Page 1

AC SERVO DRIVE

Servo Control

Series 29M

Installation

1/98 MN1230

& Operating Manual

Page 2

Table of Contents

Section 1

Receiving & Inspection

Receiving

Section

General Information 2-1.

Introduction 2-1

Limited Warranty 2-2.

Safety

Section

Installation 3-1.

Location

Mechanical

Electrical

AC

Motor

Dynamic

Resolver

Simulated

Control

Analog

External T

Opto-Isolated

Pre-Operation

Power-Up

& Inspection

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notice

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote

Overload

Power

Protection Devices 3-3.

and DC Power Connections

Connections

Circuit Connections

Active

Keypad

Standard

15

Speed 2-Wire Mode

Fan

Fan

Bipolar

Process

Specific

Inputs and Outputs

Analog

Analog

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Considerations

Installation

Keypad Installation

Installation

Protection

Disconnect

Brake Resistor

Feedback

Encoder Output

High/Low Description

Mode

Run 3 Wire Mode

Pump 2 Wire Control Mode

Pump 3 Wire Control Mode

Speed or T

Mode Connections

Process Mode Outputs

Inputs

Outputs

rip Input

Outputs

Checklist

Procedure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

orque Control Mode with Multiple Parameter Sets

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1.

1-1.

2-3.

3-1.

3-1.

3-2.

3-3.

3-3.

3-3.

3-6.

3-6.

3-6.

3-8.

3-9.

3-10.

3-11.

3-12.

3-14.

3-16.

3-18.

3-20.

3-22.

3-24.

3-26.

3-28.

3-28.

3-30.

3-30.

3-31.

3-32.

3-33.

MN1230

Table

of Contents i

Page 3

Section 1

General Information

Section 4

Programming and Operation 4-1.

Overview 4-1

Display

Program

Parameter

Section

Troubleshooting 5-1.

Section

Manually T

5

Overview 5-1

Control T

How

Electrical

Wiring Practices 5-17.

Optical

Plant

6

Manually T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode

Adjusting

Display

Fault Log Access 4-4.

Parameter

Changing

Reset

Initialize

No

Keypad Display - Display Contrast Adjustment

How

to Clear the Fault Log

How

Causes

Special

Drive

Radio Transmitters 5-15.

Control

Special

Isolation

Ground

uning the Series 29M Control

Definition

Definition

Definition

Definition

Definition

Current

Current

Speed

Speed

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Contrast

Screens & Diagnostic Information Access

Mode

roubleshooting Procedure

to Access the Fault Log

to Access Diagnostic Information

Noise Considerations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blocks Access for Programming

Parameter V

Parameters to Factory Settings

New Software EEPROMs

Adjustments

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and Cures

Drive Situations

Power Lines

Enclosures

Motor Considerations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of Input Command

of Feedback

of Error

of “P” (Proportional gain)

of “I” (Integral gain)

uning the Control

Prop Gain Parameter

Int Gain Parameter

Prop Gain Parameter

Int Gain Parameter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

alues when Security Code Not Used

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2.

4-2.

4-3.

4-5.

4-5.

4-6.

4-7.

4-8.

4-9.

5-2.

5-2.

5-4.

5-4.

5-5.

5-12.

5-12.

5-15.

5-15.

5-16.

5-16.

5-18.

5-18.

6-1.

6-1.

6-1.

6-1.

6-2.

6-3.

6-5.

6-5.

6-6.

6-6.

6-6.

ii T

able of Contents

MN1230

Page 4

Section 1

General Information

Section 7

Specifications and Product Data

Identification 7-1

Servo

Control Specifications:

Keypad

Differential

Analog

Digital

Inputs:

Digital

Outputs:

Diagnostic

DB

Resistor Selection

Terminal T

Dimensions 7-7

Mounting

Appendix

Appendix

A

Parameter Values A-1.

B

Remote

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display:

Analog Input:

Outputs:

Indications:

ightening T

Hole Location

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Mounting T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

orque Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emplate B-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1.

7-2.

7-3.

7-3.

7-4.

7-4.

7-4.

7-4.

7-5.

7-6.

7-8.

A-1.

B-1.

MN1230

Table

of Contents iii

Page 5

Section 1

General Information

iv T

able of Contents

MN1230

Page 6

Section 1

Receiving & Inspection

Receiving & Inspection Baldor

When you receive your control, there are several things you should do immediately

Controls are thoroughly tested at the factory and carefully packaged for shipment.

.

1.

Observe the condition of the shipping container and report any damage

immediately to the commercial carrier that delivered your control.

2.

Remove the Control from the shipping container and remove all packing

materials. The container and packing materials may be retained for future

shipment.

3. V

erify that the part number of the control you received is the same as the part

number listed on your purchase order

4.

Inspect the control for external physical damage that may have been sustained

during shipment and report any damage immediately to the commercial carrier

that delivered your control.

5.

If the control is to be stored for several weeks before use, be sure that it is

stored in a location that conforms to published storage humidity and

temperature specifications. (Refer to Section 7 of this manual).

.

MN1230

Receiving

& Inspection 1-1

Page 7

Section 1

General Information

1-2

Receiving & Inspection

MN1230

Page 8

Section 2

General Information

Introduction

Baldor Controls represent the latest technology in microprocessor based motor controls.

The Series 29M control adjusts current to produce maximum torque (to zero speed).

This provides instantaneous adjustment in response to the speed and position feedback

from a shaft mounted resolver

A keypad interface is used to program the Series 29M parameters to customize your

application. The keypad is used to program the control parameters, set the mode of

operation, monitor the Local mode operation status, perform diagnostics, and examine

fault log.

Baldor has tried to ensure that the information in this manual is correct at the time of

printing. The information is subject to change without prior notice.

.

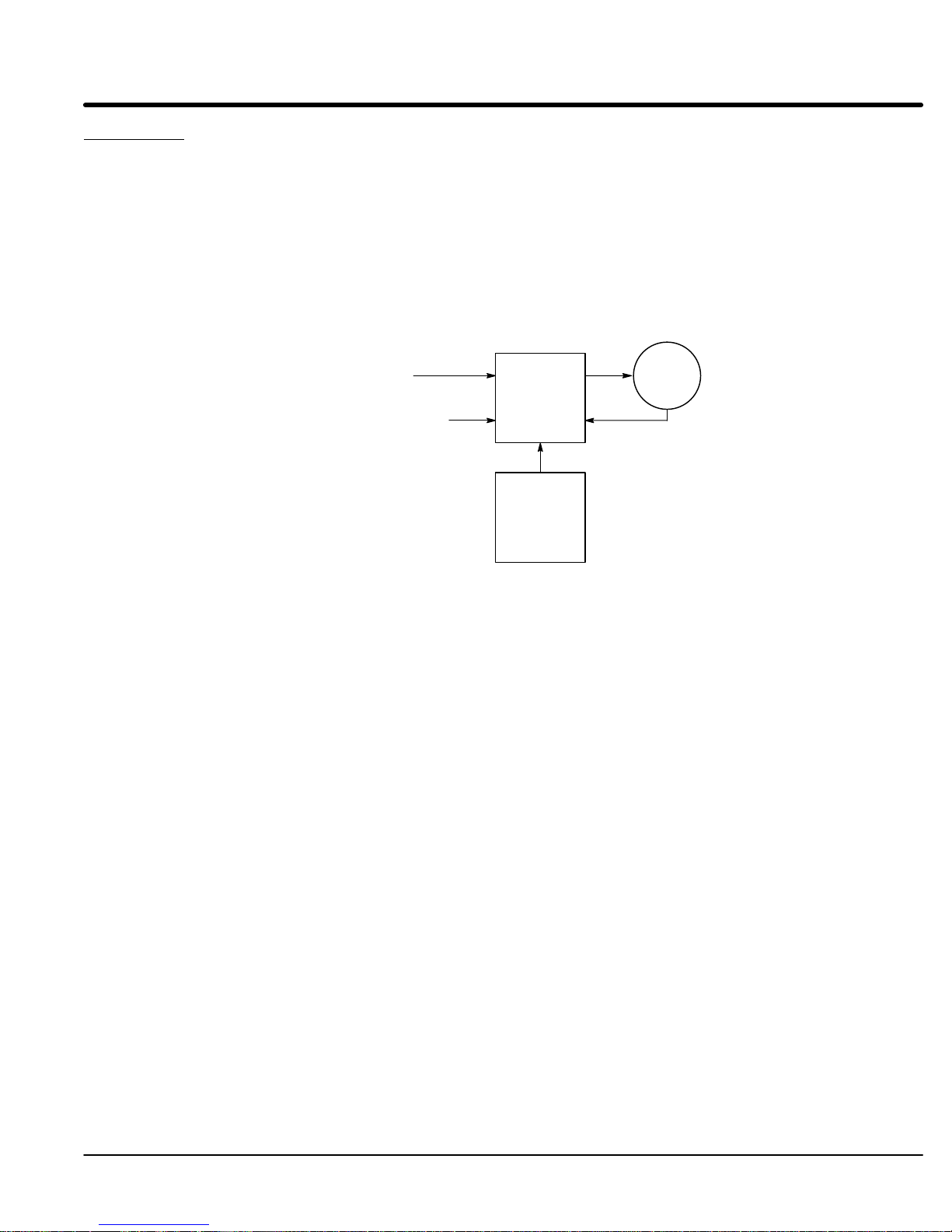

Figure 2-1 29M Control and Motor

AC Power

29M

Motor

Control

Speed

Command

DB

Assembly

Feedback

MN1230

General

Information 2-1

Page 9

Limited Warranty

For a period of one (1) year from the date of original purchase, BALDOR will

repair or replace without charge controls which our

be

defective

in material or workmanship. This warranty is valid if the unit has

not been tampered with by unauthorized persons, misused, abused, or

improperly

installed and has been used in accordance

and/or ratings supplied. This warranty is in lieu of any other warranty or

guarantee

expressed or implied. BALDOR shall not be held responsible for

any expense (including installation and removal), inconvenience, or

consequential

damage, including injury to any person or property caused by

items of our manufacture or sale. (Some states do not allow exclusion or

limitation of incidental or consequential damages, so the above exclusion

may

not

apply

.) In any event, Baldor’s total liability

shall

not exceed the full purchase price of the

price

refunds, repairs, or replacements must be referred to BALDOR with all

pertinent

data as to the defect, the date purchased, the task performed

the control, and the problem encountered. No liability is assumed for

expendable

items such as fuses.

Goods may be returned only with written notification including a BALDOR

Return

Authorization Number and any return shipments must be prepaid.

examination proves to

with the instructions

, under all circumstances,

control. Claims for purchase

by

2-2

General Information

MN1230

Page 10

Safety Notice: This

Only qualified personnel should attempt the start–up procedure or troubleshoot this

equipment.

This equipment may be connected to other machines that have rotating parts or parts

that are driven by this equipment. Improper use can cause serious or fatal injury

qualified personnel should attempt the start–up procedure or troubleshoot this equipment.

PRECAUTIONS:

equipment contains high voltages. Electrical shock can cause serious or fatal injury

. Only

W

ARNING:

Do not touch any circuit board, power device or electrical

connection before you first ensure that power has been

disconnected and there is no high voltage present from this

equipment or other equipment to which it is connected. Electrical

shock can cause serious or fatal injury

. Only qualified personnel

should attempt the start–up procedure or troubleshoot this

equipment.

W

ARNING:

Be sure that you are completely familiar with the safe operation of

this equipment. This equipment may be connected to other

machines that have rotating parts or parts that are controlled by

this equipment. Improper use can cause serious or fatal injury

.

Only qualified personnel should attempt the start–up procedure or

troubleshoot this equipment.

W

ARNING: Do not attempt to service this equipment while bus voltage is

present within the control. Remove input power and wait at least 5

minutes for the residual voltage in the bus capacitors to dissipate.

.

W

ARNING:

Be sure all wiring complies with the National Electrical Code and all

regional and local codes. Improper wiring may result in unsafe

conditions.

W

ARNING:

Be sure the system is properly grounded before applying power

Do not apply AC power before you ensure that grounds are

connected. Electrical shock can cause serious or fatal injury

W

ARNING:

Do not remove cover for at least five (5) minutes after AC power is

disconnected to allow capacitors to discharge. Electrical shock can

cause serious or fatal injury

W

ARNING: Improper operation of control may cause violent motion of the

.

motor shaft and driven equipment. Be certain that unexpected

motor shaft movement will not cause injury to personnel or damage

to equipment. Peak torque of several times the rated motor torque

can occur during control failure.

W

ARNING:

Motor circuit may have high voltage present whenever AC power is

applied, even when motor is not rotating. Electrical shock can

cause serious or fatal injury

W

ARNING: The motor shaft will rotate during the autotune procedure. Be

.

certain that unexpected motor shaft movement will not cause injury

to personnel or damage to equipment.

W

ARNING:

A DB Resistor may generate enough heat to ignite combustible

materials. T

o avoid fire hazard, keep all combustible materials and

flammable vapors away from brake resistors.

.

.

Continued on next page.

MN1230

General Information 2-3

Page 11

Section 1

General Information

Caution: T

Caution: To prevent equipment damage, be certain that the input power has

CAUTION: A

CAUTION: A

Caution: Do not connect any shields to the motor frame. At a minimum,

o prevent equipment damage, be certain that the electrical service

is not capable of delivering more than the maximum line short

circuit current amperes listed for 1

correctly sized protective devices installed as well as a power

disconnect.

void locating control immediately above or beside heat generating

equipment, or directly below water or steam pipes.

void locating control in the vicinity of corrosive substances or

vapors, metal particles and dust.

resolver signal integrity will be compromised and damage to the

control may result.

15 V

AC or 230 V

AC control rating.

2-4

General Information

MN1230

Page 12

Section 3

Installation

Location Considerations The

from direct sunlight, corrosives, harmful gases or liquids, dust, metallic particles, and

vibration. Exposure to these can reduce the operating life and degrade performance of

the control.

Several other factors should be carefully evaluated when selecting a location for

installation:

location of the control is important. It should be installed in an area that is protected

CAUTION: A

CAUTION: A

1.

For ef

smooth, non-flammable vertical surface. The amount of heat generated within

the control can be calculated based on T

2.

At least two inches top and bottom clearance must be provided for air flow

3. Altitude derating

3300 feet, derate the continuous and peak output current by 1

feet (1000 meters) above 3300 feet.

4. T

Maximum ambient is 40°C.

void locating control immediately above or beside heat generating

equipment, or directly below water or steam pipes.

void locating control in the vicinity of corrosive substances or

vapors, metal particles and dust.

fective cooling and maintenance, the control should be mounted on a

able 3-1.

. Up to 3300 feet (1000 meters) no derating required. Above

1% for each 3300

emperature derating

. From 5°C to 40°C ambient no derating required.

.

Table 3-1 Control Efficiency

Mechanical Installation Mount

mounting surface. Use the two (2) mounting holes to fasten the control to the mounting

surface or enclosure. The location of the mounting holes are shown in Section 7 of this

manual.

115 VAC / 230 V

>97%

the control to the mounting surface. The control must be securely fastened to the

AC

MN1230

Installation

3-1

Page 13

Section 1

General Information

Remote Keypad Installation

Mounting Instructions: For tapped mounting holes

Mounting Instructions:

The keypad may be remotely mounted using the optional Baldor keypad extension

cable. The keypad assembly (grey - DC00005A-02) comes complete with the screws

and gasket required to mount it to an enclosure. When the keypad is properly mounted

to a NEMA T

Tools Required:

•

•

• 1-1/4″

• R

•

•

•

1.

2.

3.

4.

5.

6.

7.

8.

9.

For clearance mounting holes

1.

2.

3.

4.

5.

6.

7.

8.

9.

ype 4 indoor enclosure, it retains the T

Center punch, tap handle, screwdrivers (Phillips and straight) and crescent

wrench.

8-32 tap and #29 drill bit (for tapped mounting holes) or #19 drill (for clearance

mounting holes).

standard knockout punch (1-11/16″

TV sealant.

(4) 8-32 nuts and lock washers.

Extended 8-32 screws (socket fillister) are required if the mounting surface is

thicker than 12 gauge and is not tapped (clearance mounting holes).

Remote keypad mounting template. A tear out copy is provided at the end of

this manual for your convenience.

Locate a flat 4″ wide x 5.5″ minimum high mounting surface. Material should

be suf

ficient thickness (14 gauge minimum).

Place the template on the mounting surface or mark the holes as shown.

Accurately center punch the 4 mounting holes (marked A) and the large

knockout (marked B).

Drill four #29 mounting holes (A). Thread each hole using an 8-32 tap.

Locate the 1-1/4″

instructions.

Debur knockout and mounting holes making sure the panel stays clean and flat.

Apply R

Assemble the keypad to the panel. Use 8–32 screws, nuts and lock washers.

From the inside of the panel, apply R

and nuts. Cover a 3/4″

encapsulate the nut and washer

Locate a flat 4″ wide x 5.5″ minimum high mounting surface. Material should

be suf

Place the template on the mounting surface or mark the holes as shown on the

template.

Accurately center punch the 4 mounting holes (marked A) and the large

knockout (marked B).

Drill four #19 clearance holes (A).

Locate the 1-1/4″

instructions.

Debur knockout and mounting holes making sure the panel stays clean and flat.

Apply R

Assemble the keypad to the panel. Use 8–32 screws, nuts and lock washers.

From the inside of the panel, apply R

and nuts. Cover a 3/4″

encapsulate the nut and washer

TV to the 4 holes marked (A).

ficient thickness (14 gauge minimum).

TV to the 4 holes marked (A).

knockout center (B) and punch using the manufacturers

knockout center (B) and punch using the manufacturers

ype 4 indoor rating.

nominal diameter).

TV over each of the four mounting screws

area around each screw while making sure to completely

.

TV over each of the four mounting screws

area around each screw while making sure to completely

.

3-2

Installation

MN1230

Page 14

Section 1

I

Wi

Maximum

Input

General Information

Electrical Installation All

wiring. The use of shielded wire is recommended for all control wiring.

When interconnecting wires from power source, control, motor

devices it is important to make proper electrical connections. A connection must ensure

that proper electrical connection and mechanical bond of conductors. Use only UL (cUL)

listed connectors for the wire gauge and type being connected. Connectors are to be

installed using the crimp tool specified by the connector manufacturer

wiring.

Overload Protection Baldor

least 50% of the output rating of the control. Other governing agencies such as NEC

(National Electric Code) may require separate over current protection. The installer of this

equipment is responsible for complying with NEC guidelines and CE directives

(Conformite Europeene) and applicable local codes that govern wiring protection,

grounding, disconnects and other current protection.

Power Disconnect A

for a fail safe method to disconnect power

condition until all input power is removed from the control and the internal bus voltage is

depleted.

Protection Devices The

output wire size is based on the use of copper conductor wire rated at 75 °C. Use the

recommended circuit breaker or fuse types as follows:

T

protection devices.

external wires for the control should be run in conduit that is separate from power

, host controller and other

. Wire with Class 1

Controls feature motor overload protection suitable for motors that consume at

power disconnect should be installed between the input power service and the control

. The control will remain in a powered-up

control must have a suitable input power protection device installed. Input and

Circuit Breaker:

Fast Action Fuses:

T

ime Delay Fuses:

1 phase, thermal magnetic.

Equal to GE type THQ or TEB for 1

Buss KTN on 1

15 or 230 V

AC.

Buss

Buss FRN on 1

15 or 230 V

AC.

15 or 230 V

AC

able 3-2 describes the wire size to be used for power connections and the ratings of the

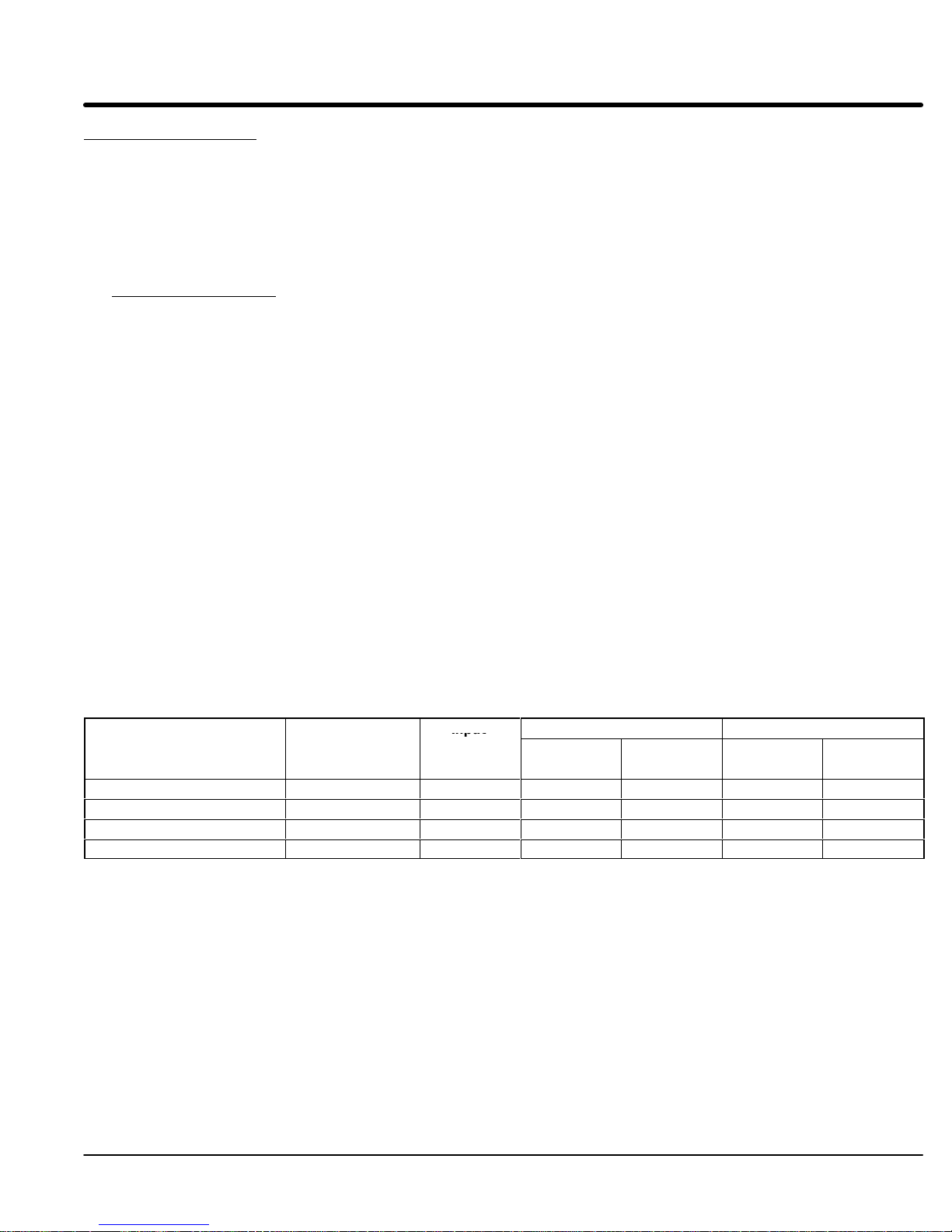

Table 3-2 Wire Size and Protection Devices

Fast

Acting

nput Fuse

Time Delay AWG mm

Input

Catalog Number

SD29M1A02-PR 2.5 18 4 4 #14 2.5

SD29M1A05-PR 5 35 8 8 #14 2.5

SD29M2A02-PR 2.5 18 4 4 #14 2.5

SD29M2A05-PR 5 35 8 8 #14 2.5

Note: All

wire sizes based on 75°C copper wire, 3% line impedance. Higher temperature smaller gauge wire may be

Maximum

Continuous

Amps

Breaker

re Gauge

used per NEC and local codes. Recommended fuses/breakers are based on 25°C ambient, maximum

continuous control output current and no harmonic current.

2

MN1230

Installation

3-3

Page 15

Section 1

General Information

Table 3-3 Short Circuit Current Ratings

115VAC 230VAC

Catalog Numbers Max. Line

Short Circuit

Current

SD29M1A02-PR 150 SD29M2A02-PR 150

SD29M1A05-PR 300 SD29M2A05-PR 300

Catalog Numbers Max. Line

Short Circuit

Current

Table 3-4 Input Current Requirements

230VAC 460VAC

Catalog Numbers Input

Amps

SD29M1A02-PR 2.6 SD29M2A02-PR 2.6

SD29M1A05-PR 5.2 SD29M2A05-PR 5.2

Catalog Numbers Input

Amps

3-4

Installation

MN1230

Page 16

Section 1

General Information

Figure 3-1 Single Phase AC Power and Motor Connections

L1 L2

Note 1

Note 2

* Circuit

Breaker

LN PE

Baldor

Control

Earth

Alternate *

Fuse

Connection

L1 L2

Note 1

UVW

PE

Note 2

VW

U

G

* Motor

Notes:

1. See Protective Device description in this section of the manual.

2. Shield wires inside a metal conduit.

* Optional components not provided with Control.

Optional Connection of

UVW

M* M* M*

PE

To Power Source

(Rated Coil

Voltage)

M-Contactor

* M-Contactor

* Optional

RC Device

Electrocube

RG1781-3

VW

U

G

* Motor

MN1230

J1

*

M Enable

7

8

9

Note: Close “Enable”

after “M” contact closure.

See Recommended Tightening Torques in Section 7.

Installation

3-5

Page 17

Section 1

General Information

AC and DC Power ConnectionsRefer

W

ARNING:

1.

2.

Motor Connections A

Dynamic Brake Resistor

motor circuit contactor (M-Contactor shown in Figure 3-1) is recommended and should

be installed to provide a positive disconnect of the motor from the control. This ensures

that the motor shaft will not rotate and cause damage or injury

open the Enable line (J1B pin 8) 20 msec before the main M-Contacts open. This will

prevent contact arcing and allows use of IEC rated contacts.

1.

2.

3.

4.

An external DB (Dynamic Brake) resistor must be installed to dissipate excess power

from the DC bus during motor deceleration operations.

W

ARNING:

to Figures 3-1 and 3-3.

Do not touch any circuit board, power device or electrical

connection before you first ensure that power has been

disconnected and there is no high voltage present from this

equipment or other equipment to which it is connected. Electrical

shock can cause serious or fatal injury

.

Connect the single phase incoming power wires from the protection devices to

the control terminal X1 pins L and N. T

orque as specified.

Connect earth ground (plant ground) to control terminal X1 pin PE.

T

orque as specified.

. The M-contactor should

Connect the “U” terminal of the 29M to the U motor lead.

Connect the “V” terminal of the 29M to the V motor lead.

Connect the “W” terminal of the 29M to the W motor lead.

Connect the “PE” terminal of the 29M to motor ground (G).

A DB Resistor may generate enough heat to ignite combustible

materials. T

o avoid fire hazard, keep all combustible materials and

flammable vapors away from brake resistors.

1.

Mount the DB resistor near the top of the enclosure.

2.

Connect one wire from the DB resistor to terminal DB+ of the control.

3.

Connect the other wire from the DB resistor to terminal DB– of the control.

Note:

For selection of the DB resistor

, refer to the Specifications located in Section 7

of this manual.

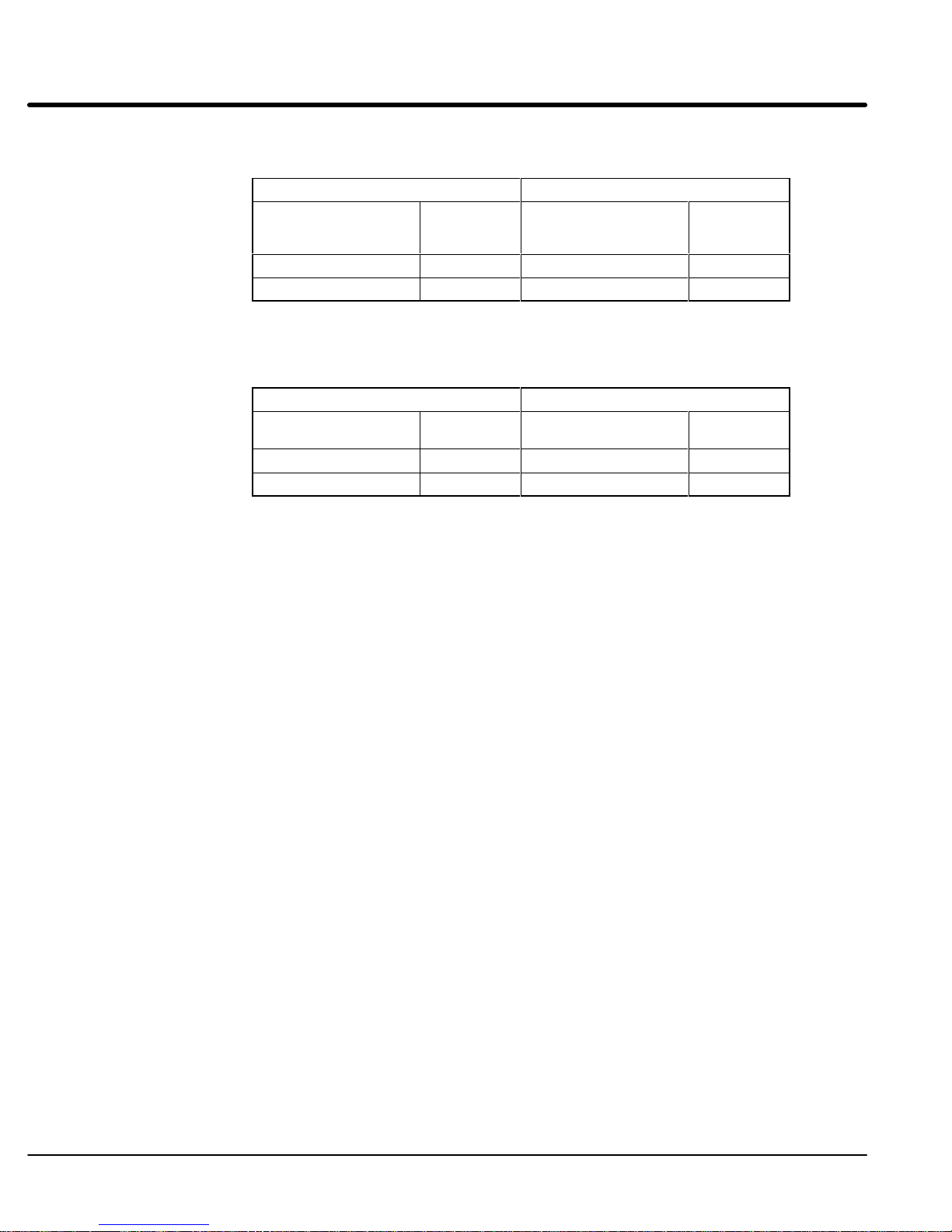

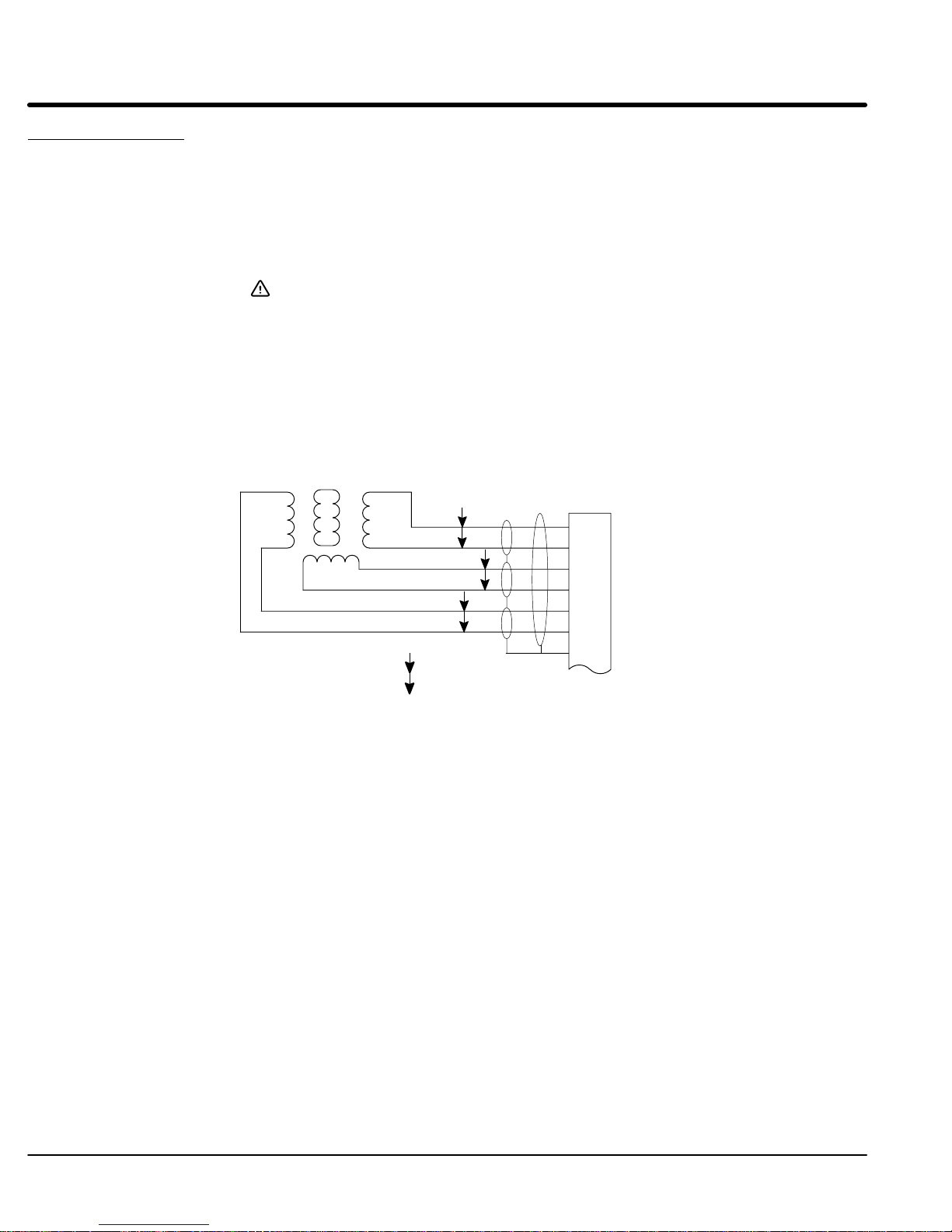

Figure 3-2 DB Resistor Installation Considerations

75°C

Maximum

near wall.

80°C

70°C

65°C

70°C

temperatures

Maximum temperatures

above the enclosure.

85°C

115°C

115°C

200°C

24″

12″

48″

36″

3-6

Installation

MN1230

Page 18

Section 1

General Information

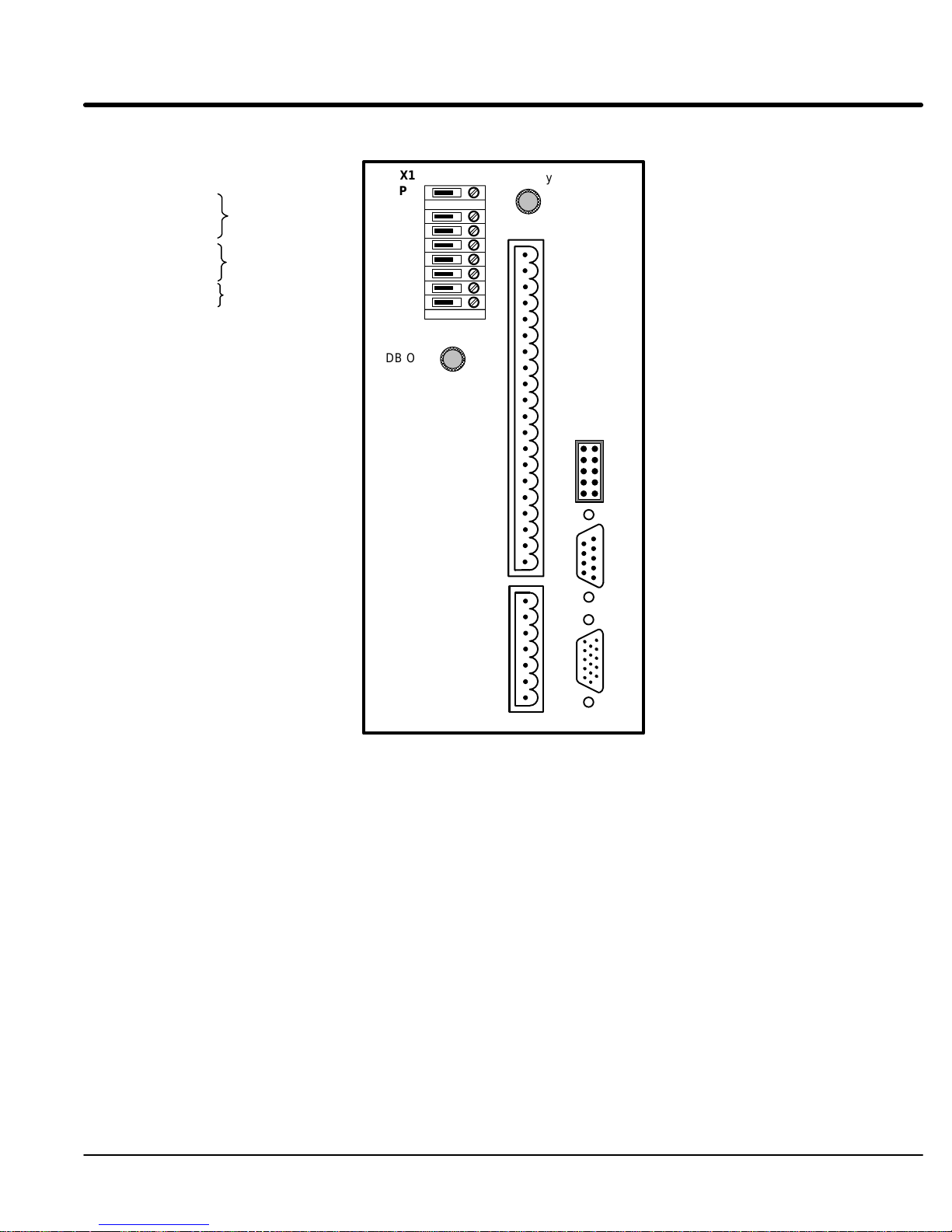

Figure 3-3 29M AC Servo Connector Locations

X1 - Power Connector

PE Earth

L AC Line

N Neutral

U Motor lead “U”

V Motor lead “V”

W Motor lead “W”

DB+ Dynamic Brake

DB– Dynamic Brake

8 Enable 18 N.C.

9 FWD CMD 19 CREF (OPTO IN)

10 REV CMD 20 OUT1–

11 IN1 21 OUT1+

12 IN2 22 OUT2–

13 IN3 23 OUT2+

14 IN4 24 OUT3–

15 IN5 25 OUT3+

16 External Trip 26 OUT4–

17 N.C. 27 OUT4+

J1A - Analog I/O

1 AGND 5 ANA IN 2–

2 ANA IN 1 6 ANA OUT1

3 Reference 7 ANA OUT2

4 ANA IN 2+

See T

erminal T

Input Power

Motor

Dynamic

Regen Resistor

J1B - Digital I/O

ightening T

Section 7 of this manual.

Brake or

orques in

X1

PE

L

N

U

V

W

DB+

DB–

DB ON

BALDOR

J1A

8

1

Ready

J1B

J2

J4

J3

J4 - Keypad

1 Shield 6 RCV–

2 N.C. 7 N.C.

3 XMIT+ 8 N.C.

4 XMIT– 9 +8VDC

5 RCV+ 10 DGND

J3 - Simulated Encoder Output

1 CHA+ 6 CHA–

2 CHB+ 7 CHB–

3 CHC+ 8 CHC–

4 N.C. 9 N.C.

5 DGND

J2 - Resolver Input

1 SIN+ 9 N.C.

2 COS+ 10 N.C.

3 REF+ 11 EXT Z

4 N.C. 12 N.C.

5 N.C. 13 AGND

6 SIN– 14 N.C.

7 COS– 15 N.C.

8 REF–

MN1230

Installation

3-7

Page 19

Section 1

General Information

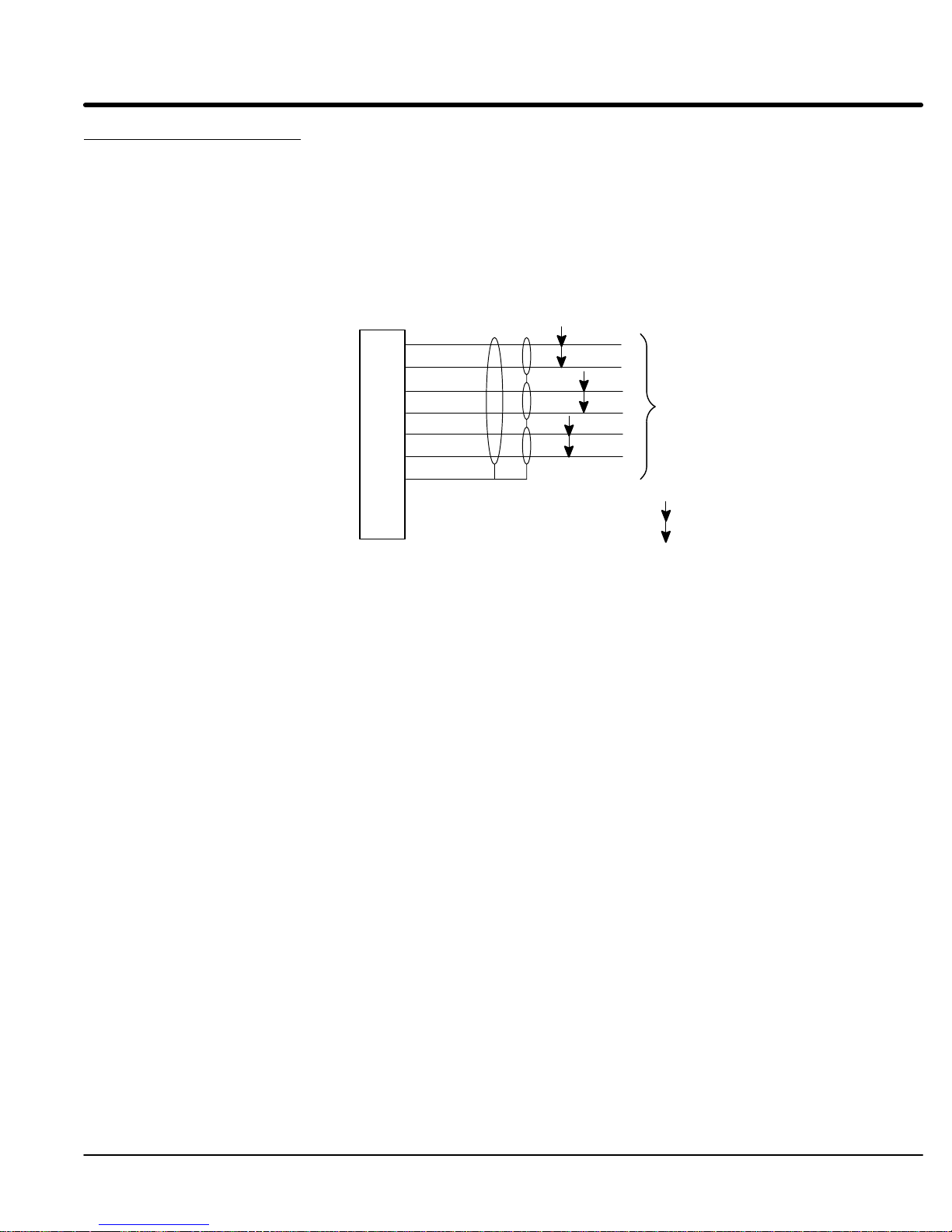

Resolver Feedback

The resolver connections are made at the J2 connector as shown in Figure 3-4. The

resolver cable must be shielded twisted pair #22 A

WG (0.34mm2) wire minimum. The

cable must also have an overall shield and not exceed 150 feet (45m) in length.

Maximum wire-to-wire or wire-to-shield capacitance is 50pf per foot (maximum of 7500pf

for 150 ft). See electrical noise considerations in Section 5 of this manual.

Resolver wiring must be separated from power wiring. Separate parallel runs of resolver

and power cables by at least 3″. Cross power wires at right angles only

. Insulate or tape

ungrounded end of shields to prevent contact with other conductors or ground.

Caution: Do not connect any shields to the motor frame. At a minimum,

resolver signal integrity will be compromised and damage to the

control may result.

1.

Connect the SIN+ to J2-1 and SIN– to J2-6.

2.

Connect the COS+ to J2-2 and COS– to J2-7.

3.

Connect the REF+ to J2-3 and REF– to J2-8.

4.

Connect the analog ground wire to J2-13.

Figure 3-4 Resolver Cable Connections

R2

R1

S2

S4

S1S3

P

P

P

= T

wisted Pair

P

J2

1 SIN+

6 SIN–

2 COS+

7 COS–

3 REF+

8 REF– (Common)

13 AGND

3-8

Installation

MN1230

Page 20

Section 1

General Information

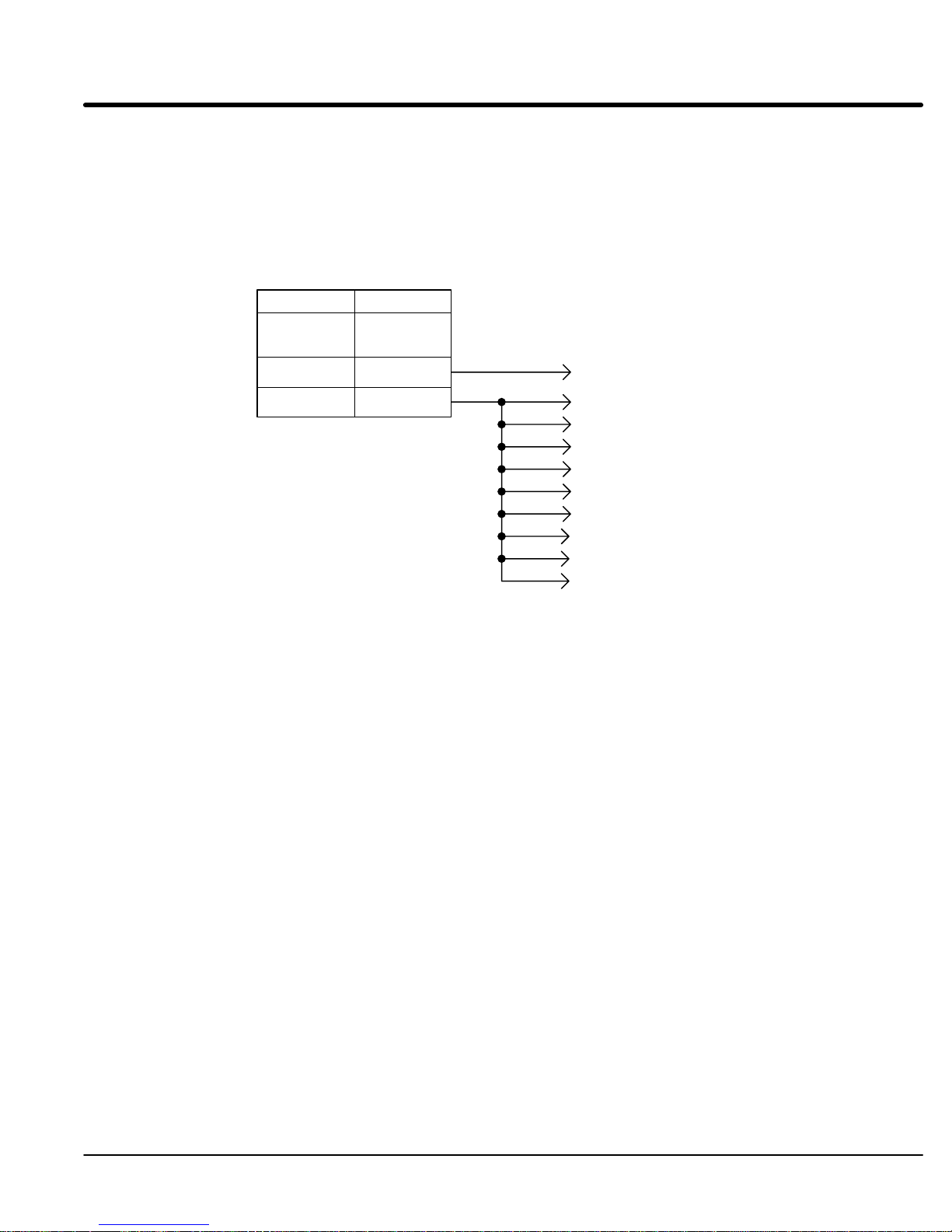

Simulated Encoder Output The

This output provides position information to the host controller

an overall shield.

This output simulates a 1024 ppr encoder with quadrature outputs. Counting in

quadrature will provide 4096 ppr with one index marker (CHC) per revolution. It is

recommended that this output only drive one output circuit load. Driving multiple loads is

not recommended.

control provides a simulated encoder output at connector J3 as shown in Figure 3-5.

. Use twisted pair wire with

Figure 3-5 Simulated Encoder Output

J3

CHA+

1

CHA–

6

CHB+

2

CHB–

7

CHC+

3

CHC–

8

DGND

5

4

N.A.

9 N.A.

1.

Connect J3-1 and J3-6 outputs to Host Position Controller CHA inputs.

2.

Connect J3-2 and J3-7 outputs to Host Position Controller CHB inputs.

3.

Connect J3-3 and J3-8 outputs to Host Position Controller CHC inputs.

4.

Connect the cable shields to J3-5.

P

P

To Host Position

P

P

Controller

= Twisted Pair

MN1230

Installation

3-9

Page 21

Section 1

General Information

Control Circuit Connections

Eight operating modes are available. These operating modes define the basic motor

control setup and the operation of the input and output terminals. After the circuit

connections are completed, the operating mode is selected by programming the Level 1

Input block Operating Mode parameter

•

Keypad Mode

•

Standard Run 3 Wire Mode (e.g. Potentiometer)

•

15 Speed 2 Wire Mode (e.g. Preset Speeds)

•

2 Wire

Multi

INP (e.g. 2 wire control mode)

•

3 Wire

Multi

INP (e.g. 3 wire control mode)

• Serial

•

Bipolar Speed or T

•

Process Mode

External devices are connected at the AC Servo Control connectors shown in Figure 3-3.

1.

Connect the Keypad to J4 on the control panel.

2.

Determine the operating mode for your application. Connect the remaining

control connections as shown in the diagram for that operating mode. (Refer to

Figures 3-7, 3-8, 3-9 and 3-12.)

Note:

Input connections at J1B can be wired as active High or active Low as shown

in Figure 3-6. J1B pin 19 is the Control Reference point (CREF) for the Opto

Isolated Input signals. Input signals are on J1B pins 8, 9, 10, 1

15, 16.

orque Mode (e.g. ±10VDC, ±5VDC or 4-20mA)

. A

vailable operating modes are:

1, 12, 13, 14,

3-10

Installation

MN1230

Page 22

Section 1

General Information

Active High/Low Description

Active Low Active High

GND

(Sink)

+24VDC

A customer supplied power source is required for operation of the Opto Inputs. The V

and GND

Active High

inputs are optional and are not provided with this control.

ext

- If pin 19 is grounded, an input is active when it is at +24VDC

(+10VDC to +30VDC).

Active Low

- If pin 19 is at +24VDC (+10VDC to +30VDC), an input is active when it

is grounded.

Figure 3-6 Active HIGH/LOW Relationship

ext

V

ext

(Source)

GND

J1B

Pin 19 - CREF

ext

Note: These

individual control of each input condition.

GND

+24VDC

pins are shown wired together

Pin 8 - Enable

Pin 9 - FWD

Pin 10 - REV

Pin 11 - IN1

Pin 12 - IN2

Pin 13 - IN3

Pin 14 - IN4

Pin 15 - IN5

Pin 16 - External Trip

. Although this can be done, each input is usually connected to a switch for

Installation

3-1

1MN1230

Page 23

Section 1

General Information

Keypad Mode

In the Keypad Operating mode:

T

o operate in the Keypad mode, set the Level 1 Input block, OPERA

parameter to KEYP

outputs (at J1A) remain active.

If the Level 2 PROTECTION block, EXTERNAL TRIP and LOCAL ENABLE INPUT

parameters remain OFF (factory setting), no terminal strip wiring is required.

1.

The External T

block, EXTERNAL TRIP parameter is set to ON. If the Level 2 PROTECTION

block, EXTERNAL TRIP parameter is programmed “ON”, make connections as

shown in Figure 3-7.

2.

The Local Enable Opto Input at J1B-8 is active if the Level 2 PROTECTION

block, LOCAL INP ENABLE parameter is set to ON. If the Level 2

PROTECTION block, LOCAL INP ENABLE parameter is programmed “ON”,

make connections as shown in Figure 3-7.

The ST

OP key can operate in two ways:

S Press ST

S Press ST

AD. In this mode, only two Opto inputs can be active. Both analog

rip Opto Input at J1B-16 is active if the Level 2 PROTECTION

OP key one time to brake or coast to stop.

OP key two times to disable control.

TING MODE

3-12

Installation

MN1230

Page 24

Section 1

General Information

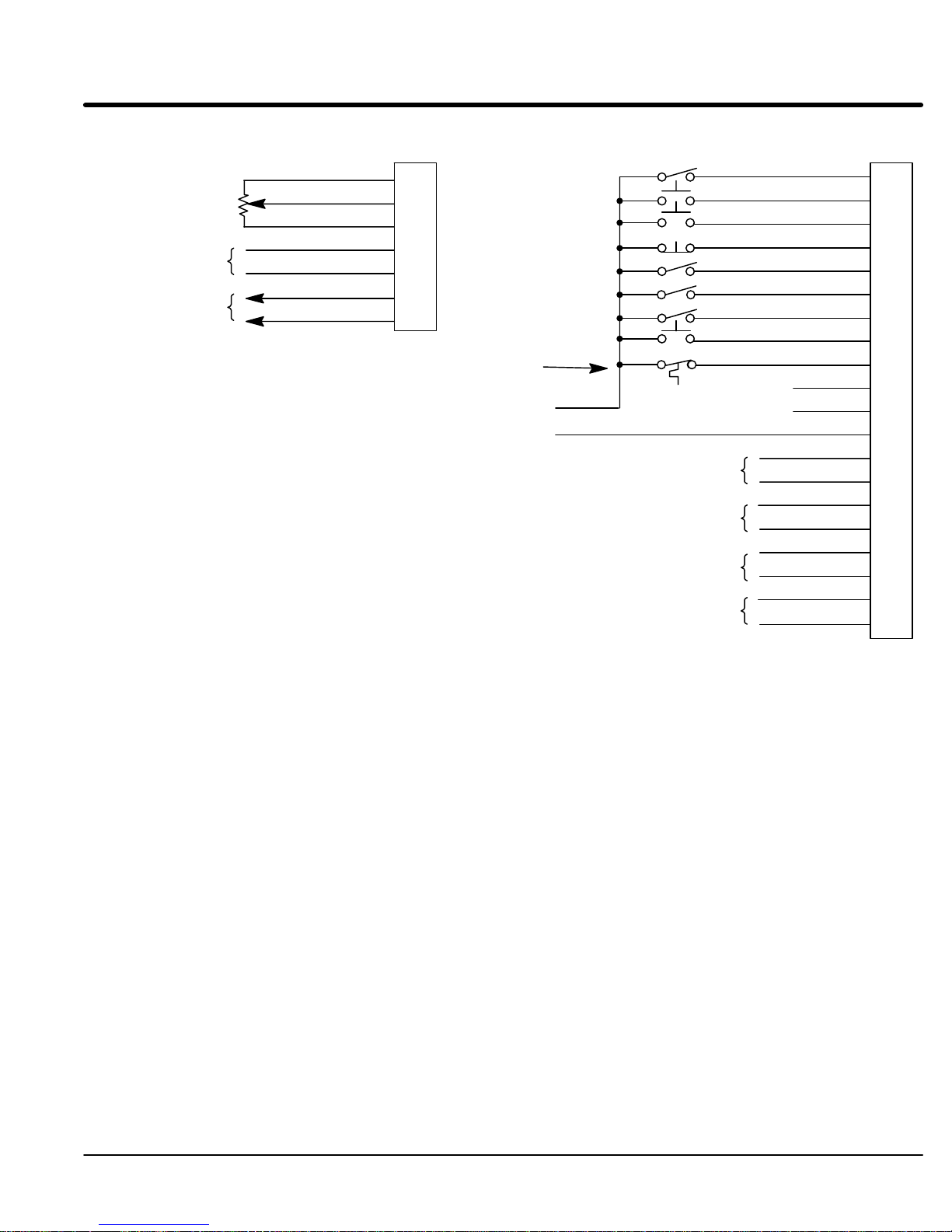

Figure 3-7 Keypad Mode Connection Diagram

J1A

ANALOG GND

No

Connection

ANALOG OUT 1

Note 1

Notes:

1. Refer to Analog Outputs description in this section.

2. Refer to Opto Isolated Outputs description in this

section.

ANALOG OUT 2

1

2

3

4

5

6

7

Refer

to Figure 3-17

Customer

Supplied

+24VDC Source

GND

V

ext

ext

Note 2

OUT 1

OUT 2

OUT 3

OUT 4

ENABLE

No

Connection

EXTERNAL TRIP

CREF

OUT 1–

OUT 1+

OUT 2–

OUT 2+

OUT 3–

OUT 3+

OUT 4–

OUT 4+

N.C.

N.C.

J1B

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

J1B-8 CLOSED allows current to flow in the motor.

OPEN disables the control and motor coasts to a stop (if Level 2 Protection block,

LOCAL ENABLE INP is set to ON). This input is optional.

J1B-16 OPEN causes an external trip to be received by control. The control will disable and

display External Trip when programmed “ON”. If J1B-16 is connected, you must set

Level 2 Protection block, External Trip to “ON” to recognize the J1B-16 input.

MN1230

Installation

3-13

Page 25

Section 1

General Information

Standard Run 3 Wire Mode

In

standard run mode, the control is operated by the Opto Isolated inputs at J1B-8

through J1B-16 and the analog command input J1A pins 1, 2 and 3 (5KW pot, 0-5VDC or

0-10VDC). J1A-4 and J1A-5 can be used as the input (0-5VDC, 0-10VDC or 4-20mA).

The Opto inputs can be switches as shown in Figure 3-8 or logic signals from another

device. The External T

Level 2 PROTECTION block, EXTERNAL TRIP parameter is set to ON.

The motor speed command may be one of the following:

Preset Speed (J1B–14)

Command Input (Potentiometer

Dif

ferential analog input (±5VDC, ±10VDC or 4-20mA)

Make control connections as shown in Figure 3-8.

rip Opto Input at J1B-16 is active if connected as shown and the

, 0-5VDC or 0-10VDC)

3-14

Installation

MN1230

Page 26

Section 1

General Information

Figure 3-8 Standard Run 3-Wire Mode Connection Diagram

J1A

ANALOG GND

5kW Command Pot

Note 1

Note 2

Notes:

1. Refer to Analog Inputs description in this section.

Note: JP1 must be properly set for either voltage or current

operation. Refer to Figure 3-16 for jumper information.

2. Refer to Analog Outputs description in this section.

3. Refer to Opto Isolated Outputs description in this section.

ANALOG INPUT 1

POT REFERENCE

ANALOG INPUT 2+

ANALOG INPUT 2–

ANALOG OUT 1

ANALOG OUT 2

1

2

3

4

5

6

7

Refer

to Figure 3-17

+24VDC Source

Both CLOSED= Forward

Customer

Supplied

GND

V

ext

ext

Note 3

FORWARD ENABLE

REVERSE ENABLE

Closed=JOG SPEED

ACC/DEC/“S” SELECT

PRESET SPEED #1

FAULT RESET

EXTERNAL TRIP

OUT 1

OUT 2

OUT 3

OUT 4

ENABLE

STOP

N.C.

N.C.

CREF

OUT 1–

OUT 1+

OUT 2–

OUT 2+

OUT 3–

OUT 3+

OUT 4–

OUT 4+

J1B

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

J1B-8 CLOSED allows current to flow in the motor and produce torque.

OPEN disables the control and motor coasts to a stop.

J1B-9 Momentary CLOSED starts motor operation in the Forward direction. In JOG mode

(J1-12 CLOSED), continuous CLOSED jogs motor in the Forward direction.

J1B-10 Momentary CLOSED starts motor operation in the Reverse direction. In JOG mode

(J1-12 CLOSED), CONTINUOUS closed JOGS motor in the Reverse direction.

J1B-11 When OPEN control removes power from motor and disables. Coasts or brakes to stop

depending on Keypad Stop Mode parameter setting.

J1B-12 CLOSED places control in JOG mode, Forward and Reverse run are used to jog the

motor.

J1B-13 CLOSED selects group 2.

OPEN selects ACC / DEC / S-CURVE group 1.

J1B-14 CLOSED selects preset speed #1.

OPEN allows speed command from Analog input #1 or #2.

J1B-15 CLOSED to reset fault condition.

OPEN to run,

J1B-16 OPEN causes an external trip to be received by control. The control will disable and

display External Trip when programmed “ON”. If J1B-16 is connected, you must set

Level 2 Protection block, External Trip to “ON” to recognize the J1B-16 input.

MN1230

Installation

3-15

Page 27

Section 1

General Information

15 Speed 2-Wire Mode

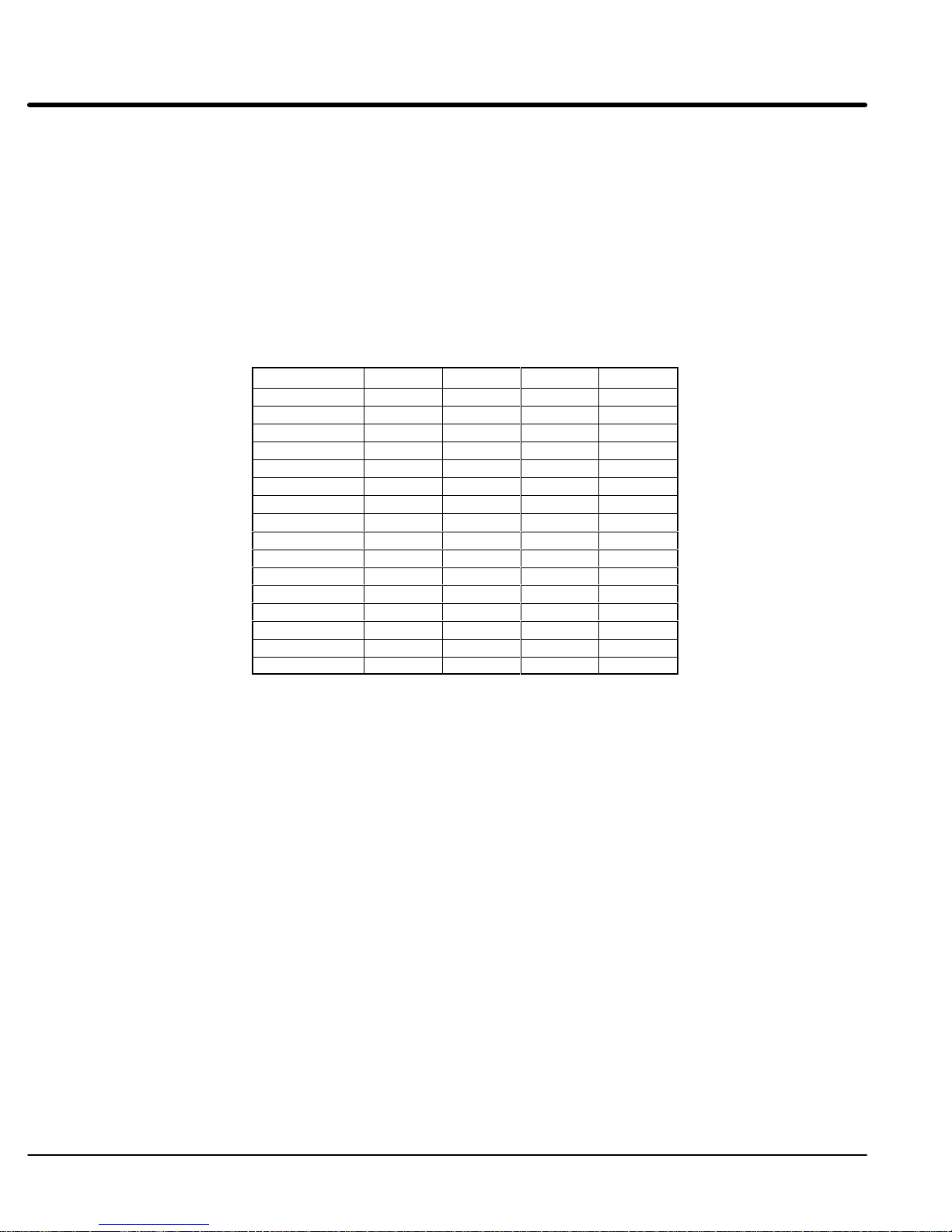

Table 3-5 Switch Truth Table for 15 Speed, 2 Wire Control Mode

In this mode, 15 preset motor speeds are stored during setup and selected during

operation. Switch T

ruth T

able is defined in T

able 3-5.

Operation in the 15 Speed 2-Wire mode is controlled by the Opto Isolated inputs at

J1B-1

1 through J1B-15. The Opto inputs can be switches as shown in Figure 3-9 or logic

signals from another device. The External T

rip Opto Input at J1B-16 is active if

connected as shown and the Level 2 PROTECTION block, EXTERNAL TRIP parameter

is set to ON.

Switched inputs at J1B-1

provide Fault Reset as defined in T

Function J1B-11 J1B-12 J1B-13 J1B-14

Preset 1 Open Open Open Open

Preset 2 Closed Open Open Open

Preset 3 Open Closed Open Open

Preset 4 Closed Closed Open Open

Preset 5 Open Open Closed Open

Preset 6 Closed Open Closed Open

Preset 7 Open Closed Closed Open

Preset 8 Closed Closed Closed Open

Preset 9 Open Open Open Closed

Preset 10 Closed Open Open Closed

Preset 11 Open Closed Open Closed

Preset 12 Closed Closed Open Closed

Preset 13 Open Open Closed Closed

Preset 14 Closed Open Closed Closed

Preset 15 Open Closed Closed Closed

Fault Reset Closed Closed Closed Closed

1 through J1B-14 allow selection of 15 preset speeds and

able 3-5.

3-16

Installation

MN1230

Page 28

Section 1

General Information

Figure 3-9 15 Speed 2-Wire Mode Connection Diagram

ANALOG GND

No

Connection

ANALOG OUT 1

Note 1

Notes:

1. Refer

2.

to Analog Outputs description in this section.

Refer to Opto Isolated Outputs description in this

section.

ANALOG OUT 2

J1A

1

2

Both CLOSED= Forward

3

4

5

6

7

Both OPEN = Stop

All CLOSED= Fault

Refer to Figure 3-17

Customer

Supplied

+24VDC Source

Reset

GND

V

ext

ext

Note 2

FORWARD ENABLE

REVERSE ENABLE

SWITCH 1

SWITCH 2

SWITCH 3

SWITCH 4

ACC/DEC/“S” SELECT

EXTERNAL TRIP

OUT 1

OUT 2

OUT 3

OUT 4

ENABLE

N.C.

N.C.

CREF

OUT 1–

OUT 1+

OUT 2–

OUT 2+

OUT 3–

OUT 3+

OUT 4–

OUT 4+

J1B

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

J1B-8 CLOSED allows current to flow in the motor and produce torque.

OPEN disables the control & motor coasts to a stop.

J1B-9 CLOSED operates the motor in the Forward direction.

OPEN coasts brakes to stop depending on Keypad Stop mode parameter setting.

J1B-10 CLOSED operates motor in the Reverse direction.

OPEN coasts or brakes to stop depending on Keypad Stop mode parameter setting.

J1B-11 to 14 Selects programmed preset speeds as defined in Table 3-5.

J1B-15 Selects ACC/DEC group. CLOSED selects group 2. OPEN selects group 1.

J1B-16 OPEN causes an external trip to be received by control. The control will disable and

display External Trip when programmed “ON”. If J1B-16 is connected, you must set

Level 2 Protection block, External Trip to “ON” to recognize the J1B-16 input.

MN1230

Installation

3-17

Page 29

Section

1

General Information

2 Wire Multi INP Control Mode

The Opto inputs can be switches as shown in Figure 3-10 or logic signals from another

device. The External T

Level 2 PROTECTION block, EXTERNAL TRIP parameter is set to ON.

J1B-8 CLOSED allows current to flow in the motor and produce torque.

J1B-9 CLOSED to start motor operation in the Forward direction.

J1B-10 CLOSED to start motor operation in the Reverse direction.

J1B-11 CLOSED selects Analog Input #1.

Note: If Level 1 Input block, Command Select parameter is set to “Potentiometer”, then

J1B-12 CLOSED selects Start/Stop and Reset commands from the terminal strip.

J1B-13 CLOSED selects terminal strip speed source (Level 1 Input block, Command Select).

Note: When changing from keypad to terminal strip (J1B-12 or 13) the motor speed and

J1B-14 OPEN selects Preset Speed #1 regardless of the Speed Command input (J1B-13).

J1B-15 OPEN selects Preset Speed #2 regardless of the Speed Command input (J1B-13).

Note: If J1B-14 and 15 are both OPEN, Preset Speed #1 is selected.

J1B-16 OPEN causes an External Trip to be received by the control (when programmed to

J1B-19 Jumper to J1B-18 (+24VDC) for “Active Low” operation of input signals at J1B-8 to 16.

rip Opto Input at J1B-16 is active if connected as shown and the

OPEN disables the control & motor coasts to a stop.

OPEN to initiate a stop command.

OPEN to initiate a stop command.

OPEN selects the value of the Level 1 Input block, Command Select parameter.

Analog Input #1 is always selected.

OPEN selects Start/Stop and Reset commands from keypad.

OPEN selects speed command from Keypad.

direction will remain the same after the change.

(FIRESTAT).

(FREEZESTAT).

“ON”). When this occurs, the control disables and an external trip error is displayed on

the keypad display (also logged into the error log).

If J1B-16 is connected, you must set Level 2 Protection block, External Trip to “ON” to

recognize the J1B-16 input.

J1B-17 is then used as switch common.

3-18 Installation

MN1230

Page 30

Section

1

General Information

Figure 3-10 2 Wire Multi INP Mode Connection Diagram

J1A

ANALOG GND

Note 1

Note 1

Note 2

5kW

Command Pot

or 0-10VDC

±5VDC, ±10VDC

or 4-20mA

Programmable

Analog Outputs.

ANALOG INPUT 1

POT REFERENCE

ANALOG INPUT +2

ANALOG INPUT –2

ANALOG OUT 1

ANALOG OUT 2

Refer

Notes:

1. Refer to Analog Inputs description in this section.

Note: JP1 must be properly set for either voltage or current

operation. Refer to Figure 3-16 for jumper information.

2. Refer to Analog Outputs description in this section.

3. Refer to Opto Isolated Outputs description in this section.

1

2

3

4

5

6

7

to Figure 3-17.

Customer

Supplied

+24VDC Source

Both Closed=

Fault Reset

GND

V

ext

ext

Note 3

FORWARD RUN

REVERSE RUN

ANALOG

OUT 1

OUT 2

OUT 3

OUT 4

INPUT SELECT

RUN COMMAND

SPEED COMMAND

PRESET SPEED #1

PRESET SPEED #2

EXTERNAL TRIP

ENABLE

N.C.

N.C.

CREF

OUT 1–

OUT 1+

OUT 2–

OUT 2+

OUT 3–

OUT 3+

OUT 4–

OUT 4+

J1B

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

MN1230

Installation 3-19

Page 31

Section

1

General Information

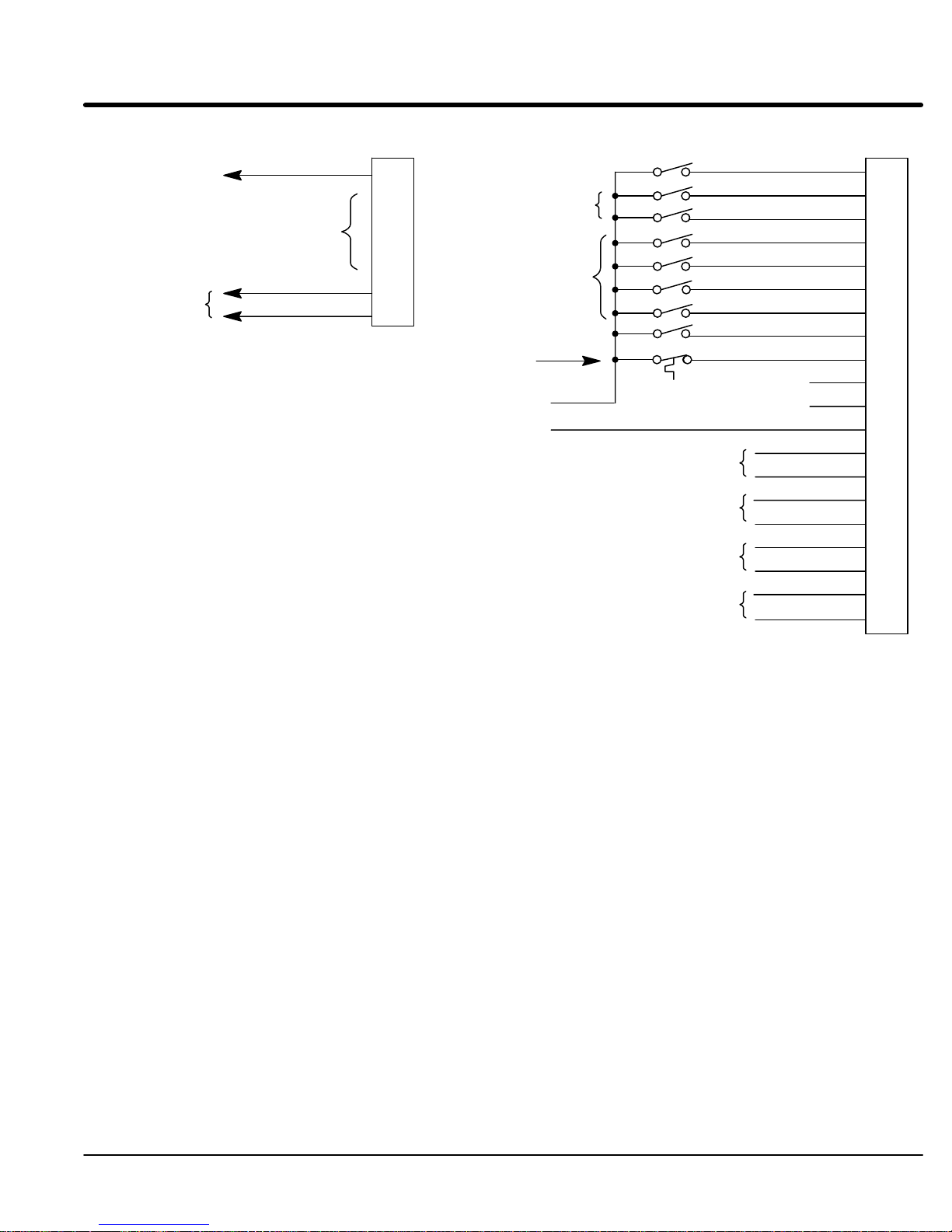

3 Wire Multi INP Control Mode

The Opto inputs can be switches as shown in Figure 3-1

device. The External T

Level 2 PROTECTION block, EXTERNAL TRIP parameter is set to ON.

J1B-8 CLOSED allows current to flow in the motor and produce torque.

J1B-9 Momentary CLOSED to start motor operation in the Forward direction.

J1B-10 Momentary CLOSED to start motor operation in the Reverse direction.

J1B-11 OPEN causes motor to decel to stop.

J1B-12 CLOSED selects Start/Stop and Reset commands from the terminal strip.

J1B-13 CLOSED selects terminal strip speed source (Level 1 Input block, Command Select).

Note: When changing from keypad to terminal strip (J1B-12 or 13) the motor speed and

J1B-14 OPEN selects Preset Speed #1 regardless of the Speed Command input (J1B-13).

J1B-15 OPEN selects Preset Speed #2 regardless of the Speed Command input (J1B-13).

Note: If J1B-14 and 15 are both OPEN, Preset Speed #1 is selected.

J1B-16 OPEN causes an External Trip to be received by the control (when programmed to

J1B-19 Jumper to J1B-18 (+24VDC) for “Active Low” operation of input signals at J1B-8 to 16.

1 or logic signals from another

rip Opto Input at J1B-16 is active if connected as shown and the

OPEN disables the control & motor coasts to a stop.

OPEN to initiate a stop command.

OPEN to initiate a stop command.

OPEN selects Start/Stop and Reset commands from keypad.

OPEN selects speed command from Keypad.

direction will remain the same after the change.

(FIRESTAT).

(FREEZESTAT).

“ON”). When this occurs, the control disables and an external trip error is displayed on

the keypad display (also logged into the error log).

If J1B-16 is connected, you must set Level 2 Protection block, External Trip to “ON” to

recognize the J1B-16 input.

J1B-17 is then used as switch common.

3-20 Installation

MN1230

Page 32

Section

1

General Information

Figure 3-11 3 Wire Multi INP Mode Connection Diagram

J1A

ANALOG GND

Note 1

Note 1

Note 2

Notes:

1. Refer to Analog Inputs description in this section.

Note: JP1 must be properly set for either voltage or current

2. Refer to Analog Outputs description in this section.

3. Refer to Opto Isolated Outputs description in this section.

5kW

Command Pot

or 0-10VDC

±5VDC, ±10VDC

or 4-20mA

Programmable

Analog Outputs.

operation. Refer to Figure 3-16 for jumper information.

ANALOG INPUT 1

POT REFERENCE

ANALOG INPUT +2

ANALOG INPUT –2

ANALOG OUT 1

ANALOG OUT 2

Refer

to Figure 3-17.

1

2

3

4

5

6

7

Customer

Supplied

+24VDC Source

Both Closed=

Fault Reset

GND

V

ext

ext

Note 3

FORWARD RUN

REVERSE RUN

RUN COMMAND

SPEED COMMAND

PRESET SPEED #1

PRESET SPEED #2

EXTERNAL TRIP

OUT 1

OUT 2

OUT 3

OUT 4

ENABLE

STOP

N.C.

N.C.

CREF

OUT 1–

OUT 1+

OUT 2–

OUT 2+

OUT 3–

OUT 3+

OUT 4–

OUT 4+

J1B

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

MN1230

Installation 3-21

Page 33

Section 1

General Information

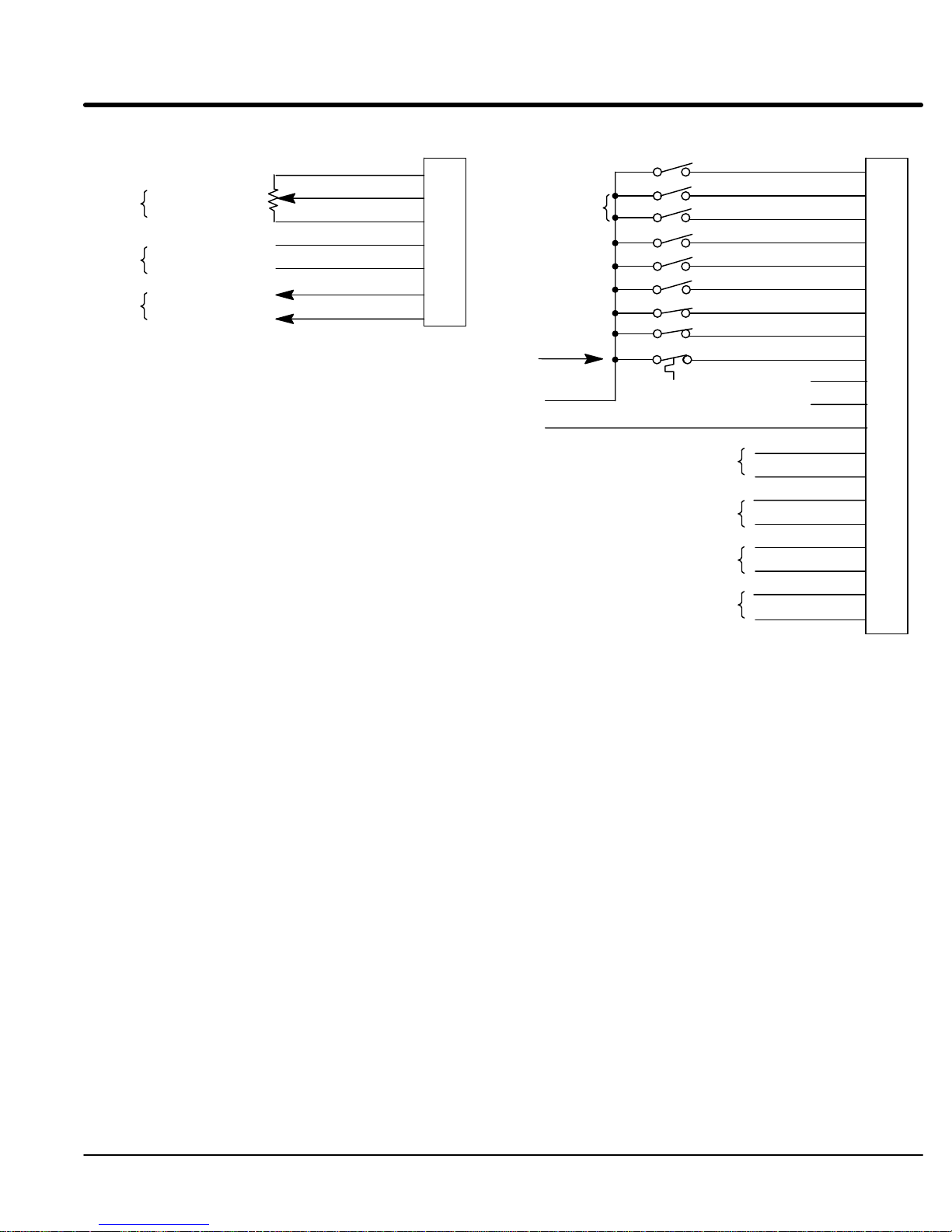

Bipolar Speed or Torque Control Mode with Multiple Parameter Sets

The

normal bipolar speed or torque control for servo motors is provided by this mode.

This mode also allows the user to store up to four (4) dif

parameters. This is important if you wish to store and use dif

dif

ferent jog speeds or to store tuning parameter values for dif

T

o use multiple parameter sets: (refer to Figure 3-12 and T

1.

Set switches J1B-13 open and J1B-14 open (Parameter T

switches J1B-9 and J1B-10 are OPEN, J1B-8 is CLOSED. Use the keypad and

enter all parameter values, and autotune as instructed later in this section. This

creates and saves the first parameter set which is numbered T

Note:

When programming each parameter set, use the ENTER key to accept and

automatically save parameter values.

2.

Set switches J1B-13 closed and J1B-14 open (Parameter T

switches J1B-9 and J1B-10 are OPEN, J1B-8 is CLOSED. Use the keypad and

enter all parameter values, and autotune as instructed later in this section. This

creates and saves the second parameter set which is numbered T

3.

Set switches J1B-13 open and J1B-14 closed (Parameter T

switches J1B-9 and J1B-10 are OPEN, J1B-8 is CLOSED. Use the keypad and

enter all parameter values, and autotune as instructed later in this section. This

creates and saves the third parameter set which is numbered T

4.

Set switches J1B-13 closed and J1B-14 closed (Parameter T

switches J1B-9 and J1B-10 are OPEN, J1B-8 is CLOSED. Use the keypad and

enter all parameter values, and autotune as instructed later in this section. This

creates and saves the final parameter set which is numbered T

ferent complete sets of operating

ferent acceleration rates,

ferent motors.

able 3-6.)

able #0). Be sure

able#0.

able #1). Be sure

able#1.

able #2). Be sure

able#2.

able #3). Be sure

able#3.

Table 3-6 Bipolar Mode Table Select Truth Table

Function J1B-13 J1B-14

Parameter Table #0 Open Open

Parameter Table #1 Closed Open

Parameter Table #2 Open Closed

Parameter Table #3 Closed Closed

3-22

Installation

MN1230

Page 34

Section 1

General Information

Figure 3-12 Bipolar Speed or Torque Mode Connection Diagram

J1A

ANALOG GND

No Connections

ANALOG INPUT +2

Note 1

Note 2

Notes:

1. Refer to Analog Inputs description in this section.

Note: JP1 must be properly set for either voltage or current

operation. Refer to Figure 3-16 for jumper information.

2. Refer to Analog Outputs description in this section.

3. Refer to Opto Isolated Outputs description in this section.

ANALOG INPUT –2

ANALOG OUT 1

ANALOG OUT 2

1

2

3

4

5

6

7

Refer

to Figure 3-17

Customer

Supplied

+24VDC Source

GND

V

ext

ext

Note 3

FORWARD ENABLE

REVERSE ENABLE

CLOSED=ORIENT

SPEED, TORQUE

TABLE SELECT

TABLE SELECT

FAULT RESET

EXTERNAL TRIP

OUT 1

OUT 2

OUT 3

OUT 4

ENABLE

N.C.

N.C.

CREF

OUT 1–

OUT 1+

OUT 2–

OUT 2+

OUT 3–

OUT 3+

OUT 4–

OUT 4+

J1B

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

J1B-8 CLOSED allows current to flow in the motor and produce torque.

OPEN disables the control & motor coasts to a stop.

J1B-9 CLOSED to enable operation in the Forward direction.

OPEN TO DISABLE Forward operation (drive will brake to a stop if a Forward command

is still present).

J1B-10 CLOSED to enable operation in the Reverse direction.

OPEN to disable Reverse operation (drive will brake to a stop if a Reverse command is

still present).

J1B-11 Causes the motor shaft to orient to a marker or external switch.

J1B-12 CLOSED puts the control in torque mode. OPEN puts the control in velocity mode.

J1B-13 & Select from four parameter tables as defined

J1B-14 in Table 3-6.

J1B-15 Momentary CLOSED to reset fault condition.

OPEN to run.

J1B-16 OPEN causes an external trip to be received by control. The control will disable and

display External Trip when programmed “ON”. If J1B-16 is connected, you must set

Level 2 Protection block, External Trip to “ON” to recognize the J1B-16 input.

MN1230

Installation

3-23

Page 35

Section

1

General Information

Process Mode Connections

The process control mode provides an auxiliary closed loop general purpose PID set

point control that is shown in Figure 3-13. The process control loop may be configured in

either of two ways.

1.

Using two (2) inputs; a set point and a process feedback input. The error signal

(between the setpoint and the feedback signals) adjusts the speed or torque of

the motor to eliminate error

2.

Using three (3) inputs; a setpoint, process feedback and feedforward inputs.

.

Instead of waiting for an error signal to develop between the setpoint and the

process feedback signals, the feedforward signal adjusts the speed or torque of

the motor to reduce the amount of error that will develop between the feedback

and setpoint inputs.

The objective of either method is to force the process feedback to be as close to the

setpoint as possible and eliminate process error

.

Two Input Configuration

For 2 input operation, several parameters must be set as follows:

1.

Level 2 Process Control block, “Process Feedback” parameter must be set to

the type of feedback signal used. The process feedback signal can be any

Analog input available at the J1A terminal strip or expansion board. Selections

are shown in Figure 3-13. A signal compatibility matrix is shown in T

2.

Level 2 Process Control block, “Setpoint Source” parameter must be set to the

able 3-7.

type of set point being used.

A.

A fixed value setpoint is a keypad programmed parameter value. T

o

program a fixed setpoint, do the following:

i.

Set the Level 2 Process Control block, “Setpoint Source” parameter

to Setpoint CMD.

ii.

Set the Level 2 Process Control block, “Setpoint CMD” parameter

to a value between –100% to +100% of the process feedback input.

B.

If a variable value setpoint is used, the Setpoint Source must be set to any

available terminal strip or expansion board input not being used for the

process feedback input. Selections are shown in Figure 3-13. A signal

compatibility matrix is shown in T

3.

Level 1 Input block “Command Select” parameter must be set to “None”.

able 3-7.

Three Input Configuration

For 3 input operation, several parameters must be set as follows:

1.

Level 2 Process Control block “Process Feedback” parameter must be set to

the type of feedback signal used. The process feedback signal can be any

Analog input available at the J1A terminal strip or expansion board. Selections

are shown in Figure 3-13. A signal compatibility matrix is shown in T

2.

Level 2 Process Control block “Setpoint Source” parameter must be set to the

able 3-7.

type of set point being used.

A.

If a fixed value setpoint is used, set the Level 2 Process Control block,

Setpoint Source parameter to “Setpoint CMD”. Set the Level 2 Process

Control block “Setpoint Command” parameter to a value between –100%

to +100% of the process feedback.

B.

If a variable value setpoint is used, set the Level 2 Process Control block,

Setpoint Source parameter to any Analog1, Analog2 or expansion board

input not being used for the process feedback input. Selections are shown

in Figure 3-13. A signal compatibility matrix is shown in T

able 3-7.

3-24 Installation

MN1230

Page 36

Section 1

General Information

3.

Level 1 Input block “Command Select” parameter must be set to the

feedforward signal type. This signal may be any Analog1, Analog2 or

expansion board input not being used for the process feedback or setpoint

source inputs. Selections are shown in Figure 3-13.

Note:

An input can only be used one time for Process Feedback, OR Setpoint

Source, OR Feedforward.

Figure 3-13 Simplified Process Control Block Diagram

SETPOINT COMMAND

PROCESS FEEDBACK

Available sources are:

Potentiometer

± 10 Volts

± 5 Volts

4 TO 20 mA

5V EXB

10V EXB

4-20mA EXB

None

PROCESS FEEDFORWARD

COMMAND SELECT

Available sources are:

Potentiometer

± 10 Volts

± 5 Volts

4 TO 20 mA

10 V w/Torq FF

EXB Pulse FOL

5V EXB

10V EXB

4-20mA EXB

Serial

None

+

–

∑

Auxiliary PID Control

Closed When Process

Mode is Enabled (J1–13)

Motor Control

ACC/DEC

S–Curve

Profiler

+

–

∑

s

+

Proportional

Gp

Existing Baldor Control System

Proportional

Gp

Differential

Gd s

Integral

Gi

s

Set Point adjustment limit

w/ integral clamp to max

limit value

Differential

Gd s

+

+

+

∑

+

+

∑

Integral

Gi

s

+

Amp

Motor

Res.

MN1230

Differentiator

Installation 3-25

Page 37

Section

Setpoint

1

General Information

Table 3-7 Process Mode Input Signal Compatibility

or

Feedforward

J1-1 & 2

J1-4 & 5

5V EXB

10V EXB

4-20mA EXB

3-15 PSI EXB

Serial

Requires

Requires expansion board EB01

Requires expansion board EB01

expansion board EB01

Conflicting inputs. Do not use same input signal multiple times.

Note:

Only one expansion board may be installed.

Specific Process Mode Outputs

Feedback

J1-1 & 2 J1-4 & 5

5V EXB 10V EXB

4-20mA

EXB

3-15 PSI

EXB

10A01 (Serial + High Resolution Analog I/O for M Series controls).

10A02 (Serial + Pulse Follower for M Series controls).

10A00 (Serial Communications for M Series controls).

Process Mode Only

, Analog Monitoring Outputs

Name Description

Process FDBK Process Feedback scaled input. Useful for observing or tuning the

process control loop.

Setpoint CMD Setpoint Command scaled input. Useful for observing or tuning the

process control loop.

Speed Command Commanded Motor Speed. Useful for observing or tuning the output of

the control loop.

Process

Name Description

Process Error CLOSED when the Process Feedback is within the specified tolerance

3-26 Installation

Mode Only

, Opto Isolated Outputs

band. OPEN when the Process Feedback is greater than the specified

tolerance band. The width of the tolerance band is adjusted by the

Level 2 Process Control block PROCESS ERR TOL parameter value.

MN1230

Page 38

Section

1

General Information

Figure 3-14 Process Mode Connection Diagram

J1A

ANALOG GND

Note 1

Note 1

Note 2

5kW

Command Pot

or 0-10VDC

±5VDC, ±10VDC

or 4-20mA

Programmable

Analog Outputs.

ANALOG INPUT 1

POT REFERENCE

ANALOG INPUT +2

ANALOG INPUT –2

ANALOG OUT 1

ANALOG OUT 2

Refer

Notes:

1. Refer to Analog Inputs description in this section.

Note: JP1 must be properly set for either voltage or current

operation. Refer to Figure 3-16 for jumper information.

2. Refer to Analog Outputs description in this section.

3. Refer to Opto Isolated Outputs description in this section.

1

2

3

4

5

6

7

to Figure 3-17.

Customer

Supplied

+24VDC Source

Both

OPEN = Stop

GND

V

ext

ext

Note 3

FORWARD ENABLE

REVERSE ENABLE

TABLE SELECT

No Connection

Process Mode Enable

JOG (FWD only)

FAULT RESET

EXTERNAL TRIP

OUT 1

OUT 2

OUT 3

OUT 4

ENABLE

N.C.

N.C.

CREF

OUT 1–

OUT 1+

OUT 2–

OUT 2+

OUT 3–

OUT 3+

OUT 4–

OUT 4+

J1B

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

J1B-8 CLOSED allows current to flow in the motor and produce torque.

OPEN disables the control & motor coasts to a stop.

J1B-9 CLOSED to enable operation in the Forward direction.

OPEN TO DISABLE Forward operation.

J1B-10 CLOSED to enable operation in the Reverse direction.

OPEN to disable Reverse operation.

J1B-11 OPEN=Table 0, CLOSED=Table 1.

J1B-13 CLOSED to enable the Process Mode.

J1B-14 CLOSED puts the control in JOG Mode. Control will only JOG in the forward direction.

OPEN allows PID & Feedforward Speed or Torque control.

J1B-15 Momentary CLOSED to reset fault condition.

OPEN to run.

J1B-16 OPEN causes an External Trip to be received by the control (when programmed to

“ON”). When this occurs, the control disables and an external trip error is displayed on

the keypad display (also logged into the error log).

If J1B-16 is connected, you must set Level 2 Protection block, External Trip to “ON” to

recognize the J1B-16 input.

MN1230

Installation 3-27

Page 39

Section 1

General Information

Analog Inputs and Outputs

Analog Inputs T

wo analog inputs are available: analog input #1 (J1A-1 and J1A-2) and analog input #2

(J1A-4 and J1A-5) as shown in Figure 3-15. Either analog input #1 or #2 may be

grounded provided the common mode range is not exceeded. Either analog input may

be selected in the Level 1 INPUT block, COMMAND SELECT parameter value. Analog

input #1 is selected if parameter value “POTENTIOMETER” is selected. Analog input #2