Page 1

DTM8000

Digital Tachometer

Installation and Operating Manual

LT49 (A-5-3196A) MN1327

Page 2

Quick Jump

What models and recommended accessories are

available?

See page 3.

Looking for detailed specifications?

See page 3.

Want to get started fast?

See basic electrical hook-up details on page 5.

See mechanical installation details on page 4.

See some sample applications starting on page 15.

Need Help?

See troubleshooting on page 19.

LIMITED WARRANTY

For a period of one (1) year from the date of original purchase, BALDOR will repair or replace without charge controls

and accessories which our examination proves to be defective in material or workmanship. This warranty is valid if

the unit has not been tampered with by unauthorized persons, misused, abused, or improperly installed and has been

used in accordance with the instructions and/or ratings supplied. This warranty is in lieu of any other warranty or

guarantee expressed or implied. BALDOR shall not be held responsible for any expense (including installation and

removal), inconvenience, or consequential damage, including injury to any person or property caused by items of our

manufacture or sale. (Some states do not allow exclusion or limitation of incidental or consequential damages, so

the above exclusion may not apply.) In any event, BALDORs total liability, under all circumstances, shall not exceed

the full purchase price of the control. Claims for purchase price refunds, repairs, or replacements must be referred

to BALDOR with all pertinent data as to the defect, the date purchased, the task performed by the control, and the

problem encountered. No liability is assumed for expendable items such as fuses.

Goods may be returned only with written notification including a BALDOR Return Authorization Number and any return

shipments must be prepaid.

WARNING

Improper installation or operation of this control may cause injury to personnel or control failure. The control must be

installed in accordance with local, state, and national safety codes. Make certain that the power supply is disconnected

before attempting to service or remove any components!!! If the power disconnect point is out of sight, lock it in

disconnected position and tag to prevent unexpected application of power. Only a qualified electrician or service

personnel should perform any electrical troubleshooting or maintenance. At no time should circuit continuity be

checked by shorting terminals with a screwdriver or other metal device.

Page 3

Table of Contents

Introduction .......................................................................................................................................2

General Features ..............................................................................................................................2

Models & Options .............................................................................................................................3

Model Table ....................................................................................................................................3

Recommended Accessories .........................................................................................................3

Specifications....................................................................................................................................3

Electrical........................................................................................................................................3

Mechanical .................................................................................................................................... 3

Environmental ...............................................................................................................................3

Mechanical Installation .....................................................................................................................4

Exploded Panel View .....................................................................................................................4

Cut-out and Mounting Dimensions ................................................................................................4

Electrical Installation & Diagrams ...................................................................................................5

P1 Terminal Block Wiring Diagram ...............................................................................................5

P1 Terminal Block Descriptions ....................................................................................................5

Basic Operating Instructions ..........................................................................................................6

Rate, Time, and Counter Modes Explained ................................................................................... 6

Visual Reference ...........................................................................................................................6

How to Change a Parameter's Value (The Short Story) ................................................................6

Operating the User Interface (The Long Story) .............................................................................. 6

Detailed Configuration Instructions ...............................................................................................7

Factory Set Configuration .............................................................................................................. 7

Resetting the Unit to Factory Settings ...........................................................................................7

JP1 (Program Enable Jumper) ...................................................................................................... 7

Software Parameters ....................................................................................................................8

Parameter Descriptions .............................................................................................................. 10

Application Examples ..................................................................................................................... 15

Pump Flow Monitor with Audible and Visual Alarm ...................................................................... 15

Conveyor Oven Time Monitor with Over-Heating Alarm .............................................................. 16

Take-up / Pay-out Reel Material Measurement with Alarm........................................................... 17

Bi-directional Incremental Position Display ................................................................................. 18

Troubleshooting ............................................................................................................................. 19

1

Page 4

Introduction

The DTM8000 Digital Meter is a powerful, microprocessor-based unit capable of being configured for

a number of todays demanding measurement needs. It can be quickly configured to operate as a digital

rate meter, timer, or feature-filled process counter. It also offers up to two alarm outputs which can be

adjusted for a number of trigger conditions. Its durable 1/8DIN aluminum housing can be easily mounted

in a panel or control cabinet. Flexibility makes the DTM8000 ideal for applications such as:

Pay-out and Take-up Limit Monitors

Conveyor Oven Tunnel-Time Monitors

Rotating Machinery Tachometers

Material Measurement Meters

General Features

- Microprocessor-based design combines responsiveness and accuracy in one package

- Selectable display update rate

- Capable of measuring shaft speeds lower than 1 RPM @ 1 pulse per revolution

- Large 4 digit, ½ LED display

- Field programmable via front-panel keypad

- Lexan membrane and gasket (which are included) meet NEMA 4X standards when used with NEMA

4X enclosures

- Internal program-enable jumper selectively prevents tampering with units configuration

- Universal power supply accepts line voltages inputs from 85-265VAC @ 50-60Hz without switches

or jumpers. The unit automatically adjusts as needed.

- Non-volatile memory stores adjustable parameters even when power has been removed

- Compatible with a variety of signal input types including: Hall-Effect Pickups, Photoelectric, TTL, etc.

Note: Open collector devices must be capable of sinking 3mA.

- Wide operating ambient temperature range of -10C to 45C (14F to 113F)

- Self-contained power supply for external sensor, limited to 5V @ 50mA

- Up to 2 programmable alarm outputs with Form C contacts rated to 250VAC @ 5A

- Multiple auto-ranging features allow the user to view display values from 0.001 to 99,990 in any userdefined unit. (GPH, MPH, RPM, etc.)

- Multiple operating modes including:

Rate Mode Displays in rate unit such as RPM, Gallons per Second, etc.

Time Mode Displays in time unit such as HH:MM, MM:SS, SS:TT, or other unit

Counter Modes Displays resettable and reloadable counter value which can optionally

increment or decrement for each input pulse. Quadrature inputs can automatically

be translated to up/down counts for bidirectional applications

2

Page 5

Model Table

Models & Options

Model

DTM8000-6 85-265VAC 1 Yes Yes Yes Yes Yes

Input Voltage

Outputs

Alarm

Measures

Rate?

Measures

Time?

Up

Counter?

Down

Counter?

Quadrature

Compatible?

Encoder

Recommended Accessories

Model

HPU10 Hall-Effect Pickup, Single Channel 10 0.1 – 10,000 RPM

RK60-56 Hall-Effect Pickup, Single Channel 60 0.02 – 1,600 RPM

RK60-145 Hall-Effect Pickup, Single Channel 60 0.02 – 1,600 RPM

Description

Pulses per

Revolution

RPM Range When Used With

DTM8000

Specifications

Electrical

Line Input Voltage----------------------------------------------------------------------------------Any Voltage from 85-265 VAC

Line Input Frequency--------------------------------------------------------------------------------- Any Freq. from 48-62 Hertz

Signal Input Frequency Range-----------------------------------------------------------------0 – 100,000 Pulses per Minute

(Higher frequenc ies are possible when using i nternal freq uency divisor)

Display Range--------------------------------------------------------------------------------------------------------- 0.001 – 99,990

Units of Operation----------------------------------------------------------------------------------User Programmable, any Unit

Sensor / Pickup Power Supply-----------------------------------------------------------------------------------------5V @ 50mA

Isolated Alarm Relay Output Ratings------------------------------------------------------------------------------240VAC @ 5A

Mechanical

Display Type ---------------------------------------------------------------------------------------------LED, Red, 4 Digit, ½” Height

Housing Type (with su pplied ga ske t in N E MA 4X p a nel )-------------------------------------------------------------- N E MA 4 X

Connector Style -----------------------------------------------------------------------------------12-position 5mm European Style

Terminal Block To rq ue Setting ------------------------------------------------------------------------------ 4 .4 in. lb. Ma x o r .5Nm

Faceplate Material--------------------------------------------------------------------------Polycarbonate with GE Lexan Overlay

Housing Material -----------------------------------------------------------------------------------------------------------------Aluminum

Length (Required Panel Depth)-----------------------------------------------------------------------------------4.625", 117.48mm

Faceplate Width ------------------------------------------------------------------------------------------------------4.539", 115.29mm

Weight ------------------------------------------------------------------------------------------------------.8425 lb, 13.48 oz, 382.14g

Environmental

Operating Temperature Range------------------------------------------------------------------------10C to 45C (15F to 115F)

Operating Humidity Range----- ------- ---- ------- ---- ------- ---- -------- --- -------- --- ---- -------- ---- ----- 95%, non-condensing

3

Page 6

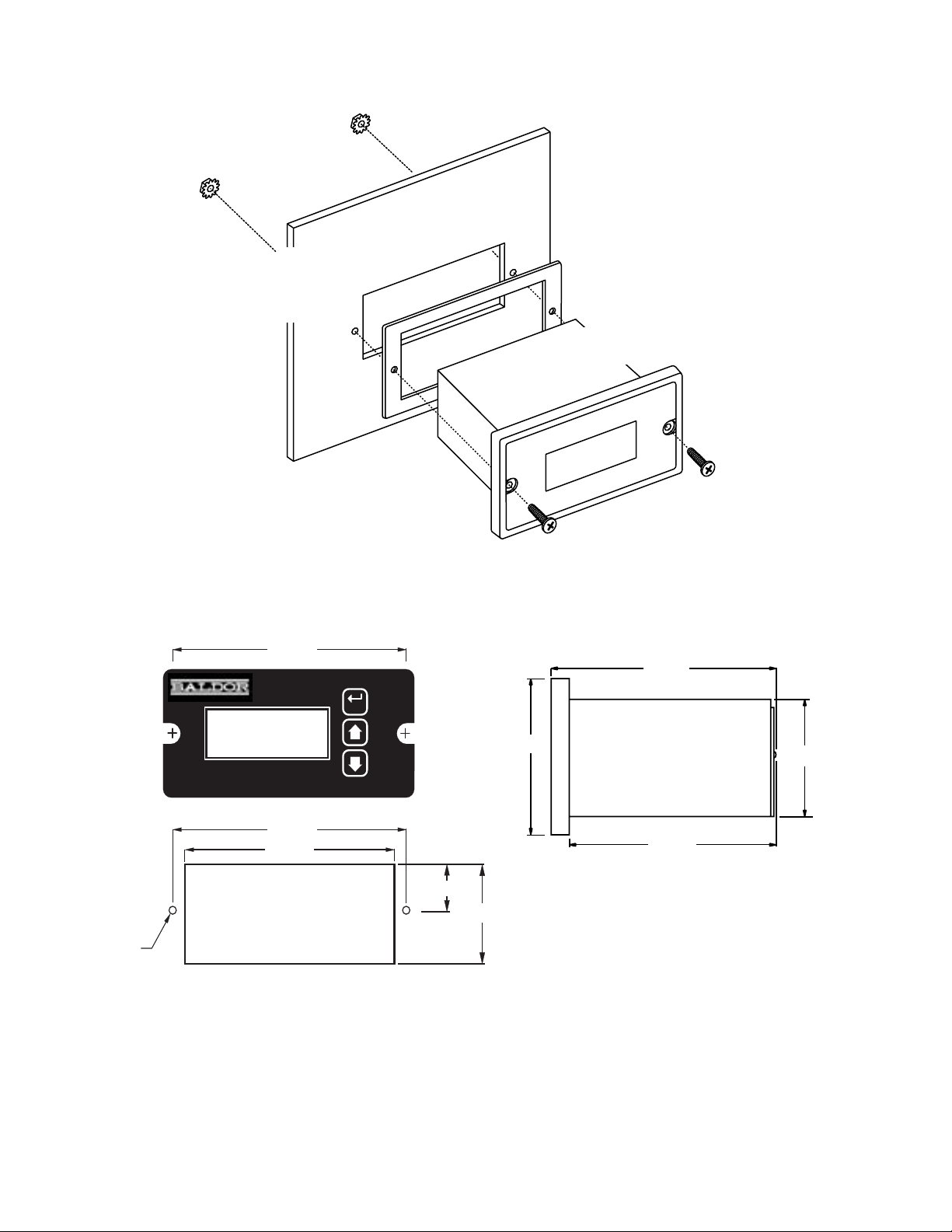

Mechanical Installation

Exploded Panel View

CUSTOMER

MOUNTING PANEL

(HOLE CUT-OUT FOR CONTROL

HOUSING APPROXIMATELY

3.622" WIDE BY 1.770" HIGH)

PANEL MOUNTING GASKET

(WITH THE ADHESIVE SIDE OF

GASKET FACING THE CUSTOMER

MOUNTING PANEL)

DTM8000 SERIES

TACHOMETER

.140" x 2

1) GASKET

2) (2) 6-32 X 3/4 PANHEAD BLACK OXIDE STAINLESS SCREWS

3) (2) #6 NUT WITH LOCKWASHER

Cut-out and Mounting Dimensions

4.000"

Tac h

ValuPage

Ite

SUPPLIED WITH EACH CONTROL:

m

TACHOMETER

4.000"

3.622

DTM8000-6

HOUSING DEPTH

4.625"

PANEL CUT-OUT

ENTER

"

0.885"

1.770"

2.289"

5.000"

1.656"

4.625"

4

Page 7

Electrical Installation & Diagrams

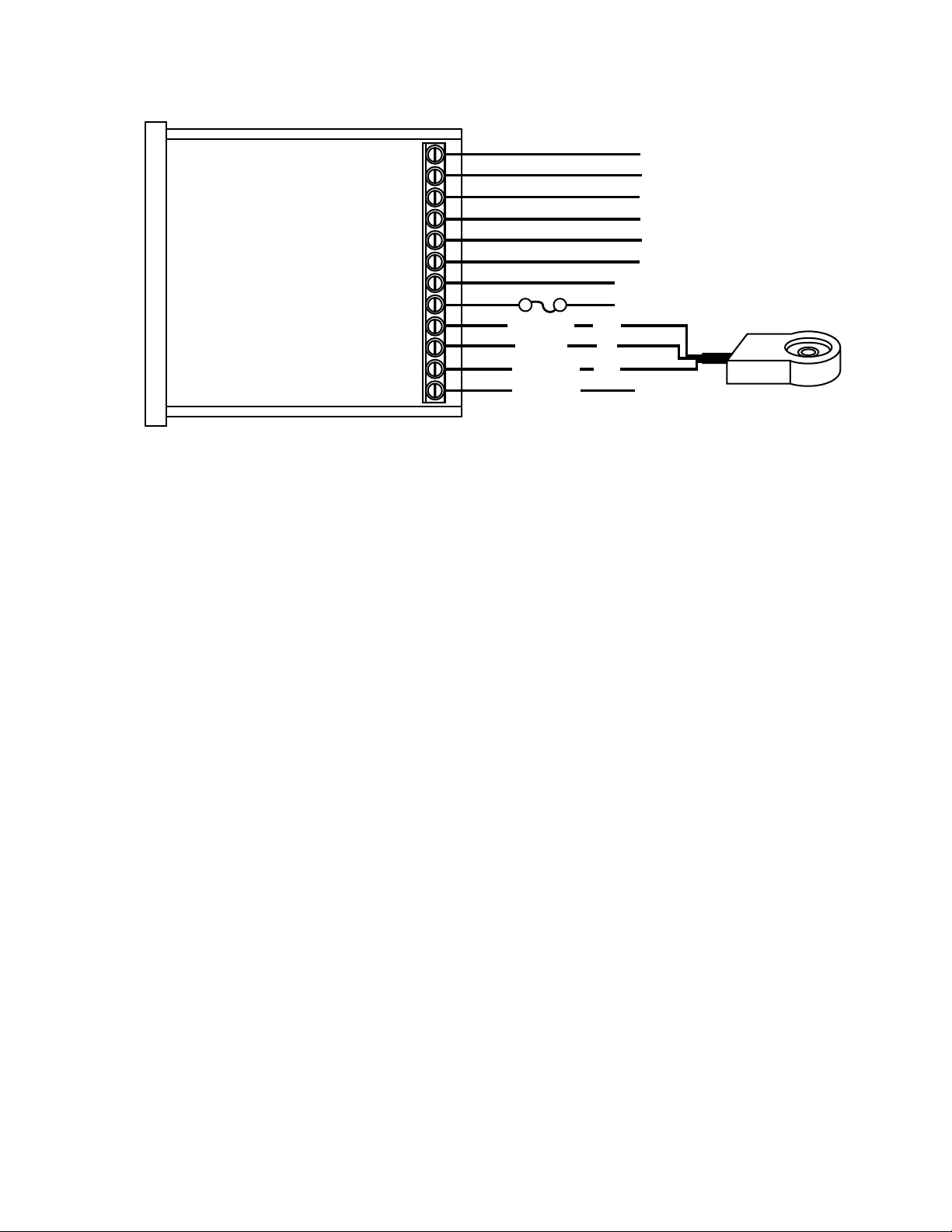

P1 Terminal Block Wiring Diagram

NC2

P1-1

P1-2

P1-3

P1-4

DTM8000-6

HOOK-UP

P1-5

P1-6

P1-7

P1-8

P1-9

P1-10

P1-11

P1-12

* Used for various functions, including quadrature counter mode.

P1 Terminal Block Descriptions

Alarm Output 2 - Normally Closed

C2

Alarm Output 2 - Common

NO2

Alarm Output 2 - Normally Open

NC1

Alarm Output 1 - Normally Closed

C1

Alarm Output 1 - Common

NO1

Alarm Output 1 - Normally Open

N

L

COM

+5V

S1

S2

AC NEUTRAL

COMMON

+5VDC

SIGNAL 1

SIGNAL 2

2 Amp

AC LINE

black

red

white

Form C Relay Output (Programmable)

}

Form C

Relay Output

}

(Programmable)

AC LINE INPUT

AC LINE INPUT

85-265VAC

}

*

PICK-UP

MOUNTED

P1-1 (2NC) This is the normally-closed contact of the second user assignable relay output.

P1-2 (2C) This is the common contact of the second user assignable relay.

P1-3 (2NO) This is the normally-open contact of the second user assignable relay output.

P1-4 (1NC) This is the normally-closed contact of the first user assignable relay output.

P1-5 (1C) This is the common contact of the first user assignable relay.

P1-6 (1NO) This is the normally-open contact of the first user assignable relay output.

P1-7 (AC / N) For single phase AC lines connect the Neutral side of your AC line to this terminal. For

systems with two hot AC lines, connect either of the Hot AC lines to this terminal.

P1-8 (AC / L) For single phase AC lines connect the Hot side of your AC line to this terminal. For

systems with two hot AC lines, connect either of the Hot AC lines to this terminal.

P1-9 (COM) This is the common point for the control logic. The speed sensor common lead as well

as any other source needing to reference the control common will be connected to this terminal.

P1-10 (+5V) This is a self-contained +5VDC power supply capable of up to 50mA. The speed sensor

supply lead can be connected to this terminal for its power source.

P1-11 (S1) This is the Signal input terminal for single channel operation or channel 1 of dual channel

operation. The signal lead of your speed or counter sensor will be connected here.

P1-12 (S2) This is the Signal input terminal for channel 2 during dual channel operation. The second

signal lead of the speed or position sensor should be connected here. This terminal is also used

as a reset input or function change input for various operations of the control. In counter modes,

this input may also be used as a counter reset or enable gate.

5

Page 8

Basic Operating Instructions

Rate, Time, and Counter Modes Explained

In Rate Mode, the DTM8000 measures the input frequency, converts it to the user-defined units, and

displays the rate in the display window of the user interface. Most applications utilize rate mode and

display in units such as gallons-per-minute, feet-per-second, and RPM.

In Time Mode, the DMT8000 measures the input frequency, converts it to the user-defined time units,

and displays the time in the display window. This mode is most-commonly used in time-sensitive

processes such as conveyor ovens and plating applications.

In Counter Modes, the DTM8000 counts each incoming pulse, scales it per the user-defined ratios, and

displays the count in the display window. Typical counting applications include linear material

measurement, cycle counters, and liquid volume measurement.

Visual Reference

ENTER (Select) Button

Tach

ENTER

Up & Down Buttons

Display Window

Ite

m

ValuPage

TACHOMETER

How to Change a Parameter's Value (The Short Story)

1. Hold down the Enter button until Parameter-Selection Mode is entered

2. Using the Up and Down buttons, select the desired parameter number to view or edit

3. Press the Enter button to change the value of the parameter

4. Using the Up and Down buttons, change the parameter's value as desired

5. Press the Enter button to permanently save the changes (Return to Parameter-Selection Mode)

6. Select parameter zero and press the Enter button to return to Running Mode

Operating the User Interface (The Long Story)

The LED display has three basic operating modes: Running Mode, Parameter-Selection Mode, and

Value Mode. Each of the three modes have specific visual indicators that allow the user to immediately

determine the current state or mode of the user interface. Parameter-Selection Mode and Value

Mode can only be entered if the Program Enable jumper is in the On position.

6

Page 9

Running Mode is the default display of the unit when power is applied. In Running Mode, the display

shows the measured value in the appropriate user-defined format of rate, time, or count. As the input

signal changes, the display is continuously updated to show the latest measurement. In this display

mode, the Up and Down buttons serve no function other that to reset or silence alarms if configured

accordingly. Example displays for rate, time, and count operating modes are 13.60, 45:30, and 9301.

Parameter-Selection Mode can be entered by simply pressing and holding the Enter button down for

three seconds. Once in Parameter-Selection Mode, the far left of the display will be a P. The right side

of the display will indicate the currently selected parameter number for editing purposes. Pressing the

Up or Down button will increase or decrease the selected parameter number on the display. Although

the parameter numbers are in numerical order, some numbers are skipped. These numbers represent

reserved parameters that are not displayed. Once the desired parameter number is displayed, a press

of the Enter button will change the display to the Value Mode. When in Parameter-Selection Mode,

pressing the Enter button with parameter 0 selected will cause the unit to return to Running

Mode. Example displays for Parameter-Selection Mode are P 1, P 11, and P 54.

Value Mode is used to modify the value of the selected parameter. When in Value Mode, the two dots

which form the colon, between digits two and three, will alternately flash (one, then the other) to inform

the user that a parameters value is being edited. Pressing the Up or Down button increases or

decreases the selected parameters value. Value changes take effect immediately. For example, when

scrolling through the alarm output conditions, the relay will activate as the always-active selection is

passed. Once the desired value is showing in the display window, pressing the Enter button again will

return to Parameter-Selection Mode. The new value is not saved in permanent memory until the Enter

button is pressed. Removing power from the unit while in Value Mode may result in the specified new

value being lost.

Detailed Configuration Instructions

Factory Set Configuration

When shipped from the factory, the following basic settings are in place:

Rate Mode Operation in RPM

S1 Signal Input Pulses-per-Revolution: 10

Decimal Point Display: Off

Auto-Ranging: Disabled

Alarm Output(s): Disabled

Resetting the Unit to Factory Settings

The factory settings can be easily restored using either of two methods. Both methods require the

Program Enable jumper to be in the On position. The first is to apply power to the unit with both the

Enter and Down buttons pressed for 3 seconds. The second is to change the value of parameter 95

to 5.

JP1 (Program Enable Jumper)

The JP1 jumper is located under the dust cover on the back end of the upper board. When the jumper

is set to the "Off" position, all programming features are locked out to the front panel user. When the

jumper is in the "On" position, the programming parameters are open to change. JP1 is shipped from

the factory set in the "On" position.

7

Page 10

Software Parameters

Parameter

0 Selecting this item exits to Running Mode n/a n/a

1 Model Number n/a 80

2 Software Build 1 – 9999 n/a

3 Hardware Version 1 – 9999 n/a

4 Serial Number – Major (reserved) n/a n/a

5 Serial Number – Minor (reserved) n/a n/a

10 Operating Mode 1 – Rate Mode

11 Display Intensity 0 – 31 (Dim – Bright) 20

14 Input Trigger / Prescaler Setup 1 - Every Rising Edge

16 Counter Mode Reset Configuration 1 – Reset Disabled

20 Display Reference 1 – 9999 (Display Units) 1000

21 Reference RPM 1 – 9999 (RPM) 1000

22 Pulses Per Revolution 1 – 9999 (PPR) 10

23 Recovery Rate 0 – 1000 (1/2 seconds)

24 Display Smoothing / Averaging 0 – 60 (seconds)

25 Decimal Poi nt Po sition 0 – DP Disabled (XXXX)

26 Auto-Ranging Configuration 0 – Auto-Ranging Off

27 Counter Mode Reset / Preload Value 0 – 9999 (counts) 0

30 Reserved

31 Reserved

32 Reserved

33 Reserved

34 Reserved

35 Reserved

36 Reserved

37 Counter Gate Configuration 1 – Disabled

Read-Only Parameters

General Setup

Signal Input #1 (S1) Setup

Description

Value Range

(units)

2 – Time Mode

3 – Up Counter

4 – Down Counter

5 – Up / Down Counter

2 – Every Falling Edge

3 – Falling Edge / 4

4 – Falling Edge / 16

2 – Reset on Keypress

3 – Reset on S2 Low

4 – Reset on S2 High

0 – Disabled

> 0 – Recovery 1/2 seconds

0 – Disabled

> 0 – Averaging Seconds

1 – X.XXX

2 – XX.XX

3 – XXX.X

4 – XXXX.

1 – Auto-Range on Overflow

2 – Auto-Ranging On

2 – Counting Enabled (Low)

3 – Counting Enabled (High)

Factory

Settings

1

1

1

10

1

0

0

1

User

Settings

8

Page 11

Software Parameters, cont'd

Parameter

40 Activation Conditions 0 – Always Off

41 Output Style & Reset Mode 1 – Constant & Auto Reset

42 Reset Configuration 1 – No Sil., Reset on Key

43 Display Flash On Active Alarm 0 – Alarm Flash Disabled

44 Pulse on Time 1 – 3600 (seconds) 1

45 Pulse off Time 1 – 3600 (seconds) 1

46 Pulse Count 0 – 9999 (pulses) 0

47 Lower Limit 0 – 9999 (display units) 0

48 Upper Limit 0 – 9999 (display units) 9999

50 Activation Conditions 0 – Always Off

51 Output Style 1 – Constant & Auto Reset

52 Reset Configuration 1 – No Sil., Reset on Key

53 Display Flash On Active Alarm 0 – Alarm Flash Disabled

54 Pulse On Time 1 – 3600 (seconds) 1

55 Pulse Off Time 1 – 3600 (seconds) 1

56 Pulse Count 0 – 9999 (pulses) 0

57 Lower Limit 0 – 9999 (display units) 0

58 Upper Limit 0 – 9999 (display units) 9999

95 Restore to Factory Settings 0 – Do Nothing & Exit

98 Save to User Setting Area 0 – Do Nothing & Exit

99 Restore from User Setting Area 0 – Do Nothing & Exit

Alarm Output #1 Configuration

Alarm Output #2 Configuration

Parameter Memory Commands

Description

Value Range

(units)

1 – Always On

2 – Active when Above

3 – Active when Below

4 – Active inside Range

5 – Active outside Range

2 – Constant & Manual Reset

3 – Pulsed & Auto Reset

4 – Pulsed & Manual Reset

2 – No Sil., Reset on S2 High

3 – No Sil., Reset on S2 Low

4 – Sil., Reset on Key

5 – Sil., Reset on S2 High

6 – Sil., Reset on S2 Low

1 – Alarm Flash Enabled

1 – Always On

2 – Active when Above

3 – Active when Below

4 – Active inside Range

5 – Active outside Range

2 – Constant & Manual Reset

3 – Pulsed & Auto Reset

4 – Pulsed & Manual Reset

2 – No Sil., Reset on S2 High

3 – No Sil., Reset on S2 Low

4 – Sil., Reset on Key

5 – Sil., Reset on S2 High

6 – Sil., Reset on S2 Low

1 – Alarm Flash Enabled

5 – Restore Factory Settings

5 – Save Setting

1 – Restore Settings

Factory

Settings

0

1

1

0

0

1

1

0

0

0

0

User

Settings

9

Page 12

Parameter Descriptions

Parameter 0 Exit to Running Mode

When parameter 0 is selected in Parameter-Selection Mode, the unit will return to Running Mode

and display the running value. This should be selected once changes to parameters are

completed.

Parameter 1 Model Number (Read Only)

This is a number which represents the base model number for the product. For the DTM8000,

the model code is 80.

Parameter 2 Software Build (Read Only)

The software build is a code which identifies the software version of the unit.

Parameter 3 Hardware Version (Read Only)

The hardware version is a code which identifies which hardware was used to build the unit.

Parameter 4 & 5 Serial Number, Major & Minor (Read Only)

These parameters are reserved for future use as an electronic serial number and are unique to

each manufactured unit.

Parameter 10 Operating Mode

This parameter defines the basic mode of operation for the entire unit. It determines if the unit

is measuring rate, time, or count information. The following modes are available:

Mode 1 Rate Mode

Rate mode displays measurements in rate units such as RPM, Gallons per Hour, or Feet

per Second.

Mode 2 Time Mode

Time mode displays measurements in time units using the format AA:BB. By default

AA:BB represents minutes (AA) and seconds (BB). Optionally, it can be configured to

represent hours (AA) and minutes (BB) or other user-defined units with a 1:60 relationship.

Mode 3 Up Counter

Counter modes (3 5), display measurements in pulse counts or user-defined units which

are proportional to pulse count. In these modes, the DTM8000 will count the pulses which

are applied to the S1 input and display the related value. In this mode, each input pulse

increments the counter.

Mode 4 Down Counter

Same as Mode 3 above except each input pulse decrements the counter.

Mode 5 Up / Down Counter

Same as Mode 3 above except each input pulse either increments or decrements the

counter depending upon the state of Signal Input #2 (S2). If S2 is tied to common, the

counter is incremented; otherwise, it is decremented.

Parameter 11 Display Intensity

This parameter adjusts the intensity of the LED display digits in the front panel of the unit. The

values of 0 31 correspond to a gradual change from very dim to very bright. This is often useful

when used in the same panel as other pieces of equipment with LED displays and a uniform

display brightness is desired.

Parameter 14 Input Triggers / Prescale

This parameter determines how the S1 signal input is processed. It specifies which signal edge

is used for the measurements and the value of the internal frequency divider or prescaler.

Modes 3 and 4 should only be used if the input pulse rate exceeds the unit's maximum native

pulse rate (see specifications for details); otherwise, timing and counting calculations may

become sluggish and unnecessarily inaccurate.

Mode 1: Every Rising Edge, No Prescaler

In this mode, the signal input is measured at every rising edge.

Mode 2: Every Falling Edge, No Prescaler

In this mode, the signal input is measured at every falling edge.

10

Page 13

Mode 3: Falling Edge, Prescaler = 4

In this mode, the signal input is measured at every 4th falling edge. This mode is especially

useful when the signal input frequency is beyond the native pulse-per-minute range of the

DTM8000. Because unit will automatically compensates for the prescaler, there is no

need to factor in the prescaler value when setting the Display and RPM Reference

parameters.

Mode 4: Falling Edge, Prescaler = 16

Same as Mode 3 except the signal input is only measures every 16th falling edge.

Parameter 16 Counter Reset Configuration

In counter applications, it is often desirable to have the user or an external signal reset the

counter value to zero or some predetermined value. This parameter specifies which actions

will cause the counter to reset to the Counter Reset / Preset Value, parameter 27.

Mode 1: Reset Disabled

The counter cannot be reset.

Mode 2: Reset On Button Press

The counter will reset to the Counter Reset / Preset Value, parameter 27, when any of the

user-interface buttons are depressed.

Mode 3: Reset On S2 Input Low (Wired To Common)

The counter will reset to the Counter Reset / Preset Value, parameter 27, when S2 (signal

2) is brought to an electrically low state or wired to the unit's common.

Mode 4: Reset On S2 Input High (Not Wired To Common)

The counter will reset to the Counter Reset / Preset Value, parameter 27, when S2 (signal

2) is brought to an electrically high state (+5V) or left to float disconnected from the unit's

common.

Parameter 20 Signal Input 1 (S1) Display Reference

This is the number to be displayed when at the user-specified motor Reference RPM. In Rate

Mode, this value represents the numerator of the rate unit such as feet, ounces, or revolutions.

In Time Mode, this value represents the reference time measured in seconds or minutes. If the

desired display is HH:MM, then all values should be entered in minutes. If MM:SS is desired, then

all values should be entered in seconds. In Counter Modes, this value is the reference count

ratio which corresponds to the number of counts which equate to the specified number of

reference pulses, parameter 21. See applications for examples.

Parameter 21 Signal Input 1 (S1) Reference RPM (Reference Pulses in Counter Modes)

This is the reference RPM at which the Display Reference value should be displayed. In Rate

and Time Modes, this value represents the RPM of the encoder to which the Display Reference

corresponds. In Counter Modes, this value is the Reference Pulses which correspond the the

specified number of displayed counter, parameter 21. See applications for examples.

Parameter 22 Signal Input 1 (S1) Pulses per Revolution

This is the number of pulses per revolution. Value may be from 1 to 9999.

Parameter 23 Signal Input 1 (S1) Recovery Rate

This is the rate at which the display will attempt to recover once the pulse train appears to have

stopped. The recovery rate is the number of half seconds which the unit will wait before dividing

(Rate Mode) or multiplying (Time Mode) the display value by 2 in an attempt to accurately

represent the current speed or time. In the absence of input pulses, this will continue at regular

intervals until either 0 (Rate Mode) or 99:99 (Time Mode) is reached. Setting this parameter to

0 will disable the automatic recovery feature. If this parameter is set too low for the application,

the division or multiplication may prematurely occur causing the reading to read too high, too low,

or unstable. This can easily be corrected by simply increasing this parameter's value or

disabling it by setting it to zero.

Parameter 24 Signal Input 1 (S1) Display Smoothing / Averaging

This is the amount of time, in 1-second increments, which will be averaged before updating the

display. Setting this parameter to 0 will disable the averaging feature.

11

Page 14

Parameter 25 Signal Input 1 (S1) Decimal Point (DP) Position

This selects the format of the display with respect to the decimal points position. This parameter

does not effect the value entry for other parameters. For example, it the user desires to display

10.00 at an input of 300RPM, then parameter 20 would be set to 1000, parameter 21 would be

set to 300, and parameter 25 would be set to 2.

Mode 0: Fixed XXXX

Mode 1: Fixed X.XXX

Mode 2: Fixed XX.XX

Mode 3: Fixed XXX.X

Mode 4: Fixed XXXX.

Parameter 26 Signal Input 1 (S1) Auto-Ranging Configuration

This selects how the unit auto-ranges and formats the numbers for the display.

Mode 0: Auto-Ranging Disabled

The auto-ranging mode is disabled. Ignoring decimal points, this limits the units display

range from 0 to 9999. Values beyond this range will display as an overflow error (-OF-).

Mode 1: Auto-Ranging On Overflow Only

In this mode, auto-ranging will only be activated if the display value exceeds the maximum

native display value. For example, in XX.XX decimal point mode, 99.99 would be the

maximum native value for a 4-digit display. When the display is in overflow, it will display

only the 4 most significant digits and the decimal point will flash.

Mode 2: Auto-Ranging Always Active

In this mode, auto-ranging is always active and continuously attempts to display the 4 most

significant digits. For example, the display will automatically range from 0.001 to 9999 as

needed. In this mode, any value over 9999 will be displayed as an overflow error (-OF-).

Parameter 27 Counter Reset / Preset Value

This is the value that will automatically be loaded into the display after the counter has been reset.

See Counter Reset Configuration, parameter 16, for more details.

Parameter 30, 31, 32, 33, 34, 35, and 36

Reserved For Future Use.

Parameter 37 Signal Input 2 (S2) Counter Gate (Enable / Disable) Configuration

This selects how the S2 input is utilized in single channel counter modes.

Mode 1: Disabled (Required For Up / Down Counter Mode)

The S2 input will not function as a gate control and instead will act as the second input for

dual-channel counter operation.

Mode 2: Counting Enabled When S2 Input Low (Wired To Common)

The unit will continue to count input pulses as long as the S2 is in an electrically low state

or connected to the unit's common terminal. When the S2 input goes high (+5V) or is

allowed to float disconnected, the counter will be frozen at its current value.

Mode 3: Counting Enabled When S2 Input High (Not Wired To Common)

The unit will continue to count input pulses as long as the S2 is in an electrically high (+5V)

state or allowed to float disconnected. When the S2 input goes low or is wired to the unit's

common, the counter will be frozen at its current value.

Parameter 40 & 50 Alarm 1 & 2 Conditions

This defines which conditions will result in the alarm 1 or alarm 2 outputs being activated.

Mode 0: Always Inactive

The alarm output will remain in an inactive state. In this state, the NC and C contacts will

be internally electrically connected.

Mode 1: Always Active (When Power Is Applied)

The alarm output will become active when the power is applied to the unit. In this state,

the NO and C contacts will be internally electrically connected.

Mode 2: Active When Display Value Above Limit

The alarm output will activate when the displayed value is above the upper limit settings,

parameters 48 and 58 accordingly.

12

Page 15

Mode 3: Active When Display Value Below Limit

The alarm output will activate when the displayed value is below the lower limit settings,

parameters 47 and 57 accordingly.

Mode 4: Active When Display Value Inside Range

The alarm output will activate when the displayed value is greater than or equal to lower

limit settings and less than or equal to the upper limit setting.

Mode 5: Active When Display Value Outside Range

The alarm output will activate when the displayed value is less than the lower limit setting

or greater than upper limit setting.

Parameter 41 & 51 Alarm 1 & 2 Output Style & Reset Configuration

This setting configures the output mode and reset method for the alarm outputs.

Mode 1: Constant & Auto Reset

In this mode, the alarm output will remain active until the alarm condition ceases to exist.

The alarm will automatically reset when the conditions return to normal.

Mode 2: Constant & Manual Reset

In this mode, the alarm output will remain active until the alarm is reset manually. See

parameters 42 and 52 for details.

Mode 3: Pulse & Auto Reset

In this mode, the alarm output will pulse on and off until the alarm condition ceases to exist.

The pulsed modes are commonly used for audible alarms where a constant output would

be considered distracting or awkward. The alarm will automatically reset when the

conditions return to normal.

Mode 4: Pulse & Manual Reset

In this mode, the alarm output will pulse on and off until the alarm is reset manually. See

parameters 42 and 52 for reset details. The pulsed modes are commonly used for audible

alarms where a constant output would be considered distracting or awkward.

Parameter 42 & 52 Alarm 1 & 2 Reset Configuration

This setting determines which actions will cause an active alarm to be silenced or reset.

Mode 1: No Silencing, Reset On Any Button Press

In this mode, an active alarm cannot be silenced. Once the alarm condition ceases to

exist, however, any user-interface button may be pressed to cause a manual reset.

Mode 2: No Silencing, Reset On S2 Input High (Not Wired To Common)

Similar to Mode 1. Once the alarm condition ceases to exist, setting the S2 input to a high

(+5V) state or allowing it to float disconnected will cause a manual reset.

Mode 3: No Silencing, Reset On S2 Input Low (Wired To Common)

Similar to Mode 1. Once the alarm condition ceases to exist, setting the S2 input to a low

(COM) state or wiring it to common will cause a manual reset.

Mode 4: Silencing Enabled, Reset On Any Button Press

When the conditions for an active alarm persist, pressing any user-interface button will

result in the alarm being silenced or deactivated, but not reset. A second attempt to reset

the alarm must be made after the condition cease to exist to clear the alarm.

Mode 5: Silencing Enabled, Reset On S2 Input High (Not Wired To Common)

Similar to Mode 4. Setting the S2 input to a high (+5V) state or allowing it to float

disconnected will cause the alarm to be silenced or reset depending on the current state

of the alarm conditions.

Mode 6: Silencing Enabled, Reset On S2 Input Low (Wired To Common)

Similar to Mode 4. Setting the S2 input to a low (COM) state or wiring it to common will

cause the alarm to be silenced or reset depending on the current state of the alarm

conditions.

Parameter 43 & 53 Alarm 1 & 2 Display Flash On Alarm

This will cause the display to flash when an alarm conduction is active.

Parameter 44 & 54 Alarm 1 & 2 Pulse on Time

This parameter defines the number of seconds the output should be enabled during the on

phase of an active pulsing alarms output. See application samples for examples.

13

Page 16

Parameter 45 & 55 Alarm 1 & 2 Pulse off Time

This parameter defines the number of seconds the output should be disabled during the off

phase of an active pulsing alarms output.

Parameter 46 & 56 Alarm 1 & 2 Pulse Count

This setting determines how many pulses are output when the alarm is activated and is

configured in pulse output style. When 0 is entered, the unit will be set for continuous pulses while

the alarm is active.

Parameter 47 & 57 Alarm 1 & 2 Lower Limit

This setting defines either the lower limit or lower end of a range for the alarm region. Alarm limits

are set in display units without regard to decimal point or colon position. In Rate and Counter

Modes, a limit of 123 could represent a display value of 123, 12.3, 1.23, or 0.123. When in Time

Mode, a limit of 123 would represent 1:23 on the display.

Parameter 48 & 58 Alarm 1 & 2 Upper Limit

This setting defines either the upper limit or upper end of a range for the alarm region. Alarm

limits are set in display units without regard to decimal point or colon position. In Rate and

Counter Modes, a limit of 123 could represent a display value of 123, 12.3, 1.23, or 0.123. When

in Time Mode, a limit of 123 would represent 1:23 on the display.

Parameter 95 Factory Settings Command

When set to a value of 5, the unit will be reset to factory settings. This can also be achieved by

applying power to the unit with both the Enter and Down buttons depressed. The programming

jumper must be in the "On" position for this method to function.

Parameter 98 Save to User Settings Area Command

When set to a value of 5, the unit will store all adjustable parameters to the user settings area.

The user settings area is intended to be a location where a user can store settings specific to

their application. A user can easily refresh their custom settings. Another common use for this

area is testing and initial setup. The user can store known-good settings here and easily

experiment without the fear of losing the optimal configuration.

Parameter 99 Restore from User Settings Area Command

When set to a value of 1, the unit will restore the all adjustable parameters from the user settings

area. See parameter 98 for additional information.

14

Page 17

Pump Flow Monitor with Audible and Visual Alarm

Description:

A pump monitor which displays the pump rate in gallons per minute with an audible and visual

alarm output which will warn the operator of excessively low flow conditions under 5.00 GPM.

The alarm should not be able to be silenced and should be reset when any front-panel button is

pressed. The display should indicate in the format xx.xx (GPM). Due to normal fluctuations in

flow rates, it is desirable to have the display filter or average the value over 3 seconds to produce

a more accurate and steady display.

Application Diagram:

Application Examples

Motor Control

Fluid

Outlet

ItemValuPage

36.24

TACHOMETER

DTM8000 Meter

Wiring Diagram:

DTM8000-6

Parameter Configuration:

Encoder

Tach

ENTER

Pump Specs:

53 Shaft Rotations = 3 Gallons

Audible

Annunciator

NC2

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

P1-7

P1-8

P1-9

P1-10

P1-11

P1-12

C2

NO2

NC1

C1

NO1

N

L

COM

+5V

S1

S2

Not Used

Not Used

Not Used

Not Used

Not Used

2 Amp

white

}

black

red

Fluid

Pump

Inlet

120VAC

Audible

Annunciator

AC Line Input 85-265VAC, 50-60 Hz

Encoder

Parameter Value Notes

10 1 Rate Mode Setting (GPM is a rate-based unit)

20 3 00 Display should indicate 3.00 GPM (300) when motor at Reference RPM, parameter 21

21 53 This is the RPM at which the Display Reference, parameter 20, should be displayed

22 10 Pulses per revolution of shaft encoder or pickup is 10 PPR

24 3 Display filtering / averaging set to 3 seconds

25 2 Decima l point p osition set to XX.XX on dis play

40 3 Alarm active when display value is below lower limit

41 2 Constant alarm output with manual reset required

42 1 No silencing, reset on any button press

43 1 Flash display when alarm is active

47 500 Lower limit setting for 5.00 GPM (500). Limits are entered without regard for decimal

point position

15

Page 18

Conveyor Oven Time Monitor with Over-Heating Alarm

Description:

An oven monitor displaying the tunnel time in minutes and seconds. The tunnel time is defined

as the time it takes for the heated object on the conveyor to travel from point A to point B in the

application diagram below. A visual indicator should activate if the tunnel time rises above a

preset limit of 22 minutes and 30 seconds which could cause overheating of the processed

material. The indicator should automatically reset when the tunnel time returns to the normal

operating range. For ease of use, the display should be averaged over a period of 1 second.

Application Diagram:

Motor Control

Wiring Diagram:

AB

Heat Source

Tunnel Oven

Tach

Ite

ValuPage

m

ENTER

18:40

TACHOMETER

DTM8000 Meter

DTM8000-6

Connect to

Coupling

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

P1-7

P1-8

P1-9

P1-10

P1-11

P1-12

Encoder

NC2

C2

NO2

NC1

C1

NO1

N

L

COM

+5V

S1

S2

Gear Motor

Drive Train Specs:

1250 RPM at non-reduced

motor shaft equates to

9 minutes and 15 seconds

of tunnel time

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

2 Amp

AC Line Input 85-265VAC, 50-60 Hz

}

black

red

white

Coupling to

Chain Drive

Encoder

Parameter Configuration:

Parameter Value Notes

10 2 Time Mode Setting

20 555 Display should indicate 9:15 (555) when motor at Reference RPM, parameter 21. In

time mode, all display values are entered in total number of seconds.

For example, 555 = (9 minutes * 60 seconds-per-minute) + 15 seconds.

21 1250 This is the RPM at which the Display Reference, parameter 20, should be displayed.

22 10 Pulses per revolution of shaft encoder or pickup is 10 PPM

24 1 Display filtering / averaging set to 1 seconds

40 4 Alarm active when display value is above upper limit

41 1 Constant alarm output with automatic reset

43 1 Flash display when alarm output is active

48 1350 Upper limit setting for 22 minutes and 30 seconds. In time mode, all limits are entered in

total number of seconds.

For example, 1350 = (22 minutes * 60 seconds-per-minute) + 30 seconds.

16

Page 19

Take-up / Pay-out Reel Material Measurement with Alarm

Description:

A take-up / pay-out system where the DTM8000 displays a measurement of dispensed or

accumulated material in linear yards. Once the desired amount of material, 1500 yards,

has been dispensed or accumulated, an external light should illuminate to indicate that the

specified material volume has passed. At this point, the user must be able to press a button

on the user interface to reset the count to zero and the process repeats.

Application Diagram:

Tension

Motor #1

Belt

Capstan

Motor

Belt

Speed Control

Pinch Rollers

Capstan Drive Specs:

28.3 Revolutions of the

Capstan motor equate to

50 linear yards of material

Belt

Tension

Motor #2

Wiring Diagram:

Torque

Control #1

DTM8000-6

Tension

Tach

ItemValuPage

3650

TACHOMETER

DTM8000 Meter

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

P1-7

P1-8

P1-9

P1-10

P1-11

P1-12

Encoder

ENTER

NC2

C2

NO2

NC1

C1

NO1

N

L

COM

+5V

S1

S2

Not Used

Not Used

Not Used

Not Used

Not Used

2 Amp

Tension

black

red

white

Pylon-Style

Illuminated

Alarm

Torque

Control #2

120VAC

Illuminated

Pylon-Style

Alarm

AC Line Input 85-265VAC, 50-60 Hz

}

Encoder

Attached to Driven

Capstan Pinch Rollers.

Parameter Configuration:

Parameter Value Notes

10 3 Up-Counter Mode Setting

16 2 Conf igure counte r to reset on any button press

20 500 Display should increment 50 linear yards for each Reference Count, parameter 21.

Because the initial val ues were 28.3 revoluti on s per 50 linear yards, each is multipli ed by

10 to gi ve an even number to in cr ease accuracy sinc e the display can be programmed in

whole numbers .

21 283 In count mode, the Reference RPM is set in revolutions. 283 has been entered here to

represen t 2 8. 3 r evoluti ons and the D i splay Refe rence h as also been multi p l ied by 10 t o

yield whole numbers.

22 10 Pulses per revolution of shaft encoder or pickup is 10 PPM

40 4 Alarm active when display value is above upper limit

41 2 Constant alarm output with manual reset required

42 1 No silencing, reset on any button press

48 1500 Upper limit setting for 1500 linear yards

17

Page 20

Bi-directional Incremental Position Display

Description:

A system is needed which will track the position of a bi-directional linear-motion platform

and allow the user to select a home or zero position. The display should read in inches

and indicate the position of the platform at all times.

Application Diagram:

Platform

Drive Train Specs:

Wiring Diagram:

40 Revolutions = 3.5 In.

of Platform Motion

Tach

ItemValuPage

ENTER

263.4

TACHOMETER

DTM8000 Meter

DTM8000-6

P1-1

P1-2

P1-3

P1-4

P1-5

P1-6

P1-7

P1-8

P1-9

P1-10

P1-11

P1-12

Encoder

NC2

C2

NO2

NC1

C1

NO1

N

L

COM

+5V

S1

S2

Linear-Motion System

Motor Control

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

2 Amp

AC Line Input 85-265VAC, 50-60 Hz

}

black

red

white

brown

Connect to

Coupling

Coupling to

Chain Drive

Gear Motor

Encoder

Parameter Configuration:

Parameter Value Notes

10 5 Up/Down Counter Mode

20 35 Beca u se th e initial values were 40 revolutions per 3.5 inches of platform motion, each is

multipli e d by 10 to give an even number to incre ase accuracy since t he disp lay can be

program m ed in whole numbers. Additionally, because of the decimal point position, the

Display Reference is multiplied by 10 to generate the proper display format. Without the

second multiplication by 10, the display would only read 3.5 inches when the drive motor

turned 400 revolutions.

21 400 In count mode, the Reference RPM is set in revolutions. 400 has been entered here to

represent 40 revolutions and the Display Reference has also been multiplied by 10 to yield

whole numbers .

22 10 Pul s es per revolution of shaft encoder or pickup is 10 PPM

25 3 Decimal point position set to XXX.X on display

18

Page 21

Troubleshooting

Problem Possible Case Solution

Display is blank Power not applied

Defective unit

Display is di m Display intensity

When power is

applied, “LF-L” is

displayed

When power is

applied, “LF-H” is

displayed

The first or second

alarm output does

not seem to

function

parameter is too low

AC line supplying

power to unit has too

much noise

AC line supplying

power to unit has an

abnormally low

frequency

AC line supplying

power to unit has too

much noise

AC line supplying

power to unit has an

abnormally high

frequency

Second alarm output

parameters not

configured proper ly

Using a volt meter, verify that a voltage between 85 and 265VAC is measured between

the L and N terminal block positions.

Contact technical support for additional help and i nstructions.

Editing and increasing the display intensity parameter should cause the display digits to

become brighter.

Review routing of power wires in machine to minimize electrical noise. Look for other

devices which share the same circuit which may be producing unacceptable levels of line

noise. In some applications, such as welding equipment, a careful regiment of applying

an AC line filter, re-routine wires, divi di ng circuits, using shielded cable, and properly

grounding devices will usually solve the problem.

The unit is designed to operate wi th AC lines from 48-62 Hertz (cycles per second).

Review routing of power wires in machine to minimize electrical noise. Look for other

devices which share the same circuit which may be producing unacceptable levels of line

noise. In some applications, such as welding equipment, a careful regiment of applying

an AC line filter, re-routine wires, divi di ng circuits, using shielded cable, and properly

grounding devices will usually solve the problem.

The unit is designed to operate wi th AC lines from 48-62 Hertz (cycles per second).

Second alarm output parameters not configured properly

Review alarm output #2 paramete rs. The fi rst and second alarm relay outputs can be

tested by selecting the “Always On” value for the Activation Condition parameters for the

respective alarm output. When doing this, the relay click should be audible and the NC

(Normally Closed) and C (Common) terminals should become internally shorted at the

terminal block.

19

Page 22

- Notes -

20

Page 23

- Notes -

21

Page 24

BALDOR ELECTRIC COMPANY

P.O. Box 2400

Ft. Smith, AR 72902–2400

(479) 646–4711

Fax (479) 648–5792

www.baldor.com

CH

TEL: +41 52 647 4700

FAX:+41 52 659 2394

I

TEL: +39 11 562 4440

FAX:+39 11 562 5660

Baldor Electric Company

MN1327

D

TEL: +49 89 90 50 80

FAX:+49 89 90 50 8491

AU

TEL: +61 29674 5455

FAX:+61 29674 2495

UK

TEL: +44 1454 850000

FAX:+44 1454 859001

CC

TEL: +65 744 2572

FAX:+65 747 1708

F

TEL: +33 145 10 7902

FAX:+33 145 09 0864

MX

TEL: +52 477 761 2030

FAX:+52 477 761 2010

Printed in USA

04/03

Loading...

Loading...