MODEL BE1004-06, BE1153, BE1209

WINDAGE SHOOTING REST

OWNER'S MANUAL

BE1005 Shown

COPYRIGHT © DECEMBER, 2011 BY GRIZZLY INDUSTRIAL, INC. REVISED JULY, 2018 (BL)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

PHONE: (570) 546-9663 • EMAIL: TECHSUPPORT@GRIZZLY.COM • #TR14645 • PRINTED IN TAIWAN

THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

Table of Contents

Controls & Terminology ................................................................................................................. 1

Introduction

Unpacking & Inventory

Initial Setup

Installing Bag

Setup & Use

Conversion for Left-Handed Shooters

Maintenance

Lubrication

BE1004 Parts Breakdown

BE1005 Parts Breakdown

BE1006 Parts Breakdown

BE1153 Parts Breakdown

BE1209 Parts Breakdown

BE1004 Specifications

BE1005 Specifications

..................................................................................................................................... 2

................................................................................................................... 2

...................................................................................................................................... 3

................................................................................................................................... 4

..................................................................................................................................... 5

................................................................................................................................... 10

..................................................................................................................................... 10

............................................................................................................. 11

............................................................................................................. 12

............................................................................................................. 13

............................................................................................................. 14

............................................................................................................. 15

.................................................................................................................. 16

.................................................................................................................. 17

.......................................................................................... 7

BE1006 Specifications

BE1153 Specifications

BE1209 Specifications

Optional Accessories

.................................................................................................................. 18

.................................................................................................................. 19

.................................................................................................................. 20

.................................................................................................................... 21

For your own safety, you

MUST read and understand

this manual before using

this product. After reading,

save this manual for later

reference. Download

the latest version from:

www.grizzly.com.

To avoid serious personal injury or death,

always follow the safety procedures supplied by the firearm manufacturer.

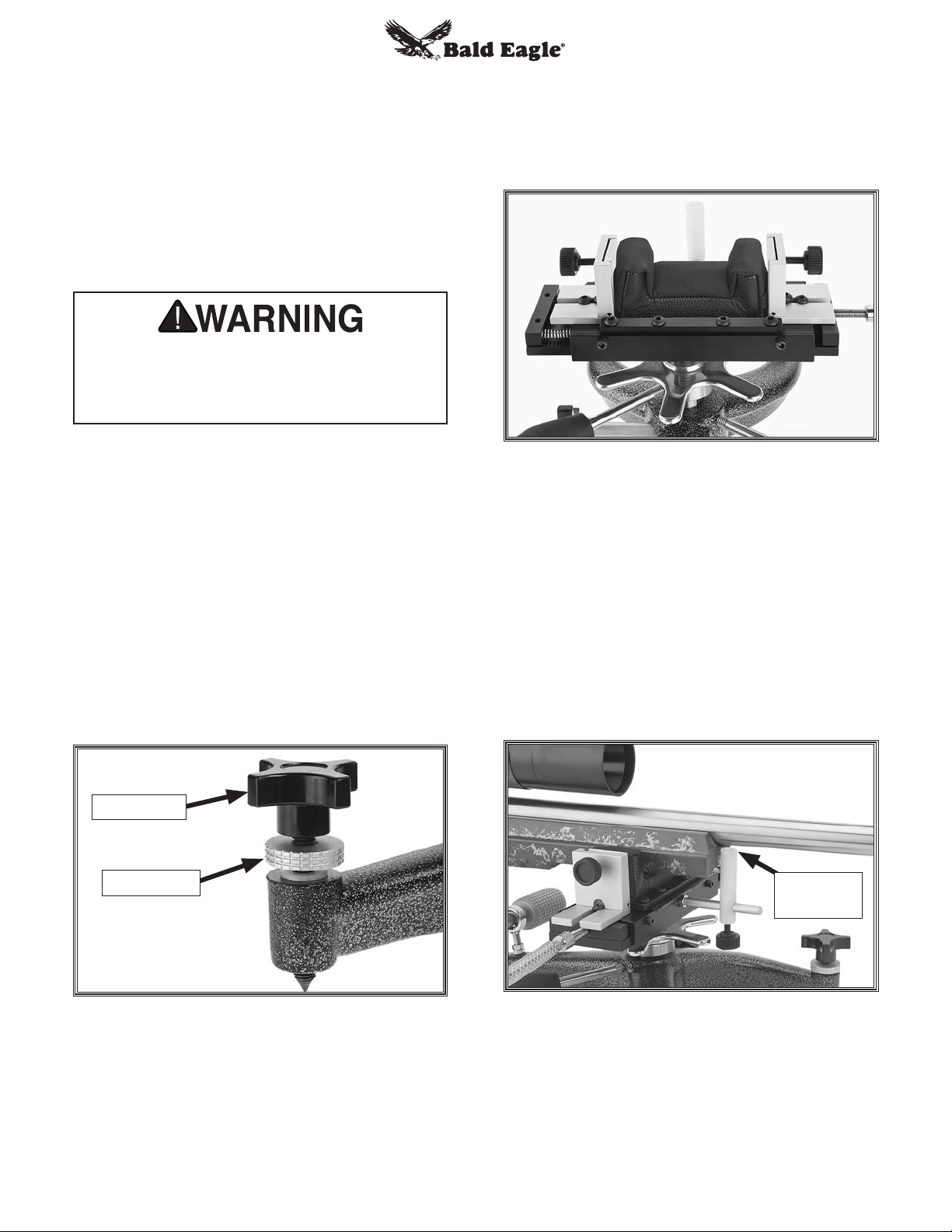

Controls & Terminology

Rear Foot

Knobs

Fore-End

Stop

Base

Quick Elevation

Knob

Clamp Shoe

Thumb Knobs

Windage

Adjustment

Knob

Front Foot

Knob

Foot Knob

Lock

BE1005 Shown

Mariner Wheel

(Fine Elevation)

Fine Elevation

Lock Handle

Quick

Elevation

Knob

FRONT

Windage Cradle

Windage Screw

REAR

Quick Elevation

Lock Handle

Windage Knob

Lock Nuts

BE1004-06, BE1153, BE1209

-1-

Introduction

Thank you for choosing a Bald Eagle Windage

Shooting Rest! Although each model has a few differences, they function the same and use identical

instructions for setup, operation, and maintenance.

Below are the main differences between the

three models:

BE1004

• Aluminum Triangle Base

• 3⁄8"-16 Foot Knobs

BE1005

• Aluminum Slingshot Base

• 3⁄8"-16 Foot Knobs

Unpacking &

Inventory

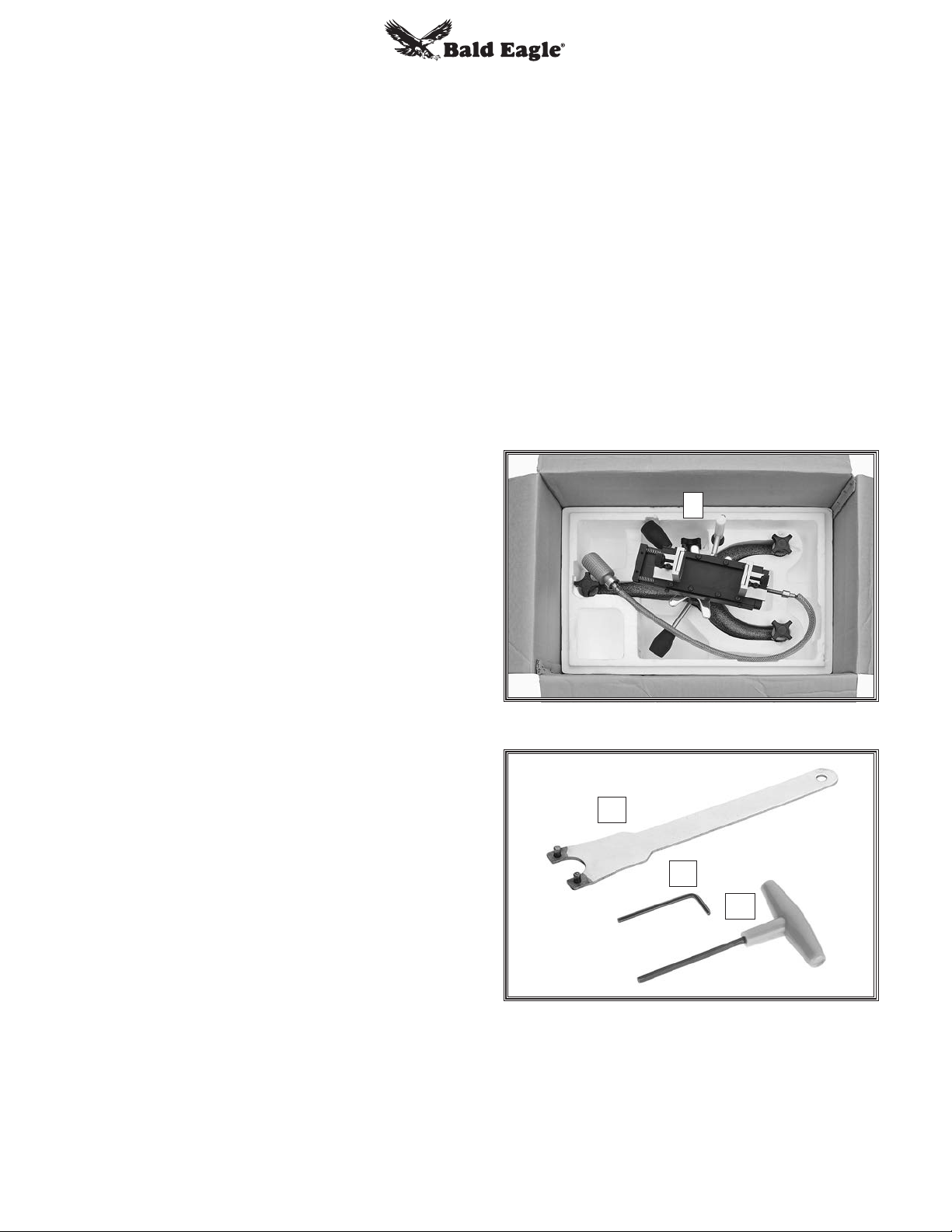

Your shooting rest was carefully packaged for

safe arrival. Please inspect all components as you

unpack them to ensure that they arrived in proper

condition.

If you find that any components are damaged,

please contact www.grizzly.com immediately.

Box Item Qty

A. Shooting Rest Assembly ............................ 1

Spanner Wrench ........................................ 1

B.

Hex Wrench 4mm ....................................... 1

C.

Hex T-Wrench 5mm ................................... 1

D.

BE1006

• Cast Iron Slingshot Base

• 1⁄2"-13 Foot Knobs

BE1153

• Cast Iron Triangle Base

• 1⁄2"-13 Foot Knobs

BE1209

• Cast Iron Triangle Base

• 5⁄8"-11 Foot Knobs

These shooting rests have been specially designed

to provide many years of trouble-free operation

through close attention to detail, ruggedly built

parts, and a rigid quality control program.

Please Note: The photos shown may not exactly

match your model because multiple models are

represented in this manual. However, the provided

procedures still apply.

A

Figure 1. Shooting rest assembly in box.

B

C

D

We stand behind our products! If you have questions about this product or its manual, please

contact us for assistance.

Contact Info

Bald Eagle, Inc.

P.O. Box 2069

Email: techsupport@grizzly.com

-2-

Bellingham, WA 98227-2069

Phone: (570) 546-9663

Figure 2. Included tools.

BE1004-06, BE1153, BE1209

Initial Setup

Your shooting rest is fully assembled but was

adjusted to fit in the box for shipping. Before using

it, you will need to make a few initial setup adjustments.

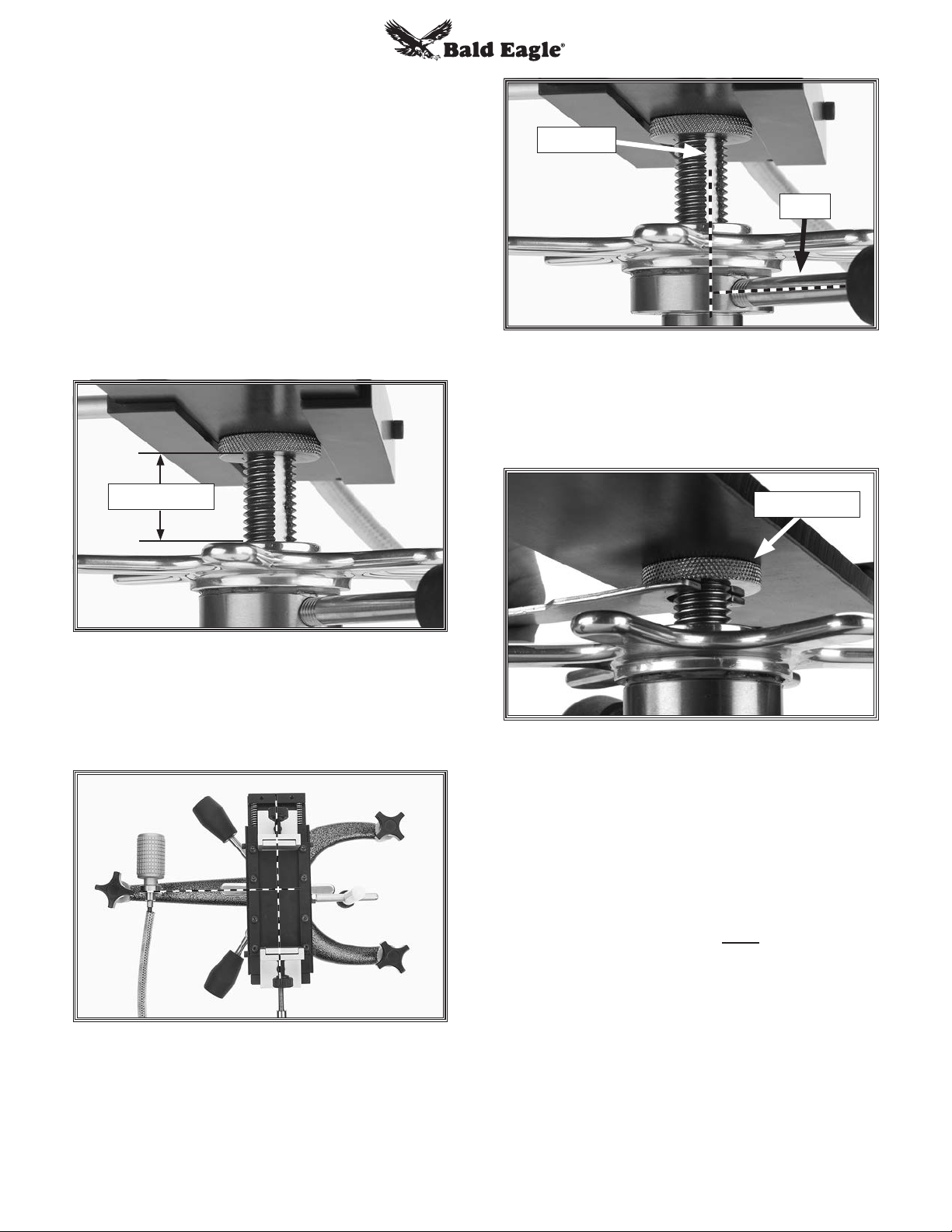

To make the initial setup adjustments:

Loosen fine elevation lock and use mariner

1.

wheel to raise windage cradle approximately

1", as shown in Figure 3. This gives you

enough room to work during the next few

steps.

1" Minimum

Keyway

Shaft

Figure 5. Keyway aligned with fine elevation

lock knob shaft.

3. Using included spanner wrench, tighten

knurled nut against underside of base plate,

as shown in Figure 6.

Knurled Nut

Figure 3. Fine elevation raised up at least 1".

Position windage cradle perpendicular to

2.

base (see Figure 4). Align keyway with fine

elevation lock knob shaft, then tighten knob

(see Figure 5).

Figure 4. Windage cradle positioned

perpendicular to base.

Figure 6. Tightening knurled nut with spanner

wrench.

4. Check to make sure windage cradle is firmly

secured by trying to rotate it, by hand, with

light pressure.

The windage base plate should NOT move

independently of the fine elevation threads,

or it will shift when subjected to shooting

recoil. If you find that it does move, then retighten the knurled nut as shown in Figure 6.

Note: Besides the knurled nut, the windage

base plate is also secured from the top with

a bevel head screw (Part #15 on Page 8). If

it becomes necessary to tighten this screw

to properly secure the base plate, loosen the

knurled nut first.

BE1004-06, BE1153, BE1209

-3-

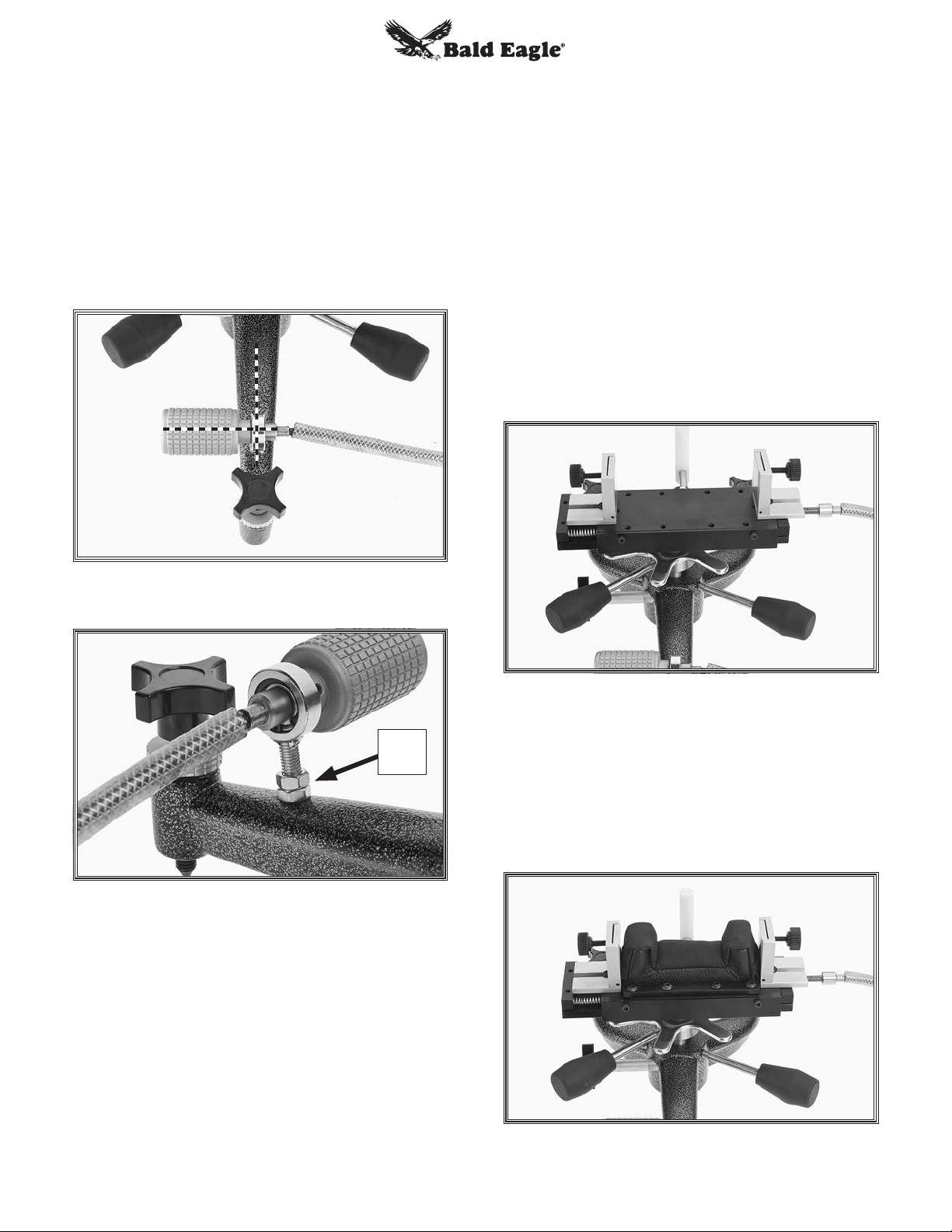

5. Position windage adjustment knob perpen-

dicular to base (see Figure 7). Using a

12mm wrench, tighten lower hex nut (Figure

8) against base, then tighten upper hex nut

against lower hex nut to lock it in place.

Note: For left-handed shooters, follow

Conversion for Left-Handed Shooters

instructions on Page 7 to position the windage control knob on the right side of the base.

After performing the conversion, return here.

Installing Bag

The windage cradle is designed to hold a front

bag with a 2" W x 4

ing flaps). Top quality bags are available from

www.grizzly.com (see back cover of manual for

details).

To install a front rest bag:

Make sure clamp shoes are adjusted straight

1.

up (not pivoted).

Remove (8) button head screws securing bag

2.

clamp bars, then remove clamp bars (see

Figure 9).

3

/4" L bottom base (not includ-

Figure 7. Windage adjustment knob

perpendicular to base.

Hex

Nuts

Figure 8. Hex nuts securing position of

windage adjustment knob.

Congratulations! You've completed the initial setup

of the shooting rest.

Before using the shooting rest, you will need to

install a front rest bag (not included), and then

make final adjustments at the shooting range with

your rifle properly positioned in the front rest bag.

Figure 9. Bag clamp bars removed.

Place bag on windage cradle and position

3.

it so tabs are between mounting holes for

clamp bar screws.

Re-install clamp bars and tighten button head

4.

screws to secure bag in place, as shown in

Figure 10.

-4-

Figure 10. Front rest bag installed.

BE1004-06, BE1153, BE1209

Setup & Use

These instructions tell you how to set up the rest

with your rifle and make adjustments while shooting at the range.

Before proceeding, make sure you have performed the previous initial setup and bag installation instructions.

Keep firearm UNLOADED until instructed.

Setting up rest with a loaded firearm may

increase risk of accidental discharge, which

could result in serious injury or death.

3. Adjust windage cradle by rotating windage

adjustment knob until cradle is centered in its

range of travel on slide. This ensures that you

will be able to move it in either direction once

you begin shooting.

To set up and use shooting rest:

Place shooting rest on a bench.

1.

Note: For F-Class or long-range shooting,

optional feet and long knobs are available

from Grizzly.com. See back cover of this

manual for model numbers and details.

Adjust base height as desired by rotating the

2.

three foot knobs. After setting base height,

tighten thumb nut (see Figure 11) to lock

knob and prevent unwanted movement while

shooting.

Foot Knob

Thumb Nut

Figure 12. Windage cradle adjusted to center

of slide.

. Place rear bag (not included) behind rest

4

(toward you).

. Insert butt of your unloaded rifle in rear bag,

5

and place fore-end of rifle on front rest bag

and against fore-end stop (the position of

fore-end stop can be adjusted as desired).

Note: The fore-end stop helps you return

your rifle to the exact same position after

each shot.

Fore-End

Stop

Figure 11. Foot adjustment controls.

BE1004-06, BE1153, BE1209

Figure 13. Fore-end stop positioned against

rifle.

-5-

6. Tighten clamp shoe thumb screws to squeeze

front rest bag against fore-end of rifle as

desired.

Clamp Shoe

Thumb Screw

Figure 14. Rifle secured in front bag.

8

. Adjust height of the front rest bag as neces-

sary using quick elevation knob. Once elevation is close to correct position, tighten quick

elevation lock knob.

9. Use mariner wheel to position exact elevation

of target. Snug (using light pressure only) the

fine elevation lock.

10. Use windage adjustment knob as necessary

to make final precise adjustments.

. Carefully load rifle and recheck sights. Make

11

additional fine adjustments to rest if necessary and tighten all knobs before shooting.

7. Position rest and rear bag as necessary to

align your rifle sights with target, making sure

fore-end of rifle remains against fore-end

stop.

To avoid serious personal injury or death,

always follow the safety procedures supplied by the firearm manufacturer.

Figure 15. Overview of an example rifle setup on the windage shooting rest (BE1005 shown).

-6-

BE1004-06, BE1153, BE1209

Conversion for

Left-Handed

Shooters

Out of the box, your shooting rest is set up

for right-handed shooters, meaning the windage

control knob is positioned to the left so it can be

adjusted with the shooter’s left hand—without

requiring the right hand to leave the gun.

Overview

The shooting rest can be converted for left-handed

shooters by removing the cradle slide and all the

components attached to it, drilling/tapping a new

hole in the opposite side of the cradle slide for the

fore-end stop post rail, and then re-installing with

the cradle assembly rotated 180° from the standard setup, the windage control knob positioned

to the right, and the stop post rail threaded into the

new hole (see Figures 16 and 17).

Drill & Tap a Hole Matching This One...

Using this same logic, left-handed shooters may

want to have the windage control knob mounted

to the right, as shown in Figure 16. The following

instructions explain how to perform the modification.

Stop Post Rail

Threaded into

New Hole

Cradle

Rotated

180°

Windage Knob

Facing Right

Figure 16. Shooting rest converted for left-

handed shooter.

Tools Needed for Drilling/Tapping Qty

• Drill Punch .................................................. 1

• Hammer ...................................................... 1

• Drill Press ................................................... 1

• Threading Tap 5⁄16 "-18 and Tap Handle ...... 1

• Drill Bit 17⁄64" (or size F) ............................... 1

• Cutting/Tapping Oil ..................... As Needed

• Vise ............................................................ 1

...on This Side

Cradle Slide

Middle Hole

Stop Post

Rail

11

16

13

12

Install #10 & #17 on

5

Opposite Sides with

10

19

17

Middle Hole Over New Hole

Figure 17. Overview of process for setting up

shooting rest for left-handed shooters.

Instructions

These instructions assume that the shooting rest

has been initially set up as described beginning

on Page 3. All part numbers referenced in the

following steps are from the parts breakdown

drawings in this manual. For clarity purposes,

we recommend referring to the parts breakdown

pages as you follow these steps.

BE1004-06, BE1153, BE1209

-7-

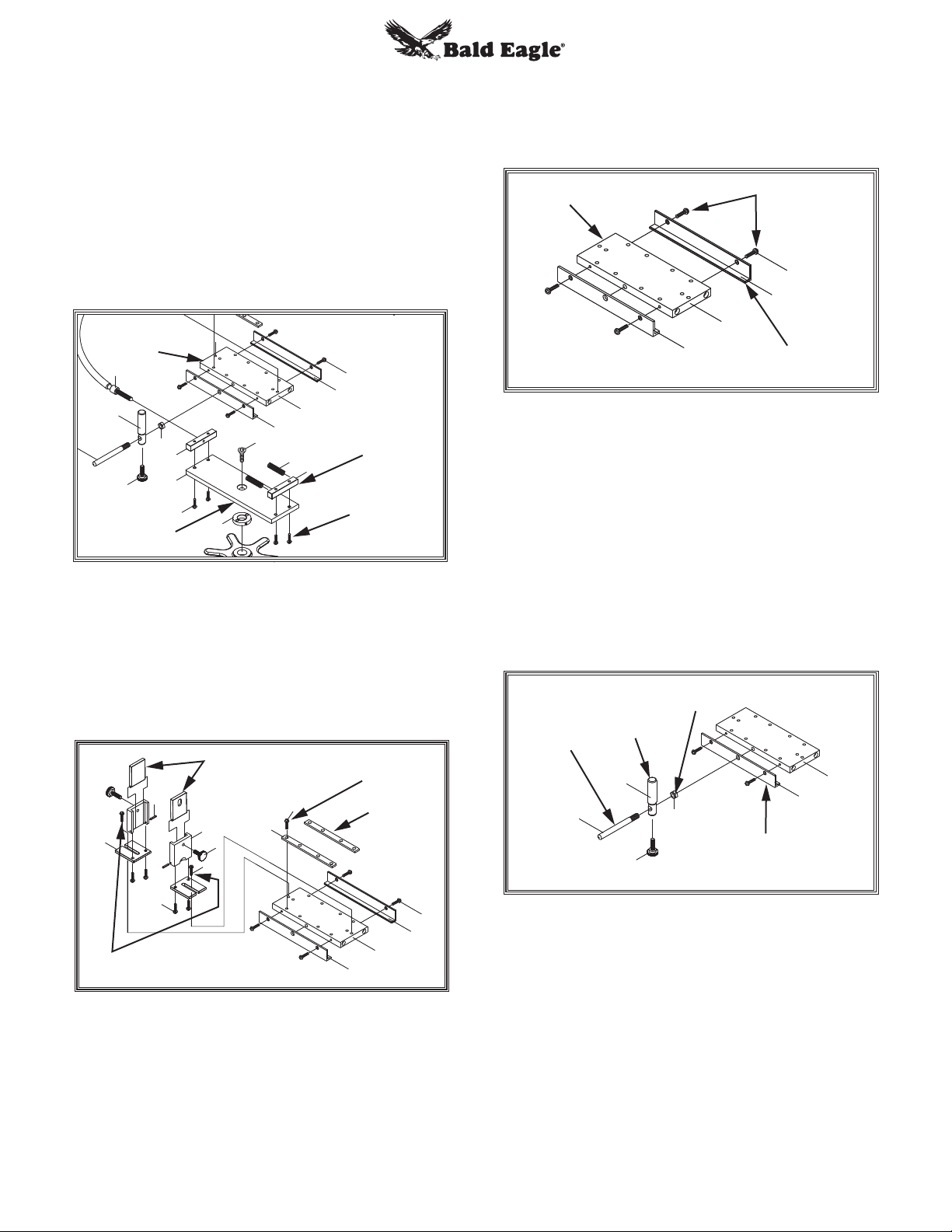

Follow these steps to convert shooting rest

18

8

18

8

for left-handed shooting:

Remove cradle slide (#16) with its attached

1.

components from slide base (#14) by first

adjusting windage control knob to release

spring tension, then removing cap screws

that secure spring bracket (#22) to slide base

(#14), as shown in Figure 18. Once spring

bracket (#22) is removed, cradle slide (#16)

will easily slide off slide base (#14).

Cradle

Slide

9

9

12

12

13

13

5

5

Slide Base

20

20

14

14

23

23

43

43

15

15

10

10

21

16

16

22

19

19

17

17

Spring

Bracket

Cap

Screws

3.

Remove screws (#19) that secure fore slide

rail (#17) to cradle slide (#16), then separate

fore slide rail from cradle slide and set it

aside.

Cradle

Screws

Slide

19

17

16

10

Fore Slide

Rail

Figure 20. Separating fore slide rail from

cradle slide

Loosen hex nut (#13) that secures stop post

4.

rail (#11) against aft slide rail (#10), then

unthread and remove stop post rail (with the

attached stop post).

Figure 18. Removing cradle slide from slide

base.

2.

Remove screws (#6) that secure clamp shoe

assemblies to cradle slide (#16), then remove

screws (#18) that secure clamp bars (#8) to

cradle slide. Separate clamp shoe assemblies and clamp bars from cradle slide.

Clamp Shoe

Screws

Assemblies

2

3

3

Screws

2

4

4

5

6

6

7

7

18

18

8

8

10

10

Clamp

Bar

16

16

17

17

Figure 19. Removing clamp shoe and clamp

bar assemblies from cradle slide.

19

19

IMPORTANT: After removing stop post rail

(#11), pay special attention to threaded hole

from which it was removed. To complete this

conversion procedure, you will need to duplicate this hole on opposite side of cradle slide.

Stop

Post

Rail

11

11

Stop

Post

12

12

Hex Nut

13

13

10

10

16

16

Aft Slide

5

5

Rail

Figure 21. Location of hex nut that secures

stop post rail against aft slide rail.

-8-

BE1004-06, BE1153, BE1209

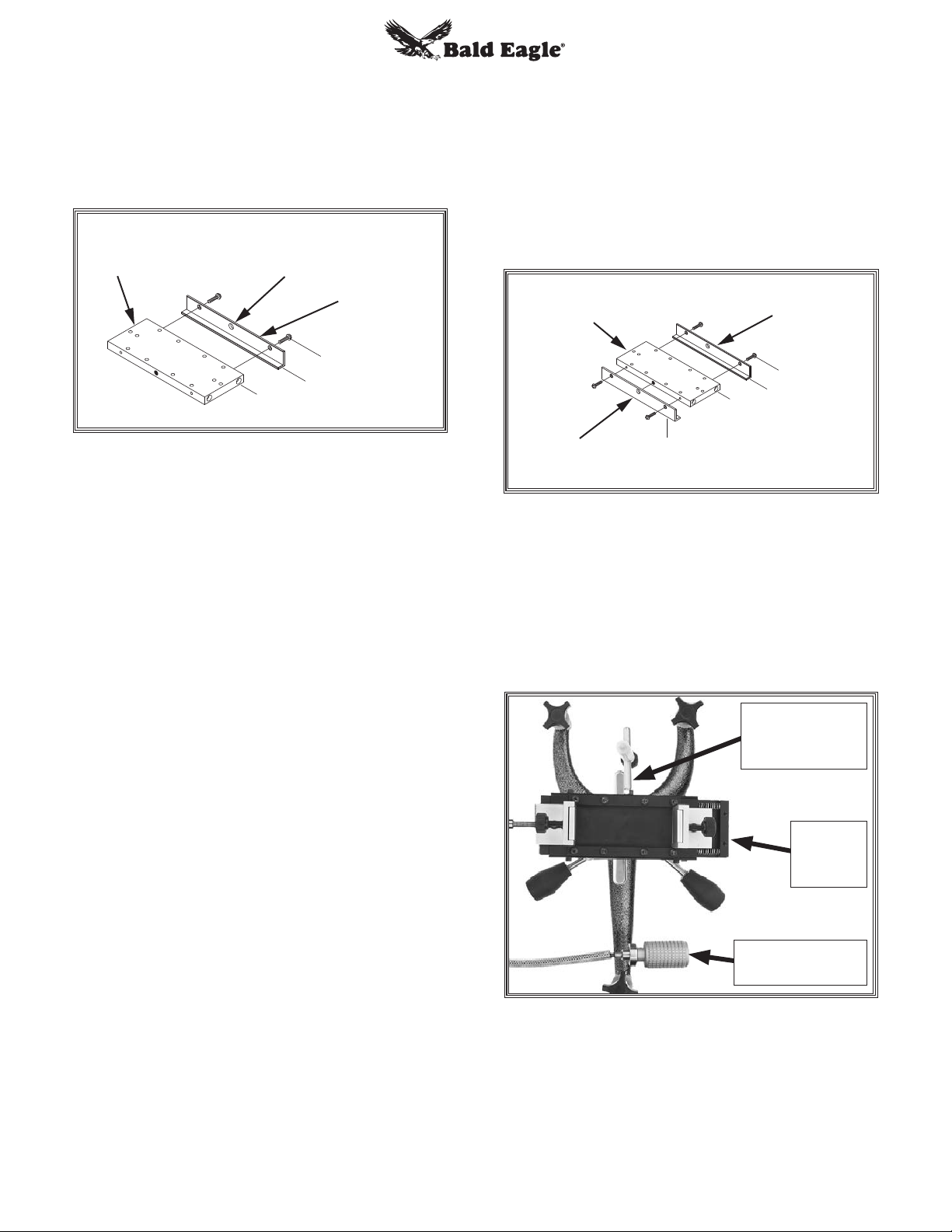

5. Remove aft slide rail (#10) and install it on

opposite side of cradle slide (#1), where fore

slide rail was originally positioned. In the next

step, you will use middle hole in aft slide rail

(#10) as a guide for marking drilling location

of new hole.

Cradle

Slide

Middle

Hole

Install aft slide rail (#10) over newly drilled

9.

hole on cradle slide, and install fore slide rail

(#17) on opposite side (see Figure 23).

TIP: Make sure that stop post rail (#11) is

able to thread into new hole before proceeding. If adjustments need to be made, it is

much easier to do so now—rather than after

full assembly.

Aft Slide

Rail

19

16

10

Figure 22. Aft side rail installed on opposite

side of cradle slide.

6.

Center tip of your drill punch in middle hole in

aft slide rail (#10) and lightly strike punch with

your hammer to make small indent in cradle

slide (brace shooting rest and cradle as necessary during this step, so you don't damage

any components). This indent will be your

starting point when you drill the new hole, so

take your time and make sure it is centered.

Remove aft slide rail before proceeding to

next step.

Use your 17⁄64" (or size F) drill bit in your drill

7.

press to drill a hole in location you marked in

previous step. The depth of newly drilled hole

should approximately match existing threaded hole on opposite side of cradle slide.

Secure cradle slide in vise, and use your 5⁄16"-

8.

18 threading tap with small amount of tapping/cutting oil to cut threads into new hole.

When finished threading, clean out hole and

clean up cradle slide.

Cradle

Slide

Fore Slide

17

16

Aft Rail

Slide

19

10

Rail

Figure 23. Aft and fore slide rails installed on

opposite sides.

10.

Re-assemble all remaining components in

reverse order of removal, but rotate cradle

180° from its original position and ensure

that windage control knob is positioned to

the right (see Figure 24), then tighten any

remaining fasteners.

Stop Post Rail

Threaded into

New Hole

Cradle

Rotated

180°

Windage Knob

Facing Right

BE1004-06, BE1153, BE1209

Figure 24. Example of shooting rest con-

verted for left-handed shooter.

-9-

Maintenance

Your shooting rest is constructed of high-quality

materials. With a small amount of care and regular maintenance, it will provide many years of reliable service.

For best results, always clean and dry the shooting rest after use. Do not allow moisture to remain

on unpainted steel parts, such as lock knob

shafts/threads, the quick elevation ram, or the fine

elevation threads.

To prevent corrosion from developing on unpainted steel surfaces, wipe them down with a light

coat of rifle oil.

2.

Lay shooting rest on its side. Using spray-

type lubricant, quickly spray fine elevation

threads and quick elevation ram. Turn shooting rest over and repeat this on other side.

Note: If using an oil can, apply 5-6 drops of

oil along each component, and use clean

brush to spread oil and coat surfaces.

Set shooting rest upright and completely

3.

lower fine and quick elevation.

Adjust windage knob to move windage cradle

4.

all the way to right.

Apply quick spray of oil (or 2 drops if using

5.

an oil can) to windage screw threads—just to

right of bracket (see Figure 26).

Lubrication

The fine elevation threads, windage screw threads,

and quick elevation ram will require a small

amount of lubrication on an "as needed" basis.

You can use your regular rifle oil for lubrication.

Since a small amount of oil may drip from the

shooting rest during this procedure, we recommend that it be performed over cardboard or

newspaper that can be discarded later.

To lubricate shooting rest components:

Raise fine and quick elevation to maximum

1.

height (see Figure 25).

Fine

Elevation

Threads

Apply

Oil Here

Bracket

Figure 26. Oil application area for windage

Adjust windage cradle all the way to the left

6.

and lubricate windage screw from left side of

bracket in same manner.

Adjust windage cradle back to center position.

7.

Wipe up any excess oil from shooting rest.

8.

The lubrication procedure is complete.

Windage Screw

screw.

Quick

Elevation

Ram

Figure 25. Oil application areas for fine and

quick elevation components.

-10-

BE1004-06, BE1153, BE1209

3

11

42

27

BE1004 Parts Breakdown

1

REF PART # DESCRIPTION

1 PBE1004001 CLAMP SHOE

2 PBE1004002 ROLL PIN 3 X 50

3 PBE1004003 ADJUSTING PLATE

4 PBE1004004 CLAMP SUPPORT

5 PBE1004005 THUMB KNOB 1/4-28 X 1-1/4

6 PBE1004006 BUTTON HD CAP SCR 1/4-20 X 1/2

7 PBE1004007 FLAT HD SCR 10-24 X 1/2

8 PBE1004008 CLAMP BAR

9 PBE1004009 DRIVE SHAFT

10 PBE1004010 AFT SLIDE RAIL

11 PBE1004011 STOP POST RAIL

12 PBE1004012 STOP POST

13 PBE1004013 HEX NUT 5/16-18

14 PBE1004014 SLIDE BASE

15 PBE1004015 FLAT HD CAP SCR 3/8-16 X 3/4

16 PBE1004016 SLIDE

17 PBE1004017 FORE SLIDE RAIL

18 PBE1004018 BUTTON HD CAP SCR 1/4-20 X 1/2

19 PBE1004019 BUTTON HD CAP SCR 10-24 X 1/2

20 PBE1004020 SLIDE ADJUST BRACKET

21 PBE1004021 COMPRESSION SPRING

22 PBE1004022 SPRING BRACKET

23 PBE1004023 BUTTON HD CAP SCR 10-24 X 1/2

24 PBE1004024 MARINER WHEEL

25 PBE1004025 ELEVATION SCREW 3/4-10

26 PBE1004026 THRUST BEARING TEFLON

27 PBE1004027 LOCK KNOB 3/8-16

28 PBE1004028 ELEVATION KNOB & PINION ASSY

29 PBE1004029 KEY 1/4 X 1/4 X 1-3/4

30 PBE1004030 ELEVATION RACK

31 PBE1004031 SET SCREW 1/4-20 X 1/2 BALL-PT

32 PBE1004032 FLAT WASHER 3/8 TEFLON

41

33 PBE1004033 KNOB BEARING

34 PBE1004034 SET SCREW 10-24 X 1/4

35 PBE1004035 LEVELING SCREW 3/8-16 X 3-1/2

36 PBE1004036 LOCKING THUMB WHEEL 3/8-16

37 PBE1004037 TRIANGLE BASE, ALUMINUM

39 PBE1004039 HEX NUT 5/16-18

40 PBE1004040 FLAT WASHER 5/16 TEFLON

41 PBE1004041 SLIDE KNOB

42 PBE1004042 SPANNER WRENCH 28MM PIN-TYPE

43 PBE1004043 KNURLED SPANNER NUT 3/4-10

44 PBE1004044 HEX WRENCH 4MM

45 PBE1004045 HEX T-WRENCH 5MM

12

36

32

2

9

35

4

44

5

45

6

7

18

8

19

17

16

10

13

20

5

14

23

43

15

21

22

24

27

25

34

26

33

39

30

40

39

29

31

37

28

19

BE1004-06, BE1153, BE1209

-11-

BE1005 Parts Breakdown

1

3

11

42

27

12

2

9

36

7

35

32

REF PART # DESCRIPTION

1 PBE1005001 CLAMP SHOE

4

44

5

45

6

18

8

19

17

16

10

13

20

5

14

23

43

15

21

22

24

27

25

34

26

33

39

30

40

39

29

31

37

28

19

2 PBE1005002 ROLL PIN 3 X 50

3 PBE1005003 ADJUSTING PLATE

4 PBE1005004 CLAMP SUPPORT

5 PBE1005005 THUMB KNOB 1/4-28 X 1-1/4

6 PBE1005006 BUTTON HD CAP SCR 1/4-20 X 1/2

7 PBE1005007 FLAT HD SCR 10-24 X 1/2

8 PBE1005008 CLAMP BAR

9 PBE1005009 DRIVE SHAFT

10 PBE1005010 AFT SLIDE RAIL

11 PBE1005011 STOP POST RAIL

12 PBE1005012 STOP POST

13 PBE1005013 HEX NUT 5/16-18

14 PBE1005014 SLIDE BASE

15 PBE1005015 FLAT HD CAP SCR 3/8-16 X 3/4

16 PBE1005016 SLIDE

17 PBE1005017 FORE SLIDE RAIL

18 PBE1005018 BUTTON HD CAP SCR 1/4-20 X 1/2

19 PBE1005019 BUTTON HD CAP SCR 10-24 X 1/2

20 PBE1005020 SLIDE ADJUST BRACKET

21 PBE1005021 COMPRESSION SPRING

22 PBE1005022 SPRING BRACKET

23 PBE1005023 BUTTON HD CAP SCR 10-24 X 1/2

24 PBE1005024 MARINER WHEEL

25 PBE1005025 ELEVATION SCREW 3/4-10

26 PBE1005026 THRUST BEARING TEFLON

27 PBE1005027 LOCK KNOB 3/8-16

28 PBE1005028 ELEVATION KNOB & PINION ASSY

29 PBE1005029 KEY 1/4 X 1/4 X 1-3/4

30 PBE1005030 ELEVATION RACK

31 PBE1005031 SET SCREW 1/4-20 X 1/2 BALL-PT

41

32 PBE1005032 FLAT WASHER 3/8 TEFLON

33 PBE1005033 KNOB BEARING

34 PBE1005034 SET SCREW 10-24 X 1/4

35 PBE1005035 LEVELING SCREW 3/8-16 X 3-1/2

36 PBE1005036 LOCKING THUMB WHEEL 3/8-16

37 PBE1005037 SLINGSHOT BASE, ALUMINUM

39 PBE1005039 HEX NUT 5/16-18

40 PBE1005040 FLAT WASHER 5/16 TEFLON

41 PBE1005041 SLIDE KNOB

42 PBE1005042 SPANNER WRENCH 28MM PIN-TYPE

43 PBE1005043 KNURLED SPANNER NUT 3/4-10

44 PBE1005044 HEX WRENCH 4MM

45 PBE1005045 HEX T-WRENCH 5MM

-12-

BE1004-06, BE1153, BE1209

BE1006 Parts Breakdown

1

3

11

42

27

12

2

9

36

7

35

32

REF PART # DESCRIPTION

4

44

5

45

6

18

8

19

17

16

10

13

20

5

14

23

43

15

21

22

24

27

25

34

26

33

39

30

40

39

29

31

37

28

19

1 PBE1006001 CLAMP SHOE

2 PBE1006002 ROLL PIN 3 X 50

3 PBE1006003 ADJUSTING PLATE

4 PBE1006004 CLAMP SUPPORT

5 PBE1006005 THUMB KNOB 1/4-28 X 1-1/4

6 PBE1006006 BUTTON HD CAP SCR 1/4-20 X 1/2

7 PBE1006007 FLAT HD SCR 10-24 X 1/2

8 PBE1006008 CLAMP BAR

9 PBE1006009 DRIVE SHAFT

10 PBE1006010 AFT SLIDE RAIL

11 PBE1006011 STOP POST RAIL

12 PBE1006012 STOP POST

13 PBE1006013 HEX NUT 5/16-18

14 PBE1006014 SLIDE BASE

15 PBE1006015 FLAT HD CAP SCR 3/8-16 X 3/4

16 PBE1006016 SLIDE

17 PBE1006017 FORE SLIDE RAIL

18 PBE1006018 BUTTON HD CAP SCR 1/4-20 X 1/2

19 PBE1006019 BUTTON HD CAP SCR 10-24 X 1/2

20 PBE1006020 SLIDE ADJUST BRACKET

21 PBE1006021 COMPRESSION SPRING

22 PBE1006022 SPRING BRACKET

23 PBE1006023 BUTTON HD CAP SCR 10-24 X 1/2

24 PBE1006024 MARINER WHEEL

25 PBE1006025 ELEVATION SCREW 3/4-10

26 PBE1006026 THRUST BEARING TEFLON

27 PBE1006027 LOCK KNOB 3/8-16

28 PBE1006028 ELEVATION KNOB & PINION ASSY

29 PBE1006029 KEY 1/4 X 1/4 X 1-3/4

30 PBE1006030 ELEVATION RACK

31 PBE1006031 SET SCREW 1/4-20 X 1/2 BALL-PT

41

32 PBE1006032 FLAT WASHER 1/2 TEFLON

33 PBE1006033 KNOB BEARING

34 PBE1006034 SET SCREW 10-24 X 1/4

35 PBE1006035 LEVELING SCREW 1/2-13 X 3-1/2

36 PBE1006036 LOCKING THUMB WHEEL 1/2-13

37 PBE1006037 SLINGSHOT BASE, CAST IRON

39 PBE1006039 HEX NUT 5/16-18

40 PBE1006040 FLAT WASHER 5/16 TEFLON

41 PBE1006041 SLIDE KNOB

42 PBE1006042 SPANNER WRENCH 28MM PIN-TYPE

43 PBE1006043 KNURLED SPANNER NUT 3/4-10

44 PBE1006044 HEX WRENCH 4MM

45 PBE1006045 HEX T-WRENCH 5MM

BE1004-06, BE1153, BE1209

-13-

BE1153 Parts Breakdown

1

2

4

3

6

44

5

45

7

18

8

9

19

17

11

42

27

12

13

15

20

5

14

23

43

24

10

21

16

22

27

25

33

39

39

40

41

36

32

35

26

30

29

31

37

28

19

REF PART # DESCRIPTION

1 PBE1153001 CLAMP SHOE

2 PBE1153002 ROLL PIN 3 X 50

3 PBE1153003 ADJUSTING PLATE

4 PBE1153004 CLAMP SUPPORT

5 PBE1153005 THUMB KNOB 1/4-28 X 1-1/4

6 PBE1153006 BUTTON HD CAP SCR 1/4-20 X 1/2

7 PBE1153007 FLAT HD SCR 10-24 X 1/2

8 PBE1153008 CLAMP BAR

9 PBE1153009 DRIVE SHAFT

10 PBE1153010 AFT SLIDE RAIL

11 PBE1153011 STOP POST RAIL

12 PBE1153012 STOP POST

13 PBE1153013 HEX NUT 5/16-18

14 PBE1153014 SLIDE BASE

15 PBE1153015 FLAT HD CAP SCR 3/8-16 X 3/4

16 PBE1153016 SLIDE

17 PBE1153017 FORE SLIDE RAIL

18 PBE1153018 BUTTON HD CAP SCR 1/4-20 X 3/4

19 PBE1153019 BUTTON HD CAP SCR 10-24 X 1/2

20 PBE1153020 SLIDE ADJUST BRACKET

21 PBE1153021 COMPRESSION SPRING

22 PBE1153022 SPRING BRACKET

23 PBE1153023 BUTTON HD CAP SCR 10-24 X 1/2

24 PBE1153024 MARINER WHEEL

25 PBE1153025 ELEVATION SCREW 3/4-10

26 PBE1153026 THRUST BEARING TEFLON

27 PBE1153027 LOCK KNOB 3/8-16

28 PBE1153028 ELEVATION KNOB & PINION ASSY

34

29 PBE1153029 KEY 1/4 X 1/4 X 1-3/4

30 PBE1153030 ELEVATION RACK

31 PBE1153031 SET SCREW 1/4-20 X 1/2 BALL-PT

32 PBE1153032 FLAT WASHER 1/2 TEFLON

33 PBE1153033 KNOB BEARING

34 PBE1153034 SET SCREW 10-24 X 1/4

35 PBE1153035 LEVELING SCREW 1/2-13 x 3-1/2

36 PBE1153036 LOCKING THUMB WHEEL 1/2-13

37 PBE1153037 TRIANGLE BASE (CAST-IRON)

39 PBE1153039 HEX NUT 5/16-18

40 PBE1153040 FLAT WASHER 5/16 TEFLON

41 PBE1153041 SLIDE KNOB

42 PBE1153042 SPANNER WRENCH 28MM PIN-TYPE

43 PBE1153043 KNURLED SPANNER NUT 3/4-10

44 PBE1153044 HEX WRENCH 4MM

45 PBE1153045 HEX T-WRENCH 5MM

-14-

BE1004-06, BE1153, BE1209

3

11

42

27

BE1209 Parts Breakdown

1

REF PART # DESCRIPTION

12

36

32

2

9

35

4

44

5

45

6

7

18

8

19

17

16

10

13

20

5

14

23

43

15

21

22

24

27

25

34

26

33

39

30

40

39

29

31

37

28

19

1 PBE1209001 CLAMP SHOE

2 PBE1209002 ROLL PIN 3 X 50

3 PBE1209003 ADJUSTING PLATE

4 PBE1209004 CLAMP SUPPORT

5 PBE1209005 THUMB KNOB 1/4-28 X 1-1/4

6 PBE1209006 BUTTON HD CAP SCR 1/4-20 X 1/2

7 PBE1209007 FLAT HD SCR 10-24 X 1/2

8 PBE1209008 CLAMP BAR

9 PBE1209009 DRIVE SHAFT

10 PBE1209010 AFT SLIDE RAIL

11 PBE1209011 STOP POST RAIL

12 PBE1209012 STOP POST

13 PBE1209013 HEX NUT 5/16-18

14 PBE1209014 SLIDE BASE

15 PBE1209015 FLAT HD CAP SCR 3/8-16 X 3/4

16 PBE1209016 WINDAGE SLIDE

17 PBE1209017 FORE SLIDE RAIL

18 PBE1209018 BUTTON HD CAP SCR 1/4-20 X 1/2

19 PBE1209019 BUTTON HD CAP SCR 10-24 X 1/2

20 PBE1209020 SLIDE ADJUST BRACKET

21 PBE1209021 COMPRESSION SPRING

22 PBE1209022 SPRING BRACKET

23 PBE1209023 BUTTON HD CAP SCR 10-24 X 1/2

24 PBE1209024 MARINER WHEEL

25 PBE1209025 ELEVATION SCREW 3/4-10

26 PBE1209026 THRUST BEARING TEFLON

27 PBE1209027 LOCK KNOB 3/8-16

28 PBE1209028 ELEVATION KNOB & PINION ASSY

29 PBE1209029 KEY 1/4 X 1/4 X 1-3/4

30 PBE1209030 ELEVATION RACK

31 PBE1209031 SET SCREW 1/4-20 X 1/2 BALL-PT

41

32 PBE1209032 FLAT WASHER 5/8 TEFLON

33 PBE1209033 KNOB BEARING

34 PBE1209034 SET SCREW 10-24 X 1/4

35 PBE1209035 LEVELING SCREW 5/8-11 X 3-1/2

36 PBE1209036 LOCKING THUMB WHEEL 5/8-11

37 PBE1209037 BIG FIFTY BASE, CAST IRON

39 PBE1209039 HEX NUT 5/16-18

40 PBE1209040 FLAT WASHER 5/16 TEFLON

41 PBE1209041 SLIDE KNOB

42 PBE1209042 SPANNER WRENCH 28MM PIN-TYPE

43 PBE1209043 KNURLED SPANNER NUT 3/4-10

44 PBE1209044 HEX WRENCH 4MM

45 PBE1209045 HEX T-WRENCH 5MM

BE1004-06, BE1153, BE1209

-15-

BE1004

Triangle Windage Shooting Rest

Product Dimensions

Weight .......................................................................................................................................... 12 lbs.

Overall Length (Front-to-Back) ..........................................................................................................14"

Overall Width (Side-to-Side) ...........................................................................................................19

Overall Height ...................................................................................................................... 7

Footprint (Pin-to-Pin).........................................................................................................12

Shipping Dimensions

Weight .......................................................................................................................................... 17 lbs.

Box Size (L x W x H) ...................................................................................................... 21" x 19" x 10"

Windage Information

1

⁄4" – 11 7⁄8"

3

⁄4" Triangle

1

⁄2"

Cradle Depth (Inside of Bag Straps)....................................................................................................2"

Maximum Front Bag Width ...............................................................................................................4

Minimum Bench-to-Cradle Base Height ...........................................................................................5

Maximum Bench-to-Cradle Base Height ..........................................................................................9

Horizontal Movement (Side-to-Side) .................................................................................................

Quick Elevation Travel (Primary Rise) ..............................................................................................1

Fine Elevation Travel (Secondary Rise) ........................................................................................ 1

Feet Elevation Travel (Base Rise) ......................................................................................................

Fore-End Stop Height (from Cradle Base) .......................................................................................1

Fore-End Stop Travel ........................................................................................................................2

Thread Size of Base Foot Knobs...................................................................................................

Construction Materials

Base ........................................................................................................................................ Aluminum

Windage Cradle ......................................................................................................... Aluminum & Steel

Fore-End Stop................................................................................High Density Poly-Ethylene (HDPE)

Other

Country of Origin ..........................................................................................................................Taiwan

BE1004 Specifications

13

13

3

⁄8"-16

3

⁄4"

1

⁄4"

1

⁄2"

⁄16"

7

⁄8"

⁄16"

3

⁄4"

7

⁄8"

1

⁄4"

-16-

BE1004-06, BE1153, BE1209

Slingshot Windage Shooting Rest

Product Dimensions

BE1005

Weight .......................................................................................................................................... 12 lbs.

Overall Length (Front-to-Back) .......................................................................................................16

Overall Width (Side-to-Side) ...........................................................................................................17

Overall Height ...................................................................................................................... 7

1

Footprint (Pin-to-Pin).....................................................................................................7

⁄4" W x 15 1⁄2" L

Shipping Dimensions

Weight .......................................................................................................................................... 17 lbs.

Box Size (L x W x H) .......................................................................................................22" x 15" x 11"

Windage Information

Cradle Depth (Inside of Bag Straps)....................................................................................................2"

Maximum Front Bag Width ...............................................................................................................4

Minimum Bench-to-Cradle Base Height ...........................................................................................5

Maximum Bench-to-Cradle Base Height ..........................................................................................9

Horizontal Movement (Side-to-Side) .................................................................................................

Quick Elevation Travel (Primary Rise) ..............................................................................................1

Fine Elevation Travel (Secondary Rise) ........................................................................................ 1

Feet Elevation Travel (Base Rise) ......................................................................................................

Fore-End Stop Height (from Cradle Base) .......................................................................................1

Fore-End Stop Travel ........................................................................................................................2

Thread Size of Base Foot Knobs...................................................................................................

1

⁄4" – 11 7⁄8"

13

13

3

⁄8"-16

1

⁄2"

1

⁄4"

3

⁄4"

1

⁄4"

1

⁄2"

⁄16"

7

⁄8"

⁄16"

3

⁄4"

7

⁄8"

1

⁄4"

Construction Materials

Base ........................................................................................................................................ Aluminum

Windage Cradle ......................................................................................................... Aluminum & Steel

Fore-End Stop................................................................................High Density Poly-Ethylene (HDPE)

Other

Country of Origin ..........................................................................................................................Taiwan

BE1005 Specifications

BE1004-06, BE1153, BE1209

-17-

Slingshot Windage Shooting Rest

Product Dimensions

BE1006 Heavy-Duty

Weight .......................................................................................................................................... 21 lbs.

Overall Length (Front-to-Back) .......................................................................................................16

Overall Width (Side-to-Side) ...........................................................................................................17

Overall Height ...................................................................................................................... 7

5

Footprint (Pin-to-Pin)................................................................................................. 7

⁄16" W x 15 19⁄32" L

Shipping Dimensions

Weight .......................................................................................................................................... 26 lbs.

Box Size (L x W x H) .......................................................................................................22" x 15" x 11"

Windage Information

Cradle Depth (Inside of Bag Straps)....................................................................................................2"

Maximum Front Bag Width ...............................................................................................................4

Minimum Bench-to-Cradle Base Height ...........................................................................................5

Maximum Bench-to-Cradle Base Height ..........................................................................................9

Horizontal Movement (Side-to-Side) .................................................................................................

Quick Elevation Travel (Primary Rise) ..............................................................................................1

Fine Elevation Travel (Secondary Rise) ........................................................................................ 1

Feet Elevation Travel (Base Rise) ......................................................................................................

Fore-End Stop Height (from Cradle Base) .......................................................................................1

Fore-End Stop Travel ........................................................................................................................2

Thread Size of Base Foot Knobs...................................................................................................

1

⁄4" – 11 7⁄8"

13

13

1

⁄2"-13

1

⁄2"

1

⁄4"

3

⁄4"

1

⁄4"

1

⁄2"

⁄16"

7

⁄8"

⁄16"

3

⁄4"

7

⁄8"

1

⁄4"

Construction Materials

Base ......................................................................................................................................... Cast Iron

Windage Cradle ......................................................................................................... Aluminum & Steel

Fore-End Stop................................................................................High Density Poly-Ethylene (HDPE)

Other

Country of Origin ..........................................................................................................................Taiwan

BE1006 Specifications

-18-

BE1004-06, BE1153, BE1209

BE1153

Taiwan

Triangle Windage Shooting Rest

Product Dimensions

Weight ....................................................................................................................................... 18.3 lbs.

Overall Length (Front-to-Back) ..........................................................................................................14"

Overall Width (Side-to-Side) ...........................................................................................................19

Overall Height ...................................................................................................................... 7

Footprint (Pin-to-Pin).........................................................................................................12

Shipping Dimensions

Weight .......................................................................................................................................... 23 lbs.

Box Size (L x W x H) ...................................................................................................... 21" x 19" x 10"

Windage Information

1

⁄4" – 11 7⁄8"

3

⁄4" Triangle

1

⁄2"

Cradle Depth (Inside of Bag Straps)....................................................................................................2"

Maximum Front Bag Width ...............................................................................................................5

Minimum Bench-to-Cradle Base Height ...........................................................................................5

Maximum Bench-to-Cradle Base Height ..........................................................................................8

Horizontal Movement (Side-to-Side) .................................................................................................

Quick Elevation Travel (Primary Rise) ..............................................................................................1

Fine Elevation Travel (Secondary Rise) ........................................................................................ 1

Feet Elevation Travel (Base Rise) ......................................................................................................

Fore-End Stop Height (from Cradle Base) .......................................................................................1

Fore-End Stop Travel ........................................................................................................................2

Thread Size of Base Foot Knobs...................................................................................................

Construction Materials

Base ......................................................................................................................................... Cast Iron

Windage Cradle ......................................................................................................... Aluminum & Steel

Fore-End Stop................................................................................High Density Poly-Ethylene (HDPE)

Other

Country of Origin ..........................................................................................................................

13

13

1

⁄2"-13

1

⁄2"

1

⁄4"

5

⁄8"

⁄16"

7

⁄8"

⁄16"

3

⁄4"

7

⁄8"

1

⁄4"

BE1004-06, BE1153, BE1209

-19-

BE1209

Big Fifty Rest w/Windage — Cast Iron

Product Dimensions

Weight .......................................................................................................................................... 27 lbs.

Overall Length (Front-to-Back) ..........................................................................................................18"

Overall Width (Side-to-Side) ..............................................................................................................20"

Overall Height .............................................................................................................................7" – 11"

Footprint (Pin-to-Pin)......................................................................................................... 18

Shipping Dimensions

Weight .......................................................................................................................................... 33 lbs.

Box Size (L x W x H) .......................................................................................................24" x 22" x 11"

Important Specifications

7

⁄8" Triangle

Cradle Depth (Inside of Bag Hold Down Straps) .............................................................................. 21⁄2"

Maximum Front Bag Width ...............................................................................................................8

Minimum Bench-to-Cradle Base Height ..............................................................................................5 "

Maximum Bench-to-Cradle Base Height ..........................................................................................8

Horizontal Movement (Side-to-Side) .................................................................................................

Quick Elevation Travel (Primary Rise) ..............................................................................................1

Fine Elevation Travel (Secondary Rise) ..............................................................................................2"

Feet Elevation Travel (Base Rise) ......................................................................................................

Fore-End Stop Height (from Cradle Base) .......................................................................................2

Fore-End Stop Travel ........................................................................................................................2

Thread Size of Base Foot Knobs...................................................................................................

Construction Materials

Base ......................................................................................................................................... Cast Iron

Cradle ........................................................................................................................ Aluminum & Steel

Fore-End Stop................................................................................High Density Poly-Ethylene (HDPE)

Other

Country of Origin ..........................................................................................................................Taiwan

13

5

⁄8"-11

1

⁄4"

3

⁄4"

⁄16"

7

⁄8"

3

⁄4"

1

⁄8"

3

⁄8"

-20-

BE1209 Specifications

BE1004 Specifications

BE1004-06, BE1153, BE1209

Optional Accessories

In addition to the products shown below, top quality bags are available from www.grizzly.com.

BE1007—3PK F-CLASS FEET (SB) BE1004-5

BE1007SS—3PK F-CLASS FEET (SS) BE1004- 5

BE1120—3PK F-CLASS FEET (SB) BE1006-53

BE1213— 3PK F-CLASS FEET (SB) BE1209

Available in satin black steel (SB) or polished

stainless steel (SS), these optional feet install

on Bald Eagle windage shooting rests for better

support when positioning the rest in soft, uneven

areas or soggy soil. Dimensions: 3" diameter,

5

⁄8" height, 3⁄8"-16 threaded holes on BE1007/

1

BE1007SS,

5

⁄8"-11 threaded holes on BE1209.

1

⁄2"-13 threaded holes on BE1120, and

BALD EAGLE FRONT BAGS

These top-quality front bags are constructed with

genuine leather and ultra-tough micro-fiber fabric

to ensure rugged durability and long-lasting performance. Bags are sold unfilled. Refer to figures

below for dimensions. Fit models BE1004–6, and

BE115 3 .

BLACK

MICRO-FIBER

DARK BROWN

LEATHER

5/8" FLAP

1-3/4"

FILL SPOUT

3"

4-5/8"

2" ON CENTER

BASE WIDTH (w/o FLAPS) = 2"

Figure 29. BE1122 3" Front Bag.

2-1/4"

BLACK

MICRO-FIBER

Figure 27. BE1007 F-Class Feet.

BE1008—3PK LONG SCREWS FOR BE1004-5

BE1121—3PK LONG SCREWS FOR BE1006-53

BE1212—3PK LONG SCREWS FOR BE1209

Used with the F-Class Feet to increase maximum

height of the shooting rest by 4". Features rub-

3

ber knobs. BE1008 thread size is

1

BE1121 thread size is

5

thread size is

⁄8"-11 x 4 3⁄4".

⁄2"-13 x 4 3⁄4". BE1212

⁄8"-16 x 4 3⁄4".

1-3/4"

4-5/8"

FILL SPOUT

2" ON CENTER

BASE WIDTH (w/o FLAPS) = 2"

Figure 30. BE1123 2 1⁄4" Front Bag.

Ø 3"

1-3/4"

FILL SPOUT

BASE WIDTH (w/o FLAPS) = 2"

4-5/8"

2" ON CENTER

Figure 31. BE1124 Radius Front Bag.

DARK BROWN

LEATHER

5/8" FLAP

BLACK

MICRO-FIBER

DARK BROWN

LEATHER

5/8" FLAP

Figure 28. BE1008 F-Class Long Screws.

BE1004-06, BE1153, BE1209

-21-

BALD EAGLE FRONT BAGS FOR BE1209

We designed three top-quality front bags for

the BE1209. They are constructed with genuine leather and ultra-tough micro-fiber fabric to

ensure rugged durability and long-lasting performance. Bags are sold unfilled. Refer to figures

below for dimensions.

3"

1-3/4"

4-5/8"

FILL SPOUT

BASE WIDTH (w/o FLAPS) = 2.5"

2" ON CENTER

BLACK

MICRO-FIBER

DARK BROWN

LEATHER

5/8" FLAP

Figure 32. BE1219 3" Front Bag.

BE1133—9" LONG REAR BAG w/1/4" SLOT

Designed with practicality and quality in mind,

these high-end rear bags are world class! They

were designed by a shooter for a shooter and

manufactured by a shooter! The body is made

of heavy top grain two-tone leather with a convenient fill spout in the back. The ears are made

of ultra-tough micro fiber fabric that is extremely

slick. Each ear has its own fill spout that easily

tucks in. The built-in handle makes it easy to carry

these on and off the line quickly. The BE1133 is 9"

1

with a

⁄4" slot.

4-1/2"

1-3/4"

5-1/2"

FILL SPOUT

2" ON CENTER

BASE WIDTH (w/o FLAPS) = 2.5"

Figure 33. BE1220 41⁄2" Front Bag.

5"

1-3/4"

2" ON CENTER

6-5/8"

FILL SPOUT

BASE WIDTH (w/o FLAPS) = 2.5"

BLACK

MICRO-FIBER

DARK BROWN

LEATHER

5/8" FLAP

BLACK

MICRO-FIBER

DARK BROWN

LEATHER

5/8" FLAP

Figure 35. BE1133 Rear Bag with 1⁄4" Slot.

BE1045—UNIVERSAL RIFLE CLEANING KIT

Anyone with a variety of rifle calibers will value

this handy cleaning kit. Cleaning tools are sized

to fit .22LR, .243, .270 and .30 caliber barrels.

Includes phosphor bronze brushes, mops, rods/

handles, slotted tips, brass jags and cleaning

patches.

-22-

Figure 34. BE1221 5" Front Bag.

Figure 36. BE1045 Universal Rifle Cleaning

Kit.

BE1004-06, BE1153, BE1209

Loading...

Loading...