Page 1

Instruction Manual for Connecting Sensors on Pillow Block Bearings

Temperature Monitor, Alarm System, Embedded Thermocouple and

Transmitter, Vibration Accelerometer, and Proximity Switch

Bearing Temperature Monitor-Alarm System

A. Connection to a PLC:

– Use an AC input card 120 VAC

– Cards available from Allen Bradley for SLC 500 are

1746-IA4, 1746-IA8 and 1746-IA16

B. If no PLC is used, the DODGE Light and Buzzer Alarm

Module can be used (DODGE Part No. 063524).

Connections are shown below.

DANGER: The user is responsible for conforming

with the National Electrical Code and all other

applicable local codes. Wiring practices, grounding,

disconnects and overcurrent protection are of

particular importance. Failure to observe these

precautions could result in severe bodily injury or

loss of life.

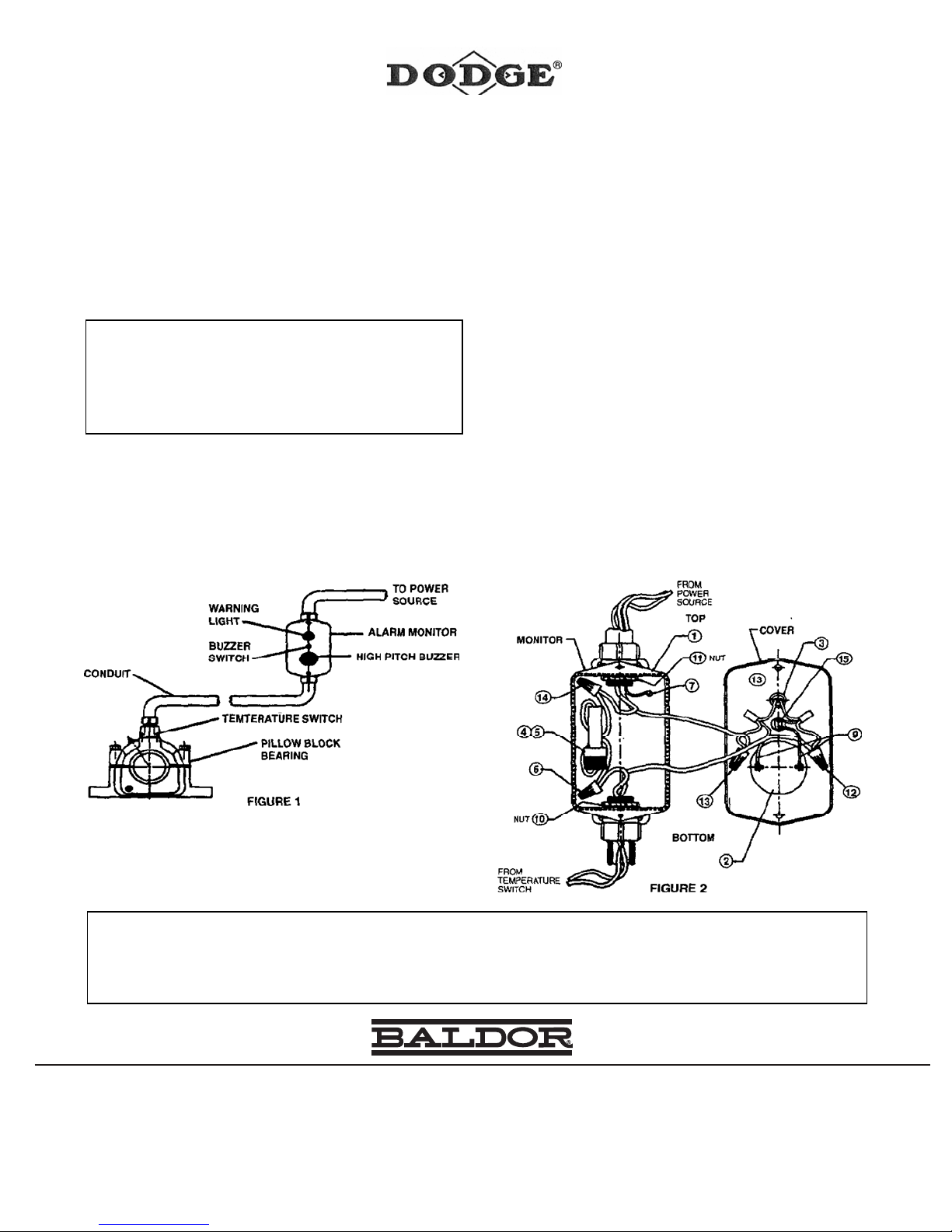

I. Bearing Temperature Alarm Monitor System:

1. A complete installation, Pillow Block with temperature

switch, conduit, and alarm is shown in Figure 1. Items

supplied by DODGE are the Pillow Block with

temperature switch and the alarm monitor. Conduit,

wires, and liquid tight fittings are supplied by the user.

2. A DODGE Pillow Block with temperature switch mounts

on the shaft exactly like a standard pillow block

.

screws on the front. (See Figure 2)

3. Install a conduit between the monitor and the bearing

1

using

/2" liquid tight fittings.

4. Use 16 AWG wires installed in the conduit to connect

the temperature switch to the alarm monitor.

5. Verify that AC power is disconnected and locked out or

tagged at the power source. Bring AC power wires to

the top of the alarm monitor and secure using

tight fitting.

6. At the bearing remove the temperature switch cover,

nect the two leads of the temperature switch to the

con

two wires installed in step 4 above using approved wire

nut connectors and reinstall the cover.

7. Connect the end of one wire that is connected to the

switch to one end of the fuse (6). Connect the second

wire from the temperature switch to the joint (12).

8. Connect the black (hot) wire from the power source to

the other end of the fuse (14). Connect the white

(neutral) wire to lead (13). Connect the green (ground)

wire to the ground screw (7) on the back of the monitor.

Make sure the screw is tight and the wire is secure.

9. Replace the cover and secu

the two screws

re with

1

/2" liquid

.

II. Alarm Monitor Installation:

1. Install the alarm monitor in a visible and close safe

place using the four mounting holes on the back of the

enclosure.

2. Remove the enclosure cover by removing the two

WARNING: Because of the possible danger to person(s) or property from accidents which may result from the improper use of products, it is important that

correct procedures be followed. Products must be used in accordance with the engineering information specified in the catalog. Proper installation,

maintenance and operation procedures must be observed. The instructions in the instruction manuals must be followed. Inspections should be made as

necessary to assure safe operation under prevailing conditions. Proper guards and other suitable safety devices or procedures as may be desirable or as may

be specified in safety codes should be provided, and are neither provided by Baldor Electric Company nor are the responsibility of Baldor Electric Company.

This unit and its associated equipment must be installed, adjusted and maintained by qualified personnel who are familiar with the construction and operation

of all equipment in the system and the potential hazards involved. When risk to persons or property may be involved, a holding device must be an integral part

of the driven equipment beyond the speed reducer output shaft.

P.O. Box 2400, Fort Smith, AR 72902-2400 U.S.A., Ph: (1) 479.646.4711, Fax (1) 479.648.5792, International Fax (1) 479.648.5895

6040 Ponders Court, Greenville, SC 29615-4617 U.S.A., Ph: (1) 864.297.4800, Fax: (1) 864.281.2433

© Baldor Electric Company

MN3043 (Replaces 499807) 06/30/09

*3043-0609*

World Headquarters

Dodge Product Support

www.baldor.com

All Rights Reserved. Printed in USA.

Page 2

Page 3

Pillow Block Assemblies with Embedded Thermocouple and Transmitter

A. Connection to a PLC:

– The transmitter output can be connected directly to an

analog input card with internal loop power supply.

– Typical cards that can be used from Allen Bradley are

1771-NBSC and 1771-NB4S.

B. If a PLC is not available, the panel mounted temperature

indicator available from DODGE can be used to power

the transmitter and display the temperature. The indicator

model is CT1010, Part No. 055221. The indicator has two

settable alarm relays for warning and shut down. The

connections are shown in the instruction manual supplied

with the indicator.

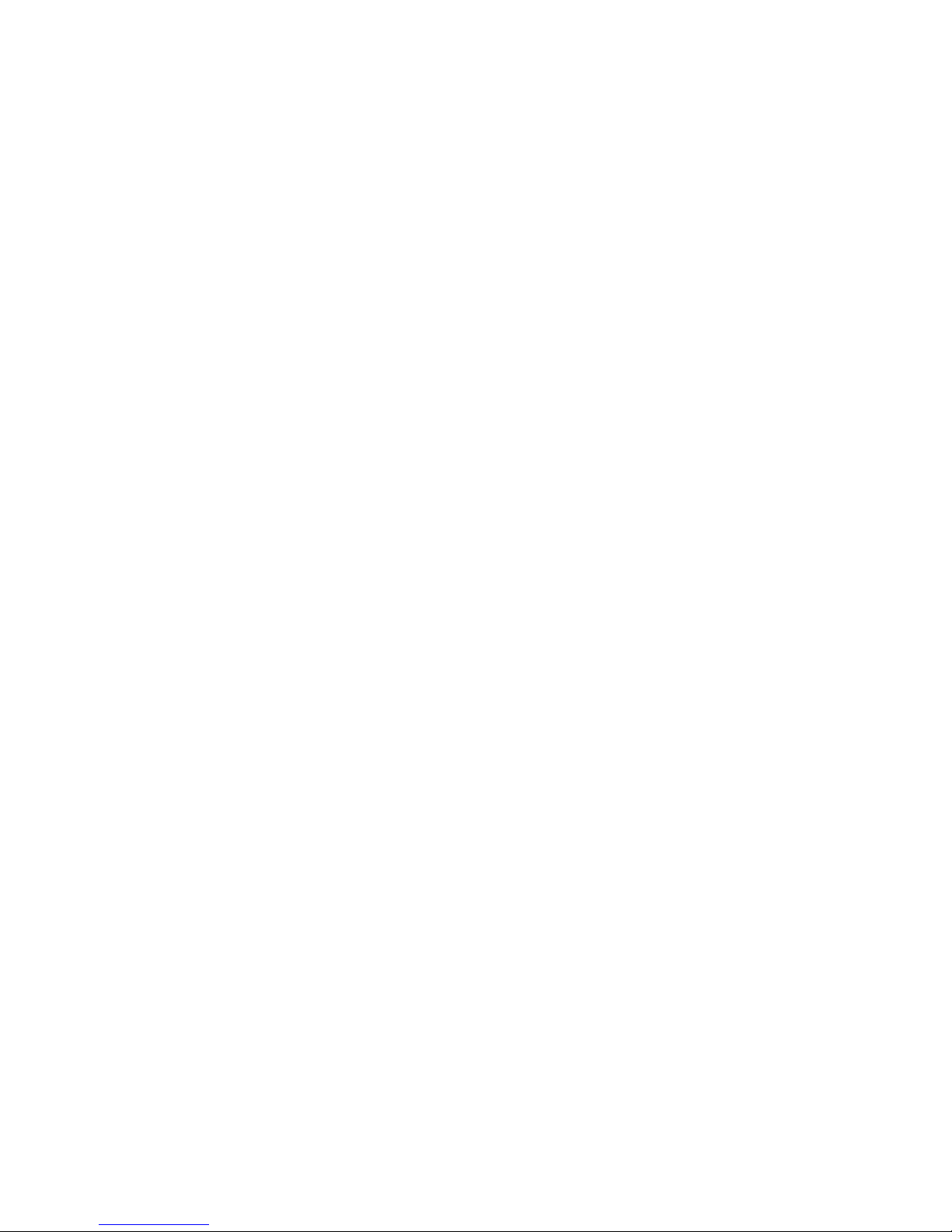

I. Pillow block assemblies equipped with embedded

thermocouple, transmitter and data acquisition system i

shown in Figure 3.

s

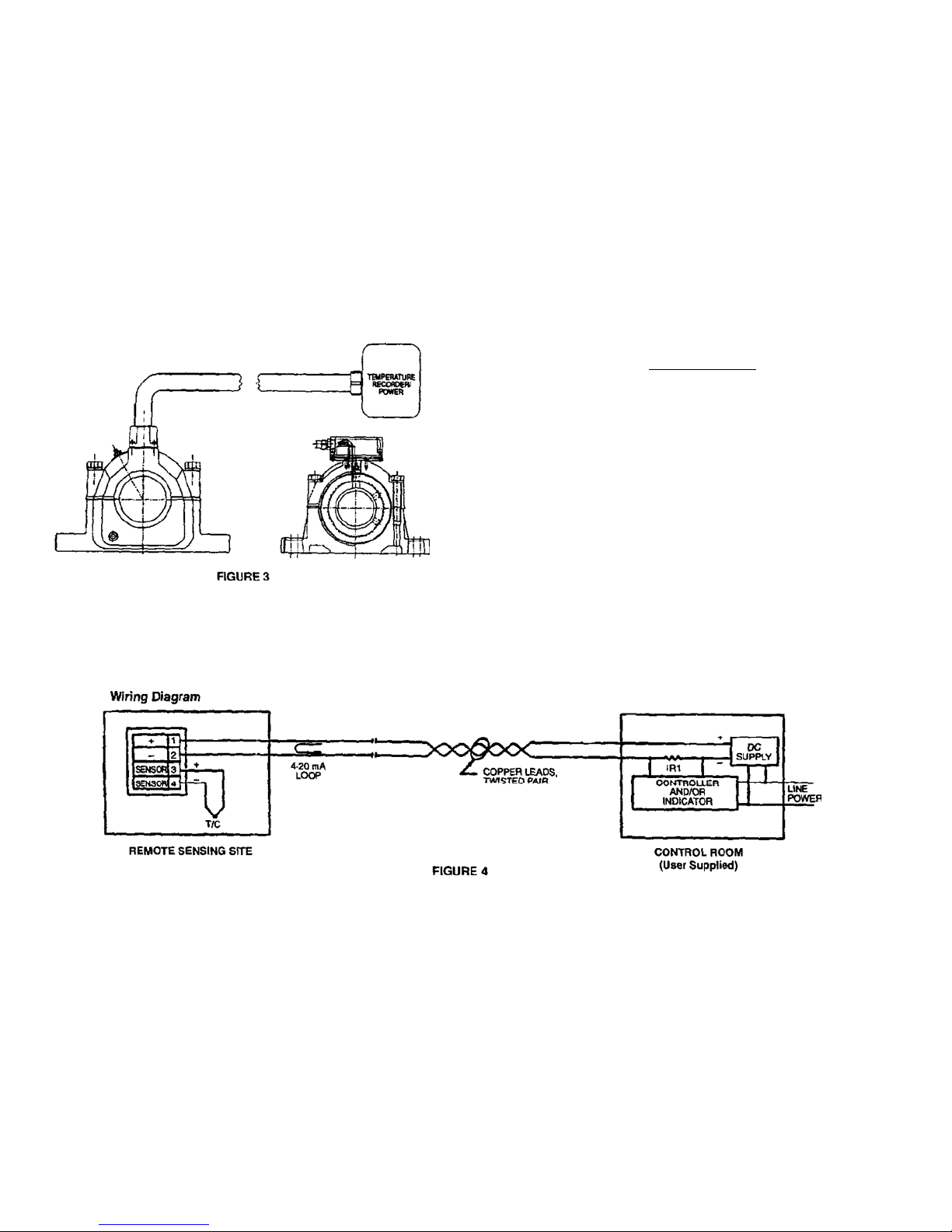

II. Connection of pillow block with loop driver or data

acquisition system is shown in Figure 4 and Figure 5.

1. Take the top cover (1) off from the housing (2) by

removing the four screws.

2. Install a

cover (1) using the hole on the side.

3. Use a flex conduit (4) between the cover and the loop

driver or your data acquisition system. Voltage supply

required is 8.5 volts to 35 volts DC with no load.

4. Install the signal wires (two twisted copper wires) (5)

inside the flex conduit.

5. Connect the ends of the two wires to the transmitter

(6) terminals 1 and 2 and secure the screws.

6. Lo

op resistance: The maximum allowable resistance

of the signal carrying load, including extension wires

and load resistance, is given by this formula:

R approximately = (V supply – 8.5V)

.02 amps

Example:

If supply voltage is 24 VDC, the loop resistance must

be less than 775 ohm (wires plus R1). Use 80% of the

calculated value to protect against drop in voltage.

7. Replace the cover and tighten the four (4) screws.

8. Connect the other ends of the two wires (5) to your

loop driver/power supply or your data acquisition

system with built-in power supply.

9. Your system should now be able to read the

temperature between 0 and 250ºF.

10. The output of the transmitter is 4–20 mA (milliamps).

1

/2" liquid tight electrical fitting (3) on the

2

Page 4

Pillow Block Assemblies with Accelerometer

A. Connection to a PLC:

– In order to connect the accelerometer to a PLC, a

vibration transmitter is needed to power the

accelerometer and to transmit the signal in a suitable

form.

– The vibration transmitter produces 4 to 20 mA

proportional to the vibration velocity and ±5 volts

signal proportional to acceleration. The transmitter

needs 20 to 30 DC voltage supply. The transmitter is

available from DODGE, Part No. 055222.

– The output of the transmitter can then be connected

to Allen Bradley 1746-NI4 card.

B. Connection to a Data Acquisition System:

– A data acquisition system is normally composed of a

PC with analog input cards plus the required software.

– In order to interface the accelerometer to the analog

input card, the above transmitter can be used. A lower

cost power conditioner module can also be used. The

power conditioner module will produce plus or min us

5 volts when powered by a 24 volts DC power supply.

The module is available from DODGE, Part No.

055223.

– The output of the transmitter or module should then

be connected to the input analog card in the PC. It is

important that the vibration be sampled at 10,000 Hz.

1. Remove the top cov er from the housing very carefully by

removing the four screws. Note that the accelerometer is

attached to the cover (1).

2. Install a

using the hole on the side.

3. Use a flex conduit (2) between the cover and the

accelerometer power supply or the data acquisition

system if the system has a built-in power supply.

4. Insert the accelerometer cable through the conduit and

secure the nuts to the accelerometer and the power

supply (3) and (4).

5. Use a DC power supply 18 to 28 volts with current

capability of 2 to 20 mA. Attached is the specifications for

the accelerometer and its power supply.

1

/2 inch liquid tight electrical fitting to the cover

DYNAMICS ENGLISH S.I.

Sensitivity (±10%)

Measurement Range ±50 g ±490 m/s2

Resolution 0.0002 g 0,0019 m/s2

Frequency Range: (±10%)

(±3 dB) 30–600,000 cpm (0.5–10,000 Hz)30–600 000 cpm (0,5–10 000 Hz)

Resonant Frequency

(A)

100 mV/g 10,2 mV/m/s2

(B)

(C)

1,080 kcpm (18 kHz) 1 080 kcpm (18 kHz)

ACCELEROMETER CHARACTERISTICS

66–300,000 cpm (1.1–5,000 Hz) 66–300 000 cpm (1,1–5 000 Hz)

3

Page 5

Transverse Sensitivity

Amplitude Linearity

ENVIRONMENTAL

Shock Limit (peak) 5,000 g 49 050 m/s2

Temperature Range -65º to + 185ºF -54º to +85ºC

Temperature Coefficient -0.05%/ºF -0,09%/ºC

Strain Sensitivity

ELECTRICAL

Setting Time

Excitation Voltage 18 to 28 volts 18 to 28 volts

Excitation Current 2 to 20 mA 2 to 20 mA

Output Impedance <100 ohms <100 ohms

Electrical Noise Broadband

Electrical Noise Spectrical: 10 Hz

100 Hz

1000 Hz

Output Bias 8 to 14 volts 8 to 14 volts

Full Scale Output Voltage ±5 volts ±5 volts

Discharge Time Constant

MECHANICAL ENGLISH S.I.

Size: Hex × Height 11/16 × 1.1 in 17.5 × 27.9 mm

Weight 1.2 oz 35 gm Single Point Calibration @ 100 Hz

Mounting Thread (female)

Mounting Torque 2 to 5 ft-lb 2,7 to 6,8 N-m (A) Conversion Factor: 1 g = 9,81 m/s2

Sensing Element Ceramic Ceramic (B) 1 Hz = 60 cpm (cycles per minute)

Case Material 316L St. Stl. 316L St. Stl. (C) Mounted Resonance (nominal)

Sealing Welded Welded (D) Zero Base Best Straight Line

Microdot 10–32 Microdot Microdot (E) Within 1% of output bias

Connector Position Side Side (F) 1/4–28 thread has no equivalent

(D)

±1% ±1%

(E)

5 sec 5 sec

(F)

1/4–28 Not Applicable

≤5% ≤5%

0.001 g/µε 0,01 m/s2/µε

200 µg 1 962 µm/s2

4.0 µg/√Hz 39,2 (µm/s2)√Hz

1.2 µg/√Hz 11,8 (µm/s2)/√Hz

0.4 µg/√Hz 3,92 (µm/s2)/√Hz

≥0.3 sec ≥0,3 sec

USAF, USN and TAF Pillow Blocks Fitted with a Proximity Switch

Supplied Accessories:

Notes:

in S.I. system.

SPEED PICKUP:

A. Connection to a PLC:

1. AC Proximity Probe:

The AC proximity probe can be connected directly to

a PLC using an AC input card such Allen Bradley

1746-IA4, 1746–IA8 or 1746-IA16. Other cards are

also available for the PLC 5.

Care must be given to the program timing to ensure

that all the pulses are captured by the PLC. If the

program is too long, DODGE offers a programmed

Allen Bradley Micrologix PLC to provide the function

of a zero speed switch.

2. DC Proximity Probe:

The DC proximity probe can be connected to a P LC

using DC input cards such as Allen Bradley 1746IV16 or 1746–IV8. Again care must be given to the

program timing to ensure capturing all the pulses

from the probe.

If the program is too long to capture all the pulses,

DODGE offers a programmed Allen Bradley

Micrologix PLC to provide the function of a zero

speed switch.

B. If a PLC is not available, DODGE offers a programmed

Allen Bradley Micrologix PLC to function as a zero speed

switch, Part No. 055224 (AC).

Note: When specifing the DODGE/AB Micrologix zero speed

switch, please specify the customer preference for 24

volts DC output or 120 volts AC output.

A speed pickup provides a means of sensing speed

variation up to 480 RPM (AC prox.) and up to 4200 RPM

(DC prox.) by sensing the rotation of a specially equipped

locknut with two raised surfaces.

USAF/USN PILLOW BLOCKS

EQUIPPED WITH SPEED PICKUP:

For USAF/USN the speed sensor has been present at the

factory. To indicate the setting a blue dye was used to mark

where the proximity probe should be screwed into the

housing. The probe was backed off and shipped loose to

protect it during shipping and during the lowering of the shaft

and the bearing. The proximity probe is made to be used

only on the cast closed end housing and the non-ex pansion

bearing of a tail pulley. For bore sizes up to 5", misalignment

must not exceed ±

1

/2 degree. Misalignment for larger bore

sizes should not exceed ± 1/4 degree.

After lowering the shaft and the bearing into the lower h alf of

the housing, screw the proximity probe into the housing up

to the blue dye mark. Use the lock nut to secure the

proximity probe in the housing. Use a tightening torque of 75

inch-lbs. for 12 mm AC switch, and 150 inch-lbs. for 18 mm

Ac switch, and 25 inch-lbs. for DC switch also used with

EZLINK. The enclosure provided can be used as the

junction box for wiring the proximity switch to the out going

cable. Follow all local and national electrical codes in wiring

the proximity probe. Check the gap between the proximity

probe and the raised portion of the shaft nut to make sure it

is correct. For the 12 mm probe the gap is .1 inch, and for

the 18 mm probe it is .12 inch. Note that for the 18 mm

probes the probe is made to be flush with the i nside of the

housing.

After wiring the probe “The cable will have to be passed

through the opening provided on the conduit box,” line up a

gasket, the spacer, a gasket and the cover with the four

screw holes on the casting. Use the four screws and the four

lock washers to secure the conduit box, the gaskets and the

spacer to the housing. Use a tightening torque on the 10–32

screws equal to 25 inch-lbs.

On some models a 90 degrees elbow is used as an

enclosure. In this case, screw in the proximity probe until the

blue dye portion is lined up with the housing. Secure the

probe using the jam nut using the above tightening torque

values. Place a silicon sealer on the bottom of the spacer

and screw it to the probe. Tighten the spacer usin g the thre e

screws and lock washers provided. Use a tightening torque

20–25 inch-lbs. Screw on the conduit elbow. The wiring

elbow can be used as a junction box for the outgoing cable.

Follow all local and national electrical codes in wiring the

proximity switch

TYPE E, DI, AND TAF PILLOW BLOCKS EQUIPPED WITH

SPEED PICKUP:

Mount the bearing to the shaft using the instruction manual

that was provided with the bearing. Be sure to secure the

4

Page 6

special proximity collar using the collar setscrews, making

sure that the shaft does not protrude beyond the collar face.

Mounting the bearing to the shaft can sometimes lead to

slight runout of the collar face. Therefore, in order to ass ure

that the collar (D) is perpendicular to the shaft, it is

necessary to minimize the collar face runout to within .015".

1. Place proximity end cover (C) on housing mating surface

using RTV on the endcover as a sealant and tighten

mounting screws. Screw the proximity probe into the end

cover (C) until it bottoms on the raised portion of the

proximity collar.

2. Back the proximity probe 1

1

/4 turn. This will provide the a

0.050" clearance gap between the proximity probe and

the setscrew collar.

3. Tighten the jam nut on the proximity probe up flush

against the endcover outer surface. Use 75 in-lb for jam

nut torque on AC probes (871 TM-B2N12-A2) and 25 inlb for jam nut torque on DC probes (871T-L2A12).

5

Page 7

4. Mount the cover (B), spacer (A) and gaskets (E) on

endcover with the 4 screws to a torque of 25 in-lbs.

The electrical enclosure (B) provided can be used as a

junction box for writing the proximity probe t o the outgoing

cable. Follow all local and national electrical codes for wiring

the probe.

With each revolution, the raised surfaces on the rotating

locknut of the USAF/USN or the undercutt on the collar of

the TAF pass the proximity switch which senses the

presence/lack of metal and closes the switch. Each time the

switch is closed an AC pulse is generated. A PLC can then

be used to count the number of pulses and detect speed

changes (see wiring diagram below).

The switch is made for pillow blocks which are grounded via

the mounting frame. An ungrounded block could lead to

electrical shock.

Features:

2-Wire Operation

40–250 V AC/DC

Normally Open

Specifications:

Load Current 5–250 MA

Inrush Current ≤2A

Operating Voltage 40–250 V AC/DC

Operating Temp (-13ºF to 158ºF)

Shock & Vibration 5G, 30–120 Hz

EZLINK Installation:

1. Blocks Equipped with Accelerometers and

Thermocouples:

The installation in this case requires screwing a deviceNet

drop cable from the main trunk to the EZLINK connector. To

communicate to the node, follow the instruction manual

provided with the configuration software disc.

2. Blocks Equipped as in 1 and with Speed Pickup:

Follow the instruction in the previous section for mounting

the proximity probe. Use the three electrical wire connectors

to couple the three pins connector to the proximity probe

wires. Make sure that the wires with matched colors are

connected together. Secure the cover of the conduit box.

Use the cable provided to connect the pins male connector

on the proximity probe conduit box to the EZLINK bottom

three pins female connector. Make sure that the pins are

lined up with holes in the connector. Proceed as in 1 above.

6

Page 8

Loading...

Loading...