Bakbar GT60HPO Installation Manual

INSTALLATION AND OPERATION MANUAL

'VEE-RAY' GAS FRYERS

GT60HPO

229280-13

MANUFACTURED BY

Moffat Limited

Rolleston 7675

New Zealand

INTERNATIONAL CONTACTS

AUSTRALIA

Moffat Pty Limited

E.Mail: vsales@moffat.com.au

Main Office: (tel): +61 (03) 9518 3888

(fax): +61 (03 9518 3838

Service: (tel): 1800 622 216

Spares: (tel): 1800 337 963

Customer Service: (tel): 1800 335 315

(fax): 1800 350 281

CANADA

Serve Canada

Web: www.servecanada.com

E.Mail: info@servecanada.com

Sales: (tel): 800 551 8795 (Toll Free)

Service: (tel): 800 263 1455 (Toll Free)

NEW ZEALAND

Moffat Limited

Web: www.moffat.co.nz

E.Mail: sales@moffat.co.nz

Main Office: (tel): 0800 663328

UNITED KINGDOM

Blue Seal

Web: www.blue-seal.co.uk

E.Mail: sales@blue-seal.co.uk

Sales: (tel): +44 121 327 5575

(fax): +44 121 327 9711

Spares: (tel): +44 121 322 6640

(fax): +44 121 327 9201

Service: (tel): +44 121 322 6644

(fax): +44 121 327 6257

UNITED STATES

Moffat

Web: www.moffat.com

Sales: (tel): 800 551 8795 (Toll Free)

(tel): +1 336 661 1556

(fax): +1 336 661 9546

Service: (tel): 800 858 4477 (Toll Free)

(tel): +1 366 661 1556

(fax): +1 336 661 1660

REST OF WORLD

Moffat Limited

Web: www.moffat.co.nz

E.Mail: export@moffat.co.nz

The reproduction or copying of any part of this manual by any means whatsoever is strictly forbidden unless authorized previously

in writing by the manufacturer.

In line with policy to continually develop and improve its products, Moffat Ltd. reserves the right to change the specifications and

design without prior notice.

© Copyright Moffat Ltd. December 2014.

Contents List

GT60HPO 'VEE-RAY' GAS FRYER (Single Tank - 31ltr)

Introduction ............................................................................................. 2

Specifications ........................................................................................... 3

Model Numbers Covered in this Specification

Gas Supply Requirements

Electrical Supply Requirements

Dimensions ............................................................................................... 4

Installation ............................................................................................... 5

Installation Requirements

Unpacking

Location

Clearances

Assembly

Electrical Connection

Gas Connection

Commissioning

Operation .................................................................................................. 9

Operation Guide

Description of Controls

Filling the Tank

Lighting the Main Burners

Setting the Operating Temperature

Turning ‘OFF’ the Fryer

Cleaning and Maintenance ..................................................................... 12

General

Draining and Daily Cleaning

Weekly Cleaning

Periodic Maintenance

Fault Finding ........................................................................................... 15

Guide to Cooking Problems with Fryer

Fault Finding the Gas System - Fault Finding Table

Circuit Wiring Schematic ........................................................................ 18

Gas Conversion and Specifications ........................................................ 19

Conversion Procedure

Gas Specifications

Replacement Parts List .......................................................................... 22

Introduction

We are confident that you will be delighted with your BLUE SEAL HPO Fryer, and it will become a most

valued appliance in your commercial kitchen.

To ensure you receive the utmost benefit from your new BLUE SEAL Appliance, there are two important

things you can do.

Firstly:

Please read the instruction book carefully and follow directions given. The time taken will be well spent.

Secondly:

If you are unsure of any aspect of the installation instructions or performance of your appliance,

contact your BLUE SEAL dealer promptly. In many cases a phone call could answer your questi on.

Warning

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS APPLIANCE.

INSTRUCTIONS

LOCATION. THIS INFORMATION SHALL BE OBTAINED BY CONSULTING THE LOCAL GAS SUPPLIER.

TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS ARE TO BE POSTED IN A PROMINENT

Warning

Warning

THE OPERATOR MUST TAKE GREAT CARE TO USE THE EQUIPMENT SAFELY TO GUARD AGAINST RISK OF FIRE AND

INJURY.

HE APPLIANCE MUST NOT BE LEFT ON UNATTENDED.

T

T IS RECOMMENDED THAT A REGULAR INSPECTION IS MADE BY A COMPETENT SERVICE PERSON TO ENSURE

I

CORRECT AND SAFE OPERATION OF YOUR APPLIANCE IS MAINTAINED.

DO NOT

OR ANY OTHER APPLIANCE.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPOURS OR LIQUIDS IN THE VICINITY OF THIS

This appliance is for professional use and is only to be used by qualified

persons.

Only authorised service persons are to carry out installation, servicing or gas

conversion operations.

Components having adjustments protected (e.g. paint sealed) by the

manufacturer should not be adjusted by the user / operator.

DO NOT operate the appliance without the legs supplied fitted.

Caution

2

Model Numbers Covered in this Specification

Specifications

GT60HPO 'VEE-RAY' GAS FRYER (Single Tank - 31 ltr).

Gas Supply Requirements

- Australia:

Input Rating (N.H.G.C.) 140 MJ/hr 140 MJ/hr

Supply Pressure 1.13 - 3.40 kPa 2.75 - 3.40 kPa

Burner Operating Pressure (*) 0.87 kPa (*) 2.55 kPa (*)

Gas Connection ¾” BSP Male

Natural Gas LP Gas (Propane)

New Zealand:

Input Rating (N.H.G.C.) 140 MJ/hr 140 MJ/hr

Supply Pressure 1.13 - 3.40 kPa 2.75 - 3.40 kPa

Burner Operating Pressure (*) 0.87 kPa (*) 2.55 kPa (*)

Gas Connection ¾” BSP Male

Natural Gas LP Gas

- All Other Markets:

Input Rating (N.H.G.C.) 140 MJ/hr 140 MJ/hr

Supply Pressure 1.13 - 3.40 kPa 2.75 - 3.40 kPa

Burner Operating Pressure 0.87 kPa (*) 2.55 kPa (*)

Gas Connection ¾” BSP Male

Natural Gas LP Gas (Propane)

Butane

140 MJ/hr

2.75 - 3.40 kPa

2.30 kPa (*)

NOTE:

(*) Measure burner operating pressure at Operating Pressure Test Point (Lower - Out)

on gas control valve with both burners operating at the 'High Flame' setting. Refer

to 'Gas Conversion and Specification' Section for further details.

NAT, LPG & Butane Only - Operating pressure is ex-factory set and is not to be

adjusted, unless when converting between gases, if required.

Refer to the information in this section for further details.

Electrical Supply Requirements

GT60HPO - 220-240 V a.c, 50 Hz, 0.5 A, 1P+N+E.

3 pin 10 A cord set fitted.

3

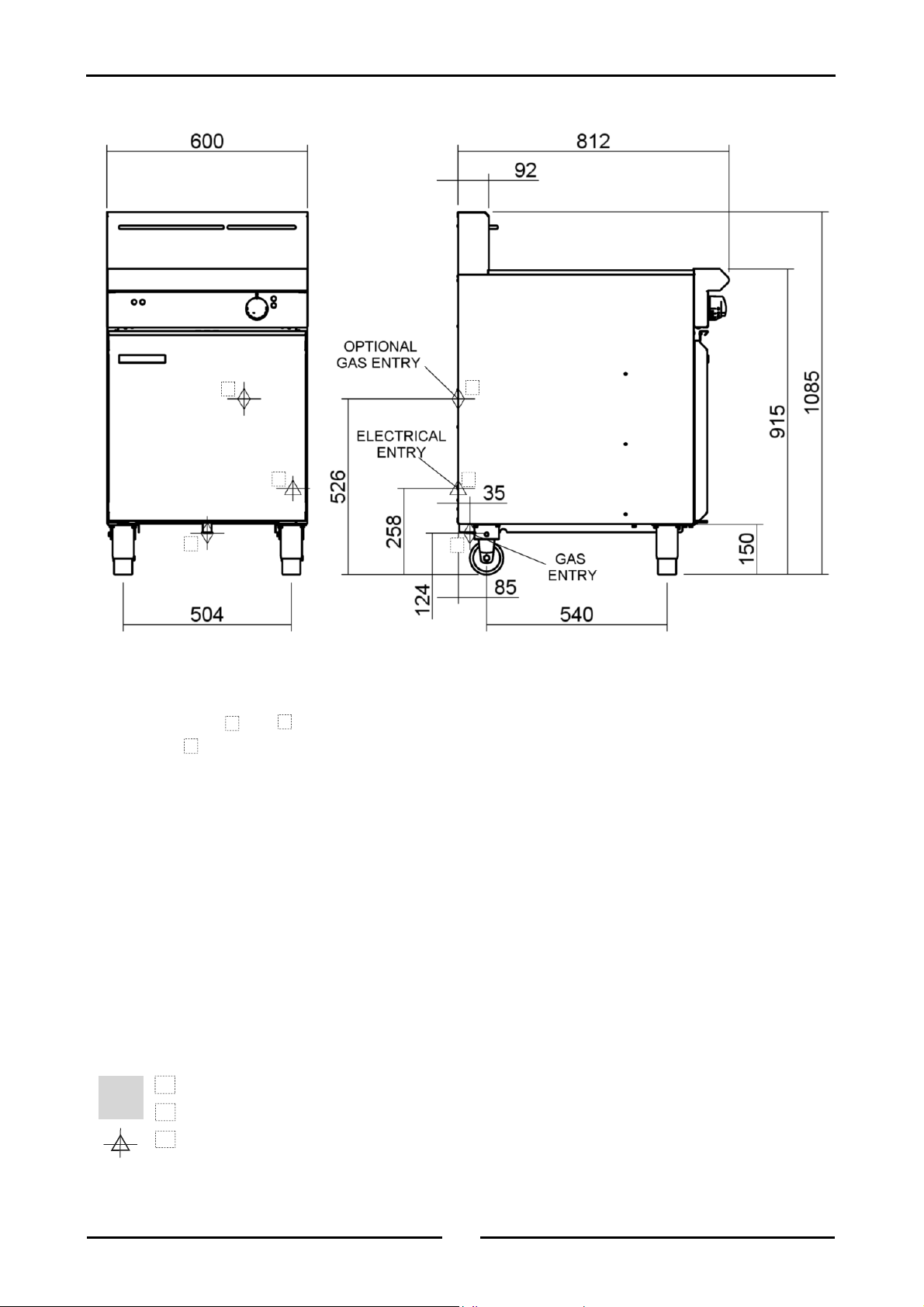

Dimensions

Dimensions: GT60HPO

2

3

1

2

1

3

2

3

1

1. Primary Gas Entry Point.

2. Optional Gas Entry Point.

3. Electrical Entry Point.

4

Installation

Installation Requirements

NOTE:

It is most important that this appliance is installed correctly and that operation is

correct before use. Installation shall comply with local gas, electrical and health and

safety requirements.

This appliance shall be installed with sufficient ventilation to prevent the occurrence

of unacceptable concentrations of health harmful substances in the room, the

Blue Seal 'Vee-Ray' HPO Fryers are designed to provide years of satisfactory service and correct installation

is essential to achieve the best performance, efficiency and trouble-free operation.

This appliance must be installed in accordance with National installation codes and in addition, in

accordance with relevant National / Local codes covering gas, electrical, fire and health and safety.

Installations must be carried out by authorised persons only. Failure to install equipment to

relevant codes and manufacturers specifications shown in this section will void the warranty.

Components having adjustments protected (e.g. paint sealed) by manufacturer are only to be

adjusted by an authorised service agent. They are not to be adjusted by the installation

person.

Unpacking

appliance is installed in.

Australia / New Zealand: - AS5601.1 - Gas Installations.

Australia / New Zealand: - AS / NZS3000 - Wiring Rules.

Remove all packaging and transit protection from appliance, including all protective plastic coating

from door, outer panel and exterior stainless steel panels.

Check equipment and parts for damage. Report any damage immediately to carrier and distributor.

Report any deficiencies to distributor who supplied the appliance.

Check available gas supply is correct to as shown on rating plate located behind access door.

Check the following parts have been supplied with the appliance:-

GT60HPO

Baskets 2

Basket Grids 1

Flue Diverter 1

Fryer Lid 1

Drain Extension 1

Drain Stick 1

Location

1. This appliance must be installed in a suitably ventilated room to prevent dangerous build up of

combustion products.

2. Installation must allow for a sufficient flow of fresh air for combustion air supply. Combustion air

requirements:-

Combustion Air Requirements

All Gas Types 24 m³/hr minimum.

3. Never directly connect a ventilation system to the appliance flue outlet.

4. A minimum of 610mm clearance must be maintained from flue outlet to any above surface.

5. Position appliance in its approximate working position.

6. All air for burner combustion is supplied from beneath the unit. Legs must always be fitted and no

obstructions placed under or around the base of the fryer, as obstructions will cause incorrect

operation and / or failure of the fryer.

NOTE: Do not obstruct or block the appliance flue. Never directly connect a ventilation

system to the appliance flue outlet.

5

Installation

Clearances

NOTE:

Only non-combustible materials can be used in close proximity to this appliance.

To allow easy operation, drainage and servicing of the appliance, a minimum of

600mm clearance should be maintained at front of the appliance.

Any gas burning appliance requires adequate clearance and ventilation for optimum and trouble-free

operation. The following minimum installation clearances are to be adhered to:

Combustible Surface Non Combustible Surface

Left / Right Hand Side 50mm 0mm

Rear 50mm 0mm

Assembly

This model is delivered completely assembled. Ensure that the legs are securely attached.

NOTE:

This appliance is fitted with adjustable feet so that it can be positioned securely and

level. This should be carried out on completion of gas connection. Refer to 'Gas

Connection' section.

Optional Accessories (Refer to Replacement Parts List)

Plinth Kit. For installation details, refer to instructions supplied with each kit.

Electrical Connection

NOTE: ALL ELECTRICAL CONNECTIONS MUST ONLY BE CARRIED OUT BY AN AUTHORISED

PERSON.

Each fryer should be connected to an adequately protected power supply and an isolation switch mounted

adjacent to, but not behind the fryer. This switch must be clearly marked and readily accessible in case of

fire.

NOTE:

This appliance must be grounded / earthed.

6

Loading...

Loading...