Page 1

Installation Manual & Technical Data

NMK Rotary Oven

BKI-Europe

Theale Technology Centre

Station Road

Theale

Reading

West Berks

RG7 4AA

Phone: 0870 990 4242 • Fax: 0870 990 4243 • www.bkideas.com

Printed in England CJM/NMKIM04006

16

Theale Technology Centre, Station Road, Theale, Reading, West Berks RG7 4AA

Phone: 0870 990 4242 • Fax: 0870 990 4243 • www.bkideas.com

ISSUE: APRIL 2006

Page 2

CONTENTS

SECTION PAGE

1. GENERAL………………………………………... 3

2. SITE REQUIREMENTS…………………………………. 4

3. CLEARANCES…………………………………………… 4-5

4. EXTRACTION……………………………………………. 6

5. ELECTRICAL CONNECTION………………………….. 7

6. SUPPLY CABLE - CONNECTION…………………… 8

7. OPERATING……………………………………………… 9

8. SAFETY CUT-OUT (RE-SET)………………………….. 10

9. GENERAL DIMENSION………………………………… 11

NOTES

10. WIRING DIAGRAM………………………………………. 12

BKI ROTARY OVENS ARE MANUFACTURED ACCORDING TO THE

FOLLOWING STANDARD:

BSEN 60 335-2-42: 2002

NOTICE : SAFETY CUT-OUT

For added safety all Rotary Ovens have a built in thermal cut-out to

protect against over-heating through component failure or incorrect

use.

If for any reason the thermal cut-out operates, the oven will automatically

shut down and should be switched `OFF` disconnected from the mains

and allowed to cool.

NOTE: THE THERMAL CUT-OUT WILL NOT RESET AUTOMATICALLY.

The oven must not be re-used until it has been checked by a

Qualified electrician or BKI Appointed Service Agent.

2

15

Page 3

NOTES

GENERAL NOTES & INFORMATION

Your `NMK` rotary display oven has been completely assembled and tested

before despatch.

It has been packed for safe shipment to you premises. Meatforks and other

accessories may have been packed separately, check all parts and accessories

against delivery note.

Before connecting to the power supply, ensure that all fittings and packaging

have been removed.

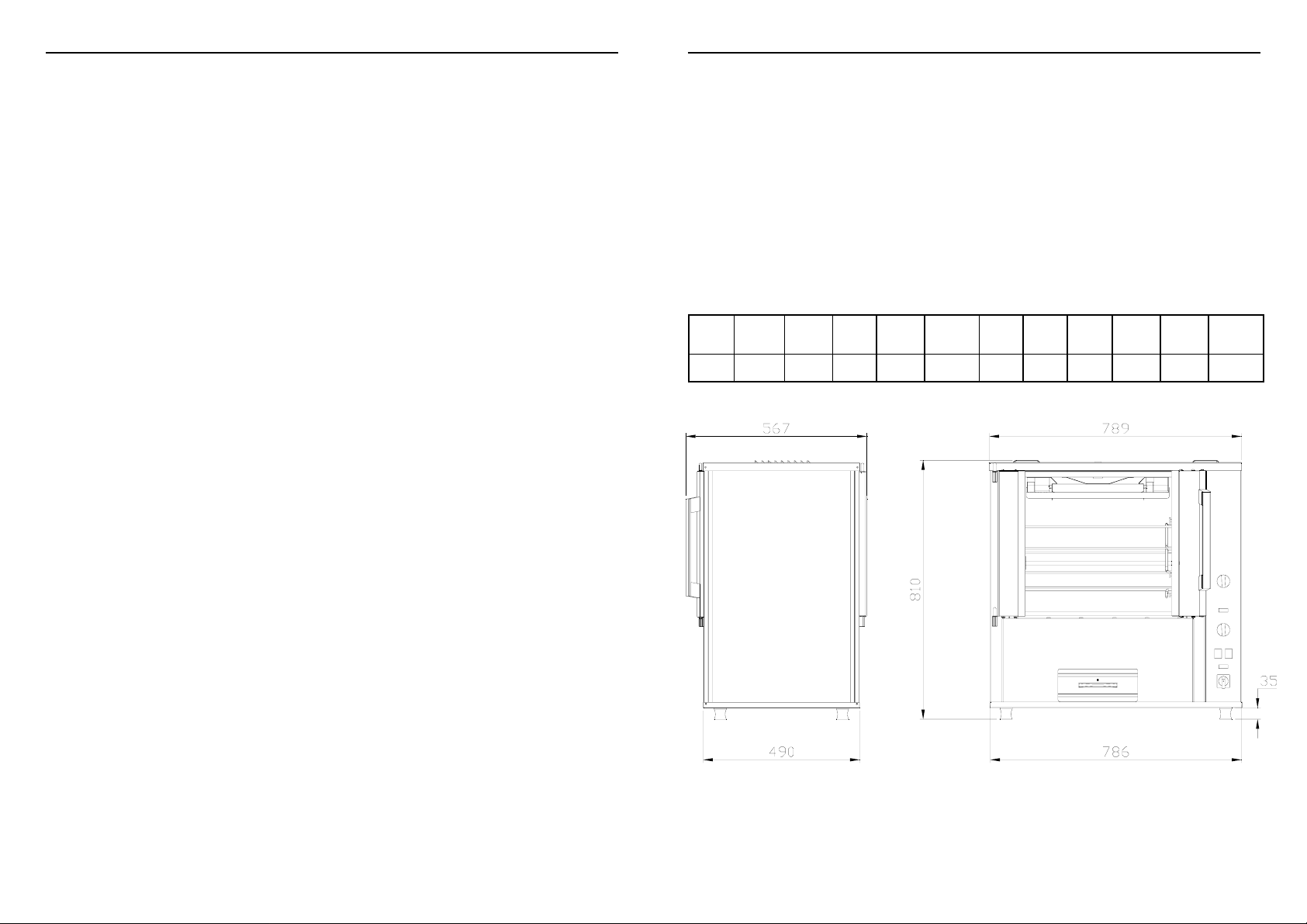

Table 1. TECHNICAL DATA

MODEL HEIGHT

mm

NMK 810 786 490 3 3 1ph 230 2.9 72 82

WIDTH

mm

DEPTH

mm

MEATFORKS

BASKETS PHASE VOLTS Kw WEIGHT

Amps

12.5

Nett

Kg

Gross

14

GENERAL DIMENSIONS

3

Page 4

SITE REQUIREMENTS

Refer to the appropriate general dimensions drawing for detail and dimen sion s o f

of model supplied (See Table 1. or General Dimensions - Page 12)

It is essential that this oven is installed in accordance with these instruction and

the installer is drawn to the following points:

• It is important that the counter top or base unit is level and can support the

full weight of the oven and its contents. Refer to Table 1 - Technical Data.

• For all types of installation it is important that adequate clearance is provided for ventilation and servicing of this appliance.

• It is recommended that this oven is sited on a stainless steel mobile base

for maximum service and cleaning access.

• Toughened glass doors are fitted to both sides of the oven for maximum

visual display and cleaning access. Door handles are fitted to the operators

side door only; customer side door handles are available as an optional

extra.

• It is important that adequate clearance is provided to enable doors to open

fully for safe loading and unloading of food items and oven removable

WIRING DIAGRAM

GND

GND

N L1

N

L1

9

9

10 GND

10GND

CLEARANCES

WARNING - HEALTH & SAFETY

Observe all safety warning labels affixed to this appliance.

We strongly recommended that careful consideration be given to the siting of this

piece of equipment in order to prevent accidental contact with hot surfaces.

The equipment is insulated but we cannot prevent certain surfaces such as glass

etc reaching temperatures, which can cause minor burns on contact .

PLEASE HELP PREVENT ACCIDENTS AND PROTECT THE SAFETY OF

YOUR STAFF AND CUSTOMERS

4

13

Page 5

GENERAL DIMENSIONS

CLEARANCES

• Restrictions must not be placed on or around this oven. Keep all ventilation

slots free from obstruction.

• Do not remove the rubber feet fitted to this oven.

• Refer to diagrams 1 & 2 for minimum recommended clearances required

from a combustible surface.

Minimum Distance from

Combustible Surface

A TOP 12”/305mm

B SIDE 2”/50mm

NOTE: DO NOT REMOVE RUBBER FEET

12

Minimum Distance from

Combustible Surface

D GLASS/DOOR 6”/152mm

WALL

D` GLASS DOOR/ 12”/305mm

WINDOW

(SHOP FRONT)

NOTE: DO NOT REMOVE RUBBER FEET

5

Page 6

EXTRACTION

Extraction is not a specific requirement for this type of appliance.

Certain conditions e.g.

Installation in a confined space, temperature controlled environment,

continuous use or high volume production cooking may require the need for

ventilation or extraction.

Consult your local Ventilation/Extraction, Air conditioning company or contact the

Technical Services Department at BKI.

ELECTRICAL CONNECTION

This appliance requires a 230V,50Hz single phase + Neutral + Earth power

Supply.

WARNING - THIS APPLIANCE MUST BE EARTHED

• Each appliance is despatched with an electrical test certificate.

• Check the details shown on the appliance data rating plate against the cer-

tificate supplied.

• Check that the voltage shown on the data plate and test certificate conforms with your power supply.

If the details do not conform contact the Technical Services Department at BKI

BKI Europe

Theale Technology Centre

Station Road

Theale

Reading

West Berkshire

RG7 4AA

Tel: (44) 0870 990 4242

Fax: (44) 0870 990 4243 Web: www.bkideas.com

Safety Cut-Out - Re-Set Button

If the safety thermal cut-out operates, first check that the oven has been installed

properly and is operated and cleaned in accordance with the installation and operating instructions.

• Turn the mains switch `OFF`, disconnect oven from mains power supply.

• Refer to the relevant wiring diagram and check all components and con-

trols before re-setting the safety thermal cut-out.

• The safety thermal cut-out is located within the oven control panel compartment. Reset the thermal cut-out as follows:-

1. Remove the two side panel securing screws, slide the panel `Up` and `Out`

at the bottom.

2. The safety thermal cut-out is sited towards the top left of the component

plate.

3. Press hard on the `Red` re-set button on top of the thermal cut-out (allow

time for the oven to cool down).

4. Replace side panel and check oven operation.

WARNING:

REPEATED OPERATION OF THE SAFETY THERMAL CUT-OUT IS A CLEAR

INDICTAION OF COMPONENT FAILURE OR MISUSE.

SERIOUS DAMAGE WILL OCCUR IF THE CAUSE IS NOT IDENTIFIED AND

RECTIFIED.

6

11

Page 7

OPERATING

Please read the operating instructions thoroughly and ensure all packaging ha s

been removed before switching mains power “ON”.

IMPORTANT:

Ensure that who-ever is operating this appliance is fully conversant with its working and is made aware of the dangers of incorrect operation.

If the operating manual is not available with the appliance, please contact the

Technical Services Department at BKI (See page 6)

Safety Cut-Out

For added safety `NMK` rotary ovens have a built in thermal cut-out to protect

against overheating through component failure or incorrect use.

If for any reason the thermal cut-out operates the oven will automatically shut

down and should be switched `OFF`, disconnected from the mains and allowed to

cool.

NOTE: THE THERMAL CUT- OUT WILL NOT RESET AUTOMATICALLY

The oven must not be re-used until it has been checked by a qualified electrician

or BKI appointed service agent.

ELECTRICAL CONNECTION

• Single phase appliances fitted with a power supply cable having a rated

input Not exceeding 3kW

means of a BS 1363 ASTA approved 13 amp plug fitted with a BS 1362

fuse.

• Do not use an adaptor or extension lead, plug directly into a 13 amp socket

outlet.

• Check the appliance data rating plate and test certificate for appliance fuse

rating.

• Where a 13 amp plug is required, please follow the instructions below:

WARNING - THIS APPLIANCE MUST BE EARTHED

IMPORTANT:

The wires in the mains lead are coloured in accordance with the following code:

GREEN & YELLOW EARTH

BLUE NEUTRAL

BROWN LIVE

As the conductors in the equipment mains lead may not correspond with the

coloured markings of the terminals in your plug, proceed as follows:

The wire that is coloured green & yellow must be connected to the terminal in the

plug that is marked with the letter E or by the Earth symbol or coloured

green or green & yellow.

The wire that is coloured blue must be connected to the terminal that is marked

with the letter N or coloured black.

The wire that is coloured brown must be connected to the terminal that is marked

with the letter L or coloured red.

may be connected to a suitable power supply by

10

7

Page 8

ELECTRICAL CONNECTION

• IMPORTANT: If this appliance is not connected to an electrical supply by

means of a BS 1363 13 amp plug it must be connected to a suitable electrical supply by a qualified electrician in accordance with the latest edition of

the I.E.E WIRING REGULATIONS.

• NOTE: A method of disconnection from the mains supply having a contact

separation of at least 3mm in all poles must be incorporated in the fixed

wiring.

• It is recommended that an R.C.D device with a 30ma trip and contact rating

to suit the appliance current is installed adjacent to the appliance.

• Type 3 circuit breakers or appropriate rated fuses are recommended for

installation at the supply end.

• NOTE: High surge currents are present when this appliance is switched

on from cold.

• Industrial plugs and sockets must comply with BS 4343/EN60.309

(IEC309.2/CEE17).

• It is recommended that the supply cable shall be an oil resistance sheathed

flexible cable to BS 6500 1990 table 6 (code designation HO5 RN-F).

• If the appliance power supply cord is damaged or changed it must be replaced to the above standard and must not be longer than 2 metres between appliance inlet and plug or socket outlet.

• It is required that, in the power supply cable connection to the appliance

terminal block; the earth conductor is to be made at least 50mm longer than

the length of the live (L) and neutral (N) conductors, so that if the cable is

strained the earth conductor is the last to become disconnected.

• For appliances with a rated current upto and including 16amps, 1.5mm

cable should be used.

2

SUPPLY CABLE - CONNECTION

• To gain access to the control panel and terminal connection block, remove

the two side panel securing screws, slide the panel “up” and “out” at the

bottom.

• The terminal connection block is sited toward the the bottom left hand side

of the control box. Cable entry is provided through the base of the oven.

• Refer to terminal connection block diagram for correct connection.

NMK MAINS BLOCK

Supply rail connections - 230V, Single Phase

WARNING - THIS APPLIANCE MUST BE EARTHED

GND

GND

10

9

L1

N

GND

10

N L1E

9

Live

Neutral

Earth

8

9

Loading...

Loading...