Baldor DBSC105-AAA-1, DBSC102-AAA, DBSC102-AAA-1, DBSC105-AAA Installation And Operating Manual

Page 1

AC Servo Drive

$25.00

DBSC 100 Series

AC Servo Control

Installation and Operating Manual

9/96MN1229

Page 2

Table of Contents

Section 1

Introduction and Conformity 1–1.

Introduction 1–1

Conformity 1–1

Limited Warranty 1–2.

Safety Notice 1–3.

Precautions 1–3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2

Specifications 2–1.

Identification 2–1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 2–2.

Signal Levels 2–4.

Regeneration 2–5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Conditions 2–5.

Optional 24VDC Input 2–5.

Section 3

Installation 3–1.

Overview 3–1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location and Mounting 3–1.

Altitude Derating 3–1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Derating 3–1.

Overload Protection 3–2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Consideration 3–2.

Protective Devices 3–2.

Power Disconnect 3–2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Power Connections 3–2.

Motor Wiring 3–4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Signal Wiring 3–4.

Active High Definition 3–4.

Active Low Definition 3–4.

Command Input 3–7.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MN1229

TOC–1

Page 3

Section

REGEN Resistor 3–8.

Resolver Wiring 3–8.

Encoder Output 3–9.

Serial Interface Wiring 3–10.

Optional Control Signal Wiring 3–11.

Fault Relay Output 3–11.

24VDC External Power Source 3–11.

Control Inputs 3–12.

Control Outputs 3–12.

Electronic Handwheel (Optional) 3–13.

Cable Preparation 3–13.

Cable Connection 3–14.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 4

System Setup 4–1.

Overview 4–1

DIP Switch Settings 4–1.

Jumper Settings 4–3.

Power Up 4–4.

First Time Power Up 4–4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 5

Troubleshooting 5–1.

Overview 5–1

DB LED 5–2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 6

Drawings 6–1.

DBSC Dimensions 6–1.

DBSC 100 Connector Descriptions 6–2.

Mounting Hole Location 6–3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOC–2

MN1229

Page 4

Section 1

Introduction and Conformity

Introduction

The Baldor Series Controls represent the latest technology in microprocessor

based motor controls. The user programmable parameters available in every

control provides the ability to customize the control to most any application.

Baldor has tried to ensure that the information in this manual is correct at the

time of printing. The information is subject to change without prior notice.

This document is copyright by Baldor and is supplied with the understanding

that it will not be reproduced or disclosed in whole or in part, without the

express permission of Baldor.

Conformity

This product is only for use in industrial applications as described in EN 60204

and VDE 0160. This means use DBSC100 in stationary ground based

applications only

within the meaning of “Safety law of appliance”, “EMC Law” or “Machine

directive”. It is the responsibility of the user to verify that the equipment the

DBSC 100 is used in complies with all applicable regulations.

The DBSC 100 Series AC Servo Control is intended for use in industrial

installations. These controls are designed for applications that require speed

control of three phase AC Servo motors.

The DBSC 100 conforms to the following standards:

. It is a component only and is not intended for immediate use

DIN VDE 0100

DIN VDE 01

DIN VDE 0160

DIN IEC 326

EN 60529

MN1229

10

Power installations with nominal voltages

Dimensioning of clearance tolerances.

Electronic equipment for use in electrical power

installations.

Design and use of printed circuit boards.

Degrees of protection provided by enclosure.

≤ 1000 VAC.

1–1

Page 5

Section

Limited Warranty

For

a period of one (1) year from the date of

or replace without charge controls which our examination proves to be defective in

material

or workmanship. This warranty is valid if the unit has not been tampered

with by unauthorized persons, misused, abused, or improperly installed and has

been used in accordance with the instructions and/or ratings supplied. This

warranty is in lieu of any other warranty or guarantee expressed or implied.

BALDOR

removal),

or

property caused by items of our manufacture or sale. (Some states do not allow

shall not be held responsible for any expense (including installation and

inconvenience, or consequential damage, including injury to any person

exclusion or limitation of incidental or consequential damages, so the above

exclusion may not apply.) In any event, BALDOR’s total liability, under all

circumstances,

purchase

shall not exceed the full purchase price of the control. Claims for

price refunds, repairs, or replacements must be referred to BALDOR

all pertinent data as to the defect, the date purchased, the task performed by the

control,

and the problem encountered. No liability is assumed

such as fuses.

Goods

may be returned only with written notification including a BALDOR

Authorization Number and any return shipments must be prepaid.

original purchase, BALDOR will repair

with

for expendable items

Return

1–2

MN1229

Page 6

Section

Safety Notice

This equipment contains high voltage. Electrical shock can cause serious or

fatal injury. Only qualified personnel should attempt the start-up procedure or

troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts or

parts that are driven by this equipment. Improper use can cause serious or

fatal injury. Only qualified personnel should attempt the start-up procedure or

troubleshoot this equipment.

PRECAUTIONS

WARNING: Do not touch any circuit board, power device or electrical

connection before you first ensure that power has been

disconnected and there is no high voltage present from

this equipment or other equipment to which it is

connected. Electrical shock can cause serious or fatal

injury. Only qualified personnel should attempt the

start-up procedure or troubleshoot this equipment.

WARNING: Be sure that you are completely familiar with the safe

operation of this equipment. This equipment may be

connected to other machines that have rotating parts or

parts that are controlled by this equipment. Improper use

can cause serious or fatal injury. Only qualified personnel

should attempt the start-up procedure or troubleshoot this

equipment.

WARNING: Be sure all wiring complies with the National Electrical

Code and all regional and local codes. Improper wiring

may result in unsafe conditions.

WARNING: Be sure the system is properly grounded before applying

power. Do not apply AC power before you ensure that all

grounding instructions have been followed. Electrical

shock can cause serious or fatal injury.

MN1229

1–3

Page 7

Section

WARNING: Do not remove cover for at least five (5) minutes after AC

power is disconnected to allow capacitors to discharge.

Dangerous voltages are present inside the equipment.

Electrical shock can cause serious or fatal injury.

WARNING: Improper operation of control may cause violent motion of

the motor shaft and driven equipment. Be certain that

unexpected motor shaft movement will not cause injury to

personnel or damage to equipment. Peak torque of

several times the rated motor torque can occur during

control failure.

WARNING: Motor circuit may have high voltage present whenever AC

power is applied, even when motor is not rotating.

Electrical shock can cause serious or fatal injury.

Caution: To prevent equipment damage, be certain that the

electrical service is not capable of delivering more than

the maximum line short circuit current amperes listed in

this manual.

Caution: To prevent equipment damage, be certain that the input

power has correctly sized protective devices installed as

well as a power disconnect.

Caution: To prevent equipment damage, DO NOT connect a 24VDC

source to terminal strip X2 if the 24 Volt option is not

installed. If you apply 24VDC to X2 without the option, the

control will be damaged.

1–4

MN1229

Page 8

Section 2

Specifications

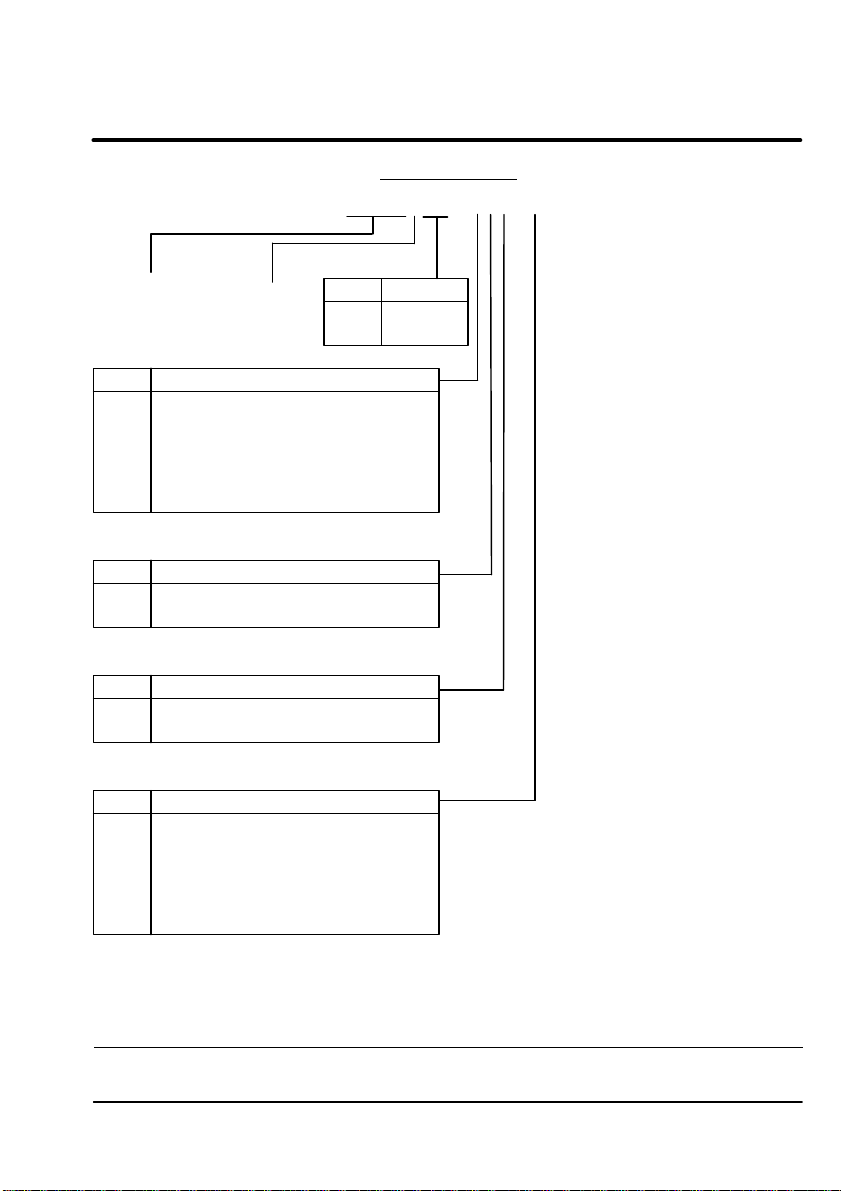

Identification

DBSC 1XX - XXX - X

Digital

Baldor

Series

Servo Control

Code Input

A

B

E

F

Code

A

B

Code

A

B

Code

Blank

1

2

3

Control Options

Pulse & Direction with RS-232

Pulse & Direction with RS-422/RS485

Electronic Handwheel (Pulse Follower)

with RS-232

Electronic Handwheel (Pulse Follower)

with RS-422/RS485

Feedback Options

Standard Resolver

Encoder

Field Bus Options

None

CAN Bus

Input Control Options

Standard 230 V

1

15 V

AC 1O Input Power

Optional external 24 VDC Logic Input

(Customer Provided)

1

15 V

AC 1O Input Power and

External 24 VDC Logic Input

AC Input Power

Code Current

02052.5 Amps

5 Amps

MN1229

2–1

Page 9

Section

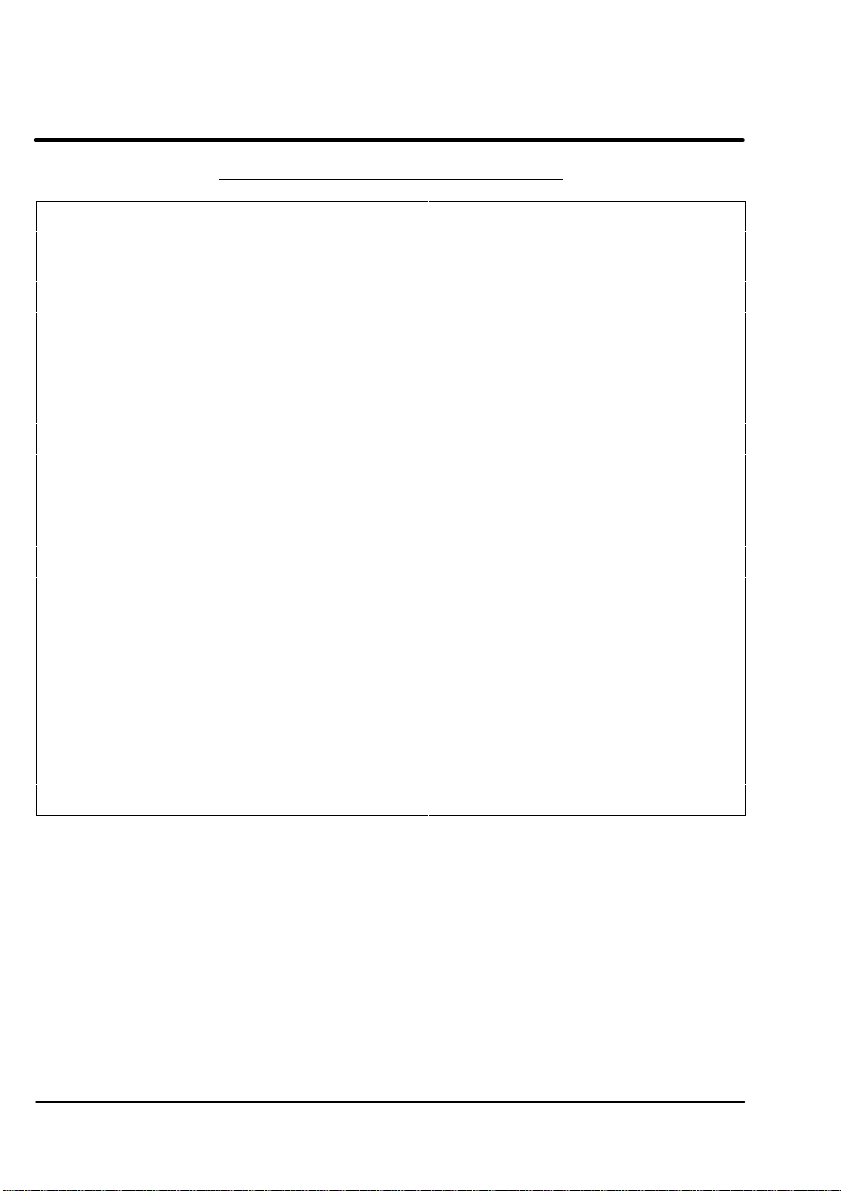

General Specifications - 230VAC

Description Unit DBSC102-AAA DBSC105-AAA

Input Voltage Range

(230V

AC 1O Nominal)

Input Frequency Hz 50/60 ±5%

Nominal Output Bus (Range)

Nominal Current (

Peak Phase Current (±10%); 2.5s

.5s

Nominal Output Power

Efficiency % >97

Minimum Load Inductance mH 400

Nominal Switching Frequency KHz 8.5

Mounting – Panel

Overall Dimensions

Weight

Operating Altitude

Operating Temperature °C

Rated

Storage T

±10%) A

emperature °C –25 to +70

VAC

VDC

RMS

±

A

RMS

KVA 1.01 2.17

in (mm)

lbs (Kg)

Feet

(Meters)

2.65x6.81x6

(67.5x173x152.5)

2.73 (1.24)

(without heatsink)

To 3300 feet (1000 meters).

Above 3300 ft, derate 11% per

220 - 250

320 (50-350)

2.5 5

5 10

3300ft (1000m).

+5 to 40

1

3.6x6.8x6

(92.5x173x152.5)

4.69 (2.13)

(with heatsink)

1

DBSC 105 with additional heatsink.

All values at ambient temperature of 25°C unless otherwise stated.

2–2

MN1229

Page 10

Section

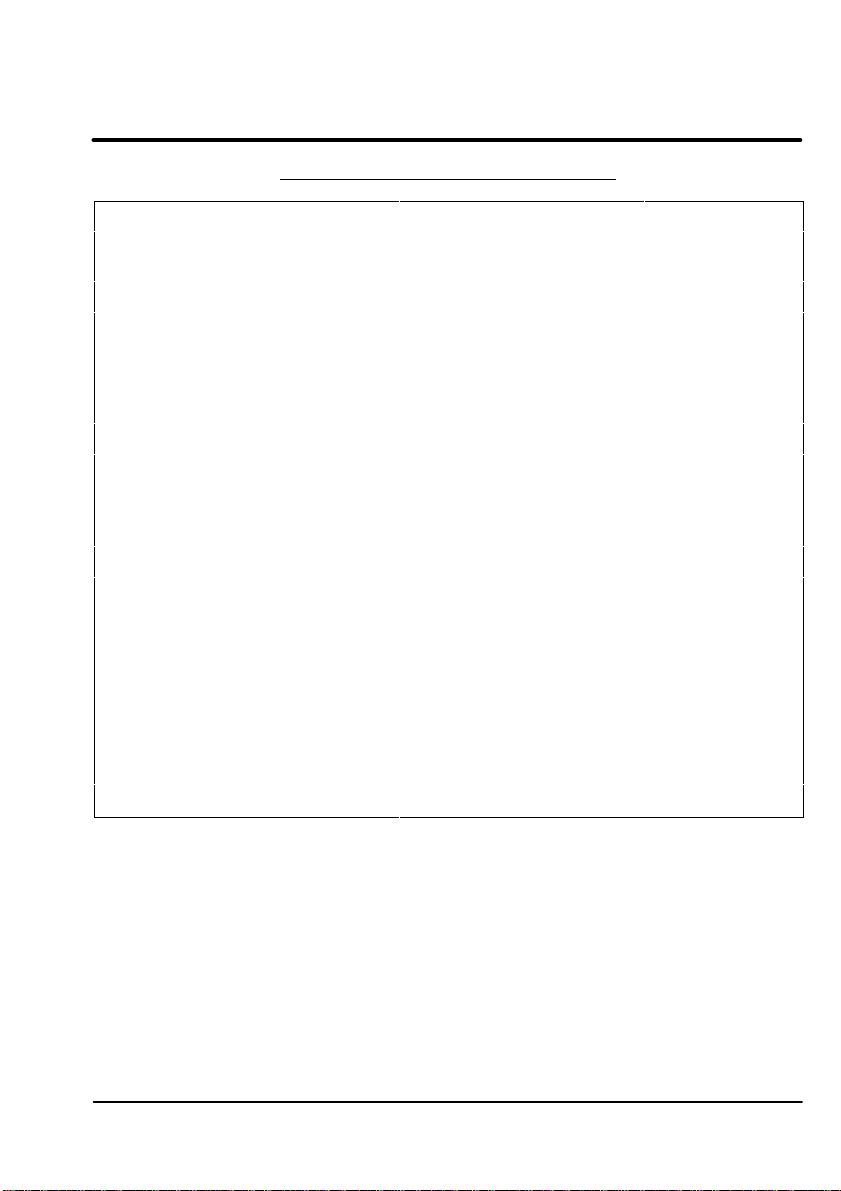

General Specifications - 115VAC

Description Unit DBSC102-AAA-1 DBSC105-AAA-1

Input Voltage Range

(115V

AC 1O Nominal)

Input Frequency Hz 50/60 ±5%

Nominal Output Bus (Range)

Nominal Current (

Peak Phase Current (±10%); 2.5s

.5s

Nominal Output Power

Efficiency % >97

Minimum Load Inductance mH 400

Nominal Switching Frequency KHz 8.5

Mounting – Panel

Overall Dimensions

Weight

Operating Altitude

Operating Temperature °C

Rated

Storage T

±10%) A

emperature °C

VAC

VDC

RMS

±

A

RMS

KVA 1.01 2.17

in (mm)

lbs (Kg)

Feet

(Meters)

2.65x6.81x6

(67.5x173x152.5)

2.73 (1.24)

(without heatsink)

To 3300 feet (1000 meters).

Above 3300 ft, derate 11% per

97 - 125

320 (50-350)

2.5 5

5 10

3300ft (1000m).

+5°C to 40°C

–25°C

1

3.6x6.8x6

(92.5x173x152.5)

4.69 (2.13)

(with heatsink)

to +70

°C

1

DBSC 105 with additional heatsink.

All values at ambient temperature of 25°C unless otherwise stated.

MN1229

2–3

Page 11

Section

Signal Levels

Description Unit DBSC 102 DBSC 105

Command Input

Command Signal Resolution bits 12

A/D Conversion Rate

Control Inputs - X3-6, X3-7, X3-9, X3-10,

X3-1

Feedback System – Resolver

Feedback Resolution V

Resolver Pole Paris

Resolver Winding Ratio

Encoder Output – RS422

Encoder Resolution ppr 512 / 10241 / 2048 / 4096

Pulse & Direction Input

Maximum Input Frequency KHz 500

Optional Handwheel Input (Pulse Follower)

Maximum Input Frequency KHz 500

Communications Interfaces

Data Communications Rate

1, X3-12, X3-13, X3-16, X3-17

elocity

V

V

≤1500 RPM

elocity

≤6000 RPM

elocity > 6000 RPM

VDC ±10

msec 476

VDC

bits 16

14

12

– 1

– RS422

– RS422

(Encoder interface - A & B)

–

Baud 9600 (Fixed)

+12 to +29

0.5

(Galvanically Isolated)

RS232 / 422 / 485

(Not galvanically Isolated)

1

Factory Setting.

2–4

MN1229

Page 12

Section

Regeneration

Description Unit DBSC 102 DBSC 105

Maximum REGEN Switching Current

Maximum Load Inductance mH 100

REGEN Resistor for

DBSC 10X-AAA (230V

REGEN Resistor for

DBSC 10X-AAA-1 (1

Continuous REGEN Power with

230V

AC (1

15V

AC) Input V

REGEN Power

AC)

15VAC)

oltage

A 7

– RG56

– RG27

Watts 44

Watt-Sec 430

Operating Conditions

Description Unit DBSC 102 DBSC 105

Ambient Operating T

Humidity % 10 to 90 RH Non-Condensing

Altitude m 1000

Shock –

Vibration –

Class of Protection

emperature °C

+5 to 40

(According to DIN40 040,

10G (DIN IEC 68-2-6/29)

1G (DIN IEC 68-2-6/29)

–

IP20 (DIN40 050/ IEC 144

class F)

Optional 24VDC Input (Optional - Must be ordered separately)

Description Unit DBSC 102 DBSC 105

Input V

oltage Range VDC

Input Ripple V

Input Current (@24VDC)

Surge Current (at Power On for

DC Bus V

with 24V option

MN1229

oltage % ±10

≤100msec) A

oltage absolute Min (Max) values

A

RMS

RMS

VDC

20 to 30

1.75

4

0 (350)

2–5

Page 13

Section 3

Installation

Overview

This section describes the proper mounting and wiring procedure for the Baldor

Series DBSC 100 AC Servo Control. If problems arise after installation, please

refer to the Diagnostics and Troubleshooting section of this manual.

Location and Mounting

CAUTION: Avoid locating control immediately above or beside heat

generating equipment, or directly below water or steam

pipes.

CAUTION: Avoid locating control in the vicinity of corrosive

substances or vapors, metal particles and dust.

Select a mounting surface for the control that will allow the control to be

mounted in a vertical position (with connector X1 at the top) using the mounting

hole(s) provided. Mounting hole location is shown in Section 6 of this manual.

The area selected should allow air to freely circulate around the control. This is

very important to maintain proper heat dissipation. Provide at least six inches

of clearance top and bottom for maximum cooling efficiency.

Refer to the Section 6 Mounting Hole Location diagram and locate and drill the

mounting hole(s) and mount the control.

Altitude Derating

Control ratings apply to 3300 feet (1000 meters) altitude without derating

required. For installations at higher altitudes derate the continuous and peak

output currents of the control by 11% for each 3300 feet (1000 meters) above

3300 feet.

Temperature Derating

Control ratings apply from 5°C to 40°C. Maximum ambient temperature is 40°C.

MN1229

3–1

Page 14

Section

Overload Protection

Baldor Controls feature UL approved motor overload protection suitable for

motors that consume at least 50% of the output rating of the control. Other

governing agencies such as NEC (National Electric Code) may require separate

over current protection. The installer of this equipment is responsible for

complying with NEC guidelines and CE directives (Conformite Europeene) and

applicable local codes that govern wiring protection, grounding, disconnects and

other current protection.

Wiring Consideration

All logic and control connections are made at the connectors shown in Figure

3-1. All external wires for the control should be run in a conduit that is separate

from power wiring. The use of shielded wire is recommended for all control

wiring.

Protective Devices

Be sure a suitable input power protection device is installed.

Slow

Blow Fuse:

Each DBSC must be fused separately. Recommended fuse

rating is determined as follows:

I

= 1.25 X I

fuse

nominal

Power Disconnect

A power disconnect should be installed between the input power source and the

DBSC for a fail safe method to disconnect power. The control will remain in a

powered-up condition until all input power is removed from the control and the

internal bus voltage has depleted.

AC Power Connections

Figure 3-1 shows the connector locations.

1. Connect the incoming AC power wires from the protection devices as

follows:

Line 1 to connector X1 pin 2 (label “L”).

Line 2 to connector X1 pin 3 (label “N”).

2. Connect earth ground to X1 pin 1 (labeled “PE”) of the control. Be sure to

comply with local codes.

3–2

MN1229

Page 15

Section

Figure 3-1 DBSC 100 Connector Locations

Power

Connector

24VDC

Supply

Input

X1

PE

L

N

U

V

W

DB+

DB–

X2

24v

0v

DB

On

AS1

Off/On

Ready

Monitor

1

2

3

4

5

6

7

8

X

9

X

6

Encoder

Input

Serial

Interface

= Optional

Hardware

MN1229

X

3

X

7

X

8

Encoder

Output

Resolver

Input

3–3

Page 16

Section

Motor Wiring

Connect the motor leads as follows:

1. Connect motor phase U to X1-U.

2. Connect motor phase V to X1-V.

3. Connect motor phase W to X1-W.

Control Signal Wiring

All wiring from external devices to the control are made at the connectors

shown in Figure 3-1.

The inputs at X3 pins 7, 9, 10, 11 and 12 can be wired for active high or active

low conditions. Pin 7 is the CREF (Control Input Reference) point.

Active High Definition

If the Control Inputs are to be wired as Active High, CREF is connected to

GND. When a control input is at +24VDC (range +12VDC to +29VDC), it is

active and when it is at GND it is inactive. Figure 3-2 shows this relationship.

Active Low Definition

If the Control Inputs are to be wired as Active Low, CREF is connected to

+24VDC (range +12VDC to +29VDC). When a control input is at GND, it is

active and when it is at +24VDC it is inactive. Figure 3-2 shows this

relationship.

Table 3-1 Control Inputs

Signal Connector Active

Enable X3-9

CW Limit

CCW Limit

Hold X3-12

3–4

X3-10

X3-11

Condition

Control Enable

CW Rotation Enabled

CCW Rotation Enabled

Hold function is Active

Inactive Condition

Control Disabled

CW Rotation Disabled

CCW Rotation Disabled

Hold function is not

active

MN1229

Page 17

Section

Active

Low

GND

ext

(Sink)

+24VDC

Control Signal Wiring Continued

Figure 3-2 Active HIGH/LOW Relationship

Active High

V

ext

(Source)

GND

X3

Pin 7 - CREF

GND

+24VDC

Pin 9 - Enable

Pin 10 - CW

Pin 1

1 - CCW

Pin 12 - Hold

Pin 13 - Reset

Pin 16 - Machine Input 1

Pin 17 - Machine Input 2

Note: These pins are shown wired together. Although this can be done,

each input is usually connected to a switch for individual control of

each input condition. Pins 16 and 17 are optional inputs and are

described later in this section.

A typical wiring control diagram is shown in Figure 3-3.

1. Connect the CREF signal wire to X3-7.

2. Connect the Enable signal wire to X3-9.

3. Connect the CW Limit signal wire to X3-10.

4. Connect the CCW Limit signal wire to X3-11.

5. Connect the Hold signal wire to X3-12 (optional).

6. Connect the Reset (Fault Reset) signal wire to X3-13 (optional).

The Reset signal (Fault Reset) can only reset the following fault types: Over

voltage, Under voltage, Resolver fault, or Control Temperature fault.

Note: Current input for each control input X3-9 to X3-17 is

Iin=10mA maximum (for each input).

MN1229

3–5

Page 18

Section

Control Signal Wiring Continued

Figure 3-3 Wiring Control Diagram (X3)

X3

Note:

Shown as Active High.

Optional

External

Power

Source

GND

+24VDC

CREF

Enable

CW Limit

CCW Limit

Hold

Reset

CMD (+)

CMD (–)

AGND

Fault (+)

Fault (–)

CIV

Ground Return

Pulse Input

Direction Input

Machine Input 1

Machine Input 2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

3–6

Machine Output 1

Machine Output 2

Drive OK

18

19

20

MN1229

Page 19

Section

Control Signal Wiring Continued

Command Input

The Analog Input at X3 pins 1, 2, and 3 can be wired for single ended or

differential input operation. Figure 3-4 shows these configurations.

Figure 3-4 Command Input Mode

X3

X3

CMD (+)

CMD

(–)

Differential Input

1

2

3AGND

CMD

1

2

3AGND

Single Ended Input

1. Determine if your application requires Single Ended Input (Step 2) or

Differential Input (Step 3) Command Signal wiring.

2. For Single Ended Input wiring:

A. Connect the CMD input wire to X3-1.

B. Connect the command common (analog ground) wire to X3-3.

C. Connect a jumper wire from X1-3 to X1-2.

3. For Differential Input wiring:

D. Connect the CMD (+) input wire to X3-1.

E. Connect the CMD (–) input wire to X3-2.

F. Connect the command common (analog ground) wire to X3-3.

MN1229

3–7

Page 20

Section

REGEN Resistor

If the motor is connected to a large inertia load that may require rapid

deceleration, an external REGEN resistor must be installed as follows:

1. Connect one wire from the REGEN Resistor to connector X1-7.

2. Connect the other wire from the REGEN Resistor to connector X1-8.

Resolver Wiring

The Resolver interface DB-9 connector is X8 on the DBSC control. Figure 3-5

shows the connector pin numbers and signal names. Use twisted pair shielded

cable with an insulated overall shield.

Figure 3-5 Resolver Interface

X8

REFERENCE+

1

COSINE+

2

SINE+

3

4

GND

5

6

7

8

9

REFERENCE

COSINE –

SINE –

–

1. Connect the Reference + to X8-1 and Reference – to X8-6.

2. Connect Cosine + to X8-2 and Cosine – to X8-7.

3. Connect Sine + to X8-3 and Sine – to X8-8.

4. Connect the Analog Ground wire to X8-5.

3–8

MN1229

Page 21

Section

Encoder Output

The encoder output provides position information to the host position controller.

Use twisted pair shielded cable with an insulated overall shield. Connect the

Encoder Output signals to the positioner as follows: (See Figure 3-6).

Figure 3-6 Encoder Output

X7

Channel A

1

Channel

2

3

4

5

6

7

8

9

1. Connect the Channel A to X7-1 and Channel A to X7-6.

2. Connect the Channel B to X7-2 and Channel B to X7-7.

3. Connect the Channel C to X7-3 and Channel C to X7-8.

4. Connect the GND to X7-5.

B

Channel C

GND

Channel A

Channel B

Channel C

The encoder resolution must be set as described in the software manual.

MN1229

3–9

Page 22

Section

Serial Interface Wiring

Serial Interface

The Serial interface (DB9 connector X6) is used for communication with a PC

(Personal Computer) or other equipment.

RS232 - Not available in model DBSC 10X-BXX.

For the RS232 interface, a standard shielded modem cable can be used for

connection to a PC. If the cable is straight through (pin to pin), a null modem

connector must be used.

These are the only RS232 signals supported by the DBSC control. Mode is

jumper selectable as described in Section 4 of this manual.

RS422/RS485 - Not available in model DBSC 10X-AXX.

RS422/RS485 is a factory installed and jumper selectable in models DBSC

10X-EXX and DBSC 10X-FXX. Mode is jumper selectable as described in

Section 4 of this manual.

Figure 3-7 RS232 Interface

X6 PC

1

2

3

4

5

6

7

8

9

RS232

RD

TD

GND

RTS

CTS

+5VDC

X6 PC

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

RS422/RS485

(Optional)

TX–

TX+

RX+

RX–

GND

RTS–

RTS+

CTS+

CTS–

1

2

3

4

5

6

7

8

9

Note: The +5VDC at X6-9 can be used to power hand held display

terminals. Maximum rating of this power source is +5VDC at 350mA.

3–10

MN1229

Page 23

Section

Optional Control Signal Wiring

Fault Relay Output (Optional)

A normally closed relay contact is provided at X3-4 and X3-5. This contact can

be used to drive an external fault indicator circuit to indicate a fault condition

has occurred. If a fault occurs the fault must be reset (X3-13). Wire the optional

external fault indicator circuit as follows: (see Figure 3-8).

1. Connect a voltage source to X3-4. (115VAC @ 0.3A or +24VDC @ 0.8A).

2. Connect the relay or circuit load to X3-5.

When a fault occurs, the internal N.C. contact will open and de-energize the

Fault Circuit.

Figure 3-8 Optional External Fault Indicator

X3

4

5

Customer

Fault Circuit

Voltage

Source

Supplied

24VDC External Power Source (Optional)

Caution: To prevent equipment damage, DO NOT connect a 24VDC

source to terminal strip X2 if the 24 Volt option is not

installed. If you apply 24VDC to X2 without the option,

damage to the control will result. Refer to Section 2 of

this manual to identify the model number and determine if

the option is installed.

An external 24 VDC power source can be used as a battery backup feature if

the 24VDC option is installed. This may be identified by the catalog number. If

AC power is lost, the DBSC control circuits are still active.

Connect the external source to connector X2 as follows:

1. Connect the + (Positive) lead to X2-24V.

2. Connect the – (Negative) lead to X2-0V.

MN1229

3–11

Page 24

Section

Optional Control Signal Wiring Continued

Control Inputs (Optional)

These control inputs are optional. Their reference (common) is CREF at X3-7

(see Figure 3-3). The voltage range is +12VDC to +29VDC for these inputs.

They may be used by a PLC or other signal source within your application.

1. Connect the Machine Input 1 (MAI1) signal to X3-16.

2. Connect the Machine Input 2 (MAI2) signal to X3-17.

These inputs are galvanically isolated. Their reference (common) is CGND at

X3-8 of Figure 3-3.

3. Connect the Pulse Input signal to X3-14.

4. Connect the Direction Input signal to X3-15.

Control Outputs (Optional)

Four Opto Isolated outputs are available for “Active Low” (Sink) use.

Connect one or more of the control outputs as follows: (see in Figure 3-9).

1. Connect the Ground Return of the power source to X3-8.

2. Connect a customer provided +24VDC source (range = +12VDC to

+29VDC) to X3-6 the CIV input (Customer Input Voltage).

3. Connect Machine Output 1 (MAO1) X3-18 to PLC.

4. Connect Machine Output 2 (MAO2) X3-19 to PLC.

5. Connect the Drive OK load to X3-20.

Figure 3-9 Optional Control Outputs

X3

Ground Return

8

18

19

20

6

T

o Customer

Provided PLC

CIV *

Machine

Machine Output 2

Output 1

Drive OK

* 24VDC nominal at 100mA minimum.

Note: These outputs are programmable. Refer to software setup manual for

further details.

3–12

MN1229

Page 25

Section

Electronic Handwheel (Optional)

The electronic handwheel (pulse follower) is an optional connection that allows

the control to follow the pulses from an encoder input. This is a factory installed

option and must be ordered with the control. This wiring must be separated

from power wiring. Separate encoder cable by at least 3″ from parallel runs of

power wires. Cross power wires at right angles only.

Cable Preparation

Encoder wiring must be shielded twisted pairs, #22 AWG (0.34mm2) minimum

size, 200′ (61m) maximum, with an insulated overall shield.

DBSC Control End (See Figure 3-10.)

1. Strip the outside jacket approximately 0.375″ (9.5mm) from the end.

2. Solder a #22 AWG (0.34mm2) wire to the braided shield. Carol cable has

a clear Mylar sleeve between the braided shield and the wire bundle.

Belden cable does not have a Mylar sleeve.

3. Connect all shields to X9-13. To do this, solder a “Drain Wire” from each

shield to the wire soldered to the braided shield in step 2.

4. Insulate or tape off ungrounded end of shields to prevent contact with other

conductors or ground.

Encoder End

1. Strip the outside jacket approximately 0.375″ (9.5mm) from the end.

2. Identify each of the four twisted pair and label or use the color codes

shown in Figure 3-10.

3. Insulate or tape off ungrounded end of shields and unused conductors to

prevent contact with other conductors or ground.

CAUTION: Do not connect any shields to the encoder case or motor

frame. Do not connect any shields to ground or another

power supply or damage to the control may result.

MN1229

3–13

Page 26

Section

Electronic Handwheel Continued

Cable Connection

1. Differential Connections Only

Connect the cable Braided Shield to DBSC control connector X9-13.

Signal Name X9 Connector

Channel A

Channel A

Channel B

Channel B

Channel C

Channel C

X9-1 (A)

X9-6 (A)

X9-2 (B)

X9-7 (B)

X9-3 C

X9-8 C

Encoder Supply +5VDC X9-11

Ground Return X9-13

2. Single Ended Connections Only

Differential inputs are recommended for best noise immunity. If only single

ended encoder signals are available, connect them to A, B, and C

(X9-1, X9-2 and X9-3 respectively).

Figure 3-10 Encoder Cables

3–14

X9-13

X9-13

MN1229

Page 27

Section 4

System Setup

Overview

The system setup section assumes that all wiring has been completed. If not,

refer to Section 3 of this manual and complete all wiring for the options you

have. It is also assumed that all power is still OFF. Be sure the DIP switch AS1

located on the DBSC panel (Figure 3-1) is properly set. Then perform the

jumper settings and power up testing.

DIP Switch Settings

The top 4 switches (1-4) set the card address as shown in Table 4-1. The

“OFF” position (to the left) represents a “0” indicated in the table. The “ON”

position (to the right) represents a “1” indicated in the table.

For example, if the card address is 3, Table 4-1 indicates the switch settings

should be AS1-1=1, AS1-2=1, AS1-3=0, and AS1-4=0.

This means AS1-1 and AS1-2 should be in the ON (right most) position, and

switches AS3 and AS4 should be OFF (left most position).

1. Place switch AS1-1 in the correct position.

2. Place switch AS1-2 in the correct position.

3. Place switch AS1-3 in the correct position.

4. Place switch AS1-4 in the correct position.

Table 4-1 Setting Card Address

AS1-1 AS1-2 AS1-3 AS1-4 Card-Address (Hexadecimal)

0 0 0 0 0

1 0 0 0 1

0 1 0 0 2

1 1 0 0 3

0 0 1 0 4

MN1229

4–1

Page 28

Section

DIP Switch Settings Continued

The top 4 switches allow communications with up to 16 different DBSC controls.

The PC software program allows selection of each individual control for

monitoring or configuration changes.

The bottom 4 switches (5-8) have the purpose shown in Table 4-2.

Table 4-2 Control Configuration

Switch Function Switch-Position

ON OFF

AS1-5 No Function – –

AS1-6 Hold-Position Hold-Position is Active Hold-Position is inactive

AS1-7 Automatic

Offset tuning

AS1-8 Enable Control is Enabled

1. Switch AS1-5 has no function. It may be placed in either position.

2. Place switch AS1-6 in the correct position. (Applicable only in the Velocity

mode). In the ON position, the motor will quickly decelerate to zero

velocity and hold position. This can also be accomplished by activating the

HOLD switch at connector pin X3-12 or software command.

3. Place switch AS1-7 in the correct position. In the ON position, automatic

offset tuning will be performed as soon as the control is “Disabled” (switch

AS1-8 OFF). This is done one time only, during initial setup. AS1-7 is

normally in the OFF position during operation.

Note: Place AS1-7 in the OFF position before placing AS1-8 in the ON

position.

4. Place switch AS1-8 in the correct position.

This can also be accomplished by activating the ENABLE switch at

connector pin X3-9 or software command.

Automatic offset tuning

is active

(Active)

Automatic offset tuning

is inactive

Control is Disabled

(inactive)

4–2

MN1229

Page 29

Section

Jumper Settings

Note: RS-232 is not available for model DBSC 10X-BXX.

Note: RS422/485 is not available for model DBSC 10X-AXX.

Determine the desired mode of operation. Refer to Table 4-3 and determine the

correct jumper positions for that mode.

Table 4-3 Jumper Setting Configuration

Jumpers Function Jumper Position Option

SB 601-609 RS232 1-2 Axx* / Exx* / Fxx

SB 601-609 RS422 or 485 2-3 Bxx* / Exx / Fxx*

* Indicates factory jumper setting.

1. Remove the DBSC cover to gain access to the jumpers.

2. For RS232 mode, check that jumpers SB 601-609 are at pins 1-2.

3. For RS422/485 mode, check that jumpers SB 601-609 are at pins 3-4.

4. Reinstall the cover.

MN1229

4–3

Page 30

Section

Power Up

Several assumptions are made. These assumptions are:

1. The system setup section assumes that all wiring has been completed.

2. All power is still OFF.

3. The DIP switch AS1 located on the DBSC panel (Figure 3-1) is properly

set.

4. The jumper at SB 601-609 is correctly set.

First Time Power Up

The following procedure is for the first time power up condition.

1. Disconnect the motor leads from X1-U, X1-V and X1-W. The initial

adjustments must be performed under a no load condition.

2. Control must be disabled (X3-9 input, Figure 3-3 switch OPEN or AS1-8

must be in the OFF position).

3. Measure the input line voltage at the power disconnect device and ensure

that it is the correct voltage.

4. Be sure a PC is connected to the serial communications interface (X6).

5. Install the software program on the PC hard disk drive as instructed in the

Software Manual.

6. Turn ON the input power to the control.

4–4

MN1229

Page 31

Section

Power Up Continued

7. When power is applied, the “Monitor” 7 segment display will display a five

(5) character succession:

A. Blank

B. 8

C. 2

D.

E. d (Indicates the control is disabled).

(Decimal point must be off to indicate control is disabled).

This indicates normal microprocessor test sequence. If the sequence

ended abnormally or the decimal point is ON, refer to the troubleshooting

section of this manual.

8. If the “Ready” LED is green and ON, and the “Monitor” display shows the

letter d the control is ready to be configured using the software program.

Refer to the Software Manual for software configuration program

operation.

When the control is properly configured, continue with step 9.

9. Turn OFF the input power to the control.

10. Connect the motor leads X1-U, X1-V and X1-W. Refer to the Motor

Wiring procedure in Section 3 of this manual.

The control is now ready for operation.

0 DBSC 10X-AAA

1 DBSC 10X-BAA

2 DBSC 10X-EAA or FAA

MN1229

4–5

Page 32

Section 5

Troubleshooting

Overview

The system troubleshooting procedures involves observing the status of the

“Ready” LED, the “DB On” LED and the “Monitor” 7 segment display. The

tables in this section provide information related to the indications provided by

these devices.

Note: The “Ready” LED can display either RED or GREEN color.

Table 5–1 Operating Mode Indications

Ready Monitor Status Cause

OFF OFF Control Disabled

Green Decimal

Point

Red 1

Red 3

Red 4

Red 5

Red 6

Red 7 I2t limit reached. After a fault is

Control Enabled

Over-voltage fault (DC Bus)

Over-current fault.

(More than 2X peak current)

Over or Under-voltage fault.

Resolver fault.

Electronic fusing

(also see fault 7)

detected, control will run at

nominal output current for 2.5

seconds then stop. The Monitor

will

display “6” fault.

Motor Over-Temperature

No Fault.

Normal operating mode. No

Fault.

Missing or wrong REGEN

resistor.

Input voltage too high.

Motor leads shorted or control

failure.

Internal 15VDC supply fault.

Resolver or cable short circuit or

not plugged in.

Control or motor current

over-load detected by software.

Cycle time between Acceleration

and Deceleration is too short.

Motor overloaded.

Red 9

MN1229

Control Over-Temperature

EEPROM fault.

Control should be relocated to

cooler area. Add fans or air

conditioning to control cabinet.

Reset control.

5–1

Page 33

Section

Table 5–1 Operating Mode Indications Continued

Ready Monitor Status Cause

Red L Both

Green H

Green d

Red U

Green J Jog mode. Jog mode activated by hardware

Green -l

Green l-

limit switches active.

Hold-Position mode.

Control Disabled.

EEPROM fault.

CW limit switch activated.

CCW limit switch activated.

Defective or missing limit switch

or wiring.

Hold mode activated by

hardware or software.

Disable mode activated by

hardware or software.

Reset control.

or software.

CW limit reached by load.

CCW limit reached by load.

DB LED

The DB LED is on whenever REGEN power is dissipated into the the optional

REGEN resistor.

5–2

MN1229

Page 34

Section 6

Drawings

DBSC Dimensions

MN1229

6–1

Page 35

Section

DBSC 100 Connector Descriptions

X1 -

Power Connector

1 Earth

2L

3N

4U

5V

6W

7 DB+

8 DB–

X2 - Optional Logic Supply

1 +24VDC

2 Common

Input Power

Motor

REGEN Resistor

X9

-

Optional Encoder

Feedback

1

CHA - Channel A

2

CHB - Channel B

3

CHC - Channel C

4

SYNC - U

5

SYNC - U/

6 CHA/

7 CHB/

8 CHC/

9

SYNC - W

10

SYNC - V

11 +5V

12

No Connection

13 DGND

14

SYNC - W/

15

SYNC - V/

X3

- Input/Output Signals

1 CMD+

2 CMD–

3 AGND

4 Fault+

5 Fault–

6 CIV

7 CREF

8 CGND

9 ENABLE

10 CW

11 CCW

12 HOLD

13 RESET

Input Command

Analog Ground

Output

User Input Voltage

Control Input Ref.

Enable Input

Limit Switch Inputs

Fault Reset

14 PULSE

15 DIRECTION

16 MAI1

17 MAI2

18 MAO1

19 MAO2

20

DRIVE OK

Machine Inputs

Machine Outputs

Input

X6 - Interface

1

No Connection

2 RXD

3 TXD

4 DTR

5 DGND

6 DSR

7RTS

8 CTS

9 +5V

X7 - Encoder Output

1

CHA - Channel A

2

CHB - Channel B

3

CHC - Channel C

4

No Connection

5 DGND

6 CHA/

7 CHB/

8 CHC/

9

No Connection

X8 - Resolver Output

1

Reference +

2

Cosine +

3

Sine +

4

No Connection

5 AGND

6

Reference –

7

Cosine –

8

Sine –

9

No Connection

6–2

MN1229

Page 36

Section

Mounting Hole Location

.2″

(5.2mm)

Location of mounting hole.

Locate and drill hole in enclosure.

Mount control to enclosure.

Heat

Sink

MN1229

6.028″

(153mm)

Alternate mounting using

two (2) tabs and four (4)

screws provided.

Rear View

6–3

Page 37

BALDOR ELECTRIC COMPANY

Baldor Electric Company Printed in USA

MN12299/96 C&J2500

P.O. Box 2400

Fort Smith, AR 72902–2400

(501) 646–4711

Fax (501) 648–5792

Loading...

Loading...