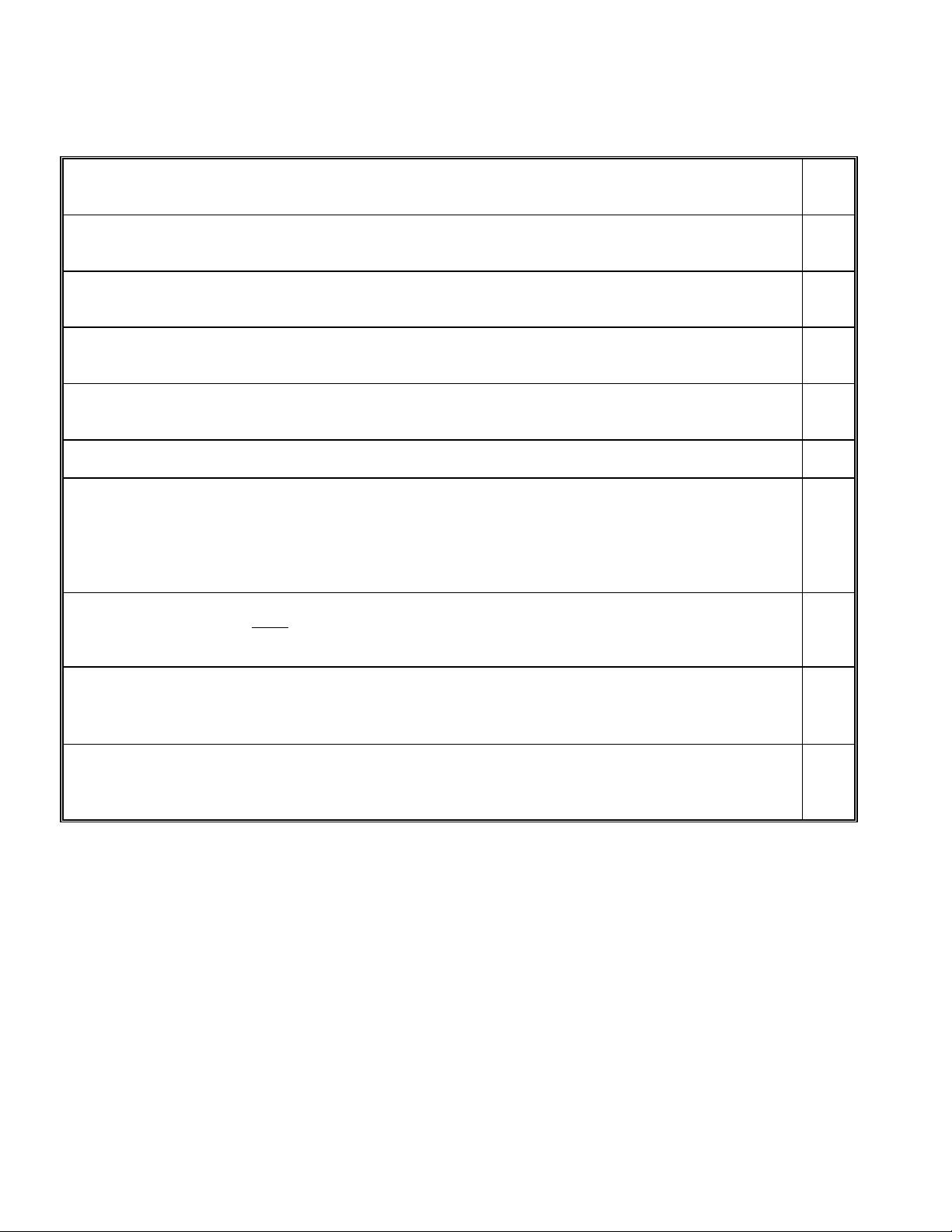

STANDBY PERMANENT- MOUNT SERIES GENERATOR

Table of Contents

ITEM PAGE

VOLTAGE RATINGS:

This informational page describes features and specifications for all Standby Permanent- Mount Series

Units.

ELECTRICAL CONNECTION INFORMATION:

This information explains how to interface your generator with the AC loads and other standard and

optional accessories.

MOUNTING AND COOLING REQUIREMENTS:

This section explains the necessary requirements for mounting and ventilating your Pow'R Gard

Generator.

EXHAUST REQUIREMENTS:

this section describes recommendations made by Pow'R Gard to assure proper exhaust applications.

CONTROL PANEL:

This includes a drawing of the control panel and a description of the components associated with it.

1

13

15

21

24

PRE-START PROCEDURE:

This describes a pre-start check that should be performed prior to initial start-up.

OPERATION GUIDE:

Information on how to start, stop, and operate the generator set is included here. Included

also is information in regards to the operation of the gen set/ engine control device and the

different fault shutdown circuits designed to protect the generator set from potential engine

operational problems.

27

28

TROUBLESHOOTING GUIDE:

Included in this guide are basic

For more troubleshooting help please contact the service department at Pow’R Gard Generator

Corporation

POW’R GARD GENERATOR CORPORATION WARRANTY:

This details the warranty provided by Pow’R Gard Generator Corporation for coverage for electrical

generator end of the generator set.

instructions to help troubleshoot most problems with your generator set.

30

34

INSTALLATION CHECKLIST:

This checklist is provided to assure that Installation has been properly performed meeting all Pow'R Gard

guidelines. It is expected that this checklist be filled out and returned to Pow'R Gard Generator

Corporation.

Other Manuals and accessories that should accompany your Standby Permanent - Mount Series Generator:

ENGINE OPERATOR’S MANUAL: This operator’s manual includes information in regards to the operation

and maintenance of the engine utilized in this generator set.

AC GENERATOR, ACCESSORIES, AND LOAD CONNECTION DIAGRAMS / ENGINE CONTROLS,

ACCESSORIES, AND REMOTE CONNECTION DIAGRAMS: These diagrams contain information in regards to the internal

wiring of the generator set, specifically the AC and Engine Control circuits. These diagrams will also include information for any

optional AC or DC powered accessories that are included.

PARTS LIST: This is a listing of all parts used by Pow’R Gard Generator Corporation to build this specific generator set.

37

Page 8

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

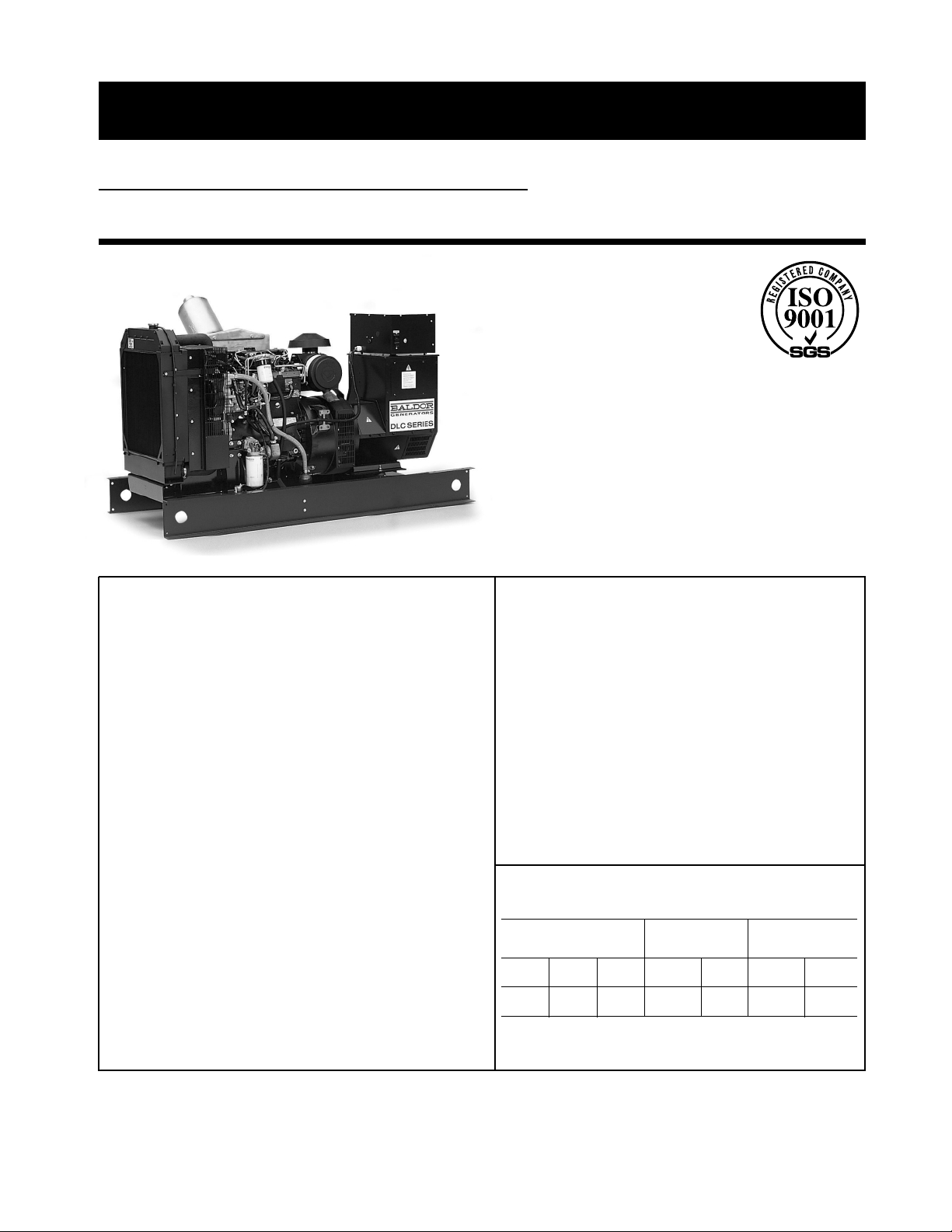

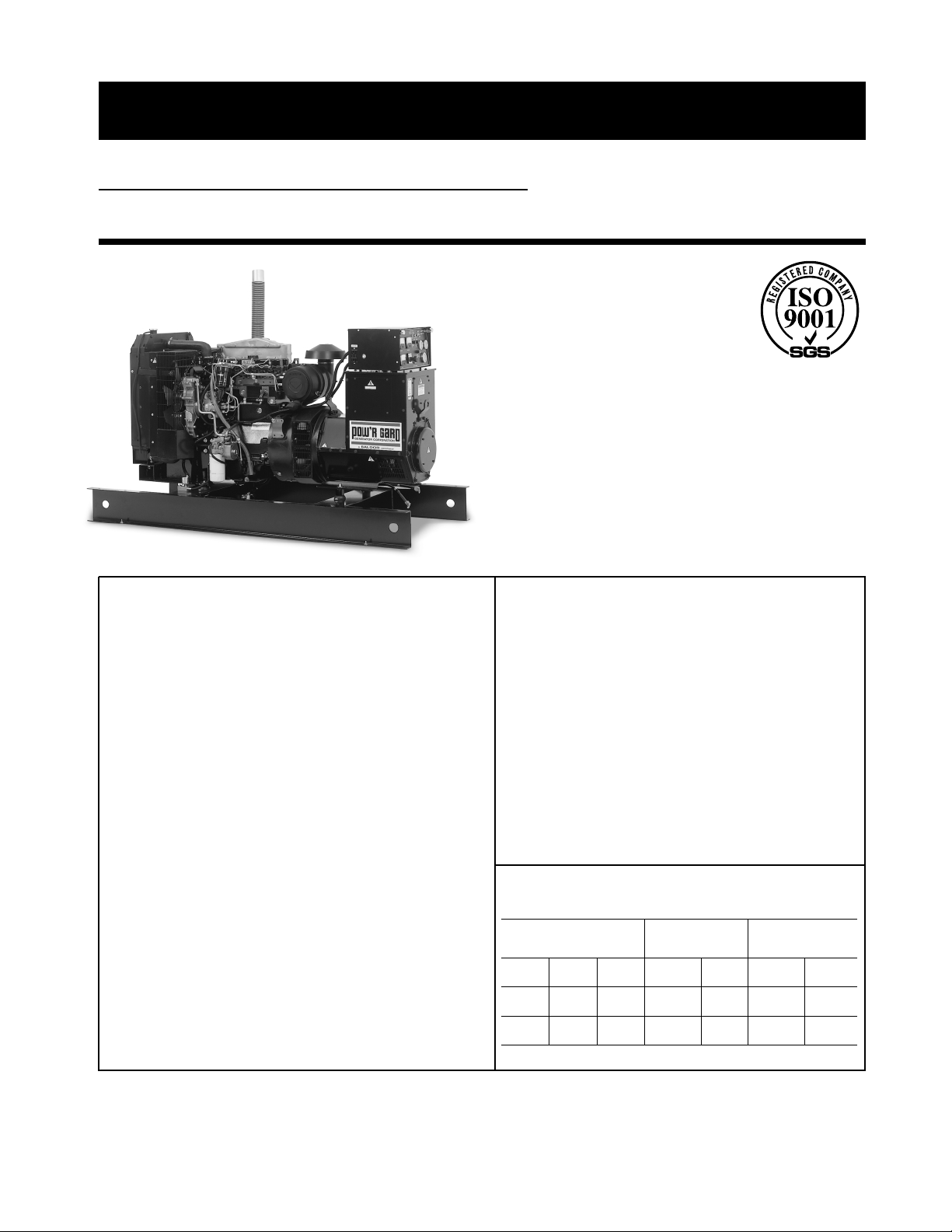

Farm Duty 1-Phase Model: DLC25

Baldor

4 Cycle

POWER SYSTEMS

Standby Power Ratings

Continuous Power Ratings

Assembled in USA

Diesel Liquid Cooled

60Hz

kW 27.5

27.5

kVA

60Hz

kW 25

kVA

25

Baldor Generator Features

✓

Baldor generators are manufactured in a certified

ISO9001 facility located in Oshkosh, Wisconsin.

✓

Every generator is design, prototype, and

production tested

✓

Brushless synchronous four-pole alternator

✓

Industrial grade exhaust silencer

✓

Engine block heater

✓

Baldor gensets attain one step load acceptance

of nameplate rating

✓

PowerPAC 4 controller includes low oil pressure

shutdown, high coolant temperature shutdown,

overspeed and overcrank indicators

✓

Flexible exhaust connection

✓

Battery rack and cables

✓

Installation and operation manual

✓

Worldwide network of parts and service

Options

Exhaust silencer: Critical

Single wall sub base fuel tank

Double wall UL 142 approved sub-base fuel tank

Battery charger 12V float

Line circuit breaker

Flexible fuel lines

Weather protective enclosure

Generator Ratings

150 C Rise 125 C Rise

Standby Rating Continuous Rating

Voltage PH Hz kW/kVA Amps kW/kVA Amps

120/240 1 60 25.0/25.0 104.2

27.5/27.5

114.6

Ratings: - Standby Ratings: Standby ratings are applicable for supplying emergency power for the duration of a utility power outage. Primary power to the installation is

utility supplied. No overload capability for standby rating. Standby ratings in accordance with ISO 3046, BS55114, DIN 6271. Continuous Power Rating: Continuous power

is the maximum power available for continuous duty. A 10% overload capacity is available for 1 hour out of 12 hours of operation. Prime power ratings in accordance with

ISO 3046, BS55114, DIN 6271. For additional information, please consult factory. Manufacturer reserves the right to implement specifications or design changes without

notice. Single phase: Single phase units are rated at 1.0 (Unity) power factor. WARNING: Do not connect generator to any building's electrical system unless a

disconnect switch has been installed

.

Page 9

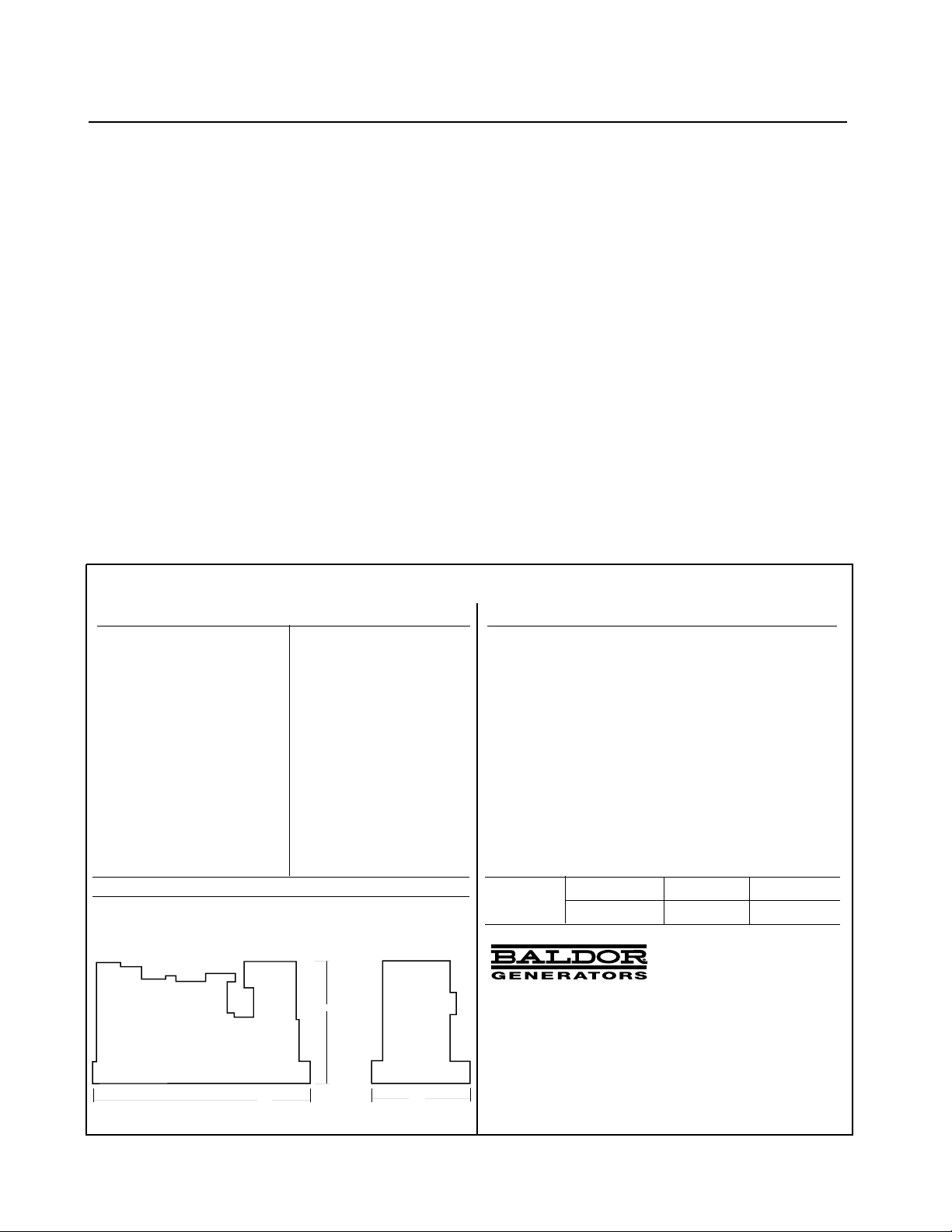

Farm Duty 1-Phase Model: DLC25

Alternator Specifications

Manufacturer Stamford/Newage

Type 4-Pole, Revolving field

Model BCI184F

Leads 4

Voltage regulator AVR

Voltage regulation 1/2%

Insulation material: Rotor Class H

Insulation material: Stator Class H

Temperature rise 125 C, Standby

Total harmonic distortion

<

5%

Bearing: quantity, type 1, Sealed

Coupling type Flexible disc

One step load acceptance 100% of Rating

Warranty: Limited 3 year warranty.

1 year or 3000 hours parts and labor.

3 years or 3000 hours parts.

Baldor reserves the right to repair or replace unit.

Engine Specifications

Alternator Features

Brushless design

Class H insulation used throughout

Solid-state voltage regulation

Sealed bearings

All wound components impregnated with varnishes

and resins to protect against harsh environment

Alternator complies with temperature rise standards:

NEMA, IEEE and ANSI

Dynamically balanced rotors

Controller Features

PowerPAC 4

Hi temp, low oil pressure, overspeed and

overcrank indicators

AC Voltage, amperage and hertz meters

Oil pressure, water temperature and battery gauges

Hour meter

Panel lights

Engine Data

Manufacturer Perkins

Model 3.1524

Cylinders 3 in-line

Cycle 4-stroke

Induction system Natural

Displacement, L (cu. in.) 2.5 (152 cu. in.)

Bore and Stroke 91.4 x 127.0

Compression Ratio 16.5:1

Lubrication capacity 6.17 Quarts

Cooling capacity (incl. radiator) 11.85 Quarts

Weight without fuel - Net 685

Weight without fuel - Shipping 950

Warranty: 2 year limited per manufacturer

Size: Length x Width x Height

1

61" x 36 x 38

/2

38.50"

Engine Features

• Mechanical governor - speed control to ISO 3046-4 Class A1

• Spin-on full fuel flow filter

• Fuel pre-filter

• Spin-on full flow oil filter

• Oil cooler

• Thermostat controlled cooling system

• Gear driven water pump

• 12V engine alternator

• 12V starter motor

• Single side servicing

Engine Performance

60 HZ

Distributed by:

Rated RPM 1800 1800

Net BHP at rated 38.4 42.2

Continuous Standby

Baldor Generators

3815 Oregon Street

Oshkosh, WI 54902

800-872-7697 • 920-236-4200

Fax 920-236-4219

www.baldor.com

61.00"

Drawing is for reference only: Contact your dealer for detailed information.

SAL-245-5M-DP

36.00"

Page 10

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

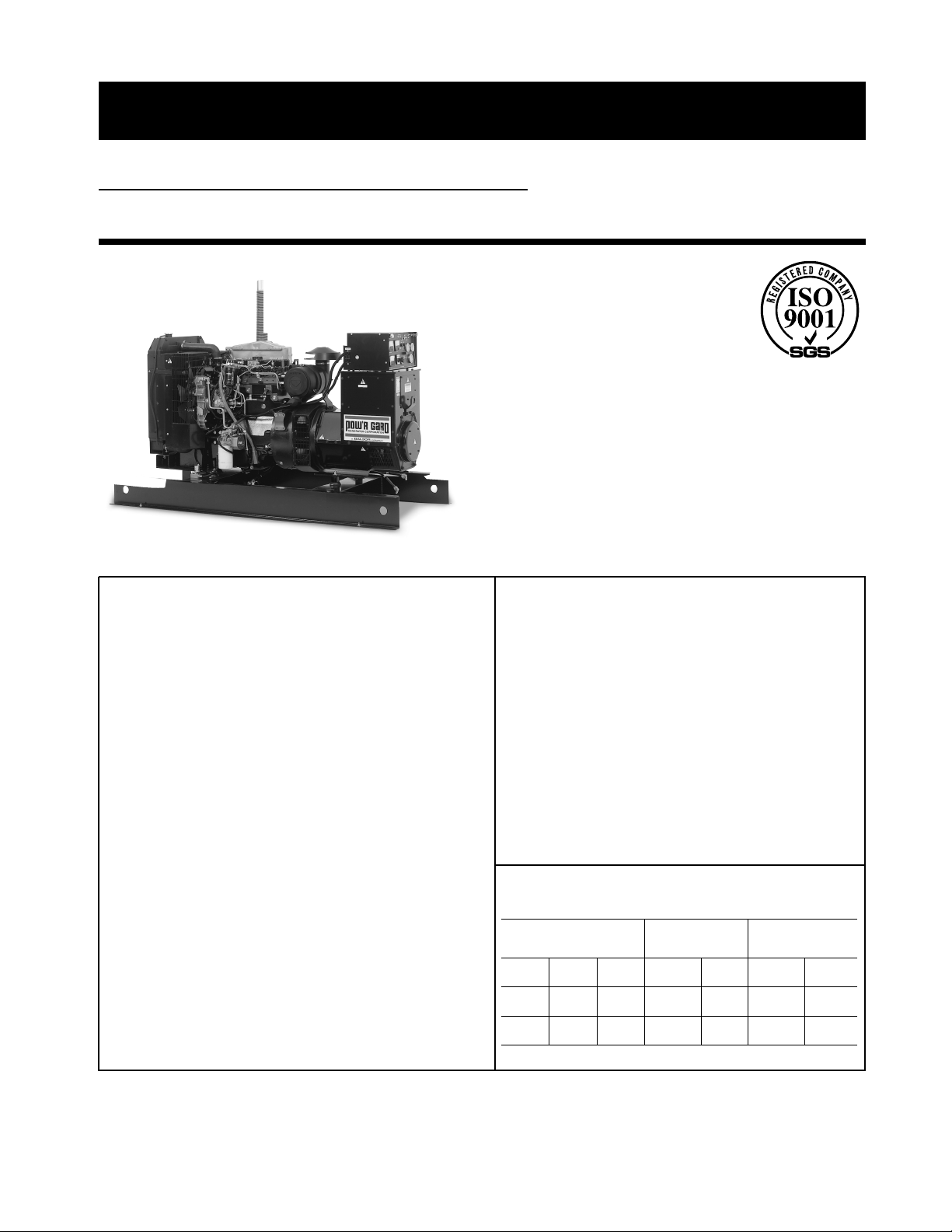

Farm Duty 1-Phase Model: D50

Baldor

4 Cycle

POWER SYSTEMS

Standby Power Ratings

Continuous Power Ratings

Assembled in USA

Diesel Liquid Cooled

60Hz 50Hz

kW 50 42

kVA 50 42

60Hz 50Hz

kW 45 38

kVA 45 38

Baldor Generator Features

✓

Baldor generators are manufactured in a certified

ISO 9001 facility located in Oshkosh, Wisconsin

✓

Every generator is design, prototype, and

production tested

✓

Brushless synchronous four-pole alternator

✓

Industrial-grade exhaust silencer

✓

Engine block heater

✓

Baldor gensets attain one step load acceptance

of nameplate rating

✓

PowerPAC 4 controller includes low oil pressure

shutdown, high coolant temperature shutdown,

overspeed and overcrank indicators

✓

Flexible exhaust connection

✓

Battery rack and cables

✓

Installation and operation manual

✓

Worldwide network of parts and service

Options

Exhaust silencer: Critical

Single wall sub-base fuel tank

Double wall UL 142 approved sub-base fuel tank

Battery charger 12V float

Line circuit breaker

Flexible fuel lines

Weather protective enclosure

Generator Ratings

150 C Rise 125 C Rise

Standby Rating Continuous Rating

Voltage PH Hz kW/kVA Amps kW/kVA Amps

120/240 1 60 50/50 208 45/45 188

110/220 1 50 42/42 191 38/38 172

Ratings: - S tandby Ratings: Standby ratings are applicable for supplying emergency power for the duration of a utility power outage. Primary power to the installation is

utility supplied. No overload capability for standby rating. Standby ratings in accordance with ISO 3046, BS55114, DIN 6271. C ontinuous P ower R ating: Continuous power

is the maximum power available for continuous duty. A 10% overload capacity is available for 1 hour out of 12 hours of operation. Prime Power ratings in accordance with ISO

3046, BS55114, DIN 6271. For additional information, please consult factory. Manufacturer reserves the right to implement specifications or design changes without notice.

Single phase: Single phase units are rated at 1.0 (Unity) power factor. WARNING: Do not connect generator to any building’s electrical system unless a disconnect switch

has been installed.

Page 11

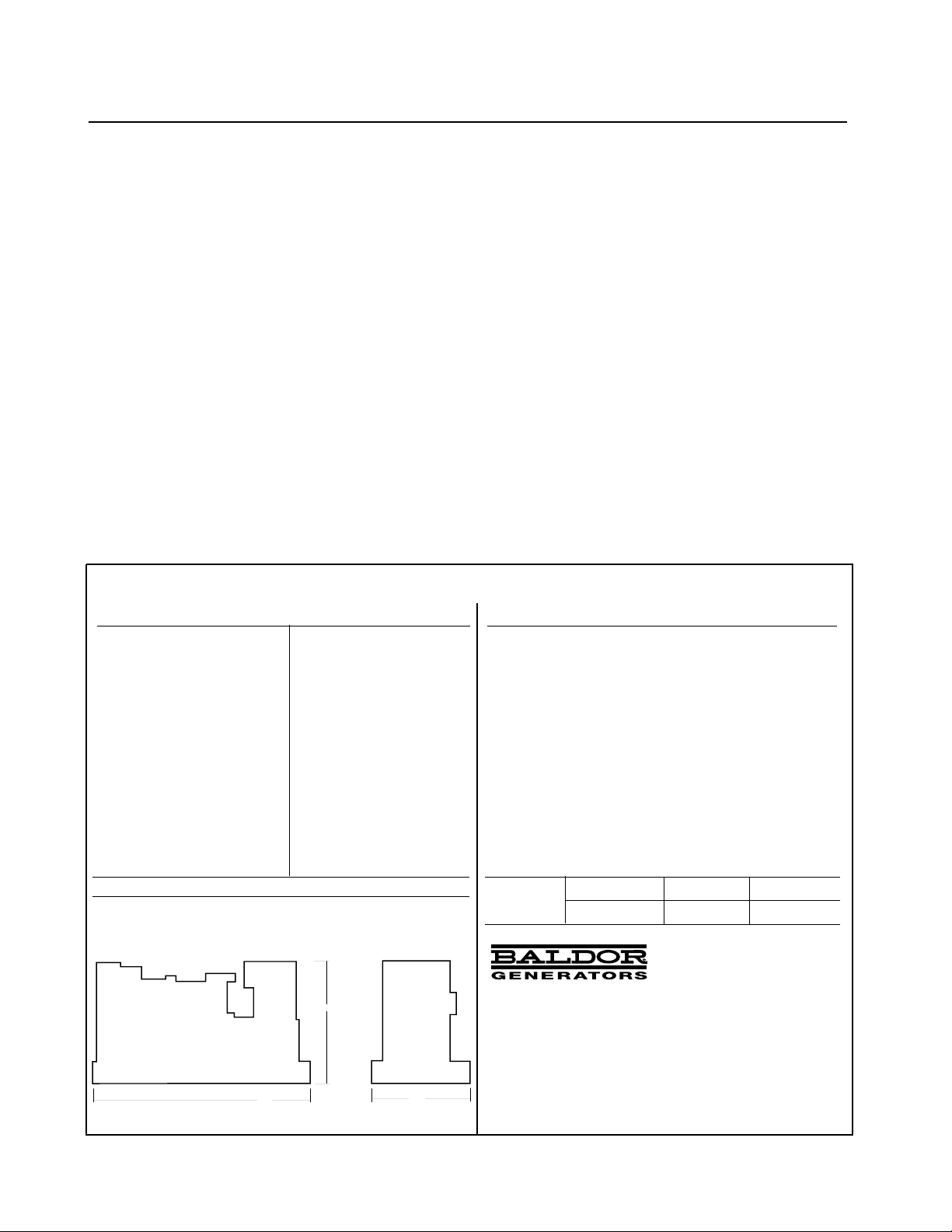

Farm Duty 1-Phase Model: DLC50

Alternator Specifications

Manufacturer Stamford/Newage

Type 4-Pole, Revolving field

Model UC224D

Leads 4

Voltage regulator AVR

Voltage regulation 1/2%

Insulation material: Rotor Class H

Insulation material: Stator Class H

Temperature rise 125 C, Standby

Total harmonic distortion

<

5%

Bearing: quantity, type 1, Sealed

Coupling type Flexible disc

One step load acceptance 100% of Rating

Warranty: Limited 3 year warranty.

1 year or 3000 hours parts and labor.

3 years or 3000 hours parts.

Baldor reserves the right to repair or replace unit.

Engine Specifications

Alternator Features

Brushless design

Class H insulation used throughout

Solid-state voltage regulation

Sealed bearings

All wound components impregnated with varnishes

and resins to protect against harsh environment

Alternator complies with temperature rise standards:

NEMA, IEEE and ANSI

Dynamically balanced rotors

Controller Features

PowerPAC 4

Hi temp, low oil pressure, overspeed and

overcrank indicators

AC Voltage, amperage and hertz meters

Oil pressure, water temperature and battery gauges

Hour meter

Panel lights

Engine Data

Manufacturer Perkins

Model 1004-40T

Cylinders 4 in-line

Cycle 4-stroke

Induction system Turbocharged

Displacement, L (cu. in.) 3.99 (243.5 cu. in.)

Bore and Stroke 100.0 MM x 127.0 MM 3.94 x 5

Compression Ratio 17.25:1

Lubrication capacity 8.4 liters (9 qts.)

Cooling capacity (incl. radiator) 18.8 liters (23.4 qts.)

Weight without fuel - Net 1727

Weight without fuel - Shipping 1812

Warranty: 2 year limited per manufacturer

Size: Length x Width x Height

3

⁄4" x 36" x 45"

78

45.00"

Engine Features

• Mechanical governor - speed control to ISO 3046-4 Class A1

• Spin-on full fuel flow filter

• Fuel pre-filter

• Spin-on full flow oil filter

• Oil cooler

• Thermostat controlled cooling system

• Gear driven water pump

• 12V engine alternator

• 12V starter motor

• Single side servicing

Engine P erformanc e

60 HZ

Distributed by:

Rated RPM 1800 1800

Net BHP at rated 95 86

Continuous Standby

Baldor Generators

3815 Oregon Street

Oshkosh, WI 54902

1-800-872-7697 • 1-920-236-4200

Fax 1-920-236-4219

www.baldor.com

78.75"

Drawing is for reference only: Contact your dealer for detailed information.

SAL-160-10M-SG

36.00"

Page 12

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

Farm Duty 1-Phase Model: D60

Baldor

4 Cycle

POWER SYSTEMS

Standby Power Ratings

Continuous Power Ratings

Assembled in USA

Diesel Liquid Cooled

60Hz 50Hz

kW 60 50

kVA 60 50

60Hz 50Hz

kW 54 45

kVA 54 45

Baldor Generator Features

✓

Baldor generators are manufactured in a certified

ISO 9001 facility located in Oshkosh, Wisconsin

✓

Every generator is design, prototype, and

production tested

✓

Brushless synchronous four-pole alternator

✓

Industrial-grade exhaust silencer

✓

Engine block heater

✓

Baldor gensets attain one step load acceptance

of nameplate rating

✓

PowerPAC 4 controller includes low oil pressure

shutdown, high coolant temperature shutdown,

overspeed and overcrank indicators

✓

Flexible exhaust connection

✓

Battery rack and cables

✓

Installation and operation manual

✓

Worldwide network of parts and service

Options

Exhaust silencer: Critical

Single wall sub-base fuel tank

Double wall UL 142 approved sub-base fuel tank

Battery charger 12V float

Line circuit breaker

Flexible fuel lines

Weather protective enclosure

Generator Ratings

150 C Rise 125 C Rise

Standby Rating Continuous Rating

Voltage PH Hz kW/kVA Amps kW/kVA Amps

120/240 1 60 60/60 250 54/54 225

110/220 1 50 50/50 227 45/45 205

Ratings: - S tandby Ratings: Standby ratings are applicable for supplying emergency power for the duration of a utility power outage. Primary power to the installation is

utility supplied. No overload capability for standby rating. Standby ratings in accordance with ISO 3046, BS55114, DIN 6271. C ontinuous P ower R ating: Continuous power

is the maximum power available for continuous duty. A 10% overload capacity is available for 1 hour out of 12 hours of operation. Prime Power ratings in accordance with ISO

3046, BS55114, DIN 6271. For additional information, please consult factory. Manufacturer reserves the right to implement specifications or design changes without notice.

Single phase: Single phase units are rated at 1.0 (Unity) power factor. WARNING: Do not connect generator to any building’s electrical system unless a disconnect switch

has been installed.

Page 13

Farm Duty 1-Phase Model: DLC60

SAL-161-10M-SG

Alternator Specifications

Manufacturer Stamford/Newage

Type 4-Pole, Revolving field

Model UC224G

Leads 4

Voltage regulator AVR

Voltage regulation 1/2%

Insulation material: Rotor Class H

Insulation material: Stator Class H

Temperature rise 125 C, Standby

Total harmonic distortion

<

5%

Bearing: quantity, type 1, Sealed

Coupling type Flexible disc

One step load acceptance 100% of Rating

Warranty: Limited 3 year warranty.

1 year or 3000 hours parts and labor.

3 years or 3000 hours parts.

Baldor reserves the right to repair or replace unit.

Engine Specifications

Alternator Features

Brushless design

Class H insulation used throughout

Solid-state voltage regulation

Sealed bearings

All wound components impregnated with varnishes

and resins to protect against harsh environment

Alternator complies with temperature rise standards:

NEMA, IEEE and ANSI

Dynamically balanced rotors

Controller Features

PowerPAC 4

Hi temp, low oil pressure, overspeed and

overcrank indicators

AC Voltage, amperage and hertz meters

Oil pressure, water temperature and battery gauges

Hour meter

Panel lights

Engine Data

Manufacturer Perkins

Model 1004-40T

Cylinders 4 in-line

Cycle 4-stroke

Induction system Turbocharged

Displacement, L (cu. in.) 3.99 (243.5 cu. in.)

Bore and Stroke 100.0 MM x 127.0 MM 3.94 x 5

Compression Ratio 17.25:1

Lubrication capacity 8.4 liters (9 qts.)

Cooling capacity (incl. radiator) 18.8 liters (23.4 qts.)

Weight without fuel - Net 1945

Weight without fuel - Shipping 2030

Warranty: 2 year limited per manufacturer

Size: Length x Width x Height

3

⁄4" x 36" x 45"

78

45.00"

Engine Features

• Mechanical governor - speed control to ISO 3046-4 Class A1

• Spin-on full fuel flow filter

• Fuel pre-filter

• Spin-on full flow oil filter

• Oil cooler

• Thermostat controlled cooling system

• Gear driven water pump

• 12V engine alternator

• 12V starter motor

• Single side servicing

Engine P erformanc e

60 HZ

Distributed by:

Rated RPM 1800 1800

Net BHP at rated 95 86

Continuous Standby

Baldor Generators

3815 Oregon Street

Oshkosh, WI 54902

1-800-872-7697 • 1-920-236-4200

Fax 1-920-236-4219

www.baldor.com

78.75"

Drawing is for reference only: Contact your dealer for detailed information.

36.00"

Page 14

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

Farm Duty 1-Phase Model: D75

Baldor

4 Cycle

POWER SYSTEMS

Standby Power Ratings

Continuous Power Ratings

Assembled in USA

Diesel Liquid Cooled

60Hz 50Hz

kW 75 63

kVA 75 63

60Hz 50Hz

kW 68 57

kVA 68 57

Baldor Generator Features

✓

Baldor generators are manufactured in a certified

ISO9001 facility located in Oshkosh, Wisconsin.

✓

Every generator is design, prototype, and

production tested

✓

Brushless synchronous four-pole alternator

✓

Industrial grade exhaust silencer

✓

Engine block heater

✓

Baldor gensets attain one step load acceptance

of nameplate rating

✓

PowerPAC 4 controller includes low oil pressure,

high coolant temperature, overspeed and overcrank

shutdowns with indicator lights

✓

Flexible exhaust connection

✓

Battery rack and cables

✓

Installation and operation manual

✓

Worldwide network of parts and service

Options

Exhaust silencer: Critical

Single wall sub base fuel tank

Double wall UL 142 approved sub base fuel

tank

Battery charger 12V float

Line circuit breaker

Flexible fuel lines

Weather protective enclosure

Generator Ratings

150 C Rise 125 C Rise

Standby Rating Continuous Rating

Voltage PH Hz kW/kVA Amps kW/kVA Amps

120/240 1 60 75/75 312 68/68 283

110/220 1 50 63/63 286 57/57 259

Ratings: - Standby Ratings: Standby ratings are applicable for supplying emergency power for the duration of a utility power outage. Primary power to the installation is

utility supplied. No overload capability for standby rating. Standby ratings in accordance with ISO 3046, BS55114, DIN 6271. C ontinuous P ower Rating: Continuous

power is the maximum power available for continuous duty. A 10% overload capacity is available for 1 hour out of 12 hours of operation. Continuous Power ratings in

accordance with ISO 3046, BS55114, DIN 6271. For additional information, please consult factory. Manufacturer reserves the right to implement specifications or design

changes without notice. Single phase: Single phase units are rated at 1.0 (Unity) power factor.

Page 15

Farm Duty 1-Phase Model: DLC75

Alternator Specifications

Manufacturer Stamford/Newage

Type 4-Pole, Revolving field

Model UCI224G

Leads 4

Voltage regulator AVR

Voltage regulation 1/2%

Insulation material: Rotor Class H

Insulation material: Stator Class H

Temperature rise 125 C

Total harmonic distortion <5%

Bearing: quantity, type 1, Sealed

Coupling type Flexible disc

One step load acceptance 100% of Rating

Warranty: Limited 3 year warranty.

1 year or 3000 hours parts and labor.

3 years or 3000 hours parts.

Baldor reserves the right to repair or replace unit.

Engine Specifications

Alternator Features

Brushless design

Class H insulation used throughout

Solid state voltage regulation

Sealed bearings

All wound components impregnated with varnishes

and resins to protect against harsh environment

Alternator complies with temperature rise standards:

NEMA, IEEE and ANSI

Dynamically balanced rotors

Controller Features

PowerPAC 4

Hi temp, low oil pressure, overspeed and overcrank

indicators

AC Voltage, amperage and hertz meters

Oil pressure, water temperature and battery gauges

Hour meter

Panel lights

Engine Data

Manufacturer Perkins

Model 1004-40TW

Cylinders 4 in-line

Cycle 4-stroke

Induction system Turbocharged

Displacement, L (cu. in.) 3.99 (243.5 cu. in.)

Bore and Stroke 100.0 MM x 127.0 MM 3.94 x 5

Compression Ratio 17.3:1

Lubrication capacity 8.5 liters (9 qts.)

Cooling capacity (inc. radiator) 22.2 liters (23.4 qts.)

Weight without fuel - Net 2035

Weight without fuel - Shipping 2110

Warranty: 2 year limited per manufacturer

Size: Length x Width x Height

3

⁄4" x 36" x 45"

78

45.00"

Engine Features

• Mechanical governor - speed control to ISO 3046-4 Class A1

• Spin-on full fuel flow filter

• Fuel pre-filter

• Spin-on full flow oil filter

• Oil cooler

• Thermostat controlled cooling system

• Gear driven water pump

• 12V engine alternator

• 12V starter motor

• Single side servicing

Engine P erformanc e

60 HZ

Distributed by:

Rated RPM 1800 1800

Net BHP at rated 102 113

Continuous Standby

Baldor Generators

3815 Oregon Street

Oshkosh, WI 54902

1-800-872-7697 • 1-920-236-4200

Fax 1-920-236-4219

www.baldor.com

78.75"

Drawing is for reference only: Contact your dealer for detailed information.

S-SAL-134-10M-SG

36.00"

Page 16

■

■

■

■

■

■

■

■

Farm Duty 1-Phase Model: D100

■

■

■

■

■

■

■

■

■

■

Baldor

4 Cycle

POWER SYSTEMS

Standby Power Ratings

Continuous Power Ratings

Assembled in USA

Diesel Liquid Cooled

60Hz 50Hz

kW 100 83

kVA 100 83

60Hz 50Hz

kW 90 74

kVA 90 74

Baldor Generator Features

✓

Baldor generators are manufactured in a certified

ISO9001 facility located in Oshkosh, Wisconsin.

✓

Every generator is design, prototype, and

production tested

✓

Brushless synchronous four-pole alternator

✓

Industrial grade exhaust silencer

✓

Engine block heater

✓

Baldor gensets attain one step load acceptance

of nameplate rating

✓

PowerPAC 4 controller includes low oil pressure,

high coolant temperature, overspeed and overcrank

shutdowns with indicator lights

✓

Flexible exhaust connection

✓

Battery rack and cables

✓

Installation and operation manual

✓

Worldwide network of parts and service

Options

Exhaust silencer: Critical

Single wall sub base fuel tank

Double wall UL 142 approved sub base fuel

tank

Battery charger 12V float

Line circuit breaker

Flexible fuel lines

Weather protective enclosure

Generator Ratings

150 C Rise 125 C Rise

Standby Rating Continuous Rating

Voltage PH Hz kW/kVA Amps kW/kVA Amps

120/240 1 60 100/100 416 90/90 375

110/220 1 50 83/83 377 74/74 336

Ratings: - Standby Ratings: Standby ratings are applicable for supplying emergency power for the duration of a utility power outage. Primary power to the installation is

utility supplied. No overload capability for standby rating. Standby ratings in accordance with ISO 3046, BS55114, DIN 6271. C ontinuous P ower Rating: Continuous

power is the maximum power available for continuous duty. A 10% overload capacity is available for 1 hour out of 12 hours of operation. Continuous Power ratings in

accordance with ISO 3046, BS55114, DIN 6271. For additional information, please consult factory. Manufacturer reserves the right to implement specifications or design

changes without notice. Single phase: Single phase units are rated at 1.0 (Unity) power factor.

Page 17

Farm Duty 1-Phase Model: DLC100

42.00"

Alternator Specifications

Manufacturer Stamford/Newage

Type 4-Pole, Revolving field

Model UCI274C

Leads 4

Voltage regulator AVR

Voltage regulation 1/2%

Insulation material: Rotor Class H

Insulation material: Stator Class H

Temperature rise 125 C

Total harmonic distortion <5%

Bearing: quantity, type 1, Sealed

Coupling type Flexible disc

One step load acceptance 100% of Rating

Warranty: Limited 3 year warranty.

1 year or 3000 hours parts and labor.

3 years or 3000 hours parts.

Baldor reserves the right to repair or replace unit.

Engine Specifications

Alternator Features

Brushless design

Class H insulation used throughout

Solid state voltage regulation

Sealed bearings

All wound components impregnated with varnishes

and resins to protect against harsh environment

Alternator complies with temperature rise standards:

per NEMA, IEEE and ANSI

Dynamically balanced rotors

Controller Features

PowerPAC 4

Hi temp, low oil pressure, overspeed and overcrank

indicators

AC Voltage, amperage and hertz meters

Oil pressure, water temperature and battery gauges

Hour meter

Panel lights

Engine Data

Manufacturer Perkins

Model 1006-6T

Cylinders 6 in-line

Cycle 4-stroke

Induction system Turbocharged

Displacement, L (cu. in.) 5.99 (365.0 cu. in.)

Bore and Stroke 100.0 MM x 127.0 MM 3.94 x 5.0

Compression Ratio 17.3:1

Lubrication capacity 16.1 liters (17.0 qts.)

Cooling capacity (inc. radiator) 27.7 liters (29.2 qts.)

Weight without fuel - Net 2260

Weight without fuel - Shipping 2448

Warranty: 2 year limited per manufacturer

Size: Length x Width x Height

95" x 42" x 53"

53.00"

Engine Features

• Mechanical governor - speed control to ISO 3046-4 Class A1

• Spin-on full fuel flow filter

• Fuel pre-filter

• Spin-on full flow oil filter

• Oil cooler

• Thermostat controlled cooling system

• Gear driven water pump

• 12V engine alternator

• 12V starter motor

• Single side servicing

Engine P erformanc e

60 HZ

Distributed by:

Rated RPM 1800 1800

Net BHP at rated 147.0 161.0

Continuous Standby

Baldor Generators

3815 Oregon Street

Oshkosh, WI 54902

1-800-872-7697 • 1-920-236-4200

Fax 1-920-236-4219

www.baldor.com

95.00"

Drawing is for reference only: Contact your dealer for detailed information.

SAL-186-10M-SG

Page 18

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

Farm Duty 1-Phase Model: D130

Baldor

4 Cycle

POWER SYSTEMS

Standby Power Ratings

Continuous Power Ratings

Assembled in USA

Diesel Liquid Cooled

60Hz 50Hz

kW 130 108

kVA 130 108

60Hz 50Hz

kW 117 97

kVA 117 97

Baldor Generator Features

✓

Baldor generators are manufactured in a certified

ISO9001 facility located in Oshkosh, Wisconsin

✓

Every generator is design, prototype, and

production tested

✓

Brushless synchronous four-pole alternator

✓

Industrial grade exhaust silencer

✓

Engine block heater

✓

Baldor gensets attain one step load acceptance

of nameplate rating

✓

PowerPAC 4 controller includes low oil pressure,

high coolant temperature, overspeed and overcrank

shutdowns with indicator lights

✓

Flexible exhaust connection

✓

Battery rack and cables

✓

Installation and operation manual

✓

Worldwide network of parts and service

Options

Exhaust silencer: Critical

Single wall sub base fuel tank

Double wall UL 142 approved sub base fuel

tank

Battery charger 12V float

Line circuit breaker

Flexible fuel lines

Weather protective enclosure

Generator Ratings

150 C Rise 125 C Rise

Standby Rating Continuous Rating

Voltage PH Hz kW/kVA Amps kW/kVA Amps

120/240 1 60 130/130 541 117/117 487

110/220 1 50 108/108 490 97/97 441

Ratings: - Standby Ratings: Standby ratings are applicable for supplying emergency power for the duration of a utility power outage. Primary power to the installation is

utility supplied. No overload capability for standby rating. Standby ratings in accordance with ISO 3046, BS55114, DIN 6271. C ontinuous P ower Rating: Continuous

power is the maximum power available for continuous duty. A 10% overload capacity is available for 1 hour out of 12 hours of operation. Continuous Power ratings in

accordance with ISO 3046, BS55114, DIN 6271. For additional information, please consult factory. Manufacturer reserves the right to implement specifications or design

changes without notice. Single phase: Single phase units are rated at 1.0 (Unity) power factor.

Page 19

Farm Duty 1-Phase Model: DLC130

Alternator Specifications

Manufacturer Stamford/Newage

Type 4-Pole, Revolving field

Model UCI274E

Leads 4

Voltage regulator AVR

Voltage regulation 1/2%

Insulation material: Rotor Class H

Insulation material: Stator Class H

Temperature rise 125 C

Total harmonic distortion <5%

Bearing: quantity, type 1, Sealed

Coupling type Flexible disc

One step load acceptance 100% of Rating

Warranty: Limited 3 year warranty.

1 year or 3000 hours parts and labor.

3 years or 3000 hours parts.

Baldor reserves the right to repair or replace unit.

Engine Specifications

Alternator Features

Brushless design

Class H insulation used throughout

Solid state voltage regulation

Sealed bearings

All wound components impregnated with varnishes

and resins to protect against harsh environment

Alternator complies with temperature rise standards:

per NEMA, IEEE and ANSI

Dynamically balanced rotors

Controller Features

PowerPAC 4

Hi temp, low oil pressure, overspeed and overcrank

indicators

AC Voltage, amperage and hertz meters

Oil pressure, water temperature and battery gauges

Hour meter

Panel lights

Engine Data

Manufacturer Perkins

Model 1006-6TA

Cylinders 6 in-line

Cycle 4-stroke

Induction system Turbocharged - aftercooled

Displacement, L (cu. in.) 5.99 (365.0 cu. in.)

Bore and Stroke 100.0 MM x 127.0 MM 3.94 x 5.0

Compression Ratio 17.3:1

Lubrication capacity 19.0 liters (20.0 qts.)

Cooling capacity (inc. radiator) 37.2 liters (39.3 qts.)

Weight without fuel - Net 2610

Weight without fuel - Shipping 3040

Warranty: 2 year limited per manufacturer

Size: Length x Width x Height

95" x 42" x 53"

53.00"

Engine Features

• Mechanical governor - speed control to ISO 3046-4 Class A1

• Spin-on full fuel flow filter

• Fuel pre-filter

• Spin-on full flow oil filter

• Oil cooler

• Thermostat controlled cooling system

• Gear driven water pump

• 12V engine alternator

• 12V starter motor

• Single side servicing

Engine P erformanc e

60 HZ

Distributed by:

Rated RPM 1800 1800

Net BHP at rated 188.0 206.5

Continuous Standby

Baldor Generators

3815 Oregon Street

Oshkosh, WI 54902

1-800-872-7697 • 1-920-236-4200

Fax 1-920-236-4219

www.baldor.com

95.00"

Drawing is for reference only: Contact your dealer for detailed information.

SAL-187-10M-SG

42.00"

Page 20

STANDBY PERMANENT - MOUNT SERIES GENERATOR

ELECTRICAL CONNECTION INFORMATION

High voltage may be present at receptacles and load studs while

engine is operating - DANGER of electrical shock is present.

Use extreme care.

Voltage is present at the 120V/15 Amp convenience receptacle only when generator is operating.

When configured for 277/480 main output, these receptacles

Will be delivering 139 VAC. Disconnection to avoid possible

equipment damage is suggested.

1. Voltage available at load block is outlined in a chart below.

2. Cables must be brought into load block cabinet.

3. Do not start engine with load turned "on". Allow engine to come up to speed and warm

up first.

AVAILABLE VOLTAGE:

CONNECTION OF

GENERATOR LEADS

120/240 4 LEAD 1-2 = 240 VAC, 1 Phase

1-N, 2-N = 120 VAC, 1 Phase

277/480 High Wye 1-2-3 = 480 VAC, 3 Phase

1-N, 2-N, 3-N = 277 VAC, 1 Phase

120/240 Delta 1-2-3 = 240 VAC, 3 Phase

2-3 = 240 VAC, 1 Phase

1-N, 2-N, 3-N = 120 VAC, 1 Phase

120/208 Low Wye 1-2-3 = 208 VAC, 3 phase

2-3 = 208 VAC, 1 Phase

1-N, 2-N, 3-N = 120 VAC, 1 Phase

HARD WIRE LOAD TERMINAL BLOCK

STUD

Page 21

CONNECTION INFORMATION

Your new Pow'R Gard Generator has all interconnecting wiring terminated at a junction box. All

wiring will be clearly labeled as being load, remote start contacts and AC input terminals and are

to be connected as described below.

LOAD - These connections are rated and sized according to the KW of the generator.

Proper lead wire from these points to the automatic transfer switch (or load switching

device) is mandatory. See enclosed transfer switch information for corresponding

generator input terminals.

REMOTE START CONTACTS - This two wire connection, once connected to an

appropriate switch, will start the generator and perform as described in the remote

start/stop literature. These contacts are connected to the "Engine Start Contacts" of the

automatic transfer switch.

A Two Pole connection switch - normally open, closed to operate switch may also

be used to start the generator.

AC INPUT - These connections are for units with float type battery chargers or engine

block heater combinations. A constant supply of 120 volts AC (or as specified) is needed at

these terminals to power these devices.

Power is not required when the unit is in operation. Internal

Battery charging and radiant heat during operation eliminate the

need for these devices.

It is recommended that units utilizing an automatic transfer switch

with adjustable time delays have the initial adjustments made

prior to startup.

Factory recommendations are: allow 2 second delay on startup, 15 second delay on

emergency to normal.

Page 22

STANDBY PERMANENT MOUNT SERIES GENERATOR

GENERATOR MOUNTING REQUIREMENTS

The generator set must be secured to a solid surface, which is non-combustible. A concrete floor is typical

of this application. Wood floors should be prepared in accordance with local and state requirements for the

load, heat and fluids that will be encountered with operation of this generator set.

This generator base shall be anchored to the concrete floor with minimum 3/8" anchors. We do not

suggest use of secondary isolators between the base and the floor surface, as durometers vary and may

affect the isolation properties of the standard generator mounts. Please note that it is not recommended by

the manufacturer that this generator be operated without being permanently mounted to a concrete slab or

similar application in accordance with your local and state regulations. We also recommend that the

generator be located 3 to 5 feet away from any permanent structure such as walls, bushes, etc. Check

with your local city hall for official requirements in your area.

The generator should be level for proper operation. When mounted, the generator should be properly

aligned and located in a well-ventilated place where the air temperature will not exceed 40

and should be accessible for cleaning. An open type generator should not be located where there are

abrasive or conductive dusts, corrosive gasses or fumes, or where excessive moisture, standing or

dripping water may be encountered. Limit dust and dirt accumulation and assure a rodent-proof

environment. A totally enclosed generator should be cleaned frequently to remove accumulated dust and

dirt , which may cause overheating.

A dimensional diagram to aid in mounting this model is included in your Bill of Materials / Technical

Diagrams Packet.

ENGINE COOLING REQUIREMENTS

O

C or 104OF,

A sufficient flow of clean, cool air is required to support combustion and to dissipate the heat produced in

the combustion process of an internal combustion engine. Approximately 60% of the heat value of fuel

consumed by an engine will be disbursed to the cooling air and to the exhaust.

All engines are either directly or indirectly cooled by air. The Air-Cooled Engine must transfer the excess

heat directly to the air surrounding it. The heated air must then be directed away from the engine so it will

not overheat.

If the engine is situated in an open installation there should not be a cooling problem, but when the engine

is installed in a building it is essential to provide:

1. Adequate control and evacuation of the heated cooling air.

2. An adequate and constant supply of incoming cooling air.

3. Adequate control and discharge of the engine's hot exhaust gases.

4. Adequate ventilation of the building when the engine shuts down.

Page 23

ENGINE COOLING AIR

The air, which will cool the engine, must be brought in from outside the building. A forced airflow of

sufficient Cubic Feet per Minute (CFM) will prevent the incoming cooling air from mixing with the air inside

the building and eventually overheating and damaging the engine. To do this requires that an exhaust fan

of sufficient CFM be placed near the generator set to exhaust the heated cooling air and to also draw in

cool external air.

The cooling air intake should be located so that the cooling air will be brought in through this intake

opening, travel across the generator set, and then be evacuated from the building via the exhaust fan.

It is recommended that the cooling air intake have at least twice the cross-sectional opening area as the

heating cooling air exhaust fan located near the generator set. It is also recommended that the air intake

opening be located as close as possible to the same level as the top of the generator set.

The exhaust fan must NOT be located where it could easily

become blocked by leaves, snow, water, debris, etc…

The cooling air intake opening of the building should be of sufficient size so as to not interfere with the

cooling air intake airflow. It is recommended that the intake opening be no less than 3 times the cross

sectional area of the exhaust fan opening. It is also recommended that this opening be located on a

vertical plane so as to not easily become plugged with debris.

If utilizing some type of covering over the intake opening (louvers, expanded metal, screening, etc…) it is

very important that the combined total of the cross-sectional area openings be no less than 3 times the

cross-sectional area of the exhaust fan opening.

The heated cooling air coming off the engine must be directed, and evacuated out of the building. An

exhaust fan of sufficient CFM will need to be used to achieve this end result. Regarding the exhaust fan

size, remember that no heated cooling air must be allowed to accumulate inside the building. For aircooled units of 8-12KW we recommend an exhaust fan of 2000 CFM.

Location of the exhaust fan for the engine's heated cooling air is important. It must be located so that the

heated cooling air evacuated from the building not be allowed to re-circulate back into the cooling air

intake of the building or generator set. It is also important that it not be located where leaves, snow, water,

debris, etc could easily block it…

The exhaust fan should be located near the generator set on it's right or left side. If the unit has a side

mounted muffler it is preferable to put the exhaust fan on this side. You must not position the exhaust fan

so as to pull the incoming cooling air away from the cool air intake of either the engine or the generator

end.

The exhaust fan must be connected to the AC power terminals of the generator set so that when the

generator set starts it will immediately engage to provide immediate cooling air flow. The fan will then stay

engaged until the generator set stops.

It is important to keep any and all flammable objects or materials

away from this generator set, the remote muffler and it's attached

piping, or any other potential hot component of the installation.

Page 24

When discharging the heated cooling air or the hot exhaust gases

out through the side of the building or compartment please

contact your local building inspector to find out what is

necessary for your application to prevent a fire from occurring.

You must clean and inspect both the exhaust fan and its louvers

along with the building's cooling air intake on a regular basis to

prevent reduction in the building's cooling air flow. This could

lead to overheating and a potential fire or explosion.

The direction of the discharged heating cooling air and the discharged hot exhaust gases is important as

they have the potential to create brown spots on the lawn. In extreme cases this extremely hot air could

cause dried grass or other debris to ignite.

Once the generator set is completely installed and fully operational, the following test should be performed

to help determine if the cooling airflow system you installed is performing adequately.

1. Place a thermometer as close to the cooling air intake of the engine's blower

housing as you can without allowing the thermometer to touch any material surface.

Secure the thermometer so it can't be drawn into the engine when it is running.

2. Place another thermometer outside of the building or compartment in the open air

(Keep the thermometer out of direct sunlight or any other heat sources).

3. Run the engine under maximum load for an extended period of time (at least one

hour).

4. The temperature difference between the two should not exceed 15 degrees F.

Please note that opening any door, window or other opening in

the building could upset the directed cooling airflow pattern

and result in a significant reduction in the cooling airflow

across the generator set. This could result in overheating, fire, or explosion.

To find out if this is true with your specific application run the above-mentioned test with all doors

and windows closed. Then repeat this test with different doors and windows open, and eventually

with all the windows and doors open. If any of these tests produce results that do not meet the

above-mentioned criteria, you must not run the generator set under the specific conditions that

created these unappreciable results.

HOT EXHAUST GASES

set must Only be installed by qualified professionals.

While it is important to supply the proper amount of clean air to the cylinder, it is equally important to

discharge the gases of combustion. If these gases remain in the cylinder, poor performance or eventual

engine damage may result. This condition results from excessive back- pressure, which could be caused

by any one or a combination of the following conditions:

1. Exhaust pipes too long or the diameter is too small.

2. Excessive number of sharp bends in the exhaust system.

3. Obstruction in the exhaust system.

Backpressure must not exceed 20" of water column.

Exhaust lines should be as short and straight as possible, since extended runs and elbows tend to clog

with carbon and resist the flow of gases. Each pipe fitting and elbow will hinder the exhaust flow.

Exhaust gases contain carbon monoxide, a poisonous and toxic

Gas. Carbon Monoxide can cause illness or death. This generator

Page 25

If you are using a remote muffler it should be mounted as close to the engine as possible, since it will clog

with carbon if it's operating temperature is too low.

If you are using a remote muffler a flexible coupling of 12" or more must be installed between the exhaust

line and the manifold to absorb the engine's vibration.

However, a short, solid section of pipe between 6" and 8" long should be placed between the connection

of the manifold and the flexible coupling. This nipple will reduce the possibility of the hot gases burning up

the flexible coupling.

Water is one of the by-products of combustion and will be present in the exhaust piping or muffler. This

water must be kept from draining back into the engine. Slanting the horizontal section of the exhaust

system piping downward slightly, away from the engine can do this.

A water trap consisting of a tee extension with a drain cock should also be provided. This water trap

should be located between the flex coupling and the muffler, but as close to the engine as possible on a

horizontal section of the exhaust piping.

It is also recommended that an exhaust rain cap be used whenever it is possible that rain could get into

the system. This will help to prevent corrosion and damage to the exhaust system and engine.

The exhaust system is subject to the engine's vibration and it must therefore be solidly secured to prevent

unnecessary stress and the potential for breakage.

The engine's exhaust system is the hottest component of the installation and extreme care and

considerations must be given to it.

Whenever possible the remote muffler should be located outside of the building or compartment. As much of

the exhaust piping as possible should be located within the engine's heated cooling are exhaust flow. This

will help to prevent the accumulation of radiant exhaust heat inside the building.

In some cases, the idea of mounting the muffler outside the building conflicts with the idea of mounting the

muffler close to the engine to prevent carbon buildup. In these cases it is best to mount the muffler near

the engine and provide an air flow around the muffler to evacuate the muffler's radiant heat out of the

compartment or building. However, the exhaust outlet must be extended outside of the building.

Under no

that the exhaust gases would be directed towards any openings

or air entry routes (doors, windows, vents, etc...) of an occupied

building.

When discharging the hot exhaust gases out of the building do

not direct them towards anything that could catch fire or explode.

If the remote muffler cannot be located outside of the building or compartment, the next best option is to

locate it in the engine's heated cooling air exhaust flow.

It is extremely important that you do not allow the hot exhaust gases to re- circulate back into the engine's

cooling air intake.

It is important to keep any and all

materials away from the generator set, the remote muffler

and its attached piping, as well as any other potentially

hot component of the installation.

conditions shall the exhaust outlet be positioned so

flammable objects or

Page 26

When discharging the heated cooling air or the hot exhaust

gases out through the side of the building please contact

your local building inspector to find out what is necessary

for your application to meet local building code requirements.

Keep all fuel and its associated piping away from all components

of the engine exhaust system.

Once the exhaust system is installed it should be inspected on

a regular basis to assure there are no toxic exhaust gas leaks.

In some areas this inspection may be provided by your local

public service.

BUILDING VENTILATION

As hot air rises you must provide some type of power ventilation at the highest possible point of the

building to permit the accumulating hot air to escape. This will help to prevent engine damage and it will

help to eliminate hot restart problems. An electric powered exhaust fan of sufficient size will satisfy this

requirement. This fan must connect to the generator set in a manner similar to the building's main heated

cooling air exhaust fan.

Generator End Cooling Requirements

The cooling air requirements for the generator end are very similar to the cooling air requirements for the

engine. These requirements are:

1. An adequate and constant supply of cooling air.

2. Adequate control and evacuation of the heated cooling air.

GENERATOR END COOLING AIR

If the above exhaust fan sizing recommendation is followed there will be an adequate supply of cooling air

for the generator end. Please remember to not position the exhaust fan so it will pull the incoming cooling

air away from the cooling air intake of either the engine or generator end.

It is important to keep any and all

away from the generator set, the remote muffler and its attached

piping, or any other potential hot component of the installation.

When discharging the heated cooling air or the hot exhaust gases

out through the side of the building please contact your local

building inspector to find out what is necessary for your application to meet

local building code requirements and to prevent fire from occurring.

You must clean and inspect both the exhaust fan and its louvers

along with the building's cooling air intake on a regular basis to

prevent reduction in the building's cooling air flow. This could lead to

overheating and a potential fire or explosion.

flammable objects or materials

Page 27

BUILDING VENTILATION

As hot air rises you must provide some type of power ventilation at the highest possible point of the

building to permit the accumulating hot air to escape. This will help to prevent engine damage and it will

help to eliminate hot restart problems. An electric powered exhaust fan of sufficient size will satisfy this

requirement. This fan must connect to the generator set in a manner similar to the building's main heated

cooling air exhaust fan.

Page 28

EXHAUST REQUIREMENTS

While it is important to supply the proper amount of clean air to the cylinder, it is equally important to

discharge the gases of combustion. If these gases remain in the cylinder, the next cycle cannot burn the

fuel completely. This condition results from excessive backpressure that is caused by any one or

combination of these conditions:

a. Exhaust pipe diameter too small.

b. Exhaust pipe too long.

c. Excessive number of sharp bends in exhaust system.

d. Inadequate muffler.

e. Incorrect construction of muffler resulting in high resistance.

f. Obstruction in exhaust system.

Backpressure must not exceed 20" (water column) on naturally aspirated engines or 27" (water column)

on turbo-charged models.

EXHAUST PIPING

Exhaust lines should be as short and straight as possible, since extended runs and elbows tend to clog

with carbon and resist the flow of gases. Each pipefitting and elbow will hinder the exhaust flow.

The muffler should be as close to the engine as possible, since it will clog up with carbon if operating

temperature is too low.

NOTE: Never mount the muffler on the manifold.

A flexible coupling must be provided between the exhaust line and the manifold. However, a short, solid

section of pipe between 6" or 8" long should be placed between the connection of the manifold and the

flexible coupling,.

Water, one of the by-products of combustion, will be present in the exhaust piping or muffler. This water

must be kept from draining back into the engine. This can be done by slanting the horizontal section of the

exhaust pipe downward slightly, away from the engine. A water trap consisting of a tee extension with a

drain cock should be provided.

FIGURE 6-1: SCHEMATIC OF EXHAUST SYSTEM

Page 29

FIGURE 6-2: DOUBLE THIMBLE - WALL OUTLET DETAILS

EXHAUST PIPING THRU WALLS AND ROOFS

Always check local and state laws pertaining to hot gas pipes before making plans for running

exhaust piping thru walls or roofs. If the exhaust pipe must pass thru combustible walls or roofs,

use an exhaust thimble to prevent exhaust pipe heat from being transmitted to the combustible

material. Construction details of a typical thru wall double sleeve thimble is shown above —

thimbles are not available. They are usually fabricated at local sheet metal shops to the

specifications furnished by the installation engineer. The minimum outside diameter of a double

thimble (inner and outer sleeves) should be at least six inches greater than the diameter of the

exhaust pipe — with single sleeve thimbles, the O.D. should be at least 12 inches greater than

the diameter of exhaust pipe. The minimum thimble diameters for some common exhaust pipe

sizes are listed in the table below. The minimum thimble diameter for some common exhaust pipe

sizes are listed in the table below. The thimbles should be constructed so that they extend at

least 10" both ways from the surface of the wall or roof. Holes are provided at both ends to allow

cooling air to circulate thru the thimble. If screening is used on the outer end to keep birds,

rodents, etc., from entering the thimble, make sure the mesh is large enough so it doesn’t impair

air circulation through the thimble. If the exhaust pipe must exit thru a roof,

EXHAUST THIMBLE - MINIMUM O.D.

EXHAUST

PIPE

DIAMETER

MINIMUM OUTSIDE DIAMETER MINIMUM OUTSIDE DIAMETER

SINGLE SLEEVE

THIMBLE*

DOUBLE SLEEVE

THIMBLE**

EXHAUST

PIPE

DIAMETER

SINGLE SLEEVE

THIMBLE*

DOUBLE SLEEVE

THIMBLE**

0.5"

0.75"

1.0"

1.25"

1.5"

2.0"

12.5"

12.75"

13.0"

13.25"

13.5"

14.0"

*DIAMETER OF PIPE PLUS 12". **DIAMETER OF PIPE PLUS 6"

6.5"

6.75"

7.0"

7.25"

7.50"

8.0"

2.5"

3.0"

3.5"

4.0"

5.0"

14.5"

15.0"

15.5"

16.0"

17.0"

8.5"

9.0"

9.5"

10.0"

11.0"

Page 30

FIGURE 6-3 — DOUBLE THIMBLE - ROOF OUTLET DETAILS

a rain shield must be included above the thimble as shown in Figure 6-3. The rain cap as shown

on the end of the exhaust pipe is recommended only in areas not subject to freezing

temperatures. In an area where freezing is common, extend the exhaust piping well beyond the

roof and use a gradual “U” bend at the end to direct the exhaust outlet downward which will keep

rain, snow, etc., out of the pipe. Some other important points relating to exhaust outlets are as

follows:

x Keep exhaust outlet well away from windows, doors, passageways, air intake vents or areas where gases

could accumulate.

x Keep exhaust piping well away from fuel lines, fuel tank filler caps and combustible materials.

Page 31

CONTROL PANEL OPERATION

AND FUNCTION

A. MASTER CONTROL SWITCH

engine control logic circuitry.

With this switch in the “Manual” mode, the engine will start and run immediately after a

10 - 20 second time delay.

CAUTION: Please note that once the engine has been told to start, the gen set

should be treated as though it is operational, even though the start

delay has not yet allowed the engine to crank.

With this switch in the “Automatic” mode, the engine can be started and stopped from a remote

contact. (Standard switch, transfer switch, etc.) There is a time delay, to cool down, of 60-90 seconds

when the unit is shut down from the remote contacts while the Master Control Switch is in the

“Automatic Mode.

With this switch in the “Off” position, the engine will immediately stop. The position must also be

utilized to clear fault shut-down conditions.

B. PANEL LIGHTS - By turning on the panel light switch, the panel lights will be energized and will

illuminate the control panel. The fuse next to the switch is to protect this circuit from damage due to

excessive current.

C. FIELD AND CONTROLLER FUSES - These fuses protect the internal workings of the generator set.

D. GAUGES - These gauges monitor some of the more critical operating parameters of the engine as

well as the run time of the generator set.

The Voltmeter displays the charging rate that is currently being produced by the engine’s alternator to

facilitate the charging of the battery. This gauge should normally be above 12.5V whenever the unit is

running. If you ever notice the gauge is reading below 12V while the engine is running please contact

the service department at Pow’R Gard Generator Corporation.

The Temperature Gauge monitors and displays the operating temperature of the engines coolant. The

point at which a fault shut-down will occur is 230

The Oil Pressure Gauge displays and monitors the current operating pressure of the engine’s oil

system. The trip point at which a fault shutdown will occur is 15 PSI or below.

Fuel level is checked at the tank fill, inside the generator.

- This switch controls the starting and stopping of the engine via the

O

F.

Page 32

The Hour Meter accumulates and displays the total running time of the generator set.

E. VOLTAGE ADJUST - The rheostat allows the user to “fine tune” the generator set’s voltage output. It

is normally used to adjust output voltage after switching the output of the generator set to a different

voltage.

F. METERS - These meters monitor and display the current operating parameters of the generator set.

The Voltmeter monitors and displays the current operating AC output of the generator set.

The Hertz Meter monitors and displays the current operating frequency of the generator set.

The Ammeter monitors and displays the amount of current that is being delivered by the generator

set. This meter works in conjunction with the Ammeter Switch (Item G) in determining which output

leg to monitor.

G. AMMETER SWITCH - The switch allows the user to switch between L1, L2 and L3 to monitor the

current in each output leg to monitor.

H. PANEL LIGHT - By turning on the panel light switch, the panel lights ( Not pictured on diagram) will

be energized and will illuminate the control panel. They will also illuminate

when a fault condition or a warning condition develops.

I - SYSTEM FAULT INDICATORS - These lights will come on when a fault condition or a warning

condition develops.

The “Low Oil Pressure” light will come on when the engine’s oil pressure drops below 15 PSI. This

condition will trigger a fault shut-down and the unit will stop.

The “Over-crank” light will come on when the engine has failed to start after four attempted crank

cycles. Each crank cycle consists of a 12 second time period followed by a 12 second rest time period.

The “Over-speed” light will come on when the engine’s operating speed rises above it’s normal

operating parameters. This condition will trigger a fault shut-down and the engine will stop.

High Temperature light will come on when the engine’s operating temperature exceeds the safety set-

point.

Page 33

Page 34

OPERATION - PRE-START PROCEDURE

1. Fill system fuel tank with clean, fresh diesel fuel.

Wipe up any and all fuel spillage

2. Fill Engine crankcase to full mark with clean, fresh lubricating oil per attached

engine operating guide.

3. Radiator Coolant should be checked at the beginning of each day and filled in

compliance with the engine manufacturer's guidelines.

4. Secure the generator for operation.

Skid mounted - the power generating system should be mounted to a smooth, hard surface

suitable for supporting the system under all stress conditions.

Adequate clearance must be provided for access doors to fully open.

OPERATION - STARTING

1. Conduct ‘Pre-start Procedures.

2. Switch the generator set to the applicable voltage setting.

3. Connect the load(s) to the circuit breaker.

WARNING: High voltage is present when the generator set is running.

4. Move the ‘Master Control Switch” to the appropriate position.

5. Adjust the voltage if necessary by turning the voltage adjustment knob located on the control panel.

Page 35

OPERATION

The Prime mover utilized in this power generating system is controlled via an engine control module.

Starting is accomplished by commanding the control to "start" the engine. This command can be given by a number

of controls;

The operator control mounted on the front panel.

The remote controls via the transfer switch or remote start terminal.

Initially, the system may be started and operated by placing the operation control in the "manual" position. To cease

operation, return the switch to the "off" position.

Clear unit of all loose objects and perform all "pre- start" procedures before operating generator system.

ENGINE CONTROL MODULE

The Engine Control Module (E.C.M.) is a microprocessor based module that monitors the control and safety inputs

and provides all the required START and STOP functions automatically.

The following front panel controls and instruments are wired into the microprocessor through the E.C.M. terminal

blocks:

1. RUN / OFF / AUTO SWITCH

A. "RUN" - run position causes the generator set to start and run immediately.

B. "AUTO" - auto position allows unit to be controlled via any remote single-pole "dry"

contact (transfer switch, etc.). Contact closure causes the unit to start and run, while

contact opening causes unit to shut down after a preset cool down period.

C. "OFF" - unit operation is terminated.

2. LAMP TEST

A. Push button energizes all alarm lights simultaneously. This feature is disabled with the

Run / stop / auto switch in the "stop" position and has no other effect on unit operation.

SAFETY INPUTS

1. Low Oil Pressure Shut-down- (LOP)

Monitoring of oil pressure begins for a preset time after unit starts and remains in effect until unit

is shut down (except as noted in "loss of frequency input". The LOP signal is derived from an oil

pressure switch gauge mounted on the control panel.

2. High Temperature Shutdown (HT)

The engine temperature monitoring begins immediately with the start signal. However, if engine

temperature is excessive prior to start (i.e. heat soak after shutdown), the unit is permitted to

start. The High temperature condition is permitted to exist for up to 60 seconds after the unit is

running before shutdown when alarm occurs. If the excessive temperature condition is corrected

within that time period, the HT circuit reverts to normal monitoring. The HT signal is derived from

a monitoring device located on the prime mover.

Page 36

3. Overspeed Adjustment (OS) - Over Frequency

Overspeed protection is provided by a frequency sensing network within the controller. The trip

point of the frequency network is adjustable via a rheostat located on the top of the controller at

the right hand side. Clockwise (CW) rotation increases the trip frequency and, thereby, raises the shutdown

speed.

CRANKING CONTROL

1. Overcrank Protection

This feature provides a preset second crank cycle. Failure of the engine to start by the end of the

crank period results in an "overcrank" shutdown and alarm indication.

2. Cranking Disconnect Adjustment (CDS Adjustment)

The cranking disconnect signal is obtained by a frequency network within the controller. The trip

point of the frequency network is not adjustable.

LOSS OF FREQUENCY

Internal protection against loss of frequency input to the cranking disconnect circuit is programmed in after the unit

has started normally. In the event the frequency goes to zero (engine runs out of fuel, frequency signal source fails,

etc.) the LOP shutdown circuit is bypassed and a 12-second wait period is initiated. If frequency returns within this