Page 1

Device Net

Expansion Board

(Baldor Binary Protocol)

Catalog No. EXB013A01

Installation and Operating Manual

8/03 MN1320

Page 2

Table of Contents

Section 1

General Information 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Warranty 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Precautions 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2

Expansion Board Description 2-1. . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3

Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Board Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Controls 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single Expansion Board Installation 3-2. . . . . . . . . . . . . . . . . .

Dual Expansion Board Installation 3-4. . . . . . . . . . . . . . . . . . .

Section 4

Hardware Setup 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch Settings 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Connection 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powerup 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Indicators 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Terminal Strip Connections 4-5. . . . . . . . . . . . . . . . . . . . .

Section 5

Software Setup 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure Control Software for Device Net Mode 5-1. . . . . . . . .

Device Net Configuration 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EXB I/O Instances 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 6

Command Language 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EXB I/O Instances 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transaction Specification 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transaction Specification Table 6-5. . . . . . . . . . . . . . . . . . . . . . . .

5 - Command Mode 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31- Terminal Strip 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36 or 37 - Optionald# 6-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41 - Watchdog Time 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Details 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents i

Page 3

ii Table of Contents

Page 4

Section 1

General Information

Introduction

The Baldor controls represent the latest technology in microprocessor

based motor controls. In addition to the user programmable parameters

available in every control, many different expansion boards are available

from Baldor to further customize the control to most any application.

Expansion boards are categorized by compatibility into two groups:

Group 1 and Group 2, see Table 1-1. A board from either group may be

used alone in a control. If two boards are to be used, one board must

be from Group 1 and the other from Group 2.

Note: Using two Group 1 or two Group 2 boards in the same control is

not allowed.

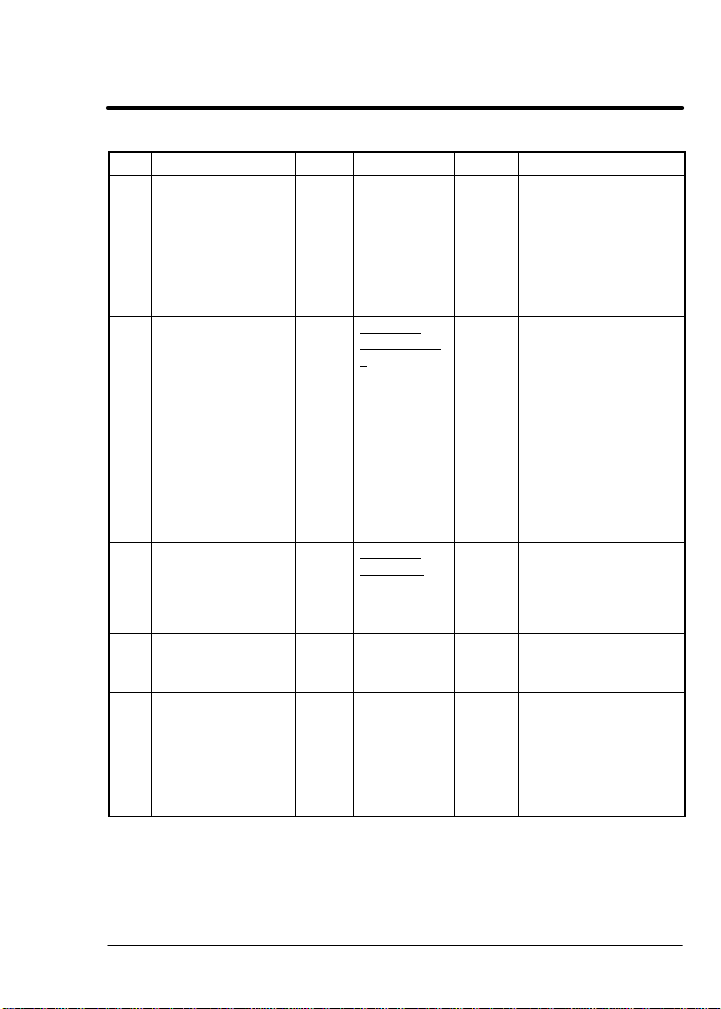

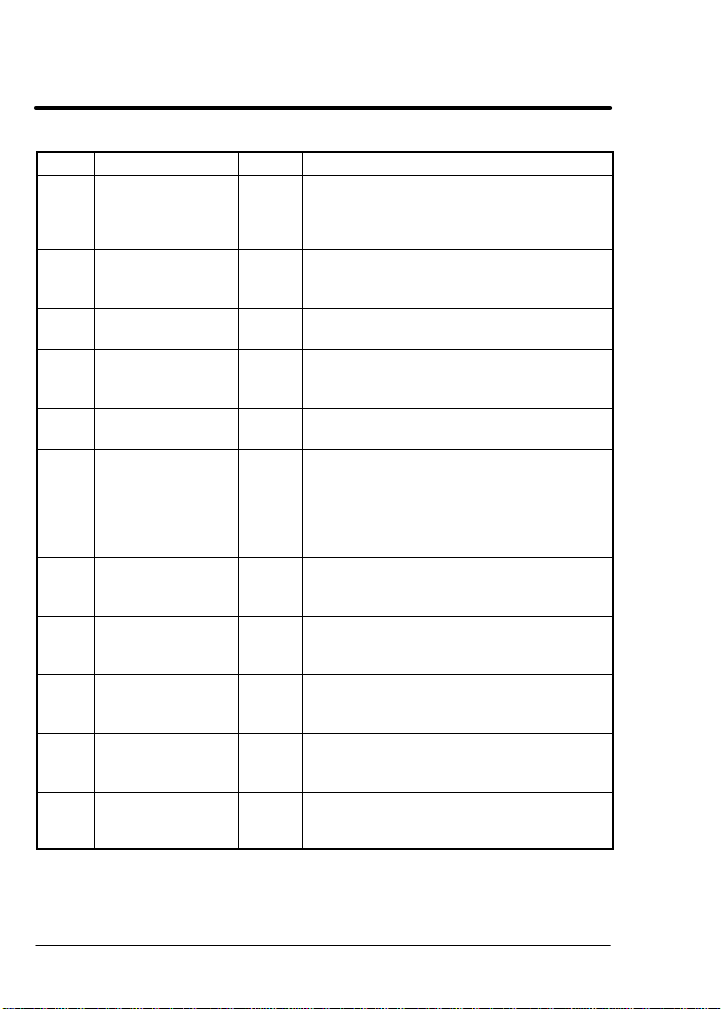

Table 1-1 Group 1 and Group 2 Board Categories

Group 1 Board Name Catalog No. Manual No.

Isolated Input EXB003A0X MN1314

Master Pulse Reference/

Isolated Pulse Follower

DC Tachometer Interface EXB006A0X MN1311

Isolated Encoder EXB008A0X MN1317

Resolver to Digital Interface EXB009A0X MN1313

Group 2 Board Name

RS-232 Serial EXB001A0X MN1310

RS-422/RS-485 Serial EXB002A0X MN1310

RS-232/485 Serial EXB012A0X MN1310

Four Output Relays/3-15 PSI

Pneumatic

High Resolution Analog I/O EXB007A0X MN1316

2 Isolated Analog Output/ 3 Relay

Output

Device Net EXB013A0X MN1320

Profibus EXB014A0X MN1323

Modbus Plus EXB015A0X MN1322

EXB005A0X MN1312

EXB004A0X MN1315

EXB010A0X MN1319

General Information 1-1

Page 5

Limited Warranty

For a period of two (2) years from the date of original purchase,

BALDOR will repair or replace without charge controls and

accessories which our examination proves to be defective in

material or workmanship. This warranty is valid if the unit has not

been tampered with by unauthorized persons, misused, abused, or

improperly installed and has been used in accordance with the

instructions and/or ratings supplied. This warranty is in lieu of any

other warranty or guarantee expressed or implied. BALDOR shall

not be held responsible for any expense (including installation and

removal), inconvenience, or consequential damage, including

injury to any person or property caused by items of our manufacture

or sale. (Some states do not allow exclusion or limitation of

incidental or consequential damages, so the above exclusion may

not apply.) In any event, BALDOR’s total liability, under all

circumstances, shall not exceed the full purchase price of the

control. Claims for purchase price refunds, repairs, or

replacements must be referred to BALDOR with all pertinent data

as to the defect, the date purchased, the task performed by the

control, and the problem encountered. No liability is assumed for

expendable items such as fuses.

Goods may be returned only with written notification including a

BALDOR Return Authorization Number and any return shipments

must be prepaid.

1-2 General Information

Page 6

Safety Notice

This equipment contains voltages that may be as great as 1000 volts!

Electrical shock can cause serious or fatal injury. Only qualified

personnel should attempt the start-up procedure or troubleshoot this

equipment.

This equipment may be connected to other machines that have rotating

parts or parts that are driven by this equipment. Improper use can

cause serious or fatal injury. Only qualified personnel should attempt

the start-up procedure or troubleshoot this equipment.

PRECAUTIONS

WARNING: Do not touch any circuit board, power device or

electrical connection before you first ensure that power has

been disconnected and there is no high voltage present

from this equipment or other equipment to which it is

connected. Electrical shock can cause serious or fatal

injury. Only qualified personnel should attempt the start-up

procedure or troubleshoot this equipment.

WARNING: Be sure that you are completely familiar with the

safe operation of this equipment. This equipment may be

connected to other machines that have rotating parts or

parts that are controlled by this equipment. Improper use

can cause serious or fatal injury. Only qualified personnel

should attempt the start-up procedure or troubleshoot this

equipment.

General Information 1-3

Page 7

WARNING: Be sure the system is properly grounded before

applying power. Do not apply AC power before you ensure

that all grounding instructions have been followed.

Electrical shock can cause serious or fatal injury.

WARNING: Do not remove cover for at least five (5) minutes

after AC power is disconnected to allow capacitors to

discharge. Dangerous voltages are present inside the

equipment. Electrical shock can cause serious or fatal

injury.

WARNING: Improper operation of control may cause violent

motion of the motor shaft and driven equipment. Be certain

that unexpected motor shaft movement will not cause injury

to personnel or damage to equipment. Peak torque of

several times the rated motor torque can occur during

control failure.

WARNING: Motor circuit may have high voltage present

whenever AC power is applied, even when motor is not

rotating. Electrical shock can cause serious or fatal injury.

Caution: To prevent equipment damage, be certain that the

electrical service is not capable of delivering more than the

maximum line short circuit current amperes listed in the

appropriate control manual, 230 VAC, 460 VAC or 575 VAC

maximum per control rating.

1-4 General Information

Page 8

Section 2

Expansion Board Description

Introduction

The Device Net expansion board is a Device Net Group 2 Only Slave

device using the predefined master/slave connection set, as defined by

the ODVA. It is capable of explicit messaging, as well as polled and/or

COS/Cyclic I/O. The interface is based on the Baldor Binary Protocol

(BBP) command set.

Group 2 board

Device Net Communications Expansion Board

Catalog No. EXB013A01

Description 2-1

Page 9

2-2 Description

Page 10

Section 3

Installation

Board Installation

This section describes the Expansion Board installation procedure.

Caution: Before you proceed, be sure to read and become

familiar with the safety precautions at the beginning of this

manual. Do not proceed if you are unsure of the safety

precautions described. If you have any questions, contact

BALDOR before you proceed.

1. Remove the expansion board from the shipping container.

2. Remove all packing material from the board.

Caution: Be sure all packing materials are removed from the

board. Conductive foam may be present on the connectors

to prevent static build up during shipping. This can prevent

proper circuit operation.

If you are installing only one board, refer to the “Single Expansion Board Installation” procedure. If you are installing two expansion boards (or a second board) refer to the “Dual Expansion Board Installation” procedure.

Installation 3-1

Page 11

AC Controls

(For all 15H Inverter, 21H Line Regen Inverter, 18H Vector, 22H Line

Regen Vector and 23H Servo).

Single Expansion Board Installation

Procedure:

1. Be sure drive operation is terminated and secured.

2. Remove all power sources from the control.

3. Wait at least 5 minutes for internal capacitors to discharge.

4. Remove the four (4) Phillips head screws (

control cover. (For A & B size, remove four screws that secure the

cover. On floor mounted G size enclosures, open the enclosure

door).

5. Remove the control cover.

6. Slide the expansion board male connector into the female

connector of the control board. See Figure

7. Securely mount the expansion board to the sheet metal mounting

plate using the #6 screws provided in the installation hardware.

See Figure 3-2.

8. The mechanical installation of the expansion board is now

complete. Refer to Section 4 of this manual and configure the

jumpers as desired. Also complete the wiring before you proceed

to step 9.

9. When complete, install the control cover using the four (4) Phillips

head screws (

1

/4 turn). (For A & B size, install four screws that

secure the cover. On floor mounted G size enclosures, close the

enclosure door).

10. Restore all power sources to the control.

11. Restore drive operation.

1

/4 turn) that secure the

3-1.

3-2 Installation

Page 12

AC Controls

Single Expansion Board Installation (Continued)

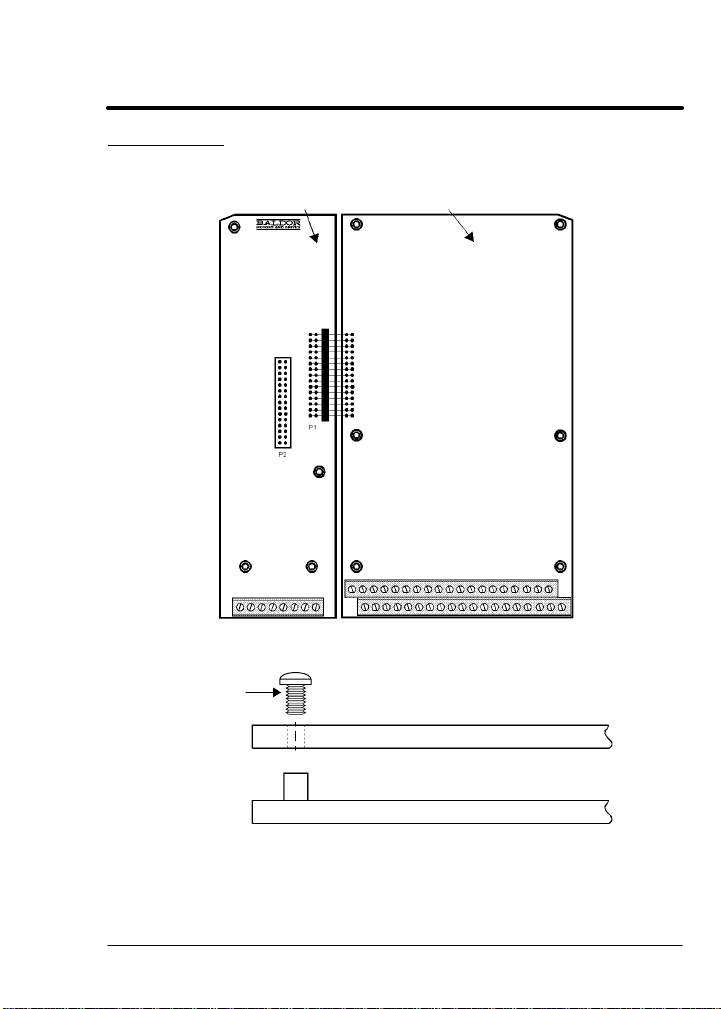

Figure 3-1 Single Expansion Board Installation

Expansion Board Motor Control Board

Terminal tightening torque is 7 lb-in (0.8 Nm) maximum.

Figure 3-2 Single Expansion Board Installation

#6 Screw

Group 1 or 2 Expansion Board

Sheet Metal Mounting Plate

Installation 3-3

Page 13

AC Controls (Continued)

Dual Expansion Board Installation

Procedure:

1. Be sure drive operation is terminated and secured.

2. Remove all power sources from the control.

3. Wait at least 5 minutes for internal capacitors to discharge.

4. Remove the four (4) Phillips head screws (

control cover. (For A & B size, remove four screws that secure the

cover. On floor mounted G size enclosures, open the enclosure

door).

5. Remove the control cover.

6. Slide the Group 1 expansion board male connector into the female

connector of the control board. See Figure 3-1.

7. Securely mount the Group 1 expansion board to the sheet metal

mounting plate using the short standoffs provided in the installation

hardware. See Figure 3-3.

8. The mechanical installation of the expansion board is now

complete. Refer to the manual for the Group 1 board and configure

the jumpers as desired. Also complete the wiring before you

proceed to step 9.

9. Install the Group 2 board on top of the previously installed Group 1

board by plugging the female connector onto the male connector of

the Group 1 board as shown in Figure 3-3.

10. Secure this Group 2 board to the Group 1 board using the #6

screws provided. See Figure 3-3.

11. The mechanical installation of the expansion board is now

complete. Refer to the manual for the Group 2 board and configure

any jumpers and switches as desired. Also complete the wiring for

this board before you install or close the cover.

1

/4 turn) that secure the

3-4 Installation

Page 14

AC Controls

Dual Expansion Board Installation (Continued)

12. When complete, install the control cover using the four (4) Phillips

head screws (

secure the cover. On floor mounted G size enclosures, close the

enclosure door).

13. Restore all power sources to the control.

14. Restore drive operation.

1

/4 turn). (For A & B size, install four screws that

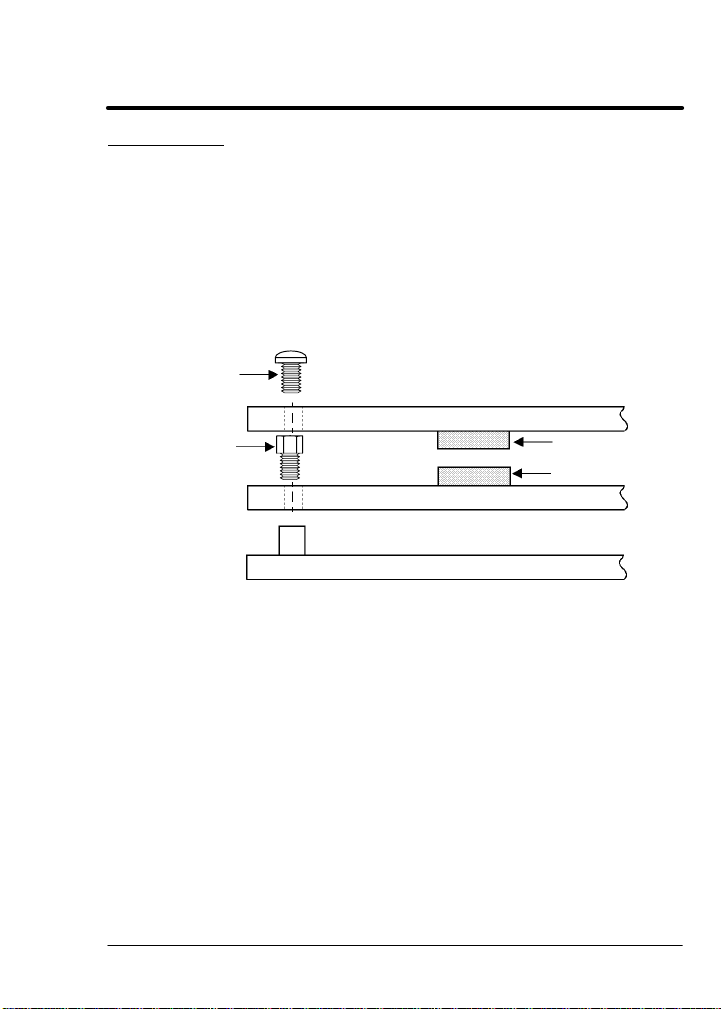

#6 Screw

Short

Aluminum

Standoff

Figure 3-3 Dual Expansion Board Installation

Group 2 Expansion Board

Female Connector

Male Connector

Group 1 Expansion Board

Control Board Mounting Plate

Installation 3-5

Page 15

3-6 Installation

Page 16

Section 4

Hardware Setup

DIP Switch Settings

This procedure will configure the Device Net Expansion Board for

communication with a computer or terminal. Reference Figure 4-1 and

Table 4-1 for the following procedure.

1. Set DIP switches 1 and 2 for the desired baud rate.

2. Set switches 3 through 8 for the ID number desired.

3. Install the Device Net expansion board in the Series H control as

instructed in Section 3 of this manual.

Note: The switch settings can be changed after the board is powered

up. However, switch changes will not take effect until the board

is reset (by pushing PB1 or by turning power off then on).

Cable Connection

1. Connect the Device Net wires to the 5 pin connector provided with

the expansion board as shown in Figure 4-1.

Note: The Device Net bus must provide 24VDC power to the

expansion board.

2. If a terminator is required, connect a 120 ohm terminating resistor

across pins 2 and 4 of the modular connector (CAN– and CAN+).

Powerup

When the Device Net expansion board is powered up it will perform the

following:

1. Perform a self test.

2. Check the switch settings for configuration information.

3. Verify communications with the Series H control board.

4. Check for power on the Device Net bus.

5. Perform a Duplicate MAC ID check to determine if any other

devices on the network have the same MAC ID number.

6. Go online.

After powerup, both LED’s should be GREEN.

Refer to the LED Indicators description in this section of the manual.

Hardware Setup 4-1

Page 17

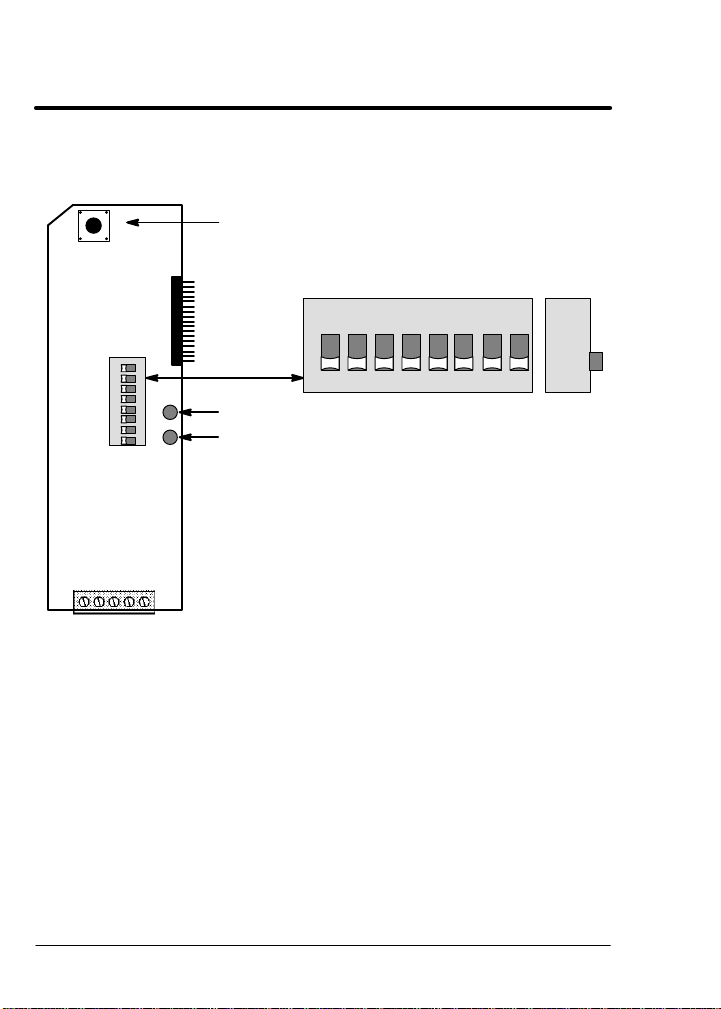

Figure 4-1 Board Configuration

Device Net Expansion Board Catalog No. EXB013A01

P3

12345

V–

(Black)

PB1

12345678

S1

CAN_–

Shield

Shield

CAN_–

(Blue)

(Bare)

ON

MS NS

V+V–CAN_+

V+

CAN_+

(Red)

(White)

Reset switch

All switches shown in OFF position.

ON

12345678

Module Status LED

Network Status LED

Side

View

4-2 Hardware Setup

Page 18

Table 4-1 Switch Settings

Description

125kBPS OFF OFF

250kBPS OFF ON

500kBPS ON OFF

MAC ID 0 OFF OFF OFF OFF OFF OFF

MAC ID 1 OFF OFF OFF OFF OFF ON

MAC ID 2 OFF OFF OFF OFF ON OFF

MAC ID 3 OFF OFF OFF OFF ON ON

MAC ID 4 OFF OFF OFF ON OFF OFF

MAC ID 5 OFF OFF OFF ON OFF ON

MAC ID 6 OFF OFF OFF ON ON OFF

MAC ID 7 OFF OFF OFF ON ON ON

MAC ID 8 OFF OFF ON OFF OFF OFF

MAC ID 9 OFF OFF ON OFF OFF ON

MAC ID 10 OFF OFF ON OFF ON OFF

MAC ID 11 OFF OFF ON OFF ON ON

MAC ID 12 OFF OFF ON ON OFF OFF

MAC ID 13 OFF OFF ON ON OFF ON

MAC ID 14 OFF OFF ON ON ON OFF

MAC ID 15 OFF OFF ON ON ON ON

MAC ID 16 OFF ON OFF OFF OFF OFF

MAC ID 17 OFF ON OFF OFF OFF ON

MAC ID 18 OFF ON OFF OFF ON OFF

MAC ID 19 OFF ON OFF OFF ON ON

MAC ID 20 OFF ON OFF ON OFF OFF

MAC ID 21 OFF ON OFF ON OFF ON

MAC ID 22 OFF ON OFF ON ON OFF

MAC ID 23 OFF ON OFF ON ON ON

MAC ID 24 OFF ON ON OFF OFF OFF

MAC ID 25 OFF ON ON OFF OFF ON

MAC ID 26 OFF ON ON OFF ON OFF

MAC ID 27 OFF ON ON OFF ON ON

MAC ID 28 OFF ON ON ON OFF OFF

MAC ID 29 OFF ON ON ON OFF ON

MAC ID 30 OFF ON ON ON ON OFF

MAC ID 31 OFF ON ON ON ON ON

MAC ID 32 ON OFF OFF OFF OFF OFF

. . . . . . . . . . . . . . . . . . . . . . . . . . .

MAC ID 63 ON ON ON ON ON ON

1 2 3 4 5 6 7 8

Switch Number

Hardware Setup 4-3

Page 19

LED Indicators

Two LED’s are located on the Device net expansion board.

MS - Module Status LED

Displays the operational status of the Device Net Interface expansion

board (EXB). Status is summarized in Table 4-2.

Table 4-2

LED State Status Description

OFF No power is applied to the EXB.

Green The EXB is operating in a normal condition.

Flashing

Green

Red The EXB has an unrecoverable fault and may need to be

Flashing

Red

Flashing

Red-Green

NS - Network Status LED

Displays the status of the connection to the Device Net network. Status

is summarized in Table 4-3.

LED State Status Description

OFF The EXB is not Online or has lost power.

Green The EXB is Online and operating. Link OK, Online, Connected.

Flashing

Green

Red Failed communications tests. EXB detected errors that prevent

Flashing

Red

Flashing

Red-Green

The EXB is in standby mode. The EXB may be attempting to

communicate with the Series H control. Be sure the Series H

control is in RS485BBP mode.

replaced.

The EXB has had a recoverable fault. This may be an invalid

DIP switch setting or the lost Bus Power (Device Net cable

disconnected).

The EXB is in a self test mode.

Table 4-3

EXB is Online but no connection is established. EXB passed

the DUP_MAC_ID test, Online, but has no connections to other

nodes.

it from communicating on the network. Duplicate MAC ID,

Bus-Off.

One or more I/O connections have timed out. Connection timed

out.

The EXB is in a self test mode.

4-4 Hardware Setup

Page 20

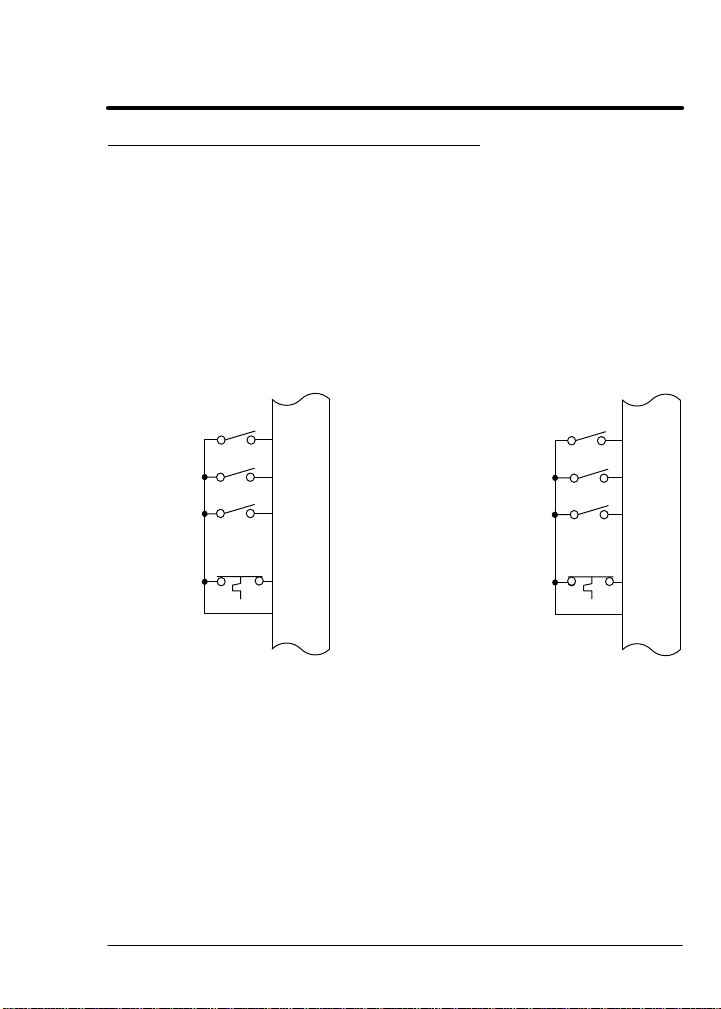

Control Terminal Strip Connections

For Serial Mode operation, the Input/Output terminal strip of the control

(J1 of the Vector and DC controls and J4 of the Inverters) is wired as

shown in Figure 4-2. Connect the Enable, Forward Enable Switch,

Reverse Enable Switch, External Trip and Opto Common connections

as shown.

Note: All opto-isolated outputs and analog outputs remain active while

operating in the Serial Mode.

When these connections are complete, refer to Section 5 of this manual

and set the software for Serial Mode.

Figure 4-2 Serial Opto Input Connections

J1*

J4**

Enable

Forward

Enable

Reverse

Enable

External

Trip

Common

8

9

10

16

17

* Series 18H, 22H and 23H controls.

** Series 15H and 21H controls.

Enable

Forward

Enable

Reverse

Enable

External

Trip

Common

Hardware Setup 4-5

8

9

10

16

17

Page 21

4-6 Hardware Setup

Page 22

Section 5

Software Setup

Configure Control Software for Device Net Mode

The Series H control operating mode must be set to Serial to use the

Device Net expansion board. There is no selection for Device Net on

the Level 1 Input block Operating mode parameter list. However,

selecting Serial with the Device Net expansion board installed will allow

operation of the Device Net board.

Many commands in the Command Language can be used regardless of

the setting of the control’s Operating Mode parameter (such as

changing and viewing parameters). However, commands intended to

control the motor shaft require the control be in the Serial (Device Net)

Mode.

Note: The firmware version of the Series H control must support the

Baldor Binary Protocol (BBP). To confirm that BBP is supported,

perform the following:

Scroll to the Level 2 Communications block, and view the

selections. If RS485BBP is available, the software version is

compatible with the Device Net expansion board. Otherwise,

contact Baldor to obtain a software update.

During power up, the control checks if the communication board

is installed. If an RS485 board is installed, the RS485BBP

protocol is automatically selected during power up.

Software Setup 5-1

Page 23

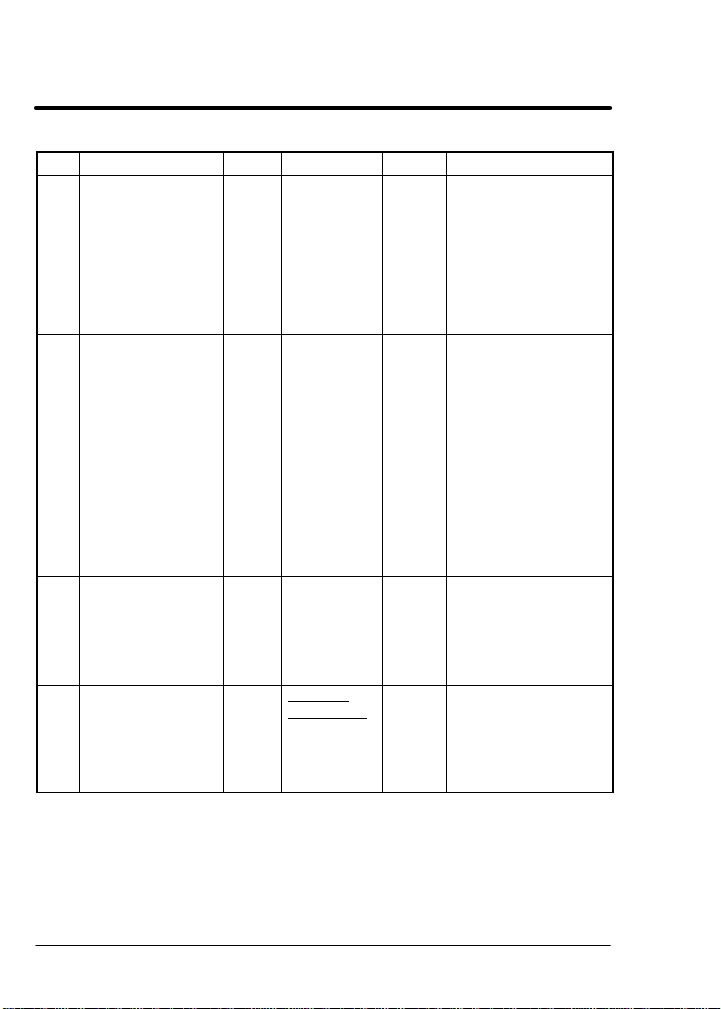

Action Description Display Comments

Apply

Power

Display illuminates

BALDOR

MOTORS & DRIVES

Logo is

displayed for 5

seconds.

If no fault is found and

control is programmed for

STP MOTOR SPEED

LOCAL 0RPM

Display mode.

local mode,OR,

If no fault is found and

control is programmed for

STP MOTOR SPEED

REMOTE 0RPM

Display mode.

remote mode

Press

PROG key

Access programming mode.

PRESS ENTER FOR

PRESET SPEEDS

First screen in

programming

mode

Press Y

or B key

Press

Enter key

Press

Enter key

Press Y

or B key

Press

Enter key

Press Y

key

Press

Enter key

Press Y

or B key

Press

Enter key

Scroll to Level 1 Input block

First selection choice

Flashing cursor indicates

mode can be changed

Scroll to Serial mode

Saves mode change value

Scroll to Command Select

parameter

Flashing cursor indicates

mode can be changed

Scroll to Serial mode

Saves change to serial

command select

PRESS ENTER FOR

INPUT

OPERATING MODE

P: KEYPAD

OPERATING MODE

OPERATING MODE

OPERATING MODE

P: SERIAL

COMMAND SELECT

P: +/–10VOLTS

COMMAND SELECT

COMMAND SELECT

COMMAND SELECT

P: SERIAL

KEYPAD

SERIAL

+/–10VOLTS

SERIAL

Input Block.

Now in keypad

mode.

Change to

Serial mode.

Now in ±10 Volt

input mode.

Change to

Serial mode.

Control is now

in Serial mode.

Note: The 15H control does not have a Command Select “Serial”,

this is not needed for this control.

5-2 Software Setup

Page 24

Action Description Display Comments

Press Y

or B key

Press

ENTER

Scroll to Level 2 blocks

Select Level 2 blocks.

PRESS ENTER FOR

LEVEL 2 BLOCKS

PRESS ENTER FOR

OUTPUT LIMITS

First screen in

Level 2 block

key

Press Y

or B key

Press

ENTER

Scroll to Communications

block

Select Level 2

Communications block.

PRESS ENTER FOR

COMMUNICATIONS

PROTOCOL

p: RS232 ASCII

key

Press

Enter key

Press Y

or B key

Press

ENTER

Flashing cursor indicates

mode can be changed

Scroll to RS 485 BBP

(Baldor Binary Protocol)

Select RS 485 BBP mode.

PROTOCOL

RS232ASCII

PROTOCOL

RS485BBP

PROTOCOL

p: RS485BBP

key

Press Y

or B key

Press

DISP key

Press

LOCAL

key

Scroll to Exit Menu

Returns to Display mode.

Changes to Serial

Operation.

PRESS ENTER FOR

MENU EXIT

STP MOTOR SPEED

LOCAL 0RPM

STP MOTOR SPEED

SERIAL 0RPM

Display mode.

Ready for

device net

operation.

The control is now configured for Device Net mode and the Host

software can now be setup.

Software Setup 5-3

Page 25

Device Net Configuration

The Device Net expansion board is a Device Net Group 2 Only Slave

device using the predefined master/slave connection set, as defined by

the ODVA. It is capable of explicit messaging, as well as polled and/or

COS/Cyclic I/O. The interface is based on the Baldor Binary Protocol

(BBP) command set.

This EDS file (Electronic Data Sheets) is used by Device Net equipment

to communicate with the BBP of the Baldor Device Net expansion

board. The Baldor EDS file is provided on a diskette that is shipped with

the expansion board. A Device Net configuration tool, such as

Allen-Bradley “Device Net Manager” software should be used to

configure the Device Net expansion board. The EDS file is also

available on the Baldor World Wide WEB page (www.baldor.com).

EXB I/O Instances

The input and output assembly instances are predefined I/O data

formats that can be selected based on your application. If an I/O

connection is being used, the selected I/O assembly instance

determines the size and format of the data. Only one input instance and

one output instance can be selected. The Input and Output instances

should be set using a Device Net configuration tool prior to connection

to a host device.

Note: Instances 105 and 155 are factory preset. These instances must

be properly set for your application.

Elements of an I/O instance can be 1 to 32 bits in length and can

reference any of the Baldor Binary Protocol (BBP) transactions

supported by the Device Net expansion board (see Section 6 of

this manual). Each assembly instance can contain no more than

8 bytes.

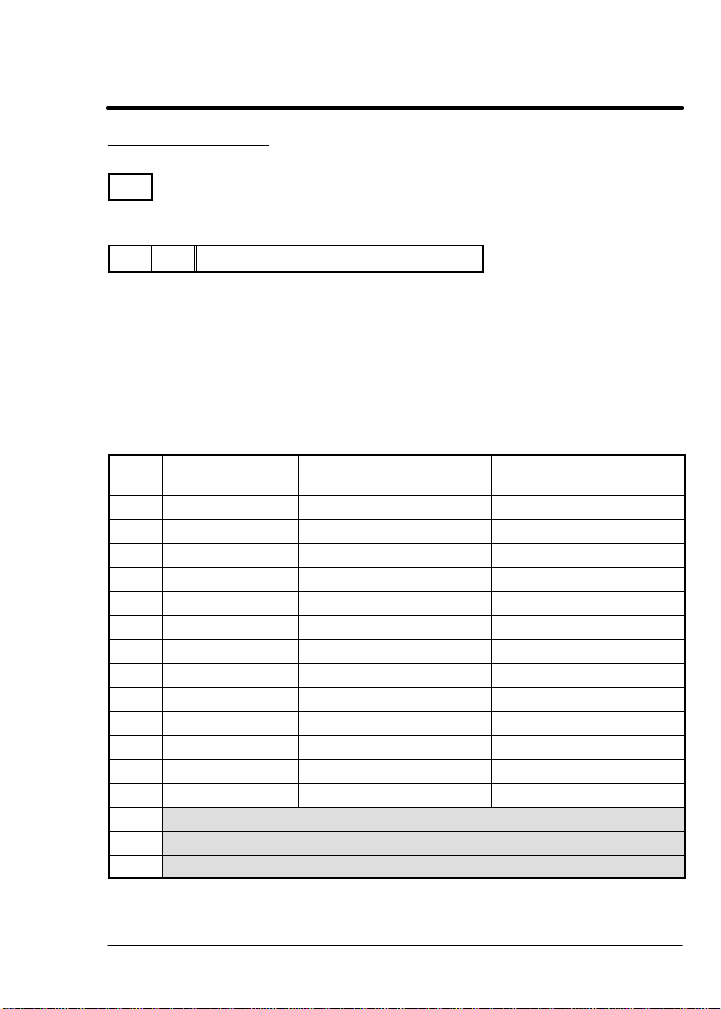

Tables 5-1 and 5-2 defines the format of the Input and Output Assembly

Instances.

5-4 Software Setup

Page 26

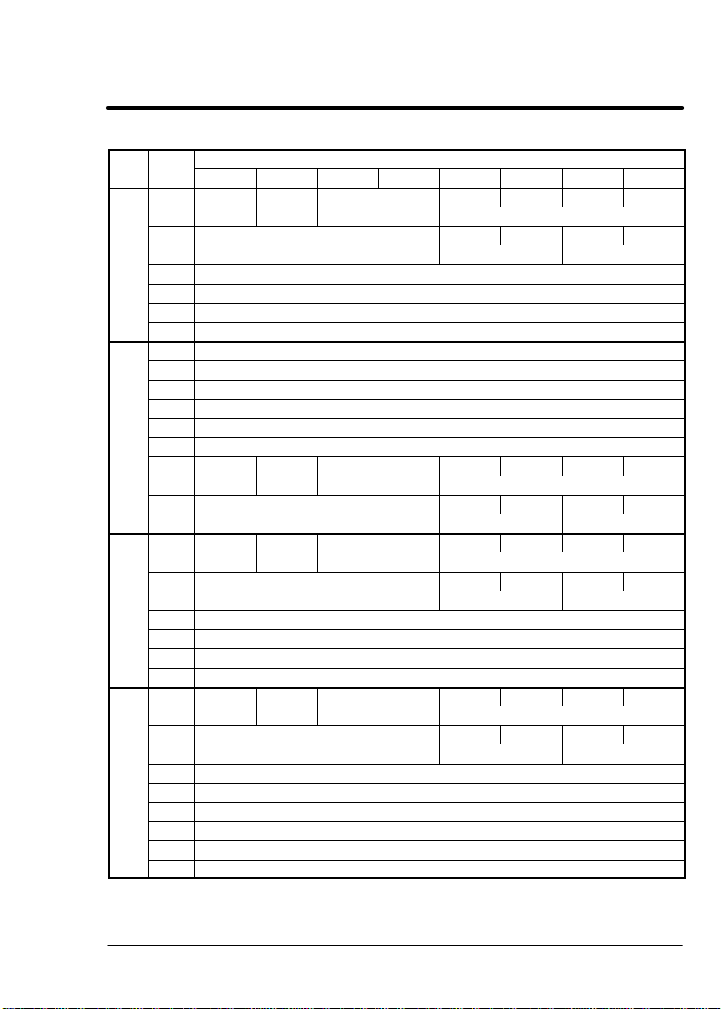

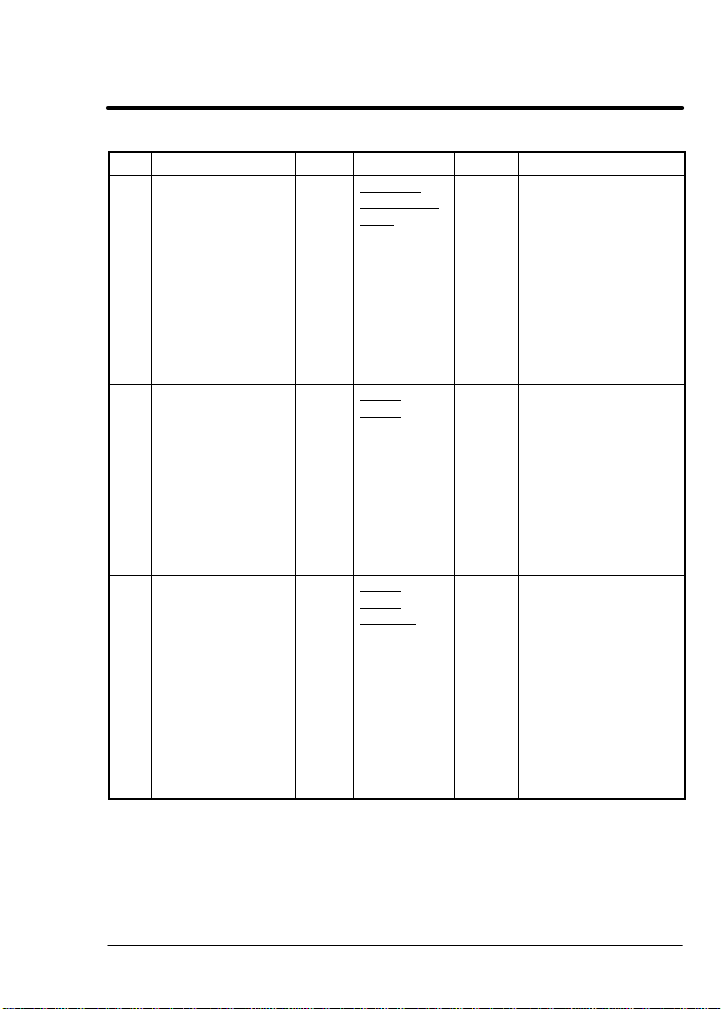

# Byte

151

152

Table 5-1 Format of Input Assembly Instances

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0

1

ControlState Warning Output1 Output2 Output3 Output4

T#4 T#27 TerminalStrip T#31

CommandMode network remote rev fwd

2

3

4

5

0

1

2

3

ZeroSpd AtSpeed Input 4 Input 5 Input 6 Input 7 Input 8 Input 9

4

T#25 T#26 TerminalStrip T#31

5

MotorDir ControlState Output1 Output2 Output3 Output4

6

T#24 T#4 TerminalStrip T#31

7

CommandMode network remote rev fwd

Instance Byte Format

T#5 CtrlSourceT#3 RunCMDT#1

SpeedActual T#18 (Low Byte)

SpeedActual T#18 (High Byte)

CurrentActual T#17 (Low Byte)

CurrentActual T#17 (High Byte)

SpeedActual T#18 (Low Byte)

SpeedActual T#18 (High Byte)

CurrentActual T#17 (Low Byte)

CurrentActual T#17 (High Byte)

FaultStatus T#45

T#5 CtrlSourceT#3 RunCMDT#1

Software Setup 5-5

Page 27

# Byte

153

154

Table 5-1 Format of Input Assembly Instances Continued

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0

1

2

3

4

5

0

1

2

3

4 Position T#15 (Low Word/Low Byte)

5 Position T#15 (Low Word/High Byte)

6 Position T#15 (High Word/Low Byte)

7 Position T#15 (High Word/High Byte)

ControlState

T#4 T#27 TerminalStrip T#31

CommandMode network remote rev fwd

Input6 Input7 Input8 Input9 Output1 Output2 Output3 Output4

CommandMode network remote rev fwd

Instance Byte Format

Warning

Output1 Output2 Output3 Output4

T#5 CtrlSourceT#3 RunCMDT#1

FreqActual T#19 (Low Byte)

CurrentActual T#17 (Low Byte)

CurrentActual T#17 (High Byte)

TerminalStrip T#31

T#5 CtrlSourceT#3 RunCMDT#1

SpeedActual T#18 (Low Byte)

SpeedActual T#18 (High Byte)

Note: For Table 5-2, use instance 103 for 15H and 21H controls (speed

is sent in Hertz). Use other instances for 18H, 22H and 23H

(speed is sent in RPM).

5-6 Software Setup

Page 28

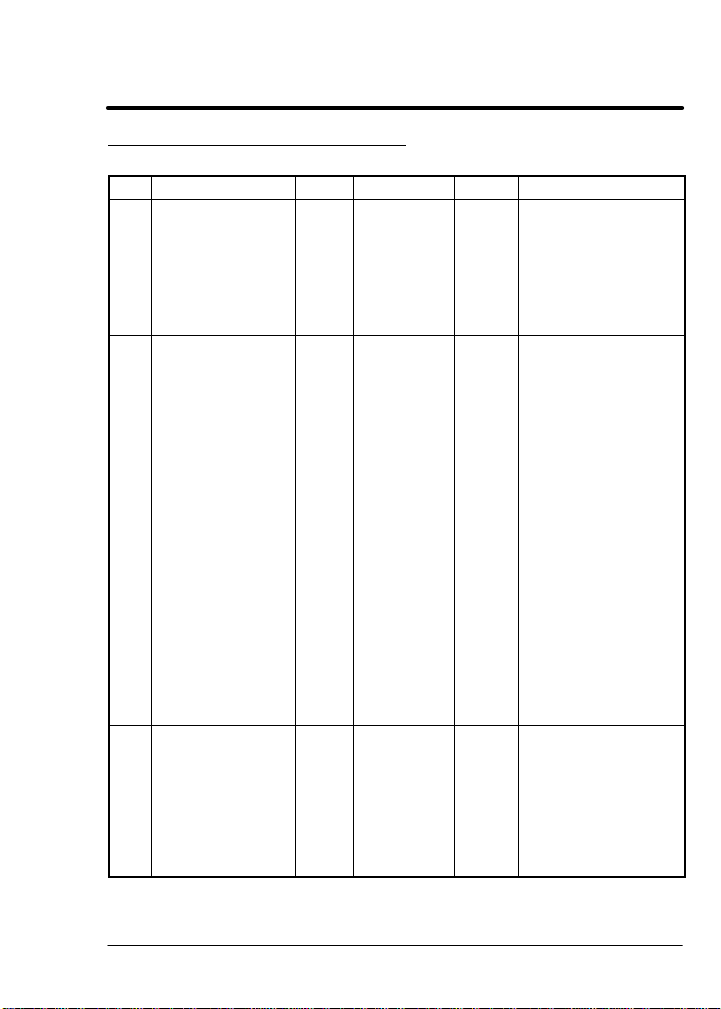

Table 5-2 Format of Output Assembly Instances

# Byte

101

102

103

104

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

FaultRst RunInhibit TableSelect Output1 Output2 Output3 Output4

0

T#46 T#2 T#39 T#75

1

2 (RPM) SpeedRef T#7 (Low Byte)

3 (RPM) SpeedRef T#7 (High Byte)

4 TorqueRef T#9 (Low Byte)

5 TorqueRef T#9 (High Byte)

0 SpeedRef T#7 or PositionSpeed T#13 Low Byte

1 SpeedRef T#7 or PositionSpeed T#13 High Byte

2 TorqueRef T#9 or TorqueRef T#12 Low Word, Low Byte

3 TorqueRef T#9 or TorqueRef T#12 Low Word, High Byte

4 TorqueRef T#9 or TorqueRef T#12 High Word, Low Byte

5 TorqueRef T#9 or TorqueRef T#12 High Word, High Byte

FaultRst ZeroPos AccDecGroup Output1 Output2 Output3 Output4

6

T#46 T#12 T#40 T#75

7

FaultRst RunInhibit TableSelect Output1 Output2 Output3 Output4

0

T#46 T#2 T#39 T#75

1

2 (0.1Hz) HzSpeedRef T#6 (Low Byte)

3 (0.1Hz) HzSpeedRef T#6 (High Byte)

4 TorqueRef T#9 (Low Byte)

5 TorqueRef T#9 (High Byte)

FaultRst ZeroPos TableSelect Output1 Output2 Output3 Output4

0

T#46 T#12 T#39 T#75

1

2 PositionSpeed T#13 (Low Byte)

3 PositionSpeed T#13 (High Byte)

4 PositionRef T#12 (Low Word/Low Byte)

5 PositionRef T#12 (Low Word/High Byte)

6 PositionRef T#12 (High Word/Low Byte)

7 PositionRef T#12 (High Word/High Byte)

CommandMode network remote rev fwd

T#5 CtrlSourceT#3 RunCMDT#1

CommandMode network remote rev fwd

T#5 CtrlSourceT#3 RunCMDT#1

CommandMode network remote rev fwd

T#5 CtrlSourceT#3 RunCMDT#1

CommandMode network remote rev fwd

T#5 CtrlSourceT#3 RunCMDT#1

Instance Byte Format

See notes on next page.

Software Setup 5-7

Page 29

Notes:

Used with CommandMode (T#5). These bytes represent the variables

SpeedRef (T#7), or Position SpeedRef (T#13).

Used with CommandMode (T#5). These bytes represent the variables

TorqueRef or PositionRef. PositionRef requires 4 bytes. TorqueRef

requires 2 bytes (Low Word).

TableSelect is not implemented at this time.

When a PLC updates memory in the middle of a double integer write of

PositionRef, a problem may occur. If the first integer is written and the

PLC updates the memory of a networked device, the position information

is wrong (second integer is missing). To avoid this problem, be sure the

CommandMode (T#5) is not set to PositionCmd until after both integers

are written.

Torque and Position commands are not implemented for the Series 15H

Control.

5-8 Software Setup

Page 30

Section 6

Command Language

Transaction Specification

This section contains a detailed list of the transactions currently

supported by the protocol. The list includes the transaction

number, name, type description, and a detailed specification of

the required and returned data.

Note: Some transactions are not supported by all control types.

Also some controls require variations in commanded data.

Where these exceptions exist, they will be identified in the

text.

How To Read The Transaction Specification

The transaction table provides quick access to relevant

information about each transaction. When necessary a

transaction will be explained in more detail in the sections that

follow.

Transaction Number (T#)

The transaction number is the identification of the command. As

mentioned in Section 3, the maximum number of transactions is

256 (250 – 255 are reserved for future use.)

Command Language 6-1

Page 31

Name

The ‘Name’ field refers to a ‘C’ style variable for function names

associated with the transaction. Use of these names is not

necessary to interface with the transaction. These names may

be used in present and future software drivers and libraries

provided by Baldor. When used in conjunction with Baldor

software tools, the transaction name is case sensitive.

Type

There are three basic transaction types: Set, Get, and those

which do both: Set/Get.

S ‘Set’ transactions are used to change internal values, or

execute one–time (nonmodal) commands. As a general rule

most ‘set’ transactions pass data to the control, but do not

return any. Most execution ‘set’ commands do not pass or

return data.

S ‘Get’ transactions are used to retrieve internal values or

control conditions. Most ‘get’ transactions return data but do

not pass data.

S ‘Set/Get’ transactions do both functions. Usually these

transaction always return data, but only accept or pass data

when a ‘set’ or change function is occurring. When no data is

passed, the ‘Set/Get’ functions as a ‘Get’ or read–only

transaction.

When a transaction does not fit these general rules, both passed

and returned data fields will be clearly specified.

6-2 Command Language

Page 32

Data Field

The Data Field defines the data transfer requirements of the

application layer message. This field describes the data using

the ‘data type’ defined in Section 2.l. Commas separate

individual elements of data.

As previously discussed in Section 3, there are two types of

application layer packets–. Command and Response.

Command packets ALWAYS contain a transaction number

(USINT). Response packets ALWAYS contain a transaction

number (USINT) and a status (USINT). The transaction

specification is only concerned with the data field portion of these

messages. The transaction number and status are assumed to

be present, and are not shown in the specification.

In transactions that fit the basic Set, Get, and Set/Get definitions,

only a single data field is described in the specification. In these

cases it is assumed that a ‘Set’ transaction has only Command

packet data. A ‘Get’ has only Response packet data. And a

‘Set/Get’ has the same data in the Command and Response

packet, unless it is being used to ‘Get’ only, in which case there

is no Command data.

Transactions are not required to conform to these basic rules.

When such exceptions exist, both their Command and Response

data fields will be described in detail. The command data field is

preceded by a C:, the response data field is preceded by a R: for

identification purposes only.

In some cases variable names are given in the data field

specification. These names are used to describe multiple

elements of a common data type. These names are not required

for use, but may be included in present and future software

drivers and libraries provided by Baldor. (When used with tools

provided by Baldor, variable names are case sensitive.)

Command Language 6-3

Page 33

Class

The class field indicates the product classes that support the

transaction. The product codes are as follows:

E = Encoderless Vector

I = Inverter

S = Servo

V = Vector

V* = Vector with custom software for positioning

Description

The description field gives information regarding the use of the

transaction. When possible the data range, scale, units, etc. are

also given. When it is not possible to fully describe the

transaction in the table, or when other information such as a

state diagram or event matrix must be given, further information

will be included in sections following the transaction table. An

asterisk is used to indicate default power up values where

applicable.

6-4 Command Language

Page 34

Transaction Specification Table

Table 6-1 Transaction Specification Table

T# Name Type Data Field Class Description

0 Null Set None All No action.

1 RunCmd Set/

2 RunInhibit Set/

USINT All Network run / stop

Get

BOOL All Commands a stop

Get

This can be used to

reset the watchdog

timer, or as a

placeholder in

conjunction with a

global Execute

Buffer transaction.

command. Get 0 =

Stop (refer to stop

mode parameter)

1 = Fwd

2 = Rev

3 = Bipolar Run *

Actual motor

direction is returned

in Motor Direction. In

fwd or rev, only the

absolute value of the

command

references (speed,

torque) are used. In

bipolar run, the

signed reference

values control the

direction. These

commands are only

valid when

CtrlSource = 2

(control from

network)

regardless of the

command source

(Local Keypad,

Remote terminal

strip, control from

network.)

1 = Stop, 0 = No

action*

* Indicates initial powerup value.

Command Language 6-5

Page 35

Table 6-1 Transaction Specification Table Continued

T# Name Type Data Field Class Description

3 CtrlSource Set USINT All 0 = Keypad (local)

4 ControlState Get USINT E,V,S 0 = Not Ready (no

5 CommandMode Set/

USINT All Command Mode

Get

1 = Terminal strip

(remote)

2 = Control from

network

main power)

1 = Ready (disabled)

2 = Enabled

3 = Stopping

4 = Fault exists

0 = None (Disabled) *

1 = Torque CMD

selected

source

2 = Torque CMD

network

3 = Speed CMD

selected

source

4 = Speed CMD

network

5 = Orient

6 = Position CMD ABS

7 = Position CMD INC

9 = Position CMD

external

10 = Home

11 = Process Torque

12 = Process Speed

13 = Auto Tune

Refer to the command

mode section for

complete operational

description.

* Indicates initial powerup value.

6-6 Command Language

Page 36

Table 6-1 Transaction Specification Table Continued

T# Name Type Data Field Class Description

6 HzSpeedRef Set/

7 SpeedRef Set/

8 SpeedRefHigh Set/

9 TorqueRef Set/

12 PositionRef Set/

13 PositionSpeed Set/

15 Position Set/

INT

Get

INT

INT

Get

INT

DINT E,S,V Speed reference

Get

INT S,V Torque reference

Get

DINT S, V* Position Reference

Get

INT S, V* Positioning Speed

Get

DINT S, V* Position counter

Get

I,

All

E,V,S,

All

Hertz Speed

Reference.

Set Units: 0.1 Hz

(one decimal place)

Speed reference

Units: RPM

(Standard Get

Resolution)

(High Resolution)

Units: 1/256 RPM .

The middle 16 bits

mirror SpeedRef.

Not supported by all

product classes.

(Current)

Scaling: ±15bit

(32767) =

programmed current

limit.

Scaling = quadrature

counts (4 x

feedback counts per

rev.)

Reference

Max speed used for

positioning

commands. Also

referred to as feed

rate or target

velocity.

Units: RPM

Scaling = quadrature

V* = Vector with custom software for positioning

Command Language 6-7

Page 37

Table 6-1 Transaction Specification Table Continued

T# Name Type Data Field Class Description

17 CurrentActual Get INT E,I,S,VActual motor phase

18 SpeedActual Get INT All Actual motor speed

19 FrequencyActual Get INT E,I,S,VActual motor

20 PowerActual Get INT E,V,S Actual output power

21 InputVoltage Get INT E,V,S Input line voltage

22 OutputVoltage Get INT E,V,S Motor phase voltage

24 MotorDirection Get BOOL E,V,S 0 = Fwd

25 ZeroSpeed Get BOOL E,S,V 1 = At zero

26 AtSpeed Get BOOL E,V,S 1 = At commanded

27 Warning Get BOOL E,V,S 1 = Warning

current

Units: 100mA RMS

Note: calculated on

inverter.

(absolute value.)

(Approximated in

some products.)

Units: RPM

frequency Units: 0.1

Hz (one decimal

place)

Units: Watts

Units: Volts RMS

(commanded)

Units: Volts RMS

1 = Rev

Actual in position

feedback products,

commanded in

others.

0 = Not at zero

speed

0 = Not at speed

0 = No warnings

present

* Indicates initial powerup value.

6-8 Command Language

Page 38

Table 6-1 Transaction Specification Table Continued

T# Name Type Data Field Class Description

28 AtPosition Get BOOL S,V 1 = At position

29 AtSetpoint Get BOOL E,V,S 1 = At setpoint

30 AtSetSpeed Get BOOL E,V,S 1 = At set speed

31 TerminalStrip Get WORD All Digital I/O status

32 SoftwareVersion Get STRING E,V,S Control software

33 SoftwareRevision Get UINT All Control software

34 ProductSeries Get UINT All Product series for

35 ProductClass Get USINT All 0 = D

36 Optionld1 Get USINT E,V,S Option ID1 (see

37 Optionld2 Get USINT E,V,S Option ID2 (see

0 = Not at position

0 = Not at setpoint

0 = Not at set speed

word. Refer to Table

6-3 for description.

version (16

characters

maximum.)

revision number. For

example S15–4.03 is

returned as 403.

Note: for custom

software revisions,

only the core

(standard) revision is

returned.

example a Series

15H returns: 15.

1 = DP

2 = E

3 = I

4 = S

5 = V

table 6-4)

0 = Not installed

table 6-4)

0 = Not installed

* Indicates initial powerup value.

Command Language 6-9

Page 39

Table 6-1 Transaction Specification Table Continued

T# Name Type Data Field Class Description

38 RunTime Get UDINT E,V,S Total time power has

39 TableSelect Get/

40 AccDecGroup Get/

41 WatchdogTime Get/

45 FaultStatus Get USINT All Request current fault

USINT E,S,V Parameter table

Set

USINT E,V,S Accel / decel group

Set

UINT All Network watchdog

Set

been applied. Units:

seconds.

select

Range 0 – 3

Note: DDC only

supports 2 tables.

Can only be

changed when under

network control

select

Range 1 – 2 Can

only be changed

when under network

control.

timer Get Units:

10mS

0 = disable

2= 20mS minimum

6000= 60S

maximum

Note: resolution

varies among

product classes.

condition

0 = No fault

1–xx = Current fault

code (See H Series

– Fault Message

Description table at

the end of this

section for

description.)

* Indicates initial powerup value.

6-10 Command Language

Page 40

Table 6-1 Transaction Specification Table Continued

T# Name Type Data Field Class Description

46 FaultRst Set BOOL All 1 = Execute fault

47 FaultLog Get C: USINT

FaultLogInde

x

R: UINT

FaultCode,

UDINT

TimeStamp

48 FaultCodeText Get C: USINT

FaultCode

R: STRING

FaultText

49 ForceFault Set BOOL All 0->1 =Force Network

50 SecurityStatus Get USINT All Requests network

reset

0 = No action

Clears any active

fault condition.

Operation resumes

at previous

command.

All Requests the

FaultCode and

TimeStamp for the

given index. The

fault log holds the

last 31 fault

conditions (1 being

most recent) The log

will return a 0 for the

code and time stamp

if the specified index

is empty. Time

stamp is in seconds.

All Returns the text

string associated

with the FaultCode.

16 characters

maximum.

Fault

0 = No action

security status.

0 = Security disabled

1 = Security

unlocked

2 = Security locked

* Indicates initial powerup value.

Command Language 6-11

Page 41

Table 6-1 Transaction Specification Table Continued

T# Name Type Data Field Class Description

51 SecurityLock Set INT or

NONE

52 CalcPresets Set BOOL E,S,V This transaction is

56 BlockStructure Get USINT

Level1Max,

Level2Max,

Level3Max,

57 BlockDetail Get C: USINT

Level, Block

R: USINT

MaxParams,

STRING

BlockName

All Unlocks or locks

network parameter

security. Passing the

valid SecurityCode

unlocks parameter

access. Any other

value (including

NONE) locks

parameter access.

used during setup to

calculate initial

values for tuning and

performance

parameters based

on motor nameplate

values. Note: this

command is not valid

for all product

classes.

1 = Execute preset

calculation

0 = No action

All Returns the number

of blocks on each

programming level.

Assumes a max of

three programming

levels.

All Returns the number

of parameters in the

block and the

BlockName (16

characters max.)

* Indicates initial powerup value.

6-12 Command Language

Page 42

Table 6-1 Transaction Specification Table Continued

T# Name Type Data Field Class Description

58 BlockParamDetail Get C: USINT

Level, Block,

Index

R: INT

Pnum,

Pvalue,

Pmin, Pmax,

Pdlft, Pprec,

Ptype,

STRING

Pname,

Punits

59 ParameterDetail Get C: INT

Pnum,

R: INT

Pnum,

Pvalue,

Pmin, Pmax,

Pdlft, Pprec,

Ptype,

STRING

Pname,

Punits

60 ParameterList Get C: INT

Pnum,

ListIndex

R: STRING

ListText

All Returns full

parameter detail

information for the

parameter specified

at the given Level,

Block and index.

All Returns full

parameter detail

information for the

given Pnum.

All Returns the

enumerated list

string for the given

parameter number

and list index. 16

characters max. If

ListIndex exceeds

the number of

elements an ‘end of

block’ status will be

returned. (Note: Use

Pmax to determine

the end of the list.)

* Indicates initial powerup value.

Command Language 6-13

Page 43

Table 6-1 Transaction Specification Table Continued

T# Name Type Data Field Class Description

61 ParameterValue Set/

62 BatchSend Get C: INT

63 BatchRcv Set INT

64 FactorySettings Set BOOL All 1 = Reset all

Get

C: INT

Pnum,

Pvalue

R: INT

Pvalue

(excluding

Pvalue from

CMD

indicates

request only).

GroupNumbe

r

R: INT

PnumN,

PvalueN, ...

N=16

PnumN,

PvalueN, ...

N=16

All Change / request

value of specified

user parameter.

Returned value will

give actual, after any

bounds checking.

Refer to the control

manual for

description.

All Batch transfer that

returns raw (data

only) from control to

host. Up to 16

parameters are sent

at a time. Last group

will be truncated if

necessary. Group

numbers start at 0. If

the GroupNumber

exceeds the number

of blocks an ‘end of

block’ status is

returned. The control

must be disabled.

All Block transfer that

accepts raw

parameter (data

only) from host to

control. Up to 16

parameters may be

sent at a time.

Parameters may be

sent in any order.

The control must be

disabled.

parameters to

factory settings.

0 = No action

* Indicates initial powerup value.

6-14 Command Language

Page 44

Table 6-1 Transaction Specification Table Continued

T# Name Type Data Field Class Description

69 ClearAll Set USINT All Reserved for factory

70 LogClear Set USINT All Reserved for factory

71 AnalogInput1 Get UINT All

72 AnalogInput2 Get UINT All

73 SetAnalogOut1 Set INT All

74 SetAnalogOut2 Set INT All

75 SetDigitalOut Set BYTE All Commands the

76 GetDebugVal Get C: INT

MemLoc

R: INT Value

use.

use.

Reads the raw value

of the A/D

converters on the

control. Update rate

control. Update rate

and resolution vary

per control. Unused

MSBs will be padded

with zero.

Commands the

DACs on the control,

and/or option card.

Analog output

parameter must be

set to Serial to be

valid. (Note 8 bit

DACs will only use

the upper byte.)

digital outputs on the

control, and/or option

card. Only lowest

four bits are used.

The LSB

corresponds to opto

out #4. The opto

output parameter

must be set to serial

to be valid.

All Reserved for factory

use.

* Indicates initial powerup value.

Command Language 6-15

Page 45

Table 6-1 Transaction Specification Table Continued

T# Name Type Data Field Class Description

250 Reserved for future

251 Reserved for future

252 Reserved for future

253 Reserved for future

254 Reserved for future

255 Reserved for future

use.

use.

use.

use.

use.

use.

6-16 Command Language

Page 46

5 - Command Mode

Command

5 USINT CommandMode

Response

5 ST USINT CommandMode

Type: Set/Get

This transaction changes the command mode of the Series H

control. The command mode is an 8–bit value. Loading the

appropriate value into the command mode register activates the

appropriate operating mode. Only one mode can be selected at

a time. Table 6-2 provides a description of the possible command

modes.

Initial Condition:

At powerup, the command mode is set to 00H (disabled).

Command Language 6-17

Page 47

Table 6-2 Command Mode Table

Value Mode Class Description

0 None ALL No mode selected. Output stage of

1 Torque CMD

selected source

2 Torque CMD

Network

3 Speed CMD

selected source

4 Speed CMD

Network

5 Orient S,V C or Index channel orient. The motor will

6 Position CMD

ABS

7 Position CMD

INC

9 Position CMD

External

11 Process Torque All Closes the torque process control loop.

12 Process Velocity All Closes the velocity process control loop.

control remains off or disabled (voltage

and current removed from the motor),

regardless of RunCmd condition.

S,V Closes the current loop with command

input from the source selected in the

COMMAND SELECT parameter.

S,V Closes the current loop with command

input from the TorqueRef register.

All Closes the velocity loop with command

input from the source selected in the

COMMAND SELECT parameter.

All Closes the velocity loop with command

input from the SpeedRef register.

be commanded in the Fwd direction at

the predefined homing speed until the

index pulse is detected. The motor will

then be commanded to hold position at

the predefined home offset.

S,V Closes the position loop with an absolute

position command from the PositionRef

register.

S,V Closes the position loop with an

incremental position command from the

PositionRef register.

S,V Closes the position loop with command

input from external option source (such

as pulse follower EXB card.)

Commands come from the appropriate

command input parameters.

Commands come from the appropriate

command input parameters.

6-18 Command Language

Page 48

31- TerminalStrip

Command

31

Response

31 ST WORD TerminalStrip

Type: Get

This transaction returns a bit–wise word representing the status

of the control digital inputs and outputs.

Table 6-3 provides a description of the codes.

Note: A bit value of 1=closed or ON, 0=open or OFF.

Table 6-3 TerminalStrip Table

Bit Name Typical Single-Axis

Location

0 Output4 J1 (J4) - 22 J1B - 13

1 Output3 J1 (J4) - 21 J1B - 12

2 Output2 J1 (J4) - 20 J1B - 11

3 Output1 J1 (J4) - 19 J1B - 10

4 Input9 J1 (J4) - 16 J1B - 9

5 Input8 J1 (J4) - 15 J1B - 8

6 Input7 J1 (J4) - 14 J1B - 7

7 Input6 J1 (J4) - 13 J1B - 6

8 Input5 J1 (J4) - 12 J1B - 5

9 Input4 J1 (J4) - 11 J1B - 4

10 Input3 J1 (J4) - 10 J1B - 3

11 Input2 J1 (J4) - 9 J1B - 2

12 Input1 J1 (J4) - 8 J1B - 1

13 Not Used

14 Not Used

15 Not Used

Typical Multi-Axis

Location

Note: J1 = for Vector Controls, J4 = for Inverter Controls.

Command Language 6-19

Page 49

36 or 37 - Optionald#

Command

36

Response

36 ST USINT Optionld

Type: Get

This transaction returns the id number for the option installed in

the specified location.

Table 6-4 provides a description of the possible values.

Table 6-4 Optionald# Table

ID EXB No. EXB Name Group

1 EXB001A01 RS232 Serial Communications 2

2 EXB002A01 RS422/485 Serial Communications 2

3 EXB003A01 Isolated Input 1

4 EXB004A01 4 Output Relays / 3-15 PSI Pneumatic 2

5 EXB005A01 Master Pulse Reference/Isolated Pulse

Follower

6 EXB006A01 DC Tachometer 1

7 EXB007A01 High Resolution Analog I/O 2

8 EXB008A01 Isolated Encoder 1

9 EXB009A01 Resolver to Digital 1

10 EXB010A01 2 Isolated Analog Output / 3 Relay 2

11 EXB012A00 RS232/485 Serial Communications 2

1

6-20 Command Language

Page 50

41 - WatchdogTime

Command

41 UINT WatchdogTime

Response

41 ST UINT WatchdogT ime

Type: Set/Get

This transaction is used to change the value of the network

watchdog timer. The value is entered in milliseconds (mS). The

watchdog timer is used to detect a communications loss. When

the time between network commands exceeds the value stored

in this register, a fault is generated and the control is disabled.

Each time a network command is received, the internal timer is

reset to zero. The host must continuously send commands to

keep the timer reset. If desired a NULL transaction can be used

to reset the timer. Setting the timer to zero disables this function.

The minimum time value (other than zero) is 20mS (2). The

maximum value is 60S (6000). Resolution varies among product

classes.

Scale/ Units: 10mS

ParameterDetails

Table 6-5 describes the data that is returned during a parameter detail

response.

Command Language 6-21

Page 51

Table 6-5 ParameterDetails Table

Field Name Description

INT Pmin Parameter minimum allowed value.

INT Pmax Parameter maximum allowed value. (Number of list items

INT Pdflt Parameter default value (factory) value.

USINT Pprec Indicates the number of decimal places to use for the

BYTE Ptype Returns bit–wise parameter type.

STRING Pname Returns string representing parameter name. For example

STRING Punits Returns the parameter engineering units string. Max

in an enumerated type parameter.)

parameter value.

Bit 0 = Numeric parameter

Bit 1 = Enumerated list parameter

Bit 2 = Can be changed while enabled

Bit 3 = Default from calculation

Bit 4 = Not set during ‘restore to factory’

Bit 5 = Signed parameter

“Preset Speed #1”. Max number of characters is 16.

number of characters is 4.

6-22 Command Language

Page 52

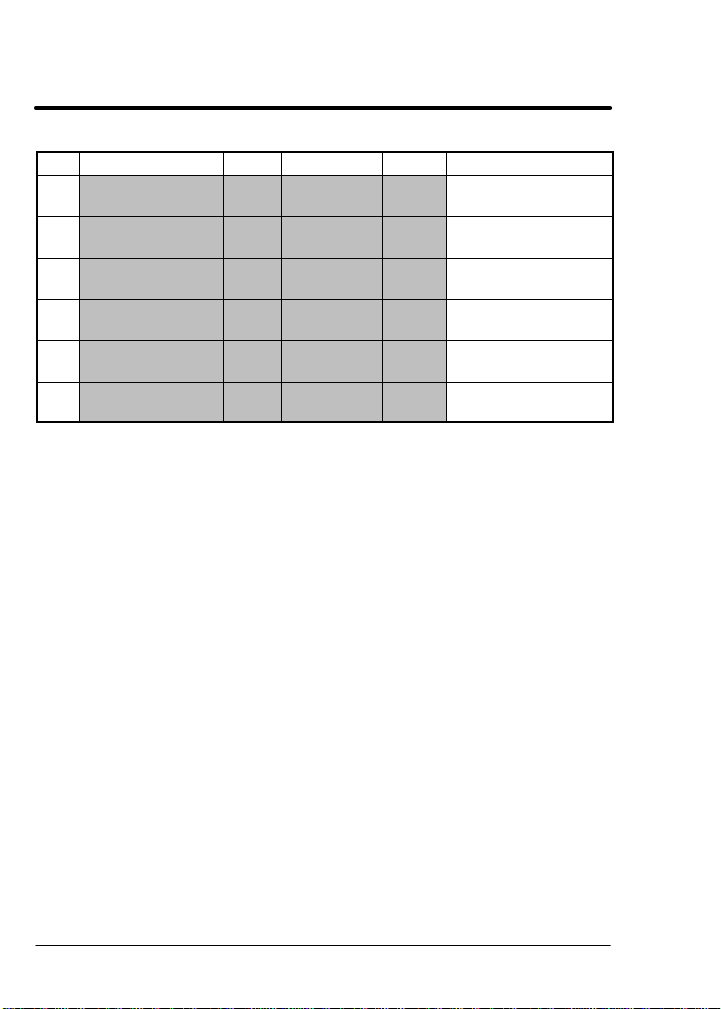

H Series – Fault Message Description

Fault Message

Line Regen 1 1 Fault in Line REGEN converter unit -

Feedback Fault 2 Loss of encoder feedback.

Invalid Base ID 3 3 Failed to read configuration from the Power

Low INIT Bus V 4 4 Low bus voltage detected on start–up.

Regen Res

Power

Current SENS

FLT

HW

Desaturation

HW Ground

Fault

Resolver Fault 9 Loss of resolv er feedbac k .

HW Power

Supply

Overcurrent 11 11 Continuous current limit exceeded.

Bus

Overvoltage

Following ERR 13 Mot or speed/pos ition does not follow comm and.

Torque Prove 14 Unbalanced current between all 3 phases.

Bus

Undervoltage

3 Sec Overload 16 16 Peak output current exceeded the 3 second

Over Speed 17 Motor RPM exceeded 110% of MAX Speed.

Motor Temp 18 Motor over temperature

Heatsink Temp 19 19 Control heatsink exceeded temperature limit.

External Trip 18 20 Connection at J1/J4 pin 16 and 17 is open.

Param

Checksum

Fault Code

15H 18H

Series 21H Line REGEN Inverter control.

Base ID value in software.

5 5 Excessive power dissipation required by

6 6 Failure to sense phase current.

7 7 High output current condition detected (greater

8 8 Ground Fault detected (output current leakage

10 10 Control Board power supply failure detected.

12 12 High DC Bus voltage.

15 15 Low DC Bus voltage condition detected.

51 21 Parameter checksum error.

Dynamic Brake Hardware.

than 400% of rated output current).

to ground).

rating value.

Fault Description

Command Language 6-23

Page 53

H Series – Fault Message Description Continued

Fault Message

µp Reset 22 22 A software watchdog timer has reset the

ROM Fault 23 ROM checksum error.

1 Min Overload 24 24 Peak output current exceeded the 1 minute

No I Feedback 25 Loss of current feedbac k

New Base ID 26 26 Control board detected a change in the Power

EXB Selection 27 27 Expansion board not installed to support the

Power module 28 Power module failure.

Co–processor 29 Co–processor error (i.e. DSP board).

Software

Version

Feedback

Module

Serial watchdog 32 Serial port transmit/receive error

FLT Network 33 33 Lost network com m unicat ions .

Hardware

Protect

Unknown FLT

Code

Bus Current

SENS

Fault Code

15H 18H

processor because a process has timed out.

rating value.

Base ID value in software.

Level 1 Input Block, Command Select

parameter.

30 Wrong control software version detected.

31 Feedback HW module failure.

54 A general hardware fault was detected but

55 34 Microprocessor detected a fault that is not

56 Failure to sense bus current.

cannot be isolated.

identified in the fault code table.

Fault Description

Note These faults may be different for custom software.

6-24 Command Language

Page 54

BALDOR ELECTRIC COMPANY

P.O. Box 2400

Fort Smith, AR 72902–2400

(479) 646–4711

Fax (479) 648–5792

Baldor Electric Company Printed in USA

MN1320 8/03 C&J500

Loading...

Loading...