Page 1

CONVEYOR OVEN SERVICE MANUAL

ICO-1848 CONVEYOR OVEN

SERVICE MANUAL

BUILT BY CRAFTSMEN. TESTED BY TIME®.

1

Page 2

Food Service Equipment Group

DEAR CUSTOMER

CONVEYOR OVEN SERVICE MANUAL

Bakers Pride Oven Company, LLC is a wholly owned

subsidiary of Standex International Corporation.

Congratulations on the purchase of your new Bakers

Pride® conveyor oven. By purchasing this new oven,

you have entered into a new era of cooking. With the

new technology and simplicity built into the combination

oven, you will receive excellent results in no time at all.

The oven’s ease and simplicity of operation will help you

realize savings in training dollars.

For more information, culinary support, and customer

service please contact 1- 800-927-6887. We will need

the following information to provide you the best service.

Appliance Model

S/N

Dealer

Installer

Date of Install

NOTICE

Please read the operations manual in full before

starting up the appliance to make sure all the

benefits and safety information is understood.

WARNING

California Residents Only

WARNING: This product can expose you to

chemicals including chromium which is known to

the State of California to cause cancer and birth

defects or other reproductive harm. For more

information go to www.P65Warnings.ca.gov.

Cooking Solutions Group

This equipment has been engineered to provide you with year round dependable

service when used according to the instructions in this manual and standard

commercial kitchen practices.

1307 N. Watters Road

Suite 180, Allen, TX

75013

9/18

www.bakerspride.com

western@standexcsg.com

central@standexcsg.com

eastern@standexcsg.com

2

800.431.2745

972.908.6100

Page 3

TABLE OF CONTENTS

CONVEYOR OVEN SERVICE MANUAL

SAFETY INFORMATION

Safety Information 4

SPECIFICATIONS

Design Features 5

Oven Specifications 6

INSTALLATION INFORMATION

Receiving 7

Set Up 7

Minimum Clearances 8

Electrical Connections 8

Terminal Block Configuration 9

CLEANING AND MAINTENANCE

Catalytic Converter 10

Jetplates And Air Returns 10

Oven Cavity 11

Oven Maintenance Guidelines 11

THEORY OF OPERATION

Impingement Air 12

Basic Operation 12

OVEN SYSTEMS

Blower Motor 13

Heater Elements 13

High Temperature Limit Switch 13

Jetplates/ Air Returns 13

Fuses 13

Reversing switch 14

24VDC Power Supply 14

Conveyor Speed Control 14

Conveyor Motor 14

Temperature Controller 14

Electrical Compartment Cooling Fan 14

Contactor 14

SPST Relay 14

TROUBLESHOOTING

Conveyor Issues 15

Heating Issues 16

WIRING DIAGRAMS

ICO-1848 (NC) 17

SERVICE PARTS

Part Numbers 18

Oven Illustrations 19-21

LIMITED WARRANTY INFORMATION 22-23

3

Page 4

SAFETY INFORMATION

CONVEYOR OVEN SERVICE MANUAL

DANGER

Not For Built-In Installation. For Use Only In

Professionally Staffed Commercial Kitchens.

Not For Use In Areas Accessible To The General

Public.

DANGER

Do not store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any other

appliance.

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the Installation,

Operating and Maintenance Instructions

thoroughly before installing or servicing this

equipment.

• Read all instructions before using the appliance

• This appliance must be grounded. Connect only

to a properly grounded outlet. See GROUNDING

INSTRUCTIONS located on page 8 of this manual.

• Install or locate this appliance only in accordance with

the provided installation instructions.

• Use this appliance only for its intended use as

described in the manual. Do not use corrosive

chemicals or vapors in this appliance. This type of

oven is specifically designed to heat, cook, or dry food.

It is no designed for industrial or laboratory use.

• As with any appliance, close supervision is necessary

when used with children.

• Do not operate this appliance if it has a damaged

cord or plug, if it is not working properly, or if its been

damaged or dropped.

• This appliance should be serviced only by qualified

service personnel. Contact the nearest authorized

service facility for examination, repair, or adjustment.

• Do not cover or block any openings on the appliance.

WARNING

Initial heating of oven may generate smoke or

fumes and must be done in a well-ventilated

area. Overexposure to smoke or fumes may cause

nausea or dizziness.

WARNING

To provide continued protection against electric

shock, connect to properly grounded outlets only.

CAUTION

This Device is to be Serviced Only by Properly

Qualified Service Personnel. Consult the Service

Manual for Proper Service Procedures.

• Do not store this appliance outdoors. Do not use this

product near water - for example, near a kitchen sink,

in a wet basement, near a swimming pool, or similar

location.

• Do not immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do not allow cord to hang over edge of table or

counter.

• To reduce the risk of fire in the oven cavity:

i) Do not over cook food. Carefully attend appliance

when paper, plastic, or other combustible materials

are placed inside the oven to facilitate cooking.

ii) Do not use the cavity for storage purposes. Do not

leave paper products, cooking utensils, or food in

the cavity when not in use.

4

Page 5

CONVEYOR OVEN SERVICE MANUAL

OVEN SPECIFICATIONS

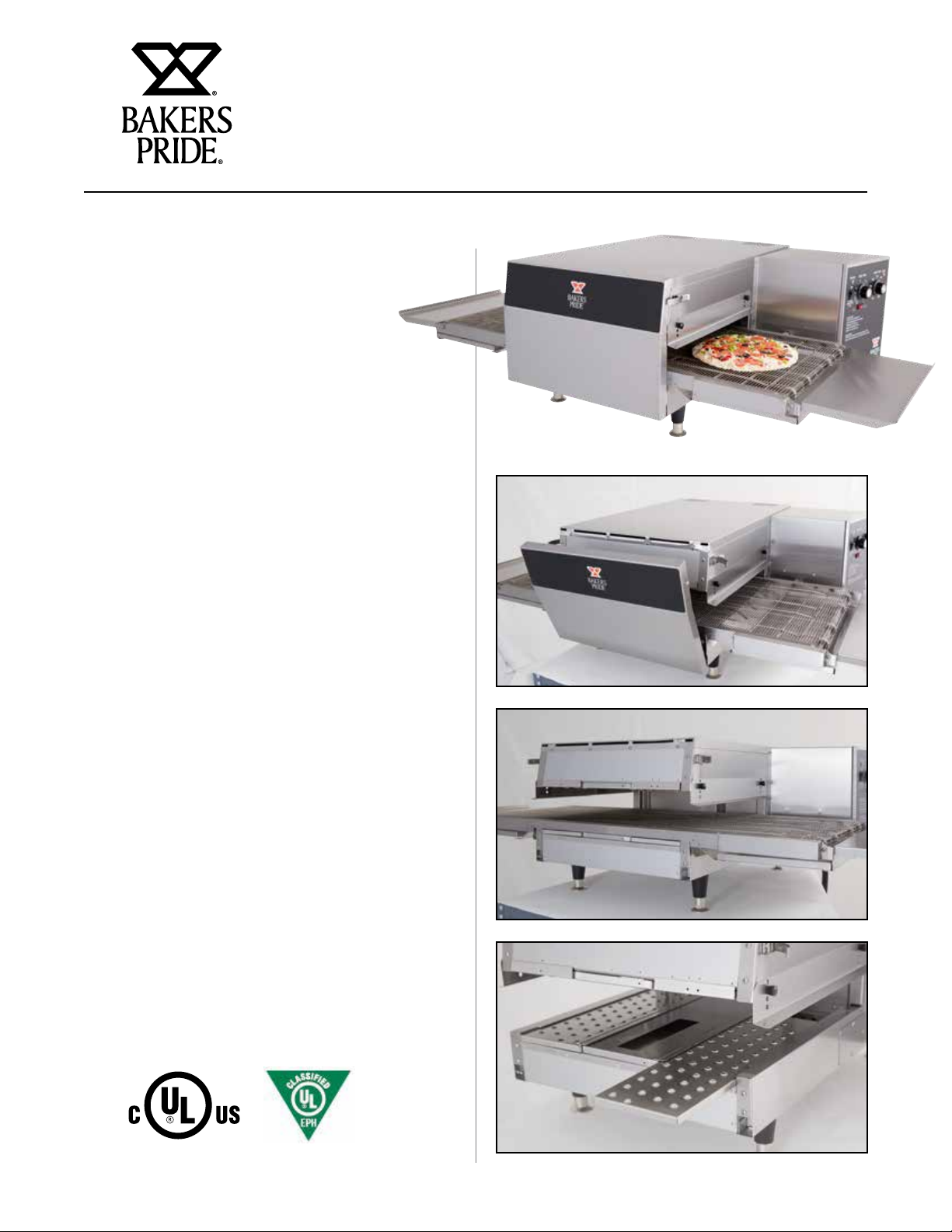

Standard Features

• Simple rotary analog controls

• Top and bottom impingement air

• 6 Independent jet plates

• Balanced air flow for enhanced cooking performance

• 1 To 18 minute belt speed control

• 150˚ – 550˚ F (65˚ - 288˚ C) temperature range

• 18” (45 cm) Wide cook cavity will accommodate a

standard large pizza

• Removable crumb and landing platforms

• 304 Stainless steel cavity

• 1 Year warranty

Design Features

• A single rocker switch changes belt direction—no

need for service

• Easy to clean:

Two simple latches secure front access door which

allows the conveyor belt assembly to easily slide out

from the front. The drive gears and sprockets are not

exposed—no safety hazards. The six independent

jet plates easily slide out from the front for cleaning.

Smooth surfaces under the jet plates make cleaning

quick and safe.

• The ovens are designed to be stacked up to 3 units

high

• A ventless option is available to greatly reduce set-up

costs

• Single and three phase options are available, 208v

and 240v

5

Page 6

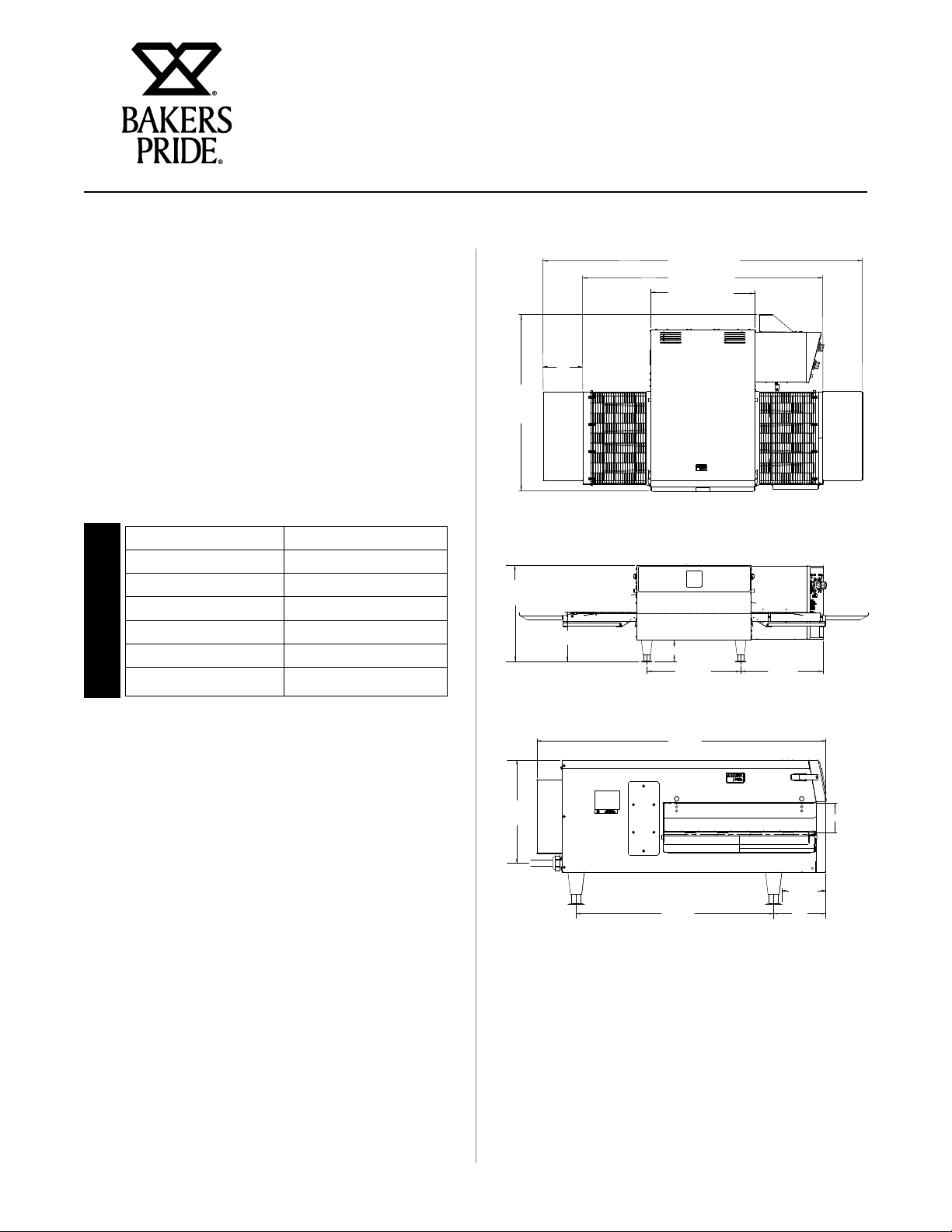

OVEN SPECIFICATIONS

CONVEYOR OVEN SERVICE MANUAL

Electrical Options

Model Volts Phase Cycle/Hz Amps Watts

ICO-1848 208 3 60 19 6,600

240 3 60 16 6,600

208 1 60 32 6,600

240 1 60 28 6,600

ICO-1848-NC 208 3 60 19 6,600

240 3 60 16 6,600

208 1 60 32 6,600

240 1 60 28 6,600

VOLTAGE 208V or 240V

FREQUENCY 60 HZ

SERVICE REQUIRED 20A 3ph 40A Single

PHASE Single or Three

TOTAL WATTAGE 6,600

HEATER WATTAGE 6,500

MODEL ICO-1848

RECEPTACLE REQUIRED 15-30P 3-ph 6-50P Single

35.25”

(895 mm)

17.75”

(451 mm)

8”

(203 mm)

9” (229 mm)

64” (1626 mm)

48” (1219 mm)

21” (533 mm)

4” (102 mm)

17.25”

(438 mm)

15.25”

(387 mm)

Cook Chamber Dimensions

Height 3.4" (9 cm)

Width 20.8" (53 cm)

Depth 18.75" (48 cm)

Volume (cubic feet) 0.77 (0.02 m3)

Weight lbs. (unpackaged) 180 lbs.

(82 kg)

Stackable Yes, Max. of 3 Units

Exterior Dimensions

Height 17.6" (45 cm)

Width 63.8"(48" w/o

Platforms)

(162 -122 cm)

Depth 35.2" (89 cm)

Clearances

Top 5 inches (13 cm)

Sides 5 inches (13 cm)

Back 3 inches (8 cm)

12.5”

(318 mm)

35.25”

(337 mm)

24”

(610 mm)

5.25”

(133 mm)

6.25”

(159 mm)

3.5”

(9 cm)

6

Page 7

CONVEYOR OVEN SERVICE MANUAL

INSTALLATION INFORMATION

Receiving

Read the notice on the outside carton regarding damage

in transit. Damage discovered after opening the carton

is “CONCEALED DAMAGE.” Carrier must be notified

immediately to send an inspector and to furnish forms

for claims against the carrier.

When the oven arrives, it should consist of:

• One conveyor section

• Two crumb trays

• Two 8” landing platforms

• Two eyebrows

• Four eyebrow mount knobs

• Four jet plates

• Two air return plates

When unpacking the oven:

• Remove all packing material from unit

• Adequate air supply to the oven for ventilation is

essential. As a minimum, observe the clearances

detailed on page 8 (Minimum Clearances and

Approved Locations). Provide adequate ventilation and

make up air in accordance with local codes.

• The intake air is located at right side of the oven.

To prevent deteriorating the life and performance

of the oven, the intake air should be as cool as

possible and not preheated by other appliances.

• Allow sufficient clearance in front of the unit for the

door to open completely.

The oven arrives ready to install on a counter or table on

4” (10 cm) legs.

The ovens are designed to be stackable at a maximum

height of THREE units. To stack units, obtain a stacking

kit accessory (21940334) for each unit to be stacked.

Proper lifting methods must be used for safety. Each

oven must have a dedicated power supply. Only the

bottom oven receives the legs.

• Never lift the oven with only one person

• Retain instruction manual for future reference

Set Up/Mounting

Your oven will be packed sitting on its bottom. The skid

may be left under the oven for convenience in further

handling. Unpack carefully, avoiding damage to the

Stainless Steel front and/or trim. If concealed damage is

found, follow the instructions detailed in the Receiving

section above.

• Keep the area around the ovens free and clear of

combustible materials.

• Do not store any materials on top of or under any

oven.

• Do not position the unit so that hot air is drawn in

from fryers, grill, griddles or other appliances.

• A heat barrier the height of the oven will be

required if installed by a burner, fryer, or excessive

heat source.

7

Page 8

CONVEYOR OVEN SERVICE MANUAL

INSTALLATION INFORMATION

NOTICE

Local codes regarding installation vary greatly

from one area to another. The National Fire

Protection Association, Inc., states in its NFPA

96 latest edition that local codes are the

“authority having jurisdiction” when it comes

to requirements for installation of equipment.

Therefore, installations should comply with all

local codes.

Minimum Clearances and Approved Locations

Move the oven to its final location keeping the minimum

clearance from the back of the oven to the wall. This

clearance is necessary for safe operation and to provide

proper air flow.

The oven is designed for countertop installation and

is not recommended for built-in installation. The oven

requires adequate air to cool the electronic controls.

Operating the oven at elevated temperatures may

reduce reliability and overall performance of the oven.

If the oven is to be installed close to a major heat source

including char grills, griddles and fryers, minimum

clearances must be observed and a radiant/thermal heat

barrier installed between the heat source and the oven.

CAUTION

Do not REMOVE THE BACK VENT COVER. IT IS

PROVIDED TO MAINTAIN PROPER CLEARANCE

IF the oven IS SET WITH its back flat against the

wall. It will not operate properly unless the VENT

COVER IS IN PLACE.

Electrical Connection

Install according to the spacing requirements listed

in the installation section of this manual. We strongly

recommend having a competent professional install

this equipment. A licensed electrician should make the

electrical connections and connect power to the unit.

Local codes should always be used when connecting

these units to electrical power. In the absence of local

codes, use the latest version of the National Electrical

Code.

CAUTION

This Appliance Must be Grounded. Failure to do

so May Result In Electrical Shock and Death.

Adequate access to electrical connections, and side

panels must be provided for any future service. The

operator may be responsible for any additional labor

fees if required.

Minimal Clearances from Combustible and

Noncombustible Construction

Sides 5” (13 cm)

Rear 3” (8 cm)

Top 3” (8 cm)

No Surrounding Heat Source

Sides 12”

(30cm)

Rear 3” (8 cm)

Top 3” (8 cm)

Major Surrounding Heat Source;

e.g Fryers, Grills & Griddles

Sides 8” (20 cm)

Rear 3” (8 cm)

Top 3” (8 cm)

Minor Surrounding Heat Source;

e.g Heat Lamps & Warmers

CAUTION

The oven, when installed, must be electrically

grounded in accordance with local codes and/

or the latest edition of the National Electrical

Code ANSI/NFPA No. 70 in the USA (Canadian

Electrical Code CSA Standard C22.1, Part 1 in

Canada).

8

Page 9

CONVEYOR OVEN SERVICE MANUAL

TERMINAL BLOCK CONFIGURATION

Terminal Block

The terminal block is used to simplify the conversion

between single and three phase applications in the

field. Two wires change positions on the output side

of the block (#55 & #39). Theese two wires are easily

identified by being striped in addition to their numbered

39

RED STRIPED

40

41

RED

RED

TERMINAL

BLOCK

RED STRIPED

RED

RED

55

56

57

T4 T3 T2 T1

T4 T3 T2 T1

OUTPUT

29

A2

CONTACTOR

A1

28

INPUT

T4 T3 T2 T1

36

L1

L2

38

ID tags.

RED STRIPED

RED STRIPED

TERMINAL

BLOCK

CONTACTOR

RED

RED

55

39

56

57

40

41

T4 T3 T2 T1

T4 T3 T2 T1

OUTPUT

29

A2

A1

28

INPUT

T4 T3 T2 T1

36

L3

L1

L2

RED

RED

38

SINGLE PHASE WIRING

CONFIGURATION

THREE PHASE WIRING

CONFIGURATION

9

Page 10

CONVEYOR OVEN SERVICE MANUAL

CLEANING AND MAINTENANCE

WARNING

Unit is not waterproof. To avoid electrical shock

or personal injury, DO NOT submerge in water. DO

NOT operate if it has been submerged in water.

DO NOT clean the unit with a water jet. DO NOT

steam clean or use excessive water on the unit.

CAUTION

Use mild detergent or soap solution for best

results. Abrasive cleaners could scratch the finish

of your unit, marring its appearance and making

it susceptible to dirt accumulation. DO NOT use

abrasive cleaners or a cleaner/sanitizer containing

chlorine, iodine, ammonia or bromine chemicals

as these will deteriorate the stainless steel and

glass material and shorten the life of the unit. Use

nylon scouring pads. Do not use steel wool.

Damage caused by unapproved cleaners may void the

manufacturers warranty.

The catalyst is located inside the unit and does not need

to be removed for cleaning.

Conveyor Section

It’s recommended that two people handle the assembly

during removal, cleaning, and installation. Remove the

door and slide the conveyor section forward. Take the

conveyor section to a sink and thoroughly clean with

warm water and a mild detergent or soap. Use a nylon

scouring pad or stiff nylon brush. The area around

the chain cover must be thoroughly cleaned. Do not

immerse the conveyor section in water.

Do not use steel wool.

Jetplates And Air Returns

Open the door and remove the jet plates and air returns

by pulling the jetplate forward. Take the panel to the

sink and thoroughly clean in warm water with mild

detergent or soap. Use a nylon scouring pad or stiff

nylon brush.

Catalytic Converter

The oven utilizes a catalytic converter system that

filters the cooking cavity air reducing grease and odors

from the room. This catalyst contains a microscopic

layer of a specific compound that reduces the ignition

temperature of grease. When the cavity air is moved

through the catalyst, the grease laden air is reduced to

CO2 and H2O. The catalyst is maintenance free and

will continue to operate without issue through the life

of the oven. However, proper care is required when

choosing the chemicals used to clean the cavity in order

to ensure longevity.

The catalyst is sensitive to particular compounds

found in common degreaser and industrial cleaners.

Potassium salts, phosphates, silicates, and other caustic

compounds can cause irreversible damage. This

damage can result in reduced catalyst performance

causing grease, smoke and odors to be in the room.

Bakers Pride provides an approved cleaner for purchase

and recommends any alternatives be checked to

determine their chemical content so not to cause

damage.

Do not use steel wool.

Oven Cavity

With the door open and the jet plates and air returns

removed, wipe out inside of the oven with a clean,

damp cloth. Use a nylon scouring pad dampened

with approved cleaning chemical or stiff nylon brush

to remove any baked on debris. Use a clean towel

dampened with clean water to thoroughly wipe out

inside to remove any cleaner residue and food particles.

Do not use steel wool.

WARNING

Keep cleaning fluids away from electrical wires,

light sockets, switches, and the control panel.

10

Page 11

CONVEYOR OVEN SERVICE MANUAL

CLEANING AND MAINTENANCE

Oven Exterior

To remove common dirt or product residue from

stainless steel, use ordinary soap and water (with or

without detergent) applied with a sponge or cloth. Dry

thoroughly with a clean cloth. Never use vinegar or

corrosive cleaner. Do not use chlorine based cleaners.

To remove grease and food splatter or condensed

vapors that have baked on the equipment, apply

cleaners to a damp cloth or sponge and rub cleanser

on the metal in the direction of the polished lines on

the metal. Rubbing cleanser as gently as possible in

the direction of the polished lines will not mar the finish

of the stainless steel. To remove discoloration, use a

non-abrasive cleaner. Never use a wire brush, steel or

abrasive scouring pads, scraper, file or other steel tools.

Never rub with a circular motion.

NOTICE

This appliance must be serviced by a factory

authorized service agent. Unauthorized service or

repairs may void the manufacturers warranty.

Oven Maintenance

• Power supply to the unit must be disconnected before

any service is performed.

• Most of the service on this unit can be performed from

the back and/or right side.

• It will be necessary to have access to the back of the

oven for service needs related to the blower motor.

However, for proper servicing, access to all sides is

recommended.

• A system wiring diagram is provided in the back of this

document as well as attached to the inside of the right

side oven panel.

• All servicing should be performed by a factoryauthorized technician only.

• For proper maintenance and repairs, call the factory

toll free (800.431.2745) for an authorized service

agency in your area.

CAUTION

This product, when stacked, has more than one

power-supply! Connection point. Disconnect all

power supplies before servicing.

11

Page 12

CONVEYOR OVEN SERVICE MANUAL

THEORY OF OPERATION

®

The Bakers Pride

intended to cook food by utilizing impingement air.

The cook time and cook temperature are individually

controlled to provide optimum settings for a variety of

items. Note that protein based foods are never to be

placed directly on the belt, but must be in a cooking

vessel capable of handling temperatures up to 550° F

(288° C).

ICO-1848 conveyor oven(-NC) is

Basic Operation

• Make sure the jet plates and air returns are

properly positioned

• Check that the door is installed correctly and the

locking clasps are closed

• Check that the conveyor section is in place and the

drive shaft is engaged with the motor shaft

WARNING

Placing protein based foods directly on the belt

may cause a fire hazard

The use of impingement allows the air to be strategically

placed in the cavity which greatly improves performance

and energy efficiency. The heated air is forced through

specifically designed holes which cause the air to

become turbulent creating a shrouding effect which

helps to keep moisture inside the product and providing

brownness and crispness when desired.

The use of impinged air greatly reduces overall cook

times. Common results are 2 - 3 times faster than a

conventional oven while still producing high quality

results.

• Install the crumb trays in the conveyor section

• Place the landing platforms (if desired)

• Set conveyor belt direction prior to power on

• When the conveyor oven is initially powered up for

use, it will take 10 to 15 minutes for it to reach set

operating temperature

• Set the desired cook temperature

• Set the desired cook time (this is the time it will

take the food product to travel the distance inside

the cooking chamber).

Four impingement jet

plates, one in each

corner of the cavity, top

and bottom

Two air return plates, one

each for top and bottom,

located in the center of the

cavity.

12

Page 13

OVEN SYSTEMS

CONVEYOR OVEN SERVICE MANUAL

Electrical Compartment Thermostat

The electrical compartment thermostat is a normally

open snap disk type switch that is mounted behind the

back electrical panel. The switch closes at 180˚ F. (82˚

C). When the oven’s On/Off switch is in the On position,

both the blower motor and cooling fan will engage.

When the power switch is placed in the Off position,

the fan operation will continue until the compartment

temperature drops below the 180˚ F. (82˚ C) set point.

NOTICE

To allow the cooling circuit to perform properly,

when the unit is powered down, 15 minutes

should be allowed to pass before the unit is

unplugged. The temperature in the unit will

continue to rise after the elements go off. In some

cases, this rise may be sufficient to engage the

cooling circuit several minutes after the unit is

placed in standby.

WARNING

Due to the design of the electrical circuit, the unit

is never truly in an “Off Mode”. When the power

switch is set to “standby” , electricity is still

present in the control panel. Always disconnect

the power from the wall before opening the

control panel

Blower Motor

The blower motor is proprietary and designed for this

particular application. Removal of the blower motor can

be performed from the rear without requiring fan wheel

removal. Care must be taken to ensure that the fan is

not damaged during removal and replacement.

Heater Element

The heating elements are located behind the catalyst

(when applicable) and in front of the fan wheel. The

ICO-1848 has one 6500-watt heater assembly. The

three elements in the assembly are fixed to a mounting

plate. The assembly is mounted on the right side of the

cook cavity. The elements are voltage specific to 208 or

240V but can be used for both single and three phase

applications. The heater element operation is controlled

by a contactor with the coil inputs from the temperature

controller.

High Temperature Limit Switch

The oven has an over temperature safety switch

located on the right side back of the unit. The switch

will interrupt all power to the conveyor oven if the

temperature in the cavity rises above 572˚ F (300˚ C).

After the oven cavity cools, the fault can be removed by

pressing the red button on the back of the unit.

Jetplates/ Air Returns, Top And Bottom

The impingement air is being pushed through the top

and bottom jet plates by the blower motor. The jet plates

and air returns are different and must be correctly

positioned for proper cooking performance. Improperly

installed jet plates and air returns will change the cooking

characteristics resulting in substandard cooking quality.

Each jet plate and air return is marked with a series of

holes that corresponds to the same indicator on the

front of the unit. In addition, there is a positioning post

inside the unit that corresponds to a notch on the back

of the jet plate/ air return. Improperly positioned jet

plates and air returns will not insert completely and will

not allow the door to latch.

Fuses

The oven uses a total of 3 fuses in the electrical system.

The two main fuses are located in the fuse block located

on the back panel. They are accessed by removing

the panel screw. The cover is held in place by a strong

magnet located inside the cabinet. It will take extra effort

to open the cover. Once disengaged from the magnet,

the cover rotates open from the bottom and is held in

place (it cannot be removed from the unit). These are

Class CC KLKR 3 amp fuses.

The other fuse is in the panel mount holder at the

bottom back of the unit. This fuse protects the conveyor

motor. It is a Class 3AG 3 amp fuse.

13

Page 14

OVEN SYSTEMS

CONVEYOR OVEN SERVICE MANUAL

Reversing Switch

The reversing switch located on the front panel changes

the direction of the conveyor belt. The direction should

be set when the unit is installed. If a change of direction

in the belt is wanted, it is highly suggested that the unit

be placed in standby and the switch changed. This will

prolong the life of the conveyor motor and controller.

24VDC Power Supply

The oven uses a 24vdc power supply to only power the

conveyor speed control board. This board is located

behind the controls on the front electrical panel and has

the 3 Amp fuse connected between it and the control

board. The 208/240 voltage is supplied from the On/Off

rocker switch.

Conveyor Speed Controller

The conveyor speed controller powers the conveyor

motor through a single Molex connector. The board uses

a potentiometer to control the desired speed which is

only sold with the board as an assembly. Once again,

the controller is powered by the 24VDC power supply.

The belt speed ranges between 1 - 18 minutes based

on the setting on the control panel.

Conveyor Motor

The conveyor motor is a proprietary motor designed for

use in this oven. It is a DC Motor using a gear reduction

drive to increase torque and speed accuracy. In the

event of an object being jammed in the conveyor, belt

assembly is protected from catastrophic damage from

the 3 amp fuse inserted in the power out put of the

power supply.

Temperature Controller

The temperature controller sends 208/240 AC coil

voltage to the contactor when calling for heat. The board

is powered by the On/Off switch and uses a Amber light

to indicate when the board is calling for heat. A separate

RTD is used to monitor the temperature in the cook

cavity.

Electrical Compartment Cooling Fan

The electrical compartment cooling fan is a 208/240V

axial fan located on the back of the compartment. The

fan pulls cooling air through the openings placed at the

bottom of the compartment and directs the air out of

the back. The fan operation is controlled by either the

On/Off rocker switch or by the electrical compartment

thermostat.

Contactor

The contactor is responsible for sending power to the

elements when the temperature controller calls for

heat. The controller sends 208/240 to the coil of the

contactor. The contactors are not voltage specific and

can be used with both single phase and three phase

power. If the oven’s voltage is converted in the field,

only the element needs to be replaced.

SPST Relay

Three single pole single throw relays are used to supply

one leg of power to the heater elements (L2). The coils

of these relays are powered by the output of the high

limit switch. When the oven is connected to power

and the high limit switch is not tripped, one side of the

elements will have power applied.

WARNING

Due to the design of the electrical circuit, the unit

is never truly in an “Off Mode”. When the power

switch is set to “standby” , electricity is still

present in the control panel. Always disconnect

the power from the wall before opening the

control panel

14

Page 15

TROUBLESHOOTING

CONVEYOR OVEN SERVICE MANUAL

Conveyor Not Moving

The conveyor motor is powered by the 24VDC power

supply through a 3 amp fuse. This fuse is designed to

limit the damage to the belt if an obstruction were to

enter the conveyor assembly. The motor is controlled

by the speed controller which uses an external

potentiometer to regulate the speed.

Remove Conveyor Assembly from Drive Shaft.

Does the Belt Move Freely by Hand?

Power Switch “On”

YES

Green LED Lit? Potentiometer Checks OK?

24VDC Across 79 and

86 of Speed Controller?

WARNING

Due to the design of the electrical circuit, the unit

is never truly in an “Off Mode”. When the power

switch is set to “standby” , electricity is still

present in the control panel. Always disconnect

the power from the wall before opening the

control panel

NO

208/240V Across

Switch Terminals?

3 Amp Fuse Open? Replace Failed

High Limit Switch

Tripped?

Incoming Power at

the Contactor?

Drive Motor

Checks OK?

Speed Controller

15

Page 16

TROUBLESHOOTING

CONVEYOR OVEN SERVICE MANUAL

No / Low Heat

The oven uses a single heater assembly consisting of

three individual elements for a total of 6500 watts. The

element operation (L1) is controlled by a contactor. The

other side of the 208/240V power (L2) is controlled by

three independent SPST relays. The coils of these relays

are powered by the high limit switch which makes this

circuit energized at all times when power is connected

to the oven (unless the high limit has tripped). The On/

Off switch does not control this entire circuit.

Power Switch “On”

YES

Amber LED Lit?

NO

208/240V Across 10

and 11 at Temp Controller?

208/240V Across 29

and 28 at the Contactor

YES

See RTD Chart Below

Due to the design of the electrical circuit, the unit

is never truly in an “Off Mode”. When the power

switch is set to “standby” , electricity is still

present in the control panel. Always disconnect

the power from the wall before opening the

control panel

Coil?

RTD Checks OK?

WARNING

208/240V Through the

Contactor?

Elements Correctly Wired

per Diagram?

NO

208/240V Across

Switch Terminals?

3 Amp Fuse Open?

High Limit Switch

Tripped?

Incoming Power at

the Contactor?

Replace Failed Temp

Control

208/240V Across Each

Element?

Replace Failed Heater

Element

RTD Chart OHM/Temp

32˚F (0˚C) 100.00 250˚F (121˚C) 146.49

300˚F (149˚C) 156.91

50˚F (10˚C) 103.90 350˚F (177˚C) 167.24

100˚F (38˚C) 114.68 400˚F (204˚C) 177.49

150˚F (65˚C) 125.37 450˚F (232˚C) 187.65

500˚F (260˚C) 197.71

212˚F (100˚C) 138.51 550˚F (288˚C) 207.69

16

Page 17

ICO-1848 CONVEYOR OVEN WIRE DIAGRAM

RELEASE FOR PRODUCTION

AMBER LIGHT

1514000

3 PHASE WIRING

CONFIGURATION

41

1

B

OF

REV.

SHEET

39

40

1

CONVEYOR

69

BLOWER

START

BLOWER

49

THERMOSTAT

1378040

23

74

MOTOR

21940421

CAPACITOR

21940215

MOTOR

21940205

70

50

SPEED

POT

68

1 2 3

CONVEYOR

48

47

24VDC

CONVEYOR

MOTOR

MOTOR

CONTROLLER

21940429

52

70

52

50

49

48

47

B

FUSE 3

POWER

SUPPLY

21940422

WHITE

RED

ORANGE

WIPER

67

69

68

25

7

27 22

1 2 3 4 5 6

26

74

3 AMP

4 3 2 1

HI LO

F/RLUM

B-B+

79

79

22 67

9

86

80

80

32

86

31

COOLING

FAN

1215610

2166 W

61

60

44

COM

55

RELAY

NO

39

55

T1

T2

T3T4

SINGLE PHASE

WIRING

CONFIGURATION

28

21

20

123

1

2

11

44

1475020

41

40

57

56

B

29

37

29

4

8

9

43

56

37

2166 W

NO

T1T2T3

A2

27

5

43

59

COM

21940428

CONTACTOR

26

678

3

5

4

2166 W

58

RELAY

A1

25

6

42

42

57

1475020

TERMINAL

BLOCK

28

9

COM

NO

21940385

38

L1

L2L3

36

L4

32

101112

16

21940200 - 208V

21940199 - 240V

46

45

RELAY

1475020

L1

L2

46

20 21

31

19

45

21

HIGH LIMIT

11

22

1380300

12

16

Cooking Solutions Group

FIELD SERVICE WIRING DIAGRAM

36

38

COVEYOR

DIRECTION

SWITCH

1305610

BAKERS PRIDE CONVEYOR OVEN

MODELS ICO-1848 and ICO-1848-NC

NONE

SCALE

SETBACK

BEND RADIUS

TOLERANCE-

19

208 & 240V 60Hz

DATE

DRAWN

BAKERS

.XX ±

.XXX ±±±

DECIMAL-

FRACTION-

PART NUMBER

Single and Three

Phase Power

12/8/16

DATE

GREG HAUN

APRVD.

APW

WYOTT

WHEN APPEARS, DEBURR EDGE

ANGLE-

21940433

FINISH

SPEC.

TYPE

SIZE

MATERIAL

STOCK NUMBER

DIVISION

PROGRAM NOTES

ECR

DATE

030817

120816

BY

GH

GH

DESCRIPTION

Removed 21940420 motor controller, fuse 3 to 3 amp,

part number changes to temp controller and contactor

B

A

REV

GREEN LIGHT

1513907

13

12

23

10

RTD

B

TEMPERATURE

CONTROLLER

62

63

ON/OFF

SWITCH

1301700

RTD

P9

RTD

8

21940444

P4

62

5

6

RTD

P8

P2

P5

14

FUSE 2

3 AMPS

FUSE

HOLDER

2

1

1504810

FUSE 1

3 AMPS

3

4

P10

41

T1

40

57

11

10

P1

63

14

T2

B

56

39

T3T4

55

21940428

A1

CONTACTOR

A2

29

38

L1

L1

36

L2L3

L2

L3

28

L4

17

Page 18

SERVICE PARTS

CONVEYOR OVEN SERVICE MANUAL

1. 21940444 Temp Control, RTD Input

2. 21940420A Potentiometer, Speed Controller

3. 1513907 Light, Indicator, Green, 250V

4. 1301700 Switch, Rocker, 16A, 250V, DPST

5. 1305610 Switch, Rocker, Lighted, SPST, 15A

6. 1514000 Light, Indicator 250V Amber

7. 8704600 Knob, Temp or Speed Control

8. 21940429 Controller, Speed, Conveyor Motor

9. 21940422 Power Supply, Conveyor Motor

10. 1380300 High Temperature Limit Switch

11. 1504830 Fuse, 3A, Class CC, 600V KLKR

12. 21940432 Fuse, 3A Conveyor Motor

13. 1215610 Fan, Cooling

14. 21940428 Contactor, 220V/240V, 4 Pole, 40A

29. 21940349 Jet Plate, Top Left (#1)

30. 21940379 Air Return Plate, Top

31. 21940350 Jet Plate, Top Right (#2)

32. 21940308 Jet Plate, Bottom Left (#3)

33. 21940342 Air Return Plate, Bottom

34. 21940307 Jet Plate, Bottom Right (#4)

35. 4883185 Probe, RTD

36. 21940200 Element, 208V 6500W

37. 21940199 Element, 240V 6500W

38. 21940440 Kit, Door Gasket Replacement (not

shown)

39. 21940441 Kit, Controller/ Speed Pot (not

shown)

40. 21940334 Stacking Kit (not shown)

15. R0180 SPST Relay, 40A

16. 21940215 Capacitor, Start, Blower Motor

17. 21940421 Motor, Conveyor, 24VDC

18. 783016 Knob-Threaded Stud 1/4-20 X 1/2

19. 21940256 Air Shutter

20. 21940436 Kit, Service, 1’ Belt Section

21. 21940437 Kit, Service, 2’ Belt Section

22. 21940438 Kit, Service, 3’ Belt Section

23. 21940439 Kit, Conveyor Assembly, ICO-1848

24. 21940288 Crumb Tray

25. 86295 Leg 4” Black

26. 1378040 Thermostat Disk, High Limit, NO,

180F

27. 21940205 Motor, Blower, 3400RPM

28. 21940362 Catalyst Field Install Kit

18

Page 19

SERVICE PARTS

CONVEYOR OVEN SERVICE MANUAL

1

2

3

4

5

6

7

13

8

9

10

11 12

19

Page 20

SERVICE PARTS

CONVEYOR OVEN SERVICE MANUAL

17

20

21

22

16

14

15

1918

26

27

23

24

25

20

Page 21

SERVICE PARTS

28

CONVEYOR OVEN SERVICE MANUAL

29

32

30

31

34

33

35

36 37

21

Page 22

CONVEYOR OVEN SERVICE MANUAL

BAKERS PRIDE LIMITED WARRANTY

What is Covered?

This warranty covers defects in material and

workmanship under normal use, and applies only to the

original purchaser providing that:

The equipment has not been accidentally or

intentionally damaged, altered or misused.

The equipment is properly installed, adjusted, operated

and maintained in accordance with National and local

codes and in accordance with the installation instruction

provided with the product.

The serial number rating plate affixed to the equipment

has not been defaced or removed.

Who is Covered?

This warranty is extended to the original purchaser and

applies only to equipment purchased for use in the

U.S.A.

Coverage Period

Full size gas and electric deck ovens: Two (2) year limited

parts and labor: Cyclone Convection Ovens: BCO Models:

One (1) year limited parts and labor; GDCO Models: Two

(2) year limited parts and labor; (5) year limited door

warranty. HD Series Models; BPHHP/BPHHPS/BPHMG/

BPHTG/BPHCB/BPHRB: Two (2) year parts and labor.

ICO-1848: Two (2) year parts and one (1) year labor.

radiants, stones and valves are covered for a period of

SIX MONTHS.

All Ceramic Baking Decks are covered for a period of

THREE MONTHS. The installation of these replacement

decks is the responsibility of the purchaser.

The extended cyclone door warranty years 3 through

5 is a parts only warranty and does not include labor,

travel, mileage or any other charges.

Exclusions

• Negligence or acts of God

• Thermostat calibrations after (30) days from

equipment installation date.

• Air and Gas adjustments.

• Light bulbs

• Glass doors and door adjustments

• Fuses

• Char broiler work decks and cutting boards.

• Tightening of conveyor chains.

• Adjustments to burner flames and cleaning of pilot

burners.

All other products: One (1) year limited parts and labor.

Warranty period begins the date of dealer invoice to

customer or ninety (90) days after shipment date from

Bakers Pride - whichever comes first.

Warranty Coverage

This warranty covers on site labor, parts and reasonable

travel time and travel expenses of the authorized service

representative up to (100) miles, round trip, and (2)

hours travel time. The purchaser, however shall be

responsible for all expenses related to travel, including

time, mileage and shipping expenses on smaller counter

models that may be carried into a Factory Authorized

Service Center, including the following models: PX-13,

PX-16, P18, and BK-18.

Exceptions

All removable parts in Bakers Pride® cooking

equipment, including but not limited to: burners, grates,

• Tightening of screws or fasteners.

• Failures caused by erratic voltages or gas supplies.

• Unauthorized repair by anyone other than a Bakers

Pride Factory Authorized Service Center.

• Damage in shipment.

• Alteration, misuse or improper installation.

• Thermostats and safety valves with broken capillary

tubes.

• Accessories - spatulas, forks, steak turners, grate

lifters, oven brushes, scrappers, peels, etc.

• Freight = other than normal UPS charges.

• Ordinary wear and tear.

22

Page 23

CONVEYOR OVEN SERVICE MANUAL

BAKERS PRIDE LIMITED WARRANTY

Installation

Leveling and installation of decks, as well as proper

installation and check out of all new equipment per appropriate installation and use of materials - is

the responsibility of the dealer or installer, not the

manufacturer.

Replacement Parts

Bakers Pride genuine Factory OEM parts receive a

(90) day materials warranty effective from the date of

installation by a Bakers Pride Factory Authorized Service

Center.

This warranty is in lieu of all other warranties, expressed

or implied, and all other obligations or liabilities on the

manufacturers part. Bakers Pride shall in no event

be liable for any special, indirect or consequential

damages, or in any event for damages in excess of the

purchase price of the unit. The repair or replacement of

proven defective part shall constitute a fulfillment of all

obligations under the terms of this warranty.

How to Arrange for Service

All warranty service should be coordinated through

the Technical Service Department at Bakers Pride.

You can reach us, toll free, at 1-800-431-2745. All

warranty service calls will be immediately dispatched

by Bakers Pride to the local Factory Authorized Service

Center in your area. When requesting service or parts

identification, always specify:

• Model Number

• Serial Number

• Type of Gas or Voltage

• Phase or Wattage

• Date Code

23

Page 24

Cooking Solutions Group

The Standex Food Service Equipment Group (FSEG) is a manufacturer of innovative commercial

food service equipment offering a wealth of refrigeration and cooking expertise. Products

include walk-in coolers and freezers; hot and cold display cabinets, cases, and storage systems;

commercial ovens, rotisseries, and cooking equipment; and rotary vane pumps.

Ask your sales representative about how the power of all Standex brands can work for you.

www.standex.com/segments/food-service

Be sure to keep up with new product

announcements and events on social media!

24

Loading...

Loading...