Baldor ID15J202-ER, ID15J101-ER, ID15J1F33-ER, ID15J1F75-ER, ID15J201F5-ER Installation And Operating Manual

...Page 1

Series 15J

Inverter Control

7/04 MN715J

Installation and Operating Manual

Page 2

Table of Contents

MN715J Table of Contents i

Section 1

Quick Start 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick Start Checklist 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-up Procedure 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2

General Information 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Compliance 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3

Receiving and Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving & Inspection 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Remote Keypad Installation 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Installation 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Grounding 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Impedance 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Reactors 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Reactors 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Current Requirements 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cover Removal 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Identification 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Line Connections 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reduced Input Voltage Derating 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Disconnect 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protective Devices 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Three Phase Wire Size and Protection Devices 3-8. . . . . . . . . . . . . . . . . . .

3 Phase Installation 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

115VAC 1 Phase Wire Size and Protection Devices 3-10. . . . . . . . . . . . . . . .

230VAC Single Phase Derating for Three Phase Controls 3-11. . . . . . . . . .

Motor Brake Connections 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Dynamic Brake Hardware 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inputs and Outputs 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Inputs 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Output 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relay Outputs 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Trip Input 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

ii Table of Contents MN715J

Selection of Operating Mode 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Connection 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Run 3 Wire Connection 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Speed Connection 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Pump 2 Wire Connection 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Pump 3 Wire Connection 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Process Control Connection 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Speed Analog 2 Wire Connection 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Speed Analog 3 Wire Connection 3-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EPOT 2 Wire Connection 3-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EPOT 3 Wire Connection 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre-Operation Checklist 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-up Procedure 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 4

Programming and Operation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation Examples 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Control from the Keypad 4-3. . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing the Keypad JOG Command 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Adjustment using Local Speed Reference 4-4. . . . . . . . . . . . . . . . . .

Speed Adjustment using Arrow Keys 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Mode 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Display Contrast 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Screens 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Log Access 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Information Access 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Mode 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Blocks Access for Programming 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Parameter Values 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset Parameters to Factory Settings 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Definitions 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Block Definitions 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 5

Troubleshooting 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Keypad Display - Display Contrast Adjustment 5-1. . . . . . . . . . . . . . . . . . . . . .

Wrong Language Selection 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Information Access 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Access the Fault Log 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Clear the Fault Log 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Noise Considerations 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relay and Contactor Coils 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wires between Controls and Motors 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Drive Situations 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Motor Considerations 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Signal Wires 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

MN715J Table of Contents iii

Section 6

Specifications and Product Data 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications: 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Conditions: 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Display: 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Specifications: 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Inputs: 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Output: 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Inputs: 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Outputs: 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Indications: 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ratings 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Tightening Torque Specifications 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting Dimensions 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Dynamic Brake Hardware A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B

Parameter Values B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C

Remote Keypad Mounting Template C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

iv Table of Contents MN715J

Page 6

Section 1

Quick Start

MN715J Quick Start 1-1

Overview

If you are an experienced user of Baldor controls, you are probably already

familiar with the keypad programming and keypad operation methods. If so,

this quick start guide has been prepared for you. This procedure will help get

your system up and running in the keypad mode quickly and will allow motor

and control operation to be verified. It assumes that the Control and Motor

are correctly installed (see Section 3 for procedures) and that you have an

understanding of the keypad programming & operation. It is not necessary to

wire the terminal strip to operate in the Keypad mode (Section 3 describes

how to wire the terminal strip).

The quick start procedure is as follows:

1. Read the Safety Notice and Precautions in section 2 of this manual.

2. Mount the control. Refer to Section 3, “Physical Installation” procedure.

3. Connect AC power. Refer to Section 3, “AC Line Connections”.

4. Connect the motor. Refer to Section 3, “AC Line Connections”.

Quick Start Checklist Check of electrical items.

1. Verify that the AC line voltage at the source matches the control rating.

2. Inspect all power connections for accuracy, workmanship and tightness

as well as compliance to codes.

3. Verify that the control and motor are grounded to each other and the

control is connected to earth ground.

4. Check all signal wiring for accuracy.

5. Be certain all brake coils, contactors and relay coils have noise

suppression. This should be an R-C filter for AC coils and reverse

polarity diodes for DC coils. MOV type transient suppression is not

adequate.

Check of Motors and Couplings

1. Verify freedom of motion of motor shaft.

2. Verify that all motor couplings are tight without backlash.

3. If holding brakes are used, verify they are properly adjusted to fully

release and set to the desired torque value.

Page 7

1-2 Quick Start MN715J

WARNING: Make sure that unexpected operation of the motor shaft during start

up will not cause injury to personnel or damage to equipment.

Power-up Procedure

1. Turn power on. Be sure no faults are displayed on the keypad display.

2. Set the Level 1 Input block, Operating Mode to “Keypad”.

3. Set the Level 2 Output Limits block, “MIN Output FREQ” parameter.

4. Set the Level 2 Output Limits block, “MAX Output FREQ” parameter.

5. If the desired peak current limit setting is not correct, set the Level 2

Output Limits block, “PK Current Limit” parameter as desired.

6. Enter the following motor data in the Level 2 Motor Data block

parameters:

Motor Rated Amps (FLA)

Motor Rated Speed (base speed)

Motor Rated Frequency (Nameplate)

7. If External Dynamic Brake hardware is used, set the Level 2 Brake

Adjust block parameters as desired.

8. Set the Level 1 V/HZ Boost block, “V/HZ Profile” parameter for the

correct V/Hz ratio for your application.

9. If the load is a high initial starting torque type, the torque boost and accel

time may need to be increased. Set the Level 1 V/HZ Boost block,

“Torque Boost” and the Level 1 Accel/Decel Rate block, “Accel Time #1”

as required.

10. Select and program additional parameters to suit your application.

The control is now ready for use in keypad mode. The terminal strip wiring

may be changed and different parameter values used for another operating

mode.

Page 8

Section 2

General Information

MN715J General Information 2-1

CE Compliance

A custom unit may be required, contact Baldor. Compliance to Directive

89/336/EEC is the responsibility of the system integrator. A control, motor and

all system components must have proper shielding grounding and filtering as

described in MN1383. Please refer to MN1383 for installation techniques for

CE compliance.

Overview

The Baldor Series 15J control is a PWM inverter motor control. The control

operates by converting AC line power into fixed DC power. The DC power is

then pulse width modulated into synthesized three-phase AC line voltage for

the motor. In this way, the control converts the fixed input frequency to

variable output frequency to cause the motor to have variable speed

operation.

The rated horsepower of the control is based on a NEMA design B four pole

motor and 60Hz operation at nominal rated input voltage. If any other type of

motor is used, or input voltage other than 230 or 460 VAC is applied to the

input terminals, the control should be sized to the motor using the rated output

current of the control.

The Baldor Series 15J control may be used in many different applications. It

can be programmed to operate in a number of operating modes, PWM rates

and output current levels for custom operation.

It is the responsibility of the user to determine the optimum operating mode for

the application. These choices are programmed using the keypad as

explained in the programming section of this manual.

Limited Warranty

For a period of two (2) years from the date of original purchase, BALDOR will repair or replace

without charge controls and accessories which our examination proves to be defective in

material or workmanship. This warranty is valid if the unit has not been tampered with by

unauthorized persons, misused, abused, or improperly installed and has been used in

accordance with the instructions and/or ratings supplied. This warranty is in lieu of any other

warranty or guarantee expressed or implied. BALDOR shall not be held responsible for any

expense (including installation and removal), inconvenience, or consequential damage,

including injury to any person or property caused by items of our manufacture or sale. (Some

states do not allow exclusion or limitation of incidental or consequential damages, so the above

exclusion may not apply.) In any event, BALDOR’s total liability, under all circumstances, shall

not exceed the full purchase price of the control. Claims for purchase price refunds, repairs, or

replacements must be referred to BALDOR with all pertinent data as to the defect, the date

purchased, the task performed by the control, and the problem encountered. No liability is

assumed for expendable items such as fuses.

Goods may be returned only with written notification including a BALDOR Return Authorization

Number and any return shipments must be prepaid.

Page 9

2-2 General Information MN715J

Safety Notice:

This equipment contains voltages that may be as great as 1000 volts!

Electrical shock can cause serious or fatal injury. Only qualified personnel

should attempt the start–up procedure or troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts

or parts that are driven by this equipment. Improper use can cause serious or

fatal injury. Only qualified personnel should attempt the start–up procedure or

troubleshoot this equipment.

PRECAUTIONS:

WARNING: Do not touch any circuit board, power device or electrical

connection before you first ensure that power has been

disconnected and there is no high voltage present from this

equipment or other equipment to which it is connected. Electrical

shock can cause serious or fatal injury. Only qualified personnel

should attempt the start–up procedure or troubleshoot this

equipment.

WARNING: Be sure that you are completely familiar with the safe operation of

this equipment. This equipment may be connected to other

machines that have rotating parts or parts that are controlled by this

equipment. Improper use can cause serious or fatal injury. Only

qualified personnel should attempt the start–up procedure or

troubleshoot this equipment.

WARNING: Do not use motor overload relays with an automatic reset feature.

These are dangerous since the process may injure someone if a

sudden or unexpected automatic restart occurs. If manual reset

relays are not available, disable the automatic restart feature using

external control wiring.

WARNING: This unit has an automatic restart feature that will start the motor

whenever input power is applied and a RUN (FWD or REV) command

is issued and maintained. If an automatic restart of the motor could

cause injury to personnel, the automatic restart feature should be

disabled by changing the “Restart Auto/Man” parameter to

MANUAL.

WARNING: Be sure the system is properly grounded before applying power. Do

not apply AC power before you ensure that grounds are connected.

Electrical shock can cause serious or fatal injury.

WARNING: Do not remove cover for at least five (5) minutes after AC power is

disconnected to allow capacitors to discharge. Electrical shock can

cause serious or fatal injury.

WARNING: Improper operation of control may cause violent motion of the

motor shaft and driven equipment. Be certain that unexpected

motor shaft movement will not cause injury to personnel or damage

to equipment. Peak torque of several times the rated motor torque

can occur during control failure.

Continued on next page.

Page 10

MN715J General Information 2-3

WARNING: Motor circuit may have high voltage present whenever AC power is

applied, even when motor is not rotating. Electrical shock can

cause serious or fatal injury.

WARNING: Dynamic brake resistors may generate enough heat to ignite

combustible materials. Keep all combustible materials and

flammable vapors away from brake resistors.

Caution: Suitable for use on a circuit capable of delivering not more than

5,000 RMS symmetrical amperes, at rated voltage.

Caution: Do not supply any power on the External Trip (motor thermostat)

leads at J4-17 or J4-18 as the control may be damaged. Use a dry

contact type that requires no external power to operate.

Caution: Disconnect motor leads (T1, T2 and T3) from control before you

perform a “Megger” test on the motor. Failure to disconnect motor

from the control will result in extensive damage to the control. The

control is tested at the factory for high voltage / leakage resistance

as part of Underwriters Laboratories Inc. requirements.

Caution: Do not connect AC power to the motor terminals T1, T2 and T3.

Connecting AC power to these terminals may result in damage to

the control.

Caution: Baldor recommends not using “Grounded Leg Delta” transformer

power leads that may create ground loops. Instead, we recommend

using a four wire Wye.

Page 11

2-4 General Information MN715J

Page 12

Section 3

Receiving and Installation

MN715J Receiving and Installation 3-1

Receiving & Inspection

The Series 15J Inverter Control is thoroughly tested at the factory and

carefully packaged for shipment. When you receive your control, there are

several things you should do immediately:

1. Observe the condition of the shipping container and report any damage

immediately to the commercial carrier that delivered your control.

2. Verify that the control you received is the same as listed on your

purchase order.

3. If the control is to be stored for several weeks before use, be sure that it

is stored in a location that conforms to published storage specifications.

(Refer to Section 6 of this manual).

Physical Installation

The mounting location of the 15J is important. It should be installed in an area

that is protected from direct sunlight, corrosives, harmful gases or liquids,

dust, metallic particles, and vibration. Exposure to these elements can reduce

the operating life and degrade performance of the control.

Several other factors should be carefully evaluated when selecting a location

for installation:

1. For effective cooling and maintenance, the control should be mounted

on a smooth, non-flammable vertical surface. Table 3-1 lists the Watts

Loss ratings for enclosure sizing.

2. At least two inches clearance must be provided on all sides for airflow.

3. Front access must be provided to allow the control cover to be opened

or removed for service and to allow viewing of the Keypad Display.

4. Altitude derating. Up to 3300 feet (1000 meters), no derating required.

Above 3300 feet, derate output current by 2% for each 1000 feet above

3300 feet.

5. Temperature derating. Up to 40°C, no derating required. Above 40°C,

derate output current by 2% per °C above 40°C.

Maximum ambient is 55°C.

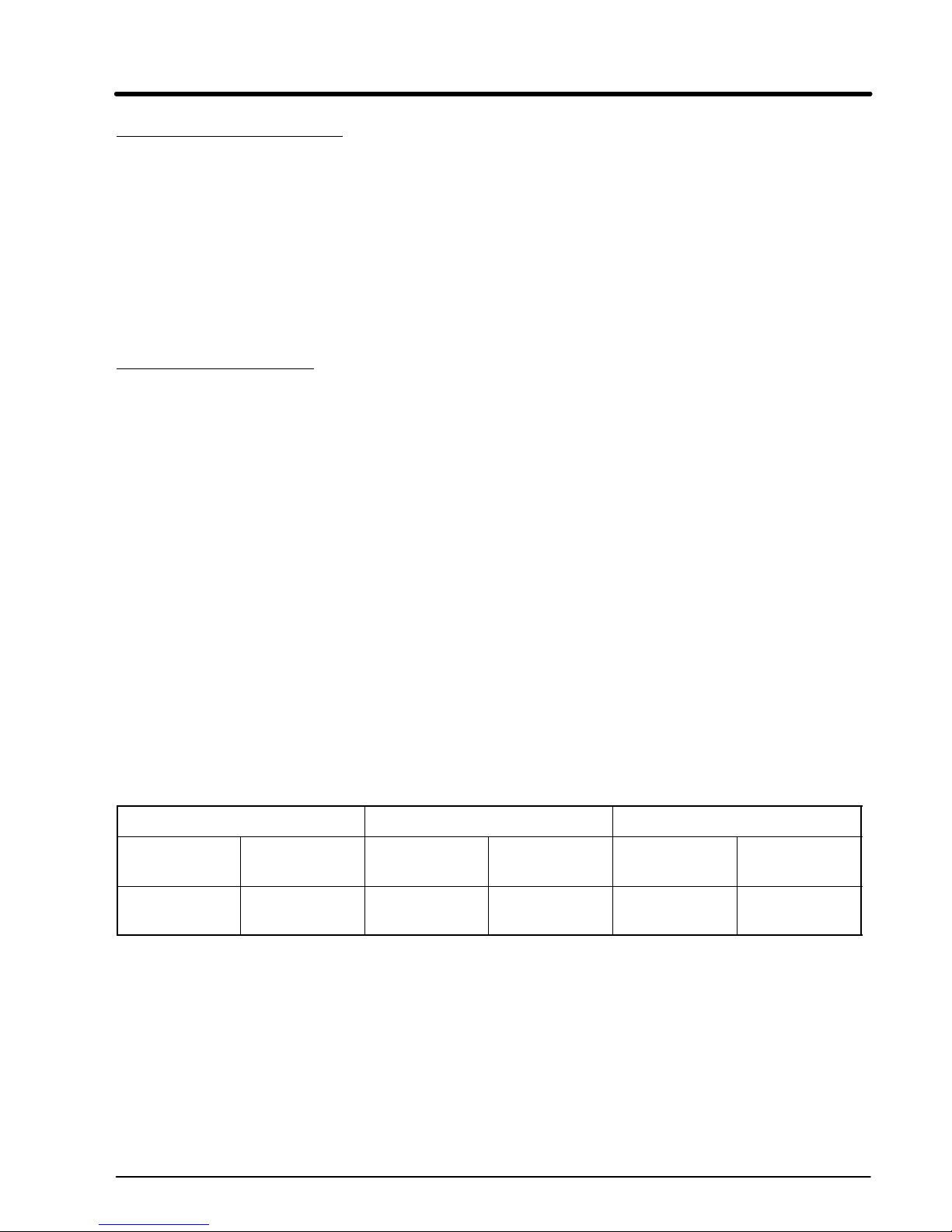

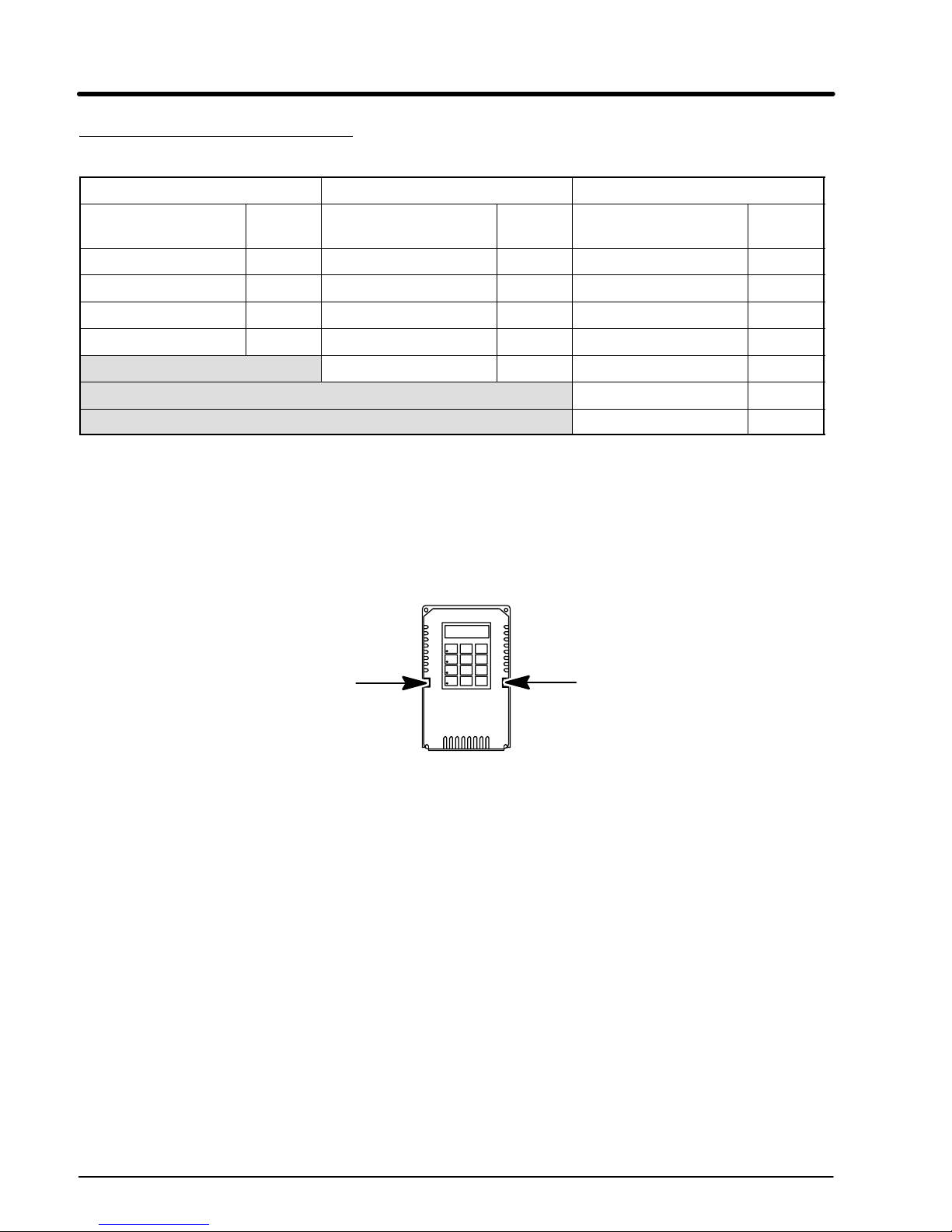

Table 3-1 Series 15J Watts Loss Ratings

115VAC 230VAC 460VAC

2.5kHz

PWM

7.5kHz

PWM

2.5kHz

PWM

7.5kHz

PWM

2.5kHz

PWM

7.5kHz

PWM

17 Watts/

Amp

20 Watts/

Amp

17 Watts/

Amp

20 Watts/

Amp

19 Watts/

Amp

28 Watts/

Amp

Control Installation

The control must be securely fastened to the mounting surface. Use the four

(4) mounting holes to fasten the control to the mounting surface or enclosure.

Shock Mounting

If the control will be subjected to levels of shock greater than 1G or vibration

greater than 0.5G at 10 to 60Hz, the control should be shock mounted.

Excessive vibration within the control could cause internal connections to

loosen and cause component failure or electrical shock hazard.

Page 13

3-2 Receiving and Installation MN715J

Optional Remote Keypad Installation

Note: Requires phone jack connector on the control board. Some models may not

have a phone jack installed. If the phone jack is not installed and you wish to

connect a remote keypad, contact Baldor.

A separate keypad may be remotely mounted using an optional Baldor

keypad extension cable (in addition to the keypad within the control). Keypad

assembly (CBLSM015KP - 5 ft, CBLSM046KP - 15 ft or CBLSM091KP - 30 ft)

comes complete with the extension cable and gasket required to mount it to

an enclosure. When the keypad is properly mounted to a NEMA Type 4X

indoor enclosure, it retains the Type 4X indoor rating.

Tools Required:

• Center punch, tap handle, screwdrivers (Phillips and straight) and

crescent wrench.

• 8-32 tap and #29 drill bit (for tapped mounting holes) or #19 drill

(for clearance mounting holes).

• 1-

1

/4″ standard knockout punch (1-11/16″ nominal diameter).

• RTV sealant.

• (4) 8-32 nuts and lock washers.

• Extended 8-32 screws (socket fillister) are required if the mounting

surface is thicker than 12 gauge and is not tapped (clearance mounting

holes).

• Remote keypad mounting template. A tear out copy is provided at the

end of this manual for your convenience. (Photo copy or tear out.)

Mounting Instruction: For tapped mounting holes

1. Locate a flat 4″ wide x 5.5″ minimum height mounting surface. Material

should have sufficient thickness (14 gauge minimum).

2. Place the template on the mounting surface or mark the holes as shown.

3. Accurately center punch the 4 mounting holes (marked A) and the large

knockout (marked B).

4. Drill four #29 mounting holes (A). Thread each hole using an 8-32 tap.

5. Locate the 1-

1

/4″ knockout center (B) and punch using the manufacturers

instructions.

6. Debur knockout and mounting holes making sure the panel stays clean

and flat.

7. Apply RTV to the 4 holes marked (A).

8. Assemble the keypad to the panel. Use 8-32 screws, nuts and lock

washers.

9. From the inside of the panel, apply RTV over each of the four mounting

screws and nuts. Cover a

3

/4″ area around each screw while making

sure to completely encapsulate the nut and washer.

Page 14

MN715J Receiving and Installation 3-3

Mounting Instructions: For clearance mounting holes

1. Locate a flat 4″ wide x 5.5″ minimum high mounting surface. Material

should have sufficient thickness (14 gauge minimum).

2. Place the template on the mounting surface or mark the holes as shown

on the template.

3. Accurately center punch the 4 mounting holes (marked A) and the large

knockout (marked B).

4. Drill four #19 clearance holes (A).

5. Locate the 1-

1

/4″ knockout center (B) and punch using the manufacturers

instructions.

6. Debur knockout and mounting holes making sure the panel stays clean

and flat.

7. Apply RTV to the 4 holes marked (A).

8. Assemble the keypad to the panel. Use 8-32 screws, nuts and lock

washers.

9. From the inside of the panel, apply RTV over each of the four mounting

screws and nuts. Cover a

3

/4″ area around each screw while making

sure to completely encapsulate the nut and washer.

Electrical Installation

Interconnection wiring is required between the motor control, AC power

source, motor, host control and any operator interface stations. Use listed

closed loop connectors that are of appropriate size for the wire gauge being

used. Connectors are to be installed using crimp tool specified by the

manufacturer of the connector. Only Class 1 wiring should be used.

System Grounding

Baldor Controls are designed to be powered from standard three phase lines

that are electrically symmetrical with respect to ground. System grounding is

an important step in the overall installation to prevent problems.

The recommended grounding method is shown in Figure 3-1.

Ungrounded Distribution System

With an ungrounded power distribution system it is possible to have a

continuous current path to ground through the MOV devices. To avoid

equipment damage, an isolation transformer with a grounded secondary is

recommended. This provides three phase AC power that is symmetrical with

respect to ground.

Input Power Conditioning

Baldor controls are designed for direct connection to standard three phase

lines that are electrically symmetrical with respect to ground. Certain power

line conditions must be avoided. An AC line reactor or an isolation

transformer may be required for some power conditions.

S If the feeder or branch circuit that provides power to the control has

permanently connected power factor correction capacitors, an input AC

line reactor or an isolation transformer should be connected between the

power factor correction capacitors and the control.

Page 15

3-4 Receiving and Installation MN715J

S If the feeder or branch circuit that provides power to the control has

power factor correction capacitors that are switched on line and off line,

the capacitors must not be switched while the control is connected to the

AC power line. If the capacitors are switched on line while the control is

still connected to the AC power line, additional protection is required.

TVSS (Transient Voltage Surge Suppressor) of the proper rating should

be installed between the AC line reactor or an isolation transformer and

the AC input to the control.

Line Impedance

The Baldor Series 15J control requires a minimum line impedance of 1%. The

input impedance of the power lines can be determined as follows:

Measure the line to line voltage at no load and at full rated load. Use

these measured values to calculate impedance as follows:

%Impedance +

(Volts

NoLoad

* Volts

FullLoad

)

(Volts

NoLoad

)

100

Line Reactors

3 phase line reactors are available from Baldor. The size of the line reactor to

use is based on the maximum continuous load. If providing your own line

reactor, use the following formula to calculate the minimum inductance

required. Table 3-3 lists the input current required for this calculation.

L +

(V

L*L

0.01)

(I 3Ǹ 377)

Where: L Minimum inductance in henrys.

V

L-L

Input volts measured line to line.

0.01 Desired percentage of input impedance (1% shown).

I Input current rating of control.

377 Constant used with 60Hz power.

Use 314 with 50Hz power.

Table 3-2 Recommended Line Reactors

230VAC, 60Hz, 3% Impendance 460VAC, 60Hz, 3% Impendance

Catalog No. HP Amps Inductance

(mH)

Catalog No. HP Amps Inductacne

(mH)

LRAC00401 1 4 3 LRAC00202 1 2 12

LRAC00801 1.5 8 1.15 LRAC00202 1.5 2 12

LRAC00801 2 8 1.15 LRAC00402 2 4 6.5

LRAC01201 3 12 1.25 LRAC00402 3 4 6.5

LRAC01801 5 18 0.8 LRAC00802 5 8 3.0

LRAC3501 7.5 25 0.5 LRAC01202 7.5 12 2.5

LRAC01802 10 18 1.5

Load Reactors

Line reactors may be used at the control output to the motor. When used this

way, they are called Load Reactors. Load Reactors serve several functions.

S Protect the control from a short circuit at the motor.

S Limit the rate of rise of motor surge currents.

S Slow the rate of change of power the control delivers to the motor.

Load reactors should be installed as close to the control as possible.

Page 16

MN715J Receiving and Installation 3-5

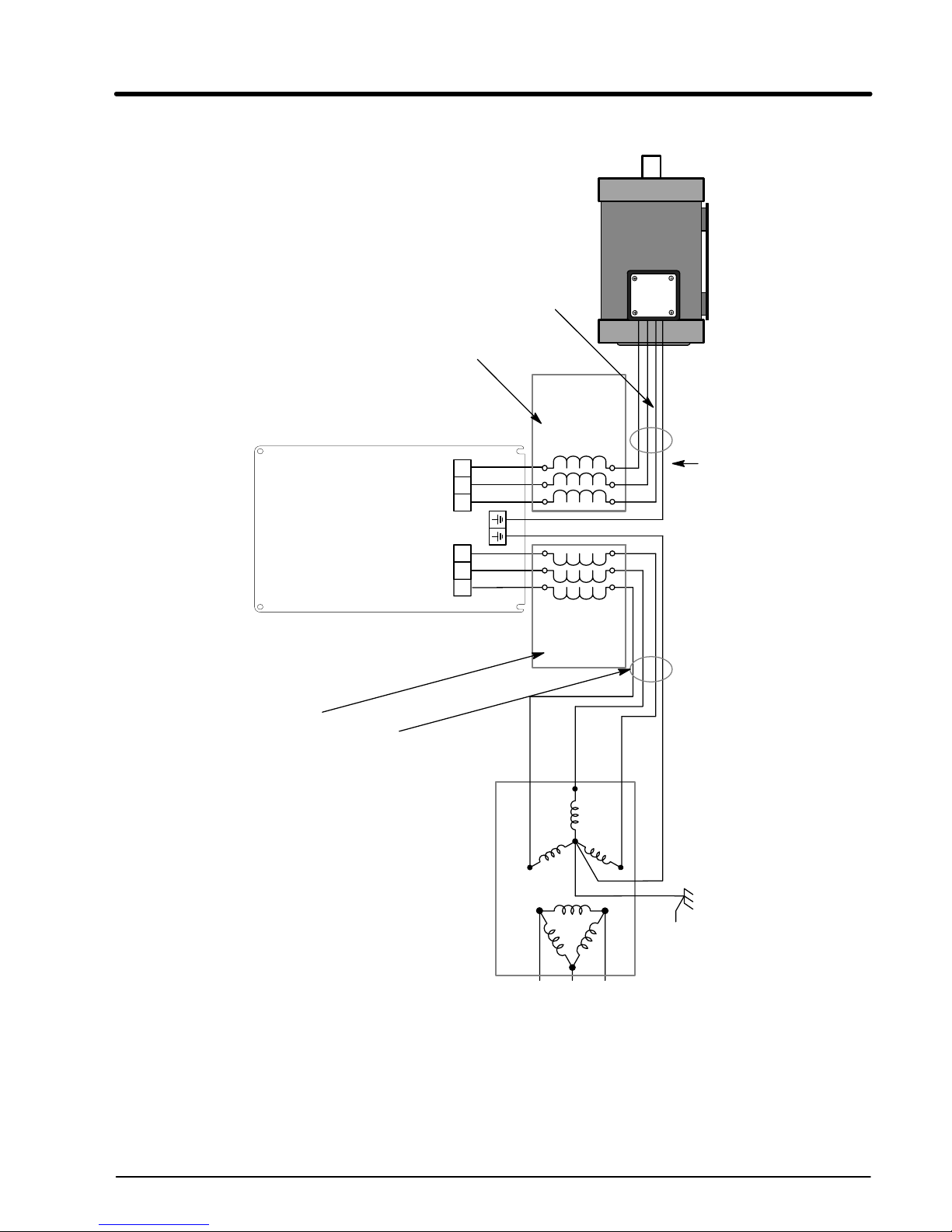

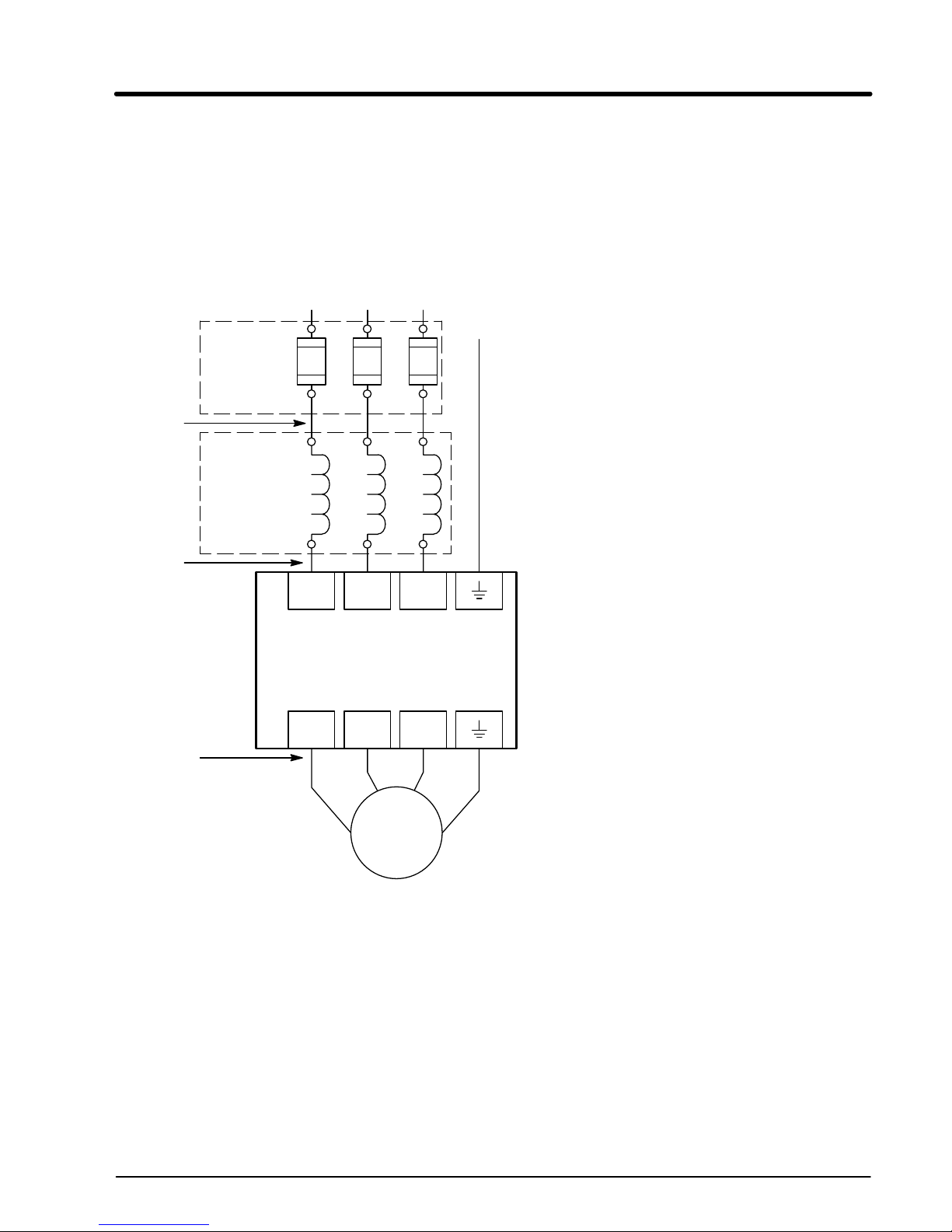

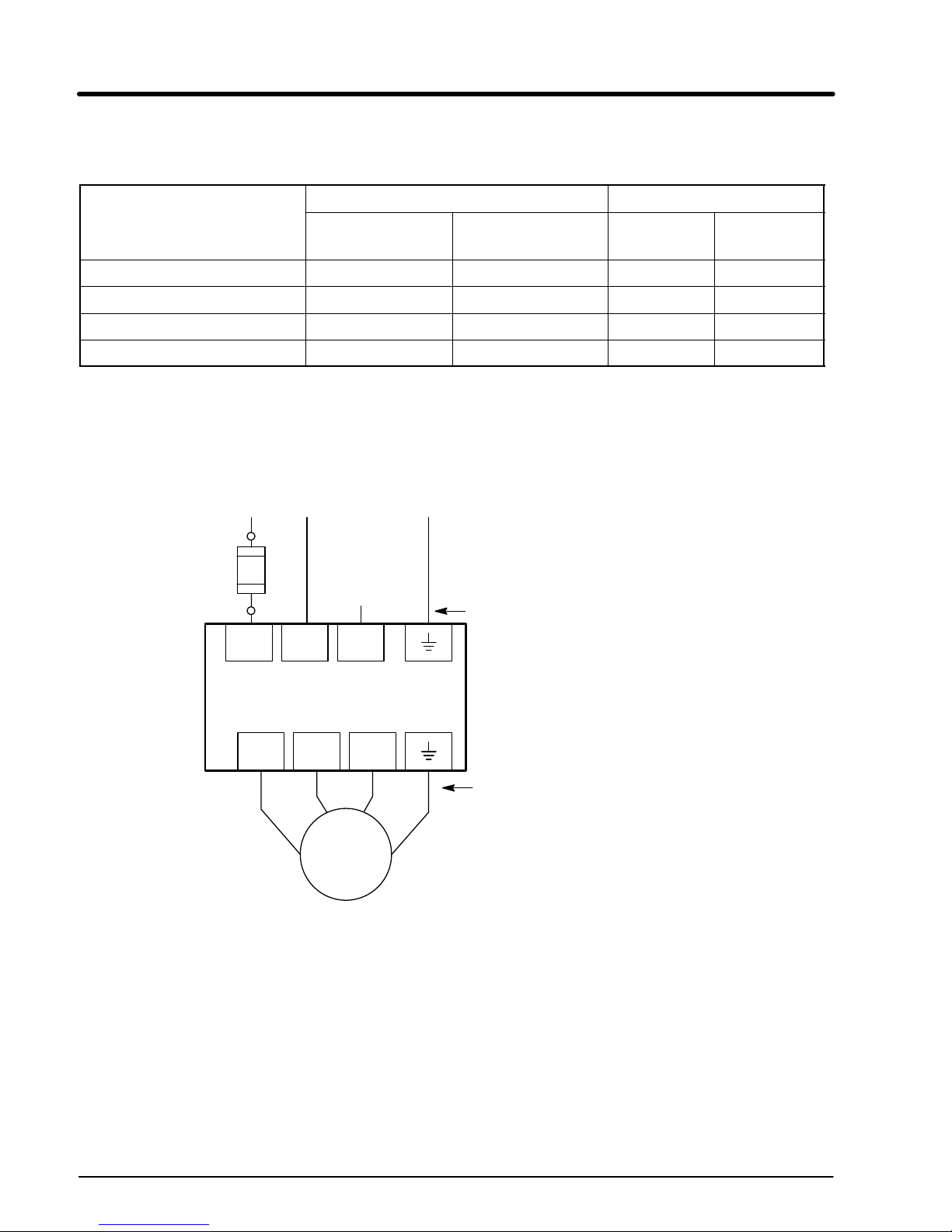

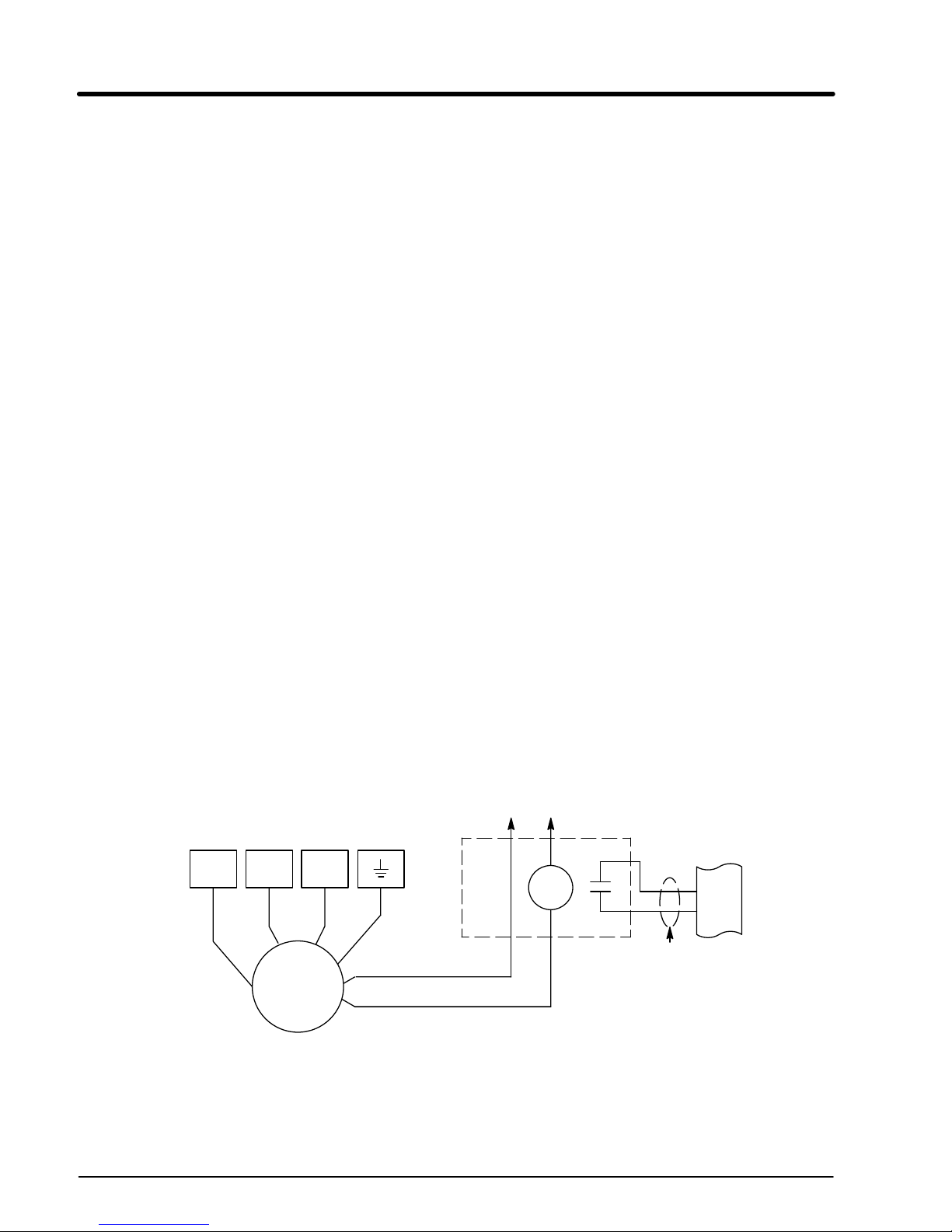

Figure 3-1 Recommended System Grounding

L1

AC Main Supply

Safety

Ground

Driven earth ground

rod (plant ground)

Four Wire

“Wye”

L1

L2

L3

Earth

L2L3 T1 T3

Line

Reactor

Load

Reactor

Route all 4 wires L1, L2, L3 and Earth

(ground) together in conduit or cable.

Route all 4 wires T1, T2, T3 and motor ground

together in conduit or shielded cable.

Connect all wires (including

motor ground) inside the

motor terminal box.

Ground per NEC and Local codes.

Note: A line reactor is recommended

and must be ordered separately.

Note: A load reactor is

recommended and must

be ordered separately.

Baldor Control

T2

Note: Use shielded cable for control

signal wires. Route control

signal wires in conduit. These

wires must be kept separate

from power and motor wires.

Page 17

3-6 Receiving and Installation MN715J

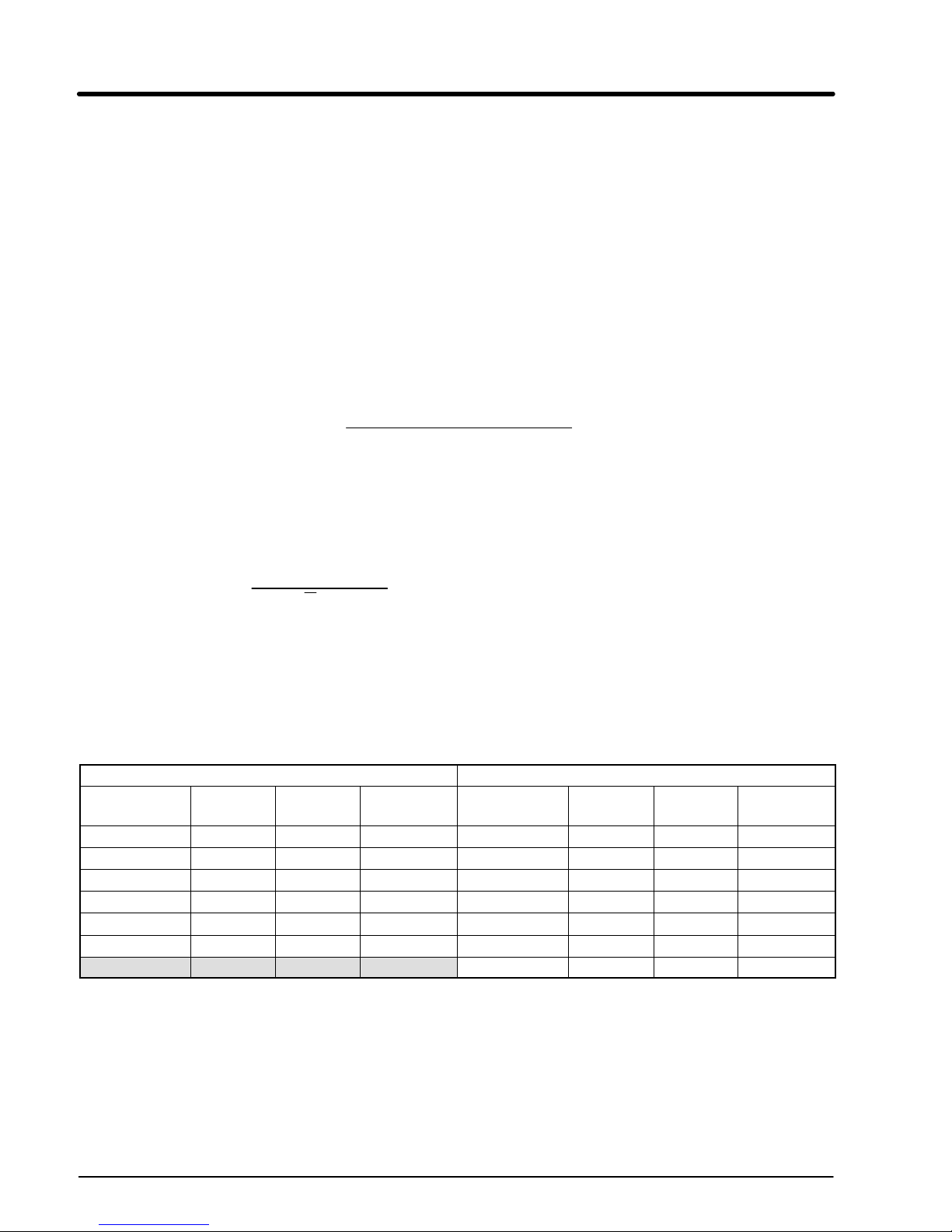

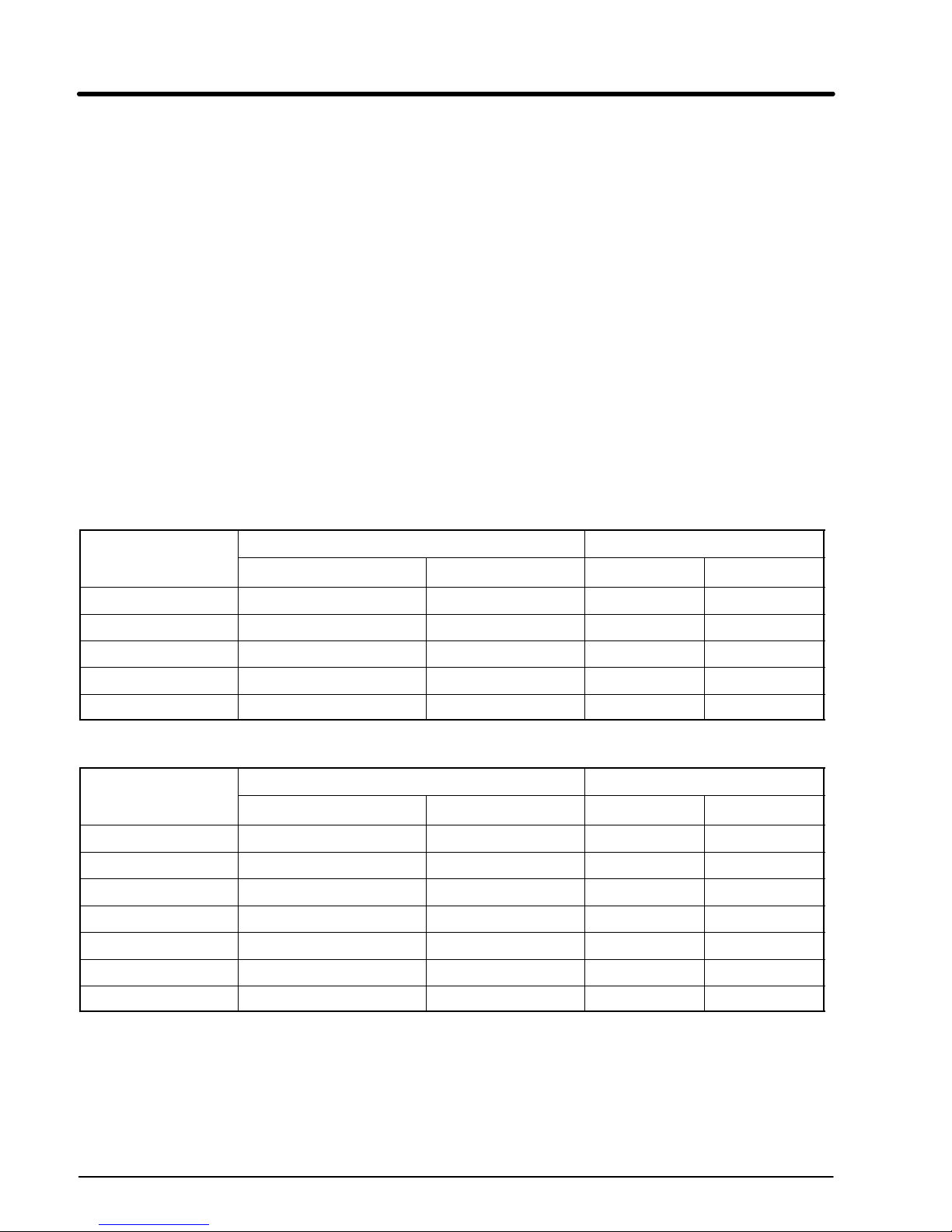

Input Current Requirements

Table 3-3 Input Current Requirements for Stock Products

115VAC - 1f 230VAC - 3f 460VAC - 3f

Catalog

Numbers

Input

Amps

Catalog

Numbers

Input

Amps

Catalog

Numbers

Input

Amps

ID15J1F33-ER 3.5 ID15J201-ER 5.0 ID15J401-ER 2.5

ID15J1F50-ER 5.0 ID15J201F5-ER 7.0 ID15J401F5-ER 3.5

ID15J1F75-ER 7.5 ID15J202-ER 8.0 ID15J402-ER 4.0

ID15J101-ER 10.0 ID15J203-ER 11.0 ID15J403-ER 5.5

ID15J205-ER 15.0 ID15J405-ER 9.0

ID15J407-ER 10.0

ID15J410V-ER 13.0

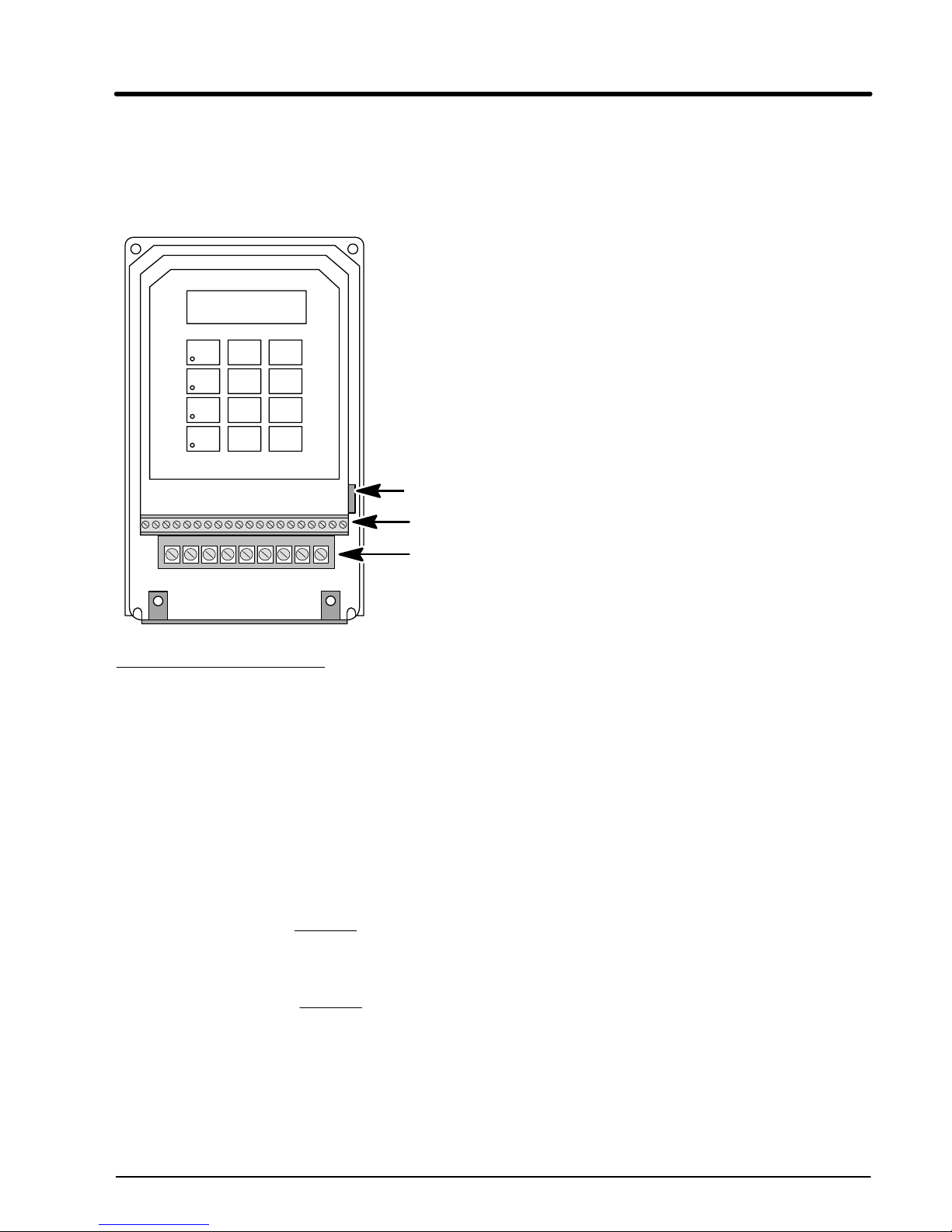

Cover Removal

The cover is made of plastic and could be damaged during removal if handled

roughly. Refer to Figure 3-2. Insert a screwdriver or small blade tool and pry

cover outward as shown to release the side.

When both sides are released, remove the cover.

Figure 3-2 Cover Removal

Use small screwdriver or suitable

tool to pry cover slightly outward

to release cover from catch.

Use small screwdriver or suitable

tool to pry cover slightly outward

to release cover from catch.

Page 18

MN715J Receiving and Installation 3-7

Terminal Identification

The terminals for signal, AC power and motor connections are shown in

Figure 3-3. Separate ground connections are provided for power and

motor grounds.

Figure 3-3 Terminal Identification

J4 Control Terminal Strip

J5 Power Terminal Strip

Power

GND

Motor

GND

L1 L2 L3 T1 T2 T3BĆR2

R1/

B+

120

Shown with cover removed.

Note: J5 is accessible with the cover on.

Keypad may be plugged in or removed

while control is ON. If remote keypad is

plugged into J5, the main keypad is

automatically disabled.

J5 Connector for Optional Remote Keypad

AC Line Connections

Be sure all power to the control is disconnected before proceeding. If power

has been applied to the control, wait at least 5 minutes after power disconnect

for residual voltage across the bus capacitors to discharge.

Reduced Input Voltage Derating

All power ratings stated in Section 6 are for the nominal AC input voltages

(115, 230, or 460). The power rating of the control must be reduced when

operating at a reduced input voltage. The amount of reduction is the ratio of

the voltage change.

Examples:

A 5hp, 230VAC control operating at 208VAC has a reduced power rating of

4.52hp.

5HP

208VAC

230VAC

+ 4.52hp

Likewise, a 5hp, 460VAC control operating at 380VAC has a reduced power

rating of 4.13hp.

5HP

380VAC

460VAC

+ 4.13hp

Power Disconnect

A power disconnect should be installed between the input power service and

the control for a fail-safe method to disconnect power. The control will remain

in a powered-up condition until all input power is removed from the control and

the internal bus voltage is discharged.

Page 19

3-8 Receiving and Installation MN715J

Protective Devices

Recommended fuse sizes are based on the following:

115% of maximum continuous current for time delay.

150% of maximum continuous current for Fast or Very Fast action.

Note: These general size recommendations do not consider harmonic currents or

ambient temperatures greater than 40°C.

Be sure a suitable input power protection device is installed. Use the

recommended fuses listed in Tables 3-4 and 3-5. Input and output wire size is

based on the use of copper conductor wire rated at 75°C. The table is

specified for NEMA B motors.

Fast Action Fuses: 230VAC, Buss KTN

460VAC, Buss KTS

Very Fast Action: 230VAC, Buss JJN

460VAC, Buss JJS

Time Delay Fuses: 230VAC, Buss FRN

460VAC, Buss FRS

Three Phase Wire Size and Protection Devices

Table 3-4 Three Phase Wire Size and Protection Devices 230VAC Controls

Control Power

I

nput Fuse

Wire G

auge

Control Power

Output Rating

Fast Acting Time Delay AWG mm

2

1 6 5 14 2.08

1.5 8 7 14 2.08

2 12 9 14 2.08

3 15 12 14 2.08

5 25 20 12 3.31

Table 3-5 Three Phase Wire Size and Protection Devices 460VAC Controls

Control Power

I

nput Fuse

Wire G

auge

Control Power

Output Rating

Fast Acting Time Delay AWG mm

2

1 3 2.5 14 2.08

1.5 4 3.5 14 2.08

2 5 4.5 14 2.08

3 8 6.3 14 2.08

5 12 10 14 2.08

7.5 17.5 15 14 2.08

10 20 17.5 12 3.31

Note: All wire sizes are based on 75°C copper wire, 1% line impedance. Higher

temperature, smaller gauge wire may be used per NEC and local codes.

Recommended fuses are based on 40°C ambient, maximum continuous

control output current and no harmonic current.

Page 20

MN715J Receiving and Installation 3-9

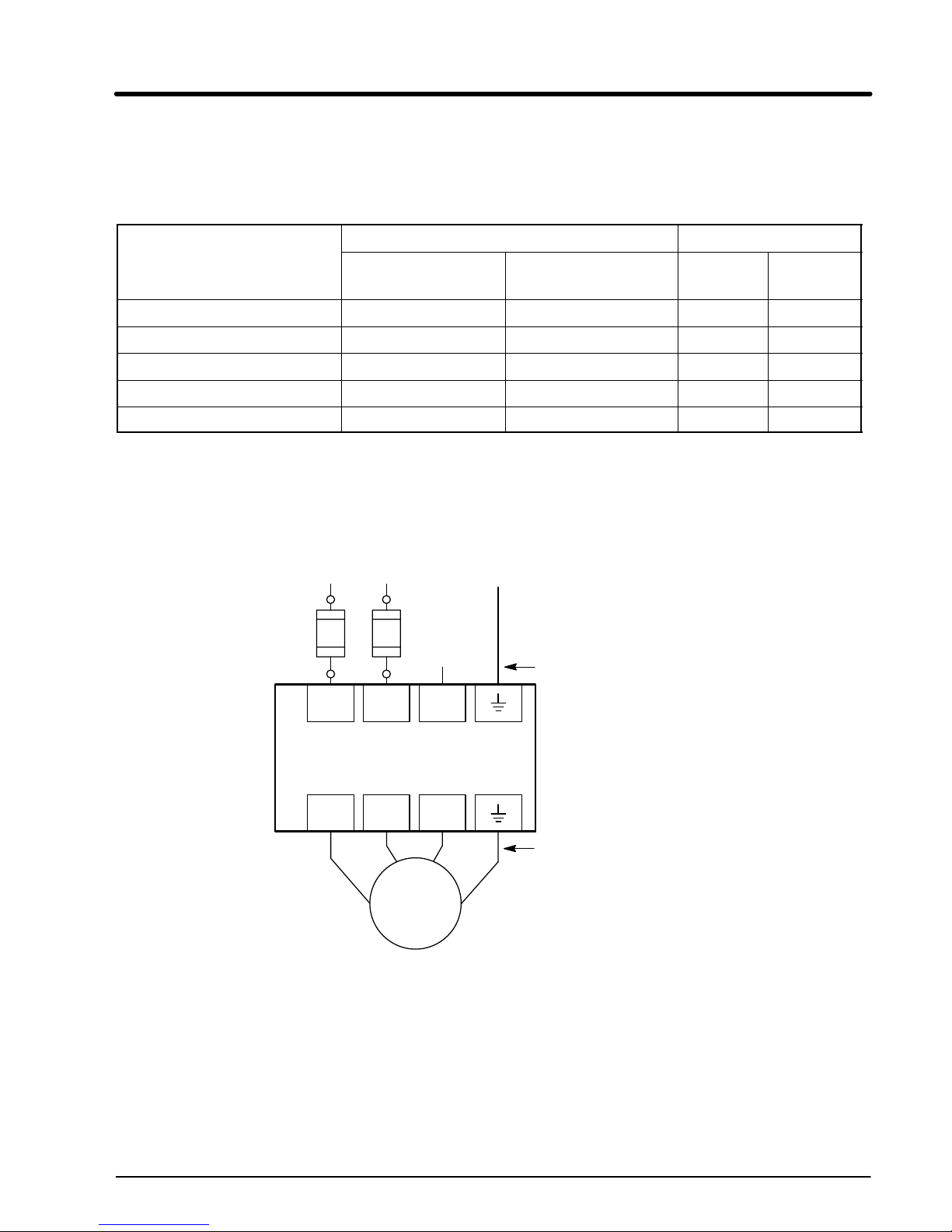

3 Phase Installation

The AC power and motor connections are shown in Figure 3-4. The 15J

control has electronic I

2

t motor overload protection. If motor overloads are

desired, they should be sized according to the manufacturers specifications

and installed between the motor and the T1, T2 and T3 terminals of the

control. Refer to Figure 3-3 for terminal locations.

Figure 3-4 3 Phase AC Power and Motor Connections

L1 L2 L3

L1 L2 L3

Earth

* AC Motor

Note 2

Note 3

Baldor

Series 15J

Control

*Optional

Line

Reactor

Note 1

Note 3

Note 3

A1 B1 C1

A2 B2 C2

T1 T2 T3

Note 4

T1

T2 T3

G

Notes:

1. See Protection Devices described in this section.

2. Use same gauge wire for Earth ground as is used for L1, L2 and L3.

3. Metal conduit should be used. Connect conduits so the use of a reactor or RC device

does not interrupt EMI/RFI shielding.

4. See Line/Load Reactors described previously in this section.

* Optional components not

provided with 15J Control.

*Optional

Fusing

Page 21

3-10 Receiving and Installation MN715J

115VAC 1 Phase Wire Size and Protection Devices

Table 3-6 Wire Size and Protection Devices - 1 phase

I

nput Fuse

Wire G

auge

C

ontro

l O

utput

Rating HP

Fast Acting

Amps

Time Delay

Amps

AWG mm

2

0.33 10 10 14 2.08

0.5 10 10 14 2.08

0.75 15 10 14 2.08

1.0 20 15 14 2.08

Note: All wire sizes are based on 75°C copper wire, 1% line impedance. Higher

temperature, smaller gauge wire may be used per NEC and local codes.

Recommended fuses are based on 40°C ambient, maximum continuous

control output current and no harmonic current.

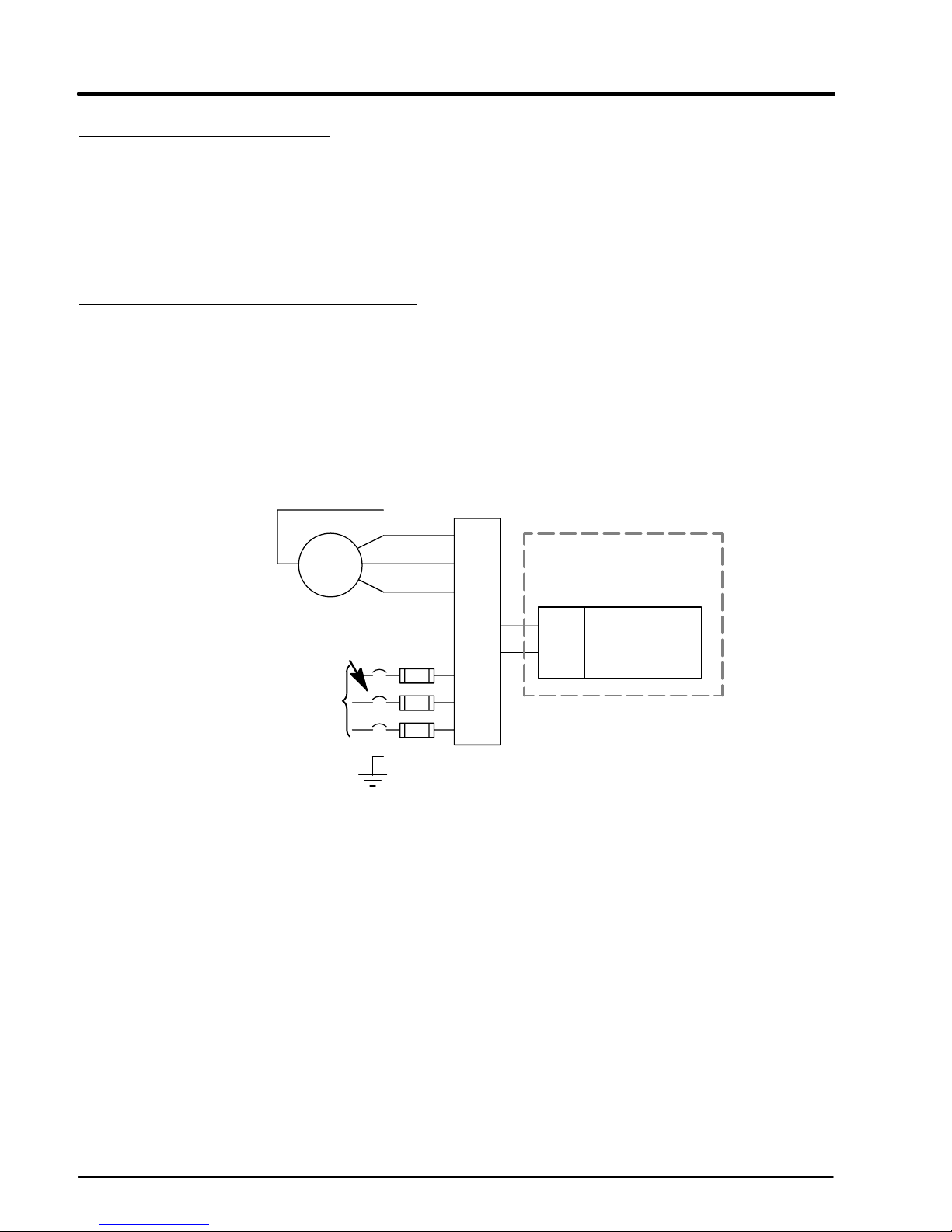

Figure 3-5 Single Phase AC Power and Motor Connections

L1 N

Earth

* AC Motor is not provided with control.

Baldor Series 15J Control

Metal conduit should be used to shield

output wires (from T1, T2, T3 of control to

T1, T2, T3 of motor).

T1 T2 T3

T1

T2 T3

G

Shield wires inside

a metal conduit.

Motor wire should be sized using the 3

phase information in Table 3Ć4.

* Optional components not

provided with 15J Control.

L1 L2 L3

*Optional

Fusing

Page 22

MN715J Receiving and Installation 3-11

230VAC Single Phase Derating for Three Phase Controls

Single phase AC input power can be used to power a three phase control.

However, the continuous and peak current ratings of the control must be

reduced by 35% (derated).

I

nput Fuse

Wire G

auge

C

ontro

l O

utput

Rating HP

Fast Acting

Amps

Time Delay

Amps

AWG mm

2

0.75 10 9 14 2.08

1 12 10 14 2.08

1.5 15 15 14 2.08

2 20 17.5 14 2.08

3 25 25 12 3.31

Note: All wire sizes are based on 75°C copper wire, 1% line impedance. Higher

temperature, smaller gauge wire may be used per NEC and local codes.

Recommended fuses are based on 40°C ambient, maximum continuous

control output current and no harmonic current.

Figure 3-6 Single Phase 230VAC Power and Motor Connections

L1 L2

L1 L2 L3

Earth

* AC Motor is not provided with control.

Baldor Series 15J Control

Metal conduit should be used to

shield output wires (from T1, T2, T3

of control to T1, T2, T3 of motor).

T1 T2 T3

T1

T2 T3

G

Shield wires inside

a metal conduit.

Motor wire should be sized using the

3 phase information in Table 3Ć4.

* Optional components not

provided with 15J Control.

*Optional

Fusing

Page 23

3-12 Receiving and Installation MN715J

Motor Brake Connections

For motors with spring set brakes, connect the brake power leads and the

motor power leads separately. Because the inverter has variable voltage

output to the motor, the inverter may not supply enough power at low

frequencies for proper brake operation. If using a motor with an internally

connected brake, the brake power leads must be connected to a separate

power source for proper brake operation.

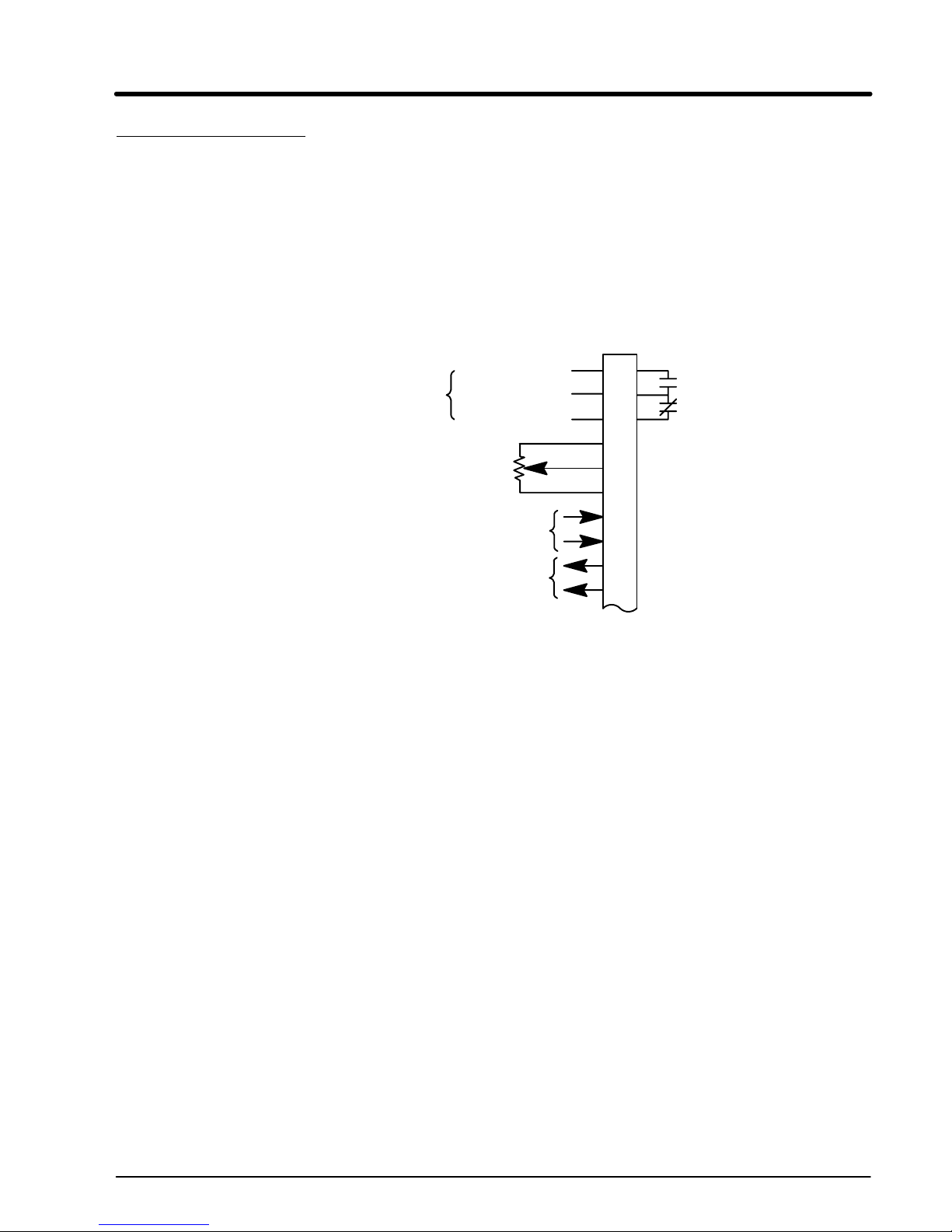

Optional Dynamic Brake Hardware

Dynamic Brake (DB) Hardware must be installed on a flat, non-flammable,

vertical surface for effective cooling and operation. See Figure 3-7 for

terminal identification.

See Appendix A of this manual for additional information.

Note: Although not shown, metal conduit should be used to shield all power wires

and motor leads.

Figure 3-7 Wiring for RGA Assembly

See recommended Terminal

Tightening Torques in Section 6.

* Optional Customer Supplied

Fuse Protection Ć

Subject to Local Codes

50/60 Hz

3 Phase

Power

Motor GND

BĆ

R1/B+

T3

T2

T1

L3

L2

L1

Power GND

GND

T1

T2

T3

* Optional

Dynamic Brake

Resistor

J5 Power Terminal Strip

DB

Terminals

R1

R2

R2

* Motor

Optional hardware. Must

be ordered separately.

Page 24

MN715J Receiving and Installation 3-13

Inputs and Outputs (Refer to Figure 3-8).

Analog Inputs

Two analog inputs are available: analog input #1 (J4-5 and J4-4) and analog

input #2 (J4-7 and J4-8) as shown. Either analog input #1 or #2 may be

grounded provided the common mode range is not exceeded. Either analog

input may be selected in the Level 1 INPUT block, ANA CMD Select

parameter value. Analog input #1 is selected if parameter value

“Potentiometer” is selected. Analog input #2 is selected if parameter value

“0-10Volts, 0-5 Volts, 4-20mA or 0-20mA” is selected.

Figure 3-8 Analog Inputs and Outputs

8

9

10

Analog Input 2Ć

Analog Output 1Ć

J4

N.O.

Relay Common

N.C.

Analog Ground

Analog Input 1

Pot Reference

Analog Input 2+

Analog Output 1+

1

2

3

4

5

6

7

5kΩ

Command Pot

Programmable Relay Outputs

0Ć5VDC, 0Ć10VDC,

4Ć20mA or 0Ć20mA

0Ć5VDC, 0Ć10VDC,

4Ć20mA or 0Ć20mA

See recommended Terminal

Tightening Torques in Section 6.

Analog Input #1

The single ended analog input #1 can be used when the controller is set to

Standard Run, 7 Speed, Fan Pump 2 Wire, Fan Pump 3 Wire, Process

Control, 3 SPD ANA 2Wire, 3 SPD ANA 3Wire, EPOT 2Wire or EPOT 3Wire

(not Keypad).

The single ended analog input #1 can be used as a Speed command (Level 1

Input block, ANA CMD Select=Potentiometer).

Note: A potentiometer value of 5kW to 10kW, 0.5 watt may be used.

1. Connect the wires from the 5KW pot at the J4 terminal strip. One end of

the pot is connected to J4-4 (analog ground) and the other end is

connected to J4-6 (reference voltage).

2. Connect the wiper of the pot to J4-5. The voltage across terminals J4-4

and J4-5 is the speed command input.

Analog Input #2

Analog input #2 accepts a differential command 0-5VDC, 0-10VDC, 4-20 mA

or 0-20 mA. The (Differential) command mode is defined in the Level 1 Input

block ANA CMD Select parameter.

Note: Analog Input #2 can be used with Standard Run, 7 Speed, Fan Pump 2 Wire,

Fan Pump 3 Wire, Process Control, 3 SPD ANA 2Wire or 3 SPD ANA 3Wire,

EPOT 2Wire or EPOT 3Wire (not Keypad).

1. Connect the Analog Input + wire to J4-7 and the - wire to J4-8.

2. If using a 0-20 mA or 4-20 mA command signal, “Level 1 Input block,

ANA CMD Select” parameter should be set to 0-20 mA or 4-20 mA.

Page 25

3-14 Receiving and Installation MN715J

Analog Output

One programmable analog output is provided at J4-10 and J4-9. The output

is scaled 0 - 5 VDC, 0 - 10 VDC, 4-20mA or 0-20mA. The output function is

programmed in the Level 1 Output block, Analog Out parameter value. The

scaling of the output is programmed in the Level 1 Output block, Analog

Scale.

Relay Outputs

One normally open (N.O.) and one normally closed (N.C.) relay contact is

available at terminals J4-1, J4-2 and J4-3. J4-2 is relay common. The output

is programmable in the Level 1 Output block, Relay Output parameter.

1. Connect the N.O. contact to another circuit by attaching the wires to J4-1

and J4-2.

2. Connect the N.C. contact to another circuit by attaching the wires to J4-3

and J4-2.

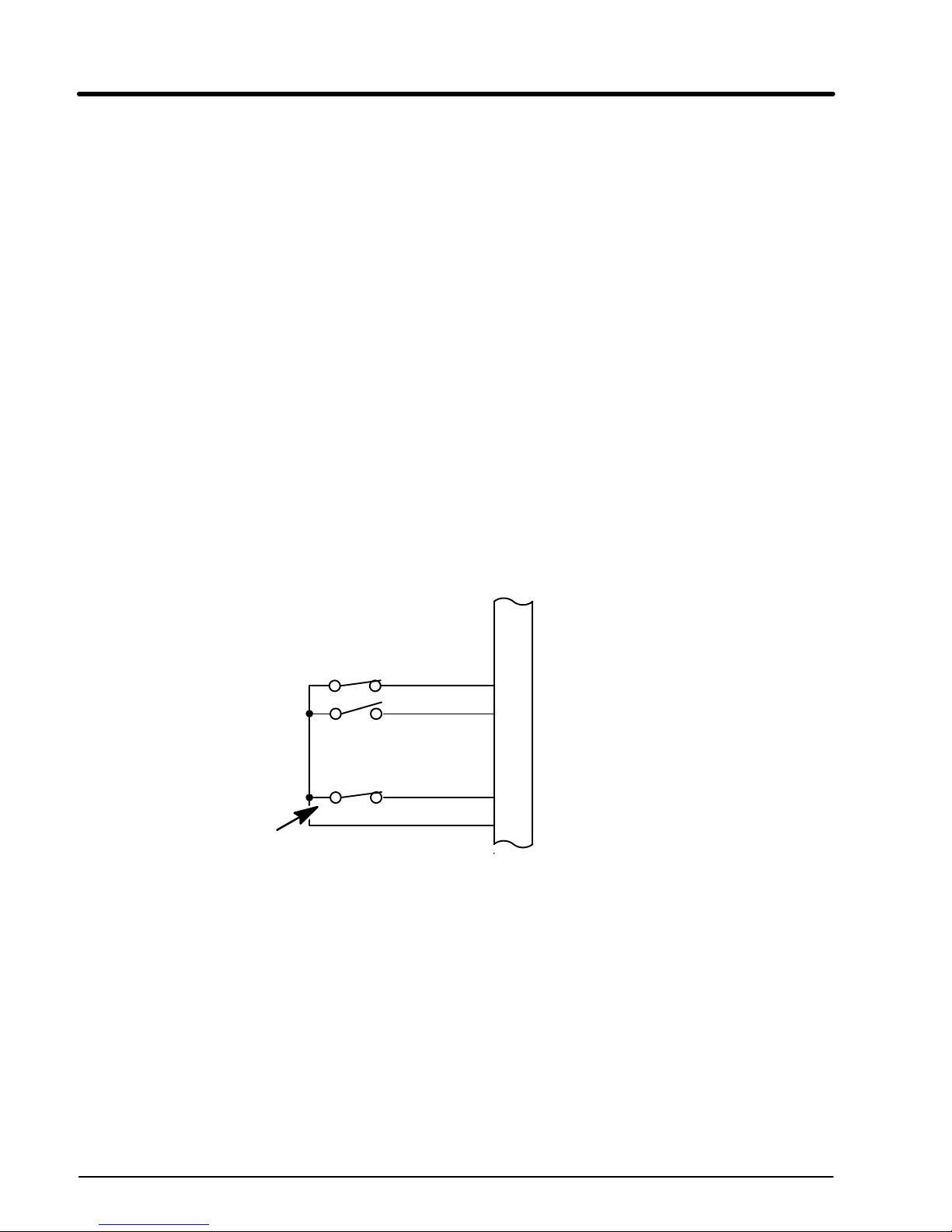

External Trip Input

Terminal J4-17 is available for connection to a normally closed thermostat or

overload relay in some operating modes as shown in Figure 3-9. The

thermostat or overload relay should be a dry contact type with no power

available from the contact. If the motor thermostat or overload relay activates,

the control will automatically shut down and give an external trip fault.

The optional relay (CR1) shown provides the isolation required. The N.O.

contact is closed when power is applied to the relay and the motor is cold.

Connect the external trip input wires to J4-17 and J4-18. Do not place these

wires in the same conduit as the motor power leads.

To activate the external trip input, the external trip parameter in the Level 2

Protection Block must be set to “ON”.

Figure 3-9 External Trip Input Connection

T1 T2 T3

T1

T2

T3

G

* Motor

17

18

J4

Do not run these wires in

same conduit as motor leads

or AC power wiring.

Customer supplied

source voltage

Motor Thermostat Leads

CR1

*

*

Optional hardware. Must be ordered separately.

See recommended terminal tightening torque in section 6.

Note: Add appropriately rated protective device

for AC relay (snubber) or DC relay (diode).

External or remote motor overload

protection may be required by National

Electrical Code or equivalent

Page 26

MN715J Receiving and Installation 3-15

Selection of Operating Mode (and Connection Diagram)

Several operating modes are available that define the basic motor control

setup and the operation of the input and output terminals. These operating

modes are selected by programming the Operating Mode parameter in the

Level 1 Input programming Block. Available operating modes include:

• Keypad

• Standard Run, 3 Wire

• 7 Speed

• Fan Pump 2 Wire

• Fan Pump 3 Wire

• Process Control

• 3 Speed Analog 2 Wire

• 3 Speed Analog 3 Wire

• Electronic Potentiometer 2 Wire

• Electronic Potentiometer 3 Wire

Each mode requires connections to the J4 terminal strip (except that all J4

connections are optional in the keypad mode).

Note: J4-19 and J4-20 are not to be used. These terminals are reserved for

manufacturing use only.

Page 27

3-16 Receiving and Installation MN715J

Keypad Connection

The Keypad operating mode allows the control to be operated from the

keypad. In this mode, no control connection wiring is required. However, the

Stop, Accel/Decel select and External Trip inputs may optionally be used. All

other digital inputs are inactive. The analog output and relay outputs remain

active at all times.

For operation in Keypad mode, set the Level 1 Input block, Operating Mode

parameter to Keypad.

To use the Stop input, J4-13 must be connected and the Level 1 Keypad

Setup block, LOC. Hot Start parameter must be set to ON. The Stop line is

normally closed. When opened, the motor will COAST or REGEN to a stop

depending upon the setting of Level 1 Keypad Setup block Keypad Stop Key

parameter value. Closing the input will immediately start the motor if a run

command was given before the stop line was opened.

The Accel/Decel select input is used to select ACC / DEC / S-CURVE group 1

or group 2. This connection is made at J4-14.

The External Trip input is used to cause a fault condition during a motor

over-temperature condition. The External Trip input (J4-17) must be

connected and the External Trip parameter in the Level 2 Protection block

must be set to ON. When J4-17 is opened, the motor will coast to a stop and

an External Trip fault will be displayed on the keypad display.

Figure 3-10 Keypad Connection Diagram

11

12

13

14

15

16

17

18

Accel/Decel Select

External Trip

J4

Input Common

Refer to Figure 3Ć9.

See recommended terminal

tightening torques in Section 6.

Stop

Keypad Only Connection

J4-13 If J4-13 is connected, you must set Level 1 Keypad Setup block, LOC. Hot Start

parameter to “ON” to activate the opto input.

CLOSED allows normal control operation.

OPEN disables the control and the motor will coast or brake to a stop. The motor

will restart when J4-13 closes after open.

J4-14 OPEN selects ACC / DEC / S-CURVE group 1.

CLOSED selects group 2.

J4-17 If J4-17 is connected, you must set Level 2 Protection block, External Trip to

“ON” to activate the opto input.

OPEN causes an external trip fault. The control will disable and the motor

coasts to a stop. An external trip fault is displayed (also logged in the fault log).

CLOSED allows normal operation.

Page 28

MN715J Receiving and Installation 3-17

Standard Run 3 Wire Connection

Figure 3-11 Standard Run 3-Wire Connection Diagram

11

12

13

14

15

16

17

18

Forward

Reverse

Stop

Accel/Decel Select

Speed Select 1

Speed Select 2

External Trip

Input Common

Refer to Figure 3Ć9.

J4

Refer to Table 3Ć7

See recommended terminal

tightening torques in Section 6.

Table 3-7 Speed Select

Function

Speed Select 1 Speed Select 2

ANA CMD Select Open Open

Preset Speed 1 Closed Open

Preset Speed 2 Closed Closed

Preset Speed 3 Open Closed

J4-11 Momentary CLOSED starts Forward motor rotation.

J4-12 Momentary CLOSED starts Reverse motor rotation.

J4-13 Momentary OPEN motor decels to stop (depending on Keypad Stop mode).

J4-14 OPEN selects ACC / DEC / S-CURVE group 1.

CLOSED selects group 2.

J4-15 Selects preset speeds as defined in Table 3-7.

J4-16 Selects preset speeds as defined in Table 3-7.

J4-17 If J4-17 is connected, you must set Level 2 Protection block, External Trip to

“ON” to activate the opto input.

OPEN causes an external trip fault. The control will disable and the motor

coasts to a stop. An external trip fault is displayed (also logged in the fault log).

CLOSED allows normal operation.

Page 29

3-18 Receiving and Installation MN715J

7 Speed Connection

Figure 3-12 7 Speed Connection Diagram

11

12

13

14

15

16

17

18

Forward

Reverse

Analog Select

Speed Select 1

Speed Select 2

Speed Select 3

External Trip

J4

Input Common

Refer to Figure 3Ć9.

See recommended terminal

tightening torques in Section 6.

Refer to Table 3Ć8

Table 3-8

Function

Speed Select 1 Speed Select 2 Speed Select 3

ANA CMD Select Open Open Open

Preset Speed 1 Closed Open Open

Preset Speed 2 Closed Closed Open

Preset Speed 3 Closed Closed Closed

Preset Speed 4 Closed Open Closed

Preset Speed 5 Open Open Closed

Preset Speed 6 Open Closed Closed

Preset Speed 7 Open Closed Open

J4-11 OPEN motor decels to stop (depending on Keypad Stop mode).

CLOSED starts Forward motor rotation.

J4-12 OPEN motor decels to stop (depending on Keypad Stop mode).

CLOSED starts Reverse motor rotation.

J4-13 OPEN selects setting of “ANA CMD Select” parameter.

CLOSED selects Analog Input #1.

J4-14 Selects preset speeds as defined in Table 3-8.

J4-15 Selects preset speeds as defined in Table 3-8.

J4-16 Selects preset speeds as defined in Table 3-8.

J4-17 If J4-17 is connected, you must set Level 2 Protection block, External Trip to

“ON” to activate the opto input.

OPEN causes an external trip fault. The control will disable and the motor

coasts to a stop. An external trip fault is displayed (also logged in the fault log).

CLOSED allows normal operation.

Page 30

MN715J Receiving and Installation 3-19

Fan Pump 2 Wire Connection

Figure 3-13 Fan/Pump 2 Wire Connection Diagram

11

12

13

14

15

16

17

18

Forward

Reverse

Analog Select

Firestat

Freezestat

Run Command

Speed Command

Input Common

Refer to Figure 3Ć9.

J4

Refer to Table 3Ć9

See recommended terminal

tightening torques in Section 6.

Table 3-9

Function

Firestat Freezestat Comment

ANA CMD Select Closed Closed Firestat and Freezestat are alarm

Preset Speed 1 Open Closed

inputs that override all speed

Preset Speed 1 Open Open

commands including

the k

eypad.

Preset Speed 2 Closed Open

J4-11 OPEN motor decels to stop (depending on Keypad Stop mode).

CLOSED starts Forward motor rotation.

J4-12 OPEN motor decels to stop (depending on Keypad Stop mode).

CLOSED starts Reverse motor rotation.

J4-13 OPEN selects setting of “ANA CMD Select” parameter.

CLOSED selects Analog Input #1.

J4-14 OPEN selects preset speed #1 regardless of the Speed Command input J4-13.

J4-15 OPEN selects preset speed #2 regardless of the Speed Command input J4-13.

J4-16 OPEN selects direction commands from Keypad.

CLOSED selects direction commands from terminal strip.

J4-17 OPEN selects speed commanded from Keypad.

CLOSED selects terminal strip speed source (selected in the Level 1 Input block,

ANA CMD Select parameter).

Page 31

3-20 Receiving and Installation MN715J

Fan Pump 3 Wire Connection

Figure 3-14 Fan/Pump 3 Wire Connection Diagram

11

12

13

14

15

16

17

18

Forward

Reverse

Stop

Firestat

Freezestat

Run Command

Speed Command

Input Common

J4

Refer to Table 3Ć10

See recommended terminal

tightening torques in Section 6.

Table 3-10

Function

Firestat Freezestat Comment

ANA CMD Select Closed Closed Firestat and Freezestat are alarm

Preset Speed 1 Open Closed

inputs that override all speed

Preset Speed 1 Open Open

commands including the keypad.

Preset Speed 2 Closed Open

J4-11 Momentary CLOSED starts Forward motor rotation.

J4-12 Momentary CLOSED starts Reverse motor rotation.

J4-13 Momentary OPEN motor decels to stop (depending on Keypad Stop mode).

J4-14 OPEN selects preset speed #1 regardless of the Speed Command input J4-13.

CLOSED allows normal operation.

J4-15 OPEN selects preset speed #2 regardless of the Speed Command input J4-13.

CLOSED allows normal operation.

J4-16 OPEN selects direction commands from Keypad.

CLOSED selects direction commands from terminal strip.

J4-17 OPEN selects speed commanded from Keypad.

CLOSED selects terminal strip speed source (selected in the Level 1 Input block,

ANA CMD Select parameter).

Page 32

MN715J Receiving and Installation 3-21

Process Control Connection

Figure 3-15 Process Control Connection Diagram

11

12

13

14

15

16

17

18

Forward

Reverse

Process/CMD Select

Jog Forward

Jog Reverse

Fault Reset

External Trip

Input Common

Refer to Figure 3Ć9.

J4

See recommended terminal

tightening torques in Section 6.

J4-11 OPEN motor decels to stop (depending on Keypad Stop mode).

CLOSED starts Forward motor rotation.

J4-12 OPEN motor decels to stop (depending on Keypad Stop mode).

CLOSED starts Reverse motor rotation.

Note: Simultaneous closure of J4-11 and J4-12 will cause the motor to regen to stop

(not coast).

J4-13 OPEN selects the input specified in the Level 1 Input block,

ANA CMD Select parameter.

CLOSED selects the closed loop feature of the Process Control mode.

Note: The process will run in one direction. For example, if the forward line (J4-11)

is closed, the process will only run in the forward direction. The PID algorithm

will not reverse the direction automatically.

J4-14 OPEN allows normal operation.

CLOSED jogs the motor in the forward direction.

J4-15 OPEN allows normal operation.

CLOSED jogs the motor in the reverse direction.

Note: Simultaneous closure of J4-14 and J4-15 selects jog forward.

J4-16 OPEN allows normal operation.

CLOSED to reset a fault condition.

J4-17 If J4-17 is connected, you must set Level 2 Protection block, External Trip to

“ON” to activate the opto input.

OPEN causes an external trip fault. The control will disable and the motor

coasts to a stop. An external trip fault is displayed (also logged in the fault log).

CLOSED allows normal operation.

Page 33

3-22 Receiving and Installation MN715J

3 Speed Analog 2 Wire Connection

Figure 3-16 3 Speed Analog 2 Wire Connection Diagram

11

12

13

14

15

16

17

18

Forward

Reverse

Analog Select

Speed Select 1

Speed Select 2

Run Command

Speed Command

Input Common

J4

Refer to Table 3Ć11

See recommended terminal

tightening torques in Section 6.

Table 3-11

Function

Speed Select 1 Speed Select 2

ANA CMD Select Open Open

Preset Speed 1 Closed Open

Preset Speed 2 Closed Closed

Preset Speed 3 Open Closed

J4-11 OPEN motor decels to stop (depending on Keypad Stop mode).

CLOSED starts Forward motor rotation.

J4-12 OPEN motor decels to stop (depending on Keypad Stop mode).

CLOSED starts Reverse motor rotation.

J4-13 OPEN selects setting of “ANA CMD Select” parameter.

CLOSED selects Analog Input #1.

J4-14 Selects preset speeds as defined in Table 3-11.

J4-15 Selects preset speeds as defined in Table 3-11.

J4-16 OPEN selects direction commands from Keypad.

CLOSED selects direction commands from terminal strip.

J4-17 OPEN selects speed commanded from Keypad.

CLOSED selects terminal strip speed source (selected in the Level 1 Input block,

ANA CMD Select parameter).

Page 34

MN715J Receiving and Installation 3-23

3 Speed Analog 3 Wire Connection

Figure 3-17 3 Speed Analog 3 Wire Connection Diagram

11

12

13

14

15

16

17

18

Forward

Reverse

Stop

Speed Select 1

Speed Select 2

Run Command

Speed Command

Input Common

J4

Refer to Table 3Ć12

See recommended terminal

tightening torques in Section 6.

Table 3-12

Function

Speed Select 1 Speed Select 2

ANA CMD Select Open Open

Preset Speed 1 Closed Open

Preset Speed 2 Closed Closed

Preset Speed 3 Open Closed

J4-11 Momentary CLOSED starts Forward motor rotation.

J4-12 Momentary CLOSED starts Reverse motor rotation.

J4-13 Momentary OPEN motor decels to stop (depending on Keypad Stop mode).

J4-14 Selects preset speeds as defined in Table 3-12.

J4-15 Selects preset speeds as defined in Table 3-12.

J4-16 OPEN selects direction commands from Keypad.

CLOSED selects direction commands from terminal strip.

J4-17 OPEN selects speed commanded from Keypad.

CLOSED selects terminal strip speed source (selected in the Level 1 Input block,

ANA CMD Select parameter).

Page 35

3-24 Receiving and Installation MN715J

EPOT 2 Wire Connection

Figure 3-18 Electronic POT 2 Wire Connection Diagram

11

12

13

14

15

16

17

18

Forward

Reverse

EPOT/CMD Select

Accel/Decel Select

Increase

Decrease

External Trip

Input Common

Refer to Figure 3Ć9.

J4

See recommended terminal

tightening torques in Section 6.

J4-11 OPEN motor decels to stop (depending on Keypad Stop mode).

CLOSED to enable operation in the Forward direction.

J4-12 OPEN motor decels to stop (depending on Keypad Stop mode).

CLOSED to enable operation in the Reverse direction.

J4-13 OPEN for normal speed mode. Terminal strip speed source is selected in the

Level 1 Input block, ANA CMD Select parameter.

CLOSED to enable the Electronic Potentiometer Mode.

J4-14 OPEN selects ACC / DEC / S-CURVE group 1.

CLOSED selects group 2.

J4-15 Momentary CLOSED increases motor speed while closed.

J4-16 Momentary CLOSED decreases motor speed while closed.

J4-17 If J4-17 is connected, you must set Level 2 Protection block, External Trip to

“ON” to activate the opto input.

OPEN causes an external trip fault. The control will disable and the motor

coasts to a stop. An external trip fault is displayed (also logged in the fault log).

CLOSED allows normal operation.

Page 36

MN715J Receiving and Installation 3-25

EPOT 3 Wire Connection

Figure 3-19 Electronic POT 3 Wire Connection Diagram

11

12

13

14

15

16

17

18

Forward

Reverse

Stop

Accel/Decel Select

Increase

Decrease

External Trip

Input Common

Refer to Figure 3Ć9.

J4

See recommended terminal

tightening torques in Section 6.

J4-11 Momentary CLOSED starts Forward motor rotation.

J4-12 Momentary CLOSED starts Reverse motor rotation.

J4-13 Momentary OPEN motor decels to stop (depending on Keypad Stop mode).

J4-14 OPEN selects ACC / DEC / S-CURVE group 1.

CLOSED selects group 2.

J4-15 Momentary CLOSED increases motor speed while closed.

J4-16 Momentary CLOSED decreases motor speed while closed.

J4-17 If J4-17 is connected, you must set Level 2 Protection block, External Trip to

“ON” to activate the opto input.

OPEN causes an external trip fault. The control will disable and the motor

coasts to a stop. An external trip fault is displayed (also logged in the fault log).

CLOSED allows normal operation.

Page 37

3-26 Receiving and Installation MN715J

Pre-Operation Checklist Check of electrical items.

1. Verify AC line voltage at source matches control rating.

2. Inspect all power connections for accuracy, workmanship and tightness

as well as compliance to codes.

3. Verify control and motor are grounded to each other and the control is

connected to earth ground.

4. Check all signal wiring for accuracy.

5. Be certain all brake coils, contactors and relay coils have noise

suppression. This should be an R-C filter for AC coils and reverse

biased diodes for DC coils. MOV type transient suppression is not

adequate for noise suppression.

Check of Motor and Couplings

1. Verify freedom of motion of motor shaft.

2. Verify that all motor couplings are tight without backlash.

3. If holding brakes are used, verify they are properly adjusted to fully

release and set to the desired torque value.

Power-up Procedure

1. Turn power on. Be sure no faults are displayed on the keypad display.

2. Set the Level 1 Input block, Operating Mode to “Keypad”.

3. Set the Level 2 Output Limits block, “MIN Output FREQ” parameter.

4. Set the Level 2 Output Limits block, “MAX Output FREQ” parameter.

5. If the desired peak current limit setting is not correct, set the Level 2

Output Limits block, “PK Current Limit” parameter as desired.

6. Enter the following motor data in the Level 2 Motor Data block

parameters:

Motor Rated Amps (FLA)

Motor Rated Speed (base speed)

Motor Rated Frequency (Nameplate)

7. If External Dynamic Brake hardware is used, set the Level 2 Brake

Adjust block parameters as desired.

8. Set the Level 1 V/HZ Boost block, “V/HZ Profile” parameter for the

correct V/Hz ratio for your application.

9. If the load is a high initial starting torque type, the torque boost and Accel

time may need to be increased. Set the Level 1 V/HZ Boost block,

“Torque Boost” and the Level 1 Accel/Decel Rate block, “ACCEL TIME

#1” as required.

10. Select and program additional parameters to suit your application.

The control is now ready for use in keypad mode. The terminal strip wiring

may be changed and different parameter values used for another operating

mode.

Page 38

Section 4

Programming and Operation

MN715J Programming and Operation 4-1

Overview The keypad is used to program the control parameters, to operate the motor

and to monitor the status and outputs of the control (by accessing the display

options, diagnostic menus and the fault log).

Figure 4-1 Keypad

JOG Ć (Green) lights when Jog is active.

FWD Ć (Green) lights when FWD direction is commanded.

REV Ć (Green) lights when REV direction is commanded.

STOP Ć (Red) lights when motor STOP is commanded.

Indicator Lights

JOG

FWD

REV

STOP

LOCAL

DISP

SHIFT

RESET

PROG

ENTER

JOG

JOG

Press JOG to select the preprogrammed jog speed. After the jog key has

been pressed, use the FWD or REV keys to run the motor in the direction that

is needed. The JOG key is only active in the local mode.

FWD

Press FWD to initiate forward rotation of the motor.

REV

Press REV to initiate reverse rotation of the motor.

STOP

Press STOP to initiate a stop sequence. Depending on the setup of the

control, the motor will either regen or coast to a stop. This key is operational

in all modes of operation unless it has been disabled by the Keypad Stop

parameter in the Keypad (programming) Setup Block.

LOCAL

Press LOCAL to change between the local (keypad) and remote operation.

DISP

Press DISP to return to display mode from programming mode. In the

Diagnostic menu, pressing this key will advance to the next diagnostic screen.

Page 39

4-2 Programming and Operation MN715J

SHIFT

Press SHIFT in the program mode to control cursor movement. Pressing the

SHIFT key once moves the blinking cursor one character position to the right.

While in program mode, a parameter value may be reset to the factory preset

value by pressing the SHIFT key until the arrow symbols at the far left of the

keypad display are flashing, then press an arrow key.

RESET

Press RESET to clear all fault messages (in local mode). This key can also

be used to return to the top of the block programming menu without saving

any parameter value changes.

PROG

Press PROG to enter the program mode to check or to edit a parameter

value.

Y - (UP Arrow).

Press Y to change the value of the parameter being displayed. Pressing Y

increments the value to the next greater value. Also, when the fault log or

parameter list is displayed, the Y key will scroll upward through the list. In the

local mode pressing the Y key will increase motor speed to the next greater

value.

ENTER

Press ENTER to save parameter value changes and move back to the

previous level in the programming menu. In the display mode the ENTER key

is used to directly set the Local Speed Reference.

B - (Down Arrow)

Press B to change the value of the parameter being displayed. Pressing B

decrements the value to the next lesser value. Also, when the fault log or

parameter list is displayed, the B key will scroll downward through the list. In

the local mode pressing the B key will decrease motor speed to the next

lesser value.

Page 40

MN715J Programming and Operation 4-3

Operation Examples

Operating the Control from the Keypad

If the control is configured for remote or serial control, the LOCAL Mode must

be activated before the control may be operated from the keypad. To activate

the LOCAL Mode, first the motor must be stopped using the keypad STOP

key (if enabled), remote commands or serial commands.

Note: Pressing the keypad STOP key (if enabled) will automatically issue a motor

stop command and change to LOCAL mode.

When the motor has stopped, the LOCAL Mode is activated by pressing the

“LOCAL” key. Selection of the LOCAL Mode overrides any remote or serial

control inputs except for the External Trip input, Local Enable Input or STOP

input.

The control can operate the motor in three (3) different ways from the keypad.

1. JOG Command.

2. Speed adjustment with Keypad entered values.

3. Speed adjustment using the Keypad arrow keys.

Note: If the control has been configured for Keypad in the operating mode

parameter (level 1, input block), then no other means of operation is permitted

other than from the keypad.

Accessing the Keypad JOG Command

Action Description Display

Apply Power If no faults and programmed for

LOCAL operation.

Press JOG key Access programmed JOG speed.

Press and hold

FWD or REV key

Move control forward or reverse at

JOG speed.

Press JOG key Disables JOG mode.

Page 41

4-4 Programming and Operation MN715J

Speed Adjustment using Local Speed Reference

Speed Adjustment using Local Speed Reference.

(This example changes the Local Speed Ref parameter from 0Hz to 10Hz).

Action

Description Display

Apply Power If no faults and programmed for

LOCAL operation.

Press ENTER key Select the local speed reference.

Press SHIFT key Move blinking cursor right one

digit.

Press Y key

Increase tens value by one digit.

Press ENTER key Save new value and return to

display mode.

Press FWD or REV

key

Motor runs FWD or REV at

commanded speed.

Press STOP key Motor stop command issued.

Speed Adjustment using Arrow Keys

Action Description Display

Apply Power If no faults and programmed for

LOCAL operation.

Press FWD or REV

key

Motor runs FWD or REV at

selected speed.

Press Y key

Increase motor speed.

Press B key

Decrease motor speed.

Press Y key

Increase motor speed.

Press STOP key Motor stop command issued.

Press FWD or REV

key

Motor runs FWD or REV at

commanded speed.

Press STOP key Motor stop command issued.

Page 42

MN715J Programming and Operation 4-5

Display Mode

During normal operation the controller is in the display mode and the keypad

displays the status of the control. Several output status values can be

monitored.

Motor Status

Control Operation

Output Status

Value and Units

The display mode also gives the user the ability to view diagnostic information

and the fault log.

Adjusting Display Contrast

When AC power is applied to the control the keypad should display the status

of the control. If there is no display visible, use the following procedure to

adjust the display.

Action

Description Display

Apply Power No visible display

Press DISP Key Places control in display mode

Press SHIFT

SHIFT

Allows display contrast adjustment

Press Y or B Key

Adjusts display intensity

Press ENTER Saves level of contrast and exits

to display mode

Page 43

4-6 Programming and Operation MN715J

Display Screens

Action Description Display

Apply Power Display of mode & drive status.

Press DISP key The fault log block.

Press DISP key The diagnostic information block.

Press DISP key The modified parameters block.

Press DISP key Display of output frequency.

Press DISP key Display of motor speed (based on

output frequency).

Press DISP key Display of motor current.

Press DISP key Display of motor voltage.

Fault Log Access

When a fault condition occurs, motor operation stops and a fault code is

displayed on the Keypad display. The control keeps a log of the last 31 faults.

If more than 31 faults have occurred the oldest fault will be deleted from the

fault log to make room for the newest fault. To access the fault log perform the

following procedure:

Action

Description Display

Apply Power Display of mode & drive status.

Press DISP key Press DISP to scroll to the Fault

Log entry point.

Press ENTER key Display first fault type and time

fault occurred.

Press Y key

Scroll through fault messages to

the end.

Press RESET key Return to display mode.

Page 44

MN715J Programming and Operation 4-7

Diagnostic Information Access

Action Description Display

Apply Power Display of mode & drive status.

Press DISP key

several times

Scroll to Diagnostic Info entry point.

Press ENTER

key

Access diagnostic information.

Press DISP key Control temperature.

25.0

Press DISP key Bus voltage.

Press DISP key PWM Frequency.

2500

Press DISP key % overload current remaining.