Page 1

®

Process Control and

Automation Solutions

from Elsag Bailey Group

®

Operator Interface Console (40 Series)

Hardware Manual

(IIOIC42)

E96-192-5

Page 2

WARNING notices as used in this instruction apply to hazards or unsafe practices that could result in

personal injury or death.

CAUTION notices apply to hazards or unsafe practices that could result in property damage.

NOTES highlight procedures and contain information that assists the operator in understanding the

information contained in this instruction.

WARNING

INSTRUCTION MANUALS

DO NOT INSTALL, MAINTAIN, OR OPERATE THIS EQ UIPMENT WITHOUT READING, UNDERSTANDING,

AND FOLLOWING THE PROPER

DAMAGE MAY RESULT.

Elsag Bailey

INSTRUCTIONS AND MANUALS; OTHER WISE, INJURY OR

RADIO FREQUENCY INTERFERENCE

MOST ELECTRONIC EQUIPMENT IS INFLUENCED BY RAD IO FREQUENCY INTERFERENCE (RFI). CAUTION SHOULD BE EXERCISED WITH REGARD TO THE USE OF PORTABLE COMMUNICATIONS EQUIPMENT IN THE AREA AROUND SUCH EQUIPMENT. PRUDENT PRACTICE DICTATES THAT SIGNS

SHOULD BE POSTED IN THE VICINITY OF THE EQUIPMENT CAUTIONING AGAINST THE USE OF PORTABLE COMMUNICATIONS EQUIPMENT.

POSSIBLE PROCESS UPSETS

MAINTENANCE MUST BE PERFORMED ONLY BY QUALIFIE D PER SONNEL AN D ONLY AFTE R SEC URING

EQUIPMENT CONTROLLED BY THIS PRODUCT. ADJUSTING OR REMOVING THIS PRODUCT WHILE IT IS

IN THE SYSTEM MAY UPSET THE PROCESS BEING CONTROLLED. SOME PROCESS UPSETS MAY

CAUSE INJURY OR DAMAGE .

AVERTISSEMENT

MANUELS D’OPÉRATION

NE PAS METTRE EN PLACE, RÉPARER OU FAIRE FONCTIONNER L’ÉQUIPEMENT SANS AVOIR LU,

COMPRIS ET SUIVI LES INSTRUCTIONS RÉGLEMENTAIRES DE

CET ÉGARD POURRAIT ÊTRE UNE C AUSE D’ACC IDENT OU DE DÉFAILL ANCE DU MA TÉRIEL.

Elsag Bailey

. TOUTE NÉGLIGENCE À

PERTURBATIONS PAR FRÉQUENCE RADIO

LA PLUPART DES ÉQUIPEMENTS ÉLECTRONIQUES SONT SENSIBLES AUX PERTURBATIONS PAR

FRÉQUENCE RADIO. DES PRÉCAUTIONS DEVR ONT ÊTRE PRISES LORS DE L’UTILISATION DU MATÉRIEL DE COMMUNICATION PORTATIF. LA PRUDENCE EXIGE QUE LES PRÉCAUTIONS À PRENDRE

DANS CE CAS SOIENT SIGNALÉES AU X ENDROITS VO ULUS DANS VOTR E USINE.

PERTURBATIONS DU PROCÉDÉ

L’ENTRETIEN DOIT ÊTRE ASSURÉ PAR UNE PERSONNE QUALIFIÉE EN CONSIDÉRANT L’ASPECT

SÉCURITAIRE DES ÉQUIPEMENTS CONTRÔLÉS PAR CE PRODUIT. L’AJUSTEMENT ET/OU L’EXTRACTION DE CE PRODUIT PEUT OCCAS IONNER DES À-COUPS AU PROCÉD É CONTRÔLE LORSQU’IL EST

INSÉRÉ DANS UNE SYSTÈME ACTIF. CES À-COUPS PEUVENT ÉGALEMENT OCCASIONNER DES

BLESSURES OU DES DOMMAGES M ATÉREILS.

NOTICE

The information contained in this docume nt is s ubj ect to change wi thout noti ce.

Elsag Bailey, i ts af fili at es , em pl oye es , an d a gen ts, a n d th e a u thor s an d co ntr ib utors to this publ ica ti on specif-

ically disclaim all liabilities and warranties, express and implied (including warranties of merchantability and

fitness for a pa rt icu lar p urp os e) , fo r the ac cur a cy, cur r en cy, co mple t en ess, an d/ o r r eliability of t he i nfo r mati on

contained herein and/or for the fitness for any particular use and/or for the performance of any material and/

or equipment selected in whole or part with the user of/or in reliance upon information contained herein.

Selection of materials and/or equipment is at the sole risk of the user of this publication.

This document contains proprietary i nformation of Elsag Baile y, Elsag Bailey Proces s Automation, and

is issued in strict confidence. Its use, or reproduc tion for use, for the re verse engineering, de velopment

or manufacture of hardware or software described herein is prohibited . No part of this docume nt may be

photocopied or reproduced without the prior written c onse nt of El sag B aile y.

Page 3

Preface

This instruction provides specific hardware installation, troubleshooting, maintenance, repair and replacement procedures

information necessary for the IIOIC42 Operator Interface Console. This operator interface console is compatible with the

IIOIS42 Operator Interface Station and with the IIOIS41 Operator Interface Station. These stations must use G.3 software or

later.

This instruction should be used in conjunction with the hardware manual for the appropriate IIOIS Operator Interface Station. There are three additional instructions that explain how

to set up and use the OIC console and OIS station. The

instructions include:

File Utilities

Operation

Configuration

Provides software load, upgrade and maintenance procedures,

as well as save and restore configuration procedures.

Gives a brief overview of the console and INFI 90® OPEN system to familiarize the reader. It then explains the operations

that can be performed after configuring the OIS console.

Gives the procedures to configure the OIS console as a system

for proper operation with its OIC console and peripherals and

the INFI 90 OPEN system. It also explains each function of the

OIS console, and gives configuration procedures and requirements.

®

Registered trademark of Elsag Bailey Process Automation.

I-E96-192-5A

Page 4

List of Effective Pages

Total number of pages in this instruction is 100, consisting of the following:

Page No. Change Date

Preface Original

List of Effective Pages Original

iii through x Original

1-1 through 1-9 Original

2-1 through 2-2 Original

3-1 through 3-31 Original

4-1 through 4-3 Original

5-1 through 5-6 Original

6-1 through 6-30 Original

7-1 through 7-2 Original

A-1 through A-4 Original

Index-1 through Index-3 Original

®

When an update is received, insert the latest changed pages and dispose of the superseded pages.

NOTE:

gin of the page adjacent to the changed area. A changed figure is indicated by a vertical bar in the

outer margin next to the figure caption. The date the update was prepared will appear beside the

page number.

On an update page, the changed text or table is indicated by a vertical bar in the outer mar-

I-E96-192-5A

Page 5

Safety Summary

®

GENERAL

WARNINGS

SPECIFIC

WARNINGS

Equipment Environment

All components, whether in transportation, operation or storage,

must be in a noncorrosive environment.

Electrical Shock Hazard During Maintenance

Disconnect power or take precautions to insure that contact with

energized parts is avoided when servicing.

Verify all covers are installed and all doors are closed before operating the console. Exposed electrical connections present a shock

hazard that can cause injury or death. (p. 3-2, 3-6)

Never clean electrical parts or components with the power on.

Doing so exposes you to a fatal electrical shock hazard. (p. 5-3)

Wear eye protection whenever working with cleaning solvents.

When removing solvents from printed circuit boards using compressed air, injury to the eyes could result from splashing solvent as

it is blown off the printed circuit board. (p. 5-3)

The monitor will slide out the rea r of the cabinet by itself wh en the

mounting bolts are removed. The moni tor weig hs approxim ately 27

kilograms (60 p ounds) and can caus e bodi ly inj ury if it is allowe d to

slide out by itself. Su ppo rt the m onitor be for e remo vi ng t he r ea r two

bolts. (p. 6-22, 6-23)

SPECIFIC

CAUTIONS

viii I-E96-192-5A

Make sure that all voltage labels and v oltage swit ch setting s on the

peripheral devices, po wer supply and power ent ry panel show the

correct operating voltage. Equipment damage may result if the

incorrect voltage i s connected. Make su re the console main power

circuit breaker is off before changing operating voltage setting or

equipment damage may result. (p. 3-4, 3-31)

Remove power from all peripheral equipment and the console

before installing or removing peripheral equipment. Equipment

damage may result. (p. 3-5, 3-31)

Failure to turn off the main power circuit breaker before removing or

inserting modules into the card cage may result i n equipment failure. (p. 6-3)

On the keyboard interface connector board, set positions 5, 6 and 7

of dipswitch SW1 to closed (on). Set positions 1 thr ough 4 and 8 of

dipswitch SW1 to open (off). Failure to configure dipswitch SW1

properly will damage the CPU in the console. (p. 6-17)

Page 6

Sommaire de Sécurité

AVERTISSEMENTS

D’ORDRE

GÉNÉRAL

AVERTISSEMENTS

D’ORDRE

SPÉCIFIQUE

Environnement de l’équipement

Ne pas soumettre les compos ants à une atm osphère corros ive lor s

du transport, de l’entreposage ou l’utilisation.

Possibilité de chocs électriques durant l’entretien

Débrancher l’alimentation ou prendre les précautions pour éviter

tout contact avec des composants sous tension durant l’entretien.

Assurez-vous que tous les couvercles sont installés et toutes les

portes fermées avant de faire fonctionner la console. L´exposition à

des connexions électriques presénte un risque de blessure ou

d´électrocution fatale. (p. 3-2, 3-6)

Il ne faut jamais nettoyer des pièceso u des compos ants él ectriq ues

lorsqu'ils sont sous tension. Ceci présente un risque d'électrocution

fatale. (p. 5-3)

Portez toujours des lu nettes de protection l orsque vous utilisez des

solvants de nettoyage. L'ai rcomprimé servant à enlever le solvant

des cartes de circuits imprimés provoque des éclaboussures qui risquent d'atteindre les yeux. (p. 5-3)

Supportez le monit eur a va nt de retir er les d eux b oul ons d 'anc rang e

à l'arriér. Lorsque ces boulons d'ancrage sont retirés , l'e moniteur

glissera et sorta à l'arriér de l'armoi re. l'e m oniteur pés e enviro n 27

kilograms (60 po unds) et pourrait entrain er des blessures si on le

laisse glisser de l'armoire. (p. 6-22, 6-23)

ATTENTIONS

D’ORDRE

SPÉCIFIQUE

I-E96-192-5A ix

Assurez-vous que toutes les indications de tension et tous les

réglages de tension sur les périphériqu es, le bloc d´alim entation et

le panneau d´entrée des alime ntat ions cor respond ent bien à la tension de service. Une tension incorrecte risque d´endommager

l´equipment. Assu res-vous que le disjonc teur d´alimentation pri ncipal de la console est étient avant de modif ier les réglages de tension de service afin d´éviter d´endommager l´équipment.

(p. 3-4, 3-31)

Coupez l´alimentation des périphériques et de la console avant

d´installer ou d e reti rer de s pér iphé rique s, s inon l´ équipm ent r isqu e

de subir des dommages. (p. 3-5, 3-31)

Si l'on omet d'eteindre l 'interrupteur du circui t d'alimentation princ ipal avant de retirer les cartes ou de les inserer dans le porte-cartes,

l'equipment pourrait faire default. (p. 6-3)

Page 7

®

Sommaire de Sécurité

ATTENTIONS

D’ORDRE

SPÉCIFIQUE

(suite)

Sur le circuit de raccordement de l'interface du clavier, règler les

interrupteurs 5, 6 et 7 de SW1 à la position fermèe (ON). Règler les

interrupteurs 1 à 4 et 8 de SW1 à l a p os ition ouverte (OFF). Si l es

interrupteurs de SW1 ne sont pas configurés adéquatement, le

CPU de la console sera endommagé. (p. 6-17)

(suite)

x I-E96-192-5A

Page 8

Table of Contents

Page

SECTION 1 - INTRODUCTION....................................................................................................1-1

OVERVIEW ..................................................................................................................1-1

INTENDED USER.........................................................................................................1-1

OIC DESCRIPTION.......................................................................................................1-1

CPU (Central Processing Unit) ................................................................................1-4

IIOIC421 Tabletop Console.....................................................................................1-4

IIOIC4221 and IIOIC4222 Console .........................................................................1-4

IIOIC423 Environmental Cabinet ...........................................................................1-4

IIOIC424 Panel Mounted........................................................................................1-5

INSTRUCTION CONTENT .............................................................................................1-5

HOW TO USE THIS INSTRUCTION ...............................................................................1-5

GLOSSARY OF TERMS AND ABBREVIATIONS .............................................................1-6

REFERENCE DOCUMENTS..........................................................................................1-6

NOMENCLATURE ........................................................................................................1-7

OIC CONSOLE SPECIFICATIONS .................................................................................1-7

SECTION 2 - DESCRIPTION AND OPERATION........................................................................2-1

INTRODUCTION...........................................................................................................2-1

OIC CONSOLE FUNCTIONAL OPERATION ...................................................................2-2

SECTION 3 - INSTALLATION .....................................................................................................3-1

INTRODUCTION...........................................................................................................3-1

SPECIAL HANDLING ....................................................................................................3-1

UNPACKING AND INSPECTION ....................................................................................3-2

INSTALLATION PROCEDURE .......................................................................................3-3

AC POWER WIRING GUIDELINES ................................................................................3-4

AC OUTLETS ...............................................................................................................3-5

OIC INSTALLATION......................................................................................................3-5

IIOIC421 Tabletop Installation and Setup...............................................................3-6

IOIC421 Tabletop Wiring Connections and Cabling ................................................3-6

IIOIC422 Console Setup and Installation................................................................3-9

IIOIC422 Console Wiring Connections and Cabling ..............................................3-12

IIOIC423 Environmental Setup and Installation ...................................................3-16

IIOIC423 Environmental Wiring Connections and Cabling ...................................3-17

IIOIC424 Panel Mount Installation and Setup ......................................................3-20

IIOIC424 Panel Mount Wiring Connections and Cabling .......................................3-21

OPERATOR INTERFACE DEVICES ............................................................................3-21

Operator Keyboard...............................................................................................3-21

Engineering Keyboard..........................................................................................3-21

IIATB05 Trackball and IIAMS04 Mouse ................................................................3-24

IIADP01 Annunciator Display Panel .....................................................................3-24

IIADP02 Annunciator Display Panel .....................................................................3-25

NADS03 Annunciator Display Panel.....................................................................3-26

Touch Screen.......................................................................................................3-27

Controller Board Installation..........................................................................3-28

Touch Screen Installation ..............................................................................3-28

Calibrating the Touch Screen.........................................................................3-29

Touch Screen Jumper and Switch Settings ....................................................3-29

PERIPHERALS ...........................................................................................................3-30

SOFTWARE INSTALLATION AND START-UP...............................................................3-31

I-E96-192-5A iii

Page 9

®

Table of Contents

(continued)

Page

SECTION 4 - TROUBLESHOOTING...........................................................................................4-1

INTRODUCTION .......................................................................................................... 4-1

TROUBLESHOOTING...................................................................................................4-1

DIAGNOSTIC POWER UP TESTS.................................................................................. 4-2

AC Power Test .......................................................................................................4-2

DC Power Test ....................................................................................................... 4-3

SECTION 5 - MAINTENANCE.....................................................................................................5-1

INTRODUCTION .......................................................................................................... 5-1

PREVENTIVE MAINTENANCE SCHEDULE................................................................... 5-1

EQUIPMENT AND TOOLS REQUIRED ......................................................................... 5-2

STANDARD PREVENTIVE MAINTENANCE PROCEDURES ........................................... 5-3

Checking Connections........................................................................................... 5-3

Cleaning the Monitor ............................................................................................. 5-3

Cleaning the Operator Keyboard ............................................................................ 5-4

Cleaning the Engineering Keyboard .......................................................................5-4

Cleaning the Printed Circuit Boards....................................................................... 5-4

General Cleaning and Washing........................................................................ 5-4

Cleaning Edge Connector ................................................................................5-5

Cleaning Female Edge Connectors................................................................... 5-5

Checking Power Supply Outputs ........................................................................... 5-5

Checking and Inspecting Power Entry Panel .......................................................... 5-6

SECTION 6 - COMPONENT DESCRIPTION AND REPLACEMENT .........................................6-1

INTRODUCTION .......................................................................................................... 6-1

IIMKM02A MULTIBUS KEYBOARD MODULE............................................................... 6-1

IIMKM02A MULTIBUS KEYBOARD MODULE REPLACEMENT ..................................... 6-3

MULTIBUS CARD CAGE .............................................................................................. 6-4

FAN ASSEMBLY FOR THE CARD CAGE....................................................................... 6-5

POWER SUPPLY REMOVAL ......................................................................................... 6-5

IIOIC421 Tabletop ................................................................................................. 6-7

IIOIC422 Console ..................................................................................................6-8

IIOIC423 Environmental Cabinet........................................................................... 6-9

IIOIC424 Panel Mount ......................................................................................... 6-10

POWER ENTRY PANEL ..............................................................................................6-10

IIOIC422 Console ................................................................................................6-11

IIOIC423 Environmental Cabinet......................................................................... 6-12

IIOIC424 Panel Mount ......................................................................................... 6-13

OPERATOR INTERFACE DEVICES............................................................................. 6-14

Operator and Engineering Keyboards, Mouse, Trackball ...................................... 6-14

Annunciator Display Panel ..................................................................................6-15

IIOIC421 Tabletop Model............................................................................... 6-15

IIOIC422 Console Model ................................................................................ 6-15

IIOIC423 Environmental Model ..................................................................... 6-16

IIOIC424 Panel Mounted Model ..................................................................... 6-16

Keyboard Interface Assembly ............................................................................... 6-17

IIOIC421 Tabletop Model............................................................................... 6-19

IIOIC422 Console Model ................................................................................ 6-19

IIOIC423 Environmental Model ..................................................................... 6-20

IIOIC424 Panel Mounted Model ..................................................................... 6-20

Color Monitor ...................................................................................................... 6-21

IIOIC421 Tabletop Model............................................................................... 6-21

iv I-E96-192-5A

Page 10

Table of Contents

SECTION 6 - COMPONENT DESCRIPTION AND REPLACEMENT

IIOIC422 Console Model ................................................................................6-23

IIOIC423 Environmental Model......................................................................6-23

IIOIC424 Panel Mounted Model......................................................................6-24

MONITOR Assembly ......................................................................................6-24

CPU REMOVAL ..........................................................................................................6-25

IIOIC421 Tabletop Model ...............................................................................6-25

IIOIC422 Console...........................................................................................6-25

IIOIC423 Environmental Cabinet ...................................................................6-27

IIOIC424 Panel Mount ...................................................................................6-28

CPU Assembly ...............................................................................................6-29

PERIPHERALS ...........................................................................................................6-30

(continued)

(continued)

Page

SECTION 7 - SUPPORT SERVICES...........................................................................................7-1

INTRODUCTION...........................................................................................................7-1

REPLACEMENT PARTS AND ORDERING INSTRUCTIONS ............................................7-1

TRAINING ....................................................................................................................7-1

TECHNICAL DOCUMENTATION ...................................................................................7-1

SPARE PARTS ..............................................................................................................7-1

APPENDIX A - QUICK REFERENCE INFORMATION ..............................................................A-1

INTRODUCTION.......................................................................................................... A-1

List of Tables

No. Title Page

1-1. IIOIC42 Models ......................................................................................................1-4

1-2. Glossary of Terms and Abbreviations .....................................................................1-6

1-3. Reference Documents ............................................................................................1-6

1-4. Hardware Nomenclature ........................................................................................1-7

1-5. OIC Console Specifications.....................................................................................1-7

3-1. OIC Wiring Color Codes .........................................................................................3-5

3-2. IIOIC421 Tabletop Cable Connections ....................................................................3-8

3-3. IIOIC422 Console Cable Connections ...................................................................3-14

3-4. IIOIC423 Cable Connections ................................................................................3-18

3-5. IIOIC424 Panel Mount Cable Connections ............................................................3-22

3-6. IIADP01 Board Connections.................................................................................3-25

3-7. Touch Screen Nomenclature ................................................................................3-27

3-8. Touch Screen Parts..............................................................................................3-28

4-1. Troubleshooting Guide...........................................................................................4-1

5-1. Preventive Maintenance Schedule and Check List ..................................................5-2

6-1. Hardware...............................................................................................................6-1

6-2. DC Distribution Board Socket Connections ............................................................6-6

6-3. DC Distribution Board Pin Outs.............................................................................6-6

7-1. Recommended Spare Parts.....................................................................................7-2

I-E96-192-5A v

Page 11

List of Figures

No. Title Page

1-1. IIOIC421 Tabletop Model ....................................................................................... 1-2

1-2. IIOIC4221 Console Model ......................................................................................1-2

1-3. IIOIC423 Environmental Model.............................................................................. 1-3

1-4. IIOIC424 Panel Mounted Model ............................................................................. 1-3

2-1. OIC Communication Levels.................................................................................... 2-1

2-2. IIOIC42 Block Diagram.......................................................................................... 2-2

3-1. IIOIC421 Tabletop (19-inch) Dimensions................................................................ 3-7

3-2. IIOIC421 Tabletop Connections (Keyboard Interface Assembly) ..............................3-7

3-3. IIOIC421 Tabletop Cable Connections.................................................................... 3-8

3-4. IIOIC422 Console Dimensions .............................................................................3-10

3-5. IIOIC422 Console Keyboard Table........................................................................ 3-11

3-6. IIOIC422 Console 15 Degree Wedge Dimensions ..................................................3-11

3-7. IIOIC422 Console 45 Degree Wedge Dimensions ..................................................3-12

3-8. IIOIC422 Console Power Entry Panel Connections ............................................... 3-13

3-9. IIOIC422 Console Cable Connections................................................................... 3-14

3-10. IIOIC423 Environmental Cabinet Dimensions...................................................... 3-16

3-11. IIOIC423 Environmental Cabinet Anchoring Dimensions .....................................3-17

3-12. IIOIC423 Environmental Cabinet Power Entry Panel Connections ........................ 3-18

3-13. IIOIC423 Environmental Cabinet Cable Connections ........................................... 3-19

3-14. IIOIC424 Panel Mount Dimensions ...................................................................... 3-20

3-15. IIOIC424 Panel Mount Power Entry Panel Connections ........................................ 3-21

3-16. IIOIC424 Panel Mount Connections ..................................................................... 3-22

3-17. Operator Keyboard .............................................................................................. 3-23

3-18. Engineering Keyboard.......................................................................................... 3-24

3-19. IIADP01 Annunciator Display Panel SW1 Settings ............................................... 3-25

3-20. IIADP02 Annunciator Display Panel..................................................................... 3-26

3-21. NADS03 Annunciator Display Panel SW1 Settings ............................................... 3-27

3-22. Touch Screen Controller Card Connections.......................................................... 3-29

3-23. Touch Screen Switch and Jumper Settings .......................................................... 3-30

6-1. IIMKM02A Multibus Keyboard Module................................................................... 6-2

6-2. IIOIC422 Multibus Card Cage (Front View) ............................................................ 6-4

6-3. IIOIC422 Multibus Card Cage (Rear View).............................................................. 6-5

6-4. Connections to DC Distribution Board................................................................... 6-6

6-5. Power Supply Removal for IIOIC421 Tabletop Console ........................................... 6-7

6-6. Power Supply Removal for IIOIC422 Consoles ........................................................ 6-8

6-7. Power Supply Removal for IIOIC423 Environmental Console .................................. 6-9

6-8. Power Supply Removal for IIOIC424 Panel Mount Console ................................... 6-10

6-9. Power Entry Panel (PEP) Removal for IIOIC422 Consoles...................................... 6-12

6-10. Power Entry Panel (PEP) Removal for IIOIC423 Environmental Cabinet ................ 6-13

6-11. Power Entry Panel Removal for IIOIC424 Panel Mount ......................................... 6-14

6-12. ADP02 Removal from IIOIC422 Console ............................................................... 6-15

6-13. NADS03 Removal from IIOIC423 Environmental Cabinet ..................................... 6-17

6-14. Keyboard Interface Assembly (IIOIC422 Model) ....................................................6-18

6-15. Keyboard Interface Assembly Removal for IIOIC422 Consoles .............................. 6-20

6-16. Color Monitor Connections .................................................................................. 6-22

6-17. CPU Removal for IIOIC421 Tabletop Console ....................................................... 6-26

6-18. CPU Removal for IIOIC422 Consoles .................................................................... 6-27

6-19. CPU Removal for IIOIC423 Environmental Console .............................................. 6-28

6-20. CPU Removal for IIOIC424 Panel Mount Console ................................................. 6-29

6-21. CPU Connector Identification............................................................................... 6-30

A-1. IIMKM02A Multibus Keyboard Module...................................................................A-1

A-2. Keyboard Interface Connector Board...................................................................... A-2

®

vi I-E96-192-5A

Page 12

List of Figures

No. Title Page

A-3. IIOIC421 Keyboard Interface Assembly.................................................................. A-2

A-4. Color Monitor........................................................................................................ A-3

A-5. Touch Screen Controller Board ............................................................................. A-3

A-6. IIADP01, IIADP02 and NADS03 ............................................................................. A-4

A-7. IIADP01 Multiple Annunciator Displays ................................................................ A-4

(continued)

I-E96-192-5A vii

Page 13

OVERVIEW

INTENDED USER

SECTION 1 - INTRODUCTION

The IIOIC42 Operator Interface Console (auxiliary console) is a

remote monitor and keyboard interface that connects to a

main console, either a IIOIS41 or IIOIS42 Operator Interface

Station (G.3 or later software). The main console connects to

the Plant Loop

In this document, auxiliary terminal refers to an IIOIC42 console (Figures 1-1 through 1-4). Read all of this instruction to

get the greatest benefit of the information it contains. Read

each procedure before doing the task. Call the local Elsag

Bailey sales office for technical assistance.

This section contains an overview of the auxiliary console. This

document contains directions and cautions for installing and

servicing the operator interface console (OIC).

System engineers and technicians with a background in process control systems should read this instruction thoroughly

before installing and using the system. Do not put the console

into operation until you read and thoroughly understand this

instruction. This instruction is a reference for installers with

installation and maintenance experience on process control

equipment. It is not a tutorial.

®

or INFI-NET® communication highway.

OIC DESCRIPTION

The operator interface console is an auxiliary console for the

main console (OIS). It provides a remote operator interface for

displaying graphics, alarm summaries, INFI 90

®

OPEN status

and for logging, trending and process control. The auxiliary

console allows more than one operator to use a single main

console. The four models of OIC42 operator consoles are

19-inch tabletop (IIOIC421), console (IIOIC422 which has two

variations), environmental cabinet (IIOIC423), and 19-inch

panel mount model (IIOIC424). The variations of the console

model (IIOIC422) can have an upper monitor (IIOIC4222) or

lower monitor (IIOIC4221).

An Ethernet network cable connects the OIC auxiliary console

to a OIS main console. Refer to Section 3 and Section 6 for more

hardware information. Four models of the OIC are shown in

Figures 1-1, 1-2, 1-3 and 1-4. Table 1-1 lists the models.

®

Registered trademark of Elsag Bailey Process Automation.

OVERVIEW

I-E96-192-5A 1 - 1

Page 14

INTRODUCTION

MONITOR

ASSEMBLY

KEYBOARD

INTERFACE

ASSEMBLY

CPU

POWER SUPPLY

AND M KM BOARD

LOCATEDINSIDE

CASE

KEYBOARD

ASSEMBLY

Baile y

MOUSE

WORK SURFACE

ASSEMBLY

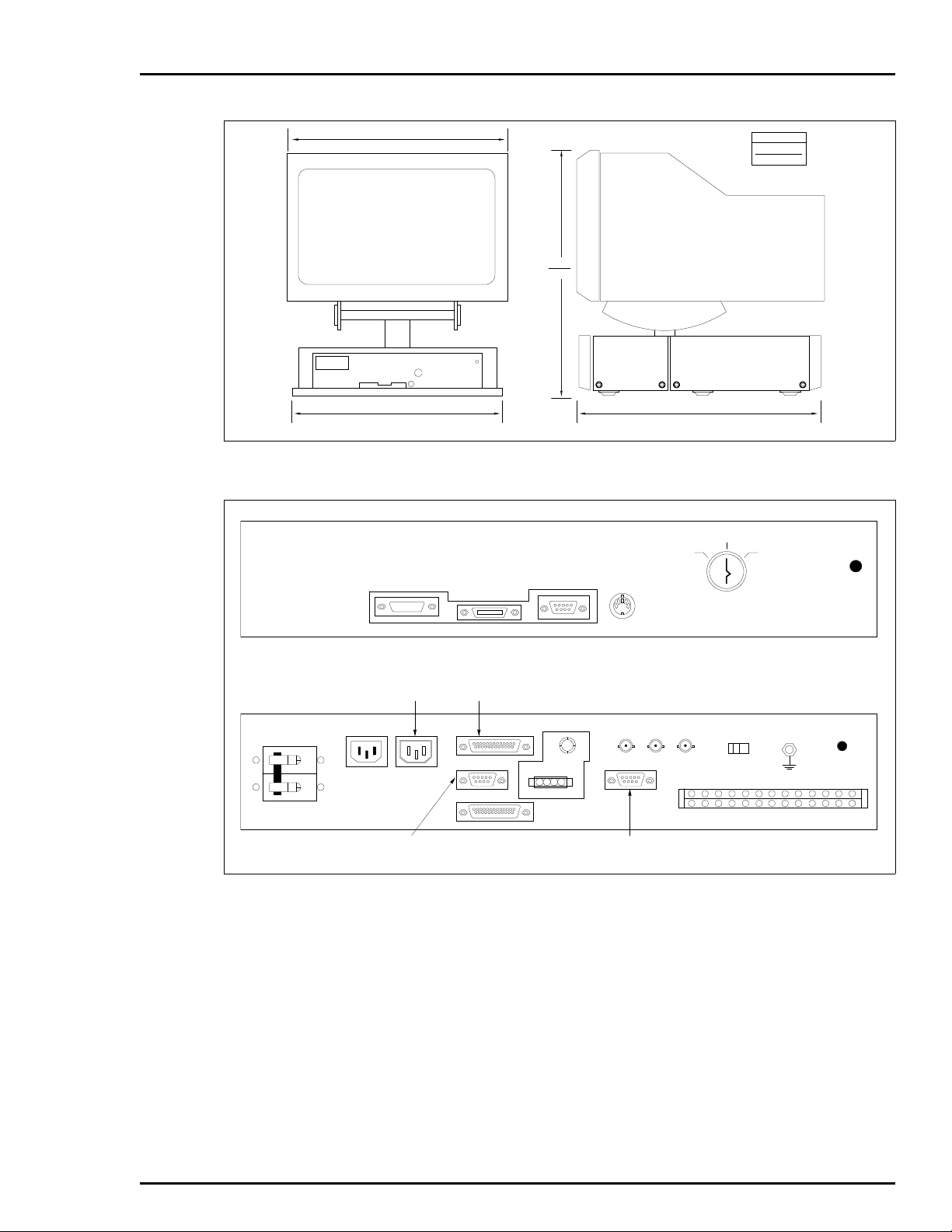

Figure 1-1. IIOIC421 Tabletop Model

®

TP80559A

ANNUNCIATOR

DISPLAY PANEL

KEYBOARD

INTE RFACE

ASSEMBLY

POWER SUPPLY

DC DISTRIBUTION

BOARD

POWER ENTRY

PANEL

REAR VIEW FRONT VIEW

MULTIBUS

CARD CAGE

CPU

ANNUNCIATOR

DISPLAY

PANEL

KEYBOARD

INTE RFACE

ASSEMBLY

KEYBOARD

POWER ENTRY

PANEL

MKM MODULE

TP80560A

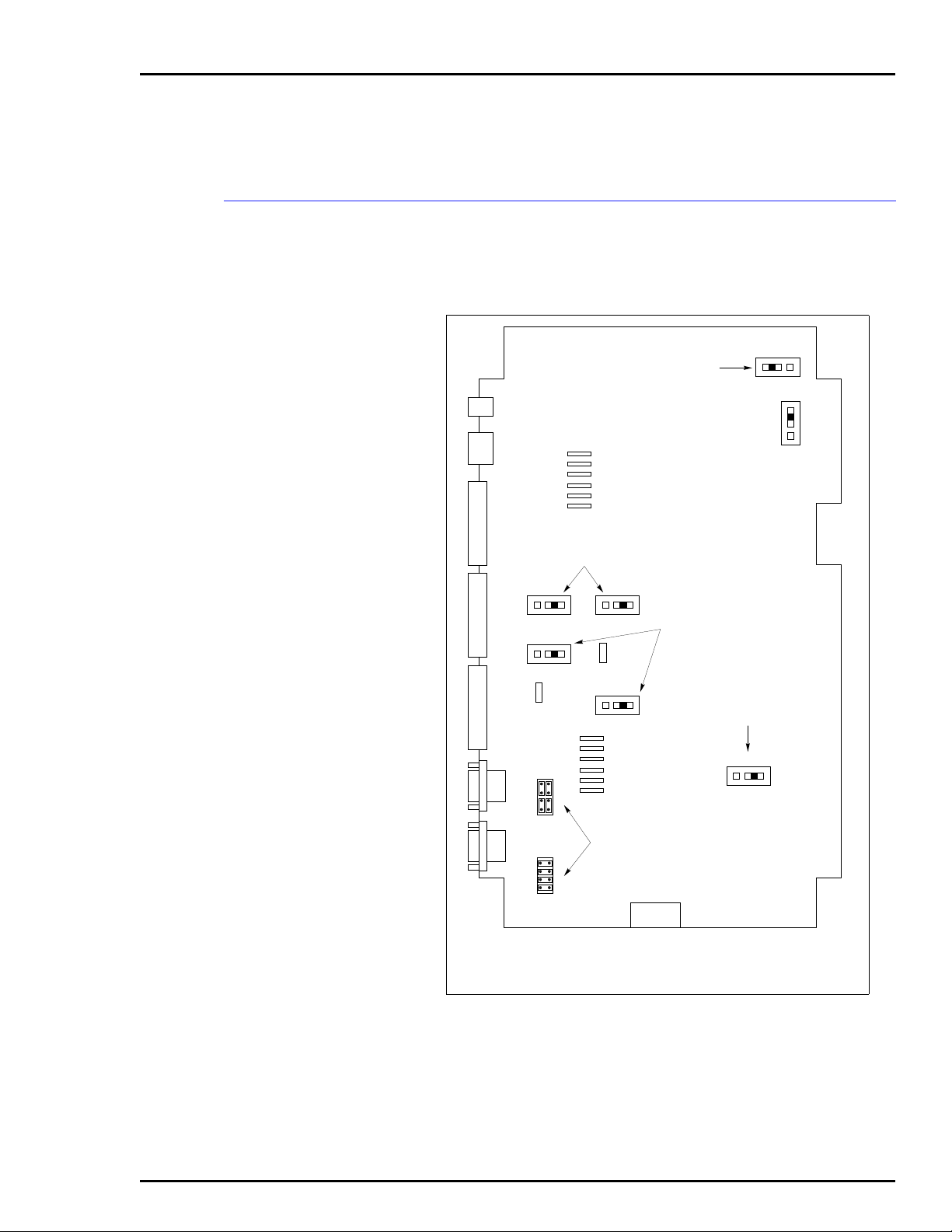

Figure 1-2. IIOIC4221 Console Model

OIC DESCRIPTION

1 - 2 I-E96-192-5A

Page 15

NADS03 ANNUNCIATOR

DISPLAY (CPU

MOUNTED BEHIND IN

VERTICAL POSITION)

QWERTY

KEYBOARD

JOYSTICK

OPERATO R

KEYBOARD

ASSEMBLY

MKM MODULE

POWER ENTRY PANEL,

POWER SUPPLY AND

KEYBOARD INTERFACE

ASSEMBLY

INTRODUCTION

MONITOR

ASSEMBLY

OFF

TUNE CONFIG

KEYBOARD

AUX 1

PORT

Figure 1-3. IIOIC423 Environmental Model

SPLIT TOP

COVER C RT

POWER EN TRY

PANEL (INCLUDES

MKM MODULE AND

POWER SUPPLY)

CPU

MOUSE/

TRACKBALL

AUX

KBD

KEYBOARD INTERFACE

ASSEMBLY

TP80561A .

TP80562A

Figure 1-4. IIOIC424 Panel Mounted Model

OIC DESCRIPTION

I-E96-192-5A 1 - 3

Page 16

INTRODUCTION

CPU (Central Processing Unit)

The CPU described in this manual is a Tektronix Model XP400.

Specifications for this CPU are listed at the end of this section

and in the manufacturer’s manuals.

IIOIC421 Tabletop Console

The hardware of the tabletop console is located in a moveable

case which sits on a work surface. The power supply and multibus keyboard module (IIMKM02A, also referred to as the

MKM) are in the case. The monitor is mounted on top of the

case and the keyboard interface assembly is located below the

monitor. The monitor can tilt and swivel.

®

Table 1-1. IIOIC42 Models

Nomenclature Description

IIOIC421 Tabletop with 19-inch monitor

IIOIC4221 Console with lower monitor

IIOIC4222 Console with upper monitor

IIOIC423 Environmental cabinet

IIOIC424 Panel mounted

The rear connector panel has an AC input, alarm relays, connectors for monitor cables and a power switch. The front panel

has the connectors for peripheral operator input devices and a

tune-off-configuration keyswitch. The CPU is located inside

the table on a shelf. Access the connections from the rear of

the cabinet. The alarm relays are for alarm annunciation only.

IIOIC4221 and IIOIC4222 Console

The hardware of the OIC422 console is very similar to the OIS

console. There are several differences. The CPU has only a

multibus keyboard module, it does not have a CIU, and it does

not have a floppy disk drive or hard disk drive.

The annunciator display panel and keyboard interface assembly are located to the right of the monitor. The power entry

panel is mounted in a vertical position in the lower part of the

cabinet. The multibus card cage and MKM module are to the

left of the power entry panel. The console may have a lower

monitor or an upper monitor.

IIOIC423 Environmental Cabinet

The environmental cabinet contains a monitor, power entry

panel, operator keyboard, annunciator display panel and

interface similar to the console model, 19-inch panel mount

and 19-inch tabletop model.

OIC DESCRIPTION

1 - 4 I-E96-192-5A

Page 17

IIOIC424 Panel Mounted

INSTRUCTION CONTENT

INTRODUCTION

The hardware of the environmental OIC console is separated

into the upper and lower half of the cabinet. The CPU and

monitor are located in the top of the cabinet. The power entry

panel and MKM module are in the lower half of the cabinet

with the power supply. The annunciator display panel and

monitor are on the front of the cabinet. The alarm relays are

for alarm annunciation only.

A sealed air conditioner provides internal cooling and the

stainless steel exterior provides corrosion protection.

The hardware of the panel mounted OIC console is located

behind the monitor and keyboard interface assembly. The

power supply, power entry panel, CPU and MKM module are

located with the monitor. The keyboard interface assembly is

mounted on a separate panel. The alarm relays are for alarm

annunciation only.

Introduction

Presents an overview of the OIC consoles and related hardware. It also provides a complete list of specifications.

Description and

Operation

Installation

Describes the theory of operation of the OIC consoles and

related hardware.

Describes the installation and cabling. It also describes the

jumper settings of the multibus modules and peripherals. Be

sure to read and follow all warnings and cautions.

Troubleshooting

Lists troubleshooting steps and provides a troubleshooting

guide.

Maintenance

Component Description

and Replacement

Support Services

Quick Reference

Information

Contains a schedule and procedures for maintenance.

Describes the hardware associated with the OIC42 and

replacement procedures for that hardware.

Includes a spare parts list and ordering instructions.

Contains jumper and switch settings and fuse locations.

HOW TO USE THIS INSTRUCTION

Read this entire instruction through in sequence before

attempting to install or use the console. It is important to

become familiar with the entire content of the instruction prior

to installing and operating the console to attain maximum system efficiency.

INSTRUCTION CONTENT

I-E96-192-5A 1 - 5

Page 18

INTRODUCTION

The instruction is organized into seven sections and a quick

reference. Its organization enables finding specific information

quickly, and using this instruction as a reference after becoming fully familiar with the console.

Be sure to read the notes which provide:

•

Additional information.

•

Information that should be considered before performing a

certain operation or function.

GLOSSARY OF TERMS AND ABBREVIATIONS

Table 1-2 contains those terms and abbreviations that are

unique to Bailey or have a definition that is different from

standard industry usage.

Table 1-2. Glossary of Terms and Abbreviations

Term Definition

ADP Annunciator display pan el.

CPU Tektronix Model XP400 Logic Module

INFI-NET Advanced data communication highway.

MKM The designation MKM in this manual refers to the IIMKM02A

multibus keyboard module.

OIS Operator interface station. Integrated operator console with

data acquisition and r eporting capabilities providing a digital

access into the process for flexible control and monitoring.

PCU Process control unit. A node on the plant-wide communication

network containing control and I/O modules.

PEP Power entry panel.

Plant Loop Network 90 data communication highway.

®

REFERENCE DOCUMENTS

Table 1-3 lists Elsag Bailey instructions referenced in this

instruction.

Table 1-3. Reference Documents

Number Document

I-E96-191-4 Hardware, Operator Interface Station, IIOIS41

I-E96-192-1 Operation, Operator Interface Station (40 Series)

I-E96-192-2 Configuration, Operator Interface Station (40 Series)

I-E96-192-3 File Utilities, Operator Interface Station (40 Series)

I-E96-192-4 Hardware, Operator Interface Station, IIOIS42

I-E96-500 Site Planning and Preparation

GLOSSARY OF TERMS AND ABBREVIATIONS

1 - 6 I-E96-192-5A

Page 19

NOMENCLATURE

INTRODUCTION

Table 1-4 contains the nomenclature used in this instruction.

Table 1-4. Hardware Nomenclature

Nomenclature Description

IIAKB04 QWERTY style auxiliary (engineering) keyboard.

IIAMS04 Mouse cursor controller.

IIATB05 Trackball cursor controller.

IIMKM02A Multibus keyboard module.

IIOIC421 Tabletop operator console w ith a 19-inc h monit or, tilt/

swivel base and keyboard .

IIOIC4221 Console styl e operato r conso le with a lower mounted

19-inch monitor and ke yboard.

IIOIC4222 Console style operator console with an upper

mounted 19-inch monitor with tilt swivel base and

keyboard.

IIOIC423 Environmental operator console with a 19-inch moni-

tor and keyboard.

IIOIC424 Panel mount operato r console with a 19-in ch monit or

and engineering keyboard.

OIC CONSOLE SPECIFICATIONS

Table 1-5 contains the specifications for the OIC Console.

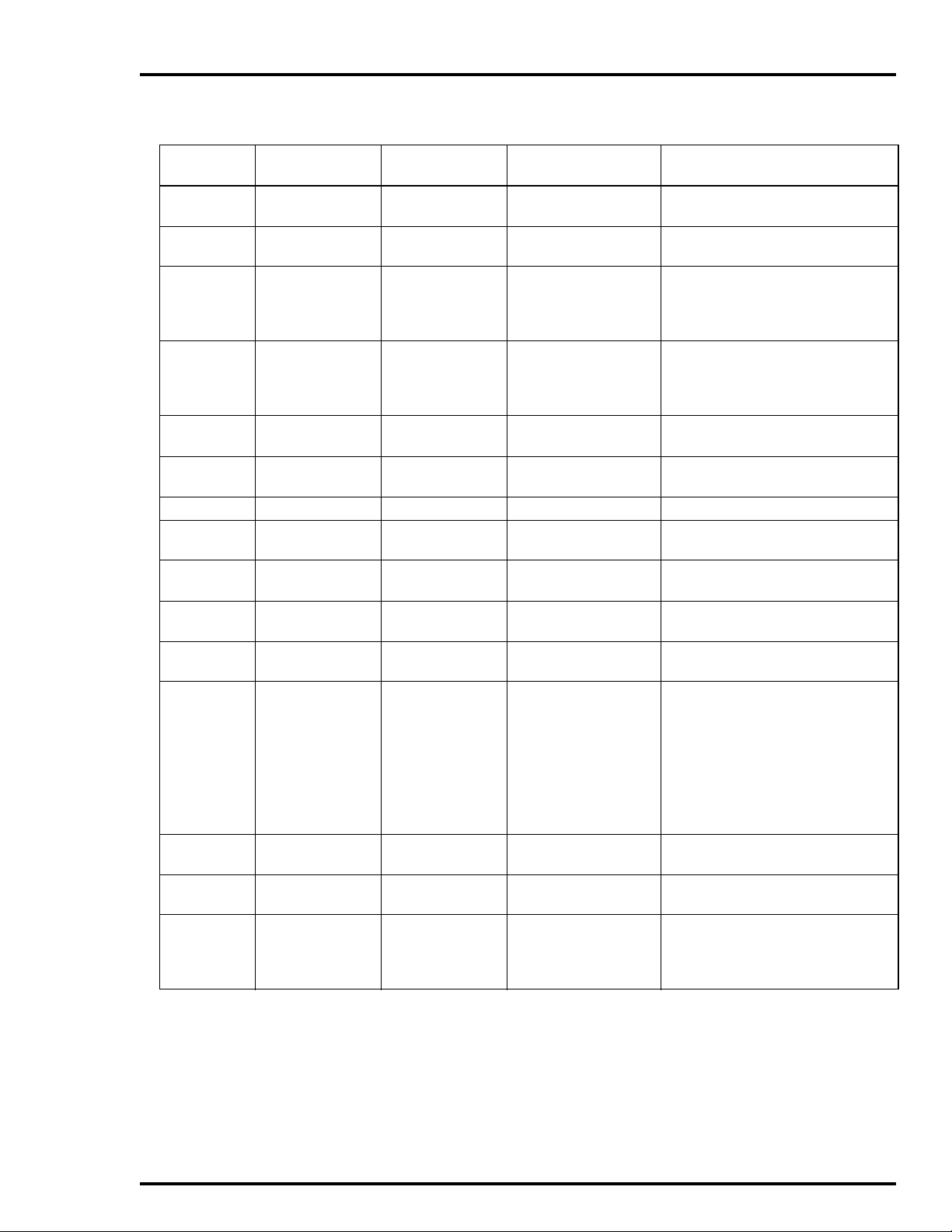

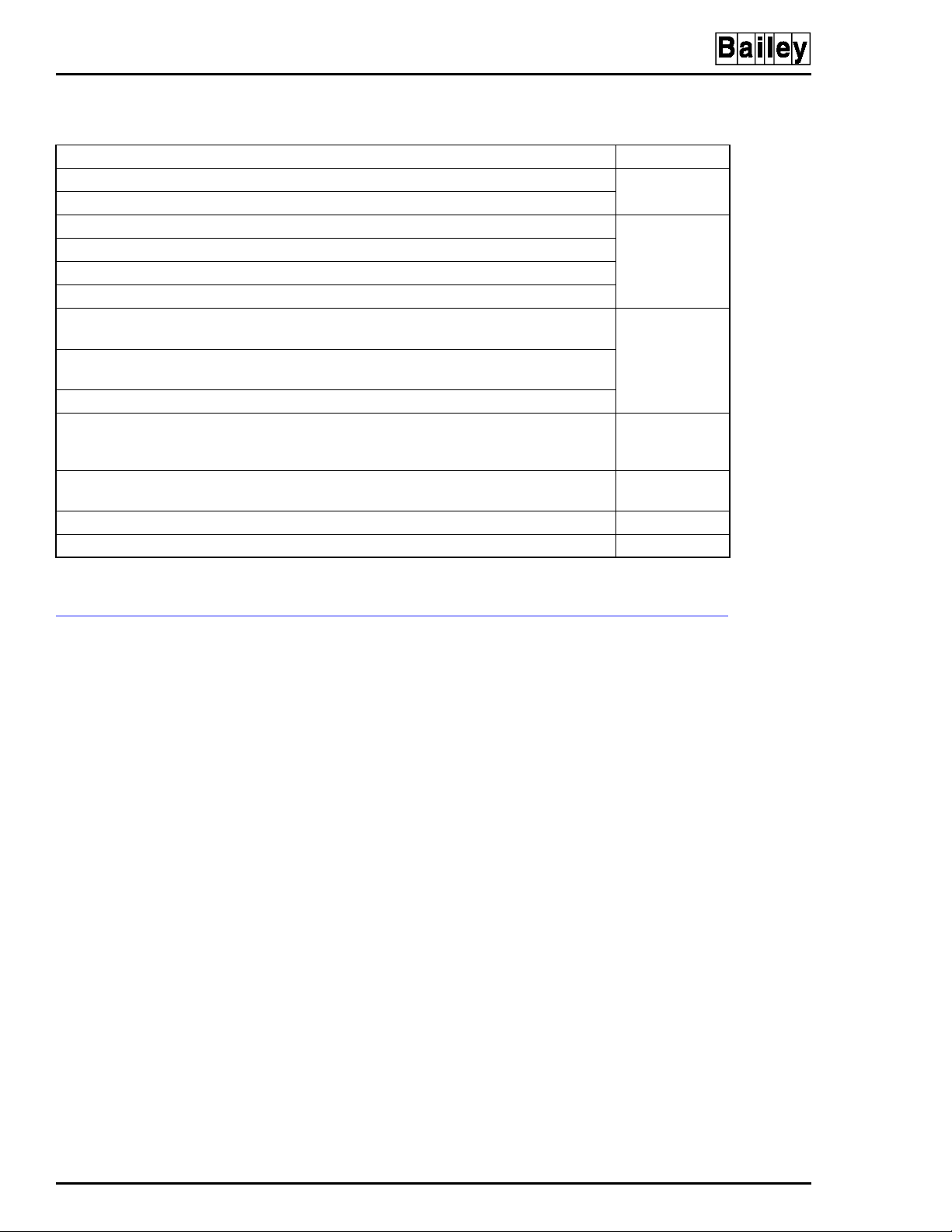

Table 1-5. OIC Console Specifications

Property Characteristic/Value

Power

Line voltage

Line frequency

Circuit breaker size

Power characteristics

240 V nominal (180 VAC to 264 VAC RMS)

120 V nominal (90 VAC to 132 VAC RMS)

47 to 63 Hz

20 A circuit breaker for IIOIC422 and IIOIC423 consoles

10 A circuit breaker for IIOIC421 and IIOIC424 consoles

Model

IIOIC421 42 2.96 0.610

IIOIC4221 42 2.34 0.730

IIOIC4222 42 2.34 0.730

IIOIC423 42 1.95 0.843

IIOIC424 42 2.96 0.610

Inrush Current

Amps Typical

Crest Factor

Power Factor

Typical

NOMENCLATURE

I-E96-192-5A 1 - 7

Page 20

INTRODUCTION

®

Table 1-5. OIC Console Specifications

(continued)

Property Characteristic/Value

Power consumption

Model Voltage

IIOIC421 120 1.96 2.55 175 227

240 1.20 1.56 175 227

IIOIC4221 120 1.80 2.34 158 205

240 1.11 1.44 162 211

IIOIC4222 120 1.80 2.34 158 205

240 1.11 1.44 162 211

IIOIC423 120 3.95 5.14 401 521

240 1.93 2.51 392 510

IIOIC424 120 1.96 2.55 175 227

240 1.20 1.56 175 227

Typical

Amps

Maximum

Amps

Power supply +5 VDC at 20 A, +12 VDC at 4 A, -12 VDC at 4 A

Keyboard Interface

Operator keyboard output relays rated at 250 mA 24-28 VDC per IIMKM02A

module.

Alarm Relays Rating

Contact Voltage 24 VDC

Contact Current 0.25 A

Contact Power 6 W

Typical

Watts

Maximum

Watts

Alarm relays

Alarm tones

6 per keyboard

5 per keyboard

Keyboards 1 Mylar (operator)

1 Engineering (QWERTY)

Annunciator display

4 (per IIMKM02A module) 32 pushbuttons and LEDs per panel

panels

Environment

Temperature

Operating: 10° to 40°C (50° to 104°F)

Nonoperating

1

: -30° to 65°C (-22° to 149°F

Storage: 5° to 50°C (41° to 122°F)

Relative humidity

Operating: 20% to 80% noncondensing

Recommended minimum: 40%

Storage: 10% to 90% noncondensing

Altitude

-0.3 to +2.4 km (-0.2 to 1.5 mi)

Cooling requirements

(Heat dissipation)

Model

IIOIC421 598 775

IIOIC4221 540 700

IIOIC4222 540 700

IIOIC423 1,339 1,742

BTU/Hr

Nominal

IIOIC424

BTU/Hr

Maximum

598 775

OIC CONSOLE SPECIFICATIONS

1 - 8 I-E96-192-5A

Page 21

INTRODUCTION

Table 1-5. OIC Console Specifications

(continued)

Property Characteristic/Value

Dimensions

Model

IIOIC421 55.80 22.00 49.53 19.50 60.96 24.00

IIOIC4221 107.27 42.23 71.12 28.00 109.01 42.92

IIOIC4222 156.94 61.78 71.12 28.00 109.01 42.92

IIOIC423 177.8 70.00 76.20 30.00 95.09 37.45

IIOIC424 614.1 24.17 116.00 45.67 94.97 37.39

Height Width Depth

cm. in. cm. in. cm. in.

Weight

Model

IIOIC421 175 386

IIOIC4221 164 360

IIOIC4222 191 420

IIOIC423 240 530

IIOIC424 71 157

Weight

kg lbs

Electrical noise Keep cabinet doors closed. Do not use portable transmitting equipment

within 2 m (6.5 ft) of a cabinet.

Certification (pending) CSA certified for use in an ordinary (non haz ard ous ) co ntro ll ed en vi ronm en t.

NOTE :

Nonoperating environment is defined as a transportation or storage period of less than 60 days.

1.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

OIC CONSOLE SPECIFICATIONS

I-E96-192-5A 1 - 9

Page 22

INTRODUCTION

SECTION 2 - DESCRIPTION AND OPERATION

This section explains the theory of operation for the operator

interface console. An operator uses the OIC console to monitor

and control the process through an OIS main console. For OIC

operating procedures, refer to the operation instruction.

The OIC console interfaces to INFI-NET and Plant Loop communication highways through the OIS main console. It can

monitor and allow manual control of a process through color

graphics displays which show equipment status and process

state. Figure 2-1 shows a block diagram of the communication

process.

DECNET

IIOIC421

IIOIS42

IIOIC422

IIOIC423

IIOIC424

COMMUNICATION HIGHWAY (INFI-NET OR PLANT LOOP)

COMMUNICATION

MODULES

CONTROL

MODULE

IIOIS20

CONTROLWAY

I/O EXPANDE R B U S

CONTROL

MODULE

Figure 2-1. OIC Communication Levels

IIOIC201

IIOIC202

IIOIC203

IIOIC204

IIOIC205

TP36271B

INTRODUCTION

I-E96-192-5A 2 - 1

Page 23

DESCRIPTION AND OPERATION

OIC CONSOLE FUNCTIONAL OPERATION

The OIC console controls and monitors a process through the

OIS console. The OIC console is a remote operator station with

a monitor and keyboard controlled by a CPU. Commands

between the OIC and OIS main console pass through an Ethernet network cable using either DECnet or TCP/IP protocol.

The OIC console uses a Tektronix model XP400 terminal logic

module. In the OIC console, the CPU sends video signals to the

monitor. A cable connects the CPU to the RGB connectors on

the monitor.

Figure 2-2 is a block diagram of the IIOIC42 operator interface

console. Refer to Section 3 for OIC CPU connections. Refer to

Section 6 for a description of the CPU.

INFI 90 O PEN

OPERATOR

KEYBOARD

®

IIAKB04

ENGINEERING

KEYBOARD

TOUCH SCREEN

JOYSTICK

(IIOIC423 ON LY)

KEYBOARD

INTER FACE

PANEL

MOUSE/

TRACKBALL

(IIOIC423 ON LY)

IIMKM02A

KEYBOARD

MODULE

CPU

RGB

MONITOR

ETHERNET

Figure 2-2. IIOIC42 Block Diagram

MOUSE/

TRACKBALL

(NOT USED ON

IIOIC423)

ADP PANEL

NETWORK

TO IIOI S 4 2

TP36273B

OIC CONSOLE FUNCTIONAL OPERATION

2 - 2 I-E96-192-5A

Page 24

INTRODUCTION

SPECIAL HANDLING

SECTION 3 - INSTALLATION

This section explains how to install and prepare the OIC consoles. This section is a guide for the system engineer or technician. Follow the procedures in this instruction carefully to

install, maintain and use the system properly. Elsag Bailey

recommends reading the entire instruction before beginning

the installation and powering up the console.

For other installation information, refer to the Site Planning

and Preparation instruction and the appropriate OIS instruction. Refer to Table 1-3 for the instruction number.

Observe these steps when handling electronic circuitry:

NOTE:

19483851) consisting of two wrist straps, ground cord assembly,

alligator clip, and static dissipating work surface when working with

static sensitive devices. The kit is designed to connect the technician and the static dissipating work surface to the same ground

point to prevent damage to the static sensitive devices by electrostatic discharge.

Always use the Elsag Bailey Field Static Kit (part number

Use the static grounding wrist strap when installing and

removing modules. Static discharge may damage static sensitive devices on modules in the cabinet. Use grounded equipment and static safe practices when working with static

sensitive devices.

1. Use static shielding bag. Keep the modules in static

shielding bag until you are ready to install them in the system.

Save the bag for future use.

2. Ground bags before opening. Before opening a bag containing an assembly with static sensitive devices, touch it to

the equipment housing or ground to equalize charges.

3. Avoid touching circuitry. Handle assemblies by the

edges; avoid touching the circuitry.

4. Avoid partial connection of static sensitive devices.

Verify that all devices connected to the modules are properly

grounded before using them.

5. Ground test equipment.

INTRODUCTION

I-E96-192-5A 3 - 1

Page 25

INSTALLATION

6. Use An Antistatic Field Service Vacuum. Remove dust

from the cards if necessary.

7. Use a grounded wrist strap. Connect the wrist strap to

the appropriate grounding plug on the power entry panel. The

grounding plug on the power entry panel is connected to the

cabinet chassis ground.

8. Do not use lead pencils to set dipswitches. To avoid

contamination of switch contacts that can result in circuit

board malfunction, do not use a lead pencil to set a dipswitch.

UNPACKING AND INSPECTION

Follow these steps for general handling:

1. Examine the console to make sure that no damage has

occurred in transit.

2. Notify the nearest Elsag Bailey sales office of any damage.

®

WARNING

AVERTISSEMENT

3. File a claim for any damage with the shipping company

that handled the shipment.

4. Use the original packing material or container to store the

console.

5. Store the console in a place with clean air; free of extremes

of temperature and humidity. Refer to Section 1 for the console

specifications.

Verify all covers are installed and all doors are closed before

operating the console. Exposed electrical connections present

a shock hazard that can cause injury or death.

Assurez-vous que tous les couvercles sont installés et toutes

les portes fermées avant de faire fonctionner la console.

L´exposition à des connexions électriques presénte un risque

de blessure ou d´électrocution fatale.

Do not remove or install circuit boards with power applied to

the console. The circuit board may be damaged. Remove power

to all AC wiring when removing or connecting AC wires to prevent personal injury and equipment damage. Remove DC

power to all DC wiring when removing or connecting DC wires

or circuit boards to prevent personal injury and equipment

damage.

UNPACKING AND INSPECTION

3 - 2 I-E96-192-5A

Page 26

INSTALLATION PROCEDURE

The following steps outline the required procedure to complete

the installation of the OIC console. Follow all related safety

procedures when doing these steps.

INSTALLATION

NOTE:

multibus card cage or doing maintenance on equipment containing

static sens itive devices, read

Before removing the multibus keyboard module from the

SPECIAL HANDLING

.

1. Install the cabinet or panel. Refer to the dimension drawings and instructions in the installation and setup sections

found later in this section.

2. Vibration during shipping and handling may unseat the

multibus keyboard module and connections, causing problems. Verify that the module is seated and that all terminal

block screws and stud fasteners are tight.

3. Refer to IIMKM02A MULTIBUS KEYBOARD MODULE in

Section 6 to check the jumper settings.

4. Connect OIC consoles to the OIS. Refer to the installation

and setup procedure for the OIC model being installed.

5. Verify that no power is present to the OIC when making

power wiring connections. Wire AC power according to the procedures in OIC INSTALLATION. Refer to the Site Planning

and Preparation instruction, the power requirements in

Section 1 and AC POWER WIRING GUIDELINES in this section.

NOTES:

1. Verify that the incoming voltage meets the rating on the label of

TB1 on the power entry panel and Table 1-5.

2. Make certain the OICs being installed are powered using the

same power source and ground as the OIS consol e. Failure to do so

may cause improper operation.

6. After completing the wiring:

•

Check that the keyboards and printers are connected to

the correct port. Refer to the appropriate wiring connections and cabling section and PERIPHERALS.

•

Ethernet network cable requires a terminator at each end

of the cable.

•

Check the AC voltage sources for proper voltage and current values. Refer to the specifications in Section 1 and AC

test in Section 4.

•

Apply power. If problems occur, refer to Section 4 for troubleshooting information.

INSTALLATION PROCEDURE

I-E96-192-5A 3 - 3

Page 27

INSTALLATION

AC POWER WIRING GUIDELINES

Make sure that all voltage labels and voltage switch settings on

the peripheral devices, power supply and power entry panel

CAUTION

ATTENTION

show the correct operating voltage. Equipment damage may

result if the incorrect voltage is connected. Make sure the console main power circuit breaker is off before changing operating voltage setting or equipment damage may result.

Assurez-vous que toutes les indications de tension et tous les

réglages de tension sur les périphériques, l e bloc d´alimentation et le panneau d´entrée des alimentations correspondent

bien à la tension de service. Une tension incorrecte risque

d´endommager l´equipment. Assures-vous que le disjoncteur

d´alimentation principal de la console est étient avant de modifier les réglages de tension de service afin d´éviter d´endommager l´équipment.

IIOIC422 AC power input connects to a terminal block on the

power entry panel. The power entry panel location and part

number will vary according the IIOIC42 model selected. The

IIOIC421 (tabletop model) does not use the power entry panel.

It has a rear connector panel with an IEC style AC input on the

keyboard interface assembly. Refer to the following sections

under OIC INSTALLATION for detailed AC power wiring connection procedures. The operator interface console can operate from 120/240 VAC, 50/60 hertz. The power entry panel

provides line filtering, transient suppression and a 20-amp circuit breaker.

®

Setting up the IIOIC42 console for 240 VAC requires no

changes. The power supply is autosensing. Refer to Section 6

for more power supply information. The color monitor is

autosensing and needs no changes for 240-VAC operation.

Monitors by other vendors may require changes. The CPU is

also autosensing and needs no change for 240-VAC operation.

The recommended minimum size for power wiring is 14 AWG

copper wire with a 600 volt, 75-degrees Celsius (167-degrees

Fahrenheit) rating and thermoplastic insulation. Wire with a

300-volt or 150-volt rating may be used if it is accepted by

local wiring codes. Wiring must be protected by cable trays or

conduit and suited for the service voltage.

Power wiring to the OIC console must include a third-wire

grounding conductor. This grounding conductor must not be a

smaller gauge than the power wiring and must be either bare,

green colored or green/yellow colored if insulated. The grounding conductor must be terminated at the system safety ground

connection on the front of the power entry panel.

AC POWER WIRING GUIDELINES

3 - 4 I-E96-192-5A

Page 28

AC OUTLETS

CAUTION

ATTENTION

INSTALLATION

Over-current protection provided for the AC distribution must

be sized to allow for the inrush current required by the OIC

hardware. Refer to the specifications in Section 1 for the peak

inrush current and duration for the OIC console.

For more information on power wiring, grounding, line conditioning and EMI (electromagnetic interference), refer to the

Site Planning and Preparation instruction.

Remove power from all equipment and the console before

installing or removing peripheral equipment. Equipment damage may result.

Coupez l´alimentation des périphériques et de la console avant

d´installer ou de retirer des périphériques, sinon l´équipment

risque de subir des dommages.

The number of AC outlets varies according to the OIC42 model

being used.

OIC INSTALLATION

NOTE:

outlets. Electrical noise may cause data to be lost or changed.

Do not connect motors, lights or test equipment to the AC

This section contains the installation and setup instructions

for the IIOIC421 tabletop, IIOIC422 console, IIOIC423 environmental cabinet and IIOIC424 panel mounted auxiliary terminals. Follow all cautions and warnings.

The OIC console is internally wired when it is shipped. Connect the communication loop cables, AC power and any

peripheral devices. Peripheral devices connect to the front of

the power entry panel, or to the keyboard interface assembly

front panel (IIOIC421 tabletop). Table 3-1 contains the color

codes for the wiring in the OIC console.

Table 3-1. OIC Wiring Color Codes

Color Function

Brown AC hot (inside PEP chassis only)

Blue AC neutral

Green/Yellow AC common

Brown +5 VDC

White/Green DC common

Violet -12 VDC

White/Violet +12 VDC

AC OUTLETS

I-E96-192-5A 3 - 5

Page 29

INSTALLATION

®

Table 3-1. OIC Wiring Color Codes

Green -Remote voltage sense signal wire

White +Remote voltage sense signal wire

Follow local wiring codes when wiring and installing cableways

or conduit. For more information, refer to the Site Planning

and Preparation instruction.

IIOIC421 Tabletop Installation and Setup

Verify all covers are installed and all doors are closed before

WARNING

operating the console. Exposed electrical connections present

a shock hazard that can cause injury or death.

Assurez-vous que tous les couvercles sont installés et toutes

AVERTISSEMENT

les portes fermées avant de faire fonctionner la console.

L´exposition à des connexions électriques presénte un risque

de blessure ou d´électrocution fatale.

The IIOIC421 tabletop model is normally used with a floor

mounted cabinet. The descriptions and procedures in this section apply only to the tabletop unit and do not apply to the

cabinet. Figure 3-1 shows the dimensions of the OIC tabletop

model.

(continued)

Color Function

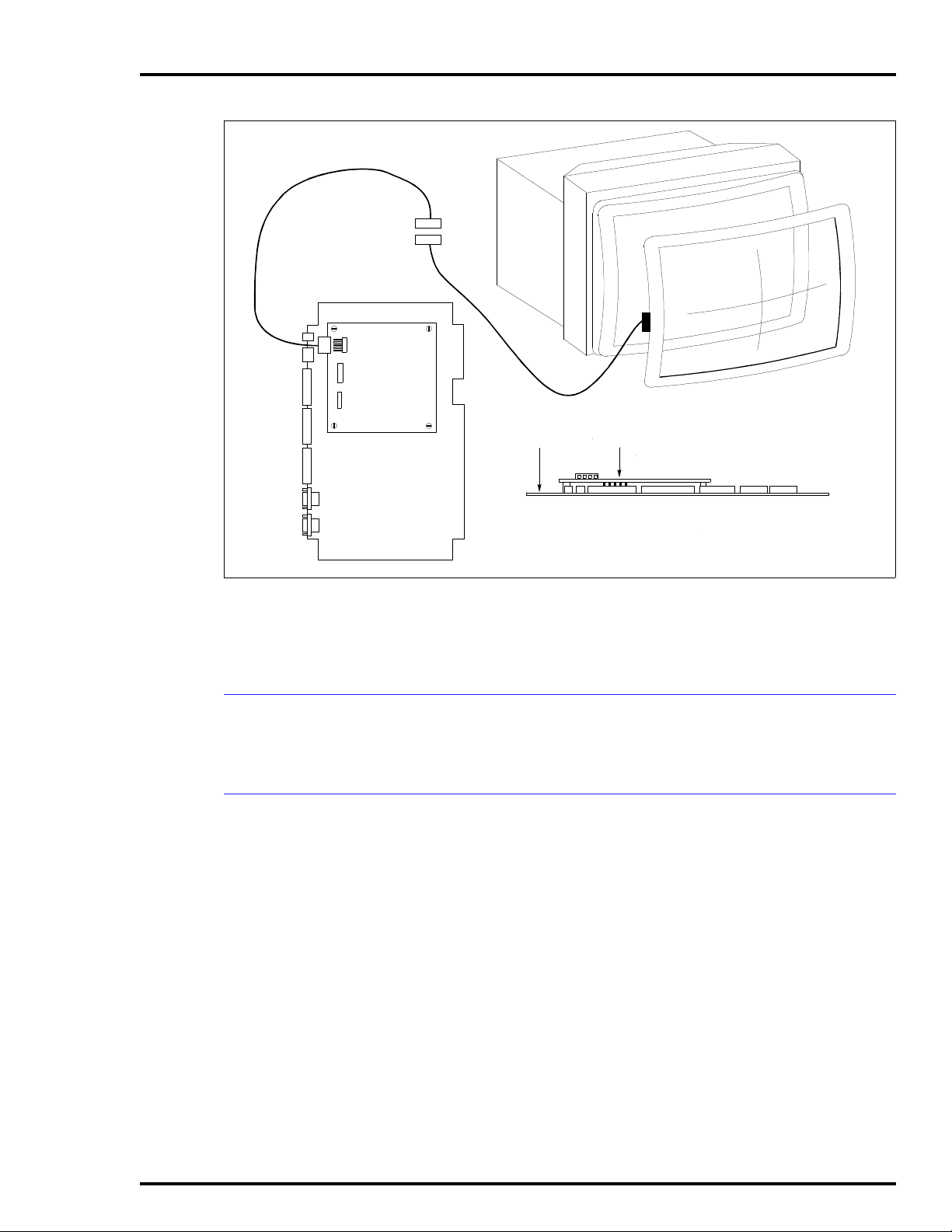

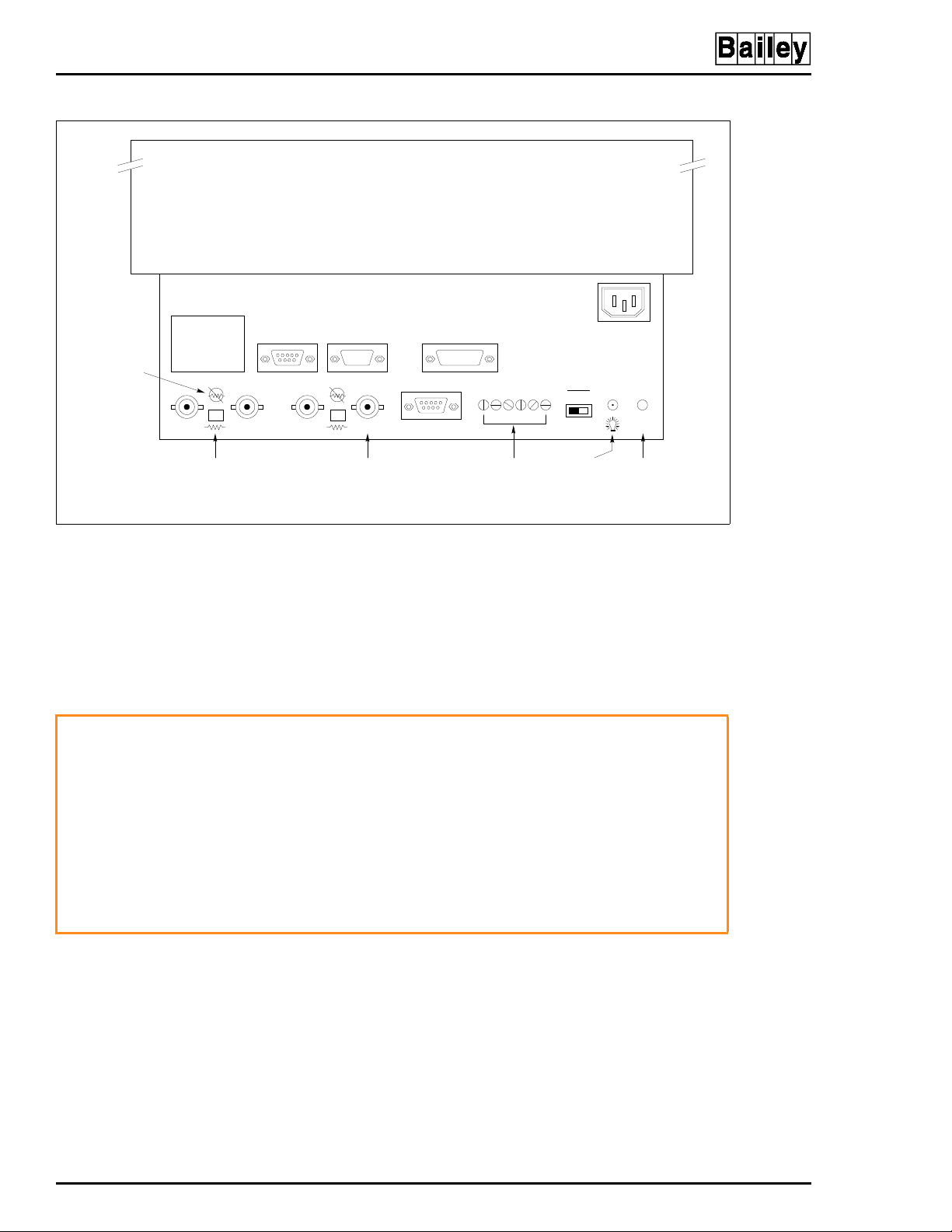

IOIC421 Tabletop Wiring Connections and Cabling

The IIOIC421 tabletop operator interface console is internally

wired when it is shipped. Connect the AC power and any peripheral devices. AC power input connects to the power connector on

the rear of the keyboard interface assembly (Figure 3-2).

Figure 3-3 shows cabling requirements. The circled numbers

illustrate the cables. Those numbers are called out in Table 3-2

which contains a description of the cabling connections.

OIC INSTALLATION

3 - 6 I-E96-192-5A

Page 30

INSTALLATION

TP80546A.

Baile y

495.3

19.5

609.6

24.0

482.6

19.0

558.8

22.0

Figure 3-1. IIOIC421 Tabletop (19-inch) Dimensions

OFF

TUNE CO NFIG

KEYBOARD

AUX 1

PORT

MOUSE/

TRACKBALL

AUX

KBD

DIMENSIONS

MILLIMETERS

INCH ES

TP35324B

POWER

TO

CPU

AC IN AC OUT

TO

COMMUNICATION

PORT

J1

J2 J3

J4

R G B RESET DEGAUSS

F1

2

4

2

2

NC

NO

4

4

NC

CO

CO

NO

6

NO

WRIST

STRAP

6

NC

6CODI

DI

2+

2–

J5

1

3

5

3

5

5

DI

NC

CO

NO

DI

NC

1+

1–

CO

TO KEYBOARD

PORT

TO MOU S E

PORT

1

1

3

NC

CO

NO

NO

Figure 3-2. IIOIC421 Tabletop Connections (Keyboard Interface Assembly)

DO

DO

2+

2–

DO

DO

1+

1–

OIC INSTALLATION

I-E96-192-5A 3 - 7

Page 31

INSTALLATION

®

IIOIC42 1

CHASSIS

FAN

9

P2

POWER

SUPPLY

P3

P1

10

J4AC O UT AC IN

TO AC PO W E R

9

11

10

RESET

SWITCH

MONITOR

AC IN

RGB

18

POWER CABLE

DEGAUSS

VIDEO CABLE

17

OPERATOR KEYBOARD MOUSE/TRACKBALL

OPTIONAL TABLETOP

ADP PANEL

9

12

6

BRIGHTNESS

CONTRAST

MONITOR

7

BEZEL

KEYBOARD

CPU

MONITOR

POWE R

AC IN

AUX

PORT

P2

P10

0PORT

MOUSE

1PORT

KEY-

BOARD

KEYBOARD

INTERFACE

BOARD

P4

IIMKM02A

KEYBOARD

P16

MODULE

P3

TERM

ETHERNET

NETWORK CABLE

(CUSTOMER

SUPPLIED)

MOUSE/

TRACK-

BALL

P6 P9

BLK

2

1

15

13

3

ENGINEERING

KEYBOARD

AUX

KBD

P8

P1

P5

P7

P8

8 14

J1

TO IIOIS41/42

4

TOUCH

SCREEN

12

J3 J5J2

= SIGNAL CABLE

5

16

TP80565A

Figure 3-3. IIOIC421 Tabletop Cable Connections

Table 3-2. IIOIC421 Tabletop Cable Connections

Figure 3-3

Cable No.

1 6642339A1 Keyboard J2 on chassis Keyboard port on OIC CPU

2 6640778A1 Communication J1 on chassis 0 port on OIC CPU

3 6634512A26N15 ADP signal P6 on IIMKM02A Terminal block on chassis

4 6634512A26N15 I/O distribution P5 on IIMKM02A P1 on keyboard interface board

5 6634512A26N15 I/O distribution P7 on IIMKM02A P8 on keyboard interface board

6 6638719A2 Reset cable P4 on IIMKM02A Reset switch on power entry panel

7 6638720A6 Monitor bezel

8 6639117A1 I/O signal P9 on IIMKM02A J1 on chassis (inside)

9 6639211A1 Power P2 on power supply Cooling fan

Cable Number Cable Name Connect From Connect To

Degauss on chassis Brightness on bezel

controls

contrast on bezel monitor

P2 on keyboard interface board

P16 on IIMKM02A

OIC INSTALLATION

3 - 8 I-E96-192-5A

Page 32

INSTALLATION

Table 3-2. IIOIC421 Tabletop Cable Connections

Figure 3-3

Cable No.

10 6639212A1 AC power Power in on chassis P1on power supply

11 6639213A1 PFI sense P3 on IIMKM02A P3 on power supply

12 6639637A1 Keyboard data P10 on keyboard

13 6640778A2 Touch screen J5 on chassis 1 port on the OIC CPU

14 6640857A1 Keyboard signal P8 on IIMKM02A J2 on chassis (inside)

15 6642341A1 Mouse J3 on chassis Mouse port on OIC CPU

16 6642342A1 Touch screen Touch screen board J5 on chassis

17 Power cable Power AC IN on OIC CPU AC OUT on chassis

18 1949448A1 Video (RGB) Monitor port on

Cable Number Cable Name Connect From Connect To

interface board

OIC CPU

(continued)

AC IN on chassis

J3 on chassis (inside)

RGB on table top chassis

IIOIC422 Console Setup and Installation

The OIC and OIS consoles are similar, except the OIC console

has no floppy disk drives or network interface unit. The cabinet size and installation are the same. Figure 3-4 shows the

dimensions.

Before the OIC console cabinet is set into place in a control

room, insure that the floor is level in the area where the cabinets will be set. Make sure the location can accommodate the

console. Figure 3-4 shows the console cabinet and anchoring

dimensions.

Adjust the leveling screws on all cabinets and connecting

tables until the monitor bezel of each cabinet lines up. The leveling screws adjust 25.6 millimeters (1.05 inches). After securing the cabinets, put the tables on the cabinets and lock them

into place by sliding the red handle above the front access door

to the right until it stops at the bottom of the slot.

The tabletops are adjustable. The brackets supporting the

tabletops are bolted through oversize holes. Loosen the bolts

and move the top up to 6.35 millimeters (0.25 inches) up,

down, forward or back toward the cabinet to line up the tabletop.

Two chrome table alignment pins shipped inside the brass

bushings located on each side of each tabletop. When two

tabletops are lined up, push the pins outward into the bushing

of the table to the right of the cabinet. Tighten the three bolts

on each tabletop support bracket. Figure 3-5 shows the keyboard table. Figure 3-6 shows the 15 degree wedge table

dimensions, and Figure 3-7 shows the 45 degree wedge table

dimensions.

OIC INSTALLATION

I-E96-192-5A 3 - 9

Page 33

INSTALLATION

724.6

28.527

471.8

18.575

1085.7

42.75

2

1568.3

61.74

®

1

281.8

11.09

1090.1

42.918

482.6

19.00

STUD

CENTER

830.4

32.693

66.0

2.60

TO REAR

DOOR

DIMENSIONS

MILLIMETERS

INCHES

108.7

4.28

Figure 3-4. IIOIC422 Console Dimensions

Protect the wires and cabling going to the OIC console. Run

cabling through conduit to the rear of the cabinet or under the

floor through the bottom of the cabinet. Follow local wiring

codes when wiring and installing cableways or conduit. Refer

to the Site Planning and Preparation instruction for more

information.

493.8

19.44

STUD CENTER

MOUNTING

1

HIGH MONITOR

2

LOW MONITO R

711.2

28.00

MODEL

IIOIC4222

IIOIC4221

108.7

4.28

TP80547A

OIC INSTALLATION

3 - 10 I-E96-192-5A

Page 34

INSTALLATION

RIGHT BUSHING

LEFT BRACKET

LEFT BUSHING

ADJUSTABLE MO U N TING BOLTS

(3 PER BRACKET)

PIN (ONE PER BUSHING)

6.35

0.25

6.35

0.25

6.35

0.25

Figure 3-5. IIOIC422 Console Keyboard Table

RIGHTBRACKET

TABLE SUPPORT

BRACKET

RIGHTBUSHING

DIMENSIONS

MILLIMETERS

INCHES

TP35437B

493.8

19.44

335.3

13.20

404.1

15.91

50.8

2.00

IICP I0 1

482.6

19.00

52.8

2.08

69.3

2.73

Figure 3-6. IIOIC422 Console 15 Degree Wedge Dimensions

493.8

19.44

DIMENSIONS

MILLIMETERS

INCHES

TP35319B

OIC INSTALLATION

I-E96-192-5A 3 - 11

Page 35

INSTALLATION

®

482.6

19.00

395.7

15.58

885.2

34.85

956.6

37.66

791.5

31.16

254.5

10.02

615.4

24.23

50.8

2.00

493.8

19.44

IICPI02

482.6

19.00

DIMENSIONS

MILLIMETERS

INCHES

TP35320B

1089.7

42.90

Figure 3-7. IIOIC422 Console 45 Degree Wedge Dimensions

IIOIC422 Console Wiring Connections and Cabling

The IIOIC422 console is internally wired when it is shipped.

Connect the AC power and any peripheral devices. Refer to

Section 6 for specific instructions on installing and configuring

replacement components.

1. Wire AC power to the proper terminals of the power entry

panel. Refer to Figure 3-8 for AC input terminal location.

NOTE:

of TB1.

Verify that the incoming vo ltage me ets the rati ng on the labe l

2. Connect only 120/240 VAC at 50/60 hertz into the terminal block on the power entry panel.

Figure 3-9 shows the IIOIC422 cable connections. The circled

numbers represent the cables. Table 3-3 contains the list of

those cables and connection descriptions.

NOTE:

sure they are powered using the same power source and ground as

the OIS and OIC console to reduce the chance of communication

problems on the network. Failure to do so may cause data to be

changed or lost.

If remote monitors are being install ed in the OIC console, be

OIC INSTALLATION

3 - 12 I-E96-192-5A

Page 36

REAR VIEW

NOTICE: CO NNECT POWER CORD

BEFORE CONN ECTING SIGN AL CAB LE

2

NO

NO

NC

COM

4

2

2

6

4

4

NO

NC

COM

INSTALLATION

U. DEGAUSS

L.DEGAUSS

R

E

S

E

T

6

6

DI

DO

DI

NC

COM

2+

DO

2+

2–

2–

NOT

USED

UPPER CRT

LOWER CRT

POWER SUPPLY

BLOWER/AUX

1

1

1

NO

NC

COM

POWER

ON ON

MAIN P OWE R - ON/OFF

E1

3

NO

5

3

NC

3

COM

5

NO

NC

5

COM

PERIPHERAL POWE R

NOTICE: CONNECT PERIPHERAL

RIBBON CA BLE BEFORE PLUGGING

AND POWERING UNIT.

LN/L2

WARNING/AVERTISSEMENT 120/240V

DI

1+

DO

DI

1+

1–

WRISTSTRAP

Figure 3-8. IIOIC422 Console Power Entry Panel Connections

DO

1–

TP80548A.

OIC INSTALLATION

I-E96-192-5A 3 - 13

Page 37

INSTALLATION

TERM

19

BLK

TERM

8

BLK

17

P5

TB2 P6

BACKP LANE

POW ER

SUPPLY

P2

20 21

P7 P8

DC DISTR.

BOAR D

P5

P6 P4

P3

P1

FANFAN

OPERATOR KEYBOARD MOUSE/TRACKBALL

OPTIONAL TABLETOP

P9

1018

P1

P2

ANNUNCIATO R

DISPLAY

PANE L ( A DP)

16

6

ADP PANEL

9

14

AUX

PORT

P2

P8

P7

KEYBO ARD

RESET

AC OUT

J1

POWER

AC IN

MOUSE/

KEY-

TRACK-

BOARD

KEYB OARD

IN TE R FA CE

BOA RD

IIMKM02A

MODULE

P6P4P3

11

5

TERM

BLK

IIOIC4 22

PEP

BALL

AUX

KBD

P5

P8

P9

AC O UT

AC OUT

DEGAUSS

ENGINEERING

KEYBOARD

P10

P1

J3

J2

4

3

2

1

15

MOUSE 1 PORT

KEYBOARD

POW ER

CABLE

CPU

2423

VIDEO

CABLE

0PORT

AC IN

AUX OUT MO NITOR

TOUCH

SCREEN

22

ETHERNET

NETWORK

CUSTOMER

SUPPLIED

TO IIOIS41/42

CONSOLE

®

TO AC

POWER

CUSTOMER SUPPLIED

=SIGNALCABLE

MONITOR

BEZEL

BRIGHTNESS

CONTRAST

12

13

AC LINE

MONITOR

RGB

TP80566A.

Figure 3-9. IIOIC422 Console Cable Connections

Table 3-3. IIOIC422 Console Cable Connections

Figure 3-9

Item No.

1 1947950A5 AC power J3 on power entry

2 6639637A4 I/O signal P9 on IIMKM02A 0 port on OIC CPU

3 6642339A1 Keyboard P8 on IIMKM02A Keyboard port on OIC CPU

4 6634512A26N72 I/O distribution P5 on IIMKM02A P1 on keyboard interface board

5 6634512A26N72 I/O distribution P6 on IIMKM02A Rear of terminal block on power

6 6637599A1 AC power J1 AC OUT on power

7 6637776A2 Wrist ground User Wrist connector on power entry

8 6638708A1 DC power TB2 on backplane Terminal block on DC distribution

9 6638713A1 Peripheral power P2 on keyboard inter-

Cable Number Cable Name Connect From Connect To

AC IN on OIC CPU

panel

entry panel

P1 on power supply

entry panel

panel

board

P3 on DC distribution board

face board

OIC INSTALLATION