Page 1

®

Process Control and

Automation Solutions

from Elsag Bailey Group

®

Plant Loop to Plant Loop Remote Interface

(INPPR01)

E96-624

Page 2

WARNING notices as used in this instruction apply to hazards or unsafe practices that could result in

personal injury or death.

CAUTION notices apply to hazards or unsafe practices that could result in property damage.

NOTES highlight procedures and contain information that assists the operator in understanding the

information contained in this instruction.

WARNING

INSTRUCTION MANUALS

DO NOT INSTALL, MAINTAIN, OR OPERATE THIS EQ UIPMENT WITHOUT READING, UNDERSTANDING,

AND FOLLOWING THE PROPER

DAMAGE MAY RESULT.

Elsag Bailey

INSTRUCTIONS AND MANUALS; OTHER WISE, INJURY OR

RADIO FREQUENCY INTERFERENCE

MOST ELECTRONIC EQUIPMENT IS INFLUENCED BY RAD IO FREQUENCY INTERFERENCE (RFI). CAUTION SHOULD BE EXERCISED WITH REGARD TO THE USE OF PORTABLE COMMUNICATIONS EQUIPMENT IN THE AREA AROUND SUCH EQUIPMENT. PRUDENT PRACTICE DICTATES THAT SIGNS

SHOULD BE POSTED IN THE VICINITY OF THE EQUIPMENT CAUTIONING AGAINST THE USE OF PORTABLE COMMUNICATIONS EQUIPMENT.

POSSIBLE PROCESS UPSETS

MAINTENANCE MUST BE PERFORMED ONLY BY QUALIFIE D PER SONNEL AN D ONLY AFTE R SEC URING

EQUIPMENT CONTROLLED BY THIS PRODUCT. ADJUSTING OR REMOVING THIS PRODUCT WHILE IT IS

IN THE SYSTEM MAY UPSET THE PROCESS BEING CONTROLLED. SOME PROCESS UPSETS MAY

CAUSE INJURY OR DAMAGE .

AVERTISSEMENT

MANUELS D’OPÉRATION

NE PAS METTRE EN PLACE, RÉPARER OU FAIRE FONCTIONNER L’ÉQUIPEMENT SANS AVOIR LU,

COMPRIS ET SUIVI LES INSTRUCTIONS RÉGLEMENTAIRES DE

CET ÉGARD POURRAIT ÊTRE UNE C AUSE D’ACC IDENT OU DE DÉFAILL ANCE DU MA TÉRIEL.

Elsag Bailey

. TOUTE NÉGLIGENCE À

PERTURBATIONS PAR FRÉQUENCE RADIO

LA PLUPART DES ÉQUIPEMENTS ÉLECTRONIQUES SONT SENSIBLES AUX PERTURBATIONS PAR

FRÉQUENCE RADIO. DES PRÉCAUTIONS DEVR ONT ÊTRE PRISES LORS DE L’UTILISATION DU MATÉRIEL DE COMMUNICATION PORTATIF. LA PRUDENCE EXIGE QUE LES PRÉCAUTIONS À PRENDRE

DANS CE CAS SOIENT SIGNALÉES AU X ENDROITS VO ULUS DANS VOTR E USINE.

PERTURBATIONS DU PROCÉDÉ

L’ENTRETIEN DOIT ÊTRE ASSURÉ PAR UNE PERSONNE QUALIFIÉE EN CONSIDÉRANT L’ASPECT

SÉCURITAIRE DES ÉQUIPEMENTS CONTRÔLÉS PAR CE PRODUIT. L’AJUSTEMENT ET/OU L’EXTRACTION DE CE PRODUIT PEUT OCCAS IONNER DES À-COUPS AU PROCÉD É CONTRÔLE LORSQU’IL EST

INSÉRÉ DANS UNE SYSTÈME ACTIF. CES À-COUPS PEUVENT ÉGALEMENT OCCASIONNER DES

BLESSURES OU DES DOMMAGES M ATÉREILS.

NOTICE

The information contained in this docume nt is s ubj ect to change wi thout noti ce.

Elsag Bailey, i ts af fili at es , em pl oye es , an d a gen ts, a n d th e a u thor s an d co ntr ib utors to this publ ica ti on specif-

ically disclaim all liabilities and warranties, express and implied (including warranties of merchantability and

fitness for a pa rt icu lar p urp os e) , fo r the ac cur a cy, cur r en cy, co mple t en ess, an d/ o r r eliability of t he i nfo r mati on

contained herein and/or for the fitness for any particular use and/or for the performance of any material and/

or equipment selected in whole or part with the user of/or in reliance upon information contained herein.

Selection of materials and/or equipment is at the sole risk of the user of this publication.

This document contains proprietary i nformation of Elsag Baile y, Elsag Bailey Proces s Automation, and

is issued in strict confidence. Its use, or reproduc tion for use, for the re verse engineering, de velopment

or manufacture of hardware or software described herein is prohibited . No part of this docume nt may be

photocopied or reproduced without the prior written c onse nt of El sag B aile y.

Page 3

Preface

The Plant Loop to Plant Loop Remote Interface (INPPR01)

enables communication between a local and remote Plant

Loop. The interface consists of three modules, the Plant Loop

to Plant Loop Transfer Module (INPPT01), the Bus Transfer

Module (INBTM01) and the Loop Interface Module (INLIM03).

Plant Loop to Plant Loop Remote Interfaces connect through

cable, modem or microwave link.

This instruction explains PPR features, specifications, and

operation. It also includes installation and troubleshooting

procedures for the interface.

The system engineer or technician using the INPPR01 should

read and understand this instruction before installing the

interface modules. In addition, a complete understanding of

the INFI 90 system is beneficial to the user.

I-E96-624A

Page 4

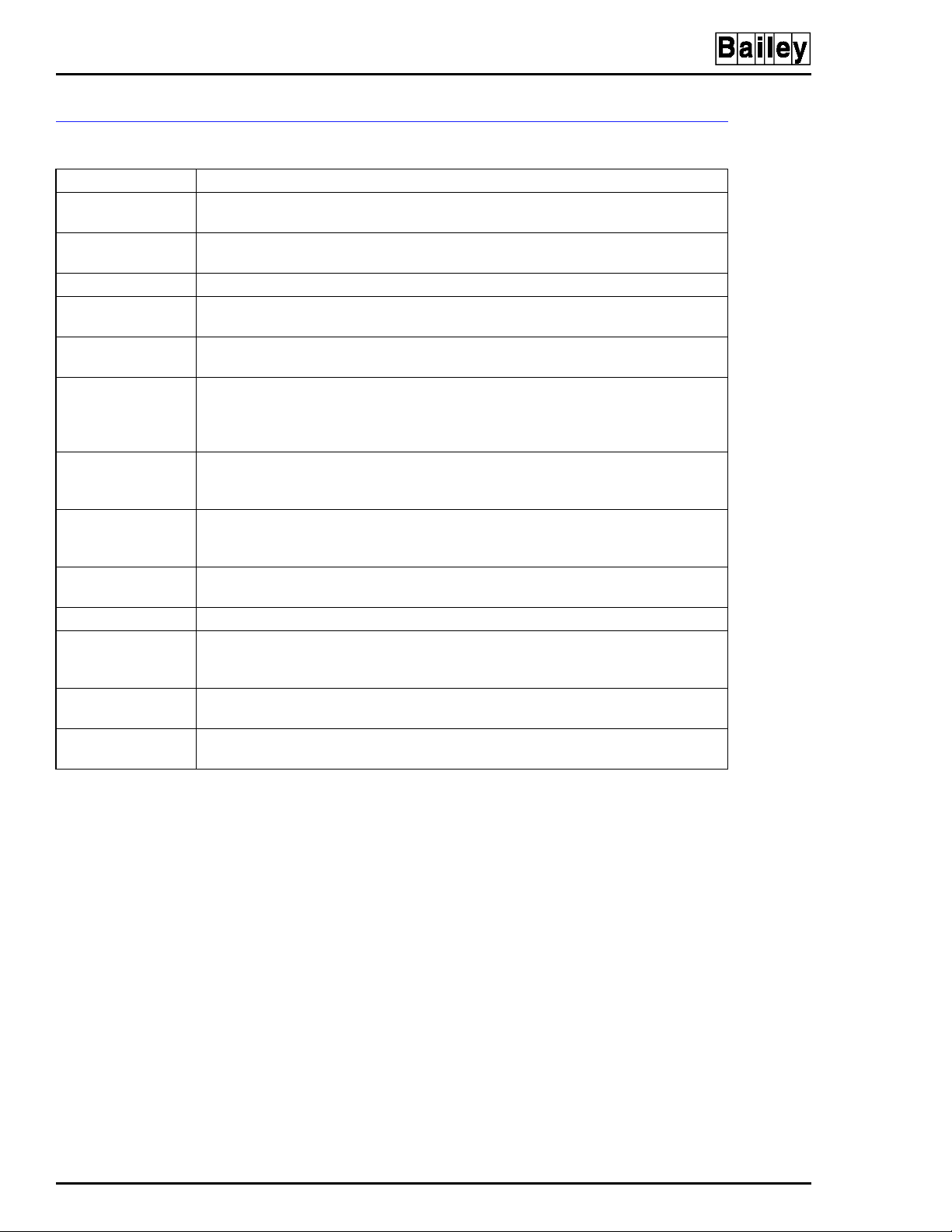

List of Effective Pages

Total number of pages in this manual is 62, consisting of the following:

Page No. Change Date

Preface Original

List of Effective Pages Original

iii through viii Original

1-1 through 1-6 Original

2-1 through 2-4 Original

3-1 through 3-13 Original

4-1 through 4-10 Original

5-1 through 5-5 Original

6-1 Original

7-1 Original

8-1 Original

A-1 through A-5 Original

B-1 through B-2 Original

C-1 through C-4 Original

D-1 through D-2 Original

®

When an update is received, insert the latest changed pages and dispose of the superseded pages.

NOTE:

gin of the page adjacent to the changed area. A changed figure is indicated by a vertical bar in the

outer margin next to the figure caption. The date the update was prepared will appear beside the

page number.

On an update page, the changed text or table is indicated by a vertical bar in the outer mar-

I-E96-624A

Page 5

Safety Summary

GENERAL

WARNINGS

SPECIFIC

WARNINGS

SPECIFIC

CAUTIONS

Equipment Environment

All components, whether in transportation, operation or storage

must be in a noncorrosive environment.

Electrical Shock Hazard During Maintenance

Disconnect power or take precautions to ensure that contact with

energized parts is avoided when servicing.

Special Handling

This unit uses Electrostatic Sensitive Devices (ESD).

Disconnect power befo re installing dip shunts for slave mo dules on

the MMU backplane (sla ve expander bus). Failure to do so could

result in severe or fatal shock. (p. 3-10)

Ensure that the cable end marked J1 is connected to P1 on the

NICL01, and J2 is connected to the LIM. Failure to do so could

result in module damage (see Figure D-1). (p. D-1)

I-E96-624A vii

Page 6

Sommaire de Sécurité

®

AVERTISSEMENTS

D’ORDRE

GÉNÉRAL

AVERTISSEMENTS

D’ORDRE

SPÉCIFIQUE

ATTENTIONS

D’ORDRE

SPÉCIFIQUE

Envirmonent de l'dquipement

Ne pas soumettre le s comp osants a une atmo sphere corr osive lors

du transport, de l'entreposage ou de l'utilisation.

Rissques de chocs electriques lors de l'entretien

S'assurer de debranche r l'alimentation ou de prendre les precautions necessaires a eviter tout contact avec des composants sours

tension lors de l'enretien.

Precautions de manutention

Ce module contient des composantes sensibles aux decharges

electro-statiques.

Couper l'alimentation avant d'installer les dipshunts sur la plaque

arrlere du chassis de montage de modules (MMU). Toute negligence a cet egard constitue un risque de choc pouvant entrainer

des blessures graves, voire moretlles. (p. 3-10)

S'assuree que L'extremite ide ntifiee par J1 est reli ee a P1 du module NICL01 et que J2 est r eliee au modu le LIM. S inon, les mo dules

pouiraient etre endommages (voir la figure D-1). (p. D-1)

viii I-E96-624A

Page 7

Table of Contents

Page

SECTION 1 - INTRODUCTION....................................................................................................1-1

OVERVIEW ..................................................................................................................1-1

INTENDED USER.........................................................................................................1-1

HARDWARE DESCRIPTION..........................................................................................1-2

Plant Loop to Plant Loop Transfer Module (INPPT01) ..............................................1-2

Bus Transfer Module (INBTM01) ............................................................................1-2

Loop Interface Module (INLIM03)............................................................................1-2

Additional Hardware ..............................................................................................1-2

FEATURES...................................................................................................................1-2

INSTRUCTION CONTENT .............................................................................................1-3

HOW TO USE THIS MANUAL .......................................................................................1-3

GLOSSARY OF TERMS AND ABBREVIATIONS .............................................................1-4

REFERENCE DOCUMENTS..........................................................................................1-5

NOMENCLATURE ........................................................................................................1-5

SPECIFICATIONS.........................................................................................................1-6

SECTION 2 - DESCRIPTION AND OPERATION........................................................................2-1

INTRODUCTION...........................................................................................................2-1

LOCAL/REMOTE COMMUNICATIONS..........................................................................2-1

DATA INTEGRITY.........................................................................................................2-2

TIMING INTERVAL .......................................................................................................2-2

Transmit/Receive Timing .......................................................................................2-3

SECTION 3 - INSTALLATION .....................................................................................................3-1

INTRODUCTION...........................................................................................................3-1

SPECIAL HANDLING ....................................................................................................3-1

UNPACKING AND INSPECTION ....................................................................................3-1

INPPT01 SWITCH SETTINGS........................................................................................3-1

Option Switch (U72)...............................................................................................3-2

Serial Port Communication Rate (U73) ...................................................................3-3

Loop Address (U75)................................................................................................3-4

INLIM03 SWITCH SETTINGS........................................................................................3-5

INBTM01 SWITCH SETTINGS.......................................................................................3-7

TERMINATION UNIT (MODULE) CONFIGURATION .......................................................3-8

NTMF01/NIMF01/NIMF02 Configuration...............................................................3-8

One-way Control..............................................................................................3-8

Two-way Control............................................................................................3-10

NTCL01/NICL01 Configuration ............................................................................3-10

INSTALLING THE INTERFACE MODULES ..................................................................3-10

Installing the INPPT01 .........................................................................................3-10

Installing the INLIM03 and INBTM01 ...................................................................3-11

INSTALLING A REDUNDANT INTERFACE...................................................................3-12

INTERFACE CONFIGURATION ...................................................................................3-12

SECTION 4 - OPERATING PROCEDURES................................................................................4-1

INTRODUCTION...........................................................................................................4-1

PLANT LOOP TO PLANT LOOP TRANSFER MODULE LEDs AND CONTROLS ................4-1

Status LED ............................................................................................................4-2

CPU LEDs..............................................................................................................4-2

Memory LEDs ........................................................................................................4-2

I-E96-624A iii

Page 8

®

Table of Contents

SECTION 4 - OPERATING PROCEDURES

Stop Pushbutton ................................................................................................... 4-2

Reset Pushbutton.................................................................................................. 4-2

LOOP INTERFACE MODULE LEDs .............................................................................. 4-3

BUS TRANSFER MODULE LED ................................................................................... 4-3

MODES OF OPERATION .............................................................................................. 4-3

Configure Mode ..................................................................................................... 4-4

Execute Mode........................................................................................................ 4-4

Error Mode............................................................................................................ 4-5

One-Way Control................................................................................................... 4-5

Two-Way Control ................................................................................................... 4-6

REDUNDANT INTERFACE OPERATION ....................................................................... 4-6

INTERFACE POINT CAPACITY ..................................................................................... 4-7

MEMORY USAGE EXAMPLE........................................................................................ 4-8

Memory Usage in the Local PPT .............................................................................4-8

Memory Usage in the Remote PPT.......................................................................... 4-8

SECURITY FUNCTIONS ............................................................................................... 4-9

Hardware Checks .................................................................................................. 4-9

Software Checks.................................................................................................... 4-9

Utilities .................................................................................................................4-9

(continued)

Page

(continued)

SECTION 5 - TROUBLESHOOTING...........................................................................................5-1

INTRODUCTION .......................................................................................................... 5-1

Status Bytes.......................................................................................................... 5-2

SECTION 6 - MAINTENANCE.....................................................................................................6-1

INTRODUCTION .......................................................................................................... 6-1

MAINTENANCE SCHEDULE ........................................................................................6-1

SECTION 7 - REPAIR/REPLACEMENT PROCEDURES...........................................................7-1

INTRODUCTION .......................................................................................................... 7-1

MODULE REPAIR/REPLACEMENT.............................................................................. 7-1

SECTION 8 - SUPPORT SERVICES...........................................................................................8-1

INTRODUCTION .......................................................................................................... 8-1

REPLACEMENT PARTS AND ORDERING INFORMATION ............................................. 8-1

TRAINING.................................................................................................................... 8-1

TECHNICAL DOCUMENTATION................................................................................... 8-1

APPENDIX A - TERMINATION UNIT CONFIGURATION (NTMF01) ........................................ A-1

INTRODUCTION ..........................................................................................................A-1

APPENDIX B - TERMINATION UNIT CONFIGURATION (NTCL01)......................................... B-1

INTRODUCTION ..........................................................................................................B-1

APPENDIX C - TERMINATION MODULE CONFIGURATION (NIMF01/NIMF02) .................... C-1

INTRODUCTION ..........................................................................................................C-1

iv I-E96-624A

Page 9

Table of Contents

(continued)

Page

APPENDIX D - TERMINATION MODULE CONFIGURATION (NICL01)...................................D-1

INTRODUCTION..........................................................................................................D-1

List of Figures

No. Title Page

1-1. Diagram of Plant Loop to Plant Loop Remote Interfaces in Two-Way Control Mode ..1-1

2-1. Send/Receive Timing Diagram ...............................................................................2-4

3-1. Switch Locations on the PPT (CPU board) ...............................................................3-2

3-2. LIM Switch Locations.............................................................................................3-5

3-3. BTM Switch (SW1) Location ...................................................................................3-7

3-4. NTMF01 and NTCL01 in a Redundant Installation .................................................3-9

3-5. NIMF01/NIMF02 and NICL01 in a Redundant Installation .....................................3-9

3-6. Redundant Transceiver ........................................................................................3-13

4-1. PPT Faceplate LEDs ...............................................................................................4-1

4-2. LIM Faceplate LEDs ...............................................................................................4-3

4-3. BTM Faceplate LEDs..............................................................................................4-4

4-4. Local Plant Loop Using Bosth Serial Ports in One-Way Control ...............................4-5

4-5. Local and Remote Plant Loops in Two-Way Control ................................................4-6

4-6. PPT Utilities Menu ...............................................................................................4-10

A-1. Dipshunt Configuration for PPT Acting as DTE (Requires Modem or Other DCE) ... A-1

A-2. Dipshunt Configuration for Direct Connection with Local PPT Acting as DTE ........ A-2

A-3. Dipshunt Configuration for Direct Connection with Remote PPT Acting as DCE ..... A-3

A-4. Dispshunt Configuration for Diagnostic Terminal (Port 1 only) .............................. A-4

A-5. DB-25 Pin Assignments and RS-232-C Signals ..................................................... A-5

B-1. NTCL01 Termination Unit and Terminal Assignments ........................................... B-2

C-1. Dipshunt Configuration for PPT Acting as DTE (requires Modem or Other DCE) .... C-1

C-2. Dipshunt Configuration for Direct Connection of Local PPT Acting as DTE ............ C-2

C-3. Dipshunt Configuration for Direct Connection of Remote PPT Acting as DCE ........ C-3

C-4. Dispshunt Configuration for Diagnostic Terminal.................................................. C-4

D-1. Typical Twinax Cable Connection for the NICL01 .................................................. D-2

I-E96-624A v

Page 10

List of Tables

No. Title Page

3-1. Option Switch (U72) Settings ................................................................................ 3-2

3-2. Serial Port Communication Rate (U73)................................................................... 3-3

3-3. Message Throughput ............................................................................................. 3-4

3-4. U75 Loop Addresses ............................................................................................. 3-4

3-5. LIM Event Counter Addresses (SW1) ...................................................................... 3-5

3-6. LIM Error Counter Addresses (SW1) ...................................................................... 3-6

3-7. LIM Node Address Setting (SW2) ............................................................................ 3-7

3-8. BTM Options (SW1) ............................................................................................... 3-8

3-9. INPPR01 Function Codes..................................................................................... 3-13

4-1. PPT Status LED States ..........................................................................................4-2

4-2. BTM Status LEDs States ....................................................................................... 4-4

4-3. Memory Usage in Receiving Communication .......................................................... 4-7

4-4. Memory Usage in Sending Communication ............................................................ 4-8

5-1. PPT Error Codes .................................................................................................... 5-1

5-2. Status Bytes.......................................................................................................... 5-2

5-3. Status Byte Definitions.......................................................................................... 5-3

5-4. LIM Edge Connector P3 Pin Assignments ............................................................... 5-3

5-5. BTM Edge Connector P1 Pin Assignments.............................................................. 5-4

5-6. PPT CPU Board Edge Connector P2 Pin Assignments .............................................5-4

5-7. PPT CPU Board Edge Connector P3 Pin Assignments .............................................5-4

6-1. Maintenance Schedule........................................................................................... 6-1

B-1. NTCL01 Terminal Assignments..............................................................................B-1

B-2. BNC Terminal Assignments ...................................................................................B-1

B-3. Jumper Settings and Cable Types..........................................................................B-2

D-1. NICL01 Terminal Assignments...............................................................................D-1

D-2. BNC Assignments..................................................................................................D-1

D-3. Jumper Settings and Cable Types..........................................................................D-2

®

vi I-E96-624A

Page 11

OVERVIEW

INTENDED USER

SECTION 1 - INTRODUCTION

The Plant Loop to Plant Loop Remote Interface (INPPR01)

enables communication between a local and remote Plant

Loop. Two modes (user-selectable) of control are available. A

local Plant Loop is able to issue control commands and receive

Exception Report (XR) data from up to 32 remote Plant Loops

when it is in the one-way mode. Only the local Plant Loop can

initiate control commands and request exception reports in the

one-way mode. The two-way mode connects only two Plant

Loops. In the two-way mode, either Plant Loop is able to initiate

control commands and request exception reports. Plant Loop

to Plant Loop Remote Interfaces can connect through cable,

modem or microwave link. Figure 1-1 shows a block diagram of

Plant Loop to Plant Loop Remote Interfaces in two-way control.

The INPPR01 is a direct replacement of the Network 90 Plant

Loop to Plant Loop Gateway (NPPG02).

System engineers and technicians should read this manual

before installing and operating the INPPR01 module. Refer to

the Table of Contents to find specific information after the

module is operating.

INPPR01 INPPR01

LIM PPT

ICL IMFIMF ICL

LEGEND:

BTM = B US TRANSFER MODULE

IMF = MULTI-FUNCTION CONTROLLER TERMINATION MOD U L E

ICL = COMM U N IC ATION TERMINATION M OD ULE

LIM = LOOP INTERFACE MO D U L E

PPT = PLANT LOOP TO PLANTLOOP T RANSFER MODULE

BTM BTMPPT LIM

DMA

CABLE

MODULE BUS MODULE BUS

PLANT LOOP PLANT LOOP

DMA

CABLE

Figure 1-1. Diagram of Plant Loop to Plant Loop Remote Interfaces in

Two-Way Control Mode

T00417A

OVERVIEW

I-E96-624A 1 - 1

Page 12

INTRODUCTION

HARDWARE DESCRIPTION

The Plant Loop to Plant Loop Remote Interface acts as another

node on the Plant Loop. The interface consists of three modules

on a dedicated module bus.

Plant Loop to Plant Loop Transfer Module (INPPT01)

This module processes incoming and outgoing Plant Loop messages, buffers data and communicates with other PPT modules

in remote Plant Loops. The PPT is a double circuit board module. It has a memory board and CPU board. The user selects

general operating characteristics and point definitions through

software configuration. Other characteristics such as type of

control (one-way or two-way), Node ID and port options are

user-configured through dipswitches on the CPU board.

Bus Transfer Module (INBTM01)

The BTM is responsible for translating messages from the LIM

and placing them on the module bus. It also receives messages

from the PPT. It translates those messages and sends them to

the LIM through a direct memory access (DMA) cable.

®

Loop Interface Module (INLIM03)

The LIM provides the communication link between the Plant

Loop and the PPT. It receives messages from Plant Loop nodes

and monitors loop status. The LIM forwards messages from the

loop to the PPT (though the BTM) via a direct memory access

(DMA) cable. Additionally, it receives messages from the PPT

(through the BTM) and sends them to the proper node on the

loop.

Additional Hardware

Some applications require additional hardware such as a

modem network, radio link or microwave link. This hardware is

not part of the INPPR01 standard hardware. INFI 90 Digital

Slave Modules (IMDSO01 through IMDSO04, IMDSM05) support control signals to these devices.

FEATURES

The Plant Loop to Plant Loop Remote Interface provides communication between a local loop and one or more remote loops.

This interface has user selectable control modes. Selecting the

one-way mode enables a local loop to receive exception reports

from up to 32 remote loops. In the one-way mode, only the

local loop can initiate control commands. The two-way mode

enables bidirectional control and exception reporting between

HARDWARE DESCRIPTION

1 - 2 I-E96-624A

Page 13

INSTRUCTION CONTENT

INTRODUCTION

a local and one remote loop. This interface handles a maximum

capacity of 5,000 blocks of exception report data.

The INPPR01 can handle a mixture of point types. Point types

include analog and digital station, remote control memory,

manual set constant and device driver. The user can select the

interface communication rate, up to 19.2 kbaud.

This document is divided into eight sections. Introduction

provides an overview of the individual modules of the PPR, a

list of related documents, glossary of terms and abbreviations

and specifications. Description and Operation explains how

PPR communication occurs. Installation covers preliminary

module setup, physical installation and configuration. Operat-

ing Procedures explains faceplate LEDs, controls and inter-

face operating modes. Troubleshooting explains how to

troubleshoot problems with the interface modules using error

codes and status byte information and lists the corrective

action. Maintenance contains a maintenance schedule for the

slave module. Repair/Replacement Procedures explain how

to replace the PPR modules. Support Services explains the

customer training Bailey Controls Company provides and

information about ordering replacement parts.

HOW TO USE THIS MANUAL

Read this manual in sequence. It is important to become familiar with the entire contents of this manual before using the

PPR. The organization of this manual enables the user to find

needed information quickly.

1. Read and do the steps in Section 3.

2. Read Section 4 thoroughly before powering up the station.

3. Refer to Section 5 if a problem occurs.

4. Refer to Section 6 for scheduled maintenance

requirements.

5. Use the Section 8 for a list of replacement parts and warranty information.

INSTRUCTION CONTENT

I-E96-624A 1 - 3

Page 14

INTRODUCTION

GLOSSARY OF TERMS AND ABBREVIATIONS

Term Definition

DCE

DTE

Dipshunt

EWS

Module Bus

Node

OIS

PCI

PCU

Plant Loop

RS-232-C

Slave Expander

Bus

XR

Data Circuit-Terminat ing Equipment - The term ination point of a communication circuit such as a line driver or modem.

Data Terminal Equipment - End-user machine of a communication circuit such as a

terminal or computer.

A dual in-line package with shorting bars.

Engineering Work Station - An integrated hardware and software personal computer

system for configuring and monitoring INFI 90/Network 90 modules.

The serial communication link between a process control module and other process

control modules.

Device(s) on the INFI 90/Network 90 Plant Loop, Superloop or INFI-NET (maximum

of 63 on Plant Loop, 250 on Superloop/INFI-NET). A node can be an Operator Interface Station (OIS), a Process Control Unit (PCU) or Engine ering Work Station (EW S)

in any combination.

Operator Interface Station - Integrated operator console with data acquisition and

reporting capabilities. It provides a window into the process for flexible control and

monitoring.

Plant Loop to Computer Interface (INPCI01/02) - A Plant Loop communication interface that provides configuration and control of the Plant Loop through a host

computer.

Process Control Unit - Rack type industrial cabinet that contains master, slave and

communication modules and their communication paths.

INFI 90 data communication highway with 63 node capacity.

One in a series of standards developed b y the Ele ctro nic s In dus try As so cia tio n (EIA)

that specifies what signals and volt ag es wil l b e used to transmit data from D TE (computer) to DCE (modem).

Parallel address/data bus between the master module and the slave.

Exception Report - A function block that reports a monitored point value when that

value changes and is polled by a communication or master module.

®

GLOSSARY OF TERMS AND ABBREVIATIONS

1 - 4 I-E96-624A

Page 15

REFERENCE DOCUMENTS

INTRODUCTION

The following documents provide additional information about

INPPR01 support hardware and software. Please refer to them

as needed.

Document Number Document

I-E96-309 Digital Slave Module (I MDSM05)

I-E96-310 Digital Slave Output Module (IMDSO01/02/03)

I-E96-313 Digital Slave Output Module (IMDSO04)

I-E93-905-2 Enhanced CIU Programmer's Reference Manual

I-E93-900-20 Function Code Application Manual

I-E96-611 Loop Interface/Bus Interface Module

(INLIM03/INBIM02)

I-E96-110 Operator Interface Station

I-E96-620 Plant Loop to Computer Interface (INPCI01)

I-E96-621 Plant Loop to Computer Interface (INPCI02)

I-E93-900-5 Site, Planning and Equipment Installation

I-E93-911 Termination Unit Manual

NOMENCLATURE

Hardware Nomenclature

Field Termination Panel NFTP01

Module Mounting Unit IEMMU01/02

Multi-Function Controller Termi nation Module

Redundant Termination Module

Cable

Multi-Funct ion Controller Termination Unit

Cable

Communication Termination Module

Cable

Communication Termination Unit

Cable

Termination Mounting Unit NTMU01/02

NIMF01

NIMF02

NKTM01

NTMF01

NKTU01

NICL01

NKLS04

NTCL01

NKLS03

REFERENCE DOCUMENTS

I-E96-624A 1 - 5

Page 16

INTRODUCTION

SPECIFICATIONS

Memory

PPT

®

256 kbytes UVROM

512 kbytes RAM

80 kbytes NVM (non-volatile memory)

LIM

BTM

I/O Ports

Communication Rates

Power Requirements

PPT

LIM

BTM

Environmental

Electromagnetic/Radio

Frequency Interference

Ambient Temperature

Relative Humidity

Altitude

2 kbytes RAM

4 kbytes ROM

32 kbytes RAM

16 kbytes ROM

2 RS-232C serial ports

50 to 19,200 baud (user selectable)

6 amps @ +5 VDC; 30 watts

37 mA @ +15 VDC; 0.55 watts

18 mA @ -15 VDC; 0.27 watts

+5 VDC @ 2.0 amps; 10 watts nominal

15 VDC @ 80 mA; 1.2 watts nominal

±

+5 VDC @ 1.0 amps; 5 watts nominal

+15 VDC @ 150 mA; 2.25 watts nominal

-15 VDC @ 120 mA; 1.80 watts nominal

Values are not avail able a t th is time. Keep cabi net doo rs clo sed. Do no t use co mmunication equipment any closer than two meters from the cabinet.

o

to 70oC (32o to 158oF)

0

0 to 95% up to 55

0 to 45% at 70

o

C (131oF) (non-condensing)

o

C (158oF) (non-condensing)

Sea level to 3 Km (1.86 miles)

Air Quality

Certification

Noncorrosive

All INPPR01 modules have been individually CSA certified for use as process

control equipment in an ordinary (nonhazardous) environment.

Specifications Subject To Change Without Notice

SPECIFICATIONS

1 - 6 I-E96-624A

Page 17

SECTION 2 - DESCRIPTION AND OPERATION

INTRODUCTION

This section explains the operation of the Plant Loop to Plant

Loop Remote Interface.

LOCAL/REMOTE COMMUNICATIONS

Local and remote PPTs communicate with each other through

a series of commands and replies over the serial ports. In the

one-way mode, the local PPT issues commands only; in

two-way, both the local and remote PPTs issue commands. The

command format is:

12345

Loop

Number

where:

Message

Byte Count

Command

Code

Command

Data

Checksum or

CRC

1. Loop number is the loop that responds to the command (1

byte field).

2. Message byte count is the total length of the message (2

byte field).

3. Command code is the command code the PPT processes (1

byte field).

4. Command data is the specific command (variable length

field).

5. Checksum is the sum of all the bytes in the command (1

byte field) or CRC, the cyclic redundancy check word computed

for all of the bytes in the command using the CRC-16 algorithm (2 byte field).

All communications between interfaces use this format.

INPPR01 commands are a modified form of Plant Loop to Computer Interface commands (refer to I-E93-905-9 for command

details). The PPT format eliminates the key field from the PCI

command. In addition to PCI commands, the PPT processes a

command (code 29) that permits passage of a required PPT

message.

INTRODUCTION

I-E96-624A 2 - 1

Page 18

DESCRIPTION AND OPERATION

DATA INTEGRITY

Verification of data integrity consists of even parity checking

and the checksum in each command and reply format. The

interface retries a transaction whenever it detects a communication error.

There are two levels of communication breakdown detection.

The first level detects a complete failure of the communication

link. Should this occur, Function Code 130 output block one

will be set (logic one) and the alarm status bit set if port 1 fails.

If port 0 fails, the output of block two will be set (logic one) and

the alarm status bit set.

The second level of communication failure concerns the loss of

a single remote interface. If this occurs, all blocks coming from

that remote interface are bad quality. The PPR makes use of a

user-configurable watchdog timer or absolute retry count in

determining the sensitivity to these failures (refer to

I-E93-200-20 for information about Function Code 130, S10

and S12).

®

TIMING INTERVAL

The local interface attempts communication twice a second

with all the remote interfaces. Each successful transaction

resets the communication watchdog timer. Therefore, if the

communication link is faulty, no transactions occur successfully. After the watchdog time period expires, the link is

marked bad.

For all communication transactions, the watchdog timer is

reset on the reception of each character. If the time interval

between characters in a transaction exceeds 1.25 seconds, the

transaction is flushed and the remote interface is marked as

being suspect. This condition causes retry logic to begin. Retry

logic consists of retrying communication once per second for a

number of times equal to one-fourth the watchdog time period

if the absolute retry count is set to zero. A non-zero absolute

retry count causes a specific number of retries (the number of

the retry count). If the failure persists after the retry period

expires, the remote interface is internally marked off-line and

the quality of all the points it provides are marked bad.

Thereafter, a single retry of the failed remote interface occurs

at a period equal to one half the watchdog timer period until a

successful transaction occurs. The local interface sets the

quality of all the points to their original state (before the communication failure). It also does a one time poll of the current

value of each point.

A user-configurable time delay envelopes each command/reply

sequence. This time delay accommodates the keying up/down

DATA INTEGRITY

2 - 2 I-E96-624A

Page 19

Transmit/Receive Timing

DESCRIPTION AND OPERATION

of modems and transmission equipment. The interface coordinates this activity through the RTS (Request-To-Send) signal of

the RS-232-C port for modems or through digital outputs when

using Digital Slave Modules (IMDSM05, IMDSO01/02/03/04)

to enable other transmission equipment.

The user can set up the RS-232-C ports to operate as Data Circuit-Terminating Equipment (DCE) or Data Terminal Equipment (DTE). In the DCE mode, the Request-To-Send (RTS) line

is always asserted. In the DTE mode, the RTS line is asserted

before data transmission and inhibited after data transmission

occurs.

The following events occur (see Figure 2-1) on port 0 when

transmitting a command:

1. Assert RTS on the RS-232-C port (DTE mode) or set digital

outputs 1 and 4 on the digital slave module.

2. A delay occurs between the time the port 0 asserts the RTS

(or the digital outputs are set) and the command transmission

occurs. Function Code 130 (S5) sets this delay (in

milliseconds).

3. Output 4 is reset.

4. A delay occurs between the time output 4 is reset and output 1 is reset. Function Code 130 (S6) sets the length of this

delay.

5. Output 1 is reset and RS-232-C RTS signal is inhibited

(DTE mode).

6. A delay set by S5 of Function Code 130 occur between the

output 1 reset and the reception of the reply.

7. The remote target issues a reply.

The following events occur (see Figure 2-1) when Port 0

receives a command:

1. The port receives the command.

2. A time delay set by S6 of Function Code 130 occurs.

3. The RS-232-C asserts the RTS signal (DTE mode) or set

outputs 1 and 4 on the digital slave modules.

4. A time delay set by S5 of Function Code 130 occurs.

TIMING INTERVAL

I-E96-624A 2 - 3

Page 20

DESCRIPTION AND OPERATION

5. The remote interface transmits a reply to the interface

sending the command.

6. Output 4 is reset.

7. A time delay set by S6 of Function Code 130 occurs.

8. Output 1 resets, RS-232-C RTS signal is inhibited (DTE

mode).

®

S5

DELAYS5DELAY

0

RTSASSERTED (DTE MODE)

SET OUT1 A ND OUT4

0

S7

DELAY

0

RTSASSERTED (DTE MODE)

SET OUT2 A ND OUT5

TRANSMIT

COMMAND

TxTxTxTxTxTx

RESET OUT4 RTS INHIBITED (DTE MOD E)

RECEIVE

COMMAND

RxRxRxRxRxRx

TRANSMIT

COMMAND

TxTxTxTxTxTx

RESET OUT5 RTS INHIBITED (DTE MOD E)

NOTE:

RTS assert and inhibit apply to DTE mode only. RTS is

always asserted for DCE mode.

SENDING A COM MAND, PORT 0 (P0)

S6

DELAY

RESET OUT1

RECEIVING A REPLY, PORT 0 (P0)

S6

DELAY

RTSASSERTED (DTE MODE)

SET OUT1 AND OUT4

SENDING A COM MAND, PORT 1 (P1)

S8

DELAY

RESET OUT2

S5

DELAY

S5

DELAY

S7

DELAY

RECEIVE

RxRxRxRxRxRx

TRANSMIT

TxTxTxTxT xTx

RECEIVE

RxRxRxRxRxRx

S6

REPLY

REPLY

RESET OUT4 RTSINH IBITED (DTE MODE)

REPLY

DELAY

S6

DELAY

RESET OUT1

S8

DELAY

TIME

TIME

TIME

RECEIVING A REPLY, PORT 1 (P1)

RECEIVE

COMMAND

0

RxRxRxRxRxRx

S8

DELAY

RTSASSERTED (DTE MODE)

SET OUT2 AND OUT5

S7

DELAY

TRANSMIT

REPLY

TxTxTxTxT xTx

S8

DELAY

TIME

RESET OUT5 RTSINH IBITED (DTE MODE)

RESET OUT2

T00418A

Figure 2-1. Send/Receive Timing Diagram

TIMING INTERVAL

2 - 4 I-E96-624A

Page 21

INTRODUCTION

SPECIAL HANDLING

SECTION 3 - INSTALLATION

This section explains special handling procedures, switch settings for each interface module, and how to install related

hardware. Complete the preliminary procedures in this section

before placing the INPPR01 into operation.

Plant Loop to Plant Loop Interface modules use Electrostatic

Sensitive (ESD) devices. Follow these handling procedures:

1. Keep the modules in their special anti-static bags until you

are ready to install them in the system. Save the bags for

future use.

2. Ground the anti-static bag before opening.

3. Verify that all devices connected to the modules are properly grounded before using them.

4. Avoid touching the circuitry when handling the module.

UNPACKING AND INSPECTION

1. Examine the PPT, LIM and BTM immediately to verify that

they have not been damaged in transit.

2. Notify the nearest Bailey Controls Sales Office of any such

damage.

3. File a claim for any damage with the transportation company that handled the shipment.

NOTE:

when working with interface modules. This kit connects the static

dissipative work surface and technician to the same ground point.

Always use the Bailey Field Static Kit (P/N 1948385A1)

4. Use the original packing material and/or container to store

the modules.

5. Store the module in an environment of good air quality and

free from temperature and moisture extremes.

INPPT01 SWITCH SETTINGS

The INPPT01 consists of two circuit boards, a memory board

and a CPU board. The memory board has no user-configurable

INTRODUCTION

I-E96-624A 3 - 1

Page 22

INSTALLATION

®

operating options. The CPU board has three dipswitches that

set the module operating characteristics. These switches provide the means of establishing the type of control, serial port

communication rate, and loop address. Figure 3-1 shows the

dipswitch locations on the CPU board.

JUMPER S

J1, J2, J3

STOPSW2

RESET SW1

Option Switch (U72)

J1 J2 J3

U72 U73 U75

1234

5678 1234

OPEN

OPTION

SWITCH

5678 1234

OPEN

BAUD RATE

SWITCH

5

OPEN

DIAGNOSTICS

SWITCH

Figure 3-1. Switch Locations on the PPT (CPU board)

U72 is an eight position dipswitch that determines the operating options of the module. Table 3-1 lists the U72 option settings. Record the U72 settings in the space provided. When

setting switches, 0 = Closed (on) and 1 = Open (off).

P1

P3

P2

T00387A

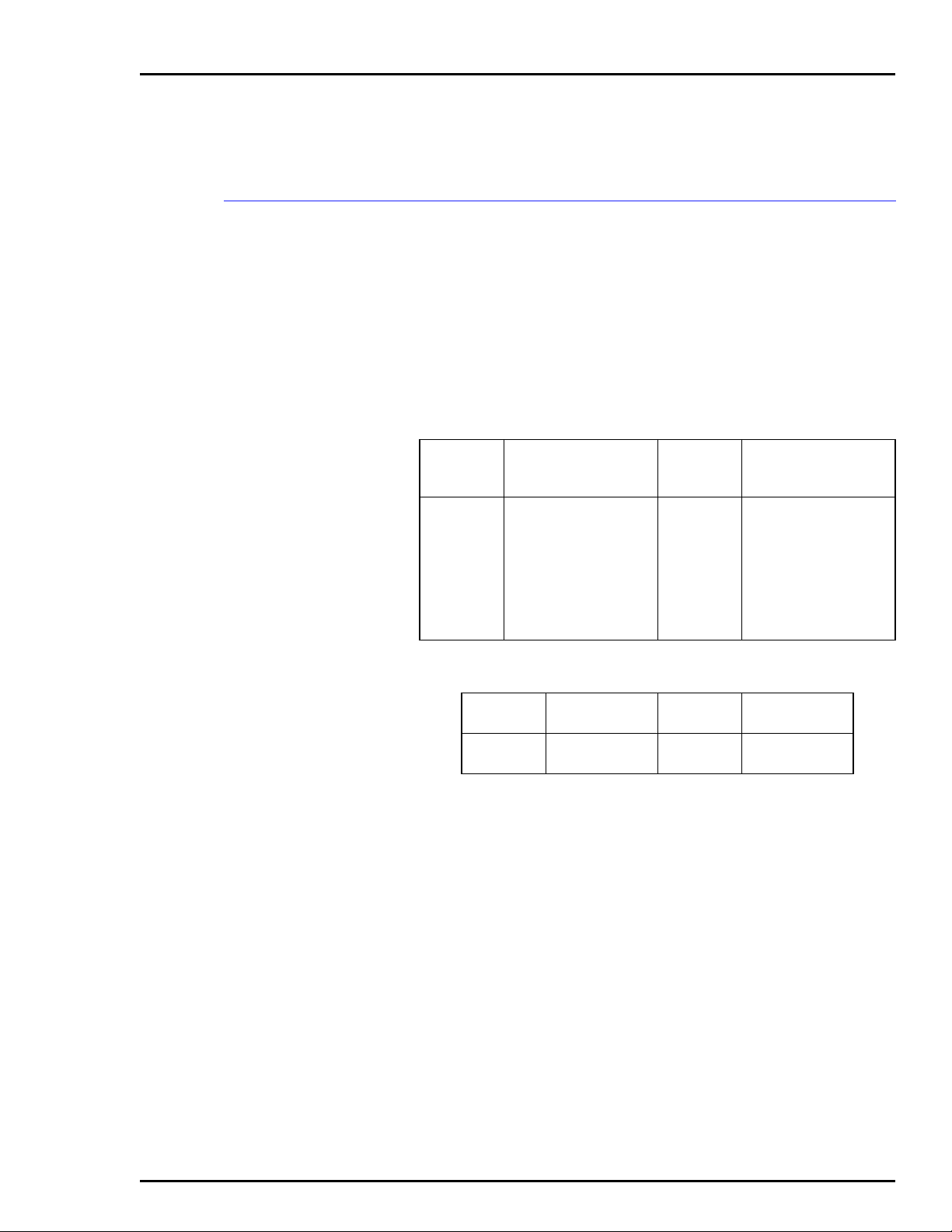

Table 3-1. Option Switch (U72) Settings

Position Setting Function

10

1

20

1

30

1

40

1

50

1

60

1

ROM checksumming enabled

ROM checksumming disabled

RS-232-C port in DCE mode (direct connecti ons )

RS-232-C port in DTE mode (modem connections)

Equipment select output de-energized

Equipment select output energized

Port 1 option interface communication

Port 1 utility option

Interface ID local

2

3

Interface ID remote

Interface mode two-way control

4

Interface mode one-way control

1

User

Setting

INPPT01 SWITCH SETTINGS

3 - 2 I-E96-624A

Page 23

INSTALLATION

Table 3-1. Option Switch (U72) Settings

Position Setting Function

70

1

80

1

0 = Closed (on), 1 = Open (off)

NOTES:

1. A unique equipment select output can exist between the primary and secondary PPT. The equipment select output is digital output three

of a digital slave (IMDSM05 or IMDSO01/02/03/04).

2. Port 1 responds as DCE when it is configured as a utility port. Set switch position 4 = 1 if port 1 is not used as a communication interface.

3. Define only one interface as a local interface (position 5).

4. The following conditions apply when using two-way control (position 6 = 0):

a. The port 1 option defaults to interface communication (position 4 = 0).

b. The local INPPR01 uses port 0 as its command port and port 1 as its reply port.

c. The remote INPPR01 uses port 1 as its command port and port 0 as its reply port.

d. Both the local and remote interface must have a loop address of 0 (U75).

Don not initialize NVM

Initialize NVM

Primary/Secondary (one module of redundant pair is set to 0,

the other module is set to 1)

(continued)

User

Setting

Serial Port Communication Rate (U73)

U73 is an eight pole dipswitch that sets the serial port communication rate. The communication rate directly affects data

throughput. Refer to Table 3-2 for communication rates. Table

3-3 lists message throughput for different point types. Record

the U73 setting in the space provided.

Table 3-2. Serial Port Communication Rate (U73)

Switch Position

Port 0

1234

Port 1

5678

0000 0000 50

1000 1000 75

0100 0100 110

1100 1100 134.5

0010 0010 150

1010 1010 300

0110 0110 600

1110 1110 1200

0001 0001 1800

1001 1001 2000

0101 0101 2400

1101 1101 3600

0011 0011 4800

1011 1011 7200

0111 0111 9600

1111 1111 19200

: 0 = Closed (on), 1 = Open (off)

NOTE

Baud Rate

User Setting

Port 0

1234

Port 1

5678

INPPT01 SWITCH SETTINGS

I-E96-624A 3 - 3

Page 24

INSTALLATION

®

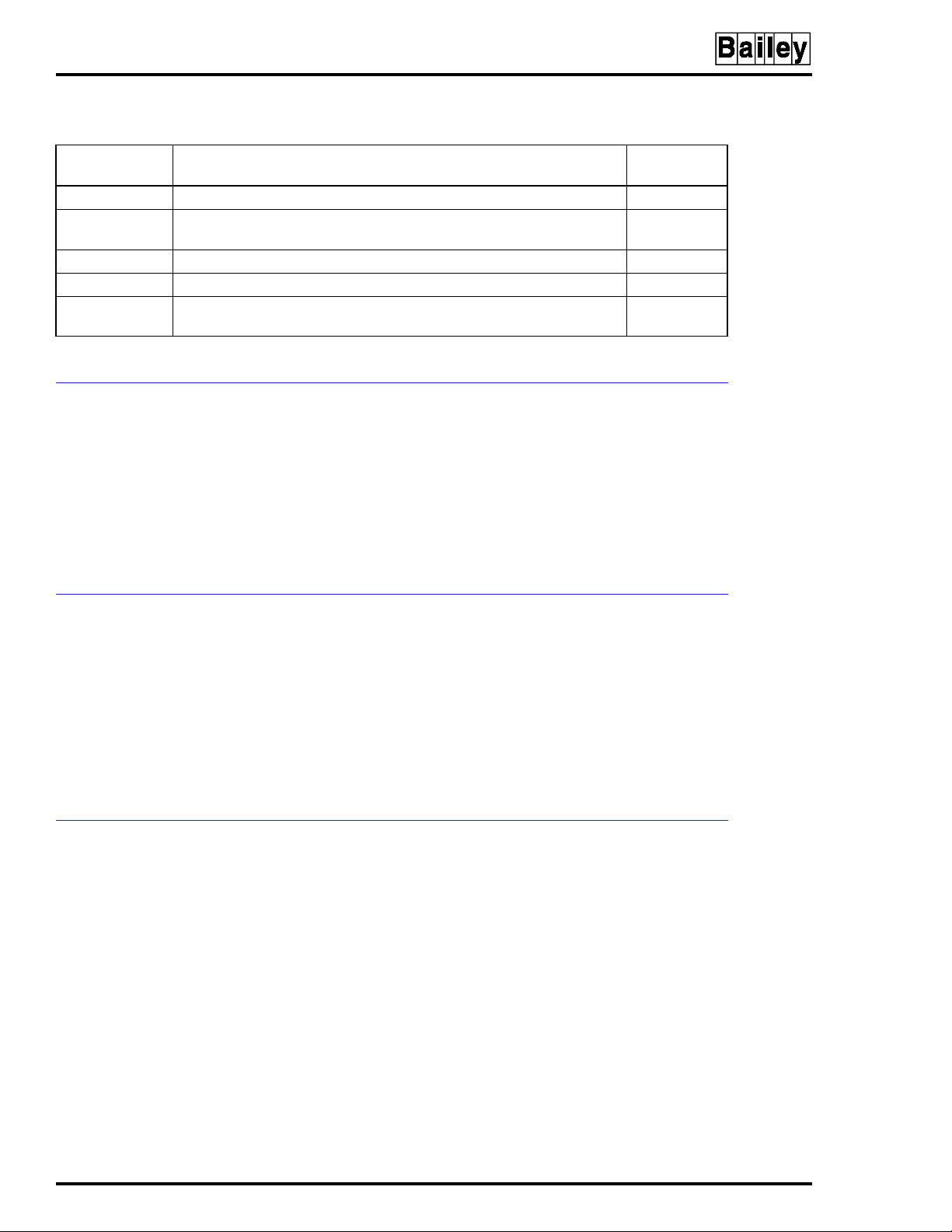

Table 3-3. Message Throughput

Loop Address (U75)

Point Type

Number of

Bytes

Time per

1

Point

Points per

Second

Station 19 10.4 msec 96

Analog 8 4.7 msec 214

Digital 5 3.1 msec 322

Remote Control Mem-

7 4.1 msec 241

ory (RCM)

Remote Manual Set

7 4.1 msec 241

Constant (RMSC)

Device Driver 7 4.1 msec 241

1. These figures are based on the calculated throughput of the various Exception Report data types

(at 19200 baud). Regard less of commun ication rat e, the software overhead is app roximatel y 0.5

millisecond per point.

Dipswitch U75 sets the loop address. Valid addresses are 0

through 31. Table 3-4 shows examples of switch settings for

the loop address. Record the loop address in the space

provided.

Table 3-4. U75 Loop Addresses

Example Settings

Address

Example

Switch Position 12345

Binary Value 168421

0 00000

9 01001

26 11010

User Setting

User

Address

0 = Closed (on), 1 = Open (off)

NOTE:

Switch Position 12345

Binary Value 168421

INPPT01 SWITCH SETTINGS

3 - 4 I-E96-624A

Page 25

INLIM03 SWITCH SETTINGS

The Loop Interface Module (INLIM03), shown in Figure 3-2, has

two user-configurable dipswitches: Event/Error Counter

Address Switch SW1 and Address Switch SW2. Tables 3-5 and

3-6 list the switch settings for the Event and Error Counters.

The LIM faceplate LEDs display the contents of the event/error

counters. Switch SW2 poles 1 and 2 are CLOSED for normal

operation. Refer to Table 3-7 for SW2 settings. The LIM can

have any address from 1 to 63.

XU4

S1

EVENT/ERROR

COUNTER ADDRESS

1234

5678

OPEN

1234

5678

OPEN

INSTALLATION

P1

EDGE

CONNECTORS

P3

P2

P4 CONNECTOR

RIBBON CABLE

ATTACHES HERE

S2

NODE ADDRESS

Figure 3-2. LIM Switch Locations

Table 3-5. LIM Event Counter Addresses (SW1)

Counter

Address

48 30 00110000 Total messages transmitted, including

49 31 00110001 Transmit retries.

50 32 00110010 Composite BTM Receive/Transmit, 4 bits

51 33 00110011 Messages taken from the BTM transmit

52 34 00110100 Messages stored in BTM receive buffer.

53 35 00110101 Interrupt Requests (IRQs) sent by BTM.

54 36 00110110 High Priority (HP) messages transmitted.

55 37 00110111 High Priority messages received.

56 38 00111000 Commands issued by the BTM.

57 39 00111001 Missed BTM transmit requests.

Hex

Address

Switch Position

12345678

Description

forwarding.

each. Receive is viewed at the top LED.

buffer.

T00403A

User

Setting

INLIM03 SWITCH SETTINGS

I-E96-624A 3 - 5

Page 26

INSTALLATION

®

Counter

Address

Hex

Address

Table 3-5. LIM Event Counter Addresses (SW1)

Switch Position

12345678

Description

(continued)

58 3A 00111010 Spurious Non-Maskable Interrupts (NMI)

caused by address present.

59 3B 00111011 HEY (request for an interrupt; generated

by BTM) message sent.

60 3C 00111100 Messages discarded when the destination

is off-line.

61 3D 00111101 HEY time expirations.

62 3E 00111110 Passes through the IDLE level

(2 bytes wide).

0 = Closed (on), 1 = Open (off)

NOTE:

Table 3-6. LIM Error Counter Addresses (SW1)

Counter

Address

64 40 01000000 Composite error count developed every

65 41 01000001 Unresolved NMI interrupts.

66 42 01000010 Unresolved IRQ interrupts.

67 43 01000011 Unresolved timer interrupts.

68 44 01000100 Unused.

69 45 01000101 Queue overflows.

70 46 01000110 Unresolved BTM IRQs.

71 47 01000111 Sequence errors.

72 48 01001000 Header CRC/OVRN errors.

73 49 01001001 Data CRC/OVRN errors.

74 4A 01001010 Messages developing data CRC errors on

75 4B 01001011 Transmission failures.

76 4C 01001100 Watchdog timer expirations.

77 4D 01001101 Data length errors.

78 4E 01001110 Loop - 1 Receive (RCV) failure.

79 4F 01001111 Loop - 2 Receive failures.

80 50 01010000 Loop - 1 Transmit (TX) failure.

81 51 01010001 Loop - 2 Transmit failures.

0 = Closed (on), 1 = Open (off)

NOTE:

Hex

Address

Switch Position

12345678

Description

handshake period - the summation of all

other error counters.

route to destination.

User

Setting

User

Setting

INLIM03 SWITCH SETTINGS

3 - 6 I-E96-624A

Page 27

1 0 0000001

T00401A

RESET

SWITCH

SW1

OPTION SWITCH

EDGE

CONNECTORS

P3

P2

P1

5

1

OPEN

9 0 0001001

63 0 0111111

NOTE: 0 = Closed (on), 1 = Open (off)

INBTM01 SWITCH SETTINGS

Address

Example

User

Address

INSTALLATION

Table 3-7. LIM Node Address Setting (SW2)

Example Settings

Switch Position 1 2345678

Binary Value 1286432168421

User Setting

Switch Position 1 2345678

Binary Value 1286432168421

The Bus Transfer Module (INBTM01), shown in Figure 3-3, has

one user-configured dipswitch (SW1). SW1 enables module

diagnostics. Refer to Table 3-8 and set SW1 for normal

operation.

Figure 3-3. BTM Switch (SW1) Location

INBTM01 SWITCH SETTINGS

I-E96-624A 3 - 7

Page 28

INSTALLATION

®

Table 3-8. BTM Options (SW1)

Switch Position

12345

00000 Normal operation.

00010 Normal BTM operation without catastrophic error checking (for Test Pur-

poses ONLY).

00100 RAM test mode. If Status LED turns red, the module has failed the test.

00110 ROM test mode. If Status LED turns red, the module has failed the test.

01000 Execute Interrupt Request (IRQ) LIM handshake diagnostic. Used in

combination with the LIM off-line diagnostics.

NOTE: 0 = Closed (on), 1 = Open (off)

Function User Setting

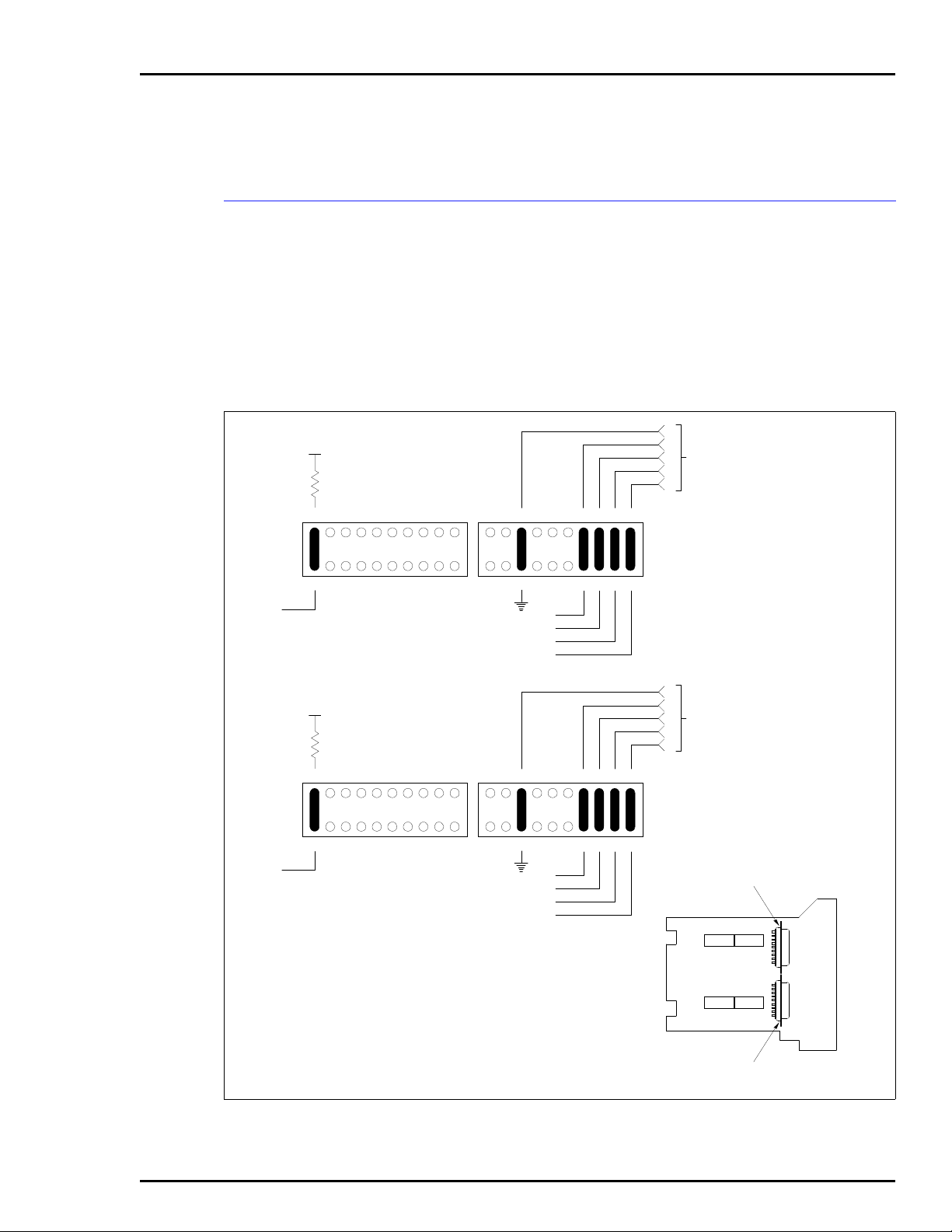

TERMINATION UNIT (MODULE) CONFIGURATION

Two of the interface modules (INLIM03, INPPT01) require termination. The INPPT01 terminates with the NTMF01 or

NIMF01/NIMF02. The INLIM03 terminates with the NTCL01 or

NICL01. Appendices A through D contain disphunt configuration information. Figure 3-4 shows a diagram of the NTMF01

and NTCL01 in a redundant installation. Figure 3-5 shows a

diagram of the NIMF01/NIMF02 and NICL01 in a redundant

installation.

NTMF01/NIMF01/NIMF02 Configuration

The TMF and IMF provide the INPPT01 with two RS-232-C

ports. Configure these ports to operate as DTE, DCE or diagnostic terminal. Refer to Figures A-1, A-2, and A-3 for NTMF01

dipshunt configurations. Refer to Figures C-1, C-2, and C-3 for

NIMF01/NIMF02 dipshunt configurations.

NOTE:

tion modules to terminate a redundant interface. Non-redundant

interfaces need only the NIMF01.

You must use the NIMF01 and NIMF02 whe n usi ng term in a-

ONE-WAY CONTROL

Configure port 0 on the local and remote interfaces to act as

DTE. One local INPPR01 can communicate with up to 32

remote interfaces in the one-way control mode. Additional

communication equipment such as a modem network, radio

link or microwave link is required when interfacing multiple

remotes. The user supplies any additional equipment that is

needed.

TERMINATION UNIT (MODULE) CONFIGURATION

3 - 8 I-E96-624A

Page 29

COMMUNICATION HIGHWAY(PLANT LOOP)

INSTALLATION

TWINAX

OR COA X

TWINAX

OR COA X

SLAVE EXPANDER BUS

NTCL01

P1 P1

NKLS03

P3

DMA

CABLE

MODULE BUS

INBTM01INLIM03 INLIM 03INPPT01

P3 P3

P1 P3

INPPT01

NKTU01NKTU01

MODULE BUS

NKLS03

INBTM01 INLIM03

DMA

CABLE

NTMF01

TERMINATION UNIT

COMMUNICATIONS

PORT 0

PORT 1

COMMUNICATIONS

OR UTILITY

TO OTHER PPR

Figure 3-4. NTMF01 and NTCL01 in a Redundant Installation

NTCL01

P3

T00419A

COMMUNICATION HIGHWAY(PLANT LOOP)

TWINAX

OR COA X

SLAVE EXPANDER BUS

NICL01

P1

P3

NKLS04

DMA

CABLE

MODULE BUS

INBTM01INLIM03 INLIM 03INPPT01

P3 P3

P1

NIMF01

TERMINATION

MODULE

J2 J3

COMMUNICATIONS

PORT 0

MODULE BUS

INPPT01

NKTM01NKTM01

P1

NIMF02

TERMINATION

MODULE

INBTM01 INLIM03

PORT 1

COMMUNICATIONS

OR UTILITY

TO OTHER PPR

Figure 3-5. NIMF01/NIMF02 and NICL01 in a Redundant Installation

DMA

CABLE

TWINAX

OR COA X

NKLS04

NICL01

P1

P3

T00420A

TERMINATION UNIT (MODULE) CONFIGURATION

I-E96-624A 3 - 9

Page 30

INSTALLATION

®

When directly connecting only one remote interface in one-way

control, set port 0 on the local interface to act as a DTE. Set

port 0 on the remote interface to act as DCE.

TWO-WAY CONTROL

The interface requires both serial communication ports in the

two-way control mode. Connect port 0 of the local Plant Loop to

port 0 of the remote Plant Loop. Connect port 1 of local Plant

Loop to port 1 of the remote Plant Loop.

Configure the termination unit to act as DTE to enable the

Plant Loop to Plant Loop Transfer Module to communicate with

DCE (i.e, a modem). Configure the termination unit to act as

DCE to enable the PPT to communicate with DTE (i.e., a terminal). Figure A-4 shows how the termination dipshunt configuration directs the RS-232-C signals.

NTCL01/NICL01 Configuration

The TCL and ICL provide the INLIM03 with Plant Loop termination. The user has the option of using Twinax or Coax cable to

connect the interface to the Plant Loop. Tables B-3 (NTCL01)

and D-3 (NICL01) show the jumper settings for twinax and

coax cables. Set the jumpers accordingly for your application.

NOTE:

interface communication port. The PPT option switch (U72) position

4 must be set to 0 (utility option). Port 1 will always act as a DCE in

this configuration.

Always configure port 1 as a utility port if it is not used as an

NOTE:

to the

For complete cable and TU/TM installation information, refer

Termination Unit Manual

l (

I-E93-911

).

INSTALLING THE INTERFACE MODULES

If the switch settings on the interface modules are complete,

they are ready to be installed in the Module Mounting Unit

(MMU).

Installing the INPPT01

WARNING Disconnect power before installing dipshunts for slave mod-

ules on the MMU backplane (slave expander bus). Failure to do

so could result in severe or fatal shock.

AVERTISSEMENT Couper l'alimentation avant d'installer les dipshunts sur la

plaque arrlere du chassis de montage de modules (MMU).

Toute negligence a cet egard constitue un risque de choc pouvant entrainer des blessures graves, voire moretlles.

INSTALLING THE INTERFACE MODULES

3 - 10 I-E96-624A

Page 31

INSTALLATION

To install the PPT:

1. Verify the PPT slot assignment in the MMU.

a. If you are installing redundant PPTs, install a 24 pin

disphunt in the Slave Expander Bus socket between the

slot used by the primary PPT and the slot used by the secondary PPT. Both PPTs must reside on the same Slave

Expander Bus.

b. Each PPT must reside on its own module bus.

2. Attach the hooded end of the cable (NTKU01 for the

NTMF01; NKTM01 for the NIMF01 and NIMF02) to the MMU

backplane cable connector opening for the PPT. The other end

of the cable attaches to the termination unit or backplane of

the Termination Mounting Unit (NTMU01).

3. Guide the top and bottom edges of the circuit card along

the top and bottom rails of MMU.

4. Slide the module into the slot; push the module until the

front panel is flush with the top and bottom of the MMU frame.

5. Turn the two captive latches a half turn to lock the module

in place.

Installing the INLIM03 and INBTM01

The LIM and BTM should be installed as a pair in adjacent

slots. To install the LIM/BTM:

1. Verify the MMU slot assignments for the modules. If you

are installing redundant LIM/BTM pairs, each BTM must be

installed on the module bus that belongs to its related PPT.

2. Attach the hooded end of the cable (NKLS03 for NTCL01;

NKLS04 for the NICL01) to the MMU backplane cable connector opening for the LIM. The other end of the cable attaches to

the termination unit or TMU backplane.

3. Connect one end of the Bailey supplied ribbon cable (DMA

cable) to the P4 connector on the LIM. Connect the other end of

the DMA cable to the P4 connector on the BTM (see Figures 3-2

and 3-3).

4. Guide the top and bottom edges of both circuit cards along

the top and bottom rails of adjacent slots in the MMU.

5. Slide the modules into the slot; push the module until the

front panels are flush with the top and bottom of the MMU

frame.

INSTALLING THE INTERFACE MODULES

I-E96-624A 3 - 11

Page 32

INSTALLATION

6. Turn the two captive latches a half turn to lock the module

in place.

INSTALLING A REDUNDANT INTERFACE

Installing a redundant interface requires an additional set of

INPPT01, INLIM03 and INBTM01 modules. Both PPT modules

must be on the same Slave Expander Bus, but reside on separate Module Bus. Each PPT has a pair of LIM/BTM modules on

a dedicated Module Bus.

Observe the following conditions when installing a redundant

interface:

1. U72 position 8 must be set to 0 on the primary PPT.

2. U72 position 8 must be set to 1 on the secondary PPT.

3. SW1 all positions must be set to 0 on both BTMs.

4. The slave expander bus of two adjacent MMUs (one on top

of the other) are connected with the expander bus extender

cable (Bailey P/N 1958502A0340).

®

5. The module bus between these MMUs are not connected.

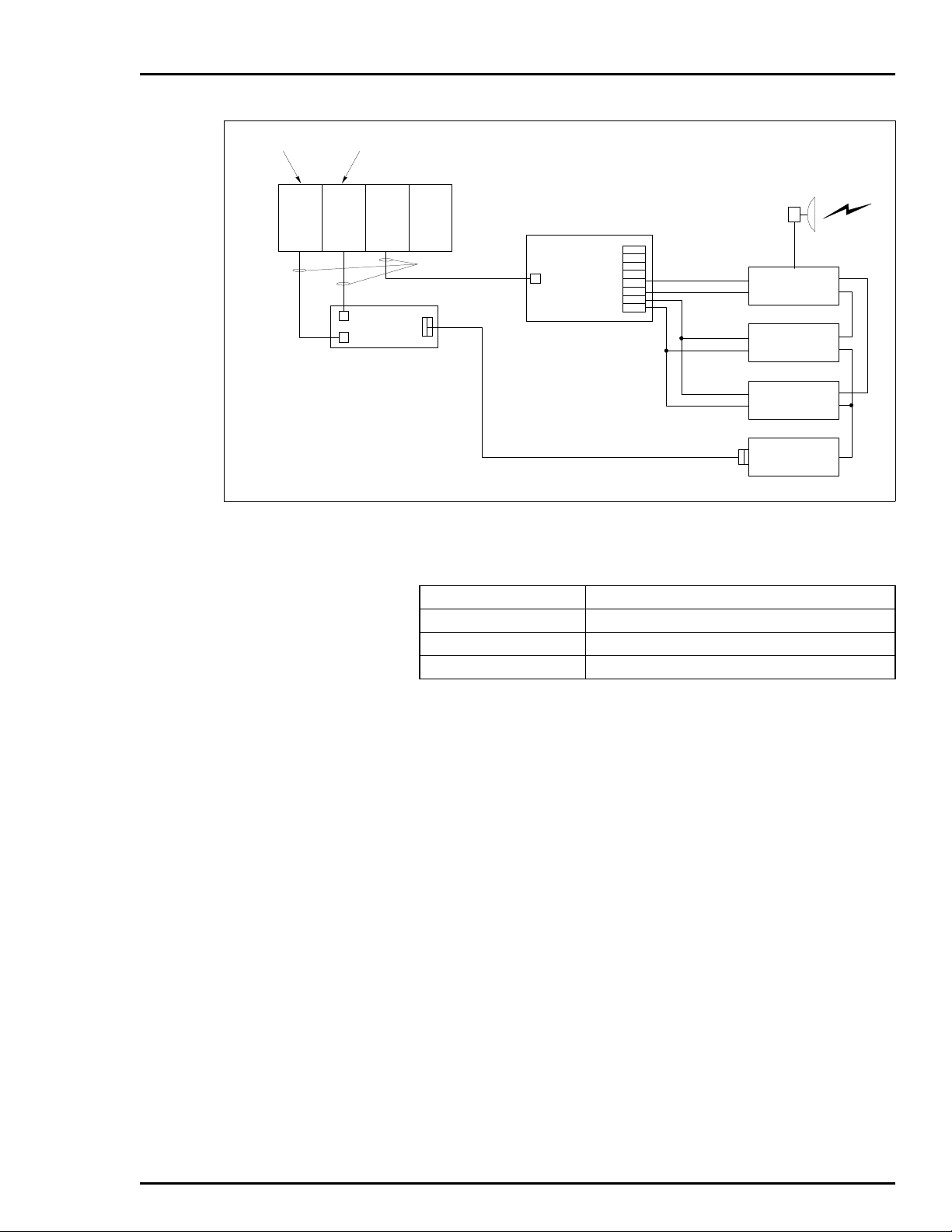

Applications that use redundant communication equipment

may require additional hardware. Figure 3-6 shows a diagram

of the interface using the IMDSM05 to enable redundant transceivers. Function Code 130 provides the software the PPT

needs to enable the transceivers. Voltage levels and polarities

of enable signals to transceivers and other communication

equipment may vary. Refer to the applicable user manual when

connecting this equipment to the IMDSM05, IMDSO01/02/

03/04 Digital Slave Module.

INTERFACE CONFIGURATIO N

The user must configure the PPT with the proper function

codes before it can be placed into service. The PPT configuration determines interface operating characteristics such as

time synchronization, serial communication rate, node definition, point definitions and general execution characteristics.

Table 3-9 lists the function codes used by the INPPR01. Refer

to the Function Code Application Manual (I-E93-900-20) for

information about the function codes in Table 3-9.

INSTALLING A REDUNDANT INTERFACE

3 - 12 I-E96-624A

Page 33

INSTALLATION

PRIMARY

SECONDARY

DSM05PPT

PPT

P1

NTMF01

P3

–

A1

NKTU01 CABLES

P1

NTDI01

RS232 (LINES 1-5, 8, 20)

+

–

A2

+

–

A3

+

–

A4

+

Figure 3-6. Redundant Transceiver

Table 3-9. INPPR01 Function Codes

SELECT

ENABLE

ENABLE

ANTENNA

SWITCH

PRIMARY

TRANSCEIVER

REDUNDANT

TRANSCEIVER

MODEM

T00421A

Function Code Title

FC 127 Plant Loop Gateway Node Map

FC 130 Plant Loop Gateway Executive

FC 131 Plant Loop Gateway Point Definition

INTERFACE CONFIGURATION

I-E96-624A 3 - 13

Page 34

SECTION 4 - OPERATING PROCEDURES

INTRODUCTION

This section explains how to place the INPPR01 in operation It

covers faceplate LEDs, modes of operation, and the two control

types. Additionally, it provides information concerning redundant operation and interface memory utilization.

PLANT LOOP TO PLANT LOOP TRANSFER MODULE LEDs AND CONTROLS

The faceplate of the PPT has the following components (see Figure 4-1):

1. Status LED

2. 8 CPU LEDs

3. 2 Memory Status LEDs

4. Stop pushbutton

5. Reset pushbutton

INPPT01

STATUS LED

1

2

3

4

CPU

5

6

7

8

STOP

RESET

PUSHBUT TON

Figure 4-1. PPT Faceplate LEDs

1

MEM

2

T00422A

INTRODUCTION

I-E96-624A 4 - 1

Page 35

OPERATING PROCEDURES

Status LED

The Status LED is a red/green LED that displays the operating

status of the PPT. It has five possible states. Table 4-1 lists the

meaning of the status LED states. Refer to Section 5 for corrective action if the status LED indicates that an operating error

exists.

Table 4-1. PPT Status LED States

LED State Meaning

Off No power to the PPT.

Solid Green The PPT is in the EXECUTE Mode.

Flashing Green (once per second) The PPT is in the EXECUTE M ode and d etects a NVM checksum

error.

Flashing Green (4 times per second) The PPT is in the CONFIGURE or ERROR Mode.

Solid Red The PPT diagnostics detect a hardware failure or configuration

problem. CPU LEDs displ ay an error co de when the status LED

is red.

®

CPU LEDs

Memory LEDs

Stop Pushbutton

During normal operation, the CPU LEDs keep a count of the

internal and external messages that pass through the PPT. If a

communication error occurs, these LEDs display an error code

and the Status LED turns RED. Refer to Table 5-1 for a list of

CPU LED error codes and corrective action.

There are two Memory LEDs. MEM LED 2 is on while the module is correcting single bit errors. Both LEDs are on when a

two-bit error or a complete memory failure occurs.

Push the stop pushbutton before removing a PPT from the

Module Mounting Unit. The stop pushbutton causes the following actions to occur:

1. Allows any NVM write in progress to complete.

2. Forces control from a primary to a secondary PPT in redundant configurations.

Reset Pushbutton

Pressing the reset pushbutton causes:

1. Restoration of PPT to power-up values after a halt.

PLANT LOOP TO PLANT LOOP TRANSFER MODULE LEDs AND CONTROLS

4 - 2 I-E96-624A

Page 36

2. Recovery from an operator-initiated stop or a module

timeout.

LOOP INTERFACE MODULE LEDs

There are eight LEDs on the LIM faceplate (see Figure 4-2).

These LEDs display the contents of event and error counters,

and pass/fail information when on-board diagnostics are run

(refer to Tables 3-4 and 3-5 for a list of event and error counter

codes).

OPERATING PROCEDURES

INLIM03

1

2

3

4

5

6

7

8

T00399A

Figure 4-2. LIM Faceplate LEDs

BUS TRANSFER MODULE LED

The Bus Transfer Module has one red/green LED that displays

the module's operating condition (see Figure 4-3). The BTM

Status LED has three possible states. Refer to Table 4-2 for

BTM Status LED states and their meaning. Section 5 explains

the corrective action to take if the Status LED displays a BTM

hardware failure.

MODES OF OPERATION

The Plant Loop-to-Plant Loop Remote Interface has three

modes of operation: Configure, Execute and Error. Within the

Execute mode the module has two methods of control: one-way

or two-way control.

LOOP INTERFACE MODULE LEDs

I-E96-624A 4 - 3

Page 37

OPERATING PROCEDURES

®

INBTM01

STATUS LED

Configure Mode

Execute Mode

T00413A

Figure 4-3. BTM Faceplate LEDs

Table 4-2. BTM Status LEDs States

LED States Meaning

Off No power to th e BTM.

Solid Green Normal Operation.

Solid Red BTM hardware failure.

This mode applies to the INPPT01 module. Module configuration requires an INFI 90 operator interface device (i.e., Operator Interface Station, Management Command System,

Engineering Work Station, etc.). Refer to Section 3 and to the

instruction for your operator interface device for information

about interface configuration.

This is the normal mode of operation for the PPR. In the execute mode, the PPR issues requests for exception reports (XRs)

twice a second, collects XRs, exercises control (local to remote),

allows the operator to adjust tunable module specifications

and configure modules in remote loops. The interface enters

one of the two control types that the user configures during

installation.

MODES OF OPERATION

4 - 4 I-E96-624A

Page 38

Error Mode

One-Way Control

OPERATING PROCEDURES

The PPT enters this mode if the built-in system diagnostics

detect a hardware or configuration error. If the PPT detects a

hardware error, the module halts and displays an error code on

the CPU LEDs. If the CPU LEDs display a configuration error,

the module remains in the error mode. Refer to Section 5 for

corrective action when the PPT enters the error mode.

The PPT option switch setting (set during installation) determines if the module is in one-way control. In one-way control,

the local Plant Loop requests XRs from all remotes twice a second. The operator does module tuning and configuration, and

issues control commands to the remote Plant Loops through

the operator interface.

This type of control requires only one serial port (port 0). Port 1

can also be used as an additional link through which the local

loop issues commands. Using both ports increases the total

throughput of the PPT (see Figure 4-4).

PCU

4

OIS

1

REMOTE

PLANTLOOP

A

PPR

10

SERIALPORT 0

LEGEND:

OIS = OPERATOR INTERFACESTATION

PCI = PLANT LOOP TO COMPUTER

INTERFACE

PCU = PROCESS CONTROL UNIT

PPR = PLANT LOOP TO PLANT LOOP

REMOTE INTERFACE

PCU

PCU

1

PCU

20

2

LOCAL PLANT LOOP

SERIAL PORT

PPR

10

PCU

1

REMOTE

PLANT LOOP

B

PPR

10

SERIALPORT 1

PCU

4

PCU

10

PCI

33

OIS

30

OIS

20

T00423A

Figure 4-4. Local Plant Loop Using Both Serial Ports in One-Way

Control

MODES OF OPERATION

I-E96-624A 4 - 5

Page 39

OPERATING PROCEDURES

Two-Way Control

In two-way control, bidirectional communication requires both

ports on both Plant Loops (Port 0 to Port 0; Port 1 to Port 1).

Both loop interfaces can issue requests, control commands

and do module tuning and configuration. The local interface

uses one serial port to issue commands and receive replies (see

Figure 4-5). The remote interface uses the other port for the

same purpose. As in one-way control, the PPT requests XRs

twice a second; control and configuration commands are

through operator action.

REDUNDANT INTERFACE OPERATION

Redundant interface configurations require two sets of LIM/

BTM and PPT modules. Each set of modules reside on a separate module bus. Redundant interfaces share a common slave

expander bus. Upon start-up, one interface assumes the primary role; the other waits in a backup role. The primary PPT

®

PCU

1

OIS

1

PPR

PPR

LOCAL

PLANTLOOP

OIS

2

PCU

4

REMOTE

PLANTLOOP

10

SERIAL PORTS

LOCAL XMIT/RCVREMOTE XMIT/RCV

SERIAL PORTS

10

PCU

4

PCU

20

T00424A

Figure 4-5. Local and Remote Plant Loops in Two-Way Control

REDUNDANT INTERFACE OPERATION

4 - 6 I-E96-624A

Page 40

downloads the interface configuration to the secondary (redundant modules are identically configured to their primary counterpart). If the primary interface fails, the redundant unit takes

over and re-establishes the point data.

INTERFACE POINT CAPACITY

There are three factors that determine the maximum number

of points in a PPT configuration. Those factors are: point type

(exception report data type), the number of devices that receive

interface generated exception reports and the total memory

available (440,000 bytes). Table 4-3 lists the required memory

bytes for all point types when memory usage is for:

1. The local PPT receiving points from the remote PPT.

2. The remote PPT (in two-way mode) receiving points from

the local PPT.

OPERATING PROCEDURES

Table 4-3. Memory Usage in Receiving Communication

Point Type

Digital 16

Analog 30

Station 76

Remote Control Memory (RCM) 22

Remote Manual Set Constant (RMSC) 38

Device Driver 22

Add 6 bytes per point per destination being sent.

NOTE:

Memory Bytes

Required

Table 4-4 lists the required memory bytes for all point types

when the memory usage is for:

1. The remote PPT sending points to the local PPT.

2. The local PPT (in two-way mode) sending points to the

remote PPT.

NOTE:

The PPT has a capacity of 5,000 blocks.

INTERFACE POINT CAPACITY

I-E96-624A 4 - 7

Page 41

OPERATING PROCEDURES

Digital 18

Analog 22

Station 70

Remote Control Memory(RCM) 22

Remote Manual Set Constant (RMSC) 26

Device Driver 22

NOTE:

that sources Exception Reports.

MEMORY USAGE EXAMPLE

In this example, a pair of interfaces in one-way mode has the

following mix of points in their configuration:

500 digital points (S3 of FC131 = 0)

200 analog points (S3 of FC131 = 1)

50 stations (S3 of FC131 = 2)

®

Table 4-4. Memory Usage in Sending Communication

Point Type Memory Bytes Required

Add 16 byte s fo r ea ch PCU th at sou rc es Ex cept ion R epo rts. Ad d 10 by te s fo r eac h mod ul e

Distribution of 750 total points on the remote loop is among 20

modules residing in 10 different PCUs. There are five OISs on

the local loop. Each OIS receives all of the points.

Memory Usage in the Local PPT

The points are coming to the local from the remote, therefore,

Table 4-3 applies. The calculations are:

500 digital points x 16 bytes/point = 8,000 bytes

200 analog points x 30 bytes/point = 6,000 bytes

50 station points x 76 bytes/point = 3,800 bytes

Each OIS receives all 750 points:

5 OIS x 750 points x 6 bytes/point = 22,500 bytes

Total memory used in the local PPT = 40,300 bytes

Memory Usage in the Remote PPT

These points are to be sent to the local, therefore, Table 4-4

applies. The calculations are:

500 digital points x 18 bytes/point = 9,000 bytes

200 analog points x 22 bytes/point = 4,400 bytes

50 station points x 70 bytes/point = 3,500 bytes

20 modules x 10 bytes/module = 200 bytes

10 PCUs x 16 bytes/PCU = 160 bytes

Total memory used in the remote PPT = 17,260 bytes