Page 1

Linear Motors

Installation & Operating Manual

1/01 MN1800

Page 2

Table of Contents

Section 1

General Information 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handling 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2

Installation & Operation 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clean Room 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting a Stage to the Machine Base and Payload To Stage 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMAC Linear Induction Motor 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMBR Series Brush DC Linear Servo Motor 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMBL Series 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brushless Linear Iron Core Servo Motor 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modular Magnet Track 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMCF Series Brushless Linear Cog Free Servo Motor 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMNC Moving Coil Type 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMNM Moving Magnet Type 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMPY Series Polynoid Linear Motor Holding Option 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMSS Series Linear Stepper 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Roller Bearing Motor 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Bearing Motor 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMDS Series Dual Axis Linear Stepper Motor 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning Stages 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handling and General Guidelines 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stage Specifications Disclaimer 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LSE Series 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LSC Series 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LSS Series 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LSX Series 2-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continued on next page

Table of Contents iMN1800

Page 3

Bearing Maintenance 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recirculating Bearing Rail And Block 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cross Roller Type Bearing 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Encoder Maintenance 2-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RSF Series MSA6x Enclosed Type 2-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RSF Series MS6x Open Type Glass Scale 2-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Renishaw RGH22 series Open Type Metal Scale 2-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELGO Mix 4 series Magnetic Type 2-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELGO Mix 5 series Magnetic Type 2-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Encoder Specifications 2-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cables and Cable Chain Procedures 2-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Cables 2-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii Table of Contents MN1800

Page 4

Section 1

General Information

Overview This manual contains general procedures that apply to Baldor Linear Motor products. Be sure to read

and understand the Safety Notice statements in this manual. For your protection, do not install, operate

or attempt to perform maintenance procedures until you understand the Warning and Caution statements.

A Warning statement indicates a condition that can cause harm to personnel. A Caution statement

indicates a condition that can cause damage to equipment.

Important: This instruction manual is not intended to include a comprehensive listing of all details for all

procedures required for installation, operation and maintenance. This manual describes general

guidelines that apply to most of the linear motor products shipped by Baldor. If you have a

question about a procedure or are uncertain about any detail, Do Not Proceed. Please contact

your Baldor distributor for more information or clarification.

Before you install, operate or perform maintenance, become familiar with the following:

NEMA Publication MG-2, Safety Standard for Construction and guide

for Selection, Installation and Use of Electric Motors and Generators.

The National Electrical Code

Local codes and practices

Limited Warranty

1. Baldor Electric motors are warranted for a period of one (1) year, from date of shipment from the factory or factory

warehouse against defects in material and workmanship. To allow for stocking and/or fabrication period and to

provide one year of actual service, the warranty period is extended for an additional period of six (6) months for a

total of eighteen (18) months from the original date of shipment from the factory or factory warehouse stock. In no

case will the warranty period be extended for a longer period. Baldor extends this limited warranty to each buyer

of the electric motor for the purpose of resale and to the original purchaser for use.

2. Baldor will, at its option repair or replace a motor which fails due to defects in material or workmanship during the

warranty period if:

a. the purchaser presents the defective motor at or ships it prepaid to, the Baldor plant in Fort Smith, Arkansas

or one of the Baldor Authorized Service Centers and

b. the purchaser gives written notification concerning the motor and the claimed defect including the date

purchased, the task performed by the Baldor motor and the problem encountered.

3. Baldor will not pay the cost of removal of any electric motor from any equipment, the cost of delivery to Fort Smith,

Arkansas or a Baldor Authorized Service Center, or the cost of any incidental or consequential damages resulting

from the claimed defects. (Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above exclusion may not apply to you.) Any implied warranty given by laws shall be limited to

the duration of the warranty period hereunder. (Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you.)

4. Baldor Authorized Service Centers, when convinced to their satisfaction that a Baldor motor developed defects in

material or workmanship within the warranty period, are authorized to proceed with the required repairs to fulfill

Baldor’s warranty when the cost of such repairs to be paid by Baldor does not exceed Baldor’s warranty repair

allowance. Baldor will not pay overtime premium repair charges without prior written authorization.

5. The cost of warranty repairs made by centers other than Baldor Authorized Service Centers WILL NOT

unless first authorized in writing by Baldor.

6. Claims by a purchaser that a motor is defective even when a failure results within one hour after being placed into

service are not always justified. Therefore, Baldor Authorized Service Centers must determine from the condition

of the motor as delivered to the center whether or not the motor is defective. If in the opinion of a Baldor

Authorized Service Center, a motor did not fail as a result of defects in material or workmanship, the center is to

proceed with repairs only if the purchaser agrees to pay for such repairs. If the decision is in dispute, the

purchaser should still pay for the repairs and submit the paid invoice and the Authorized Service Center’s signed

service report to Baldor for further consideration.

7. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

be paid

General Information 1-1MN1800

Page 5

Safety Notice: This equipment contains high voltage! Electrical shock can cause serious or fatal injury.

Only qualified personnel should attempt installation, operation and maintenance of

electrical equipment.

Be sure that you are completely familiar with NEMA publication MG-2, safety standards

for construction and guide for selection, installation and use of electric motors and

generators, the National Electrical Code and local codes and practices. Unsafe

installation or use can cause conditions that lead to serious or fatal injury. Only qualified

personnel should attempt the installation, operation and maintenance of this equipment.

WARNING: The magnetic attraction between the motor and the magnet

assembly is extremely high. Keep fingers and other body parts

away from these objects to avoid injury by this magnetic attraction.

WARNING: Use proper care and procedures that are safe during handling,

lifting, installing, operating and maintaining operations.

Improper methods may cause muscle strain or other harm.

WARNING: Do not touch electrical connections before you first ensure that

power has been disconnected. Electrical shock can cause serious

or fatal injury. Only qualified personnel should attempt the

installation, operation and maintenance of this equipment.

WARNING: Be sure the system is properly grounded before applying power.

Do not apply AC power before you ensure that all grounding

instructions have been followed. Electrical shock can cause

serious or fatal injury. National Electrical Code and Local codes

must be carefully followed.

WARNING: This equipment may be connected to other machinery that has

moving parts that are driven by this equipment. Improper use can

cause serious or fatal injury. Only qualified personnel should

attempt to install operate or maintain this equipment.

WARNING: Do not by-pass or disable protective devices or safety guards.

Safety features are designed to prevent injury to personnel or

damage to equipment. These devices can only provide protection if

they remain operative.

WARNING: Disconnect all electrical power from the motor windings and

accessory devices before disassembly of the motor. Electrical

shock can cause serious or fatal injury.

WARNING: Do not use these motors in the presence of flammable or

combustible vapors or dust. These motors are not designed for

atmospheric conditions that require explosion proof operation.

WARNING: Motors that are to be used in flammable and/or explosive

atmospheres must display the UL label on the nameplate.

Specific service conditions for these motors are defined in

NEC 70-599.

Caution: Be careful when sliding the motor from its shipping container. Slide

the motor from the box onto a level, flat surface to prevent bending.

Bending can damage the windings and commutators.

1-2 General Information MN1800

Page 6

Receiving Each Baldor motor is thoroughly tested at the factory and carefully packaged for

shipment. When you receive your motor, there are several things you should do

immediately.

1. Observe the condition of the shipping container and report any damage

immediately to the commercial carrier that delivered your motor.

2. Verify that the part number of the motor you received is the same as the part

number listed on your purchase order.

Storage If the parts are not put into service immediately, store them in a clean, dry and warm

location. If the storage location is damp or humid, the exposed metal surface of the

motors and windings must be protected from moisture. If the ambient temperature

decreases suddenly, condensation may form. Protect all parts from moisture.

Unpacking Each Baldor motor is packaged for ease of handling and to prevent entry of

contaminants.

1. To avoid condensation inside the motor, do not unpack until the motor has

reached room temperature. (Room temperature is the temperature of the room

in which it will be installed). The packing provides insulation from temperature

changes during transportation.

2. When the motor has reached room temperature, remove all protective wrapping

material from the motor.

3. The magnet track sections may come packaged in one or more boxes. Do not

flip any magnet track sections inside the box. Unpack the magnet track

sections one piece at a time. Place each section on a clean non–magnetic

surface away from other magnet track sections and any other ferrous material.

4. Always keep the magnet track sections at a safe distance from each other. If

the assemblies are to be left unattended for any period of time, precautions

should be taken to prevent accidents due to the strength of the magnets (it is

best to leave them in their packing material to prevent injury due to magnetic

attraction). Persons who will come in contact with this assembly while

receiving, transporting, storing, installing, disassembling or at any other time,

must be made aware of this danger.

Handling Be extremely careful. Keep in mind:

1. The magnetic attraction between the motor and the magnet assembly is

extremely high. Keep fingers and other body parts away from these objects to

avoid injury by this magnetic attraction.

2. Use proper care and procedures that are safe during handling, lifting, installing,

operating and maintaining operations.

Improper methods may cause muscle strain or other harm.

Repairs Baldor will not share any responsibility for damage caused by customer attempt to repair

or modify a motor. Consult Baldor for any service.

For further assistance please contact the factory:

Baldor Linear Motion Products

25026 Anza Drive

Santa Clarita, CA 91355, USA

(661) 257–0216 (phone)

(661) 257–2037 (fax)

General Information 1-3MN1800

Page 7

1-4 General Information MN1800

Page 8

Section 2

Installation & Operation

Overview Installation should conform to the National Electrical Code as well as local codes and

practices. When other devices are coupled to the motor, be sure to install protective

devices to prevent accidents. Machinery that is accessible to personnel should provide

protection in the form of guard rails, screening, warning signs etc.

Location The motor should be installed in an area that is protected from direct sunlight, corrosives,

harmful gases or liquids, dust, metallic particles, welding spatters and vibration.

Exposure to these can reduce the operating life and degrade performance. Be sure to

allow clearance for ventilation and access for cleaning, repair, service and inspections.

Ventilation is extremely important. Be sure the area for ventilation is not obstructed.

Obstructions limit the free passage of air. Motors get warm and the heat must be

dissipated to prevent damage.

These motors are not designed for atmospheric conditions that require explosion proof

operation. They must NOT

or dust.

Clean Room Stages prepared for Class 10, 100 and 10,000 clean room requirements can be ordered

as an option to our standard products. Materials must be suitable for the specified

environment. The customer must perform the final cleaning due to contamination during

shipping and handling.

The most common changes to the stages include the replacement of the bellows,

installation of special greases, elimination of bearing shields and the removal of other

non–critical components that may contribute to particle generation.

Mounting a Stage to the Machine Base and Payload To Stage

S Your stage is provided with mounting holes to attach the stage to a machine base. If

your stage is supplied with bellows, you must remove the bellows to access the

mounting holes. The mounting holes are typically non–threaded, counter–bored

holes that accommodate a variety of screw sizes. It is recommended that a

hardened machine screw be used. Refer to the mechanical drawings provided with

your stage for mounting screw size and hole locations.

S The flatness of your mounting surface will greatly influence the flatness and

straightness specification of your stage. The stage structure will tend to mirror the

flatness of the mounting surface. For the stage to maintain its specification, it must

be mounted to a surface that is flat (maximum error of 0.0005 inches per foot). A

maximum of 0.010 inches per foot is the maximum mounting surface flatness error

allowable for operation of the stage. However, at 0.010 inches per foot mounting

base flatness, the stage flatness and straightness specification will be degraded.

S The mounting surface must be clean and free of particles that could affect flatness

(particles that come between the stage and the mounting surface) . It is also

recommended that the base of the stage be cleaned to remove contamination.

Cleaning with alcohol or acetone is suggested, however avoid submersion or

contamination of the internal components.

S When mounting the payload to the slide assembly, use the same precautions

mentioned for the stage. Refer to the stage outline drawing for hole locations and

specifications.

S When pinning is required, Baldor recommends that the stage be machined and

assembled at the factory.

Note: It is strongly recommended that a thread locking compound be used when

mounting the stage to the base and when mounting the payload to the slide

assembly.

be used in the presence of flammable or combustible vapors

Installation & Operation 2-1MN1800

Page 9

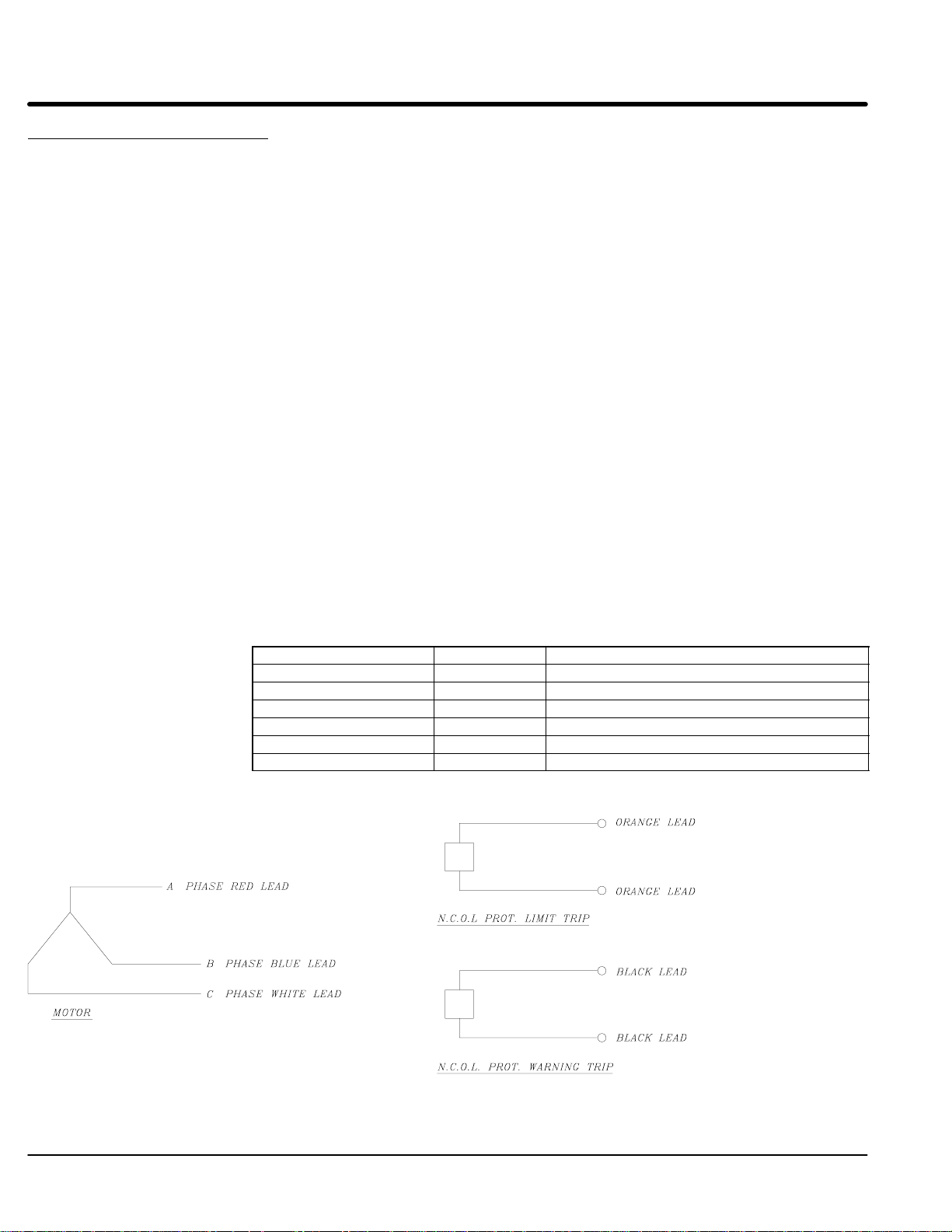

LMAC Linear Induction Motor

General Description: Single or three phase, linear AC induction motor primary.

Construction: Epoxy encapsulated and steel laminated coil assembly (motor primary) Motor secondary

(customer supplied) must conform to the following specifications: 1/8–inch aluminum or

copper plate backed by a

be at least the with of the motor coil assembly.

Maintenance: Motor should be kept dry and relatively free of contamination. This motor is water

resistant, not water proof. Avoid submersion. Avoid contact with petroleum–based

solvents. Alcohol or soapy water can be used to remove contaminants.

Motor specifications: Refer to catalog or outline drawing supplied with motor for mechanical dimensions and

electrical specifications.

Motor Mounting: Your motor may be supplied with either base or foot mounting, refer to catalog or outline

drawing supplied with motor for mounting details and hole dimensions. It is

recommended that all available coil assembly mounting holes be utilized to properly

secure the coil assembly. If the coil is in motion, the motor wires must be strain relieved.

We recommend that the motor secondary be secured with 1/4inch fasteners on the left

and right sides of the secondary, every four to six inches of its length. An air–gap of 1/8

inch is recommended. Refer to linear induction motor duty cycle–force–current curves in

this booklet for information regarding the affects of air–cap size on motor performance.

Electrical Connections For voltage and current specifications, refer to Catalog BR1800 or to documentation

enclosed for custom motors. The 10 foot flying leads can be cut to remove excess length

if required. Connectors are available; contact a Baldor representative for more

information.

For single phase motors, refer to the table supplied with this booklet for capacitor

selection.

Motor Wire

Function Gauge Color

Phase A 10 Red

Phase B 10 Blue (substituted by black in older models)

Phase C 10 White

Ground Motor housing

Thermal switch 20 Orange (two wires, interchangeable)

Thermal warning 20 Black (two wires, interchangeable)

1/4 inch cold rolled steel plate. The width of the secondary must

LMAC Connection Diagram

2-2 Installation & Operation MN1800

Page 10

LMBR Series Brush DC Linear Servo Motor

Mounting The motor primary must be aligned (parallel) to the equipment guide ways within 0.005″

(0.127mm) on each end. Use gauge blocks and shims as necessary. Precise parallel

alignment of the motor to the equipment guideways is required. Align the stationary half

of the motor to the guideways. Then align the moving half with the stationary half.

When securing the primary to the equipment base do not allow the screws to penetrate

the motor more than .25″ deep (to prevent damage to the motor windings).

To mount the motor secondary, slide the table over the secondary and align the mounting

holes. The secondary is to be secured to the moving table with screws after the proper

amount of shims are added to maintain an air gap of .015″ min. to .020″ max. (unless

otherwise specified) between the secondary and the primary. This is achieved by

ensuring that the plastic shim provided does not bind anywhere over the length of the

primary when moving the table top with secondary back and forth by hand.

The plastic shim between the primary and the secondary can now be removed. Be sure

that the secondary is centered and runs parallel to the commutator to within .005″ at each

end.

Electrical Check: With an ohmmeter across input terminals, verify that the resistance reading does not drop

to zero when the secondary / commutator assembly is moved over the entire length of the

stationary primary. If a zero reading is observed, inspect the connections between the

commutator brushes and the power input wires. In addition, inspect the connections

between the motor windings and the commutator bar.

Motor Removal: Insert the plastic shim between the primary and secondary to maintain the air gap. First,

disconnect the power input wires. Next, remove the screws between the secondary and

the moving table as this allows the secondary to sit on the primary. Then remove the

mounting screws between the primary and the base. Finally, the complete motor

assembly can be removed and placed on a level, flat surface.

Secondary Removal: If just the secondary must be removed,slide the table with the secondary attached, to one

end of the primary. Insert a .015″ minimum plastic shim between the secondary and the

primary to maintain the air gap. Remove the screws between the secondary and the

sliding table. Move the table out of the way and slide the secondary out using extreme

caution so as to not damage the brushes. If brushes are worn out, contact Northern

Magnetics for replacement.

Secondary Reinstallation: Place .015″ minimum plastic shim on primary face. Next place .015″ min fiberglass shims

on the brush assembly and completely depress the brushes into their holders. With the

brushes toward the commutator bars, slide the secondary onto the primary face (with the

shim in place). When the secondary is in place, gently remove the shim from between

the brushes and commutator bars.

Note: Ensure that the shim between commutator and brushes has rounded ends

and that they do not cut the leads to the commutator bars.

Refer to “Mounting” instructions to reinstall.

Brush Motor Connections: – Black / Red (+)

White (–)

Installation & Operation 2-3MN1800

Page 11

LMBL Series

Brushless Linear Iron Core Servo Motor

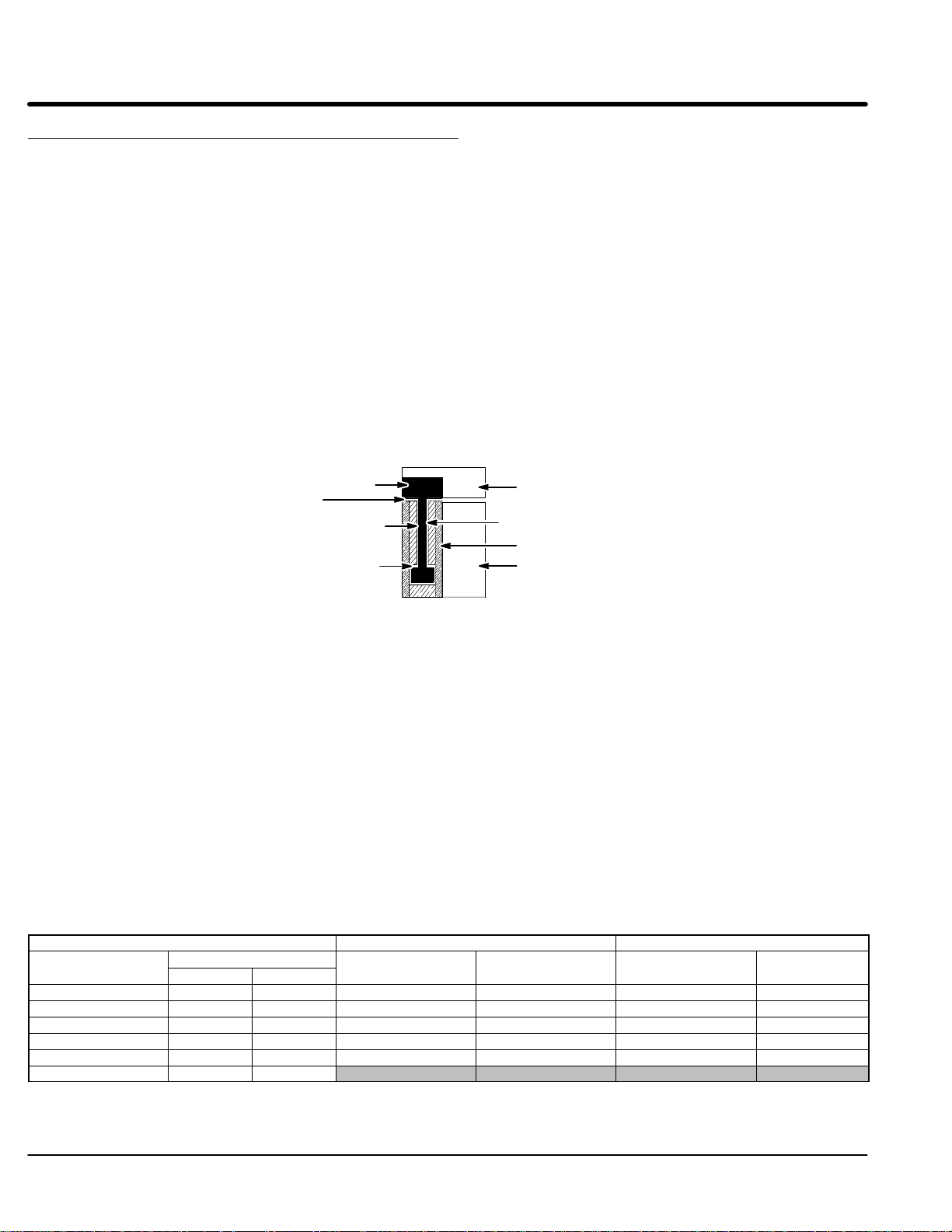

Installation Refer to Figure 2-1.

1. Install the magnet assembly onto the machine mounting base.

2. With the slide assembly removed from the rails, install the coil assembly onto

3. Place a non–magnetic shim over the magnets, sized to cover all the magnets.

4. Install and push the slide along the rails, positioning the coil assembly directly

For either method, it is extremely important to uniformly tighten the mounting screws.

Improper tightening will bend the primary or secondary and damage the motor.

If there is not enough space to install the coil assembly as described, use this alternate

procedure.

Alternate Installation Refer to Figure 2-1.

1. Place the non–magnetic shim on the magnet track.

2. With a firm grip on the coil assembly, place one end of it on the shim and slide it

3. Align the fastening screw holes on the slide with the holes on the coil assembly.

4. Loosely install all the mounting screws.

5. Insert enough shims between the slide and the coil assembly to fill the gap.

6. Tighten all the mounting screws, alternating in a systematic manner while

7. Remove the shim that sets the air gap prior to operation.

Coil Assembly

Magnet

the slide, tightening the mounting screws.

(The shim thickness must be equivalent to the air gap specification. The normal

air gap is 0.030″ ± 0.005″ unless otherwise specified).

over the shim.

(An alternate method is to install the slide on a set of rails that is identical to the

one being used. Butt the temporary rails to the system rails and transfer the

slide onto the system rails.)

into place, centered over the magnets. Be careful not to let the magnet and coil

“Slam” together.

tightening such that the coil assembly is drawn–up evenly leaving a uniform air

gap between the coil assembly and the magnets. This air gap must be

maintained along the entire length of the magnet assembly i.e.; the coil

assembly must never touch the magnets at any point when moving along the

length of the magnet assembly and the air gap specification must be

maintained at all times.

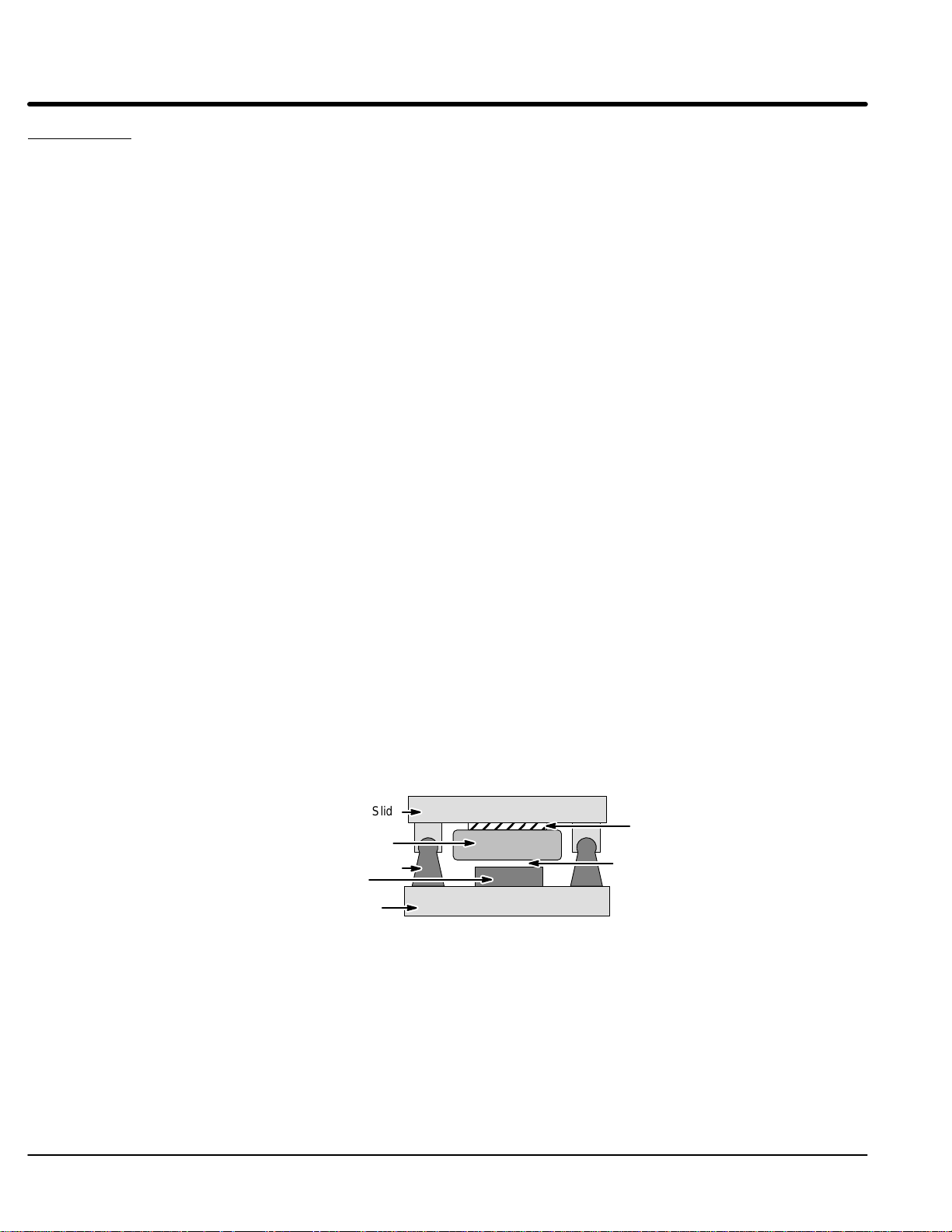

Figure 2-1 Air Gap Adjustment

Slide

Rail

Shim

(if necessary)

Air Gap (0.30 ± 0.005)

Base

2-4 Installation & Operation MN1800

Page 12

LMBL Series Continued

Brushless Linear Iron Core Servo Motor Continued

Multiple Coil Assembly Operation

In addition to maintaining an air gap, multiple coil assemblies must also maintain a

spacing factor of 1.8″. In other words, the space between coil assemblies may vary,

however, the distance from the front end of the first coil assembly to the front end of the

next must be a multiple of 1.8″. See Figure 2-2.

Ensure that this spacing is established at the time of installation.

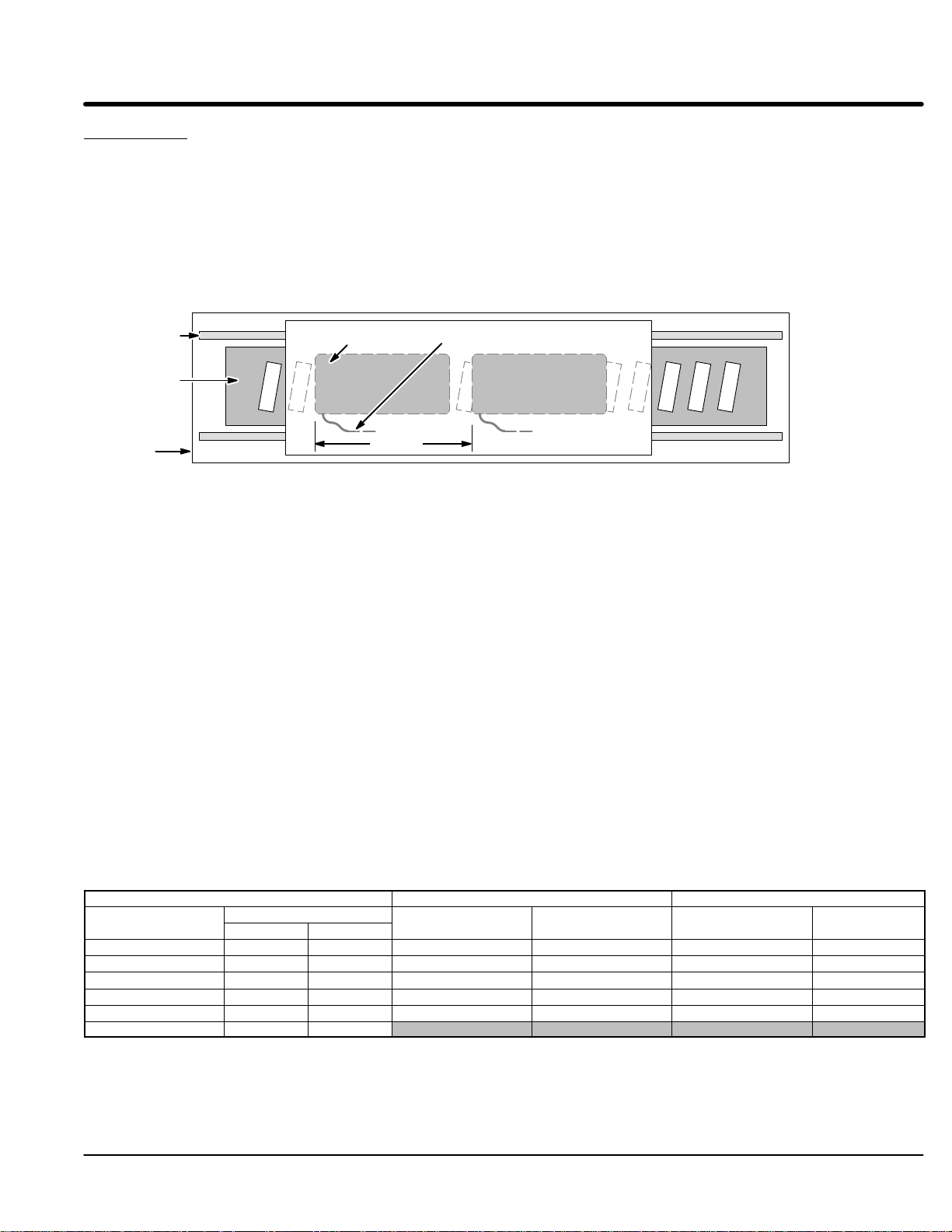

Figure 2-2 Multiple Coil Assemblies

Rail

Magnet

Assembly

Coil Assembly Cable

Base

n (1.8″)

n = 1, 2, 3 , . . .

Operation Considerations The motor must always be operated within the specified operating parameter limits.

Exceeding those limits will permanently damage the motor Refer to the motor

specifications for operating parameter limits.

The motor must never touch the magnets during operation. Refer to “Adjust Air Gap”.

Remove the shim that sets the air gap between the motor and the magnets prior to

operation.

Note: Be aware that the total bearing load includes the magnetic attractive force.

The following steps must be completed to ensure safe and proper operation.

1. Verify that all electrical wiring and cables are properly connected. Refer to the

manual provided with the control for this information.

2. Adjust the control continuous current limit to match the motor’s continuous

current specifications.

3. Adjust the servo drive current to match the motor’s current specification.

4. Refer to the motor specifications for operating parameters. Adjust the control

parameters as necessary to the motor data specifications.

5. Adjust the control for the proper P.I.D. loop tuning. Begin at a low gain setting

and increase the gain as necessary.

6. Strain relieve the wires prior to operating.

AY1763A00 Leadwire Connection

Motor Cable Hall Cable Limit Cable

Signal Name

Motor Phase A (U) Red Black Hall 1 White Limit + Output White

Motor Phase B (V) White Red Hall 2 Red Limit – Output Red

Motor Phase C (W) Black White Hall 3 Black Home Output Black

Motor Ground Green Hall Ground Green Limit & Home PWR * Brown

Thermal Switch+ Blue Hall +5VDC Brown Limit & Home GND Green

Thermal Switch– Orange

Wire Color

LinDrive Trap

Signal Name Wire Color Signal Name Wire Color

* Limit & Home power is +4 to +24VDC.

Note: Motor phasing is for LinDrive or MintDrive. Other controls may require different phasing (such as most trap

drives (U) Black, (V) Red, (W) White). Phase angle between phases is 120 degrees.

Installation & Operation 2-5MN1800

Page 13

LMBL Series Continued

Brushless Linear Iron Core Servo Motor Continued

Modular Magnet Track

Installation Refer to Figure 2-3. Some magnets are provided in modular segments. This is the

recommended procedure to install these modular magnet track sections.

Note: It is recommended that rubber coated tool handles be used to reduce injury

(pinching fingers etc.) and protect the surface of the magnets.

1. Bolt the coil assembly onto the underside of the slide (carriage). Ensure the

leads extend in the proper direction.

2. Install the magnet track on the base–plate adjacent to or between the linear

bearing. Magnet track ends should not oppose each other.

Place a 0.030″ ± 0.005″ thick non magnetic shim on the magnet track. The

shim thickness must be equal to the recommended air gap (space between the

coil assembly and the magnet track).

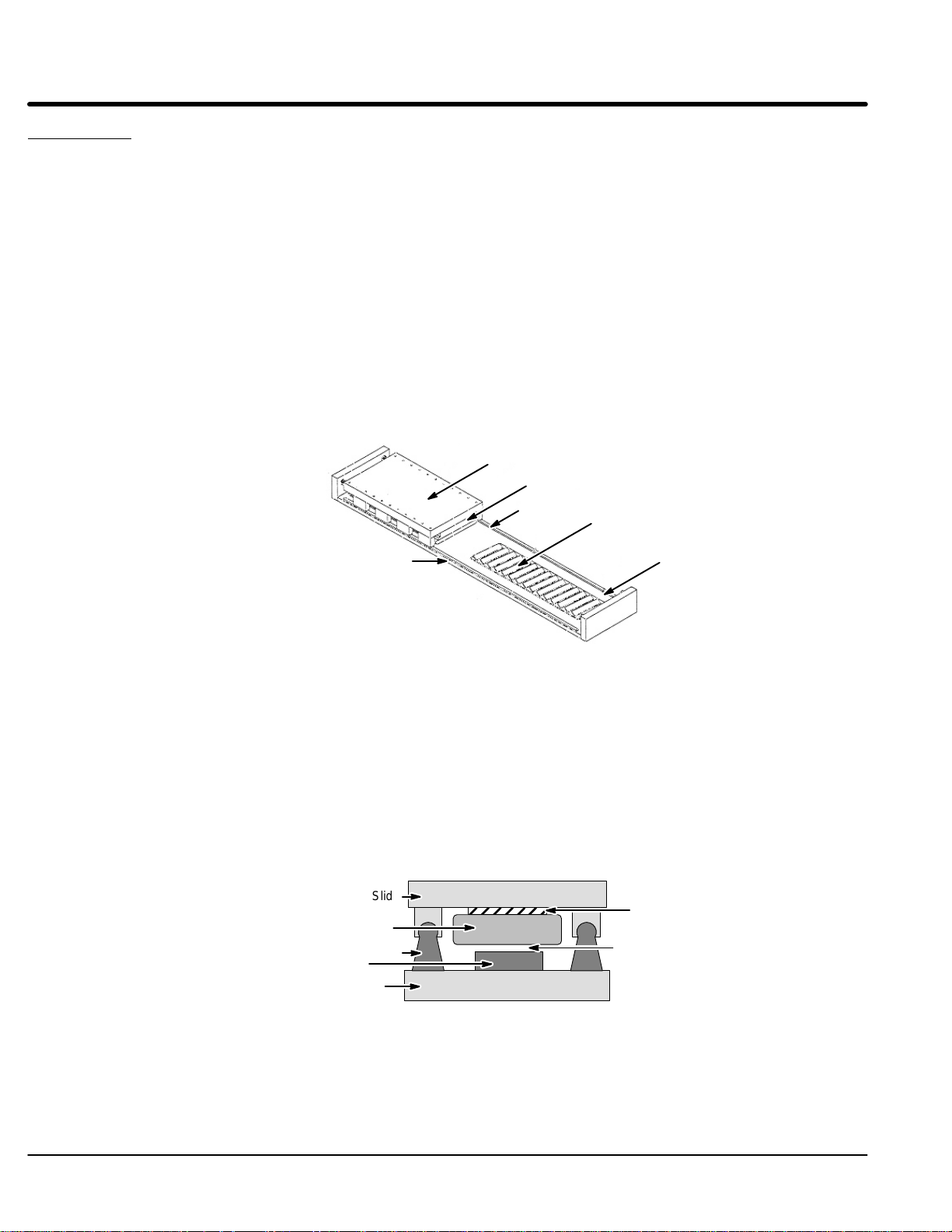

Figure 2-3 Modular Magnet Track Installation

Slide

Coil Assembly

Rail

Install one section of magnet track

Base

Move Slide to this side

after coil is installed

3. Hold the slide with a firm grip and move it over the magnet track section/shim.

Note: The slide will be drawn forcefully towards the magnet track and may

overshoot the rails if not held firmly.

Check the space between the shim and the coil assembly. If the space

between the shim and the coil assembly is large, uniformly loosen the mounting

screws allowing the coil assembly to be fully and evenly lowered onto the shim.

Insert another shim thick enough to fill the gap between the coil assembly and

the slide, see Figure 2-4. Tighten the mounting screws once again.

Figure 2-4 Air Gap Adjustment

Coil Assembly

Magnet

Base

Slide

Rail

Shim

(if necessary)

Air Gap (0.30± 0.005)

2-6 Installation & Operation MN1800

Page 14

LMBL Series Continued

Brushless Linear Iron Core Servo Motor Continued

Modular Magnet Track Continued

4. Install the remaining magnet track sections on the base plate. See Figure 2-5.

5. Remove the air–gap setting shim from the magnet track before use.

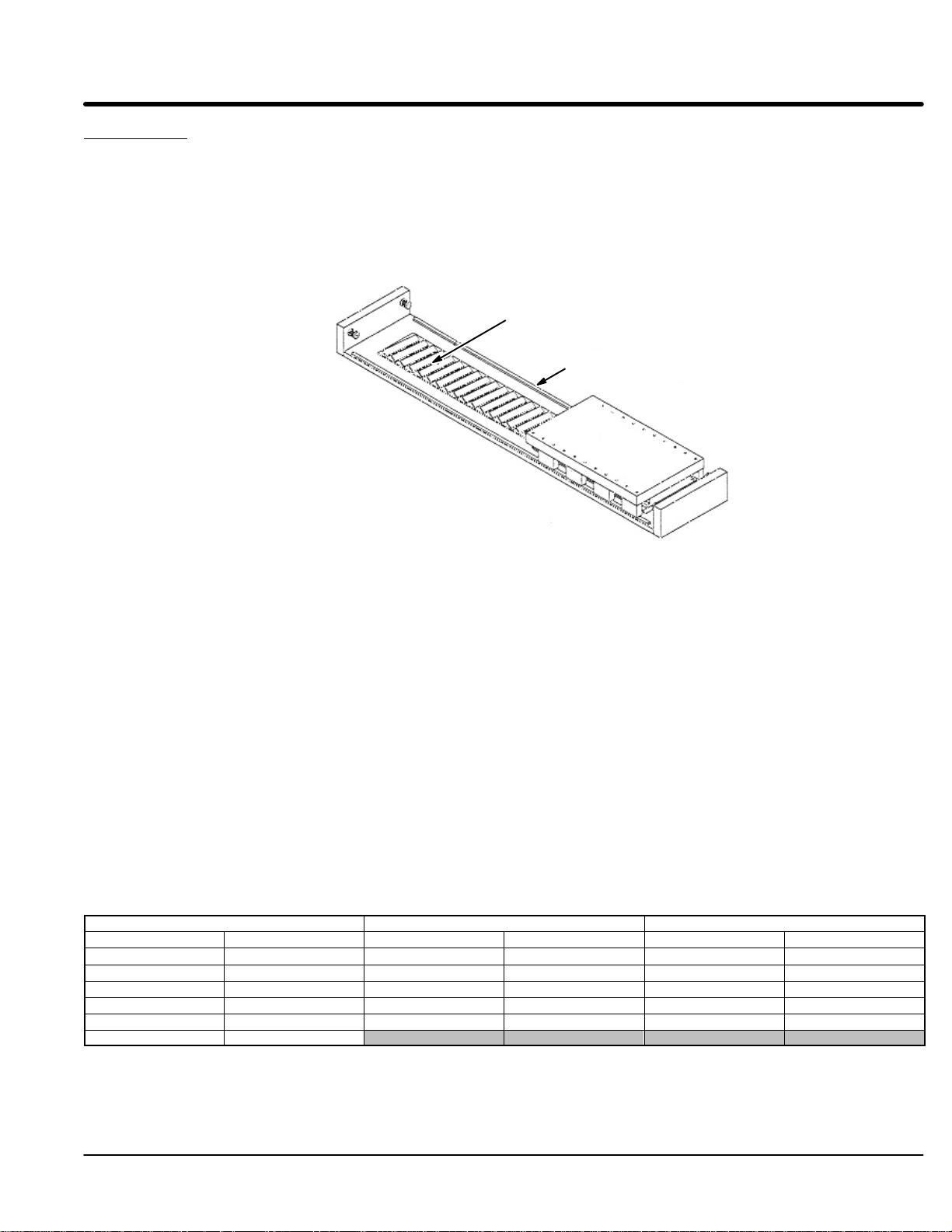

Figure 2-5 Modular Magnet Track Installation

Install other section of magnet track with

slide positioned as shown

Guide Rail

Operation Considerations The motor must always be operated within the specified operating parameter limits.

Exceeding those limits will permanently damage the motor Refer to the motor

specifications for operating parameter limits.

The motor must never touch the magnets during operation. The air gap must be

maintained over full length of travel.

Remove the shim that sets the air gap between the motor and the magnets prior to

operation.

Note: Be aware that the total bearing load includes the magnetic attractive force.

The following steps must be completed to ensure safe and proper operation.

1. Verify that all electrical wiring and cables are properly connected. Refer to the

manual provided with the control for this information.

2. Adjust the servo drive current to match the motor’s current specification.

3. Refer to the motor specifications for operating parameters. Adjust the control

parameters as necessary to the motor data specifications.

4. Adjust the control for the proper P.I.D. loop tuning. Begin at a low gain setting

and increase the gain as necessary.

5. Strain relieve the wires prior to operating.

AY1763A00 Leadwire Connection

Motor Cable Hall Cable Limit Cable

Signal Name Wire Color Signal Name Wire Color Signal Name Wire Color

Motor Phase A (U) Red Hall 1 White Limit + Output White

Motor Phase B (V) White Hall 2 Red Limit – Output Red

Motor Phase C (W) Black Hall 3 Black Home Output Black

Motor Ground Green Hall Ground Green Limit & Home PWR * Brown

Thermal Switch+ Blue Hall +5VDC Brown Limit & Home GND Green

Thermal Switch– Orange

* Limit & Home power is +4 to +24VDC.

Note: Motor phasing is for LinDrive or MintDrive. Other controls may require different phasing (such as most trap

drives (U) Black, (V) Red, (W) White). Phase angle between phases is 120 degrees.

Installation & Operation 2-7MN1800

Page 15

LMCF Series Brushless Linear Cog Free Servo Motor

1. Install the coil and magnet assemblies. While mounting the coil, be sure to

adjust coil assembly so it is centered within the magnet assembly with equal air

gap in the vertical and horizontal positions. See Figure 2-6.

2. Verify that the coil assembly is centered within the magnet assembly with equal

air gap in the vertical and horizontal positions along its entire length of travel.

The coil assembly must never be allowed to touch the magnets at any point

from one end of travel to the other.

Note: For modular magnet mounting, magnets are mounted end–to–end without

spacing. The mounting hole pattern is repeating and is unaffected by magnet

segments. Hole pattern repeats across joining ends of magnets.

Multiple Coil Assembly Operation

In addition to maintaining an air gap, multiple coil assemblies must also maintain a

spacing factor of 2.4″. In other words, the space between coil assemblies may vary,

however, the distance from the front end of the first coil assembly to the front end of the

next must be a multiple of 2.4″. See Figure 2-6.

Ensure that this factor is established at the time of installation.

Figure 2-6 Air Gap Spacing

Coil Assembly

Vertical Air Gap

Horizontal Air Gap

Vertical Air Gap

Mounting Plate

Horizontal Air Gap

Magnet Assembly

Machine Base

Operation Considerations The motor must always be operated within the specified operating parameter limits.

Exceeding those limits will permanently damage the motor.

The motor must never touch the magnets during operation. Equal horizontal and vertical

air gap must be maintained.

Remove the shim that sets the air gap between the motor and the magnets prior to

operation.

Note: Be aware that the total bearing load includes the magnetic attractive force.

The following steps must be completed to ensure safe and proper operation.

1. Verify that all electrical wiring and cables are properly connected. Refer to the

manual provided with the control for this information.

2. Adjust the servo drive current to match the motor’s current specification.

3. Refer to the motor specifications for operating parameters. Adjust the control

parameters as necessary to the motor data specifications.

4. Adjust the control for the proper P.I.D. loop tuning. Begin at a low gain setting

and increase the gain as necessary.

5. Strain relieve the wires prior to operating.

AY1763A00 Leadwire Connection

Motor Cable Hall Cable Limit Cable

Signal Name

Motor Phase A (U) Red Black Hall 1 White Limit + Output White

Motor Phase B (V) White Red Hall 2 Red Limit – Output Red

Motor Phase C (W) Black White Hall 3 Black Home Output Black

Motor Ground Green Hall Ground Green Limit & Home PWR * Brown

Thermal Switch+ Blue Hall +5VDC Brown Limit & Home GND Green

Thermal Switch– Orange

Wire Color

LinDrive Trap

Signal Name Wire Color Signal Name Wire Color

* Limit & Home power is +4 to +24VDC.

Note: Motor phasing is for LinDrive or MintDrive. Other controls may require different phasing (such as most trap

drives (U) Black, (V) Red, (W) White). Phase angle between phases is 120 degrees.

2-8 Installation & Operation MN1800

Page 16

LMCF Series Brushless Linear Cog Free Servo Motor Continued

LD9073A00 Hall Sensor Cable Connections (6 pin to flying leads)

Pin# Color Description

1 Black C

2 Red B

3 N.C.

4 Green Ground

5 White A

6 Brown +5VDC

LMNC Moving Coil Type

General Description Bi–directional DC linear motor consisting of a moving wound bobbin assembly and a

stationary magnet assembly. (Refer to catalog BR1800 for motor specifications, if your

motor is custom; refer to documentation included with shipment or contact Baldor).

Construction: Plated steel magnet housing assembly, nylon or like material wound bobbin assembly.

Your motor may or may not be supplied with a mounting flange or other mounting

provisions refer to catalog BR1800 for standard motor specifications or refer to

documentation included with shipment for custom motors.

Bearing type: Bearings are not provided with standard models. It is the purchaser’s responsibility to

supply bearings on standard models. With the magnet assembly secured, the bearing

must support the bobbin assembly so that it is mechanically centered in the magnet

assembly. Failure to center the coil assembly may lead to mechanical contact between

the coil and magnet assembly. If this occurs, motor electrical shorts are possible. If your

motor is supplied with bearings, refer to documentation included with shipment for

additional information. If this additional information is not available, contact your local

Baldor representative for assistance.

Maintenance: Motor should be kept dry and relatively free of contamination. This motor is NOT WATER

PROOF. Avoid submersion. Contact your local Baldor representative for service

information. Avoid contact with petroleum–based solvents. Alcohol can be used to

remove contaminants.

Motor specifications: Refer to catalog or outline drawing supplied with motor for mechanical dimensions and

electrical specifications.

Motor Mounting: Refer to catalog or outline drawing supplied with motor for mounting details and hole

dimensions. If you motor is supplied with drilled and tapped mounting holes, refer to the

recommended seating torque for screws in this document. It is recommended that a

thread locking compound be used with mounting screws. Motor wires must be strain

relieved.

Electrical Connections For voltage and current specifications, refer to Catalog BR1800 for catalog motors or to

documentation enclosed for custom motors. Your motor is supplied with 24 inch flying

leads*. These wires can be cut to remove excess length if required. Connectors are

available; contact a Baldor representative for more information.

Motor Wire

Function Color

– DC Black

+DC White

Ground Motor housing

* Some motors are supplied with custom cables; refer to documentation included with this

shipment for any custom motor designs.

Installation & Operation 2-9MN1800

Page 17

LMNM Moving Magnet Type Non Commutated DC Linear Servo Motor

General Description: Bi–directional DC linear motor with integral bearing. (Refer to catalog BR1 800 for motor

specifications, if your motor is custom; refer to documentation included with shipment or

contact Baldor)

Construction: Anodized aluminum or plated steel housing, aluminum end–caps, steel center shaft.

Your motor may or may not be supplied with a mounting flange or other mounting

provisions refer to catalog BR1 800 for standard motor specifications or refer to

documentation included with shipment for custom motors.

Bearing type: Depending on motor catalog number the bearing may be one of the following: linear, anti

rotational linear, rulon, sapphire, or flexure. Refer to catalog BR1 800. If your motor is

custom, refer to documentation included with shipment. Maintenance: Motor should be

kept dry and relatively free of contamination. This motor is NOT WATER PROOF. Avoid

submersion. These motors are factory assembled and aligned, the bearings must be

serviced by Baldor or a Baldor authorized repair center. Disassembly of motor will void

warranty. Avoid contact with petroleum based solvents. Alcohol can be used to remove

contaminants. Contact your local Baldor representative for service information.

Motor specifications: Refer to catalog or outline drawing supplied with motor for mechanical dimensions and

electrical specifications.

Motor Mounting: Refer to catalog or outline drawing supplied with motor for mounting details and hole

dimensions. When attaching payload to motor, avoid axial loading of the motor shaft.

Axial loading can damage the bearing thus reducing its life. If your motor is supplied with

drilled and tapped mounting holes, refer to the recommended seating torque for screws in

this document. It is recommended that a thread locking compound be used with

mounting screws.

Electrical Connections For voltage and current specifications, refer to Catalog BR1800 or to documentation

enclosed for custom motors. Your motor is supplied with 24 inch flying leads*. These

wires can be cut to remove excess length if required. Connectors are available; contact a

Baldor representative for more information.

Motor Wire

Function Color

– DC Black

+DC White

Ground Motor housing

Thermal switch Orange and Blue pair

(optional on some models)

*If your motor was supplied with custom cables; refer to enclosed documentation for any

custom motor designs.

2-10 Installation & Operation MN1800

Page 18

LMPY Series Polynoid Linear Motor Holding Option

Mounting: The rectifier package is wired externally in the stator circuit.

For 115/60Hz, rectifier package CO0126A00 is provided.

For 230/60Hz, rectifier package CO0125A00 is provided.

Rated holding force is only achieved when the keeper plate is against the holding coil. To

reduce shock loads, a shock absorbing connection between the polynoid rod and the load

is recommended.

Switching: Two switching modes can be used for various applications.

Single Holding:

Energized constantly except momentary interruption to release holding so rod

can be reversed.

Energized only during period when holding is required.

Energized only when rod is moving towards the holding end of the stator and

during the holding period.

Double Holding:

Energized constantly except momentary interruption to release holding so rod

can be reversed.

Energized only during period when holding is required.

Double holding coils may be switched together or one at a time.

Note: Double holding coil units are normally supplied with 2 yellow leads and one

small diameter black lead so that the holding coils may be operated

independently by applying rated voltage to the yellow and black lead. The wire

marker on one yellow lead indicates the lead that operates the holding coil on

the lead egress end of the stator. If desired, the 2 yellow leads can be tied

together for simultaneous operation of both holding coils.

WIRING GUIDES:

1. Single Holding

:

Installation & Operation 2-11MN1800

Page 19

LMPY Series Continued

Polynoid Linear Motor Holding Option Continued

Operation Considerations The motor must always be operated within the specified operating parameter limits.

Exceeding those limits will permanently damage the motor.

Note: Rod should not support axial loads that can induce premature bearing failure.

The following steps must be completed to ensure safe and proper operation.

1. Verify that all electrical wiring and cables are properly connected. Refer to the

manual provided with the control for this information.

2. If using a control, adjust the control continuous current limit to match the

motor’s continuous current specifications.

3. Adjust the control peak current limit so it will not exceed the motor’s peak

current specification.

Leadwire Connection

Motor Cable

Signal Name Wire Color

Motor Phase A Black

Motor Phase B Red

Motor Phase C White

Mounting Instructions Refer to the outline drawing (supplied with motor) for hole dimensions and mounting

information. When attaching the payload to the motor, avoid axial loading of the motor

shaft. Axial loading can damage the rulon bearing.

2-12 Installation & Operation MN1800

Page 20

LMSS Series Linear Stepper

Roller Bearing Motor

Installation Prior to placing the Forcer on the Platen both surfaces must be cleaned. Use this

method:

1. Apply masking tape to lamination surface of the Forcer to remove any metallic

contaminants.

2. Using alcohol, clean both surfaces to remove any adhesive residue and any

other contaminants on the Forcer and the Platen.

Note: Apply small amount of alcohol to cloth for cleaning. Never pour or drip alcohol

or other chemicals onto the forcer or platen surfaces.

3. Wax and polish Platen and Forcer surfaces. ( Turtle Wax ). Remove any visible

residue.

Adjust Air Gap Factory preset to 0.0015″.

Note: When receiving the Forcer and the Platen, the air gap is already set to

0.0015″. (Increasing the air gap will decrease the force). Use the following

instructions only if you need to reset the air gap.

1. Carefully remove the Forcer from the platen by sliding off the Forcer of the end

of the Platen. (So as not to score the Forcer and the Platen surfaces).

2. Loosen the four screws (1 turn) on the bearing kits using an Allen key.

3. Center the shim on the toothed section of the Platen.

4. Place the Forcer on the Platen. Be sure that the shim is only between the

Forcer and the Platen, and not between the wheels and the Platen.

5. Apply downward pressure on both bearing kits only (the Forcer is attached

magnetically) and then tighten the four screws to 30 in–lbs of torque.

6. Slide the Forcer down the Platen while holding the shim in place and remove

the shim.

Maintenance Waxing of the Forcer lamination for corrosion protection is recommended every month (or

as needed) depending on environmental conditions (i.e. humidity and moisture).

Operation Considerations The motor must always be operated within the specified operating parameter limits.

Exceeding those limits will permanently damage the motor.

The forcer must never touch the platen during operation. Equal horizontal and vertical air

gap must be maintained.

The following steps must be completed to ensure safe and proper operation.

1. Verify that all electrical wiring and cables are properly connected. Refer to the

manual provided with the control for this information.

2. Adjust the stepper driver current to match the motor’s current specification.

3. Strain relieve the wires prior to operating.

AY0165A00 Leadwire Connection (9 pin to flying leads)

Color Pin# Description

White 1 A1+ Winding

2 N.C.

Green 3 B1+ Winding

4 N.C.

Black 5 Ground

6 N.C.

Red 7 A1– Winding

8 N.C.

Orange 9 B1– Winding

6

7

8

9

Male (D Sub)

When a Male D Sub connector is used, use the pin numbers to connect the forcer.

1

2

3

When flying leads are used, use the color codes to connect the forcer.

4

5

Installation & Operation 2-13MN1800

Page 21

LMSS Series Continued

Air Bearing Motor

Cleaning the Forcer and Platen

Prior to placing the Forcer on the Platen both surfaces must be cleaned.

Use this method:

1. Apply masking tape to lamination surface of the Forcer. Removing the tape

removes large particle contaminants.

2. Using alcohol, clean both surfaces to remove any adhesive residue and any

other contaminants on the Forcer and the Platen.

Note: Apply small amount of alcohol to cloth for cleaning. Never pour or drip alcohol

or other chemicals onto the forcer or platen surfaces.

3. Wax and polish Platen and Forcer surfaces. ( Turtle Wax ). Remove any visible

residue.

Cleaning the Air Bearings Required if the forcer is not lifting between 0.0005″ – 0.001″ ( i.e. rubbing on the Platen ).

1. Using a small screw driver, unscrew one air bearing.

2. Blow compressed air through the bearing in both directions.

3. Screw the air bearing back to its original position.

Note: Do not mix the air bearings, they have to be installed at their original position.

Installation: Mounting the Forcer on the Platen

1. Before placing the forcer on the platen be sure there is at least 60 psi of

regulated and filtered air flowing through the forcer.

2. At one end of the platen, carefully slide the Forcer onto the Platen.

(BE EXTREMELY CAREFUL ).

Removing the Forcer from the Platen

1. Before moving the forcer, be sure there is at least 60 psi of regulated and

filtered air flowing through the forcer.

2. Carefully slide the Forcer to one end of the Platen and remove it.

(Be Extremely Careful).

Maintenance Waxing of the Forcer lamination for corrosion protection is recommended every month (or

sooner) depending on environmental conditions (i.e. humidity and moisture).

Operation Considerations The motor must always be operated within the specified operating parameter limits.

Exceeding those limits will permanently damage the motor.

The forcer must never touch the platen during operation. Equal horizontal and vertical air

gap must be maintained.

The following steps must be completed to ensure safe and proper operation.

1. Verify that all electrical wiring and cables are properly connected. Refer to the

manual provided with the control for this information.

2. Adjust the stepper driver current to match the motor’s current specification.

3. Strain relieve the wires prior to operating.

LD9145A00 9 pin Female to flying leads LD9147A00 25 pin Female to flying leads

Color Pin# Description

Red 1 A+ Winding

Green 2 A– Winding

Yellow 3 B+ Winding

Orange 4 B– Winding

Black 5 Ground

Blue 6 C+ Winding

Green 7 C– Winding

White 8 D+ Winding

Black 9 D– Winding

Use twisted pairs, shield is open at backshell.

Color Pin# Description

Red 1 1A+ Winding

Green 2 1A– Winding

Yellow 3 1B+ Winding

Orange 4 1B– Winding

Blue 5 1C+ Winding

Green 6 1C– Winding

White 7 1D+ Winding

Black 8 1D– Winding

Black 13 1Ground

Use twisted pairs, shield is open at backshell.

Color Pin# Description

Red 14 2A+ Winding

Green 15 2A– Winding

Yellow 16 2B+ Winding

Orange 17 2B– Winding

Black 18 2C+ Winding

Blue 19 2C– Winding

Green 20 2D+ Winding

White 21 2D– Winding

Black 13 2Ground

2-14 Installation & Operation MN1800

Page 22

LMDS Series Dual Axis Linear Stepper Motor

Items Required but NOT

1. A regulated 80 PSI air supply with a 5 micron filter for each motor.

A water separator is also required.

2. Two or four phase, 2 ampere (micro) stepper motor driver/controller for each motor.

Cleaning the Forcer and Platen

Cleaning the Air Bearings Required if the forcer is not lifting between 0.0005″ – 0.001″ ( i.e. rubbing on the Platen ).

Installation: Mounting the Forcer on the Platen

Maintenance Waxing of the Forcer lamination for corrosion protection is recommended every month (or

Operation Considerations The motor must always be operated within the specified operating parameter limits.

Included

Prior to placing the Forcer on the Platen both surfaces must be cleaned.

Use this method:

1. Apply masking tape to lamination surface of the Forcer. Removing the tape

removes large particle contaminants.

2. Using alcohol, clean both surfaces to remove any adhesive residue and any

other contaminants on the Forcer and the Platen.

Note: Apply small amount of alcohol to cloth for cleaning. Never pour or drip alcohol

or other chemicals onto the forcer or platen surfaces.

3. Wax and polish Platen and Forcer surfaces. ( i.e. Turtle Wax ). Remove any

visible residue.

1. Using a small screw driver, unscrew one air bearing.

2. Blow compressed air through the bearing in both directions.

3. Screw the air bearing back to its original position.

Note: Do not mix the air bearings, they have to be installed at their original position.

1. Before placing the forcer on the platen be sure there is at least 60 psi of

regulated and filtered air flowing through the forcer.

2. Use the lifting tool (in reverse) to gently, place the forcer on the platen. Be

careful not to place your fingers between forcer and platen.

Removing the Forcer from the Platen

1. Before moving the forcer, be sure there is at least 60 psi of regulated air supply

with a 5 µm air filter flowing through the forcer.

2. Place lifting tool (provided) in slot on the side of the forcer. Gently, pry the

forcer from the platen with the tool. Lift the forcer and remove it from the

platen. Be careful not to place your fingers between forcer and platen.

as needed) depending on environmental conditions (i.e. humidity and moisture).

Exceeding those limits will permanently damage the motor.

The following steps must be completed to ensure safe and proper operation.

1. Verify that all electrical wiring and cables are properly connected. Refer to the

manual provided with the control for this information.

2. Adjust the stepper driver current to match the motor’s current specification.

3. Strain relieve the wires prior to operating.

Installation & Operation 2-15MN1800

Page 23

Leadwire Connection

LD9068A00

Color Pin# Description (2 Phase 9 pin to flying leads)

Red 1 (X) A+ Winding

Green 2 (X) A– Winding

Yellow 3 (X) B+ Winding

Orange 4 (X) B– Winding

Black 5 Ground

Blue 6 (Y) A+ Winding

Green 7 (Y) A– Winding

White 8 (Y) B+ Winding

Black 9 (Y) B– Winding

Use twisted pair wires. Shield open at shell.

LD9074A00

Color Pin# Description (2 Phase 25 pin pin to flying leads)

Red 1 (X) A+ Winding

Green 2 (X) A– Winding

Yellow 3 (X) B+ Winding

Orange 4 (X) B– Winding

Black 13 Ground

Blue 14 (Y) A+ Winding

Green 15 (Y) A– Winding

White 16 (Y) B+ Winding

Black 17 (Y) B– Winding

Use twisted pair wires. Shield open at shell.

6

7

8

9

Female (D Sub)

14

15

16

17

18

19

20

21

22

23

24

25

Female (D Sub)

1

2

3

4

5

LD9092A00 (4 Phase 25 pin pin to flying leads)

X–Axis Connections

1

2

Color Pin# Description

3

Red 1 A+ Winding

4

Green 2 A– Winding

5

Yellow 3 B+ Winding

6

Orange 4 B– Winding

7

Blue 5 C+ Winding

8

9

Green 6 C– Winding

White 7 D+ Winding

10

11

Black 8 D– Winding

12

Black 13 Ground

13

Use twisted pair wires.

Shield open at shell.

Y–Axis Connections

Color Pin# Description

Red 14 A+ Winding

Green 15 A– Winding

Yellow 16 B+ Winding

Orange 17 B– Winding

Blue 18 C+ Winding

Green 19 C– Winding

White 20 D+ Winding

Black 21 D– Winding

Black 13 Ground

Use twisted pair wires.

Shield open at shell.

Positioning Stages

Unpacking Observe the condition of the shipping container and report any damage immediately to

the commercial carrier that delivered your stage. Carefully remove the positioning stage

from the shipping crate or box. Inspect the stage and report any evidence of damage to

your local Baldor sales office or authorized distributor. Save the shipping container for

future transportation.

Handling and General Guidelines Be sure to observe the following guidelines:

1. Carefully set the positing stage in place. Do not drop a positioning stage onto

the mounting surface or machine base as this can result in internal damage to

bearing and drive components.

2. Do not drill holes in a positing stage. Contact Baldor if holes must be added.

3. Avoid impact loads such as hammering and punching which may cause internal

damage to bearing and drive components.

4. Avoid submersion in liquids of all types.

5. Do not disassemble the positioning stage as this may void the product warranty.

Stage Specifications Disclaimer

Positioning stage specifications are dependant on the three following variables:

Temperature: Catalog specifications are measured at 25 degrees Celsius.

Measurements of performance at other temperatures may yield different measurements.

Minimum ambient operating temperature: 5 degrees Celsius. Maximum ambient

operating temperature: 75 degrees Celsius. The positioning stage can be modified by

Baldor to allow the unit to be operated at temperatures outside of this range. Contact

Baldor for more information.

Point of measurement: Catalog specifications are measured 25mm above the slide

mounting surface. If measurements are taken from other relative locations, results may

be different from the catalog specifications.

Mounting surface: Catalog specifications are measured with the positioning stage

supported under its entire length, fastened down (bolted) and is mounted to a machine

base that has a maximum flatness error of 0.0005”/ft.

2-16 Installation & Operation MN1800

Page 24

LSE Series Enclosed Position Stage

General Description: Single axis linear stage with linear motor, linear bearings, linear encoder, limit switches,

cable carrier, and bellows

Construction: Hard anodized aluminum

Bearing type: Recirculating ball linear bearing

Encoder type: Open glass scale, optical, magnetic

Motor type: Brushless three phase, iron core or cog free type linear motor. Refer to catalog for motor

specifications and stage model number description. Brush type DC linear motors

available upon request.

Maintenance: Refer to bearing and encoder maintenance recommendations in this manual. Exterior of

stage should be kept dry and relatively free of contamination. This stage is NOT WATER

PROOF. Avoid submersion.

Stage specifications: Refer to catalog or outline drawing supplied with stage for mechanical dimensions.

Stage Mounting: Removal of bellows is required for access to base mounting holes. Refer to mounting

recommendations.

ELECTRICAL CONNECTIONS (cables labeled accordingly)

Encoder: Refer to Encoder connections.

Motor/hall/limit switches: Your stage has flying leads 10 foot in length. These cables can be cut if required.

Connectors are available, contact Baldor for more information.

AY1763A00 Leadwire Connection

Motor Cable Hall Cable Limit Cable

Signal Name

Motor Phase A (U) Red Black Hall 1 White Limit + Output White

Motor Phase B (V) White Red Hall 2 Red Limit – Output Red

Motor Phase C (W) Black White Hall 3 Black Home Output Black

Motor Ground Green Hall Ground Green Limit & Home PWR * Brown

Thermal Switch+ Blue Hall +5VDC Brown Limit & Home GND Green

Thermal Switch– Orange

Wire Color

LinDrive Trap

Signal Name Wire Color Signal Name Wire Color

* Limit & Home power is +4 to +24VDC.

Note: Motor phasing is for LinDrive or MintDrive. Other controls may require different phasing (such as most trap

drives (U) Black, (V) Red, (W) White). Phase angle between phases is 120 degrees.

AY1780A00 Leadwire Connection for MintDrive (9 pin to flying leads)

Color Pin# Description

Brown 1 +5VDC

Pink 2 C+

Red 3 B–

Inner Shield 4 Inner Shield

Green 5 A+

Gray 6 C–

White 7 0V

Blue 8 B+

Yellow 9 A–

6

7

8

9

Male (D Sub)

Outer shield to shell.

1

2

3

4

5

Installation & Operation 2-17MN1800

Page 25

AY1775A00 LSE, Encoder (RGH24) & Hall Connections for LinDrive/MintDrive (15 pin to flying leads)

Color Pin# Description

Green 1 A+

Blue 2 B+

Pink 3 C+

White 4 Hall1

5 N/C

Yellow 6 A–

Red 7 B–

Gray 8 C–

Black 9 Hall3

Red 10 Hall2

Brown 11 +5VDC (Halls Brown)

12 N/C

White 13 Encoder GND (Halls Green)

14

15

11

12

13

14

15

Male (D Sub)

Outer shield to shell.

Inner shield to pin 13.

1

2

3

4

5

AY1779A00 LSE with Renishaw Encoder (RGH24) Flying Leads

10 ft cable for use with Renishaw RGH24.

Flying leads are color coded as shown in this diagram.

Cable 1

(Hall Cable)

Cable 2

(Motor Cable)

* Limit & Home power is +4 to +24VDC.

Cable 4

(RGH24

Encoder Cable)

Cable 3

Limit Cable

Cable

1

1

1

1

1

1

1

2

2

2

2

2

2

2

3

3

3

3

3

3

4

4

4

4

4

4

4

4

4

4

Conductor

A

B

C

D

E

F

G

A

B

C

D

E

F

G

A

B

C

D

E

F

A

B

C

D

E

F

G

H

I

J

Signal Name

Hall 3 (C)

Hall 2 (B)

N/C

Hall Ground

Hall 1 (A)

Voltage IN (+5VDC)

Shield

Motor Phase A (U)

Motor Phase B (V)

Motor Phase C (W)

Motor Ground

Thermal Switch +

Thermal Switch -

Shield

Limit/Home Ground

Home Output

Limit + Output

Shield

Limit & Home PWR *

Limit - Output

Signal A+

Signal ASignal B+

Signal BSignal C+

Signal C-

+5VDC

0VDC

Outer Shield

Inner Shield

Color

Black

Red

N/C

Blue, Green or Yellow

White

Brown or Violet

Red

White

Black

Green

Orange

Blue

Blue, Green or Yellow

Black

White

Brown

Red

Green

Yellow

Blue

Red

Pink

Gray

Brown

White

Note: Motor phasing is for LinDrive or MintDrive. Other controls may require different phasing (such as most trap

drives (U) Black, (V) Red, (W) White). Phase angle between phases is 120 degrees.

External Connections

LD9127A00 Leadwire Connection Limit/Home Switch Interface (6 pin to flying leads)

Color Pin# Description

Black 1 Home Output

White 2 Limit+ Output

Red 3 Limit– Output

Green 4 Ground

Brown 5 Limit & Home PWR *

Orange 6 Series / Parallel (Jumper 6 to 3=Series,

Jumper 6 to 5=Parallel)

* Limit & Home power is +4 to +24VDC.

6 3

5 2

4 1

(Connector viewed from cable side)

Jumper pin 3 to pin 6 for Series operation.

Jumper pin 5 to pin 6 for Parallel operation.

(Series jumper option is for Omron 670/671P limits only).

2-18 Installation & Operation MN1800

Page 26

Internal Connections

Leadwire Connection Limit Switch Pigtails

LD9125A01 Limit only

Color Pin# Description

Brown 1 Limit & Home power *

2 N/C

White 3 Limit Output

Green 4 Ground

* Limit & Home power is +4 to +24VDC.

Limit

OUT

671P

4

L

3

2

1

LD9125A02 Limit and Home

Color Pin# Description

Brown 1 Limit & Home power *

Black 2 Home Output

Red 3 Limit Output

Green 4 Ground

* Limit & Home power is +4 to +24VDC.

LD9137A01 Limit only

Color Pin# Description

Brown 1 Limit & Home power *

2 N/C

Black 3 Limit Output

Blue 4 Ground

* Limit & Home power is +4 to +24VDC.

LD9137A02 Limit and Home

Color Pin# Description

Brown 1 Limit & Home power *

Black 2 Home Output

Black 3 Limit Output

Blue 4 Ground

* Limit & Home power is +4 to +24VDC.

L

OUT

Limit

Home

HomeH–Limit

4

671P

OUT

671P

L

3

2

1

Limit

4

3

2

1

4

3

2

LD9124A00 Limit and Home, Axis 1, Internal

Connect to Limit Pigtail

Pin# Color

1 Brown

2

3 White

4

3

2

1

4 Green

Pin# Color

1 Brown

2 Black

3 Red

4

3

2

1

4 Green

Connect to Limit/Home Pigtail

1

Pin# Color

6

3

5

2

4

1

1 Black

2 White

3 Red

4 Green

5 Brown from LD9125A02

6 Brown from LD9125A01

Installation & Operation 2-19MN1800

Page 27

LSE Stage Connector Locations

Home Limit

LD9123A00

LD9125A02

LD9124A00

LD9125A01

Limit

2-20 Installation & Operation MN1800

Page 28

LSC Series Cross Roller Position Stage

General Description: Single axis linear stage with linear motor, linear bearings, linear encoder, limit switches,

cable carrier (on some models), and bellows

Construction: Hard anodized aluminum, black oxide steel

Bearing type: Cross roller linear bearing

Encoder type: Open glass scale if internal, or enclosed type if external

Motor type: Brushless three phase, iron core or cog free type linear motor. Refer to catalog for motor

specifications and stage model number description. Brush type DC linear motors

available upon request.

Maintenance: Refer to bearing and encoder maintenance recommendations in this manual. Exterior of

stage should be kept dry and relatively free of contamination. This stage is NOT WATER

PROOF. Avoid submersion.

Stage specifications: Refer to catalog or outline drawing supplied with stage for mechanical dimensions.

Stage Mounting: Removal of bellows is required for access to base mounting holes. Refer to mounting

recommendations.

ELECTRICAL CONNECTIONS (cables labeled accordingly)

Encoder: Refer to RGH24 series internal encoder connections or MSA6x series external encoder

connections in this manual.

Motor/hall/limit switches: Your stage has flying leads 10 foot in length. These cables can be cut if required.

Connectors are available, contact Baldor for more information.

AY1763A00 Leadwire Connection

Motor Cable Hall Cable Limit Cable

Signal Name

Motor Phase A (U) Red Black Hall 1 White Limit + Output White

Motor Phase B (V) White Red Hall 2 Red Limit – Output Red

Motor Phase C (W) Black White Hall 3 Black Home Output Black

Motor Ground Green Hall Ground Green Limit & Home PWR * Brown

Thermal Switch+ Blue Hall +5VDC Brown Limit & Home GND Green

Thermal Switch– Orange

Wire Color

LinDrive Trap

Signal Name Wire Color Signal Name Wire Color

* Limit & Home power is +4 to +24VDC.

Note: Motor phasing is for LinDrive or MintDrive. Other controls may require different phasing (such as most trap

drives (U) Black, (V) Red, (W) White). Phase angle between phases is 120 degrees.

AY1780A00 Leadwire Connection for MintDrive (9 pin to flying leads)

Color Pin# Description

Brown 1 +5VDC

Pink 2 C+

Red 3 B–

Inner Shield 4 Shield

Green 5 A+

Gray 6 C–

White 7 0V

Blue 8 B+

Yellow 9 A–

6

7

8

9

Male (D Sub)

Outer shield to shell.

1

2

3

4

5

Installation & Operation 2-21MN1800

Page 29

AY1775A00 Leadwire Connection for LinDrive 15 pin

Color Pin# Description

Green 1 A+

Blue 2 B+

Pink 3 C+

White 4 Hall1

5 N/C

Yellow 6 A–

Red 7 B–

Gray 8 C–

Black 9 Hall3

Red 10 Hall2

Brown 11 +5VDC

12 N/C

White 13 Encoder GND

(Halls Brown)

14

15

11

12

13

14

15

Male (D Sub)

Outer shield to shell.

Inner shield to pin 13.

1

2

3

4

5

AY1779A00 LSE with Renishaw Encoder (RGH24) Flying Leads

Cable

10 ft cable for use with Renishaw RGH24.

Flying leads are color coded as shown in this diagram.

Cable 1

(Hall Cable)

Cable 2

(Motor Cable)

* Limit & Home power is +4 to +24VDC.

Cable 4

(RGH24

Encoder Cable)

Cable 3

Limit Cable

Conductor

1

1

1

1

1

1

1

2

2

2

2

2

2

2

3

3

3

3

3

3

4

4

4

4

4

4

4

4

4

4

A

B

C

D

E

F

G

A

B

C

D

E

F

G

A

B

C

D

E

F

A

B

C

D

E

F

G

H

I

J

Signal Name

Hall 3 (C)

Hall 2 (B)

N/C

Hall Ground

Hall 1 (A)

Voltage IN (+5VDC)

Shield

Motor Phase A (U)

Motor Phase B (V)

Motor Phase C (W)

Motor Ground

Thermal Switch +

Thermal Switch -

Shield

Limit/Home Ground

Home Output

Limit + Output

Shield

Limit & Home PWR *

Limit - Output

Signal A+

Signal ASignal B+

Signal BSignal C+

Signal C-

+5VDC

0VDC

Outer Shield

Inner Shield

Color

Black

Red

N/C

Blue, Green or Yellow

White

Brown or Violet

Red

White

Black

Green

Orange

Blue

Blue, Green or Yellow

Black

White

Brown

Red

Green

Yellow

Blue

Red

Pink

Gray

Brown

White

LD9127A00 Leadwire Connection Limit/Home Switch Interface (6 pin to flying leads)

Color Pin# Description

Black 1 Home Output

White 2 Limit+ Output

Red 3 Limit– Output

Green 4 Ground

Brown 5 Limit & Home PWR *

Orange 6 Series / Parallel (Jumper 6 to 3=Series,

Jumper 6 to 5=Parallel)

* Limit & Home power is +4 to +24VDC.

6 3

5 2

4 1

(Connector viewed from cable side)

Jumper pin 3 to pin 6 for Series operation.

Jumper pin 5 to pin 6 for Parallel operation.

(Series jumper option is for Omron 670/671P limits only).

2-22 Installation & Operation MN1800

Page 30

Leadwire Connection Limit Switch Pigtails

LD9125A01 Limit only

Color Pin# Description

Brown 1 Limit & Home power *

2 N/C

White 3 Limit Output

Green 4 Ground

* Limit & Home power is +4 to +24VDC.

Limit

OUT

671P

4

L

3

2

1

LD9125A02 H–Limit and Home

Color Pin# Description

Brown 1 Limit & Home power *

Black 2 Home Output

Red 3 Limit Output

Green 4 Ground

* Limit & Home power is +4 to +24VDC.

LD9137A01 Limit only

Color Pin# Description

Brown 1 Limit & Home power *

2 N/C

Black 3 Limit Output

Blue 4 Ground

* Limit & Home power is +4 to +24VDC.

LD9137A02 Limit and Home

Color Pin# Description

Brown 1 Limit & Home power *

Black 2 Home Output

Black 3 Limit Output

Blue 4 Ground

* Limit & Home power is +4 to +24VDC.

L

OUT

Limit

Home

HomeH–Limit

4

671P

OUT

671P

L