Page 1

Product Information Packet

EPCL1317M

2HP,3470RPM,1PH,60HZ,56C,3540LC,OPEN,F1

Copyright © All product information within this document is subject to ABB Motors and Mechanical Inc. copyright © protection, unless otherwise noted.

Page 2

Product Information Packet: EPCL1317M - 2HP,3470RPM,1PH,60HZ,56C,3540LC,OPEN,F1

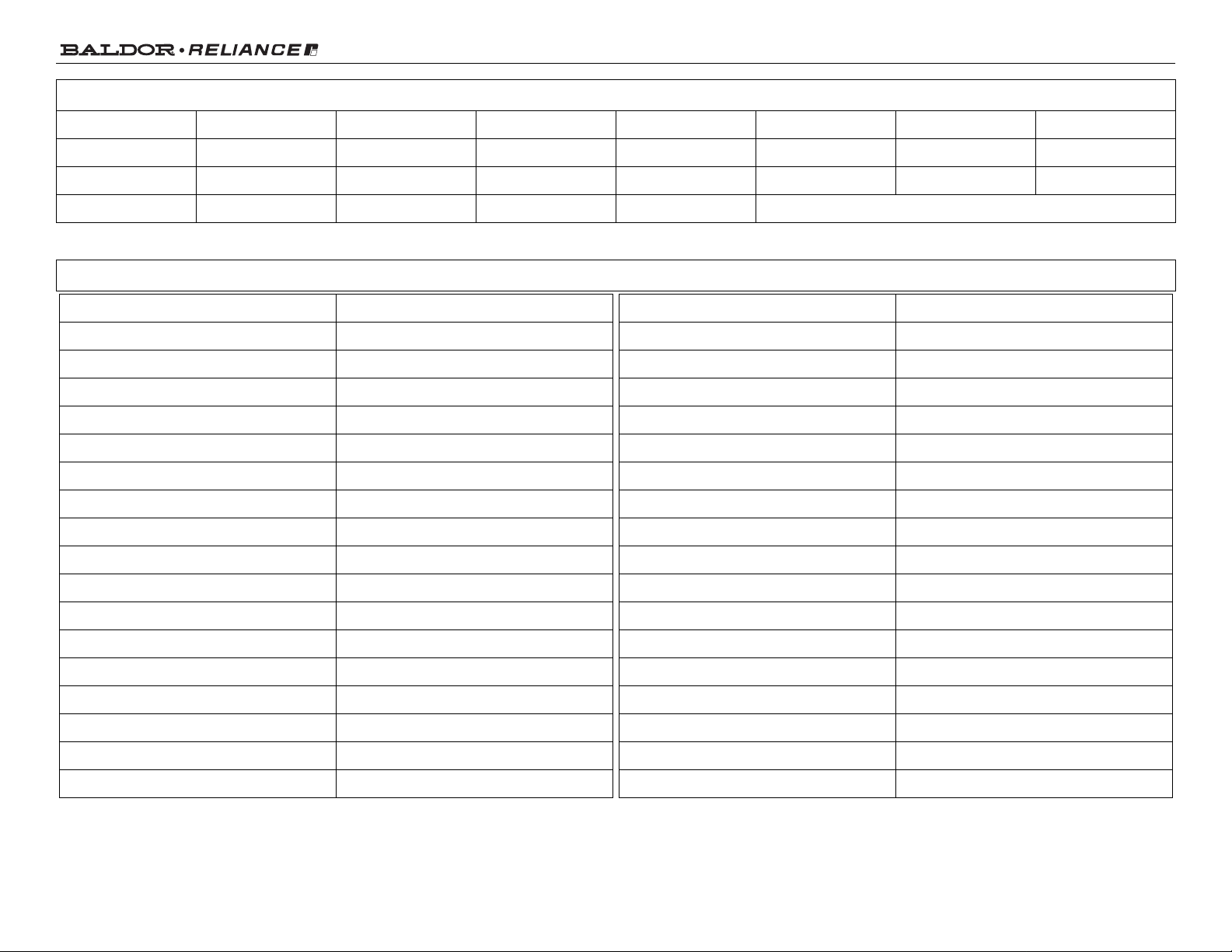

Part Detail

Revision: F Status: PRD/A Change #: Proprietary: No

Type: AC Elec. Spec: 35WGL138 CD Diagram: CD0320 Mfg Plant:

Mech. Spec: 35T967 Layout: 35LYT967 Poles: 02 Created Date: 09-15-2014

Base: RG Eff. Date: 08-15-2019 Leads: 6#16,1#14 #4TH

Specs

Catalog Number: EPCL1317M

Enclosure: OPEN

Frame: 56C

Frame Material: Steel

Output @ Frequency: 2.000 HP @ 60 HZ

Synchronous Speed @ Frequency: 3600 RPM @ 60 HZ

Voltage @ Frequency: 115.0 V @ 60 HZ

230.0 V @ 60 HZ

XP Class and Group: None

XP Division: Not Applicable

Agency Approvals: UR

CSA

Auxillary Box: No Auxillary Box

Auxillary Box Lead Termination: None

Base Indicator: Rigid

Bearing Grease Type: Polyrex EM (-20F +300F)

Blower: None

Inverter Code: Not Inverter

KVA Code: G

Lifting Lugs: No Lifting Lugs

Locked Bearing Indicator: Locked Bearing

Motor Lead Quantity/Wire Size: 6 @ 16 AWG

Motor Lead Exit: Ko Box

Motor Lead Termination: Flying Leads

Motor Type: 3540LC

Mounting Arrangement: F1

Power Factor: 99

Product Family: General Purpose

Pulley End Bearing Type: Ball

Pulley Face Code: C-Face

Pulley Shaft Indicator: Standard

Rodent Screen: None

RoHS Status: ROHS COMPLIANT

Shaft Extension Location: Pulley End

Current @ Voltage: 15.600 A @ 115.0 V

Shaft Ground Indicator: No Shaft Grounding

Page 2 of 9

Page 3

Product Information Packet: EPCL1317M - 2HP,3470RPM,1PH,60HZ,56C,3540LC,OPEN,F1

7.800 A @ 230.0 V

Design Code: L

Drip Cover: No Drip Cover

Duty Rating: CONT

Electrically Isolated Bearing: Not Electrically Isolated

Feedback Device: NO FEEDBACK

Front Face Code: Standard

Front Shaft Indicator: None

Heater Indicator: No Heater

Insulation Class: B

Shaft Rotation: Reversible

Shaft Slinger Indicator: No Slinger

Speed Code: Single Speed

Motor Standards: NEMA

Starting Method: Direct on line

Thermal Device - Bearing: None

Thermal Device - Winding: Do Not Use

Vibration Sensor Indicator: No Vibration Sensor

Winding Thermal 1: Manual Thermal Overload

Winding Thermal 1 Location: KO

Winding Thermal 2: None

Page 3 of 9

Page 4

Product Information Packet: EPCL1317M - 2HP,3470RPM,1PH,60HZ,56C,3540LC,OPEN,F1

Nameplate NP1257L

CAT.NO. EPCL1317M

SPEC. 35T967L138

HP 2

VOLTS 115/230

AMP 15.6/7.8

RPM 3470

FRAME 56C HZ 60 PH 1

SER.F. 1.15 CODE G DES L CL B

NEMA-NOM-EFF 82.9 PF 99

RATING 40C AMB-CONT

CC USABLE AT 208V

DE 6205 ODE 6203

ENCL OPEN SN

Page 4 of 9

Page 5

Product Information Packet: EPCL1317M - 2HP,3470RPM,1PH,60HZ,56C,3540LC,OPEN,F1

Parts List

Part Number Description Quantity

SA286877 SA 35T967L138 1.000 EA

RA273094 RA 35T967L138 1.000 EA

OC3070C09 AEROVOX #Z24P247OM22A1 OIL CAP 70MFD/240 1.000 EA

TPCRT38CB THERMAL 1PH 1.0 MAN 120C WELDED 1.000 EA

EC1645B06 ELEC CAP 165V 2.0 X 4.3 1.000 EA

WD3006A01 RSS-2-103JT 2W 10K RES. METAL OXIDE 5% 1.000 EA

TP5059 GENERIC THERMAL KIT 1.000 EA

NS2512A01 INSULATOR, CONDUIT BOX X 1.000 EA

35CB3007A17 35 CB .88 DIA @ 6:00, 1.00 MTO @ 3:00 1.000 EA

51XB1016A07 10-16 X 7/16 HXWSSLD SERTYB 2.000 EA

11XW1032G06 10-32 X .38, TAPTITE II, HEX WSHR SLTD U 1.000 EA

HA6015A11 EARED 1" THERMAL RETAINER (PLATED) 1.000 EA

51XB1214A10 12-14 X 5/8HX WS SL SR TYBX 2.000 EA

35EP3209G00 MASTER ODE,203 BRG 1.000 EA

51XW0832A07 8-32 X .44, TAPTITE II, HEX WSHR SLTD SE 2.000 EA

35CB3801 CAPACITOR COVER, CAST 1.000 EA

HA7010 CAPACITOR RETENTION CLAMP 1.000 EA

NS2501A02 INSULATOR, CAPACITOR BOX 1.000 EA

51XB1016A08 10-16X 1/2HXWSSLD SERTYB 2.000 EA

NS2500A02 INSULATOR, MAN THER PROT 1.000 EA

HW5100A03 WAVY WASHER (W1543-017) 1.000 EA

35EP3402C00 MASTER DE,205 BRG,OPEN 1.000 EA

35AD2000 AIR BAFFLE - GALVANNEAL 1.000 EA

15XF0632A06 6-32 X 3/8 PHILL PAN HD TYPE F 4.000 EA

Page 5 of 9

Page 6

Product Information Packet: EPCL1317M - 2HP,3470RPM,1PH,60HZ,56C,3540LC,OPEN,F1

Parts List (continued)

Part Number Description Quantity

51XN1032A20 10-32 X 1 1/4 HX WS SL SR 2.000 EA

35CB4521 35 LIPPED CB LID (GALV & PHOSPH) 1.000 EA

51XW0832A07 8-32 X .44, TAPTITE II, HEX WSHR SLTD SE 4.000 EA

HW2501D13 KEY, 3/16 SQ X 1.375 1.000 EA

HA7000A04 KEY RETAINER 0.625 DIA SHAFTS 1.000 EA

85XU0407S04 4X1/4 U DRIVE PIN STAINLESS 2.000 EA

LB1087 LABEL,MANUAL RESET (ROLL LABEL) 1.000 EA

WD1000A15 3-520132-2 AMP FLAG (4M/RL NON-CANC/NON- 4.000 EA

MJ1000A02 GREASE, MOBIL POLYREX EM - 124047 0.050 LB

MG1000G27 MED CHARCOAL METALLIC GREY 400-0096 0.017 GA

HA3100A24 THRUBOLT 10-32 X 10.625 4.000 EA

SP5181A28 MODEL 35 LC TORQ STAT SWITCH LEAD ASSY 1.000 EA

LB1119N WARNING LABEL 1.000 EA

LC0269 1PH,DV,REV,THERMAL,7 LD,L.AMP THRU HTR H 1.000 EA

MN416A01 TAG-INSTAL-MAINT no wire (1200/bx) 3/19 1.000 EA

NP1257L ALUM UL CSA CC THERMAL REV MTG 1.000 EA

36PA1000 PKG GRP, PRINT PK1016A06 1.000 EA

FE-0000001 ZRTG FE ASSEMBLY 1.000 EA

PE-0000001 ZRTG PE ASSEMBLY 1.000 EA

Page 6 of 9

Page 7

Product Information Packet: EPCL1317M - 2HP,3470RPM,1PH,60HZ,56C,3540LC,OPEN,F1

No performance data has been

assigned to this product.

Page 7 of 9

Page 8

Product Information Packet: EPCL1317M - 2HP,3470RPM,1PH,60HZ,56C,3540LC,OPEN,F1

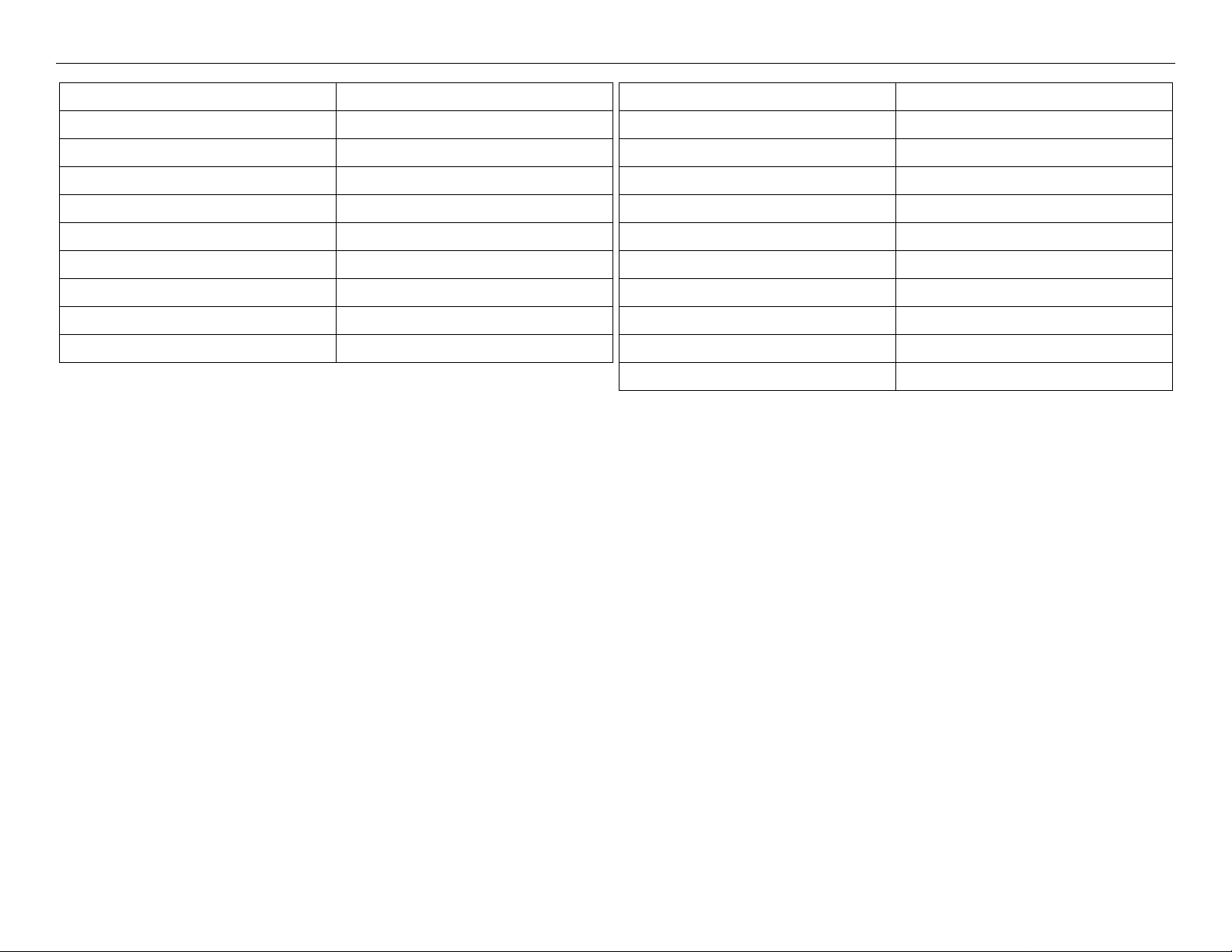

3 00 2 75

66

4 32

2 60

6250

6245

4 500

4 497

6 49

1 88

13

2 06

510-528 = 12 07

529-535 = 12 94

536-546 = 14 32

NAMEPLATE

4 SLOTS

34 WIDE

19 KEY

1 38 LONG

MANUAL

THERMAL

45°

45°

5 61

6 62

2 19

3 50

3 44

6 78

2 47 2 47

3 31 4 55

6 62

LEAD HOLE

Ø 88

4 HOLES

38-16 TAP

ON Ø5 88 B C

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

35LYT967

B

HORZ 56C OPEN 35LC W/1.00" MTO IN KBOX

REV. DESC

REV

BY

REVISED

MODEL NO.

VERSION

TDR

REF

35LYT967

LOAD INOPC CREATED SWD DRG INTO BUS - PACKAGE 16

USBUFRA

C

03 12 52 02/04/2019

-

000001098202

03

35LYT967

CUSTOMER IS RESPONSIBLE FOR DETERMINING THAT THE PRODUCT WILL PERFORM SUITABLY IN THE INTENDED APPLICATION

BALDOR - RELIANCE

®

SH 1 OF 1

Page 8 of 9

Page 9

Product Information Packet: EPCL1317M - 2HP,3470RPM,1PH,60HZ,56C,3540LC,OPEN,F1

Page 9 of 9

Loading...

Loading...