Convection Oven

MODEL MT-200

Service Manual

2812 Grandview Dr. Simpsonville, S.C. 29680, USA

864-963-3471 http://www.bkideas.com

Warranty Information

LIMITED ONE YEAR WARRANTY

BKI (The "Company") warrants to the original purchaser that at time of shipment from the

Company factory, this equipment will be free from defect in materials and workmanship. Written

notice of a claim under this warranty must be received by the Company within ONE YEAR from

the date of installation, but no longer than ONE YEAR AND THREE MONTHS from date of

shipment from the factory. Defective conditions caused by abnormal use or misuse, lack of or

improper maintenance, damage by third parties, alterations by unauthorized personnel, acts of

God, failure to follow installation and/or operating instructions, or any other events beyond the

reasonable control of the Company will NOT be covered under this warranty. The obligation of

the Company under this warranty shall be limited to repairing or replacing (at the option of the

Company) any part, with the exception of lamps, fuses, and glass (which are not covered under

warranty), which is found defective in the reasonable opinion of the Company. Any part found

defective by the Company will be repaired or replaced without charge F.O.B. factory,

Simpsonville, South Carolina or F.O.B. authorized BKI Distributor. The Company and/or its

authorized representatives will assume the normal replacement labor expense for the defective

part for the period of the warranty as stated above, excluding travel and/or other expenses

incidental to the replacement of the defective part, where replacement work is performed during

standard business hours and not subject to overtime, holiday rates, and/or any additional fees. IN

NO EVENT SHALL THE COMPANY BE LIABLE FOR LOSS OF USE, LOSS OF REVENUE OR

LOSS OF PRODUCT OR PROFIT OR FOR INDIRECT OR CONSEQUENTIAL DAMAGES

INCLUDING BUT NOT LIMITED TO, FOOD SPOILAGE OR PRODUCT LOSS. WARRANTY

DOES NOT COVER GLASS BREAKAGE. THE ABOVE WARRANTY IS EXCLUSIVE AND ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, ARE EXCLUDED INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

REPLACEMENT PARTS

Any appliance replacement part, with the exception of lamps, fuses, and glass, which proves to

be defective in material or workmanship within ninety (90) days of installation will be replaced

without charge F.O.B. Factory, Simpsonville, SC or F.O.B. authorized BKI Distributor. The user

shall have the responsibility and expense of removing and returning the defective part to the

Company as well as the cost of reinstalling the replacement or repaired part.

2812 Grandview Dr. Simpsonville, S.C. 29680, USA

864-963-3471 http://www.bkideas.com

Convection Oven Table of Contents

Table of Contents

Table of Contents........................................................................................................................................1

Introduction .................................................................................................................................................2

Safety Precautions....................................................................................................................................2

Safety Signs and Messages.................................................................................................................2

Safety Standards..................................................................................................................................3

Data Plate.................................................................................................................................................3

Power Supply Terminal Board..................................................................................................................3

Technical Data..........................................................................................................................................3

Operation .....................................................................................................................................................4

General Instructions for Use.....................................................................................................................4

Controls and Indicators.............................................................................................................................4

Start-Up and Use......................................................................................................................................5

Switching Off.............................................................................................................................................5

Installation ...................................................................................................................................................6

Safety Standards ......................................................................................................................................6

Environmental Standards .........................................................................................................................6

Transport and Unpacking .........................................................................................................................6

Installation Instructions.............................................................................................................................7

Electrical Connections ..............................................................................................................................8

Automatic Safety and Control Devices of the Oven...............................................................................10

Protection of the Auxiliary Electrical Circuit........................................................................................10

Protection of the Chamber Fan..........................................................................................................10

Oven Chamber Safety Thermostat.....................................................................................................10

Maintenance ..............................................................................................................................................11

Routine Maintenance..............................................................................................................................11

Oven Chamber Cleaning....................................................................................................................12

Cleaning the Door Glass....................................................................................................................13

Cleaning the Fan................................................................................................................................13

What to Do In Case of a Breakdown or Long Periods of Inactivity.........................................................14

Troubleshooting......................................................................................................................................14

Repair Procedures..................................................................................................................................15

Replacement of Motors......................................................................................................................15

Outer Coverings .................................................................................................................................16

Bulb, Heating Element and Motor Fan...............................................................................................16

30W Motor..........................................................................................................................................16

Heating Elements...............................................................................................................................16

Electro-Mechanical Controls ..............................................................................................................17

Chamber Face Gasket.......................................................................................................................17

Replacement of Chamber Light and Glass Gasket............................................................................17

Replacement Parts....................................................................................................................................18

Wiring Diagrams........................................................................................................................................20

Notes ..........................................................................................................................................................21

1

Convection Oven Introduction

Introduction

Thank you for purchasing our convection oven. We feel certain that the oven you have purchased will

meet your expectations, and will be a trustworthy assistant in your work for a long time to come, providing

performance of the highest levels. You will also receive efficient and timely after-sales technical and

operational service. Your oven is quick and easy to install. Nonetheless, please CAREFULLY read this

manual, and keep it for future use. We hope you enjoy your work!

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If

you have any questions, please contact your BKI Distributor. If they are unable to

answer your questions, contact the BKI Technical Service Department, toll free:

1-800-927-6887. Outside the U.S., call 1-864-963-3471.

Safety Precautions

Always follow recommended safety precautions listed in this manual. Below is the safety alert symbol.

When you see this symbol on your equipment, be alert to the potential for personal injury or property

damage.

Safety Signs and Messages

The following Safety signs and messages are placed in this manual to provide instructions and identify

specific areas where potential hazards exist and special precautions should be taken. Know a nd

understand the meaning of these instructions, signs, and messages . Damage to the equipment, death or

serious injury to you or other persons may result if these messages are not followed.

This message indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

This message indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against unsafe

practices.

This message is used when special information, instructions or identification are

required relating to procedures, equipment, tools, capacities and other spe cial

data.

2

Convection Oven Introduction

Safety Standards

This manual is part of the documentation provided with the oven and contains all required

information for proper use and maintenance of the convection oven.

Carefully read the user’s instructions contained in this manual before turning the oven on.

Special attention must be given to the standards concerning the automatic safety and control

devices (see page 10).

The user must carefully read the instructions in it and keep it where it is accessible to all

authorized users

The oven is of a professional type and must be used only by qualified personnel, cooking foods

in food service facilities.

Always turn off the main electrical switch after using the oven, especially during maintenance and

repair or in the event of long periods of disuse.

It is advisable to have the oven checked on a yearly basis by an authorized technical service

center.

The owner of the oven must periodically train their staff on the use of the machines and provide

them with safety instructions.

During cooking, the external parts of the oven (e.g. door glass) may get hot. Be careful when

touching them.

Data Plate

The data plate containing the oven characteristics is glued to the back.

Power Supply Terminal Board

The power supply terminal block is inside the right side of the oven. A small data plate positioned near the

terminal block states the types of connections which are possible.

Technical Data

Dimensions No. of Pans or Racks Power Supply Power

External dimensions:

27”x21 3/4”x25 1/4”

Internal dimensions:

21 1/2”x14 1/2”x16 1/8”

Rack dimensions:

1/2 size

4

1Phase, 15

Amp, 240V or

208V,

60Hz,

Plug NEMA

6-20P standard

Kw 3.2

3

Convection Oven Operation

Operation

General Instructions for Use

The oven may be used to bake creams, cookies, cakes, sauces and pizza, for au gratin coo king

and for defrosting frozen food convection ovens.

Avoid adding salt to foods in the cooking chamber.

Try to distribute foods evenly in the pans, avoiding accumulations.

Between one level and the next there must be a space of at least 1 1/2”. Hot air must be able to

circulate both above and below the food in order for it.

Do not use pans with sides that are higher than necessary. The sides create a barrier to air

circulation.

When using the oven for the first time, it is advisable to run it empty at maximum temperature for

about an hour. This will eliminate any unpleasant odors from protective lubricants used in the

factory.

Leave room between dishes on the same level.

Preheat the oven. It is always better to place the food in a pre-heated oven.

During cooking, racks and pans reach very high temperatures. Use caution to prevent burns.

Controls and Indicators

Key # Control Description

1 TIME SETTING KNOB Sets cooking time from 0 - 120 minutes or to

continuous operation.

2 TEMPERATURE SETTING KNOB Sets chamber temperature from 50 to 520°F.

3 ON/OFF MAIN SWITCH Energizes/de-energizes the oven.

4

Convection Oven Operation

Start-Up and Use

1. To start the oven, press the main switch (3) ON/OFF.

2. Set the cooking time by turning the time setting knob (1).

3. Then use knob (2) to set the desired cooking temperature. If knob (2) is left in position ‘0’, only

the light and fan will operate, and the oven chamber will not heat up.

Switching Off

1. Cooking ends automatically when the cooking time set on knob (1) has expired.

2. Nonetheless, turn all knobs to “O” and turn off the main switch (3) ON/OFF.

5

Convection Oven Installation

Installation

Safety Standards

The installer must read this booklet carefully before installing the convection

oven.

Installation and subsequent maintenance, cleaning, inspection and repairs must

be carried out with the electrical power supply disconnected.

Installation of the oven must be in compliance with current standards in the

country of use, otherwise BKI shall not honor the warranty in the event of direct

or indirect damage.

Installation, adjustment and assistance are to be carried out by qualified

personnel in compliance with current accident prevention legislation in the

country of use. The installer must also check for any fire prevention regulations.

BKI shall not be held liable for any damage arising from improper use of the

convection oven, unauthorized modifications and anything not covered by this

manual.

Environmental Standards

All materials used for packaging are compatible with environmental protection standards. They may be

stored without any hazard, or disposed of in accordance with current laws in the country of use. Do not

leave the plastic coverings within reach of children or animals as they are potentially hazardous. The

plastic components which can be disposed of and recycled are marked as follows:

POLYETHYLENE: packaging outer film, instructions bag, etc.

POLYPROPYLENE: clips, etc.

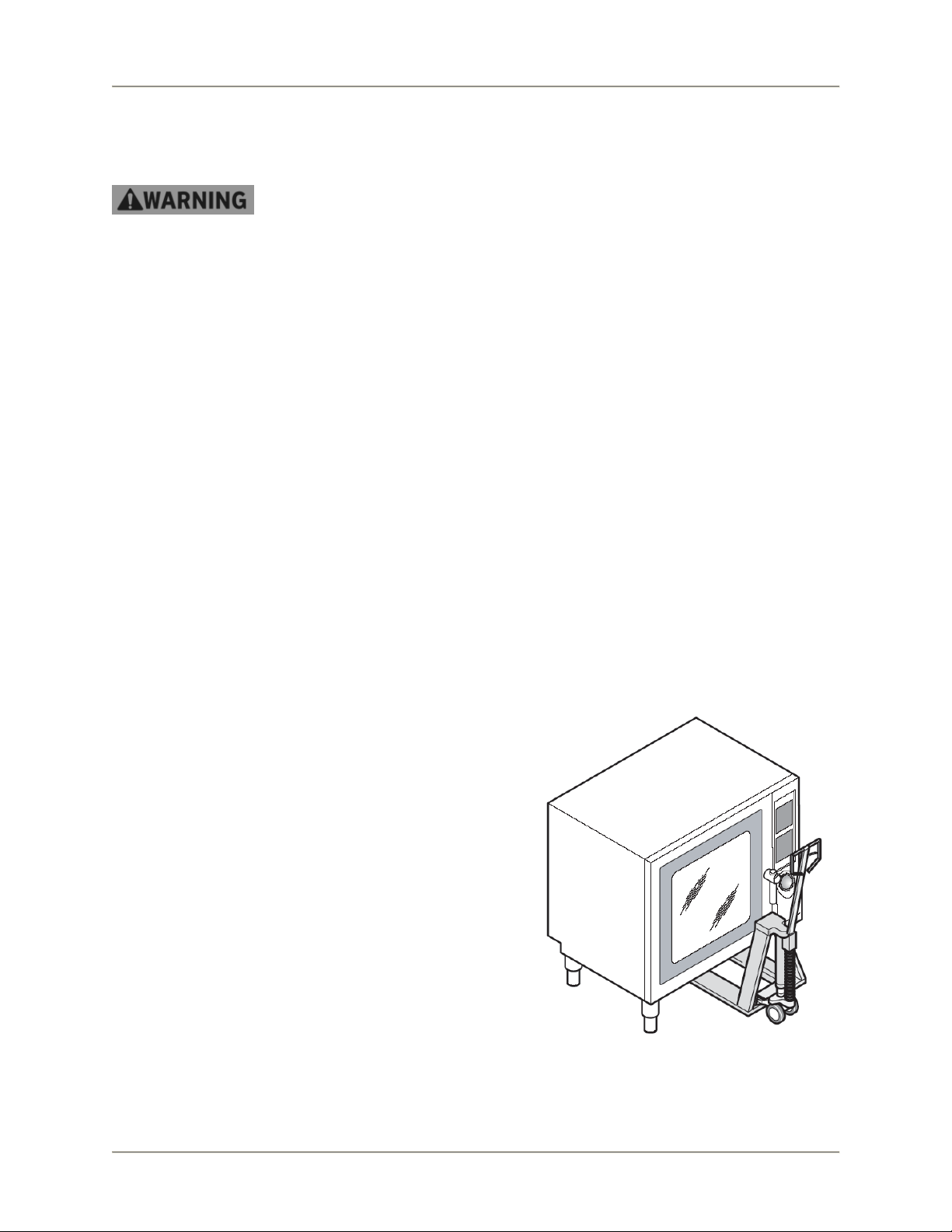

Transport and Unpacking

Any movement of the oven must be carried out by

suitable means such as a forklift or pallet loader.

These must be at least half as large as the convection

oven. If it is necessary to store the oven temporarily,

keep it in a covered, ventilated place at a temperature

from 14°F to 122°F, with humidity no higher than 95%.

Use protective gloves and remove the packaging. Lift

the oven with a forklift, remove the base and place it

in its intended location. After removing the packaging,

immediately check the condition of the oven. If in

doubt, do not use the oven. Contact an authorized

retailer.

6

Convection Oven Installation

Installation Instructions

1. Place the machine in its place of intended use in compliance with the following instructions:

Check that there is enough space (minimum 8”) from any walls or obstacles which may

prevent proper air flow.

Check that maintenance can be performed with a certain freedom of movement.

Avoid placing the oven in places with poor air circulation, in places exposed to sunlight,

where there are high temperatures, near heat sources or in windy locations.

Ambient air temperature must not exceed 89°F. Above that temperature, proper operation of

the oven cannot be ensured.

Always install the oven under a properly operating aspiration hood for the extraction of

vapors.

2. Remove the film which covers some parts of the oven before starting to use it.

7

Convection Oven Installation

3. Clean all substances, including glue residue. Do not use abrasive substances.

4. Position the machine so that it is perfectly level and set the height by means of the leveling feet.

Electrical Connections

The oven is setup for operation at the voltage set forth on the technical data plate. All ovens are provided

with a power cord.

The flexible cable for connection to the electrical mains must not have characteristics which are less than

those of a type with rubber insulation mod. H07RN F and it must have a section which corresponds with

that set forth in the section “Technical Data” of the oven. The cable must also be anchored to the frame

with the cable clamp, the screw of which can be reached through a hole in the frame. It must in any case

8

Convection Oven Installation

be positioned in such a way that at no point does it reach a temperature which is 122°F greater than the

ambient temperature. It must be type SJTO plug 20A 250V P section 3xAWG12.

The connection to the electrical line must be made by placing an automatic switch of sufficient capacity

(see “Technical data” of the oven) and with an opening distance between contacts of at least 3 mm.

Also, during operation of the oven, the power supply must not vary from the nominal voltage value by

±10%.

The oven MUST be earthed by means of the terminal which carries the earth symbol on the connection

board.

It must also be inserted in an equipotential system (the efficiency of which must be checked in

accordance with current standards) using the terminal with the equipotential symbol. It is located near the

electrical cable entry on the panel of the oven bottom.

The manufacturer will not be held liable if this accident prevention standard is not adhered to.

9

Convection Oven Installation

Automatic Safety and Control Devices of the Oven

Protection of the Auxiliary Electrical Circuit

It is checked by the fuses positioned on a terminal block at the line entry.

Protection of the Chamber Fan

A remote switch stops the fan motor in the event of a malfunction or overload. It is located behind the

oven and must be reset manually. When it cuts in, it stops the motor and shuts off the heating elements.

Oven Chamber Safety Thermostat

The safety thermostat disconnects the heating elements if the temperature in the oven chamber is too

high (644°F). It must be reset manually. If it activates, technical service must be notified. All components

are protected by the following type of fuse: CLASS CC,G 600V 20A.

10

Convection Oven Maintenance

Maintenance

Failure to comply with the maintenance below could result in a serious accident.

Electrocution, equipment failure or property damage could result if an unlicensed

electrician performs electrical repair. Ensure that a licensed electrician performs

electrical repair.

Routine Maintenance

Before performing maintenance, unplug the oven.

During cleaning, use protective gloves, mask and garments as required by

standards.

At the end of each workday clean the inside of the oven with appropriate

convection ovens following the suggestions of your supplier. Do not use

corrosive or acidic convection ovens, or convection ovens which are not suitable

for this type of cleaning.

To make cleaning easier, remove the lateral diffusers by lifting them slightly so

they are free of the holding pegs.

Clean the stainless steel parts daily with lukewarm soapy water, and rinse

thoroughly. Then dry.

Absolutely do not clean the stainless steel with steel wool or common steel

brushes, since they may leave ferrous particles which may oxidize, thus causing

rust spots.

Stainless steel wool can be used in the direction of the satin finish.

If the oven is not used for long periods, use a cotton ball to lay a coat of

petroleum jelly on all surfaces; also regularly ventilate the rooms.

11

Convection Oven Maintenance

Oven Chamber Cleaning

Remove any food and/or fat residues from the oven chamber after each cooking cycle. The

combination of fat, heat and forced circulation dirties the oven. Only by cleaning the oven daily is

it possible to avoid difficult cleaning operations.

To clean the oven, use a suitable de-greasing convection oven (non-foaming) as suggested by

your detergent retailer. A spray is preferable to reach behind the protection shield. Do not use

abrasive or corrosive substances, scrapers or steel wool.

To make cleaning the oven chamber easier, it is possible to remove the door completely in a few

simple steps as shown in figure 13. Follow the sequence in reverse order to re-in stall the doo r.

12

Convection Oven Maintenance

Adhere to safety instructions included with cleaning convection ovens for the protection of skin

and eyes. When cleaning, proceed as follows:

1. Heat the oven chamber to approx.158 - 176°F and clean it using the de-greasing detergent in

the recommended quantities.

2. Close the oven and heat it.

3. Let the cleansing convection oven act for 20-30 minutes and then turn the oven off.

4. Slowly open the oven with care to avoid eye and skin damage.

5. Remove the racks or pans from the oven, remove the rack supports attached to the side and

shield, remove the shield by loosening the fastening screws. Wash sep arately (they can also

be placed in the dishwasher).

6. Clean and rinse the oven and fan with water.

7. Re-install the shield and the rack supports.

8. Dry the oven by turning the CONVECTION cycle on.

Cleaning the Door Glass

To reach the inside glass of the oven door, use the lower latch “A”, open outer glass “B” raising it from the

bottom upwards. This will make it possible to get inside the glass for normal cleaning. Upon completion,

lose the external glass by pushing it slowly downwards until the click is heard of insertion in

component “A”.

Cleaning the Fan

Periodically check the condition of the fan. Make sure that there is not too much grease on the blades

since it may slow motor rotation (which in turn may lead to overheating) and uneven heat distribution

(resulting in uneven cooking).

13

Convection Oven Maintenance

What to Do In Case of a Breakdown or Long Periods of Inactivity

1. Switch off the main electrical switch.

2. Set all control panel knobs to zero.

3. Inform technical assistance (only in case of a malfunction).

4. Clean the oven inside and out.

Troubleshooting

Refer to the table below for troubleshooting information.

PROBLEM

PROBABLE

CAUSE

Unit unplugged Check the plug connection and reconnect if necessary

Fuses Check the fuses and replace them if necessary

REMEDY

Oven does not

turn on

Oven does not

warm up

Lights not lit Switch/lights Check the switch and the lights and replace if necessary

Motors do not

work

Oven suddenly

stops

Cables/terminal

block

Switch

Safety thermostat Che ck the safety thermostat and push the red button

Resistor contactor

Heating element

burn out

Motor

contactor/Motor

Safety thermostat Push the red button on the thermostat

Short circuit

Check the cables connection for loose wire and reconnect

if necessary

Check the switch and the voltage at the inlet and outlet.

Replace switch if necessary

Check the voltage at the inlet and outlet of the contactor

and replace if necessary

Replace the heating element

Check the temperature with a manual thermometer and if

necessary replace the thermostat

Check the voltage at the inlet and outlet of the contactor. Check the motor and replace the

contactor or the motor

if necessary

Check the fuses and replace them if necessary, if the

failure persists check all parts with an appropriate tester in

order to find which is the part to replace

14

Convection Oven Maintenance

Repair Procedures

Replacement of spare parts must be performed exclusively by qualified and

AUTHORIZED personnel.

Turn the main switch OFF and unplug the convection oven before carrying out

any spare parts replacement.

Replacement of Motors

It is necessary to remove the back by removing the 4 fastening screws “A” and the 4 screws “B” that

support them.

15

Convection Oven Maintenance

Outer Coverings

Remove the 4 rear fastening screws “C”.

Bulb, Heating Element and Motor Fan

It is necessary to access the inside of the oven, first removing pans, racks and related supports, and then

the conveyor.

30W Motor

Remove the fan by following the procedure outlined above, disconnect the motor from the electrical

system, loosen the 4 screws and replace the motor. Before re-installing the fan, check that there is no

friction between the motor shaft and the ring nut located inside the oven. If there is, loosen the fixing

screws of the ring nut and re-tighten them after eliminating the friction and having centered the ring nut on

the motor shaft.

Heating Elements

Disconnect the heating element connections outside the oven chamber. Loosen the heating elements

from inside the oven chamber and replace them.

16

Convection Oven Maintenance

Electro-Mechanical Controls

All the electric components are visible. To replace them it is necessary to disconnect the attachments,

remove the knobs, unscrew the fastening screws or nuts and replace them.

For the adjustable thermostat, safety thermostat and thermometer, unscrew the

guard and the supports and remove the bulbs. Once they have been replaced use

high-temperature resistant silicone to seal the holes. After replacement, reseal the

holes for the passage of the capillaries with high temperature silicone.

Chamber Face Gasket

It is simply pressed in. Pull to remove it. NB: Before removing it, note its position carefully so as to place

the new one in the same position.

Replacement of Chamber Light and Glass Gasket

Check and replace the glass gasket and any lights in the oven chamber.

17

Convection Oven Replacement Parts

Replacement Parts

Use the information in this section to identify replacement parts. To order replacement parts, call your

local BKI sales and service representative. Before calling, please note the serial number on the rating tag

affixed to the unit.

18

Convection Oven Replacement Parts

POS. CODE BKI # DESCRIPTION

96U

51C

10 I

136 10306 MT0018 Chamber Lamp Frame

6AH I

71A

93AH

27G

144Q

88H

92AS

7Z I

153E

47C

143Q

45I

79G

33E

38A

39P

2AA I 163

24

40G

50D

94AU 35374

1F I 14

37A

94AT 35373

11Q

35D

44

11P

13

129A

146AG

69AA

95

35350

471

35,003,001

10304

10305

35365

10024

35355

12167

35360

15203.01

10586

0364A

16754AF0

10339

10338

14075

616

35370

15062

15021

10342

617

166

10353

12

596

50

20045

20

35379

10951

MT0029

MT0022

MT0015

MT0016

MT0017

MT0024

MT0006

MT0033

MT0034

MT0035

MT0013

MT0021

MT0023

MT0028

MT0011

MT0010

MT0009

MT0007

MT0031

MT0002

MT0039

MT0030

MT0019

MT0014

MT0037

MT0038

MT0001

MT0040

MT0008

MT0036

MT0038

MT0005

MT0020

MT0012

MT0003

MT0004

MT0026

MT0027

MT0032

MT0025

Back side

Cable Lock

Chamber Lamp 15W

Chamber Lamp Gasket

Chamber Lamp Glass

Complete Door

Contactor

Conveyor

Conveyor Pin

Cover

Door glass

Flexible cord 3X12AWG SJTO

Foot

Front Panel

Fuseholder 2x20A

Fuses 20A 10,3x38 600V

Gasket

Green Light 250V

Handle

Heating Element 1500W 240V 60Hz

Heating Element 1500W 208V

Hinge

Knob

Lampholder

Profile, Front, Left

Profile Fixings

Motor 21W 240V 60Hz

Motor 21W 208V

Red Light 250V

Profile, Front, Right

Profile Fixings

Safety Thermostat 340°C (High Limit)

Switch

Terminal block

Thermostat 520°F

Timer 120min

Tray

Trayholder

Vent hole

Wiring

19

Convection Oven Wiring Diagrams

Wiring Diagrams

20

Convection Oven Notes

Notes

21

P.O. Box 80400, Simpsonville, S.C. 29680-0400, USA

864-963-3471

http://www.bkideas.com

Made and printed in the U.S.A

LI0131/0808

2812 Grandview Dr. Simpsonville, S.C. 29680, USA

864-963-3471 http://www.bkideas.com

Loading...

Loading...