Page 1

Heated Display Merchandisers

MODELS WDCG, SSWG, CSWG

Installation & Operation Manual

Page 2

Warranty Information

LIMITED ONE YEAR WARRANTY

BKI (The “Company”) warrants to the original purchaser/user, that at time of shipment from the

Company factory, this equipment will be free from defect in materials and workmanship. Written

notice of a claim under this Warranty must be given within ONE YEAR AND THREE MONTHS

from date of shipment from the factory. Defective conditions caused by abnormal use or misuse,

lack of maintenance, damage by third parties, alterations by unauthorized personnel, acts of God,

failure to follow installation instructions or any other events beyond the control of the company will

NOT be covered under Warranty. The obligation of the Company under this Warranty shall be

limited to repairing or replacing (at the option of the company) any part which is defective in

reasonable opinion of the Company. The user will have the responsibility and expense of

removing and returning the defective part to the Company as well as the cost of reinstalling the

replacement or repaired part.

IN NO EVENT SHALL THE COMPANY BE LIABLE FOR LOSS OF USE, LOSS OF REVENUE

OR LOSS OF PRODUCT OR PROFIT OR FOR INDIRECT OR CONSEQUENTIAL DAMAGES

INCLUDING BUT NOT LIMITED TO, FOOD SPOILAGE OR PRODUCT LOSS . WAR RANTY

DOES NOT COVER GLASS BREAKAGE. THE ABOVE WARRANTY IS EXCLUSIVE AND ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, ARE EXCLUDED INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

THIS WARRANTY SHALL APPLY ONLY WITHIN THE CONTINENTAL UNITED STATES, ITS

TERRITORIES, AND POSSESSIONS AND IN CANADA.

LIMITED NINETY DAY LABOR WARRANTY

All labor necessary to repair or replace factory defective parts will be performed, without charge,

to the end user, by service personnel of a BKI Authorized Distributor during the first ninety days

after the date of installation of the new equipment.

Replacement parts: Any appliance replacement part, except lamps and fuses, which proves to

be defective in material or workmanship within 90 days from date of original installation will be

repaired or replaced without charge F.O.B. Factory, Simpsonville, S.C. or F.O.B. authorized

distributor.

Page 3

Hot Food Deli Case Table of Contents

Table of Contents

Table of Contents........................................................................................................................................1

Introduction .................................................................................................................................................2

Safety Precautions....................................................................................................................................2

Safety Signs and Messages.................................................................................................................2

Specific Precautions.............................................................................................................................3

Safe Work Practices.............................................................................................................................3

Operation .....................................................................................................................................................5

Controls and Indicators.............................................................................................................................5

Hardware Controls................................................................................................................................5

Software Controls - Default Screen.....................................................................................................6

Software Controls - Viewing Settings..................................................................................................6

Software Controls - Programming the Controller................................................................................7

Preheating.................................................................................................................................................8

Temperature Adjustment..........................................................................................................................8

Operational Guidelines.............................................................................................................................8

Unit Shutdown...........................................................................................................................................8

Installation ...................................................................................................................................................9

Unpacking and Handling...........................................................................................................................9

Floor Model...............................................................................................................................................9

Leveling................................................................................................................................................9

Kick Plate Mounting............................................................................................................................10

End Panel Mounting...........................................................................................................................11

Pedestal Model.......................................................................................................................................12

Leveling..............................................................................................................................................12

Front and Rear Cover Attachment .....................................................................................................13

End Panel Mounting...........................................................................................................................13

Counter Model ........................................................................................................................................14

Wiring......................................................................................................................................................14

Case Joining Trim...................................................................................................................................15

Maintenance ..............................................................................................................................................15

Scheduled Maintenance.........................................................................................................................16

Cleaning .............................................................................................................................................16

Troubleshooting......................................................................................................................................17

Wiring Diagrams.......................................................................................................................................18

1

Page 4

Hot Food Deli Case Introduction

Introduction

Congratulations! You have chosen a Hot Food Deli Case that will give you many years of fine service

from the original manufacturer, BKI.

The BKI name and trademark on this unit assures you of the finest in design and engineering -- that it has

been built with care and dedication -- using the best materials available. Attention to the operating

instructions regarding proper installation, operation, and maintenance will result in long lasting

dependability to insure the highest profitable return on your investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If

you have any questions, please contact your BKI Distributor. If they are unable to

answer your questions, contact the BKI Technical Service Department, toll free:

1-800-927-6887. Outside the U.S., call 1-864-963-3471.

This unit is to be sealed to the floor after installation to conform to NSF

requirements. (Dow Corning RTV #732 Multi purpose Sealant.)

Safety Precautions

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol.

When you see this symbol on your equipment, be alert to the potential for personal injury or property

damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify

specific areas where potential hazards exist and special precautions should be taken. Know a nd

understand the meaning of these instructions, signs, and messages . Damage to the equipment, death or

serious injury to you or other persons may result if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against unsafe

practices.

This message is used when special information, instructions or identification are

required relating to procedures, equipment, tools, capacities and other spe cial

data.

2

Page 5

Hot Food Deli Case Introduction

Specific Precautions

Equipotential Ground Plane

When a high current flows through a conductor, differences in potent ial appear

between the conductor and nearby metallic surfaces near the appliance. As a

result, sparks may be produced between the appliance and surrounding metal

surfaces. These sparks could cause serious injury, damage, or fire.

BKI provides an Equipotential ground terminal for the connection of a bonding

conductor after the installation of the appliance per lEC60417-1. This terminal is

located on the inside of the Power Entry Supply box near the Earth connection

and is marked with this symbol.

Safe Work Practices

Beware of High Voltage

This equipment uses high voltage. Serious injury can occur if you or

any untrained or unauthorized person installs, services, or repairs this

equipment. Always Use an Authorized Service agent to Service Your

Equipment

Keep this manual with the Equipment

This manual is an important part of your equipment. Always keep it

near for easy access.

If you need to replace this manual, contact:

BKI

Technical Services Department

P.O. Box 80400

Simpsonville, S.C. 29680-0400

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Protect Children

Keep children away from this equipment. Children may not

understand that this equipment is dangerous for them and others.

NEVER allow children to play near or operate your equipment.

3

Page 6

Hot Food Deli Case Introduction

Keep Safety Labels Clean and in Good Condition

Do not remove or cover any safety labels on your equipment. Keep

all safety labels clean and in good condition. Replace any damaged

or missing safety labels.

If you need new safety labels, contact:

BKI

Technical Services Department

P.O. Box 80400

Simpsonville, S.C. 29680-0400

Or call toll free: 1-800-927-6887

Outside the U.S., call 864-963-3471

Be Prepared for Emergencies

Be prepared for fires, injuries, or other emergencies.

911

Keep a first aid kit and a fire extinguisher near the equipment. You

must use a 40-pound Type BC fire extinguisher and keep it within 25

feet of your equipment.

Keep emergency numbers for doctors, ambulance services, hospitals,

and the fire department near your telephone.

Know your responsibilities as an Employer

• Make certain your employees know how to operate the equipment.

• Make certain your employees are aware of the safety precautions

on the equipment and in this manual.

• Make certain that you have thoroughly trained your employees

about operating the equipment safely.

• Make certain the equipment is in proper working condition. If you

make unauthorized modifications to the equipment, you will reduce

the function and safety of the equipment.

4

Page 7

Hot Food Deli Case Operation

Operation

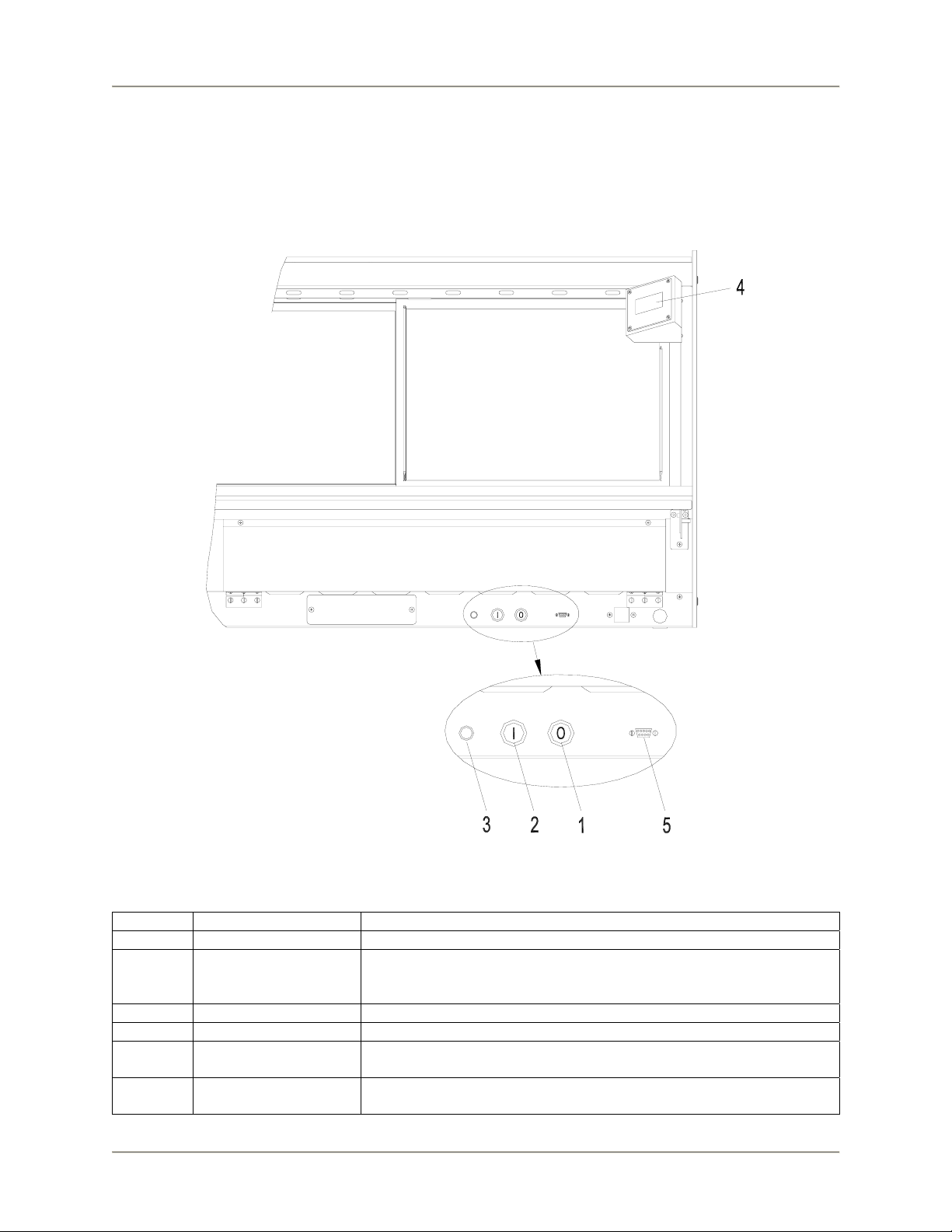

Controls and Indicators

The deli case controls are shown in the figure below. The pushbutton switches turn the power supply to

the case on and off. The touchscreen interface is used to operate the case and display temperatures.

Hardware Controls

Item # Description Function

1 Power OFF Switch Depressing the switch turns power OFF to the entire unit.

2 Power ON Switch Depressing the switch turns power ON to the entire unit.

When the unit is ON the touchscreen controller is

powered & the lights illuminate.

3 Main Power Isolator This light illuminates to indicate that power is being applied

Light to the unit from the main power isolator (circuit breaker).

4 Analog Touchscreen Used for the operation of the unit and to measure & record

Interface product temperatures.

5 Controller RS-232 Allows user to download saved product temperatures to a

Interface laptop PC using the supplied software.

5

Page 8

Hot Food Deli Case Operation

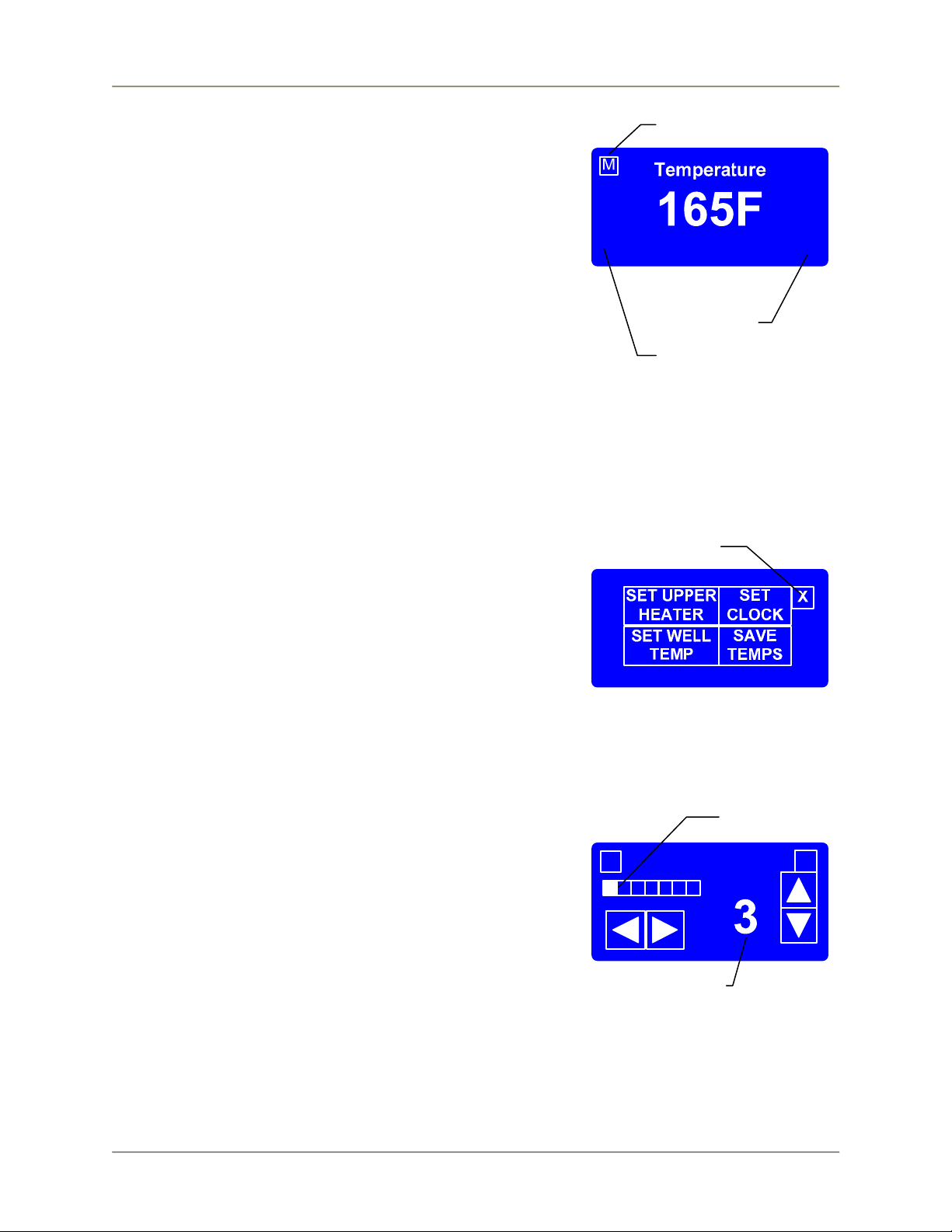

Software Controls - Default Screen

The Default Screen appears on the touchscreen during normal

operation. The screen shows the menu button and a

representive temperature.

The representative temperature does not correspond to the

internal temperature of the food products in the case. This

temperature is only an indication that the case is operating

properly and heating.

When the unit is first powered up the representative temperature

will be approximately room temperature. As the unit preheats the

representative temperature will rise. The representative

temperature will stabilize when the unit reaches operating

temperature.

The representative temperature should be approximately the

same from day to day when the unit is in operation. A significant

change in this temperature without changing any of the

temperature settings of the unit may indicate a problem with the

unit. A qualified BKI service representative should be contacted.

Software Controls - Viewing Settings

The current heater settings can be viewed by touching the Menu

Button [M] on the Default Screen. The Menu Screen will then be

displayed.

To view the current settings for either Well Temp or Upper Heater

touch the appropriate button on the Menu Screen. The View

Setting Screen for the selected heaters will be displayed.

To return to the Default Screen, touch the Exit Button [X].

If the controller is configured to control each well position

independently the View Setting Screen as shown at right will be

displayed. Use the left and right arrows to display the heater

setting for the various well positions of the unit. The progress bar

gives a visual representation of the well location for which the

setting is being displayed.

The current heater setting is displayed on the right side of the

screen. The setting is a numeric value between 1 and 10 where

10 is the hottest setting.

If the controller is configured to control all of the well positions at

the same setting, the progress bar will be solid and the left and

right arrows will not be displayed. The setting shown will be for

the heaters at all of the well positions.

To return to the Menu Screen, touch the Menu Button [M]. To

return to the Default Screen, touch the Exit Button [X].

Touching [Set Clock] on the Menu Screen will display the time

and date. To return to the Menu Screen, touch the Menu Button

[M]. To return to the Default Screen, touch the Exit Button [X].

Menu Button

Default Screen

Lower Right

Lower Left

Exit Button

Menu Screen

M

Well Heater 1

Current Setting

View Setting Screen

Progress Bar

X

6

Page 9

Hot Food Deli Case Operation

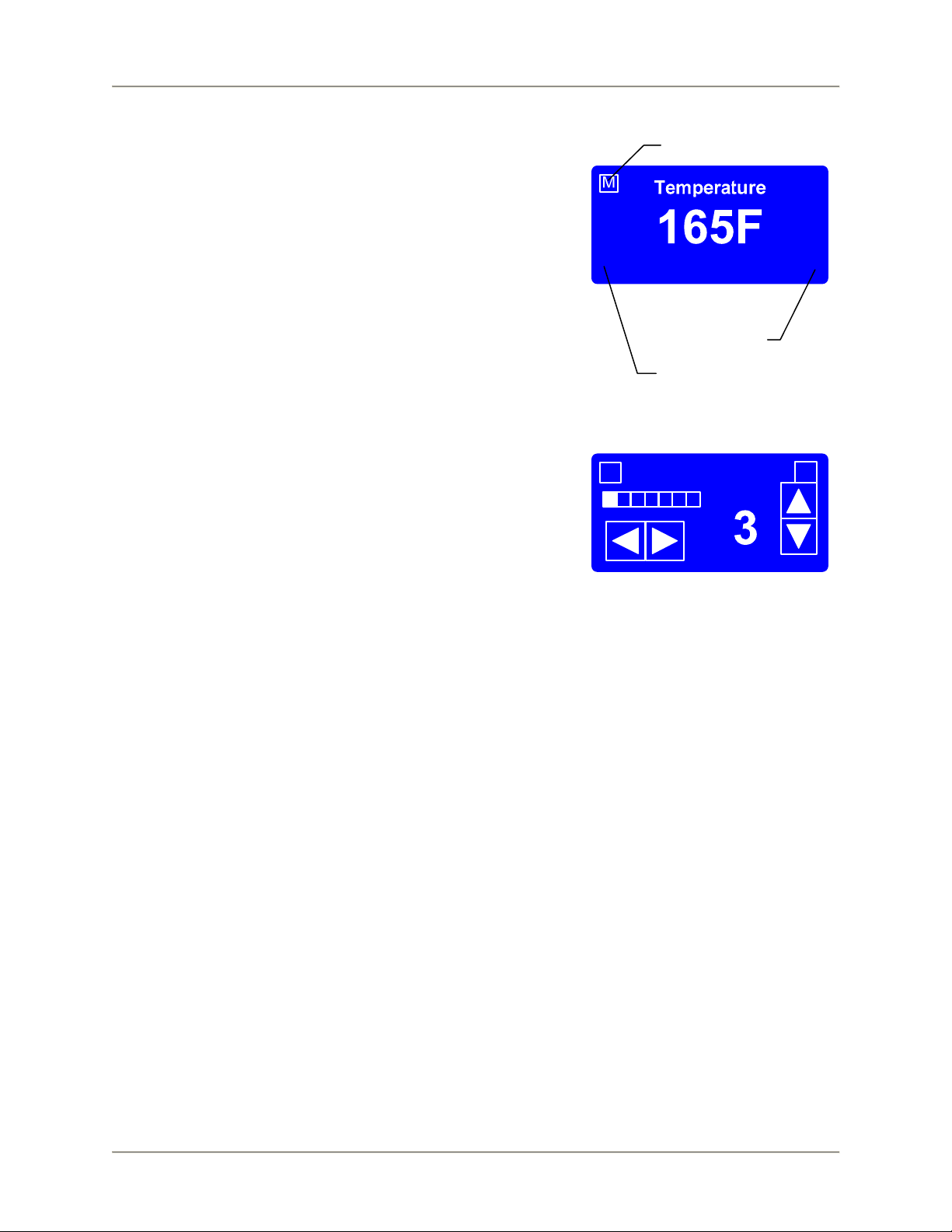

Software Controls - Programming the

Controller

There is a unique set of touches to enter the programming mode.

This prevents the case settings from being inadvertently

changed.

Enter the programming mode from the Default Screen by

touching the lower left of the touchscreen, then the lower right

and then the Menu Button [M] in that order. The Menu Screen

will then be displayed.

To edit the current settings for either Well Temp or Upper Heater

touch the appropriate button on the Menu Screen. The Edit

Setting Screen for the selected heaters will be displayed.

To return to the Default Screen, touch the Exit Button [X].

If the controller is configured to control each well position

independently the Edit Setting Screen as shown at right will be

displayed. Use the left and right arrows to display the heater

setting for the various well positions of the unit. The progress bar

gives a visual representation of the well location for which the

setting is being displayed.

The current heater setting is displayed on the right side of the

screen. Use the up and down arrows to edit the heater setting.

The setting is a numeric value between 1 and 10 where 10 is the

hottest setting.

If the controller is configured to control all of the well positions at

the same setting, the progress bar will be solid and the left and

right arrows will not be displayed. Use the up and down arrows

to edit the heater setting for all of the well positions.

To return to the Menu Screen, touch the Menu Button [M]. To

return to the Default Screen, touch the Exit Button [X].

To edit the controller time and date settings touch [Set Clock] on

the Menu Screen while in the program mode. The time and date

will need to be reset if the power supply to the case has been

disconnected.

Use the left and right arrows to move the cursor under the value

to be edited. Use the up and down arrows to edit the value.

Continue until the current date and time is displayed.

To return to the Menu Screen, touch the Menu Button [M]. To

return to the Default Screen, touch the Exit Button [X].

Menu Button

Default Screen

M

Well Heater 1

Lower Right

Lower Left

Edit Settings Screen

X

7

Page 10

Hot Food Deli Case Operation

Preheating

You should allow the equipment to preheat at the programmed temperature settings for a minimum of 30

minutes before loading it with product. For initial start up, program the controller for each well and upper

heater to a setting of 5.

Check Federal and State Health and Sanitation Regulations for internal temperature required for holding

cooked foods for sale. Maintaining these temperatures often tend to allow continued cooking of certain

products. Therefore, smaller amounts of bulk foods should be displayed at non-peak p eriods and the

warmer refilled as needed.

All meats and vegetables should be preheated to 160°F (70°C). before being placed in the case.

A screen liner can be used in the bottom of the display pans that are used for holding meats. This will

keep meats from sticking to the bottom of the pans.

Temperature Adjustment

After placing the product into the equipment, it may be necessary to adjust the programmed settings in

order to maintain the proper internal temperature for the product on display. The optional built-in product

temperature probe or a portable meat thermometer should be used to read the internal temperature of

each product. The programmed settings should be set to the lowest possible number that will maintain

the proper product temperature.

Operational Guidelines

Keep the optional built-in product temperature probe or a portable meat thermometer on hand. Che ck the

food temperatures hourly.

Rotate the food products. Foods loaded in first should be served first as much as is practical.

Foods held for long periods of time are more difficult to maintain at proper temperature. Also, freshness

and product quality diminish if foods are held too long. Most areas of the country have sanitation

regulations governing how long foods can be held. Make certain to check with your local auth orities.

Unit Shutdown

Remove all food pans holding the food product from the equipment. Depres s the OFF pushbutton switch

to turn the power to the heaters and lights off. After the temperature has cooled below 120°F (50°C),

remove any residue from the wells and clean the equipment thoroughly.

8

Page 11

Hot Food Deli Case Installation

Installation

Unpacking and Handling

YOU are responsible for filling all freight claims with the delivering truck line. Inspect all cartons and

crates for damage as soon as they arrive. If damage to cartons or crates is found, or if a shortage is

found, note this on the bill of lading (all copies) prior to signing.

If damage is found when the equipment is opened, immediately call the delivering truck line and follow up

the call with a written report indicating concealed damage to your shipment. Ask for an immediate

inspection of your concealed damage item. Packaging material MUST be retained to show the inspector

from the truck line.

Do not walk on top of deli cases or damage to the cases and serious personal

injury could occur. The cases are not structurally designed to support excessive

external loading such as the weight of a person. Do not place heavy objects on

the deli cases.

Move the deli case as close as possible to its permanent location before moving the case off of the

shipping pallet. Make certain there are no separately packed accessories b efore discarding packaging.

During shipment, the lubricant in the gas springs may have settled. This can cause the glass not to

remain open in the raised position. To avoid this, fully raise and lower the glass manually 4 or 5 times.

This unit is designed to be sealed to the floor after it is installed – to conform to

NSF Standard 4. Use Dow Corning RTV # 732 Multi-purpose Sealant.

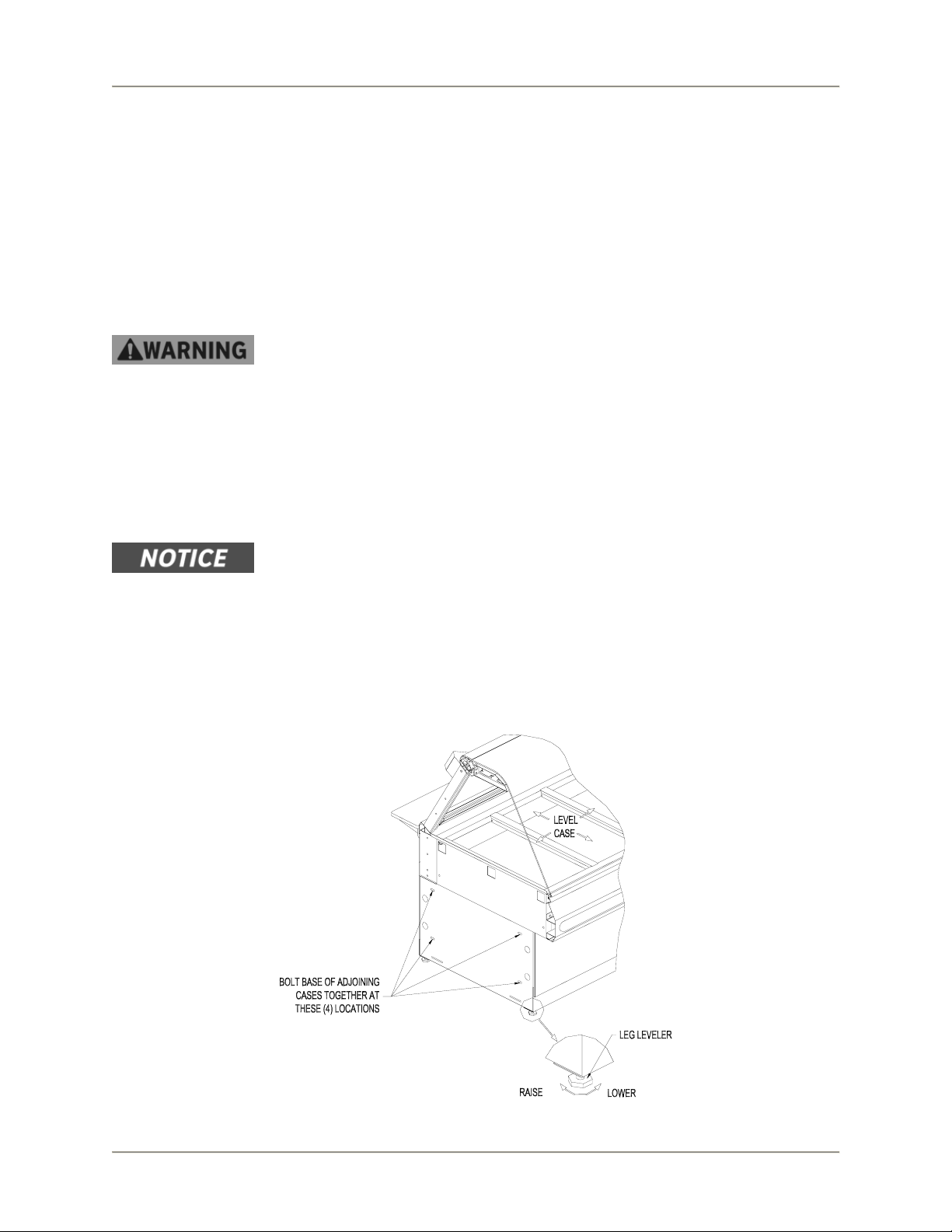

Floor Model

Leveling

Deli cases must be installed level to insure proper operation and alignment to adjoining equipment. Use a

carpenter’s level as shown in Figure 1. Begin lineup leveling from the highest point of the store floor.

Figure 1. Floor Model - Leveling & Kick Plate Mounting

9

Page 12

Hot Food Deli Case Installation

1. Level the case using the leg levelers at the corners of the case (Figure 1).

2. Raise the low end of the case to level it, do not lower the high end.

3. Check for level side-to-side and front-to-back.

4. If you are installing adjoining cases, position the next case in line beside the level case and

proceed to the next step.

5. Level this case in the same manner.

6. When level, bolt the two cases together at the locations shown in Figure 1.

NOTE: None of the end components shown in Figure 2 should be attached to adjoining case

ends

If the cases have been properly leveled, the front panels and counter tops should align with a

small, uniform gap between the front panels of the two cases.

7. Proceed in the same manner until all the cases in the line are level and bolted together.

8. Complete the line up by slipping the Counter Top Joint Cover over the end flanges of the

adjoining counter tops.

Kick Plate Mounting

A black vinyl-covered kick plate is provided for the front and back of each case.

1. Slide the front kick plate (the wider of the two) behind the lower finished front panel of the case

(see Figure 2).

2. Make certain that the ends of the kick plate are flush with the ends of the lower finished front

panel and that the kick plate is flush to the floor.

3. Drill 5/32” diameter holes in the case base to match the pre-drilled holes in the kick plate.

4. Attach the kick plate to the case base with the black sheet metal screws provided.

5. Mount the back kick plate to the case in the same manner.

6. Place the End Kick Plates in position (see Figure 2).

NOTE: There are left and right hand parts. The longer end flange faces toward the front of the case

with the black side out. The End Kick Plates fit over the ends of the front and back kick plates and

flush to the floor.

10

Page 13

Hot Food Deli Case Installation

End Panel Mounting

1. Now, attach the End Trim Panels to the base ends. The studs on the Trim Panels pass throu gh

the mounting holes in the base ends (see Figure 2). Both End Trim Panels are the same.

2. The panels are secured from inside with the #10 Pal Nuts provided.

3. Attach the End Panels to the ends of the case(s) as shown in Figure 2 using the shoulder screws

provided. For Glass End Panels only, slide the plastic bushings provided over the shoulder

screws before inserting the screw into the glass panel. Be careful that the screws do not bind in

the holes in the glass panel.

NOTE: If the ends are already attached to the case, the End Kick Plates can be lowered to the

floor. To do this loosen the End Trim Panel nuts from inside the case then slide the Kick Plates

flush with the floor and tighten the Trim Panel nuts.

4. These cases are to be sealed to the floor if required by local health codes. Seal the kick plates to

the floor using a silicone-type sealant (Dow Corning RTV #732 or equivalent).

Figure 2. Floor Model - End Kick Plate & End Panel Mounting

11

Page 14

Hot Food Deli Case Installation

Pedestal Model

Pedestal mounted cases are provided with a mounting frame that runs the full length of the case. This

allows the pedestals to be located at any point along the length of the case. Each case should be

supported by at least two pedestals. One pedestal can support the ends of two adjoining cases. If in

doubt, consult the factory for assistance in determining the proper pedestal loca tions for your particular

installation.

RETAINING CLIP CLAMPS PEDESTAL

FRAME TO BOTTOM FLANGE OF

CASE FRAME

(PAINTED or STAINLESS)

REAR COVER

INSTALL FIRST

MOUNTING RAILS ON CASE

FIT INSIDE PEDESTAL ENDS

BOLT FRAMES OF ADJOINING

CASES TOGETHER AT THESE

(3) LOCATIONS

RAISE

LEG LEVELER

LOWER

PEDESTAL

FRAME

LEVEL

CASE

FRONT COVER

(PAINTED or STAINLESS)

FITS OVER REAR COVER

Figure 3. Pedestal Model - Leveling and Cover Attachment

Leveling

Deli cases must be installed level to insure proper operation and alignment to adjoining equipment. Use a

carpenter’s level as shown in Figure 3. Begin lineup leveling from the highest point of the store floor.

1. Level the case using the leg levelers at the corners of the pedestals (see Figure 3).

2. Raise the low end of the case to level it, do not lower the high end.

3. Check for level side-to-side and front-to-back.

4. If you are installing adjoining cases, position the next case in line beside the level case and

proceed to the next step.

5. Level this case in the same manner.

6. When level, bolt the two cases together at the locations shown in Figure 3. If the cases have

been properly leveled, the front panels and counter tops should align with a small, uniform gap

between the front panels of the two cases.

12

Page 15

Hot Food Deli Case Installation

7. Proceed in the same manner until all the cases in the line are level and bolted together.

8. Complete the line up by slipping the Counter Top Joint Cover over the ends flanges of the

adjoining counter tops.

Front and Rear Cover Attachment

1. Slide the Rear Cover over the Pedestal Frame first (see Figure 3). Then slide the Front Cover

over the Frame with the sides of the Front Cover lapping over the side of the Rear Cover. The

Front Cover will extend approximately 4-1/2” from the front of the frame.

2. Drill two 5/32” diameter holes in each side of the Pedestal Frame to match the predrilled holes in

the covers.

3. Secure the covers to the frame using the #8 sheet metal screws provided.

4. These cases are to be sealed to the floor if required by local health codes. Seal the pedestal

covers to the floor using a silicone-type sealant (Dow Corning RTV #732 or equivalent).

End Panel Mounting

Figure 4. Pedestal Model - End Panel Mounting

1. Attach the End Panels to the ends of the case(s) as shown in Figure 4 using the shoulder screws

provided.

For Glass End Panels only, slide the plastic bushings provided over the shoulder screws b efore

inserting the screw into the glass panel. Be careful that the screws do not bind in the holes in the

glass panel.

13

Page 16

Hot Food Deli Case Installation

Counter Model

Counter Mounted cases must be mounted on a level surface that can su pport the weight of the case and

it contents. Use a carpenter’s level as shown in Figure 3 to level the case.

These cases are to be sealed to the counter if required by local health codes. Seal the peri meter of the

case to the counter using a silicone-type sealant (Dow Corning RTV #732 or equivalent).

Attach the End Panels to the ends of the case as shown in Figure 4 using the shoulder screws provided.

The (2) lower shoulder screws shown in Figure 4 are not required on counter mounted cases.

For Glass End Panels only, slide the plastic bushings provided over the shoulder screws before inserting

the screw into the glass panel. Be careful that the screws do not bind in the holes in the glass panel.

Wiring

A wiring diagram for the specific model is shipped with the deli case. The wiring diagram provides

electrical specifications, an electrical schematic and a parts list. Refer to this wiring diagram and the deli

case serial number plate for electrical information.

Field wiring must be sized for the components amperes printed on the serial number plate. Actual ampere

draw may be less than specified.

All electrical connections should be in compliance with the NEC and all applicable local codes by a

licensed electrician. Refer to the wiring diagram furnished with your case for the electrical specifications.

The power supply connection is located on the bottom or back of the well compartment of the case (see

Figure 5). A ¾ knockout is provided at each location for the required conduit connection. A second power

supply connection for the oven is provided on oven combo cases.

A wiring cutout is provided in the base bottom pan on floor model cases (see Figure 5). Refer to the case

specification sheet for the location of this cutout. Remove the cover over the wiring cutout and route the

wiring through the cutout. Cut a hole of the proper size and location in the cover for the conduit to pass

through and reinstall the cover.

Figure 5. Wiring Access

14

Page 17

Hot Food Deli Case Maintenance

Case Joining Trim

1. After leveling the cases and bolting the bases together, bolt the canopies together as shown i n

Fig. 6 with a ¼”-20 x ¾” Hex Head Screw and Keps Nut.

2. Mount the Upper Front & Base Front Joint Trims by holding them in place and marking the hole

locations on the case.

3. Make certain the joint covers are centered on the joint and that they align vertically with each

other.

4. Drill the case holes 5/32” and attach joint covers with screws provided. Before tightening the top

screws of the Upper Front Trim, slide the Counter Front Trim in place between the screw head

and the Upper Front Trim.

5. Attach Bumper Ends and Bumper Mounting Base to the front of the cases, centered on the

vertical surface of the upper front of the case. Cut the Bumper Top to length to fit between the

Bumper Ends and snap into place.

Figure 6. Joining WDCTY Cases

Maintenance

15

Page 18

Hot Food Deli Case Maintenance

Failure to comply with the maintenance below could result in a serious accident.

Electrocution, equipment failure or property damage could result if an unlicensed

electrician performs electrical repair. Ensure that a licensed electrician perform

electrical repair.

Scheduled Maintenance

Use the following table to help manage scheduled maintenance activities.

Frequency Performed By Part Activity

Daily User Case Clean the entire Case. Refer to the

cleaning procedure below.

Cleaning

This unit should be cleaned at the end of each day. Use the following procedure:

Failure to remove power from this unit may cause severe electrical shock. This

unit may have more than one disconnect switch.

1. Turn the machine ‘off ‘ and allow it to cool down.

2. Remove any food pans.

Using abrasive cleaners may damage the cabinet finish. Use only a mild soap and

water solution.

Never steam clean or get excess water in the interior of the cabinet as this can

damage unit.

This appliance is not intended to be cleaned with a water jet.

3. Use a mild soap and water solution to clean parts.

4. Sponge the inside and outside with a mild soap and water solution.

5. Wipe the parts and cabinet dry with a soft, clean cloth.

16

Page 19

Hot Food Deli Case Maintenance

Troubleshooting

Refer to the table below for troubleshooting information.

Problem Cause Possible Solution

Electrical

Power switch is off. Reset the power switch.

No Heat

Defective Heating Element. Contact an authorized BKI service

Defective Thermostat. Contact an authorized BKI service

Loose Wire or bad

Holding Temperature Not

Adequate

No Power to the case. Check circuit breaker or fuses at

building power panel. If problem

persists, contact an authorized

BKI service agent for corrective

action.

Power switch if off. Reset the power switch.

agent for corrective action.

agent for corrective action.

Contact an authorized BKI service

Connection.

Case and food pans have

not been preheated.

One or more heating

elements or thermostats not

operating properly.

agent for corrective action.

Refer to the preheating section on

page Error! Bookmark not

defined.. If problem persists,

contact an authorized BKI service

agent for corrective action.

Contact an authorized BKI service

agent for corrective action.

Loose Wire or bad

Product is below 160° F

when loaded.

Connection.

Check product temperature

before loading the case.

Contact an authorized BKI service

agent for corrective action.

17

Page 20

Hot Food Deli Case Wiring Diagrams

Wiring Diagrams

18

Page 21

Hot Food Deli Case Wiring Diagrams

19

Page 22

Hot Food Deli Case Wiring Diagrams

20

Page 23

Hot Food Deli Case Wiring Diagrams

21

Page 24

Hot Food Deli Case Wiring Diagrams

22

Page 25

Hot Food Deli Case Wiring Diagrams

23

Page 26

Hot Food Deli Case Wiring Diagrams

24

Page 27

Hot Food Deli Case Wiring Diagrams

25

Page 28

Hot Food Deli Case Wiring Diagrams

26

Page 29

Hot Food Deli Case Wiring Diagrams

27

Page 30

Hot Food Deli Case Wiring Diagrams

28

Page 31

Hot Food Deli Case Wiring Diagrams

29

Page 32

Hot Food Deli Case Wiring Diagrams

30

Page 33

Hot Food Deli Case Wiring Diagrams

31

Page 34

Hot Food Deli Case Wiring Diagrams

32

Page 35

Hot Food Deli Case

No

tes

33

Page 36

P.O. Box 80400, Simpsonville, S.C. 29680-0400, USA

http://www.bkideas.com

Made and printed in the U.S.A

LI0117/0607

Loading...

Loading...