Page 1

AC INVERTER

Series 10

Inverter Control

Installation and Operating Manual

2/00 MN710

Page 2

Table of Contents

Section 1

General Information 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited W arranty 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notice 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Precautions 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Watts Loss Data 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ratings 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2

Installation 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location and Mounting 2-1. . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Access Cover Removal 2-2. . . . . . . . . . . . . . . . .

Terminal and Jumper Locations 2-3. . . . . . . . . . . . . . . . . .

Wiring Considerations 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Wire Size and Protection Devices 2-5. . . . . . . . . . . . . .

Recommended Terminal Tightening Torques 2-6. . . . .

Main Circuit Wiring 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Power Connections 2-7. . . . . . . . . . . . . . . . . . . . . . .

Motor Connections 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Connections 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Wiring 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Command Inputs 2-10. . . . . . . . . . . . . . . . . . . . . .

Analog Output 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opto Isolated Inputs 2-11. . . . . . . . . . . . . . . . . . . . . . . . . .

External Trip Connection 2-11. . . . . . . . . . . . . . . . . . . . . .

Jumper J19 Input Selection 2-12. . . . . . . . . . . . . . . . . . . .

Relay Outputs 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents i

Page 3

Selection Of Operation Mode And Connection Diagrams 2-13

2 Wire Run/Stop Connections 2-14. . . . . . . . . . . . . . . . . .

3 Wire Run/Stop Connections 2-16. . . . . . . . . . . . . . . . . .

2 Wire Run/Stop, Electronic Potentiometer Connections . . .

2-17

3 Wire Run/Stop, Electronic Potentiometer Connections . . .

2-17

MOL Terminal Connections 2-18. . . . . . . . . . . . . . . . . . . .

Pre-Operation Checks 2-20. . . . . . . . . . . . . . . . . . . . . . . . . .

Check of Electrical Items 2-20. . . . . . . . . . . . . . . . . . . . . .

Check of Motors/Couplings 2-20. . . . . . . . . . . . . . . . . . . .

Temporary Application of Power 2-21. . . . . . . . . . . . . . . .

Pre-Operation Check List 2-21. . . . . . . . . . . . . . . . . . . . . .

Section 3

Operation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Key Functions 3-1. . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Status Indicator 3-3. . . . . . . . . . . . . . . . . . . . . . . . .

Description of Keypad Displays 3-4. . . . . . . . . . . . . . . . . . .

Stop Mode 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Run Mode 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Mode 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security Access/Lockout 3-6. . . . . . . . . . . . . . . . . . . . . .

Control Operation Adjustment 3-6. . . . . . . . . . . . . . . . . . . .

Level One Parameter Adjustments 3-7. . . . . . . . . . . . . . . .

07-Last Fault 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-Output Frequency 3-7. . . . . . . . . . . . . . . . . . . . . . . . .

13-Output Voltage 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

14-Output Current 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

15-Drive Load 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii Table of Contents

Page 4

16-Load Torque 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17-Heatsink Temp 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

21-Operating Mode 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

31-Min Output Frequency 3-9. . . . . . . . . . . . . . . . . . . . .

32-Max Output Frequency 3-9. . . . . . . . . . . . . . . . . . . . .

42-Accel Time #1 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

43-Decel Time #1 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

52-Torque Boost 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

65-Slip Comp Adj 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

67-Timed Overload Trip 3-11. . . . . . . . . . . . . . . . . . . . . . .

70-Analog Output Scale 3-11. . . . . . . . . . . . . . . . . . . . . . .

71-Analog Output Select 3-12. . . . . . . . . . . . . . . . . . . . . .

75-Relay Output Select 3-12. . . . . . . . . . . . . . . . . . . . . . .

Level Two Parameter Adjustments 3-13. . . . . . . . . . . . . . . .

02-Software Revision 3-13. . . . . . . . . . . . . . . . . . . . . . . . .

03-Rated Current 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

08-Second Fault 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

09-First Fault 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24-Analog Command Select 3-14. . . . . . . . . . . . . . . . . . .

33-Preset Speed #1 3-14. . . . . . . . . . . . . . . . . . . . . . . . . .

34-Preset Speed #2 3-14. . . . . . . . . . . . . . . . . . . . . . . . . .

35-Preset Speed #3 3-15. . . . . . . . . . . . . . . . . . . . . . . . . .

36-Preset Speed #4 3-15. . . . . . . . . . . . . . . . . . . . . . . . . .

37-Preset Speed #5 3-15. . . . . . . . . . . . . . . . . . . . . . . . . .

38-Preset Speed #6 3-15. . . . . . . . . . . . . . . . . . . . . . . . . .

39-Min Freq Torque Limit 3-15. . . . . . . . . . . . . . . . . . . . . .

41-Accel/Decel/Coast Select 3-16. . . . . . . . . . . . . . . . . . .

44-Accel Time #2 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents iii

Page 5

45-Decel Time #2 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

46-Decel Time Torque Limit 3-17. . . . . . . . . . . . . . . . . . . .

47-DC Brake Time 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . .

48-DC Brake Voltage 3-18. . . . . . . . . . . . . . . . . . . . . . . . .

51-V/HZ Profile 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

53-Control Base Frequency 3-20. . . . . . . . . . . . . . . . . . . .

59-Max. Output Volts 3-20. . . . . . . . . . . . . . . . . . . . . . . . .

61-Load Torque Limit FWD 3-20. . . . . . . . . . . . . . . . . . . .

62-Load Torque Limit REV 3-21. . . . . . . . . . . . . . . . . . . . .

63-Regen Torque Limit FWD 3-21. . . . . . . . . . . . . . . . . . .

64-Regen Torque Limit REV 3-21. . . . . . . . . . . . . . . . . . .

68-Number of Restarts 3-21. . . . . . . . . . . . . . . . . . . . . . . .

69-Restart Delay 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

77-External Trip Select 3-22. . . . . . . . . . . . . . . . . . . . . . . .

81-Factory Settings 3-23. . . . . . . . . . . . . . . . . . . . . . . . . . .

82-Start Options 3-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auto Restart 3-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Synchro Starts 3-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

84-Display Options 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . .

87-Security Access Code 3-26. . . . . . . . . . . . . . . . . . . . . .

Section 4

Troubleshooting 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Displays 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 5

Illustrations 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Parameters A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv Table of Contents

Page 6

Section 1

General Information

Limited Warranty

For a period of two (2) years from the date of original purchase,

BALDOR will repair or replace without charge controls which our

examination proves to be defective in material or workmanship.

This warranty is valid if the unit has not been tampered with by

unauthorized persons, misused, abused, or improperly installed

and has been used in accordance with the instructions and/or

ratings supplied. This warranty is in lieu of any other warranty or

guarantee expressed or implied. BALDOR shall not be held

responsible for any expense (including installation and removal),

inconvenience, or consequential damage, including injury to any

person or property caused by items of our manufacture or sale.

(Some states do not allow exclusion or limitation of incidental or

consequential damages, so the above exclusion may not apply.) In

any event, BALDOR’s total liability, under all circumstances, shall

not exceed the full purchase price of the control. Claims for

purchase price refunds, repairs, or replacements must be referred

to BALDOR with all pertinent data as to the defect, the date

purchased, the task performed by the control, and the problem

encountered. No liability is assumed for expendable items such as

fuses.

Goods may be returned only with written notification including a

BALDOR Return Authorization Number and any return shipments

must be prepaid.

General Information 1-1

Page 7

Safety Notice

This equipment contains voltages that may be as great as 800

volts! Electrical shock can cause serious or fatal injury. Only

qualified personnel should attempt the start-up procedure or

troubleshoot this equipment.

This equipment may be connected to other machines that have

rotating parts or parts that are driven by this equipment.

Improper use can cause serious or fatal injury. Only qualified

personnel should attempt the start-up procedure or troubleshoot

this equipment.

PRECAUTIONS

WARNING: Do not touch any circuit board, power device

or electrical connection before you first

ensure that power has been disconnected

and there is no high voltage present from

this equipment or other equipment to which

it is connected. Electrical shock can cause

serious or fatal injury. Only qualified

personnel should attempt the start-up

procedure or troubleshoot this equipment.

WARNING: Be sure that you are completely familiar with

the safe operation of this equipment. This

equipment may be connected to other

machines that have rotating parts or parts

that are controlled by this equipment.

Improper use can cause serious or fatal

injury. Only qualified personnel should

attempt the start-up procedure or

troubleshoot this equipment.

1-2 General Information

Page 8

WARNING: Be sure the system is properly grounded

before applying power. Do not apply AC

power before you ensure that all grounding

instructions have been followed. Electrical

shock can cause serious or fatal injury.

WARNING: Do not remove cover for at least five (5)

minutes after AC power is disconnected to

allow capacitors to discharge. Dangerous

voltages are present inside the equipment.

Electrical shock can cause serious or fatal

injury.

WARNING: Improper operation of control may cause

violent motion of the motor shaft and driven

equipment. Be certain that unexpected

motor shaft movement will not cause injury

to personnel or damage to equipment. Peak

torque of several times the rated motor

torque can occur during control failure.

WARNING: Motor circuit may have high voltage present

whenever AC power is applied, even when

motor is not rotating. Electrical shock can

cause serious or fatal injury.

WARNING: This unit has an automatic restart feature

that will start the motor whenever input

power is applied and a RUN (FWD or REV)

command is issued and maintained. If an

automatic restart of the motor could cause

injury to personnel, the automatic restart

feature should be disabled by changing the

AUTORESTART parameter 82 to MANUAL.

General Information 1-3

Page 9

Specifications

Horse Power 0.5 - 1 HP @ 115VAC, 1PH

Input Voltage 95 - 127 VAC, 50/60Hz, Single Phase

Phase Imbalance

(3Phase Only)

Input Frequency 50/60Hz (±10%)

Enclosure NEMA 1

Output Voltage 0 to Maximum Input AC Voltage

Output Frequency 0.1 to 400 Hz

Output Current See Control Rating Table

Service Factor 1.0

Duty Cycle Continuous

Overload Capacity See Control Rating Table

Control Method Voltage Vector PWM

Carrier Frequency 9.2kHz

Frequency Resolution 0.05Hz

V/Hz Ratio 0.24 - 8.85 (230VAC)

Output Transistor Type IGBT (Insulated Gate Bipolar Transistor)

Transistor Rise Time

Torque Boost Standard (automatic adjustment to load)

Volts/Hertz Pattern Linear to Squared Reduced (in 6 patterns)

Accel/Decel Time 0.1 to 600 seconds (for 2 assignable)

Base Frequency 26 to 960 Hz

Dynamic Brake Torque Up to 60% for 6 seconds

0.5 - 5 HP @ 230VAC, 3PH

1 - 5 HP @ 460VAC, 3PH

187 - 253VAC, 50/60Hz, Three Phase

342 - 506VAC, 50/60Hz, Three Phase

±2%

0.48 - 17.69 (460VAC)

2500Volts/msec (dv/dt)

Manual (0-15% of input voltage)

1-4 General Information

Page 10

Auto Restart Manual or Automatic

Min. Output Frequency 0.1 to 400Hz

Max. Output Frequency 20 to 400Hz

Slip Compensation 0 to 12%

Opto Input Impedance 4.5 k Ohms

Ambient Temperature 0°C to 40°C (Maximum without derating)

Humidity 90% Maximum RH non-condensing

Altitude 3300 Ft. (Maximum without derating)

Frequency Setting Keypad, 0-5VDC, 0-10VDC, 0-20mA

Frequency Setting Pot. 5k Ohm, 0.5 Watt

Operating Modes Keypad, 2 Wire, 3 Wire, Preset Speeds,

Vibration 0.6G Maximum

Agency Listings UL and cUL Listed

Electronic Potentiometer

General Information 1-5

Page 11

Operator Keypad

Display Custom Backlit LCD

Keypad 8 Key with Tactile Feel

Functions Output Status Monitoring, Digital Speed Control,

LED Indicators Red/Green for Status

Parameter Setting and Display and Fault Log

Display

Analog Outputs

Analog Outputs 1 Assignable

Full Scale Range 0 to 10VDC Maximum

Output Conditions 3 conditions plus calibration

(see Analog Output Table)

Relay Outputs

Relay Outputs 1 Assignable

Rated Voltage 115VAC

Rated Current 1 Ampere Maximum

Conditions 10 conditions (see Relay Output Table)

Fault Conditions

Automatic Shutdown 15 conditions (see Fault Code Table)

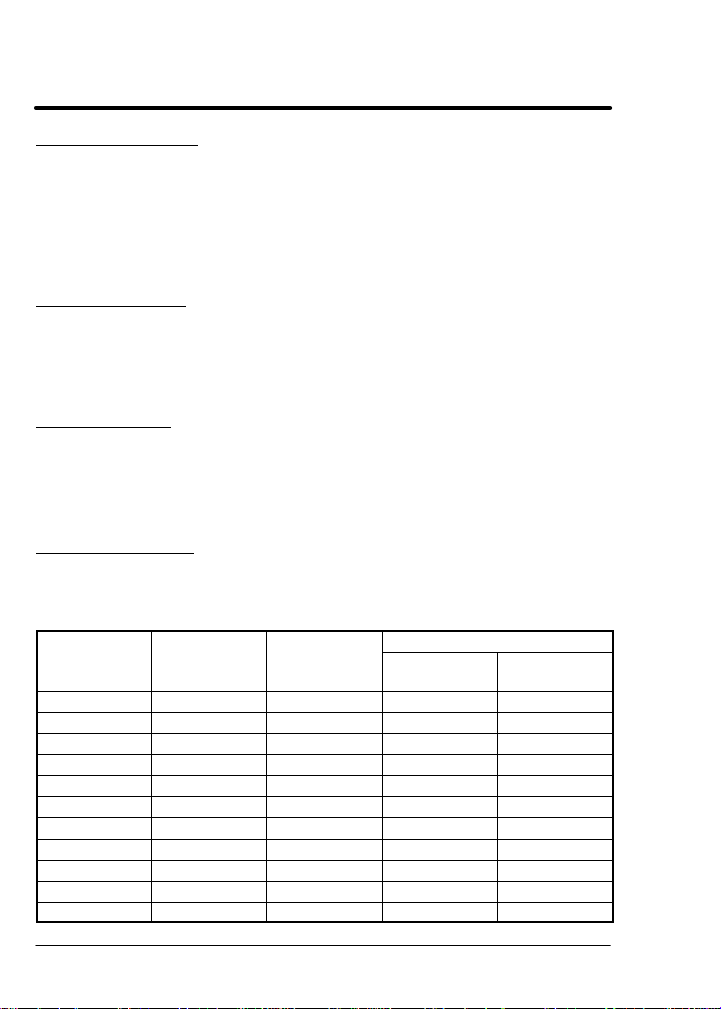

Watts Loss Data

Catalog No. Horsepower

ID101F50-E 0.5 1PH 115 24 N/A

ID10101-E 1.0 1PH 115 42 N/A

ID102F50-E 0.5 3PH 230 16 19

ID10201-E 1.0 3PH 230 28 37

ID10202-E 2.0 3PH 230 52 66

ID10203-E 3.0 3PH 230 66 70

ID10205-E 5.0 3PH 230 70 129

ID10401-E 1.0 3PH 460 N/A 40

ID10402-E 2.0 3PH 460 N/A 67

ID10403-E 3.0 3PH 460 N/A 118

ID10405-E 5.0 3PH 460 N/A 184

Input

Voltage

Total Watts Loss

Single Phase

Input

Three Phase

Input

1-6 General Information

Page 12

Ratings

Catalog No. HP

(kW)

ID101F50-E 0.5

(0.37)

ID10101-E 1.0

(0.75)

ID102F50-E 0.5

(0.37)

ID10201-E 1.0

(0.75)

ID10202-E 2.0

(1.5)

ID10203-E 3.0

(2.2)

ID10205-E 5.0

(3.7)

ID10401-E 1.0

(0.75)

ID10402-E 2.0

(1.5)

ID10403-E 3.0

(2.2)

ID10405-E 5.0

(3.7)

Input Output

VAC Amps Volts

VAC

115 4.5 230 2.2 3.3

115 8.9 230 4.0 6.0

230 1.9 230 2.2 3.3

230 3.8 230 4.0 6.0

230 7.5 230 7.5 11.3

230 10.4 230 10.6 15.9

230 17.6 230 16.7 25.1

460 2.3 460 2.2 3.3

460 5.1 460 4.1 6.2

460 6.2 460 6.1 9.2

460 10.8 460 9.9 14.9

Amps

Cont *

Amps

Peak

* Rating equals 1.1 times parameter 03-Rated Current value.

Note: 230VAC three phase units can be operated at 230VAC

single phase power if the output current AMPS

(Continuous and Peak) are derated by 25%.

General Information 1-7

Page 13

1-8 General Information

Page 14

Section 2

Installation

This section describes the proper mounting and wiring of the

BALDOR Series 10 Inverter. If problems arise, please refer to

the troubleshooting information located in Section 4.

Location and Mounting

Select a mounting surface for the inverter that will allow the

control to be mounted in a vertical position using the four

mounting holes provided. The area selected should allow for

free air circulation around the control. Provide for at least five

inches of clearance on all sides for maximum cooling efficiency.

Caution: Avoid locating the inverter immediately

above or beside heat generating equipment,

or directly below water or steam pipes.

The ambient temperature around the control should not exceed

40°C. If the control is mounted into an existing control cabinet,

the ambient temperature limits should not be exceeded or failure

of the control may result. In cases where extreme temperatures

are unavoidable, a separate blower fan or cooling system should

be considered. Please contact the factory for derating of

controls operated in temperatures above 40°C.

The standard ventilated NEMA 1 enclosure should not be used

in areas where the control will be subjected to liquids, chemicals,

large amounts of airborne material (i.e. dust or lint), or explosive

atmospheres. Appropriate protection should be provided for the

inverter when used in these environments.

If the control will be subjected to levels of vibration above 0.6G,

then the inverter should be shock mounted. Excessive vibration

within the control could cause internal connections to loosen and

cause component failure or electrical shock hazard.

Installation 2-1

Page 15

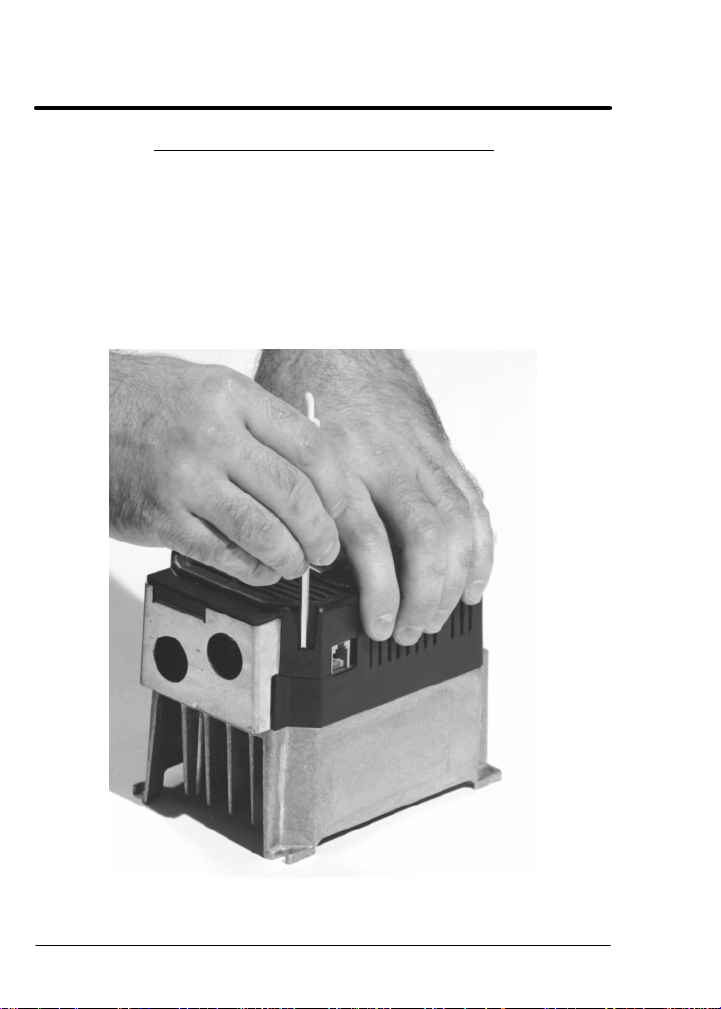

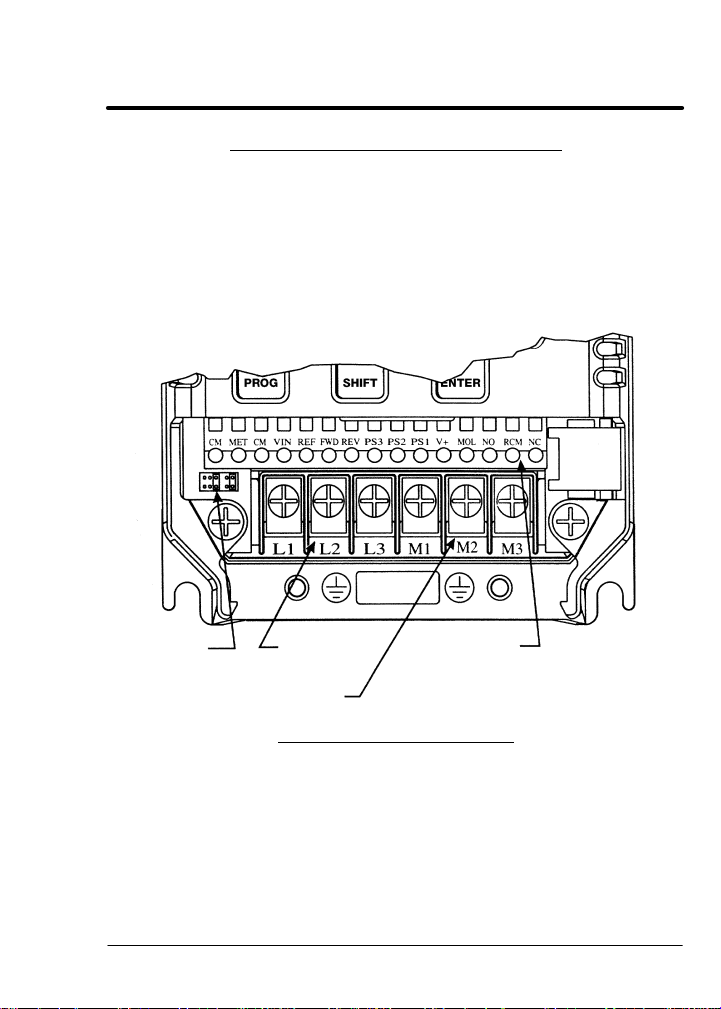

Terminal Access Cover Removal

To remove the Terminal Access Cover insert a small blade

screwdriver into the slots located on the lower left and right hand

corners of the access cover. Use a slight twisting motion while

lifting upward to loosen one side. Use the same motion to

loosen the other side then lift the cover off of the control. To

reinstall, simply snap the cover back into place. See Figure 2-1

below.

Figure 2-1

2-2 Installation

Page 16

Terminal and Jumper Locations

Figure 2-2 shows the location of the power terminal strip , control

terminal strip , ground lug, and user adjustable jumper locations.

Only motor and input power should be connected to the power

terminal strip. Motor ground and input power earth ground

should be connected to the ground lug. Only external control

wiring should be connected to control terminal strip.

Figure 2-2 Terminal and Jumper Locations

J19

AC Line

L1, L2, L3

Motor

M1, M2, M3

Control

Terminals

Wiring Considerations

Interconnection wiring is required between the motor control, AC

power source, motor, host control and any operator interface

stations. Use listed closed loop connectors that are of

appropriate size for wire gauge being used. Connectors are to

be installed using crimp tool specified by the manufacturer of the

connector. Only Class 1 wiring should be used.

Installation 2-3

Page 17

Caution: Separate over-current protection may be

required by the National Electrical Code. The

installer of this equipment is responsible for

complying with the National Electrical Code

and any applicable local codes which govern

such practices as wiring protection,

grounding, disconnects, and other current

protection.

The inverter is self protected from normal AC line transients and

surges. Additional external protection may be required if high

energy transients are present on the incoming power source.

These transients could be caused by sharing a power source

with arc welding equipment, large motors being started across

the line, or other industrial equipment requiring large surge

currents. To prevent inverter damage due to power source

disturbances the following should be considered:

1. Connect the inverter on a feeder line separate from those

supplying large inductive loads.

2. Supply power to the inverter through a suitably sized

isolation transformer. When using an isolation transformer

to power the inverter, always switch the power off and on

between the transformer secondary and the inverter input to

avoid spikes at the inverter when power is removed from

the primary side.

3. Supply power to the inverter through a suitably sized line

reactor. Line reactors serve several purposes:

4.

A. Minimize voltage spikes from the power line that may

cause the inverter to trip on over-voltage.

B. Minimize voltage harmonics from the inverter to the

power line.

C. Provide additional short circuit capability at the inverter.

2-4 Installation

Page 18

Caution: Do not use power factor correction

HP

Breaker

capacitors on the input power lines to the

inverter or damage to the control may result.

All external control wiring to the inverter should be run in a

separate conduit from all other wiring. The use of shielded

twisted pair wire is recommended for all control wiring. The

shield of the control wiring should be connected to control

terminal CM of the inverter only. The other end of the shield

should be taped to the wire jacket to prevent electrical shorts.

Conduit openings are provided at the bottom of the inverter

housing to allow power and control wiring entrance to the control.

Please refer to the inverter outline drawings located in Section 5

of this manual for sizes of the conduit openings.

The following tables show recommended wire size and

protection devices along with recommended terminal tightening

torques.

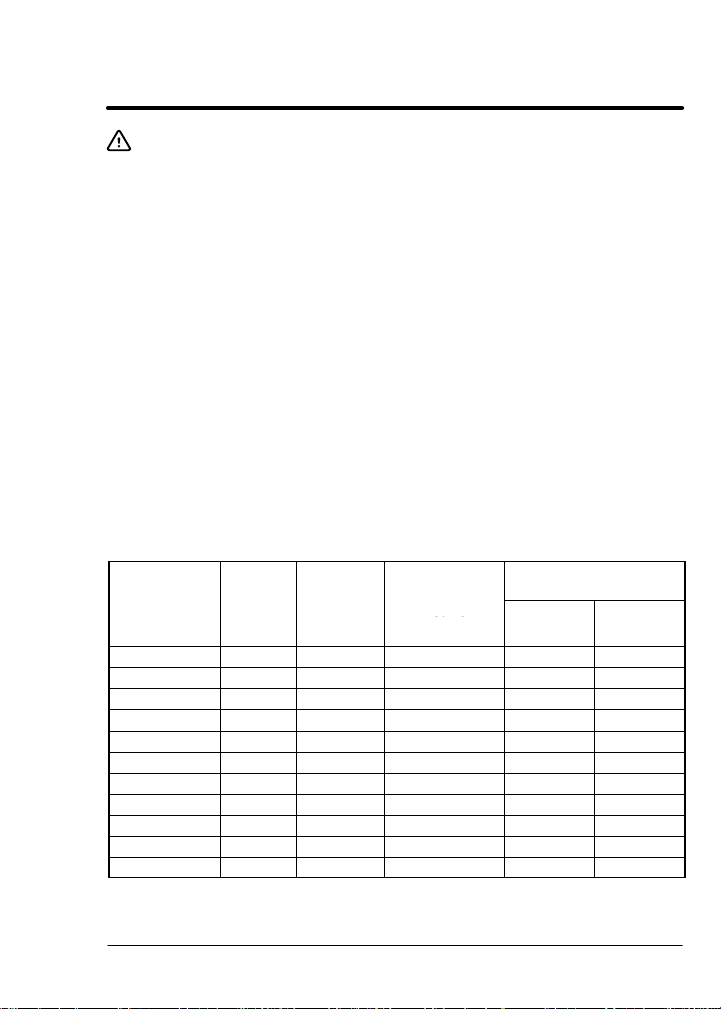

Wire Size and Protection Devices

Rated

Catalog No.

ID101F50-E 0.5 14 240V/10A 240V/5A 240V/3A

ID10101-E 1 14 240V/15A 240V/10A 240V/6A

ID102F50-E 0.5 14 240V/10A 240V/5A 240V/3A

ID10201-E 1 14 240V/15A 240V/10A 240V/6A

ID10202-E 2 14 240V/20A 240V/20A 240V/12A

ID10203-E 3 14 240V/25 240V/25 240V/15

ID10205-E 5 12 240V/40 240V/35 240V/25

ID10401-E 1 14 480V/5A 480V/5A 480V/6A

ID10402-E 2 14 480V/10A 480V/10A 480V/12A

ID10403-E 3 14 480V/15 480V/15 480V/15

ID10405-E 5 14 480V/20 480V/20 480V/25

Rated

HP

Input/

Output

Output

Wire

Wire

AWG Cu

Input

Input

Breaker

Input Fuses

Fast Time

Acting Delay

Input and output wire size is based on use of 60/75°C rated

copper conductor wire.

Installation 2-5

Page 19

Recommended Terminal Tightening Torques

Catalog No.

All Series 10 10 In-Lb (1.13 Nm) 2 In-Lb (0.23 Nm)

Tightening Torques

Power Terminal TB1 Control Terminal Strip

Caution: Do not use this control with any input

voltage other than stated on the control

nameplate. Use of control with wrong power

source can damage the control.

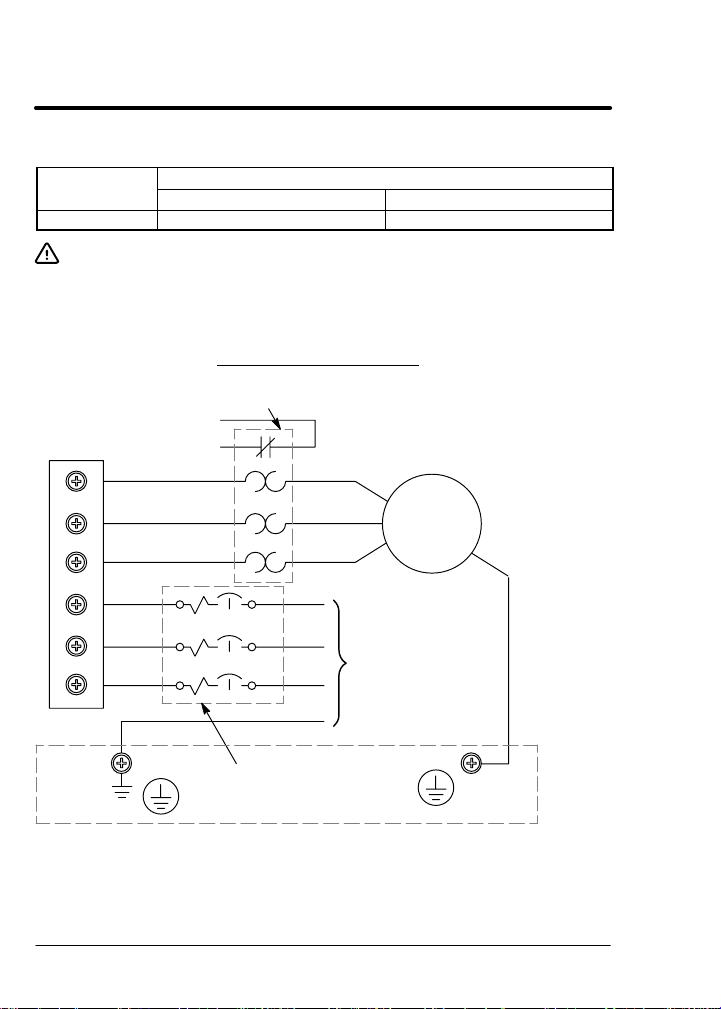

Main Circuit Wiring

External or remote motor overload protection

may be required by NEC or other regulator codes.

To External

Trip Circuit

T3

T2

T1

Motor

GND

M3

M2

M1

L3 *

L2

L1

50/60Hz

3 Phase Power

Heatsink

GND

* Note: L3 is not available on 115VAC input models.

Breaker or Fuse

Protection customer

provided option

Heatsink

GND

See recommended tightening torques for terminal connectors.

2-6 Installation

Page 20

AC Power Connections

Connect the fused three phase AC power lines to the input

power terminals L1, L2, and L3. The phase rotation of the input

power is not important since the control is not sensitive to phase

rotation of the input power. For single phase AC power connect

to input power terminals L1 and L2.

Connect an earth ground to the inverter according to any

applicable electrical code. The earth ground should be

connected to the inverter chassis ground screw.

The use of a power disconnect is recommended between the

input power and the inverter to provide a fail safe method to

disconnect the inverter from the input power. The inverter will

remain in a power up condition until all input power is removed

from the control and the internal bus voltage is depleted.

Caution: Do not attempt to service this equipment

while bus voltage is present within the

inverter. Remove input power and wait at

least 5 minutes for the residual power in the

bus capacitors to dissipate.

Caution: This unit has an automatic restart feature

that will start the motor whenever input

power is applied and a maintained external

run (FWD or REV) command is present at the

control. If an automatic restart of the motor

could cause personal injury or harm, the

auto restart feature should be defeated with

external control wiring or by adjusting

parameter 82-Start Options.

Installation 2-7

Page 21

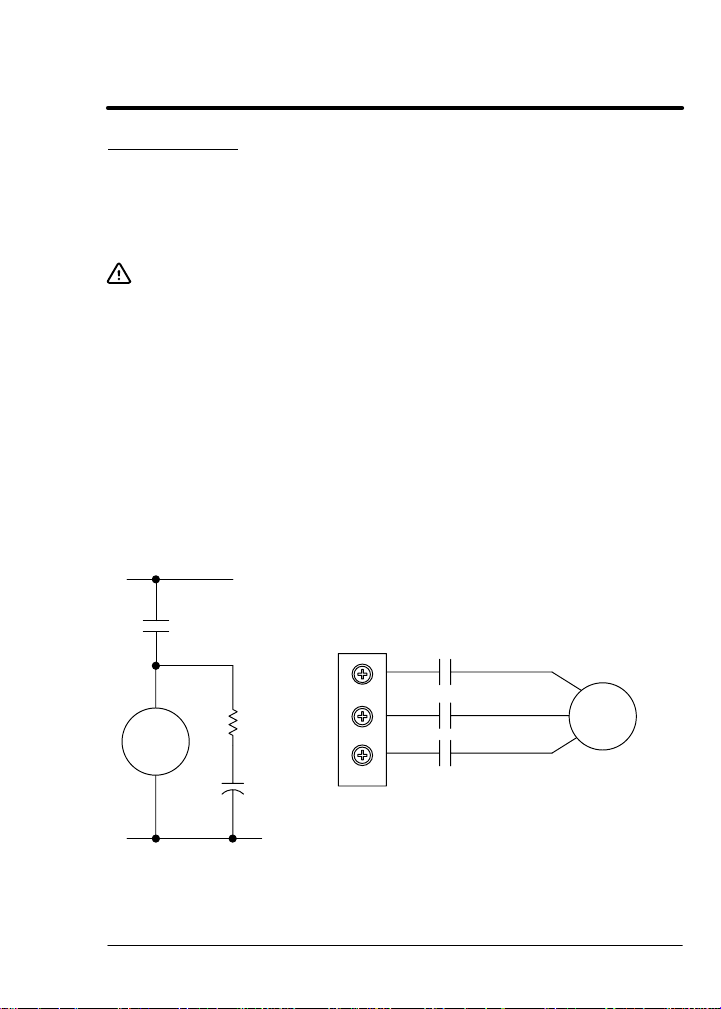

Motor Connections

Connect the three phase power leads of the AC motor to

terminals M1, M2, and M3 of the inverter power terminal strip.

The motor ground lead or case ground should be connected to

the inverter chassis ground screw. The motor should be

connected to the inverter at all times during inverter operation.

If additional motor overload protection is required, the use of

suitably sized motor overload relays are recommended. Motor

overload relays should be connected between the motor and

inverter with the relay trip indicator circuit connected into the

external inverter control circuitry to power down or trip the

inverter in the event of motor overloading.

Caution: Overload relays with an automatic reset

feature are not recommended in applications

where an automatic restart of the motor

could cause personal injury or harm. If

manual reset relays are not available, then

the automatic reset feature should be

defeated.

If the motor is equipped with a normally closed thermostat, the

thermostat should be connected at terminals MOL and CM of the

control terminal strip. The inverter will also need to be

programmed to trip if this thermostat circuit opens indicating a

motor overload condition. The inverter will need to be

programmed by adjusting parameter 77-External Trip Select and

placing the proper jumper position on jumper terminals J19.

If during initial motor start up the motor rotation is opposite to

that desired, disconnect the input power from the inverter and

wait at least 5 minutes for the bus voltage to bleed off.

Interchange any two of the three motor leads at the inverter

power terminal strip M1, M2, and M3 to change the shaft rotation

of the motor.

2-8 Installation

Page 22

M-Contactor

If required by local codes or for safety reasons, an M-Contactor

(motor circuit contactor) may be installed. However, incorrect

installation or failure of the M-Contactor or wiring may damage

the control.

Caution: If an M-Contactor is installed, the control

must be disabled at least 20msec before the

M-Contactor is opened. If the M-Contactor is

opened while the control is supplying

voltage and current to the motor, the control

may me damaged.

A motor circuit contactor provides a positive disconnect of the

motor windings from the control. Opening the M-Contactor

ensures that the control cannot drive the motor. This may be

required during certain manual operations with the load (like

cleaning cutting knives etc.). Figure 2-3 shows how an

M-Contactor is connected to the H series control.

Figure 2-3 Typical Connections for M-Contactor

Stop/E-Stop

M

M3

M2

M1

M

Motor

See recommended tightening torques for terminal connectors.

Installation 2-9

Page 23

Logic Wiring

All logic and control connections are made at the control terminal

strip located on the motor control board. Screw type terminals

are provided for easy connection to your external control station

and meters. The control terminal strip can be divided into four

major categories as follows:

1) Analog command inputs.

2) Analog outputs.

3) Opto Isolated inputs.

4) Relay outputs.

Analog Command Inputs

An external 5kohm potentiometer can be connected at terminals

CM, VIN, and REF. The potentiometer should be connected so

that full resistance is connected from CM and REF. REF is a

5VDC potentiometer reference output. The wiper of the

potentiometer should be connected at terminal VIN. The speed

command input will be recognized at terminals CM and VIN.

When using a potentiometer as the speed command, the Analog

Command Select parameter will need to be programmed to 0 or

1 and jumper J19 will need to be set properly.

An external speed command of 0-5VDC, 0-10VDC, 0-20 mA, or

4- 20mA can be used instead of a potentiometer at terminals CM

and VIN. The positive lead should be connected at terminal VIN

and the negative lead should be connected at terminal CM. The

Analog Command Select parameter should also be programmed

to 0 or 1 and jumper J19 will need to be set properly.

2-10 Installation

Page 24

Analog Output

One programmable analog output is available for external

monitoring of the drive condition. This output is available at

terminals CM and MET. The output will be 0-10VDC. The

positive lead of the external meter should be connected to

terminal MET and the negative lead should be connected at

terminal CM. The output condition is programmed in parameter

71-Analog Output Select. The analog output gain (max output

voltage) can be adjusted in parameter 70- Analog Output Scale.

Please refer to the Analog Output Table in Section 3 for the

possible monitoring conditions.

Opto Isolated Inputs

Six digital inputs are available at terminals FWD, REV, PS3,

PS2, PS1, and MOL to command various output conditions. The

available command condition at the terminal may change

depending on the operating mode selected. These inputs can be

configured for Pull- Up or Pull-Down Logic. The factory setting is

for Pull-Up Logic. The Inputs will be active when connected to

terminal V+ or when utilizing an external 0-24 VDC power supply

with the power supply common connected to terminal CM. The

selection of Pull-UP or Pull-Down Logic is set by jumper J19.

Depending on the function of the command input, a maintained

switch closure or momentary switch closure will be required.

Connection to a PLC, CNC, or host computer are also possible.

External Trip Connection

Terminal MOL is available for connection to a normally open or

normally closed thermostat in all operating modes. This

connection is available for connection to a motor thermostat or

overload relay. The thermostat or overload relay input can also

be configured for Pull-Up or Pull-Down Logic. If the state of the

motor thermostat or overload relay should ever change indicating

an over-temperature condition, the inverter will automatically

shut down and give an External Trip fault (F07) or will cause the

Installation 2-11

Page 25

motor to coast to a stop. The fault or coast to stop operation of

the MOL input terminal is selected by parameter 77-External Trip

Select. The selection of pull- up or pull-down logic is set by

jumper J19.

Jumper J19 Input Selection

Jumper J19 is a pin-jumper selector located to the left and below

the control terminal strip (See Figure 2-2). Five jumper positions

are available and are arranged in one group of three positions

and one group of two positions with one shorting jumper in each

group. The group of two located to the right hand side are used

to select the active state of the opto isolated inputs (Pull-Up or

Pull-down Logic). The group of three located to the left hand

side are used to select the type of analog speed command signal

to be used. The available analog speed command signals are

0-5VDC, 0-10VDC, 0-20 mA, and 4-20 mA. A 5kohm 1/2 watt

potentiometer can be used by configuring for 0-5VDC. The

available jumper settings are shown in the following diagram:

Jumper J19 Selections

Analog speed

command settings

0Ć10VDC Command

Signal

0Ć20mA or 4Ć20mA

Command Signal

0Ć5VDC or Potentiometer

Command Signal

(Factory Setting)

OPTO isolated

input settings

PullĆdown logic inputs are

active when connected to

terminal CM

PullĆup logic inputs are active

when connected to terminal

V+or external 0Ć24VDC supply

with it's common connected to

CM.

0Ć3VDC = Inactive

10Ć24VDC = Active

(Factory Setting)

Caution: Remove input power and wait at least 5

minutes for the residual power in the bus

capacitors to dissipate before changing the

J19 jumper positions.

2-12 Installation

Page 26

Relay Outputs

Programmable relay outputs are available for external monitoring

of the drive condition. These outputs are available at terminals

NO (Normally Open) and NC (Normally Closed) with a common

at terminal RCM (Relay Common). The circuit must be

completed by connection at terminals NO or NC and returned to

RCM. The output condition for terminals NO and NC is

programmed in parameter 75- Relay Output Select. The relay

outputs are rated at 115 VAC and 1 Amp maximum.

Selection Of Operation Mode And Connection Diagrams

Several operating modes are available within the Series 10

inverter . These operating modes define the basic operation of

the input terminal configurations and motor control setup. The

operating modes are selected by the setting of jumper J19, and

programming of parameters 21-Operating Mode, 24-Analog

Command Select, 41- Accel/Decel/Coast Select, and 77-External

Trip Select. These functions are briefly shown below. For a

more detailed discussion please refer to Section 3 of this

manual.

0-10VDC External

Speed Reference

Shield

-

+

0-5VDC External

Speed Reference

CM

-

VIN

+

REF

Shield

CM

VIN

REF

Speed

Potentiometer

Shield

CW

CM

VIN

REF

5.2VDC

Current

Reference

Shield

-

+

CM

VIN

REF

J19 J19 J19 J19

0Ć10VDC

0Ć5VDC 0Ć5VDC 0Ć20 or

4Ć20mA

See recommended tightening torques for terminal connectors.

Installation 2-13

Page 27

2 Wire Run/Stop Connections

Parameter 21 - Operating Mode = 2 or 3

Parameter 41 - Accel/Decel/Coast select = 0, 1, 2, 4, 5 or 6

Shield

Forward

Reverse

Speed Select

Speed Select

Speed Select

J19

Pull–Up Logic

Shield

CM

FWD

REV

PS3

PS2

PS1

V+

MOL

Forward

Reverse

Speed Select

Speed Select

Speed Select

J19

Pull–Down Logic

See recommended tightening torques for terminal connectors.

Speed Select

PS3 PS2 PS1 Function

Open Open Open Keypad or

Analog Command Input

Open Open Closed 33 - Preset Speed #1

Open Closed Open 34 - Preset Speed #2

Open Closed Closed 35 - Preset Speed #3

Closed Open Open 36 - Preset Speed #4

Closed Open Closed 37 - Preset Speed #5

Closed Closed Open 38 - Preset Speed #6

Closed Closed Closed 32 - Max Output Frequency

CM

FWD

REV

PS3

PS2

PS1

V+

MOL

2-14 Installation

Page 28

2 Wire Run/Stop Connections

Parameter 21 - Operating Mode = 2 or 3

Parameter 41 - Accel/Decel/Coast select = 3 or 7

Shield

Forward

Reverse

Ramp Select

Speed Select

Speed Select

J19

Pull–Up Logic

Shield

CM

FWD

REV

PS3

PS2

PS1

V+

MOL

Forward

Reverse

Ramp Select

Speed Select

Speed Select

J19

Pull–Down Logic

See recommended tightening torques for terminal connectors.

Speed Select

PS2 PS1 Function

Open Open Keypad or

Analog Command Input

Open Closed 33 - Preset Speed #1

Closed Open 34 - Preset Speed #2

Closed Closed 35 - Preset Speed #3

CM

FWD

REV

PS3

PS2

PS1

V+

MOL

Ramp Select

PS3 Function

Open 42 - Accel Time #1 Active

Closed

43 - Decel Time #1 Active

Open 44 - Accel Time #2 Active

Closed

45 - Decel Time #2 Active

Installation 2-15

Page 29

3 Wire Run/Stop Connections

Parameter 21 - Operating Mode = 4 or 5

Shield

Forward

Reverse

Stop

Speed Select

Speed Select

J19

Pull–Up Logic

Shield

CM

FWD

REV

PS3

PS2

PS1

V+

MOL

Forward

Reverse

Stop

Speed Select

Speed Select

J19

Pull–Down Logic

See recommended tightening torques for terminal connectors.

Speed Select

PS2 PS1 Function

Open Open Keypad or

Analog Command Input

Open Closed 33 - Preset Speed #1

Closed Open 34 - Preset Speed #2

Closed Closed 35 - Preset Speed #3

CM

FWD

REV

PS3

PS2

PS1

V+

MOL

2-16 Installation

Page 30

2 Wire Run/Stop, Electronic Potentiometer Connections

Parameter 21 - Operating Mode = 6

Shield

Forward

Reverse

Preset Speed #4

Increase

Decrease

J19

Pull–Up Logic

Shield

CM

FWD

REV

PS3

PS2

PS1

V+

MOL

Forward

Reverse

Preset Speed #4

Increase

Decrease

J19

Pull–Down Logic

3 Wire Run/Stop, Electronic Potentiometer Connections

Parameter 21 - Operating Mode = 7

Shield

Forward

Reverse

Stop

Increase

Decrease

J19

Pull–Up Logic

Shield

CM

FWD

REV

PS3

PS2

PS1

V+

MOL

Forward

Reverse

Stop

Increase

Decrease

J19

Pull–Down Logic

CM

FWD

REV

PS3

PS2

PS1

V+

MOL

CM

FWD

REV

PS3

PS2

PS1

V+

MOL

See recommended tightening torques for terminal connectors.

Installation 2-17

Page 31

MOL Terminal Connections (77-External Trip Select)

CM

CM

Shield

CM

Shield

CM

Shield

Normally Open

Device

V+

MOL

J19

Pull–Up Logic

Shield

V+

MOL

Normally Closed

Device

Analog Meter

Shield

-

+

CM

V

MET

V+

MOL

Normally Open

Device

J19

Pull–Down Logic

Relay Output

NO

RCM

NC

Normally Closed

Device

See recommended tightening torques for terminal connectors.

V+

MOL

2-18 Installation

Page 32

Jumper J19 - Used to select the active state of the opto isolated

inputs (Pull-Up or Pull-down Logic) and to select the type of

analog speed command signal to be applied. The available

analog speed command signals are 0-5 VDC, 0-10 VDC, 0-20

mA, and 4-20 mA. A 5kohm 1/2 Watt Potentiometer can be used

by configuring for 0-5 VDC.

21-Operating Mode - Defines the source for speed reference

command and RUN/STOP control inputs.

24-Analog Command Select - Defines the type of external

speed reference command and if the command is accepted as a

direct command or inverted command.

41-Accel/Decel/Coast Select - Selects which Accel and Decel

Time parameters are applied to the control output and also

defines if Coast to Stop is active after a STOP command.

77-External Trip Select - Defines if a normally open or normally

closed contact at control terminal MOL will generate an External

Trip Fault (F07) or a Coast to Stop condition.

82-Start Options - Sets the operation of Auto Restart and

Synchro Starts. Also enables or disables the STOP key as an

E-Stop when operating from the control terminal strip and the

Stop function due to a disconnection of an external command

line connected at the control terminal strip.

Installation 2-19

Page 33

Pre-Operation Checks

Check of Electrical Items

After completing all the installation steps and before applying line

power to the system, carefully check the following items:

1. Verify AC line voltage at source matches control rating.

2. Inspect all power terminations for workmanship and

tightness.

3. Verify control and motor are grounded to each other and the

control is connected to earth ground.

4. Check incoming signal wiring for accuracy.

Be certain all brake coils, contactors, and relay coils have

noise suppression. This should be an R-C filter for AC coils

and reverse polarity diodes for DC coils. MOV type

transient suppression is not adequate.

WARNING: MAKE SURE THA T UNEXPECTED

OPERATION OF THE MOTOR SHAFT

DURING START-UP WILL NOT CAUSE

INJURY TO PERSONNEL OR DAMAGE TO

EQUIPMENT.

Check of Motors/Couplings

Verify freedom of motion for all motor shafts and that all motor

couplings are tight without backlash.

Verify the holding brakes, if any, are properly adjusted to fully

release and set to the desired torque value.

2-20 Installation

Page 34

Temporary Application of Power

Double check electrical and mechanical connections before

applying power to the control.

Temporarily apply power and observe that the display is on. If

this indication doesn’t occur, double check all connections and

verify input voltage. If the display still is not on, refer to the

troubleshooting table in Section 4.

Pre-Operation Check List

1) Verify jumper J19 settings.

2) Verify 21-Operating Mode setting.

3) Verify 24-Analog Command Select settings.

4) Verify 41-Accel/Decel/Coast Select settings.

5) Verify 77-External Trip Select settings.

6) Verify 82-Start Options settings.

7) Review Section 3 of this manual for more detailed

information on parameter adjustments and their affects on

motor operation.

Installation 2-21

Page 35

2-22 Installation

Page 36

Section 3

Operation

Keypad Key Functions

The programming and basic operation of the Series 10 Inverter

is accomplished by simple keystrokes on the operator control

panel. The function of the keys are as follows:

Operation 3-1

Page 37

STOP Push to initiate a stop command. Depending on the

setup of the control the motor will either ramp (Regen) or Coast

to Stop. See 41-Accel/Decel/Coast Select in Section 3 for more

information.

FWD Used to initiate a forward direction run of the motor .

REV Used to initiate a reverse direction run of the motor.

PROG Used to access Level 1 Parameters. Holding the SHIFT

key then pressing the PROG key will access Level 2

Parameters. If in the Run Mode the control will only allow

viewing of the parameter values. Any attempt to change a

parameter value while in the Run Mode will result in the display

showing “-----”. If in the Stop Mode pressing PROG or holding

SHIFT then pressing PROG will enter the Programming Mode at

Level 1 and Level 2 Parameters respectively. Pressing the

PROG key while in the Programming Mode will return the control

to the Stop Mode.

SHIFT Used in the Program Mode to allow changing of a

parameter value. While in Program Mode, the factory preset

value may be reset for any parameter by pressing the SHIFT key

then the UP and DOWN ARROW keys simultaneously. The New

parameter value is stored when the ENTER key is pressed.

UP ARROW Used to change the displayed parameter or

parameter value up one increment. In the Programming Mode

the displayed parameters or parameter values will increment up

until the highest possible value is reached. The UP Arrow is also

used to increment the set speed in the Stop Mode and increment

the actual speed in the Run Mode. The value will increase at a

faster rate after holding the UP Arrow key for 5 seconds.

Pressing SHIFT while holding the UP Arrow will bypass the 5

second delay.

DOWN ARROW Used to change the displayed parameter or

parameter value down one increment. In the Programming Mode

the displayed parameters or parameter values will increment

down until the lowest possible value is reached. The DOWN

3-2 Operation

Page 38

Arrow is also used to decrement the set speed in the Stop Mode

and decrement the actual speed in the Run Mode. The value will

decrease at a faster rate after holding the DOWN Arrow key for 5

seconds. Pressing SHIFT while holding the DOWN Arrow will

bypass the 5 second delay.

ENTER Used to store a new parameter value when in the

Programming Mode. Also used in the Run and Stop Modes to

store the current output frequency as the initial output frequency

when power is applied to the inverter.

Keypad Status Indicator

The STATUS indicator consists of two LED’s, one green and one

red. They are visible through a lens in the upper right hand

corner of the keypad. The following table defines the STATUS

indicator state for the various operating conditions of the inverter.

STATUS INDICATION OPERATING CONDITION

Continuous displays

Green and Red Power on, Restart (2 Seconds)

Red Stop, Running in Torque Limit

Green Run

Intermittent Displays

Alternate Green and

Red Blinking

Green Blinking Running in and out of an Overvoltage

Red Blinking Fault Condition, Emergency Stop,

Running in and out of Torque Limit

or Undervoltage condition

Auto Restart Lock-out, Low Voltage

Operation 3-3

Page 39

Description of Keypad Displays

The custom, back-lit, LCD display provides information on drive

operation and programming. The four large 7-segment displays

show inverter output and programming data.

Two smaller 7-segment displays are used to indicate parameter

numbers. Special symbols and displays provide further

clarification of drive operation. In normal operation only those

segments that are active are displayed. The following figure

shows all segments displayed. The following table lists the

special symbols and their meaning.

3-4 Operation

Page 40

Symbol Description

FWD Forward direction commanded

REV Reverse direction commanded

PRG Program Mode Selected (Steady)

Parameter Value may be changed (Blinking)

SET Drive is Stopped or running frequency being set

OV Overvoltage condition

UV Undervoltage condition

LIM Running in Torque Limit

OC Running in Overcurrent condition (Blinking)

Overcurrent Fault (Steady)

TEMP Running in Overtemperature condition (Blinking)

Overtemperature Fault (Steady)

DB Dynamic Brake circuit is active

rpm Revolutions per minute indication

Hz Frequency in Hertz

h Time in Hours

s Time in Seconds

A Output Current in Amperes

V Output Voltage in Volts

% Display is in percent of units

C Degrees Centigrade

Stop Mode

At the time of initial power up and after a Stop command the

control is in the Stop Mode and the display will show the set

output frequency of the control.

Run Mode

When a Forward or Reverse Run command is given the control

is in the Run Mode and the display will show one of several

output status values. The displayed output can be Output

Frequency, Output Current, Drive Load, or RPM. The displayed

output is selected by parameter 84-Display Options.

Operation 3-5

Page 41

Program Mode

Use the Program Mode to customize the control to suit a variety

of applications by programming the operating parameters. From

the Stop Mode press the PROG key to access the Level 1

Program Mode. Hold the SHIFT key and press the PROG key to

access the Level 2 Program Mode. When in the Program Mode

press the SHIFT key then the UP/DOWN Arrow keys to change

a parameter value. Pressing the ENTER key will save the new

parameter value. To return to the Stop Mode, press the PROG

key. Parameters may only be programmed when accessed from

the Stop Mode. If entering the Programming Mode from the Run

Mode the parameter values may only be viewed.

Security Access/Lockout

Access to the control parameters can be protected by use of the

security code. Security is enabled, and the Security Code is

defined by setting parameter 87-Security Access Code. If the

Security Access Code is enabled and the Programming Mode is

entered then the following display is shown to prompt for the

previously defined Security Code. After the proper Security

Code is entered, the display will return to the normal

Programming Mode Display.

Control Operation Adjustment

The following control adjustments are available within the Series

10 inverter to allow custom tailoring of the drive for particular

applications. Table NO TAG user parameters lists the location

and possible values of the various control adjustments. The

following paragraphs discuss control parameter adjustments and

their effect on drive performance.

3-6 Operation

Page 42

Level One Parameter Adjustments

07-Last Fault - A view only parameter that displays the most

recent fault condition along with the elapsed time from the last

restart of the control and the fault occurrence. The elapsed time

is indicated in 0.1 hour increments with 0.9 hour maximum

displayed. The two left most digits displayed is the fault code

and the right most digits is the elapsed time.

12-Output Frequency - A view only parameter that displays

inverter output frequency in Hertz applied to the motor.

13-Output Voltage - A view only parameter that displays inverter

output voltage as a percentage of line input voltage.

14-Output Current - A view only parameter that displays

inverter output current in Amps RMS per phase. The accuracy

of the displayed current is ±20% and should not be used for

motor overload sizing.

15-Drive Load - A view only parameter that displays true part of

motor current with motor power factor considered. The

displayed value is shown as a percentage of parameter

03-Rated Current and has an accuracy of ±20%. Positive values

indicate motoring and negative values will indicate a

regenerative overhauling load.

16-Load Torque - A view only parameter that displays torque

output of the motor. The displayed value is a percentage of

rated motor torque. Positive values will indicate motoring and

negative values indicate a regenerative overhauling load. This

parameter is most useful in determining available motor torque

when operating with output frequencies above the value set in

parameter 53-Control Base Frequency.

17-Heatsink Temp - A view only parameter that displays the

inverter heatsink temperature in degrees Centigrade.

Operation 3-7

Page 43

21-Operating Mode - Sets the basic operation of the inverter

input terminals and keypad FWD and REV keys. The Series 10

inverter has several modes of operation to fit various application

requirements. Please refer to the following table to determine

which operating mode is right for your application. The available

options include keypad only, control terminal strip only,

combination keypad and control terminal strip operation,

electronic potentiometer, preset speeds, 2-wire control, and

3-wire control. The factory setting is “0”, keypad speed control

and keypad run FWD only.

Parameter 21-Operating Mode

Value

Speed

Control

0 Keypad Keypad Keypad FWD Only, 8 Speeds or 4 speeds

10 Keypad Keypad Keypad FWD and REV, 8 Speeds or 4 speeds

1 Terminals Keypad Keypad FWD Only, 8 Speeds or 4 speeds

11 Terminals Keypad Keypad FWD and REV, 8 Speeds or 4 speeds

2 Keypad Terminals 2-Wire, 8 Speeds or 4 speeds with Accel/De3 Terminals Terminals 2-Wire, 8 Speeds or 4 speeds with Accel/De4 Keypad Terminals 3-Wire, 4 Speeds

5 Terminals Terminals 3-Wire, 4 Speeds

6 Terminals Terminals 2-Wire Electronic Pot with 1 Preset Speed or

7 Terminals Terminals 3-Wire Electronic Pot

Start

Control

Type of Control

with Accel/Decel Select

with Accel/Decel Select

with Accel/Decel Select

with Accel/Decel Select

cel Select

cel Select

Accel/Decel Select

3-8 Operation

Page 44

Electronic Pot Control Terminal Logic

Parameter 21-Operating Mode = 6 or 7

COMMAND CONTROL TERMINALS

DESCRIPTION

STOP OPEN OPEN X X

Speed = 0 CLOSED CLOSED X X

FWD Decrease CLOSED OPEN CLOSED X

FWD Hold CLOSED OPEN OPEN OPEN

FWD Increase CLOSED OPEN OPEN CLOSED

REV Decrease OPEN CLOSED CLOSED X

REV Hold OPEN CLOSED OPEN OPEN

REV Increase OPEN CLOSED OPEN CLOSED

FWD REV PS1 PS2

X=Don’t Care Condition.

31-Min Output Frequency - Sets a minimum output frequency

provided to the motor. During operation the output frequency will

not be allowed to go below the minimum output frequency unless

the motor is starting from 0 Hz or is ramped to a stop. The

available values are 0 to 400 Hz. The factory setting is 0 Hz.

32-Max Output Frequency - Sets a maximum output frequency

provided to the motor. The available values are 20 to 400 Hz.

The factory setting is 60 Hz.

42-Accel Time #1 - Sets the time in seconds for the output

frequency of the inverter to linearly increase from 0 Hz to the

frequency specified by parameter 32-Max Output Frequency.

The adjustable range is from 0 Sec to 600 Sec.

43-Decel Time #1 - Sets the time in seconds for the output

frequency of the inverter to linearly decrease from the frequency

specified by parameter 32-Max Output Frequency to 0 Hz. The

adjustable range is from 0 Sec to 600 Sec.

Operation 3-9

Page 45

Note: Since the motor uses rotor slip to produce motor torque,

the motor speed will not necessarily increase/decrease

linearly with a linear increase/decrease in applied motor

frequency. Some trial and error may be necessary to find

the optimum Accel and Decel settings for your application.

If the control trips (faults) during rapid accel or decel,

selecting longer ramp times will help eliminate the trips.

52-Torque Boost - The Torque Boost parameter can be

adjusted to provide more or less starting torque from the motor

than is available with the factory setting. The boost adjustment

alters the output voltage of the inverter from the normal value (as

defined by the V/HZ Profile) by increasing or decreasing the

starting output voltage by fixed values.

The boost is set from the factory at a level that is suitable for

most applications. If adjustment is required, adjust the boost up

in small increments until the motor shaft just starts to rotate with

maximum load applied. Caution should be exercised when

adjusting the Torque Boost parameter to prevent motor

overheating at low operating speeds. The Torque Boost is

adjustable from 0% to 25% of the nominal input voltage.

65-Slip Comp Adj - The Slip Compensation Adjustment is

available to compensate for varying load conditions during

normal operation. This parameter will set the maximum amount

of allowable variation in output frequency under varying load

conditions which the control will see as changes in output

current. As the control sees the motor current increase towards

100% of parameter 03-Rated Current (Inverter Rated Current),

the inverter will automatically increase the output frequency to

compensate for slip. The range of adjustment is from 0-12%.

The factory setting is 0%.

3-10 Operation

Page 46

67-Timed Overload Trip - Sets the amount of overload that will

cause a Timed Overload fault (F20) to occur. A Timed Overload

fault will occur when the output current reaches 150% of the set

value for 1 minute. The Timed Overload Trip is active between

30-100% of the Inverter Rated Current (03-Rated Current)

parameter value. The value of the Timed Overload Trip

parameter should be calculated by the following formula:

Value of Parameter 67 +

Motor FLA X 100

03–Rated Current

The range of adjustment is from 0 to 100%. The factory setting

is 0%. The Timed Overload Trip for various output frequencies is

shown in the following figure:

Trip T ime (Min)

6

0 20 >40Hz

5

4

3

2

1

0

0

50% 100% 150%

70-Analog Output Scale - Allows scaling of the analog meter

output at control terminal MET to be more or less than the

normal 0-10 VDC level. The factory setting is for 10 VDC output

at full inverter output. The adjustable range is 0-255 in digital

units.

Operation 3-11

Page 47

71-Analog Output Select - Allows setting of the analog output

available at the control terminal MET to represent various drive

operating conditions. The analog output is 0 to 10 VDC nominal.

The analog output is useful in applications where a higher level

control is monitoring the operation of the control to make process

decisions based on the current status of the inverter. The output

can also be used to drive remote analog meters that may be

located near the operator. Please review the Analog Output

Table below for the available operating condition selections.

Parameter 71-ANALOG OUTPUT SELECT

Value Description

0 Output Off

1 Output Frequency, Full scale = Parameter 32- MAXIMUM

2 Output Current, Full Scale = 200% of Rated Current

3 Drive Load, Full Scale = 200% of Rated Load

OUTPUT FREQUENCY

75-Relay Output Select - Allows setting of the normally open

and normally closed relay outputs available at the control

terminal strip to represent various drive operating conditions.

The relay outputs are useful in applications where a higher level

control is monitoring the operation of the control to make process

decisions based on the current status of the inverter. These

outputs can also be used to interlock into mechanical brakes,

bypass contactors, and signal an operator if various operating

conditions are present. Please refer to the Relay Output Select

Table for the available operating condition selections.

3-12 Operation

Page 48

Parameter 75-RELAY OUTPUT SELECT

Value Description

0 Off

1 Ready. Inactive at Fault, Low Voltage, Idle, and in Program

2 Fault

3 Forward and Reverse Output, Output Frequency above 0.5 Hz

4 Reverse Output, Output Frequency above 0.5 Hz

5 Forward Output, Output Frequency above 0.5 Hz

6 Output Frequency less than 0.5 Hz

7 Output at Set Frequency

8 Output Frequency greater than Parameter 36-Preset Speed #4

9 Running in Torque Limit

10 Overtemperature Warning. Temperature is within 10 degrees

Mode

setting

C of maximum rating

Level Two Parameter Adjustments

02-Software Revision - A view only parameter that displays the

software revision code of the installed software version.

03-Rated Current - A view only parameter that displays the

factory set nominal output current of the inverter. The factory

setting also serves as the 100% reference for all displayed

output currents. The inverter continuous output current is 110%

of the factory setting.

08-Second Fault - A view only parameter that displays the

second most recent fault condition before the Last Fault along

with the elapsed time from the last restart of the control and the

fault occurrence. The elapsed time is indicated in 0.1 hour

increments with 0.9 hour maximum displayed. The two left most

digits displayed is the fault code and the right most digits is the

elapsed time.

09-First Fault - A view only parameter that displays the most

recent fault condition before the Last Fault along with the

elapsed time from the last restart of the control and the fault

Operation 3-13

Page 49

occurrence. The elapsed time is indicated in 0.1 hour

increments with 0.9 hour maximum displayed. The two left most

digits displayed is the fault code and the right most digits is the

elapsed time.

24-Analog Command Select - Selects the type of external

speed reference command the control should be expecting to

see in your application. The possible values are 0-10V, 0-5V,

0-20mA, and 4- 20mA. If long distances are required between

the control and the external speed command location then 0-20

mA or 4-20mA should be considered since a current loop

command scheme will allow no loss of the command signal with

long cable lengths.

Also sets if the control will recognize a high value of command

signal as a high output command or a low output command of

the inverter. If Direct is selected the control will see a low

command signal as a low speed command and a high command

signal as a high speed command. Direct is the selection used in

most applications. If Inverted is selected the control will see a

low command signal as a high speed command and a high

command signal as a low speed command.

Parameter 24-ANALOG COMMAND SELECT

Value Operation Analog Command Signal

0 Direct 0-10 VDC, 0-5 VDC, 0-20 mA

1 Inverted 10-0 VDC, 5-0 VDC, 20-0 mA

2 Direct 4-20 mA

3 Inverted 20-4 mA

33-Preset Speed #1 - Sets the output frequency when Preset

Speed #1 is commanded at the Control Terminal Strip. The

adjustable range is 0.1-400 Hz. The factory setting is 5 Hz.

34-Preset Speed #2 - Sets the output frequency when Preset

Speed #2 is commanded at the Control Terminal Strip. The

adjustable range is 0.1-400 Hz. The factory setting is 20 Hz.

3-14 Operation

Page 50

35-Preset Speed #3 - Sets the output frequency when Preset

Speed #3 is commanded at the Control Terminal Strip. The

adjustable range is 0.1-400 Hz. The factory setting is 40 Hz.

36-Preset Speed #4 - Sets the output frequency when Preset

Speed #4 is commanded at the Control Terminal Strip. The

adjustable range is 0.1-400 Hz. The factory setting is 60 Hz.

37-Preset Speed #5 - Sets the output frequency when Preset

Speed #5 is commanded at the Control Terminal Strip. The

adjustable range is 0.1-400 Hz. The factory setting is 0 Hz.

38-Preset Speed #6 - Sets the output frequency when Preset

Speed #6 is commanded at the Control Terminal Strip. The

adjustable range is 0.1-400 Hz. The factory setting is 0 Hz.

Note: Preset Speed adjustments set the commanded frequency

to be output from the control when the appropriate preset

speed is initiated. Preset speeds can be initiated by

external command at the control terminal strip. Since a

preset speed only sets an operating speed, a motor

direction command will also need to be initiated in order

for the motor to have rotation.

39-Min Freq Torque Limit - Sets the lowest output frequency

the inverter will output when in torque limit. If the motor loading

is large enough to drive the inverter below this output frequency,

the inverter will trip on an overcurrent fault (F16, F17 or F18).

The adjustable range is 0-400 Hz and the factory setting is 10

Hz. To disable torque limit set a value greater than the

frequency setting in parameter 32- Max Output Frequency. The

rate of deceleration in torque limit is set by parameter 46-Decel

Time Torque Limit.

Operation 3-15

Page 51

41-Accel/Decel/Coast Select - Sets when Accel Times 1 or 2

and Decel Times 1 or 2 are called upon to affect the output

frequency of the inverter. Also can select a Coast to Stop

deceleration after a Stop command. The factory setting is “0”

indicating that parameters 42-Accel Time #1 and 43-Decel Time

#1 are active. Please review the following table for the available

selections.

Parameter 41-ACCEL/DECEL/COAST SELECT

Value Description

0 Ramp to Stop. Parameters 42-Accel Time #1 and 43-Decel Time #1

active

1 Ramp to Stop. Parameters 42-Accel Time #1 and 43-Decel Time #1

active in Forward, Parameters 44-Accel Time #2 and 45-Decel Time #2

active in Reverse

2 Ramp to Stop. Parameters 42-Accel Time #1 and 43-Decel Time #1

active when output frequency is less than Parameter 37-Preset Speed

#5, Parameters 44-Accel Time #2 and 45- Decel Time #2 active when

output frequency is greater than or equal to parameter 37-Preset

Speed #5

3 Ramp to Stop. When Parameter 21-Operating Mode is set to

0,1,2,3,6,10 or 11 an input at PS3 when active will activate Parameters

44-Accel Time #2 and 45-Decel Time #2. Note that input PS3 cannot

be used as a preset speed selector when a value of 3 is chosen

4 Coast to Stop after STOP command. Parameters 42-Accel Time #1

and 43-Decel Time #1 active

5 Coast to Stop after STOP command. Parameters 42-Accel Time #1

and 43-Decel Time #1 active in Forward, Parameters 44-Accel Time #2

and 45-Decel Time #2 active in Reverse

6 Coast to Stop after STOP command. Parameters 42-Accel Time #1

and 43-Decel Time #1 active when output frequency is less than

Parameter 37-Preset Speed #5, Parameters 44- Accel Time #2 and

45-Decel Time #2 active when output frequency is greater than or

equal to parameter 37-Preset Speed #5

7 Coast to Stop after STOP command. When Parameter 21- Operating

Mode is set to 0,1,2,3,6,10 or 11 an input at PS3 when active will

activate Parameters 44-Accel Time #2 and 45-Decel Time #2. Note

that input PS3 cannot be used as a preset speed selector when a

value of 7 is chosen

3-16 Operation

Page 52

44-Accel Time #2 - Sets the time in seconds for the output

frequency of the inverter to linearly increase from 0 Hz to the

frequency specified by parameter 32-Max Output Frequency.

The adjustable range is from 0.1 Sec to 600 Sec.

45-Decel Time #2 - Sets the time in seconds for the output

frequency of the inverter to linearly decrease from the frequency

specified by parameter 32-Max Output Frequency to 0 Hz. The

adjustable range is from 0.1 Sec to 600 Sec.

Note: Since the motor uses rotor slip to produce motor torque,

the motor speed will not necessarily increase/decrease

linearly with a linear increase/decrease in applied motor

frequency. Some trial and error may be necessary to find

the optimum Accel and Decel settings for your application.

If the control trips (faults) during rapid accel or decel,

selecting longer ramp times will help eliminate the trips.

46-Decel Time Torque Limit - Sets the deceleration rate when

the control is operating in torque limit. Also serves as the

acceleration time when the control is in torque limit due to a

regenerative (overhauling load) condition. The adjustable range

is 0.1-30 seconds.

47-DC Brake Time - Sets the amount of time the DC Injection

Braking will be allowed. There are several available options

including Timed DC Braking, Continuous DC Braking, and Off

(disabled). The options are defined in the following table:

Operation 3-17

Page 53

Parameter 41-Parameter 47-DC BRAKE TIME

Value Braking Action / Function

0 DC Braking Disabled

Timed DC Braking (Parameter Value Sets Braking Time)

When both FWD and REV Terminals are closed (active) and

Parameter 21-OPERATING MODE = 2, 3, 4, 5, 6, or (Terminal Strip

Start/Stop Control)

0.05

0.05

When Speed Command is reduced to less than 0.1 Hz while in FWD or

to

REV Run Mode

4.95

4.95

After a STOP Command and the output frequency is reduced to less

than 0.1 Hz

Continuous DC Braking

When both FWD and REV Terminals are closed (active) and

Parameter 21-OPERATING MODE = 2, 3, 4, 5, 6, or 7 (Terminal Strip

Start/Stop Control)

5

5

When Speed Command is reduced to less than 0.1 Hz while in FWD or

REV Run Mode

48-DC Brake Voltage - Sets the amount of DC Voltage applied

to the motor windings to cause the motor to stop. Increasing the

DC Brake Voltage setting will cause the motor to have more

braking torque available for stopping. Caution should be

exercised when adjusting this parameter since DC Injection

Braking will cause additional motor heating if used in applications

requiring frequent starts and stops. The adjustable range is from

0-15 % of parameter 52-Torque Boost setting.

3-18 Operation

Page 54

51-V/HZ Profile - Sets the output V/Hz ratio for all values of

output voltage verses output frequency up to the Control Base

Frequency point. This adjustment will define how much voltage

is applied to the motor in various segments of the output

frequency range. Please note that motor voltage is related to

motor current which can then be related to motor torque. By

adjusting the V/Hz profile you can effectively adjust how much

torque is available from the motor at various speed points. The

available selections include LINEAR (0 or 1) to be used for

constant torque applications such as conveyors, and 50%

Square Law (2 or 3), or 100% Square Law (4 or 5) to be used for

variable torque applications such as centrifugal pumps and

blowers. Even number parameter values will select Auto-Boost

with the maximum amount of Torque Boost set by Parameter

52-Torque Boost. Odd number parameter values will select a

fixed amount of Torque Boost set by Parameter 52-Torque Boost.

The choices are shown graphically in Figure 3-1.

Figure 3-1 Volts/Hertz Profiles

Linear

100% V

Boost

0%

51-V/Hz Profile = 0

F Base

100% V

Boost

0%

51-V/Hz Profile = 1

F Base

100% V

50% Square

Law

Boost

0%

100% V

100% Square

Law

Boost

0%

51-V/Hz Profile = 2

F Base

51-V/Hz Profile = 4

F Base

100% V

Boost

0%

100% V

Boost

0%

51-V/Hz Profile = 3

F Base

51-V/Hz Profile = 5

F Base

Fixed BoostAuto Boost

Operation 3-19

Page 55

53-Control Base Frequency - Sets the point on the V/Hz profile

where the output voltage becomes a constant value with

increasing output frequency. The base frequency point defines

the output frequency where the motor goes from constant torque

(or variable torque) to constant horsepower operation. The

range of adjustment is from 26 to 960 HZ. The factory setting is

60 Hz.

59-Max. Output Volts - Sets the maximum output voltage

available to the motor from the control. The maximum output

voltage of the inverter can be reduced from the line input voltage

to facilitate the use of a motor with an input voltage that is less

than the input voltage to the inverter.

Note: In some cases the Max. Output Volts along with the

Control Base Frequency adjustment can be manipulated

to provide a wider constant torque or wider constant

horsepower speed range than is normally available from

the motor. The Max Output Volts and Control Base

Frequency parameters are normally set to the motors’

rated voltage and rated frequency respectively. Caution

should be exercised if any other values are set into these

parameters. Incorrect values may cause the motor to run

at extreme temperatures or fail prematurely.

61-Load Torque Limit FWD - Sets the maximum amount of

current that is supplied to the motor under a motoring forward

condition before Torque Limiting takes affect. The range of

adjustment is 30- 150% of parameter 03-Rated Current. The

factory setting is 150%.

3-20 Operation

Page 56

62-Load Torque Limit REV - Sets the maximum amount of

current that is supplied to the motor under a motoring reverse

condition before Torque Limiting takes affect. The range of

adjustment is 30- 150% of parameter 03-Rated Current. The

factory setting is 150%.

63-Regen Torque Limit FWD - Sets the maximum amount of

current that is absorbed by the control from the motor under a

regenerative forward condition before Torque Limiting takes

affect. The range of adjustment is 30-110% of parameter

03-Rated Current. The factory setting is 80%.

64-Regen Torque Limit REV - Sets the maximum amount of

current that is absorbed by the control from the motor under a

regenerative reverse condition before Torque Limiting takes

affect. The range of adjustment is 30-110% of parameter

03-Rated Current. The factory setting is 80%.

68-Number of Restarts - Sets the maximum number of

automatic restart attempts that is allowed before the control will

require a manual restart. After ten minutes without reaching the

maximum number of faults, the number of allowable restarts will

be reset to the value specified in the Number Of Restarts

parameter. This feature is useful in applications that require

unattended operation and automatic operation even in the event

of various fault conditions such as unscheduled power outages.

The control will not automatically clear faults F01 through F10.

The adjustable range is 0 - 8. the factory setting is 0 effectively

disabling the Auto Restart function.

69-Restart Delay - Sets the amount of time allowed between a

fault condition (F11 through F20) and an automatic restart. This

feature is useful in setting a sufficient time period for a fault

condition to be cleared before an automatic restart is attempted.

The adjustable range is 0 to 60 seconds.

Operation 3-21

Page 57