Bakers Pride DP-2, P-18, P-22BL, P-22S, P-24S Installation And Operating Instructions Manual

...Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

COUNTER TOP ELECTRIC OVENS

INTENDED FOR OTHER THAN HOUSEHOLD USE

! !

! !

Note: Only Pizza or Bread can have direct contact with ceramic decks. All other food products must be

placed in a pan or container to avoid direct contact with ceramic decks.

Models: PX-14, PX-16, P-18, BK-18, P-22S, P-22BL,

P-24S, P-44S, P-44BL, P-46S, P-48S, DP-2

RETAIN THIS MANUAL FOR FUTURE REFERENCE

OVEN MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

WARNING: Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this equipment.

Initial heating of oven may generate smoke or fumes and must be done in a well

ventilated area. Overexposure to smoke or fumes may cause nausea or dizziness.

This equipment has been engineered to provide you with year round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

(914) 576-0200 Phone (800) 431-2745 US & Canada

(914) 576-0605 Fax www.bakerspride.com Web Address

S

I

F

S

I

A

L

C

E

D

CC

BAKERS PRIDE OVEN CO., INC.

30 Pine Street

New Rochelle, NY 10801

1

P/N U4008A 1/08

Page 2

CONTENTS

INSTALLATION INSTRUCTIONS

SECTION ITEM PAGE

1 Location 2

2 Electrical Connections 2

3 Requirements for Installation 3

4 Initial Start Up 3

OPERATING INSTRUCTIONS

SECTION ITEM PAGE

1 General Baking 3

2 General Baking Tips 4

3 Special Features 4

4 Cleaning 5

5 Service and Trouble Shooting 5

6 Installation of Decks 6

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

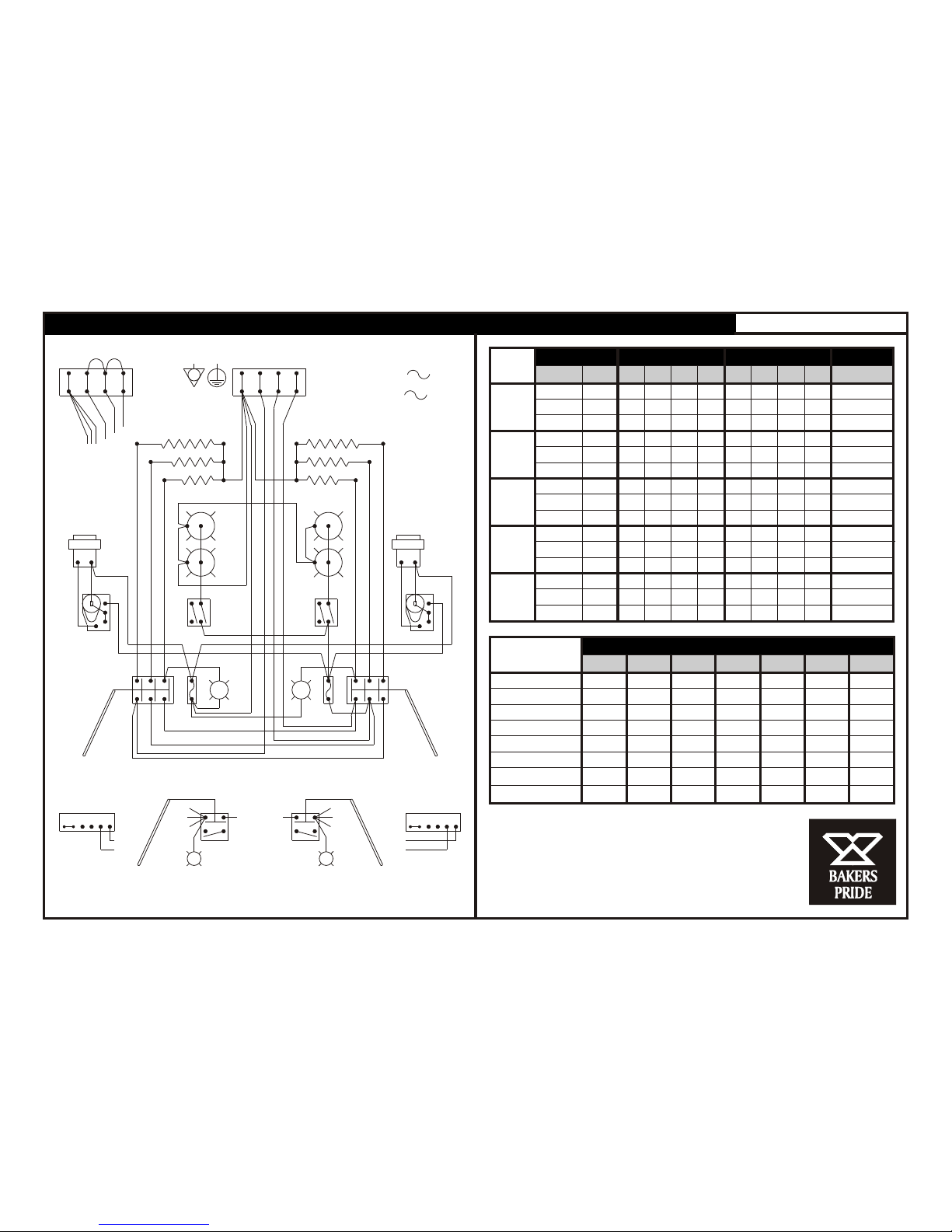

WIRING DIAGRAMS & SCHEMATICS

ITEM PAGE

P Series - 2 Chamber - 1 Ph, 2 W or 3 Ph, 3 W (Wiring Diagram) 7

P Series - 2 Chamber - 3 Ph, 4 W - Star (Wiring Diagram) 8

P Series - 1 Chamber - 3 Ph, 4 W - Star (Wiring Diagram) 9

P Series - 1 Chamber - 1 Ph, 2 W or 3 Ph, 3 W (Wiring Diagram) 10

P Series Counter Top Ovens - 2 Chamber (Schematic) 11

P Series Counter Top Ovens - 1 Chamber (Schematic) 11

PX-14 & PX-16 (Wiring Diagram & Tables) 12

PARTS LISTS & WARRANTY

ITEM PAGE

PX -14, PX-16 (New Style) 13

PX -14, PX-16 (Old Style) 14

P18-S & BK18 15-16

P-22BL, P-22S & P-24S 17-18

P-44S, P-44BL & P-48S 19-20

DP-2 21-22

Warranty 23

Model Number Serial Number Date Purchased

INSTALLATION INSTRUCTIONS

Minimum Clearance for Installation

From combustible or non-combustible construction:

Right side, Left side and Back: 3” (76mm)

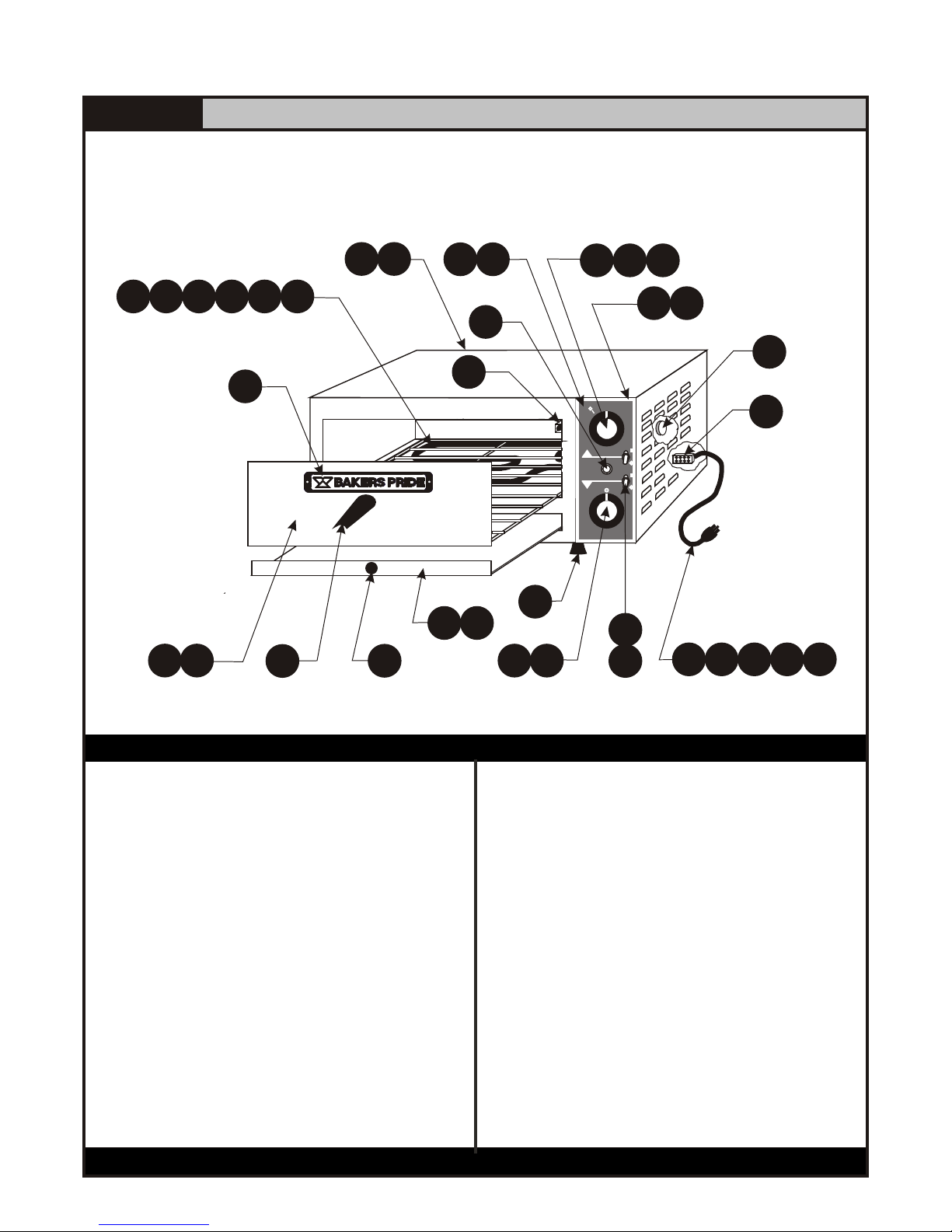

1. LOCATION

Due to the heat a counter-top oven may produce, it must be placed on a non-combustible surface.

Do not store combustible materials on top of any oven.

2. ELECTRICAL CONNECTIONS

Suitable means, which will disconnect all ungrounded conductors of the circuit simultaneously,

must be provided by the installer.

Make sure electrical supply corresponds with that specified on the rating plate located in the rear of

the oven.

When installed, the unit must be connected by an earthing cable to all other units within the

complete installation and thence to an independent earth connection.

Use copper conductors only, rated at 90° C.

If a line cord is used for the installation of the unit in Europe, it should be a minimum of H07RN-F type

conforming to EN60 335-1 and/or local codes.

2

Page 3

Use minimum conductor size as below:

! For models PX-14, PX-16, P-18, BK-18 and P-24S:

14 Gauge (1.5mm) for 220-240V, single phase supply.

! For models P-22S, P-22BL, P-44S, P-44BL, P-46S, P-48S and DP-2:

10 Gauge (2.5mm) for 220-240/380-415V, 3 phase supply.

3. REQUIREMENTS FOR INSTALLATION

For portable units (Model PX-14 and PX-16) there are no special requirements.

For shipping purposes the optional 4” (100mm) legs are not mounted. For mounting legs, follow

steps a. through g.

a. Remove the outer shipping carton and paper and place the oven on the floor or other flat

surface.

b. Remove legs, baking decks and any other materials from inside the unit.

c. With sufficient help, tilt the unit back far enough to mount the two front legs and tighten with

an adjustable wrench.

d. After the front legs are tight, lift rear of unit approximately 5” (125mm) off the surface and

block in position using wood or some other solid material. Now mount the two rear legs and

tighten.

e. Using the proper lifting equipment, move the unit to its final location.

f. Adjust the bottom portion of legs to make level.

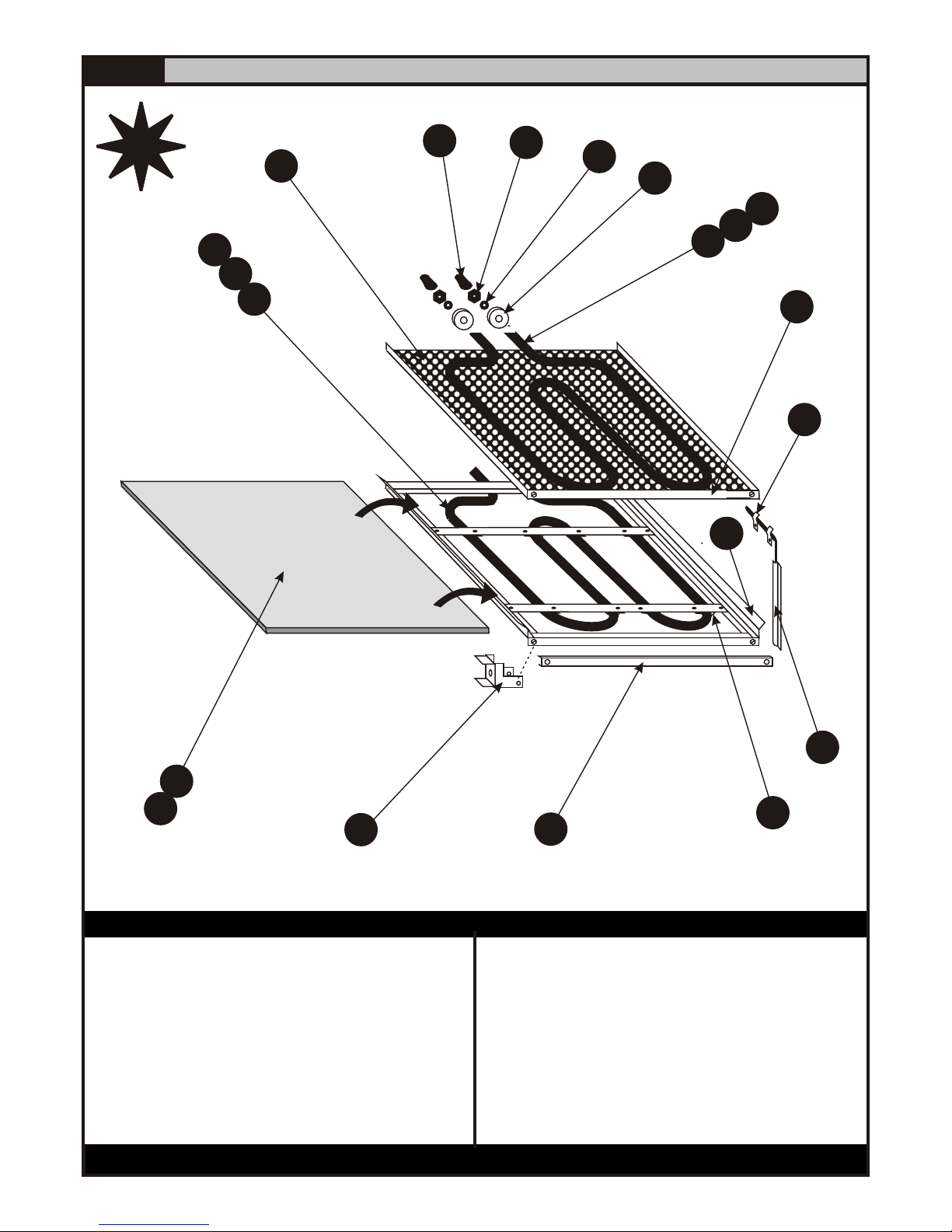

g. Slide baking decks into each shelf. (View on Page 7)

4. INITIAL START UP

After the electrical connections have been made, the oven will need approximately 2 to 3 hours to

burn off. Initial heating of the oven may generate smoke or fumes and must be done in a well

ventilated area.

CAUTION: OVEREXPOSURE TO SMOKE OR FUMES MAY CAUSE NAUSEA AND DIZZINESS.

For initial heating of the new oven, follow the steps below:

! Place the oven in a well ventilated area.

! Open the oven doors and remove any instructions or samples shipped within the unit. Make

sure the oven cavity is empty and the baking decks are properly installed.

! With the oven doors open, turn the temperature knobs to 400° F (205° C) for one hour.

! Close the oven door. Increase the temperature to 500° F (260° C) for at least 1 ½ hours.

This procedure will dry out the insulation and deck material and will help to insure optimum baking

results thereafter.

OPERATING INSTRUCTIONS

Note: Only Pizza or Bread can have direct contact with ceramic decks. All other food products must be

placed in a pan or container to avoid direct contact with ceramic decks.

1. GENERAL BAKING

Models: P-18, BK-18, P-22S, P-22BL, P-24S, P-44S, P-44BL, P-46S, P-48S, PX-14 and PX-16

Preheat the oven by setting the thermostat to the desired temperature. When the thermostat light

goes out and has cycled three times, the oven is ready for use.

These ovens have been designed to bake both fresh and frozen products. Frozen fruit pies should

be taken directly from the freezer and placed into the oven. Cooking time will vary with the size of the

pie, but under normal conditions a frozen pie should bake approximately in the same time as a fresh

pie.

3

Page 4

These ovens work well for toasting, melting cheese, baking frozen entrees, roasting small meat

items, etc.

The temperature range for pizza baking is usually between 500° F (260° C) and 575° F (300° C)

depending on the individual product.

Allow the pizza to bake until the cheese bubbles and the bottoms are evenly brown. (Rotate if

necessary)

The design of the PX-14 and PX-16 is such that normal baking temperature may be too high for

good results. Set the thermostat approximately 25° F (15° C) BELOW normal setting. Adjust

temperature as needed.

Do not keep the oven door open too long when loading since heat will escape, resulting in slower

baking.

When production requirements are low, keep the temperature low to prevent the bottoms from

burning.

As demand increases, temperature should be raised for faster recovery.

Fresh dough generally requires a slightly lower baking temperature and longer bake time than

defrosted pre-baked crusts.

2. GENERAL BAKING TIPS

! Pizza crusts should be fully defrosted before baking.

! Wet areas on the bottom of a pizza will cause them to stick to the deck. Avoid spills.

! For fresh dough pizza, flour or corn meal on the peel will prevent sticking and ease

placement of the pizza on the deck.

! Increasing bake temperature during heavy production assists in maintaining temperature.

After the rush is over, reduce temperature to prevent burning.

! Heavily topped pizzas require longer bake times at lower temperatures.

! Placing a screen under pizza will allow the top to cook without overcooking the bottom.

! Frequently scrape and brush off decks to remove burned residue which can cause an off

flavor to the product. Residue build-up can slow bake times. A deck scraper/brush

specifically designed for this is available from BAKERS PRIDE.

! Clean heavily soiled pizza decks by scraping down, brushing off, removing from oven,

turning over and putting back. This procedure will burn off the decks and should be repeated

every six months. DO NOT USE WATER TO CLEAN THE DECKS as this could cause the

decks to crack.

! Using shiny pans or screens will produce products with light bottom color. We strongly

suggest that all pans and screens be seasoned before use.

3. SPECIAL FEATURES

Timer: An electric timer is provided to give an audible, continuous signal at the end of a preset time

up to 15 minutes (18 minutes with 50Hz supply) on pizza ovens, or 60 minutes (72 minutes with

50Hz supply) on bake ovens,

Optional Electronic Timer: A Digital electronic 99 minute timer can be provided on all models to give

an audible signal at the end of a pre-set time.

Note: TIMER DOES NOT CONTROL THE OVEN.

For PX-14 and PX-16 only: Individual switches are provided to turn off the top or the bottom heating

element. This allows baking items that do not require direct top or bottom heat.

4

Page 5

For DP-2 only: Optional infinite control switches can be provided for fine balancing of top and

bottom heat.

4. CLEANING

Periodic cleaning is suggested to keep your oven in good shape.

ALWAYS CLEAN THE OVEN WHEN IT IS COLD.

WHEN CLEANING STAINLESS STEEL, ALWAYS WIPE IN THE DIRECTION OF THE GRAIN.

Scrapers, brushes and stainless steel cleaner can be ordered from BAKERS PRIDE for this

purpose.

From time to time the spillage should be scraped out. For hard to clean spillage, the following is

suggested:

! Turn the thermostat up to the highest setting and let the oven run for ½ hour with the door

! Allow the oven to cool down.

! Brush the residue from deck.

Note: DO NOT USE WATER TO CLEAN DECKS. CRACKING MAY RESULT.

Stainless steel surfaces should be cleaned with BAKERS PRIDE STAINLESS STEEL CLEANER.

closed.

5. SERVICE AND TROUBLE SHOOTING

The ovens are designed to be as trouble free as possible. Keeping the oven clean is all that is

normally required. All servicing should be performed by a factory authorized technician only.

However, if your oven stops operating, please check the following:

! Power supply cord is plugged into the supply receptacle.

! Power supply fuse/circuit breaker has not tripped.

If the oven still does not operate, take the following steps:

! Disconnect the power supply to the unit by removing the supply cord and/or turning off the

main switch.

! Contact the factory, factory representative or an authorized service agency.

Note: Infinite control switches must be in a set position (other than off) in model DP-2 with optional infinite

switches, for elements to operate.

A system wiring diagram is a part of this manual and is provided on the back of the unit.

For further information and to purchase the deck scraper/brush, or stainless steel cleaner, call BAKERS

PRIDE at: (914) 576-0200.

5

Page 6

TROUBLESHOOTING CHART

PROBLEM PROBABLE CAUSE SOLUTION

Indicator light is out

No power

Oven too Hot

Bottom of pies are

undercooked

Bottom of pies burn

before toppings are

cooked

Pies cook unevenly

Set temperature has been

reached.

The infinite top and bottom heat

control switches are "OFF". (DP-2

w/Infinite Switches only)

Power supply fuses or circuit

breakers are blown or have been

tripped.

Power cord is unplugged.

Power supply fuses or circuit

breakers are blown or have been

tripped.

Power cord is unplugged.

Thermostat set too high.

Thermostat may be defective.

Bottom infinite switch set too low.

(DP-2 w/Infinite Switches only)

Top Infinite switch set too high.

(DP-2 w/Infinite Switches only)

Deck temperature too hot especially during slow periods.

Bottom infinite switch set too high.

(DP-2 w/Infinite Switches only)

Top Infinite switch set too low.

(DP-2 w/Infinite Switches only)

Area's adjacent to oven walls are

generally hotter.

Take no action. The thermostat has

turned off the power to the heat control

switches, indicator lamps, contactors and

heating elements. When oven starts to

cool, all functions will be restored.

Turn switches to a position other than

"OFF". This will allow indicator lamps,

contactors and heating elements to

operate.

Replace fuse or reset circuit breaker.

Plug in power cord.

Replace fuse or reset circuit breaker.

Plug in power cord.

Lower the thermostat setting. Allow

ample time for heat to regulate.

Call local authorized Bakers Pride

Service Agent.

Increase setting.

Decrease setting.

Reduce Thermostat setting by 50° - 75°

below normal bake temperature. When

decks cool begin cooking and

immediately increase the thermostat

setting by 50° - 75°.

Decrease setting.

Increase setting.

Rotate pies (180°), once during each

bake or keep to the center of oven.

6. INSTALLATION OF DECKS

DECK

DECK

6

Page 7

7

BR17

21 WT

WT 21

L1

L2

TERMINAL

BLOCK

1 PHASE

BR1

BK2

WT22

WT11

BR23

BK10

BK10

BR23

BK16

BR1

BK2

WT11

WT22

BK4

BK4

WT22

ELECTRONIC

TIMER 250V

(OPT)

BR17

BK18

BR17

BK18

2 3 5 62 3 5 6

BK16

BR17

BK26

BK20

BR3

BR3

BR25

BR19

BK16

BK18

BK18

BR15

BR15

BK28

BR27

BK14

WT24

WT13

BR5

BR29

BR27

BK28

WT11

BK30

BK2

BR1

L3

200V 1 OR 3

208V 1 OR 3

240V 1 OR 3

TERMINAL

BLOCK

3 PHASE

LOWER HEATING COILS UPPER HEATING COILS

LB

LC

LT

UT

UC

UB

L2

L1

THERMOSTAT

EGO 3 POLE

THERMOSTAT

EGO 3 POLE

CIRCUIT

BREAKER

CIRCUIT

BREAKER

PILOT

LIGHT

PILOT

LIGHT

LIGHT

SWITCH

(OPT)

LIGHT

SWITCH

(OPT)

2, 3 OR 4 AS REQUIRED

250V LAMPS (OPT)

BUZZER

BUZZER

TIMER 250V

TIMER 250V

LOWER

BAKE

CHAMBER

UPPER

BAKE

CHAMBER

BR7

BK8

BK16

ELECTRONIC

TIMER 250V

(OPT)

ROBERTSHAW

THERMOSTATS

BK2

BR1

WT22

WT11

WT13

WT24

BR5

BK14

BR3

BR7

BK4

DWG. 1012-120 10/09/00

P-SERIES 2 CHAMBER - 1 PH, 2 W OR 3 PH, 3 W - ELECTRICAL WIRING DIAGRAM & TABLES

ELECTRICAL WIRING DIAGRAMS, SCHEMATICS AND TABLES

WATT PER HEATING COIL & TOTAL WATT PER UNIT

COIL LOCATION

DP2

UC - UPPER CTR

UT - UPPER TOP

UB - UPPER BOTT

LT - LOWER TOP

LC - LOWER CTR

LB - LOWER BOTT

TOTAL NO LIGHT

TOTAL W. LIGHT

1,075

- - -

1,450

1,075

- - -

1,450

5,050

5,080

P48S

1,075

- - -

1,075

1,075

- - -

1,075

4,300

4,330

P46S

1,075

1,450

1,075

1,075

- - -

1,075

5,750

5,795

P44S

1,075

1,450

1,075

1,075

1,450

1,075

7,200

7,260

P44SH

1,075

1,450

1,450

1,075

1,450

1,450

7,950

8,010

L3

L2

22.0

18.7

18.7

18.7

24.3

25.327.9

26.9

24.3

20.7

21.526.1

25.0

22.7

20.7

21.518.6

17.9

16.2

20.7

21.511.2

10.7

9.7

25.3

24.3

22.011.4

12.5

13.0

AMP - W. LIGHT

L1

L3

24.3

22.7

16.2

9.7

26.9

27.925.3

24.3

22.0

25.0

26.121.5

20.7

18.7

17.9

18.621.5

20.7

18.7

10.7

11.221.5

20.7

18.7

13.0

12.5

11.422.0

24.3

25.3

AMP - NO LIGHT

L1

L2

12.6

12.1

11.0 11.0

12.1

12.6

9.3

10.3

10.8 10.8

10.3

15.7

17.3

18.0 18.0

17.3

22.0

24.3

25.3 25.3

24.3

23.6

26.1

27.1 27.1

26.1

9.3

15.7

22.0

23.6

3 PHASE - 3 WIRE

AMPERE

25.3

24.3

22.0

18.7

20.7

21.5

25.0

27.6

28.8

31.3

34.6

36.0

34.6

38.2

39.8

NO L.

22.3

24.7

25.7

21.9

21.1

29.4

28.2

36.8

35.4

40.6

39.0

19.0

25.5

32.1

35.3

VOLT A/C

200

240

208

UNIT

COILS

200

208

230

MODEL

DP2

200

208

P48S

200

208

240

230

200

208

P46S

200

208

240

230

200

208

P44S

200

208

240

230

200

208

P44SH

200

208

240

230

I PHASE - 2 WIRE

PLUG & NO.

USA

CAN

W. L.

6-30P 6-30P

6-30P6-30P

6-30P 6-50P

6-50P6-50P

6-50P 6-50P

Page 8

8

BL34,45,45

BR1

BK2

WT11

BK2

WT11

N

N

BR1

L3L2

L1

BR54

L1

BL34,45,45

(BL53)

(BL53)

BL34

BL35

BR39

BK12

BL52

BL52

BL52

BL52

BL33

BL32

WT42

BK40

BK2

BR41

BR1

BL31

BL35

TERMINAL

BLOCK

1 PHASE

BK16

BR1

BK2

WT11

BK4

ELECTRONIC

TIMER 250V

(OPT)

BL35

BK18

BL35

BK18

2 3 5 62 3 5 6

BK16

BL35

BK 26

BK20

BK16

BK18

BK18

BK28

BL36

BR39

WT24

WT13

BR37

BK28

(230V 1)

400V 3N

TERMINAL

BLOCK

3 PHASE

LOWER HEATING COILS UPPER HEATING COILS

LB

LC

LT

UT

UC

UB

THERMOSTAT

EGO 3 POLE

THERMOSTAT

EGO 3 POLE

CIRCUIT

BREAKER

CIRCUIT

BREAKER

PILOT

LIGHT

PILOT

LIGHT

LIGHT

SWITCH

(OPT)

LIGHT

SWITCH

(OPT)

BUZZER

BUZZER

TIMER 250V

TIMER 250V

LOWER

BAKE

CHAMBER

UPPER

BAKE

CHAMBER

BK12

BK8

BK16

ELECTRONIC

TIMER 250V

(OPT)

ROBERTSHAW

THERMOSTATS

1 OR 2 AS REQUIRED

BK2

BR1

WT13

WT24

BR37

BK8

BL36

2, 3 OR 4 AS REQUIRED

250V LAMPS (OPT)

DWG. 1012-124 10/11/00

P-SERIES 2 CHAMBER - 3 PH, 4 W - STAR - ELECTRICAL WIRING DIAGRAM & TABLES

WATT PER HEATING COIL & TOTAL WATT PER UNIT

COIL LOCATION

DP2

UC - UPPER CTR

UT - UPPER TOP

UB - UPPER BOTT

LT - LOWER TOP

LC - LOWER CTR

LB - LOWER BOTT

TOTAL NO LIGHT

TOTAL W. LIGHT

1,075

- - -

1,450

1,075

- - -

1,450

5,050

5,080

P48S

1,075

- - -

1,075

1,075

- - -

1,075

4,300

4,330

P46S

1,075

1,450

1,075

1,075

- - -

1,075

5,750

5,795

P44S

1,075

1,450

1,075

1,075

1,450

1,075

7,200

7,260

P44SH

1,075

1,450

1,450

1,075

1,450

1,450

7,950

8,010

- - -- - -

- - -- - -

- - -- - -

- - -- - -

- - -- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

L3

L2

12.6

9.3

9.3

9.3

12.6

12.6

6.3

0.0

12.6

0.0

L1

L3

10.0

10.0

9.9

9.7

12.6

9.3

9.3

9.3

9.712.6

230/400

UNIT

COILS

L1

L2

230 9.3

DP2

0.0

P48S

230/400

230 9.3

P46S

230/400

230 9.3

P44S

230/400

230 9.3

P44SH

230/400

230 9.3

0.0

6.3

12.6

12.6

N

N

34.6230

230

31.3230

230

25.0230

230

18.7230

230

22.0230

230

22.3

19.0

25.5

32.0

35.3

3.3

- - -

3.0

3.3

3.3

22.0

18.7

25.0

31.3

34.6

2.9

0.4

3.6

3.3

2.6

22.3

19.0

25.5

32.0

35.3

AMPERE - W. LIGHT

VOLT A/C

AMPERE - NO LIGHT

MODEL

Page 9

9

BL31,32,34

BR1

BK2

WT22

BK2

WT22

N

N

BR1

L3L2

L1

BR54

L1

1

, 3

B

L

3

3

2

, 4

(BL53)

BR37

WT24

BR1

ROBERTSHAW

THERMOSTAT

ELECTRONIC

TIMER 250V

(OPT)

BK16

TIMER 250V

BUZZER

250V LAMPS (OPT)

1 OR 2 AS REQUIRED

LIGHT

SWITCH

(OPT)

PILOT

LIGHT

CIRCUIT

BREAKER

CIRCUIT

BREAKER

THERMOSTAT

EGO 3 POLE

TE

CE

BE

HEATING COILS

BK28

BK18

BK16

BK 26

6532

BK18

BL35

WT22

BK2

BR1

BL35

BR12

BL34

BL52

BL52

BL32

TERMINAL

BLOCK

1 PHASE

BL36

WT24

BR37

(230V 1)

400V 3N

TERMINAL

BLOCK

3 PHASE

BK12

BL31

BK4

DWG. 1012-128 10/11/00

P-SERIES 1 CHAMBER - 3 PH, 4 W - STAR - ELECTRICAL WIRING DIAGRAM & TABLES

- - -- - -

- - -- - -

- - -- - -

- - -- - -

- - -- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

L3

L2

6.3

4.7

4.8

4.3

6.7

6.7

0.2

4.7

3.7

0.2

AMPERE - W. LIGHT

L1

L3

4.7

4.7

4.8

3.7

6.3

4.7

4.7

4.3

3.7 3.7

VOLT A/C

AMPERE - NO LIGHT

230/400

UNIT

COILS

L1

L2

230 3.7

MODEL

BK18

0.0

P18S

230/400

230 3.7

P24S

230/400

230 4.7

P22S

230/400

230 4.7

P22SH

230/400

230 4.7

4.3

0.0

6.3

6.3

N

N

17.3230

230

15.7230

230

9.3230

230

12.4230

230

7.4230

230

7.6

12.7

9.5

16.0

17.6

0.0

0.6

0.0

1.4

1.6

7.4

12.4

9.3

15.7

17.3

0.2

1.0

0.2

2.0

2.0

7.6

12.7

9.5

16.0

17.6

P22SH

4,005

3,975

1,450

1,450

1,075

3,630

3,600

1,075

1,450

1,075

P22S

WATT PER HEATING COIL & TOTAL WATT PER UNIT

COIL LOCATION

TE - TOP ELEMENT

BE - BOT ELEMENT

TOTAL NO LIGHT

TOTAL W. LIGHT

P18S

850

1,000

1,000

2,850

2,880

P24S

1,075

- - -

1,075

2,150

2,1651,715

1,700

850

- - -

850

BK18

Page 10

10

(WT22 NOT USED)

TO SWITCH

(OPT)

A

BK18

BK16

BK2

BR5

WT24

BR1

ROBERTSHAW THERMOSTAT

SINGLE POLE NO SWITCH

1 PHASE ONLY

BR3

BR7

BR7

BR3

BR17

BK18

2 3 5 6

ELECTRONIC

TIMER 250V

(OPT)

ROBERTSHAW

THERMOSTAT

SINGLE POLE

WITH SWITCH

BR1

WT22

WT24

BR5

BR17

WT 21

L1

L2

TERMINAL

BLOCK

3 PHASE

BR1

BK2

WT22

BK10

BK10

BR1

BK2

WT22

BK26

BR3

BR3

BR25

BK16

BK18

BR15

BR27

WT24

BR5

BR29

BK28

WT22

BK2

BR1

HEATING COILS

BE

CE

TE

L2 (N)

L1

THERMOSTAT

EGO 3 POLE

CIRCUIT

BREAKER

CIRCUIT

BREAKER

PILOT

LIGHT

LIGHT

SWITCH

(OPT)

1 OR 2 AS REQUIRED

250V LAMPS (OPT)

BUZZER

TIMER 250V

BR7

BK16

TERMINAL

BLOCK

1 PHASE

240V 1 OR 3

208V 1 OR 3

200V 1 OR 3

120V 1

100V 1

230V 1 OR 3

L3

DWG. 1012-127 10/9/00

P-SERIES 1 CHAMBER - 1 PH, 2 W or 3 PH, 3 W - ELECTRICAL WIRING DIAGRAM & TABLES

BK18

850

- - -

850

1,700

1,715 2,165

2,150

1,075

- - -

1,075

P24S

2,880

2,850

1,000

1,000

850

P18S-2

1,830

1,800

600

600

600

P18S-1

TOTAL W. LIGHT

TOTAL NO LIGHT

BE - BOT ELEMENT

CE - CTR ELEMENT

TE - TOP ELEMENT

COIL LOCATION

WATT PER HEATING COIL & TOTAL WATT PER UNIT

P22S

1,075

1,450

1,075

3,600

3,630

1,075

1,450

1,450

3,975

4,005

P22SH

L3

L2L1L3

L2L1

12.0 7.219.212.0 6.918.8

12.1 7.419.512.1 7.019.1

12.6 7.720.312.6 7.219.9

10.2 7.217.410.2 6.917.1

10.3 7.417.710.3 7.017.3

10.8 7.718.410.8 7.218.0

10.2 0.210.410.2 0.010.2

10.3 0.210.510.3 0.010.3

10.8 0.211.010.8 0.010.8

8.8 5.113.9 8.8 4.713.5

8.9 5.214.1 8.9 4.813.7

9.3 5.414.7 9.3 5.014.3

8.1 0.1 8.2 8.1 0.0 8.1

8.2 0.2 8.4 8.2 0.0 8.2

8.5 0.2 8.7 8.5 0.0 8.5

AMP - W. LIGHT

AMP - NO LIGHT

3 PHASE - 3 WIRE

230

240

208

200

P22SH

208

200

230

240

208

200

P22S

208

200

230

240

208

200

P24S

208

200

230

240

208

200

P18S-2

208

200

P18S-1

MODEL

120

100

COILS

UNIT

100

120

VOLT A/C

200

240

208

200

208

230

120

100

100

120

BK18

N/A

1 PH - 2 W

BS 1363A

CEE 7-VII

BS 1363A

CEE 7-VII

6-30P

CEE 7-VII

5-20P

6-15P

5-20P

6-15P

6-15P

6-20P

6-20P

6-15P

5-15P

6-20P

6-30P

6-20P

6-20P

6-15P

6-15P

6-20P

5-20P

6-15P

19.2

17.4

10.4

13.9

19.5

20.319.9

19.1

18.8

17.7

18.418.0

17.3

17.1

10.5

11.010.8

10.3

10.2

14.1

14.714.3

13.7

13.5

18.8

N/A15.0

18.0

W. L.

NO L.

AMPERE

CANUSA

PLUG CONFIGURATION & NUMBER

5-15P

8.5

8.2

8.1 8.2

8.4

8.7

6-15P

17.0

14.2 14.5

17.4

5-20P

JAPAN UK

EUROPE

N/A

N/A

N/A N/A

N/A

N/A

N/A

Page 11

P-SERIES - 2 CHAMBERS - ELECTRICAL WIRING SCHEMATICS

DWG. 1012-126 10/11/00

200V 1

CB

208V 1

240V 1

P

L

LS LS

L

M

B

T

L

L

M

B

T

P

UT

UC

UB

LSLS

LT

LC

LB

L1

TH

UPPER CHAMBER

TH

LOWER CHAMBER

TH

LEGEND

N, L1, L2, L3 = FROM TERMINAL BLOCK

TH = THERMOSTAT 2 POLE (3 POLE)

P = THERMOSTAT INDICATOR LIGHT

CB = CIRCUIT BREAKER

M = SYNCHRONOUS TIMER (OR TIMER MOTOR)

T = INTERVAL TIMER CONTACTS (IF PROVIDED)

B = BUZZER (IF PROVIDED)

LS = LIGHT SWITCH DPST ON-OFF (IF PROVIDED)

L = INTERIOR LIGHTS (IF PROVIDED)

200V 3

CB

208V 3

240V 3

P

UT

UC

UB

L

LS

LS

LS

L

M

B

T

CB

L

LS

L

M

B

T

P

LT

LC

LB

HEATER COILS

UT = UPPER CHAMBER, TOP ELEMENT

UC = UPPER CHAMBER, CENTER ELEMENT (P44 & P46 ONLY)

UB = UPPER CHAMBER, BOTTOM ELEMENT

LT = LOWER CHAMBER, TOP ELEMENT

LC = LOWER CHAMBER, CENTER ELEMENT (P44 ONLY)

LB = LOWER CHAMBER, BOTTOM ELEMENT

L2

L3

TH

TH

TH

TH

N

CB

400V 3 N

P

L

L

M

B

T

L

L

M

B

T

P

L2

TH

TH

CB

TH

L1

TH

TH

L1

TH

UT

UC

UB

LS

CB

LS

TH

LT

LC

LB

L3

L2

TH

TH

TH

TH

P-SERIES - 1 CHAMBER - ELECTRICAL WIRING SCHEMATICS

CB

200V 3

208V 3

240V 3

L

LS

L

B

P

L3

L2

LS

CB

M

T

TE

CE

BE

TH

HEATER COILS

TE = TOP ELEMENT

CE = CENTER ELEMENT (IF PROVIDED)

BE = BOTTOM ELEMENT

L1

100V 1

120V 1

L2 (N)

200V 1

208V 1

230V 1

240V 1

L

LS LS

CB

TH

TH

LEGEND

N, L1, L2, L3 = FROM TERMINAL BLOCK

TH = THERMOSTAT 2 POLE (3 POLE)

P = THERMOSTAT INDICATOR LIGHT

CB = CIRCUIT BREAKER

M = SYNCHRONOUS TIMER (OR TIMER MOTOR)

T = INTERVAL TIMER CONTACTS (IF PROVIDED)

B = BUZZER (IF PROVIDED)

LS = LIGHT SWITCH DPST ON-OFF (IF PROVIDED)

L = INTERIOR LIGHTS (IF PROVIDED)

L

B

P

CB

M

T

TE

CE

BE

TH

L1

TH

TH

DWG. 1012-129 10/11/00

N

400V 3 N

L

L

CB

M

B

T

P

L1

LS

CB

TE

CE

BE

L3

L2

TH

TH

TH

11

Page 12

PX-16

PX-14

PX-14 & PX-16 WIRING DIAGRAM & TABLES

To Top Switch

To Bottom Switch

Line

Co

dr

T p

E

em

e

o l nt

m

B

otto E

le

ment

Q1-Connector

Q2-Connector

Q3-Butt Connector

Q4-Twin Adapter Terminal

Q5-Twin Adapter Terminal

Terminal Block

zBu

z

e

r

Timer

Motor

Bottom

Switch

Top

Switch

Pilot Light

o

s

t

Th

er

m at

11

22

T1

A3

A1

H4

A1

H1

H2

C1

L2 (N)

GND

L2

L1

L1

H1

S2

H2

S1

T1

C1

H4

A4

H1

H5

H3

H5

E2

E3

H1

E2

Q5

S2

H3

A4

E3

Q4

S1

A3

Brn-S1

Brn-S2

Brn

H5

Top Heating Coil

Bottom Heating Coil

Bottom

Switch

Blu-H4

Q1-P1085A

A4

uzzer

B

Timer

Motor

H1

Q2-P1085A

Brn-T1

Brn

H3

Brn-A3

Thermostat12

NOTE: All wires to be 14 AWG 600V 200°C.

Color as shown above.

Brn

Blu

Grn/Yel

(Blk)

(Wht)

(Grn)

or:

-Line Cord-

For NEMA plugs see tables

L1

L2 (N)

A1

Blu

Terminal

Block

Gnd

Pilot

Light

C1

P1069A

E2 Gry

Top

Switch

E3 Gry

Blu

Q3-Butt Connector

Blu-H1

Blu-H2

Heating Coils

Watts / Volts

Timer Motor

Volts / Hz

Volts A/C

/ Phase

Amp

USA

Canada

UK

Europe

Japan

Heating Coils

Watts / Volts

Timer Motor

Volts / Hz

Volts A/C

/ Phase

Amp

USA

Canada

UK

Europe

Japan

100/1

100/1

15

120/1

120/1

12.5

200/1

200/1

7.5

208-240/1

208-240/1

220-240/1

220-240/1

8.1

8.1

750/100

750/110

750/200

750/220

750/220

120/60

120/60

250/60

250/60

250/60

18

15

9

9.7

9.7

900/100

900/100

900/200

900/220

900/220

125/60

125/60

250/60

250/60

250/60

NEMA Plug Configuration & Number NEMA Plug Configuration & Number

5-15P

5-15P

5-20P

6-15P

6-15P6-15P

BS 1363A

CEE7-VII

5-15P

5-15P

5-20P

6-15P

6-15P6-15P

BS 1363A

CEE7-VII

12

Page 13

PARTS LISTS & EXPLODED VIEWS

PX-14/16 Electric Counter Top Oven (New Style)

PX-14 Beginning: Serial #4633, 12/09/99 (120V) or Serial #6547, 11/22/99 (208/240V)

PX-16 Beginning: Serial #959, 11/11/99 (120V) or Serial #1783, 12/01/99 (208/240V)

8

18

17

9

10

11

13

30

29

28

27

26

25

6

16

19

21

MINUTES

0

1

2

15

3

14

4

13

5

12

6

7

11

10

8

9

650

300

600

350

550

500

400

450

20

2

1

23

22

24

3

Item Part # Description Item Part # Description

13

12

14

15

31

7

4

5

32

33

34

35

1 D5023X Crumb Pan Assy w/Knob (PX-14) 19 D5043U Capillary Retainer Assy

2 D5123X Crumb Pan Assy w/Knob (PX-16) 20 S1392A Leg, each

3 S1153X Knob (Crumb Pan) 21 U1044X Bakers Pride Nameplate, 8"

4 M1335X Audio Alarm 22 D5037U

5 P1003X Terminal Block, 3 Pole 23 D5141U

6 D5027U Control Panel Assy, Front (PX-14) 24 S1031X Handle, w/Nut & Bolt

7 D5127X Control Panel Assy, Front (PX-16) 25 L1065X Element, PX-14, 120V/750W (2)

8 U1308A Control Panel Overlay, 60hz 26 L1148X Element, PX-16, 120V/900W (2)

9 U1309A Control Panel Overlay, 50hz 27 L1066X Element, PX-14, 220V/750W (2)

10 M1383A Timer, Electro-Mechanical, 15 Minutes, 120V 28 L1149X Element, PX-16, 220V/900W (2)

11 M1384A Timer, Electro-Mechanical, 15 Minutes, 220V 29 L1067X

12 M1119X

Thermostat, EGO, 300-650 deg (No Knob)

13 S1311X Knob (Thermostat & Timer) 31 P6004X Line Cord, 125V/15A

14 M1037X Switch, Toggle, On/Off 32 P6383A Line Cord, 125V/20A (Canada)

15 S1038X Rubber Boot, On/Off Switch (Export) 33 P6005X Line Cord, 250V/15A

16 P1127X Pilot Light, Amber 34 P6006X Line Cord, CEE7-VII (Europe)

17 D5038U Rear Panel Assy, (PX-14) 35 P6343X Line Cord w/Fuse, 13A/240V (U.K.)

18 D5138U Rear Panel Assy, (PX-16)

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. 10/05

30 L1156X

13

Peel Tray Assy w/Wire Rack & Hdl (PX-14)

Peel Tray Assy w/Wire Rack & Hdl (PX-16)

Element, PX-14, 100V/750W (2) Japan

Element, PX-16, 200V/900W (2) Japan

Page 14

PX-14/16 Electric Counter Top Oven (Old Style)

PX-14 Before: Serial #4633, 12/09/99 (120V) or Serial #6547, 11/22/99 (208/240V)

PX-16 Before: Serial #959, 11/11/99 (120V) or Serial #1783, 12/01/99 (208/240V)

28

19

21

22

27

20

26

25

24

23

17

14

6

5

15

16

7

MINUTES

POINTER L’ETOILE, PUIS REGLER LE TEMPS

0

1

0

2

1

2

15

3

15

3

14

13

TURN POINTER TO STAR, THEN SET FOR TIME

600

3

2

1

10

11

18

8

9

4

*

14

4

5

13

5

12

6

12

6

7

11

7

11

10

8

9

10

8

9

650

300

300

650

350

350

550

400

600

500

400

450

550

450

500

13

12

31

32

33

30

4

29

Item Part # Description Item Part # Description

1 D5023X Crumb Pan Assy w/Knob (PX-14) 18 S1392A Leg, each

2 D5123X Crumb Pan Assy w/Knob (PX-16) 19 U1044X Bakers Pride Nameplate, 8"

3 S1153X Knob (Crumb Pan) 20 D5037U Peel Tray Assy w/Wire Rack (PX-14)

4 P1003X Terminal Block, 3 Pole 21 D5141U Peel Tray Assy w/Wire Rack (PX-16)

5 M1017X

Timer, Mech, 15 Minutes (w/Knob/Plate)

22 S1031X Handle, w/Nut & Bolt

6 S1052X Knob, Timer 23 L1065X Element, PX-14, 120V/750W (2)

7 S1025X Plate, Timer 24 L1148X Element, PX-16, 120V/900W (2)

8 M1120X

9 M1119X

10 S1155X Knob, Thermostat (650F) 27 L1067X

11 S1154X Knob, Thermostat (370C) 28 L1156X

Thermostat, EGO, 650F deg (w/Knob)

Thermostat, EGO, 370C deg (w/Knob)

25 L1066X Element, PX-14, 220V/750W (2)

26 L1149X Element, PX-16, 220V/900W (2)

Element, PX-14, 100V/750W (2) Japan

Element, PX-16, 200V/900W (2) Japan

12 M1037X Switch, Toggle, On/Off 29 P6004X Line Cord, 125V/15A

13 S1038X Rubber Boot, On/Off Switch (Export) 30 P6383A Line Cord, 125V/20A (Canada)

14 P1127X Pilot Light, Amber 31 P6005X Line Cord, 250V/15A

15 D5038U Rear Panel Assy, (PX-14) 32 P6006X Line Cord, CEE7-VII (Europe)

16 D5138U Rear Panel Assy, (PX-16) 33 P6343X Line Cord w/Fuse, 13A/240V (U.K.)

17 D5043U Capillary Retainer Assy

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. 10/05

14

Page 15

P18-S, BK18 Exterior/Door/Controls (Electro-Mechanical Timers)

29

30

31

32

13

26

14

15

16

17

18

19

11

36

N

I

M

37

28

23

35

U

T

E

S

0

0

U

T

E

N

I

S

M

650

650

450

450

24

0

0

U

T

E

N

I

S

M

300

300

300

650

650

300

450

450

12

BAKERSBAKERS

BAKERSBAKERS

PRIDEPRIDE

PRIDEPRIDE

U

T

E

N

I

S

M

20

33

21

34

22

9

10

8

7

Item Part # Description Item Part # Description

1 M1098X

2 M1192X

3 M1110X

4 S1311X Knob (Thermostat & Timer) 23 U1297A

5 M1381A

6 M1382A

7 M1383A

8 M1384A

9 D3157K Control Panel 28 Q3021X

10 M1330A Circuit Breaker, 3 Amp 29 D3105K Outer Back

11 M1335X Audio Alarm (Discontinued) 30 S1316U Door Handle Assy, 10"

12 P1127X Pilot Light, Amber 31 Q2041A

13 P1089A Terminal Block, 3 Pole 32 U1044X Bakers Pride Nameplate, 8"

14 P6004X

15 P6005X

16 P6383X

17 P6009X

18 P6006X Line Cord, 230V/16A "C" Type (CE) 37 D3163U

19

P6343X Line Cord, 230V/13A (UK)

5

6

4

Thermostat w/Knob, EGO (Standard) P-18

Thermostat w/Knob, EGO (High Heat) P-18

Thermostat w/Knob, KA-72, 550deg (BK-18)

Timer, Elec-Mech, 60 Min, 120V (BK-18)

Timer, Elec-Mech, 60 Min, 220V (BK-18)

Timer, Elec-Mech, 15 Min, 120V (P-18)

Timer, Elec-Mech, 15 Min, 220V (P-18)

Line Cord 125V/15A (US) P & BK

Line Cord 250V/15A (US & Japan) P & BK

Line Cord 125V/20A (Canada)

Line Cord 250V/20A (Canada)

2

1

20 U1302X

21 U1307A

22 U1314A

Control Panel Overlay, EGO (P-18)

Control Panel Overlay, EGO Hi-Heat (P-18)

Control Panel Overlay (BK-18)

18 Minute Timer Overlay (50 cycles)

24 U1296A

72 Minute Timer Overlay (50 cycles)

25 S3019X Bushing, Door

26 D3106X Door Assy w/Handle

27 S3001X Door Rod

Door Rod Spacer Kit (1 Kit per Door)

Screw, 1/4-20 x 1/2 Rd Hd (Door Handle)

33 S1014X 4" Adjustable Leg (Set/4)

34 S1014Y 4" Adjustable Leg (each)

35 T3150A

36 D3162U

Intermediate Wire Rack (Option, BK18)

Wire Rack Support Assy, Left (Option)

Wire Rack Support Assy, Right (Option)

N/S

D2069X

Stacking Kit

3

25

27

4

3 1/4”

IZ

3 1/4”

BK18

P ZA

U

T

E

N

I

S

M

650

P18S

0

300

450

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. 10/05

DECK ARRANGEMENT BY MODEL

7 1/2”

BAKERSBAKERS

PRIDEPRIDE

15

U

T

E

N

I

S

M

BAKE

0

300

650

450

BAKERSBAKERS

PRIDEPRIDE

Page 16

Interior Components & Accessories P18, BK18

16

15

17

17

12

12

11

11

10

10

9

9

2

2

1

1

5

5

3

3

7

8

8

20

20

19

19

13

13

1

1

2

2

3

3

4

4

6

6

22

22

14

14

21

21

6

6

4

4

1

1

24

24

18

18

22

22

23

23

DescriptionPart #Item

1 L1024X

2 L1171X

3 L1025X

4 L1026X

5 L1112X

6 L1113X

7 T5118X 19 D4039K Deck Support

8 T5107Y Deck Scraper Brush 20 D3151K Element Support

9 P1019X Porcelain Spacer 21 D3131K Baffle Trim

10 Q3016A Washer, Star, #6 22 D3142K Deck Trim

11 Q1002A Nut, 6-32 23 D1134K Capillary Cover

12 S1061X 6-32 Terminal Cap 24 Q4021X Clip 3/16", Temp Sensor (2)

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. 10/05

Element 115V/600W (US/Can) P-18, T,C & B

Element 115V/850W (US/Can) BK-18, T & B

Element 208-240V/850W (US/Can/CE)P Top, BK T&B

Element 208-240V/1KW (US/Can/CE) P-18 C & B

Element 200V/850W (Japan) P-18 Top

Element 200V/1000W (Japan) P-18 C & B

Steel Bake Deck (BK18 Only)

Part #Item

13 K1355X Baffle & Top Elem. Clips (5) BK

14 P1042A Element Clip, 5/16", Center & Bottom

15 T1120Y

16 T1120X

17 D3140Z Fresh Dough Baffle

18 D3152T Hearth Frame Assy

16

Description

Ceramic Deck, 17 1/2 x 17 3/4 x 1/2 (each)

Ceramic Deck, 17 1/2 x 17 3/4 x 1/2 (set/2)

Page 17

NEW

STYLE

31

16

15

38

38

32

33

37

26

THIS PARTS LIST PERTAINS TO THE FOLLOWING UNITS:

Model # Voltage Starting Serial # Date

P-22BL All All N/A

P-22S 208VAC #7131 11/2/99

P-22S 230VAC #4160 11/2/99

P-24S All #17288 2/29/00

28

39

25

34

M

10

U

T

E

N

I

S

0

0

0

0

U

T

U

T

E

N

E

N

I

S

I

M

650

650

450

450

S

M

300

300

650

650

450

450

5

6

12

7

24

13

17

18

19

23

CONTROL PANEL WITH DIGITAL TIMER (OPTIONAL)

DIEHL micro

09 : 15

11

9

8

MIN. SEC.

START-STOP

- +

12

DECK ARRANGEMENT BY MODEL

2 3/4”

2 3/4”

ZA

IZ

P

0

U

T

E

N

I

S

M

300

650

BAKERSBAKERS

PRIDEPRIDE

450

P-22BL P-22S P-24S

Item Part # Description Item Part # Description

1 M1098X

2 M1192X

3 M1110X

4 M1342X

5 S1311X

6 M1384A

7 M1382A

8 M1275X

9 M1274X

10 D1157K

11 D1156K

Thermostat w/Knob, 650F (EGO)

Thermostat w/Knob, Control Panel

CE "430C" (High Heat)

Thermostat w/Knob, 550F, KA-72 (P-24S)

Thermostat Kit w/Knob, 250F (Special)

Knob (T-stat "F", 15 Min Timer: Rot-Elec)

Timer, Electro-Mech, 15 Min, (P-22S & P-22BL)

Timer, Electro-Mech, 60 Min (P-24S)

Timer, Electronic (Digital Readout) 60 cycle

Timer, Electronic (Digital Readout) 50 cycle

Control Panel (Rot/Elect Timer)

Control Panel (Electronic Timer)

12 M1330A Circuit Breaker, 3A 32 S1316U Door Handle

13 M1335X Audio Alarm (Discontinued) 33 Q2041A

14 P1127X Pilot Light, Amber 34 U1044X Bakers Pride Nameplate, 8"

15 P1003X Terminal Block, 3 Pole, 1 Phase 35 S1014X 4" Adjustable Leg (Set/4)

16 P1004X Terminal Block, 4 Pole, 3 Phase 36 S1014Y 4" Adjustable Leg (each)

17 P6009X

18 P6385A

19 P6005X

20 U1302X

Line Cord, 250V/20A (USA & Canada)

Line Cord, 250V/30A (Can. 208V only)P22S/BL

Line Cord, 250V/15A (P-24S)

Control Panel Overlay, 22S & 22BL

3 1/4”

3 1/4”

14

14

U

T

E

N

I

S

300

300

M

BAKERSBAKERS

BAKERSBAKERS

PRIDEPRIDE

PRIDEPRIDE

650

14

PIZ

0

U

T

E

N

I

S

M

300

650

450

20

3

2

1

0

300

450

1

A

Z

BAKERSBAKERS

PRIDEPRIDE

21 U1307A

22 U1314A

23 U1297A

24 U1296A

22

21

36

35

5

4

BAKERSBAKERS

PRIDEPRIDE

3

2

4

7 1/2”

20

5

E

K

A

B

0

U

T

E

N

I

S

M

300

650

BAKERSBAKERS

PRIDEPRIDE

450

Control Panel Overlay, Hi Heat, 22S & 22BL

Overlay, P-24S

18 Minute Timer Overlay (50 cycle)

72 Minute Timer Overlay (50 cycle)

25 S3019X Door Bushing

26 D1106X Door Assy (No Window)

27 S1020X Window Assy (Door)

28 D1143U Door Assy (w/Window)

29 S3001X Door Rod

30 Q3021X

Door Rod Spacer Kit (1 Kit per Door)

31 D1105K Outer Back

Screws, 1/4-20 x 1/2 RH (Door Handle)

37 T3139X

38 D1162U

39 D1163U

Intermediate Wire Rack (Option, P-24)

Wire Rack Support Assy, Left (Option)

Wire Rack Support Assy, Right (Option)

40 D2069X Stacking Kit

34

27

30

21

29

22

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. 10/05

17

Page 18

Interior Components & Accessories P-22BL, P-22S, P-24S

NEW

STYLE

13

12

Brick Lined

Models Only

16

10

9

8

7

5

3

1

19

6

4

2

22

17

14

15

23

24

DescriptionPart #Item

1 L1072X

2 L1071X

3 L1035X

4 L1034X

5 L1116X

6 L1117X

7 P1019A Porcelain Spacer

8 Q3016A Washer, Star, #6

9 Q1002A Nut, 6-32

10 S1061X Terminal Cap, 6-32

11 K1355X Element Clip

12 D1158U

Element, 208V/1075W, Top & Bottom

Element, 208V/1450W, Center

Element, 230V/1075W, Top & Bottom

Element, 230V/1450W, Center

Element, 200V/1075W, Top & Bottom (Japan)

Element, 200V/1450W, Center (Japan)

Ceramic Top Frame Assy (B/L Only)

18

1

11

3

5

20

Part #Item

13 T1120Y

14 T1121Y

15 T1121X

16 D4040X Fresh Dough Baffle

17 D1152T

18 D4039K Deck Support

19 D4031X Baffle Trim

20 D1142K Hearth Trim

21 D1134K Capillary Cover

22 Q4021X Clip, 3/16"

23 T1222K Steel Bake Deck (Optional)

T5107Y Deck Scraper Brush

24

Description

Deck, ea 17 3/4 x 17 1/2 x 1/2 (P-22BL Only)

Deck, 20 13/16 x 20 13/16 x 1/2 (each)

Deck, 20 13/16 x 20 13/16 x 1/2 (set/2)

Hearth Frame Assy (No Element)

20

21

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. 10/05

18

Page 19

P-44S, P-44BL, P-46S, P-48S EXTERIOR/DOOR/CONTROLS (No Lights, Electro-Mechanical Timers)

THIS PARTS LIST PERTAINS TO THE FOLLOWING UNITS:

Model # Voltage Starting Serial # Date

P-44BL All All N/A

P-44S 208VAC #9503 11/12/99

P-44S 230VAC #6475 11/12/99

P-46S All #17309 3/1/00

P-48S All #17161 2/18/00

NEW

STYLE

35

31

32

36

37

28

41

27

18

17

38

29

43

30

19

20

15

42

44

16

1

0

300

650

650

450

U

T

E

N

I

S

M

7

5

6

25

26

5

3

4

2

0

450

44

16

U

T

E

N

I

S

300

M

5

11

6

12

21

7

22

39

23

24

40

CONTROL PANEL WITH LIGHTS & DIGITAL TIMERS (OPTIONAL)

15

15

16

13

16

14

DIEHL micro

09 : 15

8

9

MIN. SEC.

START-STOP

- +

0

650

300

450

Item Part # Description Item Part # Description

1 M1098X

2 M1192X

3 M1342X

4 M1110X

5 S1311X

6 M1384A

7 M1382A

8 M1275X

9 M1274X

10 M1259X

11 D2157K

12 D2101K

13 D2156K

14 D2102K

Thermostat w/Knob, 650F EGO, 44(2) 46(1)

Thermostat w/Knob, CE "430C" High Heat 44

Thermostat Kit w/Knob, 250F (Special)

Thermostat w/Knob, 550F KA72, 46 (1), 48 (2)

Knob (T-stat "F", 15 Min Timer: Rot-Elec)

Timer, Elec-Mech, 15 Min, 44(2) 46(1)

Timer, Elec-Mech, 60 Min, 46(1) 48(2)

Timer, Electronic (Digital Readout) 60 cycle

Timer, Electronic (Digital Readout) 50 cycle

Toggle Switch (Lights, On/Off)

Control Panel (Rot/Elect Timer-No Lights)

Control Panel (Rot/Elect Timer-w/Lights)

Control Panel (Electronic Timer-No Lights)

Control Panel (Electronic Timer-W/Lights)

15 M1330A Circuit Breaker, 3A

16 P1127X Pilot Light, Amber

17 P1003X Terminal Block, 3 Pole, 1 Phase

18 P1004X Terminal Block, 4 Pole, 3 Phase

19 P6399A Line Cord, 125/250V, 50A

20 P6385A Line Cord, 250V, 30A (P-46 & P-48)

21 U1304A

22 U1310A

23 U1316A

24 U1318A

Control Panel Overlay (44 & 44BL)

Control Panel Overlay, Hi Heat (44 & 44BL)

Control Panel Overlay (P-46)

Control Panel Overlay (P-48)

0

650

450

10

25 U1297A

26 U1296A

300

16

18 Minute Timer Overlay (50 cycles)

72 Minute Timer Overlay (50 cycles)

DIEHL micro

09 : 15

MIN. SEC.

START-STOP

27 S3019X Door Bushing

28 D1106U

29 S1020X

30 D1143U

31 P1145X

P1129X

32 P1147X

P1020X

P1122X

Door Assy (No Window)

Window Assy (Door)

Door Assy (w/Window)

Light Fixture

Light Fixture

Light Bulb, 240V/15W

Light Bulb, (Old Style, 115V)

Light Bulb, (Old Style, 250V)

33 S3001X Door Rod

34 Q3021X

Door Rod Spacer Kit (1 Kit per Door)

35 D2105K Outer Back

36 S1316U Door Handle

37 Q2041A

Screws, 1/4-20 x 1/2 RH (Door Handle)

38 U1044X Bakers Pride Nameplate, 8"

39 S1014X

40 S1014Y

41 T3139A

42 D1162U

43 D1163U

4" Adjustable Leg (Set/4)

4" Adjustable Leg (each)

Intermediate Wire Rack (Option 46 & 48)

Wire Rack Support Assy, Left (Option)

Wire Rack Support Assy, Right (Option)

44 M1335A Audio Alarm (Discontinued)

D2069X

45

Stacking Kit

34

22

8

23

- +

21

(w/240V,15W Bulb)

(Old Style, 3” Diameter)

33

9

24

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. 10/05

19

Page 20

Interior Components & Accessories P-44S, P-44BL, P-46S, P-48S

NEW

STYLE

23

15

14

24

12

13

Brick Lined

Models Only

16

10

9

8

7

5

3

1

19

6

4

2

22

17

20

10

11

12

1

2

3

4

5

6

7

8

9

5

18

3

1

20

DECK ARRANGEMENT BY MODEL

2 3/4”

2 3/4”

2 3/4”

2 3/4”

U

T

E

N

I

S

M

A

ZZ

PI

A

ZZ

PI

U

0

300

650

450

T

0

E

N

I

S

M

650

300

450

3 1/4”

3 1/4”

3 1/4”

3 1/4”

U

T

E

N

I

S

M

650

0

300

450

PIZZA

PIZ

0

650

300

450

AZ

U

T

E

N

I

S

M

P-44BL P-44S P-46S P-48S

DescriptionPart #Item

L1072X

L1071X

L1035X

L1034X

L1117X

L1116X

P1019A

Q3016A

Q1002A

S1061X

K1355X

D1158U

Element, 208V/1075W, Top & Bottom

Element, 208V/1450W, Center

Element, 230V/1075W, Top & Bottom

Element, 230V/1450W, Center

Element, 200V/1075W, Top & Bottom (Japan)

Element, 200V/1450W, Center (Japan)

Porcelain Spacer

Washer, Star, #6

Nut, 6-32

Terminal Cap, 6-32

Element Clip

Ceramic Top Frame Assy (P-44BL Only)

Item

13

14

15

16

17

18

19

20

21

22

23

24

3 1/4”

3 1/4”

7”

U

T

E

N

I

S

M

Part #

T1120Y

T1121Y

T1121X

D4040X

D1152T

D4039K

D4031K

D1142K

D1134K

Q4021X

T1222K

T5107Y

A

Z

PIZ

AKE

B

U

0

300

650

450

T

0

E

N

I

S

M

650

300

450

Description

Deck, ea 17 3/4 x 17 1/2 x 1/2 (P-44BL Only)

Deck 20 13/16 x 20 13/16 x 1/2 (each)

Deck 20 13/16 x 20 13/16 x 1/2 (Set/2)

Fresh Dough Baffle

Hearth Frame Assy (No Element)

Deck Support

Baffle Trim

Hearth Trim

Capillary Cover

Clip, 3/16"

Steel Deck (Optional)

Deck Scraper Brush

11

7”

7”

0

U

T

E

N

I

S

M

300

650

450

A E

B K

A E

B

0

650

300

450

21

K

U

T

E

N

I

S

M

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. 10/05

20

Page 21

DP-2 EXTERIOR / DOOR / CONTROLS (ELECTRO-MECHANICAL TIMERS)

THIS PARTS LIST PERTAINS TO THE FOLLOWING UNITS:

Model # Starting Serial # Date

DP-2 19062 5/25/00

NEW

STYLE

27

30

32

31

25

10

8

15

26

17

16

3

2

1

7

23

7

U

T

E

N

I

S

M

18

3

4

13

LOWER CHAMBER

0

1

4

.

6

5

3

10

1

2

9

8

3

7

4

15

CONTROL PANEL WITH DIGITAL TIMERS & INFINITE SWITCHES (OPTIONAL)

9

DIEHL micro

09 : 15

MIN. SEC.

START-STOP

- +

2

3

14

20

U

14

T

E

N

I

S

M

12

11

14

0

300

450

650

0

0

300

650

650

10

1

7

14

20

9

8

300

450

19

650

450

8

2

0

6

5

19

3

4

33

34

8

0

300

450

1

2

3

4

5

0

6

UPPER CHAMBER

15

10

1

2

9

8

3

7

4

5

24

28

29

9

10

0

DIEHL micro

10

09 : 15

9

MIN. SEC.

8

7

START-STOP

6

- +

5

6

22

15

8

14

21

5

Item Part # Description Item Part # Description

1 M1098X Thermostat w/Knob, EGO 18 P6385A Line Cord, 250V/30A

2 M1192X T-stat w/Knob, CE "430C" (High Heat) 19 U1304A Control Panel Overlay

3 S1311X Knob (Thermostat & Timer) 20 U1310A Control Panel Overlay (High-Heat)

4 M1384A Timer, Elec-Mech, 15 Min (220V) 21 U1289A Overlay, Top Infinite Controls

5 M1275X Timer, Electronic, 60Hz (Domestic) 22 U1288A Overlay, Bottom Infinite Controls

6 M1274X Timer, Electronic, 50Hz (CE) 23 U1297A 18 Minute Timer Overlay (50 cycles)

7 M1335X Audio Alarm (Discontinued) 24 S3019X Door Bushing

8 M1259X Toggle Switch (Lights, On/Off) 25 D4006X Door Assembly

9 M1367A Infinite Switch, 208V 26 P1145X Light Fixture (w/240V, 15W Bulb)

M1368A Infinite Switch, 240V

10 S1205X Knob, Infinite Switch

11 D2101U Control Panel

12 D4046U Control Panel

13 D4045U Control Panel

(Rot-ElecTimer)

(Rot-ElecTimer/Infinite Sw.)

(ElectronicTimer/Infinite Sw.)

14 M1330A Circuit Breaker, 3A

15 P1127X Pilot Light, Amber

16 P1003X Terminal Block, 3 Pole (Domestic)

17 P1004X Terminal Block, 4 Pole (CE)

27 P1147X Light Bulb, 240V/15W

28 S3001X Door Rod

29 Q3021X Door Rod Spacer Kit (1 Kit per Door)

30 S1316U Door Handle

31 Q2041A Screws, 1/4-20 x 1/2 RH

(Door Handle)

32 U1044X Bakers Pride Nameplate, 8"

33 S1014Y 4" Adjustable Leg (each)

34 S1014X 4" Adjustable Leg (Set/4)

N/S

D2069X Stacking Kit

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. 10/05

6

21

Page 22

DP-2 Interior Components

NEW

STYLE

10

14

9

8

7

5

3

6

1

4

2

17

19

15

15

12

13

Item

Part #

1 L1072X Element, 208V/1075W, Top 11 K1355X Element Clip

2 L1071X Element, 208V/1450W, Bottom 12 T1121Y Hearth Deck

3 L1034X Element, 230V/1075W, Top 13 T1121X Hearth Deck

4 L1035X Element, 230V/1450W, Bottom 14 D4040X Fresh Dough Baffle

5 L1117X Element, 200V/1075W, Top

6 L1116X Element, 200V/1450W, Bottom

7 P1019X Porcelain Spacer 17 D4031K Baffle Trim

8 Q3016A Washer, Star, #6 18 D4034K Capillary Cover

9 Q1002A Nut, 6-32 19 Q4021X Clip, 3/16" (Capillary)

10 S1061X Terminal Cap, 6-32 20 D1142K Deck Trim

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. 10/05

Description

16

(Japan)

(Japan)

20

Item Part # Description

15 D1152T Hearth Frame Assy

16 D4039K Deck Support

22

18

18

11

20 13/16 x 20 13/16 x 1/2 (each)

20 13/16 x 20 13/16 x 1/2 (Set/2)

Page 23

BAKERS PRIDE LIMITED WARRANTY

914 / 576 - 0200 ♦ US & Canada: 1 - 800 - 431 - 2745 ♦ fax 914 / 576 - 0605

30 Pine Street New Rochelle, New York 10801

WHAT IS COVERED This warranty covers defects in material and workmanship under normal use, and applies only to the original purchaser

WHO IS COVERED This warranty is extended to the original purchaser and applies only to equipment purchased for use in the U.S.A.

COVERAGE PERIOD Full size gas and electric deck ovens: Two (2) year limited parts and labor: Cyclone Convection Ovens: BCO Models: One (1)

WARRANTY This warranty covers on-site labor, parts and reasonable travel time and travel expenses of the authorized service

COVERAGE representative up to (100) miles. round trip, and (2) hours travel time. The purchaser. however, shall be responsible for all

EXCEPTIONS All removable parts in BAKERS PRIDE Char-broilers, including but not limited to: Burners, Grates. Radiants, Stones and

EXCLUSIONS

♦ Negligence or acts of God,

♦ Thermostat calibrations after (30) days from equipment

installation date,

♦ Air and Gas adjustments,

♦ Light bulbs,

♦ Glass doors and door adjustments.

♦ Fuses,

♦ Char-broiler work decks and cutting boards,

♦ Tightening of conveyor chains,

♦ Adjustments to burner flames and cleaning of pilot burners,

♦ Tightening of screws or fasteners.

providing that:

♦ The equipment has not been accidentally or intentionally damaged, altered or misused;

♦ The equipment is properly installed, adjusted, operated and maintained in accordance with National and local codes. and

in accordance with the installation instruction provided with the product;

♦ The serial number rating plate affixed to the equipment has not been defaced or removed.

Year limited parts and labor; GDCO Models: Two (2) Year limited parts and labor; CO II Models: Two (2) Year limited parts

and labor; (5) Year limited door warranty.

All Other Products: One (1) Year limited parts and labor.

Warranty period begins the date of dealer invoice to customer or ninety (90) days after shipment date from BAKERS PRIDE whichever comes first.

expenses related to travel, including time. mileage and shipping expenses on smaller counter models that may be carried into

a Factory Authorized Service Center, including the following models: PX-14. PX-16, PI8, and BK-I8.

Valves, are covered for a period of SIX MONTHS.

All Ceramic Baking Decks are covered for a period of THREE MONTHS. The installation of these replacement decks is the

responsibility of the purchaser.

The extended Cyclone door warranty years 3 through 5 is a parts only warranty and does not include labor, travel, milage or

any other charges.

♦ Failures caused by erratic voltages or gas supplies,

♦ Unauthorized repair by anyone other than a BAKERS PRIDE

Factory Authorized Service Center,

♦ Damage in shipment,

♦ Alteration, misuse or improper installation,

♦ Thermostats and safety valves with broken capillary tubes.

♦ Accessories - spatulas, forks. steak turners, grate lifters,

oven brushes, scrapers, peels. etc.,

♦ Freight - other than normal UPS charges,

♦ Ordinary wear and tear.

INSTALLATION Leveling and installation of decks. as well as proper installation and check out of all new equipment - per appropriate

installation and use materials - is the responsibility of the dealer or installer, not the manufacturer.

REPLACEMENT BAKERS PRIDE genuine Factory OEM parts receive a (90) day materials warranty effective from the date of installation by a

PARTS BAKERS PRIDE Factory Authorized Service Center.

This Warranty is in lieu of all other warranties, expressed or implied, and all other obligations or liabilities on the manufacturers part. BAKERS PRIDE

shall in no event be liable for any special, indirect or consequential damages, or in any event for damages in excess of the purchase price of the unit. The

repair or replacement of proven defective parts shall constitute a fulfillment of all obligations under the terms of this warranty.

Form #U4177A 1/07

23

Page 24

(914) 576-0200 Phone (800) 431-2745 US & Canada

(914) 576-0605 Fax www.bakerspride.com Web Address

BAKERS PRIDE OVEN CO., INC.

30 Pine Street

New Rochelle, NY 10801

24

Loading...

Loading...