Bakbar GT45 Installation Manual

INSTALLATION AND OPERATION MANUAL

'VEE-RAY' GAS FRYERS

GT45

GT46

GT60

For use in GB & IE

228574-8

MANUFACTURED BY

Moffat Limited

PO Box 10001

Christchurch

New Zealand

Ph: (03) 389 1007

Fax: (03) 389 1276

WORLD-WIDE BRANCHES

UNITED KINGDOM

Blue Seal

67 Gravelly Business Park

Gravelly Park

Birmingham

West Midlands

B24 8TQ

Ph: (121) 327 5575

Fax: (121) 327 9711

UNITED STATES

Moffat Inc

3765 Champion Blvd

Winston-Salem

North Carolina 27115

Ph: (336) 661 0257

Fax: (336) 661 9546

CANADA

Serve Canada

22 Ashwarren Road

Downview

Ontario M3J1Z5

Toll Free:800 263 1455

Ph: (416) 631 0601

Fax: (416) 631 0315

info@servecanada.com

www.servecanada.com

www.moffat.com

NEW ZEALAND

Christchurch

Moffat Limited Moffat Limited

PO Box 10-001 4 Waipuna Road

16 Osborne Street Mt Wellington

Christchurch Auckland

Ph: (03) 389 1007 Ph: (09) 574 3150

Fax: (03) 389 1276 Fax: (09) 574 3159

AUSTRALIA

Victoria

Moffat Pty Limited Moffat Pty Limited

740 Springvale Road 3/142 James Ruse Drive, Rose Hill

Mulgrave, Melbourne PO Box 913, Smithfield

Victoria 3171 Sydney, N.S.W. 2142

Ph: (03) 9518 3888 Ph: (02) 8833 4111

Fax: (03) 9518 3838 Fax: (02) 8833 4133

Western Australia

Moffat Pty Limited Moffat Pty Limited

67 Howe Street 30 Prosperity Place

Osbourne Park Geebung, Brisbane

WA 6017 Queensland 4034

Ph: (08) 9202 6820 Ph: (07) 3630 8600

Fax: (08) 9202 6836 Fax (07) 3630 8623

Auckland

New South Wales

Queensland

The reproduction or copying of any part of this manual by any means whatsoever is strictly forbid den unle ss author ized p reviously

in writing by the manufacturer.

In line with policy to continually develop and improve its products, Moffat Ltd. reserves the right to change the specifications and

design without prior notice.

© Copyright Moffat Ltd. November 2008.

Contents

GT45 ‘FAST FRI’ GAS FRYER (Single Tank - 20Ltr)

GT46 ‘FAST FRI’ GAS FRYER (Twin Tank - 26Ltr)

GT60 ‘FAST FRI’ GAS FRYER (Single Tank - 31Ltr)

Introduction ............................................................................................. 2

Specifications ........................................................................................... 3

Model Numbers Covered in this Specification

General

Optional Accessories

Gas Connection

Gas Supply Requirements

Dimensions ............................................................................................... 5

Installation ............................................................................................... 7

Installation Requirements

Unpacking

Location

Clearances

Assembly

Gas Connection

Commissioning

Operation................................................................................................ 11

Operation Guide

Description of Controls

Before Use

Filling the Tank(s)

Lighting the Pilot Burners

Lighting the Main Burners

Turning ‘OFF’ the Fryer

Setting the Operating Temperature

Frying Guide and Care of Frying Oils and Fats

Frying Temperature Guide and Care of Frying Medium

Cleaning and Maintenanc e ..................................................................... 18

General

Draining and Cleaning

Daily Cleaning

Weekly Cleaning

Periodic Maintenance

Fault Finding........................................................................................... 20

Guide to Cooking Problems with the Fryer

Fault Finding the Gas System

Wiring Schematics.................................................................................. 25

Gas Conversion and Specifications......................................................... 27

Conversion Procedure

Gas Specifications

Replacement Parts List........................................................................... 31

1

Introduction

We are confident that you will be delighted with your BLUE SEAL Fryers, and it will become a most valued

appliance in your commercial kitchen.

To ensure you receive the utmost benefit from your new BLUE SEAL Appliance, there are two important

things you can do.

Firstly:

Please read the instruction book carefully and follow the directions given. The time taken will be well

spent.

Secondly:

If you are unsure of any aspect of the installation, instructions or performance of your appliance,

contact your BLUE SEAL dealer promptly. In many cases a phone call could answer your question.

CE Only:

These instructions are only valid if the country code appears on the appliance. If the code does not

appear on the appliance, refer to the supplier of this appliance to obtain the technical instructions for

adapting the appliance to the conditions for use in that country.

WARNING:

MPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

I

DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS APPLIANCE.

WARNING:

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS ARE TO BE POSTED IN A PROMINENT

LOCATION. THIS INFORMATION SHALL BE OBTAINED BY CONSULTING THE LOCAL GAS SUPPLIER.

WARNING:

REAT CARE MUST BE TAKEN BY THE OPERATOR TO USE THE EQUIPMENT SAFELY TO GUARD IT AGAINST

G

RISK OF FIRE.

• T

• I

• DO NOT

•

HE APPLIANCE MUST NOT BE LEFT ON UNATTENDED.

T IS RECOMMENDED THAT A REGULAR INSPECTION IS MADE BY A COMPETENT SERVICEMAN TO ENSURE

CORRECT AND SAFE OPERATION OF YOUR APPLIANCE IS MAINTAINED.

STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPOURS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

C

AUTION

:

This appliance is;

•

For professional use and is to be used by qualified persons only.

•

Only authorised service persons are to carry out installation, servicing and

gas conversion operations.

•

Components having adjustments protected (e.g. paint sealed) by the

manufacturer should not be adjusted by the user / operator.

•

DO NOT operate the appliance without the legs supplied fitted.

2

2

Model Numbers Covered in this Specification

Specifications

GT45 ‘FAST FRI’ GAS FRYER (Single Tank - 20Ltr).

GT46 ‘FAST FRI’ GAS FRYER (Twin Tank - 13Ltr per Tank).

GT60 ‘FAST FRI’ GAS FRYER (Single Tank - 31Ltr).

General

A commercial heavy duty, gas fired Fryer having a fast fry infra red burner system which an intense

even heat through the tank.

It is available in 3 model types. All model types are fitted with dual main burners and pilot burners,

with the single tank models fitted with a single gas controller which controls both pilot and main

burners where the twin tank model is fitted with twin gas controllers which work independently for

each burner.

These Fryers feature an Over Temperature Safety Cut Out system with Full Flame Failure Safety

Controls.

State of the art gas controls with snap action thermostat sensitive to changes in oil temperature

which improves both recovery and output.

An open tank design for both single and twin tank units to make cleaning a simple and easy task.

Optional Accessories

This appliance can be fitted with the following optional accessories, (refer to the 'Replacement Parts

List' for details).

• Plinth Kit.

Gas Connection

- Inlet Location

For all Appliances other than UK models:

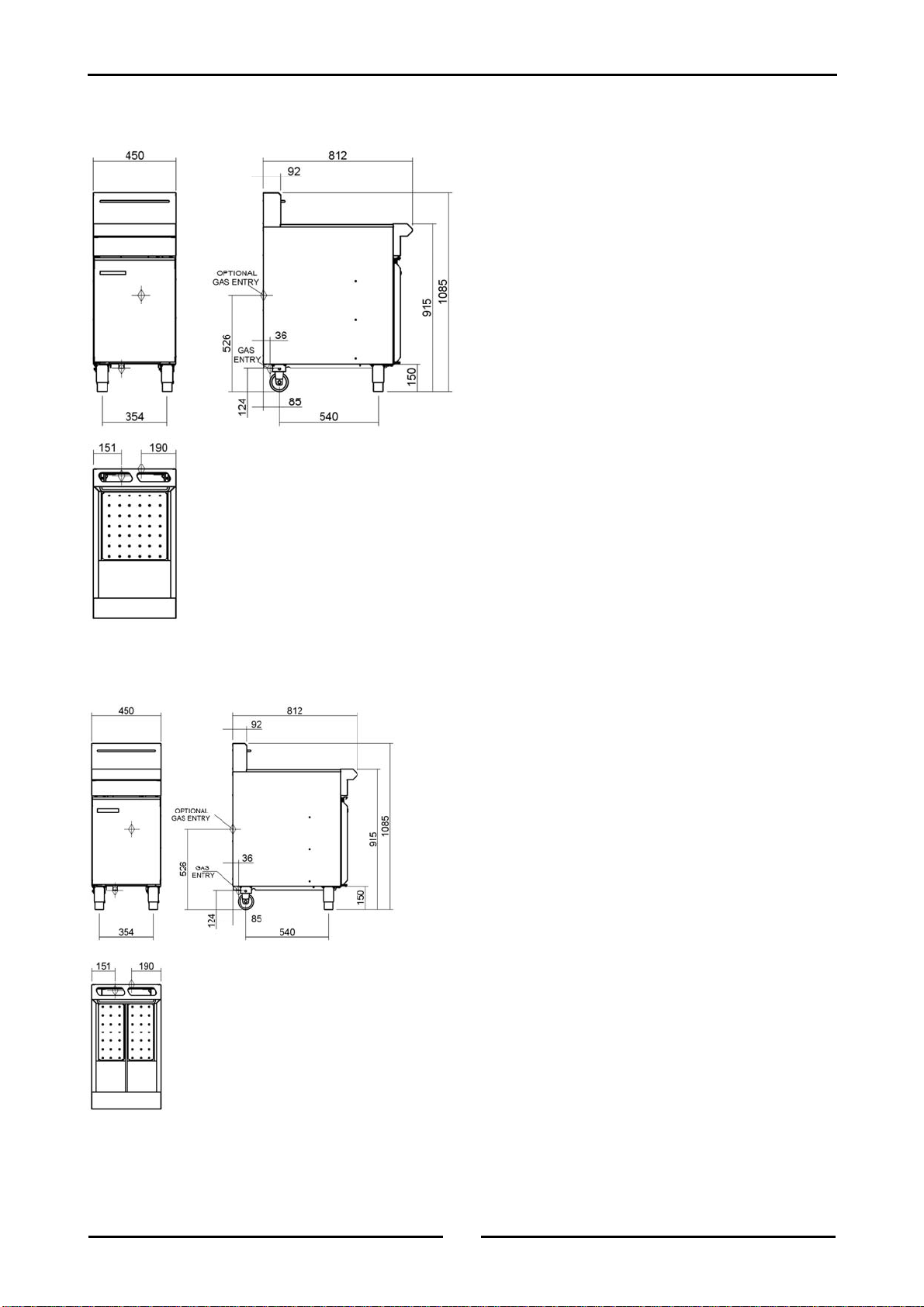

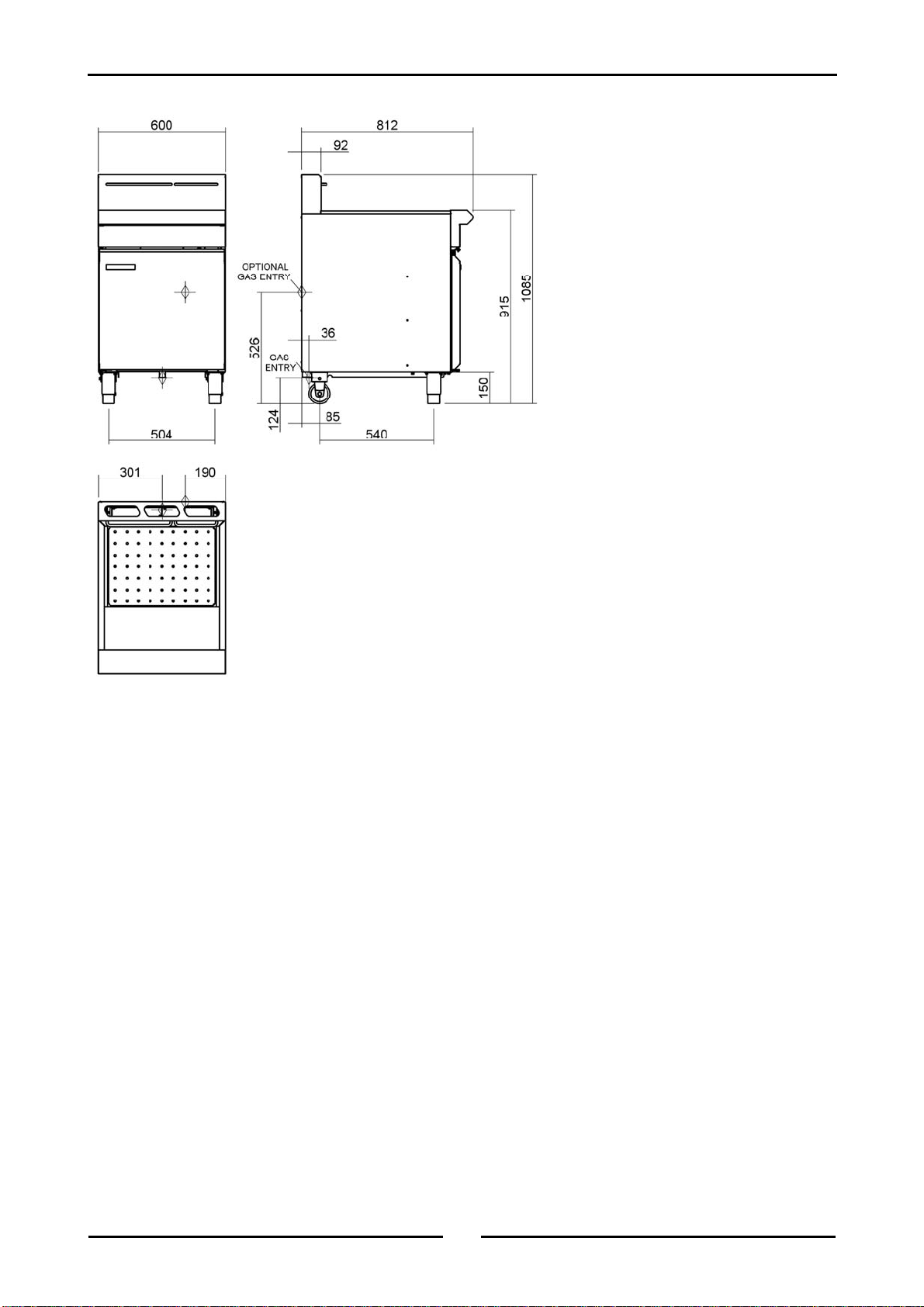

Gas supply connection point is located 151 mm from the left hand side, 36 mm from the rear and

124 mm from the floor and is entered from beneath the appliance. An optional rear entry connection is available.

For UK Appliances Only:

Gas supply connection point is located 190 mm from the right hand side and 526 mm from the floor

and is entered from the rear of the appliance. An optional lower entry connection is available.

3

For all Appliance Options, gas connection is

/4” BSP male.

- Flexible Hose Connection

If a Gas Hose assembly is used to connect this appliance, the hose and all fittings must have a

minimum

¾” (Natural Gas) or ½” (LPG) inside bore diameter to ensure gas flow rate capacity

required by this appliance is achieved.

This must be verified by the operating pressure testing at the maximum gas supply demand condition.

The Gas Hose assembly should also be classified for use in the commercial kitchen conditions, the

appliance will be used in.

Recommended Gas Hose Assembly Specification:

- AS/NZS 1869 Class B or D compliant or equivalent, that meets the following requirements:-

Class

Max Working Pressure

at 23 ± 2ºC

B 7.0 kPa

D 2.6 MPa

Working Temperature

Range

- 20ºC to + 125ºC

3

Resistance to Oil

Oil resistant

lining and cover.

Specifications

Gas Supply Requirements

- Australia / New Zealand:

Input Rating 90 MJ/hr 90 MJ/hr

(N.H.G.C.) (85,300 Btu/hr)

Supply Pressure

Burner Operating Pressure

Gas Connection ¾” BSP Male

- UK Only:

Heat Input (nett) 22.5 kW 22.5 kW

Gas Rate 1.75 kg/hr

Supply Pressure 20 mbar 37 mbar

Burner Operating Pressure 9.8 mbar (*) 25 mbar (*)

Gas Connection

NOTE:

(

) The burner operating pressure is to be measured at the lower test point (Out) on the gas

*

control valve located behind the access door and through the access hole in the control

panel, this is to be carried out with all burners operating at the 'High Flame'

setting. Refer to the ‘Gas Conversion and Specification’ Section for further details.

Natural Gas (G20) Propane (G31)

Natural Gas LP Gas (Propane)

(85,300 Btu/hr)

1.13 - 2.00 kPa 2.75 - 3.00 kPa

(4.5” - 8.0” w.c.) (11” - 12” w.c.)

0.98 kPa (*) 2.50 kPa (*)

(3.9” w.c.) (10.0” w.c.)

2.26 m3/hr

3

/4” BSP Male

4

Dimensions

GT45 ‘VEE - RAY’ GAS FRYER (Single Tank - 20Ltr)

GT46 'VEE - RAY' GAS FRYER (Twin Tank - 26Ltr)

5

Dimensions

GT60 ‘VEE - RAY’ GAS FRYER (Single Tank - 31.5Ltr)

6

Installation

Installation Requirements

NOTE:

• It is most important that this appliance is installed correctly and that operation is

correct before use. Installation shall comply with local, gas, health and safety

requirements.

• This appliance shall be installed with sufficient ventilation to prevent the occurrence

of unacceptable concentrations of health harmful substances in the room, the

appliance is installed in.

Blue Seal ‘FAST FRI’ gas fryers are designed to provide years of satisfactory se rvice and correct installation

is essential to achieve the best performance, efficiency and trouble-free operation.

This appliance must be installed in accordance with National installation codes and in addition, in

accordance with relevant National / Local codes covering gas and fire safety.

Australia: AS 5601 - Gas Installations.

New Zealand: NZS 5261 - Gas Installation.

United Kingdom: Gas Safety (Installation and Use) Regulations 1998.

Ireland: IS 820 - Non Domestic Gas Installations.

Installations must be carried out by qualified service persons only. Failure to install

equipment to the relevant codes and manufacturer’s specifications shown in this section will

void the warranty.

Components having adjustments protected (e.g. paint sealed) by manufacturer, are only

allowed to be adjusted by an authorised service agent. They are not to be adjusted by the

installation person.

Unpacking

• Remove all packaging and transit protection from the appliance including all protective plastic

coating from the door outer panel and exterior stainless steel pan els.

• Check equipment and parts for damage. Report any damage immediately to the carrier and

distributor.

• Report any deficiencies to the distributor who supplied the appliance.

• Check that the available gas supply is correct to that shown on the rating plate located on the inside

of the access door.

• Check that the following parts have been supplied with the appliance:

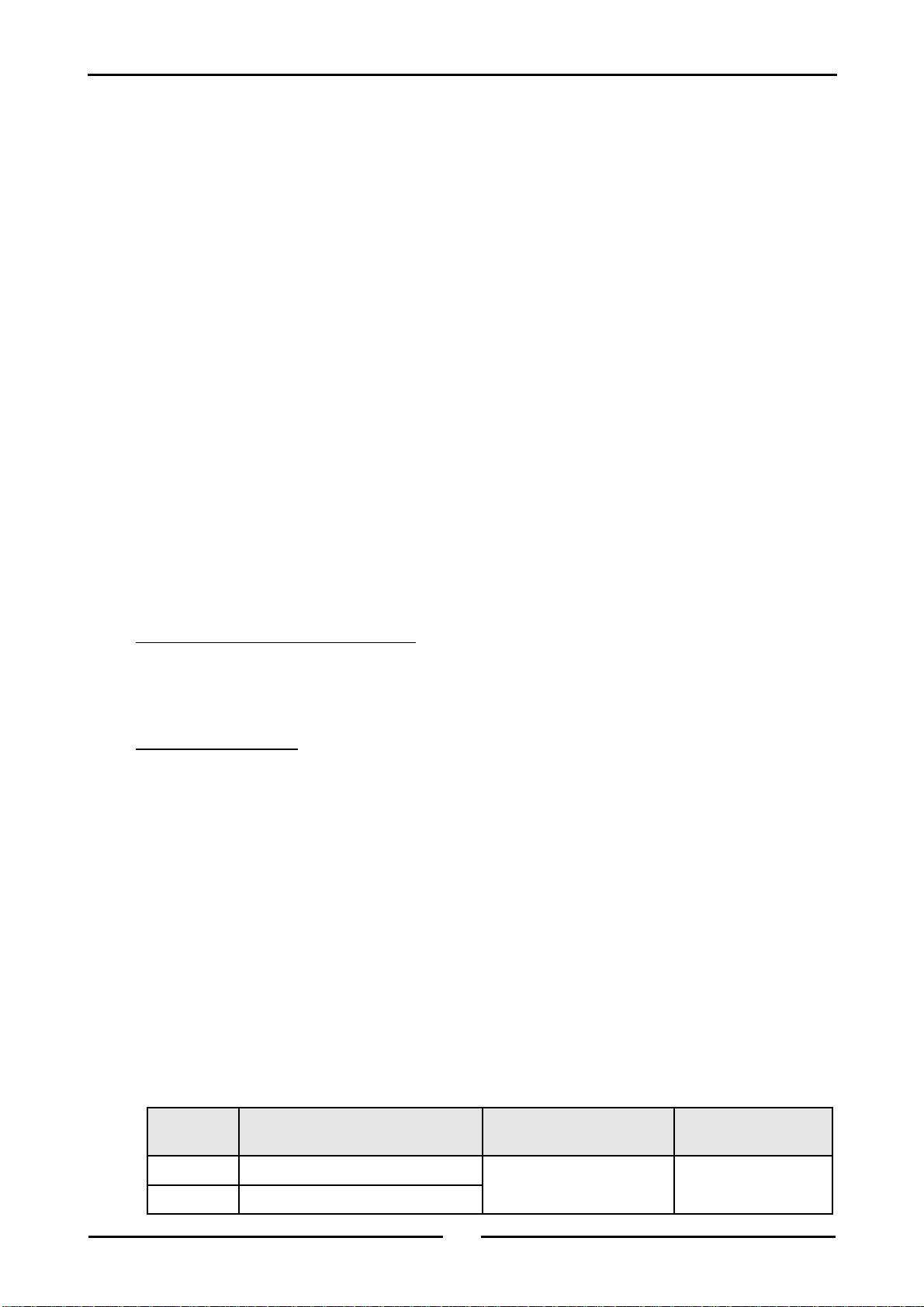

GT45 GT46 GT60

Baskets 2 2 3

Basket Trays 1 2 1

Lid 1 1 1

Drain Stick 1 1 1

Location

1. This appliance must be installed in a suitably ventilated room to prevent dangerous build up of

combustion products.

2. Installation must allow for a sufficient flow of fresh air for the combustion air supply.

Combustion Air Requirements

Natural Gas 24 m³/hr minimum.

LPG / Propane 24 m³/hr minimum.

3. Position the appliance in its approximate working position.

7

Installation

4. All air for burner combustion is supplied from underneath the appliance. The legs must always be

fitted and no obstructions placed on the underside or around the base of the appliance, as

obstructions will cause incorrect operation and / or failure of the appliance.

5. Components having adjustments protected (e.g. paint sealed) by manufacturer are only allowed to

be adjusted by an authorised service agent. They are not to be adjusted by the installation person.

NOTE: Do not obstruct or block the appliances flue. Never directly connect a ventilation system to

the appliance flue outlet.

Clearances

NOTE:

• Only non-combustible materials can be used in close proximity to this appliance.

• In order to facilitate easy operation, drainage and servicing of the appliance, a

minimum of 600 mm clearance should be maintained at the front of the appliance.

Any gas burning appliance requires adequate clearance and ventilation for optimum and trouble-free

operation. The following minimum installation clearances are to be adhered to:

Combustible Surface Non Combustible Surface

Left/Right hand side 50 mm 0 mm

Rear 50 mm 0 mm

Assembly

This model is delivered completely assembled. Ensure that the legs are securely attached.

NOTE:

• This appliance is fitted with adjustable feet to enable the appliance to be positioned

securely and level. This should be carried out on completion of the gas connection.

Refer to the 'Gas Connection' section below.

Optional Accessories (Refer to Replacement Parts List)

• Plinth Kit. For installation details, refer to the instructions supplied with each kit.

Gas Connection

NOTE: ALL GAS FITTING MUST ONLY BE CARRIED OUT BY A QUALIFIED SERVICE PERSON.

1. Blue Seal Fryers do not require an electrical connection, they function totally on the gas supply only.

2. It is essential that the gas supply is correct for the appliance to be installed and that adequate

supply pressure and volume are available. The following checks should therefore be made before

installation:-

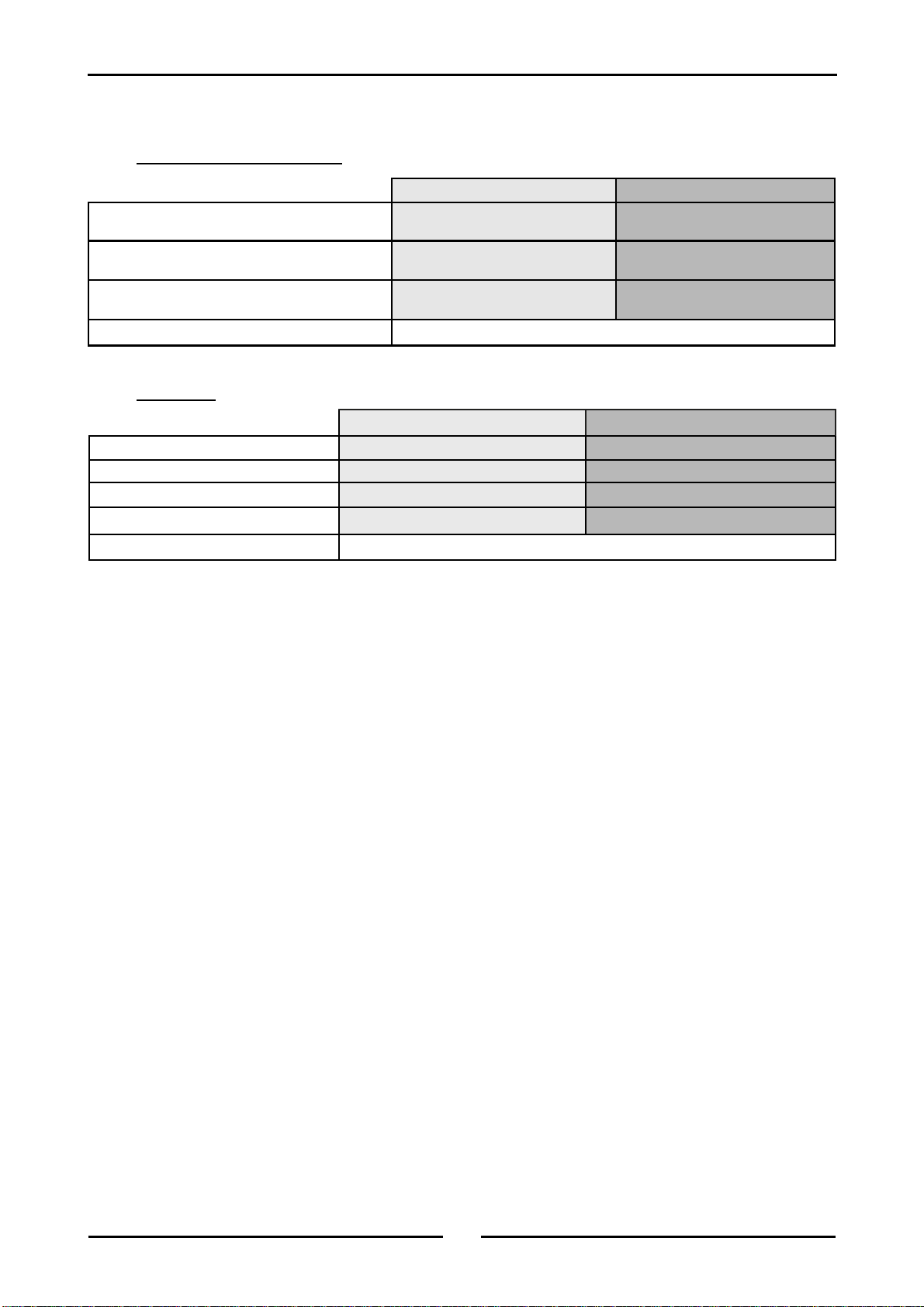

a. The Gas Type the appliance has been supplied for is shown on

coloured stickers located above the gas entry point and next to

the rating plate. Check that this is correct for the gas supply

the appliance is being installed for. The gas conversion

procedure is detailed in this manual.

b. Supply Pressure required for this appliance is shown in the

'Specifications' section of this manual. Check the gas supply to

Rating Plate

Location

ensure that adequate supply pressure exists.

c. Input Rate of this appliance is also stated on the Rating Plate

fitted to the inside of the access door and in the 'Specifications'

section of this manual. The input rate should be checked

against the available gas supply line capacity. Particular note

should be taken if the appliance is being added to an

Fig 1

existing installation.

8

Installation

NOTE: It is important that adequately sized piping runs directly to the connection joint on the

appliance, with as few tees and elbows as possible to give maximum supply volume.

3. A suitable joining compound which resists the breakdown action of LPG must be used on every gas

line connection, unless compression fittings are used.

3

The connection to the appliance is

/4” BSP male.

NOTE: A Manual Isolation Valve must be fitted to the individual appliance supply line.

4. Correctly locate the appliance into its final operating position and using a spirit level, adjust the legs

so that the unit is level and at the correct height.

5. Connect the gas supply to the appliance.

6. Check gas operating pressure to as shown in the 'Specifications' section. If the pressure is incorrect,

adjust the pressure by adjusting the regulator screw of the gas control valve as shown in the ‘Gas

Conversion and Specifications’ section.

7. Check all gas connections for leakages using soapy water or other gas detecting equipment.

WARNING:

DO NOT USE A NAKED FLAME TO CHECK FOR GAS LEAKAGES.

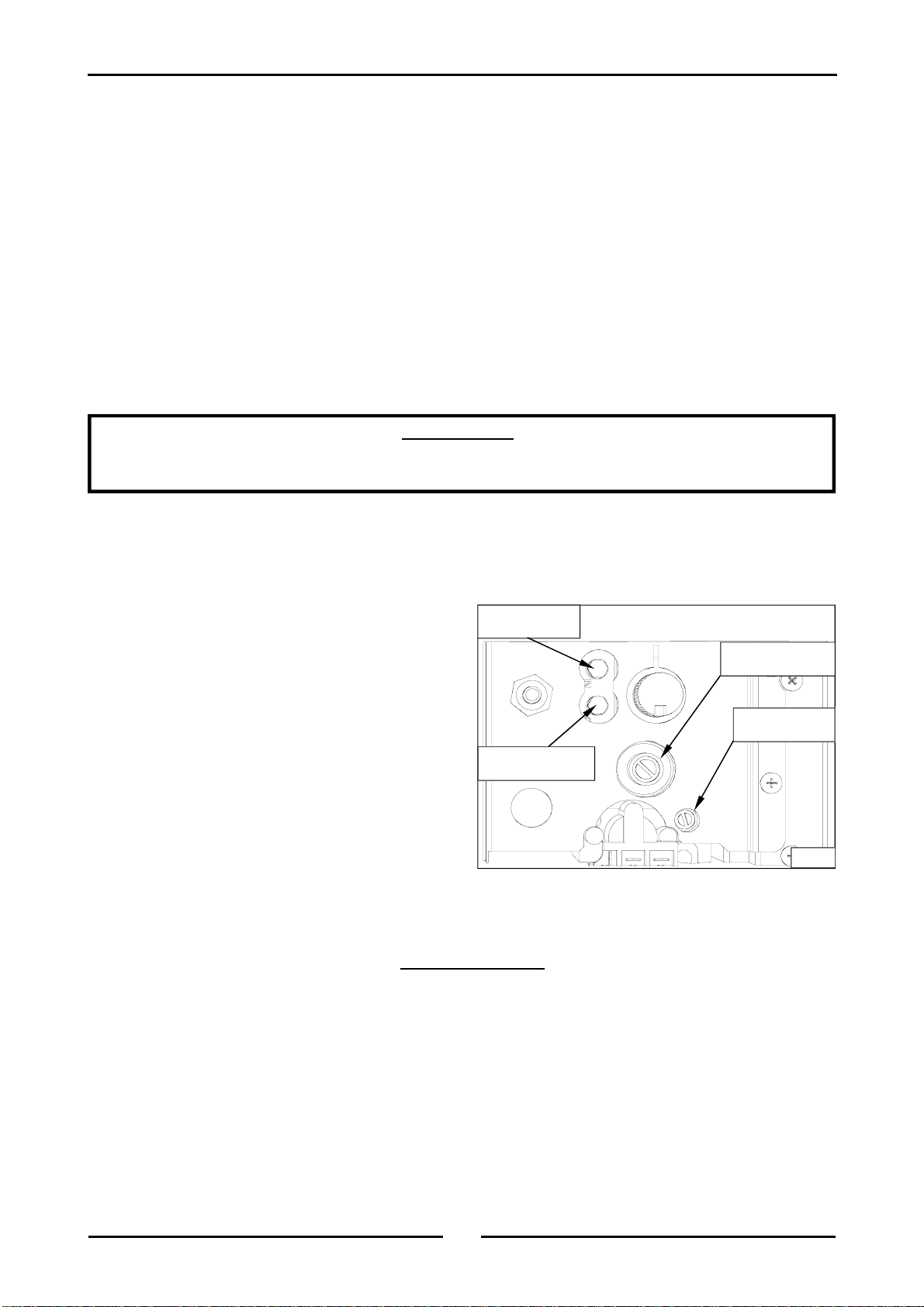

NOTE: The operating pressure is to be measured at the lower test point (Out) on the gas control

valve located behind the access door and through the access hole in the control panel, this

is to be carried out with all burners operating at the 'High Flame' setting.

8. Turn ‘OFF’ the mains gas supply and bleed the

gas out of the appliance gas lines.

9. Turn ‘ON’ the gas supply and the appliance.

10. Verify the operating pressure remains correct

Supply Pressure

Test Point

Operating Pressure

Adjusting Screw

(Re-adjust if required, using the operating

pressure adjusting screw as shown in the ‘Gas

Conversion and Specifications’ section).

11. Check the pilot flame size. (Re-adjust if

required, using the pilot adjusting screw as

Operating Pressure

Test Point

Pilot Burner

Adjusting Screw

shown in the ‘Gas Conversion and

Specifications’ section).

12. Turn ‘ON’ to ‘Full’ settings all other gas

appliances / equipment supplied from the

same gas supply line and verify the operating

Fig 2

pressure remains unaffected by the maximum

gas supply demand.

NOTE: Insufficient gas supply line capacity, indicated by the operating pressure drop during the

maximum gas supply demand, is NOT ACCEPTABLE

and may invalidate the manufacturers

warranty for this appliance.

9

Loading...

Loading...