Page 1

GLC Generator

(Gaseous Liquid Cooled)

GLC30, 35, 45, 50, 60, 80, 100 and 125

Installation & Operating Manual

5/04 MN2408

Page 2

WARNING:

CALIFORNIA PROPOSITION 65 WARNING:

Engine exhaust from this product contains chemicals known

to the state of California to cause cancer, birth defects and

other reproductive harm.

WARNING:

CALIFORNIA PROPOSITION 65 WARNING:

Battery posts, terminals and related accessories are known to

the state of California to cause cancer, birth defects and other

reproductive harm.

Page 3

Table of Contents

Section 1

Product Safety Information 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Responsibility 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMPORTANT SAFETY INSTRUCTIONS 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2

General Information 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Guidelines 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site Planning 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Room Size 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Room Location 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foundation Design 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust System 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Level Of Attenuation 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Placement 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi–Engine Installations 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Gas Restriction 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Piping 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rain Protection 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling System 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air System 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Radiator Cooling 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Engine Cooling Systems 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Crankcase Ventilation 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

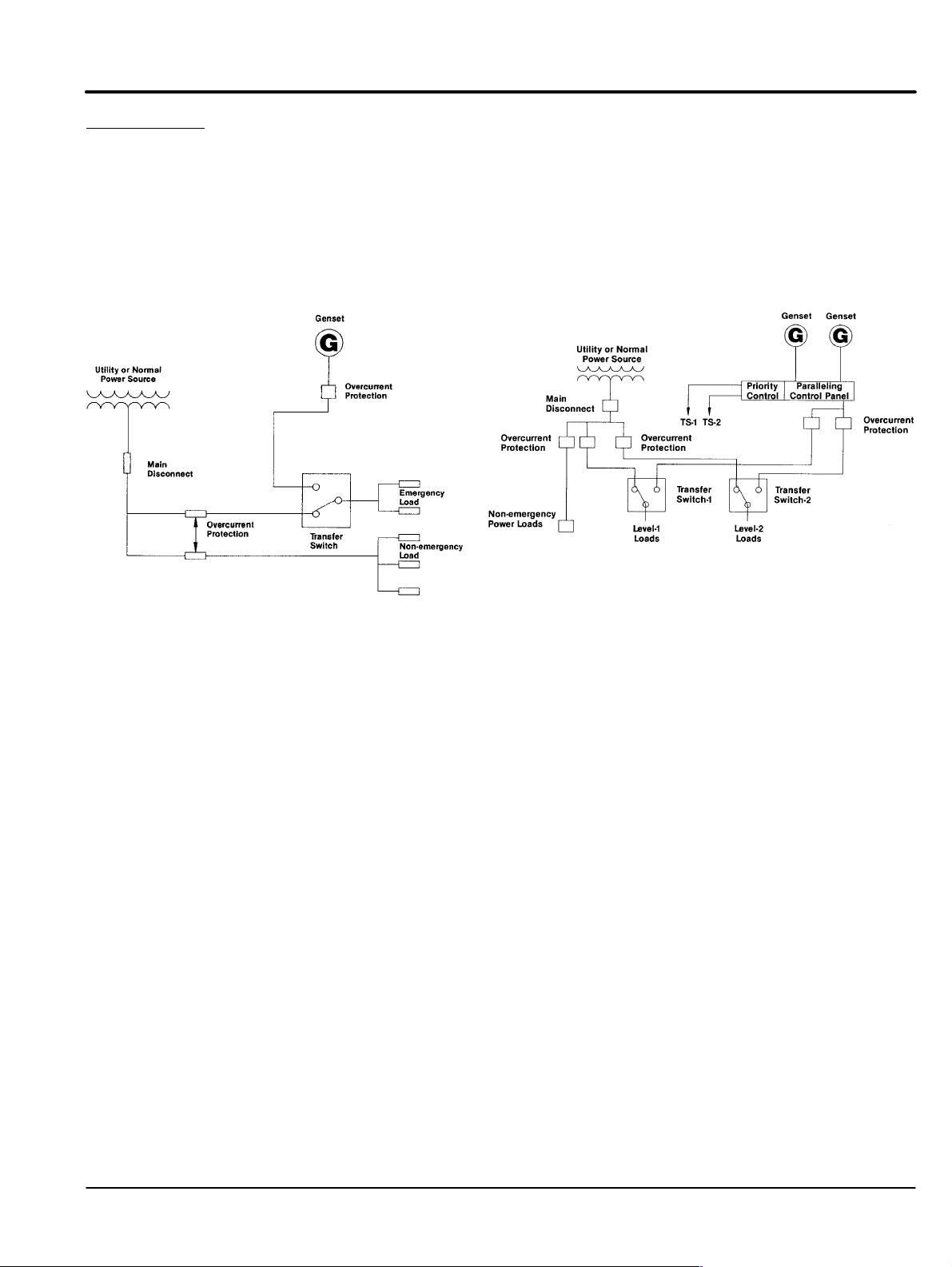

Transfer Switch 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Starting System 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Location 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Size 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Charger 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Cables 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3

Receiving & Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving & Inspection 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lifting the Generator 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Location 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Secure the Generator 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Cooling 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hot Exhaust Gasses 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Connections 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Connections 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Connections 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Engine Oil and Battery Type 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Post Installation Checks 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents iMN2408

Page 4

Section 4

Operation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Control Panel (Digital Engine Controller Only) 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedures 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Start/Stop 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Start/Stop 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Fault Shutdown 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Mains Failure (AMF) 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Faults 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Contacts 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Modes 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Status 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Display 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timer Countdown 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator AC Metering 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Parameter Display 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Menus 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Menu Loop 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Fault Menu Loop 4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Fault Menu Loop 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Menu Loop 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage Sensing Calibration 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage Calibration Procedure 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Sensing Calibration 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Voltage Calibration 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Temperature & Oil Pressure Calibration 4-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Control Panel (Analog Engine Controller Only) 4-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedures 4-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Start/Stop 4-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Start/Stop 4-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Fault Shutdown 4-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Garretson Model KN Fuel Valve Considerations 4-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 5

Troubleshooting and Maintenance 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Problems and Solutions 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Series GLC Parts & Wiring Diagrams A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Parts A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GLC Circuit Breaker & Electrical Data A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GLC Wire Size A-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagrams A-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start–up Inspection Form A-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii Table of Contents MN2408

Page 5

Section 1

Product Safety Information

Safety Notice

Be sure that you are completely familiar with the safe operation of this equipment. This

equipment may be connected to other machines that have rotating parts or parts that are

controlled by this equipment. Improper use can cause serious or fatal injury. Always

disconnect all electrical loads before starting the generator.

Installation and repair procedures require specialized skills with electrical generating equipment

and liquid cooled engine systems. Any person that installs or repairs this generator must have

these specialized skills to ensure that this generating unit is safe to operate. Contact Baldor

service department for repairs or any questions you may have about the safe installation and

operation of this system.

The precaution statements are general guidelines for the safe use and operation of this

generator. It is not practical to list all unsafe conditions. Therefore, if you use a procedure that is

not recommended in this manual you must determine if it is safe for the operator and all

personnel in the proximity to the generator and connected loads. If there is any question of the

safety of a procedure please contact Baldor before starting the generator.

This equipment contains high voltages. Electrical shock can cause serious or fatal injury. Only

qualified personnel should attempt the start–up procedure or troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts or parts that are

driven by this equipment. Improper use can cause serious or fatal injury. Only qualified

personnel should attempt the start–up procedure or troubleshoot this equipment.

– System documentation must be available to anyone that operates this equipment at all

times.

– Keep non-qualified personnel at a safe distance from this equipment.

– Only qualified personnel familiar with the safe installation, operation and maintenance

of this device should attempt start-up or operating procedures.

– Always stop engine before making or removing any connections.

– Always stop engine and allow it to cool before refueling.

Responsibility

Read This Manual Thoroughly

When your generator is delivered, it becomes the responsibility of the owner/operator of the

generator set to prevent unsafe conditions and operation of the equipment. Some

responsibilities include (but are not limited to) the following:

1. It is the responsibility of the owner/operator of this generator to ensure that this

equipment is correctly and safely installed.

2. It is the responsibility of the owner/operator of this generator to ensure that this

equipment, when installed fully complies with all federal, state and local codes.

3. It is the responsibility of the owner/operator of this generator to ensure that any person

operating this equipment has been properly trained.

4. It is the responsibility of the owner/operator of this generator to ensure that any person

operating this equipment has access to all manuals and information required for the

safe use and operation of this equipment.

5. It is the responsibility of the owner/operator of this generator to ensure that it is properly

maintained and safety inspected at regular scheduled intervals.

6. It is the responsibility of the owner/operator of this generator to ensure that any person

who has not been trained on the safe use of this equipment does not have access to

this equipment.

If you do not understand any concept, any procedure, any safety warning statement, any safety

caution statement or any portion of this manual, contact Baldor or your nearest authorized Baldor

representative. We are happy to make sure you understand the information in this manual so

that you can safely enjoy the full use of this generator.

Baldor Generators

3815 Oregon Street

Oshkosh, WI 54902

(920) 236–4200 (voice); or (920) 236–4219 (fax); or www.baldor.com

Product Safety Information 1-1MN2408

Page 6

Symbols

This symbol is shown throughout the manual to indicate a connection to ground reference point.

Indicates a potentially hazardous situation which, if not avoided, could result in injury or death.

Indicates a potentially hazardous situation which, if not avoided, could result in injury or death.

Precaution Statements Used In This Manual

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in injury or

Caution: Indicates a potentially hazardous situation which, if not avoided, could result in damage to

Note: Additional information that is not critical to the installation or operation.

There are three classifications of precautionary statements used in this manual. The most critical

is a WARNING statement, then the Caution statement and the least critical is the Note

statement. The usage of each statement is as follows:

death.

property.

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS – This manual contains important instructions for the generator that

should be followed during installation, operation and maintenance of the generator and battery (batteries).

For ease of reading, the Warning statements are divided into four categories: Operation, Burn, Installation,

and Maintenance.

Operation

WARNING: Never operate this generator in a manner other than as described in this manual. Operation

in any manner not described in this manual should be considered unsafe and should not be

attempted. Never start the engine unless you have first verified that the installation and

operation of the generator are as described in this manual.

WARNING: Be sure that you are completely familiar with the safe operation of this equipment. This

equipment may be connected to other machines that have rotating parts or parts that are

controlled by this equipment. Improper use can cause serious or fatal injury.

WARNING: Exhaust fumes/gases are extremely dangerous and can cause severe illness or death. Never

breath exhaust fumes produced by a running engine. Only run the engine outdoors where

ventilation is plentiful. Exhaust gases contain carbon monoxide, a colorless, odorless and

extremely dangerous gas that can cause unconsciousness or death. Symptoms of carbon

monoxide poisoning include: dizziness, nausea, headaches, sleepiness, vomiting or

incoherence. If you or anyone else experiences these symptoms, get out into fresh air

immediately. Stop the engine and do not restart the engine until it has been inspected and if

necessary repaired or reinstalled in a well ventilated area.

WARNING: Hot exhaust gasses must never be directed toward anything that may catch fire or explode.

WARNING: This generator must not be used on or near any forest covered, brush covered, or grass

covered land unless the engine’s exhaust system is equipped with a spark arrestor. The

spark arrestor must be maintained in effective working order by the operator.

WARNING: Some parts of this generator rotate during operation. Rotating parts can present extreme

danger if clothing or body extremities are caught by the rotating part and can cause serious

or fatal injury. Never touch a part of the generator until the engine has been stopped and all

rotating parts are completely stopped. Also, disconnect the spark plug wires and battery

connection to prevent accidental engine rotation during servicing.

WARNING: Never move a generator set that is running. Loads should be connected and position secure

before starting the engine. Hazards are caused by moving a generator set that is running.

Continued on next page.

1-2 Product Safety Information MN2408

Page 7

Operation Warning Statements

WARNING: Never connect or disconnect loads during operation. Always connect load circuits before

starting the engine and use external branch disconnects etc. to switch loads On/Off.

WARNING: Be sure that you understand how to stop the engine quickly in case of an emergency situation.

Become familiar with the controls and safety systems provided with this generator set.

WARNING: Always wear safety glasses with side shields and hearing protection when working near the

generator.

WARNING: Improper operation may cause violent motion of connected equipment. Be certain that

unexpected movement will not cause injury to personnel or damage to equipment.

WARNING: Never operate the generator set indoors or in a poorly ventilated area such as a tunnel or cave.

Exhaust fumes are extremely dangerous to all personnel that are in or in contact with that area.

WARNING: Never permit anyone to operate the generator without proper instructions. Be sure to keep a

copy of this manual with the generator so that all users can be properly informed of its safe

operation.

WARNING: Never allow children or pets to be in the area where the generator is running. The generator

and the equipment being powered by the generator may cause injury or death.

WARNING: Never operate the generator unless all guards, covers, shields and other safety items are

properly installed.

WARNING: Do not put hands, feet, tools clothing or other objects near rotating parts such as drive shaft,

pulley, belt etc. Rotating parts cause extremely dangerous situations because they can catch

loose clothing or extremities and cause serious or fatal injury.

WARNING: When operating this generator remain alert at all times. Never operate machinery when

physically or mentally fatigued, or while under the influence of alcohol, drugs or medication.

WARNING: Never operate the engine when the air cleaner is removed. An engine backfire can cause

serious burns.

WARNING: Never “jump start” a generator to start the engine. If the battery charge is insufficient to start

the engine, charge or replace the battery and try to restart. Jump starting a battery can cause

the battery to explode and cause severe injury or death to anyone in the area.

WARNING: High voltage is present whenever engine is running. Electrical shock can cause serious or

fatal injury. Never operate electrical equipment while standing in water, on wet ground or with

wet hands, feet or shoes or while barefoot.

WARNING: High voltage is present whenever the engine is running. Electrical shock can cause serious

or fatal injury. Always stop engine before connecting or disconnecting power cords or

external devices.

WARNING: Do not smoke near generator during operation or when close to fuel source. LPG and natural

gas fuels are flammable and can cause fire, explosions, injury or death.

WARNING: Keep generator at least three feet away from buildings and other structures.

WARNING: Keep generator away from flammable or hazardous materials (trash, rags, lubricants,

explosives, paints etc.) and grass or leaf build up.

WARNING: Keep a fire extinguisher near the generator while generator is in use. An extinguisher rated

“ABC” by the National Fire Protection Association is appropriate.

Burn

WARNING: Parts of this generator are extremely hot during and after operation. To prevent severe burns,

do not touch any part of the generator until you have first determined if the part is hot. Wear

protective clothing and after use allow sufficient time for parts to cool before touching any

part of the generator.

WARNING: Do not touch the hot exhaust parts or the high voltage spark plug or coil terminals of the

engine. Although spark plug voltages are not normally lethal, a sudden involuntary jerk of the

hand or body part caused by contact with high voltage or a hot surface can result in injury to

yourself or others.

WARNING: Engine coolant is under pressure and is near the boiling point of water when engine is hot.

Do not open the coolant system until the engine has completely cooled. Hot coolant can

cause severe burns and other injuries. When engine is cool, coolant level can be checked.

Continued on next page.

Continued

Product Safety Information 1-3MN2408

Page 8

Warning Statements

Installation

WARNING: Installation and servicing of batteries is to be performed or supervised by personnel

knowledgeable of batteries and the required precautions. Keep unauthorized personnel away

from batteries.

WARNING: Disconnect the battery’s ground terminal before working in the vicinity of the battery or

battery wires. Contact with the battery can result in electrical shock when a tool accidently

touches the positive battery terminal or wire. The risk of such shock is reduced when the

ground lead is removed during installation and maintenance.

WARNING: An open bottom stationary engine generator set must be installed over noncombustible

materials and shall be located such that it prevents combustible materials from accumulating

under the generator set.

WARNING: Installation and repair procedures requires specialized skills with electrical generating

equipment and small engine systems. Any person that installs or performs repairs must have

these specialized skills to ensure that the generator set is safe to operate. Contact Baldor for

installation or repairs.

WARNING: Be sure all wiring complies with the National Electrical Code (NEC) and all regional and local

codes or CE Compliance. Improper wiring may cause a hazardous condition and exposure to

electrical hazards can cause serious injury or death.

WARNING: Be sure the system is properly grounded before applying power. Do not apply AC power

before you ensure that grounds are connected. Electrical shock can cause serious or fatal

injury. NEC requires that the frame and exposed conductive surfaces (metal parts) be

connected to an approved earth ground. Local codes may also require proper grounding of

generator systems.

WARNING: Place protective covers over all rotating parts such as drive shaft, pulley, belt etc. Rotating

parts cause extremely dangerous situations because they can catch loose clothing or

extremities and cause serious or fatal injury.

WARNING: Unauthorized modification of a generator set may make the unit unsafe for operation or may

impair the operation of the unit. Never start a generator set that has been modified or

tampered with. Be sure that all covers and guards are properly installed and that the unit is

safe before starting the engine. If you are unsure, contact Baldor before starting the engine.

WARNING: When moving the generator, use reasonable caution. Be careful where you place fingers and

toes to prevent injury “Pinch Points”. Never try to lift a generator without a hoist or lift means

because they are heavy and bodily injury may result.

Warning: Never connect this generator to the electrical system of any building unless a licensed

electrician has installed an approved transfer switch. The national electrical code (NEC)

requires that connection of a generator to any electrical circuit normally powered by means of

an electric utility must be connected by means of approved transfer switch equipment to

isolate the electrical circuit from the utility distribution system when the generator is

operating. Failure to isolate the electrical circuits by such means may result in injury or death

to utility power workers due to backfeed of electrical energy onto the utility lines.

WARNING: Circuit overload protection must be provided in accordance with the National Electrical Code

and local regulations.

WARNING: Check Ground Fault Circuit Interrupt (GFCI) receptacles monthly by using the “Test” and

“Reset” buttons.

WARNING: Only a professional experienced technician should install a fuel supply system. LPG and

natural gas fuels are flammable and can cause fire, explosions, injury or death. Fuel supply

lines should be kept away from sharp objects to prevent rupture. Comply with all NFPA

regulations and local codes for shut–off valves, regulators, fuel line type, connectors etc.

WARNING: Have electrical circuits and wiring installed and checked by licensed electrician or qualified

technician. Electrical shock can cause serious or fatal injury.

WARNING: Incorrect installation of this generator set could result in property damage, injury or death.

Connection of the generator to its fuel source must be done by a qualified professional

technician or contractor.

WARNING: An open bottom stationary engine generator set must be installed over noncombustible

materials and shall be located such that it prevents combustible materials from accumulating

under the generator set.

Continued

Continued on next page.

1-4 Product Safety Information MN2408

Page 9

Warning Statements

Maintenance

WARNING: Disconnect the battery’s ground terminal before working in the vicinity of the battery or

battery wires. Contact with the battery can result in electrical shock when a tool accidently

touches the positive battery terminal or wire. The risk of such shock is reduced when the

ground lead is removed during installation and maintenance.

WARNING: Installation and servicing of batteries is to be performed or supervised by personnel

knowledgeable of batteries and the required precautions. Keep unauthorized personnel away

from batteries.

WARNING: A battery presents a risk of fire and explosion because they generate hydrogen gas.

Hydrogen gas is extremely explosive. Never jump start a battery, smoke in the area around

the battery or cause any spark to occur in the area around the battery.

WARNING: Do not mutilate the battery or dispose of a battery in a fire. The battery is capable of

exploding. If the battery explodes, electrolyte solution will be released in all directions.

Battery electrolyte solution is caustic and can cause severe burns and blindness. If

electrolyte contacts skin or eyes, immediately flush the area with water and seek medical

attention quickly.

WARNING: A battery presents a risk of electrical shock hazard and high short circuit current. Electrical

shock can cause serious or fatal injury. Never wear jewelry, watch or any metal objects when

in the area around the battery.

WARNING: The battery electrolyte is a dilute sulfuric acid that is harmful to the skin and eyes. It is

electrically conductive and corrosive. If electrolyte contacts the skin, flush the area

immediately with water and wash it off using soap and water. If electrolyte contacts the eyes,

immediately flush the eye thoroughly with water and seek medical attention quickly.

WARNING: Before cleaning, inspecting, repairing or performing any maintenance to the generator set,

always be sure the engine has stopped and that all rotating parts have also stopped. After

stopping, certain components are still extremely hot so be careful not to get burned. Before

servicing the generator set, be sure to disconnect the spark plug wires and the battery

terminals to prevent accidental engine rotation or starting.

WARNING: Engine coolant is under pressure and is near the boiling point of water when engine is hot.

Do not open the coolant system until the engine has completely cooled. Hot coolant can

cause severe burns and other injuries. When engine is cool, coolant level can be checked.

WARNING: Before servicing the generator set, be sure to disconnect the spark plug wires and the battery

terminals to prevent accidental engine rotation or starting.

WARNING: Inspect all wiring frequently and replace any damaged, broken or frayed wiring or wires with

damaged insulation immediately. Electrical shock can cause serious or fatal injury.

WARNING: Disconnect all electrical wires and load devices from generator power outlets before servicing

the generator. Electrical shock can cause serious or fatal injury. Always treat electrical

circuits as if they are energized.

WARNING: Check all fuel supply piping, and their connections monthly for fuel leaks. LPG and natural

gas fuels are flammable and can cause fire, explosions, injury or death. If a leak is found,

replace only with approved pipe or components.

Continued

Continued on next page.

Product Safety Information 1-5MN2408

Page 10

Caution Statements

Caution: Avoid installing the generator set beside heat generating equipment, or directly below water

or steam pipes or in the vicinity of corrosive substances or vapors, metal particles and dust.

Heat can cause engine problems to develop and unwanted substances can cause rust or

generator failure over time.

Caution: Do not apply high voltage to windings (do not start the generator) in a moisture–saturated

condition. Moisture can cause insulation breakdown, making it necessary to return the

generator to the factory for repair, and consequent expense and loss of time.

Caution: Use only original equipment or authorized replacement parts. Using the correct parts will

assure continued safe operation as designed.

Caution: Do not support the generator from the top of the frame or enclosure.

Caution: Do not tamper with or change the engine speed. Engine speed is factory set to produce the

correct voltage and output frequency.

Caution: Never operate the engine without a muffler. The engine is designed to have the correct

exhaust components installed and operating without these components can present a fire

hazard, cause excessive exhaust gases and cause damage to engine. Inspect muffler

periodically and replace if necessary.

Caution: The Programmable Output Contacts selection must agree with the external control wiring

prior to energizing the controller. Failure to do so may cause severe equipment damage.

1-6 Product Safety Information MN2408

Page 11

Section 2

General Information

Thank you for purchasing your Baldor Generator Set. This manual contains information you need to safely and

efficiently install and operate your generator set. During the preparation of this manual every effort was made to

ensure the accuracy of its contents. This manual describes only very basic engine information. A separate owner’s

manual for the engine is supplied with this unit for your use. Please refer to the engine manual for information

relative to engine operation, maintenance, recommendations and additional safety warnings.

Copyright Baldor ! 2004. All rights reserved.

This manual is copyrighted and all rights are reserved. This document may not, in whole or in part, be copied or

reproduced in any form without the prior written consent of Baldor Electric Company, Inc.

Baldor Generators have earned the reputation of being high quality and dependable. We take pride in this fact and

continue to keep our quality standards high on our list of priorities. We are also constantly researching new

technological ideas to determine if they could be used to make our generator sets even better.

Baldor makes no representations or warranties with respect to the contents hereof and specifically disclaims any

implied warranties of fitness for any particular purpose. The information in this document is subject to change

without notice. Baldor assumes no responsibility for any errors that may appear in this document.

Limited Warranty

Baldor Generators will replace or repair free of charge any part or parts of the generator of their manufacture that

are defective in workmanship and materials for a period of time as set forth in the Warranty Period chart below.

All Baldor products requiring warranty service shall be transported or shipped freight pre–paid, at the risk of the

party requiring warranty service, to a Baldor Generator repair facility, or to Baldor Generators

Department in Oshkosh, Wisconsin. Written notification of the alleged defect in addition to a description of the

manner in which the Baldor generator is used, and the name, address and telephone number of the party requiring

warranty service must be included. Baldor is not responsible for removal and shipment of the Baldor product to the

service center or for the reinstallation of the Baldor product upon its return to the party requiring warranty service.

Problems with Baldor products can be due to improper maintenance, faulty installation, non–Baldor additions or

modifications, or other problems not due to defects in Baldor workmanship or materials. If a Baldor Generator

repair facility determines that the problem with a Baldor product is not due to defects in Baldor workmanship or

materials, then the party requesting warranty service will be responsible for the cost of any necessary repairs.

EXCEPT FOR THE EXPRESSED WARRANTY SET FORTH ABOVE, BALDOR GENERATORS DISCLAIMS ALL

OTHER EXPRESSED AND IMPLIED WARRANTIES INCLUDING THE IMPLIED WARRANTIES OF FITNESS

FOR A PARTICULAR PURPOSE AND MERCHANTABILITY. NO OTHER WARRANTY, EXPRESSED OR

IMPLIED, WHETHER OR NOT SIMILAR IN NATURE TO ANY OTHER WARRANTY PROVIDED HEREIN, SHALL

EXIST WITH RESPECT TO THE GOODS SOLD UNDER THE PROVISIONS OF THESE TERMS AND

CONDITIONS. ALL OTHER SUCH WARRANTIES ARE HEREBY EXPRESSLY WAIVED BY THE BUYER.

UNDER NO CIRCUMSTANCES SHALL BALDOR GENERATORS BE LIABLE OR RESPONSIBLE IN ANY

MANNER WHATSOEVER FOR ANY INCIDENTAL, CONSEQUENTIAL OR PUNITIVE DAMAGES, OR

ANTICIPATED PROFITS RESULTING FROM THE DEFECT, REMOVAL, REINSTALLATION, SHIPMENT OR

OTHERWISE. This is the sole warranty of Baldor Generators and no other affirmations or promises made by

Baldor Generators shall be deemed to create an expressed or implied warranty. Baldor Generators has not

authorized anyone to make any representations or warranties other than the warranty contained herein.

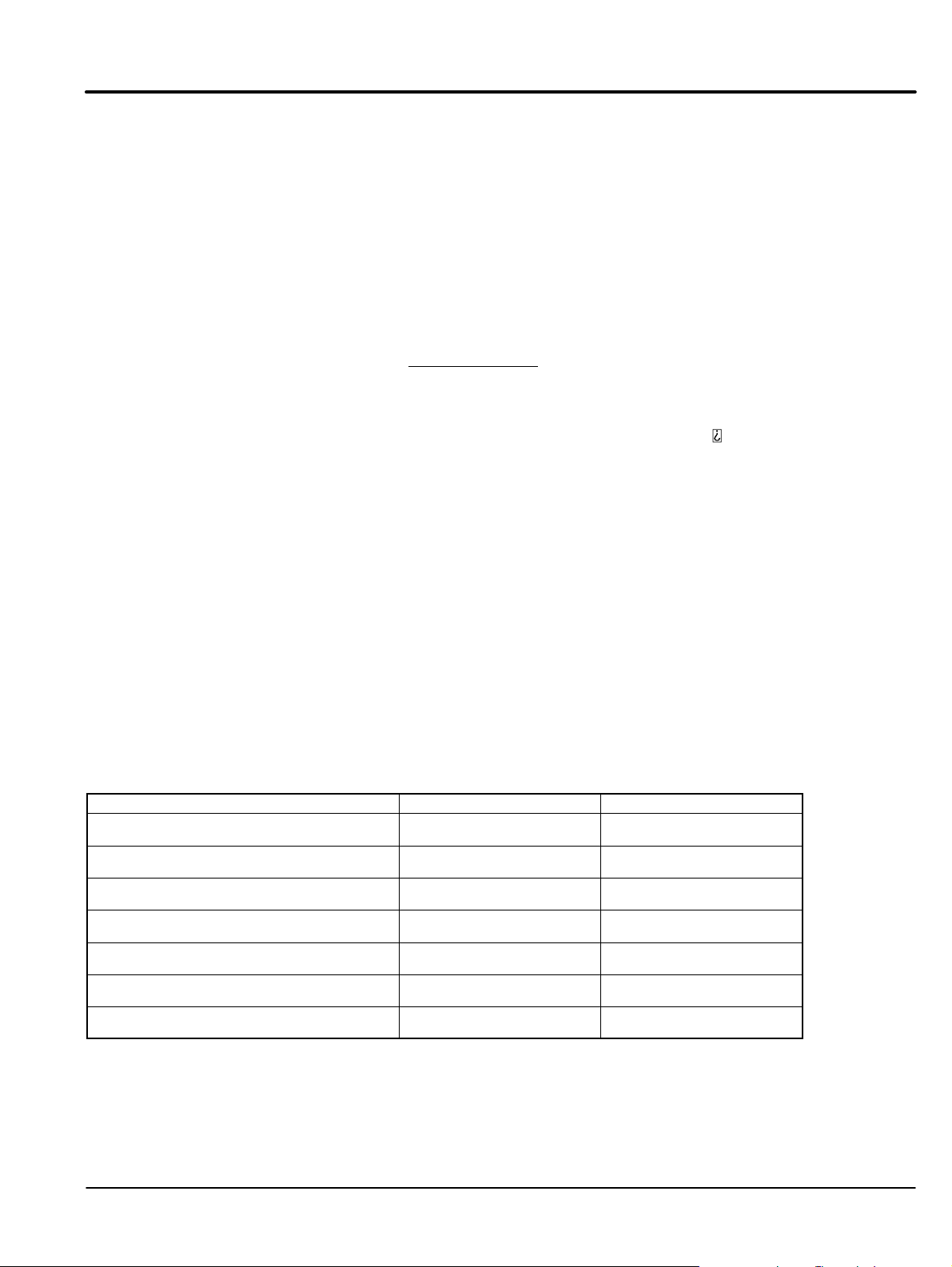

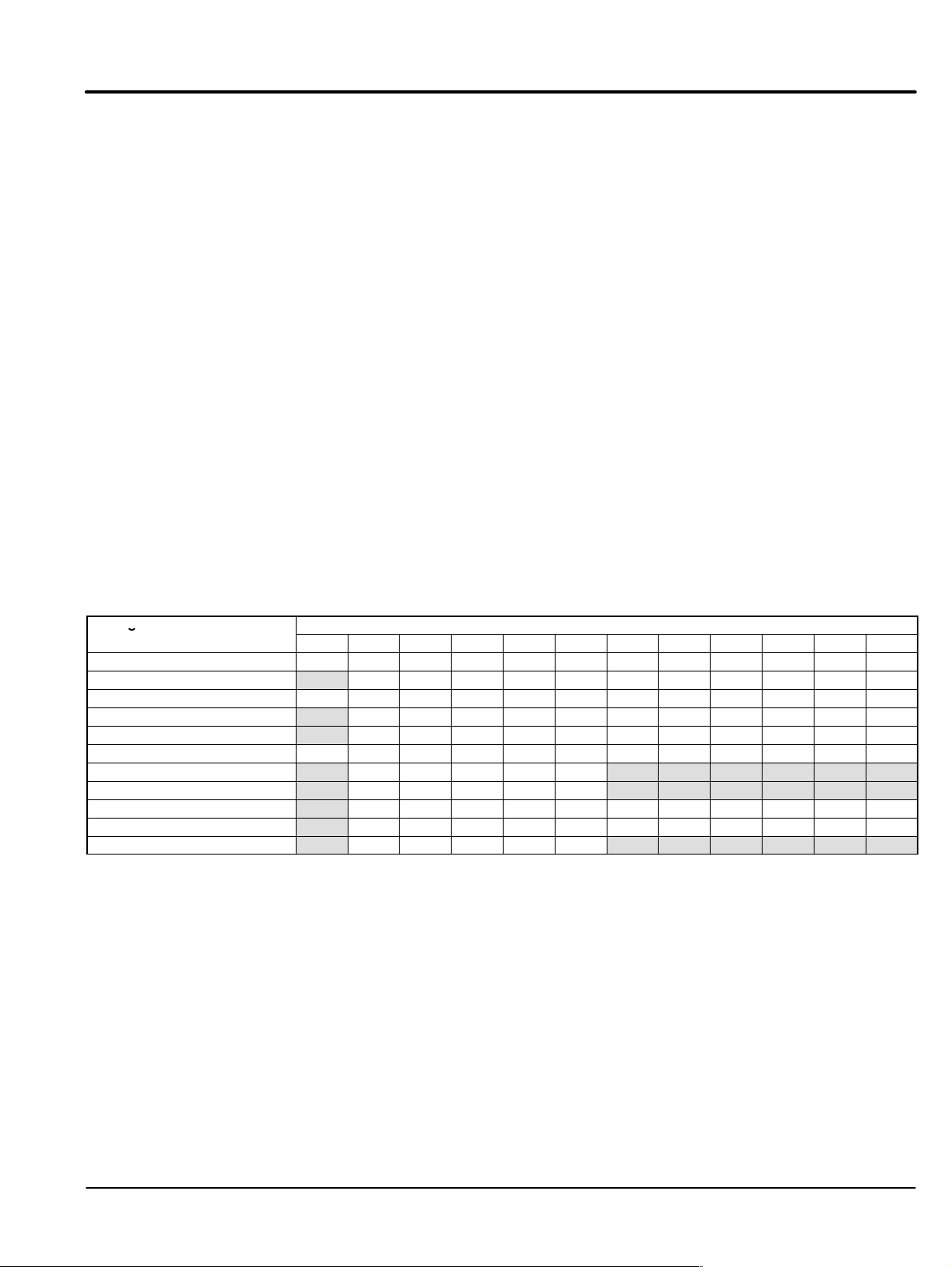

Warranty Period

Generator Series Labor* Parts

(Premier, Powerchief, DG Series, K Series)

Portable Products

Towable Products (TS) 1 Year or 3,000 Hours

3600 RPM Standby Systems

(Some AE Models)

1800 RPM Standby Systems

(Some AE Models, DLC, GLC)

Industrial Standby Systems 1 Year or 1,000 Hours

Industrial Prime Power Systems 1 Year or 1,000 Hours

International 1 Year or 1,000 Hours

Whichever comes first

1 Year or 1,000 Hours

Whichever comes first

1 Year or 3,000 Hours

Whichever comes first

Whichever comes first

Whichever comes first

Whichever comes first

*For products covered under labor coverage, travel expenses will be allowed up to 7 hours straight labor or 300

miles, whichever occurs first and only applies to permanently wired and mounted products (AE, DLC, GLC, IDLC).

No warranty registration card is necessary to obtain warranty on Baldor Generators.

You must save the purchase receipt. Proof of purchase, date, serial number and model number will be required for

all portable and Towable products to qualify for any warranty consideration.

For all other products, a start–up inspection form/warranty registration must be completed in its entirety and

submitted to Baldor Generators within 30 days of start–up to qualify for any warranty consideration.

1 Year 3 Years

3 Years or 3,000 Hours

Whichever comes first

3 Years or 1,000 Hours

Whichever comes first

3 Years or 3,000 Hours

Whichever comes first

2 Years or 1,000 Hours

Whichever comes first

1 Year or 1,000 Hours

Whichever comes first

1 Year or 1,000 Hours

Whichever comes first

General Information 2-1MN2408

Page 12

2-2 General Information MN2408

Page 13

Important Be sure you are completely familiar with all Safety Instructions detailed in Section 1 of this

manual. Do not proceed if you are unsure of any detail. Contact your Baldor Distributor, they are

experienced and are happy to assist you and to answer your questions.

Installation Guidelines

The procedures presented in this manual are suggestions and it is the responsibility of the

Owner/Operator to arrange for these procedures to be performed by licensed contractors

according to all applicable codes including local codes for your Municipality/City/County and

State. In addition to these suggestions, before installing your generator you should obtain the

most up to date copies of the following documents from the National Electrical Code and other

authorities:

S National Electric Code, Articles 230, 250, 445, 517, 700.

S National Fire Protection Association

No. 30 – Storage, Handling and Use of Flammable Liquids.

No. 37 – Stationary Combustion Engines and Gas Turbines.

No. 99 – Essential Electrical Systems for Health Care Facilities.

No. 101 – Life Safety Code No. Systems.

No. 110 – 1985 Emergency and Standby Power Systems.

S NEMA MG1

S Local Codes applicable to Genset Installation. See your local building inspector.

NFPA (National Fire Protection Association (617) 770–3000 (includes NEC)

1 Batterymarch Park, Quincy, MA 02169–7471 USA

NEMA (National Electrical Manufacturers Association) (703) 841–3200

1300 N. 17th Street, Suite 1847, Rosslyn, VA, 22209 USA

Site Planning

Room Size Open frame generators must be protected from the environment while having good ventilation

and cooling. Here are some considerations for planning a generator room or enclosure:

S Never use the Genset room for storage as well.

S The room must be large enough to contain the genset and all the accessories, such as

batteries and their charging system, transfer switch and other controls, and elements of

the cooling and fuel systems.

S A minimum of 2 feet (preferably 4 feet), must be allowed on the two sides of the engine

for service access.

S On the generator end of the engine, allow a space equal to the length of the generator

(generator length only, not the entire genset).

S At the front of the engine, 4 feet of clearance is preferable. Allow clearance between

hot parts of the system (exhaust) and structural members of the building.

S Certain safety and building codes may require the genset room not to be used to house

any other mechanical or electrical equipment.

General Information 2-3MN2408

Page 14

Room Location Often a separate building located on the site away from the main building is the most simple and

cost effective. Major considerations when housing the genset in a separate building are:

S Maintain the building at a satisfactory temperature year round (to meet applicable

codes).

S Assure the genset is not located so far from the emergency loads that reliability is

compromised.

S The floor’s load carrying capacity must be checked and must exceed the weight of the

genset and its associated equipment.

S Engine Cooling System

A genset with an engine mounted radiator is the least costly to install; however, the

room must be located in a place where sufficient radiator cooling air can be brought

into and exhausted from the room.

S Exhaust System

The exhaust system must minimize exhaust restriction. Exhaust restriction must be

limited to 3 in. Hg (76 mm Hg) maximum, to ensure proper engine operation. The

exhaust system should be as short and have as few bends as possible.

S Room Air

If the genset is cooled with an engine mounted radiator, and sufficient air is brought into

and exhausted from the room to satisfy the radiator cooling requirements and the

combustion air requirements, the room will not overheat when the genset is running.

If a remote mounted radiator or a heat exchanger is used, and adequate air is

circulated through the room to keep it at a reasonable temperature, there will be

adequate air for combustion.

S Fuel Tanks (Diesel Only)

Locate the fuel storage tank as near the genset as possible. This will minimize the cost

of fuel system installation and will maximize fuel system reliability.

S Controls and Transfer Switch

Locate the control switch gear as close to the emergency loads and the genset as

practical. This will minimize the chances that a failure of the power line to the

emergency load will go undetected. In locating the switchgear, accessibility for service

and maintenance must be considered.

S Genset Noise

Internal combustion engines produce noise, so the room should be located away from

occupied buildings. In addition the genset room can be treated to reduce noise

transmission. In locating the genset room, both engine, fan and exhaust noise must be

considered.

If noise within the genset room, or noise transmitted to the surrounding parts of the

building are a concern, then the room must be made large enough to allow for

installation of noise attenuating walls and noise absorbing walls.

Light weight concrete blocks filled with sand or special “sound block” concrete blocks

are commonly used. Noise attenuating, tight fitting windows and doors also help reduce

noise transmission to the rest of the building.

A double–walled room should be considered. Vibration isolators under the genset rails

will also reduce the transmission of noise through the floor.

S Code Requirements

Building and safety codes deal with engine location. These requirements are

concerned with fire rated walls, a location that minimizes the possibility of damage to

the genset and interruption of the emergency system due to storms, foods, fire,

vandalism, etc.

Codes often deal with the need to maintain certain temperatures in the genset room

and with fuel system location. The most important codes in the USA are the National

Fire Protection Association Code Numbers 99 and 110, but local codes must also be

observed.

2-4 General Information MN2408

Page 15

Foundation Design

WARNING: An open bottom stationary engine generator set must be installed over noncombustible

materials and shall be located such that it prevents combustible materials from accumulating

under the generator set.

Foundation Checklist

A. Evaluate if a separate, isolated foundation is required for the application.

B. Observe local codes on soil bearing capacity freezing and thawing.

C. Design the separate foundation for the genset and specify the appropriate concrete mix.

D. Determine if the application requires vibration isolators and if so, order as a factory option.

The foundation must be strong enough to support the weight of the genset and its associated

equipment, must prevent any deflection of the genset base and absorb vibration produced by the

rotating and reciprocating masses.

Setting The Genset On An Existing Concrete Floor Slab

S If an existing floor is used, the floor slab must be strong enough to carry 1.50 times the

genset wet weight (including coolant and oil) to accommodate dynamic loads.

S The actual mounting arrangement (ie., surface area in contact with the floor) will

determine the compressive strength required.

S The genset should be securely fastened to the floor slab with expansion anchors that fit

the mounting holes shown on the genset installation diagram.

S For installations not expected to be permanent, elastomer pad with non–slip surface

placed between the base and the floor will also prevent movement.

S Any floor/slab surface should be as flat as possible to prevent sub–base deflection.

Vibration Isolators

S Mounting to the pad, will result in overall reduced motion on other parts of the genset.

The trade–off is that slightly more vibration is transmitted to the structure.

S A more common practice when mounting to a concrete pad is to use vibration isolators.

The two most common types of vibration isolators are steel spring and elastomer pad.

The primary purpose of vibration isolators is to reduce the noise and vibration which

would be transmitted from the genset to the foundation or supporting structure.

S A simple and effective method of mounting and applying pad type isolators is to place

non–skidding type isolation pads directly between the sub–base and floor.

The number of pads required will be determined by the load bearing capability of the

pads and the genset’s weight.

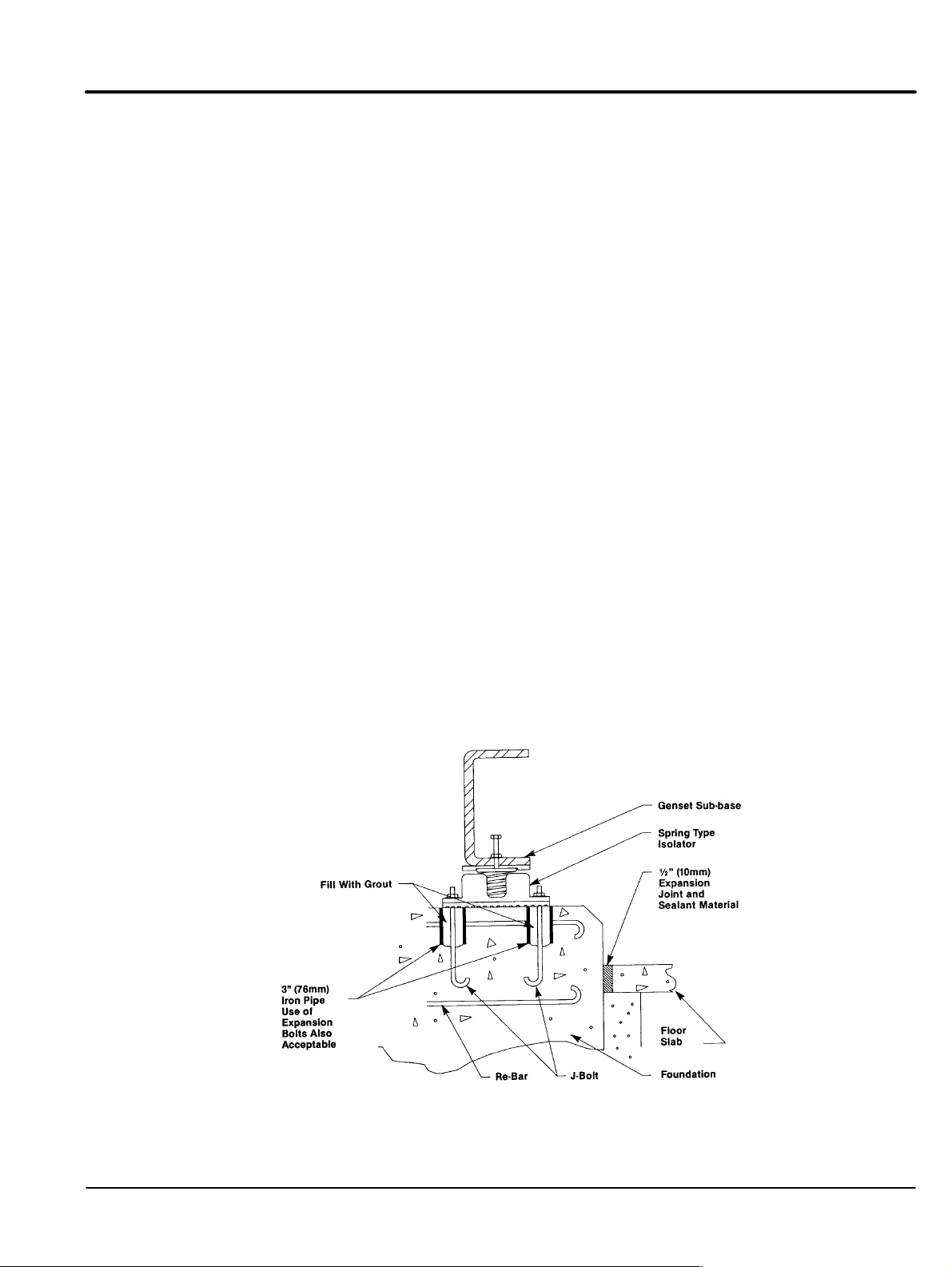

Figure 2-1 Typical Installation of Spring Type Isolator

General Information 2-5MN2408

Page 16

S Steel spring isolators are a very effective and commonly used. Steel spring isolators

are typically 95–98% efficient (reduces the transmitted vibration 95–98%) while a pad

type can be 75–88% efficient. Spring isolators also level the genset sub–base in the

event the foundation pad is not perfectly level.

Spring steel isolators offer the highest level of vibration isolation, however higher levels

of vibration (although not detrimental) may be seen on some areas of the genset when

mounted on steel springs, due to the (almost) total isolation from the foundation. The

base of most steel spring isolators contains a non–skid pad. The base should be

mounted to the foundation pad as shown in Figure 2-1 or as recommended by the

isolator manufacturer.

A common practice is to pour a concrete pad directly on top of the floor slab and to

mount the genset on this pad. The purpose of the pad is to facilitate cleaning around

the genset and to provide a more level base. When using this method, floor strength

must support the pad and the genset. The pad should be at least 6in (150mm) thick

and extend beyond the genset in all directions 12in (300mm).

Weight Of The Genset

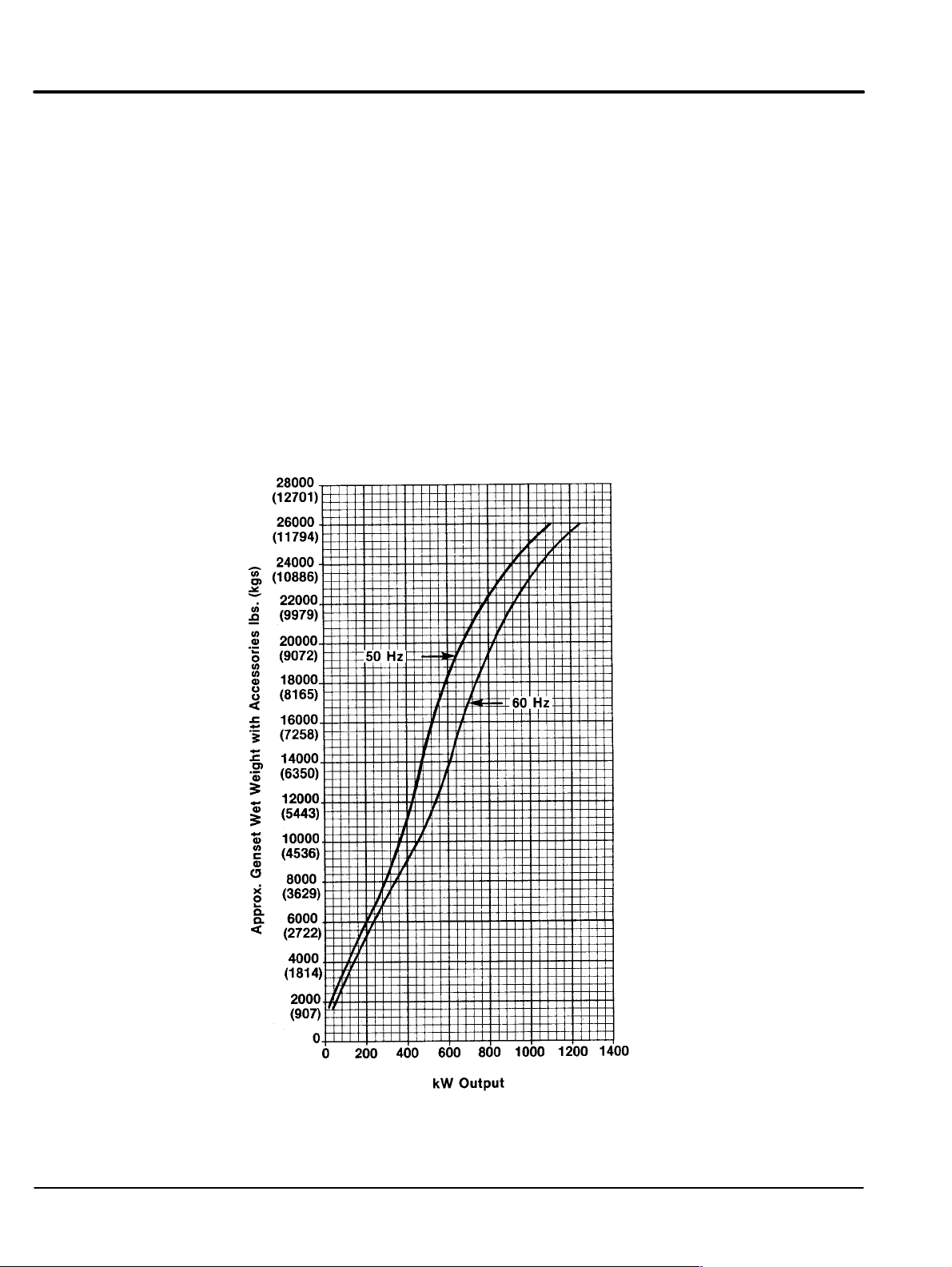

The dry weight of the entire genset is shown on the Generator Set Specification Sheet. The wet

weight includes the fluids (coolant and oil). Figure 2-2 can be used to design the foundation

except in critical situations.

Figure 2-2 Approximate Weight vs. kW Output

2-6 General Information MN2408

Page 17

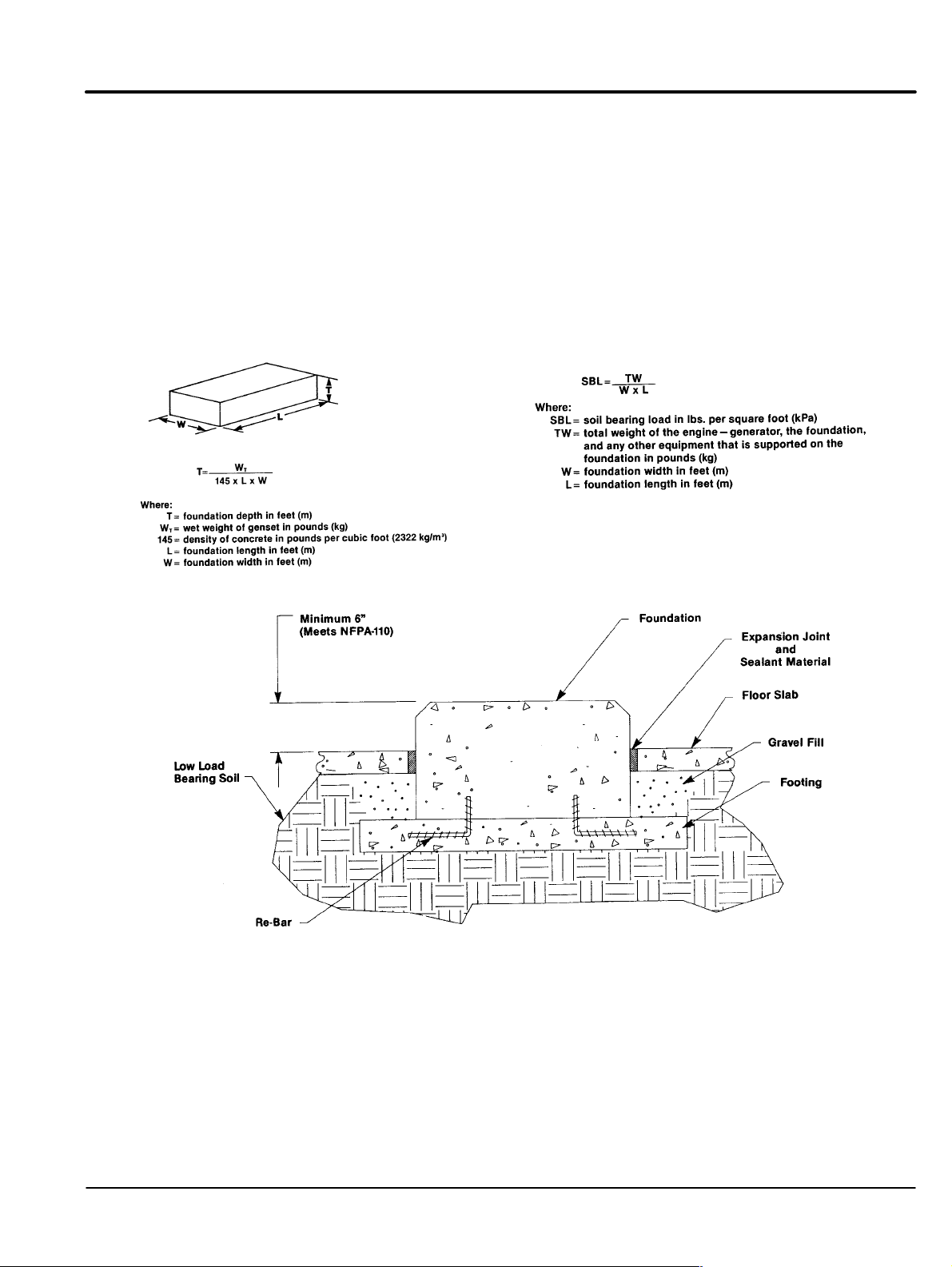

Designing An Isolated Foundation

If the genset cannot be mounted directly on a floor slab, or if it is desirable to isolate it from the

floor slab, then a separate foundation slab must be designed.

A massive concrete foundation is not required. Outside dimensions of the foundation should

exceed the outside genset dimensions by 12in (300mm).

For single genset installation, the foundation weight should be a minimum of 1.50 times the

genset wet weight.

For multiple genset installation, the foundation weight should be a minimum of 2.0 times the

genset wet weight.

Figure 2-3 shows a method to calculate foundation thickness and the soil bearing load of the

foundation and generator set. The soil load bearing capacity under the foundation must equal or

exceed the load from the foundation and genset. If it does not, then a footing, as shown in Figure

2-4 must be added to spread the load over a larger area.

Figure 2-3 Calculate Soil Bearing Load (SBL) Capacity

Figure 2-4 Typical Footing on Foundation in Soil With Low Soil Load Bearing Capacity

General Information 2-7MN2408

Page 18

Table 2-1 Approximate Load Bearing Capacities of Various Soil Types

Soil T

ype

Hard Rock – Granite etc. 50,000 – 200,000 2,395 – 9,576

Medium Rock – Shale etc. 20,000 – 30,000 958 – 1,436

Hardpan 16,000 – 20,000 766 – 958

Soft Rock 10,000 – 20,000 479 – 958

Compacted Sand and Gravel 10,000 – 12,000 479 – 575

Hard Clay 8,000 – 10,000 383 – 479

Gravel and Coarse Sand 8,000 – 10,000 383 – 479

Loose, Medium and Coarse Sand 8,000 – 10,000 383 – 479

Compacted Fine Sand 6,000 – 8,000 287 – 383

Medium Clay 4,000 – 8,000 192 – 383

Loose Fine Sand 2,000 – 4,000 96 – 192

Soft Clay 2,000 96

Safe Bearing Capacity

lb per ft

2

kilo Pascals

Table 2-1 shows approximate load bearing capacities for various types of soil if the actual load

bearing capacity of the soil under the foundation is not known.

Caution: Check the local building codes for load bearing capacity requirements.

Caution: If the soil is subject to freezing and thawing, the foundation must be extended below the frost

line. Check the local building codes.

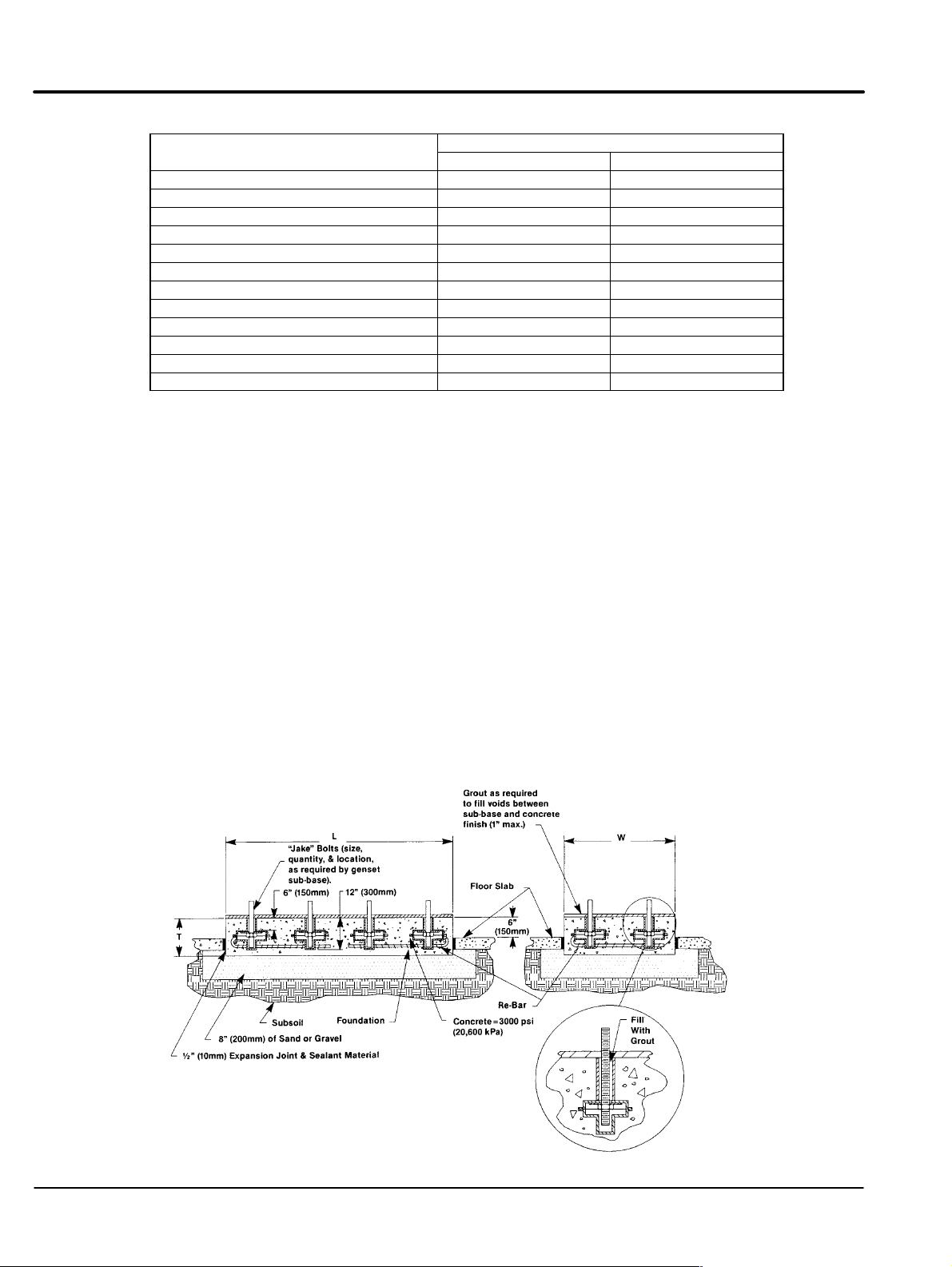

S Reinforce the foundation with No. 8 gauge steel wire mesh placed horizontally on

6in (150mm) centers. As an alternative, use No. 6 re–bars on 12in (300mm) centers

horizontally. Minimum cover over the bars should be 3in (76mm).

S Suggested concrete mixture by volume is 1 part cement, 2 parts sand, and 3 parts

aggregate. Maximum slump of 4in (100mm) and a 28–day compressive strength of

3000 psi (20,600 kPa).

S The size of the bolts holding the sub–base to the foundation should be sized to fit the

mounting holes shown on the Installation Diagram.

S Three–inch (76mm) iron pipe sleeves should be placed around the bolts in the

foundation to allow for any mislocation of the bolts after the foundation hardens. “J” or

“L” type bolts are recommended for the foundation bolts.

S After the foundation is cured and the genset is located, the sleeves are filled with grout.

Figure 2-5 shows a typical foundation installation.

Figure 2-5 Typical Foundation Installation

2-8 General Information MN2408

Page 19

Exhaust System

Exhaust Checklist

A. Exhaust outlets are not located upwind or near any building air intakes.

B. Flexible piping section is used at engine exhaust outlet.

C. Exhaust piping material is adequate for expected service.

D. Exhaust piping sizing is adequate to prevent back pressure.

E. Exhaust piping components are insulated as necessary to prevent operator burns and reduce

pipe radiant heat losses.

F. Pipe sleeves or fire proof materials are used where exhaust pipe passes through building

materials as per local and state codes.

G. Exhaust pipe includes rain cap or is horizontal.

The purpose of the exhaust system is to safely discharge the engine combustion products into

the atmosphere outside the building. A silencer should be installed in the exhaust system to

reduce noise levels. Compliance with local noise codes is always required.

Level Of Attenuation

In general, manufacturers offer three grades of silencers: industrial, residential, and critical. In

most cases, these grades are comparable from make to make. However, attenuation curves for

the silencer should be checked to assure the desired level of silencing is met.

System Placement

By this time, the general genset placement within the room or building has been decided. The

routing of the exhaust system should be as direct as possible to the building exterior.

WARNING: Never allow the exhaust outlet to be positioned so that the exhaust gases are directed

towards any openings or air entry routes (doors, windows, vents, etc...) of an occupied

building. When discharging the hot exhaust gases out of the building do not direct them

towards anything that could catch fire or explode.

For aesthetic reasons, consider exhaust placement in relation to the building. Over a period of

time, exhaust gas carbon deposits will tend to accumulate on any nearby wall or structure.

Attention must also be given to exhaust noise in selecting placement of the exhaust system.

Multi–Engine Installations

Caution: Do not connect multi–engine exhaust systems together. Each engine must have its own

exhaust system for proper operation.

Exhaust gases from an operating engine will migrate back through a non–operating engine and

cause a hydraulic lock. This may interfere with starting of the second engine. The migrating

gases will also tend to turn the turbos which are not being provided lubrication if the engine is not

running. The use of check valves in the exhaust system are discouraged due to their tendency

to “stick”.

Exhaust Manifold

There are two exhaust manifold types. Dry type which is standard and the optional water cooled.

The dry type is simply exposed to the surrounding air and becomes very hot. Shields, insulating

wraps, or other types of guards can be used to limit operator contact with the hot surfaces. This

practice is common where engine room size is small, creating cramped conditions.

Water cooled exhaust manifolds are not available on all engine models. This type manifold has

passages through which engine coolant is circulated to remove heat from the manifold surface. It

also will help protect the operator from contact with the hot manifold surface. This will reduce the

amount of heat that is radiated by the engine to the surrounding air by approximately 20%. In

addition, this type manifold significantly increases the amount of heat the cooling system must

dissipate. Marine and Mining Safety Administration (MSA) codes may require water cooled

manifolds in all genset installations. If you are in doubt on your particular application, consult your

Baldor Distributor.

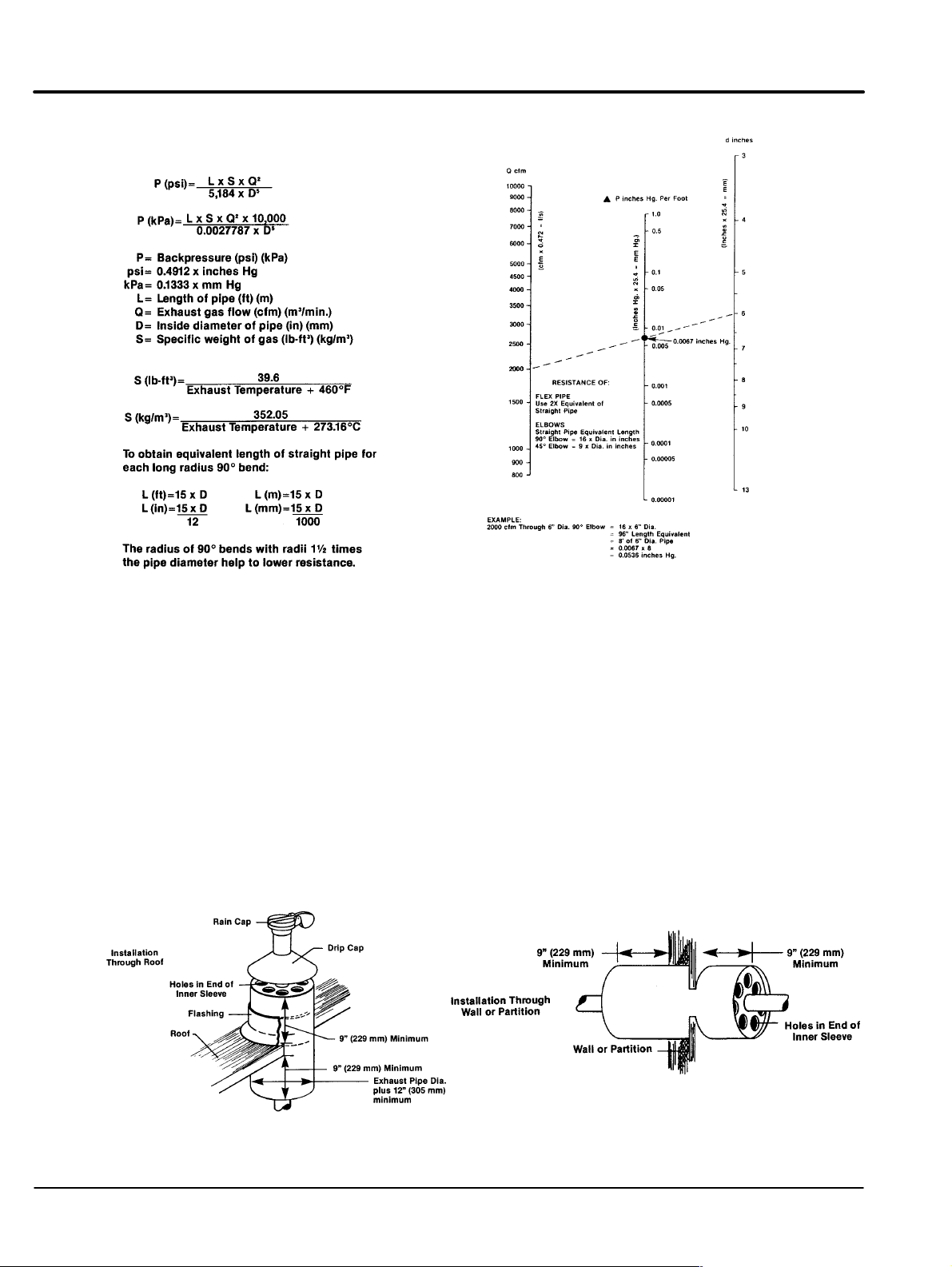

Exhaust Gas Restriction

The maximum allowable back pressure, or system restriction, is 3 inches of mercury. If this back

pressure is exceeded, the air–fuel ratio is reduced due to incomplete scavenging of the cylinders,

fuel economy and power output is reduced, engine life is reduced and exhaust temperatures and

smoke levels increase. Any restriction of the exhaust gas reduces horsepower. Take every

precaution to reduce restriction. Proper design and installation will provide safe genset operation.

It is essential that all engine exhaust systems by designed with the least possible restriction to

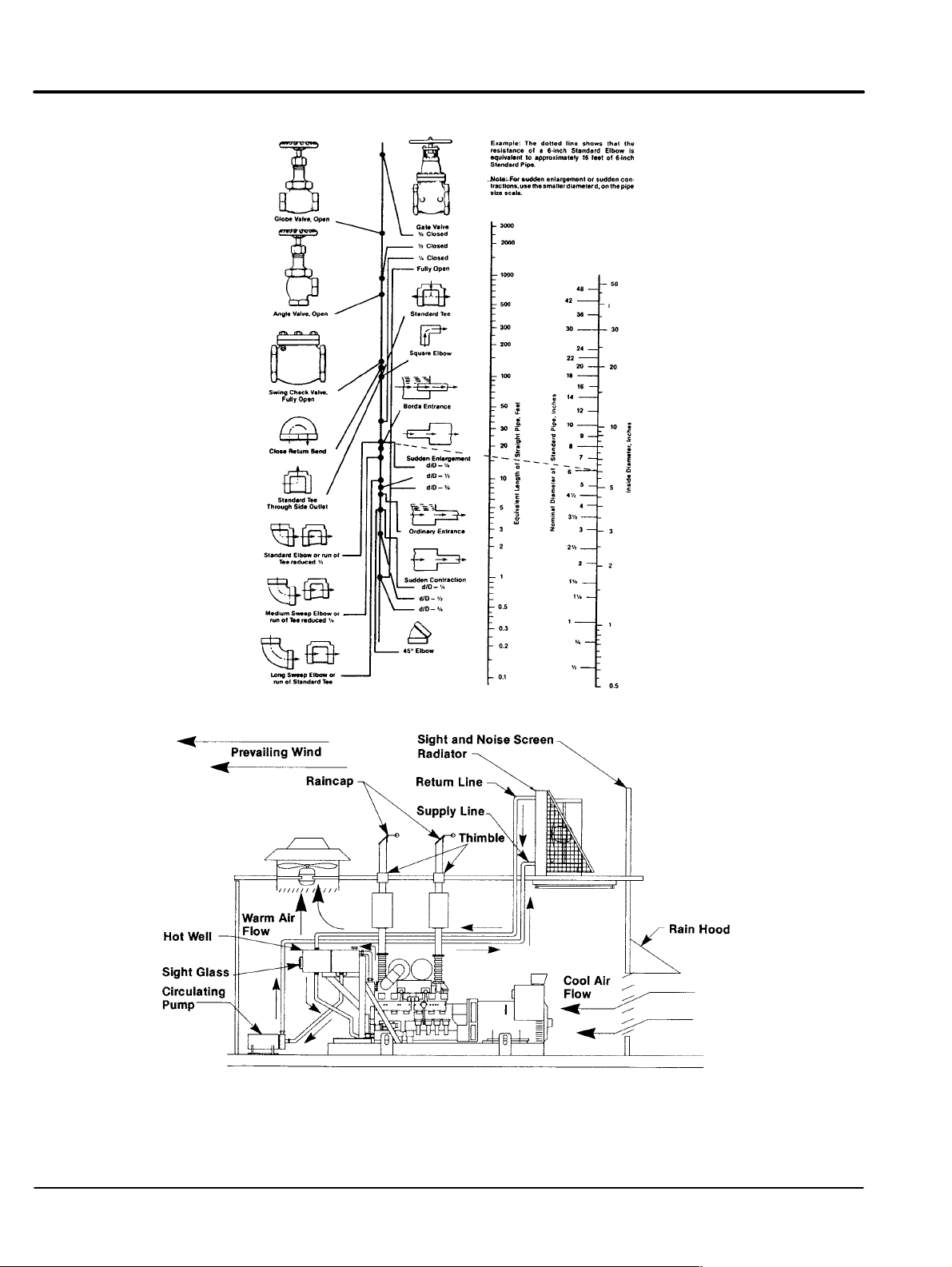

exhaust gas flow. This can be calculated through the use of Figure 2-6, or in the case of simple

exhaust systems, the nomograph in Figure 2-6 may be used.

General Information 2-9MN2408

Page 20

Figure 2-6 Exhaust System Calculations

Exhaust Piping

Caution: The weight of the exhaust system must never be imposed on the turbo–charger outlet.

Damage to the turbo–charger and other components may result.

An exhaust system must withstand the vibration and thermal expansion that they are subjected

to, yet supported well enough to remain independent of the engine.

The most common method of providing flexibility is with the use of bellows type flexible piping.

This piping component allows lateral and linear movement of the piping system without

subjecting fixed components to excessive stress. A minimum of 12 inches of flexible connection

must be provided at the engine exhaust manifold to allow for thermal expansion and vibration. If

the engine is to be mounted on spring type vibration isolators, increase the length to 24 inches.

This component can be specified to be provided by your Baldor distributor. Flexible pipe should

never be used for pipe bends or to cure misalignment problems.

Exhaust piping systems may be supported by a wide variety of methods to long as the system

remains flexible, and capable of withstanding thermal expansion.

The material most commonly used for straight runs and elbows in exhaust systems is Schedule

40 black iron. If hanging weight is a problem, other materials may be used. Galvanized piping

should never be used in exhaust system. Where exhaust piping passes through combustible

material, exhaust thimbles must be used. See Figure 2-7.

Figure 2-7 Exhaust Pipe Thimble Installation

Rain Protection

Moisture entering the engine through an exhaust system can cause extensive damage. Exhaust

outlets must have a rain cap or be horizontal to prevent such damage. See Figure 2-7.

2-10 General Information MN2408

Page 21

Cooling System

Cooling System Checklist

A. Have noise considerations been taken into account?

B. Has system piping been properly sized?

C. Has system been properly protected from freeze up and corrosion?

D. Have standby equipment heaters been specified?

E. Have all electrically driven devices been connected to load side of EPS connection points?

F. Have system drain valves and air eliminators been installed?

The system consists of the cooling medium which is generally a solution of water and ethylene

glycol, a method of rejecting engine produced heat, and a means to transport cooling medium

between the engine and heat rejection system. The first determination is the type of cooling

system to use – radiator cooling or heat exchanger cooling.

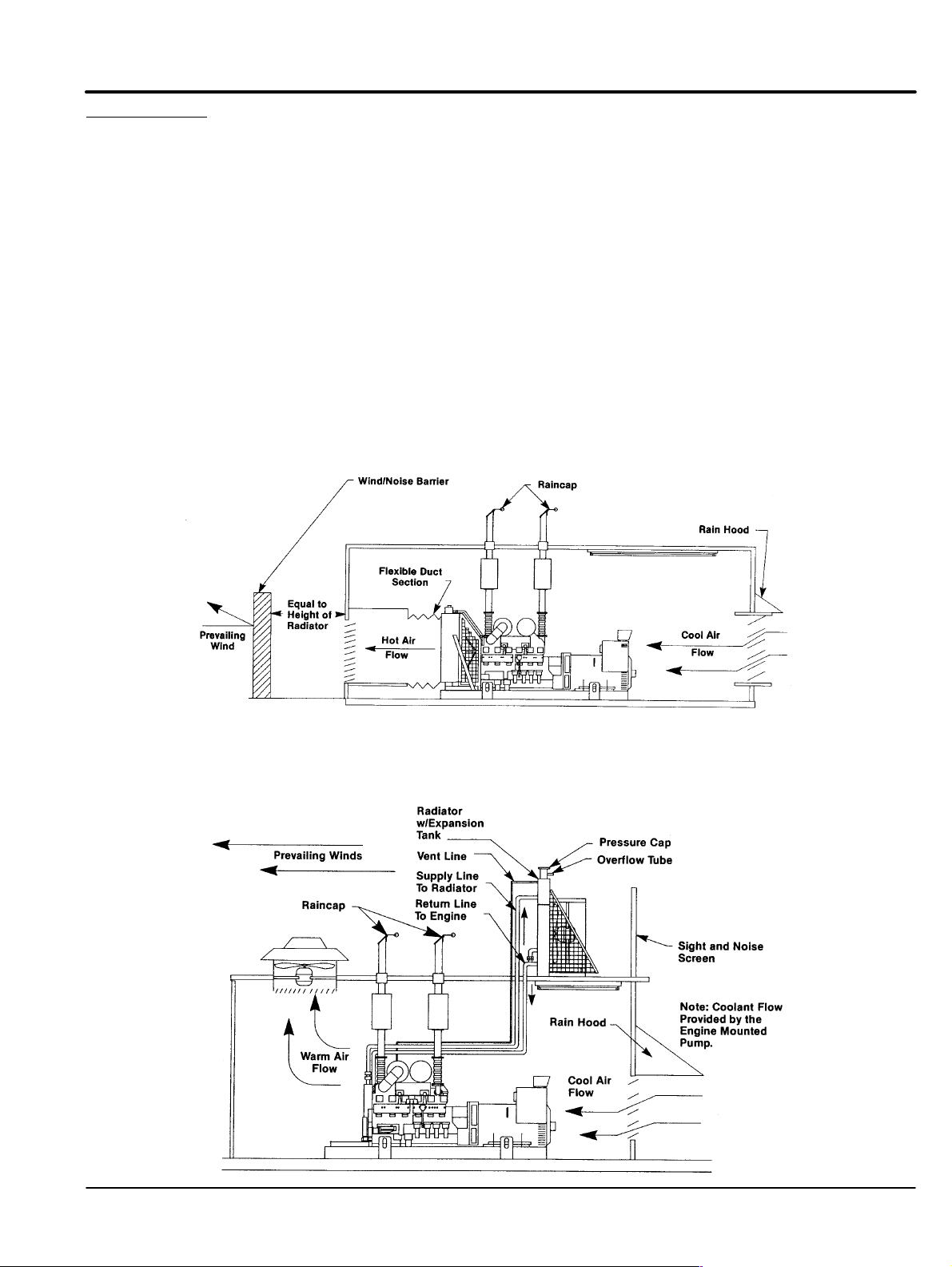

Radiator Cooling

The first and simplest is the engine mounted radiator shown in Figure 2-8. The radiator, water

circulating pump, fan and fan drive are mounted to the generator set base rails by the factory.

This method of engine cooling is the most economical, but may require large ventilation vents

and ducts. An added advantage of this arrangement is that the cooling air removes radiated heat

from the engine, generator, and other equipment located in the emergency power system room.

The only remaining design work with the engine mounted radiator is arranging a method of

providing air to the room, and exhausting it from the radiator. See “Air Systems”.

Figure 2-8 Engine Mounted Radiator Cooled System With Wind/Noise Barrier

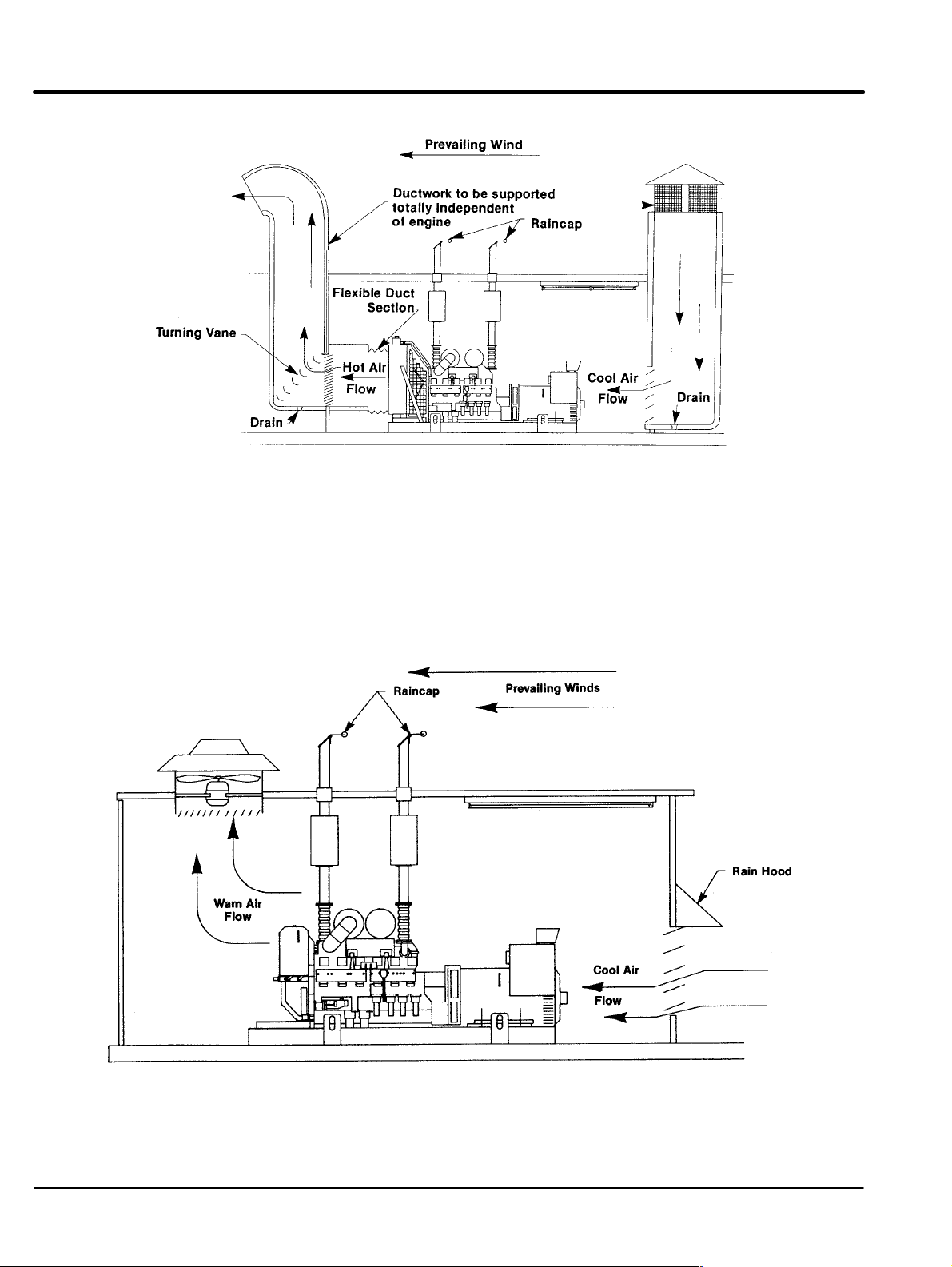

The radiator can be mounted remotely (not mounted directly at the engine). The remote/close

system uses the same radiator type except it is mounted in another room or outside the building,

but within close proximity to the genset. See Figure 2-9.

Figure 2-9 Remote Radiator Cooled System

General Information 2-11MN2408

Page 22

The remote radiator may be mounted either vertically or horizontally. In general, the radiator will

have an electric fan to provide cooling air and may be able to utilize the engine mounted coolant

pump to provide coolant flow.

The piping system friction and head loss between engine and radiator must be calculated and

not exceed the capacity of the engine pump. If the maximum coolant friction head loss external to

the engine is exceeded, a hot well system must be used. Before designing the piping system

using an auxiliary pump and hot well, the consultant should look very closely at increasing the

system’s pipe size.

The electric fan and auxiliary pump, if used, must be connected to the emergency power system.

Radiator and cooling fan must be sized to provide the cooling capacity required at an acceptable

sound level.

Caution: In cold climates, the high volume of outside air drawn into the genset room can quickly

reduce temperatures in the room to freezing. Any water piping or other equipment susceptible

to freeze damage should be properly insulated or located elsewhere.

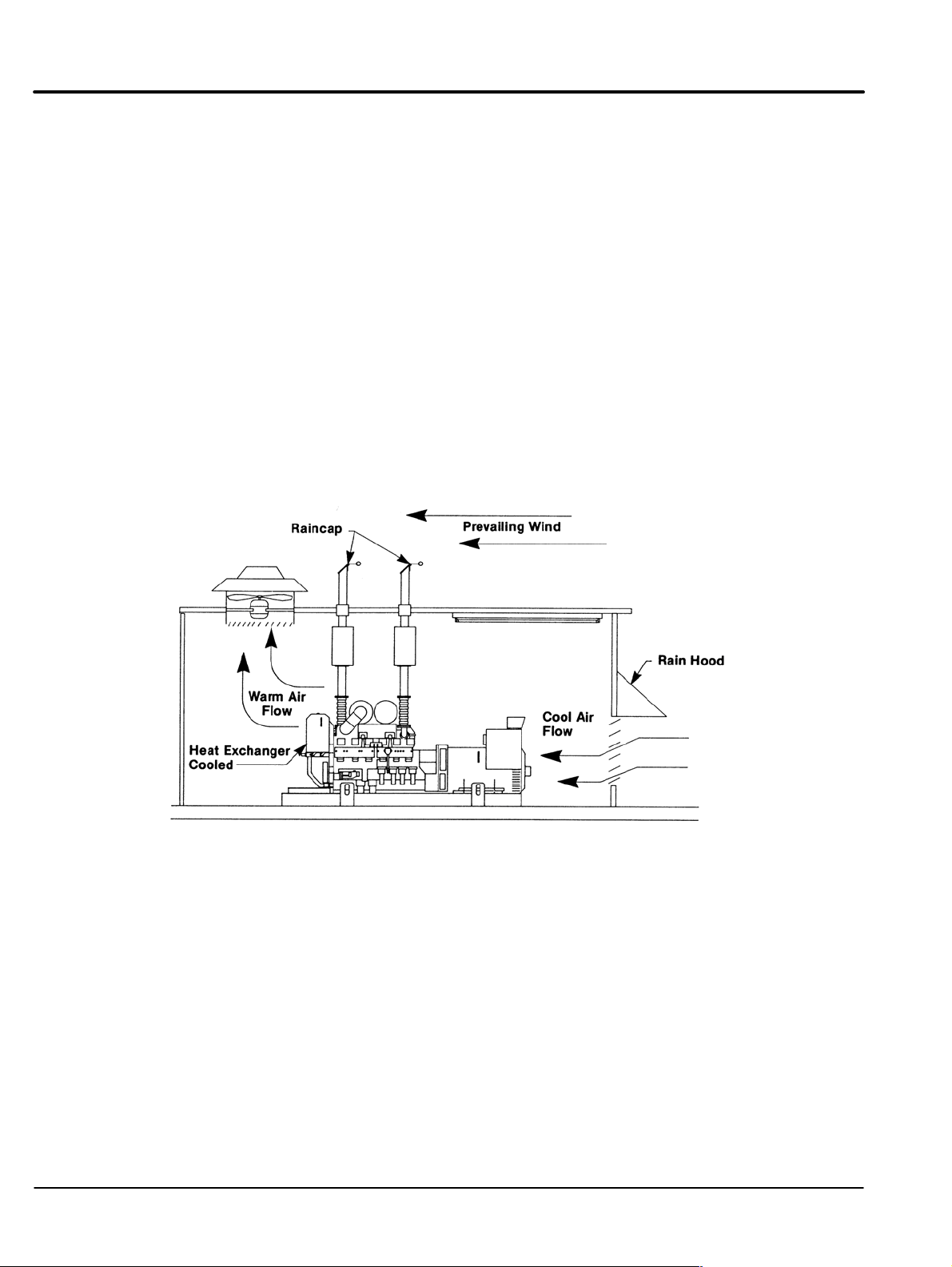

Heat Exchanger

In the heat exchanger system, engine coolant is circulated through the shell side of a heat

exchanger, while city water, well water, or some other cooling medium, is circulated through the

tube side. The primary consideration in this type cooling system is to remember that during

certain types of disasters, these cooling mediums may not be available, especially city water. The

system is relatively inexpensive to install and maintenance is low. See Figure 2-10.

Figure 2-10 Heat Exchanger Cooled System

The heat exchanger cooling system can be used with a cooling tower. These systems are

complex, and consists of circulating pumps, heat exchanger for engine coolant, and cooling

tower for heat rejection. The system design requires that several pieces of equipment be sized

and installed. Overall, this system is more expensive than other methods of engine cooling.

Cooling System Determination

After cooling system selection, gather the required basic information before proceeding through

this section. Information required includes engine heat rejection load, pumping capacity of the

engine mounted pump, engine coolant flow requirements and pressure drop through the engine,

and allowable operating temperature. This information is found on the engine data sheet.

Cooling System Design

Engine Mounted Radiator Cooling

If the engine mounted radiator is selected, the only remaining design work is arranging a method

of providing air to the room, and exhausting that air from the radiator. See “Air Systems”.

2-12 General Information MN2408

Page 23

Remote Radiator Cooling

g

Remote Radiator Airflow generally assumed there will be no external restrictions to airflow. If this

is not true, restriction must be considered in sizing and selection of a cooling fan and drive motor.

Typical examples of restrictions include landscaping, nearby buildings, air turbulence created by

buildings or other structures, and sight or noise “screens”. See Figure 2-9.

Remote Radiator Fan Motor. Remote radiator cooling systems require the use of an electrically

driven fan. This fan must be connected to the emergency power source. Size of the motor is

determined by the fan size and fan speed.

1. To specify a radiator to cool the coolant you will need to determine the amount of heat

rejected to the coolant. This is listed on the Engine Data Sheet as Heat Rejected to

Coolant in BTU/min. for engines using dry or water cooled type exhaust manifolds, as

applicable.

2. Determine the minimum water flow required at the engine, and the maximum top tank

temperature. Using this information, determine the heat rejection capacity required of

the radiator. Radiator systems should be sized with approximately 15% greater

capacity than the engine’s maximum full load heat rejection to allow for overload and

cooling system deterioration. Whether water flow is produced by an engine mounted or

auxiliary pump, total piping system friction loss must be calculated. To do this, genset

location, remote radiator location and friction loss within the radiator, and piping system

must be estimated.

3. Pressure drop through the radiator must be obtained from radiator manufacturer.

4. If total piping system pressure exceeds the allowable Maximum Coolant Friction Head

External to the engine as listed on the Engine Data Sheet, the coolant piping size

should be increased and/or a radiator with less restriction must be used.

5. Pressure drop in pipelines may be determined by the use of information in Table 2-2

Figure 2-11, and friction of water tables which may be found in most mechanical

handbooks such as “Cameron Hydraulic Data” handbook.

Table 2-2

Fitting Size Flow Restriction of Fittings Expressed as Equivalent of Straight Pipe (in inches)

1.5 2 2.5 3 4 5 6 8 10 12 14 16

90 Elbow 4.4 5.5 6.5 8 11 14 16 21 26 32 37 42

45 Elbow 2.5 3 3.8 5 6.3 7.5 10 13 15 17 19

Long Sweep Elbow 2.8 3.5 4.2 5.2 7 9 11 14 17 20 24 27

Close Return Bend 13 15 18 24 31 37 51 61 74 85 100

Tee–Straight Run 3.5 4.2 5.2 7 9 11 14 17 20 24 27

Tee–Side Inlet or Outlet 9.3 12 14 17 22 27 33 43 53 68 78 88

Globe Valve Open 55 67 82 11 0 140

Angle Valve Open 27 33 41 53 70

Gate Valve Fully Open 1.2 1.4 1.7 2.3 2.9 3.5 4.5 5.8 6.8 8 9

Gate Valve Half Open 27 33 41 53 70 100 130 160 200 230 260

Check Valve 19 23 32 43 53

Hot Well Installations

One final consideration on the water side is the Maximum Static Head. This is the maximum

height allowable from the engine crank center line to the highest point in the coolant system. The

maximum static head is specified on generator specification sheets. If this number must be

exceeded, a hot well tank system must be used. A typical example is shown in Figure 2-12.

The design of hot well tanks and piping systems is somewhat complex. Your authorized Baldor

Distributor has experience in the design and installation of hot well systems. Consult your Baldor

Distributor if the static head of the coolant system in your genset application exceeds this criteria

and requires a hot well system.

General Information 2-13MN2408

Page 24

Figure 2-11 Valves & Fittings and Fluid Flow in Pipe

Figure 2-12 Hot Well Installation

2-14 General Information MN2408

Page 25

Other Considerations

General:

1. Deaeration of the coolant. This can be accomplished through the use of the system

deaerators in very large systems, or simply ensuring the radiator top tank or surge tank

is at the highest point in the piping system. Unvented piping systems can create air

pockets which reduce coolant flow and can lead to engine overheating. Baldor

furnished radiators are equipped with deaerating top tanks.

2. Flexible hoses must be installed at all engine connections and to the radiator to isolate

vibration and allow for thermal expansion.

3. Drain valves must be installed at the lowest point of the cooling system to facilitate

system cleaning and flushing.

4. Water treatment and antifreeze must be added to system coolant. Baldor recommends

50/50 ethylene glycol and coolant treatment for all engines.

5. Thermostatically controlled engine coolant heaters are required to be installed on all

standby gensets. These will increase starting reliability under cold conditions, and

improve the start–up load handling ability.

6. According the NFPA 110, priority level 1 equipment jacket water heaters shall maintain

coolant at a minimum of 90 "F (32 "C). In outdoor installations where temperatures will

be expected to drop below 32 "F (0 "C), a battery heater should be employed to keep

the batteries at a minimum of 50 "F (10 "C), and will shut off at 90 "F (32 "C).

All heaters will shut off when the engine is operating. Adequate antifreeze protection

will be provided and ether starting aids will not be permitted.

7. The consultant should also consider oil sump heaters if conditions warrant.

Heat Exchanger Cooling:

1. If the engine is to be heat exchanger cooled, the system will require a reliable raw

cooling water source and controls to regulate water flow during genset operation.

2. The system will also need a reliable method of starting and stopping water flow

automatically. The heat exchanger cooled system may be used with a cooling tower.

3. Baldor Gensets are available with heat exchangers sized and mounted on the engine

by the factory. If a heat exchanger cooled system is required, specify with order.

4. Shell and tube type heat exchangers are connected such that raw cooling water flows

through the tube side of the heat exchanger, and engine coolant through the shell side.

Tubes are more easily cleaned and the potential for fouling is much greater on the raw

water side.

5. For economic reasons, the raw water flow can be regulated by varying the flow of raw

cooling water through the heat exchanger. This control can be accomplished with a

temperature actuated control valve. The thermostatic bulb for this control must be in

the engine jacket water discharge line. The control valve should be a fully modulated

type with a minimum flow setting. NEVER attempt to regulate engine water flow.

6. Water flow regulators are used only if raw water is from a city or well water source. Do

not attempt to regulate flow if a cooling tower is used. Maintain at least 2 ft/second of

water flow through the tube side of the heat exchanger.

7. Heat exchanger cooled systems using city or well water, and cooling, tower heat

rejection, however, will not be protected on the tube side of the heat exchanger, nor

interconnecting piping and cooling tower as engine coolant is not circulated through

these components. These systems must be heat traced, and have sump heaters

installed to protect the various components when the genset is on standby.

It must also be noted that if an antifreeze solution is used in the shell side of the engine

cooling system heat exchanger, local codes may restrict the discharge of the tube side

cooling water after flowing through the heat exchanger.

General Information 2-15MN2408

Page 26

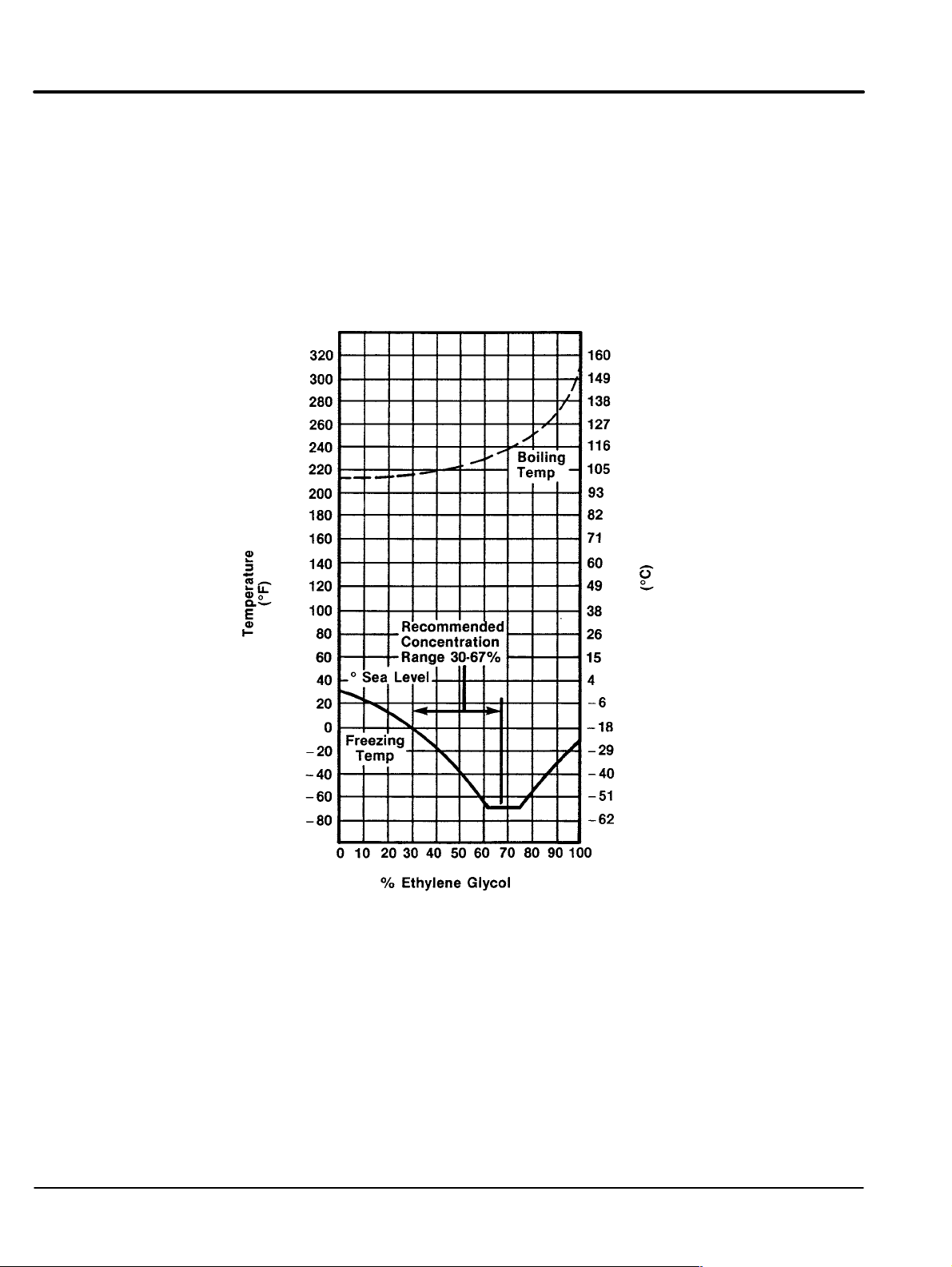

Coolant Treatment: See Figure 2-13.

1. Engine coolant should be treated with a Diesel Coolant Additive (DCA) to minimize

corrosion of the engine and cooling system components. A 50/50 ethylene glycol

antifreeze solution is recommended for all genset engines. This will provide freeze

protection and increase the boiling point of the engine coolant. A solution can be

increased to 65%. Do not exceed 65% as freeze protection begins to diminish at 65%.

2. It is recommended that the consultant specify Baldor supplied DCA and water filters,

and Baldor antifreeze.

3. When the proper solution concentration of antifreeze is used with radiators (engine

mounted as well as remote mounted), and hot well systems, the system will be

adequately protected from freeze–up.

Figure 2-13 Coolant Mixture

2-16 General Information MN2408

Page 27

Air System

Radiator Cooling

Air System Checklist

A. Air inlet faces the direction of prevailing winds.

B. Air outlet does not face noise sensitive areas without noise attenuating devices.

C. All heat loads have been taken into consideration in sizing air flow.

D. Gravity louvers face inward for air intake and outward for discharge.

E. Where electrically operated ventilation devices are used, power must be present under all

operating situations. Be certain these devices are on the emergency circuit.

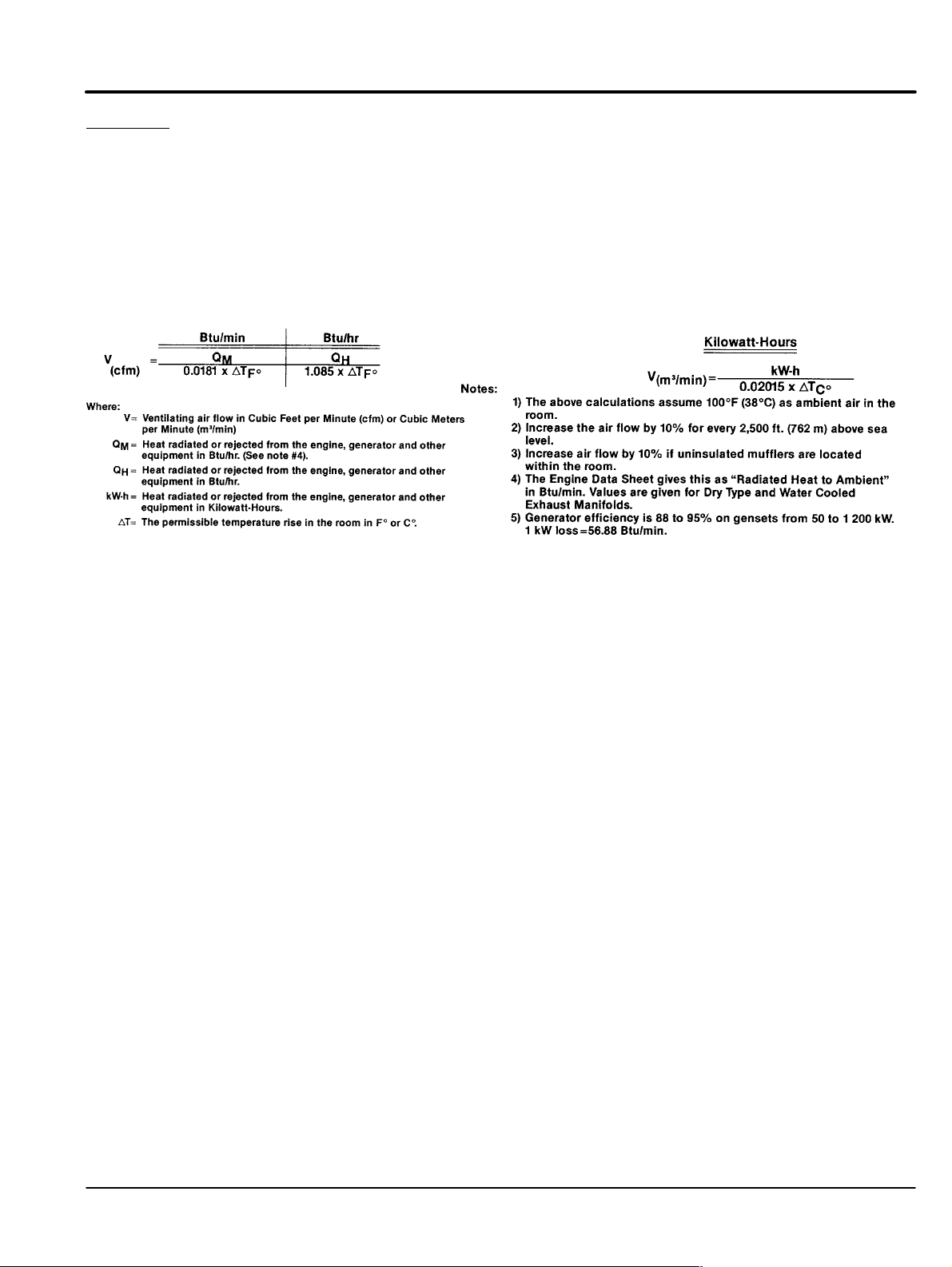

The room in which the generator set is to be installed must have adequate air flow through it to

provide combustion air, and remove heat radiated from the engine, exhaust system and

generator. See Figure 2-14 for air flow calculations.

Figure 2-14 Air Flow Calculations

The engine mounted radiator shown in Figure 2-8. With an engine mounted radiator cooling

system, air movement is provided by the engine driven radiator fan. The consultant must design

the inlet and outlet duct work and louvers to accommodate the air flow required. The radiator fan