Page 1

FlexDrive

II

/ Flex+Drive

II

Servo Controls

SERVO DRIVE

Installation Manual

10/02 MN1902

Page 2

Page 3

Contents i

MN1902

Contents

1 General Information 1-1.................................

2 Introduction 2-1........................................

2.1 FlexDriveIIfeatures 2-1.....................................

2.2 Receiving and inspection 2-2................................

2.2.1 Identifying the catalog number 2-2....................................

2.3 Units and abbreviations 2-3..................................

3 Basic Installation 3-1....................................

3.1 Introduction 3-1............................................

3.1.1 Power sources 3-1................................................

3.1.2 Hardware requirements 3-1.........................................

3.1.3 RS485 / RS422 systems 3-2........................................

3.1.4 Tools and miscellaneous hardware 3-2................................

3.1.5 Other information needed for installation 3-3...........................

3.2 Mechanical installation and location requirements 3-4...........

3.2.1 Mounting the FlexDrive

II

3-5.........................................

3.2.2 Dimensions 3-6...................................................

3.3 Connector locations 3-7.....................................

3.4 Power connections 3-8......................................

3.4.1 Single-phase connection to package sizes A, B, C, D 3-9................

3.4.2 Three-phase connection to package sizes E, G, H 3-10...................

3.4.3 Input power conditioning 3-11.........................................

3.4.4 Power disconnect and protection devices 3-11..........................

3.4.5 Power supply filters 3-12.............................................

3.4.6 Wire sizes and protection device ratings 3-13...........................

3.4.7 External customer supplied 24V control supply 3-14......................

3.5 Motor connections 3-15......................................

3.5.1 Motor circuit contactors 3-16.........................................

3.5.2 Motor power cable pin configuration - Baldor BSM rotary motors 3-16.......

3.5.3 Motor cable pin configuration - Baldor linear motors 3-17..................

3.5.4 Thermal switch connection 3-18.......................................

3.5.5 Motor brake connection 3-19.........................................

3.6 Regeneration resistor (Dynamic Brake resistor) 3-20.............

3.6.1 Controlling regeneration 3-20.........................................

3.7 Feedback connections 3-21...................................

3.7.1 Resolver option - X8 3-22............................................

3.7.2 Encoder option - X8 3-24............................................

3.7.3 EnDat (absolute encoder) option - X8 3-27..............................

Page 4

ii Contents

MN1902

3.8 Drive enable - X3 3-29.......................................

3.8.1 Drive enable - X3 3-29..............................................

3.8.2 Drive enable - SW1 DIP switch 3-30...................................

3.8.3 Drive enable command 3-30..........................................

3.9 DIP switches - SW1 3-31.....................................

3.9.1 Switches 1-4 3-31..................................................

3.9.2 Switch 5 - Hold 3-32................................................

3.9.3 Switch 6 - RS485 terminator 3-32.....................................

3.9.4 Switch 7 - Offset tuning 3-32.........................................

3.9.5 Switch 8 - Enable 3-32..............................................

3.9.6 Switches 9 and 10 - RS232/RS485 select 3-33..........................

3.9.7 Factory settings 3-33................................................

3.9.8 Preventing a program running at startup 3-34...........................

4 Input / Output 4-1......................................

4.1 Introduction 4-1............................................

4.2 Analog I/O 4-1.............................................

4.2.1 Analog input - X3 (command) 4-2....................................

4.2.2 Relay output - X3 4-4..............................................

4.3 Digital I/O 4-5..............................................

4.3.1 Digital inputs - X3 4-6..............................................

4.3.2 CREF and digital inputs 4-7.........................................

4.3.3 Special functions on DIN4 and DIN5 - pulse and direction inputs 4-7.......

4.3.4 Special functions on DIN4 and DIN5 - fast inputs 4-8....................

4.3.5 Digital outputs - X3 4-9.............................................

4.4 Other I/O 4-10..............................................

4.4.1 Encoder output - X7 4-10............................................

4.4.2 Master (auxiliary) encoder input - X9 4-12..............................

4.4.3 Serial port - X6 4-14.................................................

4.4.4 Using RS232 cable 4-15.............................................

4.4.5 Multidrop using RS485 / RS422 cable 4-16.............................

4.4.6 Connecting Baldor HMI Operator Panels 4-17...........................

4.5 Connection summary - minimum system wiring 4-18.............

4.6 Option connectors 4-19......................................

5 Operation 5-1..........................................

5.1 Introduction 5-1............................................

5.1.1 Connecting the FlexDriveIIto the PC 5-1..............................

5.1.2 Installing the software 5-1...........................................

5.1.3 Starting the FlexDrive

II

5-2..........................................

5.1.4 Preliminary checks 5-2.............................................

5.1.5 Power on checks 5-2...............................................

5.1.6 Offset tuning 5-3..................................................

Page 5

Contents iii

MN1902

5.2 WorkBench v5 5-4..........................................

5.2.1 Help file 5-4......................................................

5.2.2 Starting WorkBench v5 5-5..........................................

5.2.3 Commissioning Wizard 5-7..........................................

5.2.4 Using the Commissioning Wizard 5-7.................................

5.2.5 Completing the Commissioning Wizard 5-7............................

5.3 Further configuration 5-8....................................

5.3.1 Fine-tuning tool 5-8................................................

5.3.2 Parameters tool 5-10................................................

5.3.3 Digital I/O tool 5-11.................................................

5.3.4 Other tools and windows 5-11........................................

6 Troubleshooting 6-1....................................

6.1 Introduction 6-1............................................

6.1.1 Problem diagnosis 6-1..............................................

6.1.2 SupportMet feature 6-1............................................

6.1.3 Power-cycling the FlexDrive

II

6-1....................................

6.2 FlexDriveIIindicators 6-2....................................

6.2.1 Status display 6-2.................................................

6.2.2 DB On (Regeneration) LED 6-5......................................

6.2.3 Communication 6-5................................................

6.2.4 Power on 6-6.....................................................

6.2.5 Tuning 6-6........................................................

6.2.6 Status display shows a digit or ‘E.’ 6-6................................

7 Specifications 7-1......................................

7.1 Introduction 7-1............................................

7.1.1 AC input power and motor output - single-phase models 7-2..............

7.1.2 AC input power and motor output - 230V three-phase models 7-3..........

7.1.3 AC input power and motor output - 230-460V three-phase models 7-4......

7.1.4 Customer supplied 24VDC supply input 7-4............................

7.1.5 Regeneration 7-5..................................................

7.1.6 Analog input (X3) 7-6...............................................

7.1.7 Digital inputs (X3) 7-7..............................................

7.1.8 Digital outputs (X3) 7-7.............................................

7.1.9 Relay output (X3) 7-8..............................................

7.1.10 Serial RS232 interface (X6) 7-8......................................

7.1.11 Serial RS485 interface (X6) 7-8......................................

7.1.12 Encoder output (simulated) (X7) 7-8..................................

7.1.13 Resolver feedback option (X8) 7-9...................................

7.1.14 Encoder feedback option (X8) 7-9....................................

7.1.15 EnDat (absolute encoder) feedback option (X8) 7-9.....................

7.1.16 Master (auxiliary) encoder input (X9) 7-10..............................

7.1.17 Pulse and direction input (X9) 7-10....................................

7.1.18 Environmental 7-1 1.................................................

Page 6

iv Contents

MN1902

Appendices

A Accessories A-1........................................

A.1 Introduction A-1............................................

A.1.1 Factory fitted options A-1...........................................

A.1.2 Motor power cables A-2.............................................

A.1.3 Motor power cable part numbers A-2..................................

A.1.4 Feedback cables A-3...............................................

A.1.5 Feedback cable part numbers A-4....................................

A.1.6 EMC filters A-5....................................................

A.1.7 Regeneration resistors A-7..........................................

B Control System B-1.....................................

B.1 Introduction B-1............................................

B.1.1 Current (Torque) control B-2.........................................

B.1.2 Velocity (Speed) control B-3.........................................

B.1.3 Position control (Pulse and Direction) B-4..............................

B.1.4 Position control B-5................................................

B.2 Control system operation B-6................................

B.2.1 Position controller B-6..............................................

B.2.2 Speed controller B-7...............................................

B.2.3 Torque controller and feedback B-8...................................

C CE Guidelines C-1......................................

C.1 Outline C-1................................................

C.1.1 EMC Conformity and CE marking C-1.................................

C.1.2 Use of CE compliant components C-2.................................

C.1.3 EMC wiring technique C-2...........................................

C.1.4 EMC installation suggestions C-3.....................................

C.1.5 Wiring of shielded (screened) cables C-4..............................

Page 7

General Information 1-1MN1902

LT0160A02 Copyright Baldor (c) 2002. All rights reserved.

This manual is copyrighted and all rights are reserved. This document or attached software may not,

in whole or in part, be copied or reproduced in any form without the prior written consent of Baldor.

Baldor makes no representations or warranties with respect to the contents hereof and specifically

disclaims any implied warranties of fitness for any particular purpose. The information in this

document is subject to change without notice. Baldor assumes no responsibility for any errors that

may appear in this document.

Mintt is a registered trademark of Baldor.

Windows 95, Windows 98, Windows ME, Windows NT, Windows XP and Windows 2000 are

registered trademarks of the Microsoft Corporation. UL and cUL are registered trademarks of

Underwriters Laboratories. EnDat is a registered trademark of Heidenhain Corporation.

Limited Warranty

For a period of two (2) years from the date of original purchase, Baldor will repair or replace without

charge controls and accessories that our examination proves to be defective in material or

workmanship. This warranty is valid if the unit has not been tampered with by unauthorized persons,

misused, abused, or improperly installed and has been used in accordance with the instructions and/or

ratings supplied. This warranty is in lieu of any other warranty or guarantee expressed or implied.

Baldor shall not be held responsible for any expense (including installation and removal),

inconvenience, or consequential damage, including injury to any person or property caused by items of

our manufacture or sale. (Some countries and U.S. states do not allow exclusion or limitation of

incidental or consequential damages, so the above exclusion may not apply.) In any event, Baldor’s

total liability, under all circumstances, shall not exceed the full purchase price of the control. Claims for

purchase price refunds, repairs, or replacements must be referred to Baldor with all pertinent data as

to the defect, the date purchased, the task performed by the control, and the problem encountered. No

liability is assumed for expendable items such as fuses. Goods may be returned only with written

notification including a Baldor Return Authorization Number and any return shipments must be prepaid.

1 General Information

1

Page 8

1-2 General Information MN1902

Product notice

Only qualified personnel should attempt the start-up procedure or troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts or parts that are

controlled by this equipment. Improper use can cause serious or fatal injury. Only qualified personnel

should attempt to start-up, program or troubleshoot this equipment.

Safety Notice

Intended use: These drives are intended for use in stationary ground based applications in industrial

power installations according to the standards EN60204 and VDE0160. They are designed for

machine applications that require variable speed controlled three-phase brushless AC motors. These

drives are not intended for use in applications such as:

H Home appliances

H Medical instrumentation

H Mobile vehicles

H Ships

H Airplanes.

Unless otherwise specified, this drive is intended for installation in a suitable enclosure. The enclosure

must protect the drive from exposure to excessive or corrosive moisture, dust and dirt or abnormal

ambient temperatures. The exact operating specifications are found in section 7 of this manual. The

installation, connection and control of drives is a skilled operation, disassembly or repair must not be

attempted. In the event that a drive fails to operate correctly, contact the place of purchase for return

instructions.

Precautions

WARNING: Do not touch any circuit board, power device or electrical connection before you

first ensure that no high voltage is present at this equipment or other equipment to

which it is connected. Electrical shock can cause serious or fatal injury. Only

qualified personnel should attempt to start-up, program or troubleshoot this

equipment.

WARNING: Be sure the system is properly earthed/grounded before applying power. Do not

apply AC power before you ensure that earths/grounds are connected. Electrical

shock can cause serious or fatal injury.

WARNING: Be sure that you are completely familiar with the safe operation and programming

of this equipment. This equipment may be connected to other machines that have

rotating parts or parts that are controlled by this equipment. Improper use can

cause serious or fatal injury. Only qualified personnel should attempt to program,

start-up or troubleshoot this equipment.

Page 9

General Information 1-3MN1902

WARNING: Be sure all wiring complies with the National Electrical Code and all regional and

local codes. Improper wiring may result in unsafe conditions.

WARNING: The stop input to this equipment should not be used as the single means of

achieving a safety critical stop. Drive disable, motor disconnect, motor brake and

other means should be used as appropriate. Only qualified personnel should

attempt to program, start-up or troubleshoot this equipment.

WARNING: Improper operation or programming of the drive may cause violent motion of the

motor and driven equipment. Be certain that unexpected motor movement will not

cause injury to personnel or damage to equipment. Peak torque of several times

the rated motor torque can occur during control failure.

WARNING: The motor circuit might have high voltages present whenever AC power is

applied, even when the motor is not moving. Electrical shock can cause serious or

fatal injury.

WARNING: If a motor is driven mechanically, it might generate hazardous voltages that are

conducted to its power terminals. The enclosure must be earthed/grounded to

prevent possible shock hazard.

WARNING: When operating a rotary motor with no load coupled to its shaft, remove the shaft

key to prevent it flying out when the shaft rotates.

WARNING: A regeneration resistor may generate enough heat to ignite combustible materials.

To avoid fire hazard, keep all combustible materials and flammable vapors away

from the brake resistors.

CAUTION: To prevent equipment damage, be certain that the input power has correctly sized

protective devices installed.

CAUTION: To prevent equipment damage, be certain that input and output signals are

powered and referenced correctly.

CAUTION: To ensure reliable performance of this equipment be certain that all signals to/from

the drive are shielded correctly.

CAUTION: Suitable for use on a circuit capable of delivering not more than the RMS

symmetrical short circuit amperes listed here at rated voltage.

Horsepower

RMS Symmetrical Amperes

1-50 5,000

CAUTION: Avoid locating the drive immediately above or beside heat generating equipment,

or directly below water or steam pipes.

Page 10

1-4 General Information MN1902

CAUTION: Avoid locating the drive in the vicinity of corrosive substances or vapors, metal

particles and dust.

CAUTION: Do not connect AC power to the drive terminals U, V and W. Connecting AC

power to these terminals may result in damage to the drive.

CAUTION: Baldor does not recommend using “Grounded Leg Delta” transformer power leads

that may create earth/ground loops and degrade system performance. Instead,

we recommend using a four wire Wye.

CAUTION: Drives are intended to be connected to a permanent main power source, not a

portable power source. Suitable fusing and circuit protection devices are required.

CAUTION: The safe integration of the drive into a machine system is the responsibility of the

machine designer. Be sure to comply with the local safety requirements at the

place where the machine is to be used. In Europe these are the Machinery

Directive, the ElectroMagnetic Compatibility Directive and the Low V oltage

Directive. In the United States this is the National Electrical code and local codes.

CAUTION: Drives must be installed inside an electrical cabinet that provides environmental

control and protection. Installation information for the drive is provided in this

manual. Motors and controlling devices that connect to the drive should have

specifications compatible to the drive.

CAUTION: Violent jamming (stopping) of the motor during operation may damage the motor

and drive.

CAUTION: Do not tin (solder) exposed wires. Solder contracts over time and may cause

loose connections. Use crimp connections where possible.

CAUTION: Electrical components can be damaged by static electricity. Use ESD

(electro-static discharge) procedures when handling this drive.

CAUTION: Ensure that resolver or encoder wires are properly connected. Incorrect

installation may result in improper movement.

CAUTION: The threaded holes in the top and bottom of the enclosure are for cable clamps.

Be sure to use a M4 bolt no longer than 12mm in length. Longer bolts might

short-circuit the electrical components inside the drive.

CAUTION: Removing the cover will invalidate UL certification.

Page 11

Introduction 2-1MN1902

2.1 FlexDriveIIfeatures

Throughout this manual, both the FlexDriveIIand the Flex+DriveIIwill be referred to simply as

FlexDrive

II

. Where there is a difference in specification it will be clearly marked.

The FlexDrive

II

is a versatile compact control, providing a flexible and powerful solution for

single axis rotary systems. Standard features include:

H Single axis AC brushless drive

H Wide range of models with continuous current ratings from 2.5A to 27.5A

H Direct connection to 115V AC or 230VAC single-phase or 230-460VAC three-phase

supplies (model dependent)

H Resolver or encoder feedback

H Velocity and current control, with pulse and direction input for position control

H Auto-tuning wizard (including position loop) and software oscilloscope facilities

H 8 optically isolated digital inputs

H 3 optically isolated digital outputs

H 1 general-purpose analog input (can be used as a speed or torque command reference)

H 1 control relay

H Selectable RS232 or RS485 communications

Flex+Drive

II

only:

H Integrated motion controller for rotary and linear positioning systems

H Programmable in Mint

H Up to 16 programmable preset moves (expandable to 256 with factory-fitted CAN and I/O

option)

H Position control using preset moves, software gearing and point to point moves

H Flash memory for program storage (64k).

H Motion controller for rotary and linear positioning systems

Factory-fitted options expand the I/O capabilities of the FlexDrive

II

and provide CANopen,

DeviceNet or Profibus connectivity. See Appendix A for details about options. FlexDrive

II

will

operate with a large number of brushless servo motors - for information on selecting Baldor

servo motors, please see the sales brochure BR1202 (BR1800 for linear motors) available

from your local Baldor representative.

This manual is intended to guide you through the installation of FlexDrive

II

. The sections

should be read in sequence.

The Basic Installation section describes the mechanical installation of the FlexDrive

II

,the

power supply connections and motor connections. The other sections require knowledge of

the low level input/output requirements of the installation and an understanding of computer

software installation. If you are not qualified in these areas you should seek assistance before

proceeding.

2 Introduction

2

Page 12

2-2 Introduction MN1902

2.2 Receiving and inspection

When you receive your FlexDriveII, there are several things you should do immediately:

1. Check the condition of the shipping container and report any damage immediately to the

carrier that delivered your FlexDrive

II

.

2. Remove the FlexDrive

II

from the shipping container and remove all packing material. The

container and packing materials may be retained for future shipment.

3. Verify that the catalog number of the FlexDrive

II

you received is the same as the catalog

number listed on your purchase order. The catalog number is described in the next section.

4. Inspect the FlexDrive

II

for external damage during shipment and report any damage to the

carrier that delivered your FlexDrive

II

.

5. If FlexDrive

II

is to be stored for several weeks before use, be sure that it is stored in a location

that conforms to the storage humidity and temperature specifications shown in section 7.1.18.

2.2.1 Identifying the catalog number

The FlexDriveIIis available with different current ratings and package sizes. The catalog

number is marked on the front of the unit, just below the Baldor logo. It is a good idea to look

for the catalog number (sometimes shown as ID/No: ) and write it in the space provided here:

Catalog number:

F_H______________-________

Installed at: ________________________

Date: ______

A description of a catalog number is shown here, using the example FDH1A05TB-RC23:

Meaning Alternatives

FDH FlexDriveIIfamily FPH=Flex+Drive

II

1 Requires an AC supply voltage of 115 Volts, 1Φ

2=230V (1Φ or 3Φ);

4=230V-460V (3Φ)

A05 Continuous current rating of 5.0A

A02=2.5A; A07=7.5A; A15=15A;

A20=20A; A27=27.5A

T Built in AC power supply -

B

Dynamic Brake with a built in transistor and

resistor (available on 2.5A and 5A models only)

R= Requires external braking

resistor

R Feedback option is a resolver

E=Encoder;

D=EnDat (absolute encoder)

C Option fitted: 1 CAN channel

B=CAN & Auxiliary I/O

(Flex+Drive

II

only); D=DeviceNet;

P=Profibus DP;

N=No options specified

2 Serial port type is combined RS232 / RS485 -

3

Customer’s own 24VDC supply is required to

power the internal FlexDrive

II

logic

0= Internally generated 24VDC

supply*

* An external 24VDC supply will always be required to operate the enable input, digital inputs

and digital outputs on connector X3 . See sections 4.3.1 to 4.3.5.

Page 13

Introduction 2-3MN1902

2.3 Units and abbreviations

The following units and abbreviations are used in this manual:

V Volt (also VAC and VDC)...............

WWatt..............

A Ampere...............

Ω Ohm...............

µF microfarad..............

pF picofarad..............

mH millihenry.............

Φ phase...............

ms millisecond..............

µs microsecond..............

ns nanosecond..............

Kbaud kilobaud (the same as Kbit/s in most applications)...........

MB megabytes.............

CDROM Compact Disc Read Only Memory.........

CTRL+E on the PC keyboard, press Ctrl then E at the same time..........

mm millimeter.............

m meter...............

in inch...............

ft feet...............

lb-in pound-inch (torque).............

Nm Newton-meter (torque).............

ADC Analog to Digital Converter............

DAC Digital to Analog Converter............

AWG American Wire Gauge............

(NC) Not Connected............

Page 14

2-4 Introduction MN1902

Page 15

Basic Installation 3-1MN1902

3.1 Introduction

You should read all the sections in Basic Installation to ensure safe installation.

This section describes the mechanical and electrical installation of the FlexDrive

II

in the

following stages:

H Location considerations

H Mounting the FlexDrive

II

H Connecting the AC power supply

H Connecting the optional customer supplied 24VDC control supply

H Connecting the motor

H Installing a regeneration resistor (Dynamic Brake resistor)

H Connecting the feedback device

H Connecting the drive enable input.

These stages should be read and followed in sequence.

3.1.1 Power sources

An AC power source (IEC1010 over-voltage category III or less) in the installation area is

required. This will need to be single or three-phase depending upon the type of FlexDrive

II

.

An AC power filter is required to comply with the CE directive for which the FlexDrive

II

was

tested (see section 3.4.5).

If the FlexDrive

II

requires an external (customer supplied) 24VDC logic supply then this must

be a regulated power supply with a continuous current supply capability of 1.75A (4A power on

surge). A 24V filter may be required to comply with the CE directive for which the FlexDrive

II

was tested (see section 3.4.5).

3.1.2 Hardware requirements

The components you will need to complete the basic installation are:

H The motor that will be connected to the FlexDrive

II

H A motor power cable

H A resolver or encoder feedback cable (and Hall cable for linear motors)

H With some applications there may be a requirement for a regeneration resistor (Dynamic

Brake).

Note: Without the regeneration resistor, the drive may produce an overvoltage fault. All

FlexDrive

II

models have overvoltage sensing circuitry, but only 2.5A and 5A

models (catalog numbers FDHxxxxxB-xxxx and FPHxxxxxB-xxxx) have an

internal regeneration resistor. For 7.5A, 15A, 20A and 27.5A models a

regeneration resistor must be purchased separately if required. See Appendix A.

3 Basic Installation

3

Page 16

3-2 Basic Installation MN1902

H A serial cable.

Note: The serial connector on the FlexDrive

II

(connector X6) can be configured as either

RS232 or RS485 / RS422. Pin 9 is used to carry +8V for powering some Baldor

keypad peripherals. Ensure that pin 9 is not connected to earth/ground or to

equipment that could be damaged by the +8V supply. See sections 4.4.3 and

4.4.4. A suitable cable is available from Baldor, catalog number CBL001-501.

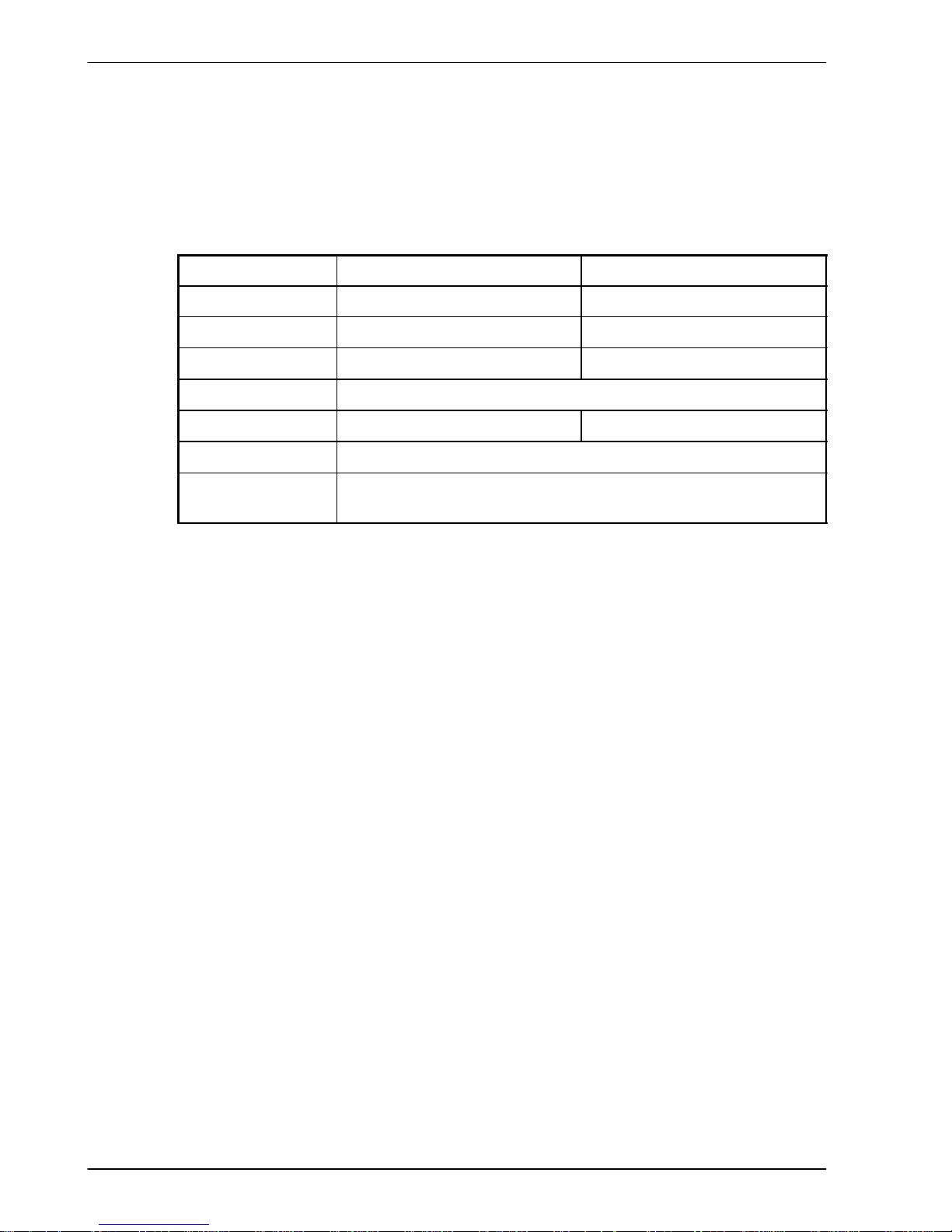

H A PC (with one free COM port) with the following specification:

Minimum specification Recommended specification

Processor Intel Pentium 133MHz Intel Pentium 200MHz or faster

RAM 32MB 64MB

Hard disk space 40MB 60MB

CD-ROM ACD-ROMdrive

Screen 800 x 600, 256 colors 1024 x 768, 256 colors

Mouse A mouse or similar pointing device

Operating system Windows 95, Windows 98, Windows ME,

Windows NT, Windows XP or Windows 2000

3.1.3 RS485 / RS422 systems

If you will be using RS485 / RS422 and your PC does not have an RS485 / RS422 connector,

an RS232 to 4-wire RS485 / RS422 converter will be required. These commercially available

devices convert the signals from the RS232/RS485 port (connector X6) to the signals

necessary for RS485 / RS422 communications. Special care must be taken with the pin

assignment on all RS485 / RS422 devices, as this can differ between products. Connectors

might need to be rewired to provide the correct pin assignment. The FlexDrive

II

pin

assignment is shown in section 4.4.3.

Note: If this is the first time you are installing a FlexDriveIIthen it is strongly

recommended that you use RS232 to get started and try RS485 later. This will

avoid any potential problems involving the RS232-RS485 converter. Selection of

RS232 or RS485 is controlled using DIP switch 10 - see section 3.9.6.

3.1.4 Tools and miscellaneous hardware

H Your PC operating system user manual might be useful if you are not familiar with

Windows

H A small screwdriver (supplied) with a blade width less than 3mm (1/10 in)

H M5 screws or bolts for mounting the FlexDrive

II

H Crimping tool.

A connector kit is supplied with your FlexDrive

II

. This contains a number of useful connectors

and a screwdriver for tightening the connections.

Page 17

Basic Installation 3-3MN1902

3.1.5 Other information needed for installation

This information is useful (but not essential) to complete the installation:

H The data sheet or manual provided with your motor, describing the wiring information of

the motor cables/connectors

H Knowledge of which digital inputs/outputs will be ‘Active Low’, ‘Active High’ or edge

triggered.

Page 18

3-4 Basic Installation MN1902

3.2 Mech an ical installation and location requirements

It is essential that you read and understand this section before beginning the

installation

.

CAUTION: To prevent equipment damage, be certain that the input power has

correctly rated protective devices installed.

CAUTION: To prevent equipment damage, be certain that input and output signals

are powered and referenced correctly.

CAUTION: To ensure reliable performance of this equipment be certain that all

signals to/from the FlexDrive

II

are shielded correctly.

CAUTION: Avoid locating the FlexDriveIIimmediately above or beside heat

generating equipment, or directly below water steam pipes.

CAUTION: Avoid locating the FlexDriveIIin the vicinity of corrosive substances or

vapors, metal particles and dust.

The safe operation of this equipment depends upon its use in the appropriate environment.

The following points must be considered:

H The FlexDrive

II

must be installed indoors, permanently fixed and located so that it can

only be accessed by service personnel using tools.

H The maximum suggested operating altitude is 1000m (3300ft).

Above 1000m (3300ft) de-rate output current 1.1% per 100m (330ft).

H The FlexDrive

II

must operate in an ambient temperature of 0°C to 40°C (32°F to 104°F).

De-rate output current 2.5% per 1°C (1.8°F) from 40°C (104°F) to 50°C (122°F) maximum.

H The FlexDrive

II

must operate in relative humidity levels of less than 90% for temperatures

up to 31°C (87°F) decreasing linearly to 50% relative humidity at 40°C (104°F)

(non-condensing).

H The FlexDriveIImust be installed where the pollution degree according to IEC664 shall not

exceed 2.

H The external customer supplied 24VDC for the logic supply must be installed so that the

24VDC supplied to the unit is isolated from the AC supply using double or reinforced

insulation.

H The inputs and outputs of the control circuit must be limited to Safety Extra Low Voltage

circuits.

H Both the AC supply and the external 24VDC supply must be fused.

H The atmosphere must not contain flammable gases or vapors.

H There must not be abnormal levels of nuclear radiation or X-rays.

H The FlexDrive

II

must be secured by the slots in the flange, with the protective

earth/ground stud bonded to a safety earth/ground by either a 25A conductor or a

conductor of three times the peak current rating - whichever is the greater.

Page 19

Basic Installation 3-5MN1902

H For effective cooling and maintenance, the FlexDriveIIshould be mounted on a smooth,

non-flammable vertical surface. The power handling capability is affected by the

temperature of the left side of the unit.

H At least 50mm (2 in) top and bottom clearance of the FlexDriveIImust be provided for

airflow.

H If multiple FlexDrive

II

are being mounted side by side there must be 13mm (0.5 in)

between them. The FlexDrive

II

nearest the side of the cabinet / enclosure must be

separated from it by at least 13mm (0.5 in).

H To comply with CE directive 89/336/EEC an appropriate AC filter must be installed. The

external customer supplied 24VDC logic supply might also require a 24V filter. See section

3.4.7.

H The threaded holes in the top and bottom of the enclosure are for cable clamps. The holes

are threaded for M4 bolts no longer than 12mm (0.47 in) in length. Longer bolts may short

circuit the electrical components inside the FlexDrive

II

.

H Each D-type connector on the front panel of the FlexDrive

II

is secured using two

hexagonal jack screws (sometimes known as “screwlocks”). If a jack screw is removed

accidentally or lost it must be replaced with an identical jack screw with an external male

threaded section of 5mm (0.2 in). Jack screws with longer threads could damage or short

circuit internal components.

3.2.1 Mounting the FlexDrive

II

Ensure you have read and understood the Mechanical installation and location requirements in

section 3.2. Mount your FlexDrive

II

on its rear side, the side opposite to the front panel.

The FlexDrive

II

must be mounted upright to ensure adequate cooling (you can check this by

ensuring that the Hazardous Voltages warning information is clearly readable to you).

M5 bolts or screws should be used to mount the FlexDrive

II

.

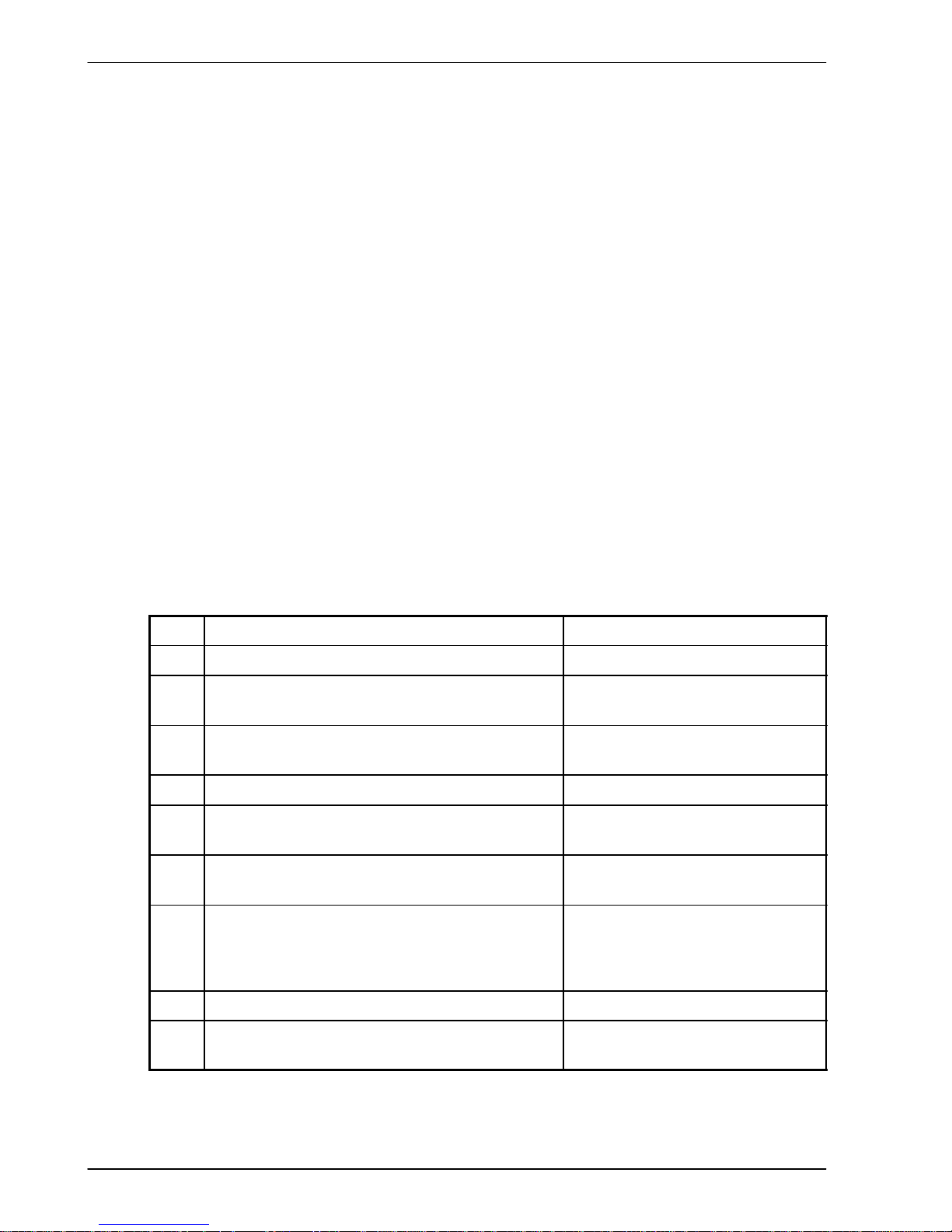

There are seven different package sizes depending on the specification of the FlexDrive

II

:

AC power

Current Factory fitted option Package size

Single-phase 2A without option A

with option B

5A without option C

with option D

7.5A without option D

with option D

230V

Three-phase

15A with or without option E

230-460V

2.5A, 5A, 7.5A with or without option G

Three-phase

15A, 20A, 27.5A with or without option H

Detailed dimensions for each package are shown in section 3.2.2.

Page 20

3-6 Basic Installation MN1902

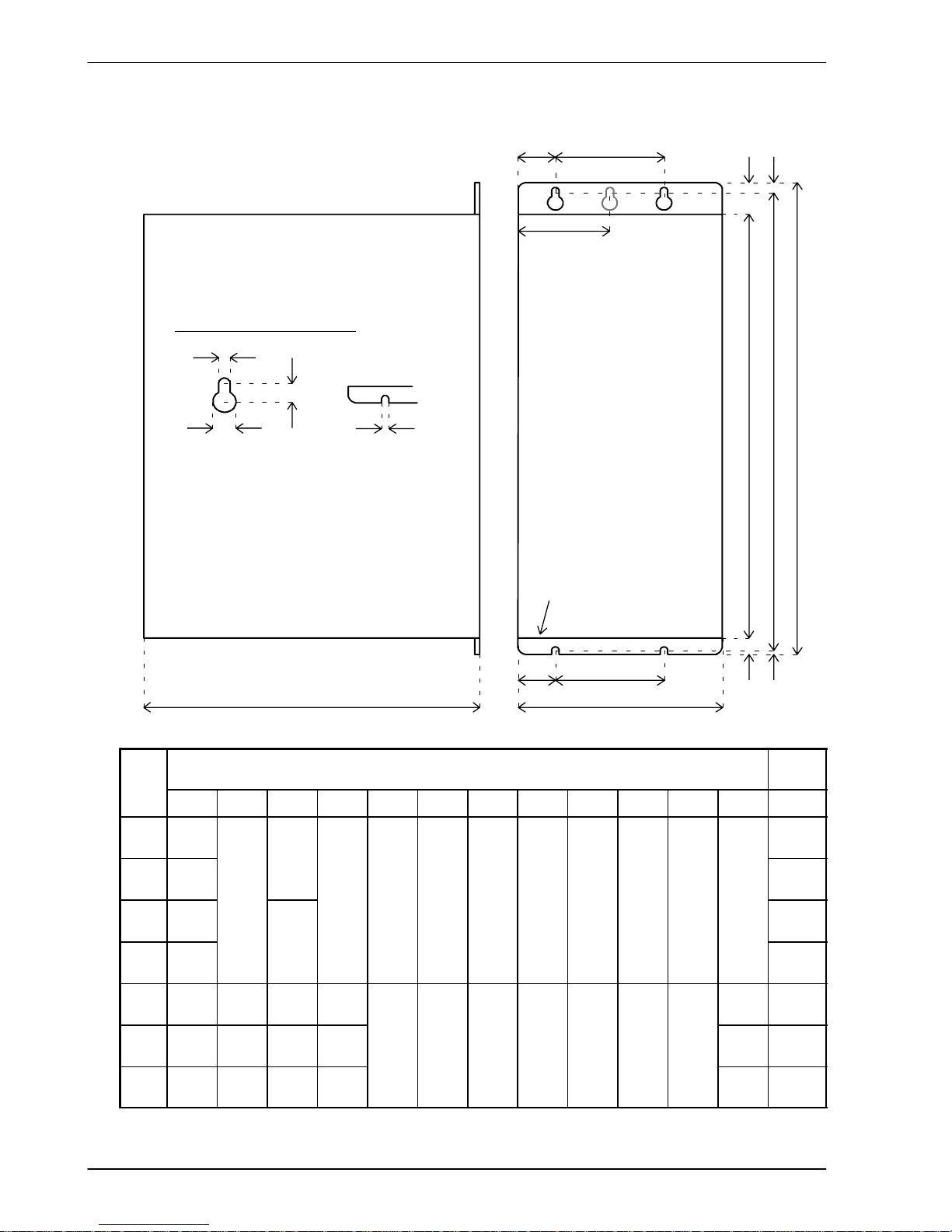

3.2.2 Dimensions

H

1

H

2

H

W

D

W

2

W

1

W

3

Package size

H only.

W

4

Package sizes E, G & H only:

W4=9.5mm.

All other sizes:

W4=W

2

H3H

4

65mm

FRONT PANEL

H5H

6

Mounting keyhole and slot detail

A

B

C

A

A 5mm (package sizes E, G and H: 6.5mm)

B 10mm (package sizes E, G and H: 12mm)

C 9mm (package sizes E, G and H: 10mm)

Dimensions

mm / inches

Weight

Case W W

1

W

2

W

3

H H

1

H

2

H

3

H

4

H

5

H

6

D kg / lb

A 67.5

2.66

15

1.25

2.76

B 84

3.31

40

1

5

0.59

40 173 195.5 205 23.5 6.5 8.5 3 152

1.55

3.42

C 92.5

3.64

4

0

1.57

23

4

0

1.57

173

6.81

195.5

7.70

205

8.07

2

3.5

0.93

6.5

0.26

8.5

0.3330.12

152

6.00

2.1

4.63

D 109

4.29

2

3

0.91

2.3

5.07

E 55

2.17361.42

27.5

1.08

- 263.5

10.37

3.3

7.28

G 65

2.56461.81

32.5

1.28

-

357

14.06

384

15.12

400

15.75

26.5

1.0480.31

16.5

0.6580.31

262

10.31

4.9

10.8

H 130

5.12

111

4.37

27.5

1.08752.95

328

12.91

9.05

19.95

Figure 1 - Package dimensions

Page 21

Basic Installation 3-7MN1902

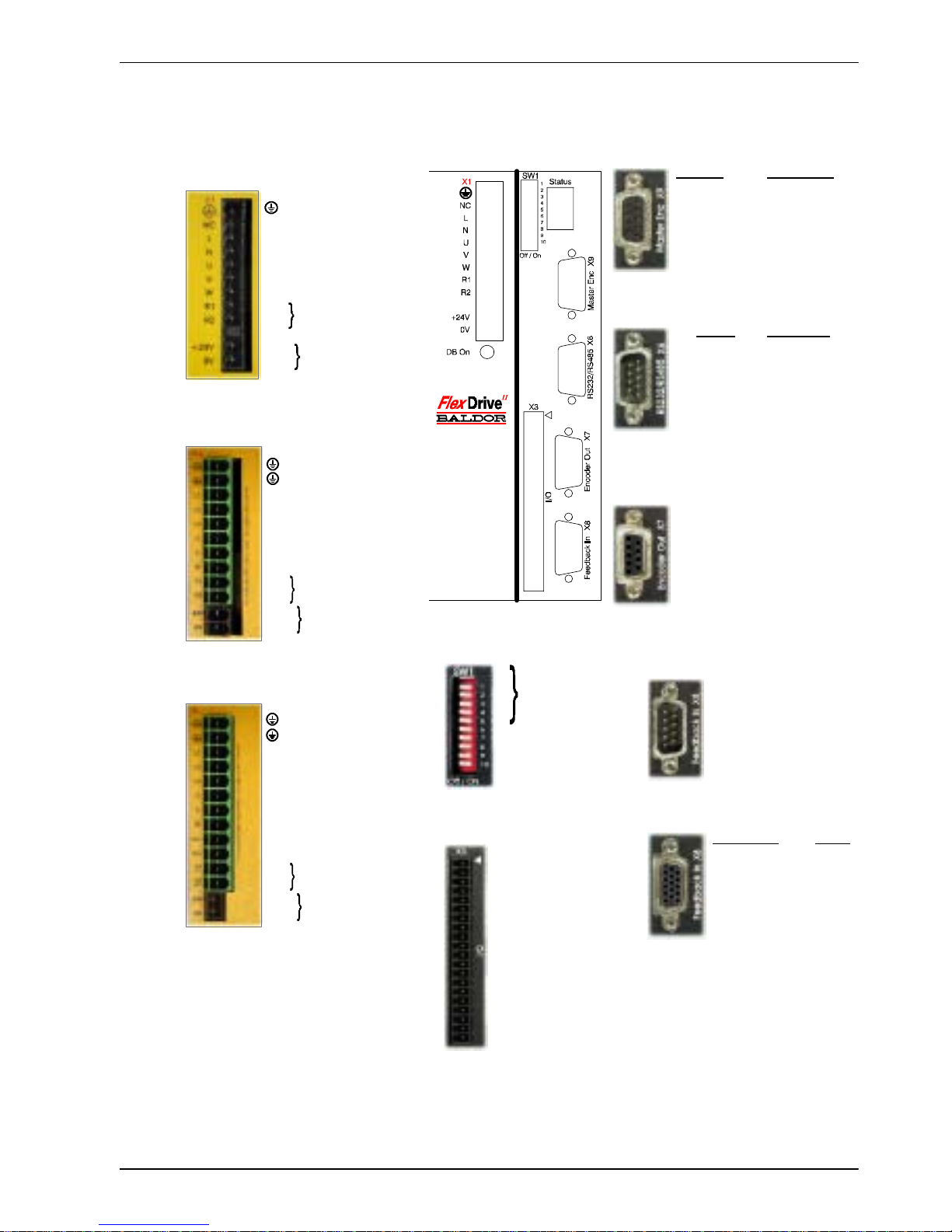

3.3 Conn ecto r locations

1 AIN0+ (Command+)

2 AIN0- (Command-)

3AGND

4 Relay+

5 Relay6UserV+

7 CREF

8CGND

9 Drive Enable

10 DIN0

11 DIN1

12 DIN2

13 DIN3

14 DIN4 (Pulse)

15 DIN5 (Direction)

16 DIN6

17 DIN7

18 DOUT0

19 DOUT1

20 DOUT2

1 CHA+

2 CHB+

3 CHZ+

4 (NC)

5DGND

6 CHA7 CHB8 CHZ9 (NC)

Encoder Pulse & Dir.

1 CHA+ Pulse+

2 CHB+ Dir.+

3 CHZ+ (NC)

4 (NC) (NC)

5DGND (NC)

6 CHA- Pulse GND

7 CHB- Dir. GND

8 CHZ- (NC)

9+5V (NC)

RS232 RS485/422

1 (NC) (NC)

2RXD RX3TXD TX4 (NC) (NC)

5 0V GND 0V DGND

6 (NC) (NC)

7 RTS TX+

8CTS RX+

9 (NC - see section 4.4.3)

1REF+

2COS+

3SIN+

4 (NC)

5AGND

6REF7COS8SIN9 Chassis

1 Node

2 number

3 selection

4

5 (Reserved)

6Hold

7 Offset tuning

8 Enable

9 (Reserved)

10 RS232/RS485

X3 General I/O

X6 RS232/RS485

X7 Encoder Out

X8 Feedback In

Resolver option

Encoder options

X1 / X1A Power

Single-phase models

Three-phase models, 230-460V

Earth

NC (NC)

LACLine

N AC Neutral

U Motor U

V Motor V

W Motor W

R1 Regen Resistor

R2 (Dynamic Brake)

- (NC)

+24V Customer

0V supplied 24V

(FDHxxxxxx-xxx3/

FPHxxxxxx-xxx3)

Options:

If there are other connectors on the

front panel of your FlexDriveII, then an

option is fitted. See the other manuals

supplied with your FlexDriveII.

Earth

Earth

L1 AC Phase 1

L2 AC Phase 2

L3 AC Phase 3

U Motor U

V Motor V

W Motor W

R1 Regen Resistor

R2 (Dynamic Brake)

+24V Customer supplied 24V

0V (FDH4xxxxx-xxx3/

FPH4xxxxx-xxx3

X9 Master Encoder

SW1 DIP switches

Earth

Earth

L1 AC Phase 1

L2 AC Phase 2

L3 AC Phase 3

U Motor U

V Motor V

W Motor W

Vcc+ (NC)*

Vcc- (NC)*

R1 Regen Resistor

R2 (Dynamic Brake)

+24V Customer supplied 24V

0V (FDH2xxxxx-xxx3/

FPH2xxxxx-xxx3

Tightening torque for terminal block

connections is 0.5-0.6Nm (4.4-5.3 lb-in)

* Warning! High voltages are present on

terminals labeled Vcc+ and Vcc-. Do not

make a connection to these terminals.

(NC) = Not Connected. Do not make a

connection to this pin.

Three-phase models, 230V

Incremental EnDat

1 CHA+ Data+

2 CHB+ Data3 CHZ+ (NC)

4 Hall U+ +5V

5HallU- DGND

6 CHA- Shield

7 CHB- Cos B8 CHZ- (NC)

9 Hall W+ Clock10 Hall V+ Clock+

11 +5V DG ND

12 (NC) Sin A13 DGND Sin A+

14 Hall W- Cos B+

15 Hall V- (NC)

Page 22

3-8 Basic Installation MN1902

3.4 Power connections

This section provides instructions for connecting the AC power supply. It is important that you

refer to the correct front panel for your FlexDrive

II

package.

The installer of this equipment is responsible for complying with NEC (National Electric Code)

guidelines or CE (Conformite Europeene) directives and application codes that govern wiring

protection, earthing/grounding, disconnects and other current protection.

WARNING: Electrical shock can cause serious or fatal injury. Do not touch any

power device or electrical connection before you first ensure that

power has been disconnected and there is no high voltage present

from this equipment or other equipment to which it is connected.

The power supply module within all FlexDrive

II

models provides rectification, smoothing and

current surge protection. On 2.5A and 5A models a regeneration resistor (Dynamic Brake

resistor) is also built-in. The power stage is internally fused and therefore self protected, but

fuses or circuit breakers are required in the input lines for cable protection (depending on local

codes and regulations).

A power disconnect should be installed between the AC supply and the input of the FlexDrive

II

for a fail safe method to disconnect power. On models with the internally generated 24VDC

logic supply (catalog numbers FDHxxxxx-xxx0 and FPHxxxxx -xxx0), the FlexDrive

II

will

remain operational until the internal bus voltage is depleted. Position and I/O information will

then be lost. On models with an external customer supplied 24VDC logic supply (catalog

numbers FDHxxxxx -xxx3 and FPHxxxxx-xxx3), position and I/O information will be retained

while the 24V supply is present.

Note: A Residual Current Device (RCD) must not be used for fusing the drive. A circuit

breaker or fuse must be used.

All interconnection wires should be in metal conduits between the FlexDrive

II

, AC power

source, motor, host controller and any operator interface stations. Use UL listed closed loop

connectors that are of appropriate size for the wire gauge being used. Connectors are to be

installed using only the crimp tool specified by the manufacturer of the connector. Only class 1

wiring should be used.

Baldor drives are designed to be powered from standard single and three-phase lines

(depending on model) that are electrically symmetrical with respect to earth/ground. Due to

the importance of system earthing/grounding for increased reliability, earthing/grounding

methods are shown in sections 3.4.1 and 3.4.2.

Note: When using unearthed/ungrounded distribution systems, an isolation transformer

with an earthed/grounded secondary is recommended. This provides three-phase

AC power that is symmetrical with respect to earth/ground and can prevent

equipment damage.

Page 23

Basic Installation 3-9MN1902

3.4.1 Single-phase connection to package sizes A, B, C, D

Location Connector X1

(Mating connector: Phoenix COMBICON MVSTBW 2,5/9-ST, 5mm pitch)

Part number FDH1A.../FPH1A... FDH2A.../FPH2A...

Nominal input

voltage

115VAC, 1Φ line to neutral 230VAC, 1Φ line to neutral

Range 97-125VAC 220-250VAC

For single-phase connection, the voltage ripple on the DC-bus is 25Vp-p for 5A peak current

rising to 50Vp-p for 10A peak current. This can limit the maximum speed of the motor.

Tightening torque for terminal block connections is 0.5-0.6Nm (4.4-5.3 lb-in).

The threaded hole in the top of the enclosure is for protective earth/ground connections.

The threaded hole in the bottom of the enclosure may be used as an additional functional

earth/ground connection for signals on connector X3. It may also be used to attach strain relief

clamps. The holes are threaded for M4 bolts no longer than 12mm (0.47 in) in length. Longer

bolts may short circuit the electrical components inside the FlexDrive

II

.

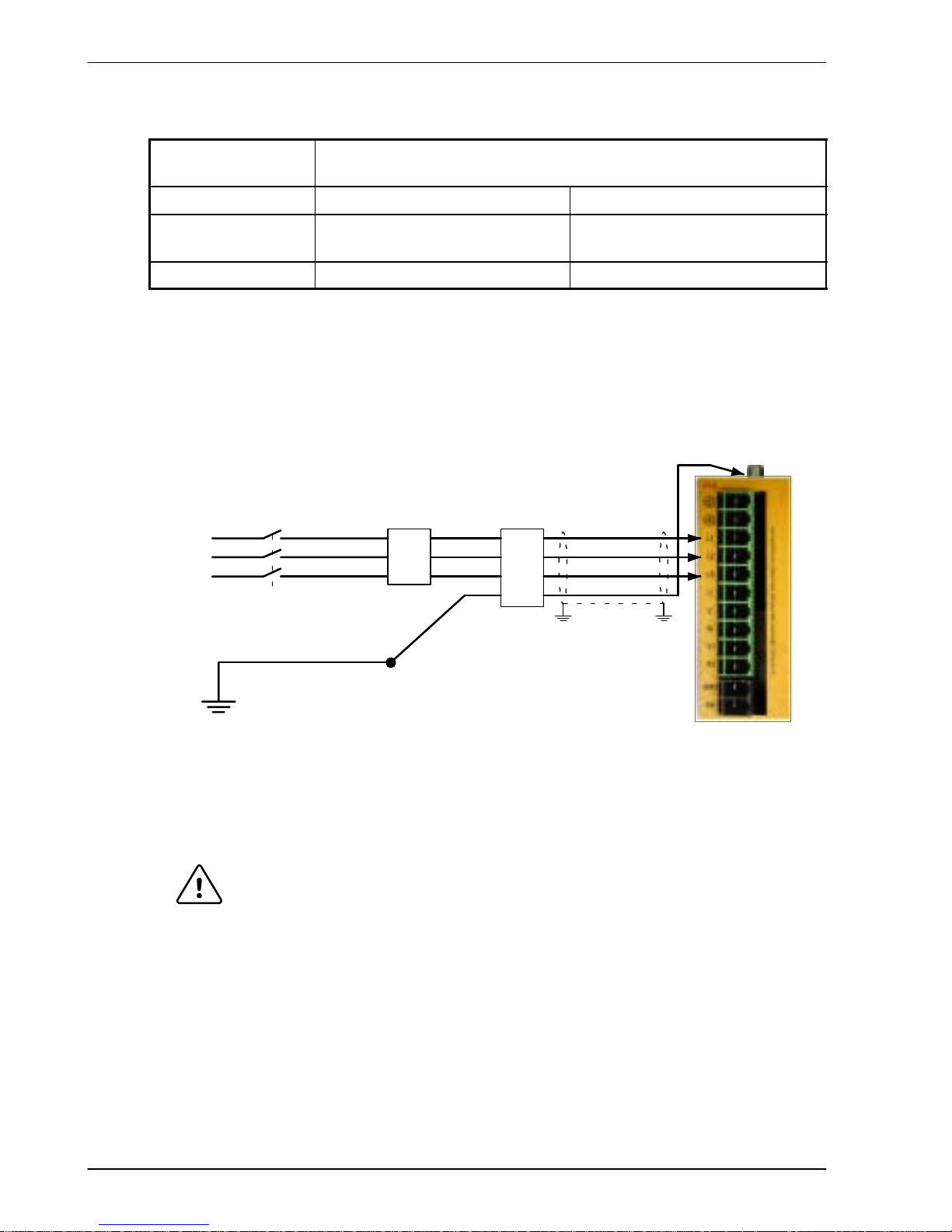

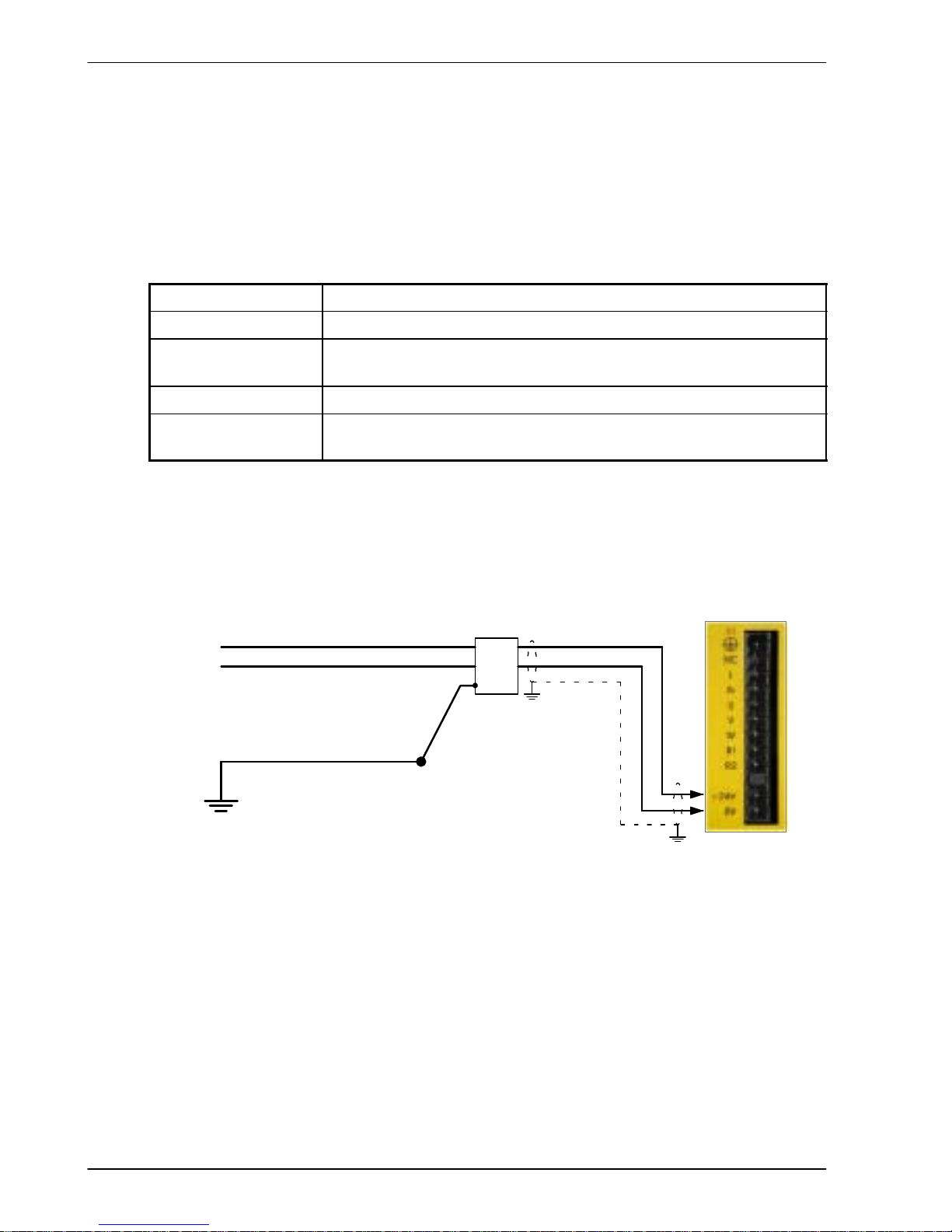

AC

Supply

Line (L)

Neutral (N)

Route L, N, and

earth/ground together

in conduit or cable

Circuit breaker or fuse.

See section 3.4.4

AC filter.

See section

3.4.5

STAR POINT

Incoming safety

earth/ground (PE)

Isolating switch

* If filter has no

output

earth/ground

terminal, earth

wire may be

connected directly

to star point.

*

If AC power wires

are shielded,

earth/ground

outer shield using

360º clamps

connected to

backplane.

Figure 2 - Earthing/grounding for single-phase installations

Note: For CE compliance, a filter must be connected between the AC power supply and

the FlexDrive

II

. If local codes do not specify different regulations, use at least the

same gauge wire for earth/ground as is used for L and N.

Page 24

3-10 Basic Installation MN1902

3.4.2 Three-phase connection to package sizes E, G, H

Location Connector X1A

(Mating connector: Phoenix POWER COMBICON PC4/..-ST- 7.62)

Part number FDH2A15.../FPH2A15... FDH4A.../FPH4A...

Nominal input

voltage

230VAC, 3Φ line to line 230-460VAC, 3Φ line to line

Range 184-253VAC 180-528VAC

Tightening torque for terminal block connections is 0.5-0.6Nm (4.4-5.3 lb-in). The threaded

hole in the top of the enclosure is for protective earth/ground connections. The threaded hole

in the bottom of the enclosure (if present) may be used as an additional functional

earth/ground connection for signals on connector X3. It may also be used to attach strain relief

clamps. The holes are threaded for M4 bolts no longer than 12mm (0.47 in) in length. Longer

bolts may short circuit the electrical components inside the FlexDrive

II

.

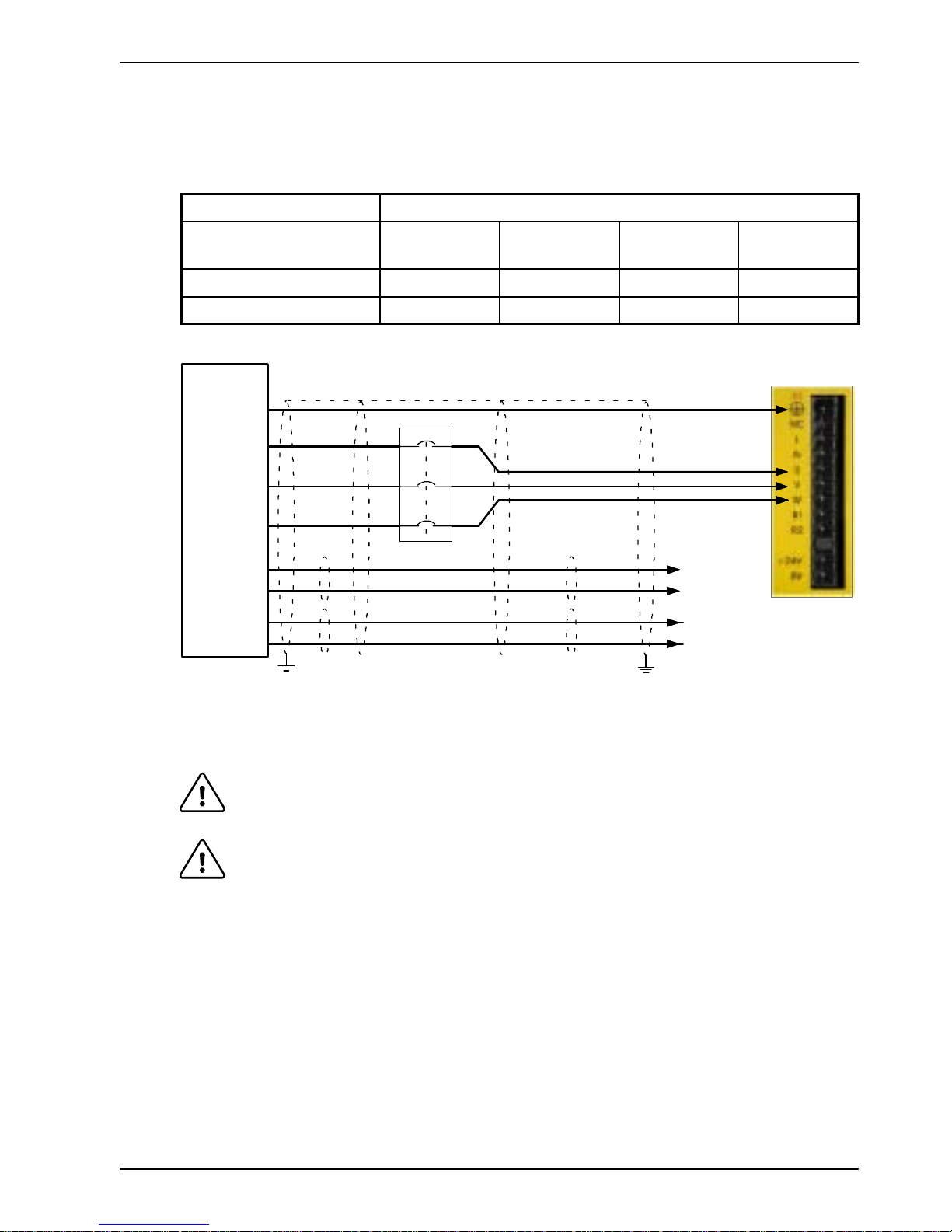

AC

Supply

Line (L1)

Route L1, L2, L3 and

earth/ground together

in conduit or cable

Circuit breaker or fuses.

See section 3.4.4

AC filter.

See section

3.4.5

Line (L2)

Line (L3)

STAR POINT

Incoming safety

earth/ground (PE)

Isolating switch

* If filter has no

output

earth/ground

terminal, earth

wire may be

connected

directly to star

point.

*

If AC power wires

are shielded,

earth/ground

outer shield using

360º clamps

connected to

backplane.

FDH4A... shown

for illustration

purposes

Figure 3 - Earthing/grounding for three-phase installations

WARNING: Drives with part numbers FDH2A15... or FPH2A15... have two

additional terminals on the X1 connector labeled Vcc+ and Vcc-.

The full output bus voltage is present on the these terminals so do not

make any connection to them.

Note: For CE compliance, a three-phase AC filter must be connected between the AC

power supply and the FlexDrive

II

. If local codes do not specify different

regulations, use at least the same gauge wire for earth/ground as is used for L

and N.

Page 25

Basic Installation 3-11MN1902

3.4.3 Input power conditioning

Baldor drives are designed for direct connection to standard single and three-phase lines

(depending on model) that are electrically symmetrical with respect to earth/ground. Certain

power line conditions must be avoided; an AC line reactor, an isolation transformer or a step

up/step down transformer may be required for some power conditions:

H If the feeder or branch circuit that provides power to the FlexDrive

II

has permanently

connected power factor correction capacitors, an input AC line reactor or an isolation

transformer must be connected between the power factor correction capacitors and the

FlexDrive

II

.

H If the feeder or branch circuit that provides power to the FlexDrive

II

has power factor

correction capacitors that are switched on line and off line, the capacitors must not be

switched while the drive is connected to the AC power line. If the capacitors are switched

on line while the drive is still connected to the AC power line, additional protection is

required. A Transient Voltage Surge Suppressor (TVSS) of the proper rating must be

installed between the AC line reactor (or isolation transformer) and the AC input to the

FlexDrive

II

.

3.4.3.1 Input power-cycling

If AC power has been removed from the FlexDrive

II

, it should not be reapplied for at least one

minute. This delay allows the input surge protection circuit to perform correctly. Power-cycling

the drive more frequently could cause nuisance trips when power is reapplied and reduce the

lifetime of the FlexDrive

II

.

3.4.4 Power disconnect and protection devices

A power disconnect should be installed between the input power service and the FlexDrive

II

for a fail-safe method to disconnect power. The FlexDriveIIwill remain in a powered condition

until all input power is removed from the drive and the internal bus voltage has depleted.

The FlexDrive

II

must have a suitable input power protection device installed. Recommended

circuit breakers are thermal magnetic devices (1 or 3 phase as required) with characteristics

suitable for heavy inductive loads (D-type trip characteristic). Recommended time delay fuses

are Buss FRN on 230V AC or equivalent, following the UL 508C recommendation of a fuse

size of four times the continuous output current of the drive. Dual element, time delay fuses

should be used to avoid nuisance trips due to inrush current when power is first applied.

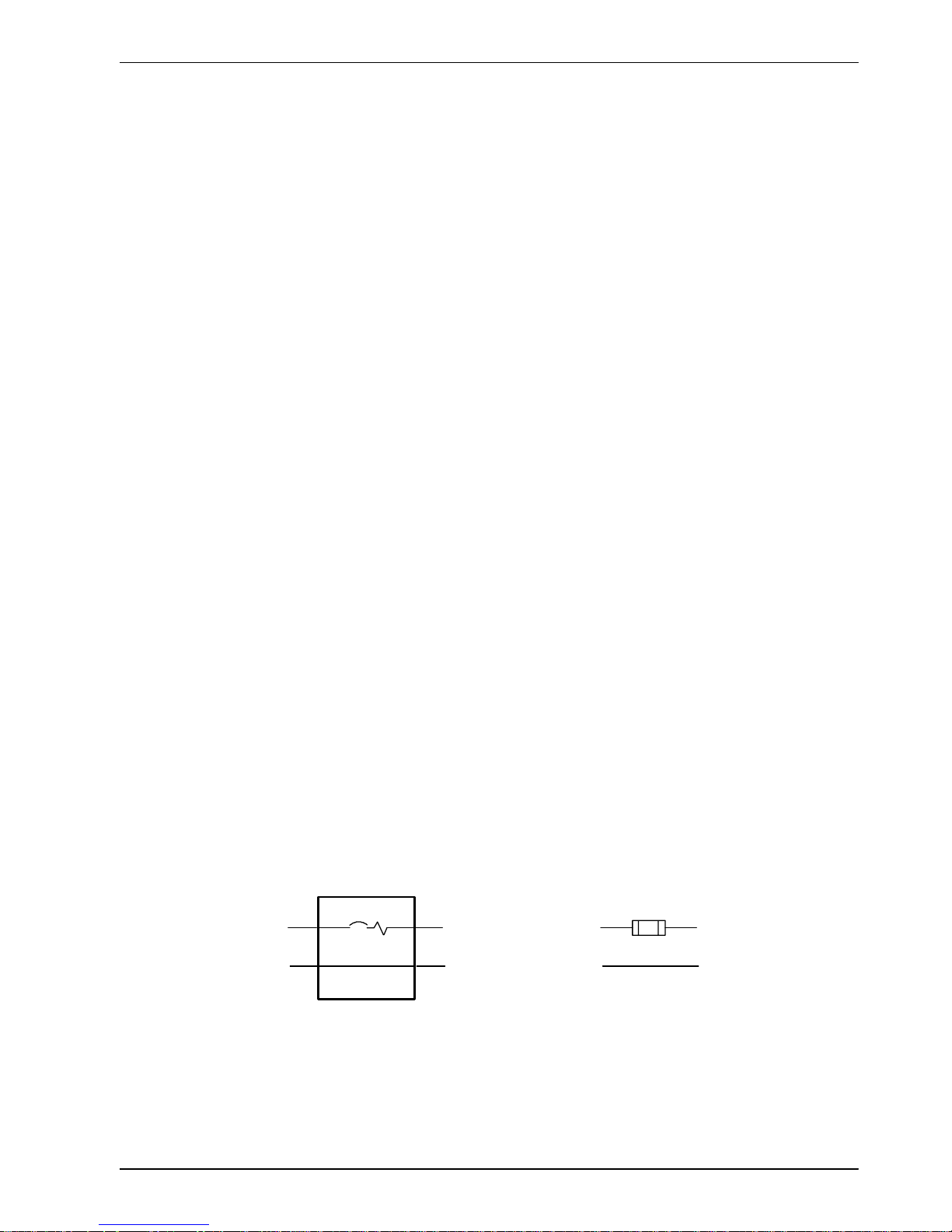

Circuit Breaker

L

N

From

supply

L

N

From

supply

Fuse

L

N

L

N

Figure 4 - Circuit breaker and fuse, single-phase (package sizes A, B, C, D)

Page 26

3-12 Basic Installation MN1902

Note: Power to single phase models may be derived by connecting two phases of an

appropriate three-phase supply (L1 and L2 for example). When supplying

AC

power in this way, the voltage between the two phases must not exceed the

rated

input voltage of the FlexDrive

II

. A two pole breaker must be used to isolate both

lines. Fuses must be fitted in both lines. Circuit breaker or fuse are not supplied.

For CE compliance, see Appendix C.

Circuit Breaker

Circuit breaker or fuse are not supplied.

For CE Compliance, see Appendix C.

L1

From

supply

Fuses

L2

L3

L1

L2

L3

From

supply

L1

L2

L3

Figure 5 - Circuit breaker and fuse, three-phase (package sizes E, G, H)

Note: Metal conduit or shielded cable should be used. Connect conduits so the use of a

line reactor or RC device does not interrupt EMI/RFI shielding.

3.4.5 Power supply filters

To comply with EEC directive 89/336/EEC, an AC power filter of the appropriate type must be

connected. This can be supplied by Baldor and will ensure that the FlexDrive

II

complies with

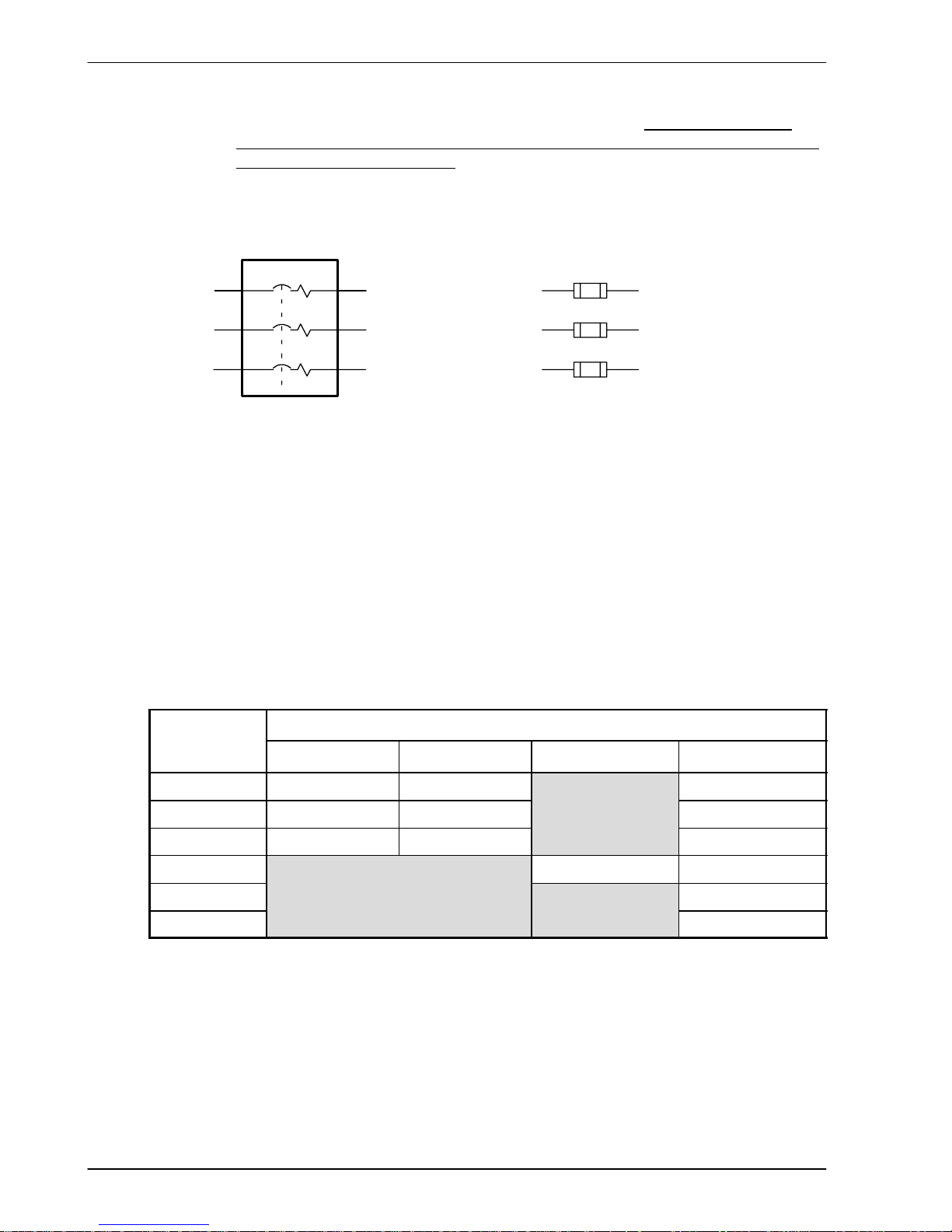

the CE specifications for which it has been tested. Table 1 lists the appropriate filters:

FlexDrive

II

Input voltages

curren

t

rating

115VAC, 1Φ 230VAC, 1Φ 230VAC, 3Φ 230-460VAC, 3Φ

2.5A FI0014A00 FI0019A00 FI0018A00

5A FI0015A00 FI0015A00

FI0018A00

7.5A FI0015A01 FI0015A01* FI0018A00

15A FI0018A01 FI0018A01

20A FI0018A01

27.5A FI0018A01

Ta ble 1 - Baldor filter part numbers

* If this model requires a customer supplied 24V control supply (catalog numbers

FDH2A07Tx-xxx3 or FPH2A07Tx -xxx3), use filter FI0015A02. For further details of power

supply filters see section A.1.6.

Page 27

Basic Installation 3-13MN1902

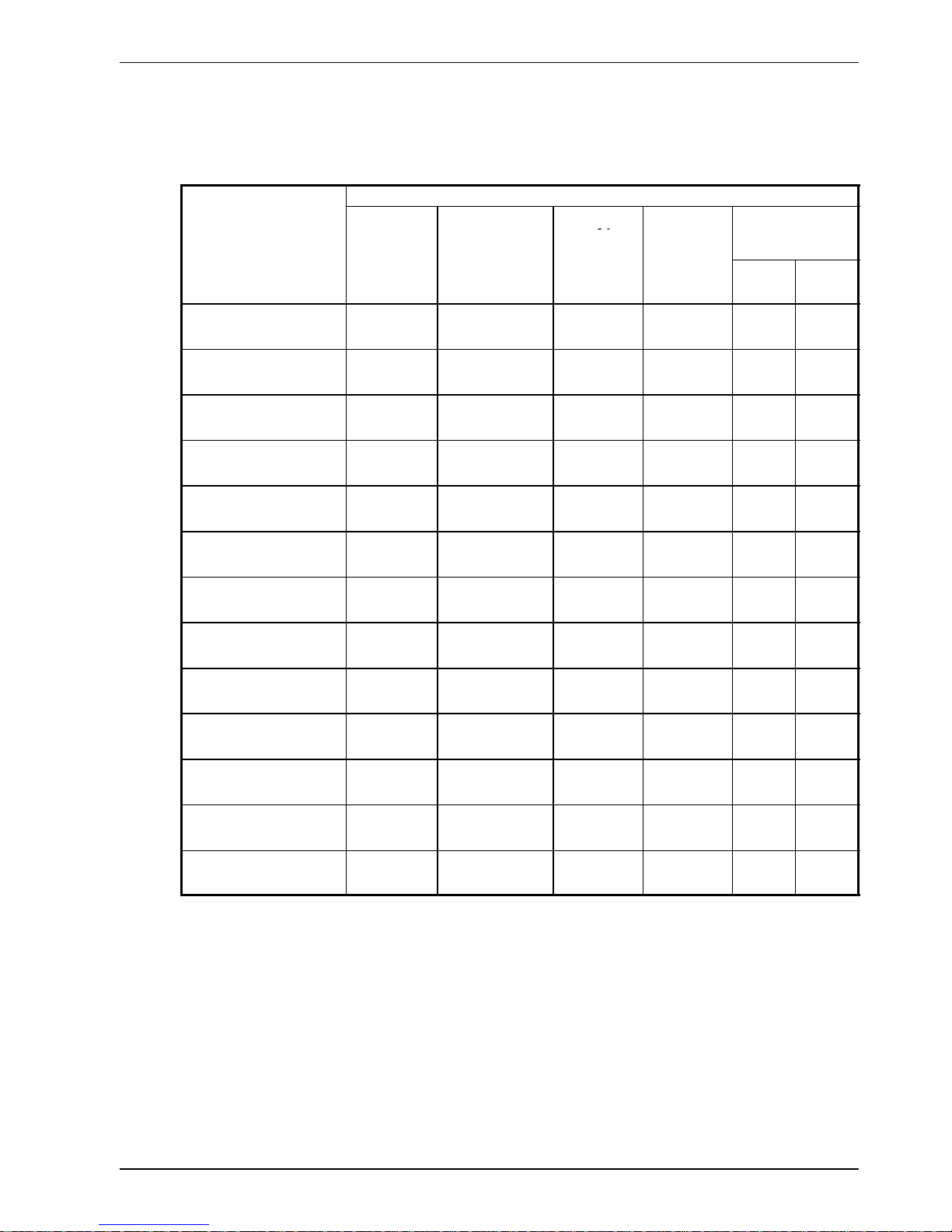

3.4.6 Wire sizes and protection device ratings

Table 2 describes the wire size to be used for power connections and the ratings of the

protection devices.

Incoming Power

Nominal

Continuous

D-Type

Time

Minimum

Catalog Number

Input

Output

y

p

Input

Dela

yMinimu

m

Wire Gauge

Vol

t

age

A

mps

(RMS)

B

reaker

(A)

I

npu

t

Fuse

(A)

AWG mm

2

FDH1A02xx-xxxx

FPH1A02xx-xxxx

115V

(1Φ)

2.5A 6 6 14 2.0

FDH2A02xx-xxxx

FPH2A02xx-xxxx

230V

(1Φ)

2.5A 6 6 14 2.0

FDH1A05xx-xxxx

FPH1A05xx-xxxx

115V

(1Φ)

5A 10 10 14 2.0

FDH2A05xx-xxxx

FPH2A05xx-xxxx

230V

(1Φ)

5A 10 10 14 2.0

FDH1A07xx-xxxx

FPH1A07xx-xxxx

115V

(1Φ)

7.5A 16 16 14 2.0

FDH2A07xx-xxxx

FPH2A07xx-xxxx

230V

(1Φ)

7.5A 16 16 14 2.0

FDH4A02xx-xxxx

FPH4A02xx-xxxx

230-460V

(3Φ)

2.5A 6 6 14 2.0

FDH4A05xx-xxxx

FPH4A05xx-xxxx

230-460V

(3Φ)

5A 10 10 14 2.0

FDH4A07xx-xxxx

FPH4A07xx-xxxx

230-460V

(3Φ)

7.5A 16 16 14 2.0

FDH2A15xx-xxxx

FPH2A15xx-xxxx

230V

(3Φ)

15A 32 32 12 3.3

FDH4A15xx-xxxx

FPH4A15xx-xxxx

230-460V

(3Φ)

15A 32 32 12 3.3

FDH4A20xx-xxxx

FPH4A20xx-xxxx

230-460V

(3Φ)

20A 40 40 10 5.3

FDH4A27xx-xxxx

FPH4A27xx-xxxx

230-460V

(3Φ)

27.5A 60 60 10 5.3

Table 2 - Protection device and wire ratings

Note: All wire sizes are based on 75°C (167°F) copper wire. Higher temperature smaller

gauge wire may be used per National Electric Code (NEC) and local codes.

Recommended fuses/breakers are based on 25°C (77°F) ambient, maximum

continuous control output current and no harmonic current. Earth/ground wires

must be the same gauge, or larger, than the Line and Neutral wires.

Page 28

3-14 Basic Installation MN1902

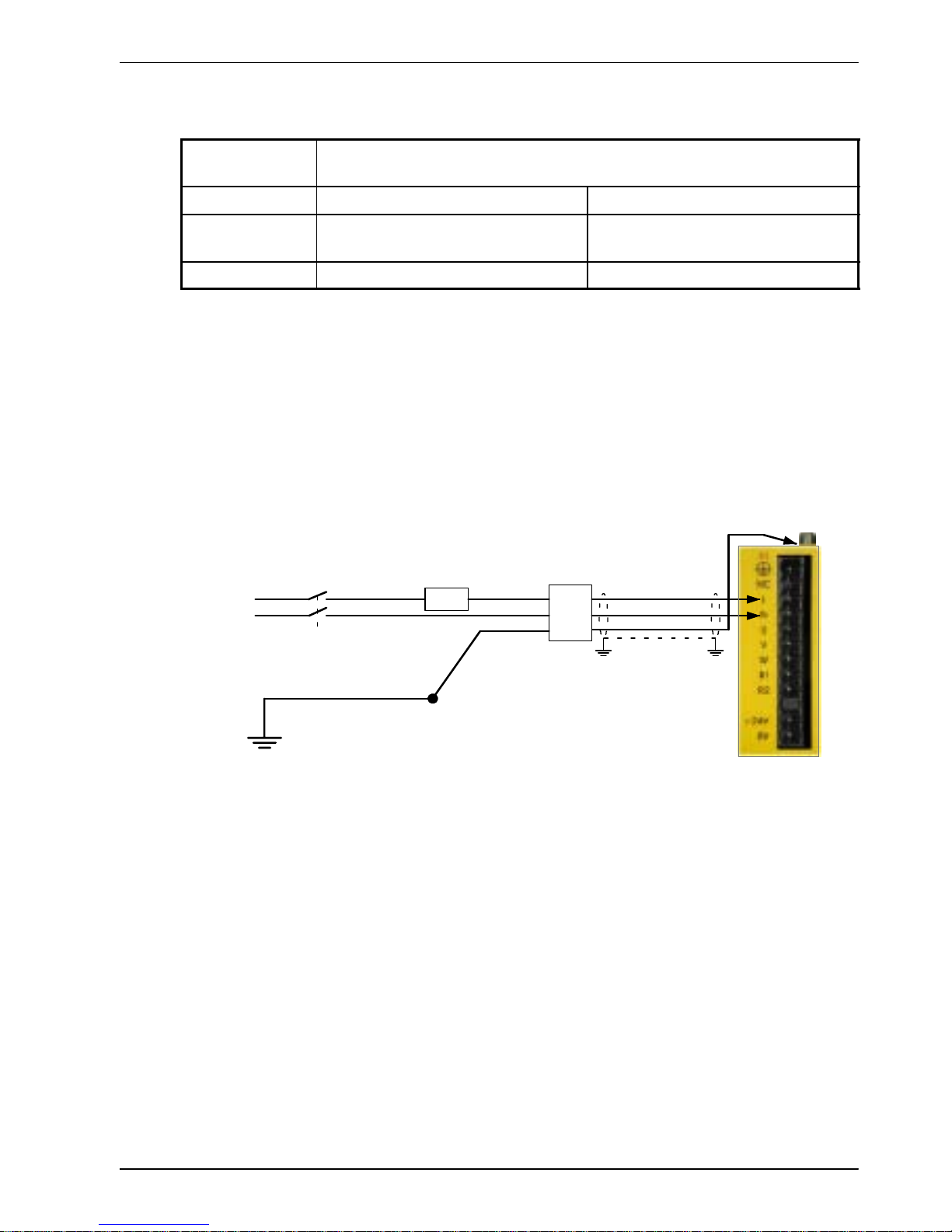

3.4.7 External customer supplied 24V control supply

Depending on model (catalog numbers FDHxxxxx-xxx3 and FPHxxxxx -xxx3) a 24VDC

control supply must be provided to power the control electronics. This is useful for safety

reasons where AC power needs to be removed from the power stage but the control

electronics must remain powered to retain position and I/O information. It is recommended

that a separate fused 24V supply is provided for the FlexDrive

II

. If other devices are likely to

be powered from the same 24V supply then a filter (Baldor catalog number FI0014A00) should

be installed to isolate the FlexDrive

II

from the rest of the system.

Location

Connector X1 / X1A

Part number FDHxxxxx -xxx3 or FPHxxxxx-xxx3

Nominal input

voltage

24V

Range 20.4-28.8VDC

Input current

(maximum)

1.75A continuous (4A power on surge)

Tightening torque for terminal block connections is 0.5-0.6Nm (4.4-5.3 lb-in)

Note: Connect 24V to connector X1 only if your model has this feature. Connecting 24V

to a model that does not require an external 24V supply (FDHxxxxx-xxx0 and

FPHxxxxx-xxx0) could damage the unit.

Customer supplied

24VDC (fused)

+24V

24V filter

(optional)

GND

Single-phase model

shown for illustration

purposes

STAR

POINT

Incoming safety

earth/ground (PE)

If 24V wires are

shielded,

earth/ground

outer shields,

using 360º

clamps connected

to backplane.

Figure 6 - Customer supplied 24V supply connections

Page 29

Basic Installation 3-15MN1902

3.5 Motor connections

The motor can be connected directly to the FlexDriveIIor through a motor contactor

(M-Contactor).

Location

Connector X1 / X1A

Part number

FDH1A...

FPH1A...

FDH2A...

FPH2A...

FDH2A15...

FPH2A15...

FDH4A...

FPH4A...

Nominal output voltage 160VDC 320VDC 320VDC 565/650V

Output voltage range 135-176VDC 306-350VDC 258-355VDC 254-746VDC

See

section

3.5.4

V

W

U

Motor

To earth/ground outer shield, use 360° clamps connected to backplane

Thermal

switch

A

B

Brake

(if present)

C

D

See

section

3.5.5

Unshielded

lengths should be

as short as

possible.

Optional motor

circuit contactors

Figure 7 - Motor connections

CAUTION: Do not connect supply power to the FlexDriveIIUVW outputs. The

FlexDrive

II

might be damaged.

CAUTION: The motor leads U, V and W must be connected to their corresponding U,

V or W terminal on the motor. Misconnection will result in uncontrolled

motor movement.

The motor power cable must be shielded for CE compliance. The connector or gland used at

the motor must provide 360 degree shielding. The maximum recommended cable length is

30.5m (100ft).

Note: For CE compliance the motor earth/ground should be connected to the drive

earth/ground.

Page 30

3-16 Basic Installation MN1902

3.5.1 Motor circuit contactors

If required by local codes or for safety reasons, an M-Contactor (motor circuit contactor) may

be installed to provide a physical disconnection of the motor windings from the FlexDrive

II

(see section 3.5). Opening the M-Contactor ensures that the FlexDriveIIcannot drive the

motor, which may be necessary during equipment maintenance or similar operations. Under

certain circumstances, it may also be necessary to fit a brake to a rotary motor. This is

important with hanging loads where disconnecting the motor windings could result in the load

falling. Contact your local supplier for details of appropriate brakes.

CAUTION: If an M-Contactor is installed, the FlexDriveIImust be disabled at least

20ms before the M-Contactor is opened. If the M-Contactor is opened

while the FlexDrive

II

is supplying voltage and current to the motor, the

FlexDrive

II

may be damaged. Incorrect installation or failure of the

M-Contactor or its wiring may result in damage to the FlexDrive

II

.

Ensure that shielding of the motor cable is continued on both sides of the contactor.

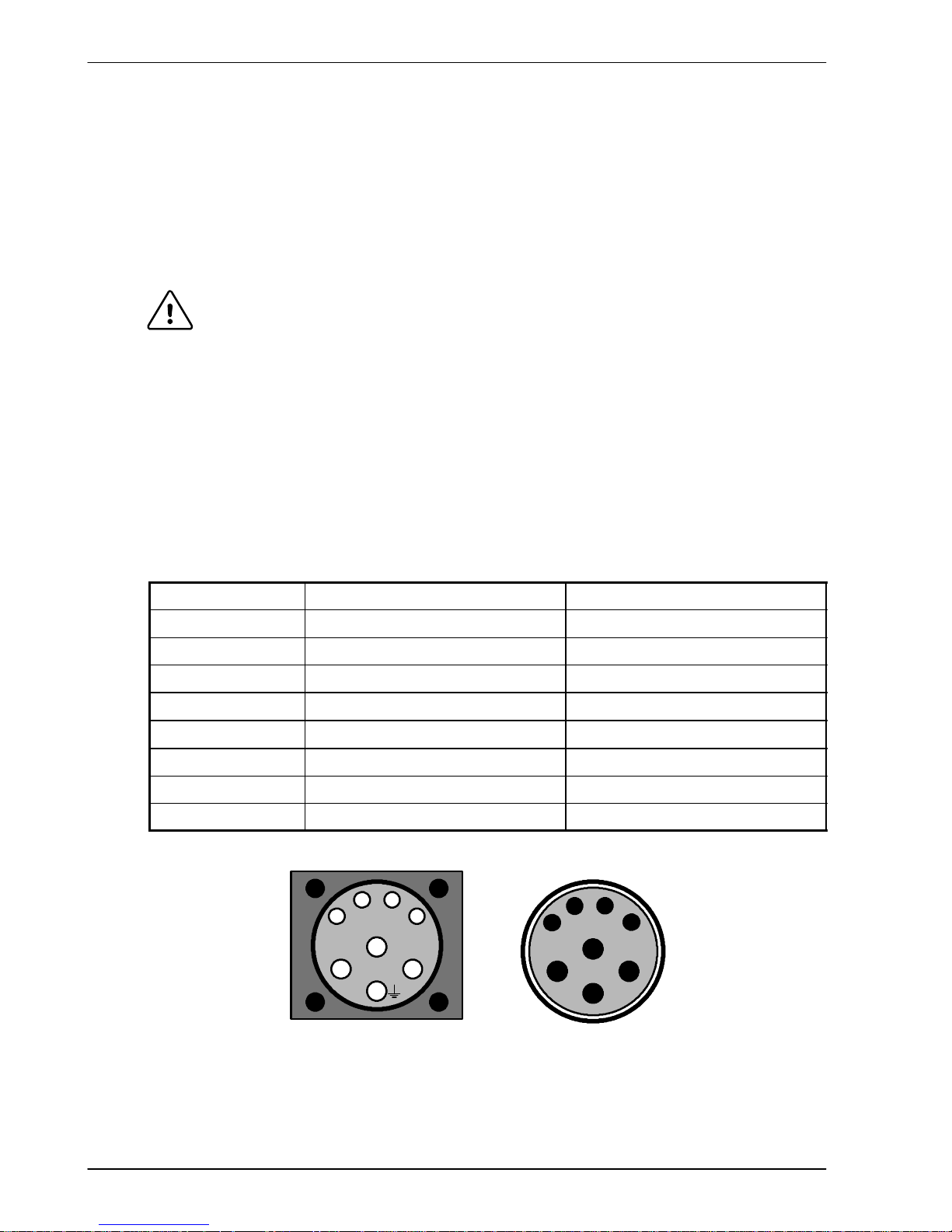

3.5.2 Motor power cable pin configuration - Baldor BSM rotary motors

Figure 8 shows the pin configuration for a typical Baldor motor cable, part number

CBL030SP-MHCE:

Signal name

Motor / cable pin Motor cable wire color

Motor U 1 Black, labeled ‘1’

Motor V 4 Black, labeled ‘2’

Motor W 3 Black, labeled ‘3’

Earth/ground 2 Green/Yellow

Thermal switch A Green

Thermal switch B White

Brake C Blue

Brake D Red

Cable connector end view

(female)

1

B

A

3

2

4

Motor power connector

(male)

1

B

A

3

2

4

C

D

C

D

Note:

Not all motors

arefittedwith

a brake so

pins C and D

might not be

connected.

Figure 8 - Baldor motor power cable pin configuration

Page 31

Basic Installation 3-17MN1902

3.5.3 Motor cable pin configuration - Baldor linear motors

The following table shows the pin colors used in a typical Baldor linear motor cable set, part

number A Y1763A00:

Signal name

Motor cable wire color

Motor U Black

Motor V Red

Motor W White

Motor ground Green

Thermal switch Blue

Thermal switch Orange

Signal name Hall cable wire color

Hall 1 (U) White

Hall 2 (V) Red

Hall 3 (W) Black

Hall ground Green

Hall +5VDC Brown

Page 32

3-18 Basic Installation MN1902

3.5.4 Thermal switch connection

You might wish to wire the motor’s thermal switch contacts (normally open), using a relay, to a

digital input on connector X3 (see section 4.3.1). Using the WorkBench v5 Digital I/O tool, the

input can be configured to be the motor trip input. This allows the FlexDrive

II

to respond to

motor over-temperature conditions. The Mint keyword MOTORTEMPERATUREINPUT can also

be used to configure a digital input for this purpose. A typical circuit, using DIN1 as the input,

is shown in Figure 9.

A

B

motor

thermal

switch

CREF

X3

7

DIN0 (INX.0)

Relay

Customer

supplied

24VDC

supply

+24VDC 0V

10

11

12

13

14

15

16

17

DIN1 (INX.1)

DIN3 (INX.3)

DIN7 (INX.7)

DIN5 (INX.5)

DIN4 (INX.4)

DIN2 (INX.2)

DIN6 (INX.6)

Separate

customer

supplied

24VDC supply

+24VDC 0V

Figure 9 - Motor thermal switch circuit

CAUTION: The 24VDC power supply connected to the thermal switch must be a

separate supply as shown in Figure 9. Do not use the 24V supply used

for the drive enable signal, or the internally generated supply (if present).

The thermal switch wires often carry noise that could cause erratic drive

operation or damage. The thermal switch contacts must never be wired

directly to a digital input.

The separate 24VDC supply used for the thermal switch may also be

used for the motor brake circuit (section 3.5.5).

Page 33

Basic Installation 3-19MN1902

3.5.5 Motor brake connection

You might wish to wire a motor’s brake, via relays, to digital outputs on connector X3 (see

section 4.3.1). This provides a way for the Mint program to control the motor’s brake. A typical

circuit is shown in Figure 10.

C

D

from motor brake

connections

Separate

customer

supplied

24VDC supply

X3

8

18

19

DOUT0 (OUTX.0)

DOUT1 (OUTX.1)

CGND

Relay 2

Relay 1

+24VDC 0V

The inner shield

surrounding the

brake wires should

be earthed/grounded

at one point only.

The relays have normally open

contacts and are shown deactivated

(contacts open, brake engaged).

Figure 10 - Motor brake control circuit

This circuit uses the drive enable signal (configured using DRIVEENABLEOUTPUT to appear

on DOUT0) in conjunction with DOUT1. With this configuration, the following sequences can

be used to control the brake.

To engage the brake:

H The motor is brought to rest under normal control;

H Relay 2 is deactivated, causing the brake to engage;

H The drive is disabled. This removes power from the motor and causes Relay 1 to be

deactivated.

To disengage the brake:

H The drive is enabled, activating Relay 1;

H Power is applied to the motor to hold position under normal control;

H Relay 2 is activated, causing the brake to be disengaged.

CAUTION: The 24VDC power supply must be a separate supply as shown in Figure

10. Do not use the 24V supply powering the FlexDrive

II

digital outputs, or

the internally generated supply (if present). The brake wires often carry

noise that could cause erratic drive operation or damage. The brake

contacts must never be wired directly to the digital outputs. The relay(s)

should be fitted with a protective flyback diode, as shown.

The separate 24VDC supply used for the motor brake may also be used

to power the relay in the thermal switch circuit (section 3.5.4).

Page 34

3-20 Basic Installation MN1902

3.6 Regeneration resistor (Dynamic Brake resistor)

The 2.5A and 5A FlexDriveIIboth have an internally fitted regeneration resistor *. For 7.5A,

15A, 20A and 27.5A FlexDrive

II

, an external regeneration resistor must be installed to

dissipate excess power from the internal DC bus during motor deceleration.

Suitable regeneration resistors are listed in section A.1.7.

WARNING: A regeneration resistor may generate enough heat to

ignite combustible materials. To avoid fire hazard,

keep all combustible materials and flammable vapors

away from the resistors.

The regeneration resistor should be mounted near the top of an enclosure

to maximize heat dissipation. When the motor regenerates, the yellow

DB On LED on the front panel of the FlexDrive

II

will illuminate.

* If required by the application, additional external resistors connected to R1 and R2 will be

connected in parallel with the internal resistor.

3.6.1 Controlling regeneration

Some regeneration resistor assemblies include an overload switch to indicate when too much

power is being dissipated by the resistor. This switch can be wired to a digital input on the

FlexDrive

II

. Using the WorkBench v5 Digital I/O tool, the input can be configured to be the

brake trip input. This allows the FlexDrive

II

to respond to resistor overload conditions.

The Mint keyword DBEXTTRIPINPUT can also be used to configure a digital input for this

purpose. On three-phase FlexDrive

II

models, the operation of the regeneration resistor can be

controlled by further Mint keywords. These also begin with the letters DB..., for example

DBEXTPEAKPOWER. See the Mint help file for details.

R1

R2

Page 35

Basic Installation 3-21MN1902

3.7 Feed b ack connectio n s

Two feedback options are available for use with linear and rotary motors - commutating

encoder or resolver. Confirm the catalog number of your FlexDrive

II

(see section 2.2.1) to

ensure you are wiring the correct feedback device. There are some important considerations

when wiring the feedback device:

H The feedback device wiring must be separated from power wiring.

H Where feedback device wiring runs parallel to power cables, they must be separated by at

least 76mm (3 in)

H Feedback device wiring must cross power wires at right angles only.

H To prevent contact with other conductors or earths/grounds, unearthed/ungrounded ends

of shields must be insulated.

H Some larger D-type connector shells may be obstructed by neighboring connector X3.

H Linear motors use two separate cables (encoder and Hall). The cores of these two cables

will need to be wired to the appropriate pins of the 15-pin D-type mating connector

(supplied).

An encoder output signal is available on connector X7 for supplying other equipment.

FlexDrive

II

models with the resolver option provide a simulated encoder output, while the

encoder based FlexDrive

II

duplicates the encoder signals entering X8. See section 4.4.1 for

details.

Page 36

3-22 Basic Installation MN1902

3.7.1 Resolver option - X8

The resolver connections are made using the 9-pin D-type male connector X8. Twisted pair

cables must be used for the complementary signal pairs e.g. SIN+ and SIN-. The overall cable

shield (screen) must be connected to the metallic shell of the D-type connector.

Location

Connector X8, 9-pin D-type male connector

Pin Resolver function

1 REF+

2 COS+

3 SIN+

4 (NC)

5 Analog Ground

6 REF-

7 COS-

8 SIN-

9 Chassis Ground

Description Resolver input with 14-bit resolution

The resolver input is used to create an encoder signal inside the FlexDriveII. This provides the

FlexDrive

II

with an equivalent resolution of 4096 pulses per revolution (ppr), although this can

be reconfigured in the WorkBench v5 Commissioning Wizard to provide 1024 ppr. The

FlexDrive

II

provides an input accuracy of ±3 counts. When used with a typical Baldor BSM

series resolver motor the combined accuracy is ±11 counts (calculated with the input

equivalent resolution set to the factory preset value of 4096 ppr).

1

6

2

7

3

8

5

R2

R1

S2

S4

S1S3

X8

SIN+

SIN-

COS+

COS-

REF+

REF-

AGND

+

Twisted

pairs

Baldor motor

resolver connector

5

6

3

4

1

2

Connect overall shield

to connector backshells.

Connect internal

shields to AGND.

+

+

Figure 11 - Resolver cable connections

1

5

6

9

Page 37

Basic Installation 3-23MN1902

3.7.1.1 Resolver cable pin configuration

Figure 12 shows the pin configuration for a typical Baldor resolver feedback cable, part

number CBL030SF-ALCE.

Signal name

FlexDrive

II

X8 pin

Motor / cable

pin

Baldor resolver cable

internal wire colors

REF+ 1 1 Red

REF- 6 2 Blue

COS+ 2 3 Green

COS- 7 4 Yellow

SIN+ 3 5 Pink

SIN- 8 6 Grey

1

2

3

45

6

7

89

101112

Motor resolver connector

(male)

Pins 7-12

are not us ed

and may not

be present

1

2

3

45

6

7

89

10

11

12

Cable connector end view

(female)

Figure 12 - Baldor motor resolver cable pin configuration

The maximum recommended cable length is 30.5m (100ft).

Page 38

3-24 Basic Installation MN1902

3.7.2 Encoder option - X8

The encoder connections (ABZ channels and Hall signals) are made using the 15-pin D-type

female connector X8. Twisted pair cables must be used for the complementary signal pairs

e.g. CHA+ and CHA-. The overall cable shield (screen) must be connected to the metallic

shell of the D-type connector.

Location

Connector X8, 15-pin D-type female connector

Pin Encoder function

1 CHA+

2 CHB+

3 CHZ+

4 Hall U+

5 Hall U-

6 CHA-

7 CHB-

8 CHZ-

9 Hall W+

10 Hall V+

11 +5V out

12 (NC)

13 DGND

14 Hall W-

15 Hall V-

Description Commutating (UVW) encoder input, non-isolated. Pin 11

provides +5V for encoders requiring power (200mA max)

CHA+

CHA-

CHB+

CHB-

+5V

DGND

1

6

2

7

3

8

11

X8

CHZ+ (INDEX)

CHZ- (INDEX)

4

5

9

14

10

15

13

Hall U+

Hall U-

Hall W+

Hall WHall V+

Hall V-

12 (NC)

Hall

Feedback

Connect overall shield

to connector backshells.

Twisted pai rs

Connect internal

shields to DGND.

Encoder

Feedback

Motor

Figure 13 - Encoder cable connections - rotary motors

1

5

15

6

11

10

Page 39

Basic Installation 3-25MN1902

3.7.2.1 Encoder cable pin configuration - rotary motors

Figure 14 shows the pin configuration for a typical Baldor encoder feedback cable, part

number CBL030SF-KPCEA3.

Signal name

FlexDrive

II

X8 pin

Motor / cable

pin

CHA+ 1 3

CHA- 6 4

CHB+ 2 5

CHB- 7 6

CHZ+ 3 7

CHZ- 8 8

Hall U+ 4 10

Hall U- 5 11

Hall V+ 10 12

Hall V- 15 13

Hall W+ 9 14

Hall W- 14 15

+5V 11 1

DGND 13 2

Motor encoder connector

(male)

Pins 9 and 16

are not

connected

1

2

3

4

5

6

7

8

9

10

11

12

13

1415

16

Cable connector end view

(female)

1

2

3

4

5

6

7

8

9

10

11

12

13

14 15

16

Figure 14 - Baldor rotary motor encoder cable pin configuration

The maximum recommended cable length is 30.5m (100ft).

Page 40

3-26 Basic Installation MN1902

3.7.2.2 Encoder cable connections - linear motors

CHA+

CHA-

CHB+

CHB-

+5V

DGND

1

6

2

7

3

8

11

X8

Encoder

Feedback

CHZ+ (INDEX)

CHZ- (INDEX)

4

5

9

14

10

15

13

Hall U+

Hall U-

Hall W+

Hall WHall V+

Hall V-

12 (NC)

Hall

Feedback

Connect overall shield to

connector backshells.

Twisted pai rs

Connect internal

shields to DGND.

Leave pins

5, 12, 14, 15

unconnected

Motor

Figure 15 - Encoder cable connections - linear motors

3.7.2.3 Encoder cable pin configuration - linear motors

Linear motors use two separate cables (encoder and Hall). The cores of these two cables

must be wired to the appropriate pins of the 15-pin D-type mating connector (supplied):

Signal name

FlexDrive

II

X8 pin

Encoder cable internal wire colors

CHA+ 1

CHA- 6

CHB+ 2

Please refer to MN1800 Linear Motors

CHB- 7

PleaserefertoMN1800

LinearMotor

s

Installation & Operating Manual for details.

CHZ+ 3

CHZ- 8

Baldor Hall cable internal wire colors

Hall U+ 4 White

Hall V+ 10 Red

Hall W+ 9 Black

+5V 11 Brown

Hall GND 13 Green

Page 41

Basic Installation 3-27MN1902

3.7.3 EnDat (absolute encoder) option - X8

The absolute encoder interface supports both incremental and absolute (multi and single turn)

feedback using SinCos technology. It is possible to read and write information to the encoder.

The absolute encoder connections are made using the 15-pin D-type female connector X8.

Twisted pair cables must be used for the complementary signal pairs e.g. SinA+ and SinA-.

The overall cable shield (screen) must be connected to the metallic shell of the D-type

connector.

Location