© 2021 Baileigh Industrial Holdings LLC

REPRODUCTION OF THIS MANUAL IN ANY FORM WITHOUT WRITTEN APPROVAL OF BAILEIGH INDUSTRIAL

negligence, or other occurrence.

Baileigh Industrial Holdings LLC

OPERATOR’S MANUA L

VARIABLE SPEED VERTICAL BAND SAW

MODEL: BSV-24VS-V2

HOLDINGS LLC IS PROHIBITED. Baileigh Industrial Holdings LLC, Inc. does not assume and hereby disclaims any

liability for any damage or loss caused by an omission or error in this Operator’s Manual, resulting from accident,

Manitowoc, WI 54221-0531

Baileigh-Sales@jpwindustries.com

P.O. Box 531

Phone: 920.684.4990

Fax: 920.684.3944

Rev. 03/2022

Table of Contents

THANK YOU & WARRANTY .......................................................................................... 1

INTRODUCTION ............................................................................................................. 3

GENERAL NOTES .......................................................................................................... 3

SAFETY INSTRUCTIONS .............................................................................................. 4

SAFETY PRECAUTIONS ............................................................................................... 6

Dear Valued Customer: ................................................................................................... 6

TECHNICAL SPECIFICATIONS ..................................................................................... 8

TECHNICAL SUPPORT ................................................................................................. 9

UNPACKING AND CHECKING CONTE NTS ................................................................ 10

TRANSPORTING AND LIFTING .................................................................................. 11

INSTALLATION ............................................................................................................. 11

Anchoring the Machine .............................................................................................. 12

GETTING TO KNOW YOUR MACHINE ....................................................................... 13

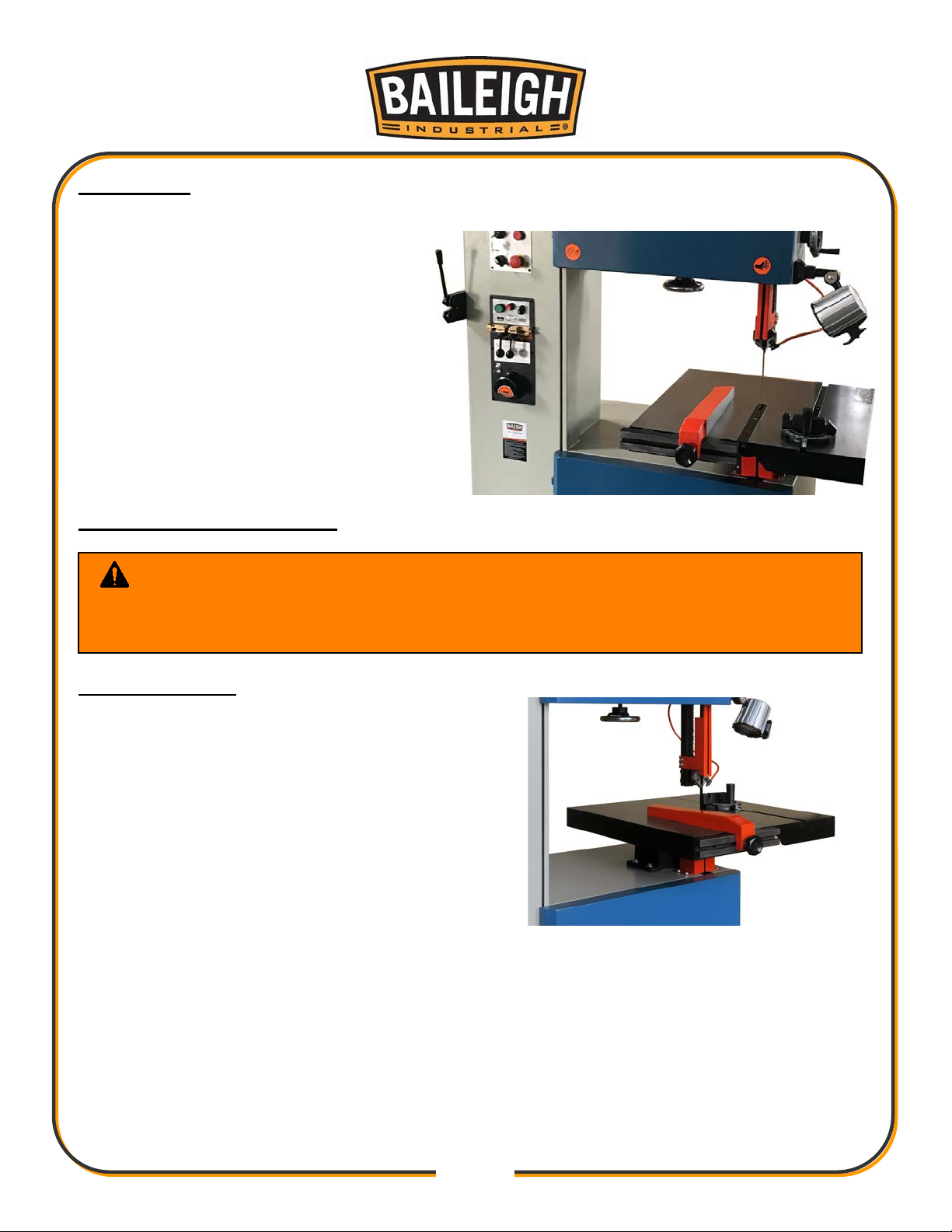

Control Panel ............................................................................................................. 15

Fence Guide .............................................................................................................. 18

ASSEMBLY AND SET UP ............................................................................................ 18

ELECTRICAL ................................................................................................................ 19

BEFORE EACH USE .................................................................................................... 21

Whenever Saw is Running ........................................................................................ 21

Blade Terminology ..................................................................................................... 22

Breaking in a Band Saw Blade .................................................................................. 22

Metal Chip Indicators ................................................................................................. 23

BLADE CARE ............................................................................................................... 23

Choosing A Saw Blade .............................................................................................. 23

Width of Blade ........................................................................................................... 24

Length of Blade ......................................................................................................... 24

BLADE BREAKAGE ...................................................................................................... 24

MATERIAL SELECTION ............................................................................................... 25

SAW OPERATION ........................................................................................................ 26

OPERATION OF BLADE WELDER .............................................................................. 27

Overall Description .................................................................................................... 27

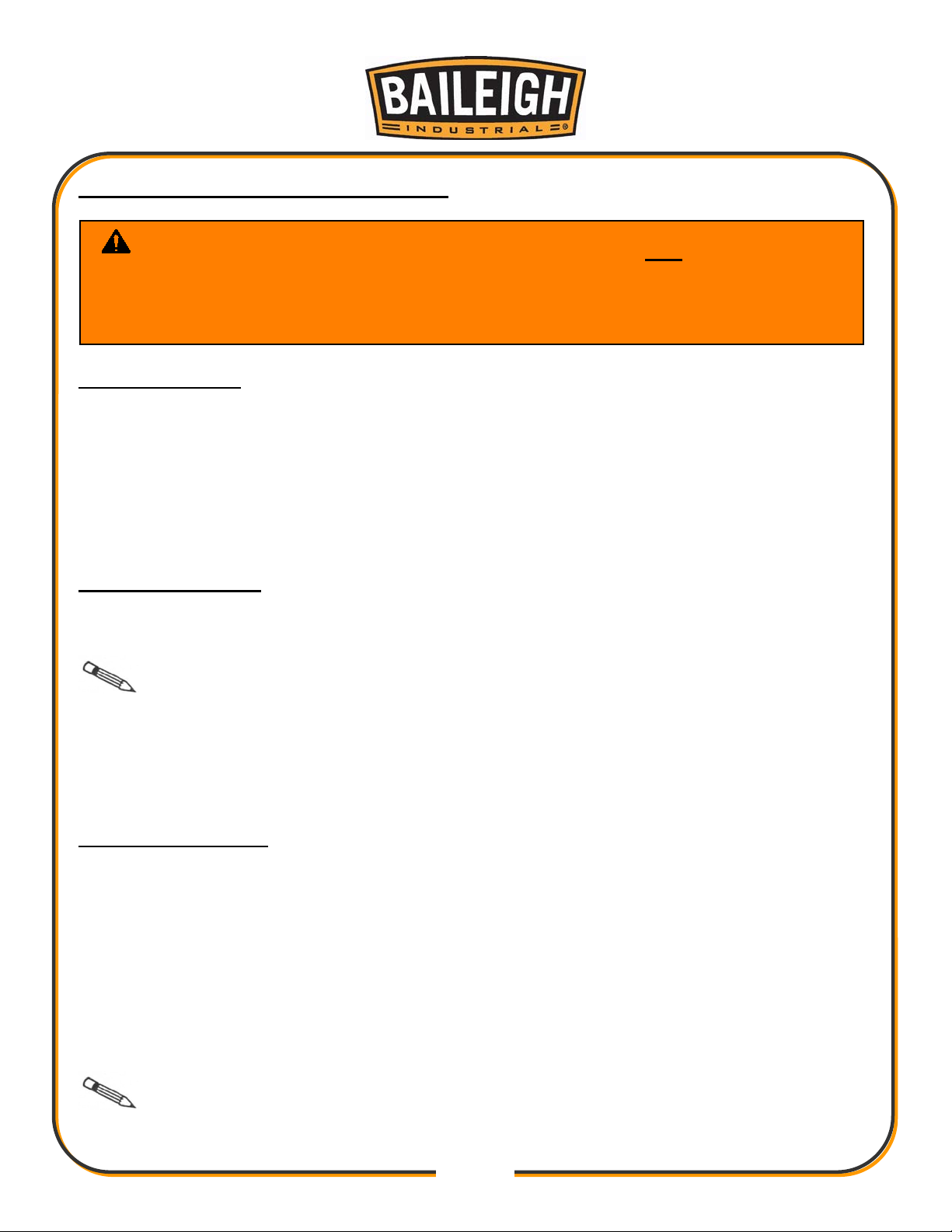

Preparing the Saw Band Prior to Welding ................................................................. 28

Preparing the Blade Welder....................................................................................... 29

Making the Weld ........................................................................................................ 29

Annealing the Weld ................................................................................................... 31

Grinding the Weld ...................................................................................................... 31

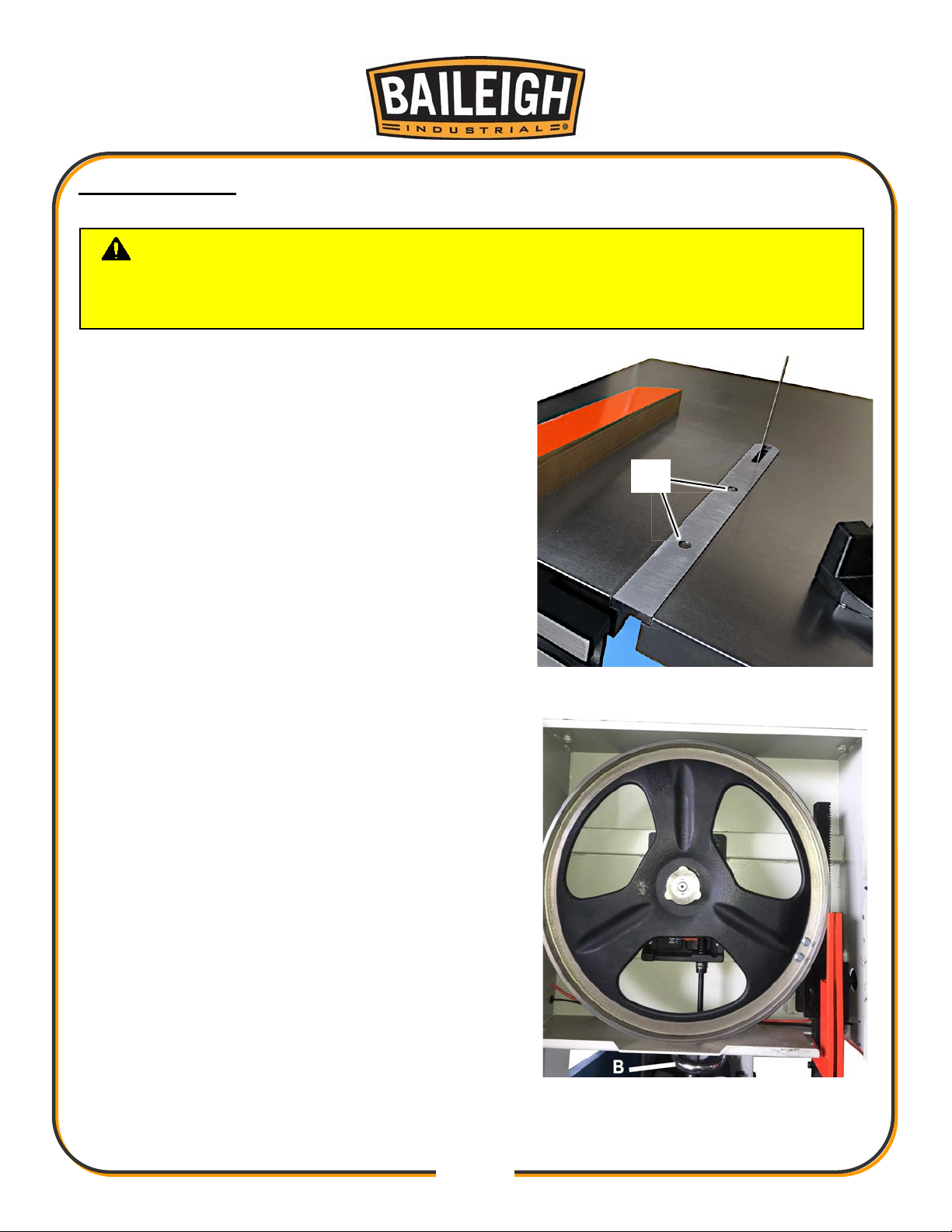

SAW ADJUSTMENTS .................................................................................................. 32

Guide Post ................................................................................................................. 32

Graduated Scales to Show Tilt of Table .................................................................... 32

Adjusting the Blade Guides ....................................................................................... 33

Blade Tension Adjustment Wheel .............................................................................. 34

Changing a Blade ...................................................................................................... 35

BLADE TRACKING ....................................................................................................... 36

Regular Adjustment ................................................................................................... 36

LUBRICATION AND MAINTENANCE .......................................................................... 38

Blade Shear Lubricatio n ............................................................................................ 39

Upper Wheel Housing Items ...................................................................................... 39

Table Support Lubrication ......................................................................................... 39

CABINET ASSEMBLY – BREAKDOWN ....................................................................... 40

Cabinet Assembly – Part List..................................................................................... 41

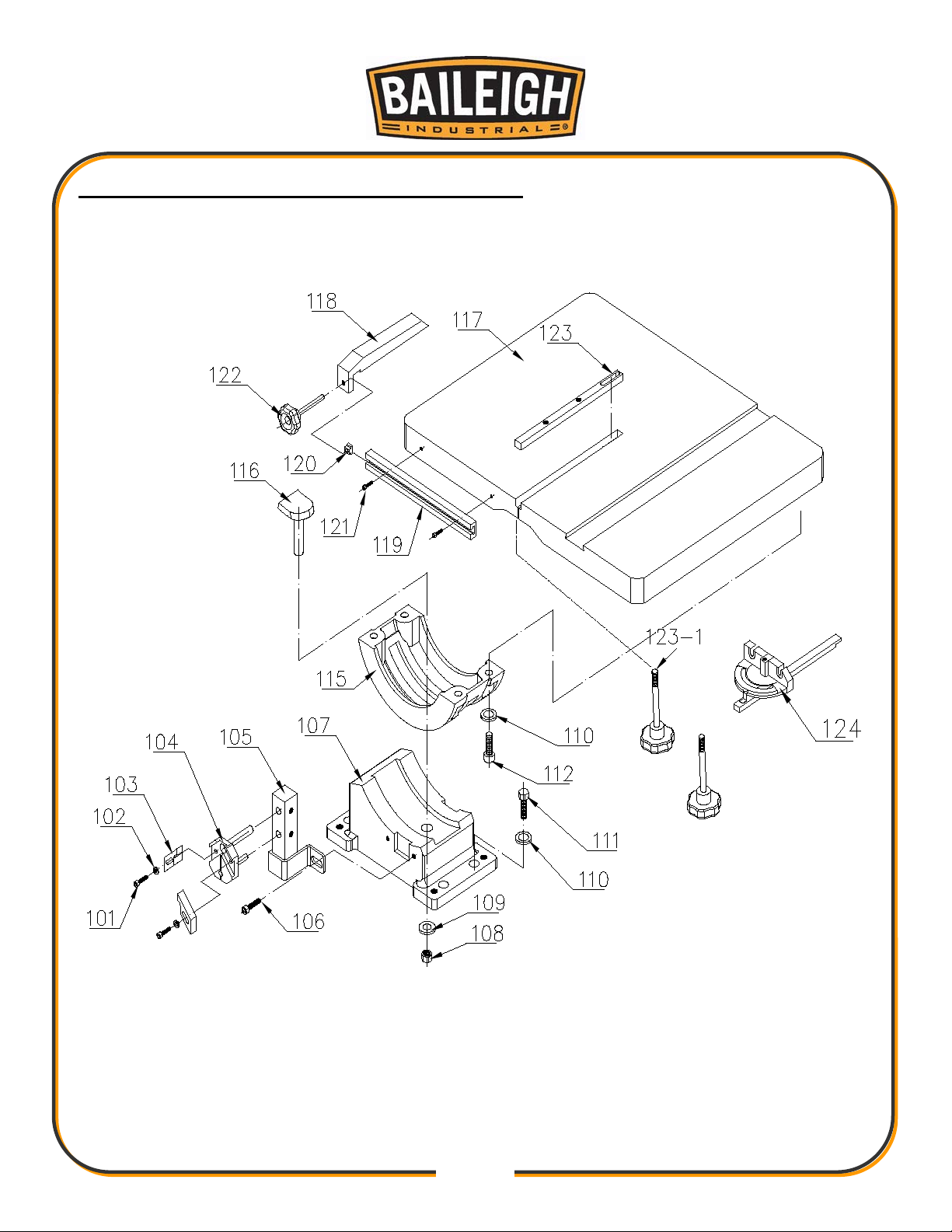

WORK TABLE ASSEMBLY – BREAKDOWN ............................................................... 42

Work Table Assembly – Part List ............................................................................... 43

LOWER WHEEL SET ASSEMBLY – BREAKDOWN .................................................... 44

Lower Wheel Set Assembly – Part List ...................................................................... 45

GUIDEPOST ASSEMBLY – BREAKDOWN ................................................................. 46

Guidepost Assembly – Part List................................................................................. 47

UPPER WHEEL SET ASSEMBLY – BREAKDOWN .................................................... 48

Upper Wheel Set Assembly – Part List ...................................................................... 49

WELDER ASSEMBLY- BREAKDOWN ......................................................................... 50

Welder Assembly – Part List ..................................................................................... 51

ELECTRICAL DIAGRAM .............................................................................................. 53

Electrical Diagram Part List ....................................................................................... 54

1

1

THANK YOU & WARRANTY

Thank you for your purchase of a machine from Baileigh Industrial Holdings LLC. We hope that

you find it productive and useful to you for a long time to come.

Inspection & Acceptance. Buyer shall inspect all Goods within ten (10) days after receipt thereof. Buyer’s

payment shall co nstitute fin al accepta nce of t he Goo ds and shall ac t as a w aiver of the Buyer’s r ights to inspect or

reject the goods unless otherwise agreed. If Buyer rejects any merchand ise, Buyer must first obtain a Returned

Goods Authorization (“ RGA ”) number bef ore retur ning any go ods to S eller. Go ods retur ned witho ut an RGA w ill be

refused. Seller will not be responsible for any freight costs, damages to goods, or any other costs or liabilities

pertaining to goods ret urne d withou t a RG A. Sel ler sh all have the r ight to su bstit ute a co nformin g tender . B uyer wil l

be responsible for all freight costs to and from Buyer and repackaging costs, if any, if Buyer refuses to accept

shipment. If Goods are returned in unsalable condition, Buyer shall be responsible for full value of the Goods.

Buyer may not retur n any special-order G oods. Any Goods ret urned her eunder s hall be s ubject to a restoc king fee

equal to 30% of the invoice price.

Specifications. Seller may, at its o ption, mak e cha nges in the d esigns , spec ifica tions or com ponents of t he G oods

to improve the safety of su ch Goods, or if in Seller’s judgment, suc h chang es will be benef icial to the ir operatio n or

use. Buyer may not m ake any c hanges in t he s pecif icatio ns f or th e Goods un less Sell er appr oves of s uch c hanges

in writing, in which event Seller may impose additional charges to implement such changes.

Limited Warranty. Seller warrants to the original end-user that the Goods manufactured or provided by Seller

under this Agreement sh all be free of defects in mate rial or workmanship for a per iod of twelve (12) months from

the date of purchase, provided that the Goods are installed, used, and maintained in accordance with any

instruction manual or technical guidelines provided by the Seller or supplied with the Goods, if applicable. The

original end-user mus t give written not ice to Seller of any suspected defect in the Goods prior to the expiration of

the warranty period. The original end-user must also obtain a RGA from Seller prior to returning any Goods to

Seller for warranty ser vice under th is para graph . Selle r will not accept a ny res pons ibility for G oods r eturne d without

a RGA. The original end-us er shall be responsible for all costs and expenses associated with returni ng the Goods

to Seller for warranty s ervice. In th e event of a defect, Sel ler, at its sol e option, s hall repa ir or replace t he defectiv e

Goods or refund to the original end-user the purchase price f or such defective Goods . Goods are not eligible f or

replacement or return after a period of 10 days from date of receipt. The foregoing warranty is Seller’s sole

obligation, and the or iginal end-user’s exclusive rem edy, with r egard to any defective Goo ds. This lim ited warranty

does not apply to: ( a) die s ets, to oling, and saw b lades ; (b) per iod ic or ro utine maint enanc e and setup , (c) r epair or

replacement of the Go ods due t o norm al wear and t ear, (d) defects or d amage t o the Go ods res ulting fr om misuse,

abuse, neglect, or accidents, (f) defects or damage to the Goods resulting from improper or unauthorized

alterations, modifications, or changes; and (f) any Goods that has not been installed and/or maintained in

accordance with the instruction manual or technical guidelines pr ovid ed by Se ller .

EXCLUSION OF OTHER WARRA NTIES. THE FOR EGOING LIMITED WARRANTY IS IN LIEU OF ALL O THER

WARRANTIES, EXPRESS OR IMPLIED. ANY AND ALL OTHER EXPRESS, STATUTORY OR IMPLIED

WARRANTIES, I NCLUDING BUT NOT LIMITED TO, ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE ARE EXPRESSLY DISCLAIMED. NO WARRANTY IS MADE WHICH

EXTENDS BEYOND THAT WHICH IS EXPRESSLY CONTAINED HEREIN.

Limitation of Liability. IN NO EVEN T SHALL SELLER B E LIABLE TO BUYER OR ANY OTHER PART Y FOR

ANY INCIDENTIAL, CONSEQUENTIAL OR SPECIAL DAMAGES (INCLUDING, WITHOUT LIMITATION, LOST

PROFITS OR DOWN TIME) ARISING FROM OR IN MANNER CONNECTED WITH THE GOODS, ANY BREACH

BY SELLER OR ITS AGENTS OF THIS AGREEMENT, OR ANY OTHER CAUSE WHATSOEVER, WHETHER

BASED ON CONTR ACT, TORT O R ANY OTHER TH EORY OF LIAB ILITY. BUYER ’S REMEDY WIT H RESPECT

TO ANY CLAIM ARISING UNDER THIS AGREEMENT IS STRICTLY LIMITED TO NO MORE THAN THE

AMOUNT PAID BY THE BUYER FOR THE GOODS.

2

2

Force Majeure. Seller shal l not be responsib le for any delay in the delivery of, or failure to deliver, Goods due t o

causes beyond Seller’s reasonable control inclu ding, with out lim itat ion, ac ts of God, acts of war or terror ism, enemy

actions, hostilities, strikes, labor difficulties, embargoes, non-delivery or late delivery of materials, parts and

equipment or transportation delays not caused by the fault of Seller, delays caused by civil authorities,

governmental regulations o r orders , fir e, lighte ni ng, nat ur al disas ters or any other cause beyond Seller’s reasonable

control. In the event of any such delay, performance will be postponed by such length of time as may be reasonably

necessary to compensate for the delay.

Installation. If Buyer purchases any Goods that require installation, Buyer shall, at its expense, make all

arrangements and connections necessary to install and operate the Goods. Buyer shall install the Goods in

accordance with any Se ller instructions and shall ind emnify Seller against any and a ll damages, demands, suits,

causes of action, claims an d expenses (including ac tual attorneys’ fees and c osts) arising directly or indirectly out

of Buyer’s failure to properly install the Goods.

Work By Others; Safety Devices. Un less agreed to in wri ting by Seller, Seller has no responsibility f or labor or

work performed by Buyer or other s, of any nature, relating to desig n, manufacture, fabrication , use, installation or

provision of Goods . Buyer is sole ly respons ible for furnishi ng and requirin g its employees and customers t o use a ll

safety devices, guards and safe operating procedures required by law and/or as set forth in manuals and instruction

sheets furnished by Seller. Buyer is responsible for cons ulting all operator manuals, ANSI or comparable safety

standards, OSHA regulations and other sources of safety standards and regulations applicable to the use and

operation of the Goods.

Remedies. Each of the rights and rem edies of Seller under this Agreement is c umulative and in addition to any

other or further remedies provided under this Agreement or at law or equity.

Attorney’s Fees. In the event legal action is necessary to recover monies due from Buyer or to enforce any

provision of this Agreement, Buyer shall be liable to Seller for all costs and expenses associated therewith,

including Seller’s actual attorney fees and costs.

Governing Law/Venue. This Agreement shall be construed and governed under the laws of the State of

Wisconsin, without applic ation o f conf lict of law pr inci ples. Eac h p arty agr ees that all acti ons or proce edings ar ising

out of or in connection with this Agreement shall be commenced, tried, and litigated only in the state courts sitting in

Manitowoc County, Wisconsin or the U.S. Federal C ourt for the Eastern Distr ict of Wisconsin. Each par ty waives

any right it may h ave to asser t the doctrine of “forum non conv eniens” or to object to venu e to the exten t that any

proceeding is brought in accordance with this section. Each party consents to and waives any objection to the

exercise of personal jurisdiction over it by courts described in this section. Each par ty waives to the fullest extent

permitted by applicable law the right to a trial by jury.

Summary of Return Policy.

• 10 Day accep tance period from date of delivery. Damage claims and order discrepancies w ill not be accepted

after this time.

• You must obtain a Baileigh issued RGA number PRIOR to returning any materials.

• Returned materials must be received at Baileigh in new condition and in original packaging.

• Altered items are not eligible for return.

• Buyer is responsible for all shipping charges.

• A 30% re-stocking fee applies to all returns.

Baileigh Industrial Hold ings LLC makes every effort to ensure that our posted specifications, ima ges, pricing and

product availability are as correct and timely as possible. We apologize for any discrepancies that may occur.

Baileigh Industrial Holdings LLC reserves the right to make any and all changes deemed necessary in the course of

business including but not limited to pricing, product specifications, quantities, and product availability.

For Customer Service & Technical Support:

Please contact one of our knowledgeable Sales and Service team members at:

(920) 684-4990 or e-mail us at Baileigh-Service@jpwindustries.com

3

3

INTRODUCTION

The quality and reliability of the components assembled on a Baileigh Industrial Holdings LLC

machine guarantee near perfect functioning, free from problems, even under the most

demanding working conditions. However, if a situation arises, refer to the manual first. If a

solution cannot be found, contact the distributor where you purchased our product. Make sure

you have the serial number and production year of the machine (stamped on the nameplate).

For replacement parts refer to the assembly numbers on the parts list drawings.

Our technical staff will do their best to help you get your machine back in working order.

In this manual you will find: (when applicable)

• Safety procedures

• Correct installation guidelines

• Description of the functional parts of the machine

• Capacity charts

• Setup and start-up instructions

• Machine operation

• Scheduled maintenance

• Parts lists

GENERAL NO TE S

After receiving your equipment remove the protective container. Do a complete visual

inspection, and if damage is noted, photograph it for insurance claims and contact your

carrier at once, requesting inspection. Also contact Baileigh Industrial Holdings LLC and inform

them of the unexpected occurrence. Temporarily suspend installation.

Take necessary precautions while loading / unloading or moving the machine to avoid any

injuries.

Your machine is designed and man uf actured to work smoothly and effic i entl y. Following proper

maintenance instructions will help ensure this. Try and use original spare parts, whenever

possible, and most importantly; DO NOT overload the machine or make any modifications.

Note: This symbol refers to useful information throughout the manual.

4

4

IMPORTANT

PLEASE READ THIS OPERATORS MANUAL CAREFULLY

It contains important safety information, instructions, and necessary operating procedures.

The continual observance of these procedures will help increase your production and

extend the life of the equipment.

SAFETY INS TRUCTIONS

LEARN TO RECOGNIZE SAFETY INF ORMATION

This is the safety alert symbol. When you see this symbol

on your machine or in this manual, BE ALERT TO THE

POTENTIAL FOR PERSONAL INJURY!

Follow recommended precautions and safe operating practices.

UNDERSTAND SIGNAL WORDS

A signal word – DANGER, WARNING, or CAUTION – is used with the safety alert symbol.

NOTICE, which is not related to personal injury, is used without a symbol.

DANGER: Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING: Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION: Indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE: Indicates a situation which, if not avoided, could

result in property damage.

DANGER

WARNING

CAUTION

NOTICE

5

5

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

PROTECT EYES

Wear safety glasses or suitable eye protection

when working on or around machinery.

PROTECT AGAINST NOISE

Prolonged exposure to loud noise can cause impairment or loss of

hearing. Wear suitable hearing protective devices such as earmuffs or

earplugs to protect against objectionable or uncomfortable loud noises.

DUST HAZARD

Wear appropriate dust mask. Dust created while using machinery can

cause cancer, birth defects, and long-term respiratory damage. Be aware

of the dust hazards associated with all types of materials.

CALIFORNIA PROPOSITION 65

WARNING: Cancer and Reproductive Harm.

www.P65Warnings.ca.gov

BEWARE OF CUT AND PINCH POINTS

Moving saw blade may result in loss of fingers or limb. DO

NOT operate with guard removed. Follow lockout/tagout

procedures before servicing.

EMERGENCY STOP BUTTON

In the event of incorrect operation or dangerous conditions, the machine

can be stopped immediately by pressing the E-STOP button. Twist the

emergency stop button clockwise (cw) to reset. Note: Resetting the EStop will not start the machine.

6

6

SAFETY PRECAUTIONS

Metal working can be dangerous if safe and proper operating procedures are not followed. As

with all machinery, there are certain hazards involved with the operation of the product. Using

the machine with respect and caution will considerably lessen the possibility of personal injury.

However, if normal safety precautions are overlooked or ignored, personal injury to the operator

may result.

Safety equipment such as guards, hold-downs, safety glasses, dust masks and hear i ng

protection can reduce your potential for injury. But even the best guard will not make up for poor

judgment, carelessness or inattention. Always use common sense and exercise caution in

the workshop. If a procedure feels da ngerous, don’t try it.

REMEMBER: Your personal safety is your responsibility.

WARNING: FAILURE TO FOLLOW THESE RULES MAY RESULT IN

SERIOUS PERSONAL INJURY

Dear Valued Customer:

• All Baileigh machines s hould be used only for their intended use.

• Baileigh does not recommend or endorse making any modifications or alterations to a

Baileigh machine. Modifications or alterations to a machine may pose a substantial risk of

injury to the operator or others and may do substantial damage to the machine.

• Any modifications or alt er ati ons to a Bail ei gh machine will invalidate the mac hi ne’s warranty.

PLEASE ENJOY YOUR BAILEIGH MACHINE! ....PLEASE ENJOY IT SAFELY!

1. FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFO RE OPERATING THE

MACHINE. Learn the machine’s application and limitations as well as the specific hazards.

2. Only trained and qualified personnel can operate this machine.

3. Make sure guards are in place and in proper working order before operating

machinery.

4. Remove any adju sti ng tools. Before operating the machi ne, make sure any adjusting tools

have been removed.

5. Keep work area clean. Cluttered areas invite injuries.

6. Overloading machine. By overloading the machine, you may cause injury from flying parts.

DO NOT exceed the specified machine capacities.

7. DO NOT bypass or defeat any safety interlock systems.

8. Dressing material edges. Always chamfer and deburr all sharp edges.

7

7

9. Do not force tool. Your machine will do a better and safer job if used as intended. DO NOT

use inappropriate attachments in an attempt to exceed the machine’s rated capacity.

10. Use the right tool for the job. DO NOT attempt to force a small tool or attachment to do the

work of a large industrial tool. DO NOT use a tool for a purpose for which it was not

intended.

11. Dress appropriately. DO NOT wear loose fitting clothing or jewelry as they can be caught in

moving machine parts. Protective clothing and steel toe shoes are recommended when

using machinery. Wear a restri c ti ve hai r covering to contain long hair.

12. Use eye protection. Always wear ISO approved protective eye wear when operating

machinery. Wear a full -face shield if you are producing metal filings. Eye wear shall be

impact resistant, protective safety glasses with side shields which comply with ANSI Z87.1

specification. Use of e ye wear which does not comply with ANSI Z87.1 specification could

result in severe injury from breakage of eye protection.

13. Do not overreach. Maintain proper footing an d bal ance at al l tim es. DO NOT reach ov er or

across a running machine.

14. Stay alert. Watch what you are doing and use common sense. DO NOT operate any tool or

machine when you are tired.

15. Check for damaged parts. Before using any tool or machine, carefully check any part that

appears damaged. Check for alignment and binding of moving parts that may affect proper

machine operation.

16. Observe work area conditions. DO NOT use machines or power tools in damp or wet

locations. Do not expose to rain. Keep work area well lighted. DO NOT use electri cal l y

powered tools in the presence of flammable gases or liquids.

17. Blade adjustments and maintenance. Always keep blades sharp and properly adjusted for

optimum performance.

18. Keep children away. Children must never be allowed in the work area. DO NOT let them

handle machines, tools, or extension cords.

19. Keep visitors a safe distance from the work area.

20. Store idle equipment. When not in use, tools must be stored in a dry location to inhibit rust.

Always lock up tools and keep them out of reach of children.

21. DO NOT operate machine if under the influence of alcohol or drugs. Read warning

labels on prescriptions. If there is any doubt, DO NOT oper ate the mac hine.

22. Turn off power before checking, cleaning, or replacing any part s.

23. Be sure all equipment is properly installed and grounded according to national, state, and

local codes.

24. Keep all cords dry, free from grease and oil, and protected from sparks and hot metal.

25. Inspect power and control cables periodically. Replace if damaged or bare wires are

exposed. Bare wiring can kill! DO NOT touch live electrical components or parts.

8

8

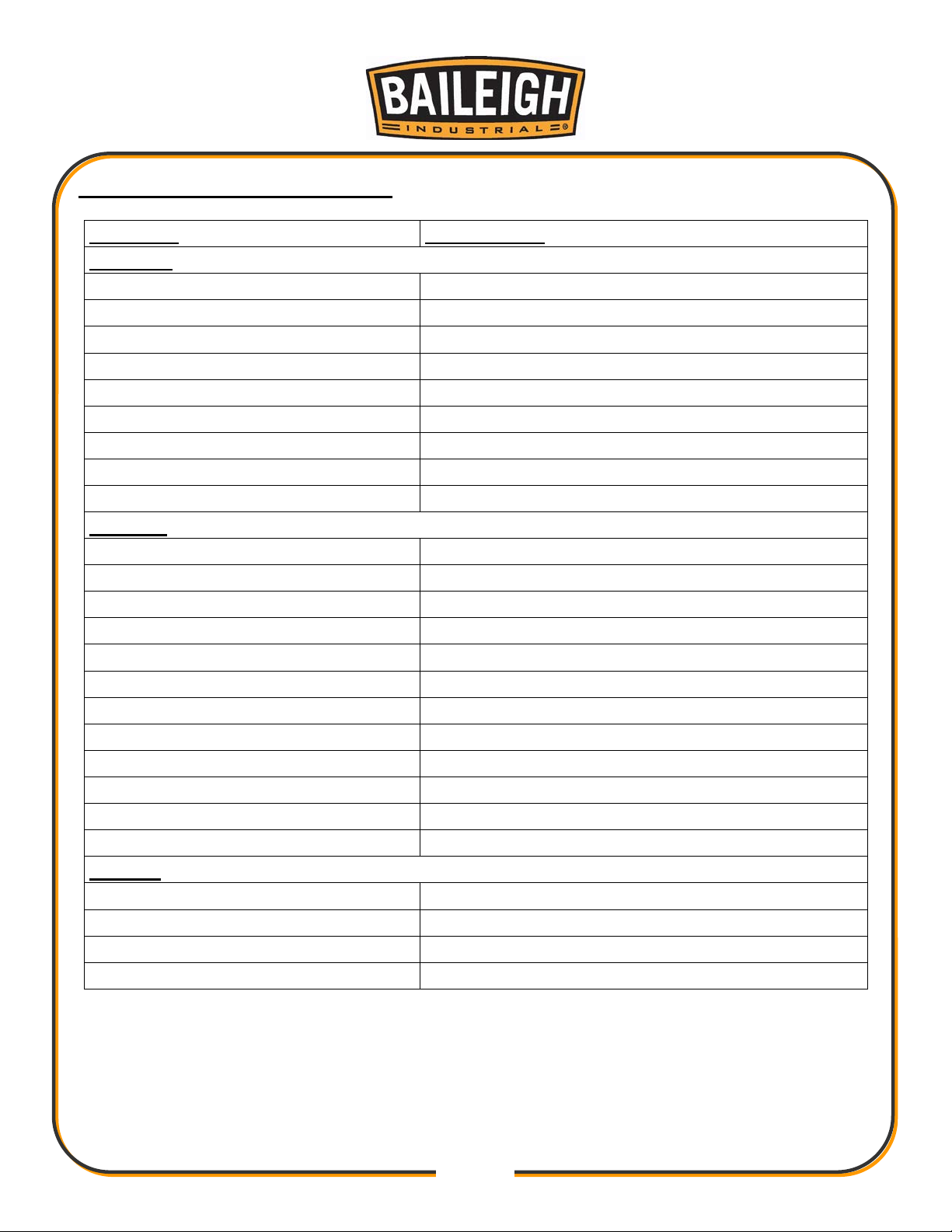

Model No.

BSV-24VS-V2

Electrical

Power Supply

230V, 3ph, 60Hz

Main Drive Motor

3HP (2.2kw), 230V, 9.8A, 6P, 3Ph, 60Hz

Grinder Motor

1/8HP/ 230V, 1ph

Welding Type / Transformer

Butt Welder / 4.2KVA

Weld Capacity (Width)

.118” – .625” (3 – 16mm)

Speed Meter

DM94C

Work Lamp

LED Lamp 220V 9W

Inverter

3HP/ 230V /3ph RM6 RHYMEBUS

Power Cord

14WAG X4C 2.08MM X4C 105℃/ 300VAC UL

Capacity

Blade Speed

Variable Speed

Cutting Capacity (Height)

12.2” (310mm)

Throat Depth

23.62" (600mm)

Blade Width (Min-Max.)

0.12" – 0.63" (3 – 16mm)

Blade Thickness

Blade Length (Min-Max.)

177.95" – 179.13" (4520 – 4550mm)

Standard Machine Blade (included)

Blade Speed

85 – 2200 FPM

Table Tilt

15° L & 45° R

Table Height

36.22" (920mm)

Table Area

24.4" x 24.4" (620 x 620mm)

Blade Wheel Dimension

24.4” (620mm)

Packing

Net Weight

935lbs (425kgs)

Gross Weight

1031lbs (469kgs)

Machine Overall Dimension (LxHxW)

451.18” x 77.95” x 33.07” (1300 x 1980 x 840mm)

Packaging Overall Dimension (LxHxW)

53.54” x 85.43” x 33.46” (1360 x 2170 x 850mm)

TECHNICAL SPECIFICATIONS

.025” (0.64mm)

0.511” (13mm) 14T

9

9

TECHNICAL SUPPORT

Our technical support department can be reached at 920.684.4990 and asking for the support

desk for purchased machines. Tech Support handles questions on machine setup, schematics,

warranty issues, and individual parts needs: (other than die sets and blades).

For specific application needs or future machine purchases contact the Sales Department at:

Baileigh-Service@jpwindustries.com, Phone: 920.684 . 49 90, or Fax: 920.684.3944.

Note: The photos and illus tr ati ons us ed in this manual are representative only and

may not depict the actual color, labeling or accessories and may be intended to illustrate

technique only.

Note: The specifications and dimensions presented here are subject to change

without prior notice due to improvements of our products.

10

10

discard any plastic

the machine. They have low flash points and can explode or cause fire.

UNPACKING AND CHECKING CONTENTS

Your Baileigh machine is shipped complete . Separate all parts from the packin g mat er ial and

check each item carefully. Make certain all items are accounted for before discarding any

packing material.

WARNING: SUFFOCATION HAZARD! Immediately

bags and packing materials to elimina te choking and suffocation hazards to children

and animals.

If any parts are missing, DO NOT place the machine into service until the missing

parts are obtained and installed correctly.

Cleaning

WARNING: DO NOT USE gasoline or other petroleum products to clean

CAUTION: When using cleaning solvents work in a well-ventilated area.

Many cleaning solvents are toxic if inhaled.

Your machine may be shipped with a rust pr oof waxy coating and/or grease on the exposed

unpainted metal surfac es . Fully and completely remove this protective coating using a

degreaser or solvent cleaner. Moving items will need to be moved along their trav el path t o

allow for cleaning the entire surface. For a more thorough cleaning, some parts will occasionally

have to be removed. DO NOT USE acetone or brake clea ner as th ey may dama ge pai nted

surfaces.

Follow manufacturer’s label instructions when using any type of cleaning product. After cleaning,

wipe unpainted metal surfaces with a light coating of quality oil or grease for protection.

Important: This waxy coat ing is NOT a lubricant and will cause the machine to

stick and lose performance as the coating continues to dry.

GAS

11

11

NOTICE: Lifting and carrying operations should be carried out by skilled workers, such as a

chain carefully, making sure the machine is well balanced.

TRANSPORTING AND LIFTING

truck operator, crane operator, etc. If a crane is used to lift the machine, attach the lifting

Follow these guidelines when lifting with truck or trolley:

• The lift truck must be able to lift at least 1.5 – 2 times

the machines gross weight.

• Make sure the machine is balanced. While

transporting, avoid rough or jerky motion, and maintain

a safe clearance zone around the transport area.

• Use a forklift with sufficient lifting capacity and forks

that are long enough to reach the complete width of

the machine.

• Remove the securing bolts that attach the machine to

the pallet.

• Approaching the machine from the side, lift the machine on the frame taking care that there

are no cables or pipes in the area of the forks.

• Move the machine to the required position and lower gently to the floor.

• Level the machine so that all the supporting feet are taking the weight of the machine and no

rocking is taking place.

INSTALLATION

IMPORTANT:

Consider the following when looking for a suitable location to place the machine:

• Overall weight of the machine.

• Weight of material being processed.

• Sizes of material to be processed through the machine.

• Space needed for auxiliary stands, worktables, or other machinery.

• Clearance from walls and other obstacles.

• Maintain an adequate working area around the machine for safety.

• Have the work area well illuminated with proper lighting.

• Keep the floor free of oil and make sure it is not slippery.

12

12

.31"

(7.87mm)

.50"

(12.7mm)

• Remove scrap and waste materials regularly, and make sure the work area is free from

obstructing objects.

• If long lengths of material are to be fed into the machine, make sure that they will not extend

into any aisles.

• LEVELING: The machine should be sited on a level, concrete floor. Provisions for securing it

should be in position pri or to placin g the mac hi ne. T he acc ur acy of any mac hine depends on

the precise placement of it to the mounting surface.

• FLOOR: This machine distributes a large amount of weight over a small area. Make certain

that the floor is capable of supporting the weight of the machine, work stock, and the

operator. The floor should also be a level surface. If the unit wobbles or rocks once in place,

be sure to eliminate by using shims.

• WORKING CLEARANCES: Take into consideration the size of the material to be

processed. Make sure that you allow enough space for you to operate the machine freely.

• POWER SUPPLY PLACEMENT: The power supply should be located close enough to the

machine so that the power cord is not in an area where it would cause a tripping hazard. Be

sure to observe all electrical codes if installing new circuits and/or outlets.

Anchoring the Machine

• Once positioned, anch or the machi ne to the floor, as shown in

the diagram. Use bolts and expansion plugs or sunken tie rods

that connect through and are sized for the holes in the base of

the stand.

• This machine requires a solid floor such as concrete at a

minimum of 4” (102mm) thick. 6” (153mm) minimum is preferred.

13

13

GETTING TO KNOW YOUR MACHINE

14

14

Item

Description

Function

Verify machine power requirements before making

connections. Verify 11 0V or 220 V

Grinds welded area of blade back to ori gi nal mat er ial

thickness.

C

Blade Welding Station

Welds blade together.

D

Blade Shear

Trims end of blade square prior to welding

Removes power to the operating controls and stops

operation.

Push buttons to start and run the saw blade and stop the

saw blade when the cut is complete.

Changes the speed of the saw blade. Used while the

machine is running.

Displays the speed of the blade in MPM (Meters Per

Miniute).

J

Upper Access Door

Houses the upper pulley, and tensioner.

Guide Post Tension Knob

(not visible in this view)

Located on the back side of the upper whell housing,

use this to loosen the guide post fo adjustment.

Use to raise or lower the guide post to provide minimum

clearence to the work piece.

M

Work Lamp

Provide additional light to the cut area.

N

Blade Tension Adjustment

Turn to incease or decrease blade tension.

Sets a specific and repeatable distance for cutting

material to a specific width.

Provide air to the work site to blow chip away from cut

area.

Q

Upper Blade Guide

Holds the blade in position and minim izes blade twist.

Supports material and provide several ways to control

angle cuts.

Trunions used to allow the tabl e to tilt up to 15° left or

right.

T

Lower Blade Access Door

Houses the drive pulley.

Miter Gauge (not shown)

Sets a specific and repeatable angle for cutting material.

A Power Cord

B Grinder

E Emergency Stop Switch

F Start / Stop Control

G Variable Speed Hand Wheel

H Speed Display

K

L Guide Post Adjustment Knob

O Fence

P Air Tube

R Work Table

S Table Tilt

15

15

BG C

A

H F D

E

Control Panel

A DRO Indicator. Displays the speed of the

blade in FPM (Feet Per Minute).

B Speed Control. This potentiometer will vary

the input signal to the VFD which in turn will vary the

frequency output to the motor thus controlling the

speed of the motor and then the blade.

C Power Indicator Lamp. The power indicator

lamp will illuminate when the key switch is turned to

the ON position.

D Key Switch. The key switch powers the

operating controls On to allow either cutting or

welding.

E Function Selector Switch. This selector

switch provides for one opera ti on at a tim e. In t he Left

position, the welder will be active. In the Right

position, the saw will be active.

F On Push Button. Press this button to start and

run the blade when operating conditions are safe for

the blade to move. Make sure the blade is rotating

downward towards the work table .

G Stop Push Button. Press this button to stop

the blade any time that the operator is not directly and

actively engaged in a cutting operation.

H Emergency Stop Button (E-Stop). In the

event of incorrect operation or dangerous conditions,

the machine can be stopped immediately by pressing

the E-STOP button. Twist the emergency stop button

clockwise (cw) to reset. Note: Resetting the E-Stop

will not start the machine.

16

16

J

K

L

Blade Shear

The blade shear is attached to the saw frame, just left

and up from the saw band weld station.

It will cut saw bands ranging in width from 0.062” to 1”

(1.6mm to 25.4mm) and thickness of 0.025” to 0.035”

(0.63mm to 0.89mm).

Weld Station

J Welde r Control s. The Dial is used to set the

pressure or force used to press the ends of the blade

together.

Press and hold the Green push button to complete the

weld. Press and hold the Red push button to Anneal

the weld.

K Weld Jaws / Electrodes. The weld jaws clamp

and hold the blade in position during the weld. The left

jaw moves toward the right using the Pressure Dial.

Both jaws are the electrodes which transfer the

electrical current to the blad e materi al bei n g w elded t o

create the weld puddle (melted metal) which will flow

together to melt the end together as one piece.

L Grinder Switch. Toggle the switch to the ON

position to start and run the grinding wheel. Grind the

blade to remove rough spots and create a smooth

surface without making the area thinner than the rest

of the blade.

17

17

Upper

Lower

Lower Wheel Housing

The lower wheel housing has the lower wheel (drive

wheel), the debris brush, and the debris tray.

• The lower wheel is the drive wheel which is

connected via a shaft to the drive sheave and thus

the motor through the drive belt.

• The brush is used to help control / remove chips

and metal fillings from getting between the blade

and wheel. Keep it clean and adjust as it wears.

The bristles should have a slight pressure against

the pulley at all times.

• The debris tray will collect larger chips and metal

fillings. The tray will slide out and back in for

regular cleaning.

Tilting Work Table

The work table may be tilted from 15° to 45°. The

outboard side of the table will lift to create a 15° angle

or lowered to a 45° angle.

Tilting the table is done on the back side of the saw.

Just under and forward of the degree scale is the

clamping nut. Loosen the nut, tilt the table to the

desired angle and tighten the nut to hold the angle.

Upper and Lower Blade Guides

The blade guides provide side-to-side and back support for keeping the blade straight while

cutting material. The blade guides are tungsten steel where they come in contact with the blade

to reduce wear on the guides. The guides must be kept properly adjusted for accurate cuts.

18

18

Fence Guide

A fence guide is provided with this saw to ad in

precise cut lengths and repeat cuts.

ASSEMBLY AND SET UP

WARNING: For your own safety, DO NOT connect the machine to the

power source until the machine is completely assembled and you read and

understand the entire instruction manual.

Fence Installation

• Remove and retain the two hex head cap screws

installed into the front work table edge.

• Position the fence mounting bar onto the front

edge of the work table and install and tighten the

two hex head cap screws.

• Install the fence by setting the clamping body over

the fence rail with the clamping handle lifted.

• Slide the fence left or right as needed and press

down on the lock handle with just enough force to

hold the fence in position.

19

19

ELECTRICAL

WARNING: Baileigh Industrial Holdings LLC is not responsible for any

damage caused by wiring up to an alternative 3-phase power source other than direct

3-phase. If you are using an alternate power source, consult a certified electrician or

contact Baileigh Industrial Holdings LLC prior to energizing the machine.

CAUTION: HAVE ELECTRICAL UTILITIES CO NNECTED TO MACHINE BY

A CERTIFIED ELECTRICIAN!

Check if the available power supply is the same as listed on the machine nameplate.

WARNING: Make s ure the grounding wire (green) is properly connected

to avoid electric shock. DO NOT switch the position of the green grounding wire if

any electrical plug wires are switched during hookup.

Power Specifications

Your machine is wired for 230 volts, 60hz alternating current. Verify the input power supply

before making any electr i cal connec ti ons. Before connecting the machine to the power source,

make sure the power source is OFF.

Before switching on the power, you must check the voltage and frequency of the power to see if

they meet with the requireme nt, t he allow ed range for the voltage is ±5%, and for the frequency

is ±1%.

Considerations

• Observe local electrical codes when connecting the machine.

• The circuit should be protected with a time delay fuse or circuit breaker with an amperage

rating slightly higher than the full load current of machine.

• A separate electrical circuit should be used for your machines. Before connecting the motor

to the power line, make sure the switch is in the “OFF” position and be sure that the electric

current is of the same characteristics as indicated on the machine.

• All line connections should make good contact. Running on low voltage will damage the

motor.

• In the event of a malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock. This machine is equipped with an electric

cord having an equipment-grounding conductor and a grounding plug. The plug must be

plugged into a matching outlet that is properly installed and grounded in accordance with all

local codes and ordinances.

20

20

WARNING: In all cases, make certain the receptacle in question is

properly grounded. If you are not sure, have a qualified electrician check the

receptacle.

• Improper connection of the equipment-grounding conductor can result in risk of electric

shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal.

• Check with qualified electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the machine is properly grounded.

• Repair or replace damaged or worn cord immediately.

Power cord connection:

1. Turn the main disconnect switch on the control panel to the OFF position.

2. Unwrap the power cord and route the cord away from the machine toward the power supply.

a. Route the power cord so that it will NOT become entangled in the machine in any

way.

b. Route the cord to the power supply in a way that does NOT create a trip hazard.

3. Connect the power cord to the power supply and check that the power cord has not been

damaged during installation.

4. When the machine is clear of any obstruction. The main power switch may be turn ON to test

the operation.

5. Turn the switch OFF when the machine is not in operation.

21

21

BEFORE EACH USE

• For dusty operations, wear a face shield along with safety goggles.

• It is important to choose the right blade for the material and the type of cutting you plan to

do. This saw is equipped with a bi-metallic blade which can be used to cut stainless steel,

steel, iron, brass, aluminum, wood, plastic.

• Make sure the direction of rotation arrow on the blade matches the direction arrow on the

saw. The blade teeth should always point downward at the front of the saw.

• Make sure the blade is sharp, undamaged and properly aligned. With the saw unplugged,

push the power-head all the way down. Rotate the blade by hand checking for clearance. If

the blade hits anything, make the adjustments shown in the Maintaining Maximum Cutting

Capacity section.

• Never cut freehand.

• Make sure the cut-off piece can move sideways after it is cut off. Otherwise, it could get

wedged against the blade and thrown violently.

• Never turn the saw "ON" before clearing everything except the work piece beneath the

blade.

• Never put lubricants on the blade while it is spinning.

Whenever Saw is Running

• Never confine the piece being cut out.

• Never hold it, clamp it, touch it, or use length stops against it. It must be free to move

sideways. If confined, it could get wedged against the blade and thrown violently.

• Avoid awkward hand positions where a sudden slip could cause a hand to move into the

blade.

• Let the blade reach full speed before cutting.

• Feed the saw into the work piece only fast enough to let the blade cut without bogging down

or binding.

• Before freeing jammed material, turn the switch off and unplug the saw. Wait for all moving

parts to stop.

• After finishing a cut, keep holding the saw bow down, release the switch, and wait for all

moving parts to stop before moving your hands.

22

22

The widest part of the blade measured from the back edge of the

blade to the tip of the tooth.

B

GULLET DEPTH

The distance from the tooth tip to the bottom of the curved area.

The angle of the tooth face from a line perpendicular to the length

of the blade.

The distance between the back edge of the blade and the bottom

of the gullet.

E

TOOTH PITCH

The distance between tooth tips.

The number of teeth per inch when measured from gullet to

gullet.

G

GAUGE

The thickness of the blade.

H

TOOTH SET

The distance a tooth is bent from the blade.

I

KERF

The width of material that is removed by the blade when cutting.

A

B

C

D

E

F

G

H

I

Blade Terminology

A BLADE WIDTH

C TOOTH RAKE

D BLAD E BAC K

F TPI

Breaking in a Band Saw Blade

Sharp cutting edges with extremely small edge radii are required for high cutting capacity. To

achieve the optimal tool life we recommend breaking-in the blade accordingly. The correct

cutting speed is determined by the material being cut and its dimensions. It is very important

that the new blade is first used with only 50% of the determined feed rate. This will avoid microbreakages of the blade because of too large chip thicknesses. New band saw blades may tend

toward vibrations and vibration sounds. In this case a slight reduction of the cutting speed is

helpful. With small workpiece dimensions approximately 300cm² of the material should be cut

for breaking-in. If large work piece dimensions are to be cut we recommend a breaking-in period

of about 15 minutes. After breaking-in you may slowly increase the feed rate up to the

determined value.

23

23

Metal Chip Indicators

Chips are the best indicator of correct material feed force. Monitor chip information and adjust

feed accordingly.

• Thin or Powdered Chips – increase feed rate or reduce saw speed

• Burned Chips – reduce feed rate and / or saw speed

• Curly Silvery and Warm Chips – optimum feed rate and saw speed

Baileigh Industrial offers a wide selection of tooth styles for various cutting applications. Please

phone Baileigh Industrial at (920.684.4990) or fax to (920.684.3944) to have one of our

technicians assist you in selecting the proper band saw blade for your cutting applications.

BLADE CARE

The bandsaw blade is subjected to a tremendous amount of strain. Make sure to always use the

appropriate feed rate for the type material you are cutting.

Be sure to select a blade of the proper width, style, and pitch that will produce the best cut in

your material. Choosing the wrong blade can produce excess heat that can adversely affect the

life of the blade.

A clean blade performs much better than one that is dirty. Blades that are gummed up and dirty

offer more resistance when cutting through the material. This in turn creates unnecessary heat

in the blade.

Choosing A Saw Blade

A general-purpose blade is furnished with this band saw.

To achieve a quality, economical, and efficient saw cut, the following points must be taken into

consideration:

• Type of material being cut (ferrous or non ferrous)

• Material hardness and phy si cal di me nsi ons

• Blade descent rate

• Longitudinal speed of blade

• Blade tooth profile

24

24

Choose a tooth pitch that is suitable for the workpiece. Thin walled profiles, including tubes and

pipes require close toothing. At least 3-6 teeth should be in contact with the material while

cutting. Large solid or transverse sections require widely spaced toothing to allow for greater

volume of chips and better tooth penetration. Soft materials such as plastics, light alloys, mild

bronze, Teflon, etc. require widely spaced toothing to avoid clogging.

Width of Blade

The blade width determines the largest and the smallest curve that can be cut. Usually the wider

a blade is, the more accurate and straighter it will cut.

Length of Blade

The length of the band saw blade can be measured with a tape measure at its circumference or

by the formula below:

Blade Length = (2 x A) + (3.14 x B)

A = the distance in inches between the band saw pulley centers (when the upper pulley is

midway in its adjustment range).

B = the band saw pulley diameter.

BLADE BREAKAGE

In some cases, blade breakage is unavoidable due to the stresses that are imparted on the

blade. Avoidable breakage is often the result of poor care, or poor operator judgment when it

comes to adjusting or mounting the blade or blade guides.

Listed below are some of the more common reasons for blade breakage.

• Top blade guide assembly is set too high above the piece part.

• The blade is tensioned incorrectly.

• Piece part is fed into the blade too quickly.

• Blade teeth are dull or broken.

• Blade is not properly aligned with the guides.

• Forcing a large width blade to cut a sm all radius.

• Using a blade with an improperly finished weld joint.

• Allowing the blade to run when not in use. (NEVER leave an unattended blade running.)

25

25

potentially hazardous to operator or

personnel working nearby.

MATERIAL SELECTION

CAUTION: It must be determined by the customer that materials being

processed through the machine are NOT

When selecting materials keep these instructions in mind:

• Material must be clean and dry. (without oil)

• Material should have a smooth surface, so it processes easily.

• Dimensional properties of material must be consistent and not exceed the machine capacity

values.

• Chemical structure of material must be consistent.

• Buy certificated steel from the same vendor when possible.

26

26

SAW OPERATION

CAUTION: Always wear proper eye protection operating the saw. The

bandsaw blade is sharp and will cut fingers and hands. Keep hands and fingers clear

of the blade. Use a block of wood as a pusher for the material being cut. It is

recommended to always wear leather gloves when working near the blade.

1. Verify the work area including the table is clear

of obstructions.

2. Set the guide post (A) to approximately .25”

(6.35mm) above the piece part and tighten the

guide post knob.

3. Set the table and if being used, the fence as

needed to complete the cut. Have a push block

within reach without crossing the blade path or

vision of the cut area. Simulating the cut without

power may be helpful.

4. Set the work lamp position to provide additional

light at the cut site without inter

material or the ability to maintain control of the

material for the entire cut.

5. Have proper support for the material to be cut.

This should include both the finished piece and

the excess material.

6. Press the start button to energize the motor

stating the blade. The saw blade should now be

moving. If any abnormal sounds or vibrations

are noticed, press the red stop button

immediately.

7. Adjust the variable speed (B) until the desired

speed is indicated on the speed display.

8. Carefully place the material on the table.

9. When positioned, feed the material into the blade using a steady smooth motion.

10. When the cut is complete, press the red stop button on the control panel and wait until the

blade stops before removing any material near the blade.

fering with the

27

27

CAUTION:

blade.

OPERATION OF BLADE WELDER

Overall Description

The bandsaw blade is sharp and can cut your hand or fingers.

Always disconnect power to the saw and wear leather gloves when working near the

The weld station on the Baileigh band saw can butt weld and anneal blades from 0.118” (3mm)

to 0.625” (16mm) wide by 0.032” (0.8mm) thick. It is a resistance type welder with two jaws that

secure the blade ends during the welding process. A selector knob is turned counterclockwise

(ccw) to pre-load the left jaw, forcing the blade ends against one another. When the operator

presses the weld button, electric current passes through the butted blade ends. The left jaw

blade end is pushed into the molten puddle and welded to the right blade end. Remove the

blade from the jaws if any weld flash is present and carefully grind it off. The blade joint must

now be placed back into the jaws where annealing of the weld joint takes place. This procedure

will reheat the weld area so it is not so brittle and should return it to its original condition.

It may become necessary to weld blades when:

• They break unexpectedly and the teeth are still sharp enough to cut.

• You need to make blades from a bulk saw blade coil.

• When you need to weld a blade that was cut to make an internal contour cut on a piece part.

28

28

CAUTION:

Grind

Here

Good Weld

Poor Weld

Weld centered

in gullet of blade

Consistent tooth

spacing

Weld not centered

in gullet of blade

Unremoved tooth

embedded in weld

Inconsistent

tooth spacing

Incomplete weld

Blow-out

hole

Preparing the Saw Band Prior to Welding

Blade Cutter To cut the band apart or to cut the band

to a specified length, use the blade shear. The shear is

capable of cutting saw bands from 0.118” to .625”

(3mm to 16mm) in width and 0.025” to 0.035” (0.63mm

to 0.89mm) in thickness. To use the blade cutter, raise

the handle, lay between the blades perpendicular to

the cutting knife, and make the cut.

If the saw band is not square after shearing, use the

grinding wheel to square it up. Take small cuts so as

not to overheat the blade band. To get both ends of

the band to match perfectly, twist it and hold the ends

so that the teeth are on opposite sides and pointing in

opposite directions. Now grind as shown below.

Tooth Spacing on Blade Band Occasionally one or

more teeth may have to be ground off on either side of

the cut to ensure blade tooth uniformity.

Shear Hazard – Keep Hands From Under Blade.

29

29

WARNING:

Preparing the Blade Welder

The electrical current that flows through the blade welder

when operating could cause Serious Personal Injury or Death.

To avoid the risk of electrocution, never touch any metal part of the weld station

during welding or annealing of the blade.

1. Make sure the jaws of the welder are clean to

make good electrical contact.

2. Check that the jaws will adequately hold the

thickness of blade you are usin g.

3. The left jaw should slide easily when turning the

weld force selector knob.

4. Check over the grinding wheel and make sure it is

in good condition.

Making the Weld

1. Before making a weld, turn off the band saw motor

by pressing the red “stop” button.

2. Turn the weld pressure selector knob clockwise

(cw) to the “0” position.

3. After squaring the ends of the blade, insert the

spine edge of the blade into each jaw butting the

cut ends together and centered between the jaws.

4. Secure the blade by raising the handles. Check that the blade ends fit together with no gap.

If a gap is noticed, remove and re-sq uar e th e blade.

5. Turn the weld force selector knob from “0” to the third marker. This would be for a 0.25”

(6.3mm wide blade. (Every 2mm of blade width = 1 marker approx.). this applies pressure to

hold the ends of the blade togeth er.

30

30

WARNING:

Good Weld

Poor Weld

Weld centered

in gullet of blade

Consistent tooth

spacing

Weld not centered

in gullet of blade

Unremoved tooth

embedded in weld

Inconsistent

tooth spacing

Incomplete weld

Blow-out

hole

2 3 4 5

Check blade band misalignment

with a straight edge

Sparks from the blade welding operation can be thrown in all

directions and can cause serious personal injury or fire. When using the blade

welder, always protect yourself and others from flying sparks. Keep fire extinguisher

equipment close by and DO NOT weld near flammables.

6. Press and hold the green weld button until the left jaw blade end is pushed into the molten

puddle and welded to the right blade end. As soon as the left jaw moves into the right jaw,

release the green weld button. Electric current passes through the butted blade ends. The

left jaw blade end is pushed into the molten puddle and welded to the right blade end.

Inspect the weld carefully after removing from the welder.

7. If you see what appears to be an excessive amount of flashing you can try backing off on the

weld force setting.

31

31

CAUTION:

CAUTION:

Bend Like This

Not Like This

Annealing the Weld

The bandsaw blade is sharp and can cut your hand or fingers.

Heat from the welding and annealing process can cause severe burns. Always wear

leather gloves when working near the blade.

1. When a saw band is butt welded, the site of the weld “air hardens” and will become brittle.

To return the metal to its approximate original state it must be gradually heated and cooled

several times called annealing.

2. Turn the weld force selector knob to “0”.

3. Clamp the saw band in the jaws making sure to carefully cent er th e wel d. It is still brittle.

4. Press the red annealing button quickly with a few short bursts to ma ke th e weld ar ea a dull

orangish-red. (The wider the blade, the more bursts and time it will take.) After reaching a

dull orangish-red, allow the area to cool 15-30 seconds and then repeat the heat twice more.

Too much heat can damage the temper or burn through and destroy the weld.

5. After welding and tempering the blade, test the strength and flexibility of the saw band by

bending it in an arc similar to the pulley on the saw.

Grinding the Weld

The bandsaw blade is sharp and can cut your hand or fingers.

Keep hands and fingers away from rotating grinding wheel. Wear proper eye

protection. Always wear leather gloves when working near the blade.

1. The grinding wheel is used for both preparing the saw band for welding and rem ov ing f lash

after annealing. Flash must be removed from both sides of the weld to maintain the blades

actual thickness. This w i ll then allow the bl ad e to pass t hr ou gh the gui des with out any

obstructions.

2. DO NOT burn or overheat the weld area when grinding.

32

32

A

B

SAW ADJUSTMENTS

Guide Post

The guide post assembly serves two purposes.

• First, it positions the orange blade guard between

the piece part and the upper pulley housing to

protect the operator fro m the ex pos ed bl ad e.

• Second, it positions the upper blade guides close

to the piece part for support of the blade.

To properly position the guide post:

1. DISCONNECT POWER FROM THE BANDSAW.

2. Loosen the guide post knob (A).

3. Use the handwheel (B) to lower or raise the guide

post.

4. Locate the bottom of the blade guides .25”

(6.35mm) above the piece part and tighten the

guide post knob to hold it securely.

Graduated Scales to Show Tilt of Table

The table can be tilted either forward or back and left

or right, or in combination.

It can be tilted 15° left and 45° right. For left and right

tilting, the table has a scale to indicate the tilt angle.

33

33

Blade guide bracket

Adjusting the Blade Guides

1. DISCONNECT POWER FROM THE BAND SAW.

2. Check to make sure the guide post is secure, and the blade has been properly tensioned.

3. Using a 5mm hex wrench you need to loosen the socket cap screws “A” and “B”.

4. Slide the blade guide bracket so the blade guides are approximately 0.06” (1.58mm) behind

the tooth gullets as shown. Tighten socket cap screw “A” only.

Note: The blade guides need to be adjusted far enough back so they are behind

the tooth gullets when the blade is pushed back against the blade support.

"C"

5. With socket capscrew “ B” still loose, slide the blade support rod up to, but not touching the

back end of the blade. Re-tighten socket capscrew “B”.

Blade guides

"A"

"B"

Blade support

0.06"

[1.58mm]

Table

6. Next the blade needs to be centered between the blade guides. To do this, first loosen the

socket capscrews “C” using a 5mm hex wrench. Now slide a piece of copy machine paper or

a dollar bill between each side of the blade guide and the blade. Either of them should be

0.004” (0.1mm) thick. Gently pinch the paper between the blade guides and the blade. Now

tighten each socket capscrew “C”. (Check the position of the air nozzle). The guides should

now be positioned correctly without touching the blade.

Note: Over time the blade inserts will wear. When this happens, flip over and

reverse the guides. If the blade wears a groove into the blade support, loosen and rotate it to a

new spot.

3 4

3 4

Blade Tension A dj ustm ent Wheel

W ithout proper tension a bandsaw blade cannot

deliver the necessary cutting efficiency. N ot enough

tension can lead to blade runout, increased wear, and

poor finish on the piece part. Too much tension can

cause the blade to break. To check the blade tension,

you can use a blade tensioner or by hand as

ex plained below.

To properly tension the blade, follow the procedure

below.

1. D I S C O N N E C T P O W E R F R O M TH E B A N D S A W .

2 . O pen the upper pulley access door.

3 . Loosen the guide post adjusting knob and raise

the upper blade guide as high as it will go and

secure it.

4. C heck the blade deflection at a point halfway

between the table and the upper blade guide. I t

should be about 0 .3 7” (9 .5mm) when applying a moderate side

pressure.

5. I f a tension adj ustment is necessary, make small adjustments to

the handwheel. Turning the handwheel clockwise (cw) increases

the tension and turning it counterclockwise (ccw) will decrease

the blade tension. A fter adjusting the hand wheel, rotate the top

pulley several times by hand and then re-che ck the deflection.

Note: As the top pulley is rotated, make sure the blade

does not touch the flange of the pulley.

IMPORTANT: To prolong the life of the blade, release

the tension on the blade if the bandsaw will be idle for an extended

period of time.

0 .3 7"

(9 .5mm)

3 5

3 5

A

C hanging a Blade

C A UTI O N : The bandsaw blade is sharp and c an c ut y our hand or f ingers.

A lway s disc onnec t power to the saw and wear leather glov es when working near the

blade.

1. D I S C O N N E C T P O W E R F R O M TH E B A N D S A W .

2 . U nlatch and swing open the upper and lower

pulley access doors.

3 . F rom under the table, remove the two hand knobs

(A ) and lift the insert out of the table.

4. R elease the blade tension by rotating the tension

wheel (B ) c ounterclockwise (ccw).

5. P ut on gloves to protect your hands. N ow slide the

blade off of the upper and lower sheaves, around

the blade guards, and through the slot in the table.

6 . I nstall the new blade in the reverse order with the

teeth facing forward toward the door and the tips

of the teeth pointing downward toward the

worktable.

7. M ake sure the blade is centered on the wheels

and engaged between the upper and lower blade

guides.

8 . Turn the tension wheel to tighten the blade

following the “ B lade Tension A djustment W heel”

procedure.

9 . C arefully make a few rotations of the top sheave by

hand to make sure the blade band is tracking

evenly.

36

36

A

B

BLADE TRACKING

Regular Adjustment

CAUTION: This adjustment will have the blade exposed to possible The

bandsaw blade is sharp and can cut your hand or fingers. Use extreme care when

blade.

When changing blade and especially when changing

the width of the blade, it may be necessary to adjust

the tracking the keep the blade centered on drive

wheel.

1. DISCONNECT POWER FROM THE BANDSAW.

2. Open the upper wheel door.

3. Loosen the lock knob (A).

4. Turn the Speed Control down (counterclockwise)

to the lowest speed setting.

5. Connect the saw to the power supply and power

on.

6. Watch the blade travel over the drive wheel. The

blade should track in the middle of the wheel.

7. Slowly and a little at a time, turn the adjustment knob (B) to cause the blade to move toward

the middle of the wheel. Allow the blade to run several rotations after any adjustment.

8. When the tracking is centered, tighten the lock knob (A).

9. Continue to allow the blade to rotate several more times to verify the setting.

10. Stop the saw and close the wheel door(s) before returning the saw to service.

37

37

Coarse Adjustment

Note: Blade tracking has been set at the factory and should not require adjusting.

Before making any tracking adjustments, try a new blade. Warped blades will not track properly.

If a tracking issue occurs, adjust the top sheave.

When the blade band is tracking towards the flange:

1. Loosen the (4) bearing plate mounting bolts.

2. Back out the top (2) jack screws a bit.

3. Re-tighten the (4) mounting bolts and check the tracking again.

4. Reverse the procedure to track the blade band away from the flange.

Side View of

Top Sheave

Mounting Bolts

Jack Screws

Plan View of

Top S

heave

38

38

LUBRICATION AND MAINTENANCE

WARNING: Make sure the electrical disconnect is OFF before working on

the machine.

Maintenance should be performed on a regular basis by qualified personnel.

Always follow proper safety precautions when working on or around any machinery.

Daily Maintenance

• Do a general cleaning by removing dust and metal chips from the machine.

• Clean the blade brush.

• Inspect the saw blade for wear.

• Check that the blade guards and emergency stop button are in good working order.

• If you did blade welding, clean the clamping pads.

Weekly Maintenance

• Thoroughly clean the machine.

• Remove chips from inside the guard housing for the saw blade.

Note: When cleaning chips and debris from the machine, use a brush and a shop

vacuum. DO NOT blow off the machine with compressed air. The force of the compressed air

may force chips into critical mechanisms or may inflict injury to yourself or others.

• Use compressed air to clean the blade guides.

• Inspect the grinding wheel for wear.

Monthly Maintenance

• Check the blade guides and blade support for wear. (rotate or replace if necessary)

• Tighten any loose bolts, nuts, or screws on the machine.

• Re-grease the drive bearings.

• Inspect the blade brush for wear. (Adjust or replace)

• Grease the pivot of the blade shear.

• Wipe shafts and threaded rods with a light lubricant.

• Inspect the V-belts for wear (every 3 months)

Note: Proper maintenance can increase the life expectancy of your machine.

39

39

Blade Shear Lubrication

Apply a light coating of grease to the pivot mechanism as

necessary.

Upper Wheel Housing Items

Apply grease to the tension slide blocks, tension adjustment screw,

and the blade guide post rack as needed to keep them moving

freely and free from rust.

Table Support Lubrication

Grease the pivoting table support as often as needed.

40

40

CABINET ASSEMBLY – BREAKDOWN

41

41

Item

Part No.

Description

Size

Qty.

1

BSV24VS-V2-01

Lower Wheel Door

1 2 BSV20VS-V2-02

Hing Pin Lower

2 3 TS-2245102

Socket Head Button Screw

M5*0.8P*8mm

6 4 BSV20VS-V2-04

Control Panel

1

4-1

BSV20VS-V2-4-1

Blade Speed Digital Readout Meter

1

4-2

BSV20VS-V2-4-2

Start Button

1

4-3

BSV20VS-V2-4-3

Stop Button

1

4-4

BSV20VS-V2-4-4

Power Button

1

4-5

BSV20VS-V2-4-5

Select Switch Button

1

4-6

BSV20VS-V2-4-6

Emergency Stop Button

1 5 BSV24VS-V2-5

Blade Cleaning Brush

1

6

TS-1503061

Socket Hex Cap Screw

M6*1.0P*25mm

1 7 BSV24VS-V2-7

Upper Wheel Door

1 8 BSV20VS-V2-8

Hinge Pin Upper

2 9 TS-1490021

Hex Cap Screw

M8x16mm

2

10

BSV20VS-V2-10

Blade Shear

1

11

BSV20VS-V2-11

Air Pump

1

12

BSV24VS-V2-12

Bandsaw Cabinet

1

13

BSV20VS-V2-13

Air Hose

4*6mm

1

14

BSV20VS-V2-14

Air Nozzle

1

15

BSV20VS-V2-15

Work Lamp (Led)

220V

1

16

BSV20VS-V2-16

Door Knob

2

17

TS-1503041

Socket Hex Cap Screw

M6*1.0P*15mm

2

18

TS-1502041

Socket Hex Cap Screw

M5x16mm

4

19

TS-1550041

Flat Washer

M6

10

20

TS-2246102

Socket Head Button Screw

M6*1.0P*10mm

10

21

BSV24VS-V2-21

Back Cover

1

22

BSV24VS-V2-22

Chip Pan

1

23

BSV20VS-V2-23

Lower Blade Guard Set

2

24

BSV20VS-V2-24

Hex Cap Screw

M6-1*10mm

4

25

TS-1550041

Flat Washer

M6

4

Cabinet Assembly – Part List

42

42

WORK TABLE ASSEMBLY – BREAKDOWN

43

43

Item

Part No.

Description

Size

Qty.

101

TS-1503051

Socket Hex Cap Screw

M6*1.0P*20mm

2

102

TS-1550041

Flat Washer

M6

2

103

BSV20VS-V2-103

Tungsten Support

2 104

BSV20VS-V2-104

Guide Seat (lower)

1

105

BSV20VS-V2-105

Lower Guide Rod

1 106

TS-1503061

Socket Hex Cap Screw

M6*1.0P*25mm

2

107

BSV20VS-V2-107

Trunnion Base

1 108

TS-2311101

Hex Nut

M10

1

109

TS-1550071

Flat Washer

M10

1

110

TS-1550061

Flat Washer

M8

4

111

TS-1490031

Hex Cap Screw

M8*1.25P*20mm

4

112

TS-1504041

Socket Hex Cap Screw

M8*1.25P*20mm

4

115

BSV20VS-V2-115

Trunnion

1 116

BSV20VS-V2-116

Lock plate

1 117

BSV24VS-V2-117

Table

1 118

BSV24VS-V2-118

Fence

1

119

BSV20VS-V2-119

Fence Rail

1 120

BSV20VS-V2-120

T - Block

M12

1

121

TS-1504041

Socket Hex Cap Screw

M8x20mm

2

122

BSV20VS-V2-122

Lock Screw

1 123

BSV24VS-V2-123

Table Insert

1 123-

BSV24VS-V2-123-1

Plastic Knob

2 124

BSV24VS-V2-118

Miter Gauge Assembly

1

Work Table Assembly – Part List

44

44

LOWER WH EEL SET ASSEMBLY – BREAKDOWN

45

45

Item

Part No.

Description

Size

Qty.

201

BSV24VS-V2-201

Rubber ring

500mm

2

202

BSV24VS-V2-202

Lower Wheel

1 202-1

BSV24VS-V2-202-1

Saw Blade (not show)

1 203

TS-2311201

Hex nut

M20

1

204

TS-2360201

Flat Washer

M20

1

205

BSV24VS-V2-205

Key

7x7mm

206

BSV24VS-V2-206

Lower Wheel Shaft

207

BSV24VS-V2-207

Key

7x7x46mm

208

BB6206

Ball Bearing

6206

2

209

BSV24VS-V2-209

Bearing Housing

1 210

BSV24VS-V2-210

Special Screw

4

211

BSV24VS-V2-211

Hex Cap Screw

M10x1.5x50mm

4

212

BSV24VS-V2-212

Hex Nut

M28x1.75

2

213

BSV20VS-V2-214

Wheel Pulley

1 213-1

BSV24VS-V2-A63

Belt

A63

2

214

TS-1492031

Hex Cap Screw

M12*1.5*35mm

2

214-1

TS-1540081

Hex nut

M12

2

214-2

TS-2361121

Lock Washer

M12

2

215

BSV20VS-V2-217

Motor Pulley

1 216

TS-1524021

Set Screw

M8*1.25P*10mm

2

3HP/ 220V/ 3Ph/

6P

218

TS-1490041

Hex Cap Screw

M8x1.25x25mm

8

219

BSV24VS-V2-219

Motor Bracket

1 220

TS-1550061

Flat Washer

M8

16

221

TS-1540061

Hex Nut

M8

8

Lower Wheel Set Assembly – Part List

217 BSV24VS-V2-217 Motor

1

46

46

GUIDEP OST ASSEMBL Y – BREAKDOWN

47

47

Item

Part No.

Description

Size

Qty.

501

TS-1503051

Socket Hex Cap Screw

M6-1*20

2

502

TS-1550041

Flat Washer

M6

2

503

BSV20VS-V2-503