Page 1

OPERATION MANUAL

SUPERDECK SERIES GAS DECK OVENS

SERIES: Y600 & Y800

BUILT BY CRAFTSMEN. TESTED BY TIME®.

Page 2

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

FLOOR MODEL GAS DECK OVENS

Series:

Y600 and Y800

Bakers Pride Oven Company, LLC is a wholly owned

subsidiary of Standex International Corporation.

All gas operated Bakers Pride® deck ovens are intended

for use with the type of gas specified on the rating plate

and for installation will be in accordance with National

Fuel Gas Code ANSI Z223.1 (latest edition).

WARNING

FOR YOUR SAFETY: Do not store or use gasoline

or other flammable vapors or liquids in the vicinity

of this or any other appliance.

WARNING

IMPORTANT INSTRUCTIONS: After the gas

supply has been connected to your unit, it is

extremely important to check piping for possible

leaks. To do this, use soap and water solution or

solutions that are expressly made for this purpose.

DO NOT USE matches, candles, flames, or other

sources of ignition since these methods are

extremely dangerous. Post in a prominent location

instructions to be followed in the event you smell

gas. Obtain these instructions from your local gas

supplier.

NOTICE

CAUTION

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the installation,

operating and maintenance instructions

thoroughly before installing or servicing this

equipment.

NOTICE

Instructions to be followed in the event the user

smells gas must be posted in a prominent location

in the kitchen area. This information shall be

obtained from the local gas supplier.

WARNING

California Residents Only

WARNING: This product can expose you to

chemicals including chromium which is known to

the State of California to cause cancer and birth

defects or other reproductive harm. For more

information go to www.P65Warnings.ca.gov.

Please retain this manual for future references.

This equipment is design engineered for commercial

use only.

Only Pizza or Bread can have direct contact with

Fibrament decks. All other food products must

be placed in a pan or container to avoid direct

contact with ceramic decks.

BAKERS PRIDE OVEN COMPANY, LLC.

1307 N. Watters Rd., Suite 180

Phone: 800.527.2100 | Fax: 914.576.0605 | www.bakerspride.com

Allen, TX 75013

P/N U4282A 9/18

Page 3

TABLE OF CONTENTS

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

INSTALLATION INSTRUCTIONS 2

RECEIVING 2

CLEARANCES 2

ASSEMBLING THE STAND 3

INSTALLATION WITH CASTERS 4

PIZZA DECKS 4

(A) THREE DECK INSTALLATION 4

(B) FIVE DECK INSTALLATION 4

GAS AND ELECTRIC CONNECTIONS 5

FLUE CONNECTION-VENTILATION 6

(A) UNDER VENTILATION HOOD 6

(B) DIRECT VENTING 6

MAIN BURNER SAFETY PILOT OPERATION 6

(A) PILOT BURNER LIGHTING PROCEDURE 7

(B) PILOT BURNER FLAME ADJUSTMENTS 7

BURNER OPERATION 7

(A) MAIN BURNER 7

(B) AERATION &BY-PASSFLAME ADJUSTMENT 7

THERMOSTAT CALIBRATION 7

FLAME DIVERTERS 7

OPERATING INSTRUCTIONS 8

LIGHTING PROCEDURE 8

BREAKING IN 8

BAKING 8

RECOMMENDED OPERATING PROCEDURE 8

HELPFUL HINTS 9

CLEANING AND MAINTENANCE 9

OVEN EXTERIOR 9

CONTROL PANEL 9

FLUE VENT 10

OVEN INTERIOR 10

(A) BAKING CHAMBER 10

(B) BAKING DECKS 10

(C) BURNER COMPARTMENT 10

TROUBLESHOOTING CHART 11

EXPLODED VIEWS & PARTS LISTS 12

WIRING DIAGRAMS 16

WARRANTY 17

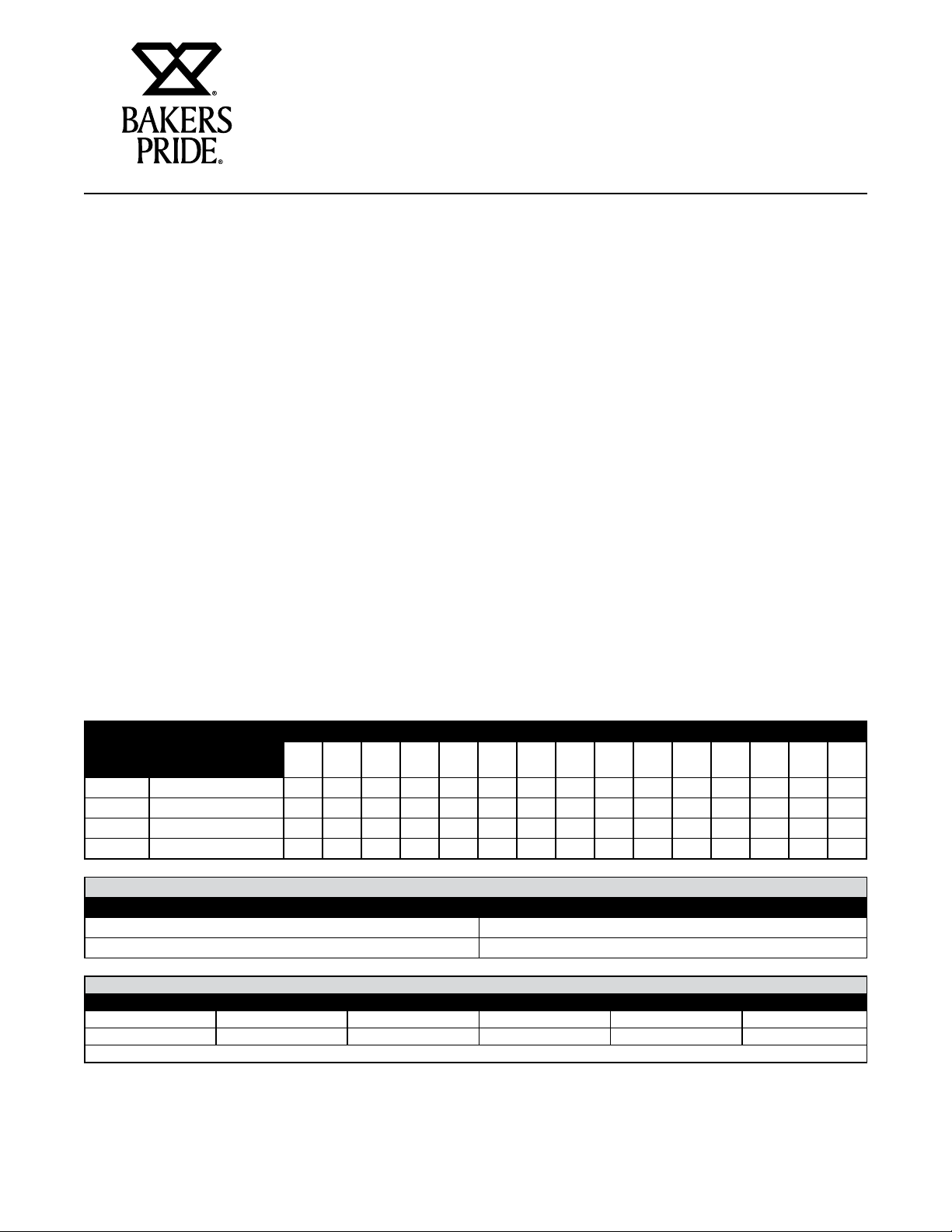

EN 437

Gas Cat.

I2H G20 @ 20mbar

I2L G25 @ 25mbar

I2E G20 @ 20mbar

I2E+ G20/25 @ 20/25mbar

LP Gas models are not available for European Community Countries.

Gas and Supply

Pressures

TYPE OF GAS MANIFOLD PRESSURE

MODEL BTU/HR KW MODEL BTU/HR KW

Y-600 120,000 35.15

Y-800 120,000 35.15

A TB ED KF IF RG RD EI

u u u u u u u u u

u u

For North America:

Natural 3.5” Water Column

LP 10” Water Column

Models Covered:

Designated European Market = u

I

E

T

u u

L UN LP TE SS EG

u

B

1

Page 4

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

INSTALLATION INSTRUCTIONS

Receiving:

Read the notice on the outside carton regarding damage

in transit. Damage discovered after opening crate(s)/

carton(s) is ‘CONCEALED DAMAGE’ and the carrier

must be notified immediately to send an inspector and

also to furnish forms for the consignee’s claim.

When the oven arrives, it should consist of:

a) A crate or carton containing your new oven.

b) A carton containing 4 legs with mounting hardware.

c) A strapped skid containing baking decks.

Place the oven and parts as close as possible to the area

of final installation before uncrating.

WARNING

In MASSACHUSETTS: All gas products must be

installed by a “Massachusetts” licensed plumber

or gas fitter. Ventilation hoods must be installed in

accordance with NFPA-96, current edition, with

interlocks as described in that standard.

WARNING

Installation must conform with local codes and/

or with the latest edition of the ANS Z-223.1

National Fuel Gas Code in USA (CAN/CGA-B

149.1 or 2 Installation Code in Canada).

WARNING

This appliance must be installed by a competent

person in accordance with the rules in force. In

the U.K. Corgi registered installers (including the

regions of British Gas) undertake to work to safe

and satisfactory standards. This appliance must

be installed in accordance with the current Gas

Safety (Installation and Use) Regulations and the

relevant Building Regulations/lEE Regulations.

Detailed recommendations are contained in the

British Standard Codes Of Practice BS 6172, BS

5440:Part 2 and BS 6891.

Clearances:

Combustible

Construction

Minimum Clearance from: Left

Side

Minimum Clearance from: Right

Side

Minimum Clearance from: Rear 3” (75mm) 2” (51mm)

3” (75mm) 0”

1” (25mm) 2”

Non-Combustible

Construction

Set Up:

The oven must be installed in a well-ventilated area.

Your oven is packed standing on its back. Leave it on

its back while unpacking. The skid may be left under

the oven for convenience in further handling. Unpack

carefully to avoid damage to the oven. If concealed

damage is found, follow the instructions detailed in

Receiving Section.

Keep the area around the oven free and clear of

combustible materials. Do not store any materials on

top of or under any oven. The provision of an adequate

air supply to your oven for ventilation and proper gas

combustion is essential. As a minimum, observe the

clearances detailed in Section 2. Provide adequate

ventilation and make up air in accordance with local

codes.

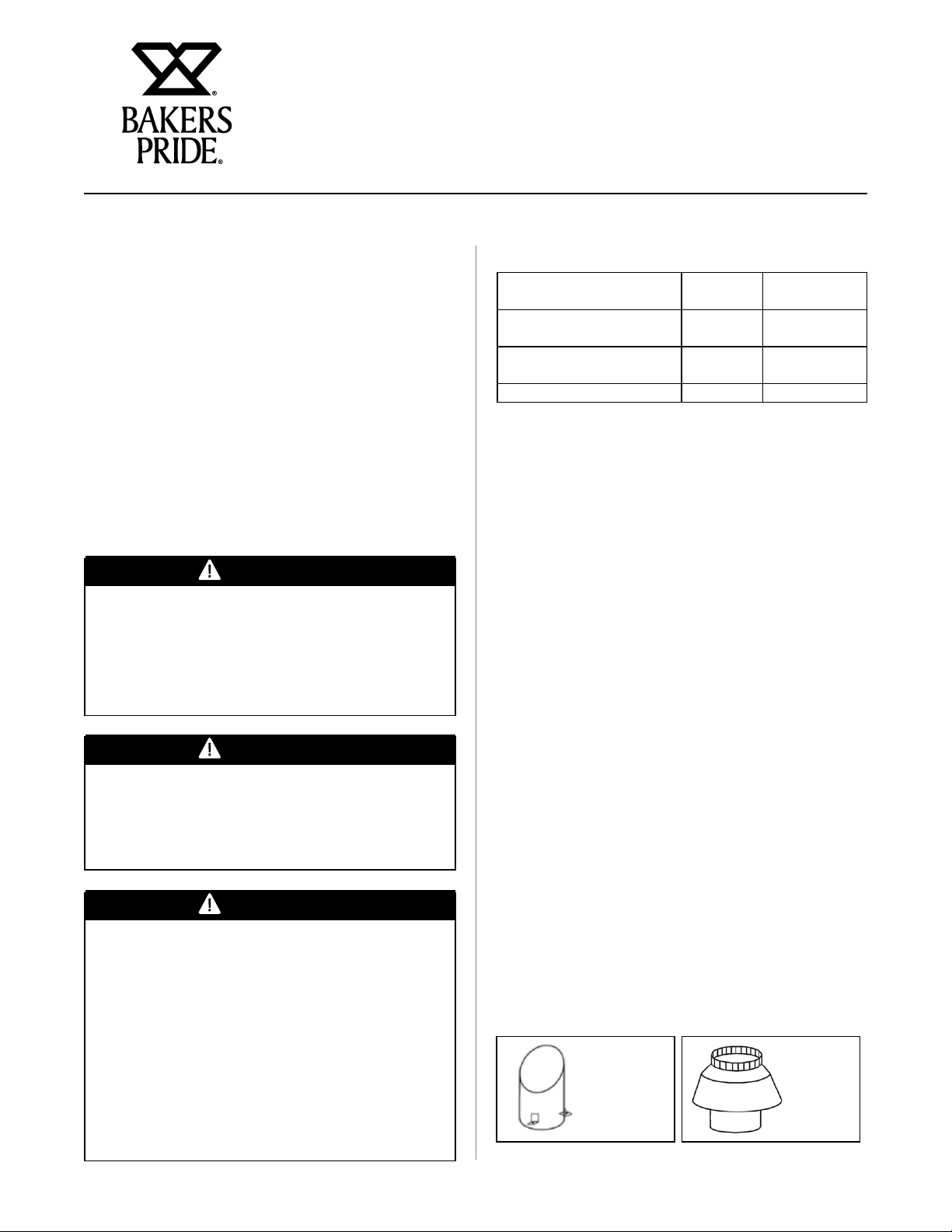

Fit the flue diverter supplied (See Fig.1) into the hole

located at top near the left rear of the oven and secure

with screws for installing the oven under a ventilation

hood. For Direct Venting, Optional Draft Hood (Fig.

2) must be placed into the hole. Direct Venting not

available for European Community Countries. Local

inspectors and ventilation specialists should be

consulted to make sure that the installation of the

hood conforms to the local codes and requirements

(See Fig. 3). In UK ventilation requirements as

detailed in BS 5440 should be followed.

Access to the bottom front door and left side control

panel is for day to day operation of the oven and for

servicing. Make these areas are kept unobstructed for

easy access.

Figure 1

Flue Diverter

(For use w/

Collection

Hood)

Draft Hood

(For use

w/Direct

Venting)

Figure 2

2

Page 5

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

INSTALLATION INSTRUCTIONS

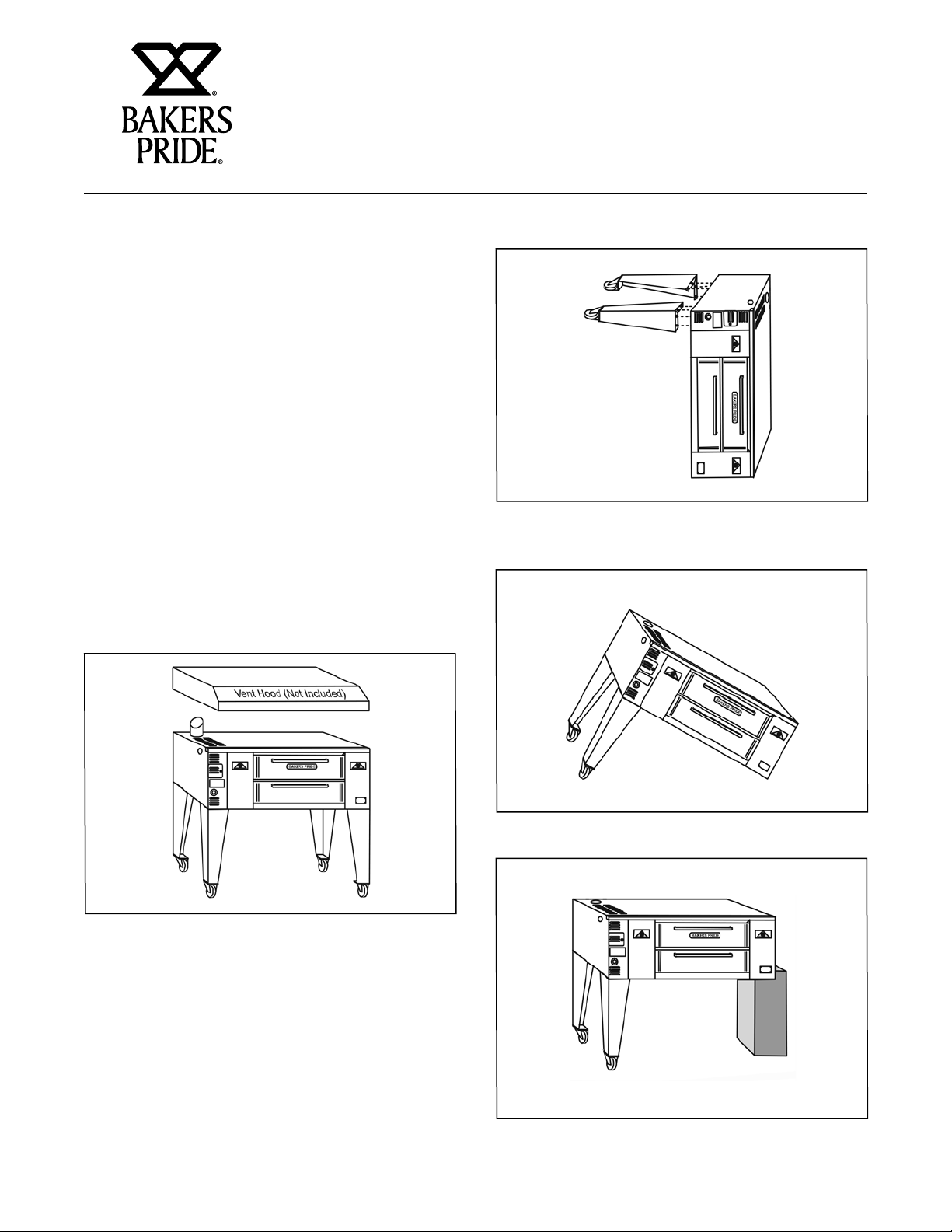

Assembling The Stand:

Legs are shipped in a separate carton complete with

mounting bolts.

a) Bolt four legs to the four of the stand using the

supplied 3/8-16 x 3/4 bolts, flat washers, and lock

washers. (See Fig. 4).

b) Bolt side braces and rear brace to legs using

supplied 3/8-16 x 3/4 bolts, lock washer, and flat

washer. (See Fig. 5).

c) Using proper lifting equipment, lower the oven

from its back to its bottom. Lift the unit and set on

stand. (See Fig.6).

d) Move the oven to its final location keeping the

minimum clearances from the back of the oven

to the wall. This clearance is necessary for safe

operation and to provide proper air-flow to the

burner chamber.

Figure 4

Figure 3

Figure 5

Figure 6

3

Page 6

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

INSTALLATION INSTRUCTIONS

Installation With Casters (Optional):

Four Casters (two with wheel brakes) and the mounting

hardware is packed and included in the shipment if

ordered. Install casters with wheel brakes on the front of

the unit.

NOTICE

Installation should be made with a connector that

complies with the latest edition of the Standard

for Connectors for Movable Gas Appliances ANSI

Z21.69 in the USA (CAN CGA-6.16 in Canada)

and a quick disconnect device that complies

with the latest edition of the Standard for Quick

Disconnect Devices for use with gas fuel ANSI

Z21.41 in the USA (CAN CGA 1-6.9 in Canada)

and adequate means must be provided to limit

the movement of the appliance without depending

on the connector and any quick disconnect device

or its associated piping.

The restraint should be attached to the rear legs of the

oven on which casters are mounted. lf disconnection of

the restraint is necessary to move the oven for servicing

needs, the restraint should be reconnected after the

appliance has been returned to its originally installed

position.

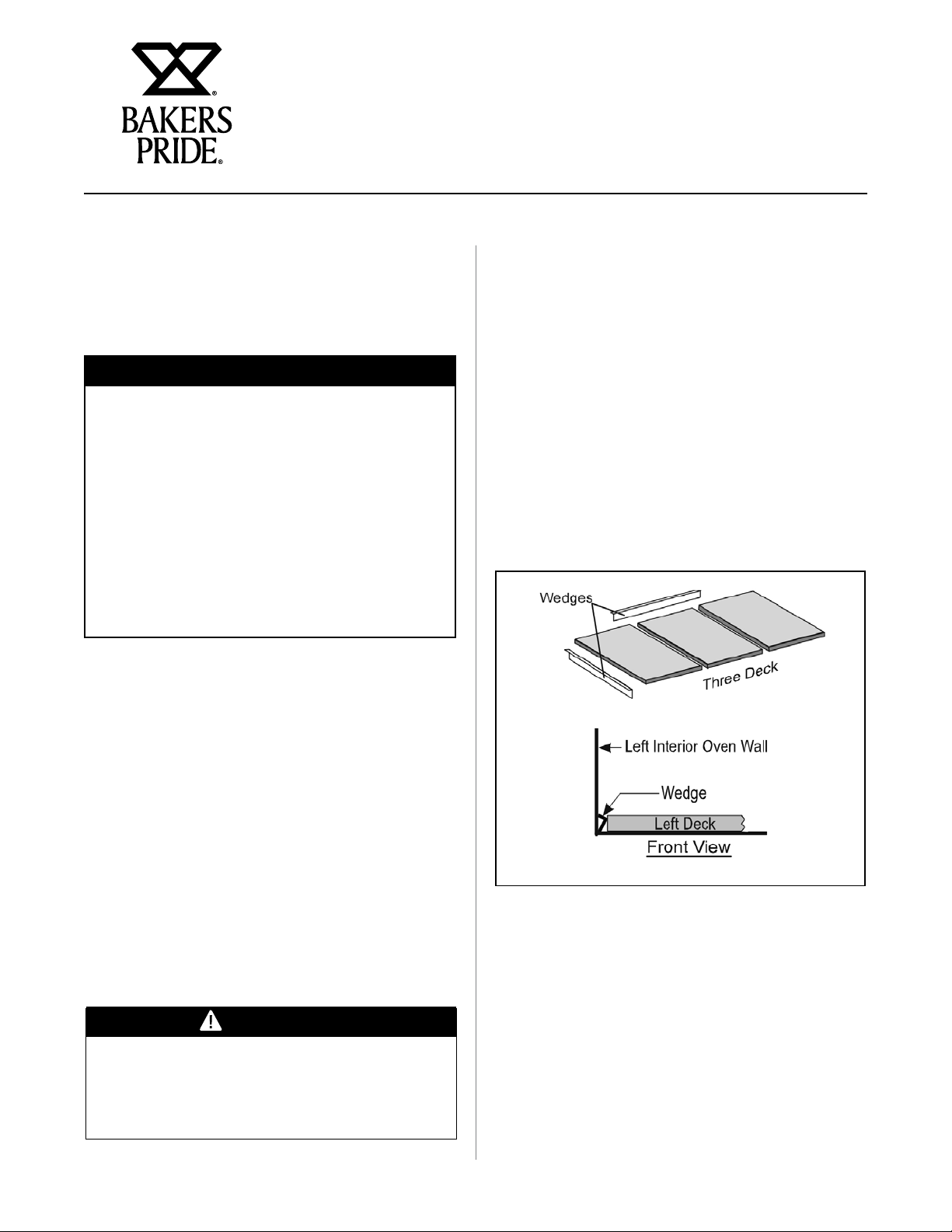

A. Three Deck Installation:

(a) Slide one deck into the baking chamber and

push it as far as possible to one side.

(b) Slide the second deck into the baking chamber

on the side opposite to the first deck.

(c) Slide the third deck into the center section.

(d) Use metal shims to level the decks.

(e) Use wedges in the back and on the sides of the

deck if the decks are loose. The three decks

should be tight against each other with no gap

between them (See Fig. 7).

(f) Put the hearth trim in place between the deck

and the door.

Pizza Deck:

(a) Remove all packing material, samples, shims, etc.

from the baking chamber leaving the two metal

hearth liner sheets on the baking chamber floor.

Make sure that the two metal hearth liner sheets

cover the entire bottom of the chamber.

(b) Depending on the model, three or five slabs of

the Pizza Deck are provided with the oven. This

material is heavy, and fragile, and should be

handled carefully.

WARNING

DO NOT install the baking stones until you have

read the pre-drying instructions. Failure to pre-dry

the stones can result in severe damage to your

oven and void the manufacturer’s warranty.

Figure 7

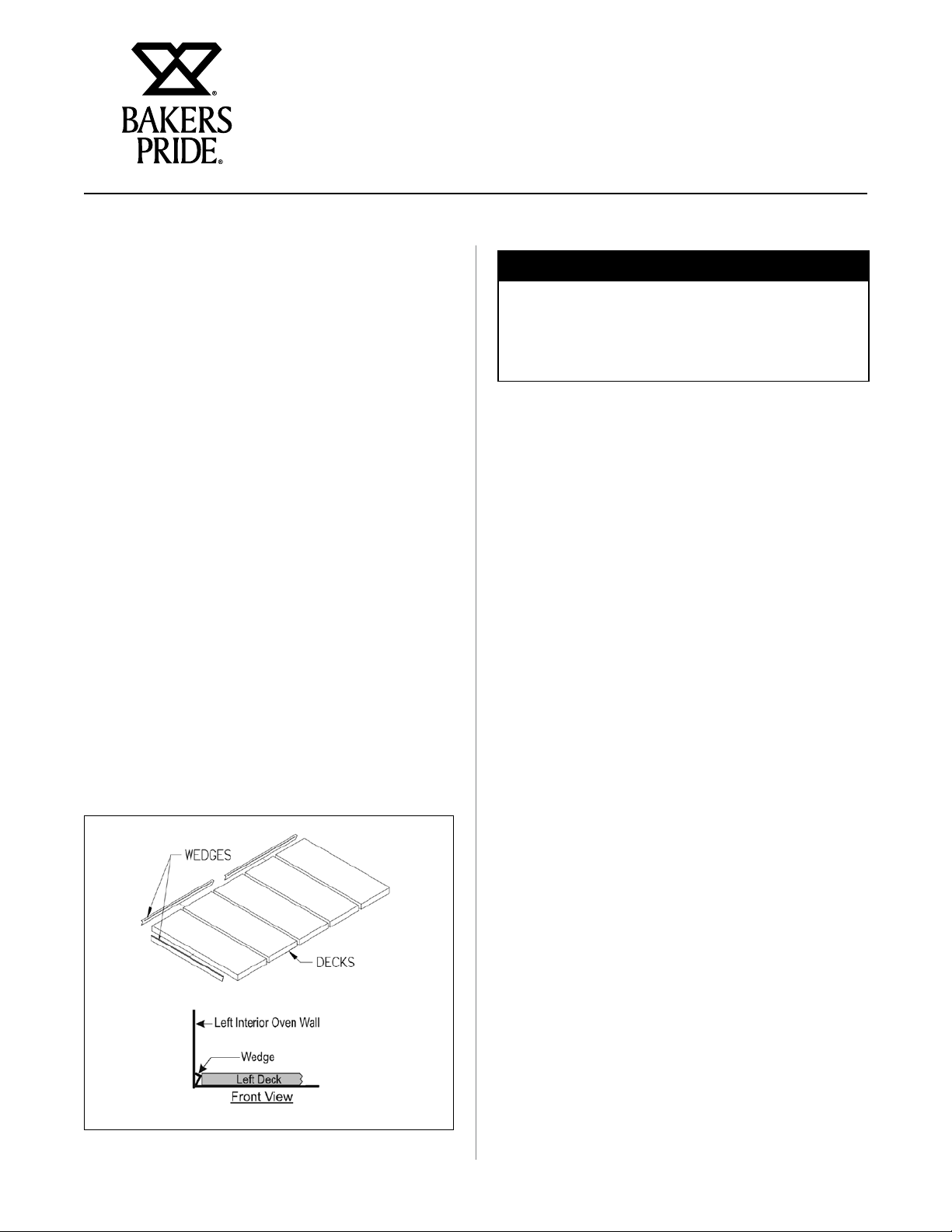

B. Five Deck Installation:

(a) Slide one deck into the baking chamber and

push it as far as possible to one side.

(b) Slide the second deck into the baking

chamber on the side opposite to the first deck.

(c) Slide the third and the fourth decks in the

same as the first two decks.

(d) Slide the fifth deck into the center section.

4

Page 7

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

INSTALLATION INSTRUCTIONS

(e) To minimize warpage and extend the life of

the Fibrament Stones, they must be pre-dried

before use.

(1) KEEP THE OVEN DOOR CLOSED DURING

THE ENTIRE PRE-DRYING PROCESS.

(2) Let the baking stones adjust to room

temperature before beginning.

(3) Preheat the stones with the pilot burner on

for 1 hour.

(4) Increase the temperature to below 300°F

to maintain a flame height of less than a

1/4”). Maintain this setting for 3 hours

(5) After 3 hours increase temperature to

300°F for 1 hour, then 400°F for 1 hour,

and then 500°F for 1 hour.

(6) DO NOT ALTER THIS PROCESS, failure to

properly pre dry stones can cause warping,

cracking, or shattering with explosive

force.

(f) Use metal shims as needed to level the decks.

(g) Use wedges in the back and on the sides of

the deck if the slabs are loose. The five decks

should be tight against each other with no gap

between them (See Fig. 8).

(h) Put the hearth trim in place between the deck

and the door.

NOTICE

If the side wedges are pushed in too tight, the

heat controls, operated by the black knobs,

located on the front of the oven, will not slide

freely.

Gas and Electric Connections:

Propane gas units are not available in the European

Community Countries.

(a) The appliance when installed must be electrically

grounded in accordance with local codes and/or

the latest edition of the National Electric Code

ANSI/NFPA 70 in USA (Canadian Electric Code

CSAC22.2 in Canada).

(b) In Europe, appliance must be connected by an

earthing cable to all other units in the complete

installation and thence to an independent earth

connection in compliance with EN 60335-1 and/

or local codes.

(c) The ovens should not be installed on the same line

with space heaters, boilers or other gas equipment

with high intermittent demand.

(d) Use a pipe joint compound that is resistant to the

action of liquefied petroleum gases when making

gas connections.

Figure 8

(e) For Propane gas, use at least 1/2” (13 mm) pipe

or tubing with a 5/8” (16 mm) inside diameter.

For Natural gas, use 3/4” (19 mm) pipe.

(f) The appliance must be isolated from the gas

supply piping system by closing its manual shutoff valve during any pressure testing of the gas

supply piping system at test pressures equal to or

less than 1/2 psig (3.45kpa).

(g) The appliance and its shut-off valve must be

disconnected from the gas supply piping system

during any pressure testing of that system attest

pressures in excess of 1/2” psig (3.45kpa).

5

Page 8

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

INSTALLATION INSTRUCTIONS

(h) The gas pressure regulator is part of the

combination valve and is adjusted to yield a

pressure of 3.5”water column (9mbar) for Natural

Gas. If the oven is ordered for use on Propane Gas,

the pressure regulator in the combination valve

is preset at the factory to yield a pressure of 10”

water column (25 mbar). Units for use on Propane

Gas are not available for European Community

Countries.

(i) A separate shut-off valve for each oven must be

provided. It should be as close as possible to the

place where the gas supply line goes into the oven.

It must be located such that it is easily accessible.

(j) When stacking with another oven, two shut-off

valves, one for each of the two ovens, must be

provided.

WARNING

After the Gas Supply has been connected, it is

extremely important to check all the piping for

leaks. Use a soap and water solution or a product

expressly made for this purpose. Do not use

Matches, Candles or a flame etc to check leaks

since these methods are extremely dangerous.

NOTICE

Do not put a damper in the flue and do not

connect a blower directly to the flue.

If the flue runs directly to the free air outside the

building, use a wind deflector or a UL listed vent cap at

the end of the flue pipe. Termination of the vent must

be at least 2 feet above the highest part of the roof

within 10 feet (Ref: American Gas Association Catalog

No.Xh0474).

Figure 1

Flue Diverter

(For use w/

Collection

Hood)

Figure 2

Draft Hood

(For use

w/Direct

Venting)

Flue Connection - Ventilation:

(A) Installation Under Ventilation Hood (Standard):

If the oven is installed under a collection hood,

use the flue diverter (Fig. 1) supplied. Local

inspectors and ventilation and environmental

specialists should be consulted so that the design

and the installation of the hood conforms to the

local/ municipal codes (see Fig. 3).

(B) Direct Venting (Optional) Not Available For European

Community Countries:

If direct venting, it is necessary to install a draft

hood (Fig. 2). The flue pipe from the draft hood

must not run downwards at any point from the

oven to the final outlet. It should always slant

slightly upwards. For best results it should rise

straight up.

Figure 3

Main Burner Safety Pilot Operation:

The purpose of the safety pilot system is to lock the

gas supply to the main burner at the safety valve, if for

any reason the pilot burner is not lit. Oven should be

re-lighted by following the steps given below. However,

in normal service, the pilot flame stays lit indefinitely,

day and night or weekends. This prolongs the life of the

safety valve.

The safety pilot valve is in effect a two-stage control.

After initial lighting, the pilot burner stays on without the

gas cock dial being held pressed in. After 1-2 minutes,

the valve opens fully to let the gas flow past the safety

pilot valve into the burner system.

6

Page 9

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

INSTALLATION INSTRUCTIONS

Pilot Burner Lighting Procedure:

(a) Turn the red handle on gas shut off valve to ‘OFF’

(horizontal) position.

(b) Wait for five minutes to allow gas, which may

have accumulated in the burner compartment, to

escape.

(c) Depress “RED” button on pilot safety valve and

light Pilot Burner. Hold in pressed position for

about 1/2 minute (30 seconds), and release

the “RED” button. The Pilot Burner should now

remain lit.

If Pilot Burner fails to ignite or does not remain lit, repeat

the steps (a) through (c).

Pilot Burner Flame Adjustment:

It is important to have the correct Pilot Burner Flame

size as shown in Fig. 10. If necessary, adjust the Pilot

Burner Flame by turning Pilot Adjust Screw (See Fig.

11) clockwise to reduce or counterclockwise to increase.

Burner Operation:

(A) Main Burner:

After the pilot burner is ignited, when heat is

desired, turn gas cock dial to ‘ON’() position and

set the thermostat dial to the desired temperature.

The oven burner flame should always have a blue

appearance. That indicates a good mixture of gas

and air. When using LP gas, the flame will have a

blueyellow appearance.

Should the Burner fail to light, check to see if

there is a problem with the gas supply. lf there are

other appliances on the same line, shut them off

temporarily and see if the burner comes back on,

or it fluctuates as other gas appliances are turned

on and off. That would indicate overloading of the

gas supply lines or a faulty gas pressure regulator.

Contact an authorized Service Agency or your local

Gas Supply Company.

(B) Aeration And By-Pass Flame Adjustment:

Flame and air mixer adjustments and the By-Pass

Flame adjustment for the Main Burner are done at

the factory. These adjustments are sealed before

the oven leaves the factory. Contact an authorized

Service Agency if you need help.

Figure 10

Thermostat Calibration:

No attempt should be made to calibrate the thermostat

because it is accurately calibrated and sealed by the

manufacturer. Contact an authorized Service Agency if

you need help.

Flame Diverters:

Flame diverters distribute the heat evenly below the

baking deck. They must be in good condition and

properly placed above the burners in the burner

chamber in order to be effective. Damaged or

improperly installed flame diverters adversely affect

the oven performance. Make sure that the ‘V’ shaped

diverters are pushed all the way to the back of the oven

as far as they will go. Check them periodically and

replace them as necessary.

Figure 11

7

Page 10

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

OPERATING INSTRUCTIONS

NOTICE

Only Pizza and Bread Products can have direct

contact with Fibrament Decks. All other food

products must be placed in a pan or containers to

avoid direct contact with Fibrament Decks.

WARNING

If gas odor is detected at any time, immediately

shut-off the gas supply valve for the oven. Do

not permit any open flames in the area of the

oven. Immediately contact an authorized Service

Agency or your local Gas Supply Company.

CAUTION

Initial heating of the oven must be done in a

well ventilated area as it may generate smoke

or fumes. Over exposure to smoke or fumes may

cause nausea or dizziness.

Lighting Procedure:

(a) Light the Main Burner following the instructions in

Lighting Section of the Installation Instructions.

(b) Keep the Push/Pull Slides fully open.

Breaking In:

It is important to break-in, to dry out the deck and the

insulation, before baking in a new oven:

(a) Set the thermostat at least 50°F (10°C) lower than

your baking temperature.

(b) Pre-heat the oven for 1 to 3 hours before use.

(c) After pre-heating, raise the temperature to your

baking temperature.

(d) Experiment baking until you get the feel of the

oven and the speed of the bake.

Baking:

Pizza can be baked on the deck, on a screen or

in a pan. When you determine the combination of

ingredients and temperature that gives the right bake for

your crust, sauce, and cheese combination, and your

customer’s taste, mark and keep it.

Deck baking refers to baking Pizza directly on the deck.

Generally it is a thin product that requires temperature

of at least 550°F (290°C).

Screen baking refers to baking Pizza on a screen. The

screen lifts the Pizza off the deck. The screen may

be removed near the end of the bake time to give the

bottom of the Pizza crispier crust and a darker color.

Bake temperatures range from 500°F (260°C) to 550°F

(290°C).

Pan baking refers to baking Pizza in pans. Crusts can

be thick or thin and toppings range from light to heavy.

Baking temperatures for pan baking range from 450°F

(235ºC) to 500ºF (260ºC).

Recommended Operating Procedure:

It is very important that at the end of day’s operation, the

gas cock dial of the Main Burner is turned to the pilot

position, leaving only the pilot burner ‘ON’ overnight.

Keep the Pizza Push/Pull slides fully open.

Pre-heating:

(a) Turn the gas cock dial of the main burner to the

‘ON’ position.

(b) Preheat the oven for 1 to 3 hours at 50°F (10°C)

lower than your baking temperature, with Push/

Pull Slides fully open.

Baking:

(a) After pre-heating, raise the thermostat setting to

your baking temperature.

(b) Check the bottom color of the Pie and close the

push/pull slides partially (halfway) after the 4th or

5th bake to maintain the desired color.

When slow or idling, open the push/pull slides

fully and set the thermostat at least 50°F (10°C)

lower than your baking temperature.

8

Page 11

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

OPERATING INSTRUCTIONS

Helpful Hints:

(a) An instructions plate is attached behind the

damper knobs indicating how to set the oven for

more top or bottom heat. Opening the dampers

allow more heat to enter the baking chamber from

the combustion/burner compartment. Closing the

dampers keep more heat in the combustion/burner

compartment to keep the baking deck hotter.

(b) If the oven is up to Pizza baking temperature

and has not been used for a while, there is a

tendency for the baking deck to get hotter. In

this condition, when you put in one Pizza, TURN

THE THERMOSTAT UP, so that the main burner

flame is burning at its fullest, providing the extra

heat needed to balance the bottom heat. The

thermostat should be turned down back to the

normal setting as soon as you have baked the

Pizza.

CLEANING AND MAINTENANCE

This appliance must be serviced by an Authorized

Service Technician only. Disconnect the power supply

before cleaning or servicing the oven.

Regular and thorough cleaning will help to keep the

ovens operating properly. If service is required, contact

an Authorized Service Agency, your dealer or the

factory to obtain a qualified technician for the required

maintenance/service.

Oven Exterior:

(a) Deposits of baked-on splatter and grease, or

discoloration may be removed with the stainless

steel cleaner or by using any commercial cleaner

recommended for stainless steel. RINSE WELL

(b) A thin coat of light oil will add to the appearance

of the oven.

(c) Frequently scrape and brush off decks to remove

burnt residue which can cause an ‘off’ flavor and

bake times to increase.

(d) Heavily topped Pizza or Pan Pizza requires

lower bake temperatures and longer bake times

as compared to a regular thin Pizza with light

toppings.

(e) Bubbles in fresh dough indicate under proofed

or cold product. Allow the dough balls to proof

to double in size and warm temperature before

baking.

(f) Any type of Pan or Screen may be used in this

oven. When choosing pans, be sure to pick a pan

which is closest in height of your product. Dark

color pans and screens transfer heat better than

light colored aluminum pans or screens. They

must be seasoned before use.

NOTICE

Apply stainless steel cleanser only when the oven

is cold. Always rub with the grains and apply very

light pressure.

Painted Surfaces:

(a) Washing with mild soap and water solution is

adequate to keep the painted surfaces clean.

(b) Apply a thin coat of oil to protect and enhance the

finish.

Control Panel:

Every six months (more frequently if the oven is used

heavily) the bottom door spring mechanism and all

moving parts must be inspected for wear.

NOTICE

Do not apply grease to spring lever shoulder bolt,

spring roller or the door rod and the door pin.

They have a self-lubricating insert that will be

damaged if lubricated.

9

Page 12

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

CLEANING AND MAINTENANCE

Flue Vent:

Ventilation system must be inspected every six months

and maintained clean and free of obstructions.

Oven Interior:

Clean the oven interior only when the oven is cold. Use

only the detergent solutions and cleaners that meet the

national and / or local codes.

(A) Baking Chamber:

Clean the ceiling and the walls of the baking

chamber with a mild soap and water solution.

Do not use oven cleaners, caustic solutions or

mechanical means as they will damage the interior

aluminized surface.

(B) Baking Decks:

The baking decks are heavy and fragile. They

should be handled carefully. The baking decks

should be cleaned by using a long-handled scraper

and stiff wire brush. At the end of each day, turn

the thermostat up to its maximum setting and let

the oven sit at that temperature for at least 1/2

hour. This will burn off the food spilled onto the

baking decks during day’s production and turn it

into ash. This ash can be brushed off the next day

before turning the oven on. The baking decks

should be scraped and brushed during the day

also to help keep them clean. To remove excessive

crumbs or carbon, the baking decks and the oven

cavity may vacuumed when the oven is cold. Do

not use water or other liquids on the baking decks

as that may cause them to crack. After long use,

heavily soiled baking decks may be cleaned by

turning over after scraping down and brushing off.

This will burn off the heavily soiled side of the

baking decks. This procedure may be repeated

as needed.

(C) Burner Compartment:

Vacuum out any carbon, crumbs or residue in the

burner compartment and all around the doors. The

holes and louvers on the outer surfaces of the oven

must be kept free of obstructions to allow free

movement of air into the controls and for proper

combustion. The burner ports and crossover holes

should be kept free of carbon and other deposits.

10

Page 13

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

CLEANING AND MAINTENANCE

Troubleshooting Chart

PROBLEM PROBABLE CAUSE REMEDY

No Pilot Light Gas valve feeding oven may be in the closed

position

Main Burner(s) do not light Gas valve feeding oven may be in the closed

position

Thermopile may not be positioned in pilot flame. Ensure that the tip of thermopile is in pilot flame.

Thermopile may be defective Call local authorized Bakers Pride Service Agent.

Oven too Hot Thermostat set too high. Lower the thermostat setting and see if flame

Thermostat may be defective Call local authorized Bakers Pride Service Agent.

Bottom of pies are undercooked If the same area of the deck is used repeatedly,

the deck temperature in that area will be reduced.

Micro slides are open too much. Close micro-slides (pull out) until desired

Bottom of pies burn before

toppings are cooked

Pies cook Unevenly Area’s adjacent to oven walls are generally hotter. Rotate pies (180°), once during each bake or keep

Oven does not turn On or Off on

time. (Ovens equipped w/auto oven

starter only)

Unit takes too long to reach temp. Gas volume or gas pressure may be inadequate. Contact gas supplier.

Deck temperature too hot - especially during slow

periods.

Micro slides are closed too much Open micro slides (push-in) to increase top heat.

Oven was left “ON” overnight Oven must be turned to “Pilot” position overnight.

Exhaust fan too powerful. Reduce fan speed.

Power cord not plugged in. Plug unit in.

Electrical outlet fuse/circuit breaker is tripped. Replace fuse or reset circuit breaker.

Timer incorrectly set. Reset Timer.

Turn gas valve on. Relight pilot.

Turn gas valve on. Relight pilot.

reduces in size. Allow several hours for heat to

regulate.

Rotate pies to unused areas of the bake deck that

are hotter and will cook the bottoms faster.

combination is reached. This will help decrease

top heat

Reduce thermostat setting by 50° - 75° below

normal bake temperature. When decks cool begin

cooking and immediately increase the thermostat

setting by 50° - 75°.

It should not be left on a high temperature setting.

to the center of oven.

Call local authorized Bakers Pride Service Agent.

11

Page 14

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

EXPLODED VIEWS & PARTS LISTS

Exploded View – Y600/Y800

12

Page 15

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

EXPLODED VIEWS & PARTS LISTS

Exploded View – Y600/Y800 Controls/Burners

13

Page 16

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

EXPLODED VIEWS & PARTS LISTS

Parts List – Y600

ITEM PART # QTY DESCRIPTION

1 21910330 1 ASSY, BOTTOM DOOR Y600/800

2 21910331 1 ASSY, TOP DOOR Y600/800

3 A8057K 1 BOTTOM TRIM

4 A4980T 1 CONTROL PANEL SLEEVE, SS

5 21910188 1 PANEL, FRONT CONTROL SIDE

6 A8056K 1 TOP TRIM

7 21910189 1 PANEL, FRONT RT SIDE

8 21910332 1 WELDMENT, LOWER DOOR ARM LT

9 21910316 1 WELDMENT, LOWER DOOR ARM RT

10 Q2025A 10 BOLT, 1/4-20 X 3/4 HEX HD ZINC

11 21910310 1 WELDMENT, TOP DOOR ARM LEFT

12 Q2401A 2 NUT, HEX 9/16-18

13 S3276A 1 DOOR SPRING ARM, 2.78” BOTTOM

14 Q3007A 1 WASHER, 9/16 SPLIT LOCK

15 S3007A 2 BUSHING ASSY, PTFE 5/.63 X .56

16 Q3010A 4 WASHER, 3/8-7/16 X 1” X 5/64 FLAT

17 Q2301A 1 BOLT, 3/8-16 X 9/32 X 1 SHOULDER

18 A3079K 2 FLAME DIVERTER SLIDE (35”)

19 A8035K 2 HANGER, FLAME DIVIDER

20 A8030T 4 FRAME ASM, HEARTH SUPPORT

21 A4132Z 1 HEARTH LINER SHEET, 36 X 39.25

22 A4133Z 1 HEARTH LINER SHEET, 36 X 20.75

23 A8036K 1 HANGER, FLAME DIVIDER CENTER

24 T1381A 3 STONE HEARTH, AWMCO 36” X 20” X 2”

25 S3134A 5 BUSHING, .81/.88 ID X 1 X 1.25 OD

26 S3133A 5 SLEEVE, DURALON .75 ID X .88 OD

27 A8017K 2 ANGLE, DOOR JAM BOTTOM

28 A8016K 2 ANGLE, DOOR JAM

29 R3115A 1 FLUE DEFLECTER

30 U1356A 2 PUSH-PULL PLATE

31 S1005A 2 KNOB, PUSH-PULL 3/8-16 BLK

32 8808902 1 NAMEPLATE, BAKERS PRIDE, DECK OVENS

33 21910312 1 WELDMENT, TOP DOOR ARM RIGHT

34 A8061K 1 COVER, HEARTH TRIM

35 A8082K 1 COVER FRONT LEFT ACCESS DOOR

36 S1004Y* 1 LEG, 30” [SET OF 4]

37 S1120Y* 1 LEG & CASTER 30” [SET OF 4]

38 S1003Y* 1 LEG, 16” [SET OF 4]

39 S1119Y* 1 LEG & CASTER 16” [SET OF 4]

40 M1242P 1 CONTROL ASSY, Y600

41 N5014A 1 NIPPLE, 1/2” X 5”, BLK PIPE

42 N3021A 2 REDUCING ELBOW, 3/4” X 1/2” 90° BLKSTL

ITEM PART # QTY DESCRIPTION

43 N5232A 1 NIPPLE, 3/4” X 6-3/4” BLK PIPE, 3/4

OFFSET

44 N3002A 1 TEE, 3/4” X 3/4” X 1”, BLK PIPE REDUCING

45 K1332B 2 BACK COVER PATCH, SS

46 N3008A 2 BUSHING, 1” X 3/4” REDUCING, BLK PIPE

47 N3022A 2 PLUG, 3/4” STEEL PIPE, W/1/2” SQ

REECESS

48 N5217P 1 NIPPLE, 3/4” X 27-3/4”, BLK PIPE

49 N3007A 1 COUPLIING, 1”X3/4” REDUCING, BLK PIPE

50 N5009A 6 NIPPLE, 1/2” X 15/16”, BLK PIPE

51 N 5231P 1 NIPPLE, 3/4” X 34-1/4”, BLK PIPE

52 00235 2 3/4” BLK STL UNION

53 N5218A 1 NIPPLE, 3/4” X 3” BLK STL

54 N3004A 1 ELBOW, 3/4” 90 ° BLK STL

55 N5213A 1 NIPPLE, 3/4” X 1-1/2” BLK STL

56 N3012A 1 REDUCING TEE, 1/2” X 1/2” X 3/4” BLK STL

57 L5001A 2 INSPIRATOR, #3 BLK

58 L5121T 1 BURNER ASSY, LH

59 L5122T 1 BURNER ASSY, RH

60 N3009A 4 1/2” BLK STL UNION

61 R3004A 2 SPUD HOLDER #3

62 R3006A 2 LOCKING DISK, SPUD

63 R3005A 2 ADJUSTING DISK #3 SPUD

64 R3117P 2 ORIFICE, #25 NAT, #3 SPUD

65 R3129P* 2 ORIFICE, #43 LP, #3 SPUD

66 A4143K 1 PILOT MOUNTING BRACKET

67 M1265A 1 THERMOPILE, Q313

68 Q1401A 2 SCREW, 10-32 X 1/2” PAN HD

69 M1220A 1 PILOT BURNER NAT

70 M1245A *1 PILOT BURNER LP

71 S1056A 1 KNOB, THERMOSTAT, 650 “F”, GAS BLACK

72 M1005A 1 THERMOSTAT, 650°F, FDTH

73 N3068P 1 PRESSURE TAP ASSY

74 M1242P 1 CONTROL ASSY BMVR NAT

75 M1248P* 1 CONTROL ASSY BMVR LP

76 A8006K* 1 BRICK LINED SUPPORT BRACE

77 T1375A* 7 BAKING DECK, CERAMIC

78 S3275A 1 DOOR SPRING ARM, 2.78”

* INDICATES NOT SHOWN

14

Page 17

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

CLEANING AND MAINTENANCE

Parts List – Y800

ITEM PART # QTY DESCRIPTION

1 21910330 1 ASSY, BOTTOM DOOR Y600/800

2 21910331 1 ASSY, TOP DOOR Y600/800

3 A8057K 1 BOTTOM TRIM

4 A4980T 1 CONTROL PANEL SLEEVE, SS

5 21910288 1 PANEL, FRONT CONTROL SIDE

6 A8056K 1 TOP TRIM

7 21910289 1 PANEL, FRONT RT SIDE

8 21910332 1 WELDMENT, LOWER DOOR ARM LT

9 21910316 1 WELDMENT, LOWER DOOR ARM RT

10 Q2025A 10 BOLT, 1/4-20 X 3/4 HEX HD ZINC

11 21910310 1 WELDMENT, TOP DOOR ARM LEFT

12 Q2401A 2 NUT, HEX 9/16-18

13 S3276A 1 DOOR SPRING ARM, 2.78” BOTTOM

14 Q3007A 1 WASHER, 9/16 SPLIT LOCK

15 S3007A 2 BUSHING ASSY, PTFE .5/.63 X .56

16 Q3010A 4 WASHER, 3/8-7/16 X 1” X 5/64 FLAT

17 Q2301A 1 BOLT, 3/8-16 X 9/32 X 1 SHOULDER

18 A3079K 2 FLAME DIVERTER SLIDE (35”)

19 A8035K 2 HANGER, FLAME DIVIDER

20 A8030T 4 FRAME ASM, HEARTH SUPPORT

21 A4132Z 1 HEARTH LINER SHEET, 36 X 39.25

22 A4133Z 1 HEARTH LINER SHEET, 36 X 20.75

23 A8036K 1 HANGER, FLAME DIVIDER CENTER

24 T1381A 3 STONE HEARTH, AWMCO 36” X 20” X 2”

25 S3134A 5 BUSHING, .81/.88 ID X 1 X 1.25 OD

26 S3133A 5 SLEEVE, DURALON .75 ID X .88 OD

27 A8017K 2 ANGLE, DOOR JAM BOTTOM

28 A8016K 2 ANGLE, DOOR JAM

29 R3115A 1 FLUE DEFLECTER

30 U1356A 2 PUSH-PULL PLATE

31 S1005A 2 KNOB, PUSH-PULL 3/8-16 BLK

32 8808902 1 NAMEPLATE, BAKERS PRIDE, DECK OVENS

33 21910312 1 WELDMENT, TOP DOOR ARM RIGHT

34 A8061K 1 COVER, HEARTH TRIM

35 A8082K 1 COVER FRONT LEFT ACCESS DOOR

36 S1004Y* 1 LEG, 30” [SET OF 4]

37 S1120Y* 1 LEG & CASTER 30” [SET OF 4]

38 S1003Y* 1 LEG, 16” [SET OF 4]

39 S1119Y* 1 LEG & CASTER 16” [SET OF 4]

40 M1242P 1 CONTROL ASSY, Y600

41 N5014A 1 NIPPLE, 1/2” X 5”, BLK PIPE

42 N3021A 2 REDUCING ELBOW, 3/4” X 1/2” 90° BLKSTL

ITEM PART # QTY DESCRIPTION

43 N5232A 1 NIPPLE, 3/4” X 6-3/4” BLK PIPE, 3/4 OFFSET

44 N3002A 1 TEE, 3/4” X 3/4” X 1”, BLK PIPE REDUCING

45 K1332B 2 BACK COVER PATCH, SS [

46 N3008A 2 BUSHING, 1” X 3/4” REDUCING, BLK PIPE

47 N3022A 2 PLUG, 3/4” STEEL PIPE, W/1/2” SQ REECESS

48 N5252A 1 NIPPLE, 3/4” X 36”, BLK PIPE

49 N3007A 1 COUPLIING, 1/X3/4” REDUCING, BLK PIPE

50 N5009A 6 NIPPLE, 1/2” X 15/16”, BLK PIPE

51 N5220P 1 NIPPLE, 3/4” X 37-1/4”, BLK PIPE

52 300235 2 3/4” BLK STL UNION

53 N5218A 1 NIPPLE, 3/4” X 3” BLK STL

54 N3004A 1 ELBOW, 3/4” 90° BLK STL

55 N5213A 1 NIPPLE, 3/4” X 1-1/2” BLK STL

56 N3012A 1 REDUCING TEE, 1/2” X 1/2” X 3/4” BLK STL

57 L5001A 2 INSPIRATOR, #3 BLK

58 L5124T 1 BURNER ASSY, LH

59 L5125T 1 BURNER ASSY, RH

60 N3009A 4 1/2” BLK STL UNION

61 R3004A 2 SPUD HOLDER #3

62 R3006A 2 LOCKING DISK, SPUD

63 R3005A 2 ADJUSTING DISK #3 SPUD

64 R3117P 2 ORIFICE, #25 NAT, #3 SPUD

65 R3129P* 2 ORIFICE, #43 LP, #3 SPUD

66 A4143K 1 PILOT MOUNTING BRACKET

67 M1265A 1 THERMOPILE, Q313

68 Q1401A 2 SCREW, 10-32 X 1/2” PAN HD

69 M1220A 1 PILOT BURNER NAT

70 M1245A * 1 PILOT BURNER LP

71 S1056A 1 KNOB, THERMOSTAT, 650 “F”, GAS BLACK

72 M1005A 1 THERMOSTAT, 650°F, FDTH

73 N3068P 1 PRESSURE TAP ASSY

74 M1242P 1 CONTROL ASSY BMVR NAT

75 M1248P* 1 CONTROL ASSY BMVR LP

76 A8006K* 1 BRICK LINED SUPPORT BRACE

77 T1375A* 8 BAKING DECK, CERAMIC

78 S3275A 1 DOOR SPRING ARM, 2.78”

* INDICATES NOT SHOWN

15

Page 18

FLOOR MODEL GAS DECK OVEN OPERATION MANUAL

WIRING DIAGRAM

Wiring Diagram – Gas Oven Series – 120V, 208, OR 230V, 1PH –Auto Starter Option

16

Page 19

CONVEYOR OVEN SERVICE MANUAL

BAKERS PRIDE LIMITED WARRANTY

WHAT IS COVERED This warranty covers defects in material and workmanship under normal use, and applies only to the original purchaser

• The equipment has not been accidentally or intentionally damaged, altered or misused;

• The equipment is properly installed, adjusted, operated and maintained in accordance with National

• The serial number rating plate affixed to the equipment has not been defaced or removed.

WHO IS COVERED This warranty is extended to the original purchaser and applies only to equipment purchased for use in the U.S.A.

COVERAGE PERIOD Cyclone Convection Ovens: BCO Models: One (1) Year limited parts and labor; (1) Year limited door warranty.

GDCO Models: Two (2) Year limited parts and labor; (2) Year limited door warranty.

CO11 Models: Two (2) Year limited parts and labor; (5) Year limited door warranty.

All Other Products: One (1) Year limited parts and labor. Warranty period begins the date of dealer invoice to customer

WARRANTY This warranty covers on-site labor, parts and reasonable travel time and travel expenses of the authorized service

COVERAGE Representative up to (100) miles, round trip, and (2) hours travel time. The purchaser, however, shall be responsible

EXCEPTIONS All removable parts in Bakers Pride

providing that:

and local codes and in accordance with the installation instruction provided with the product;

or ninety (90) days after shipment date from Bakers Pride - whichever comes first.

for all expenses related to travel, including time, mileage and shipping expenses on smaller counter models that may be

carried into a Factory Authorized Service Center, including the following models: PX-14, PX-16, P18, P22S, P24S, PD-4,

PDC, WS Series and BK-18.

®

and Valves, are covered for a period of SIX MONTHS. All Ceramic Baking Decks are covered for a period of THREE

MONTHS. The installation of these replacement decks is the responsibility of the purchaser. The extended Cyclone door

warranty years 3 through 5 is a parts only warranty and does not include labor, travel, mileage or any other charges.

cooking equipment, including but not limited to: Burners, Grates, Radiants, Stones

EXCLUSIONS

INSTALLATION Leveling and installation of decks as well as proper installation and check out of all new equipment —per appropriate

REPLACEMENT PARTS Bakers Pride genuine Factory OEM parts receive a (90) day materials warranty effective from the date of installation by a

This Warranty is in lieu of all other warranties, expressed or implied, and all other obligations or liabilities on the manufacturer’s part. Bakers Pride

shall in no event be liable for any special, indirect or consequential damages, or in any event for damages in excess of the purchase price of the unit.

The repair or replacement of proven defective parts shall constitute a fulfillment of all obligations under the terms of this warranty.

• Negligence or acts of God,

• Failures caused by erratic voltages or gas supplies,

• Thermostat calibrations after (30) days from

equipment installation date,

• Unauthorized repair by anyone other than a Bakers

Pride Factory Authorized Service Center,

• Air and Gas adjustments,

• Damage in shipment,

• Light bulbs,

• Alteration, misuse or improper installation,

• Glass doors and door adjustments,

installation and use materials — is the responsibility of the dealer or installer, not the manufacturer.

Bakers Pride Factory Authorized Service Center.

• Thermostats and safety valves with broken capillary

tubes,

• Fuses,

• Char-broiler work decks and cutting boards,

• Tightening of conveyor chains,

• Adjustments to burner flames and cleaning of pilot

burners,

• Tightening of screws or fasteners,

• Accessories — spatulas, forks, steak turners, grate

lifters, oven brushes, scrapers, peels. etc.,

• Freight — other than normal UPS charges,

• Ordinary wear and tear.

Form #U4177A 1/07

17

Page 20

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For Warranty Service and/or

Parts, this information is required.

Model Number Serial Number Date Purchased

NOTES

18

Page 21

NOTES

19

Page 22

Food Service Equipment Group

The Standex Food Service Equipment Group (FSEG) is a manufacturer of innovative commercial food

service equipment offering a wealth of refrigeration and cooking expertise. Products include walk-in

coolers and freezers; hot and cold display cabinets, cases, and storage systems; commercial ovens,

rotisseries, and cooking equipment; and rotary vane pumps.

Ask your sales representative about how the power of all Standex brands can work for you.

www.standex.com/segments/food-service

Be sure to keep up with new product announcements

and events on social media!

Loading...

Loading...