BAKERSBAKERS

PRIDEPRIDE

INSTALLATION AND OPERATING INSTRUCTIONS

Cyclone SERIES

ELECTRIC CONVECTION OVENS

Models: CO11-E and COC-E

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

OVEN MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

FOR YOUR SAFETY

! !

Do not store or use gasoline or other flammable vapors and liquids in the vicinity

of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause

! !

! !

This equipment has been engineered to provide you with year round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

+1 (800) 431-2745 US & Canada

+1 (914) 576-0200 Phone sales@bakerspride.com E-Mail

+1 (914) 576-0605 Fax www.bakerspride.com Web Address

property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this equipment.

Initial heating of oven may generate smoke or fumes and must be done in a wellventilated area. Overexposure to smoke or fumes may cause nausea or dizziness.

Form #U4158A 9/07

BAKERS PRIDE OVEN CO., INC.

30 Pine Street

New Rochelle, NY 10801

1

INDEX

INSTALLATION INSTRUCTIONS

SECTION ITEM PAGE

1 Receiving 2

2 Location & Minimum Clearances 2

3A Set-Up & Mounting for COC-E1 3

3B Set-up & Mounting for CO11-E 3

4 Electrical Connections 4

5 Initial Start Up 5

6 System Check & Rotary Controls 5

7 Steam Injection (Optional) 6

OPERATING INSTRUCTIONS

SECTION ITEM PAGE

1 General Instructions 6

2 System Operation Sequence 6

1. Cook Only (Rotary Control) 6

2. Timed Cooking (Rotary Control) 6

3. Cook & Hold (Rotary Control) 6

4. Steam Injection [Optional] (Rotary Control) 7

5. Oven Cool Down (Rotary Control) 7

3 Cleaning 8

4 Servicing 9

5 Wiring Diagrams 10

a. COC-E & CO11-E, 208 or 220-240V w/Invensys Temperature Controller 10

b. COC-E & CO11-E, 230-400V CE w/Invensys Temperature Controller 11

c. COC-E & CO11-E, 208 or 220-240V w/FAST Temperature Controller (G-6) 12

d. COC-E & CO11-E, 230-400V CE w/FAST Temperature Controller (E-6) 13

6 Parts Lists w/Exploded Views 14

a. CO11-E 14

b. COC-E 17

7 Warranty 20

INSTALLATION INSTRUCTIONS

1. RECEIVING

Read the notice on the outside carton regarding damage in transit. “CONCEALED DAMAGE”,

damage discovered after opening the crate(s), must be reported immediately to the carrier. The carrier

will perform an inspection of the damage and furnish forms for the consignee's claim against the carrier.

Retain all packing material - including outer carton until the inspection has been completed. When the

oven arrives, it should consist of: A crate (or carton) containing your new oven, and a carton containing

four 30” legs with mounting hardware (for CO11-E1 oven only). A set of four 6” legs (for CO11-E2

stacked installations) and legs for COC-E are packed inside the oven.

2. LOCATION & MINIMUM CLEARANCES

a. Provision of adequate air supply to the oven for ventilation is essential. Minimum clearances must

be maintained at all times.

2

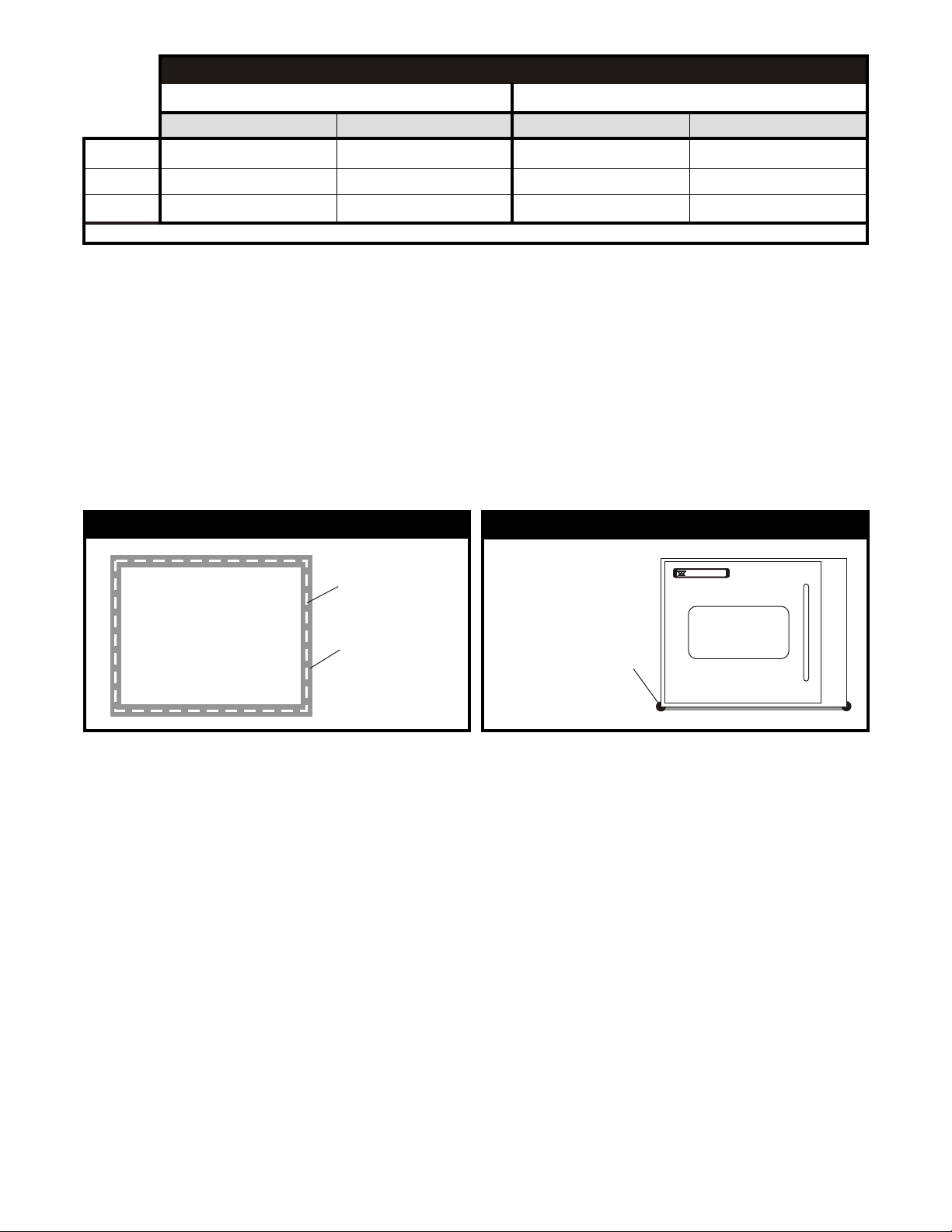

MINIMUM CLEARANCES

COC-E1 CO11-E1

Inches mm Inches mm

Right 1 25 1 25

Left 1 25 2 50

Rear 1 25 1 25

Suitable for installation on combustible floors when installed on factory supplied legs or casters.

3A.SET-UP / MOUNTING FOR COC-E1

Counter-top installation must conform to one of the following methods:

1. COC-E1: Direct Placement On Counter

a. Make sure the counter is level.

b. Clean the area where unit is to be installed.

c. Place the unit in position on the counter and mark the outline of the unit.

d. Remove the unit and apply 1 ¼” bead of sealer (Dow Corning RTV 732 Multipurpose

Sealant or its equivalent) directly onto the counter following the traced outline (see Sketch “A”).

e. Place the unit in position, over the sealer, on the counter.

f. With the unit in place, apply an additional heavy bead of sealer along all edges (see

Sketch“B”).

G. Wipe clean any excess sealer.

SKETCH “A” - TOP VIEW

SKETCH “B” - FRONT VIEW

BAKERS PRIDE

Traced Outline

1 1/4” Bead of

sealer applied

Bead of sealer

along oven edges

onto counter

2. COC-E1: Installation / Mounting 6” Legs (optional)

a. The adjustable legs are not shipped mounted to unit. The legs are packed inside the unit

with the wire shelves.

b. After unpacking the unit, remove legs and any other material from inside the oven.

c. Place the unit on a counter or other flat, stable surface.

d. With sufficient help, tilt the unit back far enough to mount the two front legs.

e. Tighten the upper part of the leg with an adjustable wrench.

f. After installing the front legs, lift the rear of the unit more than 6” off the surface and block in

position using wood or some other solid material.

g. Mount the two rear legs and tighten them in the same fashion.

h. Using proper equipment, move the unit to its final location.

i. To ensure proper operation, the unit must be level. Each leg can be adjusted separately to

achieve proper leveling.

j. Install the shelf supports and the wire shelves.

3B SET-UP / MOUNTING FOR CO11-E

Note: Units must be leveled after leg installation. Each leg is individually adjustable.

1. CO11-E1: Installation / Mounting 30” Legs

a. After unpacking the unit, remove legs and any other material from inside the oven.

b. Tilt the oven onto its left side and attach the two right legs using three ½” bolts and washers for

each leg. Tighten firmly.

c. Use proper lifting equipment to raise the unit, and while suspended attach the two left legs in the

same manner.

3

2. CO11-2E: Installation / Mounting 6” Legs

a. After unpacking the unit, remove legs and any other material from inside the oven.

b. Tilt the bottom oven onto its left side and attach the two mounting plates to the right underside

using ½” bolts and washers and tighten firmly. Screw the 6” legs into the center holes.

c. Use proper lifting equipment to raise the unit, and while suspended attach the two left mounting

plates and legs in the same manner.

d. Use the lifting equipment to raise the top oven to the proper height, and slide it on top of the

bottom oven. Line up the sides and front and use the supplied stacking brackets, screws and

lock washers to fasten the two ovens in the back.

3. CO11-E1: Assembly Of An Open Rack Stand (see Sketch “D”)

a. Slightly loosen the (12) 30” leg bolts.

b. Remove (4) inner bolts, (1) from each of the four legs, place the top right angle underneath as

shown, and tighten these (4) bolts.

c. Insert Open Rack Shelf and tighten into place with (8) 3/8”-16 screws, washers and nuts.

d. Position Rack Supports and tighten in place using (4) 5/16”-18 hex nuts and flat washers.

4. COC-E / CO11-E1: Installation Of Casters (Optional)

a. (4) Casters (2) with wheel brakes and the mounting hardware is packed and included in the

shipment if ordered.

b. Install casters with wheel brakes on the front of the unit. Note: See page 9, sketch D.

c. Install rear legs with casters on the back of the unit with the restraining plate affixed firmly

between the right rear leg & the bottom of the appliance as shown on page 9.

d. Provide a suitable restraining chain or cable to securely tether the appliance to the building

structure. The restraining chain or cable should be of such length, that it will stop movement of

the appliance before there is any strain on the power supply cable.

4. ELECTRICAL CONNECTIONS

1. General Instructions

a. A licensed electrician must make electrical connections.

b. When installed, unit must be electrically grounded in accordance with the local codes and/or the

latest edition of the National Electrical Code ANSI/NFPA No. 70 in USA or Canadian Electrical

Code, CSA Standard C22.1, Part 1 in Canada.

c. Make sure electrical supply corresponds with that specified on the rating plate.

d. For single phase 2-wire or three phase 3-wire supplies, the controlling branch circuit is

designed to operate at 208-240 volts AC and is pre-wired at the factory between L1 and L2 of

the field wiring terminal block (in North America).

e. For three phase 4-wire 230/400 Volts AC 50hz supplies, the controlling branch circuit is

designed to operate at 230 volts AC and is pre-wired at the factory between L2 and N of the field

wiring terminal block.

f. Only use copper conductors rated at 90°C.

g. All pole disconnect must be provided by the installer.

h. FOR CE UNITS: The appliance must be connected by an earthing cable to all other units in the

complete installation and thence to an independent earth connection in compliance with EN

60335-1 and/or local codes. If flexible line cordage is used to connect the equipment, it should

be a minimum of H07RN-F type conforming to EN60335-1, EN60335-2-42 and/or local codes.

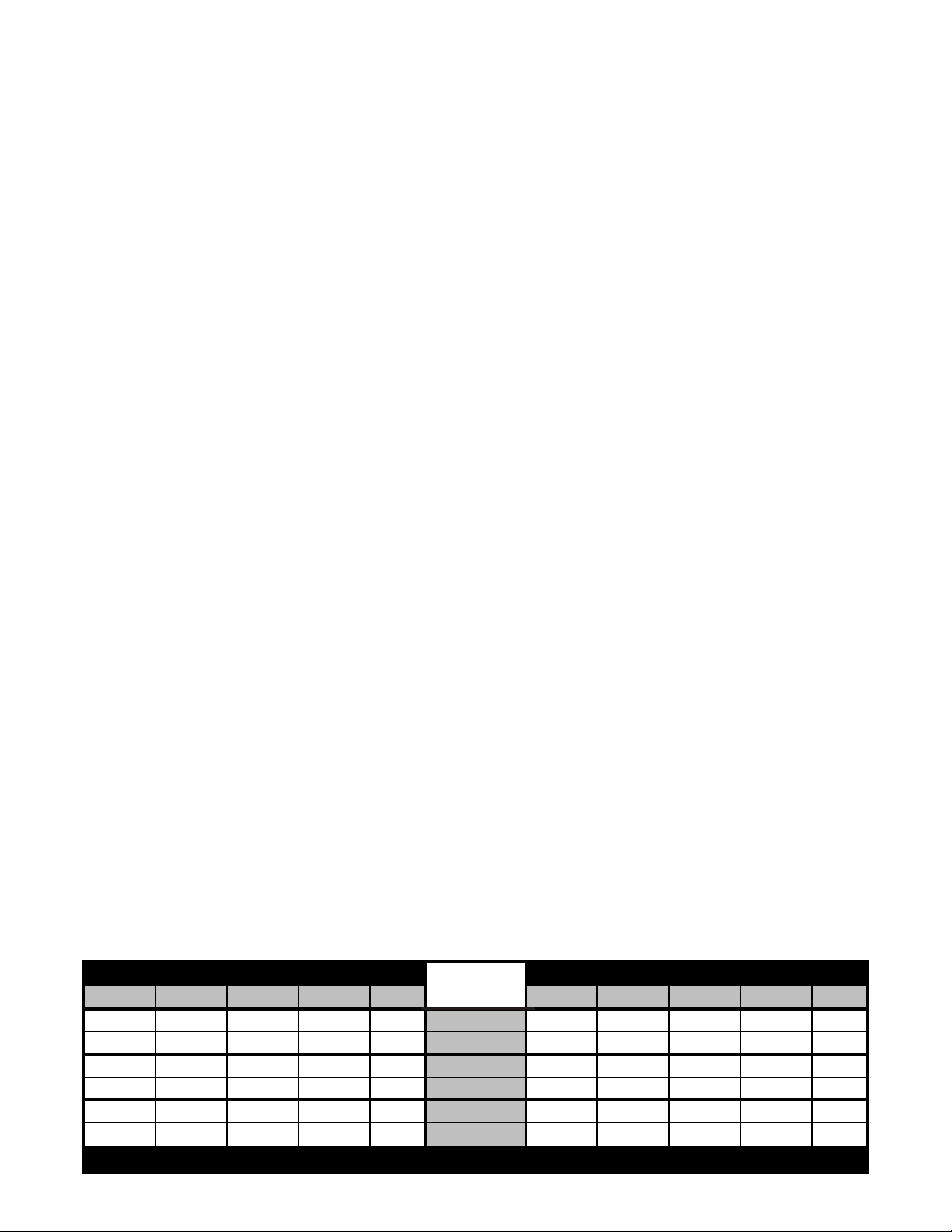

COC-E Power and Current per Deck CO11-E Power and Current per Deck

KW L1 (amp) L3 (amp) L2 (amp) N (amp) KW L1 (amp) L3 (amp) L2 (amp) N (amp)

Power Supply

Volts (Phase)

9.5 45.7 45.7 208 (1) 10.5 50.5 50.5

9.5 27.0 25.0 27.0 208 (3) 10.5 30.0 27.8 30.0

8.7 - 10.3

8.7 - 10.3

39.5 - 43.0 39.5 - 43.0 220-240 (1) 9.6 - 11.4 43.7 - 47.6 43.7 - 47.6

23.4 - 25.5 21.6 - 23.6 23.4 - 25.5 220-240 (3) 9.6 - 11.4 25.8 - 28.2 24.0 - 26.2 25.8 - 28.2

9.5 41.3 41.3 400-Y (1) 10.5 45.7 45.7

9.5

13.0

15.2 13.0 2.2 400-Y (3) 10.5 14.5 16.7 14.5 2.2

NOTE: EACH OVEN REQUIRES A SEPARATE CONNECTION !

4

208V and 220-240V (60hz)

Motor / Blower

400-Y (50hz)

High = 1725 RPM

2. Field Connections

a. Remove access panel from the right side of the oven.

b. Feed power cable (supplied by the customer) through the access hole in the rear of

the oven and pull the cable to the front of the oven under the access panel where it

may be attached to the cable support bracket.

c. Following the appropriate wiring diagram conforming to the rating plate, connect the

power supply leads to the field wiring terminal block. The ground wire should be

connected to the grounding lug attached to the cable support bracket.

d. Make sure all connections are tight, and replace the access cover.

5. INITIAL START-UP

After installation, your oven will need approximately 1 hour to burn off. The following steps must be

completed before your new oven is ready for use:

a. Place the oven in a well ventilated area as the following procedure may produce smoke and

fumes.

b. Open the door(s) and remove any instructions or samples shipped with the unit. Make sure

the oven cavity is empty and the wire shelves are properly installed.

c. Close the oven door(s) and set the temperature knob to 300°F (150°C) for ½ hour.

d. After ½ hour, increase the temperature to 500°F (260°C) for at least ½ hour more. This

procedure will dry out the insulation and will help to insure best baking results.

Low = 1140 RPM

Speeds

High = 1425 RPM

Low = 950 RPM

CAUTION: Overexposure to smoke or fumes may cause nausea and dizziness.

! !

6. SYSTEM CHECK: ROTARY CONTROL

Be sure the oven is placed in a well ventilated area.

a. Open the oven door(s).

b. Turn selector switch to high. The green indicator light near the selector switch and oven light(s)

will illuminate.

c. Close the door(s). Oven light(s) will go off and fan will run. Make sure fan is rotating clockwise

looking from front.

d. Press oven light switch. Oven light(s) will go on and go off as the switch is released.

e. Turn the thermostat knob. The amber indicator light near the thermostat will illuminate and the

elements will come on.

f. Turn the timer knob and set a time of 2 minutes. At the end of 2 minutes, you will hear the buzzer.

Turn the timer knob to “0”.

g. Open the oven door(s). Oven light(s) will go on, and elements and fan will go off.

h. With the door(s) open turn the selector switch to “Cool Down” position. The fan will run to cool

down the oven.

i. Turn selector switch to “0” position.

j. Close the oven door(s).

IMPORTANT: The oven will begin to heat as soon as the door(s) is/are closed, if

the oven temperature is lower than the temperature set and the selector switch

is in the “High” or “Low” cook position.

! !

The thermostat indicator light will turn on and stay on while the oven is heating

up, and will turn off when the set temperature has been reached.

The door(s) interlock switch will deactivate the motor and heating elements and

turn on the light when the door(s) is/are opened.

5

7. STEAM INJECTION OPTION

The solenoid valve for steam injection is mounted behind the service panel on the right hand side of

the unit on COC-E and on the back of the unit on CO11-E. It is pre-wired at the factory. The

electronic timer is pre-set at the factory.

A ¼” copper tubing with a compression fitting for water connection is provided on the solenoid valve. Be

sure to check for leaks after installation.

OPERATING INSTRUCTIONS

1. GENERAL INSTRUCTIONS

a. This equipment has an electronic temperature control.

b. Due to increased efficiency of this oven, the temperature required for standard recipes may be

reduced by 50°F (30°C).

c. Always load each shelf evenly and space pans away from each other and the back and

sides of oven to allow for maximum airflow around the product.

d. Large tempered glass window(s) and interior light(s) allow for a close check of the product

making it unnecessary to open the door(s) too frequently.

e. Products cook faster in a convection oven as compared to a conventional oven, therefore,

depending upon the product and type of pans used, time saving may range anywhere from

20% to 50%.

2. SYSTEM OPERATING SEQUENCE

1. Cook Only Rotary Control

a. Close the oven door(s).

b. Turn selector switch to “High” or “Low” position. The green indicator light near the selector

switch will be illuminated.

c. Turn the thermostat knob to the desired cooking temperature.

d. Upon reaching the set temperature, the amber indicator light near the thermostat will turn off.

e. Load the oven with the product to be cooked.

f. Remove the product from the oven when done.

2. Timed Cooking Rotary Control

a. Close the oven door(s).

b. Turn selector switch to “High” or “Low” position. The green indicator light near the selector

switch will be illuminated.

c. Turn the thermostat knob to the desired cooking temperature.

d. Upon reaching the set temperature, the amber indicator light near the thermostat will turn off.

e. Load the oven with the product to be cooked.

f. Turn the timer knob to the desired bake time and timer will begin counting down.

g. When the timer reaches zero, a buzzer will sound.

h. Turn the timer knob to “0” position.

NOTE: The timer does not control the oven. It is only a reminder that the set

! !

time has elapsed.

3. Cook & Hold Rotary Control

a. Close the oven door(s).

b. Turn selector switch to “High” or “Low” position. The green indicator light near the selector

switch will be illuminated.

c. Turn the thermostat knob to the desired cooking temperature.

d. Upon reaching the set temperature, the amber indicator light near the thermostat will turn off.

6

e. Load the oven with the product to be cooked.

f. Turn the timer knob to the desired bake time and timer will begin counting down.

g. When the timer reaches zero, a buzzer will sound.

h. Turn the timer knob to “0” position.

i. Turn the thermostat knob to the desired holding temperature.

j. Remove the product from the oven as desired.

4. Optional Steam Injection Rotary Control

a. The solenoid valve for steam injection is mounted behind the service panel on the right hand

side of the unit on COC-E and on back of the unit on CO11-E1.

b. The electronic timer is pre-set at the factory.

c. For steam injection, press the steam injection switch.

NOTE: Do not steam injection at temperatures below 275°F (135°C)

! !

5. Oven Cool Down Rotary Control

To cool down the oven to a lower desired temperature, follow the steps detailed below:

a. Open the oven door(s).

b. Turn selector switch to “Oven Cool Down” position. Fan will now operate and cool down the oven.

c. When the oven has cooled to the desired temperature, turn the selector switch to the “0” position.

PROGRAMMING MENUS: MiniChef or FAST Option

! !

See Set-Up & Operation Booklet for Programmable Oven Control with Bakers

Pride Software for Cyclone Series Convection Ovens supplied with this option.

7

3. CLEANING

Always clean equipment thoroughly before first use. Clean unit daily.

WARNING: To avoid any injury, turn the power switch off at the fuse disconnect switch/circuit

OVEN INTERIOR:

Clean The Racks And Rack Support Guides:

any maintenance or cleaning.

WARNING: Unit is not waterproof. To avoid electrical shock or personal injury, DO NOT submerge

in water. DO NOT operate if it has been submerged in water. DO NOT clean the unit with a water jet.

!

DO NOT steam clean or use excessive water on the unit.

CAUTION: Use mild detergent or soap solution for best results. Abrasive cleaners could scratch

the finish of your unit, marring it’s appearance and making it susceptible to dirt accumulation. DO

NOT use abrasive cleaners or cleaners/sanitizers containing chlorine, iodine, ammonia or bromine

!

Open the doors and remove all wire racks and rack support guides. Take them to the sink and

thoroughly clean in warm water with mild detergent or soap. Use a nylon scouring pad or stiff nylon

brush. DO NOT USE STEEL WOOL.

chemicals as these will deteriorate the stainless steel and glass material and shorten the life of the

unit. Use nylon scouring pads. DO NOT use steel wool.

breaker or unplug the unit from the power source and allow to cool completely before performing

!

!

!

!

Clean The Stainless Steel Interior:

Baked on splatter, oil, grease or discoloration on the stainless steel inside of the oven may be removed

with stainless steel cleaner, or any other similar cleaning agent. NEVER use vinegar or any corrosive

cleaner. Use only cleaners approved for stainless steel. NEVER use cleaning solvents with a

hydrocarbon base. NEVER use a wire brush, steel or abrasive scouring pads, scraper, file or other steel

tools. NOTE: ALWAYS RUB THE STAINLESS STEEL ALONG THE GRAINS.

Clean The Blower Wheel:

To clean the blower wheel, remove and immerse in ammoniated water for 20 to 25 minutes. Then, scrub

it off with a small, stiff brush. The same procedure can be followed for wire racks and rack supports. To

remove the blower wheel, loosen the set screws (2) on the hub of the blower wheel and tighten the 3/8”

wheel puller bolt (supplied) in center of hub (See Fig. 1).

Clean The Porcelain Interior:

Porcelain enamel interiors are designed to be as maintenance free as possible. However, for best

results, the oven should be cleaned regularly. Enameled interiors can be easily cleaned with oven

cleaners. KEEP CLEANING FLUIDS AWAY FROM ELECTRICAL WIRES, LIGHT SOCKETS,

SWITCHES AND CONTROL PANEL.

OVEN EXTERIOR:

Clean The Exterior Stainless Steel:

To remove normal dirt or product residue from stainless steel, use ordinary soap and water (with or

without detergent) applied with a sponge or cloth. Dry thoroughly with a clean cloth. Never use vinegar

or corrosive cleaner. Do not use chorine based cleaners.

To remove grease and food splatter or condensed vapors that have baked on the equipment, apply

cleaners to a damp cloth or sponge and rub cleanser on the metal in the direction of the polished lines on

the metal. Rubbing cleanser as gently as possible in the direction of the polished lines will not mar the

finish of the stainless steel. To remove discoloration, use a non-abrasive cleaner. NEVER use a wire

brush, steel or abrasive scouring pads, scraper, file or other steel tools. NEVER RUB WITH A

CIRCULAR MOTION.

8

SKETCH “C” - CLEANING THE BLOWER WHEEL

Blower Wheel

Set Screw (2)

Wheel Puller Bolt 3/8” Hex

Motor

4. SERVICING

1. The power supply to the unit must be disconnected prior to service.

2. Most of the service to this unit can be performed from the front and/or the control panel side.

3. For proper service, access to the control panel side of the unit is required.

4. It is necessary to have access to the back of the oven when the motor and/or contactor require

service.

5. A system wiring diagram is provided in this manual as well as on the back of the service panel on the

right side of the oven.

6. All service should only be performed by a factory-authorized technician.

7. Call the factory toll-free number (800) 431-2745 for the name of an authorized service location in

your area.

8. Replacement parts manual sent with unit should be saved for future use.

SKETCH “D” - OPEN RACK STAND ASSEMBLY INSTRUCTIONS

30” Legs

3/8”-16 x 3/4” Large

Truss Head Screw

w/Nut & Washer (8)

Open Rack Shelf

Rack Support

F ON

R

Top Left Angle

Top Right Angle

L

b

la e

e

a

L b l

T

Warning Label, Restraining Device

for Casters

9

Restraining Plate for

Legs w/Casters

½” Flat Washer

(4 Corners Only)

½” - 13 x 1” Large

Hex Head Bolt (12)

5/16” Flat Washer (4)

5/16”-18 Hex Nut (4)

5A. WIRING DIAGRAM - COC-E & CO11-E - w/LIGHTS (w/Invensys Temperature Controller) 208/220-240V 1 or 3 Phase DWG. 1040-70A 8/11/98

CIRCUIT

BREAKER

17

B

L

K

6 WHT

TERMINAL

BLOCK

9

B

L

K

12

B

L

K

32A

16A

16A

32A

SELECTOR

SWITCH

C1 BLK

A3B

LK

S

B

L

K

A5

W

H

T

USED ONLY ON

CO11-E

1

TIMER

2

S

4

14

18

B

W

L

H

K

T

BUZZER

8 BRN

9 BLK

5 BLK

4 BRN

7 WHT

A6 WHT

DOOR

SWITCH

H6 WHT

NO

C

NC

LIGHT

SWITCH

2

B

L

K

T4

L4

T3

L3

T2

L2

T1

L1

4 POLES,40 AMP

CONTACTOR

C2

WHT

1

B

L

K

P4

4

OOOX

P3

P2

P1

H5

W

H3 WHT

H

T

28 BRN

S2 WHT

3

OOXO

S1 WHT

2

OXOO

1

OXXO

250V

LIGHTS

10 BLK

HEATING ELEMENTS

23 BLK

24 BLK

25 BRN

26 WHT

27 WHT

11 WHT

PILOT

LIGHT

(POWER)

250V

2 SPEED

LO

MOT

COM

HI

28 BRN

ROBERTSHAW

THERMOSTAT

GC20-3006

L1

NOTE:

L2

2

B

L

K

NO

1

B

L

K

A3 BLK

COM

A4

W

H

T

A4 WHT

TC-

TC+

AMBER

PILOT LIGHT

(THERMOSTAT)

RED

SENSOR

WHT

POTENTIOMETER (TIMER)

H2

STEAM TIMER

A1

1

2

3

A1 BLK

BUTT

CONNECTOR

4

5

6

7

H2

A2 WHT

STEAM OPTION

H1

H1

STEAM

SWITCH

31 BLK

29 BLK

WATER SOLENOID

VALVE

BLK

YEL

RED

BLU

1- # 5 BLK & #7 WHT WIRES TO BE # 10 AWM. ALL OTHER WIRES

208V 1

220-240V 1

208 V 3

220-240 V 3

TO BE # 14 AWM.

2- ALL INTERNAL WIRES TO BE RATED 200° C AND 600 VOLTS.

3- ALL HEATING ELEMENTS TO BE 208V OR 230V - 3 Kw FOR COC-E

AND 3.3 Kw FOR CO11-E.

16

W

H

T

3 PHASE

3 WIRE

L1

L3

L2

TERMINAL

BLOCK

GND

10

1 PHASE

2 WIRE

L1

L2

TERMINAL

BLOCK

3 PHASE

3 WIRE

L1

L3

L2

1

4 BRN

8 BRN

16 WHT

GRN/YEL

13 WHT

15

4 BRN

8 BRN

16 WHT

LK

B

5

13 WHT

15 BLK

5 BLK

4 BRN

8 BRN

7 WHT

16 WHT

LK

B

5 BLK

7

W

7 WHT

13

W

H

T

H

T

13 WHT

5 BLK

5B. WIRING DIAGRAM - COC-E & CO11-E CE STAR CONNECTION (w/Invensys Temperature Controller) 230/400V 3 Phase DWG. U4204A 8/98

CIRCUIT

BREAKER

16 BRN

3 PHASE

N

L1

L2

L3

4 WIRE

TERMINAL

BLOCK

15 B

4 BLK

8 WHT

16 BRN

13 BRN

LU

5 BLU

7 BRN

GRN/YEL

GND

11

6 BRN

17

B

L

U

TERMINAL

BLOCK

9

B

L

U

12

B

L

U

10 BLU

S

B

L

U

C1 BLU

A3 BLU

A5

B

R

N

Used ONLY

on CO11-E

DOOR

SWITCH

NO

C

NC

LIGHT

SWITCH

A6 BRN

H6 BRN

C2

BRN

SELECTOR

SWITCH

S2 BRN

S1BRN

11 BRN

2 SPEED

250V

LO

PILOT

LIGHT

(POWER)

10

B

L

U

COM

MOT

L1

L2

NO

HI

1

2

B

B

R

L

N

U

H3 BRN

COM

TC-

TC+

A4

B

R

N

S

B

L

U

P4

4

OOOX

3

P3

OOXO

P2

2

OXOO

P1

1

OXXO

H5

250V

B

LIGHTS

R

N

C1 BLU

AMBER

PILOT LIGHT

(THERMOSTAT)

RED

WHT

SENSOR

RC

ROBERTSHAW

THERMOSTAT

GC20-3006

STEAM OPTION

3 PHASE

4 WIRE

N

L1

L2

L3

L

15 B

4 BLK

8 WHT

16 BRN

U

5 BLU

7

BRN

13 BRN

4

5

6

7

H2

A2 BRN

H1 BRN

31 BLU

H1

BLK

YEL

RED

BLU

WATER SOLENOID

STEAM SWITCH

29 BLU

VALVE

1

TIMER

2

S

4

14

18

B

W

L

H

K

T

4 BLK

7 BRN

m

1 F, 250VAC

1 F, 250VACm

BUZZER

5 BLU

8 WHT

2

B

L

U

T4

L4

T3

L3

T2

L2

T1

L1

4 POLES,40 AMP

CONTACTOR

1

B

R

N

23 BLU

24 BLU

HEATING ELEMENTS

28 BRN

A3 BLU

A4 BRN

25 BLU

26 BLK

27 WHT

28 BRN

NOTES:

1- # 5 BLUE WIRES TO BE # 10 AWM. ALL OTHER WIRES

H2

B

POTENTIOMETER

R

N

STEAM TIMER

A1

A1 BLU

BUTT

CONNECTOR

1

2

3

TO BE # 14 AWM.

2- ALL INTERNAL WIRES TO BE RATED 200° C AND 600 VOLTS.

m1 F, 250VAC

230/400 3N

3- ALL HEATING ELEMENTS TO BE 230 VOLTS - 3 Kw FOR COC-E

AND 3.3 Kw FOR CO11-E

4- ALL POLES DISCONNECT MUST BE PROVIDED BY THE

INSTALLER

5C. WIRING DIAGRAM - COC-E & CO11-E (w/FAST Temperature Controller) G-6 Board 208/220-240V 1 or 3 Phase DWG. U4212Q 8/07

A5 C2

LIGHT

SWITCH

H5

C2

13

L2 PRESENTON CO11ONLY

13

14

L1

15

15

L2

ROTARY

SWITCH

1P1

H6

P2

P3

P4

A6

A6

NC

H5

NO

4

12

COM

6 A5

DOOR

SWITCH

S1

TIMER

A6

13

6

13 17

16

15

3332

31

341516

7

2

S1

3

S2

4

T4

PROBE

12

T6 T7 T8 T9 T10 T11

L1

31

L2

32

L3

33

L4

34

1516

34323331

POWER

INDICATOR

T5

THERMOSTAT

THERMOSTAT RELAY

16 3

18

A1

K 1

A2

16

77

T1

28

T2

T3

26

T4

27

HEATING ELEMENTS ARE 208V OR 230V

R1 3000 WATT 3333 WATT

R2 3000 WATT 3333 WATT

R3 3000 WATT 3333 WATT

30

RTD PROBE

HEAT

INDICATOR

R 1

0

X

1

Y

Z

2

FUSES 30 AMP (3)

CO11-E 208V 1PH ONLY

223

R 2

224

R 3

225

COCE CO-11E

30

TERMINAL

BLOCK 2

1

2

3

18

2 SPEED

MOTOR

LO

S1

S2

1412

1017

433

Y

26

Z

27

28

X

COM

10

HI

STEAM

STEAM OPTION

SWITCH

42

40

WATER

SOLENOID

VALVE

43

41

POTENTIOM ETER (TIMER)

44 45

42

3

TIMER

BLU

46

RED

YEL

BLK

47

1

2

41

6

4

5

TB1

THREE PHASE

X EY Z

TB1

X EY Z

SINGLE PHASE

5D. WIRING DIAGRAM - COC-E & CO11-E CE (w/FAST Temperature Controller) E-6 Board 230/400V 1 or 3 Phase DWG. U4203Q 8/07

A5 C2

LIGHT

SWITCH

H5

C2 14

L1

13

L2PRESENTON CO11ONLY

13

L2

15

15

ROTARY

SWITCH

1P1

H6

P2

P3

P4

A6

A6

NC

H5

NO

13

4

COM

6 A5

DOOR

SWITCH

S1

TIMER

A6

13

6

13 17

16

15

7

2

S1

3

S2

4

12

POWER

INDICATOR

PROBE

30

HEAT

2 SPEED

MOTOR

S1

S2

LO

COM

10

HI

INDICATOR

RELAY

L1

31

L2

32

L3

33

L4

34

COM100120240RELAY

3167

30

TERMINAL

BLOCK 2

16

A1

T1

28

T2

K 1

T3

26

T4

27

A2

18

X

Y

Z

R 1 3000 WATTS

23

24

R 2 3000 WATTS

25

R 3 3000 WATTS

1412

1

1017

2

183

3

43

Y

26

Z

27

28

X

42

STEAM

STEAM OPTION

SWITCH

40

WATER

SOLENOID

VALVE

43

41

POTENTIOM ETER (TIMER)

44 45

42

3

TIMER

BLU

46

RED

YEL

BLK

47

1

2

41

6

4

5

31

TB1

X EY Z

THREE PHASE

3332

341516

TB1

X EY Z

1516

34323331

SINGLE PHASE

6. PARTS LISTS & EXPLODED VIEWS

30 Pine Street • New Rochelle • New York • 10801

914 / 576 - 0200

CO11-E

914 / 576 - 0605

1 - 800 - 431 - 2745

Full Size Electric Convection Oven

www.bakerspride.com

Figure A Exterior / Interior / Elements / Controls / Door

fax

US & Canada

web address

BAKERS

PRIDE

22

16

44

45

89

15

41

42

3

38

39

80

81

56

88

82

8

10

36

55

14

2

1

82

75

76

77

78

9

6

5

12

4

83

B

B

34

29

A

A

K

K

E

E

R

R

S

S

P

P

R

R

I

I

D

D

18

17

E

E

19

20

35

86

11

67

79

21

84

85

48

13

7

33

57

87

74

51

52

54

69

53

66

65

57

23

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. U6002A 8/07 Page 2 of 4

25

26

47

92

37

40

31

49

43

50

70

63

32

58

71

58

59

46

24

S

S

w

w

r

r

i

i

t

t

o

o

c

c

o

o

D

D

h

h

27

28

31

62

61

70

71

30

60

68

90

64

70

91

14

30 Pine Street • New Rochelle • New York • 10801

914 / 576 - 0200

BAKERS

PRIDE

Item Part # Description Item Part # Description

914 / 576 - 0605

1 - 800 - 431 - 2745

www.bakerspride.com

fax

US & Canada

web address

CO11-E

Full Size Electric Convection Oven

Exterior / Interior / Elements / Controls / Door

1 E3450X Door Seal, Top & Bottom (2) 47 Q1407A Screw, Hx Hd, #10x1/2

2 E3451K Door Seal, Sides (2) 48 K1375E Element Bracket, Flat (4)

3 E3466U Door Closure Strip 49 Q3017A Star Washer #10

4 S1317U Door Handle 50 Q1402A Nut, 10-32

5 Q1477A Screw, FH 10-32x1/2 (4) 51 M1030X Contactor, 208/240V

6 Q3047A #10 Lockwasher, Countersunk, Ext. (4) 52 E3616X Contactor Bracket

7 E3487X Vertical Trim 53 P1145X Snap-In Light Assy (w/240V Bulb)

8 E3485K Outer Cover (Left) 54 P1147X Light Bulb (15W,240V)

9 E3486K Outer Cover (Right) 55 P1082A Conduit BX, 3/8"

10 E3618K Outer Cover (Top) 56 P1084A Bushing, Anti-Short, 3/8"

11 E3499X Access Cover (Side) 57 P1003X Terminal Block (3 Pole)

12 E3488X Top Trim 58 M1049X Switch, Momentary (SPST)

13 E3583U Bottom Apron 59 S1171A Plug Button, 7/16"

14 E3514X S/S Perforated Rear Panel 60 M1326X Switch, Rotary (EGO)

15 E3454X Door Assy Left (No Window) 61 M1339A Pilot Light Amber (Thermostat)

16 E3458X Door Assy Left (w/Window) 62 P1128X Pilot Light Green (Power)

17 E3456X Door Assy Right (No Window) 63 M1346X Timer, 60 Minutes (208/240V)

18 E3460X Door Assy Right (w/Window) 64 M0110A T-stat, G6, FAST (Domestic)

19 S3229A Door Rod

20 Q4033A Roll Pin 1/4 x 1 1/4

21 S1048X Window Assy

22 E3053K Baffle Plate

23 Q2009A Thumb Screw, 1/4-20x1/2 (4)

24 E3095X Baffle Plate Bracket Assy (4)

25 Q1414A Screw, Hex Hd, #10x3/4 (8)

26 E3471K Door Switch Actuator

27 M1102X Microswitch (Rotary)

28 M1172X Microswitch (Minichef)

29 U1043X Bakers Pride Name Plate (13 3/4")

30 U1437A Control Panel Overlay (Rotary)

M1356A Solid State Relay, CE

31

32 U1296A Timer Overlay (50 cycle only)

33 U1299A Rating Plate (Bi-Lingual)

34 U1192A Caution Hot Label (Bi-Lingual)

35 U1169A Motor Rotation Arrow

36 U1210A Installation Warning (English)

37 L1087X Element, Front, 208V, 3333W

38 L1088X Element, Center, 208V, 3333W

39 L1089X Element, Rear, 208V, 3333W

40 L1090X Element, Front, 230V, 3333W

41 L1091X Element, Center, 230V, 3333W

42 L1092X Element, Rear, 230V, 3333W

43 L1104X Element, Front, 460V, 3333W

44 L1105X Element, Center, 460V, 3333W

45 L1106X Element, Rear, 460V, 3333W

46 K1100X Element Bracket, Bent (4)

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. U6002A 8/07 Page 3 of 4

M1553A

65 M1555A RTD Temperature Probe

66 E3219K Clamp, Temperature Sensor (1)

67 P1042A Victor Clamp, Temp Sensor (3)

68 M1176X Potentiometer

69 M1335X Bell Audiolarm

70 S1311X Knob (3)

71 M1352X

P1166A

72

73

P1164A

74 M1174X Transformer (208/240V-24V)

75 M1217X Motor, 1/4HP, 2Spd, 200-230V,50-60

76 Q3008A Flat Washer (4)

77 Q3014A Lock Washer, Split (4)

78 Q2204A Nut, 5/16 HX, 5/16-18 (4)

79 S1195X Blower Wheel

80 Q2302A Bolt, Wheel Puller 3/8-16x2 Hx (2)

81 P1108A Conduit Connector, 3/8x24"

82 E3225X Stacking Bracket,

83 T3044A Rack Support

84 T3043A Wire Rack

85 E3531K Door Limit Block

86 M1238X Transformer, 480/240V, (

87 P1004X Terminal Block (4 Pole)

88 E3614K Cut-Out Cover, Offset (L & R)

89 E3615K Cut-Out Cover

90 M1231A Steam Timer 208/230V

91 E3772K Control Panel, Rotary

T-stat, E6, FAST (CE)

Ckt Breaker, 120-240V, 15A

Fuse Block, 3 Pole, 600V, 30A

Fuse, KTK Class CC, 600V, 30A

CO11-E2 Only

Not Shown

Not Shown

(each)

480 Elem only)

15

CO11-E

Full Size Electric Convection Oven

30 Pine Street • New Rochelle • New York • 10801

914 / 576 - 0200

914 / 576 - 0605

1 - 800 - 431 - 2745

www.bakerspride.com

fax

US & Canada

web address

BAKERS

PRIDE

Figure B

1

Item Part #

8

9

19

Description

Door Chain / Legs & Open Rack Stand

Door Chain Assy

16

2

3

Labe

l

15

14

13

11

22

10

FR

ON

T

24

Legs & Open Rack Stand

Item

Part #

Description

5

4

6

7

17

18

21

20

abL el

25

23

26

12

1

2

3

4

5

6

7

8

9

10

11

12

13

N/S

N/S

N/S

N/S

N/S

N/S

S3228A

S3231X

S3226A

S3227A

S3145X

S3112X

S3224A

S3223A

Q2039A

S1050Y

Q4017V

S1217Y

S1252T

M1114X

M1115X

N3039A

N3040A

N5831A

N3041A

Flange Bearing (4)

Door Chain Assy (Complete)

Door Chain Rod (Short)

Door Chain Rod (Long)

Sprocket

Roller Chain #35

Chain Connection Link #41

Turnbuckle 1/4-20x3"

1/4-20 Hex Nut, Left Hand Thread (2)

30" Leg (Set of 4)

Leg Bolt, Set (For 4 Legs)

24 1/2" S/S Leg (Set/4) Used w/Casters

24 1/2" S/S Leg (each) Used w/Casters

Steam Option (Not Shown)

Solenoid Valve

Coil (For Solenoid Valve)

1/8 Brass Coupling

1/8 Brass Elbow

1/8x4" Brass Nipple

1/8NPT-1/4 Compression Fitting

14

15

16

17

18

19

20

21

22

23

24

25

26

N/S

N/S

N/S

N/S

N/S

N/S

S1081X

S1022X

S1023X

K1357E

S1049Y

S1049A

E3148U

E3149U

T3051X

T3052X

T8075X

U1460A

S1267K

N5814A

N5815A

N1019X

M1231A

M1176X

M1049X

Casters, 4" (Set of 4)

Caster, 4" (No Lock), each

Caster, 4" (w/Lock), each

Mounting Plate (for Casters) each

6" Bullet Legs (Set of 4)

6" Bullet Legs (each)

Top Right Angle, Open Rack Stand

Top Left Angle, Open Rack Stand

Left Rack Support, Open Rack Stand

Right Rack Support, Open Rack Stand

Bottom Shelf w/Hardware, Open Rack Stand

Label, Restraining Device

Restraining Plate

1/8x2 3/8 Nipple

1/4 Tubing x 9"

Steam Injection Nozzle

Steam Timer, 208/230V

Steam Potentiometer

Momentary Switch (Steam)

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. U6002A 8/07 Page 4 of 4

16

30 Pine Street • New Rochelle • New York • 10801

914 / 576 - 0200

COC-E

Half Size Electric Convection Oven

914 / 576 - 0605

1 - 800 - 431 - 2745

www.bakerspride.com

fax

US & Canada

web address

Figure A Exterior / Interior / Elements / Controls / Door

1

14

71

13

12

4

5

39

6

8

7

11

16

18

19

21

20

66

65

60

33

27

26

25

BAKERS

PRIDE

2

28

3

44

40

9

10

58

57

55

56

15

14

13

12

50

46

17

45

22

53

51

24

54

52

60

59

63

23

36

37

38

60

35

61

62

34

42

30

69

31

43

31

41

29

33

35

32

60

33

H

ea

ea

C

C

o

o

o

o

o

wDnowDn

S

S

e

e

etl

etl

e

e

nuM

nuM

64

70

67

t

t

in

inH

g

g

11

l

l

tS

2

2

ea

mtSeam

44

33

c

c

UpU

p

55

St t

St t

a

a

r

r

tS

o

o

p

ptS

66

Dn

Dn

ow

ow

47

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. U6004A 8/07 Page 2 of 4

48

49

68

17

30 Pine Street • New Rochelle • New York • 10801

914 / 576 - 0200

BAKERS

PRIDE

Item Part # Description Item Part # Description

914 / 576 - 0605

1 - 800 - 431 - 2745

www.bakerspride.com

fax

US & Canada

web address

COC-E

Half Size Electric Convection Oven

Exterior / Interior / Elements / Controls / Door

1 E1178K Outer Shell

2 E1179K Outer Side (Right)

3 E1180X Access Cover Assy.

4 E1052X Door Assy. (With Window)

5 S1048X Window Assy.

6 S1317U Door Handle Assy.

7 Q1477A Screw, FH 10-32x1/2 (4)

8 Q3047A #10 Lock Washer, Countersunk ext. (4)

9 S3029X Door Catch

10 Q2008A Screw, FH 1/4-28x5/8 (4)

11 E1165K Hinge Assy (Top)

12 Q2025A Bolt, HH 1/4-20x3/4 (2)

13 Q3005A 1/4 Lockwasher, Split (2)

14 E1087B Hinge Shim (2)

15 E1167K Hinge Assy (Bottom)

16 Q2209A Screw, TH, 5/16-18x3/4 (8)

17 T3041A Wire Rack (5)

18 T3042A Rack Support (2)

19 K1088K Horizontal Seal Strip (2)

20 K1089K Vertical Seal Strip (2)

21 S6037X Door Gasket

22 E1186K Bottom Apron

23 E1183K Front Column Assy.

24 S3030X Door Latch Assy.

25 P1128X Pilot Light (Green)

26 M1326X Rotary Switch

27 Q1705A Screw, 4x6mm (2)

28 P1127X Pilot Light (Amber)

29 Q1406A Screw, SL HD #10x1/2 (2)

30 M0110A Thermostat, G6, FAST (Domestic)

M1553A

31 M1049X Push Button Switch (Light)

32 M1346A Timer, 60 Minutes (208/240VAC)

33 S1311X Knob (3)

34 S1171A Plug Button, 7/16

35 M1352A Circuit Breaker

36 E1195K Control Panel (GC-20)

37 U1284A Overlay (Rotary Controls)

38 Q1406A Screw, TR HD #10x1/2 (4)

39 U1044A Bakers Pride, Name Plate, 8"

40 U1192A Caution Hot, Label, Bi-Lingual

41 U1299A Rating Plate, Bi-Lingual

42 U1205A Service Connection w/Neutral

Thermostat, E6, FAST (CE)

43 U1206A Service Connection

44 U1169A Motor Rotation Arrow, Label

45 S1195X Blower Wheel

46 Q2318A Bolt, Wheel Puller 3/8-16x1 1/2 Hx (1)

47 E1026K Baffle Plate

48 Q2009A Thumb Screw, 1/4-20x1/2 (4)

49 E3095T Baffle Plate Bracket Assy (4)

50 Q1414A Screw, HX HD #10x3/4 (8)

51 K1100X Element Bracket, Bent (3)

52 K1375E Element Bracket, Flat (3)

53 Q1407A Screw HX HD #10x1/2 (6)

54 L1079X Element, Rear 208V 3KW

55 L1080X Element, Center 208V 3KW

56 L1081X Element, Front 208V 3KW

57 L1082X Element, Front 230V 3KW

58 L1083X Element, Center 230V 3KW

59 L1084X Element, Rear 230V 3KW

60 Q3017A Star Washer #10

61 Q1402A Nut 10-32 (12)

62 S1062X Terminal Cap (6)

63 Q1408X Nut 10-24 (6)

64 Q1436A Bolt, Hx Hd 10-32x5/8

65 S1153X Knob

66 Q1206A Screw, 8-32 x 3/8 RD HD

67 E1253A

68 U1428A

69

M1049X Push Button Switch (Steam)

U1296A

70

E1051X

71

Control Panel

Overlay

Timer Overlay (50 cycle only)

Door Assy, No Window (Option)

Optional Steam Injection (Not Shown)

N/S M1114X Solonoid Valve

N/S M1115X Coil (For Solonoid Valve)

N/S N1019X Steam Injection Nozzle

N/S N3039A 1/8 Brass Coupling

N/S N3040A 1/8 Brass Elbow

N/S N3041A 1/8NPT-1/4 Compression Fitting

N/S N5814A 1/8x2 3/8 Nipple

N/S N5815A 1/4 Tubing x 9"

N/S M1231A Steam Timer, 208/230V

N/S M1176X Steam Potentiometer

Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. U6004A 8/07 Page 3 of 4

18

COC-E

Half Size Electric Convection Oven

30 Pine Street • New Rochelle • New York • 10801

914 / 576 - 0200

914 / 576 - 0605

1 - 800 - 431 - 2745

www.bakerspride.com

fax

US & Canada

web address

BAKERS

PRIDE

Figure B

9

18

10

Door Latch / Electrical Components

22

21

32

20

33

3

28

25

11

12

24

19

5

4

13

17

14

16

15

34

26

31

30

29

8

7

1

27

6

24

ar

eR

2

23

Item Part # Description

1 U1210A Installation Warning, Label 18 K1087E Spring Bracket

2 U1120A Element Terminal, Plate 19 Q3017A Star Washer #10

3 M1555A RTD Temperature Probe 20 M1030X Contactor, 208/240V

4 Q4021X Clip 3/16 Closed, Temp Sensor (2) 21 Q1210A Screw, Pan Hd, 8-32x1/2 (4)

5 Q1406A Screw, #10x1/2 (2) 22 E3210U Contactor Bracket

6 M1217X Motor, 1/4HP, 2 Spd, 200-230V, 50-60 23 E1018K Terminal Box

7 Q3014A Lockwasher, Split 5/16 (4) 24 Q1407A Bolt, Hx Hd, #10x1/2 (2)

8 Q2204A Nut, HX, 5/16-18 (4) 25 E1176K Cable Support

9 S3005X Spring, 2 1/2x5/16 26 P1018A Bushing, Snap, 7/8 (2)

10 M1102X Micro-Switch (Rotary) 27 P1084A Bushing, Anti-Short, 3/8 (2)

11 M1172X Micro-Switch (Minichef) 28 P1045A Bushing, Snap, 2"

12 M1173X Actuator 29 P1082A Conduit, BX Flex, 3/8x24"

13 P1003X Terminal Block, 3 Pole 30 P1017A Conduit Connector, 3/8x1/2-Straight

14 Q1205A Screw, Rd Hd, 8-32x1 1/4 (2) 31 P1079A Wire Nut (3)

15 P1004X Terminal Block, 4 Pole 32 P1126X Lighting Assy (W/Bulb & Lens)

16 M1335X Audio Alarm 33 P1122A Light Bulb (40W, 240V)

17 E1199U Control Bracket Assy. 34 P1124X Lens, Lighting Assy

Page 4 of 4 Note: When ordering, ALWAYS specify Part #, Model #, Serial # and Voltage/Phase. U6004A 8/07

Item Part # Description

19

7. BAKERS PRIDE LIMITED WARRANTY

914 / 576 - 0200 ♦ US & Canada: 1 - 800 - 431 - 2745 ♦ fax 914 / 576 - 0605

30 Pine Street New Rochelle, New York 10801

WHAT IS COVERED This warranty covers defects in material and workmanship under normal use, and applies only to the original purchaser

WHO IS COVERED This warranty is extended to the original purchaser and applies only to equipment purchased for use in the U.S.A.

COVERAGE PERIOD Full size gas and electric deck ovens: Two (2) year limited parts and labor: Cyclone Convection Ovens: BCO Models: One (1)

WARRANTY This warranty covers on-site labor, parts and reasonable travel time and travel expenses of the authorized service

COVERAGE representative up to (100) miles. round trip, and (2) hours travel time. The purchaser. however, shall be responsible for all

EXCEPTIONS All removable parts in BAKERS PRIDE Char-broilers, including but not limited to: Burners, Grates. Radiants, Stones and

EXCLUSIONS

♦ Negligence or acts of God,

♦ Thermostat calibrations after (30) days from equipment

installation date,

♦ Air and Gas adjustments,

♦ Light bulbs,

♦ Glass doors and door adjustments.

♦ Fuses,

♦ Char-broiler work decks and cutting boards,

♦ Tightening of conveyor chains,

♦ Adjustments to burner flames and cleaning of pilot burners,

♦ Tightening of screws or fasteners.

providing that:

♦ The equipment has not been accidentally or intentionally damaged, altered or misused;

♦ The equipment is properly installed, adjusted, operated and maintained in accordance with National and local codes. and

in accordance with the installation instruction provided with the product;

♦ The serial number rating plate affixed to the equipment has not been defaced or removed.

Year limited parts and labor; GDCO Models: Two (2) Year limited parts and labor; CO II Models: Two (2) Year limited parts

and labor; (5) Year limited door warranty.

All Other Products: One (1) Year limited parts and labor.

Warranty period begins the date of dealer invoice to customer or ninety (90) days after shipment date from BAKERS PRIDE whichever comes first.

expenses related to travel, including time. mileage and shipping expenses on smaller counter models that may be carried into

a Factory Authorized Service Center, including the following models: PX-14. PX-16, PI8, and BK-I8.

Valves, are covered for a period of SIX MONTHS.

All Ceramic Baking Decks are covered for a period of THREE MONTHS. The installation of these replacement decks is the

responsibility of the purchaser.

The extended Cyclone door warranty years 3 through 5 is a parts only warranty and does not include labor, travel, milage or

any other charges.

♦ Failures caused by erratic voltages or gas supplies,

♦ Unauthorized repair by anyone other than a BAKERS PRIDE

Factory Authorized Service Center,

♦ Damage in shipment,

♦ Alteration, misuse or improper installation,

♦ Thermostats and safety valves with broken capillary tubes.

♦ Accessories - spatulas, forks. steak turners, grate lifters,

oven brushes, scrapers, peels. etc.,

♦ Freight - other than normal UPS charges,

♦ Ordinary wear and tear.

INSTALLATION Leveling and installation of decks. as well as proper installation and check out of all new equipment - per appropriate

REPLACEMENT BAKERS PRIDE genuine Factory OEM parts receive a (90) day materials warranty effective from the date of installation by a

PARTS BAKERS PRIDE Factory Authorized Service Center.

This Warranty is in lieu of all other warranties, expressed or implied, and all other obligations or liabilities on the manufacturers part. BAKERS PRIDE

shall in no event be liable for any special, indirect or consequential damages, or in any event for damages in excess of the purchase price of the unit. The

repair or replacement of proven defective parts shall constitute a fulfillment of all obligations under the terms of this warranty.

installation and use materials - is the responsibility of the dealer or installer, not the manufacturer.

Form #U4177A 1/07

20

Loading...

Loading...