Page 1

INSTALLATION

AND

OPERATING

INSTRUCTIONS

Models: VH1620E, VHVA1620E, VH1828E & VHVA1828E

COUNTERTOP MODEL

ELECTRIC CONVEYOR OVENS

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

OVEN MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

!!

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this equipment.

Initial heating of oven may generate smoke or fumes and must be done in a well ventilated area.

Overexposure to smoke or fumes may cause nausea or dizziness.

This equipment has been engineered to provide you with year-round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

ANSI/NSF4

P/N U4173A 12/05

BAKERS PRIDE OVEN CO., INC.

30 Pine Street

New Rochelle, NY 10801

(914)576-0200 Phone (800)431-2745 US& Canada

(914)576-0605 Fax www.bakerspride.com WebAddress

!!

1

Page 2

Bakers Pride takes pride in thedesign and quality of our products. When used as intended and with proper

care and maintenance, you will experience years of reliable operation from this equipment. To ensure best

results, it is important that you carefully read and follow the instructions in this manual.

Installation and start-up should be performed by a qualified installer who has thoroughly read, understands

and follows these instructions.

If you have questions concerning the installation, operation, maintenance or service of this product, contact

our Technical Service Department at (800) 431-2745.

SAFETY PRECAUTIONS

Before installing and operating this equipment be sure everyone involved in its operation are fully trained

and are aware of all precautions.Accidents and problems can result by a failure to follow fundamental rules

and precautions.

The following words and symbols, found in this manual, alert you to hazards to the operator, service

personnel or the equipment. The wordsare defined as follows:

DANGER:

!

WARNING:

!

seriousinjuryor death.

CAUTION:

moderateinjuryorproductor property damage.

!

NOTICE:

eventhoughnot dangerous.

!

Thissymbolwarnsof imminent hazard which will result inseriousinjuryor death.

This symbol refers to a potential hazard or unsafe practice, which could result in

Thissymbol refers to a potential hazard or unsafepractice,which may result in minor or

This symbol refers to informationthat needs special attentionormust be fullyunderstood

GENERAL INFORMATION

THIS MANUAL SHOULD BE RETAINED FOR FUTURE REFERENCE

CAUTION:

positioned so the general public can use the equipment make sure that cautions, warnings, and

!

operating instructions are clearly posted near each unit so that anyone using the equipment will

useit correctly and not injure themselvesorharmtheequipment.

WARNING:

!

andfrequencylistedon the data plate. Connect only to 1or 3 phase as listedonthe data plate.

WARNING:

!

nationalelectricalcodeand/orotherlocal electrical codes.

These models are designed, built, and sold for commercial use. If these models are

Checkthe data plate on thisunit before installation.Connect the unit onlyto the voltage

Electrical and grounding connections must comply with the applicable portions of the

!

!

!

!

!

!

!

WARNING:

!

powerplug,indicatingthatyou are working on thecircuit.

WARNING:

strongly recommend having a competent professional install the equipment.Alicensed electrician

should make the electrical connections and connect power to the unit. Local codes should always

!

be used when connecting these units to electrical power. In the absence of local codes, use the

latestversionof the National Electrical Code.

WARNING:

codes, or in the absence of local codes, with the National Electrical code, ANSI/NFPA 70, Latest

Edition to protect the user from electrical shock. It requires a grounded system and a dedicated

!

circuit, protected by a fuse or circuit breaker of proper size and rating. Canadian installation must

complywiththe CanadianElectricalCode, CSAC22.2,asapplicable

Disconnect device from electrical power supply and place a Tag Out-Lockout on the

Installper the spacing requirements listed in the installationsection of this manual. We

This device should be safely and adequately grounded in accordance with local

2

!

!

!

Page 3

WARNING:

!

maintenanceorrepair, contact Bakers Pride.

Afactoryauthorizedagentshouldhandle all maintenance and repair. Before doing any

!

WARNING:

!

surface.

WARNING:

installationandfromthereto an independent earth connection.

!

NOTICE:

the absence of local codes, with the national electrical code ANSI/NFPA70- latest edition.

!

Canadian installation must comply with CSA-STANDARD C.22.2 Number 0 M1982 General

Requirements-CanadianElectrical Code PartII,109-M1981-CommercialCookingAppliances.

WARNING: -

!

equipment.

NOTICE:

!

NOTICE:

Fire ProtectionAssociation, Inc. states in its NFPA96 latest edition that local codes are Authority

Having Jurisdiction when it comes to requirements for installation of equipment. Therefore,

!

installationshouldcomplywithalllocalcodes.

Never clean any electrical unit by immersing it in water. Turn off before cleaning

An earthing cable must connect the appliance to all other units in the complete

The unit when installed, must be electrically groundedand comply with local codes, or in

SHOCK HAZARD

Thisproductis intended for commercial use only.Notforhouseholduse.

Local codes regarding installation vary greatly from one area to another. The National

De-energize all power to equipment before cleaning the

IMPORTANT FOR FUTURE REFERENCE

!

!

!

!

!

!

Notes:

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

3

Page 4

TABLE OF CONTENTS

SECTION ITEM PAGE

1 Receiving 5

2 Location & Minimum Clearances 5

3 Installation 5

4 Stacking 6

5 Electrical Connections 6

6 System Check 8

7 Initial Start-Up 10

8 Shutdown 11

9 Special Features 11

10 Cleaning 12

11 Operator Maintenance 13

12 Rating Plate 14

13 Conveyor Removal 15

14 Conveyor Installation 15

15 Conveyor Belt Speed Calibration 16

16 Troubleshooting Guide 18

17 Temperature Control Conversion Chart 23

18 Solid State Relay Identification 24

19 Electrical Schematics & Wiring Diagrams 26

A.

VHVA1620E Schematic, 208, 220 or 240VAC, 1 Phase 26

B.

VHVA 1620E Wiring Diagram, 208, 220 or 240VAC, 1 Phase 27

C. 3

VHVA1620E Schematic, 208, 220 or 240VAC, Phase 28

D. VHVA 1620E Wiring Diagram, 208, 220 or 240VAC, 3 Phase 29

E. VH 1620E Schematic, 208, 220 or 240VAC, 1 Phase 30

F. VH 1620E Wiring Diagram, 208, 220 or 240VAC, 1 Phase 31

G. VH 1620E Schematic, 208, 220 or 240VAC, 3 Phase 32

H. VH 1620E Wiring Diagram, 208, 220 or 240VAC, 3 Phase 33

I. VHVA 1828E Schematic, 208, 220, or 240, 1 Phase 34

J. VHVA 1828E Wiring Diagram, 208, 220, or 240, 1 Phase 35

K. VHVA 1828E Schematic, 208, 220, or 240, 3 Phase 36

L. VHVA 1828E Wiring Diagram, 208, 220, or 240, 3 Phase 37

M. VH 1828E Schematic, 208, 220, or 240, 1 Phase 38

N. VH 1828E Wiring Diagram, 208, 220, or 240, 1 Phase 39

O. VH 1828E Schematic, 208, 220, or 240, 3 Phase 40

P. VH 1828E Wiring Diagram, 208, 220, or 240, 3 Phase 41

20 Parts Lists & Exploded Views 42

A. External Covers 42

B. Conveyor Assembly 42

C. Blower Motor Cover Assembly 43

D. Blower Assembly 43

E. VH Series Only 43

F. Plenum “Finger” Assembly 43

G. Main Power Control Box 44

H. Electric Control Box 45

I. Cool Down Thermostat, Elements, Switch & Probe 46

21 Warranty 47

4

Page 5

I. INSTALLATION INSTRUCTIONS

MODELS COVERED TOTAL KW PHASE

VH1620E 6.4 1 or 3

VHVA1620E 6.4 1 or 3

VH1828E 12.4 1 or 3

VHVA1828E 12.4 1 or 3

1. RECEIVING

Read the notice on the outside carton regarding damage in transit. "CONCEALED DAMAGE", damage

discovered after opening the crate(s), MUST be reported immediately to the carrier. The carrier will perform

an inspection of the damage and furnish forms for the consignee's claim against the carrier. Retain ALL

packaging material - including outer carton, until the inspection hasbeen completed.

Proper and secure storage facilities should be arranged for the conveyor oven(s) if necessary to protect it

from outdoor or damp conditions at all times prior toinstallation.

2. LOCATION AND MINIMUM CLEARANCES

Adequate air space must be provided for the proper venting of the rear exhaust air and provision made for

venting of cooking vapors. The ConveyorOven must be installed in awell-ventilated area.

NOTE:

Attached rear rubber bumpers must not be removedand can contact a rear wallif present.

Conveyor Ovens can be installed with "ZERO" clearances (back and sides) from combustible and noncombustible materials. (Rear rubber bumpers are the “Zero” clearance points on theback of the unit.) S e e

rating plate attached to the control box doorpanel.

The Conveyor Oven is intended for countertop mounting if mounted on the 4" legs provided. The Oven is

NOT approved for mounting on any floor. Keep the area around your conveyor oven free and clear of all

combustible materials.

3. INSTALLATION

Place the conveyor oven and parts as close to the area of final installation before uncrating. Your conveyor

oven is packed sitting on its bottom. Leave it this way until unpacked. The pallet may be left under the

conveyor oven for convenience in further handling. Unpack carefully to avoid damage to the unit. If

concealed damage is discovered, follow the instructions detailed in Section1 above.

DO NOT LIFT EXCESSIVE WEIGHT

A. Legs are shipped unattached. Make sure each leg is attached and tightened before placing the

conveyor oven in place. Each leg isadjustable to accommodate variationsin the mounting surface.

B. Using sufficient help (2 or more people), lift the conveyor oven upward and place on the countertop

surface. Lift the conveyor oven by gripping the bottom of the unit. THE FOLLOWING ITEMS ARE

NOT TO BE USED AS LIFTING "HANDLES": Side-mounted control boxes (2), removable front door

(with handles), the conveyor belt assembly, the rear fan housing assembly.

C.

THE CONVEYOR BELT ASSEMBLY IS MOUNTED BACKWARDS FOR SHIPPING. THE

CONVEYOR BELT ASSEMBLY MUST BE REMOVED AND REVERSED PRIOR TO OPERATION.

See Section 6a, b for further instructions.

D. Position the conveyor oven in its final location, maintaining the minimum clearances specified in

Section 2 above.

5

Page 6

E. Remove all loose parts and packages from the interior of the conveyor oven. The conveyor oven has

(4) air-directing "plenum fingers" in the interior cooking chamber. Check these items for proper

mounting. For further information on removal and mounting of interior panels, see Section 10,

cleaning.

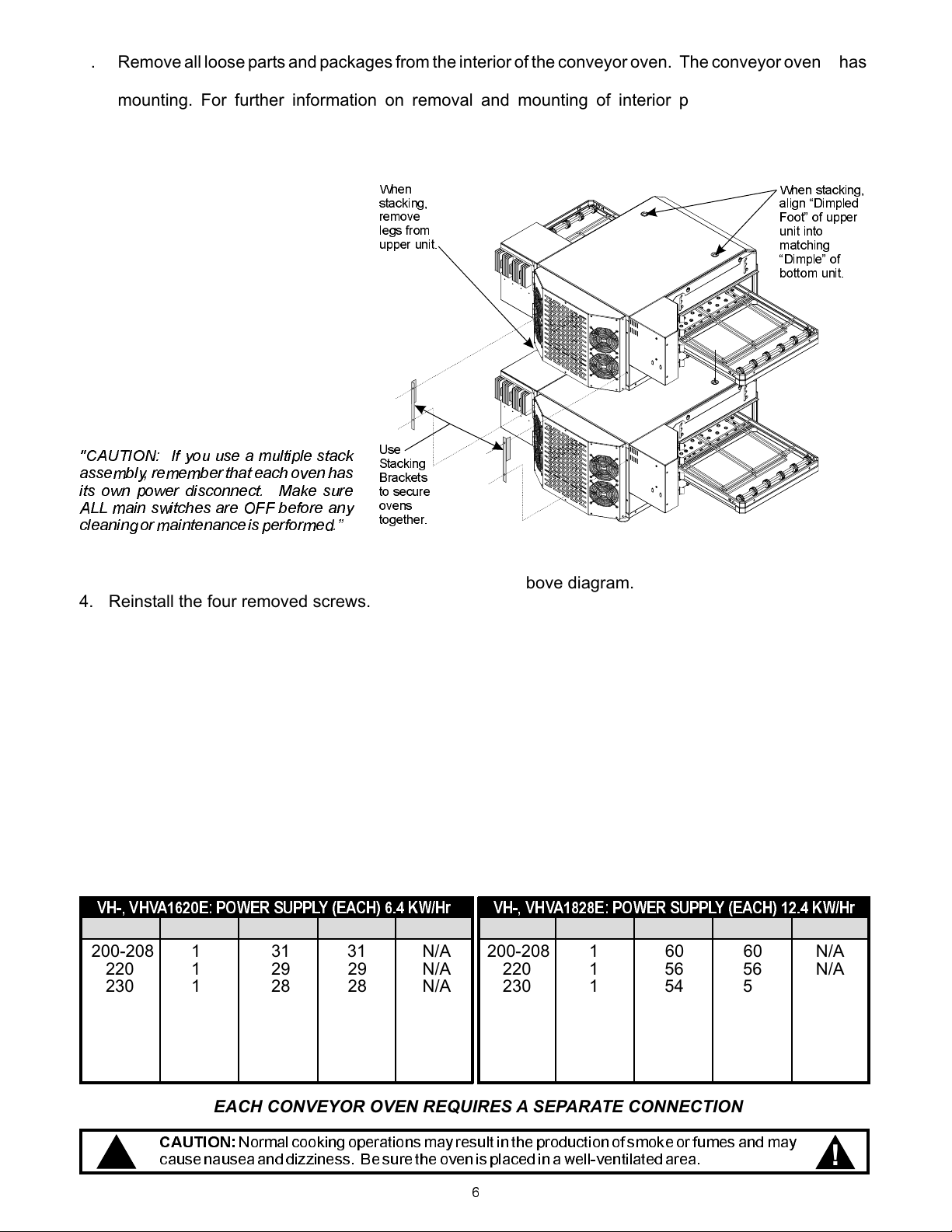

4. STACKING

Your conveyor oven(s) can be

stacked up to (3) high. Each unit is

built exactly the same, so it does not

matter in which order they are

When

stacking,

remove

legs from

upper unit.

stacked. For stacking of (2) units,

remove the legs from the second

(upper) unit prior to mounting on top

of the bottom unit. For stacking of (3)

units, it is preferable to use a

"stacking kit", which allows all

conveyor ovens to be supported by

an external framework, such as a

table, with each conveyor oven

having all legs removed.

"CAUTION: If you use a multiple stack

assembly, remember that each ovenhas

its own power disconnect. Make sure

ALL main switches are OFF before any

cleaningormaintenanceisperformed.

Use

Stacking

Brackets

to secure

ovens

together.

1. Remove two bottom screws from the top oven rear panel.

2. Remove two top screws from the bottom oven rear panel.

3. Install the right and left stacking brackets as shown in above diagram.

4. Reinstall the four removed screws.

When stacking,

align Dimpled

Foot of upper

unit into

matching

Dimple of

bottom unit.

5. ELECTRICAL CONNECTIONS

General Instructions

a

) Only use copper conductor wires rated at 90°C suitably sized for the electric current drawn.

b) Dual Air Model 1828E ovens are constructed for permanent connections - no power cord is supplied.

c) Dual Air Model 1620E ovens are supplied with a flexible power cord and plug.

d) Make sure the electrical supply corresponds with that specified on the rating plate.

e) Only a licensed electrician should make the electrical connections.

f) Proper connections are shown on the wiring diagrams as well as the rating plate.

g) Wiring diagrams are located in the control box containing the Main Switch (green rocker).

h) When installed, the unit must be electrically grounded in accordance with the local codes and/or the

latest edition of the national Electrical Code ANSI/NFPA No. 70 in the USA or Canadian Electrical

Code, CSA Standard C22.1, Part 1 in Canada.

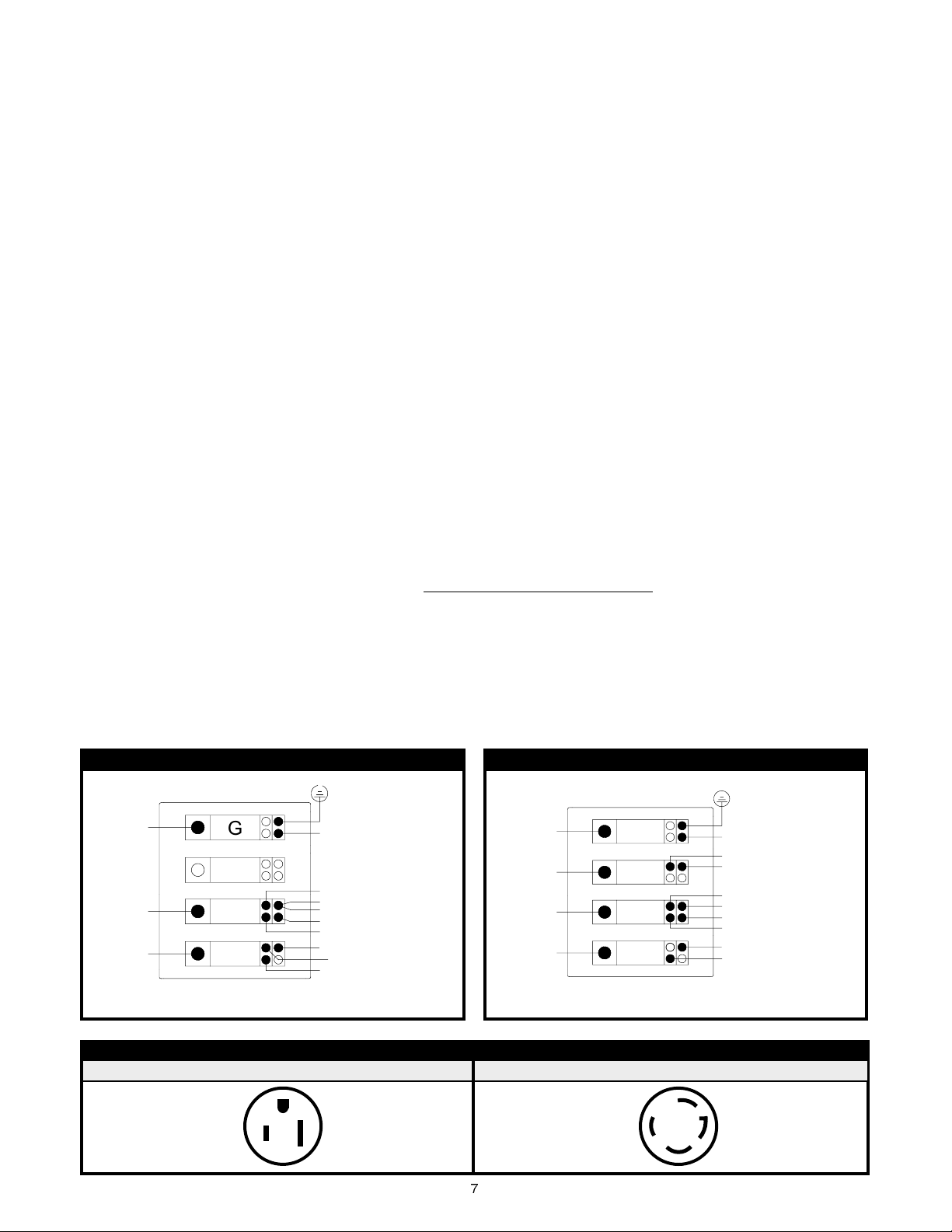

VH-, VHVA1620E: POWER SUPPLY (EACH) 6.4 KW/Hr VH-, VHVA1828E: POWER SUPPLY (EACH) 12.4 KW/Hr

Volts Phase L1 L2 L3 Volts Phase L1 L2 L3

200-208 1 31 31 N/A 200-208 1 60 60 N/A

220 1 29 29 N/A 220 1 56 56 N/A

230 1 28 28 N/A 230 1 54 54 N/A

240 1 27 27 N/A 240 1 52 52 N/A

200-208 3 14 21 19 200-208 3 27 40 38

220 3 13 18 17 220 3 25 38 36

230 3 12 17 16 230 3 24 36 34

240 3 12 18 17 240 3 23 35 33

EACH CONVEYOR OVEN REQUIRES A SEPARATE CONNECTION

CAUTION:

!

causenauseaanddizziness. Besure the oven is placedina well-ventilatedarea.

Normalcooking operations may resultin the productionof smoke or fumes and may

!

6

Page 7

Field Connections

NOTE: VERIFY THAT INPUT POWER MATCHES THE OVEN POWER REQUIREMENTS STATED

ON THE RATING PLATE, WHICH IS LOCATED ON THE POWER CONTROL BOX.

IF INPUT VOLTAGE DOES NOT MATCH OVEN VOLTAGE REQUIREMENTS, THE CORRECT

CONVEYOR OVEN MUST BE INSTALLED. THE CONVEYOR OVEN CANNOT BE MODIFIED IN THE

FIELD TO MATCH INPUT POWER.

CAUTION: VERIFY VOLTAGE OF EACH LEG. IF ANY LEG HAS A

FOR 3 PHASE UNITS ONLY:

VOLTAGE GREATER THAN 240V THIS LEG MUST BE CONNECTED TO L-3 ON THE POWER

DISTRIBUTION BLOCK.

FOR DUAL AIR MODELS VH1620E, VHVA1620E:

These units are supplied with a flexible power cord, according to the specification placed with the

original order, which specified either single-phase or three-phase operation. No internal field

connection is necessary. All internal connections are complete. Connect the power cord to the

proper power receptacle. (see diagram below).

Note: If a different power cord is required than supplied, the correct power cord must be obtained

from a factory authorized service agent. Only an authorized service agent is to replace a power

cord.

FOR DUAL AIR MODELS VH1828E, VHVA1828E:

a)

Remove the cover from the Power Distribution Box Panel ( on right side when

under the control box

facing front of unit).

b)

Locate the 4-pole Power Distribution Terminal Block mounted in the Power Distribution Box.

c)

Install the proper strain relief for the utilizing the knock-out hole

PERMANENT CONNECTION

provided. The strain relief should be securely fastened.

d)

Supply the proper conduit to the conveyor oven and connect through the strain relief. Connect

properly-sized, copper-only conductorwires (rated 90°C) to the Power DistributionTerminal Block in

accordance with the schematic shown on the rating plate, as well as the wiring diagram provided.

NOTE: For three-phase connections, if any “High Voltage Leg” conductor is present, it be

mounted to L3 Replace thecover and fasten securely with removedscrews.

ONLY.

MUST

SINGLE-PHASE CONNECTION

G

G4

L3

L2

5

R (BROWN)

L2

L2

4

A

FIELD WIRING

L2

L1

SERVICE CONNECTIONS

6-50P

E(BROWN)

FACTORY WIRING

TO INTERNAL CIRCUITS

NEMA SPECS.

7

THREE PHASE CONNECTION

FIELD WIRING

G

L3

L2

L1

G4

E(BROWN)

R (BROWN)

L2

5

L2

L2

4

A

SERVICE CONNECTIONS

1620E 3 PHASE1620E 1 PHASE

L15-30P

FACTORY WIRING

TO INTERNAL CIRCUITS

Page 8

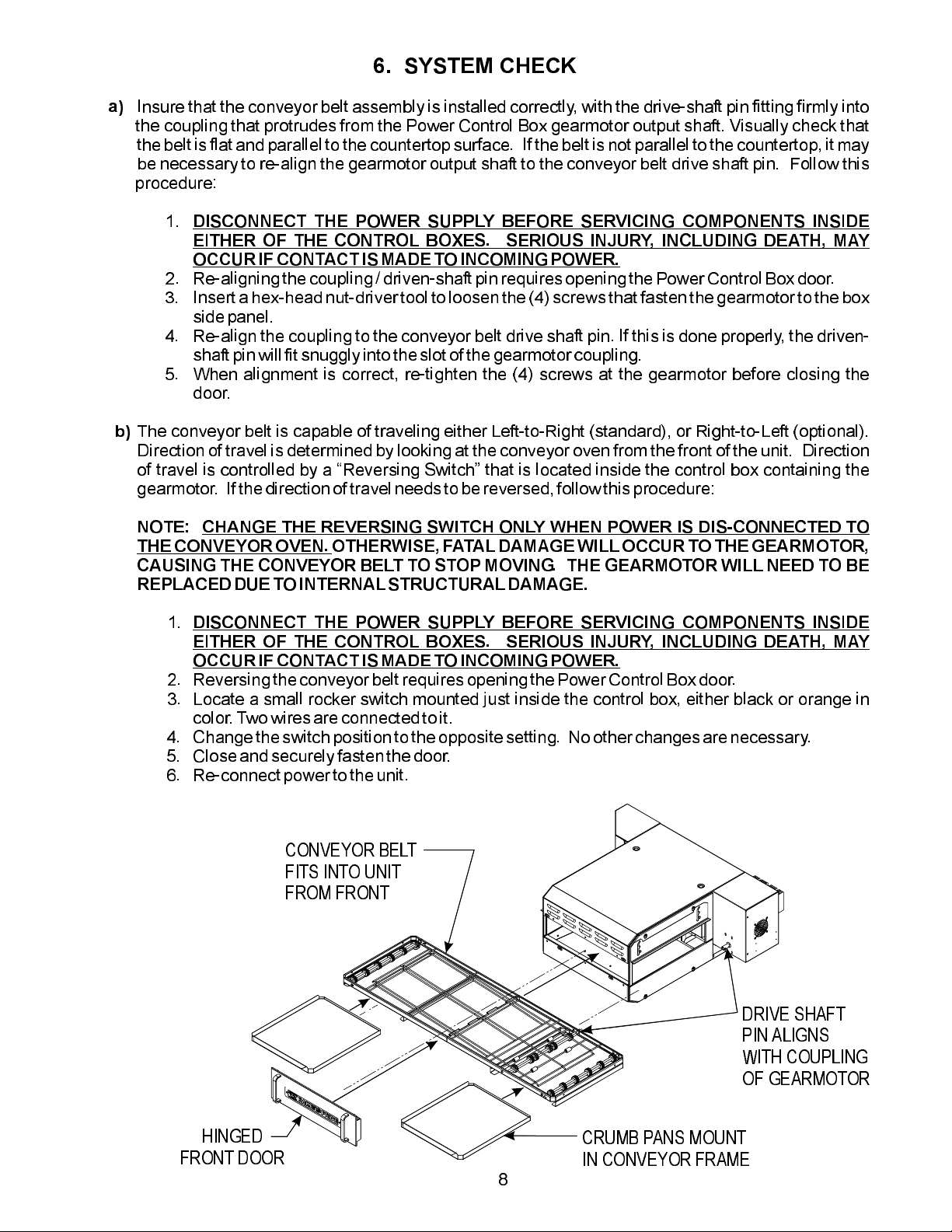

6. SYSTEM CHECK

a)

Insure that the conveyor belt assembly is installed correctly, with the drive-shaft pin fitting firmly into

the coupling that protrudes from the Power Control Box gearmotor output shaft. Visually check that

the belt is flatand parallelto thecountertop surface. If the beltis not parallel to the countertop, it may

be necessary to re-align the gearmotor output shaft to the conveyor belt drive shaft pin. Follow this

procedure:

DISCONNECT THE POWER SUPPLY BEFORE SERVICING COMPONENTS INSIDE

1.

EITHER OF THE CONTROL BOXES. SERIOUS INJURY, INCLUDING DEATH, MAY

OCCURIF CONTACTIS MADE TOINCOMING POWER.

2. Re-aligningthe coupling/ driven-shaft pin requiresopening thePower Control Boxdoor.

3. Inserta hex-head nut-drivertool to loosen the (4) screws that fasten the gearmotorto the box

sidepanel.

4. Re-align the coupling to the conveyor belt drive shaft pin. If this is done properly, the driven-

shaftpin will fit snuggly intothe slot of the gearmotorcoupling.

5. When alignment is correct, re-tighten the (4) screws at the gearmotor before closing the

door.

b)

The conveyor belt is capable of traveling either Left-to-Right (standard), or Right-to-Left (optional).

Direction of travel is determined by looking at the conveyor oven from the front of the unit. Direction

of travel is controlled by a Reversing Switch that is located inside the control box containing the

gearmotor. If the directionof travel needsto bereversed, follow thisprocedure:

NOTE:

THE CONVEYOR OVEN.

CAUSING THE CONVEYOR BELT TO STOP MOVING. THE GEARMOTOR WILL NEED TO BE

REPLACEDDUE TO INTERNALSTRUCTURAL DAMAGE.

CHANGE THE REVERSING SWITCH ONLY WHEN POWER IS DIS-CONNECTED TO

OTHERWISE,FATALDAMAGE WILL OCCUR TO THE GEARMOTOR,

DISCONNECT THE POWER SUPPLY BEFORE SERVICING COMPONENTS INSIDE

1.

EITHER OF THE CONTROL BOXES. SERIOUS INJURY, INCLUDING DEATH, MAY

OCCURIF CONTACTIS MADE TOINCOMING POWER.

2. Reversing theconveyor belt requiresopening the PowerControl Boxdoor.

3. Locate a small rocker switch mounted just inside the control box, either black or orange in

color. Twowires areconnected to it.

4. Changethe switch positionto theopposite setting. No other changesare necessary.

5. Close and securelyfasten the door.

6. Re-connectpower to theunit.

CONVEYOR BELT

FITS INTO UNIT

FROM FRONT

HINGED

FRONT DOOR

DRIVE SHAFT

PIN ALIGNS

WITH COUPLING

OF GEARMOTOR

CRUMB PANS MOUNT

IN CONVEYOR FRAME

8

Page 9

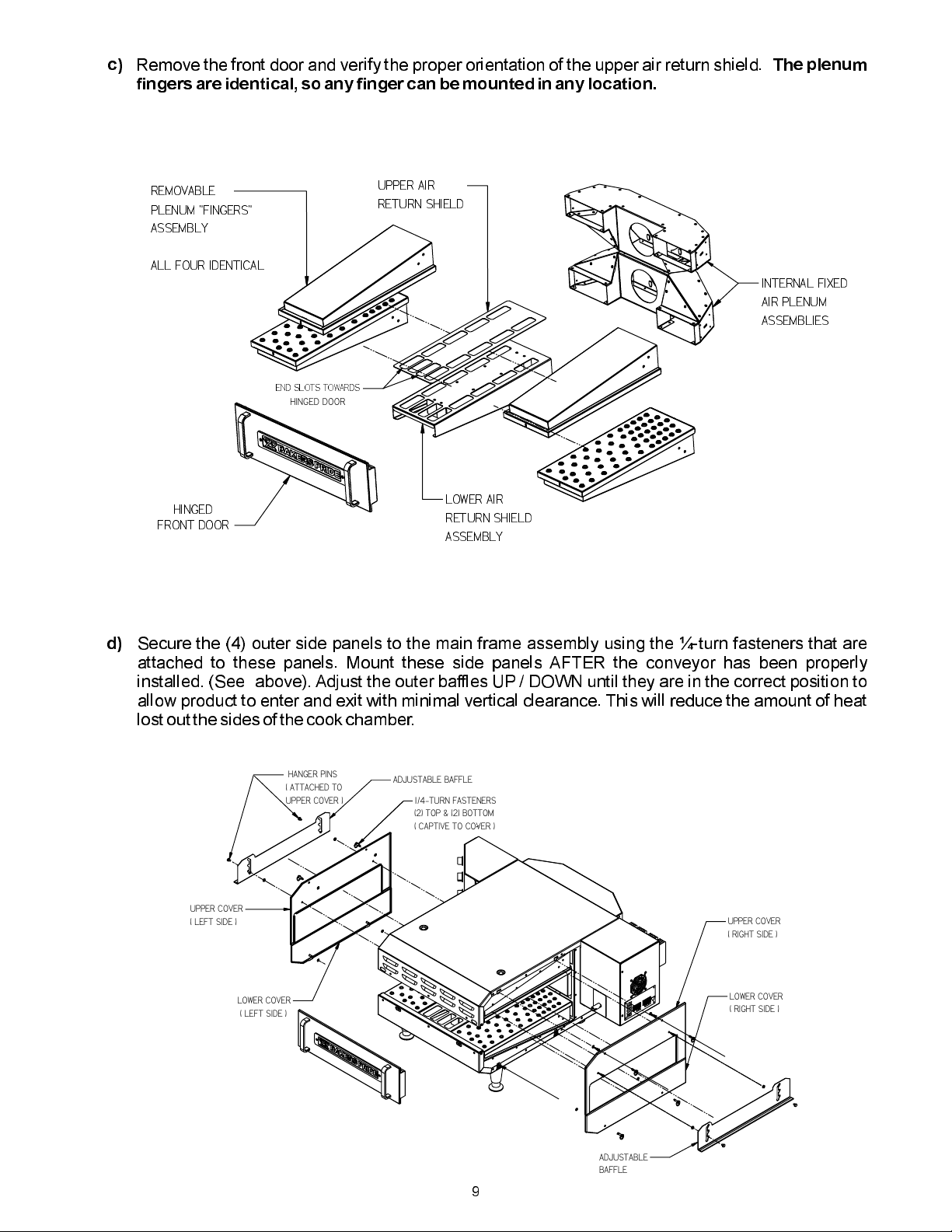

Remove the front door and verify the proper orientation of the upper air return shield.

c) The plenum

fingersare identical,so any fingercan be mountedin anylocation.

REMOVABLE

PLENUM "FINGERS"

ASSEMBLY

ALL FOUR IDENTICAL

HINGED

FRONT DOOR

UPPER AIR

RETURN SHIELD

INTERNAL FIXED

AIR PLENUM

ASSEMBLIES

END SLOTS TOWARDS

HINGED DOOR

LOWER AIR

RETURN SHIELD

ASSEMBLY

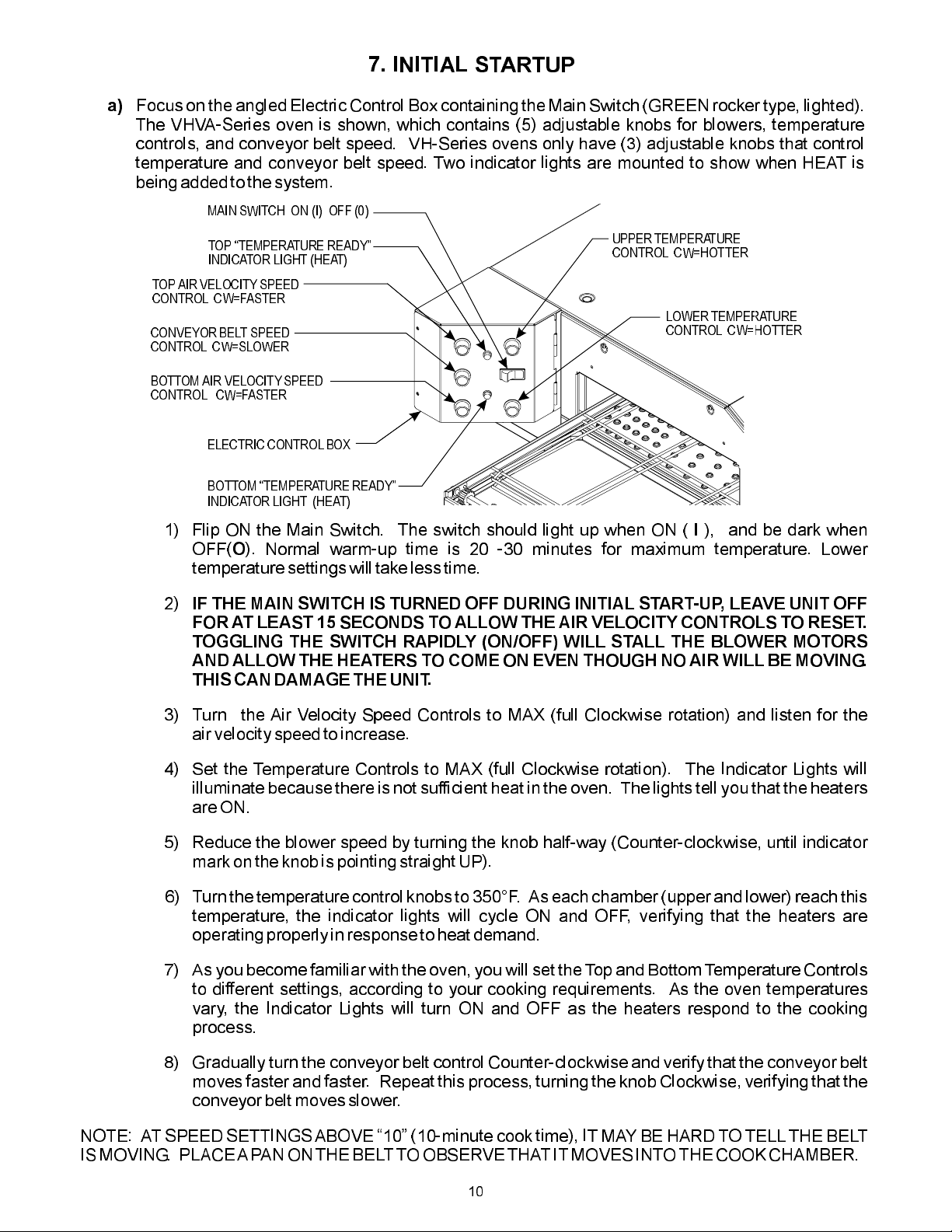

d)

Secure the (4) outer side panels to the main frame assembly using the ¼-turn fasteners that are

attached to these panels. Mount these side panels AFTER the conveyor has been properly

installed. (See above).Adjust the outer baffles UP / DOWN until they are in the correct position to

allow product to enter and exit with minimal vertical clearance. This will reduce the amount of heat

lostout thesides of the cook chamber.

HANGER PINS

(ATTACHEDTO

UPPER COVER )

UPPER COVER

(LEFTSIDE)

LOWER COVER

(LEFTSIDE)

ADJUSTABLE BAFFLE

1/4-TURN FASTENERS

(2) TOP & (2) BOTTOM

( CAPTIVE T O COVER )

UPPER COVER

( RIGHT SIDE )

LOWER COVER

( RIGHT SIDE )

ADJUSTABLE

BAFFLE

9

Page 10

7. INITIAL STARTUP

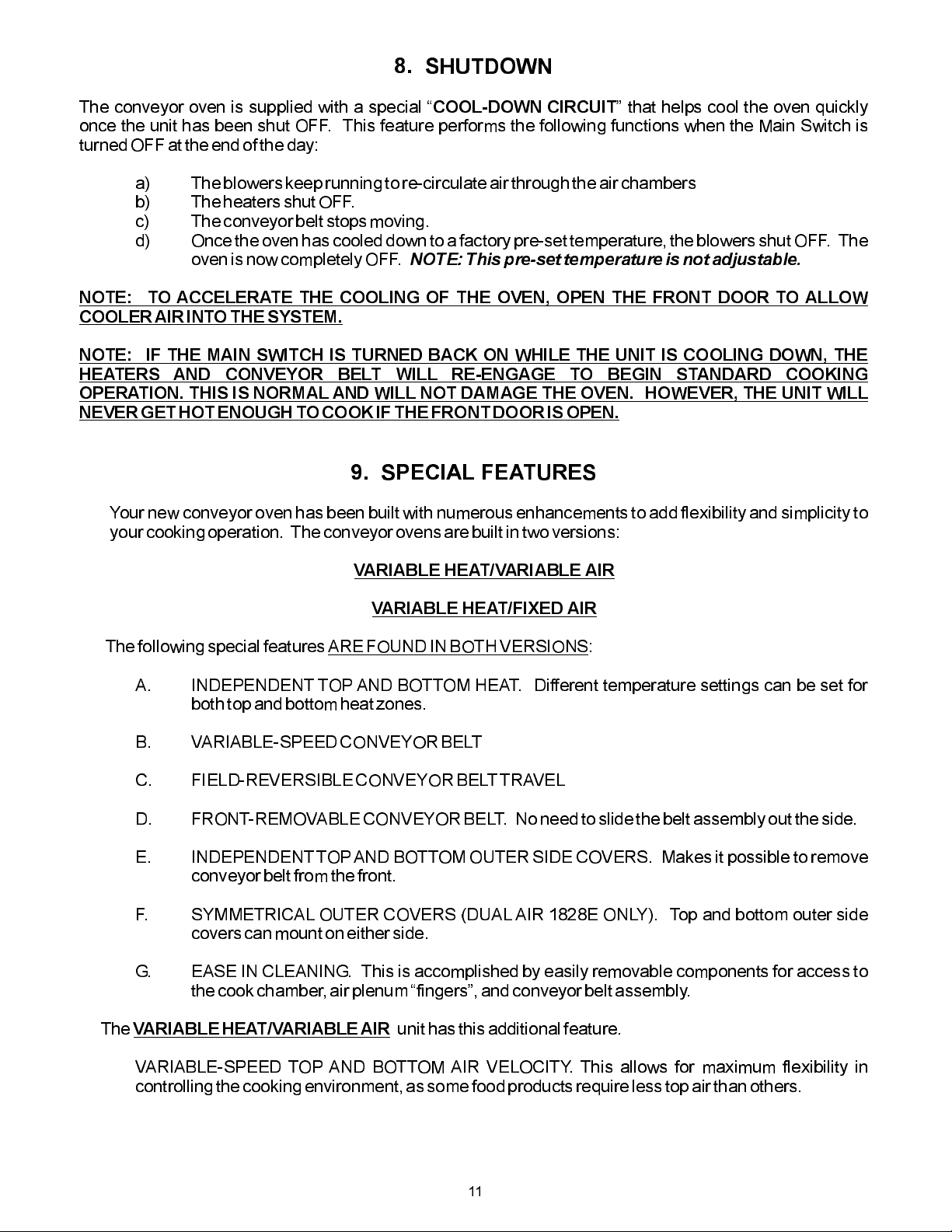

a)

Focus on the angled Electric Control Box containingthe Main Switch (GREEN rocker type, lighted).

The VHVA-Series oven is shown, which contains (5) adjustable knobs for blowers, temperature

controls, and conveyor belt speed. VH-Series ovens only have (3) adjustable knobs that control

temperature and conveyor belt speed. Two indicator lights are mounted to show when HEAT is

beingadded tothe system.

MAIN SWITCH ON (I) OFF (0)

TOP TEMPERATURE READY

INDICATOR LIGHT (HEAT)

TOPAIR VELOCITY SPEED

CONTROL CW=FASTER

CONVEYOR BELTSPEED

CONTROL CW=SLOWER

BOTTOMAIR VELOCITYSPEED

CONTROL CW=FASTER

ELECTRIC CONTROLBOX

BOTTOM TEMPERATURE READY

INDICATOR LIGHT (HEAT)

1) Flip ON the Main Switch. The switch should light up when ON ( ), and be dark when

O

OFF( ). Normal warm-up time is 20 -30 minutes for maximum temperature. Lower

UPPER TEMPERATURE

CONTROL CW=HOTTER

LOWER TEMPERATURE

CONTROL CW=HOTTER

I

temperaturesettings will takeless time.

IF THE MAIN SWITCH IS TURNED OFF DURING INITIAL START-UP, LEAVE UNIT OFF

2)

FOR AT LEAST 15 SECONDS TOALLOW THE AIR VELOCITY CONTROLS TO RESET.

TOGGLING THE SWITCH RAPIDLY (ON/OFF) WILL STALL THE BLOWER MOTORS

AND ALLOW THE HEATERS TO COME ON EVEN THOUGH NO AIR WILL BE MOVING.

THISCAN DAMAGETHE UNIT.

3) Turn the Air Velocity Speed Controls to MAX (full Clockwise rotation) and listen for the

airvelocity speedto increase.

4) Set the Temperature Controls to MAX (full Clockwise rotation). The Indicator Lights will

illuminate because there is not sufficient heat in the oven. The lights tell you that the heaters

are ON.

5) Reduce the blower speed by turning the knob half-way (Counter-clockwise, until indicator

markon theknob is pointingstraight UP).

6) Turnthe temperature control knobs to 350°F. Aseach chamber (upper andlower) reachthis

temperature, the indicator lights will cycle ON and OFF, verifying that the heaters are

operatingproperly in responseto heatdemand.

7) As you become familiar with the oven, you will set the Topand BottomTemperature Controls

to different settings, according to your cooking requirements. As the oven temperatures

vary, the Indicator Lights will turn ON and OFF as the heaters respond to the cooking

process.

) Gradually turn the conveyor belt control Counter-clockwise and verify that the conveyor belt

8

moves faster and faster. Repeat this process, turning the knob Clockwise, verifying that the

conveyorbelt moves slower.

NOTE: AT SPEED SETTINGSABOVE 10 (10-minute cook time), IT MAYBE HARD TOTELL THE BELT

IS MOVING. PLACEAPAN ONTHEBELTTOOBSERVETHAT IT MOVESINTOTHE COOK CHAMBER.

10

Page 11

8. SHUTDOWN

The conveyor oven is supplied with a special that helps cool the oven quickly

once the unit has been shut OFF. This feature performs the following functions when the Main Switch is

turnedOFF atthe end of the day:

a) Theblowers keeprunning to re-circulateair through theair chambers

b) Theheaters shutOFF.

c) The conveyorbelt stopsmoving.

d) Once the oven has cooled down to a factory pre-set temperature,the blowersshut OFF. The

ovenis nowcompletely OFF.

NOTE: TO ACCELERATE THE COOLING OF THE OVEN, OPEN THE FRONT DOOR TO ALLOW

COOLERAIR INTOTHE SYSTEM.

NOTE: IF THE MAIN SWITCH IS TURNED BACK ON WHILE THE UNIT IS COOLING DOWN, THE

HEATERS AND CONVEYOR BELT WILL RE-ENGAGE TO BEGIN STANDARD COOKING

OPERATION. THIS IS NORMAL AND WILL NOT DAMAGE THE OVEN. HOWEVER, THE UNIT WILL

NEVERGET HOT ENOUGHTO COOK IFTHE FRONTDOOR IS OPEN.

COOL-DOWN CIRCUIT

NOTE:This pre-settemperatureis notadjustable.

9. SPECIAL FEATURES

Your new conveyor oven has been built with numerous enhancementsto add flexibility and simplicity to

yourcooking operation. The conveyor ovensare built in two versions:

VARIABLE HEAT/VARIABLE AIR

VARIABLE HEAT/FIXED AIR

Thefollowing special features :

A. INDEPENDENT TOP AND BOTTOM HEAT. Different temperature settings can be set for

bothtop andbottom heat zones.

B. VARIABLE-SPEEDCONVEYOR BELT

C. FIELD-REVERSIBLECONVEYOR BELTTRAVEL

D. FRONT-REMOVABLECONVEYOR BELT. No need toslide thebelt assembly outthe side.

E. INDEPENDENTTOPAND BOTTOMOUTER SIDE COVERS. Makes it possible to remove

conveyorbelt from the front.

F. SYMMETRICAL OUTER COVERS (DUAL AIR 1828E ONLY). Top and bottom outer side

coverscan mounton either side.

G. EASE IN CLEANING. This is accomplished by easily removable components for access to

thecook chamber, air plenumfingers, and conveyorbelt assembly.

AREFOUND IN BOTH VERSIONS

VARIABLE HEAT/VARIABLE AIR

The unithas this additionalfeature.

VARIABLE-SPEED TOP AND BOTTOM AIR VELOCITY. This allows for maximum flexibility in

controllingthe cooking environment,as some food products require lesstop airthan others.

11

Page 12

10. CLEANING

CAUTION: THE CONVEYOROVEN CONTAINS ELECTRICALCOMPONENTS. TURN OFFTHE OVEN

ANDDISCONNECT THE POWERBEFORE CLEANING BEGINS.

DONOT CLEANTHE CONVEYOR OVENWITHAWATER JET.

WEEKLYCLEANING:

Oven Exterior: CLEAN ONLY WHEN THE OVEN IS COLD.

of stainless steel.

Deposits of baked-on splatter and grease, or discoloration may be removed by using any commercial

cleaner recommended for stainless steel. Always rub with the grains and apply very light pressure.

Rinsewith aMOIST,NOT SOAKING, cloth.

Oven Interior: CLEAN ONLY WHEN THE OVEN IS COLD.

(cookchamber) is of aluminized steel,and requires carenot toover-clean and scratchthe surface.

CAUTION: DO NOT USE OVEN CLEANERS, CAUSTIC SOLUTIONS OR MECHANICAL MEANS

BECAUSETHESE WILLDAMAGE THE ALUMINIZEDSURFACES

and cleaners that meet national and/or local codes. Clean the walls of the cook chamber with a mild

soapand watersolution.

To clean the interior of the conveyor oven, it is necessary to remove the front door, the (4) outer sides

panels,the conveyor beltassembly, andthe (4) air plenum fingers.(See page 9.)

ConveyorBeltAssembly

1. Remove crumb pans.

2. Remove plenum fingerassembliesand disassemblefor cleaning.

Removeconveyor belt assembly.

Useonly adamp cloth.

Standard constructionof the exterioris

Standard construction of the interior

. Use only thedetergent solutions

1. CONVEYOR BELT STILL MOUNTED IN OVEN:

NOTE: USE CARE IF CLEANING THE CONVEYOR BELT WHILE IT IS STILL MOUNTED IN

THE OVEN. EXCESSIVE FORCE MAY PRODUCE AN OVERLOAD CONDITION THAT

COULD DAMAGE THE GEARMOTOR AND CAUSE THE OVEN TO BE RENDERED UN-

USABLE.

Using a plastic abrasive pad, wipe the conveyor belt in a back-and-forth motion to remove

baked-on product. Wipe clean with a hot, damp cloth.

2. CONVEYOR BELT REMOVED FROM OVEN:

Using a plastic abrasive pad, wipe the conveyor belt in a back-and-forth motion to remove

baked-on product. Wipe clean with a hot, damp cloth.

NOTE: IT IS NOT NECESSARY TO REMOVE THE BELT FROM THE FRAME ASSEMBLY FOR

CLEANING.

3. Check the belt links for any sign of damage. If any links are bent, use a needle-nose pliers to

repairprior to re-installationinto the unit.

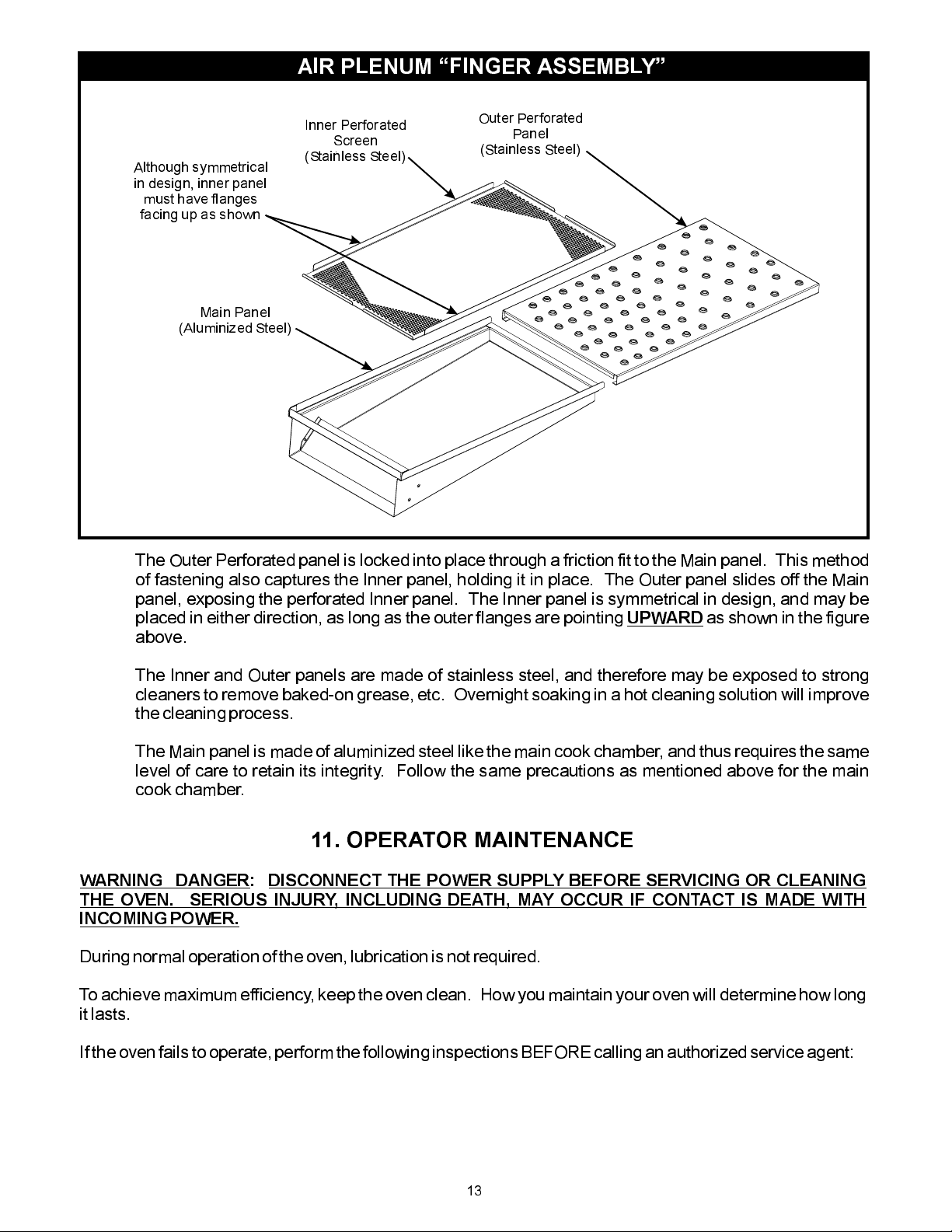

Plenum Fingers

The conveyor oven contains (4) plenum fingers that direct air onto the product surface while

cooking. This 3-piece assemblycomes apart forcleaning, as shownbelow:

12

Page 13

AIR PLENUM FINGER ASSEMBLY

Outer Perforated

Panel

(Stainless Steel)

Although symmetrical

in design, inner panel

must have flanges

facing up as shown

Main Panel

(Aluminized Steel)

Inner Perforated

Screen

(Stainless Steel)

The Outer Perforated panel is locked into place through a friction fit to the Main panel. This method

of fastening also captures the Inner panel, holding it in place. The Outer panel slides off the Main

panel, exposing the perforated Inner panel. The Inner panel is symmetrical in design, and may be

placed in either direction, as long as the outer flanges are pointing as shown in the figure

UPWARD

above.

The Inner and Outer panels are made of stainless steel, and therefore may be exposed to strong

cleaners to remove baked-on grease, etc. Overnight soaking in a hot cleaning solution will improve

thecleaning process.

The Main panel is made of aluminized steel like the main cook chamber, and thus requires the same

level of care to retain its integrity. Follow the same precautions as mentioned above for the main

cookchamber.

11. OPERATOR MAINTENANCE

WARNING DANGER DISCONNECT THE POWER SUPPLY BEFORE SERVICING OR CLEANING

THE OVEN. SERIOUS INJURY, INCLUDING DEATH, MAY OCCUR IF CONTACT IS MADE WITH

INCOMINGPOWER.

Duringnormal operation of the oven,lubrication is notrequired.

To achieve maximum efficiency,keep the oven clean. How you maintainyour oven will determine how long

it lasts.

If the ovenfails to operate, perform thefollowing inspections BEFOREcallingan authorizedservice agent:

:

13

Page 14

1. Check to see ifthe maincircuit breaker isON atthe breaker panel.

.

2. Check the (2) 5-amp fuses located in the bottom of the Power Control Box

IF FUSES ARE BAD, REPLACE ONLY WITH IDENTICAL FUSES. DO NOT

SUBSTITUTE HIGHER VALUE FUSES, AS THIS MAY NULLIFY NEEDED PROTECTION

FORTHE INTERNALELECTRICAL COMPONENTS.

3. Check that the Main Switch is ON. If operating properly, the rocker switch will be lighted

whenON.

4. Check the setting of the temperature control thermostats (knobs). If operating properly,they

will activate theamber indicatorlightsas youturn theknobs backand forth, calling for heat. It

is very unlikelythat the lightwill burnout.

5. If there is noair blowing,check the following:

i. RESET

ii.

DUALAIR MODELVHVA-SERIES

for at east15 seconds and then turning it back ON. This resets the blower speed

controls. If this is not successful, turn off the wall circuit breaker for one minute and

thenturn iton again.

DUAL AIR MODEL VH-SERIES WARNING

section, open the Power Control Box and locate the overload relay (above

gearmotor). . TrytheMain Switchagain.

1. NOTE:

PUSHIN THERESET BUTTON

The Overload Relay is both a current limiting and a thermal

device

overload relay shuts the motor(s) OFF if there is excessive current going to

the motor(s), or if excessive heat builds up in the overload relay due to an

overload condition. Because it takes time for the relay to cool down, do not

assume that there is another problem IF pushing the RESET button doesn't

accomplish the task Both settings,

notoverheated

, meaning that if one or both of the blower motors get jammed, the

, must becorrect for properoperation.

: theunit by turningthe MainSwitch OFF

: Observing the at the beginning of this

RESET button pushed IN & overload

CAUTION

:

If the conveyor belt does not move, check to see that the coupling setscrew is tight on the

6.

gearmotoroutput shaft.

If the oven still does not operate, turn OFF the Main Switch and disconnect the power supply to the

unit(if possible). Contactthe factory, factory representative,or an authorized serviceagency.

ALL SERVICING SHOULD BE PERFORMED ONLY BY A FACTORY AUTHORIZED SERVICE

TECHNICIANORAGENT

.

12. RATING PLATE

A copy of the rating plate is shown here for reference.

MODEL VH-SERIES MODEL VHVA-SERIES

14

Page 15

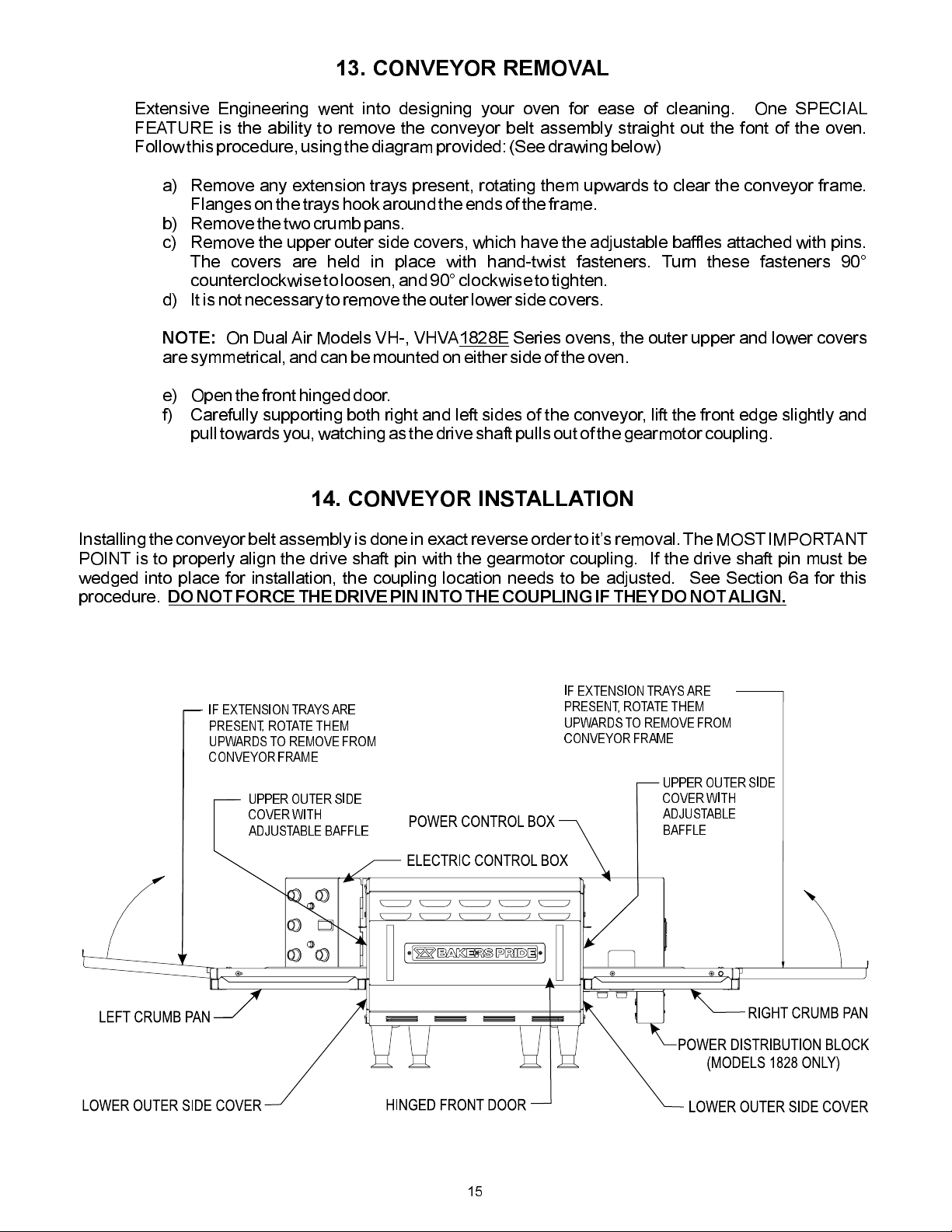

13. CONVEYOR REMOVAL

Extensive Engineering went into designing your oven for ease of cleaning. One SPECIAL

FEATURE is the ability to remove the conveyor belt assembly straight out the font of the oven.

Followthis procedure,usingthe diagramprovided: (See drawingbelow)

a) Remove any extension trays present, rotating them upwards to clear the conveyor frame.

Flangeson thetrays hook aroundthe ends of the frame.

b) Remove thetwo crumb pans.

c) Remove the upper outer side covers, which have the adjustable baffles attached with pins.

The covers are held in place with hand-twist fasteners. Turn these fasteners 90°

counterclockwiseto loosen, and90° clockwiseto tighten.

d) It isnot necessaryto remove theouter lower sidecovers.

NOTE:

On Dual Air Models VH-, VHVA Series ovens, the outer upper and lower covers

1828E

aresymmetrical, and can be mountedon either sideof theoven.

e) Open thefront hinged door.

f) Carefully supporting both right and left sides of the conveyor, lift the front edge slightly and

pulltowards you,watching as thedrive shaft pullsout ofthe gearmotor coupling.

14. CONVEYOR INSTALLATION

Installingthe conveyorbelt assemblyis done in exact reverse order to its removal. The MOST IMPORTANT

POINT is to properly align the drive shaft pin with the gearmotor coupling. If the drive shaft pin must be

wedged into place for installation, the coupling location needs to be adjusted. See Section 6a for this

procedure.

DONOT FORCETHE DRIVE PININTO THE COUPLINGIF THEY DO NOTALIGN.

IF EXTENSION TRAYSARE

IF EXTENSION TRAYSARE

PRESENT, ROTATE THEM

UPWARDSTO REMOVE FROM

CONVEYOR FRAME

UPPER OUTER SIDE

COVER WITH

ADJUSTABLE BAFFLE

PRESENT, ROTATE THEM

UPWARDSTO REMOVE FROM

CONVEYOR FRAME

UPPER OUTER SIDE

COVER WITH

ADJUSTABLE

BAFFLE

15

Page 16

15. CONVEYOR BELT SPEED CALIBRATION

The conveyor belt requires calibration to properly align the speed control knob on the Electric Control Box.

Calibration is done by timing the belt as it passes between two timing marks located on the conveyor frame.

This method will work regardless of belt travel direction. Follow the instructions below.

Idler Shaft

Belt Travel

(Standard)

Timing Marks

on Conveyor Frame

Conveyor Frame

A. Remove the adjustment knob of the conveyor belt speed control (see page 10) using a small,

standard screwdriver to loosen the setscrew.

B. Locate the two timing marks as shown above. For the Dual Air VH-, VHVA1620E series, the marks

are 5 inches apart; for the Dual Air VH-, VHVA1828E the marks are 7 inches apart. IF the timing

marks are NOT present, use ablack markingpen to mark the frame in the same manner.

C. These distances represent exactly ¼ of the distance of the cook chamber: ¼ x 20” cook chamber

(DualAir 1620E) = 5”; ¼ x28” cook chamber (DualAir 1828E)= 7”.

D. With this 1:4 ratio,it is possible to calibrate the belt speed. For example:

1. For a cook time of 1 minute, the time required to pass between timing marks would be: 60

seconds / 4 = 15 seconds. If the belt passes from one mark to the next in 15 seconds, this is

exactly the same as a 1-minute cook time.

2. For a cook time of 6 minutes, the required time to pass between timing marks would be: 6

minutes x 60 seconds / 4. This equals 360 seconds / 4 = 90 seconds between marks. The

belt needs to take 90 seconds (1-1/2 minutes) to move from one mark to the next to equal a

6-minute cook time.

E. Using a black marking pen, mark any belt link near the outer edge. Using a stopwatch, check the

time it takes for this link to move between the timing marks. Repeat this procedure several times

until the distance is traveled in 90 seconds (recommended calibration interval), which equals a 6minute cook time.

F. Now that the belt is moving at this calibrated speed, CAREFULLY re-mount the adjustment knob

onto the belt conveyor speed control shaft, and tighten the setscrew so that the KNOB indicating

mark is pointing at the number “6” on the surrounding label.

G. The conveyor belt is now calibrated for ALL ranges as indicated on the label. The label numbers are

COOK TIME in MINUTES. Simply point the knob indicating line to the desired cook time.

NOTE:

timing results using the method described.

H Cook/Bake Time is not the same as time of delivery. is the actual time required

for the first item, leading edge to trailing edge. is leading edge to leading

edge. For example, the for a 16” pizza with a 6 minute (using the

DualAir 1828 conveyor) is 9.4 minutes.

The label COOK TIME marks are close approximates, and may vary slightly from actual

Time of Delivery Bake/Cook Time

5” (1620E), or 7” (1828E)

Time of Delivery

Cook/Bake Time

16

Page 17

Time will be the same for any size product.

Time of delivery will be different for

different sizes of products.

Bake Time

Leading Edge of Product

Time of Delivery (TOD) = X (Bake Chamber Length + Product Diameter)

Bake Time

Bake Chamber Length

Trailing Edge of Product

Time of Delivery

Example 1:

Bakers Pride , 6 Minute Bake Time, 16” pizza (time required for the 1st item):

Dual Air Model 1620

(TOD) = X (20 + 16) = 10.8 Minutes

6 Minutes

20”

Example 2:

Dual Air Model 1828Bakers Pride , 6 Minute Bake Time, 16” pizza (time required for the 1st item):

(TOD) = X (28 + 16) = 9.4 Minutes

6 Minutes

28”

I. To calculate production capacity per conveyor, per hour use the following formula.

Oven Capacity/Hour (OCH) =X

Bake Chamber Length X Bake Chamber Depth 60 Min/Hr

Product Diameter Bake Time

2

Example 1:

Dual Air Model 1620Bakers Pride , 6 Minute Pizza, 16” Pizza

OCH = X = 12.5

(20 X 16)

2

16

60

6

Example 2:

Dual Air Model 1828Bakers Pride , 6 Minute Pizza, 16” Pizza

OCH = X = 19.7

(28 X 18)

2

16

60

6

17

Page 18

16. TROUBLESHOOTING GUIDE

THE PROBLEM THE CAUSE THE SOLUTION

Oven doesn't start

Conveyor belt

doesn't move, or it

moves unevenly.

Unexpected speed

changes.

Blown fuse(s)

Main Switch OFF Turn ON

Main Switch broken

Main circuit breaker OFF

Power cord disconnected (1620E only)

Power connections broken

Conveyor belt running backwards

Belt loose. Drive sprockets not engaging

belt links.

Belt master link(s) missing, broken, or

installed incorrectly.

Conveyor belt installed backwards or

upside down

Speed setting very high (long cook time)

Speed knob loose

Conveyor drive shaft not engaged to

coupling

Drive coupling loose

Drive coupling missing

Conveyor belt jammed

Drive shaft pin missing

Drive sprockets worn out, missing, or mis-

aligned

Conveyor gearmotor failed

Replace fuse with identical type - 5 amp

Replace

Turn ON

Plug cord in (1620E only)

Check power distribution terminal block

below Power Control Box

CAUTION: TURN OFF POWER

Power Control Box, and flip Reversing

Switch to opposite position.

Tighten conveyor belt using adjustable

tensioner at one end of belt frame.

Verify that all sprockets are tight and

properly aligned with belt "segments".

If belt still too loose, remove one belt link.

Install master link(s) properly

Proper belt orientation is for outer belt

loops to be facing in oppositie direction of

travel, and the outer loops to be on top of

the trailing link.

Adjust speed to FAST to verify if knob is

tight and potentiometer working correctly

Tighten setscrew in knob on pot shaft.

NOTE:

mark on label to indicate cook time in

minutes. This may require calibration of

belt movement using timing marks on

conveyor frame.

Section 15.

Align and engage shaft pin to slot in drive

coupling

Tighten setscrew to gearmotor output

shaft (shaft is "flatted" for setscrew grip)

Properly re-attach and tighten to

gearmotor output shaft

Remove belt assembly to identify

obstruction to belt movement. Remedy

problem. Straighten bent belt links

Locate and re-install or replace

Replace sprockets or entire drive shaft

assembly. Tighten sprockets to shaft.

CAUTION: THE FOLLOWING TESTS

ARE PERFORMED WITH LIVE POWER

WITH CONTROL BOX OPEN. THESE

TESTS TO BE PERFORMED ONLY BY

Mark on knob should line up with

For CALIBRATION, see

, open

18

1. Test by disconnecting conveyor belt. If

no shaft rotation or motor noise when

power applied, test power supply.

2. Test power supply input connections @

3. Remove cover from power supply

enclosure and verify integrity of internal

Page 19

THE PROBLEM THE CAUSE THE SOLUTION

Conveyor belt

doesn't move, or it

moves unevenly.

Unexpected speed

changes.

(Continued)

No air or not

enough air coming

from blower(s)

Conveyor gearmotor failed

(Continued)

Blower motor(s) "stalled" (not running

when Main Switch ON)

Blower motor(s) "jammed"

4. Verify wire connectors from power

supply to gearmotor (2 wires

w/connectors). If power supply doesn't

5. Verify potentiomter connections to

gearmotor (3 wires w/connectors). If

speed doesn't change when knob is

turned, test with spare pot before replacing

original pot.

If all previous tests verify power and

control to gearmotor, replace gearmotor.

Turn Main Switch OFF for at least 15

seconds, then turn it ON again. This

resets speed controls. If this doesnt help,

turn OFF Main Circuit Breaker for

Minute

Remove source(s) of obstruction.

CAUTION: TURN OFF MAIN CIRCUIT

BREAKER BEFORE REACHING INTO

BLOWER WHEEL COMPARTMENT.

SERIOUS INJURY COULD RESULT

OTHERWISE!!

, then turn it ON again.

1

Blower speed control(s) at minimum or low-

speed setting (model VHVA-Series only)

No sound or noise coming from blower(s)

Blower(s) turning backwards.

(Applies to models VH-, VHVA Threephase units, and VHVA Single-phase

units. Does NOT apply to VH Singlephase units.)

Turn speed knob(s) clockwise to increase

air flow

Turn both blower speed controls to

minimum, then adjust each one separately

to hear for sound changes which indicate

air movement. (model VHVA-Series only)

Verify correct rotation - counterclockwise

when standing in front of machine.

Remove the front door, the conveyor belt

assembly, and both upper and lower air

return shilelds. Turn the Main Switch ON

and OFF one time to start the blowers, and

observe the rotation as the blowers slow

down to stop. If rotation is incorrect, (threephase motors only), then two of the three

power wires need to be swapped @ the

terminal block to reverse direction of

rotation. Re-check with same method.

19

Page 20

THE PROBLEM THE CAUSE THE SOLUTION

No air or not

enough air coming

from blower(s)

(Continued)

Wire connections broken or loose between

speed controls and blower motor(s)

(model VHVA-Series only)

Wire connections broken or loose between

blower motor(s) and terminal block.

Wire connections broken or loose between

potentiometer and speed control

CAUTION: THE FOLLOWING TESTS 14 ARE PERFORMED WITH LIVE POWER

WITH CONTROL BOX OPEN, OR REAR

MOTOR COVER REMOVED. THESE

TESTS TO BE PERFORMED ONLY BY

AN AUTHORIZED SERVICE AGENT.

1. Speed control wire connections are

labeled U, V, and W. Insure connectors

are tight.

2. Insure these (3) wires are tight on

terminal block located in blower motor

compartment.

3. Tighten wires from pot to speed control

at the header terminal on speed control

board.

4. One pot wire contains a 15K ohm

resistor at the pot body. Verify this solder

connection is good.

Blower speed control(s) failed

Blower motor(s) failed

5. Blower(s) can stop if speed controls

have not been reset (model VHVA-Series

only). If yellow "FAULT" light on speed

control circuit board is ON, first turn OFF

main Switch for 15 seconds to rest

control(s). If yellow "FAULT" light remains

ON, disconnect main power cord or circuit

breaker for 1 minute. If "FAULT" light

persists, and all previous tests show

normal, speed control can be tested in the

following manner: swap motor wires from

"good" speed control to "bad" control, and

see if blower motor works. If YES, then

"FAULTY" control is bad and needs

replacing. If NO, then "FAULTY" control is

OK, and motor may need replacing.

6. Test potentiometer by swapping "bad"

pot to "good" speed control. If motor then

works properly, pot is OK, and other speed

control needs testing. (model VHVA-Series

only).

7. If all previous tests are normal, then

blower motor has failed. Replace.

20

Page 21

THE PROBLEM THE CAUSE THE SOLUTION

Oven not hot

enough

Temperature setting too low

Cooking too soon

Temperature control not working properly

Turn temperature control knob to right

(clockwise)

Oven takes 30-40 minutes to get up to

stabilized operating temperature.

Turn temperature knobs back and forth.

Do both lights go ON & OFF? If YES, then

temperature controls are OK. If NO, then

malfunctioning light indicates which control

needs further investigation. Use the

following steps to check.

CAUTION: THE FOLLOWING TESTS

ARE PERFORMED WITH LIVE POWER

WITH CONTROL BOX OPEN. THESE

TESTS TO BE PERFORMED ONLY BY

AN AUTHORIZED SERVICE AGENT.

1. Locate the two temperature contols

mounted on the hinged door, near the

cooling fan. Verify that ALL connections

and connectors are properly fastened and

tight. Power should be connected to

terminals labeled 240 & VAC COM.

2. Locate the two wires from each of the

temperature sensors (top left terminals

labeled PROBE). These have braided

insulation. Verify their integrity.

3. If necessary to test, disconnect one

sensor at a time, and use voltmeter to

measure resistance at sensor wires.

Compare to resistance chart in back of this

manual. If sensors show INFINITE

resistance, sensor is bad. Replace.

4. If resistance reads value within range of

chart, sensor is good, control needs further

investigation. Re-connect sensor wire

leads. (See diagram at back of manual for

proper identification of controls).

NOTE: temperature sensor lead wires

are NOT polarity sensitive, since sensor

is an RTD-type.

5. If both sensors are good, swap sensor

leads between controls. Turn temperature

knobs ON & OFF. Whichever light works

properly, the

Replace.

OPPOSITE

control is bad.

Page 22

Notes:

22

Page 23

17. TEMPERATURE CONTROL CONVERSION CHART

The temperature sensor (probe) that is supplied with this conveyor oven is an RTD type, which yields an

output based on Ohms of resistance. This particular RTD device has a linear resistance curve that

produces a very predictable amount of resistance that can be converted to degrees Fahrenheit. This

particular device produces a resistance increase of 2 Ohms per every 1 degree F. The baseline value is

approx. 1000 ohms at 32 °F (0°C).

Ohms

1002

1004

1017

1025

1038

1046

1059

1067

1080

1088

1101

1109

1122

1130

1143

1151

1164

1172

1184

1193

1205

1214

1226

1234

1247

1255

1267

1276

1288

1286

1309

1317

1329

1338

1350

°F

32

34

40

44

50

54

60

64

70

74

80

84

90

94

100

104

110

114

120

124

130

134

140

144

150

154

160

164

170

174

180

184

190

194

200

Ohms

1358

1370

1379

1391

1399

1411

1420

1432

1440

1452

1460

1473

1481

1493

1501

1513

1521

1533

1541

1554

1562

1574

1582

1594

1602

1614

1622

1634

1642

1654

1662

1674

1682

1694

1702

°F

204

210

214

220

224

230

234

240

244

250

254

260

264

270

274

280

284

290

294

300

304

310

314

320

324

330

334

340

344

350

354

360

364

370

374

Ohms

1714

1722

1734

1742

1753

1761

1773

1781

1793

1801

1813

1821

1832

1844

1852

1860

1872

1879

1891

1899

1911

1918

1930

1938

1950

1957

1969

1977

1988

1996

2008

2027

2035

2046

°F

380

384

390

394

400

404

410

414

420

424

430

434

440

446

450

454

460

464

470

474

480

484

490

494

500

504

510

514

520

524

530

540

544

550

23

Page 24

18. Solid State Relay Labeling I.D. - Models VH-, VHVA1620E Conveyor Ovens

UPPER ELEMENTS

POWER BLOCK

WIRING - SINGLE

PHASE

G

L2

L1

POWER BLOCK

WIRING - THREE

PHASE

G

L3

L2

L1

GREEN 10 GA ( GRND )

GREEN 14 GA ( G4 )

WHITE 14 GA ( L2 )

BROWN

14GA (R)

WHITE 14 GA ( L2 )

WHITE 14 GA ( L2 )

BLACK 18 GA ( #4 )

BROWN 10 GA ( E )

BLACK 10 GA ( A )

GREEN 10 GA ( GRND )

GREEN 14 GA ( G4 )

BROWN 14 GA(R)

BROWN 10 GA ( E )

BROWN 10 GA ( E )

WHITE 14 GA ( L2 )

WHITE 18 GA ( #5 )

WHITE 14 GA ( L2 )

WHITE 14 GA ( L2 )

BLACK 18 GA ( #4 )

BLACK 10 GA ( A )

WHITE 18 GA

(#5)

WIRE DESIGNATIONS

(LETTERSOR#s)

A

C

SSR 1 SSR 2 SSR 3

30 29 3430 29 29

PROBE

B

DE F

PROBE

UPPERTEMPCONTROL LOWERTEMPCONTROL

VAC

COM

240

VAC

VAC

COM

240

VAC

CONTROL BOX DOOR

LOWER

ELEMENTS

Solid State Relay

RESISTANCE VALUES OF VARIOUS CIRCUITS

Dual Air Models: VH-, VHVA1620E Conveyor Ovens

NOTE: Fuses removed; (4) elements @ 1.5kw = 6.0kw; Ohms = Volts x Volts / Watts

Single Phase Units

Circuit Leads 208 Volt 240 Volt

Between C & L2 Ohms 38.9 Ohms28.3

Between D & L2 Ohms 38.9 Ohms28.3

Between C & D 56.2 Ohms 77.6 Ohms

Between C & F 42.5 Ohms 58.1 Ohms

Between D & F 42.3 Ohms 58.1 Ohms

Between F & L2 14.5 Ohms 19.5 Ohms

Three Phase Units

Circuit Leads 208 Volt 240 Volt

Between C & L3 28.3 Ohms 38.9 Ohms

Between D & L2 28.3 Ohms 38.9 Ohms

Between C & D 1.2M Ohms 1.3M Ohms

Between C & F 1.2M Ohms 1.3M Ohms

Between D & F 42.3 Ohms 58.1 Ohms

Between F & L2 14.5 Ohms 19.5 Ohms

24

Page 25

Solid State Relay Labeling I.D. - Models VH-, VHVA1828E Conveyor Ovens

UPPER ELEMENTS

POWER BLOCK

WIRING - SINGLE

PHASE

G

L2

L1

POWER BLOCK

WIRING - THREE

PHASE

G

L3

L2

L1

GREEN 10 GA ( GRND )

GREEN 14 GA ( G4 )

WHITE 1 4 GA ( L2 )

R14GA

WHITE 14 GA ( L2 )

WHITE 1 4 GA ( L2 )

BLACK 18 GA ( #4 )

BROWN 10 GA ( E )

BLACK 10 GA ( A )

GREEN 10 GA ( GRND )

GREEN 14 GA ( G4 )

R14GA

BROWN 10 GA ( E )

BROWN 10 GA ( E )

WHITE 1 4 GA ( L2 )

WHITE 18 GA ( #5 )

WHITE 14 GA ( L2 )

WHITE 1 4 GA ( L2 )

BLACK 18 GA ( #4 )

BLACK 10 GA ( A )

WHITE 1 8 GA

(#5)

WIRE DESIGNATIONS

(LETTERSOR#s)

B

A

C

DE F

SSR 1 SSR 2 SSR 3

30 29 3430 29 29

PROBE

PROBE

UPPERTEMPCONTROL LOWERTEMPCONTROL

VAC

COM

240

VAC

VAC

COM

240

VAC

CONTROL BOX DOOR

LOWER

ELEMENTS

Solid State Relay

RESISTANCE VALUES OF VARIOUS CIRCUITS

Dual Air Models: VH, VHVA1828E Conveyor Ovens

NOTE: Fuses removed; (4) elements @ 3kw = 12kw; Ohms = Volts x Volts / Watts

Single Phase Units

Circuit Leads 208 Volt 240 Volt

Between C & L2 14.3 Ohms 18.2 Ohms

Between D & L2 14.3 Ohms 18.2 Ohms

Between C & D 28.5 Ohms 36.2 Ohms

Between C & F 21.4 Ohms 27.3 Ohms

Between D & F 21.4 Ohms 27.2 Ohms

Between F & L2 7.3 Ohms 9.3 Ohms

Element Resistance Chart - VH-,VHVA-Series Conveyor Oven

VH-,VHVHA1620E

VH-,VHVHA1828E

1500

3000

Three Phase Units

Circuit Leads 208 Volt 240 Volt

Between C & L3 14.5 Ohms 18.2 Ohms

Between D & L2 14.3 Ohms 18.2 Ohms

Between C & D 4.7M Ohms 3.4M Ohms

Between C & F 4.7M Ohms 3.4M Ohms

Between D & F 21.4 Ohms 27.2 Ohms

Between F & L2 7.2 Ohms 9.4 Ohms

208 VOLTS 220 VOLTS 240 VOLTSELEMENT WATTAGEMODEL

28.8 ohms 32.3 ohms 38.4 ohms

14.4 ohms

25

16.1 ohms

19.2 ohms

Page 26

19. ELECTRICAL SCHEMATICS & WIRING DIAGRAMS

VHVA1620E Schematic 208, 220 or 240VAC, 50/60Hz, 1 Phase

POWER BLOCK

FUSE

1

MAIN SWITCH MAIN SWITCH

12

14

BROWN

C

16

N.O.

BROWN

18

BROWN

48

VACUUM SWITCHES.

CLOSE ON BL OWER V ACUUM

20

BROWN

50

ELEMENT CONTACTOR

UPPER

TEMPERATURE

ADJUST MENT

POTENTIOMETER

LOWER

TEMPERATURE

ADJUST MENT

POTENTIOMETER

BROWN

R

FAN

RELAY

COOL-DOWN THERMOSTATS.

E

CLOSEON TEMPERATURE RISE.

15 KOHM

RESI STOR

15 KOHM

RESI STOR

D

44

C1

10

A

40

A

42

UPPER BLOWER

MOTOR SPEED

CONTROL AND

POTENTIOMETER

LOWER B LOWER

MOTOR SPEED

CONTROL AND

POTENT IOMETER

BRN S 3

BLK S 2

BRN S3

BLK S 2

38

10 GA. BLACK

E

SSR 3

BLACK

SSR 1

B

SSR 2

BLACK

E2

E1

S1

S2

S3

DIR

RED

S1

BLOWE R MOTO R

SPEE D CO NTROL S

1~ IN; 1 or 3~ OUT

E2

E1

S1

S2

S3

DIR

RED

S1

BROWN

20

INPUT OUTPUT

GEARMOTOR

POWER SUPPLY

BLUE

43

BROWN

PURPLE

YELLOW o r BLUE

ORANGE

RTD SE NSOR

PURPLE

YELLOW o r BLUE

ORANGE

RTD SE NSOR

5AMPS

468

10 GA. BROWN

F

C

D

24

21

-

-

+

+

+

L1 L2 G

1500 WATTS EACH

G

1500 WATTS EACH

TOP ELEMENTS

A1

A2

A3

22

B1

B2

B3

WHITE

41

39

46

GEARMOTOR

REVERSING

SWITCH

UPPER

TEMPERATURE

CONTROL

3

1

2

5

4

3

1

2

5

4

LOWER

TEMPERATURE

CONTROL

BOTTOM ELEMENTS

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

19

BLACK ( 2 )

RED

+

11

10

9

8

7

6

11

10

9

8

7

6

23

BLACK

BLACK

BLACK

WHITE

123

26

J

BRN

J

28

WHITE

37

25

32

BLUE

FUSE 2

5AMPS

5

I

RIGHT

J

LEFT

H

RIGHT

K

LEFT

REAR E XHAUST FAN S

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

G2

A

Y

A

R

G

BROWN

G3

27

GRN / YLW

29

GRAY

36

34

COOLI NG FAN

IN CONTROL

BOX DOOR

79

19

COOLI NG FAN

IN CONTROL

BOX

14 GA WHITE

M

N

Q

P

BLACK

BLACK

ORANGE

YELLOW

GREEN

33

GRY

A

BROWN

WHITE

C1

C1

C1

C1

35

GRAY

G1

18 GA. GREEN/ YE LLOWS TRIPE

11

14 GA WHITE

14 G A BRO WN

R

BLACK

T1

3~

T2

CCW

T3

UPPER BLOWER

MOTOR

T1T1

3~

T2

CCW

T3

LOWER BLOWER

MOTOR

BLUE

GREEN / YELLOW STRI PE

J

30

J

BROWN

J

BLUE

10 GA. GREEN/ YELLOW STRIPE

19

14 G A WHI TE

GRN

GEARMOTOR

AND S PEED

POT

BLUE

C

O

I

L

C

O

I

L

C

O

I

L

GRN

15

BLUE

WHITE

ND

G

G2

13

G4

GREEN

17

18 GA. GREEN / YELLOW STRIPE

BLUE

G

25

G2

31

SSR 1

SSR 2

SSR 3

U4160Q

26

Page 27

27

MAIN

SWITCH

l

(ON)

13

12

TERMINAL

O

10

11

UPPER

LOWER

18 GA.BLUE

BLOCK #4

18 GA.BLACK

18GA. WHITE

GRAY

A

GRAY

GRAY

A

GRAY

18 GA BLU

15

18 GA. BROW N

18 GA.BROWN

14

16

COOL-DOW N RELAY

COOLING FAN

(AIRPULLEDINTOCONTROLBOX)

N.O.

C

(OFF)

18 GA.BROWN

ITEMS LO CATED IN ANGL ED CONTROL BOX

VHVA1620E Wiring Diagram 208, 220 or 240VAC, 50/60Hz, 1 Phase

WHITE 18 GA.23

UPPER

BLOWER

MOTOR

SPEED

CONTROL

1~ INPUT

3~ OUTPUT

BROWN 2 2G A. TO S3

BLACK 22GA. TO S2

RED 22GA. TO S1

17

18

PURPL E

YELLOWorBLUE

ORANGE

PURPLE

YELLOWorBLUE

ORANGE

20

15K OHMR ESISTOR

LOWER

BLOWER

MOTOR

SPEED

CONTROL

1~ INPUT

3~ OUTPUT

15K OHM RESI STOR

BLACK 22 GA. ( 2 PLCS )

-

46

GEARMOTOR

POWER

SUPPLY

3

2

1

REVERSING

SWITCH

FROM

POWER

SUPPLY

BROWN 22GA. TO S3

BLACK 2 2 GA. TO S2

RED 22GA. TO S1

BLK

+

WHT

22 GA.

CONVEYOR

GEARMOTOR

GREEN 22 GA.

ORANGE 22 GA.

DISTRIBU TION

GREEN G

WHIT E L2

BLACK L1

RED 22 GA.

POWER

BLOCK

SPEED POT

SPEED P OT

8

18 GA.BLACK

18 GA. WHIT E

9

TO

32

TEMP

CONTROLS

33

36

TO

TERMINAL

35

BLOCK #2

18 GA. BLUE

48

18 GA. BROWN

18 GA.BROWN

18 GA. BROWN

BLACK

BLACK

UPPER

TEMPERATURE

CONTROL PO TS

VACUUM SWIT CHES

LOWER

50

18 GA. BROW N

CONVEYOR

SPEED POT

---+++

~

BLACK 18 GA.

A1

A2

BLACK 18 GA.

A3

BLACK 18 GA.

E2E1S1 S2 S3 DIR

J

21

TE

I

H

W

B1

BLACK 18 GA.

B2

BLACK 18 GA.

B3

BLACK 18 GA.

E2E1 S1S2 S3 DIR

J

39

41

44

RED 22 GA.

24VDC

OUTPUT

RED

37

+

RED

BLACK

YELLOW

22 GA.

GROUND

SCREW

G

Y

R

E

E

L

E

L

N

O

GREEN 10 GA.

/

W

G1

G

L2

L1

G2

A

(L1 )

O

R

B

ELEMENT CONTACTOR

18 GA.

N

W

BLACK 22 GA.

43

BLUE 18 GA.

TO TERM.

BLOCK 3

18 GA.

22

19

18GA. BROWN

20

18 GA.BLACK

18 GA. WHIT E

18 GA. BLUE

18 GA.BROWN

BLUE

BROWN

Q

WHITE

P

WHIT E

N

WHITE 14 GA.

WHITE 14 GA.

BROWN 14 GA.

WHITE L2 14 GA .

BROWN 14 GA.

R

L2

L2

18

M

WHITE 14 GA.

WHITE L2 1 4GA .

L2

WHITE 18 GA.

WHITE

WHITE L2 1 4GA .

TO TERM.

BLOCK 3

BLACK F1 1 8G A.

WHITE F2 18 GA.

WHIT E L 2 18 G A.

BLUE 18 GA.31

14 G A. H IGH

TEMP

17

WHITE

TERMI NAL

BLOCK #1

6

7

5

5

9

BROWN

BLUE

H

K

J

I

9

BLACK

8

8

38

ITEMS LOCATEDIN CONTROL BOX ENCLOSURE

25 26

4

BLACK L1 18 GA.

4

38

F1

5

AMP

F2

5

AMP

PROBE

H

J

BROWN L1 10 G A.

BLACK L1 10 GA.

BLACK 18 GA.24

42

C

COOL-DOWN

THERMOSTAT

D

UPPER

H

40

14 GA . HI-T EMP

I

K

C

PROBE

A

E

18 GA. BROWN

18 GA.BLUE

TERMINAL

BLOCK #4

E

A

G4

ELEMENTS

COOL-DOWN

THERMOSTAT

LOWER

ELEMENTS

G

G

F

C

B

SSR 1 SSR 2

BLUE J

BROWN JUMPER

ORG

PUR

910

J

26

BROWN

25

18 GA. GRAY

G2

14 GA . HI-T EMP

14 GA . HI-T EMP

14 GA . HI-T EMP

14GA. HI-TEMP

14GA. HI-TEMP

D

BLUE

JUMPER

TO

REMOTE

POT

YEL

LOWE R TEMP C ONTROL

678

11

GREEN / YELLOW - GROUND

F

14GA. HI-TEMP

A

30

TO

REMOTE

POT

45213

UPPER TEMP CONTROL

18 GA.BROWN

67 8

30

18 GA. GRAY

32

TO

36

18 GA. GR EEN / YELLOW - GR OUND

CONTROL BOX

COOLING FAN

( AIR PULLED INTO CONTROLBOX )

ITEMS LOCATEDON MAIN CONTROL BOX DOOR

18 GA. GRE EN / YEL LOW ( MO TOR GROUND )

E

SSR 3

5213

4

J

28

BLUE

PURPLE

BLACK

F

18 GA.BLUE

910

27

BLACK

ORANGE

18GA. BROWN

YELLOW

11

G3

K

J

K

D

34

29

BLUE

29

34

14GA. HI-TEMPJUMPER

REAR EXHAUST FANS

(AIRPUSHEDOUTOFOVEN)

SPLICES

BLACK

BLACK

BLACK

BLACK

SPLICES

TO TERMINAL

BLOCK #4

GREEN (GROUND)

GREEN ( GROUND)

G

UPPER

BLOWER

MOTOR

LOWER

BLOWER

MOTOR

CLOCKWIS E ROTATION

WHEN LOOKING AT

BACK OF MO TOR

ITEMS LOC ATED IN BLOWE R COMPARTMENT

T1 YEL

T2 YEL

T3 YEL

G

T3 YEL

33

35

T1 YEL

T2 YEL

18GA.

GRAY

18GA.

GRAY

TERMINAL

BLOCK #2

TERMINAL

BLOCK #3

42

24

23

31

A1

A2

A3 BLK

B1

B2

B3 BLK

TO UPPER

BLOWE R

MOTOR

SPEED

CONTROL

TO LOWER

BLOWER

MOTOR

SPEED

CONTROL

GREEN /

YELLOW GROUND

G4

G4

G

U4160Q

Page 28

VHVA1620E Schematic 208, 220 or 240VAC, 50/60Hz, 3 Phase

CAUT ION: L1 & L2 INP UTS MUS T BE 1 00-125 VOL T PO TEN TIAL.

IF A "HIGH- VOLTA GE LEG" GREAT ER THAN 125 V OLTS

IS PRESENT, IT MUST CONNECT TO L3.

MAIN SWITCH MAIN SWITCH

12

14

BROWN

C

16

N.O.

FAN

RELAY

10

38

A

10 GA. BLACK

E

BROWN

SSR 3

18

BROWN

48

VACUUM SWITCHES.

CLOSE ON BLOWER VACUUM

BROWN

50

UPPER

TEMPERATURE

ADJUSTMENT

POTENTIOMETER

LOWER

TEMPERATURE

ADJUSTMENT

POTENTIOMETER

40

COOL-DOWN THERMOSTATS.

CLOSE ON TEMPERATURE RISE.

42

BROWN

20

15 K OHM

RESISTOR

15 K OHM

RESISTOR

D

E

R

44

C1

ELEMENT CONTACTOR

BLACK

A

UPPER BLOWER

MOTOR SPEED

CONTROL AND

POTENTIOMETER

BRN S3

BLK S2

RED

S1

LOWERBLOWER

MOTOR SPEED

CONTROL AND

POTENTIOMETER

BRN S3

BLK S2

RED

S1

INPUT

PURPL E

YELLOW

YELLOWorBLUE

ORANGE

PURPL E

YELLOWorBLUE

YELLOW

ORANGE

20

B

BLACK

E2

E1

S1

S2

S3

DIR

BLOWER MOTOR

SPEED CONTROLS

1~ IN; 1 or 3~OUT

E2

E1

S1

S2

S3

DIR

BROWN

GEARMOTOR

POWER SUPPLY

43

BLUE

BROWN

RTD SENSOR

RTD SENSOR

SSR 1

SSR 2

OUTPUT

FUSE

1

5AMPS

468

10 GA. BROWN

F

C

D

24

21

-

-

-

+

+

+

POWER BLOCK

L1 L2 L3 G

1500 WATTS EACH

G

1500 WATTS EACH

TOP ELEMENTS

A1

A2

A3

22

B1

B2

B3

WHITE

41

39

RED

46

GEARMOTOR

REVERSI NG

SWITCH

UPPER

TEMPERATURE

CONTROL

3

1

2

5

4

3

1

2

5

4

LOWER

TEMPERATURE

CONTROL

BOTTOM ELEMENTS

BLACK

BLACK

23

WHITE

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

19

BLACK

BLACK ( 2 )

37

+

WHITE

123

26

11

10

9

8

32

J

7

6

28

BRN

11

10

9

8

J

7

6

FUSE 2

5AMPS

5

I

RIGHT

J

LEFT

H

RIGHT

K

LEFT

REAR EXHAUST FANS

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

YELLOW

25

G2

Y

A

R

G

27

BLUE

GRN / YLW

GRAY

COOLING FAN

IN CONTROL

BOX DOOR

BROWN

G3

79

19

COOLING FAN

IN CONTROL

BOX

14 GA WHITE

M

N

Q

P

BLACK

BLACK

ORANGE

YELLOW

GREEN

33

GRY

A

29

36

BROWN

34

WHITE

C1

C1

C1

C1

35

GRAY

A

G1

18 GA. GREEN / YELLOW STRIPE

11

14 GA WHITE

14 GA BROWN

R

BLACK

T1

T2

3~

CCW

T3

UPPER BLOWER

MOTOR

T1T1

T2

3~

CCW

T3

LOWER BLOWER

MOTOR

BLUE

GREEN / YELLOW STRIPE

J

30

J

BROWN

J

BLUE

10 GA. GREEN / YELLOW S TRIPE

19

14 GA WHITE

GEARMOTOR

AND SPEED

POT

BLUE

C

O

I

L

C

O

I

L

C

O

I

L

GRN

GRN

15

BLUE

WHITE

13

ND

G

G2

G4

GREEN

17

18 GA. GREEN / YELLOW STRIPE

BLUE

G

25

G2

31

SSR 1

SSR 2

SSR 3

U4162Q

28

Page 29

29

MAIN

SWITCH

l

(ON)

(OFF)

13

12

TERMINAL

O

BLOCK #4

10

18 GA.BLACK

11

18 GA. W HITE

GRAY

UPPER

A

GRAY

GRAY

LOWER

A

GRAY

18 GA.BLUE

18 GA.BROWN

18 GABLU

15

N.O.

18 GA.BROWN

18 GA.BROWN

C

14

16

COOL-DO WN RELAY

COOLING FA N

( AIR PULLED INTO CONTROLBOX )

ITEMS LOCATED IN ANGLEDCONTROLBOX

VHVA1620E Wiring Diagram 208, 220 or 240VAC, 50/60Hz, 3 Phase

WHITE 18 GA.

23

UPPER

BLOWER

MOTOR

SPEED

CONTROL

1~ INPUT

3~ OUTPUT

BROWN 22 GA. TO S3

BLACK 22 GA. TO S 2

RED 2 2 G A. TO S1

17

PURPLE

YELLOW

YELLOW o r BLUE

ORANGE

YELLOW

YELLOW orBLUE

ORANGE

15K O HM RESI STOR

LOWER

BLOWER

MOTOR

SPEED

CONTROL

1~ INPUT

3~ OUTPUT

BROWN 22 GA. TO S3

BLACK 22 GA. TO S2

RED 22 GA. TO S1

15K OHMRESISTOR

BLACK 22 GA. ( 2 PLCS )

-

46

GEARMOTOR

18

POWER

SUPPLY

20

3

BLK

2

RED 22 GA.

1

+

WHT

REVERSING

22 GA .

SWITCH

PURPL E

CONVEYOR

GEARMOTOR

GREEN 22 GA.

ORANGE 2 2 GA.

SPEED POT

SPEED POT

8

18G A.BLACK

18 GA. WHI TE

9

TO

32

TEMP

CONTROLS

33

36

TO

TERMINAL

35

BLOCK #2

18 GA. BLUE

48

18 GA.BROWN

18 GA. BR OWN

18 GA. BROWN

BLACK

BLACK

UPPER

TEMPERATURE

CONTROL P OTS

VACUUM SW ITCHES

LOWER

50

18 GA. BR OWN

CONVEYOR

SPEED POT

DISTRIBUTION

GREEN G

FROM

RED L3

POWER

WHITE L2

SUPPLY

BLACK L1

41

---+++

~

POWER

BLOCK

L3

L2

L1

39

24VD C

OUTPUT

RED

+

YELLO W

22 GA.

G

E2E1 S1 S2 S3DIR

J

E2 E1S1 S2 S3 DIR

J

RED

BLACK

A1

A2

A3

B1

B2

B3

BLACK 18 GA.

BLACK 18 GA.

BLACK 18 GA.

BLACK 18 GA.

BLACK 18 GA.

BLACK 18 GA.

44

GREEN 10 GA.

G1

RED 22 GA.

GROUND

SCREW

Y

E

L

A

(L1 )

TO TERM.

BLOCK 3

18 GA.

18 GA.

21

22

E

N

W

WHIT

O

R

B

19

18 GA.BROWN

20

18 GA. BLA CK

18 GA.WHITE

18 GA.BLUE

18 GA.BROWN

BLACK 22 G A.

43

BLUE

37

BROWN

Q

WHITE

P

WHITE

N

BLUE 18 GA.

18

M

WHITE 18 GA.

TO TERM.

BLOCK 3

WHITE

BLUE 18 GA.

31

14 GA. HIGH

TEMP

8

9

17

BROWN

BLUE

H

K

J

I

9

WHITE

8

BLACK

38

WHITE 14 GA.

WHITE 14 GA.

WHIT E 1 4 G A.

BROWN 14 GA.

TERMINAL

BLOCK #1

ELEMEN T CONTACTOR

G

R

E

E

L

N

O

/

W

BROWN 14 GA.

G2

R

L2

6

BLACK F1 18 GA.

WHITE F2 18 GA.

7

E (L3 )

WHITE L2 18 GA.

5

5

WHITE L2 14 GA.

WHITE L2 14 GA.

WHITE L2 14 GA.

L2

L2

ITEMS L OCATED IN CON TROL BOX ENCL OSURE

BLACK 18 GA.

24

42

C

PROBE

H

38

J

C

PROBE

A

E

26

25

F1

4

5

AMP

F2

5

AMP

BLACK L1 1 8 GA.

BROWN L 3 10 GA.

4

BLACK L 1 1 0 GA.

A

COOL -DOWN

THERMOSTAT

H

40

COOL -DOWN

THERMOSTAT

14GA. HI-TEMP

G

F

I

K

14 GA.HI-TEMP

A

SSR 1 SSR 2

30

BROWN JUMPER

TO

REMOTE

POT

452

UPP ER TE MP CON TROL LO WER TE MP CON TROL

18 GA.BROWN

67 8

30

18 GA. BR OWN

18 GA.BLUE

18 GA. GRAY

32

TO

TERMINAL

36

BLOCK #4

18 GA. G REEN / YEL LOW - G ROUND

E

CONTROL BO X

COOLING FA N

( AIR PULLED INTO CONTR OL BOX )

ITEMS LOCATED ON MAIN CONTROL BOXD OOR

18 GA. GREEN / YELLOW ( MOTOR GROUN D)

G4

UPPER

ELEMENTS

K

LOWER

ELEMENTS

G

14 GA.HI-TEMP

14 GA.HI-TEMP

14 GA.HI-TEMP

14 GA.HI-TEMP

F

14 GA.HI-TEMP

C

B

D

E

SSR 3

BLUE

BLUE J

JUMPER

TO

REMOTE

POT

PURPLE

YEL

ORG

PUR

JJ

26

18 GA.GRAY

52 1 3

1 34

91011 67 891011

28

BROWN

25

BLUE

G2

GREEN / YELLOW - G ROUND

BLACK

F

18 GA.BLUE

ORANG E

27

BLACK

18G A.BROWN

YELLOW

G3

J

34

29

BLUE

29

34

D

REAR EXHAUST FANS

( AIR PU SHED OUT OF OVE N )

K

D

ITEMSLOCATED IN BLOWER COMPARTMENT

SPLICES

UPPER

BLOWER

MOTOR

G

LOWER

BLOWER

MOTOR

CLOCKWI SE ROTATIO N

WHEN LOOKING AT

BACK O F MOTO R

14 GA.HI-TEMPJUMPER

BLACK

BLACK

BLACK

BLAC K

SPLI C E S

33

35

TO TERMINAL

BLOCK #4

GREEN (GROUND)

GREEN (GROUND)

G

T1 YEL

T2 Y EL

T3 YEL

T1 YEL

T2 Y EL

T3 Y EL

18GA.

GRAY

18GA.

GRAY

TERMINAL

BLOCK #2

TERMINAL

BLOCK #3

42

24

23

TO UPPER

BLOWER

MOTOR

SPEED

CONTROL

GREEN /

YELLOWGROUND

G

A1

A2

A3 BLK

TO LOWER

BLOWER

MOTOR

SPEED

CONTROL

B1

B2

B3 BL K

U4162Q

31

G4

G4

Page 30

VH1620E Schematic 208, 220 or 240VAC, 50/60Hz, 1 Phase

48

50

POWER BLOCK

FUSE

1

MAIN SWITCH MAIN SWITCH

12

14