INSTALLATION AND OPERATING INSTRUCTIONS

Open Burner Range

Models:

XOB-212

XOB-424

XOB-636

XOB-848

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

For Your Safety: Do not store or use flammable liquids or vapors in the vicinity of this

!

This equipment has been engineered to provide you with year round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

or any other appliance.

Warning: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance instructions thoroughly before installing or servicing this equipment.

XOB-212SU

XOB-424SU

XOB-636SU

XOB-848SU

!

!!

Instructions must be posted in a prominent location. All safety precautions must be taken in the

event the user smells gas. Safety information can be obtained from your local gas supplier.

I

G

S

N

E

D

R

C

E

D

R

E

I

T

I

F

R

CERTIFIED

R

SANITATION

NSF/ANSI 4

P/N U4192A 1/08

BAKERS PRIDE OVEN CO., INC.

30 Pine Street

New Rochelle, NY 10801

(914) 576-0200 Phone (800) 431-2745 US & Canada

(914) 576-0605 Fax www.bakerspride.com Web Address

1

Notes:

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

2

CONTENTS

1. INSTALLATION INSTRUCTIONS

SECTION ITEM PAGE

A Safety Precautions 3

B Unpacking Instructions 4

C Gas Connection 4

3. MAINTENANCE INSTRUCTIONS

SECTION ITEM PAGE

A Cleaning Instructions 5

B Maintenance Instructions 5

C Troubleshooting Chart 5

D Parts List & Exploded View 6

2. LIGHTING INSTRUCTIONS

SECTION ITEM PAGE

4. WARRANTY 8

A Lighting Instructions 4

B Shutdown Instructions 4

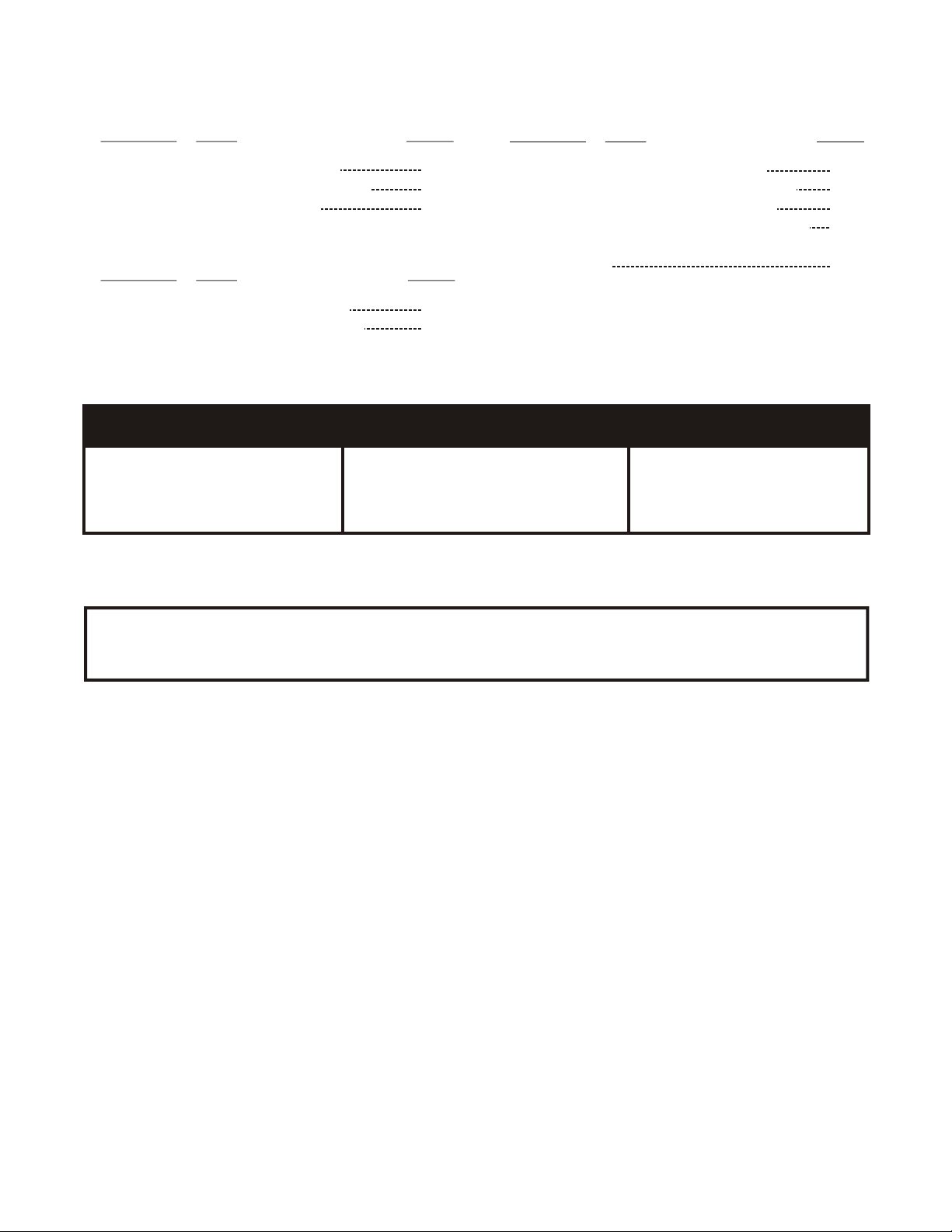

GAS SPECIFICATIONS

Propane Gas Natural Gas

BTU/HR @ 10” W.C. BTU/HR @ 3.5” W.C.

Model Number

XOB-212, XOB-212SU

XOB-424, XOB-424S

XOB-636, XOB-636SU

XOB-848, XOB-848SU

240,000 240,000

60,000 60,000

120,000 120,000

180,000 180,000

1. INSTALLATION INSTRUCTIONS

In MASSACHUSETTS: All gas products must be installed by a “Massachusetts” licensed plumber or

gas fitter. Ventilation hoods must be installed in accordance with NFPA-96, current edition, with

interlocks as described in that standard.

A. SAFETY PRECAUTIONS

FOR YOUR SAFETY, THE FOLLOWING SAFETY PRECAUTIONS SHOULD BE FOLLOWED

AND ENFORCED.

IF YOU SMELL GAS: SHUT OFF GAS SUPPLY TO APPLIANCE

EXTINGUISH OPEN FLAMES

· IMMEDIATELY CALL YOUR GAS SUPPLIER

Instructions must be posted in a prominent location. All safety precautions must be taken in the event the

user smells gas. Safety information can be obtained from your local gas supplier.

1. A separate gas shut-off valve must be installed in the gas line ahead of the unit, as required by

codes.

2. LIGHTING: Follow the instructions on page 4.

3. At least 24 inches must be provided at the front of for servicing.

4. When installing, never enclose the bottom area of the unit with a raised curb or other

construction that would obstruct the flow of air into the unit.

5. This unit may be operated with 0” (sides and back) minimum clearance to non-combustible

construction in areas that are non-combustible locations only.

6. This installation must conform to local codes, or in absence of local codes to the National Fuel

Gas Code ANSI Z223.1/NFPA 54, latest edition. In Canada it must conform to current Natural

Gas Installation Code CAN/CGA B 149.1 (natural gas) or CAN/CGA B 149.2 Propane

Installation Code for Gas Burning Appliances & Equipment.

7. The appliance and its individual shut-off valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of ½ psi (3.45

3

kPa).

8. The appliance must be isolated from the gas supply piping system by closing its individual

manual shut-off valve during any pressure testing of the gas supply piping system at test

pressures equal to or less then ½ psi (3.45 kPa).

9. This appliance must be installed under a ventilation hood.

10. Do not obstruct the flow of combustion and ventilation air.

11. The area around this and any other gas appliance must always be kept free and clear from

combustibles.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

B. UNPACKING INSTRUCTIONS:

Carefully unpack the open burner range and inspect immediately for shipping damages. Your open

burner range was shipped in a carton designed to give maximum protection in normal handling. It

was thoroughly inspected before leaving the factory and the carrier accepted and signed for it. File

any claims for shipping damage or irregularities with the carrier.

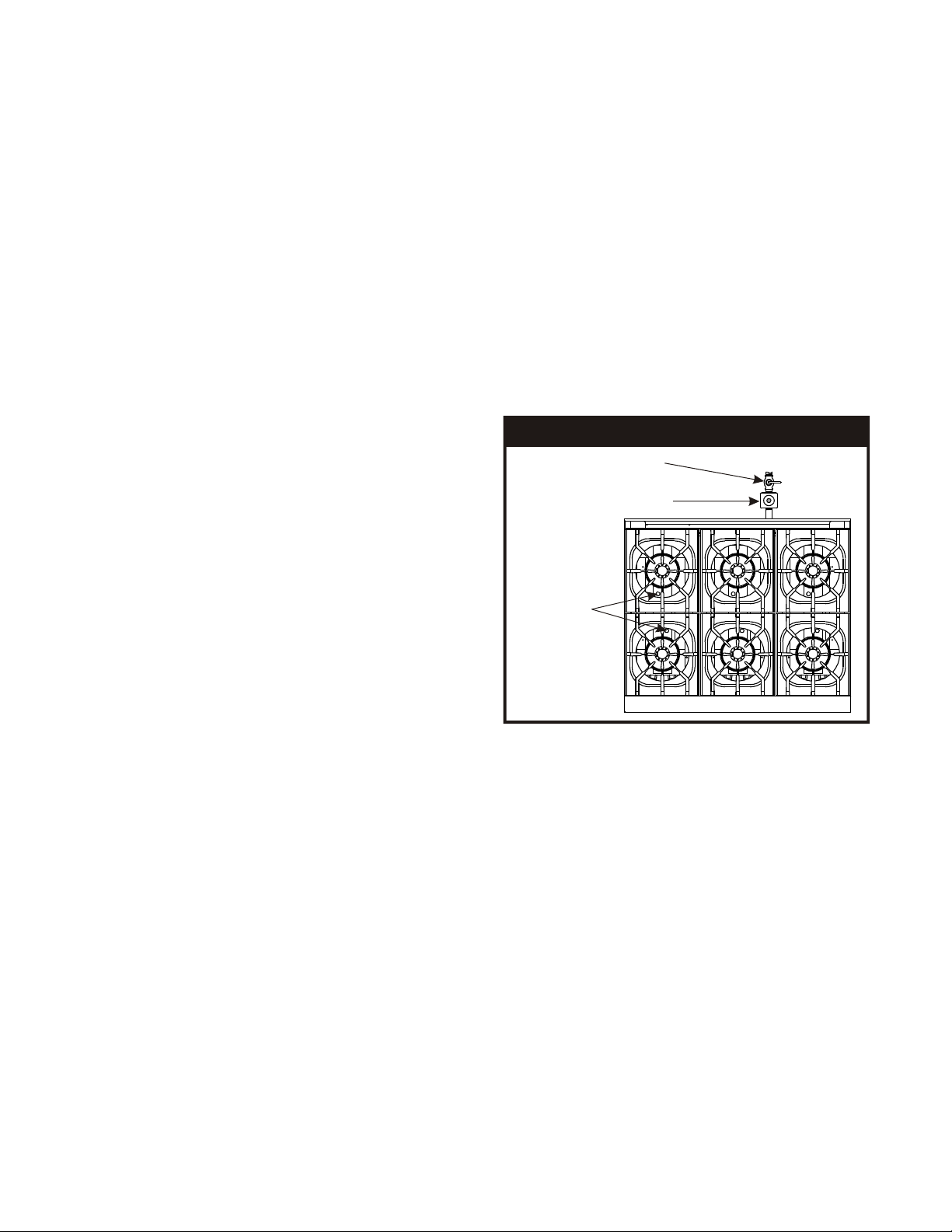

C. GAS CONNECTIONS

A separate gas shut off valve (supplied with

unit) must be installed in the gas line ahead of

the unit, as required by codes (see Fig. A).

Figure “A”

MAIN SHUT-OFF VALVE

Gas supply line must be ¾” or larger. If flexible

semi rigid connections are used, the inside

PRESSURE REGULATOR

diameter must be the equivalent of ¾” iron

pipe or larger. All connections of the flexible

and semi rigid type must be AGA listed and

comply with applicable ANSI standards. Make

sure gas piping is clean and free of dirt, piping

compound and obstruction. To insure

maximum operating efficiency, this appliance

STANDING

PILOT

must be connected with a Gas Supply Line of

solid pipe or with a Commercial Type Flexible

Connector with I.D. (inside diameter) equal or

larger than the gas pipe inlet on this

appliance.

CAUTION: BEFORE LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS. USE

SOAP AND WATER SOLUTION. DO NOT USE OPEN FLAME.

If the gas connections are leak-free, the unit is ready to use. Follow the lighting instructions.

2. LIGHTING INSTRUCTIONS

A. LIGHTING INSTRUCTIONS

1. Turn off all gas valves and main Shut-off valve and wait 5 minutes.

2. Turn the main gas valve to ON position and light standing pilots adjacent to each main

burner. (FIG. A & B)

3. Repeat the above step for all standing pilots. There should be slight yellow tip on the pilot flame.

Make sure all the pilots are lit.

Pilot should be approximately ½”- ¾” in height. Adjust as required

by turning the pilot adjusting screw located on the manifold pipe.

4. Turn the main burner valve to the ON position.

5. To relight follow steps 1-4.

B. SHUTDOWN INSTRUCTIONS

For complete shut down turn all the main burner valves and main gas valve to OFF position.

4

3. MAINTENANCE INSTRUCTIONS

A. CLEANING INSTRUCTIONS

!

Clean the unit regularly after use. Burner ports and burner rest should be thoroughly cleaned. Top

grates are easily removable. After cleaning rinse with clean water and dry with a dry cloth.

!

Heavy sputtering or spills may require cleaning with a mild oven cleaner.

!

Use mild soap or detergent to clean chassis and stainless steel parts.

!

To service burners or pilots TURN OFF GAS SUPPLY and remove top grates.

B. MAINTENANCE INSTRUCTIONS

To provide proper operation and insure the safety of the user, this equipment must be maintained

and serviced by a trained maintenance person or an authorized service agency at regular intervals.

1. Burner ports must be thoroughly cleaned. Venturi must be free from grease and lint.

2. All places where oil, grease or food can accumulate must be kept clean all the time.

3. Pilot light must be kept clean and adjusted at the proper flame height to assure constant ignition and

to prevent fire flash-outs caused by delayed ignition.

4. Carelessness, abusive handling, or altering equipment can shorten the life of the equipment and

jeopardize the limited warranty offered by Baker's Pride.

If you have any questions concerning the installation, operation, maintenance or service of this

product please contact: Technical Service Department at (800) 431-2745 US & Canada

Figure “B”

GAS VALVE

C. TROUBLESHOOTING CHART

PROBLEM PROBABLE CAUSE SOLUTION

Burners & pilots will

not turn on

Burners produce

excessive carbon

deposits

Pilot will not remain lit.

Burners don't seem

hot enough

Main gas supply to range is not

turned on.

Incorrect gas type.

Incorrect gas supply pressure.

Incorrect orifices.

Primary air not adjusted properly.

Pilot flame adjusted incorrectly.

Draft condition.

Orifices may be dirty/clogged.

Low gas pressure.

Improper ventilation system.

Turn on main gas supply.

Supply correct type gas.

Call local gas supplier.

Call Bakers Pride authorized service center.

Adjust air shutter.

Adjust pilot flame.

Remove draft.

When unit cools, check & clean orifices.

Increase gas pressure to 3.5" W.C. (Nat) or

10" W.C. (L.P.)

Call an HVAC specialist.

5

BAKERS

PRIDE

30 Pine Street • New Rochelle • New York • 10801

XOB -212, -424, -636, -848,

-212SU, -424SU, -636SU, -848SU

Open Burner Range

1 - 914 / 576 - 0200

1 - 914 / 576 - 0605

1 - 800 - 431 - 2745

www.bakerspride.com

D. PARTS LIST & EXPLODED VIEW

Models: XOB-212, -424, -636, -848, -212SU, -424SU, -636SU, -848SU

fax

US & Canada

web address

Cookline

SERIES

44

Inst/Op

Manual

33

89

4

32

10

37

40

29

16

41

24

23

18

17

35

22

1

19

)( V

XOB

BA

BA

KE

KE

RS

RS

PR

PR

I

I

DE

DE

and

t

S

e n

rd rsio

a

39

2

42

43

31

Type

SU

14

15

6

12

13

Serial Number

tep V

Type of Gas

Natural

L.P.

S

B

e

O

X

-Up i

Other

U

rs

)(S

n

o

3

5

6

7

20

21

Model Number - Width

XOB-212

XOB-424

Page 1 of 2 Note: When ordering, ALWAYS specify Part #, Model #, Serial #, Voltage/Phase & type of Gas. U6020A 5/07

12”

24”

XOB-636

XOB-848

30

34

36

38

36”

48”

25

26

27

28

STD

BAKERS

PRIDE

XOB -212, -424, -636, -848,

-212SU, -424SU, -636SU, -848SU

Open Burner Range

30 Pine Street • New Rochelle • New York • 10801

1 - 914 / 576 - 0200

1 - 914 / 576 - 0605

1 - 800 - 431 - 2745

www.bakerspride.com

fax

US & Canada

web address

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

P/N

G7002K

G7003K

G7010K

G7011K

G7018K

G7019K

G7020K

G7026K

G7027K

G7028K

G7046K

G7051K

G7052K

G7053K

G7054K

Description

Outer Side, Left

Outer Side, Right

Front Panel, 48”

Front Trim, 48"

Front Panel, 12"

Front Panel, 24"

Front Panel, 36"

Front Trim, 12"

Front Trim, 24"

Front Trim, 36"

Pilot Clip (Not Shown)

Crumb Tray, 48"

Crumb Tray, 36"

Crumb Tray, 24"

Crumb Tray, 12"

Item

25

26

27

28

29

30

24

31

32

33

34

35

36

37

38

P/N

R1148P

R1149P

R1150P

R1151P

R3020A

R3023A

N5880P

R3032A

R3203A

R3204A

R3205A

R3206A

R3222P

R3249A

R3250P

Description

Manifold Assy, 12"

Manifold Assy, 24"

Manifold Assy, 36"

Manifold Assy, 48"

Valve, Pilot-Dual, 1/8-27 x 3/16"

Orifice, Blank

Pilot (SU, Rear) Not Shown

Valve, LML-15 1/8-27 X 3/8-27 Hood

Front Venturi

Venturi, Rear, Std

Orifice #38, Nat Gas

Valve, Gas Shut-Off

Orifice #52, LP Gas

Venturi, Rear, Step-Up

Orifice #53, But/Prop Gas

16

17

18

19

20

21

22

23

Item

N/S

N/S

N/S

N/S

N/S

L5105A

M1009A

M1184A

M1460A

N3023A

N3068P

N5856P

N5857P

P/N

Q1406A

Q1407A

Q1445A

Q1472A

Q1475A

Burner, Open Top Burner (CI)

Pressure Regulator, 3/4",10.0 WC, LP

Pressure Regulator, 3/4", 3.5 WC, Nat

Pilot Burner, Nat Gas

Plug, 1/8" Brass

Pressure Tap Nozzle Assy

Pilot Tubing, S/S, 3/16" (Standard & SU, Front)

Pilot Tubing, S/S, 3/16" (Standard & Rear)

HARDWARE (NOT SHOWN)

Description

Screw, #10 x 1/2", Truss Hd, Slot

Screw, #10 x 1/2", Hex Hd, Slot

Screw, 10 x 3/4", Hex Hd w/Washer

Screw, 1/4-20 x 1/4",Button Hd S/S

Screw, 10-32 x 1/2",Truss Hd S/S

39

40

41

42

43

44

45

46

Item

N/S

N/S

N/S

N/S

N/S

S1395A

S1416A

T1247A

U1044X

U1381A

U4192A

X1019A

X1046A

P/N

Q1502A

Q2002A

Q2046A

Q2335A

Q3044A

Leg, 6"

Knob, Gas Valve, On-Off

Grate, 12' x 13", Cast Iron

Name-Plate, Bakers Pride Logo 8"(Small)

Label, Lighting Instruction

Inst/Op Manual

Carton (12" & 24" Units) Not Shown

Carton (36" & 48" Units) Not Shown

Description

Screw, #10 x 1", Pan Hd, Php

Screw, 1/4-20 x 1/2", Truss Hd, Slot

Nut, 1/4-20, Hex, Lock

Nut, 3/4-10, Hex, Heavy

Washer, .437 0.260 I.D,.062 Thk Flat

N/S

Q1478A

Page 2 of 2 Note: When ordering, ALWAYS specify Part #, Model #, Serial #, Voltage/Phase & type of Gas. U6020A 5/07

Nut, 10-32,Hex Hd, Lock

N/S = Not Shown

7

4. BAKERS PRIDE LIMITED WARRANTY

914 / 576 - 0200 ♦ US & Canada: 1 - 800 - 431 - 2745 ♦ fax 914 / 576 - 0605

30 Pine Street New Rochelle, New York 10801

WHAT IS COVERED This warranty covers defects in material and workmanship under normal use, and applies only to the original purchaser

WHO IS COVERED This warranty is extended to the original purchaser and applies only to equipment purchased for use in the U.S.A.

COVERAGE PERIOD Full size gas and electric deck ovens: Two (2) year limited parts and labor: Cyclone Convection Ovens: BCO Models: One (1)

WARRANTY This warranty covers on-site labor, parts and reasonable travel time and travel expenses of the authorized service

COVERAGE representative up to (100) miles. round trip, and (2) hours travel time. The purchaser. however, shall be responsible for all

EXCEPTIONS All removable parts in BAKERS PRIDE Char-broilers, including but not limited to: Burners, Grates. Radiants, Stones and

EXCLUSIONS

♦ Negligence or acts of God,

♦ Thermostat calibrations after (30) days from equipment

installation date,

♦ Air and Gas adjustments,

♦ Light bulbs,

♦ Glass doors and door adjustments.

♦ Fuses,

♦ Char-broiler work decks and cutting boards,

♦ Tightening of conveyor chains,

♦ Adjustments to burner flames and cleaning of pilot burners,

♦ Tightening of screws or fasteners.

providing that:

♦ The equipment has not been accidentally or intentionally damaged, altered or misused;

♦ The equipment is properly installed, adjusted, operated and maintained in accordance with National and local codes. and

in accordance with the installation instruction provided with the product;

♦ The serial number rating plate affixed to the equipment has not been defaced or removed.

Year limited parts and labor; GDCO Models: Two (2) Year limited parts and labor; CO II Models: Two (2) Year limited parts

and labor; (5) Year limited door warranty.

All Other Products: One (1) Year limited parts and labor.

Warranty period begins the date of dealer invoice to customer or ninety (90) days after shipment date from BAKERS PRIDE whichever comes first.

expenses related to travel, including time. mileage and shipping expenses on smaller counter models that may be carried into

a Factory Authorized Service Center, including the following models: PX-14. PX-16, PI8, and BK-I8.

Valves, are covered for a period of SIX MONTHS.

All Ceramic Baking Decks are covered for a period of THREE MONTHS. The installation of these replacement decks is the

responsibility of the purchaser.

The extended Cyclone door warranty years 3 through 5 is a parts only warranty and does not include labor, travel, milage or

any other charges.

♦ Failures caused by erratic voltages or gas supplies,

♦ Unauthorized repair by anyone other than a BAKERS PRIDE

Factory Authorized Service Center,

♦ Damage in shipment,

♦ Alteration, misuse or improper installation,

♦ Thermostats and safety valves with broken capillary tubes.

♦ Accessories - spatulas, forks. steak turners, grate lifters,

oven brushes, scrapers, peels. etc.,

♦ Freight - other than normal UPS charges,

♦ Ordinary wear and tear.

INSTALLATION Leveling and installation of decks. as well as proper installation and check out of all new equipment - per appropriate

REPLACEMENT BAKERS PRIDE genuine Factory OEM parts receive a (90) day materials warranty effective from the date of installation by a

PARTS BAKERS PRIDE Factory Authorized Service Center.

This Warranty is in lieu of all other warranties, expressed or implied, and all other obligations or liabilities on the manufacturers part. BAKERS PRIDE

shall in no event be liable for any special, indirect or consequential damages, or in any event for damages in excess of the purchase price of the unit. The

repair or replacement of proven defective parts shall constitute a fulfillment of all obligations under the terms of this warranty.

installation and use materials - is the responsibility of the dealer or installer, not the manufacturer.

Form #U4177A 1/07

8

Loading...

Loading...