BAKERS

PRIDE

30 Pine Street • New Rochelle • New York • 10801

914 / 576 - 0200

914 / 576 - 0605

1 - 800 - 431 - 2745

www.bakerspride.com

fax

US & Canada

web address

DESIGN & INSTALLATION

GUIDELINES

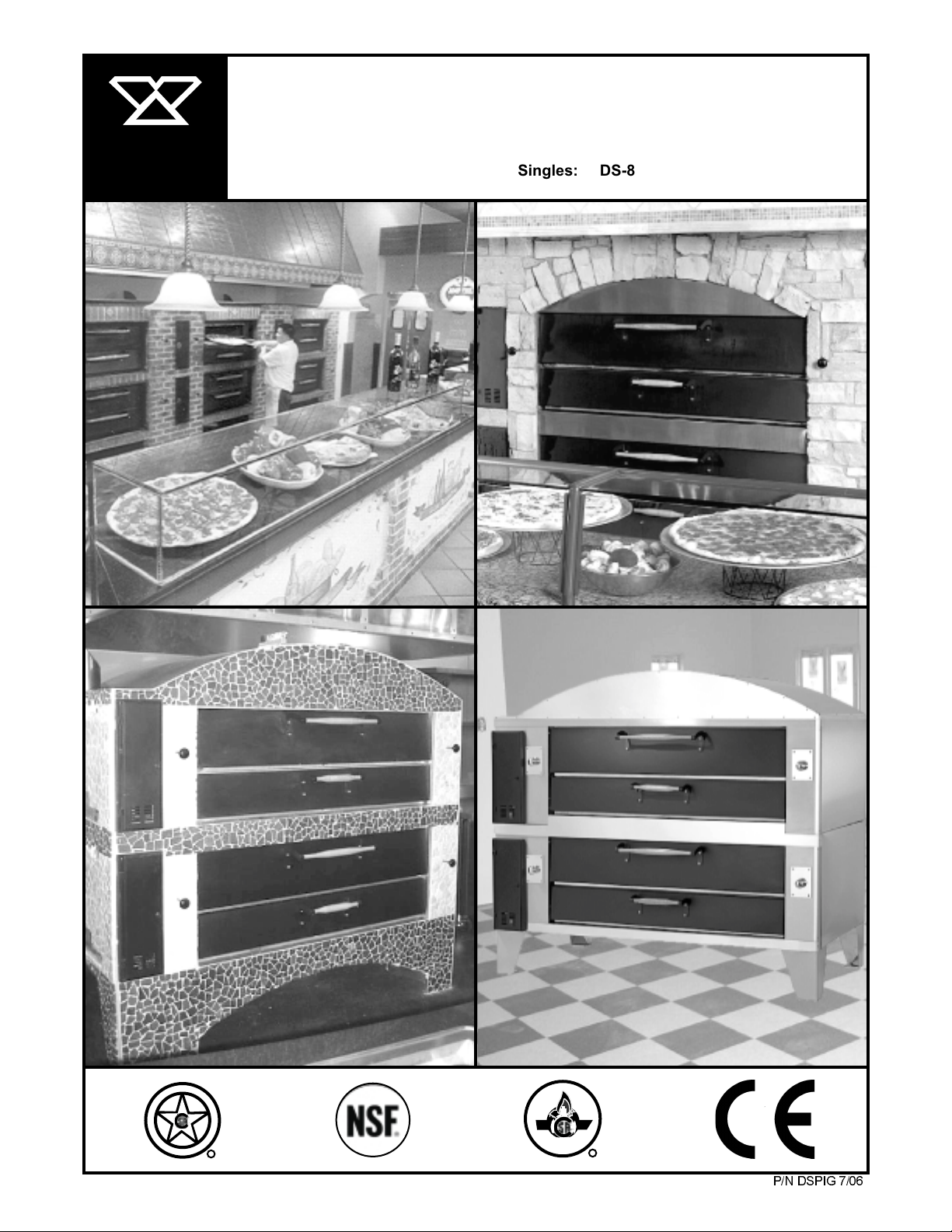

DSP DISPLAY OVENS

Singles: DS-805 D-125 Y-600 Y-800

Doubles: DS-990 D-250 Y-602 Y-802

I

G

S

N

E

D

C

E

D

R

E

I

T

I

F

R

CERTIFIED

R

P/N DSPIG 7/06

1

Y-602-DSP - FINISHED IN SANDSTONE

Black Powder Coated Doors

with Hardwood Handles

Front or Side Mounted

Control Panel Covers

Decorative

Dome/Riser

Hearth

Baking

Decks

Feather-Touch Spring

Balanced Doors

Push-Pull Rods for

Top & Bottom

Heat Control

Solid Unitized

Construction

All Welded

Angle Iron &

Plate Steel

Frame

Front Skirt

Energy Saving

Thermostatic Controls

Slide Out Flame Diverters

for Even Heat Distribution

Side Skirt

Extra Thick Industrial

Insulation Throughout

Stackable

2

TABLE OF CONTENTS

ITEM SKETCH PAGE

SPECIFICATION / ORDER GUIDE CHECK LIST 4

SPECIFICATION SHEETS 5-8

DS-805 & DS-990 5, 6

!

!

D-125 & D-250 7, 8

!

Y-600 & Y-602, Y-800 & Y-802 9, 10

GETTING STARTED 1-4 11-14

PLAIN 'AS IS' 515

DECORATIVE-TRIM INSTALLATION GUIDELINES 6 15

“DSP” STYLE INSTALLATION GUIDELINES 7, 8 16

3

SPECIFICATION / ORDER GUIDE CHECK LIST

Date:

Dealer Name:

Project Name:

P. O. Number:

Signature:

How do you intend to finish/build-in your oven(s)? (Choose One)

As Is / Decorative Exterior Trim - Casters optional

DSP Style - Apply tile/stone directly on to oven(s) - Skirts provided

Single Oven or f Stacked InstallationUpper Oven o

Hinged Control Panel Door

(Choose One)

Bake Chamber Door

(Choose One)

MODEL (Choose One)

DS-805-DSP Single

D-125-DSP Single

Y-600DSP Single

Y-800DSP Single

DS-990-DSP Double

D-250-DSP Double

Y-602DSP Double

Y-802DSP Double

Automatic Oven Starter

(Optional)

Front Mounted

Side Mounted

Hinged Control Panel Door

(Choose One)

Black Powder Coated

Stainless Steel

Lower Combustion Chamber Door

(Choose One)

Black Powder Coated

Stainless Steel

Lower Oven of Stacked Installation

Hinged Control Panel Door

(Choose One)

Front Mounted

Side Mounted

Hinged Control Panel Door

(Choose One)

Black Powder Coated

Stainless Steel

Casters

(Set of 4)

Not suitablefor DSP stylefinish with skirts

Yes

No

Gas Type

(Choose One)

Natural Gas

L.P. Gas

Bake Chamber Door

(Choose One)

Black Powder Coated

Stainless Steel

Automatic Oven Starter

(Optional)

Allows operatorto establish automatic

oven start& stop times

Yes

No

Decorative Upper

Riser Panel / Dome

Note: CurvedDome on YSeries Ovens &

Rectangular Riser on D Series Ovens

Yes

No

Legs

Legs (total height with or without

casters) included. Please specify.

30” (Standard on all single deck

models)

Black Powder Coated

Stainless Steel

Lower Combustion Chamber Door

(Choose One)

Black Powder Coated

Stainless Steel

Gas Type

(Choose One)

Natural Gas

L.P. Gas

NOTE:

See specification sheets for additional options & accessories.

Allows operatorto establish automatic

oven start& stop times

Yes

No

Casters

(Set of 4)

Not suitablefor DSP stylefinish with skirts

Yes

No

4

16” (Standard on all double deck

models except D-250)

12” (Standard on model D-250)

Special height legs - specify

length - optional extra charge

DSP CHECK LIST 4/06

SUPER DECK

BAKERS

PRIDE

BAKERS PRIDE Super Deck DS DSP gas Deck Ovens

display cooking and exhibition kitchens. These ovens are designed

and engineered to be "built-in" behind brick, stone or tile applied

directly to ovens exterior or finished and trimmed in brass, copper,

stainless or powder-coated trim.

Ovens may be stacked two high. Oven exteriors are all heavygauge, type 403 stainless steel and are fully insulated up to 5"

(127mm) thick for cooler outer temperatures and consistent interior

temperatures.

Interior oven frame is constructed of 1/4" (6mm) heavy-duty angle

iron frame, completely welded to form a single, unitized section.

The oven body and lining are then welded to the framework.

Oven interiors are manufactured of high-heat resistant 16-gauge

aluminized steel. Doors are fully insulated, spring balanced to

remain open or closed until moved and finished in black powder

coat with hard wood handles.

All models feature independent, operator-controlled top & bottom

heat control dampers and micro slides for perfectly balanced

results.

DS DSP Series features a 300°-650° F (149°-343°C)

thermostat, 6 3/4" (171mm) interior deck height with

(38mm) thick hearth stone

supported by a 1/4" (6mm) angle iron frame.

Combination gas control incorporates a manual gas valve, pilot

safety and pressure regulator. Easily removable, slide-out, heavyduty flame diverters distributes the burner flame uniformly in the

burner chamber. A 3/4" (19mm) NPT gas connection is located on

the left side and left rear of oven - operator/installer may choose.

Heavy-duty, 7-gauge hot rolled steel legs are standard and finished

with durable Bakertone Gray.

2 Year limited part and labor warranty standard.

DS DSP SERIES

GAS DECK OVENS

DS -805 DSP

shown without top riser

and without skirts

SPECIFICATIONS

decks (steel decks optional) and are

are ideal for

throttling

1 1/2"

Job ____________ Item # ___________

GAS DECK OVENS

q Model DS-805 DSP Single

q Model DS-990 DSP Double

STANDARD FEATURES

q

DS Series @ 70,000 BTUH per deck, natural or LP gas

q

300°-650° F (149°-343°C) throttling thermostat

q

Top & bottom heat control dampers & micro-slides

q

Combination gas controls with valve, regulator & pilot safety

q

Heavy-duty, slide-out flame diverter

q

6 3/4" (171mm) interior deck heights with 1 1/2" (38mm)

thick hearth stone decks

q

All stainless steel exteriors

q

Aluminized steel interiors

q

Spring balanced, fully insulated doors finished in black powder

coat with custom hardwood handles or stainless steel with

tubular steel handles

q

Front or side mounted controls with large, hinged access door

in black powder coat or stainless steel

q

Riser top removable for field installations

q

Front & side skirts

q

Side or rear gas connections on models with front mounted

controls - rear gas connections only on models with side

mounted controls

q

7-Gauge legs finished in Bakertone Gray

q

Fully insulated throughout

q

2 Year limited part and labor warranty

OPTIONS & ACCESSORIES

q

Steel decks in lieu of hearth decks

q

150°-550° F (65°-288°C) thermostat

q

350°-700° F (149°-371°C) thermostat

q

Set of 4 casters - two with locks - not for use with skirts

q

Stainless steel leg covers

q

Special height legs

q

Automatic oven starter

q

Draft flue for direct vent (not available on CE units)

q

Without dome/riser and/or without skirts

CERTIFICATIONS

G

I

S

N

E

D

CANADIANGASAS SOCIATION

®

CERTIFIED

C

D

E

E

R

I

T

I

F

G

BAKERS

PRIDE

BAKERS PRIDE OVEN COMPANY, INC.

30 Pine Street, New Rochelle, NY 10801

914/576-0200 1-800-431-2745 fax 914/576-0605

www.bakerspride.com

Continuous product improvement is a policy of Bakers Pride Oven Company.

Therefore, specifications and design are subject to change without notification

5

ALL DIMENSIONS NOMINAL

SHIPPING INFORMATION

Shipping Weight Crate Size

Lbs.

Model

DS-805

Kilos

Inches

1073 78

31 60 86487 2.8

Each oven ships separately

Hearth Decks and Legs ship in separate cartons

SPECIFICATIONS

Deck Sizes

Model

DS-805

DS-990

in.

48 x 36

48 x 36

mm

1219 x 914

1219 x 91412

* Overall height excludes dome/riser top

MINIMUM CLEARANCES

Noncombustible Construction Combustible Construction

Inches Inches

mm mm

Right

Left

Rear

BAKERS

PRIDE

0

0

2

BAKERS PRIDE OVEN COMPANY, INC.

30 Pine Street, New Rochelle, NY 10801

914/576-0200 1-800-431-2745 fax 914/576-0605

www.bakerspride.com

1

0

3

0

3

51

Width Depth Height

Carton Dimensions

Inches Inches

mm mm mm

787 1365 2184

Overall Dimensions

# Decks

Width Depth

Inches

65 1/4

1651

65 1/4

1651

25

76

76

Cubic

Cubic

Feet

Meter

54 7/8

65 3/4

Height*

1394

1670

Inches Inchesmm mm mm

43

1092

43

1092

6

GAS SUPPLY

Model

DS-805

DS-990

CE

BTUH

70,000

140,000

6"

(152mm)

12"

(305mm)

For Direct Venting For Installation Under

MUST BE SPECIFIED

AT TIME OF ORDER

Continuous product improvement is a policy of Bakers Pride Oven Company.

Therefore, specifications and design are subject to change without notification

KW CONNECTION

20.5

41.0

3/4”

3/4”

(152mm)

12"

(305mm)

Ventilation Hood

STANDARD

TSW:07/06

6"

BAKERS

PRIDE

SUPER DECK

D-DSP SERIES

GAS DECK OVENS

Job ____________ Item # ___________

GAS DECK OVENS

q Model D-125 DSP Single

q Model D-250 DSP Double

STANDARD FEATURES

G

10"

INTERIOR

DECK HEIGHT

D-125 DSP

shown without top riser

and without skirts

SPECIFICATIONS

BAKERS PRIDE D Series DSP Deck Ovens are ideal for display

cooking and exhibition kitchens. These ovens are designed and

engineered to be "built-in" behind brick stone or tile applied directly

to ovens exterior or finished and trimmed in brass, copper, stainless

or powder-coated trim.

Ovens may be stacked two high. Oven exteriors are all heavygauge, type 403 stainless steel and are fully insulated up to 5"

(127mm) thick for cooler outer temperatures and consistent interior

temperatures.

Interior oven frame is constructed of 1/4" (6mm) heavy-duty angle

iron frame, completely welded to form a single, unitized section.

The oven body and lining are then welded to the framework.

Oven interiors are manufactured of high-heat resistant 16-gauge

aluminized steel. Doors are fully insulated, spring balanced to

remain open or closed until moved and are finished in black powder

coat with hard wood handles.

q

D Series @ 125,000 BTUH per deck natural gas or 105,000

BTUH in LP gas (LP gas not CE certified)

q

300°-650° F (149°-343°C) throttling thermostat

Top & bottom heat control dampers & micro-slides

q

q

Combination gas controls with valve, regulator & safety pilot

q

Heavy-duty, slide-out flame diverters

q

10 3/4" (273mm) interior deck heights with 1 1/2" (38mm)

thick stone hearth decks

q

All stainless steel exteriors

q

Aluminized steel interiors

q

Spring balanced, fully insulated doors finished in black powder

coat with custom hard wood handles or stainless steel with

tubular steel handles

q

Front or side mounted controls with large, hinged access

cover in black powder coat or stainless steel

q

Riser top - removable for field installation

q

Front & side skirts

q

Left side or rear gas connections on models with front

mounted controls - rear gas connection only on models with

side mounted controls

q

7-Gauge legs

q

Fully insulated throughout

q

2 Year limited part and labor warranty

OPTIONS & ACCESSORIES

All models feature independent, operator-controlled top & bottom

heat control dampers and micro slides for perfectly balanced

results.

D Series features a 300°-650° F (149°-343°C) thermostat,

10 3/4" (273mm) interior deck height with

throttling

1 1/2" (38mm) thick

hearth stone decks (steel decks optional) and are supported by a

1/4" (6mm) angle iron frame.

Combination gas control incorporates a manual gas valve, safety

and pressure regulator. Easily removable, slide-out, heavy-duty

pilot

flame diverters distribute the burner flame uniformly in the burner

chamber. A 3/4" (19mm) NPT gas connection is located on the left

side and left rear of oven - operator/installer may choose.

Heavy-duty, 7-gauge hot rolled steel legs are standard and finished

with durable Bakertone gray paint.

2 Year limited part and labor warranty standard.

BAKERS PRIDE OVEN COMPANY, INC.

BAKERS

PRIDE

30 Pine Street, New Rochelle, NY 10801

914/576-0200 1-800-431-2745 fax 914/576-0605

www.bakerspride.com

q

Steel decks

q

150°-550° F (65°-288°C) bake thermostat

q

Set of 4 casters - two with locks - not for use with skirts

q

Stainless steel leg covers

q

Special height legs

q

Automatic oven starter

q

Draft flue for direct vent (not available on CE units)

q

Black powder coated doors with hard wood handles

q

Black powder coated hinged control access door panel

q

Without dome and/or without skirts

CERTIFICATIONS

G

I

S

N

E

D

CANADIANGASAS SOCIATION

®

Continuous product improvement is a policy of Bakers Pride Oven Company.

Therefore, specifications and design are subject to change without notification

7

CERTIFIED

C

D

E

E

R

I

T

I

F

ALL DIMENSIONS NOMINAL

SHIPPING INFORMATION

Shipping Weight Crate Size

Lbs.

Model

D-125

Kilos

Inches

1385 88

31 53 82626 2.5

Each oven ships separately

Hearth Decks and Legs ship in separate cartons

SPECIFICATIONS

Deck Sizes

Model

D-125

D-250

in.

48 x 36

48 x 36

mm

1219 x 914

1219 x 91412

* Overall height excludes dome top

MINIMUM CLEARANCES

Noncombustible Construction Combustible Construction

Inches Inches

mm mm

Right

Left

Rear

BAKERS

PRIDE

0

0

2

BAKERS PRIDE OVEN COMPANY, INC.

30 Pine Street, New Rochelle, NY 10801

914/576-0200 1-800-431-2745 fax 914/576-0605

www.bakerspride.com

1

0

3

0

3

51

Width Depth Height

Carton Dimensions

Inches Inches

mm mm mm

787 1364 2083

Overall Dimensions

# Decks

Width Depth Height*

Inches

65 1/4

1657

65 1/4

1657

25

76

76

Cubic

Cubic

Feet

Meter

Inches Inchesmm mm mm

43

43

1092

1092

59

1499

70

1778

8

GAS SUPPLY

Model

D-125

D-250

D-125

D-250

CE

natural

natural

BTUHGAS TYPE

125,000

250,000

LP

105,000

LP

210,000

6"

(152mm)

12"

(305mm)

For Direct Venting

NOT CE APPROVED

MUST BE SPECIFIED

AT TIME OF ORDER

Continuous product improvement is a policy of Bakers Pride Oven Company.

Therefore, specifications and design are subject to change without notification

KW CONNECTION

36.6

30.7

73.2

61.4

3/4”

3/4”

3/4”

3/4”

(152mm)

12"

(305mm)

For Installation Under

Ventilation Hood

STANDARD

TSW:07/06

6"

SUPER DECK

BAKERS

PRIDE

BAKERS PRIDE Y-DSP Display Ovens are ideal for display cooking

and exhibition kitchens. These ovens are designed and engineered

to be "built-in" behind brick, stone or tile applied directly to ovens

exterior or finished and trimmed in brass, copper, stainless or

powder-coated trim.

Ovens may be stacked two high. Oven exteriors are all heavygauge steel and are fully insulated up to 5" (127mm) thick for

cooler outer temperatures and consistent interior temperatures.

Interior oven frame is constructed of 1/4" (6mm) heavy-duty angle

iron frame, completely welded to form a single, unitized section.

The oven body and lining are then welded to the framework.

Oven interiors are manufactured of high-heat resistant 16-gauge

aluminized steel. Doors are fully insulated, spring balanced with

natural black finish and custom wood handles.

Lintel plates support the masonry or tile for ease of installation.

Standard features include dome top plus front and side skirts.

All models feature independent, operator-controlled top & bottom

heat control dampers and micro slides for perfectly balanced

results.

Y Series features a 300°-650° F (149°-343°C) thermostat,

8" (203mm) interior deck height with

decks (steel decks optional) and are supported by a 1/4"

stone

(6mm) angle iron frame.

Combination gas control incorporates a manual gas valve, pilot

safety and pressure regulator. Easily removable, slide-out, heavyduty flame diverters distribute the burner flame uniformly in the

burner chamber. A 3/4" (19mm) NPT gas connection is located on

the left side and left rear of oven - operator/installer may choose.

Heavy-duty, 7-gauge hot rolled steel legs are standard and finished

with durable Bakertone.

2 Year limited part and labor warranty standard.

Y-DSP SERIES

GAS DISPLAY OVENS

Model Y-602-DSP

with optional stone finish

SPECIFICATIONS

throttling

1 1/2" (38mm) thick hearth

Job ____________ Item # ___________

GAS DECK OVENS

q Model Y-600-DSP Single

q Model Y-602-DSP Double

q Model Y-800-DSP Single

q Model Y-802-DSP Double

STANDARD FEATURES

q

Y Series @ 120,000 BTUH per deck, natural or LP gas

q

300°-650° F (149°-343°C) throttling thermostat

q

Top & bottom heat control dampers & micro-slides

q

Combination gas controls with valve, regulator & pilot safety

q

Heavy-duty, slide-out flame diverters

q

8" (203mm) interior deck heights with 1 1/2" (38mm) thick

hearth stone decks

q

Black powder coated doors with custom hardwood handles or

stainless doors with tubular steel handles

q

Front or side mounted controls with large, hinged access

cover door in black powder coat or stainless steel

q

Dome top - removable for field installations

q

Front & side skirts

q

Aluminized steel interiors

q

Spring balanced, fully insulated doors

q

Rear gas connections

q

7-Gauge legs

q

Fully insulated throughout

q

2 Year limited part and labor warranty

OPTIONS & ACCESSORIES

q

Side-mounted controls

q

Steel decks in lieu of hearth stone decks

q

150°-550° F (65°-288°C) thermostat

q

Automatic oven starter

q

Draft flue for direct vent (not available on CE units)

q

Fire brick hearth decks (Y-600/602 only)

q

Without dome and/or without skirts

q

Set of 4 casters - two with locks - not for use with skirts

CERTIFICATIONS

G

I

S

N

E

D

CANADIANGASAS SOCIATION

®

CERTIFIED

C

D

E

E

R

I

T

I

F

G

BAKERS

PRIDE

BAKERS PRIDE OVEN COMPANY, INC.

30 Pine Street, New Rochelle, NY 10801

914/576-0200 1-800-431-2745 fax 914/576-0605

www.bakerspride.com

Continuous product improvement is a policy of Bakers Pride Oven Company.

Therefore, specifications and design are subject to change without notification

3

9

D

C

B

A

D

LEFT SIDE VIEW

Single Unit With Side Controls

.

LEFT SIDE VIEW

Stacked Unit With Side Controls

TOP VIEW

FRONT VIEW

Stacked Unit With Front Controls

ALL DIMENSIONS NOMINAL

SHIPPING INFORMATION

Model

Y-600-DSP

Y-800-DSP

Each oven ships separately

Hearth Decks and Legs ship in separate cartons

SPECIFICATIONS

Model

Y-600-DSP

Y-602-DSP

Y-800-DSP

Y-802-DSP

* Overall height excludes dome top

BAKERS

PRIDE

Shipping Weight Crate Size

Lbs.

Kilos

Inches

626

1385

726

1600

Deck Sizes

AxB

36 x 60

36 x 60

44 x 66

44 x 66

BAKERS PRIDE OVEN COMPANY, INC.

30 Pine Street, New Rochelle, NY 10801

914/576-0200 1-800-431-2745 fax 914/576-0605

www.bakerspride.com

914 x 1524

914 x 1524

1118 x 1676

1118 x 1676

Width Depth Height

31

31

mm

Carton Dimensions

Inches Inches

mm mm mm

787

787

# Decks

1364

53

1365

60

Inches

1

78

2

78

1

84

2

84

Cubic

Cubic

Feet

Meter

2083

82

2184

86

Overall Dimensions

C D Height*

Inches Inchesmm mm mm

43

1981

43

1981

51

2134

51

2134

1092

1092

1295

1295

2.4

76

2.8

78

55 1/8

66 1/4

55 1/8

66 1/4

10

1400

1683

1400

1683

GAS SUPPLY

Model

Y-600-DSP

Y-602-DSP

Y-800-DSP

Y-802-DSP

CE

BTUH

120,000

240,000

120,000

240,000

KW CONNECTION

35.15

70.30

35.15

70.30

3/4”

3/4”

3/4”

3/4”

MINIMUM CLEARANCES

Noncombustible Construction Combustible Construction

Inches Inches

mm mm

Right

Left

Rear

Continuous product improvement is a policy of Bakers Pride Oven Company.

Therefore, specifications and design are subject to change without notification

0

0

2

1

0

0

51

3

3

25

76

76

TSW:07/06

GETTING STARTED

Thank you for choosing DSP style display ovens. We recommend you thoroughly read and consider steps #1

thru #8 prior to designing your kitchen and prior to ordering your oven(s). We also recommend that you

thoroughly read and understand these installation guidelines priorto installing your newoven(s).

Step #1 Choosewhich oven sizeis right for you. DSPdisplay ovens are available in 4 models.

STEP #1

MODEL DESCRIPTION DECK SIZE NO. OF DECKS CAPACITY

DS-805 DSP Single Deck 48”w x 36”d 1 4 each 16” Pizzas

D-125 DSP Single Deck 48”w x 36”d 1 4 each 16” Pizzas

Y-600 DSP Single Deck 60”w x 36”d 1 6 each 16” Pizzas

Y-800 DSP Single Deck 66”w x 44”d 1 8 each 16” Pizzas

DS-990 DSP Double Deck 48”w x 36”d 2 8 each 16” Pizzas

D-250 DSP Double Deck 48”w x 36”d 2 8 each 16” Pizzas

Y-602 DSP Double Deck 60”w x 36”d 2 12 each 16” Pizzas

Y-802 DSP Double Deck 66”w x 44”d 2 16 each 16” Pizzas

Choose single, or double deck for increasedcapacity and productionthrough put.

Refer to individual specification sheets for more details.

1A SINGLE DECK

Step #2 Choose front-mounted or side-mounted control panel(s). The exterior finish style and location of

STEP #2

controls often work together tocreate the “look”you want.

1B DOUBLE DECK

2A SINGLE OVEN W/FRONT-MOUNTED CONTROLS 2B DOUBLE UNIT W/SIDE-MOUNTED CONTROLS

11

Step #3 Decide how you intend to “finish” or “build-in” your oven(s) prior to ordering. Installation instructions

STEP #3

are available for each “finish” style. There arethree basic styles:1, 2,3.

3A PLAIN “AS-IS” - STYLE 1

Plain, AS-IS ready to use. No decorative finish.

Available with black powder coated doors or all

stainless steel exterior.

3B DECORATIVE TRIM - STYLE 2

Finish your oven with decorative trim-pieces of

brass, copper, tile etc., in black powder coated

doors or all stainless steelexterior.

3C DSP - STYLE 3

12

“DSP” Style. Stone, tile, thin brick or

other masonry finish is applied

directly to the oven exterior. Skirts

provided, casters excluded.

Step #4 Ventilation: Choose either a canopy style hood or directvent .

STEP #4

4A

Canopy Style Hood

Our is for

Standard flue

exhausting into a canopy hood.

Vent Hood (Not Included)

P

E

E

I

D

S

K

R

R

A

B

4B

Direct Vent

Our flue is for

Direct Vent

venting into a chimney and

is optional at no extra cost.

E

I

D

R

P

S

R

E

K

A

B

NOTE: Minimum clearance may be reduced when using UL listed hood assemblies and installed in accordance with

the terms of the listing and the manufacturer instructions. Consult NFPA standard number 96 and local codes

concerning ventilation requirements and fireextinguishing system requirements.

13

Step #5 Choosegas type: Naturalor L.P.Gas.

STEP #5

STEP #6

Step #7

Choose options and accessories

!

!

!

!

!

!

!

STEP #7

!

!

!

!

Casters - Set of 4.

NOTE:

DO NOT

Natural wood essence smoke boxes.

Automatic oven starter.

Front or Side mounted controls.

Bake chamber door and combustion chamber door in stainless steel or black powder coated with

hard wood handles.

Hinged control panel access doorin stainless steel or black powdercoated.

Black powder coated doors may be mixedor matched withstainless steel doorson special request.

Choose leg height

30” (Standard on all single deck models)

16” (Standard on all double deck models except D-250)

12” (Standard on model D-250)

Special height legs - specify length - optional extra charge

Provision for restraints on thelegs with castersmust be made.

use casters with DSP style built-in ovens asthe casters interferewith theskirts.

(total height with or without casters) included. Please specify.

!

!

If you choose non-standard legheights, skirts will notfit properly (DSPstyle installations).Note:

STANDARD HEIGHTS

Inches mm

6 152

12 305

16 406

24 610

30 762

36 914

38 965

Other Key Provisions And Notes

Emergency gas shut off valve in an easily accessible location must be provided by the customer.

Gasoline or other flammable vapors and liquids should never be stored in the vicinity of the unit.

Standard legs are provided

at no extra charge. Casters

optional. Stainless steel leg

covers available. You may

specify a cut-to-order

custom height up to 38” as

an option.

BE SPECIFIC WHEN ORDERING

14

DSP DISPLAY OVENS

PLAIN “AS-IS” STYLE INSTALLATION

Your DSP Display oven(s) may be used “as-is” without

decorative finishes or architecturally designed facades.

For best-looking results consider your preference for

stainless steel doors or black powder coated doors with

wood handles and other exterior finish options.

Oven(s), decks and legs are shipped in separate

cartons. Uncrate, attach legs, install decks then

connect gas and electric utilities. Refer to operating

instruction manual for details .provided with oven(s)

DSP DISPLAY OVENS

DECORATIVE TRIM STYLE INSTALLATION

5 PLAIN “AS-IS” STYLE

Plain, AS-IS ready to use. No decorative finish.

Available with black powder coated doors or all

stainless steel exterior.

Rather than 'building-in' your oven(s) or applying

masonry finishes directly to the oven(s) exterior,

consider finishing your oven(s) with decorative trimpieces of brass, copper, powder-coated colored trim or

L-shaped tile pieces.

For best-looking results consider your preference for

stainless steel doors or black powder coated doors with

wood handles and other exterior finish options. Control

panel access cover, combustion chamber door and

flue-front may be ordered in black-powder-coated

finish or stainless steel.

Metal trim pieces are fastened by the foodservice

equipment contractor directly to the oven exterior using

3/8” to 1/2” sheet metal screws. Pre-drill holes for best

results.

The design is only limited by yourimagination.

Disclaimers: Continuous product improvement is a policy of Bakers Pride. Therefore specifications and designs are

subject to change without notice. Ultimately, the proper design and execution of any appliance installation is the

responsibility of the property owner. That party or their representative is expected to engage the service of a qualified

professional to carry out that responsibility. This includes matters of compliance with local codes. The above

information is provided as guidelines to the installation professional. Job site conditions vary considerably, and

therefore Bakers Pride Oven Company can assume no responsibility or liability for the proper installation and

operation of the gas-fired appliance. The above assumes certain conditions, which are specified. A quality

professional may modify these recommendations as jobsite conditions dictate. Forexample, 70°F airis assumed.

6 DECORATIVE TRIM STYLE

Finished with decorative trim-pieces of brass,

copper, tile etc. In black powder coated doors or

all stainless steel exterior.

15

DSP DISPLAY OVENS - DSP STYLE INSTALLATION

Anyone with some experience laying tile shouldbe able tocomplete thisproject with relativeease.

Step #1 Uncrate oven(s),attach legs, setin place.

Step #2 Attach front sheet metal skirt (provided) by drilling holes in oven legs using pre-punched holes in sheet

metal skirt as a template.

NOTE:

Step #3 Secure skirtusing sheet metalscrews.

Step #4 If youplan on finishing the ovensides with tile,etc, followsteps #2 and #3for sideskirts.

Bottom flange on skirt facesoutward.

Step #5 Fasten 3/8” thick fire resistant “Wonder Board” (7mm) to oven front (and sides if appropriate) using 1/2” to

5/8” sheet metal screws.

NOTE: “

Step #6 Attach tile, stone, thin-brick or the material of choice over “Wonder Board” using either a latex/polymer

based high-heat ceramic thin-set mortar, “spec” mix mortar or type “S” mortar. Best results will be achieved

using tile, etc. no more than 5/8”thick.

NOTE:

Step #7 Consider L-shaped tile or brick trim pieces along front vertical corners and top edges of oven front and side

to complete a finished look.

Step #8 Grout betweenbrick joints. Itis best toallow the thin-set mortar to dryover nightprior to grouting.

Step #9 Allow groutto dry for 24 hoursprior to starting ovens.

NOTE: Wonder Board equivilents; Harde Backer Board,various trade names.

Wonder Board” must be cut to fit. Allow access for push-pull rod holes, oven control access

doors and combustion and bake chamber doors.

Start at the floor and work up to top of oven. Cut stone, etc. to fit as required based on your design

and to create the look you want.

i

7 Y-602 DSP WITH TILEWORK

NOTE:

Dome/Riser tops may be removed when required to allow access through doors or under canopy during installations.

16

Loading...

Loading...