Baldor ID15P1F33-ER, ID15P1F50-ER, ID15P1F75-ER, ID15P101-ER, ID15P201-ER Installation And Operating Manual

...Page 1

Series 15P

Inverter Control

2/07 MN715P

Installation and Operating Manual

Page 2

Page 3

Table of Contents

MN715P Table of Contents i

Section 1

Quick Start 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2

General Information 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Compliance 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3

Receiving and Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving & Inspection 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Installation 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Grounding 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Current Requirements 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cover Removal 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Identification 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Line Connections 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protective Devices 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Impedance 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Reactors 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Three Phase Wire Size and Protection Devices 3-5. . . . . . . . . . . . . . . . . . .

115VAC 1 Phase Wire Size and Protection Devices 3-7. . . . . . . . . . . . . . . .

230VAC Single Phase Derating for Three Phase Controls 3-8. . . . . . . . . .

Motor Brake Connections 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Dynamic Brake Hardware 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Input 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Inputs 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 4

Setup and Operation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S1 Settings 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Potentiometers P1 - P6 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation Examples 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 5

Troubleshooting 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 6

Specifications and Product Data 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Conditions: 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display: 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Specifications: 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Input: 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Inputs: 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ratings 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dynamic Brake Resistors 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Tightening Torque Specifications 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting Dimensions 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Section 1

Quick Start

1-1 Quick Start MN715P

Overview

The quick start procedure is as follows:

1. Read the Safety Notice and Precautions in section 2 of this manual.

2. Mount the control. Refer to Section 3, “Physical Installation” procedure.

3. Connect AC power. Refer to Section 3 “Control Installation”.

4. Connect the motor. Refer to Section 3, “Control Installation”.

5. Set the switches and adjust the potentiometers for desired operation.

See Figure 1-1.

The following procedure will help get your system up and running quickly, and

will allow you to prove the motor and control operation. This procedure

assumes that the control and motor are correctly installed.

WARNING: Make sure that unexpected operation of the motor shaft during start

up will not cause injury to personnel or damage to equipment.

Power-up Procedure

1. Open cover.

2. Be sure all S1 switches are OFF.

3. Rotate the % Speed control on the front panel to 0% speed (fully

counterclockwise position).

4. Turn power on. Be sure the “Fault” LED is off.

5. Press FWD. The LED on the FWD button should be on.

6. Rotate the % Speed control to 30%. The motor should rotate in the

forward direction.

Note: If the motor rotates in the reverse direction, turn power off and

reverse any two of the three motor lead connections (J5-T1, T2 or T3).

Turn power on and start at step 3 again.

7. Press STOP. The motor should decel to a stop and the LED on the

STOP button should be on.

8. Press REV. The LED on the REV button should be on.

9. Rotate the % Speed control to 30%. The motor should rotate in the

reverse direction.

10. Turn power off.

The control is now ready to be configured for your application and placed into

service. Refer to the appropriate connection diagram and setup procedure to

configure your system.

Page 5

MN715P Quick Start 1-2

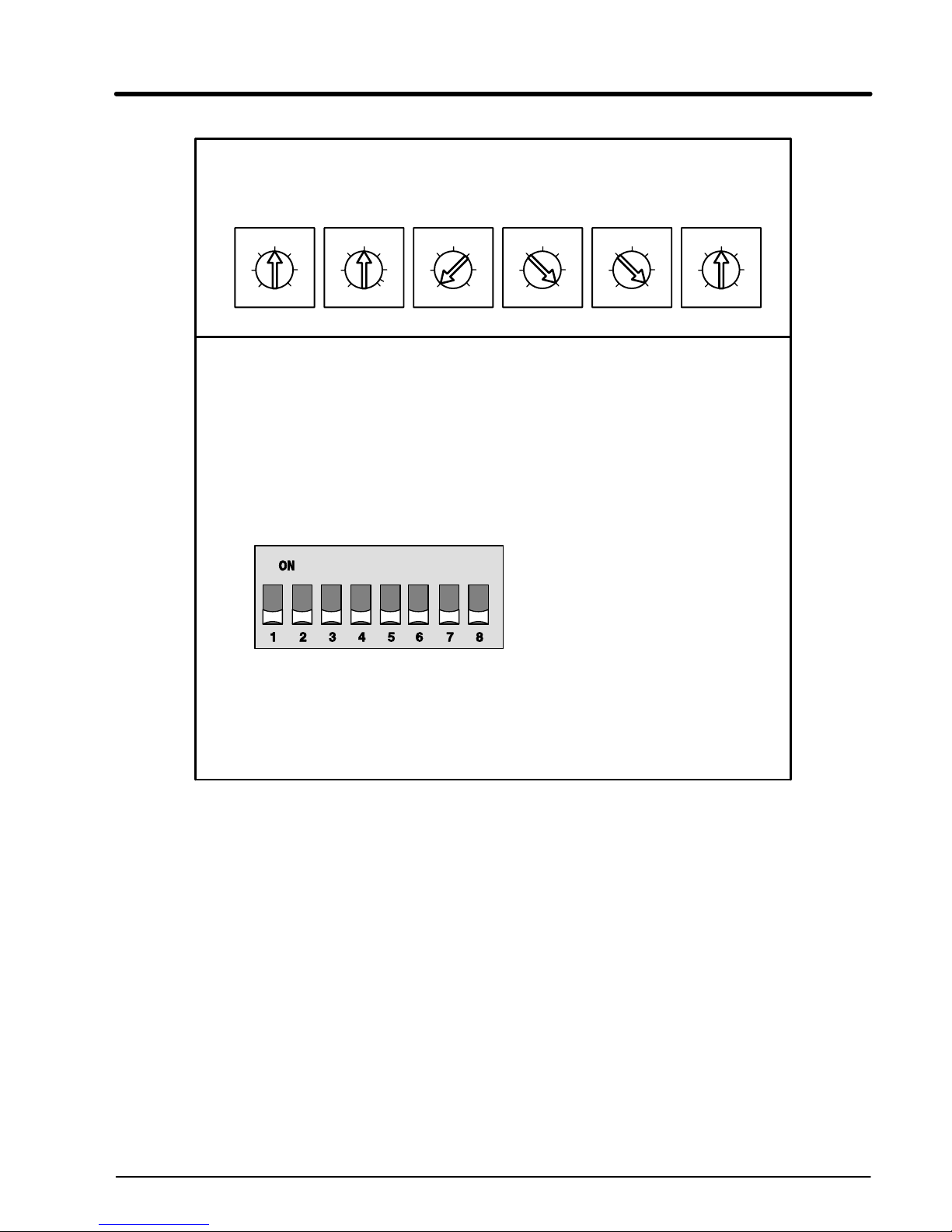

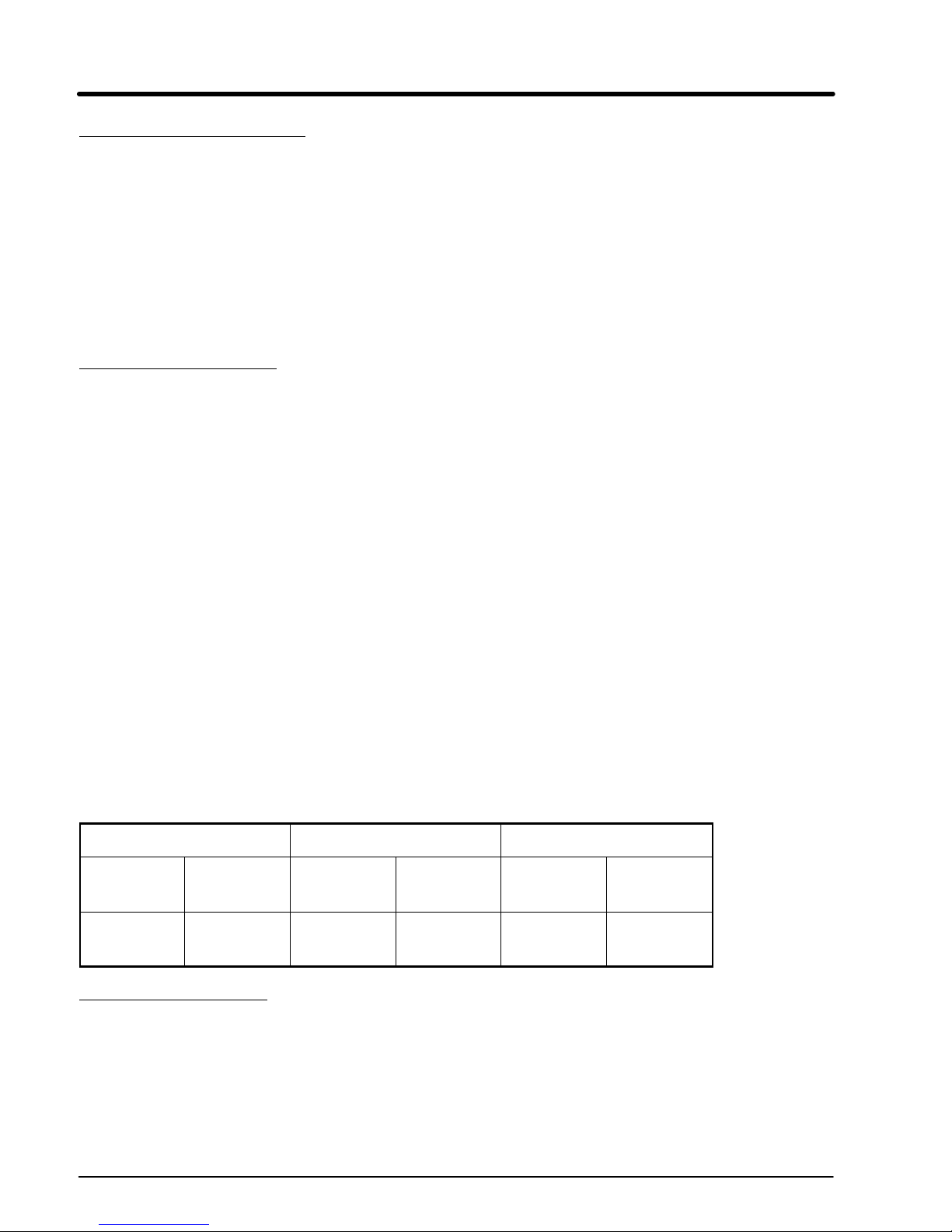

Figure 1-1 Factory Settings

S1

2X Base1X Base

50 Hz60 Hz

REV DisabledREV Enabled

AutoManual

3 Wire2 Wire

4-20mA Current0-10V Voltage

Remote SpeedLocal Speed

Remote CommandLocal Command

1 Base Frequency

2 Max Frequency Limit

3 Enable/Disable Reverse Rotation

4 Manual/Automatic Restart

5 2 Wire/3 Wire Operation

6 Voltage or Current Input Select

7 Local/Remote Speed Reference

8 Local/Remote Speed Command

10

0.1 60

Accel

10

0.1

Decel

0

1

/

2

Base

Minimum

Frequency

1

/

2

Lim

Lim

Maximum

Frequency

50% 100%

Current

Limit

0 15%

Torque

Boost

60

Coast

Potentiometers P1 to P6 (arrows indicate factory settings).

Switch S1, shown with all switches in OFF position (factory settings).

Page 6

Section 2

General Information

2-1 General Information MN715P

CE Compliance

A custom unit may be required, contact Baldor. Compliance to Directive

89/336/EEC is the responsibility of the system integrator. A control, motor and

all system components must have proper shielding, grounding and filtering as

described in MN1383. Please refer to this manual for installation techniques

for CE compliance.

Limited Warranty

For a period of two (2) years from the date of original purchase, BALDOR will repair or replace

without charge controls and accessories which our examination proves to be defective in

material or workmanship. This warranty is valid if the unit has not been tampered with by

unauthorized persons, misused, abused, or improperly installed and has been used in

accordance with the instructions and/or ratings supplied. This warranty is in lieu of any other

warranty or guarantee expressed or implied. BALDOR shall not be held responsible for any

expense (including installation and removal), inconvenience, or consequential damage,

including injury to any person or property caused by items of our manufacture or sale. (Some

states do not allow exclusion or limitation of incidental or consequential damages, so the above

exclusion may not apply.) In any event, BALDOR’s total liability, under all circumstances, shall

not exceed the full purchase price of the control. Claims for purchase price refunds, repairs, or

replacements must be referred to BALDOR with all pertinent data as to the defect, the date

purchased, the task performed by the control, and the problem encountered. No liability is

assumed for expendable items such as fuses.

Goods may be returned only with written notification including a BALDOR Return Authorization

Number and any return shipments must be prepaid.

Safety Notice:

This equipment contains voltages that may be as great as 1000 volts!

Electrical shock can cause serious or fatal injury. Only qualified personnel

should attempt the start−up procedure or troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts

or parts that are driven by this equipment. Improper use can cause serious or

fatal injury.

PRECAUTIONS:

WARNING: Do not touch any circuit board, power device or electrical

connection before ensuring that power has been disconnected and

there is no high voltage present from this equipment or other

equipment to which it is connected. Electrical shock can cause

serious or fatal injury. Only qualified personnel should attempt the

start−up procedure or troubleshoot this equipment.

WARNING: Be sure that you are completely familiar with the safe operation of

this equipment. This equipment may be connected to other

machines that have rotating parts or parts that are controlled by this

equipment. Improper use can cause serious or fatal injury. Only

qualified personnel should attempt the start−up procedure or

troubleshoot this equipment.

Continued on next page.

Page 7

MN715P General Information 2-2

WARNING: Do not use motor overload relays with an automatic reset feature.

These are dangerous since the process may injure someone if a

sudden or unexpected automatic restart occurs. If manual reset

relays are not available, disable the automatic restart feature using

external control wiring.

WARNING: This unit has an automatic power up start feature that will start the

motor whenever input power is applied and a RUN (FWD or REV)

command is issued and maintained. If an automatic power up start

of the motor could cause injury to personnel, this feature should be

turned off.

WARNING: Be sure the system is properly grounded before applying power. Do

not apply AC power before you ensure that grounds are connected.

Electrical shock can cause serious or fatal injury.

WARNING: Do not remove cover for at least five (5) minutes after AC power is

disconnected to allow capacitors to discharge. Electrical shock can

cause serious or fatal injury.

WARNING: Motor circuit may have high voltage present whenever AC power is

applied, even when motor is not rotating. Electrical shock can

cause serious or fatal injury.

WARNING: Dynamic brake resistors may generate enough heat to ignite

combustible materials. Keep all combustible materials and

flammable vapors away from brake resistors.

Caution: Suitable for use an a circuit capable of delivering not more

than 5,000 RMS symmetrical amperes, at rated voltage.

Caution: Disconnect motor leads (T1, T2 and T3) from control before

you perform a “Megger” test on the motor. Failure to

disconnect motor from the control will result in extensive

damage to the control. The control is tested at the factory for

high voltage / leakage resistance as part of Underwriters

Laboratories Inc. requirements.

Caution: Do not connect AC power to the Motor terminals T1, T2 and

T3. Connecting AC power to these terminals may result in

damage to the control.

Caution: Baldor recommends not using “Grounded Leg Delta”

transformer power leads that may create ground loops.

Instead, we recommend using a four wire Wye.

Page 8

Section 3

Receiving and Installation

3-1 Receiving and Installation MN715P

Receiving & Inspection

The Series 15P Inverter control is thoroughly tested at the factory and

carefully packaged for shipment. When you receive your control, there are

several things you should do immediately.

1. Observe the condition of the shipping container and report any damage

immediately to the commercial carrier that delivered your control.

2. Verify that the control you received is the same as listed on your

purchase order.

3. If the control is to be stored for several weeks before use, be sure that it

is stored in a location that conforms to published storage specifications.

(Refer to Section 6 of this manual).

Physical Installation

The mounting location is important. The control should be installed in an area

that is protected from direct sunlight, corrosives, harmful gases or liquids,

dust, metallic particles and vibration. Exposure to these elements can reduce

the operating life and degrade performance of the control.

Several other factors should be carefully evaluated when selecting a location

for installation:

1. For effective cooling and maintenance, the control should be mounted

on a smooth, non-flammable vertical surface. Table 3-1 lists the Watts

Loss ratings for enclosure sizing.

2. Provide at least two inches of clearance on all sides for airflow.

3. Front access must be provided to allow the control cover to be opened

or removed for service and to allow viewing of the Keypad LEDs.

4. Altitude derating. Up to 3300 feet (1000 meters), no derating is

required. Above 3300 feet, derate peak or continuous output current by

2% for each 1000 feet above 3300 feet.

5. Temperature derating. Up to 40°C, no derating is required. Above

40°C, derate peak or continuous output current by 2% per °C above

40°C.

Maximum ambient is 55°C.

Table 3-1 Series 15P Watts Loss Ratings

115VAC 230VAC 460VAC

2.5kHz

PWM

7.5kHz

PWM

2.5kHz

PWM

7.5kHz

PWM

2.5kHz

PWM

7.5kHz

PWM

17 Watts/

Amp

20 Watts/

Amp

17 Watts/

Amp

20 Watts/

Amp

19 Watts/

Amp

28 Watts/

Amp

Control Installation

The control must be securely fastened to the mounting surface. Use the four

(4) mounting holes to fasten the control to the mounting surface or enclosure.

Shock Mounting

If the control will be subjected to levels of shock greater than 1G or vibration

greater than 0.5G at 10 to 60Hz, the control should be shock mounted.

Excessive vibration within the control can cause internal connections to

loosen and could lead to component failure or electrical shock hazard.

Page 9

MN715P Receiving and Installation 3-2

Electrical Installation

Interconnection wiring is required between the motor control, AC power

source, motor, host control and any operator interface stations. Use UL listed

closed loop connectors that are of an appropriate size for the wire gauge

being used. Connectors are to be installed using crimp tool specified by the

manufacturer of the connector. Only Class 1 wiring should be used.

System Grounding

Baldor controls are designed to be powered from standard three phase lines

that are electrically symmetrical with respect to ground. System grounding is

an important step in the overall installation to prevent problems.

Input Current Requirements

Table 3-2 Input Current Requirements for Stock Products

115VAC − 1f

230VAC − 3f 460VAC − 3f

Catalog

Numbers

Input

Amps

Catalog

Numbers

Input

Amps

Catalog

Numbers

Input

Amps

ID15P1F33−ER 3.5 ID15P201−ER 4.5 ID15P401−ER 2.5

ID15P1F50−ER 5.0 ID15P201F5−ER 7.0 ID15P401F5−ER 3.5

ID15P1F75−ER 7.5 ID15P202−ER 8.0 ID15P402−ER 4.0

ID15P101−ER 10.0 ID15P203−ER 11.0 ID15P403−ER 5.5

ID15P205−ER 15.0 ID15P405−ER 9.0

ID15P407−ER 10.0

ID15P410V−ER 13.0

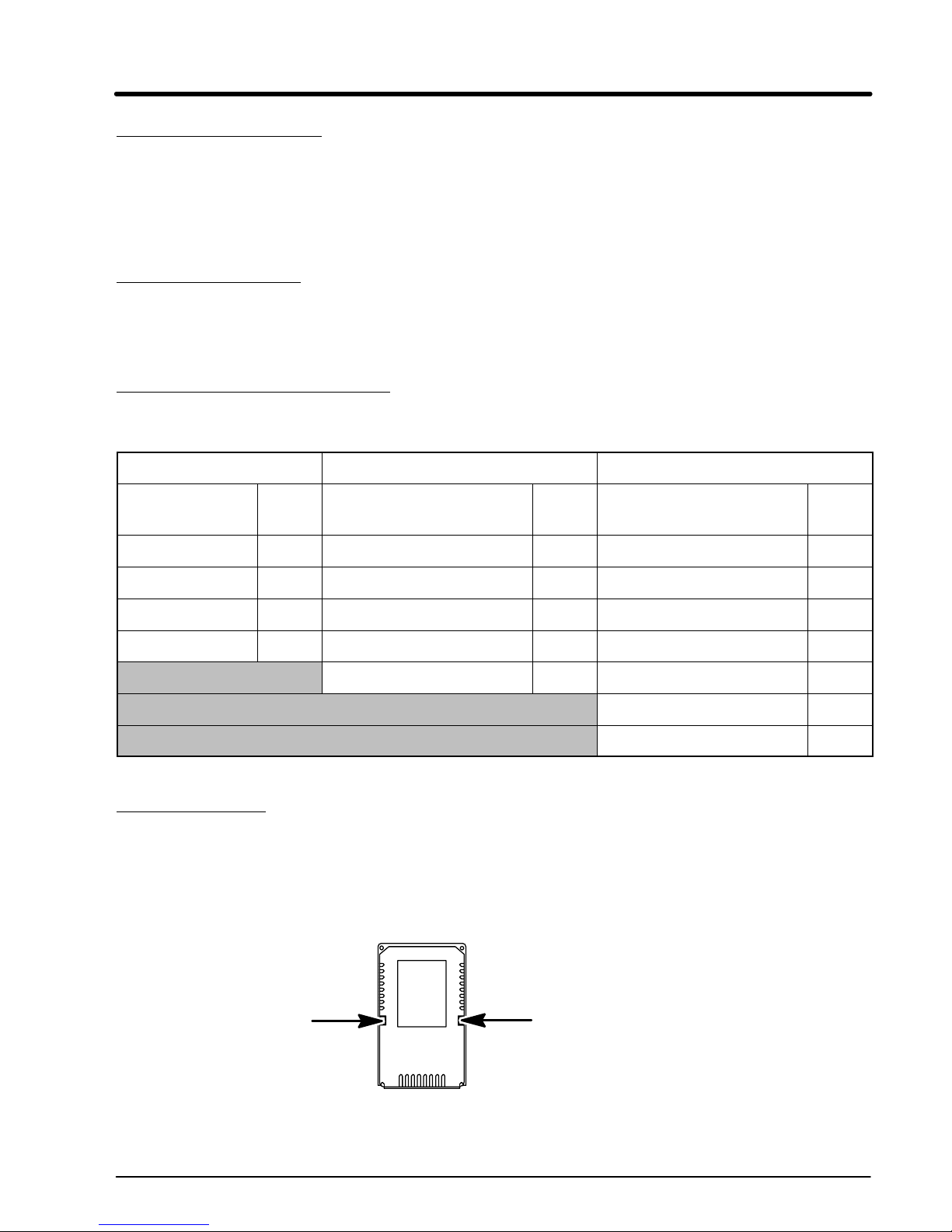

Cover Removal

The cover is made of plastic and could be damaged during removal if handled

roughly. Refer to Figure 3-1. Insert a screw driver or small blade tool and pry

the cover outward as shown to release the side.

When both sides are released, remove the cover.

Figure 3-1 Cover Removal

Use small screw driver or

suitable tool to pry cover

slightly outward to release

cover from its catch.

Use small screw driver or

suitable tool to pry cover

slightly outward to release

cover from its catch.

Page 10

3-3 Receiving and Installation MN715P

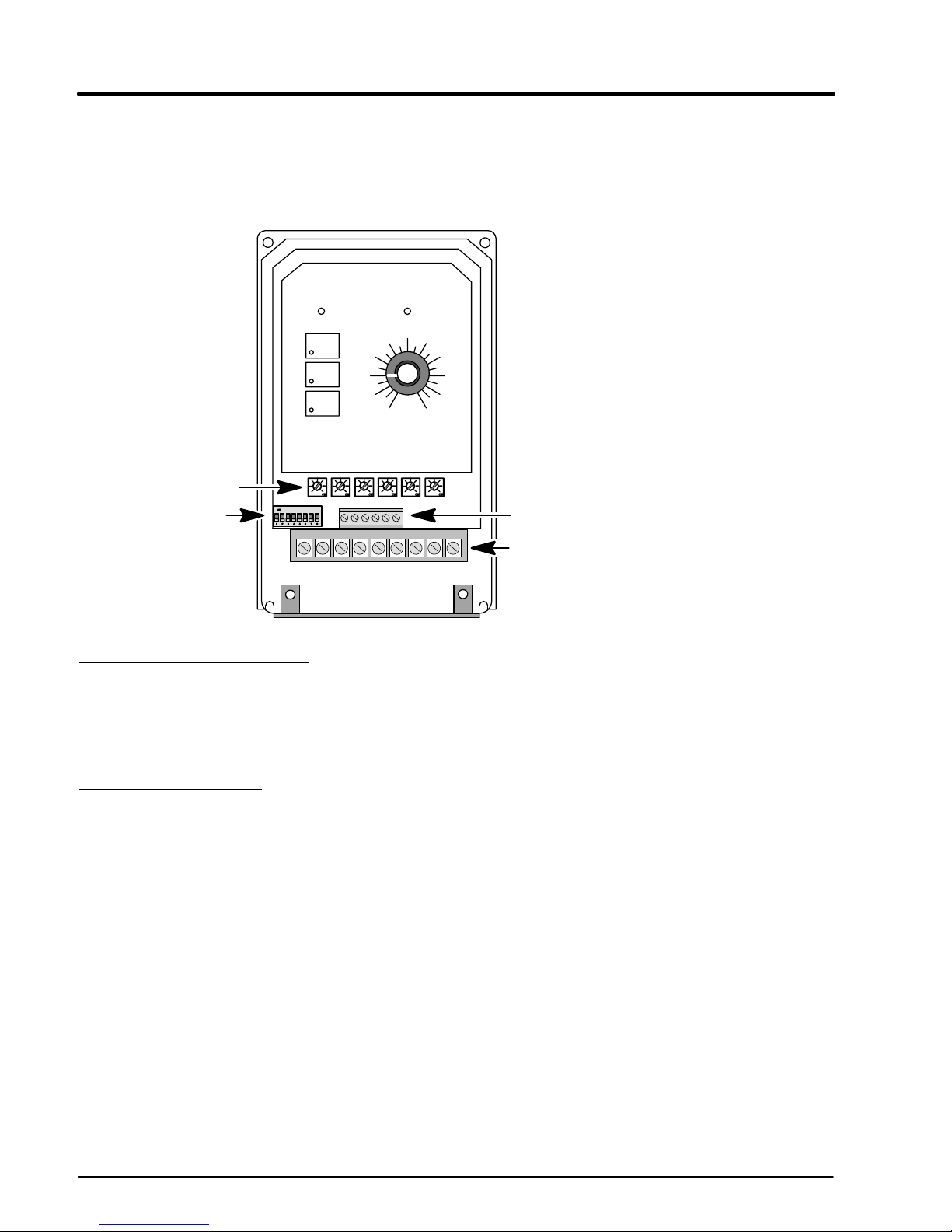

Terminal Identification

The terminals for signal, AC power and motor connections are shown in

Figure 3-2. Separate ground connections are provided for power and

motor grounds.

Figure 3-2 Terminal Identification

J4 Control Terminal Strip

J5 Power Terminal Strip

Power

GND

Motor

GND

L1 L2 L3 T1 T2 T3B−R2 R1

1

P1 P2 P3 P4 P5 P6

S1 DIP Switch

Potentiometers

P1 − P6

POWER FAULT

FWD

REV

STOP

0

10

20

30

40

50

60

70

80

90

100

% Speed

AC Line Connections

A power disconnect should be installed between the input power service and

the control for a fail-safe method to disconnect power. The control will remain

in a powered-up condition until all input power is removed from the control and

the internal bus voltage is discharged.

Protective Devices

Recommended fuse sizes are based on the following:

115% of maximum continuous current for time delay.

150% of maximum continuous current for Fast or Very Fast action.

Note: These general size recommendations do not consider harmonic currents or

ambient temperatures greater than 40°C.

Be sure a suitable input power protection device is installed. Use the

recommended fuses listed in Tables 3-4 and 3-5 (Wire Size and Protection

Devices). Input and output wire size is based on the use of copper conductor

wire rated at 75 °C. The table is specified for NEMA B motors.

Fast Action Fuses: 115/230VAC, Buss KTN

460VAC, Buss KTS

Very Fast Action 115/230VAC, Buss JJN

Fuses: 460VAC, Buss JJS

Time Delay Fuses: 115/230VAC, Buss FRN

460VAC, Buss FRS

Page 11

MN715P Receiving and Installation 3-4

Line Impedance

The Baldor Series 15J control requires a minimum line impedance of 1%. The

input impedance of the power lines can be determined as follows:

Measure the line to line voltage at no load and at full rated load. Use

these measured values to calculate impedance as follows:

%Impedance +

(Volts

NoLoad

* Volts

FullLoad

)

(Volts

NoLoad

)

100

Table 3-3 Recommended Line Reactors

230VAC, 60Hz, 3% Impendance 460VAC, 60Hz, 3% Impendance

Catalog No. HP Amps Inductance

(mH)

Catalog No. HP Amps Inductacne

(mH)

LRAC00401 1 4 3 LRAC00202 1 2 12

LRAC00801 1.5 8 1.15 LRAC00202 1.5 2 12

LRAC00801 2 8 1.15 LRAC00402 2 4 6.5

LRAC01201 3 12 1.25 LRAC00402 3 4 6.5

LRAC01801 5 18 0.8 LRAC00802 5 8 3.0

LRAC3501 7.5 25 0.5 LRAC01202 7.5 12 2.5

LRAC01802 10 18 1.5

Line Reactors

3 phase line reactors are available from Baldor. The size of the line reactor to

use is based on the maximum continuous load. If providing your own line

reactor, use the following formula to calculate the minimum inductance

required. Table 3-2 lists the input current required for this calculation. Line

reactors may be used at the control output to the motor. When used this way,

they are called Load Reactors.

L +

(V

L*L

0.01)

(I 3Ǹ 377)

Where: L Minimum inductance in henrys.

V

L-L

Input volts measured line to line.

0.01 Desired percentage of input impedance (1% shown).

I Input current rating of control.

377 Constant used with 60Hz power.

Use 314 with 50Hz power.

Page 12

3-5 Receiving and Installation MN715P

Three Phase Wire Size and Protection Devices

Table 3-4 Wire Size and Protection Devices - 3 phase

Control

Control

Rating

I

nput Fuse

Wire G

auge

Input

Volts

Output HP

Fast Acting

Amps

Time Delay

Amps

AWG mm

2

230 1 6 5 14 2.08

230 1.5 8 7 14 2.08

230 2 12 9 14 2.08

230 3 15 12 14 2.08

230 5 25 20 12 3.31

460 1 3 2.5 14 2.08

460 1.5 4 3.5 14 2.08

460 2 5 4.5 14 2.08

460 3 8 6.3 14 2.08

460 5 12 10 14 2.08

460 7.5 17.5 15 14 2.08

460 10.0 20 17.5 12 3.31

Note: All wire sizes are based on 75°C copper wire, 1% line impedance.

Figure 3-3 Three Phase AC Power and Motor Connections

L1 L2 L3

L1 L2 L3

Earth

AC Motor is not provided with control.

Baldor

Series 15P

Control

Metal conduit should be used to shield output wires

(from T1, T2, T3 of control to T1, T2, T3 of motor).

T1 T2 T3

T1

T2 T3

G

Shield wires inside a metal conduit.

*Optional

Line

Reactor

A1 B1 C1

A2 B2 C2

* Optional components not

provided with 15P Control.

Page 13

MN715P Receiving and Installation 3-6

115VAC 1 Phase Wire Size and Protection Devices

Table 3-5 Wire Size and Protection Devices - 1 phase

Control

I

nput Fuse

Wire G

auge

Output

Rating

HP

Fast Acting

Amps

Time Delay

Amps

AWG mm

2

0.33 10 10 14 2.08

0.5 10 10 14 2.08

0.75 15 10 14 2.08

1.0 20 15 14 2.08

Note: All wire sizes are based on 75°C copper wire, 1% line impedance.

Figure 3-4 Single Phase AC Power and Motor Connections

L1 N

Earth

AC Motor is not provided with control.

Baldor

Series 15P

Control

Metal conduit should be used to shield output wires

(from T1, T2, T3 of control to T1, T2, T3 of motor).

T1 T2 T3

T1

T2 T3

G

Shield wires inside a metal conduit.

Motor wire should be sized using the 3 phase

information in Table 3-4.

L1 L2 L3

Page 14

3-7 Receiving and Installation MN715P

230VAC Single Phase Derating for Three Phase Controls

Single phase AC input power can be used to power a three phase control.

However, the continuous and peak current ratings of the control must be

reduced by 35% (derated).

Control

I

nput Fuse

Wire G

auge

Output

Rating

HP

Fast Acting

Amps

Time Delay

Amps

AWG mm

2

0.75 10 9 14 2.08

1 12 10 14 2.08

1.5 15 15 14 2.08

2 20 17.5 14 2.08

3 25 25 12 3.31

Note: All wire sizes are based on 75°C copper wire, 1% line impedance.

Figure 3-5 Single Phase 230VAC Power and Motor Connections

L1 L2

L1 L2 L3

Earth

AC Motor is not provided with control.

Baldor

Series 15P

Control

Metal conduit should be used to shield output wires

(from T1, T2, T3 of control to T1, T2, T3 of motor).

T1 T2 T3

T1

T2 T3

G

Shield wires inside a metal conduit.

Motor wire should be sized using the 3 phase

information in Table 3-4.

Page 15

MN715P Receiving and Installation 3-8

Motor Brake Connections

For motors with spring set brakes, connect the brake power leads and the

motor power leads separately. Because the inverter has variable voltage

output to the motor, the inverter may not supply enough power at low

frequencies for proper brake operation. If using a motor with an internally

connected brake, the brake power leads must be connected to a separate

power source for proper brake operation. Refer to Figure 3-2 for terminal

locations.

Optional Dynamic Brake Hardware

Dynamic Brake (DB) Hardware must be installed on a flat, non-flammable,

vertical surface to obtain effective cooling and operation. The ambient

temperature must not exceed 80°C. DB connections are shown in Figure 3-6.

Figure 3-6 Wiring for RGA Assembly

See recommended Terminal

Tightening Torques in Section 6.

R1

Optional

Dynamic Brake

Resistor

J5

Power Terminal Strip

DB

Terminals

R1

R2

R2

Note: Although not shown, metal conduit should be used to shield all power wires

and motor leads.

General Machinery Load Calculations:

1. Calculate braking duty cycle:

Duty Cycle +

Braking Time

Total Cycle Time

2. Calculate deceleration torque:

T

Decel

+

RPM change Wk

2

308 time

* Friction

(Lb.Ft.)

where: T

Decel

= Deceleration torque in lb-ft.

Wk

2

= Inertia in lb-ft

2

time = In seconds

3. Calculate watts to be dissipated in dynamic braking resistor:

Watts + T

Decel

ǒS

max

* S

min

Ǔ

Duty Cycle (0.0712

)

where: S

max

= Speed to start braking

S

min

= Speed after braking

4. Multiply watts calculated in step 3 by 1.25 to allow for unanticipated

loads (safety factor).

Page 16

3-9 Receiving and Installation MN715P

Analog Input

(S1-7 = OFF)

If S1-7 is OFF, the front panel % Speed potentiometer is selected. The J4

inputs are ignored.

(S1-7 = ON)

One analog input is available at J4-2 and J4-1 as shown in Figure 3-7. The

input may be connected to a potentiometer as shown or an input signal can be

applied to pin J4-2. The analog signal can be 0-10VDC or 4-20 mA as

selected by S1−6 (see Table 3-6).

Note: A potentiometer value of 5k to 10k, 0.5 watt may be used.

Figure 3-7 Analog Input

Analog Ground

Analog Input 1

Pot Reference

Command

Pot

5k or 10k

See recommended terminal tightening torque in section 6.

J4

1

2

3

−

+

Analog Ground

Analog Input 1

Not Used

J4

1

2

3

Signal

Source

0-10VDC or

4-20mA

Table 3-6 S1-6 Switch Settings

S1-6 J4 Description

“OFF”

Voltage

Mode

J4-1 is ground.

J4-2 accepts a 0-10VDC input (from a potentiometer or other signal source).

“ON”

Current

Mode

J4-1 is negative side of the 4-20mA connection.

J4-2 is positive side of the 4-20mA connection.

Page 17

MN715P Receiving and Installation 3-10

Digital Inputs

(S1-8 = OFF)

If S1-8 is OFF, the front panel commands FWD, REV and STOP are selected.

The J4 inputs are ignored.

(S1-8 = ON)

Three inputs are available on the J4 connector. Switch S1-5 determines

whether two wire or three wire operation is used. If two wire is selected

(S1-5= OFF) the STOP input at J4-6 is not used.

Note: Pressing the STOP switch on the front panel keypad will override the J4

commands and cause the motor to decel to a stop.

2 Wire Operation of Digital Inputs (S1-5 = OFF)

J4

4

5

6

Reverse

Not

Used

Forward

J4-4 Forward

Open − Disables forward operation.

Decel to stop.

Closed − Starts forward motor rotation.

J4-5 Reverse

Open − Disables reverse operation.

Decel to stop.

Closed − Starts reverse motor rotation.

1

GND

3 Wire Operation of Digital Inputs (S1-5 = ON)

J4

1

4

5

6

Reverse

Stop

Forward

GND

J4-4 Forward

Momentary Closed − Starts forward

motor rotation.

J4-5 Reverse

Momentary Closed − Starts reverse

motor rotation.

J4-6 Stop

Momentary Open − Motor decels to

stop.

Note: Simultaneous closure of J4-4 and J4-5 will cause the motor to decel to stop if

the motor is running. If the control is in a fault condition, simultaneous closure

of these inputs will attempt a fault reset.

Page 18

Section 4

Setup and Operation

4-1 Setup and Operation MN715P

Overview The operator interface panel is shown in Figure 4-1.

Figure 4-1 Operator Interface

J4 Control Terminal Strip

J5 Power Terminal Strip

Power

GND

Motor

GND

L1 L2 L3 T1 T2 T3B−R2 R1

1

P1 P2 P3 P4 P5 P6

S1

DIP Switch

(All OFF =

factory settings)

POWER FAULT

FWD

REV

STOP

0

10

20

30

40

50

60

70

80

90

100

% Speed

Potentiometers

P1 - P6

POWER

LED is on when AC input power is applied to the control.

FAULT

LED is on when a fault condition is present in the control.

FWD

Press FWD to initiate forward rotation of the motor, in local command mode.

LED is on when control is in forward run mode.

REV

Press REV to initiate reverse rotation of the motor, in local command mode.

LED is on when control is in reverse run mode.

STOP

Press STOP to initiate a stop sequence, in local or remote modes. Depending

on the setting of potentiometer P2, the motor will either ramp or coast to a

stop. The LED is on when the control is in stop mode.

Page 19

MN715P Setup and Operation 4-2

S1 Settings (OFF = Open; ON = Closed)

S1

2X Base1X Base

50 Hz60 Hz

REV DisabledREV Enabled

AutoManual

3 Wire2 Wire

4-20mA Current0-10V Voltage

Remote SpeedLocal Speed

Remote Command

Local Command

Page 20

4-3 Setup and Operation MN715P

S1 Settings Continued

Switch

Setting Description

OFF Base Frequency = 60Hz

1

ON Base Frequency = 50Hz

OFF Maximum frequency limit = Base Frequency (60/50Hz)

2

ON Maximum frequency limit = 2 X Base Frequency (130 or 110 Hz)

OFF Reverse motor rotation ENABLED

3

ON Does not allow reverse motor rotation

OFF Power up Start DISABLED (see notes)

4

ON Power up Start ENABLED the control will resume operation as soon

as power is applied. Power up start is disabled the first time you

power up the drive (see notes).

OFF Terminal 2 wire mode (If S1-8 = ON)

5

ON Terminal 3 wire mode (If S1-8 = ON)

OFF Analog input VOLTAGE (if S1-7 = ON)

6

ON Analog input CURRENT (if S1-7 = ON)

OFF Use local speed reference (front panel potentiometer)

7

ON Use remote speed reference (J4 connector)

OFF Use local commands (front panel FWD, REV, STOP)

8

ON Use remote commands (J4 connector)

Note 1: If power up start is ON and local commands are used, the drive will resume

operation in the same FWD or REV direction when power is applied.

Note 2: If power up start is ON and remote 2 wire commands are used, the drive will

resume operation if the forward or reverse switch is still closed (2 wire).

Note 3: If power up start is ON and remote 3 wire commands are used, the drive will

not allow power up start operation (unless the momentary contacts stop and

forward or reverse are manually held closed during power up).

Note 4: After power down, if any S1 switch position is changed, power up start is

cancelled.

Page 21

MN715P Setup and Operation 4-4

Potentiometers P1 - P6 (270° of rotation)

Refer to Figure 4-1 for location of potentiometers.

ACCEL time − P1

The time required to reach the Maximum Frequency setting of P4.

Accelerates at a linear rate.

First half (0 to 135° )= 0.1 sec to 10 sec

last half (135 - 270°)=10sec to 60 sec

10 Sec.

0.1 Sec.

60 Sec.

DECEL time − P2

The time required to ramp to a stop. Decelerates at a linear rate.

First half (0 to 135° )= 0.1 sec to 10 sec

last half (135 - 265°)=10 sec to 60 sec

(265 - 270°)= Coast - Allows motor to coast to stop.

10 Sec.

0.1 Sec.

60

Sec.

Coast

Minimum frequency − P3

Sets the minimum output frequency to the motor . This is a

percentage of the S1-1 base frequency setting.

0

1

/2 F

Base

Maximum frequency − P4

Sets the maximum output frequency to the motor. This is a

percentage of the S1-2 frequency limit setting.

1

/2 LIM

LIM

Current Limit − P5

50% to 100% of control rated amps (see output current rating in

Section 6).

50%

100%

Torque Boost − P6

Increases the nominal motor starting voltage from 0 to 15% to

increase starting torque.

0%

15%

Page 22

4-5 Setup and Operation MN715P

Operation Examples

Operating the Control from the Front Panel

To place the control in local speed and command mode, place S1-7 and S1-8

in the OFF position. Refer to Figure 4-1 for switch location.

Table 4-1 Active Switches for Local Operation

S1

Pos. Position and Description

7 OFF Local Speed Reference (front panel potentiometer)

8 OFF Local command input (front panel FWD, REV, STOP)

The control can operate as follows:

1. Set the P1 through P6 potentiometers as desired.

2. Set switches S1-1, S1-2, S1-3 and S1-4 as desired.

3. Adjust the motor’s speed using the potentiometer on the front panel.

4. Press the FWD or REV keys on the front panel.

5. Press STOP on the front panel to stop motor rotation.

Note: S1-7 and S1-8 can be set so that either or both can be local or remote

inputs. The front panel potentiometer can be used with remote command

inputs by placing S1-7 OFF and S1-8 ON. Also, a remote speed reference

can be used while the front panel switches are used by placing S1-7 ON and

S1-8 OFF.

Speed Adjustment using a Remote Speed Reference

To use an external potentiometer or other signal source, refer to Figures 4-2,

4-3 and 4-4.

Figure 4-2 Remote Potentiometer 2 Wire Operation

J4

1

2

3

4

5

6

Reverse

Not Used

Speed Command

Forward

+10VDC

GND

S1 Pos. Description

5 OFF 2 Wire

6 OFF Voltage mode

7 ON Remote Speed Ref.

8 ON Remote commands

1. Set the P1 through P6 potentiometers as desired.

2. Set switches S1-1, S1-2, S1-3 and S1-4 as desired.

3. Close the FWD or REV key (both Open = Stop).

4. Adjust the motor’s speed using the potentiometer at

J4-2.

5. Press STOP on the front panel to stop motor rotation.

Page 23

MN715P Setup and Operation 4-6

Figure 4-3 Remote 0-10VDC 3 Wire Operation

J4

1

2

3

4

5

6

Reverse

Stop

Speed Command

Forward

Not used

GND

S1 Pos. Description

5 ON 3 Wire

6 OFF Voltage mode

7 ON Remote Speed Ref.

8 ON Remote commands

0-10VDC signal input

Figure 4-4 Remote 4-20mA 2 Wire Operation

J4

1

2

3

4

5

6

Reverse

Not used

+Speed Command

Forward

Not used

−Speed Command

S1 Pos. Description

5 OFF 2 Wire

6 ON Current mode

7 ON Remote Speed Ref.

8 ON Remote commands

4-20mA signal input

Page 24

Section 5

Troubleshooting

5-1 Troubleshooting MN715P

The Baldor Series 15P Control requires very little maintenance, if any, and

should provide years of trouble free operation when installed and applied

correctly. Occasional visual inspection to ensure tight wiring connections and

cleaning to remove dust, dirt, or foreign debris which can reduce heat

dissipation should be considered.

Operational failures called faults are displayed on the LED’s as they occur.

Procedures in this section describe how to recognize a fault and restore

normal operation.

Before service is performed, all input power must be removed from the control

to avoid electrical shock hazard. Most troubleshooting can be performed

using only a digital voltmeter having an input impedance exceeding 1

megohm. In some cases, an oscilloscope with 5 MHz minimum bandwidth

may be useful. Before consulting the factory, check that all power and control

wiring is correct and installed per the recommendations given in this manual.

Figure 5-1 LED Identification

POWER FAULT

FWD

REV

STOP

0

10

20

30

40

50

60

70

80

90

100

% Speed

Fault

LED

FWD LED

REV LED

STOP LED

POWER LED

Fault Code Determination

When the Fault LED is blinking, a failure has been detected. One of five fault

codes is displayed by the flashing Fault LED. To determine the fault code,

carefully observe the blinking pattern. The blinking (2Hz rate) should stop for

1.5 seconds. This 1.5 second pause is the start of the display sequence.

Count the number of blinks that occur between the 1.5 second pauses. One

blink = Fault code 1, two blinks = fault code 2 etc. When the fault code is

determined, refer to Fault Code Descriptions.

Fault Code Descriptions

Five fault codes can be displayed. Carefully examine all LED’s (Power, Fault,

FWD, REV and Stop) to determine the cause of the fault condition. Press

Stop to reset the control.

Page 25

MN715P Troubleshooting 5-2

Fault Code 1

− Non Resettable hardware fault (Power LED is blinking).

May indicate a HW Surge Current, HW Protect or a Power Module fault is

detected.

Power

LED

Fault

LED

Action

Blinking 1 Blink a. Check wiring to ensure a ground fault is not present.

b. Make sure the load is not excessive.

Fault Code 2 − 2 or 60 second Overload or a % Overload Timer fault.

2 or 60 Second Overload May indicate an overcurrent condition but the

control has not tripped, the FWD or REV LED is blinking.

FWD or

REV LED

Fault

LED

Action

Blinking 2 Blinks Press Stop to reset the control. If error remains, try these steps to correct

the fault. (You may have to wait for the % Overload timer to expire if the

STOP LED is blinking).

a. Verify proper sizing of control and motor.

b. If error occurred while ramping motor, check motor, coupling and load.

c. Increase ACCEL time (P1).

d. Increase/Decrease Torque Boost value (P6).

% Overload Timer Indicates that fault code 2 has occurred to many times

and the control needs to cool down. The STOP LED blinks, a timer begins

and all drive operations are suspended until 100% Overload capacity is

regained.

STOP

LED

Fault

LED

Action

Blinking 2 Blinks

During this error, the drive is not resettable. When the drive reaches 100%

Overload left, the fault LED will continue to blink, however, the STOP LED will

remain continuously ON.

Page 26

5-3 Troubleshooting MN715P

Fault Code 3

− Bus faults. May indicate an Over-voltage, Under-voltage or

Precharge fault was detected.

Power LED Fault LED Action

ON 3 blinks Press Stop to reset the control. If error remains, try these steps to

correct the fault.

a. Lengthen DECEL time (P2).

b. Add external dynamic braking assemblies.

c. Correct problem with motor load.

d. Check dynamic brake hardware wiring.

e. Verify proper AC line voltage. May need step down transformer or

line reactor.

f. Check power line disturbances (sags caused by start-up of other

equipment). Monitor power line fluctuations with date and time

imprint to isolate power problem.

Fault Code 4 − Dynamic Brake or Over-temperature faults.

Power LED Fault LED Action

ON 4 Blinks

Press Stop to reset the control. If error remains, try these steps to

correct the fault.

a. Correct motor loading. Verify proper sizing of control, motor and

brake resistor.

b. Relocate control to a cooler operating area. Add cooling fans or air

conditioner to control cabinet.

c. Remove debris from fan and heatsink surfaces.

d. Verify fan operation. Replace fan or check fan wiring.

Fault Code 5 − Microprocessor faults. May indicate a Communication timeout,

incompatible front end and power boards, EEPROM or Power Base ID fault

was detected.

Power LED Fault LED Action

ON 5 Blinks Cable defect or other internal problem.

a. Press Stop to reset the control.

b. Turn power OFF then ON (cycle power). If fault remains call Baldor.

Page 27

Section 6

Specifications and Product Data

MN715P Specifications and Product Data 6-1

Specifications:

Horsepower 0.33-1HP @ 115VAC

1-5 HP @ 230VAC

1-7.5 HP @ 460VAC

Input Frequency 50/60Hz ± 5%

Output Voltage 0 to Maximum Input Voltage (RMS)

Output Current See Ratings Table

Output Frequency 0 to 130Hz

Service Factor 1.0

Duty Continuous

Overload Capacity Constant Torque Mode: 200% for 2 seconds

150% for 60 seconds

Frequency Setting 0-10VDC, 4-20mA or the front panel potentiometer

Frequency Setting

Potentiometer

5k or 10k, 1/2 Watt

Rated Storage Temperature: − 30°C to +65°C

Operating Conditions:

Voltage Range:

115 VAC Models

230 VAC Models

460 VAC Models

90-132 VAC 1 60/50Hz

180-264 VAC 3 60Hz/180-230 VAC 3 50Hz

342-528 VAC 3 60Hz/342-457 VAC 3 50Hz

Input Line Impedance: 1% Minimum Required

Ambient Operating

Temperature:

0 to +40°C

Derate Output 2% per °C

over 40°C to 55°C (130°F) Maximum

Enclosure: NEMA 1: ER (suffix) Models

Humidity: NEMA 1: To 90% RH non-condensing

Altitude: Sea level to 3300 feet (1000 meters)

Derate 2% per 1000 feet (303 meters) above 3300 feet

Shock: 1G

Vibration: 0.5G at 10Hz to 60Hz

LED Indicators Power

Fault

Forward run command

Reverse run command

Stop command

Page 28

6-2 Specifications and Product Data MN715P

Control Specifications:

Control Method Sine wave Carrier input, PWM output

PWM Frequency Rated @ 7.5kHz

V/Hz Ratio Linear with adjustable Torque Boost

Transistor Type IGBT (Insulated Gate Bipolar Transistor)

Torque Boost 0 to 15% adjustable

Brake Torque Up to 60%, external resistor required

Accel/Decel Time Separate rates, 0.1 to 60 sec.

Base Frequency 50 or 60Hz

Frequency Setting 0-10VDC, 4-20mA, and Rotary on front panel

Accel/Decel Separate Accel/Decel rates (0.1 - 60 seconds)

Auto Start ON or OFF

Protective Functions Inverter trip − Over voltage, over current, under voltage, motor

overload

Short Circuit − Phase to phase and phase to ground

Analog Input:

Potentiometer Input 0 - 10VDC

Input Full Scale Range 0-10VDC and 4-20mA

Differential Input Common

Mode Rejection

40db

Input Impedance

20k

Digital Inputs: (3 Inputs)

Digital Inputs Forward

Reverse

Stop

Input Impedance

6.8k (Closed contacts standard)

Leakage Current

10A Maximum

Page 29

MN715P Specifications and Product Data 6-3

Ratings Series 15P Stock Products

Rated Rated

Output Current

Catalog No.

Rated

Input

Volts

Rated

Output

Volts

HP kW

Continu-

ous

60 Sec.

Overload

2 Sec.

Overload

ID15P1F33-ER 115 230 0.33 0.25 1.6 2.4 3.2

ID15P1F50-ER 115 230 0.5 0.37 2.3 3.5 4.6

ID15P1F75-ER 115 230 0.75 0.56 3.2 4.8 6.4

ID15P101-ER 115 230 1.0 0.75 4.2 6.3 8.4

ID15P201-ER 230 230 1 0.75 4.2 6.3 8.4

ID15P201F5-ER 230 230 1.5 1.1 6.0 9.0 12.0

ID15P202-ER 230 230 2 1.5 6.8 10.2 13.4

ID15P203-ER 230 230 3 2.2 9.6 14.4 19.2

ID15P205-ER 230 230 5 3.7 15.2 22.8 30.4

ID15P401-ER 460 460 1 0.75 2.1 3.2 4.2

ID15P401F5-ER 460 460 1.5 1.1 3.0 4.5 6.0

ID15P402-ER 460 460 2 1.5 3.4 5.1 6.8

ID15P403-ER 460 460 3 2.2 4.8 7.2 9.6

ID15P405-ER 460 460 5 3.7 7.6 11.4 15.2

ID15P407-ER 460 460 7.5 5.6 11.0 16.5 22.0

Note: All specifications are subject to change without notice.

Dynamic Brake Resistors

Table 6-2 Dynamic Braking Resistor Assemblies (RGJ)

Control

Minimum

Continuous Rated Watts

VAC Ohms

100 200 300 600 1200 2400 4800

115/230 60 RGJ160 RGJ260 RGJ360 RGA660 RGA1260 RGA2460 RGA4860

460 120 RGJ1120 RGJ2120 RGJ3120 RGA6160 RGA12120 RGA24120

Terminal Tightening Torque Specifications

Table 6-3 Torques for “ER”

Tightening

Torque

C

ontro

l Vol

tage

Rating VAC

Control Terminals

(J4)

Power Terminals

(J5)

Lb−in Nm Lb−in Nm

115, 230 and 460 4 0.45 7 0.8

Page 30

6-4 Specifications and Product Data MN715P

Mounting Dimensions

4.396

(112)

7.210

(183)

7.602

(193)

B

POWER FAULT

FWD

REV

STOP

0

10

20

30

40

50

60

70

80

90

100

% Speed

A

A = 5.660 (144) for 230VAC, 5hp and

460VAC 7.5

A = 4.910 (125) all other sizes

B = 4.886 (124) for 230VAC, 5hp and

460VAC 7.5

B = 4.834 (123) all other sizes

For mounting, use four #8 x 1−3/8” long screws.

OM000A03,

OM001A13

0.870 Dia.

inches (mm)

Page 31

Baldor District Offices

Page 32

BALDOR ELECTRIC COMPANY

P.O. Box 2400

Fort Smith, AR 72901−2400

(479) 646−4711

Fax (479) 648−5792

© Baldor Electric Company Printed in USA

MN715P 2/07

Loading...

Loading...