Page 1

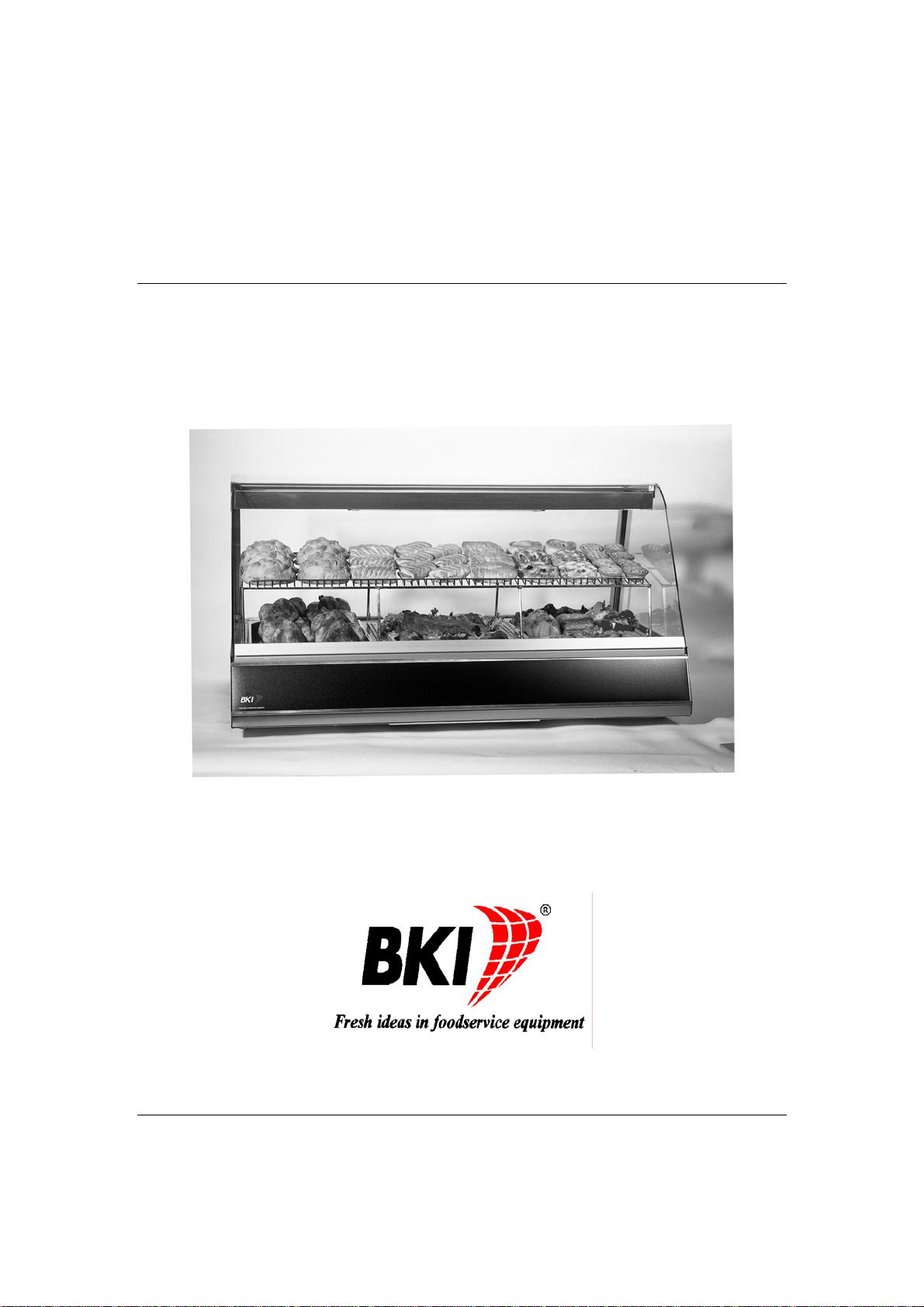

HOT FOOD DISPLAY CABINETS

MODELS:- CHS/1N, CHS/2N,CHS/3N

OPERATING INSTRUCTIONS

Page 2

CONTENTS

SECTION

PAGE

WARRANTY 2

INTRODUCTION 3

GENERAL NOTES 3

KNOW YOUR “HOT SHOP” 4-5

OPERATING 6-7

HOLDING TIMES 7

CLEANING & MAINTENANCE 8

GLASS & LAMPS 8-9

TROUBLE-SHOOTING 10

GASTRONORM PANS & SPARE PARTS 11

BKI ‘HOT FOOD DISPLAY’ CABINETS ARE MANUFACTURED

ACCORDING TO THE FOLLOWING STANDARD:-

BS EN 60 335-2-2.50:1992

1

Page 3

WARRANTY

Each appliance is despatched with a pre-paid warranty registration card, this card

should be filled in at the time of installation.

Please Note:- No warranty is given on glass/bulbs or quartz tubes.

All BKI equipment is supplied to the following Warranty from Standex International

Ltd T/A BKI - Europe (hereinafter called “the Manufacturer”)

1. Subject to the other terms of this Warranty the Manufacturer will provide free

replacement of detective materials and other components within a period of 12

months from delivery, where any defective part or component is reasonably

attributable to faulty materials or workmanship and provided that the equipment or

alleged defective part is forwarded pre-paid to the manufacturer. Except for

quartz and halogen lamps, bulbs and glass doors which are not covered by

warranty.

2. The Manufacturer shall not be under any liability under this warranty if the

equipment or any part thereof shall have been altered in any way or operated from

the incorrect voltage circuit or used in a manner inconsistent with the

Manufacturer’s instructions or otherwise neglected or misused or if any parts not

supplied or approved by the Manufacturer shall be fitted to the equipment.

3. The Manufacturer’s liability is limited to the terms of this Warranty which is

given in consideration of the Purchaser’s agreeing that it shall be so limited and

that the Manufacturer shall be under no liability for any direct or consequential

loss or for any personal injury or damage to property caused by any defect in the

equipment or any part thereof howsoever the same may occur and whether or not

the same is due to the negligence of the Manufacturer. Except for the foregoing

no warranty or condition whether express or implied by common law statue or

otherwise shall apply to any BKI equipment.

4. This warranty shall be construed in accordance with English Law.

2

Page 4

OPERATING INSTRUCTIONS

INTRODUCTION

Thank you for deciding to purchase a “Hotshop” food display cabinet from BKI.

Your “Hot Shop” food display has been designed for the modern caterer and serves

the following needs:-

•

As a Merchandiser : It will attract customers, enhance the appearance of the

food and act as a “silent salesman” to help sell your

Product.

•

For Health & Safety: It will maintain hot food at the correct temperature to

meet statutory requirements.

•

For The Operator: It is designed for safety, is user friendly and easy to

Maintain.

Please read these instructions carefully and if you follow them faithfully you will

have years of trouble free use.

GENERAL NOTES & INFORMATION

Your “Hot Shop” food display cabinet has been completely assembled and tested

before despatch.

It has been packed for safe shipment to your premises, any accessories against the

delivery note.

•

This appliance requires a 220/240v,50Hz single phase power supply.

•

It is recommended that this appliance is installed by a qualified electrician.

•

Check that the voltage shown on the data rating plate conforms with your power

supply.

Warning – This appliance must be earthed

Important:- Read the installation & operating instructions thoroughly and ensure all

Packaging has been removed before connecting to the power supply.

3

Page 5

Sliding doors

Controls

Serial Number

Water Drawer

Rubber Feet

Know your “Hot Shop”

Operator Control View

Data rating

plate

Controls

Temperature Controller Heater “ON” Main Power Switch

Light (Illuminated)

4

Page 6

CONTROLS

Mains Power Switch :- Controls the light, fans and supplies

power to the heating elements via the

temperature controller.

Temperature Controller :- (Simmerstat) Regulates cabinet

temperature by switching the heat

elements on/off

Heater “ON” Light :- Indicates Simmerstat` on (heating) or

`off``

Water Drawer :- Provide humidity to help prevent hot

FOOD CONTAINERS

foods drying out.

“Hot Shop” food display cabinets are supplied with a mezzanine shelf and 65mm deep

1/1 gastronorm pans fitted with wire inserts as standard.

Wet Foods :- Chicken, cooked meats etc, should be placed in the gastonorm

pans, on the wire inserts to allow for drainage.

Pies, Pastries :- Should be placed above on the mezzanine shelf.

The gastronorm pan section can be split up using the various sizes available in the

gastronorm pan range, to a maximum depth of 65mm see page 11 (spare parts) for full

listing.

5

Page 7

OPERATING

In order to comply with the Food Safety Act 1990 and the Food Safety (General Food

Hygiene) regulations 1995, hot food must be kept at a temperature of at least 63.5oc.

Follow these instructions carefully to ensure compliance.

• Fill water drawer to level marked with fresh clean cold water,

Water drawer holds approximately: 4 Ltrs (CHS2/3)

2 Ltrs (CHS1)

Do not overfill !

Water – Level

Fill to top of baffle

• Turn mains switch “ON”, interior heat lamp & fan will operate.

• Set the Simmerstat to number 3 and allow 25-30mins for the cabinet to pre-heat

before loading with freshly cooked products.

• Ensure that all cabinet doors are closed to retain heat during Pre-heat & Operation.

• Do Not set Simmerstat to “full” as this will cause the water to boil and fill

cabinet with steam.

• Check Product temperatures every hour using a digital thermometer and adjust

the Simmerstat to maintain a minimum product internal temperature of 63.50C.

• Check Water level every 2-3 hours.

• Do Not allow the water drawer to boil dry as serious damage to the cabinet

could occur.

6

Page 8

OPERATING

•

IMPORTANT:- Always allow time for the cabinet to pre-heat before loading any

food items.

Keep sliding doors closed to retain heat after loading or unloading.

•

Check water drawer every 2-3 hours, carefully add fresh water to maintain correct

level, Do Not Over Fill.

HOLDING TIMES

Many factors will affect the length of holding time possible with the variety of

foods available in todays market place.

In order to comply with the current Food Hygiene & Safety Regulations we offer the

following advice.

• The “Hot Shop” display cabinet is intended for display and holding of hot food

direct from cooking or re-heating.

• Microwaved or re-heated foods will generally have a shorter storage life than

freshly cooked foods.

• Do not over cook or overheat food items that are to be held hot, (overcooking will

result in excessive moisture loss that will not be re-gained, even in a humidified

cabinet).

• Always serve food products from the cabinet in strict rotation ie: first in –first out.

• Keep sliding doors closed after loading or unloading.

• Keep water drawer full to level indicated at all times.

• Take regular product internal temperatures using a digital thermometer, any

products found below 63.5oc must be removed and blast chilled or wasted.

• Adjust temperature controller according to ambient conditions, set to the lowest

possible setting that will maintain a safe product internal temperature.

• Keep your “Hot Shop” display cabinet clean.

Important:- The “Hot Shop” display cabinet must not be used to re-heat

foods.

7

Page 9

CLEANING & MAINTENANCE

IMPORTANT:- This cabinet should be cleaned at the end of each working day.

Always disconnect the cabinet from the power supply before

the start of any cleaning or maintenance.

• Remove any food items left at the end of business.

• Turn mains switch “off”, disconnect from power supply and allow cabinet to

cool.

• Remove sliding doors by first lifting upwards to release bottom runner from

track, then out and down from top runner.

• Remove mezzanine shelf & gastronorm food pans, allow to soak in a hot cleaning

solution.

• Open front curved glass, support glass & clean using a bactericidal detergent

sanitiser then a clear liquid glass cleaner.

• Remove water drawer, empty old water, refill with mild cleaning solution, rinse

and wipe clean.

• Wipe over cabinet interior with a mild solution of warm water and bactericidal

detergent cleaner using a damp cloth, avoid getting excess water into the cabinet

interior or over the control panel section.

• Do not attempt to clean the elements or lamp.

• Do not use a water jet or steam cleaner.

• Do not use abrasive or corrosive cleaners.

GLASS

All flat and curved glass panels fitted to “Hot Shop” holding cabinets are

manufactured from toughened or tempered safety glass.

IMPORTANT:- Take care when cleaning or handling glass, allow glass

to cool before cleaning, for best results use a clear liquid

smear free glass cleaner.

Do not use abrasive cleaners or scouring pads on glass panels.

8

Page 10

The Front Curved glass and Side glass panels can be removed for maintenance or

cleaning as follows:

CURVED GLASS

• Lift front curved glass section forwards from the top.

(The front glass section is attached to the cabinet at the bottom by the aluminium

strip).

Hold the glass in the forward position for cleaning or tilt forwards and lift out of

track for complete removal

IMPORTANT:- Do not leave the front curved glass section unsupported in the

open position.

• Slide the side panels our from the front

• Replace in reverse order

LAMPS

The “Hot Shop” display cabinets are illuminated with T5 Fluorescent lamps fitted

with a protective over tube.

Replace failed lamps as soon as possible as follows:-

• Remove any food items from the cabinet, then switch “off”.

• Disconnect the cabinet from the power supply, allow to cool.

• Remove sliding doors.

• Remove mezzanine shelf and any food pans.

• Remove lamp, grip lamp through lamp cover & twist ¼ turn clockwise towards

front of cabinet to release ends.

• Replace with a new lamp of the correct voltage and rated input.

Important:- Do Not forget to refit lamp cover. Replace cover if damaged.

Important:- In the event of a glass breaking whilst the

cabinet is in use, any food items held at that time must

be wasted.

The cabinet must be thoroughly inspected and cleaned before future use.

9

Page 11

TROUBLE-SHOOTING

1. Read and understand the Operating Instructions.

2. Clean the unit each day.

3. Refer to the troubleshooting guide if the unit does not operate properly.

4. Have only an authorised serviceman check and repair unit when needed

PROBLEM CORRECTIVE ACTION

Unit fails to operate

1. No Power 1. Assure that power supply is sound

2. Circuit breaker is off 2. Rest circuit breaker

No Heat

1. Circuit breaker is off 1. Check circuit breaker

2. Defective heating element 2. Replace heating element

3. Defective Simmerstat 3. Replace Simmerstat

4. Loose wire or bad connection 4. Repair

Holding Temperature not Adequate

1. Door is open 1. Keep doors closed when not in use

2. Food temperature is too low 2. Food under cooked / over cooked or

held too long (See Holding Times)

3. Cabinet temperature too low 3. Adjust Simmerstat, allow time for

cabinet to pre-heat before loading

products.

Cabinet too hot or steamed up

1. Food temperature is too high 1. Adjust Simmerstat, check water level

2. Food items drying out 2. Food over cooked or held too long,

Simmerstat set to high, water drawer

empty.

3. Cabinet steamed up 3. Hot water used when cabinet

switched on from cold.

Hot food loaded before cabinet has been

preheated.

Simmerstat set to Full

10

Page 12

GASTRONORM PANS & SPARE PARTS

Contact your distributor or the spares department at BKI for spare gastronorm pans or

replacement lamps, quoting the following code numbers, check the appliance rating

plate for model type

GASTRONORM

CONTAINER SIZE DEPTH CAPACITY (Ltrs) CODE

GN 1/1 40mm 5 PN001

GN 1/1 65mm 9 PN006

WIRE GRID (1/1) TY013

GN 2/3 40mm 3 PN012

GN 2/3 65mm 5.5 PN010

GN 1 /2 40mm 2 PN013

GN 1 /2 65mm 4 PN009

GN 1 /3 40mm 1.5 PN014

GN 1 /3 65mm 2.5 PN008

Spare Parts List

PART CODE DESCRIPTION

CA 069 Element, 2500 W (CHS/N2)

CA 070 Element, 2000 W (CHS/N3)

CO 009 Schrack relay, 25A (RM 805730) (CHS/N3)

FA 010 Fan

GL 060 Curved Glass (CHS/N2)

GL 069 Curved Glass (CHS/N3)

GL 121 Side Glass (All models)

LI 023 Fluorescent lamp, T5, 535mm, F13W / White

LI 026 Lamp over-tube

LI 024 T5 lamp holder, ¼ turn, snap-in

LI 025 Ballast 13W, screw terminal

LI 027 Fluorescent starter, glow type, 4 – 80W

LI 028 Starter holder

LI 012 Neon indicator, amber, round

SI 001 Simmerstat c/w knob

SW 019 Switch, rocker c/w neon

11

Loading...

Loading...